3000A Series

Precision Multi Product Calibrator

Operation Manual

Version 5.00: February 2011

All product names are trademarks of their respective companies

3000A SERIES OPERATION MANUAL

IMPORTANT NOTICE

THIS CALIBRATOR

WILL

REQUIRE AN

UNLOCK CODE

AFTER THE EVALUATION

PERIOD HAS EXPIRED.

(60 Days after invoice date)

AFTER THE EVALUATION PERIOD HAS EXPIRED THE

OPERATION OF THE CALIBRATOR IS LOCKED AND THE DISPLAY

SHOWS A NUMBER WHICH MUST BE QUOTED TO TRANSMILLE

TO RECEIVE THE UNLOCK CODE

THE UNLOCK CODE IS AVAILALBLE

FROM TRANSMILLE

ONLY AFTER PAYMENT

HAS BEEN RECEIVED.

This code only needs to be entered once

in the life of the instrument.

Please contact Transmille or use the form in the

back of the manual to obtain the unlock code.

Transmille Ltd.

Staplehurst, Kent.

Tel: 44 (0)1580 890700 Fax: 44(0)1580 890711

Email: sales@transmille.com

TRANSMILLE LTD. Version 5.00: February 2011 Page 2

3000A SERIES OPERATION MANUAL

DECLARATION OF CONFORMITY

Manufacturer’s Name: Transmille Ltd.

Manufacturer’s Address: Unit 4, Select Business Centre

Lodge Road

Staplehurst

TN12 0QW

Declares, that the product

Product Name: Multi-product Calibrator

Model Number: 3050A / 3041A / 3010A

Product Options: This declaration covers all options of the above product(s)

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage

Directive 73/73EEC and the EMC Directive 89/336/EEC (including 93/68/EEC)

and carries the CE Marking accordingly

Conforms with the following product standards:

EMC

EN 61326-1:1997+A1:1998 • EN55011:1991 (Group 1 : Class A)

Standard Limit

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995 4kV CD, 8kV AD

IEC 61000-4-3:1995 / EN 61000-4-3:1995 3 V/m, 80-1000 MHz

IEC 61000-4-4:1995 / EN 61000-4-4:1995 0.5kV signal lines, 1kV power lines

IEC 61000-4-5:1995 / EN 61000-4-5:1995 0.5kV line-line, 1kV line-ground

IEC 61000-4-6:1996 / EN 61000-4-6:1996 3V, 0.15-80 MHz / cycle, 100%

IEC 61000-4-11:1994 / EN 61000-4-11:1994 Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

SAFETY

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

16/01/2006

Revision No: 1.0 Managing Director

Date: 16/01/2006

TRANSMILLE LTD. Version 5.00: February 2011 Page 3

3000A SERIES OPERATION MANUAL

TABLE OF CONTENTS

3000A SERIES CALIBRATOR INTRODUCTION .................................................................................6

MAIN FEATURES ...................................................................................................................................6

ACCURACY AND FUNCTIONALITY............................................................................................................7

TRUE MULTIPRODUCT CALIBRATION FROM ONE INSTRUMENT ...................................................7

RETRO FIT OPTIONS ALLOWS ADDITIONAL FUNCTIONS TO BE ADDED. ...........................7

SERIAL LINE RS232 INTERFACE FITTED AS STANDARD..............................................................8

OUTPUT CONNECTION ..........................................................................................................................8

PREPARING THE CALIBRATOR FOR USE. .......................................................................................9

INITIAL INSPECTION. ..............................................................................................................................9

LIFTING AND CARRYING THE CALIBRATOR ..............................................................................................9

POSITIONING THE CALIBRATOR............................................................................................................10

REAR PANEL CONNECTIONS AND CONTROLS .......................................................................................11

SETTING AND CHECKING THE LINE VOLTAGE. .......................................................................................12

POWER LINE INLET FUSE AND RATING..................................................................................................12

CONNECTING TO A COMPUTER.............................................................................................................13

POWERING UP THE CALIBRATOR ..........................................................................................................13

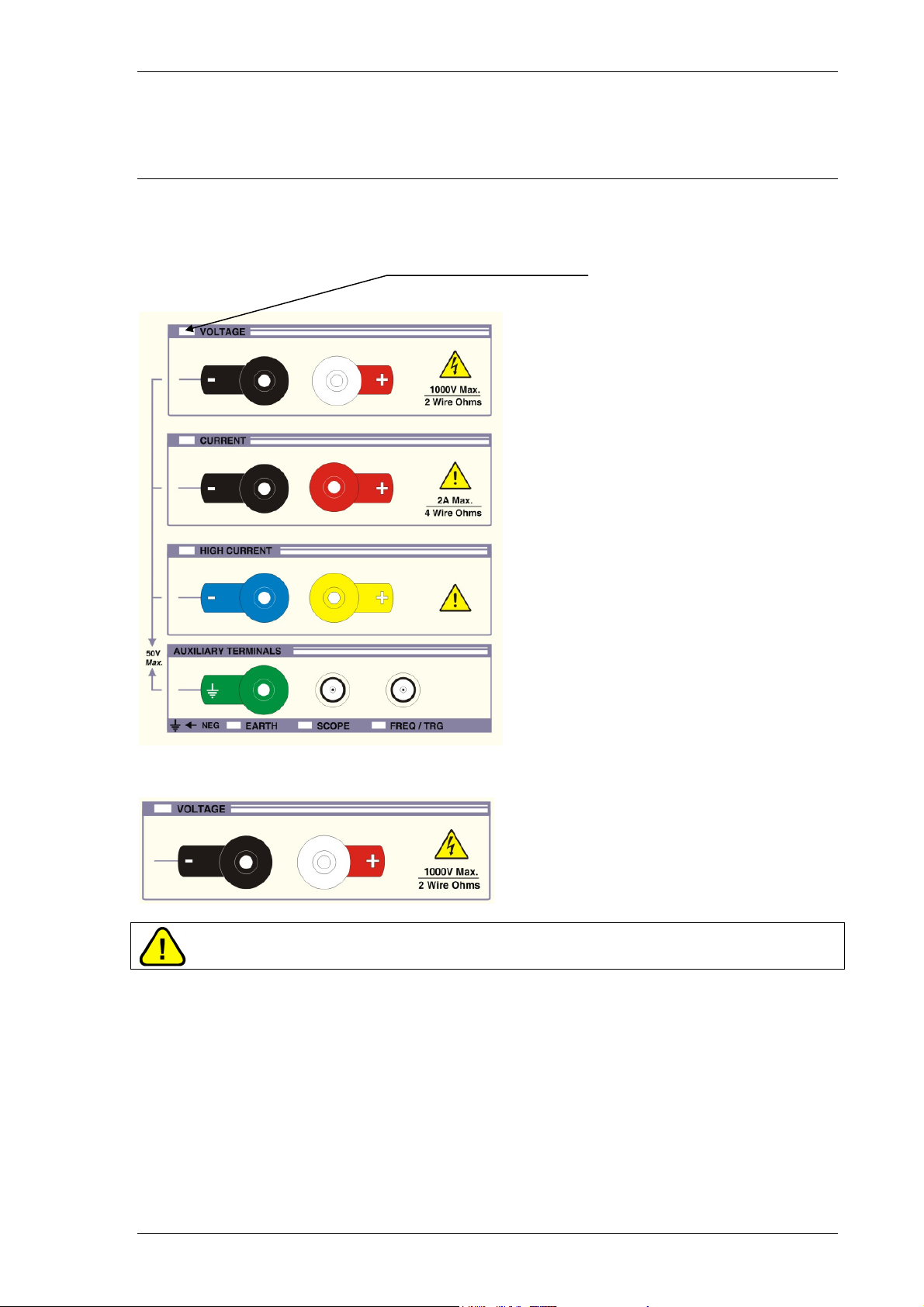

OUTPUT CONNECTIONS ......................................................................................................................14

OUTPUT OVERLOADS..........................................................................................................................15

OPERATION ........................................................................................................................................16

SAFETY WARNINGS ............................................................................................................................16

INTRODUCTION TO OPERATION ............................................................................................................16

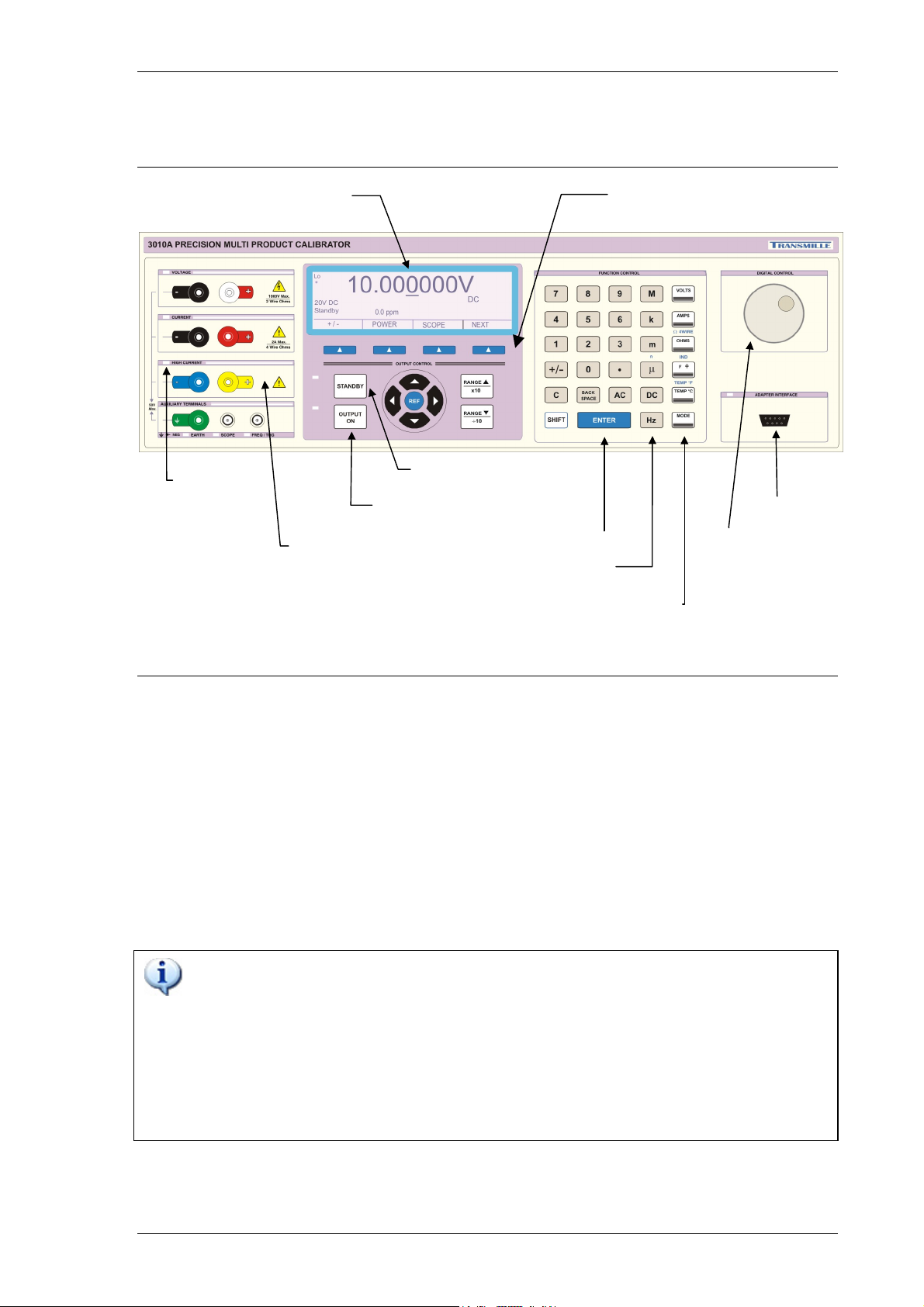

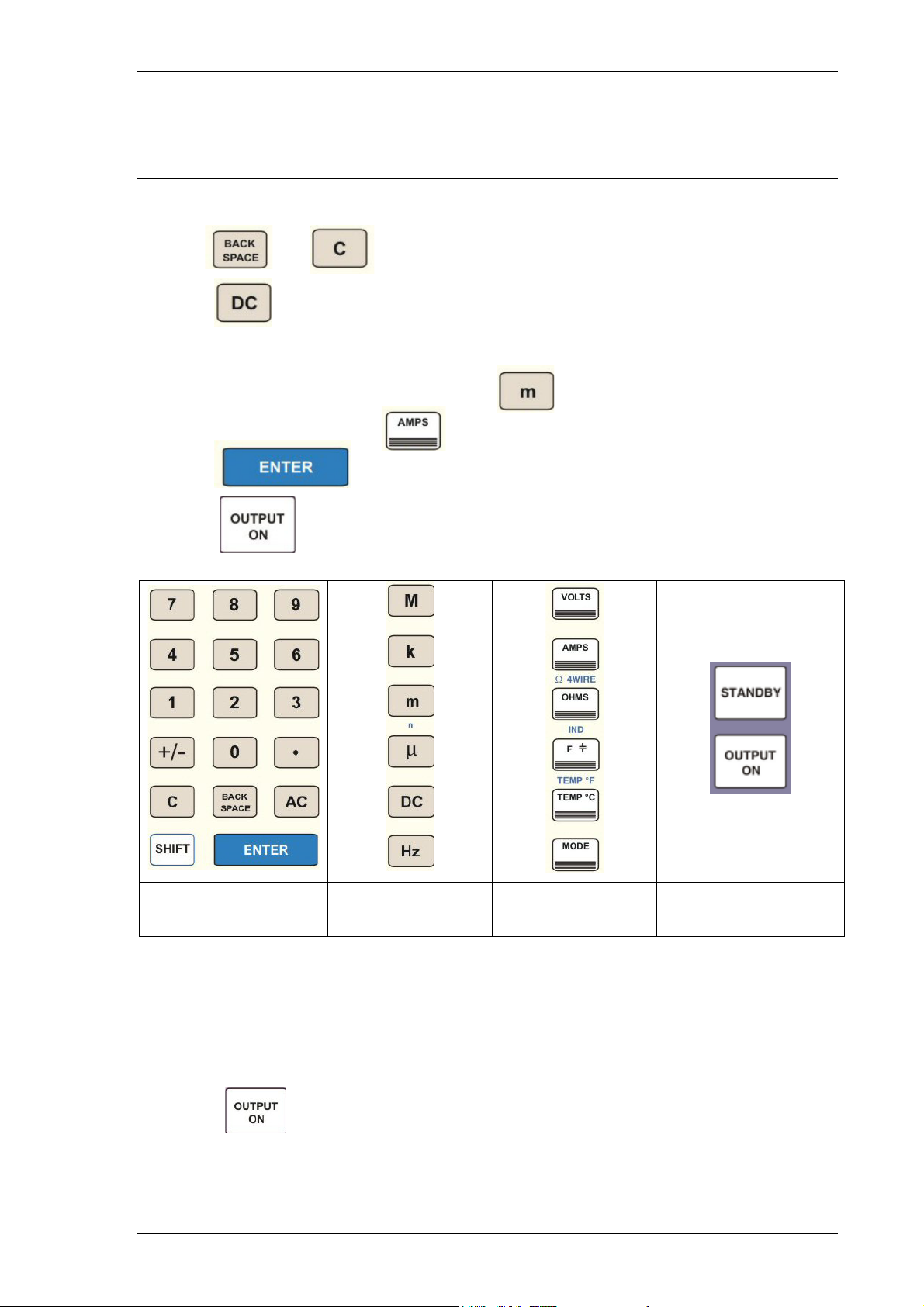

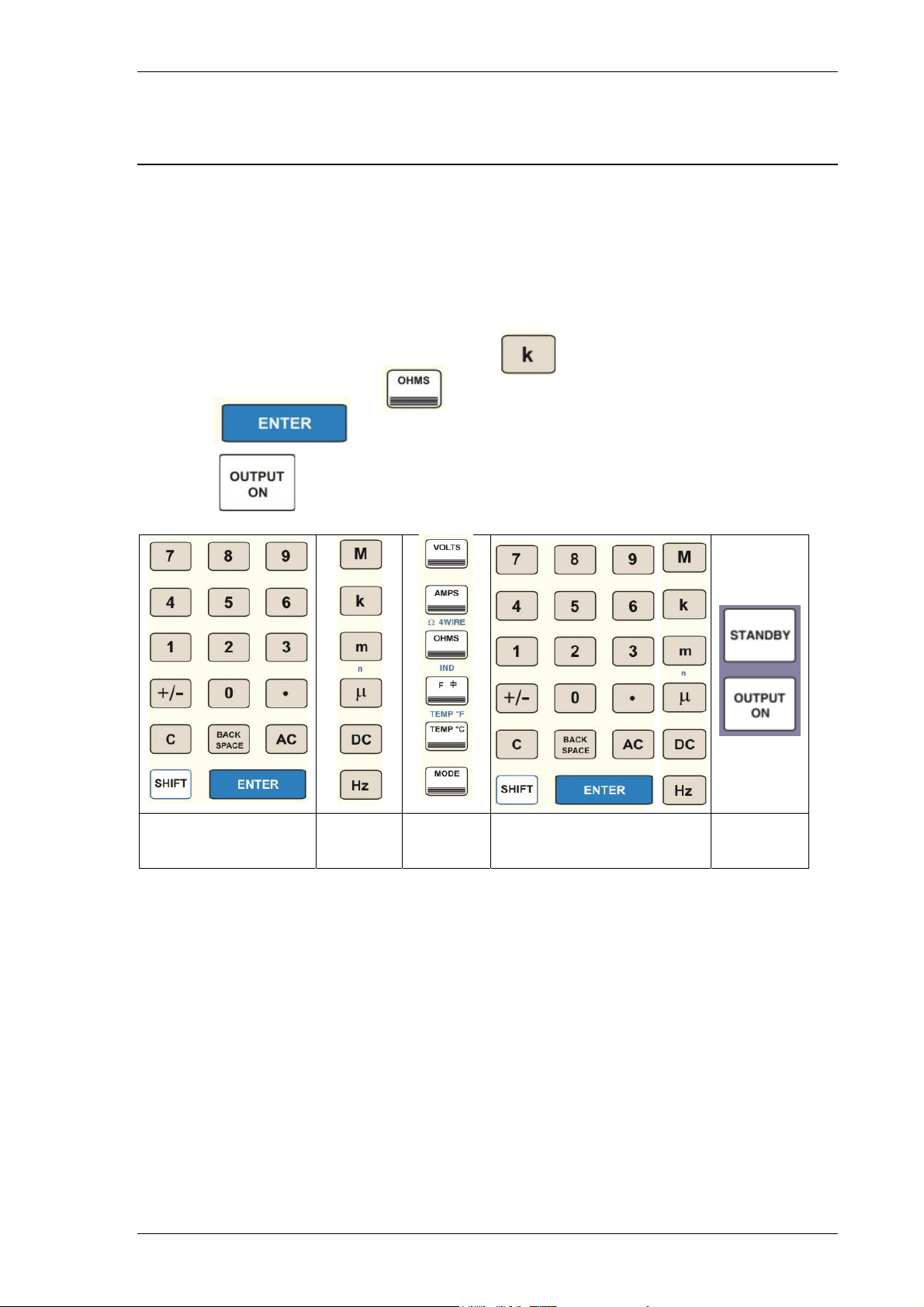

FRONT PANEL CONTROLS AND INDICATORS .........................................................................................17

FRONT PANEL KEYBOARD ...................................................................................................................17

FRONT PANEL KEYBOARD – CONTROL SECTIONS ................................................................................18

GRAPHIC LCD DISPLAY ......................................................................................................................19

DIGITAL CONTROL ..............................................................................................................................20

TERMINAL STATUS LED’S....................................................................................................................21

9 PIN ADAPTER INTERFACE CONNECTOR. ............................................................................................23

SETTING DC VOLTAGE AND CURRENT OUTPUT....................................................................................24

ADJUSTING THE SET OUTPUT USING THE DIGITAL CONTROL ...................................................................25

AUTOMATIC DISPLAY OF % OR PPM ERROR AND REF. KEY ...................................................................26

SETTING AC VOLTAGE AND CURRENT OUTPUT. ...................................................................................27

RETURNING THE CALIBRATOR TO DC ...................................................................................................28

SETTING 2 WIRE RESISTANCE OUTPUT. ..............................................................................................29

SETTING 2 WIRE SIMULATED RESISTANCE (OPTION)............................................................................31

SETTING 4 WIRE RESISTANCE OUTPUT. ..............................................................................................32

SETTING 4 WIRE RESISTANCE OUTPUT. ..............................................................................................32

USING CURRENT COILS (OPTION) .......................................................................................................34

SETTING CAPACITANCE OUTPUT. ........................................................................................................36

SETTING INDUCTANCE OUTPUT (OPTION) ............................................................................................37

THERMOCOUPLE SIMULATION (OPTION)...............................................................................................38

SPECIAL FUNCTIONS AVAILABLE USING THE ‘SOFT’ KEYS ......................................................................43

CONNECTING OUTPUT NEGATIVE TO LINE EARTH (GROUND)..................................................................43

SELECTING FRONT PANEL CONTROL.....................................................................................................43

SETTING TTL LOGIC FREQUENCY OUTPUT. .........................................................................................44

SETTING RPM OUTPUT WITH EA003 ADAPTOR (OPTION) ....................................................................45

SETTING PWM (MARK SPACE RATIO) .................................................................................................46

SELECTING PRT (PT100) RESISTANCE OUTPUT (OPTION) ..................................................................47

SELECTING SIMULATED PRT (RO) OUTPUT (OPTION)..........................................................................48

SELECTING AC POWER CALIBRATION OUTPUT (OPTION)......................................................................50

SELECTING DC POWER CALIBRATION OUTPUT (OPTION) .....................................................................53

SELECTING OSCILLOSCOPE CALIBRATION OUTPUT (OPTION)................................................................54

CALIBRATE .........................................................................................................................................56

SETUP (BEEPER / PASSWORD / ADAPTERS).........................................................................................56

TRANSMILLE LTD. Version 5.00: February 2011 Page 4

3000A SERIES OPERATION MANUAL

WARNING AND OUTPUT OVERLOAD INDICATIONS. .................................................................................58

HIGH VOLTAGE TIMEOUT.....................................................................................................................58

30 AMP TEMPERATURE CUT-OUT ........................................................................................................58

INTERFACE TYPES ............................................................................................................................59

RS232 INTERFACE .............................................................................................................................60

USB INTERFACE.................................................................................................................................62

REMOTE PROGRAMMING .................................................................................................................63

PROGRAMMING COMMANDS OVERVIEW ...............................................................................................64

DC VOLTAGE COMMANDS...................................................................................................................66

AC VOLTAGE COMMANDS ...................................................................................................................68

DC CURRENT COMMANDS ..................................................................................................................70

AC CURRENT COMMANDS ..................................................................................................................72

RESISTANCE COMMANDS ....................................................................................................................74

CAPACITANCE COMMANDS ..................................................................................................................76

SIMULATED RESISTANCE COMMANDS (OPTION) ...................................................................................77

SIMULATED CAPACITANCE COMMANDS (OPTION) .................................................................................78

TTL FREQUENCY COMMANDS (OPTION) ..............................................................................................80

PULSE WIDTH MODULATION COMMANDS (OPTION) ..............................................................................82

INDUCTANCE COMMANDS (OPTION) .....................................................................................................84

PRT100 COMMANDS (OPTION)...........................................................................................................86

THERMOCOUPLE SIMULATION COMMANDS (OPTION) ............................................................................88

MISCELLANEOUS COMMANDS..............................................................................................................91

OSCILLOSCOPE CALIBRATION COMMANDS (OPTION) ............................................................................92

AC POWER CALIBRATION COMMANDS (OPTION) ................................................................................101

TECHNICAL DESCRIPTION..................................................................................................................104

GENERAL .........................................................................................................................................104

CONSTRUCTION................................................................................................................................105

INTERNAL FUSES ..............................................................................................................................106

OPENING THE CASE .........................................................................................................................107

ACCESS TO INTERNAL FUSES – TOP PCB..........................................................................................108

ACCESS TO INTERNAL FUSES – FRONT PANEL PCB...........................................................................109

POWER SUPPLY AND OUTPUT SWITCHING BOARD................................................................................110

PROCESSOR BOARD .........................................................................................................................110

MAIN ANALOGUE AMPLIFIER AND FEEDBACK BOARD ............................................................................111

HIGH VOLTAGE AMPLIFIER AND OUTPUT ............................................................................................112

CURRENT TRANSCONDUCTANCE AMPLIFIER.......................................................................................112

OUTPUT CURRENTS SENSING & SHUNTS...........................................................................................113

CALIBRATION TUTORIAL................................................................................................................114

GETTING THE BEST OUT OF THE CALIBRATOR. ....................................................................................114

CALIBRATION AND MAINTENANCE ..............................................................................................116

GENERAL .........................................................................................................................................116

ELECTRICAL SAFETY TESTS ..............................................................................................................116

CLEANING OF THE FAN DUCT ............................................................................................................117

CLEANING THE EXTERNAL CASE .........................................................................................................117

CALIBRATION....................................................................................................................................118

GUARANTEE AND SERVICE.................................................................................................................119

TRANSMILLE LTD. Version 5.00: February 2011 Page 5

3000A SERIES OPERATION MANUAL

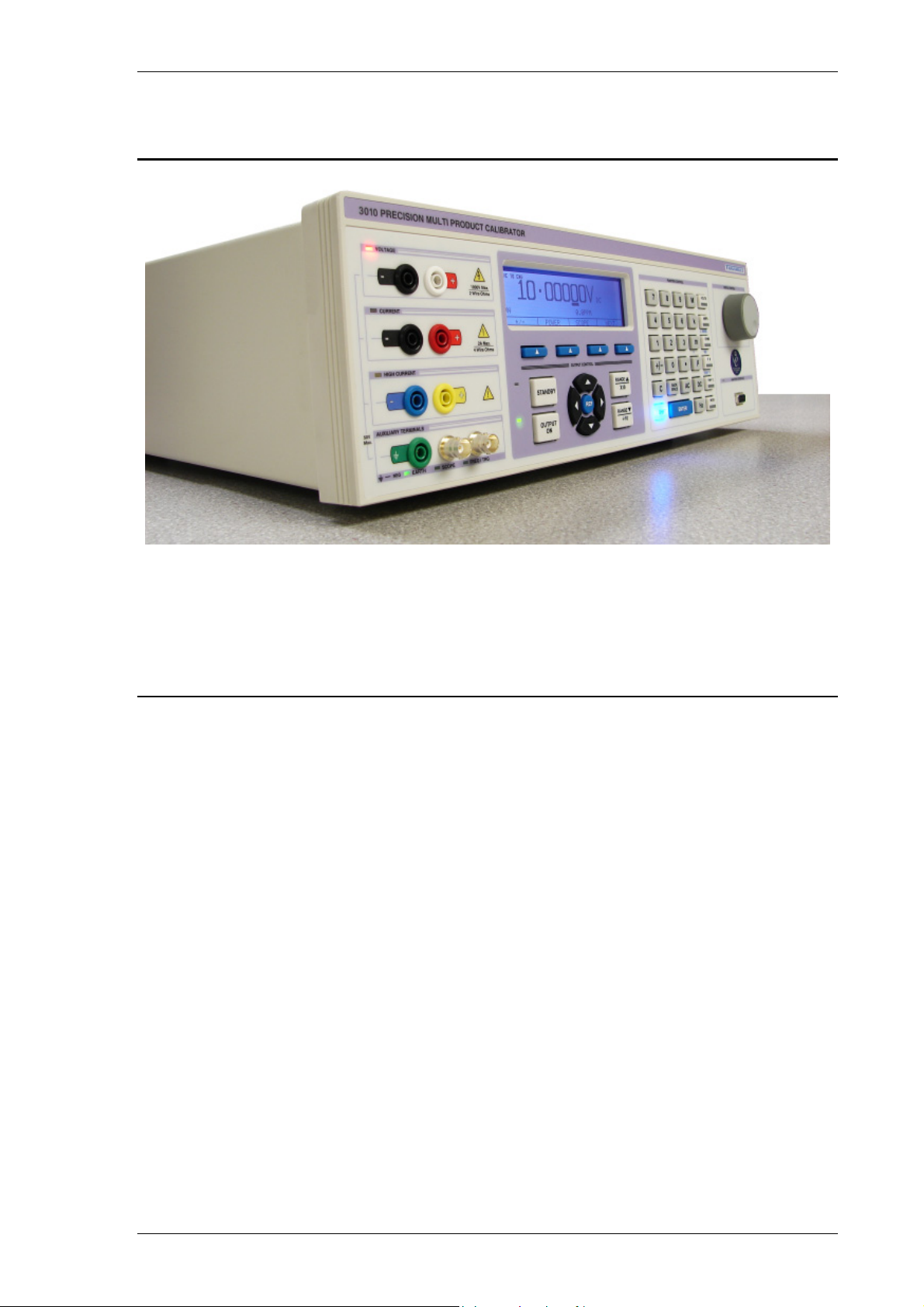

3000A Series Calibrator Introduction

The 3000A series of calibrators offer the smallest and by far the most portable multi

product multi-function calibrator in the world. The 3000A series calibrator provides a

fully functioned precision programmable calibration source.

Main Features

AC/DC Volts to 1025V

AC/DC Current to 30 Amps (20Amps for 3050A)

AC/DC Current to 1500 Amps with 50 Turn Clamp coil Adapter

2 and 4 Wire Resistance to 1GΩ (10 MΩ for 3050A)

Capacitance

Inductance (Option)

Logic Level Frequency

Mark Space Ratio

PT100 resistance Simulation (Option)

RTD Simulation active (Option)

Thermocouple Simulation (°C & °F)

DDS Power / Harmonics (Internal Option)

250/350/600MHz Oscilloscope Calibration (Internal Option)

RS232 Serial Interface GPIB (IEEE488) Interface Option

Extendable Range Of Adaptors via the Adapter Interface

TRANSMILLE LTD. Version 5.00: February 2011 Page 6

3000A SERIES OPERATION MANUAL

Accuracy and Functionality

The 3000A Series calibrators are available in 3 accuracy grades, the 3010A basic

DC accuracy of 5ppm, the 3041A of 25ppm and the 3050A of 50ppm. The

appearance of the instruments is the same however the model type is indicated on

the front and rear panels and also shown on the display at switch on. The

calibrators are also available with reduced functions e.g. DC volts only etc.

True Multiproduct Calibration

From one instrument

Designed to provide an accurate cost effective portable instrument for the calibration

of multimeters, clamp meters, frequency meters, temperature meters, and

capacitance meters. Internal retro fit options allow the calibration of power meters,

oscilloscopes to 600MHz, inductance and LCR meters.

Designed for use in the laboratory or portable onsite calibration.

The 3000A series calibrator is suitable for use in the standards laboratory. The fast

warm up time combined with the small case and low weight make the 3000A series

calibrator also ideal for onsite calibration. The serial interface allows direct

connection to a PC/laptop.

Retro Fit Options

Allows additional functions to be added.

Several internal retro fit options including oscilloscope, power, inductance and PRT

allow the user to select the most cost effective solution for the calibration work with

the ability to add extra functions at a later date. External options for the calibration of

clamp meters, high accuracy thermocouple simulation with auto CJC (cold junction

compensation) built into the TC (thermocouple) connector, optical tachometers,

torque drivers etc. are also available via the front panel adapter interface.

TRANSMILLE LTD. Version 5.00: February 2011 Page 7

3000A SERIES OPERATION MANUAL

Serial Line RS232 Interface

Fitted as standard.

All functions and outputs of the series 3000A calibrator are fully programmable over

the RS232 interface. The use of the RS232 interface saves the cost of fitting GPIB

cards to the PC, and also allows easy connection to portable PC’s, reducing the set

up time for on-site calibration.

Output Connection

The output terminal configuration is designed to match the majority of multimeter

input connections, e.g. volts/ohms, low current and high current eliminating the need

for lead changing during calibration. All outputs are isolated when not in use and an

L.E.D. indicator shows the active output(s).

TRANSMILLE LTD. Version 5.00: February 2011 Page 8

3000A SERIES OPERATION MANUAL

Preparing The Calibrator For Use.

Initial inspection.

After shipment the calibrator should be inspected for any signs of external damage.

Should external damage be found contact the carrier immediately. Do not connect a

damaged instrument to the line power as this may result in internal damage. Please

retain the original packaging; this should be used when returning the calibrator for

service and recalibration.

Lifting and Carrying the Calibrator

The calibrator weighs 14.5kg with most of the weight at the right rear corner. The

calibrator can be carried by one person supporting the underneath (note: observe all

normal practices for health and safety when carrying). A custom carry case with

shoulder strap is available if the calibrator is to be regularly transported - see options

list. The calibrator should always be placed down on a firm flat surface on its base

feet. Avoid knocking or banging the calibrator and always place down smoothly.

Warning: DO NOT DROP THE CALIBRATOR

This may cause internal damage.

TRANSMILLE LTD. Version 5.00: February 2011 Page 9

3000A SERIES OPERATION MANUAL

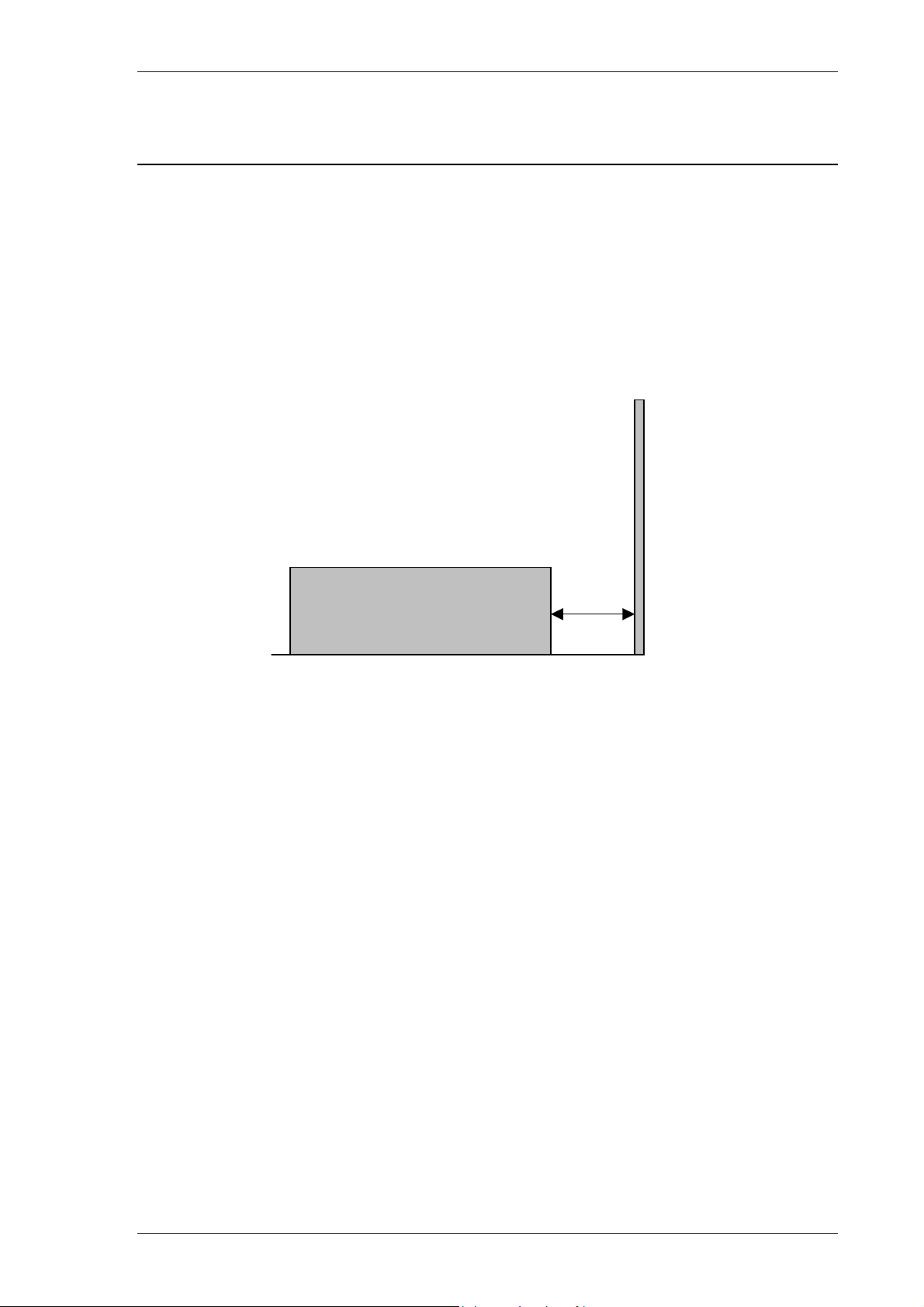

Positioning the Calibrator.

The calibrator can be used free standing on a bench or mounted in a standard 19”

rack enclosure. The calibrator can be operated at any angle; the two front feet have

tilt legs for bench operation. For all installations care must be taken not to cover the

ventilation slots underneath or block the fan. A 2” (5cm) space behind the instrument

is also required for line and interface connections.

Minimum 2” (5cm) Clearance

TRANSMILLE LTD. Version 5.00: February 2011 Page 10

3000A SERIES OPERATION MANUAL

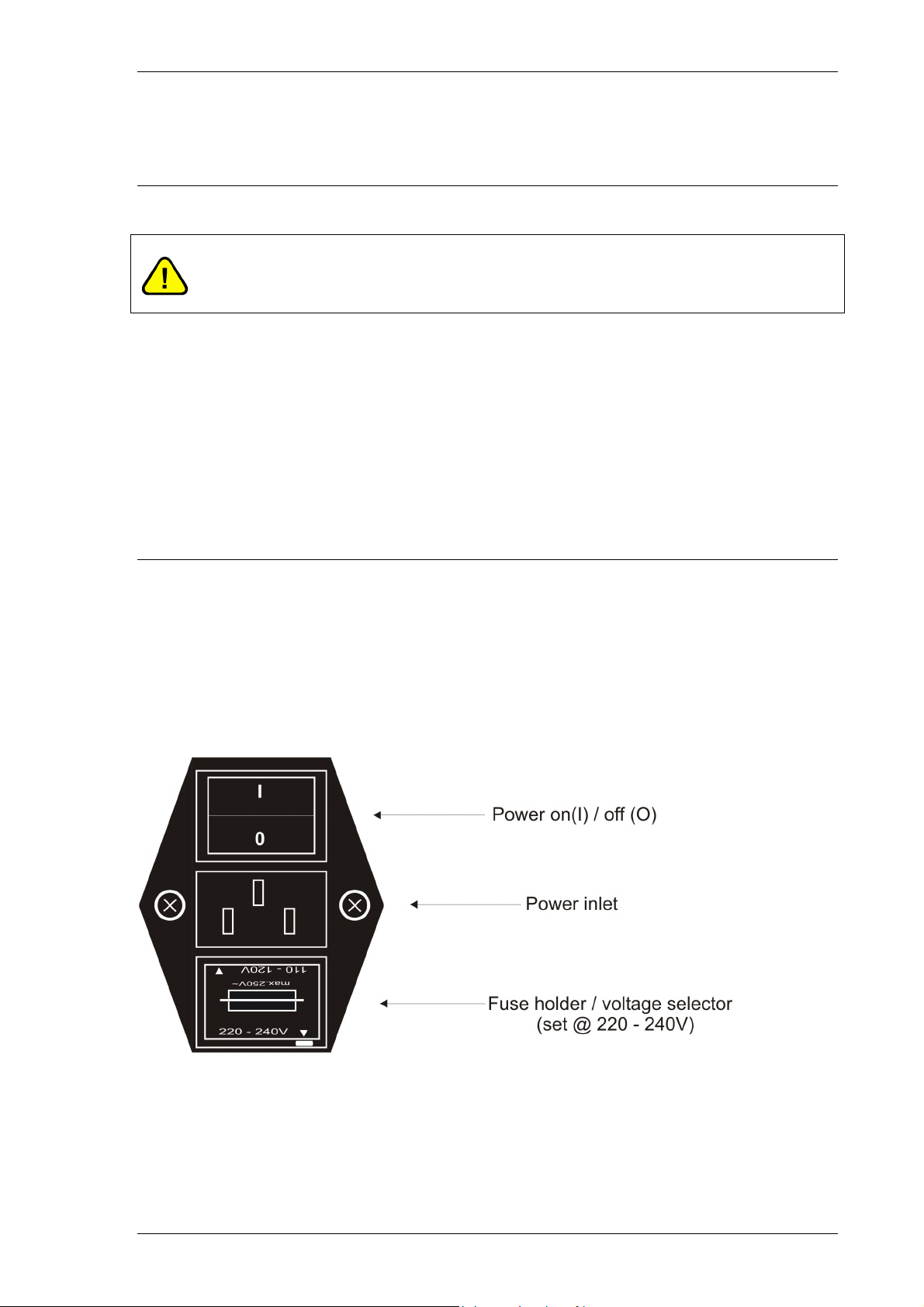

Rear Panel Connections and Controls

Connections on the rear panel are for Line Power via a 3 Pin IEC connector

incorporating the Line fuse and on-off switch; Note the mains inlet is filtered. A 9 Pin

Serial interface connector for the computer interface, this is optically isolated from

the calibrators output. On some models a third connector for the 10kV Extension

amplifier is also present.

Power

Switch

Cooling Fan Vent

(Keep Clear)

RS232 Connector

(COM Port)

Fuse Holder / Line Voltage Selector

Mains / Line Inlet

(IEC) Connector

TRANSMILLE LTD. Version 5.00: February 2011 Page 11

3000A SERIES OPERATION MANUAL

Setting and checking the Line Voltage.

Warning: The line power cord must have an earth

conductor to avoid risk of shock.

This instrument must be correctly earthed.

The calibrator has been designed to work from either 100-120 Volt line supply or

200 - 240 Volt line supply. Check that the voltage selector is set at the correct

voltage before connecting the power to the instrument. Connecting the calibrator to

the wrong supply will cause internal damage to the instrument. To change the line

voltage, remove the fuse / voltage selector housing, rotate through 180° and replace

with the required voltage setting at the bottom of the housing indicated by the arrow,

ensure that the correct fuse is fitted. The calibrator is set for 110V operation in the

USA, 230V operation in the UK and Europe.

Power Line Inlet Fuse and rating

The power line inlet fuse is located directly below the power inlet within the voltage

selector housing. The correct fuse rating is 3.15A anti-surge for 230V operation and

5A anti-surge for 110V operation.

TRANSMILLE LTD. Version 5.00: February 2011 Page 12

3000A SERIES OPERATION MANUAL

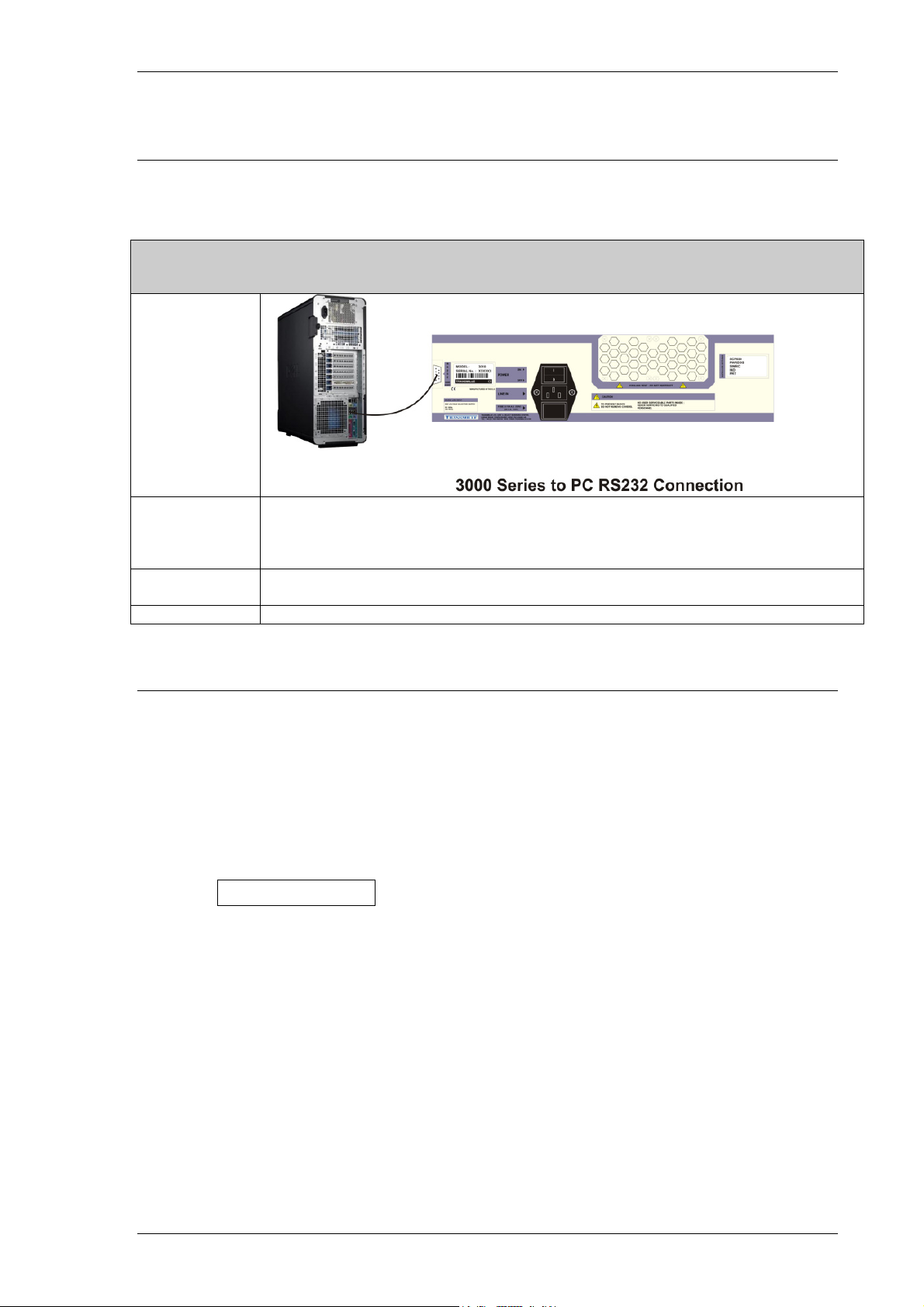

Connecting to a computer

A standard serial 9 pin cable (supplied) should be used to connect the calibrator to a

COM port on the PC. A Null modem cable is not needed.

RS232 Interface

Connection

Configuration

Cable Type Male to Female Serial Cable

Driver N/A

BAUD RATE : 9600

PARITY : NONE

DATA BITS : 8

STOP BITS : 1

Straight Though Pin Connection (Not Null MODEM)

Powering up the calibrator

After connecting line power, the calibrator can be switched on with the line power

switch above the mains inlet socket on the rear panel.

The fan will start and the front panel display will illuminate indicating power. The

display will show a firmware version number and after a short delay, during which

time the processor performs a self-test of the instrument, the display will show an

output of 0.00000mV DC. Allow the calibrator to warm up for 30 minutes to

obtain full accuracy; the fast start feature of the calibrator will give approx. 90% of

full specifications within 10 minutes. The calibrator has been designed to be

powered up continuously, automatically switching to a standby mode after a pre-set

period of time from the last command. In standby mode the display back light will

turn off.

The control program can now be started on the computer, the program will establish

communication with the calibrator at which time the calibrator will download the

values of the internal standards.

TRANSMILLE LTD. Version 5.00: February 2011 Page 13

3000A SERIES OPERATION MANUAL

Output Connections

Warning: Risk of shock.

High voltages may be present on the output sockets.

Output sockets are all 4mm safety type, the voltage pair contacts are low thermal

gold plated for minimum thermal EMF.

The 3000A series calibrator’s outputs have been designed to allow most multimeters

to be calibrated without changing connections. There are 3 separate pairs of

outputs:

1) Voltage, Resistance, Capacitance, Frequency & Inductance

2) Current and 4 Wire Resistance

3) High 30A Current.

When an output terminal pair is not active they are completely open circuit and

isolated from the other outputs. As only one pair is active at a time on (except on 4

wire ohms) they may be combined together if required to match the meters input

arrangement.

One example is the configuration of multimeters inputs with a single common low

and inputs with voltage, low and high current. To match this to the calibrator, simply

connect the 3 low outputs of the calibrator together and connect the voltage, low &

high current outputs to the appropriate meters inputs. Note that when outputting

resistance, the calibrator will use the voltage output terminals.

TRANSMILLE LTD. Version 5.00: February 2011 Page 14

3000A SERIES OPERATION MANUAL

A second example is where the meter has separate voltage and current inputs, often

using four wire ohms on both pairs. In this case simply connect the voltage and

current outputs to the meter’s inputs, the calibrator will use both the voltage and

current pair on 4 wire ohms.

It is recommended that the voltage and low current leads be high quality screened

cable with gold plated 4mm plugs fitted. The cable must be able to withstand 1025

volts AC and have an insulation resistance greater than 1TΩ to avoid introducing

any shunting effect on the high resistance ranges.

Poor quality test leads will introduce noise, thermal e.m.f. and leakage errors on low

voltage & current ranges and also unstable readings on resistance and capacitance

outputs (see measurement techniques). Special test leads are available from

Transmille, see accessories.

Warning: Under no circumstances should any voltage

be connected to the calibrator outputs

The low output can be connected to line earth or allowed to float as selected - see

operation section of this manual. It is recommended that the low is earthed which

will help to reduce noise on high ohms and low current. If allowed to float with

respect to line earth the low must remain within 50 volts of line earth. Outputs are

optically isolated from the RS232 interface

Output Overloads

If the calibrator is unable to drive the load then the output will be turned off and the

calibrator returned to standby mode. The message Standby will be displayed on

the front panel. The output will be automatically reset on setting the output again.

TRANSMILLE LTD. Version 5.00: February 2011 Page 15

3000A SERIES OPERATION MANUAL

Operation

Safety Warnings

WARNING: The information in this section is intended only

for qualified personnel. The user must at all times be

adequately protected from electric shock. Qualified

personnel must ensure that operators of the equipment are

adequately insulated from connection points.

WARNING: This instrument is capable of generating both

DC and AC high voltages.

A soft carry-case and a hard transit case are available for

regular transportation of the calibrator.

Introduction to Operation

All functions of the 3000A Series Calibrator can be controlled from the front panel, or

controlled remotely by a computer over the interface. The front panel controls are

‘locked out’, but local control may be resumed by selecting a soft key - it must be

remembered that this action may disrupt the computer program.

TRANSMILLE LTD. Version 5.00: February 2011 Page 16

3000A SERIES OPERATION MANUAL

Front Panel Controls and Indicators

Active

Terminal

LEDs

LCD Display with

integral Backlight

Safety Output

Terminals

Standby Button

Output On Button

Numeric Keypad

Menu buttons

(Soft Keys)

Adapter Interface

Digital Control

Multiplier Keys

Function Keys

Front Panel Keyboard

The front panel of the 3000A Series Calibrator utilises a high quality custom rubber

keyboard with tactile feel buttons and integral display window. The front panel is

therefore sealed against the ingress of moisture and dirt enabling the calibrator to be

used in most working environments without risk of early failure of the operating

buttons. The front panel can easily be wiped clean with a soft cloth. Care should be

taken not scratch the display window. All graphics are ‘under printed’ making them

rugged and durable.

IMPORTANT NOTE

The front panel key buttons are for use with fingers only - do not press

the key with hard or sharp objects e.g. Ball-point pens, pencils,

screwdrivers etc. Repeated actions like this will almost certainly cause

the keyboard to fail. (This will not be covered under warranty). Care

should also be taken when transporting the instrument, do not place

test leads or other objects on top of the panel which may come into

contact with the display area and cause damage.

TRANSMILLE LTD. Version 5.00: February 2011 Page 17

3000A SERIES OPERATION MANUAL

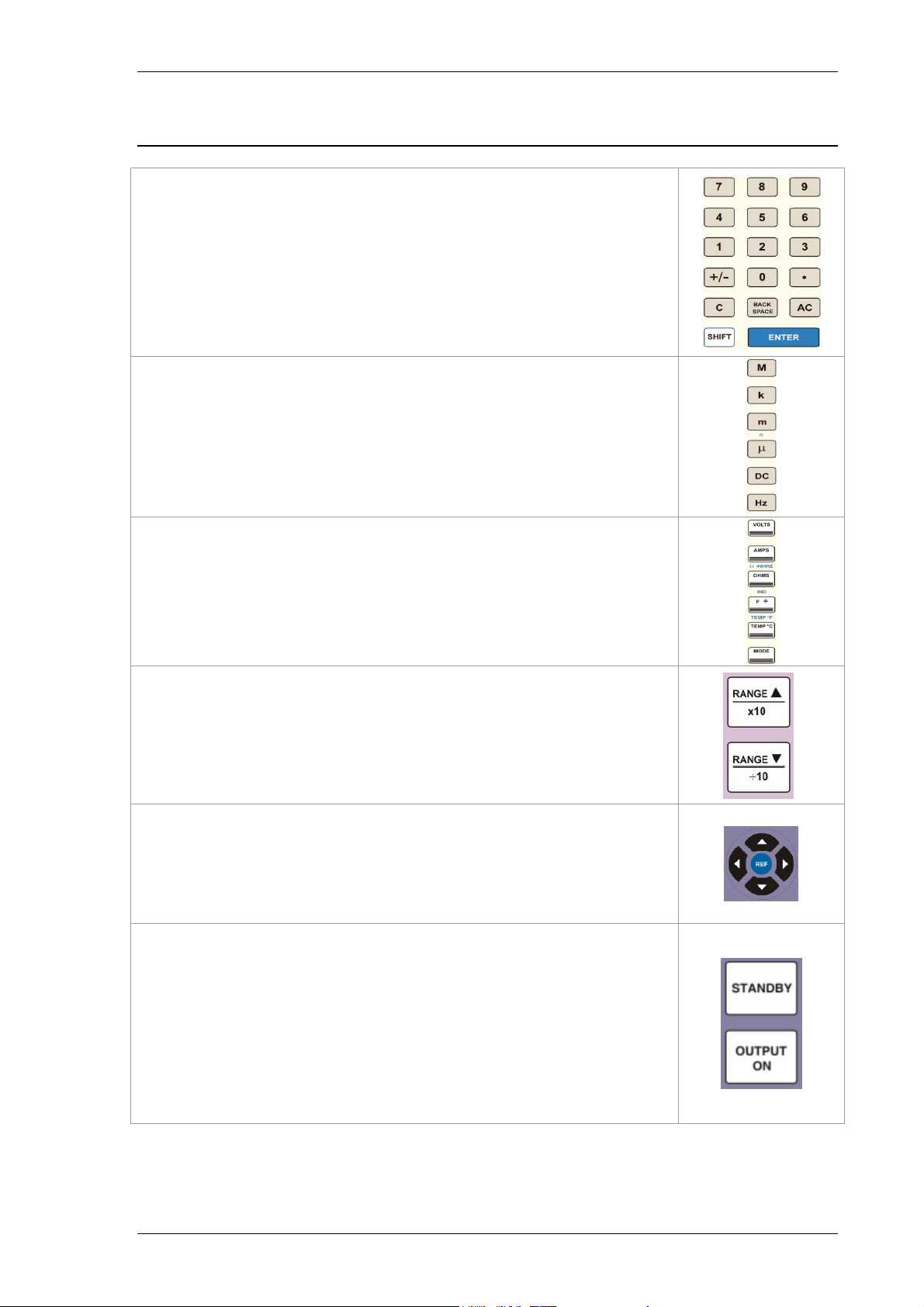

Front Panel Keyboard – Control Sections

The Keyboard is divided into sections to allow easy operation.

Numeric section

Allows numeric values to be entered

Multiplier section

Mega (M), kilo (k), milli (m), micro(u) or nano (n)

Function section

Volts (V), Amps(A), Ohms (2 & 4 Wire),

Farads(F), Celsius(C), & Frequency(Hz)

Range Up / Range Down

Allow the output to be multiplied / divided by 10.

Left / Right / Up / Down Arrow Keys

To select the digit to be controlled by the rotary control.

Output On / Standby keys

Allow the calibrators output to be disconnected from the

terminals. LED indicators are incorporated in these switches to

clearly show the output status.

TRANSMILLE LTD. Version 5.00: February 2011 Page 18

3000A SERIES OPERATION MANUAL

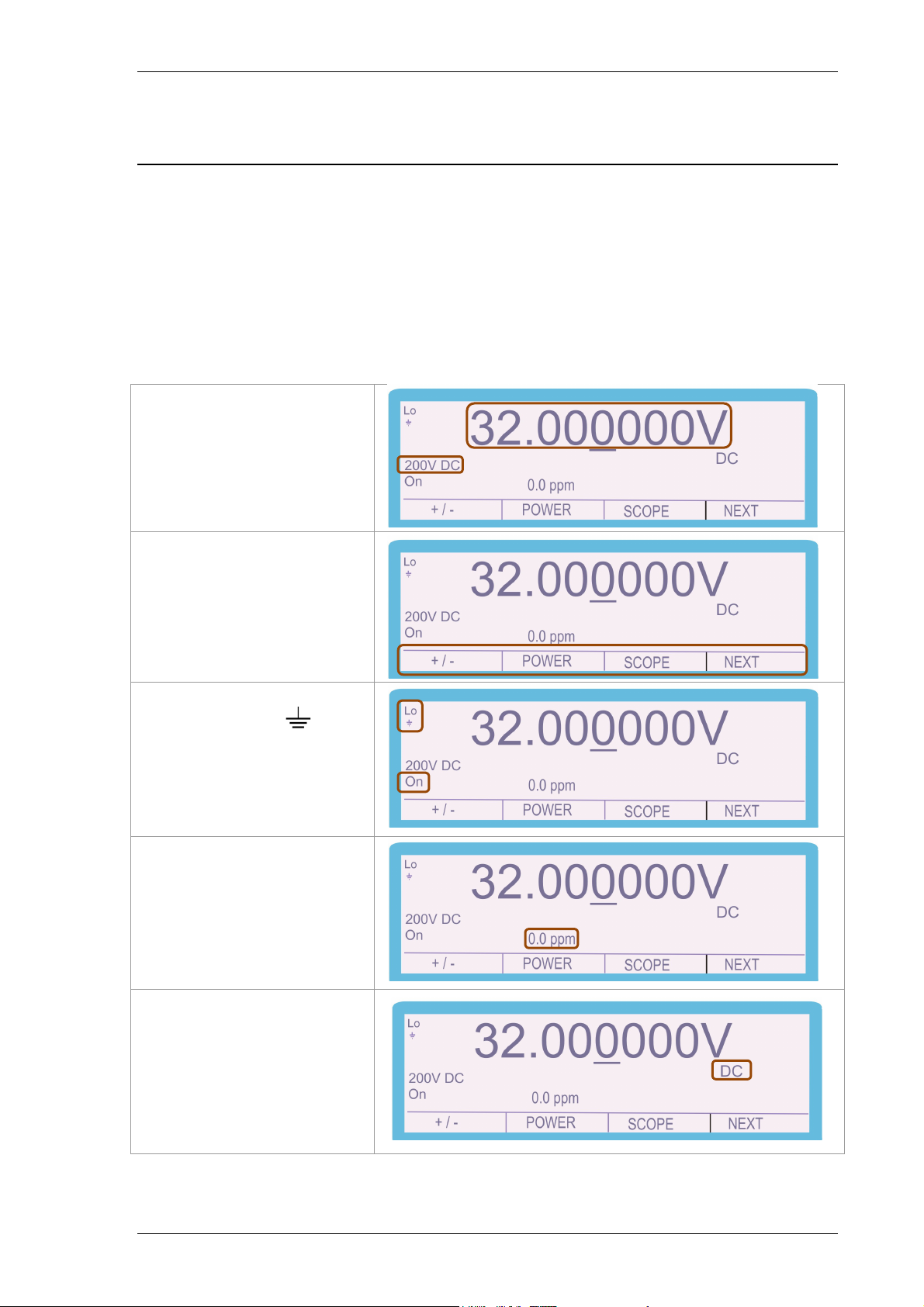

Graphic LCD Display

The graphic backlit LCD display shows the present output, instrument status, % or

ppm change from the entered value, and also the new value being entered. The

bottom portion of the display is used to assign the function of the four ‘soft (menu)

keys’. The display utilises a back light which automatically turns off if no activity

occurs either from the front panel keys or via a remote command.

Output Value &

Range

Dynamic

Soft key Menu

Lo to

Output On / Standby

Indicators

Deviation (ppm)

Function Specific

Configuration

Display

TRANSMILLE LTD. Version 5.00: February 2011 Page 19

3000A SERIES OPERATION MANUAL

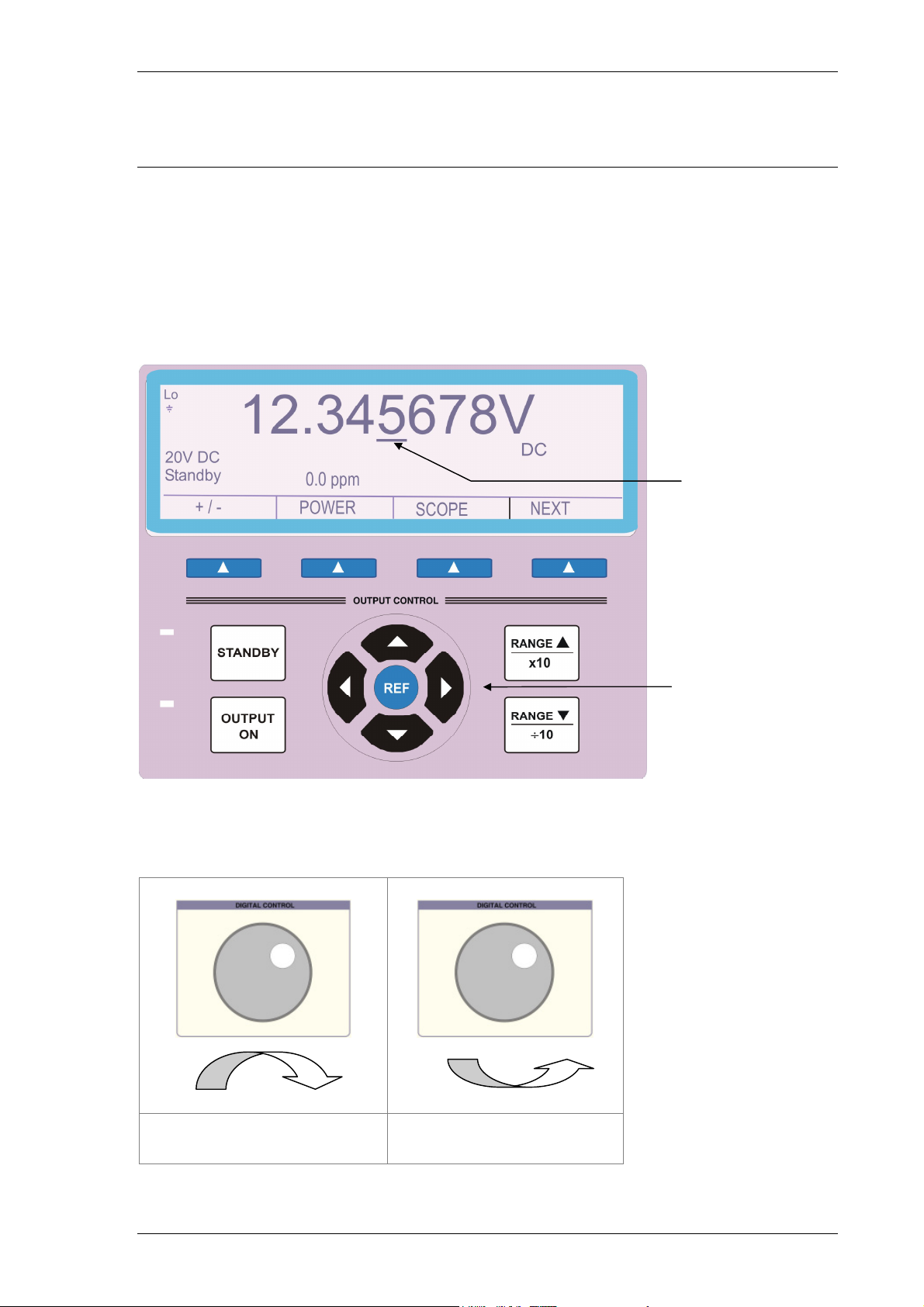

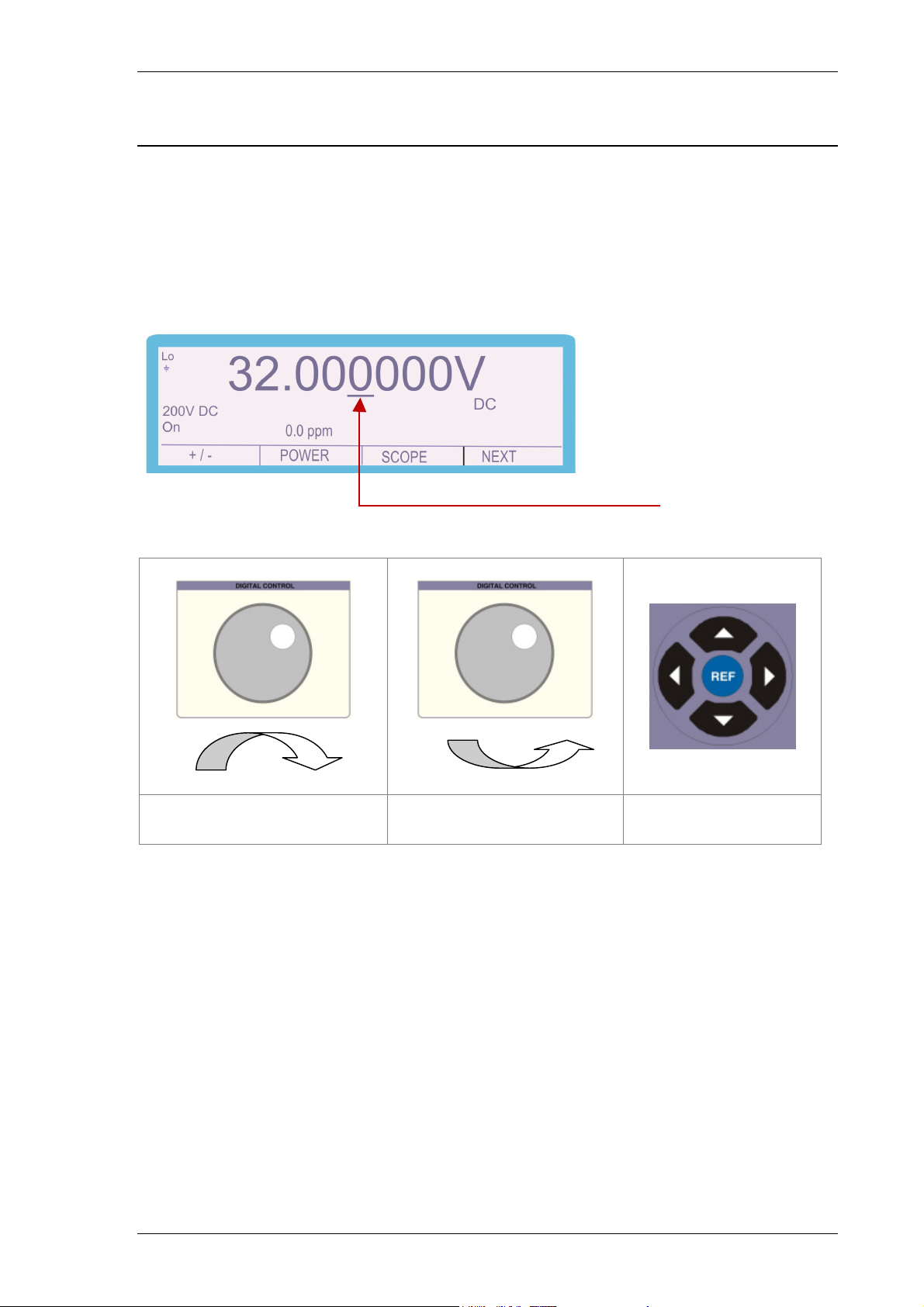

Digital Control

A digital potentiometer allows the ‘highlighted digit’ on the display to be incremented

(turning clockwise) or decrement (turning anti-clockwise). As an output is changed

the deviation from the original value entered on the keyboard is shown in either % or

ppm.

Selected digit marker.

Cursor Keys can be used to

move the position of the

digit marker, and increment /

decrement the digit.

Clockwise Rotation

(Increment Digit)

Anti-Clockwise Rotation

(Decrement Digit)

TRANSMILLE LTD. Version 5.00: February 2011 Page 20

3000A SERIES OPERATION MANUAL

Terminal status LED’s

LED’s above the terminals indicate which pair is active. When terminals are not

active they are electrically isolated from each other, this enables terminals to be

linked together if required.

Active terminals

indicated by

illuminated LED

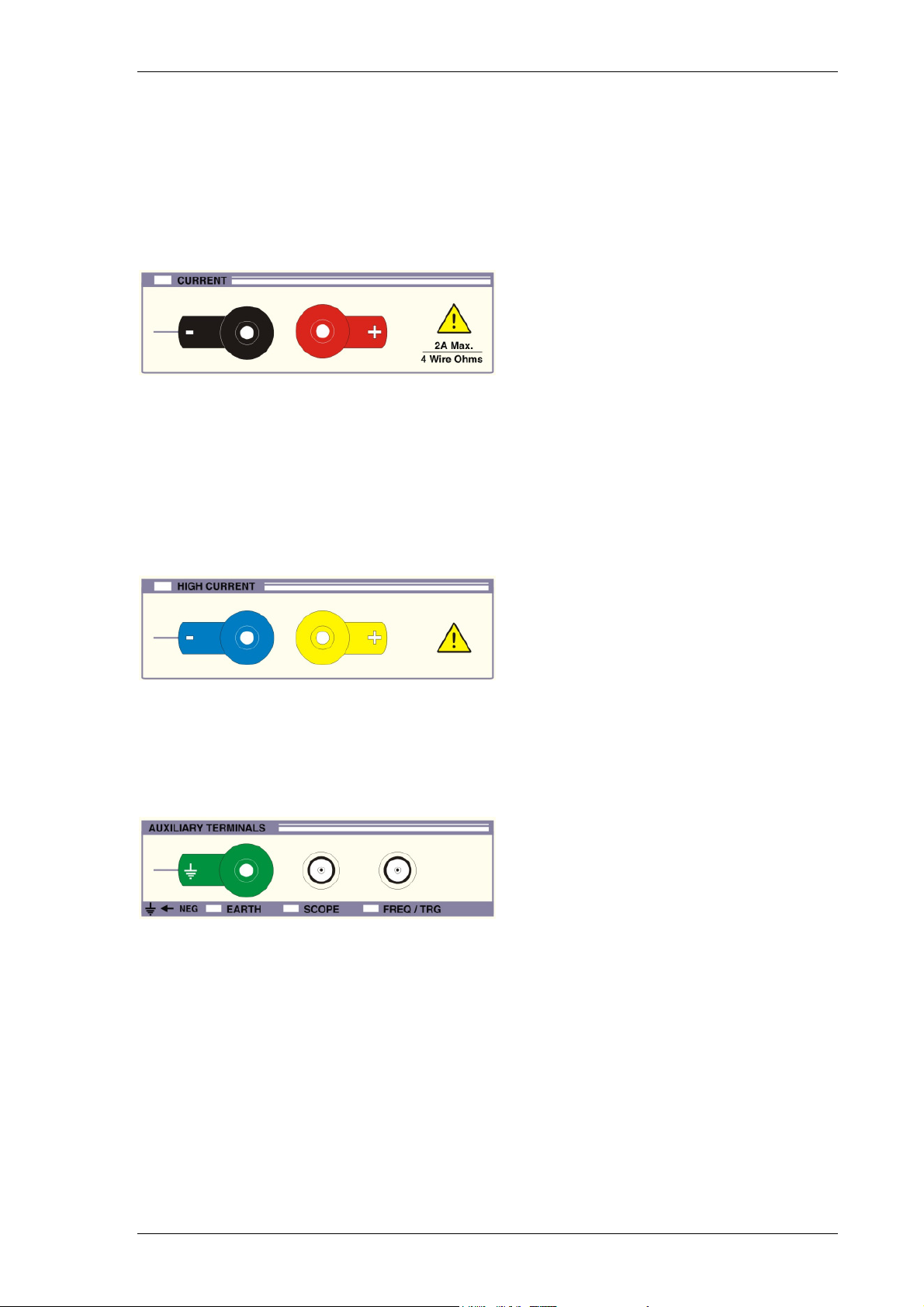

Voltage Output Terminal Pair (Black & White)

WARNING:

Dangerous voltage may be present on these terminals.

Low thermal 4mm safety terminals

Used for all voltage outputs up to 1025V, for 2 wire/4 wire resistance, capacitance

and inductance (optional). Note the low ‘black’ terminal can be internally switched to

line earth by a soft key function. When floating, the maximum voltage on this

terminal with respect to ground should not exceed 50 Volts peak.

TRANSMILLE LTD. Version 5.00: February 2011 Page 21

3000A SERIES OPERATION MANUAL

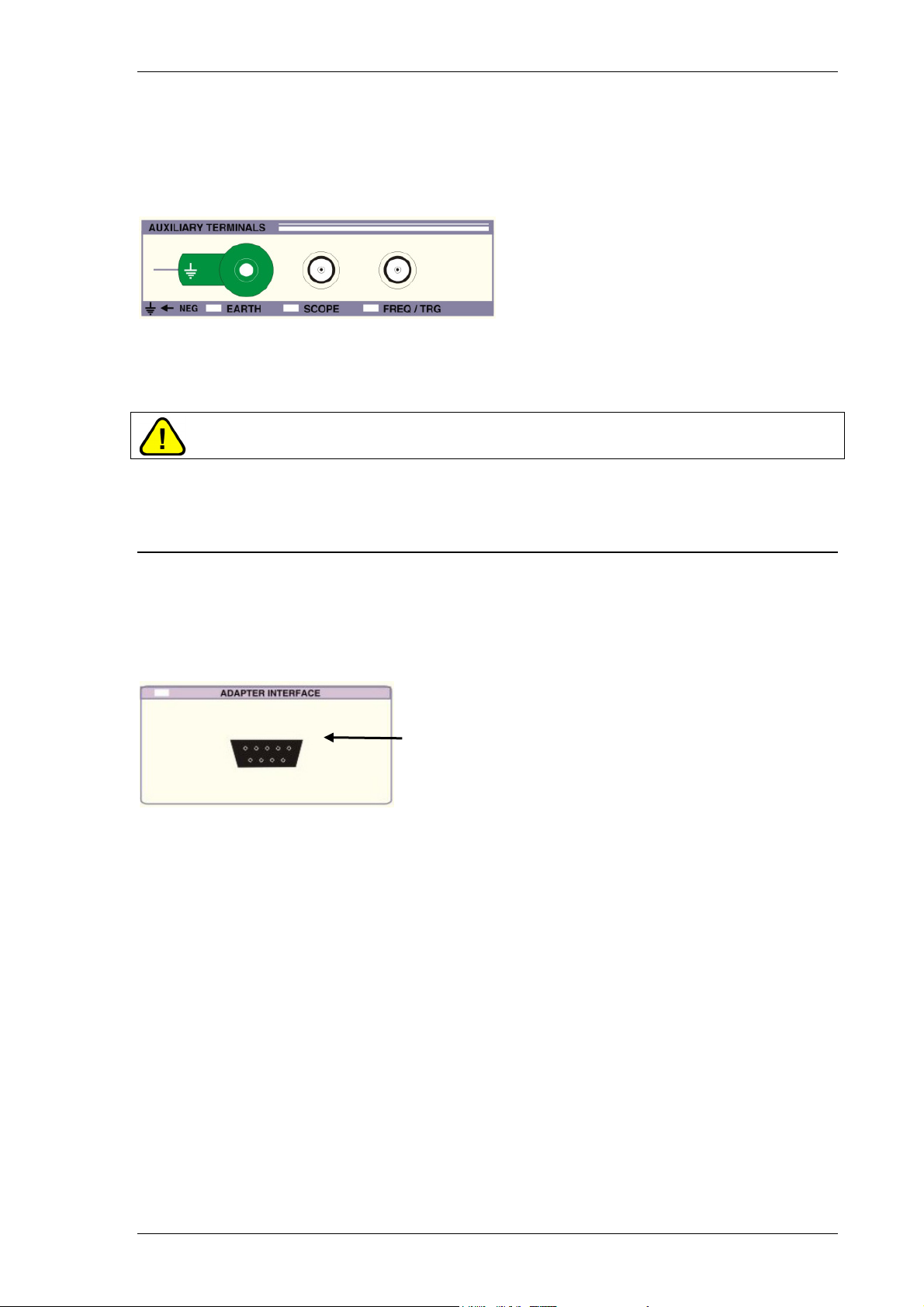

Current Output Terminals (Black & Red)

4mm safety terminals for all current outputs up to 2 Amps, TTL frequency and for

sense connection for 4 wire resistance.

Note the low ‘black’ terminal can be internally switched to line earth by a soft key

function. When floating, the maximum voltage on this terminal with respect to

ground should not exceed 50 Volts peak

30 Amps Output Terminals (Blue and Yellow)

4mm Safety terminals used for all currents above 2 Amps.

Earth Terminal (Green)

Connected directly to line earth and case. Incorporates green LED indication of

negative to earth (grounded or floating) selection

TRANSMILLE LTD. Version 5.00: February 2011 Page 22

3000A SERIES OPERATION MANUAL

Scope & Freq/Trg BNC Connector Outputs

Isolated BNC sockets for frequency and oscilloscope function outputs. They

incorporate a green LED indicator to show when the terminal is active.

WARNING:

Dangerous voltages up to 400V may be present on these terminals.

9 Pin Adapter Interface Connector.

Used for connection to external pods used for extending calibration capability, e.g.

Thermocouple simulation etc.

Adapter Interface 9 Way ‘D’ type

connector (Female)

Incorporates a green LED to indicate when the adapter interface is active.

The pins connections are as follows:

Pin 1 – +15V

Pin 2 – Digital ground

Pin 3 – Strobe

Pin 4 – Data

Pin 5 – Select

Pin 6 – -15V

Pin 7 – Analogue ground

Pin 8 – Output

Pin 9 – Input

TRANSMILLE LTD. Version 5.00: February 2011 Page 23

3000A SERIES OPERATION MANUAL

Setting DC Voltage and Current Output

Complete the following procedure to set a dc voltage or current output.

Use the and (clear) keys to edit the entry.

1) Press

2) Press the numeric and decimal point keys to enter the required value, e.g. 12.345

3) Press the multiplier key (if required), e.g.

4) Press the function key e.g.

5) Press

6) Press to activate the calibrator output.

Key Digits

12.345

Press ‘m’

Multiplier

Press

Function Key

Select

Output On

The calibrator will now produce 12.345 mA D.C. at the appropriate terminals.

Once on a range, any new output within that range can be set without the calibrator

returning to standby. When a high voltage or high current values are entered the

calibrator will automatically go into standby mode. To output the voltage or current,

press the key. This safety feature stops the accidental selection of high

voltage or current.

TRANSMILLE LTD. Version 5.00: February 2011 Page 24

3000A SERIES OPERATION MANUAL

Adjusting the set output using the digital control

After the output has been set, any digit of the output display can be incremented or

decremented using either the digital control or the up and down arrow keys. The

digit selected is indicated by the cursor and can be changed by using the left and

right arrow keys.

Highlighted digit

Clockwise Rotation

(Increment Digit)

Anti-Clockwise Rotation

(Decrement Digit)

Up / Down

Cursor Buttons

TRANSMILLE LTD. Version 5.00: February 2011 Page 25

3000A SERIES OPERATION MANUAL

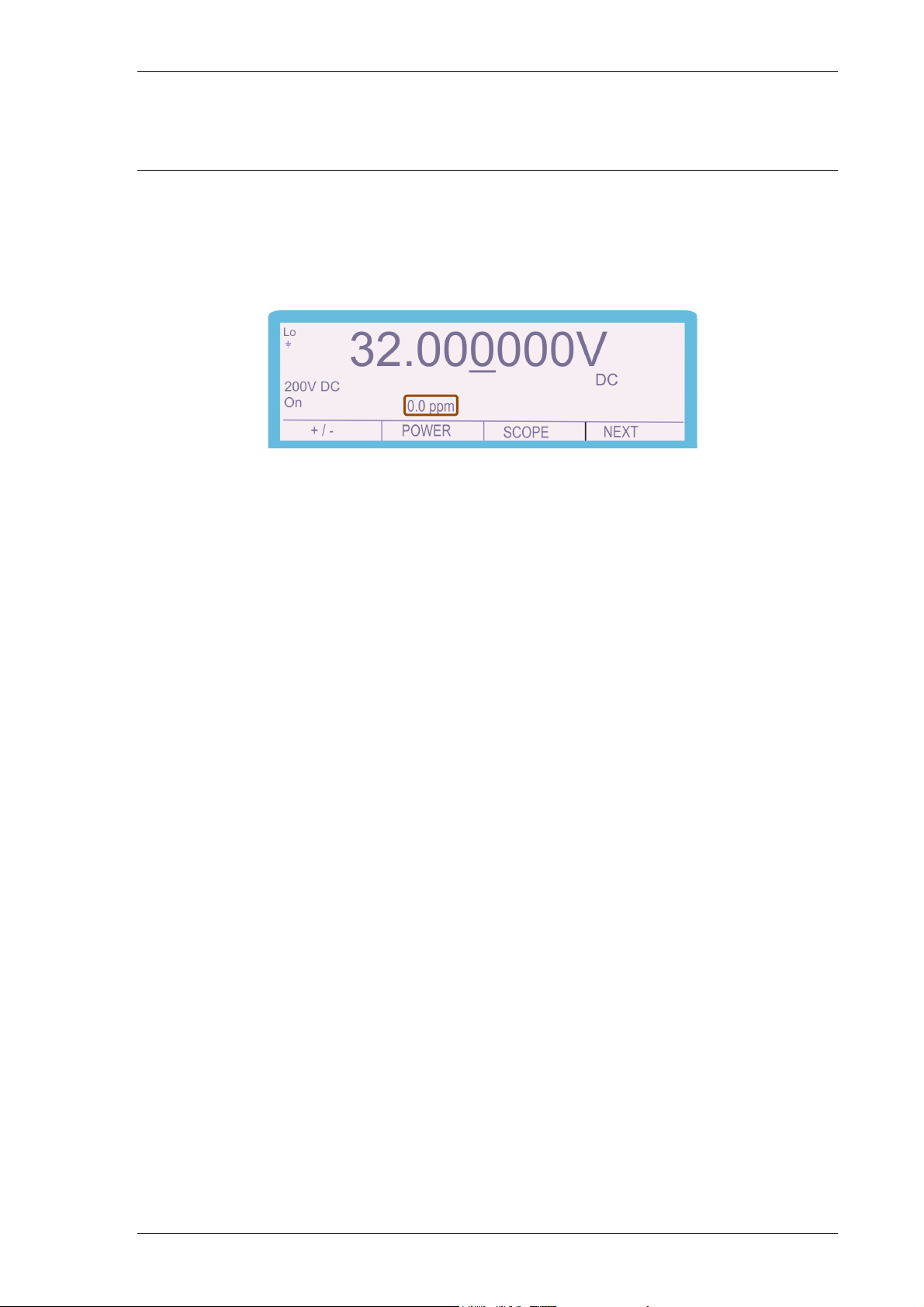

Automatic Display of % or ppm Error and Ref. Key

When the output value is changed by the methods above, the display will show the

change in ppm or % from the original reference value entered from the keyboard. If

needed, the reference value can be reset to the present value on the display by the

REF key.

This feature is ideal for displaying the error in a meter under test by adjusting the

output from the calibrator to make the meter read the nominal value.

TRANSMILLE LTD. Version 5.00: February 2011 Page 26

3000A SERIES OPERATION MANUAL

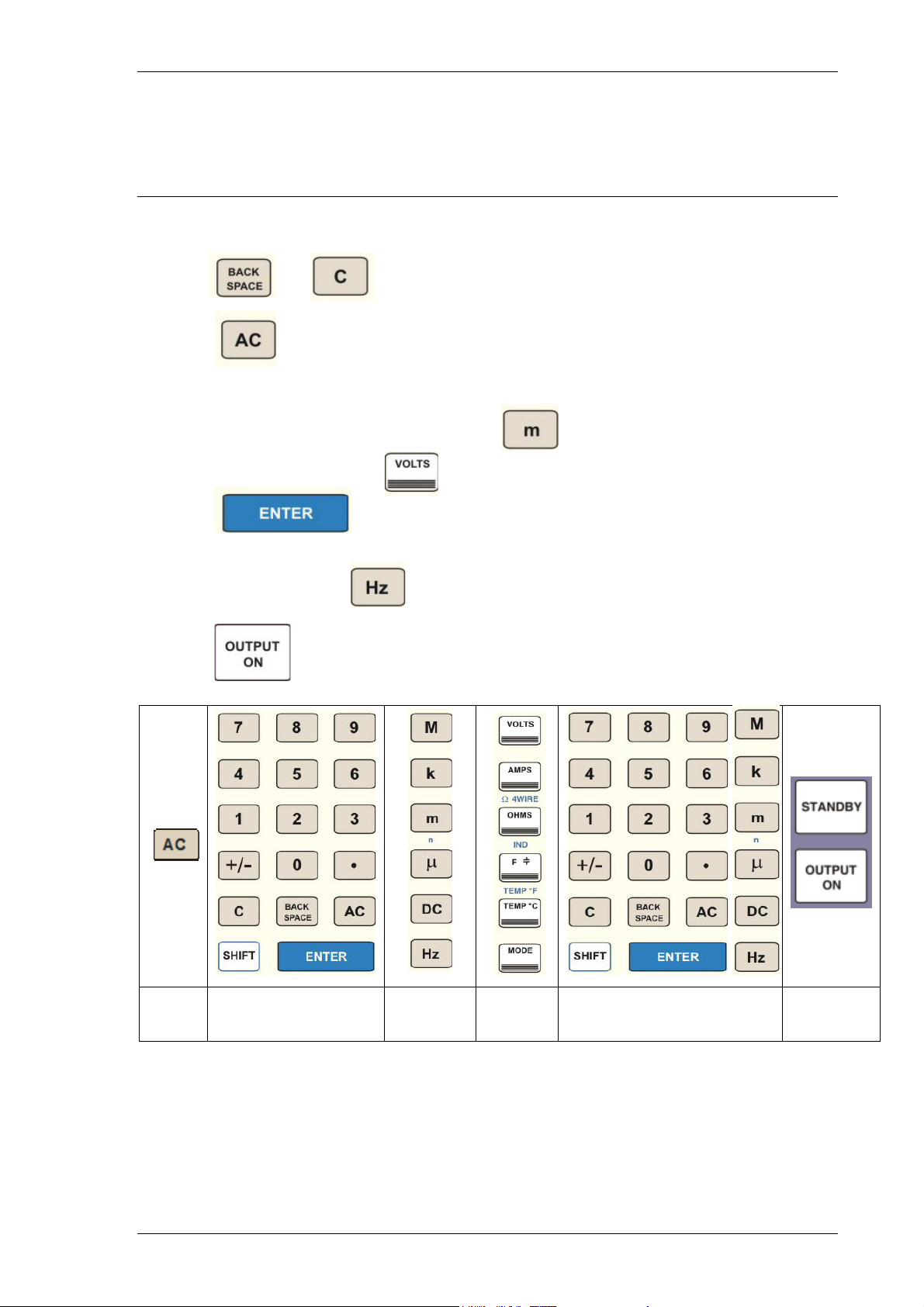

Setting AC Voltage and Current Output.

Complete the following procedure to set an ac voltage or current output.

Use the and (clear) keys to edit the entry.

1) Press

2) Press the numeric and decimal point keys to enter the required value, e.g. 16.789

3) Press the multiplier key (if required), e.g.

4) Press the function key e.g.

5) Press

6) Press the numeric and decimal point keys to enter the frequency value, e.g. 1000

7) Press the function key

8) Press to activate the calibrator output.

Select

AC

Key in Voltage /

Current Value

Select

Multiplier

Select

Function

Set Frequency Followed by

Hz Key

Select

Output On

The display will show the frequency in the bottom right hand corner of the display.

For safety, AC/DC changes will maintain the set output value; the output will switch

off and then back on again. The frequency can be adjusted using the digital control.

TRANSMILLE LTD. Version 5.00: February 2011 Page 27

3000A SERIES OPERATION MANUAL

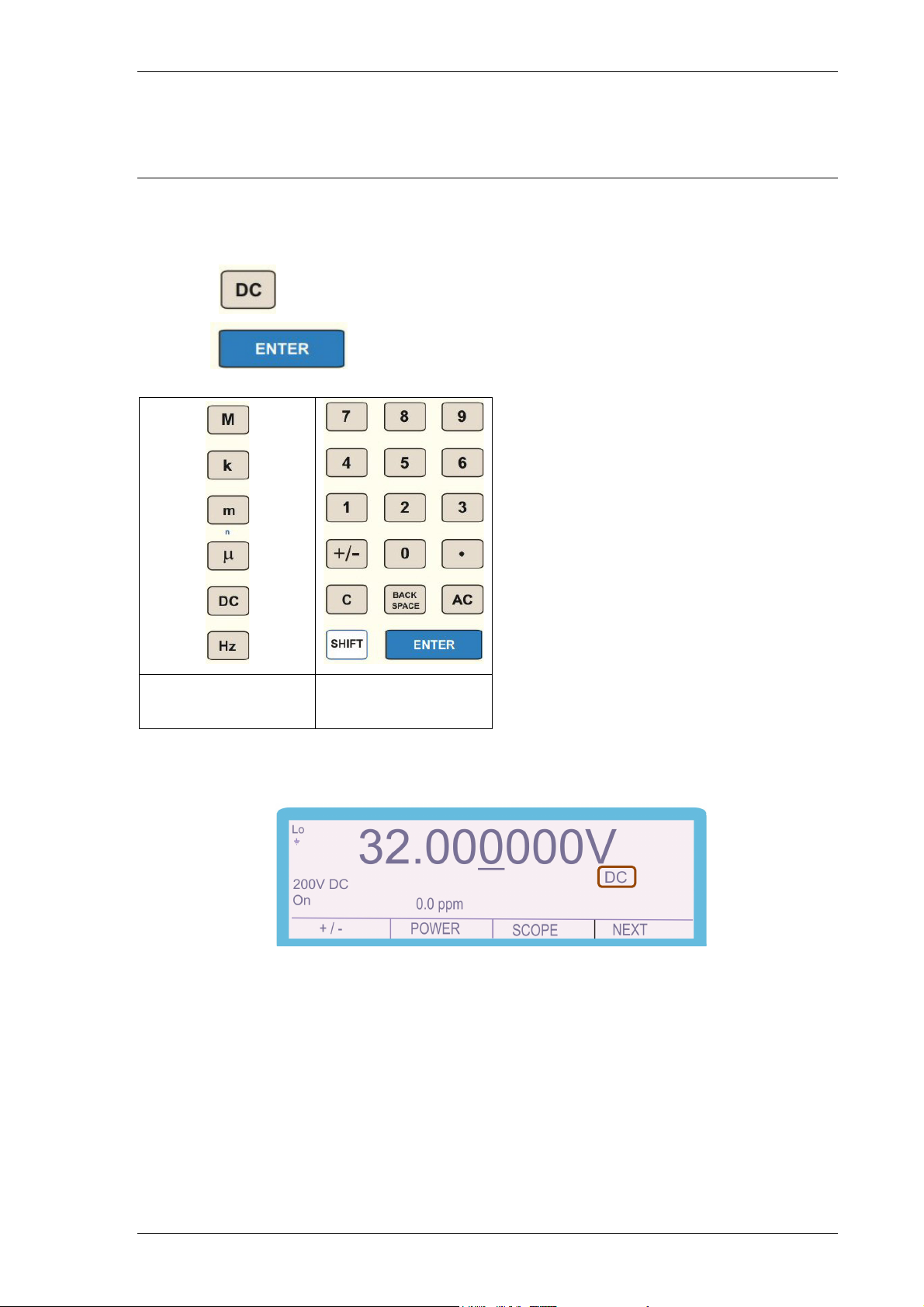

Returning the calibrator to DC

Complete the following procedure to return the output to DC:

1: Press

2: Press

Select DC

Key

Press

Enter

The display will indicate DC as shown above. The voltage or current setting will

remain as the previous setting.

TRANSMILLE LTD. Version 5.00: February 2011 Page 28

3000A SERIES OPERATION MANUAL

Setting 2 Wire Resistance Output.

Note: The calibrator uses standard resistors of fixed decade values. The nearest

available resistance to the entered value will be automatically selected. Complete

the following procedure to select 100kΩ in 2 wire mode.

1) Press the numeric keys to enter the required value, e.g. 100

2) Press the multiplier key (if required), e.g.

3) Press the function key e.g.

4) Press

5) Press

Key in

Resistance Value

Select

Multiplier

Select

Function

Press

Enter

Select

Output On

The resistance displayed will be the calibrated value held in the non-volatile

calibration memory for that standard. Note the values are different for two and four

wire ohms.

Nulling DMM

The calibrated values displayed for 2 wire ohms are the values present at the

terminals. Therefore the measuring instrument should be zeroed (Nulled) with the

leads shorted before connection to the calibrator.

TRANSMILLE LTD. Version 5.00: February 2011 Page 29

3000A SERIES OPERATION MANUAL

2 Wire Ohms Operation

Two wire ohms is output on the voltage terminals as indicated by the terminal LED’s.

2 Wire Ohms Connection

Connect the measuring instrument 2-Wire input to the calibrator

2-Wire resistance output.

Use shielded connection cables – 50 Ohm co-axial recommended

Connect Guard / Earth if required – see notes

Select 2 Wire resistance measurement mode on meter

TRANSMILLE LTD. Version 5.00: February 2011 Page 30

Loading...

Loading...