Page 1

WSHP-DS-6

WSHP-DS-6

March 2000

Water Source

Heat Pump

Water-to-Water

Model WPWD

Page 2

Introduction

The WPWD product is a heating

and cooling hydronic fluid water-towater heat pump capable of producing water temperature up to

F or temperatures down to

130

25 F. This extended operating

range offers great opportunities in

commercial, residential and industrial applications.

There are many load side applications for which the WPWD is suited.

Typical usages include:

q Hydronic baseboard heating

q Radiant slab heating

q Space heating or cooling with

Trane fan coils

q Ice and snow removal

q High volume water heating (non

potable)

q Boiler replacement (@130

F)

In the heating mode, the water-towater unit efficiently extracts heat

from a water source (source side)

such as a well, lake, boiler/tower

loop or closed ground loop heat-exchanger, then transfers the heat to

another flow of water (load side).

The amount of heat added to the

load side is greater than the

amount taken from the source side.

The electrical energy supplied to

the compressor is added to the output heat of compression.

The Trane water-to-water product

package includes:

q High efficient scroll compressor

q Compressor protection

q Water to refrigerant condensing

coil

q Freeze protection

q Water to refrigerant evaporator

coil

q Expansion valve

q Filter Drier

q Reversing Valve

q Internal desuperheater

(optional)

©An American Standard Company

2

Page 3

Table

of

Contents

Introduction 2

Features and Benefits 4

Model Number Description 7

General Data 8

Application Considerations 9

Electrical Data 18

Performance Data 19

Dimensional Data 25

Wiring Diagram 28

Accessory Options 30

Mechanical Specifications 31

3

Page 4

Features

and

Benefits

General

General

The water source heat pump model

WPWD (water-to-water) offers a

range of capacities from 2 tons to 6

tons. All units are housed in one

standard compact cabinet.

Cabinet

The cabinet, which allows easy access for installation and service, is

constructed of heavy gauge metal.

The cabinet finish is produced by a

corrosion resistant electrostatic

powder paint coating in the color

“soft dove”.

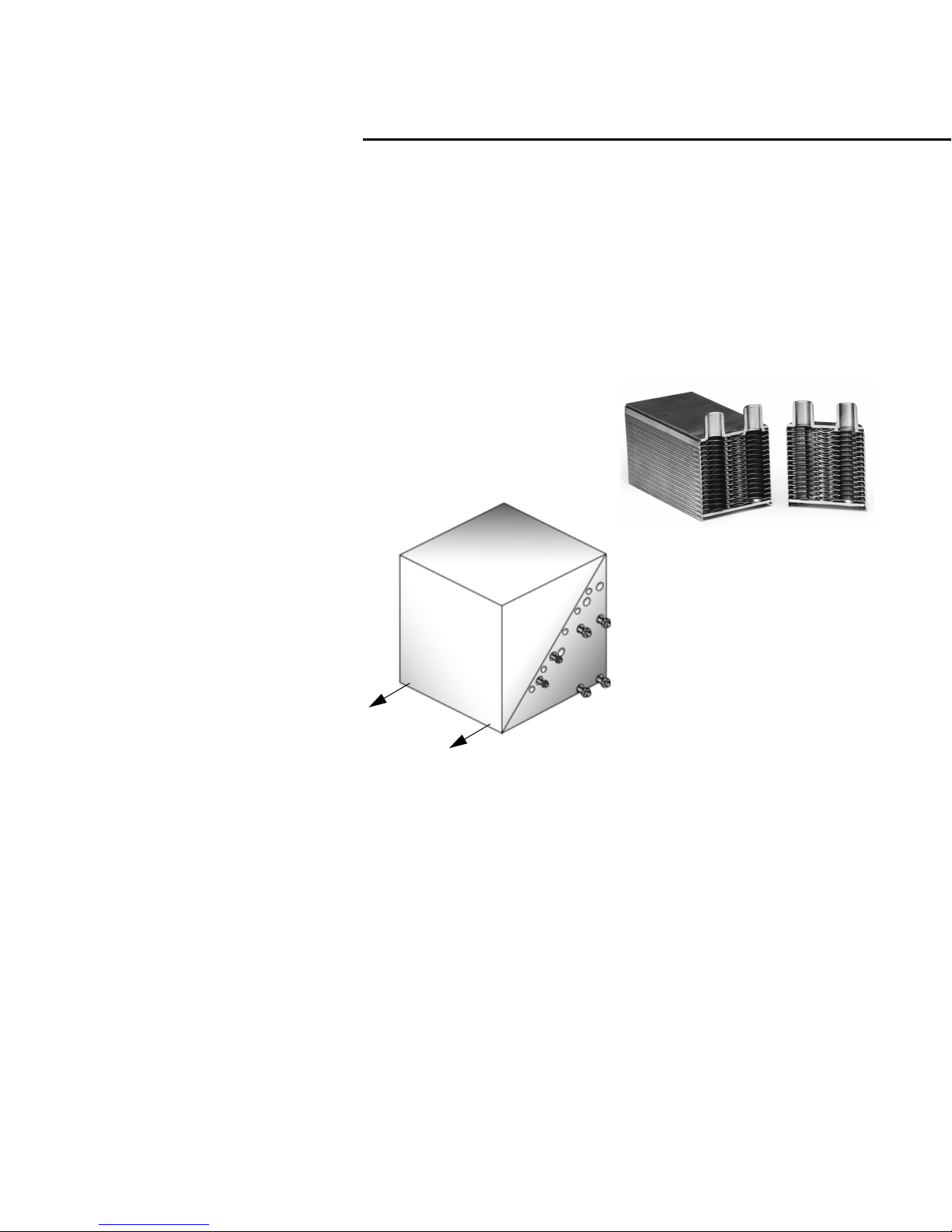

The top half of the diagonal cabinet

is removable for access to the internal components by removing two

screws. (See Figure 1).

Figure 1: Unit access

Insulation

To reduce condensation and compressor noise, the cabinets are insulated with 1/2-inch thick,

neoprene backed, acoustical fiberglass insulation.

Compressor

The model WPWD contains a high

efficiency scroll compressor for reliable and efficient operation. The

scroll compressor’s unique design

lends itself to having one of the lowest sound levels in the industry.

The compressor is internally isolated and placed on a stiff base plate

designed to further reduce vibration

noise. As an added benefit, the

WPWD cabinet includes full length

channel stiffeners underneath the

unit.

Heat Exchanger

The water to refrigerant heat exchangers are made of stainless

steel brazed plate. This design provides a larger amount of surface

area for heat exchange between

the water and the refrigerant. (See

Figure 2 for cut-away).

.

Figure 2: Brazed plate heat exchanger

Piping

All low-side copper tubing in the refrigeration circuit is insulated to prevent condensation at low entering

liquid temperatures.

Filter Drier

A filter drier is provided in each unit

for dehydration and cleaning of the

refrigeration circuit. This feature

adds to the unit life.

Expansion Valve

As standard, Trane provides a balanced port thermal expansion

valve. This valve precisely meters

the refrigerant flow through the circuitry to achieve the desired heating or cooling over a wide range of

fluid temperatures.

Water Connections

All water connections feature

1-inch brass swivel connectors. Because the connectors are swivel, a

back-up wrench is not necessary

when tightening.

4

Page 5

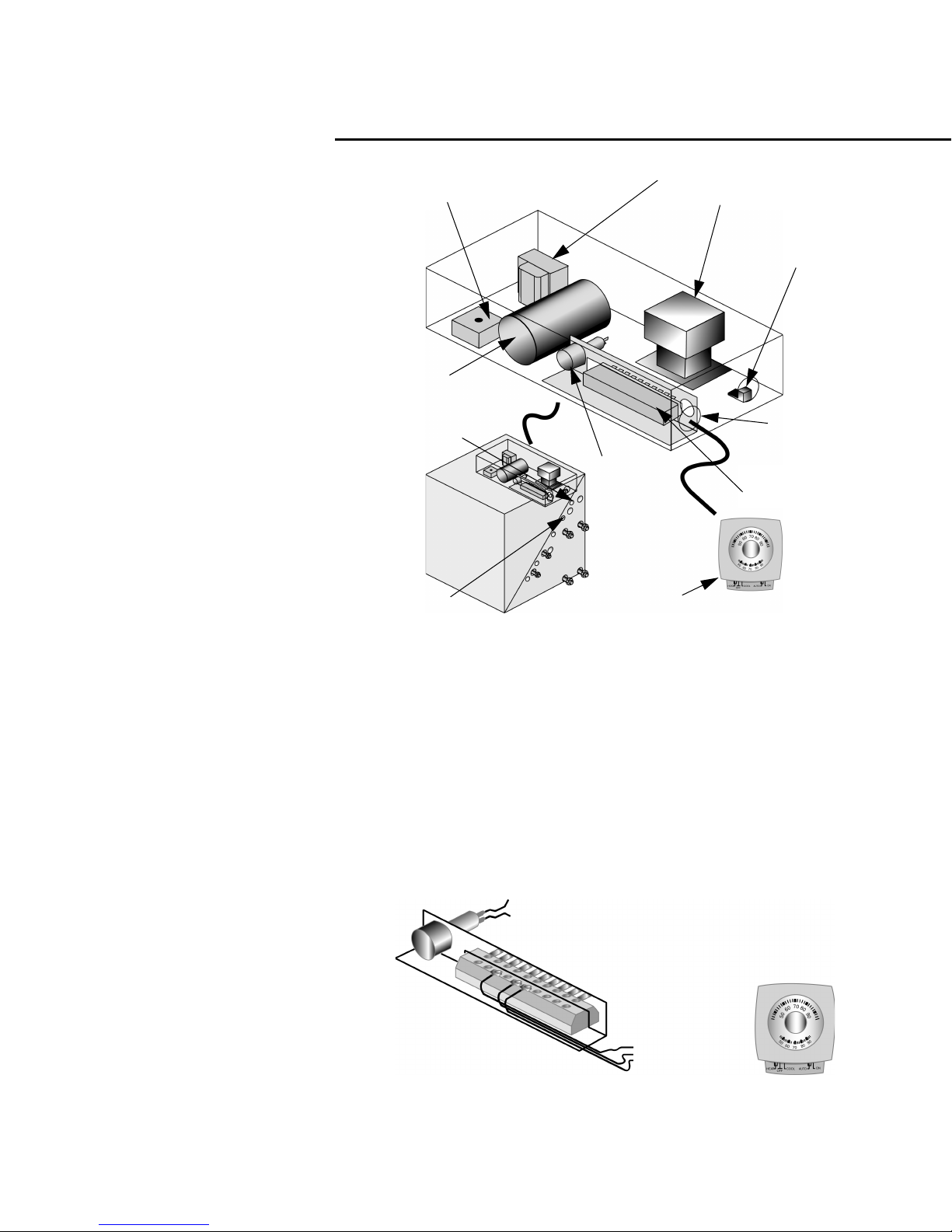

24 Volt Controls

All electrical controls and safety devices are factory wired, tested, and

mounted in the unit. The control

package includes:

and

Benefits

Lockout

Relay

ControlsFeatures

50 VA Transformer

24 VAC Contactor

q Compressor contactor

q 24 Volt transformer

q Lockout relay

q Compressor run capacitor (1-

phase units only)

q Reversing valve coil (For heat

pump only)

q Fuse (for desuperheater)

A terminal strip with 1/4” fork connections will be provided for field

thermostat control wiring. (See Fig-

ure 3).

Safety Devices

Each Trane water-to-water unit contains safety devices to prevent compressor damage. These include:

q Low pressure switch

q High pressure switch

q Temperature sensor (freezestat)

q Internal overload protection

Low Pressure Switch

The low pressure switch prevents

compressor operation under low

charge or in excessive loss of

charge situations. This device is set

to activate at refrigerant pressures

of 35 psig when a 35

ature detection thermostat is applied. An optional 7 psig pressure

switch is available when using a 20

F temperature low temperature detection thermostat.

F low temper-

High Pressure Switch

For internal overload protection,

Trane provides a high pressure

switch. This de-energizes the compressor when discharge pressure

become excessive.

Compressor

Run Capacitor

High Voltage

Low Voltage

Low Temperature

Detection Thermostat

The low water temperature detection thermostat is provided to protect the water-to-refrigerant heat

exchanger from freezing. This device prevents compressor operation if leaving water temperature is

below 35

perature thermostat may be applied

for low water temperatures where

an appropriate antifreeze solution is

used.

F. An optional 20 F tem-

Figure 4: Typical thermostat termination points

Low Voltage

2 Amp Fuse

(for use with

desuperheater

option)

Thermostat

10 Pole Terminal

Strip

Figure 3: Controls

Lockout Relay

When the safety controls are activated to prevent compressor short

cycling, the lockout relay (circuit)

can be reset at the thermostat, or by

cycling power to the unit.

Thermostat Hook-up

Low voltage and high voltage

knockouts are provided in the top

half of the unit. All control wiring to

the unit should be 24 Volt.

(See Figure 4 for termination

points).

24V Power

Compressor

Reversing Valve

(energized in clg)

Ground

5

Page 6

Features

Heat

and

Benefits

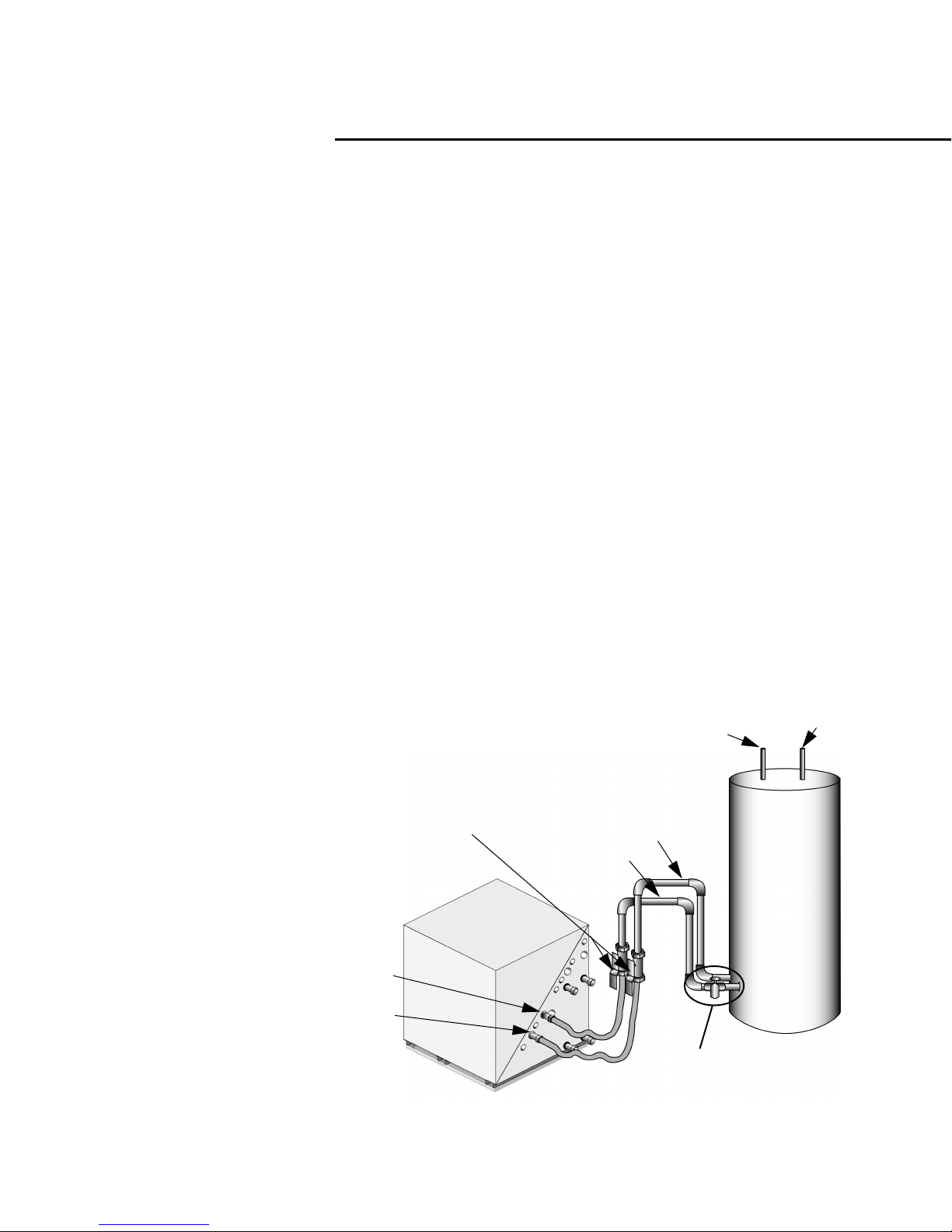

Desuperheater Option

The desuperheater option is a heat

recovery system packaged within

the water-to-water unit. This option

captures heat energy from the heat

pump for considerable cost savings

all year. Since it is active in either

operating mode, it can provide hot

water at a reduced cost while in

heating or virtually free hot water

while in cooling.

Standard equipment includes:

q Desuperheater (heat

exchanger)

q Circulating pump

q Entering water temperature

detector (125 F stops pump)

q Discharge refrigerant

temperature detector (145 F

starts pump)

q Fuse

q Water heater hook-up kit

Recovery

The unit employs a circulating pump

to move water through a double wall

heat exchanger. It then returns the

heated water to the water tank. This

water is heated by superheated refrigerant discharge gas from the

compressor. This heat energy can

now be utilized as a cost savings in

water heating.

Circulating Pump

The pump is a circular, single stage

open system pump. Its specifications include:

q 1/25 HP (horsepower)

q 230 Volt / 60 Hertz / 1 phase

q 90 Watts

q .40 Amps

q 2865 rpm (revolutions per

minute)

q 2 MF (microfarad) / 400 Volt

capacitor

The pump contains a minimum fluid

temperature rating of 50 F, a maximum fluid temperature (open system) of 140 F, and a maximum

working pressure of 145 psi.

Desuper-out

Desuper-in

Isolation

Valves

(by others)

6

from Desuperheater

to Desuperheater

Hot water

(Supply)

Water heater

hook-up kit with

drain valve

Cold water

(Supply)

Page 7

Model Number

Description

1 5 10 15

Digits 1 & 2: Product Type

WP = Trane Commercial Water

Source Heat Pump

Digit 3: Product Configuration

W = Water-to-Water

Digit 4: Development Sequence D

Digits 5-7: Unit Nominal Capacity

024 = 24.0 MBh

036 = 36.0 MBh

042 = 42.0 MBh

048 = 48.0 MBh

060 = 60.0 MBh

072 = 72.0 MBh

Digit 8: Voltage / Hertz / Phase

1 = 208-230/60/1

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

6 = 220-240/50/1

7 = 265/60/1

9 = 380-415/50/3

Digit 9: Unit Arrangement

0 = Water-to-Water

Digit 11: Freeze Protection

(source side)

1 = Brazed Plate Heat Exchanger

with 35 F (1.67 C) Freezestat

2 = Brazed Plate Heat Exchanger

with 20 F (-6.67 C) Freezestat

Digit 12: Freeze Protection

(load side)

1 = Brazed Plate Heat Exchanger

with 35 F (1.67 C) Freezestat

2 = Brazed Plate Heat Exchanger

with 20 F (-6.67 C) Freezestat

Digit 13: Desuperheater Option

0 = No Desuperheater

1 = With Desuperheater

Digit 14: Open

0 = Open Digit

Digit 15: Open

0 = Open Digit

Digit 16: Sticker Option

T = Trane

C = Command-Aire

Digit 10: Design Sequence C

7

Page 8

General

Data

Table G-1: Physical Data (English)

Model: WPWD 024 036 042 048 060 072

Width of cabinet (in) 23 23 23 23 23 23

Unit Size

Compressor Type Scroll Scroll Scroll Scroll Scroll Scroll

R-22 Refrigerant (lbs) 3.25 3.375 3.50 4.00 4.25 4.25

Approximate Weight

(lbs)

Table G-2: Specifications (English)

Source and Load GPM 4.0 6.0 7.0 7.50 10 10

Source and Load Ft. Hd. 1.4 3.2 4.4 5.0 9.2 9.2

Cooling Load EWT 45 F (MBH) 18.24 26.74 31.3 35.55 45.98 51.01

Cooling Load EWT 45 F (EER) 15.0 15.7 15.7 15.4 15.5 14.9

Heating Load EWT 100 F (MBH) 25.38 33.34 39.69 42.87 57.15 67.47

Heating Load EWT 100 F (COP) 3.64 3.62 3.7 3.45 3.62 3.62

Width of cabinet and connections (in) 24.8 24.8 24.8 24.8 24.8 24.8

Height (in) 24.3 24.3 24.3 24.3 24.3 24.3

Depth (in) 23.3 23.3 23.3 23.3 23.3 23.3

With crate (lbs) 163 183 203 214 244 277

Model: WPWD 024 036 042 048 060 072

Note:

q Source EWT (entering water temperature) is at 75 F

q Unit selection should be based upon extended specifications at lowest or highest expected source and load

EWT (entering water temperature)

q Refer to pages 19-25 for extended performance tables.

8

Page 9

Application

Considerations

Closed Loop System

Closed loop systems (both ground source

and surface water) provide heat rejection

and heat addition to maintain proper water

source temperatures.

Operating and maintenace cost are low

because an auxillary fossil fuel boiler and

cooling tower are not required to maintain

the loop temperature. The technology has

advanced to the point where many electric

utilities and rural electric cooperatives are

offering incentives for the installation of

geothermal systems. These incentives are

offered because of savings to the utilities

due to reduced peak loads that flatten out

the system demand curve over time.

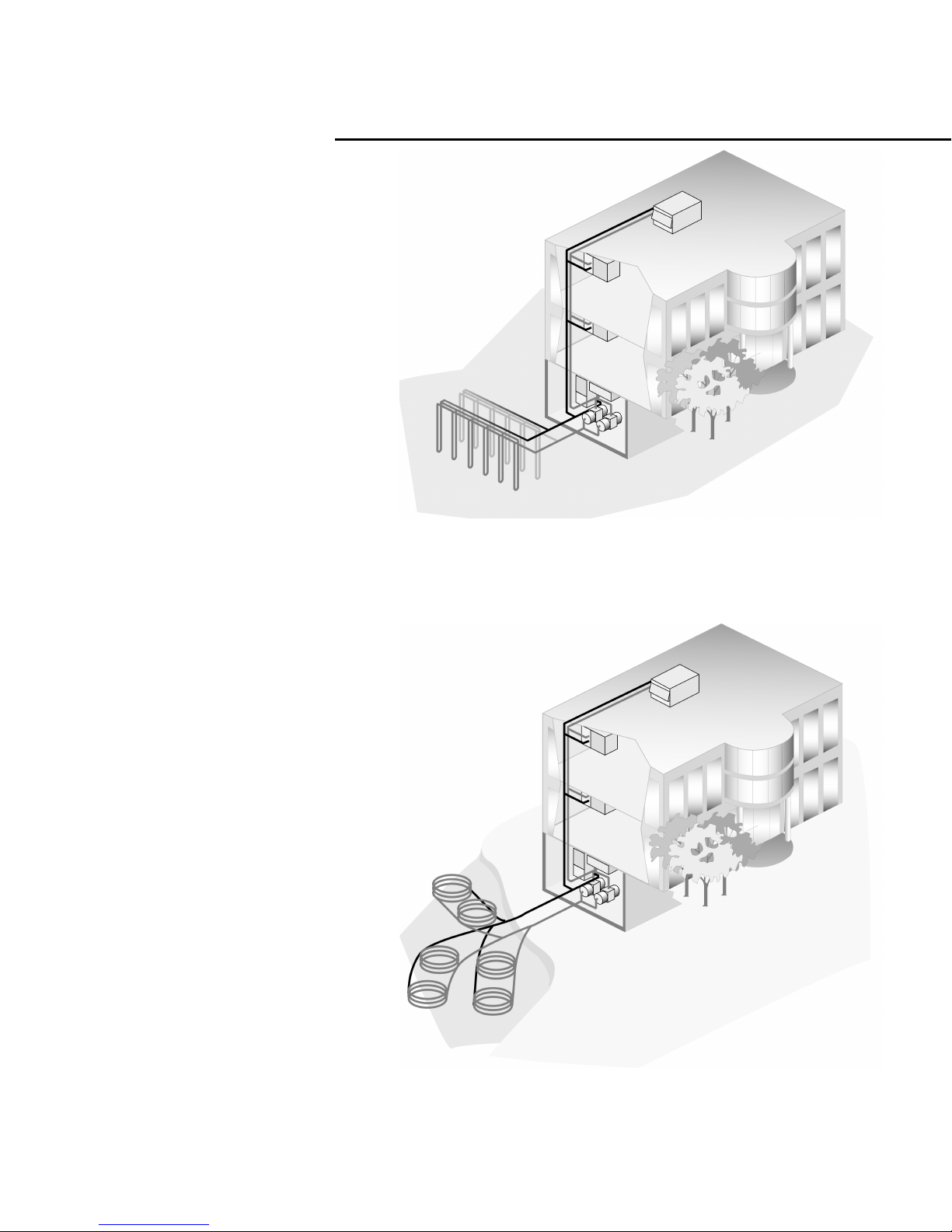

For ground source geothermal systems,

(See Figure 5), when building cooling

requirements cause loop water

temperatures to rise, heat is dissapated into

the cooler earth through buried polyethylene

pipe heat exchangers. If reversed, heating

demands cause the loop temperature to fall,

enabling the earth to add heat to meet load

requirements.

Where local building codes require water

retention ponds for short term storage of

surface run-off, a ground source surface

water system, (See Figure 6), can be very

cost effective. This system has all the

advantages as the geothermal system in

cooling dominated structures.

Another benefit of the ground source system

is that it is environmentally friendly. The loop

is made of chemically inert, non-polluting

polyethylene pipe. The heat pumps use

HCFC-22 refrigerant, which has a lower

ozone depletion potential than CFC-12.

Because the closed loop system does not

require a heat adder, there are no CO

emissions. Less electric power consumed

reduces secondary emissions from the

power plant. Therefore, the system offers

advantages not seen by other central

furnace or heat pump systems.

Figure 5: Ground source geothermal system

2

Figure 6: Ground source surface water system

9

Page 10

Application

Considerations

Open Loop System

Where an existing or proposed well can

provide an ample supply of suitable quality

water, ground water systems may be very

efficient. (See Figure 7)

Operation and benefits are similar to those

for closed loop systems. There are however

several considerations that should be

addressed prior to installation.

q An acceptable way to discharge the

significant volume of used water from

the heat pump should be defined. It may

be necessary to install a recharge well to

return the water to the aquifer.

q Water quality must be acceptable, with

minimal suspended solids. To help

ensure clean water, a straining device

may be required.

Cooling Tower/Boiler System

A cooling tower/boiler system (see Figure 8)

utilizes a closed heat recovery loop along

with multiple water source heat pumps in a

more conventional manner.

Typically, a boiler is employed to maintain

closed loop temperatures above 60

cooling tower to maintain closed loop

temperature below 90

function independantly, either by adding

heat, or removing heat from the closed

water loop, making this system more

efficient than air cooled systems.

The cooling tower/boiler system provides a

low installation cost to the owner than other

systems. A good selection for large building

design needs.

F. All the units

F and a

Figure 7: Open Loop system

Figure 8: Cooling tower/boiler system

10

Page 11

Application

Source Side

Considerations

Source vs. Load

The model WPWD water-to-water

system contains two water to refrigerant heat exchangers. The two

heat exchangers enable the system

to be divided into a source and load

separation.

The “source side” heat exchanger

performs as in a standard water to

air heat pump system. The source is

typically supplied through a cooling

tower, boiler, closed loop, or open

well system. During the refrigeration

cycle, heat is transferred from the

vs.

Load Side

source side heat exchanger to the

load side heat exchanger.

The “load side” heat exchanger

takes the place of a DX (direct expansion) air coil. It provides treated

fluid (hot or cold) to a mechanical

device. These mechanical devices

include designs such as radiant slab

heating, hydronic coils, or fresh air

ventilation units.

See Figure 9 for a basic schematic

of source side verses load side of a

water-to-water system.

Water-In

(Load Side)

Fluid traveling

TO or FROM a

mechanical device

such as hydronic coil,

concrete slab, or flooring

Water-Out

(Load Side)

Figure 9: Source/Load schematic

Refrigeration

Circuit

Water-In

(Source Side)

Fluid traveling

TO or FROM a cooling

tower, boiler, ground

loop or open well

system

Water-Out

(Source Side)

11

Page 12

Application

Closed Loop

Considerations

Hydronic Ice

Melting Via

a Water-to-Water

Unit

Geothermal

Geothermal Space

Temperature

Heating / Cooling

Refrigeration

Equipment

Geothermal

Integrated System

The Trane ground source heat

pump is highly efficient in service

station applications.

This integrated system design

takes advantage of the earths

relatively constant temperature

(45 F to 70 F) to space condition

the building.

appliances such as freezers, ice

makers and a display coolers may

be added to the loop for further

gains in the reduction of consumed

energy.

In addition,

Cold climates may take an even

greater advantage of the heat

rejected by the stores refrigeration

equipment and space conditioning

heat pumps. This rejected heat

may be used by Trane’s water-towater heat pump(s) to heat water

for a car wash and melt ice off of a

driveway (allowing the car wash to

remain open all winter).

This integrated system also

eliminates thermal short circuiting

between the intakes and the

exhausts of an air cooled

refrigeration system.

(Closed) Ground Loop

Heat Exchanger

Typical Benefits

q Annual energy savings means

lower operational costs

q Takes advantage of the earths

constant temperature rather

than high fluctuation of ambient

temperature

q Heat energy rejected from the

space conditioner can be

utilized for ice or snow melting

of a parking lot in colder

climates

q Two to three year estimated

payback on installation costs

12

Page 13

Application

Fresh Air

Fresh Air Ventilation

with Water-to-Water Units

Exhaust

Air

Considerations

Fresh

Air

Ventilation

Water-Out

(load)

Water-In

(load)

Geothermal Space

Heating and Cooling

Water-Out

(source)

Water-In

(source)

Water-to-Water

and Fresh Air

Ventilation

Geothermal energy systems take

advantage of the fact that

subsurface earth temperatures are

constant year-round, which makes

the earth an ideal heat source and

heat sink for heat pumps.

The above design goes further than

just space heating and cooling.

Fresh air ventilation is achieved by

using Trane water-to-water units

teamed with a hydronic outside air

unit, and exhaust air unit to meet

total building requirements.

In the cooling season, the

evaporator water from the heat

pumps is circulated through a

hydronic coil in the makeup air unit

to provide cooling and

dehumidification. The condenser

water is used to provide reheat

energy to temper the ventilated air

in accordance with the building

needs. After leaving the reheat

hydronic coil, the condenser water

is then returned to the building loop

for further heat rejection.

In heating, the water-to-water units

switch to hot water generation. The

water for ventilation air tempering

first circulates through the hydronic

coil to the exhaust air unit to pick

up heat from the building exhaust

airstream. The water then

circulates through the water-towater heat pumps for further heat

introduction before being used by

(Closed) Ground

Loop Heat

Exchanger

the makeup air unit hydronic coil to

heat the makeup air to maintain

building requirements. This

ventilation system incorporates its

own constant volume pumps to pull

system water off the loop and

return it. There is no need for

additional heat injection using

boilers for this system. (See Page

14 for mechanical example).

Typical Benefits

q Annual energy savings means

lower energy costs

q Building comfort and climate

control

13

Page 14

Application

Fresh Air

HOT WATER

COIL

Considerations

EXHAUST

AIR

AIR

HANDLER

EXHAUST AIR

FROM TOILET RMS

OUTSIDE

AIR

AIR

HANDLER

Ventilation

Mechanical

AUTOMATIC

AIR VENT

EXP TANK

BALL VA

EXHAUST AIR

TO HEAT PUMPS

WPWD

WPWD

WPWD

WPWD

HAND

PUMP

PRESSURE

RELIEF VA

DRAIN VA

SUPPLY

RETURN

14

Page 15

Application

Central

Considerations

7

5

Pumping

System

6

1

General

A central pumping system involves

a single pump design usually located within a basement or mechanical

room to fulfill pumping requirements

for the entire building system. With

a central pumping system, an auxiliary pump is typically applied to

lessen the likelihood of system

down-time if the main pump malfunctions.

(See Figure 10 for unit installation of

a central pumping system).

4

Figure 10: Central pumping system installation

3

Central Pump

Application

The sound attenuation pad

Ball valves should be installed

in the supply and return lines

for unit isolation and unit water

flow rate balancing (if an automatic flow device is not

selected). This connection,

along with hoses, are also recommended for backflushing

and chemical cleaning of the

water to refrigerant heat

exchanger.

Flexible hoses may be used

to connect the water supply

and return lines to the water

inlets and outlets. These hoses

reduce possible vibration

between the unit and the rigid

system.

Note: Hoses and or pipes

should be made of braided

stainless steel, and sized suitably for the systems water

pressure and flow rate.

Load side connections are

typically used to supply the ter-

The low voltage control con-

The central systems supply

The field supplied line voltage

2

minal devices with 45 F or

120 F fluid.

should be slightly oversized for

unit. This field supplied product

is recommended for sound

absorption of unit.

nection provided on the unit is

large enough for attaching conduit.

and return lines should be

sized to handle the required

flow with a minimum pressure

drop.

Note: Pipe will sweat if low

temperature water is run

through the supply or return

lines. Trane recommends that

these lines be insulated to prevent damage from condensation.

disconnect should be

installed for branch circuit protection. The unit is supplied

with an opening for attaching

conduit.

Page 16

Application

Well Water

Considerations

7

5

9

Systems

6

8

w

o

l

f

r

e

v

O

n

r

u

t

e

R

y

l

p

p

u

S

4

General

A well water application involves an

open loop water supply. The water

is drawn from an open well or pond

into the unit. A straining device is

required with this application.

Similar to the closed loop design,

an open water supply usually

remains at a constant temperature

year round utilizing maximum

efficiency in unit design.

See Figure 11 for open well water

installation.

3

2

Figure 11: Well water installation

Well W ater

Application

Ball valves should be installed

in the supply and return lines

for unit isolation and unit water

flow rate balancing (if automatic flow device is not

selected). This connection,

along with hoses, are also recommended for backflushing

and chemical cleaning of the

evaporator and the condenser.

Flexible hoses may be used to

connect the water supply and

return lines to the water inlets

and outlets. These hoses

reduce possible vibration

between the unit and the rigid

system.

Note: Hoses and or pipes

should be braided stainless

steel, and sized suitable for the

system’s water pressure and

flow rate.

Load side connections are

used to supply the terminal

device.

1

The sound attenuation pad

should be slightly oversized for

the unit. This field supplied

product is recommended for

sound absorption of unit.

The low voltage control con-

nection provided on the unit is

large enough for attaching conduit.

The expansion tank should be

sized to maintain pressure on

the system.

The line voltage disconnect

should be installed for branch

circuit protection. The unit is

supplied with an opening for

attaching conduit.

The water regulating valve

assembly is used to maintain

refrigerant pressure in refrigerant circuit as the entering water

temperature varies or is cooler

than ideal.

Schrader connections are

factory installed for ease of

attaching the water regulating

valve assembly.

16

Page 17

Application

Distributed

Considerations

7

5

Pumping

System

8

6

1

2

General

A distributed pumping system contains either a single or dual pump

module connected directly to the

units supply and return source side.

This design requires individual

pump modules specifically sized for

each water source heat pump. Centralized pumping is not required.

See Figure 12 for a distributed

pumping installation.

4

3

Figure 12: Distibuted pumping installation

Earth Coupled

Application

Ball valves should be installed

in the supply and return lines

for unit isolation.

Flexible hoses may be used

to connect the water supply

and return lines to the water

inlets and outlets. These hoses

reduce possible vibration

between the unit and the rigid

system.

Note: Hoses and or pipes

should be braided stainless

steel, and sized suitable for the

system’s water pressure and

flow rate.

Load side connections are

used to supply the terminal

device.

The sound attenuation pad

should be slightly oversized for

the unit. This field supplied

product is recommended for

sound absorption of unit.

The low voltage control con-

nection provided on the unit is

large enough for attaching conduit.

The ground loop pump mod-

ule is designed for circulating

commercial loops that require

a maximum flow rate of 20

gpm.

The line voltage disconnect

should be installed for branch

circuit protection. The unit is

supplied with an opening for

attaching conduit.

All polyethene pipe in the

closed loop design should be

insulated to eliminate the risk

of sweating.

17

Page 18

Electrical

Data

Table E-1: Electrical Data

Model: WPWD

Voltage 208-230/60hz/1phase

Compressor RLA 11.4 15 18.4 20.4 28 32.1

Compressor LRA 56 73 95 109 169 169

Minimum Circuit Ampacity 16 21 25.8 28.6 39 45

Max Fuse Size 25 30 40 45 60 70

Aux Pump Amps 2.5 2.5 2.5 2.5 2.5 2.5

Desuperheater Min Cir Ampacity 14.3 18.8 23 25.5 35 40.1

Desuperheater Pump RLA 0.4 0.4 0.4 0.4 0.4 0.4

Voltage 208-230/60hz/3phase

Compressor RLA - 10.7 11.4 13.9 20 19.3

Compressor LRA - 63 77 88 123 137

Minimum Circuit Ampacity - 15 16 19.4 28 27

Max Fuse Size - 20 25 30 45 40

Aux Pump Amps - 2.5 2.5 2.5 2.5 2.5

Desuperheater Min Cir Ampacity - 13.4 14.3 17.4 25 24.1

Desuperheater Pump RLA - 0.4 0.4 0.4 0.4 0.4

Voltage 460/60hz/3phase

Compressor RLA - 5 5.7 7.1 7.5 10

Compressor LRA - 31 39 44 49.5 62

Minimum Circuit Ampacity - 7 8 10 10.5 14

Max Fuse Size - 15 15 15 15 20

Aux Pump Amps - 2.5 2.5 2.5 2.5 2.5

Desuperheater Min Cir Ampacity - 6.3 7.1 8.9 9.4 12.5

Desuperheater Pump RLA - 0.4 0.4 0.4 0.4 0.4

Voltage 575/60hz/3phase

Compressor RLA - - - - 6.4 7.8

Compressor LRA - - - - 40 50

Minimum Circuit Ampacity - - - - 9 11

Max Fuse Size - - - - 15 15

Aux Pump Amps - - - - 2.5 2.5

Desuperheater Min Cir Ampacity - - - - 8 9.8

Desuperheater Pump RLA - - - - 0.4 0.4

Voltage 265/60hz/1phase

Compressor RLA 9.6 14.3 16.4 17.1 - Compressor LRA 47 71 83 98 - Minimum Circuit Ampacity 13.5 20 23 24 - Max Fuse Size 20 30 35 35 - Aux Pump Amps 2.5 2.5 2.5 2.5 - Desuperheater Min Cir Ampacity 12 17.9 20.5 21.4 - Desuperheater Pump RLA 0.4 0.4 0.4 0.4 - -

024 036 042 048 060 072

18

Loading...

Loading...