Trane GSWD, WPWD, EXWA User Manual

Installation

Owner

Diagnostics

Water-to-Water

Water-Source Heat Pump

Models WPWD, GSWD and EXWA

Models

WPWD

024-072 – 60 HZ

GSWD

024-072 – 60 HZ

“A” and later Design Sequence

EXWA

240 – 60 HZ

WSHP-SVX02A-EN

Notice

Warnings and Cautions appear at appropriate sections throughout this manual.

Read these carefully.

NOTICE:

WARNING -Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION -Indicates a potentially hazardous situation which, if

not

avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

CAUTION -Indicates a situation that may result in equipment or

property-damage-only accidents.

Important!

Equipment is shipped FOB (Free on

Board) at the manufacturer. Therefore,

freight claims for damages against the

carrier must be initiated by the receiver.

NOTICE:

Unit contains HCFC (R-22) Refrigerant

Instructions!

Section 608, Paragraph C of the 1990 Clean Air Act states:

Effective July 1, 1992, it shall be unlawful for any person, in course of

maintaining, servicing, repairing, or disposing of an air conditioning system, to

knowingly vent or release any CFC or HCFC refrigerant. Minimal releases (air

purges or refrigerant hoses) associated with good faith attempts to recapture or

recycle are exempt from the ban on venting.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the

environment, our customers, and the air conditioning industry. All technicians

who handle refrigerants must be certified. The Federal Clean Air Act (Section 608)

sets forth the requirements for handling, reclaiming, recovering and recycling of

certain refrigerants and the equipment that is used in these service procedures.

In addition, some states or municipalities may have additional requirements that

must also be adhered to for responsible management of refrigerants. Know the

applicable laws and follow them.

© 2002 American Standard Inc. WSHP-SVX02A-EN

Contents

Installation/Startup/Commissioning

Pre-installation Checklist

General Information

Dimensions/Weights

Installation Instructions

Electrical Requirements

Pre-Startup Checklist

Startup/Commissioning

Sequence of Operation

Operating Pressures

Startup Checklist & Log

Maintenance

4

4

5

6

10

19

20

21

21

22

30

24

25

Warranty Information

Troubleshooting Checklist

Unit Wiring

WSHP-SVX02A-EN 3

26

28

29

Pre-installation

Checklist

WARNING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the insulation in this

product during installation, maintenance or repair will expose you to

airborne particles of glass wool fibers and ceramic fibers known to the

state of California to cause cancer through inhalation. Glass wool fibers

may also cause respiratory, skin or eye irritation.

Jobsite Inspection

Always perform the following checks before accepting a unit:

1. Verify that the nameplate data matches the data on the sales order and bill of

lading (including electrical data).

2. Verify that the power supply complies with the unit nameplate specifications.

3. Visually inspect the exterior of the unit, for signs of shipping damage. Do not

sign the bill of lading accepting the unit(s) until inspection has been completed. Check for damage promptly after the unit(s) are unloaded. Once the

bill of lading is signed at the jobsite, the unit(s) are now the property of the

SOLD TO party and future freight claims MAY NOT be accepted by the

freight company.

4. Verify that the refrigerant charge has been retained during shipment by use

of gauges. Schrader taps are located external to the cabinet on the 2-ton

through 6-ton equipment.

5. After assuring that charge has been retained, reinstall the schrader caps to

assure that refrigerant leakage does not occur.

WARNING

Microbial Growth!

Wet interior unit insulation can become an amplification site for

microbial growth (mold), which may cause odors and damage to the

equipment and building materials. If there is evidence of microbial

growth (mold) on the interior insulation, the insulation should be

removed and replaced prior to operating the system.

Jobsite Storage

This unit is intended for indoor use only. To protect the unit from damage due to

the elements, and to prevent possible IAQ contaminant sources from growing,

the unit should be stored indoors. If indoor storage is not possible, the following

provisions for outdoor storage must be met:

1. Place the unit(s) on a dry surface or raise above the ground to assure adequate air circulation beneath the unit.

2. Cover the unit(s) with a water proof tarp to protect them from the elements.

3. Make provisions for continuous venting of the covered units to prevent

moisture from standing on the unit(s) surfaces. Wet interior unit insulation

can become an amplification site for microbial growth (mold) which has

been determined to be a cause of odors and serious health related indoor air

quality problems.

4. Store units in the normal UP orientation to maintain oil in the compressor.

5. Do not stack more than three units in total height for the WPWD/GSWD 2-ton

through 6-ton configurations, and no more than two units high for the EXWA

20-ton configuration.

4 WSHP-SVX02A-EN

General

Information

Unit Nameplate

The unit nameplate is located at the

front of the unit. It includes the unit

model number, serial number, electrical characteristics, refrigerant charge,

and other pertinent unit data.

Compressor Nameplate

The nameplate for the compressors

are located on the compressor shell.

Unit Description

Before shipment, each unit is leak tested, dehydrated, charged with refrigerant and run tested for proper control

operation.

Water-to-Refrigerant Coils

The brazed-plate water-to-refrigerant

heat exchangers for the 2-ton through

6-ton equipment are constructed of

stainless steel.

The water-to-refrigerant heat exchangers for the 20-ton equipment are

an inner copper tube or cupro-nickel

(option available on the source-side

only) and steel tube (tube-within-atube) design.

Both heat exchanger types are leak

tested to assure there is no cross leakage between the water and refrigerant

gas.

Water Connections

One inch brass swivel connections are

provided for the 2-ton through 6-ton

equipment. Each brass fitting has a

one inch gasket for the connector. The

gaskets are shipped in the electrical

compartment to prevent loss at the job

site.

Water connections for the 20-ton are

located inside the unit at the units

front (source-side) and back (loadside). The fitting consist of a 2-inch female pipe threaded connection.

Controls

The control system offered to control

the unit is a Basic 24 volt control for

the 2-ton through 6-ton unit sizes, and

a deluxe 24 volt micro processing

board for the 20-ton unit.

All power wiring to the equipment is

made at the unit contactor for the 2-

ton through 6-ton equipment, and at

the power block for the 20-ton equipment.

All low voltage wiring is made at the

unit’s low voltage terminal board.

Wiring Connections

Troubleshooting and connection diagrams for the equipment may be located in the back of this manual.

Basic 24V Controls

(for 2-ton through 6-ton units)

Safety devices for equipment containing the basic 24V control option include a low pressure switch and a

freezestat to prevent compressor operation during low temperature activity. The switch is set to activate at

refrigerant pressures of 35 psig or 7

psig to fit most applications.

A high pressure switch prevents compressor operation during high or excessive discharge pressures

exceeding 395 psig.

The lockout relay communicates the

low or high pressure situation to the

compressor to prevent operation. The

relay may be reset at the thermostat,

or by cycling power to the unit.

General alarm may be accomplished

through the lockout relay to drive light

emitting diodes (LEDs) on a field supplied status indicating thermostat. Terminal 6 on the lockout relay is open for

field use in malfunction indications.

This feature will drive dry contacts

only, and cannot be used to drive field

installed control inputs.

Deluxe 24V Controls

(for 20-ton unit)

Units containing the Deluxe 24V control design will incorporate a microprocessor-based control board. The

Trane microprocessor board is factory

wired to a terminal strip to provide all

necessary terminals for field connection. The deluxe board is equipped

with a random start relay, anti-short

cycle timer, brown out protection,

compressor disable, unit safety control, diagnostics and a generic relay

(which may be available for field use).

See page 17 for diagnostic information.

Desuperheater

(Option for 2-ton through 6-ton units)

For units containing the desuperheater option, the unit is shipped from the

factory with a desuperheater water

coil and pump mounted internal to the

unit cabinetry. For domestic hot water

hook-up instructions, see manual

WSHPC-IN-4 or 72-9006-02.

The desuperheater pump fuse is located in the control box within a container. The fuse is not factory installed to

avoid possible pump damage at initial

start-up. If the fuse in installed and the

unit is started without water in the system, the pump will be damaged. See

page 17 for fuse installation.

Schrader Connections

Connections for the low and high side

of the refrigeration system are located

conveniently on the unit’s right side

for the 2-ton through 6-ton units, and

behind the front, refrigeration access

panel for the 20-ton unit.

WSHP-SVX02A-EN 5

Table 1: Unit weights

Size

024 163 153

036 183 173

042 203 193

048 214 204

060 244 234

072 277 267

240 1222 1156

Shipping

Weight

with pallet (lb)

w/o pallet (lb)

Shipping

Weight

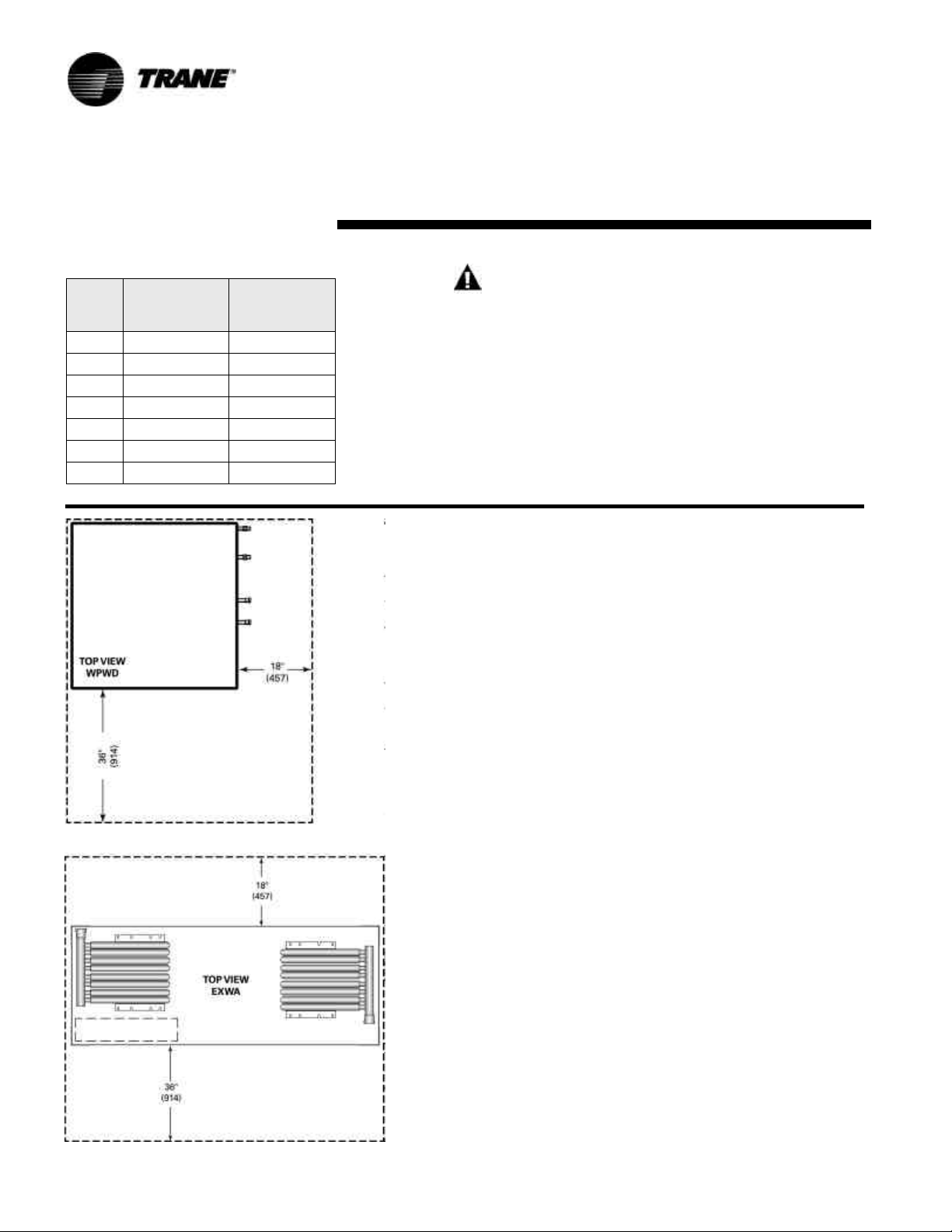

Dimensions/Weights/

Clearance

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in death or serious injury

or possible equipment or property-only damage.

Unit Location and Clearances

Locate the unit in an indoor area. The

ambient temperature surrounding the

unit must not be less than 45°F. Do

not locate the unit in areas subject to

freezing.

Attention should be given to service

clearance and technician safety. The

unit access panels may be easily removed. There must be enough space

for service personnel to perform maintenance or repair. Provide sufficient

room to make water, and electrical

connection(s). Local and national

codes should be followed in providing

electrical power connections. See Fig-

ure 1 for mechanical clearances.

Figure 1: Mechanical clearances

6 WSHP-SVX02A-EN

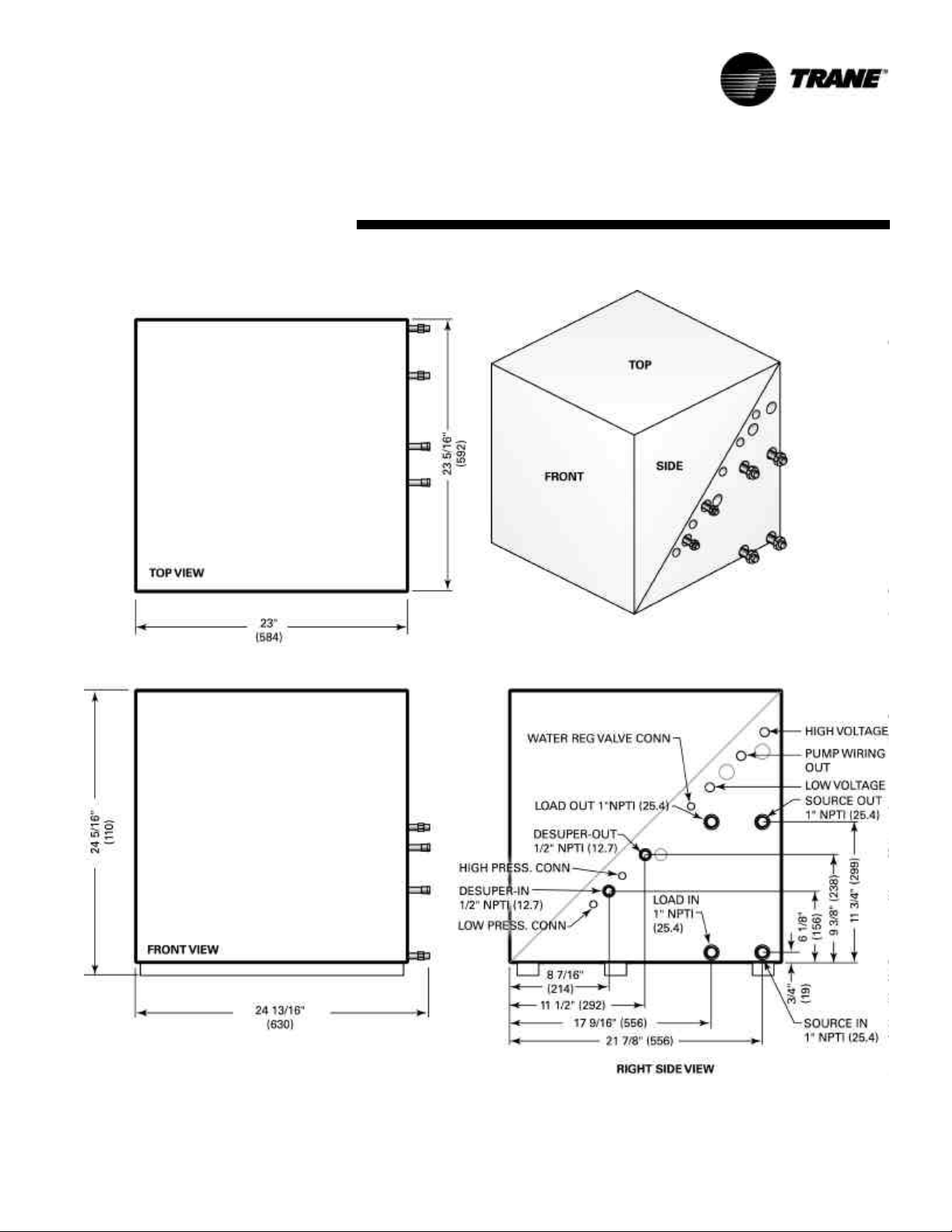

Dimensions

WPWD/GSWD 024-036

WSHP-SVX02A-EN 7

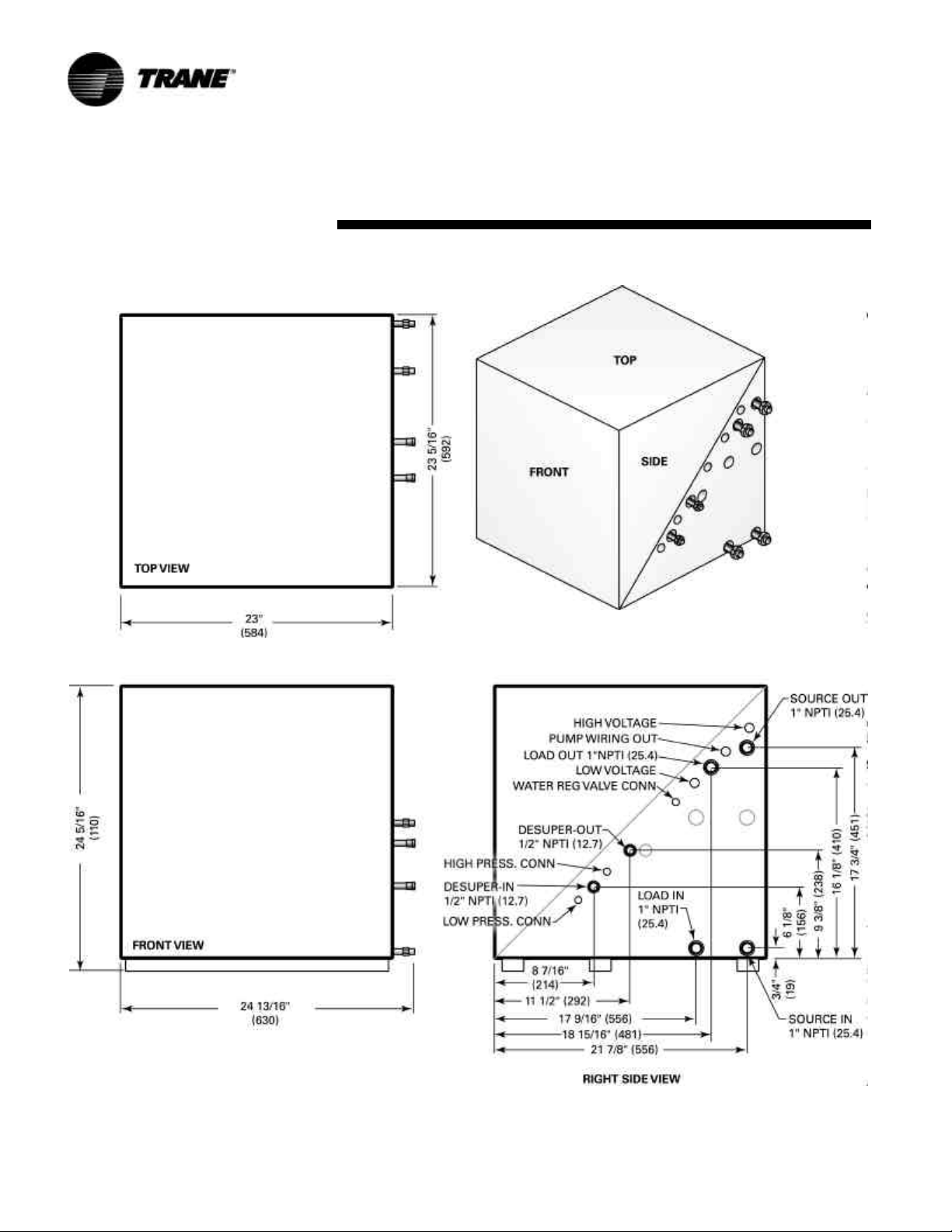

Dimensions

WPWD/GSWD 042-072

8 WSHP-SVX02A-EN

Dimensions

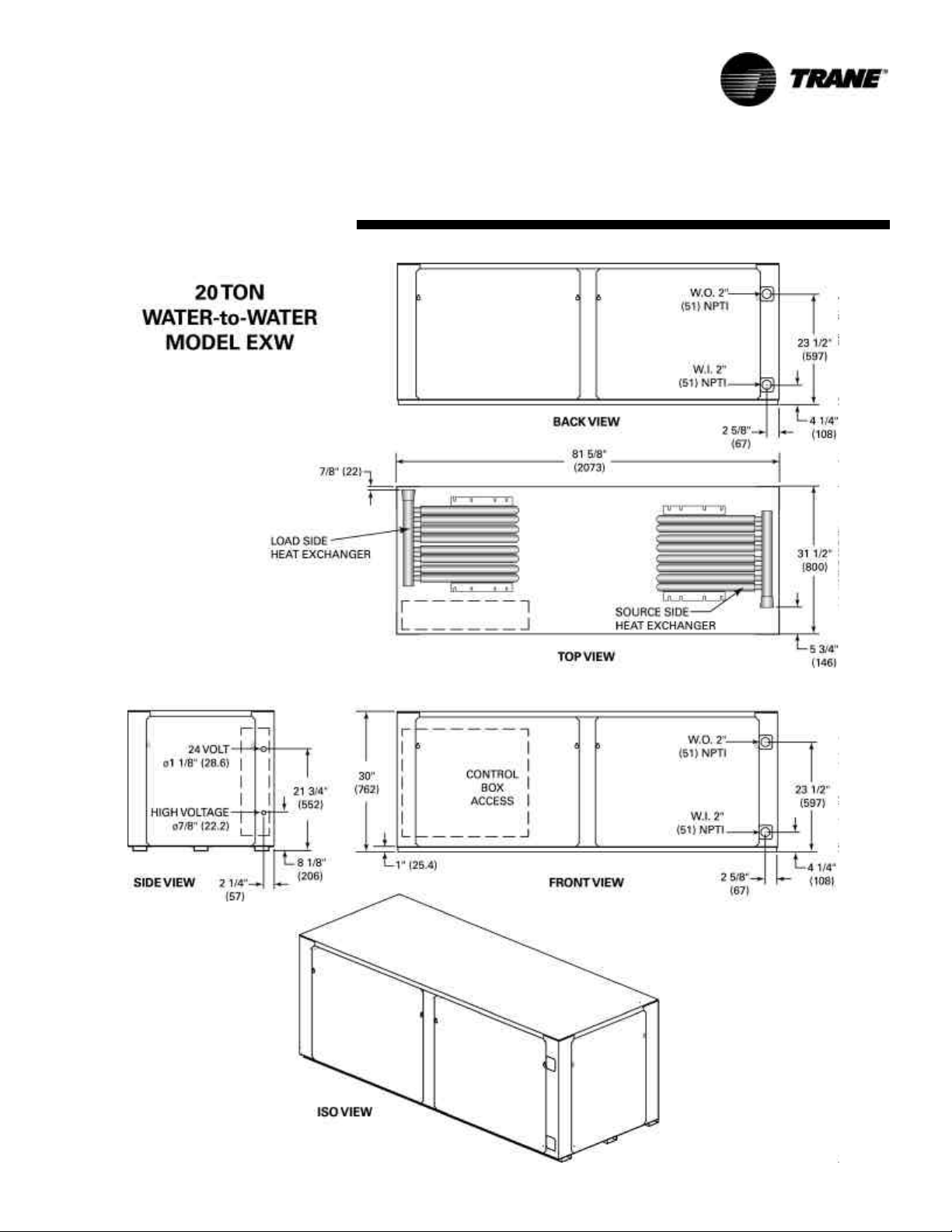

EXWA 240

WSHP-SVX02A-EN 9

Installation

General Installation Checks

The checklist below is a summary of

the steps required to successfully install a unit. This checklist is intended to

acquaint the installing personnel with

procedures required in the installation

process. It does not replace the detailed instructions called out in the applicable sections of this manual.

1 Remove packaging and inspect the

unit. Check the unit for shipping

damage and material shortage; file

a freight claim and notify appropriate sales representation.

Note: The units have been tied to

the skid by (4) angle brackets. Remove these brackets from the unit

to slide unit from skid.

2 Verify the correct model, options

and voltage from the unit nameplate.

3 Verify the installation location of

the unit will provide the required

clearance for proper operation.

4 Remove refrigeration access panel

and inspect the unit. Be certain the

refrigerant tubing has clearance

from adjacent parts.

WARNING

Hazardous

Voltage!

Disconnect all electric power,

including remote disconnects

before servicing. Follow proper

lockout/tagout procedures to

ensure the power can not be

inadvertently energized. Failure to

disconnect power before

servicing could result in death or

serious injury.

Main Electrical

5 Verify the power supply complies

with the unit nameplate specifications.

6 Inspect all control panel compo-

nents; tighten any loose connections.

7 Connect properly sized and pro-

tected power supply wiring to a

field-supplied/installed disconnect

switch and to the main power terminal block (1TB1) in the unit control box for the 20-ton equipment,

or (1K1) for the 2-ton through 6ton equipment.

8 Install proper grounding wires to

an earth ground.

Note: All field-installed wiring must

comply with NEC and applicable local

codes.

Low Voltage Wiring (AC & DC)

Requirements

9 Connect properly sized control wir-

ing to the proper termination

points between the field supplied

thermostat and the terminal strip

located in the equipment control

box.

10 WSHP-SVX02A-EN

Loading...

Loading...