Page 1

Installation, Operation,

and Maintenance

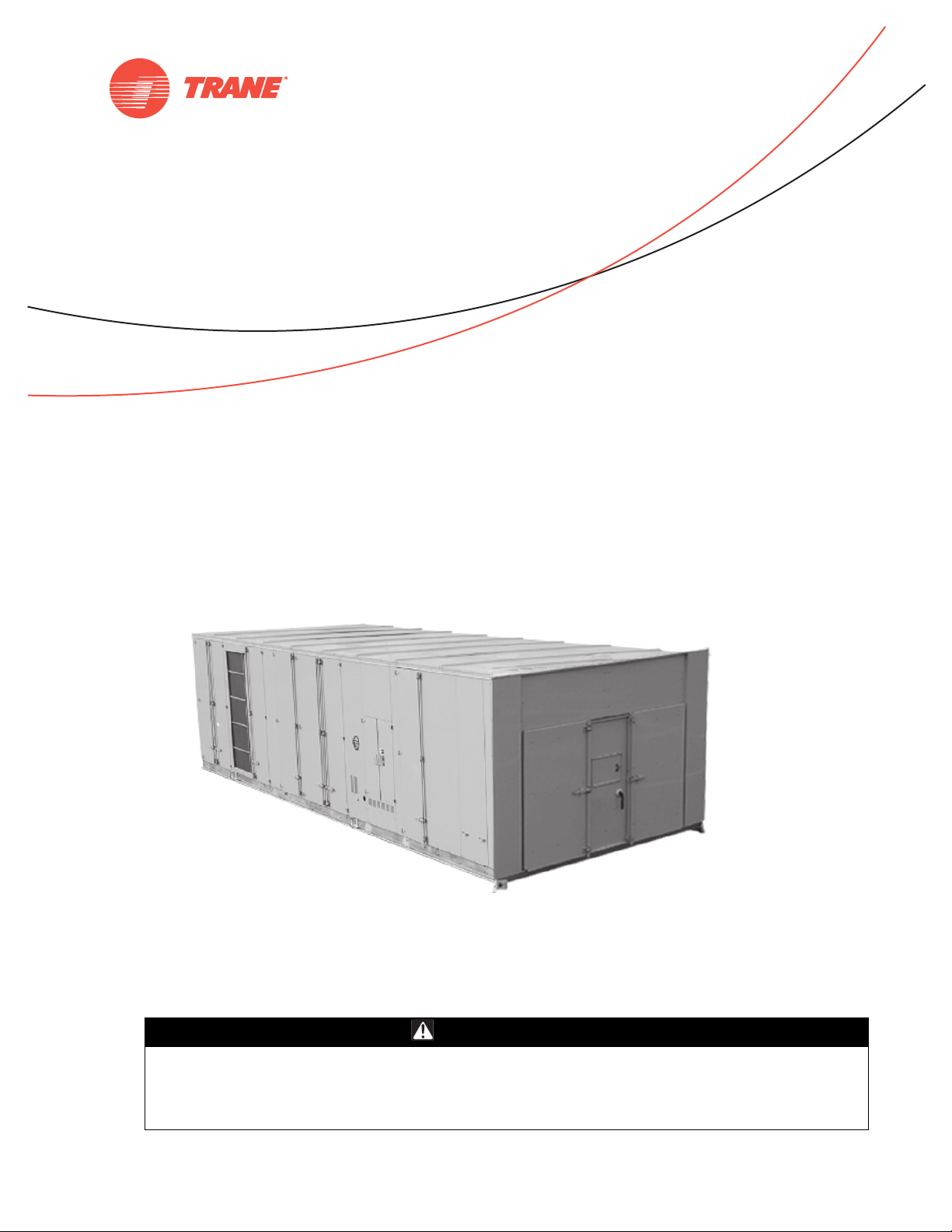

IntelliPak™ II

Commercial Rooftop Air Handlers with

CV, VAV, or SZVAV Controls

‘F0’ and later design sequence

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

October 2011 RT-SVX28E-EN

WEHC WSHC

WFHC WXHC

WLHC

SAFETY WARNING

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. Warnings are provide to alert installing contractors

to potential hazards that could result in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

Read this manual thoroughly before operating or servicing this unit.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout this

literature. Read these carefully:

WARNI NG

CAUTIONs

NOTICE:

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only

accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally

occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the

identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants-including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

WARNING

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

© 2011 Trane All rights reserved RT-SVX28E-EN

Page 3

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS

• If there is a risk of arc or flash, technicians MUST put on all Personal Protective Equipment

Failure to follow recommendations could result in death or serious injury.

Overview of Manual

Notes:

• This document is the customer property and must be retained by the unit owner for use by

• The procedures discussed in this manual should only be performed by qualified, experienced

This booklet describes proper installation, start-up, operation, and maintenance procedures for

Casings A-C rooftop air handlers designed for Constant Volume (CV), Single Zone Variable Air

Volume (SZVAV) and Variable Air Volume (VAV) applications. By carefully reviewing the

information within this manual and following the instructions, the risk of improper operation and/

or component damage will be minimized.

Note: One copy of the appropriate service literature ships inside the control panel of each unit.

It is important that periodic maintenance be performed to help assure trouble free operation.

Should equipment failure occur, contact a qualified service organization with qualified,

experienced HVAC technicians to properly diagnose and repair this equipment.

Warnings, Cautions and Notices

WARNING

Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

sheets and OSHA guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

(PPE) in accordance with NFPA 70E or other country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

maintenance personnel.

HVAC technicians.

RT-SVX28E-EN 3

Page 4

Table of Contents

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Commonly used Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Input Devices and System Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Overview of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Constant Volume (CV) and Variable Air Volume (VAV) Units . . . . . . . . . 13

Constant Volume (CV) Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Variable Air Volume (VAV) Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Single Zone Variable Air Volume (SZVAV) Only . . . . . . . . . . . . . . . . . . . 17

Space Temperature Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unit Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

General Unit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Rigging the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main Electrical Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Field Installed Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Requirements for Electric Heat Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Requirement for Gas Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Requirements for Hot Water Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Requirements for Steam Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Requirements for Chilled Water Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . 30

O/A Pressure Sensor and Tubing Installation (all units with Statitrac) . . 30

Condensate Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Units with Gas Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing Supply and Exhaust Fan Shipping Channels . . . . . . . . . . . . . 31

Spring Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

O/A Sensor and Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Units with Statitrac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Roof Curb and Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pitch Pocket Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

If a Trane Curb Accessory Kit is not used . . . . . . . . . . . . . . . . . . . . . . . . . 37

Field Converting Horizontal Ductwork from Right to the Left Side . . . . . 38

Unit Rigging and Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Lifting the External Piping Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Gas Heat Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 RT-SVX28E-EN

Page 5

Connecting the Gas Supply Line to the Furnace Gas train . . . . . . . . . . . 43

Hot Water Heat Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Steam Heat Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

General Coil Piping and Connection Recommendations . . . . . . . . . . . . . . . . 49

Chilled Water Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

General Coil Piping Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Coil Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

External Piping Enclosure Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Disconnect Switch w/External Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electric Heat Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Main Unit Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Power Wire Sizing and Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . 61

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Field Installed Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Controls using 24 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Controls using DC Analog Input/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . 65

Constant Volume System Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Variable Air Volume System Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Constant Volume or Variable Air volume System Controls . . . . . . . . . . 66

Emergency Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Ventilation Override Module (VOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Temperature vs. Resistance Coefficient . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Cooling Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Gas Heating Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Electric Heat Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

CV Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

VAV Occupied Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Demand Control Ventilation Sequence of Operation . . . . . . . . . . . . . . . . 84

Return Fan Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Wet Heat Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Verifying Proper Fan Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

System Airflow Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Exhaust Airflow Measurement (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . 91

Traq™ Sensor Airflow Measurement (Optional with all units equipped with

an economizer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Supply Fan (with or without Variable Frequency Drive) . . . . . . . . . . . . . . . . 93

Exhaust Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Return Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Component Static Pressure Drops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

RT-SVX28E-EN 5

Page 6

Unit Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Economizer Damper Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

To Adjust the Fresh Air Damper Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Chilled Water Cooling Startup (Constant Volume & Variable Air

Volume Systems)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Electric, Steam and Hot Water Start-Up (Constant Volume & Variable Air Volume Systems)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Gas Furnace Start-Up

(Constant Volume and Variable Air Volume Systems)

Two Stage Gas Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Full Modulating Gas Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . 105

Final Unit Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Fan Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

VFD Programming Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Cooling Season . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Heating Season . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Final Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Warranty and Liability Clause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6 RT-SVX28E-EN

Page 7

Model Number Descriptions

WEHCA0040A0411F70001A0000A0D0A00000000

1 2 3 4 567 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38

DIGIT 1 — UNIT TYPE

W Self-Contained (Packaged

Air Handler)

DIGIT 2 — UNIT FUNCTION

E Electric Heat

F Natural Gas Heat

L Hot Water Heat

S Steam Heat

X No Heat

DIGIT3—SYSTEMTYPE

H Single Zone

DIGIT 4 — DEVELOPMENT

SEQUENCE

C Third

DIGIT 5 — UNIT SIZE

A 16,000 - 31,000 CFM

B 20,000 - 38,000 CFM

C 20,000 - 45,000 CFM

DIGIT6—COOLING COIL

0 No Cooling Coil

2 2 Row Chilled Water

4 4 Row Chilled Water

6 6 Row Chilled Water

8 8 Row Chilled Water

DIGIT 7 — CHILLED WATER COIL

FIN SERIES

0 No Chilled Water Coil

A Series 80 without Turbulators

B Series 80 with Turbulators

C Series 108 without Turbulators

D Series 108 with Turbulators

E Series 144 without Turbulators

F Series 144 with Turbulators

G Series 168 without Turbulators

H Series 168 with Turbulators

DIGIT 8 — VOLTAGE SELECTION

4 460/60/3 XL

5 575/60/3 XL

DIGIT 9 — HEAT CAPACITY

SELECTION

0 No Heat

1 Electric Heat 90 kW

2 Electric Heat 140 kW

3 Electric Heat 265 kW

4 Electric Heat 300 kW

A Low Gas Heat - 2 stage

B Medium Gas Heat - 2 stage

C High Gas Heat - 2 stage

D Low Gas Heat - Modulating

E Medium Gas Heat - Modulating

F High Gas Heat - Modulating

Low Heat Options

H Low Heat - 1.25 in. (32mm) Valve

J Low Heat - 1.5 in. (38mm) Valve

K Low Heat - 2.0 in. (50mm) Valve

L Low Heat - 2.50 in. (64mm) Valve

M Low Heat - 3.0 in. (76mm) Valve

High Heat Options

P High Heat - 1.25 in.(32mm) Valve

Q High Heat - 1.5 in. (38mm) Valve

R High Heat - 2.0 in. (50mm) Valve

T High Heat - 2.50 in. (64mm) Valve

U High Heat - 3.0 in. (76mm) Valve

DIGIT 10 & 11— DESIGN

SEQUENCE

AO

DIGIT 12 — UNIT

CONFIGURATION SELECTION

4 1 Piece Unit - without Blank

Section

5 1 Piece Unit with 4 ft. Blank

Section

6 1 Piece Unit with 8 ft. Blank

Section

DIGIT 13 — AIRFLOW DIRECTION

1 Downflow Supply/Upflow Return

2 Downflow Supply/Horizontal End

Return

3 Downflow Supply/Horizontal

Right Return

4 Right Side Horizontal Supply/

Upflow Return

5 Right Side Horizontal Supply/

Horizontal End Return

6 Right Side Horizontal Supply/

Horizontal Right Return

DIGIT 14 — FAN MOTOR

SELECTION

1 Standard Fan

3 Standard Fan w/ TEFC Motor

DIGIT 15 — SUPPLY FAN MOTOR

SELECTION

F15Hp

G20Hp

H25Hp

J30Hp

K40Hp

L50Hp

M60Hp

N75Hp

DIGIT 16 — SUPPLY FAN RPM

SELECTION

7700

8800

9900

A1000

B1100

C 1200

D 1300

E 1400

F 1500

G 1600

H 1700

J 1800

K 1900

L2000

DIGIT 17 — EXHAUST/RETURN

FAN OPTIONS

0 None

1 High CFM Exhaust w/o Statitrac

CV Only

2 Low CFM Exhaust w/o Statitrac

CV Only

3 High CFM Exhaust w/o VFD w/

Statitrac

4 Low CFM Exhaust w/o VFD w/

Statitrac

5 High CFM Exhaust w/ VFD w/

Bypass w/ Statitrac

6 Low CFM Exhaust w/ VFD w/

Bypass w/ Statitrac

7 High CFM Exhaust w/ VFD w/o

Bypass w/ Statitrac

8 Low CFM Exhaust w/ VFD w/o

Bypass w/ Statitrac

A Return w/o Statitrac CV Only

C Return w/ VFD w/ Bypass w/

Statitrac

E Return w/ VFD w/o Bypass w/

Statitrac

DIGIT 18 — EXHAUST/RETURN

FAN MOTOR SELECTION

0 None

D 7.5 Hp

E10Hp

F15Hp

G20Hp

H25Hp

J30Hp

K40Hp

L50Hp

M60Hp

RT-SVX28E-EN 7

Page 8

Model Number Descriptions

DIGIT 19 — EXHAUST/RETURN

RPM SELECTION

0 None

3300

4400

5500

6600

7700

8800

9900

A1000

B1100

C 1200

D 1300

E 1400

DIGIT 20 — SYSTEM CONTROL

SELECTION

1 Constant Volume (Zone

Temperature Control)

2 VAV (Discharge Air Control)

4 VFD Supply w/o Bypass

(Discharge Air Control)

5 VFD Supply w/Bypass (Discharge

Air Control)

6 Single Zone VAV w/VFD w/o Bypass

(Zone Temperature Control)

7 Single Zone VAV w/VFD w/Bypass

(Zone Temperature Control)

DIGIT 21 — FRESH AIR AND

ECONOMIZER OPTIONS/

CONTROLS

A 0 - 25% Motorized Damper

B Econ w/Dry Bulb

C Econ w/Reference Enthalpy

D Econ w/Comparative Enthalpy

E Econ w/Fresh Air Measure /Dry

Bulb

F Econ w/ Fresh Air Measure /Ref

Enth

G Econ w/Fresh Air Measure /Comp

Enth

H Econ w/DCV /Dry Bulb

J Econ w/DCV /Ref Enth

K Econ w/DCV /Comp Enth

DIGIT 22 — DAMPER OPTION

0 Standard

1 Low Leak

2 Ultra Low Leak

DIGIT 23 — PRE COOLING COIL

FILTER SELECTION

0 2" High Efficiency Throw Away

1 2" Throw Away Rack / Less Filters

2 90 - 95%, Bag Filters w/ Pre Filters

3 Bag Filter Rack / Less Filters

4 90 - 95%, Cartridge Filters w/

Pre Filters

5 Cartridge Rack / Less Filters

6 90 - 95% Low PD Cartridge w/

Pre Filters

7 Low PD Cartridge Rack / Less

Filters

DIGIT 24 — BLANK SECTION

APPLICATION OPTIONS

0 None

A 90 - 95% Bag w/Pre Filters

B 90 - 95% Low PD Cartridge w/

Pre Filters

C 90 - 95%, Cartridge Filters w/

Pre Filters

D 90 - 95% Hi Temp Cartridge w/

Pre Filters

E HEPA w/Pre Filters

F Hi Temp HEPA w/Pre Filters

DIGIT 25 — FUTURE

DEVELOPMENT

0

DIGIT 26 — UNIT MOUNTED POWER

CONNECTION SELECTION

A Terminal Block

B Non Fused Disconnect

C Non Fused Disconnect w/

Pwrd conv outlet

D Circuit Breaker w/ SCWR

E Ckt Brkr w/ SCWR/ Pwrd conv

outlet

DIGIT 27 — (FUTURE

DEVELOPMENT)

0 None

DIGIT 28 — COIL/DRAIN PAN

D No Drain Pan

E Galvanized Drain Pan

DIGIT 29 — CHILLED WATER

COIL VALVE

0 None

A 1.5" Cooling Valve

B 2" Cooling Valve

C 2.5" Cooling Valve

D 3" Cooling Valve

DIGIT 30 — (FUTURE

DEVELOPMENT)

0 None

DIGIT 31 — (FUTURE

DEVELOPMENT)

0 None

DIGIT 32 — HIGH DUCT

TEMPERATURE THERMOSTAT

0 None

1 High Duct Temp Thermostat

DIGIT 33 — REMOTE HUMAN

INTERFACE

0 None

1 RHI & IPCB

2 IPCB

DIGIT 34 — MODULE OPTIONS

0 None

A 0-5 Volt GBAS

B 0-10 Volt GBAS

C 0-5 / 0-10 Volt GBAS

F LonTalk Communication Interface

(LCI)

D Ventilation Override

G 0-5 Volt GBAS / Ventilation

Override

H 0-10 Volt GBAS / Ventilation

Override

J 0-5 / 0-10 V GBAS / Ventilation

Override

L LCI & Ventilation Override

M BACnet Communication

Interface (BCI)

N BCI & Ventilation Override

DIGIT 35 — ZONE SENSOR

OPTION

0 None

A Dual Setpoint w/Man/Auto

Changeover

B Dual Stpt w/Man/Auto Chgovr &

Sys Lights

C Room Sensor w/Timed Override

& Cancel

D Room Snsr w/TO & Cancel &

Local Stpt Adj

G VAV w/System Lights

L Programmable Night Setback

DIGIT 36 — AGENCY APPROVAL

OPTION

0 None

1 cULus

DIGIT 37 — SERVICE

ENHANCEMENTS

0 Single Side Access Doors

A Dual Side Access Doors

B Single Side Access Doors /

Marine Lights

C Dual Side Access Doors / Marine

Lights

DIGIT 38 — BELT GUARDS/

BURGLAR BARS/MARINE LIGHTS

0 None

1 Belt Guards

2 Burglar Bars

3 Belt Guards / Burglar Bars

8 RT-SVX28E-EN

Page 9

General Information

Unit Nameplate

One Mylar unit nameplate is located on the outside upper left corner of the control panel door. It

includes the unit model number, serial number, electrical characteristics, weight, refrigerant

charge, as well as other pertinent unit data. A small metal nameplate with the Model Number, Serial

Number, and Unit Weight is located just above the Mylar nameplate, and a third nameplate is

located on the inside of the control panel door.

Precautionary Measures

• Avoid breathing fiberglass dust

• Use a NIOSH approved dust/mist respirator

• Avoid contact with the skin or eyes. Wear long-sleeved, loose-fitting clothing, gloves, and

eye protection

• Wash clothes separately from other clothing: rinse washer thoroughly

• Operations such as sawing, blowing, tear-out, and spraying may generate fiber concentrations

requiring additional respiratory protection. Use the appropriate NIOSH approved respiration in

these situations.

First Aid Measures

Eye Contact

– Flush eyes with water to remove dust. If symptoms persist, seek medical attention.

Skin Contact

– Wash affected areas gently with soap and warm water after handling.

Commonly used Acronyms

For convenience, a number of acronyms and abbreviations are used throughout this manual.

These acronyms are alphabetically listed and defined below.

• AHU = Air Handler Unit • LCI-I = LonTalk Communication Interface for IntelliPak

• BAS = Building automation systems • LH = Left-hand

• BCI = BACnet Communication Interface module • MWU = Morning warm-up

• CFM = Cubic-feet-per-minute • NSB = Night setback

• CV = Constant volume • O/A = Outside air

• CW = Clockwise • psig = Pounds-per-square-inch, gauge pressure

• CCW = Counterclockwise • R/A = Return air

• E/A = Exhaust air • RH = Right-hand

• ECEM = Exhaust/comparative enthalpy module • RPM = Revolutions-per-minute

• F/A = Fresh air • RTM = Rooftop module

• GBAS = Generic building automation system • S/A = Supply air

• HGBP = Hot gas bypass • SZ = Single-zone (unit airflow)

• HI = Human Interface • SZVAV = Single zone variable air volume

• HVAC = Heating, ventilation and air conditioning • UCM = Unit control modules

• I/O = Inputs/outputs • VAV = Variable air volume

• IOM = Installation/operation/ maintenance manual • VCM = Ventilation control module

• IPC = Interprocessor communications • VOM = Ventilation override module

• IPCB = Interprocessor communications bridge • w.c. = Water column

RT-SVX28E-EN 9

Page 10

General Information

Unit Description

Each Trane commercial, single-zone rooftop air handler ships fully assembled from the factory.

An optional roof curb, specifically designed for the W_HC units is available from Trane. The roof

curb kit must be field assembled and installed according to the latest edition of the roof curb

installation manual.

Trane Commercial Rooftop Air Handlers are controlled by a microelectronic control system that

consists of a network of modules and are referred to as Unit Control Modules (UCM). The acronym

UCM is used extensively throughout this document when referring to the control system network.

These modules through Proportional/Integral control algorithms perform specific unit functions

which provide the best possible comfort level for the customer.

They are mounted in the control panel and are factory wired to their respective internal

components. They receive and interpret information from other unit modules, sensors, remote

panels, and customer binary contacts to satisfy the applicable request for economizing, mechanical

cooling, heating, and ventilation. Refer to the following discussion for an explanation of each

module function.

Rooftop Module (RTM - Standard on all units)

The rooftop Module (RTM) responds to cooling, heating, and ventilation requests by energizing the

proper unit components based on information received from other unit modules, sensors, remote

panels, and customer supplied binary inputs. It initiates supply fan, exhaust fan, exhaust damper,

or variable frequency drive output, and economizer operation based on that information.

Human Interface Module (HI - standard on all units)

The Human Interface module enables the operator to adjust the operating parameters for the unit

using a 16 key keypad. The 2 line, 40 character LCD screen provides status information for the

various unit functions as well as menus for the operator to set or modify the operating parameters.

Heat Module (used on heating units)

The Heat module, upon receiving a request for Heating, energizes the appropriate heating stages

or strokes the Modulating Heating valve as required.

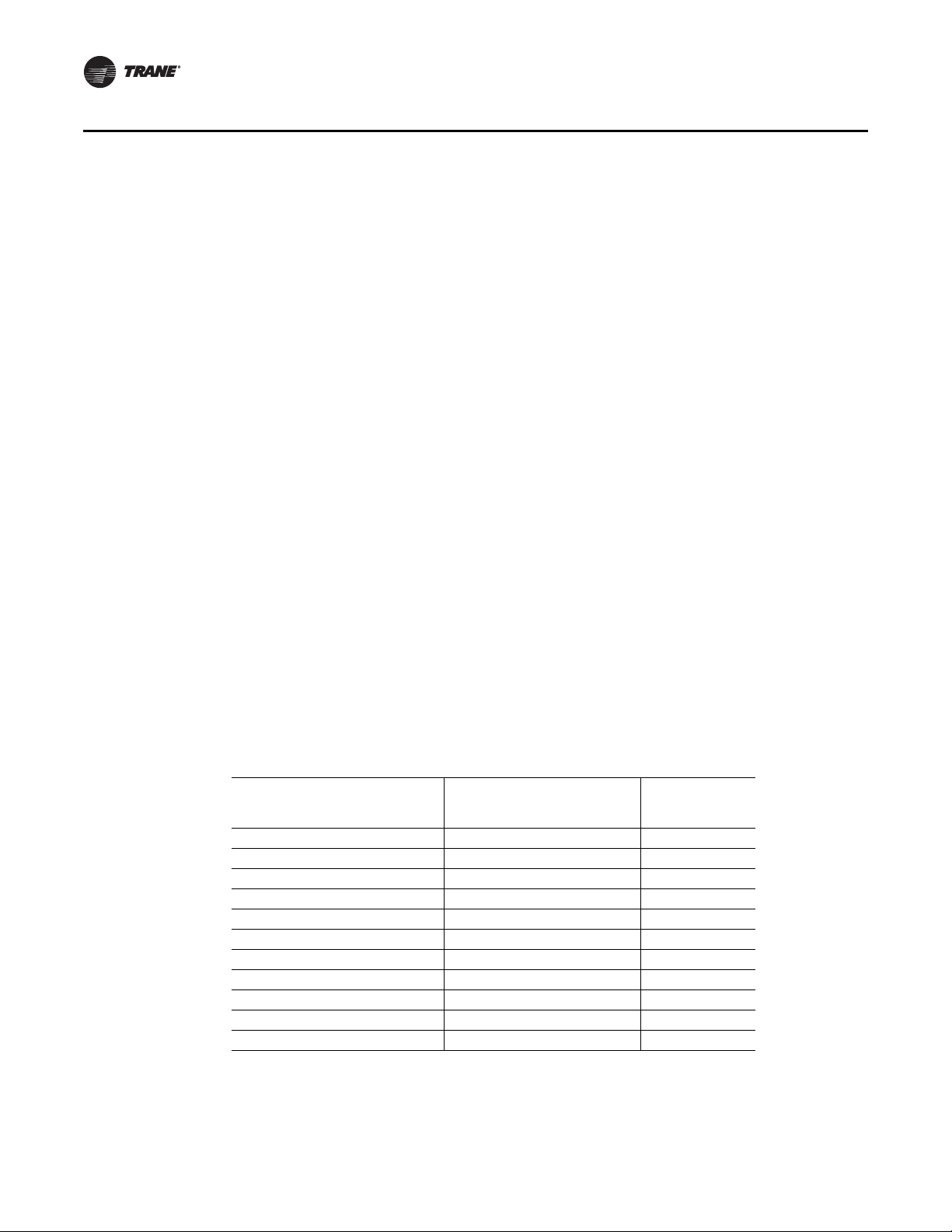

Table 1. Resistance input vs. setpoint temperature

RTM cooling or heating setpoint

input used as the source for a

ZONE temp setpoint (F)

40 40 1084

45 45 992

50 50 899

55 55 796

60 60 695

65 65 597

70 70 500

75 75 403

80 80 305

n/a 85 208

n/a 90 111

RTM cooling setpoint input

used as the source for SUPPLY

AIR temp setpoint cooling (F)

Resistance

(Ohms) Max.

Tolerance 5%

10 RT-SVX28E-EN

Page 11

General Information

Table 2. Resistance value vs. system operating mode

Resistance applied to RTM MODE

input Terminals (Ohms) Max.

Tolerance 5% Constant Volume Units

2320 Auto Off

4870 Auto Cool

7680 Auto Auto

10770 On Off

13320 On Cool

16130 On Auto

19480 Auto Heat

Ventilation Override Module (VOM - Optional)

Important: The ventilation override system should not be used to signal the presence of smoke

caused by a fire as it is not intended nor designed to do so.

The Ventilation Override module initiates specified functions such as; space pressurization,

exhaust, purge, purge with duct pressure control, and unit off when any one of the five (5) binary

inputs to the module are activated. If more than one ventilation sequence is activated, the one with

the highest priority is initiated.

Interprocessor Communications Board (IPCB - Optional used with the Optional

Remote Human Interface)

The Interprocessor Communication Board expands communications from the unit UCM network

to a Remote Human Interface Panel. DIP switch settings on the IPCB module for this application

should be; Switches 1 and 2 "Off", Switch 3 "On".

Lontalk/BACnet Communication Interface Module (LCI/BCI - Optional - used

™

on units with Trane ICS

or 3rd party Building Automation Systems)

The LonTalk/BACnet Communication Interface modules expand communications from the unit

UCM network to a Trane Tracer Summit™ or a 3rd party building automation system and allow

external setpoint and configuration adjustment and monitoring of status and diagnostics.

Exhaust/Comparative Enthalpy Module (ECEM - Optional used on units with

Statitrac and/or comparative enthalpy options)

The Exhaust/Comparative Enthalpy module receives information from the return air humidity

sensor, the outside air humidity sensor, and the return air temperature sensor to utilize the lowest

possible humidity level when considering economizer operation. In addition, it receives space

pressure information which is used to maintain the space pressure to within the setpoint

controlband. Refer to Figure 1, p. 12 for the Humidity vs. Voltage input values.

RT-SVX28E-EN 11

Page 12

General Information

Figure 1. Humidity vs. current

Ventilation Control Module (VCM)

The Ventilation Control Module (VCM) is located in the filter section of the unit and is linked to the

unit UCM network. Using a "velocity pressure" sensing ring located in the fresh air section allows

the VCM to monitor and control the quantity of fresh air entering the unit to a minimum airflow

setpoint.

An optional temperature sensor can be connected to the VCM which enables it to control a field

installed fresh air preheater.

An optional CO

adjusts the minimum CFM upward as the CO

(reset) setpoint value for fresh air entering the unit is limited to the systems operating CFM. The

following table lists the Minimum Outside Air CFM vs. Input Voltage.

sensor can be connected to the VCM to control CO2 reset. The reset function

2

concentrations increase. The maximum effective

2

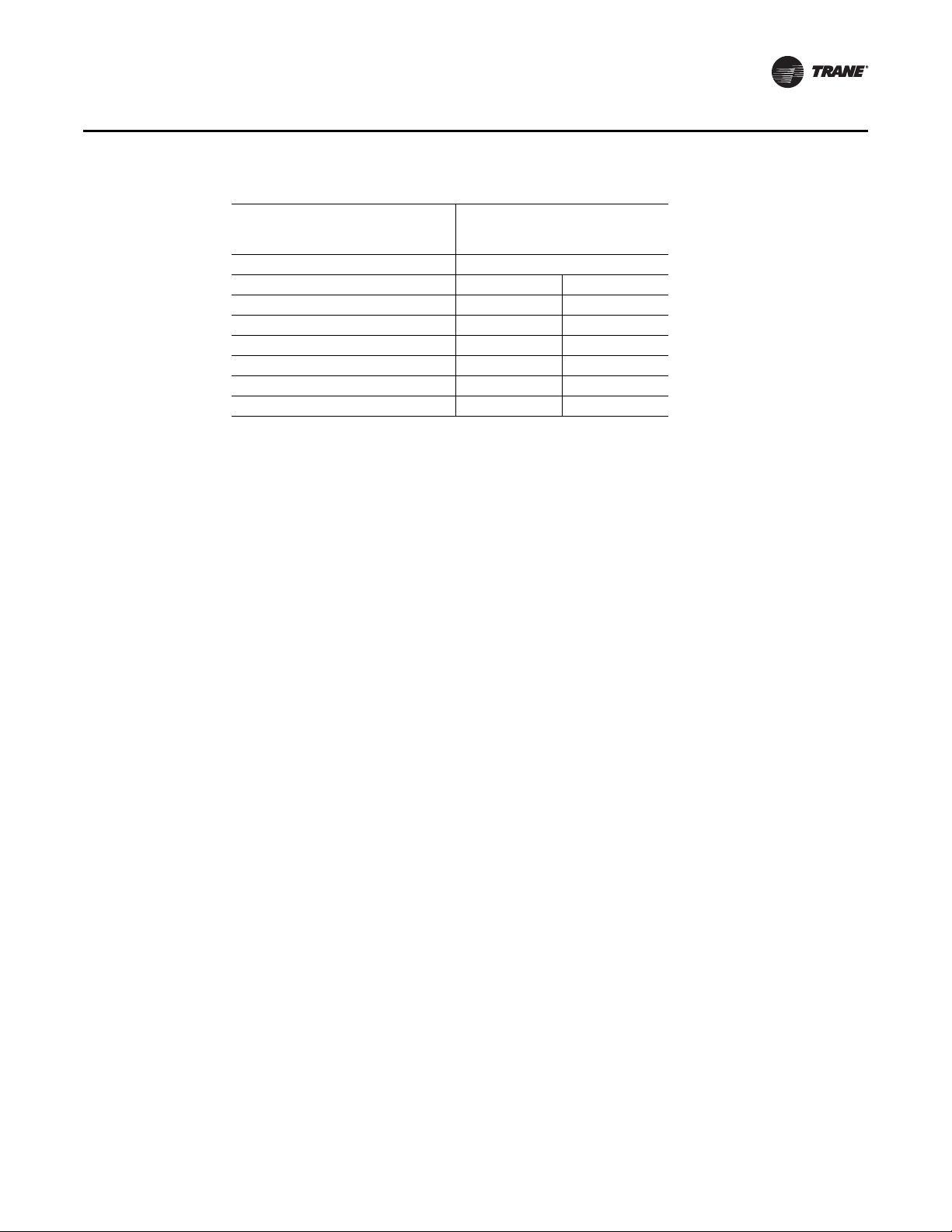

Table 3. Minimum outside air setpoint w/VCM and Traq™ sensing

Unit Input Volts CFM

Casings A-Cs 0.5 - 4.5 VDC 0 - 45000

The velocity pressure transducer/solenoid assembly is illustrated below. Refer to the “Units with

Traq™ Sensor,” p. 81 section for VCM operation.

Table 4. Velocity pressure transducer/solenoid assembly

12 RT-SVX28E-EN

Page 13

Generic Building Automation System Module (GBAS - Optional used with

non-Trane building control systems)

The Generic Building Automation System (GBAS) module allows a non-Trane building control

system to communicate with the air handler unit and accepts external setpoints in the form of

analog inputs for cooling, heating, supply air pressure, and a binary Input for demand limit. Refer

to the "Field Installed Control Wiring" section for the input wiring to the GBAS module and the

various desired setpoints with the corresponding DC voltage inputs for CV, VAV, and SZ VAV

applications.

Input Devices and System Functions

The descriptions of the following basic Input Devices used within the UCM network are to acquaint

the operator with their function as they interface with the various modules. Refer to the unit

electrical schematic for the specific module connections.

Constant Volume (CV) and Variable Air Volume (VAV) Units

Chilled Water Valve Control

The 0 to 10 VDC output from the heat module doubles as the chilled water controller. The unit has

isolating relays to switch between heat and cool.

Supply Air Temperature Sensor

An analog input device used with CV and VAV applications that monitors the supply air

temperature for: supply air temperature control (VAV), supply air temperature reset (VAV), supply

air temperature low limiting (CV), supply air tempering (CV/VAV). It is mounted in the supply air

discharge section of the unit and is connected to the RTM.

General Information

Return Air Temperature Sensor

An analog input device used with a return humidity sensor on CV and VAV applications when the

comparative enthalpy option is ordered. It monitors the return air temperature and compares it to

the outdoor temperature to establish which temperature is best suited to maintain the cooling

requirements. It is mounted in the return air section and is connected to the ECEM.

Filter Switch

A binary input device used on CV and VAV applications that measures the pressure differential

across the unit filters. It is mounted in the filter section and is connected to the RTM. A diagnostic

SERVICE signal is sent to the remote panel if the pressure differential across the filters is at least 0.5"

w.c. The contacts will automatically open when the pressure differential across the filters decrease

to 0.4" w.c. The switch differential can be field adjusted between 0.17" w.c. to 5.0" w.c. ± 0.05" w.c.

Supply and Exhaust Airflow Proving Switches

Supply Airflow Proving Switch is a binary input device used on CV and VAV applications to signal

the RTM when the supply fan is operating. It is located in the supply fan section of the unit and is

connected to the RTM. During a request for fan operation, if the differential switch is detected to

be open for 40 consecutive seconds; heat operation is turned "Off", the request for supply fan

operation is turned "Off" and locked out, exhaust dampers (if equipped) are "closed", economizer

dampers (if equipped) are "closed", and a manual reset diagnostic is initiated.

Exhaust Airflow Proving Switch is a binary input device used on all air handler units equipped with

an exhaust fan. It is located in the exhaust fan section of the unit and is connected to the RTM.

During a request for fan operation, if the differential switch is detected to be open for 40 consecutive

seconds, the economizer is closed to the minimum position setpoint, the request for exhaust fan

operation is turned "Off" and locked out, and a manual reset diagnostic is initiated. The fan failure

lockout can be reset at the Human Interface located in the unit control panel, by Tracer, or by cycling

the control power to the RTM Off/On).

RT-SVX28E-EN 13

Page 14

General Information

Supply and Exhaust Fan Circuit Breakers

The supply fan and exhaust fan motors are protected by circuit breakers. They will trip and interrupt

the power supply to the motors if the current exceeds the breaker's "must trip" value. The rooftop

module (RTM) will shut all system functions "Off" when an open fan proving switch is detected.

Outdoor Air Humidity Sensor

An analog input device used on CV and VAV applications with 100% economizer. It monitors the

outdoor humidity levels for economizer operation. It is mounted in the fresh air intake section and

is connected to the RTM.

Return Air Humidity Sensor

An analog input device used on CV and VAV applications with the comparative enthalpy option.

It monitors the return air humidity level and compares it to the outdoor humidity level to establish

which conditions are best suited to maintain the cooling requirements. It is mounted in the return

air section and is connected to the ECEM.

Space Humidity Sensor

Analog input device used on CV and VAV applications with modulating dehumidification option

and/or humidification field installed option. It is used to monitor the humidity level in the space and

compared to dehumidification and humidification setpoints to maintain space humidity

requirements. It is field mounted in the space and connected to the RTM.

Status/Annunciator Output

An internal function within the RTM module on CV and VAV applications that provides:

1. diagnostic and mode status signals to the remote panel (LEDs) and to the Human Interface

2. control of the binary Alarm output on the RTM

3. control of the binary outputs on the GBAS module to inform the customer of the operational

status and/or diagnostic conditions

Table 5. Transducer voltage output vs. pressure input w/ multiple sensors

Space Pressure Transducer

An analog input device used on CV and VAV applications with the Statitrac option. It modulates the

exhaust dampers to keep the space pressure within the building to a customer designated

controlband. It is mounted in the filter section just above the exhaust damper actuator and is

14 RT-SVX28E-EN

Page 15

General Information

connected to the ECEM. Field supplied pneumatic tubing must be connected between the space

being controlled and the transducer assembly.

Morning Warm-Up—Zone Heat

When a system changes from an unoccupied to an occupied mode, or switches from STOPPED to

AUTO, or power is applied to a unit with the MWU option, the heater in the unit or external heat

will be brought on if the space temperature is below the MWU setpoint. The heat will remain on

until the temperature reaches the MWU setpoint. If the unit is VAV, then the VAV box/unocc relay

will continue to stay in the unoccupied position and the VFD output will stay at 100% during the

MWU mode. When the MWU setpoint is reached and the heat mode is terminated, then the VAV

box/unocc relay will switch to the occupied mode and the VFD output will be controlled by the duct

static pressure. During Full Capacity MWU the economizer damper is held closed for as long as it

takes to reach setpoint. During Cycling Capacity MWU the economizer damper is allowed to go to

minimum position after one hour of operation if setpoint has not been reached.

Supply Air Temperature Low Limit

Uses the supply air temperature sensor input to modulate the economizer damper to minimum

position in the event the supply air temperature falls below the occupied heating setpoint

temperature.

Freezestat - Heating

A binary input device used on CV and VAV units with Hydronic Heat. It is mounted in the heat

section and connected to the Heat Module. If the temperature of the air entering the heating coil

falls to 40 F, the normally open contacts on the freezestat closes signalling the Heat Module and the

Rooftop Module (RTM) to:

1. drive the Hydronic Heat Actuator to the full open position

2. turn the supply fan "Off"

3. closes the outside air damper

4. turns "On" the SERVICE light at the Remote Panel

5. initiates a "Freezestat" diagnostic to the Human Interface

Freezestat - Cooling

A binary input device used on CV and VAV units with Chilled Water. The freezestat is mounted on

the upstream side of the cooling coil. If the temperature of the air entering the cooling coil falls to

40 F, the normally closed contacts on the freezestat open signalling the Rooftop Module (RTM) to:

1. drive the Chilled Water Actuator to the full open position

2. turn the supply fan "Off"

3. closes the outside air damper

4. turns "On" the SERVICE light at the Remote Panel

5. initiates a "Freezestat" diagnostic to the Human Interface

Chilled Water Valve Control

The 0 to 10 VDC output from the heat module doubles as the chilled water controller. The unit has

isolating relays to switch between heat and cool.

Constant Volume (CV) Units

Zone Temperature—Cooling

Relies on input from a sensor located directly in the space, while a system is in the occupied

"Cooling" mode. It modulates the economizer (if equipped) and/or stages the mechanical cooling

"On and Off" as required to maintain the zone temperature to within the cooling setpoint deadband.

RT-SVX28E-EN 15

Page 16

General Information

Zone Temperature—Heating

Relies on input from a sensor located directly in the space, while a system is in the occupied

"Heating" mode or an unoccupied period, to stage the heat "on and off" or to modulate the heating

valve (hydronic heat only) as required to maintain the zone temperature to within the heating

setpoint deadband. The supply fan will be requested to operate any time there is a requested for

heat. On gas heat units, the fan will continue to run for 60 seconds after the furnace is turned off.

Supply Air Tempering

On CV units equipped with staged heat, if the supply air temperature falls 10 F below the occupied

heating setpoint temperature while the heater is "Off", the first stage of heat will be turned "On".

The heater is turned "Off" when the supply air temperature reaches 10º F above the occupied

heating setpoint temperature.

Variable Air Volume (VAV) Units

Occupied Heating—Supply Air Temperature

When a VAV unit is equipped with "Modulating Heat", and the system is in an occupied mode, and

the field supplied changeover relay contacts have closed, the supply air temperature will be

controlled to the customer specified supply air heating setpoint. It will remain in the heating status

until the changeover relay contacts are opened.

Occupied Cooling—Supply Air Temperature

When a VAV unit is in the occupied mode, the supply air temperature will be controlled to the

customer specified supply air cooling setpoint by modulating the economizer and/or staging the

mechanical cooling "On and Off" as required. The changeover relay contacts must be open on units

with "Modulating Heat" for the cooling to operate.

Daytime Warm-up

On VAV units equipped with heat, if the zone temperature falls below the daytime warm-up initiate

temperature during the occupied mode, the system will switch to full airflow. During this mode, the

VAV box/unocc relay will be energized (this is to signal the VAV boxes to go to 100%). After the VAV

box max stroke time has elapsed (factory set at 6 minutes), the VFD output will be set to 100%. The

airflow will be at 100% and the heat will be turned on to control to the occupied heating setpoint.

When the zone temperature reaches the daytime warm-up termination setpoint, the heat will be

turned off, the relay will be de-energized, releasing the VAV boxes, the VFD output will go back to

duct static pressure control and the unit will return to discharge air control. If the occ zone heating

setpoint is less than the DWU terminate setpoint, the heat will turn off when the occ zone heat

setpoint is reached, but it will stay in DWU mode and cycle the heat to maintain setpoint.

Unoccupied Heating—Zone Temperature

When a VAV unit is equipped with gas, electric, or hydronic heat and is in the unoccupied mode,

the zone temperature will be controlled to within the customer specified setpoint deadband. During

an unoccupied mode for a VAV unit, the VAV box/unocc relay will be in the unoccupied position and

the VFD output will be at 100%. This means that if there is a call for heat (or cool) and the supply

fan comes on, it will be at full airflow and the VAV boxes in the space will need to be 100% open

as signaled by the VAV box/unocc relay.Supply Air Tempering

On VAV units equipped with "Modulating Heat", if the supply air temperature falls 10

supply air temperature setpoint, the hydronic heat valve will modulate to maintain the supply air

temperature to within the low end of the setpoint deadband.

F below the

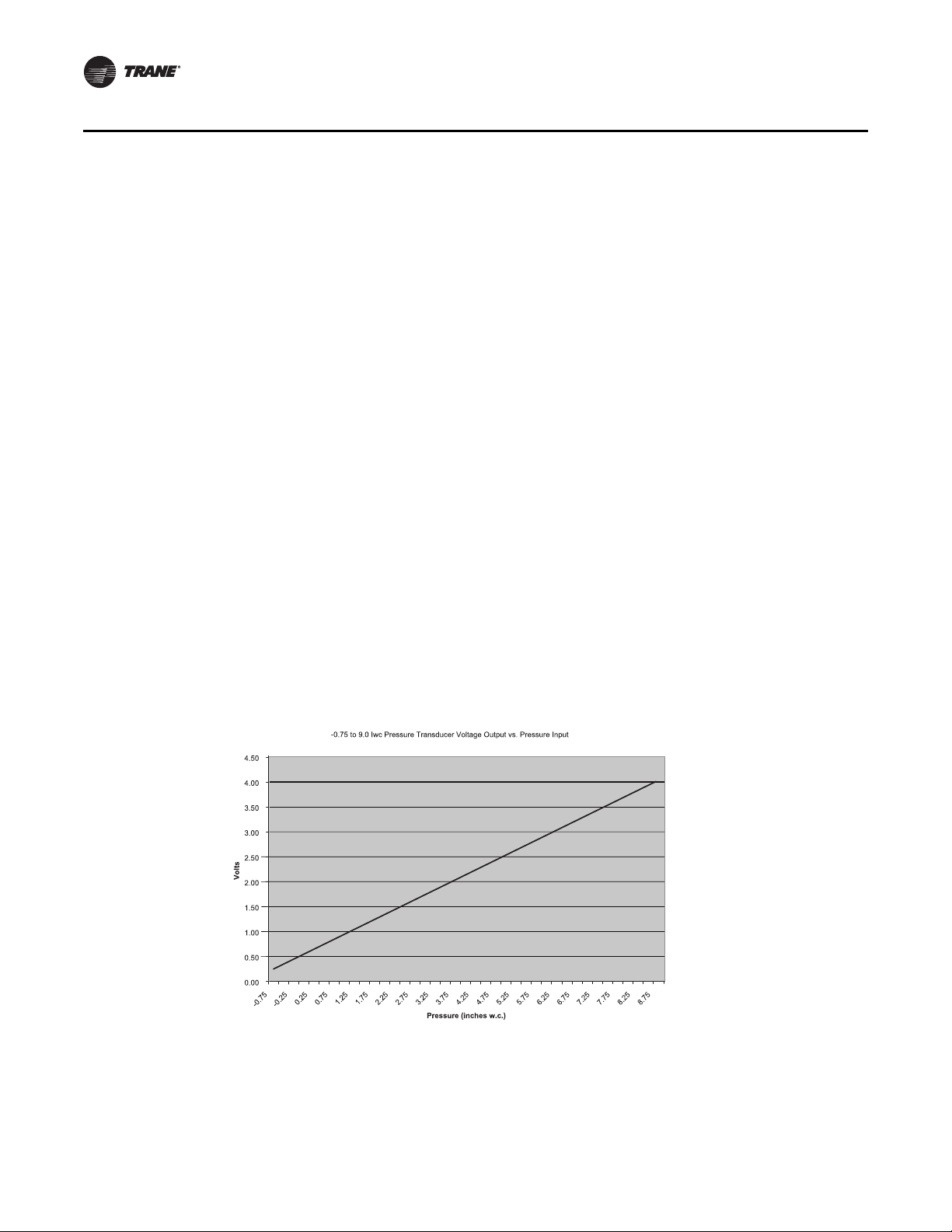

Supply Duct Static Pressure Control (Occupied)

The RTM relies on input from the duct pressure transducer when a unit is equipped with a Variable

Frequency Drive to position the supply fan speed to maintain the supply duct static pressure to

within the static pressure setpoint deadband. Refer to Figure 2, p. 17.

16 RT-SVX28E-EN

Page 17

Figure 2. Transducer voltage output vs. pressure input with multiple sensors

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

-0.5 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Pressure (inches w.c.)

Volts

Single Zone Variable Air Volume (SZVAV) Only

The IntelliPak controls platform will support Single Zone VAV as an optional unit control type in

order to meet ASHRAE 90.1. The basic control will be a hybrid VAV/CV configured unit that provides

discharge temperature control to a varying discharge air temperature target setpoint based on the

space temperature and/or humidity conditions. Concurrently, the unit will control and optimize the

supply fan speed to maintain the zone temperature to a zone temperature setpoint.

General Information

Supply Fan Output Control

Units configured for Single Zone VAV control will utilize the same supply fan output control scheme

as on traditional VAV units except the VFD signal will be based on zone heating and cooling demand

instead of the supply air pressure.

VFD Control

Single Zone VAV units will be equipped with a VFD-controlled supply fan which will be controlled

via a 0-10VDC signal from the Rooftop Module (RTM). With the RTM supply fan output energized

and the RTM VFD output at 0VDC, the fan speed output is 37% (22Hz) from the VFD by default; and

at 10VDC the fan speed output is 100% (60Hz). The control scales the 0-10VDC VFD output from the

RTM linearly to control between the 37-100% range. The VFD will modulate the supply fan motor

speed, accelerating or decelerating as required to maintain the zone temperature to the zone

temperature setpoint. When subjected to high ambient return conditions the VFD will reduce its

output frequency to maintain operation. Bypass control is offered to provide full nominal airflow

in the event of drive failure.

Ventilation Control

Units configured for Single Zone VAV control will require special handling of the OA Damper

Minimum Position control in order to compensate for the non-linearity of airflow associated with

the variable supply fan speed and damper combinations. Units configured for TRAQ with or

without DCV will operate identically to traditional units with no control changes.

RT-SVX28E-EN 17

Space Pressure Control

For units configured with Space Pressure Control with or without Statitrac, the new schemes

implemented for economizer minimum position handling require changes to the existing Space

Pressure Control scheme in order to prevent over/under pressurization. The overall scheme will

remain very similar to VAV units with Space Pressure Control with the exception of the dynamic

Exhaust Enable Setpoint.

For SZVAV an Exhaust Enable Setpoint must be selected during the 100% Fan Speed Command.

Once selected, the difference between the Exhaust Enable Setpoint and Design OA Damper

Page 18

General Information

Minimum Position at 100% Fan Speed Command will be calculated. The difference calculated will

be used as an offset and added to the Active Building Design OA Minimum Position Target in order

to calculate the dynamic Exhaust Enable Target, which will be used throughout the Supply Fan

Speed/OA Damper Position range.

The Exhaust Enable Target could be above or below the Active Building Design OA Minimum

Position Target Setpoint, based on the Active Exhaust Enable Setpoint being set above or below

the Building Design Minimum Position at 100% Fan Speed Command. Note that an Exhaust Enable

Setpoint of 0% will result in the same effect on Exhaust Fan control as on VAV applications with and

without Statitrac.

Occupied Cooling Operation

For normal cooling operation, cooling capacity will be staged or modulated in order to meet the

calculated discharge air target setpoint. If the current active cooling capacity is controlling the

discharge air within the deadband, no additional cooling capacity change will be requested. As the

Discharge Air Temperature rises above the deadband, the algorithm will request additional

capacity as required (additional compressors or economizer). As the Discharge Air Temperature

falls below the deadband, the algorithm will request a reduction in active capacity.

Default Economizer Operation

By default, the unit will be setup to optimize the minimum supply fan speed capability during

Economizer Only operation. If the economizer is able to meet the demand alone, due to desirable

ambient conditions, the supply fan speed will be allowed to increase above the minimum prior to

utilizing mechanical cooling if discharge air setpoint falls below the discharge air Lower Limit

(Cooling) setpoint.

Unoccupied Mode

In Unoccupied mode the unit will utilize setback setpoints, 0% Minimum OA Damper position, and

Auto Fan Mode operation as on normal CV units. The Supply Fan speed, and cooling and

modulating types of heat, will be controlled to the discharge air target setpoint as is done during

occupied periods. The Supply fan speed during staged heat control will be forced to 100% as on

normal CV units.

Occupied Heating Operation

Occupied heating operation has two separate control sequences; staged and modulated. All staged

heating types will drive the supply fan to maximum flow and stage heating to control to the Zone

Heating Setpoint. For units with Hydronic and Gas heat, modulated SZVAV Heating. On an initial

call for heating, the supply fan will drive to the minimum heating airflow. On an additional call for

heating, the heat will control in order to meet the calculated discharge air target setpoint. As the

load in the zone continues to request heat operation, the supply fan will ramp-up while the control

maintains the heating discharge air temperature. Heating can be configured for either the energy

saving SZVAV Heating solution as described above, or the traditional, less efficient CV Heating

solution.

Compressor (DX) Cooling

Compressor control and protection schemes will function identical to that of a traditional unit.

Normal compressor proving and disable input monitoring will remain in effect as well as normal

3-minute minimum on, off, and inter-stage timers. Also, all existing head pressure control schemes

will be in effect.

Cooling Sequence

If the control determines that there is a need for active cooling capacity in order to meet the

calculated discharge air target setpoint, once supply fan proving has been made, the unit will begin

to stage compressors accordingly. Note that the compressor staging order will be based on unit

configuration and compressor lead/lag status.

18 RT-SVX28E-EN

Page 19

Once the discharge air target setpoint calculation has reached the Minimum Setpoint and

compressors are being utilized to meet the demand, as the discharge air target setpoint value

continues to calculate lower the algorithm will begin to ramp the supply fan speed up toward 100%.

Note that the supply fan speed will remain at the compressor stage’s associated minimum value

(as described below) until the discharge air target setpoint value is calculated below the discharge

air temperature Minimum Setpoint (limited discharge air target setpoint).

As the cooling load in the zone decreases the zone cooling algorithm will reduce the speed of the

fan down to minimum per compressor stage and control the compressors accordingly. As the

compressors begin to de-energize, the supply fan speed will fall back to the Cooling Stage’s

associated minimum fan speed, but not below. As the load in the zone continues to drop, cooling

capacity will be reduced in order to maintain the discharge air within the ± ½ discharge air target

deadband.

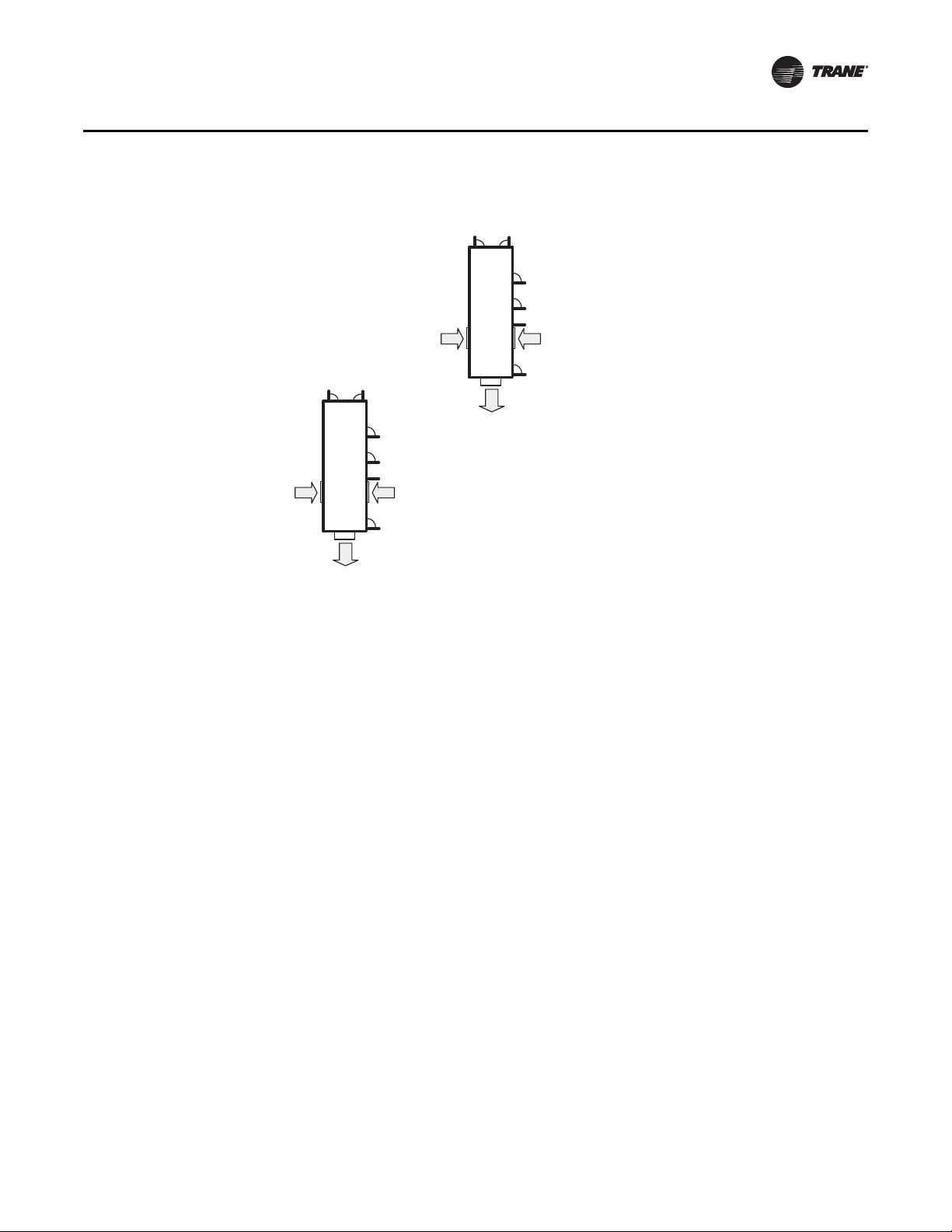

Space Temperature Averaging

Space temperature averaging for Constant Volume applications is accomplished by wiring a

number of remote sensors in a series/parallel circuit.

The fewest number of sensors required to accomplish space temperature averaging is four. The

Space Temperature Averaging with Multiple Sensors figure illustrates a single sensor circuit

(Single Zone), four sensors wired in a series/parallel circuit (Four Zone), nine sensors wired in a

series/parallel circuit (Nine Zone). Any number squared, is the number of remote sensors required.

Wiring termination will depend on the type of remote panel or control configuration for the system.

Refer to the wiring diagrams that shipped with the unit.

General Information

Table 6. Space temperature averaging with multiple sensors

RT-SVX28E-EN 19

Page 20

General Information

Return/

Exhaust

Fan

Fresh Air

Dampers

Supply Fan

Heating

Section

Exhaust Damper

Hood

Variable

Frequency

Drive (VFD)

Filter Section

Chilled Water Coil

Fresh Air

Dampers

Return Air Dampers

Flue Vent

Access

Variable

Frquency

Drive (VFD)

Hot Water/Steam

Hydronic Connection

valves and actuator

Outside Air

Static Kit and

sensors

Baysens set

Controls

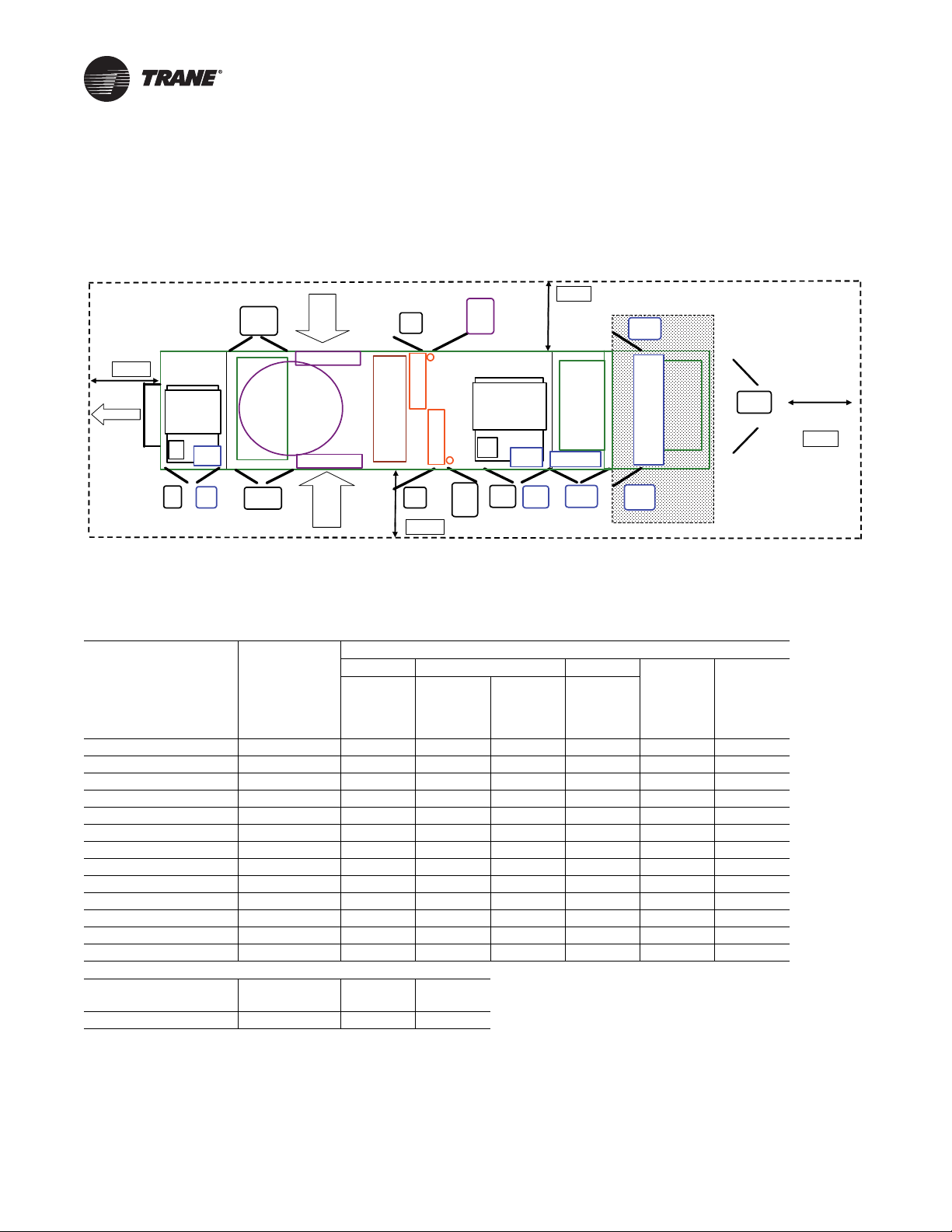

Table 7. Unit component layout and "ship with" locations

Unit Control Modules

Unit control modules are microelectronic circuit boards designed to perform specific unit

functions. These modules, through proportional/integral control algorithms, provide the best

possible comfort level for the customer. They are mounted in the control panel and are factory

wired to their respective internal components. They receive and interpret information from other

unit modules, sensors, remote panels, and customer binary contacts to satisfy the applicable

request for economizing, mechanical cooling, heating, and ventilation. Figure 3, p. 21 illustrates

the typical location of each designated module.

20 RT-SVX28E-EN

Page 21

Figure 3. Control module locations

BCI

General Information

RT-SVX28E-EN 21

Page 22

Dimensional Data

Blank Section

Cool

Coil

(F)

Fltr

(F)

Sup

Mtr

Sup

VFD

Fltr

(R)

Cool

Coil

(R)

Heat

(L&R)

OptionStd

As Req. As Req.StdStd

Std

Rtn

Mtr

Rtn

VFD

As Req.

Std

ER Fltr

(L&R) (F)

Std

ER Fltr

(L&R) (R)

Std

Final

Filter

Fnl

Fltr (F)

As Req.

Fnl

Fltr (R)

As Req.

Filters

VFD

Heat

VFD

Ctrl Box

(L&R)

Std

Exhaust

Air

Air

Exh

AH R

AH L

C Box

Unit Clearance

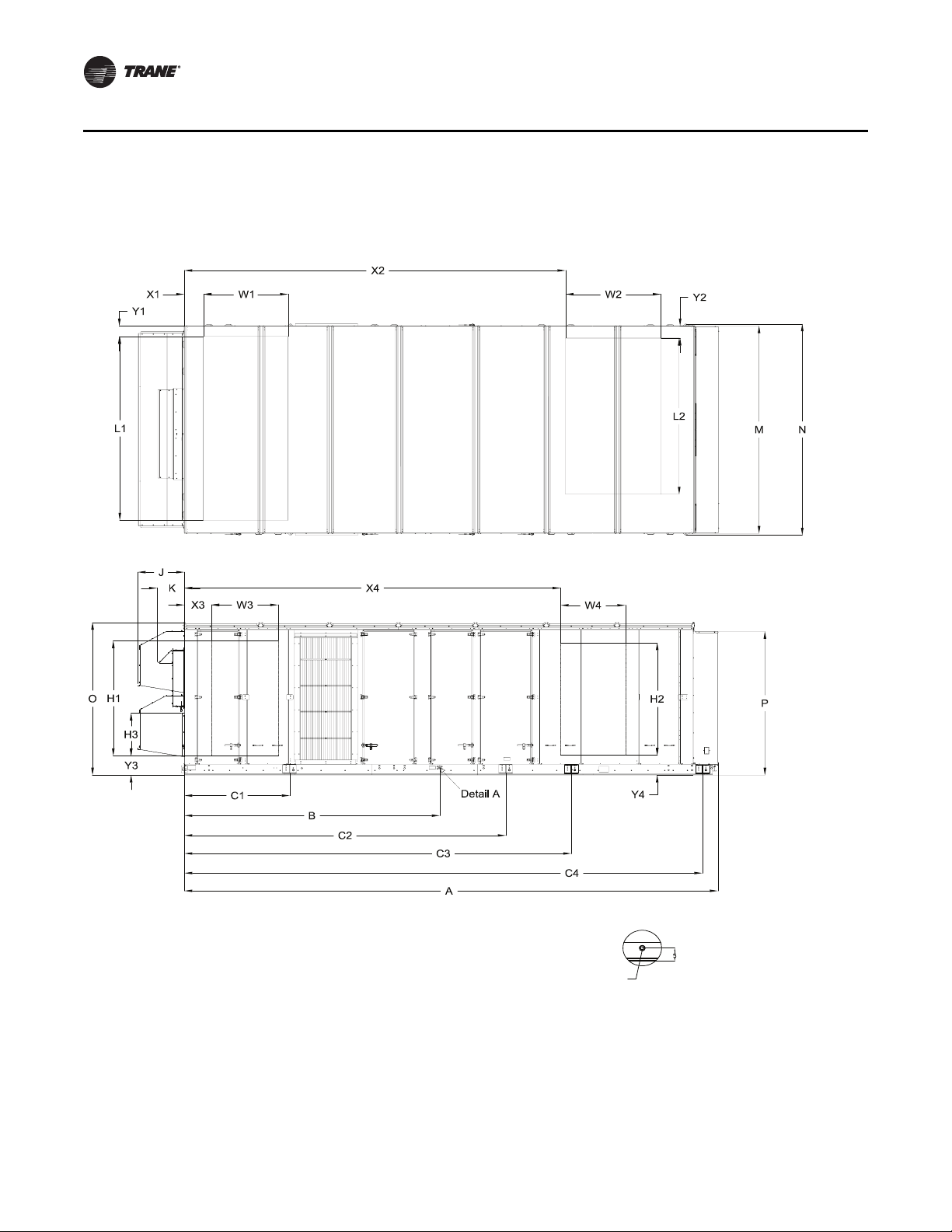

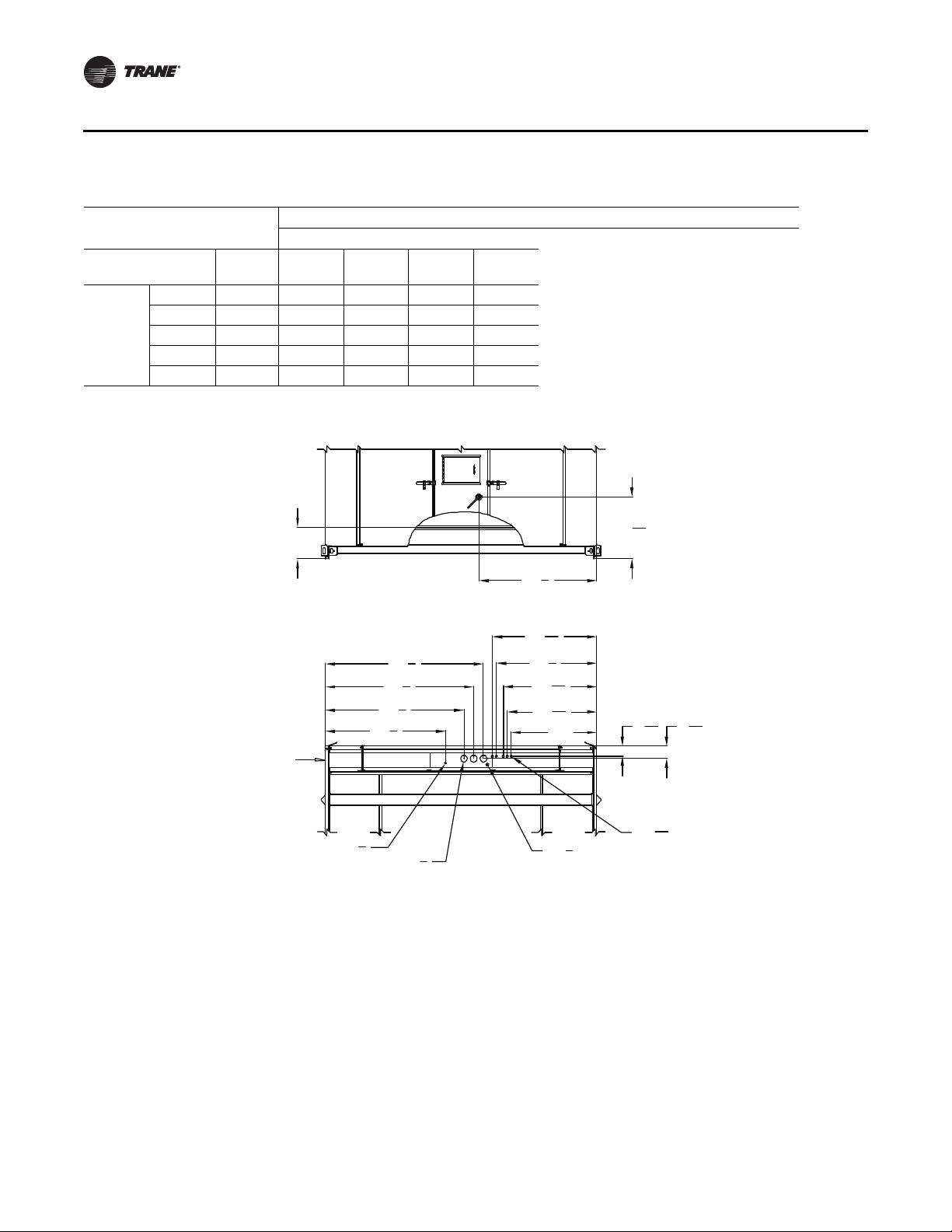

Figure 4. Minimum required clearance

(i) Unit drawing is representative only and may not accurately depict all models.

Table 8. Minimum required clearance

Door Location Availability A,B,C

Exhaust Motor Std 2' 2" * * * * *

Exhaust VFD As Req. * 2' 2" * * * *

Filter (Front) Std2' 8"*****

Filter (Rear) Option * * * * 2’ 2" *

Cooling Coil (Front) Std 2' 2" * * * * *

Cooling Coil (Rear) Std 2' 8" * * * * *

or Cooling Coil (Rear)Option******

Supply Motor Std2' 8"*****

Supply VFD As Req. * * 2' 2" * * *

Heat (Left & Right) As Req. * * * 2' 2" * *

Final Filter (Front) As Req. * * * * * 2' 2"

Final Filter (Rear) As Req. * * * * * 2' 2"

Control Box (L & R)Std3' 2"*****

Minimum Required Clearance (Ft.)

AH_L AH_R Exh

8’ 8’ 8’ 6’

(i)

Fresh

Fresh

Unit Option Selection (Door Swing Ft. and In.)

Standard VFD Heat

Return/

Exhaust Supply

Control

Box

Electric/

Water/

Steam

Hot

Two-side

Access Final Filter

22 RT-SVX28E-EN

Page 23

Figure 5. Multiple units placement

Outdoor

Air Intake

Outdoor

Air Intake

Exhaust

Air

Outdoor

Air Intake

Outdoor

Air Intake

Exhaust

Air

Dimensional Data

Important: Stagger units to minimize span deflection which deters sound transmission and to

maximize proper diffusion of the exhaust air before it reaches the adjacent unit fresh

air intake.

RT-SVX28E-EN 23

Page 24

Dimensional Data

1-1/4 NPT. DRAIN

2X TYP. LEFT & RIGHT SIDES OF UNIT

Detail A

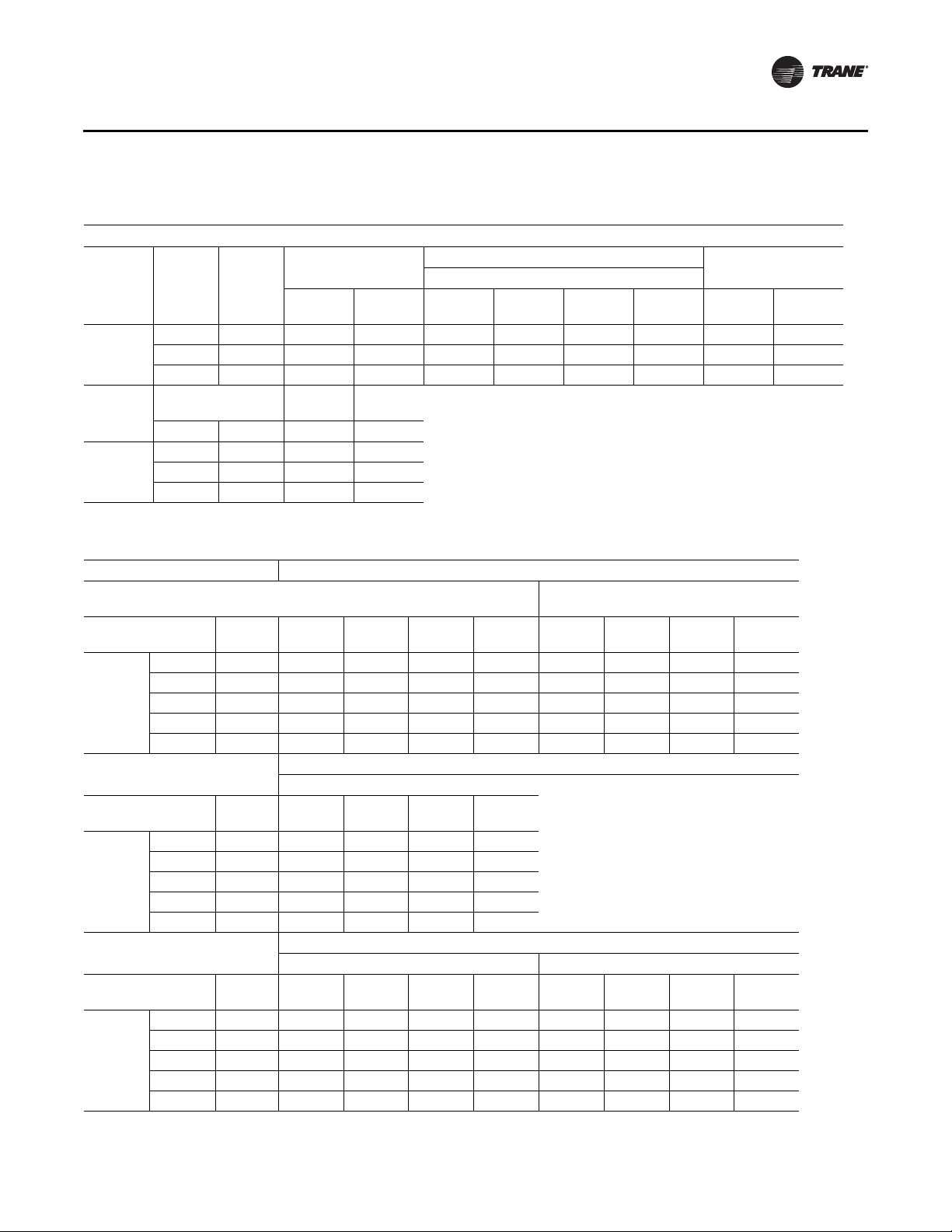

Unit Dimensions

Figure 6. Unit top/front view

24 RT-SVX28E-EN

Page 25

Table 9. Unit dimensions (In.)

ONE-PIECE Dimensions

Lifting Lug Locations

Unit Dimensions Air Handler Side Unit Width

Blank

Casing

A, B, C

Section A B C1C2C3C4 M N

None 334 2/16 159 15/16 66 252 14/16 n/a n/a 139 13/16 143 8/16

4Ft 382 5/16 159 15/16 66 252 14/16 368 6/16 n/a 139 13/16 143 8/16

8Ft 430 9/16 159 15/16 66 252 14/16 416 10/16 n/a 139 13/16 143 8/16

Unit Height

Return

Fan

Exhaust

Fan

Casing O P J K

103 12/16 97 9/16 29 3/16 17

A, B, C

103 12/16 97 9/16 29 3/16 17

103 12/16 97 9/16 29 3/16 17

Table 10. Downflow/horizontal airflow configuration dimensions (in.)

Dimensional Data

Casing Gas Heat

No Gas None 14 13/16 8 14/16 48 3/16 121 15/16 14 13/16 42 14/16 48 3/16 53 14/16

No Gas 4Ft 14 13/16 8 14/16 48 3/16 121 15/16 14 13/16 42 14/16 48 3/16 53 14/16

A, B, C

No Gas 8Ft 14 13/16 8 14/16 48 3/16 121 15/16 14 13/16 42 14/16 48 3/16 53 14/16

Gas None 14 13/16 8 14/16 48 3/16 121 15/16 14 13/16 42 14/16 48 3/16 53 14/16

Gas 8Ft 14 13/16 8 14/16 48 3/16 121 15/16 14 13/16 42 14/16 48 3/16 53 14/16

Casing Gas Heat

No Gas None 256 1/16 13 47 14/16 102 8/16

No Gas 4Ft 304 4/16 13 47 14/16 102 8/16

A, B, C

No Gas 8Ft 352 8/16 13 47 14/16 102 8/16

Gas None 256 1/16 13 47 14/16 102 8/16

Gas 8Ft 352 8/16 13 47 14/16 102 8/16

Casing Gas Heat

No Gas None 9 5/16 10 10/16 54 12/16 84 15/16 6 5/16 8 3/16 35 3/16 127 2/16

No Gas 4Ft 9 5/16 10 10/16 54 12/16 84 15/16 6 5/16 8 3/16 35 3/16 127 2/16

A, B, C

No Gas 8Ft 9 5/16 10 10/16 54 12/16 84 15/16 6 5/16 8 3/16 35 3/16 127 2/16

Gas None 9 5/16 10 10/16 54 12/16 84 15/16 6 5/16 8 3/16 35 3/16 127 2/16

Gas 8Ft 9 5/16 10 10/16 54 12/16 84 15/16 6 5/16 8 3/16 35 3/16 127 2/16

DOWNFLOW Opening Dimensions

Return Opening—with or

without Exhaust Fan

Return Opening—with Return Fan

Blank

SectionX1Y1W1L1X1Y1W1L1

DOWNFLOW Opening Dimensions

Supply Opening

Blank

Section X2 Y2 W2 L2

HORIZONTAL Opening Dimensions

Return Side Opening Return End Opening

Blank

SectionX3Y3W3H1X1Y3H3H1

RT-SVX28E-EN 25

Page 26

Dimensional Data

16

60

3

4

71

1

4

76

1

4

81

1

4

46

1

16

48

1

16

61

3

4

44

Ø3

5

8

Ø1

1

16

Ø

7

8

6

5

16

5

5

16

Marine lights

customer supplied

power service

entrance

Unit power

External customer

connection points

Outside edge of

base rail

51

5

8

53

11

16

31

11

16

Ø1

1

2

Table 10. Downflow/horizontal airflow configuration dimensions (in.)

HORIZONTAL Opening Dimensions

Supply Opening

Casing Gas Heat

No Gas None 254 12/16 10 10/16 54 12/16 84 15/16

No Gas 4Ft 302 15/16 10 10/16 54 12/16 84 15/16

A, B, C

No Gas 8Ft 351 3/16 10 10/16 54 12/16 84 15/16

Gas None 254 12/16 10 10/16 54 12/16 66 11/16

Gas 8Ft 351 3/16 10 10/16 54 12/16 84 15/16

Blank

Section X4 Y4 W4 H2

Figure 7. Electrical entry details/bottom view

26 RT-SVX28E-EN

Page 27

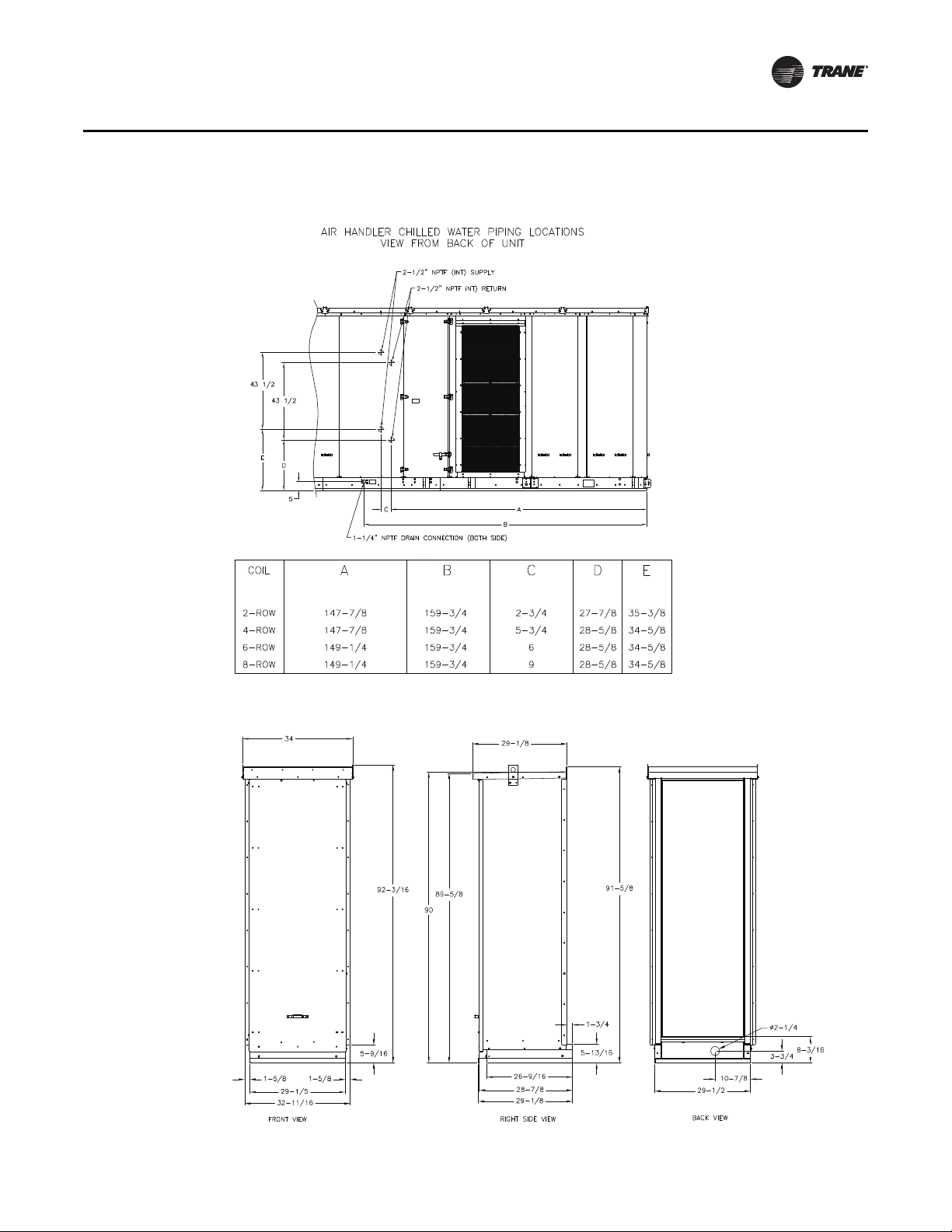

Figure 8. Chilled water piping locations

Dimensional Data

Figure 9. Piping enclosure

RT-SVX28E-EN 27

Page 28

Pre-Installation

General Unit Requirements

The checklist below is a summary of the steps required to successfully install a commercial rooftop

air handler. This checklist is intended to acquaint the installing personnel with what is required in

the installation process. It does not replace the detailed instructions called out in the applicable

sections of this manual.

• Check the unit for shipping damage and material shortage; file a freight claim and notify Trane

office.

• Verify that the installation location of the unit will provide the required clearance for proper

operation.

• Assemble and install the roof curb. Refer to the current edition of the roof curb installer’s guide.

• Install and connect condensate drain lines to each cooling coil drain connection.

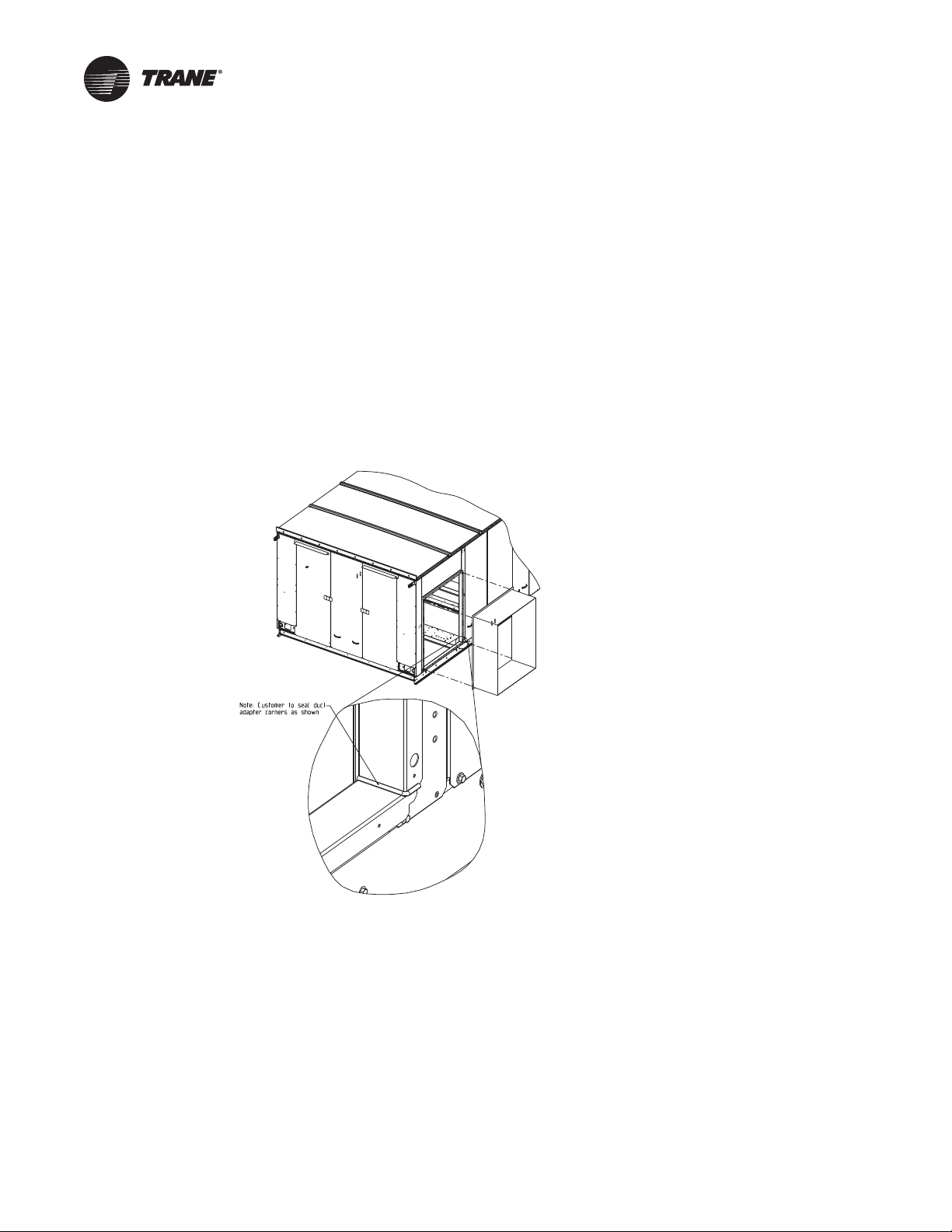

Figure 10. Sealed ductwork

• Fabricate and install ductwork; secure ductwork to curb. Seal the corners of duct adapters as

shown in Figure 10. Ducting attached to the unit should be self supporting. Do not use the unit

to support the weight of the ducting

• Install pitch pocket for power supply through building roof. (If applicable)

28 RT-SVX28E-EN

Page 29

Rigging the Unit

• Set the unit onto the curb; check for levelness.

• Ensure unit-to-curb seal is tight and without buckles or cracks.

• Remove the shipping hold-down bolts and shipping channels from the supply and exhaust fans

with spring isolators.

• Check all supply and exhaust fan spring isolators for proper adjustment.

Main Electrical Power Requirements

• Verify that the power supply complies with the unit nameplate specifications.

• Inspect all control panel components; tighten any loose connections.

• Connect properly sized and protected power supply wiring to a field-supplied/installed

disconnect and unit

• Properly ground the unit.

• All field-installed wiring must comply with NEC and applicable local codes.

Field Installed Control Wiring

• Complete the field wiring connections for the constant volume controls as applicable. Refer to

"Field Installed Control Wiring" for guidelines.

• Complete the field wiring connections for the variable air volume controls as applicable. Refer

to "Field Installed Control Wiring" for guidelines.

Note: All field-installed wiring must comply with NEC and applicable local codes.

Pre-Installation

Requirements for Electric Heat Units

• Verify that the power supply complies with the electric heater specifications on the unit and

heater nameplate.

• Inspect the heater junction box and control panel; tighten any loose connections.

• Check electric heat circuits for continuity.

Requirement for Gas Heat

• Gas supply line properly sized and connected to the unit gas train.

• All gas piping joints properly sealed.

• Drip leg Installed in the gas piping near the unit.

• Gas piping leak checked with a soap solution. If piping connections to the unit are complete,

do not pressurize piping in excess of 0.50 psig or 14 inches w.c. to prevent component failure.

• Main supply gas pressure adequate.

• Flue Tubes clear of any obstructions.

• Factory-supplied flue assembly installed on the unit.

• Connect the 3/4" CPVC furnace drain stubout to a proper condensate drain.

Requirements for Hot Water Heat

• Route properly sized water piping through the base of the unit into the heating section.

• Install the factory-supplied, 3-way modulating valve.

• Complete the valve actuator wiring.

RT-SVX28E-EN 29

Page 30

Pre-Installation

Base rail

Cleanout Plug

1-

1

4

Inch NPT

Female Connection

Field supplied

condensate piping

5.5"

2.5"

Requirements for Steam Heat

• Route properly sized steam piping through the base of the unit into the heating section.

• Install the factory-supplied, 2-way modulating valve

• Complete the valve actuator wiring.

• Install 1/2", 15-degree swing-check vacuum breaker(s) at the top of each coil section. Vent

breaker(s) to the atmosphere or merge with return main at discharge side of steam trap.

• Position the steam trap discharge at least 12" below the outlet connection on the coil.

• Use float and thermostatic traps in the system, as required by the application.

Requirements for Chilled Water Cooling

• Install and connect condensate drain lines to each cooling coil drain connection.

• Route properly sized water piping through the back of the unit.

• Install external piping enclosure.

• Install the factory-supplied, 3-way modulating valve.

• Complete the valve actuator wiring.

O/A Pressure Sensor and Tubing Installation (all units with Statitrac)

• O/A pressure sensor mounted to the roof bracket.

• Factory supplied pneumatic tubing installed between the O/A pressure sensor and the

connector on the vertical support.

• Field supplied pneumatic tubing connected to the proper fitting on the space pressure

transducer located in the filter section, and the other end routed to a suitable sensing location

within the controlled space.

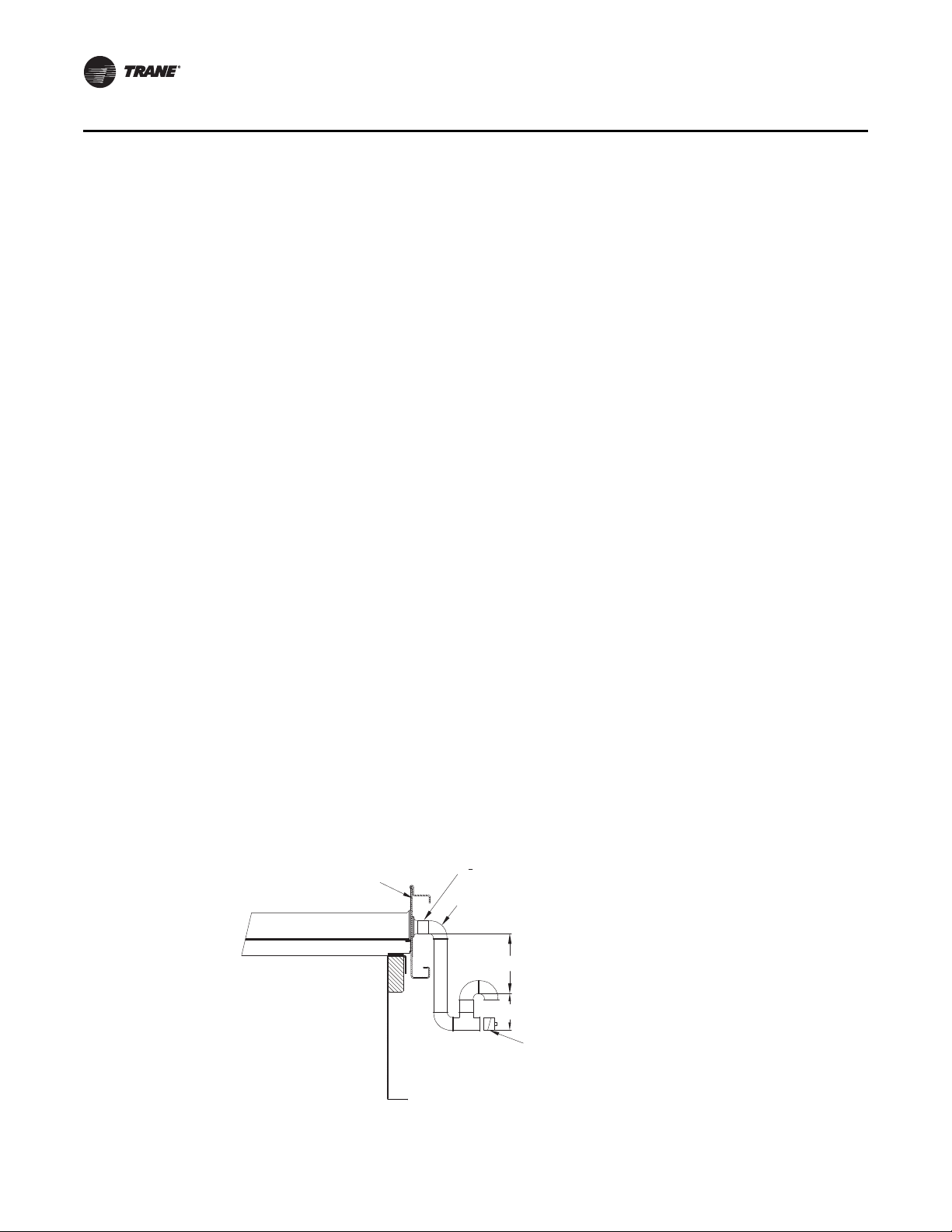

Condensate Drain Connections

Each unit provides two 1-1/4" cooling coil condensate drain connections on each side of the unit.

Due to the size of these units, all condensate drain connections must be connected to the cooling

coil drain connections. Refer to Detail A in Figure 6, p. 24 for the location of these drain connections.

A condensate trap must be installed due to the drain connection being on the "negative pressure"

side of the fan. Install the P-Traps at the unit using the guidelines in Figure 11.

Figure 11. Condensate trap installation

30 RT-SVX28E-EN

Page 31

Figure 12. Trap installation inside external piping enclosure

Pre-Installation

Pitch the drain lines at least 1/2 inch for every 10 feet of horizontal run to assure proper condensate

flow. Do not allow the horizontal run to sag causing a possible double-trap condition which could

result in condensate backup due to "air lock".

For units with an external piping enclosure, the condensate trap must be run through the external

piping enclosure on the rear side of the unit. Use Figure 12 as a guideline to install a P-Trap at the

back of the unit when an external piping enclosure is mounted around the condensate drain

connection.

Units with Gas Furnace

Units equipped with a gas furnace have a 3/4" CPVC drain connection stubbed out through the

vertical support in the gas heat section. It is extremely important that the condensate be piped to

a proper drain. Refer to the appropriate illustration in Figure 6, p. 24 for the location of the drain

connection.

Note: Units equipped with an optional modulating gas furnace will likely operate in a condensing

mode part of the time.

Ensure that all condensate drain line installations comply with applicable building and waste

disposal codes.

Removing Supply and Exhaust Fan Shipping Channels

Each supply fan assembly and exhaust fan assembly is equipped with spring isolators. Shipping

channels are installed beneath each fan assembly and must be removed. To locate and remove

these channels, refer to Figure 13, p. 32 and use the following procedures.

Spring Isolators

Spring isolators for the supply and/or exhaust fan are shipped with the isolator adjusting bolt

backed out. Field adjustment is required for proper operation. Figure 13, p. 32 shows isolator

locations. To adjust the spring isolators use the following procedure.

1. Remove and discard the shipping tie down bolts but leave the shipping channels in place during

the adjustment procedure. See Figure 13, p. 32.

RT-SVX28E-EN 31

Page 32

Pre-Installation

2. Tighten the leveling bolt on each isolator until the fan assembly is approximately 1/4" above

each sh ipp ing chann el.

3. Secure the lock nut on each isolator.

4. Remove the shipping channels and discard.

Figure 13. Removing fan assembly shipping hardware

O/A Sensor and Tubing Installation

An Outside Air Pressure Sensor is shipped with all units designed to operate on variable air volume

applications or constant volume units with 100% modulating exhaust w/Stratitrac.

On VAV systems, a duct pressure transducer and the outside air sensor is used to control the

discharge duct static pressure to within a customer-specified parameter.

On CV & VAV units equipped with 100% modulating exhaust w/Stratitrac, a space pressure

transducer and the outside air sensor is used to control the exhaust fan and dampers to relieve

static pressure, to within a customer-specified parameter, within the controlled space. Refer to

Figure 14, p. 33 and the following steps to install the sensor and the pneumatic tubing.

1. Remove the O/A pressure sensor kit located inside the "ship with" item container. The kit

contains the following items:

a. O/A static pressure sensor with slotted mounting bracket

b. 50 ft. 0.188 in tubing

c. Mounting hardware

2. Remove the two roof cap screws and install the provided L mounting bracket as shown in the

figure.

3. Place the sensor mounting slotted bracket to the L mounting bracket with the slot located to the

top.

4. Install the sensor vertically to the slotted bracket and secure it with provided bolt and nut.

5. Connect one end of factory provided tubing to the top port of sensor and pass it through the

two slots in the mount and the other end to the port in the base.

6. Secure the tubing with the mounting hardware located in the ship with item container.

32 RT-SVX28E-EN

Page 33

Units with Statitrac

Sensor

Sensor mounting

slotted bracket

0.188in OD tubing

L bracket

Sensor mounting

screws

1. Open the filter access door, and locate the DSP control devices illustrated in Figure 15. There

Figure 14. Outside air sensing kit

Pre-Installation

are three tube connectors mounted on the left of the solenoid and transducers. Connect one

end of the field provided1/4" (length 50-100 ft.) or 3/8" (length greater than 100 ft.) O.D.

pneumatic tubing for the space pressurization control to the bottom fitting. Route the opposite

end of the tubing to a suitable location inside the building. This location should be the largest

open area that will not be affected by sudden static pressure changes.

Figure 15. DSP control device

RT-SVX28E-EN 33

Page 34

Installation

Unit Weights

Table 11. Approximate operating weights (lbs.)

Nominal Tons Unit (Minimum)

A 8580 1066

B 8782 1066

C 8910 1066

Notes:

1. Weights shown include the following features: standard coils, 0-25% Fresh Air, throwaway filters, low cfm supply fan,

minimum motor sizes, constant volume, 460 XL, No heat.

2. Weights shown represent approximate operating weights and have a + 5% accuracy. To calculate weight for a specific

unit configuration, utilize TOPSS or contact the local Trane sales representative. ACTUAL WEIGHTS ARE STAMPED ON THE

UNIT NAMEPLATE.

Roof Curb

(Minimum)

Table 12. Component weights (lbs.)

AB C

Size Wt (lbs.) Size Wt (lbs.) Size Wt (lbs.)

Supply Fan Assembly

Supply Fan & FanBoard Assy. 25" 1226 32" 1419 36" 1530

Belt Guard 116 116 116

Supply VFD (50 HP and below) 233 233 233

Supply VFD (60 thru 75 HP) 284 284 284

Supply-Exh Fan Motor - 15 HP 181 181 181

Supply-Exh Fan Motor - 20 HP 206 206 206

Supply-Exh Fan Motor - 25 HP 358 358 358

Supply-Exh Fan Motor - 30 HP 413 413 413

Supply-Exh Fan Motor - 40 HP 495 495 495

Supply-Exh Fan Motor - 50 HP 604 604 604

Supply-Exh Fan Motor - 60 HP - 776 776

Supply-Exh Fan Motor - 75 HP - - 879

Return/Exhaust Fan Assembly

Return Fan & Dampers 36" 2284 40" 2333 40" 2333

Exhaust Fan & Dampers - Low CFM 25" 879 25" 879 28" 963

Exhaust Fan & Dampers - Std CFM - - 28" 963 32" 1417

Belt Guard 119 119 119

Exhaust VFD (50 HP and below) 244 244 244

Exhaust VFD (60 HP) 295 295 295

Exh Fan Motor - 7.5 HP 160 160 -

Exh Fan Motor - 10 HP 181 181 181

Exh Fan Motor - 15 HP 206 206 206

Exh Fan Motor - 20 HP 206 206 206

Exh Fan Motor - 25 HP 358 358 358

Exh Fan Motor - 30 HP - 413 413

Exh Fan Motor - 40 HP - 495 495

Exh Fan Motor - 50 HP - 604 604

Exh Fan Motor - 60 HP - - 776

34 RT-SVX28E-EN

Page 35

Table 12. Component weights (lbs.) (continued)

AB C

Size Wt (lbs.) Size Wt (lbs.) Size Wt (lbs.)

Chilled Water Assy.

2 Row 5W Chilled Water Coil - 80 FPF 992 992 992

2 Row 5W Chilled Water Coil - 108 FPF 1042 1042 1042

2 Row 5W Chilled Water Coil - 144 FPF 1106 1106 1106

2 Row 5W Chilled Water Coil - 168 FPF 1148 1148 1148

4 Row W Chilled Water Coil - 80 FPF 1523 1523 1523

4 Row W Chilled Water Coil - 108 FPF 1622 1622 1622