Page 1

Installation, Operation, and

Maintenance

Wireless Sensors

Models WTS, WZS, and WDS

April 2008

BAS-SVX04C-EN

Page 2

Copyright

© 2008 Trane All rights reserved

This document and the information in it are the property of Trane and may not be used

or reproduced in whole or in part, without the written permission of Trane. Trane reserves

the right to revise this publication at any time and to make changes to its content without

obligation to notify any person of such revision or change.

Trademarks

Trane and its logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

Warnings, Cautions, and Notices

Warnings, cautions, and notices are provided in appropriate places throughout this

document:

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

NOTICE: Indicates a situation that may result in equipment or property-damage-

only accidents.

Page 3

Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Height Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Address Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting the Receiver Back Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring the Receiver to the Unit Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing the Receiver Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Applying Power to the Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Observing the Receiver for Readiness to Associate . . . . . . . . . . . . . . . . . . . 18

Associating the Sensor to the Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Testing Signal Strength and Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mounting the Sensor Back Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring the Wireless Sensor (Model WDS only) . . . . . . . . . . . . . . . . . . 22

Configuration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replacing the Sensor Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Temporary Occupancy (Timed Override) . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Model WZS Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Model WDS Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Service Pin Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Model WZS Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Model WDS Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Star(*)/Double Star(**) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

End-of-Range Temperature Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Receiver Power-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Sensor Transmission Time and Temperature Variables . . . . . . . . . . . . . . . 32

BAS-SVX04C-EN • Wireless Sensors 3

Page 4

Contents

Operating Mode (Model WDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Changing Room Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Changing Heating and Cooling Room Temperature Settings (applies to

some systems) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Changing the System Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Changing the Fan Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Requesting Temporary Occupancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lock Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Testing Signal Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Testing Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Locations of LEDs, Test button, Test Symbols, and Error Codes . . . . . . . . 35

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Testing Signal Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Testing Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

24 V Power Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Using the Wireless Sensor System to Check Signal Strength on a Site . . 39

Replacing Sensor Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Battery Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Manual Association . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Disassociation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Sensor/Receiver Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing a Failed Sensor or Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Servicing and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Servicing and Testing Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Procedure for Testing the Wireless Sensor System . . . . . . . . . . . . . . . . . 43

Procedure for Testing the Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Forcing a Sensor to Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Output Power Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Output Values—Failure and Default Modes of Operation . . . . . . . . . . . . . . 44

Measuring Output Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cleaning the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Appendix A: Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Single Transformer Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Multiple Transformer Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4 BAS-SVX04C-EN • Wireless Sensors

Page 5

Contents

Appendix B: Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

BAS-SVX04C-EN • Wireless Sensors 5

Page 6

Page 7

General Information

This section provides a description of the sensors, as well as part numbers and

dimensions.

Product Description

Tra ne® wireless sensor sets are compatible with any Trane unit controller that uses a

standard 10 kΩ temperature input. The sets include sensor, receiver, wiring harness, and

two AA lithium batteries. No further software or hardware is necessary for site

evaluation, installation, or maintenance. Zone temperature is standard on all models.

Notes:

• The information in this manual applies to both factory and field installed versions of

the Trane wireless sensor sets.

• A service tool cannot be connected to a Trane wireless sensor.

Trane wireless sensors include the following models:

Model WDS

This configurable sensor has an LCD display. It provides the same functions as many

currently available Trane wired sensors. Configurable features include:

– Temperature units: Fahrenheit (ºF) or Celsius (ºC)

– Temperature resolution: 1.0, 0.5, or 0.1 degrees

– Ability to display setpoint only (zone temperature does not display)

– Single, dual, or no setpoint

– System settings: auto, off, cool, heat, emergency heat

– Dead band (heat/cool setpoint offset for dual setpoint systems)

– Fan settings: high, medium, low, auto, off

– Timed override request function

– Lockable settings to protect agains unauthorized use

– Service pin request

Model WTS

This sensor measures and transmits the zone temperature only.

Model WZS

This sensor set transmits the zone temperature, all zone temperature setpoint functions,

temporary occupancy (timed override), and unoccupied (cancel) information to the

receiver. The receiver electrically reproduces the zone temperature resistance, all zone

temperature setpoint function resistances, and temporary occupancy/unoccupied

information as sent by the sensor.

BAS-SVX04C-EN • Wireless Sensors 7

Page 8

General Information

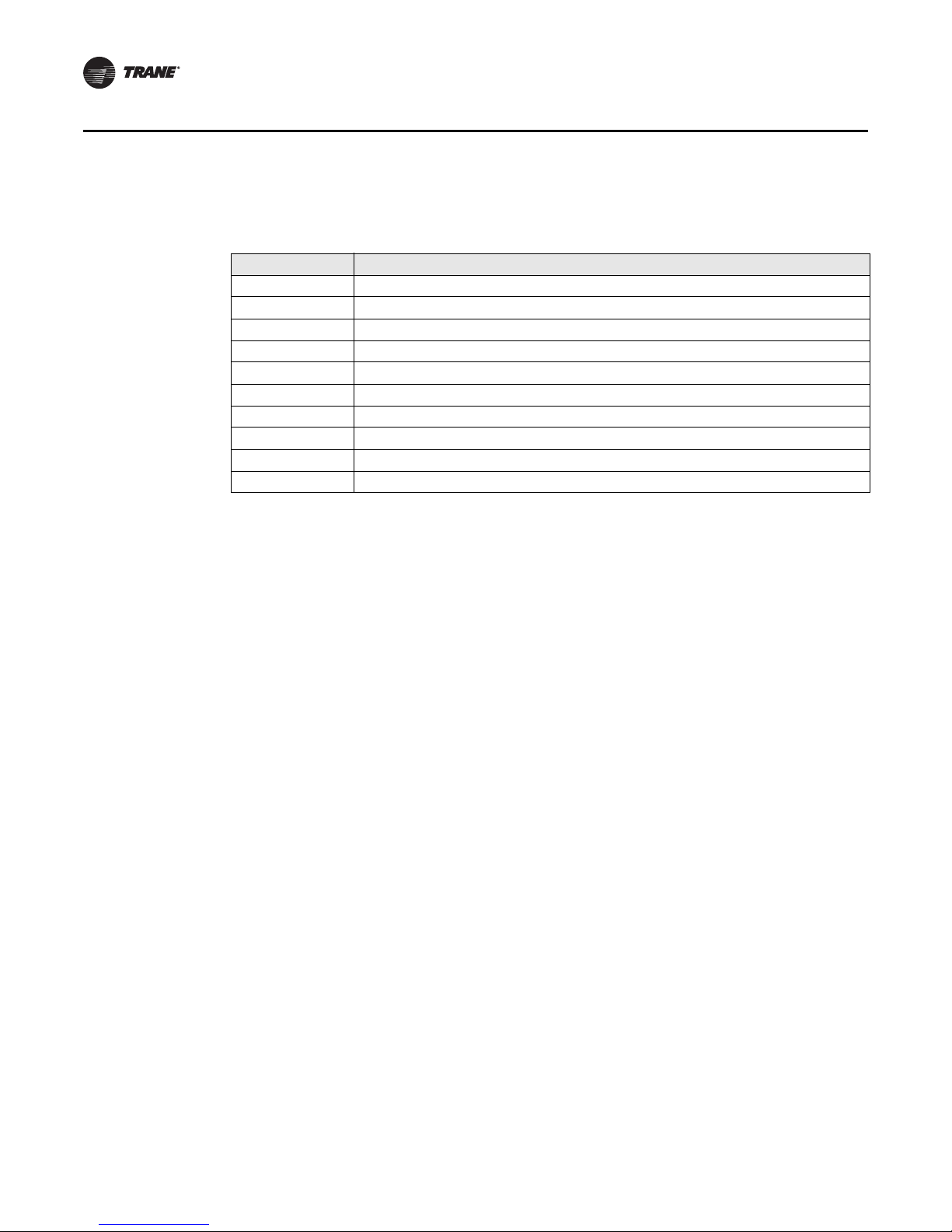

Part Numbers

The following table lists available models by part number:

Part number Description

X1379082101 Model WTS sensor only

X1379082201 Model WDS sensor only

X1379082301 Model WTS sensor set

X1379082401 Model WDS sensor set

X13790492 Model WZS, sensor only, Fahrenheit

X13790494 Model WZS, sensor only, Celsius

X13790496 Model WZS sensor set, Fahrenheit

X13790498 Model WZS sensor set, Celsius

X13790854 Receiver only, all models

X1905211201 Wire harness, seven conductor, for wireless receiver

8 Wireless Sensors • BAS-SVX04C-EN

Page 9

Dimensions

2.9 in (73.5 cm)

1.08 in (27.5 mm)

4.68 in (118.9 mm)

1.45 in (36.8 mm)

0.63 in (15.9 mm)

0.31 in (8 mm)

0.12 in (3 mm)

TYP R.07 in

(R1.9) mm)

3.39 in (86 mm)

2.48 in (63 mm)

2.62 in (66.5 mm)

TYP 0.24 in (6 mm)

General Information

The following illustration provides specific dimension details. The dimensions are the

same for all models.

BAS-SVX04C-EN • Wireless Sensors 9

Page 10

Pre-Installation

This section provides the following pre-installation information:

• Location considerations

• Height requirements

• Mounting surfaces

• Address settings

Location Considerations

Placement of the sensor and the receiver is critical to proper operation. For most

installations, barriers limit proper radio signal strength more than distance. For best

radio transmission range and reliability, mount the receiver and sensor in line of sight.

Where this is not possible, try to minimize the number of barriers between the pair of

devices. In general, sheetrock walls and ceiling tiles offer little restriction to the

transmission of the radio signal throughout the building.

Receiver

Sensor

The transmission range for the sensor is as follows:

• Open range: 2,500 ft (762 m) (packet error rate = 2%)

• Usable range: 200 ft (61 m)

• Typical range: 75 ft (23 m)

When selecting a receiver location, avoid the following:

• Locations that are outside the operating temperature and humidity range (refer to

“Specifications,” p. 47)

• Metal barriers between the receiver and the sensor (for example, plastered walls with

metal lathe or metal roof decks)

• Thick, solid concrete walls between the receiver and the sensor

• Placing the receiver inside metal enclosures

• Mounting on rooftop without a careful site evaluation and confirmation

When selecting a sensor location, avoid the following:

• Areas of direct sunlight

• Areas in the direct airstream of air diffusers

• Exterior walls and other walls that have a temperature differential between the two

sides

• Areas that are close to heat sources such as sunlight, appliances, concealed pipes,

chimneys, or other heat-generating equipment

• Drafty areas

• Dead spots behind doors, projection screens, or corners

• Walls that are subject to high vibration

• Areas with high humidity

10 Wireless Sensors • BAS-SVX04C-EN

Page 11

• High traffic areas (to reduce accidental damage or tampering)

• Metal barriers between the receiver and the sensor (for example, plastered walls with

metal lathe or metal roof decks)

• Thick, solid concrete walls between the receiver and the sensor

• Placing the sensor inside metal enclosures

Height Requirements

It is recommended that you mount the back plate a maximum distance of 54 inches above

the floor. If a parallel approach by a person in a wheelchair is required, reduce the

maximum height to 48 inches.

Note: Consult section 4.27.3 of the 2002 ADA (Americans with Disability Act) guideline,

and local building codes, for further details regarding wheelchair requirements.

Mounting Surfaces

Pre-Installation

Using the hardware provided, mount the back plate of the receiver and the sensor to a

flat surface such as sheetrock or plaster, or an electrical junction box. The sensor must

be mounted plumb for accurate temperature control and to ensure proper air movement

through the sensor.

• Receivers: Use the included hardware.

•Sensors:

Address Setting

The process of establishing communication between a receiver and sensor is referred to

as association. The following limitations apply:

• Each associated receiver/sensor set that communicates within the reception range of

• It is not possible to associate more than one sensor to a receiver, nor is it possible to

To associate a receiver and sensor, the two devices must have their rotary address

switches set to the same address.

Important: Set the addresses before applying power to the receiver and before

– If mounting onto sheetrock or plaster, use the plastic threaded anchors (pre-

drilling holes is not usually necessary) and the two M3.5 x 20 mm mounting

screws.

– For mounting onto an electrical junction box, use the two 6-32 x 3/4 in. screws.

the wireless system must have a unique address.

associate more than one receiver to a sensor.

removing the insulation strip (Figure 1, p. 12) from the sensor.

BAS-SVX04C-EN • Wireless Sensors 11

Page 12

S

5

GND

R77

C35

S1

S2

C33

LED4

S4

S5

S3

LED1

LED2

LED3

LED5

C34

J1

COMM -

24VAC/DC

SETPOINT

HEATING SET

SIGNAL

POWER

ADDDRESS

FAN/SYSTEM

ZONE

COMM +

IN

S

TAL

L

WIRELESS

GND

!

B1 +

INSTALL

WIRELESS

S4

S3

S2

S1

ADDRESS

STATUS

BATTERY

LED5

SIGNAL

LED3

L

ED2

LED1

Pb

Pb-FREE

STATUS

LED4

T

A

S

S

Do not remove the

insulation strip yet.

Pre-Installation

To set the receiver and sensor addresses:

1. Using a small screwdriver, set the three rotary address switches (locations S1, S2, S3)

on the receiver to an address between 001 and 999 (see Figure 1). (You do not have

to remove the covers to access the rotary address switches.)

Note: Do not use 000 as an address. An address of 000 returns the receiver outputs

to their factory defaults (zone temperature and setpoint outputs: 72.5°F

[22.5°C]), removes all association knowledge, and prevents association with a

sensor.

Figure 1. Setting the rotary address switches on the receiver and the sensor

2. Set the three rotary address switches (locations S1, S2, S3) on the sensor to the same

address as the receiver (see Figure 1).

Note: Do not use 000 as an address. Add address of 000 removes all association

knowledge, reverts the sensor to a low-power hibernation mode, and sends a

disassociation request to the receiver.

3. Record the address and location of the receiver and sensor pair.

12 Wireless Sensors • BAS-SVX04C-EN

Page 13

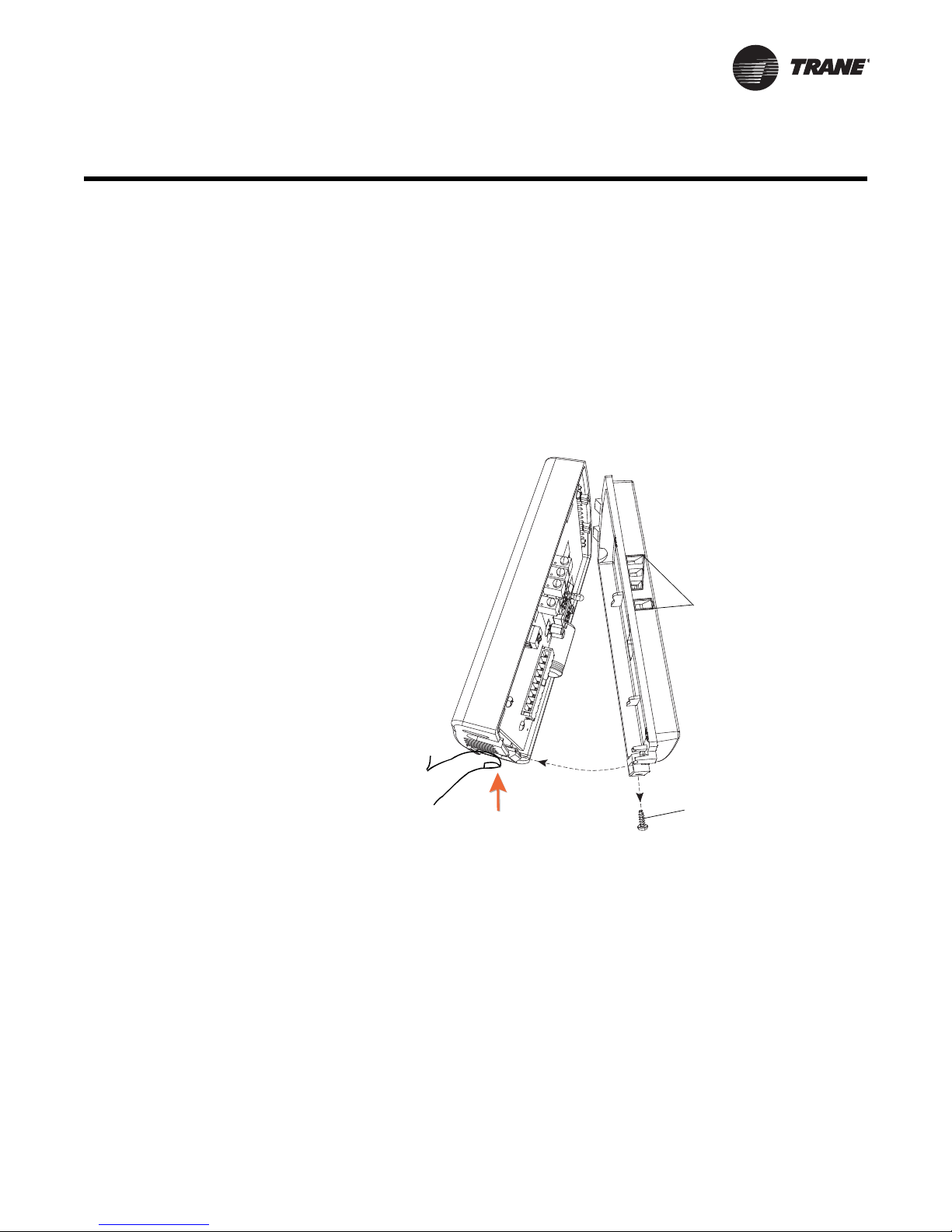

Installation

LEDs

Security screw

This section provides step-by-step installation instructions. Read through the preinstallation information before proceeding with installation.

Important: It is recommended that you install the sensor set in the order presented in

this section.

Mounting the Receiver Back Plate

To mount the receiver back plate:

1. Remove the cover by firmly pressing the thumb tab at the bottom of the cover and

pulling the cover away from the back plate.

Note: If present, remove the security screw before removing the cover.

2. Hold the back plate against the mounting surface and mark the screw locations.

Note: Locate the receiver to ensure that the LEDs are easy to view.

3. Secure the back plate of the mounting surface using the included hardware.

BAS-SVX04C-EN • Wireless Sensors 13

Page 14

Installation

Wiring the Receiver to the Unit Controller

Power requirements and wiring instructions for the receiver are described in this section.

Power Requirements

The required power for the receiver is 24 Vac or 24 Vdc and less than 1 VA. The receiver

is designed to be powered by the host unit controller. A dedicated transformer to power

the receiver is seldom necessary and is not recommended. It should be used only when

the host transformer does not have enough volt-ampere (VA) capacity to power the

receiver (see “Specifications,” p. 47 for receiver power consumption).

Wiring diagrams for single transformer wiring and multiple transformer wiring are

located in “Appendix A: Wiring Diagrams,” p. 48.

Wiring Procedure

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow

proper lockout/tagout procedures to ensure the power cannot be inadvertently

energized. Failure to disconnect power before servicing could result in death or serious

injury.

NOTICE

Equipment damage!

Applying excessive voltage to the receiver module will permanently damage it.

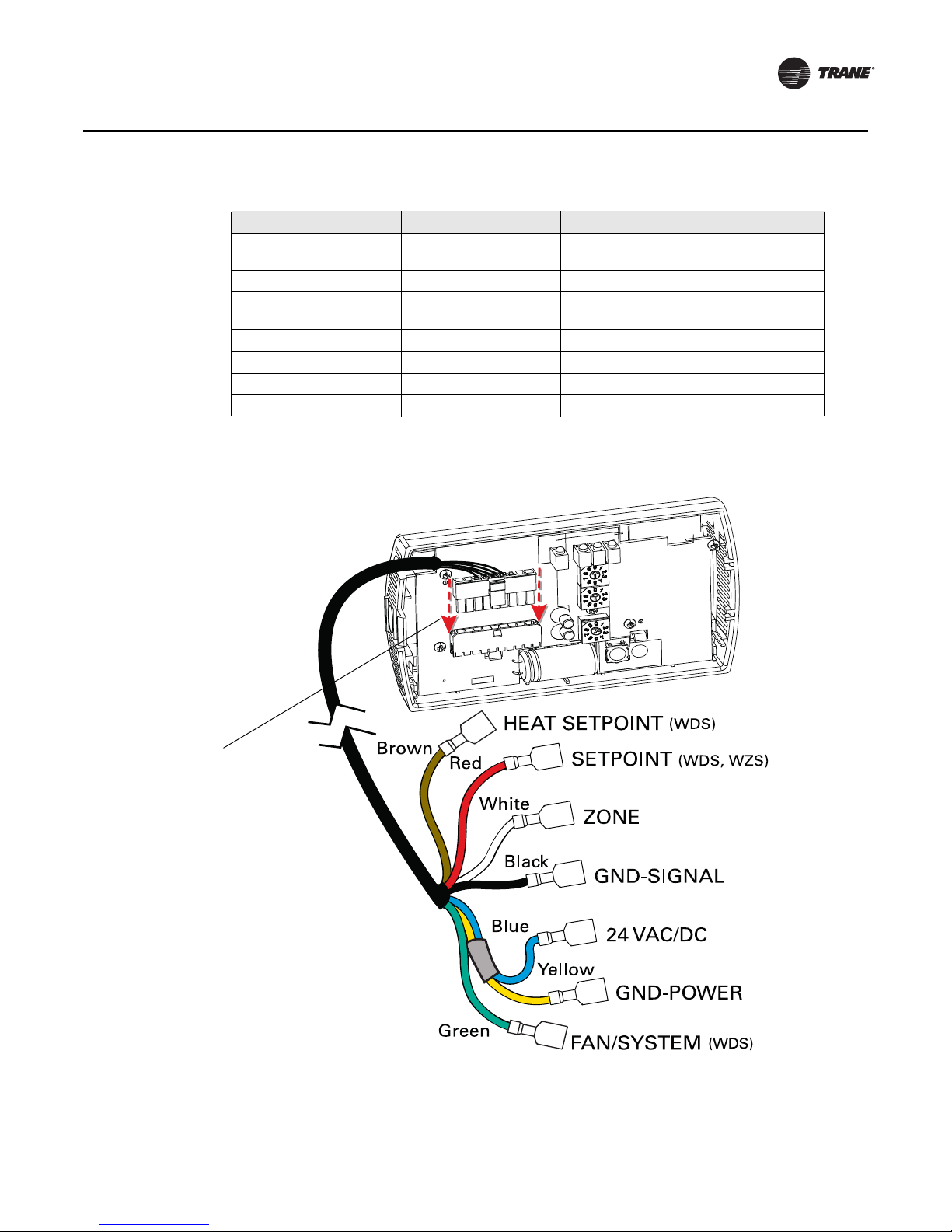

To wire the receiver to the unit controller:

1. Shut off power to the unit controller to which you are wiring the receiver.

2. Connect the wiring harness (provided) to the receiver (Figure 2, p. 15).

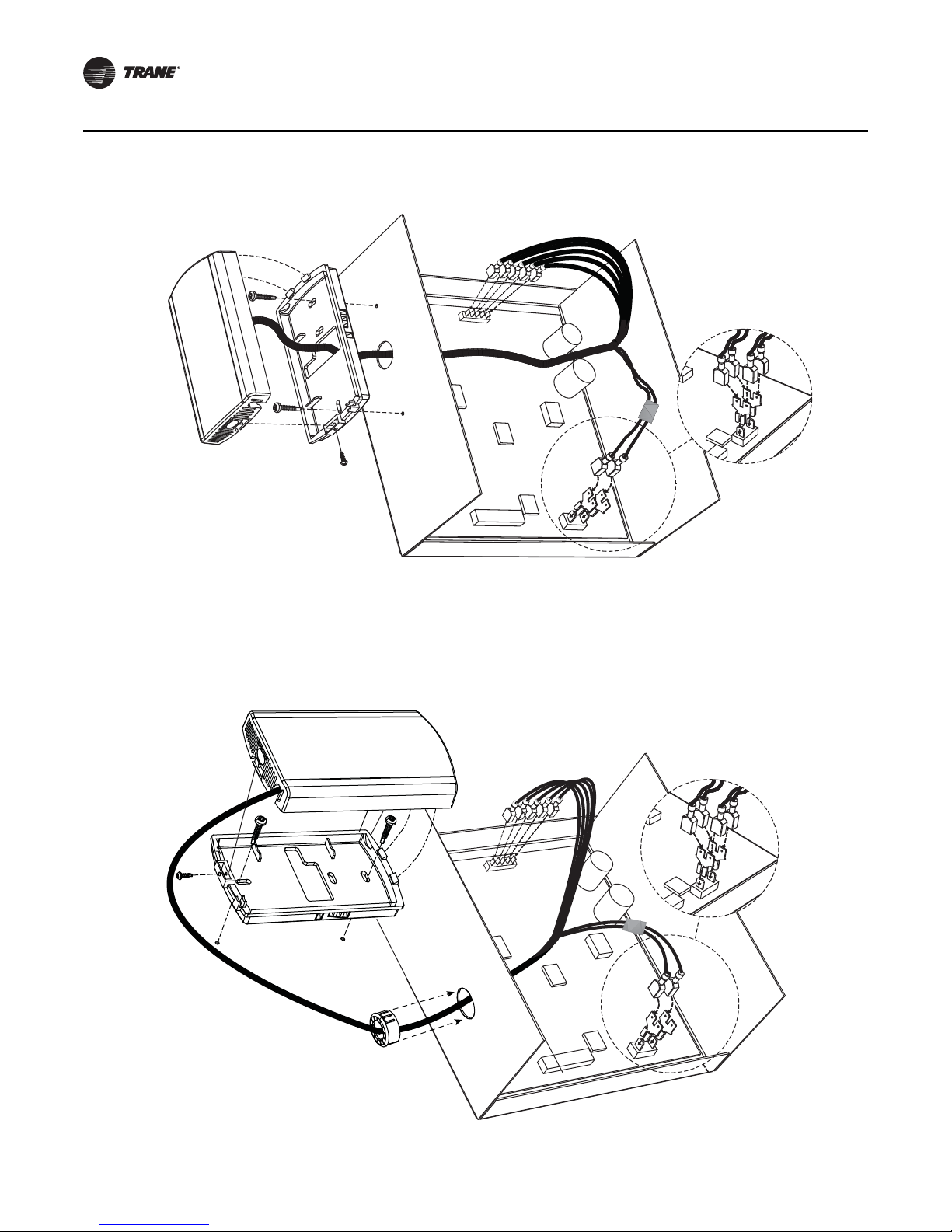

3. Route the wires from the receiver to the unit controller through either:

a. The opening at the back of the back plate (see Figure 3, p. 16 for an example).

b. The hole in the bottom of the cover (see Figure 4, p. 16 for an example).

4. Terminate wires at the unit controller. Refer to Table 1, p. 15 and Figure 2, p. 15 to

determine which wires to use and where to terminate them on the controller.

Notes:

• To maintain agency compliance, ensure that length of the wiring harness is no more

than 3 m.

• Adaptors are provided, which allow connecting multiple wires to the power

terminals of the host unit controller (see Figure 3 and Figure 4, p. 16.

• An anti-short bushing is provided; use it to prevent the wire from shorting out if the

steel penetrates the wiring harness (see Figure 4, p. 16).

5. Trim off any unused terminals. Insulate exposed wire with tape or a wire nut.

14 Wireless Sensors • BAS-SVX04C-EN

Page 15

Connect wiring

harness to

receiver

Table 1. Wiring harness: Wire identification

Wire label Color Function

HEATING SET Brown Space temperature heating setpoint

(WDS only)

FAN SYSTEM Green Fan and system control (WDS only)

SETPOINT Red Space temperature setpoint

(WDS and WZS only)

ZONE White Zone temperature

GND-SIGNAL Black Ground for setpoint and zone signal

24VAC/DC Blue 24 Vac/Vdc power

GND-POWER Yellow Ground for 24 Vac/dc

Figure 2. Wiring harness

Installation

BAS-SVX04C-EN • Wireless Sensors 15

Page 16

Installation

Figure 3. Wiring a receiver to a unit controller through the opening in the back of the receiver back plate

Figure 4. Wiring a receiver to a unit controller through the bottom slot in receiver cover

16 Wireless Sensors • BAS-SVX04C-EN

Page 17

Replacing the Receiver Cover

Security screw

LED5 stays constantly On after

applying power to the receiver

To replace the cover:

1. Hook the cover over the top of the back plate. Apply light pressure to the bottom of

the cover until it snaps in place.

2. Install the security screw into the bottom of the cover.

Installation

Applying Power to the Receiver

Restore power to the UCM. Observe LED5 on the receiver; it will light and stay constantly

On when 24 V power is normal.

BAS-SVX04C-EN • Wireless Sensors 17

Page 18

Installation

Observing the Receiver for Readiness to Associate

After initial power up, the receiver conducts a channel scan for 20 seconds. During this

time, the receiver selects from 16 available channels the clearest channel on which to

operate. LED1, LED2, and LED3 flash rapidly in succession (round-robin style) while the

channel scan is in progress, as shown in part 1 of the illustration.

Important: Do not attempt association (leave the insulation strip in place) until the

channel scan is finished.

After the channel scan is finished, LED3 begins blinking (one-blink pattern) to show that

the receiver is ready to be associated with a sensor. See part 2 of the illustration.

1

0

Sec.

20

2

LED3

18 Wireless Sensors • BAS-SVX04C-EN

Page 19

Associating the Sensor to the Receiver

To associate the sensor to the receiver:

1. Remove the sensor cover by firmly pressing the thumb tab at the bottom of the cover

and pulling the cover away from the back plate.

2. Verify that the sensor is set to the same address as the receiver it is to be associated

with.

3. Power the sensor by removing the insulation strip from between the two batteries.

Installation

Association is automatically initiated between the sensor and the receiver. When LED3

on the receiver stops blinking, association has been established.

If the first association attempt is unsuccessful, the sensor automatically re-attempts

association with the receiver every 10 minutes.

Note: An associated sensor that has lost communication with the receiver will transmit

an association request every 50 minutes. You can manually initiate association

(see “Manual Association,” p. 41”).

BAS-SVX04C-EN • Wireless Sensors 19

Page 20

LED1

LED2

LED3

LED5

Model WTS and WZS sensors Model WDS sensors

Test button

Push firmly,

then release

Push firmly,

then release

Test button

Installation

Testing Signal Strength and Battery Status

To verify that the association process was successful and that the batteries have adequate

charge:

1. Firmly press and release the Test button on the bottom of the sensor (as illustrated

below).

2. For models WTS and WZS, view LED1, LED2, and LED3 to determine the signal

strength. View LED5 to determine the battery status. (See the illustration for model

WTS and WZS sensors.)

Note: The LEDs will turn Off after 5 seconds to conserve battery strength.

For model WDS, determine the signal strength and battery status by viewing the

symbols on the sensor display. (See the illustration for model WDS sensors.)

3. Record the results in your commissioning statement.

Note: For more information, see “Testing Signal Strength,” p. 37 and “Testing Battery

Status,” p. 38.

20 Wireless Sensors • BAS-SVX04C-EN

Page 21

Mounting the Sensor Back Plate

To mount the sensor back plate:

1. Hold the back plate against the mounting surface and mark the screw locations.

2. Secure the back plate against the mounting surface using included hardware.

The figure shows an example of mounting the back plate of the sensor into sheetrock

or plaster.

Installation

BAS-SVX04C-EN • Wireless Sensors 21

Page 22

Configuration button

Installation

Configuring the Wireless Sensor (Model WDS only)

The configuration of the sensor determines which system features can be accessed and

changes can be made by the tenant (for example, changes to cooling/heating mode,

setpoint, or fan speed. Verify system and associated unit features before configuring the

sensor.

The building owner or operator may choose to limit tenant access to certain features. This

can be done through configuration. Or, if a sensor is configured to match all control

capabilities of the building automation system, the locking feature can be used to restrict

the tenant from making changes.

Configuration Procedure

To configure settings on the model WDS sensor, follow this procedure in the order

presented.

1. Press the configuration button for 3 seconds.

The display will change to configuration mode. When the sensor is in configuration

mode, a wrench symbol appears on the display and the menus are separated by lines,

as illustrated below.

22 Wireless Sensors • BAS-SVX04C-EN

Page 23

1. Press the center button on the keypad to begin the configuration process.

Center button

dual setpoint

no

setpoint

single

setpoint

.

heat/cool setpoint offset

(1.8˚F – 10.8˚F, 1˚C – 6˚C)

2. Configure the sensor options in the order shown in the table.

• Press or to scroll to the next selection (as illustrated).

• Press or to move to the next menu (as illustrated).

Setting Configuration options

Temperature

• Choose Fahrenheit or

Celsius

• Choose the degree

resolution (whole degrees,

half degrees, or tenths of

degrees).

.

. .

Installation

.

.

.

Setpoint

Deadband (available for dual

setpoint system only)

Note: Deadband refers to the

minimum difference

between the heating and

cooling setpoints.

System

a) Single setpoint

BAS-SVX04C-EN • Wireless Sensors 23

Page 24

auto/off/low

med/high

auto/off/

low/high

auto/off

off/high (on)

off/low/high off/low/

med/high

no fan options

enabled

auto/high (on)

Installation

Setting Configuration options

System (continued)

b) Dual setpoint

c) No setpoint

Fan

Note: Not all fan options are

available for all systems.

Occupancy (timed

override)

emergency heat/

heat/cool/auto/off

no system

options enabled

heat/cool/

auto/off

emergency heat/

heat/cool/off

24 Wireless Sensors • BAS-SVX04C-EN

Page 25

The example shows a display that has been

configured for:

• Dual setpoint

• Temperature units (Fahrenheit)

• Temperature resolution to tenths of a degree

• System settings: Heat, Cool, Off

• Fan settings: Auto or On

• Occupied/unoccupied option enabled

Display shows the following:

• Temperature units (Fahrenheit)

• Temperature resolution to tenths of a degree

• System setting: Cooling

• Fan setting: Auto

• Occupied/Unoccupied option enabled

Installation

3. Review the display to ensure that you have selected the correct configuration options.

4. To return the display to operating mode, press the configuration button (see step 1,

p. 22).

Note: The sensor will revert to operating mode if no buttons are pressed for 10

minutes.

The following example shows a configured display in operating mode.

If an error code exists, it appears at the bottom of the display between the occupancy

symbols, as shown below. See Table 2, p. 36, for error code definitions.

BAS-SVX04C-EN • Wireless Sensors 25

Page 26

Arrow

indicates

setpoint is

shown on

display

Setpoint

System menu

Fan menu

Installation

Optional Features

Displaying Setpoint or Temperature

You can configure the sensor to display either the temperature (default) or setpoint. To

select either option:

1. Verify that the sensor is in operating mode and at the home screen.

2. Press the up and down arrows for 3 seconds. The arrow indicates setpoint display, as

shown in the illustration.

Locking or Unlocking Settings

You can lock or unlock the setpoint, system, or fan setting to prevent changes.

To lock or unlock a setting:

1. Verify that the sensor is in operating mode and at the home screen.

2. Choose a setting to lock or unlock:

• Select the setpoint by pressing the up or down arrow.

• Select the system menu by pressing the center button. Use the left or right arrow

to choose the setting.

• From the system menu press the down arrow to select the fan menu. Use the left

or right arrow to choose the setting.

26 Wireless Sensors • BAS-SVX04C-EN

Page 27

Security screw

Installation

3. Press the left and right arrows for 4 seconds.

Note: If you try to access a feature that is locked, the locked symbol will appear on

the display.

If you press a keypad button to try change a locked setting, the locked symbol will

flash.

Replacing the Sensor Cover

To replace the cover:

1. Hook the cover over the top of the back plate. Apply light pressure to the bottom of

the cover until it snaps in place.

2. Install the security screw into the bottom of the cover (if desired).

BAS-SVX04C-EN • Wireless Sensors 27

Page 28

Occupied button

Unoccupied button

Operation

This section describes sensor operations.

Temporary Occupancy (Timed Override)

Temporary occupancy (timed override) is available on models WDS and WZS. Temporary

occupancy is selected for after-business-hours adjustment of temperature setting, fan

settings, or heat/cool settings, when the system has changed to unoccupied mode.

System control will revert to unoccupied after a pre-determined time period.

Note: Not all systems support the occupancy function.

Model WZS Sensor

The model WZS sensor has Occupied and Unoccupied buttons for requesting and

canceling temporary occupancy.

To request temporary occupancy, press the Occupied button (Figure 5) for 0.2–6 seconds.

The following occurs:

• Space temperature output is driven to 10 Ω (nominal).

• The output generates for 4 seconds.

To cancel temporary occupancy, press the Unoccupied button (Figure 5) for 0.2–6

seconds. The following occurs:

• Space temperature output is driven to 1330 Ω (nominal).

• The output generates for 4 seconds.

Figure 5. WZS sensor: Locations of occupied button and unoccupied buttons

Model WDS Sensor

To request and cancel temporary occupancy on a model WDS sensor, see “Requesting

Temporary Occupancy,” p. 34.

28 Wireless Sensors • BAS-SVX04C-EN

Page 29

Service Pin Request

Center button

Right arrow key

Model WZS and WDS sensors can communicate a service pin request to their associated

receivers.

Model WZS Sensor

To initiate a service pin request, press the Occupied button (Figure 5, p. 28) for 10–25

seconds. The following occurs:

• Space temperature output is driven to 10 Ω (nominal).

• The output generates for 15 seconds.

Model WDS Sensor

To initiate a service pin request, the sensor must be configured to support occupancy and

must be in operating mode (see “Configuring the Wireless Sensor (Model WDS only),”

p. 22).

Operation

To initiate a service pin request:

1. With the sensor in operating mode, navigate to the occupancy menu.

2. Press the right arrow on the keypad (Figure 6). The occupied symbol remains on the

screen; the unoccupied symbol leaves the screen.

3. Press and hold the center button for 10 seconds. The following occurs:

• The wrench symbol appears.

• A service pin request is initiated.

• Space temperature output is driven to 10 Ω (nominal).

• The output generates for 15 seconds.

• After 15 seconds, the wrench symbol disappears.

Figure 6. WDS sensor: Location of keys for service pin request

BAS-SVX04C-EN • Wireless Sensors 29

Page 30

** on thumb wheel

(* is hidden from view)

Operation

Star(*)/Double Star(**) Function

The star/double star function is available on models WDS and WZS. Consult the

appropriate unit controller documentation for information about this function.

The WZS sensor set supports star(*) and double star(**) on the sensor thumb wheel

(Figure 7).

• Star(*): A value of 95ºF (35ºC) is communicated.

• Double star(**): A value of 44.6ºF (7ºC) is communicated.

Figure 7. WZS sensor: Thumb wheel

The WDS sensor set supports star(*) and double star(**) functions if the sensor is

configured for single setpoint operation. Press the up or down arrow on the keypad to

display the star(*) or double star(**), respectively, on the sensor display.

• If the setpoint is increased one increment above 89.6ºF (32ºC), the star (*) appears. A

value of 95ºF (35ºC) is communicated.

• If it is decreased one increment below 50ºF (10ºC), the double star(**) appears. A

value of 44.6ºF (7ºC) is communicated.

End-of-Range Temperature Values

Receiver: The end-of-range temperature limits of the receiver for all models are 32°F to

122°F (0°C to 50°C). The receiver cannot replicate temperature values outside this range.

If the sensor transmits a temperature value to the receiver that is out of the receiver

replication range, the receiver will “freeze” the output at the end-of-range values. This

value will remain frozen until the transmitted temperature moves to between the end-ofrange temperature limits.

Sensor: The end-of-range temperature setpoint limits for the model WDS sensor is 50°F

(10°C) to 89.6°F (32°C). The end-of-range temperature setpoint limits for the model WZS

sensor is 45°F (7.22°C) to 95°F (35°C).

30 Wireless Sensors • BAS-SVX04C-EN

Page 31

Receiver Power-up Sequence

When power is applied to the receiver, one of the following sequences occurs. The

sequence is dependent on the address setting and the association status of the receiver.

Address set to 000 and receiver is not associated with a sensor

• LED5 is constantly On, indicating power is applied and the receiver is functional.

• All models: Zone temperature and cooling setpoint default to 72.5°F (22.5°C).

WDS only: The heating setpoint defaults to 70.5°F (21.4°C) and the fan/system

output will be 2230 Ω (see “Output Values—Failure and Default Modes of

Operation,” p. 44).

• Status LED3 will display a 2-blink pattern diagnostic (Table 3, p. 36).

Address set from 001 to 999 and receiver is not associated with a sensor

• LED5 is constantly On, indicating power is applied and the receiver is functional.

• All models: Zone temperature and cooling setpoint default to 72.5°F (22.5°C).

WDS only: The heating setpoint defaults to 70.5°F (21.4°C) and the fan/system

output will be 2230 Ω (see “Output Values—Failure and Default Modes of

Operation,” p. 44).

• The receiver conducts an energy scan for 20 seconds to determine the clearest

channel on which to operate.

• LED3 flashes On every 2 seconds when it is ready to accept a sensor association

request. When an association request is made by a sensor, the receiver instructs

the sensor on which power level to operate. Then the receiver and sensor begin

operation at the appropriate channel and power level (see “Observing the Receiver

for Readiness to Associate,” p. 18).

Operation

Address set from 001 to 999 (and not changed since most recent power-up)

and receiver is associated with a sensor

• LED5 is constantly On, indicating power is applied and the receiver is functional.

• Zone temperature and setpoint default to 72.5°F (22.5°C). WDS only: Heating setpoint

defaults to 70.5°F (21.4°C), Fan = Auto, System = Off.

• The receiver waits for a broadcast transmission from its associated sensor. When a

transmission is received, the receiver positions its zone temperature and setpoint

outputs appropriately.

• If the receiver does not receive a communicated signal from its associated sensor

within 35 minutes, zone temperature and setpoint outputs fail, generating a unit

controller alarm (see “Output Values—Failure and Default Modes of Operation,”

p. 44).

Note: Once a receiver communicates to a WTS sensor, the receiver disables (opens)

its zone setpoint output indefinitely.

BAS-SVX04C-EN • Wireless Sensors 31

Page 32

.

Keypad

Test button

T est symbols (appear only when T est button is pushed

Occupancy indicator/Error code

Temperature

System settings

Fan settings

Operation

Sensor Transmission Time and Temperature Variables

Sensor transition time variables are as follows:

• The maximum time between sensor temperature transmissions is 15 minutes.

• The minimum time between sensor temperature transmissions is 30 seconds.

• The minimum time for transmitting temperature setpoint changes is 10 seconds.

Note: If a sensor transmits a message to the receiver and the receiver does not reply,

the sensor will retransmit the message to the receiver every 30 seconds until

communication to the receiver is re-established.

Sensor temperature time variables are as follows:

• The minimum change in zone temperature required to force a sensor transmission

is:

– 0.2°F (0.11°C) when the temperature range is between 60°F (15.6°C) and 80°F

(26.7°C)

– 0.5°F (0.28°C) when the temperature range is between 32°F (0°C) and 60°F (15.6°C)

or between 80°F (26.7°C) and 122°F (50°C))

• The minimum change in temperature setpoint required to force a sensor

transmission is:

– 1°F (0.56°C) for a model WZS sensor

– 0.1°F for model WZS sensor

– 0.1°C for a model WDS sensor

Operating Mode (Model WDS)

This section describes how to operate the Trane wireless sensor, model WDS. Figure 8

shows an example of a model WDS that has been configured and is in operating mode.

Figure 8. Wireless sensor (model WDS) in operating mode

32 Wireless Sensors • BAS-SVX04C-EN

Page 33

Changing Room Temperature

Operation

This symbol shows the current room

temperature, or your setpoint selection

.

while you are making an adjustment.

When you select a setpoint, this symbol

appears.

1. To increase the room temperature, press .

To decrease the room temperature, press .

2. To confirm, press or wait 5 seconds. The display will

return to the home screen.

Changing Heating and Cooling Room Temperature Settings (applies to some systems)

Some systems allow you to select both

heating and cooling room temperature

settings. If your system has this option , this

symbol appears when you adjust the

temperature setting.

When you adjust the cooling setting, the top

arrow and snowflake flash.

When you adjust the heating setting, the

bottom arrow and flame flash.

1. Press or to select the heating/cooling

setting.

2. If in cooling mode, press to change to heating

mode. If in heating mode, press to change to

cooling mode.

3. Press or to select the heating/cooling

setting.

4. To confirm, press or wait 5 seconds. The home

screen will appear.

Changing the System Setting

Indicates that the system is in cooling mode.

Indicates that the system is in heating mode.

Indicates emergency heat. It is used by

facility operators or service technicians only.

Indicates that the system automatically

switches between heating and cooling as

needed.

Indicates that the system is Off.

1. From the home screen, press . The system setting

menu appears.

2. Press or to choose the desired system setting.

3. When the symbol for the desired setting appears,

confirm your choice by

• Pressing (the home screen will appear), or

• Pressing or (the next menu will appear),

or

• Waiting five seconds.

Changing the Fan Setting

Indicates that the fan will operate as

needed to reach the selected

temperature.

Indicates that the fan setting is On.

The number of arrows indicates fan

speed

(3: high, 2: medium, 1: low).

The example shown indicates a fan on

high speed. Not all systems offer all

three speeds.

Indicates that the fan setting is Off.

BAS-SVX04C-EN • Wireless Sensors 33

1. From the home screen, activate the fan setting menu by

pressing and then .

2. Press or to choose the desired fan setting.

3. When the symbol for the desired setting appears, confirm

your choice by

• Pressing (the home screen will appear), or

• Pressing or (the next menu will appear), or

• Waiting five seconds.

Page 34

Operation

Requesting Temporary Occupancy

Select to request

occupancy

Select to cancel

occupancy

• If you need heating or cooling after normal business hours, you can

• To cancel temporary occupancy, press and hold for 2 seconds. The

Error codes

Indicates an error code

Lock Symbol

Indicates that a

setting is locked

Testing Signal Strength

Indicates

excellent

signal

strength

“request” temporary occupancy by pressing and holding it for 2 seconds.

The occupied symbol remains on the screen and the unoccupied symbol

disappears. After 30 seconds, unoccupied symbol will re-appear.

unoccupied symbol will remain on the screen and the occupied symbol will

disappear. After 30 seconds the occupied symbol will re-appear.

If an error code (E0–E7) is displayed, technical assistance may be required.

The lock symbol appears if you try to adjust a setting that cannot be changed.

Indicates

satisfactory

signal

strength

Indicates

poor signal

strength

Press the Test button to display the

signal strength symbols.

Testing Battery Status

Indicates full

battery power

34 Wireless Sensors • BAS-SVX04C-EN

Indicates 50%

of battery life

left.

Indicates 25% of

battery life left.

Replace batteries.

Flashing symbol

indicates that

approximately 14 days

of operation remain.

Press the Test button to display the

battery status symbols.

Use only UL-listed non-rechargeable

1.5 V lithium AA batteries (Trane p/n

X13770035010 or equivalent).

Page 35

LED1

LED2

LED3

LED5

.

Test symbols

Error code

Test button

LED1

LED2

LED3

LED5

Test button

WTZ, WZS sensor WDS sensor

Maintenance and Troubleshooting

This section describes features of the receiver and sensor that are to be used for

maintenance and troubleshooting.

Locations of LEDs, Test button, Test Symbols, and Error Codes

The receiver for all models has four LEDs: LED1, LED2, LED3, and LED5. Figure 9 shows

their locations.

Figure 9. LED locations on the receiver

The sensor for models WTS and WZS have four LEDs: LED1, LED2, LED3, and LED5. The

sensor for model WDS has test symbols and error codes that appear on the display. All

three sensor models have a Test button. Figure 10 shows their locations.

Figure 10. LED, Test button, and symbol locations on the sensor

BAS-SVX04C-EN • Wireless Sensors 35

Page 36

Maintenance and Troubleshooting

Diagnostics

LED1, LED2, and LED3, located on the sensor of models WTS and WZS, respond to

diagnostics by exhibiting specific blinking patterns. View their response by pressing the

Test button. (See Tab le 2.)

Error codes appear on the display of the model WDS sensor when diagnostics occur. (See

Ta bl e 2 .)

Table 2. Diagnostics on the sensor

LED state when Test button is pressed

(WTS, WZS sensors)

N/A E0, E5, E7 Sensor failure

LED1: Off

LED2: Off

(a)

LED3

LED1: Off

LED2: Off

LED3

LED1: Off

LED2: Off

LED3

LED1: Off

LED2: Off

LED3

(a)Blink pattern is On for 1/4 s, Off for 1/4 s, with 2 s Off between repetitions.

: 1-blink pattern repeated 3 times

(a)

: 2-blink pattern repeated 3 times

(a)

: 3-blink pattern repeated 3 times

(a)

: 4-blink pattern repeated 3 times

Error code (WDS

sensor display)

E1 Disassociated

E2 Address set to 000

E3 Software error

E4 Input voltage too high

Indicates...

•Replace sensor

• Sensor is not associated with a receiver.

• Address not set to between 001–999.

•Replace sensor

• No RF transmission is permitted with an input

battery voltage greater than 3.9 V.

LED1, LED2, and LED3, located on the receiver of all models, respond to diagnostics by

exhibiting specific blinking patterns. They respond independently of any user action.

(See Tab le 3 .)

Table 3. Diagnostics on the receiver

LED state Indicates...

LED1: Off

LED2: Off

LED3: 1-blink pattern repeated continuously

LED1: Off

LED2: Off

LED3: 2-blink pattern repeated continuously

LED1: Off

LED2: Off

LED3: 3-blink pattern repeated continuously

(a)Blink pattern is On for 1/4 s, Off for 1/4 s, with 2 s Off between repetitions.

36 Wireless Sensors • BAS-SVX04C-EN

Disassociated

• Receiver is not associated, waiting for a sensor.

(a)

• Receiver lost communication with sensor.

• Receiver has no devices on its wireless personal area network.

• Association with a device has been manually removed.

Address set to 000

• Address not set to between 001–999.

(a)

Not configured

• Receiver configuration properties not properly set (defective receiver).

(a)

Page 37

Testing Signal Strength

To initiate a signal strength test, push the Test button on the sensor (see location of Test

button in Figure 10, p. 35).

• Models WTS, WZS: LED1, LED2, and LED3 respond by indicating signal strength. You

can view them on the sensor (Ta bl e 4 ) and the receiver (Table 5, p. 38).

• Model WDS: Test symbols on the sensor display indicate signal strength (Tab le 4).

LED1, LED2, and LED3, on the receiver, respond by indicating signal strength (Tab l e 5 ,

p. 38).

Table 4. Observing signal strength on the sensor

Symbol (WDS

User action LED state (WTS, WZS sensors)

None LED1: Off

LED2: Off

LED3: Off

Press Test

button on the

sensor

LED1: Off

LED2: Off

LED3: Off

sensor display)

No Test symbols

appear

Maintenance and Troubleshooting

Indicates...

Normal state

• No Test button press.

Associated; no communication with receiver

• Associated, but no signal from the receiver after

pressing Test button.

LED1: On

LED2: On

LED3: On

Displays for 5 seconds, then

constantly Off

LED1: Off

LED2: On

LED3: On

Displays for 5 seconds, then

constantly Off

LED1: Off

LED2: Off

LED3: On

Displays for 5 seconds, then

constantly Off

Excellent signal strength

• Good signal margin for reliable communication.

Satisfactory signal strength

• Adequate signal strength for reliable communication.

• Moving sensor or receiver may improve signal

strength.

• Increased channel switching may reduce battery

life.

Poor signal strength

• Unreliable communication.

• Strongly recommend moving the sensor or receiver

to a better location.

BAS-SVX04C-EN • Wireless Sensors 37

Page 38

Maintenance and Troubleshooting

Table 5. Observing signal strength on the receiver

User action LED state (receiver, all models) Indicates...

None LED1: Off

LED2: Off

LED3: Off

Press Test

button on the

sensor

LED1: On

LED2: On

LED3: On

Displays for 5 seconds, then constantly Off

LED1: Off

LED2: On

LED3: On

Displays for 5 seconds, then constantly Off

LED1: Off

LED2: Off

LED3: On

Displays for 5 seconds, then constantly Off

Normal state

• No Test button press.

Excellent signal strength

• Good signal margin for reliable communication.

Satisfactory signal strength

• Adequate signal strength for reliable communication.

• Moving sensor or receiver may improve signal strength.

• Increased channel switching may reduce battery life.

Poor signal strength

• Unreliable communication

• Strongly recommend moving the sensor or receiver to a

better location

Testing Battery Status

Initiate a battery status test as follows:

• On models WTS and WZS, push the Test button on the sensor (see location on

Figure 10, p. 35). LED5 on the sensor responds by indicating the level of battery

strength, as shown in Ta bl e 6 .

• On model WDS, push the Test button on the sensor (see location on Figure 10, p. 35).

In response, a battery test symbol appears on the display. The symbol shown

indicates battery life expectancy (see Table 7, p. 39).

Table 6. Battery status: LED5 on model WTS and WZS sensors

User action LED state (WTS, WZS) Indicates...

Press Test

button

None Blinking red: 1-blink pattern

(a)Blink pattern is On for 1/4 s, Off for 3/4 s, with 2 s Off between repetitions.

Solid green for 5 seconds Battery is adequate for proper operation.

Solid red for 5 seconds 25% battery life left. Batteries should be replaced.

No light Batteries life expired or not installed properly, or sensor is

defective.

(a)

repeated 5

times. Cycle repeats every 15 minutes.

Approximately 14 days of operation remain before the battery

is too weak to power the sensor.

38 Wireless Sensors • BAS-SVX04C-EN

Page 39

Maintenance and Troubleshooting

Table 7. Battery status: Battery symbol on model WDS sensor display

Battery

test

User action

Press Test

button

symbol

Indicates...

Full battery power.

50% battery life left.

25% battery life left. Replace batteries.

Flashing symbol indicates that approximately 14 days of operation

remain before the battery is too weak to power the sensor.

24 V Power Status Indicator

LED5 on the receiver of all models (Figure 9, p. 35) lights and stays constantly On when

24 V power is normal.

Using the Wireless Sensor System to Check Signal Strength on a Site

Follow these steps to check the signal strength on a site:

1. Power up a receiver with a 24 V transformer (user supplied)

2. Associate the sensor to a receiver of the same model intended for the job

3. Place the receiver at the desired location

4. Place or hold the sensor at the desired location

5. Press the Test button (S5) on the sensor and observe the signal strength as

indicated by LED1, LED2, and LED3 on models WTS and WZS, and on the display

on model WDS (Figure 10, p. 35).

For more information on interpreting the LEDs and the display symbols that indicate

signal strength, see “Testing Signal Strength,” p. 37.

BAS-SVX04C-EN • Wireless Sensors 39

Page 40

Maintenance and Troubleshooting

Replacing Sensor Batteries

Sensor battery type, length of life, and installation are addressed in this section.

Battery Type

NOTICE

Equipment Damage!

The batteries are manufactured in a ready-to-use state. They are not designed for

recharging. Recharging can cause battery leakage or, in some cases, can cause the

safety release vent to open.

NOTICE

Equipment Damage!

Do not attempt to hook up the sensor to a power supply. Equipment damage may

result.

Use two non-rechargeable 1.5 V lithium AA batteries in the sensor. To maintain UL rating,

use only UL-listed lithium batteries. The sensor ships with Energizer™ L91 batteries

already installed. Replacement batteries are available at Trane Service Parts Centers (p/

n X13770035010) or other local suppliers.

Battery Life

Battery life is five years under normal conditions. If the sensor is not used for an extended

period of time, do one of the following:

• Set the sensor address to 000 to place the sensor into a low-power hibernation mode.

• Remove the batteries

Notes:

• If lithium batteries are temporarily unavailable, alkaline batteries can be used.

• The battery life for a model WDS may decrease with extended LCD display activity.

Battery Installation

WARNI NG

Prevent Injury!

Batteries can explode or leak and cause burns if installed backwards, disassembled,

charged, or exposed to water, fire, or high temperature.

However, alkaline battery life is very short by comparison.

WARNI NG

Prevent Injury!

Keep away from small children. If swallowed, contact your local poison control center

immediately.

40 Wireless Sensors • BAS-SVX04C-EN

Page 41

1. Observe the polarity indicators that are molded into the cover.

2. Install two batteries (of the type specified in “Battery Type,” p. 40) in the battery-

holding slot that is molded into the sensor cover.

The sensor has been designed to prevent damage if the batteries are installed backwards,

to reduce the potential for injury.

Manual Association

At any time, the manual association method can be used to associate the receiver with

the sensor. If an association was previously established between a receiver and a sensor

and needs to be re-established, the manual association process may be used. If an

association has not yet been established, the automatic association process is

recommended (see “Associating the Sensor to the Receiver,” p. 19).

1. Using a small screwdriver, set the three rotary address switches (Figure 1, p. 12,

locations S1, S2, S3) on the receiver to an address between 001 and 999.

Maintenance and Troubleshooting

2. Set the three rotary address switches (Figure 1, p. 12, locations S1, S2, S3) on the

3. Record the address and location of the receiver and sensor pair.

• After verifying that the receiver and sensor are powered up, press the Test button on

Disassociation

The receiver disassociates from the sensor (by removing all stored association

information), conducts a channel scan, and restarts itself, if any of the following are true:

• The receiver address is changed from its current setting (001–999)

• The receiver receives a disassociation notification from its associated sensor

• The receiver does not receive a communication from its associated sensor within

• The sensor and receiver are associated and communicating at the time the sensor is

Note: A disassociated sensor will transit an association request every 10 minutes.

Notes:

• An address can be changed without powering down the receiver or sensor.

• An address can be changed at any time after initial association has been

established.

sensor to the same address as the receiver.

the sensor to establish that the signal strength (“Testing Signal Strength,” p. 37) and

the battery life “Testing Battery Status,” p. 38) are adequate for proper functioning.

50 minutes.

set to 000 and the Test button is pressed.

BAS-SVX04C-EN • Wireless Sensors 41

Page 42

Maintenance and Troubleshooting

Sensor/Receiver Compatibility

Version 1.5 (p/n X13790854 and X13790855) and higher receivers are compatible with all

sensors models and support all functions. Receivers released prior to version 1.5 are

compatible with only models WTS and WZS.

Replacing a Failed Sensor or Receiver

To replace a failed sensor or receiver:

1. Confirm that the device is disassociated (see Ta bl e 2 and Ta ble 3, p . 3 6).

2. Set the rotary address switch of the new device to match the address of the remaining

sensor or receiver.

Note: There is no need to remove power from the remaining device.

3. Apply power to the new device. Association between the new and the remaining

devices will automatically occur.

Notes:When replacing a WDS sensor, the receiver (version 1.5 or higher) will

automatically configure the sensor to match the last stored configuration, if the

sensor has not been placed into configuration mode and the factory default

configuration is still valid. If the sensor configuration does not match the desired

system features, it can be manually configured (see “Manual Association,” p. 41).

Servicing and Testing

If the wireless sensor system is not working as expected, use the tools and procedure

described in this section.

Servicing and Testing Tools

No special tools or software are necessary to service and test the wireless sensor system.

Test the system by using:

• The LEDs on the receiver, LEDs on the model WTS and WZS sensor, and the

display on the model WDS sensor

• The Test button on the sensor

• The address test mode on the receiver

• A common volt-ohm meter

42 Wireless Sensors • BAS-SVX04C-EN

Page 43

Procedure for Testing the Wireless Sensor System

If the wireless sensor system is not working as expected:

1. Observe LED5 on the receiver. LED5 is On solid green whenever the receiver is

powered.

2. Verify that the receiver is properly grounded. Both the GND-SIGNAL (black) wire

and the GND-POWER (yellow) wire must be grounded (see Figure 3, p. 16 or

Figure 4, p. 16 for wiring diagrams).

3. Press the Test button on the sensor.

• Models WTS, WZS: LED5 should turn On solid green, indicating proper battery

strength. LED1, LED2, and LED3 will indicate signal strength.

Note: When checking signal strength, both LED1 and LED3 on the receiver and

sensor illuminate in unison if the sensor and receiver are associated. Use

this feature to confirm association.

• Model WDS: Battery life (“Testing Battery Status,” p. 34) and signal strength

(“Testing Signal Strength,” p. 34) are indicated on the display.

Maintenance and Troubleshooting

Procedure for Testing the Receiver

If the receiver is not working as expected:

1. Verify that the receiver is powered.

2. Set the receiver address to 000 to force the zone temperature output and zone

temperature setpoint output to their default mode values (see “Output Values—

Failure and Default Modes of Operation,” p. 44).

3. Measure the receiver output resistance (see “Measuring Output Resistance,” p. 44).

4. When the test is complete, reset the receiver address to its previous setting.

5. Press the Test button on the sensor to force re-association.

6. Confirm association and communication by noting LED1, LED2, and LED3 as

described in “Testing Signal Strength,” p. 37.

Forcing a Sensor to Transmit

To force a wireless sensor to transmit during servicing, press the Test button on the

sensor.

Output Power Level

The maximum output power level of a wireless sensor set is controlled by software and

restricted by channel of operation and agency requirements per country or region. The

sensor has a default maximum power level of 10 mW, but the receiver determines the

ultimate output power level of the sensor.

BAS-SVX04C-EN • Wireless Sensors 43

Page 44

Maintenance and Troubleshooting

Output Values—Failure and Default Modes of Operation

The following table provides output values for failure and default modes of operation,

which can be used for troubleshooting.

Zone

temperature

Situation

Receiver address = 000 11.17 kΩ,

Receiver address = 001 to 999 and:

• Receiver is powered up, but not is associated, or

• Receiver has received a disassociation request

from the associated sensor.

Receiver address = 001 to 999 and receiver has

not received a communication within 35 minutes

from the associated sensor.

Receiver has no power. Open Open Open Open

Thermistor in sensor has failed to either open or

close.

Setpoint potentiometer has failed to either ope n or

close.

output

72.5°F (22.5°C),

indefinitely

11.17 kΩ,

72.5°F (22.5°C)

Hold for 15

minutes, then

open

Open Open Open Open

Open Normal value Normal value N/A

Normal value Open Open N/A

Zone setpoint

output

451 Ω, 72.5°F

(22.5°C),

indefinitely

451 Ω, 72.5°F

(22.5°C),

Hold for 15

minutes, then

open

Heating

setpoint

output

501 Ω, 70.5°F

(21.4°C),

indefinitely

501 Ω, 70.5°F

(21.4°C),

indefinitely

Fan/System

output

2320 Ω

Fan = Auto

System = Off

2320 Ω

Fan = Auto

System = Off

Measuring Output Resistance

To measure the resistance of receiver outputs for zone temperature and setpoints for all

models, and heating setpoint and fan/system for the WDS:

1. Ensure that the GND-SIGNAL (black) wire and the GND-POWER (yellow) wire are

grounded to the transformer (see Figure 4, p. 16 or Figure 3, p. 16 for wiring

diagrams).

2. Disconnect the ZONE (white) and SETPOINT (RED) wires from the controller.

Disconnect the HEAT SETPOINT (brown) and FAN/SYSTEM (green) wires from the

controller, if applicable.

3. Measure resistance as follows:

a. All models: Measure between the grounded GND-SIGNAL (black) wire and either

the SETPOINT (red) or ZONE (white) wire. Compare resistance measurements to

those in Ta bl e 8 .

b. WDS only: Measure between the grounded GND-SIGNAL (black) wire and the

FAN/SYSTEM (green) wire. Compare resistance measurements to those given in

Ta bl e 9 .

44 Wireless Sensors • BAS-SVX04C-EN

Page 45

Maintenance and Troubleshooting

Note: The output circuits are not electrically powered; consequently, resistance can

be measured without risk of damage to the volt-ohm meter.

Table 8. Receiver resistance table for all models

Nominal setpoint and

Zone or setpoint

temperature

55°F (12.8°C) 17.47 kΩ 792 Ω

60°F (15.6°C) 15.3 kΩ 695 Ω

65°F (18.3°C) 13.49 kΩ 597 Ω

70°F (21.1°C) 11.9 kΩ 500 Ω

75°F (23.9°C) 10.5 kΩ 403 Ω

80°F (26.7°C 9.3 kΩ 305 Ω

85°F (29.4°C) 8.25 kΩ 208 Ω

Nominal zone temperature

output resistance

heating setpoint output

resistance

Table 9. Receiver resistance table for model WDS

Nominal output

Fan command System command

Auto or invalid Emergency heat 35,000 Ω

Auto or invalid Heat 19,480 Ω

Auto or invalid Auto 7680 Ω

Auto or invalid Off 2320 Ω

Auto or invalid Cool 4870 Ω

On Emergency heat 43,450 Ω

On Heat 27,930 Ω

On Auto 16,130 Ω

On Off 10,770 Ω

On Cool 13,320 Ω

High Invalid 16,130 Ω

Med Invalid 13,320 Ω

Low Invalid 10,770 Ω

Auto Invalid 2320 Ω

Off Invalid 4870 Ω

Valid Valid 7680 Ω

Invalid Valid 7680 Ω

Valid Invalid 2320 Ω

Invalid Invalid —

resistance

BAS-SVX04C-EN • Wireless Sensors 45

Page 46

Maintenance and Troubleshooting

Cleaning the Sensor

NOTICE

Equipment damage!

Spraying glass cleaner or any other solution directly on the sensor may damage it.

You can clean the sensor by applying glass cleaner to a soft, non-abrasive cloth, and

gently wiping the face, including the buttons and LCD display. Use of a pre-moistened

towelette designed for lens or screen cleaning is also acceptable.

Avoid inadvertent pressing of the Occupied/Unoccupied buttons on the model WZS

sensor or the keypad on the WDS sensor, as this may result in an unwanted timed

override or settings change.

46 Wireless Sensors • BAS-SVX04C-EN

Page 47

Specifications

The following table presents specifications for all models of the wireless sensor sets.

Sensor operating temperature 32 to 122ºF (0 to 50ºC)

Receiver operating temperature -40 to 158ºF (-40 to 70ºC)

Storage temperature -40 to 185ºF (-40 to 85°C)

Storage and operating humidity range 5% to 95%, non-condensing

Accuracy 0.5 °F over a range of 55 to 85°F (12.8 to 29.4°C)

Resolution 0.125ºF over a range of 60 to 80ºF

Setpoint functional range (WZS only) 45 to 95ºF (7.22 to 35ºC)

Setpoint functional range (WDS only) 50 to 89.6ºF (10 to 32ºC)

Setpoint thumb wheel markings (WZS only) 50 to 85ºF (stamped every 5ºF) and *, **

Receiver voltage 24 V nominal ac/dc ± 10%

Receiver power consumption <1 VA

Housing Polycarbonate/ABS blend, UV protected, UL 94-5VA

Mounting 3.24 in (8.26 cm) for 2 mounting screws (supplied)

Sensor battery (2) AA, 1.5 V, 2800 mAh, lithium, 5-year life, UL listed

(a)

Range

Output power 100 mW

Radio frequency 2.4 GHz (IEEE Std 802.15.4-2003 compliant)

Radio channels 16

Address range 000–999

Minimum time between transmissions 30 seconds

Maximum time between transmissions 15 minutes

(a)Range values are estimated transmission distances for satisfactory operation. Actual distance is job specific and

must be determined during site evaluation.

(15.56 to 26.67°C)

0.25ºF when outside this range

11 to 29ºC (stamped every 3ºC) and *, **

flammability rating, suitable for application in a

plenum

Open range: 2,500 ft (762 m)

(packet error rate = 2%)

Usable: 200 ft (61 m)

Typical: 75 ft (23 m)

(2405–2480 MHz, 5 MHz spacing)

BAS-SVX04C-EN • Wireless Sensors 47

Page 48

Appendix A: Wiring Diagrams

Single Transformer Wiring

Typically, a single transformer powers the unit controller, which provides power to the

receiver. This is the recommended method of wiring.

48 Wireless Sensors • BAS-SVX04C-EN

Page 49

Multiple Transformer Wiring

WARNI NG

Shock Hazard!

If the use of multiple transformers is necessary, locate them so that they do not allow

simultaneous human contact. Touching both 24 Vac outputs simultaneously on two

electrically connected transformers could result in death or serious injury.

Using a dedicated transformer to power the receiver is seldom necessary and is not

advised. Use it only when the host transformer does not have enough volt-ampere (VA)

capacity to power the receiver (see “Specifications,” p. 47 for receiver power

consumption).

If you are using a dedicated transformer to power the receiver, make sure the grounds

(commons) of the multiple transformers are electrically connected to one another, as

shown in the diagram.

Appendix A: Wiring Diagrams

BAS-SVX04C-EN • Wireless Sensors 49

Page 50

Appendix B: Agency Compliance

The following table presents agency compliance information for wireless sensor set

models as shown.

United States compliance

(all models)

Canada compliance

(all models)

IEEE compliance for radio

frequency range

(all models)

UL listed:UL 94-5VA Flammability rating

UL 916: Energy management equipment

FCC CFR47, Section 15.247 & Subpart E Digital Modulation Transmission with no SAR (FCC

Identification TFP-13651127)

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received,

including interference that may cause undesired operation.

Warning:

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to

operate the equipment.

20 cm separation distance:

To comply with FCC’s RF exposure limits for general population/uncontrolled exposure, the

antenna(s) used for this trans mitte r must be in stalled to provide a separation distance of at

least 20 cm from all persons and must not be co-located or operating in conjunction with

any other antenna or transmitter.

CSA22.2 No. 205-M1983 Signal Equipment

Industry Canada (Certification no: IC: 6178A-13651127)

Industry Canada statement:

the term “IC” before the certification/registration number signifies only that the Industry

Canada technical specifications were met.

Section 14 of RSS-210:

The installer of this radio equipment must ensure that the antenna is located or pointed such

that it does not emit RF field in excess of Health Canada limits for the general population.

IEEE 802.15.4-2003, IEEE Standard for Information Technology—Telecommunications and

information exchange between systems—Local and metropolitan area networks—Specific

requirements, Part 15.4: Wireless Medium Access Control (MAC) and Physical Layer (PHY)

Specifications for Low Rate Wireless Personal Area Networks (LR-WPANs)

50 Wireless Sensors • BAS-SVX04C-EN

Page 51

Page 52

www.trane.com

For more information, contact your local Trane

office or e-mail us at comfort@trane.com

Literature Order Number BAS-SVX04C-EN

Date April 2008

Supersedes New

Trane has a policy of continuous product and product data improvement and reserves the right to

change design and specifications without notice.

Loading...

Loading...