Page 1

Installation, Operation, and

Maintenance

S&P Unit Heaters

Model Numbers:

UHSA

UHPA

May 2007 UH-SVX01A-EN

Page 2

Preface and Warnings and Cautions

Hazard Identification

Warnings and Cautions appear at

appropriate sections throughout this

literature. Read these carefully.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

CAUTION

Indicates a situation that may result

in equipment or property-damage

only accidents.

WARNING

Operational Hazards!

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury or

death. Read the installation,

operating and maintenance

instructions thoroughly before

installing or servicing this

equipment.

WARNING

Compliance Hazards!

Failure to comply with the general

safety information may result in

extensive property damage, severe

personal injury or death.

WARNING

Unit Alterations!

Do not alter the unit heater in any

way or damage to the unit and/or

severe personal injury or death may

occur!

WARNING

Voltage Hazard!

Disconnect all power supplies before

installing or servicing the heater. If

the power disconnect is out of sight,

lock it in the open position and tag it

to prevent unexpected application of

power. Failure to do so could result in

fatal electric shock, or severe

personal injury.

WARNING

Voltage Hazard!

Do not depend upon a thermostat or

other switch as sole means of

disconnecting power when installing

or servicing heater. Always

disconnect power at main circuit

breaker as described above. Failure

to do so could result in fatal electric

shock.

CAUTION

Equipment Damage!

Insure that all power sources

conform to the requirements of the

unit heater or damage to the unit will

result!

Follow installation instructions

CAREFULLY to avoid creating unsafe

conditions. All external wiring must

conform to applicable current local

codes, and to the latest edition of the

National Electric Code ANSI/NFPA

No. 70. In Canada, all external wiring

must conform to the Canadian

Electric Code, Part 1 CSA Standard

C22.1 All wiring should be done and

checked by a qualified electrician

using copper wire only. All steam

and hot water connections should be

made and leaktested by a suitably

qualified individual, per instructions

in this manual. Also follow

procedures listed on the “Unit

Equipment Start-Up Sheet” located

in this manual.

Make certain that the power source

conforms to the electrical

requirements of the heater.

Special attention must be given to

any grounding information

pertaining to this heater. To prevent

the risk of electrocution, the heater

must be securely and adequately

grounded. This should be

accomplished by connecting a

grounded conductor between the

service panel and the heater. To

ensure a proper ground, the

grounding means must be tested by

a qualified electrician.

Do not insert fingers or foreign

objects into the heater or its air

moving device. Do not block or

tamper with the heater in any

manner while in operation or just

after it has been turned off, as some

parts may be hot enough to cause

injury.

Note: To meet CSA and OSHA

requirements, units mounted

below 8 feet (2.4m) from the

floor must be equipped with

an OSHA fan guard.

It is good practice to have a shutoff

switch on the electrical power lines

controlling the heater. Whenever a

unit is serviced, shut power off to the

unit.

Since these units are installed in

most instances higher than 8 feet

(2.4m), proper type of ladders or

scaffolding should be used, as set up

by OSHA requirements. It is the

owner’s responsibility to provide any

scaffolding or other apparatus

required to perform emergency

service or annual/periodic

maintenance to this equipment.

In industrial plants, professional

maintenance crews should service

this equipment.

All Horizontal Unit Heaters are

shipped fully assembled and may be

used for steam or hot water

applications. Coils are factory tested

at 250 psig (1723.5 kg).

All Vertical Unit Heaters are shipped

fully assembled and may be used for

steam or hot water applications.

Coils are factory tested at 400 psig air

under water. Fans are balanced and

motors are prelubricated.

Unless otherwise specified, the

following conversions may be used

for calculating SI unit measurements:

1 foot = 0.305 m

1 inch = 25.4 mm

1 psig = 6.894 kPa

1 pound = 0.453 kg

1 gallon = 3.785 L

1 inch water column = 0.249 kPa

meter/second = FPM ÷ 196.8

liter/second = CFM x 0.472

1000 Btu per hour = 0.293 kW

1000 Btu/Cu. Ft. = 37.5 MJ/m

1 cubic foot = 0.028 m

3

3

© 2007 American Standard All Rights Reserved UH-SVX01A-EN

Page 3

Contents

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan Guard/Louver Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Te c h n i c a l D a t a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Motor Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Steam Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Hot Water Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Warranty Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

UH-SVX01A-EN 3

Page 4

Model Number Description

UHSBA181TAA101A0A0A1

1234567891011121314151617181920

Description

Vertical hydronic unit heaters are

designed for installation requiring

down flow air delivery, offered in 15

sizes ranging from 41,300 to 705,000

BTU/Hr., and use with steam or hot

water. Low output (increased

airflow) units are available for high

ceiling applications.The designs are

certified by CSA (per CAN/CSA-C22.2

and UL1995). Do not alter these units

in any way and do not attach any

ductwork to these units. If you have

any questions after reading this

manual, contact the manufacturer.

Figure 1. Vertical Unit (bottom)

Figure 2. Vertical Unit (top)

Horizontal hydronic unit heaters are

available in both serpentine and

header type units. Serpentine units

offer outputs from 8,030 to 35,900

BTU’s (2.4 to 10.5 kW) and are ideal

for hot water (only) installations with

limited clearances. Header type

horizontal units range from 18,000 to

360,000 (5.3 to 105.5 kW) and can

operate with either hot water or

steam. Both units are furnished with

totally enclosed motors, with

explosion proof motors as optional

on header types. The designs are

certified by CSA (per CAN/CSA-C22.2

and UL1995). Do not alter these

units in any way and do not

attach any ductwork to the

units. If you have any questions

after reading this manual, contact

the manufacturer.

Figure 3. Serpentine Type

Figure 4. Header Type

Service Model Number

Description

DIGIT 1,2,3 — PRODUCT TYPE

UHP

UHS

DIGIT 4— DEVELOPMENT

SEQUENCE

B

DIGIT 5, 6, 7—CAPACITY/COIL

TYPE

Hot Water Only (Coil Type A

"Serpentine")

A08 8,030 BTU/HR

A18 18,400 BTU/HR

A25 24,800 BTU/HR

A36 35,900 BTU/HR

Steam or Hot Water

042 41,300 BTU/HR

064 65,500 BTU/HR

080 80,600 BTU/HR

102 101,80 0 BTU/HR

122 124,400 BTU/HR

146 152,000 BTU/HR

166 173,000 BTU/HR

202 210,200 BTU/HR

252 249,800 BTU/HR

280 283,800 BTU/HR

336 333,400 BTU/HR

384 386,000 BTU/HR

500 496,000 BTU/HR

600 585,000 BTU/HR

720 705,000 BTU/HR

Steam or Hot Water "Header

Type Coil"

018 18,0 0 0 BTU/HR

024 24,000 BTU/HR

036 36,000 BTU/HR

048 48,000 BTU/HR

060 60,000 BTU/HR

072 72,000 BTU/HR

084 84,000 BTU/HR

096 96,000 BTU/HR

108 108,000 BTU/HR

120 120,000 BTU/HR

132 132,000 BTU/HR

144 144,000 BTU/HR

156 156,000 BTU/HR

4 UH-SVX01A-EN

Page 5

Model Number Description

180 180,000 BTU/HR

204 204,000 BTU/HR

240 240,000 BTU/HR

280 280,000 BTU/HR

300 300,000 BTU/HR

360 360,000 BTU/HR

DIGIT 8—VOLTAGE

1 115/1/60

3 230/1/60 (115 V motor with

Transformer)

4 208/3/60

5 230/3/60

6 460/3/60

7 575/60/3 (Totally Enclosed)

(P only)

DIGIT 9 - MOTOR TYPE

T Totally Enclosed

E Explosion Proof

DIGIT 10- DESIGN SEQUENCE

A

DIGIT 11- TUBE MATERIAL

A Copper

B Steel (P only)

DIGIT 17 - Manual Starter

0None

AManual Starter

DIGIT 18 - STEAM & HOT WATER

CONTROL

0None

1 Strap on Hot Water Control

2 Steam Pressure Control (Open

on rise in pressure)

3 Steam Pressure Control

(Close on rise in pressure)

4 5.0 Amp Speed Control

Switch ( Capacities 18 - 108

only)

DIGIT 19 - VERTICAL LOUVER

0None

A Vertical Louver

B Fin Diffuser (P only)

C Fin Diffuser w/ Coating (Ponly)

DIGIT 12- FAN GUARD

1 OSHA Fan Guard

2 Standard Fan Guard (3 phase

or Explosion Proof motors

only)

3 Standard Fan Guard (Unit

Capacities 240 - 360)

DIGIT 13 - SPECIAL COATING

0 No Special Coating

A Phenolic Coating (Baked)

BEpoxy

C Epoxy Phenolic

DIGIT 14 - DISCONNECT SWITCH

0None

1 Disconnect switch

DIGIT 15 - THERMOSTATS (LINE

VOLTAGE)

0None

A Light Duty TSTAT w/ subbase

Line Volts 8 Amps

B Heavy Duty TSTAT w/

subbase&guard Line Volts 16

Amps+A32

DIGIT 16 - THERMOSTAT COVER

0None

A Locking Thermostat Cover

UH-SVX01A-EN 5

Page 6

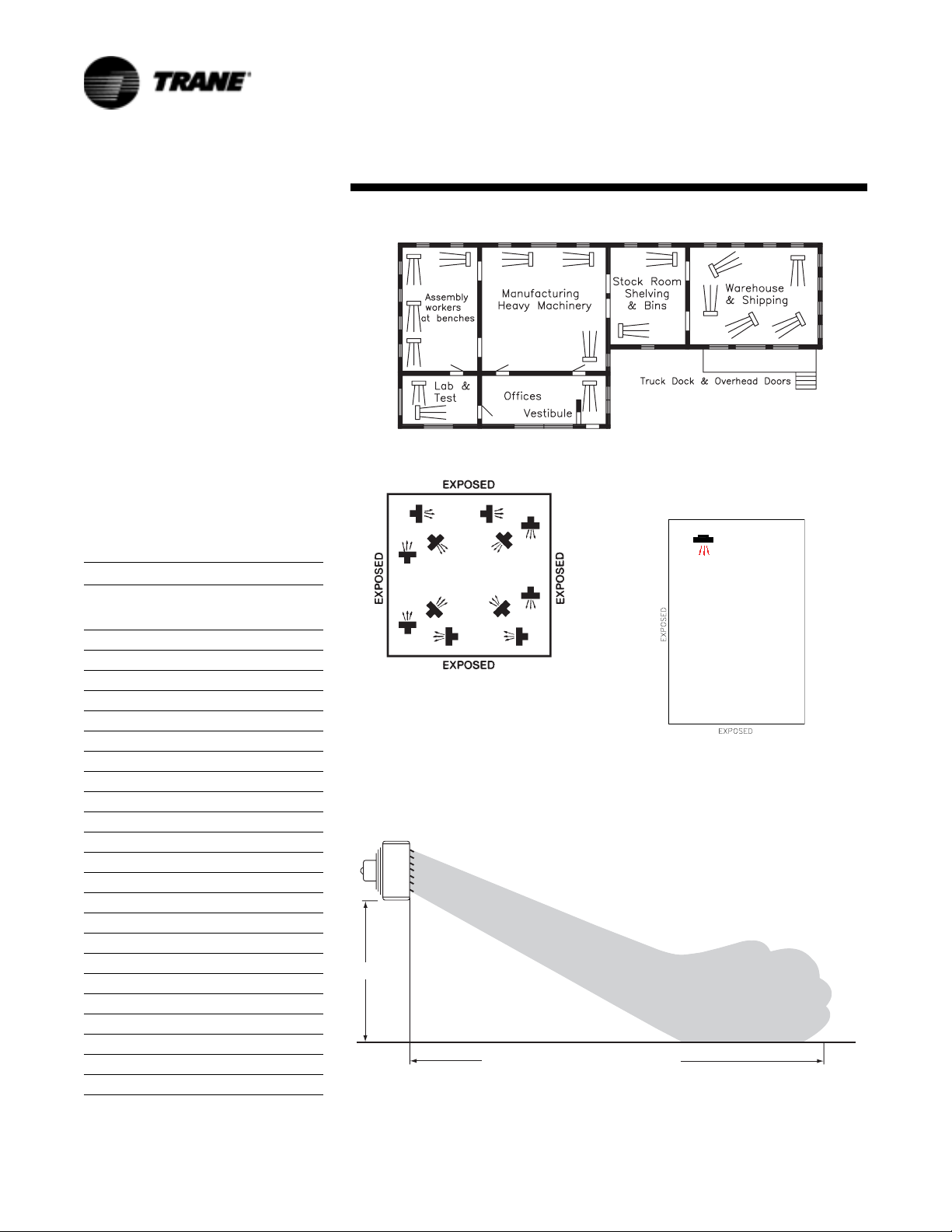

It is assumed that the design

engineer has selected, sized, and

located in the area to be heated.

However, the information given here

may be of additional help to the

installer. These sketches indicate

suggested basic locations for

different types of unit heaters.

Horizontal unit heaters should be

located to give a circulatory motion,

preferably in the outer perimeter of

the building. The units should be

spaced to properly blanket the areas

with warm air.

The unit should be suspended from

connections provided in the unit by

means of rods. The rods should then

be attached to solid supports of the

building.

Ta b l e 1.

Model

No

A08 8 (2.4) 20 (6.1)

A18 8 (2.4) 25 (7.6)

A25 9 (2.7) 29 (8.8)

A36 9 (2.7) 29 (8.8)

108 11 (3.4) 40 (12.2)

120 12 (3.7) 40 (12.2)

132 13 (4.0) 54 (16.5)

144 13 (4.0) 55 (16.8)

156 13 (4.0) 55 (16.8)

180 13 (4.0) 53 (16.2)

204 13 (4.0) 55 (16.8)

240 14 (4.3) 57 (17.4)

280 14 (4.3) 57 (17.4)

300 15 (4.6) 58 (17.7)

360 15 (4.6) 60 (18.3)

Maximum

Mounting HT.

ft (m)

18 8 (2.4) 20 (6.1)

24 8 (2.4) 24 (7.3)

36 9 (2.7) 28 (8.5)

48 9 (2.7) 30 (9.1)

60 10 (3.0) 30 (9.1)

72 10 (3.0) 29 (8.8)

84 10 (3.0) 30 (9.1)

96 11 (3.4) 38 (11.6)

Approx. Max.

Throw ft (m)

Location

Figure 5.

A narrow area with four exposed

walls either with or without roof

exposure.

Figure 6.

Figure 6 represents a large square

area with exposed walls and roof;

units are blanketing all exposed

surfaces.

Figure 7 is based on 2 PSI (13.8 kPa)

steam pressure and 60 °F (16 °C)

entering air temperature.

H

MAXIMUM DISTANCE OF THROW = T

Figure 7. Mounting Height and Approx. Heat Throw

Figure 8.

A small area with exposed walls

requiring one unit.

6 UH-SVX01A-EN

Page 7

Location

A

BC

UNIT SIZE

048/060

072

084 & 120

096/108

1-3/4

C

132/144/156

180/204

240/280

300/360

A

15-5/16

16-9/16

19-1/16

17-13/16

21-9/16

22-13/16

26-1/16

31-9/16

1-7/8

2-1/2

3"

2-1/2

3-1/2

4"

4-1/2

11-11/16

10"

6"

1"

BB

C

L

Figure 9. Four Point Suspension-Shelf Mounted Motors Only

C

1-3/4

4 PT. SUSPENSION

USE 3/8-16

THREADED RODS

(4 LOCATIONS)

C

L

D6340

UH-SVX01A-EN 7

Page 8

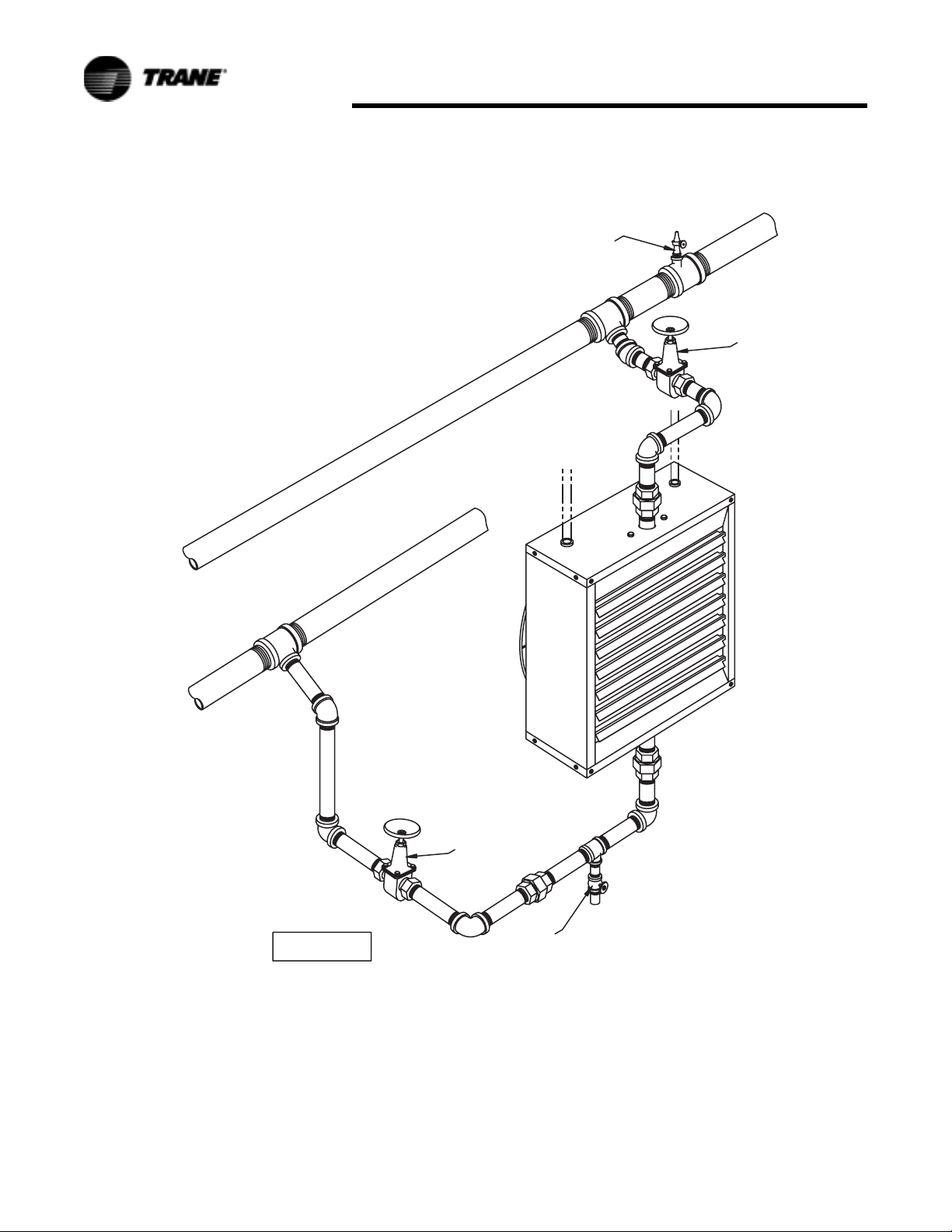

Location

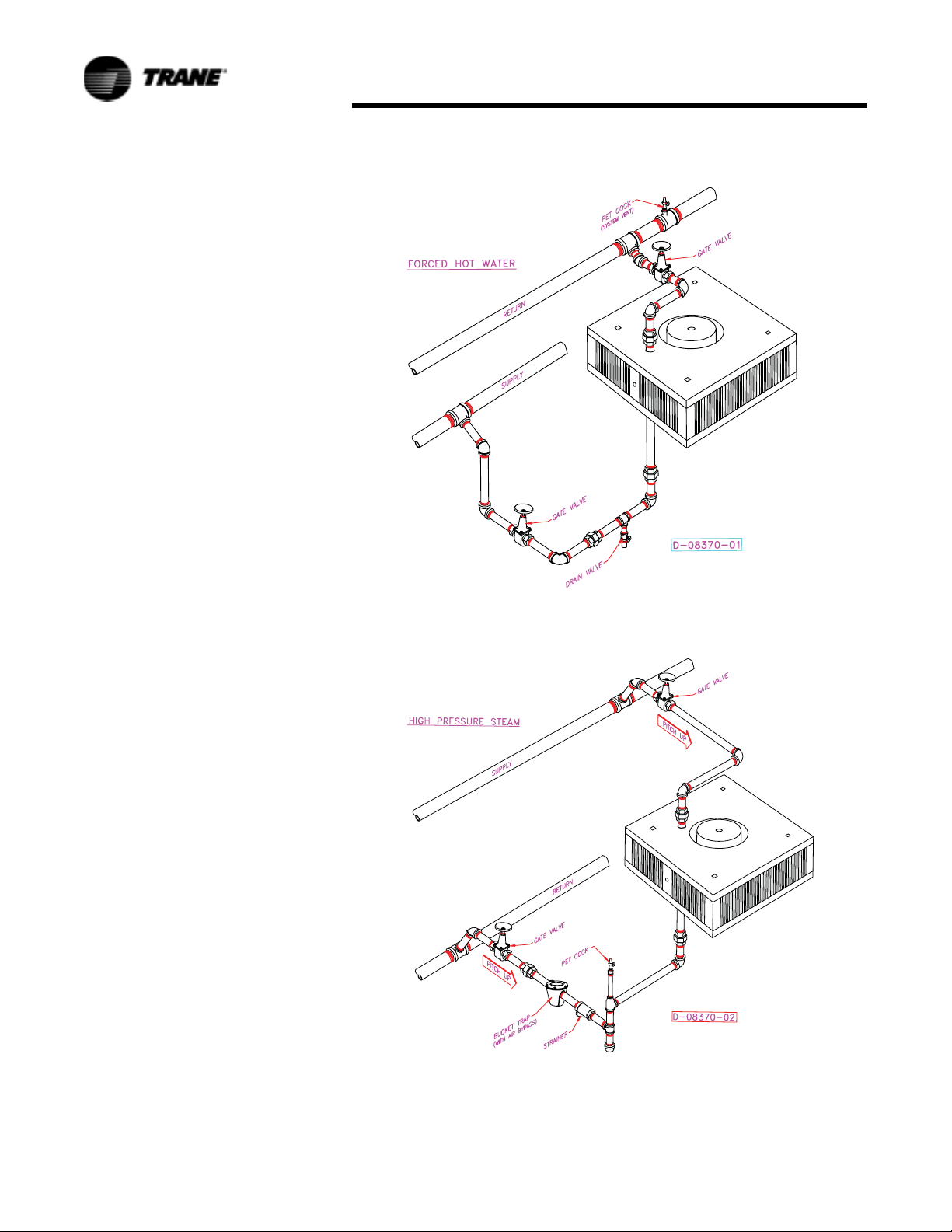

"FORCED HOT WATER"

PET COCK

(SYSTEM VENT)

GATE VALVE

RETURN

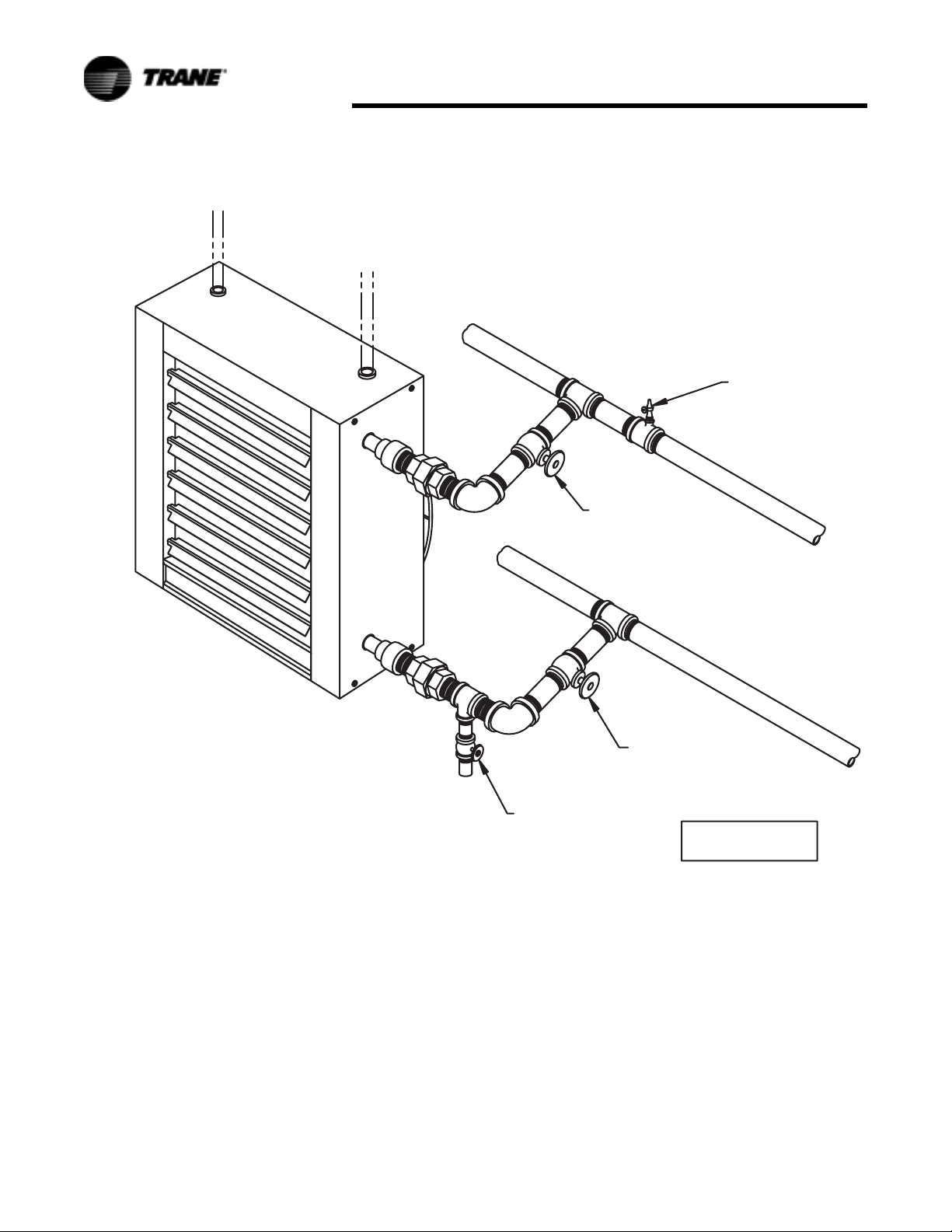

Figure 10. Forced Hot Water

SUPPLY

GATE VALVE

D-6056

DRAIN VALVE

8 UH-SVX01A-EN

Page 9

Location

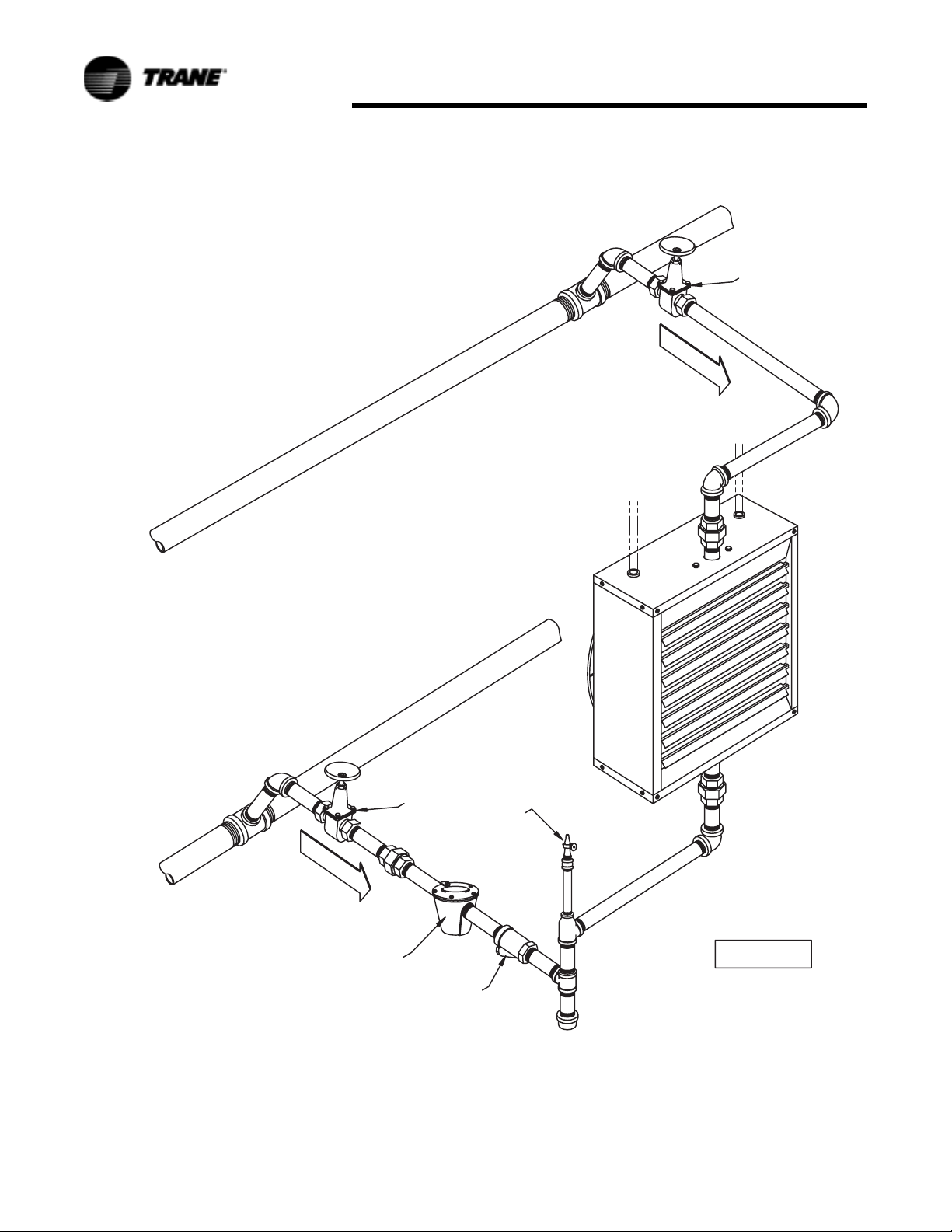

PET COCK

(SYSTEM VENT)

RETURN

GATE VALVE

"FORCED HOT WATER"

(Serpentine Units)

Figure 11. Forced Hot Water: Serpentine Unit Only

SUPPLY

GATE VALVE

DRAIN VALVE

D-6057

UH-SVX01A-EN 9

Page 10

Location

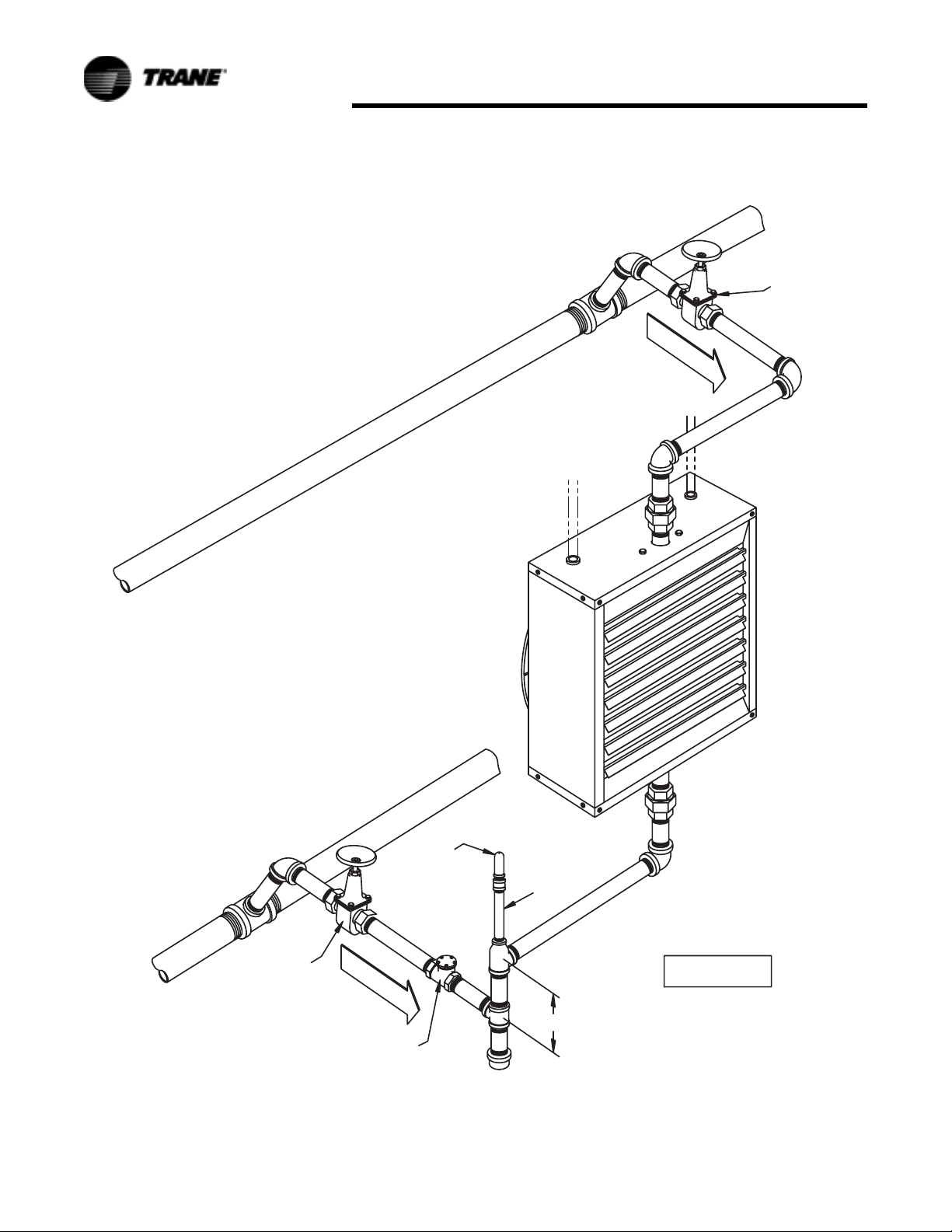

GATE VALVE

"HIGH PRESSURE STEAM"

SUPPLY

PITCH UP

RETURN

GATE VALVE

PITCH UP

PET COCK

D-6058

BUCKET TRAP

(WITH AIR BYPASS)

Figure 12. High Pressure Steam

10 UH-SVX01A-EN

STRAINER

Page 11

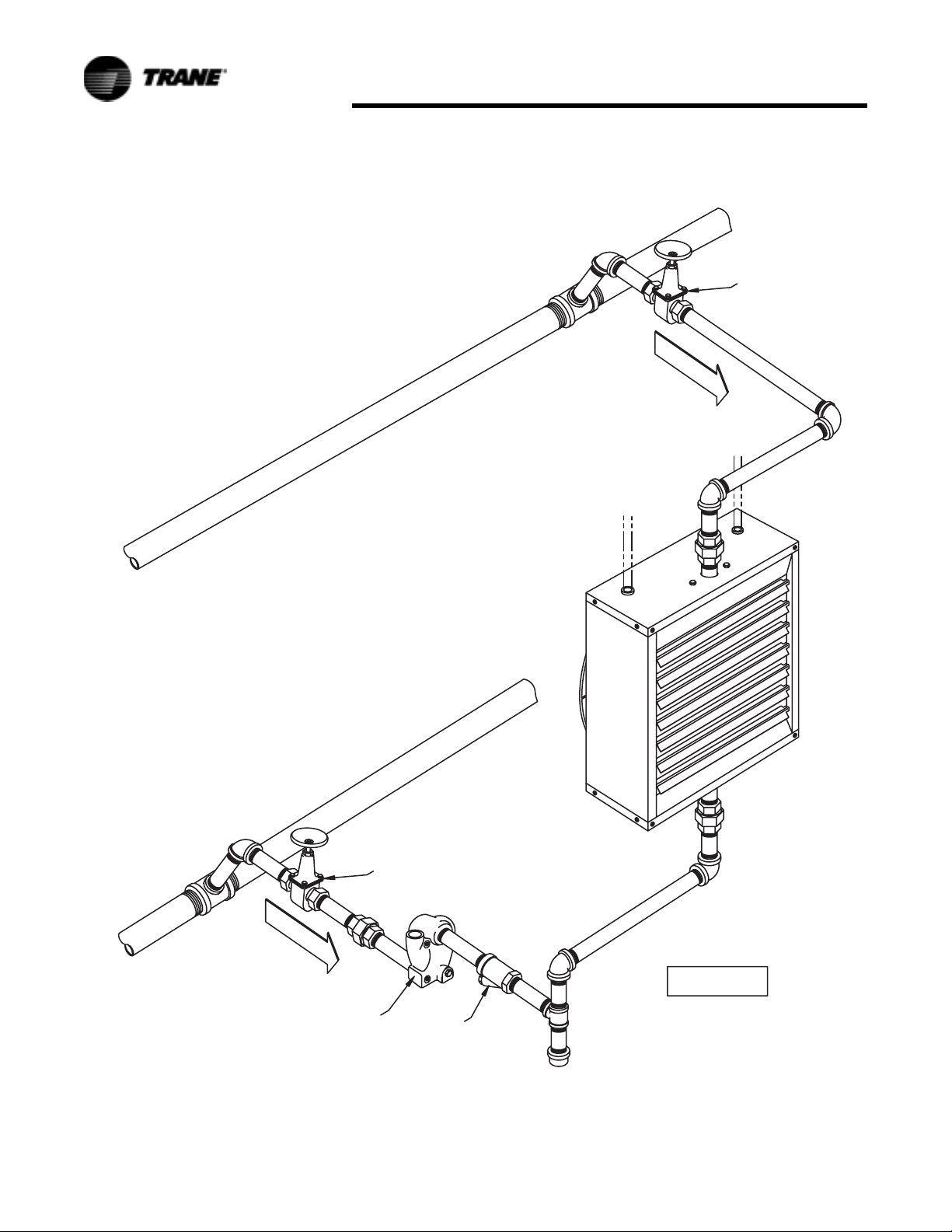

Location

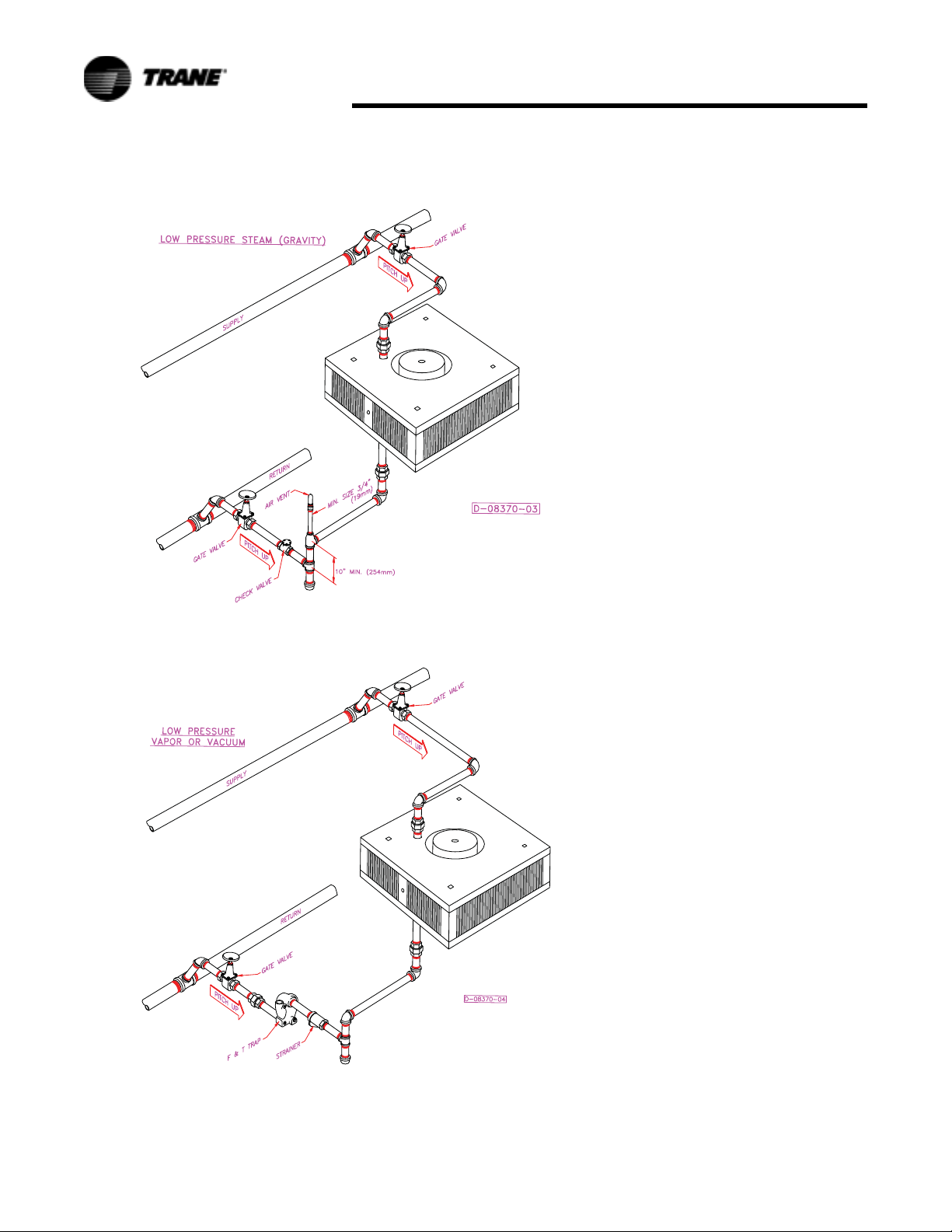

"LOW PRESSURE STEAM GRAVITY"

SUPPLY

GATE VALVE

PITCH UP

RETURN

AIR VENT

PITCH UP

GATE VALVE

CHECK VALVE

Figure 13. Low Pressure Steam Gravity

UH-SVX01A-EN 11

MIN. SIZE 3/4

D-6059

10" MIN. (254 MM)

Page 12

Location

GATE VALVE

"LOW PRESSURE

VAPOR OR VACUUM"

SUPPLY

PITCH UP

RETURN

GATE VALVE

PITCH UP

D-6060

F & T TRAP

Figure 14. Low Pressure Vapor Or Vacuum

12 UH-SVX01A-EN

STRAINER

Page 13

Installation

Installation: P Type

Periodic Service

WARNING

Heavy Objects!

Ensure that all hardware used in the

suspension of each unit heater is

more than adequate for the job.

Failure to do so may result in

extensive property damage, severe

personal injury or death.

CAUTION

Lifting/Suspension Methods!

Make certain that the lifting

methods used to lift the heater and

the method of suspension used in

the field installation of the heater are

capable of uniformly supporting the

weight of the heater at all times.

Failure to heed this warning may

result in property damage or

personal injury!

CAUTION

Structural Integrity!

Make certain that the structure to

which the heater is mounted is

capable of supporting its weight.

Under no circumstances must the

piping or the electrical conduit be

used to support the heater; or

should any other objects (i.e. ladder,

person) lean against the heater or

the electrical conduit for support.

CAUTION

Performance Failure!

Unit heaters must be hung level

from side to side and from front to

back. Failure to do so will result in

poor performance and or premature

failure of the unit.

It is assumed that the design

engineer has selected, sized, and

located in the area to be heated by

the design engineer. However, the

information given here may be of

additional help to the installer.

Vertical unit heaters should be

located to give spot heating or a

circulatory distribution, preferably

near the outer perimeter of the

building. The units should be spaced

to properly blanket the areas with

warm air. Place the units at points of

greatest heat loss. Blanket outside

doorway and provide ample

coverage of window areas. Keep

units away from obstructions that

will impede the full and natural air

delivery of the units.

Install unit heaters to meet CSA and

OSHA requirements; Vertical Unit

Heaters mounted lower than 2.4

meters (8 feet) from the floor must

be equipped with an OSHA fan

guard. Weldnuts are provided at the

top of all units for suspension

purposes. The unit should be

suspended from connections

provided in the unit by means of

rods. The rods should then be

attached to solid supports of the

building.

Units must hang level vertically and

horizontally.

Provide sufficient clearance around

units for maintenance purposes. This

includes at least 7 inches above all

Vertical Unit Heaters even though

the motor is removable through the

bottom.

Isolators are not required but may be

desirable for some applications.

Refer to Table 2 for Unit Weights.

Table 2. Unit Weights-Lbs

Vertical Unit Heaters

Unit Weights (Lbs.)

042 26

064 32

080 36

102 51

122 54

146 69

166 69

202 75

252 115

280 120

336 120

384 126

500 267

600 210

720 260

EXAMPLE

Tabl e 4 lists maximum mounting

height and floor spread data of warm

air coverage at floor level with louver

cone diffusers. Correction factors for

various water temp. and psig of

steam are in Ta b l e 7.

An approximation of the floor spread

when operating on other than 2 lb.

Steam or 219 degree may be

obtained by ratioing the new floor

spread and the maximum mounting

height to that at 2 lb. steam or 219

degree hot water.

Following is an example:

Determine the floor spread and the

maximum mounting height of a std.

model 80 unit heater with a cone

diffuser set at 90 degrees, operating

on 280 degree hot water.

From Ta b l e 6 , maximum mounting

height of a model 80 at 219 degree

hot water is 18.5 ft. with floor

coverage of 14.0 ft. diameter. The

maximum mounting height

correction factor at 280 degree hot

water is 0.80.

18.5 ft. x 0.80 = 14.8 ft.

Maximum mounting height of a

model 80 using 280 degree hot

water.

“X” = floor spread of model 80 using

280 degree hot water.

X = 14.8 x 14.0 / 18.5

X = 207.2 / 18.5

X = 11.2 ft.

UH-SVX01A-EN 13

Page 14

Installation

Table 3. Maximum Mounting Height in Feet with and without Louver Cone Diffuser

Unit Size Steam Pressure (PSI) Unit Size Steam Pressure (PSI)

042

042*

042L

042L*

064

064*

064L

064L*

080

080*

2

(13.8)5(34.5)10(68.9)50(344.7)75(517.1)

10.5

(3.2)

12.5

(3.8)

7.5

(2.3)

9.0

(2.7)

12.5

(3.8)

14.5

(4.4)

9.0

(2.7)

10.5

(3.2)

12.0

(3.7)

14.5

(4.4)

9.5

(2.9)

11.5

(3.5)

15.0

(4.6)

19.0

(5.8)

11.5

(3.5)

14.0

(4.3)

15.0

(4.6)

18.5

(5.6)

11.0

(3.4)

13.5

(4.1)

10.0

(3.0)

12.0

(3.7)

7.5

(2.3)

8.5

(2.6)

12.0

(3.7)

14.0

(4.3)

8.5

(2.6)

10.0

(3.0)

11.5

(3.5)

14.0

(4.3)

9.0

(2.7)

11.0

(3.4)

14.5

(4.4)

18.5

(5.6)

11.0

(3.4)

13.5

(4.1)

14.5

(4.4)

18.0

(5.5)

10.5

(3.2)

13.0

(4.0)

10.0

(3.0)

12.0

(3.7)

7.5

(2.3)

8.5

(2.6)

12.0

(3.7)

13.5

(4.1)

8.5

(2.6)

10.0

(3.0)

11.5

(3.5)

14.0

(4.3)

9.0

(2.7)

11.0

(3.4)

14.5

(4.4)

18.5

(5.6)

11.0

(3.4)

13.5

(4.1)

14.0

(4.3)

17.5

(5.3)

10.5

(3.2)

13.0

(4.0)

9.0

(2.7)

11.0

(3.4)

7.5

(2.3)

7.5

(2.3)

10.5

(3.2)

12.0

(3.7)

7.5

(2.3)

9.0

(2.7)

10.0

(3.0)

12.0

(3.7)

8.0

(2.4)

9.5

(2.9)

12.5

(3.8)

16.5

(5.0)

9.5

(2.9)

12.0

(3.7)

12.0

(3.7)

15.5

(4.7)

9.0

(2.7)

11.5

(3.5)

8.0

(2.4)

10.0

(3.0)

7.5

(2.3)

7.5

(2.3)

9.5

(2.9)

11.5

(3.5)

7.5

(2.3)

8.5

(2.6)

9.5

(2.9)

11.5

(3.5)

8.0

(2.4)

9.0

(2.7)

12.0

(3.7)

16.0

(4.9)

9.0

(2.7)

11.5

(3.5)

11.5

(3.5)

15.0

(4.6)

8.5

(2.6)

11.0

(3.4)

080L

080L*

102

102*

102L

102L*

122

122L

146

146L

2

(13.8)5(34.5)10(68.9)50(344.7)75(517.1)

18.0

(5.5)

22.0

(6.7)

13.0

(4.0)

17.0

(5.2)

14.0

(4.3)

17.0

(5.2)

11.0

(3.4)

13.5

(4.1)

17.5

(5.3)

21.5

(6.6)

15.0

(4.6)

18.5

(5.6)

16.0

(4.9)

19.5

(5.9)

21.0

(6.4)

26.0

(7.9)

15.5

(4.7)

19.0

(5.8)

18.0

(5.5)

22.5

(6.9)

17.5

(5.3)

21.0

(6.4)

12.5

(3.8)

16.5

(5.0)

13.5

(4.1)

16.5

(5.0)

10.5

(3.2)

13.0

(4.0)

17.0

(5.2)

21.0

(6.4)

14.5

(4.4)

18.0

(5.5)

15.5

(4.7)

19.0

(5.8)

20.5

(6.2)

25.5

(7.8)

15.0

(4.6)

18.5

(5.6)

17.5

(5.3)

22.0

(6.7)

17.5

(5.3)

21.0

(6.4)

12.0

(3.7)

16.0

(4.9)

13.0

(4.0)

16.0

(4.9)

10.5

(3.2)

13.0

(4.0)

16.5

(5.0)

20.5

(6.2)

14.5

(4.4)

18.0

(5.5)

15.5

(4.7)

18.5

(5.6)

20.0

(6.1)

25.0

(7.6)

14.5

(4.4)

18.0

(5.5)

17.5

(5.3)

21.5

(6.6)

15.0

(4.6)

19.0

(5.8)

11.0

(3.4)

14.0

(4.3)

11.5

(3.5)

14.0

(4.3)

9.5

(2.9)

12.0

(3.7)

15.0

(4.6)

18.5

(5.6)

13.0

(4.0)

16.0

(4.9)

14.0

(4.3)

17.0

(5.2)

17.5

(5.3)

22.5

(6.9)

13.0

(4.0)

16.0

(4.9)

15.0

(4.6)

18.5

(5.6)

14.0

(4.3)

18.0

(5.5)

10.5

(3.2)

13.5

(4.1)

11.0

(3.4)

13.5

(4.1)

9.0

(2.7)

11.5

(3.5)

14.5

(4.4)

17.5

(5.3)

12.5

(3.8)

15.0

(4.6)

13.5

(4.1)

16.0

(4.9)

17.0

(5.2)

21.5

(6.6)

12.0

(3.7)

15.5

(4.7)

14.0

(4.3)

18.0

(5.5)

NOTES:

* = Low Speed

L = Low output model with all air ports open

Figures in bold face show maximum mounting height with louver cone diffusers set vertically.

Above table based on 60°F entering air temperature. In providing for the use of diffusers, it must be remembered that adjustment of a LCD to deflect air

toward horizontal immediately lowers the mounting height limit.

14 UH-SVX01A-EN

Page 15

Installation

Table 4. Maximum Mounting Height in Feet with and without Louver Cone Diffuser

Steam Pressure (PSI)

Unit Size

166

166L

202

202L

252

252L

280

280L

336

2

(13.8)5(34.5)10(68.9)50(344.7)75(517.1)

18.0

(5.5)

22.5

(6.9)

22.0

(6.7)

27.5

(8.4)

22.0

(6.7)

27.5

(8.4)

25.5

(7.8)

31.5

(9.6)

20.0

(6.1)

25.0

(7.6)

24.0

(7.3)

29.5

(9.0)

21.0

(6.4)

26.0

(7.9)

25.5

(7.8)

32.0

(9.8)

24.0

(7.3)

30.0

(9.1)

17.5

(5.3)

22.0

(6.7)

21.5

(6.6)

27.0

(8.2)

21.5

(6.6)

27.0

(8.2)

25.0

(7.6)

31.0

(9.4)

19.5

(5.9)

24.0

(7.3)

23.5

(7.2)

28.5

(8.7)

20.5

(6.2)

25.5

(7.8)

25.0

(7.6)

31.0

(9.4)

23.0

(7.0)

29.0

(8.8)

17.0

(5.2)

21.5

(6.6)

21.0

(6.4)

26.5

(8.1)

21.0

(6.4)

26.5

(8.1)

24.5

(7.5)

30.5

(9.3)

19.0

(5.8)

23.5

(7.2)

23.0

(7.0)

28.0

(8.5)

20.0

(6.1)

25.0

(7.6)

24.5

(7.5)

30.0

(9.1)

22.0

(6.7)

28.0

(8.5)

14.5

(4.4)

19.0

(5.8)

18.5

(5.6)

23.5

(7.2)

18.5

(5.6)

24.0

(7.3)

22.0

(6.7)

27.0

(8.2)

17.0

(5.2)

20.5

(6.2)

20.0

(6.1)

24.5

(7.5)

17.5

(5.3)

22.0

(6.7)

21.0

(6.4)

26.0

(7.9)

20.0

(6.1)

25.0

(7.6)

14.0

(4.3)

18.0

(5.5)

17.5

(5.3)

22.5

(6.9)

17.5

(5.3)

23.0

(7.0)

21.0

(6.4)

26.0

(7.9)

16.0

(4.9)

19.5

(5.9)

19.0

(5.8)

23.5

(7.2)

17.0

(5.2)

21.0

(6.4)

20.0

(6.1)

25.0

(7.6)

19.0

(5.8)

24.0

(7.3)

Unit Size

336L

384

384L

500

500L

600

600L

720

720L

2

(13.8)5(34.5)10(68.9)50(344.7)75(517.1)

29.0

(8.8)

36.0

(11.0)

28.5

(8.7)

35.5

(10.8)

32.5

(9.9)

41.0

(12.5)

29.5

(9.0)

36.5

(11.1)

35.0

(10.7)

43.5

(13.3)

34.0

(10.4)

42.5

(13.0)

37.0

(11.3)

46.5

(14.2)

38.5

(11.7)

48.0

(14.6)

42.5

(13.0)

53.0

(16.2)

Steam Pressure (PSI)

28.5

(8.7)

35.0

(10.7)

28.0

(8.5)

35.0

(10.7)

31.5

(9.6)

40.0

(12.2)

29.0

(8.8)

36.0

(11.0)

34.0

(10.4)

42.5

(13.0)

33.0

(10.1)

41.5

(12.6)

36.0

(11.0)

45.5

(13.9)

37.5

(11.4)

47.0

(14.3)

41.5

(12.6)

52.0

(15.8)

28.0

(8.5)

34.0

(10.4)

27.5

(8.4)

34.0

(10.4)

30.5

(9.3)

39.0

(11.9)

28.5

(8.7)

35.5

(10.8)

33.0

(10.1)

41.5

(12.6)

32.0

(9.8)

40.5

(12.3)

35.0

(10.7)

44.5

(13.6)

36.5

(11.1)

46.0

(14.0)

40.5

(12.3)

51.0

(15.5)

25.0

(7.6)

30.0

(9.1)

24.0

(7.3)

30.0

(9.1)

27.5

(8.4)

35.0

(10.7)

25.0

(7.6)

32.0

(9.8)

29.0

(8.8)

35.0

(10.7)

28.0

(8.5)

36.0

(11.0)

31.0

(9.4)

39.0

(11.9)

32.0

(9.8)

40.0

(12.2)

35.0

(10.7)

44.0

(13.4)

24.0

(7.3)

29.0

(8.8)

23.0

(7.0)

29.0

(8.8)

26.5

(8.1)

33.5

(10.2)

24.0

(7.3)

30.5

(9.3)

28.0

(8.5)

34.0

(10.4)

27.0

(8.2)

34.5

(10.5)

30.0

(9.1)

37.0

(11.3)

30.5

(9.3)

39.0

(11.9)

33.5

(10.2)

42.0

(12.8)

NOTES:

* = Low Speed

L = Low output model with all air ports open

Figures in bold face show maximum mounting height with louver cone diffusers set vertically.

Above table based on 60°F entering air temperature. In providing for the use of diffusers, it must be remembered that adjustment of a LCD to deflect air

toward horizontal immediately lowers the mounting height limit.

Table 5. Maximum Spread

MODEL No. 42 64 80 102 122 146 166 202 252 280 336 384 500 600 720

Spread ft (m) 15

Note: The "spread" is the diameter of the comfort zone at floor level. The above table represents the spread for standard units without a louver cone

diffuser and mounted at its maximum height at 2 psi (13.8 kPa) steam pressure and 60°F (16*C) entering air. (See Tables 21 and 22 for maximum moun

ing heights.)

(4.6)17(5.2)20(6.1)24(7.3)26(7.9)27(8.2)28(8.5)32(9.8)35(10.7)37(11.3)45(13.7)50(15.2)54(16.5)57(17.4)60(18.3)

UH-SVX01A-EN 15

Page 16

Installation

Table 6. Maximum Mounting Height and Diameter at Floor (Based on 60°F EAT and 219°F EWT or 2 psig steam)

Diffuser Cone 90°

See Figure 5A

Standard Low Output Standard Low Output

HDH D H D H D

Model ft (m) ft (m) ft (m) ft (m) ft (m) ft (m) ft (m) ft (m)

42 12.5

64 14.5

80 18.5

102 17.0

122 19.5

146 19.0

166 22.5

202 27.5

252 25.0

280 26.0

336 30.0

384 35.5

500 36.5

600 42.5

720 48.0

(3.8)

(4.4)

(5.6)

(5.2)

(5.9)

(5.8)

(6.9)

(8.4)

(7.6)

(7.9)

(9.1)

(10.8)

(11.1)

(13.0)

(14.6)

11.0

(3.4)

12.0

(3.7)

14.0

(4.3)

18.0

(5.5)

19.0

(5.8)

20.0

(6.1)

21.0

(6.4)

25.0

(7.6)

27.0

(8.2)

29.0

(8.8)

34.0

(10.4)

39.0

(11.9)

42.0

(12.8)

45.0

(13.7)

46.0

(14.0)

14.5

(4.4)

19.0

(5.8)

22.0

(6.7)

21.5

(6.6)

26.0

(7.9)

22.5

(6.9)

27.5

(8.4)

31.5

(9.6)

29.5

(9.0)

32.0

(9.8)

36.0

(11.0)

41.0

(12.5)

43.5

(13.3)

46.5

(14.2)

53.0

(16.2)

16.0

(4.9)

19.0

(5.8)

23.0

(7.0)

26.0

(7.9)

29.0

(8.8)

30.0

(9.1)

31.0

(9.4)

35.0

(10.7)

38.0

(11.6)

40.0

(12.2)

47.0

(14.3)

52.0

(15.8)

57.0

(17.4)

60.0

(18.3)

63.0

(19.2)

9.0

(2.7)

10.0

(3.0)

12.5

(3.8)

11.0

(3.4)

13.0

(4.0)

12.0

(3.7)

13.0

(4.0)

14.0

(4.3)

13.0

(4.0)

15.0

(4.6)

18.0

(5.5)

20.0

(6.1)

24.0

(7.3)

26.0

(7.9)

28.0

(8.5)

Diffuser Cone 45°

See Figure 5B

20.0

(6.1)

24.0

(7.3)

26.0

(7.9)

31.0

(9.4)

33.0

(10.1)

39.0

(11.9)

42.0

(12.8)

45.0

(13.7)

47.0

(14.3)

50.0

(15.2)

55.0

(16.8)

59.0

(18.0)

65.0

(19.8)

70.0

(21.3)

75.0

(22.9)

11.0

(3.4)

12.0

(3.7)

15.0

(4.6)

14.0

(4.3)

16.0

(4.9)

15.5

(4.7)

18.0

(5.5)

21.0

(6.4)

19.0

(5.8)

21.0

(6.4)

24.0

(7.3)

28.0

(8.5)

30.0

(9.1)

34.0

(10.4)

38.0

(11.6)

25.0

(7.6)

29.0

(8.8)

31.0

(9.4)

35.0

(10.7)

38.0

(11.6)

44.0

(13.4)

48.0

(14.6)

53.0

(16.2)

55.0

(16.8)

60.0

(18.3)

66.0

(20.1)

71.0

(21.6)

76.0

(23.2)

78.0

(23.8)

87.0

(26.5)

16 UH-SVX01A-EN

Page 17

Installation

Figure 15.

Notes: To meet OSHA requirements, units mounted lower than 8 feet from the floor must be equipped with an OSHA fan guard.

Table 7. Mounting Height Correction Factors

Water °F 150 160 170 180 190 200

Temperature (°C) (66) (71) (77) (82) (88) (93)

Steam PSI - - - - - -

Pressure (kPa) - - - - - -

Correction Factor 1.32 1.27 1.23 1.18 1.14 1.09

Water °F 210 219 227 239 250 259

Temperature (°C) (99) (104) (108) (115) (121) (126)

Steam PSI - 2 5 10 15 20

Pressure (kPa) - (13.8) (34.5) (68.9) (103.4) (137.9)

Correction Factor 1.05 1.00 0.97 0.94 0.89 0.86

Water °F 267 280 287 298 307 320

Temperature (°C) (131) (138) (142) (148) (153) (160)

Steam PSI 25 35 40 50 60 75

Pressure (kPa) (172.4) (241.3) (275.8) (344.7) (413.6) (517.1)

Correction Factor 0.83 0.80 0.76 0.73 0.70 0.69

UH-SVX01A-EN 17

Page 18

Piping

To provide proper coil operation,

follow all piping recommendations

listed in this manual.

Threaded pipe headers are provided

on all Vertical Units for piping

connections. See Figure 25.

Connections are given in Figure 18

and Figure 19 and Table 27 and

Table 28.

Follow standard practices and codes

when installing the piping. Provide

swing joints for expansion purposes,

unions and shut-off valves for

servicing purposes and as illustrated

in Figure 6 through Figure 9, valves

and traps for control purposes. Use

45 degree angle run-offs from all

supply and return mains.

Dirt pockets should be the same pipe

size as the return tapping of the unit

heater. Also, pipe size in the

branchoff should be the same size as

the tapping in the traps. Beyond the

trap, the return lateral pipe should be

increased one size up to the return

main.

Properly support all piping to unit!

Do not allow piping to place a strain

on the coil or unit. Noise or coil

failure may occur.

It is assumed that the type of system

to be used has been selected by

design engineer. The sketches shown

are for different type of steam

systems or hot water systems. For

sizing of piping, traps, filter, etc.,

consult ASHRAE guides of the

manufacturer’s literature on these

products.

Installation

Figure 16.

Figure 17.

18 UH-SVX01A-EN

Page 19

Installation

Figure 18.

Figure 19.

UH-SVX01A-EN 19

Page 20

Installation

Installation: S Type

Unit Mounting

WARNING

Heavy Objects!

Ensure that all hardware used in the

suspension of each unit heater is

more than adequate for the job.

Failure to do so may result in

extensive property damage, severe

personal injury or death.

WARNING

Structural Integrity!

Make certain that the structure to

which the heater is mounted is

capable of supporting its weight.

Under no circumstances must the

gas lines, the venting system, or the

electrical conduit be used to support

the heater; or should any other

objects (i.e. ladder, person) lean

against the heater gas lines, venting

system, electrical conduit for

support. Failure to heed these

warnings may result in property

damage, personal injury, or death.

CAUTION

Lifting/Suspension Methods!

Make certain that the lifting methods

used to lift the heater and the

method of suspension used in the

field installation of the heater are

capable of uniformly supporting the

weight of the heater at all times.

Failure to heed this warning may

result in property damage or

personal injury!

CAUTION

Performance Failure!

Unit heaters must be hung level from

side to side and from front to back.

Failure to do so will result in poor

performance and or premature failure

of the unit.

Install unit heaters to meet

Occupational Safety and Health Act

(OSHA) and CSA requirements. Unit

heaters mounted lower than 8 feet

(2.4m) from the floor must be

equipped with an OSHA fan guard.

Note: Units equipped with the

motor mounted to the fan

guard require two point

suspension. Units equipped

with a shelf mounted motor

are required to be suspended

at four points. Refer to

Figure 20 and Figure 21 for

two point suspension and

refer to Figure 9 for four point

suspension.

Nutserts are provided at the top of all

units for suspension purposes.

Support rods should support the total

unit weight to assure that no strain is

placed on supply and return piping.

Provisions for removal of the unit

from the suspension rods may be

desirable for servicing purposes.

Units must hang level vertically and

horizontally.

Provide sufficient clearance around

units for maintenance purposes.

Isolators are not required but may be

desirable for some applications.

Refer to “Dimensional Data.”

Piping

To provide proper coil operation,

follow all piping recommendations

listed in this manual.

See Figure 13 through Figure 17 for

proper pipe connections.

Follow standard practices and codes

when installing the piping. Provide

swing joints for expansion purposes,

unions and shut-off valves for

servicing purposes and as illustrated

in Figure 13 through Figure 17,

valves and traps for control

purposes. Use 45 degree angle runoffs from all supply and return mains.

Dirt pockets should be the same pipe

size as the return tapping of the unit

heater. Also, pipe size in the

branchoff should be the same size as

the tapping in the traps. Beyond the

trap, the return lateral pipe should be

increased one size up to the return

main.

It is assumed that the design

engineer has selected the type of

system to be used. The sketches

shown are for different types of

steam systems or hot water systems.

For sizing of piping, traps, filter, etc.,

consult ASHRAE guides of the

manufacturer’s literature on these

products.

It is important that the system be

kept clean. Care should be exercised

that excessive joint materials or

foreign substances be kept out of the

system.

On steam systems it is

recommended that the unit be

installed level for proper condensate

drainage. Swing joints should be

used in piping, and pipes should be

pitched down from units so that

condensate can drain freely.

20 UH-SVX01A-EN

Page 21

OSHA Fan Guard/Louver

Cone Diffuser Installation

Detail

WARNING

Hazardous Voltage

Do not mount either the Louver

Cone Diffuser or OSHA Fan Guard

while unit is in operation or severe

personal injury may occur.

Disconnect all power supplies to the

unit before installing the Louver

Cone Diffuser or OSHA Fan Guard.

The figures below show how both

the OSHA Fan Guard and the Louver

Cone Diffuser are installed on the

Vertical Steam and Hot Water Unit

Heater. Figure 20 and Figure 21

detail how the louver cone diffuser

and OSHA guard are attached to the

unit. Figure 22 and Figure 23 show

full views of the vertical steam and

hot water unit with a Louver Cone

Diffuser and OSHA Fan Guard

attached.

To meet CSA and OSHA

requirements, units mounted below

8 feet (2.4 meters) must be equipped

with an OSHA Fan Guard.

The same screws and washers are

provided with both the OSHA fan

guard and Louver Cone Diffuser. The

screws and washers are used in

conjunction with the Nutserts to

support the wire guard or diffuser to

the orifice panel (bottom of vertical

unit).

Fan Guard/Louver Installation

Figure 20. Louver Cone Diffuser

\

Figure 21. OSHA Fan Guard

UH-SVX01A-EN 21

Page 22

Fan Guard/Louver Installation

Figure 22. Vertical Unit with Louver Cone Diffuser

Figure 23. Vertical Unit with OSHA Fan Guard

22 UH-SVX01A-EN

Page 23

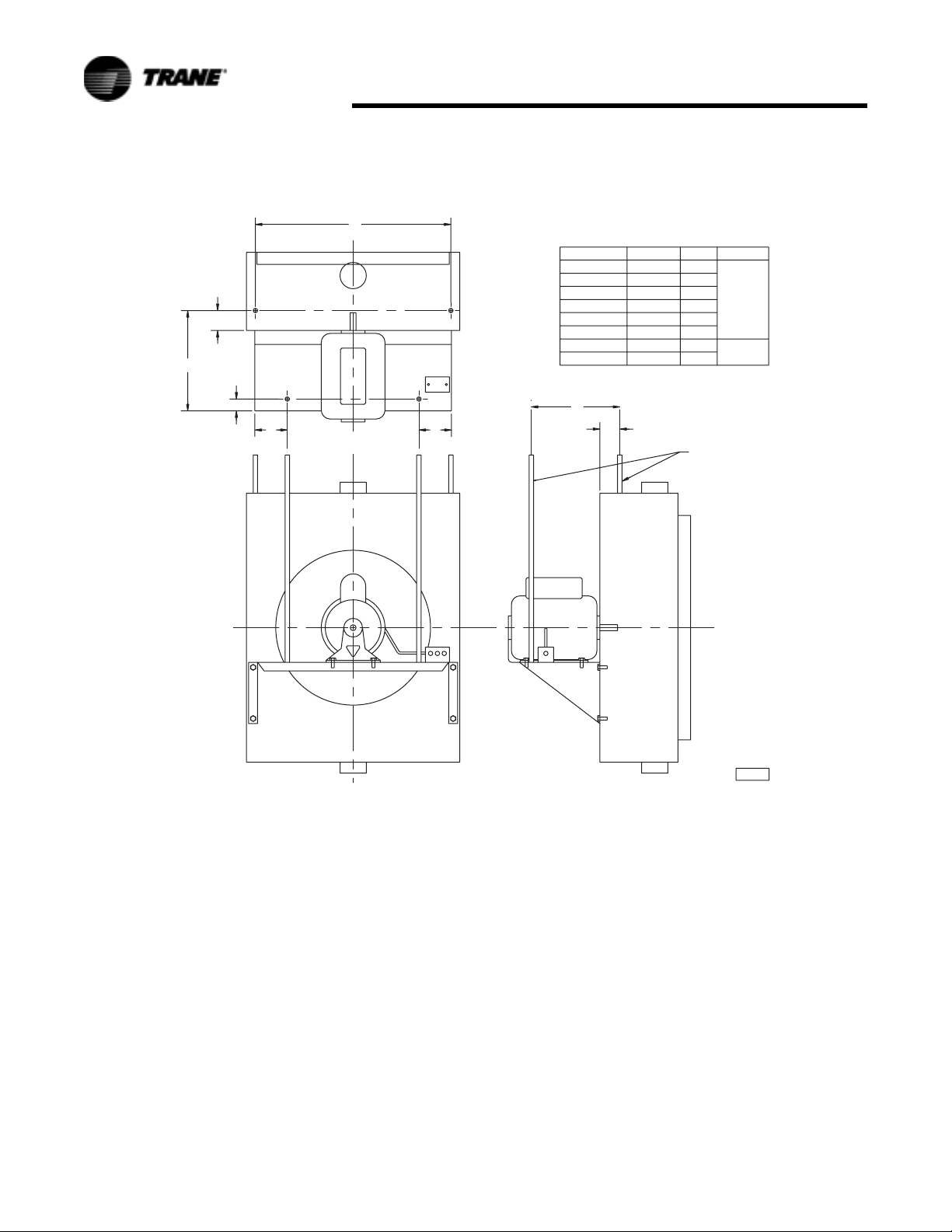

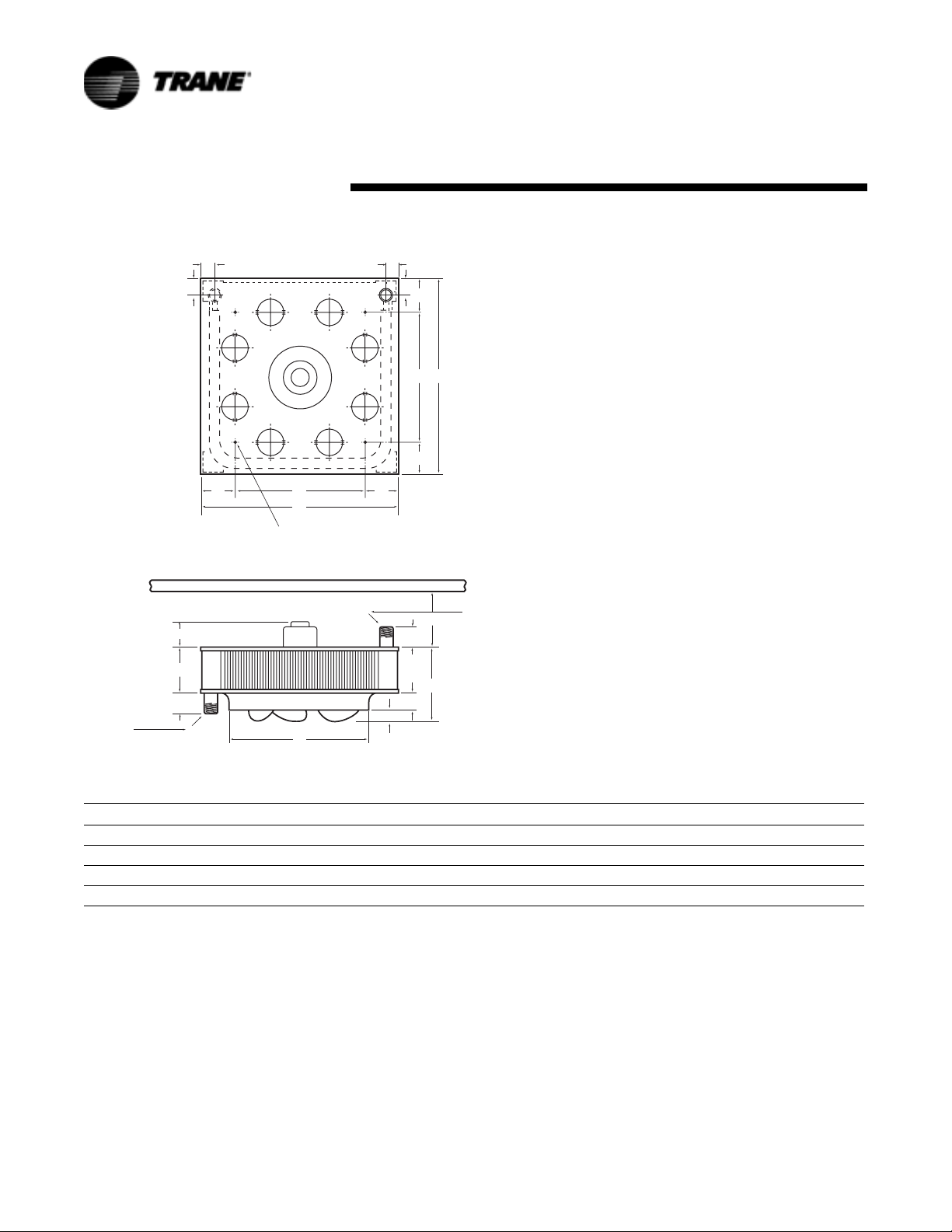

Dimensional Data: P Model

Dimensional Data

H

K

F

B

STEAM

RETURN

OR

HOT WATER

SUPPLY

T

P

Figure 24. Models 42-80

GR

A

(4) MOUNTING HOLES

THREAD TAPS

CEILING

D

H

K

R

3

/8 - 16 FOR 42P-80P

P

T

C

E

V

G A

R

L

S

STEAM

SUPPLY

OR

HOT WATER

RETURN

Table 8. Roughing in Dimensional Data - Model Size 42-80

Unit Capacity (MBH) Fan Dia. A B C D E F G H K L (Min.) P (NPT) R S T U V

042 11 1/4 18 1/4 4 5/8 1 1/4 11 3/4 3/4 4 11 1 3/8 1 7/8 7 1 1/2 3 5/8 6 5/8 2 3/4 11 3 5/8

064 13 1/2 21 1/4 4 5/8 1 5/8 14 1 4 14 1 3/8 1 7/8 7 1 1/2 3 5/8 7 1/8 2 3/4 14 3 5/8

080 13 1/2 21 1/4 6 1/8 1 5/8 14 1 3 14 1 3/8 1 7/8 7 1 1/2 3 5/8 8 5/8 2 3/4 14 3 5/8

UH-SVX01A-EN 23

Page 24

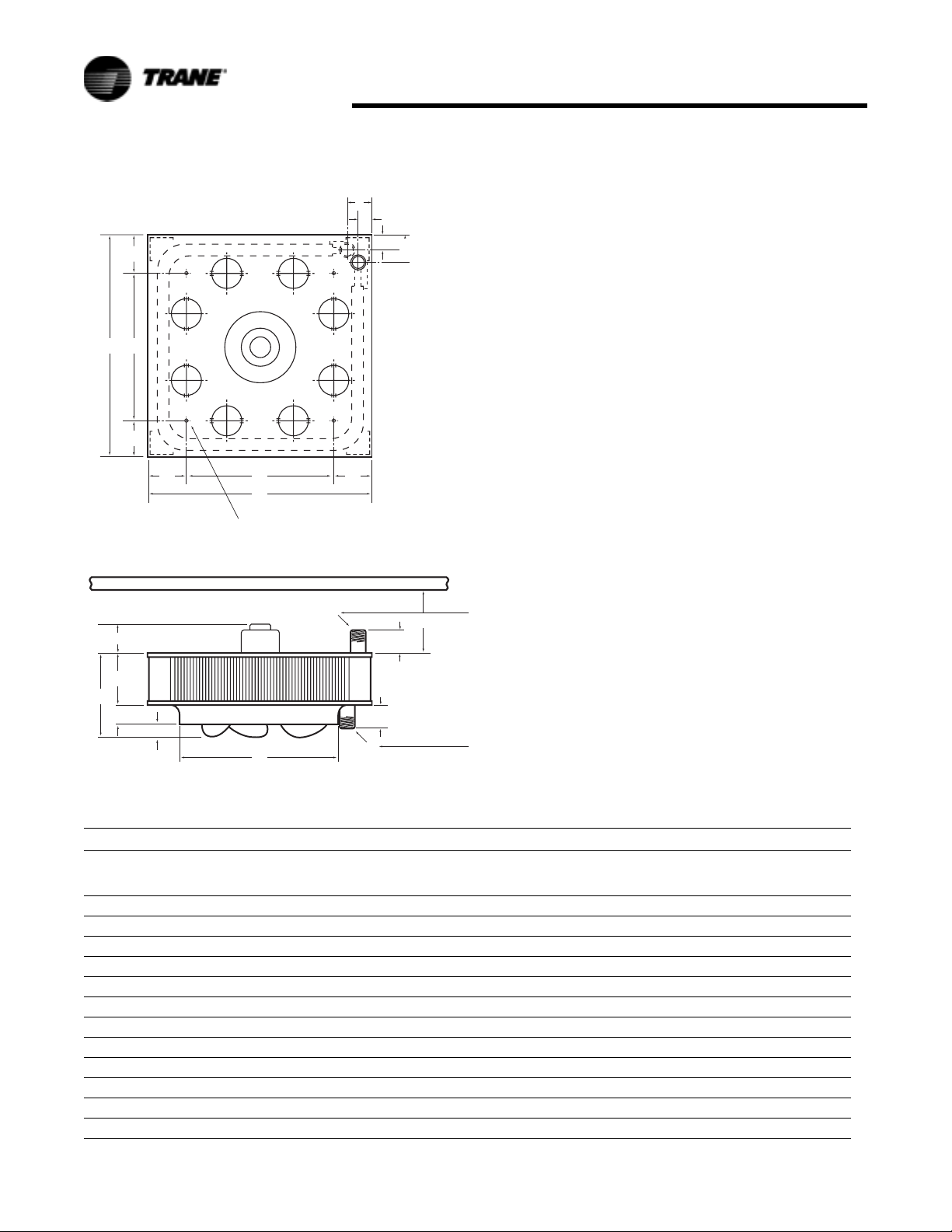

Dimensional Data

K

H

H

V

UA

V

K

GR

A

(4) MOUNTING HOLES 3/8 - 16 FOR 102P-384P

THREAD TAPS

CEILING

F

B

S

C

E

D

R

1

/2 - 13 FOR 500P-720P

P

T

T

P

L

STEAM

SUPPLY

OR

HOT WATER

RETURN

STEAM

RETURN

OR

HOT WATER

SUPPLY

Figure 25. Models 102-720

Table 9. Roughing in Dimensional Data - Model Size 102-720

Unit

Capacity

(MBH)

102 16 3/4 25 1/4 6 1/8 2 17 1/2 1 1/8 3 17 1 3/8 2 3/4 7 1 1/2 4 1/8 9 1/8 2 3/4 17 4 1/8

122 16 3/4 25 1/4 6 1/8 2 17 1/2 1 3/4 3 17 1 3/8 2 3/4 7 1 1/2 4 1/8 9 3/4 2 3/4 17 4 1/8

146 19 3/4 29 1/2 6 1/8 2 3/8 20 5/8 1 1/4 4 20 1/2 1 3/4 3 1/2 7 2 4 1/2 9 5/8 2 3/4 20 1/2 4 1/2

166 19 3/4 29 1/2 6 1/8 2 3/8 20 5/8 1 3/4 4 20 1/2 1 3/4 3 1/2 7 2 4 1/2 10 1/8 2 3/4 20 1/2 4 1/2

202 19 3/4 29 1/2 7 5/8 2 3/8 20 5/8 2 4 20 1/2 1 3/4 3 1/2 7 2 4 1/2 12 2 3/4 20 1/2 4 1/2

252 25 1/4 37 1/2 7 5/8 3 26 3/8 1 3 1/2 28 1 3/4 3 1/2 7 2 4 3/4 11 5/8 2 3/4 18 9 3/4

280 25 1/4 37 1/2 7 5/8 3 26 3/8 1 1/4 3 1/2 28 1 3/4 3 1/2 7 2 4 3/4 11 3/4 2 3/4 18 9 3/4

336 25 1/4 37 1/2 7 5/8 3 26 3/8 2 1/8 4 28 1 3/4 3 1/2 7 2 4 3/4 12 3/4 2 3/4 18 9 3/4

384 25 1/4 37 1/2 9 1/8 3 26 3/8 2 3 1/2 28 1 3/4 3 1/2 7 2 4 3/4 14 1/8 2 3/4 18 9 3/4

500 30 1/2 42 9 1/8 3 1/2 31 1/4 1 5/8 3 30 2 1/4 4 1/4 7 2 1/2 6 14 1/4 3 30 6

600 30 1/2 42 12 1/8 3 1/2 31 1/4 2 1/8 3 30 2 1/4 4 1/4 7 2 1/2 6 17 3/4 3 30 6

720 30 1/2 42 13 5/8 3 1/2 31 1/4 3 4 30 2 1/4 4 1/4 7 2 1/2 6 20 1/4 3 30 6

Fan

Dia. A B C D E F G H KL (Min.)P (NPT) R S T U V

24 UH-SVX01A-EN

Page 25

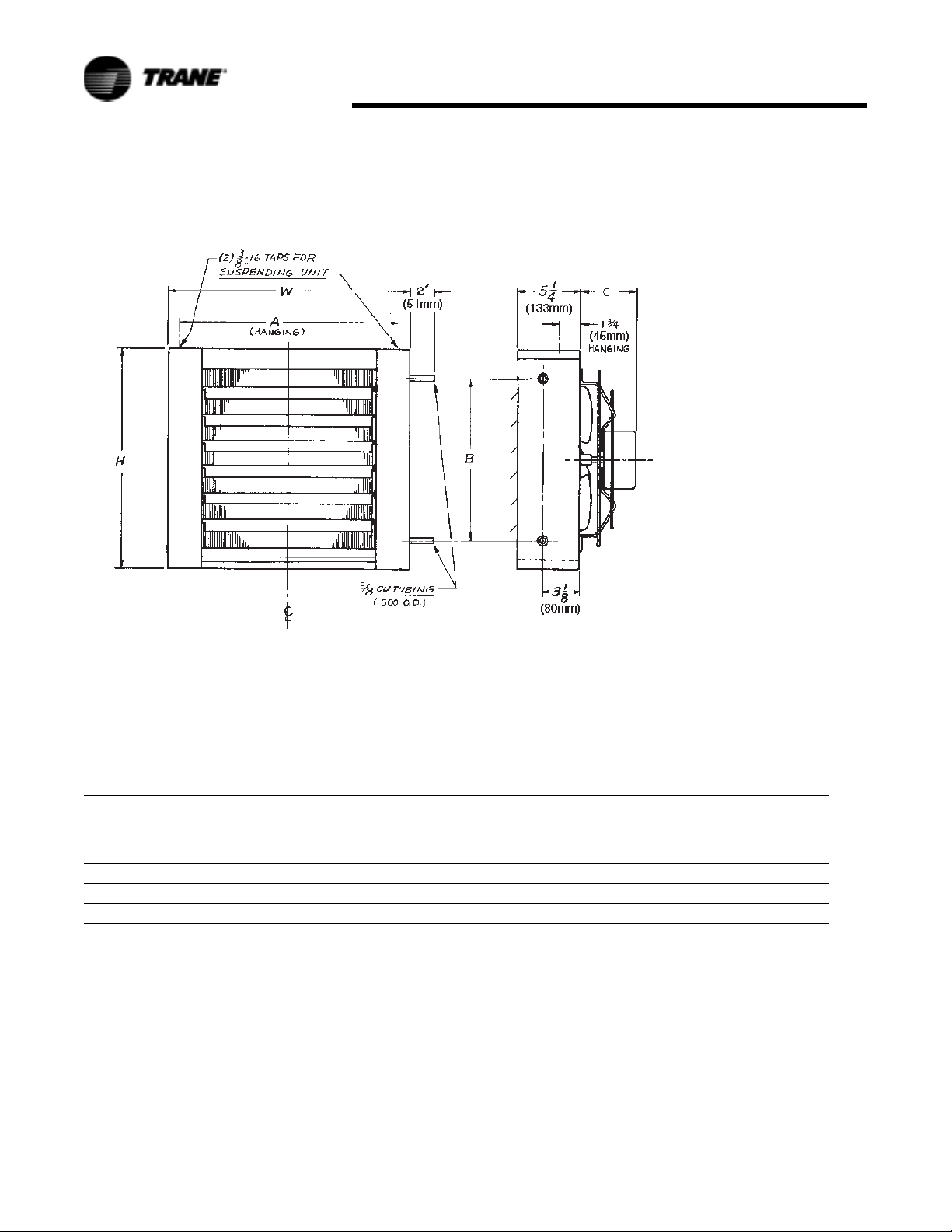

Dimensional Data: S Model

Dimensional Data

Figure 26. Serpentine Type Models A08, A18, A25, A36

Note: Motors are totally enclosed, thermally protected, sleeve bearing, with 4" (w) x 2" (h) conduit connection boxes.

3/8-16 nutserts are attached to enclosure for balanced hanging.

Table 10. Table 3- Serpentine Models

MODEL

A08 16 (406) 18 (457) 16 7/32 (412) 11 1/4 (286) 4 1/4 (108) 5 9 (229) 22 (10.0)

A18 16 (406) 18 (457) 16 7/32 (412) 11 1/4 (286) 4 1/4 (108) 5 10 (254) 24 (10.9)

A25 16 (406) 18 (457) 16 7/32 (412) 11 1/4 (286) 4 1/4 (108) 5 10 (254) 25 (11.3)

A36 18 1/2 (470) 20 1/2 (521) 18 22/32 (475) 13 3/4 (349) 5 1/8 (130) 6 12 (305) 31 (14.0)

H inches

(mm)

W inches

(mm)

A inches

(mm)

B inches

(mm)

C inches

(mm)

NO. OF

LOUVERS

NOM. FAN

DIAM. inches

(mm)

APPROX.

SHIP WT. lbs.

(kg)

UH-SVX01A-EN 25

Page 26

Dimensional Data

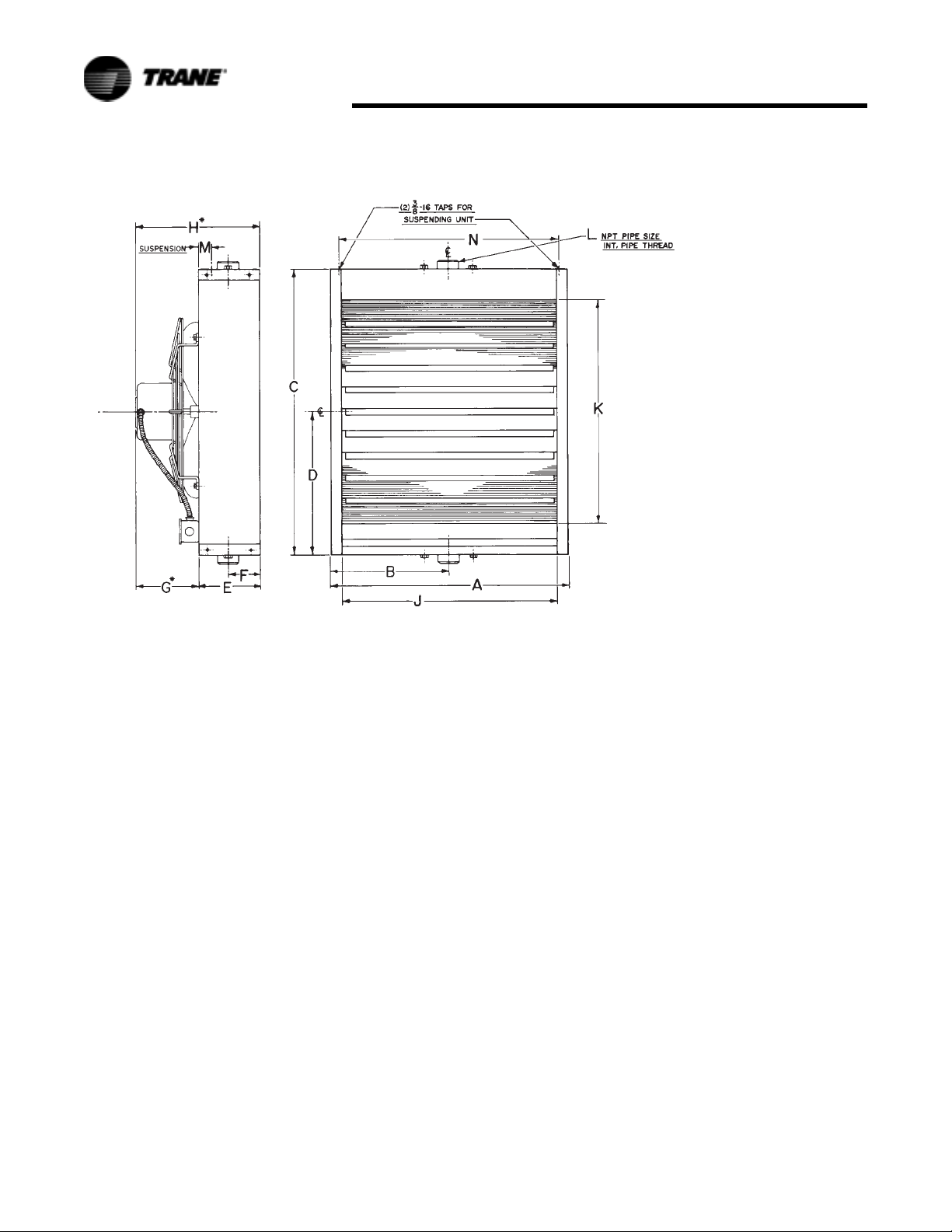

Figure 27. Header Type Models 18 thru 360

Note: Motors are totally enclosed, thermally protected, sleeve bearing, with 4" (w) x 2" (h) conduit connection boxes.

3/8-16 nutserts are attached to enclosure for balanced hanging.

26 UH-SVX01A-EN

Page 27

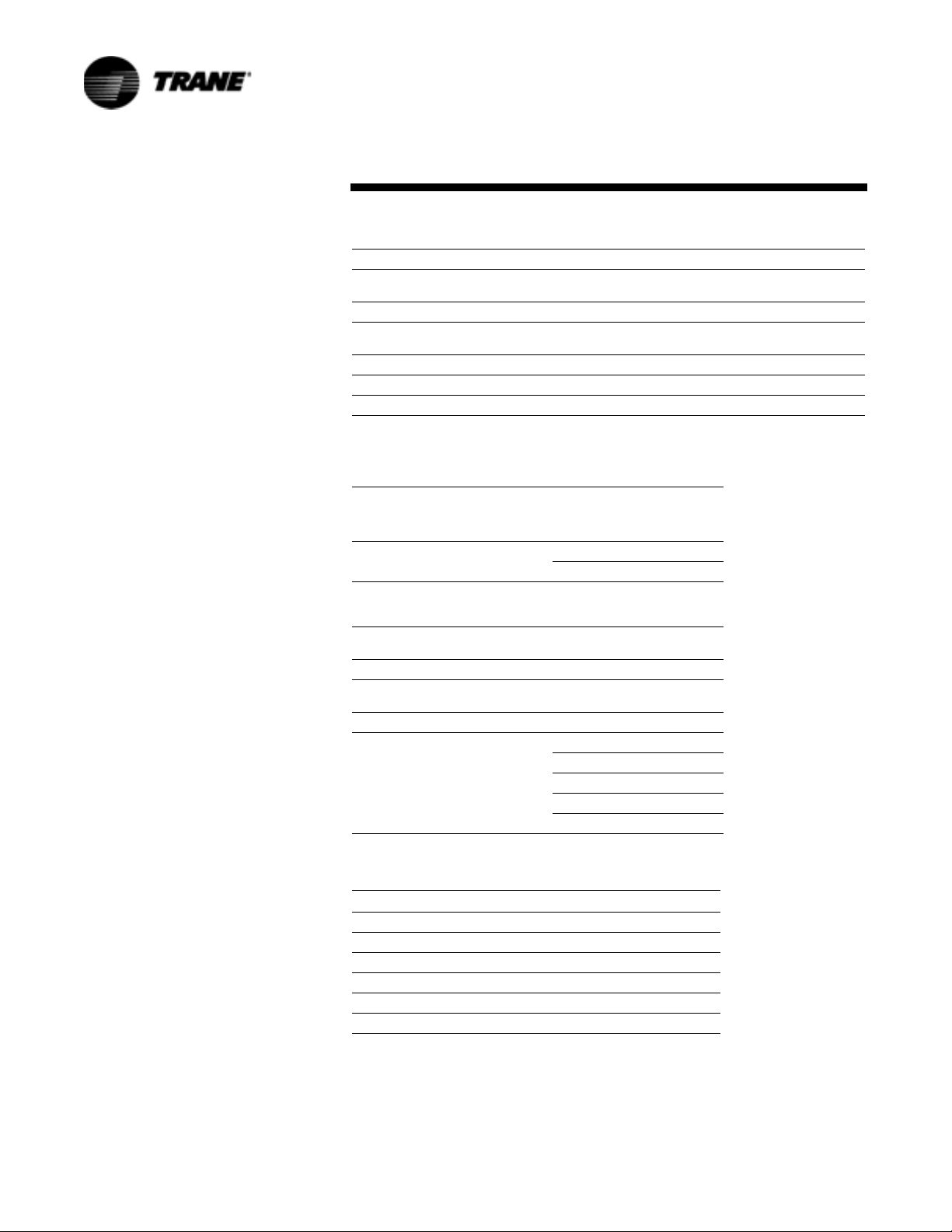

Table 11. Header Models

MODEL

inches

(mm)

18 14 5/8

(371)

243614 5/8

(371)

486017 1/8

(435)

72 18 3/8

(467)

84 20 7/8

(530)

96

19 5/8

108

(498)

120 20 7/8

(530)

132

23 3/8

144

(594)

156 23 3/8

(594)

180

24 5/8

204

(625)

240 27 7/8

(708)

280 27 7/8

(708)

300

33 3/8

360

(848)

A

B

inches

(mm)

7 5/16

(186)

7 5/16

(186)18(457)9(229)

8 9/16

(217)

9 3/16

(233)

10 7/16

(265)

9 13/16

(249)24(610)12(305)

10 7/16

(265)

11 11/16

(297)

11 11/16

(297)

12 5/16

(313)29(737)

13 15/16

(354)

13 15/16

(354)

16 11/16

(424)

C

inches

(mm)

15

(381)

20 1/2

(521)

21 3/4

(552)

24 1/4

(616)

25 1/4

(641)

27 3/4

(705)

27 3/4

(705)

30 1/4

(768)

30 1/4

(768)

37 3/4

(959)

D

inches

inches

(mm)

(mm)

7 1/2

6 1/8

(191)

(156)

6 1/8

(156)

10 1/4

10 7/8

12 1/8

12 5/8

13 7/8

13 7/8

14 1/2

15 1/8

15 1/8

18 7/8

5 7/8

(260)

(149)

(276)6(152)

6 1/8

(308)

(156)

6 5/16

(160)

6 5/16

(321)

(160)

6 5/16

(352)

(160)

6 5/16

(352)

(160)

6 3/8

(368)

(162)

8 1/8

(384)

(206)

8 1/8

(384)

(206)

(479)9(229)

Dimensional Data

E

F

inches

(mm)

2 15/16

(75)

2 15/16

(75)

2 15/16

(75)

2 15/16

(75)

2 15/16

(75)

3 3/16

(81)

3 3/16

(81)

3 3/16

(81)

3 3/16

(81)

3 3/16

(81)

3 3/16

(81)

3 3/16

(81)

3 3/16

(81)

G*

inches

(mm)

3 1/4

(83)

3 1/4

(83)

5 1/16

(129)

5 1/16

(129)

5 11/16

(144)

7 1/2

(191)

6 11/16

(170)13(330)

7 5/8

(194)14(356)21(533)

7 7/16

(189)

7 7/16

(189)

5 7/8

(149)14(356)

9-5/8

(244)

9 5/8

(244)

H*

inches

(mm)

9 3/8

(238)

9 3/8

(238)

10 15/16

(278)

11 1/16

(281)16(406)

11 13/16

(300)

13 13/16

(351)

13 3/4

(349)

13 3/4

(349)

17 3/4

(451)

18 5/8

(473)31(787)

J

inches

inches

(mm)

(mm)

12 1/4

12 1/4

14 3/4

18 1/2

17 1/4

18 1/2

22 1/4

25 1/2

25 1/2

9 1/2

(311)

(241)

12 1/2

(311)

(318)

(375)15(381)

16 1/4

(413)

18 3/4

(470)

(476)

17 1/2

(438)

(445)

18 3/4

(470)

(476)

21 1/4

(540)

21

21 1/4

(533)

(540)

22 1/2

(565)

(572)

23 3/4

(648)

(603)2(51)

23 3/4

(648)

(603)2(51)

31 1/4

(794)2(51)

K

L

inches

(mm)

1 1/4

(32)

1 1/4

(32)

1 1/4

(32)

1 1/4

(32)

1 1/4

(32)

1 1/2

(38)

1 1/2

(38)

1 1/2

(38)

1 1/2

(38)

1 1/2

(38)

M

inches

(mm)

2 1/4

(57)

2 1/4

(57)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

1 3/4

(44)

N

inches

(mm)

12 7/8

(327)

12 7/8

(327)

15 3/8

(391)

16 5/8

(422)

19 1/8

(486)

17 7/8

(454)

19 1/8

(486)

21 5/8

(549)

21 5/8

(549)

22 7/8

(581)

26 1/8

(664)

26 1/8

(664)

31 5/8

(803)

NOM.

NO.

FAN

OF

DIAM.

LOU-

inches

VERS

(mm)

49

(229)26(11.8)

510

(254)30(13.6)

612

(305)41(18.6)

714

(356)44(19.9)

814

(356)47(21.3)

816

(406)49(22.2)

818

(457)59(26.7)

918

(457)74(33.5)

918

(457)74(33.5)

918

(457)90(40.8)

10 20

(508)

10 20

(508)

13 24

(610)

APPROX.

SHIP

WT. lbs.

(kg)

125

(57)

118

(53)

154

(69.8)

* Applies to standard motor with standard fan guard. When optional motors or OSHA fan guards are requested, dimensions will change according to the

substitutions made.

NOTES

1. Standard motor and standard guard shown.

2. Optional OSHA guards available for all units with 1 phase motors.

3. All 3 phase and explosion proof motors are shelf mounted.

UH-SVX01A-EN 27

Page 28

Technical Data: S Models

The performance data listed in

Tab l e 11 includes sound ratings. The

ratings provide a guide in

determining the acceptable degree

of loudness in particular occupancy

situations.

Certain general rules apply to

specific selection of unit heaters with

regard to degree of quietness (or

loudness);

• The greater the fan diameter, the

higher the sound level.

• The higher the motor RPM, the

higher the sound level. Note that

on most units the lower the

speed mode results in lowering

the sound rating one increment.

• Selecting a larger number of

smaller units generally results in

lower overall noise levels than

fewer large units.

All horizontal steam and hot water

unit heater motors, whether fan

guard or shelf-mounted, are isolated

from the mechanical mount by

resilient isolators. This mounting

along with balanced fan blades and

excellent overall construction

integrity, assures you the utmost in

quiet operation.

The following table outlines SOUND

RATING for various applications. The

lower the number, the quieter the

unit and the lower the sound

requirement.

Te c h n i c a l D a t a

CATEGORY OF AREA SOUND RATING

apartment, assembly hall, classrooms, churches, courtrooms, executive

offices, hospitals, libraries, museums, theatres

dining rooms, general offices, recreation areas, small retail stores II

restaurants, banks, cafeterias, department stores, public buildings,

service stations

gymnasiums, health clubs, laundromats, supermarkets IV

garages, small machine shops, light manufacturing V

Factories, foundries, steel mills III-VII*

*Depending on specific use in these facilities,

size of operation, etc.

Table 12. Corrections When Using Glycol Solution in System

Propylene

Glycol

Heat transfer @ 180°F (82°C) with

no increase inflow rate

G.P.M. Req'd. @ 180°F (82°C), 20°F

(11°C) ∆

curve)

Pump Head Req'd. @ 180°F (82°C)

w/increase in G.P.M.

Specify gravity (water = 1.0) 1.045-1.055*

Pounds/Gallons @ 60°F (16°C)

(water = 8.3453 Pound/Gallon)

pH @ 50% by volume 9.5

Freezing Point by volume

t (no correction to pump

*Compared to water.

20% solution .97*

50% solution .90*

1.10%*

1.23%*

8.77

55% -

50% -28°F (-33°C)

40% -13°F (-25°C)

30% + 4°F (-16°C)

20% +17°F (- 8°C)

I

III

Table 13. Approximate factors at varying altitudes

Altitude Factor

Sea level - 1000 ft. (305m) 1.00

1000 ft. - 3000 ft. (915m) .958

3000 ft. - 5000 ft. (1524m) .929

5000 ft. - 7000 ft. (2134m) .900

7000 ft. - 10000 ft. (3048m) .871

28 UH-SVX01A-EN

Page 29

Technical Data

Technical Data: P Model

The performance data listed in

Ta b l e 1 3, Ta b l e 1 4 , and Ta b l e 1 5

include sound ratings. The ratings

provide a guide in determining the

acceptable degree of loudness in

particular occupancy situations.

Certain general rules apply to specific

selection of unit heaters with regard

to degree of quietness (or loudness);

• The greater the fan diameter, the

higher the sound level.

• The higher the motor RPM, the

higher the sound level. Note that

on most units the lower the

speed mode results in lowering

the sound rating one increment.

• Selecting a larger number of

smaller units generally results in

lower overall noise levels than

fewer large units.

All vertical steam and hot water unit

heater motors, whether fan guard or

shelf-mounted, are isolated from the

mechanical mount by resilient

isolators. This mounting along with

balanced fan blades and excellent

overall construction integrity, assures

you the utmost in quiet operation.

The following table outlines sound

ratings for various applications. The

lower the number, the quieter the

unit and the lower the sound

requirement.

Category of Area Sound Rating

apartment, assembly hall, classrooms, churches, courtrooms, executive

offices, hospitals, libraries, museums, theatres

dining rooms, general offices, recreation areas, small retail stores II

restaurants, banks, cafeterias, department stores, public buildings,

service stations

gymnasiums, health clubs, laundromats, supermarkets IV

garages, small machine shops, light manufacturing V

factories, foundries, steel mills III-VII*

* Depending on specific use in these facilities,

size of operation, etc.

I

III

Table 14. Corrections When Using Glycol Solution in System

Propylene

Glycol

Heat transfer @ 180°F with no

increase inflow rate

G.P.M. Req'd. @ 180°F, 20°F ∆ t (no

correction to pump curve)

Pump Head Req'd. @ 180°F w/

increase in G.P.M.

Specify gravity (water = 1.0) 1.045-1.055*

Pounds/Gallons @ 60°F (water =

8.3453 Pound/Gallon)

pH @ 50% by volume 9.5

Freezing Point by volume

*Compared to water.

20% solution .97*

50% solution .90*

1.10%*

1.23%*

8.77

55% -

50% -28°F

40% -13°F

30% + 4°F

20% +17°F

Table 15. Approximate factors at varying altitudes

Altitude Factor

Sea level - 1000 ft. 1.00

1000 ft. - 3000 ft. .958

3000 ft. - 5000 ft. .929

5000 ft. - 7000 ft. .900

7000 ft. - 10000 ft. .871

UH-SVX01A-EN 29

Page 30

Options

Options: S Models

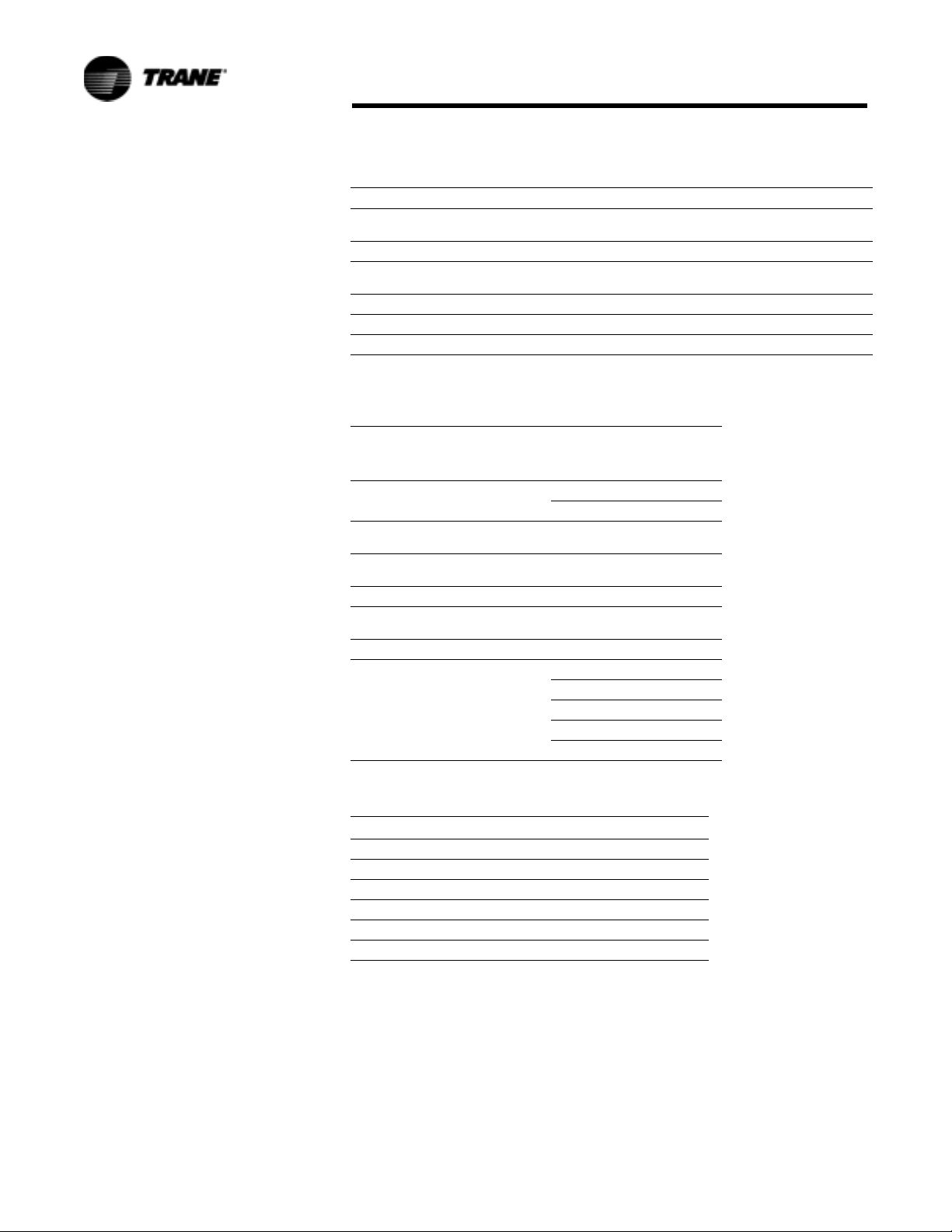

Variable Speed Control 115 Volt

Only (optional)

The solid state speed controller may

be installed at any convenient

location and is suitable for surface or

flush type mounting. A Standard

electrical single or double gang wall

box is recommended as in Figure 28.

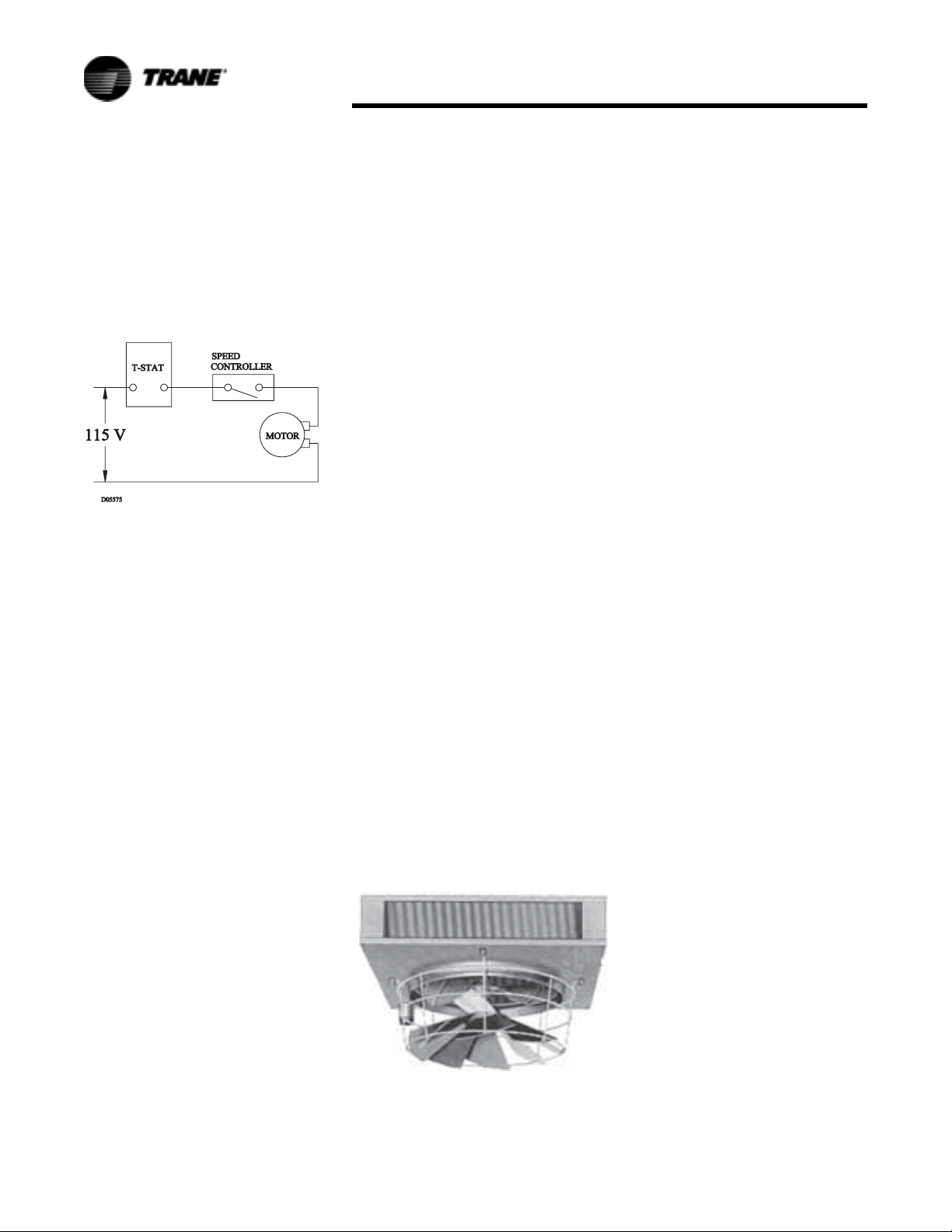

Figure 28. Wiring Diagram of

Speed Control Installation

Installation Procedure:

1. Attach the control's leads to the

electrical leads in the control box

using wire nuts. The speed

control is to be wired in series

with the motor. See wiring

diagram in

2. Make certain wire nuts are tight

with no copper wire being

exposed.

3. Place wires and wire nuts back

into box allowing room for the

control to fit in box also.

4. Mount speed control to box

using number 6 flathead screws

provided.

Setting the Control:

1. Tu r n t h e c o n t rol shaft fully

clockwise. If the motor is not

running at the desired low

speed, adjust the trim on the

face of the control for low speed

setting using a small

screwdriver.

2. Rotate the control shaft counter

clockwise. The speed will

increase smoothly from

minimum to maximum and then

switch off.

Figure 28.

3. Mount face plate with screw

provided and attach control

knob.

Strap-On Water Control

A SPDT strap-on type hot water

control with 100° to 240°F (38 to

116°C) rated at 10 amps at 120V is

also available. Control can be used

for direct or reverse acting

applications as high or low limit.

Steam Pressure Control

SPDT switch opens on a rise in

pressure. Control is automatically

reset, has a range of 0 to 15 PSIG (0

to 103 kPa) and has an adjustable

differential. Other actions, ranges,

circuits and manual reset

models are available on request.

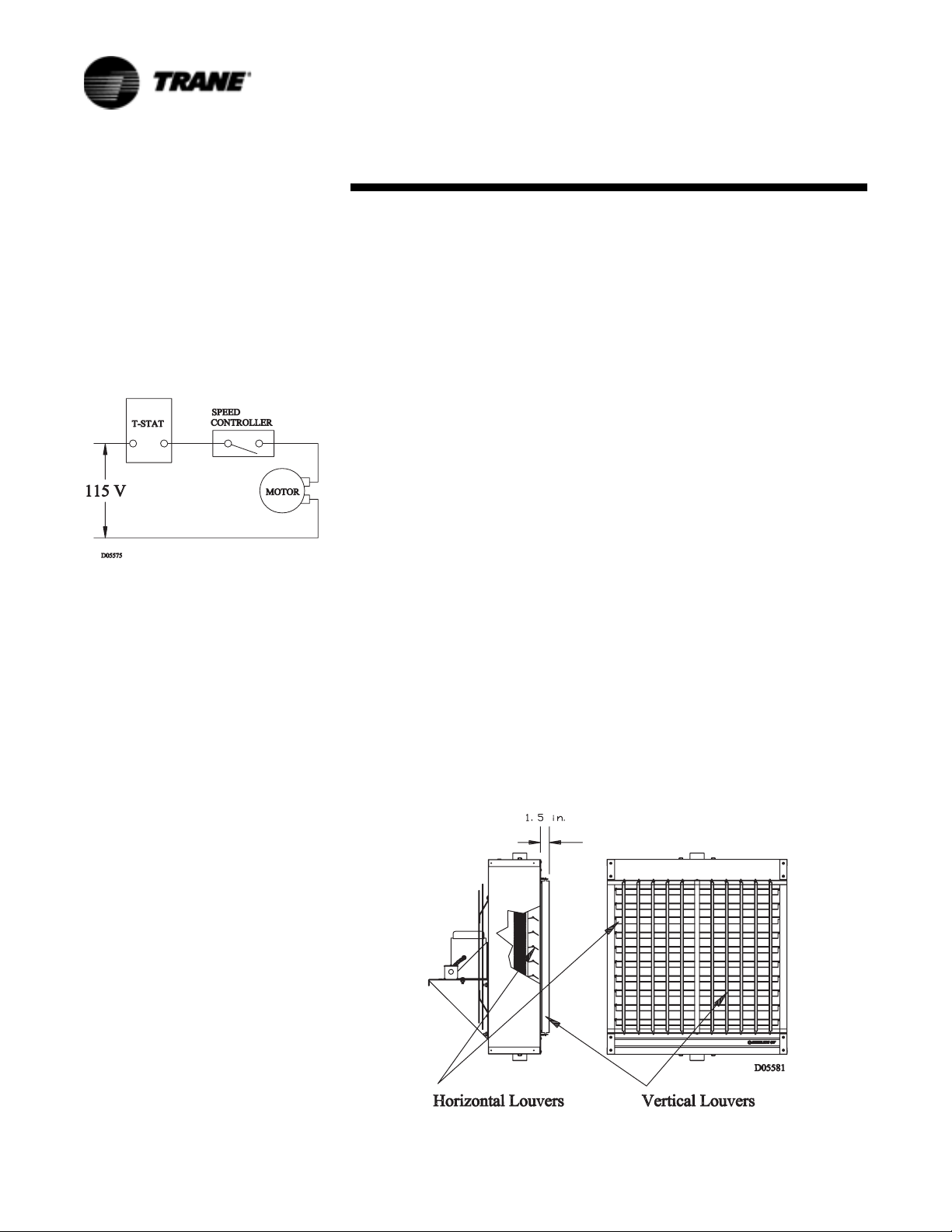

Horizontal and Vertical Louvers

Horizontal louvers are standard on

all models. Vertical louvers are an

optional accessory on all models.

Vertical louvers are installed on built

to order units or shipped loose for

field installation.

Thermostats

Line voltage wall thermostats are in

stock for immediate shipment. All

models are SPST with bimetal

thermometer, knob-type set point

adjustment, 40 to 90°F (5 to 30°C)

range and selector switches.

Standard duty models with "offauto" and "auto-off-fan" and a heavy

duty model with "auto-off-fan"

switching are available. Other

models available on request. Plastic

tamperproof one size fits all

thermostat guards are also available.

Manual Starters

Single and three-phase models are

available. Standard models are

single-speed, toggle-operated,

NEMA Type 1 and are surfacemounted.

Wall Mounted Speed Controllers

Units with standard motors up to

Model 108 (115/1/60) can be operated

at reduced speeds by addition of

optional speed controller. Controller

is 5 amps, pre-set at factory for

maximum and minimum speeds,

with intermediate speeds infinitely

controllable. All 1/3, 1/2 HP and 230V

motors operate only at rated speed

and CFM - See Tables.

CAUTION

When using electrical accessories,

always refer to the accessory

manufacturer's installation manual

for proper use, location and wiring

instructions.

Figure 29. Horizontal and Vertical Louver Mounting

30 UH-SVX01A-EN

Page 31

Options

Options: P Models

Variable Speed Control 115 Volt

Only (optional)

The solid state speed controller may

be installed at any convenient

location and is suitable for surface or

flush type mounting. A standard

electrical single or double gang wall

box is recommended as in Figure 30.

Figure 30. Wiring Diagram of

Speed Control Installation

Installation Procedure:

1. Attach the control's leads to the

electrical leads in the control box

using wire nuts. The speed

control is to be wired in series

with the motor. See wiring

diagram in

2. Make certain wire nuts are tight

with no copper wire being

exposed.

3. Place wires and wire nuts back

into box allowing room for the

control to fit in box also.

4. Mount speed control to box

using number 6 flathead screws

provided.

Setting the Control:

1. Turn the control shaft fully

clockwise. If the motor is not

running at the desired low

speed, adjust the trim on the face

of the control for low speed

setting using a small

screwdriver.

2. Rotate the control shaft counter

clockwise. The speed will

increase smoothly from

minimum to maximum and then

switch off.

Vertical Louver Cone Diffuser

(optional)

Rubber mounts and mounting nuts

and bolts are provided with each

louver cone diffuser. Attach the

Figure 30.

diffuser to the bottom of the unit

heater as shown in Figure 51.

Mounting holes are provided in the

unit base plate.

Adjust the diffuser to provide the

desired air pattern.

Strap-On Water Control

A SPDT strap-on type hot water

control with 100° to 240°F (38 to

116°C) rated at 10 amps at 120V is

also available. Control can be used

for direct or reverse acting

applications as high or low limit.

Steam Pressure Control

SPDT switch opens on a rise in

pressure. Control is automatically

reset, has a range of 0 to 15 PSIG (0

to 103 kPa) and has an adjustable

differential. Other actions, ranges,

circuits and manual reset models

are available on request.

Thermostats

Line voltage wall thermostats are in

stock for immediate shipment. All

models are SPST with bimetal

thermometer, knob-type set point

adjustment, 40 to 90°F (5 to 30°C)

range and selector switches.

Standard duty models with "off-auto"

and a heavy duty model with "autoofffan" switching are available. Other

models available on request. Plastic

tamperproof one size fits all

thermostat guards are also available.

Wall Mounted Speed Controllers

Motors up to and including 1/8 HP

(115V) can be operated at reduced

speeds by addition of optional speed

controller. Controller is 5 amps, preset at factory for maximum and

minimum speeds, with intermediate

Figure 31. Louver Cone Diffuser

Attached to Vertical Unit Heater

speeds indefinitely controllable. All 1/

3, 1/2 HP and 230V motors operate

only at rated speed and CFM - See

Charts.

Manual Starters

Single and three-phase models are

available. Standard models are

single-speed, toggle-operated,

NEMA Type 1 and are surfacemounted.

CAUTION:

When using electrical accessories,

always refer to the accessory

manufacturer's installation manual

for proper use, location and wiring

instructions.

UH-SVX01A-EN 31

Page 32

Electrical Connections

Electrical Connections: P

Model

WARNING

Hazardous Voltage

Disconnect all electric power

including remote disconnects before

servicing. Failure to disconnect

power before servicing can cause

severe personal injury or death.

WARNING

Hazardous Voltage

Do not use any tools (i.e.

screwdriver, pliers, etc.) across the

terminals to check for power. Use a

voltmeter. Failure to disconnect

power before servicing can cause

severe personal injury or death.

Standard units are shipped for use

on 115 volt, 60 hertz single phase

electric power. The motor nameplate

and electrical rating on the

transformer should be checked

before energizing the unit heater

electrical system. All external wiring

must conform to ANSI/NFPA No. 702002, National Electrical Code (or the

latest edition) and applicable current

local codes; in Canada, to the

Canadian Electrical Code, Part 1 CSA

Standard C22.1.

It is recommended that the electrical

power supply to each unit heater be

provided by a separate, fused and

permanently live electrical circuit. A

disconnect switch of suitable

electrical rating for each unit heater

should be located as close to the

controls as possible. Each unit heater

must be electrically grounded in

accordance with National Electric

Code, ANSI/NFPA No. 70-2002 (or

the latest edition of) or CSA

Standard C22.1. Sample wiring

connections are depicted in

Figure 38 through Figure 40.

Operation

Most basic unit heater systems are

controlled by a room thermostat.

Locate thermostat on inner wall or

column so that optimum control

could be obtained for that area. Set

thermostat for desired temperature.

On steam systems a low limit may

be used to prevent fan from blowing

cold air unless the heater has steam

passing through the coil.

Small hot water systems could have

the circulating pump controlled

directly by the room thermostat. On

large systems, zone valves could be

used to control the individual unit

heater where constant water

circulation is used on the main

system.

A louvered cone air diffuser is

readily available as an optional

accessory for vertical unit heaters.

See catalog for details.

Thermostat Wiring and Location

Note: The thermostat must be

mounted on a vertical

vibration-free surface free

from air currents and in

accordance with the

furnished instructions.

Mount the thermostat approximately

5 feet (1.5 m) above the floor in an

area where it will be exposed to a

free circulation of average

temperature air. Always refer to the

thermostat instructions as well as

our unit wiring diagram and wire

accordingly. Avoid mounting the

thermostat in the following

locations:

1. Cold areas - Outside walls or

areas where drafts may affect

the operation of the control.

2. Hot areas - Areas where the

sun’s rays, radiation, or warm air

currents may affect control

operation.

3. Dead areas - Areas where air

cannot circulate freely, such as

behind doors or in corners.

Note: For all wiring connections,

refer to the wiring diagram

on the motor nameplate.

Should any original wire

supplied with the heater

have to be replaced, it must

be replaced with wiring

material having a

temperature rating of at least

105° C .

Motors

The standard 115/1/60 motors

provided on Vertical Unit Heaters are

totally enclosed, Class “B” insulated

and have built-in thermal overload

protection.

Vertical Units 42 through 80 use

sleeve type bearings. Vertical Units

122 through 280 use permanent split

capacitor motors with ball bearings.

All sleeve bearing motors have oil

holes to allow lubrication. Ball

bearing motors are permanently

lubricated although some three

phase or special motors have

removable plugs which will allow

field installation of grease fittings.

The standard 42 through 102 motors

can be converted to variable speed

operation with the addition of the

solid state speed control.

See Figure 32 through Figure 37 for

typical wiring diagrams.

32 UH-SVX01A-EN

Page 33

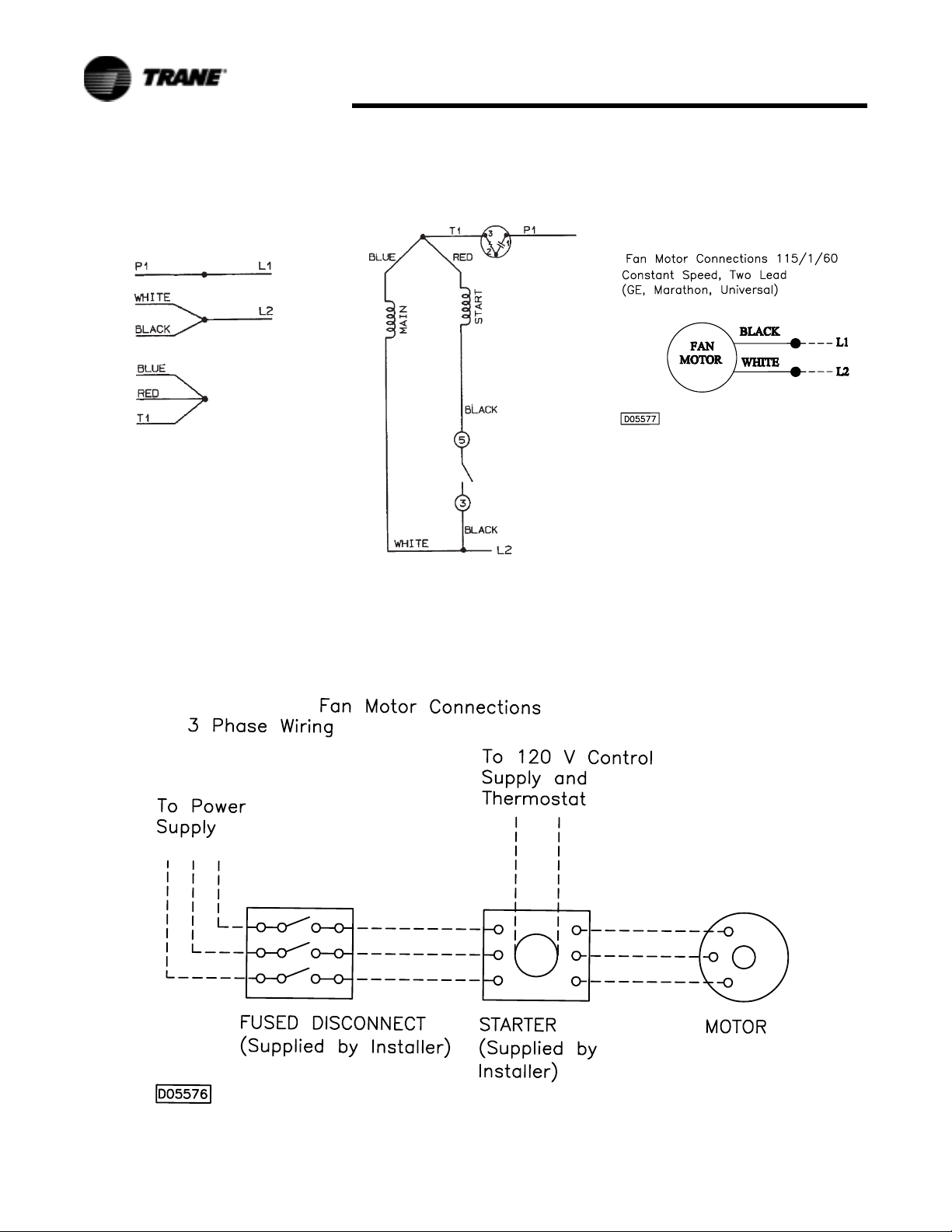

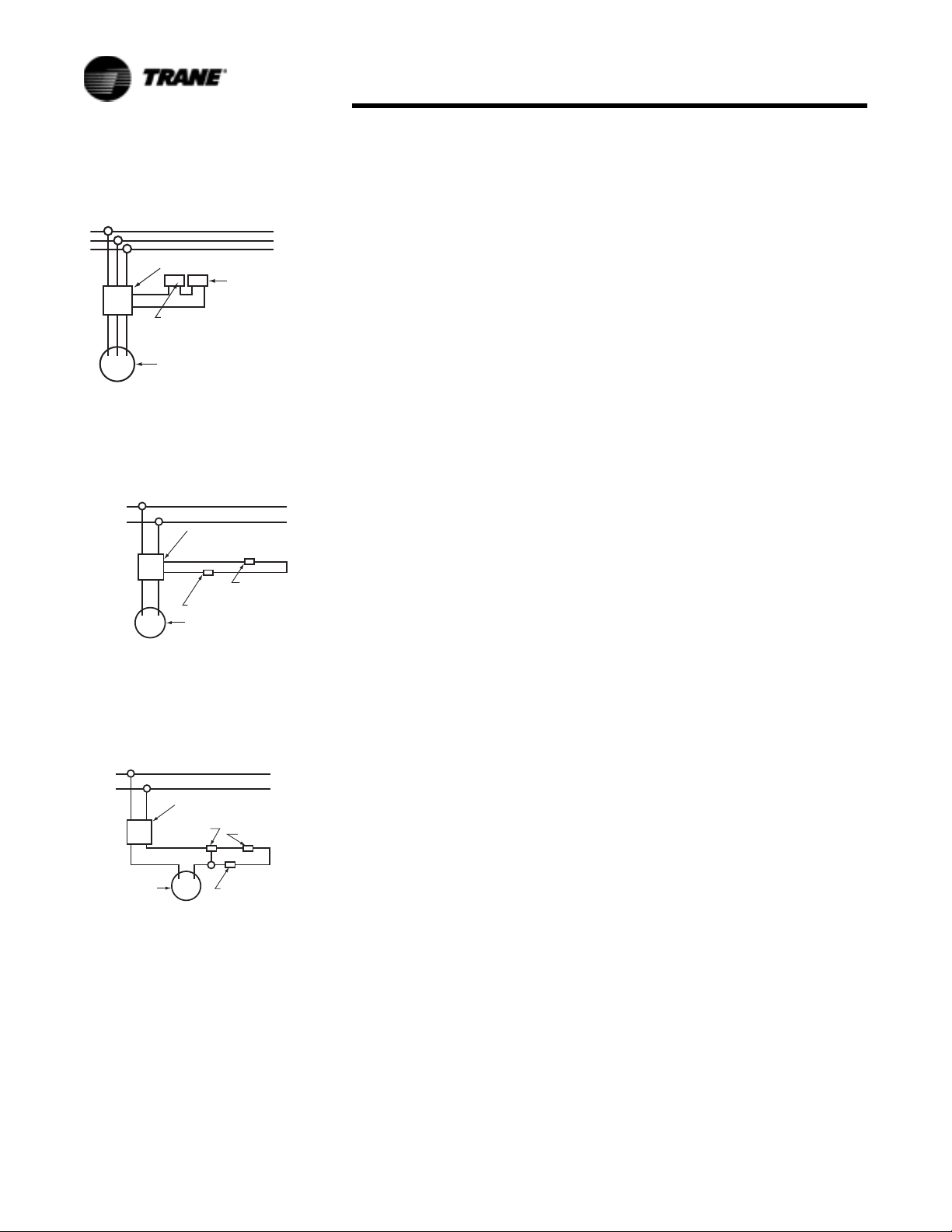

Figure 32. Fan Motor Connections

Low Voltage with Protector Select

Rotation (CCW shown)(Marathon)

For CW Rotation Interchange (Red

and black lead)

Electrical Connections

Figure 35. Fan Motor Connections

115/1/60 Constant Speed, Two Lead

(GE, Marathon, Universal)

Figure 34. Fan Motor Connections

Low Voltage CCW Internal

(Marathon)

Figure 33.

UH-SVX01A-EN 33

Page 34

Electrical Connections

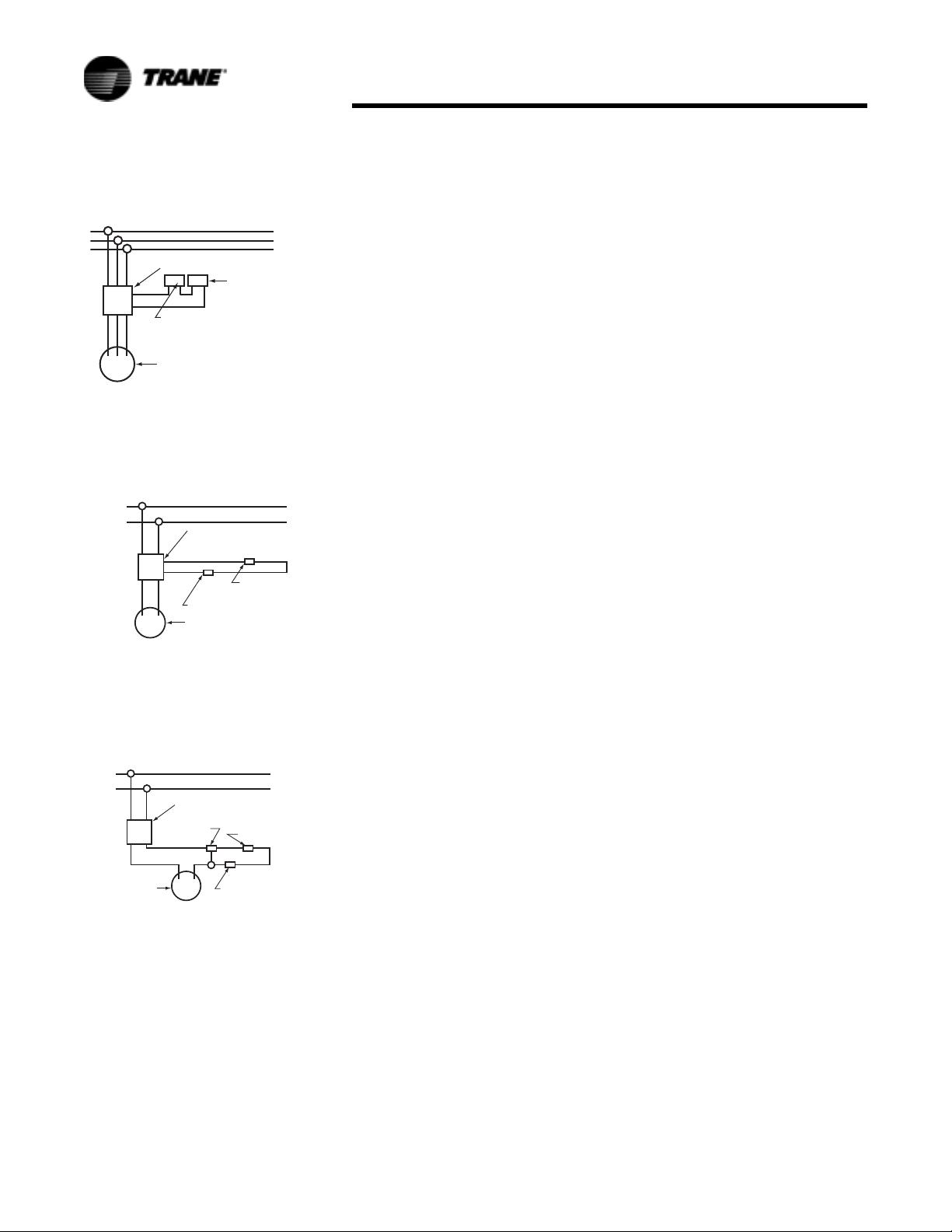

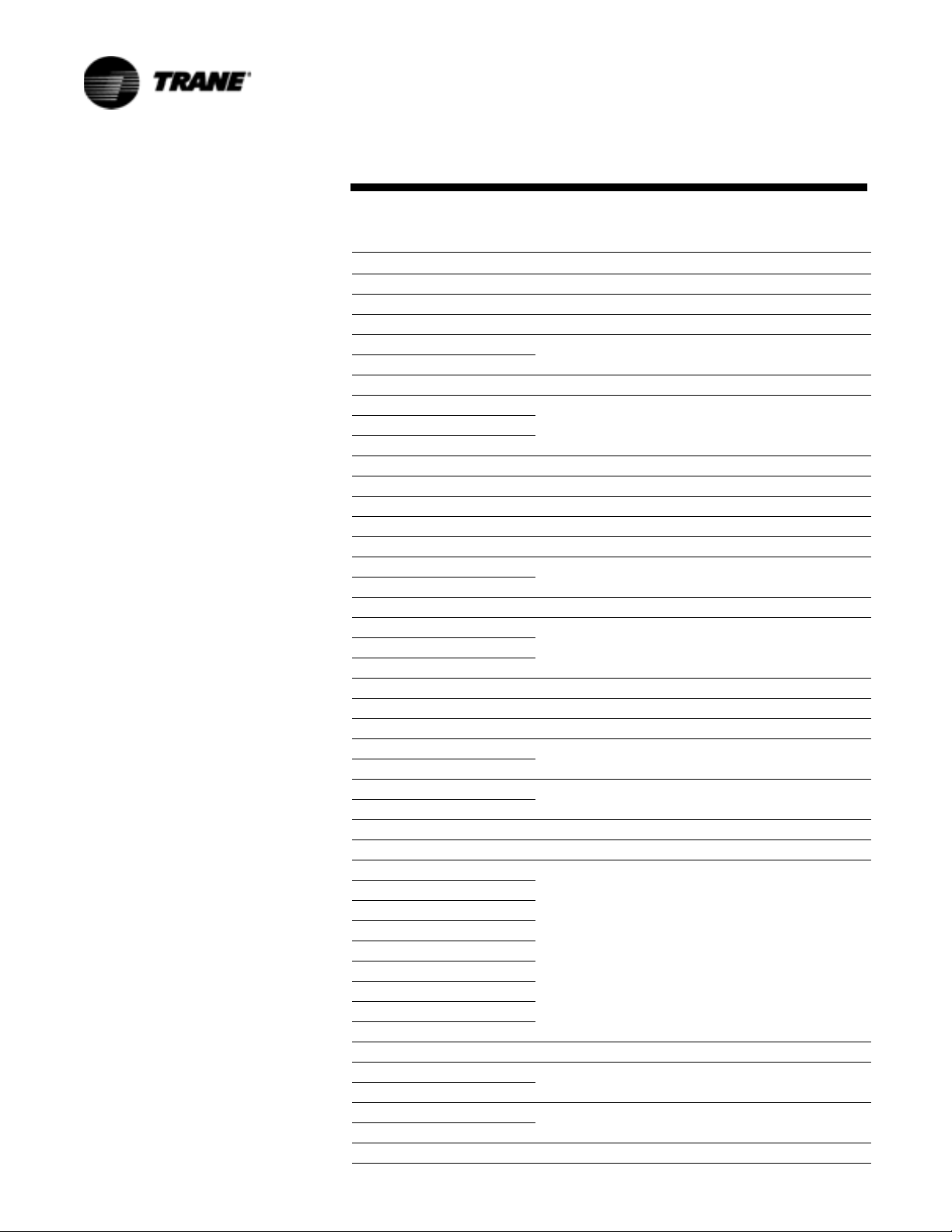

Wiring Installation: P Model

Notice

1. When using a speed controller,

always locate the thermostat

between the speed controller

and the line, not between the

motor and the controller.

2. For internal wiring and overload

protection on all starters, consult

the control manufacturer for

details.

3. When using thermostatic control

with a manual starter, be sure

that the electrical rating of the

thermostat is sufficient to carry

the motor current.

1 PHASE LINE

MANUAL STARTING

SWITCH

MOTOR

1 PHASE LINE

MAGNETIC

STARTING SWITCH

THERMOSTAT

MOTOR

THERMOSTATIC CONTROL

USING MAGNETIC STARTER

OPERATING SEVERAL UNITS

Figure 38.

1 PHASE LINE

MANUAL STARTING

SWITCH

THERMOSTAT

MOTOR

3 PHASE LINE

MANUAL STARTING

SWITCH

MOTOR

MANUAL CONTROL WITH

THREE PHASE MOTOR

Figure 41.

3 PHASE LINE

MAGNETIC

STARTING SWITCH

THERMOSTAT

MOTORS

MANUAL CONTROL WITH

SINGLE PHASE MOTOR

Figure 36.

1 PHASE LINE

MANUAL STARTING

SWITCH

MOTOR

ROOM THERMOSTAT

THERMOSTATIC CONTROL

WITH MANUAL STARTER

Figure 37.

SPEED CONTROLLER

SPEED CONTROLLER WITH

MANUAL STARTING SWITCH

Figure 39.

1 PHASE LINE

MAGNETIC

STARTING SWITCH

THERMOSTAT

SPEED CONTROLLERS WITH

MAGNETIC STARTING SWITCH

FOR OPERATING SEVERAL UNITS

MOTORS

SPEED

CONTROLLERS

Figure 40.

MOTOR

THERMOSTATIC CONTROL

OF SEVERAL THREE PHASE UNITS

Figure 42.

1 PHASE LINE

MANUAL STARTING

SWITCH

MOTOR

LIMIT CONTROLLER

ROOM THERMOSTAT

THERMOSTATIC CONTROL WITH

ACTING LIMIT CONTROLLER

AND MANUAL STARTER

REVERSE ACTING

Figure 43.

34 UH-SVX01A-EN

Page 35

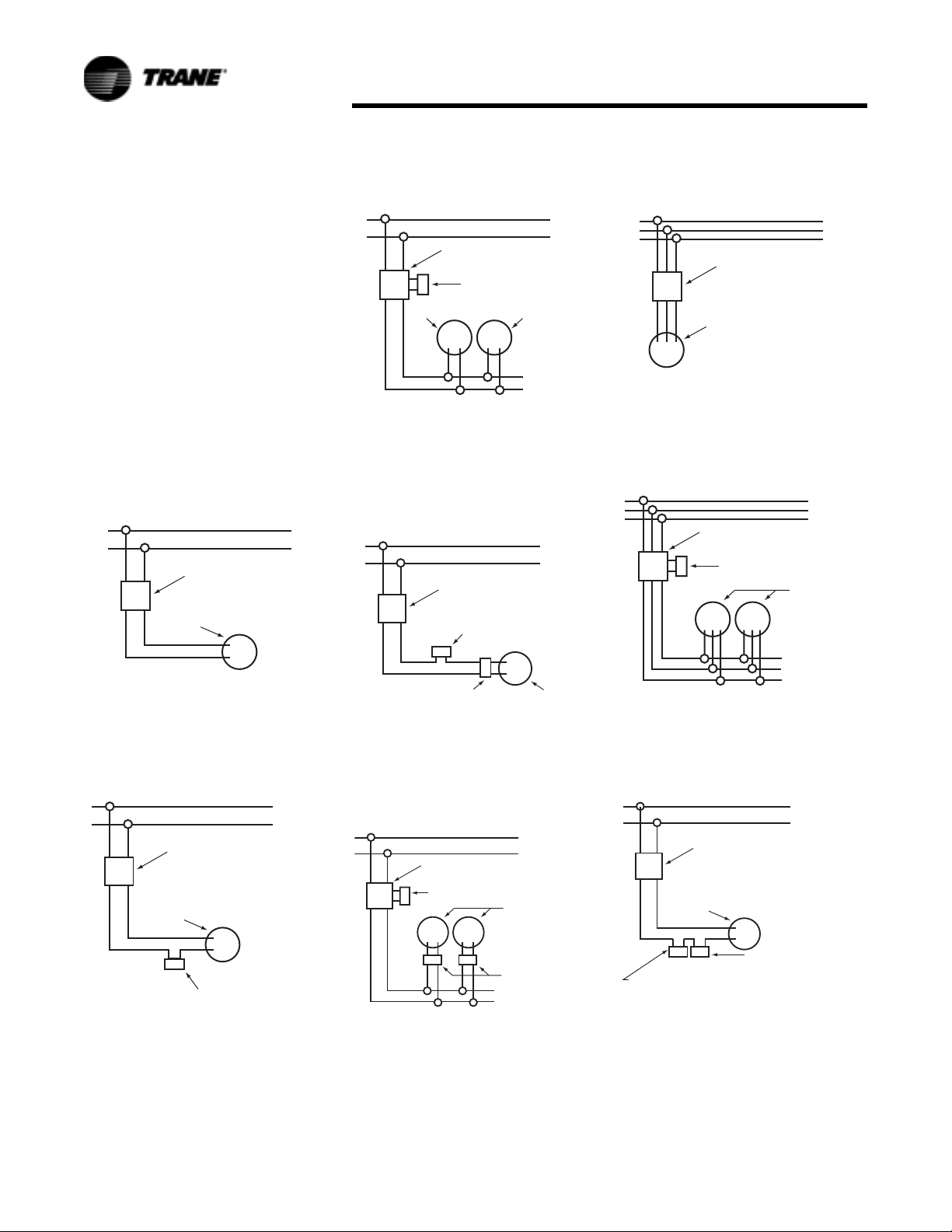

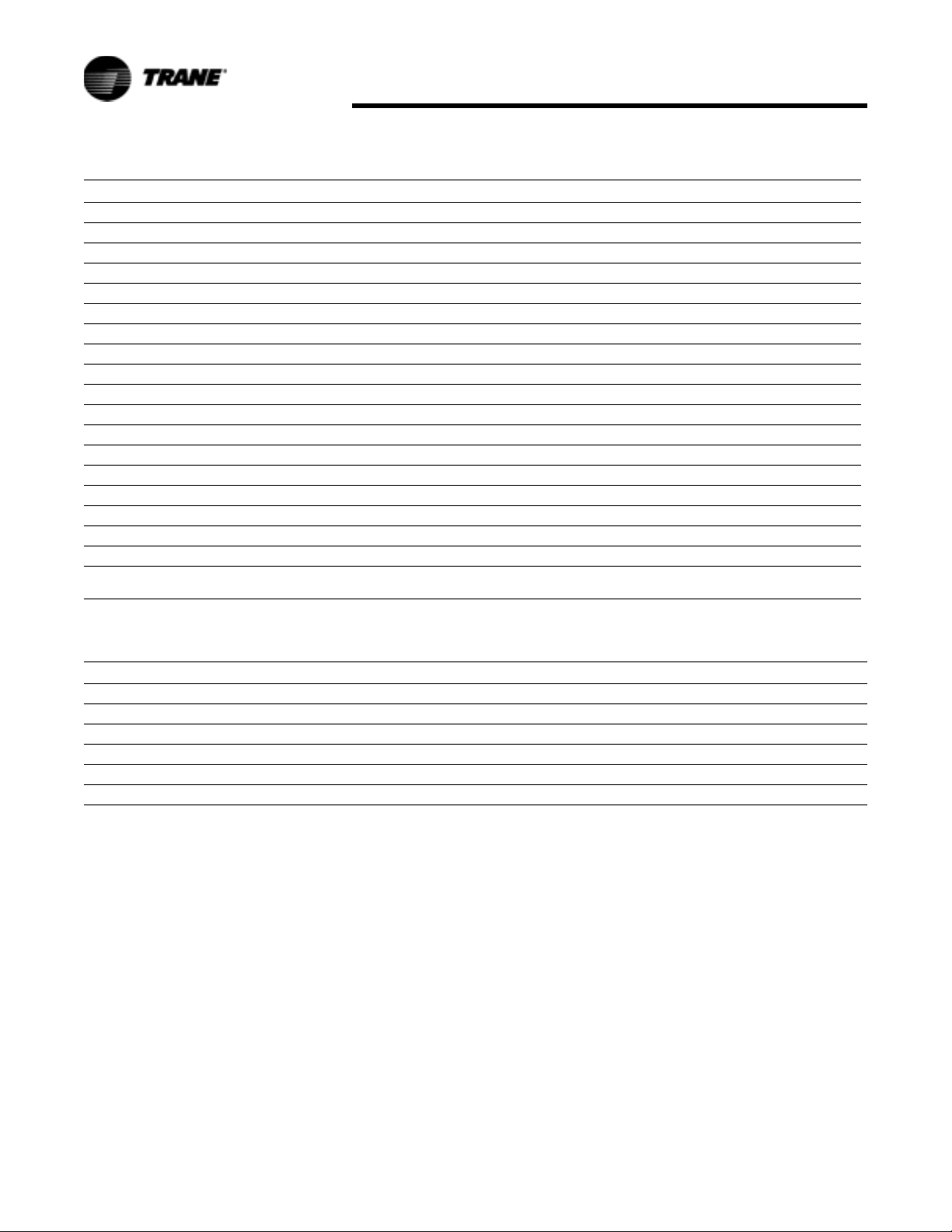

Electrical Connections

3 PHASE LINE

MANUAL STARTING

SWITCH

LIMIT CONTROLLER

REVERSE ACTING

MOTOR

MANUAL CONTROL WITH

THREE PHASE MOTOR

THERMOSTAT

Figure 44.

1 PHASE LINE

MANUAL STARTER

WITH BUILT IN

SELECTOR SWITCH

THERMOSTAT

LIMIT CONTROLLER

MOTOR

THREE POSITION SELECTOR SWITCH

BUILT INTO MAGNETIC STARTER FOR

MANUAL OR THERMOSTATIC CONTROL

Figure 45.

1 PHASE LINE

MANUAL STARTING

SWITCH

SELECTOR

SWITCH

MOTOR

THREE POSITION SELECTOR SWITCH

USED FOR EITHER MANUAL

OR THERMOSTATIC CONTROL

THERMOSTAT

LIMIT CONTROLLER

Figure 46.

Electrical Connections: S

Model

WARNING

Hazardous Voltage

Disconnect all electric power

including remote disconnects before

servicing. Failure to disconnect

power before servicing can cause

severe personal injury or death.

WARNING

Hazardous Voltage

Do not use any tools (i.e. screwdriver,

pliers, etc.) across the terminals to

check for power. Use a voltmeter.

Failure to disconnect power before

servicing can cause severe personal

injury or death.

Standard units are shipped for use

on 115 volt, 60 hertz single phase

electric power. The motor nameplate

and electrical rating on the

transformer should be checked

before energizing the unit heater

electrical system. All external wiring

must conform to ANSI/NFPA No. 702002, National Electrical Code (or the

latest edition) and applicable current

local codes; in Canada, to the

Canadian Electrical Code, Part 1 CSA

Standard C22.1.

It is recommended that the electrical

power supply to each unit heater be

provided by a separate, fused and

permanently live electrical circuit. A

disconnect switch of suitable

electrical rating for each unit heater

should be located as close to the

controls as possible. Each unit heater

must be electrically grounded in

accordance with National Electric

Code, ANSI/NFPA No. 70-2002 (or the

latest edition) or CSA Standard C22.1.

Sample wiring connections are

depicted in Figure 49 through

Figure 57.

Operation

Most basic unit heater systems are

controlled by a room thermostat.

Locate thermostat on inner wall or

column so that optimum control can

be obtained for that area. Set

thermostat for desired temperature.

On steam systems a low limit may be

used to prevent fan from blowing

cold air unless the heater has steam

passing through the coil.

Small hot water systems could have

the circulating pump controlled

directly by the room thermostat. On

large systems, zone valves could be

used to control the individual unit

heater where constant water

circulation is used on the main

system.

Horizontal louvers are standard

equipment on horizontal unit

heaters, vertical louvers are available

as an optional accessory.

Thermostat Wiring and Location

Note: The thermostat must be

mounted on a vertical

vibration-free surface free

from air currents and in

accordance with the

furnished instructions.

Mount the thermostat approximately

5 feet (1.5 m) above the floor in an

area where it will be exposed to a

free circulation of average

temperature air. Always refer to the

thermostat instructions as well as our

unit wiring diagram and wire

accordingly. Avoid mounting the

thermostat in the following locations:

1. Cold areas - Outside walls or

areas where drafts may affect the

operation of the control.

2. Hot areas - Areas where the