Page 1

Propeller Unit

Heaters/Unitary

17.4 to 705.6 MBh

Two Versatile Models - Various Sizes

Easy Installation

October 1999

UH-PRC00 1 -EN

Page 2

Introduction

The Industrial Designed Model P Unit Heater

The square, compact design of the

Model P and rectangular Model S allow

easy handling and installation. In most

cases, only one person is needed to

carry a unit. And because both feature

compact Sigma-Flo

lightweight, making them easy to hoist

and put into place.

©American Standard Inc. 2000

®

fins they’re

The Clean-Line Appearance of the Model S Unit Heater

What’s more, the Model P can be stored

standing on end. This means several

units can be loaded on a single skid for

moving from one point to another. Trane

maintains a complete stock of both

Model P and S units that are available to

ship anywhere in the United States.

Y et, the benefits of this compact design

go beyond ease of installation. They

continue with attractive styling. The

Model S unit’s simple, clean-line

symmetry and the Model P unit’s classic

modern shape enhance any industrial

facility.

UH-PRC001-EN

Page 3

Contents

Introduction

Featur es and Benefits

Application Considerations

Selection Procedur e

Manual Selection Procedure

Model Number Description

P erformance Data

Electric P o wer

Dimension and W eights

Mechanical Specifications

2

4

8

11

19

21

23

44

47

50

UH-PRC001-EN

3

Page 4

Features and

Benefits

Two Units in One – the Versatile Model P

The T rane Model P can be quic kly field

converted from standard to low final

temperature PL design simply by

removing the unit’s patented knockout

air ports. This unique two-in-one design

allows the stocking wholesaler to cut

inventories in half and still meet most

customer application requirements.

T rane propeller unit heaters feature the

largest selection of standard sizes from

any line in the industry . In fact, vertical

Model P and horizontal Model S unit

heaters provide enough ‘of f-the-shelf’

selections to fit almost any application.

The versatile two-in-one Model P is

available in 15 sizes with capacities from

41 .3 MBh to 705.6 MBh while the

companion standard and bypass Model

The Space-Saving Model S

The Model S features attractive,

functional styling in a space-saving,

compact design.

In addition, T rane of fers an exclusive

bypass Model S design to meet low final

temperature, high cfm requirements. This

design uses a modified coil which allows

some of the air to flow over the top of the

coil without being heated. This cooler

band of air prevents the heated air from

rising so warm air throw is increased

while efficiency is improved.

S is available in 29 sizes with the

capacities from 17.4 MBh up to 404 MBh.

Both are designed for durability,

attractiveness and compactness. These

features combined with economical

operation, give strategically sized T rane

unit heaters an edge unmatched by any

other manufacturer.

Put Heat Where It’s Needed

Exclusive louver fin diffusers featured on

T rane unit heaters put heat where it’s

needed.

Patented Trane louver cone diffusers allow

directional flexibility of heated air.

Trane Model S features louve red disc har ge as

standard.

These patented T rane dif fusers provide

an unlimited combination of air diffusion

patterns as well as greater air throw

distance. In fact, when the louver cone

diffuser is added to the Model P, up to 45

percent greater air throw distance is

possible.

On Model S units, the combination of

horizontal louver blades and patented

vertical diffuser fins provide fourdirectional control of air delivery.

Optional low cost louver fin diffusers can

be adjusted to provide up to 25 percent

more air throw.

UH-PRC001-EN4

Page 5

Features and

Benefits

The Model S Coil

The Model S unit heater features a

unique single tube serpentine coil. This

compact, efficient coil has piping

connections at the back for added space

savings, convenience and appearance.

Model S single circuit coils use threaded

connectors at the back of the unit.

The Model P Motor

The Model P motor is mounted below

the top panel inside the heater casing.

This reduces unit height and permits the

unit to be installed closer to the ceiling

for added headroom.

Compact Design

T rane designed Model S and P propeller

unit heaters for easy installation and low

maintenance. The Trane Sigma-Flo

design allows coil size to be reduced

while maintaining high capacity

performance equal to larger flat-fin coils.

Reduced size and weight makes T rane

unit heaters easy to handle and install.

Rectangular Draw -Thr u Coils

The Model P draw-thru coils use short

lengths of steel pipe threaded for supply

and return connections. These features

make piping connections much easier

for the installer.

®

fin

5UH-PRC001-EN

Page 6

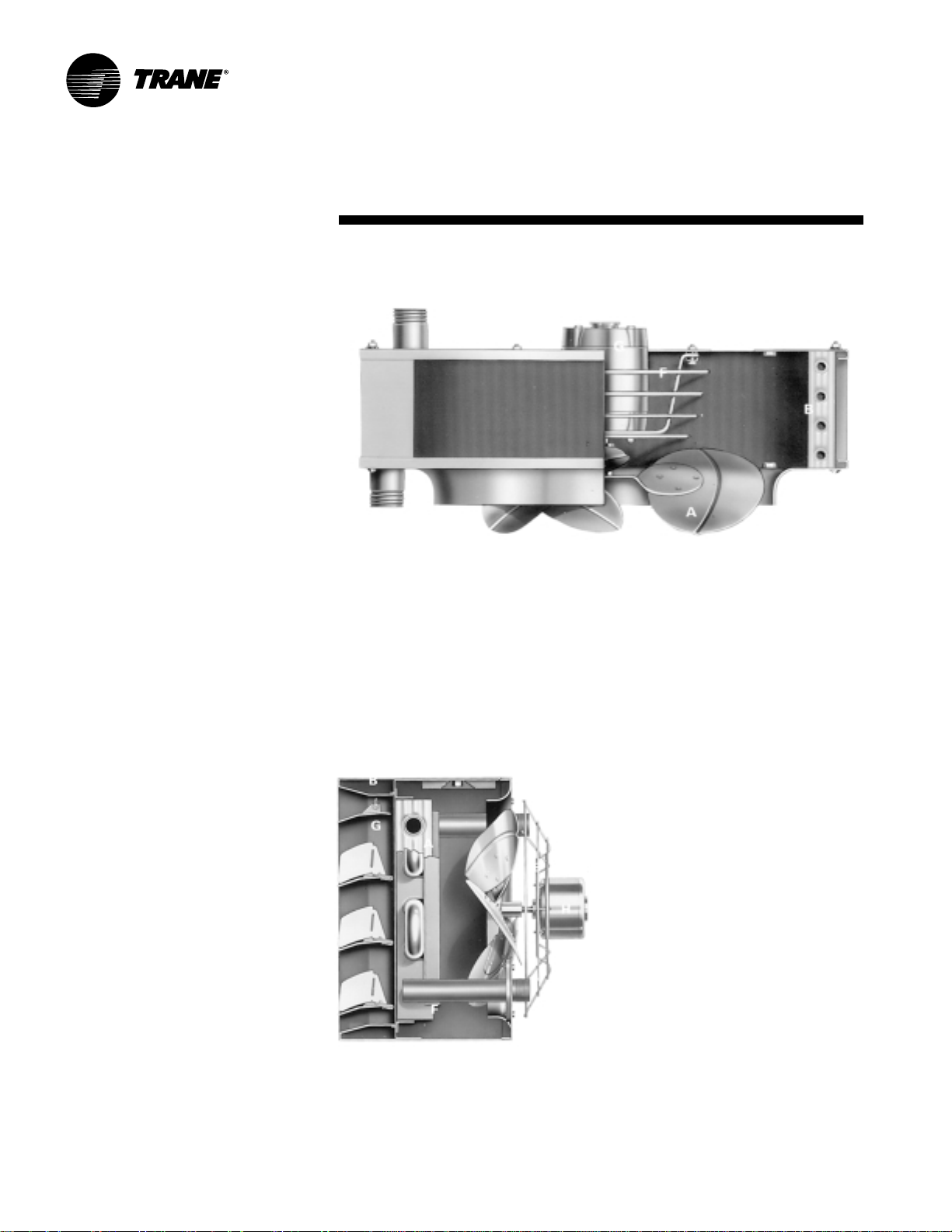

Model P

A

Exclusive T rane designed aluminum fans

provide smooth, nonsurge performance.

This, in turn, provides efficient, quiet

operation.

B

High performance Sigma-Flo

one-row coil have more efficient heat

transfer characteristics than flat fin coils.

C

Steel pipe headers are electrically

induction-brazed to coil tubes.

D

Top panel features knockout air ports

that, when removed, convert the unit

from standard to low final air

temperature, higher cfm operation.

E

Bottom plate provides drawn fan orifice

to assure smooth airflow.

F

Sturdy motor mounts absorb vibration

and anchor the motor securely .

G

Totally enclosed industrial designed

motors feature built-in overload

protection.

®

fins in a

Features and

Benefits

C

B

C

G

A

F

G

F

D

B

E

A

Model S

A

Exclusive, compact one-row

serpentine coil features high

performance Sigma-Flo fins.

B

One-piece wraparound casing with

picture-frame front panel combines

attractiveness with durability.

C

Heavy-gauge, one-piece bac k panel

can be easily removed for quick coil

access.

E

H

D

D

Rear connections and a compact

design provide more headroom than

conventional units.

E

Sturdy fan guard provides stronger

motor mount and quiet operation.

F

Unique coil supports anc hor coil

tubes without restricting expansion.

G

T rane horiz ontal louvers stay in

position with the exclusive louver

keeper design.

H

Totally enclosed industrial design

motors feature built-in overload

protection.

UH-PRC001-EN6

Page 7

Model P

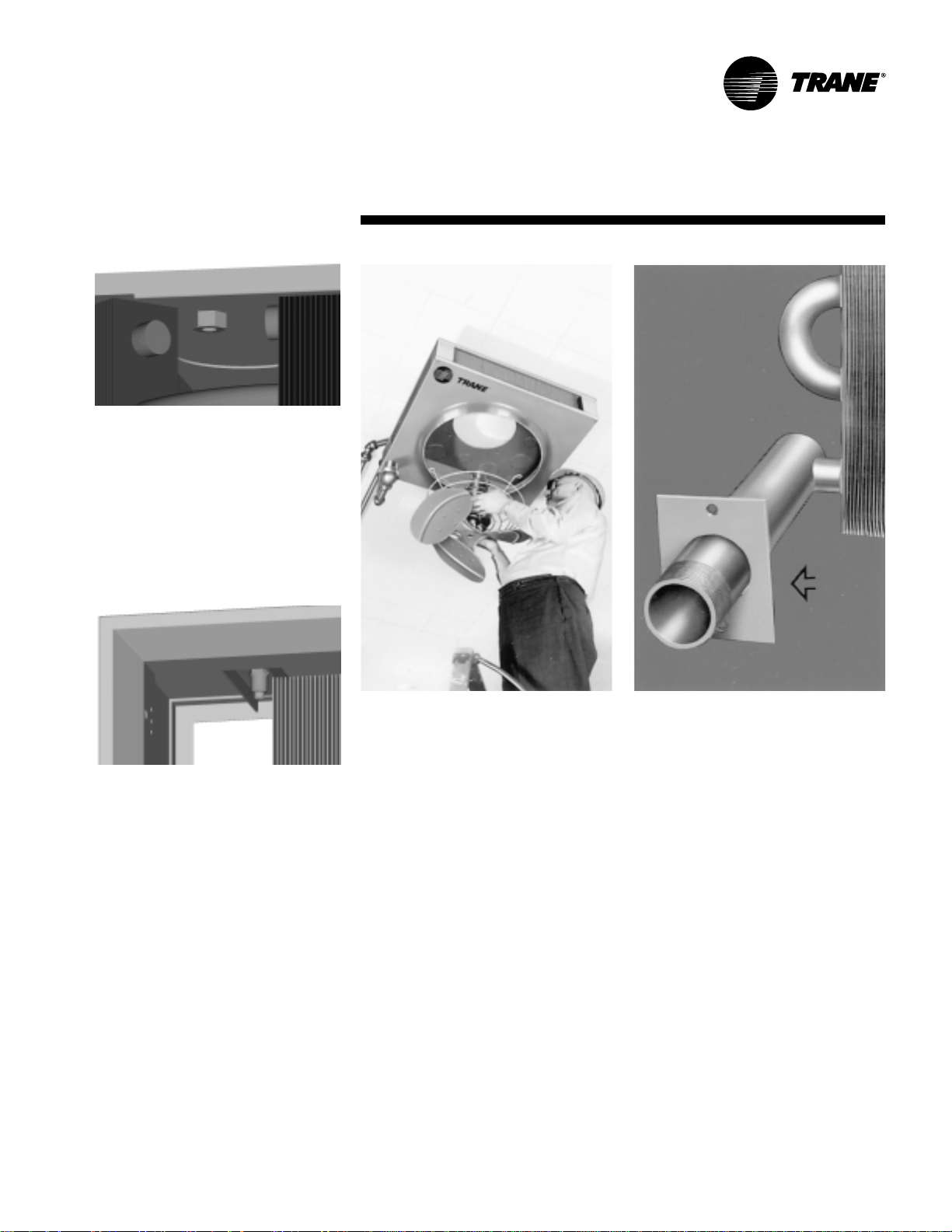

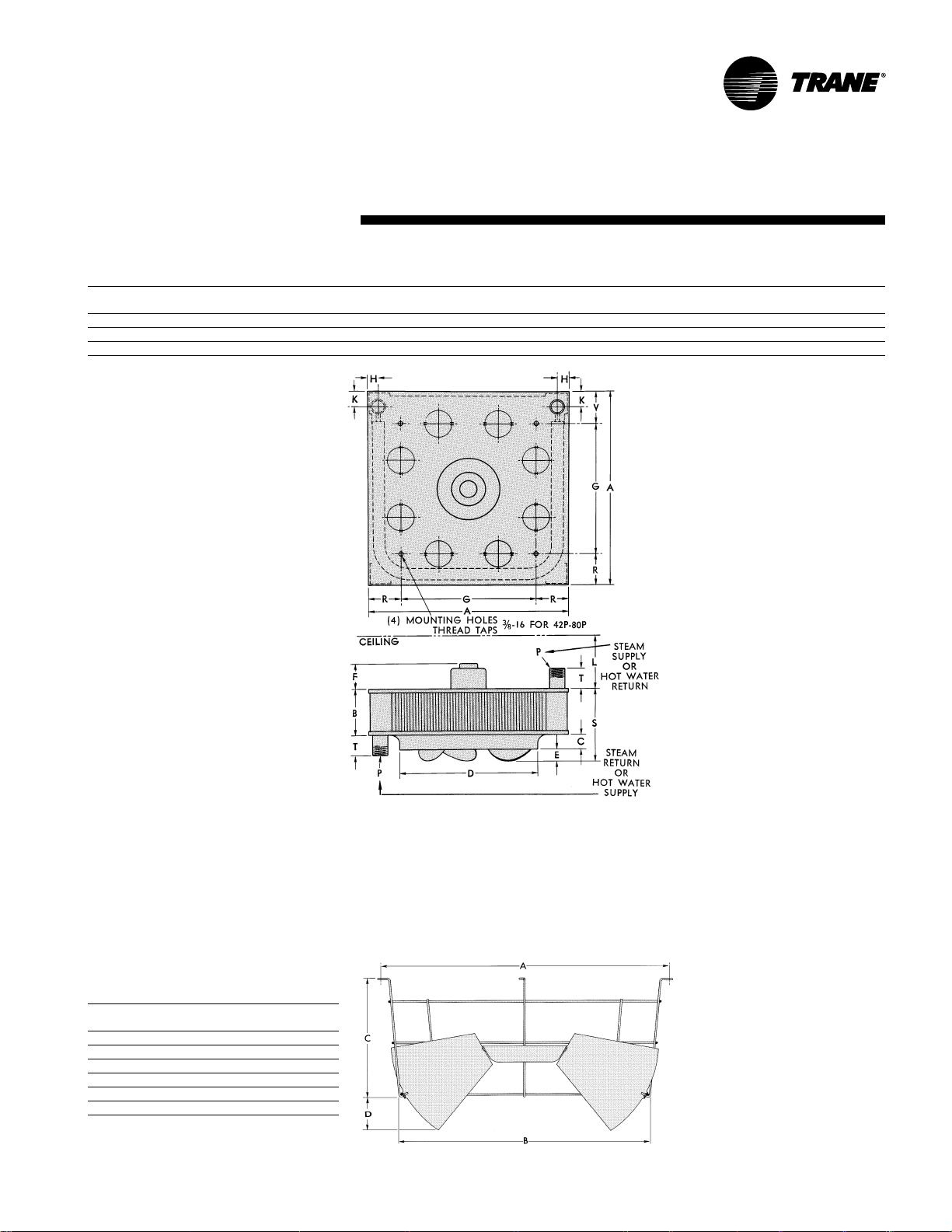

Simple Hanger and Piping Connections

The Model P uses weldnut type hanger

connections, while the Model S uses a

nutsert type hanger connection. Hanger

rods screw easily into threaded anchor

points. Piping connections can be made

equally as easy. Model P units pro vide

threaded connections for inlet and outlet,

top and bottom.

Features and

Benefits

Model S

Fully A ccessible f or Easy Maintenance

Model S and P unit heaters are fully

accessible for maintenance. Only four

main bolts are needed to disassemble

the Model P. And when quick access is

needed, the Model S features a

one-piece back that can be easily

removed and slid over pipes without

breaking connections.

Motors can also be easily removed. Both

units feature totally enclosed motors

with thermal overload protection. As an

added benefit, Model P fan-motor

assemblies can be conveniently

removed from below through the fan

outlet.

External Couplings

The Model S provides threaded

connections for supply and return on the

back of its casing. In addition, bac k

connections reduce the amount of space

needed for installation.

7UH-PRC001-EN

Page 8

General Rules

In locating or spotting Trane Propeller

Unit Heaters – either the Model S

Horizontal or Model P Projection Unit

Heater – the following general rules

should be considered.

1 . Spot units at points of greatest heat

loss. Blanket outside doorways

effectively and provide ample coverage

for exposed window areas.

2. Units, especially in the case of the

Model S Horizontal Unit Heater , should

be arranged to blow toward or along

exposed walls, preferably striking the

wall at a slight angle so that the heated

air exerts a wiping effect along the w all.

Balance of units required to supply Btu

requirements should be spaced

strategically in balance of the area.

3. Unit heaters should be arranged to

blow into open spaces such as aisles and

not directly at any worker. An exception

to this rule involves the use of the Model

P Unit Heater equipped with the Louver

Cone Diffuser . This combination can be

used effectively over closely spaced bins

or machines without regard for open

space. But not even the Model P Unit

Heater with Louver Cone Diffuser should

be in such close proximity to the workers

to cause discomfort.

4. The T rane solid-state speed control will

provide maximum capacity flexibility and

quieter operation. Note that this speed

controller is available only on selected

models.

5. Mounting heights and distance of

throw recommendations as given

elsewhere in this catalog should be

carefully observed.

6. In the case of Model P Units, they

should be spotted so that they will most

effectively prevent stratification of

excessively warm air at the ceiling. By

carefully observing this rule, this type of

unit may be used between seasons to

tap waste heat at the ceiling and drive it

down to occupied zones, thereby

eliminating the need for added heat on

the system.

7. Do not spot units close to any

obstruction that will impede the full and

natural air delivery of the unit.

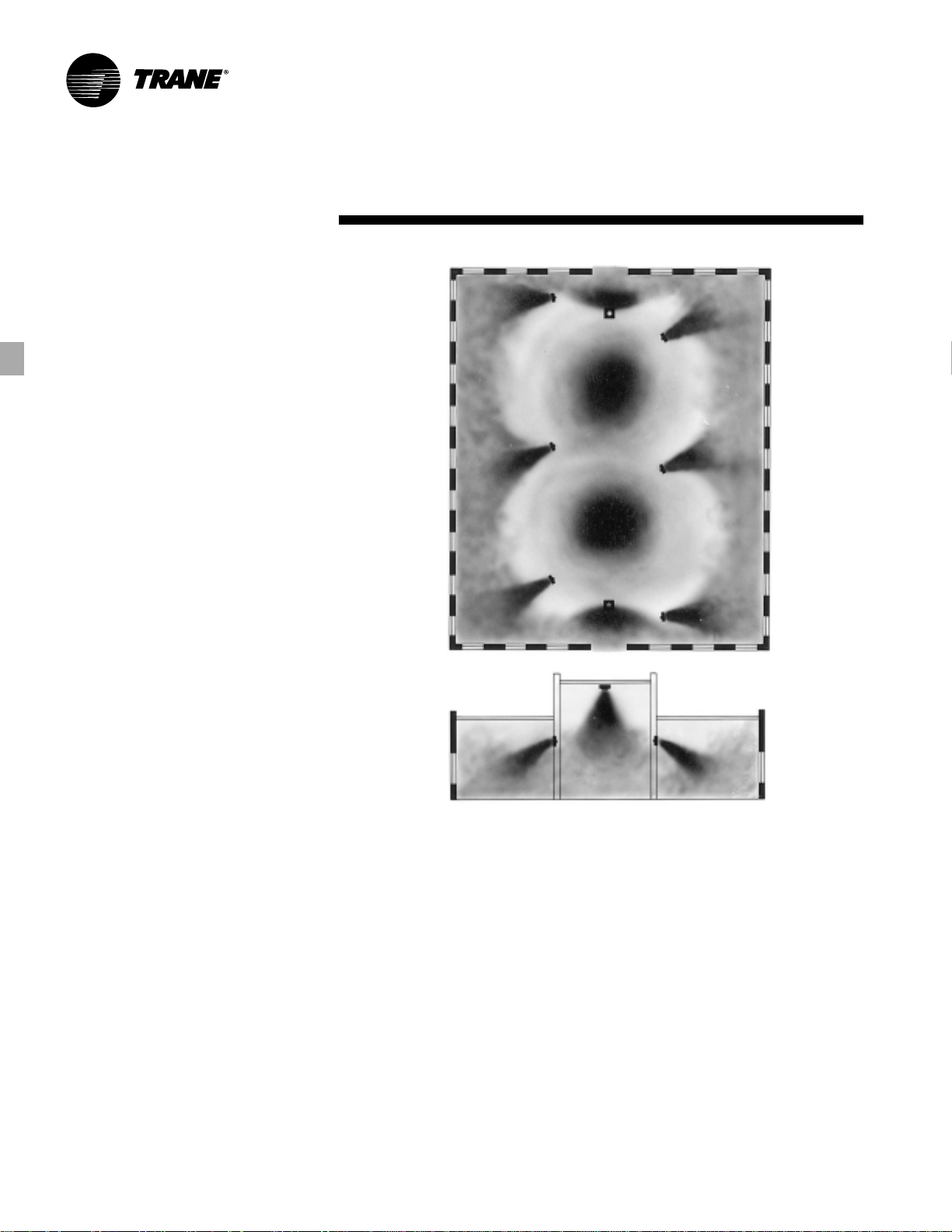

Typical Factory

In the typical industrial building, where

ceilings are high, Model P Unit Heaters

may be used without diffusers.

Application Considerations

Figure A C-1 – The floor plan and elevation of a typical industr ial building showing ho w a

Trane Unit Heater System will heat var ious par ts. Where ceilings are high in the main

manufactur ing section, l arg e Projection Heat ers without dif fusers are used. Where ceilings

are exceptionally high, as in cr ane bays, Model P Units with Louver Cone Dif fusers pr ovide

up to 45% greater thr ow t o top the “ceiling heat r eservoir.” Model P Units with half closed

Louver Cones blanket doorwa ys. Model S Units with Louver Fins blank et windows.

In plants where the ceilings are

exceptionally high, such as in crane bays

as illustrated in Figure AC-1, Model P

Units with Louver Cone Diffusers can

increase the downward projection of

heat by as much as 45% over units

without diffusers.

Model P Units with the Louver Cone

Diffusers can also be used to blanket

doorways effectively, as shown in Figure

AC-1 by simply adjusting half of the

louvers vertically, and half closed.

Model S horizontal-type units are ideal

for mounting in plant areas where

ceilings are low. In fact, due to the

extremely small height of the Model S,

and because all piping connections are

made at the back of the unit, the Model S

provides a greater saving in headroom

than other horizontal unit heater makes.

As illustrated in Figure AC-1, the Model S

Unit Heaters may be mounted

conveniently from the ceiling, or from

building structural supports and beams.

With Louver Fin Diffusers, they are ideal

for blanketing windows, and Model S

“Bypass” Unit Heaters, provide further

flexibility of application where greater

throw and more effective distribution of

air in the living zone is required.

UH-PRC001-EN8

Page 9

Application

Considerations

General Notes

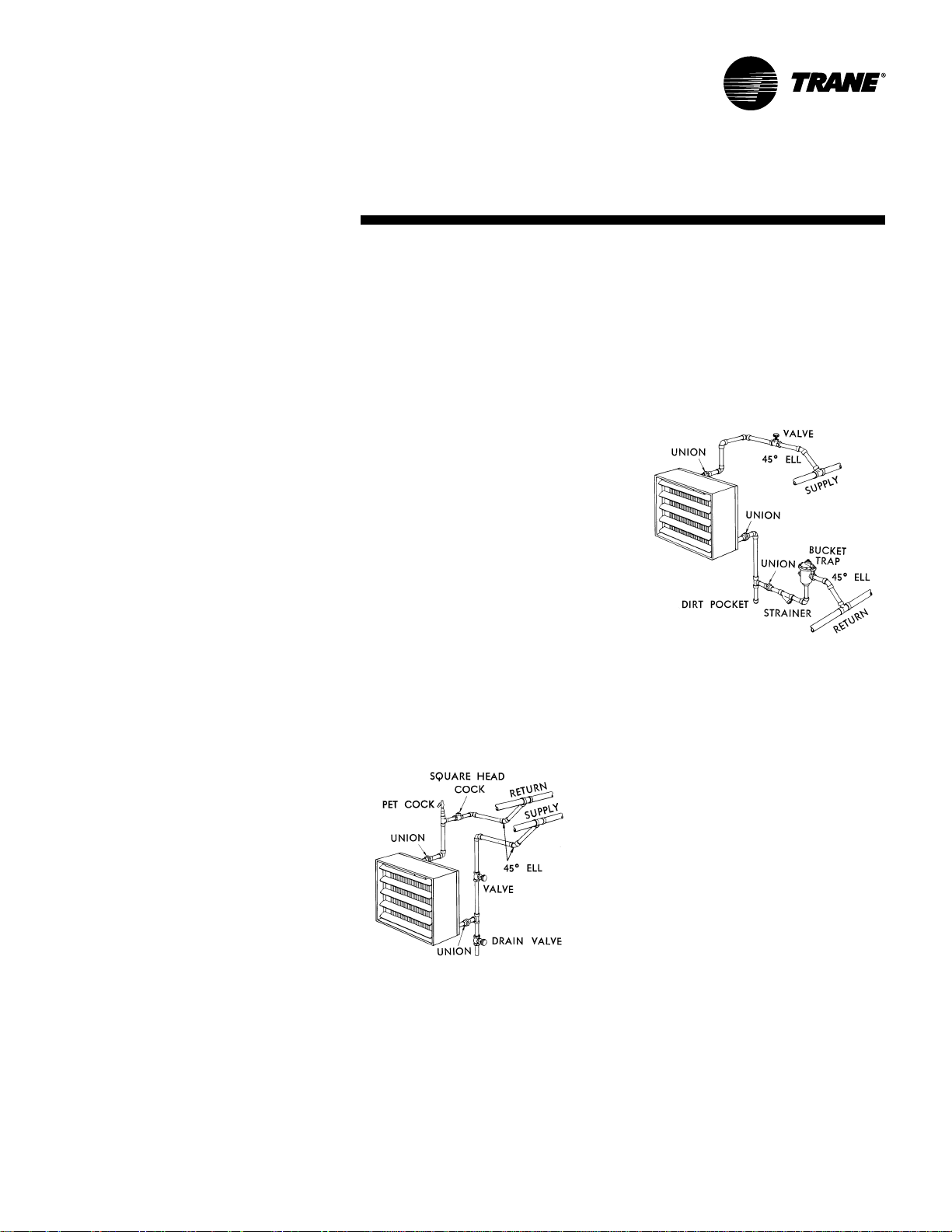

The following general notes on piping

propeller unit heaters are presented

based on competent engineering and

installation practice:

1 . Suspend unit heaters securely with

provisions for easy removal.

2. Make certain units hang level vertically

and horizontally .

3. Provide for expansion in supply lines

(note swing joints in suggested piping

arrangements).

4. Provide unions adjacent to unit heaters

in both supply and return laterals. Also

provide shut-off valves in all supply

laterals.

5. Use 45' angle runoffs from all supply

and return mains.

6. Provide at least 7" (more if necessary)

clearance above tops of Model P

Projection Unit Heaters. Motors are

removable from below on all sizes.

It is desirable to form dirt poc kets with

pipe of the same size as the return

tapping of the unit heater. Pipe in the

branch-of f should be the same siz e as the

tapping in the trap. Beyond the trap, the

return lateral should be increased one

size to the return main.

Hot Water System – Using Cir culating

Pump

Overhead supply and return mains are

used with bottom connections to mains.

Manual vent (pet cock) is used at high

point on return main. Automatic air vent

may be substituted if desired. Refer to

Figure AC-2.

Figure AC-3

High Pressure Steam Syst em

Overhead supply main is used with

lower return main. Where steam

pressure fluctuates over a wide range, a

swing chec k valve should be placed in

the return lateral between strainer and

bucket trap to prevent reverse flow of

condensate of flash steam when

pressure drops suddenly. Top of buc ket

trap must be located below return outlet

of coil for complete drainage of

condensate. Refer to Figure A C-3.

Figure AC-2

9UH-PRC001-EN

Page 10

Application

Considerations

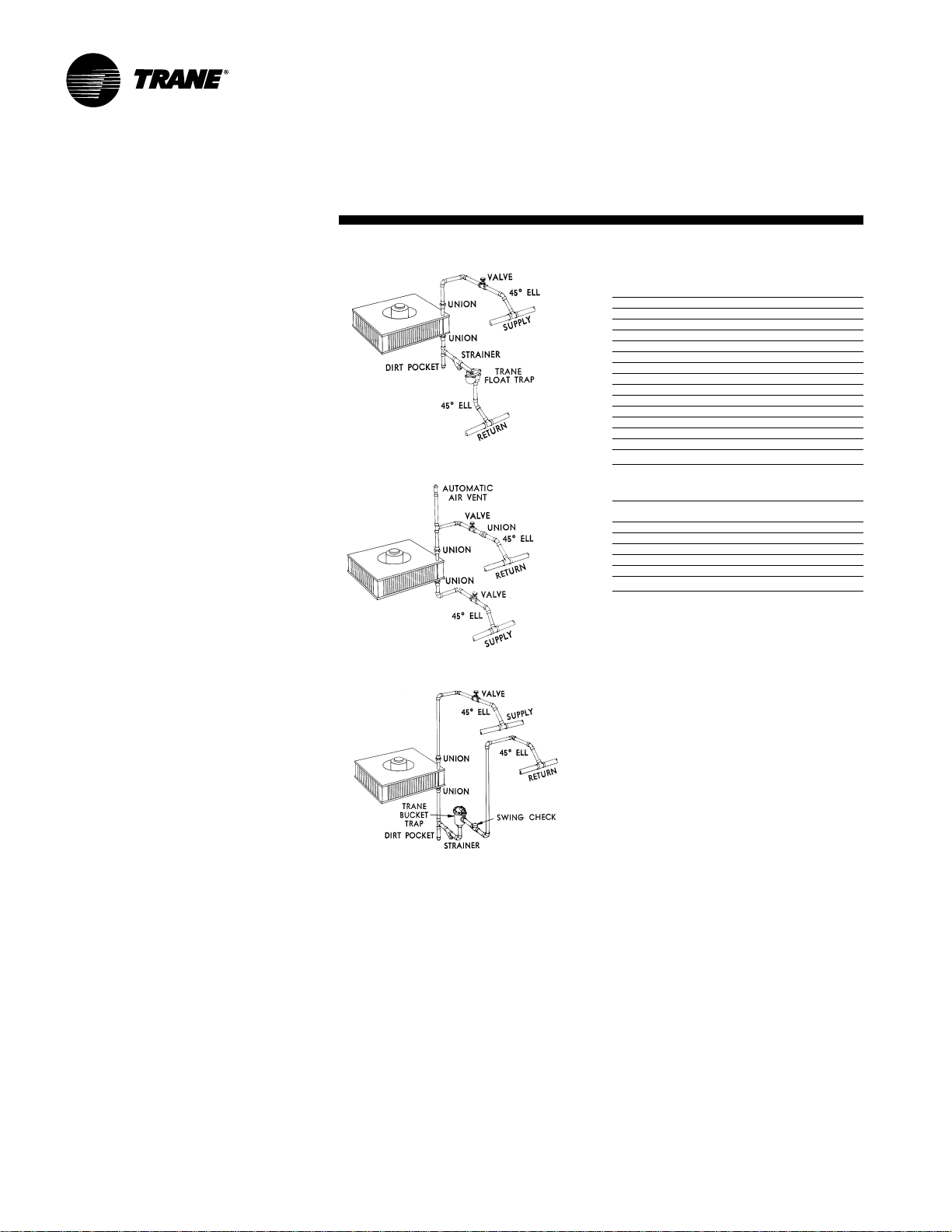

Figure AC-4

Table AC-1 - Model P Coil F ace Area

Unit Numbers Fin Area In Sq. Ft

42-P & P-L 1 .20

64-P & P-L 1 .49

80-P & P-L 1 .98

102-P & P-L 3.28

122-P & P-L 3.28

146-P & P-L 3.88

166-P & P-L 4.85

202-P & P-L 4.85

252-P & P-L 6.52

280-P & P-L 6.52

336-P & P-L 6.52

384-P & P-L 7 .82

500-P & P-L 8.72

600-P & P-L 11.63

720-P & P-L 13.08

Table AC-2 - Supply and Retur n Sizes at 2 Psi

Capacity In Lbs. Of Size Of Size Of

Steam Per Hour Supply Gravity Return

39 1” 3/4”

87 1 1/4” 3/4”

134 1 1/2” 1”

272 2” 1 1/4”

449 2 1/2” 1 1/2”

822 3” 2”

Note: This table is based on 1/2 lb. drop per 100 ft. of

equivalent run of steam line and approximately 1/4 lb. drop

in the return line per 100 ft. increase steam run-outs one

size if more than 8 ft. long.

Figure AC-5

Figure AC-6

V apor or V acuum S ystem

Lower supply and return mains are used.

Piping should be similar to that used with

overhead supply main if it is separately

vented and trapped. Bottom supply for

steam mains may be used if steam is dry.

Refer to Figure A C-4. F or proper pipe size,

refer to T able AC-2.

Hot Water System with Cir culating

Pump

Lower supply and return mains are

shown. Overhead supply and return

main connections, similar to those in

Figure AC-2 may be used. The automatic

air vent is shown here but a manual vent

(pet cock) may be substituted. Refer to

Figure AC-5.

High Pressure Steam S ystem

Overhead supply and return mains are

used. The top of the bucket trap must be

located below bottom return outlet of coil

for complete drainage of condensate.

Refer to Figure A C-6.

UH-PRC001-EN10

Page 11

Selection Pr ocedure

Trane Propeller Unit Heaters

Both Model S and Model P Propeller

Unit Heaters are ideally suited to such a

wide variety of installations that there

can be no hard and fast rules regulating

their selection.

In determining the type and size of the

units for any building, the following

points are generally considered:

BTU Requirements

While the choice of units depends upon

several important factors, the total Btu

requirement is usually determined first.

In calculating heat loss, methods as

recommended by the ASHRAE Guide

may be used, or any other procedure

which is known to be acceptable.

Type of Building

Once the total Btu requirement is known,

the type of building together with its

architecture and its purpose is

considered.

In the many cases where a combination

of space characteristics is found, a

combination of Model S and Model P

Unit Heaters may be used to create the

most satisfactory heating system.

The Model P Unit Heater has the natural

ability to tap the reservoir of heated air

which collects at the ceiling level and

return it to active service in the floor

zone.

The Model P can be used on either high

or low ceilings. From high mounting

positions the Model P will allow ample

clearance for moving objects and can

project heat down into occupied areas

regardless of obstacles which would

restrict the flow of air from horizontal

units.

From low mounting positions the Model

P, with proper diffusion, can be used

without disturbing nearby occupants

with direct blasts of high velocity heated

air, or requiring return lines so low as to

leave insufficient head room.

The superior horizontal action of the

Model S, on the other hand, is ideal for

creating a wiping effect of warm air

along exposed walls which neutraliz es

drafts at their source, beaming heat

down narrow aisles and production

lines, and blanketing large windows,

doors and other points of high heat loss.

Spacing of Units

It is the usual practice to divide the

building into areas with like exposures,

or in relation to heat load distribution

desired.

In general, Model S Unit Heaters may

be selected for buildings where direct

horizontal air currents are desired and

where there are no obstacles to

interrupt the flow of air from the

heaters.

Model P Unit Heaters are successfully

used where high or low mounting

heights are required and should

ordinarily be specified with diffusers,

depending upon the mounting height

and application.

Mounting Heights

maximum

The

height is determined by the outlet

temperature of the air, the outlet

velocity, the cfm for whic h the heater is

designed, and if a diffuser is used – the

setting of its blades.

The higher the outlet temperature of

the air, the more dif ficult it is to force it

down into the living zone.

The cfm also affects the mounting

height as a large volume of air will

travel farther than a small volume

under the same initial conditions of

temperature and velocity.

In the preliminary planning stages, it is

well to remember that the lowest

possible mounting height is desirable in

order to get the most heat down to the

floor line and to allow the greatest

possible diffusion adjustment to

provide tailor-made distribution for

each area.

effective mounting

In providing for the use of diffusers

please remember, adjustment of a

Louver Cone Diffuser to deflect the air

toward the horizontal immediately

lowers the mounting height limit.

Adjustment for lateral deflection with

the Louver Fin Diffuser shor tens the

distance of throw.

Diffusion

The use of T rane L ouver Cone or

Louver Fin Diffusers influences the

selection of units in two principal ways:

First: It is seldom necessary to install

oversized heaters to extend the

maximum effective mounting height of

the Model P or the distance of throw of

the Model S. Conversely, Trane Diffusers

enable extremely low mounting since the

adjustable blades direct heat where it is

wanted without creating uncomfortable

hot spots near the units.

Second: Af ter the original selection has

been made, units may be located with

confidence because adjustments in heat

distribution are possible to

accommodate future changes or

unforeseen draft conditions.

Air Changes

Better diffusion and more even

temperatures can be maintained in a

heated space when the rate of air

recirculation through the heaters is

relatively high. For buildings where large

numbers of people are engaged, it is

desirable to provide for a greater number

of air changes than for sparsely occupied

areas.

A greater number of small units are used

where wide diffusion and even

temperatures are necessary. A few

centrally located units of large capacity

would be used where there are few

occupants.

Comfort Conditions and Econom y

Air circulation, diffusion and spacing of

units are closely related to economy and

comfort in the selection of unit heaters.

The more units used to provide the

required number of Btu’s, the more

comfortable will be the conditions for

personnel. On the other hand, a few

large units can be selected to provide

plenty of heat at low first cost, but may

be slower in response and thorough

distribution of heat.

Here again, adjustable diffusion

equipment can go a long way toward

saving the buyer first cost expense while

still providing completely satisfactory

comfort conditions.

11UH-PRC001-EN

Page 12

Selection

Pr ocedure

Formula

The following formula is used to arrive at

final air temperature volume when 70 F

(Standard Air Basis) is known or vice

versa:

Cfm at final temp. =

Cfm at 70 F x

Cfm at 70 F =

Cfm final air x

Determining Special Steam Capacities

Where capacity of the unit under

standard conditions is known – 2 lbs.

steam, 60 F entering air – and it is

desired to know the capacity of this

same unit under different steam and air

conditions, follow instructions given in

Example 1 below.

Where a set of conditions is given – Btu,

temperature rise, final temperature, cfm,

steam pressure available, etc. Refer to

Example 2.

Useful Data

Btu

= Sq. ft. of radiation (EDR)

240

Sq. ft. of radiation =Lbs. of condensate

Btu

Latent heat

460 + Final temp.

460 + 70

460 + 70

460 + Final temp.

4 per hour

= Lbs. of water per hour

Example 1

Given: Model 60S Horizontal Propeller

Unit Heater with a rated capacity of

60,500 Btu at 2 lbs. steam with 60 F

entering air.

Desired: Capacity of this unit using

15 lbs. steam and 40 F entering air.

Under 40 F and across from 15 lbs. in

SP-2, page 14, we find the factor 1.34.

60,500 x 1.34 = 81,070 Btu per hour .

Equivalent Direct Radiation

If working in EDR, rather than Btu,

multiply the EDR by the same factor in

the same way. Thus:

252 (From Table 3) x 1.34 =

81,070

338 sq. ft. or

Determining Amount of Condensate

To determine the amount of condensate,

divide the capacity in BTU by the latent

heat of steam:

81,070

945

945 = Latent Heat of Steam at 15 psi.

240

= 86 lbs per hour.

(See Table SP -9, page 18.)

Determining Final Temperature

Final temperature of air leaving T rane

Unit Heaters may be determined as

follows:

Inlet Air T emp. + Btu rating = FinalTemp

Cfm at 70F x 1 .085

Inlet Air Temp. 40F + 81,070 = FinalTemp

815(from table 3) x 1 .085

Example 2:

Problem: A Trane Model S Horizontal

Unit Heater is desired to deliver 280,000

Btu per hour in a garage where

ventilation is required. Entering air

temperature is 40 F. Steam at 30 lbs.

pressure is available. Temperature to be

maintained is 70 F.

Solution: Under 40 F and across from 30

lbs. in Table SP-2 page 1 4, find the factor

1 .51.

Equivalent capacity of required unit at

2 lbs. steam 60 F entering air is

Required Btu per hour = 280,00 =185,400

F 1 .51 Btu

From Table SP -3, page 15, select a

Number 186S Unit Heater with a

capacity of 185,200 Btu per hour with

standard coil, and at 2 lbs. steam and 60

F entering air.

Cfm x Temp. rise x 1.085 = Btu.

Specific heat of air (70 F) = .241

Specific weight of one cubic foot of air

(70 F) =.075.

Cfm x 60 = cfh.

Therefore, .241 x .075 x 60 = 1 .085

The capacity of this unit at 30 lbs. steam

and 40 F entering air is

1 .51 x 1 85,200 = 279,650 Btu per hour.

Surplus Capacity

While the ventilation load is being

handled, any air entering the space over

the desired room temperature should be

considered in the heating calculations.

This surplus capacity can be found by

multiplying the difference between the

final temperature leaving the heater and

the room temperature to be maintained

by 1 .085 and that by the cfm. That

amount of heat can be used to offset

heat losses.

UH-PRC001-EN12

Page 13

Selection

Pr ocedure

Model S Nomenclature

UHS A 0 1 8 S 2 E A A 1 T A W D A D B E

123 4 5 6 7 8 9 10 11 12 13 1 4 1 5 1 6 17 18 19 20 21

Digits 1,2,3 – Product T ype

Digit 4 – Development Sequence

Digits 5,6,7 – Unit Size

Digit 8 – Coil T ype

S = Hot Water or Steam

W= Hot W ater with Turbulators

Digit 9 – Fin Series

2 = 132

8 = 108

Digit 10 – Design Sequence

Digit 1 1 – Tube Material

Digit 12 – Fin Material

Digit 13 — Voltage

Digit 14 — Motor Type

Digit 15 — Motor Mount/Fan Guar d

Digit 16 — Special Coatings

Table SP-1 – Max. Mounting Heights and Distance of Throw for Model S Units

(Based on 2 Lbs. Steam Pressure 60 F Entering Air)

Unit V elocity CFM (F) Height Diffuser Maximum Throw

18-S 162 280 117 8 12 15

20-S2 186 318 118 8 15 18

38-S 319 544 126 9 18 22

42-S 347 590 125 9 20 25

60-S 343 815 129 9 22 27

70-S 454 1 1 00 1 17 10 28 35

90-S 382 1214 127 1 1 28 35

100-S 47 6 1535 118 12 28 35

126-S 41 1 1760 126 13 32 40

168-6 452 2380 127 14 40 50

186-S 528 2808 121 14 45 56

230-S 431 3300 124 15 40 50

260-S 529 4100 118 15 50 62

320-S 442 4480 127 15 50 62

354-S 550 5660 118 15 60 75

400-S 583 6017 122 15 65 80

19-S2 220 390 106 8 18 22

31-S 359 635 104 8 20 25

45-S 363 897 107 9 25 31

53-S 439 1090 105 10 28 35

69-S 407 1337 108 12 30 37

77 -S 458 1510 107 13 32 40

91-S 394 1740 108 14 32 40

127-S 448 2440 108 15 40 50

137-S 495 2700 107 15 45 56

181-S 430 3392 109 15 42 52

207-S 514 4059 107 15 48 60

243-S 439 4607 108 15 55 68

273-S 536 5644 105 15 60 75

Outlet Temp. Mounting Without Set for

Final With Louver Fin

Maximum Throw

Digit 17 — Diffuser

Digit 18 — Manual Starter

Digit 19 — Speed Controller (1 15/60/1

standard motors)

Digit 20 — Thermostats

Digit 21 — Subbase

Digit 22 — Voltage

13UH-PRC001-EN

Page 14

Selection

Pr ocedure

Model S

Maximum mounting heights for Model

S Unit Heaters are given in Table SP-1.

When equipped with standard Louver

Fin Diffusers the distance of throw may

be increased as much as 25% by “toeing-

in” the ver tical blades.

Distance of throw

decreases in proportion to the amount of

deflection given the airstream to either

side of the heater.

Mounting the unit at or below maximum

mounting height will insure that heated

air reaches the living zone.

Model P

Maximum mounting heights for Model P

Unit Heaters are given in Table SP-1 0,

page 19. These distances are figured

from the floor line to the bottom plate of

the unit heater.

Where ceilings are unusually low, a

nearly horizontal flow of air can be

obtained by equipping these units with

Louver Cone Diffusers. The individually

adjustable blades of the Louver Cone

permit an infinite variety of adjustments

to meet any on-the-job problems. By

setting the blades vertically to straighten

the airstream, as much as 45% increase

in throw can be obtained.

Table SP-2 – Factors for Det er mining Steam Capacity of Model S Horizontal Unit Heaters at Various Pressures and Temperatures

Through 15 1.80 1 .71 1.61 1.53 1.44 1.34 1 .28 1.1 9 1.1 2 1.04 0.97 0.90

Notes:

To determine the Btu per hour capacity of a Model S Horizontal Unit Heater at any steam pressure and entering air temperature multiply rated capacity at 2 psig steam 60 F entering air (Table

SP-3) by factor from above table. Factors in italics: Units should not be operated when entering air is below freezing at steam pressures below 10 psig.

T able Based on 2 PSIG and 60 F Entering Air

Steam T emperature of Entering Air (F)

Pressure PSIG -10 0 10 20 30 40 50 60 70 80 90 100

Blow- 10

Type 20 1.86 1 .77 1.68 1.58 1.50 1.42 1 .33 1.25 1 .17 1.1 0 1.02 0.95

0

2

5

30 1.97 1.87 1.78 1.68 1.60 1.51 1 .43 1 .35 1.27 1.1 9 1.12 1.04

40 2.06 1 .96 1.86 1.77 1.68 1.60 1 .51 1.43 1 .35 1.27 1.19 1.12

50 2.13 2.04 1.94 1 .85 1.76 1.67 1.58 1.50 1 .42 1.34 1.26 1.19

60 2.20 2.09 2.00 1.90 1 .81 1.73 1.64 1 .56 1.47 1.39 1.31 1.24

70 2.26 2.16 2.06 1.96 1 .87 1.78 1.70 1 .61 1.53 1.45 1.37 1.29

75 2.28 2.18 2.09 1 .99 1.90 1.81 1 .72 1 .64 1 .55 1.47 1.40 1.32

1.54 1.45 1.37 1.27 1 .1 9

1.59 1.50 1.41 1.32 1.24

1.64 1.55 1.46 1.37 1.29

1.73 1.64 1.55 1.46 1.38

1.11 1.03 0.96 0.88 0.81 0.74 0.67

1 .16 1.08 1 .00 0.93 0.85 0.78 0.71

1.21 1.13 1 .05 0.97 0.90 0.83 0.76

1.29 1.21 1 .13 1 .06 0.98 0.91 0.84

UH-PRC001-EN14

Page 15

Selection

Pr ocedure

Table SP-3 – Model S Horizontal Unit Heat er Steam Capacities

2 Lbs. Steam 60 F Entering Air Temp

Size HP RPM P er Hour EDR Lbs Per Hr T emp Air Basis Velocity Weight

18-S 1/50

20-S2 1/50

38-S 1/20

42-S 1/20

60-S 1/20

70-S 1/8

90-S 1/8

100-S 1/8

126-S 1/6 1 100 125,700 525 130 126 1760 411 100

168-8 1/6 1100 172,000 716 178 127 2380 452 145

186-S 1/4 1 1 00 185,200 775 191 121 2808 528 145

230-S 1/4 1 100 229,700 957 237 124 3300 431 190

260-S 1/2 1 100 256,300 1070 265 118 4100 529 195

320-S 1/2 1 1 00 324,000 1350 335 127 4480 442 245

354-8 1/2 1 100 355,500 1480 368 118 5660 550 250

400-S 3/4 11 45 404,073 1684 418 122 6017 583 260

Notes:

1. Constant speed units are rated at capacities shown in regular type: Capacities in italic faced type apply only to

units with multi-speed motors.

2. Capacities based on 2 psi steam and 60 F entering air.

Motor Motor BTU Condensate Final CFM 70 F Outlet Oper.

Standard Units

1050 17,400 72 18 1 17 280 162

950 16,600 69 17 1 18 266 154 40

800 13,900 58 14 1 18 224 130

1050 20,000 84 21 118 318 186

950 19,000 79 20 120 298 173 40

800 15,500 64 17 120 250 145

1550 38,700 162 40 126 544 319

1300 35,900 150 37 130 472 279 40

1100 32,700 136 33 135 399 238

1550 41,600 174 43 125 590 347

1300 38,000 158 39 130 495 294 40

1100 34,700 145 35 136 420 251

1550 60,500 252 64 129 815 343

1300 56,000 234 58 133 706 300 55

1100 51,200 214 52 139 597 256

1550 68,200 285 70 117 1 100 454

1300 64,900 271 67 123 953 397 60

1100 59,700 248 61 128 806 339

1550 87 ,600 366 90 127 1214 382

1300 81,200 340 84 131 1053 334 75

1100 74,200 310 76 137 891 285

1550 96,000 400 99 118 1535 476

1300 91,500 380 94 123 1330 417 85

1100 84,000 350 86 128 1 126 356

15UH-PRC001-EN

Page 16

Selection

Pr ocedure

Table SP-4 – Model S Horizontal Unit Heat er Steam Capacities con’t

2 Lbs. Steam 60 F Entering Air T emp

Size HP RPM P er Hour EDR Lbs Per Hr Temp Air Basis Velocity Weight

19-S2 1/25

31-S 1/20

45-S 1/20

53-S 1/8

69-S 1/8

77-S 1/8

91-S 1/6 1 100 91,000 380 94 108 1740 394 95

127-S 1/6 1100 125,800 524 130 108 2440 448 135

137-S 1/4 1 100 135,800 567 140 107 2700 495 135

181-S 1/4 1100 180,700 755 187 109 3392 430 180

207-S 1/2 1100 206,900 863 214 107 4059 514 185

243-S 1/2 1100 238,700 995 248 108 4607 439 230

273-S 1/2 1100 272,200 1135 283 105 5644 536 235

Notes:

1. Constant speed units are rated at capacities shown in regular type: Capacities in italic faced type apply only to units with multi-speed motors.

2. Capacities based on 2 psi steam and 60 F entering air.

Motor Motor BTU Condensate Final CFM 70 F Outlet Oper.

Low Final Temp. “Bypass” Units

1050 19,300 80 20 1 06 390 220

950 18,300 77 19 1 08 360 205 40

800 16,300 68 17 11 0 300 173

1550 30,400 127 31 104 635 359

1300 27,800 116 29 109 520 302 40

1100 25,300 106 26 1 1 2 450 257

1550 45,800 191 47 107 897 363

1300 41,300 173 43 1 1 2 740 304 55

1100 37,300 156 39 116 630 259

1550 53,300 223 55 105 1090 439

1300 50,200 209 52 109 940 383 55

1100 46,200 192 48 1 14 795 327

1550 69,400 290 72 108 1337 407

1300 63,400 264 66 112 1125 346 70

1100 57,600 240 60 116 955 295

1550 76,600 320 79 107 1510 458

1300 71,700 299 74 111 1304 300 80

1100 65,800 274 68 1 1 6 1100 341

UH-PRC001-EN16

Page 17

Selection

Pr ocedure

Table SP-5 – Model P Projection Unit Heater Steam Capacities

2 Lbs. Steam 60 F Entering Air T emperature

Motor Motor BTU Condensate Final CFM 70 F CFM at Outlet Oper.

Size HP RPM Per Hour EDR Lbs Per Hr Temp. Air Basis Final Temp. Velocity Weight Lbs.

42-P 1/25 1550 41,300 172 43 124 595 660 877 30

64-P 1/20 1550 65,500 273 68 121 989 1085 1005 35

80-P 1/20 1550 80,600 336 83 122 1200 1320 1220 40

102-P 1/8 1070 101,800 424 106 123 1490 1635 980 55

122-P 1/6 1070 124,400 518 129 124 1790 1970 1170 55

146-P 1/6 1 070 152,000 633 157 123 2220 2440 1045 80

166-P 1/6 1 070 173,000 720 179 121 2620 2870 1230 80

202-P 1/4 1070 210,200 838 208 118 3200 3490 1495 85

252-P 1/4 1070 249,800 1040 260 115 4180 4550 1205 135

280-P 1/2 1070 283,800 1180 294 1 1 9 4430 4840 1275 135

336-P 3/4 1120 333,400 1390 345 1 19 5210 5690 1500 135

384-P 3/4 1120 386,000 1610 400 1 18 6140 6700 1770 175

500-P 1-1/2 1120 496,000 2070 514 117 8020 8750 1640 250

600-P 1-1/2 1120 585,000 2440 605 1 17 9450 10,300 1 930 260

720-P 3 1 120 705,000 2940 729 1 1 9 1 1,000 12,020 2250 325

42-P-L 1/25 1150 34,800 145 36 108 668 716 950 30

64-P-L 1/20 1550 57 ,200 238 59 104 1200 1280 1 1 90 35

80-P-L 1/20 1550 68,000 283 71 106 1360 1455 1350 40

102-P-L 1/8 1070 85,400 356 89 108 1640 1760 1050 55

122-P-L 1/6 1070 111,000 462 115 107 2180 2330 1390 55

146-P-L 1/6 1070 125,800 524 130 109 2360 2530 1080 80

166-P-L 1/6 1070 149,000 620 154 107 2920 3130 1340 80

202-P-L 1/4 1070 176,800 736 183 108 3390 3640 1560 85

252-P-L 1/4 1070 214,900 895 224 104 4500 4800 1270 135

280-P-L 1/2 1070 251,800 1 050 260 106 5040 5380 1420 135

336-P-L 3/4 1120 291,000 121 0 302 107 5700 6100 1610 135

384-P-L 3/4 1120 344,000 1430 356 108 6600 7080 1870 175

500-P-L 1-1/2 1120 428,000 1785 446 102 9380 9940 1860 250

600-P-L 1-1/2 1120 515,000 2140 533 106 10,300 11,000 2060 260

720-P-L 3 1 120 620,000 2580 642 108 1 1,900 12,750 2380 325

Notes:

Constant speed units are rated at capacities shown in regular type; capacities in italic faced type apply only to units with multi-speed motors.

To determine BTU per hour capacities at various steam pressures and entering air temperatures, use conversion factors from Table SP-7, page 18.

Final temperatures at new conditions can be calculated by applying basic formula.

1150 33,600 140 35 131 436 495 658

1150 52,800 220 55 129 706 785 727

1150 65,100 271 67 130 858 954 894

850 87,900 366 91 129 1 1 80 1315 783

Low Final Temperature Models - Standard Model P Units With All Air P or ts Open

1150 26,000 108 27 1 11 470 506 672

1150 45,800 191 48 109 862 925 858

1150 55,000 229 57 1 11 995 1070 992

850 71,200 296 74 111 1290 1390 827

Standard Models

Table SP-6 – Maximum Spread (Ft.)

Unit No. 42P 64P 80P 102P 122P 146P 166P 202P 252P 280P 336P 384P 500P 600P 720P

Spread (Ft.) 15 17 20 24 26 27 28 32 35 37 45 50 54 57 60

Note:

The “spread” is the diameter of the comfort zone at floor level, projected by the Model P unit without the louver cone diffuser, based on two pounds steam pressure and 60 F entering air.

17UH-PRC001-EN

Page 18

Selection

Pr ocedure

Model P Nomenclature

Digit 15 – Fan Guard

UHP A 0 4 2 P 4 C A A 1 T A R C A D B E

123 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Digits 1,2,3 – Product T ype

Digit 4 – Development Sequence

Digits 5,6,7 – Unit Size

Digit 8 – Coil T ype

Digit 9 – Fin Series

Table SP-7 – Factors F or Deter mining St eam Capacity Of Model P Projection Unit Heat ers At Various Pressures And Temperatur es

Note:

To determine the Btu per hour capacity of a Model P projection unit heater at any steam pressure and entering air temperature, multiply rated capacity at 2 psig steam 60 F entering air (Table

SP-5) by factor from above table.

T able Based on 2 PSIG and 60 F Entering Air

Steam T emperature of Entering Air (F)

Pressure PSIG -10 0 10 20 30 40 50 60 70 80 90 100

0 1.49 1 .41 1.33 1.25 1.18 1 .11 1.03 0.96 0.90 0.83 0.76 0.69

2 1.52 1 .45 1.37 1.29 1.22 1.15 1 .07 1.00 0.93 0.86 0.80 0.73

5 1.58 1. 50 1.42 1.34 1.27 1.20 1.12 1.05 0.98 0.91 0.85 0.78

Draw- 15 1 .70 1.62 1.55 1.47 1.40 1.32 1 .25 1 .18 1.11 1.04 0.97 0.90

Through 20 1.75 1 .67 1.60 1.52 1.45 1.37 1 .30 1.23 1.16 1 .09 1.02 0.96

Unit 30 1.83 1.75 1.68 1 .61 1.53 1.46 1.39 1.32 1 .25 1.18 1.11 1.04

10 1.64 1 .57 1.49 1.41 1.34 1.27 1 .1 9 1.12 1 .05 0.98 0.91 0.85

40 1.90 1.82 1.75 1.68 1.61 1.53 1 .46 1.39 1.32 1.25 1.18 1.11

50 1.96 1.87 1.81 1.74 1.67 1.59 1 .52 1.45 1.38 1.31 1.24 1 .17

60 2.02 1 .94 1.87 1.79 1.72 1.64 1 .57 1.50 1.43 1 .36 1.29 1.22

70 2.07 1 .99 1.92 1.84 1 .7 6 1.69 1.62 1.55 1 .47 1.40 1.33 1.27

75 2.10 2.02 1.94 1 .86 1.79 1.71 1.64 1.57 1 .49 1.42 1.36 1.29

Digit 10 – Design Sequence

Digit 1 1 – Tube Material

Digit 12 – Fin Material

Digit 13 – Voltage

Digit 14 – Motor T ype

Digit 16 – Unit Coating

Digit 17 – Diffuser

Digit 18 – Manual Starter

Digit 19 – Speed Controller (1 15/60/1

standard motors)

Digit 20 – Thermostats

Digit 21 – Subbase

Additional Selection Da ta

Motor and Fan Speeds

Motor and fan speeds are selected to

provide efficient performance. The

solid-state speed control will provide an

infinite number of speeds between the

highest and the lowest cataloged fan

speeds. The speed control is not

calibrated in specific fan speeds. For use

on units with 115 volt/60 cycle/

1 phase, 1/8 hp and smaller standard

motors only.

Standard and Bypass Units

Standard models meet most

requirements and are most economical.

Bypass units meet conditions as

mentioned above, and are also used

where low final temperature is specified.

25 and 50 Cycle Unit Heat Capacities

Table SP-8 shows the Btu, cfm, and the

hp required on unit heaters when

operated on 25 or 50 cycle circuits.

The multipliers in T able SP-8 may be

applied to standard 60 cycle unit

capacities to determine the capacities of

the same unit when operating on

25 or 50 cycle current. These multipliers

may be used on units cataloged at

1050 to 1150 RPM.

For the smaller T rane Unit Heaters

cataloged at 1550 RPM, the capacity data

in the catalog may be applied to either

25 or 50 cycle service.

Table SP-8 – Factors for Det er mining Unit

Heater Capacities at 25 or 50 Cycles

RPM 60-Cycle 11 00 RPM Ratings

25 CY 50 CY BTU CFM HP

1425 1425 1.17 1 .2 5 1 .9 5

710 710 .7 .623 .242

Table SP-9 – Properties of Steam

950 .87 .833 .572

Gauge Pressure Temp. Latent

Lbs. F Heat

2 219 965

5 227 960

10 239 952

15 250 945

20 259 939

25 267 933

30 274 928

40 287 919

50 298 911

60 307 904

70 316 897

75 320 891

Multiplier T o Be Applied To

UH-PRC001-EN18

Page 19

Selection

Pr ocedure

Table SP-10 - Maximum Mounting Heights in F eet f or Model P Unit Heaters

with and without Louver Cone Diffuser

Unit Steam Pressure (PSI)

Size 2 5 10 50 75

42-P 10.5 10.0 10.0 9.0 8.0

42-P LS* 8.0 8.0 8.0 8.0 8.0

42-P-L** 12.5 12.0 12.0 10.5 9.5

42-P-L LS 9.0 8.5 8.5 8.0 8.0

64-P 12.0 11.5 11.5 10.0 9.5

64-P LS 9. 5 9.0 9.0 8.0 8.0

64-P-L 15.0 14.5 14.5 12.5 12.0

64-P-L LS 1 1.5 11.0 11.0 9.5 8.0

80-P 15.0 14.5 14.0 12.0 4.5

80-P LS 11.0 10.5 10.5 9.0 8.5

80-P-L 18.0 17.5 17.5 15.0 14.0

80-P-L LS 13.0 12.5 12.0 11.0 10.5

102-P 14.0 13.5 13.0 11.5 11.0

102-P LS 11.0 10.5 10.5 9.5 9.0

102-P-L 17.5 17 .0 16.5 15.0 14.5

102-P-L LS 15.0 14.5 14.5 13.0 12.5

122-P 16.0 15.5 15.5 14.0 13.5

122-P-L 21.0 20.5 20.0 17.5 17.0

146-P 15.5 15.0 14.5 13.0 12.0

Notes:

*LS = Low speed.

**PL = Model P low final temperature model with all air ports open.

Figures in bold face show maximum mounting height with louver cone diffusers set vertically.

To meet CSA and OSHA requirements, Model P Unit Heaters mounted lower than 8.0 ft. from the floor must be equipped with

an OSHA fan guard. Above table based on 60 F entering air temperature. In providing for the use of diffusers, it must be

remembered that adjustment of a LCD to deflect air toward horizontal immediately lowers the mounting height limit.

12.5 12.0 12.0 11.0 10.0

9.0 8.5 8.5 8.0 8.0

14.5 14.0 13.5 12.0 11.5

10.5 10.0 10.0 9.0 8.5

14.5 14.0 14.0 12.0 11.5

1 1.5 11.0 11.0 9.5 9.0

19.0 18.5 18.5 16.5 16.0

14.0 13.5 13.5 12.0 11.5

18.5 18.0 17.5 15.5 13.5

13.5 13.0 13.0 11.5 11.0

22.0 21 .0 21.0 19.0 18.0

17.0 16.5 16.0 14.0 13.5

17.0 16.5 16.0 14.0 13.5

13.5 13.0 13.0 12.0 11.5

21 .5 21.0 20.5 18.5 17.5

18.5 18.0 18.0 16.0 15.0

19.5 19.0 18.5 17.0 16.0

26.0 25.5 25.0 22.5 21.5

19.0 18.5 18.0 16.0 15.5

Unit Steam Pressure (PSI)

Size 2 5 10 50 75

146-P-L 18.0 17.5 1 7.5 15.0 14.0

166-P 18.0 17.5 1 7.0 14.5 14.0

166-P-L 22.0 21.5 21 .0 18.5 17 .5

202-P 22.0 21.5 21.0 18.5 17.5

202-P-L 25.5 250 24.5 22.0 21.0

252-P 20.0 19.5 19.0 17 .0 16.0

252-P-L 24.0 23.5 23.0 20.0 19.0

280-P 21.0 20.5 20.0 17.5 17.0

280-P-L 25.5 25.0 24.5 21.0 20.0

336-P 24.0 23.0 22.0 20.0 19.0

336-P-L 29.0 28.5 28.0 25.0 24.0

384-P 28.5 28.0 27.5 24.0 23.0

384-P-L 32.5 31.5 30.5 27.5 26.5

500-P 29.5 29.0 28.5 25.0 24.0

500-P-L 35.0 34.0 33.0 29.0 28.0

600-P 34.0 33.0 32.0 28.0 27.0

600-P-L 37.0 36.0 35.0 31.0 30.0

720-P 38.5 37.5 36.5 32.0 30.5

720-P-L 42.5 41.5 40.5 35.0 33.5

22.5 22.0 21.5 18.5 18.0

22.5 22.0 21.5 19.0 18.0

27.5 27.0 26.5 23.5 22.5

27.5 27.0 26.5 24.0 23.0

31 .5 31.0 30.5 27.0 26.0

25.0 24.0 23.5 20.5 19.5

29.5 28.5 28.0 24.5 23.5

26.0 25.5 25.0 22.0 21.0

32.0 31 .0 30.0 26.0 25.0

30.0 29.0 28.0 25.0 24.0

36.0 35.0 34.0 30.0 29.0

35.5 35.0 34.0 30.0 29.0

41 .0 40.0 39.0 35.0 33.5

36.5 36.0 35.5 32.0 30.5

43.5 42.5 41.5 35.0 34.0

42.5 41 .5 40.5 36.0 34.5

46.5 45.5 44.5 39.0 37.0

48.0 47 .0 46.0 40.0 39.0

53.0 52.0 51.0 44.0 42.0

Hot W ater Selection Example

Selection Procedure

Select the proper size of unit heater for

whatever application desired, as

illustrated by the following examples.

Example 1:

Select a Model S horizontal unit heater to

deliver 95 MBH with 220°F entering

water temperature (EWT), 70°F entering

air temperature (EA T) and a 30°F water

temperature drop (WTD).

Step 1 .

Determine GPM:

Btu/hr = 95000 = 6.53

GPM =

Step 2.

Refer to Table SP -11 to select the

conversion factor at 220° EWT and 70°

EA T. Factor is 1.058.

Step 3.

Determine equivalent MBH at standard

conditions (200° EWT, 60° EAT).

Equiv. MBH =

Step 4.

Select unit size by entering the hot water

tables at the 200 °F EWT column. Select

the unit which will provide 89.8 MBH at

6.53 GPM. In this example, the selection

indicates a Model S

from Table PD-2, page 28.

To determine the actual capacity of this

Model S

(220° EWT and 70° EA T) proceed as

follows.

(485) WTD 485 x 30

MBH = 95 = 89.8

Factor 1 .058

126W2 unit heater,

126W2 at operating conditions

Step 1 .

Determine the MBH at 6.53 GPM by

interpolation in the 200° column. (In this

90.8 MBH.) Multiply this MBH by the

case

conversion factor 90.8 MBH x 1 .058 = 96

MBH.

Step 2.

The GPM remains constant = 6.53 GPM.

Step 3.

Calculate the water temperature drop

WTD =

Btu/hr = 96000 = 30.3

GPM x 485 (6.53) (485)

19UH-PRC001-EN

Page 20

Selection

Pr ocedure

Step 4.

Determine the pressure drop at 6.53

GPM. Pressure drops are cataloged for

both standard wall (SWT) and heavy

wall. (HWT) tube coils. In this example, if

a SWT coil is selected the pressure drop,

by interpolation is

2.38 feet of water.

Example 2

Determine the capacity of a Model 336P

unit heater operating at 180° (EWT), 100°

(EA T) and 15° (WTD).

Step 1 .

Find conversion factor (in T able SP-11)

= 0.546

Step 4.

WTD = 27.5 x 0.546 = 15°

Step 5.

Btu/hr =123,000

GPM =

485xWTD (485)(15)

Step 6.

= 16.9

Pressure drop interpolated at 27.5° WTD

Step 5.

Calculate the final air temperature

F.T. = E.A.T. +

= 70 +

Btu/hr

CFM x 1 .085

96000 =

1661 x 1.085

70 + 53.2 = 123.2°

Step 2.

Adjust the water temperature drop

Adj. WTD =

15

.546

= 27.5°

Step 3.

Multiply the MBH (interpolated) at

27.5° WTD, 200° EWT and 60° EAT by the

factor to obtain the MBH at desired

for a SWT coil is 1 .82 feet of water.

Step 7.

Calculate final temperature

F.T. = E.A.T. +

= 100° +

Btu/hr

CFM x 1.085

123,000

5210 x 1.085

= 121 .8°

conditions.

Note:

If a constant water temperature drop is desired, apply the conversion factor to the WTD and to the desired MBH and enter 200° EWT column at these conditions. Select the unit which will

provide the equivalent MBH at the adjusted WTD. The GPM can then be interpolated from the table at the adjusted WTD. To determine the actual capacity at operating conditions proceed as

outlined in example #2.

If a constant GPM is desired, enter the 200° EWT column at the given or calculated GPM. Select the unit which will provide the equivalent MBH at this GPM. To determine the actual capacity

at operating conditions in this case proceed as outlined in example #1.

Table SP-1 1 – Unit Heater Hot Water Con version Factors (Applies To Tables PD-1 - PD-5)

Ent.

Air Entering Water T emperature

T emp. 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 340 350 360 370 380 390 400

30 .962 1 .036 1.110 1 .182 1.259 1.331 1.408 1.482 1.554 1 .627 1.702 1 .780 1.850 1.925 2.000 2.070 2.142 2.220 2.295 2.370 2.440 2.515 2.590 2.660 2.735

40 .880 .954 1 .024 1.100 1 .171 1.249 1 .318 1.391 1.468 1.539 1.612 1 .686 1.759 1.831 1.909 1.976 2.048 2.120 2.193 2.268 2.348 2.417 2.488 2.560 2.632

50 .795 .869 .940 1.011 1.085 1.158 1.230 1.301 1 .37 4 1.448 1.520 1 .590 1.664 1 .735 1.809 1 .882 1.953 2.024 2.095 2.168 2.242 2.312 2.388 2.459 2.530

60 .715 .785 .859 .929 1.000 1.071 1.141 1 .215 1.285 1 .359 1.429 1.500 1.571 1.642 1 .715 1.785 1 .858 1.930 2.000 2.070 2.140 2.215 2.285 2.360 2.430

70 .634 .704 .774 .845 .917 .988 1.058 1.129 1.200 1.270 1.340 1.41 0 1.482 1.552 1 .622 1.694 1.764 1.838 1.907 1.976 2.045 2.116 2.188 2.258 2.332

80 .568 .628 .698 .768 .838 .908 .978 1.048 1.118 1.188 1.258 1 .328 1.398 1 .468 1.538 1.604 1.674 1.742 1 .815 1.884 1 .952 2.020 2.091 2.162 2.230

90 .484 .552 .622 .690 .760 .829 .898 .967 1 .036 1.106 1 .173 1.244 1 .311 1.380 1.450 1.515 1.585 1.655 1.723 1.795 1.862 1.930 1.998 2.067 2.137

100 .410 .478 .546 .615 .684 .753 .820 .889 .957 1.025 1 .095 1.161 1.230 1.300 1.368 1 .433 1.499 1 .569 1.638 1.705 1.776 1.843 1.91 0 1.977 2.046

Apply to the 200 F entering water capacities only.

0.546 x 224.9 = 123.0 MBH

Corr ection F actors for Pr opylene

Glycol/W ater

When sizing equipment for systems that

will utilize a propylene glycol solution,

consider the following factors:

1 . Heat transfer @1 80F with no increase

in flow rate

Propylene

Glycol

20% solution .97*

50% solution .90*

Table SP-12 – Trane Unit Heater Nomenclature (Applies T o Tables PD-1 - PD-5)

Abbreviations Definitions

MBH 1000 BTU Per Hour

GPM Gallons Per Minute

FT Final Temperature °F

PD-S.W.T. Feet Of Water Pressure Drop - Standard Wall Tubes.

PD-H.W.T Feet Of Water Pressure Drop - Heavy Wall Tubes

Propylene

2. GPM required @180F, Glycol

20°D (no correction to

pump curve) 1 .10%

3. Pump head required

7. pH@50% by volume. 9.5

8. Freezing Point 55% by volume —

@180F w/increase in

GPM 1 .23%*

4. Specific gravity

(water = 1.0) 1 .045-1.055*

**Compared to water

5. Pounds/Gallons@60F

(water = 8.3453

Pounds/Gallons) 8.77

Propylene

Glycol

50% -28F

40% -13F

30% +28F

20% +17F

UH-PRC001-EN20

Page 21

Model Number Description

MODEL P UNIT HEATER

UHP A 0 4 2 P 4 C A A 1 T A R C A D B E

123 4 5 6 7 8 9 10 11 12 1 3 1 4 1 5 1 6 17 18 19 20 21

Digits 1,2,3 — Product Type

UHP

Digit 4 — Development Sequence

A

Digits 5,6,7 — Unit Size

042

064

080

102

122

146

166

202

252

280

336

384

500

600

720

Digit 8 — Coil T ype

P = Steam or Hot W ater*

Digit 9 — Fin Series

4 = 144*

Digit 10 — Design Sequence

C

Digit 1 1 — Tube Material

A = Copper*

C = Red Brass

F = Steel

Digit 12 — Fin Material

A = Aluminum*

C = Copper

Digit 13 — Voltage

1 = 1 1 5/60/1*

2 = 208/60/3

3 = 230/60/3

4 = 460/60/3

5 = 575/60/3 (T otally Enclosed)

Digit 14 — Motor Type

T = T otally Enclosed*

E = Explosion Proof

Digit 15 — Fan Guard

0 = Standard*

A = OSHA Guard**

Digit 16 — Unit Coating

0 = None

R = Epoxy

T = Epoxy Phenollic

W = Baked Phenolic

Digit 17 — Diffuser

0 = None

A = Fin Diffuser

C = Fin Diffuser w/coating

Digit 18 — Manual Starter

0 = None

A = Manual Starter w/o overload protection

Digit 19 — Speed Controller (115/60/1

standard motors)

0 = None

D = Solid-State Speed Controller

(only available up to unit size 102)

Digit 20 — Thermostats

0 = None

B = Light-Duty T -stat

C = Heavy-Duty T -stat

Digit 21 — Subbase

0 = None

E = Light-Duty

F = Heavy-Duty

Motors

Standard motors are 1 1 5/60/1, totally

enclosed, with thermal overload

protection for all units through size 280P.

Standard motors for 42P, 64P and 80P

are standard pole, sleeve bearing. The

102P motor is permanent split capacitor

type with sleeve bearings. Motor for unit

sizes 122P through 280P are permanent

split capacitor type with permanently

lubricated ball bearings. Motors used on

unit sizes 336P through 720P are 230/460/

60/3, totally enclosed, with permanently

lubricated ball bearings. Unit sizes

smaller than 336P are also available with

230/460/60/3 motors.

All motors, fractional hp and integral hp,

have Class “B” insulation. The 115/60/1

motors used as standard on unit sizes

42P through 102P can be operated at

multiple speeds with the addition of a

solid-state control.

All units available with explosion-proof

motors.

* Standard features of stock vertical heaters.

**For the 3-phase and explosion-proof motors, the OSHA

guard ships separately.

21UH-PRC001-EN

Page 22

Model

Number

Description

MODEL S UNIT HEA TER

UHS A 0 1 8 S 2 E A A 1 T A W D A D B E

123 4 5 6 7 8 9 10 11 12 1 3 1 4 1 5 16 17 18 1 9 20 21

Digits 1,2,3 — Product Type

UHS

Digit 4— Development Sequence

A

Digits 5,6,7 — Unit Size

Standard Modified

018 019

020 031

038 045

042 053

060 069

070 077

090 091

100 127

126 137

168 181

186 207

230 243

260 273

320

354

400

Digit 8 — Coil T ype

S = Steam or Hot W ater*

W = Hot W ater (Adds a Spiral)

Digit 9 — Fin Series

2 = 132

8 = 108**

DIGIT 10 — Design Sequence

E

Digit 1 1 — Tube Material

A = Copper*

C = Red Brass

F = Steel

Digit 12 — Fin Material

A = Aluminum*

C = Copper

Digit 13 — Voltage

1 = 1 15/60/1*

2 = 208/60/3

3 = 230/60/3

4 = 460/60/3

5 = 575/60/3 (T otally Enclosed)

Digit 14 — Motor T ype

T = T otally Enclosed*

E = Explosion Proof

Digit 15 — Motor Mount/Fan Guar d

0 = Standard**

A = OSHA Fan Guard/Motor Mount (1 15 v olt

totally enclosed motors ONL Y)

B = Standard Fan Guard with Motor Base (3

phase or explosion proof motors ONL Y)

Digit 16 — Special Coatings

0 = No Special Coatings

R = Epoxy Coating

T = Epoxy Phenolic Coating

W = Baked Phenolic Coating

Digit 17 — Diffuser

0 = None

B = Fin Diffuser

D = Fin Diffuser w/coating

Digit 18 — Manual Starter

0 = None

A = Manual Starter w/o overload protection

(Single Phase Only)

Digit 19 — Speed Controller (1 15/60/1

standard motors)

0 = None

D = Solid-State Speed Controller

(only available up to unit size 100)

Digit 20 — Thermostats

0 = None

B = Light-Duty T -stat

C = Heavy-Duty T -stat

Motors

Totally enclosed, 11 5/60/1 Class “B”

insulated, shaded pole and PSC motors

are STD. 1/25 through 1/8 hp are sleeve

bearing. 1/6 through 3/4 hp are ball

bearing. All single phase motors have

built-in overload protection. Sleeve

bearing motors can be oiled. Ball

bearing motors are permanently

lubricated. The

115/60/1 motors used as standard on unit

sizes 18S through 1 00S can be operated

at multiple speeds with the addition of a

solid-state control.

All units available with explosion-proof

motors.

*Standard features of stock horizontal unit heaters.

**Units equipped with 115 volt totally enclosed motors

come with a standard fan guard/motor mount. Units

equipped with 3 phase or explosion proof motors come

with no guard and the motors are base mounted.

Digit 21 — Subbase

0 = None

E = Light-Duty

F = Heavy-Duty

UH-PRC001-EN22

Page 23

P erformance Data

Table PD-1 – Model S Unit Heater Hot Water Capacities – 60°F Ent. Air Temp.

(Conversion Factors in Table SP-11 Apply Only to 200 F Entering Water Temperature Columns)

Water 180 F 200 F 220 F 240 F

Unit T emp. PD PD PD PD PD PD PD PD

Size Drop °F MBH GPM FT S.W.T. H.W.T. MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T.

18-S 5 9.9 4.07 92.4 .17 .21 12.0 4.94 99.4 .24 .28 14.1 5.81 106.4 .31 .37 16.2 6.69 1 13.3 .39 .47

CFM 280 10 7.0 1.45 83.1 .03 .03 9.2 1.89 90.1 .04 .05 1 1.3 2.32 97.0 .06 .07 13.4 2.76 104.0 .08 .10

RPM 1075 15 4.2 .58 73.8 .01 .01 6.3 .87 80.8 .01 .01 8.4 1.16 87.7 .02 .02 10.6 1.45 94.7 .03 .03

HP 1/50

20-S2 5 1 1.8 4.86 94.5 .24 .28 14.3 5.90 101.9 .33 .39 16.9 6.95 109.4 .43 51 19.4 8.00 116.8 .54 .64

CFM 315 10 8.3 1.71 84.2 .04 .04 10.8 2.23 91.7 .06 .07 13.4 2.76 99.1 .08 .10 15.9 3.28 106.6 .1 1 .13

RPM 1075 15 4.8 .66 74.0 .0 1 .01 7 .3 1.01 81 .5 .0 1 .02 9.9 1.36 88.9 .02 .03 12.4 1 .71 96.4 .04 .04

HP 1/50

38-S 10 21.4 4.42 96.4 .28 .33 26.2 5.40 104.5 .38 .46 31.0 6.38 112.5 .51 .61 35.7 7.36 120.6 .64 .77

CFM 543 15 17.9 2.46 90.3 .10 .12 22.6 3.11 98.4 .14 .17 27 .4 3.76 106.5 .20 .24 32.2 4.42 11 4.6 26 .31

RPM 1550 20 14.3 1.47 84.3 .04 .05 19.1 1.97 92.4 .06 .08 23.8 2.46100.5 .09 .11 28.6 2.95 108.5 .13 .15

HP 1/20 25 10.8 .89 78.2 .02 .02 15.5 1.28 86.3 .03 .04 20.3 1.67 94.4 .05 .06 25.0 2.06 102.5 .07 .08

42-S 10 22.5 4.64 95.1 .30 .36 27.5 5.67 102.9 .42 .50 32.5 6.69 110.7 .55 .66 37 .5 7.72 118.4 .70 .84

CFM 591 15 18.8 2.58 89.3 .11 .13 23.8 3.26 97.1 .16 .19 28.8 3.95 104.8 .22 .26 33.7 4.64 1 1 2.6 28 .34

RPM 1550 20 15.0 1.55 83.5 .04 .05 20.0 2.06 91.2 .07 .09 25.0 2.58 99.0 .10 .12 30.0 3.09 106.8 .14 .17

HP 1/20 25 11.3 .93 77.6 .02 .02 16.3 1.34 85.4 .03 .04 21.3 1.7 6 93.2 .05 .06 26.3 2.17 101.0 07 .09

60-S 10 35.2 7.25 99.8 .83 1.00 42.3 8.72 107.8 1 .12 1.34 49.5 1 0.1 9 115.9 1.45 1.7 4 56.6 11.67 124.0 1.81 2.17

CFM 815 15 31 .3 4.30 95.4 .33 .40 38.4 5.28 103.5 .46 .55 45.6 6.26 111.6 .62 .74 52.7 7.25 11 9.6 .78 .94

RPM 1550 20 27.4 2.83 91.0 .16 .19 34.6 3.56 99.1 .23 .28 41 .7 4.30 107.2 .32 .38 48.9 5.04 115.3 .41 .49

HP 1/20 25 23.6 1.94 86.7 .08 .10 30.7 2.53 94.7 .13 .15 37.9 3.12 102.8 .18 .22 45.0 3.71 11 0.9 .24 .29

70-S 15 36.6 5.03 90.7 .44 .52 45.0 6.18 97.7 .61 .73 53.3 7.33 104.7 .81 .97 61 .7 8.48 1 11.7 1.03 1.24

CFM 1100 20 32.1 3.30 86.9 .21 .25 40.4 4.17 93.9 .30 .36 48.8 5.03100.9 .42 .50 57.2 5.89 107.9 .54 .65

RPM 1550 25 27 .5 2.27 83.0 .11 .13 35.9 2.96 90.1 .17 .20 44.3 3.65 97.1 .24 .28 52.6 4.34 104.1 .32 .38

HP 1/8 30 23.0 1.58 79.2 .06 .07 31.3 2.15 86.2 .1 0 .1 1 39.7 2.73 93.3 .14 .17 48.1 3.30 100.3 .20 .23

90-S 20 45.3 4.67 94.4 .47 .56 55.7 5.74 102.3 .65 .78 66.1 6.81 1 10.2 .86 1.03 76.5 7.88 118.1 1.10 1.32

CFM 1214 25 41.0 3.38 91.1 .26 .32 51.4 4.24 99.0 .38 .45 61.8 5.09 106.9 .52 .62 72.2 5.95 1 1 4.8 .67 .80

RPM 1550 30 36.7 2.52 87.9 .16 .19 47.1 3.24 95.8 .24 .28 57.5 3.95 103.7 .33 .40 67.9 4.67 111.6 .44 .52

HP 1/8 40 28.1 1.45 81 .3 .06 .07 38.5 1.98 89.2 .10 .12 48.9 2.52 97.1 .15 .18 59.3 3.06 105.0 .21 .25

100-S 20 50.8 5.23 90.5 .57 .68 62.5 6.44 97.5 .80 .95 74.2 7 .65104.6 1.06 1.27 86.0 8.86 111.6 1.35 1.62

CFM 1535 25 45.9 3.78 87.5 .32 .39 57.6 4.75 94.6 .47 .56 69.3 5.72 101 .6 .63 .76 81.1 6.68 108.7 .82 .98

RPM 1550 30 41.0 2.82 84.6 .19 .23 52.7 3.62 91.6 .29 .35 64.4 4.43 98.7 .40 .48 76.2 5.23 105.7 .53 .64

HP 1/8 40 31.2 1.61 78.7 .07 .09 42.9 2.21 85.8 .12 .15 54.6 2.82 92.8 .18 .22 66.4 3.42 99.9 .25 .30

126-S 20 69.8 7.20 96.6 1.23 1.47 84.9 8.74104.4 1.68 2.01 99.9 10.29112.3 2.20 2.64 1 14.9 11.84120.2 2.77 3.32

CFM 1760 25 64.8 5.34 93.9 .73 .87 79.8 6.58 101.8 1.02 1.22 94.8 7.82 109.6 1.36 1.62 109.8 9.05 1 17.5 1 .73 2.07

RPM 1 100 30 59.7 4.10 91.3 .46 .55 74.7 5.13 99.1 .66 .79 89.7 6.16 107.0 .89 1.07 104.7 7 .20 114.9 1.15 1.38

HP 1/6 40 49.5 2.55 85.9 .20 .24 64.6 3.33 93.8 .31 .37 79.6 4.10 10 1.7 .44 .52 94.6 4.87 109.5 .58 .70

5 25.0 10.30 102.4 1 .23 1.48 29.8 12.27 11 0.5 1.64 1 .96 34.5 14.23 11 8.6 2.09 2.50 39.3 16.19 126.7 2.58 3.09

30 ———— —11.9 .82 80.3 .01 .02 16.7 1.15 88.4 .02 .03 21.5 1.47 96.4 .04 .06

5 26.2 10.81 100.9 1.34 1.61 31.2 12.87 108.7 1.78 2.13 36.2 14.93 116.5 2.28 2.72 41.2 16.98 124.3 2.81 3.36

30 ———— — 1 2.6 .86 79.6 .02 .02 17.6 1.21 87.4 .03 .03 22.6 1.55 95.2 .04 .05

5 39.0 16.09 104.1 3.40 4.07 46.2 19.03 112.2 4.46 5.33 5.33 21.98 120.3 5.65 6.76 —————

30 19.7 1.35 82.3 .04 .05 26.9 1.84 90.4 .07 .09 34.0 2.34 98.5 .1 1 .13 41 .1 2.83 106.5 .15 .18

40 12.0 .62 73.5 .01 .01 19.1 .99 81.6 .02 .03 26.3 1.35 89.7 .04 .05 33.4 1.72 97 .8 .06 .07

5 45.7 18.84 98.3 4.49 5.38 54.1 22.29 105.3 5.90 7.06 ————— —————

10 41.1 8.48 94.5 1.10 1.32 49.5 10.21 101.5 1.48 1.77 57.9 11.93 108.5 1.92 2.30 66.3 13.66 115.5 2.40 2.87

40 13.9 .71 71 .6 .01 .02 22.2 1.15 78.6 .03 .04 30.6 1.58 85.6 .05 .06 39.0 2.01 92.7 .08 .10

10 53.9 1 1.10 100.9 2.14 2.56 64.3 13.25 108.8 2.84 3.40 74.7 15.39 11 6.7 3.64 4.36 85.1 17.54 124.6 4.50 5.39

15 49.6 6.81 97.6 .91 1.08 60.0 8.24 105.5 1.23 1.47 70.4 9.67 113.4 1.60 1.92 80.8 11.10 121 .3 2.01 2.40

50 19.5 .80 7 4.8 .02 .03 29.9 1.23 82.7 .04 .05 40.3 1.66 90.6 .07 .09 50.7 2.09 98.5 .11 .13

10 60.6 12.48 96.4 2.63 3.15 72.3 14.90 103.4 3.50 4.19 84.0 17 .32 1 10.5 4.49 5.37 95.8 19.7 4 117.5 5.55 6.64

15 55.7 7.65 93.4 1 .11 1.33 67.4 9.26 100.5 1.51 1.81 79.1 10.87 107.5 1 .97 2.36 90.9 12.48 114.6 2.47 2.96

50 21.4 .88 72.8 .03 .03 33.1 1.37 79.9 .05 .06 44.8 1.85 86.9 .09 .10 56.6 2.33 94.0 .13 .15

60 ———— —23.3 .80 74.0 .02 .02 35.0 1.20 81.0 .04 .05 46.8 1.61 88.1 .07 .08

10 80.0 16.48 101.9 5.29 6.33 95.0 19.58 109.7 6.97 8.34 110.0 22.68 117.6 8.88 10.62 —————

15 74.9 10.29 99.2 2.31 2.76 89.9 12.36 107.1 3.09 3.70 104.9 14.42 11 5.0 3.99 4.78 120.0 16.48 122.8 4.97 5.95

50 39.4 1.62 80.6 .09 .11 54.4 2.24 88.5 .15 .19 69.4 2.86 96.4 .23 .28 84.4 3.48 104.2 .32 .39

60 29.2 1.00 75.3 .04 .05 44.3 1.52 83.2 .08 .09 59.3 2.04 91.0 .13 .15 74.3 2.55 98.9 .19 .22

Entering Water T emperature

23UH-PRC001-EN

Page 24

P erformance

Data

Table PD-1 (Continued) — Model S Unit Heater Hot Water Capacities – 60°F Ent. Air Temp.

(Conversion Factors in Table SP-1 1 Apply Only to 200 F Entering Water Temperature Columns)

Water 180 F 200 F 220 F 240 F

Unit T emp. PD PD PD PD PD PD PD PD

Size Drop °F MBH GPM FT S.W.T. H.W.T. MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T.

168-S 25 89.6 7.38 94.7 1 .51 1 .81 109.4 9.02 102.4 2.08 2.48 129.3 10.66 110.0 2.7 4 3.28 149.1 12.29 117.7 3.47 4.15

CFM 2381 30 83.6 5.75 92.4 .97 1 .1 7 103.5 7.11 100.1 1.37 1.63 123.4 8.47 107.7 1.83 2.19 143.2 9.84 115.4 2.34 2.80

RPM 1100 40 71.8 3.70 87.8 .45 .54 91.7 4.72 95.5 .67 .80 111.5 5.75 103.2 .92 1 .11 131 .4 6.77 11 0.9 1.21 1.45

HP 1/6 50 60.0 2.47 83.2 .22 .27 79.8 3.29 90.9 .36 .43 99.7 4.11 98.6 .51 .61 119.5 4.93 106.3 .69 .83

186-S 25 97.5 8.04 92.0 1.76 2.10 11 9.1 9.81 99.1 2.41 2.88 140.6 11.59 106.1 3.18 3.80 162.1 13.36 113.2 4.02 4.81

CFM 2808 30 91.2 6.27 89.9 1 .14 1.36 112.7 7.74 97 .0 1 .59 1.90 134.3 9.22 104.1 2.13 2.54 155.8 10.70 111.1 2.72 3.25

RPM 1100 40 78.6 4.05 85.8 .53 .63 100.1 5.16 92.8 .78 .93 121.6 6.27 99.9 1.08 1 .29 143.1 7.37 107.0 1.41 1.69

HP 1/4 50 65.9 2.72 81.6 .26 .32 87.4 3.60 88.7 .42 .50 109.0 4.49 95.8 .60 .72 130.5 5.38 102.8 .81 .97

230-S 25 123.6 10.1 9 94.5 .63 .75 152.2 12.54 102.5 .88 1.05 180.7 14.90 11 0. 5 1 .17 1.40 209.3 17.25 118.5 1 .4 9 1 .7 8

CFM 3299 30 114.1 7.84 91.9 .40 .47 142.6 9.80 99.8 .57 .68 171.2 11.76 107.8 .77 .92 199.7 13.72 115.8 .99 1.19

RPM 1100 40 95.0 4.89 86.5 .17 .21 123.5 6.36 94.5 .27 .32 152.1 7.84 102.5 .38 .45 180.6 9.31 110.5 .50 .60

HP 1/4 50 75.8 3.13 81.2 .08 .10 104.4 4.30 89.2 .13 .16 133.0 5.48 97.1 .20 .24 161.5 6.66 105.1 .28 .33

260-S 25 138.0 11.38 91.0 .76 .92 170.2 14.03 98.3 1.07 1. 28 202.3 16.68 105.5 1.42 1 . 70 234.5 19.33 112.7 1.82 2.17

CFM 4099 30 127.1 8.73 88.6 .48 .58 159.2 10.94 95.8 .69 .82 191.4 13.15 103.0 .94 1.12 223.5 15.35 1 10.3 1 .21 1.45

RPM 1100 40 105.1 5.42 83.6 .21 .25 137.3 7 .07 90.9 .32 .38 169.4 8.73 98.1 .46 .55 201.6 10.39 105.3 .61 .73

HP 1/2 50 83.2 3.43 78.7 .09 .11 115.3 4.75 85.9 .16 .19 147.5 6.08 93.2 .24 .29 179.6 7.40 100.4 .34 .40

320-S 30 171 .7 1 1.79 95.3 .97 1.16 211.6 14.54 103.5 1.34 1 . 61 251 .6 17.28 111 .7 1.79 2.15 291.5 20.03 120.0 2.29 2.74

CFM 4481 40 149.0 7 .68 90.6 .46 .55 189.0 9.74 98.9 .67 .80 228.9 11.79 107.1 .92 1.10 268.9 13.85 115.3 1.20 1.43

RPM 1100 50 126.3 5.21 86.0 .23 .28 166.3 6.85 94.2 .36 .43 206.2 8.50 102.4 .52 .62 246.2 10.15 110.6 .69 .83

HP 1/2 60 103.7 3.56 81.3 .12 .14 143.6 4.93 89.5 .20 .24 183.6 6.31 97.8 .30 .36 223.5 7.68 106.0 .42 .51

354-S 30 193.7 13.31 91.5 1 .20 1 .43 239.0 16.42 98.9 1 . 67 1 . 99 284.2 19.53 106.3 2.22 2.66 329.5 22.63 113.6 2.84 3.40

CFM 5661 40 167.8 8.65 87.3 .56 .67 213.1 10.98 94.7 .83 .99 258.3 13.31 102.1 1.13 1 .36 303.5 15.64 109.4 1.48 1.77

RPM 1100 50 141.9 5.85 83.1 .28 .34 187.2 7.71 90.5 .45 .53 232.4 9.58 97.8 .64 .76 277.6 11.44 105.2 .86 1.03

HP 1/2 60 1 1 6.0 3.99 78.9 .15 .17 161.3 5.54 86.3 .25 .30 206.5 7.09 93.6 .38 .45 251.7 8.65 10 1.0 .52 .63

400-S 30 229.0 15.73 94.3 1 .52 1 .73 286.0 19.66 102.8 2.29 2.59 345.0 23.71 111.6 3.16 3.83 403.0 27.69 120.8 4.21 5.13

CFM 6017 40 198.0 10.20 89.5 .68 .88 256.0 13.19 98.3 1.11 1.32 314.0 16.18 107.0 1.61 1.82 372.0 19.17 115.6 2.17 2.47

RPM 1140 50 168.0 6.93 85.1 .37 .43 227.0 9.36 94.0 .60 .73 283.0 11.67 102.3 .89 1.07 341.0 14.06 111.0 1.26 1.45

HP 3/4 60 143.0 4.91 81.4 .21 .28 196.0 6.74 89.3 .34 .42 252.0 8.66 97.7 .53 .65 314.0 10.79 107.0 .78 .92

See Table SP-12 for abbreviations.

15 101.4 13.93 99.2 4.60 5.51 121.2 16.66 106.9 6.12 7.33 141.1 19.39 1 1 4.6 7 .87 9.41 161.0 22.12 122.3 9.75 11.67

20 95.5 9.84 97.0 2.50 2.99 11 5.3 11.88 104.6 3.37 4.04 135.2 13.93 112.3 4.39 5.26 155.015.98120.0 5.50 6.58

60 48.1 1.65 78.6 .11 .13 68.0 2.34 86.3 .20 .23 87.9 3.02 94.0 .30 .36 107.7 3.70 10 1.7 .42 .50

15 11 0.2 15.14 96.2 5.33 6.38 131.7 18.10 103.2 7.09 8.48 153.2 21.05 11 0.3 9.10 10.89 —————

20 103.9 10.70 94.1 2.90 3.47 125.412.92 101.2 3.91 4.68 146.9 15.1 4108.2 5.09 6.09 168.4 17.36 115.3 6.37 7.62

60 53.3 1.83 77.5 .13 .16 74.8 2.57 84.5 .23 .28 96.3 3.31 91.6 .35 .42 117.8 4.05 98.7 .49 .59

15 142.7 19.61 99.9 1.98 2.37 171 .3 23.53 107.8 2.65 3.18 199.8 27.46 115.8 3.43 4.1 0 228.4 31.38 123.8 4.26 5.10

20 133.213.72 97.2 1 .06 1 .27 161.716.67105.2 1.44 1.73 190.319.61 113.2 1.89 2.26 218.822.55 121.1 2.38 2.85

60 56.7 1.95 75.9 .03 .04 85.3 2.93 83.8 .07 .08 113.9 3.91 91.8 .11 .13 142.4 4.89 99.8 .16 .19

70 ———— —66.2 1.95 78.5 .03 .04 94.8 2.79 86.5 .06 .07 123.3 3.63 94.5 .10 .1 1

15 160.0 21.98 96.0 2.43 2.91 192.1 26.40 103.2 3.25 3.89 224.3 30.81 110.4 4.20 5.03 256.4 35.23 117.7 5.23 6.26

20 149.015.35 93.5 1.29 1 .55 181 .118.67100.7 1.77 2.11 213.3 21.98 108.0 2.32 2.77 245.4 25.29 11 5.2 2.92 3.49

60 61.3 2.10 73.8 .04 .05 93.4 3.21 81.0 .08 .10 125.6 4.31 88.2 .13 .16 157.7 5.42 95.5 .19 .23

70 ———— —71.5 2.10 76.1 .04 .05 103.6 3.05 83.3 .07 .09 135.8 4.00 90.5 .11 .14

15 205.7 28.26 102.3 4.47 5.35 245.6 33.75 110.5 5.93 7.09 285.6 39.24 118.7 7.60 9.10 325.5 44.73 127.0 9.41 1 1.27

20 194.420.03100.0 2.44 2.92 234.3 24.15108.2 3.28 3.93 274.328.26 116.4 4.26 5.10 314.232.38 124.6 5.33 6.37

70 81.0 2.38 76.7 .06 .07 120.9 3.56 84.9 .12 .14 160.9 4.74 93.1 .18 .22 200.8 5.91 101.3 .27 .32

80 ———— —98.3 2.53 80.2 06 .08 138.2 3.56 88.4 .1 1 .13 178.2 4.59 96.6 .17 .21

15 232.6 31.96 97.9 5.55 6.65 277 .8 38.17 105.2 7.37 8.82 323.1 44.38 112.6 9.46 11.32 —————

20 219.622.63 95.8 3.03 3.63 264.9 27.30 103.1 4.08 4.88 310.1 31 .96 1 10.5 5.30 6.34 355.436.62 117 .9 6.62 7.92

70 90.1 2.65 74.7 .07 .09 135.3 3.99 82.0 .14 .17 180.6 5.32 89.4 .23 .27 225.8 6.65 96.8 .33 .40

80 ———— —109.4 2.82 77.8 .08 .09 154.7 3.99 85.2 .14 .16 199.9 5.15 92.5 .21 .25

15 278.0 38.21 101.6 7.36 8.69 335.0 46.18 11 0.3 10.06 11 .81 391.0 53.74 1 1 8.5 12.80 15.14 —————

20 263.5 27.16 99.4 4.06 4.95 321.033.09 108.0 5.79 6.91 379.039.07 11 6.7 7.65 9.02 435.544.89 125.1 9.60 11.28

70 1 18.0 3.47 77 .7 .11 .13 166.0 4.89 84.8 .21 .28 222.0 6.54 93.2 .32 .41 285.0 8.39 102.6 .51 .62

80 ———— — ——— —— ————— —————

Entering Water T emperature

UH-PRC001-EN24

Page 25

P erformance

Data

Table PD-1 (Continued) — Model S Unit Heater Hot W a ter Capacities – 60°F Ent. Air Temp.

(Conversion Factors in Table SP-11 Apply Only to 200 F Entering Water Temperature Columns)

Water 260 F 300 F 340 F 380 F

Unit T emp. PD PD PD PD PD PD PD PD

Size Drop °F MBH GPM FT S.W.T. H.W.T. MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T.

18-S 10 15.5 3.19 111.0 .10 .12 19.7 4.07 124.9 .15 .18 24.0 4.94 138.8 .21 .25 28.2 5.81 152.7 .27 .32

CFM 280 20 9.8 1.01 92.3 .01 .02 14.1 1 .45 106.3 .02 .03 18.3 1 .89 120.2 .04 .05 22.5 2.32 134.1 .05 .06

RPM 1075 30 ———— —8.4 .58 87.6 .00 .01 12.6 .87 10 1.5 .01 .01 16.9 1.16 1 1 5.5 .02 .02

HP 1/50 40 ———— — ——— —— ————— 1 1.2 .58 96.8 .00 .01

38-S 20 33.4 3.44 116.6 .16 .20 42.9 4.42 132.8 .25 .30 ————— —————

CFM 543 30 26.2 1.80 104.5 .05 .06 35.7 2.46 120.7 .09 .10 45.3 3.11 136.8 .13 .15 —————

RPM 1550 40 19.1 .98 92.4 .02 .02 28.6 1.47 108.6 .04 .04 38.1 1.97 124.7 .06 .07 47.7 2.46 140.9 .08 10

HP 1/20 50 ———— —21.5 .89 96.5 .01 .02 31 .0 1.28 112.7 .03 .03 40.5 1.67 128.8 04 .05

42-S 20 35.0 3.61 114.6 .18 .21 45.0 4.64 130.2 .27 .32 55.0 5.67 145.7 .37 .44 —————

CFM 591 30 27 .6 1.89 103.0 .06 .07 37.5 2.58 118.5 .1 0 .11 47.5 3.26 134.1 .14 .17 —————

RPM 1550 40 20.1 1.04 91.3 .02 .02 30.1 1.55 106.9 .04 .05 40.1 2.06 122.5 .06 .07 50.1 2.58 138.1 .09 .11

HP 1/20 50 ———— —22.6 .93 95.3 .02 .02 32.6 1.34 1 10.9 .03 .04 42.6 1.76 126.4 .05 .05

60-S 40 40.6 2.09 105.9 .09 .10 54.9 2.83 122.0 .14 .17 69.2 3.56 138.2 .20 .25 —————

CFM 815 50 32.8 1.35 97 .1 .04 .05 47.1 1.94 113.3 .07 .09 61.4 2.53 129.5 .11 .13 75.7 3.12 145.6 .16 .19

RPM 1550 60 25.1 .86 88.4 .02 .02 39.4 1.35 104.6 .04 .05 53.7 1.84 120.7 .06 .08 68.0 2.34 136.9 .09 .11

HP 1/20 80 ———— — ——— ——38.3 .99 103.3 .02 .03 52.5 1.35 1 19.4 .04 .04

70-S 40 47 .4 2.44 99.7 .11 .14 64.1 3.30 1 13.7 .1 9 .22 80.8 4.17 127.7 .27 .32 97.6 5.03 141 .8 .36 .43

CFM 1100 50 38.3 1.58 92.1 .05 .06 55.0 2.27 106.1 .10 .12 71.8 2.96 120.1 .15 .18 88.5 3.65 134.2 .21 .25

RPM 1550 60 29.2 1.00 84.4 .02 .03 45.9 1.58 98.5 .05 .06 62.7 2.15 112.5 .08 .10 79.4 2.73 126.5 .12 .15

HP 1/8 80 ———— —27.7 .71 83.2 .01 .02 44.5 1.15 97 .2 .03 .03 61.2 1.58 1 11.3 .05 .06

90-S 50 61 .1 2.52 106.4 .15 .17 82.0 3.38 122.2 .24 .28 102.8 4.24 138.0 .34 .40 —————

CFM 1214 60 52.6 1.81 99.9 .08 .10 73.4 2.52 1 15.7 .14 .17 94.2 3.24 131.5 .21 .25 115.0 3.95 147.3 .29 .34

RPM 1550 80 35.4 .91 86.9 .02 .03 56.2 1.45 102.7 .05 .06 77 .0 1.98 1 18.5 .09 .11 97.8 2.52 134.3 .13 .16

HP 1/8 100 ———— —39.0 .80 89.6 .02 .02 59.8 1.23 105.4 .04 .05 80.7 1.66 121.2 .06 .08

100-S 60 58.5 2.01 95.1 .10 .12 82.0 2.82 109.2 .17 .20 105.4 3.62 123.3 .26 .31 128.9 4.43 137.4 .35 .42

CFM 1535 80 38.9 1.00 83.4 .03 .03 62.4 1.61 97.4 .06 .08 85.8 2.21 111.5 .1 1 .13 109.3 2.82 125.6 .16 .19

RPM 1550 100 19.3 .40 71.6 .01 .01 42.8 .88 85.7 .02 .03 66.2 1.37 99.8 .05 .06 89.7 1 .85 113.9 .08 .09

HP 1/8 120 ———— — ——— ——46.6 .80 88.0 .02 .02 70.1 1.20 102.1 .04 .04

126-S 80 69.0 1.78 96.1 .10 .12 99.1 2.55 1 11.9 .18 .21 129.1 3.33 127.6 .27 .33 159.2 4.10 143.3 .38 .46

CFM 1760 100 48.7 1.00 85.5 .04 .04 78.8 1.62 101.3 .08 .10 108.8 2.24 1 17.0 .14 .17 138.9 2.86 132.7 .20 .24

RPM 1100 120 28.4 .49 74.9 .01 .01 58.5 1.00 90.6 .03 .04 88.5 1.52 106.4 .07 .08 118.6 2.04 122.1 .1 1 .14

HP 1/6 140 ———— — ——— ——68.2 1.00 95.7 .03 .04 98.3 1.45 111.5 .06 .07

168-S 60 127 .6 4.38 109.4 .56 .67 167.3 5.75 124.8 .87 1.04 207.0 7.11 140.1 1.22 1.46 —————

CFM 2381 80 103.9 2.68 100.2 .23 .28 143.6 3.70 1 15.6 .40 .48 183.3 4.72 131.0 .60 .71 223.0 5.75 146.3 .81 .97

RPM 1100 100 80.2 1 .65 91.1 .10 .12 120.0 2.47 106.4 .20 .24 159.7 3.29 121.8 .32 .38 199.4 4.11 137.2 .45 .54

HP 1/6 120 56.6 .97 81.9 .04 .05 96.3 1.65 97.3 .10 .12 136.0 2.34 112.6 .17 .21 175.7 3.02 128.0 .26 .32

10 40.5 8.34 128.7 .79 .94 50.0 10.30 144.9 1.10 1.32 ————— —————

60 ———— — ——— ——23.9 .82 100.6 .01 .01 33.4 1.15 116.7 ’02 .03

10 42.5 8.75 126.2 .86 1.02 52.4 10.81 141.8 1.20 1.43 ————— —————

60 ———— — ——— ——25.2 .86 99.2 .01 .02 35.1 1 .21 114.8 .02 .03

20 56.0 5.77 123.4 .51 .62 70.3 7.25 139.5 .74 .89 ————— —————

30 48.3 3.32 114.6 .19 .23 62.6 4.30 130.8 .30 .35 ————— —————

100 ———— — ——— —— ————— 37.1 .76 101 .9 .01 .02

20 65.5 6.75 114.9 .68 .81 82.3 8.48 129.0 .98 1.17 99.0 10.21 143.0 1.31 1.56 —————

30 56.4 3.88 107.3 .26 .31 73.2 5.03 121.3 .39 .47 89.9 6.18 135.4 .54 .65 —————

100 ———— — ——— —— —————43.0 .89 96.0 .02 .02

40 69.7 3.59 112.9 .27 .32 90.6 4.67 128.7 .41 .50 ————— —————

120 ———— — ——— ——42.7 .73 92.4 .02 .02 63.5 1.09 108.2 .03 .04

40 78.1 4.02 106.9 .33 .40 1 01.6 5.23 121.0 .51 .61 125.0 6.44 135.1 .71 .84 —————

50 68.3 2.82 101.0 .18 .21 91.8 3.78 115.1 .29 .34 115.2 4.75 129.2 .41 .49 138.7 5.72 143.3 .55 .66

140 ———— — ——— ——27.0 .40 76.2 .01 .01 50.5 .74 90.3. .02 .02

50 99.5 4.10 112.1 .42 .51 129.5 5.34 127.8 .65 .78 159.6 6.58 143.6 .90 1.08 —————

60 89.3 3.07 106.8 .25 .30 11 9.4 4.10 122.5 .41 .49 149.4 5.13 138.2 .59 .70 —————

160 ———— — ——— ——47.9 .62 85.1 .01 .02 78.0 1.00 100.8 .03 .04

40 151 .2 7.79 118.5 1.53 1.83 191.0 9.84 133.9 2.23 2.66 ————— —————

50 139.4 5.75 114.0 .90 1.07 179.1 7.38 129.3 1.35 1.61 218.8 9.02 144.7 1.84 2.21 —————

140 ———— —72.6 1.07 88.1 .05 .05 112.3 1.65 103.5 .1 0 .1 1 152.1 2.24 1 1 8.9 .16 .19

160 ———— —49.0 .63 79.0 02 .02 88.7 1.14 94.3 .05 .06 128.4 1.65 109.7 .09 .11

180 ———— — ——— ——65.0 .74 85.2 .02 .03 104.7 1 .20 100.5 .05 .06

Entering Water T emperature

25UH-PRC001-EN

Page 26

P erformance

Data

Table PD-1 (Continued) — Model S Unit Heater Hot Water Capacities – 60°F Ent. Air Temp.

(Conversion Factors in Table SP-1 1 Apply Only to 200 F Entering Water Temperature Columns)

Water 260 F 300 F 340 F 380 F

Unit T emp. PD PD PD PD PD PD PD PD

Size Drop °F MBH GPM FT S.W.T. H.W.T. MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T MBH GPM FT S.W.T. H.W.T.

186-S 80 11 4.1 2.94 97.4 .28 .33 157.1 4.05 111.6 .47 .56 200.2 5.16 125.7 .70 .83 243.2 6.27 139.8 .94 1.13

CFM 2808 100 88.8 1.83 89.1 .12 .14 131.8 2.72 103.3 .23 .28 174.9 3.60 117.4 .37 .45 217.9 4.49 131.5 .53 .63