Page 1

Installation/

Operator

Programming

UCM 4.0 and

Wireless VAV

Communication

May 2001

VAV-SVX01B-EN

Page 2

Contents

Chapter 1 – General Information 4

UCM Control Module 4.0 (UMC 4.0)

Specifications

UCM 4.0 Enhancements

UCM 4.0 Features

Shipping

Storage

Chapter 2 – VAV Start-Up/Check-Out Procedure 6

Pre-power Up Checkout for the UCM 4.0

UCM Operational LEDs

Zone Sensor Checkout

Chapter 3 – UCM 4.0 Installation and Wiring 7

UCM 4.0 Power Wiring

Zone Sensor Wiring

Communication Wiring

DIP Switch Settings

Chapter 4 – UCM 4.0 Programming and Operation 14

Typical UCM Operating Behavior

UCM Status

UCM Set Points

UCM Setup

Chapter 5 – Sequence of Operations 24

Single Duct Units

Parallel Fan-Powered Units

Series Fan-Powered Units

Zone Sensor Ffunctions

Flow Sensor

Failure Modes

©American Standard Inc. 1999 VAV-SVX01B-EN

Page 3

Contents

Chapter 6 – Air and Water Balancing 28

Air Balancing

Water Balancing

Chapter 7 – Wireless VAV Systems 30

Chapter 8 – Trouble-Shooting 38

UCM 4.0 Problems

Wireless Receiver Problems

Chapter 9 – Appendix 42

VAV-SVX01B-EN 3

Page 4

General

Information

Chapter Overview

This chapter contains information

about the following

Unit Control Module 4.0 (UCM 4.0)

Specifications

UCM 4.0 Enhancements

UCM 4.0 Features

Shipping

Storage

CHAPTER 1: GENERAL INFORMATION

Unit Control Module 4.0

(UCM 4.0)

The UCM 4.0 is a microprocessorbased, Direct Digital Controller (DDC)

for the (Variable Air Volume) VAV

terminal unit. It contains the control

logic to modulate the flow of supply air

through the VAV terminal in response

to the load requirements within the VAV

zone.

The function of the UCM is to control

the VAV terminal unit to vary the

volumetric airflow rate to the zone. VAV

units are available with either

pneumatic, analog electronic, or

microprocessor controls (DDC VAV).

This manual discusses only terminal

units with DDC/VAV controls. Factory

installed DDC/VAV controls are

available with all single duct terminal

units, including parallel fan-powered,

and series fan-powered units. Two

UCMs are required for dual duct units

(one for the heating duct and one for

the cooling duct).

The UCM modulates a VAV’s damper

blade based on a zone temperature,

measured airflow, and set points to

continuously control conditioned air

delivery to the space. The volume of

incoming air is monitored and the

damper adjusts to provide accurate

control independent of the duct

pressure. The damper modulates

between operator set points depending

on space conditions. Additionally, fan

and heat outputs may be energized

depending on the application. Available

inputs include a twisted/shielded

communication link, zone sensor,

auxiliary temperature sensor (optional),

CO2 Sensor (optional), and Occupy/

Unoccupy Sensor (optional), and 24

VAC power.

Specifications

Power Requirements

The UCM 4.0 requires 24 VAC, 50/60 Hz,

and up to 50 VA, depending on the

number of heat outputs (stages), which

consume 10 VA each.

Operating Environments – UCM 4.0

0°– 140°F (0°– 60°C), 10% to 90% relative

humidity, non-condensing

Storage Environments – UCM 4.0

-40°– 150°F (-40°–65.6°C), 10% to 90%

relative humidity, non-condensing

Mounting

Typically, the UCM 4.0 is factory

installed. However, UCM 4.0 is available

with retrofit kits, in which case it must

be field installed.

See Chapter 8 for wireless system

mounting.

Tracer Summit and UCM 4.0

Communications Link Wiring

Communications Link wiring must be

18 AWG twisted shielded pair wire.

Each conductor must be stranded

tinned copper. The maximum total wire

length is 5,000 feet (1,524 m). Refer to

Chapters 2 and 3 for further information

about wire selection.

UCM 4.0 Enhancements

The enhanced VAV UCM is backward

compatible with VariTrane

boxes (VXXD and VXXE) VariTrac

dampers, and VariTrac II dampers.

UCM 4.0 adds support for operation

with VariTrane Series F valves (¼-turn

blade dampers) via 90-second drive

time.

UCM 4.0 adds a second, CO

interfacing, mode of operation to the

auxiliary analog input (TB3-5). This is a 1

to 10 volt DC input with a mapping of

input voltage to CO

of 200 parts per million (PPM) of CO

per volt. The use of this new auxiliary

analog input as an interface to a CO

detector is mutually exclusive with the

use of the input as auxiliary

temperature input. Therefore, the use of

the C0

not recommended for stand-alone

applications requiring auto-changeover.

UCM 4.0 adds a binary 24 VAC, dry

contact input. It can be configured

either as a generic input or as an

occupancy detector input.

UCM 4.0 adds a VariTrac Bypass

Damper mode of operation. In this

®

D VAV

®

2

output data value

2

2

2

interfacing mode of operation is

2

4

VAV-SVX01B-EN

Page 5

General

Information

mode, supply air temperature and

supply air pressure is made available

on the Com 4 link. The damper position

is a COM 4-control parameter. A Com 4

configurable failsafe position was

added. The supply air temperature uses

a new “s” input (TB3-7). The use of this

new input is mutually exclusive with the

Zone temp input (TB3-1).

UCM 4.0 now assumes the hot water

valve is closed after reset. This prevents

a reset during hot water override from

causing the valve to stop moving. This

also changes the behavior after reset,

when there is a reheat demand, the hot

water valve now opens (from assumed

closed position) to the desired reheat

position.

In a wireless system, the hard-wired

sensor can now be configured as not

present. The hard-wired sensor failures

will not be reported as long as at least

one wireless zone sensor is reporting

valid temperature values.

For standalone units, series or parallel

fan operation will use the unoccupied

fan control when the local unoccupied

request (** function) is received. In

UCM 3.3 and prior, the fan would

operate as if occupied during local

unoccupied request

UCM 4.0 adds a local minimum heating

flow set point. The use of and value of

this set point is configurable.

UCM 4.0 Backward Compatibility

UCM 4.0 can be used to replace UCM I,

UCM II, and UCM III with no compatibility issues. However, if the communicating device (i.e. Command Unit I or

Comfort Manager™ I) is a COM 3

device (1992 or earlier), then you will

need an upgrade chip. The Comfort

Manager chip upgrade is Kit 1511 and

the Command Unit chip upgrade is Kit

1512.

UCM 4.0 Features

Heat and Fan Outputs

All fan outputs are rated for 10 VA each.

Magnetic contactors are rated for 10

VA. Mercury contactors are rated for 12

VA.

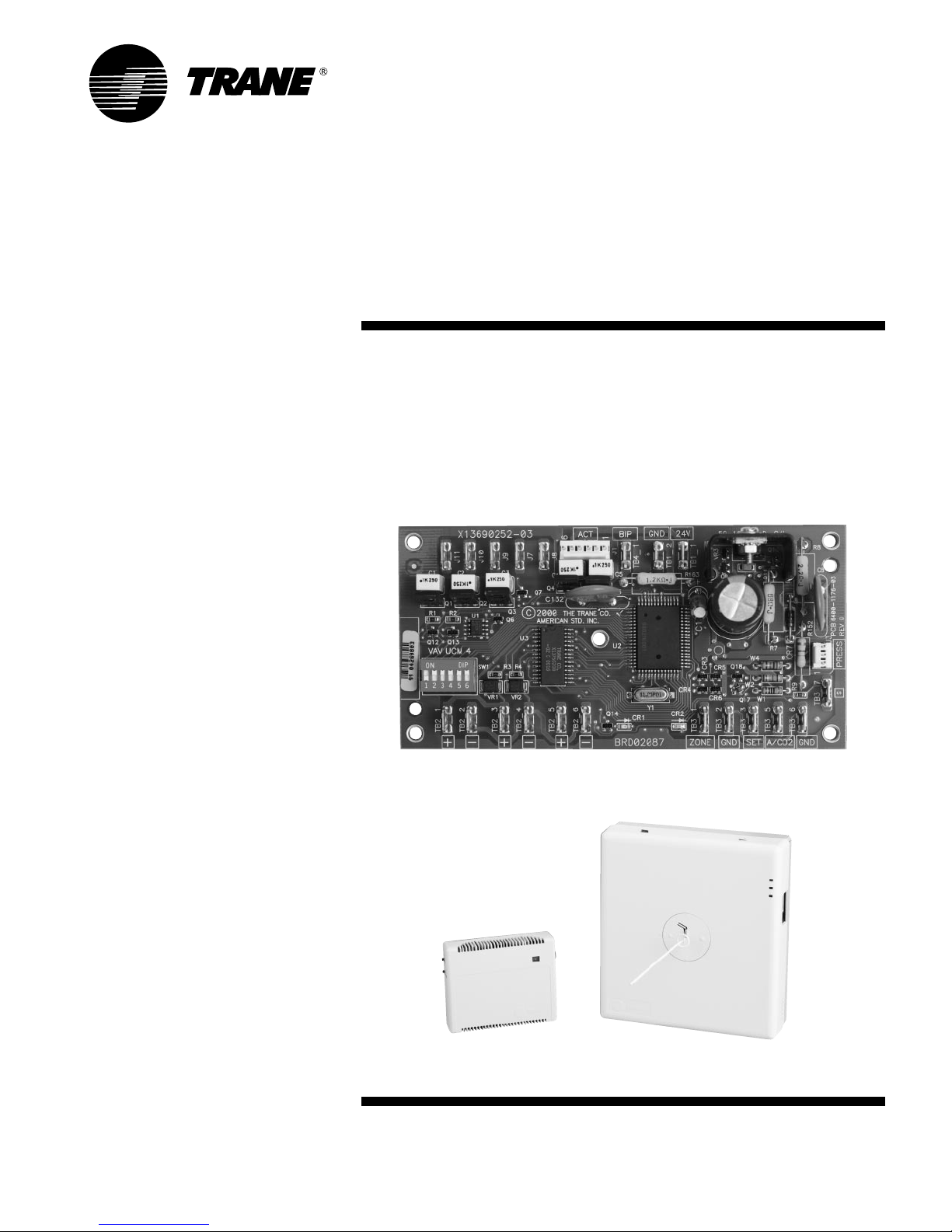

Wiring Diagram

Figure 1 shows a typical wiring diagram

for the redesigned UCM hardware. The

new service part number is BRD 2087.

VAV-SVX01B-EN 5

Figure 1. UCM 4.0 Board Layout

Zone Sensor, Auxiliary Sensor, and

Thumbwheel Set Point Calibration

If there is a discrepancy between a

measured temperature and what the

UCM reports, a calibration offset value

can be edited in the UCM setup screen

to correct the displayed value.

Flow Sensor Calibration

If there is a discrepancy between a

measured flow and what the UCM

reports, the measured value can be

entered, which automatically calculates

a calibration multiplier to correct the

displayed value.

Water Valve Override

Each UCM that has proportional or

staged hot water heat outputs can be

edited to override the water valve to its

maximum position.

Ventilation Set Points and Ratio

Calculation

Set point values needed for a space to

satisfy indoor air quality requirements

are provided. A resultant ventilation

ratio can be used to calculate an air

handler’s outside air damper minimum

position or other control strategies.

Water Heat Output Configuration

UCMs that have hot water heat outputs

can be configured for normally open or

normally closed.

Zone Sensor Functions

Zone sensor functions now include: air

valve drive to maximum, use unoccupied set points, timed override, and

cancel timed override.

Slaving of Zone Sensors

Up to three (3) UCM 4.0s may be

connected to a single zone sensor.

Generic UCM Capability

UCM 4.0 can be configured to control

non-Trane VAV boxes.

Shipping

Each VAV product and its service

literature are shipped in the same

package. When unpacking, make sure

that the literature is not lost or discarded with the packing material.

Visually inspect the individual components for obvious defects or damage.

All components are thoroughly

inspected before leaving the factory.

Any claims for damage incurred during

shipment must be filed with the carrier.

Storage

When any component of the VAV

system and/or field installed accessories must be stored for a period of time

prior to being installed, they must be

protected from the elements. The

storage location temperature should be

between -40° – 150°F (-40°– 65.6°C) and

the relative humidity should be 10% to

90%, non-condensing.

The warranty will not cover damage to

the VAV system or controls due to

negligence during storage. A controlled

indoor environment must be used for

storage.

Page 6

VAV Start-Up/

Check-Out Procedure

Chapter Overview

This chapter contains information

pertaining to the following:

Pre-power up check-out for the UCM

4.0

UCM operational LEDs

Zone Sensor check-out

UCM 4.0 Pre-Power

Check-out

[ ]Check the supply voltage at TB1. Proper

polarity must be maintained. TB1-1 is

the hot side (+) and TB1-2 is the ground

side (-) of the 24 VAC input. The UCM

cannot be powered from a common 24

VAC transformer that is supplying

power to a device containing a fullwave rectifier bridge in its power

supply. The acceptable voltage is 20 to

28 VAC (24 VAC cataloged). However,

voltages at either extreme may result in

increased system instability.

[ ]Verify that communications wiring has

properly been terminated atTB2-1 (+)

and TB2-2 (-). Polarity is very important

on the communications link.

[ ]Verify that the zone sensor connections

are correct as detailed in the UCM

wiring chapter.

[ ]Verify that the proper unit DIP switch

settings have been set on each UCM.

[ ]Verify that the tubing is properly

connected to the transducer.

CHAPTER 2: VAV START-UP/CHECK-OUT PROCEDURE

Light Emitting Diode (LED)

Operations

The UCM has one green LED located

near TB3 and one yellow LED located

near TB2 on the UCM circuit board. These

LED’s are used to help diagnose communication (yellow) or circuit board problems (green).

The green LED (red on older boards) is a

power indicator. It is steady on when the

power is on and the software is

functioning correctly. If it blinks with a 1

second on 1 second off cycle when

power is applied, then the board is not

functioning and must be replaced.

Table 1 - Green LED Power Function Indication

LED State Indication

“On” Board functioning correctly

Blinking Board malfunction (Replace Board)

“Off” Board does not have power

The yellow LED functions as the

communication indicator. The indication

from the yellow LED is as follows:

Table 2 – Yellow LED Communication Indicator

Function

LED State Indication

“On” Incorrect (reversed)

Blinking slowly Communication is occurring on the

approx. 1 link but not for that particular UCM.

blink/sec.

Blinking quickly Communication is occurring on the

(multiple blinks link, specifically with that UCM.

blinks/sec.

“Off” Polarity is correct and no

communication polarity, no

connection, or shorted lines.

communication is occurring on the

link

Zone Sensor Check-out

If an erroneous temperature is being

reported to the UCM, use the Zone

Sensor Temperature-Resistance Table to

verify the integrity of the adjustable set

point potentiometer or sensor. The

resistance should be measured across

the terminals to which the device is

connected.

Note: Disconnect the zone sensor from

the UCM when making the checks listed

in the table below.

Table 3 – Zone Sensor Temperature-Resistance

Table

Temp. Resistance Resistance

(°F) (Ohms) (k Ohms)

55 792 17.0

56 772 16.5

57 753 16.1

58 733 15.7

59 714 15.4

60 694 15.0

61 675 14.6

62 656 14.3

63 636 14.0

64 617 13.6

65 597 13.3

66 578 13.0

67 558 12.6

68 539 12.3

69 519 12.1

70 500 11.8

71 481 11.5

72 461 11.2

73 442 11.0

74 422 10.7

75 403 10.4

76 383 10.2

77 364 10.0

78 344 9.7

79 325 9.5

80 306 9.3

81 286 9.0

82 267 8.8

83 247 8.6

84 228 8.4

85 208 8.2

Thermostat

Thumbwheel Sensor

6

Note: Thumbwheel resistance checks

are made at terminal 2 and 3 on the zone

sensor. Temperature sensor resistance is

measured at terminal 1 and 2 of the zone

sensor.

VAV-SVX01B-EN

Page 7

UCM 4.0 Installation

and Wiring

CHAPTER 3: UCM 4.0 INSTALLATION AND WIRING

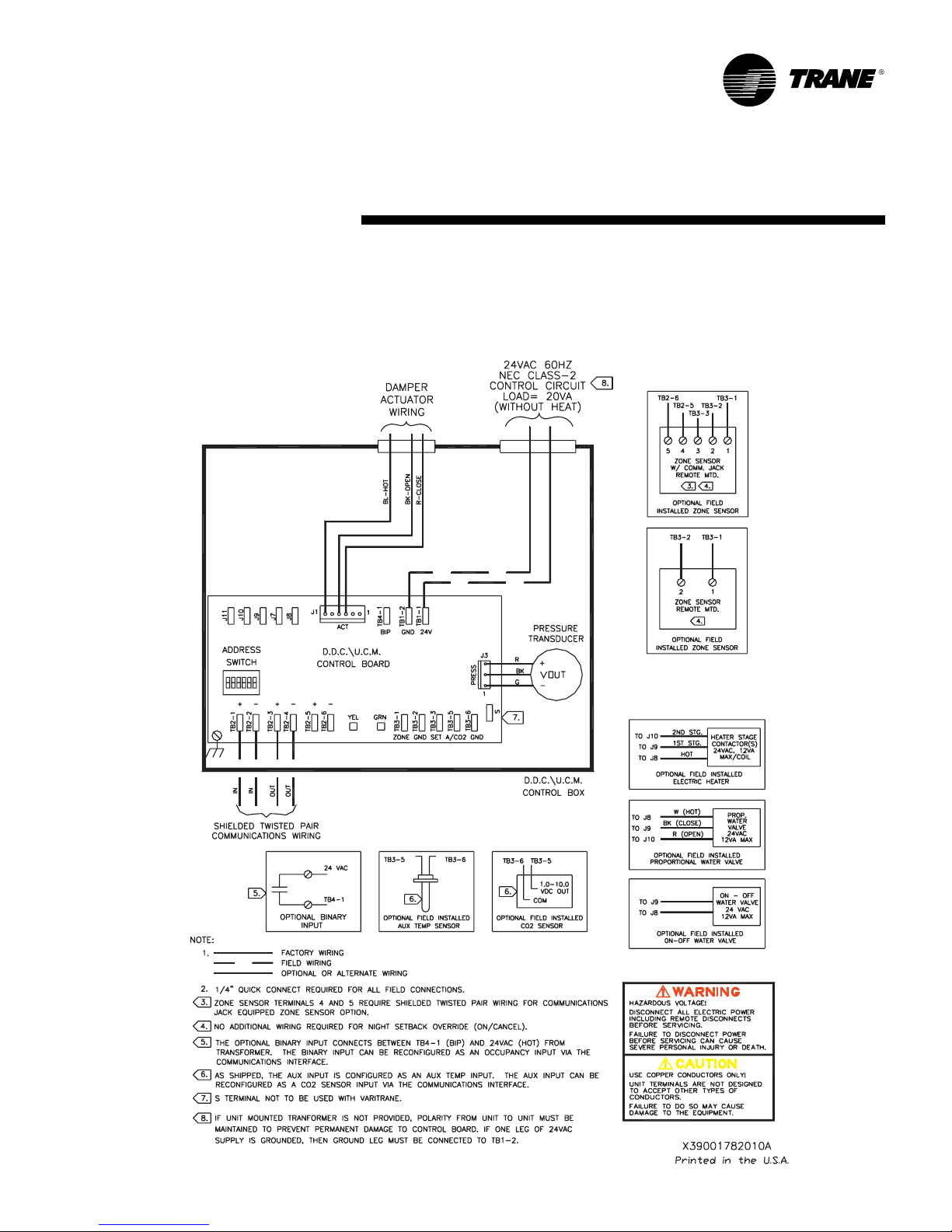

Figures 2 – 5 show wiring diagrams for typical applications of UCM 4.0

Figure 2. Wiring Diagram for Single Duct Units with Field Installed Re-heat

VAV-SVX01B-EN 7

Page 8

UCM 4.0 Installation

and Wiring

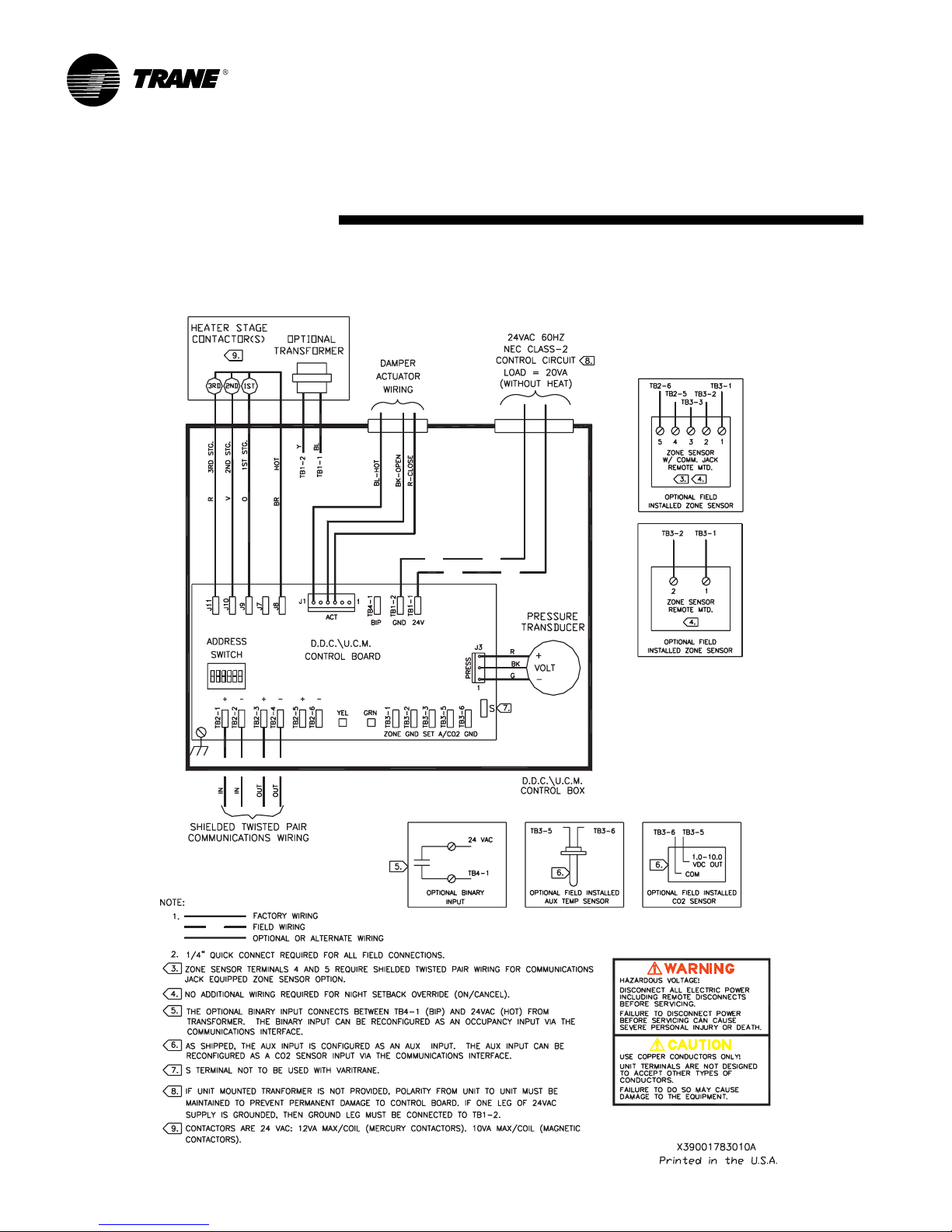

Figure 3. Wiring Diagram for Single Duct Units with Factory Installed Electric Re-heat

8

VAV-SVX01B-EN

Page 9

UCM 4.0 Installation

and Wiring

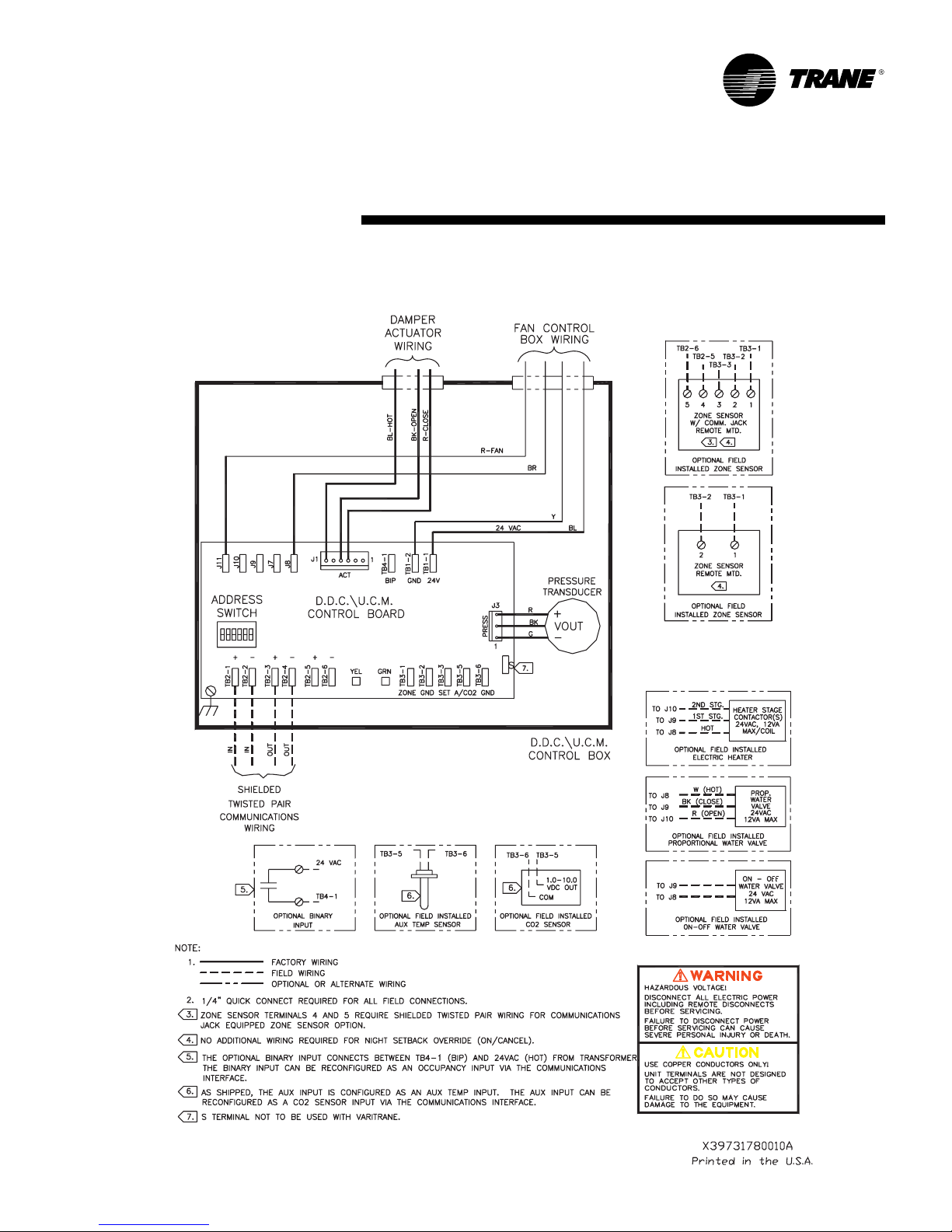

Figure 4. Wiring Diagram for Fan-Powered Units with Field Installed Re-heat

VAV-SVX01B-EN 9

Page 10

UCM 4.0 Installation

and Wiring

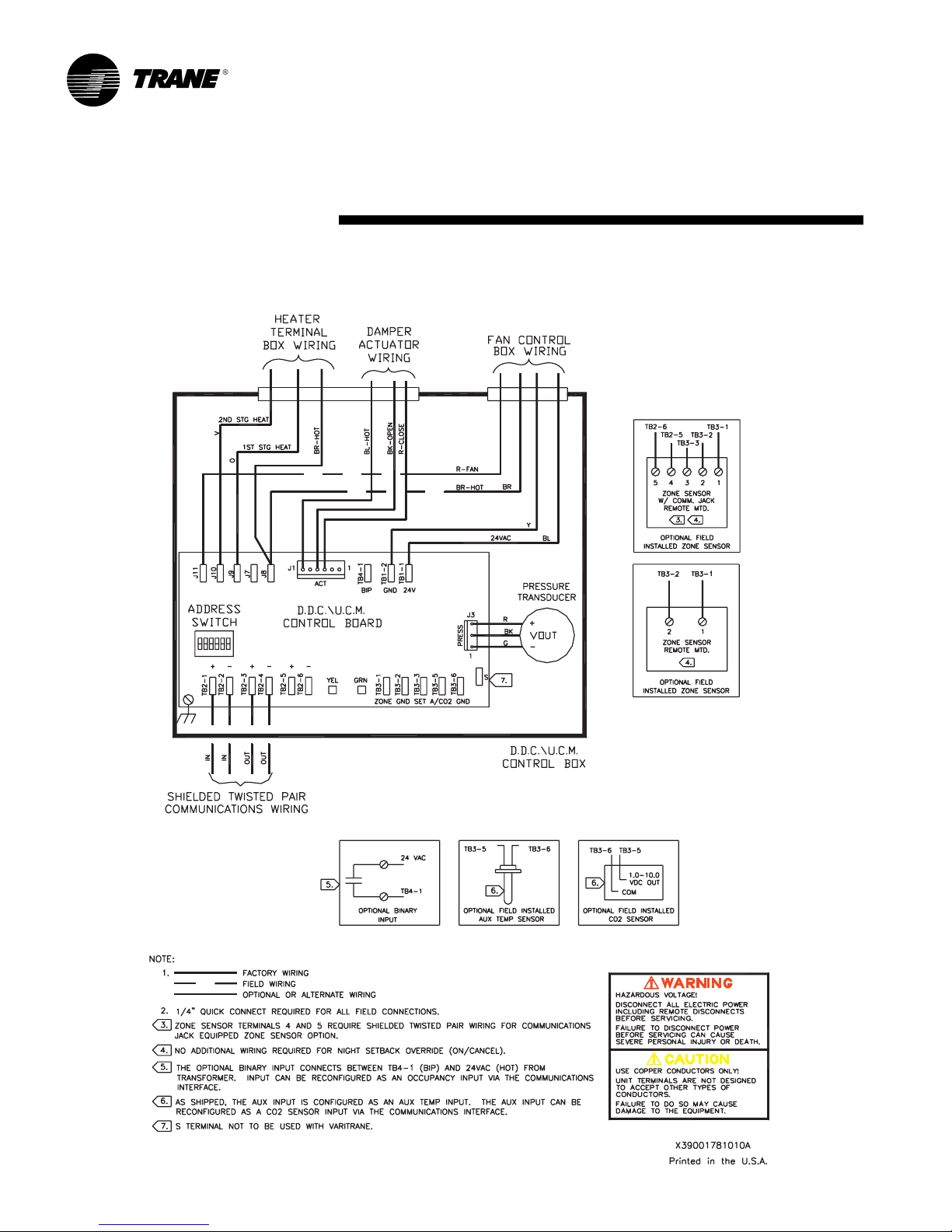

Figure 5. Wiring Diagram for Fan-Powered Units with Factory Installed Electric Re-heat

10

VAV-SVX01B-EN

Page 11

UCM 4.0 Installation

and Wiring

Chapter Overview

This chapter contains information

about the following:

UCM 4.0 Power Wiring

Zone Sensor Wiring

Communication Wiring

DIP switch Settingsire Selection

UCM 4.0 Power Wiring

Power Requirements

Caution: Disconnect all power external

to the unit to prevent injury or death

from electrical shock. Use copper

conductors only. The use of aluminum

or other types of wire may result in

overheating and equipment damage.

Use at least 16 AWG for power wiring

and connect to terminal TB1-1 (+) and

TB1-2 (-). 24 VAC is required to power

the UCM control and has an acceptable

voltage tolerance of 20 to 28 VAC.

Replace the UCM control box cover

after field wiring to prevent any

electromagnetic interference.

NOTE: A dedicated 24 VAC, 50VA NEC

class 2 transformer is recommended to

power the UCM. When powering

multiple UCM’s from one transformer,

polarity must be maintained. Terminal

TB1-1 is designated positive (+) and

terminal TB1-2 is negative (-) to the unit

casing ground. All wiring must comply

with the National Electric Code (NEC)

and local codes. Maximum wire lengths

should be based on NEC specifications.

The power consumption for cooling

only Series F Models (VariTrac and

VariTrane) is 12 VA (4 VA for the air

valve/actuator and 8 VA for the board).

Units with fans and/or reheat outputs

are rated at 10 VA maximum for

magnetic contactors and 12 VA

maximum for mercury contactors for

each output. To determine the total UCM

power requirement, add the power

consumption per stage to the circuit

board power requirement. For example,

a Series F unit containing magnetic

contactors with three stages of reheat

would consume 42 VA.

NOTE: VariTrane and VariTrac cooling only

Series D and E models consume 20 VA

(12 VA for the actuator and 8 VA for the

board). The heating output ratings

remain the same.

Refer to Figure 1 for UCM terminal

locations.

Zone Sensor Wiring

Location and Mounting

A zone sensor in each control zone

should be located in the most critical

area of the zone. Sensors should not be

mounted in direct sunlight or in the

area’s supply air stream. Subdivision of

the zone may be necessary for adequate control and comfort.

Avoid mounting zone sensors in areas

subject to the following:

Drafts or “dead spots” behind doors or

corners.

Hot or cold air ducts.

Radiant heat from the sun or

appliances.

Concealed pipes or chimneys.

Unheated or uncooled surfaces behind

the sensor such as outside walls.

Air flows from adjacent zones or other

units.

Wiring

Each unit must be controlled by a zone

sensor that is designated specifically

for use with the UCM control. Field

wiring for the zone sensors must meet

the following requirements:

Must be 14 to 18 AWG.

Refer to the sensor instructions for

terminal connections.

If local codes require enclosed

conductors, the zone sensor wires

should be installed in conduit. Do not

route zone sensor wires in conduit with

24 VAC or other high power conducting

wires.

Multiple UCM’s Per Zone Sensor

Up to three (3) UCM’s may be connected to a single zone sensor and

thumbwheel set point.

Connect terminal connections TB3-1,

TB3-2, and TB3-3 in parallel (i.e. daisy

chain) from the master UCM to the

slaved UCM(s). NOTE: Proper polarity

must be maintained.

Cut jumper wires W1 and W2 on the

slaved UCM’s (never cut jumper wires

W1 and W2 on the master UCM).

VAV-SVX01B-EN 11

Page 12

UCM 4.0 Installation

and Wiring

Multiple UCM’s per Auxiliary Duct

Temperature Sensor

Up to three (3) UCMs may be connected to a single auxiliary duct

temperature sensor.

Connect terminal connections TB3-5

and TB3-6 in parallel (i.e. daisy chain)

from the master UCM to the slaved

UCM(s). NOTE: Proper polarity must be

maintained.

Cut jumper wire W4 on the slaved

UCMs (never cut jumper wire W4 on

the master UCM).

Zone Sensor Options

Depending on the zone sensor options

used, a maximum of five wires may be

required to run from the UCM to the

zone sensor. The zone sensor options

are:

Zone sensor only (2 wires) – Part

Number X13510609-01.

Zone sensor with external adjustable

set point and communications jack (5

wires) – Part Number X13510606-01.

Zone sensor with external adjustable

night set back, timed override (TOV) on/

cancel button, and communications

jack (5 wires) – Part Number

X13510606-02.

Sensor with night set back, timed

override (TOV) on/cancel button, and

communications jack (4 wires) – Part

Number X13510606-03.

Digital zone sensor - Part Number

X13511067-01

NOTE: All wiring from the zone sensor to

the Com link must be twisted shielded

pair wiring.

Communication Wiring

Communication Link Wiring

The “Communication Link” is the

communication wiring between Tracer

Summit and all VAV box Unit Control

Modules (UCM). Tracer Summit

be connected to the UCM communication link in a “daisy chain” configuration.

®

can

Note: It is not necessary for each UCM

to be connected to the line in sequential

order by address. Also, multiple

communication links may be run and

terminated at the Tracer Summit.

However, a consistent, documented

wiring path will help troubleshoot

communication problems after

installation.

Field wiring for the communication

link must meet the following

requirements:

1. All wiring must be in accordance with

the National Electrical code and local

codes.

2.Communication link wiring must be at

least 18 AWG twisted shielded pair

wire. Shields must be grounded at the

Tracer Summit or Central Control

Panel (CCP) only. More than one

ground reference will cause

communications failures. Shields

must be daisy chained. Tape the shield

at the last VAV UCM to prevent any

connection between the shield and

ground. Wire specifications are as

follows:

Plenum Cable

Stranded, tinned copper insulated

with extruded FEP. Conductors cabled

and shielded with overall aluminum/

Mylar tape and stranded, tinned

copper drawn wire. Extruded jacket,

300 volt, 150°C NEC 725-2 (b) class 2,

type CL2P, 25 pF/ft.

Non-Plenum Cable

Stranded tinned copper insulated with

polyethylene. Conductors cabled and

shielded with overall aluminum/

polyester tape and stranded, tinned

copper drain wire. Chrome gray PVC

jacket, 300 volt, 60°C NEC type CM, 24

pF/ft.

Wire Capacitance

Wire capacitance must comply with the

following table:

Max. Communication Max.

Link Wiring Length Wire Capacitance

1,000 feet (304.8m) Up to 60 pF/ft. (196.9 pF/m)

2,000 feet (609.6 m) Up to 50 pF/ft. (164.0 pF/m)

3,000 feet (914.4m) Up to 40 pF/ft. (131.2 pF/m)

4,000 feet (1,219.2 m) Up to 30 pF/ft. (98.4 pF/m)

5,000 feet (1,524 m) Up to 25 pF/ft. (82.0 pF/m)

3.The maximum wire length should not

exceed 5,000 feet (1,524 m).

4.Communication link wiring cannot pass

between buildings.

5.A maximum of 63 UCMs can be

connected to each COM Link. Daisy

chaining is a typical configuration.

“STAR” chaining is also acceptable.

Note: Polarity is extremely important

and must be observed on communication link connections.

6.At the VAV box, communication link

wires must be connected to TB2-1, 3 (+)

and TB2-2, 4 (-) terminals on the UCM.

7. Verify that the UCM address is properly

set (DIP switch SW1). See Table 4 for

proper DIP switch settings.

12

VAV-SVX01B-EN

Page 13

UCM 4.0 Installation

and Wiring

DIP Switch Settings

DIP Switch SW1 contains six switches

for addressing the UCM. These

switches allow a user to set a unique

communication address for each UCM.

Each UCM on a given communication

link must have a unique address in

order for Tracer Summit or the CCP to

communicate to it. Refer to Table 3 for

UCM 4.0 DIP switch settings.

Note: When using Eware to communicate to the UCM, you must add 64 to the

DIP switch address. For example, a UCM

with the DIP switch address set to 1

would be UCM Number 65 in Eware.

Table 4 – DIP Switch Settings for UCM 4.0

UCM Eware

Unit # Address Dip 1 Dip 2 Dip 3 Dip 4 Dip 5 Dip 6

1 65 OFF ON ON ON ON ON

2 66 ON OFF ON ON ON ON

3 67 OFF OFF ON ON ON ON

4 68 ON ON OFF ON ON ON

5 69 OFF ON OFF ON ON ON

6 70 ON OFF OFF ON ON ON

7 71 OFF OFF OFF ON ON ON

872 ONONONOFFONON

9 73 OFF ON ON OFF ON ON

10 74 ON OFF ON OFF ON ON

11 75 OFF OFF ON OFF ON ON

12 76 ON ON OFF OFF ON ON

13 77 OFF ON OFF OFF ON ON

14 78 ON OFF OFF OFF ON ON

15 79 OFF OFF OFF OFF ON ON

16 80 ON ON ON ON OFF ON

17 81 OFF ON ON ON OFF ON

18 82 ON OFF ON ON OFF ON

19 8 3 OFF OFF ON ON OFF ON

20 84 ON ON OFF ON OFF ON

21 85 OFF ON OFF ON OFF ON

22 86 ON OFF OFF ON OFF ON

23 87 OFF OFF OFF ON OFF ON

24 88 ON ON ON OFF OFF ON

25 89 OFF ON ON OFF OFF ON

26 90 ON OFF ON OFF OFF ON

27 91 OFF OFF ON OFF OFF ON

28 92 ON ON OFF OFF OFF ON

29 93 OFF ON OFF OFF OFF ON

30 94 ON OFF OFF OFF OFF ON

31 95 OFF OFF OFF OFF OFF ON

32 96 ON ON ON ON ON OFF

33 97 OFF ON ON ON ON OFF

34 98 ON OFF ON ON ON OFF

35 99 OFF OFF ON ON ON OFF

36 100 ON ON OFF ON ON OFF

37 101 OFF ON OFF ON ON OFF

38 102 ON OFF OFF ON ON OFF

39 103 OFF OFF OFF ON ON OFF

40 104 ON ON ON OFF ON OFF

41 105 OFF ON ON OFF ON OFF

42 106 ON OFF ON OFF ON OFF

43 107 OFF OFF ON OFF ON OFF

44 108 ON ON OFF OFF ON OFF

45 109 OFF ON OFF OFF ON OFF

46 110 ON OFF OFF OFF ON OFF

47 111 OFF OFF OFF OFF ON OFF

48112 ONONONONOFFOFF

49 113 OFF ON ON ON OFF OFF

50 114 ON OFF ON ON OFF OFF

51 115 OFF OFF ON ON OFF OFF

52 116 ON ON OFF ON OFF OFF

53 117 OFF ON OFF ON OFF OFF

54 118 ON OFF OFF ON OFF OFF

55 119 OFF OFF OFF ON OFF OFF

56 120 ON ON ON OFF OFF OFF

57 121 OFF ON ON OFF OFF OFF

58 122 ON OFF ON OFF OFF OFF

59 123 OFF OFF ON OFF OFF OFF

60 124 ON ON OFF OFF OFF OFF

61 125 OFF ON OFF OFF OFF OFF

62 126 ON OFF OFF OFF OFF OFF

63 127 OFF OFF OFF OFF OFF OFF

VAV-SVX01B-EN 13

Page 14

UCM Programming

and Operation

Chapter Overview

This chapter contains information

about the following:

Typical UCM Operating Behavior

UCM Status

UCM Set Points

UCM Setup

CHAPTER 4: UCM PROGRAMMING & OPERATION

Typical UCM Operating

Behavior

VariTrac Bypass Damper Mode of

operation

In the VariTrac Bypass Damper mode of

operation, the decisions of damper

position are made by a higher-level

system controller, e.g., the VariTrac 4.0

Central Control Panel (CCP). The

VariTrac bypass mode supports the

reporting of supply air temperature

(SAT), supply air static pressure (SAP),

and supply air CO

(CO2). This mode supports the following:

Control of damper position from the

higher-level system controller.

The control of the damper to a failsafe

bypass position upon lack of

communication to the VAV UCM for a

period of one minute.

Damper calibration from the fully open

position while the system fan is off.

Upon power up, damper calibration

and then damper movement to its

failsafe bypass position.

By convention of the VariTrac 4.0

system, DIP switch setting of 63 has

been reserved for the VariTrac Bypass

Damper. Note: DIP switch setting 63 can

be used for non-VariTrac systems.

Typical UCM Operating Behavior

VariTrane and VariTrac (zone damper,

not bypass damper) Modes of

operation

Unoccupied Mode:

Zone temperature is controlled to the

unoccupied set points. If the AHU

system fan is off the valve will be

operating in a pressure dependent

mode.

Normally the minimum flow set point is

not enforced. This allows the control

algorithm to close the valve in response

to zone temperature and set points. If

the minimum flow set points are being

enforced the valve will position itself at

a percentage equivalent to the

minimum flow set point.

concentration

2

Morning Warm Up:

Tracer Summit places the UCM in heat

mode and drives the UCM to maximum

flow. The AHU system fan is turned on

and the UCM operates in pressure

independent mode and controls the

airflow to the maximum flow set point.

NOTE: VariTrac units

pressure dependent mode.

Morning Cool Down:

Tracer Summit places the UCM into

cool mode and drives the UCM to

maximum flow. The AHU system fan is

turned on and the UCM operates in

pressure independent mode and

controls the airflow to the maximum

flow set point. NOTE: VariTrac units

always operate in pressure dependent

mode.

Occupied:

Zone temperature is controlled to the

occupied set points. Set points are

determined from the local thumbwheel

if enabled.

Cooling:

Zone temperature is controlled to the

cooling set point. Both types of reheat

(hot water and electric) are available if

needed to keep the zone from cooling

below the heating set point.

Heating:

Zone temperature is controlled to the

heating set point. Hot water reheat will

always be available if needed to keep

the zone from cooling below the

heating set point. Electric reheat may be

permitted to turn on if using auto

changeover and the supply air temp (or

auxiliary temperature for stand-alone

units) is not too high.

The following table briefly describes the

typical behavior of various UCM

configurations during normal operating

modes.

always operate in

14

VAV-SVX01B-EN

Page 15

UCM Programming

and Operation

The following table briefly describes the typical behavior of various UCM configurations during normal operating modes.

Single Control to cooling Control to heating Tracer may place Tracer may place Control to cooling Control to heating

Duct setpoint. setpoint. UCM in max flow and UCM in max flow setpoint. setpoint.

Reheat All types of local Electric reheat is Electric reheat is All types of local All types of local Electric reheat is

Fan Fan runs until valve Fan runs until valve Fan on. Fan on. Fan on. Fan on.

Series is fully closed

Fan Fan off unless local Fan off unless local Fan off unless local Fan off unless local Fan on if needed Fan on if needed

Parallel reheat is on. reheat is on. reheat is on. reheat is on. for heat. for heat.

(temp.)

Fan Fan off unless local Fan off unless local Fan off unless local Fan off unless local Fan on if needed Fan off unless local

Parallel reheat is on. reheat is on. reheat is on. reheat is on. for ventilation or reheat is on.

(flow) reheat is on.

Cooling Heating Morning Warm Up Morning Cool Down Cooling Heating

reheat available to available if using auto available if using auto reheat available to reheat available to available if using auto

keep zone above changeover and the changeover and the keep zone above keep zone above changeover and the

heating setpoint. supply air temperature supply air temperature heating setpoint. eating setpoint. supply air temperature

reheat is off. reheat is off.

Unoccupied Transition to occupied Occupied

supplies hot air. and supplies cold

Control to heating air. Control to

setpoint. cooling setpoint.

(or auxiliary temperature) (or auxiliary temperature) (or auxiliary temperature)

is below 70

hot water reheat is hot water reheat is hot water reheat is

always available to always available to always available to

keep the zone above keep the zone above keep the zone above

the heating setpoint. the heating setpoint. the heating setpoint.

AND is fully closed AND

o

F. Local is below 70oF. Local is below 70oF. Local

VAV-SVX01B-EN 15

Page 16

UCM Programming

and Operation

Calibration of Flow Sensor and Position

of Valves (Air and Water)

Calibration that is initiated via a reset is

staggered to prevent duct over pressurization. The calibration process consists

of 2 steps:

1.Establishing the true valve position.

This is done by overdriving the valve

closed (open in the case when UCM4 is

configured for VariTrac Bypass Damper

Mode of operation) for 30 seconds

beyond the configured stroke time (water

valve stroke time plus 15 seconds).

2.Adjusting the D/A output to correct any

transducer offset.

The D/A output is fed into an op amp

along with the signal from the transducer

to remove any zero offset voltage from

the pressure transducer.

Communication Protocol Selection

UCM 4.0 can communicate using either

COM 3 or COM 4 protocols. The UCM will

automatically determine whether the

front-end system is a COM 3 or COM 4

device.

Adjustable Air Valve Stroke Times

Stroke times are adjustable for all units

over the communication link as long as

the communication protocol used is

COM 4. If the UCM is in COM 3 mode, the

stroke time is only configurable for

generic and VariTrane Series F configurations. Stroke times for non-generic, nonseries F COM 3 systems are hard coded

into the UCM for the following valves:

Series F All sizes 90 seconds

Series D & E Sizes 3, 6, and 11 6 min. 24 sec.

Series D & E Sizes 17, 24, 32, and 42 6 minutes

VariTrac Round 57 seconds

VariTrac Rectangular 60 seconds

Series C Sizes all but 20, 40 7 min. 12 sec.

Series C Sizes 20, 40 9.25 min.

Timed Override (TOV) Button Functions

There are two buttons that the user can

access. Pushing the timed override

button (on) in an unoccupied period

provides two hours of occupied control.

The UCM will switch into occupied mode

and control to the occupied set points for

two hours. The cancel button stops a

timed override sequence and returns to

unoccupied control. The UCM will revert

back to unoccupied mode immediately.

Timed override (TOV) and cancel

buttons are recognized if they have

been pushed for at least 0.5 seconds

and no more than 15 seconds. Pushing

the buttons for longer than 15 seconds

will simulate a zone temperature sensor

failure. The failure is non-latching and

ceases as soon as the button is

released.

“*” And “**” Functions

Also in conjunction with the

thumbwheel, the timed override button

can cause an override to maximum

flow or unoccupied. The TOV button

must be pushed for at least 2 seconds

and no more than 15 seconds with the

thumbwheel in one of the override

positions to recognize an override

condition. With the thumbwheel in the

“*” position an override to maximum

flow is generated. With the thumbwheel

in the “**” position an override to

unoccupied is generated. The maximum flow and unoccupied overrides

are held until the thumbwheel is moved

into the normal operating region.

Note: If the thumbwheel is not enabled,

locally generated overrides (“*” or “**”)

are not possible.

Local Occupancy detector.

Local occupancy detection was added

with UCM4 on input TB4-1. TB4-1 is a 24

VAC input operated in a negative logic

mode wherein the absence of signal

indicates occupancy and the presence

of 24 VAC indicates non-occupancy. The

occupancy detector’s interface is two

dry relay contacts. Relay closure (short

between two dry relay contacts and

presence of 24 VAC at TB4-1) shall

indicate unoccupancy. The VAV UCM

has a COM 4 configuration bit to

indicate if the VAV UCM has an occupancy sensor connected.

When configured for an occupancy

sensor and communications are active,

an occupancy input state will be

reflected by the UCM to an upper level

system controller. The upper level

system controller is responsible for

causing any system changes necessary

to provide occupied control.

When configured for an occupancy

sensor and communications are not

active and occupancy is detected, the

UCM shall transition to the occupied

mode of operation. Upon loss of the

occupancy indication from the

occupancy detector, the VAV UCM will

revert back to unoccupied mode.

When configured for an occupancy

sensor and communications are active,

loss of COM 4 communications does

not result in the VAV UCM defaulting to

occupied mode.

When configured as a generic input

and communications are active an

occupancy input state will be reflected

by the UCM to an upper level system

controller. The upper level system

controller shall be responsible for

causing any system changes necessary

to provide occupied control. When

configured for generic mode, loss of

COM 4 communications will result in

the UCM defaulting back into occupied

mode.

Reheat Control

Reheat operation is allowed provided

the following conditions are satisfied:

1. The unit is not calibrating.

2.Flow overrides (open or closed) are not

in affect.

3.Reheat lockout is not enabled.

4.If maximum flow override or fan

lockout is present then parallel fan with

any electric heat is not allowed.

5.If the zone temperature sensor has

failed cold (open), reheat is not allowed.

6.While in the heat mode only hot water

heat can be used. If using auto

changeover, UCM 3.3 and later will

enable electric heat in the heat mode if

the auxiliary temperature is less than

the electric heat on set point and will

disable electric heat when the auxiliary

air temperature is greater than the

electric heat off set point.

Modulating Hot Water Reheat

When the zone temperature reaches the

heating set point + 0.5°F the reheat is

turned completely off. The modulating

hot water valve is over driven closed

(by 15 seconds) any time reheat is no

longer required.

16

VAV-SVX01B-EN

Page 17

UCM Programming

and Operation

Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM)

modulates 2 stages 0 to 100% with a 3minute time base. The first stage (J9) of

PWM modulates 0 to 100% to supply 0

to 50% of the reheat need. The second

stage (J10) modulates 0 to 100% to

supply 51% to 100% of the reheat need.

Hot Water Heat Maximum Override

(Maximum Heat Required)

A UCM with hot water outputs can be

commanded to override the water valve

position to maximum position. For

units with 1 - 3 stages hot water will

turn on all of its water outputs (possible

fan is not affected). For units with

proportional hot water the hot water

valve will be driven open, and if no fan

is present, output 3 (J11) will energize.

The hot water override can be commanded via communications and can

be used to assist in water balancing.

See Chapter 7 for Water Balancing

Procedure.

Auto Changeover

Auto changeover is based on zone

temperature and the supply air temperature as communicated or measured by the auxiliary temperature

sensor.

1. When the supply air temperature is 10

degrees above the zone temperature

the control action will be Heat.

2.When the supply air temperature is

below or equal to the zone temperature

the control action will be Cool.

3.If the supply air temperature is between

the zone temperature and the zone

temperature +10

supply air temperature < zone

temperature + 10

remains the same and the UCM

controls to the minimum flow set point.

Flow Overrides

During flow overrides of drive to

minimum or maximum the flow is

controlled to the appropriate set point.

With UCM 3.3 and prior during flow

overrides of open or closed, the valve is

continuously driven in that direction

forever. UCM 3.3 and prior rely on the

limit switches to protect the drive train.

UCM 4.0 drives for the stroke time, then

stops.

o

F (zone temperature <

o

F), the control action

Enforce Minimum Flow Set Points

The UCM can be told not to enforce the

minimum flow set point (energy saver)

via communications. This allows the

control algorithm to choose any value

from 0 to the maximum flow set point.

The primary use of this is VariTrac

systems, but it is available for any

configuration.

Calculated Cool Ventilation Ratio (Z

Factor)

As a measurement of zone ventilation,

a “Z” factor is computed and available

over communications (only if using the

COM 4 protocol). The UCM does not

use this value for any control purposes.

It is computed as follows:

Z = (Ventilation Target)/Sensed Flow

Where the ventilation target is

dependent on occupancy and ranges

from 0 to 100.

Z will be set to zero if the active

minimum flow set point is 0.

Z will be set to zero if the sensed flow

(or valve position) is 0.

If position control is being used the

sensed flow is replaced with the valve

position.

The Z factor may then be used by BAS

equipment to satisfy ASHRAE 62-89

and calculate the outside air flow set

point.

IAQ Set Point Modification

Ventilation rate change for IAQ purposes is accomplished by setting the

active minimum flow set point to the

edited cooling minimum flow set point

* IAQ multiplier when no heat is being

supplied to the zone. When heat is

being supplied (heat mode or reheat

active) the active minimum flow set

point is the greater of heating minimum

flow and cooling minimum flow * IAQ

multiplier. The result of cooling minimum flow * IAQ multiplier is limited to

the maximum flow set point. Reheat

continues to stage on/off based upon

the heating minimum flow set point.

The IAQ multiplier range is from 0.0 to

10.0 in tenths.

Wireless Compatibility

Up to five wireless sensors may be

assigned to a UCM. Four sensors may

be classed as “averaging”; one sensor

can be classed as “backup”. The

hardwired sensor is optional and can

be classified as:

“Averaging” (A peer with the averaging

wireless sensors)

“Primary Backup” (Supersedes any

backup wireless sensor)

“Secondary Backup” (Used only if the

wireless backup sensor is not

functional)

“Not Present” (UCM 4.0 only, UCM 3.3

and prior treated this selection the

same as Secondary Backup)

The backup sensors are optional.

Backup sensors for temperature and

set point inputs only affect the UCM if

all averaging sensors are failed. Backup

button functions are always used. Any

combination of backup strategies is

permitted.

Although the hardwired sensor is

optional in a wireless system, having

one provides valid set point and zone

temperature values for the UCM to use

during the time between a reset (power

cycle or via communication) and the

reception of the next wireless data

update. During this time, if there is no

hardwired sensor the zone temperature

used by the UCM is 0

and hardwired set point and zone

temperature will be indicated as failed.

In a wireless system with a hardwired

sensor enabled and configured as

averaging, primary backup or

secondary backup after a reset the

UCM will use the hardwired sensor

values until the wireless sensor values

are received.

Button pushes from any sensor

assigned to a UCM will be accepted

and used without regards to source,

(i.e., any assigned sensor can cause

any button function). The priority of

button pushes is: 1. Override to

maximum flow, 2. Override to

unoccupied, 3. Timed override, and 4.

Cancel. Any sensor that is generating a

local override will not be used to

calculate the local thumbwheel setting.

The UCM must receive an update from

a wireless sensor at least every 24

minutes for that sensor to continue to

affect the zone control. Sensors that do

o

F and the global

VAV-SVX01B-EN 17

Page 18

UCM Programming

and Operation

not update at least every 24 minutes will

be viewed as failed.

Composite zone temperatures and

thumbwheel settings are derived from

the transmitted data and the hardwired

sensor if applicable. Data for the zone

temperature and thumbwheel value

comes first from the averaging sensors

then the primary backup, then the

secondary backup. Zone temperature is

the simple average of the available

sensors. The thumbwheel setting is the

weighted average of the available

sensors.

zone temperature = (measured

temperature + zone temperature

correction)/(Number of sensors)

thumbwheel setting = ((thumbwheel

setting + thumbwheel

correction)*weighting factor))/(weighting

factor)

Flow (or Supply Pressure in the case of

bypass damper mode)

Each VAV valve contains a “flow ring.” It

is a multi-ported Pitot tube. The differential flow transducer connects to the flow

ring. One side of the flow ring is exposed

to the duct static pressure, the other is

exposed to static and velocity pressure.

The difference is velocity pressure. By

knowing the air velocity in the duct and

the size of the air valve, the air volume

can be calculated. See Chapter 7 for Air

Balancing Procedures.

UCM STATUS

The status display does not contain any

editable data. If Communications are

down (UCM NOT COMMUNICATING is

shown), the rest of the status display will

not appear. Note: The following screen

shots are taken from Trane EveryWare™

Software (Eware). When communicating

with a UCM 4.0 or greater via Eware,

you must have Eware software revision

1.35 or greater. The display will be similar

when using a CCP. However, when

communicating to VAV UCM using

Tracer Summit, although the display will

be completely different, the various

functions of the UCM perform the same.

Please reference the VariTrac Operators

Guide or the Tracer Summit System

Programming Guide (BMTW-SVP01AEN) for exact CCP and Summit (respectively) displays.

When viewed from the Eware, the UCM status display appears as follows:

Following are descriptions of each line on the UCM status screen.

Zone Temperature

This line displays the temperature as recorded by the zone sensor. If the zone sensor

has failed, this line will read FAIL.

Active Cooling Set Point and Active Heating Set Point

These set points are the active (actual) cooling and heating set points currently used

by the UCM. If the zone sensor is enabled, the zone sensor set point will be used as

the Active Cooling set point during occupied mode.

Control Mode

This line shows whether the UCM is in the occupied or unoccupied mode. The

control mode determines which heating and cooling set points to use.

Control Action

This line shows the heat or cool control action of the UCM. The cool control action

will modulate the air valve as if the supply duct air is colder than the space temperature. The heat control action will modulate the air valve opposite the cool control

action (supply duct air is warmer than the space temperature).

Flow

This line displays the unit’s airflow rate expressed in the flow units selected in the

setup menu. This line will not be shown if the UCM is using position control instead

of flow control. The UCM will use position control if the flow sensor is failed or not

installed. The UCM will also use position control if the unit’s airflow rate is less than

5% or greater than 110% of the unit’s cataloged CFM. For example, the UCM will use

position control for a size 600 CFM unit if the flow is less than 30 CFM (5%) or greater

than 660 CFM (110%). NOTE: Although the UCM will read flow down to 5% of

cataloged and up to 110% of cataloged, the range of MIN FLOW settings is 0%, or

10% to 100% of cataloged. The range of MAX FLOW settings is 100% of cataloged. In

the example above, the lowest allowable MIN FLOW set point is 60 CFM (zero is also

permissible) and 600 CFM is the highest allowable MAX FLOW set point.

Flow Control

This line displays the actual flow control override of the UCM. These overrides can be

AUTO, OPEN, CLOSED, MIN, and MAX.

Position

This line displays the UCM’s air valve position.

18

VAV-SVX01B-EN

Page 19

UCM Programming

and Operation

Present Minimum

If the UCM is using flow control, this

line will show the present minimum

expressed in the flow units selected in

the setup menu. If the UCM is using

position control, the minimum will be

expressed as the percentage open.

Ventilation Ratio

The ventilation ratio is equal to the

“outside air requirement” divided by

the air valve flow. The UCM set points

screen provides entry for the occupied

and unoccupied outside air requirement.

Zone Sensor Set Point

This line will not be shown if the zone

sensor thumbwheel functions have

been edited to DISABLE on the UCM

setup menu nor on zone sensors

without the thumbwheel.

The following describes what may be

displayed on this line:

Zone sensor set point 70.1

This text displays the current zone

sensor set point.

Zone sensor set point MAX

This text will be displayed if “*” appears

on the zone sensor thumbwheel and

has been overridden to MAX (“*”

means the high limit and TOV

pushbutton have been depressed).

Zone sensor set point UNOCC

This text will be displayed if “**”

appears on the zone sensor

thumbwheel and has been overridden

to UNOCC (“**” means the low limit

and TOV pushbutton have been

depressed).

Zone sensor set point FAIL

Displayed if no zone sensor module is

supplying the UCM with a valid set

point.

Unit Type, Heat Type, and Fan Type

These lines show the different types of

units, the type of heat and the type of

fan. Further descriptions of these types

are found under the UCM setup

section.

Auxiliary Temperature

The displayed value will reflect the

auxiliary sensor temperature. This field

will not be shown if the unit does not

have an auxiliary sensor.

Software Revision

This line shows the version of the UCM

firmware that is being used.

The following lines will only appear if

the condition exists:

UCM Memory Failure

This text will be displayed if the UCM’s

EEPROM has failed.

Calibrating

This will be displayed if the UCM is

calibrating. The UCM will calibrate after

a power-up or as commanded by an

ICS device.

Control Offset Active

This line will be shown if the control

offset is currently being used. It will

only be shown if the edited occupied

set points are being used and the

control offset is active for the UCM.

Max Hot Water Override

This line will be shown if Max hot water

override is edited to YES on the UCM

setup menu.

UCM SET POINTS

In Eware, the UCM set points display

appears as follows:

Following are descriptions of each line

on the UCM set points screen.

Active Cooling Set Point

Active Heating Set Point

The set points cannot be edited and

reflect the set points currently being

used for temperature control.

Occupied Cooling Set Point

Occupied Heating Set Point

Both set points have a range of 30.0°–

100.0°F (-1.1° – 37.8°C). If a zone sensor

thumbwheel set point is not being

used, these set points will be used as

the UCM’s active set points during

occupied times. The cooling set point

must be greater than or equal to the

heating set point plus 2.0°F (1.1°C).

NOTE: Occupied cooling and heating set

points must be set within the cooling set

point high limit and the heating set point

low limit in order to control to the proper

set points.

Unoccupied Cooling Set Point

Unoccupied Heating Set Point

Both set points have a range of 30.0° –

100.0°F (-1.1° – 37.8°C). These set points

are used when the UCM is unoccupied.

The unoccupied cooling set point must

be greater than or equal to the unoccupied heating set point plus 2.0°F (1.1°C).

VAV-SVX01B-EN 19

Page 20

UCM Programming

and Operation

NOTE: Unoccupied cooling and heating

set points must be set within the cooling

set point high limit and the heating set

point low limit in order to control to the

proper set points.

Cooling Set Point Low Limit

Heating Set Point High Limit

These limits apply to both occupied and

unoccupied modes of operation. Both

limits have a range of 30.0° – 100.0°F

(-1.1° – 37.8°C). The set point limits will

be applied to the active set points by

the UCM but will not restrict operator

entry of set points.

NOTE: These limits are allowed to cross

(i.e. the cooling set point low limit can be

greater than, less than, or equal to the

heating set point high limit).

The UCM will enforce these limits

regardless of the source of the active

set points.

Cooling Set Point High Limit

Heating Set Point Low Limit

These limits apply to both occupied and

unoccupied mode. Occupied and

unoccupied cooling and heating set

points are subject to high and low

limits. The cooling set point high limit

and the heating set point low limit

“cap” your unoccupied set points,

which directly impacts energy savings.

The upper level device is responsible

for preventing the resulting set points

from being crossed. This may happen if

the heating set point low limit is above

the cooling set point high limit. Having

the cooling set point high limit and the

heating set point low limit set to the

factory defaults (cooling high limit =

102°F, heating low limit = 43°F) should

prevent them from impacting field

operation.

Heat Offset

The set point has a range of 2° – 10°F

(1.1° – 5.6°C). When a zone sensor

thumbwheel set point is being used, the

cooling set point will equal the zone

sensor thumbwheel set point and the

heating set point will equal the zone

sensor set point minus the Zone

Sensor Heating Set Point Offset. The

offset will always be displayed and will

always be editable even if a zone sensor

set point is not being used.

Control Offset Value

The Control Offset has a range of 0° –

5°F (0° – 2.8°C). When Control Offset is

active, this value will be added to the

edited occupied cooling set point and

subtracted from the edited occupied

heating set point to determine the

active set points.

Note: The control-offset value will not

effect a zone sensor thumbwheel set

point.

Fan Control Set Point

The entry on this line determines when

a parallel fan will be turned ON and OFF.

If “Parallel fan control” has been edited

to “DEG” the fan control offset will be

entered as a temperature offset (2° –

10°F) which will be added to the heating

set point. If “Parallel fan control” has

been edited to “FLOW” this line will be

entered as a percent (0 to 100%) if the

unit is a VariTrane unit. The entry field on

this line will appear as “—“ if the unit

does not have a parallel fan.

BP Failsafe Position

This setting only applies to VariTrac

Bypass mode of operation. If the CCP

stops communicating with the Bypass

Damper UCM for more than 60

seconds, the UCM will drive to the

failsafe position.

BP Command Position

This setting only applies to VariTrac

Bypass mode of operation. The CCP

uses this parameter to set the proper

position of the Bypass damper.

Maximum Flow/Position

This range is 10% to 100% of the unit’s

cataloged CFM size. Cooling and

heating flow can be edited to zero.

Minimum Flow/Position

Although the UCM will read flow down

to 5% of cataloged, the range of MIN

FLOW settings is 0%, or 10% to 100% of

cataloged.

Min Heating Flow

The UCM will not drive its position/flow

below this value under normal operating conditions while in the HEAT mode

(warm air in the supply duct) or while it

is using local heat. The Min Heating

Flow value must be less than or equal

to the Maximum Flow value. If the Min

Local Heat Flow is enabled, then the

Min Local Heat Flow is used to determine the minimum position/flow

instead of the Min Heating Flow when

local heat is on.

Min Local Heat Flow

This input allows a separate heating

minimum flow set point to be used for

local reheat. When local reheat is on,

your active minimum flow can not be

less than your minimum local heat flow

set point.

20

VAV-SVX01B-EN

Page 21

UCM Programming

and Operation

UCM SETUP

In Eware, the UCM SETUP display appears as follows:

The following are descriptions of each line on the UCM setup screen.

Unit Type

The possible Unit Types are, VariTrac Rectangular, VariTrane F Rectangular, VariTrane F

Round, Bypass-Damper Rectangular, Bypass Damper Round, Generic, VariTrane D,

VariTrac Round, and VariTrane C.

Editing the unit type will affect the following:

Heat type (defaults to NONE)

Fan type (defaults to NONE)

Unit size (defaults to the smallest unit size)

Air Valve drive time

Control algorithm gains (KP, reset times, valve flow constant) for air valve and water

valve.

Note: This means that the unit type should be edited before any of the items in the list

are edited.

Heat Type

The heat type assignment identifies what kind of heat control algorithm is to be used

by the UCM. Possible selections include the following:

NONE – No heat available

1-3 stages electric

Slow pulse width modulation – Electric (3 min. time base).

Prop hot water and aux. output

1-3 stages hot water/perimeter

If the unit type is edited, the heat type will automatically be changed to NONE. If the

heat type is edited or changed automatically, all 3 of the UCM outputs will be set to

Normally Open and the “Max hot water override” will be canceled if it is active.

Fan Type

This entry identifies the fan type to be

controlled by the UCM (None, Series or

Parallel) and shows whether the unit’s

fan has been enabled or disabled. The

enable/disable field on this line will not

appear if the unit has a series fan and

only indicates if the parallel fan has

been disabled. The UCM may lockout

the fan on its own if any of the following

apply: control action HEAT; flow

override to drive OPEN, CLOSE, or

MAX; or if the zone temperature sensor

has failed.

NOTE: This line will not appear if the unit

does not have a fan.

BIP Configuration (Default is Generic)

The BIP Configuration interface is for

dry relay contacts. There are two modes

of operation available at TB4-1, Generic

BIP and OCC Detector. In generic mode,

the state of the input is only passed on

from the UCM to Summit. CPL code

must be written in order for Summit to

utilize any signal received from this

generic input. When configured as a

generic input and communications are

active, an occupancy input state will be

reflected by the UCM to the upper level

system controller. The upper level

system controller shall be responsible

for causing any system changes

necessary to provide occupied control.

When configured for generic mode,

loss of communications will result in

the UCM defaulting back into occupied

mode.

In occupancy detector mode, the

absence of a 24 VAC signal at TB4-1

indicates occupancy and the presence

of 24 VAC indicates non-occupancy.

When configured for an occupancy

sensor and communications are active,

an occupancy input state will be

reflected by the UCM to an upper level

system controller. The upper level

system controller shall be responsible

for causing any system changes

necessary to provide occupied control.

When configured for an occupancy

sensor and communications are not

active and occupancy is detected, the

UCM shall transition to the occupied

mode of operation. Upon loss of the

occupancy indication from the

VAV-SVX01B-EN 21

Page 22

UCM Programming

and Operation

occupancy detector, the VAV UCM will

revert back to unoccupied mode.

However, when configured for an

occupancy sensor and

communications are active, loss of

communications does not result in the

VAV UCM defaulting to occupied mode.

Unit Size

The unit size range is dependent on the

unit type selected.

Use Local Heat Set Point (Default is No)

When “No” is selected, the UCM will

use the Min Heating Flow. When “Yes”

is selected, the UCM will use the Min

Local Heat Flow Set Point. See UCM set

points for more information regarding

Min Heating Flow and Min Local Heat

Flow Set Points.

Thumbwheel Set Point

If DISABLE is selected, the following

features of the UCM’s zone sensor

thumbwheel functions will be disabled:

set point; ability to generate a “drive to

max” command; ability to generate a

“go unoccupied” command.

Note: Disabling thumbwheel functions

does not disable the ON/Cancel

pushbutton feature.

Aux Input Select (Defaults to Aux Tmp

Sensor)

This entry determines the configuration

of the A/CO

the UCM. Selecting AUX TMP SENSOR

configures the input to use an auxiliary

temperature sensor. Selecting CO

Sensor configures the input to use a

CO2 sensor.

Parallel Fan Control

This entry will determine if a parallel fan

will be controlled based on zone

temperature or on flow conditions. If

“Parallel fan control” has been edited to

“DEG” the fan control offset will be

entered as a temperature offset (2° –

10°F) which will be added to the heating

set point. If “Parallel fan control” has

been edited to “FLOW” this line will be

entered as a percent (0 to 100%) if the

unit is a VariTrane unit. The entry field on

this line will appear as “—“ if the unit

does not have a parallel fan.

input on terminal TB3-5 of

2

2

Note: See the Sequence of Operations

section of this manual for details on

parallel fan operation.

Auxiliary Temperature

The current auxiliary temperature will

be displayed on this line. If the auxiliary

temperature sensor has failed or is not

present, “—“ will be displayed instead

of the temperature.

Output “X” Normally

These lines will always be shown as

Normally Open or Normally Closed, but

can only be edited if the heat type is “1-3

stages hot water”. If the unit has a fan,

output 3 will be set to Normally Open

and will not be editable. If output 3 is

not controlling a fan, it is editable for

proportional hot water units. If the unit’s

heat type is changed, all of the outputs

will be set Normally Open.

Aux Temp Calibration

This line allows an auxiliary temperature calibration offset to be entered with

a range of -10.0°– 10.0°F (-5.6° – 5.6°C).

The UCM will add the offset to the value

being read by the UCM’s auxiliary

temperature sensor. For example, if the

auxiliary temperature sensor is indicating that the temperature is 74°F (23.3°C),

and the auxiliary temperature calibration offset is -1.5°F (-0.8°C), the actual

temperature used by the UCM and

reported to the ICS will be 72.5°F

(22.5°C).

Wired Zone Temperature

This is the temperature being reported

by the zone sensor. The temperature

will be displayed with the temperature

calibration offset applied. If the temperature sensor has failed or been

disabled, “—“ will be displayed instead

of the temperature.

Wired Zone Temp Calib

The zone sensor calibration offset has a

range of -10° – 10°F (-5.6° – 5.6°C). The

temperature will be displayed with the

temperature calibration offset applied.

The UCM will add the offset to the value

being read by the UCM’s zone temperature sensor. For example, if the temperature sensor is indicating that the

temperature is 74.0°F (23.3°C) and the

temperature calibration offset is -1.5°F

(-0.8°C), the actual temperature used by

the UCM and reported to the ICS will be

72.5°F (22.5°C).

Max Hot Water Override

Entering YES for this line forces the

UCM to turn on all of its hot water

outputs or drive open its proportional

hot water valve. This may be useful for

water system balancing (see Chapter 7

for water balancing information).

Only units with the following heat types

will be affected:

1-3 stages hot water

All three of the heat outputs will be

energized. If the unit has a fan, output 3

will not be affected.

Proportional hot water and aux. output

The hot water valve connected to

outputs 1 and 2 will be driven open.

Output 3 will energize if it is not

controlling a fan.

The UCM will maintain the “Max hot

water override” condition over power

failures. The only way to cancel a “Max

hot water override” is by editing this

line to NO.

If the unit does not have “1-3 stages hot

water” or “proportional hot water and

aux. output”, “—“ will be displayed

instead of the ON/OFF descriptor.

Note: Unit heat must be enabled in

order for the Max hot water override to

be effective.

Wired Thumbwheel Set Point

This is the set point being reported by

the zone sensor. The set point will be

displayed with the set point calibration

offset applied. If the zone sensor has

failed or been disabled, “—“ will be

displayed instead of the set point.

Flow Override

The flow override entered on this line

has the highest priority of all the flow

overrides (group, binary inputs, or

upper level system functions). Possible

entries include AUTO, OPEN, CLOSED,

MIN, and MAX. When a non-auto flow

override is edited from the UCM level,

the flow override will be maintained

over power failures. See Sequence of

Operations for more information.

22

VAV-SVX01B-EN

Page 23

UCM Programming

and Operation

Wired Thumbwheel Calib

The thumbwheel calibration offset has

a range of -10° – 10°F (-5.6° – 5.6°C). The

set point will be displayed with the set

point calibration offset applied. The

UCM will add the offset to the value

being read by the UCM’s thumbwheel.

Cooling Flow Correct

Present Cooling Flow

Measured Cooling Flow

This Present Cooling Flow shows the

current flow being reported by the

UCM. If the Present Cooling Flow is

incorrect, the operator can enter the

Measured Cooling Flow and the

Cooling Flow Correct calibration factor

will automatically be recalculated. For

example, if a measured flow indicates

330 CFM, and the UCM’s flow sensor

reports 300 CFM, the measured flow

(330) can be entered, which will calculate a calibration factor of 1.10. If the

UCM is using position control, the

current flow reported by the UCM

should be 0 and any entry on the line

will generate an “Entry too large.” See

Chapter 7 for more information.

Wired Sensor Type

This line is used to edit the type of

temperature sensor being used. The

sensor type can be selected as either

Thermistor or RTD. Note: Factory

supplied sensors are Thermistors.

Wired Sensor Use

This input determines the function of

the wired zone temperature sensor.

Select Averaged to use the sensor as

part of a wired system OR to use the

sensor as an averaging sensor in a

wireless system. Average will use the

sensed temperature in the temperature

averaging calculation and set point

temperature will be averaged according

to the set point vote. If this is the only

sensor the average will be the sensed

temperature. Backup means the UCM

will use this temperature only if the

primary sensor assigned to the UCM

has stopped communicating. First

backup means the UCM will look for a

wired sensor first if the wireless sensor

fails. Second backup means the UCM

will look for a wireless backup sensor

first if the wireless sensor fails. Select

not used if no sensor is present or to

ignore the wired zone sensor.

Wired Set Point Vote

Set point vote determines the weighting

of the set point vote. The range is 0-9.

This number represents the number of

votes the sensor gets when the set

points are averaged. If “0” is selected

the sensor gets no vote.

VAV-SVX01B-EN 23

Page 24

Sequence Of

Operations

Chapter Overview

This chapter describes the sequence of

operation of the available unit types.

Unit operation during the available

override commands will also be

described. This chapter contains

sequence of operations pertaining to

the following:

Single Duct Units

Parallel Fan-Powered Units

Series Fan-Powered Units

Zone sensor functions

Flow Sensor

Failure Modes

24

CHAPTER 5: SEQUENCE OF OPERATIONS

Single Duct Units

When the UCM control action is COOL,

the UCM controls the modulation of the

air valve as a cooling source to maintain the “active cooling set point”.

Airflow is varied between the minimum

and maximum flow set points to

maintain temperature set points. A PI

control algorithm is utilized to minimize

the measured difference between the

active zone set point and the actual

zone temperature.

It is possible for units to utilize electric

or hot water heating coils to maintain

temperature set points. After the

temperature loop calls for minimum

cooling flow and the zone temperature

is at or below the heating set point,

these units shall control to their

respective “Minimum Heating Flow”.

Once this “Minimum Heating Flow” is

established, heat is allowed to operate

according to the “Heat Control Type”

specified for the controller. For electric

heat units, this heating minimum flow

set point must be at or above 20% of

the unit cataloged airflow. Electric heat

may be pulse width modulation or

staged electric heat. Staging has the

following ON and OFF switch points.

UCM 3.3 and later allow hot water to

turn on regardless of flow/position.

Stage ON Switch point Off Switch point

1 At the heating 0.5°F above the

set point heating set point

2 1°F below the 0.5°F below the

heating set point heating set point

3 2°F below the 1.5°F below the

heating set point heating set point

Hot water heat control may be either

ON/OFF or proportional. ON/OFF hot

water is activated on the same schedule

as staged of electric heat.

Utilization of the “Heating Minimum

Flow” set point allows separate

minimum flows to be active depending

on whether or not the unit heat is

active.

Override Conditions

Unoccupied

If the control mode is unoccupied

(either as edited by software or as

determined by the binary input), the

unoccupied cooling and heating

temperature set points are used for

temperature control. Heat outputs

remain active.

Heating

If the control action is edited to HEAT,

the UCM controls the air valve as a

heating source rather than cooling.

Electric reheat is available the supply air

temperature (or auxiliary temperature)

is below 70

always available to keep the zone above

the heating set point. The “Heating

Minimum Flow Set Point” will set the

minimum flow.

Flow Control Override

Flow control may be overridden by any

of the following commands:

Drive Air Valve Fully Open

The air valve will be fully open and heat

outputs disabled.

Drive Air Valve Fully Closed

The air valve is driven fully closed and

heat outputs disabled.

Drive Air Valve to Minimum Flow

The air valve is driven to the minimum

airflow set point. The heat outputs

remain operational.

Drive Air Valve to Maximum Flow

The air valve is driven to the maximum

airflow set point. The heat outputs

remain operational.

Heat Control Override

Heat control can be disabled, locking

out heat outputs.

Control Offset

Control offset may be enabled, which

adjusts the edited cooling and heating

set points.

Recalibrate (Reset)

The recalibrate function can be enabled.

If enabled, the unit will perform a

recalibration.

(Single Duct)

The UCM occupied controls can be

overridden by the following override

commands:

o

F. Local hot water reheat is

VAV-SVX01B-EN

Page 25

Sequence Of

Operations

Fan-Powered Units

Fan Actuation Schedule

FAN TYPE OCCUPIED UNOCCUPIED

Series ON OFF if valve closed

Parallel based on Cool mode: ON if zone temp Cool mode: OFF if zone OFF unless local

Temperature <heating set point + fan temp > heating set point + reheat is on

Parallel based Cool mode: ON if flow < fan Cool mode: OFF if flow > OFF unless local

on Flow set point OR if flow < active fan set point + 5% AND reheat is on

Parallel Fan-Powered Units

Occupied Units

Air valve control for parallel fanpowered units is the same as for single

duct units.

The first heat output is utilized to

control the fan. The remaining outputs

are utilized to control heat. Fan

energization is a function of the

“Parallel Fan Control Offset”. The

parallel fan control can be specified as

an offset temperature in degrees above

the heating set point or as a flow offset

in CFM. The fan will be energized above

the fan control offset if reheat is

required.

offset fan offset + 0.5°F Heat mode: fan off unless

Heat mode: fan off unless reheat is on

reheat is on

minimum flow set point flow > active minimum

Heat mode: fan off unless flow set point

reheat is on Heat mode: fan off unless

reheat is on

Heat stages are energized on the

following schedule:

Stage ON Switch point OFF Switch

point

1 At the heating 0.5°F above the

set point heat set point

2 1°F below the 0.5°F below the

heat set point heat set point

Whenever the fan is energized, the

primary airflow is controlled at the

“Heating Minimum Flow” set point.

Override Conditions

(Parallel Fans)

The UCM occupied controls can be

overridden by the following override

commands:

Note: The fan control offset is entered in

CFM when used on a VariTrane unit.