Trane UCCA Catalogue

Catalog

Performance Climate Changer Air Handler

Model UCCA

Sizes 3-30

December 20 13

CLCH-PRC024A-EN

Trane Performance Climate Changer™ Air Handlers

Mixing box with

angled filter rack

Coil

Direct-drive

fan

2-inch double-wall

foam injected casing

VFD

Low voltage

control enclosure

T rane has a Performance Climate Changer air handler adaptable to almost every environment. The

Performance model UCCA is designed for budget-conscience applications, but does not sacrifice

on construction, quality, or performance.

• 2-inch R13 foam insulated panels and doors

• Less than 0.005 inches at +/-4 inches w.g. panel and door deflection

• All airfoil bladed dampers meet ASHRAE 90.1 lowest specified leakage

• Quick-connect wiring minimizes installation costs and provides wiring integrity between

sections

• Factory engineered and mounted control packages

• Hinged and handled access doors

• UL/CUL listed

• AHRI Standard 430-certified air-handling unit

• AHRI Standard 410-certified coils

• 2-inch/4-inch combination filter, or 2-inch/4-inch combination filter in a mixing box

• Fan options including forward curved (FC) and direct-drive plenum (DDP) fans

• Electric heat including full modulating control

• Units ship on skid for forklift transportation at job site

• Building Information Modeling (BIM) drawing to minimiz e jobsite ductwork, electrical, p iping,

and structural interference

2 CLCH-PRC024A-EN

Table of Contents

Trane Performance Climate Changer™ Air Handlers . . . . . . . . . . . . . . . . . . . . . 2

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Construction and Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Engineered for Good IAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Proven Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

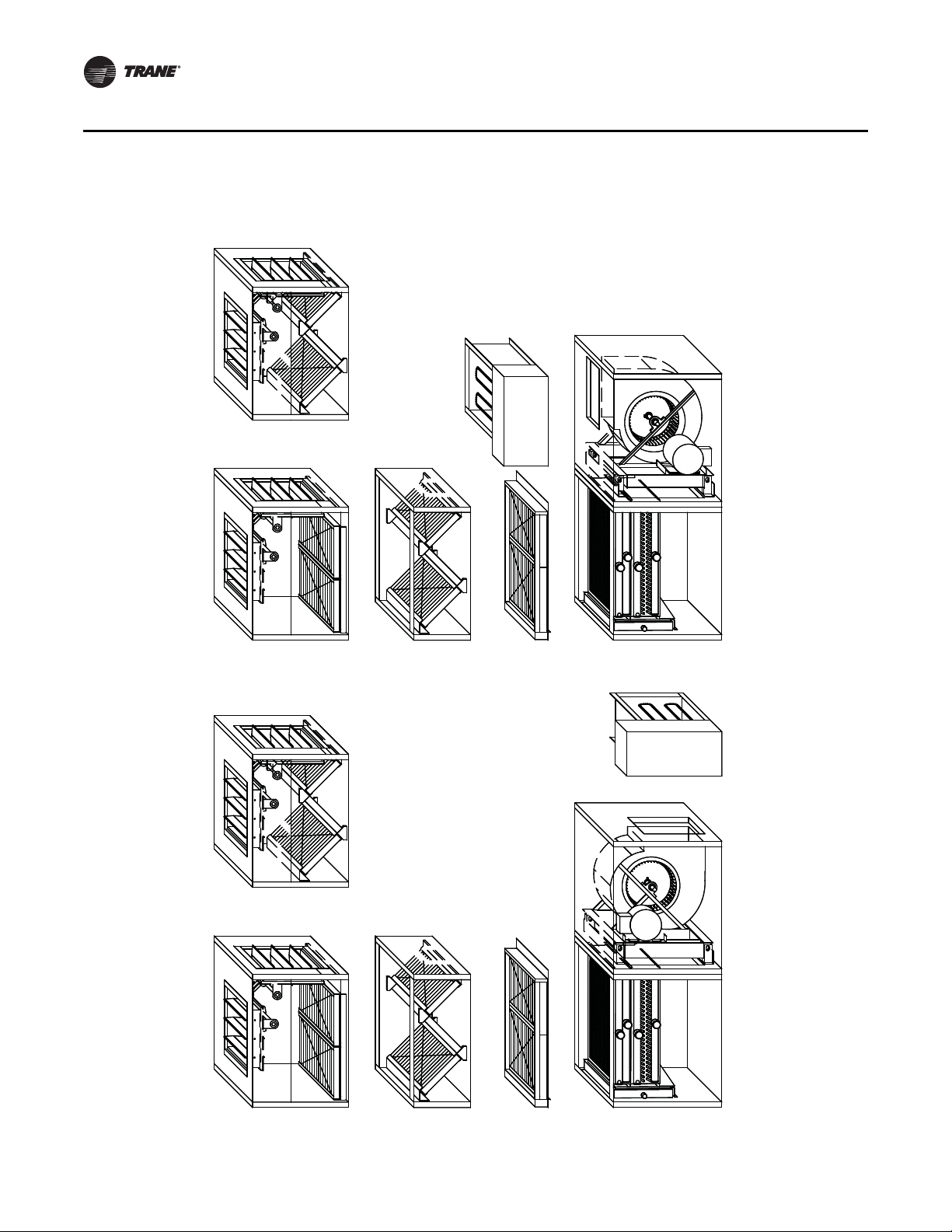

Standard AHU Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DX Cooling Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sloped Drain Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Serviceability/Cleanability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Single Source Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AHRI Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

UL Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ISO Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Horizontal Draw-Thru . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

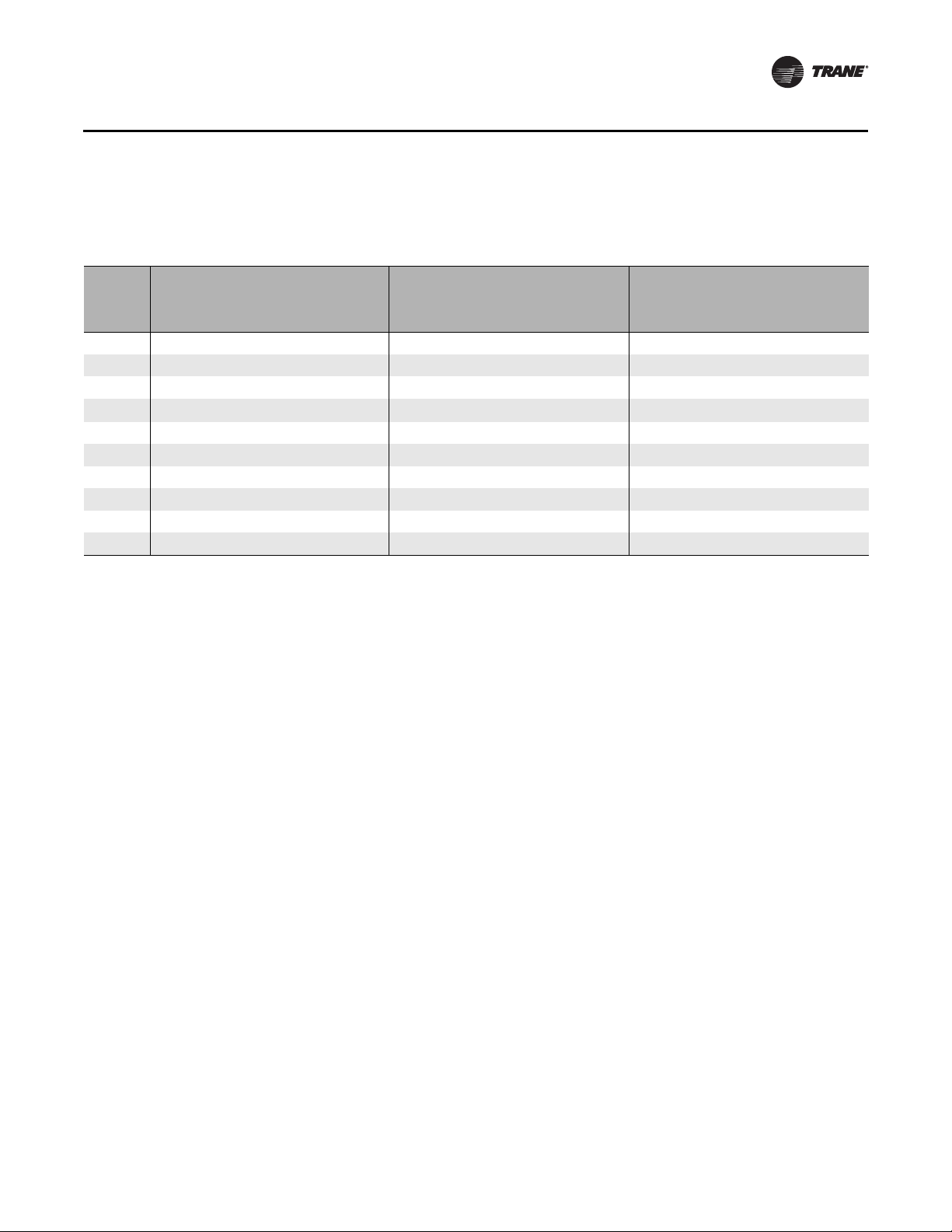

Vertical Draw-Thru . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Components and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

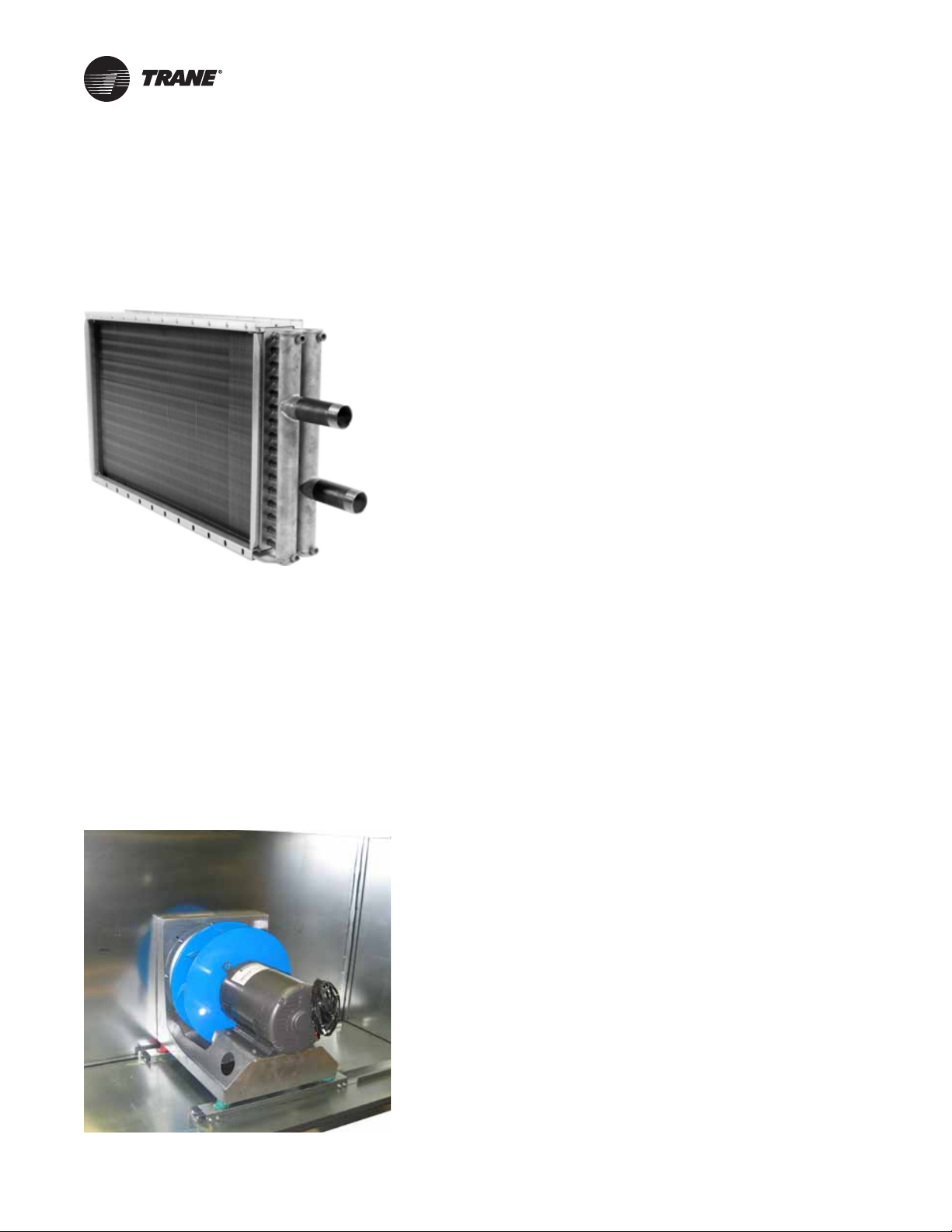

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

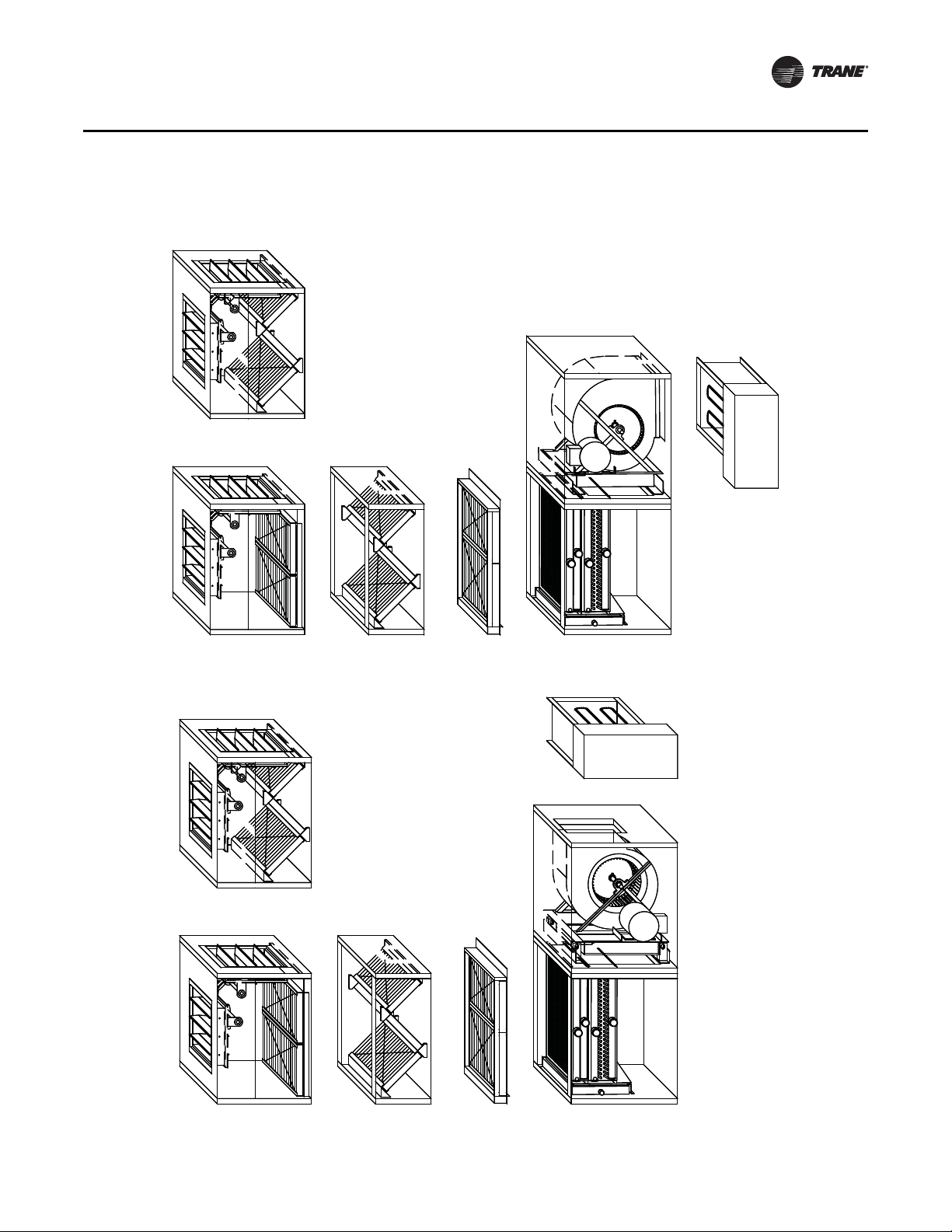

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mixing Box/Filter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electric Heat Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unit Configurations and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Coil Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Coil Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fan Motor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fan Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Direct-Drive Plenum Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FC Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Filter Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CLCH-PRC024A-EN 3

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Controls Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Fuse Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Motor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Horizontal Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Vertical Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

VFD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Hydronic Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Steam Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

DX Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Mixing Box/Filter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Filter Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

UL and C-UL Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Unit Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Casing Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Unit Flooring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Drain Pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Access Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

FC Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Direct-Drive Plenum Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fan Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fan Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fan Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Hydronic Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4 CLCH-PRC024A-EN

Refrigerant Cooling Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Steam Heating Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Mixing Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Control Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

CLCH-PRC024A-EN 5

Model Number Descriptions

Digit 1, 2, 3, 4— Unit Model

UCCA = Performance Climate Changer

Air Handler

Digit 5 - Configuration

A = Horizontal/front top with housed fan

B = Horizontal/top front with housed fan

C = Vertical/front top with housed fan

D = Vertical/top front with housed fan

E = Vertical/back top with housed fan

F = Vert ical/top back with housed fan

G = Horizontal/front top with DDP fan

H = Horizontal/top front with DDP fan

S = Special

Digit 6, 7 - Unit size

3 = Unit size 3

6 = Unit size 6

8 = Unit size 8

10 = Unit size 10

12 = Unit size 12

14 = Unit size 14

17 = Unit size 17

21 = Unit size 21

25 = Unit size 25

30 = Unit size 30

Digit 8 - Unit voltage

0 = No motor, controls, or electric heat

A = 208 volt/60 hertz/3 phase odp

B = 230 volt/60 hertz/3 phase odp

C = 460 volt/60 hertz/3 phase odp

D = 575 volt/60 hertz/3 phase odp

S = Special

Digit 9 - Open

0 = Open for future use

Digit 10, 11 - Design sequence

A0 = A0

Digit 12 - Connections

R = Polymer drain pan, RH coil/RH motor

L = Polymer drain pan, LH coil/LH motor

C = Polymer drain pan, RH coil/LH motor

D = Polymer drain pan, LH coil/RH motor

E = Stainless steel drain pan, RH coil/

RH motor

F = Stainless steel drain pan, LH coil/

LH motor

G = Stainless steel drain pan, RH coil/

LH motor

H = Stainless steel drain pan, LH coil/

RH motor

S = Special

Digit 13 - Coil #1 first in

airstream

0 = No unit coil #1

A = 1 row preheat hydronic/9 fins per in.

B = 1 row preheat hydronic/12 fins per in.

C = 1 row preheat hydronic/14 fins per in.

D = 2 row preheat hydronic/9 fins per in.

E = 2 row preheat hydronic/12 fins per in.

F = 2 row preheat hydronic/14 fins per in.

G = 1 row preheat steam/6 fins per in.

H = 4 row hydronic/9 fins per in.

J = 4 row hydronic/12 fins per in.

K = 4 row hydronic/14 fins per in.

L = 6 row hydronic/9 fins per in.

M = 6 row hydronic/12 fins per in.

N = 6 row hydronic/14 fins per in.

P = 8 row hydronic/9 fins per in.

R = 8 row hydronic/12 fins per in.

T = 8 row hydronic/14 fins per in.

U = 4 row DX/9 fins per in.

V = 4 row DX/12 fins per in.

W = 4 row DX/14 fins per in.

Y = 6 row DX/9 fins per in.

Z = 6 row DX/12 fins per in.

1 = 6 row DX/14 fins per in.

S = Special

Digit 14 - Coil #2 second in

airstream

0 = No unit coil #2

A = 1 row reheat hydronic/9 fins per in.

B = 1 row reheat hydronic/12 fins per in.

C = 1 row reheat hydronic/14 fins per in.

D = 2 row reheat hydronic/9 fins per in.

E = 2 row reheat hydronic/12 fins per in.

F = 2 row reheat hydronic/14 fins per in.

G = 1 row reheat steam/6 fins per in.

H = 4 row hydronic/9 fins per in.

J = 4 row hydronic/12 fins per in.

K = 4 row hydronic/14 fins per in.

L = 6 row hydronic/9 fins per in.

M = 6 row hydronic/12 fins per in.

N = 6 row hydronic/14 fins per in.

P = 8 row hydronic/9 fins per in.

R = 8 row hydronic/12 fins per in.

T = 8 row hydronic/14 fins per in.

U = 4 row DX/9 fins per in.

V = 4 row DX/12 fins per in.

W = 4 row DX/14 fins per in.

Y = 6 row DX/9 fins per in.

Z = 6 row DX/12 fins per in.

1 = 6 row DX/14 fins per in.

S = Special

Digit 15 - Coil options

0 = None

1 = Aluminum fin, galvanized coil casing

2 = Aluminum fin, stainless steel coil

casing

S = Special

Digit 16 - Controller options

0 = None

1 = Unwired end devices

2 = Control interface

S = Special

Digit 17 - Electric heat/factory

mounted

0 = No electric heat

1 = Electric heat with 1 stage

2 = Electric heat with 2 stages

4 = Electric heat with 4 stages

5 = SSR control

S = Special

Digit 18, 19, 20 - Electric

heater kW

000 = None

006 = 6.0 kW

007 = 7.0 kW

008 = 8.0 kW

009 = 9.0 kW

010 = 10.0 kW

011 = 11.0 kW

012 = 12.0 kW

013 = 13.0 kW

014 = 14.0 kW

015 = 15.0 kW

016 = 16.0 kW

017 = 17.0 kW

018 = 18.0 kW

020 = 20.0 kW

022 = 22.0 kW

024 = 24.0 kW

026 = 26.0 kW

027 = 28.0 kW

030 = 30.0 kW

032 = 32.0 kW

034 = 34.0 kW

036 = 36.0 kW

038 = 38.0 kW

041 = 41.0 kW

044 = 44.0 kW

047 = 47.0 kW

050 = 50.0 kW

053 = 53.0 kW

056 = 56.0 kW

059 = 59.0 kW

063 = 63.0 kW

067 = 67.0 kW

071 = 71.0 kW

075 = 75.0 kW

079 = 79.0 kW

083 = 83.0 kW

087 = 87.0 kW

091 = 91.0 kW

095 = 95.0 kW

100 = 100 kW

105 = 105 kW

110 = 110 kW

115 = 115 kW

120 = 120 kW

SSS = Special

Digit 21 - Electric heat options

0 = None

A = Line fuse, door interlocking

disconnect switch and airflow switch

S = Special

6 CLCH-PRC024A-EN

Model Number Descriptions

Digit 22 - Refrigerant circuit

options

0 = None

1 = Single refrigerant circuit arr with

1 stage DX 1/4-in. distributor

2 = Face split refrigerant circuit arr with

2 stage DX 1/4-in. distributor

3 = Intertwined refrigerant circuit arr with

2 stage DX 1/4-in. distributor

4 = Single refrigerant circuit arr with

2 stage DX 1/4-in. distributor

5 = Face split refrigerant circuit arr with

4 stage DX 1/4-in. distributor

6 = Intertwined refrigerant circuit arr with

4 stage DX 1/4-in. distributor

A = Single refrigerant circuit arr with

1 stage DX 3/16-in. distributor

B = Face split refrigerant circuit arr with

2 stage DX 3/16-in. distributor

C = Intertwined refrigerant circuit arr with

2 stage DX 3/16-in. distributor

D = Single refrigerant circuit arr with

2 stage DX 3/16-in. distributor

E = Face split refrigerant circuit arr with

4 stage DX 3/16-in. distributor

F = Intertwined refrigerant circuit arr with

4 stage DX 3/16-in. distributor

S = Special

Digit 23 - Motor horsepower

0 = No motor

A = 1 hp (0.746 kW)

B = 1 1/2 hp (1.119 kW)

C = 2 hp (1.492 kW)

D = 3 hp (2.238 kW)

E = 5 hp (3.730 kW)

F = 7 1/2 hp (5.595 kW)

G = 10 hp (7.460 kW)

H = 15 hp (11.190 kW)

S = Special

Digit 24 - Volume control

0 = None

A = FC fan constant volume with variable

pitch sheaves

B = FC fan constant volume with fixed

pitch sheaves or DDP fan

C = FC fan with fixed pitch sheaves or

DDP fan and variable frequency drive

D = FC fan with fixed pitch sheaves or

DDP fan and variable frequency drive

and shaft grounding

E = FC fan constant volume with fixed

pitch sheaves or DDP and shaft

grounding

S = Special

Digit 25 - Drives

0 = None

A = 650 rpm fixed/600-700 rpm variable

B = 700 rpm fixed/650-750 rpm variable

C = 750 rpm fixed/700-800 rpm variable

D = 800 rpm fixed/750-850 rpm variable

E = 850 rpm fixed/800-900 rpm variable

F = 900 rpm fixed/850-950 rpm variable

G = 950 rpm fixed/900-1000 rpm variable

H = 1000 rpm fixed/950-1050 rpm variable

J = 1050 rpm fixed/1000-1100 rpm variable

K = 1100 rpm fixed/1050-1150 rpm variable

L = 1150 rpm fixed/1100-1200 rpm variable

M = 1200 rpm fixed/1150-1250 rpm

variable

N = 1250 rpm fixed/1200-1300 rpm

variable

P = 1300 rpm fixed/1250-1350 rpm

variable

R = 1350 rpm fixed/1300-1400 rpm

variable

T = 1400 rpm fixed/1350-1450 rpm

variable

U = 1450 rpm fixed/1400-1500 rpm

variable

V = 1500 rpm fixed/1450-1550 rpm

variable

W = 1550 rpm fixed/1500-1600 rpm

variable

Y = 1600 rpm fixed/1550-1650 rpm

variable

Z = 1650 rpm fixed/1600-1700 rpm

variable

1 = 1700 rpm fixed/1650-1750 rpm

variable

2 = 1750 rpm fixed/1700-1800 rpm

variable

3 = 1800 rpm fixed/1750-1850 rpm

variable

4 = 1850 rpm fixed/1800-1900 rpm

variable

5 = 1900 rpm fixed/1850-1950 rpm

variable

6 = 1950 rpm fixed/1900-2000 rpm

variable

7 = 2000 rpm fixed/1950-2050 rpm

variable

8 = Direct-drive plenum fan

S = Special

Digit 26, 27 - VFD setting/DDP

fan speed

00 = Housed fan

54 = 54 hertz/1604 rpm

55 = 55 hertz/1634 rpm

56 = 56 hertz/1663 rpm

57 = 57 hertz/1693 rpm

58 = 58 hertz/1723 rpm

59 = 59 hertz/1752 rpm

60 = 60 hertz/1782 rpm

61 = 61 hertz/1872 rpm

62 = 62 hertz/1841 rpm

62 = 63 hertz/1871 rpm

64 = 64 hertz/1901 rpm

65 = 65 hertz/1931 rpm

66 = 66 hertz/1960 rpm

67 = 67 hertz/1990 rpm

68 = 68 hertz/2020 rpm

69 = 69 hertz/2049 rpm

70 = 70 hertz/2079 rpm

71 = 71 hertz/2109 rpm

72 = 72 hertz/2138 rpm

73 = 73 hertz/2168 rpm

74 = 74 hertz/2198 rpm

75 = 75 hertz/2228 rpm

76 = 76 hertz/2257 rpm

77 = 77 hertz/2287 rpm

78 = 78 hertz/2317 rpm

79 = 79 hertz/2346 rpm

80 = 80 hertz/2376 rpm

81 = 81 hertz/2406 rpm

82 = 82 hertz/2435 rpm

83 = 83 hertz/2465 rpm

84 = 84 hertz/2495 rpm

85 = 85 hertz/2525 rpm

86 = 86 hertz/2554 rpm

87 = 87 hertz/2584 rpm

88 = 88 hertz/2614 rpm

89 = 89 hertz/2643 rpm

90 = 90 hertz/2673 rpm

91 = 91 hertz/2703 rpm

92 = 92 hertz/2732 rpm

93 = 93 hertz/2762 rpm

94 = 94 hertz/2792 rpm

95 = 95 hertz/2822 rpm

96 = 96 hertz/2851 rpm

97 = 97 hertz/2881 rpm

98 = 98 hertz/2911 rpm

99= 99 hertz/2941 rpm

A0 = 100 hertz/2970 rpm

A1 = 101 hertz/3000 rpm

A2 = 102 hertz/3030 rpm

A3 = 103 hertz/3060 rpm

A4 = 104 hertz/3089 rpm

A5 = 105 hertz/3119 rpm

A6 = 106 hertz/3149 rpm

A7 = 107 hertz/3178 rpm

A8 = 108 hertz/3208 rpm

A9 = 109 hertz/3238 rpm

B0 = 110 hertz/3267 rpm

B1 = 111 hertz/3297 rpm

B2 = 112 hertz/3327 rpm

B3 = 113 hertz/3357 rpm

B4 = 114 hertz/3386 rpm

B5 = 115 hertz/3416 rpm

B6 = 116 hertz/3446 rpm

B7 = 117 hertz/3475 rpm

B8 = 118 hertz/3505 rpm

B9 = 119 hertz/3535 rpm

C0 = 120 hertz/3564 rpm

SS - Special

Digit 28 - Mixing Box/Filter

section

0 = None

A = 2-in. flat filter rack

B = 2-in. flat filter/mixing box

C = 2-in. angle filter section

D = 2-in. angle filter/mixing box

E = 2-in./4-in. combination filter rack

F = 2-in./4-in. combination filter/ mixing

box

S = Special

CLCH-PRC024A-EN 7

Model Number Descriptions

Digit 29 - Filter type

0 = Customer supplied/no filters

A = 2-in. MERV 8

B = 2-in. MERV 13

C = 2-in. MERV 8/4-in. MERV 11

D = 2-in. MERV 8/4-in. MERV 13

E = 2-in. MERV 13/4-in. MERV 13

S = Special

Digit 30 - Controls options 1

0 = None

1 = Low limit switch, condensate overflow

switch, dirty filter switch and fan

status switch

S = Special

Digit 31 - Controls options 2

0 = None

A = Discharge air sensor

B = Discharge air sensor and mixed air

sensor

C = Discharge air sensor, mixed air

sensor, factory-mounted n.o. mixing

box actuator

D = Discharge air sensor, mixed air

sensor, factory-mounted n.c. mixing

box actuator

S = Special

Digit 32 - Controls options 3

0 = None

A = Outdoor air temperature sensor

hard wired

B = Duct static pressure sensor hard

wired

C = Outdoor air temperature sensor and

duct static pressure sensor hard

wired

S = Special

Digit 33 - Special

0 = Standard order

S = Special order

8 CLCH-PRC024A-EN

Features and Benefits

The Performance Climate Changer air handler, model UCCA, provides a cost-effective solution to

meet cataloged air handling needs. As a customizable, cataloged air handler, components are

available to meet a wide range of commercial and institutional applications for the indoor air

handler market. Pre-engineered options expand that flexibility while ensuring proven, tested

performance and dependability. These features add flexibility and are engineered to provide good

indoor air quality, including:

• Single point power

• Factory mounted, wired and tested controls

• Two-inch double-wall injected foam casing

• Direct-drive plenum fans

• Filter options including MERV 11 and MERV 13 filters, which help ac hi eve points toward LEED

certification

• Variety of coil options that include hydronic, DX, steam and electric heat

Construction and Integrity

Panels and doors are designed to provide extraordinary insulating capabilities for efficient and

cost-effective performance. Standard double-wall panels and doors include two-inch closed cell

foam insulation providing a minimum R-value of 13, in addition to premium panel strength and

0.005 inch deflection at +/- 4 inches w.g.

Heavy-duty door handles and hinges are surface-mounted and a removable hinge pin allows for

easy door removal.

Engineered fo r Good IAQ

The building industry is continuously evolving and the rate of change is accelerating. The

Performance air handler is engineered to address today’s multifaceted design issues required to

provide good indoor air quality (IAQ). Building owners must give particular attention to

maintaining and documenting IAQ to ensure occupa nt comfort and to meet industry and

government regulatory standards.

ASHRAE Standard 62.1 provides guidance regarding suitable outside air volume to be brought into

the building, recommended air filtration, and procedures to control microbial growth. The

Performance air handler enables you to configure an IAQ-ready air-handling system that addresses

these concerns.

Sloped Drain Pan

The drain pan is positively sloped in every plane to assure proper drainage and help maximize

protection from microbial growth.

Drain pans are made from a noncorrosive polymer material, double-wall construction, and foamed

in place to help eliminate condensation beneath the drain pan. An optional stainless steel drain pan

is also available.

CLCH-PRC024A-EN 9

Features and Benefits

Serviceability/Cleanability

• Full-size access doors are provided for cleaning of internal components

• Removable coil panels

• Smooth, cleanable interior double-wall surfaces help improve indoor air quality

• Coils are raised up out of the drain pan to ma ke all coils removab le from the side and pr ovide

easier access to the drain pan for cleaning

Filtration

Performance air handlers are available with a wide variety of filtra tio n op tions, including:

• Two-inch MERV 8 or MERV 13 flat or angled filters

• Combination filter racks including two-inch MERV 8 or MERV 13 and four-inch MERV 11 or

MERV 13

A factory-mounted dirty filter switch can be used to indicate when the filter needs replacement.

Ventilation

An optional mixing box with ultra low-leak dampers is available for use when ventilation air is

delivered directly to the unit. This mixing box can also function as a zero to 100 percent economizer

to improve energy efficiency.

Dehumidification

Performance air handler model UCCA can be configured for either a constant-volume or VAV

application. VAV systems generally provide effective, coincidental dehumidification over a wide

range of indoor load conditions. As long as any space needs cooling, the VAV air handler supplies

dry (low dew point) air to all of the VAV terminal units.

For direct control of space humidity in a constant-volume application, the Performance air handler

can be configured with a hydronic or steam heating coil in the reheat position. This would allow

the cooling and heating coils to modulate inde pendently to directly control both temperature and

humidity in the space. A unit-mounted electric heater, with a single-point connection, is also

available in the reheat position.

10 CLCH-PRC024A-EN

Control Solutions

Performance air handlers are available with an optional control interface. This package can be used

as part of a stand-alone operation, or it can be fully integrated into a comprehensive control system.

The T rane Earthwi se™ system incor porates the bene fits of factory-installed cont rols and links the

air handler to the Tracer™ SC system controls building management system. This option is

designed to lower installation costs and risk while dramatically improving the quality of the

application and the performance of the air handler. The entire air handler control system is

engineered, mounted, wired, and tested before leaving the factory. As a result of strict quality

manufacturing methods, these control options bring consistency and reliability to the controlsystem package and provide single-source responsibility.

The following control devices are available as stand ard mounted on fan sections:

• Variable-frequency drives (VFDs)

• Control interface package

– Fan motor disconnect switch

– Fused transformer(s)

– Fan contactor

– Customer terminal strip for field-provided controls

• Various end device options, including:

– Low limit protection

– Condensate overflow switch

– Fan status switch

– Filter status switch

– Discharge air sensor

– Mixed air sensor

– Damper actuator

Features and Benefits

Single Source Responsibility

Equipment and interoperable controls, engineered and provided by a single manufacturer, provide

faster construction cycles and simplify job-site coordination efforts. This simplification reduces

installation time, expense, and risk.Trane equipment and controls package provides the optimal

performance when integrated in a Trane Earthwise™ system. This is a powerful system

architectur e that unifi es Trane HVA C equipme nt, direct d igital contr ol, and bui lding manage ment

into a cohesive whole with an assured source of support. This system is managed with the Tracer™

building management system.

CLCH-PRC024A-EN 11

Features and Benefits

Pro ven Performance

AHRI Standards

Figure 1. AHRI Standard 430

Figure 2. AHRI Standard 410

UL Listing

Trane combines comprehensive performance certification by AHRI with thorough

laboratory testing and advanced manufacturing methods. Together , these elements help

assure that each Trane air handler operates predictably and reliably throughout the life

of the unit.

Unlike other rating methods that check fan performance alone, Trane units are

performance-tested in accordance with AHRI Standard 430. This certification process

evaluates the air handler on the basis of airflow, static pressure, fan speed, and brake

horsepower.

Heating and cooling coils are rigorously tested and certified with AHRI Standard 410 to

assure that they, too, deliver published performance.

AHRI Standard 260 is the first ducted-air-handler sound rating procedure. It i s intended

to provide engineers with better, more accurate, ducted sound power levels so that they

can design quieter and more cost-effective comfort systems. Sound ratings for Trane air

handlers have been developed from extensive AHRI Standard 260 testing and laboratory

data.

Trane air han dlers are UL-listed to U.S. and Canadian safety standards.

ISO Certification

Certification by the International Standardization Organization (ISO) ensures that an

organization can consistently deliver a product or service that meets the customer’s

contractual requirements by following documented processes. The ISO 9001 quality

assurance model establishes the requirements for an organization whose business

processes range from design and development to production. Having the quality

management system of our manufacturing pl ants ISO 9001-certified directly benefits

Trane customers because our continuous process improvements can reduce business

costs, improve product quality, and en able faster ship cycles

12 CLCH-PRC024A-EN

Application Considerations

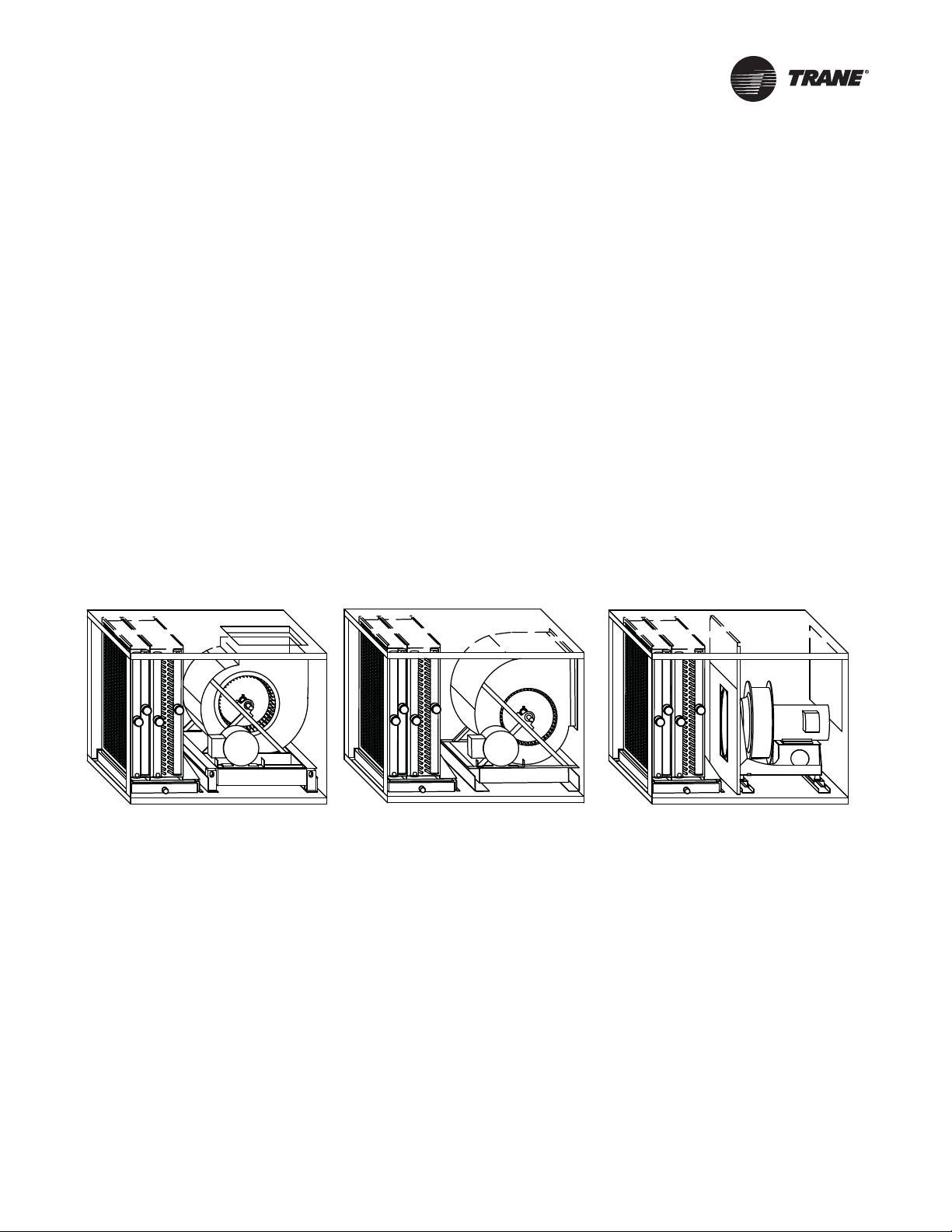

FC fan with top front discharge FC fan with front top discharge Direct-drive fan with front discharge

The Performance Climate Changer air handler, model UCCA, offers a wide range of application

flexibility while maintaining a simple, easy to install unit design. These units are a great choice

when a compact, reliable air handler is needed when budget is a critical factor.

Typical applications include many different types of buildings such as: schools, office buildings,

hospitals and retail. Applications can be either constant volume or variable air volume. Some

applications include:

• Two-pipe hydronic system for cooling and/or heating

• Two-pipe hydronic cooling system with electric heat

• Four-pipe system with dedicated heating and cooling coils

• Direct expansion (DX) split systems with hydronic heat

Standard AHU Arrangements

T o complete the air -handling system, the unit must be arranged in a way that fits the available space

and meets the application requirement. The Performance air handler provides a draw-thru AHU

arrangement that places the coils and filters upstream of a ducted supply fan.

Horizontal Draw-Thru

Figure 3. Hori zontal draw-thru units

T rane air handlers in a horizontal draw-thru arrangement provide the system components that are

required in a single-level unit. An optional blow-thru electric heater is also available. Accepted

system design practices are generally the only restrictions in a horizontal draw-thru application.

CLCH-PRC024A-EN 13

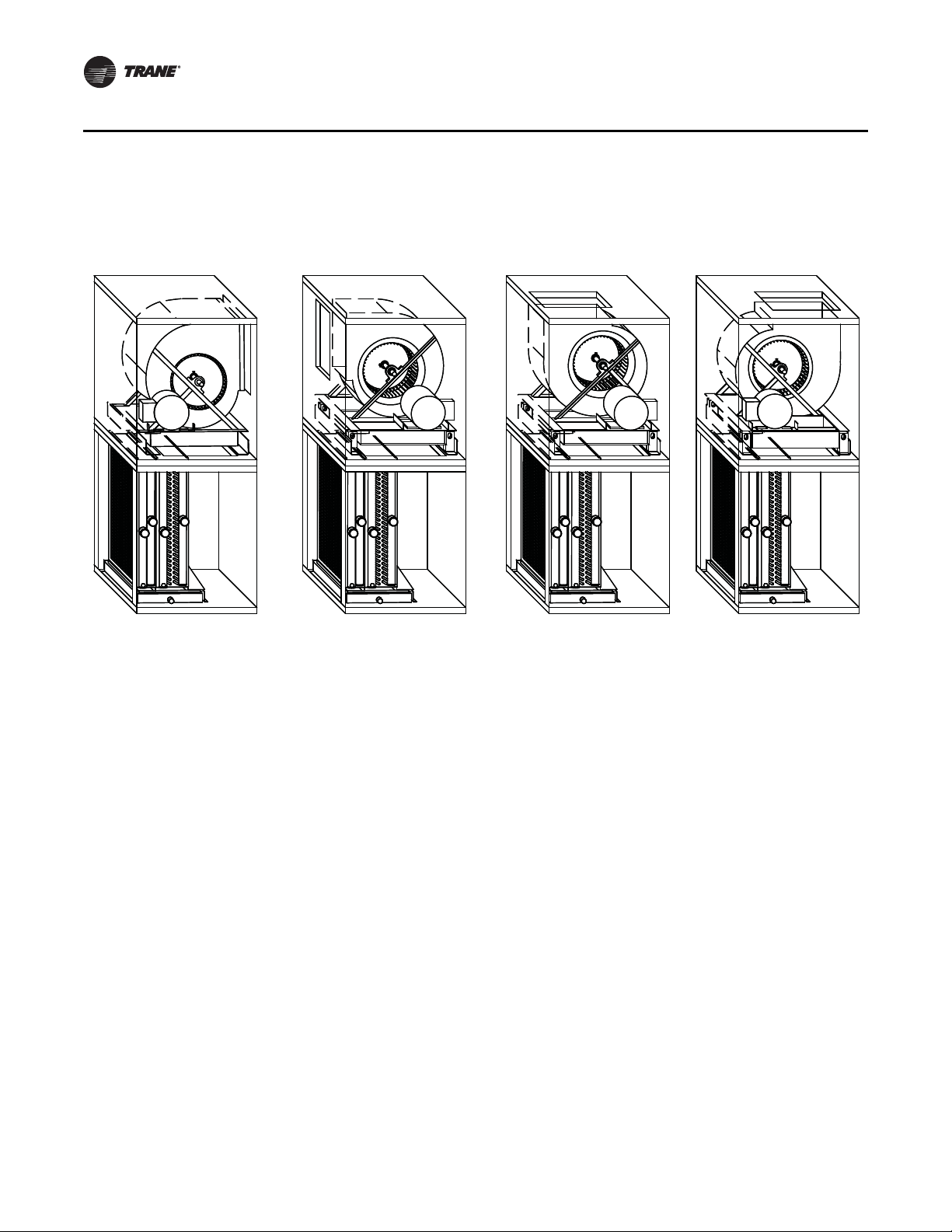

Application Considerations

FC fan with

back top discharge

FC fan with

top back discharge

FC fan with

front top discharge

FC fan with

top front discharge

Vertical Draw-Thru

Figure 4. Vertical draw-thru units

Installation

T rane air handlers in a vertical draw-thru arrangement result in a shorter footprint than horizontal

draw-thru units. This arrangement stacks a fan on top of the coil section. When designing an air

handler in this configuration, a vertical draw-thru fan performance curve should be used to account

for the airflow impingement by a coil as the air flows through the coil and turns up into the fan.

Horizontal units can be floor-mounted on a house-keeping pad or suspended from the ceiling.

V ertical units are floor-mounted on a house-keeping pad. Refer to CLCH-S VX009A-EN Installation,

Operation, Maintenance (IOM) manual for installation instructions.

All units are shipped with isolation system tied down for shipment purposes. To utilize standard

internal isolation, remove shipping tie-downs per the IOM. If external isolation is being utilized,

install units with external vibration isolation on all connection points, including the ductwork

connections and piping connections.

It is important to consider pr oper condensate management before installation. You must mount the

unit high enough so that the condensate drain pan can be properly trapped. Refer to

CLCH-SVX009A-EN IOM for specific trapping instructions.

Install units in accordance to all applicable ASHRAE standards, SMACNA, and local code

requirements.

14 CLCH-PRC024A-EN

Operating Limitations

Do not operate unit above maximum fan speed or unit airflow as shown in the unit fan curves. Unit

operation at greater than maximum fan speed can drastically reduce bearing life and result in a

catastrophic failure. Operating at greater than the maximum allowable airflow in the cooling mode

may result in unsatisfactory operation due to moisture carryover from the coil. In addition, it is often

not economical to operate a unit at its maximum fan speed due to the greater motor power

requirements.

Do not operate units with electric heat below the minimum airflow listed in CLCH-SVX009A-EN

IOM. This is to prevent excessive leaving air temperatures and electric heat limit trips.

Do not operate a hydronic (or steam) coil and electric heat simultaneously. This is to prevent

excessive leaving air temperatures and limit trips . Electric heat units are equipped with a lockout

switch to disable the electric heater if the temperature of the hydronic (or steam) coil is greater than

95°F (35C).

Do no operate coils above the fluid flow limits listed in the installation manual. This is to prevent

noise and erosion within the coil. A minimum or “self venting” fluid flow rate is also listed in the

installation manual. If coils operate below this flow rate, you should periodically vent them by

flushing at a higher flow rate. These low fluid flow rates may also be too low to be included in the

AHRI certification.

DX Cooling Units

Application Considerations

Performance air hand lers with a DX cooling coil will often be connected to an air -cooled condensing

unit. Some condensing un its have two, independent re frigeration circuits, while the DX coil in size

3 through 10 units can be configured with a single circuit. Do not manifold two, independent

refrigeration circuits into a single-circuited DX (evaporator) coil. If the condensing un it does have

two, independent refrigeration circuits, configure the DX coil to have either two or four distributors.

DX coils, equipped with either two or four distributors, can be configured with either intertwined

or horizontal split circuiting. Intertwined circuited is preferred in VAV applications. At low loads,

refrigerant is fed to alternating tubes, and the coil performs as though its fin surface area is

substantially greater. Therefore, the coil surface can be warmer at part load, whic h reduces the risk

of frost and still provides a constant leaving-air temperature.

CLCH-PRC024A-EN 15

Components and Options

Performance Climate Changer air handler model UCCA provides a standard configuration with

coil(s) and fan, and then allows customization with various optional accessory sections.

Figure 5. A variety of coils are available on

Performance air handlers

Coils

The variety of T rane coil types, sizes, arrangements, and materials allows

you to select a coil that is optimized for pressure drop and capacity

requirements. Published coil performance is certified in accordance with

AHRI Standard 410 and meets CRN standards.

Trane is at the leading edge of coil technology. Through extensive

laboratory testing and numerous job-site installations, Trane has

developed an enhanced fin surface that has superior heat transfer

characteristics and allows greater velocities of air to move through the

cooling coil without causing moisture carryover.

The industry is familiar with the 500 fpm limit through a cooling coil as a

“rule of thumb” to safeguard ag ainst moisture carryo ver. However , some

applications have tight dimensiona l constraints that require high coil face

velocities. Trane’s fin design extends this limit in excess of 625 fpm,

depending upon air conditions, coil siz e, and spacing. Tested data for

moisture carryover is incorporated in the T rane Official Product Se lection

System (TOPSS™). In cases where moisture carryover is possible, the

TOPSS program alerts you to this fact with a moisture carryover warning.

Coil options include the following:

• Four- to eight-row, ½-inch OD (outside diameter) chilled water coils

• Four-to six-row, ½-inch OD refrigerant coils

• One- or two-row ½-inch OD hot water coils

• One-row, 1-inch OD distributing-type steam coils

Figure 6. Direct-drive plenum fans and FC

fans are available

16 CLCH-PRC024A-EN

Fans

T rane offers flexible fan types and options, including variable-frequency

drives (VFDs) for modulation in variable-air-volume systems. Fan types

include:

• Single-width/single-inlet (SWSI) direct-drive plenum fans with front

or top discharge

• Double-width/double-inlet (DWDI) centrifugal forward-curved (FC)

fans with front or top discharge

Each fan is rated in accordance with Standard 430 of the Air Conditioning

Heating and Refrigeration Institute (AHRI) and all DWDI fans are AHRI

Standard 430-certified to assure published performance.

To verify that fan performance will satisfy design requirements, use the

TOPSS selection program. The AHRI Standard 430-certified fan curves

include the fan section casing effect. TOPSS also takes into account air

density, fan and motor heat, drive losses, and use of high-performance

filters that affect fan performance.

Components and Options

Figure 7. Mixing box with angled filter rack

Figure 8. Electric heat

Mixing Box/Filter Section

A mixing box is available for those applications where both return air and

fresh air are delivered directly to the unit or as part of an economizer

control strategy. The mixing box also has the flexibility to provide a wide

variety of filtration options, including 2-inch flat or angled filters and 2inch/4-inch combination flat filters.

Effectively controlling particulates by removing them from the air stream

is key to good IAQ. That necessitates proper filter selection. In addition

to mixing box/filter sections, filter sections are also available with angled

or flat filters.

Electric Heat Section

In addition to hydronic and steam coil options, the unit is also available

with a unit mounted electric heater in the reheat position. The unit will

have single point power connection to the elect ric heater. The heater is

available with step control or SSR-full modulating control.

CLCH-PRC024A-EN 17

General Data

Mixing box /flat filter section

Mixing box /angle filter section

Angle filter

FC fan with top front discharge

FC fan with front top discharge

Direct-drive fan with front discharge

Flat

filter

Electric heat

Electric heat

Electric heat

Unit Configurations and Components

Figure 9. Horizontal configurations and components

18 CLCH-PRC024A-EN

Figure 10. Vertical configurations and components

Mixing/angle fileter section

Mixing/flat filter section Angle filter

Flat

filter

FC fan with top back discharge

Electric heat

Mixing/angle fileter section

Mixing/flat filter section Angle filter

Flat

filter

FC fan with front top discharge

Electric heat

General Data

CLCH-PRC024A-EN 19

General Data

Mixing/angle fileter section

Mixing/flat filter section Angle filter

Flat

filter FC fan with back top discharge

Electric heat

Mixing/angle fileter section

Mixing/flat filter section Angle filter

Flat

filter

FC fan with top front discharge

Electric heat

Figure 11. Vertical configurations and components

20 CLCH-PRC024A-EN

-

Table 1. Performance air handler model UCCA data

General Data

Nom airflow (CFM)

1500 3000 4000 5000 6000 7000 3500 10500 12500 15000

Unit size 3 6 8 10 12 14 7 21 25 30

Horz unit height (in.) 27.50 32.50 38.00 38.00 41.80 45.60 48.10 54.30 60.60 60.60

Horz unit width (in.) 34.00 47.00 51.00 63.00 71.00 71.00 79.00 79.00 81.00 94.00

Horz unit length (in.) 51.90 54.90 52.30 54.70 54.70 56.20 60.20 60.20 62.90 69.60

Vert unit height (in.) 51.40 61.30 65.10 69.90 80.10 83.80 92.90 99.20 n/a n/a

Vert unit width (in.) 34.00 47.00 51.00 63.00 71.00 71.00 79.00 79.00 n/a n/a

Vert unit length (in.) 34.10 37.10 29.40 32.10 36.10 36.10 42.10 42.10 n/a n/a

Coils

Hydronic/DX coils

Area (ft2) 2.80 5.60 7.60 9.90 12.30 14.30 16.30 20.4.00 24.00 28.50

Width (in.) 17.50 22.50 27.50 27.50 30.00 35.00 35.00 43.75 50.00 50.00

Length (in.) 23.00 36.00 40.00 52.00 59.00 59.00 67.00 67.00 69.00 82.00

Velocity (fpm) 536.60 533.30 523.60 503.50 488.10 488.1 522.00 515.80 521.70 526.80

Dry Weight (lb.)

- 1-row 26 39 47 58 72 80 87 112 126 145

- 2-row 35 55 69 86 107 120 132 168 192 223

- 4-row 53 89 114 144 177 201 223 281 325 380

- 6-row 72 122 158 201 247 282 314 394 457 536

- 8-row 90 156 203 258 316 363 405 507 589 693

Wet Weight (lb. )

- 1-row 29 43 53 66 82 91 99 128 145 167

- 2-row 40 64 81 102 127 143 158 200 230 268

- 4-row 63 107 138 175 216 247 274 345 400 470

- 6-row 85 149 195 248 305 350 391 491 570 671

- 8-row 108 192 251 321 394 454 508 636 740 873

Steam coils

Area (ft2) 1.8 4.4 6.5 8.5 9.8 13.315.116.821.325.3

Width (in.) 12 18 24 24 24 33 33 36 45 45

Length (in.) 22353951595866676881

Velo ci ty (FPM) 818 686 615 588 610 527 562 627 588 593

Weight (lb.) 44 67 85 102 112 139 154 191 241 276

CLCH-PRC024A-EN 21

General Data

Table 1. Performance air ha nd ler model UCCA data

Nom airflow (CFM)

1500 3000 4000 5000 6000 7000 3500 10500 12500 15000

Unit size 3 6 8 10 12 14 7 21 25 30

Fan/Motor data

FC fans

Wheel size (in.) 9x7 12x9 12x12 15x15 18x15 18x18 20x15 20x20 20x18 22x20

Maximum RPM 2000 1500 1700 1400 1200 1200 1100 1000 1300 1150

Motor HP 1-2 1-3 1-5 1 - 5 1 - 7 1/2 1 - 7 1/2 1 - 10 2 - 15 3 - 15 1 1/2 - 15

Minimum design CFM 1050 2100 2800 3500 4200 4900 5950 7350 8750 10500

DDP fans

Wheel size (in.) 11 14 16 18 18 20 20 2 x 18 2 x 20 2 x 20

Maximum RPM 3600 3600 3400 3025 3025 2720 2720 3025 2720 2720

Motor HP 1-2 1 1/2 - 5 2- 7 1/2 3 - 7 1/2 3 - 10 3 - 15 3 - 15 3- 10 3- 10 5 - 15

Filters (height x width) with quantity per size

2 in. and 2/4 in. combination flat filter

- 16 x 20 4 2 2 4 2

- 16 x 25 4 1 1 2 2 6

- 20 x 20 2 2 4 2

- 20 x 25 1 2 1 1 2 6 4

Area (ft2) 3.5 6.9 8.9 11.1 16.3 16.3 20.0 22.5 26.4 30.6

Nominal Velocity (fpm) 432.0 432.0 450.0 450.0 369.2 430.8 425.0 466.7 473.7 490.9

2-in. Angle Filter

- 16 x 20 2 6 6 6 4 12

- 16 x 25 2 3 3 8

- 20 x 20 4 2 4 6 8

- 20 x 25 2 12

Area (ft2) 5.6 11.1 12.5 15.6 21.7 21.7 30.0 31.1 41.7 48.9

Nominal Velocity (fpm) 270.0 270.0 320.0 321.4 276.9 323.1 283.3 337.5 300.0 306.8

Mix Box

Damper Area (ft2) 1.3 2.4 3.1 4.1 5.1 5.6 7.0 8.2 10.3 12.0

Nominal Velocity (fpm) 1166.9 1224.7 1288.5 1205.6 1178.0 1239.2 1217.0 1277.9 1208.1 1247.1

Notes: Coil weight based on 12 fins per inch, galvanized casing

Coil width = length in direction of coil header, typically vertical.

Coil length = length of coil in direction of the coil tubes, typically horizontal and perpendicular to airflow.

Unit sizes 21-30 have two stacked steam coils

Fan wheel size is diameter x length of blade (width).

Minimum airflow limit is for units with hot water, steam, or electric heat. There is no minimum airflow for cooling-only units.

22 CLCH-PRC024A-EN

General Data

Coil Data

Table 2. Number of circuits and distributors

Single Horizontal Face Split Intertwined

Coil Fin

Unit Size

10 1 10 27.50 52.00 2 10 27.50 52.00 2 10 27.50 52.00

12 - - - - 2 11 30.00 59.00 2 11 30.00 59.00

14 - - - - 2 13 35.00 59.00 2 13 35.00 59.00

17 - - - - 2 13 35.00 67.00 2 13 35.00 67.00

21 - - - - 2 17 43.75 67.00 4 17 43.75 67.00

25 - - - - 2 19 50.00 69.00 4 19 50.00 69.00

30 - - - - 4 39 50.00 82.00 4 39 50.00 82.00

Dist Circuits

3 1 3 17.50 23.00 - - - - - - - -

6 1 5 22.50 36.00 - - - - - - - -

8 1 7 27.50 40.00 2 7 27.50 40.00 2 7 27.50 40.00

Width Length Width Length Width Length

Dist Circuits

Coil Fin

Coil Fin

Dist Circuits

CLCH-PRC024A-EN 23

Performance Data

Coil Data

Table 3. Hydronic/DX coil performance data

Size Width (in) Length (in) Coil Area (ft2)

3 17.50 23.00 2.80

6 22.50 36.00 5.60

8 27.50 40.00 7.60

10 27.50 52.0 9.90

12 30.00 59.00 12.30

14 35.00 59.00 14.30

17 35.00 67.00 16.30

21 43.75 67.00 20.40

25 50.00 69.00 24.00

30 50.00 82.00 28.50

Table 4. Steam coil performance data

Size Width (in) Length (in) Coil Area (ft2)

3 12.00 22.00 1.80

6 18.00 35.00 4.40

8 24.00 39.00 6.50

10 24.00 51.00 8.50

12 24.00 59.00 9.80

14 33.00 58.00 13.30

17 33.00 66.00 15.10

21

25

30

18.00 67.00

18.00 67.00

12.00 68.00

33.00 68.00

12.00 81.00

33.00 81.00

16.80

21.30

25.30

24 CLCH-PRC024A-EN

Performance Data

1.00 bhp

1.50 bhp

2.00 bhp

1000 RPM

1500 RPM

2000 RPM

2500 RPM

3000 RPM

3500 RPM

3600 RPM

45 %WO

50 %WO

60 %WO

70 %WO

80 %WO

90 %WO

26

0

1

2

3

4

5

6

7

8

0 500 1000 1500 2000 2500

Total Static Pressure (in H2O)

Airow (cfm)

Fan Motor Data

Table 5. Fan motor data

Unit Size 3 6 8 10 12 14 17 21 25 30

Nominal Airflow

(cfm) 1500 3000 4000 5000 6000 7000 8500 10,500 12,500 15,000

FC Fan Wheel size (in) 9x7 12x9 12x12 15x15 18x15 18x18 20x15 20x20 20x18 22x20

DDP Fan Wheel Size (in) 11 14 16 18 18 20 20 2 x 18 2 x 20 2 x 20

Maximum RPM (FC) 2000 1500 1700 1400 1200 1200 1100 1000 1300 1150

Maximum RPM (DDP) 3600 3600 3400 3025 3025 2720 2720 3025 2720 2720

Motor HP (FC) 1-2 1-3 1-5 1 - 5 1 - 7 1/2 1 - 7 1/2 1 - 10 2 - 15 3 - 15 1 1/2 - 15

Motor HP (DDP) 1-2 1 1/2 - 5 2- 7 1/2 3 - 7 1/2 3 - 10 3 - 15 3 - 15 3- 10 3- 10 5 - 15

Minimum Design CFM 1050 2100 2800 3500 4200 4900 5950 7350 8750 10500

Maximum Design CFM 1800 3600 4800 6000 7200 8400 10200 12600 15000 18000

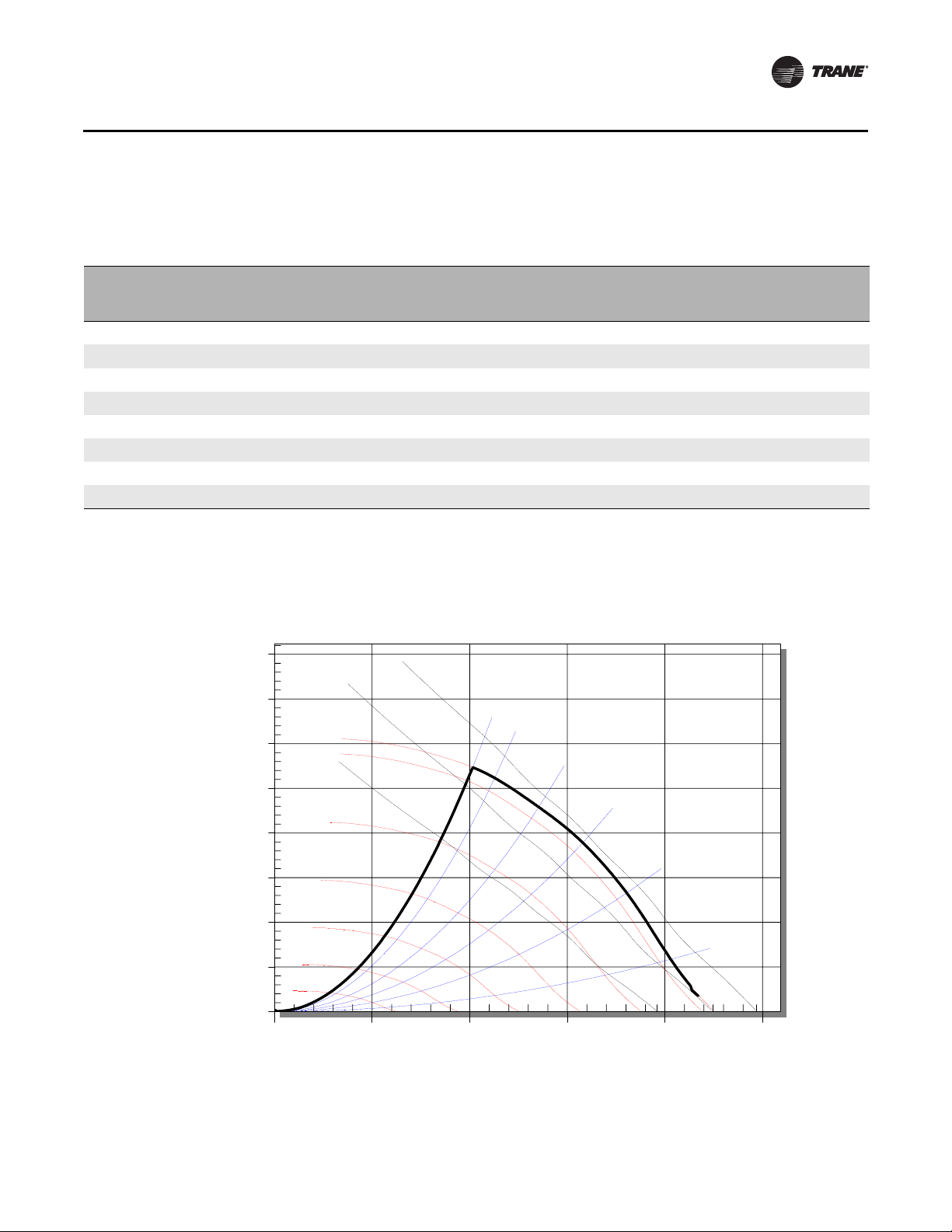

Fan Curves

Direct-Drive Plenum Fans

Figure 12. Size 3 horizontal 11-inch DDP single fan

CLCH-PRC024A-EN 25

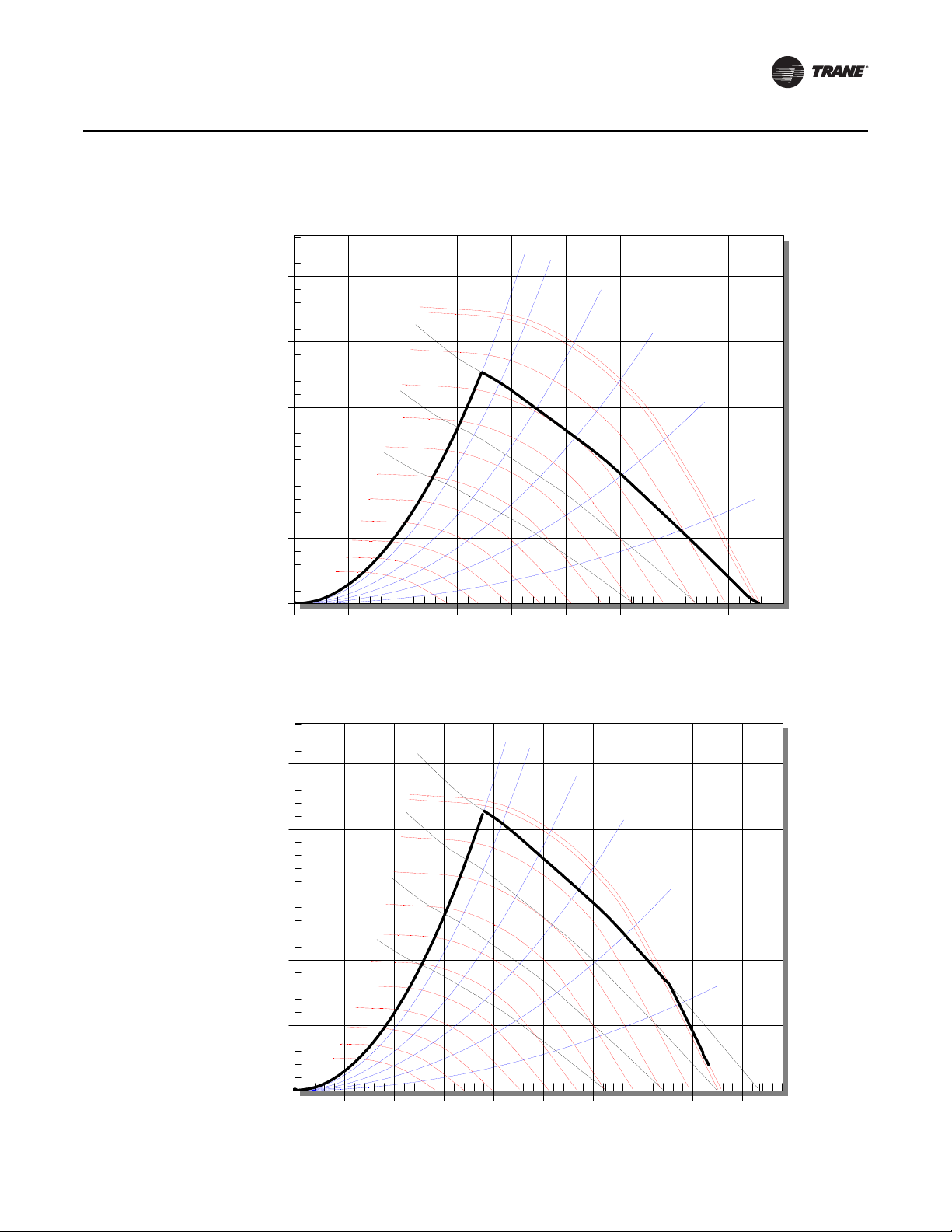

Performance Data

1.50 bhp

2.00 bhp

3.00 bhp

5.00 bhp

1000 RPM

1500 RPM

2000 RPM

2500 RPM

3000 RPM

3500 RPM

3600 RPM

45 %WO

50 %WO

60 %WO

70 %WO

80 %WO

90 %WO

26

0

1

2

3

4

5

6

7

8

9

10

11

12

0 500 1000 1500 2000

2500 3000

3500 4000

4500

5000

Total Static Pressure (in H2O)

Airow (cfm)

2.00 bhp

3.00 bhp

5.00 bhp

7.50 bhp

1000 RPM

1200 RPM

1400 RPM

1600 RPM

1800 RPM

2000 RPM

2200 RPM

2400 RPM

2600 RPM

2800 RPM

3000 RPM

3200 RPM

3400 RPM

45 %WO

50 %WO

60 %WO

70 %WO

80 %WO

90 %WO

32

0.0

2.5

5.0

7.5

10.0

12.5

0

1000

2000 3000 4000 5000

6000 7000

Total Static Pressure (in H2O)

Airow (cfm)

Figure 13. Size 6 horizontal 14-inch DDP single fan

26 CLCH-PRC024A-EN

Figure 14. Size 8 horizontal 16-inch DDP single fan

Figure 15. Size 10 horizontal 18-inch DDP single fan

3.00 bhp

5.00 bhp

7.50 bhp

1000 RPM

1200 RPM

1400 RPM

1600 RPM

1800 RPM

2000 RPM

2200 RPM

2400 RPM

2600 RPM

2800 RPM

3000 RPM

3025 RPM

45 %WO

50 %WO

60 %WO

70 %WO

80 %WO

90 %WO

31

0.0

2.5

5.0

7.5

10.0

12.5

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Total Static Pressure (in H2O)

Airow (cfm)

3.00 bhp

5.00 bhp

7.50 bhp

10.00 bhp

1000 RPM

1200 RPM

1400 RPM

1600 RPM

1800 RPM

2000 RPM

2200 RPM

2400 RPM

2600 RPM

2800 RPM

3000 RPM

3025 RPM

45 %WO

50 %WO

60 %WO

70 %WO

80 %WO

90 %WO

31

0.0

2.5

5.0

7.5

10.0

12.5

0 1000

2000

3000 4000 5000 6000 7000

8000

9000

Total Static Pressure (in H2O)

Performance Data

Figure 16. Size 12 horizontal 18-inch DDP single fan

CLCH-PRC024A-EN 27

Airow (cfm)

Loading...

Loading...