Trane TWE061D-E***A, TWE090D-E**BA, TWE120D-E**BA, TWE150E**BA, TWE180E**BA Installation and Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Split System Air Conditioners

Odyssey™™

Air Handler — 5 to 25 Tons

MMooddeell ((6600 HHzz))

TWE061D/E***A

TWE090D/E**BA

TWE120D/E**BA

TWE150E**BA

TWE180E**BA

TWE240E**BA

TWE300E**BA

MMooddeell ((5500 HHzz))

TWE051D***A

TWE076D/E***A

TWE101D/E***A

TWE126E***A

TWE156E***A

TWE201E***A

TWE251E***A

SSAAFFEETTYY WWAARRNNIINNGG

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

March 2015

SSA-SVX06E-EN

Page 2

Introduction

WARNING

CAU

TION

NOTICE

Read this manual thoroughly before operating or

servicing this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper

operation of this machine depend upon the strict

observance of these precautions.

The three types of advisories are defined as follows:

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury. It could also be used to alert

against unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are

refrigerants that contain Chlorine, Fluorine and Carbon

(CFCs) and those containing Hydrogen, Chlorine,

Fluorine and Carbon (HCFCs). Not all refrigerants

containing these compounds have the same potential

impact to the environment. Trane advocates the

responsible handling of all refrigerants-including

industry replacements for CFCs such as HCFCs and

HFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the

air conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management

of refrigerants. Know the applicable laws and follow

them.

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee eelleeccttrriiccaall ccooddeess..

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE))

RReeqquuiirreedd!!

TTeecchhnniicciiaannss,, iinn oorrddeerr ttoo pprrootteecctt tthheemmsseellvveess ffrroomm

ppootteennttiiaall eelleeccttrriiccaall,, mmeecchhaanniiccaall,, aanndd cchheemmiiccaall

hhaazzaarrddss,, MMUUSSTT ffoollllooww pprreeccaauuttiioonnss iinn tthhiiss mmaannuuaall

aanndd oonn tthhee ttaaggss,, ssttiicckkeerrss,, aanndd llaabbeellss,, aass wweellll aass tthhee

iinnssttrruuccttiioonnss bbeellooww::

•• BBeeffoorree iinnssttaalllliinngg//sseerrvviicciinngg tthhiiss uunniitt,,

tteecchhnniicciiaannss MMUUSSTT ppuutt oonn aallll PPPPEE rreeqquuiirreedd ffoorr

tthhee wwoorrkk bbeeiinngg uunnddeerrttaakkeenn ((EExxaammpplleess;; ccuutt

rreessiissttaanntt gglloovveess//sslleeeevveess,, bbuuttyyll gglloovveess,, ssaaffeettyy

ggllaasssseess,, hhaarrdd hhaatt//bbuummpp ccaapp,, ffaallll pprrootteeccttiioonn,,

eelleeccttrriiccaall PPPPEE aanndd aarrcc ffllaasshh ccllootthhiinngg))..

AALLWWAAYYSS rreeffeerr ttoo aapppprroopprriiaattee MMaatteerriiaall SSaaffeettyy

DDaattaa SShheeeettss ((MMSSDDSS))//SSaaffeettyy DDaattaa SShheeeettss

((SSDDSS)) aanndd OOSSHHAA gguuiiddeelliinneess ffoorr pprrooppeerr PPPPEE..

•• WWhheenn wwoorrkkiinngg wwiitthh oorr aarroouunndd hhaazzaarrddoouuss

cchheemmiiccaallss,, AALLWWAAYYSS rreeffeerr ttoo tthhee aapppprroopprriiaattee

MMSSDDSS//SSDDSS aanndd OOSSHHAA//GGHHSS ((GGlloobbaall

HHaarrmmoonniizzeedd SSyysstteemm ooff CCllaassssiiffiiccaattiioonn aanndd

LLaabbeelllliinngg ooff CChheemmiiccaallss)) gguuiiddeelliinneess ffoorr

iinnffoorrmmaattiioonn oonn aalllloowwaabbllee ppeerrssoonnaall eexxppoossuurree

lleevveellss,, pprrooppeerr rreessppiirraattoorryy pprrootteeccttiioonn aanndd

hhaannddlliinngg iinnssttrruuccttiioonnss..

•• IIff tthheerree iiss aa rriisskk ooff eenneerrggiizzeedd eelleeccttrriiccaall

ccoonnttaacctt,, aarrcc,, oorr ffllaasshh,, tteecchhnniicciiaannss MMUUSSTT ppuutt

oonn aallll PPPPEE iinn aaccccoorrddaannccee wwiitthh OOSSHHAA,, NNFFPPAA

7700EE,, oorr ootthheerr ccoouunnttrryy--ssppeecciiffiicc rreeqquuiirreemmeennttss

ffoorr aarrcc ffllaasshh pprrootteeccttiioonn,, PPRRIIOORR ttoo sseerrvviicciinngg

tthhee uunniitt.. NNEEVVEERR PPEERRFFOORRMM AANNYY SSWWIITTCCHHIINNGG,,

DDIISSCCOONNNNEECCTTIINNGG,, OORR VVOOLLTTAAGGEE TTEESSTTIINNGG

WWIITTHHOOUUTT PPRROOPPEERR EELLEECCTTRRIICCAALL PPPPEE AANNDD

AARRCC FFLLAASSHH CCLLOOTTHHIINNGG.. EENNSSUURREE

EELLEECCTTRRIICCAALL MMEETTEERRSS AANNDD EEQQUUIIPPMMEENNTT AARREE

PPRROOPPEERRLLYY RRAATTEEDD FFOORR IINNTTEENNDDEEDD VVOOLLTTAAGGEE..

©2015 Trane All rights reserved

SSA-SVX06E-EN

Page 3

IInnttrroodduuccttiioonn

WWAARRNNIINNGG

RReeffrriiggeerraanntt uunnddeerr HHiigghh PPrreessssuurree!!

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree

bbeeffoorree ooppeenniinngg tthhee ssyysstteemm.. SSeeee uunniitt nnaammeeppllaattee ffoorr

rreeffrriiggeerraanntt ttyyppee.. DDoo nnoott uussee nnoonn--aapppprroovveedd

rreeffrriiggeerraannttss,, rreeffrriiggeerraanntt ssuubbssttiittuutteess,, oorr rreeffrriiggeerraanntt

aaddddiittiivveess..

WWAARRNNIINNGG

RR--441100AA RReeffrriiggeerraanntt uunnddeerr HHiigghheerr

PPrreessssuurree tthhaann RR--2222!!

TThhee uunniittss ddeessccrriibbeedd iinn tthhiiss mmaannuuaall uussee RR--441100AA

rreeffrriiggeerraanntt wwhhiicchh ooppeerraatteess aatt hhiigghheerr pprreessssuurreess

tthhaann RR--2222.. UUssee OONNLLYY RR--441100AA rraatteedd sseerrvviiccee

eeqquuiippmmeenntt oorr ccoommppoonneennttss wwiitthh tthheessee uunniittss.. FFoorr

ssppeecciiffiicc hhaannddlliinngg ccoonncceerrnnss wwiitthh RR--441100AA,, pplleeaassee

ccoonnttaacctt yyoouurr llooccaall TTrraannee rreepprreesseennttaattiivvee..

Copyright

This document and the information in it are the

property of Trane, and may not be used or reproduced

in whole or in part without written permission. Trane

reserves the right to revise this publication at any time,

and to make changes to its content without obligation

to notify any person of such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

• With the change to Microchannel, the Odyssey split

system now offers a 50Hz, 6.25 standard air handler

(TWE076E) and a 60Hz, 7.5 ton standard/SZVAV/2Speed VFD air handler (TWE090E). See

performance data for additional details on this new

split system.

• Odyssey air handlers now have the ability to

convert from Single Zone VAV to 2–Speed Fan

control in order to comply with certain sections of

California Title 24 and ASHRAE 90.1. See

“Installation, 2-Speed VFD Units,” p. 25 for

configuration details.

SSA-SVX06E-EN

3

Page 4

Table of Contents

Model Number Description. . . . . . . . . . . . . . . . . 5

Air Handler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . .. . . . . . . . . . . . . .. . . . . . . . 6

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pre-Installation . . . . . . . . . . . . . . . . . . . . . .. . . . . . . 7

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inspection Checklist . . . . . . . . . . . . . . . . . . . 7

Testing for Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Lifting Recommendations . . . . . . . . . . . . . . . . . 7

Repositioning Drain Pan. . . . . . . . . . . . . . . . . . . 7

Field Conversion to 460 Volt . . . . . . . . . . . . . . . 9

Converting Motor to 460 Volt. . . . . . . . . . . 9

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . 9

Reorienting Evaporator Coil

(TWE126/150 and 156/180) . . . . . . . . . . . . . 9

Preparation for Refrigerant

Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installations, Limitations and

Recommendations. . . . . . . . . . . . . . . . . . . . . . . 10

Dimensional Data . . . . . . . . . . . . . .. . . . . . . . . . . 11

Weights . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . 20

Air Handler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Air Flow Settings . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Units. . . . . . . . . . . . . . . . . . . . . . . 24

SZVAV Units . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-Speed VFD Units . . . . . . . . . . . . . . . . . . . 25

Minimum Supply Fan Output . . . . . . . . . 25

Electrical Connections . . . . . . . . . . . . . . . . . . . 26

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

EDC Switch Wiring . . . . . . . . . . . . . . . . . . . 27

Heating and Cooling Setpoint

Arbitration . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Checkout Procedure . . . . . . . . . . . . . . . . . . . . . 28

Installation Checklist . . . . . . . . . . . . . . . . . . . . . 28

Thermostat and Control

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electromechanical Controls . . . . . . . . . . . 29

ReliaTel Controls . . . . . . . . . . . . . . . . . . . . . 29

Electrical Data . . . . . . . . . . . . . . . . . . . . . . .. . . . . . 31

60 Hz Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

50 Hz Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Start-Up . . . . . . . . . . . . . . . . .. . . . . .. . . . . . . . . . . . 42

Sequence of Operation. . . . . . . . . . . . . . . . . . . 42

Variable Air Volume Applications

(SZVAV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2–Speed VFD Applications . . . . . . . . . . . . 43

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . 22

Horizontal Suspension . . . . . . . . . . . . . . . . . . . 22

Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Auxiliary Drain Pan. . . . . . . . . . . . . . . . . . . 22

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . 22

Condensate Piping. . . . . . . . . . . . . . . . . . . . . . . 23

Filter Replacement. . . . . . . . . . . . . . . . . . . . . . . 23

Duct Connections. . . . . . . . . . . . . . . . . . . . . . . . 24

Maintenance . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . 44

Fan Belt Adjustment . . . . . . . . . . . . . . . . . . . . . 44

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Annually (Cooling Season) . . . . . . . . . . . . . . . 45

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . 46

Wiring Diagram Matrix . . . . . . . . . . . . . . . . . . .. 47

4

SSA-SVX06E-EN

Page 5

Model Number Description

Air Handler

T WE 2 40 E D 0 0 * *

1 2 3 4 5 6 7 8 9 10 11 12

T WE 201 E D 0 0 * *

1 2 3 4 5 6 7 8 9 10 11 12

NNoottee:: When ordering replacement parts or requesting

service, be sure to refer to the specific model

number, serial number, and DL number (if

applicable) stamped on the unit nameplate.

DDIIGGIITTSS 11 -- 33:: PPrroodduucctt TTyyppee

TWE = Split System Heat Pump/Cooling Air Handler

DDIIGGIITTSS 44 -- 66:: NNoommiinnaall GGrroossss CCoooolliinngg CCaappaacciittyy

((MMBBhh))

061 = 5 Tons (60 Hz)

090 = 7.5 Tons (60 Hz)

120 = 10 Tons (60 Hz)

150 = 12.5 Tons (60 Hz)

180 = 15 Tons (60 Hz)

240 = 20 Tons (60 Hz)

300 = 25 Tons (60 Hz)

051 = 4.6 Tons (50 Hz)

076 = 6.25 Tons (50 Hz)

101 = 8.33 Tons (50 Hz)

126 = 10.4 Tons (50 Hz)

156 = 13.0 Tons (50 Hz)

201 = 16.7 Tons (50 Hz)

251 = 20.9 Tons (50 Hz)

DDIIGGIITT 77:: MMaajjoorr DDeevveellooppmmeenntt SSeeqquueennccee

D = Single Refrigeration Circuit

E = Dual Refrigeration Circuit

DDIIGGIITT 88:: EElleeccttrriiccaall CChhaarraacctteerriissttiiccss

3 = 208–230/60/3

4 = 460/60/3

W = 575/60/3

D = 380-415/50/3

K = 380/60/3

DDIIGGIITTSS 99 -- 1100:: FFaaccttoorryy IInnssttaalllleedd OOppttiioonnss

00 = Packed Stock (Standard)

03 = 2-Speed Variable Frequency Drive (VFD) standard

motor (electromechanical condenser only)

04 = 2-Speed Variable Frequency Drive (VFD) oversized

motor (electromechanical condenser only)

R3 = Single Zone Variable Air Volume (VFD) standard

motor - (ReliaTel condenser only)

R4 = Single Zone Variable Air Volume (VFD) oversized

motor - (ReliaTel condenser only)

DDIIGGIITTSS 1111:: MMiinnoorr DDeessiiggnn SSeeqquueennccee

* = Current Design Sequence

1

DDIIGGIITTSS 1122:: SSeerrvviiccee DDiiggiitt

* = Current Design Sequence

1

1.

* = sequential alpha character

SSA-SVX06E-EN

5

Page 6

General Information

This manual describes proper installation, operation,

and maintenance procedures for air cooled systems. By

carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component damage will be

minimized. It is important that periodic maintenance be

performed to help assure trouble free operation.

Should equipment failure occur, contact a qualified

service organization with qualified, experienced HVAC

technicians to properly diagnose and repair this

equipment.

IImmppoorrttaanntt:: All phases of this installation must comply

with the NATIONAL, STATE & LOCAL

CODES. In addition to local codes, the

installation must conform with National

Electric Code -ANSI/NFPA NO. 70 LATEST

REVISION.

Any individual installing, maintaining, or servicing this

equipment must be properly trained, licensed and

qualified.

IImmppoorrttaanntt:: Do not remove the VFD without first

contacting technical support! For

performance-related questions and

diagnostic support in North America call 1877-872-6363. Any return requires a claim

number FIRST. Removal of the VFD prior to

this step will void the unit’s warranties.

Installation procedures should be performed in the

sequence that they appear in this manual. Do not

destroy or remove the manual from the unit. The

manual should remain weather-protected with the unit

until all installation procedures are complete.

NNoottee:: It is not the intention of this manual to cover all

possible variations in systems that may occur or

to provide comprehensive information

concerning every possible contingency that may

be encountered during an installation. If

additional information is required or if specific

problems arise that are not fully discussed in this

manual, contact your local sales office.

Use the installation checklist provided In this manual to

verify that all necessary installation procedures have

been completed. Do not use the checklist as a

substitute for reading the information contained in the

manual. Read the entire manual before beginning

installation procedures.

Unit Description

These air handler models incorporate a single slab coil

assembly, improved application flexibility, servicing,

maintenance accessibility and an improved accessory

line. They are fully convertible, (vertical to horizontal

discharge) without field removal of the coil assembly.

They are shipped ready for horizontal installation.

All units have one drain pan that can be installed in any

one of four positions. This allows for vertical or

horizontal applications and right or left exit.

IImmppoorrttaanntt:: All dual circuit (digit 7 = E) have an

intertwined coil, except for the 25 ton,

TWE251 and TWE300 units.

6

SSA-SVX06E-EN

Page 7

Pre-Installation

The final position for the air handler must be dictated

by required service access to it, weight distribution

over structural supports, and by the locations of

electrical, refrigerant and condensate drainage

connections. After this is determined, the following

preparations should be made.

Unit Inspection

Inspect material carefully for any shipping damage. If

damaged, it must be reported to, and claims made

against the transportation company. Compare the

information that appears on the unit nameplate with

ordering and submittal data to ensure the proper unit

was shipped. Available power supply must be

compatible with electrical characteristics specified on

component nameplates. Replace damaged parts with

authorized parts only.

Inspection Checklist

To protect against loss due to damage incurred in

transit, complete the following checklist upon receipt of

the unit.

Inspect individual pieces of the shipment before

accepting the unit. Check for obvious damage to the

unit or packing material.

Inspect the unit for concealed damage before it is

stored and as soon as possible after delivery.

Concealed damage must be reported within 15

days. If concealed damage is discovered, stop

unpacking the shipment. Do not remove damaged

material from the receiving location. Take photos of

the damage if possible. The owner must provide

reasonable evidence that the damage did not occur

after delivery.

Notify the carrier’s terminal of damage immediately

by phone and by mail. Request an immediate joint

inspection of the damage by the carrier and the

consignee.

Notify the sales representative and arrange for

repair. Do not repair the unit until the damage is

inspected by the carrier’s representative.

Testing for Leaks

All TWE units are shipped with a holding charge of

nitrogen in each circuit and should be leak tested

before installation.

1. Remove the access panel.

2. Locate the liquid line or suction line access valve for

each circuit.

3. Install gauges to determine if the circuits are still

pressurized. If not, the charge has escaped and

should be repaired as required to obtain a leak-free

circuit.

Lifting Recommendations

WWAARRNNIINNGG

IImmpprrooppeerr UUnniitt LLiifftt!!

TTeesstt lliifftt uunniitt aapppprrooxxiimmaatteellyy 2244 iinncchheess ttoo vveerriiffyy

pprrooppeerr cceenntteerr ooff ggrraavviittyy lliifftt ppooiinntt.. TToo aavvooiidd

ddrrooppppiinngg ooff uunniitt,, rreeppoossiittiioonn lliiffttiinngg ppooiinntt iiff uunniitt iiss

nnoott lleevveell..

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

UUssee sspprreeaaddeerr bbaarrss ttoo pprreevveenntt ssttrraappss ffrroomm

ddaammaaggiinngg tthhee uunniitt.. IInnssttaallll tthhee bbaarrss bbeettwweeeenn lliiffttiinngg

ssttrraappss,, bbootthh uunnddeerrnneeaatthh tthhee uunniitt aanndd aabboovvee tthhee

uunniitt ttoo pprreevveenntt tthhee ssttrraappss ffrroomm ccrruusshhiinngg tthhee uunniitt

ccaabbiinneett oorr ddaammaaggiinngg tthhee ffiinniisshh..

Before preparing the unit for lifting, estimate the

approximate center of gravity for lifting safety. Because

of placement of internal components, the unit weight

may be unevenly distributed. See “Weights,” p. 20 for

approximate unit weights.

The crated unit can be moved using a forklift of suitable

capacity. For lifting the unit into an elevated mounting

position, run lifting straps or slings under the unit and

attach securely to the lifting device.

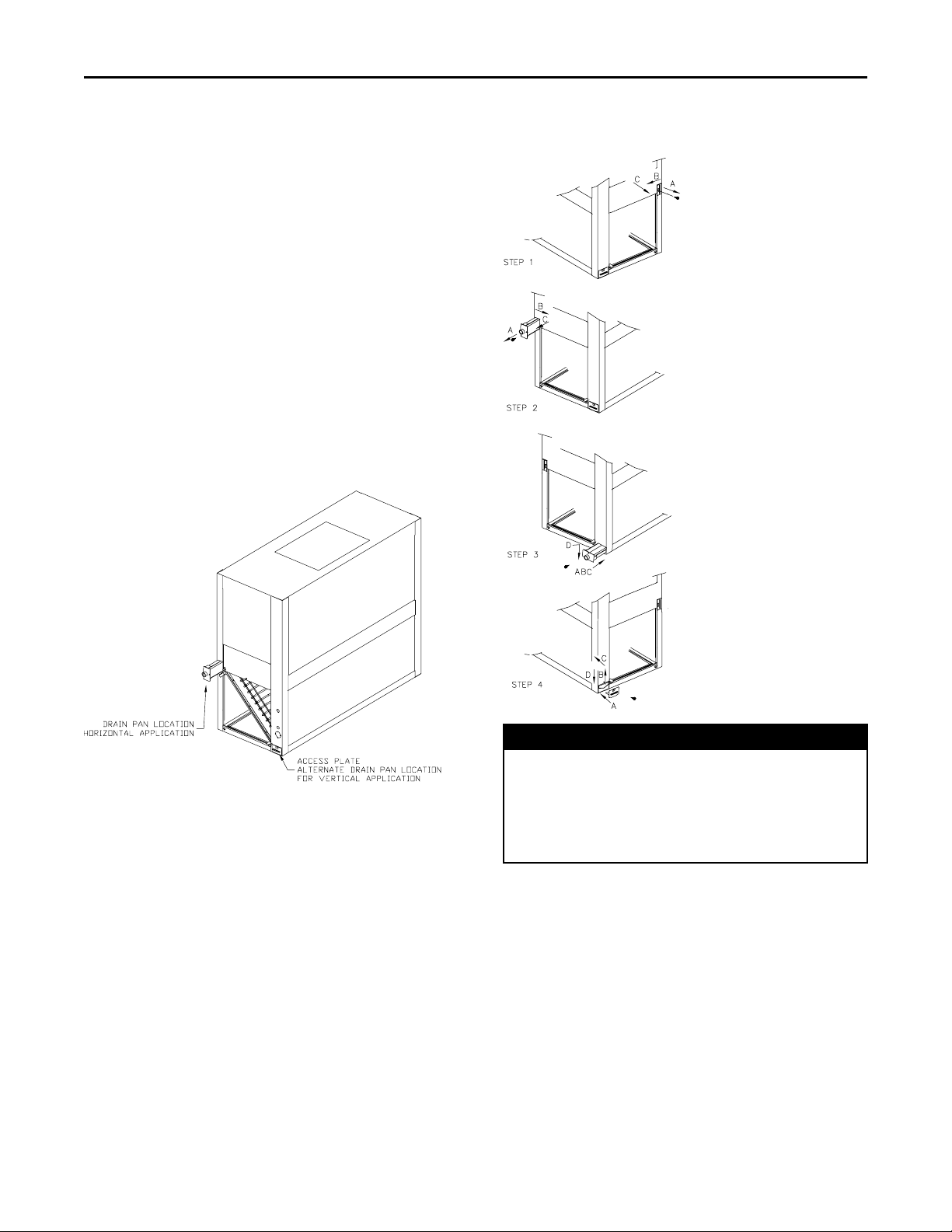

Repositioning Drain Pan

Air handlers come with one drain pan that can be

installed in any one of four positions; this allows for

vertical or horizontal application and right or left

condensate line connection.

NNoottee:: Important! All air handlers are shipped with the

drain pan installed in the horizontal position and

the connection on the left side (as shown in

Figure 1, p. 8. If an alternate position is required,

the drain pan should be repositioned before

setting the air handler.

1. Remove the access plate at the opposite end of the

drain connection. This plate secures and lifts the

back end of the drain pan for sloping. It must be

removed before the drain pan can be removed. This

is done as follows:

a. Remove the screw

b. Lift the access plate up

c. Pull the plate out. If the drain pan is to be moved

to the vertical position also remove the other

two access plates.

2. Remove the screw securing the drain pan.

a. Lift the pan up

b. Slide the pan out

3. Install the drain pan into the new position.

SSA-SVX06E-EN

7

Page 8

PPrree--IInnssttaallllaattiioonn

a. Slide the drain pan into the opening

b. Lift the drain pan up

c. Push it in all the way

d. Drop it down over the lip of the opening, secure

with screw

4. Install the access plate on the opposite end of the

drain pain.

a. Slide the edge of the access plate under the

drain pan

b. Lift the access plate and drain pan up

c. Push the access plate in

d. Drop the access plate down over the lip of the

opening, secure with screw

NNoottee:: If the drain pan is being moved to the vertical

position, install the other access plates over

the horizontal position opening

Figure 1. Drain pan location

Figure 2. Drain pan relocation

NNOOTTIICCEE

SSyysstteemm CCoommppoonneenntt DDaammaaggee!!

TThheessee aaiirr hhaannddlleerrss aarree sshhiippppeedd wwiitthh aa ddrryy nniittrrooggeenn

hhoollddiinngg cchhaarrggee iinn tthhee ccooiill.. DDeepprreessss oorr rreemmoovvee tthhee

aacccceessss vvaallvvee ccoonnee ttoo bblleeeedd ooffff tthhee nniittrrooggeenn pprriioorr ttoo

bbrraazziinngg.. TTeemmppoorraarriillyy ccaapp ooffff ttuubbeess iiff tthhee

rreeffrriiggeerraanntt lliinnee ccoonnnneeccttiioonnss aarree ttoo bbee mmaaddee llaatteerr..

8

SSA-SVX06E-EN

Page 9

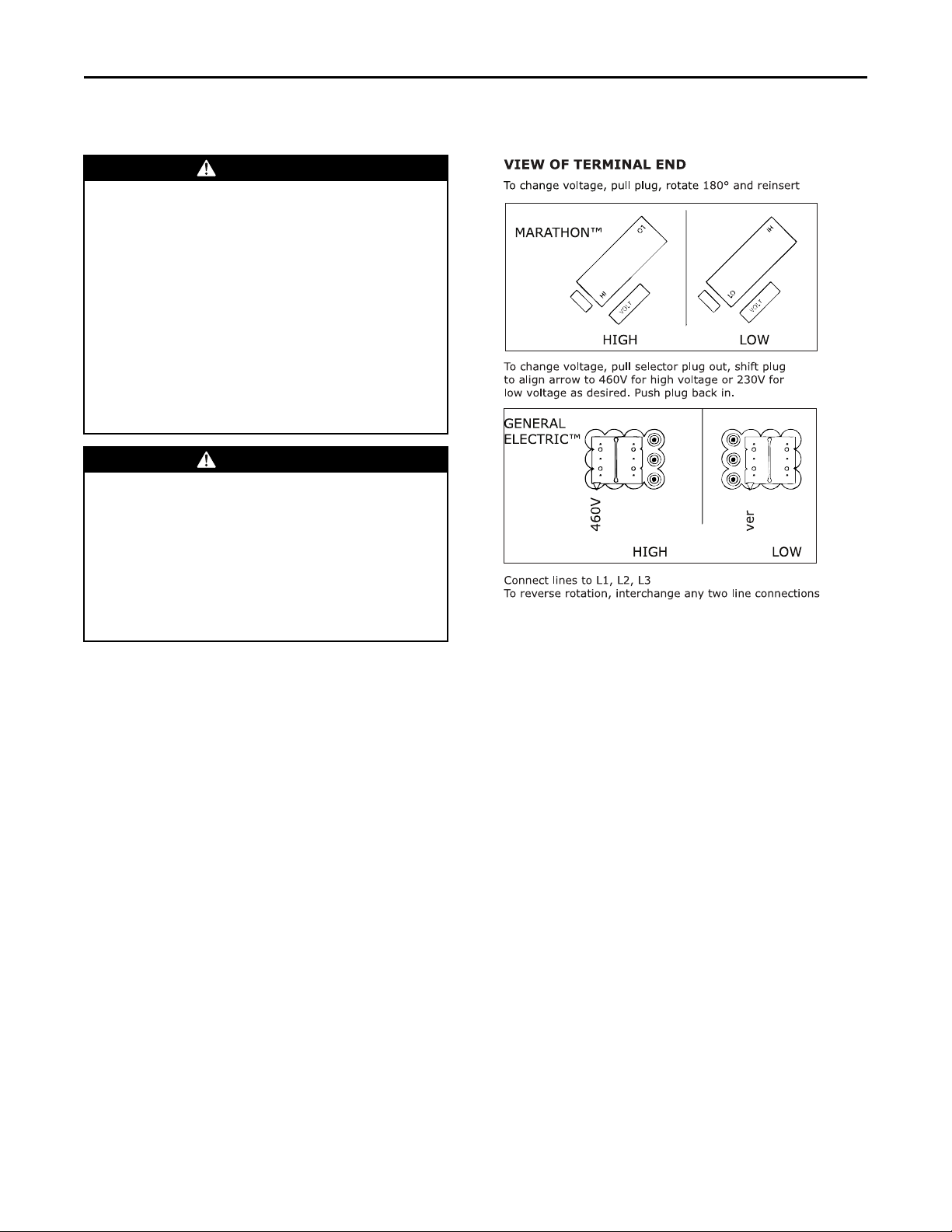

To cha nge voltage , pull plug, ro tate 18 0° a nd reins e rt

VIE W OF TERMI NAL EN D

GENERAL

ELECTRIC™

MARATHON™

HIGH LOW

HIGH LOW

To cha nge voltage , pull s e lect or plu g o ut, sh ift plug

to align arrow t o 460V for h igh voltage or 23 0V for

low volta ge a s de sire d . Pus h p lug back in.

460V

ver

Conn e ct lines to L1, L2, L3

To revers e rota tion, intercha n ge a ny two lin e conn ect ions

PPrree--IInnssttaallllaattiioonn

Field Conversion to 460 Volt

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee ww//CCaappaacciittoorrss!!

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss aanndd ddiisscchhaarrggee aallll mmoottoorr ssttaarrtt//rruunn

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr lloocckkoouutt//

ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr ccaannnnoott bbee

iinnaaddvveerrtteennttllyy eenneerrggiizzeedd.. FFoorr vvaarriiaabbllee ffrreeqquueennccyy

ddrriivveess oorr ootthheerr eenneerrggyy ssttoorriinngg ccoommppoonneennttss

pprroovviiddeedd bbyy TTrraannee oorr ootthheerrss,, rreeffeerr ttoo tthhee

aapppprroopprriiaattee mmaannuuffaaccttuurreerr’’ss lliitteerraattuurree ffoorr

aalllloowwaabbllee wwaaiittiinngg ppeerriiooddss ffoorr ddiisscchhaarrggee ooff

ccaappaacciittoorrss.. VVeerriiffyy wwiitthh aann aapppprroopprriiaattee vvoollttmmeetteerr

tthhaatt aallll ccaappaacciittoorrss hhaavvee ddiisscchhaarrggeedd..

FFoorr aaddddiittiioonnaall iinnffoorrmmaattiioonn rreeggaarrddiinngg tthhee ssaaffee

ddiisscchhaarrggee ooff ccaappaacciittoorrss,, sseeee PPRROODD--SSVVBB0066AA--EENN..

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee eelleeccttrriiccaall ccooddeess..

• Available power supply must agree with electrical

data on component nameplate.

• Some standard air handlers are shipped wired for

208-230 volt applications and can be converted for

460 volt by rewiring the blower motor. (This

includes models TWE090D3, TWE090E3,

TWE120D3, TWE120E3, TWE150E3 and TWE180E3).

Converting Motor to 460 Volt

1. Ensure power is disconnected to unit by following

the warning above.

2. Remove unit access panels closest to motor.

3. Open terminal cover on lead end of motor.

4. Pull voltage selector plug from low voltage

selection (see Figure 3, p. 9).

5. Shift the plug (or rotate 180°) to align plug for high

voltage selection and re-insert plug.

IImmppoorrttaanntt:: When re-inserting voltage selection

plug, ensure it is fully seated.

6. Replace terminal cover on lead end of motor.

7. Replace unit access panels.

Figure 3. Voltage change plug

Refrigerant Piping

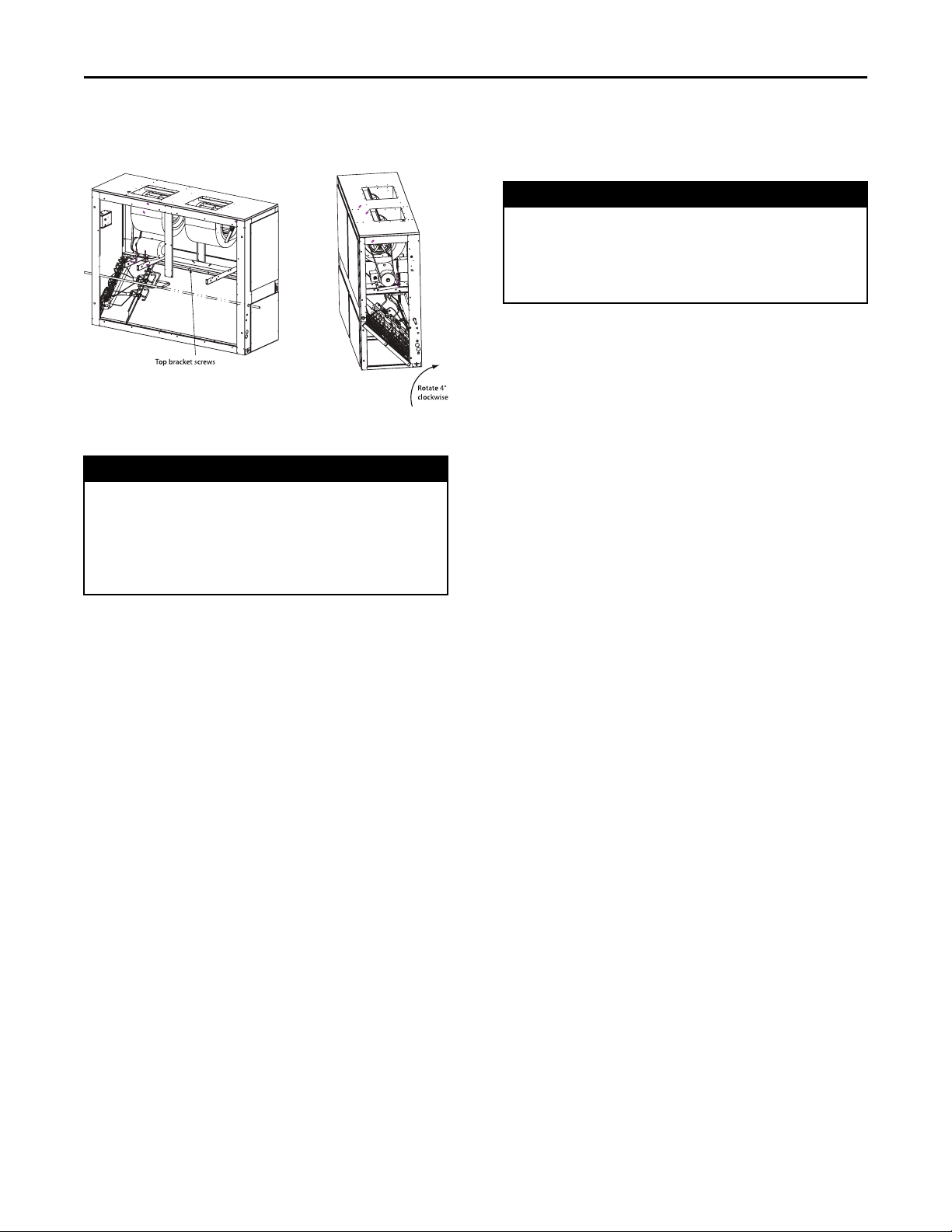

Reorienting Evaporator Coil (TWE126/ 150 and 156/180)

IImmppoorrttaanntt:: Applies to TWE126/150 and 156/180 when

positioned for vertical upflow. Unit is

shipped in the horizontal position. If

installing in the vveerrttiiccaall ppoossiittiioonn, the coil

mmuusstt bbee reoriented by rotating the coil 4

degrees (control box side) from the

shipped position.

1. Remove screws from top evaporator coil bracket

(bracket that attaches coil to cabinet and runs the

length of the unit).

2. Rotate evaporator coil approximately 4 degrees

clockwise - looking from the control box end. When

the evaporator coil is rotated, the lower set of

evaporator coil bracket holes will align with the

support bracket (from which it was originally

fastened).

3. Reinsert screws in evaporator coil bracket.

SSA-SVX06E-EN

9

Page 10

Top bracket screws

Rotate 4°

clockwise

PPrree--IInnssttaallllaattiioonn

Figure 4. Evaporator coil reorientation for TWE126,

150, 156, 180

Preparation for Refrigerant Piping

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

DDoo nnoott aappppllyy hheeaatt ttoo rreemmoovvee sseeaall ccaappss uunnttiill tthhee

ggaauuggee ppoorrtt ccoorreess hhaavvee bbeeeenn rreemmoovveedd.. IIff sseeaall ccaappss

aarree iinnttaacctt,, aapppplliiccaattiioonn ooff hheeaatt mmaayy ggeenneerraattee

eexxcceessssiivvee pprreessssuurree iinn tthhee uunniitt aanndd rreessuulltt iinn

ddaammaaggee ttoo tthhee ccooiill oorr eexxppaannssiioonn vvaallvvee..

The air handler is designed so that refrigerant piping

can enter from either the right or left hand side. It is

shipped with the intent that the refrigerant lines will

enter from the left hand side. To convert to right hand

entry, unbraze the elbow on the suction line and rotate

180° and rebraze.

IImmppoorrttaanntt:: Access to refrigerant lines is limited in all

horizontal and some vertical applications.

Therefore, refrigerant lines should be

stubbed out and temporarily capped prior

to setting the air handler. Protect adjacent

surfaces from heat damage when brazing

in and around the air handler.

Installations, Limitations and Recommendations

NNOOTTIICCEE

SSyysstteemm CCoommppoonneenntt DDaammaaggee!!

PPrrooppeerrllyy iinnssuullaattee aallll rreeffrriiggeerraanntt ggaass ppiippiinngg ttoo

pprreevveenntt ppoossssiibbllee wwaatteerr ddaammaaggee dduuee ttoo

ccoonnddeennssaattiioonn aanndd ttoo pprreevveenntt ccaappaacciittyy lloossss aanndd

ppoossssiibbllee ccoommpprreessssoorr ddaammaaggee..

The general location of the air handler is normally

selected by the architect, contractor and/or buyer. For

proper installation, the following items must be

considered:

• Available power supply must agree with electrical

data on component nameplate.

• If external accessories are installed on the unit,

additional clearances must be provided.

• All duct work should be properly insulated to

prevent condensation and heat loss.

• Refrigerant gas piping must be insulated.

It is recommended that the outline drawings in the

Dimensional Data section be studied and dimensions

properly noted and checked against the selected

installation site. By noting in advance which features

are to be used, proper clearance allowances can be

made for installation and possible future service.

IImmppoorrttaanntt:: When installing these units “free standing”

with discharge grills and isolators, a top

support with isolator should be added to

prevent tipping. Support and isolator can

be attached to a wall or other appropriate

structure.

If adding external accessories to the unit,

additional clearances must be considered

for the overall space needed.

For installation of accessories available for this air

handler, follow the installation instructions that are

shipped with each accessory.

10

SSA-SVX06E-EN

Page 11

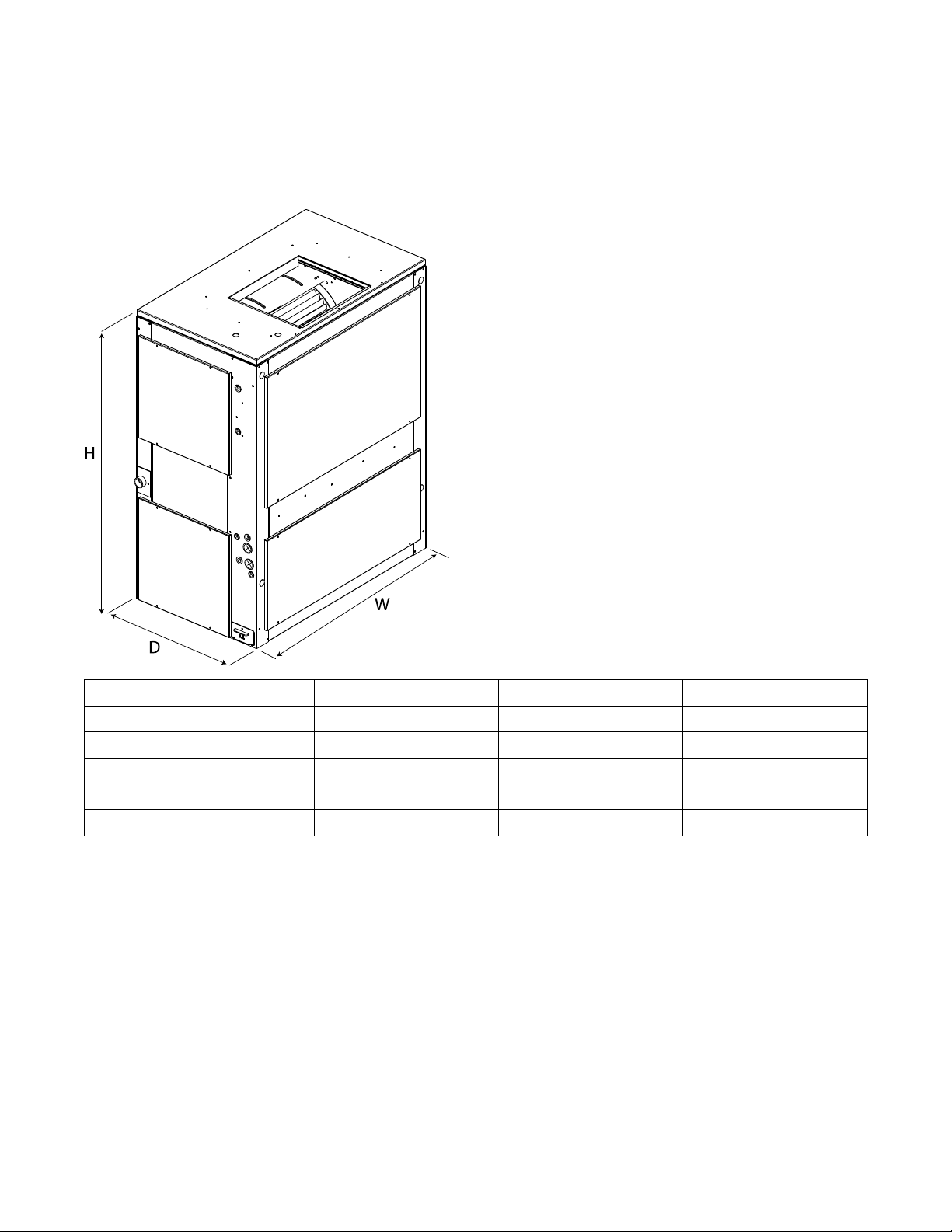

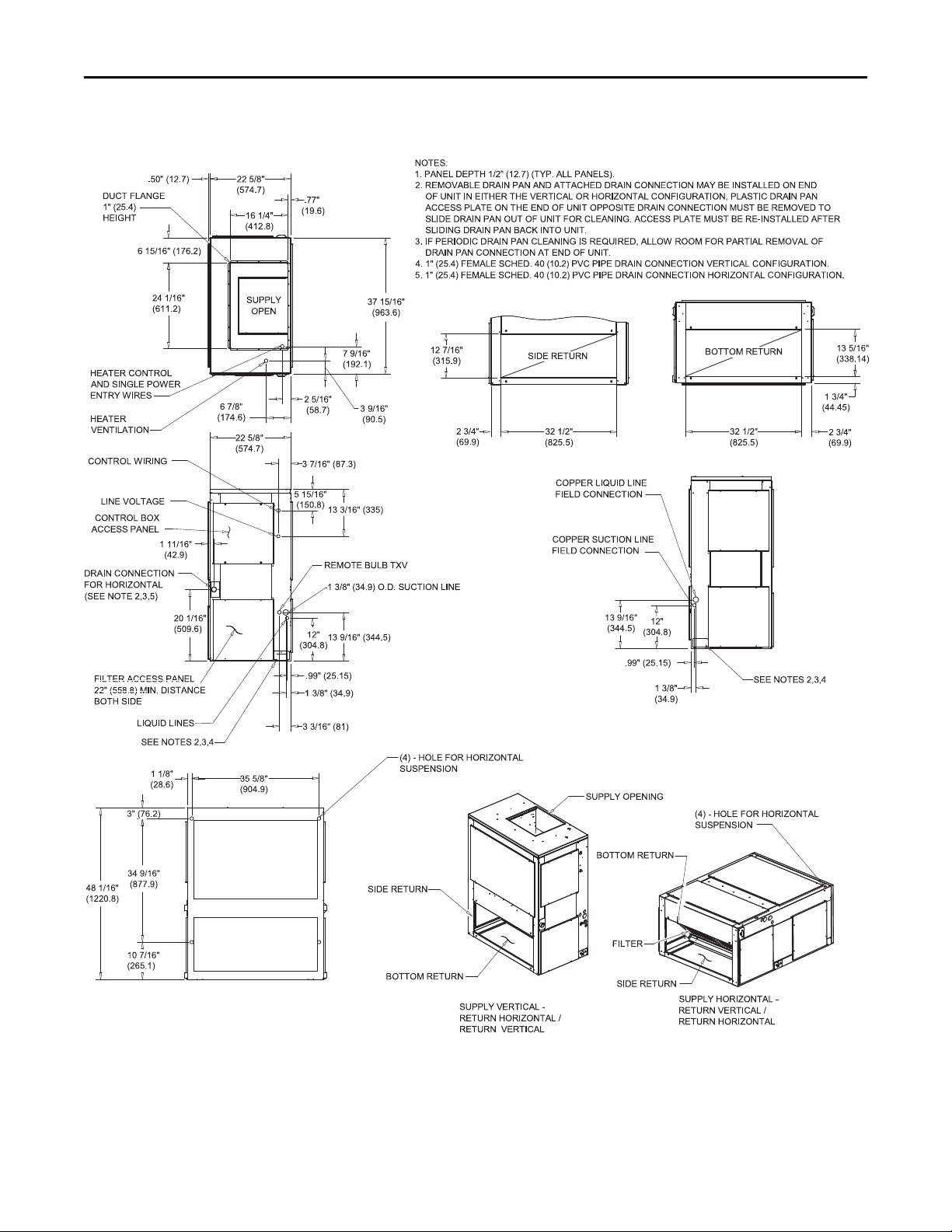

Dimensional Data

H

D

W

Figure 5. Height, width and depth measurements

Model Number

TWE051, 061 48-1/8 (1222.4) 39-5/8 (1006.5) 23-5/8 (600.0)

TWE076, 090 54-1/8 (1374.8) 49-1/8 (1247.8) 26-1/2 (673.1)

TWE101, 120 54-1/8 (1374.8) 65-1/8 (1654.2) 26-1/2 (673.1)

TWE126, 150, 156, 180 69-1/8 (1756.0) 81-1/4 (2063.7) 30 (762.0)

TWE201, 240, 251, 300 71-7/8 (1806.6) 94-1/4 (2394.0) 32-1/8 (816.0)

Note: Full dimensional data is available on the following pages.

H - in. (mm) W - in. (mm) D - in. (mm)

SSA-SVX06E-EN

11

Page 12

3" (76.2)

48 1/16"

(1220. 8)

10 7/16"

(265. 1)

34 9/16"

(877. 9)

35 5/8"

(904. 9)

1 1/8"

(28.6)

12"

(304. 8)

13 9/16" (344.5)

20 1/16"

(509. 6)

1 11/16"

(42.9)

5 15/16"

(150. 8)

13 3/16" (335)

12"

(304.8)

13 9/16"

(344.5)

13 5/16"

(338.14)

1 3/4"

(44.45)

2 3/4"

(69.9)

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

32 1/2"

(825.5)

12 7/16"

(315.9)

1 3/8"

(34.9)

.99" (25.15)

.99" (25.15)

1 3/8" (34.9)

3 3/16" (81)

3 7/16" (87.3)

22 5/8"

(574.7)

22 5/8"

(574.7)

16 1/4"

(412.8)

.77"

(19.6)

.50" (12.7)

3 9/16"

(90.5)

7 9/16"

(192.1)

37 15/16"

(963.6)

24 1/16"

(611.2)

2 5/16"

(58.7)

6 7/8"

(174.6)

6 15/16" (176.2)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCES S P ANEL

NOTES :

1. P ANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOSITE DRAIN CONNECTION MUST BE REMOVED TO

S LIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCES S P LATE MUST BE RE-INSTALLED AFTER

S LIDING DRAIN PAN BACK INTO UNIT.

3. IF P ERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES 2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUS PENSION

COP PER LIQUID LINE

FIELD CONNECTION

COPPER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

1 3/8" (34.9) O.D. SUCTION LINE

REMOTE BULB TXV

FILTER ACCES S PANEL

22" (558.8) MIN. DISTANCE

BOTH SIDE

FILTER

SUP PLY OPENING

BOTTOM RETURN

SIDE RETURN

BOTTOM RETURN

SUP PLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

(4) - HOLE FOR HORIZONTAL

SUS PENS ION

SIDE RETURN

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE POWER

ENTRY WIRES

32 1/2"

(825.5)

2 3/4"

(69.9)

DDiimmeennssiioonnaall DDaattaa

Figure 6. 4.6, 5 ton air handler, single circuit

12

SSA-SVX06E-EN

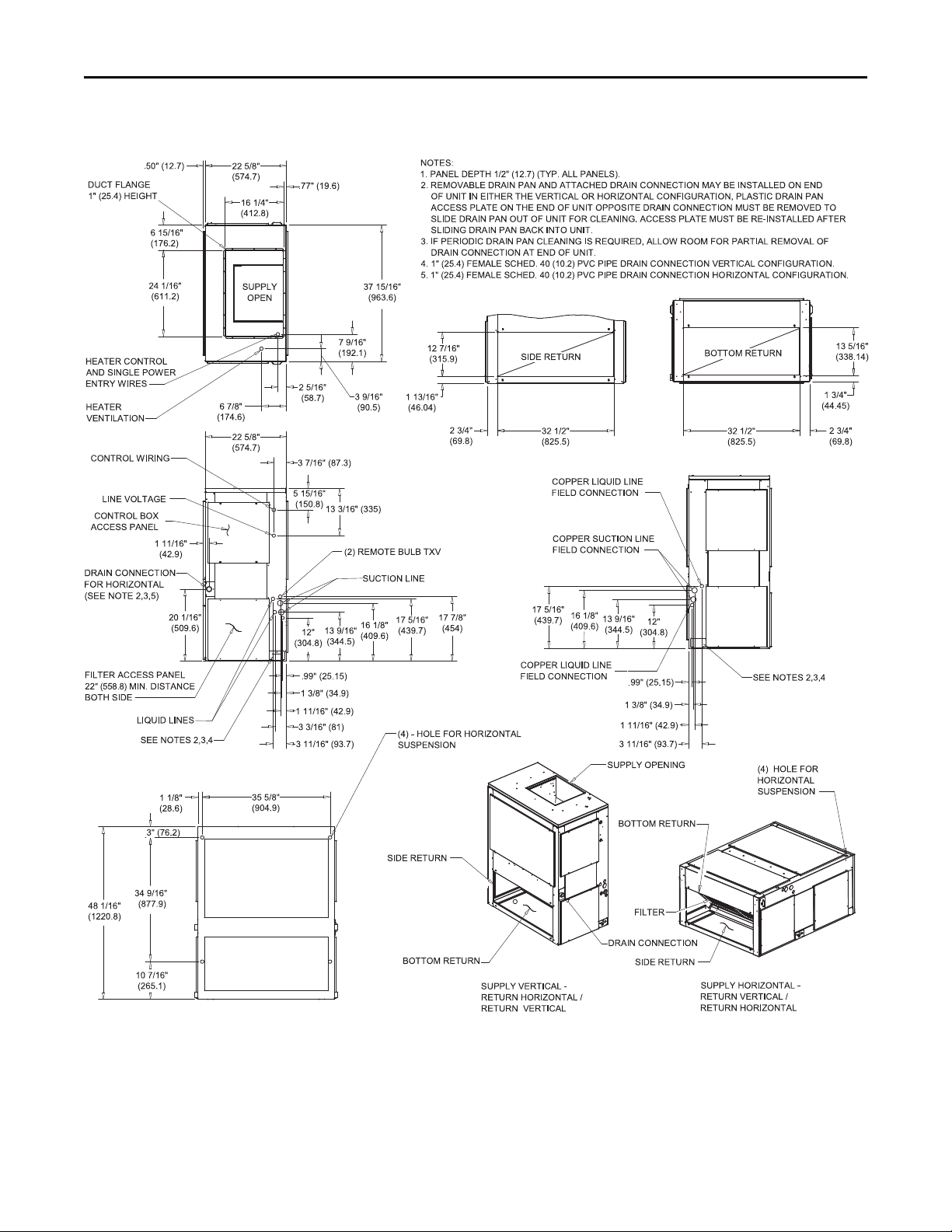

Page 13

Figure 7. 5 ton air handler, dual circuit

3" (76.2)

48 1/16"

(1220. 8)

10 7/16"

(265. 1)

34 9/16"

(877. 9)

35 5/8"

(904. 9)

1 1/8"

(28.6)

12"

(304. 8)

13 9/16"

(344. 5)

20 1/16"

(509. 6)

1 11/16"

(42.9)

5 15/16"

(150. 8)

13 3/16" (335)

16 1/8"

(409. 6)

17 5/16"

(439. 7)

17 7/8"

(454)

12"

(304.8)

13 9/16"

(344.5)

16 1/8"

(409.6)

17 5/16"

(439.7)

3 5/16"

(338.14)

1 3/4"

(44.45)

2 3/4"

(69.8)

32 1/2"

(825.5)

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

12 7/16"

(315. 9)

3 11/16" (93.7)

1 11/16" (42.9)

1 3/8" (34.9)

.99" (25.15)

.99" (25.15)

1 3/8" (34.9)

1 11/16" (42.9)

3 3/16" (81)

3 11/16" (93.7)

3 7/16" (87.3)

22 5/8"

(574. 7)

1 13/16"

(46.04)

22 5/8"

(574. 7)

16 1/4"

(412. 8)

.77" (19.6)

.50" (12.7)

3 9/16"

(90.5)

7 9/16"

(192. 1)

37 15/16"

(963. 6)

24 1/16"

(611. 2)

2 5/16"

(58.7)

6 7/8"

(174. 6)

6 15/16"

(176. 2)

BOTTOM RETURN

SIDE RETURN

DUCT FLANGE

1" (25.4) HEIGHT

SUP PLY

OPEN

CONTROL WIRING

LINE VOLTAGE

CONTROL BOX

ACCES S PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, P LASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOS ITE DRAIN CONNECTION MUST BE REMOVED TO

S LIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

S LIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VE

RTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONF IGURATION.

SEE NOTES 2,3,4

SEE NOTES 2,3,4

SUPPLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

(4) - HOLE FOR HORIZONTAL

SUS PENSION

COP PER LIQUID LINE

FIELD CONNECTION

COP PER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

(2) REMOTE BULB TXV

FILTER ACCESS PANEL

22" (558.8) MIN. DISTANCE

BOTH S IDE

SIDE RETURN

SIDE R ETURN

BOTTOM RETURN

BOTTOM RETURN

SUP PLY OPENING

FILTER

(4) HOLE FOR

HORIZONTAL

SUS PENSION

DRAIN CONNECTION

SUCTION LINE

COP PER LIQUID LINE

FIELD CONNECTION

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

32 1/2"

(825.5)

2 3/4"

(69.8)

DDiimmeennssiioonnaall DDaattaa

SSA-SVX06E-EN

13

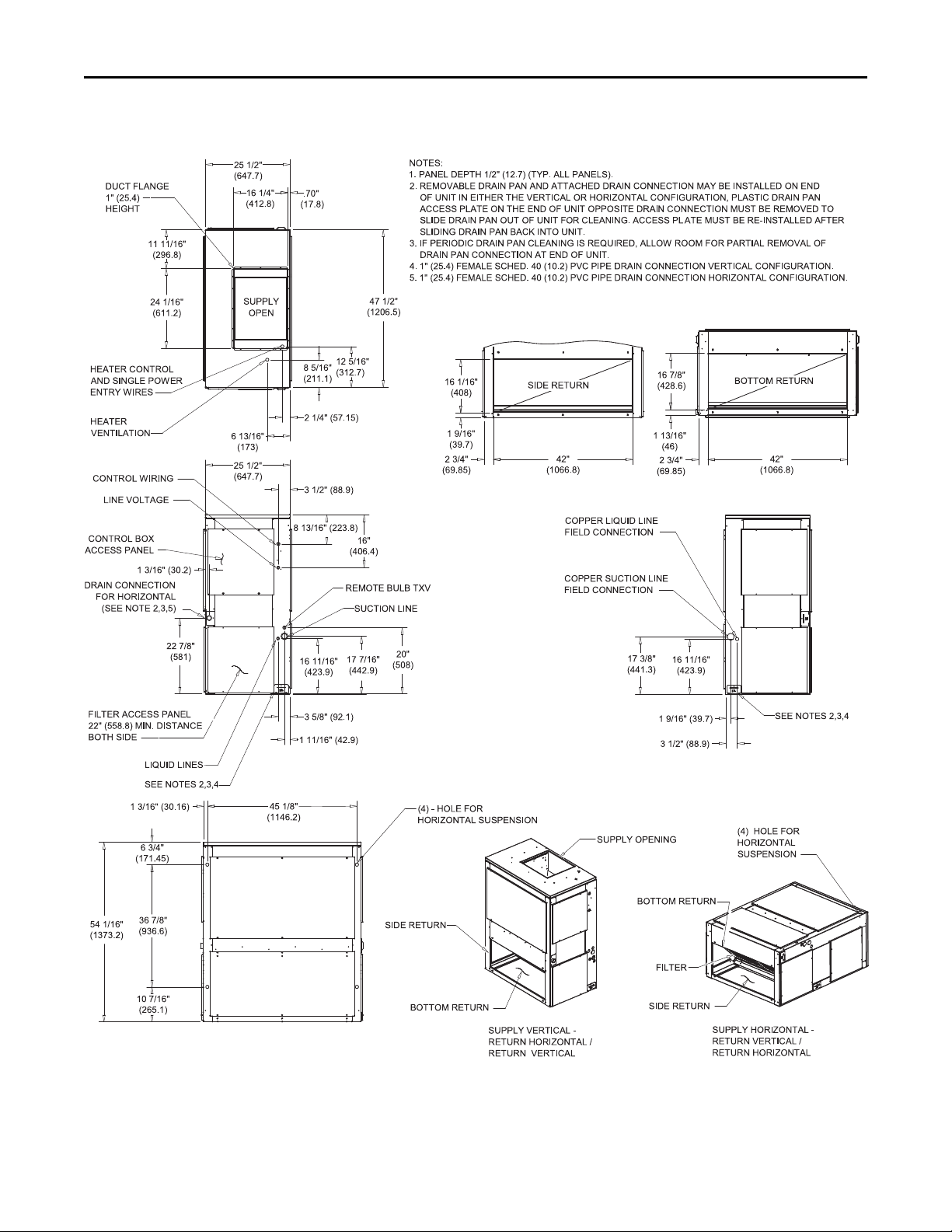

Page 14

16 7/8"

(428.6)

1 13/16"

(46)

2 3/4"

(69.85)

42"

(1066.8)

1 9/16"

(39.7)

16 1/16"

(408)

16"

(406. 4)

8 13/16" (223.8)

3 1/2" (88.9)

1 3/16" (30.2)

22 7/8"

(581)

45 1/8"

(1146. 2)

6 3/4"

(171. 45)

36 7/8"

(936. 6)

10 7/16"

(265. 1)

54 1/16"

(1373. 2)

1 3/16" (30.16)

16 11/16"

(423. 9)

17 7/16"

(442. 9)

20"

(508)

3 5/8" (92.1)

1 11/16" (42.9)

16 11/16"

(423.9)

17 3/8"

(441.3)

1 9/16" (39.7)

3 1/2" (88.9)

25 1/2"

(647. 7)

16 1/4"

(412. 8)

.70"

(17.8)

25 1/2"

(647. 7)

24 1/16"

(611. 2)

11 11/16"

(296. 8)

47 1/2"

(1206. 5)

8 5/16"

(211. 1)

12 5/16"

(312. 7)

2 1/4" (57.15)

6 13/16"

(173)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCESS PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOS ITE DRAIN CONNECTION MUST BE REMOVED TO

SLIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCES S PLATE MUST BE RE-INSTALLED AFTER

SLIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC P IPE DRAIN CONNECTION VE

RTICAL CONFIGURATION.

5. 1" (25.4) FEMALE S CHED. 40 (10.2) P VC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES 2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR

HORIZONTAL SUSPENSION

COP PER LIQUID LINE

FIELD CONNECTION

COPPER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

SUCTION LINE

REMOTE BULB TXV

FILTER ACCESS PANEL

22" (558.8) MIN. DISTANCE

BOTH S IDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

FILTER

BOTTOM RETURN

SUP PLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

(4) HOLE FOR

HORIZONTAL

SUS PENSION

SIDE RETURN

BOTTOM RETURN

SIDE RETURN

SUP PLY OPENING

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

42"

(1066.8)

2 3/4"

(69.85)

DDiimmeennssiioonnaall DDaattaa

Figure 8. 6.25, 7.5 ton air handler, single circuit

14

SSA-SVX06E-EN

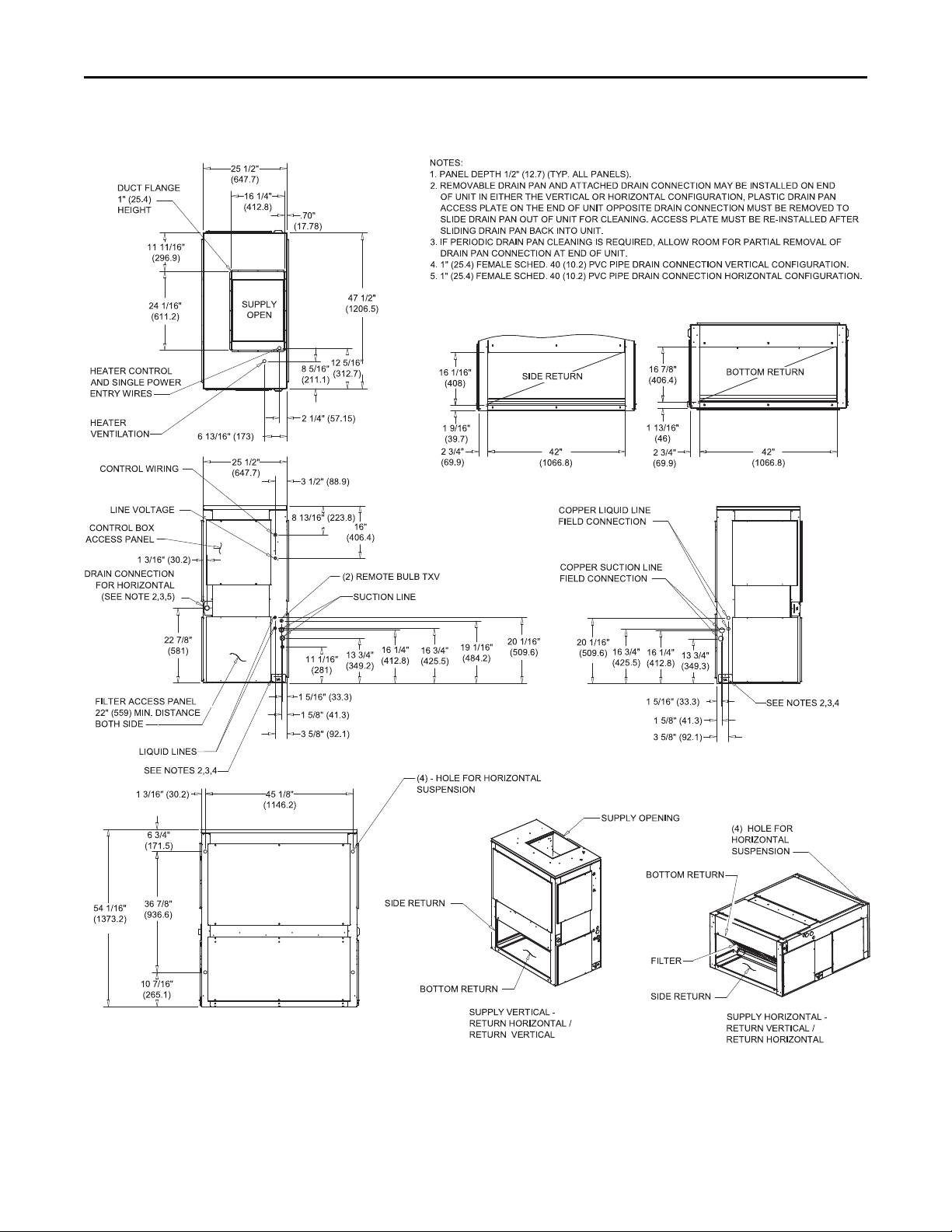

Page 15

Figure 9. 6.25, 7.5 ton air handler, dual circuit

16 7/8"

(406.4)

1 13/16"

(46)

2 3/4"

(69.9)

42"

(1066.8)

1 9/16"

(39.7)

16 1/16"

(408)

20 1/16"

(509.6)

16 3/4"

(425.5)

16 1/4"

(412.8)

13 3/4"

(349.3)

3 5/8" (92.1)

1 5/8" (41.3)

1 5/16" (33.3)

11 1/16"

(281)

13 3/4"

(349. 2)

16 1/4"

(412. 8)

16 3/4"

(425. 5)

19 1/16"

(484. 2)

20 1/16"

(509.6)

3 5/8" (92.1)

1 5/8" (41.3)

1 5/16" (33.3)

16"

(406. 4)

8 13/16" (223.8)

3 1/2" (88.9)

1 3/16" (30.2)

22 7/8"

(581)

45 1/8"

(1146. 2)

6 3/4"

(171. 5)

36 7/8"

(936. 6)

10 7/16"

(265. 1)

54 1/16"

(1373. 2)

1 3/16" (30.2)

25 1/2"

(647. 7)

16 1/4"

(412. 8)

.70"

(17.78)

25 1/2"

(647. 7)

24 1/16"

(611. 2)

11 11/16"

(296. 9)

47 1/2"

(1206. 5)

8 5/16"

(211. 1)

12 5/16"

(312. 7)

2 1/4" (57.15)

6 13/16" (173)

BOTTOM RETURN

SIDE RETURN

CONTROL WIRING

LINE VOLTAGE

CONTROL BOX

ACCES S PANEL

NOTES :

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOS ITE DRAIN CONNECTION MUST BE REMOVED TO

SLIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

SLIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES 2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUS PENSION

COP PER LIQUID LINE

FIELD CONNECTION

COP PER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

SUCTION LINE

(2) REMOTE BULB TXV

FILTER ACCESS PANEL

22" (559) MIN. DISTANCE

BOTH S IDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

FILTER

SUP PLY OPENING

BOTTOM RETURN

SIDE RETURN

BOTTOM RETURN

SUP PLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

(4) HOLE FOR

HORIZONTAL

SUS PENSION

SIDE RETURN

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

42"

(1066.8)

2 3/4"

(69.9)

DDiimmeennssiioonnaall DDaattaa

SSA-SVX06E-EN

15

Page 16

3 1/2" (89)

8 7/8"

(225. 4)

16 1/16"

(408)

1 3/16"

(30.2)

22 7/8"

(581)

61 1/8"

(1552. 6)

6 3/4"

(171. 45)

36 7/8"

(936. 63)

10 7/16" (265.1)

54 1/16"

(1373. 2)

58"

(1473.2)

2 3/4"

(69.8)

1 13/16"

(46)

16 7/8"

(428.6)

15 15/16"

(404. 8)

1 11/16"

(42.9)

16 11/16"

(423. 9)

17 3/8"

(441. 4)

20"

(508)

1 11/16" (42.9)

3 5/8" (92.1)

16 11/16"

(423.9)

17 3/8"

(441.3)

1 11/16" (42.9)

3 5/8" (92.1)

63 1/2"

(1613)

1 3/16" (30.2)

16 1/4"

(412. 8)

.70" (17.8)

25 1/2"

(647. 7)

19 11/16"

(500. 1)

24 1/16"

(611. 2)

63 1/2"

(1612. 9)

20 5/16"

(515. 9)

16 5/16"

(414. 3)

2 1/4" (57.2)

6 13/16" (173)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCES S PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOS ITE DRAIN CONNECTION MUST BE REMOVED TO

S LIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

S LIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) P VC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC P IPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES

2,3,4

SEE NOTES 2,3,4

COP PER LIQUID LINE

FIELD CONNECTION

COP PER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

SUCTION LINE

REMOTE BULB TXV

FILTER ACCESS PANEL

22" (559) MIN. DISTANCE

BOTH S IDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

BOTTOM RETURN

SUP PLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUPPLY OP ENING

SIDE RETURN

(4) - HOLE FOR

HORIZONTAL

SUS PENSION

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

25 1/2"

(647. 7)

58"

(1473.2)

2 3/4"

(69.8)

BOTTOM RETURN

SIDE RETURN

(4) HOLE FOR

HORIZONTAL

SUS PENSION

FILTER

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

DDiimmeennssiioonnaall DDaattaa

Figure 10. 8.33, 10 ton air handler, single circuit

16

SSA-SVX06E-EN

Page 17

3 1/2" (89)

8 7/8"

(225. 4)

16 1/16"

(408)

1 3/16"

(30.2)

22 7/8"

(581)

61 1/8"

(1552. 6)

6 3/4"

(171. 45)

36 7/8"

(936. 6)

10 7/16" (265.1)

54 1/16"

(1373. 2)

11" (279.4)

13 11/16"

(347. 7)

16 1/4"

(412. 8)

16 11/16"

(423. 9)

19"

(482.6)

20"

(508)

1 5/16" (33.4)

1 5/8" (41.3)

3 5/8" (92.1)

3 5/8" (92.1)

1 5/8" (41.3)

1 5/16" (33.3)

13 3/4"

(349.3)

16 1/4"

(412.8)

16 3/4"

(425.5)

20 1/16"

(509.6)

58"

(1473.2)

2 3/4"

(69.8)

1 13/16"

(46)

16 7/8"

(428.6)

15 15/16"

(404. 8)

1 11/16"

(42.9)

1 3/16"

(30.2)

25 1/2"

(647. 7)

16 1/4"

(412. 7)

.70" (17.8)

25 1/2"

(647. 7)

19 11/16"

(500. 1)

24 1/16"

(611. 2)

63 1/2"

(1613)

20 5/16"

(515. 9)

16 5/16"

(414. 3)

2 1/4" (57.15)

6 13/16" (173)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCES S PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOS ITE DRAIN CONNECTION MUST BE REMOVED TO

S LIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

S LIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) P VC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES

2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUS PENSION

COP PER LIQUID LINE

FIELD CONNECTION

COP PER SUCTION LINE

FIELD CONNECTION

SUCTION LINE

(2) REMOTE BULB TXV

FILTER ACCESS PANEL

22" (558.8) MIN. DISTANCE

BOTH S IDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

LIQUID LINES

FILTER

BOTTOM RETURN

SIDE RETURN

BOTTOM RETURN

SUP PLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

SIDE RETURN

SUP PLY OPENING

(4) HOLE FOR

HORIZONTAL

SUS PENSION

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

58"

(1473.2)

2 3/4"

(69.8)

Figure 11. 8.33, 10 ton air handler, dual circuit

DDiimmeennssiioonnaall DDaattaa

SSA-SVX06E-EN

17

Page 18

19 1/2"

(495.3)

74 1/8"

(1882.8)

3 7/16" (87.3)

2 3/4"

(69.8)

17 7/8"

(454)

3 5/16" (84.1)

4 1/4" (108)

20"

(508)

12 13/16" (325.4)

22"

(558.8)

21 1/2"

(546. 1)

18 11/16"

(474. 7)

18 5/16"

(465. 1)

15 13/16"

(401. 6)

12" (304.8)

21 1/2"

(546.1)

1 5/16" (33.3)

2 1/8" (54)

2 7/16" (62)

4 1/4" (108)

25 1/8"

(638. 2)

18 11/16"

(474.6)

18 3/8"

(466.7)

15 13/16"

(401.64)

4 1/8" (104.8)

2 5/16" (58.7)

2" (50.8)

9 5/8"

(244. 5)

48"

(1219. 2)

11 7/16" (290.5)

1 3/16"

(30.2)

69 1/16"

(1754. 2)

79 5/8"

(2022. 5)

1 1/4"

(31.8)

77 3/16"

(1960. 6)

29 1/16"

(738. 2)

2 7/8" (73)

16 5/16"

(414. 3)

29 1/16"

(738. 2)

4 5/16" (109.5)

12 1/8"

(308)

79 9/16"

(2020. 9)

54 15/16"

(1395. 4)

12 3/8" (314.3)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCES S PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOS ITE DRAIN CONNECTION MUST BE REMOVED TO

S LIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER SLIDING

DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) P VC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC P IPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES

2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUS PENSION

COPPER LIQUID LINE

FIELD CONNECTION

COP PER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

SUCTION LINE

(2) REMOTE BULB TXV

FILTER ACCESS PANEL

22" (559) MIN.

DISTANCE

BOTH S IDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

SIDE RETURN

BOTTOM RETURN

FILTER

SUP PLY OPENING

BOTTOM RETURN

SIDE RETURN

BOTTOM RETURN

SUP PLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

(4) HOLE FOR

HORIZONTAL

SUS PENSION

SIDE RETURN

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

74 1/8"

(1882.8)

2 3/4"

(69.8)

SUP PLY

OPEN

DDiimmeennssiioonnaall DDaattaa

Figure 12. 10.4, 13, 12.5, 15 ton air handler, dual circuit

18

SSA-SVX06E-EN

Page 19

20 15/16"

(531.8)

2 15/16"

(74.6)

4 3/4"

(120.6)

83 1/8"

(2111.4)

3"

(76.2)

20 15/16"

(531.8)

20" (508)

12 13/16"

(325. 4)

25 1/2"

(647.7)

21 13/16"

(554)

21 3/8"

(542. 9)

19 1/8"

(485. 8)

18 3/8"

(466.7)

15 7/8"

(403. 2)

12 7/8"

(327)

25 1/2"

(647.7)

11 7/16"

(290.5)

50 13/16"

(1290.6)

9 5/8"

(244.5)

71 7/8"

(1825.6)

1 11/16"

(42.9)

89 3/16"

(2265.4)

92 9/16"

(2351.1)

4" (101.6)

3 3/8" (85.7)

1 15/16" (49.2)

1 11/16" (42.9)

3 7/8" (98.4)

3 1/4" (82.5)

1 7/8" (47.6)

1 9/16" (39.7)

28 1/2"

(724)

1 3/16"

(30.2)

31 1/8"

(790.6)

4 1/4" (108)

16 5/16"

(414.3)

31 1/8"

(790.6)

4 15/16" (125.4)

92 9/16"

(2351.1)

18 5/8"

(473.1)

6 7/16" (163.5)

18 7/8"

(479.4)

54 15/16"

(1395.4)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCESS PANEL

NOTES :

1. P ANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOSITE DRAIN CONNECTION MUST BE REMOVED TO

S LIDE DRAIN PAN OUT OF UNIT CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

S LIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED .40 (10.2) PVC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED .40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

SEE NOTES

2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUS PENSION

COP PER LIQUID LINE

FIELD CONNECTION

COP PER SUCTION LINE

FIELD CONNECTION

SUCTION LINE

REMOTE BULB TXV

FILTER ACCESS PANEL

22" (559) MIN. DISTANCE

BOTH S IDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

SIDE RETURN

BOTTOM RETURN

LIQUID LINES

(4) HOLE FOR

HORIZONTAL

SUS PENSION

SUP PLY HORIZONTAL -

RETURN VERTICAL /

RETURN HORIZONTAL

SUPPLY VERTICAL -

RETURN HORIZONTAL /

RETURN VERTICAL

BOTTOM RETURN

SIDE RETURN

FILTER

SUP PLY OPENING

BOTTOM RETURN

SIDE RETURN

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUP PLY

OPEN

HEATER CONTROL

AND SINGLE P OWER

ENTRY WIRES

21 13/16"

(554)

19 1/8"

(485.8)

18 3/8"

(466.7)

15 7/8"

(403.2)

83 1/8"

(2111.4)

4 3/4"

(120.6)

Figure 13. 16.7, 20.9, 20, 25 ton air handler, dual circuit

DDiimmeennssiioonnaall DDaattaa

SSA-SVX06E-EN

19

Page 20

Weights

T

op View

Control Box Access

Air Handler

Table 1. Standard air handler (TWE) — unit and corner weights - (60 Hz)

Tons

7.5

12.5 TWE150E 730 676 168 192 181 135 196 164 145 171

Model

Number

TWE061D/E

5

TWE090D/E

TWE120D/E

10

15 TWE180E 729 675 167 192 181 135 196 163 145 171

20 TWE240E 891 818 258 168 161 231 256 181 146 235

25 TWE300E 972 899 211 229 184 275 272 176 228 223

Shipping

Max (lbs)

263 232 55 71 51 55 54 67 50 61

360 323 67 99 75 82 56 92 87 88

429 393 77 121 110 85 79 118 77 119

Net Max

(lbs)

Table 2. SZVAV and 2-Speed VFD air handler (TWE) — unit and corner weights - (60 Hz)

Tons

7.5 TWE090E 360 323 67 99 75 82 56 92 87 88

12.5 TWE150E 730 676 168 192 181 135 196 164 145 171

Model

Number

TWE120D/E

10

15 TWE180E 729 675 167 192 181 135 196 163 145 171

20 TWE240E 891 818 258 168 161 231 256 181 146 235

25 TWE300E 972 899 211 229 184 275 272 176 228 223

Shipping

Max (lbs)

429 393 77 121 110 85 79 118 77 119

Net Max

(lbs)

Corner Weights - Vertical Corner Weights - Horizontal

1 2 3 4 1 2 3 4

Corner Weights - Vertical Corner Weights - Horizontal

1 2 3 4 1 2 3 4

Table 3. Standard air handler (TWE) — unit and corner weights - (50 Hz)

Tons

4.6 TWE051D 263 232 55 71 51 55 54 67 50 61

6.25

8.33

10.4 TWE126E 730 676 168 192 181 135 196 164 145 171

16.7 TWE201E 891 818 258 168 161 231 256 181 146 235

20.9 TWE251E 972 899 211 229 184 275 272 176 228 223

Model

Number

TWE076D/E

TWE101D/E

13 TWE156E 729 675 167 192 181 135 196 163 145 171

Shipping

Max (lbs)

360 323 67 99 75 82 56 92 87 88

429 393 77 121 110 85 79 118 77 119

Net Max

(lbs)

Corner Weights - Vertical Corner Weights - Horizontal

1 2 3 4 1 2 3 4

Figure 14. Vertical — TWE051, 076, 101, 061, 090, 120

20

SSA-SVX06E-EN

Page 21

Figure 15. Vertical — TWE126, 156, 201, 251, 150, 180, 240, 300

op View

Control Box Access

Top View

Control Box

Access

Top View

Control Box

Access

Figure 16. Horizontal — TWE051, 076, 101, 061, 090, 120

WWeeiigghhttss

Figure 17. Horizontal — TWE126, 156, 201, 251, 150, 180, 240, 300

SSA-SVX06E-EN

21

Page 22

Installation

Horizontal Suspension

If the air handler will be suspended, use a suspension

mounting kit to isolate the unit from the structure. This

is usually accomplished with spring or rubber isolators,

which are offered as an accessory.

Mounting rods must be field supplied. Isolator

selection is dependent upon total unit weight including

accessories — see “Weights,” p. 20 for approximate

unit weights.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

BBeeffoorree hhaannggiinngg tthhee uunniitt oonn ssuussppeennssiioonn rrooddss,,

rreeiinnffoorrccee tthhee ccaabbiinneett aarroouunndd tthhee ssuussppeennssiioonn hhoolleess

bbyy uussiinngg aa llaarrggee wwaasshheerr iinnssiiddee tthhee ccaabbiinneett..

WWaasshheerrss sshhoouulldd bbee bbeettwweeeenn tthhee sskkiinn ooff tthhee aaiirr

hhaannddlleerr aanndd tthhee nnuutt oonn tthhee ssuussppeennssiioonn rroodd..

Align holes in the cabinet with structural supports and

secure suspension rods to the structure, then to the air

handler cabinet. If hole locations do not permit proper

alignment with existing structure, it may be necessary

to field fabricate cross members on existing structural

beams.

NNoottee:: When other than bottom return is to be used,

side panel removal for return duct installation

must be secured over the bottom opening.

Leveling

This air handler has a double sloped drain pan. In order

to assure proper drainage along the length of the drain

pan, it is important to have the unit properly leveled. Be

sure the air handler is level.

Auxiliary Drain Pan

A field fabricated, auxiliary drain pan should be

installed under the unit for all horizontal applications

and when air handlers are installed above ceilings or in

other locations where condensate overflow may cause

damage.

This drain pan will eliminate any excess condensation

that may be due to extreme humidity or an obstructed

drain in the primary drain pan. Drain lines from this

pan must be installed, but should not be connected to

the primary drain line from the unit. Isolate the

auxiliary drain pan from both the air handler and the

structure.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

EEnnssuurree tthhaatt tthhee rreeffrriiggeerraanntt lliinneess ppaassssiinngg tthhrroouugghh

tthhee ccaabbiinneett aarree nnoott rreessttiinngg oonn sshhaarrpp sshheeeett mmeettaall

eeddggeess aanndd tthhaatt tthhee bbuullbb((ss)) aarree aattttaacchheedd ttoo tthhee

ssuuccttiioonn lliinnee ooff tthhee ssaammee cciirrccuuiitt..

1. Locate cloth bag(s) attached to the refrigerant tube

of the coil that contains a stainless steel clamp and

insulation material (approximately 9” long by 4”

wide) for each refrigerant circuit. This is for

attaching and insulating the expansion valve bulb(s)

to the suction line(s).

2. Attach the expansion valve bulb(s)

oonn aaiirr hhaannddlleerrss tthhaatt wwiillll hhaavvee rreeffrriiggeerraanntt lliinneess

eenntteerriinngg tthhee ccaabbiinneett ffrroomm tthhee lleefftt ssiiddee::

a. Remove the split rubber grommet from the

knockout in the end of the air handler. Uncoil the

cap tube with the bulb attached at the expansion

valve and place the grommet on the cap tube.

b. With the grommet around the tube, push the

bulb through the hole and position the grommet

back into its original position (one bulb and cap

tube on single circuit units, and two bulbs and

cap tubes on dual circuit units).

oonn aaiirr hhaannddlleerrss tthhaatt wwiillll hhaavvee rreeffrriiggeerraanntt lliinneess

eenntteerriinngg tthhee ccaabbiinneett ffrroomm tthhee rriigghhtt ssiiddee::

a. Attach the bulb(s) to the suction tube(s) inside

the cabinet, approximately 10” from the right

end of the unit.

3. Attach the bulb(s) on a horizontal section of tube

where the entire length of the bulb is in contact with

the tube (see Figure 18, p. 23), approximately 45

degrees off vertical (a 10 or 2 o’clock position).

4. After attaching to the suction line(s), either inside or

outside of the cabinet, wrap the insulation around

the bulb(s) and suction tube(s).

NNoottee:: Suction piping should be insulated.

Refrigerant Piping

Installation, brazing, leak testing and evacuation of

refrigerant lines are covered in the installation

instructions that shipped with the outdoor unit. Read

the instructions before beginning installation of

refrigerant lines.

22

SSA-SVX06E-EN

Page 23

Between

10 and 2 O’Clock

Bulb

Retaining

Clip

Insulating

Tape

V

ENT

DRAIN

CLEAN

OUT

Materials

2 each - TEE

2 each - 90° ELL

1 each - PLUG

2 each - 6” NIPPLE

2 each - 2” NIPPLE

1 each - 1” NPT to PVC or

COPPER ADAPTER

IInnssttaallllaattiioonn

WWAARRNNIINNGG

FFiibbeerrggllaassss WWooooll!!

YYoouu MMUUSSTTwweeaarr aallll nneecceessssaarryy PPeerrssoonnaall PPrrootteeccttiivvee

EEqquuiippmmeenntt ((PPPPEE)) iinncclluuddiinngg gglloovveess,, eeyyee pprrootteeccttiioonn,,

aa NNIIOOSSHH aapppprroovveedd dduusstt//mmiisstt rreessppiirraattoorr,, lloonngg

sslleeeevveess aanndd ppaannttss wwhheenn wwoorrkkiinngg wwiitthh pprroodduuccttss

ccoonnttaaiinniinngg ffiibbeerrggllaassss wwooooll..

PPrreeccaauuttiioonnaarryy MMeeaassuurreess::

•• AAvvooiidd bbrreeaatthhiinngg ffiibbeerrggllaassss dduusstt..

•• UUssee aa NNIIOOSSHH aapppprroovveedd dduusstt//mmiisstt rreessppiirraattoorr..

•• AAvvooiidd ccoonnttaacctt wwiitthh tthhee sskkiinn oorr eeyyeess.. WWeeaarr

lloonngg--sslleeeevveedd,, lloooossee--ffiittttiinngg ccllootthhiinngg,, gglloovveess,,

aanndd eeyyee pprrootteeccttiioonn..

•• WWaasshh ccllootthheess sseeppaarraatteellyy ffrroomm ootthheerr ccllootthhiinngg;;

rriinnssee wwaasshheerr tthhoorroouugghhllyy..

•• OOppeerraattiioonnss ssuucchh aass ssaawwiinngg,, bblloowwiinngg,, tteeaarr-oouutt,, aanndd sspprraayyiinngg mmaayy ggeenneerraattee ffiibbeerr

ccoonncceennttrraattiioonnss rreeqquuiirriinngg aaddddiittiioonnaall

rreessppiirraattoorryy pprrootteeccttiioonn.. UUssee tthhee aapppprroopprriiaattee

NNIIOOSSHH aapppprroovveedd rreessppiirraattoorr..

FFiirrsstt AAiidd MMeeaassuurreess::

•• EEyyee CCoonnttaacctt -- FFlluusshh eeyyeess wwiitthh wwaatteerr ttoo

rreemmoovvee dduusstt.. IIff ssyymmppttoommss ppeerrssiisstt,, sseeeekk

mmeeddiiccaall aatttteennttiioonn..

•• SSkkiinn CCoonnttaacctt -- WWaasshh aaffffeecctteedd aarreeaass ggeennttllyy

wwiitthh ssooaapp aanndd wwaarrmm wwaatteerr aafftteerr hhaannddlliinngg..

Figure 18. Remote bulb installation

NNoottee:: When air handler is installed in the vertical

position and close proximity trapping of

condensate is required, use of a subbase

accessory to raise the air handler for clearance of

the drain trap is recommended. See Figure 19, p.

23 for a typical drain trap assembly.

Figure 19. Typical drain trap assembly

Filter Replacement

WWAARRNNIINNGG

FFiibbeerrggllaassss WWooooll!!

YYoouu MMUUSSTT wweeaarr aallll nneecceessssaarryy PPeerrssoonnaall PPrrootteeccttiivvee

EEqquuiippmmeenntt ((PPPPEE)) iinncclluuddiinngg gglloovveess,, eeyyee pprrootteeccttiioonn,,

aa NNIIOOSSHH aapppprroovveedd dduusstt//mmiisstt rreessppiirraattoorr,, lloonngg

sslleeeevveess aanndd ppaannttss wwhheenn wwoorrkkiinngg wwiitthh pprroodduuccttss

ccoonnttaaiinniinngg ffiibbeerrggllaassss wwooooll..

PPrreeccaauuttiioonnaarryy MMeeaassuurreess::

•• AAvvooiidd bbrreeaatthhiinngg ffiibbeerrggllaassss dduusstt..

•• UUssee aa NNIIOOSSHH aapppprroovveedd dduusstt//mmiisstt rreessppiirraattoorr..

•• AAvvooiidd ccoonnttaacctt wwiitthh tthhee sskkiinn oorr eeyyeess.. WWeeaarr

lloonngg--sslleeeevveedd,, lloooossee--ffiittttiinngg ccllootthhiinngg,, gglloovveess,,

aanndd eeyyee pprrootteeccttiioonn..

•• WWaasshh ccllootthheess sseeppaarraatteellyy ffrroomm ootthheerr ccllootthhiinngg;;

rriinnssee wwaasshheerr tthhoorroouugghhllyy..

•• OOppeerraattiioonnss ssuucchh aass ssaawwiinngg,, bblloowwiinngg,, tteeaarr-oouutt,, aanndd sspprraayyiinngg mmaayy ggeenneerraattee ffiibbeerr

ccoonncceennttrraattiioonnss rreeqquuiirriinngg aaddddiittiioonnaall

rreessppiirraattoorryy pprrootteeccttiioonn.. UUssee tthhee aapppprroopprriiaattee

NNIIOOSSHH aapppprroovveedd rreessppiirraattoorr..

Condensate Piping

The drain pan condensate connection is a female slip

joint type for 1” Schedule 40 PVC pipe. Use PVC cement

and tubing as required (field supplied) to construct a

trap. A union or flexible tubing and clamps may be

installed if the drain pan is to be removed periodically

for cleaning.

SSA-SVX06E-EN

FFiirrsstt AAiidd MMeeaassuurreess::

•• EEyyee CCoonnttaacctt -- FFlluusshh eeyyeess wwiitthh wwaatteerr ttoo

rreemmoovvee dduusstt.. IIff ssyymmppttoommss ppeerrssiisstt,, sseeeekk

mmeeddiiccaall aatttteennttiioonn..

•• SSkkiinn CCoonnttaacctt -- WWaasshh aaffffeecctteedd aarreeaass ggeennttllyy

wwiitthh ssooaapp aanndd wwaarrmm wwaatteerr aafftteerr hhaannddlliinngg..

Air handlers are shipped with throwaway filters

installed. For replacement filters consult the air handler

service facts for correct size and number.

23

Page 24

Filter

Frame

IInnssttaallllaattiioonn

To replace filters from the end of the unit, remove lower

access panel (either end) and slide old filters out and

replace with new ones.

To replace from the front of the unit, remove one “L”

shaped angle. Remove and replace filters and reinstall

“L” shaped angle. See Figure 20, p. 24.

To convert from 1” filter to a 2” filter on units so

equipped, remove lower access panels from both ends

of the air handler. Remove screws and rotate the “L”

shaped angles from both the top and bottom of the

filter track 180° to increase the width of the filter

opening.

Figure 20. Filter location

SZVAV Units

For SZVAV units, air flow is set by using potentiometer

R-136 on the ReliaTel options module found in the air

handler control box, see Figure 21, p. 24. The

potentiometer will adjust the maximum air flow

between the range of 60 Hz to 44.50 Hz. If the desired

maximum operating point from the catalog fan table is

lower than 44.50 Hz, parameter 6-15 on the VFD must

be reprogrammed to 50 Hz. The VFD is preset from the

factory to a default of 25 Hz for the lower limit and does

not need to be reprogrammed.

Figure 21. ReliaTel options module

Duct Connections

The supply and return ducts should be connected to

the unit with flame retardant duct connectors to reduce

vibration transmission. The return duct should be sized

to the same dimensions as the return inlet of the unit.

IImmppoorrttaanntt:: Duct flanges are provided for attachment of

the duct work and are packaged on the

outside of the cabinet for TWE150, 180, 240,

300 and TWE126, 156, 201, 251. The duct

flanges are fastened to the pallet below the

coil (bottom return) on the TWE051, 061,

076, 090, 101 and 120 models.

Air Flow Settings

Standard Units

Unit is shipped for nominal airflow with nominal static

pressure. Please refer to the fan performance table in

either the product catalog or unit service facts and

select the proper drive package for each application.

Failure to do so could result in improper airflow

causing coil frosting or condensate management

problems. Condensate management problems such as

water blow off could be the result of too great of air

face velocity across the coil. To ensure proper

operation refer to “Fan Belt Adjustment,” p. 44.

Measure the voltage between TP1 on the RTOM and

ground. Use Table 4, p. 24 to set the desired maximum

operating supply fan speed.

Table 4. SZVAV air handler speed to voltage

Parameter 6-15 Set to 60 Hz

TP1

High Speed

(Hz)

38.00 <0.10 44.00 1.65

38.40 0.20 44.40 1.70

38.80 0.30 44.80 1.75

39.20 0.45 45.20 1.83

39.60 0.55 45.60 1.90

40.00 0.70 46.00 1.95

40.40 0.80 46.40 2.00

40.80 0.95 46.80 2.05

41.20 1.05 47.20 2.10

41.60 1.15 47.60 2.13

42.00 1.25 48.00 2.17

42.40 1.30 48.40 2.21

(RTOM)

Voltage

(Vdc)

High Speed

(Hz)

TP1

(RTOM)

Voltage

(Vdc)

24

SSA-SVX06E-EN

Page 25

IInnssttaallllaattiioonn

Table 4. SZVAV air handler speed to voltage

(continued)

Parameter 6-15 Set to 60 Hz

TP1

High Speed

(Hz)

42.80 1.35 48.80 2.27

43.20 1.45 49.20 2.30

43.60 1.55 49.60 2.35

— — 50.00 >2.40

44.50 <0.10 52.25 1.65

45.02 0.20 52.77 1.70

45.53 0.30 53.28 1.75

46.05 0.45 53.80 1.83

46.57 0.55 54.32 1.90

47.08 0.70 54.83 1.95

47.60 0.80 55.35 2.00

48.12 0.95 55.87 2.05

48.63 1.05 56.38 2.10

49.15 1.15 56.90 2.13

49.67 1.25 57.42 2.17

50.18 1.30 57.93 2.21

50.70 1.35 58.45 2.27

51.22 1.45 58.97 2.30

51.73 1.55 59.48 2.35

— — 60.00 >2.40

(RTOM)

Voltage

(Vdc)

High Speed

(Hz)

TP1

(RTOM)

Voltage

(Vdc)

2-Speed VFD Units

To configure units with an RTOM for 2-speed operation

move plug PPM 10 from PPF 10 to TP. Refer to “Heating

and Cooling Setpoint Arbitration,” p. 27 for setpoint

connection. Complete the configuration by

reprogramming VFD parameter 6-10 to 5.00 V and

parameter 6-11 to 7.60 V. For 2-Speed VFD controlled

units the desired maximum air flow (High Speed) is set

by reprogramming parameter 6-15 on the VFD to the

frequency value that best meets the RPM requirement

as shown in the catalog fan tables.

The minimum air flow (Low Speed) is set by

reprogramming parameter 6-14 on the VFD. Refer to

Table 5, p. 25 to see the allowed Low Speed range for a

given High Speed. Use the Menu button and up and

down arrows on the keypad to access the parameters.

Table 5. 2-Speed VFD programming speeds

High

Speed

(Hz)

60.00 25.00 - 39.60 48.00 25 - 31.68

59.00 25.00 - 38.94 47.00 25 - 31.02

58.00 25.00 - 38.28 46.00 25 - 30.36

57.00 25.00 - 37.62 45.00 25 - 29.70

56.00 25.00 - 36.96 44.00 25 - 29.04

55.00 25.00 - 36.30 43.00 25 - 28.38

54.00 25.00 - 35.64 42.00 25 - 27.72

53.00 25.00 - 34.98 41.00 25 - 27.06

52.00 25.00 - 34.32 40.00 25 - 26.40

51.00 25.00 - 33.66 39.00 25 - 25.74

50.00 25.00 - 33.00 38.00 25 - 25.08

49.00 25.00 - 32.34 — —

Low Speed

(Hz)

Ranges

High Speed

(Hz)

Low Speed

(Hz)

Ranges

Minimum Supply Fan Output

Refer to Table 6, p. 25 for details on minimum supply

fan output signals associated with each unit function.

Note that each value represents the actual Fan Output

% based on 100% being the customers selected

maximum operating speed.

Table 6. Minimum supply fan speeds for SZVAV units

VFD Parameter 6-15 Set to 60 Hz

Minimum

Function

Ventilation Only

Cool 1 (C1 or C2)

Cool 2 (C1 + C2 Energized)

CV Staged Heat

VFD Parameter 6-15 Set to 50 Hz

Function

Ventilation Only

Cool 1 (C1 or C2)

Cool 2 (C1 + C2 Energized)

CV Staged Heat

Table 7. Minimum supply fan speeds for 2-Speed units

Fan Output %

58%

58%

80%

100%

Minimum

Fan Output %

64%

64%

83%

100%

SSA-SVX06E-EN

Function

Ventilation Only

Cool 1 (C1)

Fan Output %

42 - 66%

42 - 66%

(a)

(a)

25

Page 26

Heater Control

Single Point Power

Line Voltage Entrance

Control Wiring

IInnssttaallllaattiioonn

Table 7. Minimum supply fan speeds for 2-Speed units

(continued)

Function

Cool 2 (C1 + C2 Energized)

CV Staged Heat

(a)

Fan Output percentage is based on the customer chosen upper and

lower speed settings.

Fan Output %

100%

100%

IImmppoorrttaanntt:: Do not remove the VFD without first

contacting technical support! For

performance-related questions and

diagnostic support in North America call 1877-872-6363. Any return requires a claim

number FIRST. Removal of the VFD prior to

this step will void the unit warranty.

Electrical Connections

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee ww//CCaappaacciittoorrss!!

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss aanndd ddiisscchhaarrggee aallll mmoottoorr ssttaarrtt//rruunn