Page 1

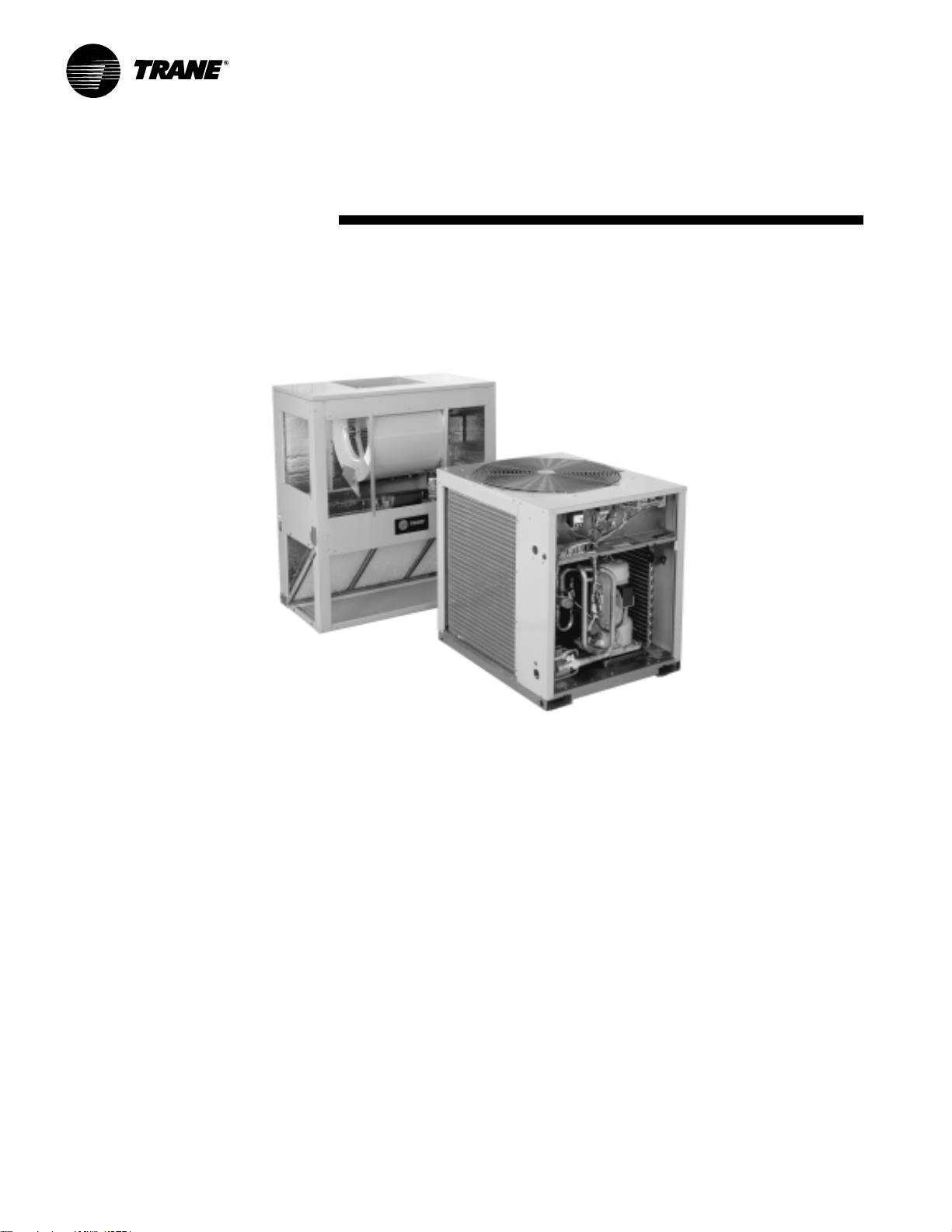

Split System Heat Pumps

Split System Heat Pumps

TWA075A-TWA200B

Air Handlers

TWE050A-TWE200B

50 Hz

January 2004

SSP-PRC002-EN

Page 2

Introduction

Split System Heat Pump Units . . .

Designed With Your Needs In Mind.

The Trane reputation for quality and

reliability in air conditioning continues

with the Odyssey™ family of light

commercial split systems. Trane paid

attention to your needs to make sure you

get a system that will meet your job

requirements every time...and at a

competitive price.

Couple Trane’s reputation for quality and

reliability in split system air conditioners

with efficiency, flexibility and installation

ease...and you have systems that will

give you “Simply The Best Value.’’

Manufacturing Control

Trane’s exclusive control over the design

and manufacturing of all major

components is unique in the industry.

This approach assures us total control

over both the quality and reliability of

these components. And allows us to

custom match components to deliver the

best in split system performance.

©American Standard Inc. 2001

Designing the Details

Careful attention was given to designing

the details — from control wiring to the

access panels. Odyssey units feature

time-saving colored and numbered

wiring and removable panels which

allow complete access to all major

components and controls. All outdoor

units feature external high and low

pressure switches for easy diagnosing

and servicing of the unit. Service valves

with gauge ports are provided on all

units.

Standardized Cabinets

In addition, all cabinets have been

standardized. When you are servicing an

outdoor unit or an air handler, all

components are in the same location

from unit to unit.

Filters

The TWE050A, 075A, 100A and 100B air

handlers are supplied with 1" (25.4 mm)

throwaway filters as standard. The filter

racks were designed to easily convert for

installation of 2" (50.8 mm) filters. The

TWE155B and 200B air handlers have 2"

(50.8 mm) filters as standard.

UL Listed and ARI Certified

Trane meets or exceeds all nationally

recognized agency safety and design

standards. Each condensing unit is UL

designed, approved and labeled in

accordance to UL Standards: UL 1995 for

central cooling air conditioners,

refrigeration and air conditioning

condensing and compressor units. Each

air handler is designed, approved and

labeled in accordance to UL 465 and UL

1995 standard for heat pumps. Each unit

is certified in accordance with ARI

Standard 210/240 or 340/360.

SSP-PRC002-EN

Page 3

Contents

Introduction

Features and Benefits

Application Considerations

Selection Procedure

Model Number Description

General Data

Performance Data

Cool and Heat Performance

Fan Performance

Electric Power

Connection and Wiring

Dimension and Weights

Mechanical Specifications

2

4

6

7

8

9

12

12

24

31

33

39

52

SSP-PRC002-EN

3

Page 4

Features and Benefits

Condensing Units Options

The TWA075A and 100A single

compressor models feature single

refrigeration circuitry, lowering job

installation costs by requiring only one

set of refrigerant lines. These units are

ideal for the low cost, new construction

jobs as well as renovation and

replacement buildings.

In addition, Odyssey includes TWA155B

and 200B dual compressor units to give

true stand-by protection; if one

compressor fails, the second will

automatically start-up. Also, the first

compressor can be serviced without

shutting down the unit since the

refrigerant circuits are independent.

Dual compressors are not just for

protection, they also save energy costs.

Most buildings are designed for the peak

load requirements yet the building

usually operates at less than peak load.

During light load conditions, only one

compressor functions to maintain the

space comfort thus reducing the need

for energy.

Trane split systems have been specified

in thousands of applications and you’ll

find Odyssey will win you even more

jobs with its small manageable cabinet.

This light, compact design will save time

and money for rigging and installation.

And the compactness will permit Trane’s

unit to replace almost any unit —

effortlessly.

Low Ambient Cooling Operation

Each heat pump unit can operate to 50°F

(10°C) as standard in the cooling mode.

An accessory Head Pressure Control

gives you the capability to operate to 0°F

(-18°C). All heat pumps offer these

accessories:

• Head Pressure Control

• Coil Guard Kits

• Isolators both Rubber-in-Shear and

Spring Type

• Anti-Short-Cycle Kit

• Time Delay Relay

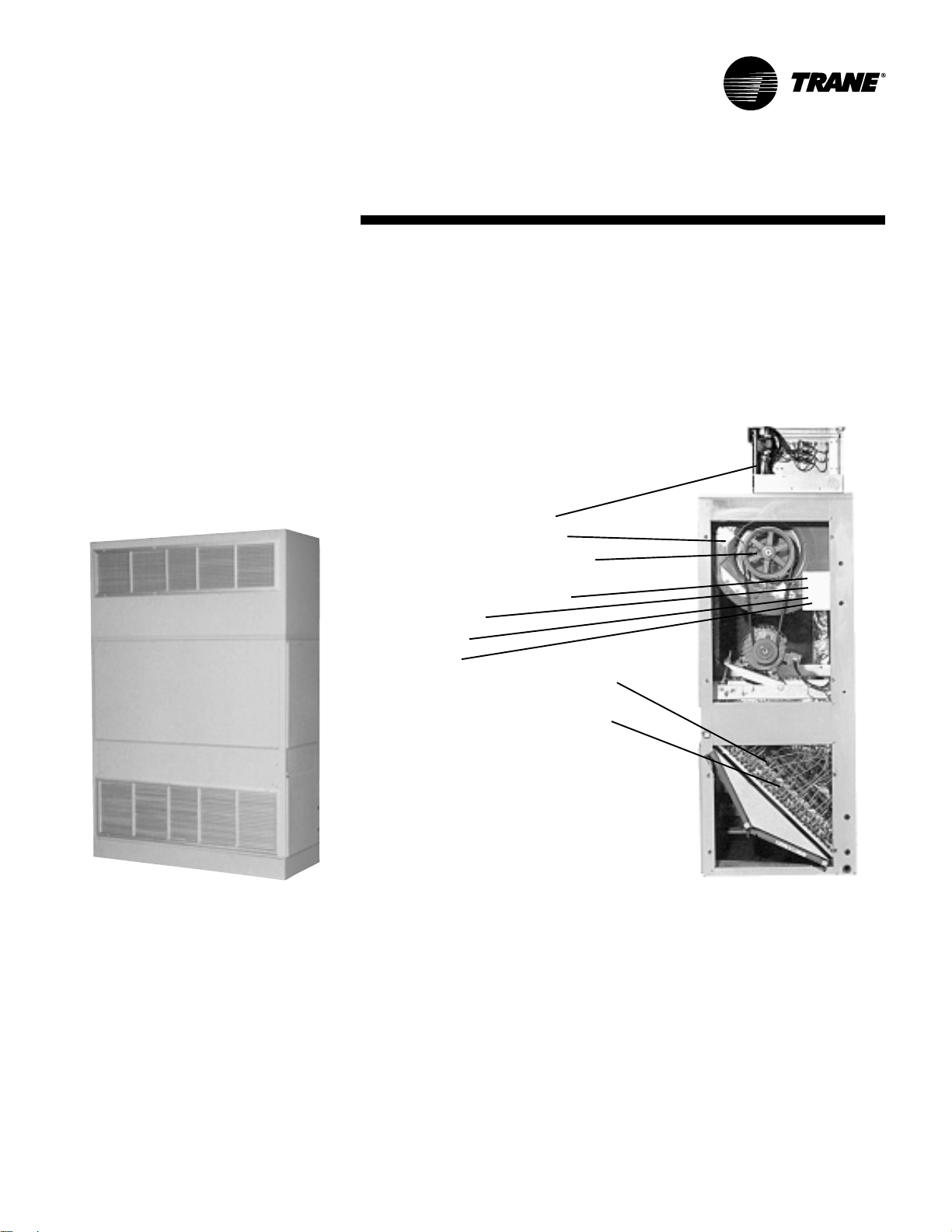

Air Handlers Offer More

Flexibility

Flexibility is a key to meeting changing

market requirements. Odyssey split

sytems offer not only heat pumps but

also convertible air handlers. The air

handlers can be installed either vertically

in a mechanical room or horizontally

above a ceiling. And it doesn’t require

any removal of panels to make either

airflow application work. These air

handlers have a double sloped

condensate drain pan that allows for

either airflow configuration. And the

drain pan can easily be removed for

cleaning. All the air handlers feature

factory installed belt drive and ball

bearing evaporator fans with adjustable

sheaves for maximum airflow

performance. In fact, the standard motor

on the TWA100A air handler will deliver

3325 cfm (5649 m

ESP. Plus oversized motors are available

for higher static applications.

3

/hr) at 1.4" (349 Pa)

4 SSP-PRC002-EN

Page 5

Features and

Benefits

Odyssey air handler versatility is further

increased by a complete line of

accessories designed to match and

install smoothly:

• Discharge Plenum and Grille

• Return Grille

• Subbase

• Electric Heaters

• High Static Evaporator Motor

• Isolators both Rubber-in-Shear

and Spring Type

• A Full Line of Thermostats

• Outdoor Thermostat

Odyssey Lowers Installation

Costs

Your installation costs are reduced with

Odyssey. Both outdoor units and air

handlers are factory packaged and

assembled so jobsite installation is quick

and easy. You get a complete unit with

all the components, controls and the

internal wiring factory ready for a

smooth jobsite start-up.

Unlike some competitive models the

following components are factoryinstalled in Trane air handlers:

• Single Point Power Entry

• Blower wheel and housing

• Evaporator motor with sheaves

andpulleys

• Low Voltage Terminal Board

• Transformer

• Contactor

• Fan relay

• DX Coil with complete refrigeration

circuitry

• Expansion Valve and Check Valves

Odyssey — A Complete Split

System

Odyssey delivers the flexibility to select

a complete system that meets your

particular job requirements. Air

handlers are designed, tested, and

rated with outdoor units to let you

select the proper match between

capacity and load. Heat pumps can also

be matched with Trane built-up air

handlers. Also, these matched systems

can be quickly engineered for specific

applications using Trane’s computerized

selection and load programs.

There’s no need to install components

and put together the air handler on the

job. This provides you with less labor

cost and fewer chances for installation

errors which cause callbacks. All this

means saving you money both in

replacement and new construction

applications.

5SSP-PRC002-EN

Page 6

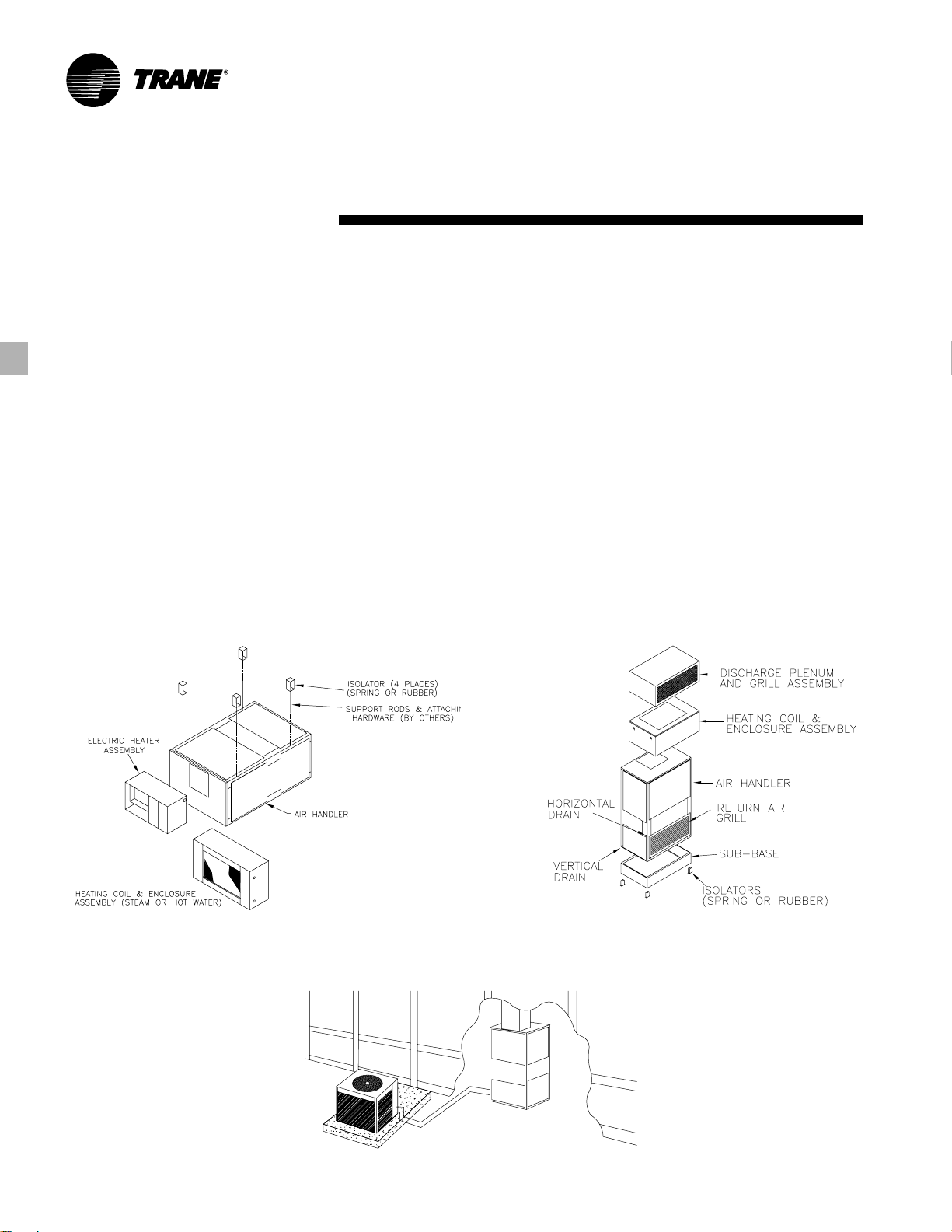

Application Considerations

Application of this product should be

within the catalogued airflow and

performance considerations.

Clearance Requirements

The recommended clearances identified

with unit dimensions should be

maintained to assure adequate

serviceability, maximum capacity and

peak operating efficiency. Actual

clearances which appear inadequate

should be reviewed with the local Trane

Representative.

180° Blower Rotation

The TWE050, 075 and 100 air handler

blower section can be rotated 180° to

change the discharge pattern. This

modification must be done in the field

and requires an addition of kit. See unit

installer's guide.

Typical Horizontal Air Handler Application Typical Vertical Air Handler Application

Low Ambient Cooling

As manufactured, these units can

operate to 50°F (10°C) in the cooling

mode of operation. An accessory head

pressure control will allow operation to

0° F (-17.8°C) outdoor ambient. When

using these units with control systems

such as bypass changeover Variable Air

Volume, make sure you consider the

requirement for a head pressure control

to allow low ambient cooling.

Typical Split System Application

6 SSP-PRC002-EN

Page 7

Selection Procedure

Cooling Capacity

Step 1 — Calculate the building’s total

and sensible cooling loads at design

conditions.

Step 2 — Size the equipment using Table

PD-1. Match the cooling loads at design

conditions.

Example: The following are the building

cooling requirements

a

Electrical Characteristics: 380-415/50/3

b

Summer Design Conditions: Entering

Evaporator Coil: 80 DB/67 WB

(27 DB/19 WB°C)

Outdoor Ambient: 95°F (35° C)

c

Total Cooling Load: 75 MBh (22kW)

d

Sensible Cooling Load: 53 MBh

(15.5 kW)

e

Airflow: 2500 cfm (4247 m

External Static Pressure: 0.77 in. wg

(193 Pa)

Table PD-1 shows that a TWA075A

matched with a TWE075A has a gross

cooling capacity of 85.1 MBh (24.9 kW)

and 60.8 MBh (17.8 kW) sensible capacity

at 95 DB (35°C) ambient and 2500 cfm

(4247 m

WB) air entering the evaporator.

To find the net cooling capacities, fan

motor heat must be subtracted.

Determine the total unit static pressure:

External Static 0.77 in (193 Pa)

Standard Filter 0.10 in (25 Pa)

Supplementary Electric Heat

Total Static Pressure 1.10 in (275 Pa)

3

/h) and 80 DB/67 WB (27 DB/19

3

/h)

0.23 in (57 Pa)

Note: The Evaporator Fan Performance

Table has included the effect of a 1 in.

(250 Pa) filter already. Therefore, the

actual Total Static Pressure is 1.10 - 0.10 =

1.00 in. (275 - 25 = 250 Pa).

3

With 2500 cfm (4247 m

inches (250 Pa), Table PD-15 shows a 1.07

bhp (0.8 kW).

Note: The formula below the table can be

used to calculate Fan Motor Heat,

Constant x Motor Power =

Fan Motor Heat

3.5 x bhp = MBh

3.5 x 1.07 = 3.75 MBh

1.375 x (kW) = kW

1.375 x 0.8 = 1.1 kW

Net Total Cooling Capacity

= 85.1 MBh – 3.75 = 81.35 MBh

= 24.9 kW - 1.1 = 23.8 kW

Net Sensible Cooling Capacity

= 60.8 MBh – 3.75 = 57.05 MBh

= 17.8 MBh - 1.1 = 16.7 kW

Heating Capacity

Step 1 — Calculate the building heating

load using the Trane calculation form or

any other standard accepted method.

Step 2 — Size the equipment using Table

PD-9 to match the heating loads at

design conditions. The following are

building heating requirements:

a

Total Heating Load: 110 MBh (32.2 kW)

b

Outdoor Ambient (Winter): 17°F

(-8.3°C) DB

c

Indoor Return Temperature: 70°F

(21.1°C) DB

d

Airflow: 2500 cfm (4247 m

/h) and 1.00

3

/h)

Table PD-9 indicates the mechanical

heating portion of the heat pump will

provide 49.1 MBh (14.4 kW) for the

winter design conditions.

Step 3 — Because 49.1 MBh (14.4 kW) is

less than the building’s required heating

capacity, a supplementary heater must

be selected. 110 - 49.1 = 60.9 MBh (32.2 -

14.4 = 17.8 kW) minimum heater

capacity.

From Table PD-25, the 24.22 kW heater

has a capacity of 82,670 Btu. From Table

ED-5, the 24.22 kW heater at 400V

indicates the heater model number is

BAYHTRL435A. This heater will be

adequate to cover the residual heat

capacity needed for the application.

Air Delivery Selection

External static pressure drop through the

air distribution system has been

calculated to be 0.77 inches (192.5 Pa) of

water gauge. From Table PD-24 static

pressure drop through the electric heater

is 0.12 inches (30 Pa) of water (0.77 + 0.12

= .89 in.) (192.5 + 30 = 222.5 Pa). Enter

Table PD-15 for TWE090A4 at 2500 cfm

(4247 m

pressure. The standard motor at 790 rpm

will give the desired airflow.

3

/h) and .90 in. (225 Pa) static

7SSP-PRC002-EN

Page 8

Model

Number

Description

Split System Heat Pump Model Nomenclature

TWA075 AD0 0 DA

12 3 456 7 8 910 11 12

Digits 1, 2, 3 - Product Type

TWA = Split System Heat Pump

Digits 4, 5, 6 - Nominal Gross Cooling Capacity

(MBh)

075 = 75

100 = 100

155 = 155

200 = 200

Digit 7- Major Development Sequence

A = Single Compressor

B = Dual Compressor

Digit 8 - Electrical Characteristics

D = 380-415/3/50

Digits 9, 10 - Factory - Installed Options

00 = No Options

0S = Black Epoxy Coated Coil

Digit 11- Minor Design Sequence

D = Fourth

Digit 12- Service Digit

A= First

Air Handler Model Nomenclature

TWE 050 A D 0 0 C A

12 3 456 7 8 910 11 12

Digits 1, 2, 3 - Product Type

TWE = Cooling Convertible

Digits 4, 5, 6 - Nominal Gross Cooling

Capacity (MBh)

050 = 50

075 = 75

10 0 = 10 0

155 = 155

200 = 200

Digit 7- Refrigerant Circuit

A = Single

B = Dual

Digit 8 - Electrical Characteristics

D = 380-415/3/50

Digit 9, 10 - Factory - Installed Options

00 = No Options

Digit 11- Minor Design Sequence

C = Third

Digit 12- Service Digit

A= First

8 SSP-PRC002-EN

Page 9

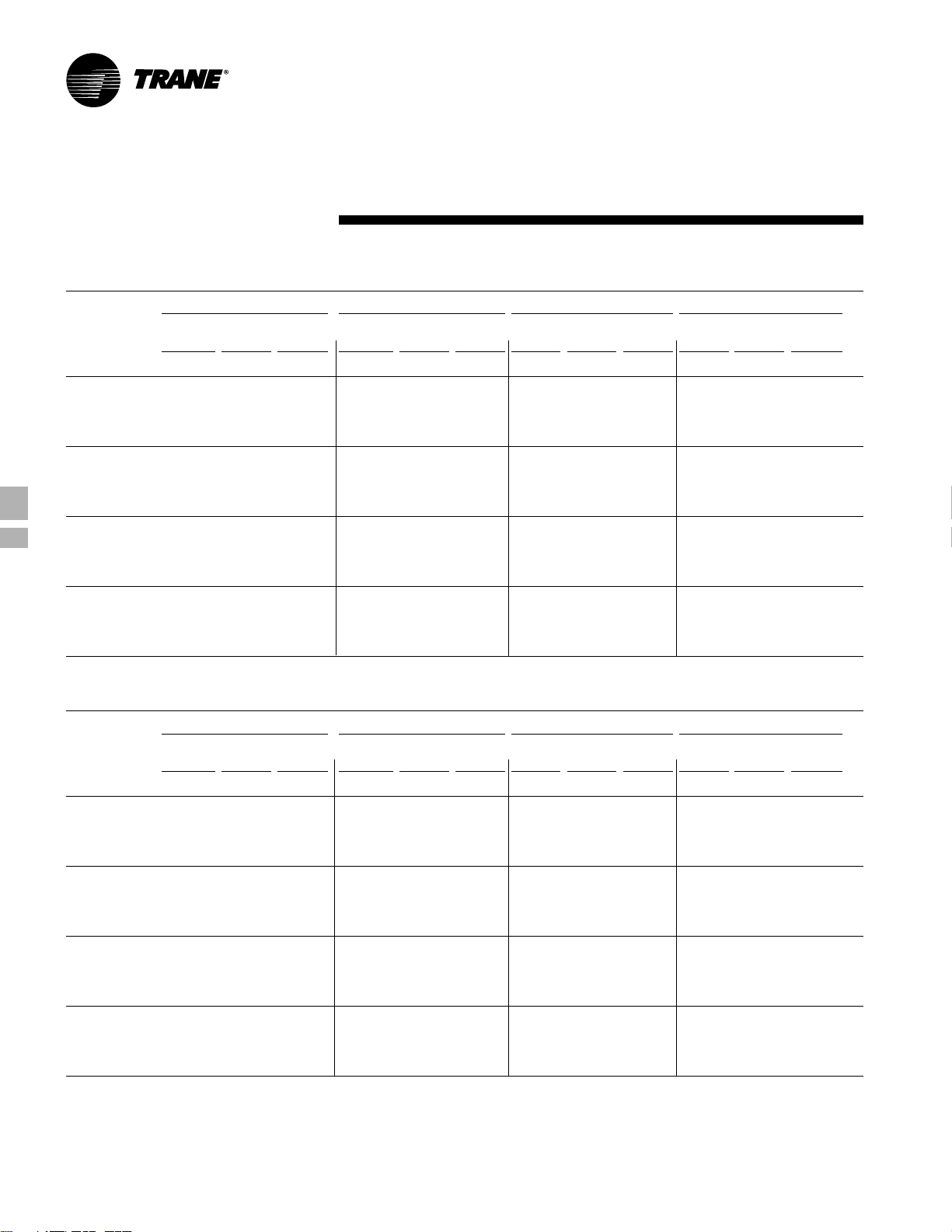

General Data (Heat Pumps)

Table GD-1 — General Data — Heat Pumps

Cooling Performance

1

Gross Cooling Capacity, Btu (kW)

Matched Air Handler, Btu (kW) 85,000 (24.89) 112,000 (32.79)

Heat Pump Only

ARI Net Cooling Capacity

2

, Btu (kW) 85,000 (24.89) 112,000 (32.79)

3

System Power kW 7.91 10.27

Heat Pump Only Power kW 7.12 9.32

Heating Performance

ARI Heating with Matched Air Handler

High Temperature Capacity, Btu (kW) 81,000 (23.72) 110,000 (32.21)

Low Temperature Capacity, Btu (kW) 49,000 (14.35) 71,000 (20.79)

Compressor

Number 1 1

Type 3D

No. Motors 1 1

Motor HP (kW) 6.25 (4.7) 8.33 (6.21)

Motor RPM 2875 2875

ARI Sound Rating (Bels)

System Data

5

4

No. Refrigerant Circuits 1 1

Suction Line, in. (mm) OD 1.375 (34.9) 1.375 (34.9)

Liquid Line, in. (mm) OD 0.500 (12.7) 0.500 (12.7)

Outdoor Coil — Type Plate Fin Plate Fin

Tube Size, in. (mm) OD 0.375 (9.5) 0.375 (9.5)

Face Area, sq. ft (m

2

) 19.2 (1.78) 29.5 (2.74)

Rows 2 2

Fins Per Inch 18 18

Outdoor Fan Type Propeller Propeller

No. Used 1 1

Diameter, in. (mm) 26.00 (660.4) 28.00 (711)

Drive Type Direct Direct

No. Speeds 1 1

6

CFM

, (m3/h) 4900 (8325.1) 670 0 (11383.30)

No. Motors 1 1

Motor HP (kW) 0.33 (.25) 0.75 (.56)

Motor RPM 925 925

R-22 Refrigerant Charge, lb7 (kg) 18.0 (8.16) 31.5 (14.29)

Notes:

1. Cooling Performance is rated at 95°F (35°C) ambient, 80°F (26.7°C) entering dry bulb, 67°F (19.4°C) entering wet

bulb and nominal cfm listed. ARI rating cfm is 350 cfm/ton for this product. Gross capacity does not include the

effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable for

operation to ±20% of nominal cfm. Rated accordance with ARI Standard 340/360-00.

2. Condensing Unit Only Gross Cooling Capacity rated at 45°F (7.2°C) saturated suction temperature and at 95°F

(35°C) ambient.

3. ARI Net Cooling Capacity is calculated with matched blower coil and 25 ft (7.2 m) of 1.375, 0.500 OD interconnecting tubing. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures. Integrated

Part Load Value is based on ARI Standard 340/360-00. Units are rated at 80°F (26.7°C) ambient, 80°F (26.7°C) entering dry

bulb, and 67°F (19.4°C) entering wet bulb at ARI rated cfm.

4. ARI Sound Rating is rated in accordance with ARI Standard 270 or 370.

5. System Data based on maximum linear length 80 ft (26.7 m). Maximum lift: suction 60 ft (18.3 m) liquid 60 ft (18.3

m). For greater lengths, refer to refrigerant piping applications manual.

6. Outdoor Fan cfm is rated with standard air-dry coil outdoor.

7. Refrigerant (operating) charge is for condensing unit (all circuits) with matching blower coils and 25 ft (7.6 m) of

interconnecting refrigerant lines.

TWA075A TWA100A

83,000 (24.30) 108,000 (31.62)

®

Scroll 3D®Scroll

8.8 8.8

9SSP-PRC002-EN

Page 10

General

Data (Heat Pumps)

Table GD-2 General Data — Heat Pumps

Cooling Performance

1

Gross Cooling Capacity, Btu (kW)

Matched Air Handler, Btu (kW) 167,000 (48.9) 218,000 (63.83)

Condensing Unit Only

ARI Net Cooling Capacity

2

, Btu (kW) 167,000 (48.9) 218,000 (63.83)

3

System Power kW 15.67 21.51

Condensing Unit Power kW 13.91 19.1

Heating Performance

ARI Heating with Matched Air Handler

High Temperature Capacity, Btu (kW) 166,000 (48.6) 214,000 (62.66)

Low Temperature Capacity, Btu (kW) 101,000 (29.57) 139,000 (40.70)

Compressor

Number 2 2

Type 3D

No. Motors 2 2

Motor HP 6.25 (4.7) 8.33 (6.21)

Motor RPM, (kW) 2875 2875

ARI Sound Rating (Bels)

System Data

5

4

No. Refrigerant Circuits 2 2

Suction Line, in. (mm) OD 1.375 (34.9) 1.375 (34.9)

Liquid Line, in. (mm) OD 0.500 (12.7) 0.500 (12.7)

Outdoor Coil — Type Plate Fin Plate Fin

Tube Size, in. (mm) OD 0.375 (9.5) 0.375 (9.5)

Face Area, sq. ft (m

2

) 38.4 (3.57) 48 (4.46)

Rows 2 2

Fins Per Inch 18 18

Outdoor Fan Type Propeller Propeller

No. Used 2 2

Diameter, in. (mm) 26.00 (660.4) 28.00 (711)

Drive Type Direct Direct

No. Speeds 1 1

6

CFM

, (m3/h) 9800 (16650.2) 13400 (22766.60)

No. Motors 2 2

Motor HP (kW) 0.33 (.25) 0.75 (.56)

Motor RPM 925 925

R-22 Refrigerant Charge, lb7 (kg) 36.0 (16.33) 48.5 (22.0)

Notes:

1. Cooling Performance is rated at 95°F (35°C) ambient, 80°F (26.7°C) entering dry bulb, 67°F (19.4°C) entering wet

bulb and nominal cfm listed. ARI rating cfm is 350 cfm/ton for this product. Gross capacity does not include the

effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable for

operation to ±20% of nominal cfm. Rated accordance with ARI Standard 340/360-00.

2. Condensing Unit Only Gross Cooling Capacity rated at 45°F (7.6°C) saturated suction temperature and at 95°F

(35°C) ambient.

3. ARI Net Cooling Capacity is calculated with matched blower coil and 25 ft (7.6 m) of 1.375, 0.500 OD interconnecting tubing. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures. Integrated

Part Load Value is based on ARI Standard 340/360-00. Units are rated at 80°F (26.7°C) ambient, 80°F (26.7°C) entering dry

bulb, and 67°F (19.4°C) entering wet bulb at ARI rated cfm.

4. ARI Sound Rating is rated in accordance with ARI Standard 270 or 370.

5. System Data based on maximum linear length 80 ft (26.7 m)Maximum lift: suction 60 ft (18.3 m) liquid 60 ft (18.3

m) For greater lengths, refer to refrigerant piping applications manual.

6. Outdoor Fan cfm is rated with standard air-dry coil outdoor.

7. Refrigerant (operating) charge is for condensing unit (all circuits) with matching blower coils and 25 ft (7.6 m) of

interconnecting refrigerant lines.

TWA155B TWA200B

162,000 (47.43) 211,000 (61.78)

®

Scroll 3D®Scroll

8.8 8.8

10 SSP-PRC002-EN

Page 11

General

Data (Air Handlers)

Table GD-3 — General Data — Air Handlers

System Data

No. Refrigerant Circuits 1 1 1 2

Suction Line, in. (mm) OD 1.120 (28.4) 1.380 (35.0) 1.380 (35.0) 1.380 (35.0)

Liquid Line, in. (mm) OD 0.38 (9.7) 0.50 (12.7) 0.50 (12.7) 0.50 (12.7)

Indoor Coil — Type Plate Fin Plate Fin Plate Fin Plate Fin

Tube Size, in. (mm) OD 0.375 (9.5) 0.375 (9.5) 0.375 (9.5) 0.375 (9.5)

Face Area, sq. ft (m

Rows 3344

Fins Per Inch 12 12 12 12

Refrigerant Control Expansion Valve Expansion Valve Expansion Valve Expansion Valve

Drain Connection No. 4 4 4 4

Drain Connection Size, in. (mm) 0.75 (19.0) 0.75 (19.0) 0.75 (19.0) 0.75 (19.0)

Drain Connection Type PVC PVC PVC PVC

Indoor Fan Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used 1 1 1 1

Diameter, in. (mm) 12.0 (304.8) 15.0 (381) 15.0 (381) 15.0 (381)

Width, in. (mm) 12.0 (304.8) 15.0 (381) 15.0 (381) 15.0 (381)

Drive Type Belt Belt Belt Belt

No. Speeds 1 1 1 1

CFM, (m

No. Motors 1 1 1 1

Motor HP (kW)

— Standard/Oversized 0.75/1.0 (.55/.74) 1.0/1.5 (.74/1.11) 1.5/2.0 (1.11/1.49) 1.5/2.0 (1.11/1.49)

Motor RPM (Standard) 1425 1425 1425 1425

Motor Frame Size (Standard) 56 56 56 56

Filters — Type Throwaway Throwaway Throwaway Throwaway

Furnished Yes Yes Yes Yes

No. 1/1 3 4 4

Recommended Size, in. (mm) 16x20x1/20x20x1 16x25x1 16x25x1 16x25x1

1

2

) 5.00 (.47) 8.07 (.75) 11.18 (1.0) 11.18 (1.0)

3

/h) 1670 (2837) 2500 (4247) 3325 (5649) 3325 (5649)

TWE050A TWE075A TWE100A TWE100B

(406.4x508x25.4/ (406.4/635/25.4) (406.4/635/25.4) (406.4/635/25.4)

4/508x508x25.4)

Table GD-3 — General Data — Continued

System Data

No. Refrigerant Circuits 2 2

Suction Line, in. (mm) OD 1.38 (35.0) 1.38 (35.0)

Liquid Line, in. (mm) OD 0.500 (12.7) 0.500 (12.7)

Indoor Coil — Type Plate Fin Plate Fin

Tube Size, in. (mm) OD 0.375 (9.5) 0.375 (9.5)

Face Area, sq. ft (m

Rows 3 3

Fins Per Inch 12 12

Refrigerant Control Expansion Valve Expansion Valve

Drain Connection No. 4 4

Drain Connection Size, in. (mm) 1.00 0 (25.4) 1.000 (25.4)

Drain Connection Type PVC PVC

Indoor Fan Type FC Centrifugal FC Centrifugal

No. Used 2 2

Diameter, in. (mm) 15.0 (381) 15.0 (381)

Width, in. (mm) 15.0 (381) 15.0 (381)

Drive Type Belt Bel t

No. Speeds 1 1

3

CFM, (m

No. Motors 1 1

Motor HP (kW)

— Standard/Oversized 2.0/3.0 (1.49/2.24) 3.0/5.0 (2.24/3.72)

Motor RPM (Standard) 1425 1425

Motor Frame Size (Standard) 145T 184T

Filters — Type Throwaway Throwaway

Furnished Yes Yes

No. 8 4/4

Recommended Size, in. (mm) 15x20x2 16x20x2/16x25x2

Notes:

1. ARI certified with various condensing units per ARI Standard 210/240 or 340/360-00 certification program. Refer to

Performance Data section in this catalog.

2

) 16.33 (1.52) 21.63 (2.01)

/h) 500 0 (8494) 6650 (11297)

TWE155B TWE200B

(381x508x50.8) (406.4x508x50.8/406.4x635x50.8)

11SSP-PRC002-EN

Page 12

Performance Data

(System)

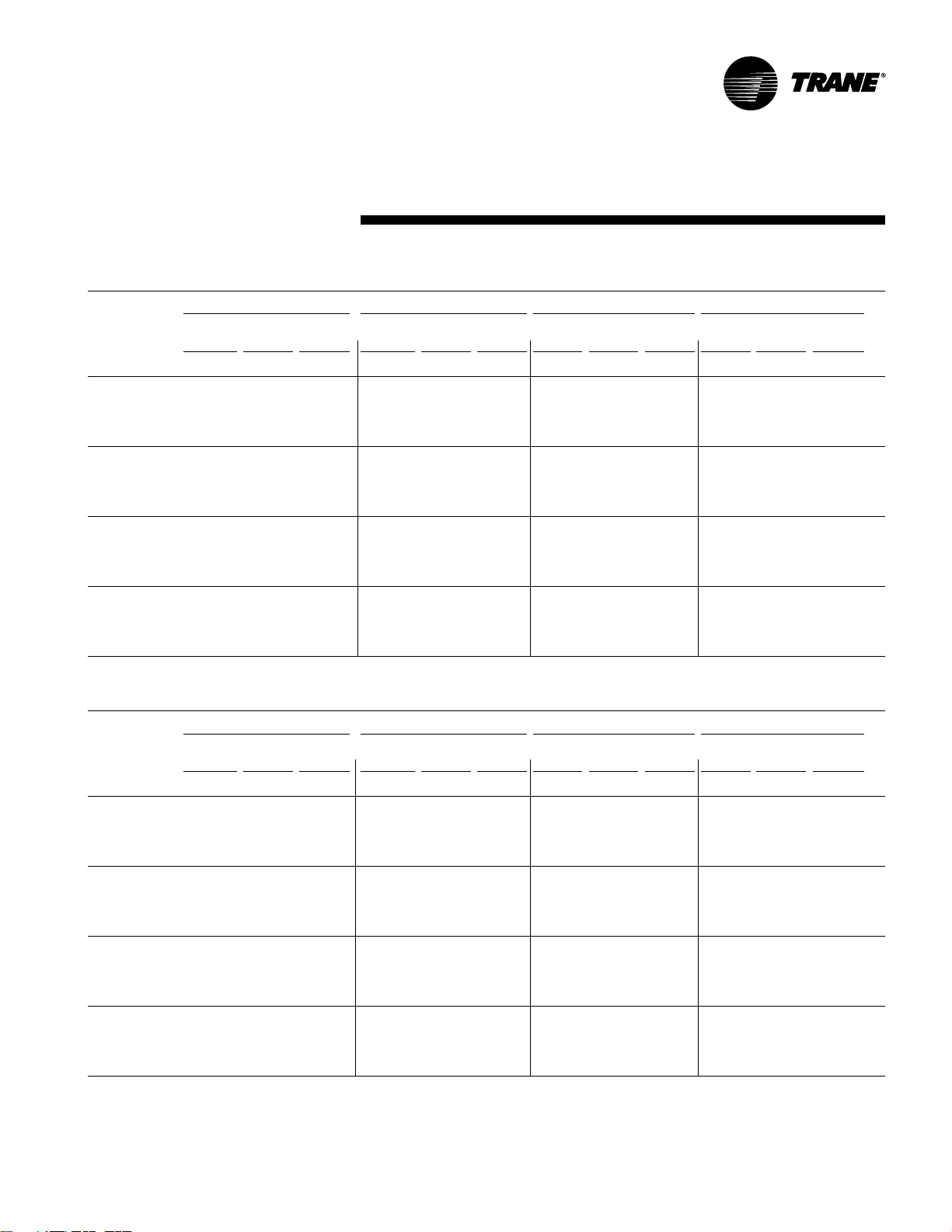

Table PD-1 — Gross Cooling Capacities (MBh) TWA075A Heat Pump with TWE075A Air Handler (I-P)

85 95 105 115

Enter.

Dry Entering Wet Bulb (°F)

Bulb616773 61 6773616773616773

CFM (°F) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

2250 75 78.1 61.6 86.4 51.4 95.4 35.1 75.4 60.3 83.4 50.1 91.9 33.9 72.3 58.8 79.9 48.7 88.0 32.5 68.7 57.0 75.9 47.1 83.7 31.0

80 78.4 71.9 86.6 59.4 95.4 46.0 75.9 70.6 83.6 58.1 92.0 44.7 72.8 69.1 80.1 56.6 88.1 43.2 69.4 67.4 76.0 54.8 83.7 41.6

85 80.2 80.2 86.7 69.6 95.5 56.5 78.0 78.0 83.7 68.2 92.1 55.2 75.4 75.4 80.2 66.7 88.2 53.8 72.3 72.3 76.3 64.9 83.9 52.2

90 84.3 84.3 87.1 79.9 95.6 67.0 82.0 82.0 84.2 78.6 92.2 65.7 79.3 79.3 80.9 77.0 88.3 64.1 76.1 76.1 77.1 75.4 84.0 62.4

2500 75 79.6 64.6 88.1 50.6 96.9 35.8 76.9 63.2 84.9 49.3 93.4 34.6 73.6 61.6 81.3 47.8 89.3 33.2 69.9 59.8 77.2 46.1 84.8 31.6

80 80.2 75.9 88.2 62.1 97.0 47.5 77.6 74.5 85.1 60.8 93.4 46.2 74.5 73.0 81.4 59.1 89.4 44.7 70.7 70.6 77.3 57.3 85.0 43.1

85 82.9 82.9 88.3 73.2 97.1 59.0 80.6 80.6 85.2 71.8 93.6 57.7 77.8 77.8 81.6 70.2 89.6 56.3 74.6 74.6 77.6 68.5 85.2 54.7

90 87.2 87.2 89.0 84.5 97.1 70.3 84.7 84.7 86.1 83.2 93.7 68.9 81.8 81.8 82.6 81.7 89.7 67.4 78.6 78.6 78.6 78.6 85.3 65.7

2750 75 81.0 67.3 89.4 52.3 98.2 36.5 78.1 65.9 86.1 51.0 94.6 35.1 74.8 64.3 82.4 49.5 90.4 33.7 71.0 62.5 78.2 47.8 85.8 32.0

80 81.8 79.7 89.4 64.6 98.3 48.9 79.1 78.3 86.2 63.2 94.7 47.6 75.7 75.7 82.5 61.6 90.5 46.2 72.5 72.5 78.3 59.8 86.0 44.6

85 85.3 85.3 89.7 76.6 98.4 61.4 82.8 82.8 86.5 75.3 94.8 60.1 79.9 79.9 82.9 73.7 90.7 58.6 76.6 76.6 78.8 71.9 86.2 57.0

90 89.7 89.7 90.8 89.1 98.5 73.5 87.1 87.1 87.8 87.7 94.9 72.1 84.1 84.1 84.2 84.2 90.9 70.6 80.6 80.6 80.7 80.7 86.4 68.9

3000 75 82.1 70.0 90.5 54.0 99.3 36.9 79.2 68.6 87.2 52.6 95.6 35.6 75.8 67.0 83.3 51.1 91.3 34.1 71.9 65.1 79.1 49.4 86.6 32.5

80 82.8 82.8 90.6 67.0 99.4 50.3 80.4 80.4 87.3 65.6 95.7 49.0 77.5 77.5 83.5 64.0 91.5 47.5 74.1 74.1 79.2 62.2 86.9 45.9

85 87.4 87.4 90.9 80.0 99.5 63.7 84.8 84.8 87.7 78.6 95.9 62.4 81.7 81.7 84.0 77.0 91.6 60.7 78.3 78.3 79.9 75.2 87.0 59.0

Note: All temperatures are in degrees Fahrenheit. Airflow is in cfm.

90 91.9 91.9 92.0 92.0 99.7 76.6 89.2 89.2 89.3 89.3 96.0 75.2 86.0 86.0 86.1 86.1 91.8 73.6 82.5 82.5 82.6 82.6 87.3 71.9

Ambient Temperature (°F)

Table PD-1— Gross Cooling Capacities (kW) TWA075A Heat Pump with TWE075A Air Handler (SI)

29.4 35.0 40.6 46.1

Enter.

Dry Entering Wet Bulb (°C)

Bulb 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8

m3/h (°C) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

3823 24 22.9 18.0 25.3 15.0 27.9 10.3 22.1 17.7 24.4 14.7 26.9 9.9 21.2 17.2 23.4 14.3 25.8 9.5 20.1 16.7 22.2 13.8 24.5 9.1

27 23.0 21.1 25.4 17.4 27.9 13.5 22.2 20.7 24.5 17.0 26.9 13.1 21.3 20.2 23.4 16.6 25.8 12.7 20.3 19.7 22.3 16.0 24.5 12.2

29 23.5 23.5 25.4 20.4 28.0 16.5 22.8 22.8 24.5 20.0 27.0 16.2 22.1 22.1 23.5 19.5 25.8 15.7 21.2 21.2 22.3 19.0 24.6 15.3

32 24.7 24.7 25.5 23.4 28.0 19.6 24.0 24.0 24.7 23.0 27.0 19.3 23.2 23.2 23.7 22.6 25.9 18.8 22.3 22.3 22.6 22.1 24.6 18.3

4248 24 23.3 18.9 25.8 14.8 28.4 10.5 22.5 18.5 24.9 14.4 27.3 10.1 21.6 18.0 23.8 14.0 26.2 9.7 20.5 17.5 22.6 13.5 24.8 9.2

27 23.5 22.2 25.8 18.2 28.4 13.9 22.7 21.8 24.9 17.8 27.4 13.5 21.8 21.4 23.8 17.3 26.2 13.1 20.7 20.7 22.6 16.8 24.9 12.6

29 24.3 24.3 25.9 21.4 28.4 17.3 23.6 23.6 25.0 21.0 27.4 16.9 22.8 22.8 23.9 20.6 26.2 16.5 21.8 21.8 22.7 20.0 24.9 16.0

32 25.5 25.5 26.1 24.8 28.4 20.6 24.8 24.8 25.2 24.4 27.4 20.2 24.0 24.0 24.2 23.9 26.3 19.7 23.0 23.0 23.0 23.0 25.0 19.2

4672 24 23.7 19.7 26.2 15.3 28.8 10.7 22.9 19.3 25.2 14.9 27.7 10.3 21.9 18.8 24.1 14.5 26.5 9.9 20.8 18.3 22.9 14.0 25.1 9.4

27 24.0 23.3 26.2 18.9 28.8 14.3 23.2 22.9 25.3 18.5 27.7 13.9 22.2 22.2 24.2 18.0 26.5 13.5 21.2 21.2 22.9 17.5 25.2 13.0

29 25.0 25.0 26.3 22.4 28.8 18.0 24.3 24.3 25.3 22.0 27.8 17.6 23.4 23.4 24.3 21.6 26.6 17.2 22.4 22.4 23.1 21.1 25.2 16.7

32 26.3 26.3 26.6 26.1 28.8 21.5 25.5 25.5 25.7 25.7 27.8 21.1 24.6 24.6 24.6 24.6 26.6 20.7 23.6 23.6 23.6 23.6 25.3 20.2

5097 24 24.0 20.5 26.5 15.8 29.1 10.8 23.2 20.1 25.5 15.4 28.0 10.4 22.2 19.6 24.4 15.0 26.7 10.0 21.1 19.1 23.1 14.5 25.4 9.5

27 24.3 24.3 26.5 19.6 29.1 14.7 23.5 23.5 25.6 19.2 28.0 14.4 22.7 22.7 24.5 18.7 26.8 13.9 21.7 21.7 23.2 18.2 25.4 13.4

29 25.6 25.6 26.6 23.4 29.1 18.7 24.8 24.8 25.7 23.0 28.1 18.3 23.9 23.9 24.6 22.5 26.8 17.8 22.9 22.9 23.4 22.0 25.5 17.3

Note: All temperatures are in degrees Celsius. Airflow is in liters per second.

32 26.9 26.9 26.9 26.9 29.2 22.4 26.1 26.1 26.1 26.1 28.1 22.0 25.2 25.2 25.2 25.2 26.9 21.6 24.2 24.2 24.2 24.2 25.6 21.1

Ambient Temperature (°C)

12

SSP-PRC002-EN

Page 13

Performance

Data

(System)

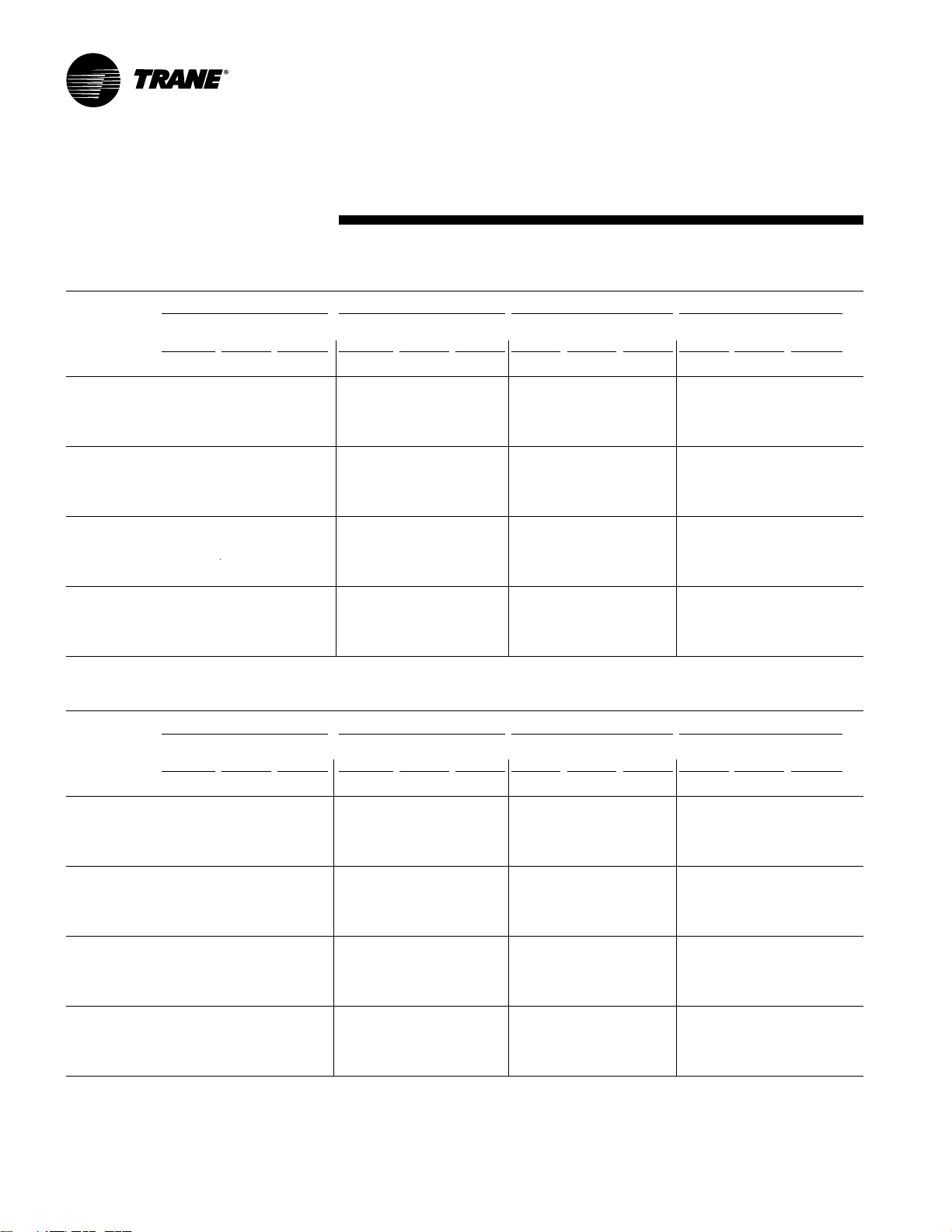

Table PD-2 — Gross Cooling Capacities (MBh) TWA100A Heat Pump with TWE100A Air Handler (I-P)

85 95 105 115

Enter.

Dry Entering Wet Bulb (°F)

Bulb616773 61 6773616773616773

CFM (°F) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

3000 75 103.1 81.2 113.7 68.1 125.2 46.1 99.3 79.2 109.5 66.4 120.5 44.4 95.2 77.2 105.1 64.6 115.7 42.7 91.0 75.1 100.5 62.7 110.6 41.0

80 103.4 94.5 113.9 77.5 125.1 59.9 99.7 92.6 109.7 75.6 120.5 58.2 95.8 90.6 105.3 73.7 115.7 56.3 91.7 88.5 100.7 71.8 110.6 54.4

85 105.4 105.4 113.9 90.8 125.2 73.3 102.2 102.2 109.7 88.8 120.6 71.5 98.9 98.9 105.4 86.8 115.8 69.7 95.3 95.3 100.8 84.8 110.8 67.8

90 110.6 110.6 114.3 103.9 125.3 86.6 107.3 107.3 110.2 102.0 120.7 84.8 103.8 103.8 106.0 100.1 115.9 83.0 100.2 100.2 101.6 98.1 110.9 81.1

3325 75 105.0 84.7 115.8 66.1 127.2 46.9 101.1 82.8 111.4 64.3 122.4 45.3 96.9 80.7 106.9 62.4 117.4 43.5 92.5 78.5 102.2 60.4 112.2 41.6

80 105.6 99.3 115.9 80.8 127.1 61.8 101.8 97.4 111.6 78.9 122.4 60.0 97.8 95.3 107.0 77.0 117.4 58.1 93.7 93.3 102.3 75.1 112.2 56.2

85 108.7 108.7 115.9 95.1 127.2 76.3 105.4 105.4 111.6 93.2 122.5 74.5 101.9 101.9 107.1 91.1 117.5 72.6 98.2 98.2 102.5 89.1 112.4 70.7

90 114.1 114.1 116.6 109.5 127.3 90.7 110.6 110. 6 112.5 107.6 122.6 88.9 107.0 107.0 108.2 105.6 117.7 87.1 103.2 103.2 103.8 103.7 112.4 84.9

3650 75 106.6 88.1 117.4 68.2 128.8 47.8 102.6 86.1 113.0 66.3 123.9 46.0 98.3 84.0 108.3 64.4 118.8 44.1 93.9 81.9 103.5 62.4 113.4 42.2

80 107.6 103.9 117.6 84.0 128.8 63.5 103.7 102.0 113.1 82.1 123.9 61.7 99.1 99.1 108.5 80.2 118.8 59.8 95.4 95.4 103.6 77.9 113.5 57.9

85 111.6 111.6 117.6 99.3 128.9 79.1 108.1 108.1 113.2 97.3 124.1 77.3 104.5 104.5 108.7 95.3 119.0 75.5 100.6 100.6 104.0 93.2 113.7 73.5

90 117.1 117.1 118.7 114.9 129.0 94.7 113.5 113.5 114.5 113.0 124.2 92.9 109.8 109.8 109.7 109.7 119.0 90.7 105.8 105.8 105.7 105.7 113.8 88.6

3975 75 108.1 91.4 118.9 70.1 130.2 48.3 103.9 89.3 114.3 68.3 125.2 46.5 99.6 87.2 109.6 66.3 120.0 44.7 95.1 85.1 104.6 64.3 114.5 42.8

80 109.4 108.4 119.0 87.0 130.3 65.2 105.0 105.0 114.4 84.9 125.3 63.3 101.3 101.3 109.7 82.9 120.1 61.5 97.5 97.5 104.7 80.8 114.7 59.5

85 114.2 114.2 119.1 103.3 130.4 81.9 110.6 110.6 114.7 101.3 125.4 80.1 106.8 106.8 110.1 99.3 120.2 78.2 102.8 102.8 105.3 97.2 114.8 76.2

Note: All temperatures are in degrees Fahrenheit. Airflow is in cfm.

90 119.9 119.9 120.7 120.2 130.4 98.3 116.2 116.2 116.1 116.1 125.4 96.3 112.2 112.2 112.2 112.2 120.3 94.3 108.1 108.1 108.1 108.1 114.9 92.3

Ambient Temperature (°F)

Table PD-2 — Gross Cooling Capacities (kW) TWA100A Heat Pump with TWE100A Air Handler (SI)

29.4 35.0 40.6 46.1

Enter.

Dry Entering Wet Bulb (°C)

Bulb 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8

m3/h (°C) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

5097 24 30.2 23.8 33.3 19.9 36.6 13.5 29.1 23.2 32.1 19.4 35.3 13.0 27.9 22.6 30.8 18.9 33.9 12.5 26.6 22.0 29.4 18.4 32.4 12.0

27 30.3 27.7 33.3 22.7 36.6 17.5 29.2 27.1 32.1 22.1 35.3 17.0 28.0 26.5 30.8 21.6 33.9 16.5 26.9 25.9 29.5 21.0 32.4 15.9

29 30.9 30.9 33.3 26.6 36.7 21.5 29.9 29.9 32.1 26.0 35.3 20.9 28.9 28.9 30.8 25.4 33.9 20.4 27.9 27.9 29.5 24.8 32.4 19.8

32 32.4 32.4 33.5 30.4 36.7 25.4 31.4 31.4 32.3 29.9 35.3 24.8 30.4 30.4 31.0 29.3 33.9 24.3 29.3 29.3 29.8 28.7 32.5 23.7

5649 24 30.7 24.8 33.9 19.4 37.2 13.7 29.6 24.2 32.6 18.8 35.8 13.3 28.4 23.6 31.3 18.3 34.4 12.8 27.1 23.0 29.9 17.7 32.8 12.2

27 30.9 29.1 33.9 23.7 37.2 18.1 29.8 28.5 32.7 23.1 35.8 17.6 28.6 27.9 31.3 22.6 34.4 17.0 27.4 27.3 30.0 22.0 32.9 16.5

29 31.8 31.8 33.9 27.8 37.3 22.3 30.9 30.9 32.7 27.3 35.9 21.8 29.8 29.8 31.4 26.7 34.4 21.3 28.7 28.7 30.0 26.1 32.9 20.7

32 33.4 33.4 34.1 32.1 37.3 26.6 32.4 32.4 32.9 31.5 35.9 26.0 31.3 31.3 31.7 30.9 34.4 25.5 30.2 30.2 30.4 30.3 32.9 24.8

6201 24 31.2 25.8 34.4 20.0 37.7 14.0 30.0 25.2 33.1 19.4 36.3 13.5 28.8 24.6 31.7 18.9 34.8 12.9 27.5 24.0 30.3 18.3 33.2 12.4

27 31.5 30.4 34.4 24.6 37.7 18.6 30.4 29.9 33.1 24.0 36.3 18.1 29.0 29.0 31.8 23.5 34.8 17.5 27.9 27.9 30.3 22.8 33.2 17.0

29 32.7 32.7 34.4 29.1 37.8 23.2 31.7 31.7 33.2 28.5 36.3 22.6 30.6 30.6 31.8 27.9 34.8 22.1 29.5 29.5 30.4 27.3 33.3 21.5

32 34.3 34.3 34.8 33.7 37.8 27.7 33.2 33.2 33.5 33.1 36.4 27.2 32.1 32.1 32.1 32.1 34.8 26.5 31.0 31.0 31.0 31.0 33.3 25.9

6754 24 31.6 26.7 34.8 20.5 38.1 14.2 30.4 26.2 33.5 20.0 36.7 13.6 29.2 25.5 32.1 19.4 35.1 13.1 27.8 24.9 30.6 18.8 33.5 12.5

27 32.0 31.7 34.8 25.5 38.1 19.1 30.8 30.8 33.5 24.9 36.7 18.5 29.7 29.7 32.1 24.3 35.2 18.0 28.5 28.5 30.7 23.7 33.6 17.4

29 33.4 33.4 34.9 30.2 38.2 24.0 32.4 32.4 33.6 29.7 36.7 23.4 31.3 31.3 32.2 29.1 35.2 22.9 30.1 30.1 30.8 28.5 33.6 22.3

Note: All temperatures are in degrees Celsius. Airflow is in liters per second.

32 35.1 35.1 35.3 35.2 38.2 28.8 34.0 34.0 34.0 34.0 36.7 28.2 32.9 32.9 32.8 32.8 35.2 27.6 31.7 31.7 31.6 31.6 33.6 27.0

Ambient Temperature (°C)

SSP-PRC002-EN

13

Page 14

Performance

Data

(System)

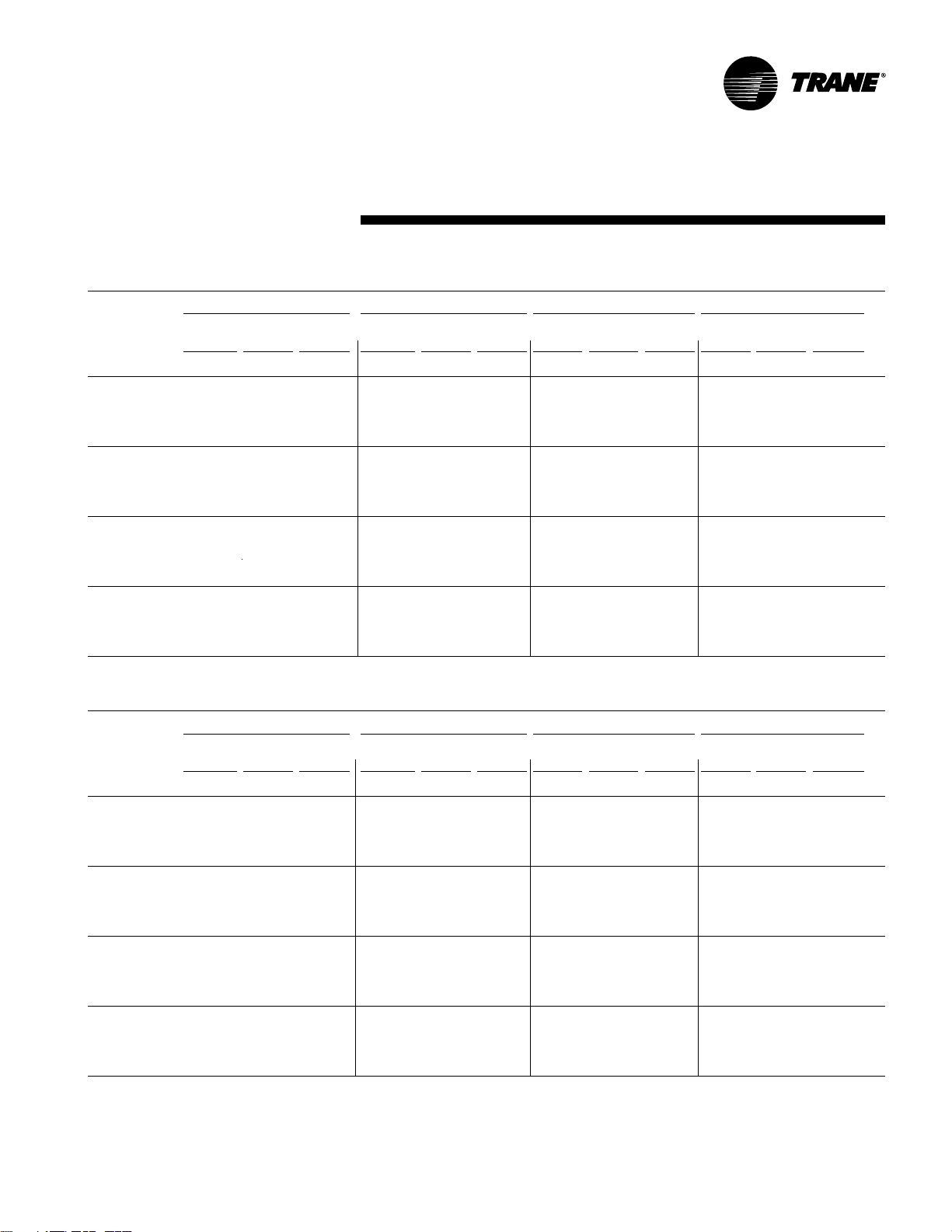

Table PD-3 — Gross Cooling Capacities (MBh) TWA155B Heat Pump with TWE155B Air Handler (I-P)

85 95 105 115

Enter.

Dry Entering Wet Bulb (°F)

Bulb616773 61 6773616773616773

CFM (°F) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

4500 75 153.9 122.2 170.3 101.7 187.8 69.2 148.7 119.6 164.4 99.3 181.0 66.9 142.5 116.5 157.4 96.5 173.3 64.2 135.4 113.0 149.5 93.3 164.6 61.2

80 154.6 142.7 170.6 117.7 187.8 90.9 149.6 140.2 164.7 115.2 181.1 88.4 143.6 137.2 157.6 111.9 173.4 85.5 136.8 133.8 149.8 108.5 164.9 82.4

85 158.5 158.5 170.8 138.0 188.1 112.0 154.2 154.2 165.0 135.4 181.4 109.5 149.0 149.0 158.1 132.3 173.8 106.7 143.0 143.0 150.3 128.9 165.3 103.5

90 166.7 166.7 171.7 158.7 188.2 132.8 162.1 162.1 166.0 156.1 181.6 130.1 156.7 156.7 159.3 153.1 174.0 127.1 150.5 150.5 152.0 149.8 165.5 123.8

5000 75 157.0 128.0 173.4 100.2 190.8 70.5 151.6 125.3 167.3 97.7 183.8 68.1 145.1 122.2 160.0 94.7 175.8 65.4 137.8 118.6 152.0 91.4 166.9 62.2

80 158.1 150.6 173.5 122.9 190.9 94.0 152.9 148.0 167.4 120.2 184.0 91.4 146.8 145.0 160.3 117.1 176.1 88.5 139.6 139.6 152.3 113.6 167.3 85.4

85 163.9 163.9 174.0 145.2 191.2 117.0 159.3 159.3 167.9 142.5 184.3 114.5 153.7 153.7 160.8 139.4 176.5 111.6 147.4 147.4 152.9 135.9 167.7 108.5

90 172.3 172.3 175.4 168.0 191.4 139.5 167.5 167.5 169.6 165.3 184.5 136.8 161.7 161.7 162.9 162.3 176.7 133.7 155.2 155.2 155.4 155.4 168.0 130.4

5500 75 159.6 133.5 176.0 103.6 193.4 71.9 154.0 130.8 169.6 101.0 186.1 69.3 147.3 127.6 162.2 98.0 177.9 66.3 139.8 124.0 153.9 94.7 168.8 63.2

80 161.2 158.2 176.2 128.0 193.5 96.9 156.0 155.6 169.9 125.2 186.4 94.3 149.6 149.6 162.5 122.0 178.3 91.4 143.2 143.2 154.3 118.5 169.3 88.2

85 168.5 168.5 176.7 152.1 193.8 121.9 163.6 163.6 170.5 149.4 186.8 119.3 157.8 157.8 163.2 146.2 178.4 116.0 151.2 151.2 155.2 142.8 169.6 112.6

90 177.2 177.2 178.8 177.0 194.1 145.9 172.1 172.1 172.3 172.3 187.0 143.2 166.1 166.1 166.2 166.2 179.0 140.1 159.3 159.3 159.5 159.5 170.1 136.7

6000 75 161.7 138.8 178.2 106.8 195.5 72.8 156.0 136.0 171.6 104.2 188.1 70.2 149.3 132.8 164.1 101.2 179.7 67.2 141.7 129.2 155.6 97.9 170.4 64.0

80 163.6 163.6 178.4 132.8 195.7 99.7 158.8 158.8 172.0 130.0 188.4 97.1 152.9 152.9 164.4 126.8 180.1 94.2 146.3 146.3 156.1 123.2 171.0 91.0

85 172.6 172.6 179.1 158.8 196.0 126.5 167.5 167.5 172.7 156.1 188.6 123.4 161.4 161.4 165.4 152.9 180.4 120.3 154.6 154.6 157.3 149.4 171.4 116.9

Note: All temperatures are in degrees Fahrenheit. Airflow is in cfm.

90 181.5 181.5 181.7 181.7 196.3 152.1 176.2 176.2 176.4 176.4 189.1 149.3 169.9 169.9 170.1 170.1 180.9 146.2 162.9 162.9 163.1 163.1 171.9 142.8

Ambient Temperature (°F)

Table PD-3 — Gross Cooling Capacities (kW) TWA155B Heat Pump with TWE155B Air Handler (SI)

29.4 35.0 40.6 46.1

Enter.

Dry Entering Wet Bulb (°C)

Bulb 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8

m3/h (°C) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

7646 24 45.1 35.8 49.9 29.8 55.0 20.3 43.5 35.0 48.1 29.1 53.0 19.6 41.7 34.1 46.1 28.2 50.7 18.8 39.6 33.1 43.8 27.3 48.2 17.9

27 45.3 41.8 50.0 34.5 55.0 26.6 43.8 41.0 48.2 33.7 53.0 25.9 42.0 40.2 46.1 32.8 50.8 25.0 40.1 39.2 43.9 31.8 48.3 24.1

29 46.4 46.4 50.0 40.4 55.1 32.8 45.1 45.1 48.3 39.6 53.1 32.1 43.6 43.6 46.3 38.7 50.9 31.2 41.9 41.9 44.0 37.7 48.4 30.3

32 48.8 48.8 50.3 46.5 55.1 38.9 47.5 47.5 48.6 45.7 53.2 38.1 45.9 45.9 46.7 44.8 50.9 37.2 44.1 44.1 44.5 43.9 48.5 36.3

8495 24 46.0 37.5 50.8 29.3 55.9 20.7 44.4 36.7 49.0 28.6 53.8 19.9 42.5 35.8 46.9 27.7 51.5 19.1 40.3 34.7 44.5 26.8 48.9 18.2

27 46.3 44.1 50.8 36.0 55.9 27.5 44.8 43.3 49.0 35.2 53.9 26.8 43.0 42.4 46.9 34.3 51.6 25.9 40.9 40.9 44.6 33.3 49.0 25.0

29 48.0 48.0 50.9 42.5 56.0 34.3 46.6 46.6 49.2 41.7 54.0 33.5 45.0 45.0 47.1 40.8 51.7 32.7 43.2 43.2 44.8 39.8 49.1 31.8

32 50.5 50.5 51.3 49.2 56.0 40.8 49.0 49.0 49.6 48.4 54.0 40.0 47.4 47.4 47.7 47.5 51.7 39.2 45.4 45.4 45.5 45.5 49.2 38.2

9345 24 46.7 39.1 51.5 30.3 56.6 21.0 45.1 38.3 49.7 29.6 54.5 20.3 43.1 37.4 47.5 28.7 52.1 19.4 40.9 36.3 45.1 27.7 49.4 18.5

27 47.2 46.3 51.6 37.5 56.7 28.4 45.7 45.6 49.7 36.7 54.6 27.6 43.8 43.8 47.6 35.7 52.2 26.8 41.9 41.9 45.2 34.7 49.6 25.8

29 49.3 49.3 51.7 44.5 56.8 35.7 47.9 47.9 49.9 43.7 54.7 34.9 46.2 46.2 47.8 42.8 52.2 34.0 44.3 44.3 45.4 41.8 49.7 33.0

32 51.9 51.9 52.3 51.8 56.8 42.7 50.4 50.4 50.4 50.4 54.8 41.9 48.6 48.6 48.7 48.7 52.4 41.0 46.6 46.6 46.7 46.7 49.8 40.0

10194 2 4 4 7. 4 40. 6 5 2.2 31.3 5 7. 2 2 1. 3 4 5.7 39 .8 5 0.3 30 .5 55. 1 2 0.5 43 .7 3 8.9 48 .0 29. 6 5 2.6 19.7 41.5 3 7. 8 45 .6 28. 7 49 .9 18. 8

27 47.9 47.9 52.2 38.9 57.3 29.2 46.5 46.5 50.4 38.1 55.2 28.4 44.8 44.8 48.2 37.1 52.7 27.6 42.8 42.8 45.7 36.1 50.1 26.6

29 50.5 50.5 52.4 46.5 57.4 37.0 49.0 49.0 50.6 45.7 55.2 36.1 47.3 47.3 48.4 44.8 52.8 35.2 45.3 45.3 46.0 43.7 50.2 34.2

Note: All temperatures are in degrees Celsius. Airflow is in liters per second.

32 53.2 53.2 53.2 53.2 57.5 44.5 51.6 51.6 51.6 51.6 55.4 43.7 49.8 49.8 49.8 49.8 53.0 42.8 47.7 47.7 47.8 47.8 50.3 41.8

Ambient Temperature (°C)

14

SSP-PRC002-EN

Page 15

Performance

Data

(System)

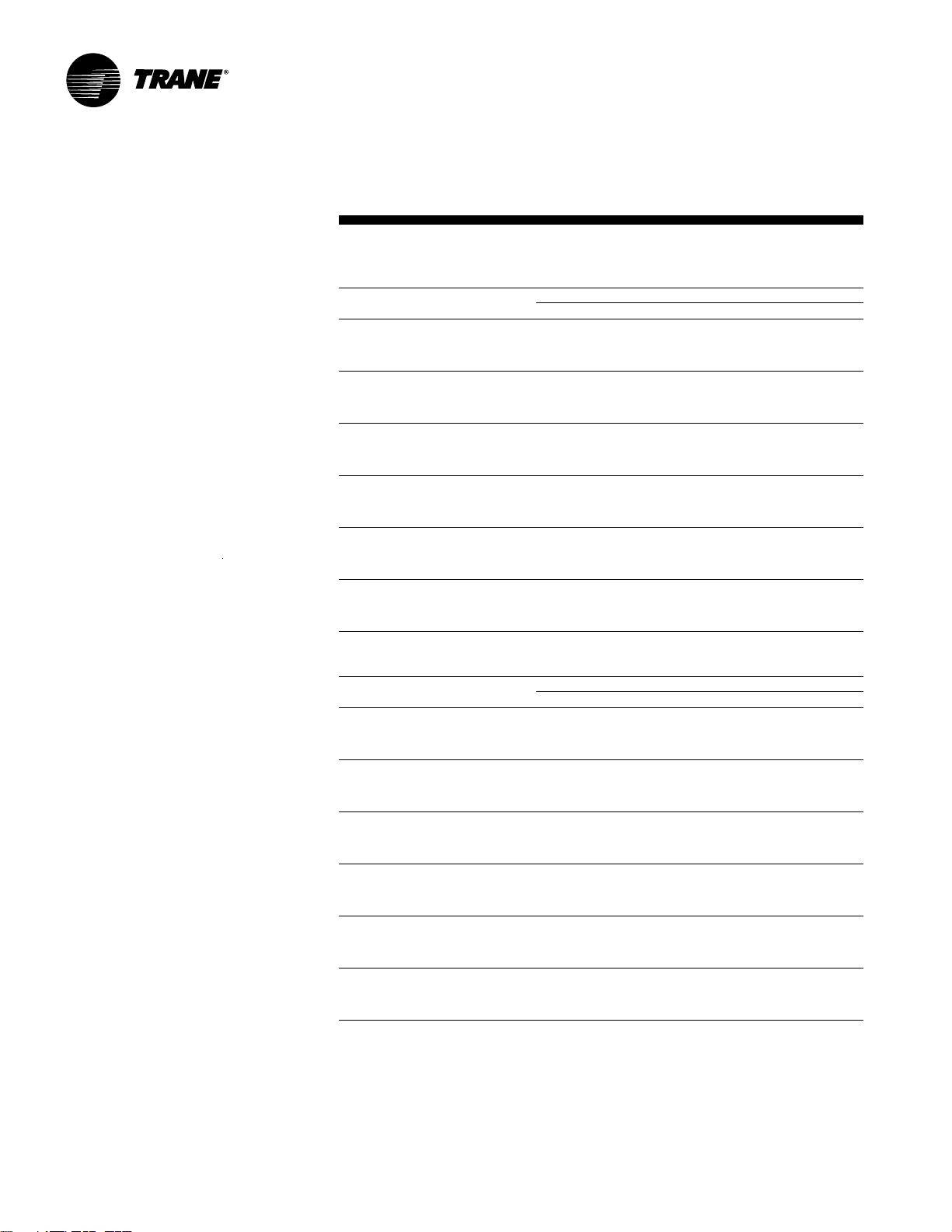

Table PD-4 — Gross Cooling Capacities (MBh) TWA200B Heat Pump with TWE200B Air Handler (I-P)

85 95 105 115

Enter.

Dry Entering Wet Bulb (°F)

Bulb616773 61 6773616773616773

CFM (°F) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

6000 75 203.1 161.9 223.6 134.6 245.6 90.5 195.3 158.0 215.0 131.1 236.2 87.2 187.1 153.8 206.1 127.5 226.3 83.8 178.5 149.6 196.9 123.8 216.2 80.4

80 204.0 189.2 223.9 154.6 245.5 118.7 196.4 185.3 215.4 150.9 236.2 115.1 188.5 181.3 206.5 147.1 226.5 111.5 180.4 177.1 197.1 142.8 216.4 107.8

85 209.2 209.2 224.1 181.3 245.8 146.0 202.6 202.6 215.6 177.5 236.5 142.5 195.6 195.6 206.8 173.4 226.8 138.8 188.4 188.4 197.6 169.3 216.8 135.1

90 219.3 219.3 225.1 208.3 246.0 173.3 212.6 212.6 216.9 204.5 236.8 169.7 205.4 205.4 208.4 200.6 226.9 165.4 198.1 198.1 199.8 196.6 217.0 161.4

6675 75 206.9 169.4 227.5 131.5 249.5 92.2 198.8 165.3 218.7 127.8 239.7 88.9 190.3 161.2 209.5 124.0 229.7 85.4 181.6 156.9 200.0 120.1 219.2 81.6

80 208.4 199.4 227.8 161.7 249.5 122.5 200.6 195.4 218.8 157.5 239.8 119.0 192.7 191.4 209.7 153.5 229.8 115.3 184.1 184.1 200.3 149.3 219.5 111.5

85 215.7 215.7 228.0 190.5 249.7 152.4 208.8 208.8 219.3 186.6 240.1 148.8 201.6 201.6 210.3 182.5 230.2 145.1 194.0 194.0 201.0 178.4 219.9 141.3

90 226.3 226.3 229.8 220.2 249.8 181.5 219.2 219.2 221.5 216.4 240.3 177.7 211.7 211.7 213.0 212.4 230.4 173.8 204.0 204.0 203.9 203.9 220.1 169.7

7350 75 210.0 176.5 230.7 135.8 252.6 93.8 201.8 172.4 221.7 132.1 242.7 90.2 193.1 168.2 212.3 128.3 232.3 86.5 184.3 163.9 202.6 124.4 221.6 82.8

80 212.3 209.2 230.9 167.8 252.7 126.2 203.5 203.5 221.9 163.9 242.8 122.6 196.3 196.3 212.6 159.8 232.6 118.9 188.6 188.6 202.9 155.6 222.0 115.1

85 221.4 221.4 231.4 199.3 253.0 158.4 214.2 214.2 222.6 195.4 243.2 154.8 206.7 206.7 213.4 191.3 233.0 151.1 198.9 198.9 204.0 187.2 222.4 147.3

90 232.3 232.3 234.1 231.7 253.1 189.6 225.0 225.0 224.8 224.8 243.4 185.8 217.2 217.2 217.1 217.1 233.2 181.8 209.2 209.2 209.1 209.1 222.7 177.7

8025 75 212.7 183.3 233.5 140.0 255.3 95.0 204.4 179.2 224.2 136.2 245.1 91.4 195.6 175.0 214.6 132.4 234.6 87.7 186.7 170.6 204.8 128.4 223.7 83.9

80 215.3 215.3 233.7 174.0 255.5 129.7 208.1 208.1 224.5 170.0 245.4 126.1 200.5 200.5 215.0 165.9 234.9 122.4 192.7 192.7 205.2 161.7 224.1 118.6

85 226.5 226.5 234.4 207.9 255.8 164.2 219.0 219.0 225.5 203.9 245.7 160.6 211.3 211.3 216.2 199.8 235.1 156.3 203.2 203.2 206.6 195.7 224.4 152.2

Note: All temperatures are in degrees Fahrenheit. Airflow is in cfm.

90 237.7 237.7 237.6 237.6 256.0 197.4 230.1 230.1 230.0 230.0 246.0 193.5 222.1 222.1 222.0 222.0 235.6 189.5 213.7 213.7 213.6 213.6 224.9 185.4

Ambient Temperature (°F)

Table PD-4 — Gross Cooling Capacities (kW) TWA200B Heat Pump with TWE200B Air Handler (SI)

29.4 35.0 40.6 46.1

Enter.

Dry Entering Wet Bulb (°C)

Bulb 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8 16.1 19.4 22.8

m3/h (°C) Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

10194 2 4 59.5 47.4 6 5.5 39 .4 71.9 2 6.5 57. 2 46. 3 6 3.0 38. 4 6 9.2 25 .5 54. 8 45 .0 60. 3 37.3 6 6.3 24 .5 5 2.3 43 .8 5 7. 6 36 .2 63. 3 23 .5

27 59.7 55.4 65.6 45.3 71.9 34.7 57.5 54.3 63.1 44.2 69.2 33.7 55.2 53.1 60.5 43.1 66.3 32.6 52.8 51.9 57.7 41.8 63.4 31.6

29 61.2 61.2 65.6 53.1 72.0 42.8 59.3 59.3 63.1 52.0 69.2 41.7 57.3 57.3 60.5 50.8 66.4 40.6 55.2 55.2 57.9 49.6 63.5 39.5

32 64.2 64.2 65.9 61.0 72.0 50.7 62.2 62.2 63.5 59.9 69.3 49.7 60.2 60.2 61.0 58.7 66.4 48.4 58.0 58.0 58.5 57.6 63.5 47.3

11341 24 60.6 49.6 66.6 38.5 73.0 27.0 58.2 48.4 64.0 37.4 70.2 26.0 55.7 47.2 61.3 36.3 67.2 25.0 53.2 45.9 58.6 35.2 64.2 23.9

27 61.0 58.4 66.7 47.3 73.0 35.9 58.7 57.2 64.1 46.1 70.2 34.8 56.4 56.0 61.4 44.9 67.3 33.8 53.9 53.9 58.6 43.7 64.3 32.7

29 63.2 63.2 66.8 55.8 73.1 44.6 61.1 61.1 64.2 54.6 70.3 43.6 59.0 59.0 61.6 53.4 67.4 42.5 56.8 56.8 58.9 52.2 64.4 41.4

32 66.2 66.2 67.3 64.5 73.1 53.1 64.2 64.2 64.8 63.4 70.4 52.0 62.0 62.0 62.4 62.2 67.5 50.9 59.7 59.7 59.7 59.7 64.5 49.7

12488 24 61.5 51.7 67.6 39.8 74.0 27.5 59.1 50.5 64.9 38.7 71.1 26.4 56.5 49.2 62.2 37.6 68.0 25.3 54.0 48.0 59.3 36.4 64.9 24.2

27 62.2 61.2 67.6 49.1 74.0 36.9 59.6 59.6 65.0 48.0 71.1 35.9 57.5 57.5 62.2 46.8 68.1 34.8 55.2 55.2 59.4 45.6 65.0 33.7

29 64.8 64.8 67.8 58.4 74.1 46.4 62.7 62.7 65.2 57.2 71.2 45.3 60.5 60.5 62.5 56.0 68.2 44.2 58.2 58.2 59.7 54.8 65.1 43.1

32 68.0 68.0 68.5 67.8 74.1 55.5 65.9 65.9 65.8 65.8 71.3 54.4 63.6 63.6 63.6 63.6 68.3 53.2 61.3 61.3 61.2 61.2 65.2 52.0

13634 24 62.3 53.7 68.4 41.0 74.8 27.8 59.8 52.5 65.7 39.9 71.8 26.8 57.3 51.2 62.8 38.8 68.7 25.7 54.7 50.0 60.0 37.6 65.5 24.6

27 63.0 63.0 68.4 51.0 74.8 38.0 60.9 60.9 65.7 49.8 71.8 36.9 58.7 58.7 63.0 48.6 68.8 35.8 56.4 56.4 60.1 47.3 65.6 34.7

29 66.3 66.3 68.6 60.9 74.9 48.1 64.1 64.1 66.0 59.7 72.0 47.0 61.9 61.9 63.3 58.5 68.8 45.8 59.5 59.5 60.5 57.3 65.7 44.6

Note: All temperatures are in degrees Celsius. Airflow is in liters per second.

32 69.6 69.6 69.6 69.6 74.9 57.8 67.4 67.4 67.3 67.3 72.0 56.7 65.0 65.0 65.0 65.0 69.0 55.5 62.6 62.6 62.6 62.6 65.9 54.3

Ambient Temperature (°C)

SSP-PRC002-EN

15

Page 16

Performance

Data

(TWA075A)

Table PD-5 — Gross Cooling Performance (MBh) TWA075A Heat Pump Only (I-P)

OD Temp Suction Reference Temperature °F

°F 30 35 40 45 50 55

Head press PSIG 166 171 177 183 189 196

65 Cap. Btuh/1000 72.2 79.8 87.7 95.9 104.3 112.8

OD Unit KW 4.91 5.01 5.13 5.25 5.39 5.52

Head press PSIG 192 198 204 210 217 223

75 Cap. Btuh/1000 70.3 77.5 85.0 92.7 100.5 108.5

OD Unit KW 5.42 5.54 5.66 5.80 5.94 6.08

Head press PSIG 220 227 233 240 247 254

85 Cap. Btuh/1000 67.5 74.4 81.5 88.8 96.2 103.7

OD Unit KW 6.01 6.15 6.28 6.42 6.57 6.72

Head press PSIG 251 258 265 272 279 286

95 Cap. Btuh/1000 64.1 70.7 77.4 84.2 91.2 98.3

OD Unit KW 6.71 6.84 6.98 7.12 7.27 7.42

Head press PSIG 284 291 298 306 313 321

105 Cap. Btuh/1000 60.2 66.3 72.6 79.1 85.7 92.5

O D U ni t K W 7. 4 8 7.6 1 7. 7 5 7. 89 8 . 0 4 8 . 19

Head press PSIG 320 327 334 342 350 358

115 Cap. Btuh/1000 55.9 61.6 67.5 73.5 79.8 86.2

OD Unit KW 8.32 8.45 8.59 8.72 8.87 9.02

Table PD-5 — Gross Cooling Performance (kW) TWA075A Heat Pump Only (SI)

OD Temp Suction Reference Temperature °C

°C -1.1 1.7 4.4 7.2 10 12.8

Head pressure (kPA) 1142 1180 1220 1262 1305 1350

18.3 Capacity (kW) 21.2 23.4 25.7 28.1 30.5 33.0

OD Unit Power (kW) 4.91 5.01 5.13 5.25 5.39 5.52

Head pressure (kPA) 1324 1364 1406 1449 1494 1541

23.9 Capacity (kW) 20.6 22.7 24.9 27.1 29.4 31.8

OD Unit Power (kW) 5.42 5.54 5.66 5.80 5.94 6.08

Head pressure (kPA) 1519 1563 1607 1653 1701 1749

29.4 Capacity (kW) 19.8 21.8 23.9 26.0 28.2 30.4

OD Unit Power (kW) 6.01 6.15 6.28 6.42 6.57 6.72

Head pressure (kPA) 1733 1778 1825 1873 1922 1973

35.0 Capacity (kW) 18.8 20.7 22.7 24.7 26.7 28.8

OD Unit Power (kW) 6.71 6.84 6.98 7.12 7.27 7.42

Head pressure (kPA) 1961 2009 2057 2107 2159 2212

40.6 Capacity (kW) 17.6 19.4 21.3 23.2 25.1 27.1

OD Unit Power (kW) 7.48 7.61 7.75 7.89 8.04 8.19

Head pressure (kPA) 2206 2255 2305 2357 2411 2467

46.1 Capacity (kW) 16.4 18.0 19.8 21.5 23.4 25.2

OD Unit Power (kW) 8.32 8.45 8.59 8.72 8.87 9.02

16

SSP-PRC002-EN

Page 17

Performance

Data

(TWA100A)

Table PD-6— Gross Cooling Performance (MBh) TWA100A Heat Pump Only (I-P)

OD Temp Suction Reference Temperature °F

°F 30 35 40 45 50 55

Head press PSIG 164 169 174 179 185 191

65 Cap. Btuh/1000 99.4 109.5 120.0 130.9 142.2 153.9

OD Unit KW 6.39 6.53 6.67 6.83 6.99 7.16

Head press PSIG 188 193 199 204 210 216

75 Cap. Btuh/1000 95.1 104.5 114.4 124.8 135.5 146.6

O D U ni t K W 7. 0 6 7.2 1 7. 3 6 7. 52 7. 6 9 7. 8 8

Head press PSIG 215 220 226 232 238 245

85 Cap. Btuh/1000 90.3 99.2 108.6 118.5 128.7 139.3

OD Unit KW 7.85 8.01 8.18 8.35 8.54 8.74

Head press PSIG 245 250 256 263 269 276

95 Cap. Btuh/1000 85.2 93.7 102.7 112.1 121.8 131.8

OD Unit KW 8.79 8.95 9.13 9.32 9.51 9.71

Head press PSIG 277 283 289 296 302 309

105 Cap. Btuh/1000 79.8 88.0 96.6 105.5 114.7 124.2

OD Unit KW 9.84 10.03 10.22 10.41 10.61 10.81

Head press PSIG 312 318 325 331 338 346

115 Cap. Btuh/1000 74.2 82.1 90.3 98.8 107.6 116.4

OD Unit KW 11.02 11.22 11.42 11.63 11.83 12.02

Table PD-6 — Gross Cooling Performance (kW) TWA100A Heat Pump Only (SI)

OD Temp Suction Reference Temperature °C

°C -1.1 1.7 4.4 7.2 10 12.8

Head pressure (kPA) 1129 1163 1199 1237 1276 1316

18.3 Capacity (kW) 29.1 32.1 35.1 38.3 41.6 45.1

OD Unit Power (kW) 6.39 6.53 6.67 6.83 6.99 7.16

Head pressure (kPA) 1299 1334 1370 1409 1449 1491

23.9 Capacity (kW) 27.8 30.6 33.5 36.5 39.7 42.9

O D Un i t P o w er ( kW ) 7.0 6 7.2 1 7. 3 6 7. 5 2 7. 6 9 7. 8 8

Head pressure (kPA) 1483 1520 1559 1600 1643 1688

29.4 Capacity (kW) 26.4 29.1 31.8 34.7 37.7 40.8

OD Unit Power (kW) 7.85 8.01 8.18 8.35 8.54 8.74

Head pressure (kPA) 1688 1726 1767 1810 1855 1901

35.0 Capacity (kW) 25.0 27.4 30.1 32.8 35.7 38.6

OD Unit Power (kW) 8.79 8.95 9.13 9.32 9.51 9.71

Head pressure (kPA) 1910 1950 1993 2038 2085 2133

40.6 Capacity (kW) 23.4 25.8 28.3 30.9 33.6 36.4

OD Unit Power (kW) 9.84 10.03 10.22 10.41 10.61 10.81

Head pressure (kPA) 2149 2192 2238 2285 2333 2382

46.1 Capacity (kW) 21.7 24.0 26.4 28.9 31.5 34.1

OD Unit Power (kW) 11.02 11.22 11.42 11.63 11.83 12.02

SSP-PRC002-EN

17

Page 18

Performance

Data

(TWA155B)

Table PD-7 — Gross Cooling Performance (MBh) TWA155B Heat Pump Only (I-P)

OD Temp Suction Reference Temperature °F

°F 30 35 40 45 50 55

Head press PSIG 165 170 176 182 188 194

65 Cap. Btuh/1000 142.4 157.4 173.0 189.2 205.9 222.8

OD Unit KW 9.59 9.80 10.02 10.26 10.52 10.78

Head press PSIG 191 197 203 209 215 222

75 Cap. Btuh/1000 138.7 153.0 167.9 183.1 198.7 214.6

OD Unit KW 10.58 10.82 11.06 11.32 11.59 11.87

Head press PSIG 219 225 232 238 245 252

85 Cap. Btuh/1000 133.3 147.0 161.1 175.6 190.3 205.3

OD Unit KW 11.75 12.01 12.27 12.54 12.82 13.11

Head press PSIG 250 257 263 270 277 285

95 Cap. Btuh/1000 126.8 139.8 153.1 166.7 180.6 194.9

OD Unit KW 13.10 13.36 13.63 13.91 14.20 14.49

Head press PSIG 283 290 297 304 312 319

105 Cap. Btuh/1000 119.1 131.3 143.9 156.7 169.9 183.4

OD Unit KW 14.61 14.87 15.14 15.41 15.70 16.00

Head press PSIG 319 326 333 340 348 356

115 Cap. Btuh/1000 110. 6 122.0 133.7 145.9 158.4 171.2

OD Unit KW 16.26 16.51 16.77 17.04 17.32 17.62

Table PD-7 — Gross Cooling Performance (kW) TWA155B Heat Pump Only (SI)

OD Temp Suction Reference Temperature °C

°C -1.1 1.7 4.4 7.2 10.0 12.8

Head pressure (kPA) 1136 1173 1213 1254 1297 1341

18.3 Capacity (kW) 41.7 46.1 50.7 55.4 60.3 65.2

OD Unit Power (kW) 9.59 9.80 10.02 10.26 10.52 10.78

Head pressure (kPA) 1317 1356 1398 1441 1485 1531

23.9 Capacity (kW) 40.6 44.8 49.1 53.6 58.2 62.8

OD Unit Power (kW) 10.58 10.82 11.06 11.32 11.59 11.87

Head pressure (kPA) 1512 1555 1599 1644 1691 1739

29.4 Capacity (kW) 39.0 43.0 47.2 51.4 55.7 60.1

OD Unit Power (kW) 11.75 12.01 12.27 12.54 12.82 13.11

Head pressure (kPA) 1725 1770 1816 1863 1912 1963

35.0 Capacity (kW) 37.1 40.9 44.8 48.8 52.9 57.1

OD Unit Power (kW) 13.10 13.36 13.63 13.91 14.20 14.49

Head pressure (kPA) 1953 2000 2048 2097 2149 2201

40.6 Capacity (kW) 34.9 38.5 42.1 45.9 49.8 53.7

OD Unit Power (kW) 14.61 14.87 15.14 15.41 15.70 16.00

Head pressure (kPA) 2197 2246 2295 2347 2400 2456

46.1 Capacity (kW) 32.4 35.7 39.2 42.7 46.4 50.1

OD Unit Power (kW) 16.26 16.51 16.77 17.04 17.32 17.62

18

SSP-PRC002-EN

Page 19

Performance

Data

(TWA200B)

Table PD-8 — Gross Cooling Performance (MBh) TWA200B Heat Pump Only (I-P)

OD Temp Suction Reference Temperature °F

° F 303540455055

Head press PSIG 173 179 185 191 198 205

65 Cap. Btuh/1000 196.4 215.5 235.3 255.8 276.9 298.5

OD Unit KW 12.94 13.25 13.58 13.93 14.30 14.69

Head press PSIG 198 204 211 217 224 232

75 Cap. Btuh/1000 187.3 205.2 223.9 243.3 263.4 284.0

OD Unit KW 14.32 14.65 15.00 15.38 15.79 16.22

Head press PSIG 226 233 240 247 254 262

85 Cap. Btuh/1000 177.5 194.5 212.3 230.8 249.9 269.5

OD Unit KW 15.95 16.32 16.71 17.12 17.56 18.01

Head press PSIG 257 264 271 278 286 294

95 Cap. Btuh/1000 167.2 183.4 200.3 218.0 236.1 254.8

OD Unit KW 17.84 18.24 18.66 19.10 19.56 20.02

Head press PSIG 290 298 305 313 321 330

105 Cap. Btuh/1000 156.3 171.9 188.1 205.0 222.3 239.9

OD Unit KW 19.96 20.40 20.86 21.33 21.80 22.27

Head press PSIG 326 334 342 350 359 368

115 Cap. Btuh/1000 145.0 160.1 175.7 191.8 208.2 224.8

OD Unit KW 22.32 22.80 23.30 23.79 24.27 24.73

Table PD-8 — Gross Cooling Performance (kW) TWA200B Heat Pump Only (SI)

OD Temp Suction Reference Temperature °C

°C -1.1 1.7 4.4 7.2 10.0 12.8

Head pressure (kPA) 1193 1232 1274 1318 1363 1411

18.3 Capacity (kW) 57.5 63.1 68.9 74.9 81.1 87.4

OD Unit Power (kW) 12.94 13.25 13.58 13.93 14.30 14.69

Head pressure (kPA) 1368 1409 1453 1499 1547 1599

23.9 Capacity (kW) 54.8 60.1 65.5 71.2 77.1 83.2

OD Unit Power (kW) 14.32 14.65 15.00 15.38 15.79 16.22

Head pressure (kPA) 1561 1605 1652 1701 1752 1805

29.4 Capacity (kW) 52.0 56.9 62.2 67.6 73.2 78.9

OD Unit Power (kW) 15.95 16.32 16.71 17.12 17.56 18.01

Head pressure (kPA) 1773 1819 1869 1920 1974 2030

35.0 Capacity (kW) 48.9 53.7 58.7 63.8 69.1 74.6

OD Unit Power (kW) 17.84 18.24 18.66 19.10 19.56 20.02

Head pressure (kPA) 2001 2051 2104 2159 2215 2273

40.6 Capacity (kW) 45.8 50.3 55.1 60.0 65.1 70.2

OD Unit Power (kW) 19.96 20.40 20.86 21.33 21.80 22.27

Head pressure (kPA) 2248 2302 2358 2416 2475 2536

46.1 Capacity (kW) 42.5 46.9 51.5 56.2 61.0 65.8

OD Unit Power (kW) 22.32 22.80 23.30 23.79 24.27 24.73

SSP-PRC002-EN

19

Page 20

Performance

Data

(System)

Table PD-9 — Gross Heating Capacities (MBh)

TWA075A Heat Pump with TWE075A Air Handler At 2500 CFM (I-P)

Outdoor Heating Capacity (Btu/1000) At Total Power in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°F) 60707580 60707580

-18 33.0 28.7 27.1 25.9 5.6 5.7 5.9 6.0

-13 34.1 30.4 29.0 27.9 5.5 5.7 5.9 6.1

-8 35.6 32.4 31.2 30.3 5.5 5.8 5.9 6.2

-3 37.5 34.8 33.9 33.2 5.5 5.8 6.0 6.3

2 40.0 37.7 37.0 36.4 5.5 5.9 6.1 6.4

7 42.8 41.1 40.5 40.1 5.6 6.0 6.2 6.5

12 46.2 44.9 44.4 44.2 5.6 6.1 6.3 6.6

17 50.0 49.1 48.7 48.5 5.7 6.2 6.5 6.8

22 54.4 53.6 53.4 53.2 5.8 6.3 6.6 7.0

27 59.2 58.6 58.4 58.2 5.9 6.4 6.8 7.1

32 64.5 63.9 63.7 63.5 6.0 6.6 6.9 7.3

37 69.9 69.4 69.1 68.8 6.1 6.7 7.1 7.5

42 75.7 75.1 74.7 74.3 6.2 6.9 7.2 7.6

47 81.8 81.1 80.6 80.1 6.4 7.0 7.4 7.8

52 88.3 87.4 86.8 86.2 6.5 7.2 7.6 8.0

57 95.1 93.9 93.2 92.4 6.7 7.4 7.7 8.1

62 102.0 100.6 99.8 98.9 6.8 7.5 7.9 8.3

67 109.0 107.4 106.5 105.5 7.0 7.7 8.1 8.5

7 2 11 6 . 3 11 4 . 5 11 3 . 4 11 2 . 3 7.2 7.9 8.2 8.6

Table PD-9 — Gross Heating Capacities (kW)

TWA075A Heat Pump with TWE075A Air Handler At 4247 m3/h (SI)

Outdoor Heating C apaci ty (kW ) At To tal Power in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°C) 15.6 21.1 23.9 26.7 15.6 21.1 23.9 26.7

-27.8 9.7 8.4 7.9 7.6 5.5 6.0 6.2 6.5

-25.0 10.0 8.9 8.5 8.2 5.6 6.1 6.3 6.6

-22.2 10.4 9.5 9.1 8.9 5.7 6.2 6.5 6.7

-19.4 11.0 10.2 9.9 9.7 5.8 6.3 6.6 6.9

-16.7 11.7 11.0 10.8 10.7 5.9 6.5 6.7 7.0

-13.9 12.5 12.0 11.9 11.7 6.0 6.6 6.9 7.2

-11.1 13.5 13.1 13.0 12.9 6.2 6.7 7.0 7.4

-8.3 14.7 14.4 14.3 14.2 6.3 6.9 7.2 7.5

-5.6 15.9 15.7 15.6 15.6 6.5 7.0 7.4 7.7

-2.8 17.3 17.2 17.1 17.0 6.6 7.2 7.5 7.9

0.0 18.9 18.7 18.7 18.6 6.8 7.4 7.7 8.1

2.8 20.5 20.3 20.2 20.1 6.9 7.6 7.9 8.3

5.6 22.2 22.0 21.9 21.8 7.1 7.8 8.1 8.5

8.3 24.0 23.7 23.6 23.4 7.3 8.0 8.4 8.8

11.1 25.9 25.6 25.4 25.2 7.5 8.2 8.6 9.0

13.9 27.8 27.5 27.3 27.1 7.7 8.4 8.8 9.2

16.7 29.9 29.5 29.2 29.0 7.9 8.7 9.1 9.5

19.4 31.9 31.5 31.2 30.9 8.1 8.9 9.3 9.8

22.2 34.1 33.5 33.2 32.9 8.4 9.2 9.6 10.0

Correction Factors - Other Airflows

(Table Value x Correction Factor = Value at new airflow)

Airflow 2250 cfm 2750 cfm

Heating Capacity x 0.99 x 1.01

Comp ress or kW x 1.02 x 0.98

Values at ARI Rating Conditions of:

70F (21.1C) and 47/43F (8.3/6.1C)(High Temp.Cond.)

70F (21.1C) and 17/15F (-8.3/-9.4C)(Low Temp. Cond)

3822 m3/h 4672 m3/h

Airflow = 2500 cfm (4247 m3/h)

Heating Capacity (High Temp.) = 81,000 (23.72)

Heating Capacity (Low Temp.) = 49,000 (14.35)

Compressor Power (High Temp) = 5.67 kW

Compressor Power (Low Temp) = 4.80 kW

Coeff. Of Perf. (High Temp) = 3.4

Coeff. Of Perf. (Low Temp) = 2.3

Outdoor Fan Power = 550 watts

Indoor Fan Power = 800 watts

Note:

1. Rated with 25 feet of 1-3/8" suction and 1/2" liquid line.

20

SSP-PRC002-EN

Page 21

Performance

Data

(System)

Table PD-10 — Gross Heating Capacities (MBh)

TWA100A Heat Pump with TWE100A Air Handler At 3325 CFM (I-P)

Outdoor Heating Capacity (Btu/1000) At Total Power in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°F) 60707580 60707580

-18 20.4 37.3 41.2 43.6 5.7 7.3 7.9 8.5

-13 31.4 41.8 44.6 46.4 6.2 7.5 8.0 8.6

-8 39.0 46.3 48.4 49.7 6.5 7.6 8.1 8.6

-3 45.5 50.8 52.4 53.3 6.8 7.8 8.2 8.7

2 51.8 55.6 56.7 57.3 7.0 7.9 8.4 8.8

7 57.9 60.6 61.3 61.6 7.2 8.0 8.5 9.0

12 64.1 65.8 66.2 66.3 7.3 8.2 8.6 9.1

17 7 0 .4 7 1.3 7 1.4 7 1.3 7.5 8.3 8.7 9.2

22 76.9 77.1 77.0 76.7 7.6 8.4 8.9 9.4

27 83.6 83.3 82.9 82.5 7.8 8.6 9.0 9.5

32 90.7 89.7 89.2 88.7 7.9 8.8 9.2 9.7

37 97.6 96.2 95.5 94.9 8.1 8.9 9.4 9.9

42 104.6 102.9 102.1 101.4 8.2 9.1 9.6 10.1

47 112.0 109.9 109.0 108.2 8.4 9.3 9.7 10.3

52 119.5 117.2 116.2 115.2 8.6 9.5 10.0 10.5

57 127.1 124.6 123.5 122.5 8.8 9.7 10.2 10.7

62 134.8 132.1 130.8 129.7 9.0 9.9 10.4 11.0

67 142.6 139.7 138.3 137.2 9.2 10.1 10.7 11.2

72 150.7 147.5 146.1 144.8 9.4 10.4 10.9 11.5

Table PD-10 — Gross Heating Capacities (kW)

TWA100A Heat Pump with TWE100A Air Handler At 5649 m3/h (SI)

Outdoor Heati ng Cap acity (kW ) At Total Po wer in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°C) 15.6 21.1 23.9 26.7 15.6 21.1 23.9 26.7

-27.8 6.0 10.9 12.1 12.8 5.5 6.0 6.2 6.5

-25.0 9.2 12.2 13.1 13.6 5.6 6.1 6.3 6.6

-22.2 11.4 13.5 14.2 14.6 5.7 6.2 6.5 6.7

-19.4 13.3 14.9 15.3 15.6 5.8 6.3 6.6 6.9

-16.7 15.2 16.3 16.6 16.8 5.9 6.5 6.7 7.0

- 1 3 . 9 1 7. 0 1 7. 7 1 7. 9 1 8 . 0 6 . 0 6 . 6 6 . 9 7. 2

-11.1 18.8 19.3 19.4 19.4 6.2 6.7 7.0 7.4

-8.3 20.6 20.9 20.9 20.9 6.3 6.9 7.2 7.5

-5.6 22.5 22.6 22.5 22.5 6.5 7.0 7.4 7.7

-2.8 24.5 24.4 24.3 24.1 6.6 7.2 7.5 7.9

0.0 26.5 26.3 26.1 26.0 6.8 7.4 7.7 8.1

2.8 28.6 28.2 28.0 27.8 6.9 7.6 7.9 8.3

5.6 30.6 30.1 29.9 29.7 7.1 7.8 8.1 8.5

8.3 32.8 32.2 31.9 31.7 7.3 8.0 8.4 8.8

11.1 35.0 34.3 34.0 33.7 7.5 8.2 8.6 9.0

13.9 37.2 36.5 36.2 35.9 7.7 8.4 8.8 9.2

16.7 39.5 38.7 38.3 38.0 7.9 8.7 9.1 9.5

19.4 41.7 40.9 40.5 40.2 8.1 8.9 9.3 9.8

22.2 44.1 43.2 42.8 42.4 8.4 9.2 9.6 10.0

Correction Factors - Other Airflows

(Table Value x Correction Factor = Value at new airflow)

Airflow 3000 cfm 3675 cfm

Heating Capacity x 0.99 x 1.01

Comp ress or kW x 1.02 x 0.98

Values at ARI Rating Conditions of:

70F (21.1C) and 47/43F (8.3/6.1C)(High Temp.Cond.)

70F (21.1C) and 17/15F (-8.3/-9.4C)(Low Temp. Cond)

5097 m3/h 6243 m3/h

Airflow = 3325 cfm (5649 m3/h)

Heating Capacity (High Temp.) = 110,000 (32.21)

Heating Capacity (Low Temp.) = 71,000 (20.79)

Compressor Power (High Temp) = 7.59 kW

Compressor Power (Low Temp) = 6.60 kW

Coeff. Of Perf. (High Temp) = 3.4

Coeff. Of Perf. (Low Temp) = 2.4

Outdoor Fan Power = 615 watts

Indoor Fan Power = 1,030 watts

Note:

1. Rated with 25 feet of 1-3/8" suction and 1/2" liquid line.

SSP-PRC002-EN

21

Page 22

Performance

Data

(System)

Table PD-11 — Gross Heating Capacities (MBh)

TWA155B Heat Pump with TWE155B Air Handler At 5000 CFM (I-P)

Outdoor H eating Capacity (BTUH/1000) At Total Power in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°F) 60707580 60707580

-18 68.8 60.9 58.1 55.9 11.9 12.3 12.5 12.8

-13 71.2 64.2 61.7 59.9 11.9 12.3 12.6 12.9

-8 74.3 68.2 66.2 64.7 11.9 12.4 12.7 13.2

-3 78.2 73.2 71.6 70.5 11.9 12.5 12.9 13.4

2 83.0 79.0 77.8 77.0 11.9 12.7 13.1 13.7

7 88.7 85.7 84.8 84.4 12.0 12.9 13.4 14.0

12 95.5 93.2 92.6 92.4 12.2 13.1 13.7 14.3

17 103.3 101.6 101.2 101.1 12.3 13.4 14.0 14.7

22 112.1 110.9 110. 6 110.6 12.5 13.6 14.3 15.1

27 121.8 120.9 120.7 120.6 12.8 14.0 14.7 15.5

32 132.5 131.7 131.4 131.2 13.1 14.3 15.0 15.8

37 143.4 142.6 142.2 141.8 13.3 14.7 15.4 16.2

42 154.8 153.9 153.3 152.7 13.6 15.0 15.8 16.6

47 167.0 165.7 165.0 164.1 14.0 15.4 16.1 17.0

52 179.9 178.2 177.2 176.1 14.3 15.7 16.5 17.3

57 193.3 191.2 189.9 188.6 14.6 16.1 16.9 17.7

62 207.2 204.5 203.0 201.4 15.0 16.4 17.2 18.0

67 221.3 218.2 216.4 214.5 15.3 16.8 17.6 18.4

72 235.8 232.2 230.3 228.2 15.7 17.2 18.0 18.8

Table PD-11 — Gross Heating Capacities (kW)

TWA155B Heat Pump with TWE155B Air Handler At 8494 m3/h (SI)

Outdoor Heating C apaci ty (kW ) At To tal Power in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°C) 15.6 21.1 23.9 26.7 15.6 21.1 23.9 26.7

-27.8 20.1 17.8 17.0 16.4 5.5 6.0 6.2 6.5

-25.0 20.9 18.8 18.1 17.5 5.6 6.1 6.3 6.6

-22.2 21.8 20.0 19.4 19.0 5.7 6.2 6.5 6.7

-19.4 22.9 21.4 21.0 20.6 5.8 6.3 6.6 6.9

-16.7 24.3 23.1 22.8 22.6 5.9 6.5 6.7 7.0

-13.9 26.0 25.1 24.8 24.7 6.0 6.6 6.9 7.2

-11.1 28.0 27.3 27.1 27.0 6.2 6.7 7.0 7.4

-8.3 30.2 29.8 29.6 29.6 6.3 6.9 7.2 7.5

-5.6 32.8 32.5 32.4 32.4 6.5 7.0 7.4 7.7

-2.8 35.7 35.4 35.3 35.3 6.6 7.2 7.5 7.9

0.0 38.8 38.6 38.5 38.4 6.8 7.4 7.7 8.1

2.8 42.041.741.641.5 6.9 7.6 7.9 8.3

5.6 45.3 45.0 44.9 44.7 7.1 7.8 8.1 8.5

8.3 48.9 48.5 48.3 48.1 7.3 8.0 8.4 8.8

11.1 52.7 52.2 51.9 51.6 7.5 8.2 8.6 9.0

13.9 56.6 56.0 55.6 55.2 7.7 8.4 8.8 9.2

16.7 60.7 59.9 59.4 59.0 7.9 8.7 9.1 9.5

19.4 64.8 63.9 63.4 62.8 8.1 8.9 9.3 9.8

22.2 69.0 68.0 67.4 66.8 8.4 9.2 9.6 10.0

Correction Factors - Other Airflows“(Table Value

Correction Factor = Value at new airflow)

Airflow 4500 cfm 5500 cfm

Heating Capacity x 0.99 x 1.01

Comp ress or kW x 1.02 x 0.98

Values at ARI Rating Conditions of:

70F (21.1C) and 47/43F (8.3/6.1C)(High Temp.Cond.)

70F (21.1C) and 17/15F (-8.3/-9.4C)(Low Temp. Cond)

7645 m3/h 9344 m3/h

Airflow = 5000 cfm (8495 m3/h)

Heating Capacity (High Temp.) = 166,000 (48.60)

Heating Capacity (Low Temp.) = 101,000 (29.57)

Compressor Power (High Temp) = 11.67 kW

Compressor Power (Low Temp) = 9.66 kW

Coeff. Of Perf. (High Temp) = 3.2

Coeff. Of Perf. (Low Temp) = 2.2

Outdoor Fan Power = 1100 watts

Indoor Fan Power = 2570 watts

Note:

1.Rated with 25 feet of 1-3/8"" suction and 1/2"" liquid line."

22

SSP-PRC002-EN

Page 23

Performance

Data

(System)

Table PD-12 — Gross Heating Capacities (MBh)

TWA200B Heat Pump with TWE200B Air Handler At 6675 CFM (I-P)

Outdoor H eatin g Capacity (BTUH/1000) At Total Power in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°F) 60707580 60707580

-18 42.4 79.1 84.7 87.4 11.5 15.4 16.6 17.6

-13 68.2 86.2 90.2 92.3 13.0 15.6 16.7 17.7

-8 81.5 93.8 96.7 98.0 13.6 15.9 16.9 17.9

-3 93.1 101.8 103.7 104.5 14.1 16.2 17.1 18.1

2 104.2 110.2 111.4 111.7 14.5 16.4 17.4 18.3

7 115.2 119.2 119.8 119.7 14.9 16.7 17.6 18.6

12 126.6 128.8 128.9 128.5 15.2 17.0 17.9 18.9

17 138.2 139.1 138.8 138.2 15.5 17.3 18.2 19.2

22 150.3 150.1 149.5 148.6 15.9 17.6 18.6 19.6

27 162.9 161.8 160.9 159.8 16.2 18.0 18.9 20.0

32 176.1 174.3 173.2 171.9 16.5 18.3 19.3 20.4

37 189.2 186.9 185.6 184.3 16.9 18.7 19.7 20.8

42 202.8 200.0 198.6 197.2 17.2 19.1 20.2 21.3

47 216.9 213.8 212.3 210.8 17.6 19.5 20.6 21.8

52 231.9 228.5 226.8 225.3 18.0 20.0 21.1 22.3

57 247.4 243.6 241.9 240.3 18.4 20.5 21.7 22.9

62 263.2 259.1 257.2 255.6 18.9 21.0 22.2 23.5

67 279.3 274.8 272.8 271.0 19.4 21.6 22.8 24.1

72 295.9 291.1 289.0 287.0 20.0 22.2 23.4 24.7

Table PD-12 — Gross Heating Capacities (kW)

TWA200B Heat Pump with TWE200B Air Handler At 11340 m3/h (SI)

Outdoor Heati ng Cap acity (kW ) At Total Po wer in Kilowatts At

Temperature Indicated Indoor Dry Bulb Temperature Indicated Indoor Dry Bulb Temperature

(°C) 15.6 21.1 23.9 26.7 15.6 21.1 23.9 26.7

-27.8 12.4 23.2 24.8 25.6 5.5 6.0 6.2 6.5

-25.0 20.0 25.3 26.4 27.0 5.6 6.1 6.3 6.6

-22.2 23.9 27.5 28.3 28.7 5.7 6.2 6.5 6.7

-19.4 27.2 29.8 30.4 30.6 5.8 6.3 6.6 6.9

-16.7 30.5 32.3 32.6 32.7 5.9 6.5 6.7 7.0

-13.9 33.7 34.9 35.1 35.1 6.0 6.6 6.9 7.2

- 11 . 1 3 7. 1 3 7. 7 3 7. 8 3 7. 6 6 . 2 6 . 7 7.0 7.4

-8.3 40.5 40.7 40.7 40.5 6.3 6.9 7.2 7.5

-5.6 44.0 43.9 43.8 43.5 6.5 7.0 7.4 7.7

-2.8 47.7 47.4 47.1 46.8 6.6 7.2 7.5 7.9

0.0 51.6 51.0 50.7 50.3 6.8 7.4 7.7 8.1

2.8 55.4 54.7 54.3 54.0 6.9 7.6 7.9 8.3

5.6 59.4 58.6 58.1 57.7 7.1 7.8 8.1 8.5

8.3 63.5 62.6 62.2 61.7 7.3 8.0 8.4 8.8

11.1 67.9 66.9 66.4 66.0 7.5 8.2 8.6 9.0

13.9 72.4 71.3 70.8 70.3 7.7 8.4 8.8 9.2

16.7 77.1 75.9 75.3 74.8 7.9 8.7 9.1 9.5

19.4 81.8 80.5 79.9 79.4 8.1 8.9 9.3 9.8

22.2 86.6 85.2 84.6 84.0 8.4 9.2 9.6 10.0

Correction Factors - Other Airflows

(Table Value x Correction Factor = Value at new airflow)

Airflow 6000 cfm 7325 cfm

Heating Capacity x 0.99 x 1.01

Comp ress or kW x 1.02 x 0.98

Values at ARI Rating Conditions of:

70F (21.1C) and 47/43F (8.3/6.1C)(High Temp.Cond.)

70F (21.1C) and 17/15F (-8.3/-9.4C)(Low Temp. Cond)

10194 m3/h 12445 m3/h

Airflow = 6700 cfm (11383 m3/h)

Heating Capacity (High Temp.) = 214,000 (62.66)

Heating Capacity (Low Temp.) = 139,000 (40.70)

Compressor Power (High Temp) = 15.83 kW

Compressor Power (Low Temp) = 13.50 kW

Coeff. Of Perf. (High Temp) = 3.2

Coeff. Of Perf. (Low Temp) = 2.3

Outdoor Fan Power = 1,200 watts

Indoor Fan Power = 2,300 watts

Note:

1. Rated with 25 feet of 1-3/8” suction and 1/2" liquid line."

SSP-PRC002-EN

23

Page 24

Performance

Data

(Air Handler)

Table PD-13 — Evaporator Fan Performance — TWE050A (I-P)

External Static Pressure (Inches of Water Column)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1400 ————6460.376980.427510.478030.528560.569080.619410.65 9730.6810060.71

1500 — — 607 0.36 661 0.40 713 0.45 764 0.50 816 0.54 867 0.59 919 0.64 952 0.67 984 0.71 — —

1600 — — 625 0.38 676 0.43 727 0.48 778 0.52 828 0.57 879 0.62 930 0.67 963 0.70 995 0.74 — —

1700 601 0.35 648 0.40 696 0.44 744 0.49 792 0.54 841 0.59 889 0.64 937 0.69 971 0.73 1005 0.77 — —

1800 625 0.36 671 0.41 716 0.46 762 0.51 807 0.56 853 0.61 898 0.66 944 0.71 979 0.76 ————

1900 642 0.40 687 0.45 731 0.50 776 0.55 820 0.60 865 0.66 909 0.71 951 0.75 987 0.80 ————

2000 659 0.44 703 0.49 745 0.54 790 0.60 833 0.65 877 0.70 920 0.75 957 0.80 994 0.84 ————

2100 674 0.48 722 0.54 770 0.60 817 0.65 857 0.70 897 0.75 936 0.80 973 0.85 1009 0.89 ————

0.75 HP Standard Motor and Standard Static Drive 1.0 HP Oversized Motor and High Static Drive

Notes:

1. Performance based on a wet coil and 1 inch (25.4 mm) throwaway filters.

2. Tabulated brake horsepower is the motor shaft output required.

3. Factory setting of motor sheave is 1.5 turns open. Adjustments are made in 0.5 turn increments.

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00" 1.10"

Table PD-13— Evaporator Fan Performance — TWE050A (SI)

External Static Pressure (Pascal)

m3/h r RPM k W RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

2379 ————6460.286980.317510.358030.398560.429080.459410.489730.5110060.53

2549 — — 607 0.27 661 0.30 713 0.34 764 0.37 816 0.40 867 0.44 919 0.48 952 0.50 984 0.53 — —

2718 — — 625 0.28 676 0.32 727 0.36 778 0.39 828 0.43 879 0.46 930 0.50 963 0.52 995 0.55 — —

2888 601 0.26 648 0.30 696 0.33 744 0.37 792 0.40 841 0.44 889 0.48 937 0.51 971 0.54 1005 0.57 — —

3058 625 0.27 671 0.31 716 0.34 762 0.38 807 0.42 853 0.45 898 0.49 944 0.53 979 0.57 ————

3228 642 0.30 687 0.34 731 0.37 776 0.41 820 0.45 865 0.49 909 0.53 951 0.56 987 0.60 ————

3398 659 0.33 703 0.37 745 0.40 790 0.45 833 0.48 877 0.52 920 0.56 957 0.60 994 0.63 ————

3568 674 0.36 722 0.40 770 0.45 817 0.48 857 0.52 897 0.56 936 0.60 973 0.63 1009 0.66 ————

0.56 kW Standard Motor and Standard Static Drive 0.75 kW Oversized Motor and High Static Drive

Notes:

1. Performance based on a wet coil and 1 inch (25.4 mm) throwaway filters.

2. Tabulated brake horsepower is the motor shaft output required.

3. Factory setting of motor sheave is 1.5 turns open. Adjustments are made in 0.5 turn increments.

25 50 75 100 125 150 174 199 224 249 274

24

Table PD-14 — Blower Speeds — TWE050A

Drive 6543210

Stand ard N/A 590 639 688 737 786 835

High Static N/A 713 772 832 891 951 1009

Motor DriveTurns Open

SSP-PRC002-EN

Page 25

Performance

Data

(Air Handler)

Table PD-15 — Evaporator Fan Performance TWE075A (I-P)

External Static Pressure (In. Of Water Column)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2000 — — 443 0.44 489 0.49 535 0.54 581 0.59 627 0.64 673 0.69 719 0.74 765 0.79 791 0.83 818 0.89

2125 — — 453 0.46 499 0.52 546 0.57 592 0.63 638 0.68 684 0.74 730 0.79 771 0.85 798 0.90 825 0.96

2250 — — 463 0.49 510 0.55 556 0.61 602 0.67 649 0.73 695 0.79 742 0.85 776 0.91 804 0.97 831 1.03

2375 — — 473 0.51 520 0.57 567 0.64 613 0.70 660 0.77 706 0.83 753 0.90 782 0.97 810 1.03 838 1.10

2500 445 0.47 489 0.54 533 0.60 578 0.67 622 0.73 667 0.80 711 0.86 756 0.93 784 0.99 813 1.07 842 1.14

2625 464 0.50 506 0.57 548 0.63 589 0.69 631 0.76 672 0.82 714 0.88 757 0.95 786 1.01 815 1.09 844 1.17

2750 484 0.53 523 0.59 562 0.66 601 0.72 640 0.78 678 0.84 717 0.91 758 0.97 787 1.03 817 1.12 847 1.21

2875 504 0.56 540 0.62 576 0.68 612 0.74 648 0.81 684 0.87 720 0.93 759 0.99 789 1.05 819 1.15 850 1.24

3000 524 0.59 557 0.65 590 0.71 624 0.77 657 0.83 690 0.89 723 0.95 760 1.01 790 1.07 821 1.17 853 1.27

Notes:

1. Performance based on a wet coil and 1 inch (25.4 mm)

2. Tabulated brake horsepower is the motor shaft output

3. Factory setting of motor sheave is 1.5 turns open.

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10

1.0 HP Standard Motor 1.0 HP Standard Motor 1.5 HP Oversized Motor

and Low Static Drive and Drive and High Static Drive

throwaway filters.

required.

Adjustments are made in 0.5 turn increments.

Table PD-15— Continued

External Static Pressure (In. Of Water Column)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2000 844 0.96 871 1.02 897 1.09 924 1.15 950 1.21

2125 852 1.03 879 1.09 906 1.16 933 1.22 — —

2250 859 1.10 886 1.17 914 1.23 942 1.30 — —

2375 866 1.17 894 1.24 922 1.30 950 1.37 — —

2500 870 1.21 899 1.29 928 1.36 ————

2625 874 1.25 903 1.33 932 1.42 ————

2750 877 1.29 907 1.38 937 1.47 ————

2875 880 1.33 911 1.43 942 1.52 ————

3000 884 1.37 915 1.48 946 1.58 ————

1.0 HP Standard Motor

1.20 1.30 1.40 1.50 1.60

1.5 HP Oversized Motor

and High Static Drive

and Drive

Table PD-15 — Evaporator Fan Performance TWE075A (SI)

m3/h r RPM k W RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

3338 — — 443 0.33 489 0.37 535 0.4 581 0.44 627 0.48 673 0.51 719 0.55 765 0.59 791 0.62 818 0.66

3547 — — 453 0.34 499 0.39 546 0.43 592 0.47 638 0.51 684 0.55 730 0.59 771 0.63 798 0.67 825 0.72

3755 — — 463 0.37 510 0.41 556 0.45 602 0 .5 649 0.54 695 0.59 742 0.63 776 0.68 804 0.72 831 0.77

3964 — — 473 0.38 520 0.43 567 0.48 613 0.52 660 0.57 706 0.62 753 0.67 782 0.72 810 0.77 838 0.82

4173 445 0.35 489 0.4 533 0.45 578 0.5 622 0.54 667 0.6 711 0.64 756 0.69 784 0.74 813 0 .8 842 0.85

4381 464 0.37 506 0.43 548 0.47 589 0.51 631 0.57 672 0.61 714 0.66 757 0.71 786 0.75 815 0.81 844 0.87

4590 484 0.4 523 0.44 562 0.49 601 0.54 640 0.58 678 0.63 717 0.68 758 0.72 787 0.77 817 0.84 847 0.9

4798 504 0.42 540 0.46 576 0.51 612 0.55 648 0 .6 684 0.65 720 0.69 759 0.74 789 0.78 819 0.86 850 0.92

5007 524 0.44 557 0.48 590 0.53 624 0.57 657 0.62 690 0.66 723 0.71 760 0.75 790 0.8 821 0.87 853 0.95

Notes:

1. Performance based on a wet coil and 1 inch (25.4 mm)

throwaway filters.

2. Tabulated brake horsepower is the motor shaft

output required.

3. Factory setting of motor sheave is 1.5 turns open.

Adjustments are made in 0.5 turn increments.

25 50 75 100 125 150 174 199 224 249 274

.75 kW Standard Motor .75 kW Standard Motor 1.12 kW Oversized Motor

and Low Static Drive and Drive and High Static Drive

Table PD-16 — Blower Speeds — TWE075A

Motor Drive Turns Open

Drive 6543210

Stand ard N/A 600 650 700 750 800 850

Low Sta tic N/A 428 464 499 535 571 606

Hig h Static N/A 700 750 800 850 900 950

SSP-PRC002-EN

External Static Pressure (Pascal)

Table PD-15 — Continued

m3/h r RPM k W RPM kW RPM kW RPM kW RPM kW

3338 844 0.72 871 0.76 897 0.81 924 0.86 950 0.9

3547 852 0.77 879 0.81 906 0.87 933 0.91 — —

3755 859 0.82 886 0.87 914 0.92 942 0.97 — —

3964 866 0.87 894 0.92 922 0.97 950 1.02 — —

4173 870 0.9 899 0.96 928 1.01 ————

4381 874 0.93 903 0.99 932 1.06 ————

4590 877 0.96 907 1.03 937 1.1 ————

4798 880 0.99 911 1.07 942 1.13 ————

5007 884 1.02 915 1.1 946 1.18 ————

1.12 kW Oversized Motor and High Static Drive

.75 kW Standard Motor

and Drive

299 324 349 374 398

External Static Pressure (Pascal)

25

Page 26

Performance

Data

Table PD-17 — Evaporator Fan Performance TWE100A, TWE100B (I-P)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2600 460 0.32 493 0.39 527 0.47 565 0.55 603 0.63 641 0.71 679 0.79 717 0.87 744 0.94 772 1.01 826 1.16

2775 473 0.37 506 0.45 540 0.53 576 0.61 613 0.69 649 0.77 686 0.85 723 0.93 748 1.00 775 1.07 830 1.20

2950 487 0.43 519 0.50 552 0.58 587 0.67 623 0.75 658 0.83 693 0.91 728 0.99 751 1.06 779 1.12 833 1.25

3125 501 0.49 532 0.56 565 0.64 599 0.72 632 0.81 666 0.89 700 0.97 734 1.05 755 1.11 783 1.18 737 1.30

3300 520 0.58 548 0.65 581 0.73 613 0.81 644 0.89 677 0.98 710 1.06 740 1.13 759 1.19 787 1.25 841 1.37

3475 541 0.69 568 0.76 600 0.84 631 0.93 658 1.00 691 1.08 721 1.16 746 1.21 764 1.28 793 1.34 846 1.48

3650 562 0.82 588 0.88 618 0.97 648 1.05 671 1.11 703 1.19 732 1.27 753 1.31 772 1.38 801 1.45 853 1.59

3825 582 0.96 608 1.03 637 1.11 666 1.20 685 1.26 711 1.31 739 1.38 763 1.44 787 1.51 815 1.58 862 1.74

4000 602 1.11 628 1.17 656 1.26 683 1.35 698 1.40 720 1.43 747 1.50 773 1.58 801 1.64 829 1.71 872 1.89

Notes:

1. Performance based on a wet coil and 1 inch (25.4 mm) throwaway filters.