Page 1

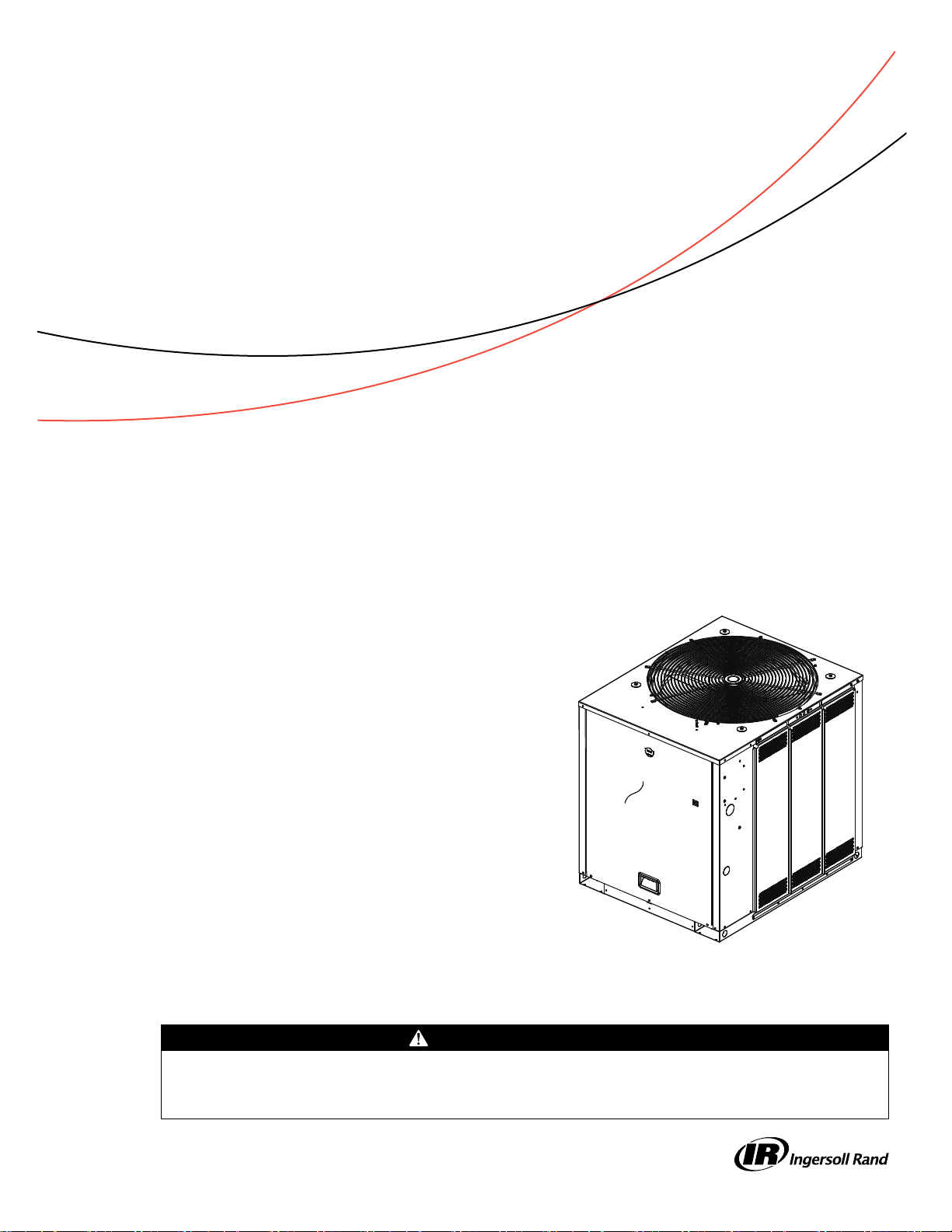

Installation, Operation,

and Maintenance

Split System Air Conditioners

Odyssey™™

R-22 Dry Charge

Heat Pump Condenser — 7.5, 10, 15 and 20 Tons

((6600 HHzz))

TWA090A***G*

TWA120A***G*

TWA180B***G*

TWA240B***G*

SSAAFFEETTYY WWAARRNNIINNGG

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

January 2014

SSP-SVX15C-EN

Page 2

Introduction

WARNING

CAU

TION

NOTICE

Read this manual thoroughly before operating or

servicing this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper

operation of this machine depend upon the strict

observance of these precautions.

The three types of advisories are defined as follows:

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury. It could also be used to alert

against unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are

refrigerants that contain Chlorine, Fluorine and Carbon

(CFCs) and those containing Hydrogen, Chlorine,

Fluorine and Carbon (HCFCs). Not all refrigerants

containing these compounds have the same potential

impact to the environment. Trane advocates the

responsible handling of all refrigerants-including

industry replacements for CFCs such as HCFCs and

HFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the

air conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management

of refrigerants. Know the applicable laws and follow

them.

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee eelleeccttrriiccaall ccooddeess..

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE))

RReeqquuiirreedd!!

FFaaiilluurree ttoo wweeaarr pprrooppeerr PPPPEE ffoorr tthhee jjoobb bbeeiinngg

uunnddeerrttaakkeenn ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

TTeecchhnniicciiaannss,, iinn oorrddeerr ttoo pprrootteecctt tthheemmsseellvveess ffrroomm

ppootteennttiiaall eelleeccttrriiccaall,, mmeecchhaanniiccaall,, aanndd cchheemmiiccaall

hhaazzaarrddss,, MMUUSSTT ffoollllooww pprreeccaauuttiioonnss iinn tthhiiss mmaannuuaall

aanndd oonn tthhee ttaaggss,, ssttiicckkeerrss,, aanndd llaabbeellss,, aass wweellll aass tthhee

iinnssttrruuccttiioonnss bbeellooww::

•• BBeeffoorree iinnssttaalllliinngg//sseerrvviicciinngg tthhiiss uunniitt,,

tteecchhnniicciiaannss MMUUSSTT ppuutt oonn aallll PPeerrssoonnaall

PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE)) rreeccoommmmeennddeedd

ffoorr tthhee wwoorrkk bbeeiinngg uunnddeerrttaakkeenn.. AALLWWAAYYSS rreeffeerr

ttoo aapppprroopprriiaattee MMSSDDSS sshheeeettss aanndd OOSSHHAA

gguuiiddeelliinneess ffoorr pprrooppeerr PPPPEE..

•• WWhheenn wwoorrkkiinngg wwiitthh oorr aarroouunndd hhaazzaarrddoouuss

cchheemmiiccaallss,, AALLWWAAYYSS rreeffeerr ttoo tthhee aapppprroopprriiaattee

MMSSDDSS sshheeeettss aanndd OOSSHHAA gguuiiddeelliinneess ffoorr

iinnffoorrmmaattiioonn oonn aalllloowwaabbllee ppeerrssoonnaall eexxppoossuurree

lleevveellss,, pprrooppeerr rreessppiirraattoorryy pprrootteeccttiioonn aanndd

hhaannddlliinngg rreeccoommmmeennddaattiioonnss..

•• IIff tthheerree iiss aa rriisskk ooff aarrcc oorr ffllaasshh,, tteecchhnniicciiaannss

MMUUSSTT ppuutt oonn aallll PPeerrssoonnaall PPrrootteeccttiivvee

EEqquuiippmmeenntt ((PPPPEE)) iinn aaccccoorrddaannccee wwiitthh NNFFPPAA

7700EE oorr ootthheerr ccoouunnttrryy--ssppeecciiffiicc rreeqquuiirreemmeennttss

ffoorr aarrcc ffllaasshh pprrootteeccttiioonn,, PPRRIIOORR ttoo sseerrvviicciinngg

tthhee uunniitt..

©2014 Trane All rights reserved

SSP-SVX15C-EN

Page 3

IInnttrroodduuccttiioonn

WWAARRNNIINNGG

RReeffrriiggeerraanntt uunnddeerr HHiigghh PPrreessssuurree!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

aann eexxpplloossiioonn wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy oorr eeqquuiippmmeenntt ddaammaaggee..

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree

bbeeffoorree ooppeenniinngg tthhee ssyysstteemm.. SSeeee uunniitt nnaammeeppllaattee ffoorr

rreeffrriiggeerraanntt ttyyppee.. DDoo nnoott uussee nnoonn--aapppprroovveedd

rreeffrriiggeerraannttss,, rreeffrriiggeerraanntt ssuubbssttiittuutteess,, oorr rreeffrriiggeerraanntt

aaddddiittiivveess..

Copyright

This document and the information in it are the

property of Trane and may not be used or reproduced

in whole or in part, without the written permission of

Trane. Trane reserves the right to revise this publication

at any time and to make changes to its content without

obligation to notify any person of such revision or

change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

Removed warranty chapter, updated with running

edits.

SSP-SVX15C-EN

3

Page 4

Table of Contents

Model Number Description . . . . . . . . . . . . . . . . . 6

Heat Pump Condenser. . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . . . . 7

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inspection Checklist . . . . . . . . . . . . . . . . . . . 8

Testing for Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lifting Recommendations . . . . . . . . . . . . . . . . . 8

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unit Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Structural Preparation . . . . . . . . . . . . . . . . . 9

Rooftop Mounting . . . . . . . . . . . . . . . . . . . . 9

Ground Level Mounting . . . . . . . . . . . . . . . 9

Snow Belt Recommendations . . . . . . . . . . . . . 9

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . 10

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heat Pump Condenser . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Refrigerant Piping Guidelines. . . . . . . . . . . . . 15

Refrigerant Piping Procedures (Outdoor

Units). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Refrigerant Piping Procedures (Indoor

Unit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Evacuation . . . . . . . . . . . . . . . . . . . 17

Insulating and Isolating Refrigerant

Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Refrigerant Charging Procedure . . . . . . . . . . 18

Liquid Charging . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unit Power Supply . . . . . . . . . . . . . . . . . . . 20

Low Voltage Wiring . . . . . . . . . . . . . . . . . . 20

ReliaTel™ Controls . . . . . . . . . . . . . . . . . . . 20

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 21

Refrigerant Circuit. . . . . . . . . . . . . . . . . . . . 22

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Charging Charts and Superheat . . . . . . . . . . . 25

Installation Checklist. . . . . . . . . . . . . . . . . . . . . . . 26

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pre-Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Control Circuit Features . . . . . . . . . . . . . . . . . . 27

Discharge Temperature Limit

(DTL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Evaporator Defrost Control

(EDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Low Pressure Cut-Out (LPCO) . . . . . . . . . 27

High Pressure Cut-Out (HPCO) . . . . . . . . 27

Internal Overload Protector

(IOL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ReliaTel™ Controls . . . . . . . . . . . . . . . . . . . . . . 28

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . 28

Functions and Features . . . . . . . . . . . . . . . 28

Service Test Modes for ReliaTel™

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Test Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Step Test Mode . . . . . . . . . . . . . . . . . . . . . . 33

Resistance Test Mode . . . . . . . . . . . . . . . . 33

Auto Test Mode . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting ReliaTel™ Controls. . . . . . . 34

System Status Checkout Procedure . . . . . . . 34

Method 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Method 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Resetting Cooling and Heating

Lockouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Method 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Method 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Zone Temperature Sensor (ZTS) Service

Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Temperature Tests . . . . . . . . . . . . . . . . . . . . . . . 36

Test 1 - Zone Temperature

Thermistor (ZTEMP). . . . . . . . . . . . . . . . . . 36

Test 2 - Cooling Set Point (CSP) and

Heating Set Point (HSP). . . . . . . . . . . . . . . 36

Test 3 - System Mode and Fan

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Test 4 - LED Indicator Test (SYS ON,

HEAT, & COOL). . . . . . . . . . . . . . . . . . . . . . . 37

Programmable & Digital Zone Sensor

Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Testing Serial Communication

Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

RLCI Loss of Communications. . . . . . . . . 37

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Annually (Cooling Season) . . . . . . . . . . . . . . . 38

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4

SSP-SVX15C-EN

Page 5

TTaabbllee ooff CCoonntteennttss

Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . 39

Wiring Diagram Matrix . . . . . . . . . . . . . . . . . . . . 40

Charging Charts and Superheat . . . . . . . . . . . . . .

Charging Charts and Superheat . . . . . . . . . . . . . .

Dimensional Data. . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging Charts and Superheat . . . . . . . . . . . . . .

SSP-SVX15C-EN

5

Page 6

Model Number Description

Heat Pump Condenser

T W A 120 A 3 0 0

1 2 3 4 5 6 7 8 9 10 11 12

All products are identified by a multiple-character

model number that precisely identifies a particular type

of unit. An explanation of the alphanumeric

identification code is provided. Its use will enable the

owner/operator, installing contractors, and service

engineers to define the operation, specific

components, and other options for any specific unit.

When ordering replacement parts or requesting

service, be sure to refer to the specific model number,

serial number, and DL number (if applicable) stamped

on the unit nameplate.

DDIIGGIITTSS 11 -- 33:: PPrroodduucctt TTyyppee

TWA = Split System Heat Pump

DDIIGGIITTSS 44 -- 66:: NNoommiinnaall GGrroossss CCoooolliinngg CCaappaacciittyy

((MMBBhh))

090 = 7.5 Tons (60Hz)

120 = 10 Tons (60Hz)

180 = 15 Tons (60Hz)

240 = 20 Tons (60Hz)

DDIIGGIITT 77:: MMaajjoorr DDeevveellooppmmeenntt SSeeqquueennccee

A = Single Compressor, Single Circuit, R-22

B = Dual Compressor, Dual Circuit, R-22

DDIIGGIITT 88:: EElleeccttrriiccaall CChhaarraacctteerriissttiiccss

3 = 208–230/60/3

4 = 460/60/3

DDIIGGIITTSS 99 -- 1100:: FFaaccttoorryy IInnssttaalllleedd OOppttiioonnss

00 = Packed Stock

DDIIGGIITTSS 1111:: MMiinnoorr DDeessiiggnn SSeeqquueennccee

* = Current Design Sequence

DDIIGGIITTSS 1122:: SSeerrvviiccee DDiiggiitt

* = Current Design Sequence

* *

1

1

1.

* = sequential alpha character

6

SSP-SVX15C-EN

Page 7

General Information

This manual describes proper installation, operation,

and maintenance procedures for air-cooled systems. By

carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component damage will be

minimized. It is important that periodic maintenance be

performed to help assure trouble free operation.

Should equipment failure occur, contact a qualified

service organization with qualified, experienced HVAC

technicians to properly diagnose and repair this

equipment.

IImmppoorrttaanntt:: All phases of this installation must comply

with the NATIONAL, STATE & LOCAL

CODES. In addition to local codes, the

installation must conform with National

Electric Code -ANSI/NFPA NO. 70 LATEST

REVISION.

Any individual installing, maintaining, or servicing this

equipment must be properly trained, licensed and

qualified.

IImmppoorrttaanntt:: Do not remove the VFD without first

contacting technical support! For

performance-related questions and

diagnostic support in North America call 1877-872-6363. Any return requires a claim

number FIRST. Removal of the VFD prior to

this step will void the unit’s warranties.

Installation procedures should be performed in the

sequence that they appear in this manual. Do not

destroy or remove the manual from the unit. The

manual should remain weather-protected with the unit

until all installation procedures are complete.

NNoottee:: It is not the intention of this manual to cover all

possible variations in systems that may occur or

to provide comprehensive information

concerning every possible contingency that may

be encountered during an installation. If

additional information is required or if specific

problems arise that are not fully discussed in this

manual, contact your local sales office.

Use the ”Installation Checklist,” p. 26 provided In this

manual to verify that all necessary installation

procedures have been completed. Do not use the

checklist as a substitute for reading the information

contained in the manual. Read the entire manual

before beginning installation procedures.

Unit Description

These condensers come with single and dual

compressor options. Single compressor outdoor units

feature a single refrigeration circuitry, requiring only

one set of refrigerant lines. Dual compressor/dual

circuit models give true stand-by protection; if one

compressor fails, the second will automatically startup. Also, the first compressor can be serviced without

shutting down the unit since the refrigerant circuits are

independent. During light load conditions, only one

compressor will operate to save energy.

SSP-SVX15C-EN

7

Page 8

Pre-Installation

Unit Inspection

Inspect material carefully for any shipping damage. If

damaged, it must be reported to, and claims made

against the transportation company. Compare the

information that appears on the unit nameplate with

ordering and submittal data to ensure the proper unit

was shipped. Available power supply must be

compatible with electrical characteristics specified on

component nameplates. Replace damaged parts with

authorized parts only.

Inspection Checklist

To protect against loss due to damage incurred in

transit, complete the following checklist upon receipt of

the unit.

Inspect individual pieces of the shipment before

accepting the unit. Check for obvious damage to the

unit or packing material.

Inspect the unit for concealed damage before it is

stored and as soon as possible after delivery.

Concealed damage must be reported within 15

days. If concealed damage is discovered, stop

unpacking the shipment. Do not remove damaged

material from the receiving location. Take photos of

the damage if possible. The owner must provide

reasonable evidence that the damage did not occur

after delivery.

Notify the carrier’s terminal of damage immediately

by phone and by mail. Request an immediate joint

inspection of the damage by the carrier and the

consignee.

Notify the sales representative and arrange for

repair. Do not repair the unit until the damage is

inspected by the carrier’s representative.

Testing for Leaks

All units are shipped with a holding charge of nitrogen

in each circuit and should be leak tested before

installation.

1. Remove the access panel.

2. Locate the liquid line or suction line access valve for

each circuit.

3. Install gauges to determine if the circuits are still

pressurized. If not, the charge has escaped and

should be repaired as required to obtain a leak-free

circuit.

Lifting Recommendations

WWAARRNNIINNGG

IImmpprrooppeerr UUnniitt LLiifftt!!

FFaaiilluurree ttoo pprrooppeerrllyy lliifftt uunniitt ccoouulldd rreessuulltt iinn uunniitt

ddrrooppppiinngg aanndd ppoossssiibbllyy ccrruusshhiinngg ooppeerraattoorr//

tteecchhnniicciiaann wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy,, aanndd eeqquuiippmmeenntt oorr pprrooppeerrttyy--oonnllyy ddaammaaggee..

TTeesstt lliifftt uunniitt aapppprrooxxiimmaatteellyy 2244 iinncchheess ttoo vveerriiffyy

pprrooppeerr cceenntteerr ooff ggrraavviittyy lliifftt ppooiinntt.. TToo aavvooiidd

ddrrooppppiinngg ooff uunniitt,, rreeppoossiittiioonn lliiffttiinngg ppooiinntt iiff uunniitt iiss

nnoott lleevveell..

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

UUssee sspprreeaaddeerr bbaarrss ttoo pprreevveenntt ssttrraappss ffrroomm

ddaammaaggiinngg tthhee uunniitt.. IInnssttaallll tthhee bbaarrss bbeettwweeeenn lliiffttiinngg

ssttrraappss,, bbootthh uunnddeerrnneeaatthh tthhee uunniitt aanndd aabboovvee tthhee

uunniitt ttoo pprreevveenntt tthhee ssttrraappss ffrroomm ccrruusshhiinngg tthhee uunniitt

ccaabbiinneett oorr ddaammaaggiinngg tthhee ffiinniisshh..

Before preparing the unit for lifting, estimate the

approximate center of gravity for lifting safety. Because

of placement of internal components, the unit weight

may be unevenly distributed. See ”Weights”, p. 14 for

approximate unit weights.

The crated unit can be moved using a forklift of suitable

capacity. For lifting the unit, attach lifting straps or

slings securely to the lifting holes at each corner (see

unit drawings in ”Weights”, p. 14). Use spreader bars to

protect the unit casing from damage. Test lift the unit to

determine proper balance and stability.

Clearances

Provide enough space around the unit to allow

unrestricted access to all service points. Refer to the

”Dimensional Data,” p. 10 for unit dimensions and

minimum required service and free air clearances.

Observe the following points to ensure proper unit

operation.

1. Do not install the unit under a low overhang.

Condenser discharge must not be restricted—refer

to notes in ”Dimensional Data drawings,” p. 10.

IImmppoorrttaanntt:: Do not obstruct condenser discharge

air. This can result in warm air

recirculation through the coil.

2. Do not locate the unit in a position where runoff

water can fall into the fan discharge openings.

3. Condenser intake air is supplied from three or four

sides of the unit. Adhere to the minimum required

clearances given in unit dimensional drawings (see

”Dimensional Data,” p. 10).

8

SSP-SVX15C-EN

Page 9

Outd oor Unit

Gas (Suction )

Line - Insulated

Liquid Line

Insulated

Unit Mounting

Chan nels

Elevation

(Mounting Fram e )

Roo f Trus sing

Ceiling

Roof

Cons truction

6”

Rad iu s

PPrree--IInnssttaallllaattiioonn

Unit Mounting

WWAARRNNIINNGG

MMoouunnttiinngg IInntteeggrriittyy!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonn bbeellooww ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy oorr ppoossssiibbllee eeqquuiippmmeenntt oorr

pprrooppeerrttyy--oonnllyy ddaammaaggee..

EEnnssuurree tthhee rrooooff ssttrruuccttuurree ssuuppppoorrttss aarree ssttrroonngg

eennoouugghh ttoo ssuuppppoorrtt tthhee wweeiigghhtt ooff tthhee uunniitt aanndd aannyy

aacccceessssoorriieess..

Structural Preparation

NNOOTTIICCEE

RRooooff DDaammaaggee!!

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RRooooffss sshhoouulldd bbee pprrootteecctteedd ffrroomm

eexxppoossuurree ttoo ooiillss aanndd rreeffrriiggeerraanntt iinn tthhee ssyysstteemm.. IIff

rrooooffttoopp iiss nnoott pprrootteecctteedd,, ddaammaaggee ttoo tthhee rrooooff mmaayy

ooccccuurr..

IImmppoorrttaanntt:: Refer to local building codes for proper

installation. All installation must comply

with local building codes.

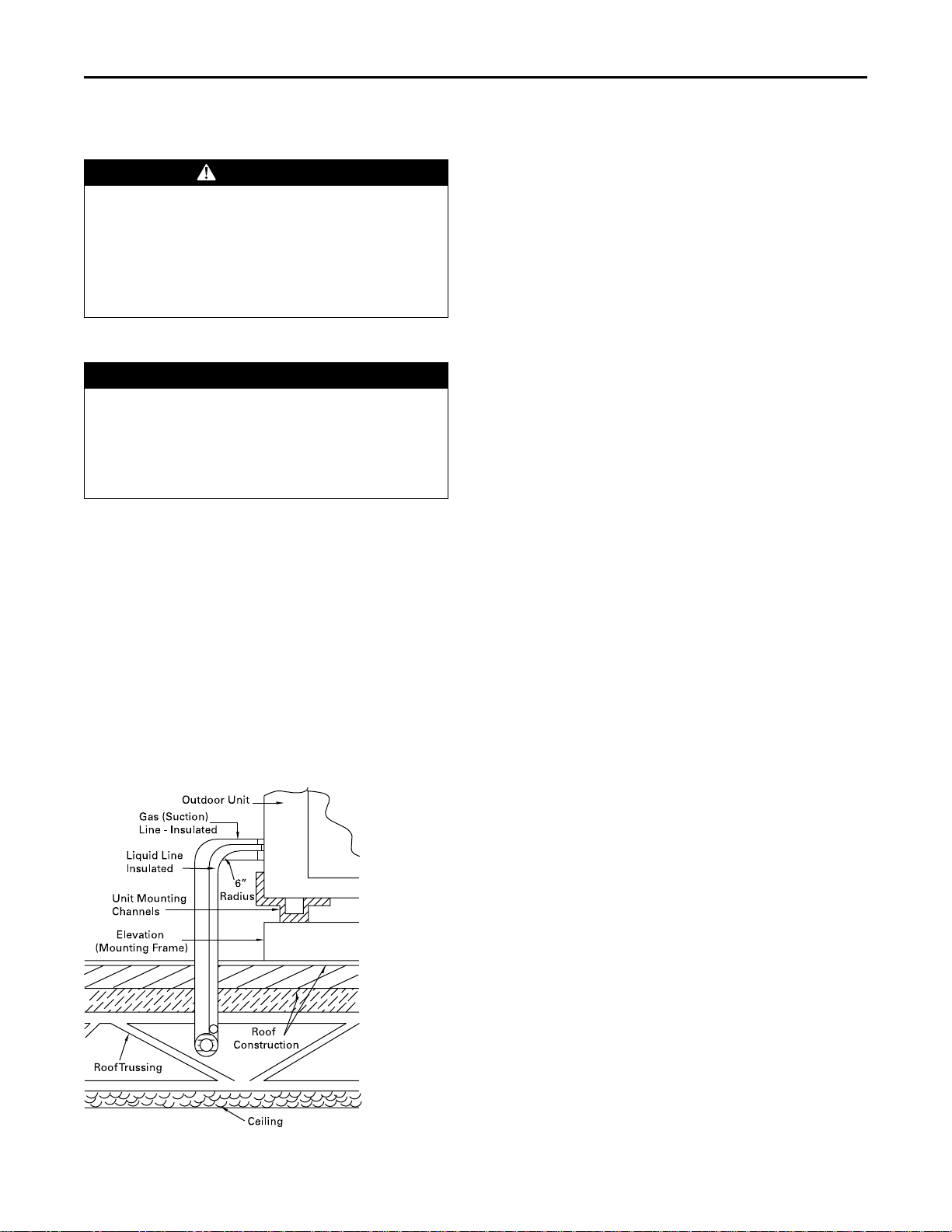

Rooftop Mounting

If the unit will be roof mounted, determine for certain

that the structure is strong enough to support the unit

and any required accessories, see ”Weights”, p. 14. The

unit should be elevated on a level, field fabricated fourinch steel or wood 4" x 4" mounting frame. Complete

the frame and secure it into position before lifting the

unit to the roof. The mounting frame must support a

minimum of three of the unit’s four sides and should

span roof supports to distribute the load on the roof.

Figure 1. Roof mounted unit

Ground Level Mounting

For ground level installation, the unit base should be

adequately supported and hold the unit near level. The

installation must meet the guidelines set forth in local

codes. The support should extend two inches beyond

the unit base channels at all points. The unit and

support must be isolated from any adjacent structure to

prevent possible noise or vibration problems. Any

ground level location must comply with required

clearances given in the unit dimensional drawings (see

”Dimensional Data,” p. 10).

Snow Belt Recommendations

In regions where deep snow is encountered, raise the

unit a minimum distance of 8 to 12 inches above the

mounting surface. This will reduce the risk of snow

blocking the coil and improves runoff of water

produced during the defrost cycle. Avoid locating the

unit where snow tends to drift. Snow accumulations

must be removed from around the unit immediately to

prevent drastic efficiency reduction. A snow drift

barrier may be constructed around the unit to prevent

snow blockage. Clearance between the snow barrier

and the unit must comply with the clearances given in

”Dimensional Data drawings,” p. 10.

SSP-SVX15C-EN

9

Page 10

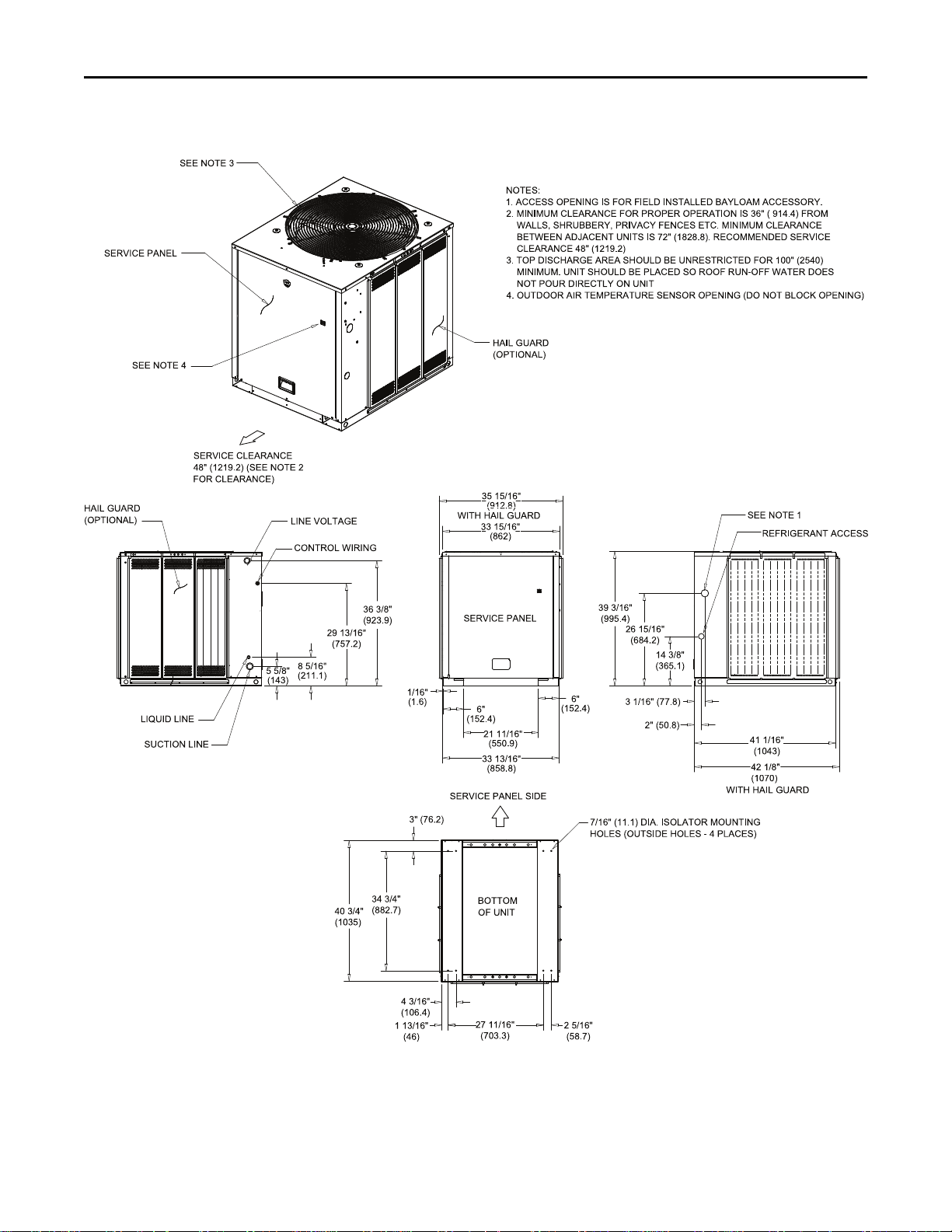

Dimensional Data

H

W

D

H

W

D

Figure 2. Height, width and depth measurements

H - in. (mm) W - in. (mm) D - in. (mm)

TWA090A

TWA120A

TWA180B, TWA240B 45.125 (1146.1) 52.125 (1324) 40 (1016)

39.125 (993.8) 42.125 (1070) 36 (914.4)

39.125 (993.8) 52.125 (1324) 40 (1016)

10

SSP-SVX15C-EN

Page 11

BOTTOM

OF UNIT

14 3/8"

(365.1)

26 15/16"

(684.2)

39 3/16"

(995.4)

3 1/16" (77.8)

2" (50.8)

33 13/1 6"

(858.8)

1/16"

(1.6)

6"

(152.4)

21 11 /16"

(550.9)

34 3/4"

(882.7)

40 3/4"

(1035)

3" (76.2)

1 13/16"

(46)

27 11/ 16"

(703.3 )

2 5/16"

(58.7)

4 3/16"

(106.4)

33 15 /16"

(862)

36 3/8"

(923.9)

29 13/16"

(757.2)

8 5/16"

(211.1)

5 5/8"

(143)

35 15 /16"

(912.8 )

41 1/16"

(1043)

42 1/8"

(1070)

NOTES:

1. ACCESS OPENING IS FOR FIELD INSTALLED BAYLOAM ACCESS ORY.

2. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36" ( 914.4) FROM

WALLS, S HRUBBERY, P RIVACY FENCES ETC. MINIMUM CLEARANCE

BETWEEN ADJACENT UNITS IS 72" (1828.8). RECOMMENDED S ERVICE

CLEARANCE 48" (1219.2)

3. TOP DISCHARGE AREA SHOULD BE UNRESTRICTED FOR 100" (2540)

MINIMUM. UNIT SHOULD BE PLACED SO ROOF RUN-OFF WATER DOES

NOT POUR DIRECTLY ON UNIT

4. OUTDOOR AIR TEMPERATURE SENSOR OPENING (DO NOT BLOCK OPENING)

SERVICE CLEARANCE

48" (1219.2) (S EE NOTE 2

FOR CLEARANCE)

SEE NOTE 1

REFRIGERANT ACCES S

HAIL GUARD

(OPTIONAL)

SUCTION LINE

LIQUID LINE

CONTROL WIRING

LINE VOLTAGE

SER VICE P ANEL

HAIL GUARD

(OPTIONAL)

SERVICE PANEL

SEE NOTE 3

SERVICE P ANEL SIDE

SEE NOTE 4

WITH HAIL GUARD

7/16" (11.1) DIA. ISOLATOR MOUNTING

HOLES (OUTS IDE HOLES - 4 P LACES)

WITH HAIL GUARD

6"

(152.4)

Figure 3. 7.5 ton heat pump, single compressor

DDiimmeennssiioonnaall DDaattaa

SSP-SVX15C-EN

11

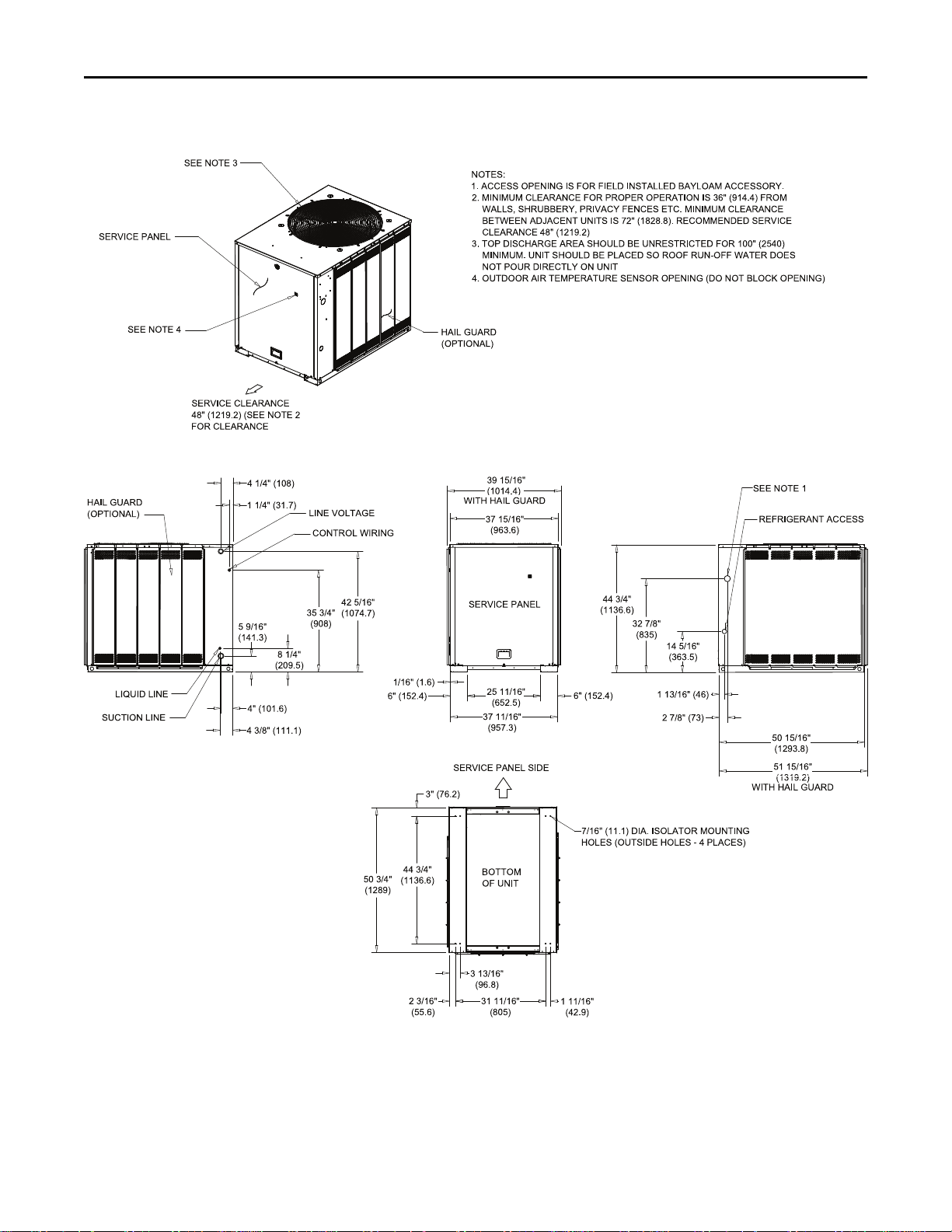

Page 12

BOTTOM

OF UNIT

51 15/16"

(1319.2)

50 15/16"

(1293.8)

1/16" (1.6)

2 7/8" (73)

32 7/8"

(835)

44 3/4"

(1136.6)

25 11 /16"

(652.5)

6" (152. 4)

1 13/16" (46)

14 5/16"

(363.5)

37 11 /16"

(957.3)

44 3/4"

(1136.6)

50 3/4"

(1289)

3" (76.2)

31 11 /16"

(805)

3 13/16 "

(96.8)

2 3/16"

(55.6)

1 11/16"

(42.9)

37 15 /16"

(963.6)

42 5/16"

(1074.7)

35 3/4"

(908)

1 1/4" (31.7)

8 1/4"

(209.5)

5 9/16"

(141.3)

4 3/8" (111.1)

4" (101. 6)

4 1/4" (108)

39 15/16"

(1014.4)

7/16" (11.1) DIA. ISOLATOR MOUNTING

HOLES (OUTS IDE HOLES - 4 PLACES)

NOTES :

1. ACCESS OPENING IS FOR FIELD INSTALLED BAYLOAM ACCESSORY.

2. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36" (914.4) FROM

WALLS, S HRUBBERY, PRIVACY FENCES ETC. MINIMUM CLEARANCE

BETWEEN ADJACENT UNITS IS 72" (1828.8). RECOMMENDED SERVICE

CLEARANCE 48" (1219.2)

3. TOP DISCHARGE AREA SHOULD BE UNRESTRICTED FOR 100" (2540)

MINIMUM. UNIT SHOULD BE PLACED SO ROOF RUN-OFF WATER DOES

NOT POUR DIRECTLY ON UNIT

4. OUTDOOR AIR TEMPERATURE SENSOR OPENING (DO NOT BLOCK OPENING)

LIQUID LINE

SUCTION LINE

SERVICE P ANEL SIDE

SERVICE CLEARANCE

48" (1219.2) (S EE NOTE 2

FOR CLEARANCE

HAIL GUARD

(OPTIONAL)

SERVICE PANEL

SEE NOTE 3

HAIL GUARD

(OPTIONAL)

SERVICE P ANEL

CONTROL WIRING

LINE VOLTAGE

REFRIGERANT ACCES S

SEE NOTE 1

SEE NOTE 4

WITH HAIL GUARD

WITH HAIL GUARD

6" (152. 4)

DDiimmeennssiioonnaall DDaattaa

Figure 4. 10 ton heat pump, single compressor

12

SSP-SVX15C-EN

Page 13

Figure 5. 15, 20 ton heat pump, dual compressor

BOTTOM OF UNIT

1/16"

(1.6)

9"

(228.6)

9"

(228.6)

25 11/16"

(652.5)

46"

(1168. 4)

93"

(2362.2)

87"

(2210)

41 1/ 2"

(1054 .1)

2 3/16"

(55.6)

3" (76.2)

6 13/16"

(173)

36 7/8"

(936.6)

6 5/16" (160.3)

3 11/16" (94)

15/16" (23.8)

1 3/16" (30.2)

39 7/8"

(1012.8)

41 5/8"

(1057.3)

9 1/4" (235)

41 3/8"

(1051)

93 5/16"

(2370.1)

45 1/8"

(1146.2)

14 1/2"

(368.3)

14 5/8"

(371.5)

12 5/8"

(320.7)

5 5/8"

(143)

4 1/4"

(108)

6 13/16" (173)

95 7/16"

(2424.112)

44 3/16"

(1122.4)

LINE VOLTAGE

SUCTION LINES

REFRIGERANT ACCES S

LIQUID LINES

NOTES:

1. MINIMUM CLEARANCE FOR PROPER OPERATION IS 36" (914.4) FROM

WALLS, S HRUBBERY, P RIVACY FENCES ETC. MINIMUM CLEARANCE

BETWEEN ADJACENT UNITS IS 72" (1829). RECOMMENDED SERVICE

CLEARANCE 48" (1219.2)

2. TOP DISCHARGE AREA SHOULD BE UNRESTRICTED FOR 100" (2540)

MINIMUM. UNIT SHOULD BE PLACED SO ROOF RUN-OFF WATER DOES

NOT POUR DIRECTLY ON UNIT

3. OUTDOOR AIR TEMPERATURE SENSOR OPENING (DO NOT BLOCK OPENING).

7/16" (11.1) ( DIA. ISOLATOR MOUNTING

HOLES (OUTS IDE HOLES - 4 P LACES)

SERVICE PANEL SIDE

SERVICE CLEARANCE

48" (1219.2) (SEE NOTE 1

FOR CLEARANCE)

HAIL GUARD

(OPTIONAL)

HAIL GUARD

(OPTIONAL)

SER VICE

PANEL

DIMENSIONAL DETAIL

FRONT DETAIL A

SEE NOTE 2

HAIL GUARD

(OPTIONAL)

DETAIL A

SERVICE PANEL

CONTROL WIRING

WITH HAIL GUARD

SEE NOTE 3

WITH HAIL GUARD

DDiimmeennssiioonnaall DDaattaa

SSP-SVX15C-EN

13

Page 14

Weights

#1

#2

#3

#4

LIFTING HOLES (BOTH SIDES)

SE

RVICE

ACCESS

SERVICE

ACCES S

SERVICE

ACCES S

#1

#2

#3

#4

LIFTING HOLES

(BOTH S IDES)

Heat Pump Condenser

Table 1. TWA unit and corner weights — lbs (60 Hz)

Tons Model No.

7.5 TWA090A 394 340 117 86 58 79

10 TWA120A 509 438 127 121 72 118

15 TWA180B 898 765 202 192 181 190

20 TWA240B 981 848 254 266 147 181

Shipping

Max (lbs)

Net Max

(lbs)

1 2 3 4

Corner Weights

Figure 6. TWA090, 120

Figure 7. TWA180, 240

14

SSP-SVX15C-EN

Page 15

Installation

Contact manufacturer for review

Accep table liquid-riser height

based on total liquid -line length

(TTA below indoor unit)

Contact manufacturer for review

Refrigerant Piping Guidelines

Figure 8. Allowable elevation difference: Cooling only TTA above indoor unit

Figure 9. Allowable elevation difference: TTA below indoor unit

NNoottee:: Route refrigerant piping for minimum linear length, minimum number of bends and fittings (no reducers) and

minimum amount of line exposed to outdoor ambients.

SSP-SVX15C-EN

15

Page 16

IInnssttaallllaattiioonn

Refrigerant Piping Procedures (Outdoor Units)

WWAARRNNIINNGG

RR--441100AA RReeffrriiggeerraanntt uunnddeerr HHiigghheerr

PPrreessssuurree tthhaann RR--2222!!

FFaaiilluurree ttoo uussee pprrooppeerr eeqquuiippmmeenntt oorr ccoommppoonneennttss aass

ddeessccrriibbeedd bbeellooww,, ccoouulldd rreessuulltt iinn eeqquuiippmmeenntt ffaaiilliinngg

aanndd ppoossssiibbllyy eexxppllooddiinngg,, wwhhiicchh ccoouulldd rreessuulltt iinn

ddeeaatthh,, sseerriioouuss iinnjjuurryy,, oorr eeqquuiippmmeenntt ddaammaaggee..

TThhee uunniittss ddeessccrriibbeedd iinn tthhiiss mmaannuuaall uussee RR--441100AA

rreeffrriiggeerraanntt wwhhiicchh ooppeerraatteess aatt hhiigghheerr pprreessssuurreess

tthhaann RR--2222.. UUssee OONNLLYY RR--441100AA rraatteedd sseerrvviiccee

eeqquuiippmmeenntt oorr ccoommppoonneennttss wwiitthh tthheessee uunniittss.. FFoorr

ssppeecciiffiicc hhaannddlliinngg ccoonncceerrnnss wwiitthh RR--441100AA,, pplleeaassee

ccoonnttaacctt yyoouurr llooccaall TTrraannee rreepprreesseennttaattiivvee..

Each TTA unit ships with a holding charge of dry

nitrogen. The nitrogen should be removed and the

entire system evacuated (at the proper time) to avoid

possible contamination.

1. Remove the compressor service access panel.

2. Locate the liquid and suction line service valves.

Check that the piping connection stubs on the

valves (Figure 10, p. 16) line up properly with the

holes in the unit cabinet.

Figure 10. Outdoor units - refrigerant piping (with dry

nitrogen)

NNOOTTIICCEE

SSyysstteemm CCoommppoonneenntt DDaammaaggee!!

DDoo nnoott rreemmoovvee tthhee sseeaall ccaappss ffrroomm rreeffrriiggeerraanntt

ccoonnnneeccttiioonnss,, oorr ooppeenn tthhee sseerrvviiccee vvaallvveess uunnttiill

pprreeppaarreedd ttoo bbrraazzee rreeffrriiggeerraanntt lliinneess ttoo tthhee

ccoonnnneeccttiioonnss.. EExxcceessssiivvee eexxppoossuurree ttoo aattmmoosspphheerree ((>>

55 mmiinn..)) mmaayy aallllooww mmooiissttuurree oorr ddiirrtt ttoo ccoonnttaammiinnaattee

tthhee ssyysstteemm,, ddaammaaggiinngg vvaallvvee sseeaallss aanndd ccaauussiinngg iiccee

ffoorrmmaattiioonn iinn ssyysstteemm ccoommppoonneennttss..

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn aanndd DDeeaaddllyy

GGaasseess!!

FFaaiilluurree ttoo ffoollllooww aallll pprrooppeerr ssaaffee rreeffrriiggeerraanntt

hhaannddlliinngg pprraaccttiicceess ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss

iinnjjuurryy..

NNeevveerr ssoollddeerr,, bbrraazzee oorr wweelldd oonn rreeffrriiggeerraanntt lliinneess oorr

aannyy uunniitt ccoommppoonneennttss tthhaatt aarree aabboovvee aattmmoosspphheerriicc

pprreessssuurree oorr wwhheerree rreeffrriiggeerraanntt mmaayy bbee pprreesseenntt..

AAllwwaayyss rreemmoovvee rreeffrriiggeerraanntt bbyy ffoolllloowwiinngg tthhee

gguuiiddeelliinneess eessttaabblliisshheedd bbyy tthhee EEPPAA FFeeddeerraall CClleeaann

AAiirr AAcctt oorr ootthheerr ssttaattee oorr llooccaall ccooddeess aass aapppprroopprriiaattee..

AAfftteerr rreeffrriiggeerraanntt rreemmoovvaall,, uussee ddrryy nniittrrooggeenn ttoo

bbrriinngg ssyysstteemm bbaacckk ttoo aattmmoosspphheerriicc pprreessssuurree bbeeffoorree

ooppeenniinngg ssyysstteemm ffoorr rreeppaaiirrss.. MMiixxttuurreess ooff

rreeffrriiggeerraannttss aanndd aaiirr uunnddeerr pprreessssuurree mmaayy bbeeccoommee

ccoommbbuussttiibbllee iinn tthhee pprreesseennccee ooff aann iiggnniittiioonn ssoouurrccee

lleeaaddiinngg ttoo aann eexxpplloossiioonn.. EExxcceessssiivvee hheeaatt ffrroomm

ssoollddeerriinngg,, bbrraazziinngg oorr wweellddiinngg wwiitthh rreeffrriiggeerraanntt

vvaappoorrss pprreesseenntt ccaann ffoorrmm hhiigghhllyy ttooxxiicc ggaasseess aanndd

eexxttrreemmeellyy ccoorrrroossiivvee aacciiddss..

3. Remove the refrigerant connection seal caps and

open the service valve slowly to release the

nitrogen from the unit.

4. Cut, fit and braze tubing, starting at the outdoor unit

and work toward the indoor unit. See

recommended tube sizes, Table 3, p. 18.

NNoottee:: Use long radius ells for all 90° bends.

All brazing should be done using a 2 to 3 psig dry

nitrogen purge flowing through the pipe being

brazed, see Figure 10, p. 16.

NNOOTTIICCEE

SSyysstteemm CCoommppoonneenntt DDaammaaggee!!

IInnssttaallll aa rreegguullaattiinngg vvaallvvee bbeettwweeeenn tthhee nniittrrooggeenn

ssoouurrccee aanndd tthhee ggaauuggee mmaanniiffoolldd.. UUnnrreegguullaatteedd

pprreessssuurree ccaann ddaammaaggee ssyysstteemm ccoommppoonneennttss..

NNOOTTIICCEE

SSyysstteemm CCoommppoonneenntt DDaammaaggee!!

WWeett--wwrraapp aallll vvaallvveess aanndd pprrootteecctt ppaaiinntteedd ssuurrffaacceess

ffrroomm eexxcceessssiivvee hheeaatt.. HHeeaatt ccaann ddaammaaggee ssyysstteemm

ccoommppoonneennttss aanndd tthhee uunniitt ffiinniisshh..

5. Shut off nitrogen supply. Shut off the manifold

valve for the line that is connected to the suction

line service valve. Disconnect the line from the

gauge port on the valve.

16

SSP-SVX15C-EN

Page 17

IInnssttaallllaattiioonn

Refrigerant Piping Procedures (Indoor Unit)

Once liquid and suction lines are complete to the

refrigerant connections on the indoor unit, remove the

gauge port core(s) on the indoor unit connection stubs

to release the dry nitrogen charge.

NNOOTTIICCEE

UUnniitt DDaammaaggee!!

DDoo nnoott aappppllyy hheeaatt ttoo rreemmoovvee sseeaall ccaappss uunnttiill tthhee

ggaauuggee ppoorrtt ccoorreess hhaavvee bbeeeenn rreemmoovveedd.. IIff sseeaall ccaappss

aarree iinnttaacctt,, aapppplliiccaattiioonn ooff hheeaatt mmaayy ggeenneerraattee

eexxcceessssiivvee pprreessssuurree iinn tthhee uunniitt aanndd rreessuulltt iinn

ddaammaaggee ttoo tthhee ccooiill oorr eexxppaannssiioonn vvaallvvee..

1. Remove both seal caps from the indoor unit

connection stubs.

NNOOTTIICCEE

UUnniitt DDaammaaggee!!

DDoo nnoott rreemmoovvee tthhee sseeaall ccaappss ffrroomm rreeffrriiggeerraanntt

ccoonnnneeccttiioonnss,, oorr ooppeenn tthhee sseerrvviiccee vvaallvveess uunnttiill

pprreeppaarreedd ttoo bbrraazzee rreeffrriiggeerraanntt lliinneess ttoo tthhee

ccoonnnneeccttiioonnss..

2. Turn on nitrogen supply. Nitrogen enters through

the liquid line gauge port.

3. Braze the liquid line connections.

4. Open the gauge port on the suction line and then

braze the suction line to the connection stub.

Nitrogen will bleed out the open gauge port on the

suction line.

5. Shut off nitrogen supply.

Leak Check

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

FFaaiilluurree ttoo ffoollllooww rreeccoommmmeennddeedd ssaaffee lleeaakk tteesstt

pprroocceedduurreess ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy

oorr eeqquuiippmmeenntt oorr pprrooppeerrttyy--oonnllyy--ddaammaaggee..

NNeevveerr uussee aann ooppeenn ffllaammee ttoo ddeetteecctt ggaass lleeaakkss.. UUssee aa

lleeaakk tteesstt ssoolluuttiioonn ffoorr lleeaakk tteessttiinngg..

After the brazing operation of refrigerant lines to both

the outdoor and indoor unit is completed, the field

brazed connections must be checked for leaks.

Pressurize the system through the service valve with

dry nitrogen to 200 psi. Use soap bubbles or other leakchecking methods to ensure that all field joints are leak

free. If not, release pressure, repair and repeat leak test.

System Evacuation

1. After completion of leak check, evacuate the

system.

2. Attach appropriate hoses from manifold gauge to

gas and liquid line pressure taps.

NNoottee:: Unnecessary switching of hoses can be

avoided and complete evacuation of all lines

leading to sealed system can be

accomplished with manifold center hose and

connecting branch hose to a cylinder of R–22

and vacuum pump.

3. Attach center hose of manifold gauges to vacuum

pump.

NNOOTTIICCEE

OOppeerraattiinngg UUnnddeerr VVaaccuuuumm!!

DDoo nnoott ooppeerraattee oorr aappppllyy ppoowweerr ttoo tthhee ccoommpprreessssoorr

wwhhiillee uunnddeerr aa vvaaccuuuumm.. FFaaiilluurree ttoo ffoollllooww tthheessee

iinnssttrruuccttiioonnss wwiillll rreessuulltt iinn ccoommpprreessssoorr ffaaiilluurree..

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

FFaaiilluurree ttoo ffoollllooww tthheessee rreeccoommmmeennddaattiioonnss ccoouulldd

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy oorr eeqquuiippmmeenntt oorr

pprrooppeerrttyy--oonnllyy ddaammaaggee..

UUssee oonnllyy ddrryy nniittrrooggeenn wwiitthh aa pprreessssuurree rreegguullaattoorr ffoorr

pprreessssuurriizziinngg uunniitt.. DDoo nnoott uussee aacceettyylleennee,, ooxxyyggeenn oorr

ccoommpprreesssseedd aaiirr oorr mmiixxttuurreess ccoonnttaaiinniinngg tthheemm ffoorr

pprreessssuurree tteessttiinngg.. DDoo nnoott uussee mmiixxttuurreess ooff aa

hhyyddrrooggeenn ccoonnttaaiinniinngg rreeffrriiggeerraanntt aanndd aaiirr aabboovvee

aattmmoosspphheerriicc pprreessssuurree ffoorr pprreessssuurree tteessttiinngg aass tthheeyy

mmaayy bbeeccoommee ffllaammmmaabbllee aanndd ccoouulldd rreessuulltt iinn aann

eexxpplloossiioonn.. RReeffrriiggeerraanntt,, wwhheenn uusseedd aass aa ttrraaccee ggaass

sshhoouulldd oonnllyy bbee mmiixxeedd wwiitthh ddrryy nniittrrooggeenn ffoorr

pprreessssuurriizziinngg uunniittss..

SSP-SVX15C-EN

4. Evacuate the system to hold a 500 micron vacuum.

5. Close off valve to vacuum pump and observe the

micron gauge. If gauge pressure rises above 500

microns in one minute, then evacuation is

incomplete or the system has a leak.

6. If vacuum gauge does not rise above 500 microns in

10 minutes, the evacuation should be complete.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

CChhaarrggee wwiitthh aacccceessss ppoorrtt oonn tthhee lliiqquuiidd lliinnee sseerrvviiccee

vvaallvvee oonnllyy..

7. With vacuum pump and micron gauge blanked off,

open valve on R–22 cylinder and allow refrigerant

pressure to build up to about 80 psig.

8. Close valve on the R–22 supply cylinder. Close

valves on manifold gauge set and remove

refrigerant charging hoses from liquid and gas

17

Page 18

IInnssttaallllaattiioonn

gauge ports.

9. Leak test the entire system. Using proper

procedures and caution, as described in the

previous section, repair any leaks found and repeat

the leak test.

Insulating and Isolating Refrigerant Lines

Insulate the entire suction line with refrigerant piping

insulation. Also insulate any portion of the liquid line

exposed to temperature extremes. Insulate and isolate

liquid and suction lines from each other. Isolate

refrigerant lines from the structure and any duct work.

IImmppoorrttaanntt::

1. To prevent possible noise or vibration

problems, be certain to isolate

refrigerant lines from the building.

2. All suction and hot gas bypass piping (if

installed) should be insulated from the

termination in the air handler to the

condensing unit cabinet entry. Failure to

do so can cause condensate drip off and

performance degradation.

3. Prior to starting a unit, it is advisable to

have the approved oils available in the

event oil needs to be added to the

system.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

TThhiiss iiss PPOOEE ooiill,, wwhhiicchh rreeaaddiillyy aabbssoorrbbss mmooiissttuurree..

AAllwwaayyss uussee nneeww ooiill aanndd nneevveerr lleeaavvee ccoonnttaaiinneerrss

ooppeenn ttoo aattmmoosspphheerree wwhhiillee nnoott iinn uussee..

Refrigerant Charging Procedure

If charging by weight, refer to Table 3, p. 18 for starting

change. If refrigerant adjustments are needed because

of length of line, refer to ”Charging Charts and

Superheat,” p. 25.

Charge by weight through the gauge port on the liquid

line. Once the charge enters the system, backseat

(open) the liquid line service valve and disconnect the

charging line and replace the cap on the gauge port.

NNootteess::

• R-22 should only be charged in the liquid

state.

• When possible, always charge the

refrigerant into the liquid line of the unit.

• If the entire charge can’t be charged into the

liquid line, the balance of the unit charge can

be metered through a charging manifold set

as liquid — preferably through a schrader

valve into the suction line to the compressor

— only while the compressor is running.

• Check and adjust superheat using Table 6, p.

25, then re-check charging charts to

determine if charge corrections are

necessary.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

NNeevveerr cchhaarrggee lliiqquuiidd rreeffrriiggeerraanntt iinnttoo tthhee ssuuccttiioonn

lliinnee ooff tthhee uunniitt wwiitthh tthhee ccoommpprreessssoorr ooffff..

Figure 11. Outdoor units - refrigerant piping

Table 2. R-22 TWA approved oils

Unit Model Number

TWA090A, TWA120A,

TWA180B, TWA240B

For units equipped with compressors containing site

glasses, the oil level must be visible through the sight

glass when the compressor is running under stabilized

conditions and a few minutes after the compressor has

stopped.

18

Approved Oils

Trane Oil Part Number OIL00027

(1 quart container)

SSP-SVX15C-EN

Page 19

Table 3. Estimated charge levels at ARI rated line lengths (25 feet)

IInnssttaallllaattiioonn

Refrigerant Charge

Matched Set

TWA090A w/TWE090A

TWA120A w/TWE120A

TWA180B w/ TWE180B

TWA240B w/ TWE240B

Circuit 1 Circuit 2

20.6 NA

27.9 NA

22.9 24.2

23.5 23.5

Liquid Charging

This procedure is accomplished with the unit

operating. Electrical connections must be complete. Do

not proceed until the system is ready to operate.

NNoottee:: The compressor access panel must be installed

when the unit is running and being charged.

Manifold hoses must be routed through

refrigerant gauge access hole(s). See

”Dimensional Data,” p. 10 for specific locations.

WWAARRNNIINNGG

LLiivvee EElleeccttrriiccaall CCoommppoonneennttss!!

FFaaiilluurree ttoo ffoollllooww aallll eelleeccttrriiccaall ssaaffeettyy pprreeccaauuttiioonnss

wwhheenn eexxppoosseedd ttoo lliivvee eelleeccttrriiccaall ccoommppoonneennttss ccoouulldd

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

WWhheenn iitt iiss nneecceessssaarryy ttoo wwoorrkk wwiitthh lliivvee eelleeccttrriiccaall

ccoommppoonneennttss,, hhaavvee aa qquuaalliiffiieedd lliicceennsseedd eelleeccttrriicciiaann

oorr ootthheerr iinnddiivviidduuaall wwhhoo hhaass bbeeeenn pprrooppeerrllyy ttrraaiinneedd

iinn hhaannddlliinngg lliivvee eelleeccttrriiccaall ccoommppoonneennttss ppeerrffoorrmm

tthheessee ttaasskkss..

1. Turn on power to the unit. Allow the system to run

for 15 minutes to stabilize operating conditions.

2. Measure airflow across the indoor coil. Compare

the measurements with the fan performance data in

the Data/Submittal or Service Facts. Once proper

airflow is established, compare discharge pressure

and liquid temperature to the ”Charging Charts,” p.

25. Add or remove refrigerant (liquid only) as

required to obtain correct discharge pressure and

liquid temperature.

3. Check suction line superheat and condenser subcooling to ensure the unit is operating properly.

4. Disconnect all power to the unit.

IImmppoorrttaanntt:: If the unit is charged and left without

power until a later date, the crankcase

heater should be energized for a

minimum of 8 hours prior to powering

the compressor(s).

Per Circuit

Liquid Line

Diameter

0.625 (5/8”) 1.375 (1 3/8”)

0.5 (1/2”) 1.375 (1 3/8”)

0.5 (1/2") 1.375 (1 3/8")

0.625 (5/8") 1.375 (1 3/8")

Vapor Line

Diameter

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee ww//CCaappaacciittoorrss!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr aanndd ddiisscchhaarrggee

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss aanndd ddiisscchhaarrggee aallll mmoottoorr ssttaarrtt//rruunn

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr lloocckkoouutt//

ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr ccaannnnoott bbee

iinnaaddvveerrtteennttllyy eenneerrggiizzeedd.. FFoorr vvaarriiaabbllee ffrreeqquueennccyy

ddrriivveess oorr ootthheerr eenneerrggyy ssttoorriinngg ccoommppoonneennttss

pprroovviiddeedd bbyy TTrraannee oorr ootthheerrss,, rreeffeerr ttoo tthhee

aapppprroopprriiaattee mmaannuuffaaccttuurreerr’’ss lliitteerraattuurree ffoorr

aalllloowwaabbllee wwaaiittiinngg ppeerriiooddss ffoorr ddiisscchhaarrggee ooff

ccaappaacciittoorrss.. VVeerriiffyy wwiitthh aann aapppprroopprriiaattee vvoollttmmeetteerr

tthhaatt aallll ccaappaacciittoorrss hhaavvee ddiisscchhaarrggeedd..

FFoorr aaddddiittiioonnaall iinnffoorrmmaattiioonn rreeggaarrddiinngg tthhee ssaaffee

ddiisscchhaarrggee ooff ccaappaacciittoorrss,, sseeee PPRROODD--SSVVBB0066AA--EENN..

5. Remove the charging system from the unit.

6. Replace all panels.

Electrical Wiring

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee eelleeccttrriiccaall ccooddeess..

Field wiring consists of providing power supply to the

unit, installing the system indoor thermostat and

providing low voltage system interconnecting wiring.

Access to electrical connection locations is shown in

”Dimensional Data,” p. 10. Determine proper wire sizes

and unit protective fusing requirements by referring to

the unit nameplate and/or the unit Service Facts. Field

SSP-SVX15C-EN

19

Page 20

NSB P anel

Zone

Sensor

T’stat

Air Handler

Disconnect S witch

(By Others)

Disconnect S witch

(By Others) Note 2

Electric

Heat Accessory

Disconnect S witch

(By Others)

Note 2

B

A

B

D

F

EC

IInnssttaallllaattiioonn

wiring diagrams for accessories are shipped with the

accessory.

Unit Power Supply

The installer must provide line voltage circuit(s) to the

unit main power terminals as shown by the unit wiring

diagrams (available through e-Library or by contacting

a local sales office) or field wiring. Power supply must

include a disconnect switch in a location convenient to

the unit. Ground the unit according to local codes and

provide flexible conduit if codes require and/or if

vibration transmission may cause noise problems.

IImmppoorrttaanntt:: All wiring must comply with applicable

local and national (NEC) codes. Type and

location of disconnect switches must

comply with all applicable codes.

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy..

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell.. IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss.. TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee eelleeccttrriiccaall ccooddeess..

ReliaTel™™ Controls

Wiring shown with dashed lines is to be furnished and

installed by the customer. All customer supplied wiring

must be copper only and must conform to NEC and

local electrical codes. Codes may require line of sight

between disconnect switch and unit.

NNootteess::

1. When electric heater accessory is used,

single point power entry or dual point power

entry is field optional. Single point power

entry option is through electric heater only.

2. ***Choose only one of the following;

Thermostat, Zone Sensor, or NSB Panel.

Figure 12. ReliaTel jobsite connections

NNOOTTIICCEE

UUssee CCooppppeerr CCoonndduuccttoorrss OOnnllyy!!

FFaaiilluurree ttoo uussee ccooppppeerr ccoonndduuccttoorrss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee aass uunniitt tteerrmmiinnaallss aarree nnoott

ddeessiiggnneedd ttoo aacccceepptt ootthheerr ttyyppeess ooff ccoonndduuccttoorrss..

Low Voltage Wiring

Mount the indoor thermostat, zone sensor, or Night

Setback Panel (NSB) in accordance with the

corresponding thermostat installation instructions.

Install color-coded, weather-proof, multi-wire cable

according to the field wiring schematics (see ”Field

Wiring”, p. 21).

20

A.

3 power wires, line voltage for 3 phase, (2 power wires for

single phase)

B. 3 power wires, line voltage for 3 phase, (2 power wires for

single phase)

C. Heat Pump thermostat: 5 to 8 wires depending on stages of

electric heat

D. 3 to 7 wires depending on type of outdoor unit(s)

E. Zone Sensor: 4 to 10 wires depending on zone sensor model

F. Night Setback Panel: 7 wires

(a)

For SZVAV air handlers: 4 additional wires are required (2 of which

require twisted pair or shielded wire) in order to make connections

between ReliaTel boards in the condenser and air handler.

SSP-SVX15C-EN

(a)

Page 21

Field Wiring

Figure 13. Night setback panel field wiring

IInnssttaallllaattiioonn

Figure 14. Zone sensor field wiring

SSP-SVX15C-EN

21

Page 22

X

X

Note A

Note A

S

D

COMPRESSOR

Note A

OUTDOOR COIL

INDOOR COIL

AIR

AIR

TXV

Note A

FILTER DRIER

TXV

FIELD SUPPLIED

INTER-CONNECTING

TUBING

EQUALIZER

TUBE

EXPANSION

VALVE BULB

CHECK

VALVES

GAUGE

CONNECTION

HIGH PRESSURE

SWITCH (HPCO)

DISCHARGE TEMPERATURE

LIMIT(DTL)

LOW PRESSURE

SWITCH (LPCO)

SERVICE

VALVE

SERVICE

VALVE

EXPANSION

VALVE BULB

4-WAY

SWITCHOVER

VALVE

EQUALIZER

LINE

NOTE A: ONLY ONE OUTDOOR AND INDOOR

COIL REFRIGERANT ENTRY AND

EXIT CIRCUIT IS SHOWN. ALL

MODELS HAVE MULTIPLE ENTRY

AND EXIT CIRCUITS.

HEAT PUMP CIRCUIT DIAGRAM

COOLING MODE

INDICATES DIRECTION OF

REFRIGERANT FLOW

NOTE B: DUAL CIRCUIT MODELS HAVE 2

REFRIGERATION CIRCUITS.

V

V

IInnssttaallllaattiioonn

Figure 15. Thermostat field wiring

Refrigerant Circuit

Figure 16. Typical split system heat pump - cooling - refrigerant circuit

22

SSP-SVX15C-EN

Page 23

Figure 17. Typical split system heat pump - heating - refrigerant circuit

NOTE A

TXV

S

D

COMPRESSOR

NOTE A

NOTE A

FIELD SUPPLIED

INTER-CONNECTING

TUBING

EQUALIZER

LINE

OUTDOOR COIL

INDOOR COIL

AIR HANDLER

AIR

AIR

TXV

SERVICE

VALVE

EXPANSION

VALVE BULB

SERVICE

VALVE

GAUGE

CONNECTIONS

DISCHARGE TEMPERATURE

LIMIT (DTL)

HIGH PRESSURE

SWITCH (HPCO)

DE-ICE LOOP

NOTE A

CHECK

VALVES

4-WAY

SWITCHOVER

VALVE

LOW PRESSURE SWITCH

(LPCO)

EQUALIZER

LINE

NOTE A: ONLY ONE OUTDOOR AND INDOOR

COIL REFRIGERANT ENTRY AND

EXIT CIRCUIT IS SHOWN. ALL

MODELS HAVE MULTIPLE ENTRY

AND EXIT CIRCUITS.

INDICATES DIRECTION OF

REFRIGERANT FLOW

HEAT PUMP CIRCUIT DIAGRAM

HEATING MODE

NOTE B: DUAL CIRCUIT MODELS HAVE 2

REFRIGERATION CIRCUITS.

V

V

FILTER DRIER

IInnssttaallllaattiioonn

SSP-SVX15C-EN

23

Page 24

Electrical Data

Table 4. Electrical characteristics — motors — heat pumps — 60 Hz

Compressor Motor

Unit Model

Tons

Number

TWA090A3 1 208-230 3 22.4 164 1 208-230 1 3.1 8.1

7.5

TWA090A4 1 460 3 10.9 100 1 460 1 1.6 3.8

TWA120A3 1 208-230 3 30.1 225 1 208-230 1 5.0 14.4

10

TWA120A4 1 460 3 15.5 114 1 460 1 2.5 5.8

TWA180B3 1 208-230 3 22.4 164 2 208-230 2 5.0 14.4

15

TWA180B4 1 460 3 10.9 100 2 460 2 2.5 5.8

TWA240B3 1 208-230 3 30.1 225 2 208-230 2 5.0 14.4

20

TWA240B4 1 460 3 15.5 114 2 460 2 2.5 5.8

Note: Electrical characteristics reflect nameplate values and are calculated in accordance with cULus and ARI

specifications.

No. Volts Phase

Amps

RLA LRA FLA LRA

(Ea.) (Ea.) (Ea.) (Ea.)

Table 5. Unit wiring — heat pumps — 60 Hz

Tons

7.5

10

15

20

Note: HACR type circuit breaker per NEC.

Unit Model

Number

TWA090A3 187-253 31.1 45

TWA090A4 414-506 15.2 25

TWA120A3 187-253 42.6 60

TWA120A4 414-506 21.9 30

TWA180B3 187-253 60.4 80

TWA180B4 414-506 29.5 40

TWA240B3 187-253 77.7 100

TWA240B4 414-506 39.9 50

Unit Operating

Voltage Range

Minimum Circuit

Ampacity

Condenser Fan Motor

Amps

No. Volts Phase

Maximum Fuse or HACR

Circuit Breaker Size

24

SSP-SVX15C-EN

Page 25

Charging Charts and Superheat

25

150

175

200

225

250

275

300

325

350

375

400

55 6 0 65 70 7 5 80 85 90 95 100 105 110 115 120 125 130 135 140

Discharg e P re ss u re, ps ig

Liqu id Te mp era tu re Le av ing OD Co il, °F

TWA090A Charging Curve

A

dd c ha rg e

em ove

ch arge

25

150

175

200

225

250

275

300

325

350

375

400

425

55 6 0 65 70 7 5 80 85 90 95 100 105 110 115 120 125 130 135 140

Discharg e P re ss u re, ps ig

Liqu id Te mp era tu re Le av ing OD Co il, °F

TWA120A Charging Curve

A

dd c ha rg e

em ove

ch arge

25

150

175

200

225

250

275

300

325

350

375

400

425

55 6 0 65 70 7 5 80 85 90 95 100 105 110 115 120 125 130 135 140

Discharg e P re ss u re, ps ig

Liqu id Te mp era tu re Le av ing OD Co il, °F

TWA180B Charg ing Curve

A

dd c ha rg e

em ove

ch arge

25

150

175

200

225

250

275

300

325

350

375

400

425

55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 1 30 135 140

Discharg e P ress ur e, p s ig

Liqu id Te mpera ture Le aving OD Co il, °F

TWA240B Charg ing Cu rve

A

dd c ha rge

em ove

ch ar ge

Figure 18. TWA090A

Figure 19. TWA120A

Figure 20. TWA180B

Figure 21. TWA240B

Table 6. TWA superheat with matched TWE air handler

Condenser Air Handler

TWA090A TWE090A 16.0 — 15.7 —

TWA120A TWE120A 16.3 — 13.1 —

TWA180B TWE180B 15.5 15.5 12.2 12.2

TWA240B TWE240B 14.7 14.7 11.4 11.4

Notes:

1. An adjustable TXV is provided for each circuit in the TWE and TWA models. If the application causes the superheat to deviate from the values shown

above by more than 1 degree - after the system has achieved steady state - the TXV should be adjusted to provide the values shown as measured at

the compressor.

2. The values given above have been tested and are approved for the matched sets shown. If an alternate combination is used, an expansion device

should be used that provides 16-20°F degrees of superheat measured at the compressor.

3. Check and adjust superheat using this table, then compare with charging chart to determine if charge corrections are necessary.

SSP-SVX15C-EN

Cooling Superheat Heating Superheat

Circuit 1 Circuit 2 Circuit 1 Circuit 2

25

Page 26

Installation Checklist

Complete this checklist once the unit is installed to

verify that all recommended procedures have been

accomplished before starting the system. Do not

operate the system until all items covered by this

checklist are complete.

Inspect unit location for proper required service

clearances.

Inspect unit location for proper free air clearances.

Inspect unit location for secure, level mounting

position.

Refrigerant Piping

Properly sized/constructed liquid and suction lines

connected to stubs at both the indoor and outdoor

units?

Insulated the entire suction line?

Insulated portions of liquid line exposed to

extremes in temperature?

Performed initial leak test?

Evacuated each refrigerant circuit to 500 microns?

Charged each circuit with proper amount of R-22?

Electrical Wiring

Provided unit power wiring (with disconnect) to

proper terminals in the unit control section?

Installed system indoor thermostat?

Installed system low voltage interconnecting wiring

to proper terminals of outdoor unit, indoor unit and

system thermostat?

26

SSP-SVX15C-EN

Page 27

Pre-Start

Control Circuit Features

NNoottee:: Not all of these features may be required for your

unit, check electrical schematic.

Discharge Temperature Limit (DTL)

The control’s sensor is located on the discharge line.

This device will shut off the compressor and the

outdoor fan(s) if the discharge temperature exceeds the

DTL setting. Once the discharge temperature has

returned to normal, the compressor will cycle back on.

Evaporator Defrost Control (EDC)

This control is located in the Air Handler. The control’s

sensing tube is embedded vertically in the evaporator

coil, near the center. This device will stop the

compressor if the indoor coil temperature drops below

its setting. The indoor air will still circulate across the

coil bringing the temperature of the coil back up to the

cut-in temperature of the evaporator defrost control.

Low Pressure Cut-Out (LPCO)

This control’s sensor is located in the suction (gas) line,

near the compressor. This control will stop the

compressor and the outdoor fans if suction pressure

drops below the Low Pressure Cut-Out setting. Once

the suction pressure has returned to normal, the

compressor and outdoor fans will cycle back on.

High Pressure Cut-Out (HPCO)

This control’s sensor is located in the discharge line.

This device will shut off the compressor and the

outdoor fan(s) if the discharge pressure exceeds the

High Pressure Cut-Out’s setting. Once the discharge

pressure has returned to normal, the compressor will

cycle back on.

WWAARRNNIINNGG

PPrreevveenntt IInnjjuurryy!!

DDuuee ttoo aaggeennccyy ssaaffeettyy rreeqquuiirreemmeennttss,, nnoo sscchhrraaddeerr

ccoorree iiss ttoo bbee iinnssttaalllleedd bbeenneeaatthh tthhee HHPPCCOO.. RReemmoovvaall

ooff tthhee HHPPCCOO wwiitthhoouutt eevvaaccuuaattiinngg tthhee ssyysstteemm cchhaarrggee

ccoouulldd ccaauussee iinnjjuurryy aanndd rreelleeaassee ooff rreeffrriiggeerraanntt..

Internal Overload Protector (IOL)

This device is embedded in the compressor. It will shut

off the compressor if the discharge temperature of the

compressor exceeds its design trip temperature.

NNoottee:: The IOL will put the compressor back in

operation once the compressor motor heat has

dropped below the trip setting; however, a check

of the refrigerant and electrical systems should

be made to determine the cause and be

corrected.

SSP-SVX15C-EN

27

Page 28

Start-Up

ReliaTel™™ Controls

The ReliaTel™ Control is a microelectronic control

feature, which provides operating functions that are

significantly different than conventional

Electromechanical units. The ReliaTel™ Refrigeration

Module (RTRM) uses proportional/integral control

algorithms to perform specific unit functions that

govern the unit operation in response to application

conditions.

The RTRM provides compressor anti-short cycle (ASC)

timing functions through minimum““OOffff”” and ““OOnn””

timing to increase reliability, performance and to

maximize unit efficiency. Upon power initialization, the

RTRM performs self-diagnostic checks to insure that all

internal controls are functioning. It also checks the

configuration parameters against the components

connected to the system. The system LED located on

the RTRM module is turned ““OOnn”” within one second

after power-up if all internal operations are correct.

The heating and cooling cycles of the heat pump are

automatic for Heat and Cool functions when using an

optional automatic changeover thermostat (TS).

The fan switch on the optional automatic changeover

thermostat can be placed in either the OONN position,

causing continuous evaporator (indoor) fan operation,

or the AAUUTTOO position causing fan operation to coincide

with heating or cooling run cycles. (In AAUUTTOO position,

the fan switch automatically changes to Heat or Cool in

response to sufficient room temperature change.)

Terminology

The following terms and acronyms may be used in this

section.

ASC

CC

CCH Crankcase Heater

CF

CHR

Anti-Short Cycle Timer

Compressor Contactor

Outdoor Fan Capacitor

Crankcase Heater Relay

COMM Communication Interface Module

CPR

CTS

DTL

EDC

FTB Outdoor Fan Terminal Block

HPC

HTB

LPC Low Pressure Cutout Switch

LTB

OAS

ODF

ODM Outdoor Fan Motor

PM Phase Monitor

RTRM

SOV Switchover Valve

TNS Transformer

Compressor

Coil Temperature Sensor

Discharge Temperature Limit Switch

Evaporator Defrost Control Switch

High Pressure Cutout Switch

High Voltage Terminal Block

Low Voltage Terminal Board

Outdoor Air Temperature Sensor

Outdoor Fan Relay

ReliaTel ™ Refrigeration Module

Functions and Features

These subsections describe the following key heat

pump functions and features:

• Processing Activated When the Disconnect Switch

is in OONN Position

• Mechanical Heat

• Auxiliary Heat

• Emergency Heat

• Cooling

• Demand Defrost

Processing Activated When the Disconnect

Switch is in the ON Position

The following table lists the processing that occurs

given the stated condition.

28

SSP-SVX15C-EN

Page 29

SSttaarrtt--UUpp

Condition

If the disconnect switch is in the

ON position…

Resulting Operations

1. Current is supplied to the compressor crankcase heater(s) (CCH) through the normally closed contacts

of the crankcase heater relay (CHR) when the compressor is not running.

2. The phase monitor (PM) is powered.

3. The phase monitor (PM) looks at the incoming power to verify that there is no reversed phase, no

phase imbalance, and no loss of phase. If the phase monitor detects any of these three conditions, it

will shut off control voltage.

4. The control transformer (TNS) is powered.

5. The ReliaTel ™ control board (RTRM) is powered and performs self-diagnostic checks to insure that all

internal controls are functioning.

6. The ReliaTel ™ control board (RTRM) checks the configuration parameters against the components

connected to the system.

7. The system LED located on the RTRM module is turned ON within one second after power-up if all

internal operations are correct.

8. The communications board (COMM) is powered if installed.

9. The indoor thermostat (TS) is powered.

Mechanical Heat

In Heat mode the switchover valve (SOV) is turned OOFFFF.

When a request for heating occurs, the control system

turns OONN the mechanical heat (compressors) to

perform heating. Dual circuit heat pumps are factory

configured to have 2-step mechanical heating enabled

(RTRM J4-3 tied to ground).

The staging sequence depends on the type of

mechanical heating that is enabled.

• If 1-Step mechanical heating is enabled (RTRM J4-3

not tied to ground), the unit will stage according to

Table 9, p. 31, as a result of the proportional/

integral control algorithms.

• Units with 2-step mechanical heating will stage

according to Table 10, p. 31, as a result of the

proportional/integral control algorithms.

With mechanical heating, when a heat request is turned

OONN, the Indoor Fan request is turned OONN. When the

heat request is turned OOFFFF, the Indoor Fan request is

turned OOFFFF after a specified delay (60 seconds on all

dual-compressor units and 80 seconds on all single

compressor units). See Table 7, p. 30, Table 8, p. 31,

Table 9, p. 31, and Table 10, p. 31 in this document for

the staging, sequence, and control.

Auxiliary Heat

Auxiliary Heat is factory disabled on all Odyssey units

(Jumper placed between J2-1 and J2-2 RTRM inputs). If

configured (Jumper wire cut or removed between J2-1

and J2-2 on RTRM) and installed, Auxiliary Heat is

enabled or disabled by Smart Recovery.

Smart Recovery

Smart Recovery dictates that if the Active Zone

Temperature is making a recovery using only

mechanical heating toward the setpoint at a rate of at

least 6°F/hour (0.1°F/minute), the electric heat is

disabled. If Smart Recovery is not disabling electric

heat, an approximate 9 minute stage-up delay (plus or

minus a few minutes) is provided for each stage to

allow time for recovery to begin. Stages of electric heat

are enabled and energized as necessary to meet

heating demand. When the request for Auxiliary Heat is

removed, the Indoor Fan request is turned OOFFFF at the

same time as the Electric Heat Stages. See Table 7, p.

30, Table 8, p. 31, Table 9, p. 31, and Table 10, p. 31 for

the staging, sequence, and control.

All split system units are also configured from the

factory for only 1-Stage of Electric Heat (Jumper placed

between J1-3 and J1-6 RTRM inputs). To enable two

stages of Electric Heat, cut or remove the jumper

between J1-3 and J1-6 RTRM inputs.

Emergency Heat

When Emergency Heat mode is requested and

Auxiliary Electric Heat is configured and installed, only

the Auxiliary Electric Heat will be turned OONN to satisfy

the Heat request. Mechanical heat will be held OOFFFF.

When the request for Emergency Heat is initiated, the

Indoor Fan request is turned OONN 1 second before the

electric heat stages are activated. See Table 7, p. 30,

Table 8, p. 31, Table 9, p. 31, and Table 10, p. 31for the

staging, sequence, and control.

Cooling

With a request for Cooling, the RTRM stages the

circuits and control normally for single and dual stage

SSP-SVX15C-EN

29

Page 30

SSttaarrtt--UUpp

cooling applications. If the unit is configured with a

zone sensor, switchover valve 1 (SOV1) and switchover

valve 2 (SOV2) are energized for the duration of the

Cooling mode and do not change states until the unit

either enters OOFFFF mode or transitions to Heat mode. If

the unit is controlled with a thermostat, SOV1 and

SOV2 are energized while the thermostat W1/O signal

output to the RTRM is active.

The outdoor fans (ODF) will turn OONN and OOFFFF with the

compressors. Circuit 1 fan cycles with compressor 1

and circuit 2 fan will cycle with compressor. If a

compressor is turned OOFFFF, the anti-short cycle timer

(ASC) will hold the compressor OOFFFF for 3 minutes. See

Table 7, p. 30, Table 8, p. 31, Table 9, p. 31, and Table

10, p. 31 for the staging, sequence, and control.

Demand Defrost

When power is first applied to the unit, the first

demand-defrost cycle will be initiated based on a

cumulative run time of exactly 30 minutes only at the

required conditions. The cumulative run time at the

required conditions is tracked separately for each

compressor.

Shortly after completion of the first defrost cycle, the

system control calculates the temperature difference

between the outdoor coil and outdoor air, using the

result as an indicator of unit performance at dry coil

conditions.

Conditions Triggering the Defrost Cycle

Over time, as moisture and frost accumulate on the

coil, the coil temperature will drop, increasing the

temperature difference. When the temperature

difference is large enough, a defrost cycle is initiated.

Demand Defrost is initiated when the outdoor air

temperature (OAS) is below 52°F and the outdoor coil

temperature (CTS) is below 33°F.

Single and Dual Circuits

When a circuit enters Defrost mode, the compressor