Trane TAM4A0A36S31SB, AAM4A0A18S11SA, TAM4A0A18S11SB, TAM4A0B42S31SB, TAM4A0C48S41SB Installation, Operation And Maintenance Manual

...Page 1

Page 2

Page 3

Page 4

Page 5

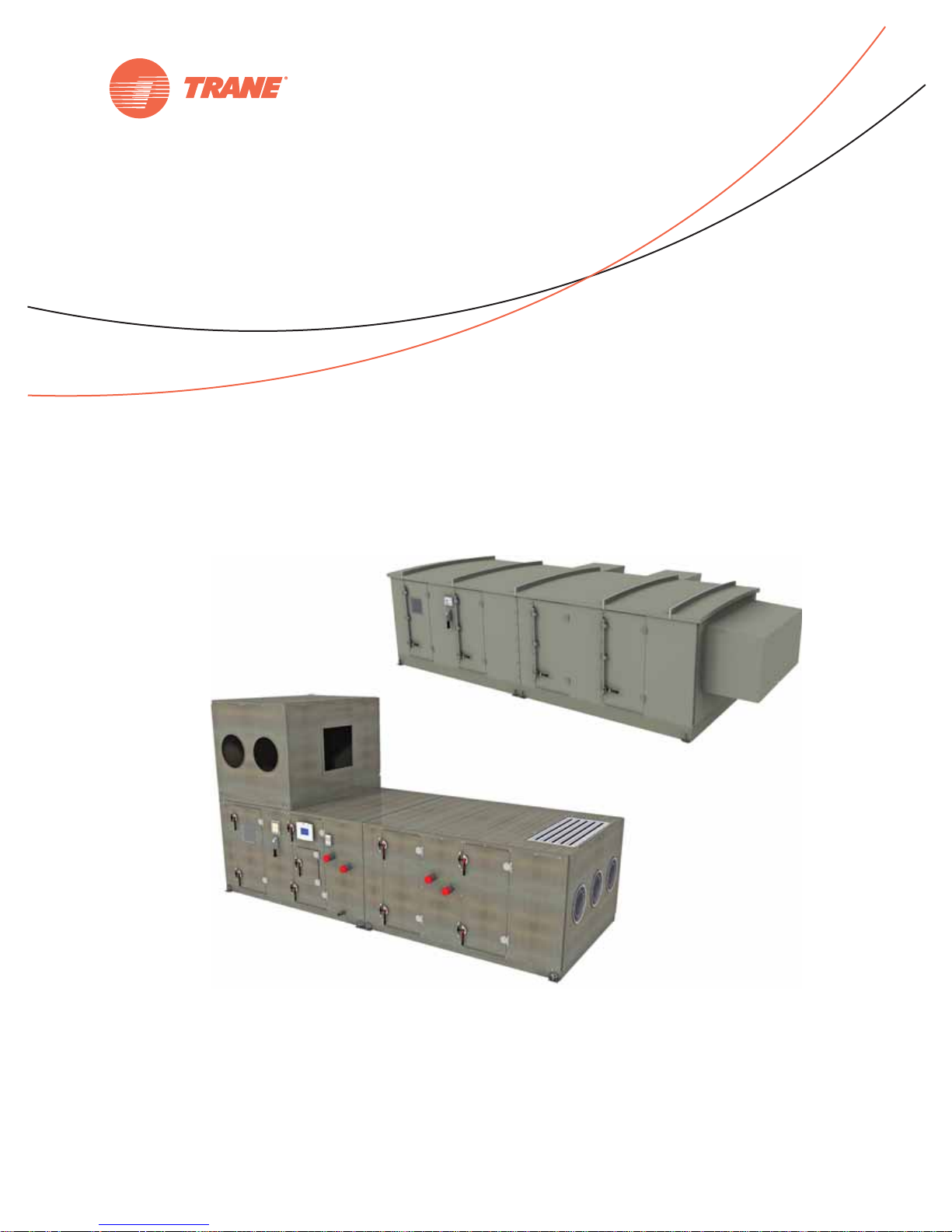

Installation, Operation

and Maintenance

Performance Climate Changer™ Air Handlers

Indoor and Outdoor Unit Sizes 3-120

SAFETY WARNING

Only qualified personnel should install and servi ce th e equi pmen t. The instal lation, star ti ng up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Impr oper ly instal led, adjust ed or alt er ed equipm ent by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that ar e attached to the equipment.

May 2011 CLCH-SVX07C-EN

X-39641152010

Page 6

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. W arnings are provided to alert installing contractors

to potential hazards that could result in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Y our personal safety and the proper operation of this mac hine depend upon the strict observance

of these precautions.

ATTENTION: Warnings, Cautions and Notices app ear at app rop riat e s ections th ro ugho ut

this literature. Read these carefully.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury . It could also be used to aler t against unsafe practices.

NOTICE: Indicates a situation that could result in equipment or property-damage-only

accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the ear th’s naturally

occurring stratospheric ozone layer when released to the atmosphere. In part icular , several of the

identified chemicals that may af fect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containin g Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all re frigerants-including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certai n refrigerants and the equipment th at is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

Ultraviolet (UV) Germicidal Irradiation Lights!

The United States Environmental Protection Agency (EP A) believes that molds and bacteria inside

buildings have the potential to cause health problems in sensitive individuals. If specified, Trane

provides ultraviolet lights (UV -C) as a factory-engineered and installed option in select commercial

air handling products for the purpose of reducin g mi cro bi ol og ical growth (mol d an d bacteria)

within the equipment. When factory provided, polymer materials that are susceptible to

deterioration by the UV -C light will be substituted or shielded from direct exposure to the light. In

addition, UV -C radiation can damage human tissue, namely eyes and skin. To reduce the potential

for inadvertent exposure to the lights by operating and maintenance personnel, electrical

interlocks that automatically disconnect power to the lights are prov ided at all unit entry points to

equipment where lights are located.

© 2011 Trane All rights reserved CLCH-SVX07C-EN

Page 7

Warnings, Cautions and Notices

WARNING

Contains Refrigerant!

System contains oil and refrigerant under high pressure. Recover refrigerant to relieve pressure

before opening the system. See unit nameplate for refrigerant type. Do not use non-approved

refrigerants, refrigerant substitutes, or refrigerant additives.

Failure to follow proper procedures or the use of non-approved refrigerants, refrigerant

substitutes, or r efrigerant additive s could result in death or serious injury or equi pment dam ag e.

WARNING

Hazard of Explosion!

Use only dry nitrogen with a pressure regulator for pressurizing unit. Do not use acetylene,

oxyg en or compr essed air or mixtur es containing them f or pressu re t esting. Do not use mixtur es

of a hydrogen containing refrigerant and air above atmospheric pressure for pressure testing as

they may become flammable and could result in an explosion. Refrigerant, when used as a tr ace

gas should only be mixed with dry nitrogen for pressurizing units. Failure to follow these

recommendations could result in death or serious injury or equipment or property-only damage.

WARNING

Equipment Damage From Ultraviolet (UV) Lights!

Trane does not r ecommend field installation of ultr aviolet lig hts in its air handlin g equipment f or

the intended purpose of improving indoor air quality. High intensity C-band ultraviolet light is

known to severely damage polymer (plastic) materials and poses a personal safety risk to

anyone exposed to the light without proper personal protective equipment (could cause

damage to eyes and skin). Polymer materials commonly found in HVAC equipment that may be

susceptible include insulation on electrical wiring, fan belts, thermal insulation, various

fasteners and bushings. Degradation of these materials can result in serious damage to the

equipment.

Trane accepts no responsibility for the performance or operation of our air handling equipment

in which ultraviolet devices were installed outside of the Trane factory.

WARNING

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) recomm ended f or th e w ork being undertaken. ALWAYS refer to appr opriate

MSDS and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to appropriate MSDS and

OSHA guidelines for information on allowable personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a r isk of arc or flash, technicians MUST put on all Personal Prot ective Equipment (PPE)

in accordance with NFPA70E or other country-specific requirements for arc/flash protection

PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

CLCH-SVX07C-EN 3

Page 8

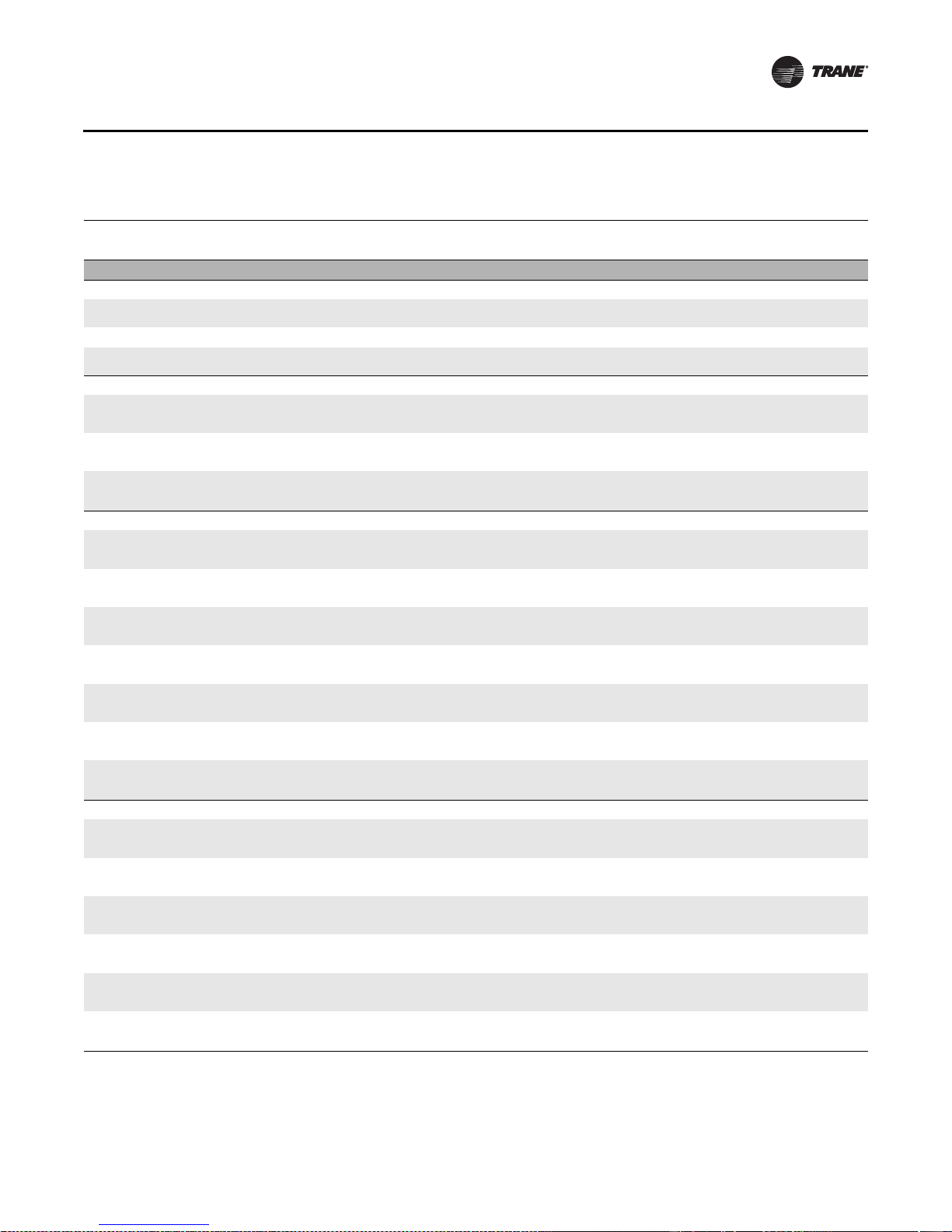

Introduction

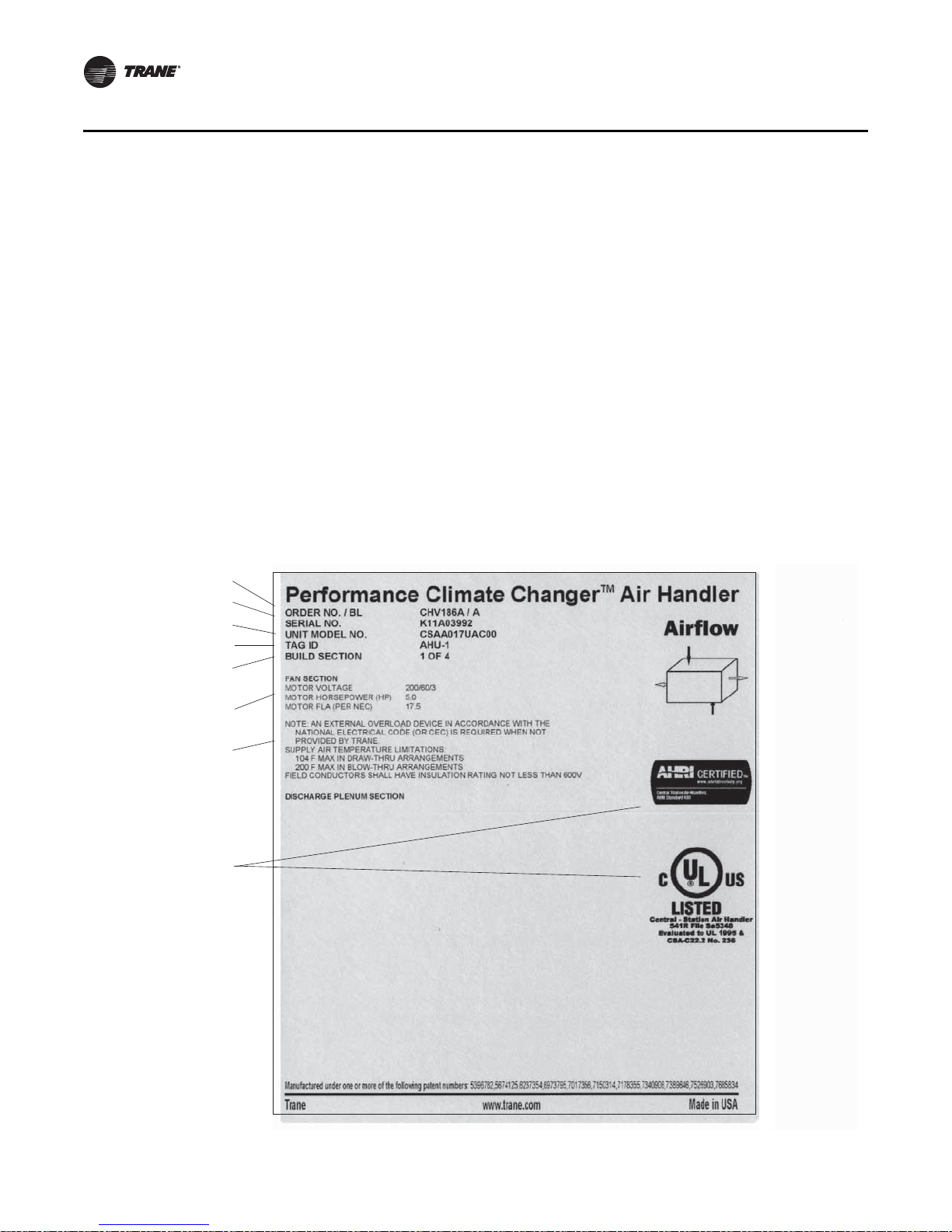

Agency listings and/or

agency certifications

Trane order number

Unit level serial number

Service model number

Unit tagging

Section location

Functional section type

Notes and additional

section information

Introduction

Overview of Manual

Use this manual to install, startup, operate, and maintain the Performance Climate Changer™ air

handler. Carefully review the procedures discussed in this manual to minimize installation and

startup difficulties.

Nameplate

Each P erformance air handler section includes one or more nameplate/label (see Figure 1), which

identifies the type of section and functional components, customer tagging information, the unit

serial number, the unit order number, the build-section position for installation, and the unit model

number.

Note: The unit serial number and order number is required when ordering parts or requesting

service for a Trane air handler.

Figure 1. Performance air handler section nameplate

4 CLCH-SVX07C-EN

Page 9

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overview of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Receiving Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Resolving Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storage Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparing the Unit Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Roof Curb Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Factory-Mounted Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-Packaged Solutions for Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Assembly Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Long-Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Outdoor Storage Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unit Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fans/Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Starter/VFD Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Motor Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installation - Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Lifting and Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Remove Shipping Tie-Downs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

General Lifting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Lifting Inlet and Exhaust Hoods and External Pipe Cabinet (Chase) . . . . 27

Forklifting Considerations for Indoor Units Size 3-30 . . . . . . . . . . . . . . . 28

Unit Placement and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Unit Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ceiling Suspension for Indoor Air Handlers Sizes 3-57 . . . . . . . . . . . . . . 30

Section-to-Section Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pipe Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Outdoor Unit Weather Hood(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Indoor Dual-Path Split Dehumidification Unit (SDU)/Winterizer Assembly 43

Horizontal SDU/Winterizer Indoor Air Handler Assembly . . . . . . . . . . . . 44

Vertical SDU/Winterizer Indoor Air Handler Assembly . . . . . . . . . . . . . . 46

CLCH-SVX07C-EN 5

Page 10

External Raceway Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Component Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Diffuser Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Filter Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Filter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Filter Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Fan Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Fan Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Adjusting the Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Seismic Isolation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Anchor Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Damper Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Damper Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Opposed-Blade and Parallel-Blade Dampers . . . . . . . . . . . . . . . . . . . . . . 71

Duct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Fan Discharge Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Damper Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Bottom Opening Duct Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Discharge Plenum Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Bellmouth Discharge Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Traq Damper Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

External Face-and-Bypass Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Other Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Coil Piping and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

General Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Drain Pan Trapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Steam Coil Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Water Coil Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Refrigerant Coil Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Suction Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Examples of Field-Installed Evaporator Piping . . . . . . . . . . . . . . . . . . . . . . . . 89

Installation - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Quick Connects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Controls Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Connecting the operator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Setting up the operator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Calibrating the operator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Adjusting brightness and contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

External communications port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6 CLCH-SVX07C-EN

Page 11

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Pre-Startup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

General Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Fan-Related Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Coil-Related Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Motor-Related Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Calculate Motor Voltage Imbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Tension the Fan Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Determine Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Align Fan and Motor Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Check Multiple Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Airflow Measuring Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Traq™ Dampers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Fan Inlet Airflow Measuring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Transmitter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Constant Factor K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

External Insulating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Throwaway Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Permanent Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Cartridge or Bag Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Drain Pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Inspecting and Cleaning Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Bearing Set Screw Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Fan Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Motor Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Fan Motor Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Steam and Water Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Refrigerant Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Coil Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Type D1, D2, WL, LL, UA, UW, UU, W, P2, P4, P8, WD, 5D, and 5W Coils .

127

Moisture Purge Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Cleaning Non-Porous Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Cleaning Porous Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

CLCH-SVX07C-EN 7

Page 12

Ultraviolet (UV) Light Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Cleaning the Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Replacing the Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Disposal of Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8 CLCH-SVX07C-EN

Page 13

General Information

Operating Environment

The Performance Climate Changer™ air handler is a central station air handler for indoor

applications. When considering the placement of the air handler, it is important to consider the

operating environment. The acc ep t able ambient temperature range for unit operation is -40ºF to

140ºF (-40ºC to 60ºC).

For heating applications, a special motor may be required to withstand the higher temperatures.

Motors with Class B insulation are acceptable for ambient temperatures up to 104º F, while motors

with Class F insulation can withstand ambient temperatures to +140º F (60º C).

Note: Units with UL approval have a maximum ambient temperature requirement of 104ºF. The

customer should provide adequate freeze protectio n for the coils. See “Coil Wint erization”

on page 126 for more information.

Unit Description

The Performance Climate Changer air handler is designed for a variety of controlled-air

applications. The basic unit consists of a fan, heatin g and/or cooling coils, filters, and dampers.

T rane air handlers ship as complete assemblies or in sub-assemblies if shipping splits are required.

Some assembly is required when the unit ships in subassemblies.

A wide variety of components is available for T rane air handlers, including numerous fan, coil, and

filter options, access sections, diffusers, discharge plen ums, face-and-bypass sections, ULapproved electric heat sections, humidifiers, mixing boxes, moisture eliminator sections, exhaust

dampers, controls, blenders and airflow monitoring stations.

For more information, refer to the following documents, available from your local Trane sales

engineer:

• CLCH-PRC01 5-E N, Performance Climate Changer™air handler catalog

• CLCH-PRC01 6-EN, Performance Climate Changer™air handler quick select

• CLCH-PRG003-EN, Performance Climate Changer™air handler guide specifications

• CLCH-SLB017-EN, Performance Climate Changer™air handler sales brochure

Factory-Mounted Controls

Trane air handlers are available with a wide selection of factory-mounted controls, including

controllers, motor starters, and variable frequency drives (VFD).

Most control components are mounted inside the uni t. Depending on the system configuration,

this may include damper actuators, dirty filter switches, averaging temperature sensors, and low

limit switches. VFDs, starters, controllers, control transformers, static pressure transducers, DC

power supplies, and customer interface relays will be in enclosures mounted on the inside of the

unit.

Small items that cannot be factory-mounted, such as space temperature sensors, outside air

temperature sensors, and humidity sensors, will ship inside the control enclosures, or packaged

and shipped inside the fan or mixing box section. Larger items are shipped inside the fan section.

Note: All control valves ship directly to the “ship-to address” from the vendor unless another

address is given on the Trane sales order.

CLCH-SVX07C-EN 9

Page 14

General Information

All factory-mounted control systems (controls that are factory-wired to a unit controller or

termination strip) ordered without starters or variable-frequency drives (VFDs) are provided with

120 to 24 V ac control transformers mounted and wired in the auxiliary control panel. The customer

must provide 120 Vac control power, 50/60 Hz, typically 3 amps for unit sizes 3 to 57 and 5 amps

for unit sizes 66 to 100. A dedicated 15-amp circuit is recommended.

Factory-mounted control systems ordered with factory-mounted starters or VFDs are supplied with

line to 24 Vac control transformers. No additional power wiring is required.

Pre-Packaged Solutions for Controls

If the air handler has been selected using one of Trane’s pre-packaged solutions options for

controls, there are a number of resources available to aid in commissioning and start-up of the unit.

These resources include commissioning sheets, graphics and technical application notes. The

technical appl ication notes include the control sequencing, T rane Graphic Programming (TGP) and

Rover set-up files for the specific unit selected. These resources are available through your local

Trane sales office.

For a more in-depth understanding of controls, refer to the following manuals:

• For programmable MP580 controllers

– CNT-SVP01A-EN

• For hardware installation

– CNT-SVN01A-EN

• For Trane TR200 Drives

– BAS-SVX19A-EN

Wiring

WARNING

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTRO CUTION hazar ds. To avoid these hazards, you MUST f ollo w

requirements for field wiring installation and grounding as described in NEC and your local/

state electrical codes. Failure to follow codes could result in death or serious injury.

Entrances are generally provided for field-installation of high and low voltage wiring through a

pipe/nipple connection in the unit depending on un it configuration with or without factorymounted controls. Before installation, consider overall unit serviceability and accessibility before

mounting, running wires (power), making penetrations, or mounting any components to the

cabinet.

Wiring to the air handler must be provided by the installer and must comply with all national and

local codes. The fan motor nameplate includes a wiring diagram. If there are any questions

concerning the wiring of the motor, write down the information on the motor nameplate and

contact your local Trane sales office.

10 CLCH-SVX07C-EN

Page 15

Pre-Installation Requirements

Based on customer requirements, Trane air handlers can ship as complete units or as individual

sections to be field assembled. Unit sizes 3-120 have an integral base frame designed with the

necessary number of lift points for safe installation. Indoor air handlers sizes 3-30 are also shipped

with a shipping skid designed for forklift transport.

Unless otherwise specified, Performance indoor air handlers ship in subassemblies if the total

length of the units exceeds 98 inches or if the total weight exceeds the limits shown in Table 1. If

either the maximum weight or maximum length is exceeded, the unit will ship in multiple pieces.

See Table 2 for limits for outdoor air handlers.

Note: These limits are based on a four-point lift.

Table 1. Shipping length and weight limitations for indoor air handlers

Unit Size Maximum Unit Weight (lb.) Maximum Unit Length (in)

3–30 <2,500 98

35 <3,900 98

40 <4,300 98

50–57 <5,100 98

66-120 <8000 98

Table 2. Shipping length and weight lim itations for outdoor air handlers

Unit Size Minimum Length (in.) Maximum Length (in.) Maximum Weight (lb.)

3–30 24.50 360.00 8,000

1

35-57

1

Notes:1Exhaust damper section can be attached to the adjacent section even if this causes length to be greater than 96

66-120

inches, up to 118.44 inches.

24.50 96.00 12,000

24.50 96.00 12,000

Receiving Checklist

Upon receipt of the air handler(s), a thorough inspection should be perfo rmed to note any shipping

damage that may have occurred and that th e shipment is complete. All factory shipping protection

should be removed immediately to allow complete access for the inspection. The shipping

protection provided by the factory is for transit protection only and should not be used as a jobsite

storage cover.

Note: Delivery cannot be refused. Trane is not responsible for shipping damage.

• Check all access doors to confirm that the latches and hinges are not damaged.

• Inspect the interior of each section for any internal damage.

Note: Concealed damage must be reported within 15 days of receipt.

• Inspect the coils for damage to the fin surface and/or coil connections.

• If the unit was ordered with factory-mounted contro ls, lo cate all sensors.

Note: Items that cannot be factory-mounted should ship inside the control enclosures or should

be packaged inside the fan or mixing box section.

• Check all control devices attached to the unit exterior and confirm that they are not damaged.

• Manually rotate the fan wheel to ensure free movement of the shaft, bearings, and drive.

• Inspect the fan housing for any foreign objects.

• If the unit is shipped in subassemblies, locate the assembly hardware, which should be

packaged and shipped inside the fan or mixing box section.

• Inspect and test all piping for possible shippi ng d amage. Nippl es m ay be i nstalled o n coi ls at

the factory but should alwa ys be tightened and tested before any connections are made. Rough

CLCH-SVX07C-EN 11

Page 16

Pre-Installation Requirements

handling during shipping, in addition to other factors can cause pipe connections to become

loose.

Note: T rane will not be responsible for any leak at the field connections. Coils have been factory

pressure tested before shipping.

Assembly Hardware

T rane air handlers ship with all necessary assembly hardware and gasket material. This hardware

is packaged in either a clear plastic envelope or cardboard box and can be found inside the fan,

mixing box, or access section. If there is not enough space inside the section, a crate or pallet will

be loaded onto the bed of the truck. Chec k the P arts List on the Field Assembly drawing against the

contents of the crate. Do not proceed with unit assembly until verification that all materials are

present. Sometimes it is necessary to use more than one section to ship hardware. Please check

all sections thoroughly before contacting your local Trane sales engineer to report missing

hardware.

Resolving Shipping Damage

T rane air handlers ship freight-on-board (FOB), meanin g that the unit belongs to the customer the

moment the delivery truck leaves the factory. If damage has occur red to the unit during shipment,

follow these instructions:

Note: Trane is not responsible for shipping da mage.

1 . Make specific notation, describing the damage, on the freight bill. Take photos of the damaged

material if possible.

2. Report all claims of shipping damage to the delivering carrier immediately and coordinate

carrier inspection if necessary.

Note: Do not attempt to repair the unit without consulting the delivering carrier.

3. Notify your Trane sales representative of the damage and arrange for repair.

Note: Do not attempt to repair the unit without consulting the Trane sales representative.

4. Keep the damaged material in the same location as it was received.

Note: It is the receiver's responsibility to provide reasonable evidence that concealed damage was

not incurred after delivery.

Storage Recommendations

NOTICE:

Corrosion!

All factory shipping protection should be removed. This wrapping is for transit protection only

and should not be used for jobsite storage.Use only canvas tarps to cover air handlers. Plastic

tarps can cause condensation to form in and on the equipment, which could result in corrosion

damage or wet storage stains.

Indoor air handlers and/or field-installed accessories that must be stored for a period of time before

installation must be protected from the elements. A controlled indoor environment is

recommended for proper storage.

Outdoor air handlers require no specia l protection for storage before installation. Keep the

equipment in the original container for protection and ease of handling.

Note: The warranty does not cover damage to the unit or controls due to negligence during

storage.

12 CLCH-SVX07C-EN

Page 17

General Storage

The unit controller and all other electrical/electroni c components should be stored in conditions of

-20ºF to 120°F and 5 to 95 percent relative humidity, non-condensing. Electrical components are

not moisture-tolerant. Factory protective coverings should be removed prior to storage.

Long-Term Storage

For longer periods of storage, allow proper clearance around the unit to perform periodic

inspection and maintenance of the equipment.

While the unit is in storage:

• Every two weeks, rotate the fan and motor shaft 30 revolutions by hand. Chec k for free rotation.

• Every six months, chec k fan shaft bearings and grease lines. Add grease using a manual grease

gun following the lubrications recommendations in “Fan Bearing Lubrication” on page 123.

• Check the motor lubrication; remove and clean grease plugs and check for the presence of

moisture in the grease. If moisture is present, remove the motor and send it to an authorized

repair shop for bearing inspection/replacement. If no moisture if present, refer to the motor

manufacturer’s lubrication reco mm end ati on for proper lu bricatio n.

Outdoor Storage Considerations

Outdoor storage is not recommended for units that will be installed indoors. However, when

outdoor storage is necessary, several things must be done to prevent damage :

Note: Keep the equipment on the o riginal wooden blocks/skid fo r protection and ease of handling.

• Select a well-drained area, preferably a concrete pad or blacktop surface.

• Place the unit on a dry surface or raised off the ground to assure adequate air circulation

beneath the unit and to assure no portion of the unit will contact standing water at any time.

• Loosen the belt tension on the drive belts.

• Cover the unit securely with a canvas tarp.

• Do not stack units.

• Do not pile other material on the unit.

Pre-Installation Requirements

Preparing the Unit Site

• Ensure the installation site can support the total weight of the unit (see “Unit Dimensions and

Weights” on page 16 for approximate section weights; refer to the unit submittals for actual

weights).

• Allow sufficient space for adequate free air and necessary service access (see “Service

Clearances” on page 16). Refer to submittals for specific minimums.

• Allow room for supply and return piping, ductwork, electrical connections, and coil removal.

• Ensure there is adequate height for condensate drain requirements. See “Drain Pan T rappi ng”

on page 80.

Note: If unit is installed in a mechanical room on a pad, inadequate height may necessitate core-

drilling the floor to attain proper trap height. Insufficient height could inhibit condensate

drainage and result in flooding the unit and/or equipment room.

CLCH-SVX07C-EN 13

Page 18

Pre-Installation Requirements

NOTICE:

Microbial Growth!

The floor or foundation must be level and the condensate drain at the proper heig ht for proper

coil drainage and condensate flow. Standing water and wet surfaces inside the equipment can

become an amplification site for microbial growth (mold), which may cause odors and damage

to the equipment and building materials.

• Confirm the roof curb or foundation of the mounting platform is level and large enough to

accommodate the unit. Refer to the unit submittals for specific dimensions.

• Provide adequate lighting for maintenance personnel to perform maintenance duties.

• Provide permanent power outlets in close proximity to the unit for installation and

maintenance.

• Depending upon job requirements, the customer may n eed to provide 120 V ac power to the unit

controller. Refer to submittals for more information. A dedicated 15-amp circuit is

recommended.

• Wiring for the air handler must be provided by the installer and must com ply with all national

and local electrical codes.

• If the unit integral base frame ceiling suspension provisions are not used, the installer/

contractor must provide a ceiling-susp ended mounting frame desig ned to support the length,

width, and weight of the entire air-handling unit. See “Ceiling Suspension for Indoor Air

Handlers Sizes 3-57” on page 30 for more information.

• Rooftop curb-mount ed units m ust be sealed tightly to the curb. Use proper sealants and roofto-curb sealing techniques to prevent water and air leakage. Refer to CLCH-SVN05A-EN Roof

Curbs for Performance Climate Changer™ Air Handlers Installation Instructions.

Note: Preparation of the roof curb or pier mount and roof openings should be completed prior to

lifting the unit to the roof.

Roof Curb Installation Checklist

See CLCH-SVN05A-EN Roof Curbs for Performance Climate Changer™ Air Handlers Installation

Instructions for information on installing roof curbs.

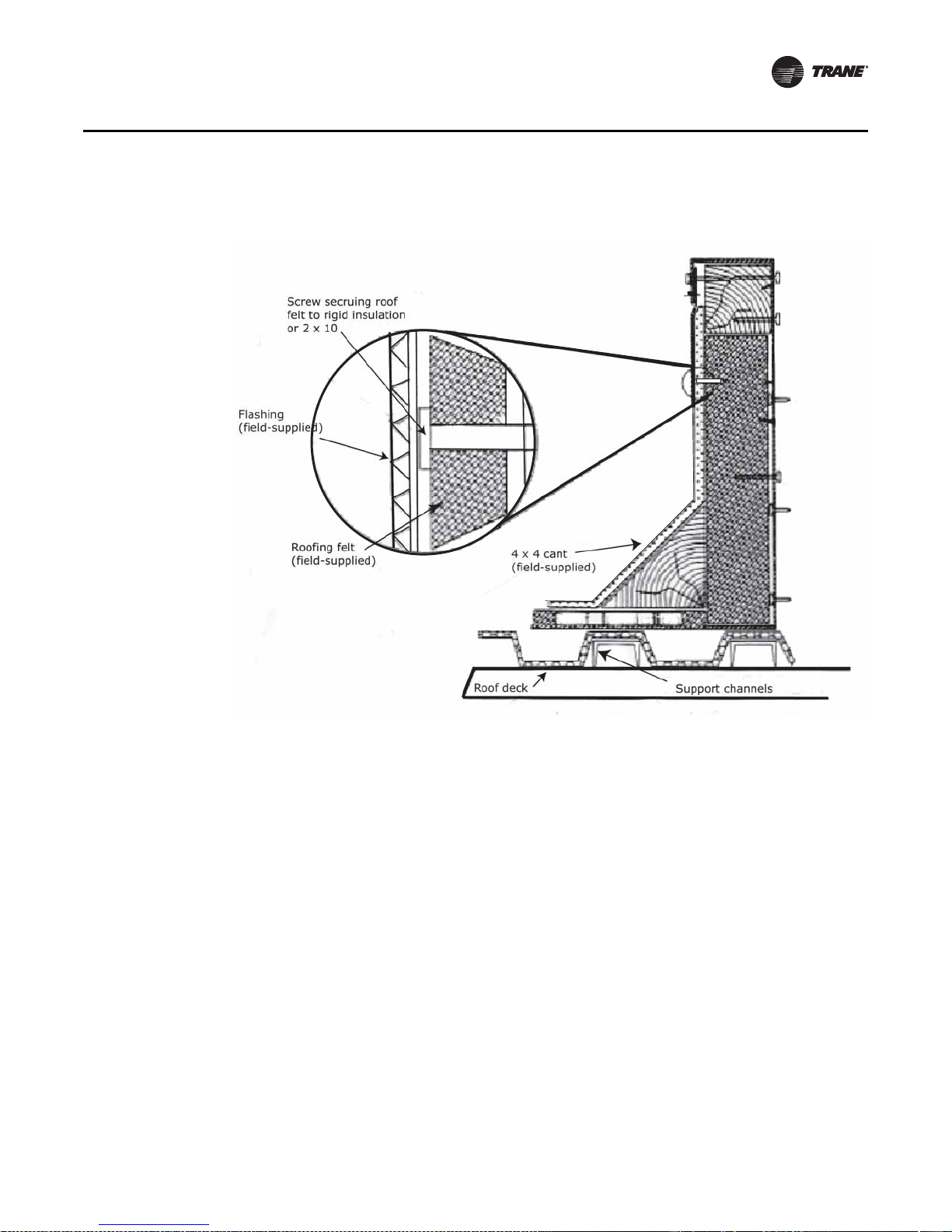

It is recommended that the curb be installed directly on the support members and fastened to the

supports using tack welds or other equivalent methods. Properly supported decking should be

installed inside the air handler section of the curb when this method is used. See Figure 2.

14 CLCH-SVX07C-EN

Page 19

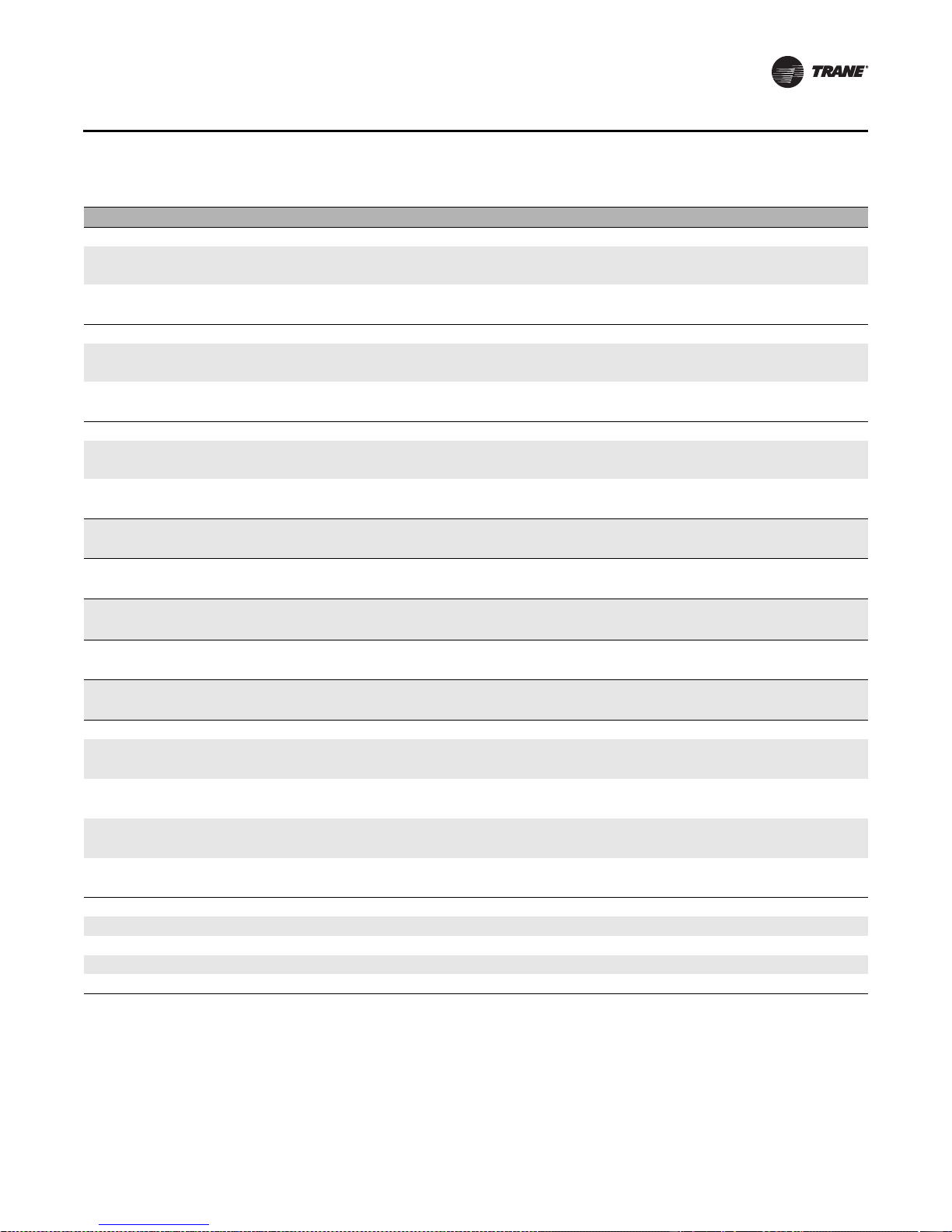

Pre-Installation Requirements

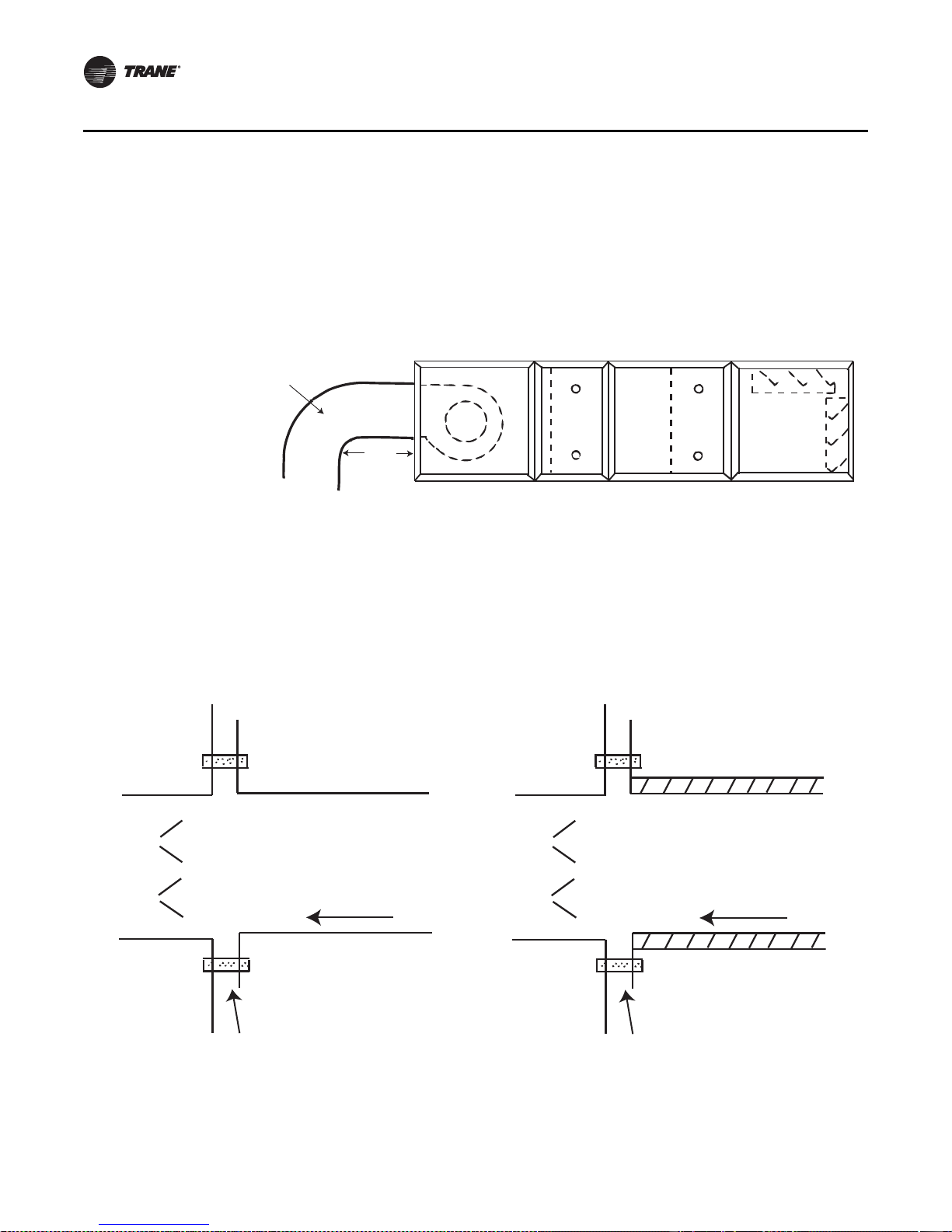

Figure 2. Cross section of typical curb installation on new construction

1 . Verify that the roof structure can adequately support the combined weight of the unit and curb

assembly.

2. Ensure that the selected installation location provides sufficient service and operational

clearances.

3. Remove any twist within the curb due to roof supports and square the curb.

4. Level the curb.

5. Secure the curb to the roof support members.

6. Install 2-inch thick boards or rigid insulation around the curb.

7. Install cant strips around the curb.

8. Bring field supplied roofing felt up to the top of the curb nailing strips. Nail felt into place.

9. Install field supplied flashing under the lip of the curb flanges and over the felt.

Apply sealant to the four corners. Caulk all joints between the curb and the roof. Attach the g asket

material to the curb’ s top flanges (entire perimeter) and to the supply and return air duct opening

panel flanges.

CLCH-SVX07C-EN 15

Page 20

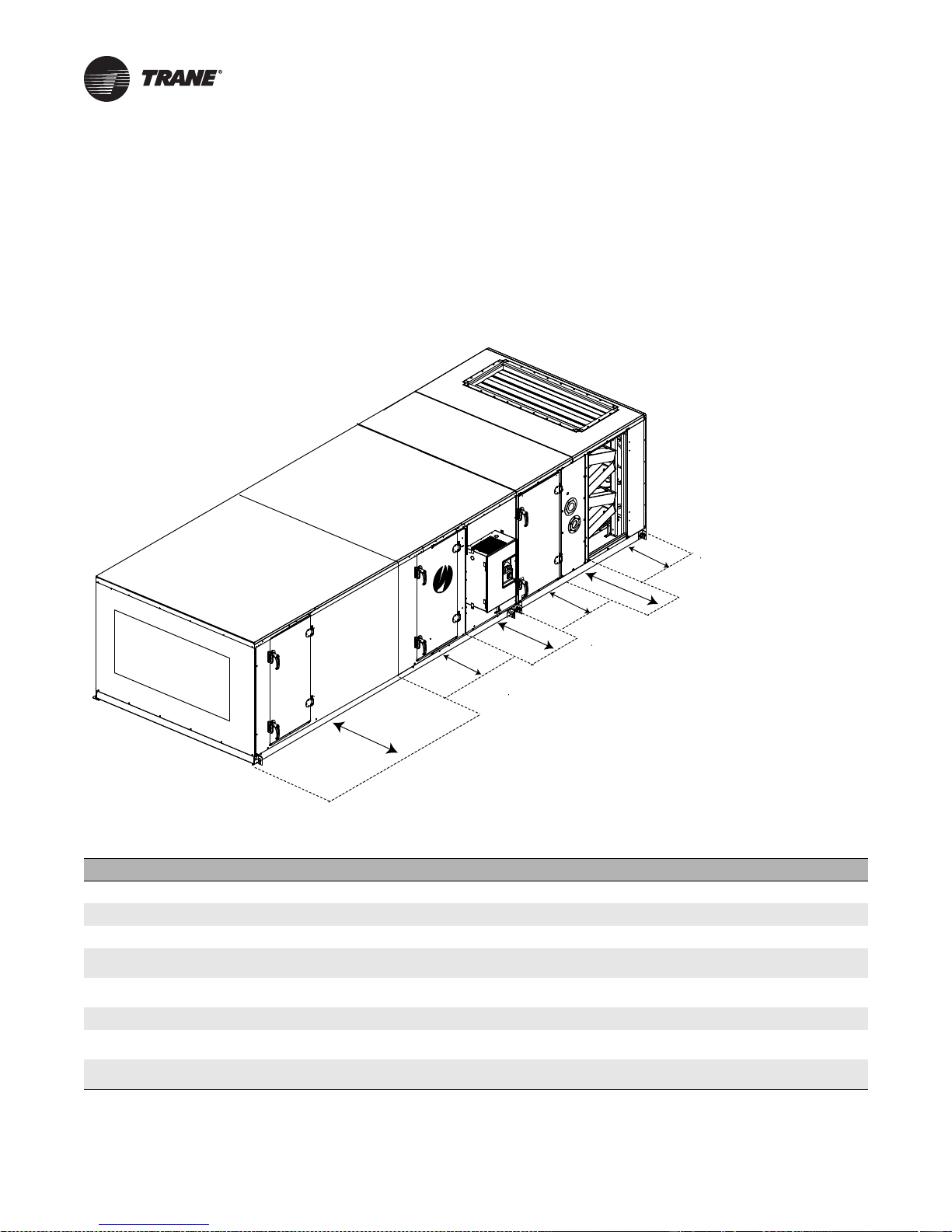

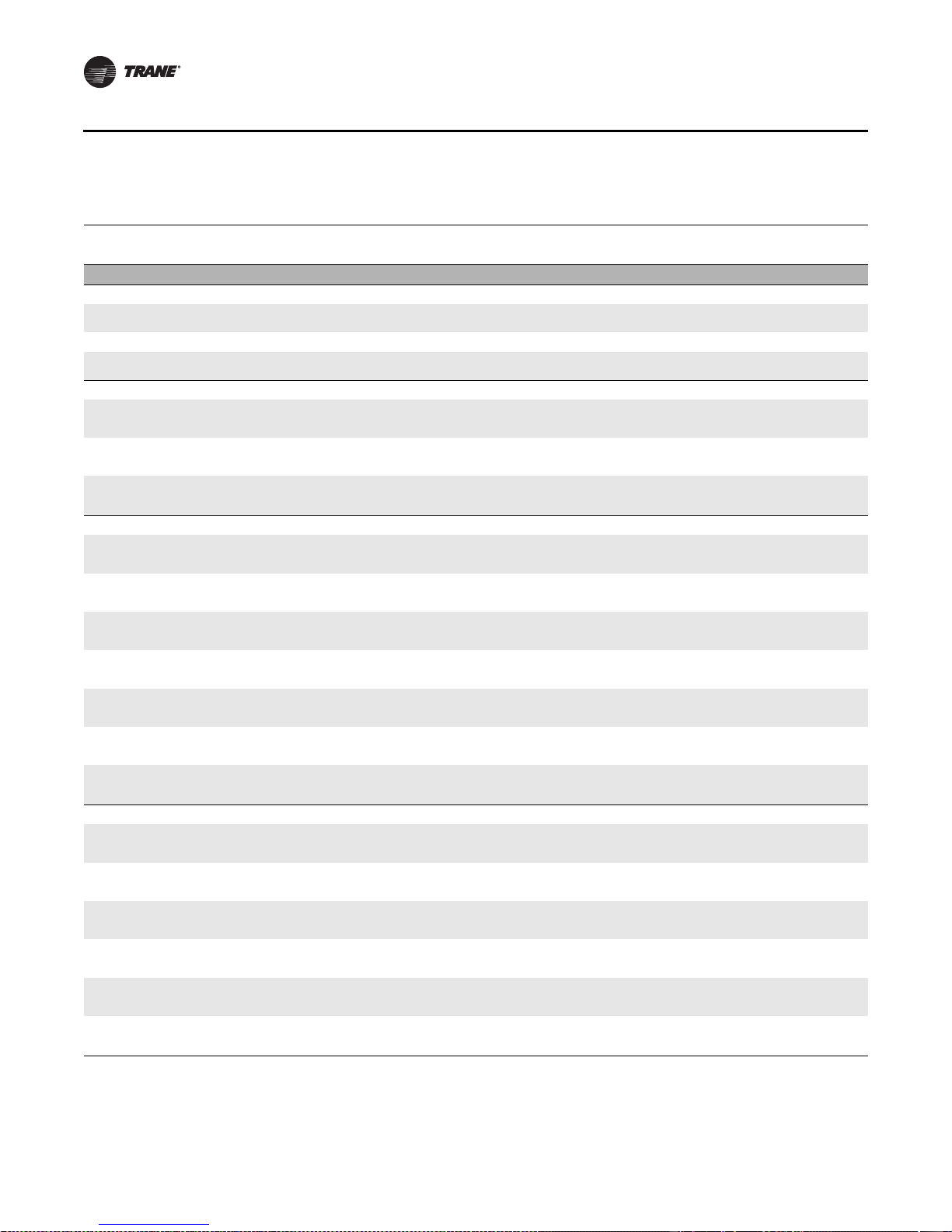

Unit Dimensions and Weights

Filter mixing box

Coil

Fan

Gas heat

Access

door

UV

lights

VFD

F

E

D

C

B

A

Note: For specific dimensional and weight information, refer to the unit submittals. The

dimensions and weights in this manual are approximate. T rane has a p olicy of continuous

product and product data improvement and reserves the right to change design and

specifications without notice.

Service Clearances

Figure 3. Service Clearance

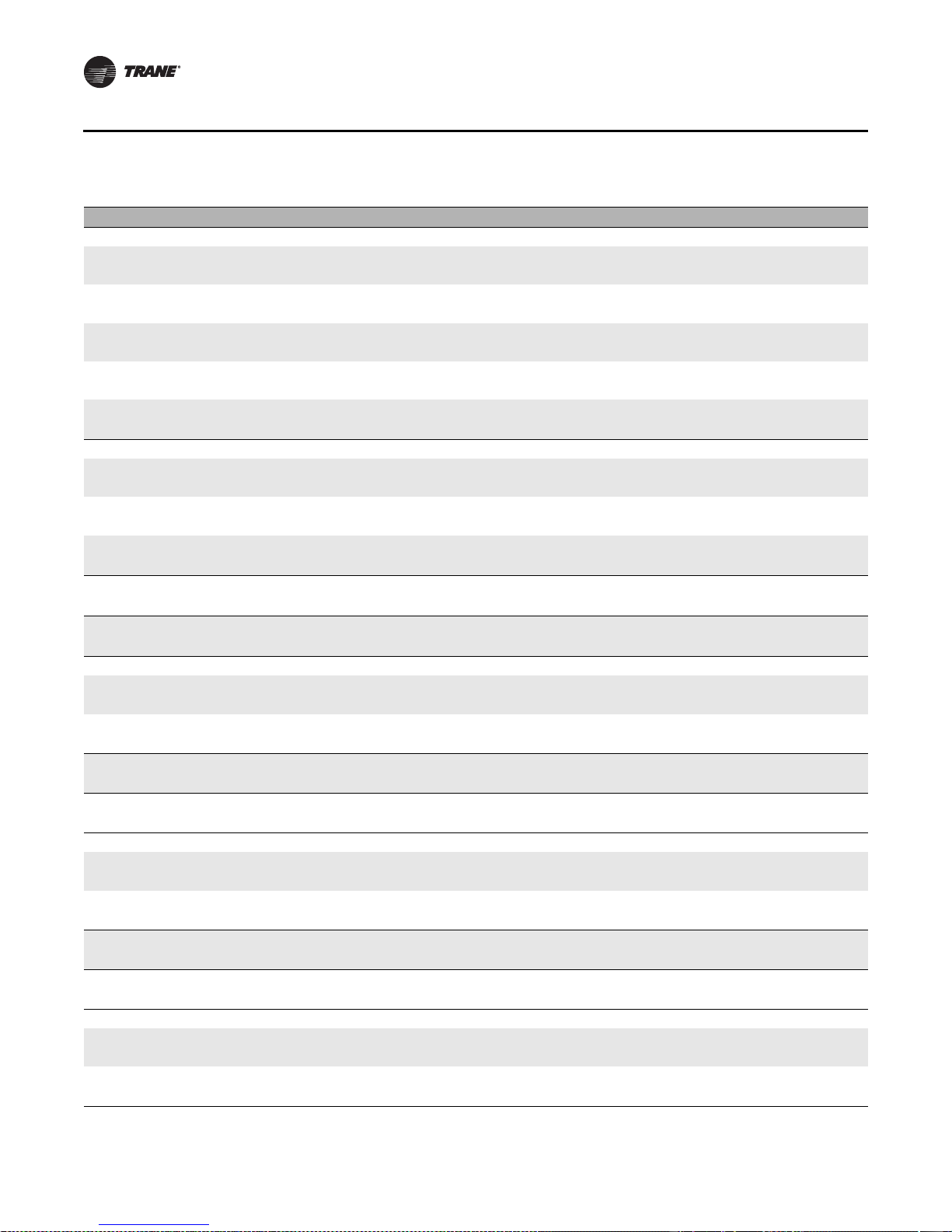

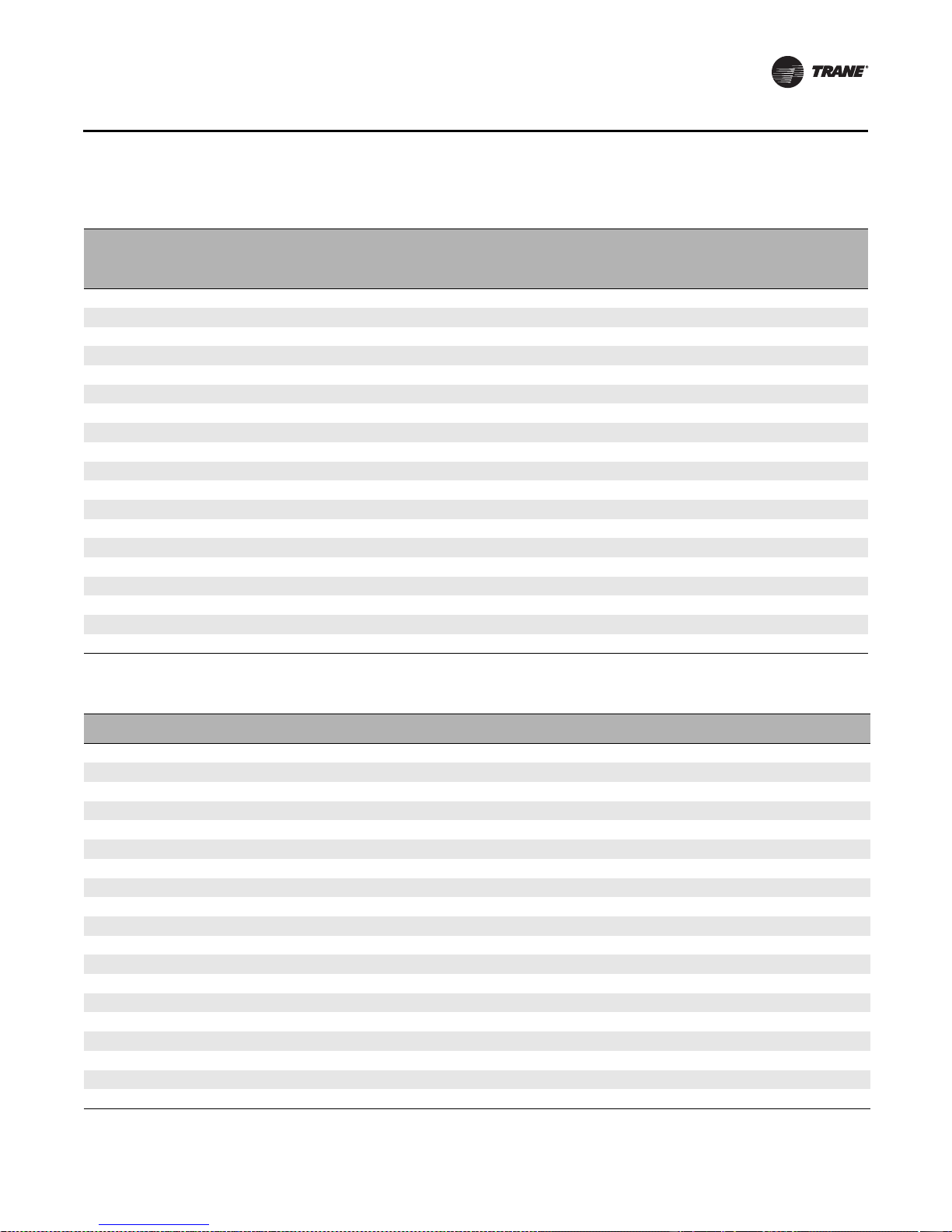

Table 3. Service clearances (inches)

Component 3 4 6 8 10 12 14 17 21 25 30 35 40 50 57 66 80 100 120

A (filter)

B (coil)

C (UV Lights)

D (external

starter or VFD)

D (internal

starter or VFD)

E (fan)

F (gas heat Ext Vestibule)

F (gas heat Int Vestibule)

Note: At a minimum, the above clearance dimensions are recommended on one side of the unit for regular service and maintenance. Refer to as-built

submittal for locations of items such as filter access doors, coil, piping connections, motor locations, hoods, pipe cabinets, etc. Sufficient clearance

must be provided on all sides of unit for removal of access panels, plug panels, or section-to-section attachment brackets. Clearance for starters, VFDs,

or other high-voltage devices must be provided per NEC requi rements.

16 CLCH-SVX07C-EN

48 48 48 48 48 48 48 48 48 48 48 48 48 48 48 52 56 58 58

48 59 59 66 77 82 87 87 95 95 109 115 128 141 141 156 156 170 197

48 48 48 48 48 48 48 48 48 48 48 48 48 48 48 52 56 58 58

61 61 61 61 61 61 61 61 64 64 64 64 64 64 64 64 64 64 64

48 48 48 48 48 48 48 48 48 48 48 48 48 48 48 48 48 48 48

48 48 48 48 51 54 58 61 60 66 66 66 70 77 77 93 93 101 101

N/A N/A 89 90 108 100 100 105 115 115 118 136 140 156 156 170 179 180 N/A

N/A N/A 56 63 74 79 84 84 92 92 106 112 125 138 138 153 153 167 194

Page 21

Unit Dimensions and Weights

Note: Add 0.19 inches to total unit length for each shipping split to account for gasketing.

Table 4. Section dimensions (inches) and weigh ts (po unds) - unit sizes 3-30

Nominal airflow

Airflow at 625 fpm

1

2

Unit size 3 4 6 8 10 12 14 17 21 25 30

Height - indoor unit (in.)

3

Height - outdoor unit (in.)4

includes base drip lip

Width (in.)

Weight add for outdoor unit

(lbs/in. of unit length)

Mixing box

-with or without angled filters

-with top Traq dampers

-with reduced length for airfoil

dampers only

Filters

-2-in. or 4-in. angled

-Cartridge 12-in. or

short bag 18-in.

-2-in. or 4-in. flat

-2-in. and 4-in. combination flat

-Long bag 30-in.

-Front-load

2-in or 4-in.flat, cartridge or HEPA

-Front-load Short Bag

Access or blank

-Small horizontal

-Medium horizontal

-Extended-medium horizontal

-Medium-large horizontal

-Large horizontal or turning

-Extra-large horizontal or turning

Note:1Nominal airflow is based on 500 fpm through a nominal coil (i.e. 500xunit size 8=4000 cfm). 2Airflow@625 fpm through the flat filter (maximum

filter velocity).

frame for sizes 3-120.

7

Nominal length and height shown for discharge plenums. Variable plenum height and length is available from 0.5 to 1.5 of nominal.

5

3

Height includes standard 2.5-inch base frame for sizes 3-57 and 6-inch base frame for sizes 66-120. 4Height includes 6-inch base

5

Variable lengths av ailable from 14-96 inches. 6Fan section weights include the heaviest fan with the largest ODP motor available.

1500 2,000 3000 4000 5000 6000 7000 8500 10,500 12,500 15,000

2169 3475 4338 4581 6075 8331 9025 11,806 13,456 16,944 19,025

29.00 29.00 35.25 37.75 37.75 41.50 41.50 49.00 52.75 61.50 61.50

37.30 37.45 43.70 46.20 46.20 50.33 50.33 57.83 61.58 70.33 70.33

31.50 44.00 44.00 50.50 61.50 66.50 72.00 72.00 80.00 80.00 93.50

1.66 1.91 1.91 2.04 2.27 2.40 2.51 2.51 2.67 2.67 2.95

34.00 34.00 34.00 36.00 36.00 36.00 36.00 36.00 34.00 46.00 46.00

192.59 219.00 237.28 277.86 313.45 346.29 365.78 391.36 423.13 539.50 595.82

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 56.50 56.50

199.73 245.85 265.79 313.60 345.77 381.04 402.17 438.43 527.04 610.12 672.97

23.38 23.38 23.38 23.38 23.38 23.38 28.38 28.38 28.38 28.38 32.50

132.81 150.12 164.65 185.54 210.93 231.01 273.01 293.45 326.35 352.21 424.41

24.50 24.50 24.50 26.50 26.50 26.50 26.50 24.50 24.50 24.50 24.50

129.35 155.03 166.86 192.04 215.56 236.22 250.34 286.12 316.30 356.90 398.99

24.50 24.50 24.50 26.50 26.50 26.50 26.50 24.50 24.50 24.50 24.50

101.83 121.39 130.06 152.86 171.58 192.72 204.20 203.82 222.30 249.79 275.06

14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00

68.56 82.62 88.08 99.49 111.80 124.66 131.47 136.82 152.24 164.95 183.13

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

86.42 103.79 110.69 124.26 139.53 161.09 171.37 179.37 198.37 224.08 247.88

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 46.00 46.00

133.38 174.65 187.12 219.08 237.62 268.97 283.79 306.36 369.18 379.56 415.84

40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00

198.25 220.89 244.19 268.72 292.11 320.14 333.11 370.55 401.66 433.13 470.67

45.00 45.00 45.00 45.00 45.00 45.00 45.00 45.00 45.00 45.00 45.00

218.15 242.55 268.05 294.69 320.16 350.45 364.47 404.55 438.50 473.05 513.15

10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00

48.05 57.43 60.55 66.67 74.92 80.55 84.67 88.41 96.28 100.65 110.78

14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00

59.91 71.18 75.25 82.74 92.66 99.61 104.57 109.45 119.10 124.79 136.97

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

74.73 88.37 93.62 102.82 114.83 123.43 129.44 135.74 147.62 154.97 169.71

24.50 24.50 24.50 26.50 26.50 26.50 26.50 24.50 24.50 24.50 24.50

111.30 124.41 131.71 154.47 173.94 187.69 197.48 195.61 214.03 225.11 248.63

34.00 34.00 34.00 36.00 36.00 36.00 36.00 36.00 34.00 46.00 46.00

145.22 160.85 170.40 196.91 221.19 238.48 250.67 263.28 274.77 369.72 406.60

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 56.50 56.50

152.36 187.71 198.92 232.65 253.52 273.22 287.07 310.34 378.68 369.72 406.60

CLCH-SVX07C-EN 17

Page 22

Unit Dimensions and Weights

Table 4. Section dimensions (inches) and weigh ts (po unds) - unit sizes 3-30

Unit size 3 4 6 8 10 12 14 17 21 25 30

Coil

-Small horizontal (with 4-row UW)

-Medium horizontal (with 8-row UW)

-Extended-medium horizontal

(with 8-row UW)

-Medium-large horizontal

(with 10-row W)

-Large horizontal or vertical

(with 10-row W)

6

Fan

-Belt-drive plenum fan with motor

-Housed fan (FC/AF/BC) with motor

-Direct-drive plenum fan with motor

Controls section (includes largest

available VFD)

Diffuser

Discharge plenum

-Horizontal

-Vertical

Blender

Electric Heat

7

Face-and-Bypass Dampers

-Internal face-and-bypass or

face damper only

-External face-and-bypass

Energy Wheel

CDQ Wheel

Integral-face-and-bypass coil

-Less than 4 rows

-4 rows

10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00

127.31 164.68 191.68 226.20 269.31 310.76 335.50 384.32 467.78 533.75 609.14

14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00

179.86 236.36 282.91 339.38 407.35 475.70 516.37 601.64 734.68 848.92 978.12

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

196.79 255.65 303.39 361.57 431.62 501.63 544.40 631.09 772.37 889.31 1021.94

24.50 24.50 24.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50

281.83 375.92 450.41 575.29 681.45 802.89 912.98 1045.42 1296.51 1509.94 1738.41

34.00 34.00 34.00 36.00 36.00 36.00 36.00 36.00 34.00 46.00 46.00

313.98 412.58 489.32 617.44 727.56 852.16 966.23 1113.15 1368.11 1683.65 1926.83

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 56.50 56.50

406.54 537.13 625.09 674.57 864.70 936.46 1052.78 1214.74 1414.95 1495.75 1736.99

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 56.50 56.50

387.54 466.14 568.41 641.41 839.41 904.62 925.53 1073.07 1403.49 1535.79 1755.04

36.00 41.00 41.00 44.00 46.75 48.50 48.50 50.00 50.25 50.25 52.50

335.20 450.11 446.52 576.33 663.63 746.10 767.31 799.69 1095.84 1182.66 1263.84

24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50

234.30 247.41 276.71 299.47 318.94 332.69 414.48 423.00 442.03 463.11 486.63

10.00 10.00 10.00 14.00 14.00 14.00 14.00 14.00 14.00 19.00 19.00

53.76 63.14 68.53 90.94 100.86 116.94 121.90 129.34 143.02 185.04 199.78

34.00 34.00 34.00 36.00 36.00 36.00 36.00 36.00 34.00 46.00 46.00

150.01 185.36 196.57 230.30 251.17 270.87 284.72 307.99 376.33 367.37 404.25

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 56.50 56.50

177.24 209.05 221.00 259.71 285.68 308.68 325.46 351.14 429.14 497.02 549.91

19.00 24.50 24.50 26.50 36.00 36.00 36.00 36.00 34.00 46.00 46.00

94.86 132.71 146.30 173.34 238.64 264.12 276.73 303.71 323.59 427.13 470.25

36.00 41.00 41.00 44.00 42.50 42.50 42.50 44.00 50.25 56.50 56.50

261.39 309.88 335.38 449.00 471.92 500.13 513.26 627.76 705.10 857.44 898.23

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

122.68 155.15 167.79 190.70 219.68 241.45 255.80 270.77 300.08 317.53 353.22

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

105.60 129.06 141.70 157.63 178.68 199.15 209.53 224.50 248.05 265.62 291.36

n/a 52.25 52.25 52.25 54.50 57.50 57.50 57.50 55.50 55.50 57.50

n/a 364.17 378.70 457.21 561.31 676.15 766.30 786.59 879.93 917.84 1135.01

52.25 52.25 52.25 52.25 54.50 57.50 57.50 57.50 55.50 55.50 57.50

284.39 406.17 420.70 484.21 661.31 756.15 884.30 905.99 1189.41 1213.44 1310.61

n/a 26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50

n/a 355.20 367.21 470.21 541.93 585.86 619.66 733.14 792.88 805.52 940.46

n/a 43.00 43.00 43.00 43.00 43.00 43.00 4 3.00 43.00 43.00 43.00

n/a 543.54 559.47 723.32 834.36 900.62 950.23 1130.33 1220.11 1403.29 1443.62

18 CLCH-SVX07C-EN

Page 23

Unit Dimensions and Weights

Table 4. Section dimensions (inches) and weigh ts (po unds) - unit sizes 3-30

Unit size 3 4 6 8 10 12 14 17 21 25 30

Humidifier

-Direct Steam

-Atmospheric

Silencer

-3 ft

-5 ft

2-deck or 3-deck Multizone

- Horizontal discharge

- Vertical discharge

UV light

Gas heat (highest MBH) n/a n/a

Horizontal end cap

Diagonal economizer for

outdoor unit

Exhaust damper section for

outdoor unit

Hoods

- Side inlet hood (add to width) for

diagonal economizer

- Side inlet hood (add to width) for

mixing box

- Back inlet hood (add to length) for

mixing box

- Exhaust hood (add to length or

width)

Pipe cabinet weight

15 inches long, 36 inches deep 104.00 104.00 116.00 120.00 120.00 127.00 127.00 141.00 148.00 164.00 164.00

24 inches long, 36 inches deep 122.00 122.00 135.00 140.00 140.00 147.00 147.00 162.00 170.00 187.00 187.00

48 inches long, 36 inches deep 169.00 169.00 184.00 191.00 191.00 200.00 200.00 218.00 228.00 249.00 249.00

96 inches long, 36 inches deep 263.00 263.00 284.00 293.00 293.00 305.00 305.00 331.00 343.00 373.00 373.00

14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00

125.26 145.84 165.02 183.76 225.95 268.70 285.76 323.51 354.22 397.93 452.06

14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 19.00

126.77 167.88 177.85 203.32 252.08 276.18 311.72 338.64 396.01 432.20 527.53

38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00

198.00 255.81 285.56 319.00 358.76 442.35 461.27 511.98 573.44 699.10 799.58

62.00 62.00 62.00 62.00 62.00 62.00 62.00 62.00 62.00 62.00 62.00

308.14 391.33 435.77 483.40 541.16 677.72 703.65 780.18 873.34 1072.96 1214.72

n/a n/a 52.00 52.00 52.00 57.00 57.00 57.00 72.00 72.00 72.00

n/a n/a 521.86 581.76 672.98 751.82 795.28 829.01 1074.90 1130.69 1260.57

n/a n/a 61.00 61.00 66.00 71.00 71.00 71.00 82.00 82.00 82.00

n/a n/a 615.93 676.27 832.69 922.38 966.31 1005.77 1228.90 1292.74 1418.36

14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00 14.00

76.02 93.64 98.69 120.26 135.22 146.68 155.07 162.95 179.84 188.71 218.33

69.00 69.00 67.00 65.00 64.00 73.00 76.00 76.00 75.00

884.80 934.90 1042.60 1070.00 1089.00 1420.50 1294.80 1394.50 1477.70

10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

59.5 68.8 72.7 80.8 91.9 99.5 105.1 110.3 121.3 127.6 142.1

45.50 49.00 49.50 48.00 53.00 53.00 56.50 52.00 62.50 57.00 62.50

203.89 247.13 270.83 289.91 348.65 378.29 425.94 431.12 554.51 565.16 689.49

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

91.70 103.30 109.30 121.00 136.07 147.60 155.50 163.30 178.90 188.10 208.20

16.63 17.88 17.38 22.25 17.38 19.38 19.38 21.38 22.63 25.63 27.75

22.11 44.51 46.71 72.36 51.90 69.11 74.11 87.31 105.51 128.29 165.87

15.38 15.38 17.50 19.75 19.75 23.00 21.13 24.75 27.75 32.13 35.25

17.38 17.38 22.37 28.48 31.07 41.83 50.11 51.75 69.06 83.64 95.67

16.63 17.88 17.38 22.25 17.38 19.38 19.38 21.38 22.63 25.63 27.75

22.11 44.51 46.71 72.36 51.90 69.11 74.11 87.31 105.51 128.29 165.87

15.38 15.38 17.50 19.75 19.75 23.00 21.13 24.75 27.75 32.13 35.25

12.36 12.36 15.95 20.47 21.26 29.08 29.65 34.70 45.03 58.67 67.02

CLCH-SVX07C-EN 19

Page 24

Unit Dimensions and Weights

Notes: Add 0.19 inches to total unit length for each shipping split to account for gasketing.

Table 5. Section dimensions (inches) and wei gh ts (poun ds) - unit sizes 35-120

Nominal airflow

Airflow at 625 fpm

1

2

Unit size 35 40 50 57 66 80 100 120

Height - indoor unit (in.)

3

Height - outdoor unit (in.)4

includes base drip lip

Width (in.)

Weight add for outdoor unit

(lbs/in. of unit length)

Mixing box

-with or without angled filters

-with top Traq dampers

-with reduced length for airfoil

dampers only

Filters

-2-in. or 4-in. angled

-Cartridge (12-in.) or

short bag (18-in.)

-2-in. or 4-in. flat

-2-in. and 4-in. combination flat

-Long bag (30-in.)

-Front-load

2-in or 4-in.flat, cartridge or HEPA

-Front-load Short Bag

Access or blank

-Small horizontal

-Medium horizontal

-Extended-medium horizontal

-Medium-large horizontal

-Large horizontal or turning

-Extra-large horizontal or turning

Note:1Nominal airflow is based on 500 fpm through a nominal coil (i.e. 500xunit size 8=4000 cfm). 2Airflow@625 fpm through the flat filter (maximum

filter velocity).

frame for sizes 3-120.

7

Nominal length and height shown for discharge plenums. Variable plenum height and length is available from 0.5 to 1.5 of nominal.

5

3

Height includes standard 2.5-inch base frame for sizes 3-57 and 6-inch base frame for sizes 66-120. 4Height includes 6-inch base

5

Variable lengths av ailable from 14-96 inches. 6Fan section weights include the heaviest fan with the largest ODP motor available.

17,500 20,000 25,000 28,500 33,000 40,000 50,000 60,000

23,263 25,519 34,375 39,581 47,225 53,475 65,106 76,388

67.25 67.25 75.75 85.50 92.50 107.50 119.75 119.75

76.075 76.075 85.45 95.20 102.20 117.20 129.45 129.45

100.00 112.50 125.50 125.50 140.50 140.50 154.50 182.00

3.02 3.28 3.74 6.13 2.88 2.88 3.11 3.55

48.00 48.00 48.00 48.00 49.00 54.00 60.00 60.00

784.64 877.19 980.34 1055.78 1344.75 1501.00 1772.41 2016.97

48.00 48.00 48.00 48.00 84.00 92.00 96.00 96.00

917.88 1019.49 1188.45 1271.47 1812.46 2030.42 2313.89 2604.03

35.50 38.50 41.50 41.50 41.50 41.50 47.00 53.00

635.84 716.69 845.71 845.71 1183.44 1272.94 1508.57 1773.61

24.50 24.50 27.50 27.50 27.50 27.50 27.50 27.50

533.86 580.66 676.42 704.29 882.20 945.62 1032.36 1136.60

24.50 24.50 27.50 27.50 27.50 27.50 27.50 27.50

428.04 438.45 549.07 566.64 775.99 807.31 927.71 1031.64

14.00 14.00 14.00 14.00 15.00 15.00 15.00 15.00

294.60 319.13 353.93 379.91 533.87 560.15 623.46 699.50

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

397.10 430.77 482.70 540.44 700.68 779.12 862.09 908.32

37.25 37.25 37.25 37.25 37.25 37.25 37.25 37.25

525.02 570.65 637.71 692.97 894.76 971.09 1061.74 1125.66

40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00

636.18 676.08 763.56 806.39 1031.28 1121.46 1250.59 1368.55

45.00 45.00 45.00 45.00 45.00 45.00 45.00 45.00

684.89 727.15 821.08 867.34 1106.39 1201.85 1337.95 1461.13

10.00 10.00 10.00 10.00 n/a n/a n/a n/a

211.11 227.92 254.69 265.35 n/a n/a n/a n/a

14.00 14.00 14.00 14.00 15.00 15.00 15.00 15.00

241.53 260.24 290.28 302.41 430.36 449.60 493.59 549.13

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

279.57 300.64 334.76 348.74 476.36 497.88 545.85 605.56

24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50

267.55 289.53 324.20 337.75 475.62 497.08 547.88 613.24

48.00 48.00 48.00 48.00 49.00 54.00 60.00 60.00

452.37 487.88 544.19 566.43 771.76 870.43 1036.54 1146.85

63.75 63.75 68.50 n/a n/a n/a n/a n/a

367.83 397.14 443.56 n/a n/a n/a n/a n/a

20 CLCH-SVX07C-EN

Page 25

Unit Dimensions and Weights

Table 5. Section dimensions (inches) and wei gh ts (poun ds) - unit sizes 35-120

Unit size 35 40 50 57 66 80 100 120

Coils

-Small horizontal (with 4-row UW)

-Medium horizontal (with 8-row UW)

-Extended-medium horizontal

(with 8-row UW)

-Medium-large horizontal

(with 10-row W)

-Large horizontal or vertical

(with 10-row W)

6

Fan

-Belt-drive plenum fan with motor

-Housed fan (FC/AF/BC) with motor

-Direct-drive plenum fan with motor

Controls section (includes largest

available VFD)

Diffuser

Discharge plenum

-Horizontal

-Vertical

Blender

Electric Heat

7

Face-and-Bypass Dampers

-Internal face-and-bypass or

face damper only

-External face-and-bypass

Energy Wheel

CDQ Wheel

Integral-face-and-bypass coil

-Less than 4 rows

-4 rows

10.00 10.00 10.00 10.00 n/a n/a n/a n/a

679.61 743.10 915.56 1023.99 n/a n/a n/a n/a

14.00 14.00 14.00 14.00 15.00 15.00 15.00 15.00

1083.29 1208.28 1543.21 1739.24 2183.23 2518.10 3045.45 3584.41

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

1137.72 1267.13 1595.08 1793.51 2237.43 2574.51 3116.83 3660.64

24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50

1944.10 2204.75 2736.01 3195.47 3838.02 4447.61 5453.04 6662.13

48.00 48.00 48.00 48.00 n/a n/a n/a n/a

2140.10 2411.83 2991.25 3459.40 n/a n/a n/a n/a

53.50 53.50 57.50 59.50 61.00 63.00 73.75 82.25

2311.19 2676.28 3178.70 3496.17 3940.63 4590.36 6035.46 7133.78

63.75 63.75 68.50 68.50 84.00 92.00 96.00 96.00

2381.09 2641.30 3148.10 3211.05 4216.56 4980.29 5866.21 6705.45

55.50 60.00 65.00 65.00 54.75 54.75 54.75 54.75

1648.42 1910.99 2793.74 2851.21 3433.31 3950.32 5356.05 5525.47

24.50 24.50 24.50 24.50 24.50 24.50 24.50 24.50

574.55 596.53 631.20 644.75 782.62 804.08 854.88 920.24

24.50 24.50 24.50 24.50 27.50 37.25 37.25 37.25

365.56 389.25 428.01 445.57 664.01 809.34 876.54 955.28

48.00 48.00 48.00 48.00 49.00 54.00 60.00 60.00

474.26 511.01 570.20 594.26 773.17 810.80 891.34 989.20

63.75 63.75 68.50 n/a n/a n/a n/a n/a

779.25 840.96 989.88 n/a n/a n/a n/a n/a

48.00 48.00 48.00 48.00 49.00 54.00 60.00 60.00

540.76 593.46 675.51 731.75 970.30 1112.23 1345.03 1567.62

n/a n/a n/a n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a n/a n/a n/a

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

543.64 636.11 713.60 803.86 1026.07 1107.46 1236.82 1361.55

22.00 22.00 22.00 22.00 39.00 39.00 39.00 39.00

473.39 556.23 630.10 714.61 888.33 973.60 1093.88 1205.53

61.25 64.75 64.75 n/a n/a n/a n/a n/a

1497.92 1733.76 1995.01 n/a n/a n/a n/a n/a

56.25 56.25 58.75 n/a n/a n/a n/a n/a

2127.92 2323.76 3275.01 n/a n/a n/a n/a n/a

29.50 29.50 29.50 29.50 29.50 29.50 29.50 29.50

1129.66 1168.40 1793.80 1956.80 2322.61 2378.60 2865.77 2936.42

43.00 43.00 n/a n/a n/a n/a n/a n/a

1681.45 1726.58 n/a n/a n/a n/a n/a n/a

CLCH-SVX07C-EN 21

Page 26

Unit Dimensions and Weights

Table 5. Section dimensions (inches) and wei gh ts (poun ds) - unit sizes 35-120

Unit size 35 40 50 57 66 80 100 120

Humidifier

-Direct steam

-Atmospheric

Silencer

-3 ft

-5 ft

2-Deck or 3-Deck Multizone

- Horizontal discharge

- Vertical discharge

UV light

Gas heat (highest MBH)

Horizontal end cap

Diagonal economizer for

outdoor unit

Exhaust damper section for

outdoor unit

Hoods

- Side inlet hood (add to width) for

diagonal economizer

- Side inlet hood (add to width) for

mixing box

- Back inlet hood (add to length) for

mixing box

- Exhaust hood (add to length or

width)

Pipe cabinet weight

15 inches long, 36 inches deep 175.00 175.00 191.00 209.00 215.00 243.00 265.00 265.00

24 inches long, 36 inches deep 199.00 199.00 216.00 236.00 243.00 273.00 298.00 298.00

48 inches long, 36 inches deep 263.00 263.00 284.00 309.00 317.00 354.00 385.00 385.00

96 inches long, 36 inches deep 392.00 392.00 421.00 454.00 466.00 517.00 558.00 558.00

14.00 14.00 14.00 14.00 15.00 15.00 15.00 15.00

544.40 599.28 781.71 897.00 1123.05 1215.33 1362.86 1551.07

19.00 19.00 19.00 19.00 19.00 19.00 19.00 19.00

581.42 664.92 723.70 802.82 977.24 1078.41 1264.58 1491.95

38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00

918.37 973.72 1225.82 1331.88 1572.80 1741.00 2195.72 2554.94

62.00 62.00 62.00 62.00 62.00 62.00 62.00 62.00

1334.66 1439.39 1795.06 1944.98 2312.54 2555.39 3230.00 3786.24

78.00 78.00 78.00 n/a n/a n/a n/a n/a

1638.97 1760.51 2002.92 n/a n/a n/a n/a n/a

92.00 92.00 96.00 n/a n/a n/a n/a n/a

1881.25 2021.32 2466.01 n/a n/a n/a n/a n/a

14.00 14.00 14.00 14.00 15.00 15.00 15.00 15.00

325.48 352.71 394.34 419.43 574.52 604.11 667.60 758.72

94.00 91.00 100.00 100.00 101.00 101.00 102.00 102.00

2469.40 2560.00 3575.20 3285.90 3700.50 3190.80 4470.00 4426.60

10.00 10.00 10.00 10.00 10.00 10.00 10.00 10.00

246.10 267.20 301.30 315.20 429.90 452.10 502.40 565.70

75.00 83.00 72.00 75.50 83.00 86.00 93.00 93.00

973.26 1100.52 1168.76 1266.21 1722.26 1919.94 2289.68 2494.18

22.40 22.40 22.40 22.40 22.40 22.40 22.40 22.40

351.40 379.60 425.10 443.70 587.70 616.90 681.10 760.20

27.75 27.75 29.50 33.00 42.63 45.13 47.00 47.00

175.86 195.13 229.85 269.82 316.87 343.85 490.93 566.15

34.00 35.00 38.75 43.38 48.63 57.13 60.50 63.00

122.04 128.02 160.97 174.27 189.35 257.94 297.76 330.05

27.75 27.75 29.50 33.00 42.63 45.13 47.00 47.00

175.86 195.13 229.85 269.82 316.87 343.85 490.93 566.15

34.00 35.00 38.75 43.38 48.63 57.13 60.50 63.00

72.80 76.89 92.81 113.92 128.56 174.08 206.04 221.35

22 CLCH-SVX07C-EN

Page 27

Unit Dimensions and Weights

Fans/Motors

Starter/VFD Weights

Fan weights do not include starter/VFD weights. The table below gives approximate starter/VFD

weights.

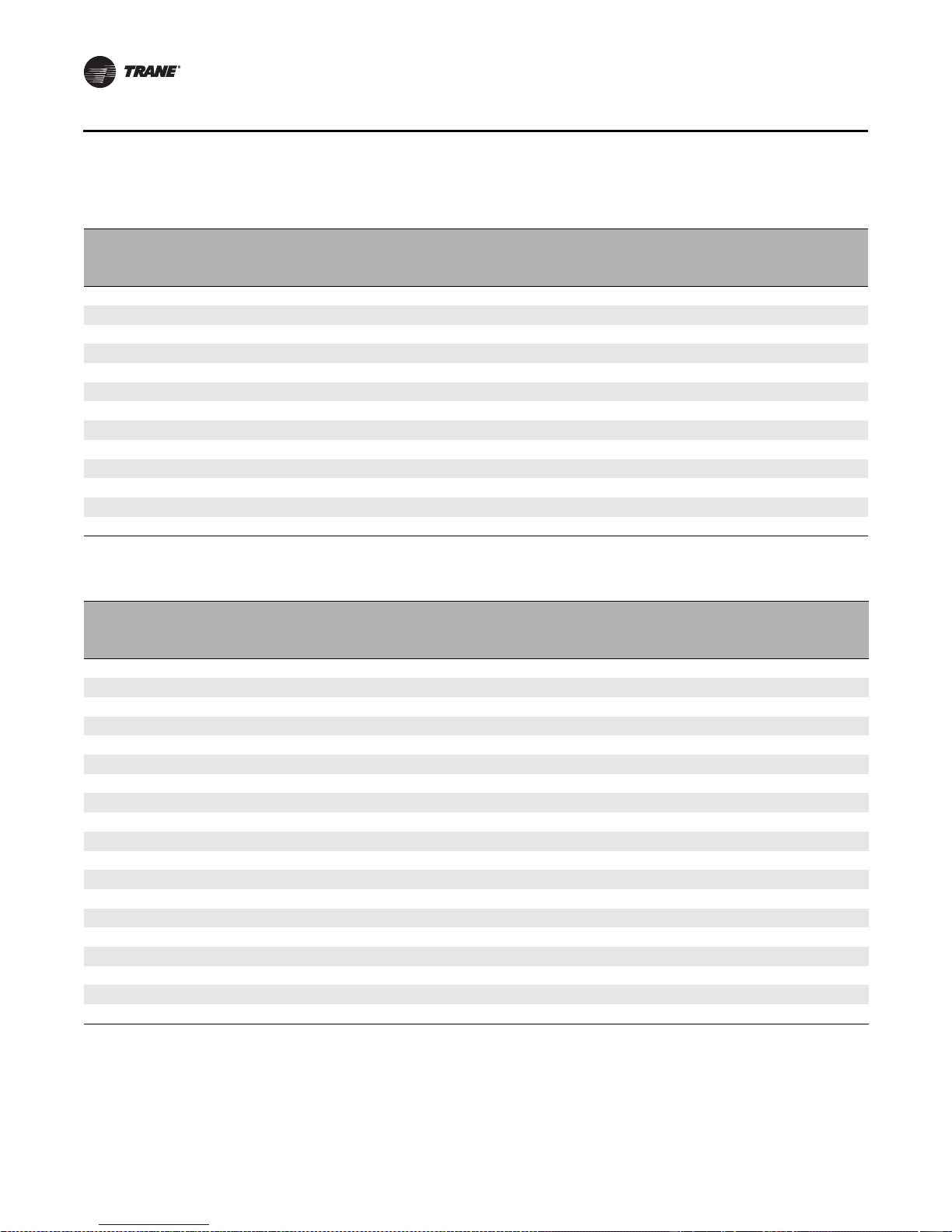

Table 6. Approximate starter and VFD weights per horsepower (lbs.)

Horsepower 1 1.5 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125

Note:1These weights represent the largest available starter. 2VFD weights include transformer, distribution block, and enclosure.

Motor Weights

Table 7. Appro x im ate motor weights (pounds)

Starter

VFD

1

2

65 65 65 65 65 65 65 65 65 97 97 97 97 97 97 97 97

123 123 132 124 125 136 151 162 177 197 241 325 332 243 258 294 314

Fan weights provided in this manual include the heaviest ODP (open drip-proof) motor.

Motor Type

Energy efficient

ODP (EEOP)

NEMA Premium

ODP (HEOP)

NEMA Premium

TEFC (HETC)

NEMA Premium

ODP (HEOP)

NEMA Premium

TEFC (HETC)

NEMA Premium

ODP (HEOP)

NEMA Premium

TEFC (HETC)

Motor

RPM

3/4 1 1-1/2 2 3 5 7-1/2 10 15 20 25 30 40 50 60 75 100 125

1800 24 29

1200/

6 pole

1800/

4 pole

3600/

2 pole

39 77 91 147 126 249 300 375 443 594 667

56 96 109 148 185 310 341 423 481 614 655

36 42 47 76 82 118 148 234 263 330 379 488 521 698 808 1114 1238

47 54 56 91 108 159 185 285 315 452 481 578 670 808 889 1239 1466

36 36 37 89 104 173 203 267 243 261 407

36 53 62 85 103 154 176 287 322 448 496

Horsepower

CLCH-SVX07C-EN 23

Page 28

Installation - Mechanical

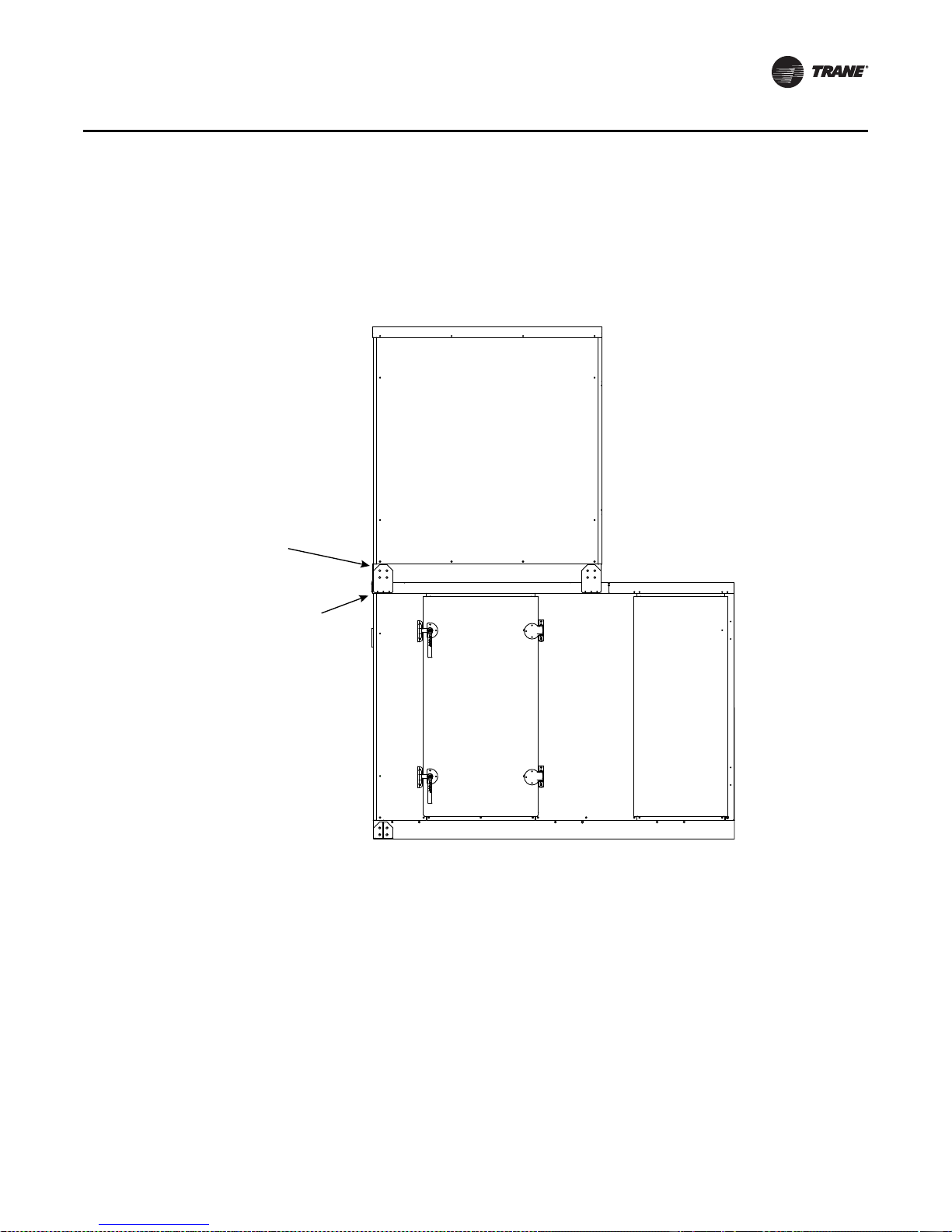

Angle, isolator

tie-down (4 required)

Screw (4 per angle)

Lockwasher and hex nut

Lifting and Rigging

Remove Shipping Tie-Downs

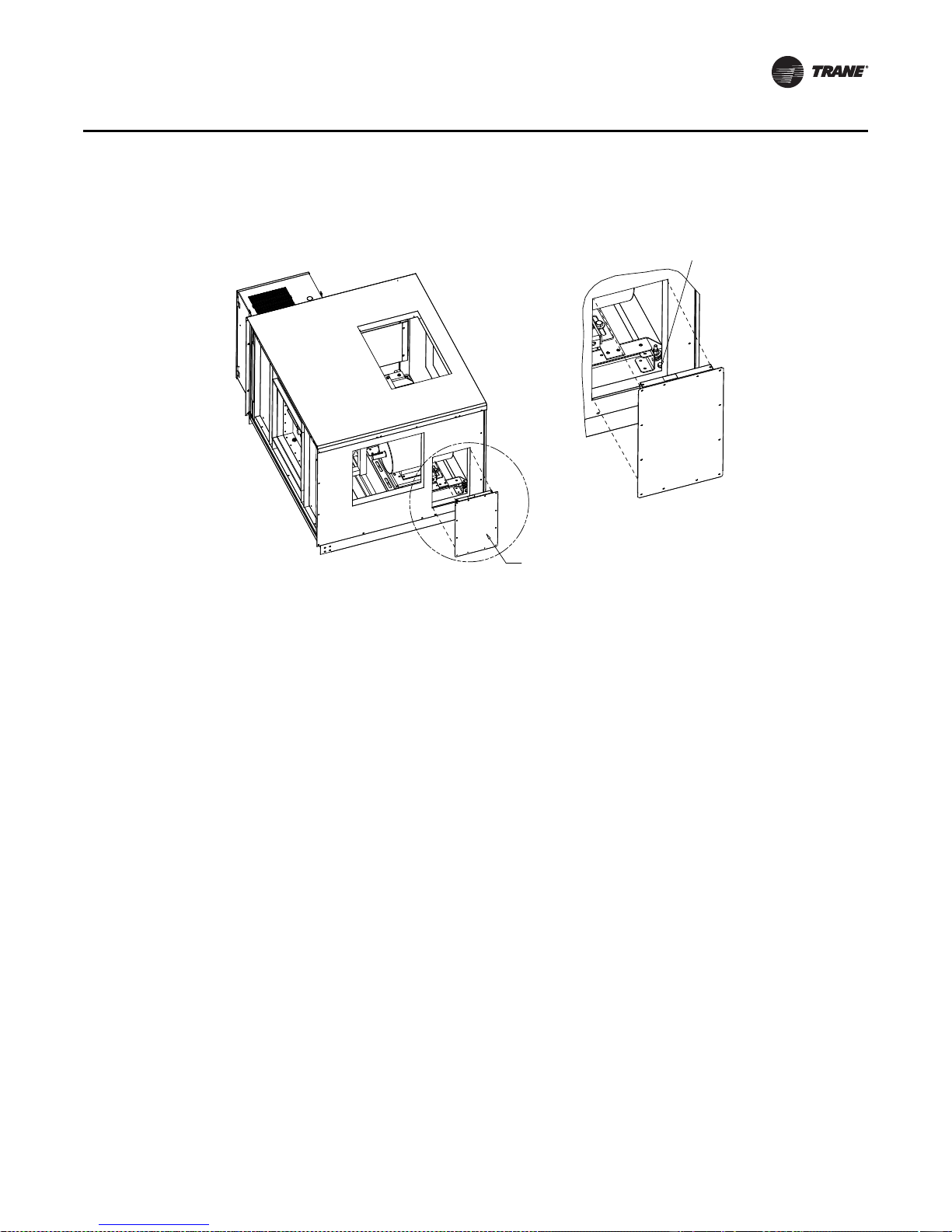

Figure 4. Isolator tie-down removal for unit sizes 35-120

Prior to unit placement, remove the shipping tie-downs per the following instructions:

• Shipping tie-downs are located at each corner of the isolation base. See Figure 51, Figure 52,

Figure 53 and Figure 54.

• Access for removal of shipping tie-downs for unit sizes 3-30 is available through th e fan section

access door or opposite drive-side plug panel. See Figure 5.

• Remove the bolt. This will release the isolator and make it possible to remove the pipe or spacer .

• Replace plug panel if applicable.

Note: For outdoor air handlers, after isolator tie-down is removed, remove the paper backing from

the butyl tape around plug panel perimeter prior to replacing plug panel.

24 CLCH-SVX07C-EN

Page 29

Figure 5. Plug panel plate

Remove Tie Down

Remove Plug Panel Plate

Installation - Mechanical

General Lifting Considerations

WARNING

Heavy Objects!

Always place, assemble, and suspend sections/subassemblies one at a time. Do not lift units in

windy conditions. Do not raise units o verhead with personnel below unit. F ailu r e to foll ow th ese

instructions could result in death, serious injury, or equipment damage.

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper center of gravity lift point. To avoid

dropping of unit, reposition lifting point if unit is not level. Failure to properly lift unit could

result in death or serious injury or possible equipment or property-only damage.

NOTICE:

Equipment Damage!

Keep skid in place until unit is r eady to set. Do not mo ve unit or su bassembly without the skid in

place as shipped from the factory. Premature skid removal could result in equipment damage.

Before preparing the unit for lifting, estimate the approximate center of gravity for lifting safety.

Because of placement of internal components, the unit weight may be unevenly distributed, with

more weight in the coil and fan areas. Approximate unit weights are pro vided in “Unit Dimensions

and Weights” on page 16. Refer to the unit submit tals for actual section weights. Test the unit for

proper balance before lifting.

For outdoor air handlers, preparation of the roof curb or pier mount and roof openings must be

completed before lifting to the roof. S e e CLCH-SVN04A-EN Roof Curbs for Performance Climate

Changer Air Handlers installation instructions for details.

CLCH-SVX07C-EN 25

Page 30

Installation - Mechanical

Rigging and spreader

bars furnished

by others

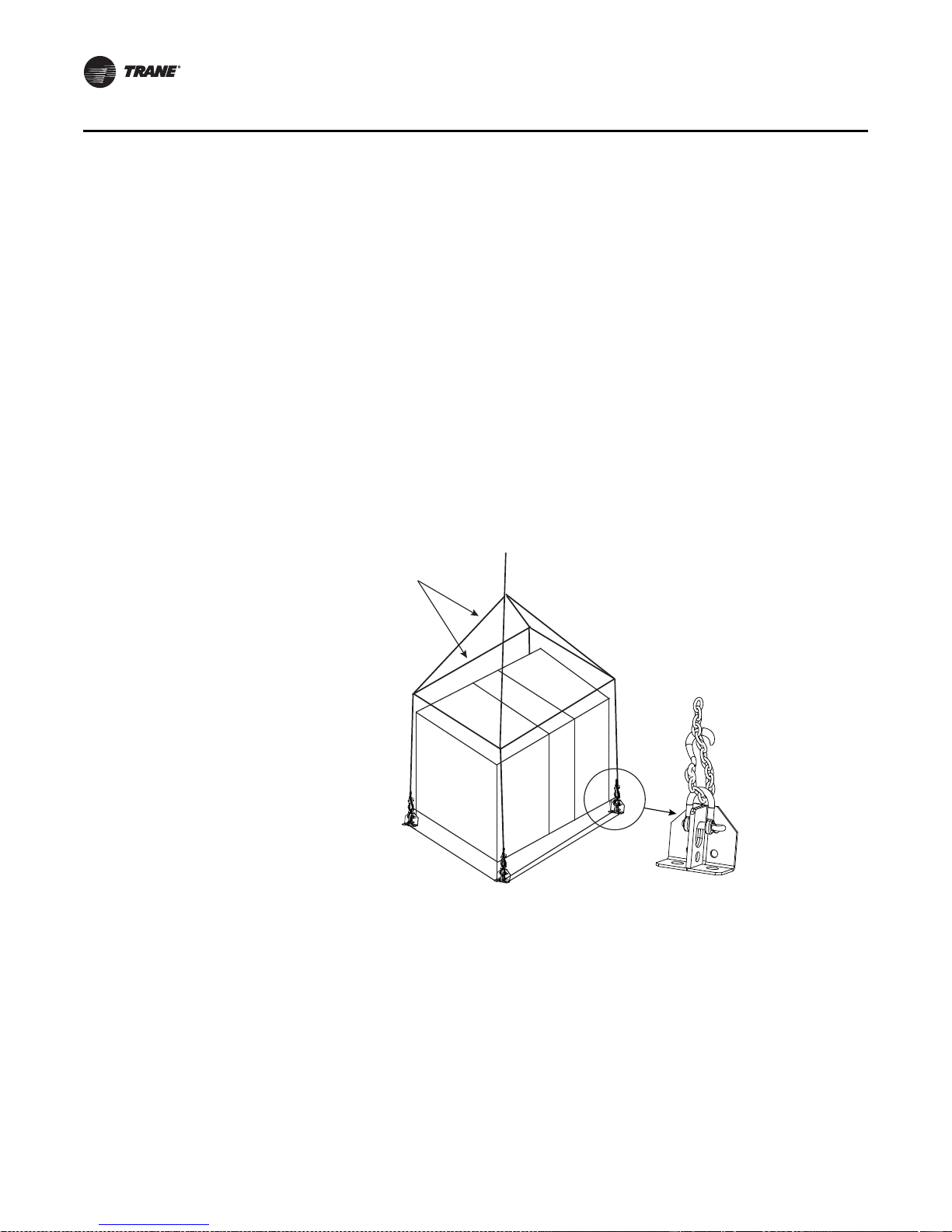

WARNING

Heavy Objects!

Do not use cables (chains or slings) except as shown. Each of the cables (chains or slings) used

to lift the unit must be capable of suppor ting the enti r e w eight of the unit. Lifting cables (chains

or slings) may not be of the same length. Adjust as necessary for even unit lift. Other lifting

arrangements may cause equipment or property-only damage. Failure to properly lift unit could

result in death or serious injury.

Always rig subassemblies or sections as they ship from the factory. Never bolt sections together

before rigging.

• Make the loop of the sling parallel to the direction of airflow, if possible.

• When hoisting the unit into position, use the proper rigging method, such as straps, slings,

spreader bars, or lifting lugs for protection and safety. Use all lifting lugs provided.

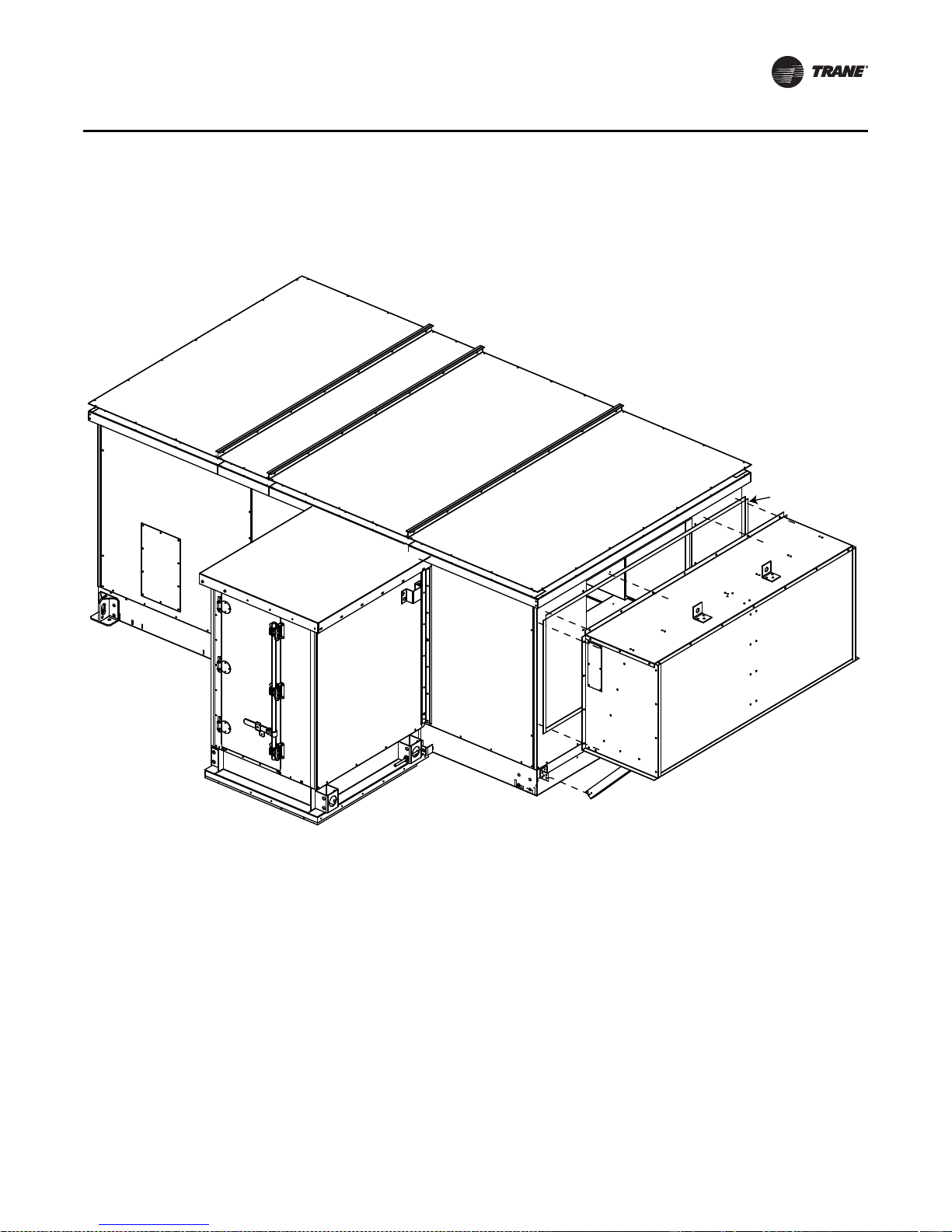

• For unit sizes 3 to 120 with integral base frame, use field-provided spreader bars and slings to

rig units and subassemblies as shown in Figure 6. The air handler is not designed to be lifted

or rigged from the top of the unit.

Figure 6. Lifting detail for unit sizes 3 to 120

26 CLCH-SVX07C-EN

Page 31

Installation - Mechanical

Unit lug

Pipe cabinet

or hood lug

Diameter

Width

Height

Figure 7. Lug holes

Table 8. Lug hole sizes

Section Location Unit Size Width Height

Indoor 3-30 0.88 1.38

Unit Lug

Hole Size

Pipe Cabinet Outdoor 3-120 2.5-in. diameter

Hood Outdoor 3-120 1-in. diameter

Indoor 35-57 1.38 1.25

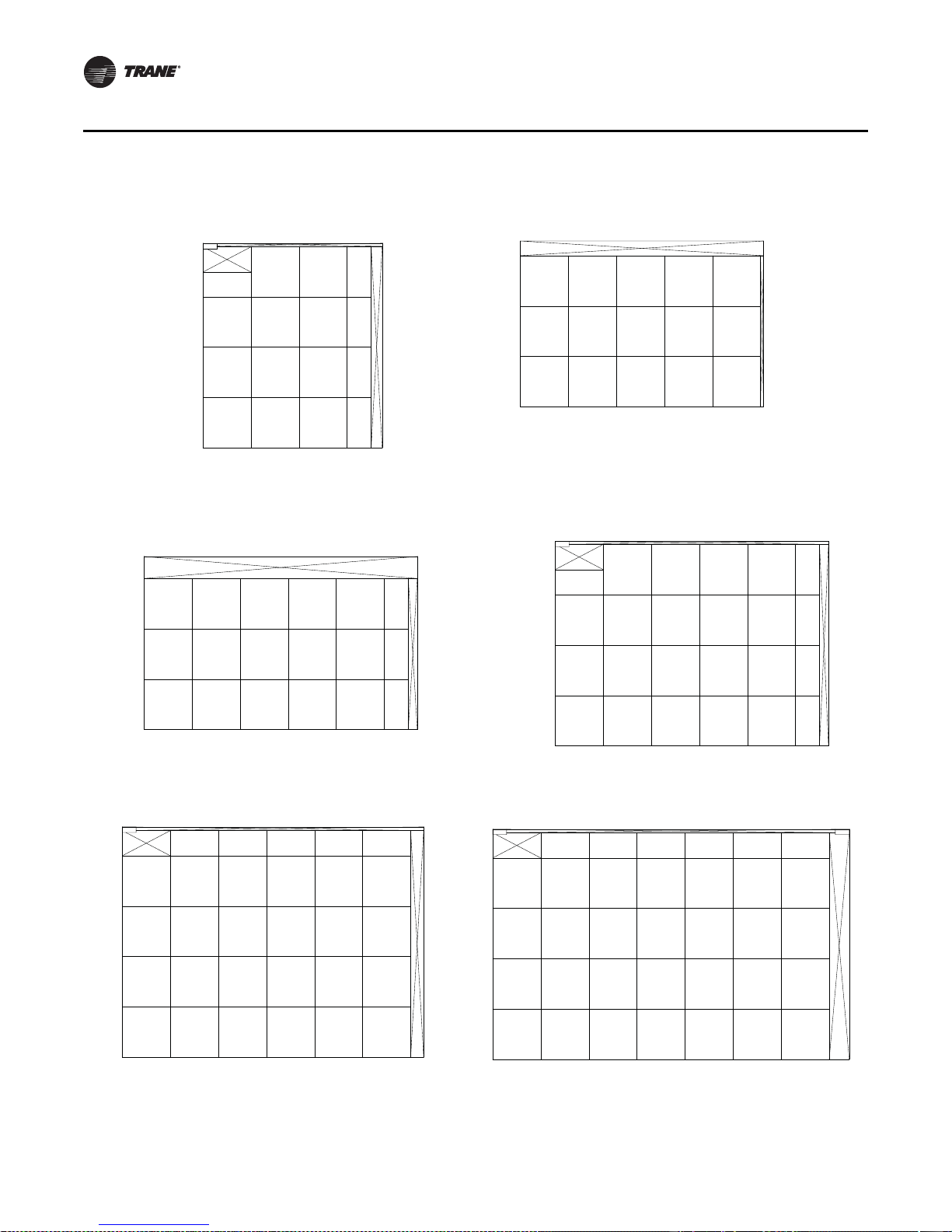

Indoor 66-120 1.25 2.75

Outdoor 3-30 1.25 2.75

• \For outdoor air handlers, never stack the pipe cabinet or inlet hood on the unit as it is being

lifted.

• Do not attach the intake/exhaust hood or pipe cabinet to the unit prior to lifting the unit. Doing

so may damage the equipment. Attac h the hoods to the unit only after all sections are in place.

• For outdoor air handlers, all shipping supports and crating on the face of the sections must be

removed to permit proper fit-up and sealing of the surfaces. Dispose of properly.

Lifting Inlet and Exhaust Hoods and External Pipe Cabinet (Chase)

WARNING

Heavy Objects!

Always place, assemble, and suspend modules/subassemblies one at a ti me. Placing,

assembling, and/or suspending more than one module/subassembly at a time could result in

death, serious injury, or equipment damage.

See Figure 7 and Table 8 for lug hole sizes.

Figure 8. Inlet and exhaust hood lifting Figure 9. Pipe cabinet lifting

CLCH-SVX07C-EN 27

Recommended

attachment to

lift lugs

Rigging and spreader

bar provided by

contractor

Recommended

attachment to

lifting lugs

Page 32

Installation - Mechanical

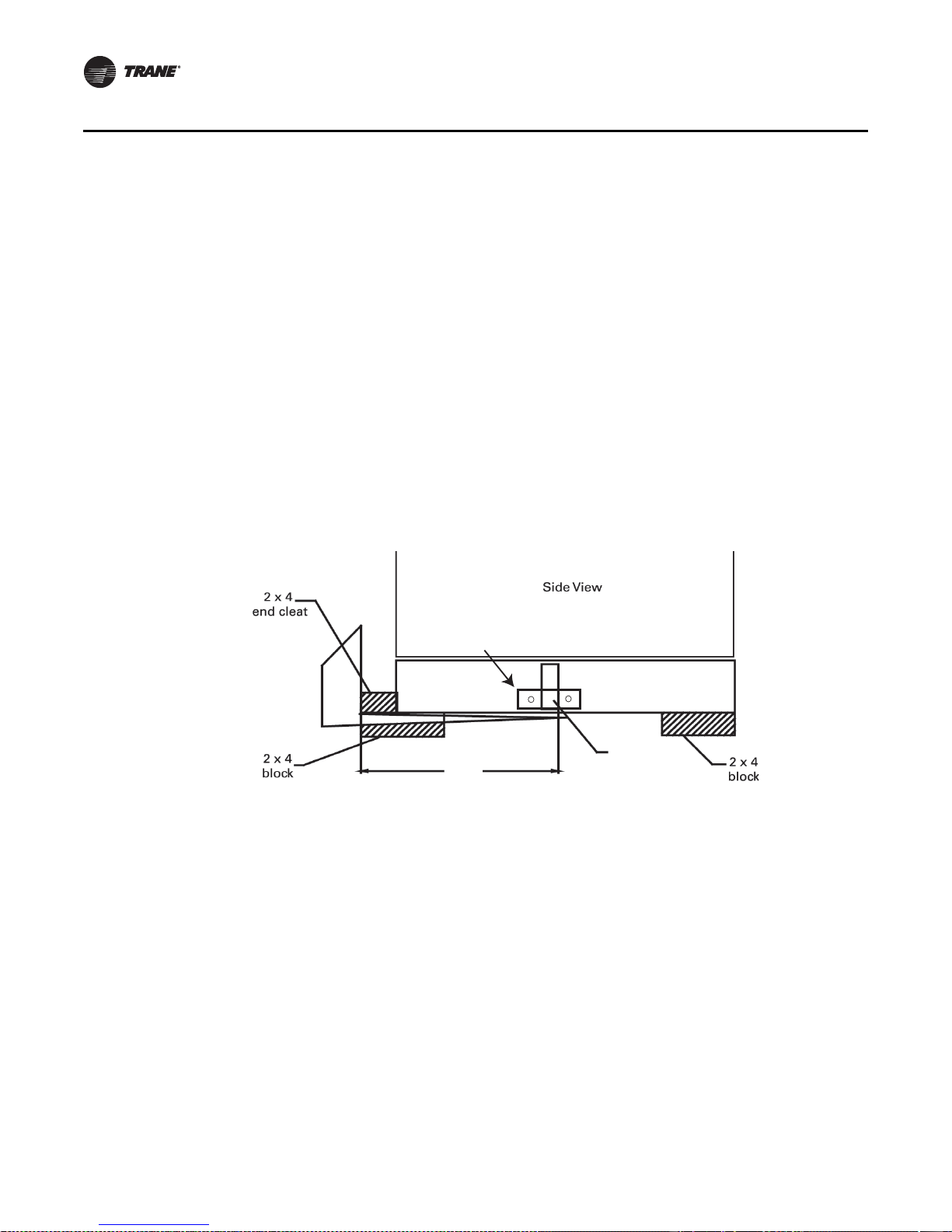

48 in.

Wooden toe

cleat or metal

cross beam

Unfasten external bracket

to remove wooden toe cleat.

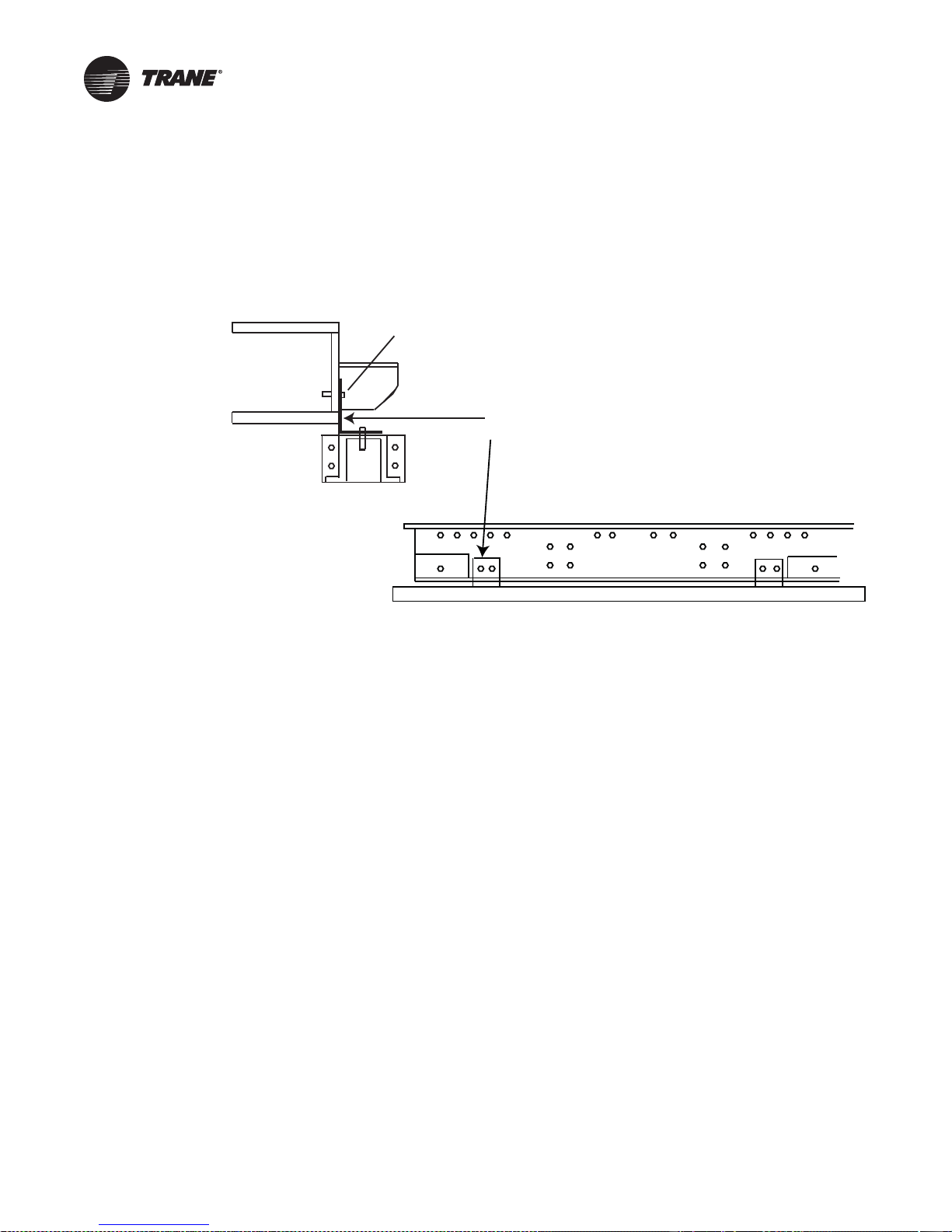

Forklifting Considerations for Indoor Units Size 3-30

NOTICE:

Equipment Damage!

Improper use of f o rk lifts could r e sul t in eq uipment damage. Fork l ifting from any location other

than that recommended by Trane and indicated on the unit labels could result in unit damage.

Trane is not responsible for equipment damage resulting from improper forklifting practices.

Note: Do not use a forklift on outdoor air handlers or indoor air handlers/subassemblies larger

than size 30.

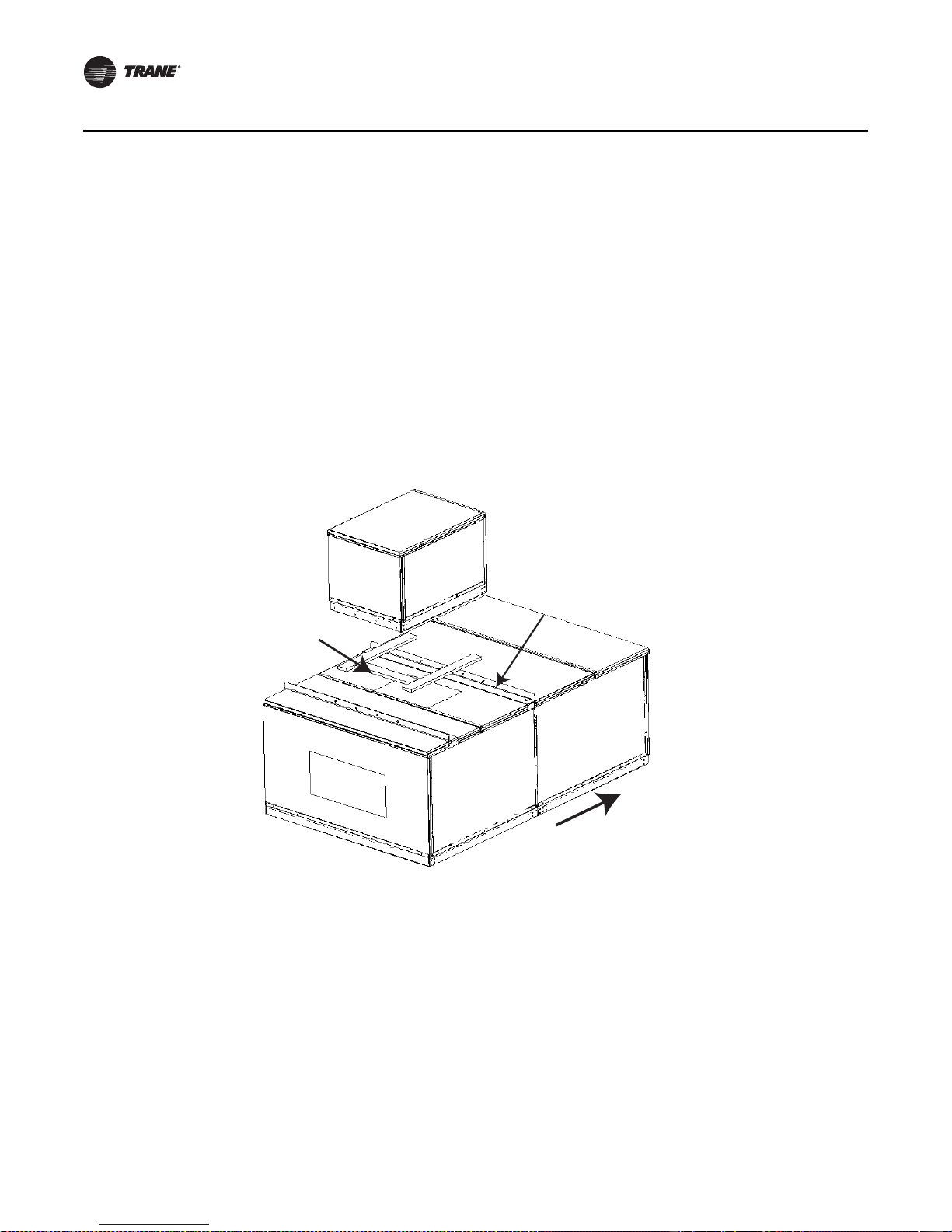

For unit sizes 3-30, a fork lift may be used to lif t a single section or smal l subassembly, provided the

forks extend under both ends of the base frame, or as indicated in Figure 10. The forks should not

contact the bottom of the air handler. Units should only be lifted from the proper end identified by

the lifting label on the unit.

A lifting crane or other means should be used for larger units where forks cannot extend under bo th

base rails.

Figure 10. Fork lift points with base rail

Unit Placement and Assembly

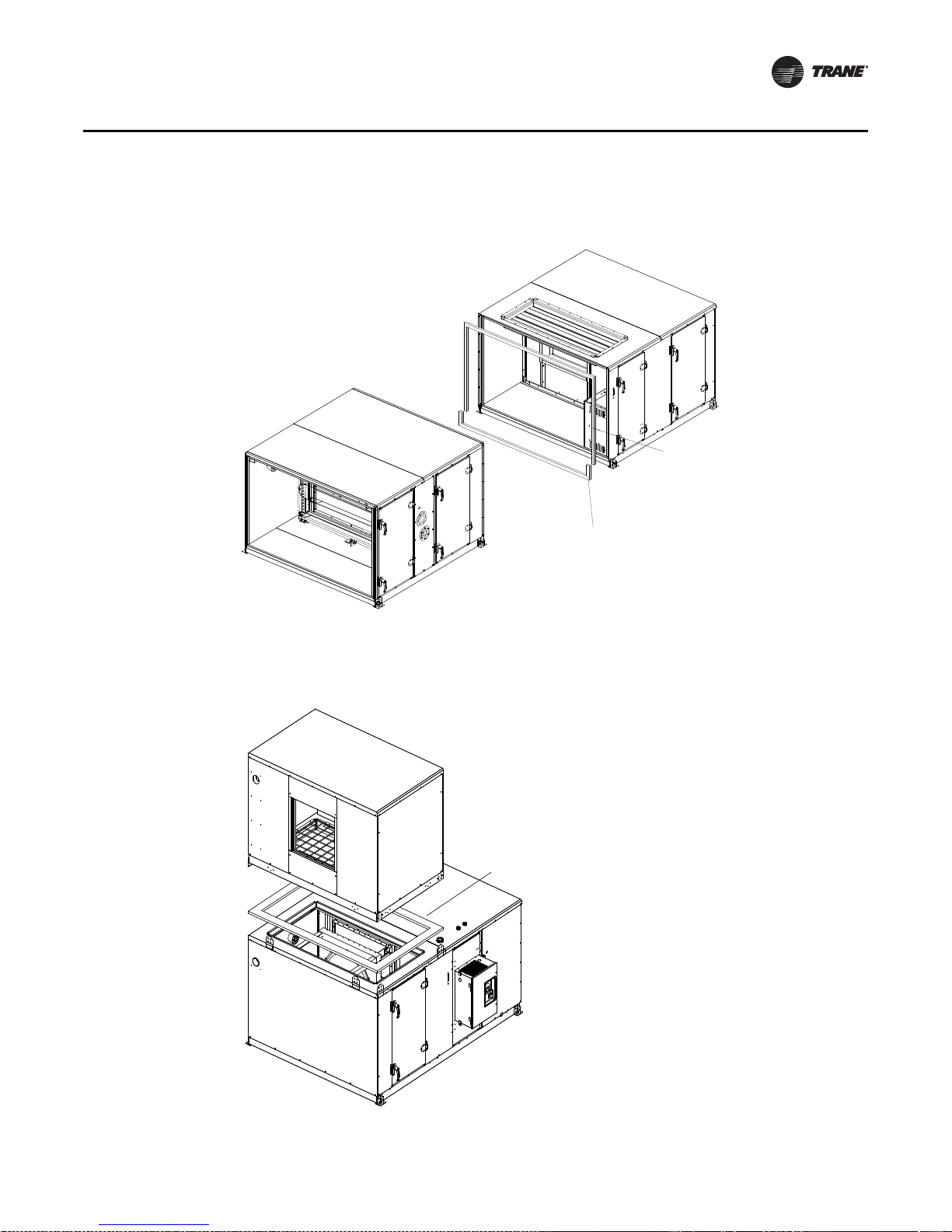

If the air handler ships in subassemblies or in individual sections, some assembly is required,

including:

• Ceiling-suspended indoor unit assem bly; see See “Ceiling Suspension f or Indoor Air Handlers

Sizes 3-57” on page 30.

• Section-to-section assembly; see “Section-to-Section Assembly” on page 32.

WARNING

Toxic Fumes!

Keep open flame away from unit exterior or interior. Do not weld or use cutting torch on the

28 CLCH-SVX07C-EN

exterior or interior of the unit. The unit contains polyurethane insulation. Failure to keep open

flame away form unit exterior or interior could result in the production of toxic gas that could

result in death or serious injury.

Page 33

Unit Placement

Installation - Mechanical

NOTICE:

Temperature Limit!

The internal sections of this unit containing electrical components must not exceed 104o F

operating temperature. Internal sections of the unit not containing electrical components must

not exceed 200o F temperature. Failure to comply with temperature requirements could cause

equipment damage.

WARNING

Heavy Objects!

Always place, assemble, and s uspend sections/subassemblies one at a time. Placing, assembling,

and/or suspending more than one section/subassembly at a time could result in death, serious

injury, or equipment damage.

NOTICE

Microbial Growth!

The roof curb or foundation must be level and the condensate drain at the proper height for

proper coil drainage and condensate flow. Standing water and wet surfaces inside the

equipment can become an amplification site for microbial growth (mold), which may cause

odors and damage to the equipment and building materials.

If a unit arrives in sections, then eac h section must be individually hoisted, set on the housekeeping

pad, roof curb, or pier mount and then assembled.

Refer to the unit submittals and unit tagging for co r rect placement of all sections. If there are any

discrepancies between the submi ttals and the unit tagging, contact your local T rane representative

before proceeding.

Following the order of the sections on the unit submittals and tagging, individually place each

unassembled section or subassembly in the appropriate installation location.

Note: Prior to placing fan section in the appropriate installation location, verify shipping tie-downs

have been removed.

For outdoor units, the pipe cabinet must also be mounted as an individual section. Refer to “Pipe

Cabinet Installation” on page40 for specific instructions.

When mounting the unit on a roof curb, make sure the gasketing between the roof curb and unit

base provides an airtight seal.

When mounting the unit on a pier mount, locate one pier at each corner as a minimum, directly

underneath any shipping split (ensure full support under each side) and then every four feet at

equally spaced intervals around the perimeter of the unit. Both the unit and the pipe cabinet should

be supported by their base around the entire perimeter. See Figure 11 and Figure 12.

For proper operation, the unit must be installed level (z ero tolerance) in both horizontal axes. For

vertical discharge units, allow space under the unit for supply air ductwork connections.

CLCH-SVX07C-EN 29

Page 34

Installation - Mechanical

Piers

4 ft

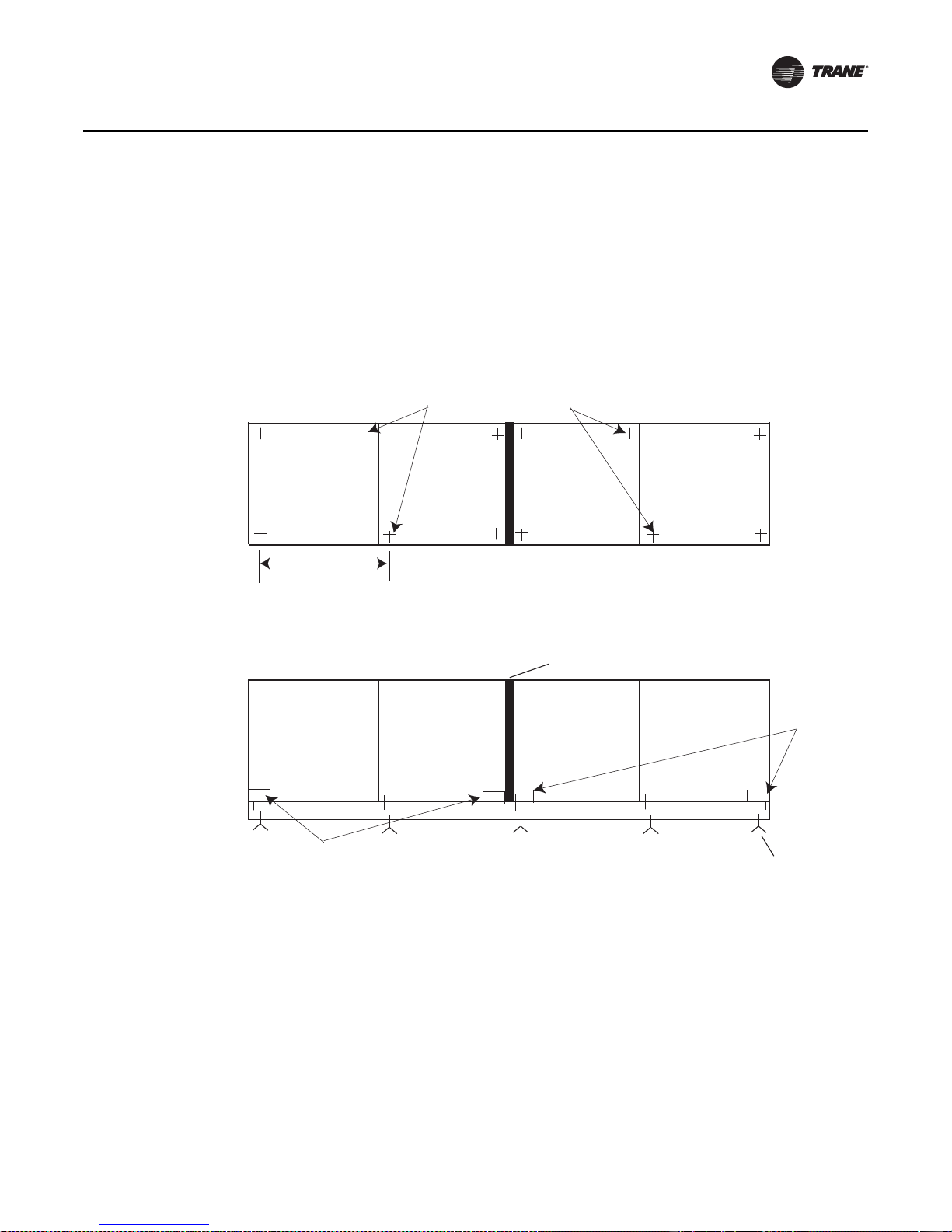

Figure 11. Piers located in each corner and spaced

evenly eve ry four feet

Note: Piers beneath shipping splits must be structurally sound to support the weight of the unit.

Figure 12. Side view with two shipping splits - locate one

pier directly under each shipping split

Unit Assembly

Note: Air handlers often include optional factory-provided casing penetration entry points for