Page 1

Modular

Multi-position

Air Handlers

GAT2A0B42S31SA

GAT2A0C48S41SA

GAT2A0C60S51SA

PUB. NO. 22-1857-03

Page 2

Features

and Benefits

• Unique Cabinet Design

- Double Wall Foamed and Formed

Cabinet System

- Water Proof Cabinet Design

- R-4.2 Insulating Value (Avg. Insulating

Value R-8.2)

- Composite Foamed Cabinet Doors

- Sweat Eliminating Cabinet Design

- Loose Fiber Eliminating Cabinet

Design

- Smooth Cleanable Cabinet Design

- 2% or Less air leakage

- Precision Applied Durable Door Seals

- Tool-free Fasteners on Blower/Filter

Door

- Modular Cabinet

• Multi-Position Upflow/ Horizontal Left

/ Horizontal Right

• Braze in Refrigerant Connection

• Primary/Secondary Condensate

Connections

• Premarked Conduit Connection

Locations

• Vortica Blower with Integrated Slide

Deck for Easy Removal

• Polarized Plug connections on

Blower

• Control Protection Pocket

• Aluminum Coil with Integrated Slide

Deck for Easy Removal

• Slide in Electric Heaters

• Polarized Plug connections for

Electric Heater

• Labeled Panels and connections

• 1-1/4" to 1" And 3/4" to 1/2" Conduit

connection on Left, Right and Top

• Molded in 1" Standard Filter rail

• R-410A Thermal Expansion Valve

(TXV)

• Low Voltage Terminal Connection

Point

• Enhanced Coil Fin Patented

• Blow Through Design

• PSC 3 Speed Motor on 3.5 & 4 ton

models

• Constant torque ECM Motor on 5 ton

model

• Maximum Width of 23.5"

• Compact 20.8" depth with doors

removed

• Integrated Horizontal Drain pans

• Single Color

• Fused 24V Power

• Safety Door Switch

• 5 year warranty

• 10-year warranty registered

• Optional extended warranty

available

© 2012 Trane

2 Pub. No. 22-1857-03

Page 3

Contents

Features and Benefits 2

Optional Equipment 4

Unique Cabinet Design Features and Benets 5

General Data 6

GAT2A0B42S31SA 6

GAT2A0C48S41SA 6

GAT2A0C60S51SA 6

Performance Data 7

Electrical Data 10

Wiring Diagrams 13

Field Wiring 15

Convertibility 17

Dimensions 18

Pub. No. 22-1857-03 3

Page 4

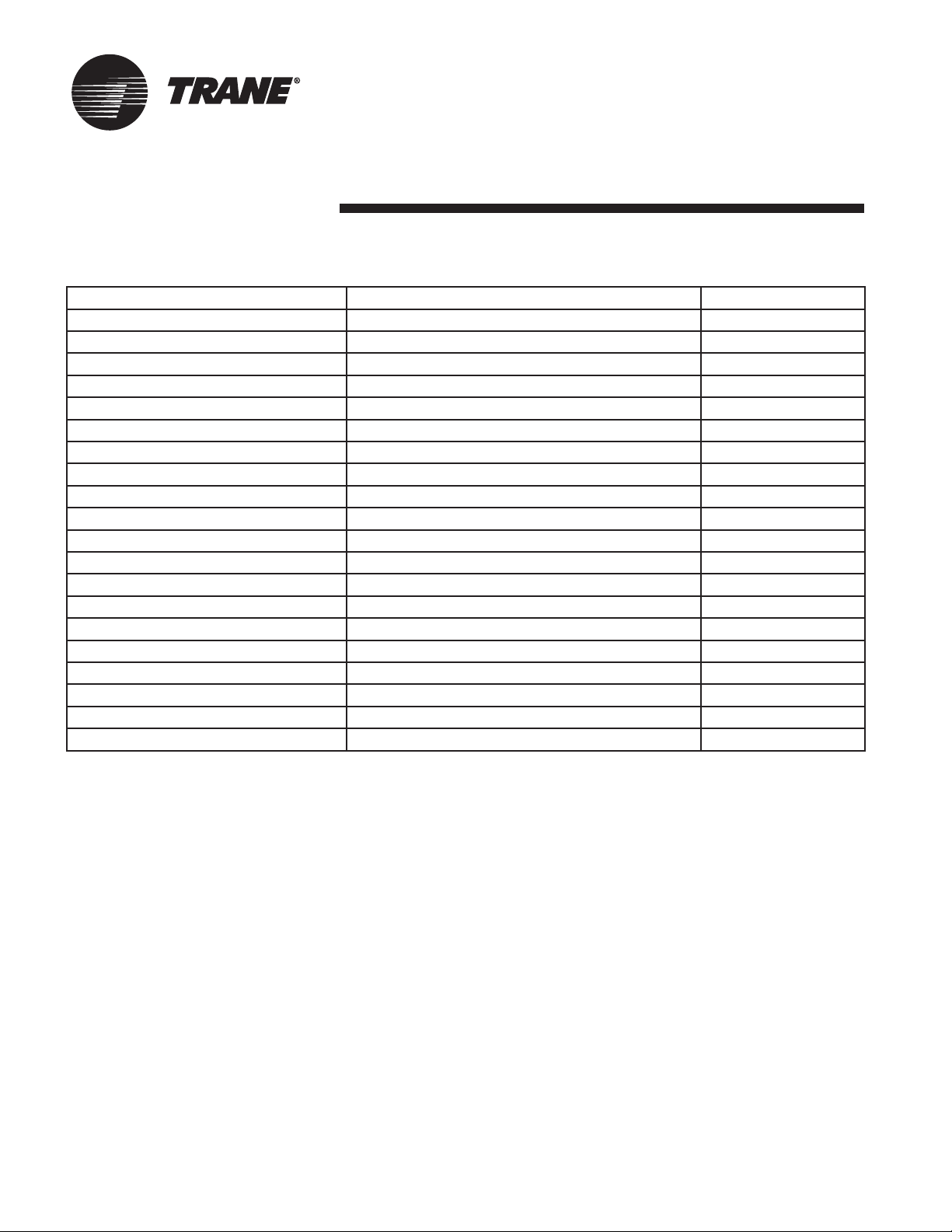

Optional Equipment

OPTIONAL EQUIPMENT FOR AIR HANDLERS

Accessory Number Description Fits Cabinet Size

BAYEAAC05BK1A Electric Heater, 5kW, Breaker, 24V Control, 1 Ph A to C

BAYEAAC05LG1A Electric Heater, 5kW, Lugs, 24V Control, 1 Ph A to C

BAYEAAC08BK1A Electric Heater, 8kW, Breaker, 24V Control, 1 Ph A to C

BAYEAAC08LG1A Electric Heater, 8kW, Lugs, 24V Control, 1 Ph A to C

BAYEAAC10BK1A Electric Heater, 10kW, Breaker, 24V Control, 1 Ph A to C

BAYEAAC10LG1A Electric Heater, 10kW, Lugs, 24V Control, 1 Ph A to C

BAYEABC15BK1A Electric Heater, 15kW, Breaker, 24V Control, 1 Ph B to C

BAYEABC20BK1A Electric Heater, 20kW, Breaker, 24V Control, 1 Ph B to C

BAYEACC25BK1A Electric Heater, 25kW, Breaker, 24V Control, 1 Ph C

BAYSUPFLGBA Supply Duct Flange B B

BAYSUPFLGCA Supply Duct Flange C C

BAYRETFLGB Return Duct Flange B B

BAYRETFLGCA Return Duct Flange C C

TASB215SB Plenum Stand B with integrated sound baffle B

TASB235SB Plenum Stand C with integrated sound baffle C

BAYSRKIT100A Side Return Kit A to C

BAYICSKIT01A Internal Condensate Switch Kit A to C

BAYHHKIT001A Horizontal Hanger Kit A to C

BAYUVCLK001A UVC Lights A to C

BAYLVKIT100A Low Voltage Conduit Entry Kit A to C

4 Pub. No. 22-1857-03

Page 5

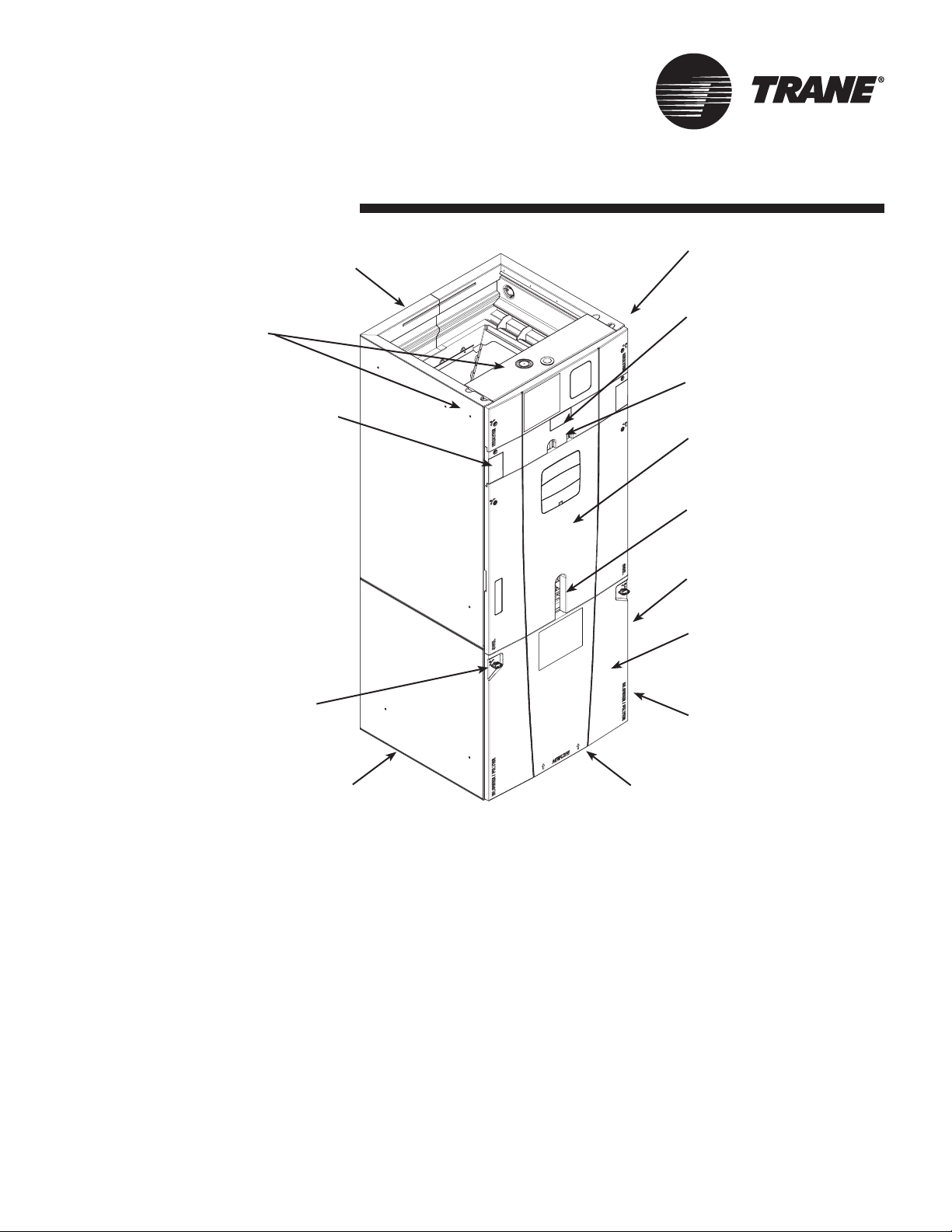

Unique Cabinet

Design Features and Benefits

1 Unique Cabinet Design

5 Conduit

Connections

e Integrated Horizontal

Drain Pans

2 Precision Durable

Door Seals

0 Thermal Expansion

Valve (TXV)

3 Refrigeration

Connections

8 All Aluminum Coil

4 Condensate

Connections

r Safety Door Switch

7 VorticaTM Blower

and Deck

6 Tool-less Door

Fasteners

w Compact 20.8” Depth

with Doors Removed

1 Unique Cabinet Design

- Double wall foamed cabinet system

- Waterproof Cabinet Design

- R-4.2 Insulating Value (Avg Insulating Value R-8.2)

- Composite Foamed Cabinet Doors

- Sweat Eliminating Cabinet Design

- Loose Fiber Eliminating Design

- Smooth Cleanable Cabinet Design

2 Precision Durable Door Seals

3 Refrigeration Connections

4 Condensate Connections

5 Conduit Connections - Conduit Connections on Left,

Right, and Top

6 Tool-less Door Fasteners

7 VorticaTM Blower and Deck - Polarized Plug on Blower

9 Labeled Panels

and Connections

q Maximum width

is 23.5”

8 All Aluminum Coil

- Integrated Slide Deck for Easy Removal

- Polarized Plug connections on Coil EEV

- Patented Enhanced Coil Fin

9 Labeled Panels and Connections

0 R-410A Thermal Expansion Valve (TXV)

q Maximum width is 23.5”

w Compact 20.8” Depth with Doors Removed

e Integrated Horizontal Drain Pans

r Safety Door Switch - Fused 24V Power

t Modular Cabinet

Pub. No. 22-1857-03 5

Page 6

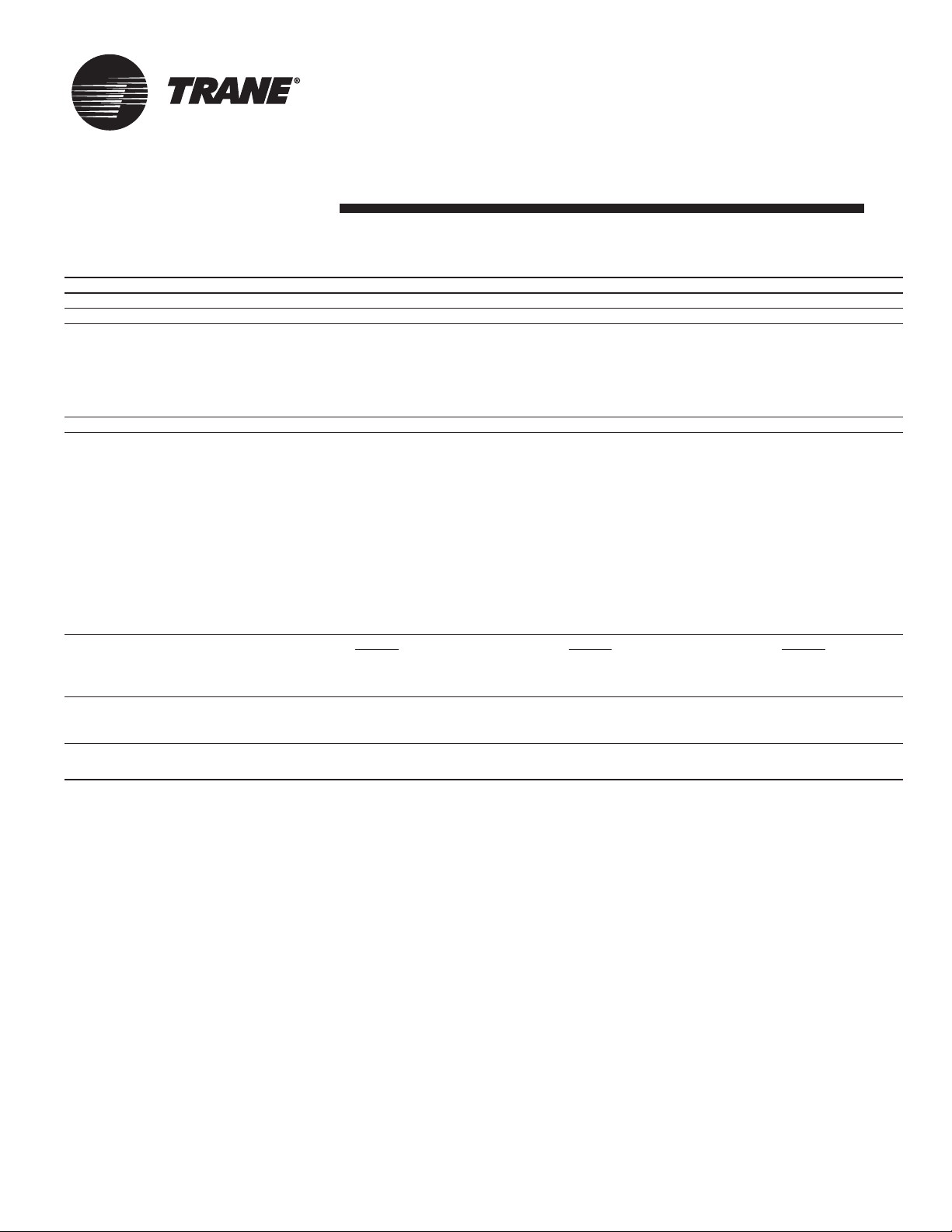

General

Data

MODEL

RATED VOLTS/PH/HZ.

RATINGS 1

INDOOR COIL — Type

Rows — F.P.I.

Face Area (sq. ft.)

Tube Size (in.)

Refrigerant Control

Drain Conn. Size (in.) 2

DUCT CONNECTIONS

INDOOR FAN — Type

Diameter-Width (In.)

No. Used

Drive - No. Speeds

CFM vs. in. w.g.

No. Motors — H.P.

Motor Speed RPM

Volts/Ph/Hz

F.L. Amps - L.R. Amps

FILTER

Filter Furnished?

Type Recommended

No.-Size-Thickness

REFRIGERANT

Ref. Line Connections

Coupling or Conn. Size — in. Gas

Coupling or Conn. Size — in. Liq.

DIMENSIONS

Crated (In.)

Uncrated

WEIGHT

Shipping (Lbs.) / Net (Lbs.)

GAT2A0B42S31SA

PRODUCT SPECIFICATIONS

208-230/1/60

See O.D. Specifications

Plate Fin

3 - 14

5.04

3/8

TXV

3/4 NPT

See Outline Drawing

Centrifugal

10 X 10

1

Direct - 3

See Fan Performance Table

1 - 1/2

1075

208-230/1/60

2.7 - 5.0

No

Throwaway

1 - 20 X 20 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

56.8 x 23.5 x 24.5

55.7 x 21.3 x 21.8

144/133

GAT2A0C48S41SA

208-230/1/60

See O.D. Specifications

Plate Fin

3 - 14

5.50

3/8

TXV

3/4 NPT

See Outline Drawing

Centrifugal

11 X 10

1

Direct - 3

See Fan Performance Table

1 - 1/2

1075

208-230/1/60

3.1 - 5.5

No

Throwaway

1 - 20 X 22 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

58 x 25.5 x 24.5

56.9 x 23.5 x 21.8

155/143

GAT2A0C60S51SA

208-230/1/60

See O.D. Specifications

Plate Fin

4 - 14

5.50

3/8

TXV

3/4 NPT

See Outline Drawing

Centrifugal

11 X 10

1

Direct - 5 3

See Fan Performance Table

1 - 1

1050

208-230/1/60

7.6 - n/a

No

Throwaway

1 - 20 X 22 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

62.8 x 25.5 x 24.5

61.7 x 23.5 x 21.8

171/159

1 These Air Handlers are AHRI certified with various Split System Air Conditioners

and Heat Pumps (AHRI STANDARD 210/240). Refer to the Split System Outdoor

Unit Product Data Guides for performance data.

2 3/4" Male Plastic Pipe (Ref.: ASTM 1785-76)

3 Constant torque Motor

6 Pub. No. 22-1857-03

Page 7

General

Data

GAT2A0B42 AIRFLOW PERFORMANCE TABLE

AIRFLOW PERFORMANCE

GAT2A0B42S31SA

EXTERNAL STATIC

(in w.g)

Speed Taps - 230 VOLTS Speed Taps - 208 VOLTS

3 2 † 1 3 2 † 1

0 1646 1495 1358 1522 1298 1138

0.1 1599 1464 1335 1489 1285 1137

0.2 1546 1421 1313 1449 1260 1120

0.3 1488 1380 1280 1401 1233 1099

0.4 1425 1329 1233 1348 1193 1065

0.5 1353 1264 1178 1281 1140 1023

0.6 1259 1182 1108 1202 1075 958

0.7 1145 1081 995 1102 965 868

0.8 982 909 839 926 817 753

0.9 788 759 731 761 713 N/A

1.0 563 N/A N/A 538 N/A N/A

NOTES:

1. Values are with wet coil and without filters.

2. Contact your particular filter manufacturer for pressure drop data.

3. Electric heater pressure drop is negligible and is included within the airflow data.

4. † Factory Setting

AIRFLOW (CFM)

GAT2A0B42S31SA MINIMUM HEATER AIRFLOW CFM

Heater Minimum Air Speed Tap

With Heat Pump Without Heat Pump

BAYEAAC05BK1AA

BAYEAAC05LG1AA

BAYEAAC08BK1AA

BAYEAAC08LG1AA

BAYEAAC10BK1AA

BAYEAAC10LG1AA

BAYEABC15BK1AA Tap 1 Tap 1

BAYEABC20BK1AA Tap 3 Tap 1

SEE AIR HANDLER NAMEPLATE FOR ADDITIONAL INFORMATION

Pub. No. 22-1857-03 7

Tap 1 Tap 1

Tap 1 Tap 1

Tap 1 Tap 1

Note: Heating and cooling

speeds are the same, factory

set at Speed Tap #2.

Page 8

Performance

Data

GAT2A0C48 AIRFLOW PERFORMANCE TABLE

AIRFLOW PERFORMANCE

GAT2A0C48S41SA

EXTERNAL STATIC

(in w.g)

Speed Taps - 230 VOLTS Speed Taps - 208 VOLTS

3 2 † 1 3 2 † 1

0 1904 1711 1541 1652 1455 1305

0.1 1881 1687 1529 1640 1450 1288

0.2 1844 1666 1511 1619 1425 1271

0.3 1806 1637 1485 1592 1410 1249

0.4 1766 1602 1454 1559 1381 1231

0.5 1716 1560 1420 1524 1351 1198

0.6 1659 1513 1380 1484 1321 1165

0.7 1594 1458 1333 1434 1283 1127

0.8 1525 1395 1277 1376 1229 1067

0.9 1442 1310 1194 1304 1149 N/A

1.0 1345 N/A N/A 1194 N/A N/A

NOTES:

1. Values are with wet coil and without filters.

2. Contact your particular filter manufacturer for pressure drop data.

3. Electric heater pressure drop is negligible and is included within the airflow data.

4. † Factory Setting

AIRFLOW (CFM)

GAT2A0C48S41SA MINIMUM HEATER AIRFLOW CFM

Heater Minimum Air Speed Tap

With Heat Pump Without Heat Pump

BAYEAAC05BK1AA

BAYEAAC05LG1AA

BAYEAAC08BK1AA

BAYEAAC08LG1AA

BAYEAAC10BK1AA

BAYEAAC10LG1AA

BAYEABC15BK1AA Tap 1 Tap 1

BAYEABC20BK1AA Tap 1 Tap 1

BAYEACC25BK1AA Tap 3

1 Not qualified for 208 V

SEE AIR HANDLER NAMEPLATE FOR ADDITIONAL INFORMATION

8 Pub. No. 22-1857-03

Tap 1 Tap 1

Tap 1 Tap 1

Tap 1 Tap 1

Tap 2 1

Note: Heating and cooling

speeds are the same, factory

set at Speed Tap #2.

Page 9

Performance

Data

GAT2A0C60 AIRFLOW PERFORMANCE TABLE

AIRFLOW PERFORMANCE

GAT2A0C60S51SA

EXTERNAL STATIC

(in w.g)

Speed Taps - 230 VOLTS Speed Taps - 208 VOLTS

5 4 † 3 2 1 5 4 † 3 2 1

0 2169 1956 1874 1739 1633 2165 2033 1871 1736 1629

0.1 2161 1916 1839 1696 1588 2155 1990 1833 1690 1582

0.2 2130 1889 1803 1667 1554 2121 1961 1795 1659 1545

0.3 2102 1850 1774 1628 1523 2090 1919 1763 1617 1511

0.4 2066 1818 1741 1596 1491 2052 1884 1727 1582 1477

0.5 2015 1785 1707 1564 1457 1998 1848 1690 1547 1440

0.6 1959 1754 1673 1520 1408 1939 1814 1653 1500 1389

0.7 1888 1716 1638 1477 1372 1880 1774 1615 1455 1349

0.8 1811 1680 1605 1440 1323 1820 1735 1580 1415 1298

0.9 1750 1628 1561 1403 1291 1770 1680 1533 1376 1263

1.0 1680 1604 1533 1368 1256 1725 1654 1503 1337 1226

NOTES:

1. Values are with wet coil and without filters.

2. Contact your particular filter manufacturer for pressure drop data.

3. Electric heater pressure drop is negligible and is included within the airflow data.

4. † Factory Setting

AIRFLOW (CFM)

GAT2A0C60S51SA MINIMUM HEATER AIRFLOW CFM

Heater Minimum Air Speed Tap

With Heat Pump Without Heat Pump

BAYEAAC05BK1AA

BAYEAAC05LG1AA

BAYEAAC08BK1AA

BAYEAAC08LG1AA

BAYEAAC10BK1AA

BAYEAAC10LG1AA

BAYEABC15BK1AA Tap 4 Tap 3

BAYEABC20BK1AA Tap 4 Tap 3

BAYEACC25BK1AA Tap 5 Tap 4

SEE AIR HANDLER NAMEPLATE FOR ADDITIONAL INFORMATION

Pub. No. 22-1857-03 9

Tap 2 Tap 2

Tap 3 Tap 2

Tap 3 Tap 2

Note: Heating and cooling

speeds are the same, factory

set at Speed Tap #4 for the

CTM motor.

Page 10

Performance

Data

WIRING DATA

GAT2A0B42S31SA

240 VOLT 208 VOLT

Heater

Model

No.

No Heater - - - 2.7** 3 15 - - 2.7** 3 15

BAYEAAC05++ 1 4.80 16400 20 28 30 3.60 12300 17.3 25 25

BAYEAAC08++ 1 7.68 26200 32 43 45 5.76 19700 27.7 38 40

BAYEAAC10++ 1 9.60 32800 40 53 60 7.20 24600 34.6 47 50

BAYEABC15++

circuit 1 9.60 32800 40 53 60 7.20 24600 34.6 47 50

circuit 2 4.80 16400 20 25 25 3.60 12300 17.3 22 25

No.

of

Circuits

Capacity

kW BTUH kW BTUH

Heater

Amps

per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Capacity

Heater

Amps

per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

BAYEABC20++

circuit 1 9.60 32800 40 53 60 7.20 24600 34.6 53 60

circuit 2 9.60 32800 40 50 50 7.20 24600 34.6 43 45

Note: ** Motor Amps

10 Pub. No. 22-1857-03

Page 11

Performance

Data

WIRING DATA

GAT2A0C48S41SA

240 VOLT 208 VOLT

Heater

Model

No.

No Heater - - - 3.1** 4 15 - - 3.1** 4 15

BAYEAAC05++ 1 4.80 16400 20.0 29 30 3.60 12300 17.3 26 30

BAYEAAC08++ 1 7.68 26200 32.0 44 45 5.76 19700 27.7 38 40

BAYEAAC10++ 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

BAYEABC15++

circuit 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

circuit 2 4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

No.

of

Circuits

Capacity

kW BTUH kW BTUH

Heater

Amps

per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Capacity

Heater

Amps

per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

BAYEABC20++

circuit 1 9.60 32800 40.0 54 60 7.20 24600 34.6 53 60

circuit 2 9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

BAYEABC25++ 1

circuit 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

circuit 2 9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

circuit 3 4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

Note: ** Motor Amps

1 Not qualified for 208 V without Heat Pump

Pub. No. 22-1857-03 11

Page 12

Performance

WHEEL

BLOWER HOUSING

BELLY BAND

MOTOR

A

A is determined per chart

Wheel is centered in

Blower Housing

Data

WIRING DATA

GAT2A0C60S51SA

240 VOLT 208 VOLT

Heater

Model

No.

No Heater - - - 7.6** 10 15 - - 7.6** 10 15

BAYEAAC05++ 1 4.80 16400 20.0 35 35 3.60 12300 17.3 31 35

BAYEAAC08++ 1 7.68 26200 32.0 50 50 5.76 19700 27.7 44 45

BAYEAAC10++ 1 9.60 32800 40.0 60 60 7.20 24600 34.6 53 60

BAYEABC15++

circuit 1 9.60 32800 40.0 60 60 7.20 24600 34.6 53 60

circuit 2 4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

BAYEABC20++

circuit 1 9.60 32800 40.0 60 60 7.20 24600 34.6 53 60

circuit 2 9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

No.

of

Circuits

Capacity

kW BTUH kW BTUH

Heater

Amps

per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Capacity

Heater

Amps

per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

BAYEABC25++

circuit 1 9.60 32800 40.0 60 60 7.20 24600 34.6 53 60

circuit 2 9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

circuit 3 4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

Note: ** Motor Amps

DISTANCE FROM BELLY BAND TO SHAFT FACE OF MOTOR FOR MINIMUM VIBRATION

MODEL DIM "A"

GAT2A0B42S31SA 3

GAT2A0C48S41SA 2-13/16

GAT2A0C60S51SA 2-1/4

12 Pub. No. 22-1857-03

Page 13

WIRING DIAGRAM FOR GAT2A0B42 AND GAT2A0C48 AIR HANDLERS

Page 14

WIRING DIAGRAM FOR GAT2A0C60 AIR HANDLERS

Page 15

GAT2 AIR HANDLERS WITH SINGLE SPEED COOLING

Air Handler Hook-up Diagram

Cooling

W2 Pink

W3 Brown

W1 White

Field

Wiring

Comfort Control

White

Green

Yellow

Orange

Red

Blue

Field wiring

W

Green

White

G

Y

O

R

B

Green

Yellow

Red

Blue

Red

Blue

Air Handler

B - Blue

Y - Yellow

• * For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat.

Air Conditioner

Blue

Yellow

Pub. No. 22-1857-03 15

Page 16

GAT2 AIR HANDLERS WITH SINGLE SPEED HEAT PUMP

Air Handler Hook-up Diagram

HP

W2 Pink

W3 Brown

W1 White

Field

Wiring

Heat Pump

Comfort Control

White

Green

Yellow

Orange

Red

Blue

Field wiring

W

Green

White

G

Y

O

R

B

Green

Yellow

Orange

Red

Blue

Red

Blue

Air Handler

R - Red

B - Blue

Y - Yellow

• * For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat

Black

Orange

(X2)

Red

Yellow

Blue

16 Pub. No. 22-1857-03

Page 17

GAT2

Convertibility

* Note: No internal modifications required for any position.

1 Badge rotation will keep brand in correct position

Multi-position

Air Handler

Refrigerant

Connections

1

Airflow

Vertical Upflow*

(as shipped)

Refrigerant

Connections

Upflow

Condensate

Drains

Refrigerant

Connections

1

Horizontal Left

Condensate

Drains

Airflow

Horizontal Left*

Pub. No. 22-1857-03 17

1

Airflow

Horizontal Right

Condensate

Drains

Horizontal Right*

Page 18

Dimensions

GAT2 AIR HANDLER DIMENSIONAL DATA

W

Model No. H W D

GAT2A0B42 55.7 21.3 21.75

GAT2A0C48 56.9 23.5 21.75

GAT2A0C60 61.7 23.5 21.75

GAT2 AIR HANDLERS ARE ALL TWO

PIECE CABINETS.

H

D

18 Pub. No. 22-1857-03

Page 19

GAT2 OUTLINE DRAWING

MODEL NO. A B C D E F H FLOW

CONTROL

GAT2A0B42 55.7 45.5 18.4 21.3 18.4 9.2 24.8 TXV 7/8

GAT2A0C48 56.9 46.7 20.5 23.5 20.5 10.3 24.2 TXV 7/8

GAT2A0C60 61.7 51.5 20.5 23.5 20.5 10.3 27.0 TXV 7/8

Pub. No. 22-1857-03 19

GAS LINE

BRAZE

Page 20

Trane

6200 Troup Highway

Tyler, TX 75707

www.trane.com

03/12

The manufacturer has a policy of continuous product and product data improvement and it reserves the right

to change design and specifications without notice.

Loading...

Loading...