Trane GAM5 Series, GAM5A0C42M31SAA, GAM5A0C48M41SAA, GAM5A0C60M51SAA, GAM5A0A18M11SAA Installer's Manual

...Page 1

18-GJ04D1-2

Installer’s Guide

Convertible Air Handlers

1-1/2 – 5 Ton

GAM5A0A18M11SAA

GAM5A0A24M21SAA

GAM5A0B30M21SAA

GAM5A0C42M31SAA

GAM5A0C48M41SAA

GAM5A0C60M51SAA

GAM5A0B36M31SAA

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

Important: This Document is customer property and is to remain with this unit. Please return to service information

pack upon completion of work.

These instructions do not cover all variations in systems

nor provide for every possible contingency to be met in

connection with the installation. Should further information be desired or should particular problems arise which

are not covered sufficiently for the purchaser’s purposes,

the matter should be referred to your installing dealer or

local distributor.

Note: The manufacturer recommends installing ONLY

A.H.R.I. approved, matched indoor and outdoor systems.

Some of the benefits of installing approved matched

indoor and outdoor split systems are maximum efficiency, optimum performance, and the best overall system

reliability.

Note: Condensation may occur on the surface of the air

handler when installed in an unconditioned space. When

units are installed in unconditioned spaces, verify that

all electrical and refrigerant line penetrations on the air

handler are sealed completely.

The GAM5 air handlers will only use

the following internal electric heaters:

BAYEAAC05BK1AA

BAYEAAC05LG1AA

BAYEAAC08BK1AA

BAYEAAC08LG1AA

BAYEAAC10BK1AA

BAYEAAC10LG1AA

BAYEABC15BK1AA

BAYEABC20BK1AA

BAYEACC25BK1AA

Page 2

Table of Contents

Section 1. Safety Information. ......................................................................... 3

Section 2. Unit Design. ........................................................................................ 4

Section 3. Unit Preparation. ............................................................................. 6

Section 4. Optional Cabinet Disassembly. ............................................... 7

Section 5. Place Unit at Location. ............................................................... 12

Section 6. Unit Location Considerations. ............................................... 13

Section 7. Setting the Unit - Vertical Installation. ................................ 18

Section 8. Setting the Unit - Horizontal Installation. ......................... 20

Section 9. Connecting the Duct work. ...................................................... 21

Section 10. Refrigerant Line. ......................................................................... 22

Section 11. Refrigerant Line Brazing. ....................................................... 23

Section 12. Condensate Drain Piping. ...................................................... 26

Section 13. Electrical - Low Voltage. .......................................................... 28

Section 14. Electrical - High Voltage. ......................................................... 33

Section 15. Time Delay Switch Adjustment. .......................................... 35

Section 16. Filters. ............................................................................................... 35

Section 17. Unit Outline Drawing. ............................................................... 36

Section 18. Start Up. ........................................................................................... 37

Section 19. Sequence of Operation. .......................................................... 39

Section 20. Checkout Procedures. ............................................................. 40

Note: Representative illustrations only included in this

document. Most illustrations display the upflow configuration.

2

Page 3

Section 1. Safety Information

▲

WARNING

!

▲

CAUTION

!

▲

WARNING

!

▲

CAUTION

!

▲

CAUTION

!

SAFETY HAZARD! This information is intended for use

by individuals possessing adequate backgrounds of electrical and

mechanical experience. Any attempt to repair a central air conditioning product may result in personal injury and/or property damage.

The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection

with its use.

LIVE ELECTRICAL COMPONENTS! During instal-

lation, testing, servicing, and troubleshooting of this product, it may

be necessary to work with live electrical components. Failure to follow all electrical safety precautions when exposed to live electrical

components could result in death or serious injury.

HAZARDOUS VAPORS! Do not install an air handler

with a non-ducted return in the same closet, alcove, or utility

room as a fossil fuel device. Hazardous vapors can be distributed

throughout the conditioned space and equipment damage can

result.

CORROSION HAZARD! To prevent shortening its service

life, the air handler should not be used during the finishing phases

of construction. The low return air temperatures can lead to the

formation of condensate. Condensate in the presence of chlorides

and fluorides from paint, varnish, stains, adhesives, cleaning compounds, and cement creates a corrosive condition which may cause

rapid deterioration of the cabinet and internal components.

SAFETY HAZARD! Sharp Edge Hazard. Be careful of sharp

edges on equipment or any cuts made on sheet metal while installing or servicing. Personal injury may result.

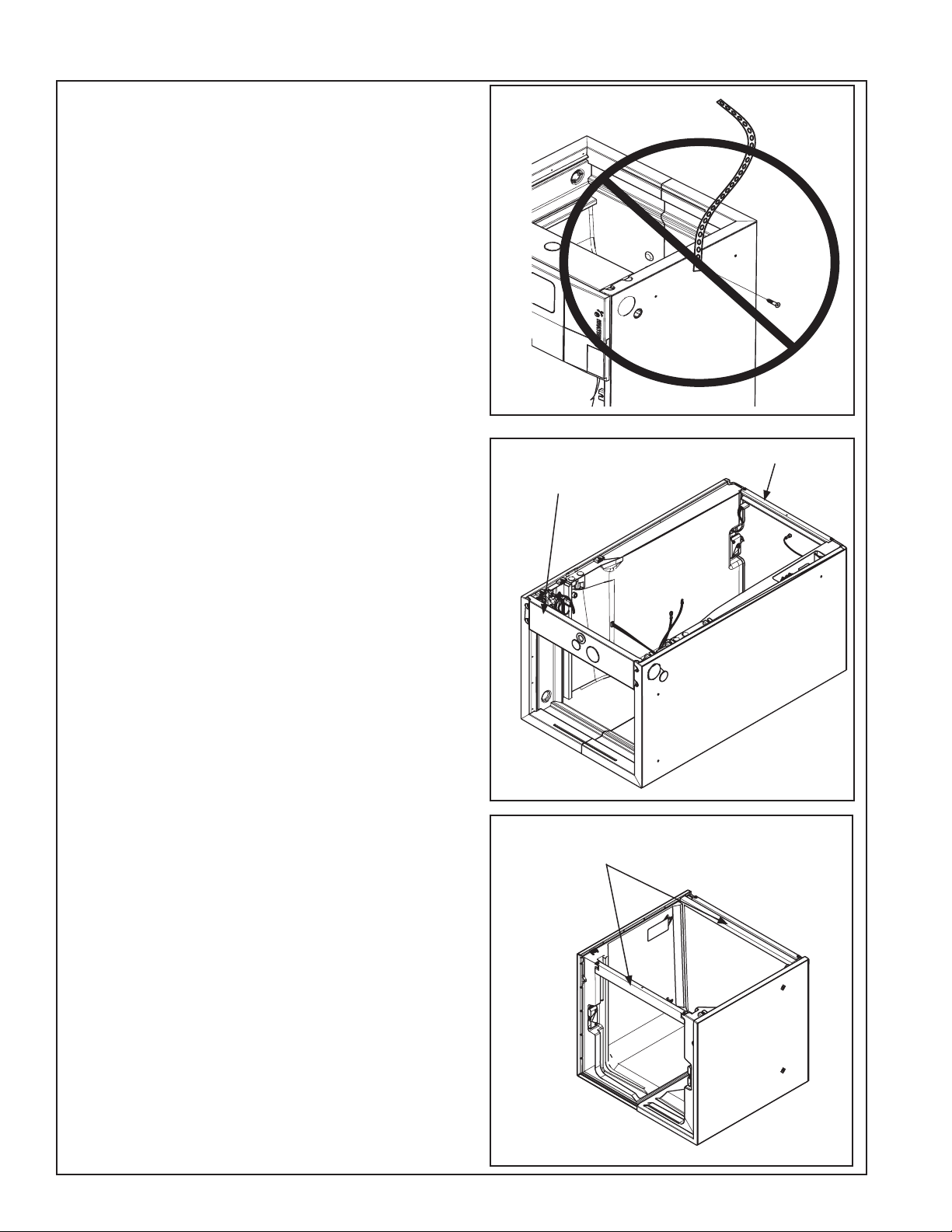

Important: Due to the unique design of this unit, which

allows the electrical wiring to be routed within the insulation, do not screw, cut, or otherwise puncture the unit

cabinet in any location other than the ones illustrated in

this Installer Guide or in an approved accessory’s Installer Guide.

Important: Under no conditions should metal strapping

be attached to the unit to be used as support mechanisms for carrying or suspension purposes.

3

Page 4

Section 2. Unit Design

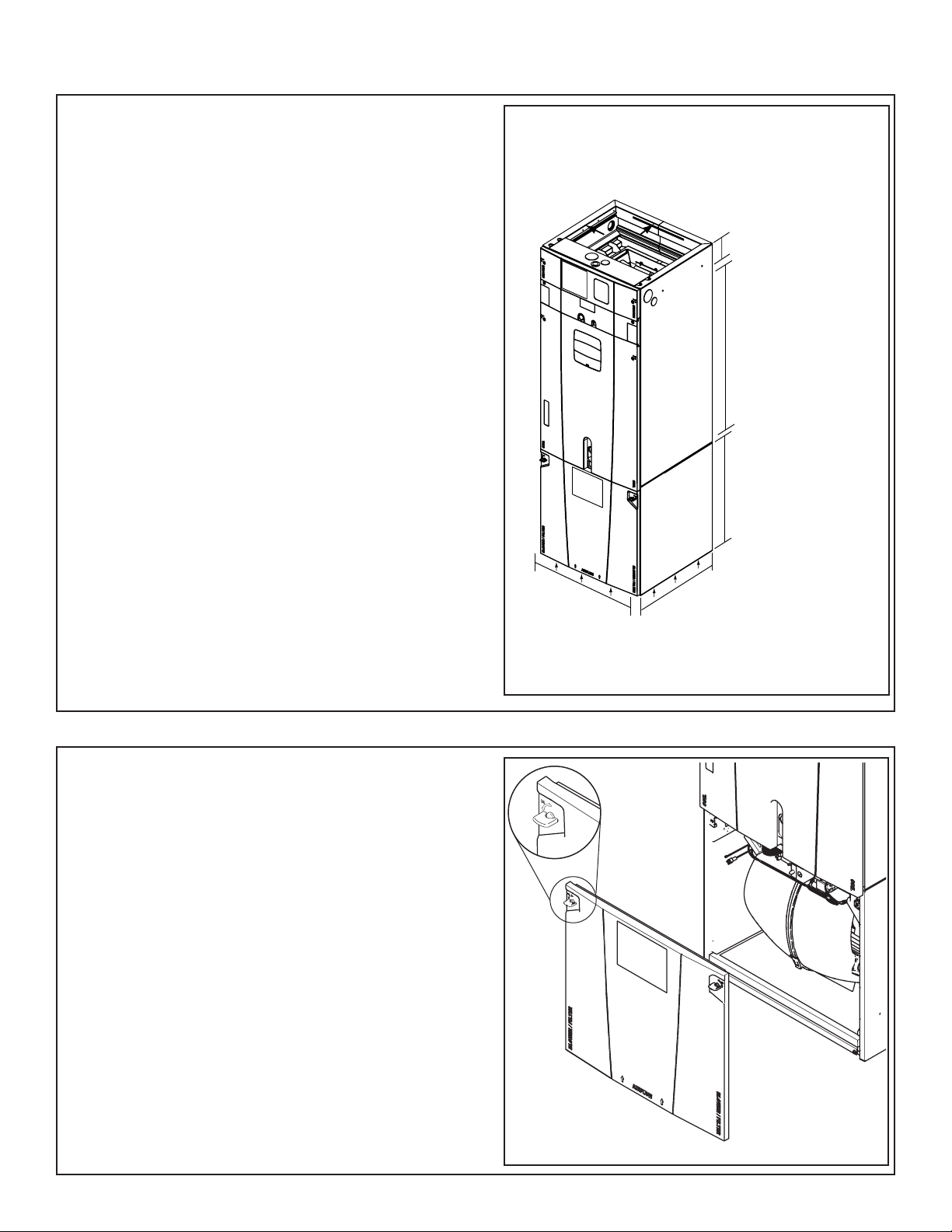

Screws can be drilled

into bottom of unit.

(1/2” max. screw length)

(Typical all sides)

Screws, saw cuts, and

other penetrations

are allowed in the

blower section for

installation of Side

Return Kit.

(Typical both sides)

Screws are allowed up to 3- 3/4”

from the top of the cabinet

(heater compartment).

(Typical both sides)

Screws for ange kit

attachment are allowed

along the interior of

the cabinet (see arrows)

(Typical all sides)

No penetrations

allowed.

(Typical all sides)

Screws allowed only in

the rst 3/4” of front

bottom of unit (in cross

member)

2.1 Cabinet Penetration

Important: Due to the unique design of this unit,

which allows the electrical wiring to be routed within

the insulation, do not screw, cut, or otherwise puncture the unit cabinet in any location other than the

ones illustrated.

Important: Under no conditions should metal strapping be attached to the unit to be used as support

mechanisms for carrying or suspension purposes.

2.2 Panel Removal

The unit contains four (4) access panels: Blower/Filter, Coil, Line Set, and Heater.

The Blower/Filter panel is removed using 1/4 turn

thumb screws.

1. Turn thumb screws on Blower/Filter panel.

2. Pull top of panel out, away from cabinet.

3. Lift panel up out of channel.

4. Set aside.

4

Page 5

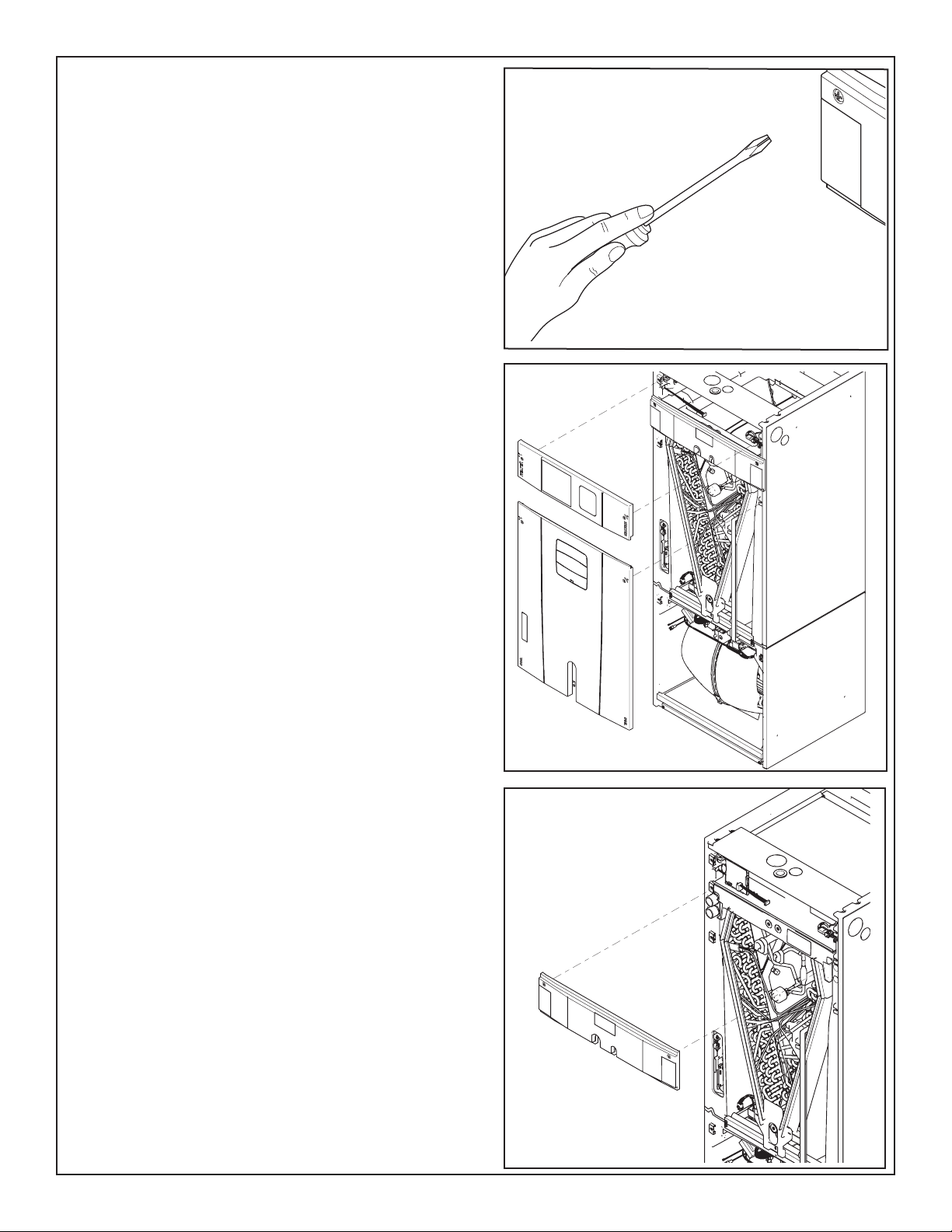

The Coil, Line Set, and Heater panels are removed

using Phillips head screws.

Coil and Heater panels must be removed prior to removing the Line Set panel.

To remove Coil Panel:

1. Turn screws on Coil panel.

2. Pull bottom of panel out, away from cabinet.

3. Pull panel down and out of channel.

4. Set aside.

#3 Size Phillips

To remove Heater Panel:

1. Turn screws on Heater panel.

2. Pull panel straight out, away from cabinet.

3. Set aside.

Removal of the Line Set panel is required for all refrigerant line brazing and some condensate line assembly

depending on your orientation.

To remove Line Set panel:

1. Remove both Heater and Coil panels.

2. Turn screws on Line Set Panel.

2. Pull panel straight out, away from cabinet.

3. Set aside.

5

Page 6

Section 3. Unit Preparation

3.1 Prepare The Unit For Installation

STEP 1 - Check for damage and report promptly to

the carrier any damage found to the unit.

Note: The unit is shipped “upside-down” in the

downflow orientation and may be easiest to transport to the job site in that orientation. If the unit

must be transported in a horizontal position, it must

be laid on its back (marked “REAR” on carton).

Note: After the unit is removed from the carton,

depress the Schrader valve to verify coil is pressurized.

3.2 Unit Accessories

Accessory Number Description Fits Cabinet Size

BAYEAAC05BK1A Electric Heater, 5kW, Breaker, 24V Control, 1 Ph A to C

BAYEAAC05LG1A Electric Heater, 5kW, Lugs, 24V Control, 1 Ph A to C

BAYEAAC08BK1A Electric Heater, 8kW, Breaker, 24V Control, 1 Ph A to C

BAYEAAC08LG1A Electric Heater, 8kW, Lugs, 24V Control, 1 Ph A to C

BAYEAAC10BK1A Electric Heater, 10kW, Breaker, 24V Control, 1 Ph A to C

BAYEAAC10LG1A Electric Heater, 10kW, Lugs, 24V Control, 1 Ph A to C

BAYEABC15BK1A Electric Heater, 15kW, Breaker, 24V Control, 1 Ph B to C

BAYEABC20BK1A Electric Heater, 20kW, Breaker, 24V Control, 1 Ph B to C

BAYEACC25BK1A Electric Heater, 25kW, Breaker, 24V Control, 1 Ph C

BAYSUPFLGA Supply Duct Flange A A

BAYSUPFLGBA Supply Duct Flange B B

BAYSUPFLGCA Supply Duct Flange C C

BAYRETFLGAA Return Duct Flange A A

BAYRETFLGB Return Duct Flange B B

BAYRETFLGCA Return Duct Flange C C

TASB175 Plenum Stand A A

TASB215 Plenum Stand B B

TASB235 Plenum Stand C C

BAYSRKIT100A Side Return Kit A to C

BAYICSKIT01A Internal Condensate Switch Kit A to C

BAYHHKIT001A Horizontal Hanger Kit A to C

BAYUVCLK001A UVC Lights A to C

BAYLVKIT100A Low Voltage Conduit Entry Kit A to C

Table 3.2

6

Page 7

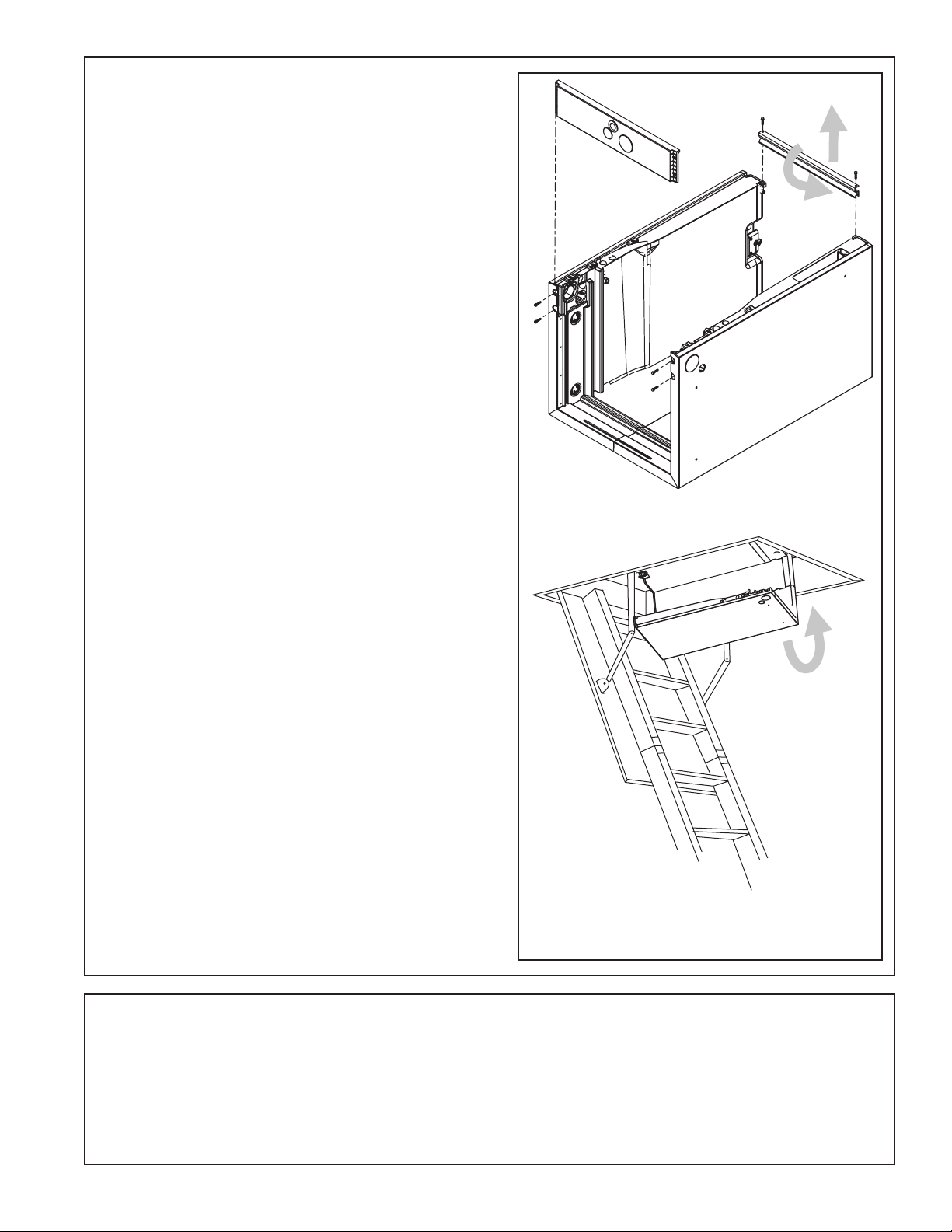

Section 4. Optional Cabinet Disassembly

4.1 Disassemble cabinet for installation in tight areas or as needed.

Note: The unit is shipped “upside-down” in the

downflow orientation and may be easiest to transport

to the job site in that orientation. If the unit must be

transported in a horizontal position, it must be laid

on its back (marked “REAR” on carton).

Note: To reassemble cabinet, follow the steps in

reverse order. Ensure electrical connections are

secure and the plug clips are engaged.

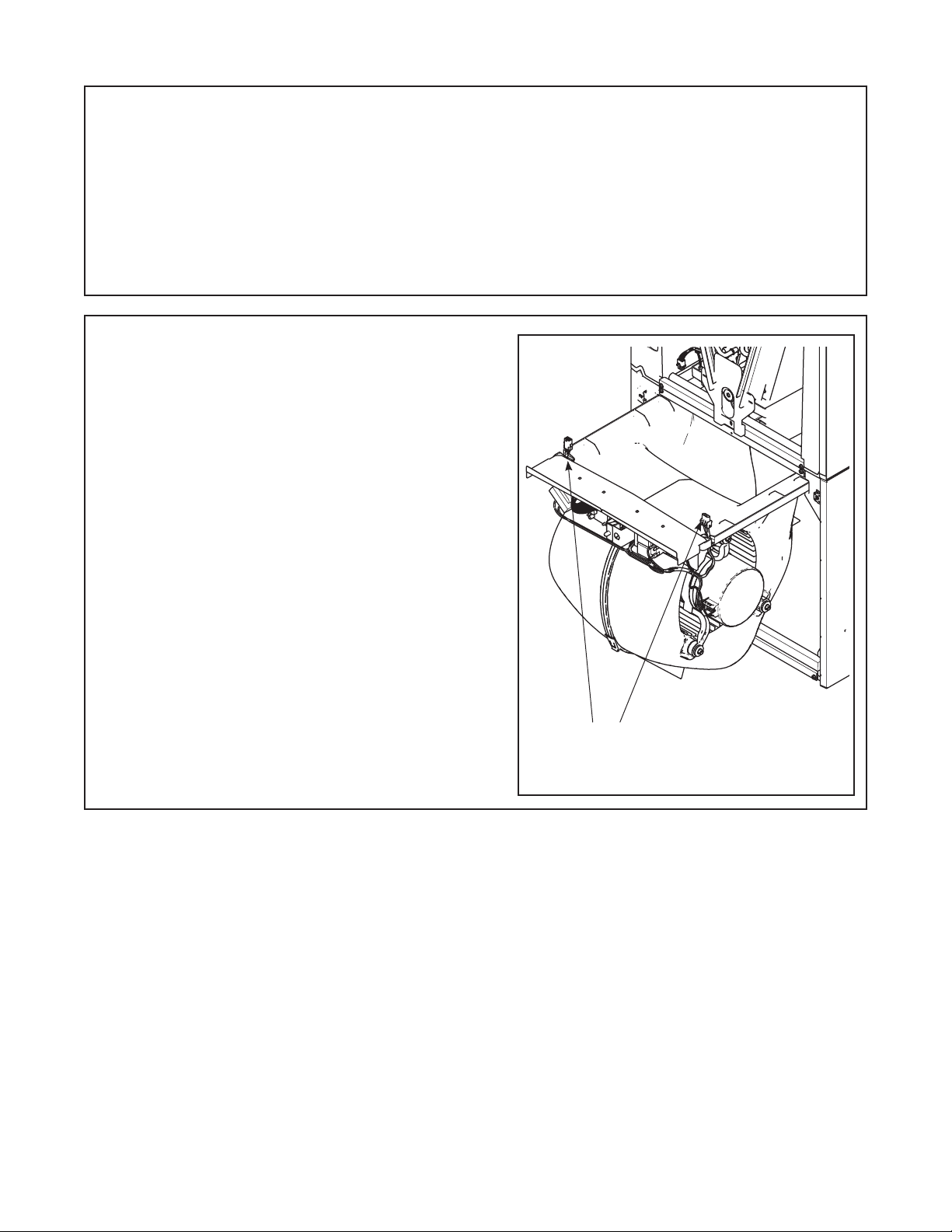

STEP 1 - Remove all four front panels. See Section

2.2.

Blower Electrical

Connections

7

Page 8

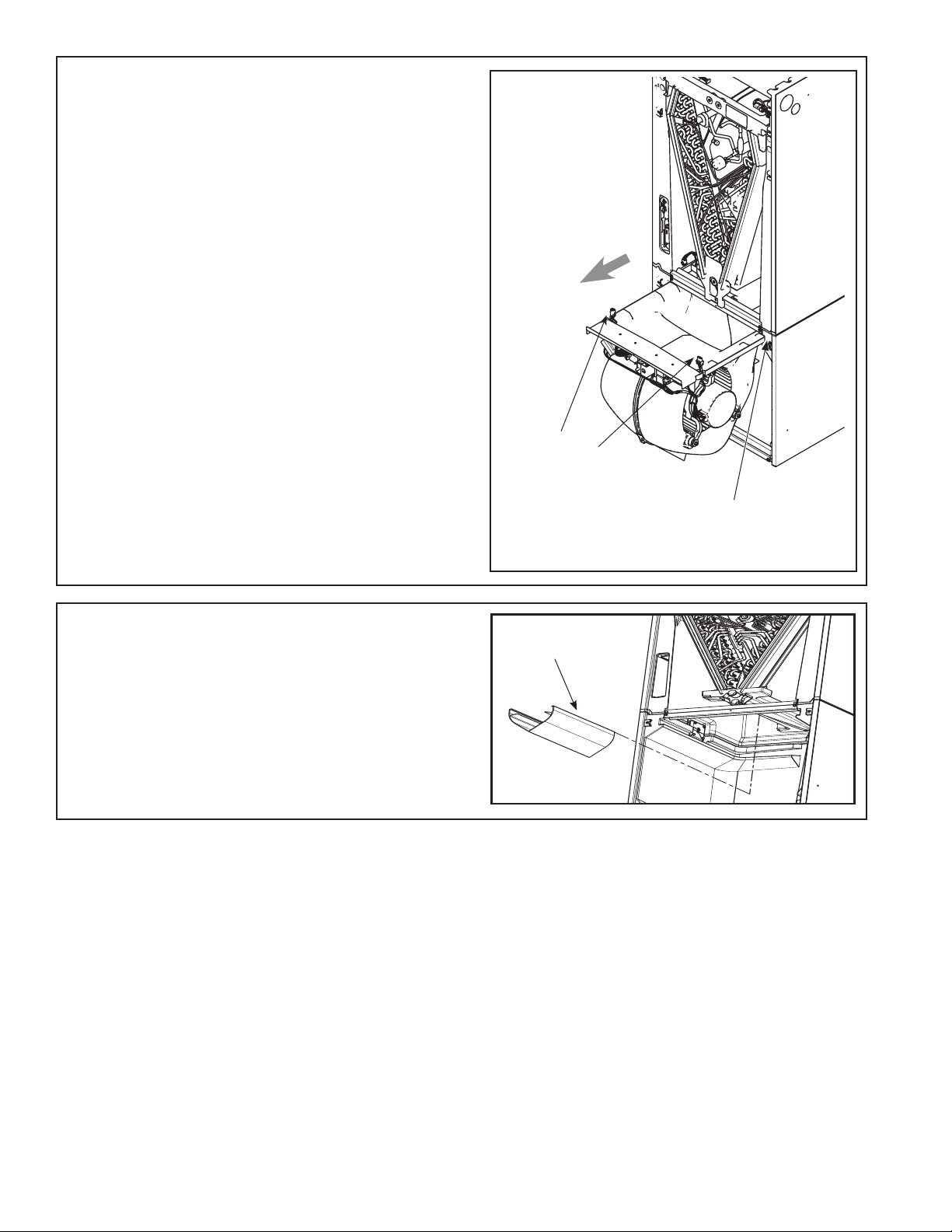

STEP 2 - Disconnect the two wiring connections

routed to the blower assembly.

STEP 3 - Slide Blower assembly out of unit using

built-in blower support channels and set aside.

Wiring

Connections

Blower Support

Channel

STEP 4 - Remove airflow diverter from the bottom of

coil drain pan by gripping the plastic diverter, using

your thumbs to spread the top of the diverter slightly

outwards, and then pulling down and out through the

blower opening as illustrated.

Diverter

8

Page 9

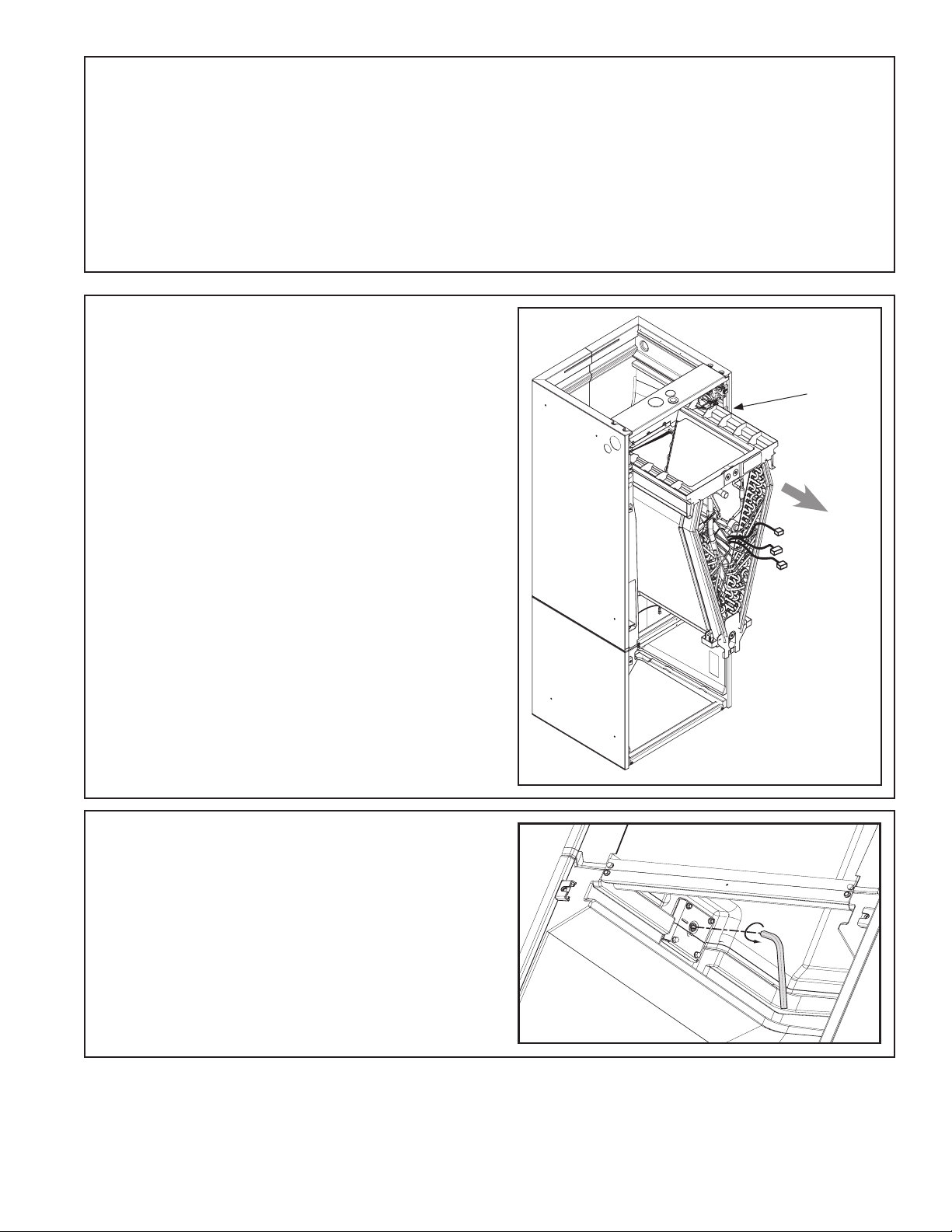

STEP 5 - Disconnect wires to the EEV motor and

sensors inside the coil assembly. Cut the wire ties

on those wire harnesses.

STEP 6 - Slide Coil assembly out of unit using builtin coil support channels and set aside.

Coil Support

Channel

STEP 7 - Use a 5/16 Allen wrench on the locking

mechanism on each side of the bottom half of the

cabinet to loosen the locking mechanism. The locks

loosen by turning counter-clockwise approximately

3/4 of a turn.

9

Page 10

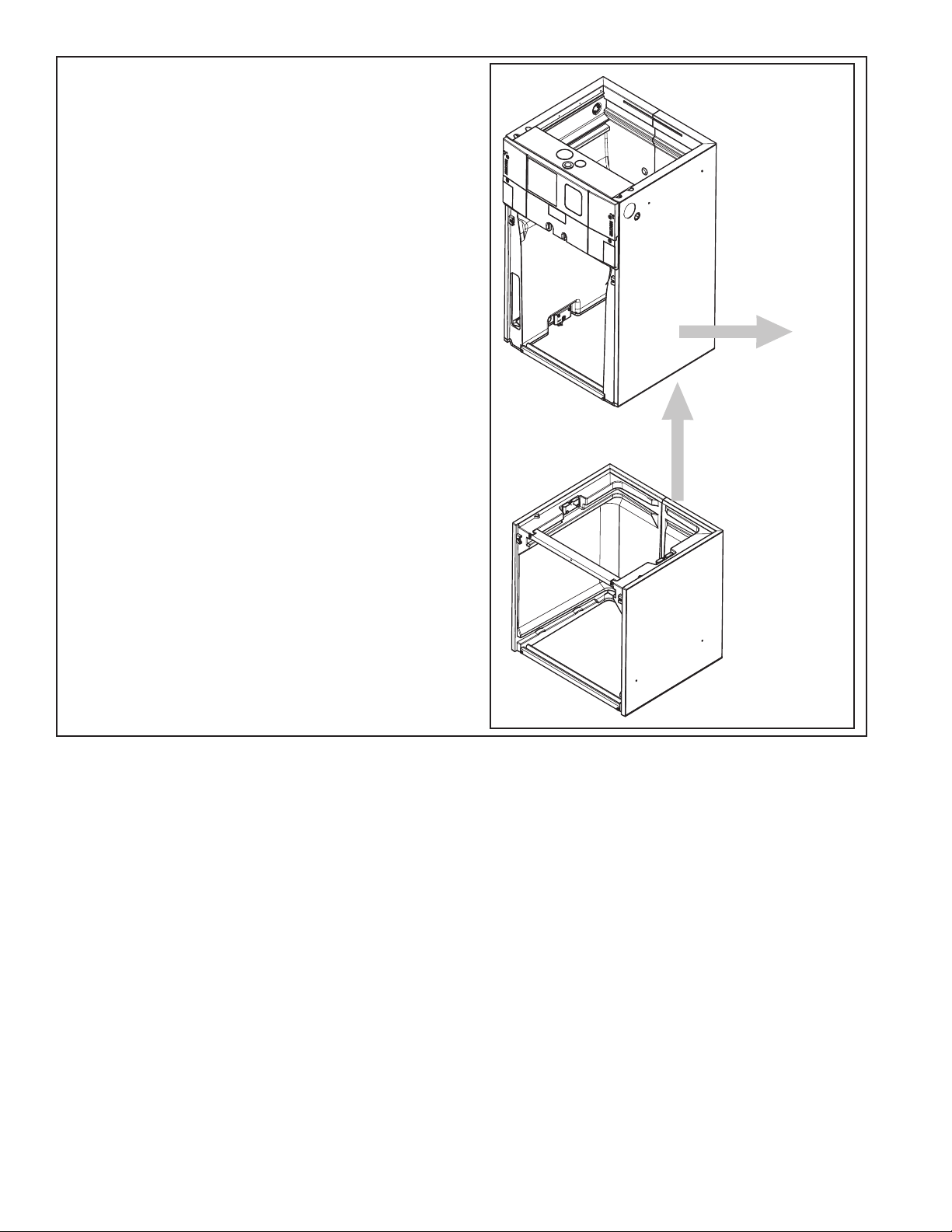

1

2

STEP 8 - Lift the Coil section up and away from the

Blower section. Set aside.

10

Page 11

STEP 9 - For extremely tight spaces where the

cabinet needs to be rotated through a small opening,

remove the top panel and all cross members. Use a

manual driver to avoid stripping screw holes.

Note: Cross Members are removed by rotating them

toward the door opening and then lifting up and out

of the unit.

2

1

STEP 10 - Continue preparation by following the

proper carrying procedures shown in Section 5.

11

Page 12

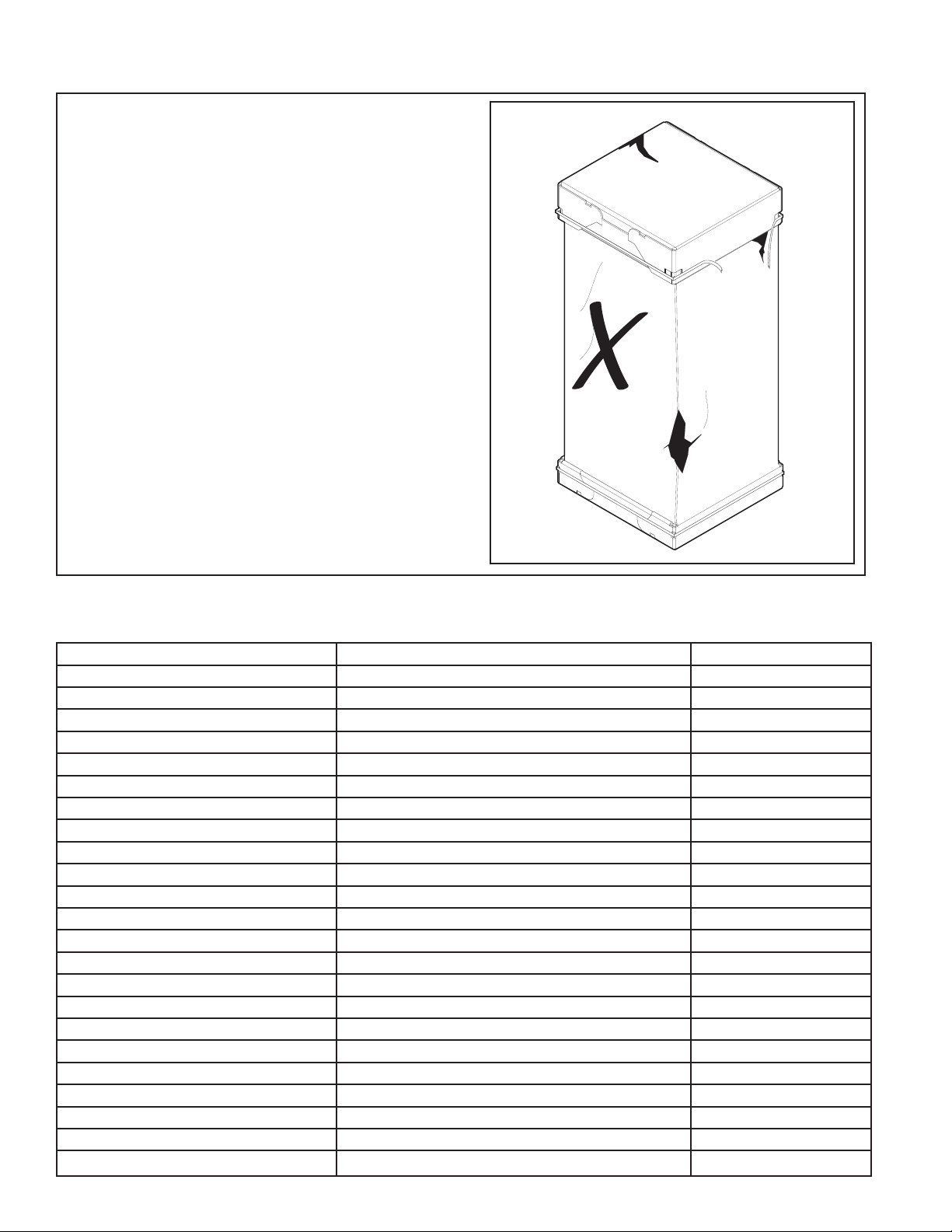

Section 5. Place Unit at Location

5.1 Carry Unit

STEP 1 - Carry the unit to the installation location.

STEP 2 - Reassemble by reversing the steps listed in

Section 4 if disassembly was required.

Important: Under no conditions should metal strapping be attached to the unit to be used as support

mechanisms for carrying or suspension purposes.

Approved carrying:

1. Hold by the cross members within the cabinet

or unit top plate and use as handles for lifting

and carrying the coil and blower sections.

Cross Member

Unit Top Plate

12

Cross Members

Page 13

2. Slip a flexible strap through both of the side

D

H

W

electrical conduit entry points and use the flexible strap to lift and carry the coil section of the

unit.

Section 6. Unit Location Considerations

6.1 Unit Dimensions and Weight

Flexible strap

Table 7.1

Model

Number

H x D x W

in.

*Blower

Compartment

in.

Unit

Net Weight

lbs.

GAM5A0A18H21SAA 50 x 22 x 17 1/2 22 120

GAM5A0A24H21SAA 50 x 22 x 17 1/2 22 120

GAM5B0A30H31SAA 52 x 22 x 21 22 133

GAM5B0A36H31SAA 56 x 22 x 21 22 143

GAM5C0A42H41SAA 57 x 22 x 23 1/2 22 158

GAM5C0A48H41SAA 62 x 22 x 23 1/2 22 174

GAM5C0A60H51SAA 62 x 22 x 23 1/2 22 178

*Subtract from total height to get Coil and Heater compartment height.

13

Page 14

6.2 Four-Way Conversion

To place the unit in the configuration your application requires (upflow, downflow, horizontal right, or horizontal left),

simply turn the unit to that orientation.

Note: The air handlers are shipped from the factory suitable for four-way conversion. They are shipped in the downflow orientation.

Refrigerant

Connections

Airflow

Low Voltage

Connections

inside unit

Low Voltage

Connections

inside unit

Downflow Configuration

(as shipped)

Control

Pocket

Inside unit

Refrigerant

Connections

Downflow

Condensate

Drains

Control

Pocket

Inside unit

Upflow

Condensate

Drains

Airflow

Upflow Configuration

14

Page 15

Airflow

Refrigerant

Connections

Airflow

Horizontal Left

Condensate

Drains

Low Voltage

Connections

inside unit

Horizontal Left Configuration

Control

Pocket

Inside unit

Control

Pocket

Inside unit

Low Voltage

Connections

inside unit

Refrigerant

Connections

Horizontal Right Configuration

Horizontal Right

Condensate Drains

15

Page 16

6.3 Non Ducted Applications

▲

CAUTION

!

HAZARDOUS VAPORS! Do not install an air handler

with a non-ducted return in the same closet, alcove, or utility

room as a fossil fuel device. Hazardous vapors can be distributed

throughout the conditioned space and equipment damage can

result.

Non-Ducted Return Installations:

Installation in a closet, an alcove, or a utility •

room without a return duct requires the use

of a plenum accessory kit as it uses the area

space as a return air plenum. Minimum clearances to combustible materials and service

access must be observed (see outline drawing).

This area may also be used for other purpos- •

es, including an electric hot water heater, but

in no case shall a fossil fuel device be installed

and/or operated in the same closet, alcove, or

utility room.

Review local codes to determine limitations if •

the unit is installed without a return air duct.

Supply Duct

Plenum

Accessory

with safety guard

Non-Ducted

Return

6.4 Ducted Applications

Ducted Return Installations:

Installation in an attic, garage, or crawl space with •

ducted supply and return air is appropriate. Minimum

clearances to combustible materials and service access must be observed (see outline drawing).

Supply Duct

Return Duct

Ducted Return

16

Page 17

6.5 Additional Unit Preparation Considerations

For proper installation the following items must be considered prior to moving the unit to its installation site:

Pursuant to Florida Building Code 13-610.2.A.2.1, this •

unit meets the criteria for a factory sealed air handler.

If a side return is needed for your application, the side •

return MUST be prepared prior to moving the air handler to its installation location. See the Side Return Kit

# BAYSRKIT100A Installer Guide for detailed instructions.

Study the unit’s outline drawing and dimensions prior •

to selecting the installation site. Note in advance

which electrical conduit entry points and condensate

drain holes are to be used, so that proper clearance

allowances can be made for installation and future

maintenance.

Installation of the air handler must be made prior to, •

or at the same time as, the installation of the outdoor

unit in order to allow access for refrigerant lines.

Consider the overall space needed when external •

accessories are used, additional height and width

requirements may exist.

These units are not approved for outdoor installation. •

These units must be installed in the proper air flow •

direction.

Any third-party heater accessories, including •

hydronic coils and duct heaters must be downstream

of the unit.

Note: No atomizing style humidifier is allowed in the •

return plenum with the use of this unit.

Excessive bypass air may cause water blow-off, •

which will adversely affect system operation and air

cleaner performance. To verify bypass airflow, follow the Bypass Humidifier Pre-Installation Checkout

and Set-Up Procedures available through your local

distributor. Ask for publication number 18-CH37D1-*

Steam and Flow-through Fan Power Duct-mounted

Humidifiers. Follow the humidifier installation instructions. These should only be installed on the supply

air side of the system.

Note: The air handlers have been evaluated in accordance with the Code of Federal Regulations, Chapter

XX, Part 3280 or the equivalent. “SUITABLE FOR

MOBILE HOME USE.”

17

Page 18

Section 7. Setting the Unit - Vertical Installation

7.1 Considerations

Provide a minimum height of 14 inches for proper

unrestricted airflow below the unit. Allow a minimum

of 21 inches clearance in front of the air handler to

permit maintenance and removal of filter.

Position unit on suitable foundation. If a manu- •

facturer approved accessory is not used, a frame

strong enough to support the total weight of the

unit, accessories, and duct work must be provided.

Isolate unit from the foundation using a suitable •

isolating material.

Typical Closet Installation

7.2 Upflow Installation

TASB Installation

1. Assemble the TASB using the TASB’s Installer

Guide.

TASB accessories can be purchased from:

Miami Tech Inc.

3611 NW 74 Street

Miami, FL 33147

Phone: 800-339-2290

Fax: 305-693-6152

www.miamitech.com

TASB175 for use with 17.5” cabinets

TASB215 for use with 21.5” cabinets

TASB235 for use with 23.5: cabinets

Airflow

AirflowAirflow

18

Typical TASB Installation

Page 19

Plenum Installation

1. Assemble the plenum using the plenum’s

Installer Guide.

On units with sheet metal returns: Return plenum

must be flanged. Sheet metal drill point screws

must be 1/2” in length or shorter.

7.3 Downflow Installation

Downflow installation must comply with national, •

state, and local codes.

The air handlers are rated for zero clearance from •

combustible materials.

Airflow

Typical Plenum Installation

STEP 1 - Prepare the location site as appropriate for

your application and per national, state, and local code

requirements.

STEP 2 - Set the unit in position.

Representative Illustration

Typical Downflow Installation

19

Page 20

Section 8. Setting the Unit - Horizontal Installation

8.1 Secure Coil (Horizontal Applications Only)

STEP 1 - Remove Coil Panel.

STEP 2 - Remove screw from documentation packet.

STEP 3 - While the air handler is in the upflow posi-

tion, use the supplied screw to secure the coil seal

plate to cross member as shown.

Important: The Coil Seal Plate and screw secure the

coil in the center of the air handler. Failure to follow

these steps can prevent the Coil Panel from being easily replaced on the unit.

8.2 Considerations

Important: Due to the unique design of this unit,

which allows the electrical wiring to be routed within

the insulation, do not screw, cut, or otherwise puncture

the unit cabinet in any location other than the ones

illustrated in this Installer Guide or in an approved accessory’s Installer Guide.

Important: Under no conditions should metal strapping be attached to the unit to be used as support

mechanisms for carrying or suspension purposes.

STEP 1 - Support the unit from the bottom (near both

ends). The service access must remain unobstructed.

Important: The unit can only be supported from the

bottom. Do not drill or screw supports into any area

of the cabinet.

Note: Do not allow the unit to be used as strain relief.

Approved bottom support methods are rails, u- •

channels (Unistrut®), or other load bearing materials.

The unit must be isolated carefully to prevent •

sound transmission. Field supplied vibration isolators are recommended.

Field Supplied

Isolators

Auxiliary Drain

Pan

Bottom Support

Near Both Ends

STEP 2 - Install an auxiliary drain pan under the

horizontal air handler to prevent possible damage to

ceilings.

Isolate the auxiliary drain pan from the unit and •

from the structure.

Connect the auxiliary drain pan to a separate drain •

line and terminate according to local codes.

20

Page 21

Section 9. Connecting the Duct work

9.1 Duct Connection Considerations

Important: Due to the unique design of this unit,

which allows the electrical wiring to be routed within

the insulation, do not screw, cut, or otherwise puncture the unit cabinet in any location other than the

ones illustrated in this Installer Guide or in an approved accessory’s Installer Guide.

Important: Under no conditions should metal strapping be attached to the unit to be used as support

mechanisms for carrying or suspension purposes.

Important: On units with sheet metal returns: Return

air plenum must be flanged. Sheet metal drill point

screws must be 1/2” in length or shorter.

The supply and return air ducts must be connected •

to the unit with non flammable duct connectors.

See the Outline drawing for sizes of the duct con- •

nections.

After the ducts are secured, seal around the sup- •

ply and return ducts to prevent air leakage.

Insulate all duct work that will be outside of condi- •

tioned spaces.

Convertible Duct Flange Kits are available to con- •

nect the supply plenum or for mounting on the

discharge opening to provide a “flush fit” for 1-1/2”

duct board applications.

If front or rear return is required, the air handler •

must be elevated - placed on a pedestal or plenum

and duct must be connected to this pedestal or

plenum.

If side return is required, the Side Return Kit # •

BAYSRKIT100A accessory must be used. A remote filter will be required.

To ensure maximum efficiency and system perfor- •

mance, the existing supply and return duct system

static pressures must not exceed the total available

static pressure of the air handler. Reference ACCA

Manual D, Manual S and Manual RS along with

the air handler Product Data and Service Facts for

additional information.

3/4”

Screws allowed in

first 3/4” of bottom

cross member.

Note: Side return is not approved without Side

Return Kit # BAYSRKIT100. More than one Side

Return Kit may be necessary depending on the

application. Refer to the Installation Guide in

BAYSRKIT100 for approved duct connections,

sizing, number, transitions, and accessory

application.

Note: Duct work must be supported as appropriate.

See National and local codes for guidelines. Do not

depend on the unit to support duct work.

21

Page 22

Section 10. Refrigerant Line

10.1 Refrigerant Line Connection Sizes

Model

GAM5A0A18H21SAA

GAM5A0A24H21SAA

GAM5B0A30H31SAA

GAM5B0A36H31SAA

GAM5C0A42H41SAA

GAM5C0A48H41SAA

GAM5C0A60H51SAA

10.2 Refrigerant System Layout

Table 8.1

Refrigerant Line Connection Sizes

Vapor Line

Connection

3/4 3/8

3/4 3/8

3/4 3/8

7/8 3/8

7/8 3/8

7/8 3/8

7/8 3/8

Liquid Line

Connection

Vapor Line

Sensor

Saturation

Sensor

Vapor Line

Check Valve

Liquid Line

Strainer

EEV Motor

22

Page 23

Section 11. Refrigerant Line Brazing

11.1 Braze The Refrigerant Lines

STEP 1 - Remove Heater, Coil, and Line Set panels.

(See Section 2.2 Panel Removal)

Important: Do NOT unseal coil refrigerant connection stubs until ready to make connections.

STEP 2 - Remove the plastic cap and Schrader valve

core from the gas line.

STEP 3 - Wrap the vapor sensor with a wet rag.

Important: Care must be taken during solder cap

removal and brazing to avoid damage to unit components

Heater

Panel

Line Set

Panel

Coil

Panel

1

3

2

STEP 4 - Apply low heat to the solder cap to slowly

heat the solder. (Do not apply direct heat to the vapor line) Use adjustable pliers to grab the flare fitting

and remove the solder cap.

STEP 5 - Remove the sealing plug from the indoor

coil liquid connection.

STEP 6 - Connect, but do not braze, field line set to

indoor coil.

Allow a minimum of three (3) inches of refrigerant

line set before using an elbow coupling. The service

access must remain unobstructed.

3” MIN

23

Page 24

STEP 7 - Braze refrigerant line connections.

150 PSI

Note: The suction line must be insulated prior to

brazing the line set to the air handler stubs.

1. Pull back the insulation before brazing the suction line.

2. Wrap the Vapor Sensor with wet rag.

3. Braze the refrigerant line connections.

Important: Care must be taken during solder cap

removal and brazing to avoid damage to unit components.

STEP 8 - Pressurize the refrigerant lines and evaporator coil to 150 PSIG using dry nitrogen.

Wet Rag on

Vapor Sensor

STEP 9 - Check for leaks by using a soapy solution

or bubbles at each brazed location.

24

Page 25

Important: Do not open the service valves until the

1 MIN.

0350

Microns

ON

OFF

refrigerant lines and indoor coil leak check and evacuation are complete.

STEP 10 - Evacuate until the micron gauge reads no

higher than 350 microns, then close off the valve to the

vacuum pump.

STEP 11 - Observe the micron gauge. Evacuation is

complete if the micron gauge does not rise above 500

microns in one (1) minute.

Once evacuation is complete blank off the vacuum

pump and micron gauge, and close the valves on the

manifold gauge set.

Note: Charge system using Outdoor unit’s Installer

Guide or Service Facts.

STEP 12 - Replace the Line Set panel.

1. Allow time for tubing to cool.

2. Install grommets to line set piping.

3. Slide the bottom of the Line Set panel down over the

refrigerant lines and grommets. The grommets will seal

the line openings.

4. Tighten screws.

25

Page 26

PVC

CEMENT

Section 12. Condensate Drain Piping

12.1 Condensate Drain Piping Considerations

Condensate drain plumbing must comply with na- •

tional, state, and local codes.

Route condensate drain lines away from air handler •

so they do not interfere with access panels.

Slope the drain lines downward a minimum of 1/4” •

per foot, support per local codes.

Do not use reducing fittings in the condensate drain •

lines.

12.2 Connect Condensate Drain Piping

STEP 1 - Select the drain connections that are ori-

ented for your application.

STEP 2 - Prepare the condensate drain connections.

From the factory, the unit comes with plugs in both •

upflow condensate drains and an additional plug in

the documentation packet.

For upflow applications, remove upflow condensate •

plug(s) and connect condensate piping.

For all other applications, do not remove upflow •

condensate plugs. Remove the cover from the

needed condensate drain connections and connect

condensate piping.

If the secondary drain connection is not used, close •

secondary drain with plug from documentation

packet (all applications except for upflow).

Note: Upflow and horizontal orientations require the

Coil panel to be removed in order to make the drain

connections. Note: Make certain that the unit has

been installed in a level position to allow for proper

draining.

Do not connect the drain line to a closed drain •

system.

Do not use a torch or flame near the plastic drain •

pan coupling.

A P-trap is not required for proper drainage due to •

the positive pressure of the air handler; however,

it is recommended to prevent efficiency loss of

conditioned air.

Downflow

Condensate

Drains

P

S

Horizontal Left

Condensate Drains

Condensate

S P

S

P

Upflow

Drains

Condensate Drains

Horizontal Right

P

S

STEP 3 - Connect 3/4” PVC pipe to the primary drain

connection (and the secondary drain connection if

used) using threaded drain nipples.

Use Teflon tape on the air handler drain line con- •

nections. Do not use pipe joint compound or PVC/

CPVC cement on drain nipple.

Hand tighten the drain pipe. •

26

Teflon Tape

Drain Nipple

3/4” PVC pipe

PVC/CPVC Cement

Page 27

STEP 4 - Install a clean-out tee in the primary

drain line for future maintenance. It is recommended that you install a cap on the top of the

tee.

STEP 5 - Insulate the primary drain line to

prevent sweating where dew point temperatures

may be met. (Optional depending on climate

and application needs.)

Cap

Tee

Insulation

Provide a means of drainage to prevent winter

freeze-up of condensate line. (Optional depending on climate and application needs.)

STEP 6 - Support the condensate piping outside

the unit per local codes for proper drainage and

to prevent sagging.

Allow 1/4” of downward slope for each foot of

pipe.

Condensate

Piping

Supports

27

Page 28

Section 13. Electrical - Low Voltage

5”

13.1 Low Voltage Maximum Wire Length

Table 11.1 defines the maximum total length of low

voltage wiring from the outdoor unit, to the indoor

unit, and to the thermostat.

13.2 Low Voltage Hook-up Instructions

STEP 1 - Route control wiring to unit. Remove the

external sheathing of the wiring approximately 5”.

STEP 2 - Remove Coil panel by turning the quarter

turn Phillips head door fasteners, rotating the door

away from the cabinet, and removing..

Table 11.1

24 VOLTS

WIRE SIZE MAX. WIRE LENGTH

18 AWG 150 Ft.

16 AWG 225 Ft.

14 AWG 300 Ft.

28

Page 29

STEP 3 - Remove the control board from the control

1

2

pocket by sliding the control pocket mounting plate

out until the first stop is reached.

Control

Pocket

Inside

unit

Control

Board

For Horizontal Right installations Only

Remove the control board completely from the

control pocket. Rotate the control board180 degrees.

Place the control board 4-6 inches back into the control pocket. Attach wiring per appropriate hook-up

diagram or perform service.

Important: After wires have been connected or service performed, the control board MUST be rotated

back to the original orientation before inserting into

control pocket in the cabinet.

29

Page 30

STEP 4 - Make connections per hookup diagrams.

Air Handler Hook-up Diagram

Cooling

Red

Yellow

Green

White

Blue

Yellow

Green

White

Blue

B

B - Blue

Blue

W

G

Y

Y - Yellow

Yellow

R

Red

O

Orange

Comfort Control

Air Handler

Air Conditioner

Field wiring

O **

R **

B

YI

W1

YO

G

W2

W3

30

* For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat. •

** R to • O jumper must be in place as shown for cooling only, non-heat pump systems for proper operation.

YI and YO connections must be made as shown for freeze protection and internally mounted condensate overflow circuits to work properly. •

Internally mounted condensate switch is optional and must be ordered separately. •

If 3rd party condensate overflow switches are installed, they should be wired in series between YO and Y to the outdoor unit. •

Page 31

Air Handler Hook-up Diagram

Heat Pump

Comfort Control

Air Handler

Field wiring

Yellow

Blue

Black

(X2)

Red

Orange

Heat Pump

Red

Yellow

Orange

Green

White

Blue

Yellow

Green

White

Blue

B

B - Blue

W

G

Y

Y - Yellow

R

Red

O

Orange

O **

R **

B

YI

W1

YO

G

W2

W3

R - Red

O - Orange

W1 - White

SW1

410

22

1

2

3

SW1

410

22

1

2

3

SW1

410

22

** R to O jumper must be removed for heat pump system. •

* For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat •

YI and YO connections must be made as shown for freeze protection and internally mounted condensate overflow circuits •

to work properly

Internally mounted condensate switch is optional and must be ordered separately •

If a 3rd party condensate overflow switch is installed, it should be wired in series between YO and Y to the outdoor unit •

STEP 5 - Secure the sheathed wiring to the control

pocket mounting plate using the factory supplied zip

ties attached to the tabs to as shown.

STEP 6 - Refrigerant Switch

Set the system refrigerant to either R-410A or R-22

using the Refrigerant Switch located on the Expansion

Valve Control board (EVC) in the Control Pocket.

Factory default is R-410A.

Note: The power must be shut off and then reapplied in order for the EVC to recognize the

change.

Wire Ties

31

Page 32

STEP 7 - Slide control plate assembly into the control

pocket until fully seated. The control plate should be

flush with the outer edge of the unit.

STEP 8 - Replace Coil panel making sure that the

wires are located within the wire pass-through provided in the panel.

32

Pass through

notch in coil

access door

Page 33

Section 14. Electrical - High Voltage

▲

WARNING

!

14.1 High Voltage Power Supply

The high voltage power supply must match the

equipment nameplate.

Power wiring, including ground wiring, must comply

with national, state, and local codes.

Field wiring diagrams for supplementary electric

heaters are shipped with the heater.

14.2 Make Electrical Connections

LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and troubleshooting of this

product, it may be necessary to work with live electrical components. Failure to follow all electrical safety precautions when

exposed to live electrical components could result in death or

serious injury.

STEP 1 - Route High Voltage wiring to unit.

STEP 2 - Select a conduit entry point.

1. Select the entry point you will use to bring in your

high voltage wiring.

2. Remove plug from the entry point.

Conduit Entry Points

33

Page 34

BLACK

RED

GREEN - GROUND

GREEN

GROUND

WIRES CIRCLE

BACK AND GO

THROUGH

STRAIN RELIEF

CLAMP

STEP 3 - Route conduit (if used) to the entry point

and connect.

1. Remove the plug from the entry point.

2. Use one hand to secure the conduit nut from inside of

the heater compartment.

3. Connect a field supplied 3/4" or 1-1/2" conduit to

conduit nut.

Note: Reducing bushings may be required for your

application.

STEP 4 - Connect L1, L2, and ground wiring

to pigtail harness and single green ground in

Heater Compartment using wire nuts. The incoming ground wiring will mate up with both the

green wires shown in the illustration.

STEP 5 - If the L1, L2, and ground wires enter

the case from the left side, use a field supplied

1/2”-5/8” maximum length screw and wire tie to

hold the wires to the top center of the Heater

Compartment.

34

Page 35

Section 15. Time Delay Switch Adjustment

90

0

15.1 Remove the blower door panel.

The Blower/Filter panel is removed using 1/4 turn

thumb screws.

1. Turn thumb screws on Blower/Filter panel.

2. Pull top of panel out, away from cabinet.

3. Lift panel up out of channel.

4. Set aside.

15.2 Time Delay Relay (TDR) Switch

Set the fan off delay setting using the Fan Delay

Relay Switch (TDR) located on the blower control

mounting plate located on the front of the blower.

Factory default delay is 90 seconds.

Section 16. Filters

16.1 Filter Considerations

A filter must be installed within the system. •

A filter channel is provided in the unit, at the bot- •

tom of the Blower/Filter compartment.

For customer ease of fil ter maintenance, it is •

recommended that a properly sized remote filter

grill(s) be installed for units that are difficult to

access. Airflow should not exceed the maximum

rated velocity of the filter being used.

Choke Coil

3/4 &1 HP

motors only

Door Switch

Fan Delay

Relay Switch

Transformer

Table 16.1 Filter Sizes

Cabinet Size* A B C

Filter Size 16 x 20 20 x 20 22 x 20

* Cabinet size is indicated by the 7th digit in model number.

Filter in

air handler

cabinet

(Upflow

Application)

35

Page 36

Section 17. Unit Outline Drawing

36

Page 37

Section 18. Start Up

18.1 System Charge Adjustments

The following combinations should be charged to 8

degrees sub-cooling to maintain rated HSPF.

Indoor Unit Model No. Outdoor Unit Model No.

GAM5A0A18M11SAA 4A6B4018E1

4A6H5018E1

GAM5A0A24M21SAA 4A6B4024E1

4A6H5024E1

GAM5A0B30M21SAA 4A6B4030E1

4A6H5030E1

GAM5A0B36M31SAA 4A6B4036E1

4A6H5036E1

GAM5A0C42M31SAA

GAM5A0C48M41SAA 4A6B4048E1

4A6H5048E1

4A6B4049E1

4A6H5049E1

GAM5A0C60M51SAA 4A6B4060E1

4A6H5060E1

4A6B4061E1

4A6H5061E1

All other non-rated matches must be charged

per the nameplate charging instructions.

The following combinations should be charged to 8

degrees sub-cooling to maintain rated HSPF.

Indoor Unit Model No. Outdoor Unit Model No.

GAM5A0A18M11SAA 4TWB4018E1

4TWR5018E1

GAM5A0A24M21SAA 4TWB4024E1

4TWR5024E1

GAM5A0B30M21SAA 4TWB4030E1

4TWR5030E1

GAM5A0B36M31SAA 4TWB4036E1

4TWR5036E1

GAM5A0C42M31SAA

GAM5A0C48M41SAA 4TWB4048E1

4TWR5048E1

4TWB4049E1

4TWR5049E1

4TWX5049E1

GAM5A0C60M51SAA 4TWB4060E1

4TWR5060E1

4TWB4061E1

4TWR5061E1

4TWX5061E1

All other non-rated matches must be charged

per the nameplate charging instructions.

37

Page 38

OFF

DON

E

CANCEL

ON

OFF

ON

DON

E

CANCEL

18.2 System Start Up

STEP 1 - Make sure all panels are securely in place

and that all wiring has been properly dressed and

secured.

STEP 2 - Set the system thermostat to OFF.

STEP 3 - Turn on electrical power disconnect(s) to

apply power to the indoor and outdoor units.

STEP 4 - Set the system thermostat to ON.

38

Page 39

Section 19. Sequence of Operation

19.1 Sequence of Operation

GAM5 Sequence of Operation:

Abbreviations

• TDR = Time Delay Relay

• EVC = Expansion Valve Control

• EEV = Electronic Expansion Valve

• YI = Y signal into the EVC from the comfort control

• Yo = Y signal out of the EVC from the comfort control

• OEM = Original Equipment Manufacturer

See unit, electric heat, and field wiring diagrams for ad-

ditional information.

Continuous Fan

IMPORTANT: If the indoor air exceeds 60% relative humidity or simply feels uncomfortably humid, it

is recommended that the indoor fan only be used in

the AUTO mode.

1. R-G contacts close on comfort control sending 24VAC

to the G terminal on the fan TDR

2. Low speed contacts close in the TDR and send

24VAC on terminal labeled “LOW’.

3. Blower motor will now run on low speed. Speed is

field selectable.

Heat Pump OD (cooling)

1. R-Y contacts close on the comfort control sending

24VAC to Y terminal on TDR and the YI (Y In) terminal on the EVC.

2. R-G contacts also close on the comfort control send-

ing 24VAC to the G terminal on the TDR. (The combination of 24VAC on terminals Y and G on the TDR

will close the high speed contacts of the TDR)

3. R-O contacts on the comfort control close sending

24VAC to the O terminal on the EVC. This signals

the EVC that the unit is in cooling mode. The EVC

will control the EEV to maintain the correct superheat.

4. Normally closed contacts on the EVC will pass 24VAC

to the Yo terminal providing power to the outdoor unit

control circuit

5. The blower motor will now run on high speed. Speed

is field selectable.

Heat Pump OD (heating)

1. R-Y contacts close on the comfort control sending

24VAC to Y terminal on TDR and the YI (Y In) terminal on the EVC

2. R-G contacts also close on the comfort control

sending 24VAC to the G terminal on the TDR. (The

combination of 24VAC on terminals Y and G on the

TDR will close the high speed contacts of the TDR)

The blower motor will now run on high speed.

3. The combination of 24VAC on the Y terminal and zero

volts on the O terminal signals the EVC that the unit is in

heat-pump heating mode.

4. Normally closed contacts on the EVC will pass 24VAC

to the Yo terminal providing power to the outdoor unit

control circuit

5. The blower motor will now run on high speed

Cooling OD

1. R-Y contacts close on the comfort control sending 24VAC

to Y terminal on TDR and the YI (Y In) terminal on the

EVC

2. R-G contacts also close on the comfort control sending

24VAC to the G terminal on the TDR. (The combination

of 24VAC on terminals Y and G on the TDR will close

the high speed contacts of the TDR)

3. R-O jumper on the TDR sends 24VAC to the O terminal

on the EVC. This signals the EVC that the unit is in cooling mode. The EVC will control the EEV to maintain the

correct superheat.

4. Normally closed contacts on the EVC will pass 24VAC

to the Yo terminal providing power to the outdoor unit

control circuit

5. The blower motor will now run on high speed

Electric Heating

1. R-W contacts close on the comfort control sending 24VAC

to the W terminal on the TDR. 24VAC is also sent to

EHC to energize the heat relay.

2. R-G contacts close on the comfort control sending 24VAC

to the G terminal on the TDR. (The combination of

24VAC on terminals W and G on the TDR will close the

high speed contacts of the TDR)

3. WJ contacts on the TDR close providing an interlock

circuit to allow the electric heat relays to operate.

The comfort control must be setup to control R-G contacts

with a call for electric heat. This closes the interlock

circuit and allows the heat relay circuit to be energized.

Optional Condensate Switch

1. An optional OEM condensate switch can be installed

within the unit. This switch is only available through the

National Distribution Center or Global Parts.

2. Switch contacts are normally open and close when water

level rises. The closed switch will interrupt current flow to

the Yo terminal and de-energize the OD unit.

3. Switch is only operational during cooling mode. Condensate overflow is not operational during heating or defrost

modes.

Standard aftermarket condensate switches cannot be used

within the unit but can be installed exterior of the unit.

Switch should be wired in series with Yo wiring to the

OD unit.

39

Page 40

Freeze Protection

1. The EVC control has the ability to sense when the coil is

beginning to ice. When this event occurs, the contacts to

the Yo circuit will open and de-energize the OD unit.

2. The indoor blower motor will continue to run to aid in defrosting the coil. After the coil has sufficiently defrosted,

the Yo contacts will close and cooling operation will

begin again.

Fan Off Delay

1. The TDR has a dip switch that can enable a 90 second

fan off delay anytime a fan call is made from the comfort

control. The factory default is ON. To disable the delay,

turn power off to the unit, turn the dip switch to the off

position and turn power back on to the unit.

Section 20. Checkout Procedures

20.1 Operational And Checkout Procedures

Final phases of this installation are the unit Operational and Checkout Procedures. To obtain proper performance,

all units must be operated and charge adjustments made in accordance with procedures found in the Service

Facts of the Outdoor Unit.

CHECKOUT PROCEDURE

After installation has been completed, it is recommended that the entire system be checked against the following list:

1. Be sure unit suspension (if used) is secure and that there

are no tools or loose debris in or around or on top of the

unit. .............................................................................. [ ]

2. Properly insulate suction lines and fittings. .................. [ ]

3. Properly secure and isolate all refrigerant lines. .......... [ ]

4. Verify that all electrical connections are tight. .............. [ ]

5. Check all duct outlets; they must be open and unrestrict-

ed. ................................................................................ [ ]

6. Check drain lines and be sure all joints are tight. ........ [ ]

7. Be sure the return air filter is installed. ......................... [ ]

8. Be sure that the correct airflow setting is used.

(Indoor Blower Motor). ................................................. [ ]

9. Operate complete system in each mode to

verify proper performance. Verify operation of supplemen-

tary electric heater. ....................................................... [ ]

6200 Troup Highway

Tyler, TX 75707

www.trane.com

www.americanstandardair.com

The manufacturer has a policy of continuous product and product

data improvement and it reserves the right to change design and

specifications without notice.

© Trane U.S. Inc. 2010

Loading...

Loading...