Trane FD14DCLFR000D, FD175CLFR000D, FD17DCLFR000D, FD21DCLFR000D, FD24DCLFR000D Installation Operation & Maintenance

...Page 1

Installation

▲

▲

Operation

Maintenance

Whole House Air Cleaner

18- HE53D1- 11

Upflow Furnace

Models

*FD145CLFR000D

*FD175CLFR000D

*FD210CLFR000D

*FD245CLFR000D

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit.

Downflow Furnace

Models

*FD14DCLFR000D

*FD17DCLFR000D

*FD21DCLFR000D

*FD24DCLFR000D

Please return to service information pack upon completion of work.

Air Handler

Models

*FD175CLAH000D

*FD215CLAH000D

*FD235CLAH000D

*FD260CLAH000D

Contents

A. Duct Support Installation 3

B. Application Information 3

C. Door Operation 4

D. Installation Guidelines 5

Upflow Furnace and Upflow Air Handler Installation 5

Downflow Air Handler Installation 5

Downflow Furnace Installation 6

Side Return Furnace Installation 7

E. Electrical Connections 8

Electrical Connections to a COM Sys Air Handler in

Conventional 24 V Mode 10

Electrical Connections to a COM Sys Air Handler 11

Electrical Connections to a COM Sys Furnace

in 24 V Mode 12

Electrical Connections to a COM Sys Furnace 13

Electrical Connections to an Oil Furnace 14

Electrical Connections for Dual Whole House

Air Cleaners 15

F. Air Cleaner Operation 17

G. SET-UP Mode 17

Installer Set-Up Mode 17

Pre-Filter Setting 17

Cell Cleaning Setting 18

Field Charger Power Level 18

Field Charger Power Level Setting 18

H. Maintenance 18

Cleaning 18

I. Outline Drawings 23

!

WARNING

This information is for use by individuals having adequate

backgrounds of electrical and mechanical experience. Any

attempt to repair a central air conditioning product may

result in personal injury and/or property damage. The

manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any

liability in connection with its use.

J. Pressure Drop Information 26

!

WARNING

RISK OF ELECTRIC SHOCK: These servicing instructions

are for use by qualified personnel only. To reduce the risk

of electric shock, do not perform any servicing other than

that contained in these operating instructions unless you

are qualified to do so.

50 Hz Air Handler

Models

*FD215CLAH005D

*FD235CLAH005D

*FD260CLAH005D

* May be "A" or "T"

© Trane 2011

Page 2

Installer’s Guide

44

4

44

99

9

99

11

1

11

33

3

33

55

5

55

66

6

66

77

7

22

2

22

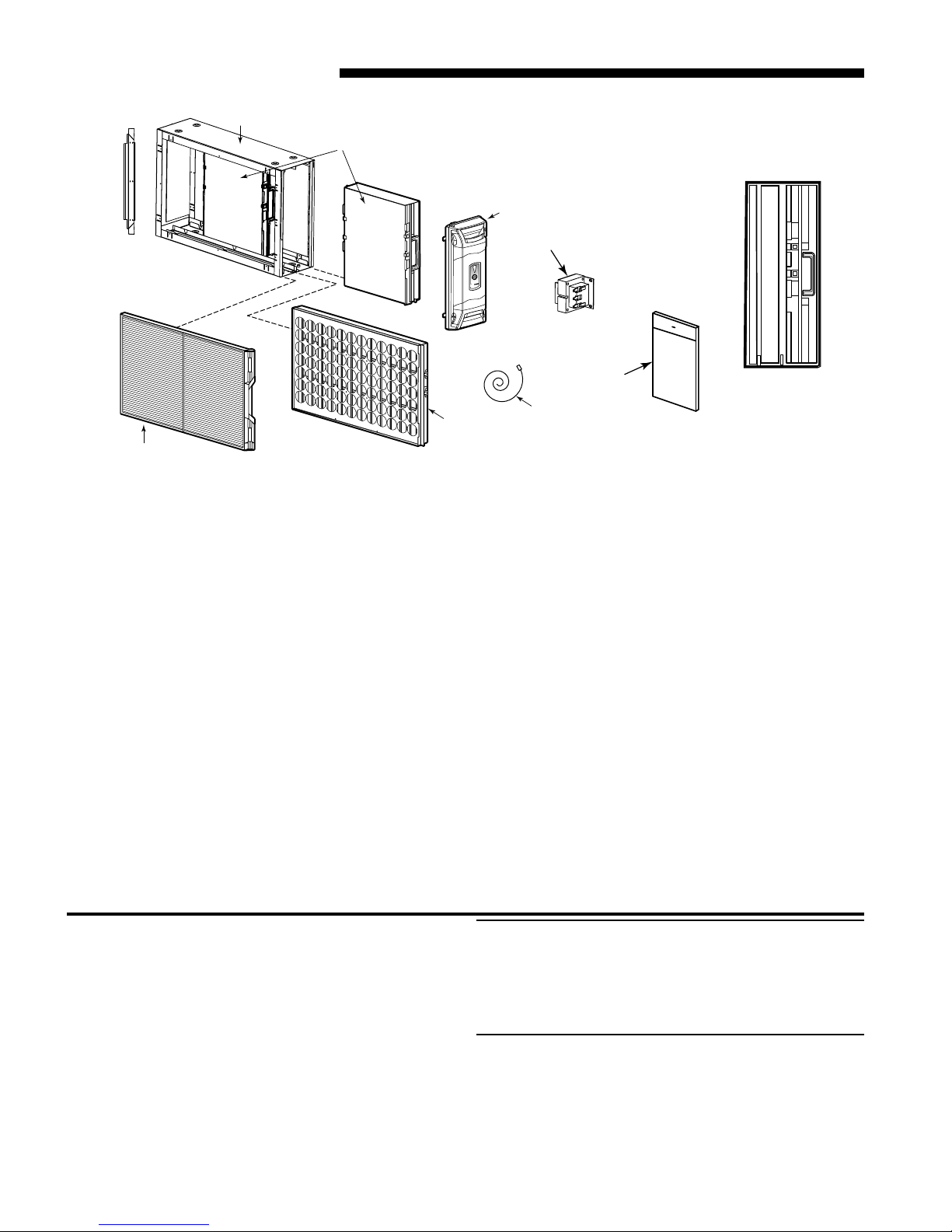

Figure 1 Components of the Air Cleaner

77

88

8

88

11

1

11

22

2

22

33

3

33

Unpack the Air Cleaner and check to make sure all

components are included. They consist of:

1) PRE-FILTER - traps large particles such as hair and

lint before they can enter the cell section.

2) FIELD CHARGER - Charges the contaminants. Only

to be removed, cleaned or serviced by a qualified

technician.

3) COLLECTION CELL (2) - removes and collects very

small impurities from the air.

4) CABINET - mounts between the furnace/air handler

and return air ductwork and houses the COLLECTION CELLS, FIELD CHARGER and PRE-FILTER.

5) POWER DOOR - the solid state power supply components that convert the 24 Volt AC to the high-voltage,

direct current required to power the FIELD CHARGER

and COLLECTION CELLS. Allows access to the

COLLECTION CELLS, FIELD CHARGER and PREFILTER.

The whole house air cleaner can be installed either as

part of a Communicating heating and air conditioning

system or as part of a traditional 24 volt system.

When installed as part of a Communicating System in

which the indoor unit, outdoor unit, and 900 series

comfort control are equipped with our exclusive

Communicating technology, this system performs a

continuous loop of system diagnostics and data output.

The Communicating System monitors itself and quickly

identifies any operational faults, automatically issuing a

service alert if needed.

6) TRANSFORMER - supplies 24 Volts to the indoor unit

and air cleaner

7) 24 VOLT POWER/CONTROL CABLE

8) GASKET, LITERATURE AND HARDWARE PACKET

9) UPFLOW AIR HANDLER BAFFLE - This baffle is only

included with Air Handler models. See note below.

NOTE: Be careful not to discard the baffle. It is

located under the collection cells in the

shipping box.

Check carefully for any shipping damage. This must be

reported to and claims made against the transportation

company immediately. Check to be sure all major

components are in the unit. Any missing parts should

be reported to your supplier at once, and replaced with

authorized parts only.

NOTE: International (50 Hz) Timings:

Due to differences in electrical systems outside the

United States, customers with 50 Hz electrical

systems will need to be aware of minor differences

in the timings shown in this guide. 50 Hz timings

will appear in [brackets] following the standard 60 hz

timings.

(not included with 50 Hz units)

The whole house air cleaner can also be installed as

part of a traditional 24 volt heating and air conditioning

system.

2 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 3

Installer’s Guide

▲

▲

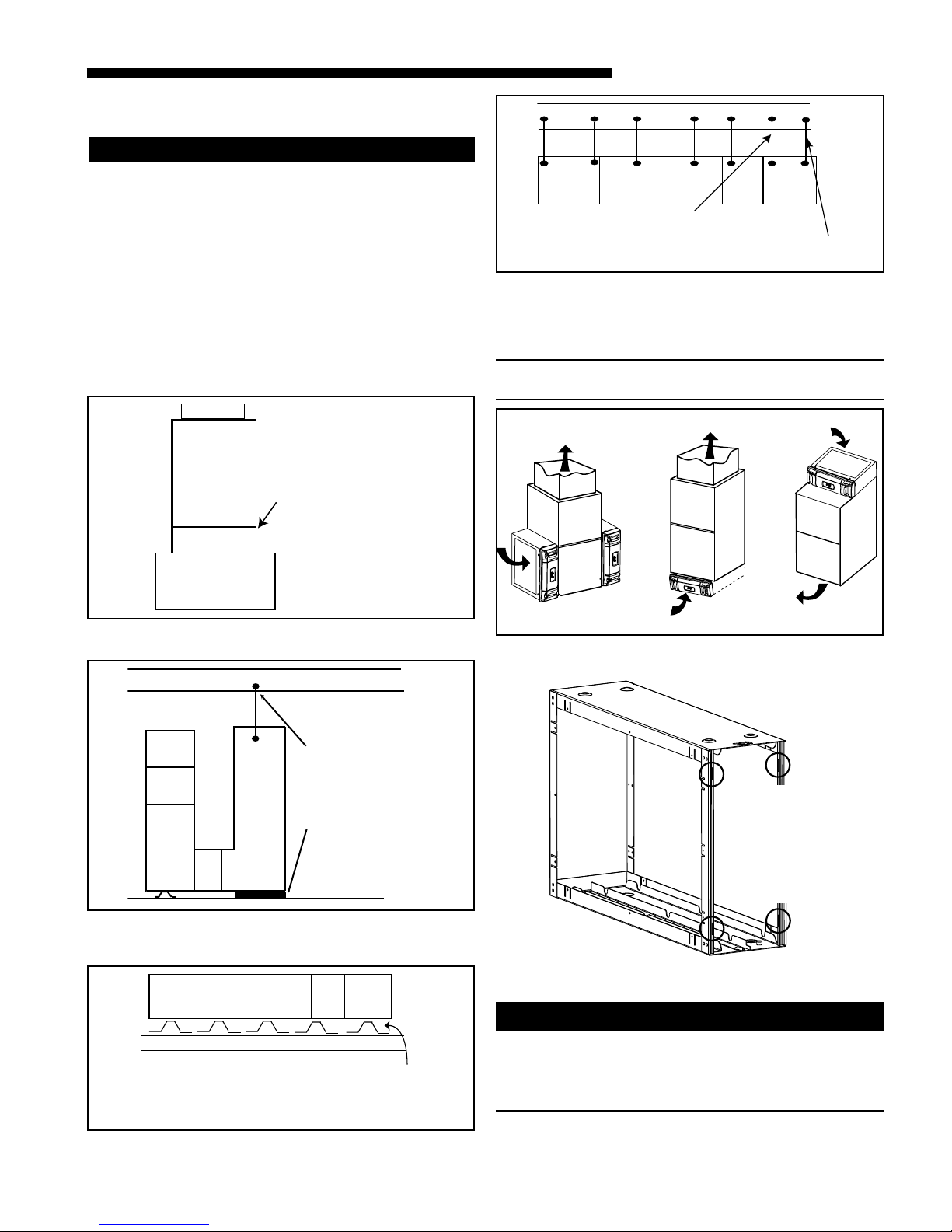

A. DUCT SUPPORT INSTALLATION

!

CAUTION

▲

SAFETY HAZARD

Sharp Edge Hazard. Be careful of sharp edges on equipment or any cuts made on sheet metal while installing or

servicing. Personal injury may result.

Step 1: Review the figures below and determine which

one looks like your application.

Step 2: To prevent racking of the air cleaner, support duct

per the illustration.

Furnace

or

air handler

Air Cleaner

Air cleaner cabinet

must align with

furnace or air handler

cabinet to prevent air

cleaner cabinet deflection

Rafter or Joist

Supply

Plenum

Furnace or

Air Handler

Air

Cleaner

Return

Plenum

Return Air Plenum must be

supported from building structure

to prevent air cleaner cabinet deflection

Figure 5

B. APPLICATION INFORMATION

NOTE: Do NOT install the air filter in the discharge air

stream of either the air handler or furnace.

Airflow

Airflow

Airflow

Return

Joist or Rafter

Supply

Coil

Furnace

ONLY

Cleaner

Supply

Plenum

Air

Figure 2

Return Air Duct must

be supported from

building structure to

R/A Duct

prevent air cleaner

cabinet deflection.

Use either a support

from the ceiling or

Air

Figure 3

Furnace or

Air Handler

Joist or Flooring

Return Air Plenum must

be supported from building

structure to prevent air cleaner

cabinet deflection

support from the floor.

Air

Cleaner

Return

Plenum

Left or Right Side Mounting

(Furnace ONLY)

Bottom Return

(Furnace / Air Handler)

Top Return

(Furnace / Air Handler)

Figure 6 Mounting Location of Air Cleaner

When attaching the air

cleaner to air handler,

furnace, or ductwork,

please keep screws

out of the circled

areas. The door

attaches to the slots in

these locations.

Figure 7 Avoiding Screw Interference

!

CAUTION

Do NOT install air cleaner where the filter can be

exposed to UV light. UV light can cause the plastic

material to deteriorate, which may lead to filter damage.

Figure 4

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 3

This air cleaner cabinet must be mounted in the return air

duct of a central forced-air Furnace/Air Handler.

Page 4

Installer’s Guide

▲

▲

Select a location that meets the following:

1. The face of the cell must be at a right angle to the air

stream.

2. Allow a minimum of 28 inches clearance in front of the

air cleaner to permit removal of cells and Pre-Filter.

3. Flow-through Bypass Humidifiers

Excessive bypass air may cause water blow-off, which

will adversely affect system operation and air cleaner

performance. To verify bypass airflow, follow the

Bypass Humidifier Pre-Installation Checkout and SetUp Procedures available through your local distributor.

Ask for publication number 18-CH37D1-*.

Steam and Flow-through Fan Power Duct-mounted

Humidifiers

Follow the Humidifier installation instructions. These

should only be installed on the supply air side of the

system.

Other Duct Mounted Humidifiers

Not recommended for installation with the air cleaner.

!

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

4. Install the air cleaner such that the airflow direction

arrow on the cabinet always points towards the furnace/ air handler. See Figure 8.

5. The PRE-FILTER must be on the entering airstream

side of the air cleaner cabinet. The mounting flange on

this side of the cabinet has the single row of holes for

attaching ductwork.

6. On side return furnace applications, the air cleaner

may be installed on either side of the cabinet or both

sides of the furnace if two air cleaners are required to

reduce system static.

Position the PRE-FILTER on the side away from the

furnace. The COLLECTION CELL guide key, installed

in the cabinet will only allow the cells to be installed in

the proper direction. Airflow direction must agree with

airflow arrows on the cabinet.

7. It is recommended that sheet metal turning vanes be

installed inside an elbow on ductwork attached to the

entering airstream side of the air cleaner. This improves

the air distribution over the COLLECTION CELLS. See

Figure 9.

8. Use transition fittings where return air duct dimensions

do not match the air cleaners opening dimensions.

Gradual transitions are preferred for greatest efficiency.

Four inches per linear foot (approximately 20° angle)

should be allowed, space permitting.

9. Seal all joints in the return air system to prevent dust

from entering the air stream.

Figure 8 Airflow Direction

Air Cleaner

Cabinet

Airflow

Turning

Vanes

Airflow

Direction Arrow

NOTE: Do NOT use a silicon based sealant. This

causes a coating on the FIELD CHARGER pins that will

decrease the efficiency of the air cleaner.

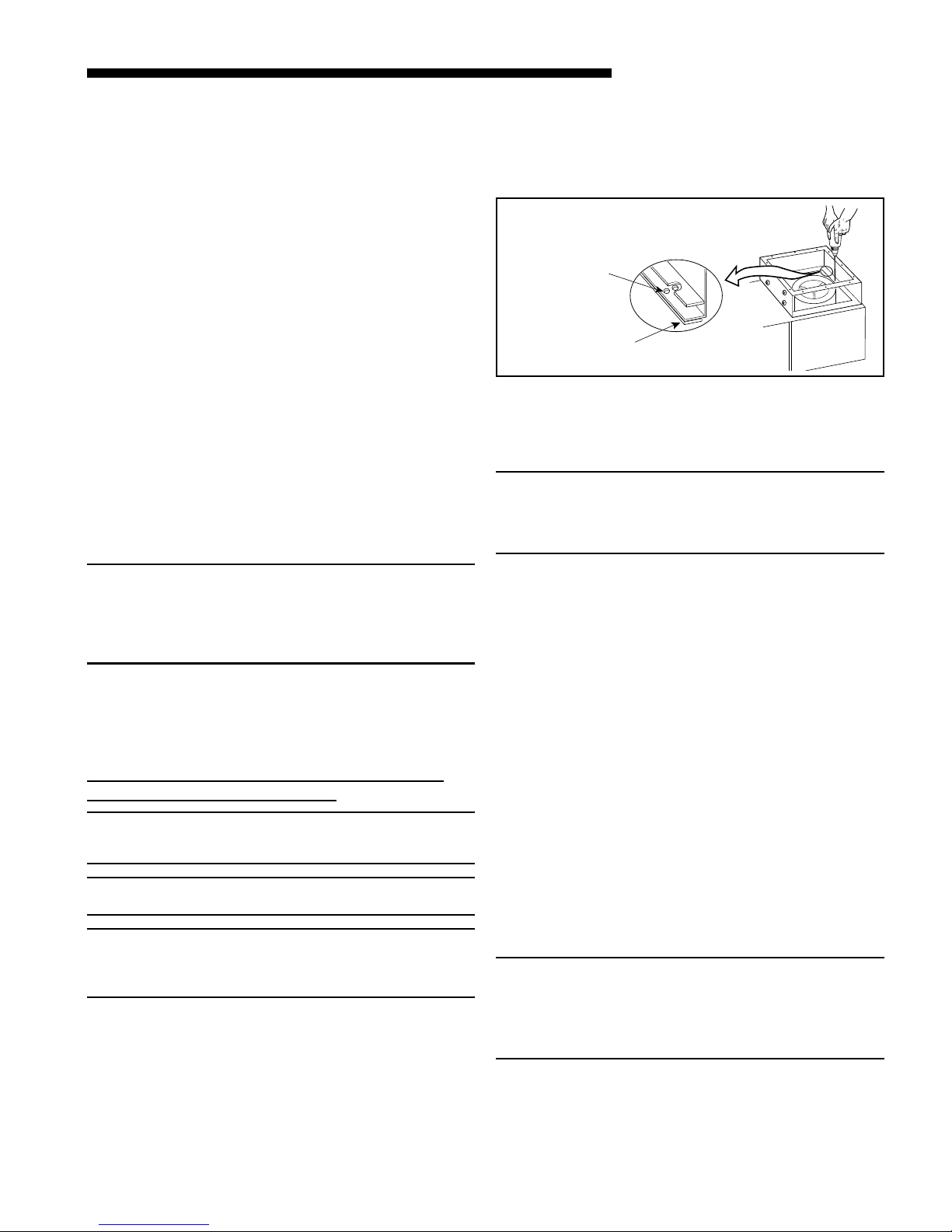

C. DOOR OPERATION

The air cleaner comes with the Power Door installed on the

unit. The Power Door and the internal components will

need to be removed before installation. Follow these

guidelines for removing and reinstalling the door:

REMOVING THE POWER DOOR:

Step 1: To remove the door, hold handles and rotate

latches as shown in Figure 10.

!

CAUTION

Handle the door only by using the handles on the

front of the door. Grasp the door by the handles as

depicted in Figure 10 to remove and replace the

door. Do not handle the door on the edges. Metal

edges may be sharp and could result in injury if the

door is not handled properly.

Before removing the door from the unit, remove the power

cable plug from the socket located in the corner of the door.

Rotate Latches

Figure 9 Turning Vanes

4 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Power cable connection

Figure 10 Rotating Door Latches

Page 5

Installer’s Guide

Rotate door away from unit to remove

Air Cleaner

Step 2: Rotate the door to fully remove from the air

cleaner. See Figure 11.

Rotate door away from unit to remove

Figure 11 Door Rotation

REINSTALLING THE POWER DOOR:

Step 1: Hold door so that tabs are aligned with slots in

cabinet as shown in Figure 12.

Figure 12 Aligning door tabs

Step 2:

Insert tabs into cabinet slots. Edge of door

should fit into channel against gasket (see detail). See

Figure 13.

Gasket

Figure 13 Inserting door tabs into cabinet slots

Step 4:

Rotate latches to secure door as shown in Figure

15.

Figure 15 Door Latch Detail

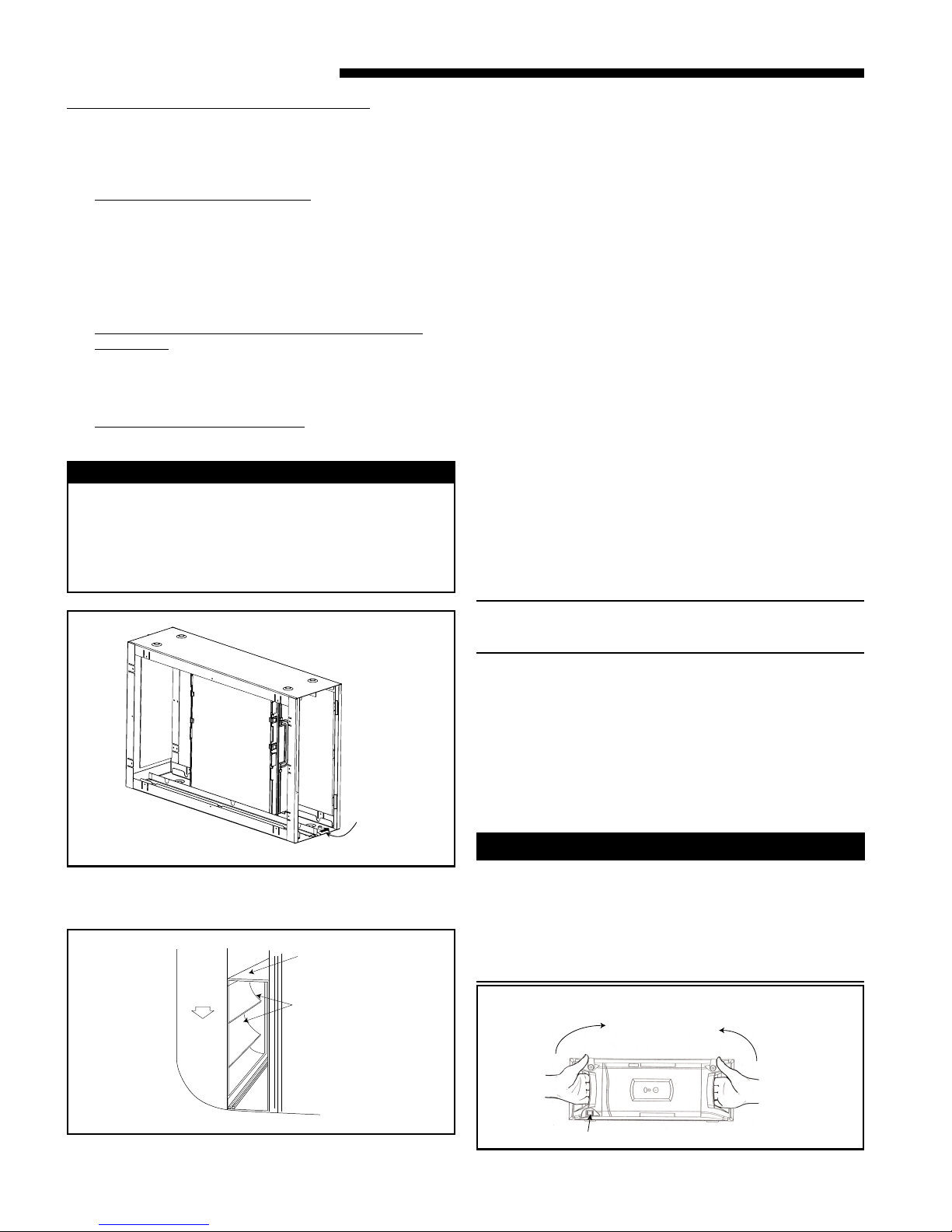

D. INSTALLATION GUIDELINES

UPFLOW FURNACE AND UPFLOW AIR

HANDLER INSTALLATION

DOWNFLOW AIR HANDLER INSTALLATION

1. Rotate the two quarter turn latches on the Power Door

outward then rotate the Power Door to remove it from

the cabinet. See Door Operation Section C. Remove

the PRE-FILTER, FIELD CHARGER, and both COLLECTION CELLS. Set the components aside until the

cabinet is installed and the indoor unit is in place.

2. Install the self-adhesive gasket material on the side of

the air cleaner cabinet flange that will mate with the

indoor unit. This flange has a double set of holes. See

Figure 16.

3. On a protective pad, lay the indoor unit on its side.

4. Position the air cleaner on the return opening of the

indoor unit with the air cleaner cabinet gasket against

the indoor unit. Check that the front of the air cleaner

cabinet is facing the front of the indoor unit.

5. Align the rear of the air cleaner flush with the rear of

the indoor unit.

6. Align the sides of the cabinet with the sides of the unit.

7. The front of the cabinet will NOT align flush with the

front of the unit.

8. Securely fasten the unit using the self-tapping sheet

metal screws provided. See Figures 16.

Step 3: Rotate door to closed position. Ensure ends of

door overlap the cabinet (see detail). See Figure 14.

Figure 14 Rotating Door Closed

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 5

Cabinet Edge

Use inner double

set of mounting

holes.

Install gasket material.

Cut to length required.

Figure 16 Installation Details

Page 6

Installer’s Guide

UPFLOW AIR HANDLER APPLICATIONS ONLY

Position the baffle onto the air cleaner as indi-

9.

cated in Figure 17. The baffle should be positioned on the leaving air side of the air cleaner

cabinet opposite the power door. Ensure that the

bracket is located correctly inside the air cleaner

enclosure so that the baffle or screws do not

interfere with the filter cell installation. (See Figure

17 inset.)

NOTE: The upflow air handler baffle is required

to protect the air cleaner in the event of a drain

pan overflow. This baffle is required for all

upflow air handler installations.

AIRFLOW

Attach upflow air

handler baffle to air

cleaner and air

handler using the

self-tapping sheet

metal screws

provided.

Be sure tab at end

of baffle is

the channel before

attaching.

INSIDE

DOWNFLOW FURNACE INSTALLATION

NOTE: On 90% Downflow Furnaces, the intake and

exhaust (flue) are located on top. A field supplied

transition is needed between the furnace and the air

cleaner. The transition must be long enough to avoid

any interference between the intake and exhaust pipe

routing and the door of the air cleaner. The door and

internal components must be removable for servicing.

NOTE: Optional Side Vent Kit BAYVENT500A may be

used if a 90% downflow furnace is installed with a

whole house air cleaner. This optional side venting

kit allows access to the front door of the whole

house air cleaner for easy filter cleaning and

maintenance. This kit eliminates the need for the

transition between the furnace and air cleaner.

1. Rotate the two quarter turn latches on the Power Door

outward then rotate the Power Door to remove it from

the cabinet. Remove the PRE-FILTER, FIELD

CHARGER, and both COLLECTION CELLS. Set the

components aside until the cabinet is installed and the

indoor unit is in place.

NOTE: Cut the front duct flange 2" from each side and

fold flat to clear the Power Door latches. Some applications may require a transition for piping clearances.

See Figure 19.

Figure 17 Upflow Air Handler Baffle Installation Details

10. Install unit in place and secure.

11. Reinstall the FIELD CHARGER and lock into place by

bending one locking tab on the cabinet. See Figure 18.

12. Reinstall the PRE-FILTER and COLLECTION CELLS.

13. Each cell must be oriented with handles toward the

front.

14. The door can be installed in either direction. Determine which direction will best allow access to the

latches and 24 Volt power cord. Insert the 2 tabs on the

door into the slots in the cabinet flange and rotate the

door into the closed position. Rotate the two quarterturn latches on the Power Door inward. See Door

Operation Section C.

15. Remove stickers (two stickers both are 5.5" x 7.5")

from packet and attach to furnace, air handler, or

ductwork in a location visible to the homeowner.

16. Demonstrate Maintenance (Section H) and Door

Operation (Section C) to the homeowner.

Figure 19 Duct Flanges

NOTE: Remove filter rack from downflow Furnace and

discard.

2. Bend the 4 mounting tabs down on the two sides of the

air cleaner cabinet. These can be used to attach the air

cleaner cabinet to the furnace. See Figure 20.

Field Charger Locking Tab

Figure 18 Locking Tab

6 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Actuator Tab for

Interlock Switch

Figure 20 Mounting Tabs

3. Install the self-adhesive gasket material on the side of

the air cleaner cabinet flange that will mate with the

indoor unit. This flange has a double set of holes. See

Figure 16.

Page 7

Installer’s Guide

Use inner

mounting holes

for Side Installation

Install gasket material.

Cut to length required.

4. Apply transitions or spacer as required to clear flue

piping and to ensure the opening of the air cleaner

matches the opening in the furnace.

Position the air cleaner on the return opening of the

furnace with the air cleaner cabinet gasket against the

furnace. Check that the front of the air cleaner cabinet

is facing the front of the furnace.

5. Align the rear of the air cleaner flush with the rear of

the indoor unit.

6. Align the sides of the cabinet with the sides of the unit.

7. The front of the cabinet will NOT align flush with the

front of the unit.

8. Securely fasten the unit using the self-tapping sheet

metal screws provided. See Figure 16.

9. Reinstall the FIELD CHARGER and lock into place by

bending one locking tab on the cabinet. See Figure 18.

10. Reinstall the PRE-FILTER and COLLECTION CELLS.

11. Each COLLECTION CELL must be oriented with the

handles toward the front.

12. The door can be installed in either direction. Determine which direction will best allow access to the

latches and 24 Volt power cord. Insert the 2 tabs on the

door into the slot in the cabinet flange and rotate the

door into the closed position. Rotate the two quarterturn latches on the Power Door inward. See Door

Operation, Section C.

NOTE: The door has a safety switch to ensure power is

interrupted when the door is removed. This switch is

open when the door is removed from the cabinet. When

the door is properly installed, an actuator tab located in

the cabinet will close the switch, allowing power to the

electronics.

13. Remove stickers (two stickers both are 5.5" x 7.5")

from the packet and attach to furnace, air handler, or

ductwork in a location visible to the homeowner.

14. Demonstrate Maintenance (Section H) and Door

Operation (Section C) to the homeowner.

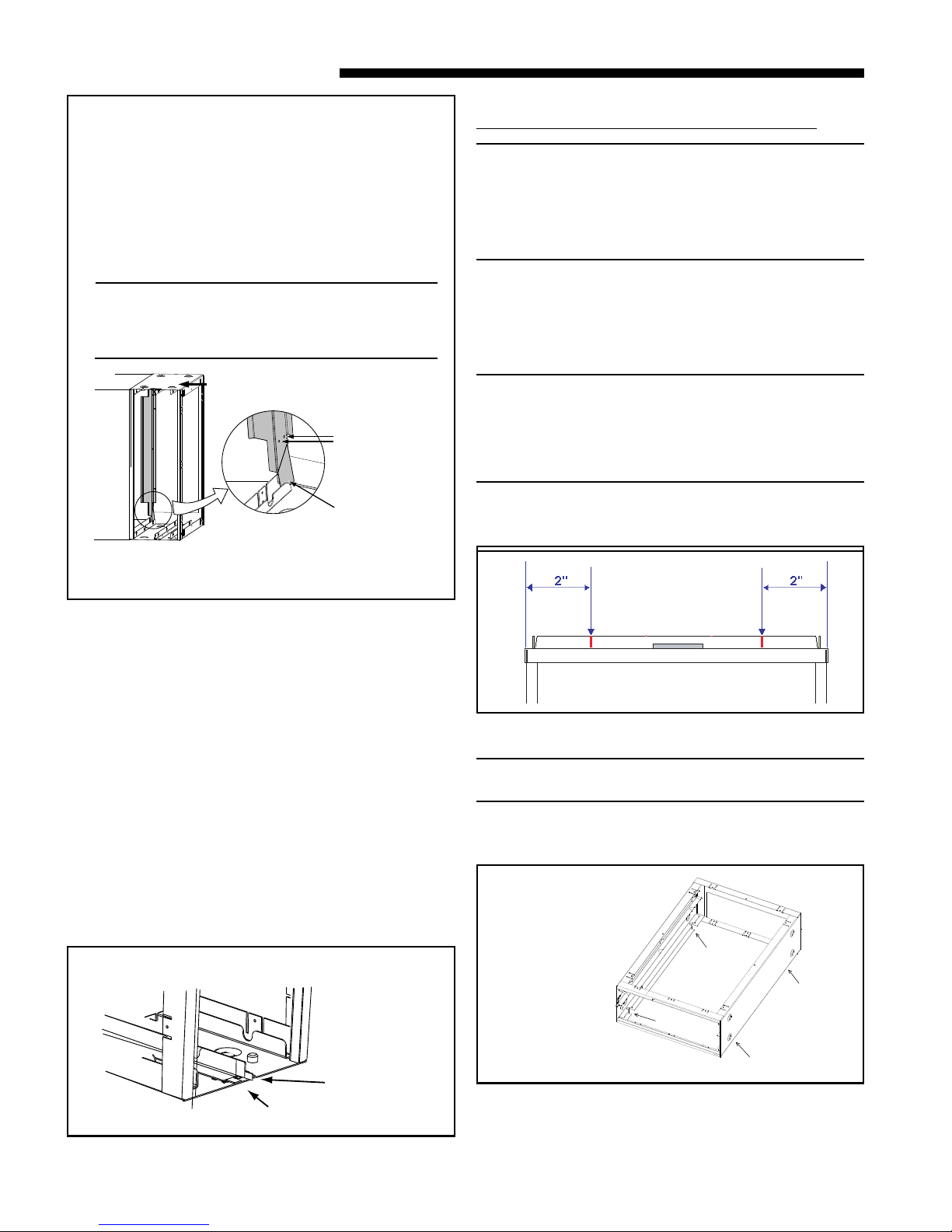

SIDE RETURN FURNACE INSTALLATION

14.5" & 17.5" MODELS ONLY

NOTE: The 21" and 24 1/2" air cleaner cabinet heights

require a transition between the air cleaner cabinet and

the Furnace in side return applications.

NOTE: Do NOT install the air cleaner cabinet on the

side of an air handler.

NOTE: It is recommended that sheet metal turning

vanes be installed inside an elbow on ductwork attached to the entering airstream side of the air cleaner.

See Figure 9 on Page 4.

1. Rotate the two quarter turn latches on the Power Door

outward then rotate the Power Door to remove it from

the cabinet. Remove the PRE-FILTER, FIELD

CHARGER, and both COLLECTION CELLS. Set the

components aside until the cabinet is installed and the

indoor unit is in place.

2. Install the self-adhesive gasket material on the side of

the air cleaner cabinet flange that will mate with the

indoor unit. This flange has a double set of holes. See

Figure 21.

3. On a protective pad, lay the indoor unit on its side.

Position the furnace with the return air side of the

cabinet facing up.

4. Align the bottom of the air cleaner cabinet 1/4" ABOVE

the bottom of the furnace and flush with the rear of the

furnace.

Figure 21 Side Installation Details

5. Mark the inside of the opening in the air cleaner

cabinet on the side of the furnace using the inside

edge of the air cleaner cabinet as a guide. Remove the

cabinet and cut the opening in the side of the furnace.

NOTE: Do NOT use the standard furnace indents for the

opening. The opening for the air cleaner must be larger

than the standard furnace opening. Install transition as

required for air cleaner opening to match furnace

opening as described below.

6. Position the air cleaner on the return opening of the

indoor unit with the air cleaner cabinet gasket against

the indoor unit. Check that the front of the air cleaner

cabinet is facing the front of the indoor unit.

7. Align the rear of the air cleaner flush with the rear of

the indoor unit.

8. Align the sides of the cabinet with the sides of the unit.

9. The front of the cabinet will NOT align flush with the

front of the unit.

10. Securely fasten the unit using the self-tapping sheet

metal screws provided. See Figure 21.

11. Reinstall the FIELD CHARGER and lock into place by

bending one locking tab on the cabinet. See Figure 18.

12. Reinstall the PRE-FILTER and COLLECTION CELLS.

13. Each cell must be oriented with the handles toward the

front.

14. The door can be installed in either direction. Determine which direction will best allow access to the

latches and 24 volt power cord. Insert the 2 tabs on the

door into the slots in the cabinet flange and rotate the

door into the closed position. Rotate the two quarterturn latches on the Power Door inward. See Door

Operation, Section C.

NOTE: The door has a safety switch to ensure power is

interrupted when the door is removed. This switch is

open when the door is removed from the cabinet. When

the door is properly installed, an actuator tab located in

the cabinet will close the switch, allowing power to the

electronics.

15. Remove stickers (two stickers both are 5.5" x 7.5")

from the packet and attach to the furnace, air handler,

or ductwork in a location visible to the homeowner.

16. Demonstrate Maintenance (Section H) and Door

Operation (Section C) to the homeowner.

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 7

Page 8

Installer’s Guide

▲

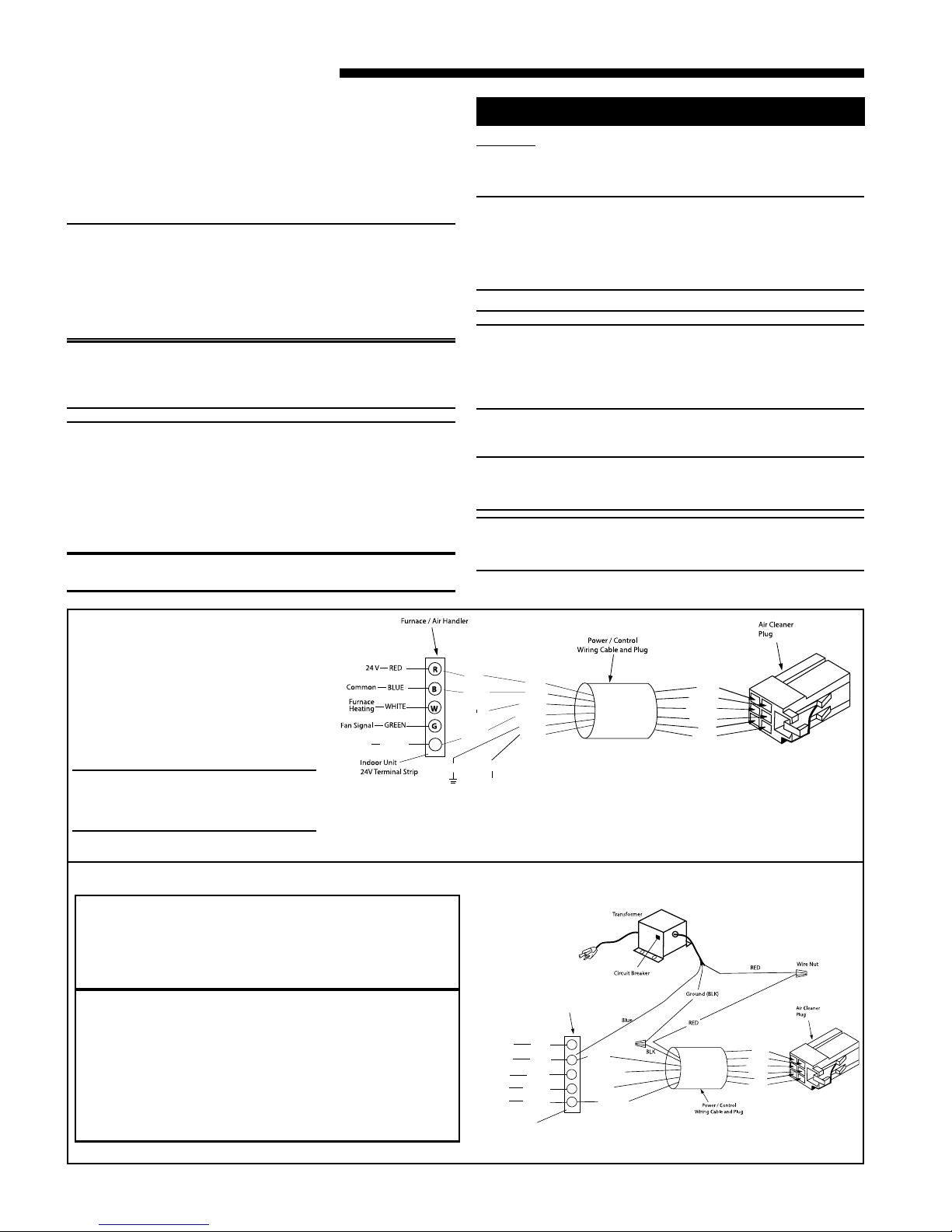

E. ELECTRICAL CONNECTIONS

The air cleaner requires 24 VAC power and indoor fan

signal to operate. A transformer adequately sized to

power both the system and air cleaner is provided with

the air cleaner. Remove the transformer in the indoor unit

and replace with the transformer provided.

N

OTE: A 50 VA transformer is required for Trane/

American Standard Heating & Air Conditioning

furnace applications and 75 VA required for Trane/

American Standard Heating & Air Conditioning air

handler applications. If the indoor air handler

already has a properly sized transformer, no

replacement is required.

NOTE: When more than one whole house air cleaner

is used, the 24 volt transformer which supplies

power to the air cleaner will need to be increased by

25 VA for each additional air cleaner added.

NOTE: Trane/American Standard Heating & Air

Conditioning dual circuited air handlers matched

with heat pumps and Trane/American Standard

Heating & Air Conditioning oil furnaces will require

an accessory Transformer KIT# BAYTRANS12024

power the air cleaner. Do NOT replace air handler

transformer with the transformer supplied with the

air cleaner.

NOTE: Provide adequate strain relief for the low

voltage cable at the indoor unit.

◆◆

◆

◆◆

to

!

CAUTION

DO NOT attach the power/control cable to a 120 Volt

EAC tap. The air cleaner uses 24 Volt power. Failure

to use 24 VAC results in permanent damage to the air

cleaner.

• Plug the air cleaner power/control cable into the air

cleaner door and route the cable into the indoor unit

low voltage wiring location.

• Connect the power/control wiring per Figures 22 &

22A.

NOTE: Wiring penetration must be sealed.

NOTE: For non-Trane/American Standard Heating & Air

Conditioning systems order a 120 VAC to 24 VAC

transformer, KIT# BAYTRANS12024

◆◆

◆

to provide 24 volt

◆◆

power only to the air cleaner. Access to 120 VAC outlet

is required.

• Connect the power/control wiring per Figures 22 &

22A.

NOTE: Trane/American Standard Heating & Air

Conditioning Communicating Furnaces require KIT #

BAYACCECOMM101.

NOTE: Wiring diagrams for the Communicating Air

Handler, Communicating Furnaces and Oil Furnaces

are on pages 9-10, 11-13 and 14 respectively.

Figure 22 - Wiring Diagram

Communicating Mode

Data Line

BROWN

NOTE: The Black wire must be

connected to chassis ground to

ensure proper operation.

BAYTRANS12024

◆◆

◆

Transformer

◆◆

Air Handler may not have a Low Voltage Terminal board. Connect Electronic Air Cleaner wires to

the Air Handler Low Voltage Color coded wires.

Install Transformer, one is supplied with the Electronic Air Cleaner, in the Furnace or Air Handler.

• Transformer must have a grounded 120 VAC

power source. Do not defeat ground plug on the

transformer.

• Mount transformer to building structure with the

four provided wood screws.

NOTE: BAYTRANS12024C complies with the California

Code of Regulation,Title 20, Sections 1601 through

1608 dated December 2006. BAYTRANS12024A with

vendor’s manufacturing date codes after 0625 (YYWW)

cannot be installed in California because the transformer

does not satisfy the requirements set forth by California

Code of Regulations, Title 20, Sections 1601 through

1608 dated December 2006.

Transformer not applicable to 50 Hz units.

D

BLACK

GRD

RED

BLUE

Unused

GREEN

BROWN

WHITE

Unused

Furnace

Heating Signal

Fan Signal

Data Line

24 V

Common

RED

BLUE

GREEN

BROWN

BLACK

WHITE

Furnace / Air Handler

RED

BLUE

WHITE

GREEN

BROWN

Indoor Unit

24 V Terminal Strip

BLUE

GREEN

BROWN

BLACK

RED

WHITE

R

BLUE

B

Unused

WHITE

W

Unused

G

GREEN

BROWN /

D

Dataline

The ◆ represents an alpha character.

GREEN

BROWN

BLACK

WHITE

BLUE

RED

8 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 9

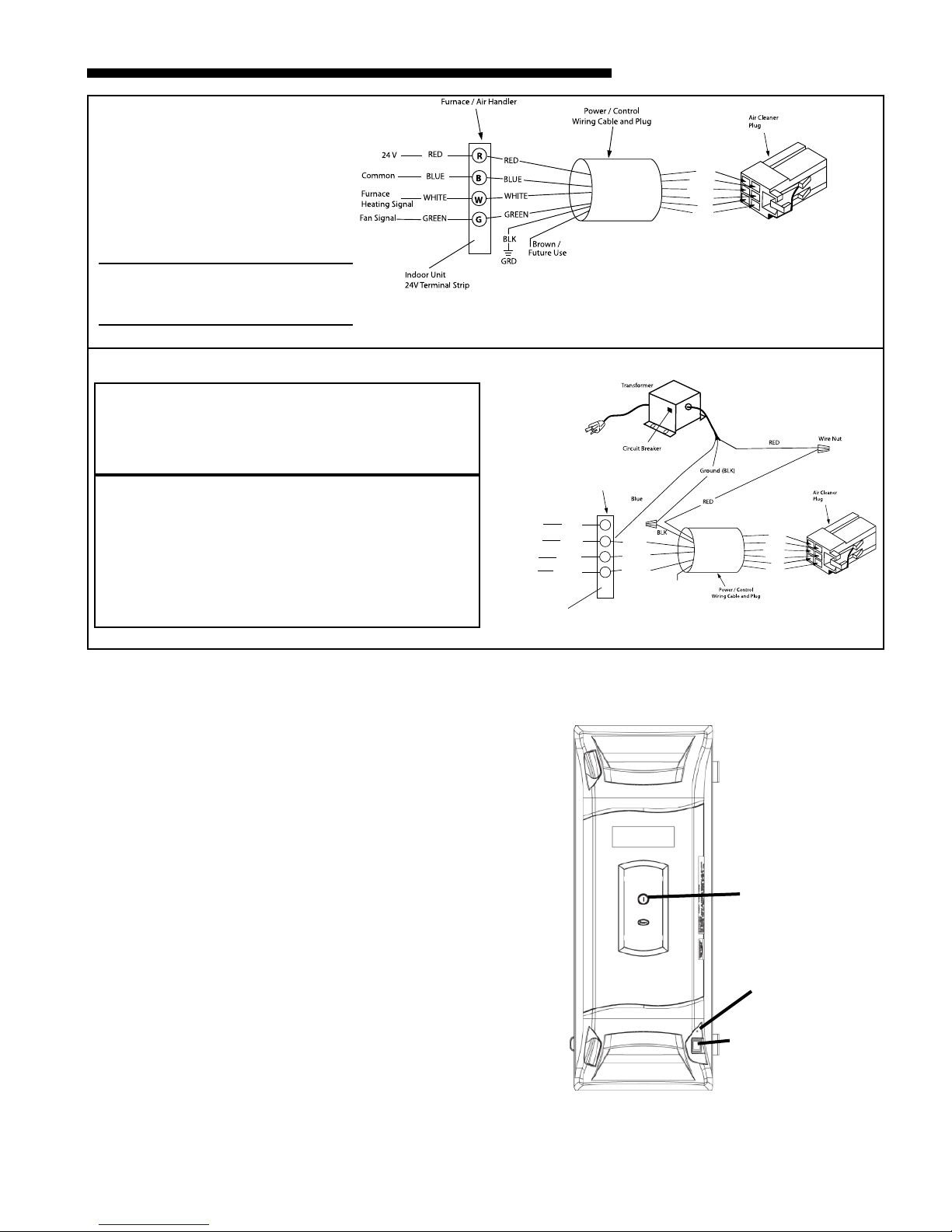

Plug Power Cord

in here

Power Button

Amber Light

Figure 22A - Wiring Diagram

for 24 V Mode

NOTE: The Black wire must be connected to chassis ground to ensure

proper operation.

◆◆

BAYTRANS12024

◆

Transformer

◆◆

• Transformer must have a grounded 120 VAC

power source. Do not defeat ground plug on the

transformer.

• Mount transformer to building structure with the

four provided wood screws.

NOTE: BAYTRANS12024C complies with the California

Code of Regulation,Title 20, Sections 1601 through

1608 dated December 2006. BAYTRANS12024A with

vendor’s manufacturing date codes after 0625 (YYWW)

cannot be installed in California because the transformer

does not satisfy the requirements set forth by California

Code of Regulations, Title 20, Sections 1601 through

1608 dated December 2006.

Transformer not applicable to 50 Hz units.

Air Handler may not have a Low Voltage Terminal board. Connect Electronic Air Cleaner wires to

the Air Handler Low Voltage Color coded wires.

Install Transformer, one is supplied with the Electronic Air Cleaner, in the Furnace or Air Handler.

Common

Furnace

Heating Signal

Fan Signal

24 V

24 V Terminal Strip

Furnace / Air Handler

RED

BLUE

WHITE

GREEN

Indoor Unit

Installer’s Guide

BLUE

GREEN

BROWN

BLACK

RED

WHITE

R

BLUE

B

WHITE

W

GREEN

G

BROWN /

Dataline

The ◆ represents an alpha character.

GREEN

BROWN

BLACK

WHITE

BLUE

RED

MODES OF OPERATION

The whole house air cleaner can be connected in one of

two modes of operation; either a 24 V mode or a

communicating mode. To know how the whole house air

cleaner is set up, reference Figure 23 to find the amber

light.

A steady amber light indicates that the unit is wired in

the 24 V mode.

A blinking amber light indicates that the unit is wired in

the communicating mode.

No light present means that the unit is not connected.

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 9

Figure 23 - Amber Light showing

Mode of Operation

Page 10

Installer’s Guide

BK R

O G Y1 Y2

D

B W1 W2 W3

BK R

O G Y1 Y2

D

B W1 W2 W3

GREEN

WHITE

▲

ELECTRICAL CONNECTIONS TO A COMMUNICATING SYSTEM AIR HANDLER

IN CONVENTIONAL 24 V MODE

!

WARNING

HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC

POWER, INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FOLLOW PROPER LOCKOUT/TAGOUT

PROCEDURES TO ENSURE THE POWER CAN NOT BE

INADVERTENTLY ENERGIZED. FAILURE TO

DISCONNECT POWER BEFORE SERVICING COULD

RESULT IN DEATH OR SERIOUS INJURY.

PROCEDURE:

1) Remove electrical power going into the air handler.

2) On the communicating systems air handler, remove

the blower access panel.

3) Remove the communicating control box cover.

4) Locate the red jumper wire which is attached from

EAC to R on the Communicating Systems PCB.

Confirm it is connected. If there is not a jumper wire

installed, then one must be installed in this location

in order for the air cleaner to function properly.

Detach female spade terminal

from white EAC wire and

crimp to green wire

5) Replace the Communicating control box cover.

6) Locate the white wire coming from the

Communicating System Air Handler PCB labeled

“EAC”. The wire will have a male spade terminal

connected to it and a female spade terminal

inserted into the male terminal. Remove the

female spade terminal and crimp it to the green

wire on the air cleaner harness.

7) Connect the green wire from the air cleaner

harness to the white wire on the Communicating

Systems Air Hand nected to the metal air handler

chassis.

10) Replace the blower access panel.

11) Reconnect electrical power to the air handler.

Control box panel cover

(Shown removed)

24V RED

jumper wire

from EAC to R

BEFORE AFTER

WHITE

WHITE

GREEN

Indoor Unit

24V

Terminal

Strip Detail

10 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

GREEN

EAC

GREEN

BLUE

RED

WHITE

Unused

BLACK

GRD

Wiring Cable and Plug

BROWN /

Future Use

For use with Whole House

Air Cleaner

Power / Control

Air Cleaner

Plug

EAC

R

PCB Detail

Page 11

▲

ELECTRICAL CONNECTIONS TO A STANDARD 24 VOLT AIR HANDLER

!

WARNING

HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC

POWER, INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FOLLOW PROPER LOCKOUT/TAGOUT

PROCEDURES TO ENSURE THE POWER CAN NOT BE

INADVERTENTLY ENERGIZED. FAILURE TO

DISCONNECT POWER BEFORE SERVICING COULD

RESULT IN DEATH OR SERIOUS INJURY.

Installer’s Guide

Field wiring

W3

W2

W1

G

YI

O

R

B

YO

GREEN

BLUE

RED

WHITE

Unused

GAM5 / A/TAM4

BLACK

GRD

BROWN /

Future Use

For use with Whole House

Power / Control

Wiring Cable and Plug

Air Cleaner

Air Cleaner

Plug

W3

W2

W1

BK

G

Y2

YI

O

R

B

YO

GREEN

BLUE

RED

WHITE

Unused

(In)

(Out)

BLACK

GRD

Wiring Cable and Plug

BROWN /

Future Use

A/TAM7

For use with Whole House

Air Cleaner

Power / Control

Air Cleaner

Plug

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 11

Page 12

Installer’s Guide

▲

BK R

O G Y1 Y2

D

B W1 W2 W3

BK R

O G Y1 Y2

D

B W1 W2 W3

ELECTRICAL CONNECTIONS TO A COMMUNICATING SYSTEMS AIR HANDLER

IN COMMUNICATING MODE

WARNING

HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC

POWER, INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FOLLOW PROPER LOCKOUT/TAGOUT

PROCEDURES TO ENSURE THE POWER CAN NOT BE

INADVERTENTLY ENERGIZED. FAILURE TO

DISCONNECT POWER BEFORE SERVICING COULD

RESULT IN DEATH OR SERIOUS INJURY.

Control box panel cover

4TEE3C A/TAM8

(Shown removed)

1) Remove electrical power going into the air handler.

2) On the communicating systems air handler, remove

the blower access panel.

3) Connect Red stripped wire to "R" terminal on the

air handler terminal strip.

4) Connect Blue stripped wire to "B" terminal on the

air handler terminal strip.

5) Connect the brown wire from the air cleaner

harness to the "D" terminal on the Communicating

Systems Air Handler.

6) Connect the Black wire from the air cleaner wire

harness to earth ground by attaching the wire to a

grounded screw that is connected to the metal air

handler chassis or control plate assembly.

7) The Green and White wires on the air cleaner

wiring harness are unused in this application and

should be insulated separately.

8) Replace the blower access panel.

9) Reconnect electrical power to the air handler.

10) Check air cleaner and air handler operation.

!

PROCEDURE:

Indoor Unit

24V Terminal

Strip Detail

BLUE

RED

BROWN /

Dataline

WHITE

Unused

BLACK

GRD

GREEN

Unused

Black wire to

chassis

ground

12 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

For use with Whole House

Air Cleaner

Power / Control

Wiring Cable and Plug

Air Cleaner

Plug

Y2

Y1

O

R

B

D

BROWN /

Dataline

BLUE

RED

WHITE

Unused

BLACK

GRD

For use with Whole House

Air Cleaner

Power / Control

Wiring Cable and Plug

GREEN

Unused

Air Cleaner

Plug

Page 13

Installer’s Guide

▲

ELECTRICAL CONNECTIONS TO A COMMUNICATING FURNACE IN 24 V MODE

!

WARNING

HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC

POWER, INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FOLLOW PROPER LOCKOUT/TAGOUT

PROCEDURES TO ENSURE THE POWER CAN NOT BE

INADVERTENTLY ENERGIZED. FAILURE TO DISCONNECT

POWER BEFORE SERVICING COULD RESULT IN DEATH

OR SERIOUS INJURY.

PROCEDURE:

1. Remove electrical power going into the furnace.

2. Remove blower door to up-flow or down-flow furnace.

3. Remove the two screws that secure the IFC platform to the

underside of the blower deck on an up-flow furnace or the 3

screws that secure the IFC platform to the top panel on a

down-flow furnace.

4. Carefully remove the IFC platform from the furnace.

5. On both the up-flow and down-flow furnaces, mount the 50VA

transformer supplied in the packaging with the air cleaner

onto the bottom of the IFC platform. Screws and pilot holes

are provided. See figure.

6. Remove wiring from existing 35VA transformer and reconnect

to the 50VA transformer. Note the polarity of the wires and

reconnect to the appropriate terminals. See diagram

7. Remove the EAC-H 115VAC and EAC-N wires (white and

black) out of the junction box and pull them through the

grommet in the blower deck. Attach two supplied ¼” insulated

female quick connect terminals by stripping the wires and

crimping the terminals onto the wires. Attach these wires to

the 115V terminals of the 35VA transformer as shown in the

diagram.

8. Remove the wiring harness supplied with the air cleaner from

the packaging. Attach a supplied 3/16” insulated female quick

connect terminal to the blue wire and the green wire.

9. Attach the blue wire from the air cleaner wiring harness to the

open tab on the piggyback terminal supplied in the

BAYACCECOMM101. Attach piggyback terminal to the 35VA

transformer terminal “C” (Common).

10. Insert the 12” blue stripped wire under the terminal strip

screw marked “B/C” on the IFC control board. If the application also includes an outdoor unit (communicating or noncommunicating), the B/C terminal will require 3 wires

connected. For this connection, rather than connecting the

three wires to the low voltage terminal strip on the furnace

IFC, create a pigtail using a short length of thermostat wire

and a wire nut (field supplied) to attach to the B/C terminal.

11. Connect the green wire from the air cleaner wiring harness to

the 24V terminal on the 35VA transformer labeled “RD”. See

diagram.

12. Insert the red stripped wire from the air cleaner wiring

harness under the IFC control board terminal screw marked

“R”. See diagram.

13. Attach the black stripped wire from the air cleaner wiring

harness directly to ground with a screw on the furnace

chassis. See diagram.

14. Once all of the connections have been completed, remount

the IFC control platform into the furnace.

15. Secure any loose wiring with wire ties.

16. The brown and white wires from the EAC wiring harness are

unused in this application and should be insulated. See

diagram.

17. Replace the furnace door.

18. Reconnect electrical power to the furnace.

19. Check both furnace and air cleaner operation per the furnace

and air cleaner installer guides.

BILL OF MATERIALS:

QTY: 2 Screw

QTY: 1 4" Insulated Copper Wire –

QTY: 2 1/4” Insulated Female Quick

QTY: 2 3/16" x 0.020" Insulated Female

QTY: 1 3/16" x 0.020" Receptacle & Tab

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 13

Blue (18 AWG, AWM)

Connect Terminal

Quick Connect Terminal

These instructions and listed parts are included in KIT# BAYACCECOMM101

Page 14

Installer’s Guide

▲

ELECTRICAL CONNECTIONS TO A COMMUNICATING SYSTEM FURNACE

!

WARNING

HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC

POWER, INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FOLLOW PROPER LOCKOUT/TAGOUT

PROCEDURES TO ENSURE THE POWER CAN NOT BE

INADVERTENTLY ENERGIZED. FAILURE TO DISCONNECT

POWER BEFORE SERVICING COULD RESULT IN DEATH

OR SERIOUS INJURY.

PROCEDURE:

1. Remove electrical power going into the furnace.

2. Open blower door to upflow or downflow furnace.

3. Disconnect all wires on the 35VA transformer.

4. Remove the 35VA transformer from the IFC platform.

5. Mount the 50 VA transformer supplied in the packaging with

the air cleaner onto the IFC platform where the 35VA

transformer was previously located. Use the sheet metal

screws supplied with the air cleaner to mount the 50VA

transformer. Reconnect the 115V and 24V wires that were

connected to the 35VA transformer onto the 50 VA

transformer.

6. Connect Red stripped wire to "R" terminal on the furnace control

board.

7. Connect Blue stripped wire to "B" terminal on the furnace control

board.

8. Connect Brown stripped wire to "D" terminal on the furnace

control board.

9. Attach the black stripped wire from the air cleaner wiring harness

directly to ground with a screw in the chassis.

10. The green and white wires on the air cleaning wiring harness are

unused in this application and should be insulated.

11. Replace door on furnace.

12. Reconnect electrical power to the furnace.

13. Check both furnace and air cleaner operation per the furnace and

air cleaner installer guides.

14 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 15

Installer’s Guide

▲

ELECTRICAL CONNECTIONS TO AN OIL FURNACE

!

WARNING

HAZARDOUS VOLTAGE! DISCONNECT ALL ELECTRIC

POWER, INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FOLLOW PROPER LOCKOUT/TAGOUT

PROCEDURES TO ENSURE THE POWER CAN NOT BE

INADVERTENTLY ENERGIZED. FAILURE TO

DISCONNECT POWER BEFORE SERVICING COULD

RESULT IN DEATH OR SERIOUS INJURY.

SINGLE STAGE OIL FURNACE TO AIR CLEANER

THERMOSTAT

R/

RC

NOTE 1

RH

Y

G

FURNACE

FAN CENTER

R

Y

G

AIR

CLEANER

R

BR

G

Refer to the diagrams below for proper connections

to an oil furnace. Consult the oil furnace installer's

guide for additional information.

VARIABLE SPEED OIL FURNACE TO AIR CLEANER

FURNACE

THERMOSTAT

R/

RC

NOTE 1

RH

Y/

Y1

G

LOW VOLTAGE

TERMINAL

BLOCK

R

O

Y/

Y2

G

Factory

Jumpered

AIR

CLEANER

R

BR

G

NOTE 1:

NOTE 2:

NOTE 3:

W

R1

NOTE 2

W

W

C

B

Bk

GND

OIL BURNER PRIMARY

T

R1

NOTE 2

T

If thermostat being used has separate RC and

RH terminals, jumper RC and RH together.

Oil burner primary TT contacts must be isolated

using field supplied relay (RLY00925) or equivalent.

The black wire (Bk) from ACCE unit must be connected

to chassis ground to ensure proper operation.

NOTE 3

W1

NOTE 1:

NOTE 2:

NOTE 3:

R1

B

NOTE 2

BCC

BK

W1

W

B

Bk

GND

OIL BURNER PRIMARY

T

R1

NOTE 2

T

If thermostat being used has separate RC and

RH terminals, jumper RC and RH together.

Oil burner primary TT contacts must be isolated

using field supplied relay (RLY00925) or equivalent.

The black wire (Bk) from ACCE unit must be connected

to chassis ground to ensure proper operation.

NOTE 3

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 15

Page 16

Installer’s Guide

ELECTRICAL CONNECTIONS FOR DUAL WHOLE HOUSE AIR CLEANER

Dual Whole House Air Cleaners

In some instances, two whole house air cleaners

can be utilized to manage the overall system

operational static pressure. The figure below shows

two whole house air cleaners installed on an upflow

furnace. The 24 volt transformer which supplies

power to the air cleaner will need to be increased by

25 VA for each additional air cleaner added.

See the wiring diagrams for information on how to

attach the wires in a two whole house air cleaner

system. The figure on the top of page 16 shows the

wiring hookup for two whole house air cleaners

attached to a furnace in conventional 24 V mode.

The figure on the bottom of page 16 shows the

wiring hookup for two whole house air cleaners

attached to a furnace in communicating mode.

Refer to the wiring diagrams on pages 8 through 14

for guidance on wiring the whole house air cleaners

to the system properly. All wires will be run the

same way for each of the two whole house air

cleaners.

Airflow

Dual System on Furnace

16 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 17

Installer’s Guide

ELECTRICAL CONNECTIONS FOR DUAL WHOLE HOUSE AIR CLEANERS

AND FURNACE IN CONVENTIONAL 24V MODE

FIELD SUPPLIED 50 VA TRANSFORMER

ELECTRICAL CONNECTIONS FOR DUAL WHOLE HOUSE AIR CLEANER AND

FURNACE IN COMMUNICATING MODE

FIELD SUPPLIED 75 VA TRANSFORMER

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 17

Page 18

Installer’s Guide

▲

F. AIR CLEANER OPERATION

G. SET-UP MODE

A combination of RED, YELLOW, and GREEN LED's are

CLEAN

PRE-FILTER

RESET

LED's

POWER

PRE-FILTER

RESET

used to indicate the following settings. See Figure 25.

• The three GREEN LED's are used to indicate PRE-

FILTER cleaning interval. This is measured in actual run

time of the indoor fan. The default setting is 2 months

[10 weeks]. See Figure 26.

• The four YELLOW LED's indicate the COLLECTION

CELLS cleaning interval. This is measured in actual run

time of the indoor fan. The default setting is 6 months

[31 weeks]. See Figure 27.

• The three RED LED's indicate the Power Level setting.

Figure 24 LED Display

!

CAUTION

Do NOT operate the air cleaner during construction or

remodeling of a home. The air cleaner is designed for

use in normal living conditions to capture small

particles. The volume of dust and condensate in the

presence of chlorides and fluorides from paint, varnish,

stains, adhesives, cleaning compounds, and cement

The default is maximum. See Figure 28.

INSTALLER SET-UP MODE

To enter the SET-UP Mode press and hold both the

POWER and RESET buttons for a minimum of 5 [6]

seconds. The current settings are then displayed. See

Figure 25. If this is the desired setting or at any time you

want to exit the SET-UP mode, press and hold BOTH the

POWER and RESET buttons for a minimum of 5 [6]

seconds to exit.

creates a corrosive condition which may cause rapid

deterioration of the cabinet and internal components of

the air cleaner and the air handler/furnace.

DISPLAY FEATURES (Figure 24)

The air cleaner display can be used for several

functions:

• Provide the homeowner the operating status of the

air cleaner, including an indication the PRE-FILTER or

COLLECTION CELLS need cleaning.

• The installer accesses the SET-UP mode to change

the time to clean settings for the PRE-FILTER and

COLLECTION CELLS as well as change the Power

Level setting.

• The unit will display fault codes for the homeowner

indicating there is a problem with the air cleaner and

various fault codes for the service technician to

assist in troubleshooting the problem.

Factory settings

DIRTY

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

CLEAN

G1

To change any of the settings, press the POWER button

once.

Power Level

Collection Cell

Pre-Filter

Figure 25 Factory Settings

FIELD CHARGER Power

Maximum

COLLECTION CELL

6 Months [31 weeks]

PRE-FILTER

2 Months [10 weeks]

PRE-FILTER SETTING (Figure 26) 24V Mode

Only.

One or more of the GREEN LED’s will come on

Turn the air cleaner on by pushing the POWER button.

The backlit POWER and Filter RESET buttons will

illuminate along with the first Green LED (G1) indicating

24 Volt power is present to the air cleaner.

indicating the PRE-FILTER cleaning time setting.

Repeatedly press the RESET button to cycle through the

time options for the PRE-FILTER cleaning cycle until the

desired setting is displayed. Press the POWER button

once to accept that setting and move to the

When the indoor fan is operating the first LED (G1) will

COLLECTION CELL cleaning settings.

slowly flash. This indicates the FIELD CHARGER and

COLLECTION CELLS have power and the unit is

operating normally. There is a 10 [12] minute time delay

between the indoor fan starting and LED (G1) flashing.

In normal operation, the air cleaner makes a slight sound

as the air passes through it and is cleaned. In some

applications, you may notice this sound coming from the

return air vent(s). If desired, this sound level can be

reduced with minimal impact on air cleaning efficiency

by reducing the power setting of the FIELD CHARGER in

the SET-UP mode.

NOTE: There is a 10 [12] minute delay after the

indoor fan operates, before the air cleaner starts to

operate, each time the power to the air cleaner is

turned off/on. This can be bypassed by going into

DIRTY

CLEAN

One Month

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

[5 Weeks]

DIRTY

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

CLEAN

G1

Two Months *

[10 Weeks]

DIRTY

CLEAN

Three Months

[15 Weeks]

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

and then out of the SET-UP mode.

Figure 26 Green LED Pre-Filter Settings

* Factory Setting

18 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 19

Installer’s Guide

▲

▲

CELL CLEANING SETTING (Figure 27)

One or more of the YELLOW LED’s will come on

indicating the COLLECTION CELL cleaning time setting.

Repeatedly press the RESET button to cycle through the

time options for the COLLECTION CELL cleaning cycle

until the desired setting is displayed. Press the POWER

button once to accept that setting and move to the Field

Charger Power Level Settings.

DIRTY

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

CLEAN

G1

Two Months

[10 Weeks]

DIRTY

CLEAN

Four Months

[20 Weeks]

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

DIRTY

CLEAN

Six Months*

[31 Weeks]

Figure 27 Yellow LED Collection Cells Settings

*Factory Setting

DIRTY

CLEAN

R2

Y4

Y3

Y2

Y1

G2

G1

R3

R1

G3

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

Nine Months

[46 Weeks]

FIELD CHARGER POWER LEVEL

The RED LED lights are used to set the Power Level of

the FIELD CHARGER for maximum, medium, or minimum. The number of illuminated RED LED lights indicates the current setting. The factory setting is for

maximum.

Lower settings will reduce the slight sound emitted by

the unit with minimal loss of air cleaning efficiency, if

desired. The U.S. Food and Drug Administration recommends indoor ozone concentrations should not exceed

50 parts per billion.

Your air cleaner will contribute only .3 parts per billion.

FIELD CHARGER POWER LEVEL SETTING

(Figure 28)

One or more of the RED LED lights will illuminate. To

change the Power Level setting, press the RESET

button until the desired setting is indicated.

To save your new settings and exit the SET-UP mode,

press and hold BOTH the POWER and filter RESET

buttons for a minimum of 5 [6] seconds.

H. MAINTENANCE

!

CAUTION

Before cleaning the coil or ducts in the air handler or

furnace, remove the COLLECTION CELLS, FIELD

CHARGER, and PRE-FILTER from the air cleaner.

Chemicals used during the cleaning of the air

handler, furnace, or ductwork can damage the air

cleaner components and degrade the performance of

the air cleaner.

Flashing red light indicates

CLEAN

PRE-FILTER

RESET

Figure 29 Pre-Filter Light

For maximum efficiency, the COLLECTION CELLS and

PRE-FILTER should be inspected and cleaned as

prescribed in this Installer's Guide.

The FIELD CHARGER should only be removed and

cleaned annually by a qualified service professional.

CLEANING

Cleaning Instructions:

The air cleaner utilizes a PRE-FILTER and

COLLECTION CELLS. The purpose of the PRE-FILTER

is to capture large particles before they enter the

COLLECTION CELLS which allows the collection cells

to work more efficiently.

1. Turn the air conditioning system off at the Comfort

Control (thermostat).

that it is time to clean the

COLLECTION CELLS

Red light indicates that it is

time to clean the PREFILTER

Minimum Medium Maximum*

DIRTY

CLEAN

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

Figure 28 Red LED Power Level Settings

*Factory Setting

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 19

DIRTY

CLEAN

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

DIRTY

CLEAN

R3

R2

R1

Y4

Y3

Y2

Y1

G3

G2

G1

!

WARNING

High Voltage is present within the air cleaner for

operation. Before removing the Power Door, turn the

power off and wait at least 15 seconds to allow

voltage to discharge. Failure to follow instructions

could result in death or serious personal injury.

2. Turn off power to the air cleaner by pushing and holding

the POWER button for three seconds. The LED’s will

remain on until the voltage has discharged and it is

safe to remove the door. This requires approximately

15 seconds. Do not remove the door until all the

lights are off.

3. Disconnect the power/control cable.

4. Rotate the two latches and remove the door as shown

in Figure 30. Place the door in a secure location.

5. Remove the PRE-FILTER (Figure 31) and/or the

COLLECTION CELLS (Figure 32) from the air cleaner.

Page 20

Installer’s Guide

Before removing the door from the unit, remove the power

cable plug from the socket located in the corner of the door.

Rotate Latches

Power cable connection

Figure 30 Rotating Door Latches

The air cleaner is factory set to notify the home owner to

clean the PRE-FILTER every two months [10 weeks] of

actual run time of the air cleaner. This notification can

be changed by the installer/home owner to 1 month [5

weeks] or 3 months [15 weeks] depending on the

conditions in the home (pets, smokers, etc.). Please

see “SET-UP MODE” (Page 13) to change the factory

settings.

1. Using a vacuum hose, vacuum in even strokes

across the length of the PRE-FILTER. After

vacuuming the entire PRE-FILTER using even

strokes going in one direction, repeat the

process using even strokes going in the

opposite direction as shown in Figure 33.

Figure 31 Pre-Filter

Figure 32 Collection Cells

VACUUM CLEANING

Vacuuming is the preferred method to clean the PREFILTER and COLLECTION CELLS. It is recommended

that the PRE-FILTER and the COLLECTION CELLS be

vacuumed outside the home to ensure particles on the

filters are not reintroduced into the air. Persons highly

sensitive to the collected particles should wear

appropriate respiratory protection while cleaning.

PRE-FILTER –

It is time to clean the PRE-FILTER when the red “PREFILTER” light (shown in Figure 29) is illuminated.

Figure 33 Vacuuming the Pre-filter

NOTE: Do NOT replace the plastic PRE-FILTER with

a metal type PRE-FILTER. A metal PRE-FILTER will

cause reduction in efficiency and potential failure of

the electronics in the air cleaner.

COLLECTION CELLS

The clean/dirty LED light bar indicator will illuminate as

the system cleans the air. The LED lights will progress

from green to yellow and then to red. When the last red

indicator is flashing, it is time to clean the COLLECTION

CELLS (see Figure 31). The air cleaner is factory set to

notify the home owner to clean the COLLECTION

CELLS every six months [31 weeks] of actual run time

of the air cleaner. This notification can be changed by

the installer/home owner to 2 months, 4 months, 6

months, or 9 months [10, 20, 31, or 46 weeks]

depending on the conditions in the home (pets, smokers,

etc.). Please see “SET-UP MODE” (Page 13) to change

the factory settings.

20 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 21

1. Using a vacuum hose, vacuum in even strokes across

the entire COLLECTION CELL surface. Vacuum using

even strokes in one direction, then repeat the process

using even strokes in the opposite direction, as

demonstrated in Figure 34.

Figure 34 Vacuuming the Collection Cells

2. Once vacuuming is completed on one side of the

COLLECTION CELL, turn the COLLECTION CELL

over and repeat on the other side of the COLLECTION CELL.

Installer’s Guide

Handles Fold

Flat

Figure 36 Collection Cell, Handle Folded

3. Replace the power door onto the air cleaner.

Cabinet Edge

NOTE: It is normal for COLLECTION CELLS to

discolor during operation. Vacuuming will not

restore the COLLECTION CELLS to their original

color. However, vacuuming does restore the

COLLECTION CELLS to a high efficiency.

REPLACING THE PRE-FILTER AND COLLECTION

CELLS INTO THE AIR CLEANER

1. Replace the PRE-FILTER into the air cleaner. Ensure

that the "AIRFLOW indicator arrow" on the

PREFILTER is pointing in the same direction as the

"AIRFLOW indicator arrow" on the air cleaner cabinet

as shown in Figure 35.

Figure 37 Reinstalling Power Door

4. Ensure the power cord is plugged into the air cleaner.

A steady amber light

indicates that the unit is

wired in the 24 V mode.

A blinking amber light

indicates that the unit is

wired in the

communicating mode.

No light present means

that the unit is not

connected.

Power Button

Amber Light

Plug Power Cord

in here

Figure 35 Airflow Direction

2. Reinstall the COLLECTION CELLS into the air cleaner.

Ensure the handles on both of the COLLECTION

CELLS are folded flat as shown in Figure 36.

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 21

Figure 38 Pressing Power Button

5. Press the power button to turn on the air cleaner.

NOTE: Once you press the power button, the first

LED will be on and it will start flashing after the

first 10 [12] minutes of indoor fan operation. This

is normal operation.

Page 22

Installer’s Guide

▲

Alternate Cleaning option for homeowners with 200

or 200-1 COLLECTION CELLS ONLY

Vacuuming the PRE-FILTER and COLLECTION CELLS

restores them to a high efficiency. However, some

environmental conditions, like tobacco smoke, cause

the COLLECTION CELLS to need to be washed with

water. Washing the COLLECTION CELLS is acceptable

ONLY if the COLLECTION CELL has a “200/200-1”

embossed or written on the frame in the vicinity of the

manufacturing part number as shown in Figure 39.

• Do NOT use soap or detergent in cleaning the

COLLECTION CELLS.

• Do NOT immerse the COLLECTION CELLS

completely in water.

• Do NOT place the COLLECTION CELLS into a

dishwasher to clean.

• ALLOW THE COLLECTION CELLS TO DRY

THOROUGHLY BEFORE INSTALLING.

2. After washing, drain as much water as possible from

the COLLECTION CELLS.

3. Holding the sides of the COLLECTION CELLS, gently

tap the cells on a flat surface to dislodge any water

droplets inside the COLLECTION CELLS. After

tapping, wipe down the surfaces of the COLLECTION

CELLS to remove any visible droplets of water.

Figure 39 Collection Cell Identification

Carefully review both of the COLLECTION CELLS for the

“200/200-1” mark. If the “200/200-1” mark is visible on

BOTH COLLECTION CELLS, they may be washed. If

the “200/200-1” mark is NOT visible, the COLLECTION

CELLS cannot be washed.

!

CAUTION

Washing COLLECTION CELLS that do NOT have the

“200/200-1” mark on them can result in degradation

of the air cleaner system. Failure to follow

instructions could result in property damages.

Tap

Gently

Figure 40 Collection Cell

4. When there are no visible water droplets left in the

COLLECTION CELLS, reinstall them into the air

cleaner cabinet. Be sure to fold the COLLECTION

CELL handles flat as shown in Figure 41.

Handles Fold

Flat

1. If the COLLECTION CELLS do have the “200/200-1”

mark on them, they may be washed using a low

pressure water spray, such as a sink sprayer or garden

hose. Residue like tobacco smoke may require warm

water to be removed.

22 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Figure 41 Collection Cell, Handle Folded

Page 23

Installer’s Guide

5. Replace the door onto the air cleaner cabinet (see

Reinstalling the Power Door, page 5).

Cabinet Edge

Figure 42 Reinstalling Power Door

6. Ensure that the power cord is connected to the air

cleaner and press the power button.

A steady amber light

indicates that the unit is

wired in the 24 V mode.

A blinking amber light

indicates that the unit is

wired in the

communicating mode.

No light present means

that the unit is not

connected.

Power Button

NOTE: The pre-filter may also be washed ONLY if

the COLLECTION CELLS show a "200/200-1".

Follow the same instructions to wash the PREFILTER - being sure to tap gently and wipe off any

visible water droplets.

RESET TIMERS

When installed as part of a Communicating System with

a 900 series comfort control, the filter timer can be reset

at either the Comfort Control or the air cleaner.

To reset the PRE-FILTER timer at the comfort control

Select Filter 1 Change Reminder, then press the More

key to access the filter timer value and then press the

Reset key. For additional information please refer to the

Installers Guide and/or Service Facts for the 900 Series

control.

To reset at the air cleaner press and hold the RESET

key until the PRE-FILTER LED turns off (1 to 2

seconds).

To reset the Collection Cell timer at the Comfort Control

select Filter 2 Change Reminder, then press the More

key to access the filter timer value and then press the

Reset key.

To reset the Collection Cell timer at the air cleaner press

and hold the RESET key until the COLLECTION CELL

LED turns off (1 to 2 seconds).

If two air cleaners are connected on the same system,

reset all timers on both air cleaners at the same time to

the same settings. The comfort control will only report

one air cleaner timer and this methodology will allow the

air cleaners to remain on the same cleaning schedule.

Reset the filter timer at the comfort control using the

instructions given above.

Amber Light

Plug Power Cord

in here

Figure 43 Pressing Power Button

NOTE: Once you press the power button, the first

LED will be on and it will start flashing after the

first 10 [12] minutes of indoor fan operation. This

is normal operation.

7. On the Comfort Control (thermostat), reset the indoor

fan operation to the desired mode. Turn the air system

back on at the Comfort Control.

NOTE: The field charger should never be subjected

to water. The field charger should only be cleaned

by a trained service professional.

FAULT CODES

The air cleaner LED’s will display a fault indication, three

Yellow or three Red LED’s, when a fault has been

detected. A log of the last three faults is recorded and

can be accessed by going into the Set-Up mode. The

unit will repetitively check the system to determine if the

fault persists. The fault indication will be displayed as

long as the fault condition remains.

If the fault is no longer present, the system will return to

normal operation and no longer display the fault

indication. Even if the fault has been cleared, a log of

the last 3 faults is recorded.

NOTE: If more than one whole house air cleaner is

installed, each unit will retain its own fault codes.

REPETITIVE ARC FAULT INDICATION

If the unit detects 10 consecutive run cycles where an

arc occurs during the cycle, it will go into a lock out

period for one hour. This is indicated by three FLASHING

YELLOW LED’s. The PRE-FILTER and COLLECTION

CELLS should be cleaned to ensure no large material is

trapped in the filters and causing the fault. Check the

FIELD CHARGER for material that can cause the fault.

If the unit detects any other type of fault, this will be

indicated by three FLASHING RED LED’s. See the

Service Facts for fault code information.

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 23

Page 24

Installer’s Guide

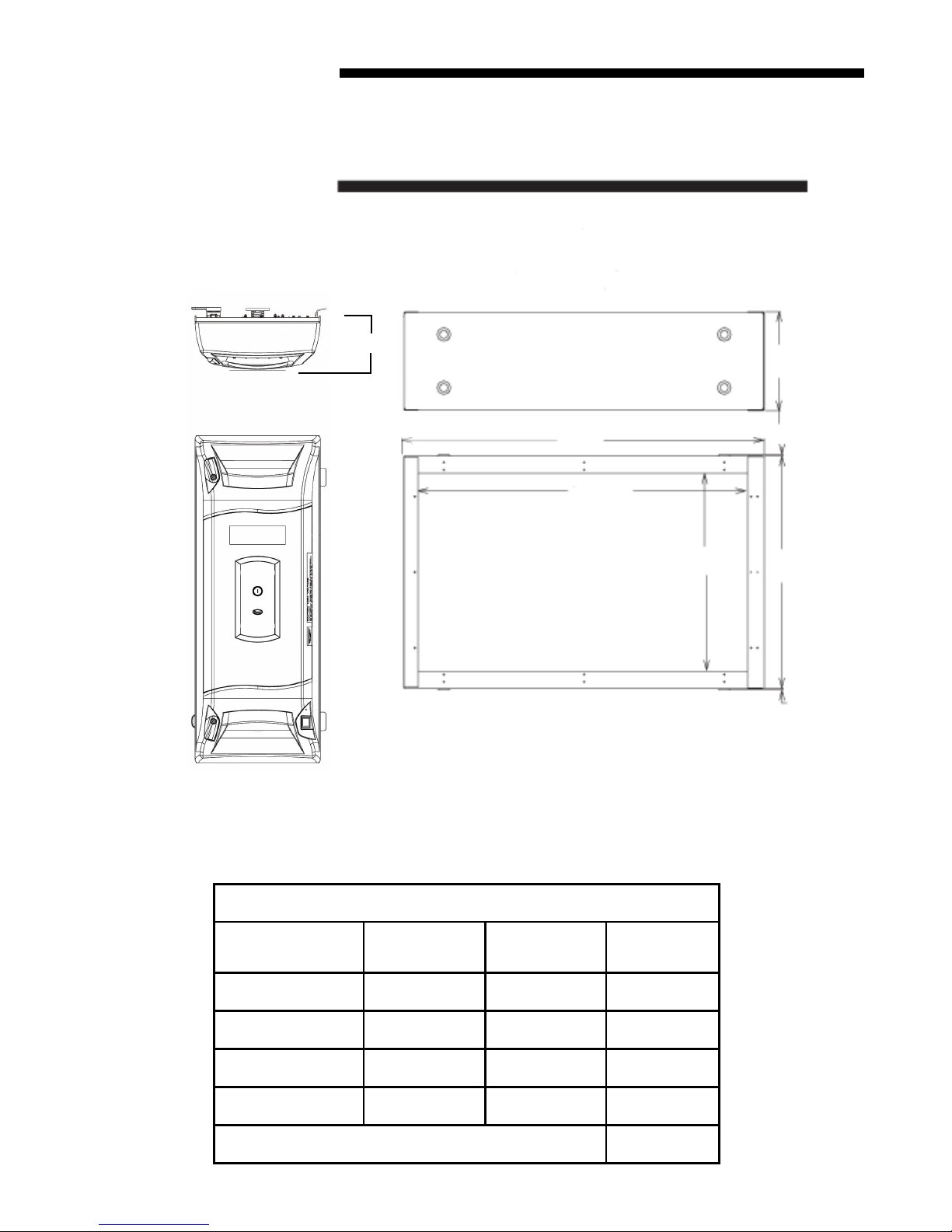

I. OUTLINE DRAWINGS

OUTLINE DRAWING FOR UPFLOW FURNACES

Dimensions

(all dimensions in inches)

27” DEPTH CABINET

ADD DOOR DEPTH FOR TOTAL

2.8”

Side View

27

24-13/16

7-7/16

1/8

B

A

Cabinet

Front

of

UPFLOW FURNACE MODEL NUMBERS

ifD Air Cleaner A B (multiple

piece cabinet)

*FD145CLFR000D 14.5 11.9 12

*FD175CLFR000D 17.5 14.9 15

*FD210CLFR000D 21.0 18.4 18.5

*FD245CLFR000D 24.5 21.9 22

* May be "A" or "T"

B (one piece

cabinet)

1/8

24 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

Page 25

Installer’s Guide

Dimensions

(all dimensions in inches)

OUTLINE DRAWING FOR DOWNFLOW FURNACES

21” CABINET DEPTH

ADD DOOR DEPTH FOR TOTAL

2.8”

Side View

21

18-13/16

7-7/16

1/8

B

A

Front

of

Cabinet

1/8

ifD Air Cleaner A

*FD14DCLFR000D 14.5 11.9 12

*FD17DCLFR000D 17.5 14.9 15

*FD21DCLFR000D 21.0 18.4 18.5

*FD24DCLFR000D 24.5 21.9 22

* May be "A" or "T"

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 25

DOWNFLOW FURNACE MODEL NUMBERS

B (multiple

piece cabinet)

B (one piece

cabinet)

Page 26

Installer’s Guide

OUTLINE DRAWING FOR AIR HANDLERS

Dimensions

(all dimensions in inches)

21” DEPTH CABINET

ADD DOOR DEPTH FOR TOTAL

2.8”

Side View

21

18.88

Front

of

Cabinet

ifD Air Cleaner A

*FD175CLAH000D 17.5 14.9 15

*FD215CLAH000D

TFD215CLAH005D

*FD235CLAH000D

TFD235CLAH005D

*FD260CLAH000D

TFD260CLAH005D

* May be "A" or "T"

26 Numbers in [brackets] are for 50 Hz international systems. Pub. No. 18-HE53D1-11

AIR HANDLER MODEL NUMBERS

B (multiple

piece cabinet)

21.5 18.9 19

23.5 20.9 21

26.0 23.4 23.5

B (one piece

cabinet)

Page 27

J. PRESSURE DROP INFORMATION

*FD145CLFR000D

0.06

0.10

0.16

0.23

0.30

*FD175CLFR000D

0.05

0.08

0.12

0.17

0.22

0.28

0.34

*FD210CLFR000D

0.04

0.06

0.09

0.12

0.15

0.20

0.24

0.29

0.34

*FD245CLFR000D

0.03

0.04

0.06

0.09

0.12

0.15

0.19

0.22

0.26

*FD14DCLFR000D

0.09

0.16

0.24

0.34

0.46

*FD17DCLFR000D

0.07

0.11

0.18

0.25

0.33

0.42

*FD21DCLFR000D

0.05

0.09

0.13

0.18

0.23

0.29

0.37

*FD24DCLFR000D

0.04

0.07

0.11

0.14

0.19

0.24

0.30

0.36

0.43

*FD175CLAH000D

0.07

0.11

0.18

0.25

0.33

TFD215CLAH005D

TFD235CLAH005D

PRESSURE DROP AT SPECIFIC AIRFLOW PER MODEL

400 CFM 600 CFM 800 CFM 1000 CFM 1200 CFM 1400 CFM 1600 CFM 1800 CFM 2000 CFM

Installer’s Guide

*FD215CLAH000D

*FD235CLAH000D

*FD260CLAH000D

TFD260CLAH005D

* May be "A" or "T"

0.04 0.08 0.12 0.17 0.24

0.06 0.09 0.13 0.18 0.23 0.29 0.35

0.04 0.07 0.10 0.14 0.18 0.23 0.28 0.34 0.39

Pub. No. 18-HE53D1-11 Numbers in [brackets] are for 50 Hz international systems. 27

Page 28

Installer’s Guide

Trane

6200 Troup Hwy.

Tyler, TX 75707

For more information contact

your local dealer (distributor)

07/11

The manufacturer has a policy of continuous product and product data improvement and reserves the

right to change design and specifications without notice.

Loading...

Loading...