Page 1

Installation, Operation,

and Maintenance

Packaged Fresh Air Unit

For 100% Outdoor Air Applications

Models FADA and FAHA

“BO” and later design sequence

April 2003

FAXA-SVX01B-EN

Page 2

general

information

About This Manual

Literature Change History

Use this manual for Packaged Fresh Air

units, models FADA and FAHA. This is the

“B” issue of this manual, revised to

include the total energy wheel option. It

provides specific installation, operation,

and maintenance instructions for “BO”

and later design sequences.

These units have modular DDC controls

that provide operating functions significantly different than conventional air

conditioning units. Refer to the startup

and test mode procedures within this

manual. Also, reference the Trane

publication,

Programming Guide, FAXA-SVP01B-EN.

For units with gas heat, also reference

Reznor Installation Form RGM 401

the

Installation/Operation/Service Manual.

Overview of Manual

This manual describes proper installation,

startup, operation, and maintenance

procedures for the Packaged Fresh Air

unit. Carefully review the information

within this manual and follow the

instructions to minimize risk of improper

operation and/or component damage.

The roof curb specifically designed for the

Packaged Fresh Air unit is available in

14” or 24” height from Trane. The curb

must be mounted on a permanent roof

structure before attempting to install the

unit. Reference the roof curb installation

instructions in the Trane publication,

“Accessory Roof Curb Kit” Installation

Manual, FAXA-SVN01B-EN.

data for use with curbs other than Trane,

can be found on pages 15-32 of this

manual.

Note: One copy of this manual ships

inside the control panel of each unit.

It is important that you perform periodic

maintenance to help ensure trouble free

operation. Should equipment failure

occur, contact a qualified Trane service

organization for an experienced HVAC

technician to properly diagnose and

repair this equipment.

Note: Do not release refrigerant to the

atmosphere!

Packaged Fresh Air Unit

Dimensional

If adding or removing refrigerant, the

service technician must comply with all

federal, state, and local laws.

Warnings and Cautions

WARNING

Warnings indicate potential hazardous

situations, which if not avoided, can cause

death or serious injury.

CAUTION

Cautions indicate a potentially hazardous

situation, which if not avoided, may cause

minor or moderate injury. Also, cautions

may alert against unsafe practices.

CAUTION

Cautions indicate a situation that may

cause equipment or property-damage

only.

Examples follow below.

WARNING

Hazardous voltage!

Disconnect all electrical power

including remote disconnects before

servicing unit. Follow proper lockout/

tagout procedures to ensure power

cannot be inadvertently energized.

Failure to do so can cause death or

serious injury.

CAUTION

Use copper conductors only!

Unit terminals are not designed to

accept other type conductors. Failure

to use copper conductors may cause

equipment damage.

Common HVAC Acronyms

For convenience, a number of acronyms

and abbreviations are used throughout

this manual. These acronyms are

alphabetically listed and defined below.

BAS = building automation systems

cfm = cubic-feet-per-minute

CKT. = circuit

CV = constant volume

CW = clockwise

CCW = counterclockwise

E/A = exhaust air

ECEM = exhaust/comparative enthalpy

module

F/A = fresh air

FAU = fresh air unit

GBAS = generic building automation

system

HI = human interface

I/O = inputs/outputs

IOM= installation/operation/maintenance

manual

IPC = interprocessor communications

LCI = LonTalk™ communication interface

LH = left-hand

MCM = multiple compressor module

MWU = morning warmup

NSB = night setback

O/A = outside air

psig = pounds-per-square-inch, gage

pressure

R/A = return air

RH = right-hand

RPM = revolutions-per-minute

RTM = rooftop module

S/A = supply air

SCM = single circuit module

SZ = single-zone (unit airflow)

TCI = Tracer communications module

UCM = unit control modules

VAV = variable air volume

VCM = ventilation control module

VOM = ventilation override module

ZSM = zone sensor module

Special Note on Refrigeration

Emissions

World environmental scientists have

concluded that ozone in our upper

atmosphere is being reduced due to the

release of CFC fully halogenated

compounds. Trane urges all HVAC

service personnel to make every effort to

prevent any refrigerant emissions while

installing, operating, or servicing

equipment. Always conserve

refrigerants for continued use and follow

all warnings and cautions in this manual.

©2003 American Standard Inc. FAXA-SVX01B-EN

Page 3

contents

Cross reference to related publications:

• Packaged Fresh Air Unit Programming Guide, FAXA-SVP01B-EN

• Accessory Roof Curb Installation Manual, FAXA-SVN01B-EN

• Reznor Installation Form RGM 401, Installation/Operation/Service

heat

Installation ……………………………………………………………2

General Information……………………………………………2

Pre-installation Considerations ………………………………8

Dimensions/Weights …………………………………………15

Mechanical Requirements …………………………………33

Electrical Requirements………………………………………36

Installation Procedure ………………………………………40

Pre-Startup Requirements …………………………………51

Startup …………………………………………………………52

for units with gas

Note: This document is customer property

and must be retained by the unit’s owner for

use by maintenance personnel.

Operation ……………………………………………………………54

General Information …………………………………………54

Sequence of Operation ………………………………………62

Maintenance………………………………………………………… 67

General Information …………………………………………67

Maintenance Procedures ……………………………………71

Periodic Checklists ……………………………………………77

Index ………………………………………………………………… 79

FAXA-SVX01B-EN 3

Page 4

general

Installation

information

Packaged Fresh Air unit Model Number Description

Following is a complete description of the Packaged FAU model number. Each digit in the model number has a corresponding code

that identifies specific unit options.

F A D A 040 6 G A,0 0,8,4 0 1 A 0 1 A 0,5,7 0,7 A 0 0 0 E F 0 1 0,0,0 0,0 A A A A

1 2 3 4 5,6,7 8 9 10,11 12,13,141516171 819 20 21,22,23 24,25 26 27 28 29 30 3 1 32 33 34,35,36 37,38 3 9 40 41 42

Digit 1 – Unit model

F = fresh air unit

Digit 2 – Unit configuration

A = air cooled

Digit 3 – Unit discharge direction

D= downflow

H= horizontal

Digit 4 – Development sequence

A = development sequence ‘A’

Digits 5, 6, 7 – Unit size

031 = 3100 cfm

040 = 4000 cfm

051 = 5100 cfm

066 = 6600 cfm

Digit 8 – Unit voltage

3 = 230 volt/60 hz/3 ph

4 = 460 volt/60 hz/3 ph

6 = 208 volt/60 hz/3 ph

Digit 9 – Heating system

0 = none

A = gas low rise, single bank, 2-stage

B = gas low rise, single bank, 2:1

modulate

C = gas high rise, single bank, 2-stage

D = gas high rise, single banks, 2:1

modulate

E = gas dual bank, 4-stage

F = gas dual bank 4:1 modulate

G= electric heat, 3-stage

H = electric heat, 7-stage

K = hydronic interface only

Digits 10, 11 – Design sequence

** = factory assigned

Digits 12, 13, 14 – Heat input

000 = none

020 = 20 kW

026 = 26 kW

032 = 32 kW

042 = 42 kW

056 = 56 kW

070 = 70 kW

084 = 84 kW

100 = 100 kW

122 = 122 kW

125 = 125 MBh

150 = 150 MBh

200 = 200 MBh

250 = 250 MBh

300 = 300 MBh

350 = 350 MBh

400 = 400 MBh

500 = 500 MBh

600 = 600 MBh

700 = 700 MBh

800= 800 MBh

Digit 15 – Heat exchanger material

0 = none

1 = 409 stainless steel, 409 stainless Burner

2 = 321 stainless steel, 409 stainless burner

Digit 16 – Condenser reheat coil

0 = none

1 = condenser hot gas reheat coil

Digit 17 – Ventilation damper type

0 = parallel blade damper

1 = TRAQ™ damper with air flow

measurement

Digit 18 – Energy recovery

0 = none

1 = total energy wheel w/occupancy

control

2 = total energy wheel w/dry bulb control

Digit 19 – Return air damper

0 = none

1 = bottom return/reference enthalpy

2 = bottom return/comparative enthalpy

Digit 20 – Supply fan type

A = 12 - 9 centrifugal fan

B = 15 - 11 centrifugal fan

C = 18 - 13 centrifugal fan

Digits 21, 22, 23 – Supply fan rpm

037 = 375

040 = 400

042 = 425

045 = 450

047 = 475

050 = 500

052 = 525

055 = 550

057 = 575

060 = 600

062 = 625

065 = 650

067 = 675

070 = 700

Note1: The first number in this description indicates the

fan wheel diameter (in.). The second number

indicates the fan wheel width.

072 = 725

075 = 750

077 = 775

080 = 800

082 = 825

085 = 850

087 = 875

090 = 900

092 = 925

095 = 950

097 = 975

100 =1000

102 =1025

105 =1050

1

107 =1075

110 =1100

112 =1125

115 =1150

117 = 1175

120 = 1200

122 = 1225

125 = 1250

127 = 1275

130 = 1300

132 = 1325

135 = 1350

137 = 1375

140 = 1400

142 = 1425

145 = 1450

147 = 1475

150 = 1500

152 = 1525

155 = 1550

157 = 1575

Digits 24, 25 – Supply fan horsepower

01 = 1

02 = 2

03 = 3

05 = 5

07 = 7.5

10 = 10

15 = 15

Digit 26 – Fan motor type

A = standard efficiency ODP fan motor

B = high efficiency ODP fan motor

Digit 27 – Coil protection

0 = none

A = corrosion inhibiting coating

Digit 28 – Unit cabinet protection

0 = standard prepainted steel finish

A = corrosion inhibiting coating

Digit 29 – Filter type

0 = field-provided filter

1 = dirty filter switch (DFS) with field-

provided filter

2 = 2” pleated media filters

3 = 2” pleated media filters & DFS

Digit 30 – System control

A = supply air dehumidification

B = supply air dehimidification with zone

RH reference

E = zone dehumidification

160 = 1600

162 = 1625

165 = 1650

167 = 1675

170 = 1700

172 = 1725

175 = 1750

177 = 1775

180 = 1800

182 = 1825

185 = 1850

187 = 1875

190 = 1900

192 = 1925

195 = 1950

197 = 1975

200 = 2000

202 = 2025

205 = 2050

207 = 2075

210 = 2100

4 FAXA-SVX01B-EN

Page 5

general

Installation

F = zone dehumidification with OA RH

reference

G= supply air temperature control (no

dehumidification)

J = zone temperature control (no

dehumidification)

Digit 31 – Control interface options

0 = none

A = LonTalk® communications interface

(LCI ) (comm5)

B = LCI (comm5) & generic building

automation system (GBAS) (0-5 VDC)

C = LCI (comm5) & GBAS (0-5 VDC) &

ventilation override module (VOM)

D = LCI (comm5) & VOM

E = GBAS (0-5 VDC)

F = GBAS (0-5 VDC) & VOM

G= VOM

Digit 32 – Miscellaneous system control

options

0 = none

1 = interface for remote human interface

Digit 33 – Exhaust option

0 = none

1 = exhaust interface

Digits 34, 35, 36 – Exhaust air fan rpm

000 = none

045 = 450

047 = 475

050 = 500

052 = 525

055 = 550

057 = 575

060 = 600

062 = 625

065 = 650

067 = 675

070 = 700

072 = 725

075 = 750

077 = 775

080 = 800

082 = 825

085 = 850

087 = 875

090 = 900

092 = 925

095 = 950

097 = 975

100 =1000

102 =1025

105 =1050

107 =1075

110 =1100

112 =1125

115 =1150

117 = 1175

120 = 1200

122 = 1225

125 = 1250

127 = 1275

130 = 1300

132 = 1325

135 = 1350

137 = 1375

140 = 1400

142 = 1425

145 = 1450

147 = 1475

150 = 1500

152 = 1525

155 = 1550

157 = 1575

160 = 1600

162 = 1625

165 = 1650

167 = 1675

170 = 1700

172 = 1725

175 = 1750

177 = 1775

180 = 1800

182 = 1825

185 = 1850

187 = 1875

190 = 1900

192 = 1925

195 = 1950

197 = 1975

200 = 2000

202 = 2025

205 = 2050

207 = 2075

210 = 2100

information

Digits 37, 38 – Exhaust air fan horsepower

00 = none

01 = 1

02 = 2

03 = 3

05 = 5

07 = 7.5

10 = 10

Digit 39 – Unit connection type

A = terminal block

B = non-fused disconnect switch

Digit 40 – Convenience outlet

0 = none

A = 115V, factory wired

B = 115V, field wired

Digit 41 – Extended grease lines

0 = none

A= extended grease lines

Digit 42 – Agency approval

0 = no agency approval

A = UL approval

Digit 43 – Roof curb

A = 14” curb

B = 24” curb

FAXA-SVX01B-EN 5

Page 6

general

Installation

information

Packaged Fresh Air unit Accessory Model Number Description

Following is a complete description of the Packaged FAU accessory model number. Each digit in the model number has a

corresponding code that identifies specific accessory options.

P F K A 031 3 A A0 B C 0 A A 0 A 0 A 0 A 0 A

1 2 3 4 5, 6, 7 8 9 10,11 12 1 3 14 15 16 1 7 18 19 20 2 1 22 23 24

Digit 1 – Parts/accessories

P = parts/accessories

Digit 2 – Unit type

F = fresh air unit

Digit 3 – Field installed kits

K = field installed kits

Digit 4 – Development sequence

A = development sequence

Digits 5, 6, 7 – Nominal size

031 = 3100 cfm

040 = 4000 cfm

051 = 5100 cfm

066 = 6600 cfm

Digit 8 – Unit voltage

3 = 230/60/3

4 = 460/60/3

6 = 208/60/3

Digit 9 – Roof curb

0 = none

A = 14”

B = 24”

C = acoustical

D = 14” curb for unit w/ERV

E = 24” extended for unit w/ERV

F = 24” extended, acoustical for unit w/

ERV

Digits 10, 11 – Design sequence

A0 = design sequence

Digit 12 – Filter type

0 = none

A = 2” pleated media

B = 2” cleanable

C = 2” pleated media total energy wheel

only

D = 2” cleanable total energy wheel only

E = 2” pleated media unit & total energy

wheel

F = 2” cleanable unit & total energy wheel

Digit 13 – Control interface kits

0 = none

A = LonTalk

B = LCI (comm5) & generic building

C = LCI (comm5) & GBAS (0-5 VDC) &

D = LCI (comm5) & VOM

E = GBAS (0-5 VDC)

F = GBAS (0-5 VDC) & VOM

G= VOM

Digit 14 – Time clock

0 = none

A = time clock

Digit 15 – Remote mounted human

0 = none

A = remote mounted human interface

B = remote mounted human interface with

C = interprocessor communication bridge

Digit 16 – Zone sensor

0 = none

A = zone temperature sensor

®

(LCI) (comm5)

automation system (GBAS) (0-5 VDC)

ventilation override module (VOM)

interprocessor communication bridge

module board kit

module board kit

BAYSENS017*

communications interface

interface

Digit 17 – Zone sensor with timed override

0 = none

A = zone temperature densor with timed

override BAYSENS013*

Digit 18 – Zone sensor with timed override

and local setpoint adjustment

0 = none

A = zone temperature sensor with timed

override buttons and local setpoint

adjustment BAYSENS014*

Digit 19 – Remote minimum position

potentiometer control

0 = none

A = remote minimum position

potentiomenter control BAYSTAT023*

Digit 20 – Dual setpoint sensor

0 = none

A = dual setpoint sensor

Digit 21 – Dual setpoint sensor with system

function lights

0 = none

A = dual setpoint sensor with system

function lights

Digits 22 – Space relative humidity kit

0 = none

A = space relative humidity kit

Digit 23 – Carbon dioxide sensor

0 = none

A = carbon dioxide sensor

Digit 24 – Dry-bulb duct sensor

0 = none

A = dry-bulb duct sensor

6 FAXA-SVX01B-EN

Page 7

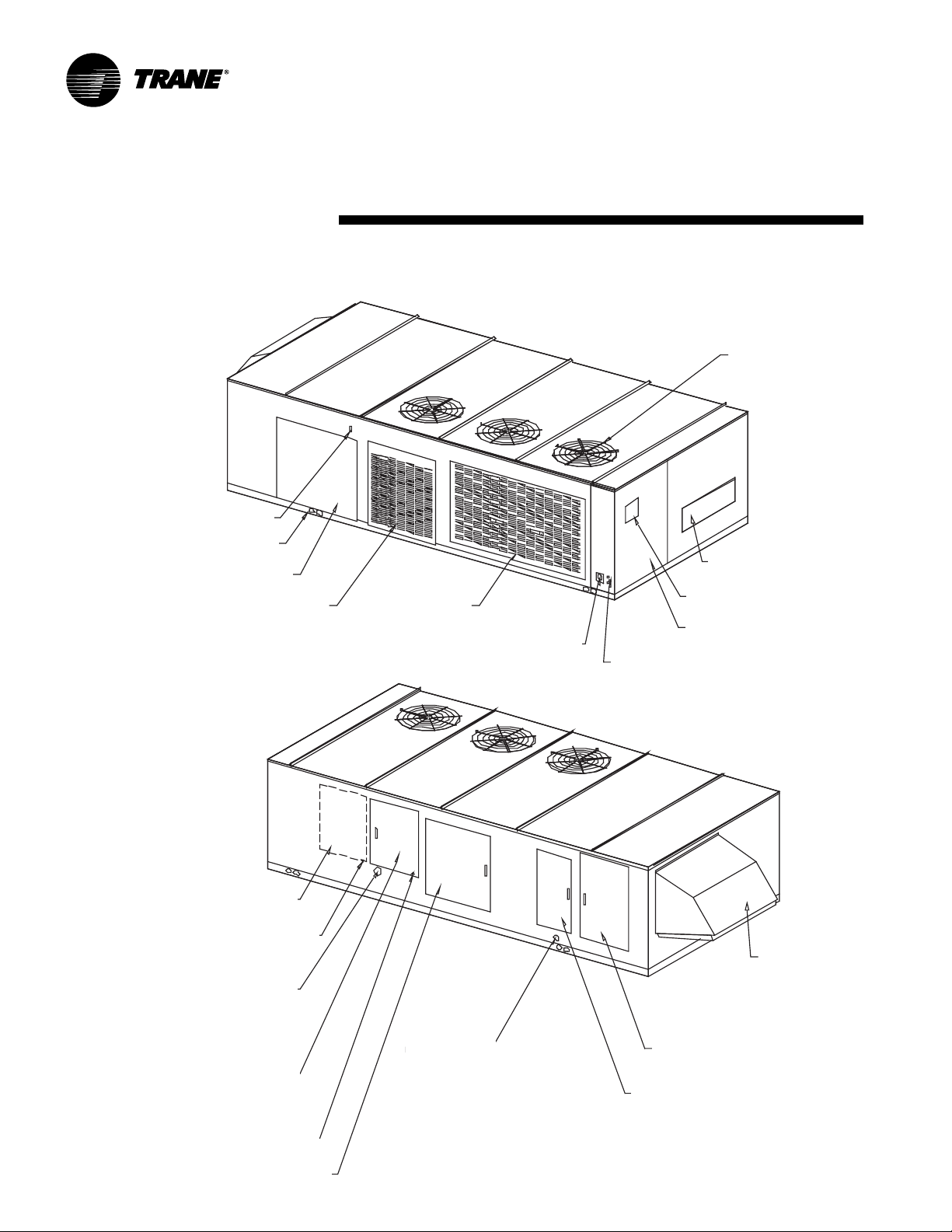

general

Installation

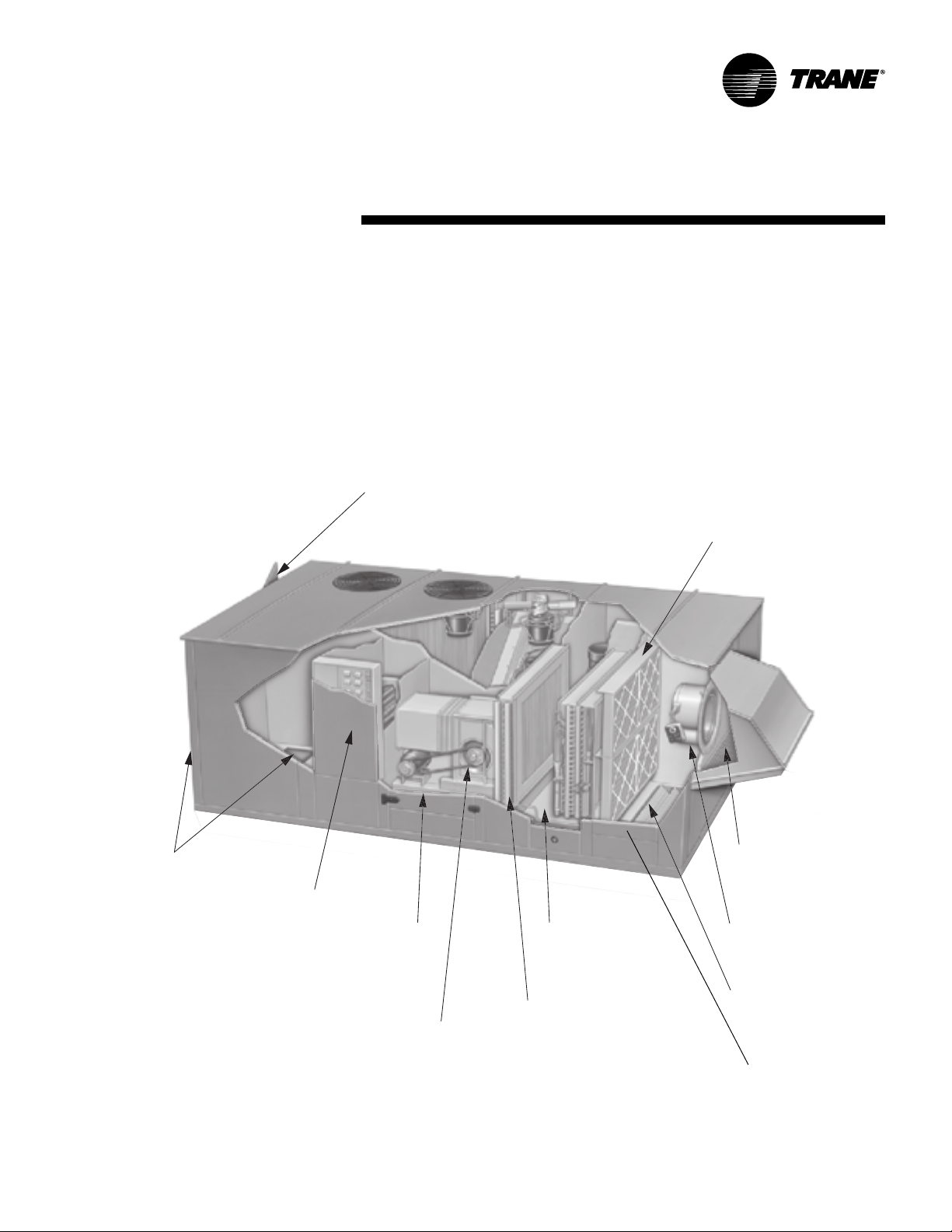

Unit Nameplate

The unit nameplate identifies the unit

model number, appropriate service

literature, and wiring diagram numbers. It

is mounted on the control panel door.

Reference this information when making

inquiries or ordering parts or literature for

the fresh air unit.

Unit mounted IntelliPak

microprocessor control

with easy-to-read human

interface

®

information

2’’ Pleated filter section with

adjustable rack to 4’’

Horizontal or vertical

discharge openings

Hi-rise electric

(or gas) heat

1’’ Solid double-wall

panels of foamedin-place construction

Quiet FC fan

Figure I-GI-1. Packaged fresh air unit components

FAXA-SVX01B-EN 7

Non-corrosive IAQ

drain pan sloped in

two directions

Optional condenser

reheat coil with

modulating control

Standard protective

bird screen on inlet

hood

Traq® damper

available for airflow

measurement

Optional return air

damper for unoccupied

recirculation

All ship-with items are

inside this compartment

Page 8

pre-installation

Installation

Installation

Pre-Installation Considerations

Checklist

The following checklist is provided to give

an overview of the factoryrecommended pre-installation

considerations. Follow the procedures in

this section to ensure the installation is

complete and adequate for proper unit

operation. Verify this checklist is complete

before beginning unit installation.

Verify the unit size and tagging with the

o

unit nameplate to ensure the correct

unit is received.

Inspect the unit for possible shipping

o

damage and make any necessary

claims with the freight delivery

company immediately.

Before installing the roof curb,

o

remember to allow minimum

recommended clearances for routine

maintenance and service. Refer to unit

dimensions and clearances on

submittals or in Dimensions and

Weights section on page 15.

Verify the unit roof curb is installed

o

properly prior to beginning unit

installation. See the

Installation Manual, FAXA-SVN01B-EN

o Make proper acoustic considerations

before installing unit. Do not install unit

above sound-senstive locations.

Allow adequate space for service and

o

operating clearances. Reference page

10.

Make provisions for correct supply

o

power and note electrical connection

knockouts locations on the unit

submittals or in the Dimensions and

Weights section on page 15. This

includes main power and dual power

connections for electric heat.

Roof Curb

considerations

Note: Verify electric stub-out within roof

curb assembly, if using bottom electrical

knockouts.

o Electrical supply power must meet

specific balance and voltage

requirements as described in the

“Electrical Requirements” section on

page 36.

Units with gas heat, ensure adequate

o

gas service and piping is available at

unit installation location.

Ensure the unit installation location is

o

level.

Receiving and Handling

Shipping Package

Packaged Fresh Air units ship fully

assembled.

Ship-Separate Accessories

Field-installed sensors ship separately

inside the unit’s filter/return air section.

Units with gas heat have temporary

panels in place for shipping. The

permanent panels are located in this

compartment and must be field-installed.

Units with the total energy wheel option

.

have an exhaust louver that ships inside

the exhaust compartment. Install the

louvers after installing the unit in its final

position.

WARNING

No step surface!

Do not walk on the sheet metal drain

pan. Walking on the drain pan can

cause the supporting metal to

collapse, causing death or serious

injury.

8 FAXA-SVX01B-EN

Page 9

pre-installation

Installation

Receiving Checklist

Complete the following checklist

immediately after receiving unit

shipment to detect possible shipping

damage. If entry into the unit is

necessary, bridge between the unit’s

main supports using multiple 2 x 12

boards.

Verify that the unit nameplate data

o

corresponds to the sales order and bill

of lading (including electrical data).

Visually inspect the unit exterior for

o

physical signs of shipping damage or

material shortages.

If a unit appears damaged, inspect it

o

immediately before accepting the

shipment. Remove access panels and

check for interiour component

damage. Make specific notations

concerning the damage on the freight

bill. Do not refuse delivery.

Report concealed damage to the

o

freight line within the allotted time

after delivery. Verify with the carrier

what their allotted time is to submit a

claim.

Note: Failure to follow these procedures

may result in no reimbursement for

damages from the freight company.

considerations

o Do not move damaged material from

the receiving location. It is the

receiver’s responsibility to provide

reasonable evidence that concealed

damage did not occur after delivery.

Do not continue unpacking the

o

shipment if it appears damaged. Retain

all packaging. Take photos of damaged

material if possible.

Notify the carrier’s terminal of the

o

damage immediately by phone and

mail. Request an immediate joint

inspection of the damage by the

carrier and consignee.

Notify your Trane representative of

o

the damage and arrange for repair.

Have the carrier inspect the damage

before making any repairs to the unit.

Unit Storage

Isolate all side panel service entrances

and base pan openings, such as conduit

holes and supply and return air openings

from the ambient air until the unit is ready

for startup.

If relocating the unit is necessary after the

initial delivery, position the unit on the

open trailer so the inlet hood is facing the

rear of the trailer.

FAXA-SVX01B-EN 9

Page 10

pre-installation

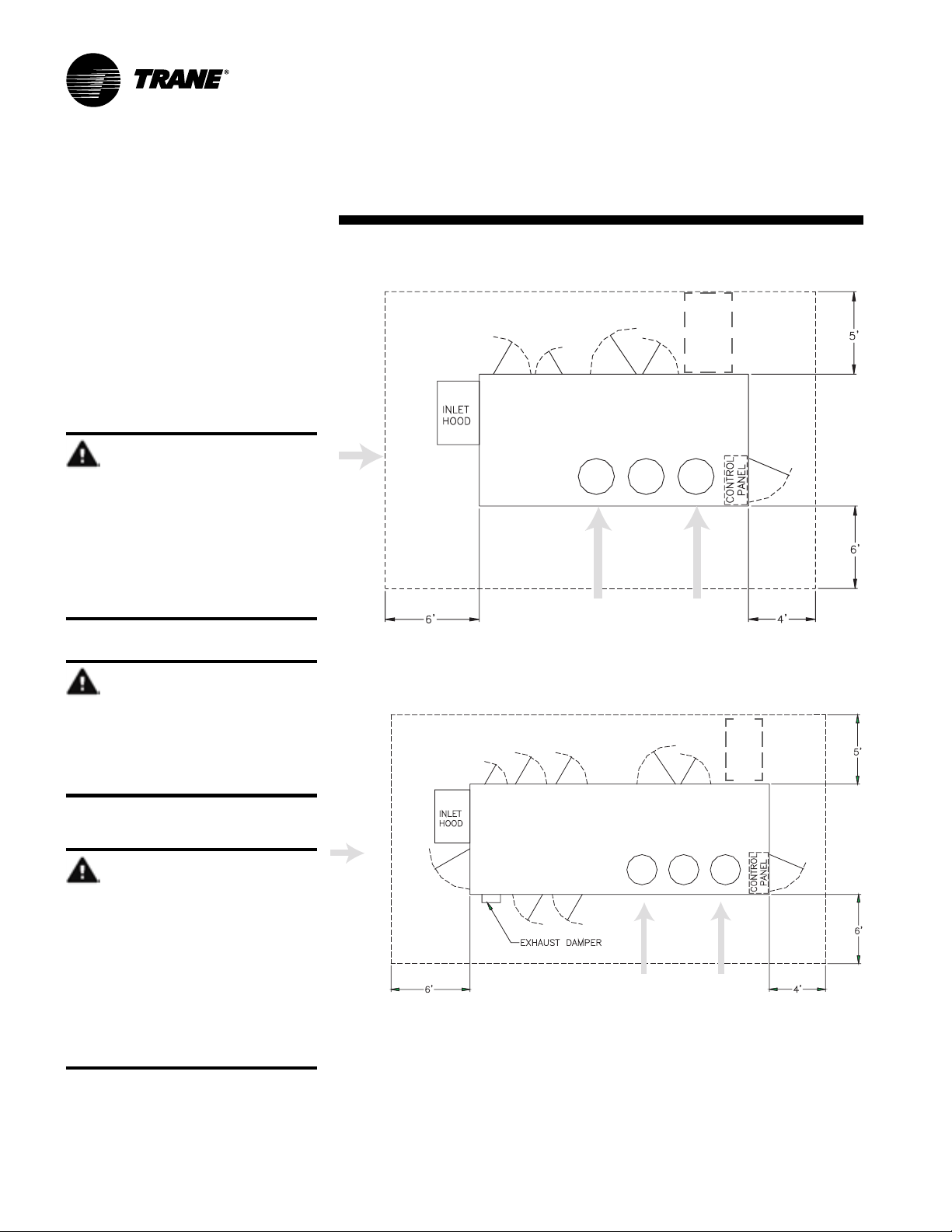

Service Access

Maintain adequate clearances around

and above the fresh air unit to ensure

proper unit operation and allow sufficient

service access. See Figure I-PC-1 for

recommended clearances. If installing the

unit higher than the typical curb elevation,

field-construct a catwalk around it to

provide safe, easy maintenance access.

WARNING!

Hazardous voltage!

Disconnect electrical power source

and remote disconnects before

servicing unit. Follow proper lockout/

tagout procedures to ensure power

cannot be inadvertently energized.

Failure to do so may cause death or

injury.

Installation

air path into unit

considerations

unit without TE wheel

service access

for removal of

gas or electric

heaters

condenser airflow and

compressor maintenance

WARNING!

Disconnect gas supply!

Before servicing unit, FIRST turn off

the gas supply. Failure to turn off the

gas supply can cause death or serious

injury.

WARNING!

Combustible materials!

Maintain proper clearance between

the unit heat exchanger, vent

surfaces, and combustible materials.

Refer to this manual for proper

clearances. Improper clearances can

cause a fire hazard. Failure to

maintain proper clearances can cause

death, serious injury, or property

damage.

unit with TE wheel

service

access for

removal of

air path into

condenser airflow

Figure I-PC-1. Top view of fresh air unit showing recommended service and code clearances.

10 FAXA-SVX01B-EN

Page 11

pre-installation

Roof Curb

You must install the roof curb before

beginning unit installation. Reference the

Roof Curb Installation Manual, FAXASVN01B-EN

instructions. For reference, installation

instructions are provided below.

Reference roof curb dimensions in the

Dimensions and Weights section on

pages 15–32.

Note: Do not tighten any of the screws

used to assemble this section until the

curb has been leveled and squared in its

installed location.

Roof Curb and Ductwork

Ensure the unit curb encloses the entire

unit base area. It is referred to as a “full

perimeter” type curb. Fabricate and

install the supply air and return air

ductwork adjoining the roof curb before

the unit is set into place. Note electrical

stub-ups within the curb.

General

Set the roof curb and Packaged Fresh Air

unit level to ensure proper operation. If

providing a field-fabricated roof curb, see

page 12 for roof curb details for units

without the total energy wheel option.

See page 13 for units with the total

energy wheel option. All installations

must conform with local building codes,

or in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1.

Note: Trane has a roof curb specifically

designed for the Packaged Fresh Air unit

available in the following options: 14” or

24” height, and an acoustic curb. To

install it, reference the Accessory Roof

Curb Installation Manual, FAXASVN01B-EN.

Roof Support

The roof must be capable of adequately

supporting the weight of the Packaged

Fresh Air unit as well as the curb. See

Figure I-IP-1 on page 40 for approximate

unit four-corner weights.

Trane Roof Curb Installation

If the building is new, the curb may be

assembled at any convenient location

and installed as soon as the roof support

members are in place. The curb must be

mounted on the roof deck and support

for complete installation

Installation

provided directly below the flanges of the

roof curb for further support and to

minimize vibration. If the fresh air unit is

to be installed on an existing building,

hoist the curb shipping container to the

roof, where the curb can be assembled

more conveniently.

Standard Perimeter Curb Rail Assembly

Follow the procedure below as an

example of how to field-assemble a field

roof curb. This procedure also applies to

the Trane standard 14” roof curb.

Reference pages 12 & 13 for assembly

drawings.

1. Attach corner angle (7) using 4 sheet

metal screws to the end of end rail (1)

adjacent to side rail (3). Place the

clearance holes in the corner angle

toward the top of the curb.

2. Attach end rail (1) to side rail (3) using 4

sheet metal screws.

3. Align side rail (4) next to side rail (3)

and attach crossmember (11)

perpendicular to both side rails at the

joint using eight sheet metal screws.

4. Attach corner angle (8) using eight

sheet metal screws to end rail (2) and

side rail (4). Place the clearance holes in

the corner angle toward the top of the

curb.

5. Attach corner angle (9) using eight

sheet metal screws to end rail (2) and

side rail (5). Place the clearance holes in

the corner angle toward the top of the

curb.

6. Align side rail (6) next to side rail (5)

and attach crossmember (11)

perpendicular to both side rails at the

joint using eight sheet metal screws.

7. Attach corner angle (10) using eight

sheet metal screws to end rail (1) and

side rail (6). Place the clearance holes in

the corner angle toward the top of the

curb.

Return and Exhaust Air Opening

Assembly

8. Place end rail (12) between side rail (3)

and side rail (6) with flanges positioned

away from the return air opening and

attach it with two sheet metal screws at

each end. Use rails (14), (15), (16), and

(17) as spacers.

9. Place side rail (14) between end rail (1)

and end rail (12) with flanges positioned

away from the return air opening and

attach it with two sheet metal screws at

each end.

considerations

10. Place side rail (15) between end rail

(1) and end rail (12) with flanges

positioned toward the return air

opening and attach it with two sheet

metal screws at each end.

11. Place side rail (16) between end rail

(1) and end rail (12) with flanges

positioned away from side rail (15) and

attach it with two sheet metal screws at

each end.

12. Place side rail (17) between end rail

(1) and end rail (12) with flanges

positioned away from the exhaust air

opening and attach it with two sheet

metal screws at each end.

Supply Air Opening Assembly

13. Place end rail (13) between side rail

(4) and side rail (5) with flanges

positioned away from the supply air

opening and attach it with two sheet

metal screws at each end. Use rails (18)

and (19) as spacers.

14. Place side rail (18) between end rail

(2) and end rail (13) with flanges

positioned away from the supply air

opening and attach it with two sheet

metal screws at each end.

15. Place side rail (19) between end rail

(2) and end rail (13) with flanges

positioned away from the supply air

opening and attach it with two sheet

metal screws at each end.

Units with the Total Energy Wheel Only

16. Attach corner angle (26) using five

sheet metal scres to the side of duct

support (25) without flanges. Place the

clearance holes in the corner angle

toward the top of the curb.

17. Align side rail (23) next to side rail (3)

and attach crossmember assembly

(25) and (26) perpendicular to both side

rails at the joint using ten sheet metal

screws.

FAXA-SVX01B-EN 11

Page 12

pre-installation

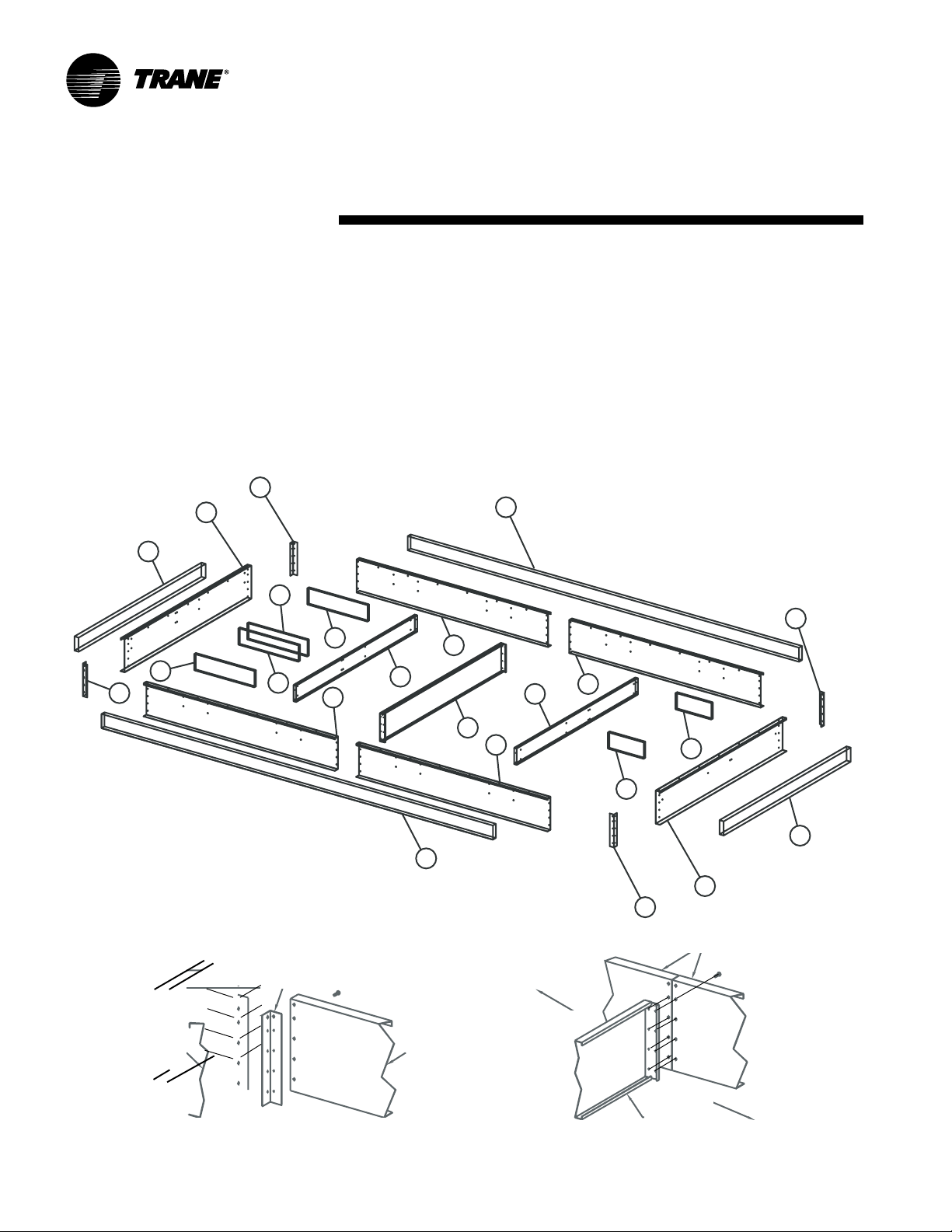

Standard roof curb assembly,

units without TE wheel option

7

1

23

15

R/A

E/A

17

10

16

Installation

Curb legend

(1) end rail (R/A end) (13) duct support end rail

(2) end rail (S/A end) (14) duct support end rail (R/A end)

(3) side rail (15) duct support side rail (R/A end)

(4) side rail (16) duct support side rail (E/A end)

(5) side rail (17) duct support side rail (E/A end)

(6) side rail (18) duct support side rail (S/A end)

(7) corner angle (19) duct support side rail (S/A end)

(8) corner angle (20) 6” wood nailer; side

(9) corner angle (21) 6” wood nailer; side

(10) corner angle (22) 6” wood nailer; end

(11) crossmember (23) 6” wood nailer; end

(12) duct support end rail

14

12

6

3

11

considerations

20

8

13

5

4

S/A

18

19

22

21

2

Note: Center lines connect

corresponding holes in the

rails and crossmember. All

screws are installed from

outside the curb.

corner angle

end rail

Typical std. curb corner assembly for units

without the total energy wheel option

12 FAXA-SVX01B-EN

side rail

return air end

Typical std. curb rail and crossmember assembly for units without

the total energy wheel option

9

side rails

supply air end

supply air end

crossmember

Note: Center lines connect

corresponding holes in the

rails and crossmember. All

screws are installed from

outside the curb.

Page 13

pre-installation

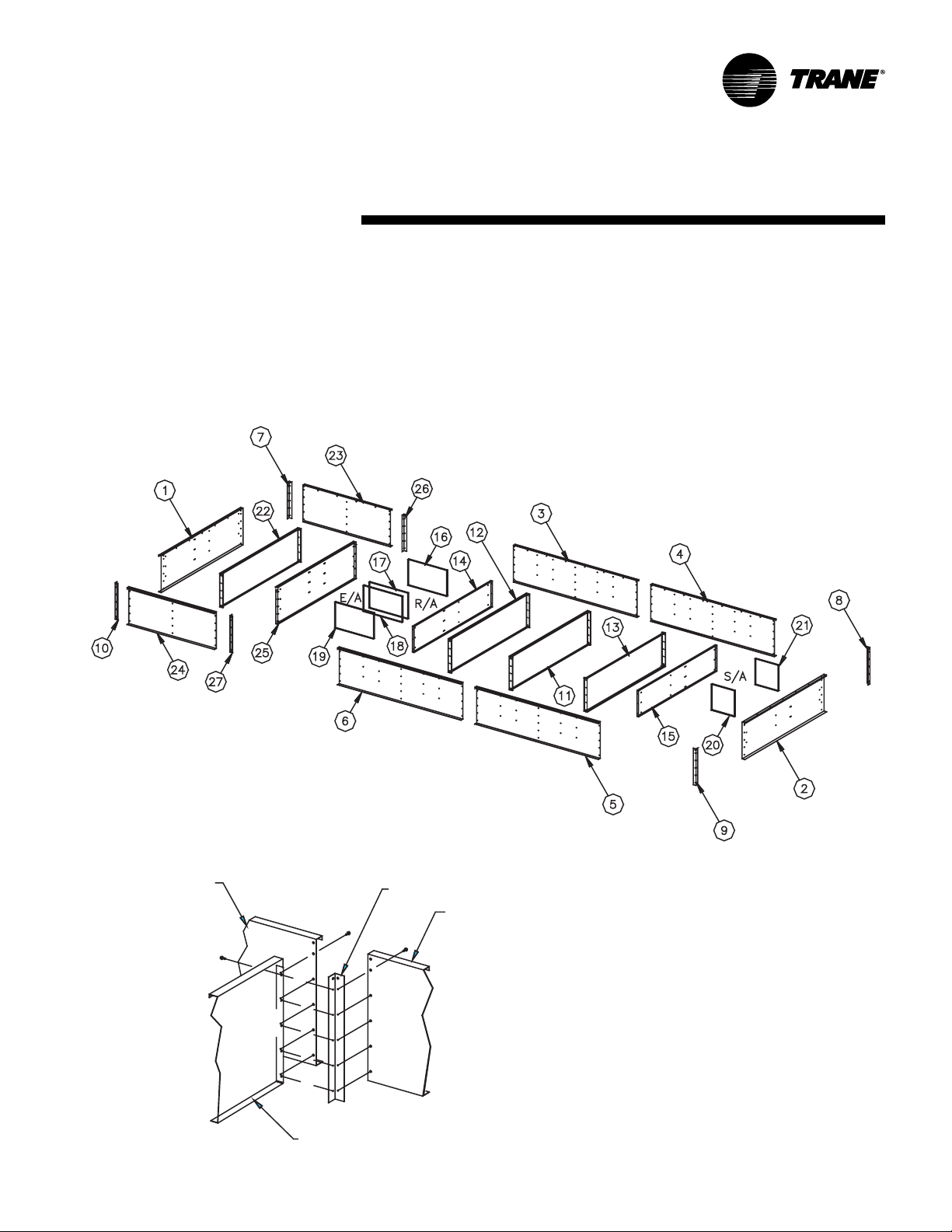

Extended Height Roof Curb Component Layout

Wi

th Total Energy Wheel

Figure 4

Standard roof curb assembly,

units with the TE wheel

Installation

Curb legend

(1) end rail (R/A, E/A end) (15) duct support end rail

(2) end rail (S/A end) (16) duct support side rail (R/A end)

(3) side rail (17) duct support side rail (R/A end)

(4) side rail (18) duct support side rail (E/A end)

(5) side rail (19) duct support side rail (E/A end)

(6) side rail (20) duct support side rail (S/A end)

(7) corner angle (21) duct support side rail (S/A end)

(8) corner angle (22) crossmember

(9) corner angle (23) side rail

(10) corner angle (24) side rail

(11) crossmember (25) duct support end rail

(12) crossmember (26) corner angle

(13) crossmember (27) corner angle

(14) duct support end rail

considerations

EN

D

side rail

duct support end rail

Typical standard roof curb assembly for units with the TE wheel

corner angle

side rail

FAXA-SVX01B-EN 13

Page 14

pre-installation

Installation

Installation

Acoustic Considerations

Before determining the final unit

installation site, remember that proper

unit placement is critical in reducing

transmitting sound levels to the building.

The ideal time to make provisions to

reduce sound transmissions is during the

design phase. The most economical

means of avoiding a potential acoustical

problem is to place units in areas that are

not acoustically sensitive. Ideal locations

are over over corridors, utility rooms,

toilets, or other areas where higher

sounds levels below the unit may be

acceptable.

Follow these basic guidelines to help

minimize sound transmission through the

building structure:

• Locate the unit’s center of gravity close

to or over a column or main support

beam.

• If the roof structure is very light, replace

roof joists using a structural shape in

the critical areas described above.

Note: Cut applicable holes only for the

supply, exhaust, and return duct penetration in the roof deck. To maintain

roof integrity and prevent possible

property damage, do not remove the

roof decking from the inside perimeter of

the curb.

considerations

Installation Preparation

Before installing the unit, perform the

following procedures to ensure proper

unit operation.

1. Verify the roof curb is level. To ensure

proper unit operation, install the unit

level (zero tolerance) in both horizontal

axes. Failure to level the unit properly

can result in condensate management

problems, such as standing water

inside the unit. Standing water and wet

surfaces inside units can result in

microbial growth (mold) in the drain

pan that may cause unpleasant odors

and serious health-related indoor air

quality problem.

2. Allow adequate service and code

clearances as recommended in

“Service Access” section on page 10.

3. Position the unit and skid assembly in

its final location. Test lift the unit to

determine exact unit balance and

stability before hoisting it to the

installation location. See Figure I-IP-2 on

page 41 for typical rigging procedures,

including cautions and proper uses of

such equipment as fork lifts, spreader

bars, and hooks.

14 FAXA-SVX01B-EN

Page 15

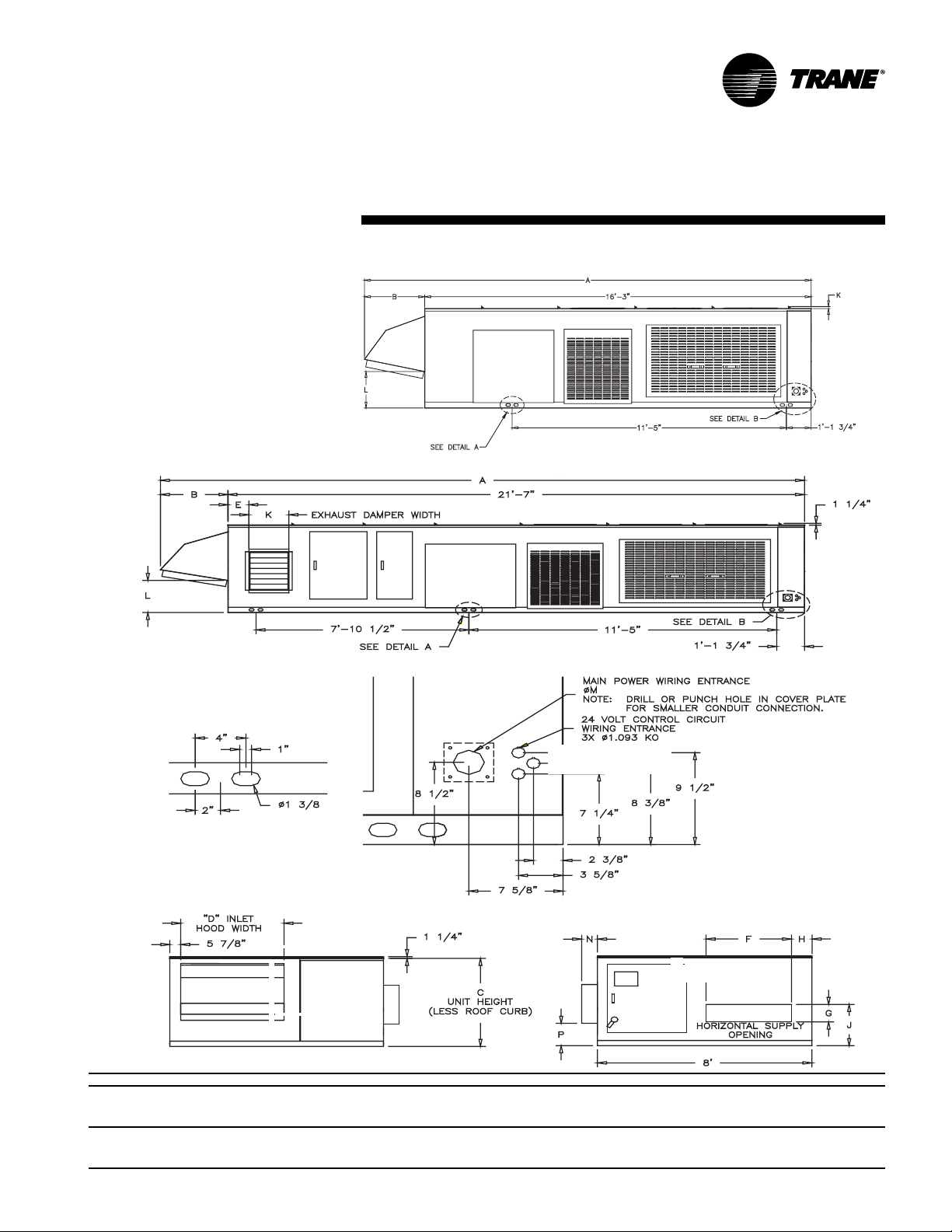

dimensions

Typical exterior dimensions,

ft./in.

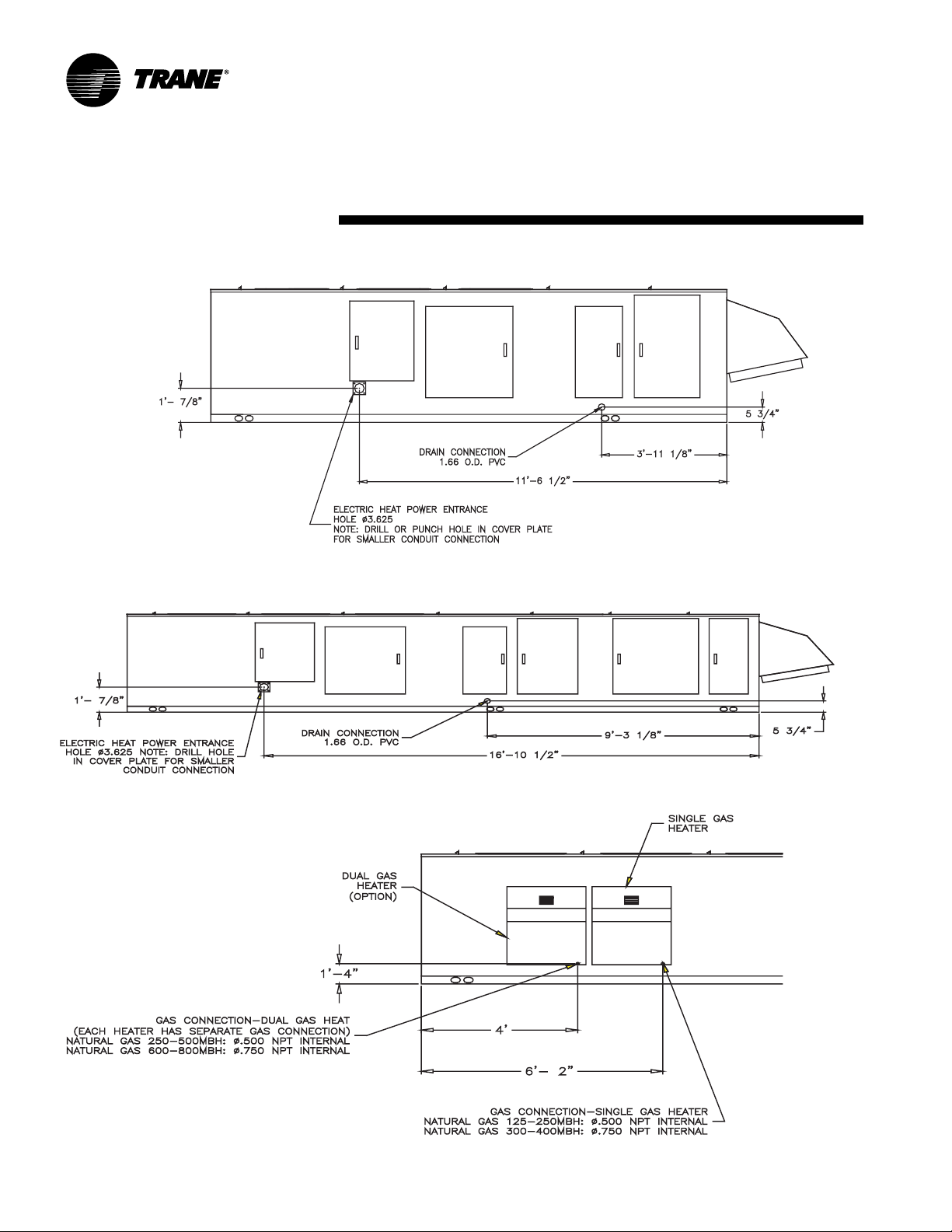

Installation

outdoor side view, unit without total energy wheel

outdoor side view, unit with total energy wheel

& weights

detail B

lifting hole detail A

CONTROL PANEL

END VIEW

inlet hood end view

unit size A B C D E F G H J K L M N P

without TE wheel

031, 041 18' - 10" 2' - 7" 4' - 2" 3' - 10" — 3' - 2" 10" 9" 1' - 11 1/2" 1 1/4" 1' - 6 1’4" ø 2 1/2" — —

051, 066 19' - 3" 3' 5' - 10" 4' - 1" — 3' - 6" 1' - 3" 10 1’4" 2' - 4 1/2" 1 1/4" 3' - 6 3/4" ø 3"

with TE wheel

031, 041 24' - 2" 2' - 7" 4' - 2" 3' - 10" 9 1/4" 3' - 2" 10" 9" 1' - 11 1/2" 1' 6" 1' - 6 1’4" ø 2 1/2" 7" 1' - 3/4"

051, 066 24' - 7" 3' 5' - 10" 4' - 1" 8" 3' - 6" 1' - 3" 10 - 1’4" 2' - 4 1/2" 1' 8" 3' - 6 3/4" ø 3" 7" 11"

control panel end view

FAXA-SVX01B-EN 15

Page 16

dimensions

Installation

unit without TE wheel - indoor side view (electric heat version shown)

unit with TE wheel - indoor side view (electric heat version shown)

& weights

single & dual gas heater options

16 FAXA-SVX01B-EN

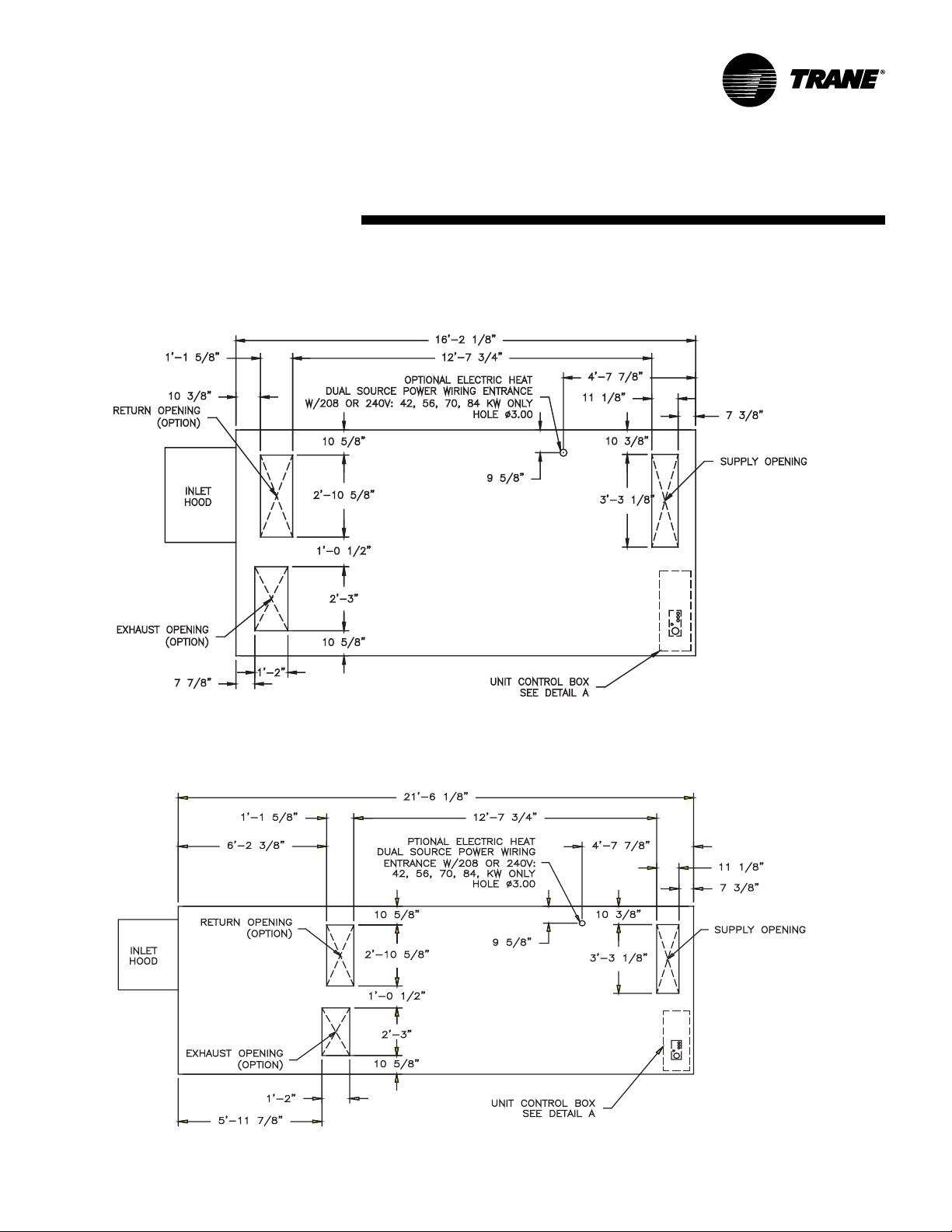

Page 17

dimensions

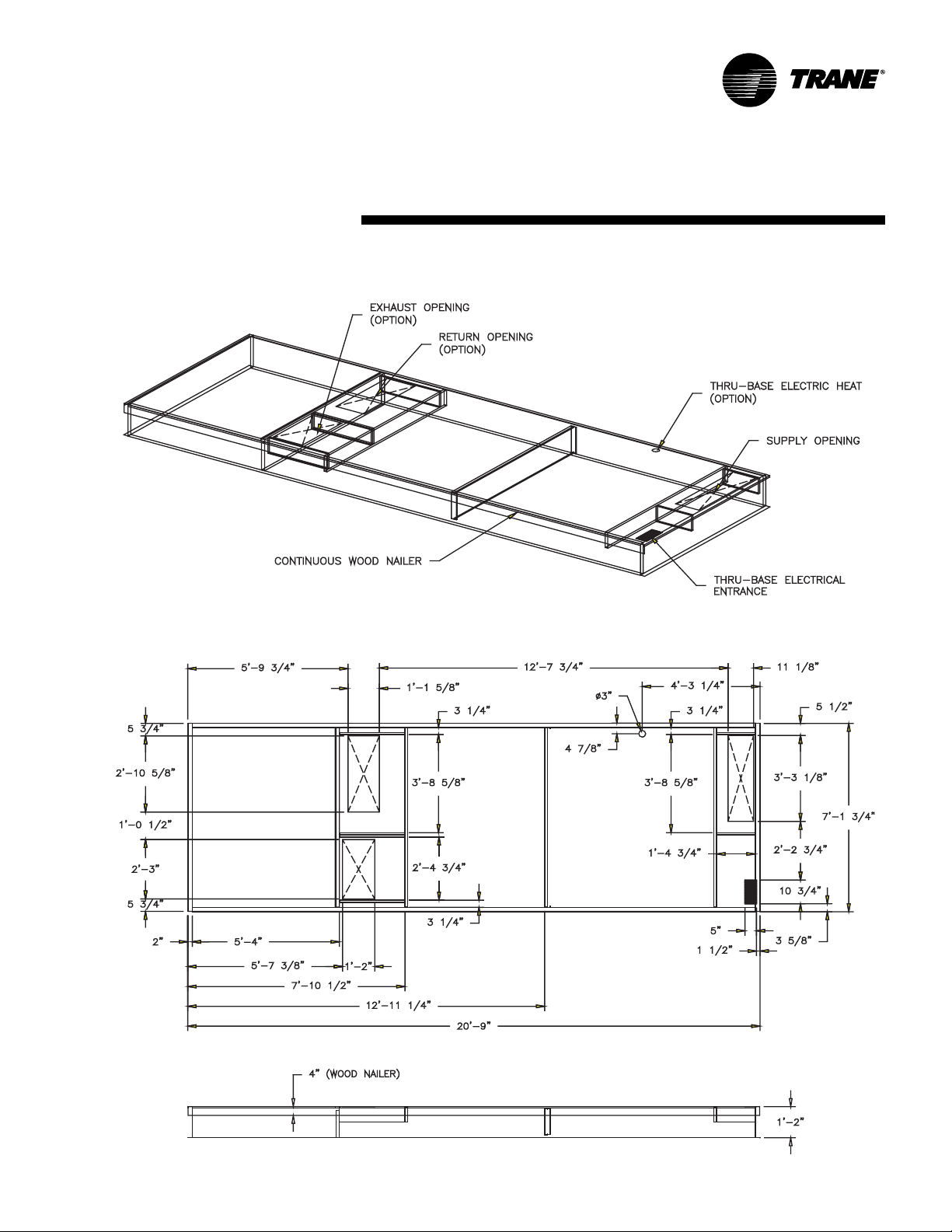

Installation

Unit base plan view, duct openings & thru-base power openings,

unit sizes 031 & 040

unit without TE wheel

& weights

unit with TE wheel

FAXA-SVX01B-EN 17

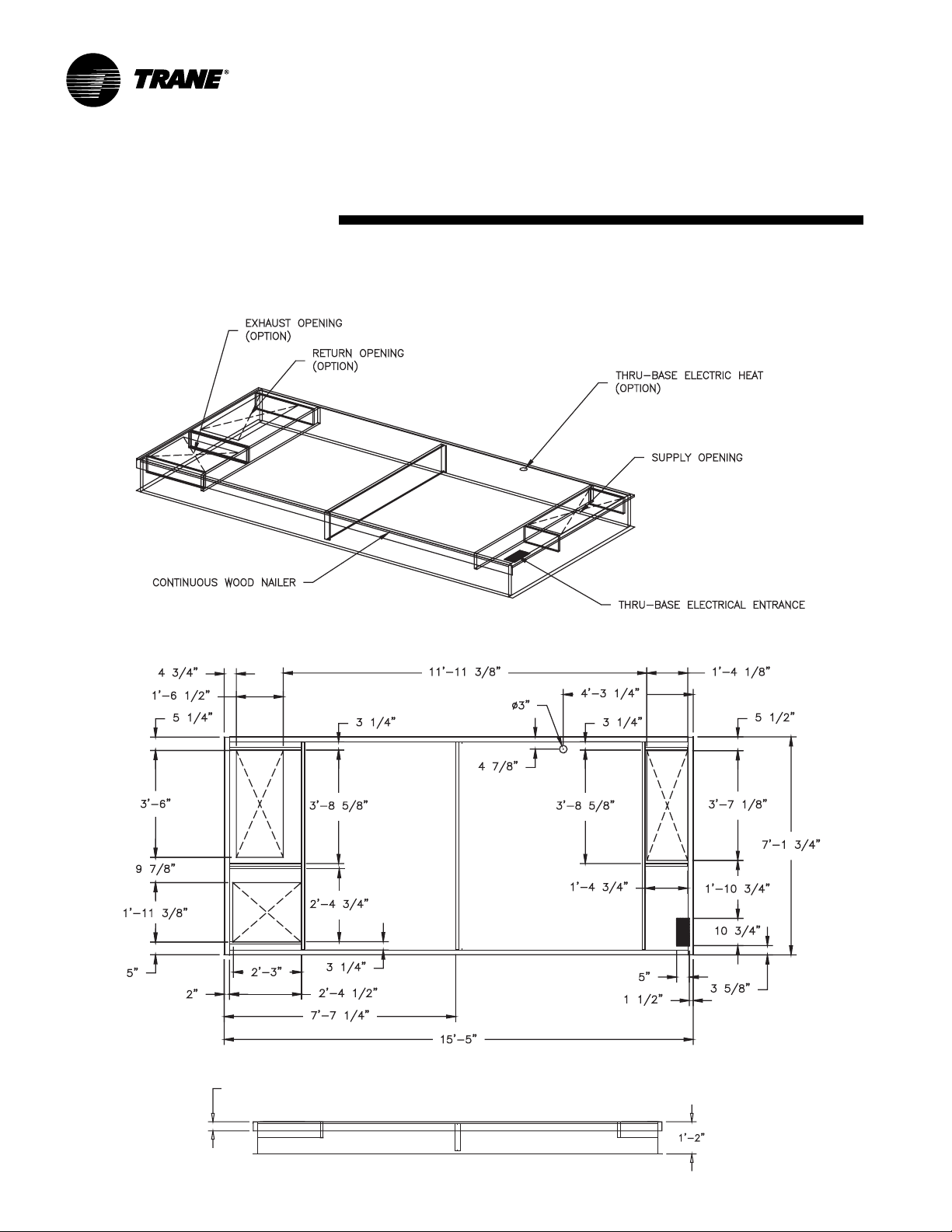

Page 18

dimensions

Installation

Unit base plan view, duct openings & thru-base power openings,

unit sizes 051 & 066

unit without TE wheel

& weights

unit with TE wheel

18 FAXA-SVX01B-EN

Page 19

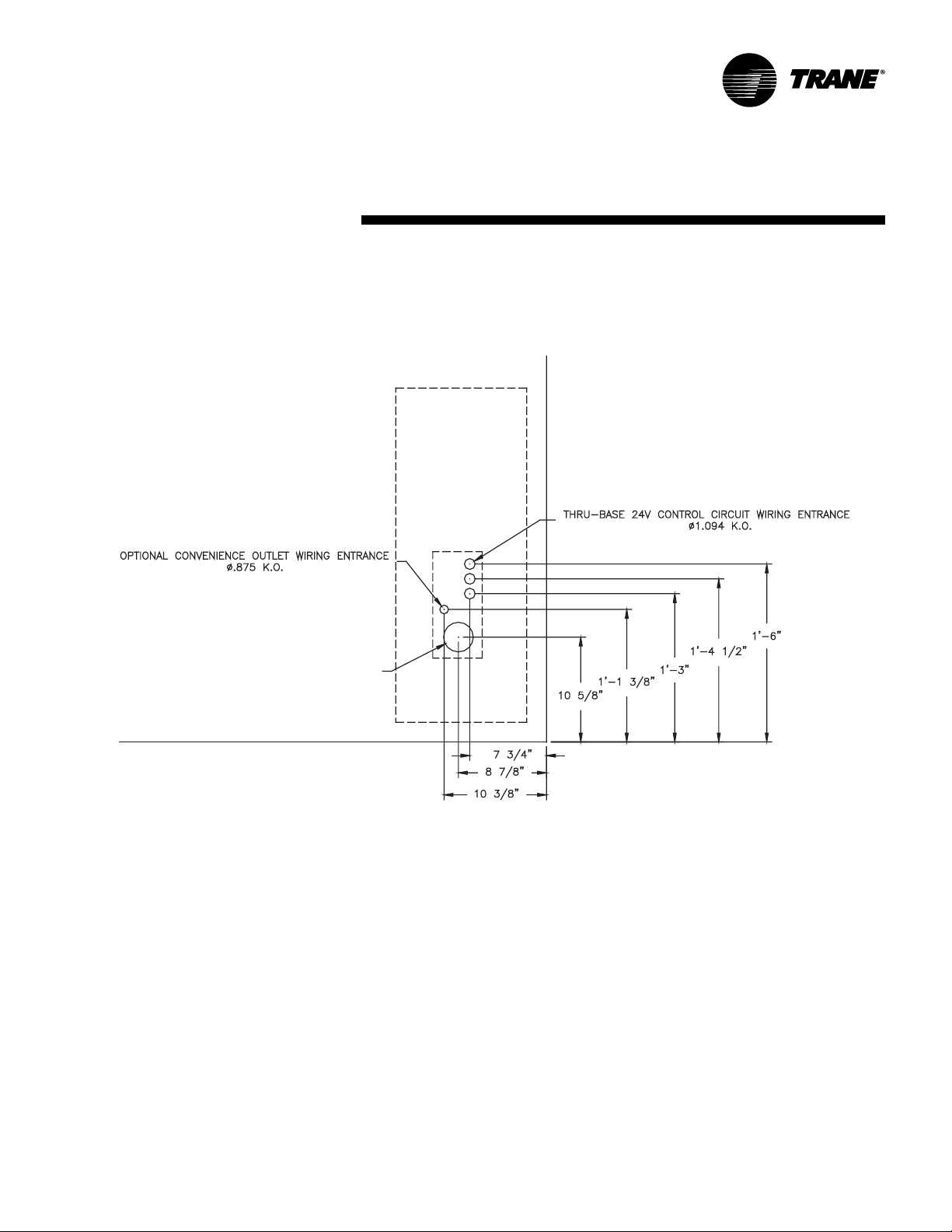

dimensions

Fresh air unit control panel detail,

all unit sizes

Installation

detail A

& weights

3x

THRU-BASE MAIN POWER WIRING ENTRANCE

NOTE: DRILL OR PUNCH HOLE IN COVER PLATE FOR

HOLE Ø3.000’’

SMALLER CONDUIT CONNECTION

top view

FAXA-SVX01B-EN 19

Page 20

dimensions

Installation

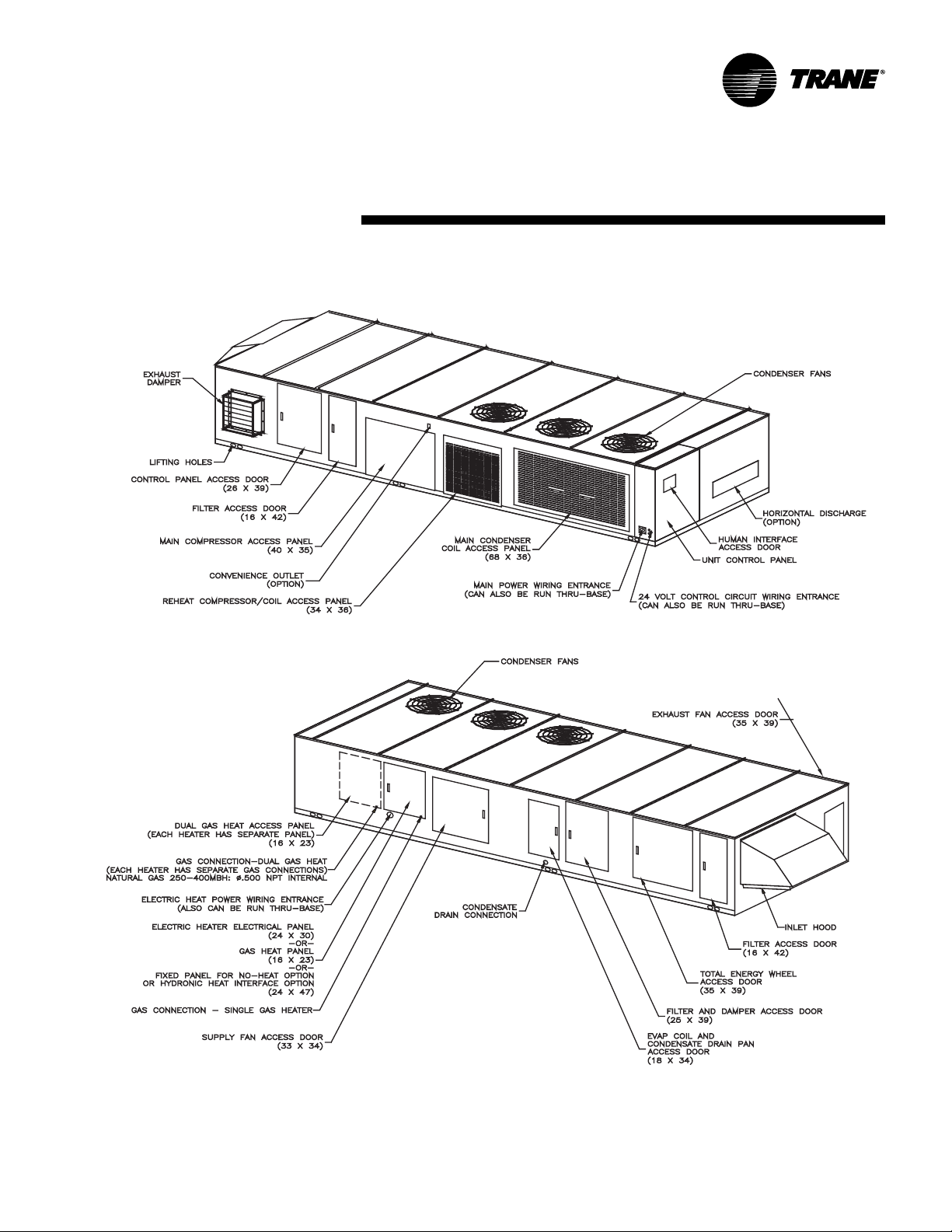

Exterior features for unit sizes 031 & 040,

without TE wheel

CONVENIENCE OUTLET (OPTION)

LIFTING HOLES

MAIN COMPRESSOR ACCESS PANEL

REHEAT COMPRESSOR/COIL ACCESS PANEL

(40x35)

(34x36)

MAIN CONDENSER

COIL ACCESS

PANEL (68x36)

MAIN POWER WIRING ENTRANCE

(CAN ALSO BE RUN THRU-

BASE)

& weights

CONDENSER FANS

HORIZONTAL DISCHARGE

(OPTION)

HUMAN INTERFACE

ACCESS DOOR

UNIT CONTROL PANEL

24 VOLT CONTROL CIRCUIT WIRING ENTRANCE

(CAN ALSO BE RUN THRU-BASE)

DUAL GAS HEAT ACCESS PANEL

(EACH HEATER HAS SEPARATE PANEL)

(EACH HEATER HAS SEPARATE GAS CONNECTIONS)

NATURAL GAS 250–400 MBH: Æ.500 NPT INTERNAL

20 FAXA-SVX01B-EN

GAS CONNECTION–DUAL GAS HEAT

ELECTRIC HEAT POWER WIRING ENTRANCE

(ALSO CAN BE RUN THRU-BASE)

ELECTRIC HEATER ELECTRICAL PANEL (24x30)

GAS HEAT PANEL (16x23)

OR HYDRONIC HEAT INTERFACE OPTION (24x47)

FIXED PANEL FOR NO-HEAT OPTION

SUPPLY FAN ACCESS DOOR

(16x23)

-OR-

-OR-

(33X34)

CONDENSATE

DRAIN CONNECTION

FILTER AND DAMPER ACCESS DOOR

(25x39)

EVAP COIL AND

CONDENSATE DRAIN PAN

ACCESS DOOR (18x34)

INLET HOOD

Page 21

dimensions

Installation

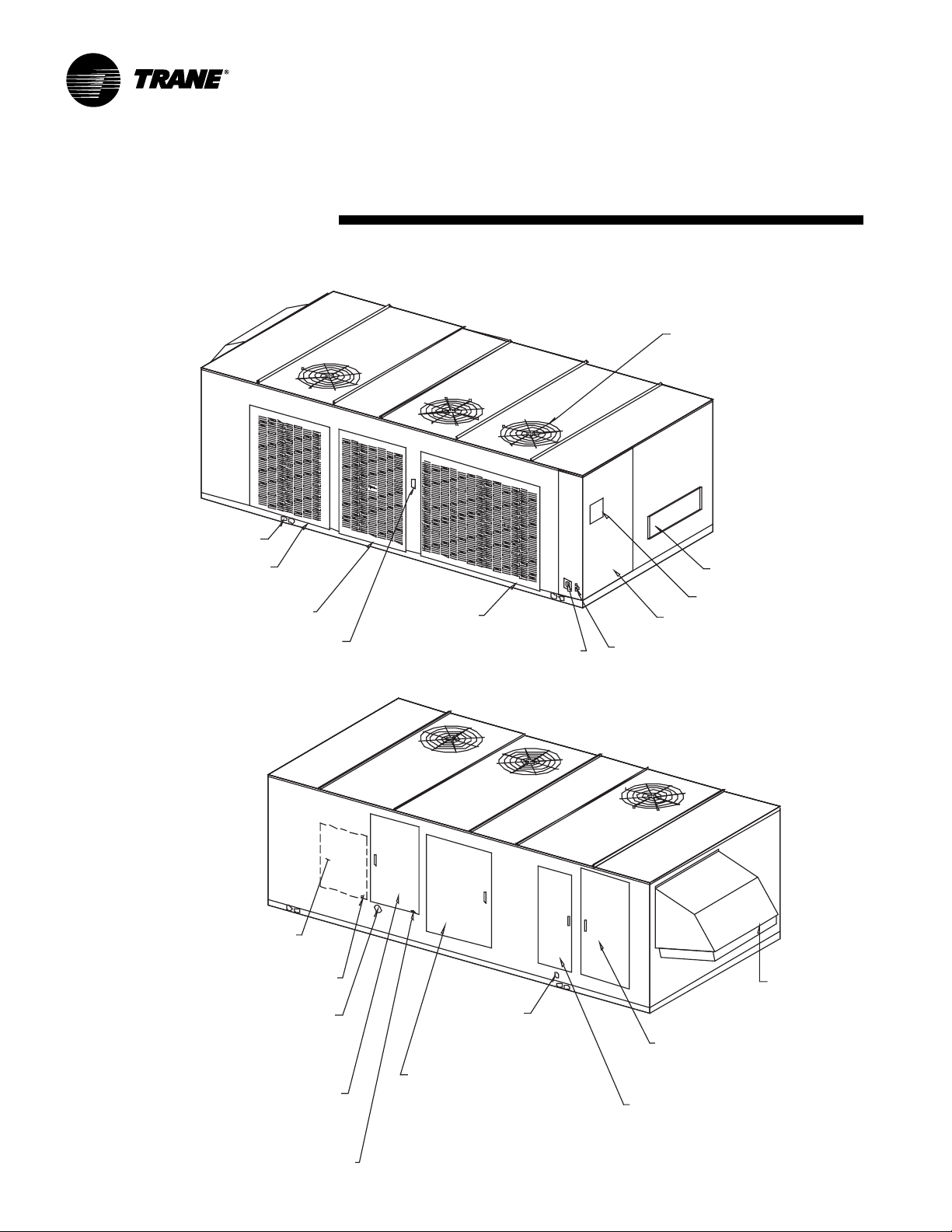

Exterior features, unit sizes 031 & 040

with TE wheel

& weights

FAXA-SVX01B-EN 21

Page 22

dimensions

Installation

Exterior features for unit sizes 051 & 066,

without TE wheel

LIFTING HOLES

REHEAT COMPRESSOR/

COIL ACCESS PANEL (40x52)

MAIN COMPRESSOR/

COIL ACCESS PANEL (34x52)

CONVENIENCE OUTLET

(OPTION)

MAIN COMPRESSOR/

COIL ACCESS PANEL

(68x52)

MAIN POWER WIRING ENTRANCE

(CAN ALSO BE RUN THRU-BASE)

& weights

CONDENSER FANS

HORIZONTAL DISCHARGE

(OPTION)

HUMAN INTERFACE

ACCESS DOOR

UNIT CONTROL PANEL

24 VOLT CONTROL CIRCUIT WIRING ENTRANCE

(CAN ALSO BE RUN THRU-BASE)

DUAL GAS HEAT ACCESS PANEL

(EACH HEATER HAS SEPARATE PANEL)

(EACH HEATER HAS SEPARATE GAS CONNECTIONS)

22 FAXA-SVX01B-EN

GAS CONNECTION–DUAL GAS HEAT

ELECTRIC HEAT POWER WIRING ENTRANCE

ELECTRIC HEATER ELECTRICAL PANEL (24x49)

OR HYDRONIC HEAT INTERFACE OPTION (24x67)

FOR 208/230 V: 70, 84, 100, 122 kW

(CAN ALSO BE RUN THRU-BASE)

SINGLE GAS HEAT ACCESS PANEL (16x23)

FIXED PANEL FOR NO-HEAT OPTION

GAS CONNECTION–SINGLE GAS HEATER

(16x23)

-OR-

-OR-

CONDENSATE DRAIN

CONNECTION

SUPPLY FAN ACCESS DOOR

(33x54)

INLET HOOD

FILTER AND DAMPER ACCESS DOOR

(25x59)

EVAP COIL & CONDENSATE DRAIN PAN

ACCESS DOOR

(18x54)

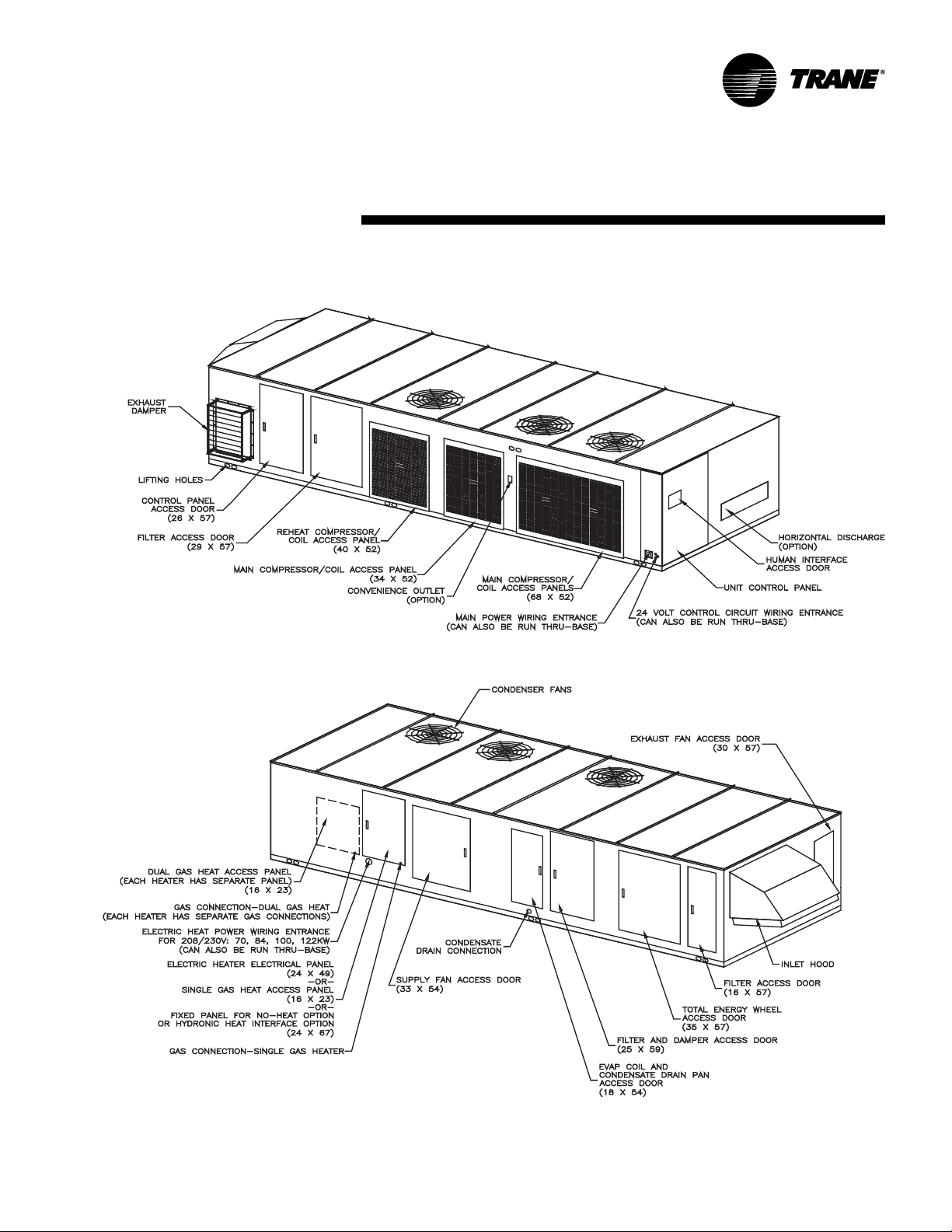

Page 23

dimensions

Installation

Exterior features for unit sizes 051 & 066

with TE wheel

& weights

FAXA-SVX01B-EN 23

Page 24

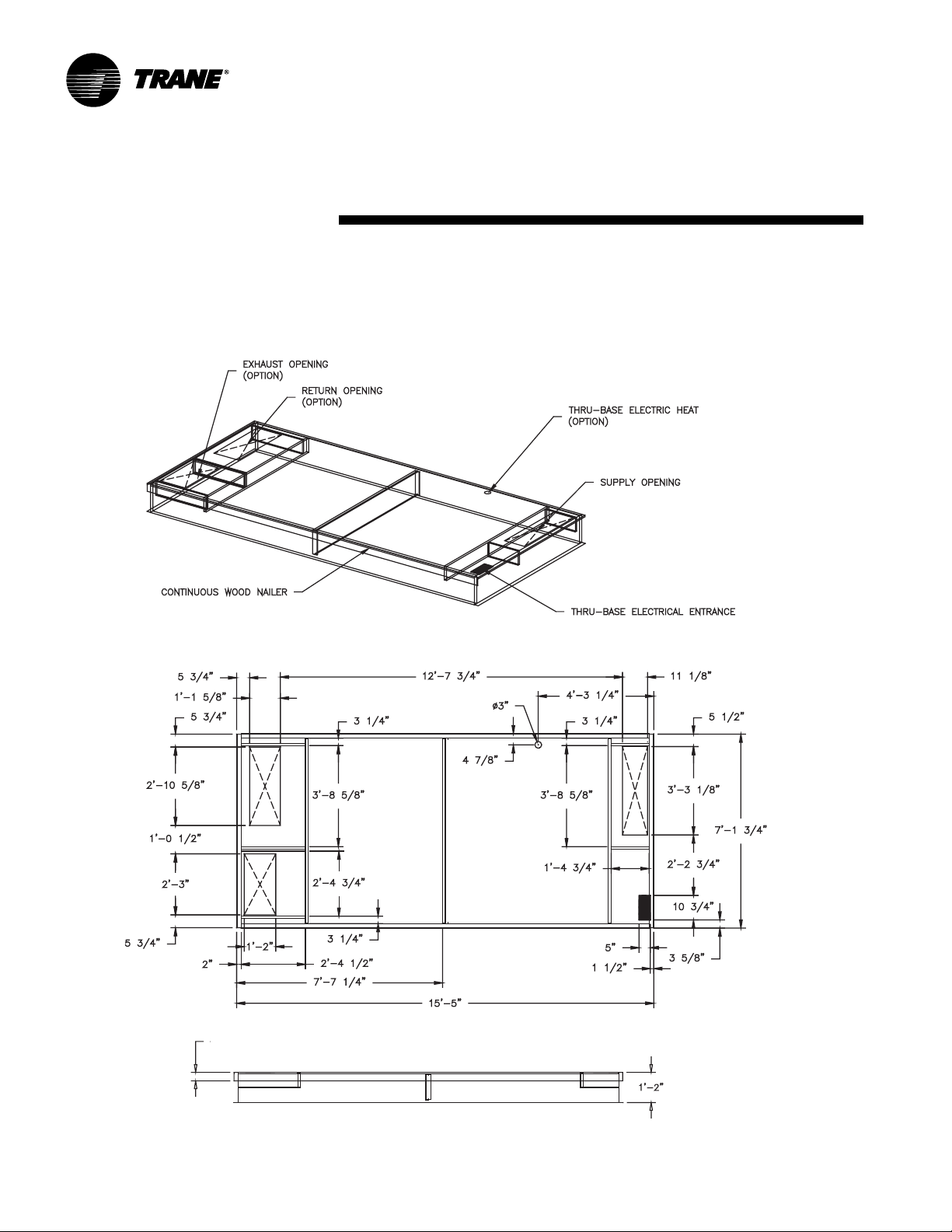

dimensions

Standard curb, unit sizes 031 & 040

without TE wheel

Installation

& weights

6’’ WOOD NAILER

24 FAXA-SVX01B-EN

Page 25

dimensions

Installation

Standard roof curb, unit sizes 031 & 040

with TE wheel

& weights

6" WOOD NAILER

FAXA-SVX01B-EN 25

Page 26

dimensions

Standard curb , unit sizes 051 & 66

without TE wheel

Installation

& weights

6’’ WOOD NAILER

26 FAXA-SVX01B-EN

Page 27

dimensions

Installation

Standard roof curb, unit sizes 051 & 066

with TE wheel

& weights

6" WOOD NAILER

FAXA-SVX01B-EN 27

Page 28

dimensions

Installation

Extended height roof curb, unit sizes 031 & 040

without TE wheel

& weights

6’’ WOOD NAILER

28 FAXA-SVX01B-EN

Page 29

dimensions

Installation

Extended height roof curb , unit sizes 031 & 040

with TE wheel

& weights

6" WOOD NAILER

FAXA-SVX01B-EN 29

Page 30

dimensions

Installation

Extended height roof curb, unit sizes 051 & 066

without TE wheel

& weights

6’’ WOOD NAILER

30 FAXA-SVX01B-EN

Page 31

dimensions

Installation

Extended height roof curb, unit sizes 051 & 066

with TE wheel

& weights

6" WOOD NAILER

FAXA-SVX01B-EN 31

Page 32

dimensions

Installation

& weights

Unit and accessory weights

Table I-DW-1. Typical unit, unit with total energy wheel, and roof curb weights

unit base unit total energy wheel unit roof curb for unit w/o TE wheel roof curb for unit with TE wheel

size weight

031 4600 1460 282 613 1500 350 766

040 4700 1520 282 613 1500 350 766

051 5600 1920 282 613 1500 350 766

066 6000 1970 282 613 1500 350 766

1. Base unit operating weight is for units with the condenser hot gas reheat option, return air, and no heat. Subtract condenser hot gas reheat weight for cooling only units. See Table

I-DW-2 for weight.

Table I-DW-2. Typical component weights

unit single gas (MBh) dual gas (MBh) electric heaters condenser hot

size 125 150 200 250 300 350 400 250 300 400 500 600 700 800 20-84 kW 100,122 kW gas reheat

031 201 217 247 295 295 333 — 402 434 — — — — — 60 — 150

040 201 217 247 295 295 333 — 402 434 494 — — — — 60 — 150

051 201 217 247 295 295 333 361 402 434 494 590 590 — — 60 100 270

066 201 217 247 295 295 333 361 402 434 494 590 590 666 722 6 0 100 270

1

base weight

1

low high acoustic low high

2

32 FAXA-SVX01B-EN

Page 33

mechanical

Duct Connections

Horizontal Discharge Units Only (Model

FAHA)

When attaching ductwork to a horizontal

discharge unit, provide a watertight

flexible connector at the unit to prevent

noise transmission from the unit into the

ductwork. Refer to the Dimensions and

Weights section on pages 13–23 for the

supply air and return air opening

dimensions. All outdoor ductwork

between the unit and the structure should

be weather proofed after installation is

complete.

WARNING!

Hazardous voltage!

Disconnect electrical power source

and remote disconnects before

servicing unit. Failure to do so may

cause death or injury.

WARNING!

Disconnect gas supply!

Before servicing unit, FIRST turn off

the gas supply. Failure to turn off the

gas supply can cause death or serious

injury.

Ductwork Considerations

Install all air ducts according to the

National Fire Protection Association

standards for the “Installation of Air

Conditioning and Ventilation Systems

other than Residence Type (NFPA 90A)

and Residence Type Warm Air Heating

and Air Conditioning Systems (NFPA

90B).

Make duct connections to the curb with a

flexible material such as heavy canvas. If

a fire hazard exists, Trane recommends

using Flexweave 1000, type FW30 or

equivalent canvas. Use three inches for

the return duct and three inches for the

discharge duct. Keep the material loose

to absorb unit vibration.

Run the ductwork as far as possible

without changing size or direction. Do not

make abrupt turns or transitions near the

unit due to increased noise and excessive

Installation

static losses. Use elbows with splitters or

turning vanes to minimize static losses.

Poorly constructed turning vanes may

cause airflow generated noise. Check

total external static pressures against fan

characteristics to be sure the required

airflow is available throughout the

ductwork.

Gas Pipe Sizing

Follow the procedure below to size the

gas piping to adequately provide gas

pressure at the gas heater.

1. Find the cu ft/hr by using the formula:

cu ft/hr = Btu/cu ft.

2. Refer to Table I-MR-1. Match “Pipe Run

in Feet” with appropriate “Gas Input Cu Ft/hr” figure. Match this figure to the

pipe size at the top of the column. For

example, requires 67 ft (20.4m) run of

gas pipe to connect a 200 MBh gas duct

furnace to a 1,000 Btu/cu ft (0.29) kW)

natural gas supply.

200,000 Btu/cu ft

1,000 Btu/cu ft = 200 cu ft/hr

Using Table I-MR-1, a 1” pipe is needed.

Before making any connections to

A MANUAL SHUTOFF VALVE WITH

1/8" N.P.T. PLUGGED TAPPING,

ACCESSIBLE FOR TEST GAGE

CONNECTION MUST BE INSTALLED

GAS

SUPPLY

LINE

3" (76 MM)

MIN.

DRIP LEG

Figure I-MR-1. Gas pipe connection

UPSTEAM OF THE GAS SUPPLY CONNECTION TO THE APPLIANCE.

PLUGGED 1/8" N.P.T.

TEST GAGE CONNECTION

requirements

existing line suppling other gas appliances, contact the local gas company to

make sure existing line is adequate size

to handle the combined load.

Gas Pipe Installation Procedure

1. Install the gas piping in accordance with

applicable local codes.

2. Check gas supply pressure. Each gas

heater must be connected to a gas

supply capable of supplying its full rated

capacity at a pressure not less than 5”

w.c. (1.62 kPa) nor greater than 14” w.c.

(0.5 psi) for natural gas. Size and install

all gas piping in accordance with ANSI

Standard Z223.1-1992 (or latest edition)

National Fuel Gas Code. In Canada, gas

piping should be according to CAN/CGA

B149. See Table I-MR-1 for correct gas

supply piping size. If gas pressure is

excessive on natural gas applications,

install a pressure regulating valve in the

line upstream from the main shutoff

valve for each independent heater.

3. Adequately support the piping to

prevent strain on the gas manifold and

controls.

4. To prevent the mixing of moisture with

gas, run the takeoff piping from the top,

or side, of the main.

GROUND JOINT UNION

TO CONTROLS

FAXA-SVX01B-EN 33

Page 34

mechanical

Installation

5. Pipe directly in to the manual shutoff

valve.

6. Install a

tapping, accessible for test gauge

connection, immediately upstream of

the gas supply connection to the

appliance.

7. Provide a drip leg in the gas piping near

the gas duct furnace.

8. Make certain that all connections have

been adequately doped and tightened.

9. Remove temporary shipping panels

and install the permanent panels that

ship in the return air section of the unit.

CAUTION

Valve stress hazard!

Do not overtighten the inlet gas piping

into the valve. This may cause stresses

that would crack the valve!

Note: Use pipe joint sealant resistant to

the action of liquefied petroleum gases

regardless of gas conducted.

1

/8" (3.2 mm) N.P.T. plugged

requirements

WARNING

Explosion hazard!

Failure to follow recommended safe

leak test procedures can cause death

or serious injury.

Note: Check all pipe joints for leakage

using a soap solution or other approved

method. The appliance and its individual

shutoff valve must be disconnected from

the gas supply piping system during any

pressure testing of that system.

Table I-MR-1. Gas pipe sizes, at 0.5 psig (3.5 Pa) or less, 0.5” w.c. (124.4 Pa), 0.60 specific gravity gas

nominal internal pipe length, ft. (m)

iron pipe, diameter, 10 20 30 40 50 60 70 80 90 100 125 150 175 200

in. in. (mm) (3.0) (6.1) (9.1) (12.2) (15.2) (18.2) (21.3) (24.4) (27.4) (30.5) (38.1) (45.7) (53.3) (61.0)

1

/

2

3

/

4

1 1.049 680 465 375 320 285 260 240 220 205 195 175 160 145 135

1 1/

4

1 1/

2

2 2.067 3950 2750 2200 1900 1680 1520 1400 1300 1220 1150 1020 950 850 800

2 1/

2

3 3.068 11000 7700 6250 5300 4750 4300 3900 3700 3450 3250 2950 2650 2450 2280

4 4.026 2300 15800 12800 10900 9700 8800 8100 7500 7200 6700 6000 5500 5000 4600

Note: 1. ft.3/hr = input / 1000. For SI, convert Btu/hr to kW. m3/hr = input (kW) x (0.0965).

2. Size natural gas select pipe directly from the table.

34 FAXA-SVX01B-EN

0.622 175 120 97 82 73 66 61 57 53 50 44 40 37 35

(16) (4.96) (3.40) (2.75) (2.32) (2.07) (1.87) (1.73) (1.61) (1.50) (1.42) (1.25) (1.13) (1.05) (0.99)

0.824 360 250 200 170 151 138 125 118 110 103 93 84 77 72

(21) (10.2) (7.08) (5.66) (4.81) (4.28) (3.91) (3.54) (3.34) (3.11) (2.92) (2.63) (2.38) (2.18) (2.04)

(27) (19.3) (13.2) (10.6) (9.06) (8.07) (7.36) (6.80) (6.23) (5.80) (5.52) (4.96) (4.53) (4.11) (3.82)

1.380 1400 950 770 660 580 530 490 460 430 400 360 325 300 280

(35) (39.6) (26.9) (21.8) (18.7) (16.4) (15.0) (13.9) (13.0) (12.2) (11.3) (10.2) (9.20) (8.50) (7.93)

1.610 2100 1460 1180 990 900 810 750 690 650 620 550 500 460 430

(41) (59.5) (41.3) (33.4) (28.0) (25.5) (22.9) (21.2) (19.5) (18.4) (17.6) (15.6) (14.2) (13.0) (12.2)

(53) (112) (77.9) (62.3) (53.8) (47.6) (43.0) (39.6) (36.8) (34.5) (32.6) (28.9) (26.9) (24.1) (22.7)

2.469 6300 4350 3520 3000 2650 2400 2250 2050 1950 1850 1650 1500 1370 1280

(63) (178) (123) (99.7) (85.0) (75.0) (68.0) (63.7) (58.0) (55.2) (52.4) (46.7) (42.5) (38.8) (36.2)

(78) (311) (218) (177) (150) (135) (122) (110) (105) (97.7) (92.0) (83.5) (75.0) (69.4) )(64.6)

(102) (651) (447) (362) (309) (275) (249) (229) (212) (204) (190) (170) (156) (142) (130)

maximum pipe capacity for gas pressures, ft.3/hr. (m3/h)

Page 35

mechanical

Installation

Condensate Drain Trapping

A fresh air unit is selected for its

dehumidifying capability. As such,

condensate can be formed at an

enormous rate. The Packaged Fresh Air

Unit, drain pan and condensate line have

been sized and designed accordingly. An

often-overlooked element of proper

condensate drainage is trapping. An

incorrectly designed and installed trap on

the piping exiting the drain pan can

restrict the flow of condensate or cause

‘‘spitting’’ or “geysering” of the

condensate water which can dampen the

interior insulation of the air handler and/

or ductwork, creating an opportunity for

mold infestation. The HVAC equipment

manufacturer’s installation and trapping

instructions must be carefully followed to

assure adequate condensate removal

under all operating conditions. Figure IMR-2 shows the proper design for a ptrap design, in an air handler with a drawthrough coil arrangement.

requirements

H = (1” for each 1” of maximum negative static

pressure) + 1”

J = half of H

L = H + J + pipe diameter + insulation

Figure I-MR-2. P-trap design for drain pan

FAXA-SVX01B-EN 35

Page 36

electrical

Electrical Requirements

Follow these guidelines, referring to unit

wiring diagrams and supply power

dimensional information to ensure

correct electrical requirements at the

installation site. Reference supply power

wiring locations on unit submittals or in

the Dimensions and Weights section on

page 13. Specific unit wiring diagrams

are provided on the inside of the control

panel door. Use these diagrams for

connections or trouble analysis.

Supply Power Wiring

It is the installer’s responsibility to provide

power supply wiring to the unit. Wiring

should conform to NEC and all applicable

code requirements. To ensure the unit

supply power wiring is properly sized and

installed, follow the guidelines below:

1. Verify the power supply available is

compatible with the unit nameplate

ratings. The supply power must be

within 10% of the rated voltage listed

on the unit nameplate.

2. Reference the electrical data in Tables

I-ER-1 through I-ER-8. Protect the

electrical service from over current and

short circuit conditions in accordance

with NEC requirements. Size protection

devices according to the electrical date

on the unit nameplate.

3. If the unit is not equipped with an

optional factory-installed disconnect,

you must install a field-supplied

disconnect at or near the unit in

accordance with NEC. Do not mount a

field-supplied disconnect on the unit.

Reference Figures I-DW-3 and I-DW-4

on pages 16–17 for the electrical

service entrance location.

4. Complete the unit power wiring

connections onto either the main

terminal block or the factory -mounted

non-fused disconnect switch located in

the control panel.

5. Provide proper unit grounding in

accordance with local and national

codes.

Installation

requirements

Table I-ER-1. Electrical service sizing data

unit reheat comp (A) main comp 1 (B) main comp 2 (C) main comp 3 (D)

size voltage tons* r la lra tons* rla lr a tons* rl a lra tons* r la lra

031 208/60/3 4.5 15 124 9.0 35 222 14.0 48 337 — — —

230/60/3 4.5 15 124 9.0 31 251 14.0 43 376 — — —

460/60/3 4.5 8 59.6 9.0 16 117 14.0 23 178 — — —

040 208/60/3 6.75 23 164 10.0 35 222 15.0 51 337 — — —

230/60/3 6.75 23 164 10.0 31 251 15.0 46 376 — — —

460/60/3 6.75 11 100 10.0 16 117 15.0 23 178 — — —

056 208/60/3 9.0 35 222 14.0 48 337 9.0 35 222 9.0 35 222

230/60/3 9.0 31 251 14.0 43 376 9.0 31 251 9.0 31 251

460/60/3 9.0 16 117 14.0 23 178 9.0 16 117 9.0 16 117

066 208/60/3 9.0 35 222 15.0 51 337 15.0 51 337 15.0 51 337

230/60/3 9.0 31 251 15.0 46 376 15.0 46 376 15.0 46 376

460/60/3 9.0 16 117 15.0 23 178 15.0 23 178 15.0 23 178

*tons refers to nominal R22 tons

electric heat FLA is determined at 208, 240, & 480 volts

Table I-ER-2. Supply fan motor fla

voltage 1 hp 2 hp 3 hp 5 hp 7.5 hp 10 hp 15 hp 1 hp 2 hp 3 hp 5 hp 7.5 hp 10 hp 15 hp

208/60/3 3.1 5.9 8.7 14.0 22.2 28.2 40.7 3.1 6.1 9.3 14.9 21.3 29.0 40.7

230/60/3 2.8 5.6 8.0 13.2 21.6 28.0 40.6 2.8 5.4 8.2 12.8 20.0 25.8 35.4

460/60/3 1.4 2.8 4.0 6.6 10.8 14.0 20.3 1.4 2.7 4.1 6.4 10.0 12.9 17.7

standard efficiency high efficiency

Table I-ER-3. Exhaust fan motor fla

voltage 1 hp 2 hp 3 hp 5 hp 7.5 hp 10 hp 15 hp 1 hp 2 hp 3 hp 5 hp 7.5 hp 10 hp 15 hp

208/60/3 3.1 5.9 8.7 14.0 22.2 28.2 40.7 3.1 6.1 9.3 14.9 21.3 29.0 —

230/60/3 2.8 5.6 8.0 13.2 21.6 28.0 — 2.8 5.4 8.2 12.8 20.0 25.8 —

460/60/3 1.4 2.8 4.0 6.6 10.8 14.0 — 1.4 2.7 4.1 6.4 10.0 12.9 —

Table I-ER-4. Energy wheel motor fla

unit size 031 040 051 066

hp

voltage

208/60/3 2.7 2.7 3.6 3.6

230/60/3 2.4 2.4 3.0 3.0

460/60/3 1.2 1.2 1.5 1.5

standard efficiency high efficiency

Table I-ER-5. Condenser fan motors

1

3

1

/

/

2

2

3

/

/

4

4

voltage f la

208/60/3 3.8

230/60/3 3.6

460/60/3 1.8

Table I-ER-6. Factory-wired convenience outlet

voltage amps

208/60/3 7.21

230/60/3 6.52

460/60/3 3.26

Table I-ER-7. total gas heat amps with combustion blower

voltage amps

208/60/3 2.54

230/60/3 2.30

460/60/3 1.15

Table I-ER-8. Control power transformer (loads greater than 1 amp)

voltage amps

208/60/3 1.20

230/60/3 1.09

36 FAXA-SVX01B-EN

Page 37

electrical

requirementsInstallation

Power Wire Sizing and

Protection Device Equations

Each type of unit has its own set of

calculations for MCA (minimum circuit

ampacity) and MOP (maximum

overcurrent protection. For units with

multiple modes of operation, you must

consider each individual field-wired

hazardous voltage circuit. Use the load

that provides the highest value in the

applicable circuit. To correctly size the

unit’s electrical service wiring, read the

load definitions that follow and then find

the appropriate set of calculations

based on your unit type.

Load Definitions

Load 1 = current of the largest motor

(compressor or fan motor)

Load 2 = sum of the currents of all

remaining motors

Load 3 = current of electric heaters

Load 4 = control power transformer

= any other load rated at one amp or

more (gas heat, factory-wired

convenience outlet)

Single-Source Power

Set #1: Cooling only units and cooling

with gas heat, single source power

MCA = (1.25 x load 1) + load 2 + load 4

MOP = (2.25 x load 1) + load 2 + load 4

Select an overcurrent protective device

rating equal to the MOP value. If the

MOP value does not equal a standard

device size as listed in NEC 240-6, select

the next lower standard device rating. If

the selected MOP is less than the MCA,

then reselect the lowest standard

maximum overcurrent protective

device size that is equal to or larger than

the MCA, provided the reselected

device size does not exceed 800 amps.

Disconnect Switch Sizing (DSS) – if field

provided and installed

If the unit has a factory-installed, nonfused disconnect switch, this sizing

equation is not necessary. If the

disconnect is field-provided and

installed, use the following equation to

determine its rating:

DSS = 1.15 x (load 1 + load 2 + load 4)

Select a disconnect switch (DSS) size

equal to or larger than the DSS value

calculated.

Set #2: Units with electric heat, single

source power, non-concurrent load

To arrive at the correct MCA and MOP

values, you must perform two sets of

calculations: one for cooling only (set #1)

and one for electric heat only (set #2).

Calculate the MCA and MOP values as if

the unit were in the cooling mode (use

the equations given in set #1). Then

repeat the calculations for MCA and

MOP for the unit in the heating mode

using set #2. When determining loads,

keep in mind that the compressors and

condenser fans do not run while the unit

is in the heating mode.

For units using heaters:

• less than 50 kW,

use the formula, MCA = 1.25 x (load 1

+ load 2 + load 4) + (1.25 x load 3)

• equal to or greater than 50 kW,

use the formula, MCA = 1.25 x (load 1

+ load 2 + load 4) + load 3

Select the nameplate MCA value that is

the larger of the cooling (set #1) or the

heating mode MCA calculated above.

MOP = (2.25 x load 1) + load 2 + load 3 +

load 4

Select an overcurrent protective device

rating equal to the MOP value. If the

MOP value does not equal a standard

device size as listed in NEC 240-6, select

the next lower standard device rating. If

the next lower standard rating is less

than 125% of the current rating of the

electric heater load, select the next

higher standard device rating. If the

selected MOP is less than the MCA, then

reselect the lowest standard device size

which is equal to or larger than the

MCA, provided the reselected device

size does not exceed 800 amps.

Select the MOP value that is the larger

of the cooling (set #1) mode MOP value

or the heating MOP value calculated

above.

Disconnect Switch Sizing (DSS) – if field

provided and installed

If the unit is ordered with a factoryinstalled non-fused disconnect switch,

this sizing equation is not necessary. If

the disconnect is to be field-provided

and installed, use the following equation

to determine its rating:

DSS = 1.15 x (load 1 + load 2 + load 3 +

load 4)

Select the DSS value that is the larger of

the cooling (set #1) mode DSS or the

heating mode DSS value calculated

above. Select a disconnect switch size

equal to or greater than the DSS value

calculated.

Set #3: Units with electric heat, single

source power, concurrent load

Concurrent load = two compressors and

first stage electric heat

Primary Heat Reheat Selection

You may enable primary heat reheat to

take advantage of the primary heat

source as supplemental reheat for the

condenser reheat. Although in most

cases, the MCA and MOP values are

unaffected by the concurrent loads of

compressors, condenser fans, and first

stage of electric heat, there are a few

circumstances where the MCA and MOP

are increased when this sequence is

employed.

You must perform three sets of calculations to obtain the correct MCA and MOP

values: one for cooling (set #1) only, one

for electric heat (set #2) only, and one for

when the unit is in the cooling mode with

compressors and electric heat on

concurrently (set #3).

For size 031 and 040 units, compressors

A (1K1) and B (1K2) can run concurrently

1

/3 of three-stage electric heat or 1/7

with

of seven-stage electric heat.

For size 051 and 066 size units, compressors A (1K1) and D (1K4) can run

concurrently with

electric heat or

heat.

For units using heaters less than 50 kW:

MCA = (1.25 x load 1) + load 2 + load 4 +

(1.25 x load 3)

For unit using heaters equal to or greater

than 50 kW:

MCA = (1.25 X load 1) + load 2 + load 3 +

load 4

Select the nameplate MCA value that is

the largest of the three sets of MCA

calculations.

MOP = (2.25 x load 1) + load 2 + load 3 +

load 4

Select an overcurrent protective device

1

/3 of three-stage

1

/7 of seven-stage electric

FAXA-SVX01B-EN 37

Page 38

electrical

Installation

rating equal to the MOP value. If the MOP

value does not equal a standard device

size as listed in NEC 240-6, select the

next lower standard device rating. If the

next lower standard rating is less than

125% of the current rating of the electric

heater load, select the next higher

standard device rating. If the selected

MOP is less than the MCA, then reselect

the lowest standard device size which is

equal to or larger than the MCA, provided the reselected device size does not

exceed 800 amps.

The MOP value selected should be the

largest of the three sets of MOP value

calculations.

Disconnect Switch Sizing (DSS) – if field

provided and installed

If the unit is ordered with a factoryinstalled non-fused disconnect switch,

this sizing equation is not necessary. If

the disconnect is to be field-provided and

installed, use the following equation to

determine its rating:

DSS = 1.15 x (load 1 + load 2 + load 3 +

load 4)

Select the DSS that is the largest of the

three sets of DSS calculations. Select a

disconnect switch size equal to or greater

than the DSS value calculated.

Set #4: Units with Electric Heat, Dual

Source Power

Dual source power is required only on

some 208V and 230V units when

provided with electric heat. Those units

are:

size voltage elec ht kW

031 208V or 230V 42 kW or

larger

040 208V or 230V 42 kW or

larger

051 208V or 230V 70 kW or

larger

066 208V or 230V 70 kW or

larger

Dual Source Power

For units with dual source power, use

two different sets or MCA and MOP

calculations, one for each power

connection. MCA1 and MOP1 represent

the values calculated for the operation of

the compressors and condenser fans.

requirements

For the calculations of MCA1 and MOP1,

use the instructions from set #1

previously in this section.

MCA2 and MOP2 represent the values

calculated for the operation of the unit in

heating mode:

MCA2 = (1.25 x load 3) if heater kW is

less than 50kW

or

(1.0 x load 3) if heater kW is 50kW or

greater, MOP2 = (1.25 x load 3)

Select an overcurrent protective device

rating for the heating circuit equal to the

MOP2 value. If the MOP2 value does not

equal a standard device size as listed in

NEC 240-6, select the next lower standard device rating. If the selected MOP2

is less than the MCA2, then reselect the

lowest standard device size that is equal

to or larger than the MCA2, provided the

reselected device size does not exceed

800 amps.

Disconnect Switch Sizing (DSS) – if field

provided and installed:

If the unit is ordered with a factoryinstalled non-fused disconnect switch, this

sizing equation is not necessary. If the

disconnect is to be field-provided and

installed, use the following equation to

determine its rating:

DSS2 = 1.15 x (load 3)

Select the DSS2 value that is the largest

of the three sets of DSS2 calculations.

Select a disconnect switch size equal to or

greater than the DSS2 value calculated.

Load Definitions

Load 1:

• supply fan • exhaust fan

• reheat comp (A) • condenser fan 1 (A)

• main comp 1 (B) • condenser fan 2 (B)

• main comp 2 (C) • condenser fan 3 (C)

• main comp 3 (D) [5100/6600]

• total energy wheel

Load 3:

• electric heat

kW < 50

kW > 50

Load 4

• control power transformer (loads > 1

amp [1T1 - 208/230])

• gas heat

• factory-wired convenience outlet

the compressors and condenser fans. For

38 FAXA-SVX01B-EN

Page 39

electrical

Installation

requirements

Table I-ER-9. Electric heat FLA

unit kW k W kW k W kW kW k W kW kW

size voltage 20 26 32 42 56 70 84 100 122

031 208/60/3 55.5 72.2 88.8 116.6 155.4 — — — —

040 208/60/3 — 72.2 88.8 116.6 155.4 194.3 233.2 — —

051 208/60/3 — — 88.8 116.6 155.4 194.3 233.2 277.6 —

066 208/60/3 — — — 116.6 155.4 194.3 233.2 277.6 338.6

Note: Electric heat FLA is determined at 208, 240 & 480 volts.

230/60/3 48.1 62.5 77.0 101.0 134.7 — — — —

460/60/3 24.1 31.3 38.5 50.5 67.4 — — — —

230/60/3 — 62.5 77.0 101.0 134.7 168.4 202.1 — —

460/60/3 — 31.3 38.5 50.5 67.4 84.2 101.0 — —

230/60/3 — — 77.0 101.0 134.7 168.4 202.1 240.6 —

460/60/3 — — 38.5 50.5 67.4 84.2 101.0 120.3 —

230/60/3 — — — 101.0 134.7 168.4 202.1 240.6 293.5

460/60/3 — — — 50.5 67.4 84.2 101.0 120.3 146.7

Table I-ER-10. Dual source electric heat - customer wire gauge, AWG

unit kW k W kW kW kW k W

size voltage 42 56 70 84 100 122

031 208/60/3 1/0 2/0 — — — —

230/60/3 1 1/0 — — — —

040 208/60/3 1/0 2/0 3/0 250 — —

230/60/3 1 1/0 2/0 4/0 — —

051 208/60/3 — — 3/0 250 300 —

230/60/3 — — 2/0 4/0 250 —

066 208/60/3 — — 3/0 250 300 500

230/60/3 — — 2/0 4/0 250 350

Table I-ER-11. Voltage utilization range

voltage range

208/60/3 187-220

230/60/3 208-254

460/60/3 416-508

utilization

FAXA-SVX01B-EN 39

Page 40

installation

Installation

Rigging and Placement

Before Rigging and Lifting the Unit

1. Verify the roof curb is installed properly

and has the prooper gaskets installed

and is level and square to ensure

adequate curb-to-unit seal.

2. Attach adequate strength lifting cables

to the lifting lugs. See Tables I-DW-1 & IDW-2 on page 32 for unit & component

weights. See Figure I-PC-4 on page 32

for the proper unit lifting procedure. To

lift the unit, use spreader bars to protect

the unit and ensure uniform lift. Note

that the minimum distance between the

lifting hook and the top of the unit

should be seven feet.

3. Test-lift the unit at a minimum height

procedure

equipment operates properly and the

unit is properly balanced.

4. Lift the unit and position it over the roof

curb. Align the unit base rails with the

roof curb.

5. Lower the unit onto the curb. Make

sure the curb gasket remains intact

when positioning the unit.

Center of Gravity and Weights

Center of gravity dimensions and corner

weights are approximate. Approximate

unit shipping weight is the sum of the four

corner weights. Reference unit weights in

the Dimensions and Weights section on

page 32. See Figure I-IP-1 for fresh air

unit center of gravity and for corner

weights.

above the ground to verify all rigging

G

H

D

E

F

J

unit without TE wheel option

Figure I-IP-1. Fresh air unit center of gravity and weight distribution

unit center of gravity max operational typical point loading — weight, lbs.

size X (in) Y (in) weight (lbs) A B C D E F G H I J

units without total energy wheel

031 90 50 4934 905 1692 1562 775

040 90 50 5194 953 1781 1644 816

051 100 51 6190 1392 1931 1703 1164

066 100 51 6722 1512 2097 1849 1264

units with total energy wheel

031 123 50 6394 1023 1023 1088 1151 1088 1023

040 123 50 6718 1075 1075 1075 1142 1142 1142

051 130 51 8081 1051 1212 1374 1616 1455 1455

066 130 51 8663 1126 1300 1473 1819 1559 1386

40 FAXA-SVX01B-EN

I

C

B

A

unit with TE wheel option

Page 41

installation

B

A

LIFTING POINT A MUST BE

ALIGNED DIRECTLY OVER UNIT

CENER OF BALANCE FOR A

LEVEL LIFT

7 FT. MINIMUM:

SHORTER LENGTHS

MAY RESULT IN LESS

LIFTING STABILITY

USE SPREADER BARS

EACH OF THE CABLES USED TO LIFT

THE UNIT MUST BE CAPABLE OF

SUPPORTING THE ENTIRE UNIT WEIGHT

LOCATION OF CENTER OF

BALANCE LABELS INDICATE

APPROX. CENTER OF BALANCE

LOCATION ALONG THE LENGTH

OF THE UNIT

USE CHAINS OR CABLES

DO NOT USE HOOKS IN

LIFTING HOLES

Rigging Procedure

1. Use spreader bars as shown in Figures

I-IP-2 and I-IP-3 to prevent upper cabinet

damage. If possible, use chains or

cables at lifting locations. Do not use

lifting hooks or chain hooks. Ensure

dimension A is not shorter than

recommended to prevent lifting

instability.

2. Cables used to lift the unit must be

capable of supporting the entire unit

weight.

3. Unit center of gravity (balance) is

located approximately at the position of

the center of balance labels along the

length of the unit. Also, you may

reference the center of gravity

locations in Figure I-IP-1 on page 40.

Leveling the Unit

The unit must be installed level to ensure

proper unit operation. The unit must be

level in both horizontal axis (max slope =

1

/4” per foot).

WARNING

Improper unit lift!

Failure to properly lift unit can cause

death, serious injury, or equipment/

property-only damage.

Installation

procedure

7 FT. MINIMUM:

SHORTER LENGTHS MAY

CAUSE LIFTING INSTABILITY

Figure I-IP-2. Proper fresh air unit rigging and handling for units without the total

energy wheel option

LIFTING POINT A MUST BE

ALIGNED DIRECTLY OVER

UNIT CENTER OF BALANCE

FOR A LEVEL LIFT

A

A

8 FT. MINIMUM:

SHORTER LENGTHS MAY CAUSE

8 FT. MINIMUM

LIFTING INSTABILITY

FAXA-SVX01B-EN 41

USE CHAINS OR CABLES. DO NOT

USE HOOKS IN LIFTING HOLES.

Figure I-IP-3. Proper fresh air unit rigging and handling for units with the total energy

wheel option

LABELS INDICATE APPROX.

CENTER OF BALANCE LOCATION

ALONG THE LENGTH OF THE UNIT

B

B

Page 42

installation

Exhaust Louver Installation

Install the exhaust louvers after installing

the unit in its final position, following the

procedure below.

1. Remove the temporary shipping panel

from the exhaust exit.

2. Locate the shipped-with gravity

damper in the main filter compartment.

A ship-with item label indicates the

door.

3. Install the gravity damper so the the

damper blades close in a downward

motion.

Installation

procedure

42 FAXA-SVX01B-EN

Page 43

installation

Installation

Zone Sensor Installation for

Temperature and Humidity

All remote sensor options ship in the

return-air filter section, and require fieldinstallation.

Mounting Location

Mount the sensor on the wall in an area

with good air circulation at an average

temperature. Avoid mounting space

temperature sensor is areas subject to

the following conditions:

• Drafts or “dead” spots behind doors or

in corners

• Hot or cold air from ducts

• Radiant heat from the sun or appliances

• Concealed pipes and chimneys

• Unheated or non-cooled surfaces

behind the sensor, such as outside walls

• Airflows from adjacent zones or other

units

To mount the sensors, remove the dust

cover and mount the base on a flat

surface or 2" x 4" junction box. Sensors

ship with mounting screws.

Mounting the Subbase

Remove the zone sensor cover from

subbase, and mount subbase on the wall

or on a 2 x 4 junction box. Route wires

through the wire access hole in the

subbase. See Figures I-IP-3 and I-IP-4 on

page 44. Seal the hole in the wall behind

the subbase.