Page 1

Installation

Owner

Diagnostics

Water-to-Water

Water-Source Heat Pump

Models WPWD, GSWD and EXWA

Models

WPWD

024-072 – 60 HZ

GSWD

024-072 – 60 HZ

“A” and later Design Sequence

EXWA

240 – 60 HZ

WSHP-SVX02A-EN

Page 2

Notice

Warnings and Cautions appear at appropriate sections throughout this manual.

Read these carefully.

NOTICE:

WARNING -Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION -Indicates a potentially hazardous situation which, if

not

avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

CAUTION -Indicates a situation that may result in equipment or

property-damage-only accidents.

Important!

Equipment is shipped FOB (Free on

Board) at the manufacturer. Therefore,

freight claims for damages against the

carrier must be initiated by the receiver.

NOTICE:

Unit contains HCFC (R-22) Refrigerant

Instructions!

Section 608, Paragraph C of the 1990 Clean Air Act states:

Effective July 1, 1992, it shall be unlawful for any person, in course of

maintaining, servicing, repairing, or disposing of an air conditioning system, to

knowingly vent or release any CFC or HCFC refrigerant. Minimal releases (air

purges or refrigerant hoses) associated with good faith attempts to recapture or

recycle are exempt from the ban on venting.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the

environment, our customers, and the air conditioning industry. All technicians

who handle refrigerants must be certified. The Federal Clean Air Act (Section 608)

sets forth the requirements for handling, reclaiming, recovering and recycling of

certain refrigerants and the equipment that is used in these service procedures.

In addition, some states or municipalities may have additional requirements that

must also be adhered to for responsible management of refrigerants. Know the

applicable laws and follow them.

© 2002 American Standard Inc. WSHP-SVX02A-EN

Page 3

Contents

Installation/Startup/Commissioning

Pre-installation Checklist

General Information

Dimensions/Weights

Installation Instructions

Electrical Requirements

Pre-Startup Checklist

Startup/Commissioning

Sequence of Operation

Operating Pressures

Startup Checklist & Log

Maintenance

4

4

5

6

10

19

20

21

21

22

30

24

25

Warranty Information

Troubleshooting Checklist

Unit Wiring

WSHP-SVX02A-EN 3

26

28

29

Page 4

Pre-installation

Checklist

WARNING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the insulation in this

product during installation, maintenance or repair will expose you to

airborne particles of glass wool fibers and ceramic fibers known to the

state of California to cause cancer through inhalation. Glass wool fibers

may also cause respiratory, skin or eye irritation.

Jobsite Inspection

Always perform the following checks before accepting a unit:

1. Verify that the nameplate data matches the data on the sales order and bill of

lading (including electrical data).

2. Verify that the power supply complies with the unit nameplate specifications.

3. Visually inspect the exterior of the unit, for signs of shipping damage. Do not

sign the bill of lading accepting the unit(s) until inspection has been completed. Check for damage promptly after the unit(s) are unloaded. Once the

bill of lading is signed at the jobsite, the unit(s) are now the property of the

SOLD TO party and future freight claims MAY NOT be accepted by the

freight company.

4. Verify that the refrigerant charge has been retained during shipment by use

of gauges. Schrader taps are located external to the cabinet on the 2-ton

through 6-ton equipment.

5. After assuring that charge has been retained, reinstall the schrader caps to

assure that refrigerant leakage does not occur.

WARNING

Microbial Growth!

Wet interior unit insulation can become an amplification site for

microbial growth (mold), which may cause odors and damage to the

equipment and building materials. If there is evidence of microbial

growth (mold) on the interior insulation, the insulation should be

removed and replaced prior to operating the system.

Jobsite Storage

This unit is intended for indoor use only. To protect the unit from damage due to

the elements, and to prevent possible IAQ contaminant sources from growing,

the unit should be stored indoors. If indoor storage is not possible, the following

provisions for outdoor storage must be met:

1. Place the unit(s) on a dry surface or raise above the ground to assure adequate air circulation beneath the unit.

2. Cover the unit(s) with a water proof tarp to protect them from the elements.

3. Make provisions for continuous venting of the covered units to prevent

moisture from standing on the unit(s) surfaces. Wet interior unit insulation

can become an amplification site for microbial growth (mold) which has

been determined to be a cause of odors and serious health related indoor air

quality problems.

4. Store units in the normal UP orientation to maintain oil in the compressor.

5. Do not stack more than three units in total height for the WPWD/GSWD 2-ton

through 6-ton configurations, and no more than two units high for the EXWA

20-ton configuration.

4 WSHP-SVX02A-EN

Page 5

General

Information

Unit Nameplate

The unit nameplate is located at the

front of the unit. It includes the unit

model number, serial number, electrical characteristics, refrigerant charge,

and other pertinent unit data.

Compressor Nameplate

The nameplate for the compressors

are located on the compressor shell.

Unit Description

Before shipment, each unit is leak tested, dehydrated, charged with refrigerant and run tested for proper control

operation.

Water-to-Refrigerant Coils

The brazed-plate water-to-refrigerant

heat exchangers for the 2-ton through

6-ton equipment are constructed of

stainless steel.

The water-to-refrigerant heat exchangers for the 20-ton equipment are

an inner copper tube or cupro-nickel

(option available on the source-side

only) and steel tube (tube-within-atube) design.

Both heat exchanger types are leak

tested to assure there is no cross leakage between the water and refrigerant

gas.

Water Connections

One inch brass swivel connections are

provided for the 2-ton through 6-ton

equipment. Each brass fitting has a

one inch gasket for the connector. The

gaskets are shipped in the electrical

compartment to prevent loss at the job

site.

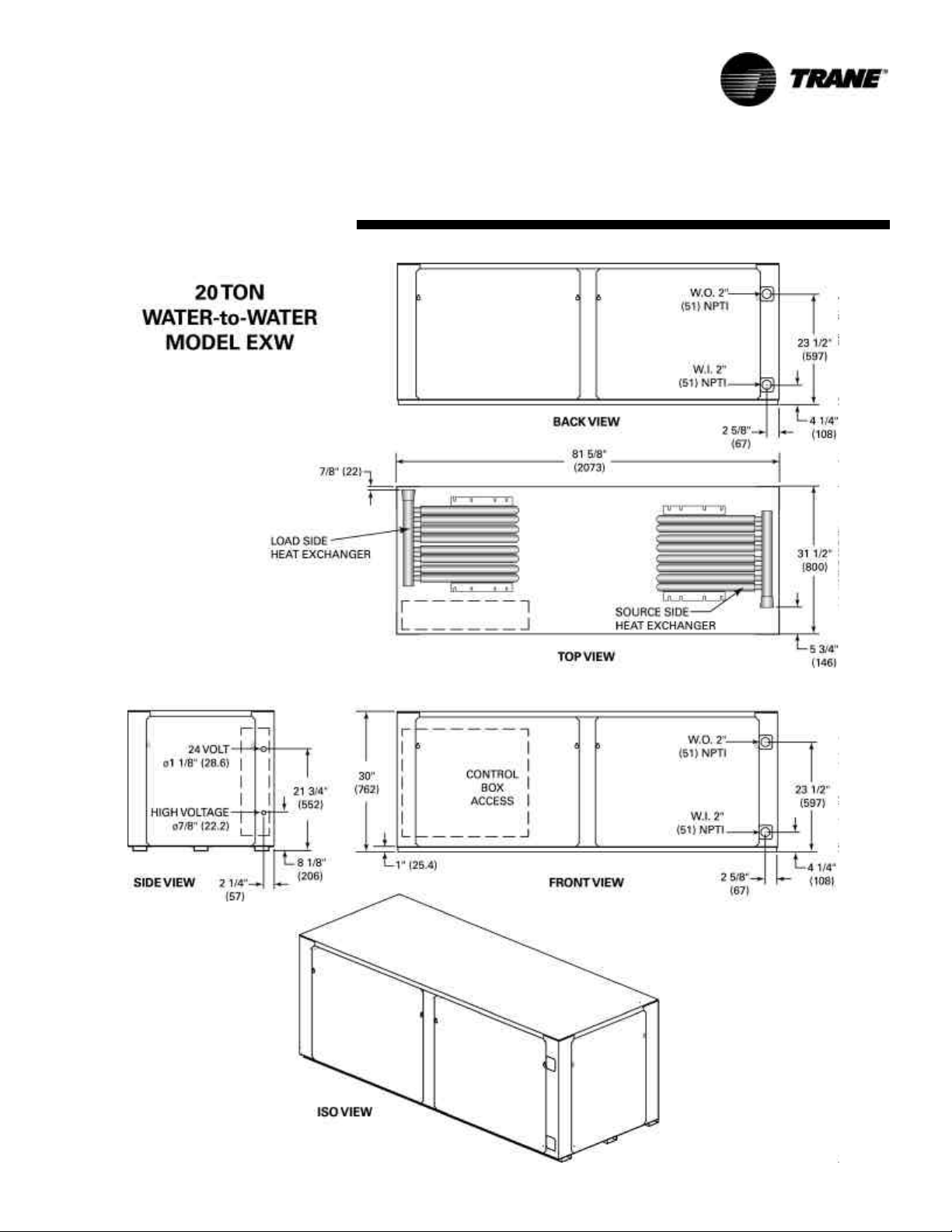

Water connections for the 20-ton are

located inside the unit at the units

front (source-side) and back (loadside). The fitting consist of a 2-inch female pipe threaded connection.

Controls

The control system offered to control

the unit is a Basic 24 volt control for

the 2-ton through 6-ton unit sizes, and

a deluxe 24 volt micro processing

board for the 20-ton unit.

All power wiring to the equipment is

made at the unit contactor for the 2-

ton through 6-ton equipment, and at

the power block for the 20-ton equipment.

All low voltage wiring is made at the

unit’s low voltage terminal board.

Wiring Connections

Troubleshooting and connection diagrams for the equipment may be located in the back of this manual.

Basic 24V Controls

(for 2-ton through 6-ton units)

Safety devices for equipment containing the basic 24V control option include a low pressure switch and a

freezestat to prevent compressor operation during low temperature activity. The switch is set to activate at

refrigerant pressures of 35 psig or 7

psig to fit most applications.

A high pressure switch prevents compressor operation during high or excessive discharge pressures

exceeding 395 psig.

The lockout relay communicates the

low or high pressure situation to the

compressor to prevent operation. The

relay may be reset at the thermostat,

or by cycling power to the unit.

General alarm may be accomplished

through the lockout relay to drive light

emitting diodes (LEDs) on a field supplied status indicating thermostat. Terminal 6 on the lockout relay is open for

field use in malfunction indications.

This feature will drive dry contacts

only, and cannot be used to drive field

installed control inputs.

Deluxe 24V Controls

(for 20-ton unit)

Units containing the Deluxe 24V control design will incorporate a microprocessor-based control board. The

Trane microprocessor board is factory

wired to a terminal strip to provide all

necessary terminals for field connection. The deluxe board is equipped

with a random start relay, anti-short

cycle timer, brown out protection,

compressor disable, unit safety control, diagnostics and a generic relay

(which may be available for field use).

See page 17 for diagnostic information.

Desuperheater

(Option for 2-ton through 6-ton units)

For units containing the desuperheater option, the unit is shipped from the

factory with a desuperheater water

coil and pump mounted internal to the

unit cabinetry. For domestic hot water

hook-up instructions, see manual

WSHPC-IN-4 or 72-9006-02.

The desuperheater pump fuse is located in the control box within a container. The fuse is not factory installed to

avoid possible pump damage at initial

start-up. If the fuse in installed and the

unit is started without water in the system, the pump will be damaged. See

page 17 for fuse installation.

Schrader Connections

Connections for the low and high side

of the refrigeration system are located

conveniently on the unit’s right side

for the 2-ton through 6-ton units, and

behind the front, refrigeration access

panel for the 20-ton unit.

WSHP-SVX02A-EN 5

Page 6

Table 1: Unit weights

Size

024 163 153

036 183 173

042 203 193

048 214 204

060 244 234

072 277 267

240 1222 1156

Shipping

Weight

with pallet (lb)

w/o pallet (lb)

Shipping

Weight

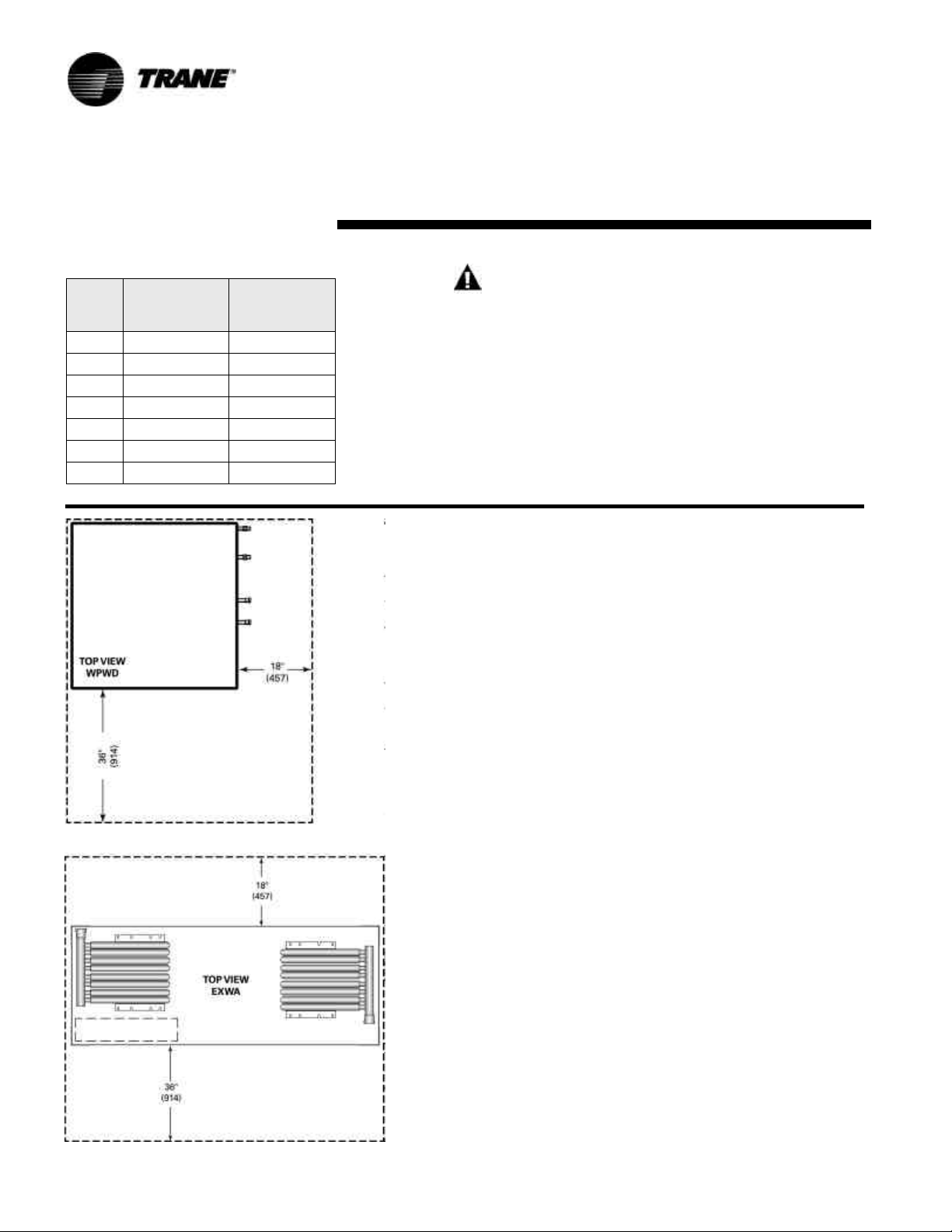

Dimensions/Weights/

Clearance

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in death or serious injury

or possible equipment or property-only damage.

Unit Location and Clearances

Locate the unit in an indoor area. The

ambient temperature surrounding the

unit must not be less than 45°F. Do

not locate the unit in areas subject to

freezing.

Attention should be given to service

clearance and technician safety. The

unit access panels may be easily removed. There must be enough space

for service personnel to perform maintenance or repair. Provide sufficient

room to make water, and electrical

connection(s). Local and national

codes should be followed in providing

electrical power connections. See Fig-

ure 1 for mechanical clearances.

Figure 1: Mechanical clearances

6 WSHP-SVX02A-EN

Page 7

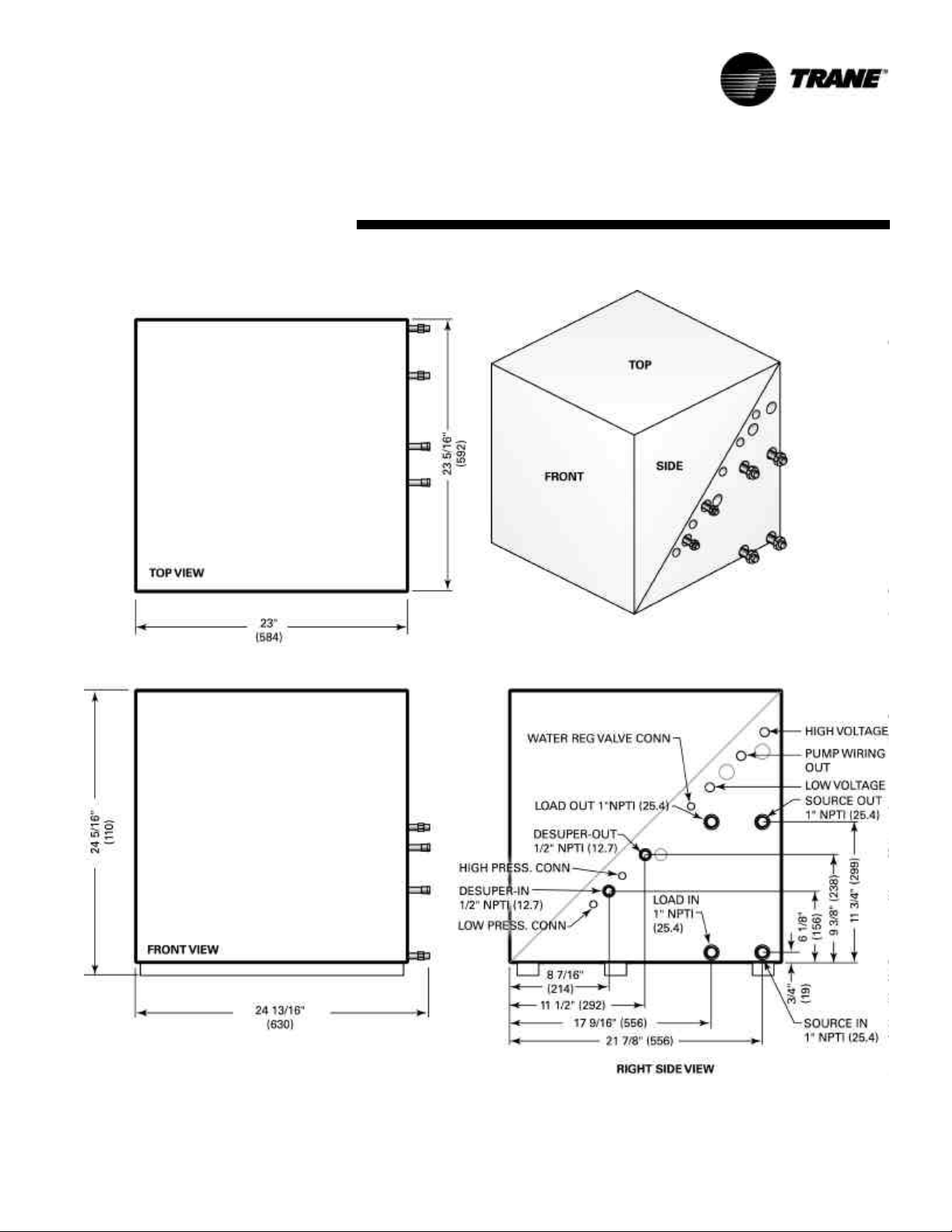

Dimensions

WPWD/GSWD 024-036

WSHP-SVX02A-EN 7

Page 8

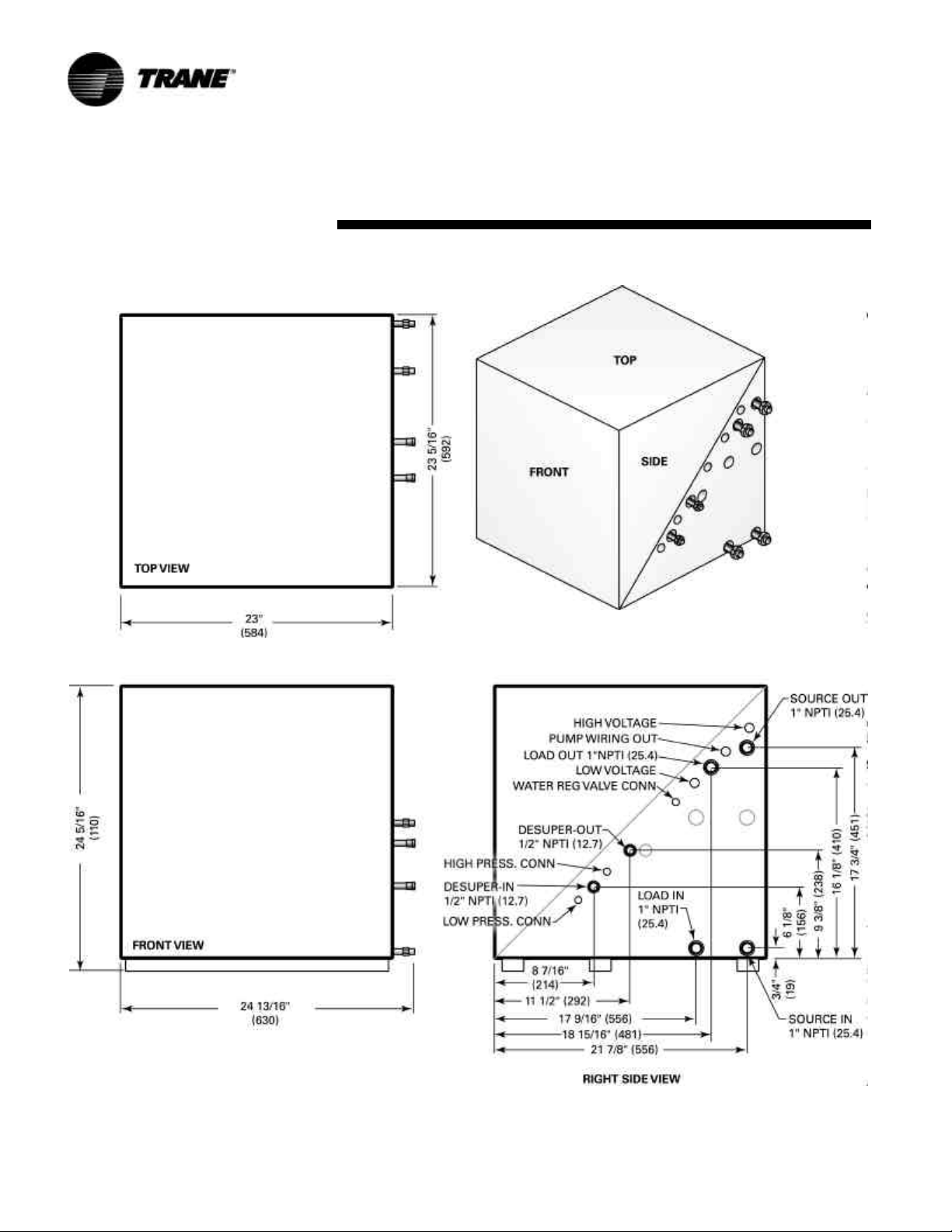

Dimensions

WPWD/GSWD 042-072

8 WSHP-SVX02A-EN

Page 9

Dimensions

EXWA 240

WSHP-SVX02A-EN 9

Page 10

Installation

General Installation Checks

The checklist below is a summary of

the steps required to successfully install a unit. This checklist is intended to

acquaint the installing personnel with

procedures required in the installation

process. It does not replace the detailed instructions called out in the applicable sections of this manual.

1 Remove packaging and inspect the

unit. Check the unit for shipping

damage and material shortage; file

a freight claim and notify appropriate sales representation.

Note: The units have been tied to

the skid by (4) angle brackets. Remove these brackets from the unit

to slide unit from skid.

2 Verify the correct model, options

and voltage from the unit nameplate.

3 Verify the installation location of

the unit will provide the required

clearance for proper operation.

4 Remove refrigeration access panel

and inspect the unit. Be certain the

refrigerant tubing has clearance

from adjacent parts.

WARNING

Hazardous

Voltage!

Disconnect all electric power,

including remote disconnects

before servicing. Follow proper

lockout/tagout procedures to

ensure the power can not be

inadvertently energized. Failure to

disconnect power before

servicing could result in death or

serious injury.

Main Electrical

5 Verify the power supply complies

with the unit nameplate specifications.

6 Inspect all control panel compo-

nents; tighten any loose connections.

7 Connect properly sized and pro-

tected power supply wiring to a

field-supplied/installed disconnect

switch and to the main power terminal block (1TB1) in the unit control box for the 20-ton equipment,

or (1K1) for the 2-ton through 6ton equipment.

8 Install proper grounding wires to

an earth ground.

Note: All field-installed wiring must

comply with NEC and applicable local

codes.

Low Voltage Wiring (AC & DC)

Requirements

9 Connect properly sized control wir-

ing to the proper termination

points between the field supplied

thermostat and the terminal strip

located in the equipment control

box.

10 WSHP-SVX02A-EN

Page 11

Installation

Figure 2: Racking installation

WARNING

Improper Unit Lift!

Test lift unit approximately 24

inches to verify proper center of

gravity lift point. To avoid

dropping of unit, reposition lifting

point if unit is not level. Failure to

properly lift unit could result in

death or serious injury or possible

equipment or property-only

damage.

Unit Placement

Units may be placed into a field supplied mechanical rack (See Figure 2),

or placed on a finished floor. Loosen

compressor bolts to release tension of

the rubber grommets to help reduce

vibration during operation. Sound

proofing material (field supplied) is

recommended to help attenuate noise

generated by compressor vibration.

It is important to leave appropriate

clearances around the unit to achieve

maintenance and

serviceability to

the equipment.

See page 6 for

service clearance

dimensions.

Water Connection

Connect the source-side and load-side

water-in/water-out from the water-towater heat pump to the source system

and the load system.

Note: The source for a water-to-water

heat pump is typically a boiler/cooling

tower or geothermal loop.

The load for a water-to-water heat

pump is typically fresh-air unit(s), fan

coil(s), hydronic coil(s), radiant heat,

wall fin, or potable water.

The source and load connections for

the 2-ton through 6-ton equipment is

on the right hand side of the unit.

The 20-ton equipment incorporates

the source-side connection at the

unit’s front, and the load-side connection at the unit’s back.

For vibration isolation, it is recommended that flexible steel braided

hoses be installed instead of hard piping the equipment to the main loop

system or mechanical device.

Trane offers 4-types of hose kit variations:

• Stainless steel braided flexible

hose with manual shut-off (ball)

valves

• Stainless steel braided flexible

hose with manual deluxe shut-off

(ball) valves

• Stainless steel braided flexible

hose with manual circuit-setter

valve

• Stainless steel braided flexible

hose with automatic balancing

valve

Additional accessories, such as a

strainer are recommended for use to

eliminate contaminants from entering

the brazed-plate or co-axial water-torefrigerant heat exchangers.

Figure 3: Water connection

WSHP-SVX02A-EN 11

Page 12

Installation

Cleaning and Flushing

the Water Loop

After the piping system is complete,

the flexible hose connectors should be

doubled back to complete the water

circuit external to the unit (avoiding

trash settle-out in the condenser). Fig-

ure 4. An extra pipe may be necessary

to connect the hose kits. See Page 14

for antifreeze/water mixture by volume.

(1) Water circulation system should be

filled with clean water using the water

make up connections. Note: Air vents

should be opened during filling.

(2) With the air vents closed, start the

circulating pump and then crack the air

vents to bleed off the trapped air, assuring circulation through all components of the system.

Note: Make up water must be available

to the system to replace the volume

formerly occupied by the air that is

Connecting a Loop Pump Kit

Closed Loop System

All piping external to the unit is the responsibility of the installer. The water

pipe installation must be done in accordance with local codes. If no local

code applies, national codes should be

followed. It is the contractor’s responsibility to know and adhere to all applicable codes.

Water inlet and outlet to the unit’s water-to-refrigerant heat exchanger are

clearly marked on the submittal drawings found on pages 7 through 9. The

supply and return piping must be installed correctly to the unit to ensure

the safety devices will work properly.

Units that are not piped accordingly

will not obtain the manufacturers warranty.

A pump module (Figure 5) and hose kit

(Figure 6) are typically used to connect

the unit to closed loop piping in domestic applications.

bled off.

(3) With the air vented and the water

circulating, the entire system

should be checked for leaks with repairs made as required.

(4) Operate the supplementary

heat system making checks per

manufacturer’s instructions. During this operation, visual checks

should be made for leaks that may

have occurred due to increased

heat. Repair as required.

(5) Open the system at the lowest

point for the initial blow down

(making sure the make up water is

equal to the water being dumped).

Continue blow down until the water

leaving the drain runs clear, but not

less than 2 hours.

(6) Shut down pumps and supplementary heat system. Reconnect the hoses

placing the water-to-refrigerant heat

exchanger in the water circulating system.

FROM UNIT’S

W.O.

TO UNIT’S

W.I.

BRONZE OR CAST IRON PUMP

PURGING CAP (2)

SHUT-OFF 3-WAY

VALVE (2)

Figure 5 Pump module

1" MPT x BARB FITTINGS,

1" MPT x BARB ELBOWS with

PRESSURE TEMPERATURE PORTS,

AND 10’ OF RUBBER HOSE with

4 HOSE CLAMPS.

Note: Vents should be open when the

pumps and supplementary heat sys-

tem are shut down.

Figure 4: Flushing water loop

Figure 6: Hose kit

12 WSHP-SVX02A-EN

Page 13

Installation

Figure 7: Loop pump kit installation

Supply/Return Pipe Connections

to the Loop Pump Kit

(1) Connect the supply and return hos-

es to the water-inlet (from supply) and

water-outlet (to return) of the unit. The

rubber gaskets for the water-in and

water-out connections are located in

the control box. These gaskets require

field installation prior to connecting

the water piping to the unit.

(2) Hand tighten the 1" FPT brass swivel quick connections to the 1" MPT

adapter with P/T ports. Using a

wrench, tighten the adapter approximately 1/2 additional turn. Care must

be taken to avoid overtightening as to

not dislodge the snap ring.

(3) The water lines should be routed

not to interfere with access to the unit.

The use of a short length of high pressure hose with the swivel fitting may

simplify the connections and prevent

vibration. Pressure/Temperature (P/T)

ports are required for troubleshooting

the hydronic side of the unit. Extreme

care should be taken by the installing

contractor to prevent dirt or other foreign matter from entering the pipes or

piping components during construction. Pipes should be capped until they

are in place and ready to be connected

to the system.

(4) Install the Trane loop pump module. See installation manual WSHPCIN-5 or 72-9006-03 for instructions. If

the unit does not contain a Trane loop

pump module, two ball valves must be

installed between the unit and the

loop’s water pump to isolate the unit

from the system’s water loop during

maintenance and emergency situations. See Figure 7.

If the unit s contain a Trane loop pump

module, shut-off valves are supplied

by the manufacturer within the pump

module assembly.

(5) Connect the unit’s water-in and water-out hose to the loop pump module.

(6) The pumps connect to the load side

230 volt compressor contactor, and require a field installed 6 amp in-line

fuse and holder.

(7) Insulate all indoor piping. Equipment is designed to operate with fluid

temperature of 25ºF to 120ºF

WSHP-SVX02A-EN 13

Page 14

Water Heater Hook-up (option)

Instructions for connection from the

desuperheater (option) water-in/out to

the domestic hot water heater may be

found in WSHPC-IN-4 or 72-9006-02.

This water heater kit (Figure 8) ships in

all units with the desuperheater option. The kit is zip tied to the compressor base; and consists of piping

connections and shut-off valve.

For units containing the desuperheater option, the desuperheater pump

fuse is located within a container inside of the control box. The fuse is not

factory installed.

Note: If the fuse is installed, and the

unit is started without water in the system, pump damage may occur.

Using Antifreeze

In areas of the country where entering

water temperatures drop below 45°F

or where piping is being run through

areas subject to freezing, the loop

must be freeze protected by using an

approved antifreeze solution to prevent the earth loop water from freezing inside the heat exchanger.

Methanol and glycols are the most

commonly used antifreeze solutions.

Consult your geothermal unit supplier

for locally approved solutions in your

area.

Propylene glycol is not recommended

in installations where the water temperature are expected to fall below

30°F. At extreme temperatures, the

viscosity increases to the point where

normal loop circulating pumps may

not maintain proper flow.

If propylene glycol is the only locally

approved solution for anti-freeze,

good engineering practices should be

used to achieve the desired flow.

Calculate the approximate volume of

water in the system by using the requirements detailed in Table 2. Add

three gallons to this total to allow for

the water contained in the hose kit and

geothermal unit.

Installation

Figure 8: Water heater kit

Table 2: Antifreeze requirements based on volume

Type of Antifreeze

Methanol 25% 21% 16% 10% 3%

Propylene Glycol - - - - 6%

Minimum Temperature for Freeze Protection

10°F 15°F 20°F 25°F 30°F

14 WSHP-SVX02A-EN

Page 15

Filling the Loop Pump Kit System

Once the loop, pump module and unit

are fully connected, the system will

need to be filled with water or water/

antifreeze solution. See Page 14 for antifreeze/water mixture by volume.

Fill both sides of the outside portion of

the loop first via the pump module.

The hose kit and unit should be filled

last after purging of the ground loop is

complete.

To fill the outside loop; (1) attach a

water hose to the 1-inch FPT brass

valve ports located on the front of the

pump module (the caps at the front of

the module should be removed). (2)

Rotate both valve 1 and valve 2 to the

"Position B" to prevent water from going to the unit. (3) Turn on the water

and allow the earth loop to slowly fill

with water. (4) Run the water until a

steady flow of water without air bubbles is observed coming out of the discharge hose.

To fill the hose kit and unit; (1) Re-

position valve 1 to the "Position A" to

fill the unit and hose kit. (2) Turn the

water on and allow the hose kit and

unit to be filled slowly with water. (3)

Run the water until a steady flow of

water without air bubbles is observed

coming out of the discharge hose.

System Pressurization

(1) Rotate both valves 1 and 2 to the

"Position D" to pressurize the system.

(2) Examine all internal unit fittings or

connections for leaks. (3) After checking for leaks, the system is ready to be

flushed.

Note: There may be a certain amount

of entrained air left in the loop system.

Cleaning and Flushing

the Water Loop

All installations must be thoroughly

flushed to remove air and dirt from the

earth loop before running the system.

The pumps used in the pump module

are not adequate to use for the flushing out of the unit. A secondary pump

capable of delivering 50 gpm at 60 feet

of head (a 1 1/2 hp or larger pump) is

Installation

Filling the Hose Kit and Unit and/or

Hose Kit and Unit Flush

Run System Full System Flush

normally suitable for jobs up to six

tons. The loop must be flushed with a

high volume of water at a minimum

velocity of (2 feet per second) in both

directions. See Table 3 for flow rates

required to flush earth loops.

Table 3: System flushing flow rates

Pipe

3/4" PE 3.02 3.8

1" PE 4.73 6.0

1 1/4" PE 7.55 9.5

1 1/2" PE 9.93 13.0

2" PE 15.36 21.0

Gallons per

100 Ft.

Minimum

Flush GPM

Filling the Outside Loop and/or

Outside Loop Flush

Note: The plastic 1-inch MPT valve

plugs must be replaced after filling

and/or flushing is completed.

See "Position C" for valve rotation to

place the valves in RUN position.

WSHP-SVX02A-EN 15

Page 16

Installation

Power Wiring

Field Installed Power Wiring

Power wiring to the equipment must

conform to National and Local Electric

Codes (NEC) by a professional electrician.

WARNING

Live Electrical

Components!

During installation, testing, servicing and troubleshooting of this

product, it may be necessary to

work with live electrical components. Have a qualified licensed

electrician or other individual

who has been properly trained in

handling live electrical components perform these tasks. Failure

to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

Verify that the power supply available

is compatible with the unit’s nameplate. Use only copper conductors to

connect the power supply to the unit.

CAUTION

Use Copper

Conductors Only!

Unit terminals are not designed

to accept other types of conductors. Failure to use copper conductors may result in equipment

damage.

The high voltage connection is made

at the 1TB1 terminal block for the 20ton equipment, and at 1K1 for the 2ton through 6-ton equipment. The terminal block or contactor is located inside the unit control box. Refer to the

customer connection diagram that is

shipped with the unit for specific termination points.

Provide proper grounding for the unit

in accordance with the local and national codes.

Control Power Transformer

The 24-volt control power transformers are to be used only with the accessories called out in this manual.

Transformers rated greater than 50 VA

are equipped with internal circuit

breakers. If a circuit breaker trips, turn

OFF all power to the unit before attempting to reset it.

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

The transformer is located in the

control box.

Main Unit Power Wiring

A field supplied disconnect switch

must be installed at or near the unit in

accordance with the National Electric

Code (NEC latest edition).

Location of the applicable electric service entrance for HIGH (line voltage)

may be found on the unit submittal at

the front of this manual (pages 7

through 9).

16 WSHP-SVX02A-EN

Page 17

Controls Using 24 VAC

Before installing any wire, refer to the

electrical access locations on the unit

submittals located on pages 7 through

9.

Ensure that the AC control wiring be-

tween the controls and the unit’s termination point does not exceed three

(3) ohms/conductor for the length of

the run.

Note: Resistance in excess of 3-ohms

per conductor may cause component

failure due to insufficient AC voltage

supply.

Check all loads and conductors for

grounds, shorts, and mis-wiring.

Use copper conductors unless otherwise specified.

Do not run the AC low voltage wiring

in the same conduit with the high voltage power wiring.

Table 4: 24V AC conductors

Distance

from unit to Control

000-460 feet 18 gauge

461-732 feet 16 gauge

733-1000 feet 14 gauge

Recommended

Wire Size

Installation

Low Voltage Wiring

Figure 9: Low voltage connection

Low voltage connection diagrams are

shown in Figure 9. Optional desuperheater fuse installation shown in Fig-

ure 10.

Figure 10: Desuperheater fuse installation

Table 5: Deluxe controller diagnostic LEDs

Color: Green Color: Red

LED1 LED2 LED3

OFF OFF OFF Control OFF

ON OFF OFF Normal/Compressor OFF

ON OFF FLASH Anti-short Cycle

ON OFF ON Normal/Compressor ON

FLASH ON OFF Brownout Condition

ON FLASH ON Soft Lockout (low pressure)

ON FLASH FLASH Soft Lockout (high pressure)

ON ON ON Manual Lockout (low pressure)

ON ON FLASH Manual Lockout (high pressure)

ON FLASH OFF Manual Lockout (condensate overflow)

ON ON OFF Compressor Disable

WSHP-SVX02A-EN 17

Controller Mode

Page 18

Installation

Changing Freezestat or Low Pressure Cutout Switches

(WPWD/GSWD models ONLY)

Each unit has two factory installed low

pressure cutout switches and one

freezestat. Only one of the low pressure cutout switches is connected to

the 24 volt control circuit, dependent

on which freezestat is being used (i.e.

35°F or 20°F). Both the freezestat and

the low pressure cutout are in the lockout relay circuit. The freezestat monitors the temperature of the water

leaving the source and load side water-to-refrigerant heat exchangers,

protecting the heat exchanger from

fluid freeze up. The low pressure cutout monitors the suction pressure of

the compressor to protect the compressor from liquid floodback or operating under loss of charge conditions.

Units can be ordered from the factory

with either the 35°F or 20°F freezestat

option. The 20°F freezestat is ONLY

used on closed loop systems with antifreeze solution. The 35°F freezestat is

used on all other systems. The type of

freezestat on a unit can be determined

from the appropriate digit in the model

number. Digit 11 and/or 12 with a selection of 1 is a 35°F freezestat, whereas selection 2 is a 20°F freezestat.

What Freezestat Should Be

Applied?

As previously mentioned, every unit is

shipped from the factory with two low

pressure cutouts installed in the refrigerant circuit. One of the low pressure

cutouts disables the compressor at 35

psig, while the other disables the compressor at 7 psig. The 35 psig cutout is

used with the 35°F freezestat, while

the 7 psig cutout is used with the 20°F

freezestat.

Occasionally it will be necessary to

change the freezestat in the field. Examples of when this change-out is

necessary include:

(1) A unit with a 35°F freezestat is going to be put on a closed loop system

with antifreeze. By definition, the unit

requires a 20°F freezestat.

(2) A unit with a 20°F freezestat is going to be put on an open well system

or a closed loop system with NO antifreeze solution. By definition, the unit

must have a 35°F freezestat installed

prior to operation.

The best time to install the freezestat/

low pressure cutout is prior to installing the unit. The freezestat is easily accessible from the top service door.

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

Changing a Freezestat and Low

Pressure Cutout

The freezestat is located in the top of

the source-side water-to-refrigerant

heat exchanger leaving water line. The

freezestat is located in the twelve

o’clock position. The capillary tube is

inserted into the well approximately 8inches. Remove the existing freezestat

and replace it with the new freezestat.

Note: The wires must be moved from

one low

pressure

cutout to

the other.

The low pressure cutouts are located in

the insu-

lated refrigerant

lines. The high

pressure cutout is located in the un-insulated

compressor discharge line and is the

only pressure cutout located

in this line. Change the wires from

the old low pressure cutout to the new

low pressure cutout.

Identifying the Low Pressure Cutouts

The 7 psig low pressure cutout is used

with a 20°F freezestat. It is installed in

the insulated line and is in the piping

tee going to the external schrader port.

The 35 psig low pressure cutout is

used with a 35°F freezestat. It is installed in the insulated line and is not

connected to any fittings.

The 395 psig high press cutout is installed in the un-insulated compressor

discharge line. It is the only cutout located in this line. Further, it is connected to an external schrader port.

If the low pressure cutout is not

changed when the freezestat is

changed, problems will occur. If the 35

psig low pressure cutout is connected

to a 20°F freezestat, the unit will go out

repeatedly on the low pressure cutout.

If the 7 psig low pressure cutout is

used with the 35°F freezestat, no problems will occur as long as the freezestat is operating normally. However,

if the freezestat does fail, the loop water could freeze before the suction

pressure dropped low enough for the

7 psig cutout to take the unit off the

line. Also, in a loss of charge situation,

the heat exchanger would freeze before the freezestat could take the unit

off-line.

Figure 11: Pressure switch location

18 WSHP-SVX02A-EN

Page 19

Electrical

Requirements

Table E-1: Electrical performance WPWD/EXWA

Model/MBH VOLTS-AC/HZ/PH Min.

Util.

Volt

WPWD024 208-230/60/1 197 253 11.4 56.0 1 14.3 25 0.4 14.7 25

220-240/50/1 198 264 9.6 47.0 1 12.0 20 0.4 12.4 20

265/60/1 239 292 9.6 47.0 1 12.0 20 0.4 12.4 20

WPWD036 208-230/60/1 197 253 15.0 73.0 1 18.8 30 0.4 19.2 30

208-230/60/3 197 253 10.7 63.0 1 13.4 20 0.4 13.8 20

220-240/50/1 198 264 14.3 71.0 1 17.9 30 0.4 18.3 30

265/60/1 239 292 14.3 71.0 1 17.9 30 0.4 18.3 30

380-415/50/3 342 456 5.0 31.0 1 6.3 15.0 0.4 6.7 15.0

460/60/3 414 506 5.0 31.0 1 6.3 15 0.4 6.7 15

WPWD042 208-230/60/1 197 253 18.4 95.0 1 23.0 40 0.4 23.4 40

208-230/60/3 197 253 11.4 77.0 1 14.3 25 0.4 14.7 25

220-240/50/1 198 264 16.4 83.0 1 20.5 35 0.4 20.9 35

265/60/1 239 292 16.4 83.0 1 20.5 35 0.4 20.9 35

380-415/50/3 342 456 5.7 39.0 1 7.1 15.0 0.4 7.5 15.0

460/60/3 414 506 5.7 39.0 1 7.1 15 0.4 7.5 15

WPWD048 208-230/60/1 197 253 20.4 109.0 1 25.5 45 0.4 25.9 45

208-230/60/3 197 253 13.9 88.0 1 17.4 30 0.4 17.8 30

380-415/50/3 342 456 7.1 44.0 1 8.9 15.0 0.4 9.3 15.0

460/60/3 414 506 7.1 44.0 1 8.9 15 0.4 9.3 15

WPWD060 208-230/60/1 197 253 28.0 169.0 1 35.0 60 0.4 35.4 60

208-230/60/3 197 253 20.0 123.0 1 25.0 45 0.4 25.4 45

380-415/50/3 342 456 7.5 49.5 1 9.4 15.0 0.4 9.8 15.0

460/60/3 414 506 7.5 49.5 1 9.4 15 0.4 9.8 15

575/60/3 517 633 6.4 40.0 1 8.0 15 0.4 8.4 15

WPWD072 208-230/60/1 197 253 32.1 169.0 1 40.1 70 0.4 40.5 70

208-230/60/3 197 253 19.3 137.0 1 24.1 40 0.4 24.5 40

380-415/50/3 342 456 10.0 62.0 1 12.5 20.0 0.4 12.9 20.0

460/60/3 414 506 10.0 62.0 1 12.5 20 0.4 12.9 20

575/60/3 517 633 7.8 50.0 1 9.8 15 0.4 10.2 15

EXWA180 380-415/50/3 342 456 16.7 133.0 2 37.58 50 -- -- -EXWA240 208/60/3 197 229 31.7 232.0 2 71.39 100 -- -- --

230/60/3 207 253 31.7 261.0 2 71.39 100 -- -- --

460/60/3 414 506 14.1 112.0 2 31.73 45 -- -- --

575/60/3 518 633 11.2 92.0 2 25.24 35 -- -- --

Table E-2: Electrical performance GSWD

Model/MBH VOLTS-AC/HZ/PH Min.

GSWD024 208-230/60/1 197 253 11.4 56.0 1 2.5 0.4 17.2 25

GSWD036 208-230/60/1 197 253 15.0 73.0 1 2.5 0.4 21.7 35

GSWD042 208-230/60/1 197 253 18.4 95.0 1 2.5 0.4 25.9 40

GSWD048 208-230/60/1 197 253 20.4 109.0 1 2.5 0.4 28.4 45

GSWD060 208-230/60/1 197 253 28.0 169.0 1 2.5 0.4 37.9 60

GSWD072 208-230/60/1 197 253 32.1 169.0 1 2.5 0.4 43.0 70

Util.

Volt

Max

Util.

Volt

Max

Util.

Volt

Compressor

Each

RLA

Compressor

Data

LRA No.

of

Comp

No.

of

Comp

Without Desup With Desup

MCA Max

Aux

Pump

Amps

Pump

RLA

Fuse

Desup

MCA Max

Desup

RLA

MCA Max

FuseRLA LRA

Fuse

WSHP-SVX02A-EN 19

Page 20

Pre-Start

Checklist

Pre-Start-up Checklist

Before energizing the unit, the following system devices must be checked:

____ Is the high voltage power supply correct and in accordance with the nameplate ratings?

____ Is the field wiring and circuit protection the correct size?

____ Is the low voltage control circuit wiring correct per the unit wiring diagram?

____ Is the piping system clean/complete and correct? (A recommendation of all system flushing of debris from the water-

to-refrigerant heat exchanger, along with air purging from the water-to-refrigerant heat exchanger be done in accordance with the Closed-Loop/Ground Source Heat Pump Systems Installation Guide).

____ Is vibration isolation provided? (i.e. unit isolation pad, hosekits)

____ Is unit serviceable? (See clearance specifications on page 6).

____ Are the low/high-side pressure temperature caps secure and in place?

____ Are all the unit access panels secure and in place?

____ Is the thermostat in the OFF position?

____ Is the water flow established and circulating through all the units?

____ Is the zone sensor correctly wired and in a good location?

____ Has all work been done in accordance with applicable local and national codes?

____ Has heat transfer fluid been added in the proper mix to prevent freezing in closed system application?

20 WSHP-SVX02A-EN

Page 21

Sequence

of Operation

Initial Unit Start-up

Start-up with the system controls is included below: Note: Air Handlers should not be operated in the construction phase of dry

walling. The air-to-refrigerant coil will foul, and the warranty will be void.

1.Set the system control to the desired mode of operation.

2.Set the control switch to fans and circulation pumps. The compressor should NOT run.

3.Reduce the temperature control setting until the compressor, reversing valve, solenoid valve, and loop pump are

energized. Adjust water flow utilizing pressure/temperature plugs and comparing to tables contained in specification

sheet data. Water leaving the heat exchanger should be warmer than the entering water temperature (approximately

9°F-12°F); compressor amps should be within data plate ratings; the suction line should be cool with no frost

observed in the refrigerant circuit.

4.Check the cooling refrigerant pressures against values in Table OP1. (Page 22).

5.Turn the system control switch to the OFF position. Unit should stop running and the reversing valve should de-ener-

gize.

6.Leave unit off for approximately FIVE minutes to allow for pressure equalization.

7.Turn the thermostat to the lowest setting.

8.Set the thermostat system switch to the opposite mode of operation.

9.Adjust the temperature setting upward until the unit is energized. A water temperature decrease of approximately 5°F-

9°F leaving the heat exchanger should be noted. The compressor operation should be smooth with no frost observed

in the refrigeration circuit.

10.Check the heating refrigerant pressures against values in Table OP1. (Page 22)

11.Set the system control to maintain the desired space temperature.

12.Instruct the owner on system operation.

WSHP-SVX02A-EN 21

Page 22

Operating Pressures

Operating Pressures

Table OP-1: Cooling mode operating pressures

Unit Size Entering

Load

(Degree F)

EXWA 240 53.6 46-56 103-143 49-59 188-228 49-59 238-278

EXWA 240 86 61-71 111-151 84-94 205-245 87-97 259-299

Table OP-2: Heating mode operating pressures

Unit Size Entering

Load

(Degree F)

EXWA 240 75 46-56 160-200 65-75 170-210 86-96 183-223

EXWA 240 104 49-59 245-285 68-78 254-294 94-107 268-308

EXWA 240 122 49-59 310-350 68-78 320-360 95-105 333-373

Suction

Pressure

Suction

Pressure

Entering Source Temperature (Degree F)

50 86 104

Discharge

Pressure

Entering Source Temperature (Degree F)

50 68 104

Discharge

Pressure

Suction

Pressure

Suction

Pressure

Discharge

Pressure

Discharge

Pressure

Suction

Pressure

Suction

Pressure

Discharge

Pressure

Discharge

Pressure

22 WSHP-SVX02A-EN

Page 23

Operating Pressures

Water Pressure Drop

Tables 6 and 7 should be used to define feet of head/pressure drop. Note: To calculate feet of head, when using gauges that read in PSIG,

multiply PSI by 2.31.

Table 6: Cooling water pressure drops (WPD) in feet of head

Unit Size

024

036

042

048

060

072

240

GPM

3.8

7.0 4.5 5.4

8.9 7.2 8.7

4.6

8.5 6.6 7.9

10.8 10.6 12.7

5.2

9.5 8.6 10.3

12.1 14.1 17.1

6.0

11.0 11.6 14.0

14.0 19.1 23.1

7.6

14.0 19.1 23.1

17.8 31.5 38.1

8.7

16.0 25.3 30.5

20.4 41.8 50.5

30.0

55.0 8.1 9.7

70.0 12.2 14.7

Source Load

EWTFFt. Head

Pressure

1.3

80

1.9

80

2.4

80

3.3

80

5.4

80

7.1

80

2.9

80

EWTFFt. Head

Pressure

1.6

53.6

2.3

53.6

3.0

53.6

4.0

53.6

6.5

53.6

8.6

53.6

3.6

53.6

Table 7: Heating water pressure drops (WPD) in feet of head

Unit Size

024

036

042

048

060

072

240

GPM

3.8

7.0 5.1 4.5

8.9 8.3 7.2

4.6

8.5 7.6 6.6

10.8 12.2 10.6

5.2

9.5 9.8 8.6

12.1 16.2 14.1

6.0

11.0 13.3 11.6

14.0 21.9 19.1

7.6

14.0 21.9 19.1

17.8 36.1 31.5

8.7

16.0 28.9 25.3

20.4 47.9 41.8

30.0

55.0 9.2 8.1

70.0 13.9 12.2

Source Load

EWTFFt. Head

Pressure

1.5

60

2.2

60

2.8

60

3.8

60

6.2

60

8.2

60

3.4

60

EWTFFt. Head

Pressure

1.3

80

1.9

80

2.4

80

3.3

80

5.4

80

7.1

80

2.9

80

Water Volume

Table 8 is provided for use in calculating glycol requirements for the unit.

Table 8: Water volume

Unit Size

024 55 0.032 0.238

036 105 0.061 0.455

042 105 0.061 0.455

048 259 0.150 1.121

060 259 0.150 1.121

072 259 0.150 1.121

240 1057 0.615 4.576

Water Side

Volume

Cubic In.

Water Side

Volume

Cubic Ft.

Water Side

Volume

Gallons

Note: The EXWA 240 has two circuits.

Flow Checks

For the operating temperature drop (heating) and rise (cooling), refer to Table OP1 and OP2 for the proper water temperature change. Depending on the unit size, entering water temperature and water flow rate, the cooling temperature rise is

from 8°F-16°F. Based on the same criteria for heating, the temperature drop is from 2°F-13°F.

Pressure

Using the P/T ports and one 0-60 psi pressure gauge with the P/T port adapter, measure the pressure difference between

the water-in and water-out connections. Compare the pressure differential to Table 6 to determine flow.

Start-up Checklist and Log

Use the form on page 24 to log system and unit temperatures during start-up.

WSHP-SVX02A-EN 23

Page 24

Start-up Checklist

and Log

Installing Contractor: Use this form to thoroughly check-out the system and units before and during

start-up. (This form need not be returned to the factory unless requested during technical service support).

Job Name:

Model Number:

Date:

Serial Number:

In order to minimize troubleshooting and costly system failures, complete the following checks and data

entries before the system is put into full operation.

MODE

Entering fluid temperature

Leaving fluid temperature

Temperature differential

Water coil heat exchanger

(Water Pressure IN)

Water coil heat exchanger

(Water Pressure OUT)

Pressure Differential

COMPRESSOR

HEAT

Source Source

F

F F

F F

PSIG PSIG

PSIG PSIG

PSIG PSIG

Load Load

F F

F F

F F

PSIG PSIG

PSIG PSIG

PSIG PSIG

COOL

F

Amps

Volts

Discharge line temperature

F F

F F

(after 10 minutes)

24 WSHP-SVX02A-EN

Page 25

Maintenance

Preventive Maintenance

Maintenance on the unit is simplified

with the following preventive suggestions:

WARNING

Hazardous

Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

Check the contactors and relays within

the control panel at least once a year.

It is good practice to check the tightness of the various wiring connections

within the control panel.

A strainer (60 mesh or greater) must

be used on an open loop system to

keep debris from entering the unit heat

exchanger and to ensure a clean system.

For units on well water, it is important

to check the cleanliness of the waterto-refrigerant heat exchanger. Should

it become contaminated with dirt and

scaling as a result of bad water, the

heat exchanger will have to be back

flushed and cleaned with a chemical

that will remove the scale. This service

should be performed by an experienced service person.

WARNING

Hazardous

Chemicals!

Coil cleaning agents can be either

acidic or highly alkaline. Handle

chemical carefully. Proper handling should include goggles or

face shield, chemical resistant

gloves, boots, apron or suit as required. For personal safety, refer

to the cleaning agent manufacturers Materials Safety Data Sheet

and follow all recommended safe

handling practices. Failure to follow all safety instructions could

result in death or serious injury.

It should be noted that the water quality should be checked periodically. See

Table 9.

Table 9: Water Quality Table

Scaling

Calcium and magnesium

(total hardness)

Corrosion

pH 7-9.5

Hydrogen Sulfide Less than 1 ppm

Sulfates Less than 25 ppm

Chlorides Less than 125 ppm

Carbon Dioxide Less than 75 ppm

Total dissolved solids

(TDS)

Biological Growth

Iron Bacteria Low

Erosion

Suspended Solids

Less than 350 ppm

Less than 1000 ppm

Low

WSHP-SVX02A-EN 25

Page 26

Warranty

Information

Warranty Information

Standard Warranty

The standard water-source heat pump warranty is Trane’s parts-only warranty, running 12-months from startup, not to exceed 18-months from shipment.

Extended Warranty

The optional extended warranty is a second through fifth year warranty. The time starts at the end of standard

1-year coverage through the fifth year.

These extended warranties apply only to new equipment installed in domestic Trane Commercial Systems

Group sales territories and must be ordered prior to start-up.

26 WSHP-SVX02A-EN

Page 27

Troubleshooting

WARNING

Hazardous Service

Procedures!

The maintenance and trouble

shooting procedures recommended in this section of the manual

could result in exposure to electrical, mechanical or other potential

safety hazards. Always refer to

the safety warnings provided

throughout this manual concerning these procedures. When possible, disconnect all electrical

power including remote disconnects before servicing. Follow

proper lockout/tagout procedures

to ensure the power can not be inadvertently energized. When necessary to work with live electrical

components, have a qualified licensed electrician or other individual who has been trained in

handling live electrical components per these tasks. Failure to

follow all of the recommended

safety warnings provided, could

result in death or serious injury.

Preliminary Trouble Inspection

If operational difficulties are encountered, be sure to perform the preliminary checks before referring to the

troubleshooting chart on page 28.

• Verify that the unit is receiving electric supply power.

• Ensure that the fuses in the fused

disconnect are intact.

After completing the preliminary

checks, inspect the unit for other obvious problems such as leaking connection, broken or disconnected wires,

etc. If everything appears to be in order, but the unit still fails to operate

properly, refer to the troubleshooting

chart on page 28.

General Operation

The standard model is designed for indoor installation. When the unit is installed in an unconditioned space, the

unit may not start in cool weather (approximately 45°F). It may then be necessary to start the unit in the cooling

mode for three to five minutes. The

unit may then be shut-off (there will be

a two minute time-out of the unit), and

restarted in the heating mode. The

freeze protection thermostat should

also be checked as it may be adversely

affected by ambient temperature.

Like any other type of mechanical

equipment, the unit performs best

when it is well maintained.

Operation with a Conventional

Thermostat

The unit is equipped with safety controls, including high pressure control,

low pressure control and a freeze protection thermostat, set to shut off the

compressor under abnormal temperature or pressure conditions. If the safeties shut off the compressor, a lockout

relay prevents short cycling from the

abnormal condition. When conditions

are corrected, the lockout control can

be reset by setting the thermostat system switch to OFF wait a few minutes

for the system pressure to equalize,

and then return to HEAT or COOL. If

the condition continues, an authorized

service person should check out the

unit.

WSHP-SVX02A-EN 27

Page 28

Troubleshooting

Checklist

Problem Heating Cooling Cause Correction

X X Main power off Check fuses

No response to any

thermostat setting

Unit short cycles X X Thermostat or sensor improperly located Relocate

Insufficient capacity

High pressure switch open

High head pressure

Low suction pressure

Low Pressure switch open

Freezestat open

X X Defective control transformer Replace

X X Broken or loose connection Repair

X X Defective thermostat Replace

X X Transformer Reset Transformer

X X Low on refrigerant charge

X X Restricted thermal expansion valve Replace

X X Defective reversing valve See WSHP-IOM-# for touch test chart

X X Thermostat improperly located Relocate

X X Unit undersized Recalculate heat gains/losses

X X Inadequate water flow Increase GPM

X X Scaling in heat exchanger Clean or replace

X Water too hot Decrease temperature

X Water too cold Increase temperature

X Inadequate GPM Increase water flow to unit

X Water too hot Decrease temperature

X X Overcharged with refrigerant Decrease charge

X X Defective pressure switch Check or replace

X Trash in heat exchanger Backflush

X Low water flow Increase GPM

X X Overcharge of refrigerant Decrease charge

X X Non-condensable in system Evacuate and recharge by weight

X X Water too hot Decrease temperature

X X Undercharged Locate leak, repair and recharge

X X Restricted thermal expansion valve Repair / replace

X Inadequate GPM Increase GPM

X Inadequate GPM Increase GPM

X Water too cold Increase temperature

X X Undercharged with refrigerant Increase charge

X X Defective pressure switch Replace

X X Heat transfer fluid too cold

X Inadequate GPM Increase GPM

X Water too cold Increase GPM

X X Defective freezestat Replace freezestat

X Heat transfer fluid too cold

Locate leak, repair and recharge by

weight (not by superheat)

Raise water temperature. For smaller

tonnage units, switch pressure switch

wires from 35 psig to 7 psig

Replace freezestat. For smaller tonnage

units, switch pressure wires from 35 psig

to 7 psig.

28 WSHP-SVX02A-EN

Page 29

Unit Wiring

2-ton through 6-Ton Equipment

WSHP-SVX02A-EN 29

Page 30

Unit Wiring

20-Ton Equipment

30 WSHP-SVX02A-EN

Page 31

Trane

An American Standard Company

www.trane.com

Literature Order Number WSHP-SVX02A-EN

File Number SV-UN-WSHP-SVX02A-8-02

Supersedes WSHPC-IOM-4 and 72-9036-02

Stocking Location Inland

For more information, contact

your local district office or e-mail us at

comfort@trane.com

Since Trane has a policy of continuous product and data improvement and reserves the right to change

design and specifications without notice.

Loading...

Loading...