Trane GEHE 072-180, EXHF 006-070, GEHE 006-060, GEVE 072-300, EXVF 006-070 Installation, Operation And Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Water Source Heat Pump

Axiom™ Horizontal/Vertical

GEH/V*, EXH/V*

.5 to 25Tons, 50/60 Hz

Model Numbers

Only qualified personnel should install and service the equipment.The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury.When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

December 2016

GEHE 006-060 - 50/60 Hz GEVE 006-060 - 50/60 Hz

GEHE 072-180 - 50/60 Hz GEVE 072-300 - 50/60 Hz

EXHF 006-070 - 60 Hz EXVF 006-070 - 60 Hz

SAFETY WARNING

WSHP-SVX01Q-EN

Page 2

Introduction

Read this manual thoroughlybefore operating or servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required.Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards.To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situationthat could resultin

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2016 Ingersoll Rand All rights reserved WSHP-SVX01Q-EN

Page 3

Copyright

This document andthe information in it arethe property of

Trane, and may not be used or reproduced in whole or in

part without written permission.Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

• Updated GEH* models in Table 53, p. 88.

• Minor running changes.

Introduction

WSHP-SVX01Q-EN 3

Page 4

Table of Contents

Copyright ............................. 3

Model Number Description - .5 to 25 Tons .5

Model Number Description - .5 to 6 Tons .. 6

Overview of Manual ..................... 7

Unit Nameplate ..................... 7

Compressor Nameplate ............... 7

Model Number Description ............ 7

General Information ..................... 8

Pre-Installation ......................... 12

Unit Inspection Checklist ............. 12

Jobsite Inspection Checklist .......... 12

Jobsite Storage .................... 12

Unit Dimensions ........................ 13

Service Clearances .................... 13

Weights ................................ 53

Weight Distribution for Hanging the GEH and

EXH Model ........................ 53

Installation ............................. 54

General Installation Checks ........... 54

Main Electrical ..................... 54

Supply-Air Ductwork ................ 55

Return-Air Ductwork ................. 55

Ducted Panel ....................... 55

Ducted Filter Rack (GEH .5 to 5 ton and EXH .5

to 6 ton only) ....................... 56

Dual Filtration (GEH .5 to 5 ton and EXH .5 to

6 ton) ............................. 56

Sound Attenuation Pad .............. 57

Hanging the Horizontal Unit .......... 57

Condensate Drain Connection ......... 57

Supply/Return Pipe Connections ...... 58

Cleaning and Flushing the Water Loop . 58

Field Installed Power Wiring .......... 58

Main Unit Power Wiring ............. 58

Control Power Transformer ........... 59

Thermostat Location ................ 59

Controls Using 24 VAC .............. 59

Blower Motor Speed-Tap Retrofit ...... 60

Hole Plug Installation ................ 61

Air Flow Adjustment .................61

Waterside Economizer Installation ......62

Waterside Economizer Installation for GEH

and GEV 6 to 25 Ton Models ...........65

Waterside Economizer Start-Up Sequence .67

Electrical Data ...........................69

Pre-Start Checklist .......................86

Start-Up ................................87

Initial Unit Start-up ....................87

Start-Up Checklist and Log ............87

Operating Pressures .................87

Water Pressure Drop ................108

Water Volume ......................110

Maintenance ...........................111

Preventive Maintenance .............111

Condensate Trap ...................112

Troubleshooting ........................113

Wiring Diagrams .......................115

Warranty Information ...................127

Standard Warranty ..................127

Extended Warranty .................127

4 WSHP-SVX01Q-EN

Page 5

Model Number Description - .5 to 25Tons

Digits 1-3 - Unit Configuration

GEH = Standard Efficiency Horizontal

GEV = Standard Efficiency Vertical

.5 to 15Tons

.5 to 25Tons

Digit4-Development Sequence

E = R-410A

Digits 5-7 - Nominal Capacity

006 = .5 Tons

009 = .75 Tons

012 = 1Tons

015 = 1.25 Tons

018 = 1.5 Tons

024 = 2Tons

030 = 2.5Tons

035 = 3Tons (Horizontal only)

036 = 3Tons (Vertical only)

042 = 3.5Tons

048 = 4Tons

060 = 5Tons

072 = 6Tons

090 = 7.5 Tons

120 = 10Tons

150 = 12.5Tons

180 = 15Tons

240 = 20Tons

300 = 25 Tons

Digit 8 - Voltage (Volts/Hz/Phase)

0 = 115/60/1

1 = 208/60/1

2 = 230/60/1

3 = 208/60/3

4 = 460/60/3

5 = 575/60/3

7 = 265/60/1

8 = 230/60/3

1

Digit 9 - Heat Exchanger

1 = Copper-Water Coil

2 = Cupro-Nickel Water Coil

7 = Insulated Copper-Water Coil

8 = Insulated Cupro-Nickel Water Coil

Digit 10 - Current Design

Sequence

Digit 11 - Refrigeration Circuit

0 = Heating and Cooling Circuit

2 = Heating and Cooling Circuit with

Hot Gas Reheat

3 = Heating and Cooling Circuit with

Waterside Economizer

4 = Heating and Cooling Circuit with HGR

and WSE

2

Digit 12 - Blower Configuration

1 = Standard Blower Motor

2 = High Static Blower Motor

A = Drive Package A

B = Drive Package B

C = Drive Package C

D = Drive Package D

E = Drive Package E

F = Drive Package F

G = Drive Package G

H = Drive Package H

J = Drive Package J

1*= 2 Speed Drive Package A

2*= 2 Speed Drive Package B

3 = 2 Speed Drive Package C

4= 2 Speed Drive Package D

5= 2 Speed Drive Package E

6= 2 Speed Drive Package F

7= 2 Speed Drive Package G

8= 2 Speed Drive Package H

9= 2 Speed Drive Package J

3

3

Digit 13 - Freeze Protection

A= 20°F Freezestat

B= 35°F Freezestat

4

Digit 14 - Open Digit = 0

Digit 15 - Supply-Air

Arrangement

B = Back Supply-Air Arrangement

F = Front Supply-Air Arrangement

L = Left Supply-Air Arrangement

R = Right Supply-Air Arrangement

T = Top Supply-Air Arrangement

Digit 16 - Return-Air

Arrangement

B = Back Return-Air Arrangement

F = Front Return-Air Arrangement

L = Left Return-Air Arrangement

R = Right Return-Air Arrangement

2

2

Digit 17 - Control Types

0 = Basic 24V Controls

D = Deluxe 24V Controls

B =Tracer® ZN524 Controls

F = UC400

G = UC400 w/Wireless Comm

5

Digit 18 - Tstat/Sensor Location

0 = Wall Mounted Location

Digit 19 - Fault Sensors

1 = Condensate Overflow Sensor

3 = Condensate Overflow and Filter

MaintenanceTimer

6 = Condensate Overflow and Fan Status

J = Fan Status, Filter MaintenanceTimer

and Condensate Overflow Sensor

Digit 20 - Temperature Sensor

0 = NoTemperature Sensor

1 = Entering Water Sensor

Digit 21 - Open

Digit 22 - Electric Heat

0 = No Electric Heat

1 = Internal Boilerless Electric Heat

4 = External Boilerless Electric Heat

5 = External Supplemental Electric Heat

3

Digit 23 - Open

Digit 24 - Filter Type

1 = 1"Throwaway Filter

2 = 2"Throwaway Filter

4=2”MERV8

5=2”MERV13

Digit 25 - Acoustic Arrangement

0 = Enhanced Sound Attenuation

1 = Deluxe Sound Attenuation

6

Digits 26-36 - Does Not Apply to

GEH or GEV

000 00000000 = Digits 26-36 are not

applicable to the GEH or GEV products

2

1

.5 to 1Ton only

2

6 to 25 Tons only

WSHP-SVX01Q-EN 5

3

.5 to 5 Tons only

4

Extended Range Geothermal

5

.5 to 5 Tons only

6

.5 to 5 Tons (horizontal only)

Page 6

Model Number Description - .5 to 6Tons

Digits 1-3 — Unit Configuration

EXH =High Efficiency Horizontal

EXV =High Efficiency Vertical

Digit 4 — Development Sequence

F

Digits 5-7 — Nominal Capacity

006 =.5 Tons

009 =.75 Tons

012 =1Tons

015 =1.25 Tons

018 =1.5 Tons

024 =2Tons

030 =2.5Tons

036 =3Tons

042 =3.5Tons

048 =4Tons

060 =5Tons

070 =6Tons

Digit 8 — Voltage (Volts/Hz/

Phase)

1 = 208/60/1

2 = 230/60/1

3 = 208/60/3

4 = 460/60/3

7 = 265/60/1

8 = 230/60/3

Digit 9 — Heat Exchanger

1 = Copper-Water Coil

2 = Cupro-Nickel Water Coil

7 = Insulated Copper Water

Coil/Suction Line

8 = Insulated Cupro-Nickel Water

Coil/Suction Line

Digit 10 — Current Design

Sequence

Digit 11 — Refrigeration Circuit

0 = Heating and Cooling Circuit

2 = Heating and Cooling Circuit with

Hot Gas Reheat

3 = Heating and Cooling Circuit with

Waterside Economizer

Digit 12 — Blower Configuration

3 = ECM Motor

Digit 13 - Freeze Protection

A = 20°F Freezestat

B = 35°F Freezestat

Digit 14 — Open Digit = 0

Digit 15 — Supply-Air

Arrangement

B = Back Supply-Air Arrangement

L = Left Supply-Air Arrangement

R = Right Supply-Air Arrangement

T =Top Supply-Air Arrangement

Digit 16 — Return-Air

Arrangement

L = Left Return-Air Arrangement

R = Right Return-Air Arrangement

Digit 17 — Control Types

D = Deluxe 24V Controls

B = Tracer® ZN524 Controls

F = UC400

G = UC400 w/ Wireless Comm

Digit 18 — Tstat/Sensor Location

0 = Wall Mounted Location

Digit 19 — Fault Sensors

1 = Condensate Overflow Sensor

3 = Condensate Overflow and Filter

MaintenanceTimer

6 = Condensate Overflow and Fan Status

J = Fan Status, Filter MaintenanceTimer

and Condensate Overflow Sensor

Digit 20 — Temperature Sensor

0 = No AdditionalTemperature Sensor

1 = Entering Water Sensor

Digit 21 — Open Digit

Digit 22 — Electric Heat

0 = No Electric Heat

1 = Internal Boilerless Electric Heat

4 = External Boilerless Electric Heat

Digit 23 — Open Digit

Digit 24 — Filter Type

1 = 1"Throwaway Filter

2 = 2"Throwaway Filter

4= MERV8

5 = MERV13

Digit 25 — Acoustic

Arrangement

0 = Enhanced Sound Attenuation

1 = Deluxe Sound Attenuation

Digits 26-36 — Does not Apply

to EXH or EXV

00000000000 Digits 26-36 are not

applicable to the EXH or EXV products

6 WSHP-SVX01Q-EN

Page 7

Overview of Manual

Note: One copy of this document ships with each unit and

is customer property. It must be retained by the

unit’s maintenance personnel.

This booklet describes proper installation, operation, and

maintenance procedures for HVAC systems. By carefully

reviewing the information within this manual and

following the instructions, the risk of improper operation

and/or component damage will be minimized.

Service and maintenance work should be performed by a

qualified technician and all electrical service and

maintenance work should be performed by a qualified

licensed electrician.

Unit Nameplate

The unit nameplate is located on the outside of the control

box access panel at thefront of the unit. Itincludes the unit

model number, serial number, electrical characteristics,

refrigerant charge, and other pertinent unit data.

Compressor Nameplate

The nameplate for the compressors are located on the

compressor shell.

Model Number Description

All products are identified by a multiple-character model

number that preciselyidentifies a particular type ofunit. Its

use will enable the owner/operator, installing contractors,

and service engineers to define the operation, specific

components, and other options for any specific unit.

When ordering replacement parts or requesting service,

be sure to refer to the specific model number and serial

number printed on the unit nameplate.

WSHP-SVX01Q-EN 7

Page 8

General Information

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and run tested for proper control

operation.

Air-to-Refrigerant Coil

The air-to-refrigerant coil is aluminum fin, mechanically

bonded to the copper tubing.

Water-to-Refrigerant Coil

The water-to-refrigerant coil is a copper or cupro-nickel

(option) and steel tube (tube-within-a-tube) design, leak

tested to assure there is no cross leakage between the

water tube (copper/cupro-nickel) and refrigerant gas (steel

tube).

Table 1. High/Low pressure switch

Trip Recover Unit

LP 40 +/-4 56 +/-4 psig

HP 650 +/-10 550 +/-10 psig

Controls

Basic 24V control is available for the GEH/V .5 -5 ton

models and the Deluxe 24V control option is available for

all unit sizes.Tracer® ZN524, LonTalk® certified control

option is available for all unitsizes. UC400 and UC400 with

wireless comm BACnet® is available in all unit sizes.

All power wiring to the equipment is made at the unit

contactor for .5to 5 ton, 1-phase units. For 3-phaseunits all

power wiring to the equipmentis made tothe contactor or

power block. For EXH/V070 units all power wiring to the

equipment is made to the power block. For the GEH/V 6 to

25 tons units all power wiring is made to the high voltage

terminal block. All low-voltage wiring is made at the unit’s

low voltage terminal board. EXH and EXV 460V units

require a neutral wire.

System Input Devices and Functions

A thermostat, zone sensor, or building automation system

is required to operate the water-source heat pump.The

flexibility of having several mode capabilities depends

upon the type of sensor and/or remote panel selected.

Troubleshooting and connection diagrams for the 24V

control systems may be locatedin the back of this manual.

All digital control troubleshooting tips and connection

diagrams are located in CNT-SVX11*-EN (ZN524). All

digital control troubleshooting tips and connection

diagrams are located in BAS-SVX065*-EN (UC400).

Basic 24V Controls

Safety devices for equipment containing the basic 24V

control option include a low-pressure switch to prevent

compressor operation during low temperature or low

suction activity.The switch is set to activate at refrigerant

pressure of 40 psig to fit most applications.

A high pressure switch prevents compressor operation

during high or excessive discharge pressures exceeding

650 psig.

The lockout relay will disable the compressor on a high or

low pressure condition. For units that contain a

condensate overflow switch option, a condensate

overflow condition will also disable the compressor

through the lockout relay.The relay may be reset at the

thermostat, or by cycling power to the unit.

General alarm is accomplished through the lockout relay.

This feature will drive dry contacts only, and cannot be

used to drive field installed control inputs.Trane provides

a 3.5-minute time delay for compressor control.

Deluxe 24V Controls (option)

Units containing the Deluxe 24V control design will

incorporate a microprocessor-based control board.The

Trane® microprocessor board is factory wired to a

terminal strip to provide all necessary terminals for field

connection.The deluxe board is equipped with a random

start relay, anti-short cycle timer, brown out protection,

compressor disable, condensate overflow, unit safety

control, diagnostics, and a generic relay (which may be

available for field use). See Table 64, p. 113 for diagnostic

information and Figure 59, p. 62 and Figure 60, p. 63 for

thermostat connections.

Tracer® UC400 (option)

TheTracer® UC400 is a BTL Listed BACnet® controller that

can operate stand- alone or within aBuilding Automations

system such asTracer® SC. For installation, operation and

Programming, see BAS-SVX065*-EN (UC400).

Tracer® ZN524 Controls (option)

The digital ZN524 controller is designed to support the .5

to 25 ton water-source heat pumps in either a standalone,

or as a full building automation (open protocol) system.

For installation, operation and diagnostics see CNTSVX11A-EN (ZN524).

Pump Module (field installed accessory)

The pump module shall consist of either a single or dual 1/

6 HP bronze pump and a brass three-way shut-off valve.

Cast iron pumps are also available.The pump module kits

shall contain the necessary components for the

installation, operation and maintenance of the water

circuit of a closed-loop distributed pumping application.

8 WSHP-SVX01Q-EN

Page 9

General Information

Waterside Economizer (Option)

Instructions for mechanical connection of the waterside

economizer to the water-source heat pump may be found

in the dimensional section of this manual.

The waterside economizer is designed to begin

economizing mode when water temperatures fall below

the field adjustable temperature of 25, 35, 45, 55 or 60°F

(for the Deluxe control option), or below the programmed

set-point (for the ZN524 or UC400 control option).

When the temperature is less than the setpoint, fluid will

flow into the economizing coil, while simultaneously

halting mechanical operation of the compressor.

Mechanical cooling will continue on a call for a second

stage from the thermostat or system control. Entering

water temperature sensor is factory provided for field

installation on the entering water side of the coil.

Boilerless Control/Electric Heat (Option)

Systems that do not contain a boiler may contain a

boilerless control with electric heat.Trane® offers both a

factory mounted electric heat option (.5 to 5 ton only), and

a field mounted duct heater option.

If the .5 to5 ton GEH, GEV andEXH/V070 unitincorporates

the factory mounted option, the unit will ship from the

factory with an internally mounted nichrome open wire

heating element, designed to start-up electric heat as the

systems primary heat in the event entering water

temperature falls below 55°F. Once the entering water

temperature rises above 60°F, the boilerless controller

returns the unit to normal compressor heating operation,

and locks out the electric heater.

For units comprised of the field installed duct heater

option, the unit will ship from the factory with controls

available to interface with the field provided electric heat

selection.

Note: For geothermal applications, the boilerless

controller has an adjustable setting of 25, 35, 45, 55,

and 60 degrees.

Supplemental or Boilerless Electric Heat

(option)

The GEH/V 6 to 25 ton models which contain boilerless

control electric heat or supplemental electric heat will

contain the controls interface ONLY for field provided

electric heat selection.The heater for this model shall be

external to the equipment by the contractor for ease of

installation. All power connections for the electric heater

will be completely separate from theunit for field supplied

electric heat.

Note: When the unit has boilerless control, the electric

heat is not used as supplemental electric heat, but

as a primary heat.

the reheat coil to control not only the space temperature,

but to also reduce therelative humidity of the space.When

operating in the reheat mode (meaning the sensible

temperature has been met in the space), the humidistat

signals the reheat relay coil to energize, allowing the high

pressure refrigerant gas to flow from the compressor

through the reheat valve, into the reversing valve and

reheat coil.

A switching relay has been provided for the reheat

application to adjust the blower motor from normal

operation to low speed when the hot gas reheat is

energized (for .5 to 5 ton and EXH/V070 equipment only).

Note: A high static blower motor is required to support

the hot gas reheat option for the GEH/V .5 -5 ton.

Note: Units containing the hot gas reheat option should

not be used as a make-up air unit.

2 Speed Blower Motor (option)

The 6 to25 ton GEH/Vmodels have indoorblowers that are

available with 2 speed motors, selectable in the model

number (Digit 12, drive packages one to nine). High speed

airflow matches the single speed motor airflow,

referenced in the Fan Performance tables. Low fan speed

airflow is approximately 50% of high fan speed airflow.

The 6 to 25 ton GEH/V two-speed blower motors are

available with the following options: Deluxe24V or UC400

controls, Heat Pump (HP) or HP w/Hot Gas Reheat or HP w/

Waterside Economizer. Not available with Boilerless or

Supplemental Electric Heat.

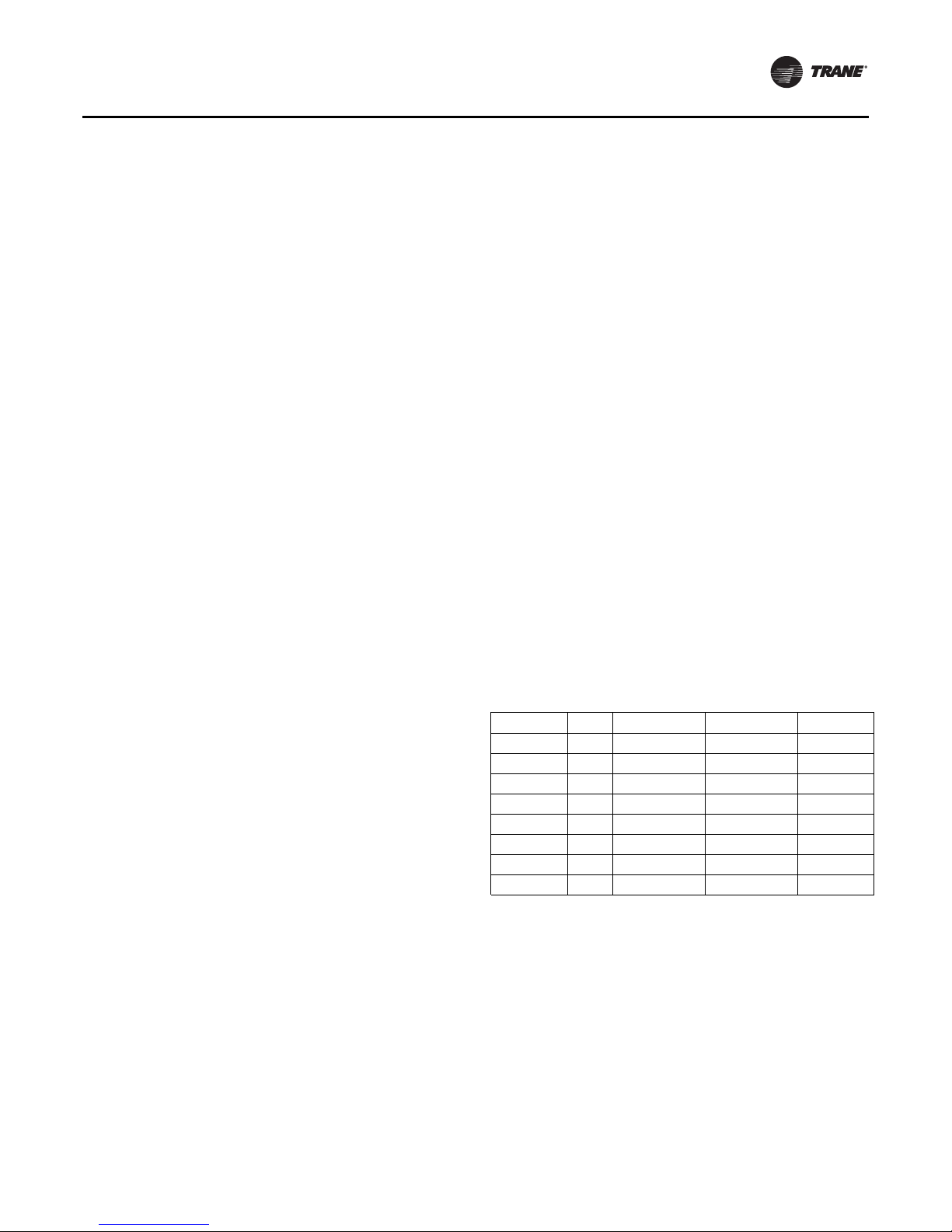

Table 2. 6 to 25 ton GEH/V fan speed for two-speed

drive packages one to nine

RV State Fan Compressor 1 Compressor 2 Fan Speed

Heat OFF OFF OFF OFF

Heat ON OFF OFF LOW

Heat ON ON OFF HIGH

Heat ON ON ON HIGH

Cool OFF OFF OFF OFF

Cool ON OFF OFF LOW

Cool ON ON OFF LOW

Cool ON ON ON HIGH

Hot Gas Reheat (option)

With the reheat option, the return-air from the space is

conditioned by the air-to-refrigerant coil, then reheated by

WSHP-SVX01Q-EN 9

Page 10

General Information

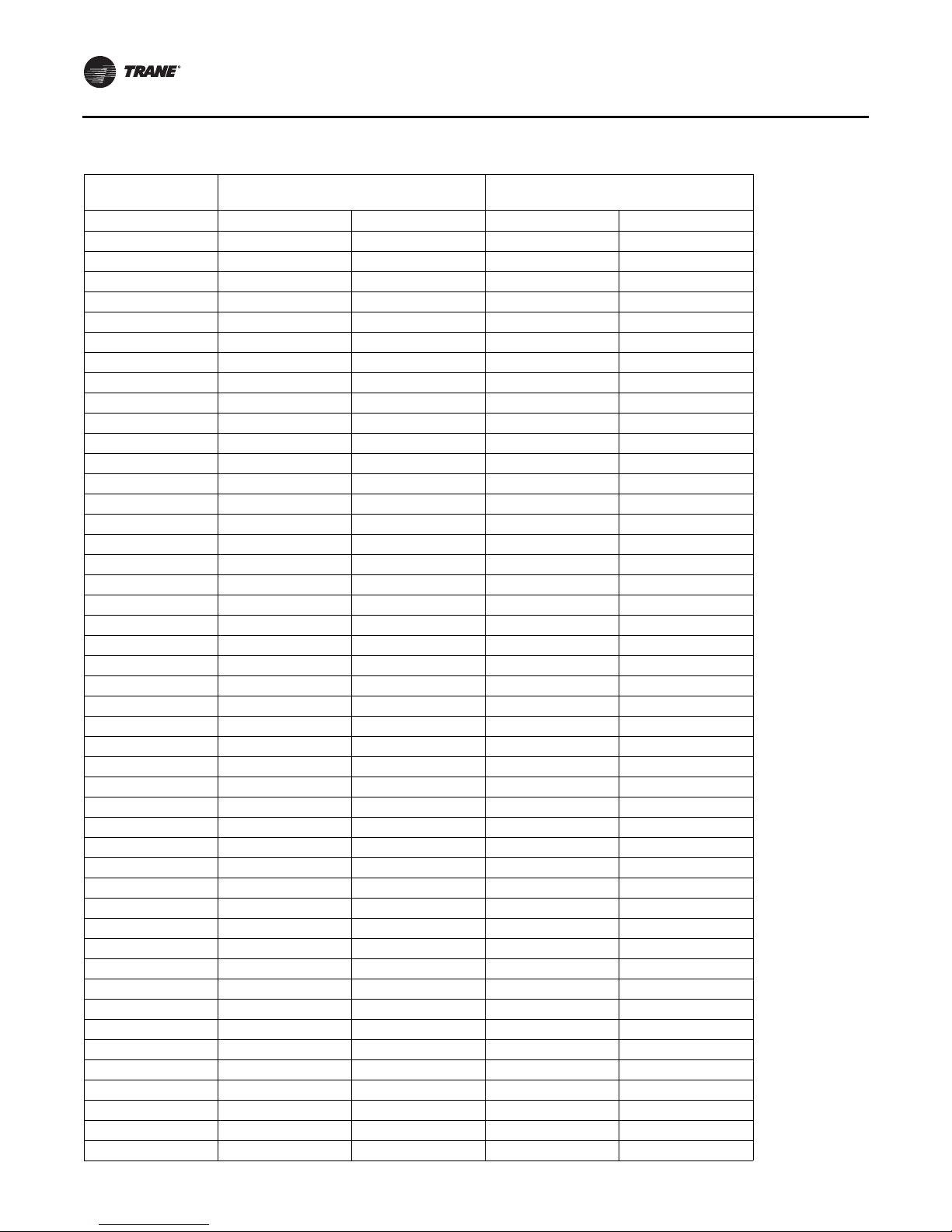

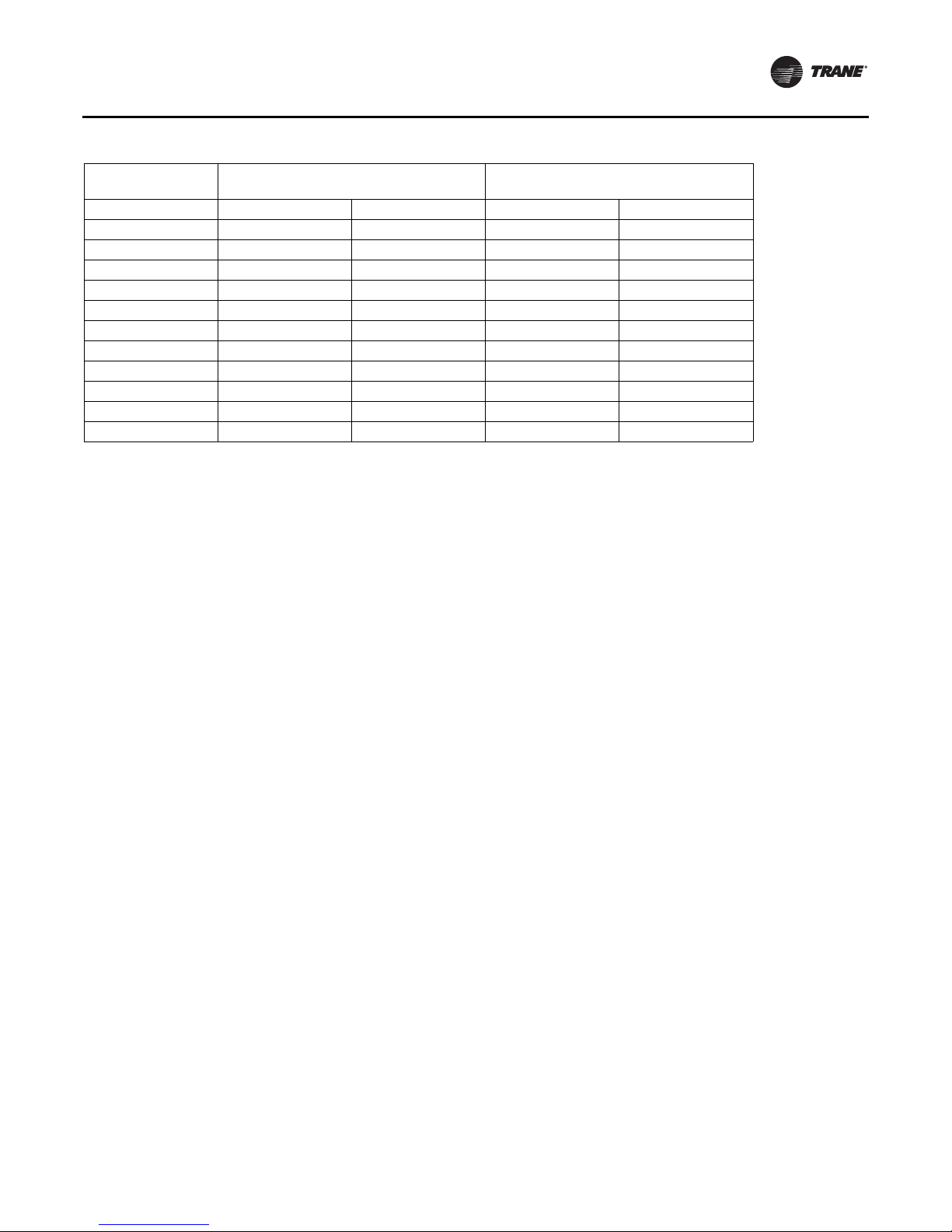

Table 3. Refrigerant charge

Model

(60 Hz)

Heat Pump

(oz)/(Kg)

Heat Pump w/HGR

(oz)/(Kg)

Circuit 1 Circuit 2 Circuit 1 Circuit 2

GEHE006 25.3 / .717 ----- 26.8 / .760 ----GEHE009 26.0 /.737 ----- 27.5 / .780 ----GEHE012 28.5 / .808 ----- 30.5 / .865 ----GEHE015 29.0 / .822 ----- 30.5 / .865 ----GEHE018 36.5 / 1.035 ----- 39.5 / 1.120 ----GEHE024 39.0 / 1.106 ----- 42.0 / 1.191 ----GEHE030 44.0 / 1.247 ----- 46.5 / 1.318 ----GEHE035 53.0 / 1.503 ----- 56.0 / 1.588 ----GEHE042 57.0 / 1.616 ----- 60.5 / 1.715 ----GEHE048 61.0 / 1.729 ----- 65.5 / 1.857 ----GEHE060 73.0 / 2.070 ----- 77.5 / 2.197 ----GEVE006 25.7 / .789 ----- 27.2 / .771 ----GEVE009 26.5 / .751 ----- 28.0 / .794 ----GEVE012 29.5 / .836 ----- 31.5 / .893 ----GEVE015 27.5 / .780 ----- 29.5 / .836 ----GEVE018 37.0 / 1.049 ----- 40.0 / 1/134 ----GEVE024 39.0 / 1.106 ----- 41.5 / 1.177 ----GEVE030 44.5 / 1.262 ----- 47.0 / 1.332 ----GEVE036 51.0 / 1.446 ----- 54.5 / 1.545 ----GEVE042 54.0 / 1.531 ----- 57.5 / 1.630 ----GEVE048 61.0 / 1.729 ----- 66.0 / 1.871 ----GEVE060 74.0 / 2.098 ----- 79.5 / 2.254 ----GEHE072 55 / 1.559 55 / 1.559 59 / 1.673 55 / 1.559

GEHE090 64 / 1.814 54 / 1.531 68 / 1.928 54 / 1.531

GEHE120 86 / 2.438 86 / 2.438 90 / 2.551 86 / 2.438

GEHE150 136 / 3.856 136 / 3.856 144 / 4.082 136 / 3.856

GEHE180 126 / 3.572 126 / 3.572 134 / 3.799 126 / 3.572

GEVE072 58 / 1.644 58 / 1.644 62 / 1.758 58 / 1.644

GEVE090 83 / 2.353 75 / 2.126 87 / 2.466 75 / 2.126

GEVE120 88 / 2.495 88 / 2.495 92 / 2.608 88 / 2.495

GEVE150 122 / 3.459 122 / 3.459 130 / 3.685 122 / 3.459

GEVE180 128 / 3.629 128 / 3.629 136 / 3.856 128 / 3.629

GEVE240 284 / 8.051 284 / 8.051 292 / 8.278 284 / 8.051

GEVE300 260 / 7.371 260 / 7.371 267 / 7.569 260 / 7.371

EXHF006 25.3 / 0.717 ----- 26.8 / 0.760 ----EXHF009 26.0 / 0.737 ----- 27.5 / 0.780 ----EXHF012 28.5 / 0.808 ----- 30.5 / 0.865 ----EXHF015 29.0 / 0.822 ----- 30.5 / 0.865 ----EXHF018 45.0 / 1.276 ----- 48.0 / 1.361 ----EXHF024 50.5 / 1.432 ----- 53.0 / 1.503 ----EXHF030 53.0 / 1.503 ----- 56.0 / 1.588 ----EXHF036 70.0 / 1.984 ----- 73.0 / 2.070 ----EXHF042 81.0 / 2.296 ----- 85.5 / 2.424 ----EXHF048 83.0 / 2.353 ----- 87.5 / 2.481 ----EXHF060 114.0 / 3.232 ----- 118.5 / 3.359 ----EXHF070 122.0 / 3.459 ----- 127.0 / 3.600 -----

10 WSHP-SVX01Q-EN

Page 11

Table 3. Refrigerant charge (continued)

General Information

Model

(60 Hz)

EXVF006 25.7 / 0.729 ----- 27.2 / 0.771 ----EXVF009 26.5 / 0.751 ----- 28.0 / 0.794 ----EXVF012 29.5 / 0.836 ----- 31.5 / 0.893 ----EXVF015 30.0 / 0.850 ----- 32.0 / 0.907 ----EXVF018 45.0 / 1.276 ----- 48.0 / 1.361 ----EXVF024 52.0 / 1.474 ----- 54.5 / 1.545 ----EXVF030 53.0 / 1.503 ----- 56.0 / 1.588 ----EXVF036 70.0 / 1.984 ----- 73.0 / 2.070 ----EXVF042 81.0 / 2.296 ----- 86.0 / 2.438 ----EXVF048 83.0 / 2.353 ----- 88.5 / 2.509 ----EXVF060 114.0 / 3.232 ----- 119.5 / 3.388 ----EXVF070 122.0 / 3.459 ----- 128.0 / 3.629 -----

Heat Pump

(oz)/(Kg)

Heat Pump w/HGR

(oz)/(Kg)

WSHP-SVX01Q-EN 11

Page 12

Pre-Installation

WARNING

Fiberglass Wool!

Exposition to glass wool fibers without all necessary

PPE equipment could result in cancer, respiratory, skin

or eye irritation, which could result in death or serious

injury. Disturbing the insulation in this product during

installation, maintenance or repair will expose you to

airborne particles of glass wool fibers and ceramic

fibers known to the state of California to cause cancer

through inhalation.You MUST wear all necessary

Personal Protective Equipment (PPE) including gloves,

eye protection, a NIOSH approved dust/mist respirator,

long sleeves and pants when working with products

containing fiberglass wool.

Unit Inspection Checklist

• Unpack all components of the kit.

• Check carefully for any shipping damage. If any

damage is found it must be reported immediately and

a claim made against the transportation company.

Important: Equipment is shipped FOB (Free on Board)

at the manufacturer.Therefore, freight

claims for damages against the carrier must

be initiated by the receiver.

• Visually inspect the components for shipping damage

as soon as possible after delivery, before it is stored.

Concealed damage must be reported within 15 days.

• If concealed damage is discovered, stop unpacking the

shipment.

• Do not remove damaged material from the receiving

location.Take photos of the damage, if possible.The

owner must provide reasonable evidence that the

damage did not occur after delivery.

• Notify the carrier’s terminal of damage immediately by

phone and by mail. Request an immediate joint

inspection of the damage by the carrier and the

consignee.

• Do not attempt to repair any damaged parts until the

parts are inspected by the carrier’s representative.

Jobsite Inspection Checklist

Always perform the following checks before

accepting a unit:

• Verify that the nameplate data matches the data on the

sales order and bill of lading (including electrical data).

• Verify that the power supply complies with the unit

nameplate specifications.

• Visually inspect the exterior of the unit, for signs of

shipping damage. Do not sign the bill of lading

accepting the unit(s) until inspection has been

completed. Check for damage promptly after the

unit(s) are unloaded. Once the billof lading is signed at

the jobsite, the unit(s) are now the property of the

SOLDTO party and future freight claims MAY NOT be

accepted by the freight company.

Jobsite Storage

NOTICE:

Microbial Growth!

Wet interior unit insulation can become an

amplification site for microbial growth (mold), which

could result in odors and damage to the equipment and

building materials. If there is evidence of microbial

growth on the interior insulation, it should be removed

and replaced prior to operating the system.

NOTICE:

Microbial Growth!

Failure to follow instructions below could result in

odors and damage to the equipment and building

materials.The floor or foundation must be level and the

condensate drain at the proper height for proper coil

drainage and condensate flow. Standing water and wet

surfaces inside the equipment can become an

amplification site for microbial growth (mold).

This unit is intended for indoor use only.To protect the unit

from damage due to the elements, and to prevent possible

IAQ contaminant sources from growing, the unitshould be

stored indoors. If indoor storage is not possible, the

following provisions for outdoor storage must be met:

• Place the unit(s) on a dry surface or raise above the

ground to assure adequate air circulation beneath the

unit.

• Cover the unit(s) with a water proof tarp to protect

them from the elements.

• Make provisions for continuous venting of the covered

units to prevent moisture from standing on the unit(s)

surfaces. Wet interior unit insulation can become an

amplification site for microbial growth (mold) which

has been determined to be a cause of odors and

serious health related indoor air quality problems.

• Store units in the normal UP orientationto maintain oil

in the compressor.

• Horizontal units may be stacked no more than three

units high. Do not stack the vertical unit configurations.

12 WSHP-SVX01Q-EN

Page 13

Unit Dimensions

Service Clearances

Per NEC requirements, 36 inches of access and working

space shall be provided and maintained around allcontrol

boxes and electrical equipment to permit ready and safe

operation and maintenance of such equipment. Local

codes may require more clearance to electrical

equipment. Check all code requirements prior to unit

installation.

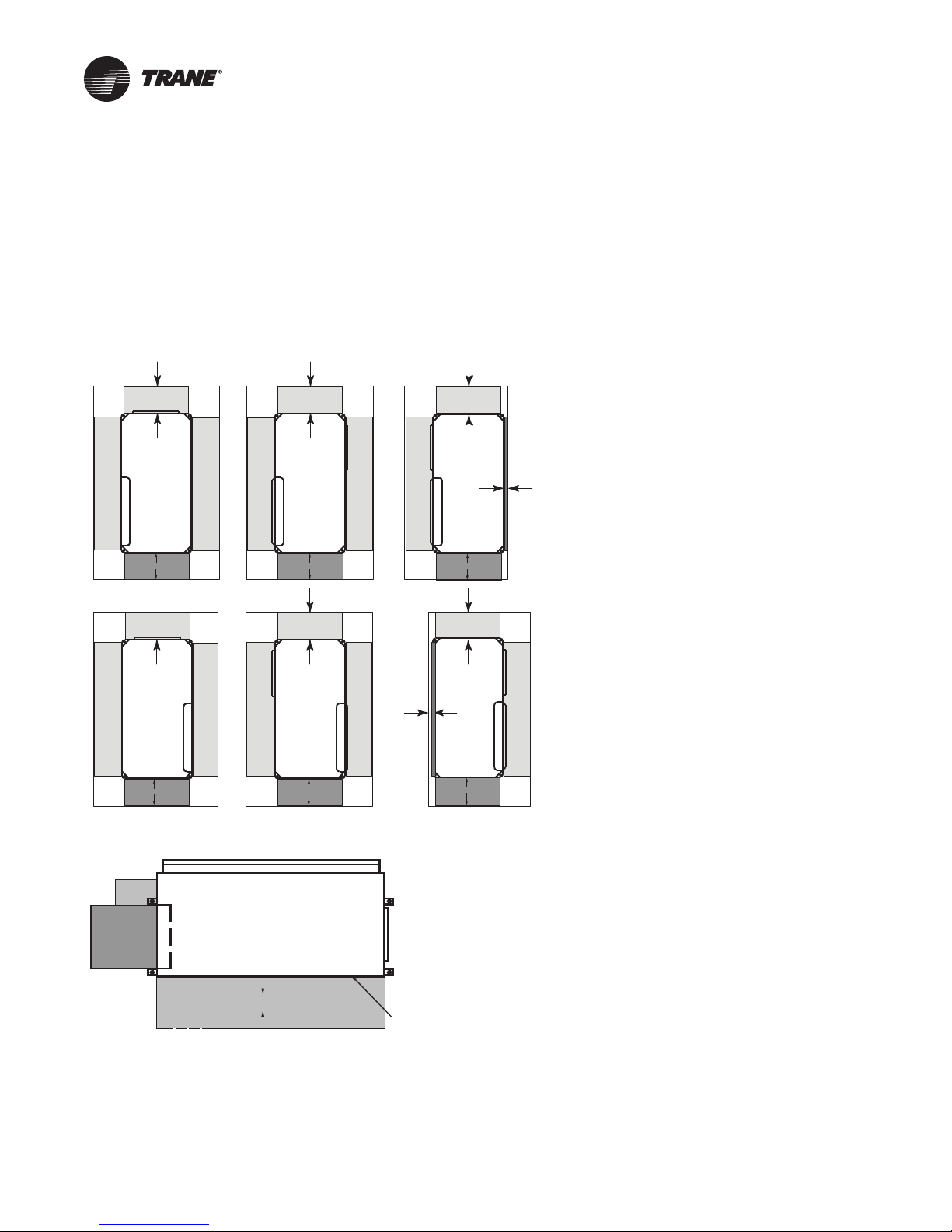

Figure 1. Clearances - GEH .5 to 5 tons & EXH .5 to 6Tons

14"

14"

LEFT RETURN

BACK SUPPLY

UNIT FRONT

36"

14"

14" 14”

LEFT RETURN

RIGHT SUPPLY

14"

UNIT FRONT UNIT FRONT

36"

14"14"

14"

14"

LEFT RETURN

LEFT SUPPLY

36"

14"

A minimum 14 inch clearancefor servicing the

unit is required for all .5 to 5 tons and EXH070

configurations from other mechanical and

electrical equipment (where shown) to enable

panel removal from the unit for service/

maintenance ability.The optimum clearance

required is 20 inches.

3"

Equipment containing a same-side supply/

return combination requires a 3 inches

limitation on one side. Access to theTXV may

not be possible with this 3 inches clearance.

This configuration is typically applied in a

corridor installation, where space limitations

force the left or right side of the unit against a

wall.

RIGHT RETURN

BACK SUPPLY

14"

UNIT FRONT

14"

36"

RIGHT RETURN

LEFT SUPPLY

14"

UNIT FRONT

36"

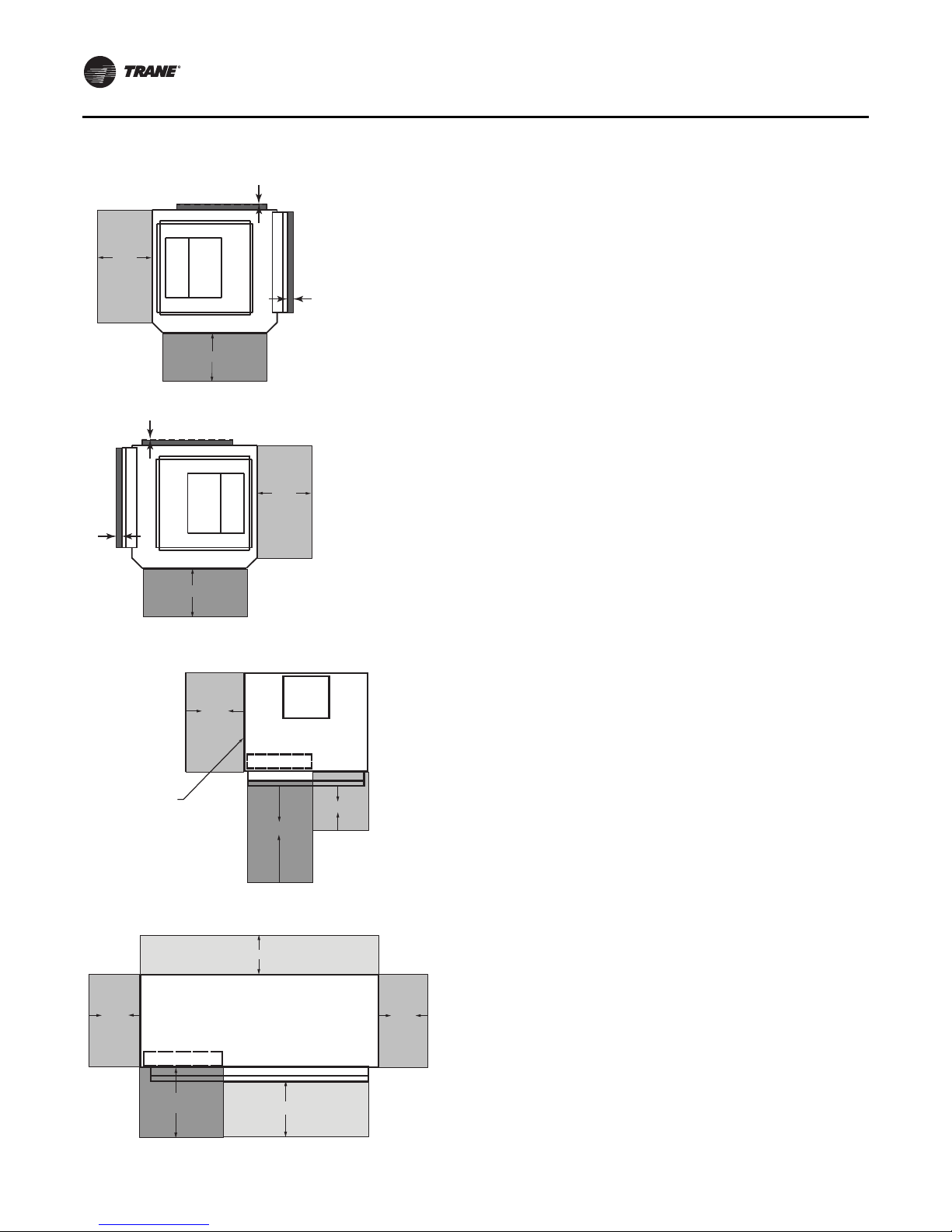

Figure 2. Clearance - GEH 6 to 15 Tons

24"

36"

CONTROL BOX

TOP VIE W

24"

14"

3"

BLOWER ACCESS

PANEL

RIGHT RETURN

RIGHT SUPPLY

UNIT FRONT

36"

14"

Service clearance dimensions for the GEH 6 to15 tons

horizontal includes a two side access appropriate for

control and blower motor/wheel access.

WSHP-SVX01Q-EN 13

Page 14

Unit Dimensions

Figure 3. Clearance - GEV .5 to 5 tons & EXV .5 to 6Tons

1"

24"

1"

1"

UNIT FRONT

UNIT FRONT

36"

36"

24"

LEFT

RETURN

TOP/BACK

SUPPLY

TOP/BACK

1"

RIGHT

RETURN

SUPPLY

A 24 inch clearance from other mechanical and electrical

equipment (where shown) is recommended for all

configurations.This will enable panel removal from the

unit for service/maintenance.

A 1 inch minimum clearance between the filterrackand any

obstacle is required for units in a free return application to

provide proper air flow to the air-to-refrigerant coil. A 12

inch minimum clearance between the filter rack and any

obstacle should be provided to properly attached

ductwork.

The 1 inch dimension shown in the back of the unit

represents the supply duct collar for the back supply

option.This clearance is needed to clear these flanges.

Figure 4. Clearance - GEV 6 to 10Tons

24"

FRONT RETURN

TOP SUPPLY

ACCESS PANEL FOR

SHEAVES AND BELTS

36"

24"

Figure 5. Clearance - GEV 12.5 to 25 Tons

18"

24"

CONTROL BOX

36"

FRONT RETURN-AIR

BACK SUPPLY-AIR

UNIT FRONT

18"

A 24 inch clearance from other mechanical and electrical

equipment (where shown) is recommended for all

configurations.The unit may be serviced through the front

access panel or remaining open sides.

A 24 inch clearance from other mechanical and electrical

equipment (where shown) is recommended for all

configurations.The unit may be serviced through the front

access panel.

24"

14 WSHP-SVX01Q-EN

Page 15

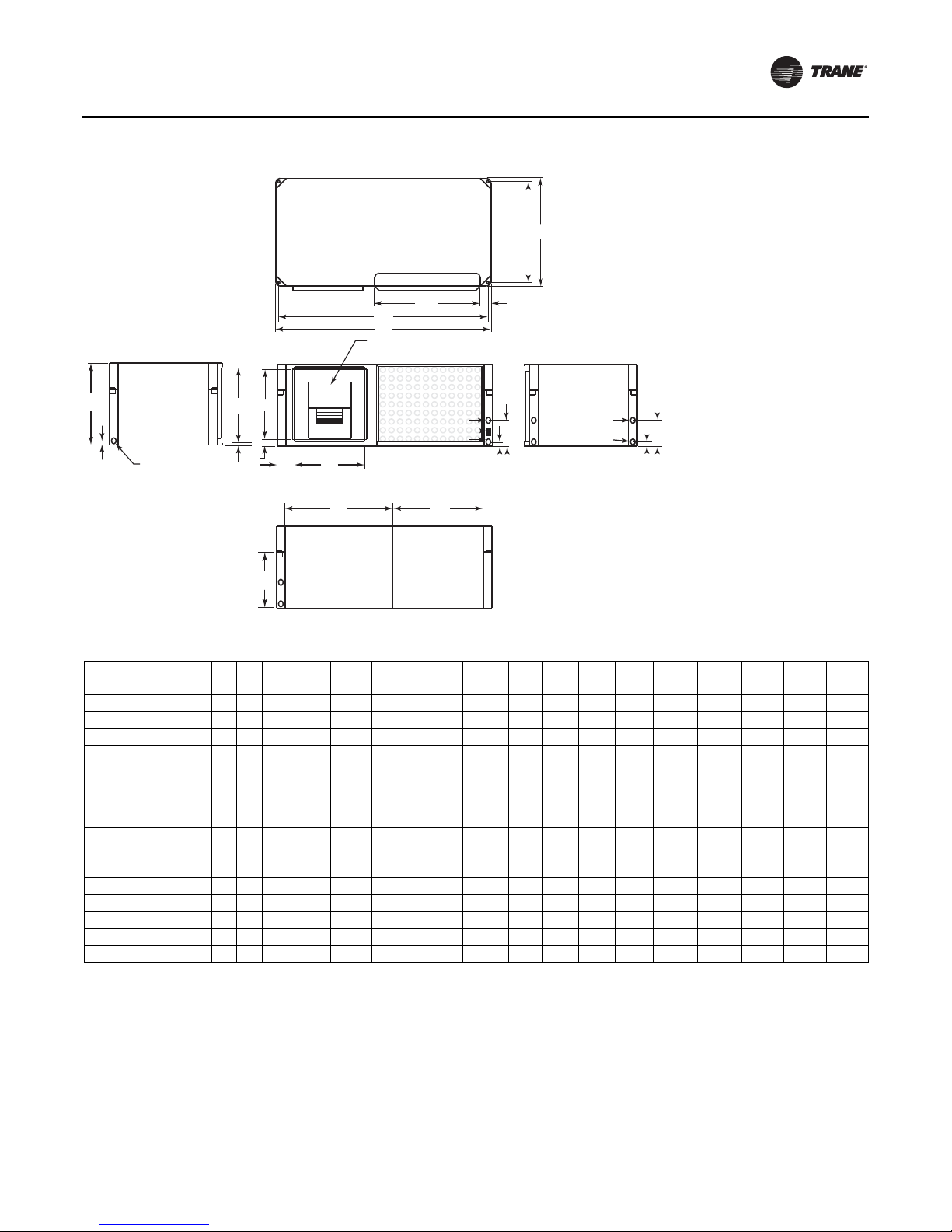

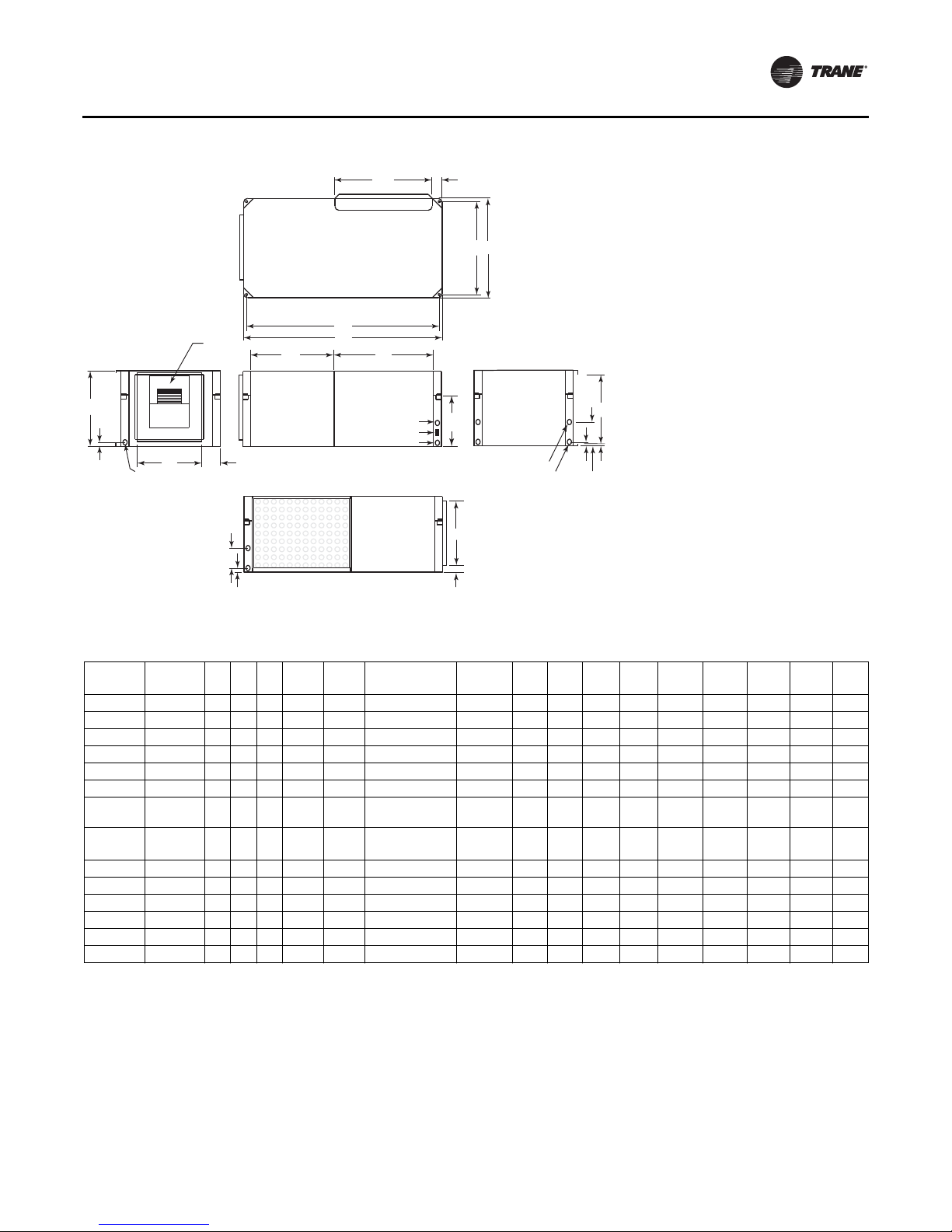

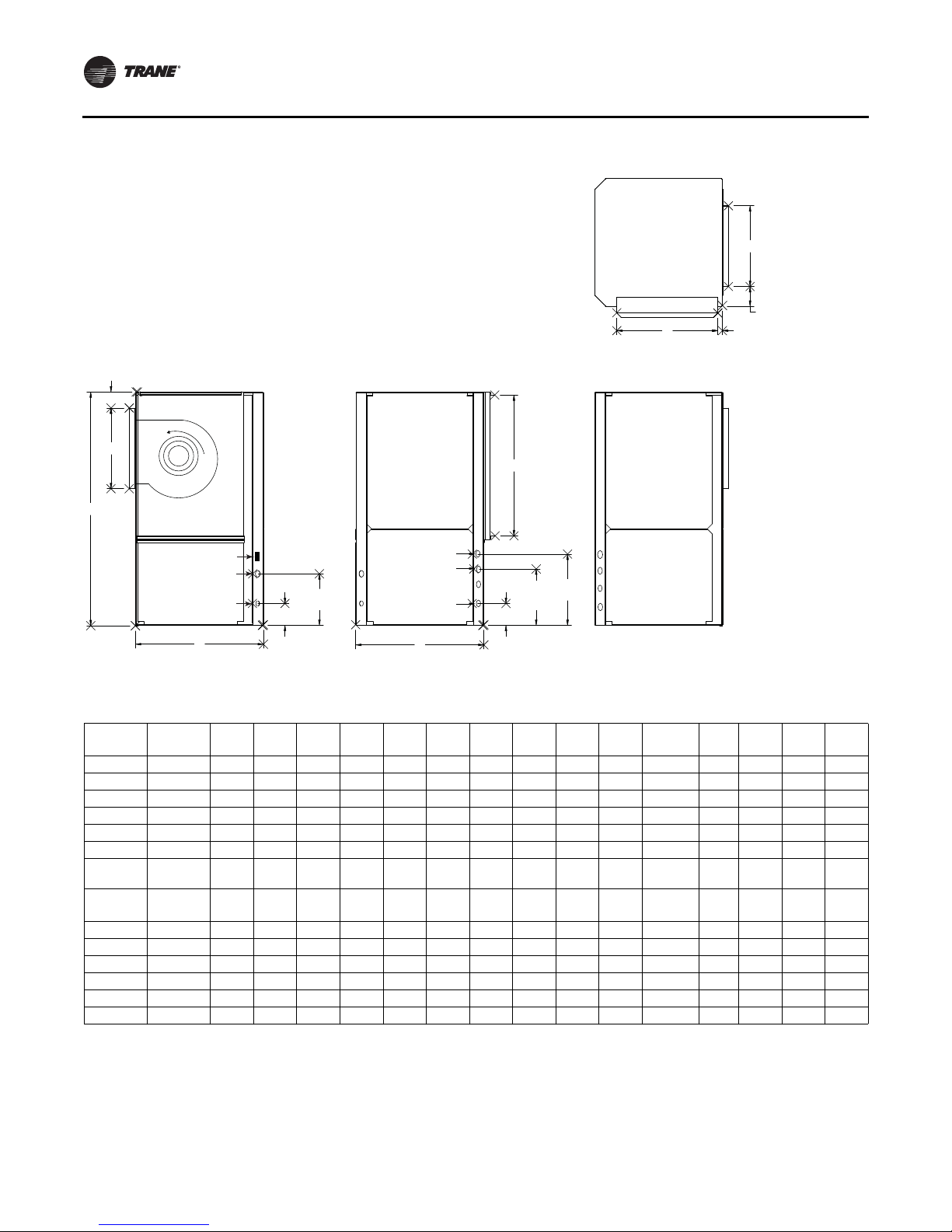

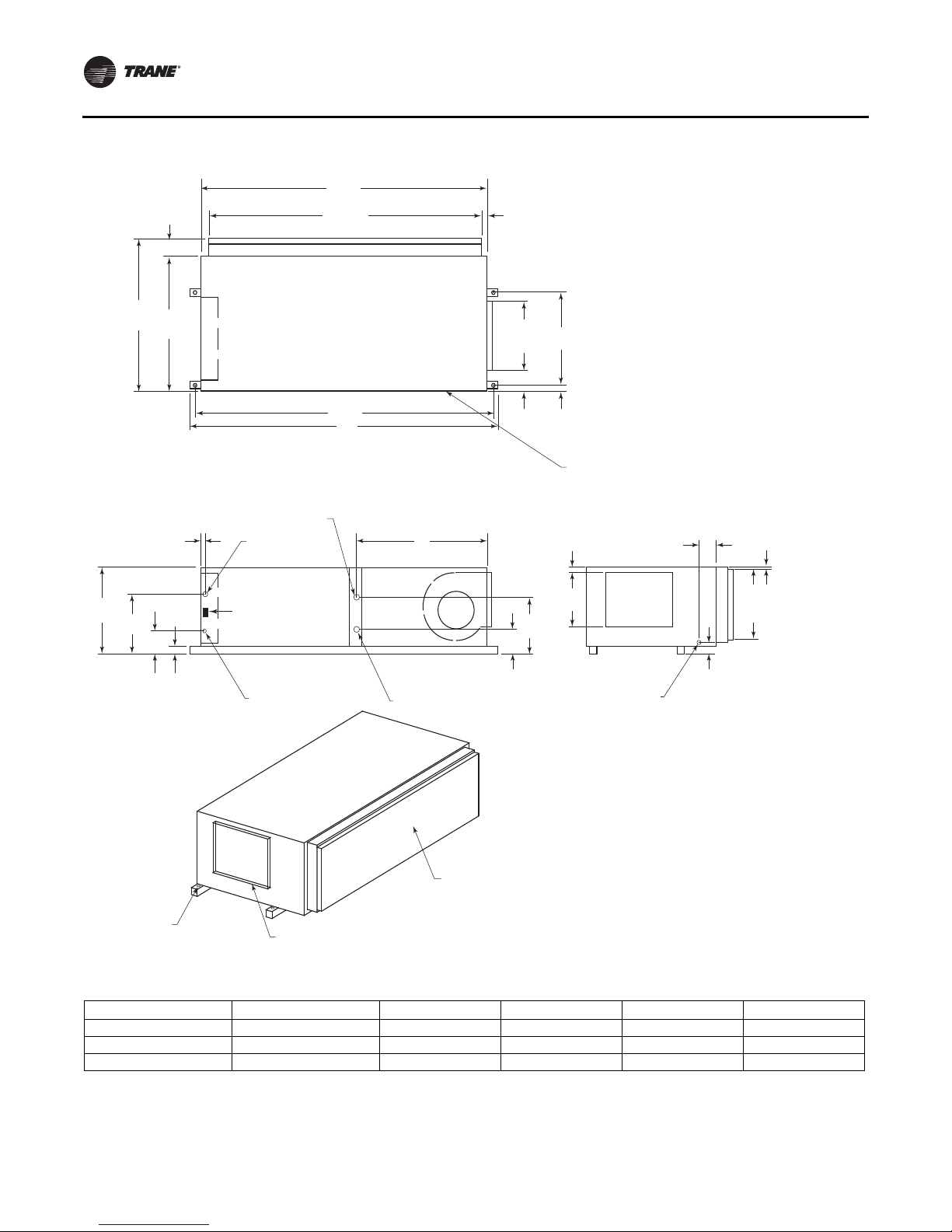

Figure 6. Left return/left supply (GEH/EXH)

TOP

F X G

OPENING

C

BLOWER

ACCESS

PANEL

1"

DRAIN

3/4" NPTI

BACK LEFT SIDE FRONT

H

Q

K

1/2"

H

J

RS

N

A

HI VOLT

WCI mounting location

LO VOLT

ED

6 3/4"

1"

Unit Dimensions

BP

REFRIG

AND

CONTROL

ACCESS

L (W.O.)

M (W.I.)

7"

1 3/8"

14"

RIGHT SIDE

Table 4. Dimensional data left return/left supply (GEH/EXH)

GEH Unit

(60 Hz)

006, 009 006 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 009, 012 40 20 15 20 15 6-7/8 x 9-7/8 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

024, 030 018, 024 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

035, 042 030, 036 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

Std-048 Std-042 58 33 21 29-1/2 23-1/2 13-1/8 x 11-3/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Hi-048,

EXH Unit

(60 Hz)

006, 009 N/A 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 N/A 40 20 15 20 15 8-1/4 x 9-3/4 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018, 024 N/A 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

030, 036 N/A 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

042-060 N/A 58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Notes:

1. When a horizontal model is ordered with the same side return and supply in a ducted application, bottom filter removal is required due to limited

2. Equipment containing a same-side supply/return combination requires a 3 in. clearance on one side. Access to the TXV may not be possible with this

(a)Return air opening dimension.

(b)Filter rack dimension.

GEH Unit

(50 Hz) A B C D

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

S

018 015 46 23 18 23 18 8-1/4 x 9-3/4 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

060

Hi-042,

048, 060

EXH Unit

(50 Hz) A B C D

58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

S

070 N/A 58 39 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 37-3/4 19-5/8 23-1/2 5-1/2

access on either side of the filter.

3 in. clearance.

WSHP-SVX01Q-EN 15

Page 16

Unit Dimensions

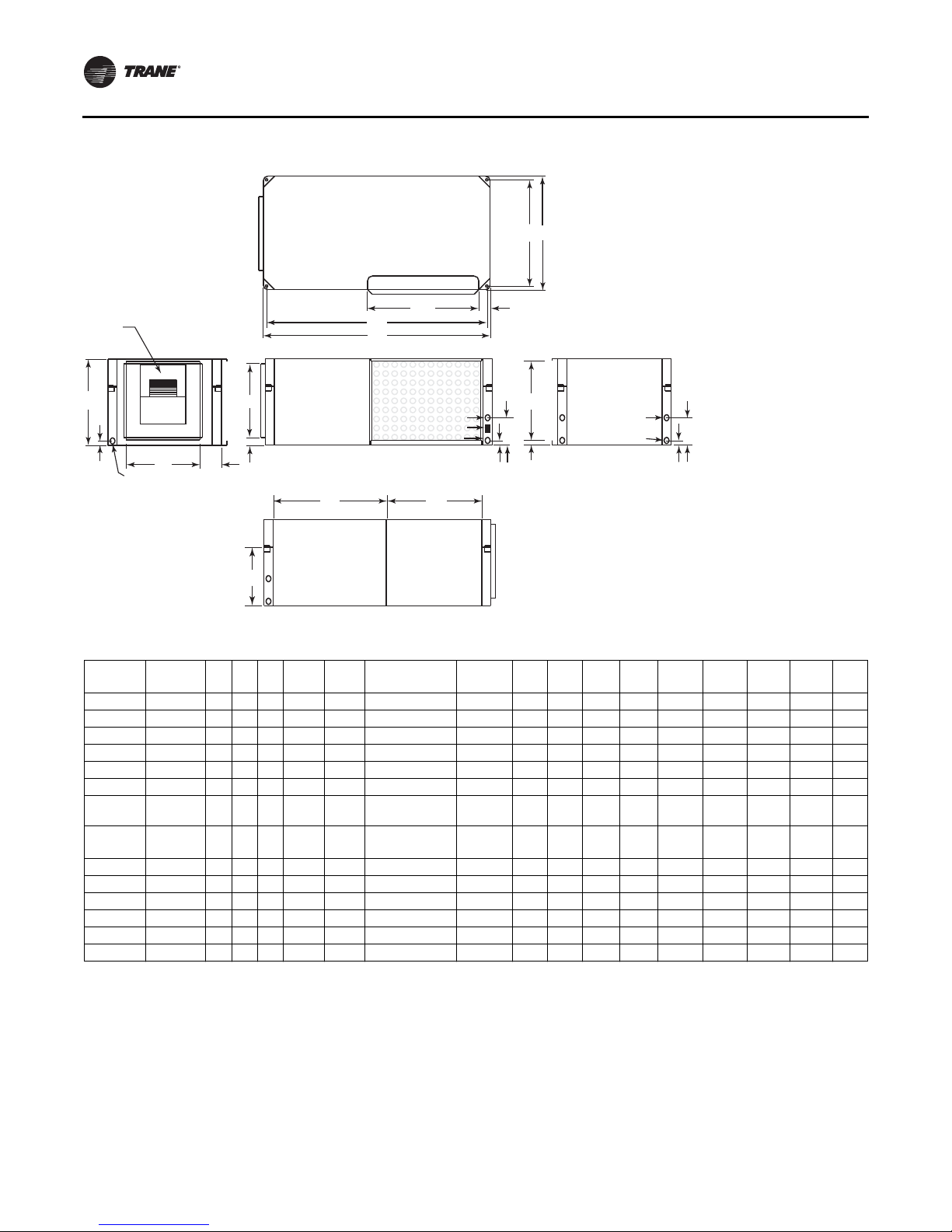

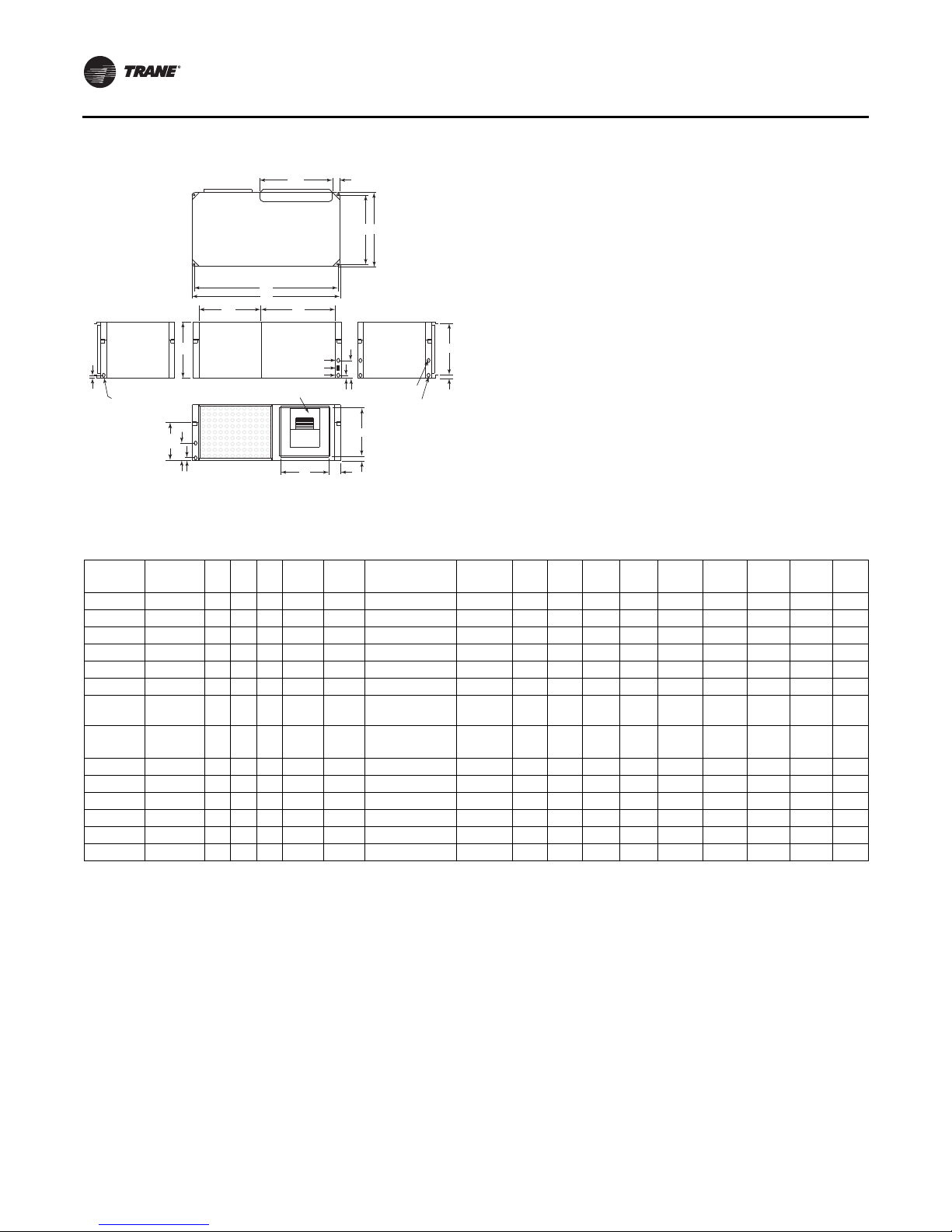

Figure 7. Left return/back supply (GEH/EXH)

TOP

F X G

OPENING

C

1"

BLOWER

H

ACCESS

PANEL

N

A

R

HI VOLT

WCI mounting location

LO VOLT

S

6 3/4"

BP

REFRIG

AND

CONTROL

Q

ACCESS

L (W.O.)

M (W.I.)

7"

DRAIN

3/4" NPTI

H

J

K

BACK LEFT SIDE FRONT

ED

14"

1"

1/2"

1 3/8"

RIGHT SIDE

Table 5. Dimensional data left return/back supply (GEH/EXH)

GEH Unit

(60 Hz)

006, 009 006 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 009, 012 40 20 15 20 15 6-7/8 x 9-7/8 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

024, 030 018, 024 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

035, 042 030, 036 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

Std-048 Std-042 58 33 21 29-1/2 23-1/213-1/8 x 11-3/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Hi-048,

EXH Unit

(60 Hz)

006, 009 N/A 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 N/A 40 20 15 20 15 8-1/4 x 9-3/4 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018, 024 N/A 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

030, 036 N/A 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

042-060 N/A 58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Notes:

1. Equipment containing a same-side supply/return combination requires a 3 in. clearance on one side. Access to the TXV may not be possible with this

(a)Return air opening dimension.

(b)Filter rack dimension.

GEH Unit

(50 Hz) A B C D

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

018 015 46 23 18 23 18 8-1/4 x 9-3/4 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

060

048, 060

EXH Unit

(50 Hz) A B C D

Hi-042,

060 58 33 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

070 N/A 58 39 21 29-1/2 23-1/213-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 37-3/4 19-5/8 23-1/2 5-1/2

3 in. clearance.

S

S

16 WSHP-SVX01Q-EN

Page 17

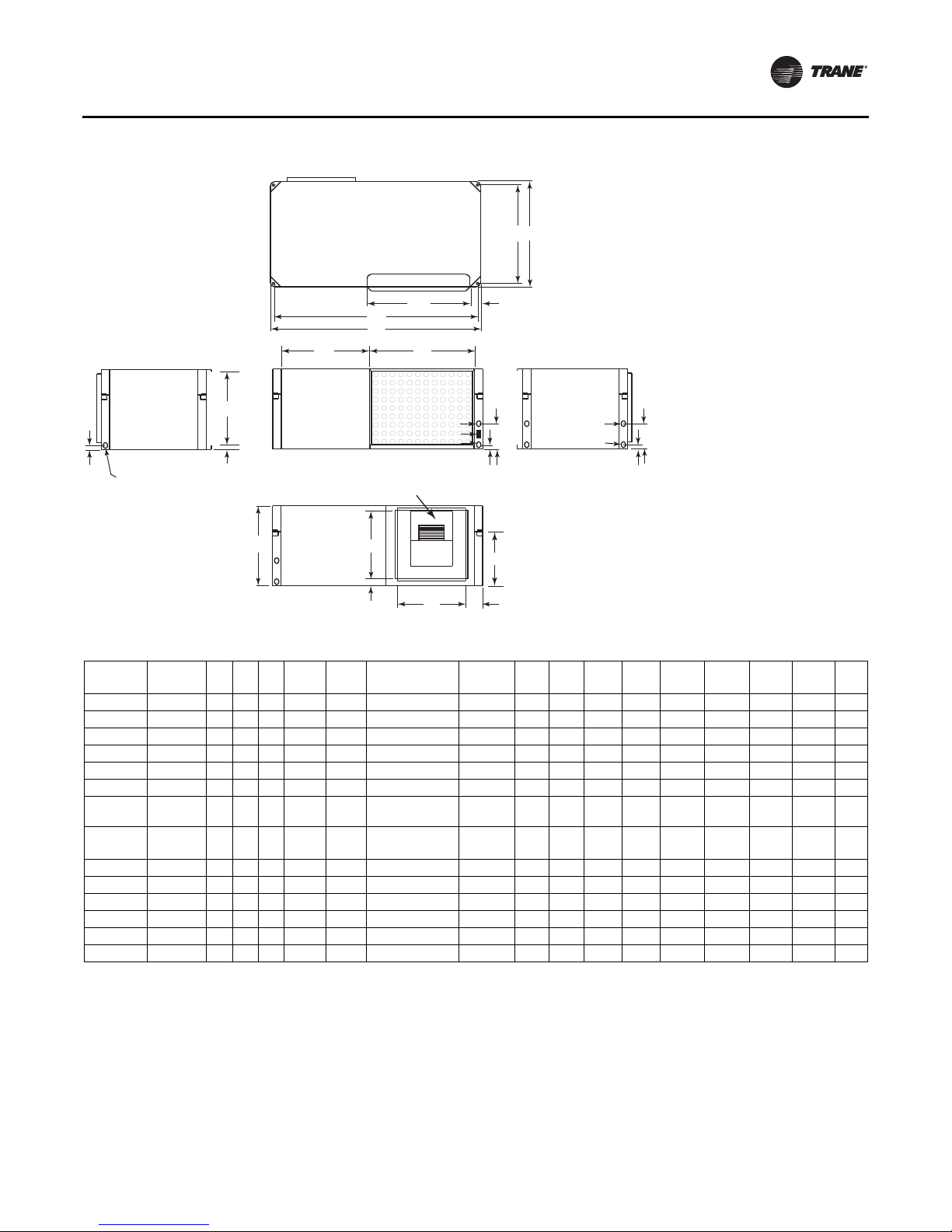

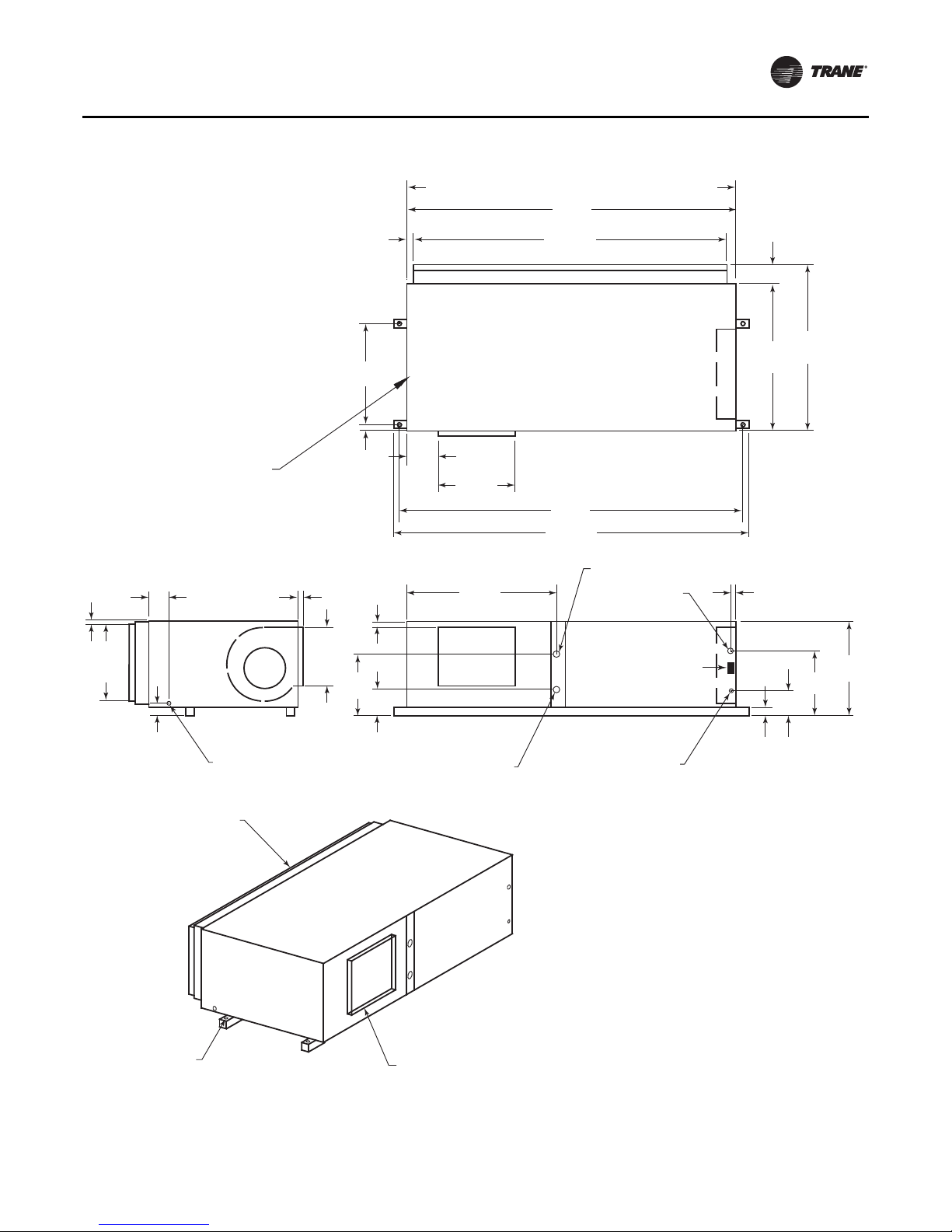

Figure 8. Left return/right supply (GEH/EXH)

TOP

N

A

ED

BLOWER

ACCESS

1"

PANEL

Q

R

HI VOLT

WCI mounting location

LO VOLT

S

6 3/4"

Unit Dimensions

BP

REFRIG

AND

CONTROL

ACCESS

L (W.O.)

M (W.I.)

7"

DRAIN

3/4" NPTI

BACK LEFT SIDE FRONT

RIGHT SIDE

1/2"

F X G

OPENING

C

H

K

H

1"

1 3/8"

14"

J

Table 6. Dimensional data left return/right supply (GEH/EXH)

GEH Unit

(60 Hz)

006, 009 006 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 009, 012 40 20 15 20 15 6-7/8 x 9-7/8 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

024, 030 018, 024 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

035, 042 030, 036 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

Std-048 Std-042 58 33 21 29-1/2 23-1/2 13-1/8 x 11-3/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Hi-048,

EXH Unit

(60 Hz)

006, 009 N/A 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 N/A 40 20 15 20 15 8-1/4 x 9-3/4 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018, 024 N/A 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

030, 036 N/A 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

042-060 N/A 58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Notes:

1. Equipment containing a same-side supply/return combination requires a 3 in. clearance on one side. Access to the TXV may not be possible with this

(a)Return air opening dimension.

(b)Filter rack dimension.

GEH Unit

(50 Hz) A B C D

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

018 015 46 23 18 23 18 8-1/4 x 9-3/4 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

060

048, 060

EXH Unit

(50 Hz) A B C D

Hi-042,

58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

070 N/A 58 39 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 37-3/4 19-5/8 23-1/2 5-1/2

3 in. clearance.

S

S

WSHP-SVX01Q-EN 17

Page 18

Unit Dimensions

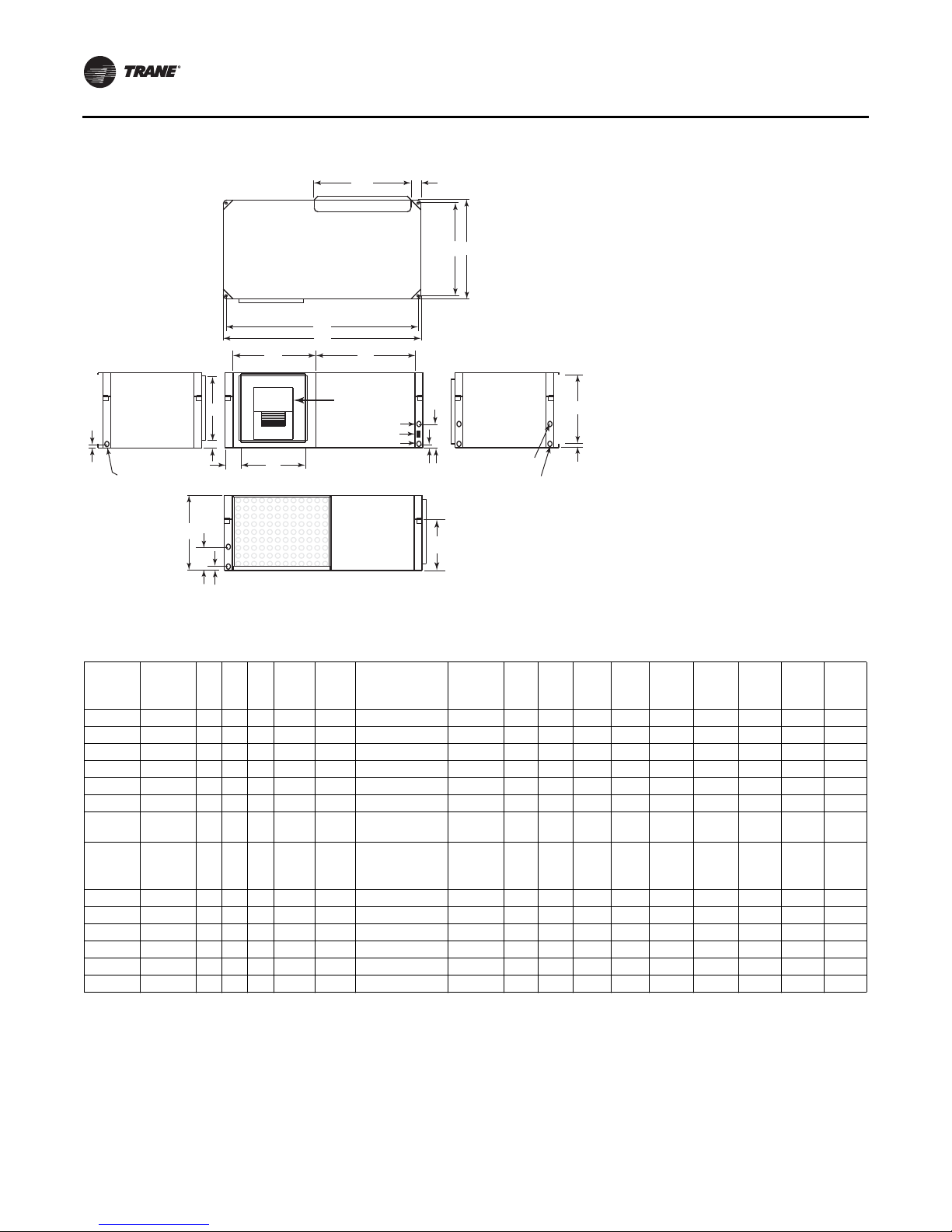

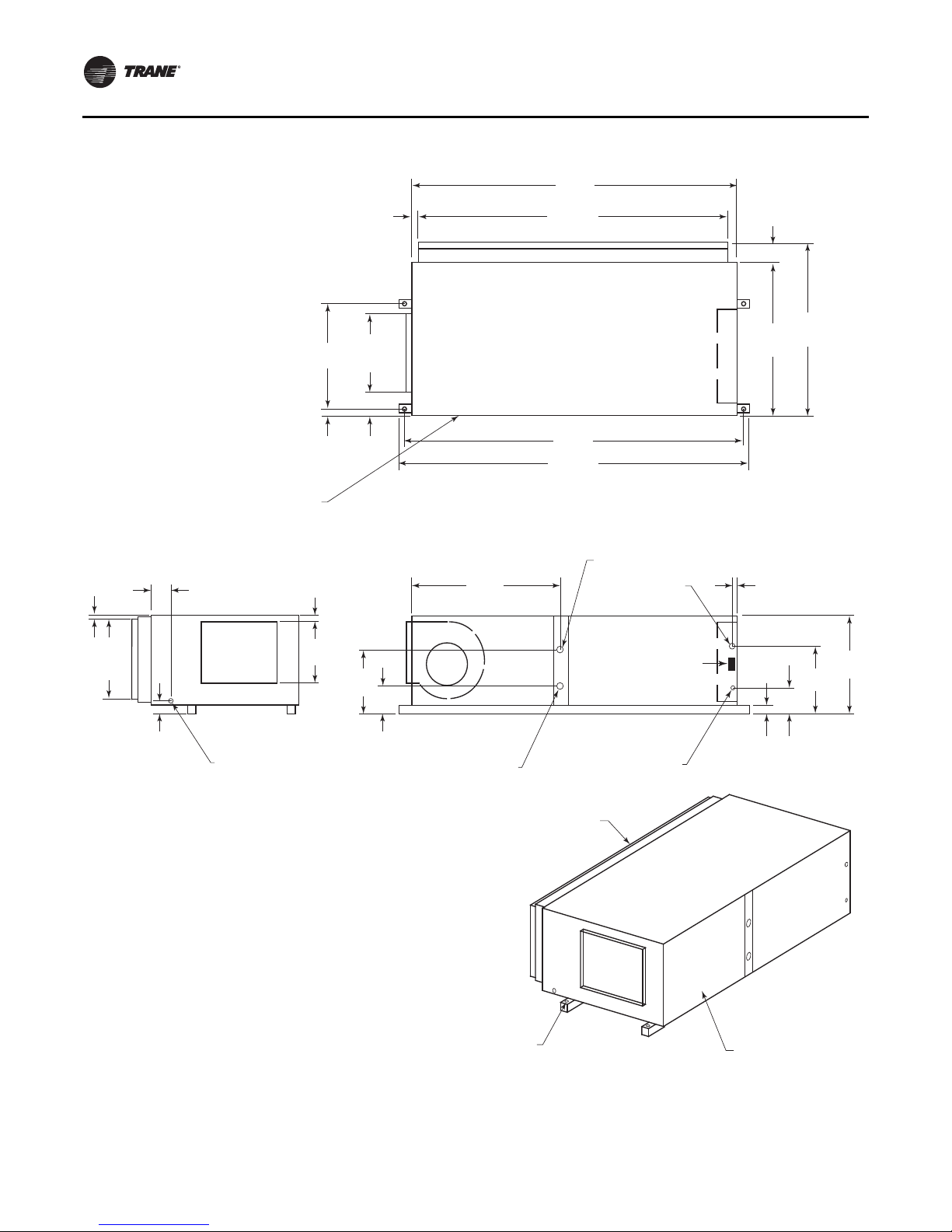

Figure 9. Right return/left supply (GEH/EXH)

R

TOP

N

A

ED

1"

BLOWER

ACCESS

PANEL

DRAIN

3/4" NPTI

RIGHT SIDE

H

K

H

BACK LEFT SIDE FRONT

J

7"

C

F X G

OPENING

WCI mounting location

HI VOLT

LO VOLT

14"

1”

S

6 3/4"

BP

REFRIG

AND

CONTROL

ACCESS

L (W.O.)

M (W.I.)

Q

1/2"

1 3/8”

Table 7. Dimensional data right return/left supply (GEH/EXH)

GEH

Unit (60

Hz)

006, 009 006 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 009, 012 40 20 15 20 15 6-7/8 x 9-7/8 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018 015 46 23 18 23 18 8-1/4 x 9-3/4 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

024, 030 018, 024 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

035, 042 030, 036 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

Std-048 Std-042 58 33 21 29-1/2 23-1/2 13-1/8 x 11-3/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Hi-048,

060

EXH

Unit (60

Hz)

006, 009 N/A 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 N/A 40 20 15 20 15 8-1/4 x 9-3/4 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018, 024 N/A 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

030, 036 N/A 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

042-060 N/A 58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

070 N/A 58 39 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 37-3/4 19-5/8 23-1/2 5-1/2

Notes:

1. Equipment containing a same-side supply/return combination requires a 3 in. clearance on one side. Access to the TXV may not be possible with this

3 in. clearance.

(a)Return air opening dimension.

(b)Filter rack dimension.

GEH

Unit (50

Hz) A B C D

Hi-042,

048, 060

58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

EXH

Unit (50

Hz) A B C D

(a)

E F x G H J KL NPTIM NPTI N P Q R

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

(b)

S

S

18 WSHP-SVX01Q-EN

Page 19

Figure 10. Right return/back supply (GEH/EXH)

R

TOP

N

F X G

OPENING

ED

A

Unit Dimensions

S

BP

REFRIG

AND

CONTROL

ACCESS

L (W.O.)

M (W.I.)

1”

Q

1/2"

6 3/4”

7"

1 3/8”

BLOWER

ACCESS

PANEL

HI VOLT

WCI mounting location

LO VOLT

14"

H

K

C

1"

H

DRAIN

3/4" NPTI

RIGHT SIDE

J

BACK LEF T SIDE FRONT

Table 8. Dimensional data right return/back supply (GEH/EXH)

GEH Unit

(60 Hz)

006, 009 006 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 009, 012 40 20 15 20 15 6-7/8 x 9-7/8 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

024, 030 018, 024 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

035, 042 030, 036 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

Std-048 Std-042 58 33 21 29-1/2 23-1/2 13-1/8 x 11-3/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Hi-048,

EXH Unit

(60 Hz)

006, 009 N/A 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 N/A 40 20 15 20 15 8-1/4 x 9-3/4 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018, 024 N/A 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

030, 036 N/A 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

042-060 N/A 58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Notes:

1. Equipment containing a same-side supply/return combination requires a 3 in. clearance on one side. Access to the TXV may not be possible with this

(a)Return air opening dimension.

(b)Filter rack dimension.

GEH Unit

(50 Hz) A B C D

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

S

018 015 46 23 18 23 18 8-1/4 x 9-3/4 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

060

048, 060

EXH Unit

(50 Hz) A B C D

Hi-042,

58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

S

070 N/A 58 39 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 37-3/4 19-5/8 23-1/2 5-1/2

3 in. clearance.

WSHP-SVX01Q-EN 19

Page 20

Unit Dimensions

Figure 11. Right return/right supply (GEH/EXH)

HI VOLT

LO VOLT

1"

S

6 3/4"

FRONT

BP

REFRIG

AND

CONTROL

ACCESS

R

TOP

N

A

ED

BLOWER

ACCESS

PANEL

1"

DRAIN

3/4" NPTI

BACK

C

WCI mounting location

LEFT SIDE

F X G

OPENING

L (W.O.)

M (W.I.)

Q

1/2"

14"

RIGHT SIDE

7"

1 3/8"

H

H

J

K

Table 9. Dimensional data right return/right supply (GEH/EXH)

GEH Unit

(60 Hz)

006, 009 006 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 009, 012 40 20 15 20 15 6-7/8 x 9-7/8 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

024, 030 018, 024 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

035, 042 030, 036 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

Std-048 Std-042 58 33 21 29-1/2 23-1/2 13-1/8 x 11-3/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Hi-048,

EXH Unit

(60 Hz)

006, 009 N/A 40 20 15 20 15 6-7/8 x 8 11-1/2 4-1/2 1-3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

012, 015 N/A 40 20 15 20 15 8-1/4 x 9-3/4 11-1/2 4-1/4 3/4 1/2 1/2 38-3/4 18-3/4 13-5/8 18-1/2 3-1/4

018, 024 N/A 46 23 18 23 18 8-1/4 x 11-3/8 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

030, 036 N/A 50 25 19 25 20 10-1/2 x 13-1/2 17 4 1 3/4 3/4 48-3/4 23-3/4 17-5/8 23-1/2 3-1/4

042-060 N/A 58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

Notes:

1. When a horizontal model is ordered with the same side return and supply in a ducted application, bottom filter removal is required due to limited

2. Equipment containing a same-side supply/return combination requires a 3 in. clearance on one side. Access to the TXV may not be possible with this

(a)Return air opening dimension.

(b)Filter rack dimension.

GEH Unit

(50 Hz) A B C D

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

S

018 015 46 23 18 23 18 8-1/4 x 9-3/4 13-1/2 4-3/4 1-3/8 3/4 3/4 44-3/4 21-3/4 16-5/8 18-1/2 4-1/4

060

048, 060

EXH Unit

(50 Hz) A B C D

Hi-042,

58 33 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 31-3/4 19-5/8 23-1/2 5-1/2

(a)

E F x G H J KL NPTIM NPTI N P Q R

(b)

S

070 N/A 58 39 21 29-1/2 23-1/2 13-7/8 x 13-7/8 18 5-1/4 1-1/2 1 1 56-3/4 37-3/4 19-5/8 23-1/2 5-1/2

access on either side of the filter.

3 in. clearance.

20 WSHP-SVX01Q-EN

Page 21

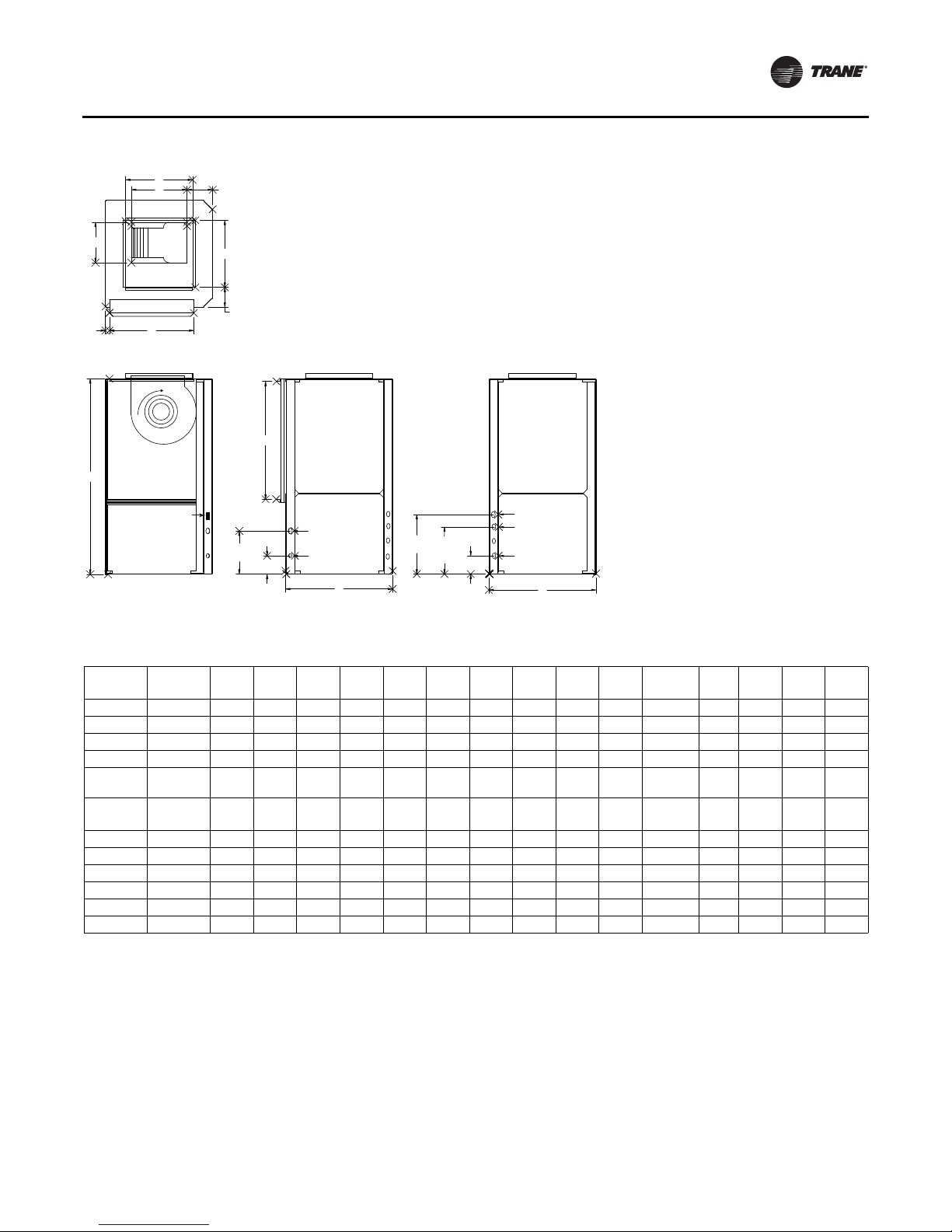

Figure 12. Left return/top supply (GEV/EXV)

D

L

F

Unit Dimensions

K

B

WCI mounting location

JM

TOP

LEFT SIDE

D

E

8 3/4”

H

8 5/8”

BLOWER

ACCESS

COMP/CONTROL

ACCESS

HI VOLT

LO VOLT

A

FRONT

12”

9 1/2”

G

3 5/8”

W.O .

DRAIN

W.I .

C

RIGHT SIDE

Table 10. Dimensional data left return/top supply (GEV/EXV)

GEV Unit

(60 Hz)

006 - 015 006-012 19-1/2 31-1/4 21-1/2 11-1/2 4 5-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

018 - 030 015-024 21-1/2 39-1/4 21-1/2 13-1/2 4 4 9-1/2 20-1/2 20 8-1/4 9-3/4 3/4 3/4 3/4 3/4

036, 042 030, 036 24-1/2 41-7/8 26-1/2 18 3-1/4 5-3/4 9-1/2 19 23 10-1/2 13-1/2 1/4 3/4 3/4 3/4

Std-48 Std-42 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-1/8 11-3/8 1/2 1 1 3/4

Hi-048,

EXV Unit

(60 Hz)

006-019 N/A 19-1/2 31-1/4 21-1/2 11-1/2 4 5-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

012-015 N/A 19-1/2 31-1/4 21-1/2 11-1/2 5-1/2 5-5/8 9-1/2 15 17 8-1/4 9-3/4 3/4 1/2 1/2 3/4

018-024 N/A 21-1/2 39-1/4 21-1/2 13-1/2 4 4 9-1/2 20-1/2 20 8-1/4 11-3/8 3/4 3/4 3/4 3/4

030-036 N/A 24-1/2 41-7/8 26-1/2 18 3-1/4 5-3/4 9-1/2 19 23 10-1/2 13-1/2 1/4 3/4 3/4 3/4

042-60 N/A 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Notes:

1. Units in a free return application will require more than a 1 in. clearance to provide proper air flow to the unit’s air-to-refrigerant coil.

060

GEV Unit

(50 Hz) A B C D E F G H J K L M

Hi-042,

048, 060

26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

EXV Unit

(50 Hz) A B C D E F G H J K L M

W.I.

NPTI

W.I.

NPTI

W.O.

NPTI

W.O.

NPTI

070 N/A 26-1/2 50-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Drain

FPT

Drain

FPT

WSHP-SVX01Q-EN 21

Page 22

Unit Dimensions

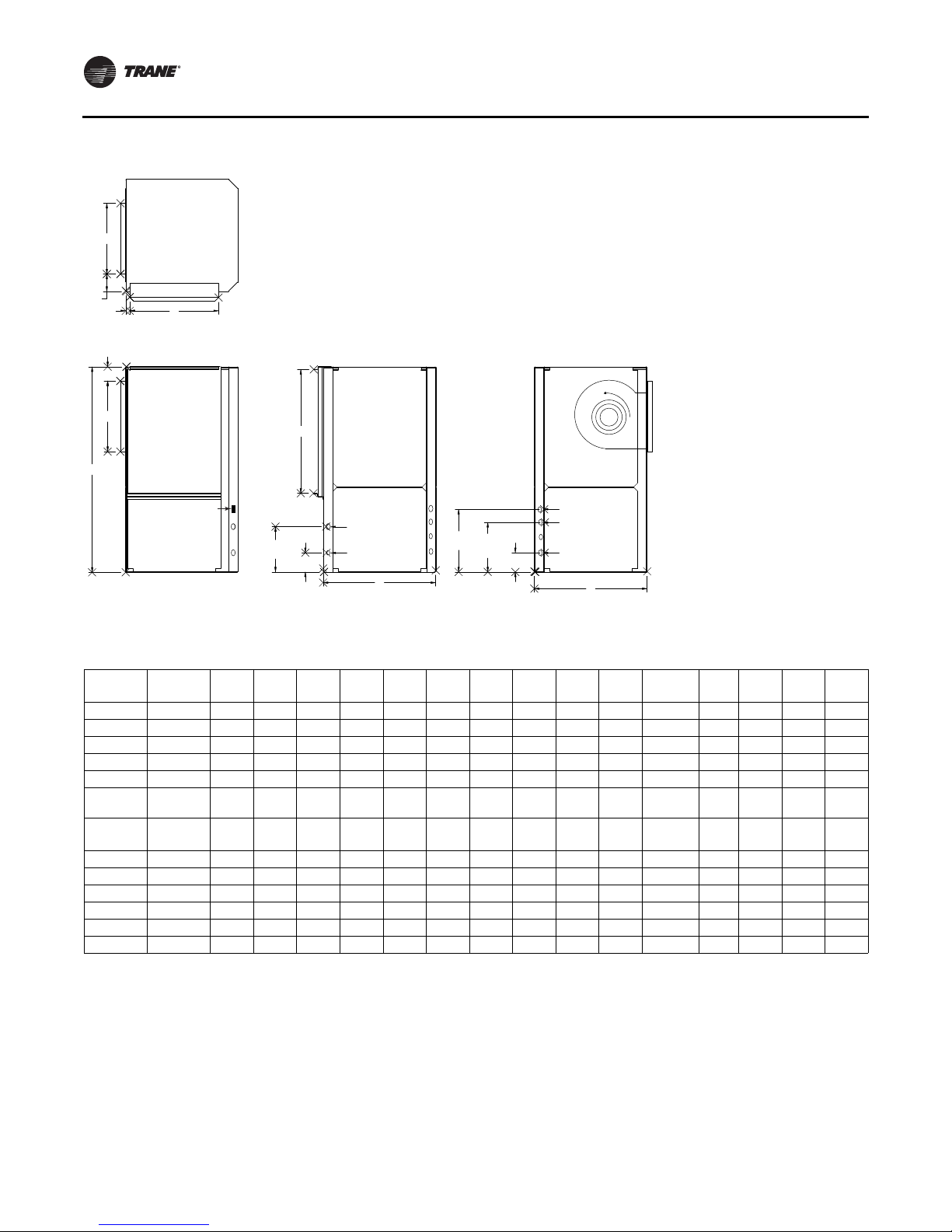

Figure 13. Left return/back supply (GEV/EXV)

D

E

M

F

D

B

J

TOP

WCI mounting location

LEFT SIDE

8 3/4”

H

3 5/8”

BLOWER

ACCESS

COMP/CONTROL

ACCESS

HI VOLT

LO VOLT

A

FRONT

W.O .

DRAIN

9 1/2”

12”

G

3 5/8”

W.I .

C

RIGHT SIDE

Table 11. Dimensional data left return/back supply (GEV/EXV)

GEV Unit

(60 Hz)

006 - 009 006 19-1/2 31-1/4 21-1/2 11-1/2 4 1-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

012 - 015 009-012 19-1/2 31-1/4 21-1/2 11-1/2 4-3/4 3-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

018 - 030 015-024 21-1/2 39-1/4 21-1/2 13-1/2 4 3-7/8 9-1/2 20-1/2 20 8-1/4 9-3/4 3/4 3/4 3/4 3/4

036, 042 030, 036 24-1/2 41-7/8 26-1/2 18 3-1/4 1-7/8 9-1/2 19 23 10-1/2 13-1/2 1/4 3/4 3/4 3/4

Std-48 Std-42 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-1/8 11-3/8 1/2 1 1 3/4

Hi-048,

EXV Unit

(60 Hz)

006-019 N/A 19-1/2 31-1/4 21-1/2 11-1/2 4 5-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

012-015 N/A 19-1/2 31-1/4 21-1/2 11-1/2 5-1/2 5-5/8 9-1/2 15 17 8-1/4 9-3/4 3/4 1/2 1/2 3/4

018-024 N/A 21-1/2 39-1/4 21-1/2 13-1/2 4 4 9-1/2 20-1/2 20 8-1/4 11-3/8 3/4 3/4 3/4 3/4

030-036 N/A 24-1/2 41-7/8 26-1/2 18 3-1/4 5-3/4 9-1/2 19 23 10-1/2 13-1/2 1/4 3/4 3/4 3/4

042-60 N/A 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Notes:

1. Units in a free return application will require more than a 1 in. clearance to provide proper air flow to the unit’s air-to-refrigerant coil.

060

GEV Unit

(50 Hz) A B C D E F G H J K L M

Hi-042,

048, 060

26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

EXV Unit

(50 Hz) A B C D E F G H J K L M

W.I.

NPTI

W.I.

NPTI

W.O.

NPTI

W.O.

NPTI

070 N/A 26-1/2 50-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Drain

FPT

Drain

FPT

22 WSHP-SVX01Q-EN

Page 23

Figure 14. Right return/top supply (GEV/EXV)

A

H

Unit Dimensions

F

D

L

K

M

B

WCI mounting location

HI VOLT

LOW VOLT

c

LEFT SIDE

3 5/8”

8 3/4”

BLOWER

ACCESS

COMP/CONTROL

ACCESS

W.O .

DRAIN

FRONT

W.I .

3 5/8”

9 1/2”

G

12”

D

E

J

TOP

RIGHT SIDE

Table 12. Right return/top supply (GEV/EXV)

GEV Unit

(60 Hz)

006 - 015 006 - 012 19-1/2 31-1/4 21-1/2 11-1/2 4 5-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

018 - 024 015-018 21-1/2 39-1/4 21-1/2 13-1/2 4 4 9-1/2 20-1/2 20 8-1/4 9-3/4 3/4 3/4 3/4 3/4

036, 042 030, 036 24-1/2 41-7/8 26-1/2 18 3-1/4 5-3/4 9-1/2 19 23 10-1/2 13-1/2 3/4 3/4 3/4 3/4

Std-48 Std-42 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-1/8 11-3/8 1/2 1 1 3/4

Hi-048,

EXV Unit

(60 Hz)

006-019 N/A 19-1/2 31-1/4 21-1/2 11-1/2 4 5-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

012-015 N/A 19-1/2 31-1/4 21-1/2 11-1/2 2-1/2 5-5/8 9-1/2 15 17 8-1/4 9-3/4 3/4 1/2 1/2 3/4

018-024 N/A 21-1/2 39-1/4 21-1/2 13-1/2 4 4 9-1/2 20-1/2 20 8-1/4 11-3/8 3/4 3/4 3/4 3/4

030-036 N/A 24-1/2 41-7/8 26-1/2 18 3-1/4 5-3/4 9-1/2 19 23 10-1/2 13-1/2 3/4 3/4 3/4 3/4

042-60 N/A 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Notes:

1. Units in a free return application will require more than a 1 in. clearance to provide proper air flow to the unit’s air-to-refrigerant coil.

GEV Unit

(50 Hz) A B C D E F G H J K L M

W.I.

NPTI

W.O.

NPTI

030 024 21-1/2 39-1/4 21-1/2 13-1/2 4 4 9-1/2 20-1/2 20 8-1/4 11-3/8 3/4 3/4 3/4 3/4

060

Hi-042,

048, 060

EXV Unit

(50 Hz) A B C D E F G H J K L M

26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

W.I.

W.O.

NPTI

NPTI

070 N/A 26-1/2 50-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Drain

FPT

Drain

FPT

WSHP-SVX01Q-EN 23

Page 24

Unit Dimensions

Figure 15. Right return/back supply (GEV/EXV)

F

D

B

COMP/CONTROL

WCI mounting location

HIGH VOLT

LOW VOLT

8 3/4”

3 5/8”

BLOWER

ACCESS

ACCESS

W.O .

DRAIN

W.I .

3 5/8”

D

E

J

TOP

H

9 1/2”

12”

G

M

C

LEFT SIDE

A

FRONT

RIGHT SIDE

Table 13. Dimensional data right return/back supply (GEV/EXV)

GEV Unit

(60 Hz)

006 - 009 006 19-1/2 31-1/4 21-1/2 11-1/2 4 1-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

012 - 015 009 - 012 19-1/2 31-1/4 21-1/2 11-1/2 6 1-1/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

018 - 024 015-018 21-1/2 39-1/4 21-1/2 13-1/2 4 3-7/8 9-1/2 20-1/2 20 8-1/4 9-3/4 3/4 3/4 3/4 3/4

036, 042 030, 036 24-1/2 41-7/8 26-1/2 18 3-1/4 1-7/8 9-1/2 19 23 10-1/2 13-1/2 3/4 3/4 3/4 3/4

Std-48 Std-42 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-1/8 11-3/8 1/2 1 1 3/4

Hi-048,

EXV Unit

(60 Hz)

006-019 N/A 19-1/2 31-1/4 21-1/2 11-1/2 4 1-3/4 9-1/2 15 17 6-7/8 8 3/4 1/2 1/2 3/4

012-015 N/A 19-1/2 31-1/4 21-1/2 11-1/2 2 1-1/4 9-1/2 15 17 8-1/4 9-3/4 3/4 1/2 1/2 3/4

018-024 N/A 21-1/2 39-1/4 21-1/2 13-1/2 4 3-7/8 9-1/2 20-1/2 20 8-1/4 11-3/8 3/4 3/4 3/4 3/4

030-036 N/A 24-1/2 41-7/8 26-1/2 18 3-1/4 1-7/8 9-1/2 19 23 10-1/2 13-1/2 3/4 3/4 3/4 3/4

042-60 N/A 26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Notes:

1. Units in a free return application will require more than a 1 in. clearance to provide proper air flow to the unit’s air-to-refrigerant coil.

GEV Unit

(50 Hz) A B C D E F G H J K L M

W.I.

NPTI

W.O.

NPTI

030 024 21-1/2 39-1/4 21-1/2 13-1/2 4 3-7/8 9-1/2 20-1/2 20 8-1/4 11-3/8 3/4 3/4 3/4 3/4

060

Hi-042,

048, 060

EXV Unit

(50 Hz) A B C D E F G H J K L M

26-1/2 46-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

W.I.

W.O.

NPTI

NPTI

070 N/A 26-1/2 50-7/8 30-1/2 18 4-1/4 2 9-1/2 29 27-7/8 13-7/8 13-7/8 1/2 1 1 3/4

Drain

FPT

Drain

FPT

24 WSHP-SVX01Q-EN

Page 25

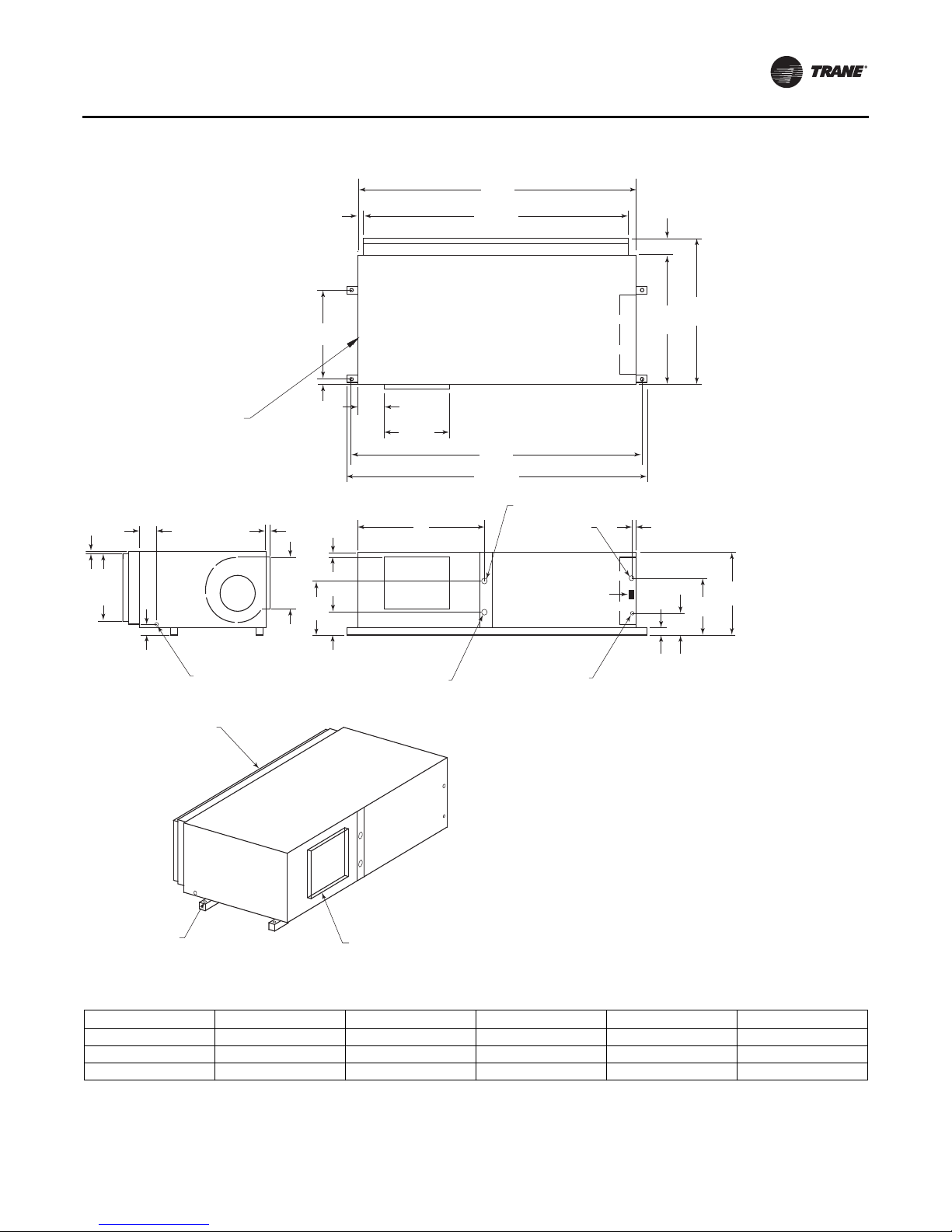

Figure 16. Right return/left supply - GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

”

79”

5/8”

BLOWER ACCESS

PANEL

4 7/8”

1 3/4”

23 7/8”

7 5/8”

(54)

2 1/8"

18 3/8”

1”

1 1/4”

A

74 1/2”

81”

85”

TOP VIE W

W.O. “D” NPTI

1 1/8” DIA.

24 VOLT

36”

1 1/2”

Unit Dimensions

4 5/8”

40 5/8”

18 3/4”

BACK SIDE

MOUNTING HOLE

3 1/8”

DRAIN CONNECTION

1/2" (22) SCHEDULE 40 PVC

RETURN AIR

OPENING

1” DIA.

4X’s

14 1/2”

B

C

W.I. “D” NPTI

SUPPLY OPENING

1” DUCT FLANGE

LEFT SIDE

WCI mounting location

HIGH VOLTAGE

7/8” DIA.

2 1/4”

23 1/4

16 1/2”

6 1/2”

Table 14. Dimensional data right return/left supply - GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

GEH (60 Hz) GEH (50 Hz) A B C D

072 — 36-1/4 in. 15-5/8 in. 6-5/8 in. 1-1/4 in.

090 072 36-1/8 in. 12-3/4 in. 6-3/4 in. 1-1/4 in.

120 090 36-1/8 in. 13 in. 7-1/4 in. 1-1/2 in.

WSHP-SVX01Q-EN 25

Page 26

Unit Dimensions

”

Figure 17. Right return/back supply - GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

79”

74 1/2”

81”

85”

23 7/8”

2 1/8"

1 3/4”

18 3/8”

6 1/8”

36”

4 5/8”

40 5/8”

5/8”

18 3/4”

3 1/8"

BLOWER ACCESS

4 7/8”

DRAIN CONNECTION

1/2" (22) SCHEDULE 40 PVC

PANEL

14 1/2”

1 1/4”

TOP VIE W

W.O. “D” NPTI

A 1 1/2”

B

C

W.I. “D” NPTI

LEFT SIDE

RETURN AIR

OPENING

24 VOLT

1 1/8” DIA.

WCI mounting location

HIGH VOLTAGE

7/8” DIA.

2 1/4”

23 1/4

16 1/2”

6 1/2”

Table 15. Dimensional data right return/back supply - GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

GEH (60 Hz) GEH (50 Hz) A B C D

072 — 36-1/4 in. 15-5/8 in. 6-5/8 in. 1-1/4 in.

090 072 36-1/8 in. 12-3/4 in. 6-3/4 in. 1-1/4 in.

120 090 36-1/8 in. 13 in. 7-1/4 in. 1-1/2 in.

26 WSHP-SVX01Q-EN

1” DIA.

MOUNTING HOLE

4X’s

SUPPLY OPENING

1” DUCT FLANGE

Page 27

Figure 18. Left return/right supply GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

79”

40 5/8”

4 5/8”

36”

74 1/2”

1 3/4”

24 3/4”

Unit Dimensions

23 1/4"

16 1/2”

1 1/2”

2 1/4”

6 1/2”

LEFT SIDE

RETURN AIR

OPENING

TOP VIE W

W.O. “D” NPTI

24 VOLT

1 1/8” DIA.

WCI mounting location

HIGH VOLTAGE

7/8” DIA.

81”

85”

18 3/8”

A

W.I. “D” NPTI

7 5/8”

1 1/4”

C

1 1/4”

14 1/2”

B

DRAIN CONNECTION

1/2” SCHEDULE 40 PVC

BLOWER ACCESS

PANEL

1”

4 7/8”

5/8”

18 3/4”

3 1/8”

BACK SIDE

1” DIA.

MOUNTING HOLE

4X’S

Table 16. Dimensional data left return/right supply - GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

GEH (60 Hz) GEH (50 Hz) A B C D

072 — 36-1/8 in. 17 in. 8 in. 1-1/4 in.

090 072 36-1/8 in. 13-3/4 in. 7-3/4 in. 1-1/4 in.

120 090 36-1/8 in. 13 in. 7-1/4 in. 1-1/2 in.

WSHP-SVX01Q-EN 27

SUPPLY OPENING

1” DUCT FLANGE

Page 28

Unit Dimensions

”

Figure 19. Left return/back supply GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

79”

23 1/4"

(591)

40 5/8”

16 1/2"

(419)

36”

1 1/2”

4 5/8”

W.O. “D” NPTI

24 VOLT

1 1/8” DIA.

WCI mounting location

74 1/2”

81”

85”

TOP VIE W

A

6 1/2”

1 3/4”

18 3/8”

B

C

24 3/4”

6 1/8”

14 1/2”

1 1/4”

BLOWER ACCESS

PANEL

1 1/4”

4 7/8”

5/8”

18 3/4

6 1/2”

1” DIA.

MOUNTING HOLE

4X’S

2 1/4”

LEFT SIDE

HIGH VOLTAGE

7/8” DIA.

SUPPLY OPENING

1” DUCT FLANGE

W.I. “D” NPTI

RETURN AIR

OPENING

DRAIN CONNECTION

1/2" SCHEDULE 40 PVC

3 1/8”

Table 17. Dimensional data left return/back supply GEH 6 to 10 tons (60 Hz); GEH 6 to 7.5 tons (50 Hz)

GEH (60 Hz) GEH (50 Hz) A B C D

072 — 36-1/8 in. 17 in. 8 in. 1-1/4 in.

090 072 36-1/8 in. 13-3/4 in. 7-3/4 in. 1-1/4 in.

120 090 36-1/8 in. 13 in. 7-1/4 in. 1-1/2 in.

28 WSHP-SVX01Q-EN

Page 29

Unit Dimensions

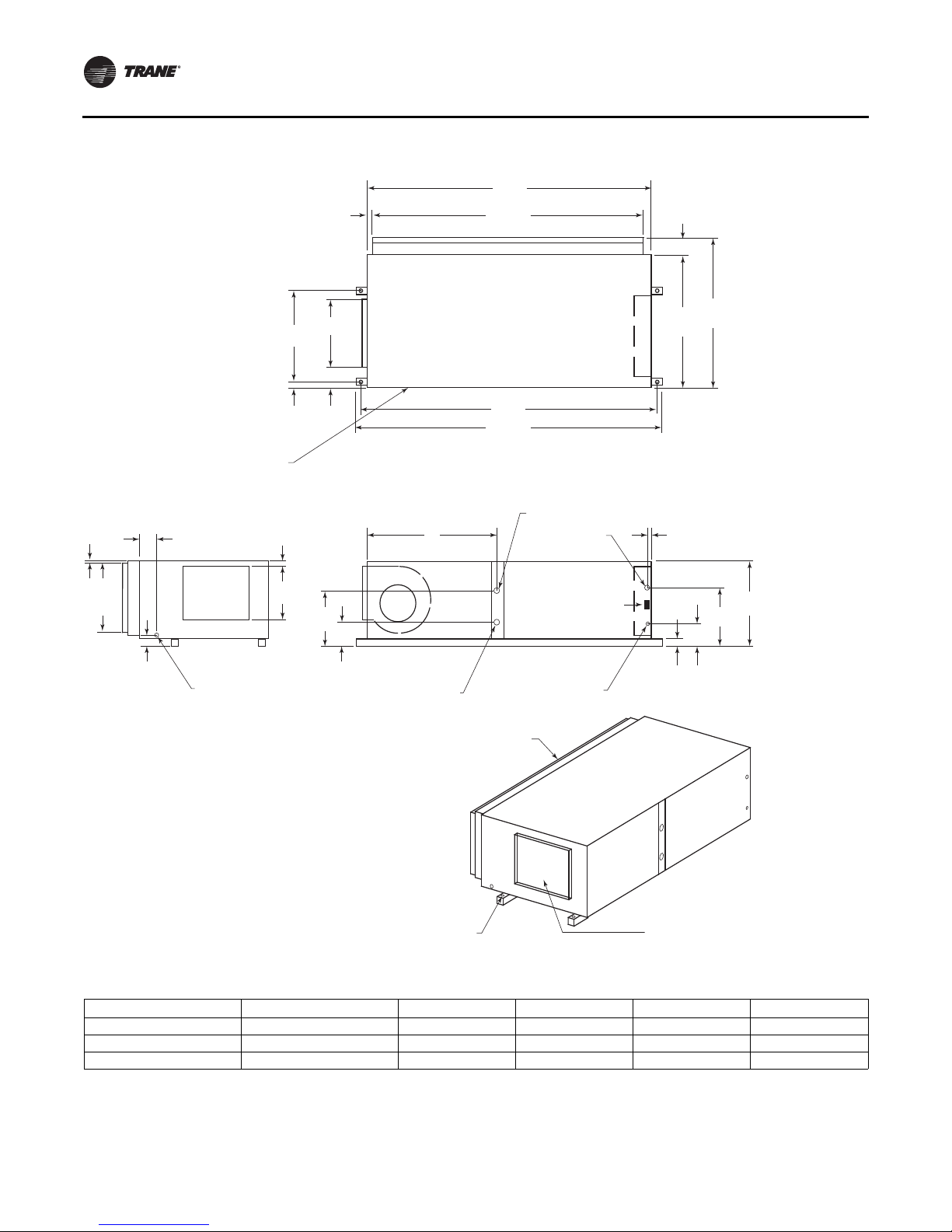

Figure 20. Right return/left supply GEH 12.5 to 15 tons (150-180) 60 Hz; GEH 10 to 12.5 tons (120-150) 50 Hz

85"

4 5/8"

42"

29 3/4"

2"

74 1/2"

46 5/8"

1 3/8"

23 3/4"

BACK SIDE

BLOWER ACCESS

4 7/8"

3 1/8"

RETURN AIR

OPENING

PANEL

1"

DRAIN CONNECTION

1/2" SCHEDULE 40 PVC

16 3/4"

24 7/8"

2 1/4"

2"

5 5/8"

7 1/8"

21 3/8"

61 1/4"

W.I. 1 1/2"

NPTI

87"

91"

LEFT SIDE

TOP VIEW

W.O. 1 1/2"

NPTI

24 VOLT

1 1/8" DIA.

WCI mounting location

HIGH VOLTAGE

7/8" DIA.

2 1/4"

2 1/4"

30 1/4"

22 3/4"

9 1/8"

MOUNTING HOLE

1" DIA.

4X'S

WSHP-SVX01Q-EN 29

SUPPLY OPENING

1" DUCT FLANGE

Page 30

Unit Dimensions

Figure 21. Right return/back supply GEH 12.5 to 15 tons (60 Hz); GEH 10 to 12.5 tons (50 Hz)

85"

1 3/8"

23 3/4"

BLOWER ACCESS

4 7/8"

PANEL

29 3/4"

2"

16 3/4"

2 1/4"

24 7/8”

2"

21 3/8"

7 1/8"

5 5/8”

TOP VIEW

61 1/4"

74 1/2"

87"

91"

W.O. 1 1/2”

NPTI

WCI mounting location

24 VOLT

1 1/8” DIA.

4 5/8"

46 5/8"

42"

1 1/2"

30 1/4"

22 3/4"

3 1/8"

DRAIN CONNECTION

1/2” SCHEDULE 40 PVC

W.I. 1 1/2" (38)

NPTI

MOUNTING HOLE

1” DIA.

4X’S

LEFT SIDE

RETURN AIR

OPENING

HIGH VOLTAGE

7/8” DIA.

2 1/4"

9 1/8"

SUPPLY OPENING

1” DUCT FLANGE

30 WSHP-SVX01Q-EN

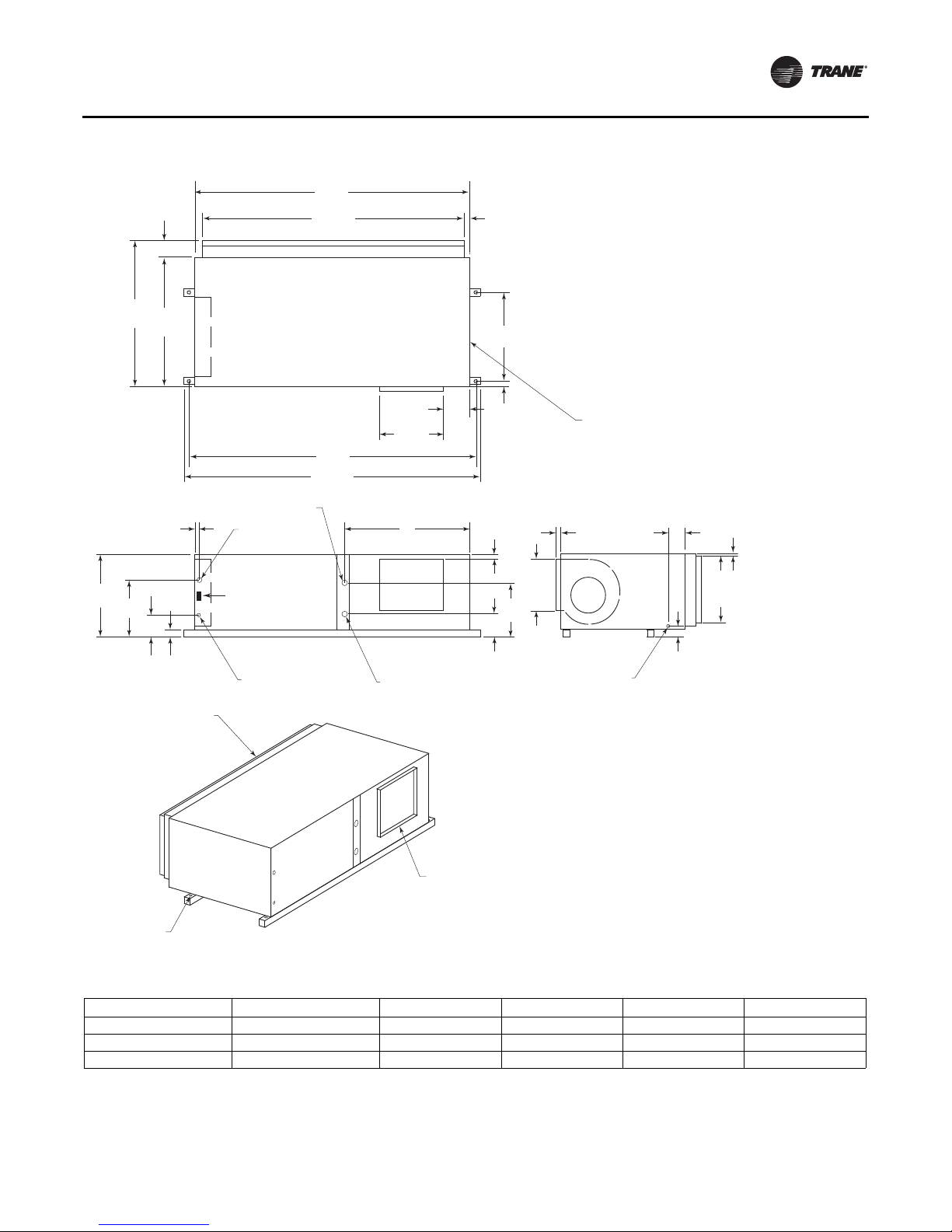

Page 31

Figure 22. Left return/right supply GEH 12.5 to 15 tons (60 Hz); GEH 10 to 12.5 tons (50 Hz)

85”

46 5/8”

42”

4 5/8”

74 1/2”

2"

29 3/4”

Unit Dimensions

30 1/4"

22 3/4"

2 1/8”

9 1/8”

LEFT SIDE

2 1/4”

TOP VIEW

W.O. 1 1/2”

NPTI

24 VOLT

1 1/8” DIA.

WCI mounting location

HIGH VOLTAGE

7/8” DIA.

RETURN AIR

87”

91”

OPENING

21 3/8”

39 1/2”

W.I. 1 1/2”

NPTI

7 1/8”

2 1/4”

2”

16 3/4"

24 7/8"

5 5/8"

DRAIN CONNECTION

1/2" SCHEDULE 40 PVC

BLOWER ACCESS

PANEL

1”

4 7/8”

1 3/8"

23 3/4"

3 1/8”

BACK SIDE

MOUNTING HOLE

1” DIA.

WSHP-SVX01Q-EN 31

SUPPLY OPENING

1” DUCT FLANGE

4X’S

Page 32

Unit Dimensions

Figure 23. Left return/back supply GEH 12.5 to 15 tons (60 Hz); GEH 10 to 12.5 tons (50 Hz)

85"

30 1/4"

46 5/8"

22 3/4"

4 5/8"

42"

2 1/8"

W.O. 1 1/2" NPTI

24 VOLT

1 1/8" DIA.

WCI mounting location

74 1/2"

87"

91"

TOP VIEW

39 1/2"

2"

21 3/8"

5 5/8"

7 1/8"

24 7/8"

29 3/4"

2 1/4"

BLOWER ACCESS

PANEL

2"

16 3/4"

4 7/8"

1 3/8"

23 3/4"

9 1/8"

2 1/4"

HIGH VOLTAGE

7/8" DIA.

LEFT SIDE

MOUNTING HOLE

1" DIA.

4X'S

32 WSHP-SVX01Q-EN

W.I. 1 1/2"

NPTI

SUPPLY OPENING

1" DUCT FLANGE

DRAIN CONNECTION

1/2" SCHEDULE 40 PVC

RETURN AIR

OPENING

3 1/8"

Page 33

Unit Dimensions

Figure 24. Front return/back supply

ACCESS PANEL FOR

SHEAVES AND BELTS

1”

13 1/2"

24 VOLT

46 1/2"

HIGH VOLTAGE

7/8" DIA.

1 5/8"

1 1/8"

WCI mounting location

15"

5"

(a)

GEV 6 to 10 tons (60 Hz); 6 and 7.5 tons (50 Hz)

15 3/4”

13 18"

39 5/8"

42"

38 7/8"

22 3/8"

W.I. "C" NPTI

3/4"

SUPPLY OPENING

1" DUCT FLANGE

W.O. "C" NPTI

DRAIN 3/4" NPTI

11 1/2"

A

1 7/8"

31 3/8"

36 1/4"

4 7/8"

62 5/8"

B

RETURN AIR

OPENING

(a)NEC requires that the GEV072-300 front return must be a non-ducted return.

Table 18. Dimensional data front return/back supply GEV 6 to 10 tons (60 Hz); 6 and 7.5 tons (50 Hz)

Unit (60 Hz) Unit (50 Hz) A B C

6 ton — 6-5/8 in. 18-3/8 in. 1-1/4 in.

7.5 ton 6 ton 6-5/8 in. 18-3/8 in. 1-1/4 in.

10 ton 7.5 ton 6-1/2 in. 18-1/2 in. 1-1/2 in.

WSHP-SVX01Q-EN 33

Page 34

Unit Dimensions

Figure 25. Front return/top supply

ACCESS PANEL FOR

SHEAVES AND BELTS

1"

38 7/8"

63"

24 VOLT

1 1/8"

22 3/8"

HIGH VOLTAGE

7/8" DIA.

WCI mounting location

15"

5"

1 5/8"

(a)

GEV 6 to 10 tons (60 Hz); 6 and 7.5 tons (50 Hz)

15 5/8

1 1/8"

13 3/8"

W.O. "C" NPTI

DRAIN 3/4" NPTI

11 1/2"

A

1 7/8"

31 3/8"

36 1/4"

4 7/8"

62 5/8"

B

3/4"

13 1/4"

W.I. "C" NPTI

SUPPLY OPENING

1" DUCT FLANGE

39 5/8"

42"

RETURN AIR

OPENING

(a)NEC requires that the GEV072-300 front return must be a non-ducted return.

Table 19. Dimensional data front return/top supply GEV 6 to 10 tons (60 Hz); 6 and 7.5 tons (50 Hz)

Unit (60 Hz) Unit (50 Hz) A B C

6 ton — 6-5/8 in. 18-3/8 in. 1-1/4 in.

7.5 ton 6 ton 6-5/8 in. 18-3/8 in. 1-1/4 in.

10 ton 7.5 ton 6-1/2 in. 18-1/2 in. 1-1/2 in.

34 WSHP-SVX01Q-EN

Page 35

Unit Dimensions

Figure 26. Back return/front supply

ACCESS PANEL FOR

SHEAVES AND BELTS

1"

38 7/8"

24 VOLT

1 1/8"

22 3/8"

3/4"

HIGH VOLTAGE

7/8" DIA.

1 5/8"

WCI mounting location

15"

5"

(a)

GEV 6 to 10 tons (60 Hz); 6 and 7.5 ton (50 Hz)

39 5/8"

13 1/8"

15 3/4”

42"

62 5/8"

W.I. "C" NPTI

4 7/8"

36 1/4"

31 3/8"

1 1/8"

13 1/2"

W.O. "C" NPTI

DRAIN 3/4" NPTI

11 1/2"

A

1 7/8"

46 1/2"

B

RETURN AIR

OPENING

SUPPLY OPENING

1" DUCT FLANGE

(a)NEC requires that the GEV072-300 front return must be a non-ducted return.

Table 20. Dimensional data back return/front supply GEV 6 to 10 tons (60 Hz); 6 and 7.5 ton (50 Hz)

Unit (60 Hz) Unit (50 Hz) A B C

6 ton — 6-5/8 in. 18-3/8 in. 1-1/4 in.

7.5 ton 6 ton 6-5/8 in. 18-3/8 in. 1-1/4 in.

10 ton 7.5 ton 6-1/2 in. 18-1/2 in. 1-1/2 in.

WSHP-SVX01Q-EN 35

Page 36

Unit Dimensions

Figure 27. Back return/top supply

ACCESS PANEL FOR

SHEAVES AND BELTS

1"

38 7/8"

24 VOLT

1 1/8"

22 3/8"

3/4"

HIGH VOLTAGE

7/8" DIA.

1 5/8"

WCI mounting location

5"

RETURN AIR

OPENING

15"

(a)

GEV 6 to 10 tons (60 Hz); 6 and 7.5 ton (50 Hz)

63"

13 1/4"

W.I. "C" NPTI

39 5/8"

15 5/8”

42"

13 1/2"

1 1/8"

W.O. "C" NPTI

DRAIN 3/4" NPTI

A

1 7/8"

11 1/2"

31 3/8"

4 7/8"

36 1/4"

62 5/8"

B

(a)NEC requires that the GEV072-300 front return must be a non-ducted return.

Table 21. Dimensional data back return/top supply GEV 6 to 10 tons (60 Hz); 6 and 7.5 ton (50 Hz)

Unit (60 Hz) Unit (50 Hz) A B C

6 ton — 6-5/8 in. 18-3/8 in. 1-1/4 in

7.5 ton 6 ton 6-5/8 in. 18-3/8 in. 1-1/4 in.

10 ton 7.5 ton 6-1/2 in. 18-1/2 in. 1-1/2 in.

36 WSHP-SVX01Q-EN

SUPPLY OPENING

1" DUCT FLANGE

Page 37

Unit Dimensions

/2

Figure 28. Front return/back supply

15 7/8"

49 1/8"

WCI mounting

location

24 VOLT

1 1/8"O.D.

6 7/8"

20 1/2"20 1

(a)

GEV 12.5 to 15 tons (60 Hz); GEV 10 and 12.5 ton (50 H)z

4 3/4"

31 1/2"

74 1/2"

81 5/8"

36 1/4"

TOP VIEW

18 5/8"

31 1/2"

38 7/8"

67 5/8"

27 1/8"

CONTROL

BOX ACCESS

10"

W.O. 1 1/2"

NPTI

DRAIN 3/4"

NPTI

12 1/2"

23 1/2

HIGH VOLTAGE

7/8" O.D.

2 3/8"

1"

FRONT VIEW

W.I. 1 1/2"

NPTI

2 5/8"

4 1/4"

SIDE VIEW

RETURN AIR

OPENING

(a)NEC requires that the GEV072-300 front return must be a non-ducted return.

WSHP-SVX01Q-EN 37

Page 38

Unit Dimensions

1

/2

"

"

"

Figure 29. Back return/front supply GEV 12.5 to 15 tons (60 Hz); GEV 10 and 12.5 ton (50 Hz)

81 5/8"

38 7/8"

27 1/8"

1/8

24 VOLT

1 1/8"

O.D.

WCI mounting

location

36 1/4"

6 7/8"

4 3/4"

15 7/8"

49 1/8"

20 1/2"

31 1/2"

67 5/8"

31 1/2"

CONTROL

BOX ACCESS

74 1/2"

TOP VIEW

18 5/8"

10"

W.O. 1 1/2"

NPTI

DRAIN 3/4"

NPTI

12 1/2"

23 1/2

1"

HIGH VOLTAGE

7/8" (22) O.D.

SIDE VIEW

FRONT VIEW

2 3/8"

W.I. 1 1/2"

RETURN AIR

OPENING

NPTI

2 5/8"

4 1/4"

38 WSHP-SVX01Q-EN

Page 39

Unit Dimensions

Figure 30. Front return/top supply

36 1/4"

4 3/4"

24 VOLT

1 1/8" O.D.

WCI mounting

location

6 7/8"

20 1/2"

(a)