Trane CGAX015, CGAX017, CGAX020, CGAX023, CGAX026 Installation Operation & Maintenance

...

Installation

Operation

Maintenance

CGAX/CXAX 015 - 060

Air-cooled scroll chillers and heat pumps

43-164 kW

CG-SVX027D-GB

Original instructions

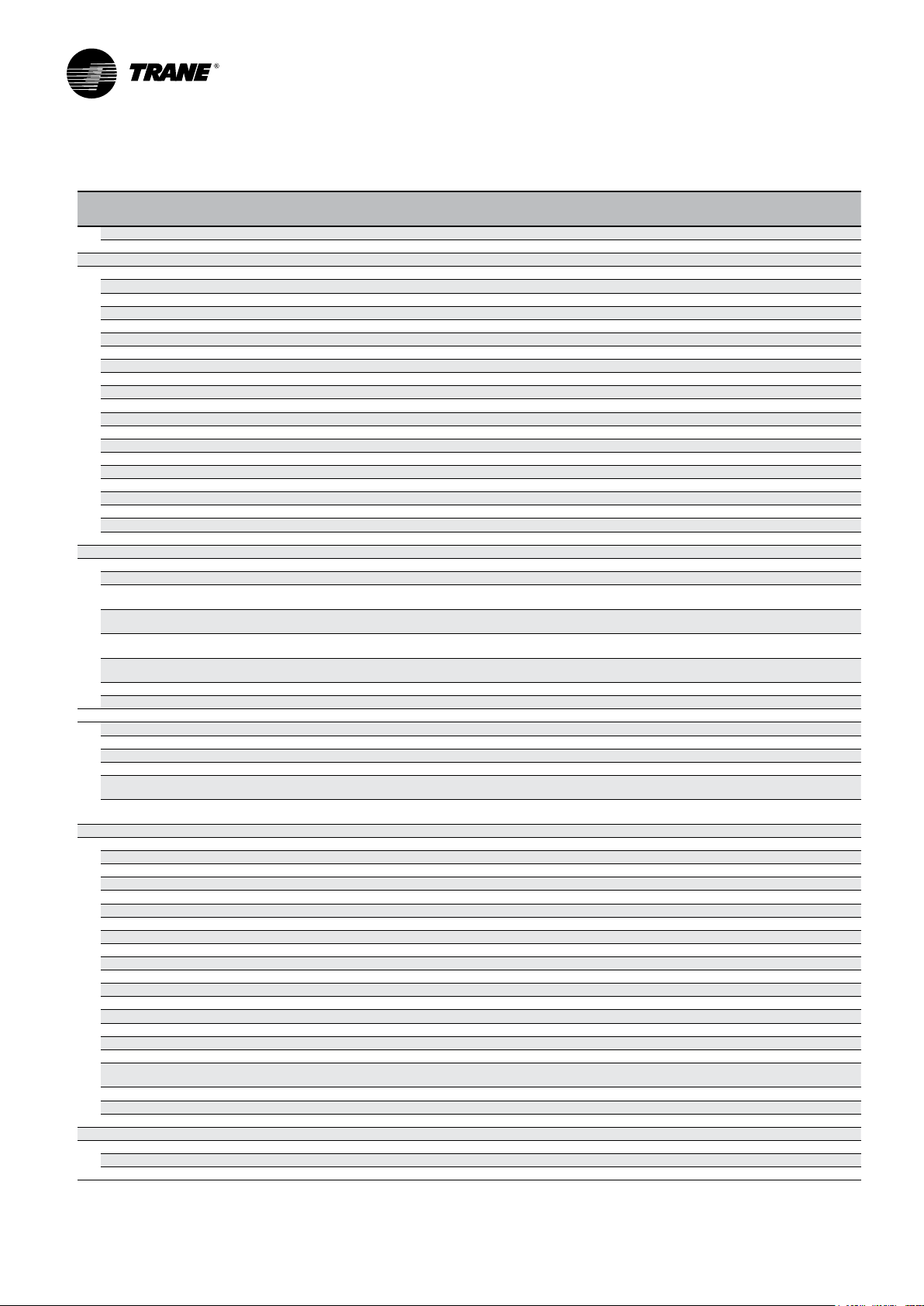

Table of Contents

General Information .......................................................................................... 3

Model Number Description ..............................................................................5

Unit Description ................................................................................................. 7

Pre-Installation ...................................................................................................8

General Data .................................................................................................... 10

Installation – Mechanical ................................................................................ 18

Hydraulic Data .................................................................................................. 23

Operating Map ................................................................................................. 25

Partial Heat Recovery ......................................................................................26

Supplemental heat .......................................................................................... 27

Installation – Electrical ....................................................................................28

Electrical Data .................................................................................................. 30

Communication Interface Options ................................................................. 34

Operating Principles ........................................................................................ 35

Variable Primary Flow ..................................................................................... 40

General Start up ..............................................................................................41

Pre-Start Check List (Sample) ........................................................................ 44

Operation .........................................................................................................45

Maintenance ....................................................................................................46

Troubleshooting Guide .................................................................................... 51

2 © 2019 Trane

CG-SVX027D-GB

General Information

Foreword

These instructions are given as a guide to good practice

in the installation, start-up, operation, and maintenance

by the user, of Trane CGAX chillers or CXAX heat pumps.

They do not contain full service procedures necessary

for the continued successful operation of this equipment.

The services of a qualified technician should be

employed through the medium of a maintenance

contract with a reputable service company. Read this

manual thoroughly before unit start-up.

Units are assembled, pressure tested, dehydrated,

charged and tested in accordance with factory standard

before shipment.

Warnings and cautions

Warnings and Cautions appear at appropriate sections

throughout this manual. Your personal safety and the

proper operation of this machine require that you follow

them carefully. The constructor assumes no liability

for installations or servicing performed by unqualified

personnel.

WARNING!: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION!: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices or for equipment or property-damage only

accidents.

CAUTION!: Time before to work on the electrical panel

of the unit with Low Ambient option: once the unit is

off (confirmed by the extinction of the display), it is

mandatory to wait five minutes before working on the

electrical panel.

Reception

On arrival, inspect the unit before signing the delivery

note. Specify any visible damage on the delivery note,

and send a registered letter of protest to the last carrier

of the goods within 7 days of delivery.

Notify the local TRANE sales office at the same

time. The delivery note must be clearly signed and

countersigned by the driver.

Any concealed damage shall be notified by a registered

letter of protest to the last carrier of the goods within

7 days of delivery. Notify the local TRANE sales office

at the same time.

Important notice: No shipping claims will be accepted

by TRANE if the above mentioned procedure is not

respected.

For more information, refer to the general sales

conditions of your local TRANE sales office.

Note: Unit inspection in France.

Delay to send registered letter in case of visible and

concealed damage is only 72 hours.

Warranty

Warranty is based on the general terms and conditions

of the manufacturer. The warranty is void if the

equipment is repaired or modified without the written

approval of the manufacturer, if the operating limits are

exceeded or if the control system or the electrical wiring

is modified. Damage due to misuse, lack of maintenance

or failure to comply with the manufacturer’s instructions

or recommendations is not covered by the warranty

obligation. If the user does not conform to the rules of

this manual, it may entail cancellation of warranty and

liabilities by the manufacturer.

Safety recommendations

To avoid death, injury, equipment or property damage,

the following recommendations should be observed

during maintenance and service visits:

1. The maximum allowable pressures for system leak

testing on low and high pressure side are given in the

chapter “Installation”. Do not exceed test pressure by

using an appropriate device.

2. Disconnect the main power supply before any

servicing on the unit.

3. Service work on the refrigeration system and the

electrical system should be carried out only by

qualified and experienced personnel.

CG-SVX027D-GB

3

General Information

Maintenance contract

It is strongly recommended that you sign a maintenance

contract with your local Service Agency. This contract

provides regular maintenance of your installation by a

specialist in our equipment.

Regular maintenance ensures that any malfunction is

detected and corrected in good time and minimizes

the possibility that serious damage will occur. Finally,

regular maintenance ensures the maximum operating

life of your equipment.

We would remind you that failure to respect these

installation and maintenance instructions may result in

immediate cancellation of the warranty.

Training

To assist you in obtaining the best use of it and

maintaining it in perfect operating condition over a long

period of time, the manufacturer has at your disposal a

refrigeration and air conditioning service school.

The principal aim of this is to give operators and

technicians a better knowledge of the equipment they

are using, or that is under their charge. Emphasis is

particularly given to the importance of periodic checks on

the unit operating parameters as well as on preventive

maintenance, which reduces the cost of owning the unit

by avoiding serious and costly breakdown.

4

CG-SVX027D-GB

Model Number Description

Digit 1-4 — Chiller Model

CGAX = Cooling-only unit

CXAX = Heat pump unit

Digit 5-7 — Unit Nominal Tonnage

015

017

020

023

026

030

036

039

045

035

040

046

052

060

Digit 8 — Unit Voltage

E = 400V/3ph/50Hz

Digit 9 — Manufacturing Plant

1 = Europe

Digit 18 — Freeze Protection (Factory-Installed Only)

X = Without freeze protection

2 = With freeze protection by heaters

3 = With freeze protection by pump activation

Digit 19, 20 — Open for future options

Digit 21 — Evaporator Application

A = Comfort application (5°C/20°C)

B = Process application (CGAX: -12°C/5°C;

CXAX: -10°C/5°C)

Digit 22 — Evaporator Water Connection

1 = Grooved pipe

3 = Grooved pipe, couplings and pipe stub

Digit 23 — Condensor

B = Standard Aluminum Fin coil for CXAX

E = Epoxy Aluminum Fin coil for CGAX

H = MCHE for CGAX

J = E-coated MCHE for CGAX

Digit 24 — Heat Recovery

X = None

2 = Partial Heat Recovey

Digit 10-11 — Design Sequence

A = Factory asigned

0 = Factory asigned

Digit 12 — Efficiency Level

1 = Standard Efficiency (SE)

2 = High Efficiency (HE)

Digit 13 — Agency Listing

E = CE Certification

Digit 14 — Pressure Vessel Code

4 = Pressure Equipment Directive (PED)

Digit 15 — Condenser Temperature Range

A = Standard ambient (5°C/46°C)

C = Low ambient CGAX (-18°C/46°C) - CXAX cooling

mode (-10°C/46°C)

Digit 16, 17 — Open for future options

Digit 25 — Open for future options

Digit 26 — Starter Type

A = Across-the-line starter

B = Solid State Soft Starter

Digit 27, 28, 29 — Open for future options

Digit 30 — Human Interface

A = Standard Display

B = Deluxe Display

X = Without Display

Digit 31 — Communication Options

X = without remote communication

1 = Modbus Interface

2 = LonTalk Interface

4 = BACnet Interface

Digit 32 — Customer Input/Output extension module

X = None

A = With (1A4)

CG-SVX027D-GB

5

Model Number Description

Digit 33 — Chiller Smart Sequencer

X = None

Digit 34 — Open for future options

Digit 35 — Pump management

X = Without contactors and pumps

2 = Contactors for single pump external to the unit

4 = Contactor for twin pump external to the unit

5 = Single pump package low pressure

6 = Single pump package high pressure

7 = Twin pump package low pressure

8 = Twin pump package high pressure

Digit 36 — Pump Flow Control

X = Constant Flow (no pump flow control)

B = Manual Flow Setpoint on VFD

C = Variable primary Flow (constant delta T)

Digit 37 — Buffer Tank

X = No Tank

1 = With Tank

Digit 44 — Literature language

B = Spanish

C = German

D = English

E = French

H = Dutch

J = Italian

M = Swedish

N = Turkish

P = Polish

R = Russian

T = Czech

U = Greek

V = Portuguese

Y = Romanian

3 = Hungarian

Digit 45 — Under/Over Voltage Protection

X = None

1 = With

Digit 46 — Open for future options

Digit 38 — Open digit for future options

Digit 39 — Installation Accessories

1 = None

4 = Neoprene pads

Digit 40 — Open digit for future options

Digit 41 — Acoustical options

2 = High external static pressure

3 = Standard

4 = Low Noise

Digit 42 — Condenser Protection

X = Without

A = Condenser Guard Grill

Digit 43 — Open digit for future options

Digit 47 — Customer witness performance test

X = None

Digit 48 — Open for future options

Digit 49 — Supplementary Heat Control

X = None

1 = With

Digit 50 — Special design

X = Standard

S = Special design

6

CG-SVX027D-GB

Unit Description

Conquest chillers, CGAX, air cooled scroll compressor

type liquid chillers and CXAX heat pumps, are

designed for outdoor installation. Units can have one

or two independent refrigerant circuits, two or more

compressors per circuit. Unit are packaged with an

evaporator made with a braze plate heat exchanger, and

one or more condenser coils.

Each unit is completely assembled, hermetic package,

refrigerant circuit factory piped, electrical components

wired, leak tested, dehydrated, charged and tested

for proper control operations prior to shipment. The

chilled water inlet and outlet openings are covered for

shipment.

A new generation of chiller control systems, providing

improved control capabilities. Integrated safety protocols

to protect both compressor and motor from electrical

faults like thermal overload and phase reversal.

Each refrigerant circuit is provided with filter, electronic

expansion valve, and charging valves.

In cooling mode on the CXAX or on the CGAX, the

evaporator is a brazed plate and frame heat exchanger

equipped with water drain and vent connections on the

water piping.

Condenser coil is available in four different

configurations: fin and tube with aluminium fins, or

black epoxy pre-coating aluminum fins for the heat

pump versions, and MicroChannel type or E-coating

Microchannel type for the cooling only versions.

Accessory/options information

Check all the accessories and loose parts which are

shipped with the unit against the original order. Included

in these items will be rigging diagrams, wiring diagrams,

and service literature, which are placed inside the control

panel and/or starter panel for shipment. Also check for

optional components, such as couplings and pipe stubs

or neoprene pads.

The following pictograms can be found on the unit. Take

necessary precautions to avoid damage and injury.

Figure 1 - Warning pictograms

1 = Risk that unit is powered up

2 = Risk hazard due to fan rotation

3 = Risk hazard of burns on compressors or refrigeration

piping

4 = Unit contains refrigerant gas. See specific warnings.

5 = Risk of residual voltage when speed drive or

softstarter or Low Ambient options are present

6 = Unit under pressure

7 = Risk to cut, particularly on heat exchanger fins

8 = Read instructions before installation

9 = Disconnect all electric power before servicing

10 = Read technical instructions

CG-SVX027D-GB

7

Pre-Installation

Mandatory Start-up Checklist

This checklist is not intended to be a substitution for

the contractors installation instruction. This checklist is

intended to be a guide for the Trane technician just prior

to unit ‘start-up’. Many of the recommended checks and

actions could expose the technician to electrical and

mechanical hazards. Refer to the appropriate sections in

the unit manual for appropriate procedures, component

specifications and safety instructions.

Except where noted; it is implied that the technician is to

use this checklist for inspection / verification of prior task

completed by the general contractor at installation.

1. Unit clearances adequate for service and to avoid air

recirculation, etc.

2. Unit exterior inspected. CXAX condensor coil will not

be obstructed at any time by snow or ice during winter

conditions.

3. Unit properly grounded

4. Crankcase heaters working for 24 hours prior to arrival

of Trane technician performing start up

5. Correct voltage supplied to unit and electric heaters

(imbalance not to exceed 2%)

6. Unit power phasing (A-B-C sequence) proper for

compressor rotation

7. Copper power wiring meets sizing requirement in job

submittal

8. All automation and remote controls installed/wired

9. All wiring connections tight

10. Prove chilled water side Interlock and Interconnecting

Wiring Interlock and externals (chilled water pump)

11. Field installed control wiring landed on correct

terminals (external start/stop, emergency stop, chilled

water reset…)

12. Verify all refrigerant and oil valves are open/back

seated

13. Compressor oil levels (1/2 -3/4 high in glass) proper

14. Verify chilled water strainer is clean and free of debris

and evaporator chilled water circuits are filled

15. A pressure switch device to detect lack of water is

not included in the pump package. Installation of

this type of device is highly recommended to avoid

sealing damage due to operation of pump without

enough water.

16. Close the fused-disconnect switches that supplies

power to the chilled water pump starter

17. Start the chilled water pump to begin circulation

of the water. Inspect piping for leaks and repair as

necessary. Check the physical presence of the water

pressure switch.

18. With water circulating through the system, adjust

water flow and check water pressure drop through

evaporator

19. Return chilled water pump to auto

20. Verify all the chiller controller Menu Items.

21. All panels/doors secured prior to start-up

22. All coil fins inspected and straightened

23. Rotate fans before starting unit to inspect for

potential audible and visual signs of rubbing.

Start unit

24. Press AUTO key. The unit will start if the chiller

control calls for cooling and the safety interlocks are

closed

25. Check the evaporator and the condenser refrigerant

pressure on the chiller controller.

26. Confirm Superheat and subcooling values are normal

27. Compressor operation normal and within amperage

rating

28. Operating log completed

29. Press stop key

30. Inspect fans again after being under load to ensure

no signs or rubbing exist

31. Verify the chilled water pump runs for at least

1 minute (possibility to configure maxi 10 mn) after

the chiller is commanded to stop (for normal chilled

water systems)

Unit storage

If the chiller is to be stored for more than one month

prior to installation, observe the following precautions:

• Store the chiller in a dry, vibration-free, secure area.

• Units charged with refrigerant should not be stored

where temperatures exceed 68°C.

• At least every three months, attach a gauge and

manually check the pressure in the refrigerant circuit.

If the refrigerant pressure is below 13 bar at 20°C

(or 10 bar at 10°C), call a qualified service organization

and the appropriate Trane sales office.

Note: if the unit is stored before servicing near a

construction site it is highly recommended to protect

micro channel coils from any concrete and iron element.

Failure to do so may considerably reduce reliablity of

the unit.

8

CG-SVX027D-GB

Pre-Installation

Installation requirements and

contractor responsibilities

A list of the contractor responsibilities typically

associated with the unit installation process is provided.

Type of requirement

Foundation Meet foundation requirements

Rigging

Isolation Neoprene pads (Optional)

Electrical

Water piping

Insulation • Insulation • Insulation (piping)

Water piping connection elements • Grooved pipe

Trane factory Supplied Trane factory Supplied Field supplied

Trane factory Installed Field Installed Field installed

• Safety chains

• Clevis connectors

• Lifting beams

Isolators

(customer supplied)

• Wiring sizes per submittals and local codes

and regulations

• Terminal lugs

• Disconnect Switch

• Unit mounted starter

• Grooved pipes coupling

and stub pipe (Optional)

• Control voltage wiring

• Ground connection(s)

• BAS Wiring (optional)

• Chilled water pump contactor and wiring

including interlock

• Option relays and wiring

• Taps for thermometers and gauges

• Thermometers

• Waterowpressuregauges

• Isolation and balancing valves in water

piping

• Vents and rains

• Pressure relief valves

• Pressure switch device to detect lack of

water

CG-SVX027D-GB

9

General Data

Table 1 - CGAX 015-036 General Data

CGAX

015

Net Cooling Capacity (1) (kW) 43 49 59 65 74 82 99

Total Power input in cooling (1) (kW) 15 17 19 22 26 29 33

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 12 12 12 12 12 12 15

Power Cable Cross Section (max) mm² 35 35 35 35 35 35 150

Disconnect switch size (A) 80 80 100 100 100 100 250

Digit 12=2 or Digit 12=1 and Digit 41=2

Maximum Power input (kW) 20.4 23.2 27.9 31.6 35.4 39.1 45.1

Unit rated amps (A) 34.5 39.2 46.9 52.0 57.1 65.5 75.4

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 117.0 161.0 168.7 184.7 189.8 191.0 199.5

Unit start up amps (with soft starter - Digit 26=B) (4) 77.8 104.2 111.9 121.5 126.6 129.0 140.7

Power factor 0.868 0.866 0.870 0.888 0.902 0.870 0.873

Digit 12=1 and Digit 15=A

Maximum Power input (kW) 19.4 22.1 25.8 29.5 33.3 37.0 43.0

Unit rated amps (A) 33.8 38.5 45.4 50.5 55.6 64.0 73.8

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 116.3 160.3 167.2 183.2 188.3 189.5 197.9

Unit start up amps (with soft starter - Digit 26=B) (4) 77.1 103.5 110.4 120.0 125.1 127.5 139.1

Power factor 0.845 0.846 0.836 0.861 0.880 0.847 0.854

Digit 12=1 and Digit 15=C

Maximum Power input (kW) 20.4 23.2 26.8 30.6 34.3 38.1 44.1

Unit rated amps (A) 34.5 39.2 46.2 51.3 56.4 64.8 74.6

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 117.0 161.0 168.0 184.0 189.1 190.3 198.7

Unit start up amps (with soft starter - Digit 26=B) (4) 77.8 104.2 111.2 120.8 125.9 128.3 139.9

Power factor 0.868 0.866 0.854 0.875 0.892 0.859 0.864

Compressor

Compressor Number per Circuit # 2 2 2 2 2 2 3

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit1 / Circuit 2 7,5+7,5 7,5+10 10+10 10+13 13+13 15+15 12+12+12

Max Compr Power input Circuit 1/Circuit 2 kW 9,2 + 9,2 9,2+ 12 12 + 12 12 + 15,7 15,7 + 15,7 17,61 + 17,6

Rated Amps Circuit1 / Circuit 2 (4) (A) 15,5 + 15,5 15,5 + 20,2 20,2 + 20,2 20,2 + 25,3 25,3 + 25,3 29,5 + 29,5

Locked Rotor Amps Circuit1 / Circuit 2 (4) (A) 98 + 98 98 + 142 142 + 142 142 + 158 158 + 158 155 + 155

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit1 / Circuit 2 (W) 0,17 / 0 0,17 / 0 0,17 / 0 0,17 / 0 0,17 / 0 0,17 / 0 0,25 / 0

Evaporator

Quantity # 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model P80x66 P80x92 P80x92 P80x92 P120Tx76 P120Tx76 P120Tx104

Evaporator Water Content volume (l) 3.8 5.3 5.3 5.3 9.2 9.2 12.5

Nominal water connection size

(Grooved coupling) - Without HYM

Nominal water connection size

(Grooved coupling) - With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 96 100 86 113 120 110 103

Motor Power (kW) 1.20 1.20 1.20 1.50 1.50 1.50 1.50

Rated Amps (A) 2.44 2.44 2.44 3.50 3.50 3.50 3.50

Single pump - High head pressure option

Max available Head Pressure (kPa) 170 174 162 152 161 152 190

Motor Power (kW) 2.30 2.30 2.30 2.30 2.30 2.30 3.00

Rated Amps (A) 5.03 5.03 5.03 5.03 5.03 5.03 6.23

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 96 100 86 113 120 110 103

Motor Power (kW) 1.20 1.20

Rated Amps (A) 2.44 2.44 2.44 3.50 3.50 3.50 3.50

Twin pump - High head pressure option

Max available Head Pressure (kPa) 170 174 162 152 161 152 190

Motor Power (kW) 2.30 2.30 2.30 2.30 2.30 2.30 3.00

Rated Amps (A) 5.03 5.03 5.03 5.03 5.03 5.03 6.23

Expansion Tank Volume (l) 25 25 25 25 25 25 35

Max User water loop Volume for factory mounted

expansion tank (1)

Optionnal water Buffer tank volume (l) 324 324 324 324 324 324 444

Antifreeze Heater without pump package (W) 120 120 120 120 120 120 180

Antifreeze Heater with pump package (W) 280 280 280 280 280 280 340

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 1 1 1 1 1 1 2

Face area per circuit (m²) 2.23 2.23 2.96 2.96 2.96 2.96 4.46

(in) -

(mm)

(in) -

(mm)

SE-SN

2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3

2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 3" OD - 76,1

(l) 1450 1450 1450 1450 1450 1450 2000

CGAX

017

SE-SN

CGAX

020

SE-SN

1.20 1.50 1.50 1.50 1.50

CGAX

023

SE-SN

CGAX

026

SE-SN

CGAX

030

SE-SN

CGAX

036

SE-SN

13,7 +

13,7 + 13,7

22,9 +

22,9 + 22,9

147 +

147 + 147

10

CG-SVX027D-GB

General Data

Table 1 - CGAX 015-036 General Data (continued)

CGAX

015

Condenser Fan

Quantity # 1 1 2 2 2 2 2

Diameter (mm) 800

Fan / motor Type Propeller fan : Fixed speed AC motor / Variable speed - EC motor / HESP MAX SPEED

Digit 12=2 or Digit 12=1 and Digit 41=2

Fan / motor Type EC motor / HESP MAX SPEED

Airowperfan m3/h 13753 13718 12248 12231 12211 12193 13727

Max Power Input Kw 1,95 1,95 1,95 + 1,95 1,95 + 1,95 1,95 + 1,95 1,95 + 1,95 1,95 + 1,95

Max Amps A 3 3 3 + 3 3 + 3 3 + 3 3 + 3 3 + 3

Motor RPM (rpm) 915 915 915 915 915 915 915

Digit 12=1 and Digit 15=A

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 13788 13828 12362 12362 12370 12375 13827

Max Power Input Kw 0,89 0,89 0,89 + 0,89 0,89 + 0,89 0,89 + 0,89 0,89 + 0,89 0,89 + 0,89

Max Amps A 2,22 2,22 2,22 + 2,22 2,22 + 2,22 2,22 + 2,22 2,22 + 2,22 2,22 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

Digit 12=1 and Digit 15=C

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 13788 13828 12362 12362 12370 12375 13827

Max Power Input Kw 1,95 1,95 1,95 + 0,89 1,95 + 0,89 1,95 + 0,89 1,95 + 0,89 1,95 + 0,89

Max Amps A 3 3 3 + 2,22 3 + 2,22 3 + 2,22 3 + 2,22 3 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

AirowperFan (m3/h) 13788 13828 12362 12362 12370 12375 13827

AirowperFanHESP(915RPM-100Pa) (m3/h) 13753 13718 12248 12231 12211 12193 13727

Power per Motor (kW) 686 686 686 686 686 686 686

Partial Heat recovery (PHR) option

Heat-Exchanger Type Stainless steel Copper Brazed plate Heat exchanger

Heat-Exchanger Model

Water connection size (Thread connection)

Water content volume (l) 0.14 0.14 0.14 0.14 0.35 0.35 0.35

Dimensions (7)

Unit Length (mm) 2346 2346 2346 2346 2346 2346 2327

Unit Width (mm) 1285 1285 1285 1285 1285 1285 2250

Std Unit Height (mm) 1524 1524 1524 1524 1524 1524 1524

LN or External SP unit -

(Additionalheightconguration)

Water Buffer tank option -

(Additionalheightconguration)

Weights

Shipping Weight (3) (kg) 519 531 574 579 608 621 853

Operating Weight (3) (kg) 497 509 552 557 587 599 819

Option Additional shipping weight

Single pump - Standard head pressure (kg) 46 46 46 49 49 49 45

Single pump - High head pressure (kg) 51 51 51 51 51 51 49

Twin pump - Standard head pressure (kg) 70 70 70 75 75 75 71

Twin pump - High head pressure (kg) 82 82 82 82 82 82 86

Pump VFD option (kg) 0

Partial heat recovery option (kg) 1.48 1.48 1.48 1.48 3.82 3.82 3.82

Water Buffer tank option (kg) 319 319 319 319 319 319 425

System data

Nb of refrigerant circuit # 1 1 1 1 1 1 1

Minimum cooling load % (6) % 50 43 50 43 50 50 33

Standard/Partial Heat Recovery Unit unit

R410A refrigerant charge Circuit1 / Circuit 2 (kg) 7.5 9.0 9.0 9.0 10.5 10.5 14.0

Oil charge Circuit1 / Circuit 2 (l) 6.0 6.3 6.6 6.6 6.6 7.2 10.5

POE Oil type (6)

(1) Indicative performance at Evaporator water temperature : 12°C / 7°C - Condenser air temperature 35°C - for detailled performances, on a given unit,

consult Order Write Up.

(2) under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

(6) OIL058E or 0IL057E are European reference for POE oil and can be mixed in any proportion with OIL00078 or OIL 00080 (same oil with US reference on

compressor nameplate).

(7)Fordimensionsdetails,dimensionsofhydraulicconnections,electricalconnections,pointloadandspecicfeaturesforheatrecoveryseesubmittals

and diagrams which are supplied with every order.

(in) -

(mm)

(mm) +223 +224 +225 +226 +227 +228 +229

(mm) +330 +330 +330 +330 +330 +330 +330

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CGAX

017

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CGAX

020

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CGAX

023

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

OIL058E / OIL057E

CGAX

026

SE-SN

B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

CGAX

030

SE-SN

B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

CGAX

036

SE-SN

B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

CG-SVX027D-GB

11

General Data

Table 1 - CGAX 039-060 General Data

CGAX

039

Net Cooling Capacity (1) (kW) 111 127 97 116 129 147 164

Total Power input in cooling (1) (kW) 38 41 35 39 47 51 58

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15 15

Power Cable Cross Section (max) mm² 150 150 150 150 150 150 150

Disconnect switch size (A) 250 250 250 250 250 250 250

Digit 12=2 or Digit 12=1 and Digit 41=2

Maximum Power input (kW) 51.1 58.7 46.4 55.8 63.3 70.7 78.2

Unit rated amps (A) 82.6 98.2 78.1 93.5 103.7 113.9 130.7

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 215.3 223.7 199.9 215.3 236.4 246.6 256.2

Unit start up amps (with soft starter - Digit 26=B) (4) 152.1 161.7 143.1 158.5 173.2 183.4 194.2

Power factor 0.901 0.870 0.866 0.870 0.888 0.902 0.870

Digit 12=1 and Digit 15=A

Maximum Power input (kW) 49.0 55.5 44.2 51.6 59.0 66.5 74.0

Unit rated amps (A) 81.0 95.8 76.5 90.4 100.6 110.8 127.6

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 213.7 221.3 198.3 212.2 233.3 243.5 253.1

Unit start up amps (with soft starter - Digit 26=B) (4) 150.5 159.3 141.5 155.4 170.1 180.3 191.1

Power factor 0.886 0.847 0.846 0.836 0.861 0.880 0.847

Digit 12=1 and Digit 15=C

Maximum Power input (kW) 50.0 56.6 46.4 53.7 61.2 68.6 76.1

Unit rated amps (A) 81.8 96.6 78.1 91.9 102.1 112.3 129.1

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 214.5 222.1 199.9 213.7 234.8 245.0 254.6

Unit start up amps (with soft starter - Digit 26=B) (4) 151.3 160.1 143.1 156.9 171.6 181.8 192.6

Power factor 0.894 0.855 0.866 0.854 0.875 0.892 0.859

Compressor

Compressor Number per Circuit # 3 3 2 2 2 2 2

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit1 / Circuit 2 13+13+13 15+15+15

Max Compr Power input Circuit 1/Circuit 2 kW

Rated Amps Circuit1 / Circuit 2 (4) (A)

Locked Rotor Amps Circuit1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit1 / Circuit 2 (W) 0,25 / 0 0,25 / 0 0,17 / 0,17 0,17 / 0,17 0,17 / 0,17 0,17 / 0,17 0,17 / 0,17

Evaporator

Quantity # 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model P120Tx104 P120Tx104 DP300x82 DP300x82 DP300x82 DP300x114 DP300x114

Evaporator Water Content volume (l) 12.5 12.5 8.5 8.5 8.5 11.8 11.8

Nominal water connection size

(Grooved coupling) - Without HYM

Nominal water connection size

(Grooved coupling) - With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 131 104 111 133 114 113 178

Motor Power (kW) 2.30 2.30 1.50 2.30 2.30 2.30 2.30

Rated Amps (A) 5.03 5.03 3.50 5.03 5.03 5.03 5.03

Single pump - High head pressure option

Max available Head Pressure (kPa) 176 151 198 179 162 162 138

Motor Power (kW) 3.00 3.00 3.00 3.00 3.00 3.00 3.00

Rated Amps (A) 6.23 6.23 6.23 6.23 6.23 6.23 6.23

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 131 104 111 133 114 113 178

Motor Power (kW) 2.30 2.30 1.50 2.30 2.30 2.30 2.30

Rated Amps (A) 5.03 5.03 3.50 5.03 5.03 5.03 5.03

Twin pump - High head pressure option

Max available Head Pressure (kPa) 176 151 198 179 162 162 138

Motor Power (kW) 3.00 3.00 3.00 3.00 3.00 3.00 3.00

Rated Amps (A) 6.23 6.23 6.23 6.23 6.23 6.23 6.23

Expansion Tank Volume (l) 35 35 35 35 35 35 35

Max User water loop Volume for factory mounted

expansion tank (1)

Optionnal water Buffer tank volume (l) 444 444 444 444 444 444 444

Antifreeze Heater without pump package (W) 180 180 120 120 120 180 180

Antifreeze Heater with pump package (W) 340 340 280 280 280 340 340

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 2 2 2 2 2 2 2

Face area per circuit (m²) 5.93 5.93 2.23 2.96 2.96 2.96 2.96

(in) -

(mm)

(in) -

(mm)

SE-SN

15,7 +

15,7 + 15,7

25,3 +

25,3 + 25,3

158 +

158 + 158

2" - 60,3 2" - 60,3 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1

3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1

(l) 2000 2000 2000 2000 2000 2000 2000

CGAX

045

SE-SN

17,6 +

17,6 + 17,6

29,5 +

29,5 + 29,5

155 +

155 + 155

CGAX

035

SE-SN

7,5+10 /

7,5+10

9,2 + 12 /

9,2 + 12

15,5 + 20,2 /

15,5 + 20,2

98 + 142 /

98 + 142

CGAX

040

SE-SN

10+10 /

10+10

12 + 12 /

12 + 12

20,2 + 20,2 /

20,2 + 20,2

142 + 142 /

142 + 142

CGAX

046

SE-SN

10+13

/10+13

12 + 15,7 /

12 + 15,7

20,2 + 25,3 /

20,2 + 25,3

142 + 158 /

142 + 158

CGAX

052

SE-SN

13+13 /

13+13

15,7 + 15,7 /

15,7 + 15,7

25,3 + 25,3 /

25,3 + 25,3

158 + 158 /

158 + 158

CGAX

060

SE-SN

15+15 /

15+15

17,6 + 17,6 /

17,6 + 17,6

29,5 + 29,5 /

29,5 + 29,5

155 + 155 /

155 + 155

12

CG-SVX027D-GB

General Data

Table 1 - CGAX 039-060 General Data (continued)

CGAX

039

Condenser Fan

Quantity # 2 3 2 4 4 4 4

Diameter (mm) 800

Fan / motor Type Propeller fan : Fixed speed AC motor / Variable speed - EC motor / HESP MAX SPEED

Digit 12=2 or Digit 12=1 and Digit 41=2

Fan / motor Type EC motor / HESP MAX SPEED

Airowperfan m3/h 14660 13595 14686 12249 12233 12447 12205

Max Power Input Kw 1,95 + 1,95

Max Amps A 3 + 3 3 + 3 + 3 3 / 3 + 0 3 + 3 / 3 + 3 3 + 3 / 3 + 3 3 + 3 / 3 + 3 3 + 3 / 3 + 3

Motor RPM (rpm) 915 915 915 915 915 915 915

Digit 12=1 and Digit 15=A

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 14690 13676 14687 12358 12363 12592 12374

Max Power Input Kw 0,89 + 0,89

Max Amps A 2,22 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

Digit 12=1 and Digit 15=C

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 14690 13676 14687 12358 12363 12592 12374

Max Power Input Kw 1,95 + 0,89

Max Amps A 3 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

AirowperFan (m3/h) 14690 13676 14687 12358 12363 12592 12374

AirowperFanHESP(915RPM-100Pa) (m3/h) 14660 13595 14686 12249 12233 12447 12205

Power per Motor (kW) 686 686 686 686 686 686 686

Partial Heat recovery (PHR) option

Heat-Exchanger Type Stainless steel Copper Brazed plate Heat exchanger

Heat-Exchanger Model

Water connection size (Thread connection)

Water content volume (l) 0.5 0.5 2x 0.14 2x 0.14 2x 0.14 2x 0.35 2x 0.35

Dimensions (7)

Unit Length (mm) 2327 2327 2327 2327 2327 2327 2327

Unit Width (mm) 2250 2250 2250 2250 2250 2250 2250

Std Unit Height (mm) 1524 1524 1524 1524 1524 1524 1524

LN or External SP unit -

(Additionalheightconguration)

Water Buffer tank option -

(Additionalheightconguration)

Weights

Shipping Weight (3) (kg) 858 912 917 1004 1014 1034 1060

Operating Weight (3) (kg) 824 879 887 973 983 1004 1029

Option Additional shipping weight

Single pump - Standard head pressure (kg) 47 47 45 47 47 47 47

Single pump - High head pressure (kg) 49 49 49 49 49 49 49

Twin pump - Standard head pressure (kg) 75 75 75 75 75 75 75

Twin pump - High head pressure (kg) 86 86 84 84 84 84 84

Pump VFD option (kg) 0

Partial heat recovery option (kg) 4.6 4.6 2x 1.48 2x 1.48 2x 1.48 2x 3.82 2x 3.82

Water Buffer tank option (kg) 425 425 425 425

System data

Nb of refrigerant circuit # 1 1 2 2 2 2 2

Minimum cooling load % (6) % 33 33 22 25 22 25 25

Standard/Partial Heat Recovery Unit unit

R410A refrigerant charge Circuit1 / Circuit 2 (kg) 14.5 15.0 8.0 / 8.0 8.0 / 8.0 8.0 / 8.0 9.0 / 9.0 9.5 / 9.5

Oil charge Circuit1 / Circuit 2 (l) 10.5 11.5 6,3 / 6,3 6,6 / 6,6 6,6 / 6,6 6,6 / 6,6 7,2 / 7,2

POE Oil type (6) OIL058E / OIL057E

(1) Indicative performance at Evaporator water temperature : 12°C / 7°C - Condenser air temperature 35°C - for detailled performances, on a given unit,

consult Order Write Up.

(2) under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

(6) OIL058E or 0IL057E are European reference for POE oil and can be mixed in any proportion with OIL00078 or OIL 00080 (same oil with US reference on

compressor nameplate).

(7)Fordimensionsdetails,dimensionsofhydraulicconnections,electricalconnections,pointloadandspecicfeaturesforheatrecoveryseesubmittalsand

diagrams which are supplied with every order.

(in) (mm)

(mm) +230 +231 +232 +233 +234 +235 +236

(mm) +330 +330 +330 +330 +330 +330 +330

SE-SN

B3-027-20-

4.5L

G 1"1/4

(31.75 mm)

CGAX

045

SE-SN

1,95 +

1,95 + 1,95

0,89 +

0,89 + 0,89

2,22 +

2,22 + 2,22

1,95 +

0,89 + 0,89

3 +

2,22 + 2,22

B3-027-20-

4.5L

G 1"1/4

(31.75 mm)

CGAX

035

SE-SN

1,95 /

1,95 + 0

0,89 /

0,89 + 0

2,22 /

2,22 + 0

1,95 /

1,95 + 0

3 / 3 + 0

2x B3-014-

14-4.5M

G 1"1/4

(31.75 mm)

CGAX

040

SE-SN

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-014-

14-4.5M

G 1"1/4

(31.75 mm)

CGAX

046

SE-SN

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-014-

14-4.5M

G 1"1/4

(31.75 mm)

425 425 425

CGAX

052

SE-SN

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-027-

14-4.5L

G 1"1/4

(31.75 mm)

1,95 + 1,95 /

0,89 + 0,89 /

2,22 + 2,22 /

1,95 + 0,89 /

CGAX

060

SE-SN

1,95 + 1,95

0,89 + 0,89

2,22 + 2,22

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-027-

14-4.5L

G 1"1/4

(31.75 mm)

CG-SVX027D-GB

13

General Data

Table 2 - CXAX 015-036 General Data

CXAX

015

Net Cooling Capacity (1) (kW) 43 49 59 65 74 82 99

Total Power input in cooling (1) (kW) 15 17 19 22 26 29 33

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 12 12 12 12 12 12 15

Power Cable Cross Section (max) mm² 35 35 35 35 35 35 150

Disconnect switch size (A) 80 80 100 100 100 100 250

Digit 12=2 or Digit 12=1 and Digit 41=2

Maximum Power input (kW) 20.4 23.2 27.9 31.6 35.4 39.1 45.1

Unit rated amps (A) 34.5 39.2 46.9 52.0 57.1 65.5 75.4

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 117.0 161.0 168.7 184.7 189.8 191.0 199.5

Unit start up amps (with soft starter - Digit 26=B) (4) 77.8 104.2 111.9 121.5 126.6 129.0 140.7

Power factor 0.868 0.866 0.870 0.888 0.902 0.870 0.873

Digit 12=1 and Digit 15=A

Maximum Power input (kW) 19.4 22.1 25.8 29.5 33.3 37.0 43.0

Unit rated amps (A) 33.8 38.5 45.4 50.5 55.6 64.0 73.8

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 116.3 160.3 167.2 183.2 188.3 189.5 197.9

Unit start up amps (with soft starter - Digit 26=B) (4) 77.1 103.5 110.4 120.0 125.1 127.5 139.1

Power factor 0.845 0.846 0.836 0.861 0.880 0.847 0.854

Digit 12=1 and Digit 15=C

Maximum Power input (kW) 20.4 23.2 26.8 30.6 34.3 38.1 44.1

Unit rated amps (A) 34.5 39.2 46.2 51.3 56.4 64.8 74.6

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 117.0 161.0 168.0 184.0 189.1 190.3 198.7

Unit start up amps (with soft starter - Digit 26=B) (4) 77.8 104.2 111.2 120.8 125.9 128.3 139.9

Power factor 0.868 0.866 0.854 0.875 0.892 0.859 0.864

Compressor

Compressor Number per Circuit # 2 2 2 2 2 2 3

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit1 / Circuit 2 7,5+7,5 7,5+10 10+10 10+13 13+13 15+15 12+12+12

Max Compr Power input Circuit 1/Circuit 2 kW 9,2 + 9,2 9,2+ 12 12 + 12 12 + 15,7 15,7 + 15,7 17,61 + 17,6

Rated Amps Circuit1 / Circuit 2 (4) (A) 15,5 + 15,5 15,5 + 20,2 20,2 + 20,2 20,2 + 25,3 25,3 + 25,3 29,5 + 29,5

Locked Rotor Amps Circuit1 / Circuit 2 (4) (A) 98 + 98 98 + 142 142 + 142 142 + 158 158 + 158 155 + 155

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit1 / Circuit 2 (W) 0,17 / 0 0,17 / 0 0,17 / 0 0,17 / 0 0,17 / 0 0,17 / 0 0,25 / 0

Evaporator

Quantity # 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model P80x66 P80x92 P80x92 P80x92 P120Tx76 P120Tx76 P120Tx104

Evaporator Water Content volume (l) 3.8 5.3 5.3 5.3 9.2 9.2 12.5

Nominal water connection size (Grooved coupling) Without HYM

Nominal water connection size (Grooved coupling) With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 96 100 86 113 120 110 103

Motor Power (kW) 1.20 1.20 1.20 1.50 1.50 1.50 1.50

Rated Amps (A) 2.44 2.44 2.44 3.50 3.50 3.50 3.50

Single pump - High head pressure option

Max available Head Pressure (kPa) 170 174 162 152 161 152 190

Motor Power (kW) 2.30 2.30 2.30 2.30 2.30 2.30 3.00

Rated Amps (A) 5.03 5.03 5.03 5.03 5.03 5.03 6.23

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 96 100 86 113 120 110 103

Motor Power (kW) 1.20 1.20 1.20 1.50

Rated Amps (A) 2.44 2.44 2.44 3.50 3.50 3.50 3.50

Twin pump - High head pressure option

Max available Head Pressure (kPa) 170 174 162 152 161 152 190

Motor Power (kW) 2.30 2.30 2.30 2.30 2.30 2.30 3.00

Rated Amps (A) 5.03 5.03 5.03 5.03 5.03 5.03 6.23

Expansion Tank Volume (l) 25 25 25 25 25 25 35

Max User water loop Volume for factory mounted

expansion tank (1)

Optionnal water Buffer tank volume (l) 324 324 324 324 324 324 444

Antifreeze Heater without pump package (W) 120 120 120 120 120 120 180

Antifreeze Heater with pump package (W) 280 280 280 280 280 280 340

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 1 1 1 1 1 1 2

Face area per circuit (m²) 2.23 2.23 2.96 2.96 2.96 2.96 4.46

(in) -

(mm)

(in) -

(mm)

SE-SN

2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3

2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 2" - 60,3 3" OD - 76,1

(l) 1450 1450 1450 1450 1450 1450 2000

CXAX

017

SE-SN

CXAX

020

SE-SN

CXAX

023

SE-SN

CXAX

026

SE-SN

1.50 1.50 1.50

CXAX

030

SE-SN

CXAX

036

SE-SN

13,7 +

13,7 + 13,7

22,9 +

22,9 + 22,9

147 +

147 + 147

14

CG-SVX027D-GB

General Data

Table 2 - CXAX 015-036 General Data (continued)

CXAX

015

Condenser Fan

Quantity # 1 1 2 2 2 2 2

Diameter (mm) 800

Fan / motor Type Propeller fan : Fixed speed AC motor / Variable speed - EC motor / HESP MAX SPEED

Digit 12=2 or Digit 12=1 and Digit 41=2

Fan / motor Type EC motor / HESP MAX SPEED

Airowperfan m3/h 13753 13718 12248 12231 12211 12193 13727

Max Power Input Kw 1,95 1,95 1,95 + 1,95 1,95 + 1,95 1,95 + 1,95 1,95 + 1,95 1,95 + 1,95

Max Amps A 3 3 3 + 3 3 + 3 3 + 3 3 + 3 3 + 3

Motor RPM (rpm) 915 915 915 915 915 915 915

Digit 12=1 and Digit 15=A

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 13788 13828 12362 12362 12370 12375 13827

Max Power Input Kw 0,89 0,89 0,89 + 0,89 0,89 + 0,89 0,89 + 0,89 0,89 + 0,89 0,89 + 0,89

Max Amps A 2,22 2,22 2,22 + 2,22 2,22 + 2,22 2,22 + 2,22 2,22 + 2,22 2,22 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

Digit 12=1 and Digit 15=C

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 13788 13828 12362 12362 12370 12375 13827

Max Power Input Kw 1,95 1,95 1,95 + 0,89 1,95 + 0,89 1,95 + 0,89 1,95 + 0,89 1,95 + 0,89

Max Amps A 3 3 3 + 2,22 3 + 2,22 3 + 2,22 3 + 2,22 3 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

AirowperFan (m3/h) 13788 13828 12362 12362 12370 12375 13827

AirowperFanHESP(915RPM-100Pa) (m3/h) 13753 13718 12248 12231 12211 12193 13727

Power per Motor (kW) 686 686 686 686 686 686 686

Partial Heat recovery (PHR) option

Heat-Exchanger Type Stainless steel Copper Brazed plate Heat exchanger

Heat-Exchanger Model

Water connection size (Thread connection)

Water content volume (l) 0.14 0.14 0.14 0.14 0.35 0.35 0.35

Dimensions (7)

Unit Length (mm) 2346 2346 2346 2346 2346 2346 2327

Unit Width (mm) 1285 1285 1285 1285 1285 1285 2250

Std Unit Height (mm) 1524 1524 1524 1524 1524 1724 1524

LN or External SP unit -

(Additionalheightconguration)

Water Buffer tank option -

(Additionalheightconguration)

Weights

Shipping Weight (3) (kg) 558 564 616 644 649 684 911

Operating Weight (3) (kg) 539 545 596 624 630 665 881

Option Additional shipping weight

Single pump - Standard head pressure (kg) 46 46 46 49 49 49 45

Single pump - High head pressure (kg) 51 51 51 51 51 51 49

Twin pump - Standard head pressure (kg) 70 70 70 75 75 75 71

Twin pump - High head pressure (kg) 82 82 82 82 82 82 86

Pump VFD option (kg) 0

Partial heat recovery option (kg) 1.48 1.48 1.48 1.48 3.82 3.82 3.82

Water Buffer tank option (kg) 319 319 319 319 319 319 425

System data

Nb of refrigerant circuit # 1 1 1 1 1 1 1

Minimum cooling load % (6) % 50 43 50 43 50 50 33

Standard/Partial Heat Recovery Unit unit

R410A refrigerant charge Circuit1 / Circuit 2 (kg) 7.5 9.0 9.0 9.0 10.5 10.5 14.0

Oil charge Circuit1 / Circuit 2 (l) 6.0 6.3 6.6 6.6 6.6 7.2 10.5

POE Oil type (6)

(1) Indicative performance at Evaporator water temperature : 12°C / 7°C - Condenser air temperature 35°C - for detailled performances, on a given unit,

consult Order Write Up.

(2) under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

(6) OIL058E or 0IL057E are European reference for POE oil and can be mixed in any proportion with OIL00078 or OIL 00080 (same oil with US reference on

compressor nameplate).

(7)Fordimensionsdetails,dimensionsofhydraulicconnections,electricalconnections,pointloadandspecicfeaturesforheatrecoveryseesubmittalsand

diagrams which are supplied with every order.

(in) (mm)

(mm) +223 +224 +225 +226 +227 +228 +229

(mm) +330 +330 +330 +330 +330 +330 +330

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CXAX

017

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CXAX

020

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CXAX

023

SE-SN

B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

OIL058E / OIL057E

CXAX

026

SE-SN

B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

CXAX

030

SE-SN

B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

CXAX

036

SE-SN

B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

CG-SVX027D-GB

15

General Data

Table 2 - CXAX 039-060 General Data

CXAX

039

Net Cooling Capacity (1) (kW) 111 127 97 116 129 147 164

Total Power input in cooling (1) (kW) 38 41 35 39 47 51 58

Unit electrical data (2) (3) (4)

Short Circuit Unit Capacity (9) (kA) 15 15 15 15 15 15 15

Power Cable Cross Section (max) mm² 150 150 150 150 150 150 150

Disconnect switch size (A) 250 250 250 250 250 250 250

Digit 12=2 or Digit 12=1 and Digit 41=2

Maximum Power input (kW) 51.1 58.7 46.4 55.8 63.3 70.7 78.2

Unit rated amps (A) 82.6 98.2 78.1 93.5 103.7 113.9 130.7

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 215.3 223.7 199.9 215.3 236.4 246.6 256.2

Unit start up amps (with soft starter - Digit 26=B) (4) 152.1 161.7 143.1 158.5 173.2 183.4 194.2

Power factor 0.901 0.870 0.866 0.870 0.888 0.902 0.870

Digit 12=1 and Digit 15=A

Maximum Power input (kW) 49.0 55.5 44.2 51.6 59.0 66.5 74.0

Unit rated amps (A) 81.0 95.8 76.5 90.4 100.6 110.8 127.6

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 213.7 221.3 198.3 212.2 233.3 243.5 253.1

Unit start up amps (with soft starter - Digit 26=B) (4) 150.5 159.3 141.5 155.4 170.1 180.3 191.1

Power factor 0.886 0.847 0.846 0.836 0.861 0.880 0.847

Digit 12=1 and Digit 15=C

Maximum Power input (kW) 50.0 56.6 46.4 53.7 61.2 68.6 76.1

Unit rated amps (A) 81.8 96.6 78.1 91.9 102.1 112.3 129.1

Unit start up amps (w/o soft starter - Digit 26=A) (4) (A) 214.5 222.1 199.9 213.7 234.8 245.0 254.6

Unit start up amps (with soft starter - Digit 26=B) (4) 151.3 160.1 143.1 156.9 171.6 181.8 192.6

Power factor 0.894 0.855 0.866 0.854 0.875 0.892 0.859

Compressor

Compressor Number per Circuit # 3 3 2 2 2 2 2

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Model Circuit1 / Circuit 2 13+13+13 15+15+15

Max Compr Power input Circuit 1/Circuit 2 kW

Rated Amps Circuit1 / Circuit 2 (4) (A)

Locked Rotor Amps Circuit1 / Circuit 2 (4) (A)

Motor RPM (rpm) 2900 2900 2900 2900 2900 2900 2900

Oil sump heater Circuit1 / Circuit 2 (W) 0,25 / 0 0,25 / 0 0,17 / 0,17 0,17 / 0,17 0,17 / 0,17 0,17 / 0,17 0,17 / 0,17

Evaporator

Quantity # 1 1 1 1 1 1 1

Type Stainless steel Copper Brazed plate Heat exchanger

Evaporator model P120Tx104 P120Tx104 DP300x82 DP300x82 DP300x82 DP300x114 DP300x114

Evaporator Water Content volume (l) 12.5 12.5 8.5 8.5 8.5 11.8 11.8

Nominal water connection size (Grooved coupling) -

Without HYM

Nominal water connection size (Grooved coupling) -

With HYM

Hydraulic Module Components

Single pump - Standard head pressure option

Max available Head Pressure (kPa) 131 104 111 133 114 113 178

Motor Power (kW) 2.30 2.30 1.50 2.30 2.30 2.30 2.30

Rated Amps (A) 5.03 5.03 3.50 5.03 5.03 5.03 5.03

Single pump - High head pressure option

Max available Head Pressure (kPa) 176 151 198 179 162 162 138

Motor Power (kW) 3.00 3.00 3.00 3.00 3.00

Rated Amps (A) 6.23 6.23 6.23 6.23 6.23 6.23 6.23

Twin pump - Standard head pressure option

Max available Head Pressure (kPa) 131 104 111 133 114 113 178

Motor Power (kW) 2.30 2.30 1.50 2.30 2.30 2.30 2.30

Rated Amps (A) 5.03 5.03 3.50 5.03 5.03 5.03 5.03

Twin pump - High head pressure option

Max available Head Pressure (kPa) 176 151 198 179 162 162 138

Motor Power (kW) 3.00 3.00 3.00 3.00 3.00 3.00 3.00

Rated Amps (A) 6.23 6.23 6.23 6.23 6.23 6.23 6.23

Expansion Tank Volume (l) 35 35 35 35 35 35 35

Max User water loop Volume for factory mounted

expansion tank (1)

Optionnal water Buffer tank volume (l) 444 444 444 444 444 444 444

Antifreeze Heater without pump package (W) 180 180 120 120 120 180 180

Antifreeze Heater with pump package (W) 340 340 280 280 280 340 340

Condenser

Type Full aluminum Micro channel heat exchanger

Quantity of coil # 2 2 2 2 2 2 2

Face area per circuit (m²) 5.93 5.93 2.23 2.96 2.96 2.96 2.96

(in) -

(mm)

(in) -

(mm)

SE-SN

15,7 +

15,7 + 15,7

25,3 +

25,3 + 25,3

158 +

158 + 158

2" - 60,3 2" - 60,3 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1

3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1 3" OD - 76,1

(l) 2000 2000 2000 2000 2000 2000 2000

CXAX

045

SE-SN

17,6 +

17,6 + 17,6

29,5 +

29,5 + 29,5

155 +

155 + 155

CXAX

035

SE-SN

7,5+10 /

7,5+10

9,2 + 12 /

9,2 + 12

15,5 + 20,2 /

15,5 + 20,2

98 + 142 /

98 + 142

CXAX

040

SE-SN

10+10 /

10+10

12 + 12 /

12 + 12

20,2 + 20,2 /

20,2 + 20,2

142 + 142 /

142 + 142

CXAX

046

SE-SN

10+13

/10+13

12 + 15,7 /

12 + 15,7

20,2 + 25,3 /

20,2 + 25,3

142 + 158 /

142 + 158

CXAX

052

SE-SN

13+13 /

13+13

15,7 + 15,7 /

15,7 + 15,7

25,3 + 25,3 /

25,3 + 25,3

158 + 158 /

158 + 158

3.00 3.00

CXAX

060

SE-SN

15+15 /

15+15

17,6 + 17,6 /

17,6 + 17,6

29,5 + 29,5 /

29,5 + 29,5

155 + 155 /

155 + 155

16

CG-SVX027D-GB

General Data

Table 2 - CXAX 039-060 General Data (continued)

CXAX

039

Condenser Fan

Quantity # 2 3 2 4 4 4 4

Diameter (mm) 800

Fan / motor Type Propeller fan : Fixed speed AC motor / Variable speed - EC motor / HESP MAX SPEED

Digit 12=2 or Digit 12=1 and Digit 41=2

Fan / motor Type EC motor / HESP MAX SPEED

Airowperfan m3/h 14660 13595 14686 12249 12233 12447 12205

Max Power Input Kw 1,95 + 1,95

Max Amps A 3 + 3 3 + 3 + 3 3 / 3 + 0 3 + 3 / 3 + 3 3 + 3 / 3 + 33 + 3 / 3 + 3 3 + 3 / 3 + 3

Motor RPM (rpm) 915 915 915 915 915 915 915

Digit 12=1 and Digit 15=A

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 14690 13676 14687 12358 12363 12592 12374

Max Power Input Kw 0,89 + 0,89

Max Amps A 2,22 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

Digit 12=1 and Digit 15=C

Fan / motor Type Fixed speed AC motor / Variable speed - EC motor

Airowperfan m3/h 14690 13676 14687 12358 12363 12592 12374

Max Power Input Kw 1,95 + 0,89

Max Amps A 3 + 2,22

Motor RPM (rpm) 686 686 686 686 686 686 686

AirowperFan (m3/h) 14690 13676 14687 12358 12363 12592 12374

AirowperFanHESP(915RPM-100Pa) (m3/h) 14660 13595 14686 12249 12233 12447 12205

Power per Motor (kW) 686 686 686 686 686 686 686

Partial Heat recovery (PHR) option

Heat-Exchanger Type Stainless steel Copper Brazed plate Heat exchanger

Heat-Exchanger Model

Water connection size (Thread connection)

Water content volume (l) 0.5 0.5 2x 0.14 2x 0.14 2x 0.14 2x 0.35 2x 0.35

Dimensions (7)

Unit Length (mm) 2327 2327 2327 2327 2327 2327 2327

Unit Width (mm) 2250 2250 2250 2250 2250 2250 2250

Std Unit Height (mm) 1524 1524 1524 1524 1524 1524 1724

LN or External SP unit -

(Additionalheightconguration)

Water Buffer tank option -

(Additionalheightconguration)

Weights

Shipping Weight (3) (kg) 954 972 1000 1098 1098 1120 1190

Operating Weight (3) (kg) 925 942 974 1072 1072 1093 1163

Option Additional shipping weight

Single pump - Standard head pressure (kg) 47 47 45 47 47 47 47

Single pump - High head pressure (kg) 49 49 49 49 49 49 49

Twin pump - Standard head pressure (kg) 75 75 75 75 75 75 75

Twin pump - High head pressure (kg) 86 86 84 84 84 84 84

Pump VFD option (kg) 0

Partial heat recovery option (kg) 4.6 4.6 2x 1.48 2x 1.48 2x 1.48 2x 3.82 2x 3.82

Water Buffer tank option (kg) 425 425 425 425 425 425 425

System data

Nb of refrigerant circuit #

Minimum cooling load % (6) % 33 33 22 25 22 25 25

Standard/Partial Heat Recovery Unit unit

R410A refrigerant charge Circuit1 / Circuit 2 (kg) 14.5 15.0 8.0 / 8.0 8.0 / 8.0 8.0 / 8.0 9.0 / 9.0 9.5 / 9.5

Oil charge Circuit1 / Circuit 2 (l) 10.5 11.5 6,3 / 6,3 6,6 / 6,6 6,6 / 6,6 6,6 / 6,6 7,2 / 7,2

POE Oil type (6) OIL058E / OIL057E

(1) Indicative performance at Evaporator water temperature : 12°C / 7°C - Condenser air temperature 35°C - for detailled performances, on a given unit,

consult Order Write Up.

(2) under 400V/3/50Hz.

(3) Rated Condition without Pump Package.

(4) Electrical & system data are indicative and subject to change without notice. Please refer to unit nameplate data.

(5) If the power line of the unit is protected by fuses gG of the same size as the disconnect switch.

(6) OIL058E or 0IL057E are European reference for POE oil and can be mixed in any proportion with OIL00078 or OIL 00080 (same oil with US reference on

compressor nameplate).

(7)Fordimensionsdetails,dimensionsofhydraulicconnections,electricalconnections,pointloadandspecicfeaturesforheatrecoveryseesubmittalsand

diagrams which are supplied with every order.

(in) -

(mm)

(mm) +230 +231 +232 +233 +234 +235 +236

(mm) +330 +330 +330 +330 +330 +330 +330

SE-SN

B3-027-20-

4.5L

G 1"1/4

(31.75 mm)

1 1 2 2 2 2 2

CXAX

045

SE-SN

1,95 + 1,95

+ 1,95

0,89 +

0,89 + 0,89

2,22 + 2,22

+ 2,22

1,95 + 0,89 +

0,89

3 + 2,22 +

2,22

B3-027-20-

4.5L

G 1"1/4

(31.75 mm)

CXAX

035

SE-SN

1,95 /

1,95 + 0

0,89 /

0,89 + 0

2,22 / 2,22

+ 0

1,95 / 1,95

+ 0

3 / 3 + 0

2x B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CXAX

040

SE-SN

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CXAX

046

SE-SN

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-014-14-

4.5M

G 1"1/4

(31.75 mm)

CXAX

052

SE-SN

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

3 + 2,22

2x B3-027-14-

4.5L

G 1"1/4

(31.75 mm)

1,95 + 1,95 /

1,95 + 1,95

0,89 + 0,89 /

0,89 + 0,89

2,22 + 2,22 /

2,22 + 2,22

1,95 + 0,89 /

1,95 + 0,89

3 + 2,22 /

2x B3-027-14-

(31.75 mm)

CXAX

060

SE-SN

3 + 2,22

4.5L

G 1"1/4

CG-SVX027D-GB

17

Loading...

Loading...