Page 1

Installation, Operation,

and Maintenance

Air Cooled Condenser

20-60Ton

Models

CCRC020 CCRC025 CCRC030

CCRC035 CCRC040 CCRC050

CCRC060

CIRC020 CIRC025 CIRC030

CIRC035 CIRC040 CIRC050

CIRC060

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury.When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

February 2013 CXRC-SVX01F-EN

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provide to alert

installing contractors to potential hazards that could result

in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that

could result in equipment or property-damage-only

accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

Read this manual thoroughly before operating or servicing

this unit.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read

these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situationthat could result in

equipment or property-damage only

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards.To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

WARNING

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives or

other energy storing components provided by Trane or

others, refer to the appropriate manufacturer’s literature

for allowable waiting periods for discharge of

capacitors. Verify with an appropriate voltmeter that all

capacitors have discharged. Failure to disconnect power

and discharge capacitors before servicing could result in

death or serious injury.

For additional information regarding the safe discharge

of capacitors, see PROD-SVB06A-EN

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put onall PersonalProtective Equipment (PPE)

recommended for the work being undertaken.

ALWAYSrefer to appropriateMSDS sheetsand OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put

on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit.

Failure to follow recommendations could result in death

or serious injury.

© 2013Trane All rights reserved CXRC-SVX01F-EN

Page 3

Warnings, Cautions and Notices

Revision Summary

NOTICE:

Use Copper Conductors Only!

Unit terminals are not designed to accept other types

of conductors. Failure to use copper conductors could

result in equipment damage.

Introduction

About This Manual

Note: One copy of this document ships inside the control

panel of each unit and is customer property. It must

be retained by the unit's maintenance personnel.

This booklet describes proper installation, operation, and

maintenance procedures for air cooled systems. By

carefully reviewing the information within this manual

and following the instructions, risk of improper operation

and/or component damage will be minimized. It is

important that periodicmaintenance be performed to help

assure trouble free operation. A maintenance schedule is

provided at the end of this manual. Should equipment

failure occur, contact a qualified service organization with

qualified, experienced HVAC technicians to properly

diagnose and repair this equipment.

R-410A Refrigerant

• System is designed to be compatible with R-410A

refrigerant.

Refer to previous IOM versions for R-407C and R-22 units,

or contact your localTrane representative.

Refer to the appropriate IOM for air-cooled condenser

CXRC-SVX01 and programming Intellipak controls PKGSVP01.

Air Cooled Condenser unitsare applied with SCRF/SIRF or

SCRG/SIRG Commercial Self Contained units with

IntelliPak controls or thermostat interface.

CXRC-SVX01F-EN (13 Feb 2013)

Remove wiring diagrams. Add wiring diagram numbers

and reference to e-library. Update operating principals to

remove obsolete reference designators.

CXRC-SVX01E-EN (23 Oct 2012)

Updated fan motor information.

Trademarks

Trane, Intellipak,Trane 3-D and theTrane logo are

trademarks ofTrane in the United States and other

countries. All trademarks referenced in this document are

the trademarks of their respective owners.

Cross References to related publications/

information

• IntelliPak® Self-Contained Programming Guide, PKGSVP01*-EN

• Commercial Self-Contained IntelliPak Signature Series

Installation, Owner, and Diagnostic Manual, SCXFSVX01*-EN

• Commercial Self-Contained IntelliPak Modular Series

Installation, Owner, and Diagnostic Manual, SCXGSVX01*-EN

• TheTrane Reciprocating Refrigeration Manual

CXRC-SVX01F-EN 3

Page 4

Table of Contents

Model Number Descriptions .............. 5

General Data ............................ 6

Unit Description ..................... 6

Pre-Installation .......................... 8

Receiving ............................. 8

Contractor Installation Responsibilities ... 8

Dimensions and Weights ................. 9

Service Clearances .................. 10

Installation - Mechanical ................ 13

Unit Handling Procedure .............. 13

Installation Preparation ................ 14

Unit Isolation ........................ 14

Leveling the Unit ................... 15

Refrigerant Piping .................... 15

General Refrigerant Recommendations . 15

Interconnecting Piping ............... 16

Installation - Electrical ................... 17

General Electrical Recommendations . . . 17

Power Supply Wiring ................ 17

Operating Principals .................... 19

Control Sequences of Operation for Units

with IntelliPak™ .................... 19

Pre-Start Checklist ...................... 20

Start-Up and Shutdown ................. 21

Start-Up ............................. 21

Normal Unit Shut Down ............... 21

Seasonal Shut Down .................. 21

Seasonal Startup ..................... 21

Maintenance ........................... 22

Refrigerant System ................... 22

Refrigerant Leak Test Procedure ....... 22

System Evacuation Procedures ........ 23

Refrigerant Charging ................ 24

Maintenance Periodic Procedures ....... 25

Cleaning the Coil ................... 25

Low Ambient Damper Adjustment ..... 26

Troubleshooting ...................... 26

Wiring Diagrams ....................... 27

4 CXRC-SVX01F-EN

Page 5

Model Number Descriptions

Digit 1 - Unit Model

C = Condenser

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

R = Remote

Digit4-Development Sequence

C=C

Digit 5, 6, 7 - Nominal Capacity

020 = 20Tons

029 = 29Tons

032 = 32Tons

035 = 35Tons

040 = 40Tons

050 = 50Tons

060 = 60Tons

Digit 8 - Unit Voltage

4 = 460 Volt/60 Hz/3 ph

5 = 575 Volt/60 Hz/3 ph

6 = 200 Volt/60 Hz/3 ph

Digit 9 -Control Option

0 = No Low Ambient, I-Pak

A= No Low Ambient,T-Stat

B = Low Ambient, I-Pak

C = Low Ambient,T-Stat

Digit 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Finish

1 = Paint - Slate Gray

2 = Protective Coating

3 = Protective Coating with

Finish Coat

Digit 13 - Coil Options

A = Non-Coated Aluminum

C = Protective Coating Aluminum

Digit 14 - Unit Isolators

0 = None

A = Spring Isolators

B = Isopads

Digit 15 - Panels

0 = None

1 = Louvered Panels

Digit 16 - Agency

0 = None

T = With UL Listing

CXRC-SVX01F-EN 5

Page 6

General Data

Unit Description

Model CCRC/CIRC unitsfunction as the outdoor condenser

unit for appropriately sized split refrigeration systems.

These units operate in conjunction with a matched indoor

compressor/evaporator configuration (Trane models

SCRF, SIRF, SCRG, or SIRG) and provide refrigerant

condensing for these systems down to a normal ambient

temperature of 45°F. Operation to 0°F ambient is possible

with the addition of the optional external mount low

ambient dampers. Refer to the “Low Ambient Damper”

section in this manual.

Model CCRC/CIRC remote air cooled condensers are

dehydrated, leak tested, and charged with a holding

charge of dry nitrogen. Units are tested for proper control

operation before shipment.

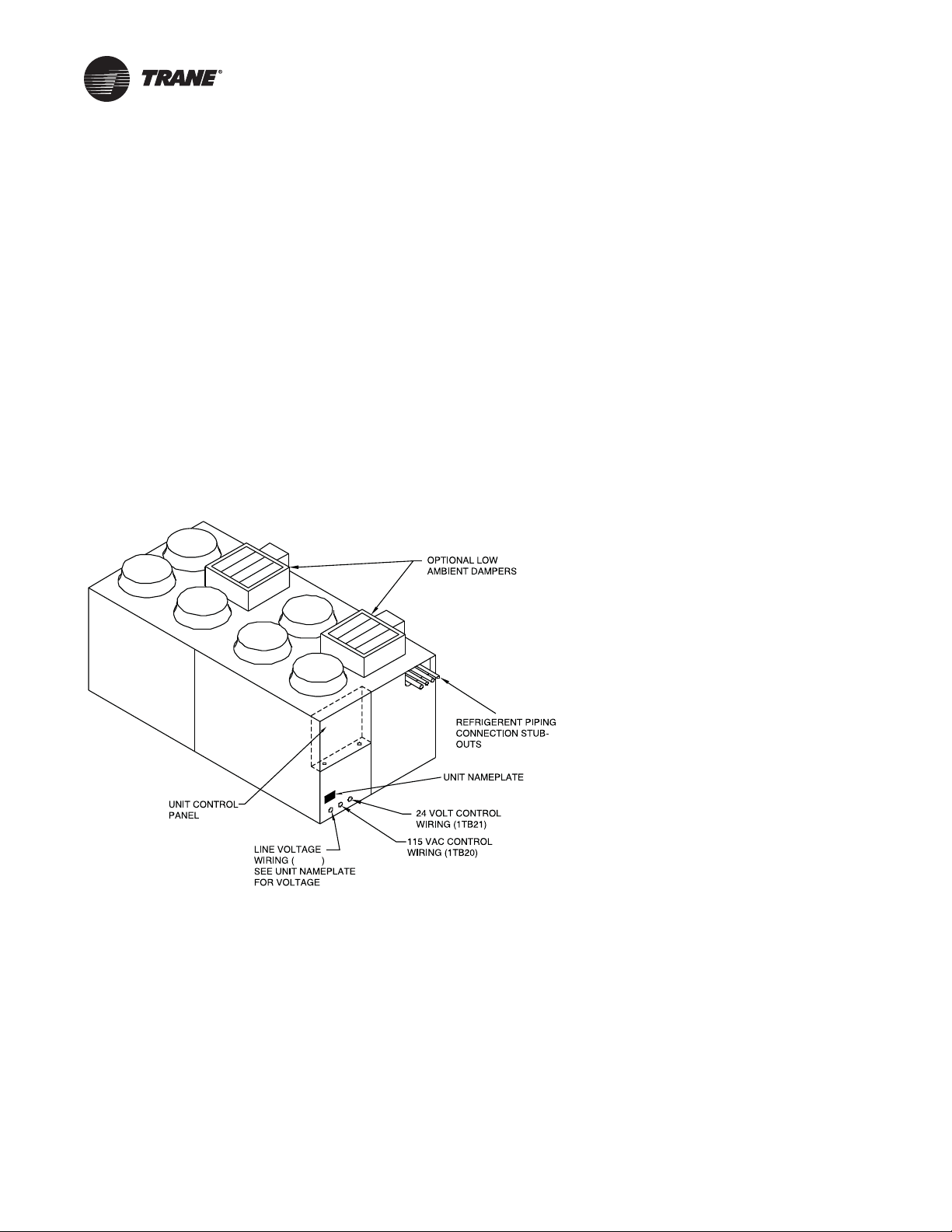

The factory provided unit-mounted control panel contains

all required fan cycling controls, compressor interlocks

Figure 1. Model CCRC/CIRC typical unit components. 60-ton unit is shown

and 115 V control power transformer. Each unit features

two independent refrigerant circuits with an integral subcooling loop.The slab condenser coils are aluminum fins

bonded to copper tubing. Louvered condenser grills are

for coil protection and are an orderable option. Direct

drive, vertical discharge fans are provided with built-in

current and overload protection. Head pressure control

dampers are available if low ambient operation is

required.

A bag containing the installation/ operation/maintenance

manual, schematics, and other pertaining literature is

provided and located in the control panel. Read all

literature pertaining to unit before installation and

operation. Figure 1 illustrates CCRC/CIRC exterior

component locations

8TB22

Unit Nameplate

The nameplate on these units provide valuable

identification information for the unitand itscomponents.

Provide all pertinent nameplate data when ordering parts

or literature and when making other inquires.

The unit nameplate for 20 – 60 ton CCRC/CIRC units is

mounted on the unit below the control box. See Figure 1.

This nameplate specifies unit power requirements and

also identifies the order number for the operation and

maintenance literature of the unit.The owner should refer

to this manual for information regarding the proper

equipment operation and maintenance.

6 CXRC-SVX01F-EN

Page 7

General Data

Table 1. SCRF/SIRF Air–cooled self–contained and CCRC/CIRC remote air-cooled condenser, refrigerant data

SCRF/SIRF & CCRC/CIRC

Unit Size 20/20 25/29 29/29 30/35 35/35 40/40 50/50 60/60

No. of Refrigerant Circuits 22222222

Operating Charge - lbs. R-410A 35.5/35.5 44.5/33.5 51/37.5 71/35.5 75/37.5 86.5/39.5 98/50 101.5/101.5

Operating Charge - kg R-410A 16.1/16.1 20.2/15.2 23.1/17 32.2/16.1 34/17 39.2/17.9 44.5/22.7 46/46

Cond. Storage Cap. - lbs. R-410A 37/37 51/37 51/37 74/37 74/37 74/51 102/51 102/102

Cond. Storage Cap. - kg R-410A 16.8/16.8 23.1/16.8 23.1/16.8 33.6/16.8 33.6/16.8 33.6/23.1 46.3/23.1 46.3/46.3

Notes:

1. Refrigerant charges are listed as circuit 1/circuit 2 and provide only an estimate. Final charge requires sound field charging practices.

2. Operating charge is for entire system, which includes the air–cooled self–contained, remote air–cooled condenser, and 25 feet of interconnecting

refrigerant piping.

3. See Table 9, p. 25 for additional charge required for alternate interconnecting piping lengths.

4. At conditions of 95° F (35° C), condenser storage capacity is 95% full.

5. To determine the correct amount of refrigerant needed for a particular application, reference the Trane Reciprocating Refrigeration Manual.

Table 2. SCRG/SIRG self-contained and CCRC/CIRC remote air-cooled condenser, refrigerant data

SCRG/SIRG & CCRC/CIRC Unit Size 20/20 25/29 32/32

No. of Refrigerant Circuits 2 2 2

Operating Charge - lbs R-410A 36.5/36.5 48.5/36 46/46

Operating Charge - kg R-410A 16.6/16.6 22/16.3 20.9/20.9

Cond. Storage Cap. - lbs R-410A 37/37 51/37 51/51

Cond. Storage Cap. - kg R-410A 16.8/16.8 23.1/16.8 23.1/23.1

Notes:

1. Refrigerant charges are listed as circuit 1/circuit 2 and provide only an estimate. Final charge requires sound field charging practices.

2. Operating charge is for entire system, which includes the air–cooled self–contained, remote air–cooled condenser, and 25 feet of interconnecting

refrigerant piping.

3. See Table 9, p. 25 for additional charge required for alternate interconnecting piping lengths.

4. At conditions of 95° F (35° C), condenser storage capacity is 95% full.

5. To determine the correct amount of refrigerant needed for a particular application, reference the Trane Reciprocating Refrigeration Manual.

CXRC-SVX01F-EN 7

Page 8

Pre-Installation

Receiving

Receiving Checklist

Complete following checklist immediately after receiving

shipment to detect any shipping damage.

• Inspect individual cartons before accepting. Check for

rattles, bent cartoncorners, or other visible indications

of shipping damage.

• If a unit appears damaged, inspect it immediately

before accepting the shipment. Make specific

notations concerning the damage on the freight bill.

Do not refuse delivery.

• Inspect the unit for concealed damage before it is

stored and as soon as possible after delivery. Report

concealed damage tothe freight linewithin the allotted

time after delivery. Check with the carrier for their

allotted time to submit a claim.

• Do not move damaged material from the receiving

location. It is the receiver’s responsibility to provide

reasonable evidence that concealed damage did not

occur after delivery.

• Do not continue unpacking the shipment if it appears

damaged. Retain all internal packing, cartons, and

crate.Take photos of damaged material if possible.

• Notify the carrier’s terminal of the damage

immediately by phone and mail. Request an

immediate joint inspection of the damage by the

carrier and consignee.

• Notify yourTrane representative of the damage and

arrange for repair. Have the carrier inspect the damage

before making any repairs to the unit.

Note: On rooftop applications be certain that the roof

structure has sufficient strength to support the

unit operating weight. See Table 4, p. 10for unit

shipping weight and operating weight, and

Table 5, p. 14 for point loading information.

• Allow minimum recommended clearances for routine

maintenance and service. Allow space at end of the

unit for shaft removal and servicing. Refer to unit

submittals for dimensions. See also

Clearances,” p. 10.

• Allow three fan diameters above the unit for the

discharge ductwork. Return air enters the rear of the

unit and conditioned supplyair dischargesthrough the

top.

• Electrical connection knockoutsare on the top, left side

of the unit.

• Allow adequate space for piping access and panel

removal. Condenser water piping, refrigerant piping,

and condensate drain connectionsare on the lower left

end panel.

Note: Unit height and connection locations will change if

using vibration isolators. The unit height may

increase up to 5 7/8” with spring type isolators.

• Electrical supply power must meet specific balance

and voltage requirements as described in section

“Installation - Electrical,” p. 17.

• Air-cooled units only:The installer is responsible for

providing and installing the remote air-cooled

condenser and refrigerant piping, including filter

driers.

“Service

Contractor Installation Responsibilities

Complete the following checklist before beginning final

unit installation.

• Verify the unit size and tagging with the unit

nameplate.

• Make certain the floor or foundation is level, solid, and

sufficient to support the unit and accessory weights.

Level or repair the floor before positioning the unit if

necessary.

Note: For a detailed discussion of base and

foundation construction see The Trane

Reciprocating Refrigeration Manual.This

manual is available through the local Trane

sales office.

8 CXRC-SVX01F-EN

Page 9

Dimensions and Weights

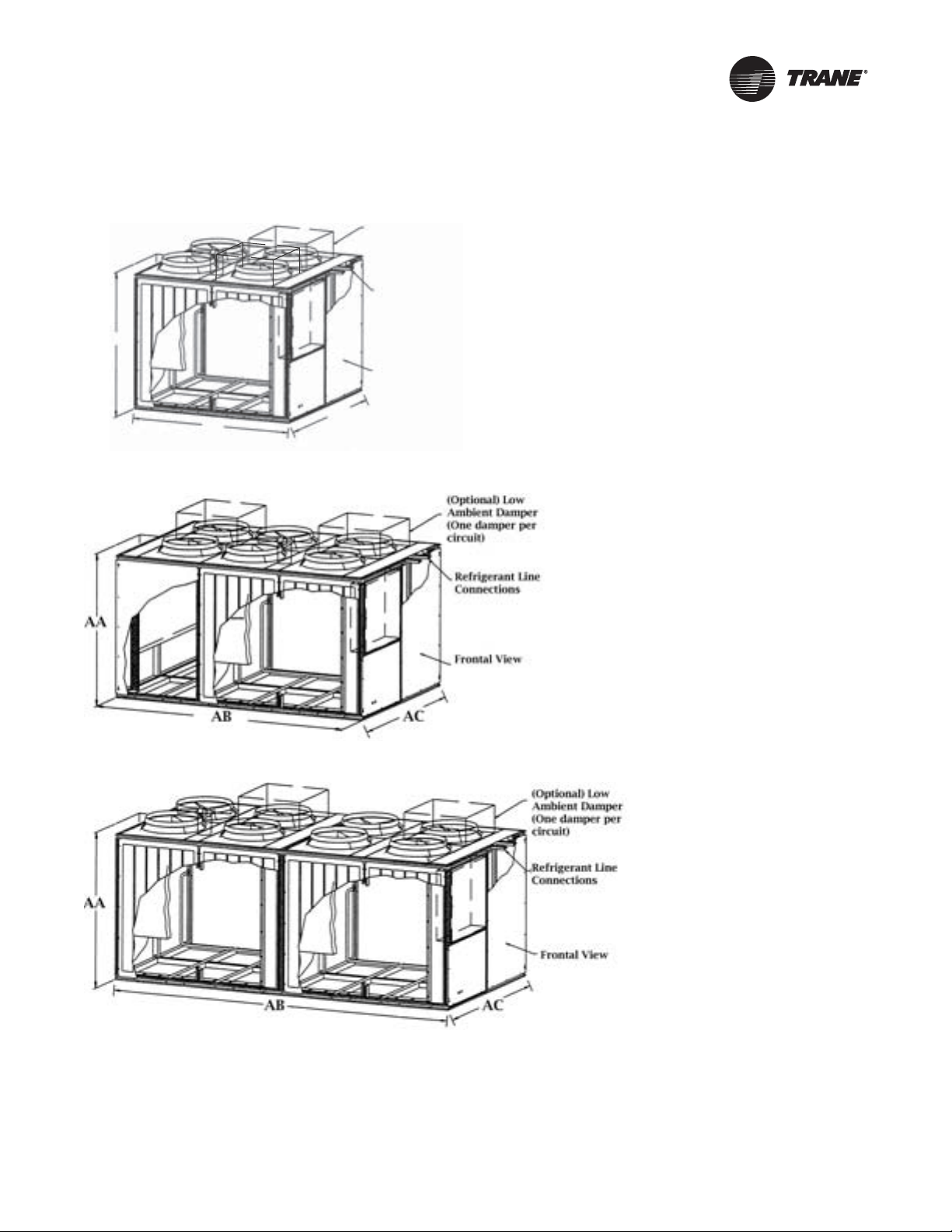

Figure 2. CCRC/CIRC 20, 29, and 32

(Optional) Low

Ambient Damper

(One damper per

circuit)

Refrigerant Line

Connections

AA

Frontal View

AB

Figure 3. CCRC/CIRC 35 and 40

Figure 4. CCRC/CIRC 50 and 60

AC

CXRC-SVX01F-EN 9

Page 10

Dimensions and Weights

Table 3. CCRC/CIRC unit dimensions, inches (mm)

Unit Tons AA AB AC

CCRC/CIRC

20, 29, 32

CCRC/CIRC

35, 40

CCRC/CIRC

50, 60

70 1/8 7' - 4 7' - 4

(1781) (2235) (2235)

70 1/8 10' - 10 3/4 7' - 4

(1781) (3321) (2235)

70 1/8 14' - 8 7' - 4

(1781) (4470) (2235)

Table 4. CCRC/CIRC unit weights

Unit

Size

CCRC/CIRC 20 2030 (920) 1906 (865)

CCRC/CIRC 29 2084 (945) 1960 (890)

CCRC/CIRC 32 2138 (970) 2014 (915)

CCRC/CIRC 35 3018 (1370) 2833 (1285)

CCRC/CIRC 40 3072 (1395) 2887 (1310)

CCRC/CIRC 50 3995 (1810) 3695 (1675)

CCRC/CIRC 60 4275 (1940) 3975 (1805)

Shipping

Weight lbs (kg).

Figure 5. Refrigerant and electrical connections (front view looking at control panel)

REFRIGERANT CIRCUIT 2

Refrigerant Circuit 2

Refrigerant Circuit 1

24 VOLT WIRE ENTRY HOLE

SIZED FOR 3/4” CONDUIT

115 VOLT WIRE ENTRY HOLE

SIZED FOR 3/4” CONDUIT

SUPPLY VOLTAGE WIRE ENTRY

HOLE SIZED FOR 1” CONDUIT

66 7/8” (1699mm)

Operating

Weight lbs.(kg)

(a)

REFRIGERANT CIRCUIT 1

4 1/2” (114mm)

10 1/2” (261mm)

17 1/2” (445mm)

(a) See Table 6, p. 16 for refrigerant connection and piping sizes.

B

C

Service Clearances

Provide sufficient clearance around the unit to allow

unrestricted access to control panel, condenser coils,

refrigerant connections and any other service points. Refer

to Figure 2, p. 9 through Figure 4, p. 9 for unit dimensions

and Figure 6, p. 11 through Figure 8, p. 11 for

recommended clearances for each specific unit.These

clearances allow for proper unit operation, airflow, and

service access and should not be infringed upon.

Note: To prevent unit capacity reduction, be certain to

provide recommended operating clearances.

If unit is installed in a pit, the depth of the pit must not

exceed 1.5 times the unit height and airflow clearances are

doubled. See Figure 10, p. 11 for specific pit installation

(LIQUID LINE CONNECTION REFRIG. CIRCUIT 1)

14 3/8” (365mm) - Liq Line Conn Refrig - ckt 1

(HOT GAS CONNECTION REFRIG. CIRCUIT 1)

18 1/2” (470mm) - Hot Gas Conn Refrig - ckt 1

(LIQUID LINE CONNECTION REFRIG. CIRCUIT 2)

24 3/4” (629mm) - Liq Line Conn Refrig - ckt 2

(HOT GAS CONNECTION REFRIG. CIRCUIT 2)

29” (737mm) - Hot Gas Conn Refrig - ckt 2

clearance instructions.

If multiple units are placed side-by-side, the minimum

distance between units must be twice the normal

recommended side clearances (8X2=16feet between

units). See Figure 11, p. 12 for specific side by side

installation clearance instructions.

Do not install unit under an overhang. Obstructing the fan

discharge in this manner can cause recirculation of the

warm discharge air and result in coil starvation.

10 CXRC-SVX01F-EN

Page 11

Dimensions and Weights

Figure 6. Top view CCRC/CIRC 20, 29, 32

96” (2132 mm)

48”

AB

(1066 mm)

CD

96” (2132 mm)

Figure 7. Top view CCRC/CIRC 35, 40

96” (2132 mm)

48”

(1066 mm)

F

BC

48”

(1066 mm)

Control

Panel

48”

(1066 mm)

Figure 8. Top view CCRC/CIRC 50, 60

96” (2132 mm)

48”

(1066 mm)

G

H

96” (2132 mm)

F

DE

BC

A

Figure 9. Typical pit installation recommended

clearances

Service clearance

35, 40T Units: 16’-0”

All other sizes: 4’-0”

16’-0”

(Minimum Distance

to Pit Side)

16’-0”

(Minimum Distance

to Pit Side)

48”

(1066 mm)

Control

Panel

DE

96” (2132 mm)

A

Control

Panel

Figure 10. Recommended clearances for typical pit installation. All unit sizes.

4’-0”

Service Clearance

CXRC-SVX01F-EN 11

Page 12

Dimensions and Weights

Figure 11. Typical side-by-side installation recommended clearances. All unit sizes.

Service Clearance

35-40T Units: 8’-0”

All other sizes: 4’-0”

Service Clearance

35-40T Units: 8’-0”

All other sizes: 4’-0”

Service Clearance

35-40T Units: 8’-0”

All other sizes: 4’-0”

12 CXRC-SVX01F-EN

Page 13

Installation - Mechanical

Unit Handling Procedure

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in unit dropping and

possibly crushing operator/technician which could

result in death or serious injury and possible

equipment or property-only damage.

Figure 12. Proper unit rigging and lifting procedure using spreader bars

Lifting brackets are provided along the base rail on both

sides of the unit. Pass lifting cables through the 1. 5-inch

diameter holes in the brackets and install spreader bars

between the cables above unit. A labelon the unitbase rail

illustrates proper lifting procedure. When rigged properly,

the unit will balance at its center of gravity.

Perform a test lift to ensure balance, equilibrium and unit

level is maintained. Adjust rigging as required based on

initial test lift.Test adjusted rigging with second test lift.

Continue test lifting unit until satisfactory results are

obtained. Do not proceed with final lift until unit remains

static, level and stable during test lift. See Figure 12, p. 13.

Note: Maintain unit level throughout the lifting process or

structural damage may occur.

.

CXRC-SVX01F-EN 13

Page 14

Installation - Mechanical

Installation Preparation

Before installing the unit, perform the following

procedures to ensure proper unit operation.

1. Position the unit and skid assembly in its final location.

2. Test lift the unit to determine exact unit balance and

stability before hoisting it to the installation location.

See

“Unit Handling Procedure,” p. 13 for proper

rigging procedures and cautions.

3. Remove the skids from under the unit. See unit IOM

SCXF-SVX01*-EN, “Skid Removal” section. If you find

internal damage, file a claim immediately to the

delivering carrier.

4. Remove the protective shipping covers from the unit.

5. Verify isolators are properly tightened for operation.

See

“Unit Isolation,” p. 14.

Unit Isolation

NOTICE:

Equipment Damage!

Proper isolator clearance and unit level must be

achieved or structural damage may occur.

The standard unit comes with 6” x 6” x 3/8” thick isolator

pads. Place these under the unit in the locations shown in

Figure 14, p. 15 through Figure 16, p. 15.

Spring Isolators

Unit mounting locations are shown in Figure 14, p. 15

through Figure 16, p. 15. Operating weights and weight

loading at each mounting location are provided in Table 5,

p. 14.Isolator placement instructions are alsoplaced in the

control panel with other unit documentation. Isolators are

identified by spring color and by the isolator part number.

All units utilize CP-1-28 “green” isolators (20–32 ton units

use 4 isolators per unit, 35-40 ton units use 6, and 50–60

ton units use 8). Install spring isolators at each unit

mounting point using the following procedure:

1. Bolt the isolators to the mounting surface using the

mounting slots in the isolators base plate. Do not fully

tighten the isolators mounting bolts at this time.

2. Set the unit on the isolators: the isolator positioning

pins must register in the unit mounting holes. See

Figure 14, p. 15 through Figure 16, p. 15 for locations.

3. Ensure clearances between upper and lower isolator

housings are between ¼” to ½“. See isolator detail in

Figure 13, p. 14. A clearance of over ½” requires shims

to level the unit (see Leveling the Unit section on this

page).

4. Make minor clearance adjustments by turning the

isolator leveling bolt clockwise to increase clearance

and counterclockwise to decrease clearance.

If proper isolator clearance cannot be obtained by turning

the leveling bolt, level the isolators themselves. A ¼”

variance in elevation is acceptable.

Figure 13. Typical CCRC/CIRC unit isolator CP-1-28

Table 5. Unit operating weight distribution at mounting locations

Unit Size Shipping Weight (lb) 1 2 3 4 5 6 7 8 Total Operating Weight (lb)

20 2030 463 463 463 517 1906

29 2084 490 463 490 517 1960

32 2138 490 490 490 554 2014

35 3018 463 463 463 463 463 518 2833

40 3072 463 463 490 463 463 518 2887

50 3995 490 490 490 490 490 350 490 405 3695

60 4275 490 490 490 490 490 490 490 545 3975

Note: Mounting locations referenced above correlate with mounting location shown in Figure 14, p. 15 through Figure 16, p. 15

14 CXRC-SVX01F-EN

Page 15

Installation - Mechanical

Figure 14. Isolator locations for CCRC/CIRC 20-32 tons

Figure 15. Isolator locations for CCRC/CIRC 35-40 tons

Leveling the Unit

Before tightening down the mounting bolts, level the unit

carefully. Use the unit base rail as a reference. Level the

unit to within ¼” over its entire length. Use shims if

adjustable isolators are not used.

Refrigerant Piping

General Refrigerant Recommendations

Liquid Line Components

Indoor portion of liquid line should include service valve,

charging valve, thermal expansion valve, sight class/

moisture indicator, filter drier and solenoid valve. (Others

as required by job specifications.) If the CCRC/CIRC is

coupled with either SCRF/SIRF or SCRG/SIRG, these

components are factory installed in theindoor unit, except

filter driers which are ship-with, for field installation.

CCRC/CIRC units also include a charging valve.

• Sight glass/moisture indicators aid in troubleshooting,

charging and servicing the system. Locate between

filter drier and expansion valve.

• Filter-driers are provided for field installation. Locate

near evaporator.

• Solenoid valves should be locatednear the evaporator.

Figure 16. Isolator locations for CCRC/CIRC 50-60 tons

Discharge Line Components

Indoor portion of discharge line should include access

valve and check valve. If the CCRC/CIRC is coupled with

either SCRF/SIRF or SCRG/SIRG, these components are

factory installed on the indoor unit. Install other discharge

line components as required by job specifications (hot gas

mufflers, pipe anchors, oil traps, etc.) to provide proper

system operation, prevent excessive vibration and assure

proper oil return to the compressor. Also recommended

are discharge shutoff valves in each hot gas line near the

condenser to facilitate refrigerant storage in the

condenser during service procedures. When optional

dischargeline ball valves are present in the indoor section,

installation of field supplied discharge line access valves

near the indoor unit may aid in installation and service.

NOTICE:

Compressor Damage!

To prevent possible refrigerant drain back into

compressor during off cycle, if no discharge check valve

is used, drop discharge line well below compressor

discharge level before beginning vertical rise. Failure to

do so could cause compressor damage.

Note: See Figure 17, p. 16 for a typical refrigerant piping

configuration that may be used in place of a double

riser system (not recommended). This

arrangement assures adequate oil return to the

suction line, even at partial load conditions. Refer

toTrane Reciprocating Refrigeration Manual for

more specific piping recommendations.

CXRC-SVX01F-EN 15

Page 16

Installation - Mechanical

Figure 17. Typical configuration for constant drain oil

trap, which can be used in place of a doubleriser system.

Refrigerant Piping Recommendation

Isolate refrigerant lines from the building to prevent

transferring line vibration to the structure. Do not secure

lines rigidly to the structure at any point, as this will defeat

the unit isolation system.

Interconnecting Piping

Refrigerant piping must be properly sized and applied.

These two factors have significant effect on both system

performance and reliability.

Important: Cleanliness is extremely important during

system installation to minimize residual

contaminants, such as oxidization and

scale. See Brazing procedure in

Maintenance section.

See Table 6, p. 16 for recommended discharge and liquid

line sizes.Table also includes unit connections sizes.

Verify compressor oil levels are near top of sight glass or

above.

Verify remote condensersystem is sealed by momentarily

depressing liquid line access port valve. If holding charge

is present, continue piping installation. If not, locate and

repair any leaks. See section “Refrigerant Leak Test

Procedure,” p. 22 and “System Evacuation Procedures,”

p. 23 in Maintenance.

Work on only one circuit at a time to minimize system

exposure to moisture in the air.

Capped discharge and liquid line connections are located

near bottom of the indoor unit,leftside for SCRF/SIRF, right

side for SCRG/SIRG. CCRC/CIRC connections are located

in the unit front, at top.

Remove cap with a tube cutter to minimize risk of getting

chips inside piping.

Table 6. Refrigerant connection and piping sizes, in.

Connection Size

Circuit 1 Circuit 2

CXRC Size Liquid Discharge Liquid Discharge

20, 29, 32 5/8 7/8 5/8 7/8

35, 40, 50 7/8 1 3/8 5/8 7/8

60 7/8 1 3/8 5/8 7/8

Circuit 1 Circuit 2

SXRF Size Liquid Discharge Liquid Discharge

20, 25, 29 5/8 7/8 5/8 7/8

30, 35, 40, 50 7/8 1 3/8 5/8 7/8

60 7/8 1 3/8 5/8 7/8

Circuit 1 Circuit 2

SXRG Size Liquid Discharge Liquid Discharge

20, 25, 32 5/8 7/8 5/8 7/8

Interconnecting Tube

SXRF/CXRC

Size

20/20 5/8 7/8 5/8 7/8

25/29 5/8 1 1/8 5/8 7/8

29/29 5/8 1 1/8 5/8 7/8

30/35 7/8 1 1/8 5/8 7/8

35/35 7/8 1 1/8 5/8 7/8

40/40 7/8 1 3/8

50/50 7/8 1 3/8 5/8 1 1/8

60/60 7/8 1 3/8 7/8 1 3/8

SXRG/CXRC

Size Liquid Discharge Liquid Discharge

20/20 5/8 7/8 5/8 7/8

25/29 5/8 1 1/8 5/8 7/8

32/32 5/8 1 1/8 5/8 1 1/8

(a) Use 1 1/8” for vertical risers.

Circuit 1 Circuit 2

Liquid Discharge Liquid Discharge

(a)

Circuit 1 Circuit 2

5/8 7/8

16 CXRC-SVX01F-EN

Page 17

Installation - Electrical

General Electrical Recommendations

WARNING

Hazardous Service Procedures!

The maintenance and troubleshooting procedures

recommended in this section of the manual could result

in exposure to electrical, mechanical or other potential

safety hazards. Always refer to the safety warnings

provided throughout this section concerning these

procedures. Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks. Failure to follow all of the recommended safety

warnings provided, could result in death or serious

injury.

NOTICE:

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of

conductors. Failure to use copper conductors could

result in equipment damage.

All wiring and disconnects must comply with local and

National Electrical Codes (NEC).Theinstaller must provide

properly sized system interconnection and power supply

wiring with appropriate fused disconnect switches.

Electrical connection types, sizes,and locations are shown

in Figure 5, p. 10.SeeTable 7, p. 18 for electrical data

(MCA, MFS).This information is also provided on the unit

nameplate. Sample wiring diagrams are provided in this

manual.

Power Supply Wiring

Run appropriately sized power wiring and field-supplied

conduit through the line voltage access opening provided

on the front of the unit. See Figure 1, p. 6 for electrical

connection locations. Run wire and field supplied conduit

up to the conduit connection point located in the bottom of

the control panel. Make appropriate connections to the

power terminal block in the control panel. Install fused

disconnects as required by local codes. Provide proper

equipment ground to the ground connections in the

control panel.

System Interconnection Wiring

Run appropriately sized field supplied conduits, 115 and 24

volt control wiring through the 115 and 24 volt access

openings provided on the front of the unit. See Figure 5,

p. 10 for electricalconnection locations. Run wire and field

supplied conduit to the conduit connection points

provided on the bottom of the control panel. Make

appropriate connections to the terminal blocks in the

control panel. Install safety devices if required by local

code. Provide proper equipment ground to the ground

connections in the control panel. See Table 7, p. 18 for

electrical data.

Unit Wiring Diagrams

Specific unit wiring diagrams are provided on the inside of

the control panel door. Use these diagrams for

connections or trouble analysis. See “Wiring Diagrams,”

p. 27 for typical unit wiring diagrams.

Unit Voltage

Electrical power to the unit must meet stringent

requirements for the unit to operate properly.Total voltage

supply and voltage imbalance between phases must be

within the following tolerances as stated in the Voltage

Imbalance section of this chapter.

Voltage Supply

WARNING

Live Electrical Components!

During installation, testing, servicing and

troubleshooting of this product, it may be necessary to

work with live electrical components. Have a qualified

licensed electrician or other individual who has been

properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical

safety precautions when exposed to live electrical

components could result in death or serious injury.

NOTICE:

Motor Damage!

Correct phase sequence is critical. Incorrect phase

sequence of the incoming line voltage could result in

motor damage.

Measure each leg of supply voltage at the line voltage

disconnect switch. Readings must fall within voltage

utilization range shownon the unitnameplate. If voltage of

any leg does not fall within tolerance, notify the power

company to correct this situation before operating the

unit. Inadequate voltage to the unit can cause control

components to malfunction and shorten the life of relay

contacts and condenser fan motors.

Voltage Imbalance

Excessive voltage imbalance between phases in a threephase system can cause motors to overheat and

eventually fail. Maximum allowable imbalance is 2%.

Voltage imbalance is defined as 100 times the maximum

deviation of the three voltages (three phases) subtracted

from the average (without regard to sign) divided by the

average voltage.

CXRC-SVX01F-EN 17

Page 18

Installation - Electrical

Example:

L1 measured = 221 V

L2 measured = 230 V

L3 measured = 227 V

221 + 230 + 227

3

Note: L1 = 221 volts is the maximum deviation of the 3

voltages from the average of the 3 voltages.

Therefore, the imbalance percentage is:

100 (226 – 221)

226

The 2.2 % imbalance that exists in the example above

exceeds the maximum allowable imbalance between

phases.

Table 7. CCRC/CIRC Condenser electrical data

Tons Voltage# Fans

20, 29,

32

35, 40

50, 60

Note: All motors for CCRC/CIRC units are rated at 1 hp (0.7457 kW).

= 226 volts

= 2.2%

FLA

(ea.)

200 4 4.1 20.7 17.43 20

460 4 1.8 9 7.65 15

575 4 1.4 7.2 5.95 15

200 6 4.1 20.7 25.63 30

460 6 1.8 9 11.25 15

575 6 1.4 7.2 8.75 15

200 8 4.1 20.7 33.83 40

460 8 1.8 9 14.85 20

575 8 1.4 7.2 11.55 15

LRA

(ea.) MCA MCB

18 CXRC-SVX01F-EN

Page 19

Operating Principals

Control Sequences of Operation for Units with IntelliPak™

Typical Unit Operation

Sequence of operation will be described fora 60-ton CCRC

condenser attached to a 60-ton Intellipak™ controlled

SCRF. All other configurations should be discernible once

the operator understands this sequence.

When evaporator unit calls for mechanical cooling, first

compressor will start. Intellipak controller will then start

reading saturated condenser temperature sensor for the

circuit that started. Saturated condenser temperature

sensor probes are factory installed on the condensing

coils of the CCRC condensing unit.

When condenser temperature rises to a point that

condensing is required the Intellipak controller will initiate

a call for condenser operation. Upon initial start-up, the

Intellipak controller will pull in K1 and K2 relays

simultaneously, thus pulling on all fans in circuit 1.

Condensing temperatures should then begin to fall as

condensing begins. As temperature falls the K1 relay will

drop out thus dropping out circuit 1A fan 1 and 2

contactors and stopping circuit 1A fans 1 and 2. (The

Intellipak controller will try to maintain a factory default

condensing temperature setpoint of 105°F.)

If saturated condenser temperatures continue to fall with

only circuit 1B fans 1 and 2 fans running, K2 relay will drop

out and K1 relay will reengage. (See stages of fan

operation on CCRC schematics). K1 relay will engage

circuit 1A fan 1 contactor, starting circuit 1A fan 1 only.

(Circuit 1B fan 1, 2 auxiliary contactor is no longer

engaged.)

If saturated temperature continues to drop with only

circuit 1A fan 1 running, the low ambient damper (if

equipped) will begin to throttle the airflow to maintain

saturated condensing temperature.The SCRF will actuate

the damper by way of a 2-10VDC signal to the low ambient

damper actuator, thus maintaining head pressure in a low

ambient condition.The unit will continue to operate in this

low ambient condition until the cooling setpoint is

satisfied at whichtime the unit will stop and stop all call for

condenser fan operation or until the saturated condenser

temperature begins to rise.

If saturated condenser temperature begins to rise, low

ambient damper will modulate open to allow more

airflow. If saturated condenser temperature continues to

rise with damper modulated fully open, K1 relay will drop

out and Intellipak controller will pull in K2 relay,

subsequently pulling in contactor Circuit 1B fan 1, 2

auxiliary contactor. Upon closure of this contactor, circuit

1B fans 1 and 2 will start. (See stages of fan operation on

CCRC schematics).

There is no low ambient operation associated with circuit

1B fans 1 and 2 operation, however the saturated

condenser temperature sensor continues to monitor

condensing temperature to be able to make necessary

adjustments to fan operation.The Intellipak controller will

continually sample saturated condenser temperature and

stage up or stage down fans as required to maintain

saturated condensing temperature as read by the

saturated condenser temperature sensor probes (see

stages of fan operation on CCRC schematics).

If saturated condenser temperature continues to rise with

only K2 relay pulledin the K1 relay willreengage and again

pull in circuit 1A fan 1 contactor.

Note: Circuit 1B fan 1, 2 auxiliary contactor is now pulled

in and will pull in circuit 1A fan 2 contactor, starting

circuit 1A fan 2.

K1 and K2 relays are now simultaneously engaged thus

starting all fan operation in circuit 1.The unit will stage

down in the reverse manner based on saturated

condensing temperature if and when saturated condenser

temperature begins to fall.

This is a detailed sequence of operation for the first circuit

to begin operation. If cooling load demands require the

second circuit to operate, the same sequence of operation

will be valid and will take place simultaneously utilizing

Intellipak controller relays K5 and K6.

Similar sequence of operation will take place on other

CCRC condensing unit sizes. See schematics, including

stages of fan operation, for specific unit installed.

Note: Low ambient dampers are optional. Not all units

may be equipped with low ambient dampers.

Low Ambient Damper Operation

Units with low ambient operation have two low ambient

dampers.The dampers are used to extend operation from

standard low limit temperature to a minimum of 0°F.

Dampers modulate airflow across condenser coils to

maintain condensing pressure during low ambient

operation.

Optional LowAmbient (LA) dampers arecontrolled by low

ambient damper control modulemounted in control panel

inside CCRC unit on a thermostat controlled unit, or by the

Intellipak controller of SCRF or SCRG.

Condenser Fan Operation

All condenser fans are direct drive 26” propeller and are

driven by one motor horsepower. Fan operation on all

units is interlocked with compressor start and stop using

customer provided compressor contactor auxiliary

contacts and liquid line pressure if thermostat-controlled

unit is used as the evaporator, or by Intellipak controller if

a SCRF or SCRG is used.

CXRC-SVX01F-EN 19

Page 20

Pre-Start Checklist

After the unit is installed, complete each step in the

checklist that followsand check off each step as completed.

When all are accomplished, the unit is ready to be started.

• Inspect all wiring connections. Connections should be

clean and tight.

• Check voltage to the unit at the line power fused

disconnect. Voltage must be within the voltage

utilization range given on the unit nameplate.Voltage

imbalance must not exceed two percent. Refer to the

“Voltage Imbalance,” p. 17.

• Check condenser fans. Condenser fan blades should

rotate freely in the fan orifices and should be mounted

securely on the motor shafts.

• Check condenser coils. Coil fins should be clean and

straight.There should be no restrictions to proper

airflow through the condenser.

• Evacuate the refrigerant system. See Maintenance

chapter of unit IOM (SCXF-SVX01*-EN or SCXGSVX01*-EN for evacuation and procedure.

• Once the system is properly evacuated, charge each

circuit with proper amount of refrigerant. See

Installation-Mechanical and Start-up chapters of unit

IOM (SCXF-SVX01*-EN or SCXG-SVX01*-EN for

refrigerant charging procedures.

• Prepare remainder of system for operation and

coordinate condenser start up with evaporator unit

startup.

20 CXRC-SVX01F-EN

Page 21

Start-Up and Shutdown

Start-Up

WARNING

Live Electrical Components!

During installation, testing, servicing and

troubleshooting of this product, it may be necessary to

work with live electrical components. Have a qualified

licensed electrician or other individual who has been

properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical

safety precautions when exposed to live electrical

components could result in death or serious injury.

NOTICE:

Compressor Damage!

Never manually or automatically pump down system

below 7 psig.This will cause the compressor to operate

in a vacuum and result in compressor damage.

NOTICE:

Compressor Damage!

Keep crankcase heaters on whenever refrigerant is in

the system. If crankcase heaters have not been on with

refrigerant in the system, turn the crankcase heaters on

for a minimum of 24hours before starting compressors.

Failure to follow the above could result in compressor

failure or reduced compressor life.

When wired properly, the unit will cycle condenser fans in

response to compressor interlock or the Intellipak

controller output.The Intellipak controller reads saturated

refrigerant temperatures and cycles the fans

appropriately.Typical wiring schematics are listed in

“Wiring Diagrams,” p. 27.

Seasonal Shut Down

If the unit will be inoperative for an extended period, lock

out unit operation by disconnecting the compressor

interlock circuits and opening and locking the main power

disconnect switch.

If desired, large amounts of liquid refrigerant can be

isolated and stored in the condenser by closing the liquid

line service valves and operating the compressors to

pump the refrigerant into the condenser and then valving

off the hot gas line near the condenser coil.

Seasonal Startup

1. Inspect the interior of the unit for debris.

2. Check control panel wiring connections for corrosion

and proper security. Check control panel door for

proper weather seal.

3. Inspect condenser fans. Blades must be secure on fan

shaft and rotate freely.

4. Inspect coil forobstructions and cleanliness. Clean coil

if required. Refer to “Maintenance”.

5. Inspect low ambientdampers. Damper blades must be

properly aligned, free from obstructions and operate

freely.You may have to disconnect actuator linkage to

inspect damper movement.

6. Close unit power supply disconnect switch.

7. Allow 24 hours of crankcase operation before starting

compressors. Crankcase heaters are energized

whenever the unit disconnect is closed and the

compressors are off.

The unit should now operate properly in response to

cooling demand at the system thermostat.

Normal Unit Shut Down

The unit can be stopped by opening the unit power supply

disconnect switch. Normally however, unit operation

stops due to interruption of the cooling demand signal by

the circuit cooling relays.The CCRC/CIRC condensing unit

should be shutdown by first shutting down the indoor

evaporative cooling unit. By stopping the indoor unit the

request for condensing has been terminated thus

stopping all condenser fans.The disconnect switch on the

CCRC/CIRC unit power supply should then beopened. Not

shutting down the evaporator unit before the condenser

unit will result in a high-pressure situation and should be

avoided if possible.

CXRC-SVX01F-EN 21

Page 22

Maintenance

Before beginning any maintenance procedures heed all

warnings and cautions.

WARNING

Hazard of Explosion!

WARNING

Hazardous Service Procedures!

The maintenance and troubleshooting procedures

recommended in this section of the manual could

result in exposure to electrical, mechanical or other

potential safety hazards. Always refer to the safety

warnings provided throughout this section concerning

these procedures. Unless specified otherwise,

disconnect all electrical power including remote

disconnect and discharge all energy storing devices

such as capacitors before servicing. Follow proper

lockout/tagout procedures to ensure the power can not

be inadvertently energized. When necessary to work

with live electrical components, have a qualified

licensed electrician or other individual who has been

trained in handling live electrical components perform

these tasks. Failure to follow all of the recommended

safety warnings provided, could result in death or

serious injury.

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Do not use acetylene, oxygen or

compressed air or mixtures containing them for

pressure testing. Do not use mixtures of a hydrogen

containing refrigerant and air above atmospheric

pressure for pressure testing as they may become

flammable and could result in an explosion.

Refrigerant, when used as a trace gas should only be

mixed with dry nitrogen for pressurizing units. Failure

to follow these recommendations could result in death

or serious injury or equipment or property-only

damage.

WARNING

Hazardous of Explosion!

Do not exceed unit nameplate design pressures when

leak testing system. Failure to follow these instructions

could result in an explosion causing death or serious

injury.

Refrigerant System

Refrigerant LeakTest Procedure

WARNING

Confined Space Hazards!

Do not work in confined spaces where refrigerant or

other hazardous, toxic or flammable gas may be

leaking. Refrigerant or other gases could displace

available oxygen to breathe, causing possible

asphyxiation or other serious health risks. Some gases

may be flammable and or explosive. If a leak in such

spaces is detected, evacuate the area immediately and

contact the proper rescue or response authority. Failure

to take appropriate precautions or to react properly to

such potential hazards could result in death or serious

injury.

WARNING

Hazard of Explosion!

Never use an open flame to detect gas leaks. It could

result in an explosion. Use a leak test solution for leak

testing. Failure to follow recommended safe leak test

procedures could result in death or serious injury or

equipment or property-only-damage.

R-410A Refrigerant under High Pressure!

The units described in this manual use R-410A

refrigerant. Use ONLY R-410A rated service equipment

or components with these units. For specific handling

concerns with R-410A, please contact your localTrane

representative.

Failure to use R-410A rated service equipment or

components could result in equipment exploding under

R-410A high pressures which could result in death,

serious injury, or equipment damage.

Note: These service procedures require working with

refrigerant. Do not release refrigerant to the

atmosphere!The service technician must comply

with all federal, state, and local laws.

When Leak-testing refrigerant systems, observe all safety

precautions.

Leak test only one circuit at a time to minimize system

exposure to potentially harmful moisture in the air.

Use R-410A refrigerant gas as a tracer for leak detection

and use oil-pumped dry nitrogen to develop required test

pressures.

Field Piping (air cooled discharge and liquid

lines)

1. Ensure all required field installed piping pressure tests

are completed inaccordance with national and/or local

codes.

2. Close liquid line angle valve.

3. Connect R-410A refrigerant cylinder to high side

charging port (at Remote Condenser or field supplied

22 CXRC-SVX01F-EN

WARNING

Page 23

Maintenance

discharge line access port). Add refrigerant to reach

pressure of 12 to 15 psig.

4. Disconnect refrigerant cylinder. Connect dry nitrogen

cylinder to high side charging port and increase

pressure to 150 psig. Do not exceed high side

(discharge) unit nameplate design pressure. Do not

subject low side (suction) components to high side

pressure.

5. Check all piping joints, valves, etc. for leaks.

Recommend using electronic detector capable of

measuring 0.1 oz/year leak rate.

6. If a leak is located, use proper procedures to remove

the refrigerant/nitrogen mixture, break connections

and make repairs. Retest for leaks.

Make sure all service valves are open.

System Repair

1. If system is water cooled with service valves, or air

cooled, high andlow side maybe tested independently

by closing liquid line angle valve and water cooled unit

discharge line ball valve. Otherwise leave all valves

open and DO NOT exceed low side design pressure.

2. Connect R-410A refrigerant cylinder to charging port,

add refrigerant to reach pressure of 12 to 15 psig.

3. Disconnect refrigerant cylinder. Connect dry nitrogen

cylinder to high side charging port and increase

pressure to 150 psig. DO NOT exceed unit nameplate

design pressures. If testing complete system, low side

design pressure is maximum.

4. Check piping and/or components as appropriate for

leaks.

5. Recommend using electronic detector capable of

measuring 0.1 oz/year leak rate.

6. If a leak is located, use proper procedures to remove

the refrigerant/nitrogen mixture, break connections

and make repairs. Retest for leaks.

Make sure all service valves are open.

System Evacuation Procedures

Each refrigeration circuit must be evacuated before the

unit can be charged and started.

Use a rotary type vacuum pump capable of pulling a

vacuum of 100 microns or less.

Verify that the unit disconnect switch and the system

control circuit switches are “OFF”.

Oil in the vacuum pump should be changed each time the

pump is used with high quality vacuum pump oil. Before

using any oil, check the oil container for discoloration

which usually indicates moisture in the oil and/or water

droplets. Moisture inthe oil addsto what must be removed

from the system, increasing pump down time.

When connecting the vacuum pump to a refrigeration

system, it is important to manifold the vacuum pump to

both the high and low sideof the system (liquid line access

valve and suction line access valve). Follow the pump

manufacturer’sdirections forthe proper methods of using

the vacuum pump.

The lines used to connect the pump to the system should

be copper and of the largest diameter that can practically

be used. Using larger line sizes with minimum flow

resistance can significantly reduce evacuation time.

Important: Rubber or synthetic hoses are not

recommended for system evacuation

because they have moisture absorbing

characteristics which result in excessive

rates of evaporation, causing pressure rise

during the standing vacuum test. This

makes it impossible to determine if the

system has a leak, excessive residual

moisture, or a continual or high rate of

pressure increase due to the hoses.

An electronic micron vacuum gauge should be installedin

the common lineahead of the vacuum pump shutoff valve,

as shown in Figure 18, p. 24. Close Valves B and C, and

open Valve A.

Start the vacuum pump, after several minutes, the gauge

reading will indicate the maximum vacuum the pump is

capable of pulling. Rotary pumps should produce

vacuums of 100 microns or less.

NOTICE:

Motor Winding Damage!

Do not use a megohm meter or apply voltage to a

compressor motor winding while it is under a vacuum.

Voltage sparkover could cause damage to the motor

windings.

OpenValves B and C. Evacuate the system to a pressureof

300 microns or less. As the vacuum is being pulled on the

system, there couldbe a time whenit would appearthat no

further vacuum is being obtained, yet,the pressure is high.

It is recommended that during the evacuation process, the

vacuum be “Broken”, to facilitate the evacuation process.

To break the vacuum:

Shutoff valves A, B, & C and connect a refrigerant cylinder

to the charging port on themanifold. Purge the airfrom the

hose. Raise thestanding vacuum pressure inthe system to

“zero” (0 psig) gauge pressure. Repeat this process two or

three times during evacuation.

Note: It is unlawful to release refrigerant into the

atmosphere. When service procedures require

working with refrigerants, the service technician

must comply with all Federal, State, and local laws.

Standing Vacuum Test

Once 300 microns or less is obtained, close Valve A and

leave valves B and C open.This will allow the vacuum

gauge to read the actual system pressure. Let the system

equalize for approximately 15 minutes.This is referred to

as a “standing vacuum test” where, time versus pressure

CXRC-SVX01F-EN 23

Page 24

Maintenance

rise.The maximum allowable rise over a 15 minute period

is 200 microns. If the pressure rise is greater than 200

microns but levels off to a constant value, excessive

moisture is present. If the pressure steadily continues to

rise, a leak is indicated. Figure 19, p. 24 illustrates three

possible results of the “standing vacuum test”.

If a leak is encountered, repair the system and repeat the

evacuation process until the recommended vacuum is

obtained. Once the system has been evacuated, break the

vacuum with refrigerant, and complete the remaining

“Pre-Start Procedures” before starting the unit.

Figure 19. Evacuation time vs. pressure rise

Figure 18. Typical vacuum pump hookup

Refrigerant Charging

CAUTION

Refrigerant at Freezing Temperature!

Avoid contact with skin. If working with refrigerant is

necessary, you MUST wear all Personal Protective

Equipment (PPE) including eye protection, safety

gloves, long sleeves, and pants. In case of contact, treat

the injury similar to frostbite. Slowly warm the affected

area with lukewarm water and seek immediate medical

attention. Direct contact with liquid refrigerant could

result in minor to moderate injury.

24 CXRC-SVX01F-EN

Compressor Damage!

Charge both circuits of dual circuited systems to

prevent compressor damage.

Important: For proper system operation, use only

refrigerant type listed on unit nameplate.

Once the system is properly installed, leak tested, and

evacuated, refrigerant charging can begin. Charge

refrigerant into the system by weight. Approximate

operating refrigerant charge capacities for 20 through 60ton CCRC/CIRC condensing units are given in Table 1, p. 7

NOTICE:

Page 25

Maintenance

and Table 2, p. 7. Calculate additional charge required for

any other units and additional piping to determine the total

system charge.

Use an accurate scale or charging cylinder to determine

the exact charge entering the system. Failureto charge the

system accurately can lead to under or overcharging and

result in unreliable operation.

NOTICE:

Compressor Damage!

Do not allow liquid refrigerant to enter the suction line.

Excessive liquid accumulation in the liquid lines could

result in compressor damage.

Liquid Line Charging

Large amounts of refrigerant should be addedthrough the

liquid line servicevalves. If system is beingrecharged after

evacuating and dehydrating, determine the approximate

weight of charge required and charge to that level. If

adding less than a full charge, charge to 14 to 20°F

subcooling as measured on the liquid lines at the

condenser coil refrigerant outlets.

Table 8. System compressors

Compressors

Unit Size Circuit 1 Circuit 2

20/20 10 10

25/29 15 10

29/29 15 10

SXRF/CXRC

SXRG/CXRC

Notes:

1. All units have dual circuits

2. The quantities shown apply to the CCRC/CIRC air-cooled condenser

(a) Multiple compressors have manifold.

30/35 10/10 10

35/35 10/10 10

40/40 10/15 10

50/50 15/15 10

60/60 15/15 15/15

20/20 10 10

25/29 15 10

32/32 15 15

Table 9. Charge add (R-410A) - lbs per 10 ft of line

Charge (lbs)

Piping Size (in) Liquid Line Discharge Line

5/8 1.07 -

7/8 2.23 0.31

1 1/8 - 0.53

1 3/8 - 0.80

(a) Amounts listed are for 10 ft of pipe above 25’. Actual requirements will

be in direct proportion to the actual length of piping.

(a)

(a)

Maintenance Periodic Procedures

This section describes specific maintenance procedures

that must be preformed as a part of the normal

maintenance program for this unit.

Periodic Maintenance Checklist

• Inspect optional coil guard for debris that may be

blocking louvers. Clean as required.

• Inspect coil surface for cleanliness. Clean as required.

Refer to “Coil Cleaning” under “Maintenance

Procedures.”

• Manually rotate fan blades to insure proper orifice

clearance. Inspect fan orifices for debris and

obstructions. Clean as required.

Annual Maintenance Checklist

• Perform all monthly maintenance inspections.

• Perform seasonal start up checks.

• Leak test refrigerant circuits. Inspect contacts of fan

motor contactors and relays. Replace all worn

contacts.

• Clean condenser fans.Check fan assembliesfor proper

orifice clearance, abnormal end play, and excessive

vibration or noise. Fan motor bearings are

permanently lubricated and do not require lubrication.

• Have a qualified service technician check condenser

fan pressure switchesfor proper operation (thermostat

controlled unit only).

• Clean and repaint any corroded surface.

Cleaning the Coil

Clean the coil at least once each year or more frequently if

located in a dirty environment, to help maintain proper

unit operating efficiency. High discharge pressures are a

good indication that the coil needs cleaning. Follow the

detergent manufacturer instructionsas closely aspossible

to avoid potential damage to the coil.

WARNING

Hazardous Chemicals!

Coil cleaning agents can be either acidic or highly

alkaline and can burn severely if contact with skin

occurs. Handle chemical carefully and avoid contact

with skin. ALWAYS wear Personal Protective Equipment

(PPE) including goggles or face shield, chemical

resistant gloves, boots, apron or suit as required. For

personal safety refer to the cleaning agent

manufacturer’s Materials Safety Data Sheet and follow

all recommended safe handling practices. Failure to

follow all safety instructions could result in death or

serious injury.

To clean the refrigerant coil, use a soft brush and sprayer,

such as a garden pump up or high pressure type. In

CXRC-SVX01F-EN 25

Page 26

Maintenance

addition, use a quality detergent; like SPREX AC, OAKITE

161 or OAKITE 166 and COILOX.

Note: If detergent is strongly alkaline (i.e. has a pH value

greater that 8.5) after mixing, an aluminum

corrosion inhibitor must be added.

Coil Cleaning Procedure

1. Disconnect power to the unit.

2. Removeenough panels and components from the unit

to gain access to the coil.

3. Use a soft brush to remove loose dirt and debris form

both sides of the coil.

4. Straighten coil fins with fin comb as required.

5. Mix the detergent with water according to the

manufacturers instructions.

Observe all recommendations of the cleanser

manufacturer.The coil cleanser manufacturer’s

recommendations, warnings and cautions will at all times

take precedence to these instructions.

WARNING

Hazardous Pressures!

Coils contain refrigerant under pressure.When cleaning

coils, maintain coil cleaning solution temperature

under 150°F to avoid excessive pressure in the coil.

Failure to follow these safety precautions could result

in coil bursting, which could result in death or serious

injury.

6. Place solution in the sprayer. Be sure to follow these

guidelines if using a high-pressure sprayer:

a. Minimum nozzle spray angle is 15°.

b. Spray solution at 90° to the coil face.

c. Keep sprayer nozzle at least six inches form the coil.

d. Sprayer pressure must not exceed 600 psi.

7. Spray leaving air side of the coil first then spray the

entering air side of the coil. Allow the detergent and

water solution to stand on the coil for five minutes.

8. Rinse both sides of the coil with cool, clean water.

9. Inspect the coil. If it still appears dirty, repeat the

cleaning procedure.

10. Reinstall all unit components and panels, and restore

electrical power to the unit.

open by applying a 9-volt battery to the positioning signal.

Dampers should stroke 90% open when 9 VDC is applied

to the positioning signal inputs.

Thermostat Controlled Units

The same procedure can be used to inspect the operation

of the low ambient dampers on the thermostat-controlled

unit.The difference is that the positioning signal on the

thermostat-controlled unit will come from the control

panel in the CCRC/CIRC unit not from the Intellipak

controller. Inspect the operation of the pressure switches.

The switches should beopen when sensing pressures less

that 170 psig and should be closed when sensing

pressures greater than 265 psig.

Troubleshooting

WARNING

Live Electrical Components!

During installation, testing, servicing and

troubleshooting of this product, it may be necessary to

work with live electrical components. Have a qualified

licensed electrician or other individual who has been

properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical

safety precautions when exposed to live electrical

components could result in death or serious injury.

If operational difficulties are encountered, perform these

preliminary checks before calling a service technician.

• Check the system thermostat to ensure that all

setpoints are set correctly and that thermostat is

getting control power.

• Verify that the unit is receiving electrical supply power

and that all fuses are intact.

• Check the condenser for proper air flow and take

temperature readings across the condensing coils.

After completing the preliminary checksabove, inspect the

unit for other obvious problems such as broken or

disconnected wires clogged grills or coils. If everything

appears to be in proper working order and the unit fails to

operate properly, contact a qualified service technician.

Low Ambient Damper Adjustment

Intellipak DDC Controlled Units

Inspect damper blade for proper alignment andoperation.

Dampers should be fully closed when positioning signal

from controller is2 volts DC and should be fully openwhen

positioning signal from controller is 10 volts DC.To adjust

position remove VDC signal from actuator and check

dampers to ensure full closure. Check the 90% position

26 CXRC-SVX01F-EN

Page 27

Wiring Diagrams

Note: Published unit wiring diagrams are available via e-

library.

Drawing Number Description

2313-1633 Schematic; Power and Controls 20-60T Intellipak

2313-1632 Schematic; Power and Controls 20-32T Thermostat Controls

2313-1635 Connections - Control Panel w/ Thermostat Controls

2313-1636 Connections - Control Panel w/ Intellipak Controls

2313-1637 Connections; Raceway 20-60T

2313-1639 Field Wiring Diagram w/ Thermostat Controls

2313-1640 Field Wiring Diagram w/ Intellipak controls

CXRC-SVX01F-EN 27

Page 28

Trane optimizes the performance of homes and buildings around the world. A business of Ingersoll Rand, the

leader in creating and sustaining safe, comfortable and energy efficient environments, Trane offers a broad

portfolio of advanced controls and HVAC systems, comprehensive building services, and parts. For more

information, visit www.Trane.com.

Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.

© 2013Trane All rights reserved

CXRC-SVX01F-EN 13 Feb 2013

Supersedes CXRC-SVX01E-EN (23 Oct 2012)

We are committed to using environmentally

conscious print practices that reduce waste.

Loading...

Loading...