Page 1

Scroll Liquid Chillers

Model CGWF and CCAF

20 to 60 Tons (60 Hz)

17 to 50 Tons (50 Hz)

Water-Cooled and Condenserless

Built For the Industrial and Commercial Markets

January 2004

CG-PRC012-EN

Page 2

Introduction

The Trane 20-60 Ton Scroll Liquid Chiller

More Than Just Another “Improved”

Chiller

— Advanced Design

— Better Reliability

— Superior Efficiency

— New CH530 Controls

— Better Availability

— Easier To Install and Operate

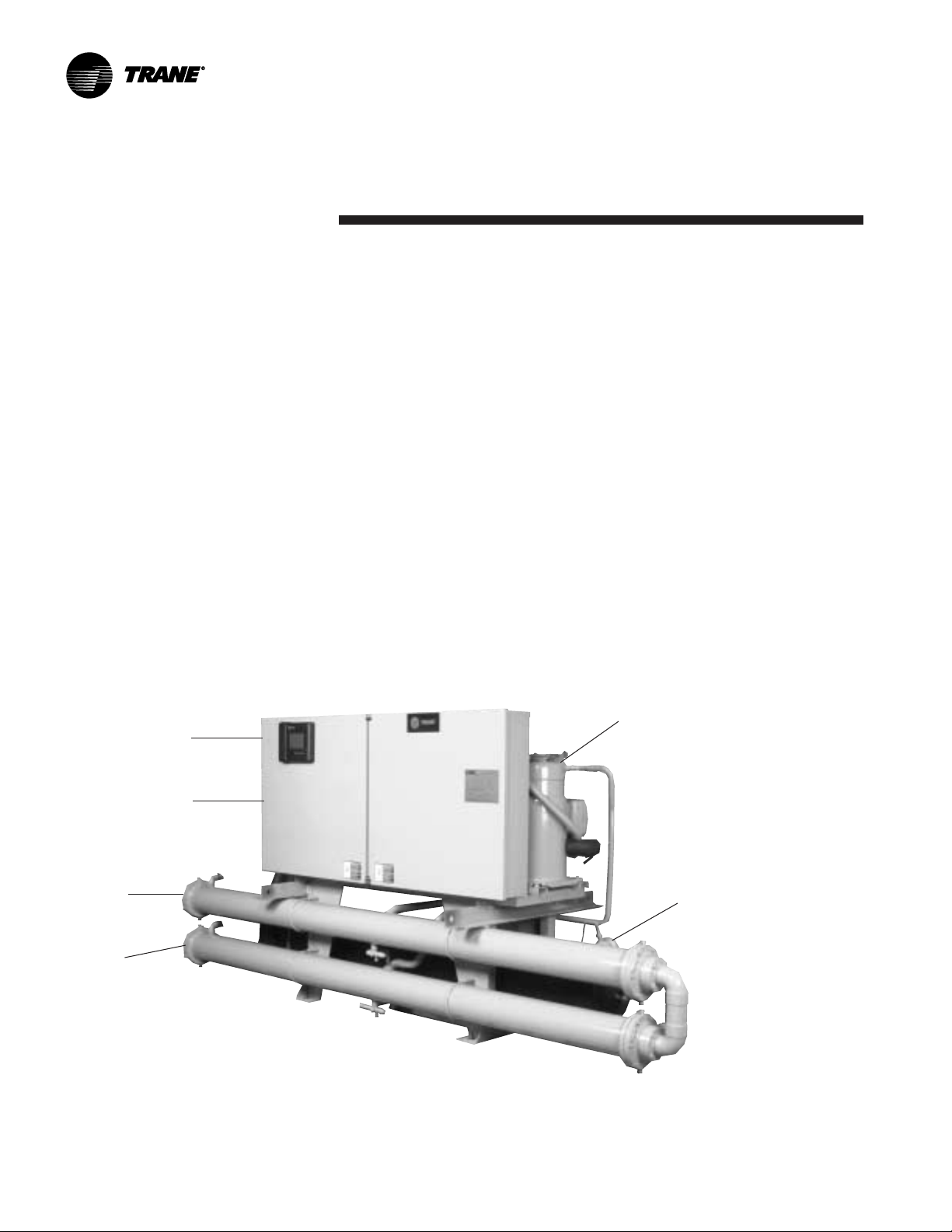

Microprocessor

Operator

Interface

Design

The Trane scroll compressor is the most

advanced scroll compressor in the

industry.

Reliability

64 percent fewer compressor parts,

compared to reciprocating compressors,

mean long and reliable life.

Efficiency

CGWF scroll chillers meet and exceed

ASHRAE Standard 90.1 full and part load

efficiencies. Part load efficiencies are

simply unmatched by reciprocating

chillers.

Control

CH530 controls enable scrolling access

to inputs and operating information via

the LCD touch-screen display. Jobspecific communication options allow

greater reporting flexibility. The CH530 is

compatable with LonMark

communications.

Availability

Fast ship cycles on both stock and builtto-order specials.

Installation

Small unit size, factory wiring, easy

lifting provisions, and start-up control

logic mean quick and easy setup.

Chillers fit through standard singlewidth door.

Operation

Smart safety features and over 60

diagnostic displays mean easy and

virtually trouble-free operation.

Rugged

Trane Scroll

Compressor

Condenser

Leaving

Water

Piping

Condenser

Entering

Water

Piping

Control

Panel

Evaporator

Leaving

Water Piping

CG-PRC012-EN© 2004 American Standard Inc. All rights reserved.

Page 3

Contents

Introduction

Features and Benefits

World Class Efficiency and Reliability

Options

Controls

Application Considerations

Model Number

General Data

Selection Procedure

Performance Data

Full Load Performance

Part Load Performance

Adjustment Factors

Pressure Drops

2

4

8

12

13

14

15

16

CG-PRC012-EN

Electrical Data and Connections

Typical Wiring Diagram

Field Layout

Dimensional Data

Weights

Mechanical Specifications

27

32

37

38

3

Page 4

Features and

Benefits

Trane Value Means Fast Availability,

Easy Installation and Quality Service

Packed Stock For Fast Delivery

When your project is a fast-track job,

Trane can help. A wide range of chillers

are stocked and can be shipped soon

after receipt of your order.

Build To Order

Need a special chiller fast? Think Trane

scroll chillers. New manufacturing

technology and inventory control means

the fastest delivery schedule in the

industry. Wide array of standard options

provides the right chiller for the job fast.

Installation

• Only one power connection hook-up —

for fast and inexpensive installation.

• Integrated Comfort™ system means

only single pair connections are

required for control interfaces and

therefore, lower total installation costs.

• Factory refrigerant and oil charged

units help speed installation.

• All units easily fit through a standard

single width door.

• CH530 provides a wealth of

information.

• Factory testing of all Trane equipment

ensures the system works, allowing

smoother start-up & reducing follow-up

costs.

Easy Serviceability

Trane 20 through 60 ton scroll chillers

are designed with service personnel in

mind. All major components are

replaceable without complete unit

disassembly. Plus, CH530 provides

diagnostic capability to aid service

personnel in analyzing problems.

Therefore, if a problem does occur, the

chiller can be up and running in a shorter

period of time.

Single-Source Responsibility

A wide range of products designed for

complete compatibility are available with

the scroll chillers. Your entire building

comfort system can be completed using

components from Trane.

The Added Value of Applications

Expertise

You get a quality chiller, properly

selected and applied in a properly

designed system. That means a comfort

system that works, the first time!

The standard ARI rating condition

(54/44°F and 85°F/3.0 gpm per ton) and

IPLV are ARI certified. All other ratings,

including the following, are outside the

scope of the certification program and

are excluded:

Glycol.

•

50 Hz.

•

Condenserless models CCAF. Water Chiller Systems Business Unit

•

CG-PRC012-EN4

Page 5

Features and

World Class Efficiency

ASHRAE Standard 90.1

meet and exceed the new efficiency

levels mandated by ASHRAE Standard

90.1. This new standard requires higher

efficiencies than past technologies can

deliver. It mandates higher efficiency

levels for scroll water chillers in

comparison to reciprocating chillers. In

fact, energy efficiency is so paramount

the US Federal Government has

adopted standard 90.1. Federal Executive

Order mandates energy consuming

devices procured must be in the top 25%

of their class. In the case of chillers,

ASHRAE 90.1 is the product standard for

measurement.

Risk.

Not only has ASHRAE 90.1 been

adopted by the US Federal Government,

it’s expected to be adopted domestically,

if not globally, in the future. Make sure

that your chillers as well as your entire

HVAC system complies, or you may be

caught retrofitting your project with new

equipment and paying extra design

dollars if the code changes during

construction.

Trane’s CGWF was designed with the

end user’s requirements in mind.

Efficiency and reliability were primary

design concerns with this latest

generation machine.

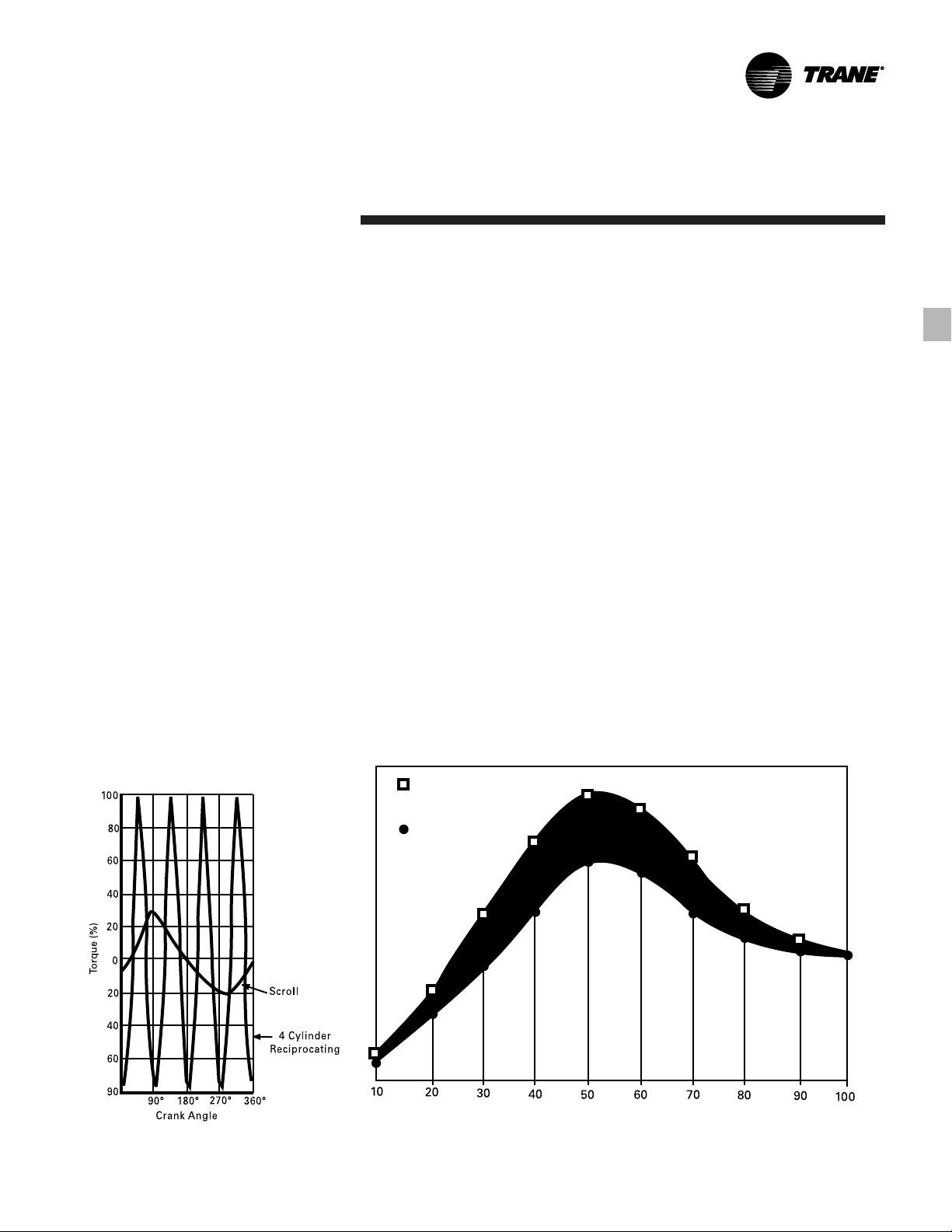

Operating Torque

All Trane chillers

Benefits

& Reliability

Leading in Efficiency and Reliability with State-Of-The-Art

Scroll Compressor Technology

Efficiency

The energy efficiency of the scroll chiller

results in energy costs lower than any

other comparable chiller. Full load

efficiencies are improved beyond

reciprocating chillers, but part load

efficiencies are simply unmatched by any

other manufacturer.

Superior efficiencies are obtained by

combining many of the traditional scroll

chiller energy efficient features with the

Trane scroll compressor technology.

HERE’S HOW:

• Scroll compressor’s positive

displacement design

• Dual refrigerant circuits (40-60 ton units)

• Multiple compressors

• Optimum system design

• Reduced friction

• No valves

• Advanced heat transfer surfaces

Scroll Chiller Energy Usage Savings

Typical Reciprocating

Chiller

Reliability

The Trane scroll chiller with many new

improvements, now brings an exciting

new compressor to the commercial

market — the Trane scroll compressor.

Trane has designed the scroll

compressor to be a leader in reliability.

HERE’S HOW:

• Simple design with 64 percent fewer

parts than equal capacity reciprocating

compressor.

• Scroll compliance allows liquid and dirt

to pass through without damaging

compressor (liquid slugging resistant).

• Advanced microelectronics protect both

compressor and motor from typical

electrical fault conditions.

• Scroll compressors have less than a

third the torque variations of a

reciprocating compressor.

• Years of laboratory testing have

optimized compressor and chiller

systems reliability.

• Water-cooled scroll chillers are factory

tested.

10-20% Annual Energy Savings

Chart illustrates low torque variation of the

Trane scroll compressor vs reciprocating

compressor.

CG-PRC012-EN

Scroll Chiller

Kilowatt Hours

Chiller Load (%)

Graph illustrates Trane scroll chiller’s superior annual energy costs vs typical reciprocating

chillers.

5

Page 6

Features and

World Class Efficiency

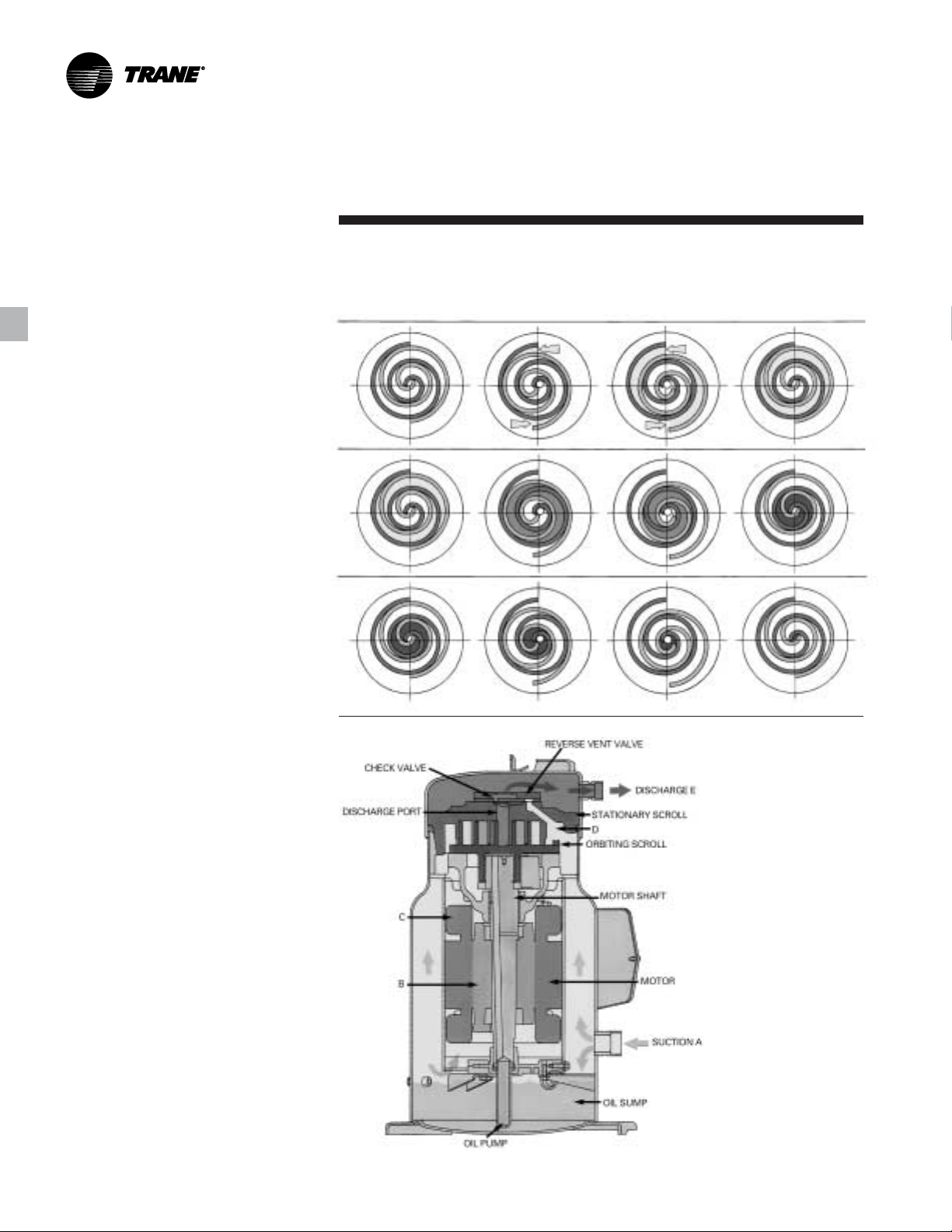

General

The scroll compressor has two scrolls.

The top scroll is fixed and the bottom

scroll orbits. Each scroll has walls in a

spiral shape that intermesh.

Inlet-First Orbit

As the bottom scroll orbits, two

refrigerant gas pockets are formed and

enclosed.

Compression-Second Orbit

The refrigerant gas is compressed as the

volume is reduced closer to the center of

the scroll.

Discharge-Third Orbit

The gas is compressed further and

discharged through a small port in the

center of the fixed scroll.

Benefits

& Reliability

Trane Scroll Compressor

— Maximum Efficiency with Enhanced Reliability

Scroll Principal Components

This is a cutaway view of a hermetic,

scroll compressor, showing the relative

positions of the principal components.

Shown is a Trane 10-ton, 3600 rpm, 60 Hz

[3000 rpm, 50 Hz] scroll compressor as

an example.

The principle of operation of this

example compressor is as follows: The

suction gas is drawn into the compressor

at A. The gas then passes through the

gap between the rotor and stator, B,

cooling the motor, before it enters the

compressor housing, C. Here, the

velocity of the gas is reduced, causing a

separation of the entrained oil from the

gas stream. The gas then enters the

intake chamber, D, that encircles the

scrolls.

Finally, the suction gas is drawn into the

scroll assembly where it is compressed

and discharged into the dome of the

compressor. The dome of this example

compressor acts as a hot gas muffler

which dampens the pulsations before the

gas enters the discharge line, E.

CG-PRC012-EN6

Page 7

Features and

Benefits

Options

Hot Gas Bypass: Hot gas bypass option

allows unit operation below the

minimum step of unit unloading. The

regulator valve, along with all associated

refrigerant piping and electrical wiring,

are factory installed and tested on one

refrigeration circuit. Unit does not start in

hot gas bypass mode. If the unit operates

in bypass mode for 30 minutes without a

call for cooling, it will pump down and

shut off. Unit starts immediately upon a

further call for cooling.

Chilled Water Reset: Front panel settable

control, microprocessor based control

strategy, and field-installed sensor for

ambient temperature based reset are

included in this option. Return water

reset sensor is standard, but panel

controller and control strategy must be

ordered as an option.

Tracer Summit Communication

Interface: Permits bi-directional

communication to the Trane Integrated

Comfort system.

LonTalk LCI-C Communication Interface:

Provides the LonMark chiller profile

inputs/outputs for use with a generic

building automation system.

Remote Input Options

Remote chilled water setpoint input

(4-20mA/2-10Vdc), compressor inhibit

which locks out the second compressor

on each circuit reducing the kW draw or

both.

Control Output Options

Programmable relays provided to

indicate: Compressor running, maximum

capacity, chiller limit mode, warning

(informational diagnostic), alarm latching

(shutdown diagnostic), alarm

nonlatching (shutdown diagnostic),

alarm latching or nonlatching.

Options

Ice Making Controls: In ice-making

mode, the unit will operate fully loaded

in response to jobsite supplied contact

closure. Ice making will terminate when

the return fluid temperature falls below

an adjustable setpoint (minimum 20°F

[-6.7°C]). When not in ice making mode,

unit will provide modulating capacity

control based on leaving chilled fluid

temperature (20-55°F) [-6.7°C to 12.8°C].

Unit Mounted Disconnect Switch: Nonfused molded case disconnect switch

factory installed in control panel for

disconnecting main three-phase power.

Isolators: Neoprene-in-shear isolators for

field installation under unit frame.

Sound Attenuation: Factory-installed

acoustical attenuation for applications

where extremely low sound level is

required.

Water Regulating Valves: Field-installed

valves provide means for control of head

pressure.

Outdoor Temperature Sensor: Fieldinstalled outdoor temperature sensor

with an adjustable setpoint provides

means for low ambient lockout.

Condenser Water Temperature Sensor:

Factory installed temperature sensor

provided for microprocessor display.

CG-PRC012-EN

7

Page 8

Controls

Human Interfaces

The Trane water-cooled 20-60 ton scroll

CGWF chiller offers an easy-to-use

operator interface panel, the DynaView.

DynaView is an LCD touchscreen display

that is navigated by file tabs. This is an

advanced interface that allows the user

to access any important information

concerning setpoints, active

temperatures, modes, electrical data,

pressures, and diagnostics.

Safety Controls

A centralized main processor offers a

higher level of machine protection. Since

the safety controls are smarter, they limit

compressor operation to avoid

compressor or evaporator failures,

thereby minimizing nuisance shutdown.

™

Chiller Controls (CH530) directly

Tracer

senses the control variables that govern

the operation of the chiller: evaporator

pressure and condenser pressure. When

any one of these variables approaches a

limit condition where damage may

occur to the unit or shutdown on a

safety, Tracer Chiller Controls takes

corrective action to avoid shutdown and

keep the chiller operating. This happens

through compressor shedding. Tracer

Chiller Controls optimizes total chiller

power consumption during normal

operating conditions. During abnormal

operating conditions, the

microprocessor will continue to optimize

chiller performance by taking the

corrective action necessary to avoid

shutdown. This keeps cooling capacity

available until the problem can be

solved. Whenever possible, the chiller is

allowed to perform its function; making

chilled water. Overall, the safety controls

help keep the building or process

running and out of trouble.

Figure C1. DynaView operator interface

Standalone Controls

Interface to standalone units is very

simple; only a remote auto/stop for

scheduling is required for unit operation.

Signals from the chilled water pump

contactor auxiliary or a flow switch are

wired to the chilled waterflow interlock.

Signals from a time clock or some other

remote device are wired to the external

auto/stop input.

Standard Features

• External Auto/Stop — A jobsite

provided contact closure will turn the

unit on and off.

• Chilled Water Flow Interlock — A

jobsite provided contact closure from a

chilled water pump contactor and/or a

flow switch is required and will allow

unit operation if a load exists and flow

is proven. This feature will allow the

unit to run in conjunction with the

pump system.

• Emergency Stop — A jobsite supplied

contact opening wired to this input will

turn the unit off and require a manual

reset of the unit microcomputer. This

closure is typically triggered by a

jobsite supplied system such as a fire

alarm.

• Chilled Water Pump Control — Unit

controls provide an output to control

the chilled water pump(s). One contact

closure to the chiller is all that is

required to initiate the chilled water

system.

• Chilled Water Temperature Reset —

Reset can be based on return water

temperature or outdoor air temperature

(optional).

• Condenser Water Pump Control — Unit

controls provide an output to control

the condenser water pump(s). One

contact closure to the chiller is all that is

required to initiate the chilled water

system.

• Condenser Water Flow Protection — A

jobsite supplied contact closure from a

flow switch or pressure switch is

required and will shut down the unit if

flow is lost.

CG-PRC012-EN8

Page 9

Controls

Easy Interface to A Generic Building

Management System

Controlling the scroll CGWF chiller with

building management systems is stateof-the-art, yet simple with either the

LonTalk Communications Interface for

Chillers (LCI-C) or Generic Building

Management System Hardwire Points.

Simple Interface with Other Control

Systems

CH530 controls afford simple interface

with other control systems, such as time

clocks, building automation systems,

and ice storage systems. This means

you have the flexibility to meet job

requirements while not having to learn a

complicated control system. This setup

has the same standard features as a

stand-alone water chiller, with the

possibility of having additional optional

features.

What are LonTalk, Echelon, and

LonMark?

LonTalk is a communications protocol

developed by the Echelon Corporation.

The LonMark association develops

control profiles using the LonTalk

communication protocol. LonTalk is a

unit level communications protocol,

unlike BACNet used at the system level.

LonTalk Communications

Interface for Chillers (LCI-C)

LonTalk Communications Interface for

Chillers (LCI-C) provides a generic

automation system with the LonMark

chiller profile inputs/outputs. The inputs/

outputs include both mandatory and

optional network variables. Note:

LonMark network variable names are in

parentheses when different from chiller

naming convention.

Chiller Inputs:

• Chiller Enable/Disable

• Chilled Liquid Setpoint (Cool Setpoint)

• Compressor Inhibit

• Chiller Mode (Ice Making)

Chiller Enable/Disable

Allows for chiller to be started or

stopped depending on if certain

operating conditions are met.

Chilled Water Setpoint

Allows for the external setting

independent of the front panel setpoint

to adjust the leaving water temperature

setpoint.

Compressor Inhibit

Locks out the second compressor on

each circuit, reducing the kW draw.

Ice Making

Provides interface with ice making

control systems. Please refer to page 11

for more information.

Chiller Outputs:

• On/Off

• Active Setpoint

• Average Percent RLA

• Compressor Inhibit

• Compressor Starts

• Compressor Run Times

• Leaving Chilled Water Temperature

• Entering Chilled Water Temperature

• Evaporator Refrigerant Temperature

• Evaporator Refrigerant Pressure

• Evaporator Water Pump Request &

Flow Status

• Leaving Condenser Water Temperature

• Entering Condenser Water Temperature

• Condenser Refrigerant Temperature

• Condenser Refrigerant Pressure

• Condenser Water Pump Request &

Flow Status

• Outdoor Air Temperature (CCAF)

• Alarm Descriptor

• Chiller Status

Active Setpoint

Indicates the current value of the leaving

water temperature setpoint

Average Percent RLA

Provides the current capacity level via %

RLA

Compressor Starts and Run Times

Provides the number of starts and run

time for each compressor

Alarm Descriptor

Provides alarm messages based on predetermined criteria

Chiller Status

Indicates the running modes and states

of the chiller, i.e. Running in alarm mode,

chiller enabled, chiller being locally

controlled, etc…

Generic Building Management

System Hardwire Points

GBAS may be achieved via hardware

input/output as well. The input/outputs

are as follows:

Chiller Hardwire Inputs Include:

• Chiller Enable/Disable

• Circuit Enable/Disable

• External Chilled Water Setpoint

• Compressor Inhibit

• Ice Making Enable

Programmable Relays and Alarms

The unit provides seven output options,

of which four can be chosen.

a) Compressor running indication

b) Maximum capacity

c) Chiller limit mode

d) Warning informational diagnostic

indication

e) Alarm latching shutdown diagnostic

indication

f) Alarm nonlatching shutdown

diagnostic indication

g) Alarm latching or nonlatching

shutdown diagnostic indication

CG-PRC012-EN

9

Page 10

Controls

Tracer Summit controls — Interface

With The Trane Integrated Comfort

System (ICS)

Trane Chiller Plant Control

The Tracer Summit Chiller Plant Building

Management System with Chiller Plant

Control provides building automation

and energy management functions

through stand-alone control. The Chiller

Plant Control is capable of monitoring

and controlling your entire chiller plant

system.

Application software available:

• Time-of-day scheduling

• Demand limiting

• Chiller sequencing

• Process control language

• Boolean processing

• Zone control

• Reports and logs

• Custom messages

• Run time and maintenance

• Trend log

• PID control loops

And of course, the Trane Chiller Plant

Control can be used on a stand-alone

basis or tied into a complete building

automation system.

When the scroll CGWF chiller is used in

conjunction with a Trane Tracer

™

Summit system, the unit can be

monitored and controlled from a remote

location. The chiller can be controlled to

fit into the overall building automation

strategy by using time of day

scheduling, timed override, demand

limiting, and chiller sequencing. A

building owner can completely monitor

the chiller from the Tracer system, since

all of the monitoring information

indicated on the unit controller’s

microcomputer can be read off the

Tracer system display. In addition, all the

powerful diagnostic information can be

read back at the Tracer system. Best of

all, this powerful capability comes over a

single twisted pair of wires! The scroll

liquid chillers can interface with many

different external control systems, from

simple stand-alone units to ice making

systems.

A single twisted pair of wires tied directly

between the CGWF chiller and a Tracer

™

Summit system provides control,

monitoring and diagnostic capabilities.

Control functions include auto/stop,

adjustment of leaving water temperature

setpoint, compressor operation lockout

for kW demand limiting and control of

ice making mode. The Tracer system

reads monitoring information such as

entering and leaving evaporator water

temperatures and outdoor air

temperature. Over 60 individual

diagnostic codes can be read by the

Tracer system. In addition, the Tracer

system can provide sequencing control

for up to 25 units on the same chilled

water loop. Pump sequencing control

can be provided from the Tracer system.

Tracer ICS is not available in conjunction

the external setpoint capability.

Required Options

Tracer Interface

External Trane Devices Required

Tracer Summit

™

, Tracer 100 System or

Tracer Chiller Plant Control

Additional Features That May Be Used

Ice Making Control

CG-PRC012-EN10

Page 11

Controls

Trane Chiller Plant Automation

Trane’s depth of experience in chillers

and controls makes us a well-qualified

choice for automation of chiller plants

using scroll liquid chillers. The chiller

plant control capabilities of the Trane

Tracer Summit

®

building automation

system are unequaled in the industry.

Our chiller plant automation software is

fully pre-engineered and tested. It is a

standard software application, not

custom programming which can prove

to be difficult to support, maintain, and

modify.

Energy Efficiency

Trane chiller plant automation

intelligently sequences starting of

chillers to optimize the overall chiller

plant energy efficiency. Individual chillers

are designated to operate as base, peak,

or swing based on capacity and

efficiency. Sophisticated software

automatically determines which chiller

to run in response to current conditions.

The software also automatically rotates

individual chiller operation to equalize

runtime and wear between chillers.

Trane chiller plant automation enables

unique energy-saving strategies. An

example is controlling pumps, and

chillers from the perspective of overall

system energy consumption. The

software intelligently evaluates and

selects the lowest energy consumption

alternative.

Keeping Operators Informed

A crucial part of efficiently running a

chiller plant is assuring that the

operations staff is instantly aware of

what is happening in the plant. Graphics

showing schematics of chillers, piping,

pumps, and towers clearly depict the

chiller plant system, enabling building

operators to easily monitor overall

conditions. Status screens display both

current conditions and upcoming

automated control actions to add or

subtract chiller capacity. CGWF and

other chillers can be monitored and

controlled from a remote location.

Tracer Summit features standard report

templates listing key operating data for

troubleshooting and verifying

performance. Reports for each type of

Trane chiller and three and six-chiller

systems are also standard. Detailed

reports showing chiller runtimes aid in

planning for preventative maintenance.

Swift Emergency Response

We understand the importance of

maintaining chilled water production

while protecting your chillers from costly

damage. If no water flow is detected to a

chiller’s piping, the start sequence is

aborted to protect the chiller. The next

chiller in the sequence is immediately

started to maintain cooling.

In the event of a problem, the operator

receives an alarm notification and

diagnostic message to aid in quick and

accurate troubleshooting. A snapshot

report showing system status just prior

to an emergency shutdown helps

operators determine the cause. If

emergency conditions justify an

immediate manual shutdown, the

operator can override the automatic

control.

Easy Documentation for Regulatory

Compliance

Comprehensive documentation of

refrigerant management practices is

now a fact of life. Trane chiller plant

automation generates the reports

mandated in ASHRAE Guideline 3.

™

Integrated Comfort

Capabilities

When integrated with a Tracer Summit

building management system

performing building control, Trane chiller

plant automation coordinates with

Tracer Summit applications to optimize

the total building operation. With this

system option, the full breadth of Trane’s

HVAC and controls experience are

applied to offer solutions to many facility

issues. If your project calls for an

interface to other systems, Tracer

Summit can share data via BACnet

™

, the

ASHRAE open systems protocol.

Ice Making Systems Controls

An ice making option may be ordered

with the 20-60 ton scroll liquid chiller.

CH530 will accept a command to initiate

ice making. When in the ice making

mode, the chiller will be fully loaded and

will continue to operate until the ice

command is removed or the evaporator

entering water temperature reaches the

active ice termination setpoint. If

terminated on the evaporator entering

water temperature, CH530 will not allow

the chiller to restart until the ice making

command is removed.

Additional Options That May Be Used In

Conjunction

Failure Indication Contacts

Communications Interface (For Tracer

Systems)

Chilled Water Temperature Reset

CG-PRC012-EN

11

Page 12

Application

Considerations

Unit Location

Units should be installed indoors where

exposure to rain or water splash is

minimal. A level foundation or flooring

must be provided which will support at

least 150 percent of the operating weight

of the unit. The chiller foundation must be

rigid to reduce vibration transmission to a

minimum. Use of vibration isolators is

recommended for applications with

sensitive vibration and noise criteria.

Allow service clearance for compressor

removal as well as evaporator and

condenser tube removal.

Condenser Water Limitations

Water-cooled scroll chillers start and

operate satisfactorily over a range of load

conditions with uncontrolled entering

water temperature.

Reducing the condenser water

temperature is an effective method of

lowering the power input required.

However, by reducing the condenser

water temperature beyond certain limits,

the effect causes a reduction in the

pressure drop across the thermal

expansion valve to a point when system

instability may occur.

In general, continuous machine operation

with entering condenser water

temperature below 60°F [15.5°C] is not

recommended. When the condenser

water temperature is expected to drop

below 60°F [15.5°C], it is recommended

that some form of condenser water

temperature control be used to ensure

optimal machine performance.

Water Treatment

Use of untreated or improperly treated

water in chillers may result in scaling,

erosion, corrosion, algae or slime. It is

recommended that the services of a

qualified water treatment specialist be

engaged to determine what treatment, if

any, is advisable. Trane assumes no

responsibility for the results of untreated,

or improperly treated water.

Water Pumps

Avoid specifying or using 3600 rpm, 60

Hz [3000 rpm, 50 Hz] condenser water

and chilled water pumps. Such pumps

may operate with objectional noise and

vibration. In addition, a low frequency

beat may occur due to the slight

difference in operating rpm between

water pumps and scroll compressor

motors. Where noise and vibration-free

operation is important, Trane

encourages the use of 1750 rpm, 60 Hz

[1450 rpm, 50 Hz] pumps.

Remote Condenser

Remote condensers should be located

as close as possible to the chiller to

ensure minimum pressure drops of

discharge refrigerant. If non-Trane

condensers are provided, a subcooling

circuit must be provided in order to

achieve cataloged performances

(16°F [-8.9°C] subcooling).

CG-PRC012-EN12

Page 13

Model Number

Description

Model Number Description

CGW F 020 4 C A0 U A A 1 C L 1 D 0 N N 0 0 N 0 X 0 X

1,2,3 4 5,6,7 8 9 10,11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

Digits 01, 02, 03, – Chiller series

CGWF = Water cooled scroll

chiller

CCAF = Scroll compressor chiller

(condenserless)

Digits 04, – Development sequence

Digits 05, 06, 07 – Unit nominal tonnage

020 = 20 Nominal tons

025 = 25 Nominal tons

030 = 30 Nominal tons

040 = 40 Nominal tons

050 = 50 Nominal tons

060 = 60 Nominal tons

Digit 08 – Unit voltage

G = 208-230/60/3

D = 380/60/3

N = 400/50/3

4 = 460/60/3

5 = 575/60/3

Digit 09 – Ship Cycle

C = Made to order

(C) = Packed stock (Contact BU)

Digit 10, 11 – Design sequence

XX = Factory/ABU assigned

Digit 12 – Agency listing

N = No agency listing

U = C/UL listing

Digit 13 – Pressure vessel code

A = ASME code

C = Canadian code

Digit 14 – Shipping package

A = Ship via flat bed truck

B = Ship w/shrink wrap bag and skid

C = Ship w/skid

Digit 15 – Condenser temperature range

0 = None - CCAF units

1 = Standard 60-90°F [15.6-32.2°C]

entering water temp

4 = High 90-130°F [32.2-54.4°C] entering

water temp

Digit 16 – Condenser tube material

N = None - CCAF units

C = Std copper finned tubes

Digit 17 – Condenser water connections

N = None - CCAF units

L = Left hand cond water connections

(default)

R = Right hand cond water connections

Digit 18 – Evaporator temperature range

1 = Standard cooling 40-60°F [4.4-15.6°C]

2 = Ice making 26-39°F [-3.3-3.9°C]

3 = Low temp 10-25°F [-12.2-(-3.9)°C]

4 = Standard cooling/Ice making 20-60°F

[-6.7-15.6°C]

Digit 19 – Power line connection type

T = Terminal block

D = Non-fused disconnect switch

Digit 20 – Short circuit rating

0 = No short circuit rating

1 = With short circuit rating

Digit 21 – Control input options

N = No options

R = Remote chilled water setpoint input

C = Remote compressor inhibit and/or

icemaking input

B = Remote CWS and compressor

inhibit/icemaking input

Digit 22 – Control output options

N = No options

P = Programmable relays for remote

alarm, run, etc.

Digit 23 – Auxiliary sensor options

0 = None

1 = Condenser water temp sensors

(CGWF only)

2 = Outdoor temp sensor -

CWR or Amb Lockout

3 = Both condenser and outdoor

temp sensor

Digit 24 – Communication options

0 = None

3 = Tracer Summit interface

5 = LonTalk LCI-C interface

Digit 25 – Hot gas bypass

N = NO HGBP valve/function

H = HGBP function included

Digit 26 – Sound attenuator

0 = No sound attenuator

1 = Sound attenuator - factory installed

Digit 27 – Ship-with accessories isolators, WRV

X = No ship-with accessories

N = Neoprene isolators

A = 1.5" 2-way water reg valve x 1

B = 2" 2-way water reg valve x 1

C = 2.5" 2-way water reg valve x 1

D = 1.5" 2-way water reg valve x 2

E = 2" 2-way water reg valve x 2

F = 2.5" 2-way water reg valve x 2

G = Neo isolators + 1.5" WRV x 1

H = Neo isolators + 2" WRV x 1

J = Neo isolators + 2.5" WRV x 1

K = Neo isolators + 1.5" WRV x 2

L = Neo isolators + 2" WRV x 2

M = Neo isolators + 1.5" WRV x 2

Digit 28 – Ship-with accessories - flow

switches

0 = No flow switches

1 = 150 psi NEMA-1 flow switch

(FS4-3) x 1

2 = 150 psi NEMA-1 flow switch

(FS4-3) x 2

4 = 150 psi NEMA-4 flow switch

(FS8-W) x 1

5 = 150 psi NEMA-4 flow switch

(FS8-W) x 2

Digit 29 – Design special

X = Unit has no special features

S = Unit has special design feature

CG-PRC012-EN

13

Page 14

General Data

Table GD-1. General data — CGWF water-cooled chiller

Size 20 25 30 40 50 60

Compressor

Quantity (1) 2 2 2 2/2 2/2 2/2

Nominal Size (tons) (2) 10/10 10/15 15/15 10-10/10-10 10-15/10-15 15-15/15-15

Steps of Unloading (%) 100,50 100,60 100,50 100,75,50,25 100,80,60,30 100,75,50,25

Evaporator

Water Storage (gallons) 12 11 16 13 21 40

Min. Flow (gpm) 24 30 36 48 60 84

Max. Flow (gpm) 72 90 108 144 180 252

Condenser

Water Storage (gallons) 5.0 6.1 7.6 11.7 13.9 14.0

Min. Flow (gpm) 30 36 50 60 72 90

Max. Flow (gpm) 90 108 146 180 216 325

General Unit

Refrigerant R-22 R-22 R-22 R-22 R-22 R-22

No. of Independent

Refrigerant Circuits 1 1 1 2 2 2

Refrigerant (pound) 50 50 90 50/50 50/50 75/75

Charge (kilogram) 22.7 22.7 40.8 22.7/22.7 22.7/22.7 34/34

Oil Charge (pints) 16 22 28 16/16 22/22 28/28

Notes

1. Data containing information on two circuits shown as follows: CKT 1/CKT 2

2. Nominal compressor sizes based on 60 Hz.

(liters) 45 42 61 49 80 151

(L/s) 1.5 1.9 2.3 3.0 3.8 4.7

(L/s) 4.5 5.7 6.8 9.1 11.4 17.3

(liters) 18.9 23.2 28.9 44.2 52.7 53.1

(L/s) 1.9 2.3 3.2 3.8 4.5 5.7

(L/s) 5.7 6.8 9.2 11.4 13.6 20.5

(liters) 7.6 10.4 13.2 7.6/7.6 10.4/10.4 13.3/13.3

Table GD-2. General data — CCAF compressor chiller

Size 20 25 30 40 50 60

Compressor

Quantity (1) 2 2 2 2/2 2/2 2/2

Nominal Size (tons) (2) 10/10 10/15 15/15 10-10/10-10 10-15/10-15 15-15/15-15

Steps of Unloading (%) 100,50 100,60 100,50 100,75,50,25 100,80,60,30 100,75,50,25

Evaporator

Water Storage (gallons) 12 11 16 13 21 19

Min. Flow (gpm) 24 30 36 48 60 84

Max. Flow (gpm) 72 90 108 144 180 252

General Unit

Refrigerant R-22 R-22 R-22 R-22 R-22 R-22

No. of Independent

Refrigerant Circuits 1 1 1 2 2 2

Refrigerant (pound) 6 8 12 6/6 8/8 12/12

Charge (kilogram) 2.7 3.6 5.4 2.7/2.7 3.6/3.6 5.5/5.5

Oil Charge (pints) 16 22 28 16/16 22/22 28/28

Notes:

1. Data containing information on two circuits shown as follows: CKT 1/CKT 2

2. Nominal compressor sizes based on 60 Hz.

(liters) 45 42 61 49 80 72

(L/s) 1.5 1.9 2.3 3.0 3.8 4.7

(L/s) 4.5 5.7 6.8 9.1 11.4 17.3

(liters) 7.6 10.4 13.2 7.6/7.6 10.4/10.4 13.3/13.3

CG-PRC012-EN14

Page 15

Selection

Procedures

The chiller capacity tables on the

following pages cover the most

frequently encountered leaving water

temperatures. For temperature drops

other than 10°F [5.6°C], refer to Table

SP-1, Performance Adjustment Factors,

shown below.

Additional chiller selections and

performance information can be

obtained through your local Trane sales

office.

To select a Trane water-cooled scroll

chiller, the following information is

required:

1. Design load in tons of refrigeration

2. Design chilled water temperature drop

3. Design leaving chilled water

temperature

4. Entering condenser water temperature

Evaporator flow rate (gpm) can be

determined by using the following

formula:

gpm =

Tons x 24

Chilled Water DT (F)

Condenser flow rate (gpm) can be

determined by using the following

formula:

gpm =

24 x (tons + (0.285 x compressor kW)

Condenser Water DT (F)

Table SP-1. Performance adjustment factors

Fouling Water Evap. Cond.

Factor Delta T Capacity GPM kW GPM

0.00010 10 1.000 1.000 1.000 1.000

Note:

This selection procedure is for water only as the

solution.

8 0.997 1.231 1.000 0.997

12 1.007 0.829 1.001 1.006

14 1.012 0.714 1.001 1.010

16 1.017 0.628 1.002 1.014

Scroll Liquid Chiller — (CGWF) —

Selection Example:

Given:

System Load = 40 tons

Leaving Chilled Water Temperature

(LCWT) = 44°F [6.7°C]

Entering Condenser Water Temperature

(EWT) = 85°F [29.4°C]

Leaving Condenser Water Temperature

(LWT) = 95°F [35°C]

Chilled Water Temperature Drop

= 10°F [5.6°C]

1. From Table PD-1 (Performance Data), a

CGWF 40 at the given conditions will

produce 39.4 tons with a compressor

power input of 30.3 kW and a unit EER

of 15.6.

2. To determine the evaporator and

condenser water pressure drops, the

flow rates (gpm) must be determined.

Using the formula above, this unit

would require an evaporator flow rate

of 95 gpm and a condenser flow rate

of 115 gpm. (Compressor kW is found

in the same table as the capacity.) The

Evaporator Pressure Drop Curve,

Chart PD-1, indicates that 95 gpm

through a 40 ton evaporator results in

a pressure drop of 13.8 feet of water.

The Condenser Pressure Drop curve,

Chart PD-2, indicates 115 gpm through

a 40 ton condenser results in a

pressure drop of 14 feet of water.

3. The final unit selection is:

— Quantity (1) CGWF 40

— Cooling Capacity = 39.4 tons

— Entering/Leaving Chilled Water

Temperatures = 54/44°F [12.2/6.7°C]

— Chilled water flow rate = 95 gpm

— Evaporator water pressure drop =

13.8 feet

— Cooling water flow = 115 gpm

— Condenser water pressure drop =

14 feet

— Compressor power input = 30.3 kW

— Unit EER = 15.6

Compressor Chiller – (CCAF) – Selection

Example:

Select the unit for the following

conditions:

A compressor chiller is required to

produce 45 tons when matched with an

air-cooled condenser. The leaving chilled

water temperature is 44°F [6.7°C]. The

evaporator temperature differential is

10°F [5.6°C]. The ambient temperature is

95°F [35°C].

1. Select the nominal unit size. The

performance data is tabulated by

leaving chilled water temperature. For

example, the standard unit capacities

at 44°F [6.7°C] leaving chilled water

temperature are found on page 21.

The system that best meets the

tonnage requirement is a CCAF 50

matched with a CAUC C50. The unit

capacity is 47.1 tons with a kW input of

56.3. The compressor chiller EER is

10.0.

2. Calculate the required chilled water

flow rate.

3. gpm = Tons x 24

Chilled Water DT (F)

From this example,

47.1 x 24 = 113

gpm =

10

4. Determine the evaporator water

pressure drop. The evaporator water

pressure drop is located on page 22.

Entering the evaporator chart at 113

gpm, the pressure drop for a CCAF 50

evaporator is 7.9 feet.

5. Unit Selection

The above procedure shows the

proper selection for this example is a

CCAF 50 with a CAUB C50 condenser

operating as follows:

— Capacity = 47.1

— Entering/leaving chilled water

temperature = 54/44°F [12.2/6.7°C]

— Chilled water flow rate = 113 gpm

— Evaporator water pressure drop =

7.9 feet

— Compressor power input = 56.3

— Unit EER = 10.0

CG-PRC012-EN

15

Page 16

Performance

Full Load

Data

Performance

Table PD-1. 60 Hz CGWF performance data in English units

Evaporator Entering Condenser Water Temperature (F)

Leaving Water Unit 75 80 85 90 95

Temperature (F) Size Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 30 28.3 20.7 16.4 27.6 21.7 15.3 27.0 22.9 14.1 26.3 24.1 13.1 25.6 25.4 12.1

42 30 29.4 20.8 17.0 28.7 21.8 15.8 28.0 23.0 14.7 27.3 24.2 13.6 26.6 25.5 12.5

44 30 30.6 20.8 17.6 29.9 21.9 16.4 29.2 22.9 15.3 28.4 24.3 14.0 27.7 25.6 13.0

46 30 31.7 20.9 18.2 31.0 22.0 16.9 30.3 23.1 15.7 29.5 24.4 14.5 28.7 25.7 13.4

48 30 32.9 21.0 18.8 32.2 22.1 17.5 31.4 23.2 16.2 30.7 24.5 15.0 29.9 25.8 13.9

50 30 34.1 21.1 19.5 33.4 22.1 18.1 32.6 23.3 16.8 31.8 24.6 15.6 31.0 25.0 14.4

Notes:

1. Rated in accordance with ARI Standard 550/590-98 with fouling factors of 0.0001 in the evaporator and 0.00025 in the condenser.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hout). Power inputs include compressors and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. Interpolation between points is permissible. Extrapolation is not permitted.

20 19.2 13.8 16.7 19.0 14.5 15.7 18.6 15.4 14.6 18.1 16.1 13.5 17.7 17.1 12.4

25 23.8 17.2 16.5 23.2 18.1 15.4 22.7 19.1 14.3 22.1 20.1 13.2 21.6 21.2 12.2

40 38.0 27.3 16.8 37.2 28.7 15.6 36.5 30.2 14.5 35.5 31.8 13.4 34.6 33.6 12.4

50 47.0 34.1 16.6 46.0 35.8 15.4 44.9 37.7 14.3 43.8 39.7 13.2 42.7 41.0 12.2

60 57.7 42.1 16.4 56.4 44.2 15.3 55.0 46.5 14.2 53.7 49.0 13.1 52.3 51.7 12.1

20 20.0 13.9 17.3 19.8 14.6 16.3 19.3 15.4 15.1 18.9 16.2 14.0 18.4 17.1 12.9

25 24.7 17.3 17.1 24.2 18.2 15.9 23.6 19.2 14.8 23.0 20.2 13.7 22.4 21.3 12.6

40 39.5 27.4 17.3 38.7 28.8 16.1 37.8 30.3 15.0 36.9 32.0 13.9 36.0 33.8 12.8

50 48.9 34.2 17.2 47.8 36.0 16.0 46.7 37.9 14.8 45.6 39.9 13.7 44.4 42.1 12.7

60 59.9 42.3 17.0 58.5 44.4 15.8 57.2 46.7 14.7 55.7 49.2 13.6 54.3 51.9 12.6

20 20.8 13.9 17.3 20.5 14.7 16.8 19.9 15.4 15.5 19.6 16.3 14.5 19.1 17.2 12.9

25 25.7 17.4 17.7 25.1 18.3 16.5 24.5 19.1 15.4 23.9 20.3 14.2 23.3 21.4 13.1

40 41.1 27.5 17.9 40.2 28.9 16.7 39.4 30.3 15.6 38.4 32.1 14.4 37.4 33.9 13.3

50 50.8 34.4 17.7 49.7 35.1 16.5 48.6 37.8 15.4 47.4 40.1 14.2 46.2 42.3 13.1

60 62.1 42.5 17.6 60.7 44.6 16.3 59.4 46.8 15.2 57.9 49.4 14.1 56.4 52.1 13.0

20 21.5 14.0 18.5 21.3 14.7 17.4 20.9 15.5 16.2 20.4 16.3 15.0 19.9 17.3 13.8

25 26.6 17.4 18.3 26.1 18.3 17.1 25.5 19.3 15.8 24.9 20.3 14.7 24.2 21.5 13.5

40 42.6 27.6 18.5 41.7 29.0 17.3 40.8 30.6 16.0 39.9 32.3 14.8 38.9 34.1 13.7

50 52.8 34.5 18.4 51.6 36.3 17.1 50.4 38.2 15.9 49.2 40.2 14.7 48.0 42.4 13.6

60 64.4 42.6 18.1 63.0 44.8 16.9 61.5 47.1 15.7 60.0 49.6 14.5 58.5 52.3 13.4

20 22.4 14.0 19.1 22.1 14.8 18.0 21.6 15.6 16.7 21.1 16.4 15.5 20.6 17.3 14.3

25 27.6 17.5 19.0 27.0 18.4 17.6 26.4 19.4 16.4 25.8 20.4 15.2 25.2 21.6 14.0

40 44.2 27.8 19.1 43.3 29.2 17.8 42.4 30.7 16.6 41.4 32.4 15.3 40.4 34.2 14.2

50 54.7 34.6 19.0 53.6 35.4 17.7 52.3 38.3 16.4 51.1 40.4 15.2 49.8 42.6 14.0

60 66.7 42.8 18.7 65.2 45.0 17.4 63.7 47.3 16.2 62.2 49.8 15.0 60.7 52.5 13.9

20 23.2 14.1 19.7 22.9 14.8 18.6 22.4 15.6 17.2 21.9 16.5 16.0 21.4 17.4 14.8

25 28.7 17.6 19.6 28.0 18.5 18.2 27.4 19.4 16.9 26.8 20.5 15.7 26.1 21.6 14.5

40 45.9 27.9 19.8 44.9 29.3 18.4 43.9 30.8 17.1 42.9 32.5 15.8 41.9 34.3 14.6

50 56.8 34.8 19.6 55.5 36.5 18.2 54.3 38.5 16.9 53.0 40.5 15.7 51.7 42.8 14.5

60 69.1 43.0 19.3 67.6 45.1 18.0 66.0 47.5 16.7 64.5 50.0 15.5 62.9 52.8 14.3

CG-PRC012-EN16

Page 17

Performance

Full Load

Data

Table PD-2. 60 Hz CGWF performance data in Metric units

Evaporator Entering Condenser Water Temperature (C)

Leaving Water Unit 25 30 35

Temperature (C) Size kWo kWi COP kWo kWi COP kWo kWi COP

6 30 104.0 21.2 4.9 99.6 23.2 4.3 95.1 25.6 3.7

8 30 111.4 21.4 5.2 106.8 23.4 4.6 102.0 25.7 4.0

10 30 119.0 21.5 5.5 114.1 23.6 21.4 109.1 25.9 4.2

Notes:

1. Rated in accordance with ARI Standard 550/590-98 with fouling factors of 0.0176 in the evaporator and

0.044 in the condenser.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/total kW). Total kW include compressors and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. Interpolation between points is permissible. Extrapolation is not permitted.

20 70.4 14.2 5.0 67.7 15.5 4.4 64.7 17.1 3.8

25 87.1 17.7 4.9 83.5 19.4 4.3 79.8 21.8 3.7

40 139.5 28.0 5.0 133.9 30.7 4.4 128.1 33.8 3.8

50 172.4 35.0 4.9 165.3 38.3 4.3 157.9 42.2 3.7

60 211.0 43.2 4.9 202.2 47.3 4.3 193.1 52.0 3.7

20 75.7 14.3 5.3 72.7 15.7 4.6 69.6 17.3 4.0

25 93.5 17.8 5.3 89.8 19.5 4.6 85.8 21.5 4.0

40 150.3 28.2 5.3 144.5 30.9 4.7 138.3 34.1 4.1

50 185.3 35.2 5.3 177.7 38.6 4.6 169.9 42.5 4.0

60 226.0 43.5 5.2 216.8 47.6 4.6 207.2 52.4 4.0

20 80.8 14.4 5.6 77.7 15.8 21.7 74.4 17.4 4.3

25 99.9 17.9 5.6 95.9 19.6 21.5 91.8 21.6 4.8

40 159.9 28.4 5.6 153.8 31.2 21.8 147.3 34.3 4.3

50 197.9 35.5 5.6 185.9 35.2 23.3 181.7 42.8 4.2

60 240.7 43.8 5.5 231.0 48.0 21.2 221.0 52.8 4.2

Performance

CG-PRC012-EN

17

Page 18

Performance

Full Load

Data

Performance

Table PD-3. 50 Hz CGWF performance data in English units

Evaporator Entering Condenser Water Temperature (F)

Leaving Wate Unit 75 80 85 90 95

Temperature (F) Size Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

42 30 24.6 16.7 17.7 24.1 17.5 16.5 23.6 18.5 15.3 23.0 19.5 14.1 22.5 20.7 13.0

44 30 25.6 16.7 18.4 25.1 17.6 17.1 24.5 18.5 15.9 24.0 19.6 14.7 23.4 20.7 13.5

46 30 26.6 16.7 19.1 26.0 17.6 17.7 25.5 18.6 16.5 24.9 19.6 15.2 24.3 20.8 14.0

48 30 27.6 16.8 19.7 27.0 17.7 18.4 26.5 18.6 17.0 25.9 19.7 15.8 25.2 20.8 14.5

50 30 28.6 16.8 20.4 28.0 17.7 19.0 27.5 18.7 17.6 26.8 19.7 16.3 26.2 20.9 15.1

Notes:

1. Rated in accordance with ARI Standard 550/590-98 with fouling factors of 0.00010 in the evaporator and 0.00025 in the condenser.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. Interpolation between points is permissible. Extrapolation is not permitted.

20 19.2 13.8 16.7 19.0 14.5 15.7 18.6 15.4 14.6 18.1 16.1 13.5 17.7 17.1 12.4

20 16.8 11.1 18.1 16.4 11.7 16.8 16.0 12.4 15.5 15.6 13.1 14.3 15.3 13.9 13.1

25 20.7 13.9 17.9 20.3 14.6 16.6 19.8 15.5 15.4 19.4 16.3 14.2 18.9 17.3 13.1

40 33.2 21.9 18.2 32.5 23.1 16.9 31.8 24.4 15.6 31.0 25.9 14.4 30.2 27.4 13.2

50 41.0 27.4 17.9 40.1 28.9 16.7 39.2 30.5 15.5 38.3 32.2 14.3 37.4 34.1 13.1

60 50.4 33.8 17.9 49.3 35.6 16.7 48.2 37.5 15.4 47.1 39.6 14.3 46.0 41.9 13.2

20 17.4 11.1 18.8 17.1 11.7 17.4 16.7 12.4 16.1 16.3 13.2 14.9 15.9 13.9 13.7

25 21.5 13.9 18.6 21.1 14.7 17.3 20.6 15.5 16.0 20.1 16.4 14.8 19.6 17.3 13.6

40 34.5 22.0 18.9 33.8 23.2 17.5 33.0 24.5 16.2 32.2 25.9 14.9 31.4 27.5 13.7

50 42.6 27.5 18.6 41.7 29.0 17.3 40.8 30.6 16.0 39.9 32.3 14.8 38.9 34.2 13.6

60 52.3 33.9 18.5 51.2 35.7 17.2 50.1 37.6 16.0 48.9 39.7 14.8 47.7 42.0 13.7

20 18.1 11.2 19.5 17.7 11.8 18.1 17.3 12.4 16.7 16.9 13.2 15.4 16.5 14.0 14.2

25 22.4 13.9 19.2 21.9 14.7 17.9 21.4 15.5 16.6 20.9 16.4 15.3 20.4 17.4 14.1

40 35.8 22.0 19.6 35.1 23.2 18.2 34.3 24.5 16.8 33.5 26.0 15.5 32.7 27.5 14.2

50 44.3 27.6 19.3 43.3 29.0 17.9 42.4 30.6 16.6 41.4 32.4 15.4 40.4 34.3 14.2

60 54.2 34.0 19.1 53.1 35.8 17.8 51.9 37.7 16.5 50.8 39.8 15.3 49.5 42.1 14.1

20 18.8 11.2 20.2 18.4 11.8 18.8 18.0 12.5 17.3 17.6 13.2 16.0 17.2 14.0 14.7

25 23.2 14.0 19.9 22.7 14.7 18.5 22.2 15.5 17.2 21.7 16.4 15.9 21.2 17.4 14.6

40 37.2 22.0 20.3 36.4 23.2 18.8 35.6 24.6 17.4 34.8 26.0 16.1 34.0 27.6 14.8

50 45.9 27.6 20.0 45.0 29.1 18.6 44.0 30.7 17.2 43.0 32.4 15.9 42.0 34.3 14.7

60 56.1 34.1 19.8 55.0 35.9 18.4 53.9 37.8 17.1 52.6 40.0 15.8 51.4 42.2 14.6

20 19.5 11.2 20.9 19.1 11.8 19.4 18.7 12.5 18.0 18.3 13.2 16.6 17.8 14.0 15.3

25 24.1 14.0 20.6 23.6 14.8 19.2 23.1 15.6 17.8 22.6 16.5 16.4 22.0 17.4 15.1

40 38.6 22.1 21.0 37.8 23.3 19.5 37.0 24.6 18.0 36.1 26.1 16.6 35.3 27.6 15.3

50 47.6 27.7 20.7 46.7 29.1 19.2 45.7 30.8 17.8 44.6 32.5 16.5 43.6 34.4 15.2

60 58.1 34.2 20.4 57.0 36.0 19.0 55.8 37.9 17.7 54.5 40.1 16.3 53.3 42.3 15.1

CG-PRC012-EN18

Page 19

Performance

Full Load

Data

Table PD-4. 50 Hz CGWF performance data in Metric units

Evaporator Entering Condenser Water Temperature (C)

Leaving Water Unit 25 30 35

Temperature (C) Size kWo kWi COP kWo kWi COP kWo kWi COP

6 30 87.3 17.0 5.1 83.9 18.7 4.5 80.3 20.7 3.9

8 30 93.5 17.1 5.5 89.9 18.8 4.8 86.1 20.8 4.1

10 30 99.9 17.2 5.8 96.2 18.9 5.1 92.2 20.9 4.4

Notes:

1. Rated in accordance with ARI Standard 550/590-98 with fouling factors of 0.0176 in the evaporator and

0.044 in the condenser.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/total kW). Total kW include compressors and control power.

5. Ratings are based on an evaporator and condenser temperature drop of 5.6°C.

6. Interpolation between points is permissible. Extrapolation is not permitted.

20 70.4 14.2 5.0 67.7 15.5 4.4 64.7 17.1 3.8

20 59.4 11.4 5.2 57.0 12.6 4.5 54.5 14.0 3.9

25 73.4 14.2 5.2 70.5 15.7 4.5 67.5 17.3 3.9

40 117.6 22.4 5.2 112.9 24.8 4.6 108.0 27.5 3.9

50 145.3 28.0 5.2 139.7 30.9 4.5 133.7 34.2 3.9

60 178.4 34.5 5.2 171.7 38.0 4.5 164.0 41.9 3.9

20 63.7 11.4 5.6 61.2 12.6 4.9 58.5 14.0 4.2

25 78.6 14.3 5.5 75.6 15.7 4.8 72.3 17.4 4.2

40 126.0 22.5 5.6 121.0 24.8 4.9 115.8 27.8 4.2

50 155.6 28.2 5.5 149.5 31.0 4.8 143.2 34.3 4.2

60 190.4 34.7 5.5 183.3 38.2 4.8 175.6 42.2 4.2

20 68.1 11.4 6.0 65.4 12.6 5.2 62.7 14.0 4.5

25 84.0 14.3 5.9 80.8 15.8 5.1 77.4 17.5 4.4

40 134.8 22.6 6.0 129.5 24.9 5.2 124.2 27.7 4.5

50 166.4 28.3 5.9 160.1 31.1 5.1 153.4 34.5 4.4

60 203.0 34.9 5.8 195.3 38.4 5.1 187.2 42.4 4.4

Performance

CG-PRC012-EN

19

Page 20

Performance

Full Load

Data

Performance

Table PD-7. 60 Hz CCAF performance data in English units

Evaporator Entering Condenser Air Temperature (F)

Leaving Water Unit Condenser 85 95 105 115

Temperature (F) Size Size Tons kW EER Tons kW EER Tons kW EER Tons kW EER

42 30 CAUC-C30 28.8 29.1 11.8 27.3 32.2 10.1 25.7 35.7 8.6 24.1 39.6 7.3

44 30 CAUC-C30 29.7 29.4 12.1 28.2 32.6 10.3 26.6 36.1 8.8 24.9 40.0 7.4

46 30 CAUC-C30 30.7 29.7 12.3 29.1 32.9 10.6 27.5 36.4 9.0 25.7 40.4 7.6

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. Interpolation between points is permissible. Extrapolation is not permitted.

7. Rated in accordance with ARI Standard 550/590-98.

20 CAUC-C20 19.4 19.5 11.8 18.4 21.6 10.1 17.3 23.9 8.6 16.1 26.6 7.2

20 CAUC-C25 19.7 18.6 12.6 18.7 20.6 10.8 17.6 23.0 9.1 16.5 25.5 7.7

25 CAUC-C25 24.1 24.9 11.5 22.8 27.6 9.9 21.5 30.6 8.4 20.0 34.0 7.0

25 CAUC-C30 24.5 23.4 12.5 23.3 26.0 10.7 22.0 28.9 9.1 20.6 32.1 7.7

30 CAUC-C40 29.2 27.0 12.9 27.8 29.9 11.1 26.3 33.2 9.5 24.7 36.9 8.0

40 CAUC-C40 38.7 38.8 11.9 36.7 43.0 10.2 34.5 47.8 8.6 32.2 53.2 7.2

40 CAUC-C50 39.1 37.4 12.5 37.1 41.6 10.6 35.0 46.2 9.0 32.7 51.4 7.6

50 CAUC-C50 47.6 50.2 11.3 45.1 55.6 9.7 42.5 61.8 8.2 39.7 68.4 6.9

50 CAUC-C60 48.4 47.0 12.3 46.0 52.2 10.5 43.5 58.2 8.9 40.8 64.6 7.6

60 CAUC-C60 56.9 58.4 11.6 54.0 64.8 10.0 50.9 71.8 8.5 47.6 79.8 7.1

60 CAUC-C80 57.5 53.6 12.8 54.7 59.6 11.0 51.8 66.4 9.3 48.6 73.8 7.9

20 CAUC-C20 20.0 19.7 12.1 19.0 21.8 10.4 17.8 24.2 8.8 16.6 26.8 7.4

20 CAUC-C25 20.4 18.8 12.9 19.3 20.8 11.0 18.2 23.2 9.3 17.1 25.7 7.9

25 CAUC-C25 24.9 25.1 11.8 23.6 27.9 10.1 22.2 30.9 8.6 20.7 34.3 7.2

25 CAUC-C30 25.3 23.7 12.7 24.1 26.3 10.9 22.7 29.2 9.3 21.3 32.4 7.9

30 CAUC-C40 30.2 27.2 13.2 28.8 30.2 11.4 27.2 33.5 9.7 25.6 37.2 8.2

40 CAUC-C40 39.9 39.2 12.1 37.8 43.4 10.4 35.6 48.2 8.8 33.3 53.6 7.4

40 CAUC-C50 40.3 37.8 12.7 38.3 42.0 10.9 36.1 46.6 9.2 33.8 51.8 7.8

50 CAUC-C50 49.1 50.6 11.6 46.6 56.2 9.9 43.9 62.2 8.4 41.0 69.0 7.1

50 CAUC-C60 50.0 47.4 12.6 47.5 52.6 10.8 44.9 58.6 9.2 42.2 65.2 7.7

60 CAUC-C60 58.7 58.5 12.0 55.7 65.4 10.2 52.6 72.6 8.7 49.2 80.6 7.3

60 CAUC-C80 59.3 54.0 13.1 56.5 60.0 11.3 53.5 66.8 9.6 50.3 74.4 8.1

20 CAUC-C20 20.7 19.9 12.4 19.6 22.0 10.6 18.4 24.4 9.0 17.2 27.1 7.6

20 CAUC-C25 21.0 18.9 13.2 20.0 21.0 11.3 18.8 23.4 9.6 17.6 25.9 8.1

25 CAUC-C25 25.7 25.4 12.1 24.3 28.2 10.3 22.9 31.2 8.8 21.4 34.6 7.4

25 CAUC-C30 26.2 23.9 13.1 24.9 26.5 11.2 23.5 29.5 9.5 22.0 32.6 8.1

30 CAUC-C40 31.2 27.4 13.6 29.7 30.4 11.7 28.2 33.8 10.0 26.5 37.5 8.4

40 CAUC-C40 41.1 38.6 12.7 39.0 43.8 10.6 36.8 48.8 9.0 34.4 54.0 7.6

40 CAUC-C50 41.6 38.0 13.1 39.5 42.2 11.2 37.3 47.0 9.5 35.0 52.2 8.0

50 CAUC-C50 50.6 51.2 11.8 48.0 56.6 10.1 45.3 62.8 8.6 42.3 69.8 7.2

50 CAUC-C60 51.6 47.8 12.9 49.1 53.2 11.0 46.4 59.0 9.4 43.6 65.6 7.9

60 CAUC-C60 60.5 59.4 12.2 57.5 66.0 10.4 54.3 73.2 8.9 50.9 81.2 7.5

60 CAUC-C80 61.2 54.4 13.4 58.3 60.6 11.5 55.2 67.4 9.8 52.0 75.0 8.3

CG-PRC012-EN20

Page 21

Performance

Full Load

Data

Table PD-8. 60 Hz CCAF performance data in English units

Evaporator Entering Condenser Air Temperature (F)

Leaving Water Unit Condenser 85 95 105 115

Temperature (F) Size Size Tons kW EER Tons kW EER Tons kW EER Tons kW EER

48 30 CAUC-C30 31.6 30.0 12.6 30.1 33.2 10.8 28.4 36.8 9.2 26.6 40.7 7.8

50 30 CAUC-C30 32.6 30.3 12.8 31.0 33.6 11.0 29.3 37.2 9.4 27.5 41.1 8.0

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. Interpolation between points is permissible. Extrapolation is not permitted.

7. Rated in accordance with ARI Standard 550/590-98.

20 CAUC-C20 21.3 20.1 12.6 20.2 22.2 10.8 19.0 24.6 9.2 17.7 27.3 7.7

20 CAUC-C25 21.7 19.1 13.5 20.6 21.2 11.6 19.4 23.6 9.8 18.2 26.2 8.3

25 CAUC-C25 26.5 25.7 12.3 25.1 28.4 10.5 23.7 31.5 9.0 22.1 34.9 7.6

25 CAUC-C30 27.0 24.1 13.4 25.7 26.7 11.5 24.3 29.6 9.8 22.8 32.9 8.3

30 CAUC-C40 32.2 27.7 13.9 30.7 30.7 11.9 29.1 34.1 10.2 27.4 37.8 8.7

40 CAUC-C40 42.4 40.0 12.6 40.2 44.4 10.8 37.9 49.2 9.2 35.5 54.6 7.8

40 CAUC-C50 42.8 38.4 13.3 40.7 42.6 11.4 38.5 47.4 9.7 36.1 52.6 8.2

50 CAUC-C50 52.2 51.6 12.1 49.5 57.2 10.3 46.7 63.4 8.8 43.7 70.2 7.4

50 CAUC-C60 53.2 48.2 13.2 50.6 53.6 11.3 47.9 59.6 9.6 45.0 66.2 8.1

60 CAUC-C60 62.4 60.2 12.4 59.3 66.6 10.6 56.0 74.0 9.1 52.5 82.0 7.7

60 CAUC-C80 63.1 54.8 13.8 60.2 61.8 11.8 57.0 67.8 10.1 53.7 75.4 8.5

20 CAUC-C20 21.9 20.3 12.8 20.8 22.5 11.0 19.6 24.9 9.4 18.3 27.6 7.9

20 CAUC-C25 22.3 19.3 13.8 21.2 21.4 11.8 20.1 23.8 10.1 18.8 26.4 8.5

25 CAUC-C25 27.3 25.9 12.6 25.9 28.7 10.8 24.4 31.8 9.2 22.9 35.2 7.8

25 CAUC-C30 27.9 24.3 13.7 26.5 26.9 11.8 25.1 29.9 10.0 23.5 33.1 8.5

30 CAUC-C40 33.2 27.9 14.2 31.7 30.9 12.2 30.0 34.3 10.4 28.3 38.1 8.9

40 CAUC-C40 43.6 40.4 12.9 41.4 44.8 11.0 39.1 49.6 9.4 36.6 55.0 8.0

40 CAUC-C50 44.1 38.8 13.6 42.0 43.0 11.7 39.7 47.8 9.9 37.2 53.0 8.4

50 CAUC-C50 53.7 52.2 12.3 51.0 57.8 10.5 48.1 64.0 9.0 45.1 71.0 7.6

50 CAUC-C60 54.8 48.6 13.5 52.2 54.0 11.5 49.4 60.0 9.8 46.4 66.6 8.3

60 CAUC-C60 64.3 60.8 12.6 61.1 67.4 10.8 57.8 74.6 9.3 54.2 82.8 7.8

60 CAUC-C80 65.1 55.4 14.0 62.1 61.4 12.1 58.8 68.4 10.3 55.4 76.0 8.7

Performance

CG-PRC012-EN

21

Page 22

Performance

Full Load

Data

Performance

Table PD-9. 60 Hz CCAF performance data in Metric units

Evaporator Entering Condenser Air Temperature (C)

Leaving Water Unit Condenser 30 35 40 45

Temperature (C) Size Size kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 30 CAUC-C30 103.0 29.6 3.5 98.2 32.4 3.0 93.1 35.6 2.6 87.9 39.1 2.2

8 30 CAUC-C30 109.1 30.2 3.6 104.0 33.0 3.1 98.9 36.2 2.7 93.2 39.8 2.3

10 30 CAUC-C30 115.2 30.7 3.7 110.1 33.7 3.3 104.6 36.9 2.8 98.9 40.4 2.4

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/total kW). Total kW include compressors and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. Interpolation between points is permissible. Extrapolation is not permitted.

7. Rated in accordance with ARI Standard 550/590-98.

20 CAUC-C20 69.4 19.8 3.5 66.2 21.7 3.0 62.5 23.8 2.6 58.7 26.2 2.2

20 CAUC-C25 70.7 18.9 3.7 67.3 20.7 3.2 63.8 22.9 2.8 60.3 25.1 2.4

25 CAUC-C25 86.2 25.3 3.4 82.1 27.8 2.9 77.8 30.5 2.5 73.1 33.5 2.2

25 CAUC-C30 87.8 23.8 3.7 84.0 26.2 3.2 79.7 28.8 2.8 75.2 31.7 2.4

30 CAUC-C40 104.7 27.4 3.8 100.3 30.1 3.3 95.3 33.1 2.9 90.2 36.4 2.5

40 CAUC-C40 138.4 39.5 3.5 131.9 43.3 3.0 124.8 47.6 2.6 117.5 52.4 2.2

40 CAUC-C50 140.0 38.1 3.7 133.6 41.9 3.2 126.8 46.0 2.7 119.5 50.7 2.3

50 CAUC-C50 170.2 51.0 3.3 162.3 56.0 2.9 153.8 61.5 2.5 144.8 67.5 2.1

50 CAUC-C60 173.5 47.8 3.6 165.7 52.5 3.1 157.6 57.9 2.7 149.0 63.7 2.3

60 CAUC-C60 203.5 59.2 3.4 194.1 65.2 3.0 184.2 71.6 2.6 173.6 78.7 2.2

60 CAUC-C80 206.0 54.5 3.8 197.0 59.9 3.3 187.6 66.1 2.8 177.5 72.7 2.4

20 CAUC-C20 73.5 20.2 3.6 70.0 22.1 3.1 66.2 24.3 2.7 62.3 26.7 2.3

20 CAUC-C25 74.8 19.2 3.9 71.5 21.1 3.4 67.7 23.3 2.9 63.9 25.5 2.5

25 CAUC-C25 91.3 25.8 3.5 86.8 28.3 3.1 82.4 31.0 2.6 77.6 34.1 2.3

25 CAUC-C30 93.3 24.3 3.8 89.1 26.6 3.3 84.6 29.3 2.9 79.9 32.1 2.5

30 CAUC-C40 111.1 27.8 4.0 106.3 30.5 3.5 101.4 33.6 3.0 96.1 36.9 2.6

40 CAUC-C40 146.1 39.5 3.7 139.3 44.0 3.1 132.2 48.5 2.7 124.6 53.2 2.3

40 CAUC-C50 148.0 38.6 3.8 141.3 42.4 3.3 134.3 46.7 2.9 126.9 51.4 2.5

50 CAUC-C50 179.9 52.0 3.4 171.5 56.9 3.0 162.8 62.5 2.6 153.3 68.7 2.2

50 CAUC-C60 183.7 48.5 3.8 175.6 53.4 3.3 167.0 58.7 2.8 158.0 64.6 2.4

60 CAUC-C60 215.1 60.4 3.5 205.4 66.3 3.1 195.1 72.8 2.7 184.3 80.0 2.3

60 CAUC-C80 217.9 55.3 3.9 208.6 61.0 3.4 198.6 67.0 3.0 188.4 73.8 2.5

20 CAUC-C20 77.4 20.6 3.7 73.8 22.6 3.3 70.0 24.7 2.8 65.9 27.1 2.4

20 CAUC-C25 78.9 19.6 4.0 75.4 21.5 3.5 71.9 23.6 3.0 67.8 25.9 2.6

25 CAUC-C25 96.4 26.2 3.7 92.0 28.8 3.2 87.2 31.6 2.7 82.4 34.6 2.4

25 CAUC-C30 98.7 24.6 4.0 94.2 27.0 3.5 89.7 29.7 3.0 84.7 32.5 2.6

30 CAUC-C40 117.5 28.3 4.1 112.7 31.0 3.6 107.3 34.0 3.1 101.8 37.4 2.7

40 CAUC-C40 154.0 40.9 3.7 147.0 44.9 3.3 139.6 49.2 2.8 131.7 54.1 2.4

40 CAUC-C50 156.0 39.3 3.9 149.3 43.1 3.4 142.0 47.4 3.0 134.0 52.1 2.6

50 CAUC-C50 189.7 52.9 3.6 181.1 57.9 3.1 171.8 63.5 2.7 162.3 69.8 2.3

50 CAUC-C60 193.9 49.3 3.9 185.6 54.1 3.4 176.6 59.6 3.0 167.1 65.4 2.5

60 CAUC-C60 227.2 61.6 3.7 216.9 67.6 3.2 206.4 74.1 2.8 195.0 81.4 2.4

60 CAUC-C80 230.4 56.1 4.1 220.8 61.6 3.6 210.2 67.9 3.1 199.4 74.7 2.7

CG-PRC012-EN22

Page 23

Performance

Part Load

Data

Performance

Table PD-5. Part-load performance for CGWF 20-60 ton – 60 Hz in English units

Unit Size 100% IPLV

20 kW 15.2 20.3

25 kW 19.0 20.5

30 kW 22.8 20.3

40 kW 30.1 20.7

50 kW 37.6 19.6

60 kW 46.5 19.8

Notes:

1. IPLV values are rated in accordance with ARI Standard 550/590-98.

2. EER and IPLV values include compressor and control kW.

3. kW input is for compressors only.

Tons 19.9

EER 15.5

Tons 24.5

EER 15.4

Tons 29.2

EER 15.3

Tons 39.4

EER 15.6

Tons 48.6

EER 15.4

Tons 59.4

EER 15.2

Table PD-6. Part-load performance for CGWF 20-60 ton – 50 Hz in English units

Unit Size 100% IPLV

20 kW 12.4 21.0

25 kW 15.5 20.9

30 kW 18.5 20.7

40 kW 24.5 21.3

50 kW 30.6 20.3

60 kW 37.6 20.4

Notes:

1. IPLV values are rated in accordance with ARI Standard 550/590-98.

2. EER and IPLV values include compressor and control kW.

3. kW input is for compressors only.

Tons 16.7

EER 16.1

Tons 20.6

EER 16.0

Tons 24.5

EER 15.9

Tons 33.0

EER 16.2

Tons 40.8

EER 16.0

Tons 50.1

EER 16.0

CG-PRC012-EN

23

Page 24

Performance

Adjustment

Data

Figure PAF-1. Ethylene glycol performance adjustment factors

Factors

Figure PAF-2. Propylene glycol performance adjustment factors

CG-PRC012-EN24

Page 25

Performance

Adjustment

Data

Figure PAF-3. Ethylene glycol and propylene glycol solution freezing points

Factors

CG-PRC012-EN

Table PAF-1. Pressure drop correction factor

Leaving

Water Percent of Ethylene Glycol

Temperature 0 10 20 30 40 50

0 NA NA NA NA 1.50 1.60

10 NA NA NA 1.38 1.46 1.55

20 NA NA 1.26 1.34 1.42 1.51

30 NA 1.15 1.22 1.30 1.38 1.47

40 1.00 1.12 1.19 1.26 1.34 1.42

50 1.00 1.09 1.16 1.23 1.31 1.39

60 1.00 1.05 1.09 1.12 1.16 1.21

Table PAF-2. Pressure drop correction factor

Leaving

Water Percent of Propylene Glycol

Temperature 0 10 20 30 40 50

0 NA NA NA NA 1.63 1.90

10 NA NA NA 1.42 1.55 1.74

20 NA NA 1.24 1.34 1.46 1.62

30 NA 1.11 1.19 1.28 1.39 1.53

40 1.00 1.07 1.15 1.23 1.33 1.45

50 1.00 1.04 1.11 1.19 1.28 1.39

60 1.00 1.00 1.03 1.08 1.13 1.20

25

Page 26

Performance

Data

Chart PD-1. CGWF evaporator

Pressure Drops

Chart PD-2. CGWF condenser

CG-PRC012-EN26

Page 27

Electrical Data

and Connections

Table E-1. Electrical data for CGWF water-cooled chillers

Unit Rated Minimum Maximum Recommended RLA LRA

Size Voltage Circuit Ampacity Fuse Size Dual Element Fuse Size Quantity Each Each kW

20 460/60 32 45 40 14 117 0.16

25 460/60 43 60 60 1-15 23/14 178/117 0.16

30 460/60 52 70 70 23 178 0.16

40 460/60 60 70 70 14 117 0.24

50 460/60 80 100 100 2-15 23/14 178/117 0.24

60 460/60 98 110 110 23 178 0.24

208-230/60 77 110 100 34 251 0.16

380/60 38 50 50 2-10 17 142 0.16

575/60 27 40 40 12 94 0.16

400/50 32 50 50 14 110 0.16

208-230/60 99 150 125 52/34 376/251 0.16

380/60 51 70 70 1-10 27/17 215/142 0.16

575/60 35 50 45 18/12 143/94 0.16

400/50 42 50 45 22/14 174/110 0.16

208-230/60 117 150 150 52 376 0.16

380/60 61 80 80 2-15 27 215 0.16

575/60 41 50 50 18 143 0.16

400/50 50 80 80 22 174 0.16

208-230/60 145 175 175 34 251 0.24

380/60 72 80 90 4-10 17 142 0.24

575/60 51 60 70 12 94 0.24

400/50 60 90 90 14 110 0.24

208-230/60 185 225 225 52/34 376/251 0.24

380/60 95 110 110 2-10 27/17 215/142 0.24

575/60 65 80 80 18/12 143/94 0.24

400/50 78 110 125 22/14 174/110 0.24

208-230/60 221 250 250 52 376 0.24

380/60 115 125 150 4-15 27 215 0.24

575/60 77 90 90 18 143 0.24

400/50 94 125 150 22 174 0.24

Table E-2. Electrical data for high temperature condenser CGWF chillers and CCAF compressor chillers

Unit Rated Minimum Maximum Recommended RLA LRA

Size Voltage Circuit Ampacity Fuse Size Dual Element Fuse Size Quantity Each Each kW

20 380/60 45 60 60 2-10 20 142 0.16

25 380/60 59 80 80 1-10 31/20 215/142 0.16

30 380/60 70 100 90 2-15 31 215 0.16

40 380/60 85 100 100 4-10 20 142 0.24

50 380/60 110 125 150 2-10 31/20 215/142 0.24

60 380/60 132 150 150 4-15 31 215 0.24

Notes:

1. Minimum circuit ampacity is 125% of the largest compressor RLA, plus 100% of the remaining compressor(s) RLA, per NEC 440-32 and NEC 440-33.

2. Maximum fuse size is 225% of the largest compressor RLA, plus 100% of the remaining compressor(s) RLA, per NEC 440-33.

3. Recommended dual element fuse size is 175% of the largest compressor RLA, plus 100% of remaining compressor(s) RLA, per NEC 440-33.

4. Use copper conductors only.

5. Voltage Utilization Range: Rated Voltage Utilization Range

6. Local codes may take precedence.

7. If unit is ordered with the High Condenser Entering Water Temperature Range (90-130), use CCAF electrical information.

208-230/60 88 125 110 39 251 0.16

460/60 38 50 50 17 117 0.16

575/60 32 45 40 14 94 0.16

400/50 38 50 50 17 117 0.16

208-230/60 112 150 150 58/39 376/251 0.16

460/60 50 70 70 1-15 26/17 178/117 0.16

575/60 40 60 60 21/14 143/94 0.16

400/50 48 70 70 25/17 178/117 0.16

208-230/60 131 175 175 58 376 0.16

460/60 59 80 80 26 178 0.16

575/60 47 60 60 21 143 0.16

400/50 56 80 80 25 178 0.16

208-230/60 166 200 200 39 251 0.24

460/60 72 80 90 17 117 0.24

575/60 60 70 70 14 94 0.24

400/50 72 80 90 17 117 0.24

208-230/60 209 250 250 58/39 376/251 0.24

460/60 93 110 110 2-15 26/17 178/117 0.24

575/60 75 90 90 21/14 143/94 0.24

400/50 90 110 110 25/17 178/117 0.24

208-230/60 247 300 300 58 376 0.24

460/60 111 125 125 26 178 0.24

575/60 89 110 100 21 143 0.24

400/50 106 125 125 25 178 0.24

208-230/60 188-253

380/60 342-418

460/60 414-506

575/60 517-633

400/50 360-440

Unit Wiring Data Compressor Controls

Unit Wiring Data Compressor Controls

CG-PRC012-EN

27

Page 28

Electrical Data

Typical Wiring

and Connections

Diagram

CG-PRC012-EN28

Page 29

Electrical Data

Typical Wiring

and Connections

Diagram

CG-PRC012-EN

29

Page 30

Electrical Data

and Connections

Field Layout

CG-PRC012-EN30

Page 31

Electrical Data

and Connections

Field Layout

CG-PRC012-EN

31

Page 32

Dimensional

Data

CGWF 20-30 Ton

Size A B C D E F G H

20 Ton 2" 8 1/2" 4'-8" 1'-3 3/8" 4 1/8" 8 5/8" 5 5/8" 2' 7 3/8"

25 Ton 2" 8 1/2" 4'-8" 1'-3 3/8" 4 1/8" 8 5/8" 5 5/8" 2' 7 3/8"

30 Ton 2 1/2" 7 3/4" 4'-6 1/2" 1'-5 3/8" 2 1/4" 12" 8" 2' 8 3/16"

Notes:

1. Dimensions in ( ) are in millimeters.

2. Dimensional tolerance ± 1/4” (6.4).

3. These dimensions for left hand condenser connections.

(51) (216) (1423) (391) (105) (218) (143) (797)

(51) (216) (1423) (391) (105) (218) (143) (797)

(64) (197) (1384) (441) (57) (305) (203) (818)

CG-PRC012-EN32

Page 33

Dimensional

Data

CGWF 40-50 Ton

CG-PRC012-EN

Size A B C D E

40 Ton 2 1/2" 1'-3 3/4" 6'-5 1/2" 1'-4 1/4" 4 3/8"

50 Ton 3" 1'-3 1/2" 6'-5" 1'-6 1/8" 2 1/2"

Notes:

1. Dimensions in ( ) are in millimeters.

2. Dimensional tolerance ± 1/4” (6.4).

3. These dimensions for left hand condenser connections.

(64) (400) (1968) (413) (111)

(76) (394) (1956) (480) (64)

33

Page 34

Dimensional

Data

CGWF 60 Ton

CG-PRC012-EN34

Page 35

Dimensional

Data

CCAF 20-30 Ton

CG-PRC012-EN

Unit Size A B C D E F

20 Ton 8 1/2” 3’-11 1/2” 2” 2’-0” 1’-3 1/2” 3’-3”

25 Ton 8 1/2” 3’-11 1/2” 2” 1’-11 3/4” 1’-3 1/2” 3’-10”

30 Ton 7 3/4” 3’-10 3/4” 2 1/2” 2’-1 7/8” 1’-5 3/8” 3’-10”

Unit Size A B C D E F

20 Ton 216 1207 51 610 394 1041

25 Ton 216 1207 51 603 394 1041

30 Ton 197 1187 64 657 441 1168

Notes:

1. Add 3/4” (19 mm) for units with insulation.

2. Dimensional tolerance ± 1/4” (6.4).

3. Tube installation at either end of evaporator.

English Dimensions

Metric Dimensions (mm)

35

Page 36

Dimensional

Data

CCAF 40-60 Ton

Unit Size A B C D E F

40 Ton 5’-1 3/4” 1’-3 3/4” 1’-11 1/4” 2 1/2” 3’-5” 1’-4 1/4”

50 Ton 5’-1 1/2” 1’-3 1/2” 2’-1 1/8” 3” 3’-10” 1’-6 1/8”

60 Ton 5’-1 1/2” 1’-3 1/2” 2’-0 7/8” 3” 3’-10” 1’-6 1/8”

Unit Size A B C D E F

40 Ton 1568 400 591 64 1041 413

50 Ton 1562 394 638 76 1168 480

60 Ton 1562 394 632 76 1168 460

Notes:

1. Dimensions in ( ) are in millimeters.

2. Add 3/4” (19 mm) for units with insulation.

3. Dimensional tolerance ± 1/4” (6.4).

4. Tube installation at either end of evaporator.

English Dimensions

Metric Dimensions (mm)

CG-PRC012-EN36

Page 37

Weights

Table W-1. Weights, CGWF chillers

Unit 20 25 30 40 50 60

Operating Wt. (pounds) 1694 1757 2249 2746 2977 3905

Shipping Wt. (pounds) 1522 1600 2014 2366 2626 3376

Table W-2. Weights, CCAF compressor chillers

Unit 20 25 30 40 50 60

Operating Wt. (pounds) 1004 1079 1274 1509 1808 1982

Shipping Wt. (pounds) 1430 1605 1836 1792 2166 2494

(kilogram) 768 797 1020 1246 1350 1771

(kilogram) 690 726 914 1073 1191 1531

(kilogram) 456 490 579 685 821 900

(kilogram) 649 729 834 814 984 1133

CG-PRC012-EN

37

Page 38

Mechanical

Specifications

General

All scroll chillers are factory tested and

monitored for power and control

operation (CGWF only). CGWF units ship

with a full operating charge of refrigerant

and oil. CCAF units ship with a full

operating charge of oil. Exposed

surfaces are painted with an air-dry

beige primer-finisher prior to shipment.

Compressor-Motor

Direct-drive, hermetic, 3600 rpm, 60 Hz

[3000 rpm, 50 Hz] fixed compression,

scroll compressors (20 to 30 tons - two

compressors; 40 to 60 tons - four

compressors). Each compressor has:

centrifugal oil pump, oil level sightglass,

oil charging valve, two point lubrication

for each motor bearing, flooded

lubrication for the journal and thrust

bearings, and a check valve on the scroll

discharge port.

Motor is suction gas-cooled,

hermetically sealed, two-pole, squirrel

cage induction type.

Evaporator

Shell and tube design with seamless

copper tubes roller expanded into tube

sheets. Designed, tested and stamped in

accordance with ASME Code for

refrigerant side working pressure of 300

psig. Water side working pressure is 300

psig for CGWF 20-50 and CCAF 20-60,

215 psig for CGWF 60. One water pass

with a series of internal baffles. Each

shell includes drain connections,

entering and leaving temperature

sensors, and ¾ inch Armaflex II (or

equal) insulation (K= 0.26).

Condenser (CGWF only)

Shell and tube design with seamless

internally enhanced copper tubes.

Designed, tested and stamped in

accordance with ASME Code (CGWF 60

only) the refrigerant side working

pressure of 450 psig. Water side

working pressure is 300 psig for CGWF

20-50, 150 psig for CGWF 60. Two pass

construction with six-inch diameter shell

(20 to 30 tons). One pass construction

with two separate condensers connected

in series (40 to 60 tons). Each condenser

includes a subcooler circuit. Tubes are

cleanable and replaceable.

Refrigerant Circuit

Each refrigeration circuit shall be

completely independent and shall

include liquid line and discharge line

service valves, filter dryer, combination

moisture indicator-sightglass, charging

port, insulated suction line, liquid line

solenoid valve and thermal expansion

valve.

Isolation valves provide means of

isolating refrigerant charge in either the

high or low pressure side while

servicing. One refrigerant circuit on

20 to 30 tons; two refrigerant circuits on

40 to 60 tons.