Trane CAUJ-C20, CAUJ-C40, CAUJ-C80, CAUJ-C25, CAUJ-C50 Installation and Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Remote Air-Cooled Condensers

Models A and Later Design Sequences

CAUJ-C20 CAUJ-C40 CAUJ-C80

CAUJ-C25 CAUJ-C50 CAUJ-D10

CAUJ-C30 CAUJ-C60 CAUJ-D12

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

January 2011 CAUJ-SVX01D-EN

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. Warnings are provide to alert installing contractors

to potential hazards that could result in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

Read this manual thoroughly before operating or servicing this unit.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout this

literature. Read these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only

accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally

occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the

identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants-including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

WARNING

R-410A Refrigerant under Higher Pressure than R-22!

The units described in this manual use R-410A refrigerant which operates at higher pressures

than R-22 refrigerant. Use ONLY R-410A rated service equipment or components with these

units. For specific handling concerns with R-410A, please contact your local Trane

representative.

Failure to use R-410A rated service equipment or components could result in equipment

exploding under R-410A high pressures which could result in death, serious injury, or

equipment damage.

© 2012 Trane All rights reserved CAUJ-SVX01D-EN

Page 3

Warnings, Cautions and Notices

WARNING

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

WARNING

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS

sheets and OSHA guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put on all Personal Protective Equipment

(PPE) in accordance with NFPA 70E or other country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

Trademarks

Trane and the Trane logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

CAUJ-SVX01D-EN 3

Page 4

Table of Contents

Model Number Descriptions .............................................6

General Information ....................................................7

Unit Inspection .................................................... 7

Dimensions and Weights ...............................................10

Unit Clearances ...................................................10

Unit Dimensions & Weight Information .............................. 10

Weights ......................................................... 26

Installation ............................................................27

General Unit Requirements ........................................ 31

Refrigerant Piping ................................................. 32

Field Installed Power Wiring ........................................ 38

Electrical Data ....................................................42

Point load and isolator location ................................. 26

Rigging and Center-of-Gravity Data .............................. 27

Unit Isolation ................................................ 28

Leveling the Unit .............................................31

Piping ...................................................... 31

Main Electrical Power Requirements ............................. 31

Field Installed Control Wiring ................................... 32

Liquid Lines ................................................. 32

Liquid Line Components ....................................... 33

Discharge (Hot Gas) Lines .....................................35

Discharge (Hot Gas) Line Components ........................... 35

Final Refrigerant Pipe Connections ..............................36

Brazing Procedures ........................................... 36

Leak Testing Procedure ........................................ 37

Main Unit Power Wiring ....................................... 39

Power Wire Sizing and Protection Device Equations ................ 40

Field Installed Control Wiring ................................... 41

Operating Principals ................................................... 43

20-60 Ton Specs ............................................. 43

80-120 Ton Specs ............................................ 44

System Pre-Start Procedures ........................................... 45

System Evacuation Procedures ................................. 45

Voltage Imbalance ............................................ 48

Electrical Phasing ............................................ 48

Start-Up .............................................................. 49

Verifying Proper Condenser Fan Rotation ......................... 50

Low Ambient Damper Adjustment (Factory or Field Installed) ........ 51

Charging the System .......................................... 52

4 CAUJ-SVX01D-EN

Page 5

Service and Maintenance ............................................... 54

Fuse Replacement Data ....................................... 54

Fall Restraint - Condenser Section Roof .......................... 54

Monthly Maintenance .........................................55

Coil Cleaning ................................................ 56

Warranty and Liability Clause ........................................... 58

Wiring Diagrams ...................................................... 59

CAUJ-SVX01D-EN 5

Page 6

Model Number Descriptions

20 to 60 Ton

Digit 1 — Unit Type

C = Condenser

Digit 2 — Condenser

A = Air-Cooled

Digit 3 — Airflow

U = Upflow

Digit 4 — Development

Sequence

J = Fourth

Digit s 5,6,7 — Nominal Capacity

C20= 20 Tons

C25= 25 Tons

C30= 30 Tons

C40= 40 Tons

C50= 50 Tons

C60= 60 Tons

Digit 8 — Power Supply

G = 200/230/60/3 XL

4 = 460/60/3 XL

5 = 575/60/3 XL

Digit 9 — Condenser Circuit

1 = Single (20-30 Ton)

2 = Dual (40-60 Ton)

Digit 10 — Design Sequence

* = Factory Assigned

Digit 11 — Ambient Control

0 = Standard

1=0F

Digit 12 — A gency Approval

0 = None

3 = cULus

Digits 13, 14 — Miscellaneous

J = Corrosion Protected Cond Coil

1 = Spring Isolators

2 = Rubber Isolators

Note: The service digit for each model

number contains 14 digits; all 14

digits must be referenced.

80 to 120 Ton

Digit 1 — Unit Type

C = Condenser

Digit 2 — Condenser

A = Air-Cooled

Digit 3 — Airflow

U = Upflow

Digit 4 — Development

Sequence

J = Fourth

Digits 5,6,7 — Nominal Capacity

C80= 80 Tons

D10= 100 Tons

D12= 120 Tons

Digit 8 — Power Supply

F = 230/60/3

4 = 460/60/3

5 = 575/60/3

E = 200/60/3

Digit 9 — Condenser Circuit

2 = Dual Circuit

Digit 10 — Design Sequence

A = First

Digit 11 — Ambient Control

0 = Standard

1=0F

Digit 12 — A gency Approval

0 = None

2 = CSA

3 = cULus

Digits 13, 14 — Miscellaneous

J = Corrosion Protected Cond Coil

1 = Spring Isolators

Note: The service digit for each model

number contains 14 digits; all 14

digits must be referenced.

6 CAUJ-SVX01D-EN

Page 7

General Information

Unit Inspection

As soon as the unit arrives at the job site

• Verify nameplate data matches data on sales order and bill of lading (including electrical data).

• Verify that the power supply complies with the unit nameplate specifications.

• Visually inspect the exterior of the unit, including the roof, for signs of shipping damage.

• Check for material shortages. Refer to the Com

illustration.

Important: If the job site inspection of the unit re

file a claim with the carrier immediately. Specify the type and extent of the

damage on the bill of lading before signing.

• Visually inspect the intern

delivery and before it is stored. Do not walk on the sheet metal base pans.

No Step Surface!

Do not walk on the sheet metal drain pan. Walking on the drain pan could cause the

supporting metal to collapse, resulting in the operator/technician to fall. Failure to follow this

recommendation could result in death or serious injury.

Bridging between unit main supports may consist of multiple 2 by 12 boards or sheet metal grating.

• If concealed damage is discovered, notify the carrier's terminal of damage immediately by

one and by mail. Concealed damage must be reported within 15 days.

ph

• Request an immediate joint inspect

remove damaged material from the receiving location. Take photos of the damage, if possible.

The owner must provide reasonable evidence that the damage did not occur after delivery.

• Notify the appropriate Trane office before installing or repairing a damaged unit.

ponent Layout and Ship with Location

veals damage or material shortages,

al components for shipping damage as soon as possible after

WARNI NG

ion of the damage by the carrier and the consignee. Do not

Unit Nameplate

One Mylar unit nameplate is located on the outside upper right corner of the control panel door.

It includes the unit model number, serial number, electrical characteristics, weight, refrigerant

charge, as well as other pertinent unit data. A small metal nameplate with the Model Number, Serial

Number, and Unit Weight is located just above the Mylar nameplate, and a third nameplate is

located on the inside of the control panel door.

When ordering replacement parts or requesting service, be sure to refer to the specific model

number, serial number, and DL number (if applicable) stamped on the unit nameplate.

Unit Description

All air cooled condensing units are designed for outdoor installations with vertical air discharge.

These units may be installed on a flat roof or placed on a concrete slab at ground level.

Before shipment, each unit is leak-tested, evacuated, a Nitrogen holding charge is added, and the

controls are tested for proper operation.

The condenser coils are an all aluminum Microchannel design. Louvered condenser grilles for coil

protection are standard. Direct-drive, vertical discharge condenser fans are provided with built-in

current and overload protection.

For “Ship with” items, see Figure 1, p. 8 for 20-60T units, or Figure 2, p. 8 for 80-120 T units.

If low ambient operation is required, low ambient dampers are available as a field or factory

installed option.

CAUJ-SVX01D-EN 7

Page 8

General Information

The unit control panel contains all required fan cycling controls, compressor interlocks, and a 115

volt control power transformer. Field wiring, electrical schematics and panel connection diagrams

are located inside the control panel access door.

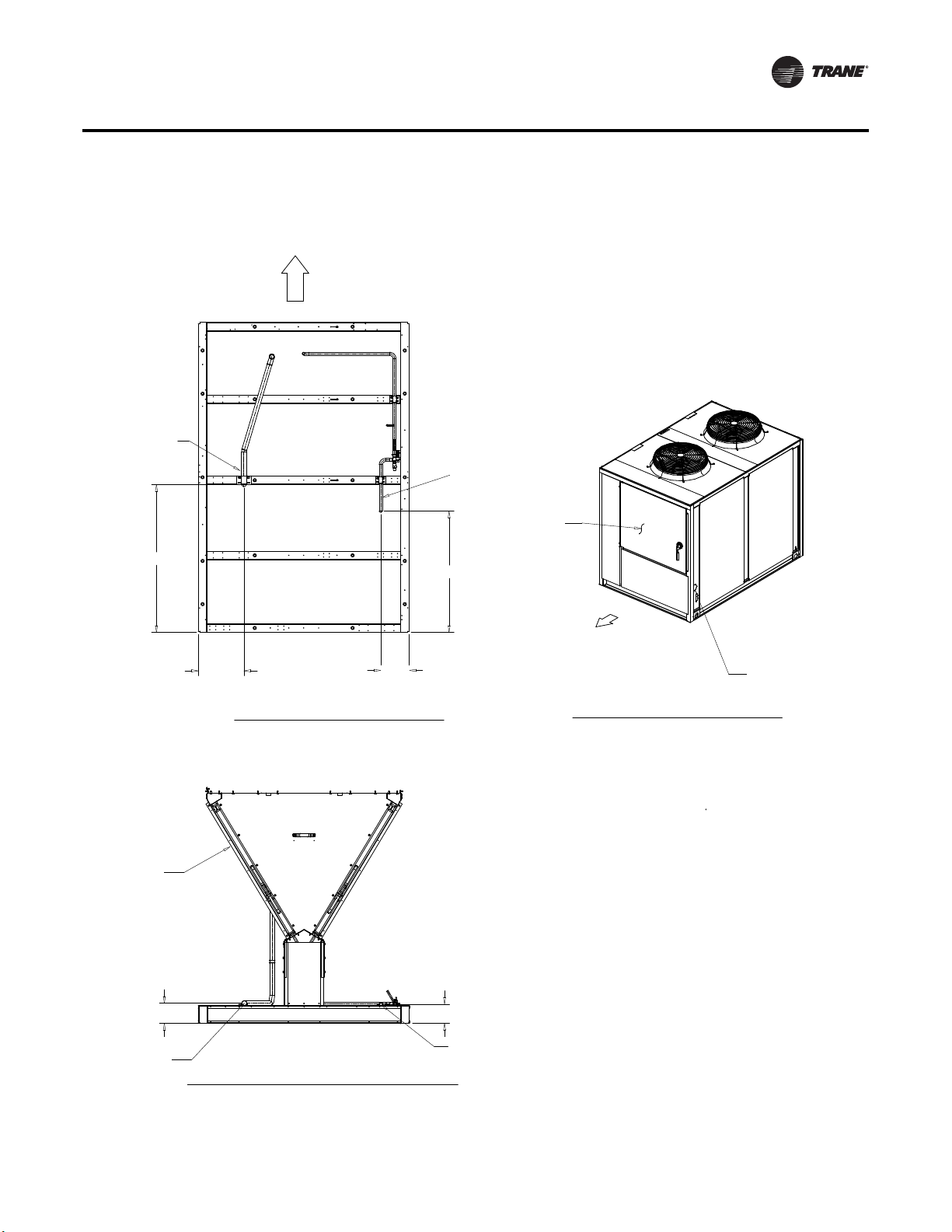

Figure 1. Unit component layout and ‘shipwith’ locations 20 - 60 ton units

Figure 2. Unit component layout and ‘shipwith’ locations 80 - 120 ton units

8 CAUJ-SVX01D-EN

Page 9

General Information

Table 1. General data

20 Ton 25 Ton 30 Ton 40 Ton 50 Ton 60 Ton 80 Ton 100 Ton 120 Ton

Model Number CAUJC-20 CAUJC-25 CAUJ-C30 CAUJ-C40 CAUJ-C50 CAUJ-C60 CAUJ-C80 CAUJ-D10 CAUJ-D12

Gross Heat Rejection

(a)

(MBh)

Condenser Fan Data

Quantity/Fan Dia. Type 2/26"/Prop 3/26"/Prop 3/26"/Prop 4/26"/Prop 6/26"/Prop 6/26"/Prop 8/26"/Prop 12/26"/Prop 12/26"/Prop

Fan Drive Type Direct Direct Direct Direct Direct Direct Direct Direct Direct

No. of Motors/HP Each 2/1.0 3/1.0 3/1.0 4/1.0 6/1.0 6/1.0 8/1.0 12/1.0 12/1.0

Nominal Total CFM 14600 20700 20700 26790 36890 40490 56490 73890 76280

Condenser Coil Data

Number of Coils/Size

(Inches)

2

) 41.4 41.4 41.4 58.2 68.0 85.4 116.4 136 170.7

Size (ft

Rows/Fin per ft 1/276 1/276 1/276 1/240 1/240 1/240 1/240 1/240 1/240

Condenser Storage

Capacity (lbs)

Typ e Microchannel

Refrigerant Data

No. Refrigerant Circuits 1 1 1 2 2 2 2 2 2

Refrigerant Type R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A

Refrigerant Operating

Charge (Lbs.)

Minimum Outdoor Air Temperature for Mechanical Cooling

Standard Ambient

Operating Range (F)

Low Ambient Option (F) 0 0 0 0 0 0 0 0 0

(a) Gross Heat Rejection is at a 30 F ITD (Initial Temperature Difference) between condensing temperature and ambient air entering condenser (includes

the effect of subcooling).

(b) At conditions of 95° ambient, condenser is 95 percent full

(c) Condensing units are shipping with nitrogen holding charge only.

(d) Operating charge is for condensing unit only, and does not include charge for low side or interconnecting lines.

(b)

(c)

(d)

350 402 456 635 819 1002 1269 1639 2004

2/42x71 2/42x71 2/42x71 2/59x71 2/51x96 2/64x96 4/59x71 4/51x96 4/64x96

18.7 18.7 18.7 23.5 25.0 31.5 47.1 50.0 62.9

11.9 11.8 11.8 22.7 23.4 26.4 57.1 59.1 65.3

40-125 40-125 40-125 40-125 40-125 40-125 40-125 40-125 40-125

CAUJ-SVX01D-EN 9

Page 10

Dimensions and Weights

Unit Clearances

Figure 3, p. 11 and Figure 4, p. 11 illustrate the minimum operating and service clearances for either

a single, multiple, or pit application. These clearances are the minimum distances necessary to

assure adequate serviceability, cataloged unit capacity, and peak operating efficiency.

Equipment Damage!

Providing less than the recommended clearances may result in condenser coil starvation or

recirculation of hot condenser air.

Locate the unit as close to the applicable system support equipment as possible, to minimize

refrigerant piping lengths.

Unit Dimensions & Weight Information

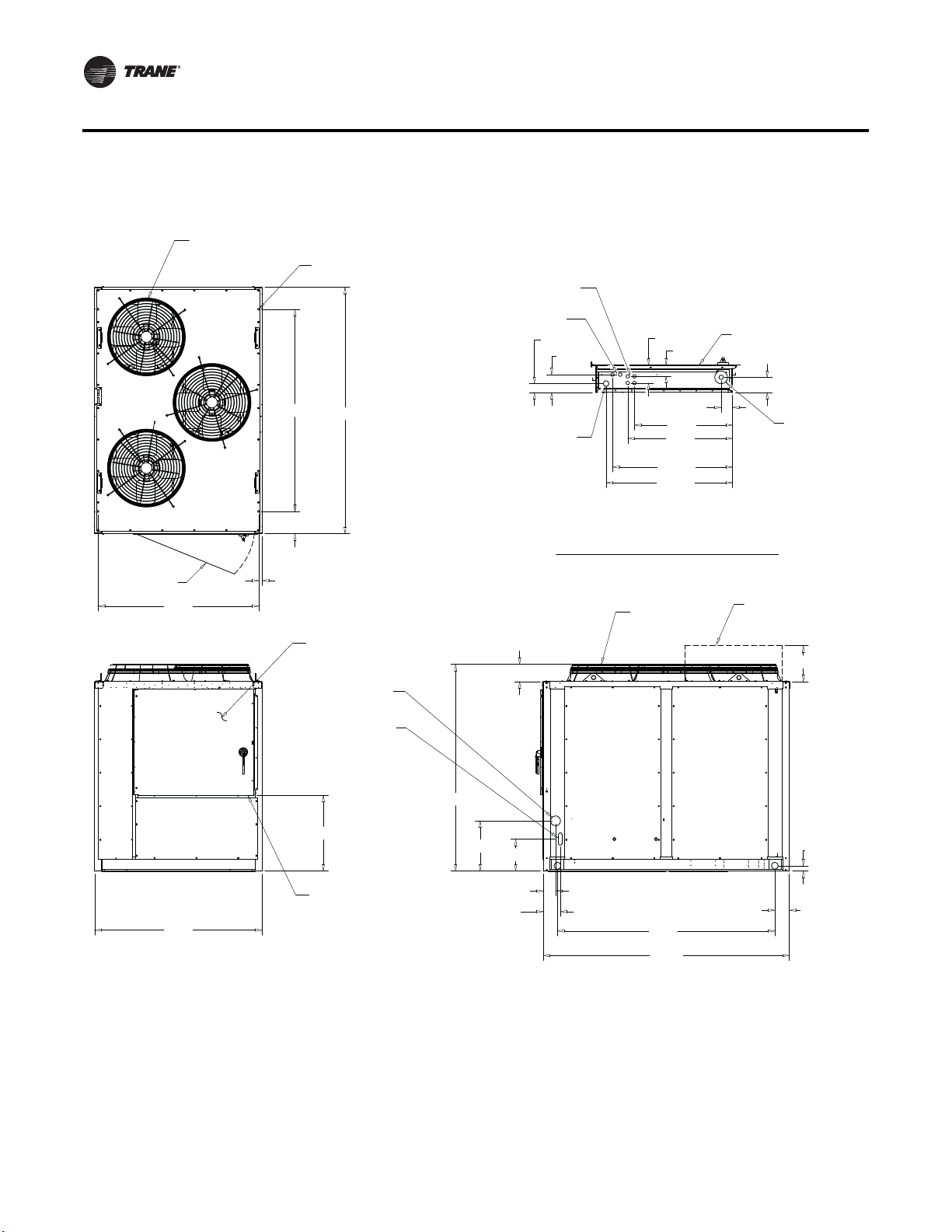

Overall unit dimensional data for each unit are illustrated in Figure 5, p. 12 to Figure 18, p. 25.

A Center-of-Gravity illustration and the dimensional data are shown in Figure 20, p. 28, Figure 21,

p. 28, and Table 3, p. 26.

Table 2, p. 26 lists the typical unit operating and point loading weights.

Foundation

If the unit is installed at ground level, elevate it above the snow line. Provide concrete footings at

each support location or a slab foundation for support. See Table 2, p. 26 for the unit operating and

point loading weights when constructing the footing foundation.

Anchor the unit to the footings or slab using hold down bolts or isolators. Isolators should be

installed to minimize the transmission of vibrations into the building. See “Unit Isolation,” p. 28 for

isolator installation instructions.

For rooftop applications, ensure the roof is strong enough to support the unit. See Table 2, p. 26

for the unit operating weights.

NOTICE:

WARNI NG

Risk of Roof Collapsing!

Confirm with a structural engineer that the roof structure is strong enough to support the

combined weight of the roofcurb and the unit. Refer to the 'Weights' Table 2, p. 26 section for

typical unit and curb weights. Failure to ensure proper structural roof support could cause the

roof to collapse, which could result in death or serious injury and property damage.

Anchor the unit to the roof with hold-down bolts or isolators. Follow the instructions in section

“Unit Isolation,” p. 28 for proper isolator placement and installation.

Check with a roofing contractor for proper waterproofing procedures.

10 CAUJ-SVX01D-EN

Page 11

Dimensions and Weights

Figure 3. Typical installation clearances for single, multiple, or pit applications: 20-60 ton units

Figure 4. Typical installation clearances for single, multiple, or pit applications: 80-120 ton units

CAUJ-SVX01D-EN 11

Page 12

Dimensions and Weights

Figure 5. 20-ton air-cooled condenser

FAN GRILLE

4 3

72 1/2"

2 1

8"

3/4" X 4 MTG HOLES

1/2" X 4 KO (115V)

1/2" X 2 KO (115V)

1 3/4" KO LOW

VOLTAGE (30V MAX.)

NOTES:

1. SEE CONNECTION DRAWING FOR CONNECTION LOCATION AND SIZES.

2. LOW AMBIENT DAMPER ONLY COMES WITH SELECTED UNIT .

2 5/8"

5 5/16"

5 3/8"

3 3/8"

3 3/8"

29 1/4"

31 1/4"

35 13/16"

37 11/16"

CONTROL PANEL

4 1/2"

4" CONDUIT

MAIN POWER

DOOR 43 1/4" W/

180 DEG SWING

57 5/8"

60"

1 1/4"

CONTROL PANEL

(SEE DETAIL A)

4" LINE

VOLTAGE

ACCESS

1 1/4" x 4 1/2"

SLOT FOR 115

VOLT CONTROL

26 13/16"

CONTROL BOX BOTTOM

(SEE DETAIL A)

74 1/4"

18"

6 1/4"

11 1/2"

4 3/8"

6 1/8"

DETAIL A

CONTROL BOX BOTTOM

FAN GRILLE

LOW AMBIENT

DAMPER (SEE NOTE 2)

78"

88 5/16"

13"

1 13/16"

5 3/16"

12 CAUJ-SVX01D-EN

Page 13

Figure 6. 20-ton air-cooled condenser (connections)

CONTROL PANEL SIDE

1 3/8" O.D.

DISCHARGE LINE

E1,000

L

SCA

7/8" O.D.

LIQUID LINE

Dimensions and Weights

NOTES:

1. VERIFY WEIGHT , CONNECTION, AND ALL DIMENSION WITH

INSTALLER DOCUMENTS BEFORE INSTALLATION

CONTROL PANEL

42"

COIL

13"

PLAN VIEW OF UNIT

CONNECTION DRAWING

8 1/16"

34 1/2"

CONTROL

PANEL SI DE

ORIENTATION VIEW OF UNIT

ISOMETRIC DRAWING

VOLTAGE ACCESS

5 3/4"

5 7/16"

LIQUID LINE

DISCHARGE LINE

CONTROL PANEL SIDE VIEW OF UNIT

CONNECTION DRAW ING

CAUJ-SVX01D-EN 13

Page 14

Dimensions and Weights

Figure 7. 25- and 30-ton air-cooled condenser

FAN GRILLE

4

1.6

2 1

DOOR 43 1/4" W/

180 DEG SWING

57 5/8"

NOTES:

1. SEE CONNECTION DRAWING FOR CONNECTION LOCATION AND SIZES.

3/4" X 4 MTG HOLES

2. LOW AMBIENT DAMPER ONLY COMES WITH SELECTED UNIT .

1/2" X 4 KO (115V)

3

1/2" X 2 KO (115V)

2 5/8"

5 5/16"

5 3/8"

CONTROL PANEL

3 3/8"

4 1/2"

72 1/2"

88 1/2"

1 3/4" KO LOW

VOLTAGE (30V MAX.)

29 1/4"

31 1/4"

3 3/8"

4" CONDUIT

MAIN POWER

35 13/16"

37 11/16"

8"

DETAIL A

1 1/4"

CONTROL PANEL

(SEE DETAIL A)

4" LINE

VOLTAGE ACCESS

6 1/4"

CONTROL BOX BOTTOM

FAN GRILLE

LOW AMBIENT

DAMPER (SEE NOTE 2)

13"

1 1/4" x 4 1/2"

SLOT FOR 115

VOLT CONTROL

74 1/4"

27 1/4"

60 1/8"

CONTROL BOX BOTTOM

(SEE DETAIL A)

18"

11 1/2"

4 3/8"

6 1/8"

78"

1 13/16"

5 3/16"

88 5/16"

14 CAUJ-SVX01D-EN

Page 15

Figure 8. 25- and 30-ton air-cooled condenser (connections)

CONTROL

PANEL SIDE NOTES:

1. VERIFY WEIGHT , CONNECTION, AND ALL DIMENSION WITH

Dimensions and Weights

INSTALLER DOCUMENTS BEFO RE INSTALLATION

1 3/8" O.D.

DISCHARGE LINE

42"

COIL

DISCHARGE LINE

00

1,0

LE

CA

S

13"

PLAN VIEW OF UNIT

CONNECTION DRAW ING

7/8" O.D. LIQUID LINE

34 1/2"

81/16"

LIQUID LINE

CONTROL PANEL

SCALE1.000

CONTROL

PANEL SIDE

ORIENTATION VIEW OF UNIT

ISOMETRIC DRAWING

VOLTAGE ACCESS

5 3/4"

5 7/16"

CONTROL PANEL SIDE VIEW OF UNIT

CONNECTION DRAWING

CAUJ-SVX01D-EN 15

Page 16

Dimensions and Weights

Figure 9. 40-ton air-cooled condenser

6

4

2

CONTROL PANEL

(SEE DETAIL A)

DOOR 43 1/4" W/

180 DEG SWING

85 5/8"

FAN GRILLE

5

3

1

FAN GRILLE

36 1/8"

36 1/8"

1 1/4"

3/4" X 6

MTG HOLES

88 9/16"

8"

NOTES:

1. SEE CONNECTION DRAWING FOR CONNECTION LOCATION AND SIZES.

2. LOW AMBIENT DAMPER ONLY COMES WITH SELECTED UNIT .

1/2" X 4 KO (115V)

1/2" X 2 KO (115V)

2 5/8"

1 3/4" KO LOW

VOLTAGE (30V MAX.)

5 5/16"

5 3/8"

3 3/8"

3 3/8"

29 1/4"

31 1/4"

35 13/16"

37 11/16"

CONTROL PANEL

DETAIL A

BOTTOM OF CONTROL BOX

LOW AMBIENT

DAMPER (SEE NOTE 2)

4 1/2"

4" CONDUIT

MAIN POWER

13"

1 15/16"

5 3/16"

BOTTOM OF CONTROL

BOX (SEE DETAIL A)

88 5/16"

79 1/4"

32 3/16"

1 1/4" x 4 1/2"

SLOT FOR 115

VOLT CONTROL

6 1/4"

4" LINE

VOLTAGE ACCESS

22 1/2"

16"

6 1/8"

4 3/8"

88 5/16"

16 CAUJ-SVX01D-EN

Page 17

Figure 10. 40-ton air-cooled condenser (connections)

Dimensions and Weights

1 3/8" O.D.

DISCHARGE

41 7/8"

27/8"

27"

27 7/16"

CONTROL PANEL SIDE

7/8" O.D. LI QUID LINE

27 7/16"

27"

7/8" O.D. LIQUID LINE

10 1/2"

49 1/2"

1 3/8" O.D.

DISCHARGE

NOTES:

1. VERIFY WEIGHT, CONNECTION, AND ALL DIMENSION WITH

INSTALLER DOCUMENTS BEFO RE INSTALLATION

CONTROL

PANEL

CONTROL

PANEL SIDE

VOLTAGE

ACCESS

5 11/16"

DISCHARGE

LIQUID LINE

5 7/16"

PLAN VIEW OF UNIT

CONNECTION DRAWING

SCALE1,000

CONTROL PANEL SIDE VIEW OF UNIT

CONNECTION DRAW ING

ORIENTATION VIEW OF UNIT

ISOMETRIC DRAWI NG

CAUJ-SVX01D-EN 17

Page 18

Dimensions and Weights

Figure 11. 50-ton air-cooled condenser

FAN GRILLE

56

48 7/8"

34

48 7/8"

3/4" X 6

MTG HOLES

NOTES:

1. SEE CONNECTION DRAWING FOR CONNECTION LOCATION AND SIZES.

2. LOW AMBIENT DAMPER ONLY COMES WITH SELECTED UNIT .

1/2" X 4 KO (115V)

1/2" X 2 KO (115V)

2 5/8"

1 3/4" KO LOW

VOLTAGE (30V MAX.)

5 5/16"

5 3/8"

3 3/8"

3 3/8"

29 1/4"

31 1/4"

35 13/16"

37 11/16"

CONTROL PANEL

4 1/2"

4" CONDUIT

MAIN POWER

DOOR 43 1/4" W/

180 DEG SWING

CONTROL PANEL

(SEE DETAIL A)

BOTTOM OF CONTROL

BOX (SEE DETAIL A)

85 5/8"

88 5/16"

12

8 1/8"

FAN GRILLE

4" LINE

VOLTAGE

ACCESS

1 1/4" x 4 1/2"

SLOT FOR 115

VOLT CONTROL

32 1/4"

79 1/4"

22 1/2"

DETAIL A

BOTTOM OF CONTROL BOX

6 1/4"

16"

LOW AMBIENT

DAMPER (SEE NOTE 2)

103 1/2"

113 13/16"

13"

1 15/16"

18 CAUJ-SVX01D-EN

Page 19

Figure 12. 50-ton air-cooled condenser (connections)

CONTROL

PANEL SIDE

LIQUID LINE

61 3/16"

27 7/16"

10 13/16"

74 7/16"

Dimensions and Weights

NOTES:

1. VERIFY WEIGHT, CONNECTION, AND ALL DIMENSION W ITH

INSTALLER DOCUMENTS BEFORE INSTALLATION

67 3/8"

10 13/16"

0

1,00

CALE

S

27 7/16"

61 3/16"

PLAN VIEW OF UNIT

CONNECTION DRAWING

7/8" O.D.

LIQUID LINE

1 3/8" O.D.

DISCHARGE LINE

CONTROL

PANEL SIDE

CONTROL

PANEL

ORIENTATION VIEW OF UNIT

ISOMETRIC DRAWING

Note List - 97075

VOLTAGE

ACCESS

SCALE1,000

5 11/16"

5 7/16"

1 3/8" O.D.

DISCHARGE LINE

7/8" O.D.

LIQUID LIN E

CONTROL PANEL SIDE VIEW OF UNIT

CONNECTION DRAW ING

CAUJ-SVX01D-EN 19

Page 20

Dimensions and Weights

Figure 13. 60-ton air-cooled condenser

FAN GRILLE

6

4

5

3

48 7/8"

48 7/8"

3/4" X 6

MTG HOLES

114"

NOTES:

1. SEE CONNECTION DRAWING FOR CONNECTION LOCATION AND SIZES.

2. LOW AMBIENT DAMPER ONLY COMES WITH SELECTED UNIT .

1/2" X 4 KO (115V)

1/2" X 2 KO (115V)

2 5/8"

5 5/16"

1 3/4" KO LOW

VOLTAGE (30V MAX.)

5 3/8"

3 3/8"

3 3/8"

29 1/4"

31 1/4"

35 13/16"

37 11/16"

CONTROL PANEL

4 1/2"

4" CONDUIT

MAIN POWER

2 1

DOOR 43 1/4" W/

180 DEG SWING

85 5/8"

CONTROL PANEL

(SEE DETAIL A)

BOTTOM OF CONTROL

BOX (SEE DETAIL A)

88 5/16"

FAN GRILLE

8 1/8"

32 3/16"

4" LINE

VOLTAGE

ACCESS

79 1/4"

22 1/2"

1 1/4" x 4 1/2"

SLOT FOR 115

VOLT CONTROL

6 1/4"

16"

DETAIL A

BOTTOM OF CONTROL BOX

LOW AMBIENT

DAMPER (SEE NOTE 2)

103 1/2"

113 13/16"

13"

1 15/16"

5 3/16"

20 CAUJ-SVX01D-EN

Page 21

Figure 14. 60-ton air-cooled condenser (connections)

CONTROL

PANEL SIDE

LIQUID LINE

61 3/16"

27 7/16"

10 13/16"

74 7/16"

Dimensions and Weights

NOTES:

1. VERIFY WEIGHT, CONNECTION, AND ALL DIMENSION W ITH

INSTALLER DOCUMENTS BEFORE INSTALLATION

67 3/8"

10 13/16"

E1,000

L

SCA

27 7/16"

61 3/16"

PLAN VIEW OF UNIT

CONNECTION DRAWI NG

7/8" O.D.

LIQUID LINE

13/8"O.D.

DISCHARGE LINE

CONTROL

PANEL SIDE

CONTROL

PANEL

ORIENTATION VIEW OF UNIT

ISOMETRIC DRAWING

VOLTAGE

ACCESS

SCALE1,000

5 11/16"

5 7/16"

1 3/8" O.D.

DISCHARGE LINE

7/8" O.D.

LIQUID LINE

CONTROL PANEL SIDE VIEW OF UNIT

CONNECTION DRAWI NG

CAUJ-SVX01D-EN 21

Page 22

Dimensions and Weights

Figure 15. 80-ton air-cooled condenser

FAN GRILLE

8

6

4 3

DOOR 43 1/4" W/

180 DEG SWING

85 5/8"

3/4" X 8

MTG HOLES

7

72 1/8"

5

176 11/16"

16"

13/4"KOLOW

VOLTAGE (30V MAX.)

72 1/8"

12

8"

11/4"

1. SEE CONNECTION DRAW ING FOR CONNECTION LOCATION AND SIZES.

2. LOW AMBI ENT DAMPER ONLY C OMES WITH SELECT ED UNIT .

1/2" X 4 KO (115V)

1/2" X 2 KO (115V)

25/8"

55/16"

53/8"

33/8"

33/8"

29 1/4"

31 1/4"

35 13/16"

37 11/16"

CONTROL PANEL

DETAIL A

DIMENSIONAL DETAIL

41/2"

4" CONDUIT

MAIN POWER

NOTES:

LOW AMBIENT

DAMPER (SEE NOTE 2)

FAN GRILLE

176 7/16"

83 1/4"

30 1/8"

13"

113/16"

BOTTOM OF CON TROL

BOX (SEE DETAIL A)

88 5/16"

CONTROL PANEL

(SEE DETAIL A)

4" LINE

VOLTAGE

ACCESS

2 1/4" x 1 1/4" 24 VOLTAGE

CONTROL WI RING

16 5/16"

11/4"x41/2"

SLOT FOR 115

VOLT CONTROL

79 1/4"

14"

61/4"

7"

9"

30 1/4"

83 1/8"

22 CAUJ-SVX01D-EN

Page 23

Figure 16. 80-ton air-cooled condenser (connections)

Dimensions and Weights

VOLTAGE

ACCESS

CONTROL

PANEL

ISOMETRIC DRAWING

ORIENTATION VIEW OF UNIT

CONTROL

PANEL SIDE

15/8"DISCHARGELINE

136 9/16"

59/16"

LIQUID LI NE

0

0

,0

1

LE

CA

S

1 1/8" O.D. LIQUID LINE

CONNECTION DRAWING

PLAN VIEW OF UNIT

48 3/8"

21 11/16"

COIL

75/16"

CONNECTION DRAWING

CONTROL PANEL SIDE VIEW OF UNIT

14 1/16"

35/16" 35/16"

DISCHARGE LINE

19 1/16"

CONTROL

PANEL SIDE

CAUJ-SVX01D-EN 23

Page 24

Dimensions and Weights

"

Figure 17. 100- and 120-ton air-cooled condenser

FAN GRILLE

3/4" X 8

MTG HOLES

NOTES:

1. SEE CONNECTION DRAW ING FOR CONNECTION LOCATION AND SIZES.

2. LOW AMBIENT DAMPER ONLY COMES WITH SELECTED UNIT .

1/2" X 4 KO (115V)

DOOR 43 1/4" W /

180 DEG SWING

CONTROL PANEL

(SEE DETAIL A)

85 13/16"

97 5/8"

16"

97 5/8"

8"

11/4"

4" LIN E

VOLTAGE ACCESS

2 1/4" x 1 1/4" 24 VOLTAGE

CONTROL WIRING

1/2" X 2 KO (115V)

13/4"KOLOW

VOLTAGE (30V MAX.)

6 1/4"

2 5/8"

5 5/16"

DETAIL A

DIMENSIONAL DET AIL

LOW AMBIENT

DAMPER (SEE NO TE 2)

FAN GRILLE

5 3/8"

33/8"

29 1/4"

31 1/4"

35 13/16"

37 11/16"

33/8"

CONTROL PANEL

41/2"

4" CONDU IT

MAIN POWER

13"

79 1/4"

1 15/16

5 3/16"

BOTTOM OF CONTROL

BOX (SEE DETAIL A)

88 5/16"

16 3/16"

1 1/4" x 4 1/2"

SLOT FOR 115

VOLT CO NTROL

14"

7"

9"

5 1/8"

20 1/16"

108 5/8"

108 11/16"

20 1/16"

24 CAUJ-SVX01D-EN

Page 25

Figure 18. 100- and 120-ton air-cooled condenser (connections)

45/16"

Dimensions and Weights

VOLTAGE

ACC E S S

CONTROL

PANEL

IS OME TR IC DR AW I N G

OR IE NT A T ION VIE W OF U NI T

CONTROL

PANEL S IDE

LIQUID LINE

162"

CONNE C T ION DR AW ING

11/8"O.D.

LIQUID LINE

90 1/8"

21 3/8"

13 1/16"

CONTROL

18 1/16"

PANEL S IDE

41/4"

PLAN VIEW OF UNIT

COIL

59/16"

SCALE1,000

CONNECTION DRAWING

CONTROL PANEL S IDE VIEW OF UNIT

75/16"

DISC H AR G E LINE

CAUJ-SVX01D-EN 25

Page 26

Dimensions and Weights

Weights

Table 2. 20 to 120 ton weights and point load data

Weight CG Locations Weight on isolator mounting location (lbs.)

Tons Model Shipping Operating X Y Loc. 1 Loc. 2 Loc 3. Loc 4. Loc. 5 Loc. 6 Loc. 7 Loc. 8

20 CAUJC20 1163 1188 41.5 32.5 296.3 340.8 358.8 192.1 --- --- --- ---

25 CAUJC25 1213 1238 41.9 32.2 357.1 300.2 318.8 261.9 --- --- --- ---

30 CAUJC30 1211 1236 41.5 32.3 360.9 302.0 316.0 257.1 --- --- --- ---

40 CAUJC40 1758 1808 43.9 46.1 385.9 212.5 181.7 441.8 377.2 208.3 --- ---

50 CAUJC50 2078 2120 52.8 45.8 239.4 211.3 367.5 339.4 495.5 466.6 --- ---

60 CAUJC60 2086 2136 53.0 45.8 238.8 210.9 370.2 342.2 501.6 472.8 --- ---

80 CAUJC80 3142 3212 85.3 54.3 513.5 474.4 459.6 200.2 452.1 196.7 561.6 354.0

100 CAUJC100 3877 3960 111.4 53.9 636.7 402.1 610.1 383.6 605.8 380.5 579.2 361.9

120 CAUJC120 4325 4451 112.2 52.6 687.8 461.8 667.7 447.8 664.4 445.5 644.4 431.5

Point load and isolator location

Figure 19. Mounting and isolator locations (see Table 3, p. 26)

X

Y

2

Control

Panel

1

20-30 Ton

X

Y

4

3

2

Control

Panel

1

4

3

40-60 Ton

X

6

5

Y

2

1

4

Control

Panel

3

6

5

80-120 Ton

Table 3. Isolator mounting locations

Mounting Location

Unit

Size 1 2 3 4 5 6 7 8

20/25/30 X 8” 8” 6' 8 1/8” 6' 8 1/8” - - - -

Y 4' 10 3/4” 1 1/4” 4' 10 3/4” 1 1/4” - - - -

40 X 8” 8” 3' 8 1/8” 3' 8 1/8” 6' 8 1/4” 6' 8 1/4” - -

Y 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” - -

50/60 X 8” 8” 4' 8 7/8” 4' 8 7/8” 8' 9 3/4” 8' 9 3/4” - -

Y 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” - -

80 X 8” 8” 6' 8 1/8” 6' 8 1/8” 9' 1/8” 9' 1/8” 14' 1/4” 14' 1/4"

Y 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4"

100/120 X 8” 8” 8' 9 5/8” 8' 9 5/8” 10' 1 5/8” 10' 1 5/8” 18' 3 1/4 18' 3 1/4”

Y 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4” 7' 3 1/8” 1 1/4"

8

7

26 CAUJ-SVX01D-EN

Page 27

Installation

Rigging and Center-of-Gravity Data

A Rigging illustration and Center-of-Gravity dimensional data table is shown in Figure 20, p. 28,

Figure 21, p. 28, and Table 2, p. 26.SeeTable 2, p. 26 for typical unit operating weights table before

proceeding.

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper center of gravity lift point. To avoid

dropping of unit, reposition lifting point if unit is not level. Failure to properly lift unit could

result in unit dropping and possibly crushing operator/technician which could result in death

or serious injury and possible equipment or property-only damage.

Heavy Objects!

Ensure that all the lifting equipment used is properly rated for the weight of the unit being

lifted. Each of the cables (chains or slings), hooks, and shackles used to lift the unit must be

capable of supporting the entire weight of the unit. Lifting cables (chains or slings) may not be

of the same length. Adjust as necessary for even unit lift. Other lifting arrangements could

cause equipment or property damage. Failure to follow instructions above or properly lift unit

could result in unit dropping and possibly crushing operator/technician which could result in

death or serious injury.

WARNING

WARNING

Note: Use spreader bars as shown in diagram. Refer to installation manual or nameplate for unit

weight. Refer to installation instructions located inside control panel for further rigging

information.

1. Rig the condensing unit as shown in Figure 20, p. 28 and Figure 21, p. 28. Attach adequate

strength lifting slings to all four lifting brackets in the unit base rail. Do not use cables, chains,

or slings except as shown.

2. Install spreader bars, as shown in Figure 20, p. 28 and Figure 21, p. 28, to protect the unit and

to facilitate a uniform lift. The minimum distance between the lifting hook and the top of the

unit should be 7 feet.

3. Test-lift the unit to ensure it is properly rigged and balanced, make any necessary rigging

adjustments.

4. Lift the unit and position it into place.

CAUJ-SVX01D-EN 27

Page 28

Installation

Figure 20. Rigging and center-of-gravity data: 20-60 ton units

Y

Figure 21. Rigging and center-of-gravity data: 80-120 ton units

Y

Unit Isolation

To minimize unit sound and vibration transmission, us one of the following installation methods:

1. Install the unit directly on an isolated (detached) concrete pad or on isolated concrete footings

located at each unit load point.

2. Install the optional spring isolators at each mounting location. See “Spring Isolators (available

for 20-120 ton units),” p. 30.

Note: 20-60 ton units may install the optional neoprene isolators at each mounting location

instead of the spring isolator. If this is the case, see “Neoprene Isolators (available for 20-

60 ton units only),” p. 29.

28 CAUJ-SVX01D-EN

Page 29

Neoprene Isolators (available for 20-60 ton units only)

Install the neoprene isolators at each unit mounting (load) point, using the following procedure:

1. Elevate the unit (one side at a time) to allow access to the base rail mounting holes.

Note: Use solid type blocks, i.e. 4" X 4" wood blocks or similar material to prevent collapsing. Keep

hands and other body limbs clear of elevated base rail while installing isolators to prevent

personal injury.

2. Align the mounting holes in the base rail of the unit with the holes in the top of the appropriate

isolator. Refer to

3. Install a 1/2" NC bolt (field supplied) through the base rail of the unit into the threaded bolt hole

of the isolator. Position the isolator to allow access to the mounting holes in the base of the

isolator, then tighten securely.

4. Lowerthe unit and isolator onto the mounting surface. The maximum isolator deflection should

be approximately 1/4 inch.

5. Secure the isolator to the mounting surface using the base holes in the isolator.

6. Level the unit carefully. See “Leveling the Unit,” p. 31.

7. After the unit is level, tighten isolator base mounting bolts to secure them to the mounting

surface.

Table 4. Typical neoprene isolator selection & location (20-60 ton units only)

Table 4, p. 29 for the appropriate isolator for each load point.

Installation

Shipping

Tons Model Loc. 1 Loc. 2 Loc 3. Loc 4. Loc. 5 Loc. 6

20 CAUJC20 1163 1188 R-3-RED R-3-RED R-3-RED R-3-BLACK --- ---

25 CAUJC25 1213 1238 R-3-RED R-3-RED R-3-RED R-3-RED --- ---

30 CAUJC30 1211 1236 R-3-RED R-3-RED R-3-RED R-3-RED --- ---

40 CAUJC40 1758 1808 R-3-RED R-3-BLACK R-3-BLACK R-3-RED R-3-RED R-3-BLACK

50 CAUJC50 2078 2120 R-3-BLACK R-3-BLACK R-3-RED R-3-RED R-3-RED R-3-RED

60 CAUJC60 2086 2136 R-3-BLACK R-3-BLACK R-3-RED R-3-RED R-3-RED R-3-RED

Weight

Operating

Weight

Isolator Part No. On Mounting Location

Figure 22. Neoprene 20-60 ton data

CAUJ-SVX01D-EN 29

Page 30

Installation

Spring Isolators (available for 20-120 ton units)

Install the spring isolators at each unit mounting (load) point using the following procedure:

1. Elevate the unit (one side at a time) to allow access to the base rail mounting holes.

Note: Use solid type blocks, i.e. 4" X 4" wood blocks or similar material to prevent collapsing. Keep

hands and other body limbs clear of elevated base rail while installing isolators to prevent

personal injury.

2. Align the mounting holes in the base rail of the unit with the positioning pin in the top of the

appropriate isolator. See

3. Position the isolator to allow access to the mounting holes in the base of the isolator.

4. Lower the unit onto the isolator. The positioning pin on the isolator must engage into the hole

of the base rail. The clearance between the upper and lower isolator housings should be

approximately 1/4 to 1/2 inch. Refer to

indicates that shims are required to level the unit. See “Leveling the Unit,” p. 31.

5. Make minor clearance adjustments by turning the isolator leveling bolt (Figure 23, p. 30)

clockwise to increase the clearance and counterclockwise to decrease the clearance. If proper

isolator clearance cannot be obtained by turning the leveling bolt, level the isolators

themselves. A 1/4 inch variance in elevation is acceptable.

6. Secure the isolator to the mounting surface using the base holes in the isolator.

7. After the unit is level, tighten the isolator base mounting

Figure 23. Spring isolator 20-120 ton data

Table 5, p. 30 for the appropriate isolator for each load point.

Figure 23, p. 30. A clearance greater than 1/2 inch

Table 5. Typical spring isolator selection and location

Mdl

Weights

CA

Tons Ship Oper X Y Loc. 1 Loc. 2 Loc 3. Loc 4. Loc. 5 Loc. 6 Loc. 7 Loc. 8

20 1163 1188 41.5 32.5 CP-1D-340 CP-1D-510 CP-1D-510 CP-1D-340 --- --- --- ---

25 1213 1238 41.9 32.2 CP-1D-510 CP-1D-340 CP-1D-340 CP-1D-340 --- --- --- ---

30 1211 1236 41.5 32.3 CP-1D-510 CP-1D-340 CP-1D-340 CP-1D-340 --- --- --- ---

40 1758 1808 43.9 46.1 CP-1D-510 CP-1D-340 CP-1D-340 CP-1D-510 CP-1D-510 CP-1D-340 --- ---

50 2078 2120 52.8 45.8 CP-1D-340 CP-1D-340 CP-1D-510 CP-1D-340 CP-1D-510 CP-1D-510 --- ---

60 2086 2136 53.0 45.8 CP-1D-340 CP-1D-340 CP-1D-510 CP-1D-510 CP-1D-510 CP-1D-510 --- ---

80 3142 3212 85.3 54.3 CP-1D-675 CP-1D-510 CP-1D-510 CP-1D-340 CP-1D-510 CP-1D-340 CP-1D-675 CP-1D-510

100 3877 3960 111.4 53.9 CP-1D-675 CP-1D-510 CP-1D-675 CP-1D-510 CP-1D-675 CP-1D-510 CP-1D-675 CP-1D-510

120 4325 4451 112.2 52.6 CP-1D-900 CP-1D-510 CP-1D-675 CP-1D-510 CP-1D-675 CP-1D-510 CP-1D-675 CP-1D-510

30 CAUJ-SVX01D-EN

CG

Locations

Isolator Part No. On Mounting Location

Page 31

Leveling the Unit

Before tightening the mounting bolts, level the unit carefully. Use the unit base rail as a reference.

Level the unit to within 1/4 inch over its entire length. Use shims if adjustable isolators (neoprene)

are not used.

If adjustable isolators (spring) are used, ensure that the proper isolator housing clearance is

maintained while leveling the unit. Isolators are identified by color and/or an isolator part number.

Shims under the isolators may be required if the unit can not be leveled using the isolator leveling

bolt.

General Unit Requirements

The checklist listed below lists steps required to successfully install a commercial air cooled

condenser. This checklist is intended to assist installing personnel with installation process. It does

not replace detailed instruction called out in the applicable sections of this manual.

• Verify that the power supply complies with unit nameplate specifications.

• Check the unit for shipping damage and material shortage; file a freight claim and notify Trane

office.

• Verify installation location of the unit will has required clearance for proper operation.

• Install appropriate isolators, if required.

Installation

Piping

• Install properly sized liquid line(s) between the liquid line connections on the unit and the

evaporator. (i.e., DX evaporator or an EVP Chiller Barrel). Refer to the

section for recommended liquid line components and guidelines.

• Install properly sized discharge (hot gas) line(s) between the discharge line connections on the

unit and the compressor unit. Refer to the

discharge line components and guidelines.

• Install shutoff valves in the liquid line(s) to isolate the filter drier(s) for service.

• Install proper filter driers in each liquid line.

• Leak test the system. Refer to the “Leak Testing Procedure,” p. 37 for recommended procedures.

Main Electrical Power Requirements

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

• Verify the power supply meets the required power requirements of the system.

• Install power wiring in accordance with all applicable codes.

• Install and connect properly sized power supply wiring, with over current protection, to the

main power terminal block (1TB1) in the unit control panel.

• Install proper grounding wires to an earth ground.

“Refrigerant Piping,” p. 32

“Refrigerant Piping,” p. 32 section for recommended

WARNING

CAUJ-SVX01D-EN 31

Page 32

Installation

Field Installed Control Wiring

• Verify the Control transformer (1T1) is wired for the proper operating voltage.

• Install the interlock circuitry wiring between the unit and the appropriate compressor unit to

permit condenser fan operation when the compressor starter auxiliary contacts closes. Refer

to the Field Connection Diagram that shipped with the unit for interlocking information.

• Verify the appropriate jumpers have been installed on the unit to allow proper condenser fan

operation (If applicable). Refer to the control wiring diagram that shipped with the unit for

jumper details.

Refrigerant Piping

Refrigerant piping must be properly sized and applied. These two factors have a very significant

effect on both system performance and reliability.

Note: Use Type “L” refrigerant grade copper tubing only.

Refrigerant Piping should be sized and laid out according to the job plans and specifications. This

should be done when the system components are selected. The primary objective when sizing

refrigerant piping for this unit is to make refrigerant line sizes as small as possible while avoiding

excessive refrigerant pressure drops.

Sizing refrigerant lines as small as possible minimizes the required refrigerant charge and

maximizes compressor life.

Trane recommends that the Refrigerant Line Sizing program in the “Trane C.D.S. Application

Toolbox" be used to size the refrigerant lines. This program supersedes the line sizing tables in both

the Trane Reciprocating Refrigeration publication and the Trane Air Conditioning Manual. If you do

not have access to this program, contact your local Trane Commercial Sales office for assistance.

Liquid Lines

Basic sizing parameters with the system operating at full load for liquid lines are:

• Maximum Liquid velocity: 600 fpm

• Maximum allowable pressure drop: 7 psig (1o F)

As the pressure drop in the liquid line increases, the potential for liquid flashing, due to reduced

refrigerant pressure corresponding to a reduced liquid temperature (subcooling), increases. Under

these conditions, liquid lines exposed to high surrounding ambient temperatures must be

insulated.

Note: Adding refrigerant to a system with improperly sized refrigerant lines will only decrease

system performance and reliability and accentuate poor operating condition.

Isolate all refrigerant lines from the building. This prevents transferring line vibration to the

structure. Do not secure the lines rigidly to the building at any point since this will defeat the

isolation system of the unit.

Refer to the appropriate unit illustration in Figure 5, p. 12 through Figure 18, p. 25 for refrigerant

line size connections and locations. Connect the liquid line piping to the stubs provided at the liquid

line shutoff valves.

Note: The installer must cut an appropriately-sized opening in the unit sheet metal for the

refrigerant piping entrance into the unit.

32 CAUJ-SVX01D-EN

Page 33

Liquid Line Components

Filter driers and valves (expansion valves, charging valves, etc.) should be provided in the liquid

lines just before the evaporator. Minimize the use of valves, reducers and tube bends as much as

possible to avoid excessive pressure drop before the expansion valve.

Liquid Line Filter Drier

Install the filter driers (provided by the installer) in the liquid lines as close as possible to the

expansion valves. Locate them upstream of the moisture indicator and solenoid valves (Solenoid

valves may not be applicable).

Liquid Line Moisture Indicators

To aid in troubleshooting, charging and servicing the system, install moisture indicators in the

liquid lines near the evaporator, down stream of the liquid line drier between the solenoid valve

(if applicable) and the expansion valve.

Liquid Line Solenoid Valves

Liquid line solenoid valves are not recommended on units when they are connected to DX coils.

Liquid line solenoid valves are recommended for refrigerant migration control when they are

connected to an EVP chiller and should be connected as described in the “Electrical Wiring”

section.

Installation

Thermostatic Expansion Valve (TXV)

Trane recommends a balance-ported externally equalized valve to maintain satisfactory superheat

control down to lower valve loading conditions and to compensate for pressure drops between

expansion valve and superheat control point (evaporator refrigerant outlet). For fin and tube

evaporator applications, a 30% bleed port TXV is required for 20-60T units, and a 15% bleed port

is required for 80-120T units.

For proper refrigerant distribution into coil, an expansion valve is required for each coil distributor.

NOTICE:

Equipment Damage!

Do not use any solenoid valve as a pumpdown device. Equipment damage will occur.

CAUJ-SVX01D-EN 33

Page 34

Installation

Table 6. Valve selections

Capacity

Bleed Selection Minimum Maximum

0

15% 80-120 MCHE

30% 20-60T MCHE

Applicable Units

Any BPHE or any Fin and

Tube OK Coils

BBIZE-1-1/2-GA 2 2

BBIZE-2-GA 2 3

BBIZE-3-GA 2.5 4

BBIZE-4-GA 3.5 5.5

BBIZE-5-GA 4.5 6.5

BBIZE-6-GA 5.5 7.5

BBIZE-8-GA 6.5 10.5

BBIZE-12-1/2-GA 8.5 13.5

BBIZE-15-GA 11 16.5

OZE-20-GA 13 22

OZE-25-GA 17 26

OZE-35-GA 20.5 39

OZE-50-GA 30.5 59

OZE-60-GA 45.5 70

BBIZE-1-1/2-GA (BP/15) 2 2.5

BBIZE-2-GA (BP/15) 2.5 3

BBIZE-3-GA (BP/15) 3 4.5

BBIZE-4-GA (BP/15) 4 6

BBIZE-5-GA (BP/15) 5 7.5

BBIZE-6-GA (BP/15) 6 9

BBIZE-8-GA (BP/15) 7 12

BBIZE-12-1/2-GA (BP/15) 9.5 15.5

BBIZE-15-GA (BP/15) 12.5 19

OZE-20-GA (BP/15) 15 25

OZE-25-GA (BP/15) 19.5 30

OZE-35-GA (BP/15) 23.5 45

OZE-50-GA (BP/15) 35 68

OZE-60-GA (BP/15) 52.5 70

BBIZE-1-1/2-GA (BP/30) 2 3

BBIZE-2-GA (BP/30) 2.5 3.5

BBIZE-3-GA (BP/30) 3.5 5

BBIZE-4-GA (BP/30) 4.5 7

BBIZE-5-GA (BP/30) 6 8.5

BBIZE-6-GA (BP/30) 7 10

BBIZE-8-GA (BP/30) 8 13.5

BBIZE-12-1/2-GA (BP/30) 11 17.5

BBIZE-15-GA (BP/30) 14 21.5

OZE-20-GA (BP/30) 17 28.5

OZE-25-GA (BP/30) 22 30

34 CAUJ-SVX01D-EN

Page 35

Discharge (Hot Gas) Lines

Discharge lines should be pitched downward 1/2 inch for each 10 feet of horizontal run in the

direction of hot gas flow and away from the compressor. Insulate any portion of the discharge

piping that is exposed to outdoor ambient temperature.

Discharge line sizing is based on minimum velocity required for good oil movement in system.

Basic discharge line parameters are:

• Maximum allowable pressure drop: 6 psig

• Maximum velocity: 3500 fpm

Minimum velocities at Minimum Load:

• Horizontal Lines: 500 fpm

• Vertical Lines: Refer to the Table 7, p. 35

A double riser system may be necessary to meet the discharge line velocity requirements.

either a single or double discharge riser is used, the line should drop well below the

When

discharge outlet of the compressor before starting the vertical rise to prevent the possibility of

refrigerant draining back to the compressor during the “Off” cycle.\

Table 7. Minimum vertical line velocities

Line Dia. Minimum Velocity (fpm) Line Dia. Minimum Velocity (fpm)

7/8" 470 2-1/8" 750

1-1/8" 540 2-5/8" 825

1-3/8" 600 3-1/8" 915

1-5/8" 650 3-5/8" 975

Installation

Discharge (Hot Gas) Line Components

Field supplied hot gas mufflers, pipe anchors, single or double risers, oil traps, etc. as applicable,

should be provide to prevent excessive line vibration and assure proper oil return to the

compressor for proper system operation.

A field supplied discharge “shutoff” valve in each hot gas line near the condenser is recommended

to facilitate refrigerant storage in the condenser during service procedures.

A “constant drain” oil trap is illustrated below and can be used as an alternative to a double riser

application. The constant drain oil trap assures adequate oil return to the suction line even at part

load conditions. Refer to “Reciprocating Direct Expansion Piping Systems” (AM-REF 1/82) for

suggested piping arrangement details.

Figure 24. Hot gas line components

1/4" Solenoid

Valve

Oil Return

Line

Hot Gas

5 feet of 1/8"

Copper Tubing

Filter

Oil Trap

Drip Leg

CAUJ-SVX01D-EN 35

Page 36

Installation

Final Refrigerant Pipe Connections

To access the refrigerant pipe connections, remove the louvered side grills. Refer to Figure 5, p. 12

through Figure 18, p. 25.

These condensing units are shipped with a Nitrogen holding charge. Install pressure gauges to the

appropriate access valve(s) and take a reading. If no pressure is present, refer to the “Leak Testing

Procedure” section. If pressure is present, relieve the pressure before attempting to unsweat the

“seal” caps. If refrigerant connections are not capped, but are “spun-end” tubes, use a tubing

cutter to remove the end from the pipe.

Equipment Damage!

To prevent damage to the system, do not drill a hole in the seal caps or saw the ends off pipe

stubs. This could introduce copper chips into the system piping.

Brazing Procedures

Proper brazing techniques are essential when installing refrigerant piping. The following factors

should be kept in mind when forming sweat connections.

Hazard of Explosion!

Use only dry nitrogen with a pressure regulator for pressurizing unit. Do not use acetylene,

oxygen or compressed air or mixtures containing them for pressure testing. Do not use

mixtures of a hydrogen containing refrigerant and air above atmospheric pressure for pressure

testing as they may become flammable and could result in an explosion. Refrigerant, when

used as a trace gas should only be mixed with dry nitrogen for pressurizing units. Failure to

follow these recommendations could result in death or serious injury or equipment or

property-only damage.

NOTICE:

WARNING

1. Whencopperis heated in the presence of air, Copper oxide forms. To prevent copper oxide from

forming inside the tubing during brazing, sweep an inert gas, such as dry nitrogen, through the

tubing. Nitrogen displaces air in the tubing and prevents oxidation of the interior surfaces. A

nitrogen flow of one to three cubic feet per minute is sufficient to displace the air. Use a pressure

regulating valve or flow meter to control the flow.

2. Ensure that the tubing surfaces to be brazed are clean, and that the ends of the tubes have been

carefully reamed to remove any burrs.

3. Make sure the inner and outer tubes of the joint are symmetrical and have a close clearance,

providing an easy slip fit. If the joint is too loose, the tensile strength of the connection will be

significantly reduced. The overlap distance should be equal to the diameter of the inner tube.

4. Wrapthe body of each refrigerant line component with a wet cloth to keep it cool during brazing.

Move any tube entrance grommets away for the brazing area.

Note: Use 40 to 45% silver brazing alloy (BAg-7 or BAg-28) on dissimilar metals. Use BCup-6

brazing alloy on copper to copper joints.

5. If flux is used, apply it sparingly to the joint. Excessive flux can enter the system which will

contaminate the refrigerant system.

6. Apply heat evenly over the length and circumference of the joint to draw the brazing material

into the joint by capillary action. Remove the brazing rod and flame from the joint as soon as

a complete fillet is formed to avoid possible restriction in the line.

7. Visually inspect the connection after brazing to locate any pin holes or crevices in the joint. The

use of a mirror may be required, depending on the joint location.

36 CAUJ-SVX01D-EN

Page 37

Leak Testing Procedure

Hazard of Explosion!

Never use an open flame to detect gas leaks. It could result in an explosion. Use a leak test

solution for leak testing. Failure to follow recommended safe leak test procedures could result

in death or serious injury or equipment or property-only-damage.

Hazard of Explosion!

Use only dry nitrogen with a pressure regulator for pressurizing unit. Do not use acetylene,

oxygen or compressed air or mixtures containing them for pressure testing. Do not use

mixtures of a hydrogen containing refrigerant and air above atmospheric pressure for pressure

testing as they may become flammable and could result in an explosion. Refrigerant, when

used as a trace gas should only be mixed with dry nitrogen for pressurizing units. Failure to

follow these recommendations could result in death or serious injury or equipment or

property-only damage.

Installation

WARNING

WARNING

When Leak-testing a refrigerant system, observe all safety precautions.

Trane condensing units are shipped with a Nitrogen holding charge. If there is no pressure, the unit

must be leak tested to determine the location of leak as follows:

Note: These service procedures require working with refrigerant, Do NOT release refrigerant to

the atmosphere! The service technician must comply with all federal, state, and local laws.

Refer to general service bulletin MSCU-SB-1 (latest edition).

Use refrigerant gas as a tracer for leak detection and use oil-pumped dry nitrogen to develop the

required test pressure. Test the high and low side of the system at pressures dictated by local codes.

1. Close the field supplied liquid line service valve(s) installed near the evaporator and the

compressor discharge service valve to isolate the system's high side from the low side.

Pressure test the liquid line, discharge line, and condenser coils at pressures dictated by local

codes. Do not exceed 10# above the pressure control settings.

2. Connect a refrigerant cylinder to the charging port of the liquid line service valve. Use the

refrigerant to raise the high side pressure to 12 to 15 psig.

3. Disconnect the refrigerant cylinder. Connect a dry nitrogen cylinder to the charging port and

increase the high side pressure. Do not exceed the condenser maximum working pressure

listed on the unit nameplate.

4. Use a halide torch, halogen leak detector or soap bubbles to check for leaks. Check all piping

joints, valves, etc...

5. Ifa leak is located, use proper procedures to remove the refrigerant/nitrogen mixture, break the

connection and remake as a new joint. Retest for leaks after making repairs.

6. Repeatthe test procedure for the low side of the system, charging through the suction pressure

gauge port or through an access provided on the suction line by the installer. Increase the

system pressure to 100 psig.

7. Ifa leak is located, use proper procedures to remove the refrigerant/nitrogen mixture, break the

connection and remake as a new joint. Retest for leaks after making repairs.

8. Open the liquid line service valve and the compressor discharge service valve.

CAUJ-SVX01D-EN 37

Page 38

Installation

Field Installed Power Wiring

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

An overall dimensional layouts for the field installed wiring entrance into the unit are illustrated in

Figure 5, p. 12 through Figure 18, p. 25. To insure that the unit’s supply power wiring is properly

sized and installed, follow the guidelines outlined below.

Note: All field installed wiring must conform to NEC guidelines as well as State and Local codes.

Verify that the power supply available is compatible with the unit’s nameplate ratings. The available

supply power must be within 10% of the rated voltage stamped on the nameplate. Use only copper

conductors to connect the 3-phase power supply to the unit.

Main Unit Power Wiring

WARNING

NOTICE:

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of conductors. Failure to use copper

conductors could result in equipment damage.

Table 8, p. 39 and Table 9, p. 39 list the field connection wire ranges for the main power terminal

block 1TB1. Table 10, p. 42 lists the condensing unit electrical data. The electrical service must be

protected from over current and short circuit conditions in accordance with NEC requirements.

Protection devices must be sized according to the electrical data on the nameplate. Refer to the

“Electrical Service Sizing Equations”, for determining;

• Electrical service wire size based on “Minimum Circuit Ampacity" (MCA).

• “Maximum Over Current Protection” (MOP) device.

• “Recommended Dual Element fuse size” (RDE).

1. A field supplied disconnect switch must be installed at or near the unit in accordance with the

National Electrical Code (NEC latest addition). Refer to the “Electrical Service Sizing Equations”

(DSS calculation), for determining the correct size.

2. Completethe unit's power wiring connections onto the main terminal block 1TB1 inside the unit

control panel. Refer to the customer connection diagram that shipped with the unit for specific

termination points.

3. Provide proper supply power (with over current protection) to the Compressor unit and Air

Handling unit (“No Control”, “VAV”, and “Constant Volume”) applications. For chilled water

systems, provide a properly sized power supply to the circulating pump motor (EVP control

applications). Be certain that these components are properly grounded.

4. Provide proper grounding for the unit in accordance with local and national codes.

38 CAUJ-SVX01D-EN

Page 39

Table 8. Customer connection wire range: 20-60 ton units

Customer wire selection and fuse replacement

Power Wire Selection to Main Terminal Block (1TB1)

Unit Voltage Terminal Block Size Connector Wire Range

All 175A (1) #14-2/0

Control Wire Selection to Control Terminal Block (1TB2) “See Note 6"

Wire Gauge OHMS per 1000 Feet

18 8

16 5

14 3

12 2

Table 9. Customer connection wire range (80-120 ton units)

Customer wire selection and fuse replacement

Power Wire Selection to Main Terminal Block (1TB1)

Unit Voltage Terminal Block Size Connector Wire Range

All 175 AMP (1) #12-2/0

Control Wire Selection to Control Terminal Block (1TB4) “See Note 6"

Wire Gauge OHMS per 1000 Feet Max Wire Length

18 8 500 FT

16 5 1000 FT

14 3 2000 FT

12 2 3000 FT

Installation

CAUJ-SVX01D-EN 39

Page 40

Installation

Power Wire Sizing and Protection Device Equations

To correctly size the main power wiring for the unit, use the appropriate calculation(s) listed below.

Read the load definitions that follow and use Calculation #1 for determining the MCA (Minimum

Circuit Ampacity), MOP (Maximum Over current Protection), and RDE (Recommended Dual

Element fuse size) for each unit. Use Calculation #2 to determine the DSS (Disconnect Switch Size)

for each unit.

Load Definitions:

• LOAD 1 = CURRENT OF THE LARGEST MOTOR (COMPRESSOR OR FAN MOTOR)

• LOAD 2 = SUM OF THE CURRENTS OF ALL REMAINING MOTORS

• LOAD 4 = CONTROL POWER TRANSFORMER = AND ANY OTHER LOAD RATED AT 1 AMP OR

MORE

Calculation #1 (MCA, MOP, and RDE)

• MCA=(1.25xLOAD1)+LOAD2+LOAD4

• MOP = (2.25 x LOAD 1) + LOAD2+LOAD4

Select a fuse rating equal to the MOP value. If the MOP value does not equal a standard fuse size

as listed in NEC 240 - 6, select the next lower standard fuse rating.

Note: If selected MOP is less than the MCA, then select the lowest standard maximum fuse size

which is equal to or larger than the MCA, provided the selected fuse size does not exceed

800 amps.

• RDE=(1.5xLOAD1)+LOAD2+LOAD4

Select a fuse rating equal to the RDE value. If the RDE value does not equal a standard fuse size as

listed in NEC 240 - 6 select the next higher standard fuse rating.

Note: Note: If the selected RDE is greater than the selected MOP value, then select the RDE value

to equal the MOP value.

Calculation #2

Disconnect Switch Sizing (DSS)

• DSS=1.15X(LOAD1+LOAD2+LOAD4)

40 CAUJ-SVX01D-EN

Page 41

Field Installed Control Wiring

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

Hazardous Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

Before installing any connecting wiring, refer to Figure 5, p. 12 through Figure 18, p. 25 for the

electrical access locations provided on the unit. Install appropriately sized control wiring for the 115

volt electrical components as required by the application.

Since the unit-mounted 115V control power transformer (1T1) is provided on all units, it is not

necessary to run a separate 115 volt control power source to the unit.

Note: 200/230 Volt units are shipped with transformer 1T1 wired for 200 volt operation. If the unit

is to be operated on a 230 volt power supply, rewire the transformer as shown on the unit

schematic.

When the 115 volt control circuit is properly connected to the field provided interlock contacts 5K1

for circuit #1 and 5K2 for circuit #2 (if applicable), proper condenser fan cycling and ambient control

for the remaining fans is achieved with corresponding compressor operation.

Note: All field wiring must conform to NEC guidelines as well as state and local codes.

Installation

WARNING

WARNING

CAUJ-SVX01D-EN 41

Page 42

Installation

Electrical Data

Table 10. Electrical data

Unit Characteristics Condenser Fan Motor

Nominal

Tons Model No.

20

25

30

40

50

60

80

100

120

Notes:

1. Electric information is for each individual motor.

2. Maximum fuse size is permitted by NEC 440-22 is 300 percent of one motor RLA plus the RLA of the remaining motors.

3. Minimum circuit ampacity equals 125 percent of the RLA of one motor plus the RLA of the remaining motors.

4. All Kw values taken at conditions of 45°F saturated suction temperature at the compressor and 95°F ambient.

5. Local codes may take precedence.

CAUJ-C20G

CAUJ-C204

CAUJ-C205

CAUJ-C25G

CAUJ-C254

CAUJ-C255

CAUJ-C30G

CAUJ-C304

CAUJ-C305

CAUJ-C40G

CAUJ-C404

CAUJ-C405

CAUJ-C50G

CAUJ-C504

CAUJ-C505

CAUJ-C60G

CAUJ-C604

CAUJ-C605

CAUJ-C80E

CAUJ-C80F

CAUJ-C804

CAUJ-C805

CAUJ-D10E

CAUJ-D10F

CAUJ-D104

CAUJ-D105

CAUJ-D12E

CAUJ-D12F

CAUJ-D124

CAUJ-D125

Electrical

Characteristics

200-230/60/3

460/60/3

575/60/3

200-230/60/3

460/60/3

575/60/3

200-230/60/3

460/60/3

575/60/3

200-230/60/3

460/60/3

575/60/3

200-230/60/3

460/60/3

575/60/3

200-230/60/3

460/60/3

575/60/3

200/60/3

230/60/3

460/60/3

575/60/3

200/60/3

230/60/3

460/60/3

575/60/3

200/60/3

230/60/3

460/60/3

575/60/3

Voltage

Range

180-220/208-254

416-508

520-635

180-220/208-254

416-508

520-635

180-220/208-254

416-508

520-635

180-220/208-254

416-508

520-635

180-220/208-254

416-508

520-635

180-220/208-254

416-508

520-635

180-220

208-254

416-508

520-635

180-220

208-254

416-508

520-635

180-220

208-254

416-508

520-635

Allowable

Circuit

Ampacity

(3),(5)

9.2

4.1

3.2

13.3

5.9

4.6

13.3

5.9

4.6

17.4

7.7

6.0

25.6

11.3

8.8

25.6

11.3

8.8

34

34

15

12

50

50

22

17

50

50

22

17

Minimum

Maximum

Fuse

Size

(2),(5)

15

15

15

20

15

15

20

15

15

20

15

15

30

15

15

30

15

15

40

40

20

15

60

60

25

20

60

60

25

20

No./HP

(1)

2/1.0

2/1.0

2/1.0

3/1.0

3/1.0

3/1.0

3/1.0

3/1.0

3/1.0

4/1.0

4/1.0

4/1.0

6/1.0

6/1.0

6/1.0

6/1.0

6/1.0

6/1.0

8/1.0

8/1.0

8/1.0

8/1.0

12/1.0

12/1.0

12/1.0

12/1.0

12/1.0

12/1.01

12/1.0

12/1.0

FLA

(Ea.)

(1)

4.1

1.8

1.4

4.1

1.8

1.4

4.1

1.8

1.4

4.1

1.8

1.4

4.1

1.8

1.4

4.1

1.8

1.4

4.1

4.1

1.8

1.4

4.1

4.1

1.8

1.4

4.1

4.1

1.8

1.4

LRA

(Ea.)

(1)

20.7

9.0

7.2

20.7

9.0

7.2

20.7

9.0

7.2

20.7

9.0

7.2

20.7

9.0

7.2

20.7

9.0

7.2

20.7

20.7

9.0

7.2

20.7

20.7

9.0

7.2

20.7

20.7

9.0

7.2

KW

(Ea.)

(1),(4)

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

0.9

42 CAUJ-SVX01D-EN

Page 43

Operating Principals

Standard air cooled condensers function as the outdoor condensing units for appropriately sized

split refrigeration systems. These units, operating in conjunction with a matched indoor

compressor/evaporator configuration, provide refrigerant condensing for these systems down to

a normal ambient temperature of 40º F. Operation to 0º F ambient is possible with the addition of

externally mounted low ambient dampers.

All condenser fans are direct drive, 26 inch propeller type. They are driven by 1 HP thermally

protected motors.

When wired properly, the unit will start and operate satisfactorily as long as the operating

temperature is above the minimum operating temperature listed in Table 13, p. 52.

The condensing unit operation starts and stops automatically when the cooling demand is initiated

and terminated by the cooling circuit interlock relays. (See illustrations in diagram numbers 23079123, 2307-9124, 2307-9125, and 2307-9126)

The control components are mounted in the various areas of the unit as illustrated in diagrams

2307-9123, 2307-9124, 2307-9125, and 2307-9126).

20-60 Ton Specs

Condenser fan cycling is accomplished through interlocking the fan operation with compressor

operation (5K1 & 5K2), liquid line pressure switches (4S11 & 4S12). When the low ambient option

is applied, ambient temperature thermostats (1S36 & 1S37) are used to provide additional fan

cycling control. Table 11, p. 43 lists the condenser fan sequencing data and Figure 27, p. 49

illustrates the condenser fan locations with their respective fan and relay designators.

Table 11. Condenser fan sequencing data: 20-60 ton units

Controlling Device (3) Fan "ON" Fan "OFF" Fan Identification

Customer Interlock Circuit 1 5K1 Closed 5K1 Open 2B1, 2B2, 2B3 (1)

Customer Interlock Circuit 2 5K2 Closed 5K2 Open 2B4, 2B5, 2B6 (1)

1S36 (2)

Fan Temperature Switch

Fan Pressure Switch

Notes:

1. Bold fan identifies fans used on 25, 30, 50 & 60 Ton units only.

2. 1S36 and 1S37 normally-closed contacts open on ambient temperature drop to 65°F. Contacts reclose on ambient

temperature rise to 65ºF and 67.5°F.

67.5º F 65º F 2B3 (1)

1S37 (2)

67.5º F 65º F 2B6

4S11

444 psig 255 psig 2B1 (1)

4S12

444 psig 255 psig 2B6

CAUJ-SVX01D-EN 43

Page 44

Operating Principals

80-120 Ton Specs

Condenser fan cycling is accomplished through interlocking the fan operation with compressor

operation (6K1 & 6K2), and ambient temperature thermostats (1S42 & 1S43) are used to provide

additional fan cycling control. Table 12, p. 44 lists the condenser fan sequencing data and

Figure 28, p. 50 illustrates the condenser fan locations with their respective fan and relay

designators.

Table 12. Condenser fan sequencing data: 80-120 ton units

Notes:

1. Bold fan identifies fans used on CAUJ-D10 & D12 units only.