Trane CAUJ 20-120 Tons Catalogue

Product Catalog

Air-Cooled Condensers — CAUJ

20-120 Tons

August 2011 ACDS-PRC003-EN

Introduction

Air-Cooled Condensers Built for Every Need

Trane has the right condenser...

If you are designing a new system or replacing an existing air-cooled condenser, Trane can satisfy

virtually any application need. Whether coupled with an industrial compressor, a single zone

commercial self-contained unit, compressor chiller or a Cold Generator® chiller, Trane has the right

air-cooled condenser for the job. When teamed with any one of a wide range of compressorevaporator combinations, Trane air-cooled condensers, available in 20 to 120 tons, are ideal for

multistory office buildings, hotels, schools, municipal and industrial facilities.

© 2011 Trane All rights reserved ACDS-PRC003-EN

Table of Contents

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Selection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Performance Adjustment Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

20 to 120 Ton Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Durable Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Microchannel Condenser Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ACDS-PRC003-EN 3

Features and Benefits

Microchannel Flat Tube

Header

(top removed)

Ribbon Fin

20 to 120 Ton Units

Trane 20 to 120 ton air-cooled condensers have an operating range of 40°F to 115°F, with a low

ambient option down to 0°F.

The control panel is factory-installed and wired to prevent potential damage and to provide

weathertight protection.

The control panel contains:

• fan motor contactors.

• fan cycling controls.

• terminal point connection for compressor interlock.

• 115-volt control power transformer.

These standard features reduce installation costs and provide easy interface with control logic.

All Trane air-cooled condenser coils are an all aluminum Microchannel design. The 20 to 30 ton

condensers are single circuit; 40 to 120 ton units are dual circuited; all feature integral subcooling.

Units can have optional corrosion protected condenser coil.

Durable Construction

Trane 20 to 120 ton condensers are built for long life. The unit frame is constructed of 14 gauge

galvanized steel. Louvered panels provide excellent coil protection while enhancing unit

appearance and strength. The unit surface is phosphatized and finished with Trane Slate Grey airdry paint. This air dry-paint finish exceeds 500 consecutive hour salt spray resistance in accordance

with ASTM B117.

Microchannel Condenser Coils

Microchannel coils are an all aluminum coil that has

been successfully used in the automotive industry for

many years, and is now being applied in the HVAC

industry. The coils have a fully-brazed construction

which increases coil rigidity making them more

rugged to withstand the rigors of jobsite handling.

Additionally, the light weight simplifies coil handling.

The all aluminum construction creates an exceptional

heat transfer capability, allowing the refrigerant

charge to be reduced to levels that exceed LEED EACredit 4 requirements. Bottom line, less refrigerant is

being used, which creates a healthier and greener

environment.

4 ACDS-PRC003-EN

Application Considerations

Certain application constraints should be considered when sizing, selecting, and installing aircooled condensers. Unit and system reliability depends on properly and completely

acknowledging these considerations. Consult your local Trane sales engineer if your application

varies from these guidelines.

Setting the Unit

A base or foundation is not required if the selected unit location is level and strong enough to

support the operating weight. Refer to the Weights section for the weight of individual units.

Isolation and Sound Emission

The most effective method of noise isolation is proper unit location. Units should be placed away

from noise sensitive areas. Structurally transmitted noise can be reduced with the use of spring

isolators and they are recommended for acoustically sensitive applications. Flexible electrical

conduit, for maximum isolation effectiveness, will reduce sound transmitted through electrical

conduit.

State and local codes on sound emissions should always be considered. Since the environment in

which a sound source is located affects sound pressure, unit placement must be carefully

evaluated.

Servicing

Recommended minimum space envelopes for servicing are located in the Dimensional Data

section and serve as guidelines for providing adequate clearance. The minimum space envelopes

also allow for control panel door swing and routine maintenance requirements.

Unit Location

Unobstructed flow of condenser air is essential to maintaining capacity and operating efficiency.

When determining unit placement, careful consideration must be given to assure a sufficient flow

of air across the condenser heat transfer surface. Two detrimental conditions are possible and must

be avoided: Warm air recirculation and coil starvation.

Warm air recirculation occurs when discharge air from the condenser fans is recycled back at the

condenser coil inlet. Coil starvation occurs when free airflow to the condenser is restricted.

Both warm air recirculation and coil starvation cause reductions in unit efficiency and capacity

because of the higher head pressures associated with them. In more severe cases, nuisance unit

shutdowns will result from excessive head pressures.

Cross winds, those perpendicular to the condenser, tend to aid efficient operation in warmer

ambient conditions. However, they tend to be detrimental to operation in lower ambients or when

hot gas bypass is used due to the accompanying loss of adequate head pressure. As a result, it is

advisable to protect air-cooled condensers from continuous direct winds exceeding 10 miles per

hour.

Debris, trash, supplies, etc., should not be allowed to accumulate in the vicinity of the air-cooled

condenser. Supply air movement may draw debris into the condenser coil, blocking spaces

between coil fins and causing coil starvation. Special consideration should be given to low ambient

units. Condenser coils and fan discharge must be kept free of snow or other obstructions to permit

adequate airflow for satisfactory unit operation.

Clearance

Vertical condenser air discharge must be unobstructed. While it is difficult to predict the degree of

warm air recirculation, a unit installed with a ceiling or other obstruction above it will lose capacity

and the maximum ambient operation will be reduced. Nuisance high head pressure tripouts may

also occur.

The inlet to the coil must also be unobstructed. A unit installed closer than the minimum

recommended distance to a wall or other vertical riser may experience a combination of coil

ACDS-PRC003-EN 5

Application Considerations

starvation and warm air recirculation, resulting in unit capacity and efficiency reductions, as well

as possible excessive head pressures. The recommended lateral distances are listed in the

Dimensional Data section.

Voltage

Nominal voltage is the nameplate rating voltage. The actual range of line voltages at which the

equipment can satisfactorily operate is given below:

Table 1. Voltage range

Nominal Voltage Voltage Utilization Range

200/230 180-220 or 208-254

460 416-508

575 520-635

200/230-volt units ship from the factory set for operation in the 180 through 220-volt range. By

changing leads on unit transformers, the unit will operate in the 208 through 254-volt range.

Effects of Altitude

The tables in the Performance Data section are for use at sea level. At elevations substantially

above sea level, the decreased air density will decrease condenser capacity. Refer to the

Performance Adjustment Factors section to correct performance at other altitudes.

Ambient Limitations

Trane condensers are designed for year-around applications in ambients from 0°F through 115°F.

For operation below 0 F or above 115 F, contact the local Trane sales office.

Start-up and operation of Trane condensers at lower ambient temperatures require that sufficient

head pressure be maintained for proper operation. Minimum operating ambient temperatures for

standard unit selections and units with hot gas bypass are shown in the General Data section.

These temperatures are based on still conditions (winds not exceeding five mph.) Greater wind

velocities will result in a drop in head pressure, therefore, increasing the minimum starting and

operating ambient temperatures.

Units with the low ambient option are capable of starting and operating in ambients down to 0°F,

10°F with hot gas bypass. Optional low ambient units use a condenser fan damper arrangement

that controls condenser capacity by modulating in response to head pressure.

Maximum cataloged ambient temperature operation of a standard condenser is 115°F. Operation

at design ambients above 115°F can result in excessive head pressures. For operation above 115°F,

contact the local Trane sales office.

6 ACDS-PRC003-EN

Model Number Descriptions

20 to 60 Ton Model

Nomenclature

Digit 1 — Unit Type

C=Condenser

Digit 2 — Condenser

A = Air-Cooled

Digit 3 — Airflow

U= Upflow

Digit 4 — Development

Sequence

J=Third

Digit s 5,6,7 — Nominal Capacity

C20 = 20 Tons

C25 = 25 Tons

C30 = 30 Tons

C40 = 40 Tons

C50 = 50 Tons

C60 = 60 Tons

Digit 8 — Power Supply

G = 200/230/60/3 XL

4 = 460/60/3 XL

5 = 575/60/3 XL

Digit 9 — Condenser Circuit

1 = Single (20-30 Ton)

2 = Dual (40-60 Ton)

Digit 10 — Design Sequence

* = Factory Assigned

Digit 11 — Ambient Control

0=Standard

1 = 0 F

Digit 12 — Agency Approval

0=None

3=cULus

Digits 13, 14 — Miscellaneous

J = Corrosion Protected Condenser

Coil

1 = Spring Isolators

2 = Rubber Isolators

Note: The service digit for each model

number contains 14 digits; all 14

digits must be referenced.

80 to 120 Ton Model

Nomenclature

Digit 1 — Unit Type

C=Condenser

Digit 2 — Condenser

A= Air-Cooled

Digit 3 — Airflow

U= Upflow

Digit 4 — Development

Sequence

J = Third

Digits 5,6,7 — Nominal Capacity

C80 = 80 Tons

D10 = 100 Tons

D12 = 120 Tons

Digit 8 — Power Supply

F = 230/60/3

4 = 460/60/3

5 = 575/60/3

E = 200/60/3

Digit 9 — Condenser Circuit

2=Dual Circuit

Digit 10 — Design Sequence

A= First

Digit 11 — Ambient Control

0=Standard

1= 0°F

Digit 12 — Agency Approval

0=None

2=CSA

3=cULus

Digits 13, 14 — Miscellaneous

J = Corrosion Protected Condenser

Coil

1 = Spring Isolators

Note: The service digit for each model

number contains 14 digits; all 14

digits must be referenced.

ACDS-PRC003-EN 7

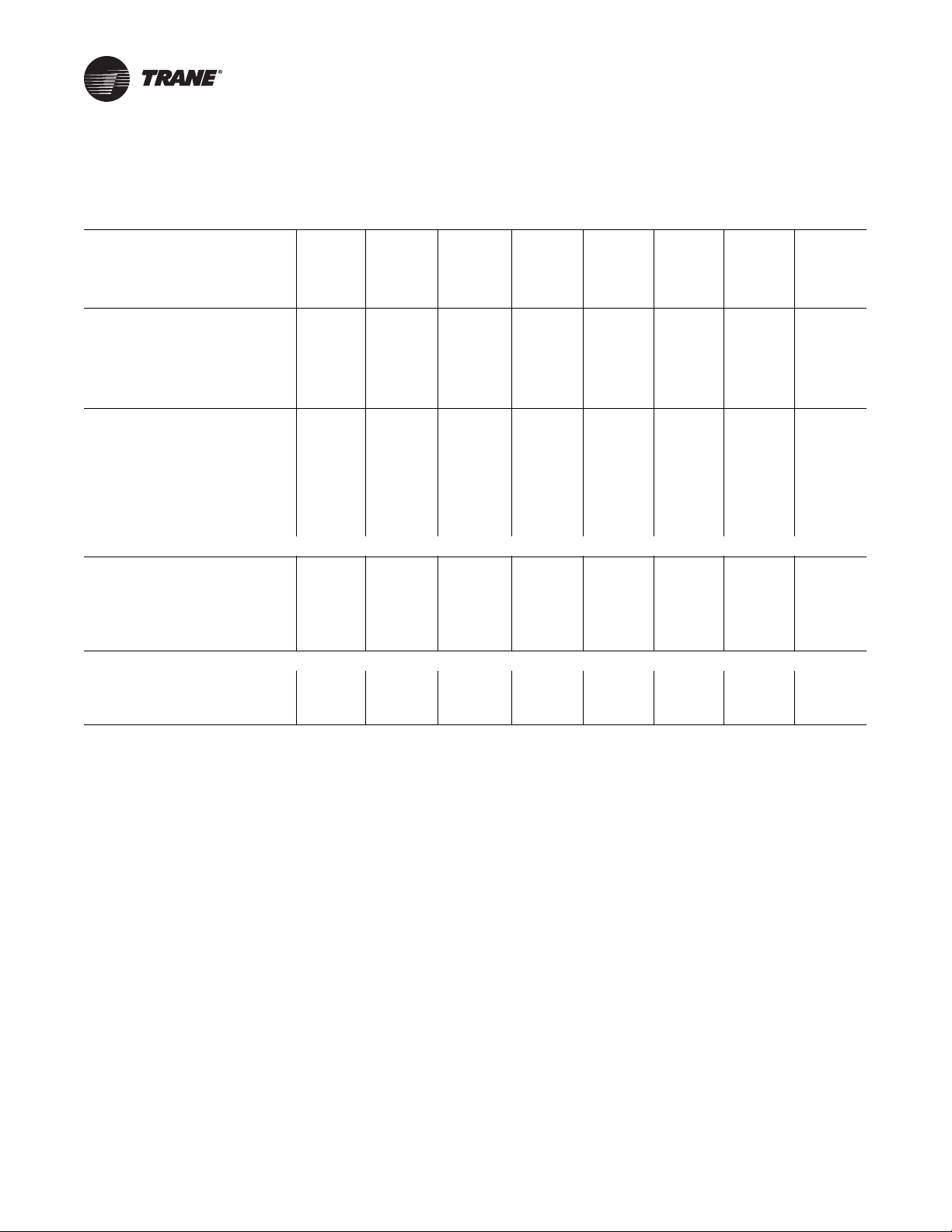

General Data

Table 2. General data

20 Ton 25 Ton 30 Ton 40 Ton 50 Ton 60 Ton 80 Ton 100 Ton 120 Ton

Model Number CAUJC-20 CAUJC-25 CAUJ-C30 CAUJ-C40 CAUJ-C50 CAUJ-C60 CAUJ-C80 CAUJ-D10 CAUJ-D12

Gross Heat Rejection

(a)

(MBh)

Condenser Fan Data

Quantity/Fan Dia. Type 2/26"/Prop 3/26"/Prop 3/26"/Prop 4/26"/Prop 6/26"/Prop 6/26"/Prop 8/26"/Prop 12/26"/Prop 12/26"/Prop

Fan Drive Type Direct Direct Direct Direct Direct Direct Direct Direct Direct

No. of Motors/HP Each 2/1.0 3/1.0 3/1.0 4/1.0 6/1.0 6/1.0 8/1.0 12/1.0 12/1.0

Nominal Total CFM 14600 20700 20700 26790 36890 40490 56490 73890 76280

Condenser Coil Data

Number of Coils/Size

(Inches)

2

) 41.4 41.4 41.4 58.2 68.0 85.4 116.4 136 170.7

Size (ft

Rows/Fin per ft 1/276 1/276 1/276 1/240 1/240 1/240 1/240 1/240 1/240

Condenser Storage

Capacity (lbs)

Typ e Microchannel

Refrigerant Data

No. Refrigerant Circuits 1 1 1 2 2 2 2 2 2

Refrigerant Type R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A

Refrigerant Operating

Charge (Lbs.)

Minimum Outdoor Air Temperature for Mechanical Cooling

Standard Ambient

Operating Range (F)

Low Ambient Option (F) 0 0 0 0 0 0 0 0 0

(a) Gross Heat Rejection is at a 30 F ITD (Initial Temperature Difference) between condensing temperature and ambient air entering condenser (includes

the effect of subcooling).

(b) At conditions of 95° ambient, condenser is 95 percent full

(c) Condensing units are shipping with nitrogen holding charge only.

(d) Operating charge is for condensing unit only, and does not include charge for low side or interconnecting lines.

(b)

(c)

(d)

350 402 456 635 819 1002 1269 1639 2004

2/42x71 2/42x71 2/42x71 2/59x71 2/51x96 2/64x96 4/59x71 4/51x96 4/64x96

18.7 18.7 18.7 23.5 25.0 31.5 47.1 50.0 62.9

11.9 11.8 11.8 22.7 23.4 26.4 57.1 59.1 65.3

40-125 40-125 40-125 40-125 40-125 40-125 40-125 40-125 40-125

8 ACDS-PRC003-EN

Selection Procedures

When manually matching condensers with compressors, performance cross plotting becomes

necessary. The following procedure should be used to determine the correct condenser.

1. Determine the total cooling load. Make a prelimary compressor selection based on the

expected evaporator SST and condensing temperature.

Example:

Given- Total cooling load = 101 tons (1212 Mbh)

Design outdoor temperature = 95°F

Assume- Evaporator SST = 45°F (used in this example - application dependent)

Condenser SCT between 115°F and 125°F (20-30°F ITD SCT-ambient)

2. Select compressors from manufacturer's data to meet the load at the evaporator SST (for chiller

low suction applications contact Trane applications) -

Table 3. Compressor capacity with subcooling

(Qty 2) CSHN611 Trane R-410A Trio Scrolls Performance data includes 15°F subcooling

SST SCT Tons Mbh

45 115 110 1320

45 125 103 1236

Notes:

1. SST = Saturated Suction Temperature

2. SCT = Saturated Condensing Temperature

a. Remove the subcooling effect from the compressor performance at two or more compressor

capacity points. R-410A capacity increases 0.75% for every degree of subcooling (0.75% x

15°F = 11.25%). So if compressor performance is at 15°F subcooling, divide capacity by 1.1125

to get capacity at 0°F subcooling. Plot these two points (SCT vs. compressor tons a 0°F

subcooling) as shown in the selection example (Figure 1, p. 11).

Table 4. Compressor capacity with subcooling removed

(Qty 2) CSHN611 Trane R-410A Trio Scrolls

Capacity

15°F subcooling 0°F subcooling

(a)

SST

45 115 110 1320 98.9 1187

45 125 103 1236 92.6 1111

(a) SST = Saturated Suction Temperature

(b) SCT = Saturated Condensing Temperature

SCT

(b)

Tons Mbh Tons Mbh

b. Select a condenser from Figure 3, p. 13 (CAUJ-D10 assumed for this example) and read two

condenser only heat rejection points. Divide the condenser heat rejection by the compressor

N factor (Table 6, p. 11) to convert from heat rejection to net capacity (Net Tons Less

Subcooling). The N factor equals the ratio of compressor heat rejection divided by

compressor capacity at 0°F subcooling. Plot these two points (SCT vs. Net Tons at 0°F

subcooling) as shown in Figure 1, p. 11 selection example.

ACDS-PRC003-EN 9

Selection Procedures

Table 5. Condenser net capacity Mbh (less subcooling)

Assumed ∆T°F ITD

Notes:

1. ITD = Initial Temperature Difference

2. SCT = Saturated Condensing Temperature

3. N Factor = Compressor Efficiency Ratio

Note: Note that evaporator selection must also meet performance requirements. For this

(SCT - ambient)

20 95 115 938 1.27 739 61.5

30 95 125 1418 1.33 1066 88.8

Ambient,

°F SCT, °F

Cond only heat

rejection, Mbh N factor

Net capacity less subcooling

Mbh Tons

c. As shown on Figure 1, p. 11, draw a line though the points representing the compressor

capacity at 0°F subcooling. Next, draw a line through the points representing condenser net

capacity less subcooling.

d. At the point of intersection of the compressor and condenser lines draw dashed lines to the

left and bottom margins as shown in Figure 1, p. 11. The end points of these lines will show

a resultant gross capacity of 92 tons at 126.1°F condensing temperature.

e. From Figure 2, p. 12 calculate the percent increase in total heat rejection due to subcooling,

and multiply by the N factor (see Tab le 6 , p . 11 ) to get the percent increase in net capacity

due to subcooling.

Example:

At 95°F ambient and 126.1°F condensing temperature Figure 2, p. 12 shows there is a 7. 8 %

increase in total heat rejection due to subcooling. Tab l e 6 shows a 1.34 N factor by linear

interpolation. This yields a system capacity of 92 tons x (1 + 7. 8 % x 1. 34 ) = 102 tons.

f. If necessary use the values in Table 7, p. 12 to adjust the system capacity for altitude.

g. Compare this result with the design capacity and condensing temperature.

The required cooling load is 101 tons, therefore, the CAUJ-D10 is the proper selection.

Repeat the process steps B through G as necessary to achieve the most economic condenser

selection.

example, the evaporator needs to provide at least 105 tons at 45°SST. A conservative

estimate for liquid temperature entering the evaporator is the SCT minus the design

subcooling (125.1 - 15°F = 110.1°F for the example above). Contact Trane Applications if

excessive refrigerant line lengths or pressure drops are required.

10 ACDS-PRC003-EN

Loading...

Loading...