Page 1

18-BC85D1-2

Installer’s Guide

Heat Pumps

4TWB3018–060

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit. Please return to service information pack upon completion of work.

These instructions do not cover all variations in systems or provide for every possible contingency to be met in connection with

the installation. Should further information be desired or should particular problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to your installing dealer or local distributor.

Note: The manufacturer recommends installing only approved matched indoor and outdoor systems. All of the manufacture’s split

systems are AHRI rated only with TXV/EEV indoor systems. Some of the benefits of installing approved matched indoor and outdoor split systems are maximum efficiency, optimum performance and the best overall system reliability.

Table of Contents

Section 1. Safety ..................................................................................... 2

Section 2. Unit Location Considerations..............................................3

Section 3. Unit Preparation .................................................................... 5

Section 4. Setting the Unit ..................................................................... 5

Section 5. Refrigerant Line Considerations ......................................... 6

Section 6. Refrigerant Line Routing .....................................................7

Section 7. Refrigerant Line Brazing ...................................................... 8

Section 8. Refrigerant Line Leak Check .............................................10

Section 9. Evacuation ...........................................................................11

Section 10. Service Valves ................................................................... 11

Section 11. Electrical - Low Voltage .................................................... 13

Section 12. Electrical - High Voltage ................................................... 16

Section 13. Start Up ..............................................................................17

Section 14. System Charge Adjustment ............................................. 18

Section 15. Checkout Procedures and Troubleshooting ................... 23

Page 2

Section 1. Safety

▲

WARNING

!

▲

WARNING

!

▲

WARNING

!

▲

WARNING

!

▲

CAUTION

!

▲

CAUTION

!

▲

WARNING

!

This information is intended for use by individuals

possessing adequate backgrounds of electrical and

mechanical experience. Any attempt to repair a central

air conditioning product may result in personal injury

and/or property damage. The manufacture or seller

cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection with its use.

These units use R-410A refrigerant which operates

at 50 to 70% higher pressures than R-22. Use only

R-410A approved service equipment. Refrigerant

cylinders are painted a “Rose” color to indicate the

type of refrigerant and may contain a “dip” tube to

allow for charging of liquid refrigerant into the system. All R-410A systems use a POE oil that readily

absorbs moisture from the atmosphere. To limit this

“hygroscopic” action, the system should remain sealed

whenever possible. If a system has been open to the

atmosphere for more than 4 hours, the compressor oil

must be replaced. Never break a vacuum with air and

always change the driers when opening the system

for component replacement. For specific handling

concerns with R-410A and POE oil reference Retrofit

Bulletins SS-APG006-EN and APP-APG011-EN or

APPAPG012-EN.

LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and troubleshooting of this product, it may be necessary to work

with live electrical components. Failure to follow all

electrical safety precautions when exposed to live

electrical components could result in death or serious

injury.

If using existing refrigerant lines make certain that all

joints are brazed, not soldered.

Scroll compressor dome temperatures may be hot. Do

not touch the top of compressor; it may cause minor to

severe burning.

UNIT CONTAINS R-410A REFRIGERANT!

R-410A operating pressures exceed the limit of R-22.

Proper service equipment is required. Failure to use

proper service tools may result in equipment damage

or personal injury.

SERVICE

USE ONLY R-410A REFRIGERANT AND AP-

PROVED POE COMPRESSOR OIL.

Extreme caution should be exercised when opening

the Liquid Line Service Valve. Turn counterclockwise

until the valve stem just touches the rolled edge. No

torque is required. Failure to follow this warning will

result in abrupt release of system charge and may

result in personal injury and /or property damage.

2 18-BC85D1-2

Page 3

Section 2. Unit Location Considerations

D

H

W

2.1 Unit Dimensions and Weight

Table 2.1

Unit Dimensions and Weight

Models H x D x W (in)

4TWB3018D

4TWB3024D

4TWB3030C

4TWB3036C

4TWB3042B

4TWB3048B

4TWB3060B

* Weight values are estimated.

29 x 30 x 33 160

29 x 30 x 33 160

33 x 30 x 33 193

33 x 34 x 37 198

33 x 34 x 37 219

37 x 34 x 37 234

41 x 34 x 37 248

When mounting the outdoor unit on a roof, be

sure the roof will support the unit’s weight.

Properly selected isolation is recommended to

alleviate sound or vibration transmission to the

building structure.

Weight* (lb)

2.2 Refrigerant Piping Limits

1. The maximum length of refrigerant lines

from outdoor to indoor unit should NOT

exceed sixty (60) feet.

2. The maximum vertical change should not

exceed sixty (60) feet.

3. Service valve connection diameters are

shown in Table 5.1.

Note: For line lengths greater than sixty (60)

feet, Refer to Refrigerant Piping Application

Guide, SS-APG006-EN or Refrigerant Piping

Software Program, 32-3312-03 (or latest revision).

Standard

Line Set

60’ Max

Line Length

60’

Max

Vertical

Change

18-BC85D1-2 3

60’

Max

Vertical

Change

Page 4

2.3 Suggested Locations for Best Reliability

Avoid Install

Ensure the top discharge area is unrestricted for

at least five (5) feet above the unit.

Three (3) feet clearance must be provided in

front of the control box (access panels) and any

other side requiring service.

Near Bedrooms

Min 5’ Unrestricted

It is not recommended to install in a location

where noise may distract the building occupants. Some examples of these types of locations are sleeping quarters and by windows of

a living area. Please discuss location with the

building owner prior to installation.

Avoid locations such as near windows where

condensation and freezing defrost vapor can

annoy a customer.

Position the outdoor unit a minimum of 12” from

any wall or surrounding shrubbery to ensure

adequate airflow.

Outdoor unit location must be far enough away

from any structure to prevent excess roof runoff

water or icicles from falling directly on the unit.

Min. 12” to

Shrubbery

Min. 12” to

Shrubbery

Min 3’

Unrestricted

Access Panel

Min. 12”

to Wall

2.4 Cold Climate Considerations

NOTE: It is recommended that these precautions be taken for units being installed in areas

where snow accumulation and prolonged below

freezing temperatures occur.

• Units should be elevated 3-12 inches above

the pad or roof top, depending on local

weather. This additional height will allow

drainage of snow and ice melted during

defrost cycle prior to its refreezing. Ensure

that drain holes in unit base pan are not

obstructed preventing draining of defrost

water.

• If possible, avoid locations that are likely to

accumulate snow drifts. If not possible, a

snow drift barrier should be installed around

the unit to prevent a build-up of snow on the

sides of the unit.

4 18-BC85D1-2

Min. 12”

Snow

Barrier

Snow Legs

3-12” Elevation

Pad

Page 5

2.5 Coastal Considerations

If installed within one mile of salt water, including seacoasts and inland waterways, models without factory supplied Seacoast Salt Shields require the addition of BAYSEAC001 (Seacoast Kit) at installation time.

Section 3. Unit Preparation

3.1 Prepare The Unit For Installation

STEP 1 - Check for damage and report prompt-

ly to the carrier any damage found to the unit.

STEP 2 - To remove the unit from the pallet,

remove tabs by cutting with a sharp tool.

Section 4. Setting the Unit

4.1 Pad Installation

When installing the unit on a support pad, such

as a concrete slab, consider the following:

• The pad should be at least 1” larger than the

unit on all sides.

• The pad must be separate from any structure.

• The pad must be level.

• The pad should be high enough above grade

to allow for drainage.

• The pad location must comply with National,

State, and Local codes.

18-BC85D1-2 5

Page 6

Section 5. Refrigerant Line Considerations

Line Length

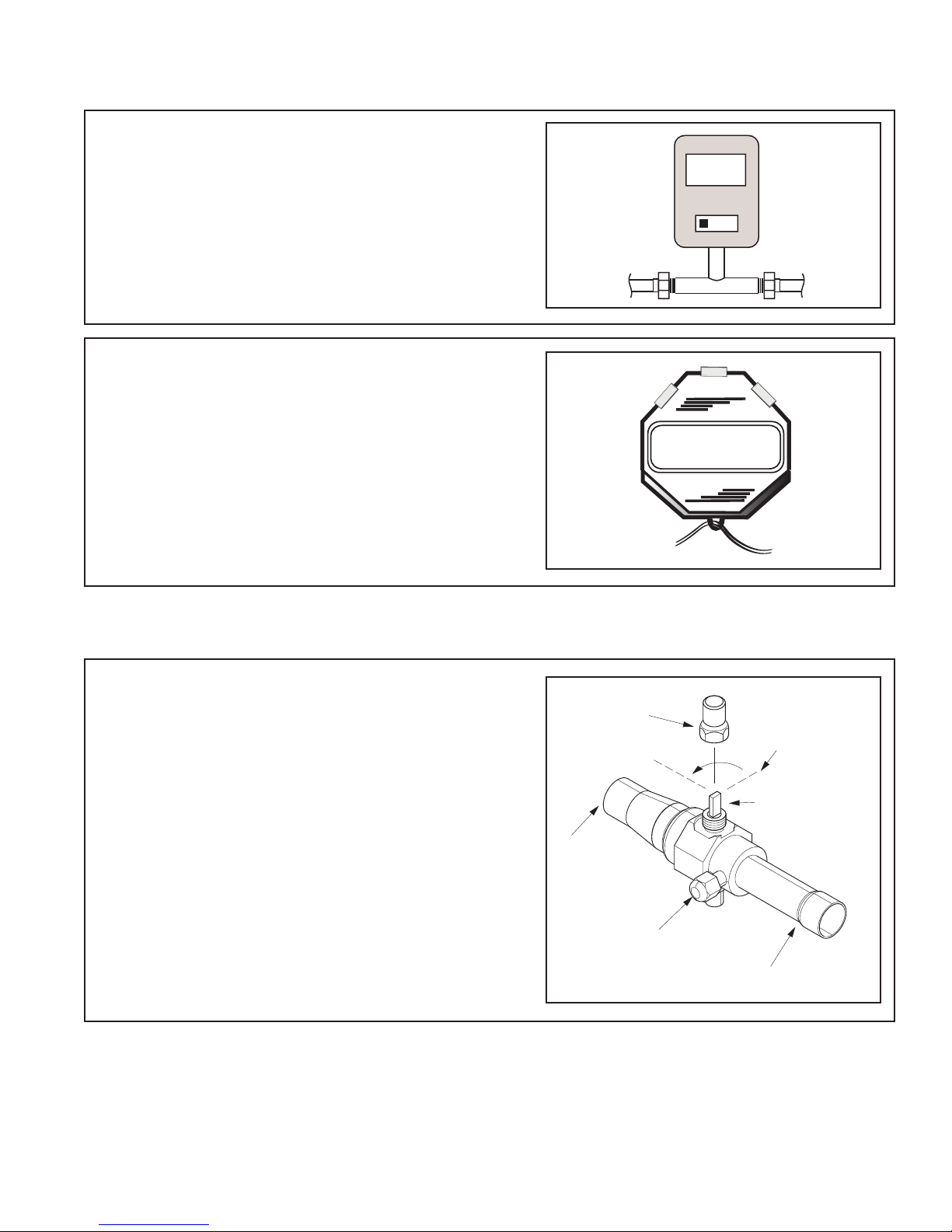

5.1 Refrigerant Line and Service Valve Connection Sizes

Table 5.1

Line Sizes Service Valve Connection Sizes

Model

4TWB3018D 5/8 3/8 5/8 3/8

4TWB3024D 5/8 3/8 5/8 3/8

4TWB3030C 3/4 3/8 3/4 3/8

4TWB3036C 3/4 3/8 3/4 3/8

4TWB3042B 3/4 3/8 3/4 3/8

4TWB3048B 7/8 3/8 7/8 3/8

4TWB3060B 7/8 3/8 7/8 3/8

Vapor

Line

5.2 Factory Charge

Outdoor condensing units are factory charged with the system charge required for the outdoor condensing unit,

fifteen (15) feet of tested connecting line, and the smallest indoor evaporative coil match. If connecting line

length exceeds fifteen (15) feet and/or a larger indoor evaporative coil is installed, then final refrigerant

charge adjustment is necessary.

Liquid

Line

Vapor Line

Connection

Liquid Line

Connection

5.3 Required Refrigerant Line Length

Determine required line length and lift. You will

need this later in STEP 2 of Section 14.

Total Line Length = __________ Ft.

Total Vertical Change (lift) = __________ Ft.

5.4 Refrigerant Line Insulation

Important: The Vapor Line must always be

insulated. DO NOT allow the Liquid Line and

Vapor Line to come in direct (metal to metal)

contact.

Liquid Line

Vapor Line

Insulation

6 18-BC85D1-2

Page 7

5.5 Reuse Existing Refrigerant Lines

▲

CAUTION

!

If using existing refrigerant lines make certain that

all joints are brazed, not soldered.

For retrofit applications, where the existing

indoor evaporator coil and/or refrigerant lines

will be used, the following precautions should

be taken:

• Ensure that the indoor evaporator coil and

refrigerant lines are the correct size.

• Ensure that the refrigerant lines are free of

leaks, acid, and oil.

Important: For more information see publication numbers SS-APG006-EN.

Section 6. Refrigerant Line Routing

6.1 Precautions

Important: Take precautions to prevent noise

within the building structure due to vibration

transmission from the refrigerant lines.

For Example:

• When the refrigerant lines have to be fastened to floor joists or other framing in a structure, use isolation type

hangers.

• Isolation hangers should also be used when refrigerant lines are run in stud spaces or enclosed ceilings.

• Where the refrigerant lines run through a wall or sill, they should be insulated and isolated.

• Isolate the lines from all ductwork.

• Minimize the number of 90º turns.

8 Feet Maximum

Side View

8 Feet Maximum

Secure Vapor line from joists using isolators every 8 ft. Secure

Liquid Line directly to Vapor line using tape, wire, or other appropriate method every 8 ft.

Comply with National, State, and Local Codes when

isolating line sets from joists, rafters, walls, or other

structural elements.

Joist/Rafter

Isolator

Line Set

18-BC85D1-2 7

Isolation From Joist/Rafter

Page 8

8 Feet Maximum

Wall

Isolator

Wall

Side View

8 Feet Maximum

Line Set

Secure Vapor Line using isolators every 8 ft. Secure Liquid Line

directly to Vapor Line using tape, wire, or other appropriate

method every 8 ft.

Isolation In Wall Spaces

Sealant

Ductwork

Insulation

Vapor Line

Isolator

Line Set

Isolation Through Wall

Section 7. Refrigerant Line Brazing

7.1 Braze The Refrigerant Lines

STEP 1 - Remove caps or plugs. Use a debur-

ing tool to debur the pipe ends. Clean both

internal and external surfaces of the tubing

using an emery cloth.

DO NOT hang line sets from ductwork

8 18-BC85D1-2

Page 9

STEP 2 - Remove the pressure tap cap and

valve cores from both service valves.

STEP 3 - Purge the refrigerant lines and indoor

coil with dry nitrogen.

STEP 4 - Wrap a wet rag around the valve

body to avoid heat damage and continue the

dry nitrogen purge.

Braze the refrigerant lines to the service

valves.

Continue the dry nitrogen purge. Do not remove the wet rag until all brazing is completed.

Important: Remove the wet rag before stopping

the dry nitrogen purge.

NOTE: Precautions should be taken to avoid

heat damage to basepan during brazing. It is

recommended to keep the flame directly off of

the basepan.

18-BC85D1-2 9

Page 10

STEP 5 - Replace the pressure tap valve cores

150 PSIG

after the service valves have cooled.

Section 8. Refrigerant Line Leak Check

8.1 Check For Leaks

STEP 1 - Pressurize the refrigerant lines and

evaporator coil to 150 PSIG using dry nitrogen.

STEP 2 - Check for leaks by using a soapy solution or bubbles at each brazed location.

Remove nitrogren pressure and repair any leaks

before continuing.

10 18-BC85D1-2

Page 11

Section 9. Evacuation

1/4 TURN ONLY

9.1 Evacuate the Refrigerant Lines and Indoor Coil

Important: Do not open the service valves until

the refrigerant lines and indoor coil leak check

and evacuation are complete.

STEP 1 - Evacuate until the micron gauge reads

no higher than 350 microns, then close off the

valve to the vacuum pump.

STEP 2 - Observe the micron gauge. Evacuation

is complete if the micron gauge does not rise

above 500 microns in one (1) minute.

Once evacuation is complete blank off the

vacuum pump and micron gauge, and close the

valves on the manifold gauge set.

0350

Microns

ON

OFF

1 MIN.

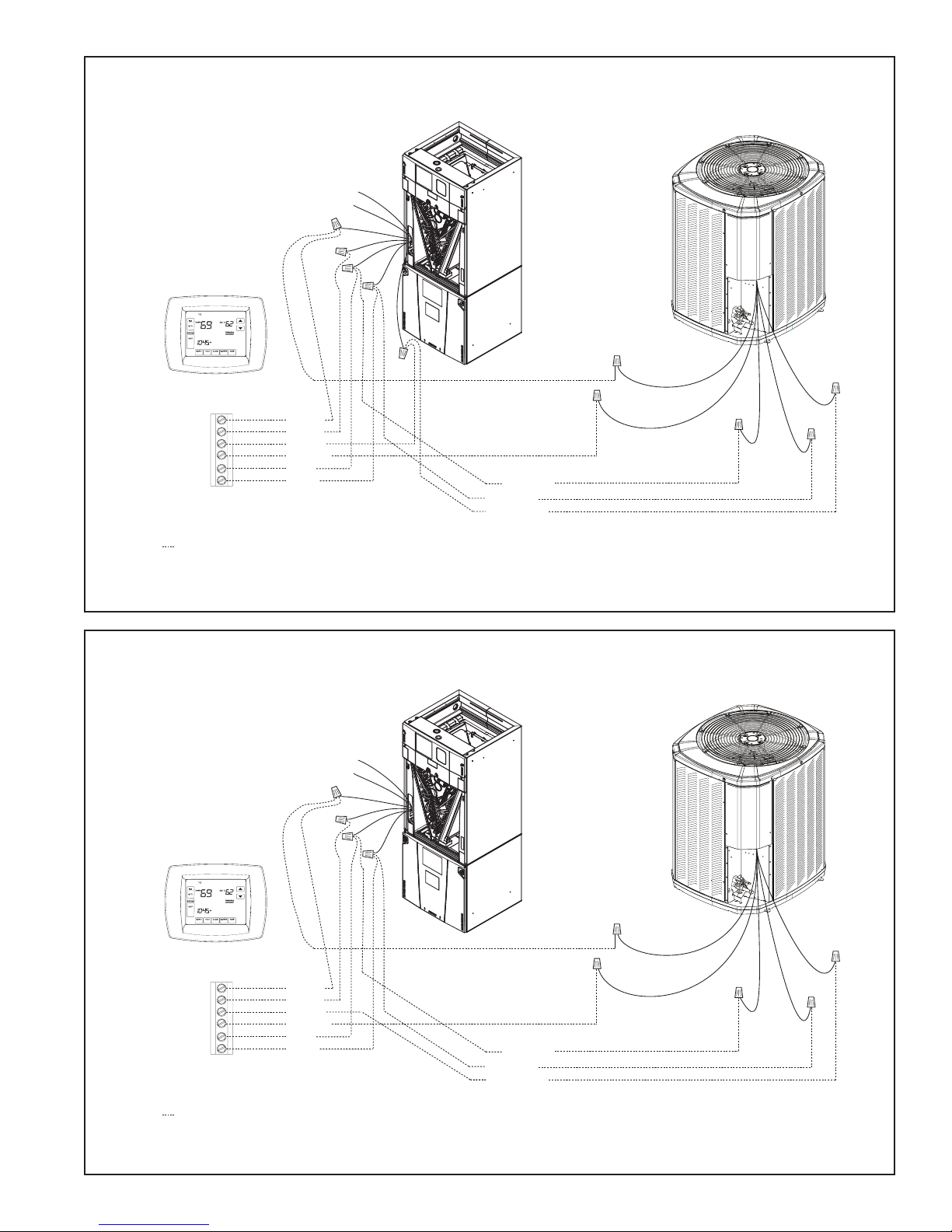

Section 10. Service Valves

10.1 Open the Gas Service Valve

Important: Leak check and evacuation must be

completed before opening the service valves.

NOTE: Do not vent refrigerant gases into the

atmosphere.

STEP 1 - Remove valve stem cap.

STEP 2 - Using an adjustable wrench, turn valve

stem 1/4 turn counterclockwise to the fully open

position.

STEP 3 - Replace the valve stem cap to prevent

leaks. Tighten finger tight plus an additional 1/6

turn.

CAP

UNIT SIDE

OF VALVE

PRESSURE TAP PORT

COUNTERCLOCKWISE

FOR FULL OPEN

POSITION

VALVE STEM

GAS LINE CONNECTION

18-BC85D1-2 11

Page 12

10.1 Open the Liquid Service Valve

▲

WARNING

!

Extreme caution should be exercised when

opening the Liquid Line Service Valve. Turn

counterclockwise until the valve stem just

touches the rolled edge. No torque is required.

Failure to follow this warning will result in abrupt

release of system charge and may result in

personal injury and /or property damage.

Important: Leak check and evacuation must be

completed before opening the service valves.

STEP 1 - Remove service valve cap.

STEP 2 - Fully insert 3/16” hex wrench into the

stem and back out counterclockwise until valve

stem just touches the rolled edge (approximately

five (5) turns.)

STEP 3 - Replace the valve cap to prevent leaks.

Tighten finger tight plus an additional 1/6 turn.

Cap

Unit Side

of Service

Valve

Service Port

3/16” Hex Wrench

Rolled Edge to

Captivate Stem

Hex Headed

Valve System

Section 11. Electrical - Low Voltage

11.1 Low Voltage Maximum Wire Length

Table 11.1 defines the maximum total length of

low voltage wiring from the outdoor unit, to the

indoor unit, and to the thermostat.

Table 11.1

24 VOLTS

WIRE SIZE MAX. WIRE LENGTH

18 AWG 150 Ft.

16 AWG 225 Ft.

14 AWG 300 Ft.

12 18-BC85D1-2

Page 13

11.2 Low Voltage Hook-up Diagrams

Orange

Heat Pump

Heat Pump

Communicating Indoor Unit

with 24 V Control Hook-up

Diagram

Comm. Variable Speed

Furnace or Air Handler

Comfort Control

R

Y1

G

W1

X2

B

O

Red

Yellow

Green

White

Blue

Orange

R

BK

D

Y1

Y2

G

W1

W2

W3

B

O

Neatly bundle all low voltage

wires as shown.

Red

Yellow

Black

Yellow

Blue

Red

Orange

Black

Notes:

1. See User Interface 24

V Mode setup menu

for control mode and

cooling CFM options.

2. W3 terminal may not

Orange

Blue

(X2)

be present on unit.

3. (Air Handlers only) If

electric heat does not

have 3rd contactor (CH), connect

a jumper wire from

W3 to W2. If electric

heat does not have

2nd contactor (BH),

connect a jumper wire

from W2 to W1.

4. W1 - X2 is a field

installed jumper.

Variable Speed Furnace

Hook-up Diagram

Comfort Control

R

Y1

G

W1

X2

B

O

Red

Yellow

Green

White

Blue

Orange

Variable Speed

Furnace

R

LO

Y

Y

BK

G

W1

W2

B

O

Neatly bundle all low voltage

wires as shown.

Red

Yellow

Yellow

Red

Black

Black

(X2)

Blue

Blue

Orange

Notes:

1. Comfort control must

be dual fuel capable

or use accessory

TAYPLUS103A.

2. Ylo and BK may not be

present on unit.

3. W1 - X2 is a field

installed jumper.

18-BC85D1-2 13

Page 14

1

1

12345

12345

HP

2(Compressor)

2(Stages)

AC (System)

}

OUTDOOR

Capacity (Tons)

OUTDOOR

}

Torque

CFM/Ton

Cool OffDelay

}

INDOOR

CFM

+12V

R13

R14

R4

1

U1

RNET1

S1

on

on

S2

RNET2

R

6

C22

C19

C15C

12

C10

D9

L1

Heat Pump

TAM7 Air Handler

Hook-up Diagram

Air Handler

Neatly bundle all low voltage

wires as shown.

Black

(X2)

Comfort Control

X2

W

G

Y1

O

R

B

White

Green

Yellow

Orange

Red

Blue

Field wiring

TAM4 Air Handler

Hook-up Diagram

W3 Brown

W1 White *

W2 Pink

W3

W2

W1

G

(In)

YI

O

R

B

(Out)

YO

DH/BK

W1 - White

O - Orange

R - Red

B - Blue

Y1 - Yellow

Orange

Red

Must configure to

“OFF” for HP Units.

Must configure to “OFF” for

single-stage compressors.

Blue

Yellow

Control Board

Green

Red

Blue

Yellow YI

Orange

Comfort Control

White

W

Green

G

Yellow

Y

Orange

O

Red

R

Blue

14 18-BC85D1-2

B

Purple YO

Air Handler

Heat Pump

Yellow

Black

(X2)

Orange

Blue

Red

Y - Yellow

O - Orange

B - Blue

R - Red

W1 - White

• * For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat

• YI and YO connections must be made as shown for proper operation, freeze protection, and internally mounted condensate

overflow circuits to work properly

• Internally mounted condensate switch is optional and must be ordered separately

• If a 3rd party condensate overflow switch is installed, it should be wired between Y of the thermostat and YI of the EEV control.

• Some models have a terminal strip. Refer to air handler Installer’s Guide.

Page 15

GAM5 Air Handler

Hook-up Diagram

Heat Pump

W2 Pink

W3 Brown

W1 White

Comfort Control

White

W

Green

G

Yellow

Y

Orange

O

Red

R

Blue

B

Field wiring

GAM2 Air Handler

Hook-up Diagram

Green

White

Green

Yellow

Orange

Red

Blue

Red

Blue

Yellow

Orange

Black

(X2)

Air Handler

R - Red

B - Blue

Y - Yellow

• * For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat

• Some models have a terminal strip. Refer to air handler Installer’s Guide.

Red

Yellow

Blue

Comfort Control

White

Green

Yellow

Orange

Red

Blue

Field wiring

Heat Pump

W2 Pink

W3 Brown

W1 White

Green

W

G

Y

O

R

B

White

Green

Yellow

Orange

Red

Blue

Red

Blue

Air Handler

R - Red

Orange

Black

(X2)

Red

Yellow

Blue

B - Blue

Y - Yellow

• * For multiple stages of electric heat, jumper W1, W2, and W3 together if comfort control has only one stage of heat

18-BC85D1-2 15

Page 16

GAF2 Air Handler

Hook-up Diagram

Heat Pump

W1 White

Green

Comfort Control

White

Green

Yellow

Orange

Red

Blue

W

G

Y

O

R

B

White

Green

Yellow

Orange

Red

Blue

Field wiring

GAF2-36M Air Handler

Hook-up Diagram

Red

Blue

Air Handler

R - Red

B - Blue

Y - Yellow

Orange

Black

(X2)

Red

Yellow

Blue

White

Green

Red

Blue

Yellow YI

Comfort Control

White

W

Green

G

Yellow

Y

Orange

O

Red

R

Blue

B

Field wiring

16 18-BC85D1-2

Orange

Purple YO

Heat Pump

Air Handler

• YI and YO connections must be made as shown

• Internally mounted condensate switch is optional and must be ordered separately

• If a 3rd party condensate overflow switch is installed, it should be wired between Y of the thermostat and YI of the EEV control.

Yellow

Orange

Blue

Red

Black

(X2)

Page 17

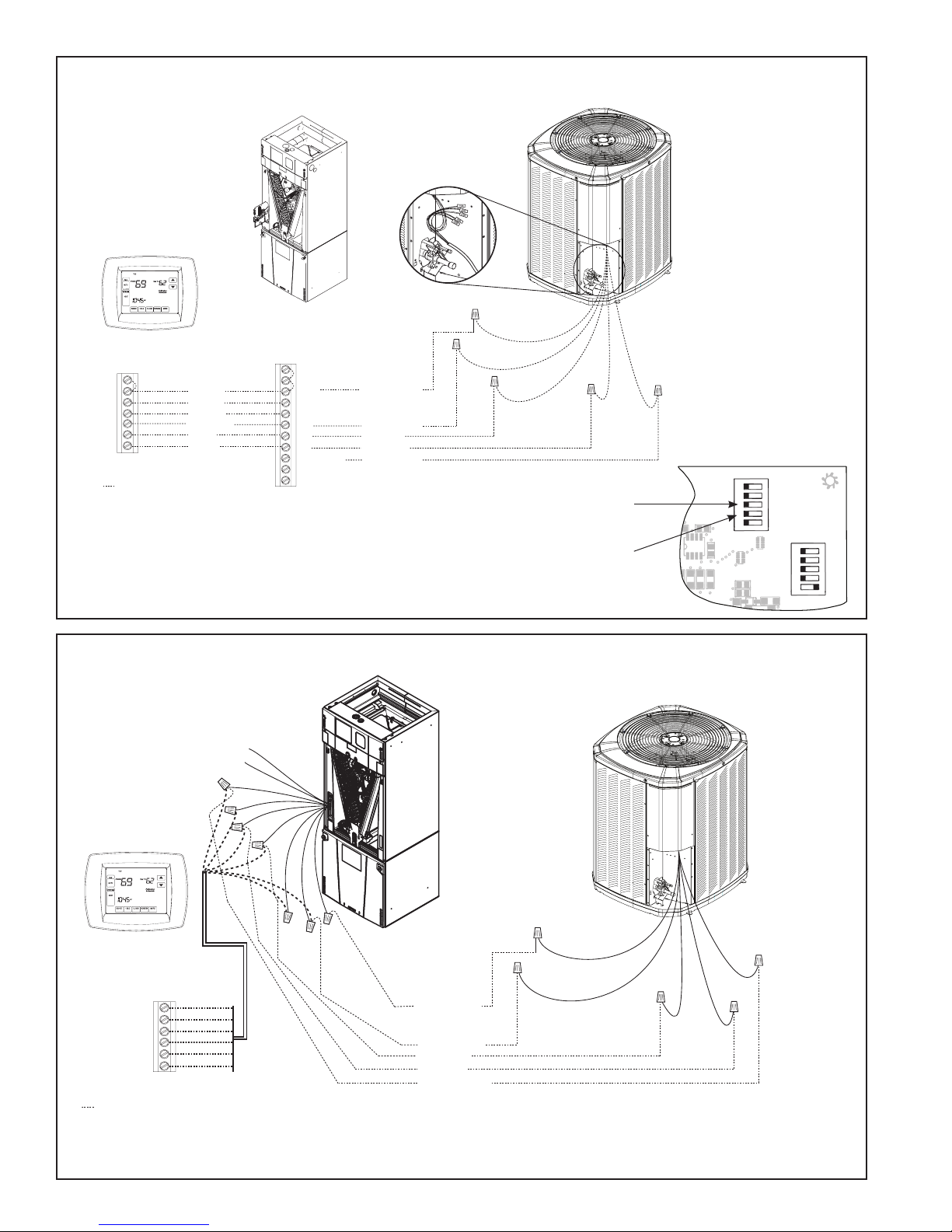

11.3 Defrost Control

Defrost controls have a selectable termination temperature. As shipped, defrost will terminate at 47°F. For a

higher termination temperature, cut Jumper J2 to achieve 70°F when at or below 30°F ambient. See Service

Facts shipped in the outdoor unit for more information.

Pin Identification (See Illustration at right)

1. TEST_COMMON (Shorting any of the other pins to this pin causes the function of the other pin to be

executed. Leaving this pin open results in the normal mode of operation.)

2. TST = Test (Shorting TEST_COMMON to this pin speeds up all defrost board timings.)

3. FRC_DFT = Forced Defrost (Short TEST_COMMON to this pin for two (2) seconds to initiate a forced

defrost. Remove the short after defrost initiates.)

Defrost Control Checkout

Normal operation requires:

• LED on board flashing 1 time/second.

• 24V AC between R & B.

• 24V AC between Y & B with unit operating.

• Defrost initiation when FRC_DFT pin is shorted to TEST_COMMON pin.

If a defrost control problem is suspected, refer to the service information in control box.

Defrost Termination Temperatures

Outdoor

Temperature

As

Shipped

Cut

Jumper 2

All < 6°F

>22°F 47°F

10°F–22°F ODT + 25°F

6°F–10°F 35°F

>30°F 47°F

6°F–30°F 70°F

Termination

Temperature

12 min. or 35°F

every 3 hrs.

Defrost Board

Detail

JUMPER 2

TEST PINS

FRC_DFT

TST

J1

J2

J3

TEST_COMMON

U1

18-BC85D1-2 17

Page 18

Section 12. Electrical - High Voltage

▲

WARNING

!

12.1 High Voltage Power Supply

LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and

troubleshooting of this product, it may be necessary to work with live electrical components.

Failure to follow all electrical safety precautions when exposed to live electrical components could result in death or serious injury.

The high voltage power supply must agree with

the equipment nameplate.

Power wiring must comply with national, state,

and local codes.

Follow instructions on unit wiring diagram located

on the inside of the control box cover and in the

Service Facts document included with the unit.

12.2 High Voltage Disconnect Switch

Install a separate disconnect switch at the

outdoor unit.

For high voltage connections, flexible electrical conduit is recommended whenever vibration transmission may create a noise problem

within the structure.

12.3 High Voltage Ground

Ground the outdoor unit per national, state, and

local code requirements.

18 18-BC85D1-2

Page 19

Section 13. Start Up

OFF

DON

E

CANCEL

ON

OFF

E

13.1 System Start Up

STEP 1 - Ensure Sections 7 through 12 have

been completed.

STEP 2 - Set System Thermostat to OFF.

STEP 3 - Turn on disconnect(s) to apply power

to the indoor and outdoor units.

STEP 4 - Wait one (1) hour before starting the

unit if compressor crankcase heater accessory is used and the Outdoor Ambient is below

70ºF.

STEP 5 - Set system thermostat to ON.

60 MIN.

ON

DON

CANCEL

18-BC85D1-2 19

Page 20

Section 14. System Charge Adjustment

14.1 Temperature Measurements

STEP 1 - Check the outdoor temperatures.

Subcooling (in cooling mode) is the only recommended method of charging above 55º F ambient outdoor temperature. See Section 14.2.

For outdoor temperatures below 55º F, see Section 14.3.

Note: It is important to return in the spring or

summer to accurately charge the system in the

cooling mode when outdoor ambient temperature is above 55º F.

See Section 14.2 for

Outdoor

Temperatures

Above 55º F

See Section 14.3 for

Outdoor

Temperatures

Below 55º F

120º F

55º F

Outdoor Temp 1

55º F

Outdoor Temp 2

For best results the indoor temperature should

be kept between 70º F to 80º F.

14.2 Subcooling Charging in Cooling (Above 55º F Outdoor Temp.)

STEP 1 - Use the refrigerant line total length

and lift measurements from Section 5.3.

Total Line Length = __________ Ft.

Vertical Change (Lift) = __________ Ft.

80º F

70º F

Indoor Temp

LIFT

20 18-BC85D1-2

Page 21

STEP 2 -

Determine the final subcooling value using total Line Length and Lift measured in STEP 1 and the charts below.

1 1/2 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Use Design Subcool Value

Add 1° of Subcooling

Add 3°

Add 2°

2 1/2 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Use Design Subcool Value

Add 2° of Subcooling

Add 1° of Subcooling

Add 4°

Add 3°

3 1/2 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Add 1° of Subcooling

Use Design Subcool Value

Add 3° of Subcooling

Add 2° of Subcooling

Add 6°

Add 5°

2 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Use Design Subcool Value

Add 1° of Subcooling

Add 4°

Add 2°

3 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Use Design Subcool Value

Add 3° of Subcooling

Add 1° of Subcooling

Add 5°

Add 4°

Add 2°

4 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Add 1° of Subcooling

Use Design Subcool Value

Add 4° of Subcooling

Add 3° of Subcooling

Add 2° of Subcooling

Add 6°

5 Ton Heat Pump

SUBCOOL CHARGING CHART CORRECTIONS TABLE (FOR LINE LENGTH AND RISE)

60

50

40

30

25

20

15

10

Design

0

REFRIGERANT LINE LIFT (FEET)

10 20 25 30 40 60

TOTAL REFRIGERANT LINE LENGTH (FEET)

Add 2° of Subcooling

Add 1° of Subcooling

Add 5° of Subcooling

Add 4° of Subcooling

Add 3° of Subcooling

Add 6°

STEP 3 - Stabilize the system by operating for a

minimum of 20 minutes.

At startup, or whenever charge is removed or

added, the system must be operated for a minimum of 20 minutes to stabilize before accurate

measurements can be made.

Design Subcooling Value = __________º F

(from nameplate or Service Facts)

Subcooling Correction = __________º F

Final Subcooling Value = __________º F

20 MIN.

18-BC85D1-2 21

Page 22

3

STEP 4 - Measure the liquid line temperature

and pressure at the outdoor unit’s service valve.

Measured Liquid Line Temp = __________ º F

Liquid Gage Pressure = __________ PSI

Final Subcooling Value = __________ º F

STEP 5 - Use the final subcooling value, refrigerant temperature and pressure from STEP 4, to

determine the proper liquid gage pressure using

Table 14.2.

Example: Assume a 12º F Final Subcooling

value and liquid temp of 90º F.

1. Locate 12º F Final Subcooling in Table 14.2.

2. Locate the Liquid Temperarature (90º F) in

the left column.

3. The Liquid Gage Pressure should be approximately 327 PSIG. (This is the shown as

the intersection of the Final Subcooling column

and the Liquid Temperature row.

Table 14.2

R-410A REFRIGERANT CHARGING CHART

LIQUID

TEMP

F)

(

°

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

FINAL SUBCOOLING (

8910 11 12 13 14

LIQUID GAGE PRESSURE (PSI)

179 182 185 188 191 195 198

195 198 201 204 208 211 215

211 215 218 222 225 229 232

229 232 236 240 243 247 251

247 251 255 259 263 267 271

267 271 275 279 283 287 291

287 291 296 300 304 309 313

309 313 318 322 327 331 336

331 336 341 346 351 355 360

355 360 365 370 376 381 386

381 386 391 396 402 407 413

407 413 418 424 429 435 441

435 441 446 452 458 464 470

464 470 476 482 488 495 501

495 501 507 514 520 527 533

From Dwg. D154557P01 Rev.

107 °F

F)

°

22 18-BC85D1-2

Page 23

Cooling

42

Heating

PRESSURE TABLES FOR 4TWB30**

*AM4A0****** Air Handler

STEP 6 - Adjust refrigerant level to attain

proper gage pressure.

Add refrigerant if the Liquid Gage Pressure

is lower than the chart value.

1. Connect gages to refrigerant bottle

and unit as illustrated.

2. Purge all hoses.

3. Open bottle.

4. Stop adding refrigerant when liquid

line temperature and Liquid Gage

Pressure matches the charging chart

Final Subcooling value.

Recover refrigerant if the Liquid Gage Pressure is higher than the chart value.

STEP 7 - Stabilize the system.

1. Wait 20 minutes for the system condition to stabilize between adjustments.

Note: When the Liquid Line Temperature and

Gage Pressure approximately match the chart,

the system is properly charged.

2. Remove gages.

3. Replace service port caps to prevent

leaks. Tighten finger tight plus an additional 1/6 turn.

STEP 8 - Verify typical performance.

Refer to System Pressure Tables in the Service

Facts to verify typical performance.

20 MIN.

(Example only - see Service Facts)

Outdoor Size & AH

OD ** 18 24 30 36

AH****** A18S11 A24S21 A30S21 A36S31 B42S31 C48S41 C60S51

Discharge Pressure (PSIG)

115 510 490 515 515 540

110 480 460 485 485 510

105 450 435 455 455 480

100 425 405 425 425 450

95 390 375 395 395 420

90 1

365 350

85 340 325 335 335 365

80 315 305 320 320 345

75 290 285 300 300 320

70 275 265 280 280 300

65 255 245 260 260 280

Outdoor Temperature (Degree F)

60 235 225 225 225 260

Outdoor Size & AH

OD ** 18 24 30 36

AH****** A18S11 A24S21 A30S21 A36S31 B42S31 C48S41 C60S51

Outdoor

Indoor Wet

Temp.

Bulb

(Degree F)

(Degree F)

110

100

90 1

80

70

60

OUTDOOR TEMPERATURE (Degree F)

Suction Pressure (PSIG)

71 154 153 154 155 154

67 146 146 147 148 146

63 138 139 139 140 137

59 131 132 133 134 130

71 149 148 150 151 150

67 141 141 143 144 142

63 134 134 136 137 134

59 127 128 129 131 126

71 145 144 147 148 146

67 2

137 137

63 130 131 133 134 131

59 123 124 127 127 123

71 141 141 144 146 144

67 134 134 137 139 136

63 127 128 131 132 128

59 120 122 124 125 121

71 138 138 141 143 141

67 131 131 134 136 133

63 124 125 128 129 126

59 117 119 122 123 118

71 135 135 139 141 138

67 128 128 132 134 131

63 121 122 125 127 123

59 114 116 119 121 116

42 3

48 60

370 4

370 390

3

48 60

139 4

141 138

65

55

45

35

25

15

Outdoor Temperature (Degree F)

5

-5

(Degree F)

Outdoor Temperature

Outdoor Size & AH

OD ** 18 24 30 36 42 48 60

AH****** A18S11 A24S21 A30S21 A36S31 B42S31 C48S41 C60S51

Indoor

Entering

(Deg.F)

Discharge Pressure (PSIG)

80 480 485 435 445 445

70 440 445 395 405 405

60 400 405 355 365 365

80 455 460 410 420 415

70 415 420 370 385 380

60 375 380 335 345 345

80 430 435 390 395 395

70 390 390 350 360 355

60 350 355 315 325 320

80 415 420 375 380 380

70 370 375 335 345 340

60 335 335 295 305 305

80 390 390 355 365 355

70 350 350 315 325 320

60 310 310 280 285 285

80 370 370 335 345 335

70 330 330 295 305 300

60 290 290 265 270 265

80 350 350 320 325 320

70 310 310 275 285 280

60 270 270 245 255 245

80 335 335 300 315 305

70 290 290 265 275 265

60 255 255 225 235 230

Outdoor Size & AH

OD ** 18 24 30 36 42 48 60

AH****** A18S11 A24S21 A30S21 A36S31 B42S31 C48S41 C60S51

Suction Pressure (PSIG)

65 142 150 138 142 134

55 120 127 116 120 114

45 100 105 96 98 94

35 83 89 82 83 81

25 69 74 67 68 66

15 56 60 53 55 53

5 44 49 42 44 42

-5 35 40 32 35 33

18-BC85D1-2 23

Page 24

STEP 9 - Record System Information for reference.

Record system pressures and temperatures

after charging is complete.

Outdoor model number = _________________

Measured Outdoor Ambient = __________ º F

Measured Indoor Ambient = __________ º F

Measured Suction Line Temp = __________ º F

Liquid Gage Pressure = __________ PSIG

Suction Gage Pressure = __________ PSIG

Measured Liquid Line Temp = __________ º F

14.3 Subcooling Charging Below 55º F Outdoor Temp. (In Heating Only)

The Subcooling Charging method in cooling is

not recommended below 55º F outdoor tem-

perature.

The only recommended method of charging at

outdoor temperatures below 55º F is weighing

in the charge in heating mode.

STEP 1 - Determine additional charge.

From the nameplate label (shown in Section

12.1), record namplate charge below.

Note: The nameplate charge value represents

the amount of refrigerant shipped in the outdoor

unit and is compatible with 15 feet of AHRI rated

Tonnage

refrigerant lines and the smallest AHRI rated

coil.

1.5 – 2 Ton 5/8" 3/8" 3 oz 8 oz 14 oz 20 oz 25 oz

Table 14.3

TUBING INFORMATION

LINE TYPE

Suction

Line

Liquid

20 ft 30 ft 40 ft 50 ft 60 ft

Line

REFRIGERANT TO ADD AT

SPECIFIED ADDITIONAL

LENGTH

Using Table 14.3, find the charge associated

with the additional length of tubing above 15 ft.

and record it below.

Namplate charge = ____________ Oz.

Charge adder = ______________ Oz.

(from Table 14.2)

24 18-BC85D1-2

2.5 – 3.5 Ton 3/4" 3/8" 3 oz 9 oz 15 oz 21 oz 27 oz

4 – 5 Ton 7/8" 3/8" 3 oz 9 oz 16 oz 22 oz 28 oz

Page 25

STEP 2 - Stabilize the system by operating for a

minimum of 20 minutes.

At startup, or whenever charge is removed or

added, the system must be operated for a minimum of 20 minutes to stabilize before accurate

measurements can be made.

STEP 3 - Check the liquid line temperature and

liquid gage pressure to obtain a minimum of 10º

subcooling in heating mode.

Measured Liquid Line Temp = __________ º F

Liquid Gage Pressure = __________ PSIG

STEP 4 - Add charge if a minimum of 10º subcooling is not obtained with the namplate charge

plus additional charge previously added.

20 MIN.

STEP 5 - Return to site for adjustment.

Important: Return in the spring or summer to

accurately charge the system in the cooling

mode with outdoor ambient above 55º F.

18-BC85D1-2 25

Page 26

Section 15. Checkout Procedures and Troubleshooting

15.1 Operational And Checkout Procedures

Final phases of this installation are the unit Operational and Checkout Procedures. To obtain proper performance, all units

must be operated and charge adjustments made.

Important: Perform a final unit inspection to be sure that factory tubing has not shifted during shipment. Adjust tubing if necessary so tubes do not rub against each other when the unit runs. Also be sure that wiring connections are tight and properly

secured.

CHECKOUT PROCEDURE

After installation has been completed, it is recommended that the entire system be checked against the following list:

1. Leak check refrigerant lines. ........................................ [ ]

2. Properly insulate suction lines and fittings. ................... [ ]

3. Properly secure and isolate all refrigerant lines. ........... [ ]

4. Seal passages through masonry.

If mortar is used, prevent mortar from coming

into direct contact with copper tubing. .......................... [ ]

5. Verify that all electrical connections are tight. ............... [ ]

6. Observe outdoor fan during on cycle for clearance

and smooth operation. .................................................. [ ]

7. Be sure that indoor coil drain line drains freely. Pour water

into drain pan. ............................................................... [ ]

8. Be sure that supply registers and return grilles are open

and unobstructed. ......................................................... [ ]

9. Be sure that a return air filter is installed. ..................... [ ]

10. Be sure that the correct airflow setting is used.

(Indoor blower motor) ................................................... [ ]

11. Operate complete system in each mode to

ensure safe operation. .................................................. [ ]

26 18-BC85D1-2

Page 27

PP

15.2 Troubleshooting

WHAT TO CHEC K MOD E

SYSTEM FAULTS

REFRIGERANT CIRCUIT

Head Pressure To o High

Head Pressure To o Low

Suction Pressure To o High

Suction Pressure To o Low

Liquid Refrig. Floodback (TXV/EEV)

Liquid Refrig. Floodback

(Cap. Tube)

I.D. Coil Frosting

Compressor Runs

Inadequate or No Cooling/Htg

ELECTRICAL

Compressor & O.D. Fan

Won’t Start

Compressor Will Not Start

But O.D. Fan Runs

O.D. Fan Won’t Start

Compressor Hums But Won’t Start

Compressor Cycles on IOL

I.D. Blower Won’t Start

DEFROST

Unit Won’t Initiate Defrost

Defrost Te rminates on Time

Unit Icing Up

HIG H VOLTAGE WIRING

COM PRE SSOR IOL

POWE R SUPPLY

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

H

P

P

P

P

START CA PAC ITOR

RUN C APACITOR

P

P

P

S

P

S

P

P

P

S

P

S

P

P

CON TROL TRA NSFO RME R

CON TAC TOR CONTACTS

LOW VOLTAGE WIR ING

START RE LAY

S

S

P

S

S

P

P

P

S

S

P

S

S

P

S

S

P

S

S

P

REF. UNDER CHA RGE

INE FFI CIEN T COMP.

P

P

P

P

P

P

P

S

S

EXC ESS IVE E VAP. LOAD

REF. OVERCH ARGE

S

S

S

S

S

S

S

S

STU CK COMPR ESSOR

LOW VOLTAGE FUSE

CON TAC TOR COIL

THE RMO STAT

S

P

S

PPP

S

P

S

S

S

S

S

S

S

S

S

S

P

S

S

P

S

NON CON DENS ABL ES

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

O.D. AIR R ECIRCUL AT ION

TXV /EE V STU CK OP EN

RES. O.D. A IRFLOW

P

S

P

S

P

S

S

S

S

S

P

S

S

S

S

S

S

S

C - Cooling H - Heating P - Primary Causes S - Secondary Causes * - 3 Phase Only

REF. CIR. RES TRI CTIONS

RES. I.D. AIRFLOW

SUP ERH EAT

S

S

S

S

P

P

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

CHE CK VALVE LEA KING

*

SOV COIL D EFEC TIV E

SOV LEAKI NG

S

P

S

S

S

P

S

S

P

P

S

P

S

P

S

DEF ROST CONTROL DEF.

DEF ROST RELAY DEF.

S

S

S

P

P

S

S

S

S

S

S

S

P

P

P

P

P

P

P

S

S

P

P

18-BC85D1-2 27

Page 28

28 18-BC85D1-2

The manufacturer has a policy of continuous product and product data improvement

and it reserves the right to change design and specifications without notice.

Representative-only illustrations included in this document.

© 2013 Trane 04/13

Loading...

Loading...