Trane 4TVW0007B100NB, 4TVW0009B100NB, 4TVW0012B100NB, 4TVW0018B100NB, 4TVW0020B100NB Installation and Maintenance Manual

...

Installation, Operation,

and Maintenance

Variable Refrigerant Flow System

High-Wall Indoor Unit Series

Models: 4TVW0007B100NB, 4TVW0009B100NB, 4TVW0012B100NB,

4TVW0018B100NB, 4TVW0020B100NB, 4TVW0024B100NB

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

February 2013 VRF-SVX30A-EN

Introduction

Read this manual thoroughly before operating or servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

CAUTIONs

NOTICE

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and Carbon

(HCFCs). Not all refrigerants containing these compounds

have the same potential impact to the environment. Trane

advocates the responsible handling of all refrigerantsincluding industry replacements for CFCs such as HCFCs

and HFCs.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants

and the equipment that is used in these service procedures.

In addition, some states or municipalities may have

additional requirements that must also be adhered to for

responsible management of refrigerants. Know the

applicable laws and follow them.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only.

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE recommended for the work

being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection, and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put

on all PPE in accordance with NFPA 70E or other

country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

Copyright

This document and the information in it are the property of

Trane and may not be used or reproduced in whole or in

part, without the written permission of Trane. Trane

reserves the right to revise this publication at any time and

to make changes to its content without obligation to notify

any person of such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

© 2013 Trane All rights reserved VRF-SVX30A-EN

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings, Cautions, and Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Purging the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Leak Testing Pipe Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Drain System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Refrigerant Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Drainage Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electronic Expansion Valve (EEV) Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using the VRF Wireless Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

The 2-Digit Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuration Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mode 2: Option Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mode 5: Option Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mode A: Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mode d: Specific Digit Changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Internal Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operating Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operating Mode for Heat Pump Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Periodic Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

VRF-SVX30A-EN 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Warranty For Trane Advantage™ VRF Systems and Related Accessories . . . 35

Basic Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Exclusions and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4 VRF-SVX30A-EN

Model Number Description

4TVD0018A100NA

1234567891011121314

Digit 1: Refrigerant

4 = R410A

Digit 2: Brand name

T = Trane

Digit 3: System type

V = Variable Refrigerant Flow

Digit 4: Configuration Type (also see separate tab)

B = mini 4-way cassette L = Slim duct type (low pressure)

C = 4-way cassette A = HSP duct type high pressure)

D = MSP duct type (mid-pressure) X = Ceiling

E = 1-way cassette W = High-wall

Digit 5: Reserved for future use

0 = Not currently used

Digit 6, 7, 8: Nominal capacity (Btu/h x 1,000)

006 = 6,00 0 Btu/h

007 = 7,000 Btu/h 024 = 24,000 Btu/h 068 = 68,000 Btu/h

009 = 9,00 0 Btu/h 030 = 30,000 Btu/h

012 = 12,000 Btu/h 036 = 36,000 Btu/h 096 = 96,000 Btu/h

018 = 18,000 Btu/h

020 = 20,000 Btu/h

048 = 48,000 Btu/h

060 = 60,000 Btu/h

076 = 76,000 Btu/h

Digit 9: Major development sequence

B = Second development sequence

Digit 10: Electric power supply characteristics

1 = 220/60/1

B = 220–240/50/1

Digit 11: Reserved for future use

0 = Not currently used

Digit 12: Controller

0 = None

R = Remote control standard

W = Wired control standard

Digit 13: Region of sale

N = North America (UL or ETL)

Digit 14: Minor design sequence

A = First design sequence

B = Second design sequence

VRF-SVX30A-EN 5

Preparing for Installation

Preparing for Installation

Accessories

In addition to product literature, the following accessories are supplied with this unit. The type and

quantity may differ, depending on the model.

Installation plate

Location Considerations

When deciding on a location for the indoor unit, the following factors must be considered:

• The air inlet and outlet must be unobstructed.

• The wall or ceiling must support the weight of the unit.

• The wall or ceiling must not be subject to vibration.

• Pre-plan for easy and short routing of the refrigerant tubing and wiring to the outdoor unit.

• The air must circulate freely in the area to be cooled/heated.

• Sufficient clearance must be maintained around the unit.

• Condensate must be managed correctly and safety away from the unit.

• The unit should be installed in a way that prevents unauthorized access.

• The unit must not be installed in an area that is damp or could come into contact with water

(such as a laundry room).

• The unit must not be exposed to direct sunshine or to other direct heat sources.

• The filter must be able to be removed and cleaned easily.

• The unit should be placed as far as possible from fluorescent lights so the remote control is not

subject to interference.

• Care should be taken to prevent harmonics generated by loose or unsupported material in close

proximity to a running unit.

• The unit must not be installed in an area that is exposed to salt, machine oil, sulfide gas, or

corrosive environmental conditions.

6 VRF-SVX30A-EN

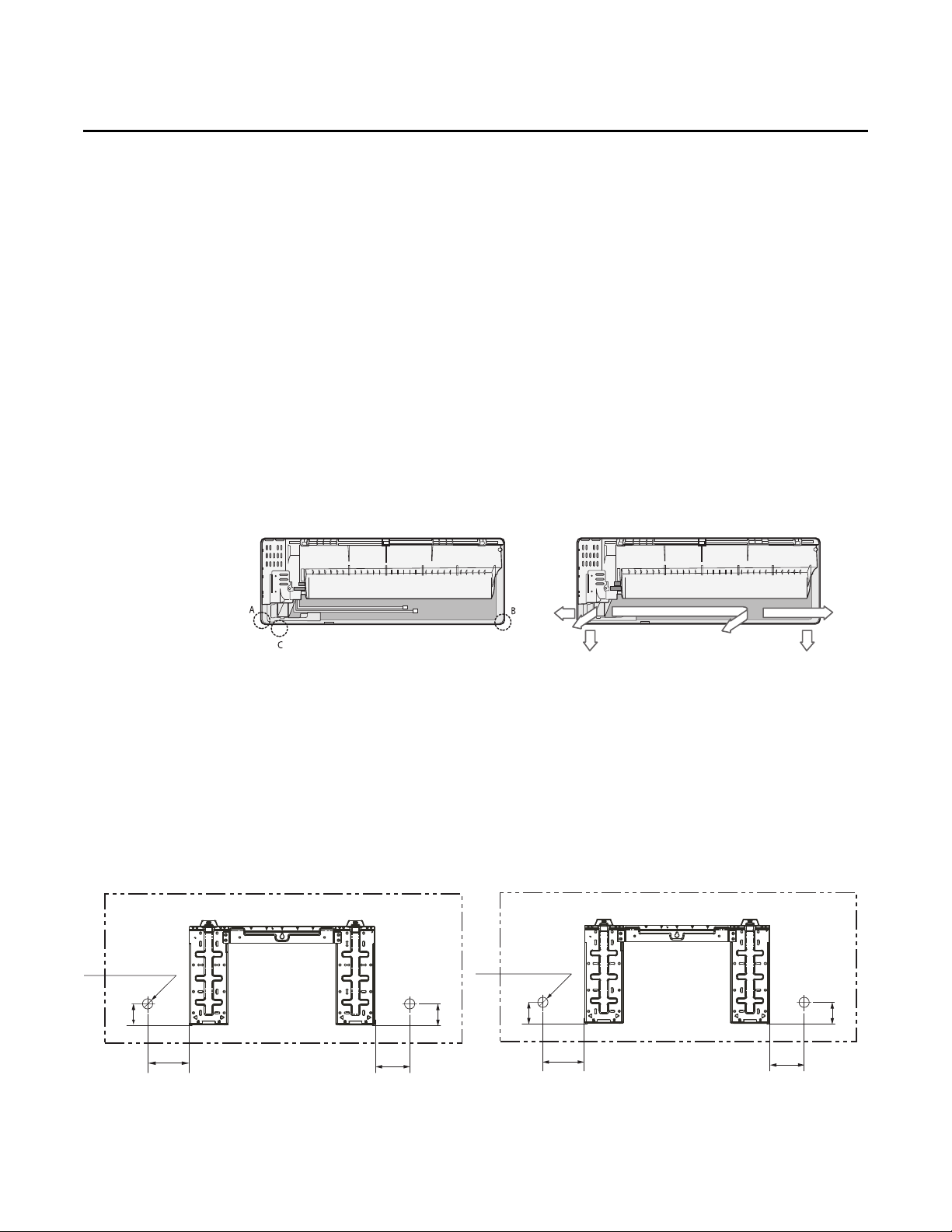

Service Clearances

11.81 in. (300 mm)

4.9 in. (125 mm)

4.9 in. (125 mm)

Preparing for Installation

VRF-SVX30A-EN 7

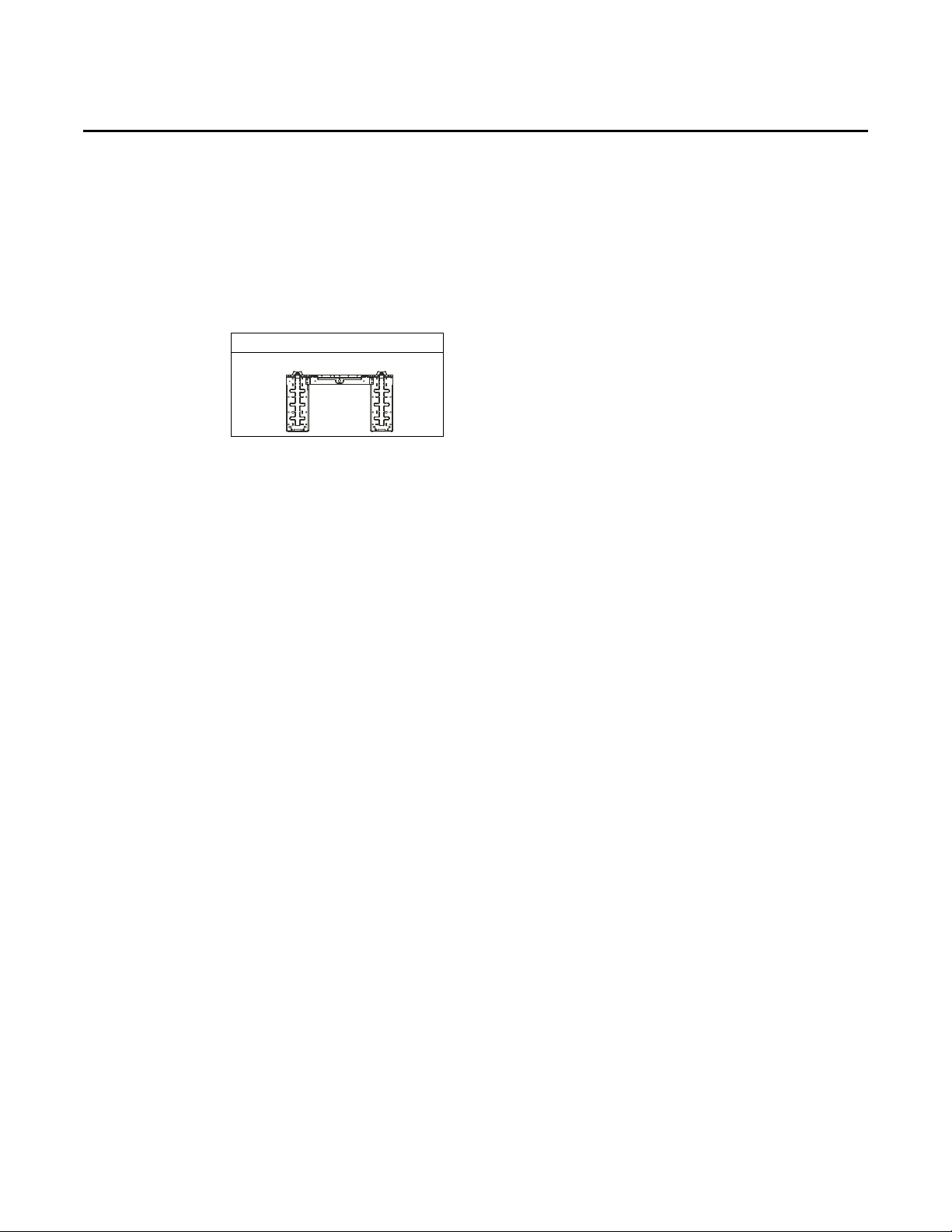

Installation

5.51

(140)

2.56 (65)

1.34 (34)

1.34 (34)

2.68

(68)

Pipe hole:

Pipe hole:

4.72

(120)

1.06 (27)

1.06 (27)

2.68

(68)

2.56 (65)

Pipe hole:

4TVW0007B100NB

4TVW0009B100NB

4TVW0012B100NB

4TVW0018B100NB

4TVW0020B100NB

4TVW0024B100NB

Installation

Review “Installation Considerations” before proceeding with installation.

Follow the procedures in these sections in the order given.

Notes:

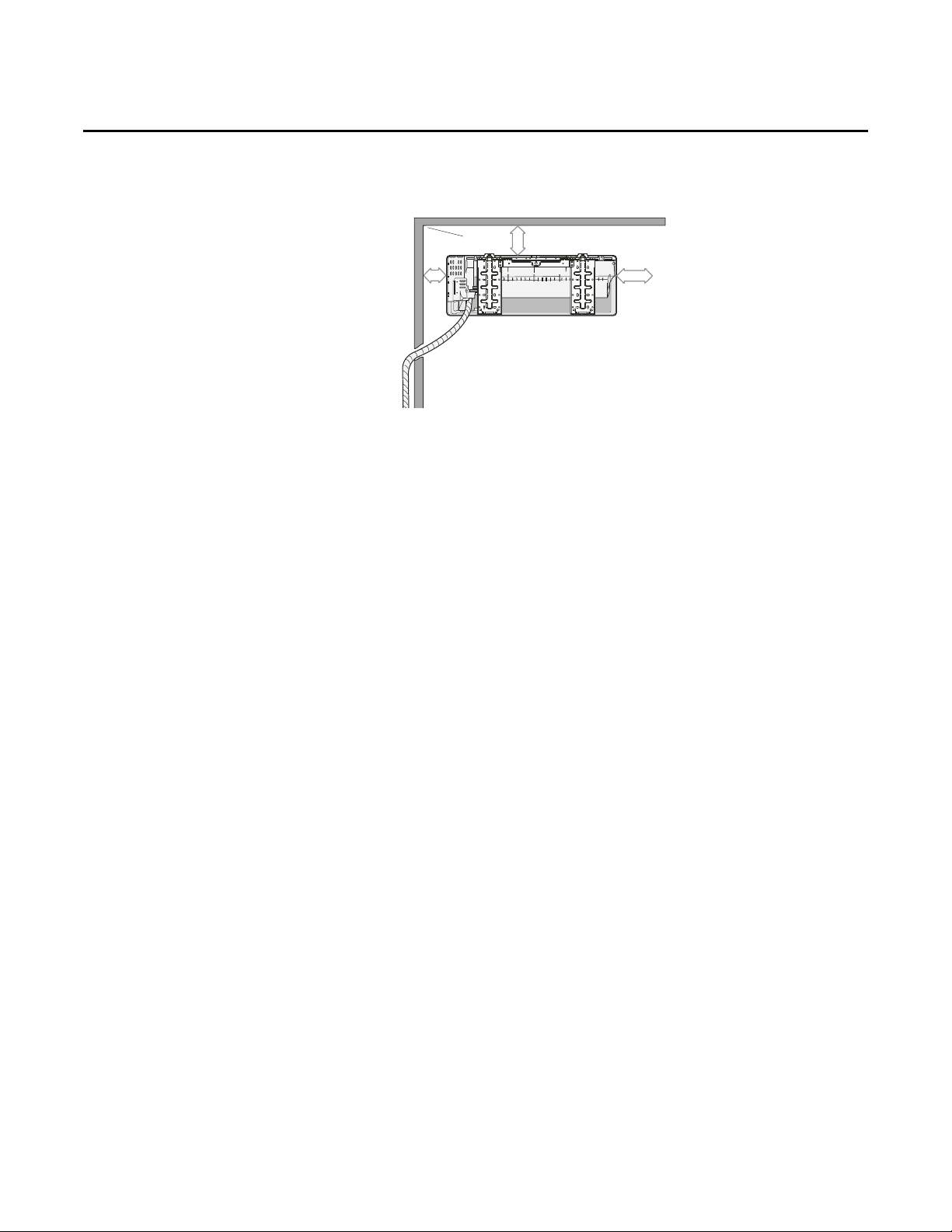

Mounting the Unit

The wiring, piping, and drain hose can be connected to run from the indoor unit in one of the

following directions:

•Right (A)

• Left (B)

• Underside (C)

• Rear (right or left)

• Install the Y-joint before installing the indoor unit.

• Install an electronic expansion valve (EEV) on this unit. Refer to the EEV Kit installation

guide (VRF-SVN43) for information.

1. Determine the position of the piping and drain hose and drill a 2.56 in. (65 mm) hole that slants

slightly upward.

2. Attach the installation plate to a wall or a window frame, considering the weight of the unit.

Refer to the following dimensional diagrams.

• If you are mounting the installation plate to a concrete wall, use anchor bolts making sure

they do not project more than 0.8 in. (20 mm).

• For an existing structure, attach the installation plate to wall studs or take other necessary

precautions for supporting the unit.

• For mounting on a window frame, install wood mounting supports for the unit. Attach the

installation plate to the wooden uprights using tapping screws.

3. Install the unit on the plate.

8 VRF-SVX30A-EN

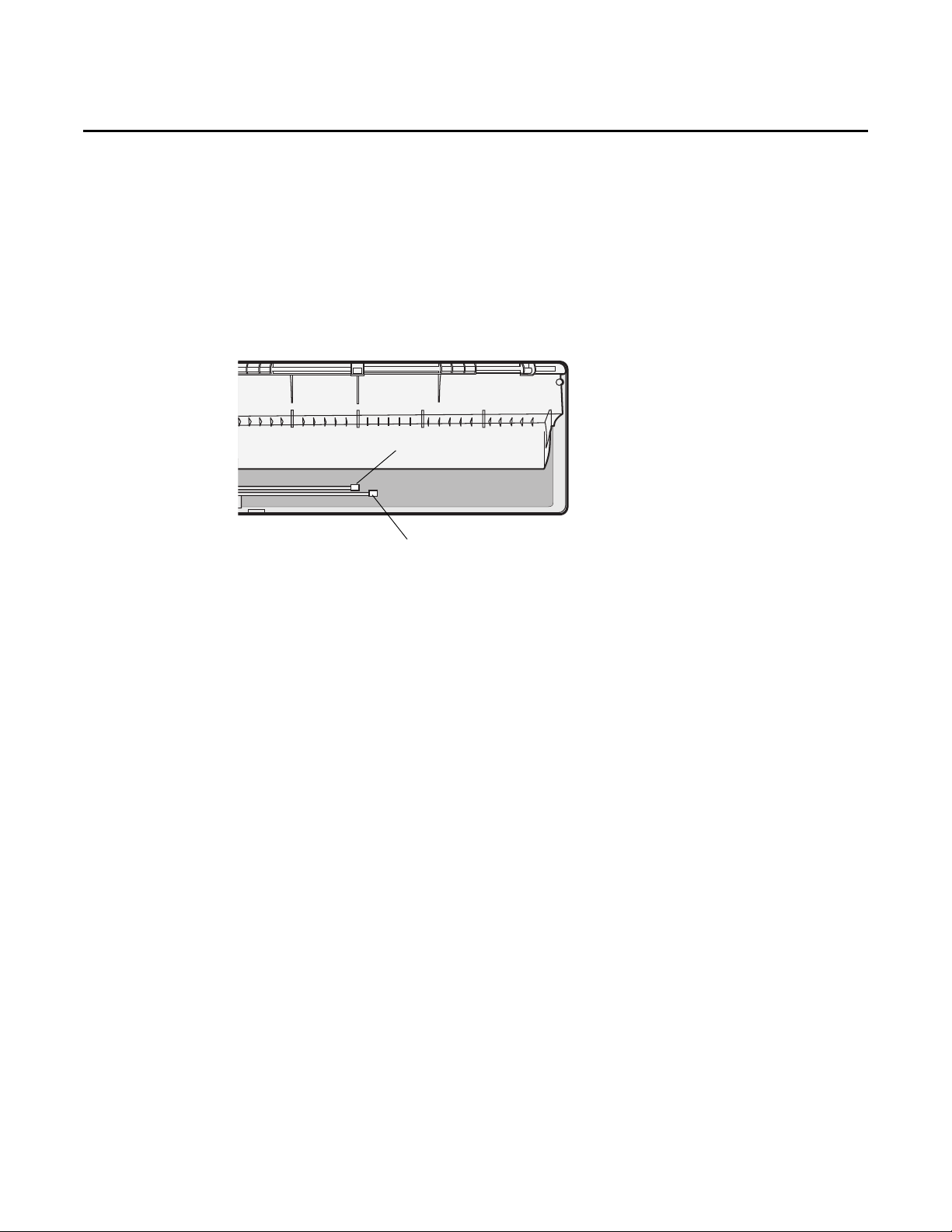

Purging the Unit

Liquid refrigerant port

Gas refrigerant port

The unit is shipped from the factory with a holding charge of nitrogen. All of this gas must be

purged from the unit.

To purge the unit, remove the caps from the ends of both gas and liquid refrigerant pipes. Make

sure all gas has escaped before connecting the piping.

Note: To prevent dirt or foreign objects from getting into the pipes during installation, do not

Installation

remove the caps completely until you are ready to connect the piping.

VRF-SVX30A-EN 9

Installation

Correct: 90º

Oblique

Rough

Burr

Length of pipe extending above flare bar

Pipe

Flaring

bar

Installing Refrigerant Piping

Connect field-supplied piping using flared connections (not supplied) or by brazing. The large unit

port is for gas refrigerant; the small one is for liquid refrigerant.

Cut or extend field-supplied piping as needed. Use the following procedures.

System Failure!

If brazing is used for pipe connections, a nitrogen purge is required to prevent the formation of

copper oxides inside the piping. Failure to follow this procedure could damage the system.

• Before connecting the pipes, make sure they are free of dirt and debris.

• Use insulated, unwelded, degreased, and deoxidized copper pipe (Cu-DHP type according to

ISO 1337 or UNI EN 12735-1) suitable for an operating pressure of at least 609.15 psi (4200 kPa)

and a burst pressure of at least 3002.28 psi (20,700 kPa). Copper pipe for hydro-sanitary

applications is unsuitable.

• For sizing and limits (height difference, line length, maximum bends, refrigerant charge, and

so on) see the outdoor unit installation manual.

• All refrigerant connections must be accessible for servicing and maintenance.

Pipe Cutting

Required tools:

•Pipe cutter

•Reamer

• Pipe holder

1. Using a pipe cutter, cut the pipe so that the cut edge is at 90° to the side of the pipe.

2. Use a reamer to remove all burrs at the cut edge.

See examples of correctly and incorrectly cut pipes.

NOTICE

Flared Pipe Connections

Clutch type and wing nut type flare tools are available for flared pipe connections.

1. Slide the flare nut over the pipe to be flared.

2. Slide the end of the pipe into the hole on the flaring bar that fits the pipe, leaving a length of

pipe, determined by tool type (see table), extending above the flaring bar. Clamp it down.

10 VRF-SVX30A-EN

Installation

Yoke

Flaring bar

Copper pipe

Flare nut

Inclined

Damaged

surface

Uneven

thickness

Correct

Cracked

R.016–.031

45°±2°

90°±2°

R-410A clutch type

Clutch type Wing nut type

Conventional flare tool

0–0.020 in. 0.04–0.06 in. 0.06–0.08 in.

3. Attach the yoke to the flaring bar, centering the conical part over the end of the pipe that is

extending above the flaring bar.

4. Tighten the yoke securely to flare the end of the pipe.

5. Remove the pipe. The end of the pipe that you flared should look like the end of a trumpet. See

examples of correctly and incorrectly flared pipes.

6. Align the pipes and tighten the flare nuts manually and then with a spanner torque wrench,

applying the torque according to pipe dimensions:

Flare

Outer diameter

(in. [mm])

1/4 (6.35) 10.3–13.3 ft·lb 0.34–0.36

3/8 (9.52) 25.1–31.0 ft·lb 0.50–0.52

1/2 (12.70) 36.1–45.0 ft·lb 0.64–0.65

5/8 (15.88) 50.2–60.5 ft·lb 0.76–0.78

VRF-SVX30A-EN 11

Connection

torque (ft·lb)

dimension

(in.)

Flare shape (in.)

Installation

Leak Testing Pipe Connections

Confined Space Hazards!

Do not work in confined spaces where refrigerant or other hazardous, toxic or flammable gas

may be leaking. Refrigerant or other gases could displace available oxygen to breathe, causing

possible asphyxiation or other serious health risks. Some gases may be flammable and or

explosive. If a leak in such spaces is detected, evacuate the area immediately and contact the

proper rescue or response authority. Failure to take appropriate precautions or to react properly

to such potential hazards could result in death or serious injury.

Explosion Hazard!

Never use an open flame to detect gas leaks. It could result in an explosion. Use a leak test

solution for leak testing. Failure to follow recommended safe leak test procedures could result

in death or serious injury or equipment or property-only-damage.

Use only dry nitrogen with a pressure regulator for pressurizing unit. Do not use acetylene,

oxygen or compressed air or mixtures containing them for pressure testing. Do not use

mixtures of a hydrogen containing refrigerant and air above atmospheric pressure for pressure

testing as they may become flammable and could result in an explosion. Refrigerant, when

used as a trace gas should only be mixed with dry nitrogen for pressurizing units. Failure to

follow these recommendations could result in death or serious injury or equipment or

property-only damage.

Do not exceed unit nameplate design pressures when leak testing system. Failure to follow

these instructions could result in an explosion causing death or serious injury.

WARNI NG

WARNI NG

Notes:

• All required piping pressure tests must be completed in accordance with national and/or

local codes.

• When leak-testing refrigerant systems, observe all safety precautions.

• Leak test only one circuit at a time to minimize system exposure to potentially harmful

moisture in the air.

• Use R-410A refrigerant gas as a tracer for leak detection and use oil-pumped dry nitrogen

to develop required test pressures.

1. Close liquid line angle valve.

2. Connect R-410A refrigerant cylinder to high side charging port (at condenser or field supplied

discharge line access port). Add refrigerant to reach pressure of 12 to 15 psig.

3. Disconnect refrigerant cylinder. Connect dry nitrogen cylinder to high side charging port and

increase pressure to 150 psig. Do not exceed high side (discharge) unit nameplate design

pressure. Do not subject low side (suction) components to high side pressure.

4. Check all piping joints, valves, etc. for leaks. Recommend using electronic detector capable of

measuring 0.1 oz/year leak rate.

5. If a leak is located, use proper procedures to remove the refrigerant/nitrogen mixture, break

connections and make repairs. Retest for leaks.

6. Make sure all service valves are open.

12 VRF-SVX30A-EN

Loading...

Loading...