Page 1

Submittal

Split System Cooling

4TTX6036J1000A

NNoottee:: “Graphics in this document are for representation

only. Actual model may differ in appearance.”

TAG:______________________________

SSAAFFEETTYY WWAARRNNIINNGG

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

October 2015

4TTX6036J-SUB-1A-EN

Page 2

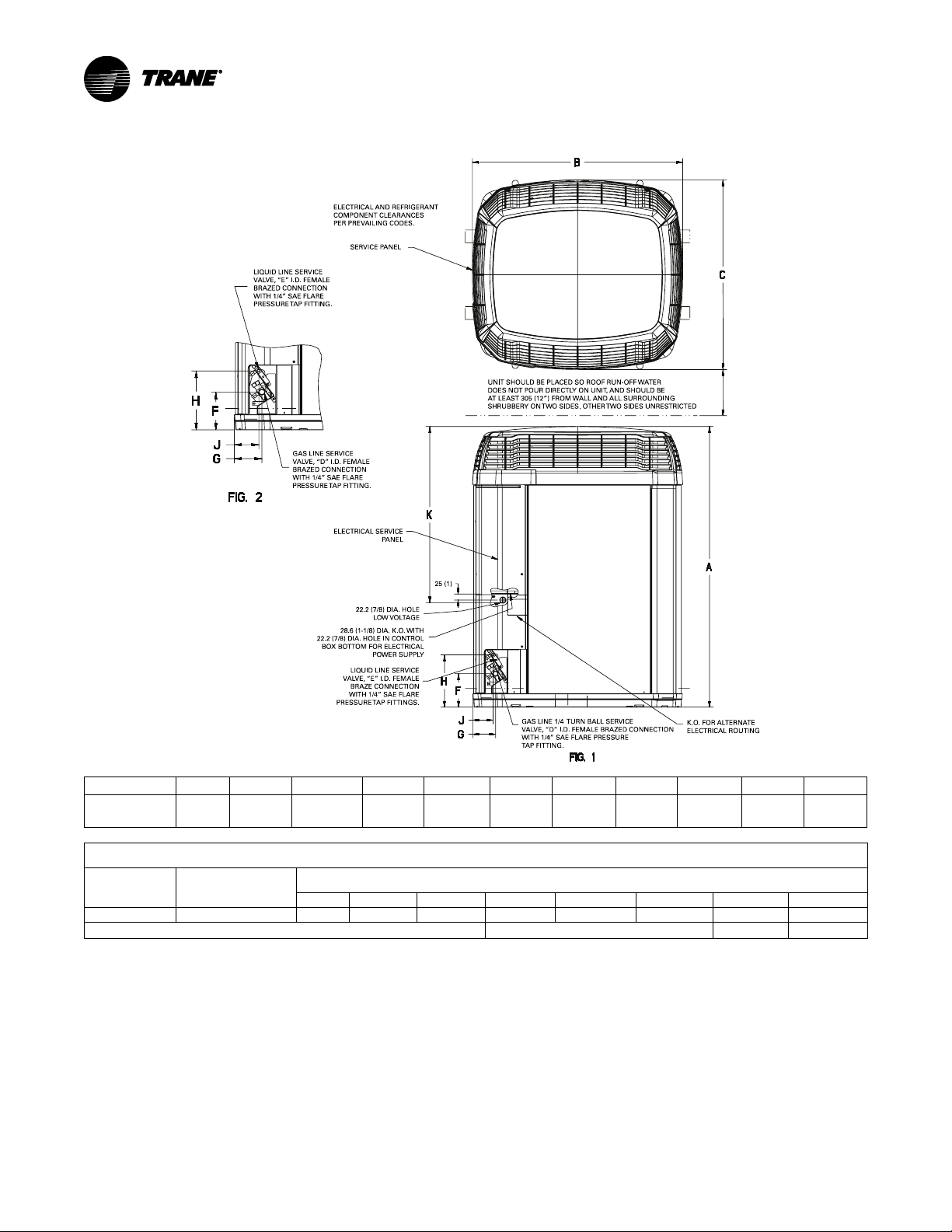

UNIT S HOULD BE PLACED SO ROOF RUN-OFF WATER

DOES NOT POUR DIRECTLY ON UNIT, AND SHOULD BE

AT LEAST 305 (12”) FRO M WALL AND ALL SURROUNDING

SHRUBBERY ON TWO SIDES. OTHER TWO SIDES UNRESTRICTED

SERVICE PANEL

ELECTRICAL AND REFRIGERANT

COMPONENT CLEARANCES

PER PREVAILING CODES.

LIQUID LINE S ERVICE

VALVE, “E” I.D. FEM ALE

BRAZED CONN ECTION

WITH 1/4” SAE FLARE

PRESSURE TAP FITTING.

GAS LINE SERVICE

VALVE, “D” I.D. FEM ALE

BRAZED CONN ECTION

WITH 1/4” SAE FLARE

PRESSURE TAP FITTING.

ELECTRICAL SERVICE

PANEL

22.2 (7/8) D IA. HOLE

LOW VOLTAGE

28.6 (1 -1/8) DIA. K.O. WITH

22.2 (7/8) D IA. HOLE IN CONTROL

BOX BOTTOM FO R ELECTRICAL

POWER S UPPLY

LIQUID LINE S ERVICE

VALVE, “E” I.D. FEM ALE

BRAZE CONN ECTION

WITH 1/4” SAE FLARE

PRESSURE TAP FITTINGS .

25 (1)

K.O. FOR ALTERNATE

ELECTRICAL ROUTING

GAS LINE 1/4 TURN BALL SERVICE

VALVE, “D” I.D. FEM ALE BRAZED CONNECTION

WITH 1/4” S AE FLARE PRESSURE

TAP FITTING.

Model Base A B C D E F G H J K

4TTX6036J 4

1165

(45–7/8)

946

(37–1/4)

870

(34–1/4)

3/4 3/8

152

(6)

98

(3–7/8)

219

(8–5/8)86(3–3/8)

730

(28–3/4)

Model

4TTX6036J 69 78 70 68 67 64 59 56 51

Note: Rated in accordance with AHRI Standard 270–2008

2

A-Weighted Sound

Power Level [dB(A)]

63 Hz* 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz

SOUND POWER LEVEL

Full Octave Sound Power [dB]

*For Reference Only

4TTX6036J-SUB-1A-EN

Page 3

Product Specifications

OUTDOOR UNIT

POWER CONNS. — V/PH/HZ

(a) (b)

4TTX6036J1000A

(c)

208/230/1/60

MIN. BRCH. CIR. AMPACITY 18

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR

CLIMATAUFF®- SCROLL

30

NO. USED — NO. STAGES 1 — 1

VOLTS/PH/HZ 208/230/1/60

R.L. AMPS

(d)

— L.R. AMPS

13.6 — 79

FACTORY INSTALLED

START COMPONENTS

(e)

INSULATION/SOUND BLANKET

NO (Uses BAYKSKT263)

NO

COMPRESSOR HEAT NO

OUTDOOR FAN PROPELLER

DIA. (IN.) — NO. USED

27.5 — 1

TYPE DRIVE — NO. SPEEDS DIRECT — 1

CFM @ 0.0 IN. W.G.

NO. MOTORS — HP

(f)

4300

1 — 1/8

MOTOR SPEED R.P.M. 850

VOLTS/PH/HZ 200/230/1/60

F.L. AMPS 0.64

OUTDOOR COIL — TYPE SPINE FIN™

ROWS — F.P.I. 1 — 24

FACE AREA (SQ. FT.)

TUBE SIZE (IN.)

24.93

3/8

REFRIGERANT

LBS. — R-410A (O.D. UNIT)

(g)

7 LBS., 11 OZ

FACTORY SUPPLIED YES

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

(h) (i)

7/8

3/8

CHARGING SPECIFICATIONS

SUBCOOLING 8°F

DIMENSIONS H X W X D

CRATED (IN.)

47.7 x 35.1 x 38.7

WEIGHT

SHIPPING (LBS.)

NET (LBS.)

255

221

(a)

Certified in accordance with the Air-Source Unitary Air-conditioner

Equipment certification program, which is based on AHRI standard

210/240.

(b)

Rated in accordance with AHRI standard 270.

(c)

Calculated in accordance with Natl. Elec. Codes. Use only HACR

circuit breakers or fuses.

(d)

This value shown for compressor RLA on the unit nameplate and on

this specification sheet is used to compute minimum branch circuit

ampacity and max. fuse size. The value shown is the branch circuit

selection current.

(e)

No means no start components. Yes means quick start kit

components. PTC means positive temperature coefficient starter.

Optional kit shown.

(f)

Standard Air — Dry Coil — Outdoor

(g)

This value approximate. For more precise value see unit nameplate.

(h)

Max. linear length 60 ft.; Max. lift — Suction 60 ft.; Max. lift — Liquid

60 ft. For greater length consult refrigerant piping software Pub. No.

32–3312–0* (* denotes latest revision).

(i)

Trane outdoor condensing units are factory charged with the system

charge required for the outdoor condensing unit and 15 feet of tested

connecting lines. If connecting line length exceeds 15 feet, then final

refrigerant charge adjustment is necessary. Each additional foot over

15 feet requires 0.6 lbs of refrigerant. See the Installer’s Guide for full

charging instructions.

4TTX6036J-SUB-1A-EN

3

Page 4

Mechanical Specification Options

GGeenneerraall

The Outdoor Units are fully charged from the factory

for up to 15 feet of piping. This unit is designed to

operate at outdoor ambient temperatures as high as

115°F. Cooling capacities are matched with a wide

selection of air handlers and furnace coils that are AHRI

certified. The unit is certified to UL 1995. Exterior is

designed for outdoor application.

CCaassiinngg

Unit casing is constructed of heavy gauge, galvanized

steel and painted with a weather-resistant powder paint

finish on all louvered panels and the fan top panel. The

corner panels are prepainted. All panels are subjected

to our 1,000 hour salt spray test . The base is made of a

CMBP-G30 weatherproof material to resist corrosion.

RReeffrriiggeerraanntt CCoonnttrroollss

Refrigeration system controls include condenser fan,

compressor contactor and high pressure switch. High

and low pressure controls are inherent to the

compressor. A factory supplied liquid line drier is

standard. Some models may require field installation.

CCoommpprreessssoorr

The compressor features internal over temperature,

pressure protection and total dipped hermetic motor.

Other features include: Centrifugal oil pump and low

vibration and noise.

CCoonnddeennsseerr CCooiill

The outdoor coil provides low airflow resistance and

efficient heat transfer. The coil is protected on all four

sides by louvered panels.

LLooww AAmmbbiieenntt CCoooolliinngg

As manufactured, this system has a cooling capacity to

55°F. The addition of an evaporator defrost control

permits operation to 40°F. The addition of an

evaporator defrost control with TXV permits low

ambient cooling to 30°F.

TThheerrmmoossttaattss—Cooling only and heat/cooling (manual

and automatic change over). Sub-base to match

thermostat and locking thermostat cover.

EEvvaappoorraattoorr DDeeffrroosstt CCoonnttrrooll — See Low Ambient

Cooling.

Trane optimizes the performance of homes and buildings around the world. A business of Ingersoll Rand, the leader in

creating and sustaining safe, comfortable and energy efficient environments, Trane offers a broad portfolio of advanced

controls and HVAC systems, comprehensive building services, and parts. For more information, visit www.Trane.com.

Trane has a policy of continuous product and product data improvements and reserves the right to change design and specifications without notice.

©2015 Trane

4TTX6036J-SUB-1A-EN

Supersedes (New)

01 Oct 2015

Loading...

Loading...