Trane 4TTR6018J1000A, 4TTR6024J1000A, 4TTR6030J1000A, 4TTR6036J1000A, 4TTR6042J1000A Product Sheet

...Page 1

Product Data

Split System Cooling

4TTR6018J1000A

4TTR6024J1000A

4TTR6030J1000A

4TTR6036J1000A

4TTR6042J1000A

4TTR6048J1000A

4TTR6049J1000A

4TTR6060J1000A

4TTR6061C1000A

August 2016

NNoottee:: “Graphics in this document are for representation

only. Actual model may differ in appearance.”

22-1916-1D-EN

Page 2

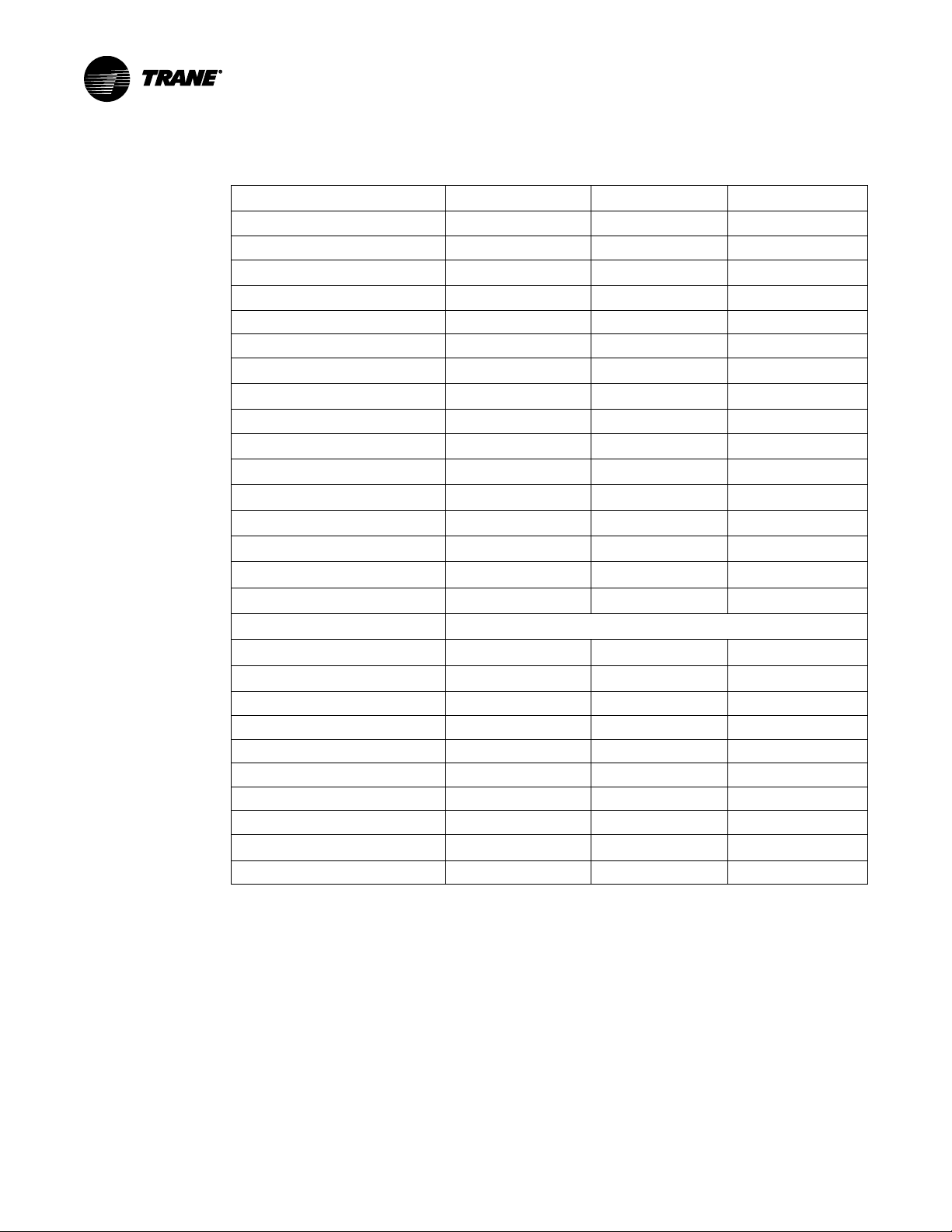

Product Specifications

Model No.

POWER CONNS. — V/PH/HZ

(a)

(b)

4TTR6018J1000A 4TTR6024J1000A 4TTR6030J1000A

208/230/1/60 208/230/1/60 208/230/1/60

MIN. BRCH. CIR. AMPACITY 12 14 17

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR

CLIMATUFF®- SCROLL CLIMATUFF®- SCROLL CLIMATUFF®- SCROLL

20 25 25

RL AMPS — LR AMPS 9 — 47.5 10.9 — 62.9 12.8 — 67.8

Outdoor Fan FL AMPS 0.64 0.64 0.64

Fan HP

Fan Dia (inches)

1/8 1/8 1/8

23.02 — 1 23.02 23.02

Coil SPINE FIN™ SPINE FIN™ SPINE FIN™

Refrigerant R-410A 4 LBS., 15 OZ 5LBS., 3 OZ 6 LBS., 7 OZ

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

Charge Spec. Subcooling

Dimensions H x W X D Crated (IN.)

Weight — Shipping (lbs.)

Weight — Net (lbs.)

(c)

3/4 3/4 3/4

3/8 3/8 3/8

8°F 8°F 8°F

34 x 30.1 x 33 34 x 30.1 x 33 42 x 30.1 x 33

189 190 220

161 162 184

Optional Accessories:

Anti-short Cycle Timer

Evaporator Defrost Control

TAYASCT501A TAYASCT501A TAYASCT501A

AY28X079 AY28X079 AY28X079

Rubber Isolator Kit BAYISLT101 BAYISLT101 BAYISLT101

Extreme Condition Mount Kit BAYECMT023 BAYECMT023 BAYECMT023

Start Kit BAYKSKT263 BAYKSKT263 BAYKSKT263

Crankcase Heater Kit BAYCCHT302 BAYCCHT302 BAYCCHT302

Seacoast Kit BAYSEAC001 BAYSEAC001 BAYSEAC001

Low Ambient Kit BAYLOAM103 BAYLOAM103 BAYLOAM103

Refrigerant Lineset

(d)

TAYREFLN7* TAYREFLN7* TAYREFLN7*

Service Valve Panel Cover TAYSVPANL0032AA TAYSVPANL0032AA TAYSVPANL0044AA

(a)

Certified in accordance with the Unitary Air-conditioner equipment certification program which is based on AHRI standard

210/240.

(b)

Calculated in accordance with N.E.C. Only use HACR circuit breakers or fuses.

(c)

Standard line lengths — 60’, Standard lift — 60’ Suction and Liquid line. For Greater lengths and lifts refer to refrigerant

piping software Pub#32–3312–0* (* denotes latest revision)..

(d)

* = 15, 20, 25, 30, 40 and 50 foot lineset available.

2

22-1916-1D-EN

Page 3

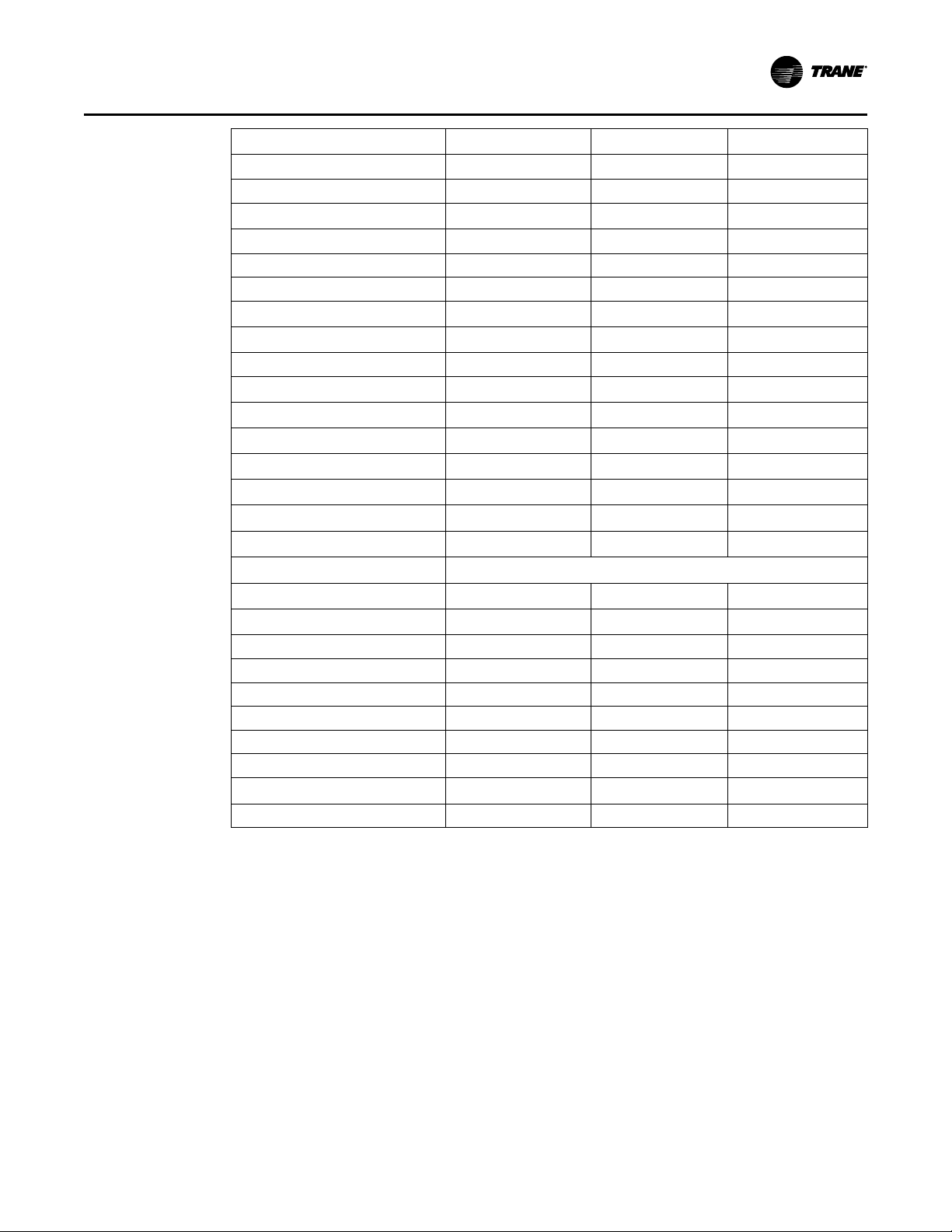

PPrroodduucctt SSppeecciiffiiccaattiioonnss

Model No.

POWER CONNS. — V/PH/HZ

(a)

(b)

4TTR6036J1000A 4TTR6042J1000A 4TTR6048J1000A

208/230/1/60 208/230/1/60 208/230/1/60

MIN. BRCH. CIR. AMPACITY 18 21 24

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR

CLIMATUFF®- SCROLL CLIMATUFF®- SCROLL CLIMATUFF®- SCROLL

30 35 40

RL AMPS — LR AMPS 13.6 — 79 16.7— 109 18.5 — 124

Outdoor Fan FL AMPS 0.77 0.64 0.93

Fan HP

Fan Dia (inches)

1/8 1/8 1/5

24 27.5 27.5

Coil SPINE FIN™ SPINE FIN™ SPINE FIN™

Refrigerant R-410A 7 LBS., 11 OZ 8 LBS., 10 OZ 8 LBS., 10 OZ

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

Charge Spec. Subcooling

Dimensions H x W X D Crated (IN.)

Weight — Shipping (lbs.)

Weight — Net (lbs.)

(c)

7/8 7/8 7/8

3/8 3/8 3/8

8°F 8°F 8°F

42 x 35.1 x 38.7 50.4 x 35.1 x 38.7 50.4 x 35.1 x 38.7

246 302 306

212 252 256

Optional Accessories:

Anti-short Cycle Timer

Evaporator Defrost Control

TAYASCT501A TAYASCT501A TAYASCT501A

AY28X079 AY28X079 AY28X079

Rubber Isolator Kit BAYISLT101 BAYISLT101 BAYISLT101

Extreme Condition Mount Kit BAYECMT004 BAYECMT004 BAYECMT004

Start Kit BAYKSKT263 BAYKSKT263 BAYKSKT263

Crankcase Heater Kit BAYCCHT302 BAYCCHT302 BAYCCHT302

Seacoast Kit BAYSEAC001 BAYSEAC001 BAYSEAC001

Low Ambient Kit BAYLOAM103 BAYLOAM103 BAYLOAM103

Refrigerant Lineset

(d)

TAYREFLN3* TAYREFLN3* TAYREFLN3*

Service Valve Panel Cover TAYSVPANL0044AA TAYSVPANL0046AA TAYSVPANL0046AA

(a)

Certified in accordance with the Unitary Air-conditioner equipment certification program which is based on AHRI standard

210/240.

(b)

Calculated in accordance with N.E.C. Only use HACR circuit breakers or fuses.

(c)

Standard line lengths — 60’, Standard lift — 60’ Suction and Liquid line. For Greater lengths and lifts refer to refrigerant

piping software Pub#32–3312–0* (* denotes latest revision)..

(d)

* = 15, 20, 25, 30, 40 and 50 foot lineset available.

22-1916-1D-EN

3

Page 4

PPrroodduucctt SSppeecciiffiiccaattiioonnss

Model No.

POWER CONNS. — V/PH/HZ

(a)

(b)

4TTR6049J1000A 4TTR6060J1000A 4TTR6061C1000A

208/230/1/60 208/230/1/60 208/230/1/60

MIN. BRCH. CIR. AMPACITY 26 32 32

BR. CIR. PROT. RTG. — MAX. (AMPS)

COMPRESSOR

CLIMATUFF®- SCROLL CLIMATUFF®- SCROLL CLIMATUFF®- SCROLL

40 50 50

RL AMPS — LR AMPS 18.5 — 124 23.7 — 152.5 23.7 — 152.5

Outdoor Fan FL AMPS 2.80 1.05 1.05

Fan HP

Fan Dia (inches)

1/3 1/5 1/5

27.5 27.5 27.6

Coil SPINE FIN™ SPINE FIN™ SPINE FIN™

Refrigerant R-410A 10 LBS., 3 OZ 9 LBS., 13 OZ 10 LBS., 15 OZ

LINE SIZE — IN. O.D. GAS

LINE SIZE — IN. O.D. LIQ.

Charge Spec. Subcooling

Dimensions H x W X D Crated (IN.)

Weight — Shipping (lbs.)

Weight — Net (lbs.)

(c)

7/8 1–1/8 1–1/8

3/8 3/8 3/8

10°F 10°F 10°F

50.4 x 35.1 x 38.7 50.4 x 35.1 x 38.7 50.4 x 35.1 x 38.7

322 327 327

272 277 277

Optional Accessories:

Anti-short Cycle Timer

Evaporator Defrost Control

TAYASCT501A TAYASCT501A TAYASCT501A

AY28X079 AY28X079 AY28X079

Rubber Isolator Kit BAYISLT101 BAYISLT101 BAYISLT101

Extreme Condition Mount Kit BAYECMT004 BAYECMT004 BAYECMT004

Start Kit BAYKSKT263 BAYKSKT263 BAYKSKT263

Crankcase Heater Kit BAYCCHT302 BAYCCHT302 BAYCCHT302

Seacoast Kit BAYSEAC001 BAYSEAC001 BAYSEAC001

Low Ambient Kit BAYLOAM103 BAYLOAM103 BAYLOAM103

Refrigerant Lineset

(d)

TAYREFLN3* TAYREFLN3* TAYREFLN3*

Service Valve Panel Cover TAYSVPANL0046AA TAYSVPANL0046AA TAYSVPANL0046AA

(a)

Certified in accordance with the Unitary Air-conditioner equipment certification program which is based on AHRI standard

210/240.

(b)

Calculated in accordance with N.E.C. Only use HACR circuit breakers or fuses.

(c)

Standard line lengths — 60’, Standard lift — 60’ Suction and Liquid line. For Greater lengths and lifts refer to refrigerant

piping software Pub#32–3312–0* (* denotes latest revision)..

(d)

* = 15, 20, 25, 30, 40 and 50 foot lineset available.

4

22-1916-1D-EN

Page 5

Sound Power Level

A-Weighted

MODEL

Sound

Power Level

Full Octave Sound Power(dB)

[dB(A)]

63

125Hz250

Hz*

4TTR6018J 73 79 69 67 70 70 64 59 53

4TTR6024J 73 79 69 67 70 70 64 59 53

4TTR6030J 73 79 69 67 70 70 64 59 53

4TTR6036J 71 78 72 69 68 66 61 58 53

4TTR6042J 72 81 75 71 70 68 63 58 53

4TTR6048J 72 81 75 71 70 68 63 58 53

4TTR6049J 72 81 75 71 70 68 63 58 53

4TTR6060J 72 81 75 71 70 68 63 58 53

4TTR6061C 74 68 56 63 73 69 64 59 51

Note: Rated in accordance with AHRI Standard 270–2008

Hz

500Hz1000Hz2000

*For Reference Only

Hz

4000

Hz

8000

Hz

22-1916-1D-EN

5

Page 6

Accessory Description and Usage

4 T W V 0 0 3 6 A 1 0 0 0 A A

AAnnttii--SShhoorrtt CCyyccllee TTiimmeerr — Solid state timing device that prevents compressor recycling until

five (5) minutes have elapsed after satisfying call or power interruptions. Use in area with

questionable power delivery, commercial applications, long lineset, etc.

EEvvaappoorraattiioonn DDeeffrroosstt CCoonnttrrooll — SPST Temperature actuated switch that cycles the condenser

off as indoor coil reaches freeze-up conditions. Used for low ambient cooling to 30°F with TXV.

RRuubbbbeerr IIssoollaattoorrss — Five (5) large rubber donuts to isolate condensing unit from transmitting

energy into mounting frame or pad. Use on any application where sound transmission needs to

be minimized.

HHaarrdd SSttaarrtt KKiitt — Start capacitor and relay to assist compressor motor startup. Use in areas with

marginal power supply, on long linesets, low ambient conditions, etc.

EExxttrreemmee CCoonnddiittiioonn MMoouunntt KKiitt — Bracket kits to securely mount condensing unit to a frame or

pad without removing any panels. Use in areas with high winds, or on commercial roof tops, etc.

AAHHRRII SSttaannddaarrdd CCaappaacciittyy RRaattiinngg CCoonnddiittiioonnss

AHRI Standard 210/240 Rating Conditions

1. Cooling 80°F DB, 67°F WB air entering indoor coil, 95°F DB air entering outdoor coil.

2. High Temperature Heating 47°F DB, 43°F WB air entering outdoor coil, 70°F DB air entering

indoor coil.

3. Low Temperature Heating 17°F DB air entering indoor coil.

4. Rated indoor airflow for heating is the same as for cooling.

AAHHRRII SSttaannddaarrdd 227700 RRaattiinngg CCoonnddiittiioonnss — (Noise rating numbers are determiend with the unit in

cooling operations.) Standard Noise Rating number is at 95°F outdoor air.

Model Nomenclature

6

22-1916-1D-EN

Page 7

Schematic Diagrams

Figure 1. 018 — 048 Models

22-1916-1D-EN

7

Page 8

SScchheemmaattiicc DDiiaaggrraammss

049 & 061 Models

8

22-1916-1D-EN

Page 9

Figure 2. 060 Models

SScchheemmaattiicc DDiiaaggrraammss

22-1916-1D-EN

9

Page 10

Outline Drawing

Model Base A B C D E F G H J K

4TTR6018J 3

4TTR6024J 3

4TTR6030J 3

4TTR6036J 4

4TTR6042J 4

4TTR6048J 4

4TTR6049J 4

4TTR6060J 4

4TTR6061C 4

10

730

(28–3/4)

730

(28–3/4)

933

(36–3/4)

943

(37–1/8)

1147

(45–1/8)

1147

(45–1/8)

1147

(45–1/8)

1147

(45–1/8)

1147

(45–1/8)

829

(32–5/8)

829

(32–5/8)

829

(32–5/8)

946

(37–1/4)

946

(37–1/4)

946

(37–1/4)

946

(37–1/4)

946

(37–1/4)

946

(37–1/4)

756

(29–3/4)

756

(29–3/4)

756

(29–3/4)

870

(34–1/4)

870

(34–1/4)

870

(34–1/4)

870

(34–1/4)

870

(34–1/4)

870

(34–1/4)

3/4 3/8

3/4 3/8

3/4 3/8

3/4 3/8

7/8 3/8

7/8 3/8

7/8 3/8

7/8 3/8

7/8 3/8

127

(5)

127

(5)

143

(5–5/8)92(3–5/8)

143

(5–5/8)98(3–7/8)

152

(6)

152

(6)

152

(6)

152

(6)

152

(6)

76

(3)

76

(3)

98

(3–7/8)

98

(3–7/8)

98

(3–7/8)

98

(3–7/8)

98

(3–7/8)

197

(7–3/4)60(2–3/8)

197

(7–3/4)60(2–3/8)

210

(8–1/4)79(3–1/8)

219

(8–5/8)86(3–3/8)

219

(8–5/8)86(3–3/8)

219

(8–5/8)86(3–3/8)

219

(8–5/8)86(3–3/8)

219

(8–5/8)86(3–3/8)

219

(8–5/8)86(3–3/8)

508

(20)

508

(20)

508

(20)

508

(20)

813

(32)

813

(32)

813

(32)

813

(32)

813

(32)

22-1916-1D-EN

Page 11

Mechanical Specification Options

GGeenneerraall

The Outdoor Units are fully charged from the factory for up to 15 feet of piping. This unit is

designed to operate at outdoor ambient temperatures as high as 115°F. Cooling capacities are

matched with a wide selection of air handlers and furnace coils that are AHRI certified. The unit is

certified to UL 1995. Exterior is designed for outdoor application.

CCaassiinngg

Unit casing is constructed of heavy gauge, galvanized steel and painted with a weather-resistant

powder paint finish on all louvered panels and the fan top panel. The corner panels are

prepainted. All panels are subjected to our 1,000 hour salt spray test . The base is made of a

CMBP-G30 weatherproof material to resist corrosion.

RReeffrriiggeerraanntt CCoonnttrroollss

Refrigeration system controls include condenser fan, compressor contactor and high pressure

switch. High and low pressure controls are inherent to the compressor. A factory supplied liquid

line drier is standard. Some models may require field installation.

CCoommpprreessssoorr

The compressor features internal over temperature, pressure protection and total dipped

hermetic motor. Other features include: Centrifugal oil pump and low vibration and noise.

CCoonnddeennsseerr CCooiill

The outdoor coil provides low airflow resistance and efficient heat transfer. The coil is protected

on all four sides by louvered panels.

LLooww AAmmbbiieenntt CCoooolliinngg

As manufactured, this system has a cooling capacity to 55°F. The addition of an evaporator

defrost control permits operation to 40°F. The addition of an evaporator defrost control with TXV

permits low ambient cooling to 30°F.

TThheerrmmoossttaattss—Cooling only and heat/cooling (manual and automatic change over). Sub-base to

match thermostat and locking thermostat cover.

EEvvaappoorraattoorr DDeeffrroosstt CCoonnttrrooll — See Low Ambient Cooling.

22-1916-1D-EN

11

Page 12

NNootteess

Ingersoll Rand (NYSE:IR) advances the quality of life by creating comfortable, sustainable and efficient environments.

Our people and our family of brands—including Club Car

®

, Ingersoll Rand®, Thermo King®and Trane®—work together

to enhance the quality and comfort of air in homes and buildings; transport and protect food and perishables; and

increase industrial productivity and efficiency. We are a global business committed to a world of sustainable progress

and enduring results. For more information, visit www.ingersollrand.com.

Ingersoll Rand has a policy of continuous product and product data improvements and reserves the right to change design and specifications without notice.

©2015 Ingersoll Rand All rights reserved

22-1916-1D-EN

Supersedes 22-1916-1C-EN (June 2016)

18 Aug 2016

Loading...

Loading...