Page 1

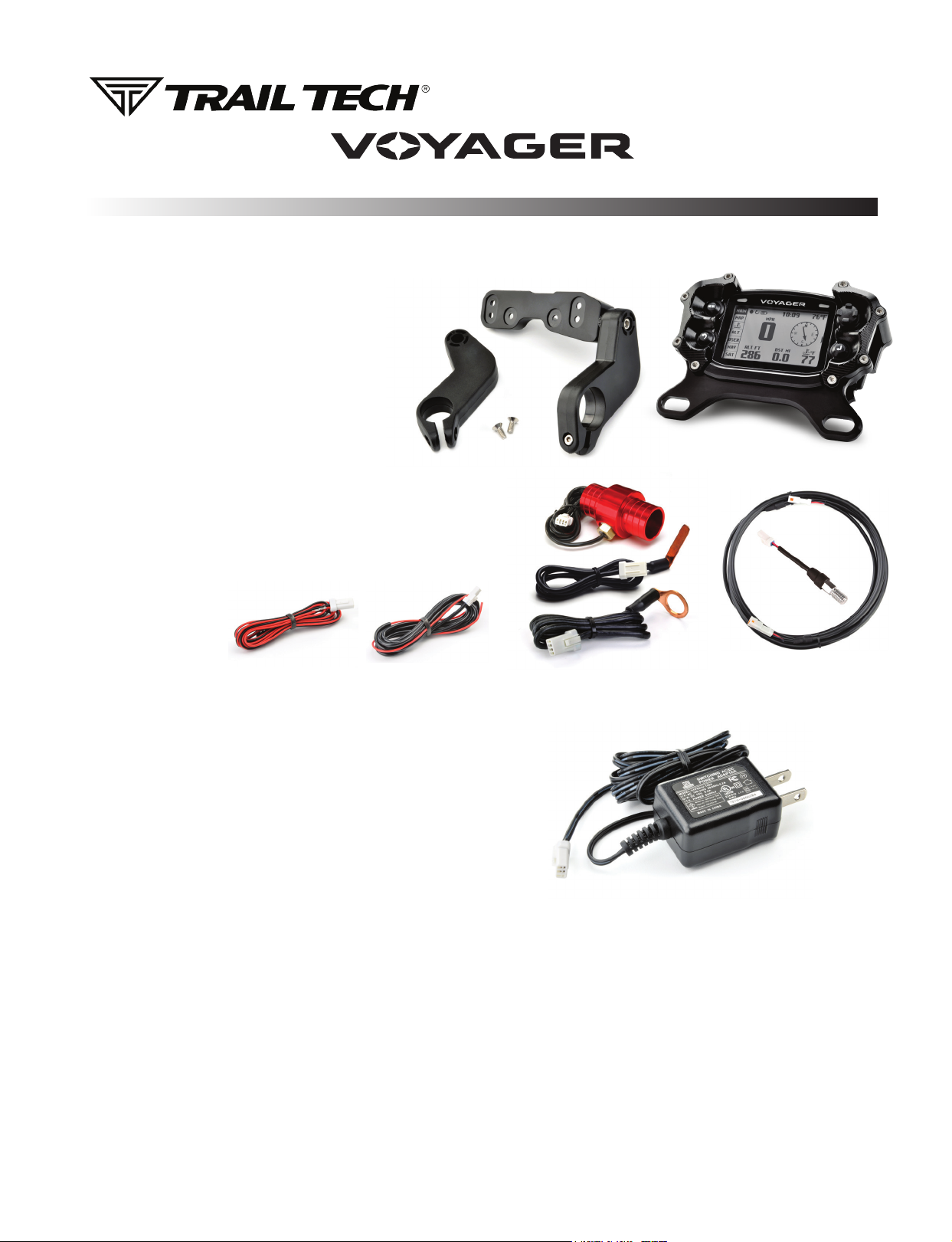

1. DC POWER REQUIRED

Do not connect Voyager directly to AC power except when

using the AC wall charger. See power section for details.

2. MOUNT VOYAGER:

Voyager is made to be bolted to the vehicle. Use the

included handlebar mounts, or refer to the manual or

www.trailtech.net for other options like the “center bar

mount” or CNC aluminum protector.

Tech Support: (844) 378-8143

010-ELV-194

technicalservice@apexproductgroup.com

QUICK-START

Included

Handlebar

Mount

Aluminum

Protector Mount

(optional)

3. VEHICLE SENSORS:

Refer to the sensor installation sections. You should install the

wheel sensor, ignition sensor, engine temperature sensor, and

vehicle power connection.

Power Wire Tach Ignition

Sensor

Temperature

Sensor (varies)

Wheel Speed

Sensor (varies)

4. CHARGE BATTERY:

Voyager’s internal battery comes pre-installed. It may need to be charged

before use. Once the vehicle power connection and the tach ignition

sensors are installed, charging will begin immediately and Voyager should

have full functionality. (There is also an AC wall charger available, sold

separately.)

AC Wall Adapter

(optional)

5. MICRO SD CARD SLOT:

The MicroSD card slot is located on the side of Voyager under the rubber weather protector. The MicroSD card enables transfer of tracks

between Voyager and a PC. During operation, make sure the card slot cover is properly seated to keep debris out. Tracks saved as GPX files on

your computer can be placed on the MicroSD memory card, then imported onto Voyager for viewing and route following. This is a great way to

share recorded tracks, or for pre-planning trips.

6. WARNING INDICATORS:

First set a threshold for max temperature, then when Voyager detects the vehicle is exceeding the temperature limits the indicator lights will alert

you of the situation. You can set when the red and yellow indicators will flash and when they will stay on solid.

Set the thresholds in the SETTINGS MENU.

Page 2

QUICK-START

7. SCREENS:

Voyager’s has seven tabbed screens. Press UP and DOWN on the joystick to move between them. On some screens you can also press

RIGHT on the joystick for full screen display or more detailed data.

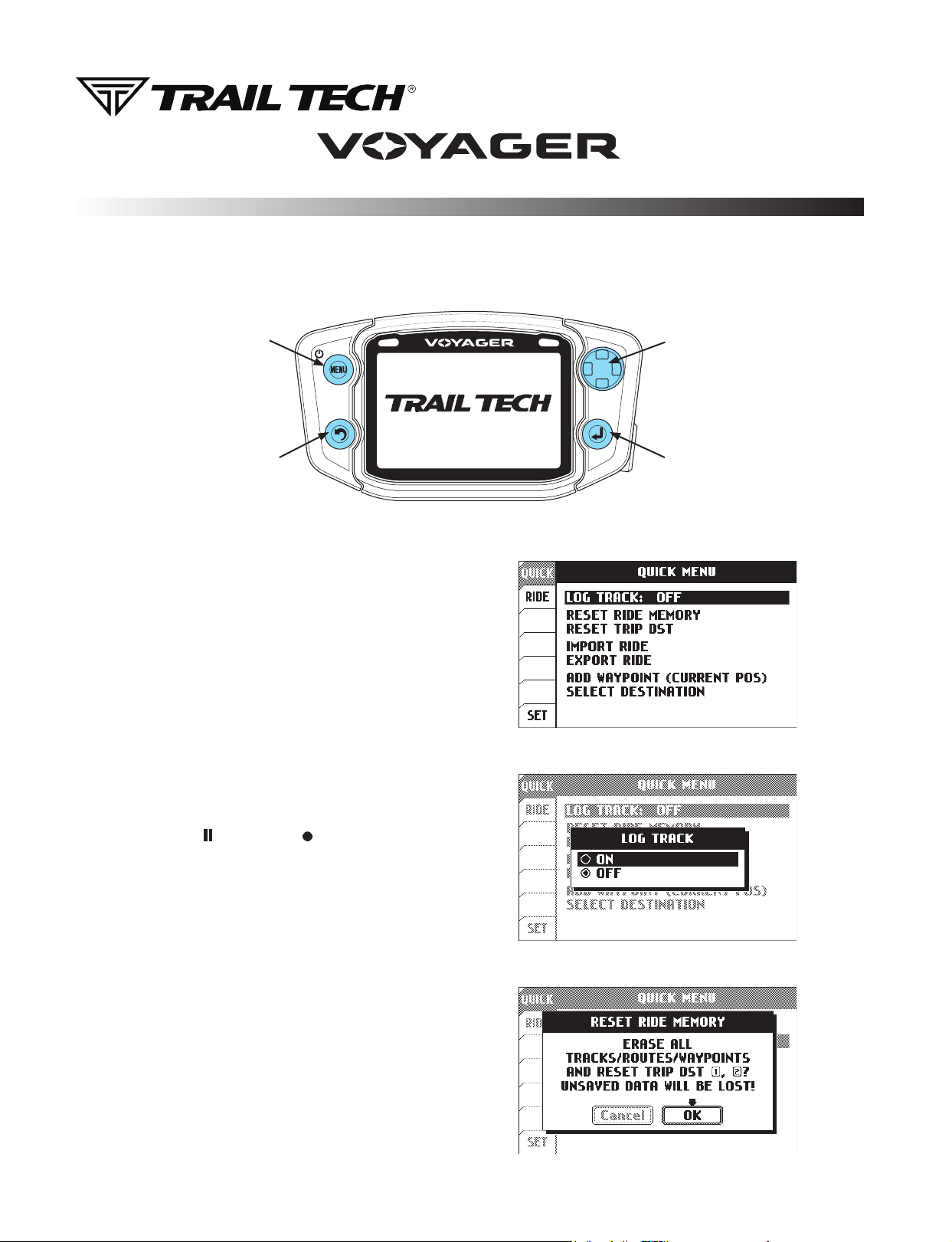

MENU/POWER

Enter or exit

menu. Hold to

power o.

BACK

Backs out of any

screen or menu.

8. QUICK-MENU:

Press the upper-left MENU button one or two times to enter the QUICK

menu. Here you can toggle logging, import/export files, change settings,

etc.

9. START LOGGING:

To start logging, press the MENU button to open the QUICK menu. The

top item should be LOG TRACK, select it and change it to ON to begin

logging. You will notice the icon in the upper-left of the MAP screen

changes from PAUSE ( ) to RECORD ( ). If it is grey, Voyager may still

be attempting to acquire a satellite signal and not logging yet. It will take

a few minutes for Voyager to acquire a satellite signal when first turned on.

Go to the SAT tab to verify satellite communication (be sure Voyager has a

clear view of the sky.) Default settings also require the engine to be on and

the wheel rolling to log. See the “Sensor Notes” section in the manual if

you are not using one of the sensors.

JOYSTICK

Navigation

ENTER

Conrm changes

or switch to next

screen.

10. RESET RIDE MEMORY:

To clear memory (erasing all tracks/routes/waypoints) select RESET RIDE

MEMORY in the QUICK menu.

Page 3

POWER AND TACH SENSORS

INSTALLS

POWER CONNECTION:

FOR USE ON 12-60V DC SYSTEMS ONLY!

Connecting to AC power will damage Voyager and void the warranty.

Use a volt meter to confirm 12-60V DC.

Fuse: Introducing a fuse into the circuit before electronics is always a good idea.

Use a 1 amp fuse with Voyager (not provided).

Vehicles with DC Power: Voyager requires DC power. Vehicles with a

battery or capacitor and regulator/rectifier produce DC power. Connect

the power wire directly to the vehicle’s 12V battery. Connect the red wire to the

positive(+) battery terminal and the black wire to the negative(-) battery terminal.

Vehicles with AC Power: Use the Voyager AC wall charger, or upgrade to a DC electrical

system. Most carbureted MX bikes put out AC power, but Voyager requires DC power.

Voyager will run approximately 5-8 hours on a full battery charge with no external power.

SENSORS:

The Voyager sensors plug securely into

Voyager using waterproof connectors.

They are different sizes (you cannot plug a

sensor into the wrong connector.)

Power Wire

Engine Temperature Sensor

TACH IGNITION SENSOR:

The ignition sensor enables tachometer readings and the

animated bar graph on the tach screen of Voyager.

OPTION 1: (Preferred option for most vehicles.)

Capacitive coupling to spark plug wire:

1.

To install ignition sensor wire, wrap the

red part of the sensor wire around the

coil wire 5 times.

If required, you may shorten the length of the ignition

sensor. Be very careful when stripping back the black

casing to avoid damaging the inner red wire.

OPTION 2:

If the coil is attached to the spark plug, then wrap the sensor like this:

Step 1:

Pull water-seal

down. Wrap

ignition sensor

around spark

plug.

Water

Seal

Step 2:

Replace

water-seal.

Wheel Sensor

Coil

Spark Plug

Ignition Sensor

Vehicle Power

Ambient Temperature Sensor

Ignition

Sensor

Wrap

Ignition

Sensor

Step 3:

Reinstall

spark plug

into motor.

Page 4

TEMPERATURE SENSORS AND ANTENNAS

INSTALLS

TEMPERATURE SENSORS:

Most Voyager kits contain a model-specific temperature sensor. Installing the temperature sensor

enables temperature readouts on Voyager’s gauge screens. Alternative sensors are available.

Vehicles cooled with water use sensors to measure the fluid temperature, while air-cooled machines take

the cylinder head’s temperature at the spark plug. The radiator fin sensor is the easiest installation for

water cooled applications.

Radiator Hose

Sensor Installation:

Drain uid.

1.

Measure inner diameter

2.

Tighten

Mark

& Cut

CVT Sensor Install:

(Continuously Variable Transmission)

200ºF+ Warning: CVT Belt wear occurs

more rapidly at high temperatures.

Let the belt cool down to increase lifespan.

Drill 13/64” (5mm) hole in

1.

hard plastic CVT exhaust.

Thread sensor into hole.

2.

The sensor threads are M6x10.

Use high temp RTV (silicone

3.

gasket sealer) to seal case cover.

Not included in kit.

of hose before cutting.

Mark hose.

3.

Cut hose.

4.

Slide on hose clamps.

5.

Install sensor & tighten

6.

hose clamps.

Sensor replaces

crush washer

Radiator Fin

Sensor Installation:

Conrm correct size.

1.

Apply thermal grease to

2.

maximize heat transfer.

Carefully press sensor

3.

between radiator ns.

If the in sensor is too large,

le it to size rather than

forcing it into the radiator.

CHT Cylinder Head

Spark Plug

Sensor Installation:

Remove crush

1.

washer from

spark plug.

Replace with

2.

temperature

sensor.

Re-install

3.

spark plug.

Screw

Sensor Installation:

1.2.Remove radiator pressure

relief bolt.

Replace with temperature

sensor.

GPS ANTENNAS:

Internal GPS Antenna:

The INTERNAL GPS antenna is

adequate for normal use. If there

is excessive metal around the

Voyager Pro mounting location,

the reception may be affected.

External GPS Antenna:

An EXTERNAL GPS antenna

can be screwed into the back

of the meter and mounted

to achieve a better antenna

position. The external GPS

antenna available from Trail

Tech should be mounted flat, on

a non-metallic surface, with an

unobstructed view of the sky.

Internal

GPS Antenna

External

GPS Antenna

(not provided)

Page 5

WHEEL SENSORS

INSTALLS

KTM WHEEL SENSOR

Trail Tech wheel

sensors work with the

KTM and Husqvarna

OEM install location.

Screw the wheel

sensor into the OEM

caliper position. Insert

the black magnet into

the pre-drilled hole in

the rotor and secure

with the retainer clip.

KTM Magnetic

Retainer

KTM OEM Wheel

Sensor Position

INVERTED FORK WHEEL SENSOR

If there are fork

guards next to the

brake rotor, then the

fork guard wheel

sensor can be

installed as shown.

Try to have the tip of

the sensor about 1/2

inch away from the

magnet in the rotor.

Rotor Bolt Magnet Rotor Shield

Inverted Fork

Wheel Sensor

CONVENTIONAL FORK SENSOR

If the fork is close to

the brake rotor, then

the VHB fork sensor

can be used. Peel

and stick the sensor

to the fork.

Try to have the tip of

the sensor about 1/2

inch away from the

magnet in the rotor.

Rotor Bolt Magnet

Conventional Fork

VHB Wheel Sensor

ROTOR SHIELD WHEEL SENSOR

For UTVs and quads

with a rotor shield,

position the sensor

there.

Drill a 3/8” hole and

use the jam nuts to

secure the sensor to

the rotor shield. Use

loctite rather than

over-tightening the

jam nuts.

Wheel Sensor

BRAKE CALIPER WHEEL SENSOR

Some ATVs require

mounting the wheel

sensor directly to the

brake caliper.

Drill a 1/8” hole

through the caliper

mount, then use the

self-tapping screw to

secure the sensor.

Brake Caliper

Wheel Sensor

MAGNET INSTALLATION:

Install a magnet on the brake rotor to trigger

the speed sensor each wheel rotation.

Remove one of the stock rotor bolts and

install the magnetic rotor bolt as shown, do

not overtighten past 10 ft-lb of torque. If the

magnetic bolt will not work, the kit includes a

spare magnet that can be installed into one

of the rotor spaces. Use the included retainer

clip or epoxy such as JB Weld to secure.

C-BRACKET WHEEL SENSOR

Some kits include

a metal C-bracket

to help mount the

sensor, as shown.

Use the jam nuts to

secure the sensor to

the C-bracket. Use

loctite rather than

over-tightening the

jam nuts.

Magnetic Retainer or Spare MagnetMagnetic Rotor Bolt

C-Bracket

Wheel Sensor

Page 6

WHEEL SENSORS

SETUP

WHEEL SENSOR TEST:

Test for correct sensor/magnet placement before permanently mounting.

1. Set the vehicle on a stand so that the front (left) wheel spins easily.

2. Plug the wheel sensor cable into the computer.

3. Install the magnetic bolt.

4. Hold the sensor in place on the caliper mount by hand. While someone

watches the computer, roll the wheel. If the computer does not register,

move the magnet or sensor and try again. There should be 1/2” or less

gap between the sensor and magnet.

Do not mount so that the magnet passes the middle section of the

sensor. Either the sensor will not register at all; or the sensor will

register twice, causing a “double trigger” effect (computer displays

twice the true speed.) If a double-trigger is unavoidable, divide the wheel

size setting in the computer by 2 to correct the problem.

MEASURE WHEEL SIZE:

Knowing your exact wheel size it critical for the wheel sensor to calculate

correct speed and distance data.

Magnet Rotation Path

When comparing calibration to GPS data, use a long straight section of road

with no tight corners or small vertical movements.

Method 1: Ruler

Find the circumference of front wheel by measuring its diameter in millimeters.

Multiply the Wheel Diameter by 3.14. The result is your wheel size.

Method 2: Rolling

On a at surface, mark the tire sidewall and the ground with a marking pen. Roll the

wheel until the mark on the tire completes one revolution and is back on the ground. Mark

the ground at this location. Measure the distance between the marks on the ground in

millimeters (multiply inches by 25.4 to convert to mm). Use this number for your wheel size.

For accuracy, the rider’s weight should be on the bike when making the measurement.

Method 3: Distance Measurement

This is the most accurate method.

1. Set the wheel size to 2110mm (motorcycle) or 1675 (ATV).

2. Find a length of road where the distance is known.

3. Ride the distance, noting how far the computer reads (i.e. the road

is known to be 5 miles and the computer shows 4.95 miles.)

4. Use the numbers to solve for X in the following equation:

(new wheel size)

(actual miles) x (current wheel size)

=

(current miles)

Wheel Size =

Wheel Diameter(mm)

x3.14

Diameter

Generic/Average Sizes:

Motorcycle:

ATV:

2110 mm

1675 mm

Wheel Size:

Enter the number you calculate from one of

the above formulas into setup mode.

x3.14

X =

5 x 2110

4.95

X =

10550

4.95

X = 2131

Loading...

Loading...