Page 1

Page 2

Page 3

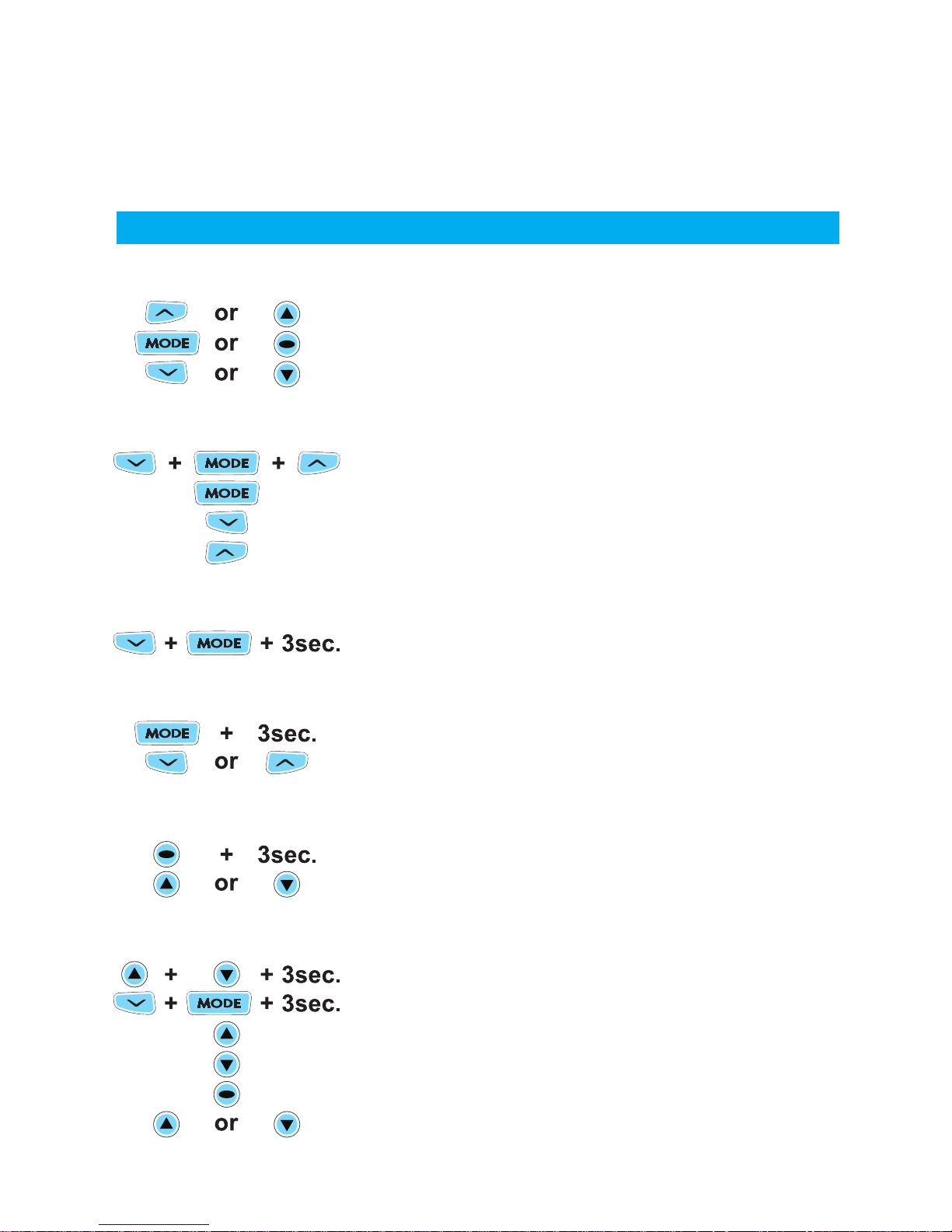

Quick-start

3

Normal Mode:

= Activate backlight manually

= Switch between screens in normal mode

= Start or stop the stop watch

Data Setting Mode:

= Enter data setting mode

= Switch between screens in data setting mode

= Scroll through current data setting

= Move to next digit of current data setting

Data Reset:

= Reset single-ride data

Adjustable Trip Distance Edit:

= Enter/exit adjustable trip distance edit mode

= Scroll distance value

Rally Mode:

= Enter/exit rally mode

= Scroll distance value

Lap Timer Mode:

= Enter/exit lap timer mode

= Clear lap timer data

= Start/stop lap timer

= Signal new lap

= Enter/exit lap data review mode

= Scroll through lap information

Page 4

Trail Tech powersport computers bring functionality and life to your

motor vehicle with high quality and innovation. To ensure you enjoy

years of trouble-free operation, this user’s manual contains valuable

information about how to operate and maintain your computer properly .

Please read this manual carefully.

A Note to You

Whenever you call to request service for Vector, you need to know

the date of purchase, dealer’s name, address, and telephone number.

PURCHASE DATE

DEALER NAME

DEALER ADDRESS

DEALER PHONE

Keep this book and sales slip together for future reference.

4

Thanks for Buying a Trail Tech

Powersport Computer:

Please Record Important Information:

Page 5

5

Precautions

When using V ector, follow basic

precautions, including the

following:

• Read all instructions before

using Vector.

• When installing radiator hose

insert temperature sensors,

make sure the sensor will fit

BEFORE cutting the radiator

hose.

• Use V ector only for its intended

function.

• To reduce the risk of injury, do

not disassemble Vector or its

accessories.

• V ector can be used in the rain

but should not be used

underwater.

• Do not leave the main unit in

direct sunlight when not riding.

• Check relative positions and

gap between speed sensor and

magnet periodically.

• Do not bend, twist, kink or

otherwise abuse the sensor

cables. A damaged cable may

produce incorrect readings.

• When installing Vector, turn

the vehicle ignition off: the wires

carry power from the vehicles

ignition system.

• Avoid contact with gasoline,

degreasers or other chemical

cleaners as they may damage

Vector.

WARNING:

REMEMBER TO PAY ATTENTION

TO THE TRAIL WHILE RIDING.

Page 6

6

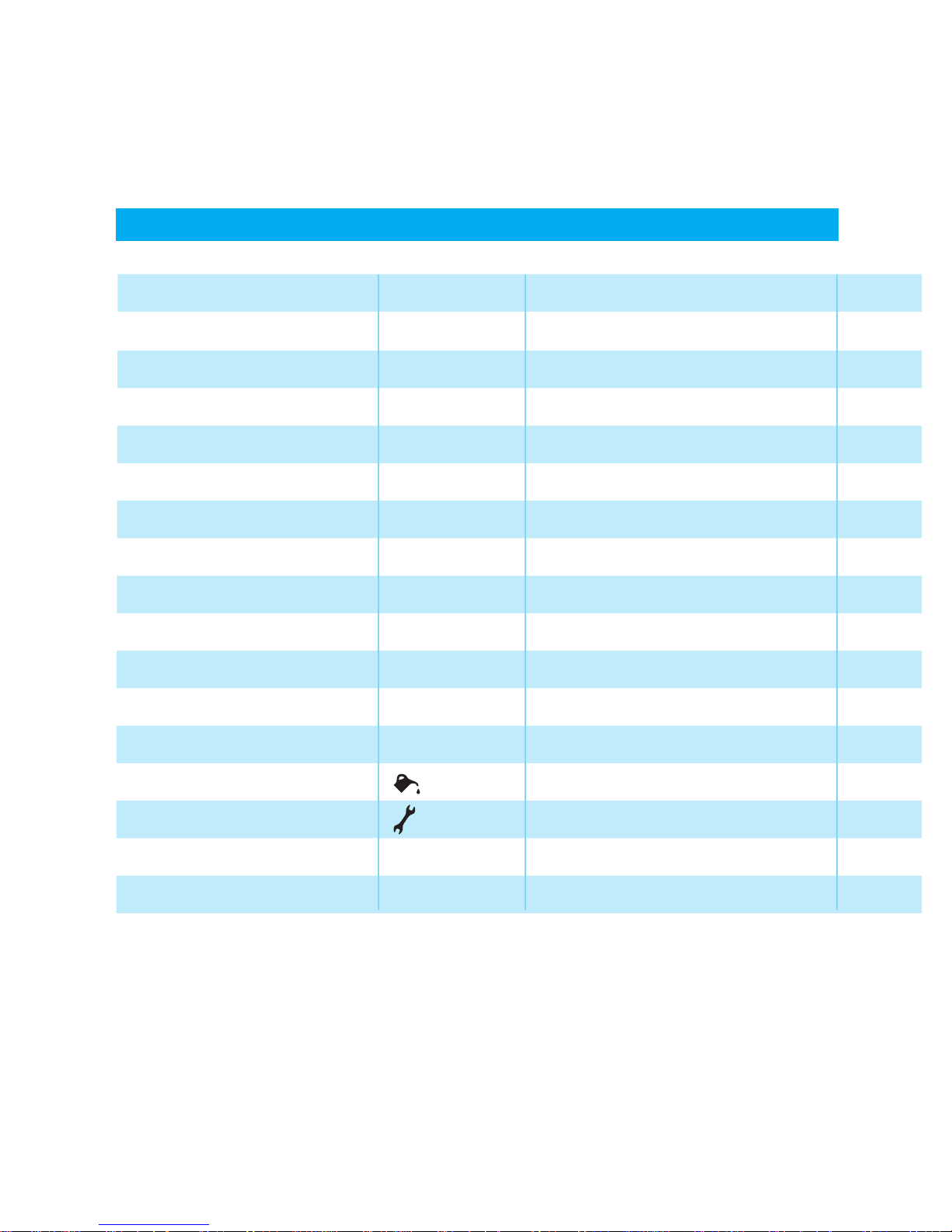

Specifications

FUNCTION

CURRENT SPEED

AVERAGE SPEED

MAXIMUM SPEED

DISTANCE

STOP WATCH

ODOMETER

RIDE TIME

ACCUM. RIDE TIME

TEMPERATURE

12H or 24H CLOCK

LOW BATTERY

TIRE SIZE

OIL REMINDER

MAINTENANCE

LAP TIMER

DISPLAY

SPD

AS

MS

DST

TT

ODO

RT

ART

°C or °F

00:00:00

LO

RANGE

4 - 399.9 KM/H or M/H

4 - 399.9 KM/H or M/H

4 - 399.9 KM/H or M/H

0.00 - 9999.99 KM or M

0 - 9999 hour 59 min

0.0 - 999999 KM or M

0 - 999 hour 59 min

0 - 9999 hour 59 min

0 - 399°

12:59:59 or 23:59:59

About 1 Year Life

0 - 3999 mm

0 -9999 KM or M

0 -9999 KM or M

0-18 Hours/Lap, 29 Laps

SPEED/DISTANCE SENSOR

TEMPERATURE SENSORS

PRODUCT DIMENSIONS

SCREEN DIMENSIONS

Non-contact Magnetic S peed Sensor

Ambient and Engine Temp. Sensors

106.93x59.46x23.7mm WxHxD

(4.21x2.34x0.93” WxHxD)

78.75 x 28.6mm WXH

(3.1 x 1.13” WxH)

Page 7

7

Specifications

UNITS

KM/H or M/H

KM/H or M/H

KM/H or M/H

KM/H or M/H

Hours:Minutes

KM or M

Hours:Minutes

Hours:Minutes

°C or °F

H:M:S

2.5 Volts

KM or M

KM or M

KM or M

INCREMENTS

0.1 KM/H or M/H

0.1 KM/H or M/H

0.1 KM/H or M/H

0.1 KM/H or M/H

1 Second

1 KM or M

1 Minute

1 Minute

1 Degree

1 KM or M

1 KM or M

1 Second

ACCURACY

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

+/- 0.1%

PRODUCT WEIGHT

WHEEL CIRCUMFERENCE

OPERATION TEMPERATURE

STORAGE TEMPERATURE

BATTERY

EXTERNAL POWER INPUT

3.9 oz. (110 grams) (0.24 lbs.)

0 to 3999 mm

0°C to 60°C (32°F to 140°F)

-20°C to 80°C (-4°F to 176°F)

3V CR2032 (About 1 Year life)

9.0-400 VAC/VDC

(No polarity requirements.)

Page 8

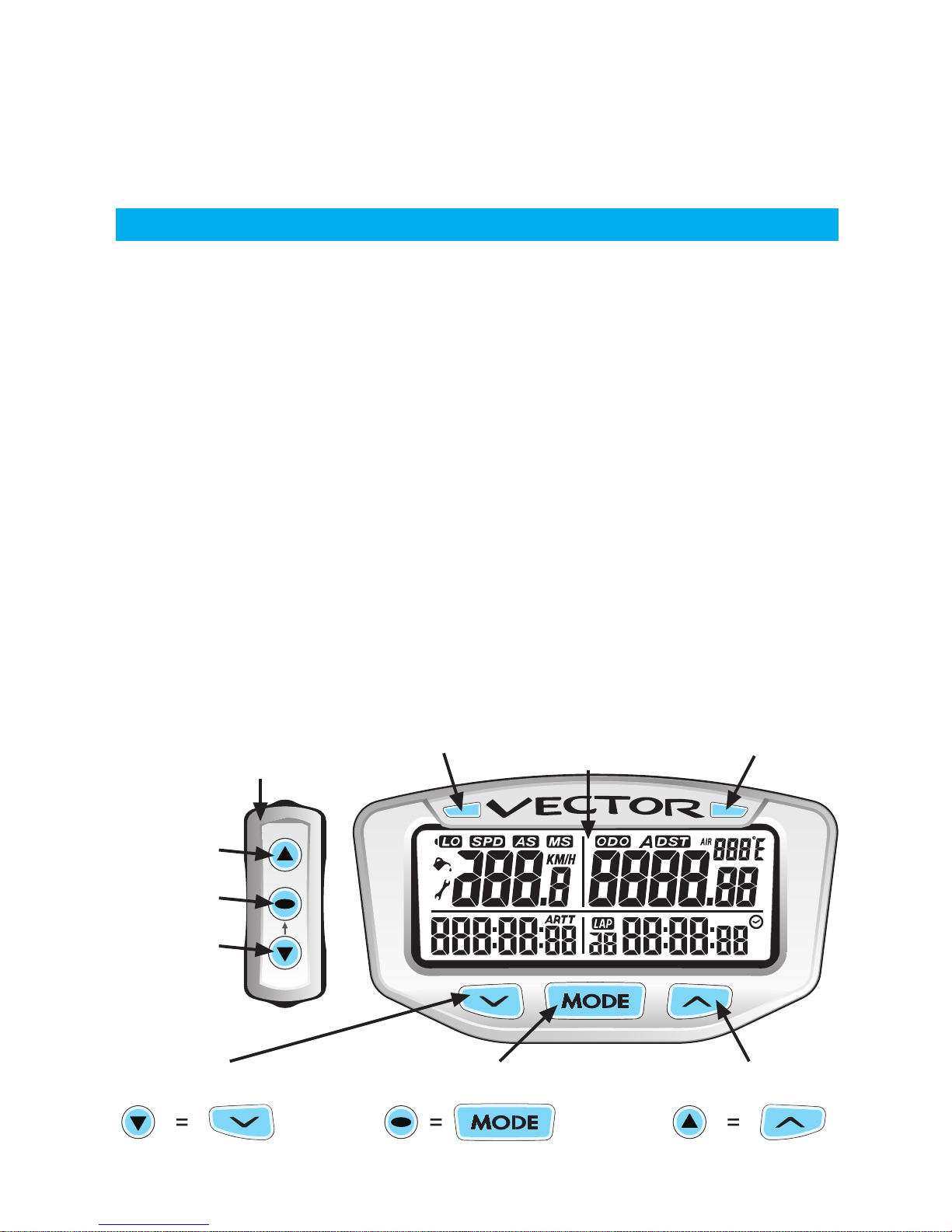

Main Computer:

LED’s:

Remote Switch:

•

•

•

•

•

The V ector computer has 3 buttons, 2 LED’s and an LCD screen.

Amber LED:

Red LED:

The remote switch (optional, sold separately) is required to

access lap timer and rally mode extended feature sets.

If not in lap timer or rally mode, the remote switch buttons function

as duplicates of the buttons on the main computer.

Overview

8

Vector Computer:

LEFT BUTTON

CENTER BUTTON

RIGHT BUTTON

RED LEDAMBER LED

Lights up for temperature warning alert and

indicates fast laps in lap timer mode.

Lights up for over-temperature alert and

indicates slow laps in lap timer mode.

TOP

BUTTON

REMOTE

SWITCH

MIDDLE

BUTTON

BOTTOM

BUTTON

LCD

SCREEN

Page 9

Parts & Features

9

TO ACTIVATE BACKLIGHT MANUALLY, PRESS

Backlight:

V ector is equipped with a backlight for easy viewing during night-time

operation.

Using External 12V Power:

•

•

•

Using Internal Battery Only:

•

•

•

•

Vector will light up with all five LED’s.

Vector will remain lit as long as it senses wheel movement. After

20 minutes of inactivity Vector shuts off the backlight. Press any

button, roll the wheels, or start the motor power and V ector will light

up again.

Shift and temperature LED’s will be enabled.

Vector will only stay lit for 3 seconds.

Vector’s backlight will light up with 10% power to conserve the

internal battery’s power.

If the LO symbol is present, the backlight will not turn on. The LO

symbol appears when battery voltage drops below 2.45V.

If ambient temperature is cold (below -5°C) the backlight will not

turn on.

Page 10

10

Parts & Features

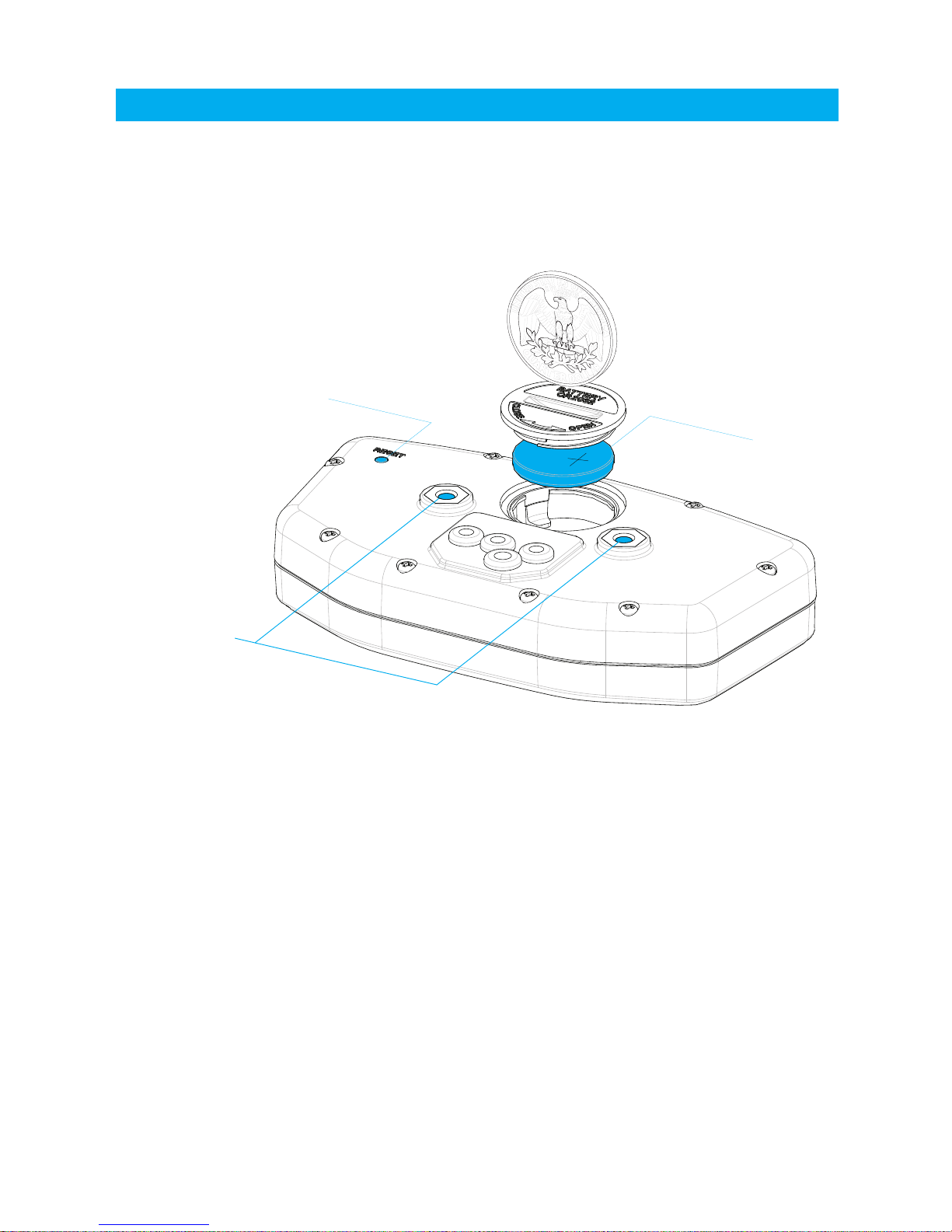

Use of the Reset Button will erase data for the current ride including

clock and trip distance.

Vector has an internal 3.0V watch type battery (#CR2032). The

computer can be run from the internal battery without being connected

to a vehicle power source.

To change the battery, unscrew the battery cap on the back of the

computer with a coin. Make sure the positive side of the battery

is facing up when replaced.

REPLACE WITH BATTERY MODEL NUMBER #CR2032

Reset Button:

Internal Battery:

BATTERY

RESET

BUTTON

MOUNTING

HOLES

•

•

•

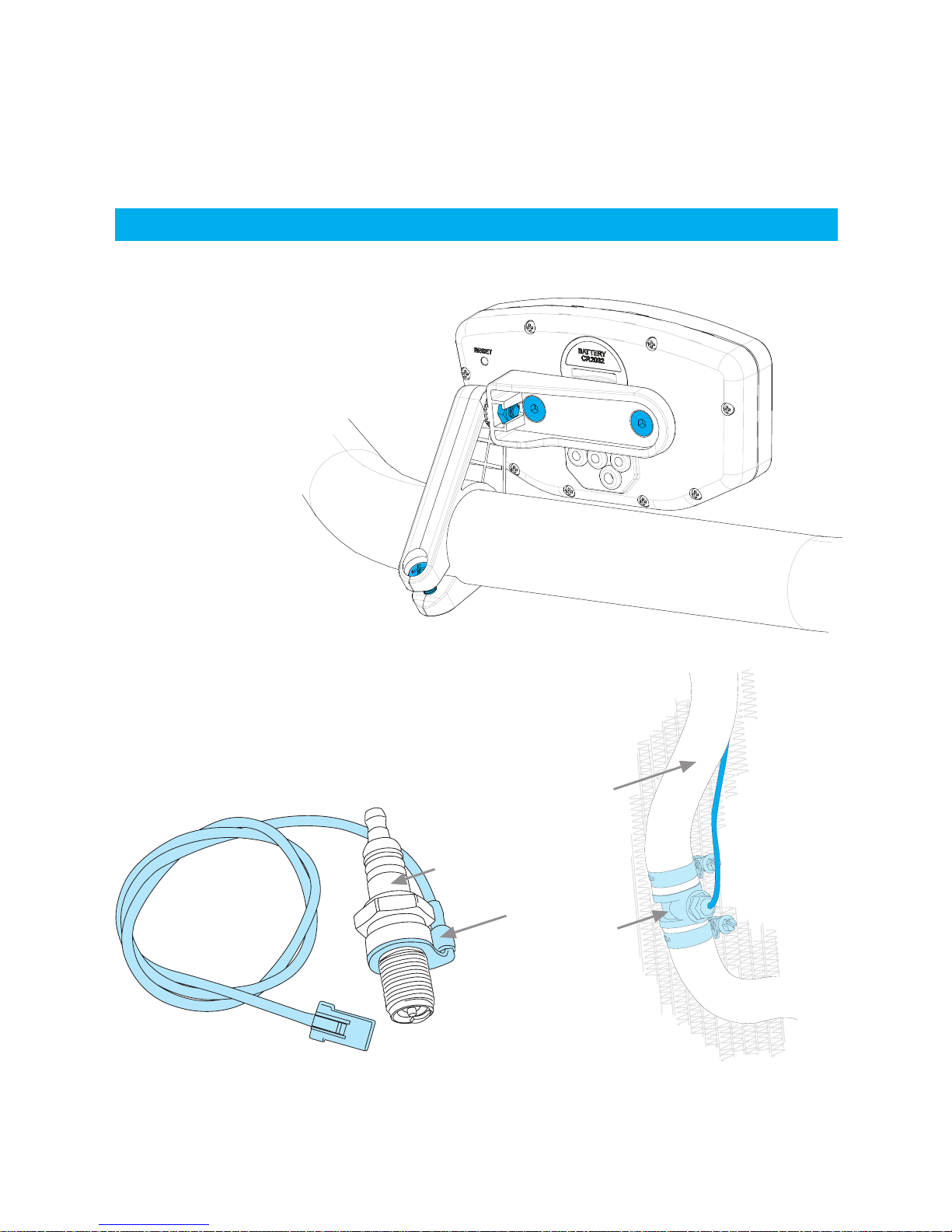

Page 11

11

Installation

Place bolts as

shown in picture.

Remember to

use provided

nuts when

placing bolts.

Bar Mounting:

Please see model-specific

instructions for mounting procedure.

Temperature

Sensors:

Temperature Sensor

in-line in radiator hose for

water-cooled machines

RADIATOR

HOSE

TEMP.

SENSOR

Cylinder Head Temperature

Sensor for air-cooled machines

SPARK

PLUG

Page 12

12

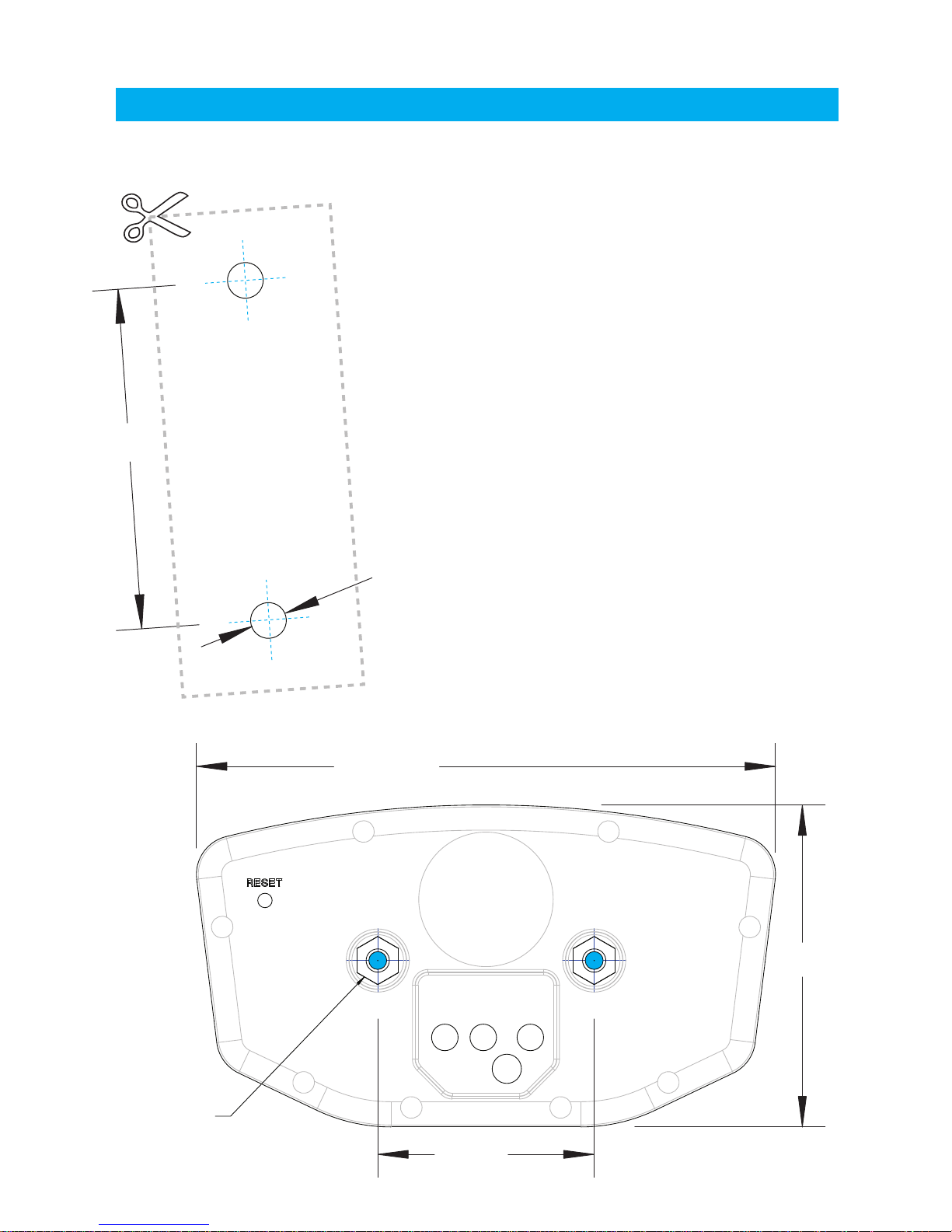

There are two screw holes on

the back of Vector. Use the

included M4 bolts to mount to

any flat surface (e.g. stock

odometer mounting bracket or

body panel).

Make sure that the cables will

not be chafed or damaged in

their mounting location.

If other than provided screws

are used, make sure they are

not too long for mounting holes.

Screws that are too long will

damage internal components of

Vector.

Flat/Surface Mount:

107.5mm

59.5mm

Mounting

Hole

Accepts

M4 Bolts

40mm

Drill Size:

• 4.2mm

• 0.165”

• M4

40mm

DRILL TEMPLATE

SCALE 1:1

Installation

Page 13

13

Installation

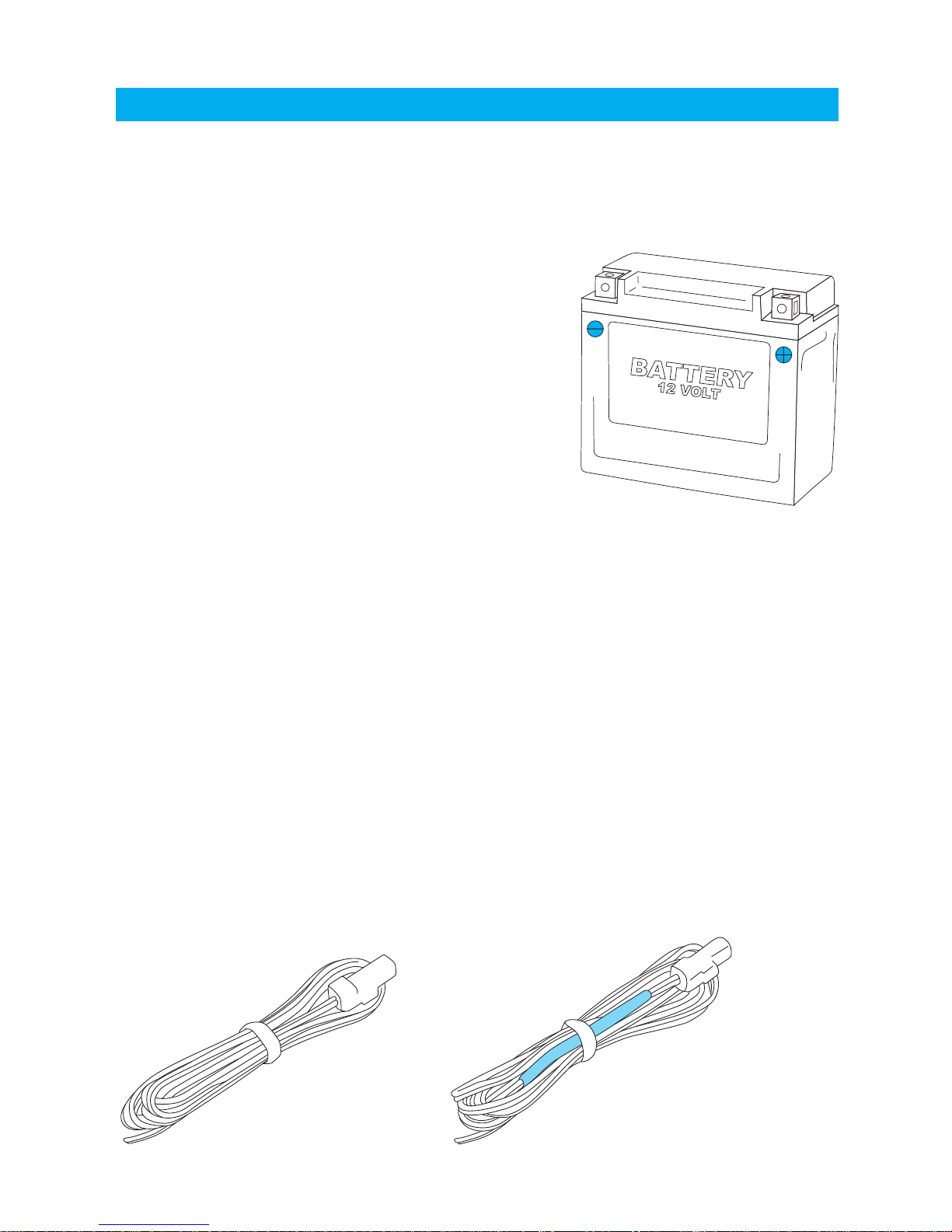

If possible, install Vector to a 12 volt system:

•

•

•

OPTION 1) BATTERY WIRED:

Connect the power cables directly to the

vehicle’s 12 volt battery.

OPTION 2) SYSTEM TAP:

As an alternative to running wires all the way to the battery, it is

possible to tap into the electrical system. It is best to connect so

power is not interrupted by key switch.

Notes:

•

•

•

•

12 Volt Systems:

Power Wire Resistor Power Wire:

Included in some kits.

The backlight will be 10 times brighter .

Vector will enter sleep mode after 20

minutes instead of 5 minutes.

The temperature indicator LED’s will

be enabled.

Vector is polarity independent.

Either lead can go to the positive or negative post on the battery.

Vector will not drain the vehicle battery.

The “LO” low battery indicator will activate if battery voltage drops

below 2.45V.

Vector will operate in the range of 6.0 - 400 VAC/VDC, but will not

draw enough power to drain a vehicle battery.

Page 14

14

Installation

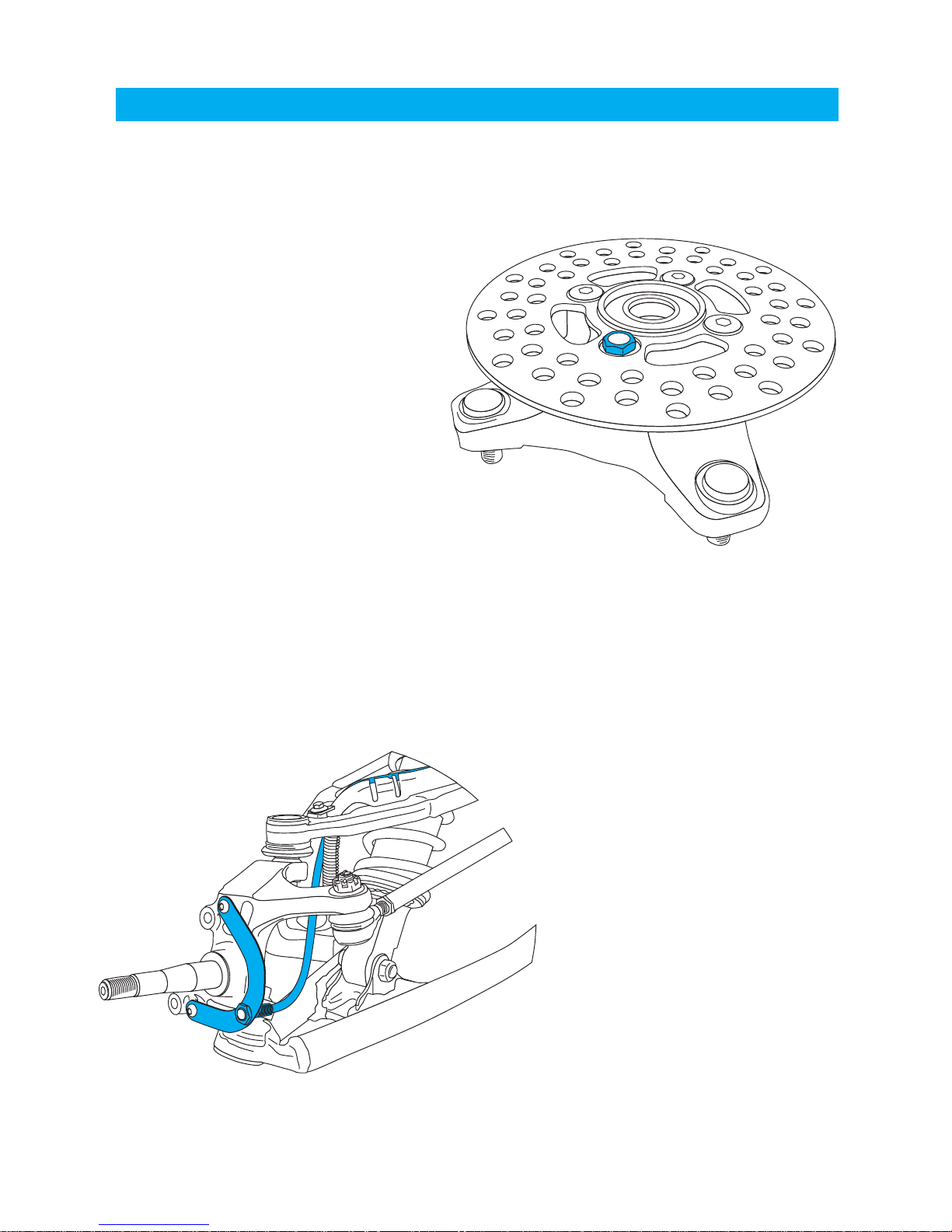

V ector needs two things to be

able to collect distance data:

1. A magnet placed on the

spinning part of the wheel.

2. A speed sensor, placed on

the non-moving part of the

wheel.

The magnet spins around

tripping the sensor switch

each time--data collected lets

V ector calculate distance and

time.

The magnet gets installed on the brake rotor because it spins with

the wheel. The provided magnetic bolt can simply replace a stock

rotor bolt (see above

picture). If that doesn’t

work, glue the spare magnet

in a hole on the brake rotor .

(JB Weld or a similar slowcure epoxy works well.)

After the magnet is in, the

sensor is placed on a nonspinning part the wheel.

The sensor typically is

placed on either the

provided C-bracket or the

ATV metal rotor shield.

ATV Sensor/Magnet Installation:

C-Bracket Installation-ATV Left Axle

Magnetic Bolt Installation

ATV Rotor

Page 15

15

Installation

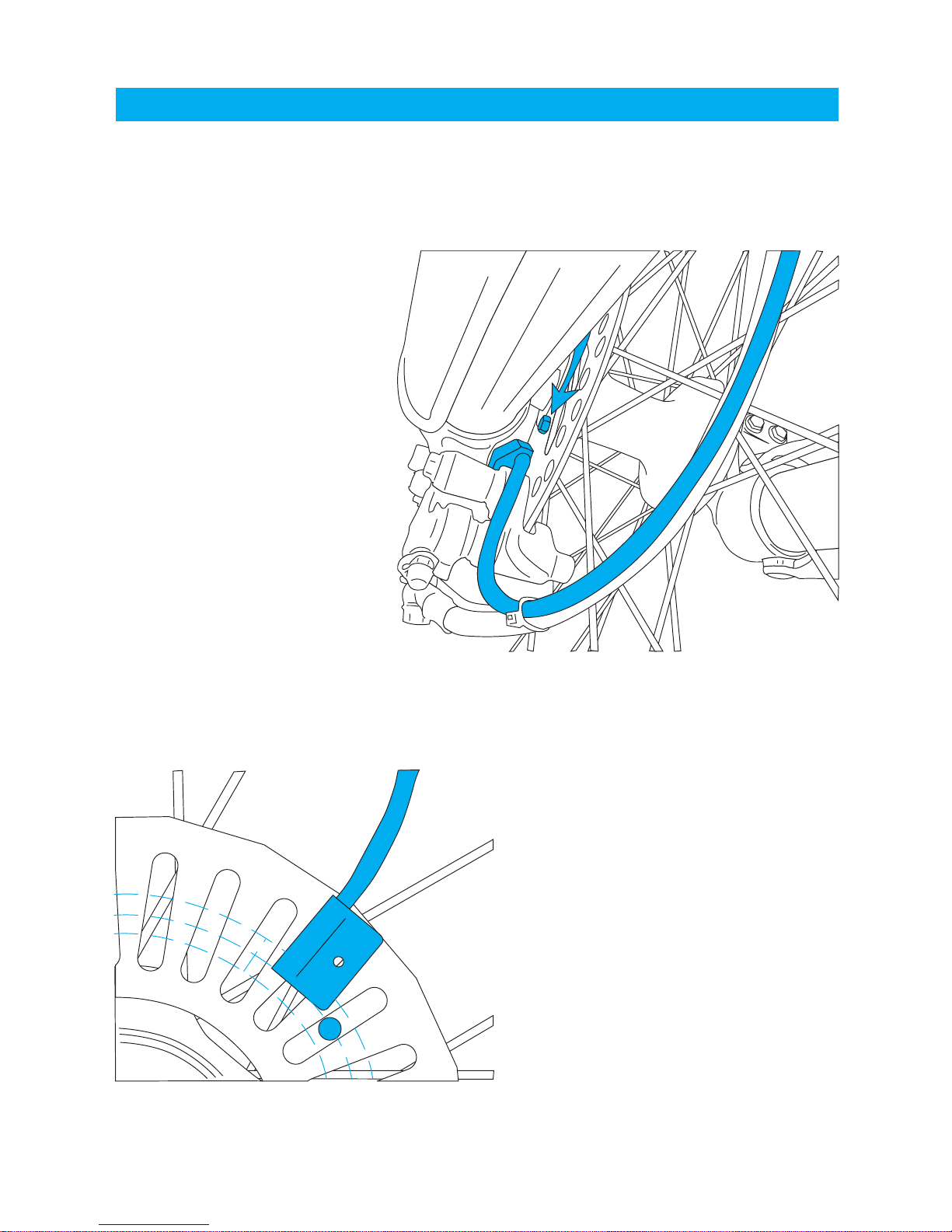

Motorcycles, like ATV’s,

need a magnet placed on

the spinning part of the

wheel and the sensor

installed to a non-spinning

part.

The magnet typically gets

bolted or glued to the

brake rotor.

The sensor wire should

come from the back of the

computer , be cable-tied to

the brake line as it travels

down the front forks, then

attached to the brake

caliper.

Motorcycle Sensor/Magnet Installation:

Vector can tell how far and fast

it’s traveled by keeping track of

how many times the magnet

passes under the sensor switch.

Many Motorcycles and ATV’s

have special installation

procedures. Refer to the

provided installation insert for

specific instructions for your

machine or visit

www.TrailTech.net.

Magnet About to Pass Under Sensor

Optimum Magnet Rotation Path

Page 16

16

Installation

You will use the wheel size number when setting up the computer for

your machine. Use Method 1, 2 or 3.

Find the

circumference

of front wheel

by measuring

its diameter in

millimeters. Multiply

the Wheel Diameter

by 3.14. The result is your

wheel size.

On a flat surface, mark the tire sidewall and the ground with a marking

pen. Roll the wheel until the mark on the tire completes one revolution

and is back on the ground. Mark the ground at this location. Measure

the distance between the marks on the ground and convert the

measurement to mm (multiply inches by 25.4). Use this number for

your wheel size. For accuracy, the rider’s weight should be on the

bike when making this measurement.

Overview:

Method 1)

Easy Ruler

Method:

Method 2)

Rolling Measurements:

Wheel Size=

Wheel Diameter(mm)

x 3.14

Diameter(mm)

x 3.14

Page 17

For the most accurate measurement, use wheel size measurement

from above or set the wheel size to 2110mm (motorcycle) or 1675

(ATV) and follow this procedure:

1.

2.

3.

2110 = 4.95 or (current wheel size) = (current miles)

X 5.00 (new wheel size) (actual miles)

4.95X = 2110 * 5.00

4.95X = 10550

X =

10550

4.95

X = 2131

4.

17

Installation

Find a length of road where the distance is known.

Ride the distance and note the distance the computer reads (for

example, the road is known to be 5 miles and the computer shows

4.95 miles.)

Use the numbers to solve for X in the following equation:

Enter number found from the above method in your computer.

Method 3) Distance Measurements:

My Wheel

Size:

Page 18

18

Data Setting Mode

Data Setting Mode is very important for Vector to operate correctly.

Available Settings:

•

•

•

•

•

After a setting is confirmed, Vector will move on to the next setting in

order. If no button is pressed for 15 seconds, Vector will return to

Normal Mode.

Overview:

TO ENTER DATA SETTING MODE, HOLD DOWN ALL THREE

BUTTONS FOR 3 SECONDS

All digits will light up.

Release buttons to

continue.

Enter Data Setting Mode:

Kilometers or Miles per Hour

Wheel Size in Millimeters

24 hour or 12 hour Clock Format

Time of Day

Temperature Unit of Measure, °F or °C

Page 19

See “Measuring Wheel Size”

section for more information.

DEFAULT ATV: 1676mm

MOTORCYCLE: 2109mm

MODIFY FLASHING DIGIT BY

PRESSING THE LEFT BUTTON.

CHANGE TO NEXT DIGIT BY

PRESSING THE RIGHT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go to the next setting.

Program Wheel Size:

Data Setting Mode

19

Program Kilometers or Miles Per Hour:

TO CYCLE BETWEEN M/H AND KM/H, PRESS THE LEFT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go to the next setting.

Page 20

20

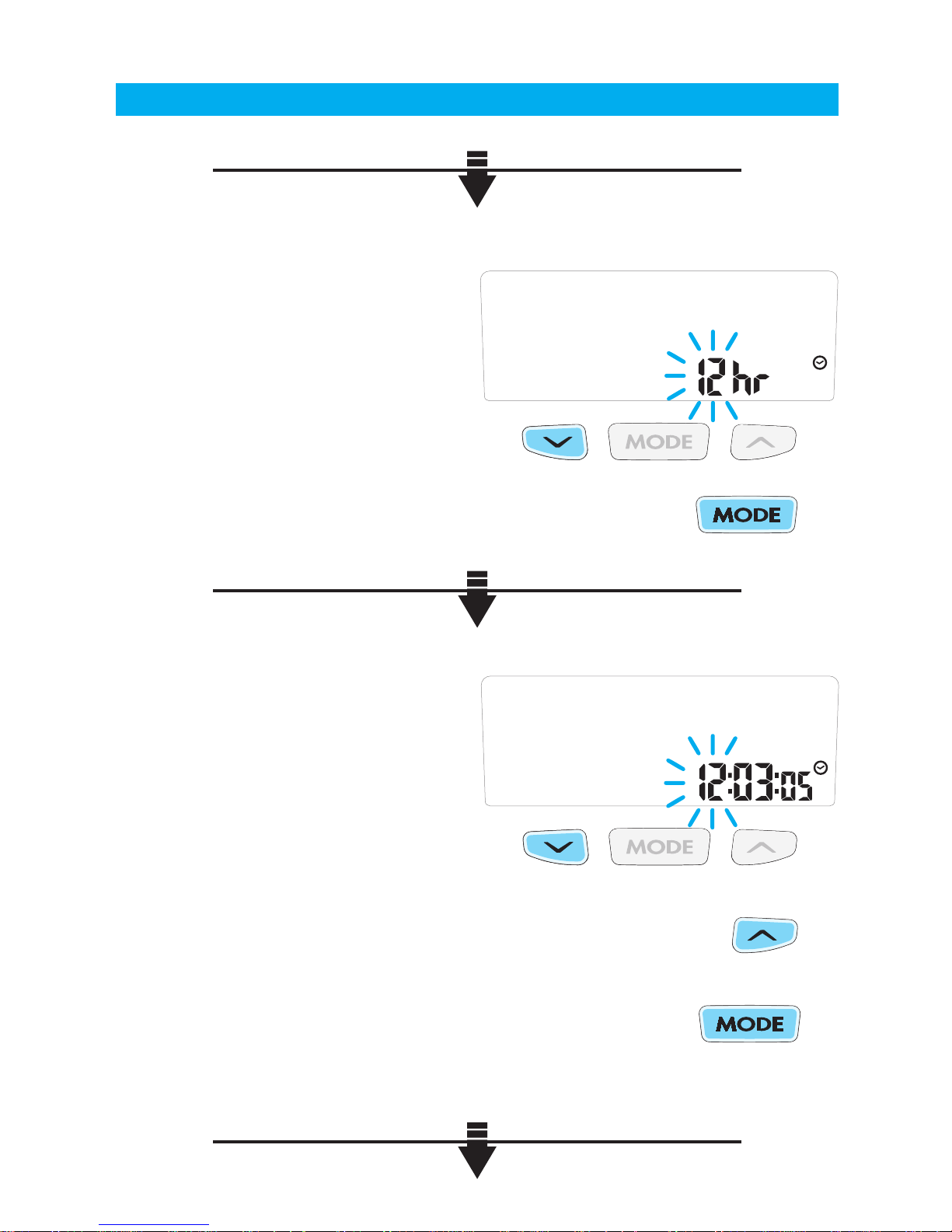

Program 12 or 24 Hour Clock Format:

Vector defaults to 12H format.

TO CYCLE BETWEEN

12H AND 24H, PRESS

THE LEFT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go to the next setting.

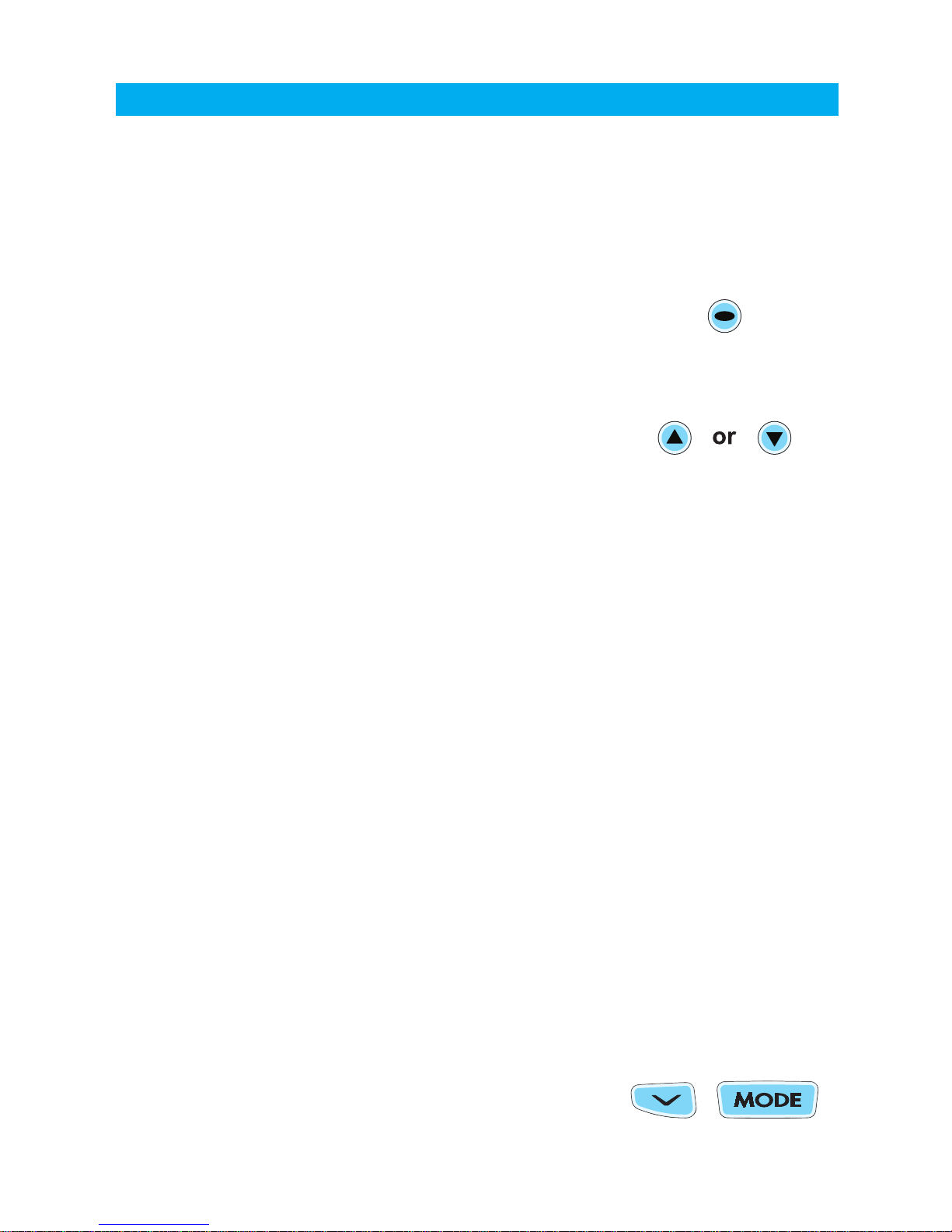

MODIFY FLASHING DIGIT BY

PRESSING THE LEFT BUTTON.

CHANGE TO NEXT DIGIT BY

PRESSING THE RIGHT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go on to the next setting.

Program Time of Day:

Data Setting Mode

Page 21

21

Data Setting Mode

Choose between °C or °F.

TO CYCLE BETWEEN

°C or °F, PRESS

THE LEFT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go on to the next setting.

Program Temperature Unit of Measure:

Page 22

When the engine temperature sensor reaches the value of this setting,

the red right LED will turn on as a critical warning. Setting to 0 disables

the alert. Vector defaults to 0°.

MODIFY FLASHING DIGIT BY

PRESSING THE LEFT BUTTON.

CHANGE TO NEXT DIGIT BY

PRESSING THE RIGHT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go on to the next setting.

Data Setting Mode

22

Program High Temp Warning Point:

When the engine temperature sensor reaches the value of this setting,

the amber left LED will turn on as a cautionary warning. Setting to 0

disables the alert. Vector defaults to 0°.

MODIFY FLASHING DIGIT BY

PRESSING THE LEFT BUTTON.

CHANGE TO NEXT DIGIT BY

PRESSING THE RIGHT BUTTON.

TO CONFIRM, PRESS THE CENTER BUTTON.

Vector will go on to the next setting.

Program Danger Temp Warning Point:

Page 23

Set the number of kilometers or miles left until Vector displays the oil

and wrench shaped reminder icons. After setting <OIL>, the <CARE>

setting screen will appear. Vector defaults to 0 KM/H or M/H.

MODIFY FLASHING DIGIT

BY PRESSING THE LEFT

BUTTON.

CHANGE TO NEXT DIGIT

BY PRESSING THE RIGHT

BUTTON.

TO CONFIRM, PRESS THE

CENTER BUTTON.

Vector will return to normal

mode after setting <CARE>.

•

•

•

•

Things that will not affect the maintenance reminders:

•

•

•

•

23

Data Setting Mode

Set Oil and Maintenance Reminders:

Each km/mile the bike travels lowers the maintenance reminder

values by 1.

When a maintenance reminder countdown reaches 0 while riding,

the respective icon ( or ) will activate (turn on).

Vector will not increase the value of the maintenance reminders

automatically; they must be manually increased in data setting

mode.

When maintenance reminder setting screens are viewed in data

setting mode, the icons will turn off if they have been activated.

Entering data setting mode

Using the adjustable trip distance feature

Resetting single-ride data

A system reset

Page 24

24

All of the information that V ector provides is on one of these 3 screens.

Switch between the 3 Normal Mode Screens:

When riding, the user has the choice of staying on Screen 1 or

Screen 2. Screen 3 will default back to Screen 1 after 5 seconds.

TO SWITCH BETWEEN SCREENS,

PRESS THE CENTER BUTTON OR

THE MIDDLE BUTTON.

Screen 1 Displays:

•

•

•

•

•

Screen 1:

Normal Mode Screens

or

Speed (SPD)

Distance (DST)

Ride Time (RT)

Time of Day

Engine

Temperature

Page 25

Screen 2 Displays:

•

•

•

•

•

Screen 3 Displays:

•

•

•

•

•

25

Normal Mode

Screen 2:

Screen 3:

Average Speed (AS)

Distance (DST)

Stop Watch (TT)

Time of Day

Air Temperature

Maximum Speed (MS)

Odometer (ODO)

Accumulated Ride Time (ART)

Time of Day

Maximum Engine

Temperature

Vector will display “- -” for engine temperature

until the temperature reaches 100ºF (38ºC.)

Page 26

Vector Features

26

Vector is in Normal Mode during regular use.

Available Features:

•

•

•

•

•

•

•

Overview:

Sleep Mode:

If V ector receives no data for 20 minutes (either wheel dat a or a button

pressed), it will enter sleep mode. It will only display the clock while

in Sleep Mode. It will exit Sleep Mode when it receives sensor data

or a button is pressed.

Sleep Mode

Speedometer (Speed, Average Speed, Maximum Speed)

Distance (Odometer, Adjustable Trip Distance)

Clock (Time of Day, Ride Time, Stop Watch,

Accumulated Ride Time)

Temperature (Ambient Air and Engine)

Shift Indicators

Reset single-ride data to zero

Page 27

Vector Features

Speedometer:

The speedometer shows the current vehicle

speed. V ector also shows average and maximum

speed since the last reset.

Speed is displayed from 0 to 399.9 M/H or KM/H

in the top left of screen 1. The SPD icon and

KM/H or M/H will also appear next to the speed

reading.

Average Speed displays on screen 2 next to the

AS icon. The average speed the vehicle has

travelled since the last reset.

Maximum speed is displayed on screen 3 next

to the MS icon. Maximum and average speed

are reset by a trip-data reset <LEFT> + <MODE>.

Description:

Speed:

Average Speed:

Maximum Speed:

27

Page 28

The odometer will provide the user with a numeric

display of total accumulated distance in miles or

kilometers. The odometer is not resettable. The

odometer is shown only on screen 3.

The trip distance meter shows how much distance

has been traveled since the last reset.

Trip dist ance is displayed in the upper right of screens

1 and 2, next to the DST icon.

Description:

Description:

Trip Distance:

Trip Distance Meter:

Vector Features

Odometer:

28

TO RESET TRIP DISTANCE, RESET

SINGLE-RIDE DATA BY HOLDING THE LEFT

AND CENTER BUTTONS FOR 3 SECONDS.

Page 29

Vector Features

29

SCROLL DISTANCE VALUE BY PRESSING

THE RIGHT OR LEFT BUTTONS.

Hold the button down and Vector will scroll faster.

TO EXIT TRIP DISTANCE EDIT, HOLD THE

CENTER BUTTON FOR 3 SECONDS.

Vector will return to normal mode.

Vector will return to normal mode automatically

after 5 seconds of inactivity.

Note: For a quicker way to adjust distance see Rally Mode, page 38.

Adjustable Trip Distance Edit:

ENTER TRIP DISTANCE EDIT BY HOLDING

THE CENTER BUTTON FOR 3 SECONDS.

The trip distance meter shows how much distance

has been traveled since the last reset.

Trip distance is displayed in the upper right during

trip distance edit mode, next to the ADST icon.

Description:

Adjustable

Trip Distance:

Page 30

Vector Features

The time-of-day clock is displayed in the bottom right

corner of all three screens next to the clock icon and

during sleep mode. The clock is displayed in either

12H or 24H format.

Time-of-Day

Clock:

Stop Watch:

Clock and Stop Watch:

30

The stop watch (TT) is displayed

on screen 2. The stop watch

functions like any simple stop

watch. Press <LEFT> or

<BOTTOM> to start or stop the

stop watch.

TO RESET THE STOP WATCH, RESET

SINGLE-RIDE DATA BY HOLDING THE LEFT

AND CENTER BUTTONS FOR 3 SECONDS.

Page 31

Vector Features

Ride Time and Accumulated Ride Time:

Accumulated Ride Time (ART) tracks the total

amount of time the vehicle has been in motion.

Accumulated Ride Time is not resettable.

The highest Accumulated Ride Time Vector can

display is 9999:59 hours (when the maximum

value is reached, V ector will not roll the number

back to 0).

Ride Time

Accumulated Ride Time:

Description:

Display:

31

Ride time is displayed in the

bottom left corner of screen 1.

Ride time shows how long the

engine has been running since

the last reset.

TO RESET RIDE TIME TO 0, RESET

SINGLE-RIDE DATA BY HOLDING THE LEFT

AND CENTER BUTTONS FOR 3 SECONDS.

Page 32

When Temperature reaches Vector’s High Temp Setting, the left

LED will light, signaling the bike is starting to get too hot.

When Temperature reaches Vector’s Danger Temp Setting, the

right LED will light, signaling the bike is dangerously hot.

Temperature measurements use user defined values to advise

when the engine is getting too hot. Temperature cut-off values

must be programmed manually. See page 22.

Vector must be connected to external power or LED’s will not

function.

Vector Features

Ambient Air Temperature/

Engine Temperature:

V ector displays dif ferent temperature information on each of the three

normal mode screens.

Screen 1:

Screen 2:

Screen 3:

Temperature LED’s:

•

•

•

•

RIGHT LED:

Over-Temp Alert

LEFT LED:

Temperature

Caution Alert

32

Vector will display “- -” for engine temperature

until the temperature reaches 100ºF (38ºC.)

Engine temperature

Air (ambient) temperature

Displays maximum engine temperature received by the

sensor since the last reset

Page 33

Resets temporary data:

•

•

This data should be reset to zero at the completion of a ride so that

new information can be logged on the next ride.

Notes:

•

•

Vector must be reset in order to recognize sensors:

•

•

33

Normal Mode

Reset Single-Ride Data to Zero:

TO RESET SINGLE RIDE DATA,

HOLD THE LEFT AND CENTER

BUTTONS FOR 3 SECONDS.

The reset can be done from any screen.

Accumulated Ride Time (ART) and Odometer (ODO) cannot be

reset and are intended to maintain cumulative information.

Maximum Speed (MS)

Stop Watch (TT)

If any wires become unplugged from Vector, do a data reset after

everything is properly re-connected.

Alternatively, push the red reset button on the back of Vector.

Maximum Speed (MS)

Stop Watch (TT)

•

•

Page 34

Lap Timer Mode Displays:

•

•

•

•

•

Individual Lap Data Screens:

•

•

•

•

Lap Timer Mode

34

This enhanced feature set is designed for race riders and time trials.

Hit the lap counter button each time around the track -- compare lap

times on the fly with pace lights, or wait and review precise lap

information afterwards. Remote switch required for lap timer Mode.

Overview:

Speed (SPD)

Distance (DST)

Lap Number (LAP)

Lap Timer (TT)

Engine Temp (All Screens)

Individual Lap Speed (SPD)

Individual Lap Distance (DST)

Individual Lap Times (TT)

Lap Number (LAP)

Lap Timer Screens:

Maximum Lap Data Screen:

•

•

•

•

Total A verage Lap Data Screen:

•

•

•

•

Max Speed All Laps (MS)

Total Distance All Laps (DST)

Total Time All Laps (TT)

Lap Icon (LAP)

Average Lap Speed (AS)

Average Lap Distance (ADST)

Average Lap Time (ATT)

Lap Icon (LAP)

Page 35

Lap Timer Mode

35

Pace Lights:

V ector keeps track of how fast each lap has been run. At the beginning

of Lap 3, the red and amber LED’s will begin working.

•

•

•

Notes:

•

•

Amber means faster than the last lap.

Red means slower than the last lap.

A blinking LED means the last lap was the record: either the fastest

or slowest lap yet. Amber for fastest or red for slowest.

LED comparison information is accurate to the second. When the

rider completes two identical laps (down to the second,) neither

LED will light up.

The LED’s will not function unless Vector is installed into a 12 volt

electrical system.

RED LEDAMBER LED

Page 36

Confirm Vector is in lap timer mode by checking for the LAP icon.

•

•

•

•

TO START OR STOP COLLECTING

LAP DATA, PRESS THE TOP BUTTON.

At the beginning of each new lap, press the bottom button on the

remote switch to end the current lap and begin a new lap. V ector will

display “LAP” for 3 seconds when the new lap begins. Repeat for

each new lap. Press the top button at the race end to stop the lap

timer.

TO SIGNAL A NEW LAP, PRESS THE

BOTTOM BUTTON WHEN LAP TIMER

IS ACTIVATED OR RUNNING.

When lap mode is first entered, “ON” will be visible, the lap timer

active and Vector will be waiting for wheel data.

Vector waits for two wheel revolutions before collecting data

(in order to activate on the start line, but before the start signal.)

“ON” will appear when lap timer is activated or running.

“LAP” will appear when the lap timer is stopped; after 3 seconds

“LAP” will change to “OFF”.

36

Lap Timer Mode

Start / Stop Lap Timer:

Signal New Lap:

Enter or Exit Lap Timer Mode:

ENTER OR EXIT LAP TIMER MODE

FROM NORMAL MODE BY HOLDING

THE TOP AND BOTTOM BUTTONS ON

THE REMOTE SWITCH FOR 3 SECONDS.

The LAP icon will appear indicating Vector is in lap timer mode.

The remote switch is required to enter lap timer mode.

Page 37

View lap information when in lap timer mode, the vehicle is stopped

and the lap timer is paused.

TO ENTER OR EXIT LAP DATA REVIEW

MODE, PRESS THE MIDDLE BUTTON ON

THE REMOTE WHILE IN LAP TIMER MODE.

LAP DATA REVIEW MODE IS A LOOP.

PRESS THE TOP OR BOTTOM BUTTON

ON THE REMOTE TO SCROLL THROUGH

LAP DATA SCREENS.

Vector shows lap data screens in order:

At the beginning of each ride, clear lap timer data so new information

can be gathered. Lap timer data can only be reset from within lap

timer mode.

TO CLEAR LAP TIMER DATA, HOLD

THE LEFT AND CENTER BUTTONS

DURING LAP TIMER MODE.

37

Lap Timer Mode

Clear Lap Timer Data:

Lap Data Review Mode:

1:

2:

3:

Individual lap data screens

“SPD, DST, TT, and LAP” will appear when viewing individual

lap data screens. Vector can record information for up to 29

laps.

Total maximum lap data screen

“MS, DST, TT, and LAP TOTAL” will appear when viewing

the maximum lap data screen.

Total average lap data screen

“AS, ADST, ATT, and LAP TOTAL” will appear when viewing

the average lap data screen.

Page 38

In Rally Mode, the adjustable distance ( ) icon will be visible.

In Rally Mode, the buttons on the main computer will operate and

all information will be visible as normal. The remote switch buttons

will be reserved for Rally Mode until Rally Mode is exited.

V ector will not return to normal mode automatically. Vector will st ay

in Rally Mode for quick distance adjustments.

38

SCROLL DISTANCE VALUE BY PRESSING

UP OR DOWN ON THE REMOTE.

Hold the button down and Vector will scroll faster.

TO EXIT RALLY MODE, HOLD THE MIDDLE

BUTTON ON THE REMOTE FOR 3 SECONDS.

Vector will return to normal mode.

On-the-Fly Adjustable Trip Distance Edit:

Rally and enduro racing requires the rider to be able to adjust the trip

distance meter quickly and easily. Rally mode requires the remote

switch.

ENTER RALLY MODE FROM NORMAL MODE BY

HOLDING THE MIDDLE BUTTON ON THE REMOTE

SWITCH FOR 3 SECONDS.

Rally Mode

•

•

•

Page 39

39

Notes

Notes:

Page 40

40

Troubleshooting

Why does nothing work?

•

•

Why doesn’t the engine temperature feature work?

•

•

•

Everything is working, but the (K)MPH reading is way off.

•

•

Vector is not displaying information correctly.

•

•

Frequently Asked Questions:

You must have the engine temperature sensor installed correctly

for this feature to function. Review installation procedure.

If a wire has become disconnected and plugged back in, perform

a reset by pressing <LEFT>+<CENTER> or the reset button on

the back of Vector. A data reset must be performed in order for

Vector to re-recognize the sensors if they become unplugged.

V ector will display “- -” for engine temperature until it reaches 100ºF

(38ºC.)

Try the reset button on the back of Vector.

The internal battery may be dead, or Vector is not hooked up to

vehicle power properly. Review installation procedure.

The speed sensor/magnet may be installed incorrectly. Double

check to make sure everything is set up right. See page 14-15.

The wheel size setting may be incorrect. Please review wheel size

measurement instructions in this manual. See page 16.

If the wires on the back of Vector become damaged, incorrect

readings may be displayed.

Avoid twisting, crimping, kinking or otherwise abusing the wires.

Page 41

41

Troubleshooting

REMEMBER TO PAY ATTENTION

TO THE TRAIL WHILE RIDING.

The screen is hazy or crazed.

•

The backlight won’t stay lit.

•

Vector’s internal battery is dead.

•

Why aren’t the LED’s working?

•

•

A wire came unplugged, and now the sensors don’t work.

•

Did gasoline, degreasers, or other chemical cleaners come in

contact with V ector’s screen? Some chemicals can damage V ector.

Vector needs to be connected to vehicle’s 12 volt system in order

for the backlight to be continuous on. Review installation procedure.

See page 9.

To replace the battery, use a coin to unscrew the round panel on

the back of Vector. Remove the old battery and install the new

one. Make sure the positive pole is facing up. Replace with

common watch battery CR2302. See page 10.

Vector needs to be connected to vehicle’s 12 volt system in order

for the LED’s to function.

Settings must be programmed manually. See pages 8, 22, and 35.

A data reset must be performed in order for Vector to re-recognize

the sensors if they become unplugged. Perform a reset by pressing

<LEFT>+<CENTER> or the reset button on the back of Vector.

Page 42

Glossary of Terms

ACCUMULATED RIDE TIME (ART): The long-term total amount of

time spent riding (all ride times added together). Cannot be reset.

ADJUSTABLE DISTANCE EDIT (ADST): Edit s the distance traveled

since the last trip data reset. Useful for rally and enduro racing.

Similar to rally mode but does not require the remote switch.

AVERAGE SPEED (AS): The median (average) speed the vehicle

has been traveling since the last trip data reset.

BACKLIGHT: The light that brightens up Vector’s display.

DATA SETTING MODE: The place to set Vector’s settings. Includes

distance units, wheel size, clock format, time, temperature units, high

temp setting, over temp setting, and oil and maintenance reminders.

DISTANCE (DST): The amount of trail covered since the last reset.

HIGH/OVER TEMP INDICATORS: The LED’s will blink when the

bike gets too hot and again when it gets dangerously hot.

LAP TIMER MODE (LAP): This enhanced feature set is designed

for race riders and time trials. Compare lap times on the fly with pace

lights, or wait and review recorded lap information after the race. Lap

timer mode requires the remote switch.

MAINTENANCE REMINDERS ( ): User programmable

countdown in miles or kilometers for oil and care reminder icons.

42

Page 43

Glossary of Terms

MAXIMUM SPEED (MS): Highest speed achieved since the last reset.

NORMAL MODE: Vector’s standard mode.

ODOMETER (ODO): The total accumulated distance Vector has

traveled. The odometer is permanent and cannot be reset.

RALLY MODE (ADST): Rally and enduro racing requires the rider

to be able to adjust the trip distance meter (DST) quickly and easily.

During rally mode, distance adjustments are as easy as pressing a

button on the remote switch. Rally mode requires the remote switch.

REMOTE SWITCH: Mounts to handlebar next to grips. The remote’ s

buttons act as duplicates of the buttons on the main computer. The

remote is required to access lap timer and rally modes.

RIDE TIME (RT): Shows how long the engine has been running since

the last reset.

SENSORS: The speed sensor works with the magnet to let Vector

collect its wheel data and a second sensor will measure the temperature.

SLEEP MODE: If Vector doesn’t receive any sensory information it

will go into Sleep Mode and only display the clock.

SPEED (SPD): The current speed the vehicle is traveling.

STOP WATCH (TT): A short term, regular stop watch.

WHEEL SIZE: V ery important. Used to determine speed and dist ance.

Refer to the Wheel Measurement section for an accurate measurement.

43

Page 44

LIMITED WARRANTY

Within one year from the date of original purchase, Trail Tech will

repair or replace, at its option, any Trail Tech powersport computer

which is deemed defective in workmanship or materials.

Please contact Trail Tech or dealer where item was purchased for

assistance.

Damage or injuries resulting from negligence or misuse are not covered

by this warranty. Incidental or consequential damages are specifically

excluded.* This warranty gives you specific legal rights. You may

also have other rights which vary from state to state. *Because some

states do not allow the exclusion of incidental or consequential

damages, this exclusion may not apply to you.

MADE IN AMERICA

Trail Tech and Vector are

trademarks of Trail Tech, Inc.

www.trailtech.net

360-687-4530

Loading...

Loading...