1. POWER OVERVIEW

Endurance II can run on the internal 3.0V watch type

battery (#CR2032).

Install the power wire to enable the continuous backlight.

Endurance II is polarity independent and has safeguards

to avoid draining the vehicle battery. See the POWER

CONNECTION section for more info.

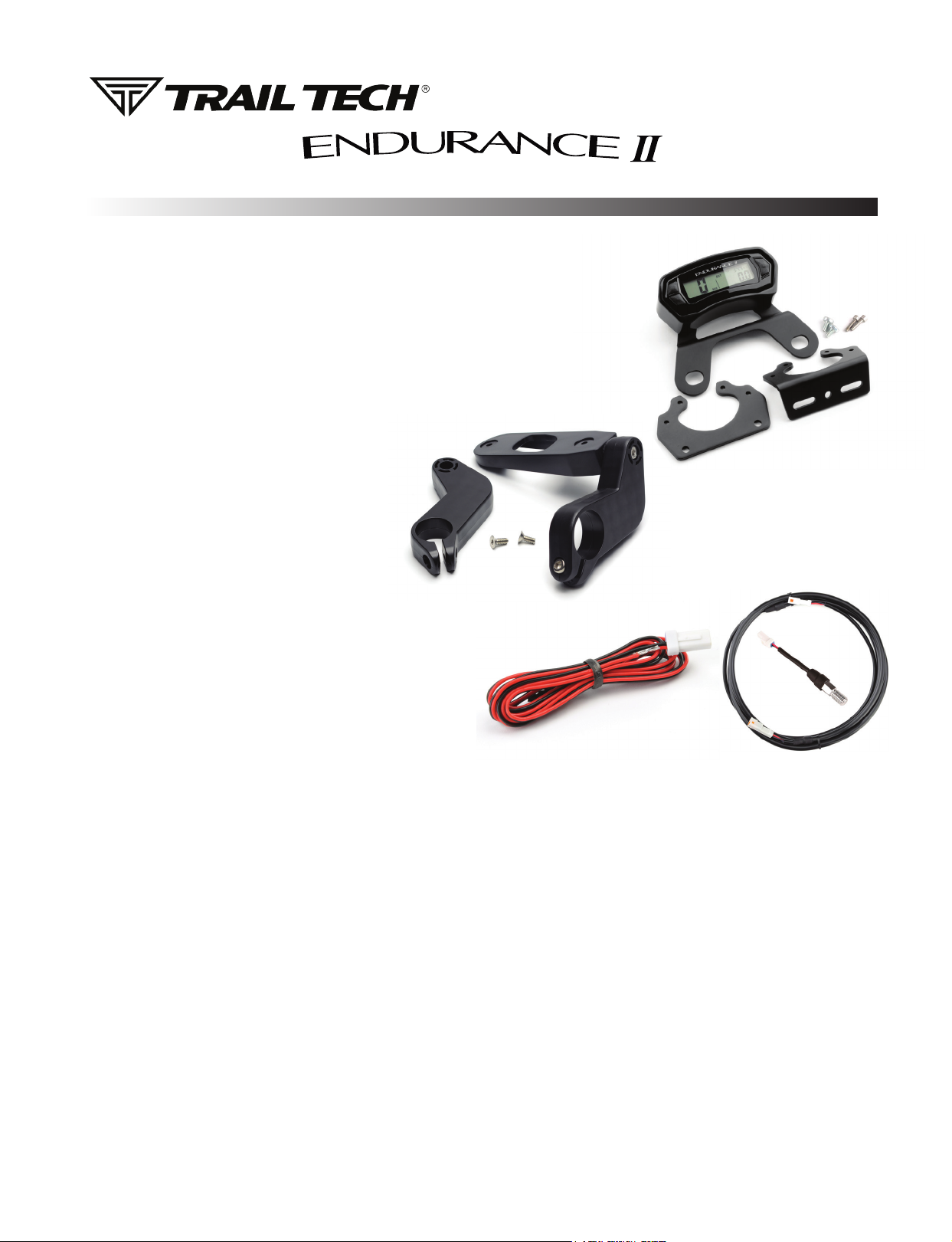

2. MOUNT ENDURANCE II:

Endurance II is made to be bolted to the vehicle. Use

the included handlebar mounts, or refer to the manual

or www.trailtech.net for other options like the CNC

aluminum protector.

Tech Support: (844) 378-8143

010-ELV-197

technicalservice@apexproductgroup.com

QUICK-START

Aluminum

Protector Mount

(optional)

Included

Handlebar

Mount

3. VEHICLE SENSORS:

Refer to the sensor installation sections. You should install

both the wheel sensor and vehicle power connection.

Installing the power wire enables a continuous and brighter backlight.

Installing the wheel sensor enables speed and distance readouts.

Power Wire Wheel Speed

4. MAINTENANCE REMINDER:

Endurance II’s maintenance icon appears after the countdown gets to 0. Increase the countdown in DATA SETTING MODE.

The countdown can be based on either DISTANCE or TIME, select your preference in DATA SETTING MODE.

5. SLEEP MODE:

Endurance II goes to sleep if no vehicle activity is detected.

During sleep mode Endurance II uses the internal battery and will not draw down vehicle power.

a. Wakes on external power

b. Wakes on wheel movement

c. Wakes on button press

d. Backlight shuts off after 90 seconds of inactivity

e. LCD shuts off and clock is displayed after 180 seconds of inactivity.

Sensor (varies)

QUICK-START

6. BUTTONS:

Endurance II has three screens. Press MODE to toggle between them.

Button 3

Next

Button 1

Increment

Up

Button 2

Decrement

Down

RESET TRIP DATA:

<LEFT> + <MODE> = HOLD TO RESET VALUES FOR:

Max Speed, Distance, Ride Time

ADJUST TRIP DISTANCE:

<MODE> + 3 sec = ENTER ADJUST MODE

<LEFT>, <RIGHT> = SCROLL VALUE

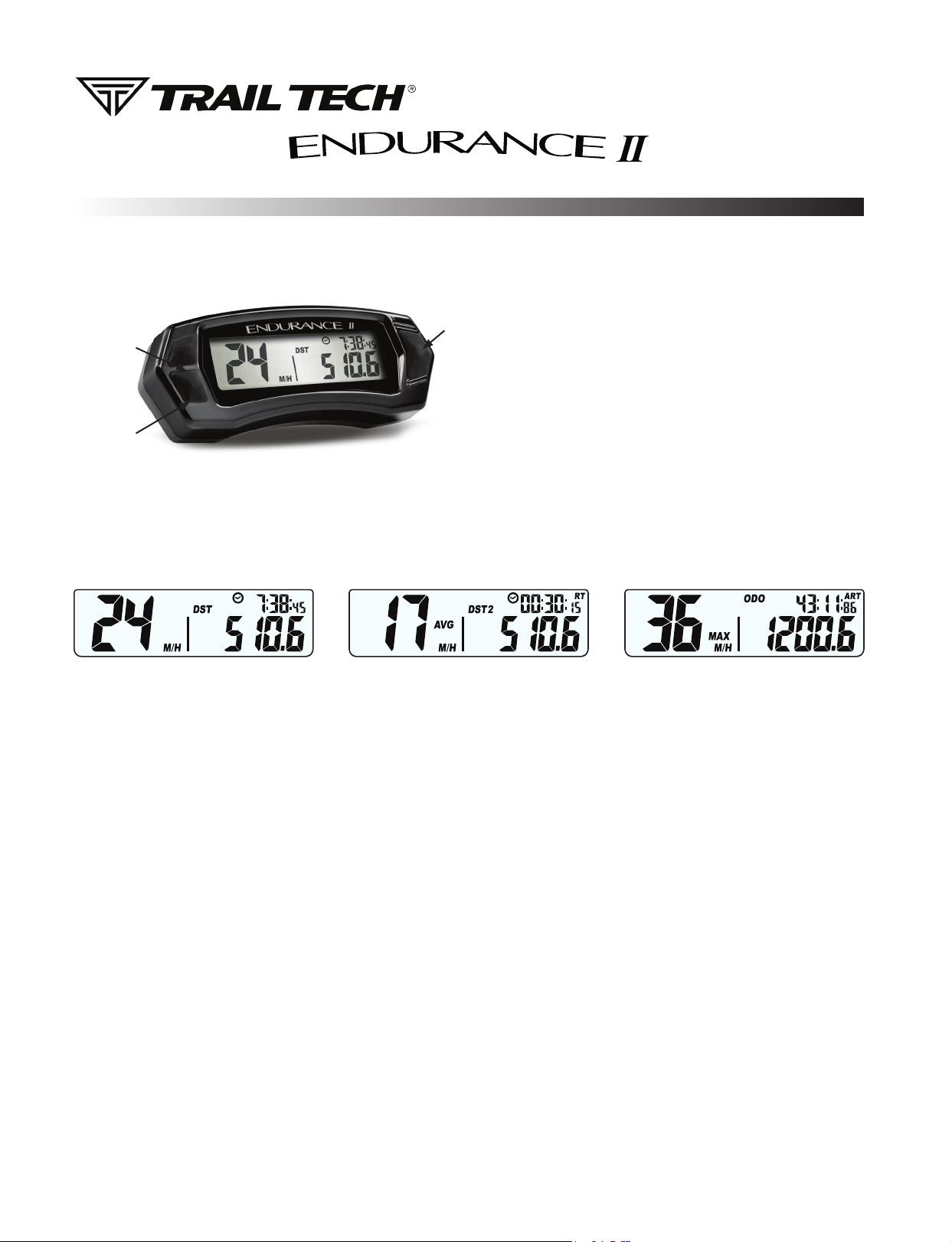

7. SCREENS:

Endurance II has 3 screens, press BUTTON 3 to cycle between screens. Hold all three buttons to enter data setting mode.

SCREEN 1

• Speed

• Trip Distance 1

• Clock

SCREEN 1 BUTTONS:

• Press and hold buttons 1 & 2 for three

seconds to reset DST.

• Press and hold button 3 to enter DST

adjustment. Use buttons 1 & 2 to increment

and decrement your DST. Press button 3 to

return to main screen.

• Speed - Average

• Trip Distance 2

• Ride Time

SCREEN 2 BUTTONS:

• Press and hold buttons 1 & 2 for three

seconds to reset DST2, Ride Time, & AVG

Speed.

• Press and hold button 3 to enter DST2

adjustment. Use buttons 1 & 2 to increment

and decrement your DST2. Press button 3

to return to main screen.

SCREEN 2

SCREEN 3

• Speed - Max

• Odometer (ODO)

• Accumulated Ride Time (ART)

SCREEN 3 BUTTONS:

• Press and hold buttons 1 & 2 to reset

Max Speed.

• To view time remaining until service

maintenance interval icon is activated

press and hold Button 3 for three

seconds.

• When the maintenance icon is

displayed, hold button 3 for three

seconds to enter maintenance interval

screen (to reset, hold button 1 & 2 for

three seconds.)

8. DATA SETTING MODE :

HOLD DOWN ALL 3 BUTTONS to enter data setting mode.

Adjust one setting at a time, then move on to the next one.

<BUTTON 1> = Increase value

<BUTTON 2> = Decrease value

<BUTTON 3> = Move to next data setting screen

ORDER OF SETUP MODE:

1. Speed and Distance Format

2. Wheel Size

3. Time Format

4. Time of Day

5. Maintenance Format

6. Maintenance Countdown

M/H or KM/H

See MEASURE WHEEL SIZE section

12H or 24H

12:00:00

Based on ODO Distance or ART Time

Distance or Time to Countdown From

WHEEL SENSORS

INSTALLS

KTM WHEEL SENSOR

Trail Tech wheel

sensors work with the

KTM and Husqvarna

OEM install location.

Screw the wheel

sensor into the OEM

caliper position. Insert

the black magnet into

the pre-drilled hole in

the rotor and secure

with the retainer clip.

KTM Magnetic

Retainer

KTM OEM Wheel

Sensor Position

INVERTED FORK WHEEL SENSOR

If there are fork

guards next to the

brake rotor, then the

fork guard wheel

sensor can be

installed as shown.

Try to have the tip of

the sensor about 1/2

inch away from the

magnet in the rotor.

Rotor Bolt Magnet Inverted Fork

Wheel Sensor

CONVENTIONAL FORK SENSOR

If the fork is close to

the brake rotor, then

the VHB fork sensor

can be used. Peel

and stick the sensor

to the fork.

Try to have the tip of

the sensor about 1/2

inch away from the

magnet in the rotor.

Rotor Bolt Magnet Conventional Fork

VHB Wheel Sensor

ROTOR SHIELD WHEEL SENSOR

For UTVs and quads

with a rotor shield,

position the sensor

there.

Drill a 3/8” hole and

use the jam nuts to

secure the sensor to

the rotor shield. Use

loctite rather than

over-tightening the

jam nuts.

Rotor Shield

Wheel Sensor

BRAKE CALIPER WHEEL SENSOR

Some ATVs require

mounting the wheel

sensor directly to the

brake caliper.

Drill a 1/8” hole

through the caliper

mount, then use the

self-tapping screw to

secure the sensor.

Brake Caliper

Wheel Sensor

MAGNET INSTALLATION:

Install a magnet on the brake rotor to trigger

the speed sensor each wheel rotation.

Remove one of the stock rotor bolts and

install the magnetic rotor bolt as shown, do

not overtighten past 10 ft-lb of torque. If the

magnetic bolt will not work, the kit includes a

spare magnet that can be installed into one

of the rotor spaces. Use the included retainer

clip or epoxy such as JB Weld to secure.

C-BRACKET WHEEL SENSOR

Some kits include

a metal C-bracket

to help mount the

sensor, as shown.

Use the jam nuts to

secure the sensor to

the C-bracket. Use

loctite rather than

over-tightening the

jam nuts.

Magnetic Retainer or Spare MagnetMagnetic Rotor Bolt

C-Bracket

Wheel Sensor

WHEEL SENSORS

SETUP

WHEEL SENSOR TEST:

Test for correct sensor/magnet placement before permanently mounting.

1. Set the vehicle on a stand so that the front (left) wheel spins easily.

2. Plug the wheel sensor cable into the computer.

3. Install the magnetic bolt.

4. Hold the sensor in place on the caliper mount by hand. While someone

watches the computer, roll the wheel. If the computer does not register,

move the magnet or sensor and try again. There should be 1/2” or less

gap between the sensor and magnet.

Do not mount so that the magnet passes the middle section of the

sensor. Either the sensor will not register at all; or the sensor will

register twice, causing a “double trigger” effect (computer displays

twice the true speed.) If a double-trigger is unavoidable, divide the wheel

size setting in the computer by 2 to correct the problem.

MEASURE WHEEL SIZE:

Knowing your exact wheel size it critical for the wheel sensor to calculate

correct speed and distance data.

Magnet Rotation Path

When comparing calibration to GPS data, use a long straight section of road

with no tight corners or small vertical movements.

Method 1: Ruler

Find the circumference of front wheel by measuring its diameter in millimeters.

Multiply the Wheel Diameter by 3.14. The result is your wheel size.

Method 2: Rolling

On a at surface, mark the tire sidewall and the ground with a marking pen. Roll the

wheel until the mark on the tire completes one revolution and is back on the ground. Mark

the ground at this location. Measure the distance between the marks on the ground in

millimeters (multiply inches by 25.4 to convert to mm). Use this number for your wheel size.

For accuracy, the rider’s weight should be on the bike when making the measurement.

Method 3: Distance Measurement

This is the most accurate method.

1. Set the wheel size to 2110mm (motorcycle) or 1675 (ATV).

2. Find a length of road where the distance is known.

3. Ride the distance, noting how far the computer reads (i.e. the road

is known to be 5 miles and the computer shows 4.95 miles.)

4. Use the numbers to solve for X in the following equation:

(new wheel size)

(actual miles) x (current wheel size)

=

(current miles)

Wheel Size =

Wheel Diameter(mm)

x3.14

Diameter

Generic/Average Sizes:

Motorcycle:

ATV:

2110 mm

1675 mm

Wheel Size:

Enter the number you calculate from one of

the above formulas into setup mode.

x3.14

X =

5 x 2110

4.95

X =

10550

4.95

X = 2131

Loading...

Loading...