DUAL-SPORT X2

FEATURES AND WIRING

RUBBER MOUNTING STRAPS:

RUBBER MOUNTING STRAPS:

The two rubber straps wrap around the forks.

They hold the light to the motorcycle and

extend the life of the light by providing

anti-vibration isolation. Rubber straps

with no tools. Use isopropyl rubbing alcohol

as lubricant when attaching the rubber straps

to the light. Take care not to rip or tear.

LOWER MOUNTING PINS:

MOUNTING PINS:

There are four holes on the bottom of X2. 2 pins go through the

holes to secure the bottom of X2 to the

the forward or rear holes to aim X2’s beam. The pins reduce

“excessive play” commonly found with other mounting techniques.

There are several pin options:

install

fender. Choose between

010-ELV-98

DUAL-SPORT X2

Tech Support: 360-687-4530

tech_support@trailtech.net

Fig.1

A) O.E.M. MOUNTING PINS:

Some motorcycles (KTM) arrive from the manufacturer

mounting pins built in (Fig.1). If they are present, use them.

B) MOUNTING PLATE:

Some motorcycles (CRF450R, WR450) arrive from the

manufacturer with the fender bolted to the triple tree (with a

56-60mm bolt spacing and M6 bolts.) Sandwich the included

mounting plate

mounting pins for X2. Use Loctite thread locking compound to

ensure the triple tree

C) DOWN-PINS:

If option A or B will not work, use the included “down pins.” To

install, place X2 on the motorcycle using the rubber fork straps.

Turn on X2 and aim the beam to the desired height.

which set of holes to use on X2 (the down-pins are reversible,

side specific, and usually look best if the screw is to the rear of the

light, as shown in Fig.3.) Use a marking pen to mark where two

holes should be drilled in the fender. Remove the light from the

motorcycle and drill the two 8mm (5/16”) holes. Screw the down

pins to X2 as shown in (Fig.3). X2 should now have two pins that

fit into two drilled holes on the fender

The down-pin drill template to the right may

be used if u

1.

Mount X2 using fork straps, align beam angle.

2. With beam angle in place,

on the fender.

template in correct position on fender.

3. Drill down-pin holes a

Drill 1 set of holes ONLY. Drilling 2 sets of

holes can cause fender plastic to break out.

between the triple tree and fender, providing

bolts do not back out during riding.

.

sing the down-pin option.

center X2 right-left

Cut out and tape down-pin drill

nd install X2.

with

Determine

Fig.2

Fig.3

DISTANCE BETWEEN HOLES

82.3mm

(3-1/4”)

DRILL SIZE

8mm

(5/16”)

DUAL-SPORT X2

FEATURES AND WIRING

CABLE GUIDE:

CABLE GUIDE:

To install, thread the cables through the cable guide, then

screw the

Be sure the cables are routed properly. The forks compress

during riding; the cables need enough room to move up and

down without causing damage.

MX bikes should use longer Enduro brake lines for optimum

X2 fitment.

WRF line, etc.

cable guide to X2 as shown to the right.

Example: CRF uses CRFX brake line, YZF uses

010-ELV-98

DUAL-SPORT X2

Tech Support: 360-687-4530

tech_support@trailtech.net

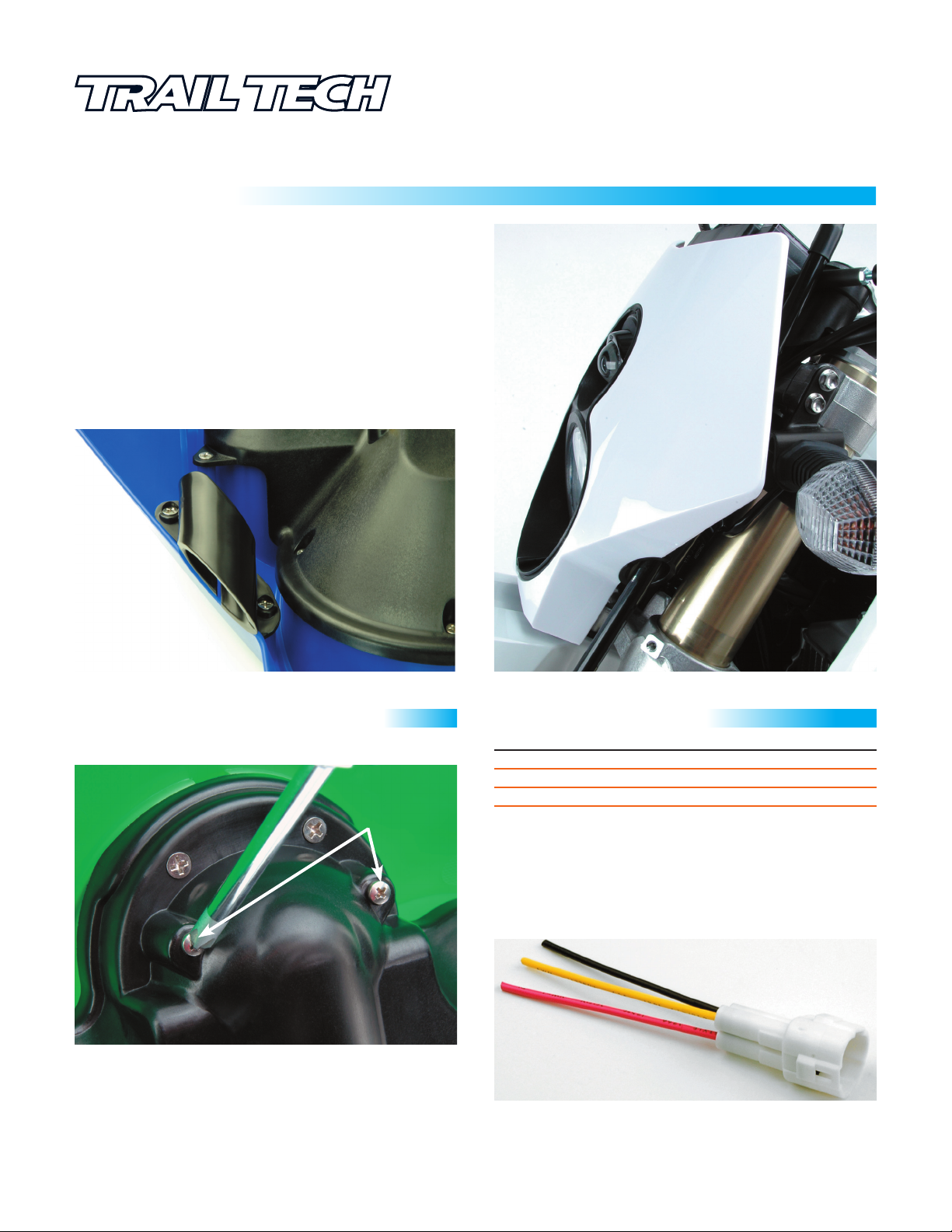

ADJUST MR16 BEAM ANGLE:

1. Turn the two screws shown below to adjust the beam.

ADJUST

SCREWS

1A. LOOSEN the two screws to LOWER the beam angle.

1B. TIGHTEN the two screws to RAISE the beam angle.

The two adjust screws are not required to be snug against

the back of X2.

STUB CONNECTOR:

WIRE COLOR

YELLOW

RED

BLACK

CONNECT TO POWER:

Use the included wire stub connector to connect X2 to

power. The white connector allows for quick disconnect

and removal of X2 from the motorcycle. An on/off switch

is recommended. A fuse (10-20 amp) will protect from any

power spikes.

This stub connector is included in generic X2 kits.

Model-specific X2 kits contain switch-wire harness with

model-correct connectors to ease installation.

FUNCTION

HIGH BEAM

LOW BEAM

GROUND

CONTROLS

4” SC4 BULB

2” MR16 BULB

GROUND

Loading...

Loading...