Traditions Deerhunter Kit User Manual

D. Install the Barrel Tenon (slope facing towards the muzzle) in the dovetail slot located underneath the Barrel. Tap the Tenon into the dovetail cut-out using a small mallet or similar tool.

Note: Barrel Tenon should fit snugly. If the fit is too tight, sparingly file the dovetail portion of the Tenon with a triangular file to reduce it slightly. If the Tenon is too loose, using a hammer and a punch, indent the surface at the base of the dovetail with the punch so as to raise the edges around the punch indentations. An additional method of tightening is to install the Tenon and tap the angular edges of the dovetail with a hammer and punch so as to capture the Tenon.

Note: It will be necessary to remove the Tenon in order to completely coat the dovetail and Tenon surfaces with blueing or browning solutions. Final fitting will happen after coloring.

E.Using the two Rear Sight Screws, attach the Rear Sight Base (incline sloping upward towards muzzle) to the corresponding screw holes on top of the Barrel.

F.Install the Front Sight into the dovetail cut-out on the top front of the Barrel using the same installation technique as with the Barrel Tenon.

Note: As with the Barrel Tenon, final fitting of sights should be done only after blueing or browning the Barrel.

IV Lock Assembly

A.Insert the Lock into its cut-out in the side of the Stock.

B.Position the Ramrod Retaining Spring into the Stock so that the end of the Spring which has the loophole is positioned towards the muzzle and the curve is downwards towards the ramrod channel.

C.Install the Front Lock Plate Screw and Washer through the hole in the Stock, passing it through the loop-hole in the Ramrod Retaining Spring and into its corresponding hole in the Lock Plate.

D.Install the second Lock Plate Screw and Washer.

Note: If holes are not perfectly aligned, enlarge one or both Stock holes with a round file or drill to permit alignment. Screws should be flush with the Lock Plate. File off any portion of the Screws that protrude outside of the Lock Plate for a cleaner look and to insure that a screw does not interfere with the hammer travel.

VInstallation of Barrel Assembly and Trigger Assembly into Stock

A.Test that the Tang Screw turns smoothly within its corresponding threaded hole in the trigger plate by turning it in and out several times to burnish the threads.

B.Test that the Trigger moves freely within the Trigger Guard. If not, move it back and forth a few times to free up any binding. Pushing the trigger sideways in its housing will also help loosen its movement.

C.Test that the Wedge transverses from the right side of the Stock and exits the cut out on the left side. Sparingly remove any wood or metal necessary for an unobstructed fit. Remove Wedge.

5

D.Place the Trigger Guard Assembly into its inlet in the Stock. Sparingly remove wood only if necessary for a close fit. Ensure that the top bar of the Trigger does not touch any wood.

E.Set Hammer in the half-cock position. Place the Barrel, with Tang attached to the breech hook, into the Stock. The Barrel Bolster should be positioned concentrically into its cut-out in the Lock Plate and the Lock Plate should be snug against the Barrel.

F.Insert the Tang Screw through the screw hole in the Tang and pass it through the Stock and into its corresponding hole in the Trigger Assembly. Do not tighten at this time.

Note: In the event the Tang Screw does not align properly, enlarge the hole in the Stock with a round file or drill.

G. Install the Wedge through right side of Stock, engaging the Barrel Tenon and exiting the left side of Stock.

Note: The wedge opening in the Stock can be slightly enlarged if necessary. If the Stock Plates interfere, enlarge opening with a file to permit unobstructed passage of the Wedge. Take care not to bend the Wedge Plates.

H. Tighten Tang Screw securely.

Note: At this point, the Wedge should fit very snugly. Bend the Wedge for a tighter fit. Flatten it for a looser fit. Be sure to always install the Wedge from the right side and always position the top of the bend facing upward.

I.At this point the Hammer should be positioned so that it will fall squarely onto the Nipple. If it does not, one or more of the following steps may be taken:

1.Remove wood from bottom of Lock recess, until Lock is flush with the Barrel.

2.Remove wood as needed from under and behind the barrel channel, including Tang area.

3.Check that the Lock Plate and Lock Plate Screws are snugly fitted into the Stock and the Lock is properly positioned in its cut-out.

4.If proper alignment is not obtained with the previous steps, the Hammer may be bent slightly by removing it from the Lock, heating it and by bending it carefully to obtain the correct alignment.

6

WARNING: NEVER attempt to change the position of the barrel bolster in the Barrel. To rotate it from its original position will impare ignition and could create a DANGEROUS situation with the potential of death or serious bodily injury resulting as well as voiding the warranty.

CAUTION: With the Lock, Barrel and Trigger Assemby installed and all Screws tightened, the hammer should remain securely in its half-cock position and the pulling of the trigger should not cause the hammer to fall. The hammer should also remain in the full-cock position until the trigger is firmly pulled. If the Lock and trigger do not function properly in both positions, remove the Lock and make the following adjustments:

1.Remove only as much wood as necessary inside the lock plate recess to eliminate any binding of the moving parts of the Lock.

2.Heat the protruding dowel like sear arm, located on the inside of the Lock. Using vise grips or pliers, slightly bend it up or down as necessary for better contact with the top of the trigger.

3.If Sear and trigger are too close to each other, it is also acceptable to file the top flat portion of the trigger that contacts the Sear to gain clearance.

VI Final Finishing of Wood and Metal

Note: This is where diligence pays off, proceed slowly and be critical of your work and you will be rewarded with a fine looking firearm.

A.Using progressively finer wood rasp and sandpaper, bring wood and metal surfaces flush with each other. File and sand adjoining surfaces of different components together to achieve a smooth transition between surfaces. Proceed carefully, deliberately and slowly.

B.Remove or tape over metal parts before staining or finishing the Stock.

C.Polish bare steel parts with varying grits of emery cloth, each one finer than the previous. Finish with fine steel wool.

D.Brown or blue steel parts with chemicals available in most gun shops.

P.O. Box 776 • Old Saybrook, CT 06475-0776

www.traditionsfirearms.com

Tel: 860-388-4656

Fax: 860-388-4657

FIT2

899-56108I

7

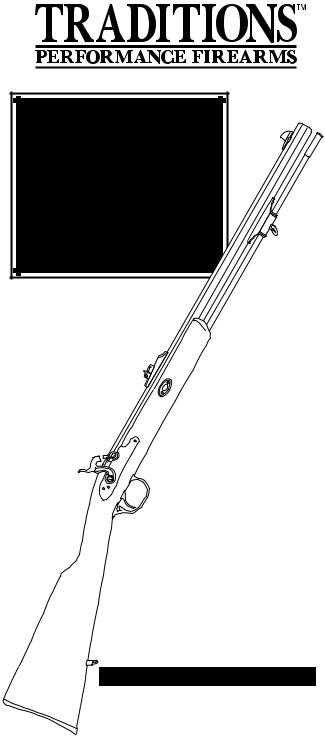

DEERHUNTERTM

RIFLE KIT

ASSEMBLY

INSTRUCTIONS

Engineered For

Today’s Shooter

I M P O R T A N T !

Thoroughly read, understand and be willing to follow the instructions and warnings in this manual before loading or firing your new TraditionsTM Muzzleloader.

Loading...

Loading...