Toyota Tacoma User Manual

Manual Name Pub. No.

7M−GE Engine Repair Manual

TOYOTA SUPRA Chassis and Body

Repair Manual

TOYOTA SUPRA Chassis and Body

Repair Manual Supplement

TOYOTA SUPRA Electrical Wiring

Diagram Manual

TOYOTA SUPRA Repair Manual

(USA and Canada)

TOYOTA SUPRA Electrical Wiring

Diagram Manual (USA and Canada)

Fundamental Body Repair Procedures

Fundamental Painting Procedures

BRM002E

36438E

M/Y Version

M/Y Version

EWD013E

RM036E

RM029E

RM027E

FOREWORD

This repair manual has been prepared to provide information on

the repair methods (including cutting and welding operations,

but excluding painting) recommended by TOYOTA for collision−

damaged body components of the TOYOTA SUPRA.

Applicable models: MA70 series

This manual consists of body repair methods, exploded diagrams and illustrations of the body components and other information relating to body panel replacement such as handling precautions, tools, equipment, etc. However, it should be noted that

the front fenders of all TOYOTA models are bolted on and require no welding.

Body construction will sometimes differ depending on specifications and country of destination. Therefore, please keep in mind

that the information contained herein is based on vehicles for

general destinations.

For the service of specifications and repair procedures other

than collision−damaged body components of the TOYOTA

SUPRA, refer to the following repair manuals.

All information contained in this manual is the most up−to−date

at the time of publication. However, specifications and procedures are subject to change without prior notice.

TOYOTA MOTOR CORPORATION

1

mm

in.

87

3.15

200

7.87

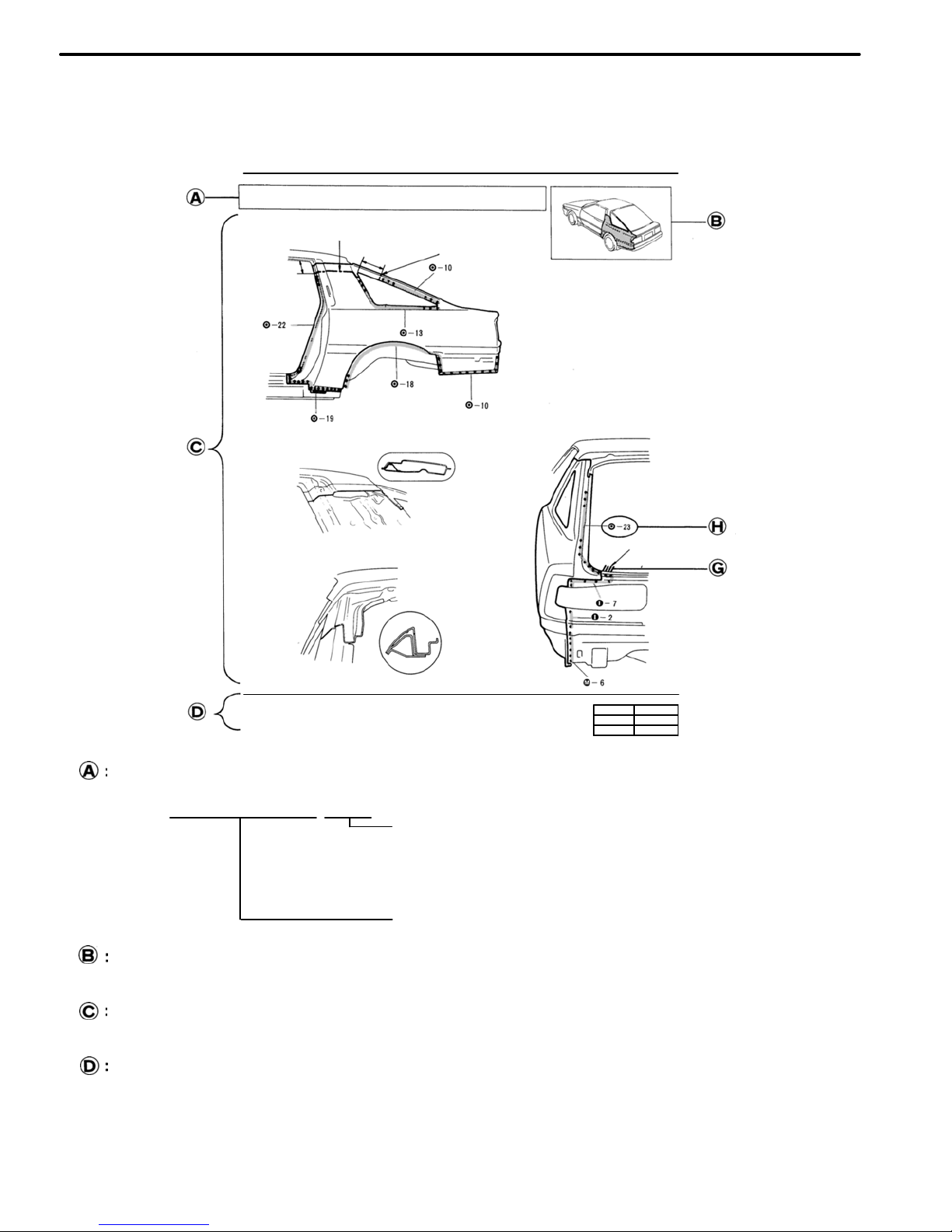

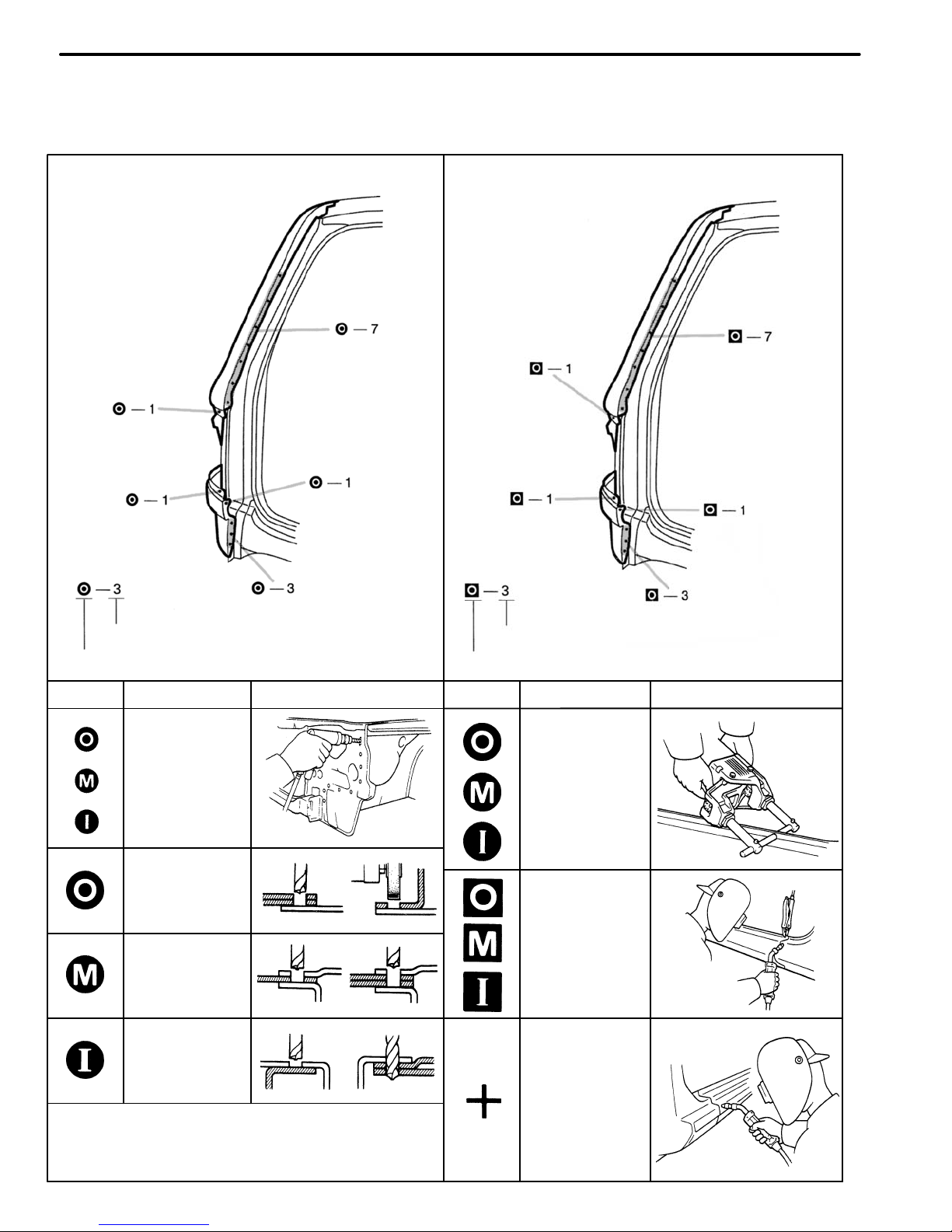

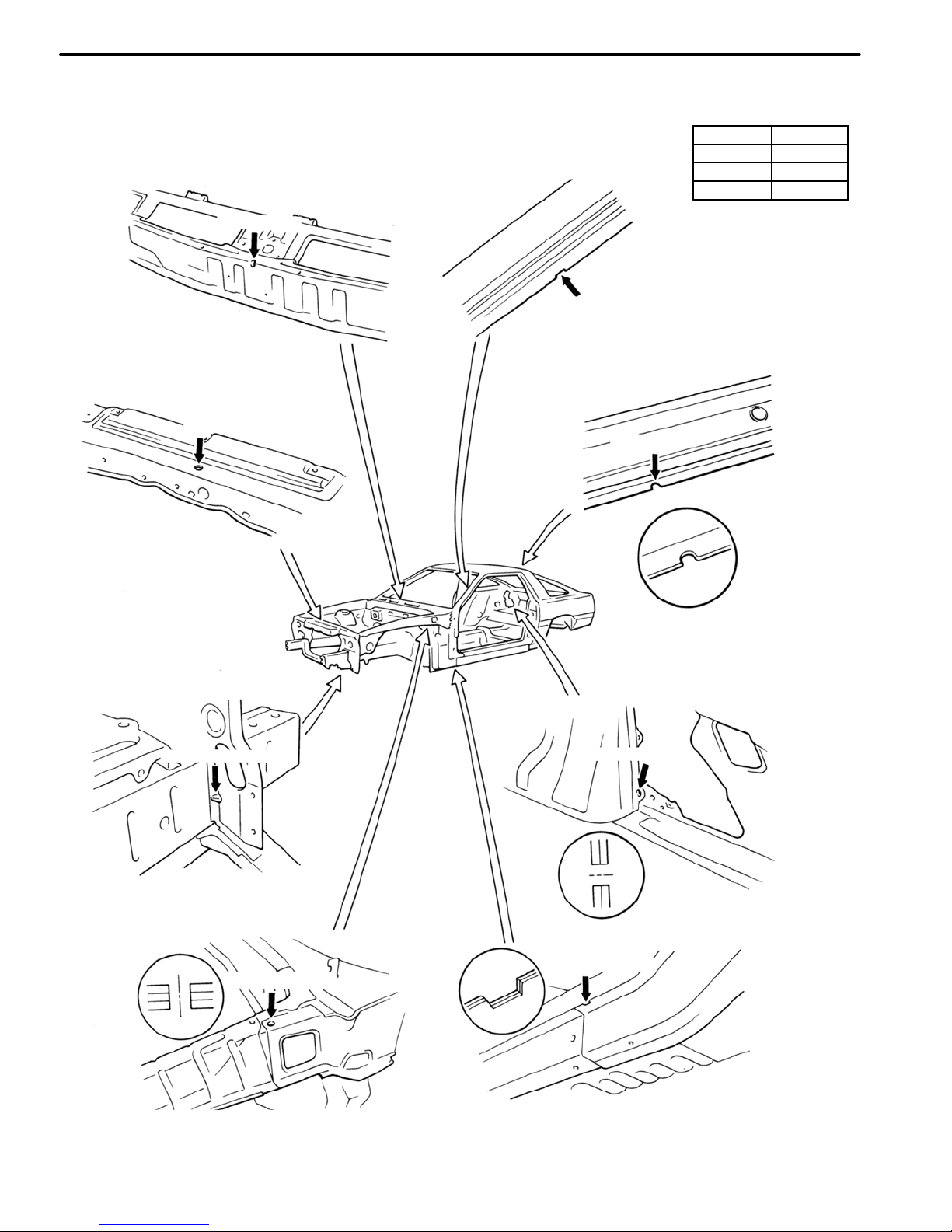

QUARTER PANEL

Cut and Join Location

HOW TO USE THIS MANUAL

Each repair method description provided in Section RE of this manual comprises two pages, divided into

2 blocks (REMOVAL AND INSTALLATION) and includes illustrations to facilitate body repair.

RE−26

BODY PANEL REPLACEMENT−Rear Body Components

QUARTER PANEL (CUT)

REMOVAL

Cut and Join Location

200 mm

80 mm

[Cut and Join Location]

Front

Braze

Rear

1. Cut and join the quarter panel as shown above.

REPLACEMENT PART AND METHOD

(CUT)

Replacement method

(ASSY) Assembly replacement. . . . .

(CUT) Major cutting (less than 1/2 of part used). . . . . .

(CUT−H) Half cutting (about 1/2 of part used). . . .

(CUT−P) Partial cutting (most of part used). . . .

Replacement part

BODY VARIATIONS AND PART LOCATION

Body variations: Non All models. . . .

REMOVAL DIAGRAM

Describes in detail removal of the damaged part involving repair by cutting.

REMOVAL GUIDE

Provides additional information to more efficiently help you perform the removal.

INTRODUCTION

IN-2

mm in.

5

0.20

1. Before temporarily installing the new part, apply

body sealer to the wheel arch portion.

NOTE:

1) Apply sealer approx. 5 mm (0.20 in.) from the

flange, avoiding any oozing.

2) Apply evenly, approx. 3 − 4 mm (0.12 − 0.16 in.)

in diameter.

3) For other sealing points, refer to section SU.

BODY PANEL REPLACEMENT−Rear Body Components

RE−27

INSTALLATION

Butt Weld

Butt Weld

Body Sealer

Braze

Body Sealer

About 5 mm

2. Temporarily installing the new part and check the fit of

the front door, luggage compartment door and rear

combination lamp.

INSTALLATION DIAGRAM

Describes in detail installation of the new part involving repair by welding and/or cutting, but excluding painting.

INSTALLATION GUIDE

Provides additional information to more efficiently help you perform the installation.

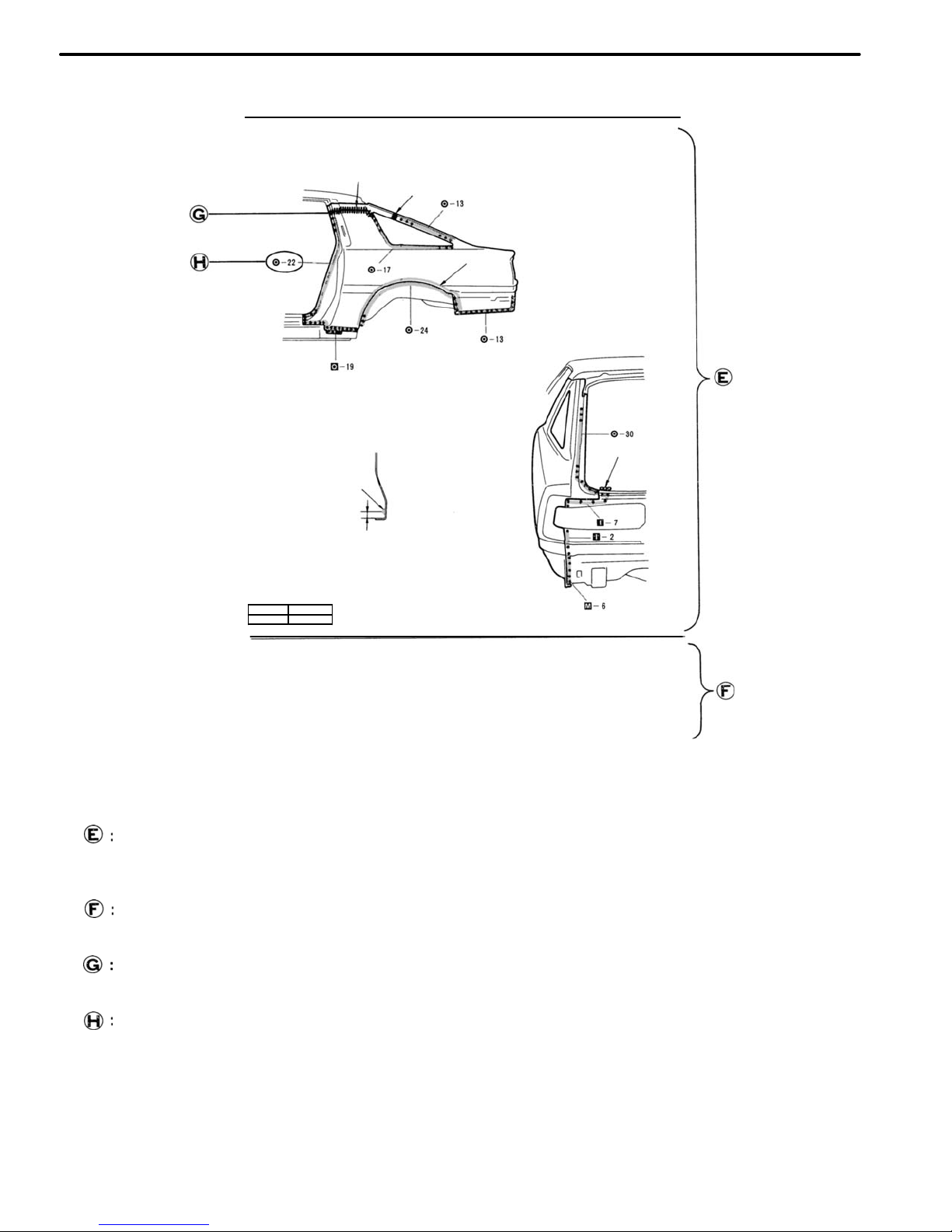

SYMBOLS

See page IN−4.

ILLUSTRATION OF WELD POINT

Weld method and panel position symbols.

See page IN−5.

INTRODUCTION

IN-3

SYMBOLS

MEANING

ILLUSTRATION

SAW CUT OR

ROUGH CUT

REMOVE BRAZE

(See page IN−5)

SPOT WELD OR

MIG PLUG WELD

WELD POINTS

BRAZE

CONTINUOUS MIG

WELD (BUTT WELD

OR TACK WELD)

BODY SEALER

SYMBOLS

The following symbols are used in the welding Diagrams in Section RE of this manual to indicate cutting

areas and the types of weld required.

INTRODUCTION

IN-4

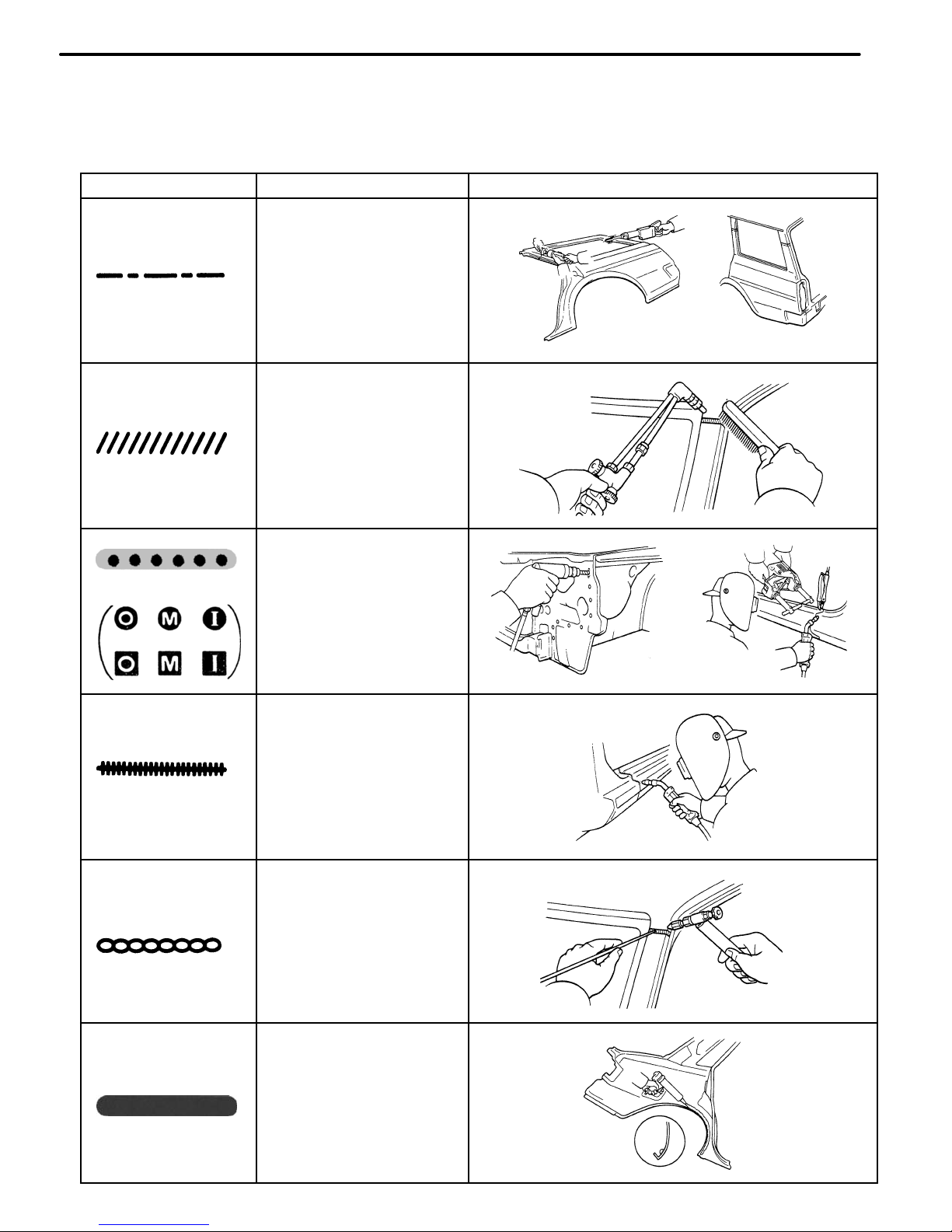

Remove weld point and panel position

Weld points

REMOVAL

Weld method and panel position

Weld points

INSTALLATION

SYMBOL MEANING ILLUSTRATION

SYMBOL

Spot Weld

MEANING

ILLUSTRATION

Remove

Weld

Points

(Outside)

Mig Plug

Weld

(Middle)

(Inside)

Spot MIG

Weld

HINT: Panel position syrnbols are as seen from the

working posture.

Illustration of Weld Point Symbols

EXAMPLE:

INTRODUCTION

IN-5

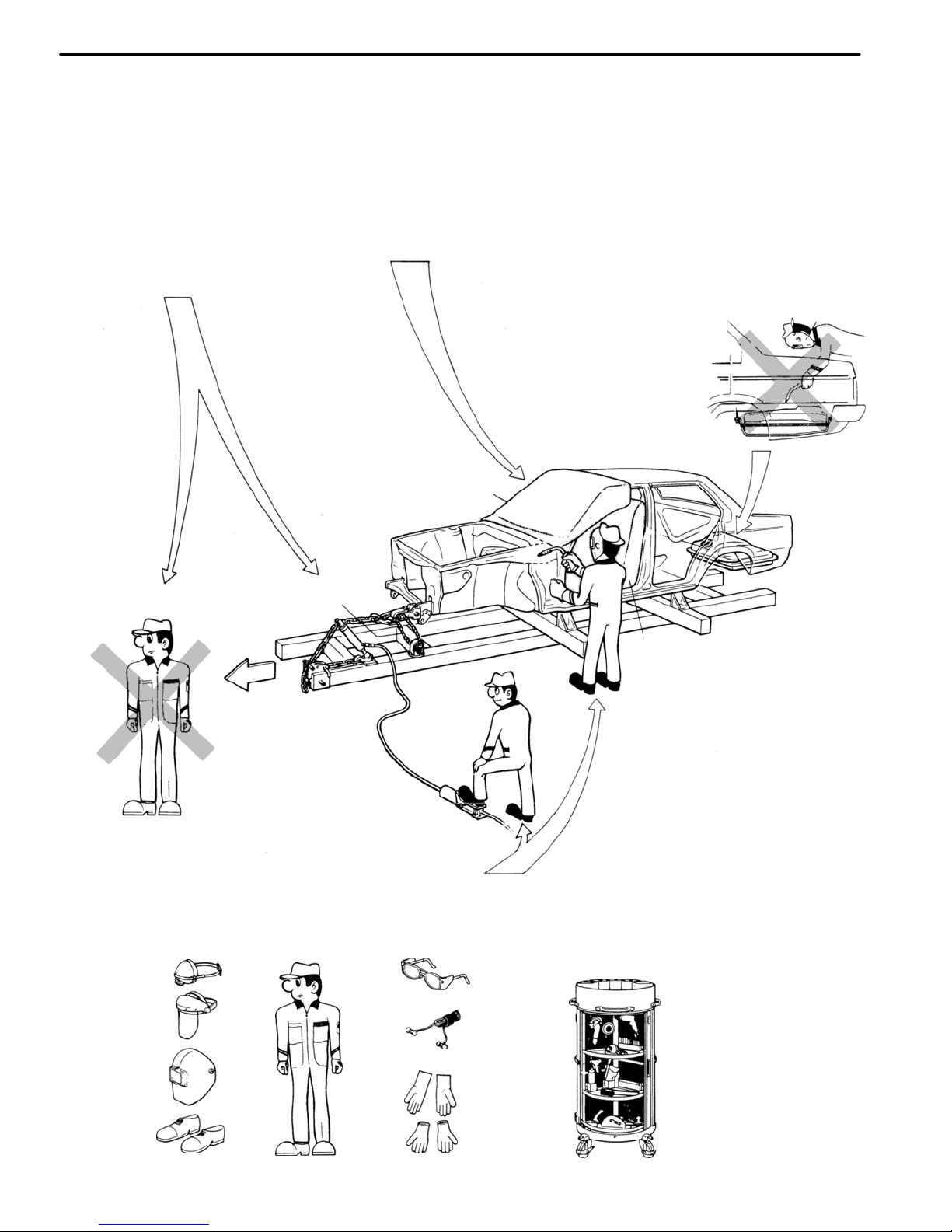

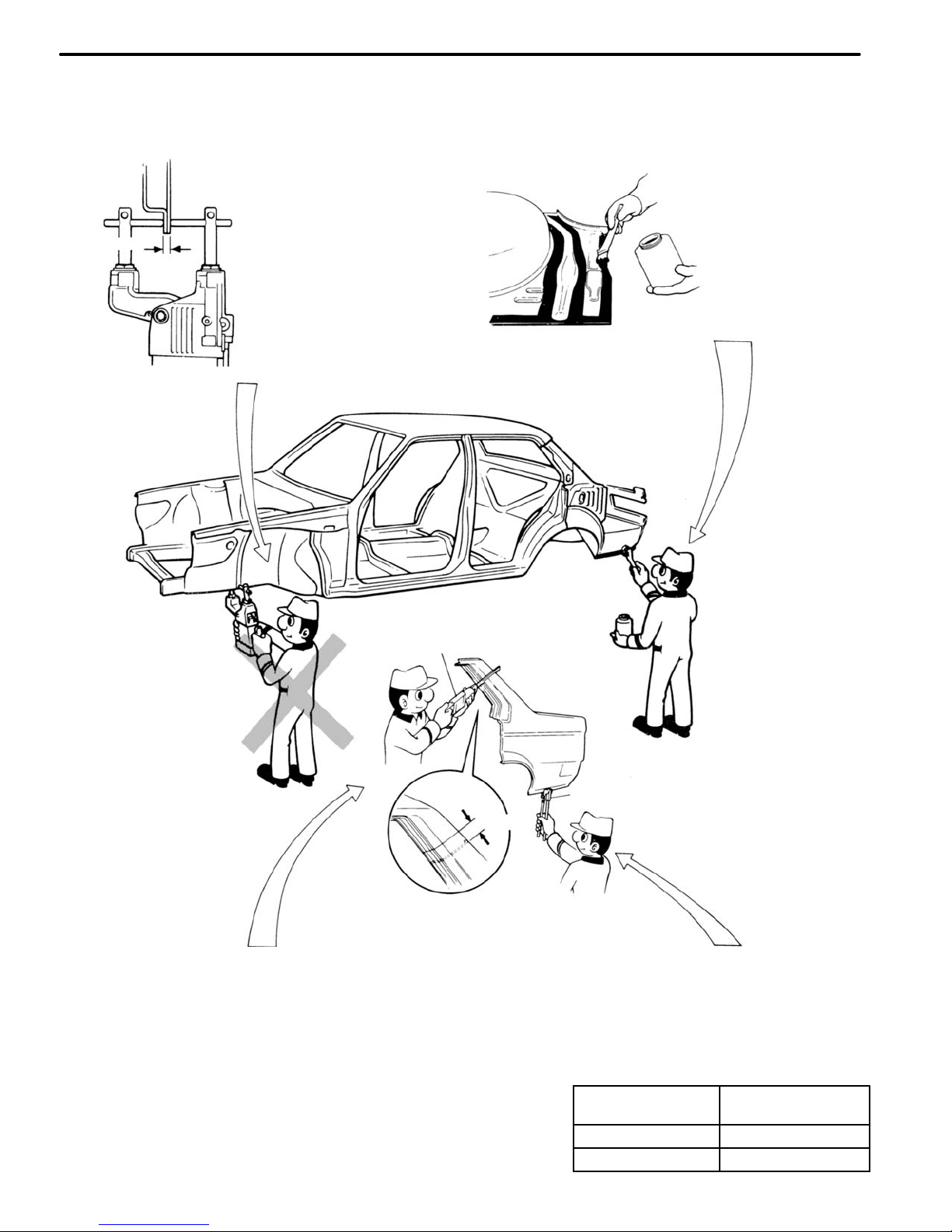

GENERAL REPAIR INSTRUCTIONS

Work Precautions

SAFETY

1. Before performing repair work, check

for fuel leaks. If a leak is found, be sure

to close the opening totally.

2. If it is necessary to use a frame in the

area of the fuel tank, first remove the

tank and plug the fuel line.

SAFETY

Never stand in direct

line with the chain when

using a puller an the

body or frame, and be

sure to attach a safety

cable.

VEHICLE PROTECTION

When welding, protect the

painted surfaces, windows,

seats and carpet with heat−

resistant, fire−proof covers.

WRONG

Glass Cover

Safety Cable

Seat Cover

WRONG

SAFETY

Before performing repair work,

disconnect the battery cables.

SAFETY WORK CLOTHES

In addition to the usual mechanic wear, cap and Safety shoes,

the necessary gloves, head protector, glasses, ear plugs, face

protector, dust−prevention mask, etc. should be worn as the

situation demands.

Welder’s

Glasses

Body

Mechanic

Stand

Dust−

Prevention

Mask

Face

Protector

Ear

Plugs

Head

Protector Welder’s

Gloves

HAND TOOLS

Keeping your hand tools

in neat order will have

an effect on your work

efficiency.

Safety

Shoes

Cotton

Gloves

INTRODUCTION

IN-6

REMOVAL OF ADJACENT

PART S

When removing adjacent parts

by avoid accidental marring,

etc., wrapping the tools used

and surrounding body parts in

protective tape.

NOTE:

1) Take particular care not

to damage any screw or

clip holes.

2) If you do scratch a

painted surface, retouch

immediatly after. Even a

small scratch will result

in rust and corrosion.

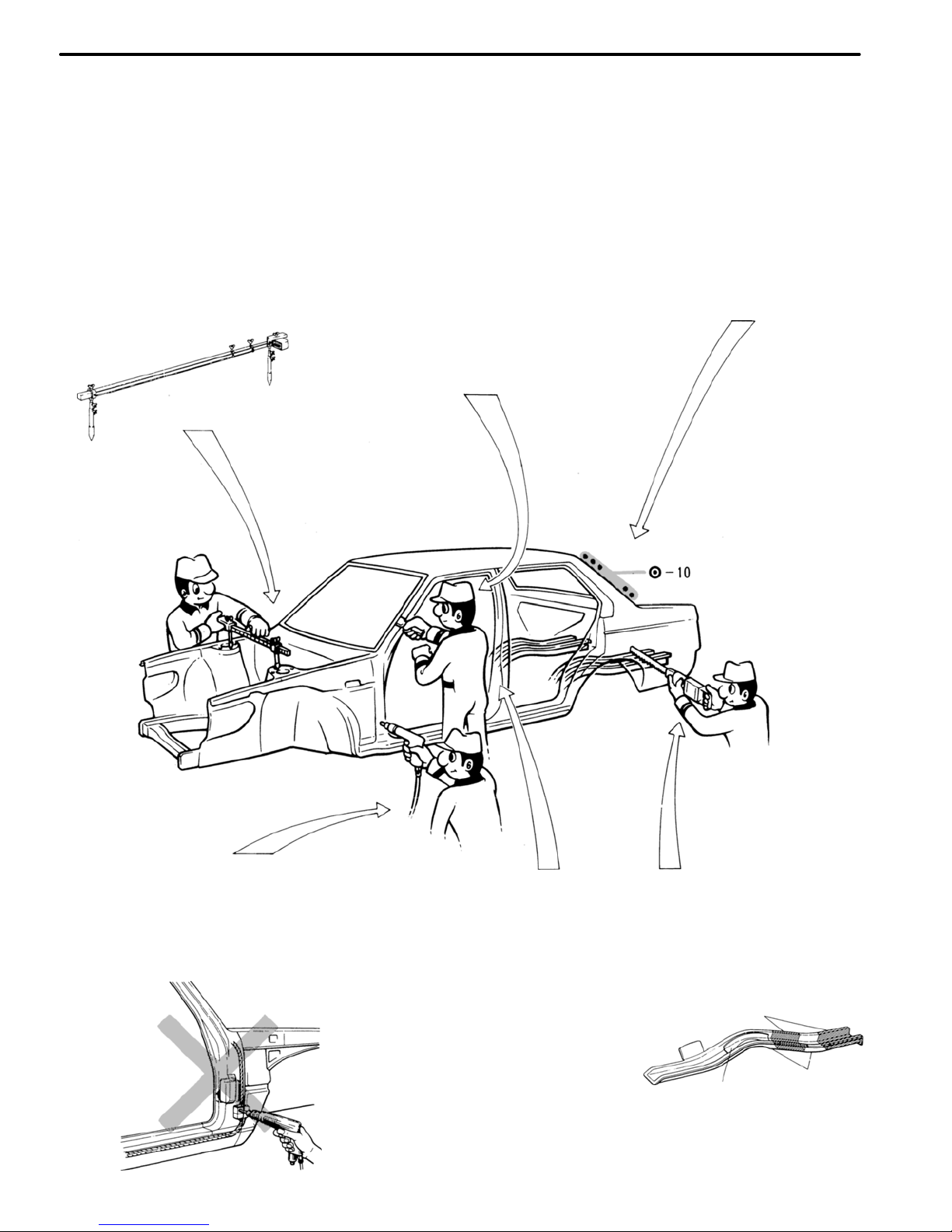

Proper and Efficient Work Procedures

REMOVAL

REMOVAL. OF ADJACENT COMPONENTS

When removing adjacent components, apply

protective tape to the surrounding body and

your tools to prevent damage.

CAUTION:

1. Be especially careful not to damage

screw or clip holes.

2. If the paint is accidently scratched, apply touch−up paint immediately. Even

the slightest scratch may result in corrosion or appearance of rust.

NO. OF SPOT WELDS

Make a note of the

number of spot welds

for later reference.

NOTE: The number

of spot welds may

vary depending on

the vehicle.

PRE−REMOVAL MEASURING

Before removal or cutting operations, take measurements in accordance with the dimension diagram. Always use a puller to

straighten a damaged body or

frame.

CUTTING AREA

Always cut in a straight

line and avoid reinforced

areas.

PRECAUTIONS FOR DRILLING OR

CUTTING

Check behind any area to be drilled or

cut to insure that there are no hoses,

wires, etc., that may be damaged.

Cutting Okay

Corners

Reinforcement

WRONG

INTRODUCTION

IN-7

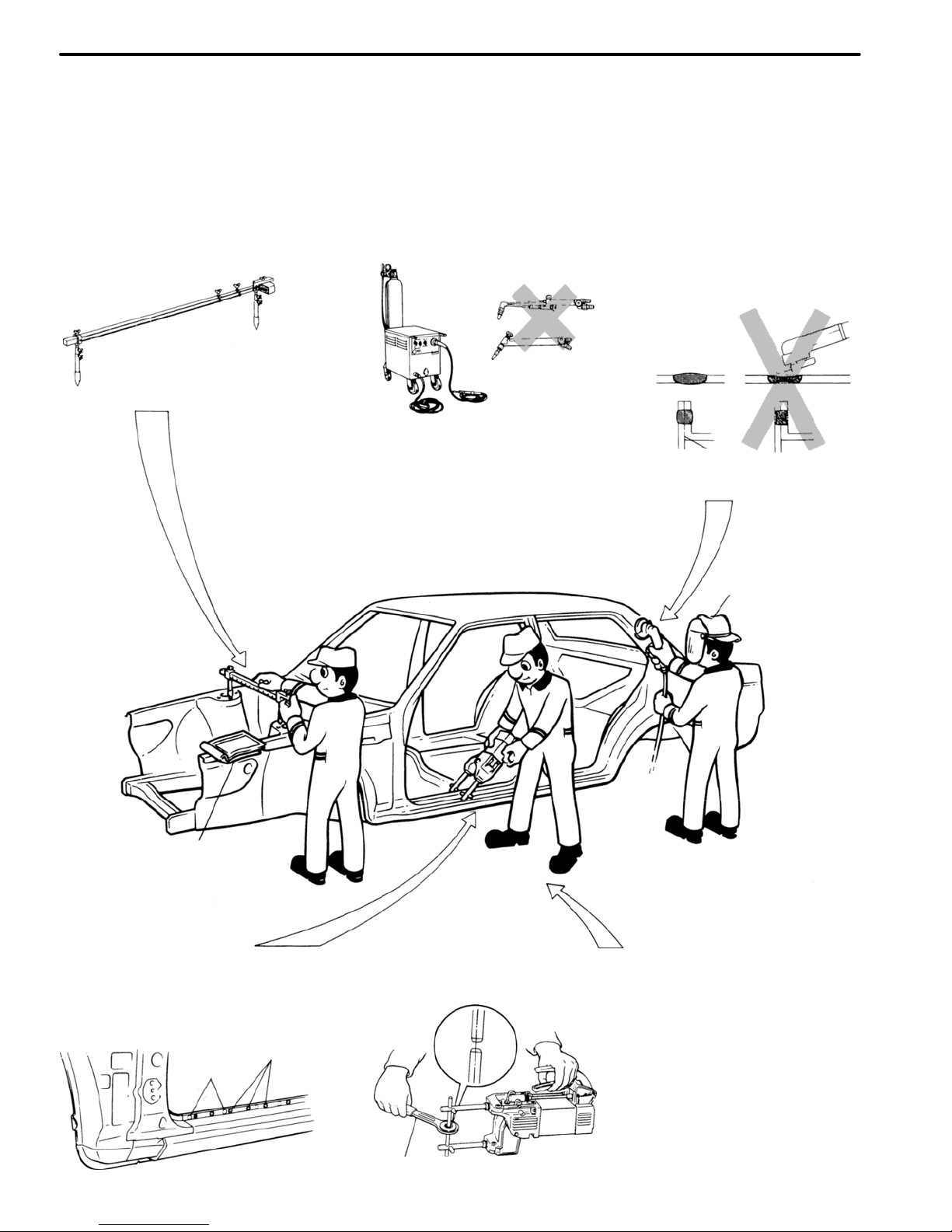

INSTALLATION

WELDING PRECAUTIONS

1. The number of welding spots

should be as follows.

Spot weld: 1.3 x No. of

manufacturer’s spots.

Plug weld: More than No. of

manufacturer’s plugs.

POST−WELDING REFINISHING

1. Always check the welded

spots to insure they are

secure.

2. When smoothing out the

weld spots with a disc

grinder, be careful not to

grind off too much as this

would weaken the weld.

PRE−WELDING MEASUREMENTS

Always take measurements before

installing underbody or engine components to insure correct assembly.

After installation, confirm proper fit.

WRONGOKAY

Seal

OKAY

WRONG

2. Plug welding should be done

with a MIG (Metal Inert Gas)

welder. Do not gas weld or

braze panels at areas other

than specified.

Safety Glass

Body

Measurement

Diagrams

SPOT WELDING PRECAUTIONS

1. The shape of the welding

tip point has an effect on

the strength of the weld.

2. Always insure that the

seams and welding tip are

free of paint.

SPOT WELD LOCATIONS

Try to avoid welding over

previous spots.

Old

Spot

Locations

New Spot

Locations

Tip Cutter

INTRODUCTION

IN-8

Thickness of

welded portion

Size of plug hole

1.0 (0.04) under

5 (0.20)

φ over

1.0 (0.04) over

6.5 (0.26)

φ over

REFERENCE:

mm (in.)

PREPARATION FOR INSTALLATION

SPOT WELD POINTS

APPLICATION OF WELD−THROUGH PRIMER

Less than

3 mm

When welding panels with a

combined thickness of over 3

mm (0.12 in.), use a MIG

(Metal Inert Gas) welder for

plug welding.

NOTE: Spot welding will

not provide sufficient durability for panels over 3 mm

(0.12 in.) thick.

For treatment

against corrosion,

remove the paint

from the portion of

the new part and

body to be welded,

and apply weld−

through primer.

Air Saw

WRONG

20 − 30 mm

Puncher

Overlap

ROUGH CUTTING OF JOINTS

For joint areas, rough

cut the new part, leaving

20 − 30 mm (0.79 − 1.18 in.)

overlap.

MAKING HOLES FOR PLUG WELDING

For areas where a spot welder cannot

he used, use a puncher or drill to make

holes for plug welding.

INTRODUCTION

IN-9

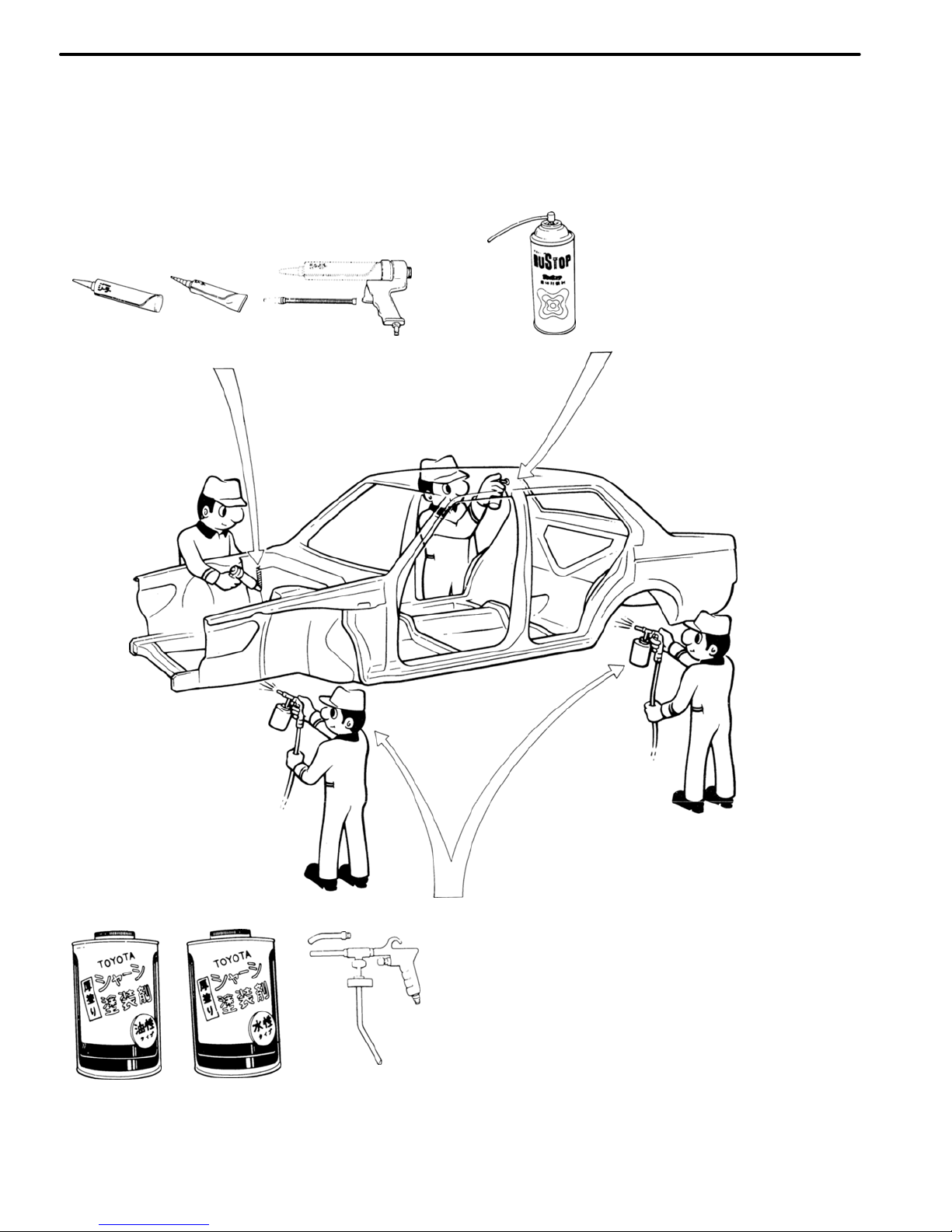

ANTI−CORROSIVE TREATMENT

When replacing body panels, always apply body sealer, anti−rust treatment or undercoating according to

the requirements of your country.

CHASSIS RUST−PROOFING

Anti−rust treatment for welding spots or inside brazed

areas (torque box).

BODY SEALER

Apply body sealer to the

required areas.

Nozzle

Tube

Type

Air Gun

Cartridge

Type

UNDERCOATING

Anti−rust treatment for underbody welding

spots and wheel housings.

Spray Gun

Undercoating

(Water base)

Undercoating

(Oil base)

INTRODUCTION

IN-10

IN0088

IN0089

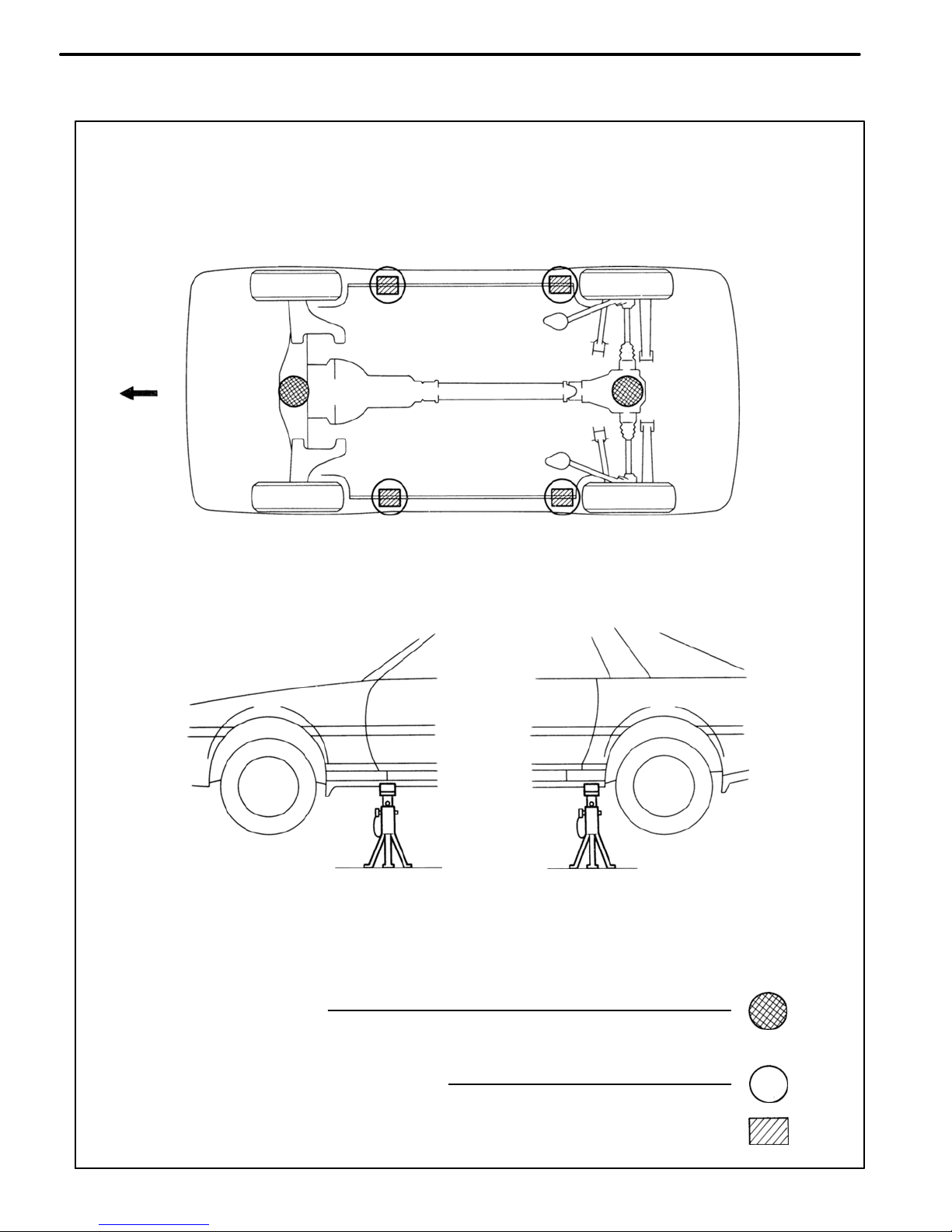

SUPPORT POSITION

PANTOGRAPH JACK POSITION

Front Center of front suspension crossmember. . . . . . . . .

Rear Center of differential carrier. . . . . . . . . .

JACK POSITION

Safety stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front

VEHICLE LIFT AND SUPPORT LOCATIONS

INTRODUCTION

IN-11

Assy, assy Assembly, assembly

Sub−assy Sub−assembly

Ex. Except

in. Inch

IRS Independent Rear Suspension

4−link 4−link Rear Suspension

MIG Metal Inert Gas

M/Y Model Year

OPN Operation

SP Spot Weld (Resistance Spot Weld)

w/ With

w/o Without

FR Front

RR Rear

RH Right−hand

RHD Right−hand Drive

LH Left−hand

LHD Left−hand Drive

ABBREVIATIONS USED IN THIS MANUAL

For convenience, the following abbreviations are used in this

manual.

INTRODUCTION

IN-12

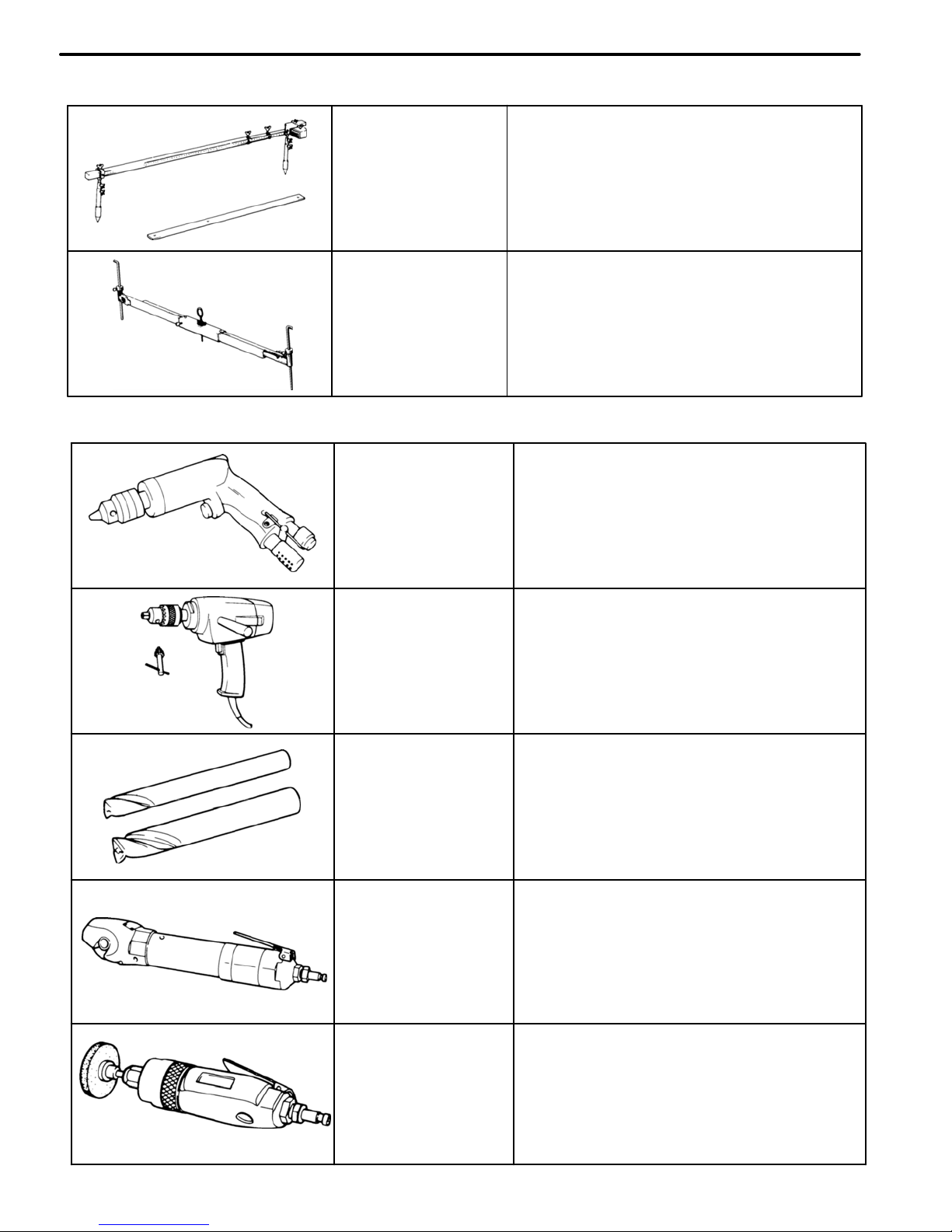

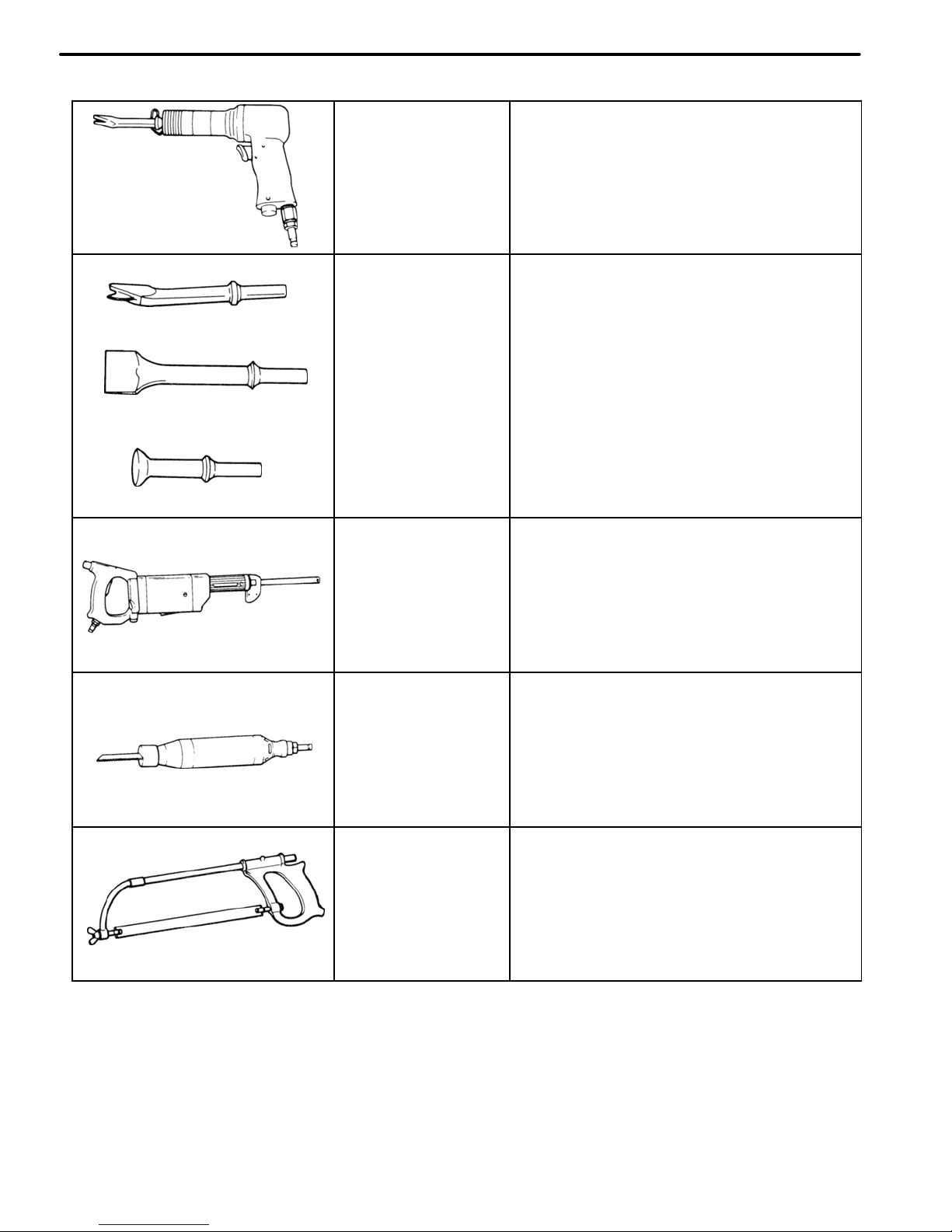

Air−powered

Drill

For separating spot welds and making

holes in the body.

Electric−

powered

Drill

For separating spot welds and making

holes in the body.

Spot Cutter

For separating spot welds.

Air−powered

Cutter

For cutting panels.

Air−powered

Chuck Grinder

For separating spot and plug welds

and grinding off traces of plug welds.

Tracking Gauge

For measuring body dimensions

Frame Centering

Gauge

When 3 or 4 are used together, measurements of twists, bends or warps in the

body and frame are possible.

MEASURING INSTRUMENTS

SEPARATING TOOLS

TOOLS AND EQUIPMENT

TE-2

Air−powered

Chisel

For rough cutting and rough flattening

of panels.

Hammer Tool

Flat Chisel

Panel Cutter

For rough flattening in hard−to−reach

areas.

For separating spot welds.

For rough cutting of panels.

Air−powered

Saw

For rough cutting of pillars, rocker

panels, etc.

Air−powered

Saw

For rough cutting of pillars, rocker

panels, etc.

Hacksaw

For rough cutting of pillars, rocker

panels, etc.

SEPARATING TOOLS (Cont’d)

TOOLS AND EQUIPMENT

TE-3

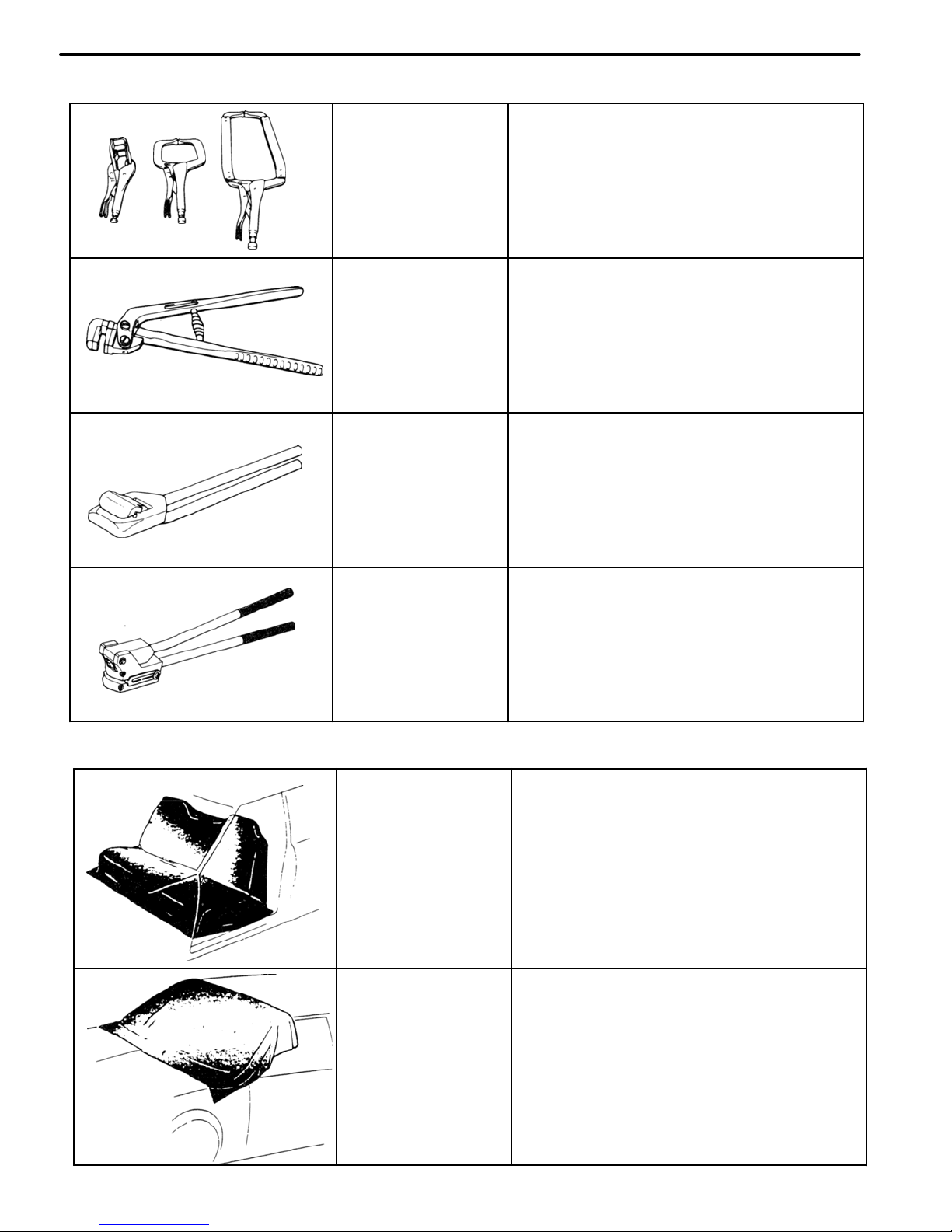

Seat Cover

For protecting the seats from welding

sparks, etc.

Glass Cover

For protecting the glass from welding

sparks, etc.

Vise Grip

Wrench

For temporary installation of panels and

holding of portions to be welded.

Flanging Tool

For making flanges in overlapping

panels.

Hemming Tool

For hemming door outer panels, etc.

Hole Punch

For making holes for MIG plug

welding.

INSTALLATION ASSISTANCE TOOLS

BODY PROTECTORS

TOOLS AND EQUIPMENT

TE-4

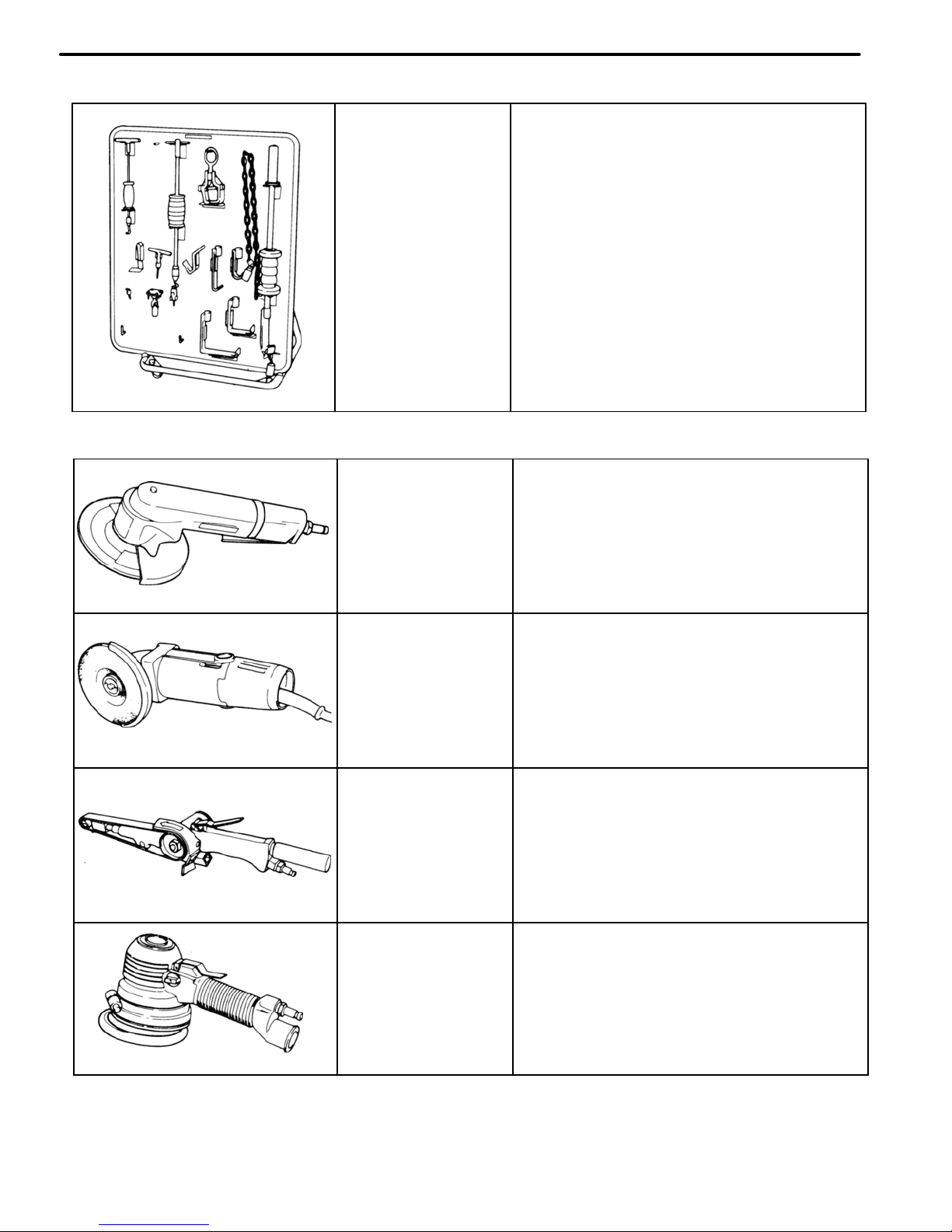

MIG Welder

(Metal Inert Gas)

For panel welding.

Spot Welder

For panel welding.

Gas Welder Torch

Gas Cutter Torch

For rough cutting of panels,

members, etc.

Acetylene Gas

Torch

For soldering and peeling of

paint.

Straightening

Machine

For straightening distorted

panels.

Panel

Extractor

For extraction of closed−in

panels.

WELDING INSTRUMENTS

TOOLS AND EQUIPMENT

TE-5

Air−powered

Disc Grinder

For grinding plug welds, butt welds

and door hems.

Electric−

powered

Disc Sander

For grinding plug welds, butt welds

and door hems.

Belt Sander

For removing paint around weld

areas.

Double−action

Sander

For rough grinding and polishing, and

feather edging.

Body Pullers

For straightening lightly

damaged panels.

LIGHT BODY REPAIR TOOLS

GRINDING AND POLISHING TOOLS

TOOLS AND EQUIPMENT

TE-6

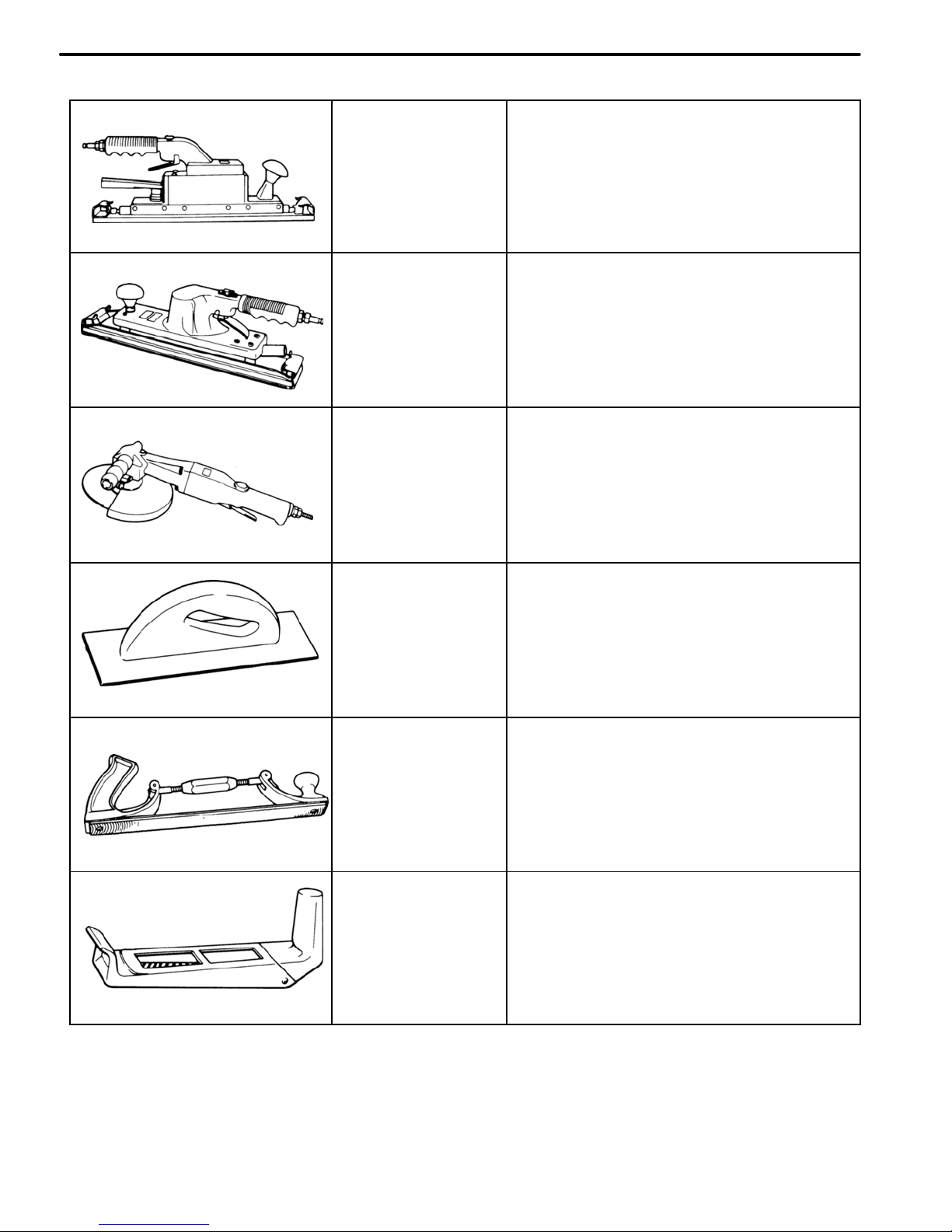

Straight−line

Sander

For rough polishing of panel putty.

Air−powered

Orbital Sander

For removing putty over a wide area, resurfacing and refinishing.

Air−powered

Disc Sander

For peeling paint.

File Holder

For paint removal.

Flexible File

Holder

For correction of soldering spots

and resurfacing of panels.

Surforrn Tool

For rough finishing of panels.

GRINDING AND POLISHING TOOLS (Cont’d)

TOOLS AND EQUIPMENT

TE-7

Master Gauge

Plate Looseness

Two−dimensional

distance

Center−to−center

Horizontal distance in

forward/rearward

Wrong

Correct

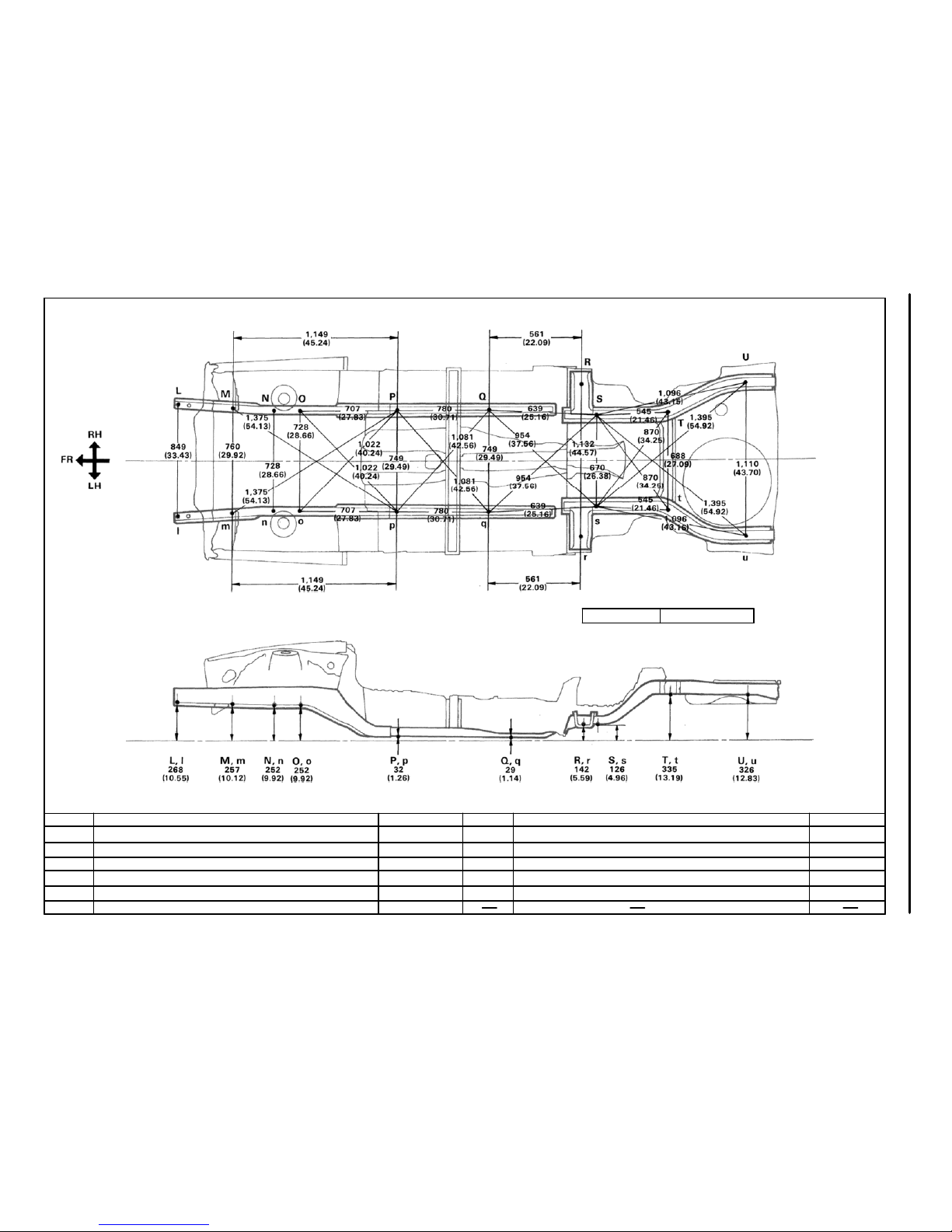

GENERAL INFORMATION

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

(Three−dimensional distance)

S Straight−line distance between the centers of two

measuring points.

(Two−dimensional distance)

S Horizontal distance in forward/rearward between

the centers of two measuring points.

S The height from an imaginary standard line.

(b) In cases in which only one dimension is given, left

and right are symmetrical.

(c) The dimensions in the following drawing indicate

actual distance. Therefore, please use the dimensions as a reference.

2. MEASURING

(a) Basically, all measurements are to be done with a

tracking gauge. For portions where it is not possible

to use a tracking gauge, a tape measure should be

used.

(b) Use only a tracking gauge that has no looseness in

the body, measuring plate, or pointers.

HINT:

1. The height of the left and right pointers must be equal.

2. Always calibrate the tracking gauge before measuring or

after adjusting the pointer height.

3. Take care not to drop the tracking gauge or otherwise

shock it.

4. Confirm that the pointers are securely in the holes.

(c) When using a tape measure, avoid twists and

bends in the tape.

(d) When tracking a diagonal measurement from the

front spring support inner hole to the suspension

member upper rear installation hole, measure

along the front spring support panel surface.

Pointer

Center−to−center

straight−line

distance

Vertical distance

in lower surface

Vertical distance

in center

Body Looseness

Pointer

Pointer Looseness

Three−dimensional

distance

Imaginary Standard Line

Front Suspension Member Rear Side

Upper Installation Hole

Along Body

Surface

Front Spring Support Inner Hole

Tape Measure

BODY DIMENSIONS

DI-2

mm (in.)

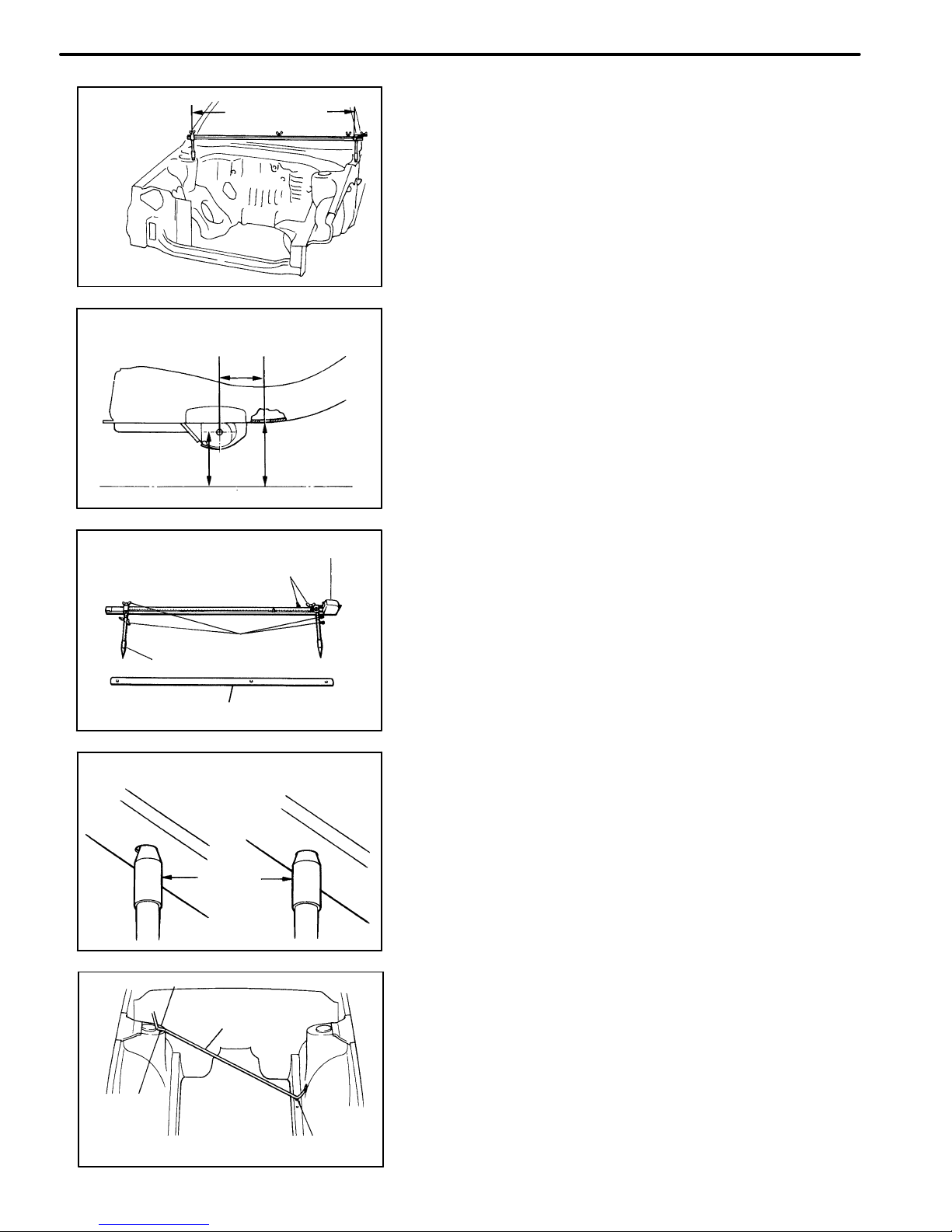

ENGINE COMPARTMENT

Symbol

Nomenclature

Hole dia.

BO1788

A, a

Front fender installation nut−front

8 (0.31)

B, b

Front spring support hole−rear

11 (0.43)

C, c

Front fender installation nut−rear

8 (0.31)

D

Cowl top panel center mark

E, e

Front side member standard hole

15 (0.59)

F, f Suspension member rear installation hole−upper

17 (0.67)

G, g Retractable light bracket installation nut−upper

11 (0.43)

H, h

Radiator seal installation hole−lower

7 (0.28)

I, i Front fonder aide installation hole 8 (0.31)

J, j

Cowl top panel standard hole

10 (0.39)

K

Hood lock support brace installation nut 7 (0.28)

BODY DIMENSION DRAWINGS

BODY DIMENSIONS

DI-3

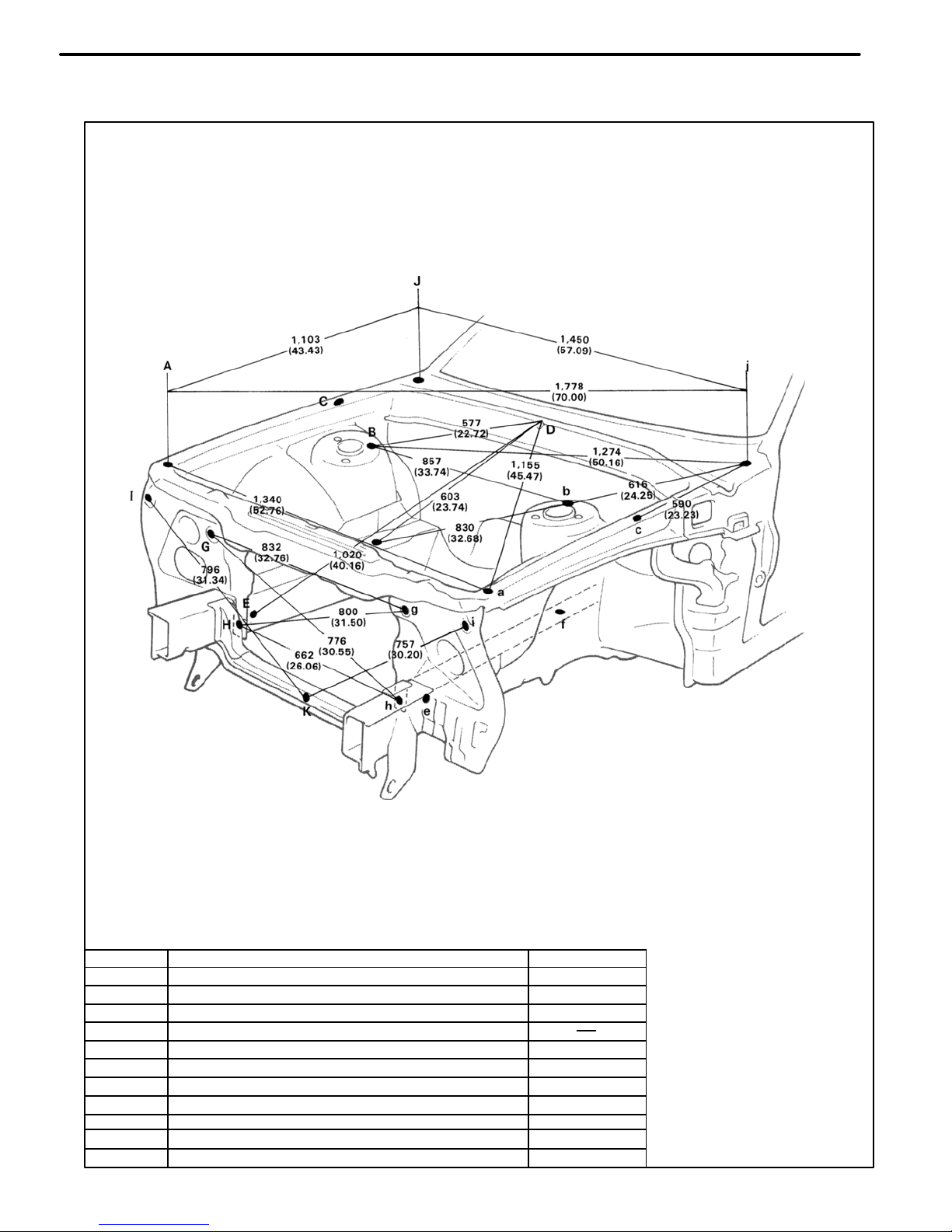

mm (in.)

Front

X, x Point

LUGGAGE COMPARTMENT

Symbol

Nomenclature

Hole dia.

BO1790

V

Back door opening frame center mark

2 (0.08)

W, w

Rear suspension spring support hole−inner

9 (0.35)

X, x

Rear floor pan bumper installation hole−front

40 (1.57)

BODY DIMENSIONS

DI-3

BO1789

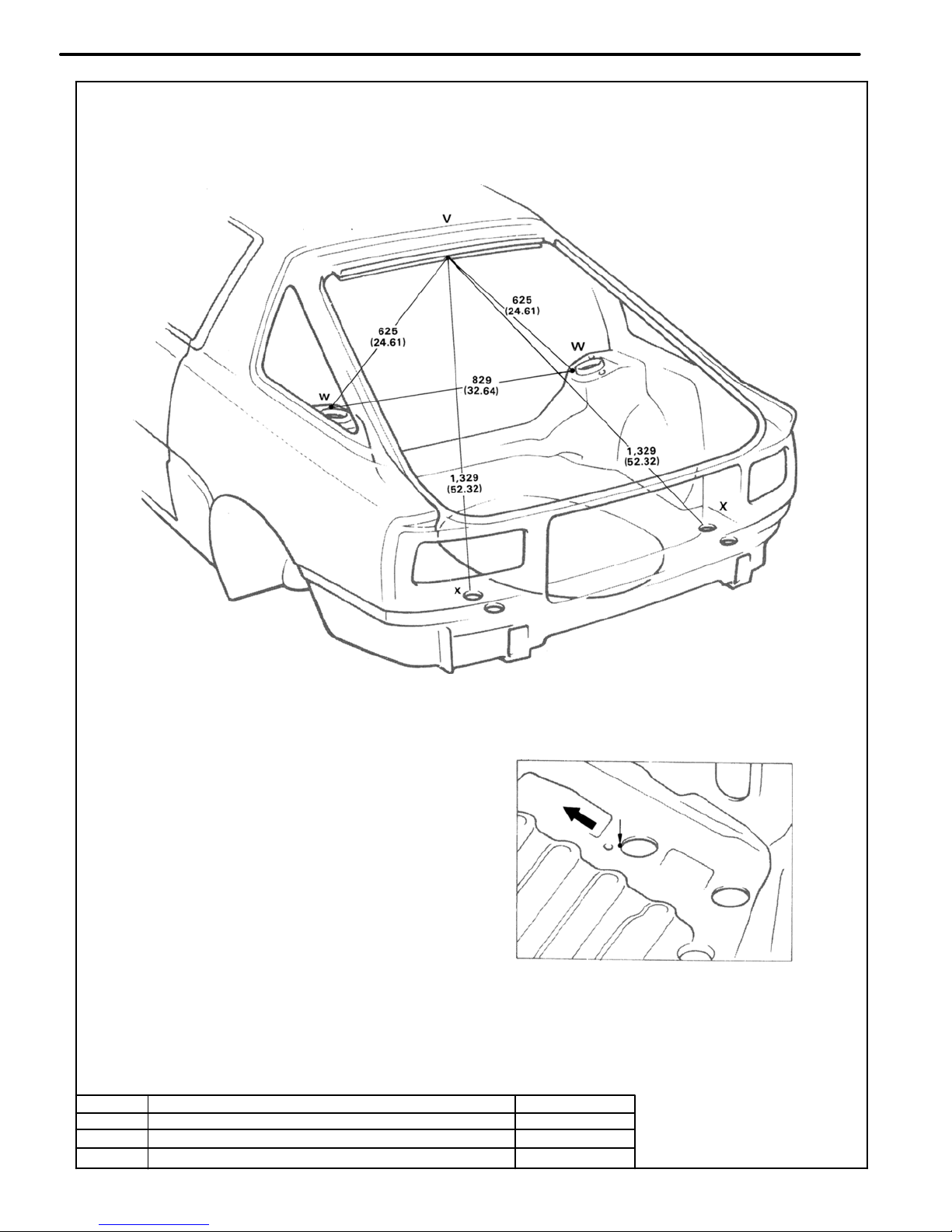

Wheel base 2,595 (102.17)

Imaginary

Standard

line

UNDER BODY

mm (in)

Hole dia.

10 (0.39)

19 (0.75)

18 (0.71)

25×18(0.98×0.71)

18 (0.71)

Nomenclature

Front floor No. 2 reinforcement standard hole

Suspension member front installation hole−outer

Center floor side member standard hole

Suspension member rear installation hole

Rear floor side member standard hole

Symbol

Q,q

R, r

S, s

T, t

U, u

Hole dia

15 (0.59)

17×15 (0.67×0.59)

11 (0.43)

17 (0.67)

17 (0.67)

10 (0.39)

Nomenclature

Front side member bumper front installation hole−Lower

Front side member bumper front installation hole−Lower

Stabilizer front installation nut

Suspension member front installation hole−lower

Suspension member rear installation hole−lower

Front floor under reinforcement standard hole

Symbol

L

I

M, m

N, n

O,o

P, p

BODY DIMENSIONS

DI-3

mm in.

2

0.08

7

0.28

10

φ

0.39

l0

φ

l0φ

l0φ

2R

Center Mark

STANDARD BODY MARKS

LIFTBACK

Assembly Mark

Center Mark

(7

φ)

Center Mark

Assembly MarkAssembly Mark

Assembly Mark

Assembly Mark

l0

φ

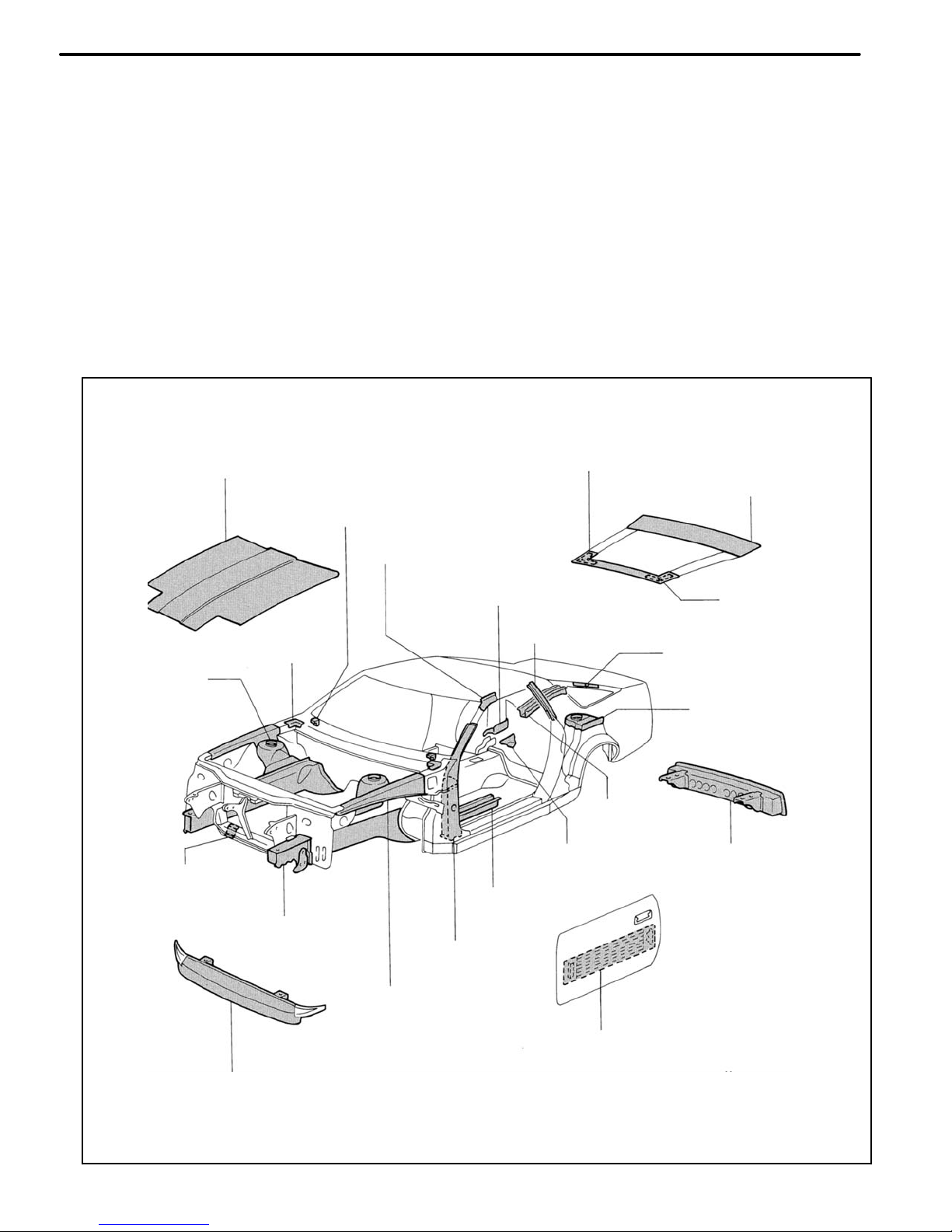

BODY PANEL CONSTRUCTION

CN-2

Door Side Impact

Protection Beam

(USA, Canada, Saudi Arabia and

Australia)

Front Bumper Reinforcement

Front Apron to Cowl

Side Upper Member

Front Body

Outer Pillar

Front side Member

Front Floor Under

Reinforcement

Front Crossmember

No. 2 Reinforcement

Rear Bumper

Reinforcement

Belt Anchor

Reinforcement

Rear Floor

Side Member

Rear Suspension

Spring Support

Front Spring

Support Plate

Belt Anchor to Roof

Side Inner Reinforcement

Cowl Top to

Apron Brace

Quarter Pillar Inner

Reinforcement

Back Door Hinge

Reinforcement

Quarter Wheel

Housing No. 1 Gusset

Front Body Pillar Upper

Inner Reinforcement

Hood Stopper

Reinforcement

Back Door Lower

Outer Panel

Engine Hood Panel

Back Door Upper

Outer Panel

The handling of HSS is the same as for mild steel, but the following should be observed.

HIGH−STRENGTH STEEL (HSS) PARTS

Generally, High−Strength Steel (HSS) is that which has an intensity value of at least 35 kg f/mm2, and

distinguished from mild steel.

1. Panel Hammering; Because HSS is thinner than mild steel, care should be taken to avoid warping

during hammering operations.

2. Removing Stop Welds: Because HSS is tougher than mild steel, damage will occur more easily to a

regular drill. Therefore, an HSS Spot Cutter is recommended.

Also, use a high−torque drill at low speed, and supply grinding oil to the drill during use.

3. Panel Welding: Panel welding procedures for HSS are exactly the same as for mild steel. Plug

welding should be done with a MIG (Metal Inert Gas) welder. Do not gas weld or braze panels at

areas other than specified.

BODY PANEL CONSTRUCTION

CN-3

Loading...

Loading...