A

INTRODUCTION

This manual consists of the following 11 sections:

N

o

.

Section

Description

A

B

C

D

E

F

INDEX

I

NTRODUCTION

HOW TO U

TH

IS MANUAL

TROU

SHOOTING

ABBREVIATIONS

GLOSSARY O

TERM

SYMBOLS

R

ELAY LOCATIONS

BLE

S A

SE

-

F

ND

Index of the contents of this m

Brief explanation of each section.

Instructions on how to use this m

Describes the basic inspection procedures for electrical circuits

Defines

Defines

Shows

This section is closely rel

the abbreviations us

the symbols and functions of major parts.

positi

on of the Electronic C

anual.

anual.

ed in this m

ontrol Unit, Relays, Relay Block, etc.

ated to the

anual.

system circui

t.

.

G

H

I

J

K

ELE

CTRIC

WIRING ROUTIN

POWER SO

(Curr

INDEX

SYSTEM CI

GRO

OVERALL

ELE

CTRIC

WIRING D

AL

URC

ent Flow Chart

RCUIT

UND POINTS

AL

IAGRA

G

E

)

S

M

Describes positi

This section is closely rel

Describes power distri

l

oads.

Index of the

Electrical circuits

ground points.

classifi

secti

T

also c

Shows gr

Provides circui

ed by code according to the connection method. (Refer to the

on, “How to use this m

he “System Outline” and “Service Hints” useful for troubleshooting are

ontained in this secti

ound positions

on of Parts Connectors

ated to the

bution from the power supply

system circuits

of each

Wiri

ng connections and their positions are show

t diagrams showi

.

system are show

anua

on.

of all the parts descri

, Splic

system circui

l”)

.

ng the circuit connections.

e points, Ground points, etc.

t.

to various electrical

n from the power supply

bed in this m

through

n and

anual.

2

HOW TO U

SE THIS

MANUAL

B

This manual provides i

by dividing them into a circuit for each

T

he actual

source is received from the battery as

diagrams are shown wi

W

hen troubleshooting any problem, firs

wher

e the problem was detected (s

s

upplying power to that circuit (s

points (s

circui

W

circui

sections

harness and

system circui

unders

Wiri

(from

Wiri

t operation.

hen the circuit operation is

t to isol

ng related to each

,to ). When overall connections are required, see the Overall Electrical

ng Diagram at the end of this m

wiri

ng of each

ee Ground Points section). See the System Outline to unders

ate the cause. Use Relay

to find each part, junction block and

wiri

ng harness connectors, splice points, and ground points of each

t. Internal

tanding of connection within a junction block.

nformation on the electrical circuits install

system circuit is shown from the point where the powe

th the switches i

ee System

ee Power Source section)

unders

wiri

ng for each junction block is also provi

system is indic

tood, begin troubleshooting of the proble

anual.

ed on vehicle

system

far as each ground point. (All circuit

n the OFF

t unders

Location and Electrical Wiri

ated in each

.

positi

tand the operation of the circuit

Circuit section), the power sourc

wiri

ng harness connectors, wiri

on.

)

, and the ground

system circui

tand the

ng Routing

ded for bette

t by arrows

s

r

e

m

ng

r

3

B HOW TO U

SE THIS

MANUAL

* T

he

system show

circuit shown i

n here is

an

n the SYSTEM CI

EXAMPLE ONLY. It is di

RCUIT

S SECTION

.

fferent to the actua

l

4

B

A :System Title

B :

Indic

ates a Relay Block. No shading is us

Relay Block N

Example: 1 Indic

C :

Indic

ates the connector to be connected to a

o. is show

ates Relay Block No. 1.

part (the numeral indic

Explanation of pin use.

T

he pins shown are only

include those in the specification.

D : C

onnector Color Connectors

whi

te in color:

E

: (

) is us

w

ed to indic

hen the vehicle model, engine type, or specification is

ate different

different.

F

:Indic

G :Indic

ates related

ates the

c

onnector. The

shown wi

th arrows (

system

wiri

ng harness and

wiri

n to disti

ates the pin No.

nguish i

)

t from the J/B.

for the highest grade, or only

ed and only

not indic

wiri

ated are

ng and connector, etc.

.

wiri

ng harness with male te

v

).

v

ng harness

milky

rminal is

the

J :Indic

ates the

wiri

ng color.

Wire colors are indic

B

= Bla

ck

BR = Brown

G = Green

GR = Gra

T

he first l

l

etter indic

y

etter indic

ates the color of the stripe.

ated by an alphabetical c

L = Bla

LG = Light Green

O = Orange

P = Pin

ates the basic

Example: L - Y

(blue)

K :

Indic

ates a

wiri

ng Splic

e Point (Codes are “E” fo

the Engine Room, “I” for the Instrument Panel,

T

he Location of Splic

secti

L :

Page No.

M :

Indic

ates a shielded cable.

on.

e Point I 5 is indicated by the shaded

ck

k

wire color

(yellow)

ode.

R

= Red

V = Violet

W

= White

Y = Yello

w

and the second

r

T

he first l

harness connector(s) indic

“E”

etter of the code for each

wiri

ng harness and

ates thecomponent’s locati

for the Engine Compartment, “I” for the Instrument Panel

and Surrounding area, and “B” for the Body and Surrounding

area.

W

hen more than one code has the firs

comm

on, followed by numbers (

the same type of

H

:Repres

ents a part (all parts are shown in

blue). The code is

parts positi

I :Juncti

on Block (The number in the circle is the

J

/B No. and the connector code is show

it)

. Junction Blo

s

eparate them from other parts .

wiri

ng harness and

the same as the code used in

on.

cks are s

Example:

haded to clearl

3B indicate

that it is inside

Juncti

N

o. 3.

t and second letters i

e.g, IH1, IH2), this indicates

wiri

ng harness connector.

sky

n besi

de

y

s

on Blo

ck

wiri

ng

on, e.g,

N :

Indic

ates a ground point.

T

he first l

the component’s locati

Compartm

etter of the code for each ground point(s) indic

on, e.g. “E” for the Engine

ent, “I” for the Instrument Panel and Surrounding

ate

s

area, and “B” for the Body and Surrounding area.

n

O :Indic

P :W

ates the pin number of the connector.

T

he numbering

c

onnectors

system is different for female and male

.

lower l

lower ri

ght

eft

hen 2 parts both use one connector in common, the part

c

onnector name used in the

s

quare brackets [ ].

wire r

outing section is shown i

s

n

5

B HOW TO U

SE THIS

MANUAL

Q

WITH TH

R

1.

HOLDING MANU

TROL RELAY THROUGH TERMINAL 3 OF THE MASTER SW TERMINAL 2 TO OPERATE A POWER WINDOW CONTROL RELAY. THUS THE

FLOWS FROM TERMINAL

NAL 3

W

(FOR THE “MANU

2.

ONCE THE “AUTO DO

OF THE MASTER SW TERMINAL

THE RELAY

MOTOR CONTINUES THE ROTATION EN

THE WINDOW DESCENDS TO TH

BETWEEN TERMINAL 2 OF THE R

3.

HOLDING THE MANUAL SW

FLOWS TERMINAL 5 OF THE R

STOPS AND CONTINUIN

4. PASSENGER’S WINDOW UP OPERATION (MASTER SW) AND WINDOW LOCK SW

HOLDIN

POWER WINDOW SW (PASSENGER’S)

TERMINAL 1 OF THE MASTER SW TERMINAL 4 TO GRO

STOPPED AND WINDOW CAN STOP AT WILL PLACE. SWITCHING THE WINDOW LOCK SW IN “LOCK” POSITION, THE CIRCUIT

TION

(FOR THE DOWN

R

P 2 POWER WINDOW CONTROL RELA

3-GRO

2-GRO

5-GRO

8-GRO

9-GRO

P 4 POWER WINDOW MASTER S

4-GRO

3-GRO

WINDOW LOCK SW

OPEN WITH THE WINDOW LOCK SW AT LOCK POSITIO

S

SYSTEM OUTLIN

E IGNITION SW T

ELAY AND TERMINAL 8 OF TH

DR

IVER’S WINDOW “MANUAL UP” OPERATION BY MASTER SW

AL SW

T

O GRO

ILL POINT

.

AL DO

DR

IVER’S WINDOW “AUTO DOWN”

TERMINAL 4

DR

IVER’S WINDOW AUTO DOWN RELEA

G PASSENGER’S WINDOW SW (MASTER SW) ON “UP”, THE CURRENT FLOWS FROM TERMINAL 3 OF THE MASTER SW

.

COD

P2 21 P4 21 P6 21

P3 21 P5 21

OPERATION,

SERVICE HINT

UND

: ALWAYS CONTINUIT

UND

: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITIO

UND

: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION AND THE MASTER SW AT U

UND

: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION AND THE MASTER SW AT AUTO DOWN POSITIO

UND

: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION AND THE MASTER SW AT DOWN OR AUTO DOWN POSITIO

UND

: ALWAYS CONTINUIT

UND

: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITIO

:

PARTS LOCATIO

E SEE PAGE

E

URNED ON, THE

E POWER WINDOW SW THROUGH THE DOOR FUSE.

(DR

IVER’S) ON “UP” POSITION LOCATED IN POWER WINDOW MASTER SW, THE CURRENT FLOWS TO TERMINAL

2 OF THE R

UND

. THE MOTOR T

WN”

OPERATION,

WN” BUTTON OF THE MASTER SW

TERMINAL 1 OF TH

(DR

IVER’S) ON “UP” POSITION IN OPERATING AUTO DOWN

ELAY AND RELEASES TH

G ON TO

CURRENT FLOWS IN THE R

S

N

CURRENT FLOWS TO TERMINAL 3 OF TH

ELAY

TERMINAL 1

URNS T

O ASCENT THE WINDOW. RELEASING TH

CURRENT FLOWS IN THE R

OPERATION BY MASTER SW

S 8 AND 9 TO OPERATE THE R

ABLING TO DESCENT THE WINDOW.

E END POSITION. THE CURRENT WILL BE CUT OFF TO R

ELAY AND TERMINAL

SE OPERATION BY MASTER SW

UCHIN

G SW. THE F

TERMINAL 4 TERMINAL

Y

Y

W

Y

TERMINAL 2 OF TH

EVERSE DIRECTION

IS PUSHED, THE CURRENT FLOW TERMINAL

E POWER WINDOW MOTOR

1 IN RELAY.

E AUTO DOWN F

UNCTION SWITCH

N

COD

E SEE PAGE

ELAY. THUS THE

UNCTION IN TH

ES TO MANUAL UP OPERATION.

UND

EVERSE DIRECTION

2 OF THE MOTOR TERMINAL 1

. THE MOTOR RUNS T

N

N

E POWER WINDOW MASTER SW, TERMINAL 2 OF THE POWER WINDOW CONTROL

E POWER WINDOW MOTOR

CURRENT INSIDE TH

TERMINAL 2

. THE CURRENT FROM TERMINAL 3 OF THE MASTER SW

OPERATION

O ASCENT THE WINDOW. RELEASING TH

BECAUSE THE TERMIN

IS SW, THE ROTATION OF MOTOR

BECAUSE THE TERMIN

TERMINAL 1 OF THE R

ELEASE TH

E POWER WINDOW CONTROL RELAY. RELEASING THE HAND FROM SW, WINDO

COD

TERMINAL 1

ALS WHERE IT FLOW ARE CHANGED).

9 OF TH

E POWER WINDOW CONTROL RELAY THROUGH TERMINAL 3

E POWER WINDOW CONTROL RELAY FLOWS FROM TERMINAL 2 O

E AUTO DOWN F

TERMINAL 9 OF TH

ALS WHERE IT FLOWS ARE CHANGED).

P POSITIO

N

E SEE PAGE

UNCTION BASED ON TH

T

: RELAY BLOCK

CODE SEE PAGE

1 16

S

R

ELAY BLOCK (RELAY BLOCK LOCATIO

R

/B NO. 1 (INSTRUMENT PANEL LEFT)

N)

U

:

J

UNCTION BLOCK AND WIRE HARN

COD

E SEE PAGE

38 14

ESS CONNECTOR

J

UNCTION BLOCK AND WIRE HARNESS (CONNECTOR

J

/B NO. 3 AND COWL WIRE (INSTRUMENT PANEL LEFT SIDE

LOCATIO

)

N)

V

: CONNECTOR JOINING WIRE

COD

E SEE PAGE

ID1 26

IH1 26

HARN

ESS

AND WIRE HARN

JOINING WIRE HARN

FRONT DOOR RH WIR

FRONT DOOR LH WIR

ESS

ESS AND WIRE HARNESS (CONNECTOR

E AND COWL WIRE (RIGHT

E AND COWL WIRE (LEFT KICK PANEL

KICK PANEL

LOCATIO

)

)

N)

W

:

GRO

UND

POINT

S

COD

E SEE PAGE GRO

I

C

24

COW

UND

L LE

POINT

FT

LOCATIO

N

X

:

SPLICE POINT

COD

E SEE PAGE

I 5 24

S

WIRE HARN

COWL WIR

ESS WITH

E

SPLICE POINT

S

COD

E SEE PAGE WIRE HARNESS WITH

5 OF TH

E POWER WINDOW CO

TERMINAL 4 OF THE R

IS STOPPED AND THE WINDOWS CAN ST

ELAY

PASSING TERMINAL

E POWER WINDOW SW

IS SW, THE ROTATION OF MOTOR

IS OPENED AND STOPPED THE MOTOR ROTA-

N

CURRENT INSIDE THE R

TERMINAL 3

E I

N

T

O GRO

NCR

EASING

PASSING TERMINAL

6 TO TERMINAL

TERMINAL 7

SPLICE POINT

ELAY

TERMI-

UND

. TH

CURREN

IS

ELAY

OP A

3 OF TH

N-

T

F

E

T

2

W

E

S

6

B

Q :Explains

R :

Indic

S :Indic

Example: Part “P 4” (Power Window Master SW) is

T :

Indic

circui

Example: Connector “1” is

U :

Indic

circui

Example: Connector “3B”c

the

system

ates values or explain the function for reference during troubleshooting.

ates the reference page showing the positi

*The letter in the code is from

parts starting with the letter.

Example: P 4

ates the reference page showing the positi

t.

instrum

ates the reference page showing the positi

t.

and is install

outline.

Part is

Power Window Master S

descri

ent panel.

onnects the Cowl

ed on the instrument panel left si

bed on page 16 on this m

on on the vehicle of the parts in the

on page 21 of the manual.

the first l

4th in orde

Wir

etter of the part, and the number indic

r

W

on on the vehicle of Relay Block Connectors i

anual and is install

on on the vehicle of J/B and

e and J/B No. 3. It is

de.

descri

ed on the left si

Wire Harness i

bed on page 14 of this m

system circui

ates its order in

n the

de of the

n the

t.

system

system

anual,

V :Indic

W :

X :Indic

ates the reference page describing

harness is show

Example: Connector “ID1”c

Indic

ates the reference page showing the positi

Example: Ground point “IC” is

ates the reference page showing the positi

Example: Splic

HINTS

:

n firs

on page 26 of this m

e point “I 5” is

the

wiri

t, followed by the male wiri

onnects the front door RH

anual, and is install

descri

on the Cowl

bed on page 24 of this m

Wire Harness

ng harness and

ng harness)

wire (female)

ed on the right si

on of the ground points on the vehicle.

on of the splic

and is

Juncti

on connector (c

include a short te

number of

tion with the short te

li

ng the

nected to any positi

grouping. Accordingly, i

positi

on in the short te

a

wir

e harness from a different part.

Wir

e harness sharing the same short te

grouping have the same color.

wiri

ng harness connector (the female

.

and cowl

de kick panel.

anual and is install

e points on the vehicle.

descri

wir

wir

e harnesses, the harnesses can be con

bed on page 24 of this m

rminal which is c

e harnesses. Always perform inspec-

rminal install

wire (male)

ed on the cowl left si

ode: J1 to J19) in this m

ed. (When insta

on within the short te

n other vehicles, the same

rminal may

be connected to

. It is

descri

anual.

anua

onnected to a

rminal

)

rminal

l-

l

-

wiri

bed

de.

ng

7

B HOW TO U

T

he “Current Flow Chart” section, describes which parts each power source (fuses

breakers) transmits curr

s

upplied to each

source

system mus

SE THIS

ent to. In the Power

system ar

t be fully

MANUAL

Source circui

e explained. Since all System

unders

tood.

t diagram, the conditions when battery

Circuit diagrams star

t from the power sourc

, fusible links

, and circuit

power is

e, the powe

r

H POWER

T

he chart below shows

etc.) and other parts.

T

he next page and following pages shown the parts to whic

SO

URCE (CURRENT FLOW

the route by which curr

ent flows from

CHART)

the battery

h each electrical source outputs current.

to each electrical source (Fusible Link,

Circuit Breaker, Fuse,

8

* T

POWER SO

he

system show

n here is

URC

E

an

EXAMPLE ONLY. It is di

fferent to the actual circuit shown in the SYSTEM CI

RCUIT

S SECTION

.

T

he ground points circuit diagram shows

W

hen troubleshooting a faulty ground point, checki

help you identify the problem ground quickly

show

n below) can als

o be checked this way

the connections from all major parts to the respectiv

. The relationship between ground points ( , and

.

J GROUND POINT

ng the

e ground points.

system circuits which use a common ground ma

EA

IB

I

C

B

y

* T

he

system show

n here is

an

EXAMPLE ONLY. It is di

fferent to the actual circuit shown in the SYSTEM CI

RCUIT

S SECTION

.

9

C TROUBLESH

OOTING

VO

LTA

GE CHE

CK

(a)Es

(b) Usi

tablish c

check

Example:

A B C-

ng a voltmeter, connect the negative l

ground point or negativ

positive lead to the connector or component te

This check can be done with a test light instead of a

voltm

eter.

CONTINUITY

(a)

Disconnect the battery

vol

tage between the check points.

(b) C

ontact the two leads of an ohmmeter to each of the

check

onditions in which vol

point.

Ignition SW on

Ignition SW and SW 1 on

Ignition SW, SW 1 and Relay on (SW2 off

e battery

AND R

point.

ESIS

TANCE CHECK

terminal or wire s

tage is pres

ead to a good

te

rminal

, and the

o there is

ent at the

rminal

no

)

.

10

If the circuit has diodes, revers

again.

W

hen contacting the negative l

and the positive lead to the negative side, there should be

c

ontinuity.

W

hen contacting the two leads in revers

no continuity.

(c) Use the volt/ohmmeter with high impedance (10

minimum)

for troubleshooting of the electrical circui

e the two leads and che

ead to the diode positive si

e, there should be

ck

kΩ/

t.

de

V

C

FINDING A SHORT CI

(a)Remove the blown fuse and disc

fuse.

(b) C

(c)Es

(d) Disconnect and reconnect the connectors while watchi

(e) Fi

CAUTION

onnect a test light in place of the fuse.

tablish c

Example:

A-Ignition SW on

B-Ignition SW and SW 1 on

C -

the test light.

T

he short lies between the connector where the test

li

ght stays lit and the connector where the light goe

out.

nd the exact location of the short by lightly shaking

the problem

:

(a)

Do not open th

absolutely necessary. (If the IC termin

th

e IC may be destroyed by static electricity.

(b)

When

replacing the internal mechanism (ECU part)

the digit

o

r cl

leads from the IC, etc. of the replacement part (spare

part)

al meter, be careful that no part of your

othing co

.

RCUIT

onnect all loads of the

onditions in whic

Ignition SW, SW 1 and Relay on (Connect the

Relay) and SW 2 off (or Disc

wir

e along the body.

e cover or th

mes in c

h the test light comes on.

onnect SW 2

e case of the ECU un

als are

ontact

with the terminals of

)

s

less

touched

)

bod

ng

,

of

y

DISCONNECTION OF MALE AND FEMAL

CONNECTOR

T

o pull apart the connectors

the

wir

e harness.

HINT

: Check to see what ki

disc

onnecting before pu

S

, pull on the connector itself, not

nd of connector you are

lli

ng apart.

E

11

C TROUBLESH

OOTING

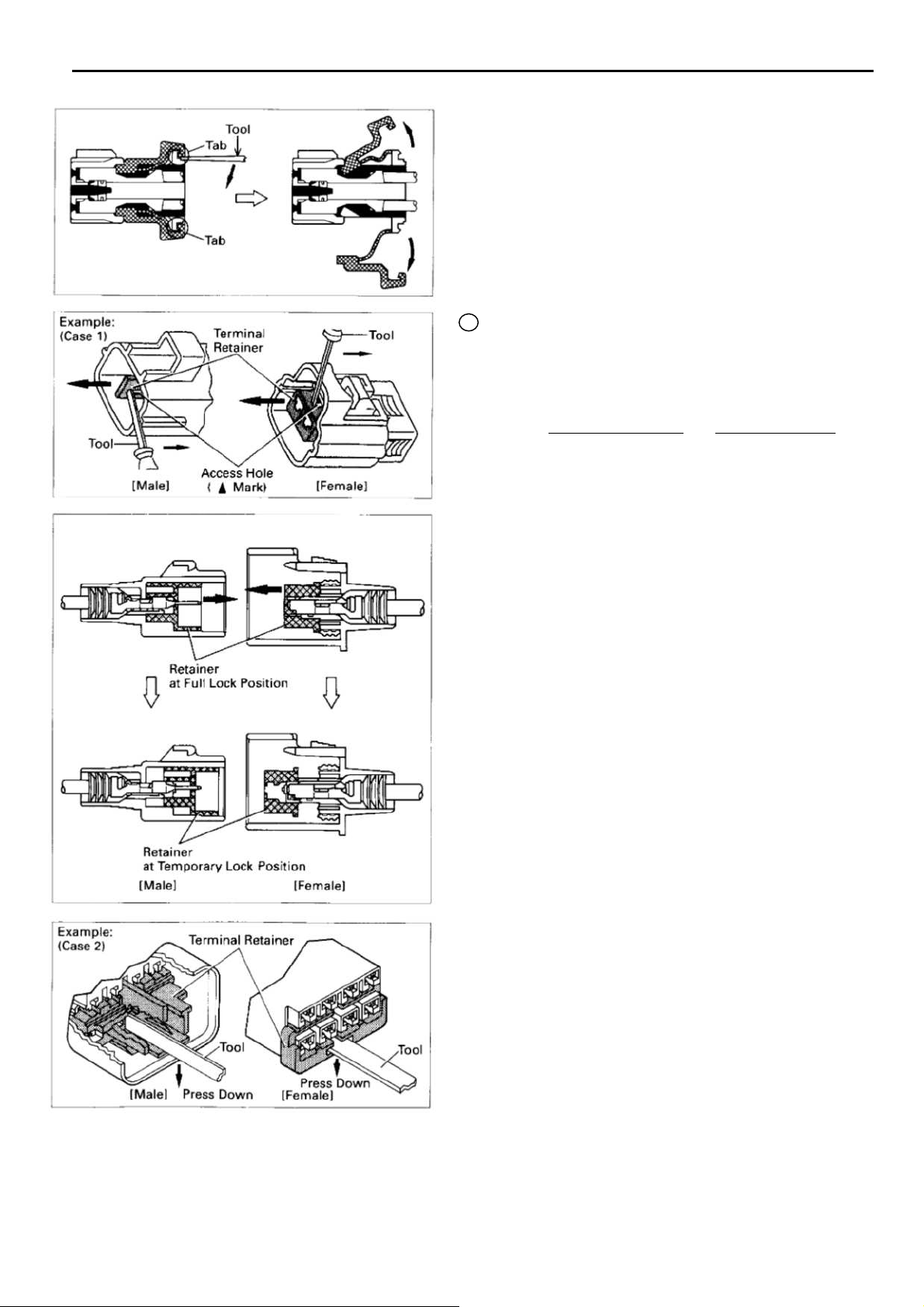

HOW TO REPLACE TERMINAL

(with terminal retainer or sec

ond

ary locking device

)

1.PR

2.DISCONNECT CONNECTO

3.DISENGAGE THE SECONDARY LOCKING DEVICE O

EPARE THE SPECIAL TOOL

HINT:To remov

construc

on the left.

TERMIN

(a)

(b) Use a special

NOTICE:

Do not

A

AL RETAINE

Locki

locking clip c

from the connector.

sec

remo

For Non-W

HINT:T

e the te

t and use the special

ng device must be dis

ondary locking device or te

ve the terminal retainer from c

aterproof Ty

he needle insertion positi

the connector’s s

etc.), so check the positi

rminal from

R

an be released and the te

tool or the te

the connector, please

tool or lik

R

engaged before the te

rminal pick to unlock the

rminal r

pe Connecto

hape (number of te

r

on varies according to

on before inserting it.

e object shown

rminal remov

etainer.

onnector bod

rminal

R

rminal

ed

y.

s

12

“Cas

“Cas

e 1

”

Raise the te

lock

positi

e 2

”

Open the secondary locking device.

rminal r

on.

etainer up to the temporary

B

For W

aterproof Ty

pe Connecto

C

r

HINT:Terminal r

according to connector body.

Example:

Terminal R

Black or White :Gray

Black or White :Dark Gray

Gray or White :Bla

“Cas

e 1

”

Type where te

pulled up to the temporary lock

positi

on (Pull Type)

Insert the special

te

rminal r

and pull the te

the temporary lock

HINT:T

he needle insertion positi

according to the connector’s s

(number

the positi

etainer color is di

etainer :Connector Bod

rminal r

.

tool into the

etainer access hole

rminal r

positi

of te

rminals etc.), so che

on before inserting it.

fferent

ck

etainer is

etainer up to

(Mark)

on.

on varie

hape

y

s

ck

“Cas

e 2

”

Type which c

Power Lock insert the tool straight

i

nto the access hole of te

r

etainer as shown.

annot be pulled as far a

rminal

s

13

C TROUBLESH

OOTING

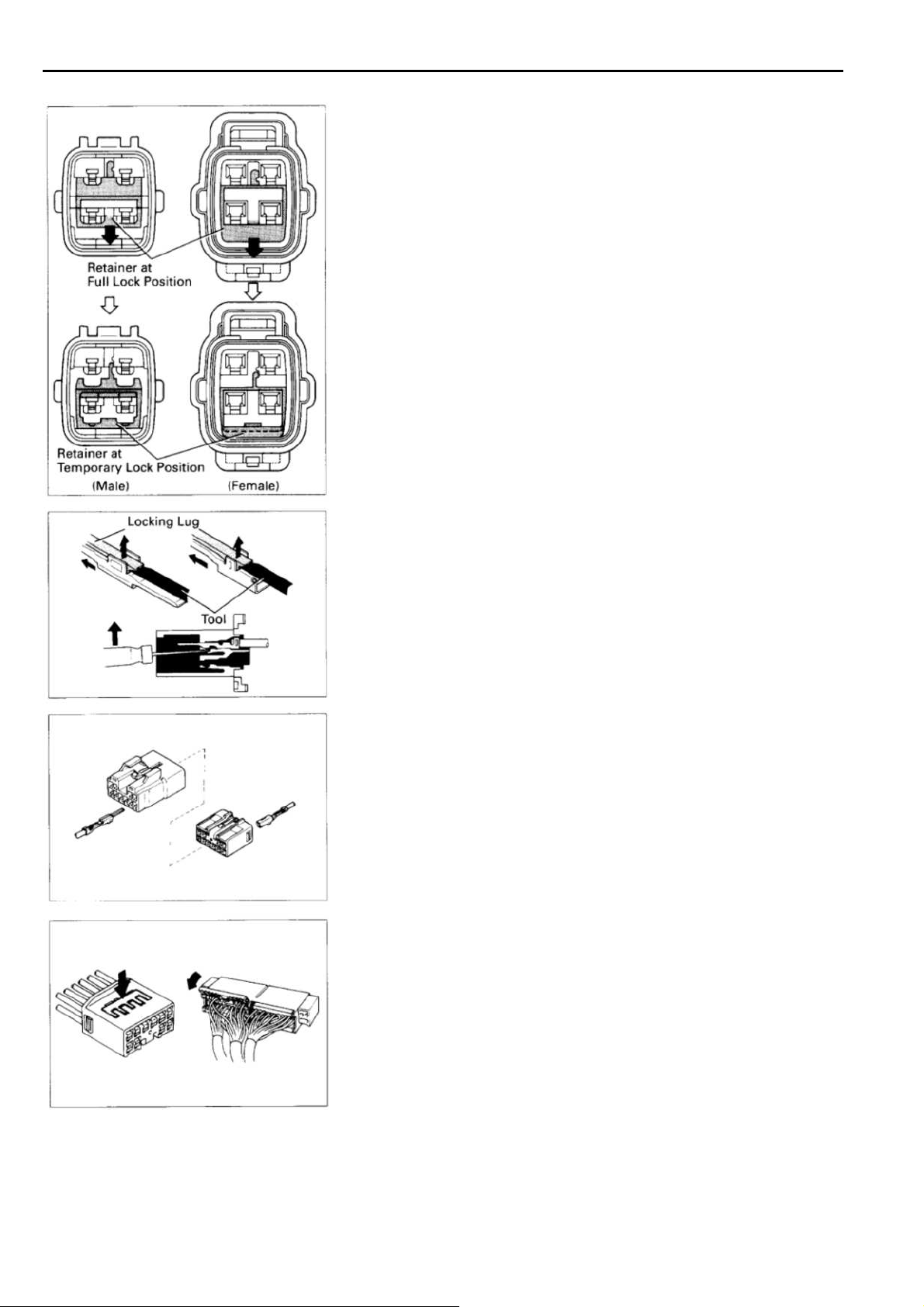

Push the te

positi

on.

(

c

) Releas

te

rminal

rminal r

e the locki

out from rear.

etainer down to the temporary lock

ng lug from te

rminal

and pull the

14

4. INSTALL TERMINAL TO CONNECTO

(a)Inser

HINT

1.Make sure the te

2. Insert the te

3. Insert the te

(b)Pus

5. CONNECT CONNECTO

t the terminal

:

temporary lock

h the secondary locking device or te

i

nto the full lock positi

.

rminal is positi

rminal

until the locki

rminal wi

positi

th te

on.

on.

R

rminal r

oned correctly

ng lug lo

etainer in the

R

.

cks firmly.

rminal r

etaine

r

C TRO

UBLESH

OOTING

DISCONNECTION AND CONNECTION OF BOLT

T

YPE CO

For

engine control module in this vehicl

which require a bolt built into the connector to be screw

to securely c

NNECTOR

onnect the connector.

S

e, connections are used

ed down

1.

2.

Disconnect the connecto

After completely looseni

c

onnector can be separated.

NOTICE:

Do not pu

c

onnecto

C

onnect the connecto

NOTICE:

Befo

the terminals are

(a) Matc

(b) Ti

ll the wire harness when disc

r.

re c

onnecting th

h the guide section of the male connecto

correctly with the female connector, then press

them together.

ghten the bolt.

Make sur

c

onnected, by tightening the bolt until there is

clearance of less than 1 mm (0.04 in.) between the

bottom of male connector and the end of female

c

onnector.

e the connectors are compl

r

ng the bolt, the two parts of the

onnecting th

r

e c

onnecto

not bent or d

r, always check tha

amaged.

etely

e

t

r

a

15

ABBREVIATIONS

T

he follow abbreviations ar

e used in this m

anual.

ABBR

EVIATIONS

D

ABS

A/

C

ACIS = Acoustic C

A/

T

COM

B. =Combination SFI = Sequential Multiport Fuel Injection

ECU. = Electronic C

EG

R

ESA = Electronic

EVAP = Evaporativ

J

/B =Junction Blo

L

H

M/T

* The titles giv

as being abbreviations

= Anti-Lock Brake Syste

= Air Conditioning PPS = Progressive Power Steering

ontrol Induction Syste

= Automatic Transmission

ontrol Unit SRS = Supplemental Restraint Syste

= Exhaust Gas Recirculation S

Spark

e Emission

ck

= Left-Hand

=Manual Transmissi

en insi

de the components are the names of the te

.

rm

Advance

on

m R

O/

D

/B =Relay Blo

RH

W

TEM

P. =Temperature

TRAC

VSV = Vacuum Switching Valv

w

/ =With

w

/o =Without

= Overdriv

=Right-Hand

= Switch

=Traction Contro

rminals (te

rminal c

e

ck

odes)

l

and are not treated

m

e

16

E GLOSS

AR

Y OF TERMS AND

BATTER

Y

Stores chemical

converts it i

nto electrical

Provides DC curr

energy and

ent for the

auto’s various electrical circuits.

SY

energy.

MBOL

S

GRO

UND

T

he point at which wiri

to the

Body, thereby providi

r

eturn path for an electrical circui

wi

thout a ground, current cannot

flow.

ng attache

ng a

s

t;

CAPACITOR (Conden

A small

stor

holding unit for temporary

age of electrical vol

ser

)

tage.

CIGARETTE LIGHTER

An electric resis

tance heating

element.

CIRCUIT BREAKER

Basically

breaker

much curr

a reusable fuse, a circuit

will

heat and open if too

ent flows

through it.

Some units automatically reset when

cool

DIOD

A semic

curr

DIOD

, others mus

E

ent flow in only

E, ZENE

A diode whic

t be manually res

onductor whic

one direction.

R

h allows curr

h allows

flow in one direction but blo

reverse flow only

vol

tage. Above that potential, it

up to a specifi

passes the excess voltage.

This acts as a simple vol

r

egulator.

ent

cks

tage

et.

c

HEADLIGHT

1.SINGL

FILAMEN

2.DOUBL

FILAMENT

LIGHT

S

Curr

ent flow causes a headlight

filament to heat up and emit light.

E

T

A headlight may have either a

single (1) filament or a double (2)

filament.

E

HORN

An electric

l

oud audible si

IGNITION COI

device which s

gnal.

L

Convert low-voltage DC current

i

nto high-vol

for f

iri

Curr

ent flow through a filament

causes

the filament to heat up

tage ingition current

ng the spark plugs

and emit light.

ounds a

.

(for Medium Curr

(for Hi

gh Current Fuse o

Fusible Link.

)

PHOTODIODE

DISTRIBUTOR

FU

SE

FUSIBLE LINK

ent Fuse

)

r

T

he photodiode is

semiconductor which c

curr

ent flow according to the

a

ontrols

the

amount of light.

, II

A

C

hannels high-voltage current

from the ignition coil to the

indivi

dual spark plugs

A thin metal strip whic

.

h burn

s

through when too much current

flows

through it, thereby stop

ping current flow and protecting a

circui

t from damage.

A heavyhigh amperage circuits whic

gauge

wir

e placed in

h

burns through on overloads,

thereby protecting the circuit.

T

he numbers indicate the cross

secti

on surface area of the

wires

LED (LIGHT EMITTING DIODE)

U

pon current flow, these diode

emit light without produci

s

ng the

heat of a comparable light.

METER, ANAL

Curr

ent flow activ

OG

ates a magnetic

coil which causes a needle to

mov

FUE

L

e, thereby providi

display

calibrati

METER, D

Curr

many

against a background

on.

IGI

TAL

ent flow activ

LED’s

displays, which provi

or digital display

, L

CD’s, or fluoresent

ng a relativ

ates one o

de a relativ

.

e

r

e

MOTOR

A power unit which converts

M

electrical

energy into mechanical

energy, especially rotary moti

on.

.

17

RELA

Y

1.NO

CLOSE

RMALLY

D

Basically

operated switch which

may

(1) or

, an electricall

be normally closed

open (2). Current

flow through a small

2.NO

OPE

RMALLY

N

coil creates a magnetic

field whic

h either open

or closes

switch.

RELA

Y, DO

UBLE THROW

A relay whic

h passes current

through one set of contacts or the

other.

an attached

E

y

s

SPEAKE

SWI

TCH, MANUAL

1.NORMALLY

2.NO

R

An electromechanical

which cr

curr

eates sound waves fro

ent flow.

O

closes circuits,

OPE

N

thereb

s

allowing (2

RMALLY

CLOSE

D

curr

device

pen and

y

topping (1) o

)

ent flow.

m

r

RESISTO

R

An electrical com

fix

ed resistance, placed in a circuit

ponent with a

to reduce voltage to a specifi

val

ue.

R

ESISTOR, TAPPE

A resistor which s

mor

e different non adjustable

resis

tance values.

R

ESISTOR, VARI

RH

EOS

TAT

D

upplies two o

ABLE o

A controllable resistor with a

variable r

Also call

r

heostat.

SENSOR

ate of resistance.

ed a potentiometer o

(Thermistor

)

A resistor which varies its

resis

tance with temperature.

SENSOR, SPEE

D

Uses magnetic impulses to open

and clos

signal for activati

com

e a switc

ponents.

h to cr

on of othe

r

eate a

SWI

TCH, DOUBLE THROW

A switch which continuousl

c

r

passes cureent through one set of

c

ontacts or the other.

SWI

TCH

,

IGNITIO

N

A key operated switch wi

y

th severa

l

positions which allows various

circuits

, particularly the p

igniti

on circuit, to become

rimar

y

operational.

r

SWI

TCH, W

Automatically returns wipers

the stop positi

switch is

TRAN

SISTO

IPER P

ARK

on when the wipe

turned off.

R

to

r

A solid state device typically used

as an electronic relay; s

r

passes current depending on the

vol

tage applied at “base.

tops o

”

r

18

SHORT PI

SOLENOI

N

Used to provi

c

onnection within a juction block.

de an unbroken

D

An electromagnetic coil which

forms

a magnetic field w

curr

ent flows

, to move a plunger,

etc.

hen

WIR

ES

(1) NOT

CONNECTE

(2)SPLICED

Wires ar

e always

drawn as straight line

on

wiri

D

ng diagrams

Cross

ed

wires (1)

wi

thout a black dot at

the junction are not

joi

ned;

crossed

wires (2)

a black dot o

octagonal

the juction as splic

(joi

ned) connections.

r

(

) mark at

s

.

and

ed

+

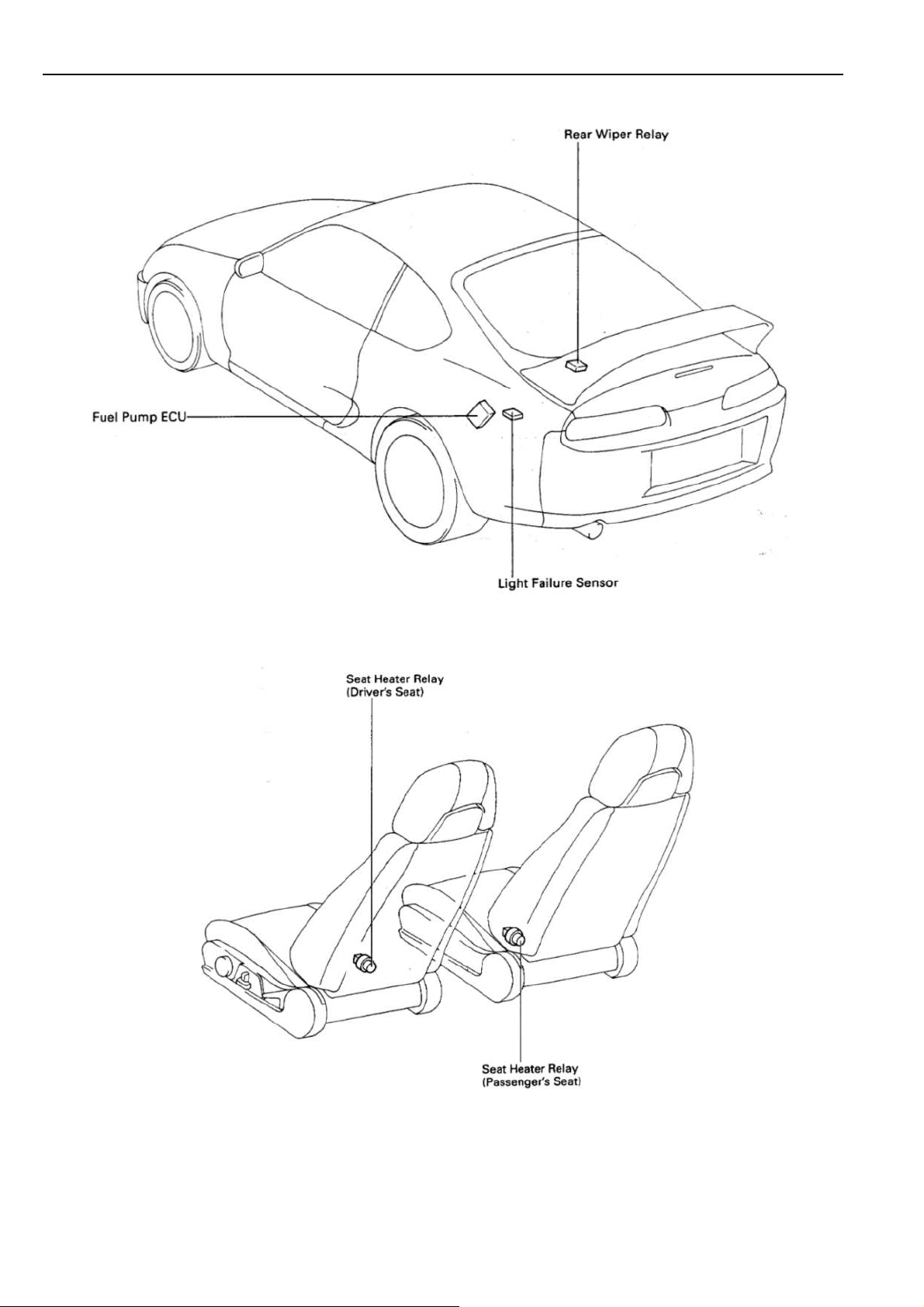

F RELAY LOCATION

S

[Engine Compart

me

nt]

[Instru

ment Panel

]

19

+

[

Body]

F

[

Sea

t]

20

F RELAY LOCATION

:

J/B No

. 1

S

Left K

ick Pan

el (See Page 18

)

21

F

[J/B No. 1 Inner C

ircui

t]

22

F RELAY LOCATION

Engi

f

t (

S

18)

2

: R/B No. 2

:

J/B No. 2

S

n

e Comp

artme

nt Le

ee Page

23

4

: R/B No. 4

Left K

ick Pan

el (See Page 18

F

)

5

: R/B No

. 5 Engine Compartment Right (

See Page 18

)

24

2

6

G ELE

CTRICAL WIRING ROUTIN

G

[2JZ-GTE]

Position of Part

s in Engine Compartme

nt

A 1 A/C Ambient Temp Senso

A 2 A/C Condensor Fan Moto

A 3 A/C

A 4 A/C Magnetic Clutc

A 5 A/T Fluid Temp. Senso

A 6 ABS Actuato

A 7 ABS Actuato

A10 ABS Speed Sensor Front L

A11 ABS Speed Sensor Front

B 1 Back-U

B 2 Brake Fluid Level Warning S

C1Camshaft Positi

C2Camshaft Positi

C3Cranks

C4Cruise Control Actuato

D1D

D2Daytime R

D3Daytime R

E 1 EGR Gas Temp. Senso

E 2 Electronically Controlled Transmissi

E 3 Engine Coolant Temp. Senso

Tripl

e Pressure S

(A/C Dual

ata Link Connector 1

and Single Pressure S

r

r

p Light SW (M/

on Sensor No.1

on Sensor No.2

haft Positi

on Senso

unning Light Relay No.3

unning Light Relay No.3

r

r

W

W)

h and Lock Senso

r

H

RH

T)

W

r

r

r

r

r

on Solenoid

E

4 Engine Coolant Temp. Sende

E 5 Engine Coolant Temp. S

E 6 Engine Hood Courtesy S

E 7 Engine Oil

F3Fr

ont Fog Light L

F4Fr

ont Fog Light

F5Fr

ont Side Marker Li

F6Fr

ont Side Marker Li

F7Fr

ont Turn Signal Light L

F8Fr

ont Turn Signal Light RH and Parking Light

F9Fr

ont Wiper Moto

G 1 Generato

G 2 Generato

H1H

eadlight Hi L

H2H

eadlight Hi

H3H

eadlight Lo L

H4H

eadlight Lo

H5H

eated Oxygen Sensor (Bank 1 Sensor 1

H8Hor

H9Horn RH

n L

Level Senso

H

RH

ght L

ght

r

r

r

H

RH

H

RH

H

r

W

W

r

H

RH

H

RH

)

24

G

[2JZ

Position of Part

s in Engine Compartme

nt

I 1 Idle AIr Control Valv

I 2 Ignite

I 3 Ignite

I 6 Ignition Coil No.1

I 7 Ignition Coil No.2

I 8 Ignition Coil No.3

I 9 Ignition Coil No.4

I10 Ignition Coil No.5

I11 Ignition Coil No.6

I12 Injector No.1

I13 Injector No.2

I14 Injector No.3

I15 Injector No.4

I16 Injector No.5

I17 Injector No.6

K 1 Knock Sensor (on Front Side

K 2 Knock Sensor (on Rear Side

M 1Mass Air Flow M

N1Noise

O 1 O/D

O 2 Oil Pressure S

r

r

Filter

Direct Clutc

e

ete

r

h Speed Senso

W

R1Radi

R2Radi

R3Radi

R20Radi

S 1 SFI Resisto

S 2 Starte

S 3 Starte

S 5 Sub Throttle Positi

S18 Sub Throttle Valve M

T1T

T2Thr

T14Tur

V 2 VSV (EGR)

)

)

r

V 3 VSV (EVAP

V 4 VSV (Exhaust Bypass Valve)

V 5 VSV (Exhaust Gas Control Valve)

V 6 VSV (Fuel Pressure Up

V 7 VSV (Intake Air Control Valve)

V 8 VSV(Waste Gate Valve)

V10 Vehicle Speed Sensor No.1 (Combination Mete

V11 Vehicle Speed Sensor No.2 (Electronicall

ator Fan Motor No.1

ator Fan Relay No.1

ator Fan Relay No.2

ator Fan Motor No.2

r

r

r

on Senso

heft Deterrent Horn

ottle Positi

bo Pressure Senso

C

ontrolled Transmission)

on Senso

)

oto

r

r

r

r

)

r)

y

P 1 PPS Solenoid

P 2 Park/N

P13 Parking Light L

eutral Positi

A/T Indic

ator Light SW (A/

on SW, Back-U

H

T)

p Light SW and

W1Washer M

oto

r

25

G ELE

CTRICAL WIRING ROUTIN

G

[

2J

Position of Part

s in Engine Compartme

nt

A 1 A/C Ambient Temp. Senso

A 3 A/C Dual Pressure S

A 4 A/C Magnetic Clutc

A 5 A/T Fluid Temp. Senso

A 6 ABS Actuato

A 7 ABS Actuato

A 8 ABS Rela

A 9 ABS Rela

A10 ABS Speed Sensor Front L

A11 ABS Speed Sensor Front

B 1 Back-U

B 2 Brake Fluid Level Warning S

C3Cranks

C4Cruise Control Actuato

D1D

ata Link Connector 1

D4Distributo

y

y

p Light SW (M/

haft Positi

r

h and Lock Senso

r

r

on Senso

r

W

r

RH

T)

r

r

E

1 EGR

E 2 Electronically Controlled Transmissi

r

H

W

E 3 Engine Coolant Temp. Senso

E 4 Engine Coolant Temp. Sende

E 6 Engine Hood Courtesy S

E 7 Engine Oil Level Senso

F3Fr

F4Fr

F5Fr

F6Fr

F7Fr

F8Fr

F9Fr

G 1 Generato

G 2 Generato

Gas Temp. Senso

ont Fog Light L

ont Fog Light

ont Side Marker Li

ont Side Marker Li

ont Turn Signal Light L

ont Turn Signal Light RH and Parking Light

ont Wiper Moto

RH

r

r

r

on Solenoid

r

r

W

r

H

ght L

H

ght

RH

H

r

RH

26

G

[2JZ-

Position of Part

s in Engine Compartme

nt

H1H

eadlight Hi L

H2H

eadlight Hi

H3H

eadlight Lo L

H4H

eadlight Lo

H8Hor

H9Horn RH

I 1 Idle Air Control Valv

I 4 Ignite

I 5 Ignition Co

I 12 Injector No.1

I 13 Injector No.2

I 14 Injector No.3

I 15 Injector No.4

I 16 Injector No.5

I 17 Injector No.6

K 1 Knock Sensor (on Front Side

K 2 Knock Sensor (on Rear Side

M1Mass Air Flow M

M2Main H

M3Main H

N1Noise

n L

H

r

Filter

H

RH

H

RH

e

il

ete

r

eated Oxygen Sensor (Bank 1 Sensor 1

eated Oxygen Sensor (Bank 2 Sensor 1

O

2 Oil Pressur

P 1 PPS Solenoid

P 2 Park/N

A/T Indic

P 3 Power Steering Pressure S

P13 Parking Light L

S 2 Starte

S 3 Starte

T1T

heft Deterrent Horn

T2Thr

V 1 VSV (ACIS

V 2 VSV (EG

V 3 VSV (EVAP

)

)

)

)

V 6 VSV (Fuel Pressure Up

V10 Vehicle Speed Sensor No.1 (Combination Mete

V11 Vehicle Speed Sensor No.2 (Electronicall

W 1Washer M

ottle Positi

C

ontrolled Transmission)

e S

W

eutral Positi

ator Light SW (A/

H

r

r

on Senso

)

R)

)

oto

r

on SW, Back-U

T)

W

r

)

p Light SW and

r)

y

27

G ELE

CTRICAL WIRING ROUTIN

G

Position of Part

s in Instrument Panel

A12 A/C Amplifie

A13 A/C Amplifie

A14 A/C Amplifie

A15 A/C Evaporator Temp. Senso

A16 A/C Room Temp. Senso

A17 A/C Solar Senso

A18 ABS E

A19 ABS E

A20 ABS E

A21 ABS E

A23 ABS Deceleration Senso

A24 Air Inlet Control Servo M

A25 Air Mix C

A26 Air Vent Mode Control Servo M

A27 Airbag Squib (Steering Wheel Pad

A28 Airbag Squib

A29 Ashtray Illumination

A30 Auto Antenna Control Rela

A34 Airbag Senso

B 3 Blower Moto

B 4 Blower Motor Control Rela

r

r

r

r

CU

CU

CU

CU

ontrol Servo M

(Fr

ont Passenger Airbag Assembly

r

r

r

r

oto

oto

r

r

r

oto

y

y

B

5 Blower Motor Control Rela

B 6 Buckl

B 7 Buckl

C6Cigar

C7Cigar

C8 Clock

C9Clutc

C10Combi

C11Combi

C12Combi

C13Combi

C14Combi

r

)

C15Cruise Control Clutch S

C16Cruise Control E

)

D5D

D6Daytime R

D7Di

D8Di

D17D

e SW L

e SW

ette Lighte

ette Lighter Illumination

h Start S

ata Link Connector 2

ode (Interior Light

ode (Idle-Up

ata Link Connector 3

H

RH

r

W

nation Mete

nation Mete

nation Mete

nation S

nation S

unning Light Relay (Main

r

r

r

W

W

CU

)

y

W

)

)

28

G

Position of Part

s in Instrument Panel

E 8 Electronically Controlled Transmissi

Select S

E 9 Engine Control Module

E10 Engine Control Module

E11 Engine Coolant Temp. Sensor (A/C Syste

F10Fr

F11Fr

G 3 Glove Box Light

G 4 Glove Box Light S

H10Hazar

H11H

H12H

H13H

I18 Ignition Key Cylinder Light

I19 Ignition S

I20 Integration Rela

J1Juncti

J2Juncti

K 4 Kick Dow

N2Noise

W

ont Tweeter (Speaker) L

ont Tweeter (Speaker)

W

d S

W

eated Oxygen Sensor (Bank 1 Sensor 2

eater Control S

eater Control S

W

on Connecto

on Connecto

n S

Filter

W

W

y

r

r

W

H

RH

on Pattern

m)

)

O

5 O/D Main SW

P 4 PPS E

P 5 Parking Brake S

R4Radi

R5Radi

R6Radi

R7Rem

R8R

S 6 Seat Heater S

S 7 Shift Lock E

S 8 Stereo Power Amplifie

S 9 Stereo Power Amplifie

S10 Stereo Power Amplifie

S11 Stop Light S

S16 Sub Heated Oxygen Sensor (Bank 1 Sensor 2

T 5Telltal

T6Telltal

T7T

T8Tracti

T13T

T15Thr

T16Thr

U1Unlock Warni

CU

o and Player (w/o Stereo Power Amplifie

o and Player (w/o Stereo Power Amplifie

o and Player (w/ Stereo Power Amplifie

ote Control

heostat

e Light L

e Light

heft Deterrent and Door Lock Control E

on Control S

heft Deterrent and Door Lock Control E

ottle E

ottle E

and A/T Indic

W

Mirror SW

W

CU

W

H

RH

CU

CU

ng S

W

ator Illumination

r)

r

r

r

CU

W

CU

r)

r)

)

29

G ELE

CTRICAL WIRING ROUTIN

G

Position of Part

s in

Bod

y

A31 ABS Speed Sensor Rear L

A32 ABS Speed Sensor Rear

A33 Auto Antenna Moto

D10Door Courtesy SW LH

D11Door Courtesy SW RH

D12Door

D13Door

D14Door

D15Door

D16Door

F12Fr

F13Fr

F14Fuel

F15Fuel

H14Hi

L 1 Licens

L 2 Light Failure Senso

L 3 Luggage Compartment Key Unlock S

L 4 Luggage Compartment Light

L 5 Luggage Compartment Light S

Key Lock and Unlock SW L

Key Lock and Unlock SW

Lock Control SW

Lock Motor and Door Unlock Detection SW L

Lock Motor and Door Unlock Detection SW RH

ont Door Speaker L

ont Door Speaker

Pump and Sende

Pump E

gh Mounted Stop Light

e Plate Light

r

RH

CU

r

H

RH

H

RH

RH

H

r

W

W

N3Noise

P 6 Pers

P 7 Power Window Control SW

P 8 Power Window Master SW and Door Lock Contro

P 9 Power Window Motor L

P10 Power Window Motor

R9Rear Combi

H

R10Rear Combi

R11Rear Si

R12Rear Si

R13Rear

R14Rear

R15Rear Wiper M

R16Rem

R17Rem

R18Rear Wi

R19Rear Wi

T11Tension Reducer Solenoid L

T12Tension Reducer Solenoid

W2W

Filter

onal Light

SW L

H

de Marker Li

de Marker Li

Speaker L

Speaker

ote Control

ote Control

ndow Defogger (+

ndow Defogger

oofer (Speake

H

RH

nation Light L

nation Light

ght L

ght

H

RH

otor and Rela

Mirror

and

Mirror

and

r)

H

RH

H

RH

)

(-)

RH

RH

y

Mirror H

Mirror H

H

eater L

eater

l

H

RH

30

Loading...

Loading...