Toyota Corolla Verso 2004 User Manual

01–1

–INTRODUCTION HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

0106E–06

GENERAL INFORMATION

1. GENERAL DESCRIPTION

(a) This manual is made in accordance with SAE J2008.

(b) Generally repair operations can be separated in the following 3 main processes:

1. Diagnosis

2. Removing and Installing, Replacing, Disassembling, Installing and Checking, Adjusting

3. Final Inspection

(c) This manual explains ”Removing and Installing, Replacing, Disassembling, Installing and Checking,

Adjusting”, but ”Final Inspection” is omitted.

(d) The following essential operations are not written in this manual, however these operations must be

done in the practical situation.

(1) Operation with a jack or lift

(2) Cleaning of a removed part when necessary

(3) Visual check

2. INDEX

(a) An alphabetical INDEX is provided as a section on the end of the book to guide you to the item to be

repaired.

3. PREPARATION

(a) Use of special service tools (SST) and special service materials (SSM) may be required, depending

on the repairing condition. Be sure to use SST and SSM when they are required and follow the working

procedure properly. A list of SST and SSM is in the Preparation section of this manual.

4. REPAIR PROCEDURES

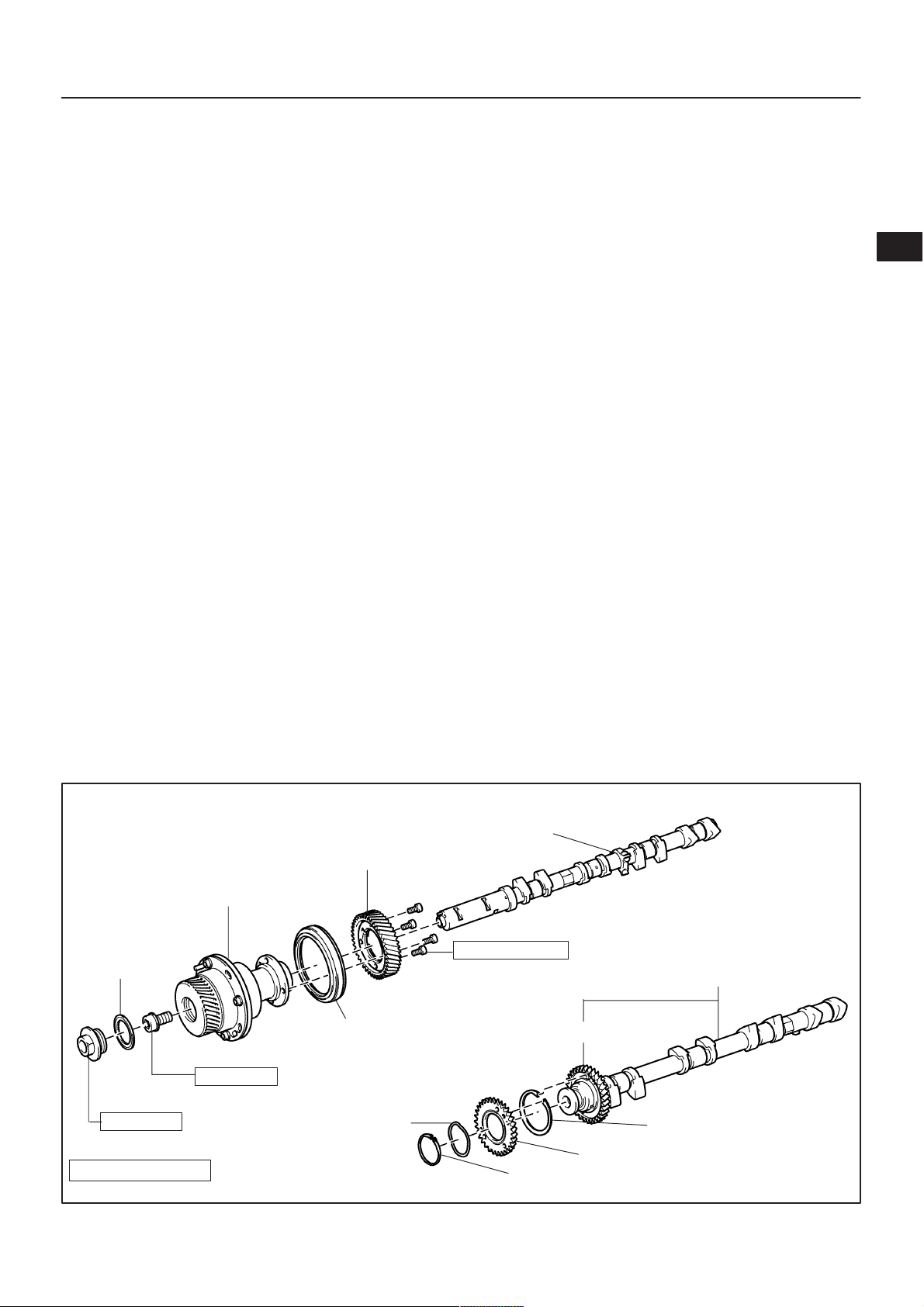

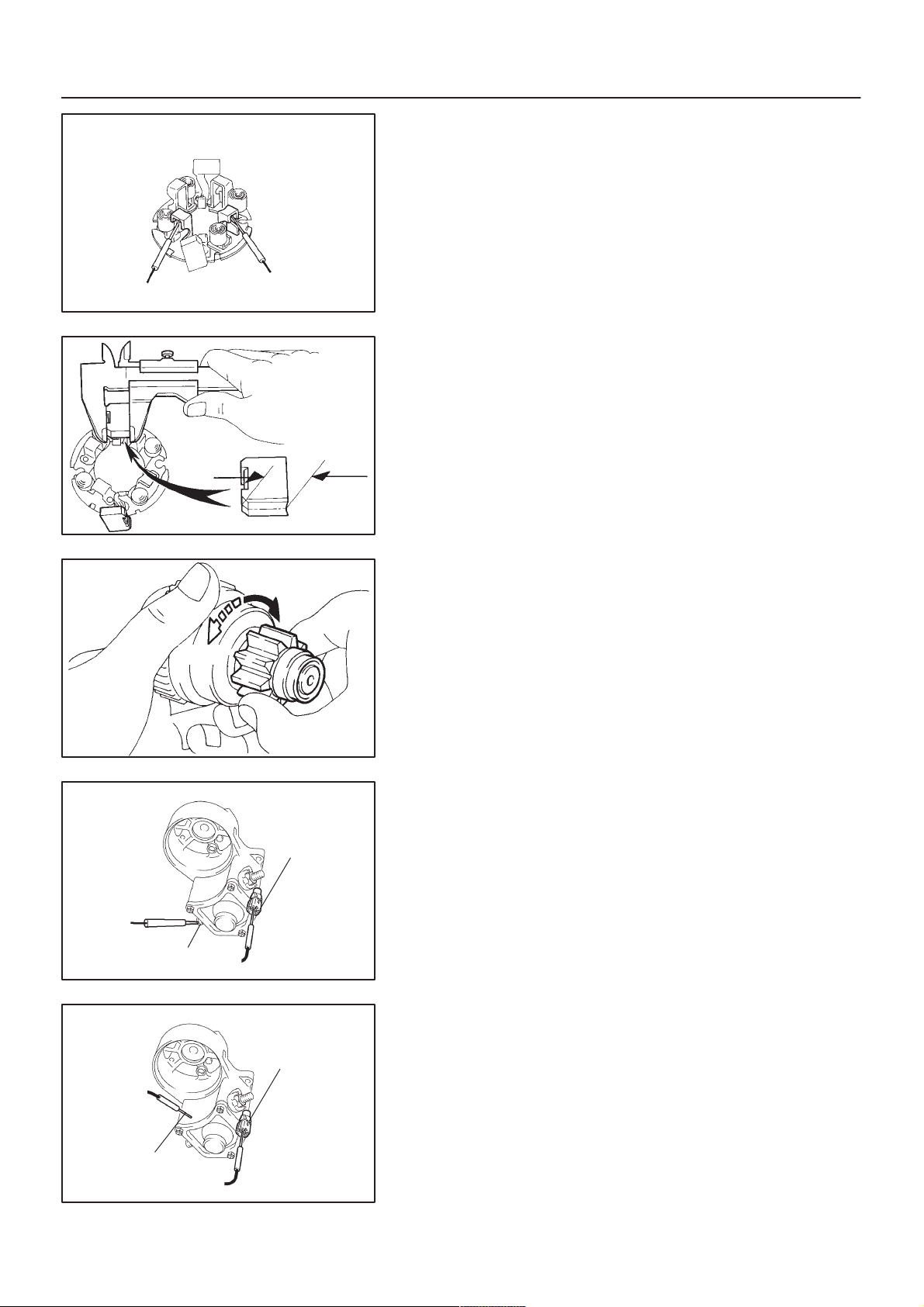

(a) Component drawing is placed as the section or title when necessary.

(b) Illustrations of the parts catalog are placed as the ”disassembled parts drawing” so that it enables you

to understand the fitting condition of the components.

(c) Non–reusable parts, grease applied parts, precoated parts and tightening torque are specified in the

components drawing.

Example:

OVERHAUL

Camshaft Drive Gear

Camshaft Timing Tube Assy

Seal Washer

! Camshaft Setting Oil Seal

Screw Plug

78 (790, 58)

15 (150, 11)

N·m (kgf·cm, ft·lbf) : Specified torque

! Non–reusable part

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

Wave Washer

Camshaft,

No. 3 Camshaft Sub–assy

7.5 (80, 66 in.·lbf)

Camshaft Driven Main Gear

Camshaft Sub Gear

Snap Ring

No. 2 Camshaft,

No. 4 Camshaft Sub–assy

Camshaft Timing Gear

Bolt Washer

A54988

01–2

–INTRODUCTION HOW TO USE THIS MANUAL

(d) Tightening torque, oil applying position, and non–reusable parts are described as important points in

the procedure.

NOTICE:

There are cases where such information can only be indicated by an illustration. In that case, all the

information such as torque, oil, etc. are described in the illustration.

(e) Installing procedure of operation items is performed in the reverse order of the removing, and only the

important points are described.

(f) Only items with points are described in the procedure, and the operational portion and content are

placed using an illustration. In the explanations, details of the operational method, standard value and

notice are placed.

(g) There may be a case where the illustrations of similar models are used. In that case the details may

be different from the actual vehicle.

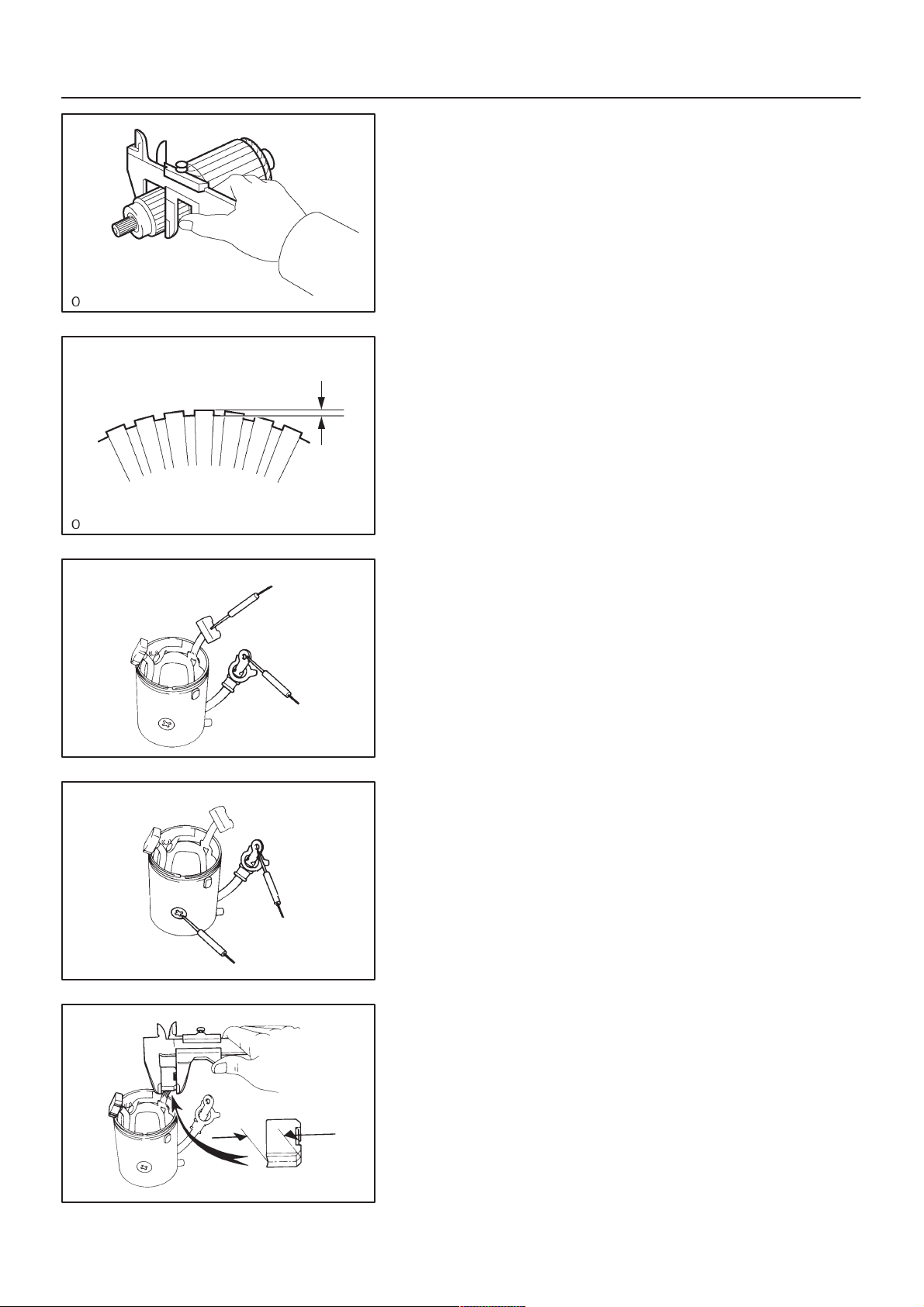

(h) The procedures are presented in a step–by–step format:

(1) The illustration shows what to do and where to do it.

(2) The task heading tells what to do.

(3) The detailed text tells how to perform the task and gives other information such as specifications

and warnings.

Example:

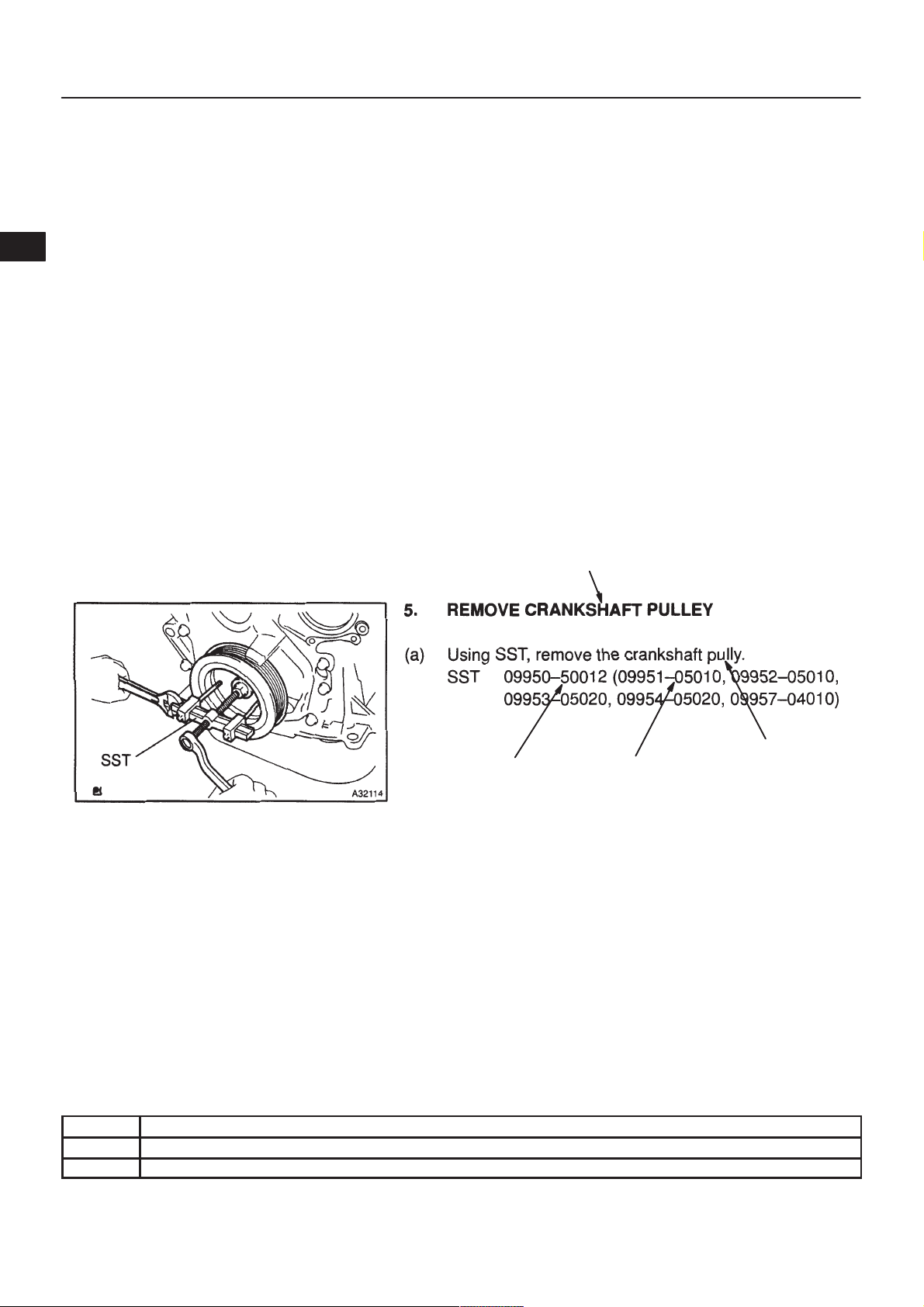

Illustration:

what to do and where

Task heading: what to do

Set part No.

Component part No.

Detailed text:

how to do task

A59974

HINT:

This format provides an experienced technician with a FAST TRACK to the necessary information. The task

heading can be read at a glance when necessary, and the text below provides detailed information. Important specifications and warnings always stand out in bold type.

5. SERVICE SPECIFICATIONS

(a) Specifications are presented in bold type throughout the manual. You never have to leave the proce-

dure to look up your specifications. The specifications are also found in the Service Specifications section for a quick reference.

6. TERMS DEFINITION

CAUTION Indicate the possibility of injury to you or other people.

NOTICE Indicate the possibility of damage to the components being repaired.

HINT Provide additional information to help you perform the repair efficiently.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

01–3

–INTRODUCTION HOW TO USE THIS MANUAL

7. SI UNIT

(a) The UNITS given in this manual are primarily expressed according to the SI UNIT (International Sys-

tem of Unit), and alternately expressed in the metric system and in the English System.

Example:

Torque: 30 N!m (310 kgf!cm, 22 ft!lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

19–32

OVERHAUL

–STARTING & CHARGING GENERATOR ASSY(130A) (1CD–FTV)

190AJ–01

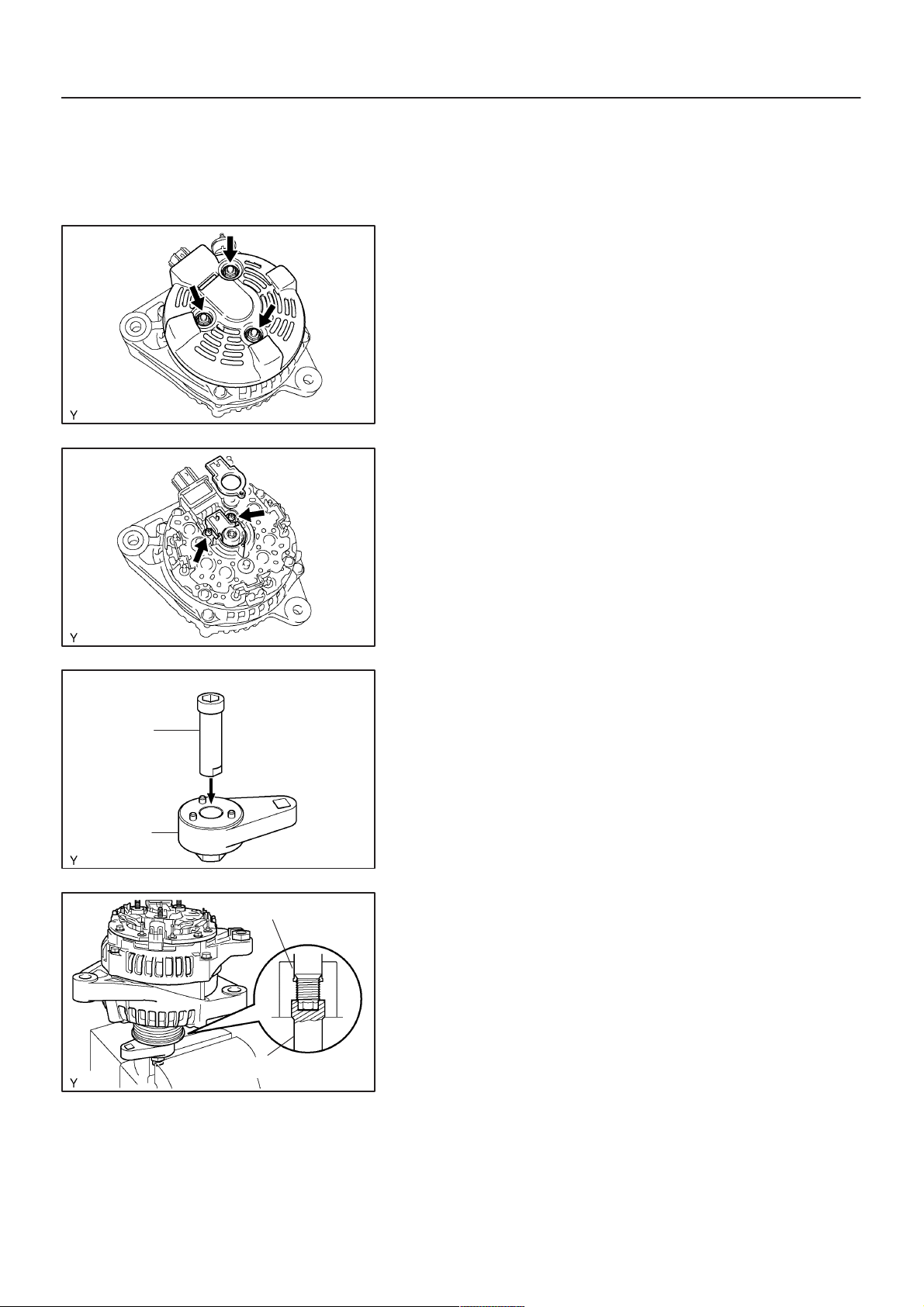

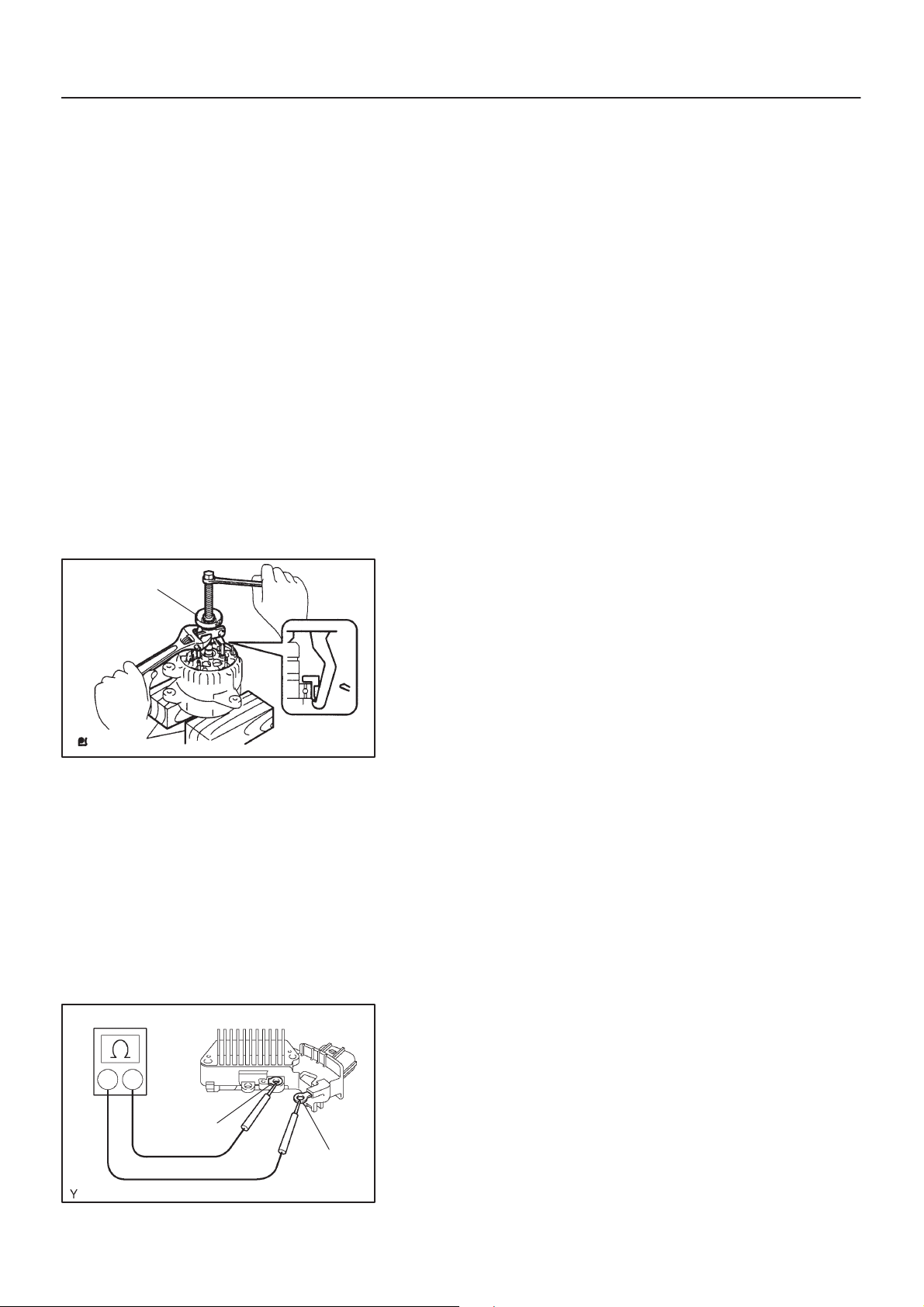

1. REMOVE GENERATOR BRUSH HOLDER ASSY

(a) Remove the 3 nuts and rear end cover.

(b) Remove the B terminal insulator.

A55648

(c) Remove the rear plate seal from the brush holder.

(d) Remove the 2 screws and brush holder.

(e) Remove the front seal plate from the rear frame.

SST (A)

SST (B)

Rotor Shaft

SST (A)

A55649

2. REMOVE GENERATOR W/CLUTCH PULLEY

(a) Set SST (A) and (B).

SST 09820–63020

A55650

(b) Mount SST (A) in a vise.

(c) Set the alternator to SST.

NOTICE:

At this time, make sure that the alternator and SST are perpendicular to one another.

A55651

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

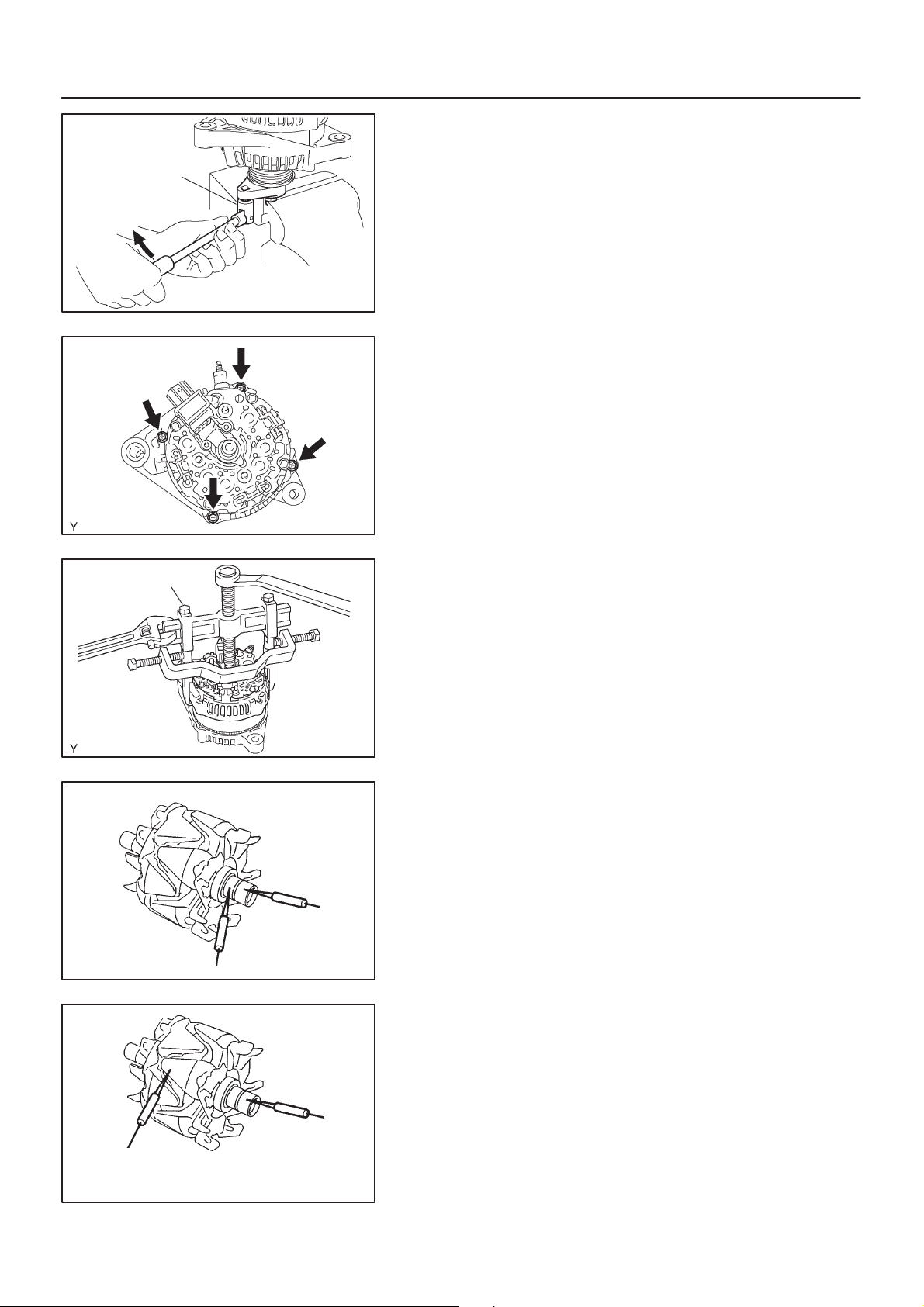

SST (B)

Turn

19–33

–STARTING & CHARGING GENERATOR ASSY(130A) (1CD–FTV)

(d) Insert the 3 tabs of SST (B) into the 3 holes on the pulley.

(e) To loosen the pulley, turn SST (B) in the direction shown

in the illustration.

(f) Remove the alternator from SST.

(g) Remove the pulley from the rotor shaft.

A57794

3. REMOVE GENERATOR ROTOR ASSY

(a) Remove the 4 through bolts.

SST

A57795

(b) Using SST, remove the coil assembly.

SST 09950–40011 (09951–04020, 09952–04010,

09953–04020, 09954–04010, 09955–04071,

09958–04011)

(c) Remove the alternator washer.

(d) Remove the rotor from the drive end frame.

A57796

4. INSPECT GENERATOR ROTOR ASSY

(a) Using an ohmmeter, check that there is continuity be-

tween the slip rings.

Standard resistance: 2.3 – 2.7 ! at 20! C (68!F)

A57797

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(b) Using an ohmmeter, check that there is no continuity be-

tween the slip ring and rotor.

A57798

19–34

A57799

A57800

–STARTING & CHARGING GENERATOR ASSY(130A) (1CD–FTV)

(c) Check that the slip rings are not rough or scored.

(d) Using vernier calipers, measure the slip ring diameter.

Standard diameter:

14.2 – 14.4 mm (0.5591 – 05669 in.)

Minimum diameter: 14.0 mm (0.551 in.)

5. INSPECT GENERATOR BRUSH HOLDER ASSY

(a) Using vernier calipers, measure the exposed brush

length.

Standard exposed length: 10.5 mm (0.4134 in.)

Minimum exposed length: 4.5 mm (0.177 in.)

HINT:

If the exposed length is less than minimum, replace the brush

holder.

Socket

Wrench

(29 mm)

6. INSTALL GENERATOR ROTOR ASSY

(a) Place the drive end frame.

(b) Install the rotor to the drive end frame.

(c) Place the alternator washer on the rear bearing.

A57801

(d) Using a socket wrench (29 mm)and press, slowly press

in the coil assembly.

A57802

(e) Install the 4 through bolts.

Torque: 5.8 N!m (59 kgf!cm, 51in.!lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

A57795

–STARTING & CHARGING GENERATOR ASSY(130A) (1CD–FTV)

7. INSTALL GENERATOR W/CLUTCH PULLEY

19–35

SST (A)

SST (B)

SST (B)

Rotor Shaft

SST (A)

Turn

(a) Temporarily install the pulley to the rotor shaft.

(b) Set SST (A) and (B).

SST 09820–63020

A55650

(c) Mount SST (A) in a vise.

(d) Set the alternator to SST.

NOTICE:

At this time, make sure that the alternator and SST are perpendicular to one another.

A55651

(e) Insert the 3 tabs of SST (B) into the 3 holes on the pulley.

(f) To torque the pulley, turn SST (B) in the direction shown

in the illustration.

Torque: 111 N!m (1132 kgf!cm, 82 ft!lbf) for using SST

HINT:

Use a torque wrench with a fulcrum length of 50 cm (19.69 in.).

(g) Remove the alternator from SST.

(h) Install a new alternator pulley cap.

A57803

Upward

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

8. INSTALL GENERATOR BRUSH HOLDER ASSY

(a) Place the front seal plate to the coil assembly.

(b) Install the brush holder with the 2 screws.

Torque: 1.8 N!m (18 kgf!cm, 16 in.!lbf)

NOTICE:

Be careful of the holder installation direction.

(c) Place the plate seal on the brush holder.

A57804

(d) Install the rear end cover with the 3 nuts.

Torque: 4.6 N!m (47 kgf!cm, 41 in.!lbf)

A55648

–STARTING & CHARGING GENERATOR ASSY(130A) (1CD–FTV)

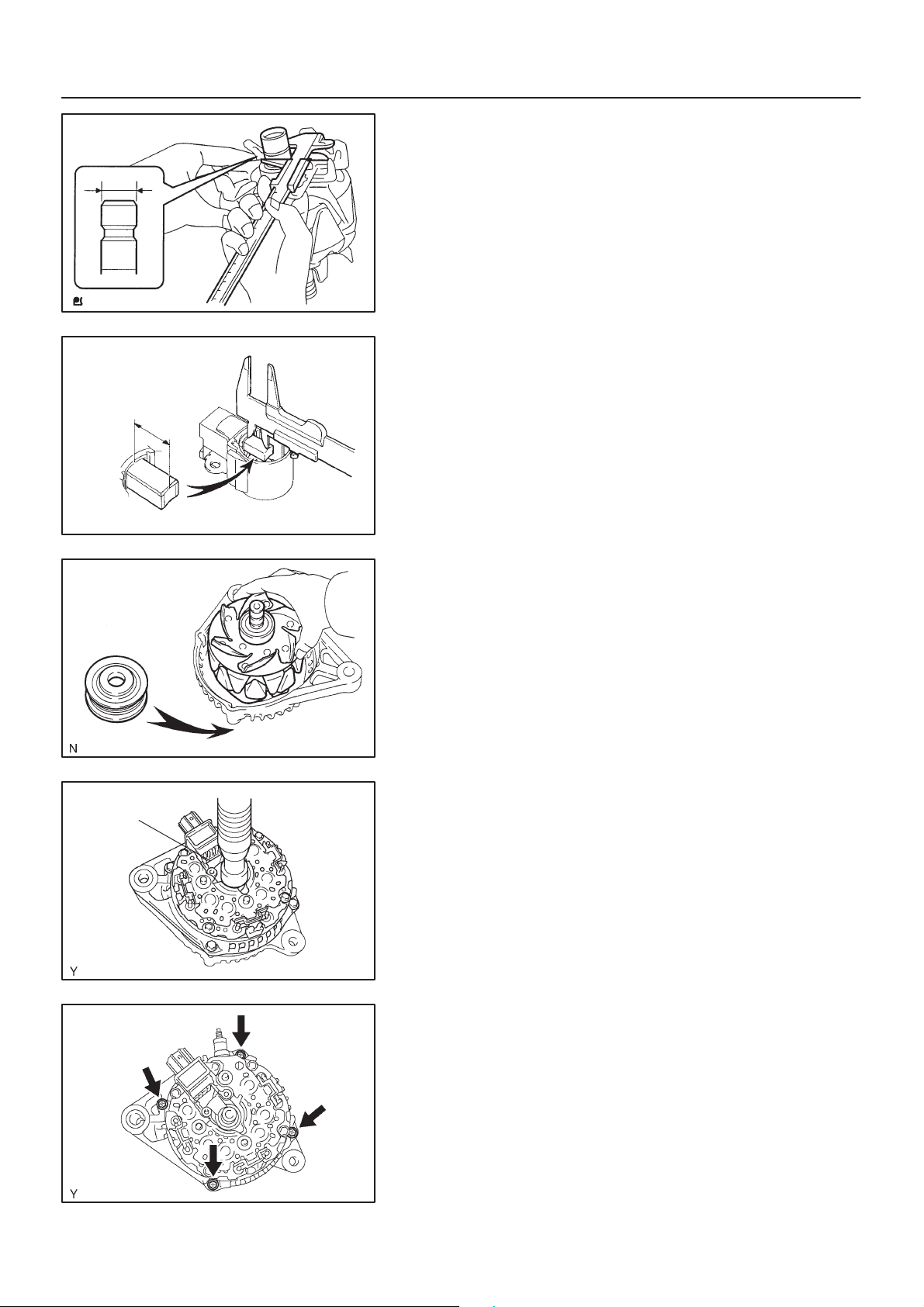

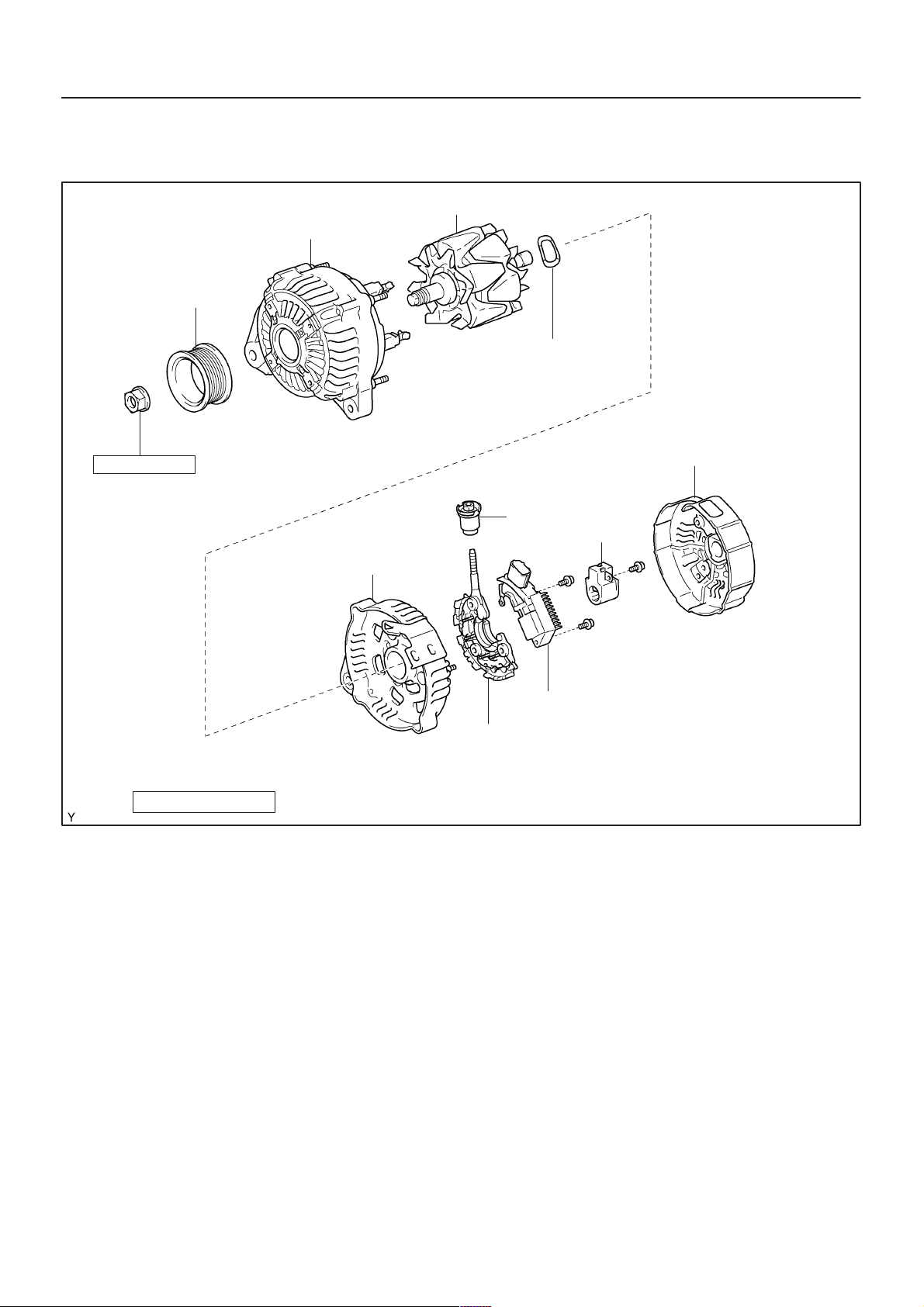

GENERATOR ASSY(130A) (1CD–FTV)

COMPONENTS

Generator Rotor Assy

Generator w/ Clutch Pulley

19–31

190AI–01

Alternator Pulley Cap

Drive End Frame Assy

4.6 (47, 41 in.·lbf)

Rear Seal Plate

Generator Brush

Holder Assy

Front Seal

Plate

1.8 (18, 16 in.·lbf)

Rear End Cover

Sub–Assy

5.8 (59, 51 in.·lbf)

Alternator Coil Assy

N·m (kgf·cm, ft·lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

: Specified torque

A62720

OVERHAUL

19–25

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

19095–02

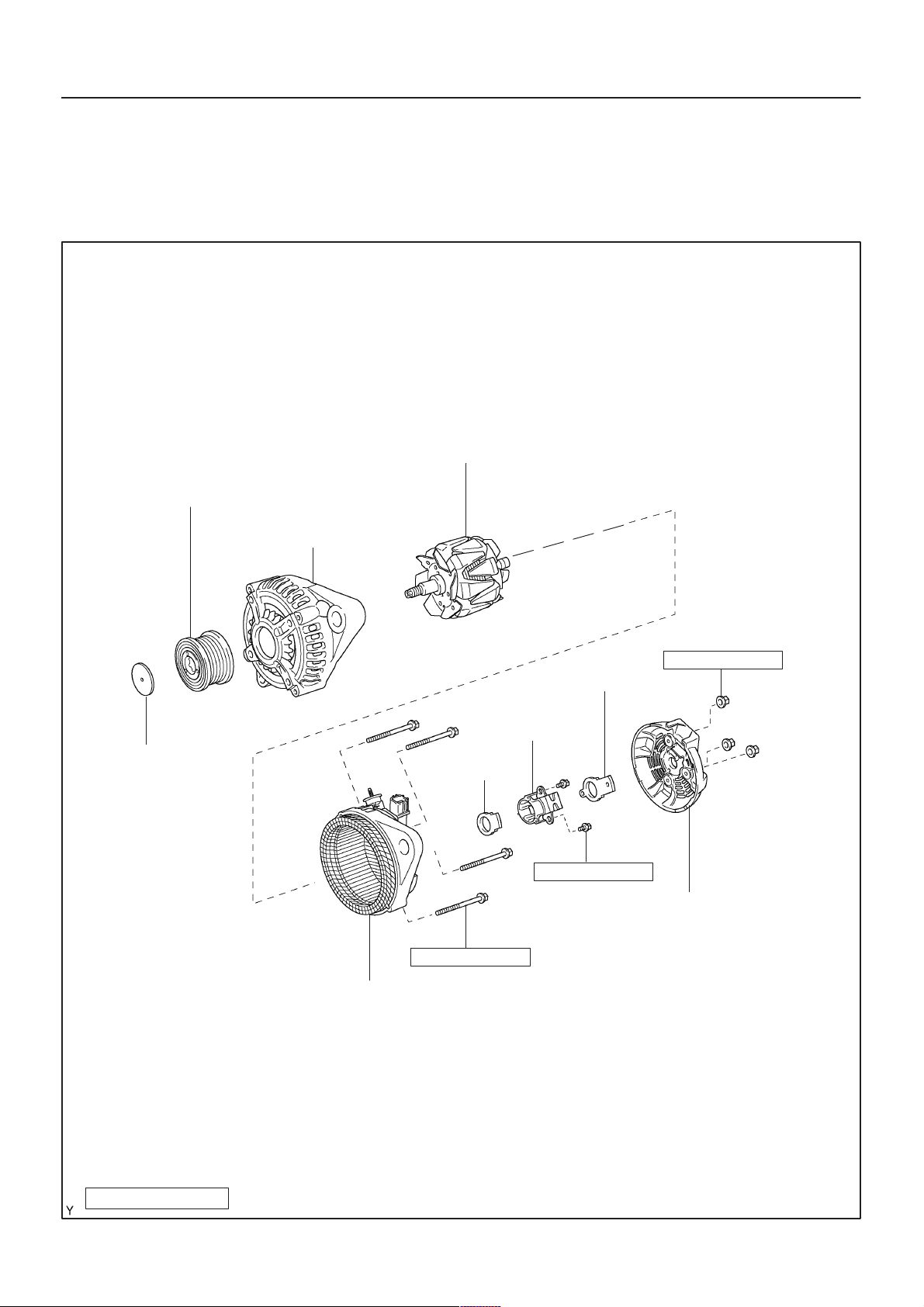

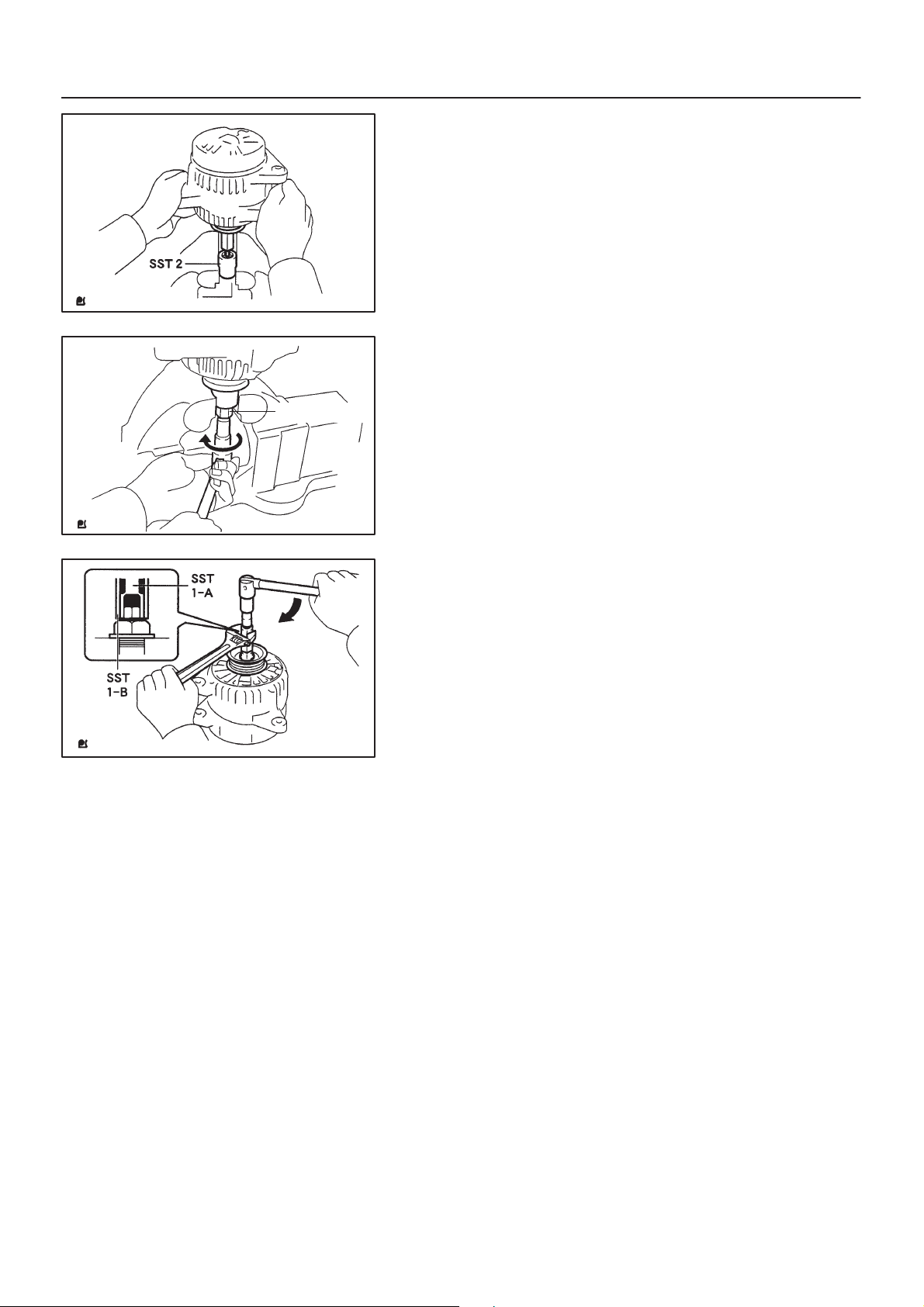

1. REMOVE GENERATOR PULLEY

SST 09820–63010 (09820–06010, 09820–06020)

HINT:

SST1 – A, B 09820–06010

SST2 09820–06020

(a) Hold SST 1 – A with a torque wrench, and tighten SST 1

– B clockwise to the specified torque.

Torque: 39 N!m (400 kgf!cm, 29 ft!lbf)

NOTICE:

Check that SST is secured to the rotor shaft.

SST 1 – A

A38024

(b) Mount SST 2 in a vise.

(c) Insert SST 1 – A, B into SST 2, and attach the pulley nut

to SST 2.

A38025

(d) To loosen the pulley nut, turn SST 1 – A in the direction

shown in the illustration.

NOTICE:

To prevent damage to the rotor shaft, do not loosen the

pulley nut more than one–half of a turn.

(e) Remove the alternator form SST 2.

A38104

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(f) Turn SST 1 – B, and remove SST 1 – A, B.

(g) Remove the pulley nut and pulley.

A38105

19–26

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

2. REMOVE GENERATOR BRUSH HOLDER ASSY

(a) Remove the nut and terminal insulator.

(b) Remove the bolt, 3 nuts, plate terminal and end cover.

(c) Remove the brush cover.

(d) Remove the 2 screws and brush holder.

3. REMOVE GENERATOR REGULATOR ASSY

(a) Remove the 3 screws and voltage regulator.

4. REMOVE GENERATOR HOLDER W/RECTIFIER

(a) Remove the 4 screws and rectifier holder.

5. REMOVE ALTERNATOR RECTIFIRE END FRAME

(a) Remove the rubber insulator.

(b) Remove the seal plate.

(c) Remove the 4 nuts.

(d) Using bearing puller set, remove the rectifier end frame.

SST

Wooden block

A51918

6. REMOVE GENERATOR ROTOR ASSY

(a) Remove the alternator washer from the rotor.

(b) Remove the rotor from drive end frame.

NOTICE:

Do not drop the rotor.

Ohmmeter

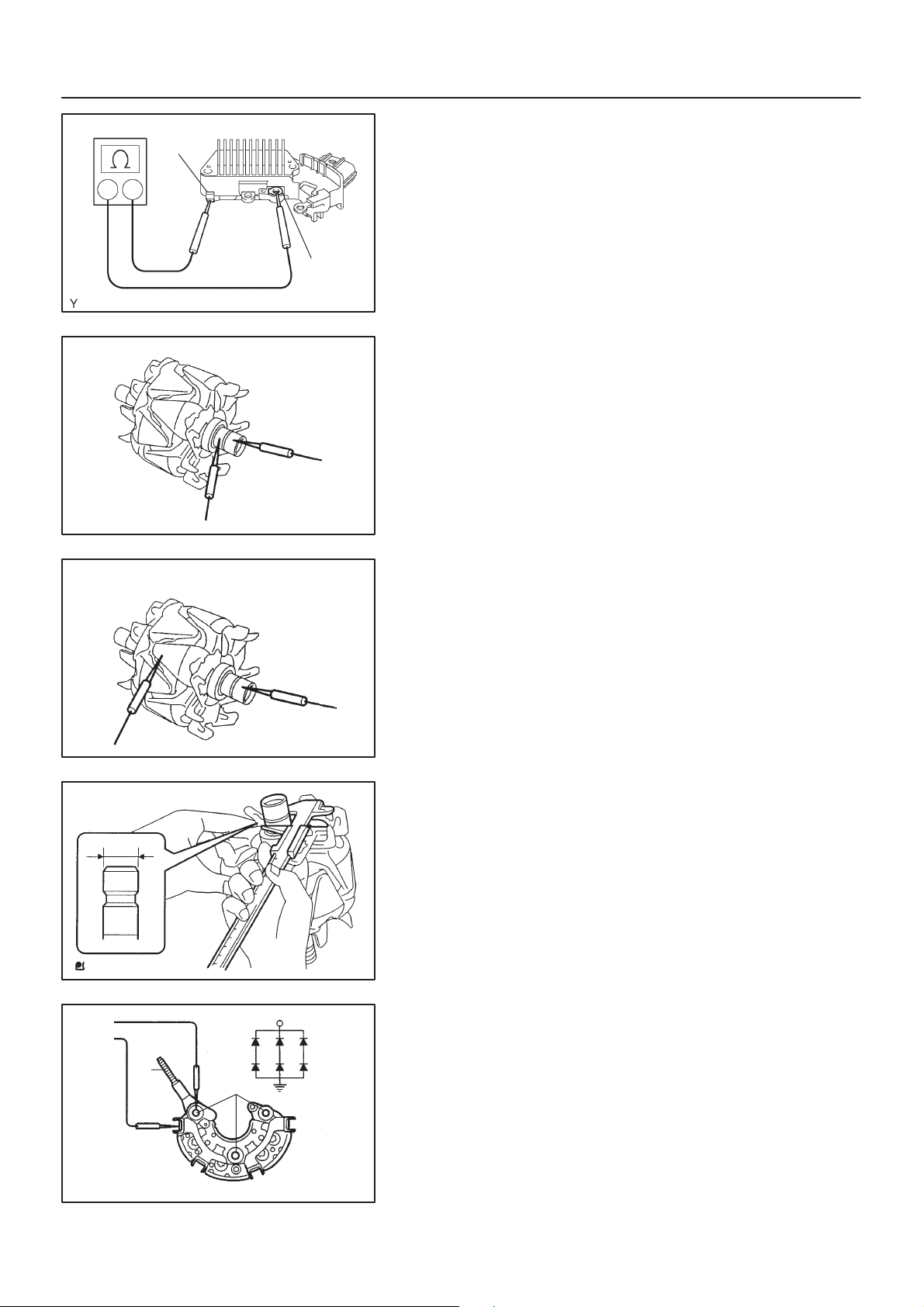

7. INSPECT GENERATOR REGULATOR ASSY

F

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

B

A59143

(a) Using an ohmmeter, check the continuity between termi-

nals F and B.

Standard:

When the positive and negative poles between termi-

nals F and B are exchanged, there is continuity in one

way but no continuity in another way.

If the continuity is not as specified, replace the voltage regulator.

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

19–27

Ohmmeter

(b) Using an ohmmeter, check the continuity between termi-

E

nals F and E.

Standard:

When the positive and negative poles between termi-

nals F and E are exchanged, there is continuity in one

way but no continuity in another way.

If the continuity is not as specified, replace the voltage regula-

F

A59144

tor.

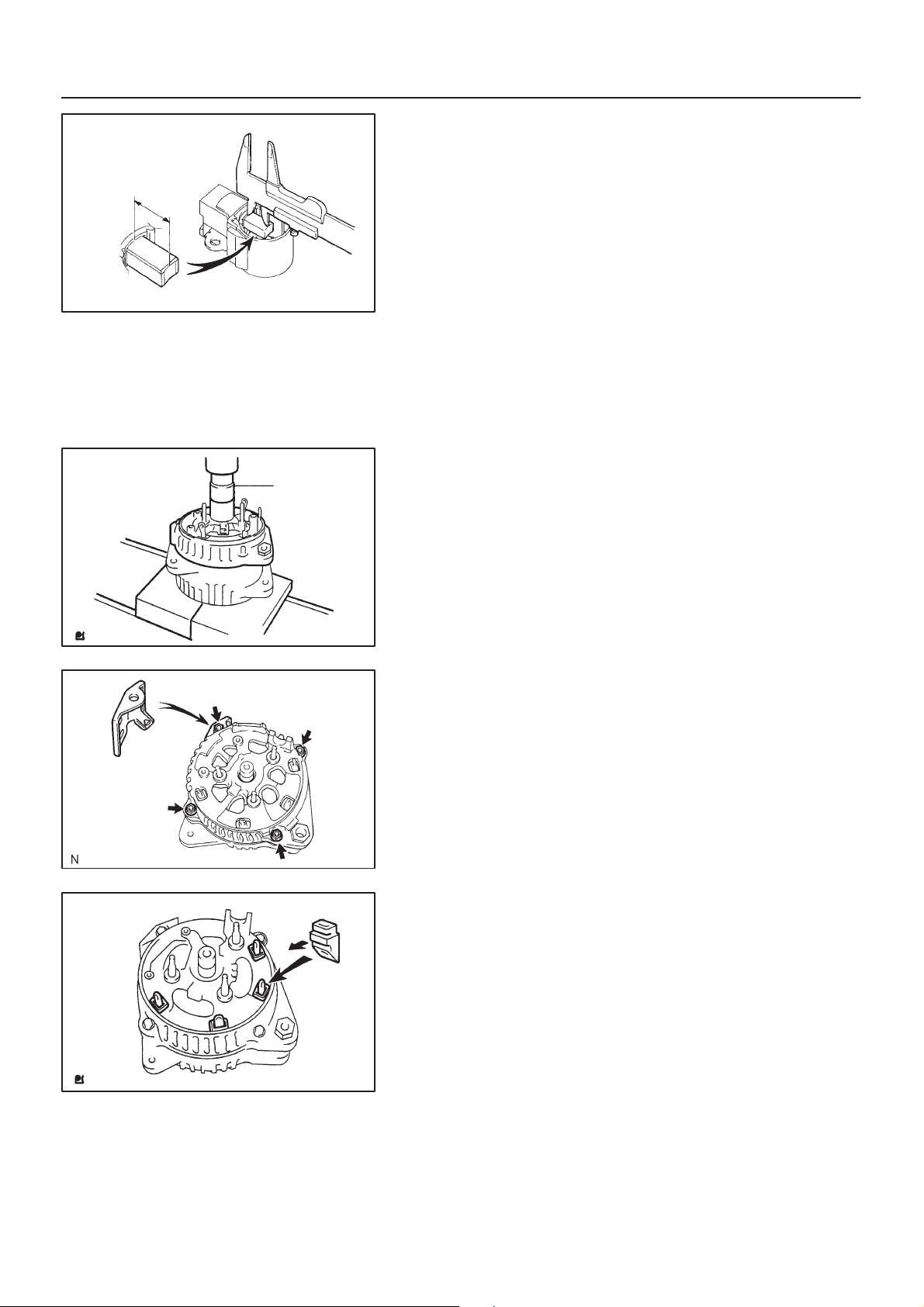

8. INSPECT GENERATOR ROTOR ASSY

(a) Inspect rotor for open circuit.

(1) Using an ohmmeter, check that there is continuity

between the slip rings.

Standard resistance: 2.7 – 3.1 ! at 20! C (68!F)

If there is no continuity, replace the rotor.

A38108

(b) Inspect rotor for ground.

(1) Using an ohmmeter, check that there is no continu-

ity between the slip ring and rotor.

If there is continuity, replace the rotor.

A38109

(c) Inspect slip rings.

(1) Using vernier calipers, measure the slip ring diame-

ter.

Standard diameter: 14.2 – 14.4 mm (0.559 – 0.567 in.)

Minimum diameter: 12.8 mm (0.504 in.)

If the diameter is less than minimum, replace the rotor.

A38110

B

P

P

1

B

E

P

1

P

2

P

P

2

3

4

!

P

4

A36999

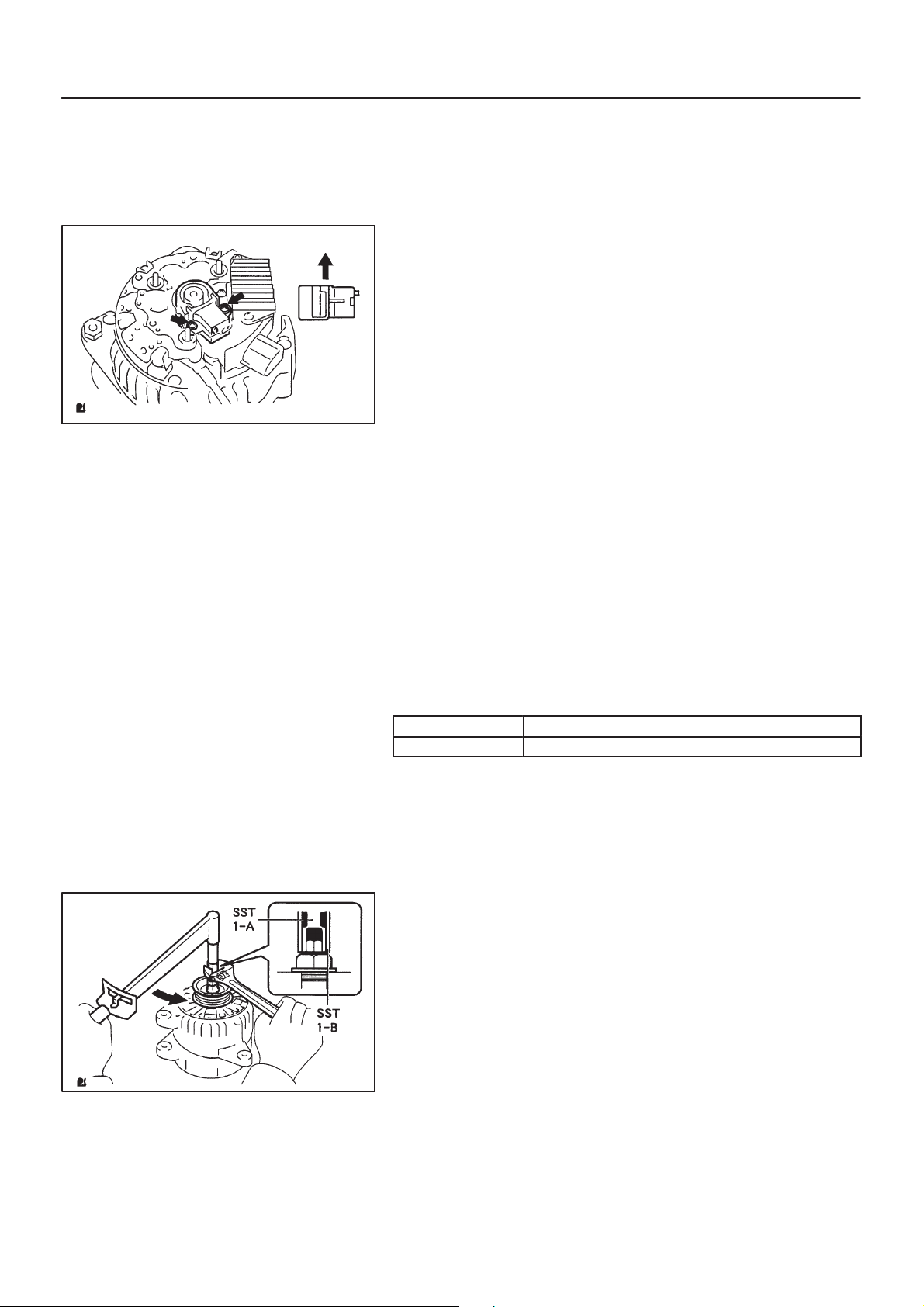

9. INSPECT GENERATOR HOLDER W/RECTIFIER

(a) Using an ohmmeter, connect one tester probe to the B or

E terminal and the other to each rectifier terminal.

(b) Reverse the polarity of the tester probes and repeat step

(a).

(c) Check that one shows continuity and the other shows no

continuity.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

19–28

10. INSPECT BRUSH

(a) Using vernier calipers, measure the exposed brush

Length

If the exposed length is less than minimum, replace the brush

holder assembly.

P13535

11. INSTALL GENERATOR ROTOR ASSY

(a) Install the generator rotor.

(b) Install the alternator washer to the rotor.

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

length.

Standard exposed length:

9.5 – 11.5 mm (0.374 – 0.453 in.)

Minimum exposed length: 1.5 mm (0.059 in.)

Cord Clip

17 mm

Socket

Wrench

A51920

(a) Using a 17 mm socket wrench and press, slowly press in

the rectifier end frame.

(b) Install the cord clip and 4 nuts.

12. INSTALL ALTERNATOR RECTIFIRE END FRAME

A

B

Torque:

Nut A 4.5 N!m (46 kgf!cm, 39 in.!lbf)

Nut B 5.4 N!m (55 kgf!cm, 47 in.!lbf)

(c) Install the seal plate on the rectifier end frame.

A

A

A64533

(d) Install the 4 rubber insulators on the lead wires.

Inside

NOTICE:

Be careful of the rubber insulators installation direction.

A51921

13. INSTALL GENERATOR HOLDER W/RECTIFIER

(a) Install the rectifier holder while pushing it with the 4 screws.

Torque: 2.9 N!m (30 kgf!cm, 26 in.!lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

14. INSTALL GENERATOR REGULATOR ASSY

(a) Install the 3 screws and voltage regulator.

Torque: 3.9 N!m (40 kgf!cm, 35 in.!lbf)

19–29

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

Upward

A51919

15. INSTALL GENERATOR BRUSH HOLDER ASSY

(a) Install the 2 screws and brush holder.

Torque: 2.0 N!m (20 kgf!cm, 18 in.!lbf)

NOTICE:

Be careful of the holder installation direction.

(b) Install the brush cover.

(c) Install the end cover and plate terminal with the bolt and

3 nuts.

Torque:

Nut 4.4 N!m (45 kgf!cm, 39 in.!lbf)

Bolt 3.9 N!m (39 kgf!cm, 35 in.!lbf)

(d) Install the terminal insulator with the nut.

Torque: 4.1 N!m (42 kgf!cm, 36 in.!lbf)

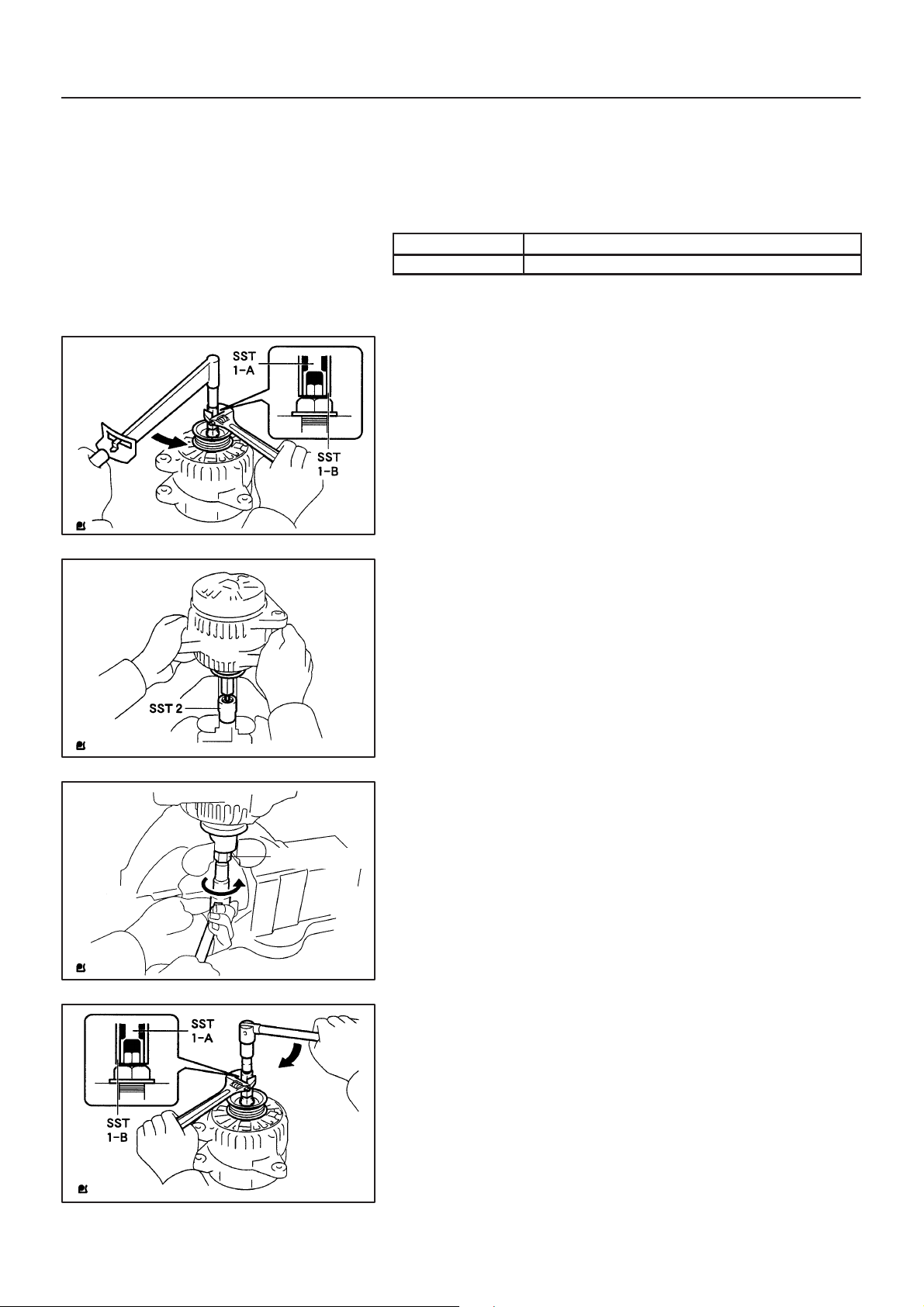

16. INSTALL GENERATOR PULLEY

SST 09820–63010 (09820–06010, 09820–06020)

HINT:

SST1 – A, B 09820–06010

SST2 09820–06020

(a) Install the pulley to the rotor shaft by tightening the pulley

nut by hand.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(b) Hold SST 1 – A with a torque wrench, and tighten SST 1

– B clockwise to the specified to torque.

Torque: 39 N!m (400 kgf!cm, 29 ft!lbf)

NOTICE:

Check that SST is secured to the pulley shaft.

A38024

19–30

A38025

SST 1 – A

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

(c) Mount SST 2 in a vise.

(d) Insert SST 1 – A, B into SST 2, and attach the pulley nut

to SST 2.

(e) Tighten the pulley nut, turn SST 1 – A in the direction

shown in the illustration.

Torque: 111 N!m (1,125 kgf!cm, 81 ft!lbf)

(f) Remove the alternator form SST 2.

A38126

A38105

(g) Turn SST 1 – B, and remove SST 1 – A, B.

(h) Turn the pulley, and check that the pulley moves smooth-

ly.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

19–24

–STARTING & CHARGING GENERATOR ASSY(90A) (1CD–FTV)

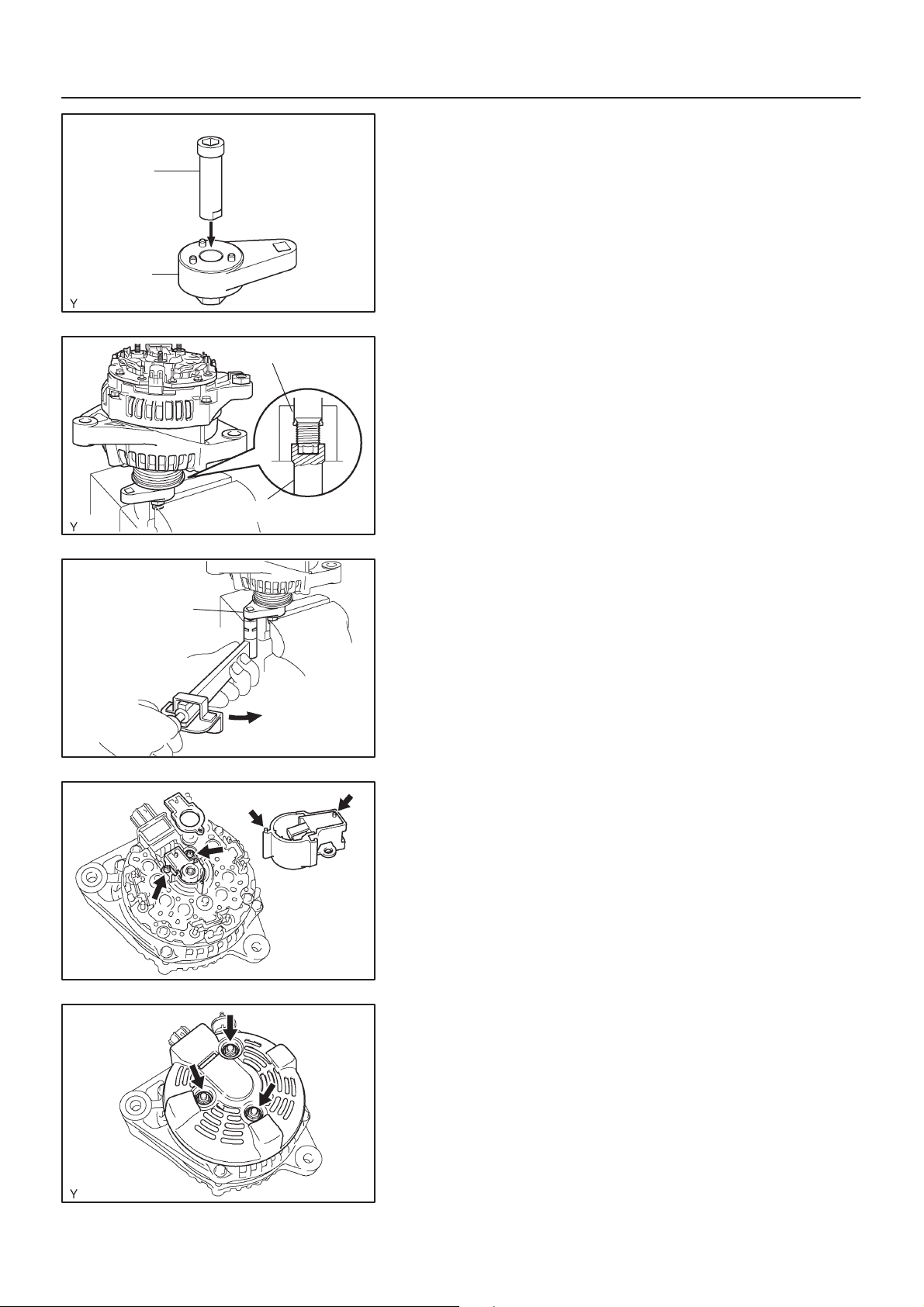

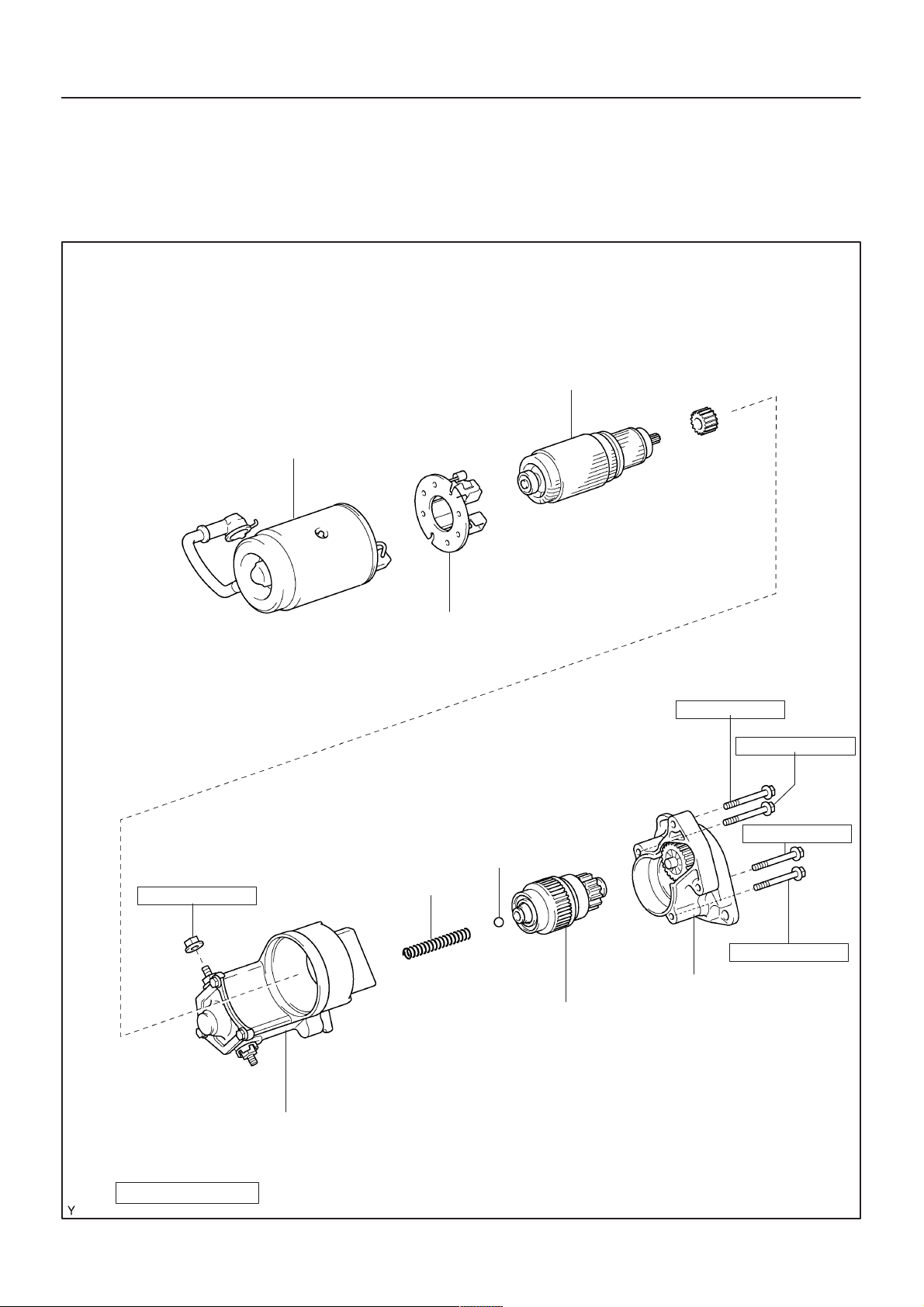

GENERATOR ASSY(90A) (1CD–FTV)

COMPONENTS

Rotor

Drive End Frame

Pulley

Alternator Washer

19094–02

111 (1125, 81)

N·m (kgf·cm, ft·lbf)

Rear End Cover

Brush Holder Cover

Brush Holder

Rectifier End Frame

Voltage Regulator

Rectifier Holder

: Specified torque

A59147

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

19–18

OVERHAUL

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

1906H–02

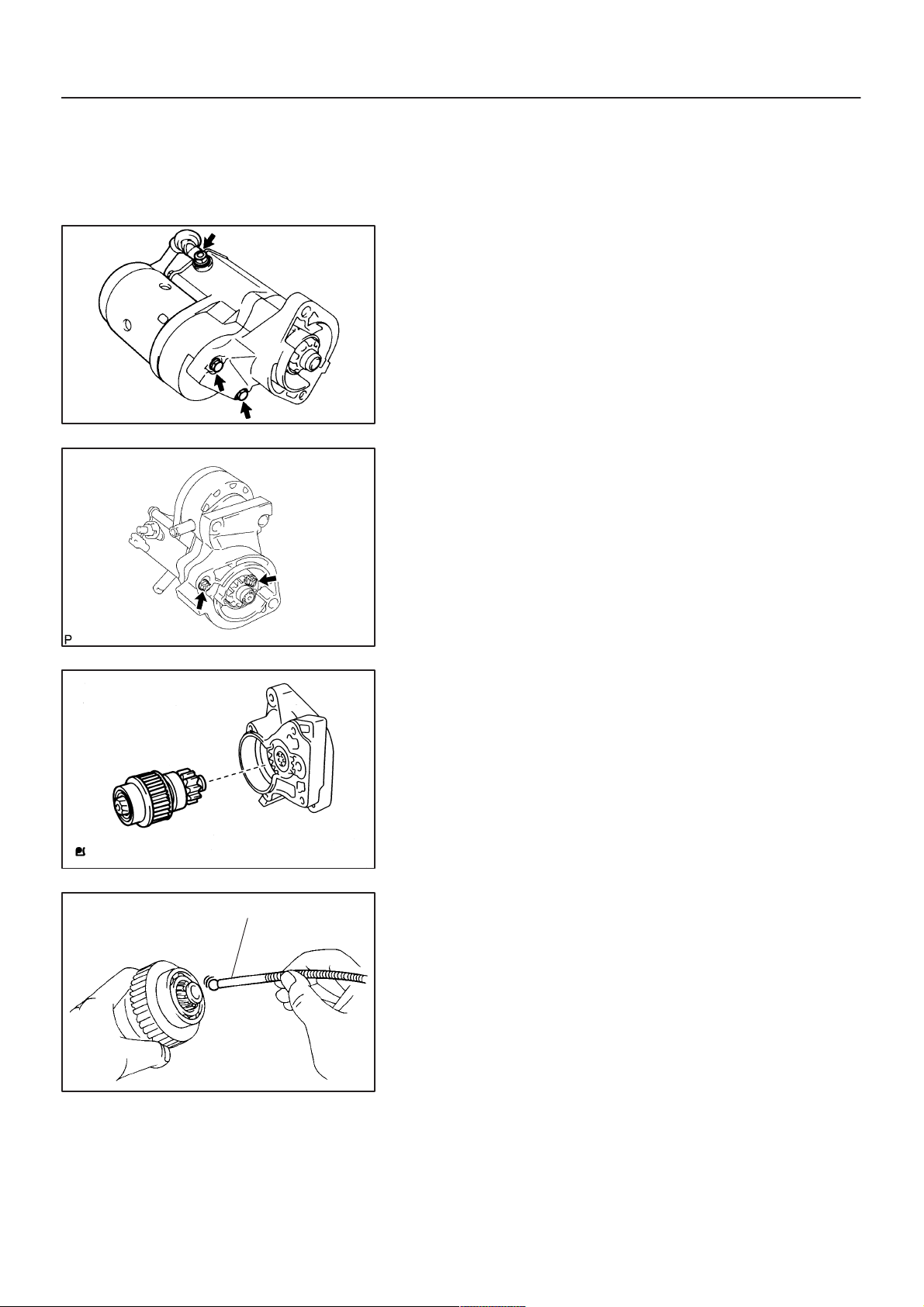

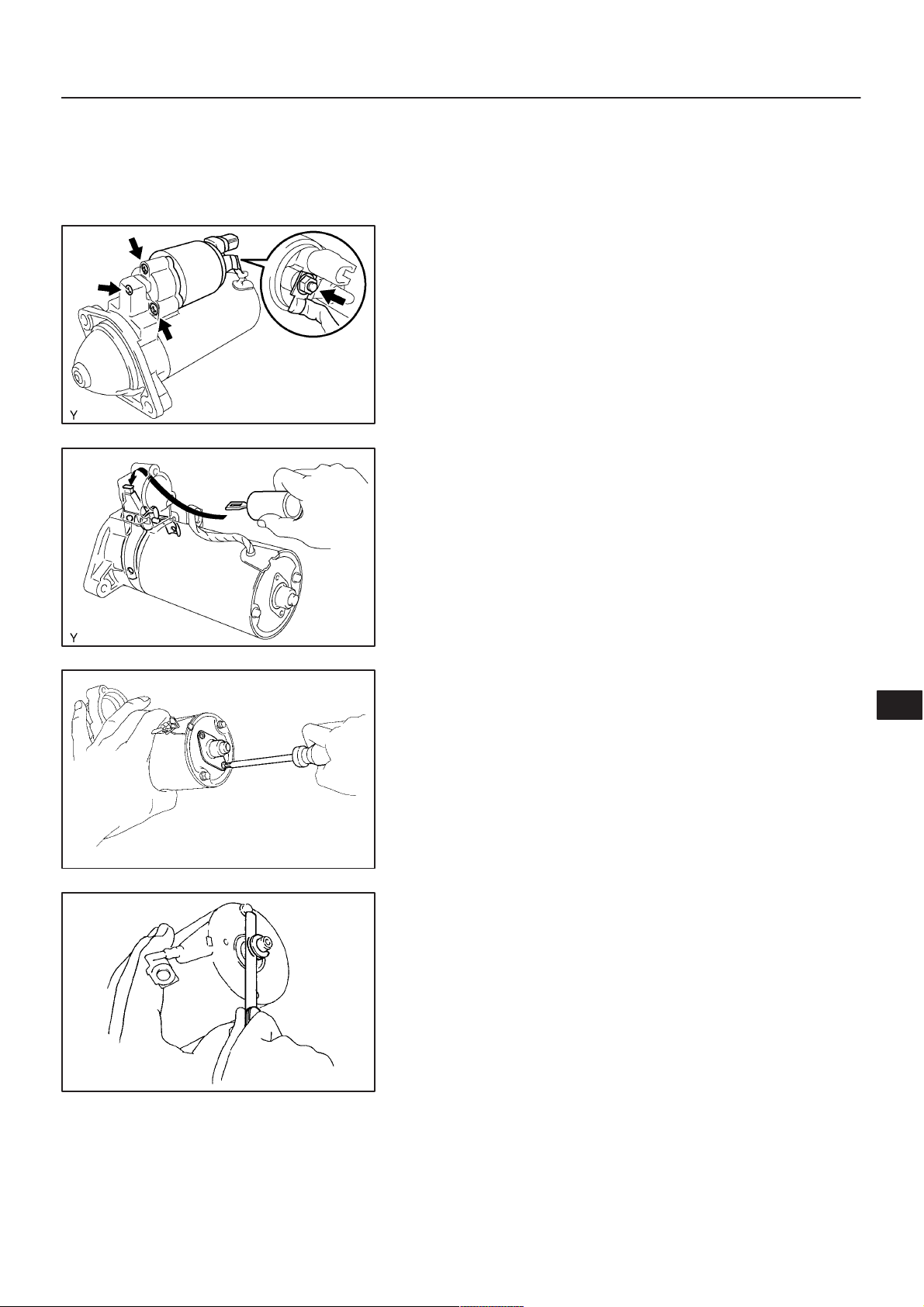

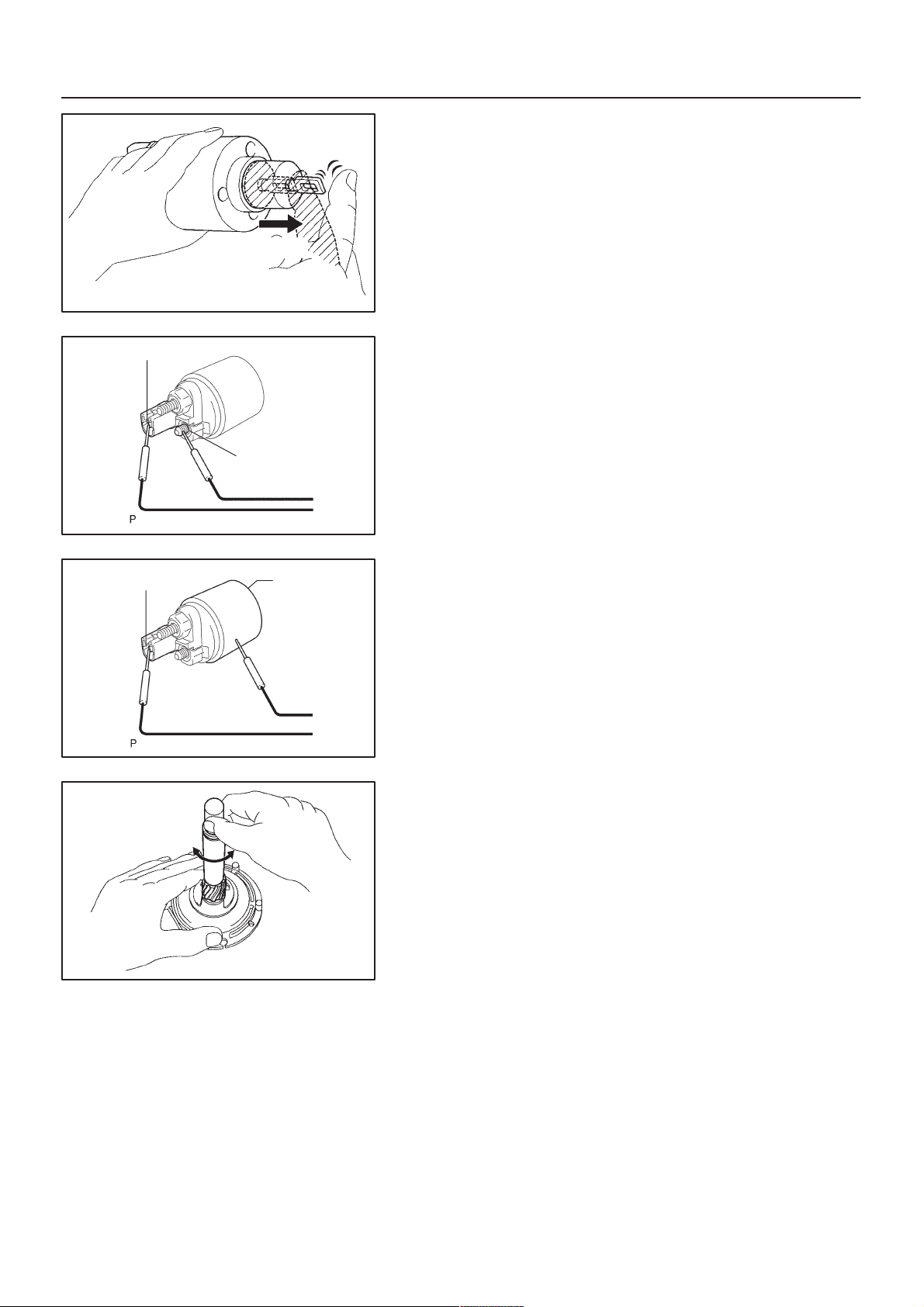

1. REMOVE STARTER YOKE ASSY

(a) Remove the nut, and disconnect the lead wire from the

magnetic switch terminal.

(b) Remove the 2 through bolts.

(c) Pull out the yoke together with the armature from the mag-

netic switch.

A55633

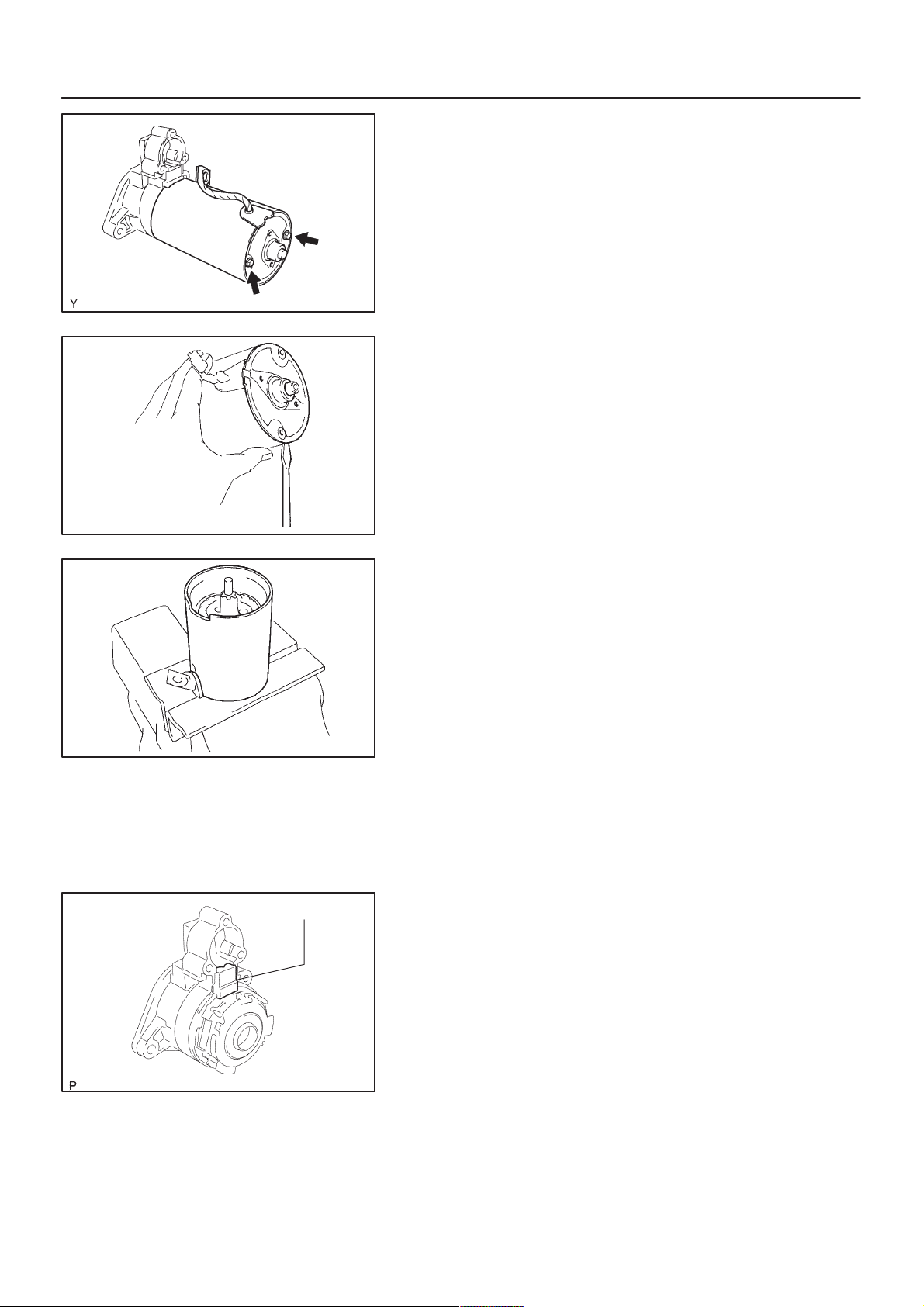

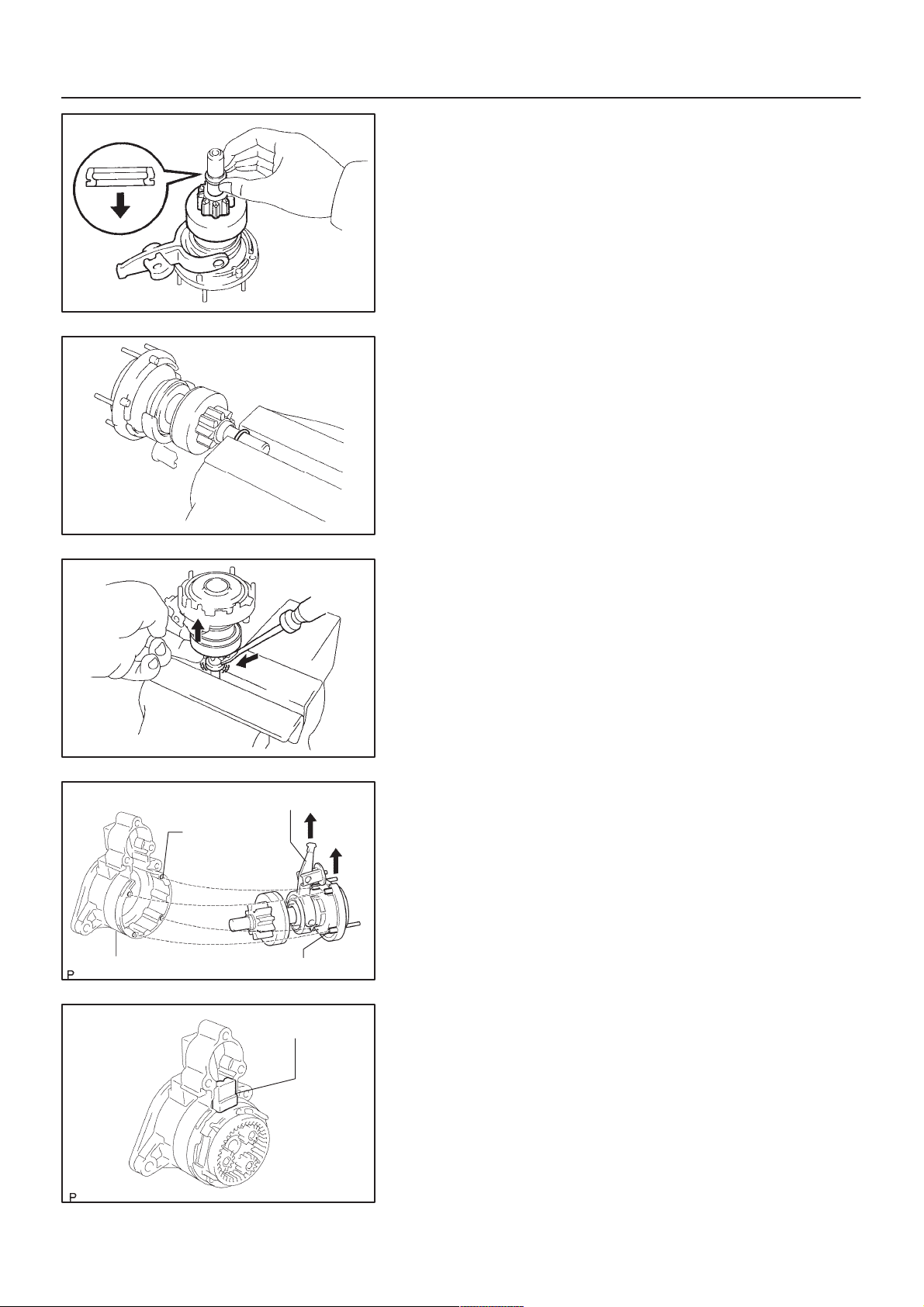

2. REMOVE STARTER CLUTCH SUB–ASSY

(a) Remove the 2 bolts and drive housing.

Magnetic Finger

B13607

(b) Remove the clutch from the drive housing

A55635

(c) Using a magnetic finger, remove the ball from the clutch

shaft hole.

A55636

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

A51182

19–19

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

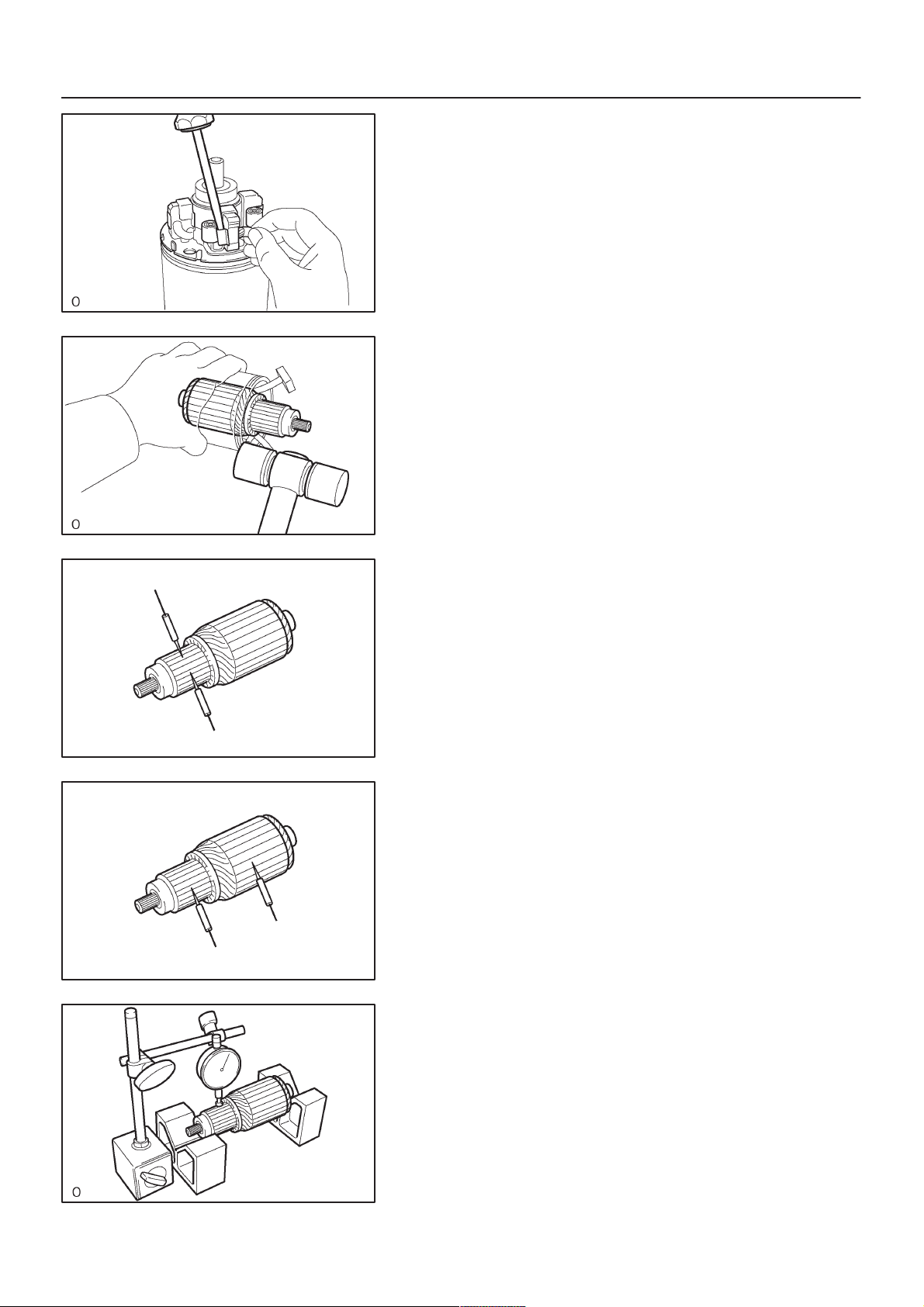

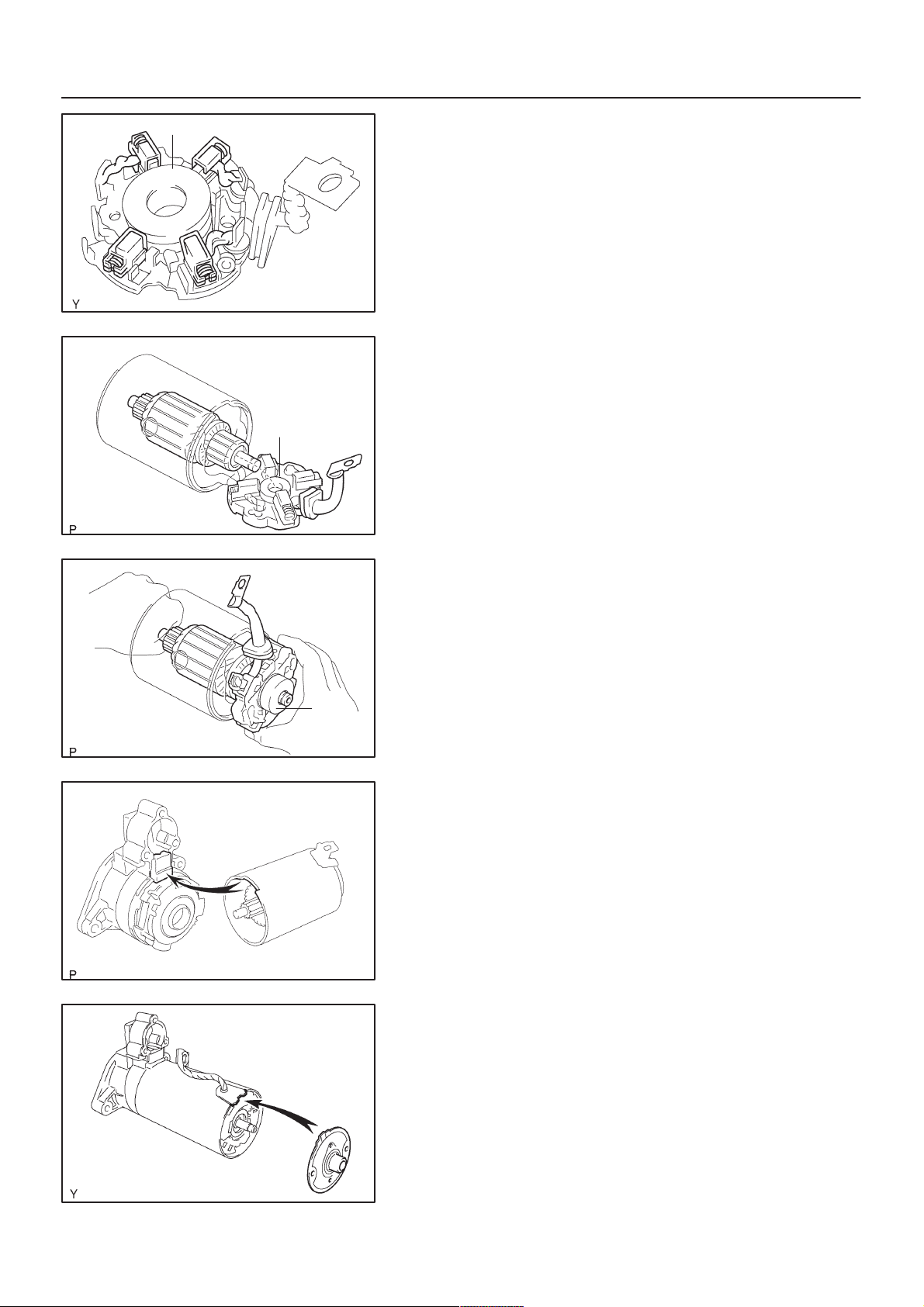

3. REMOVE STARTER BRUSH HOLDER ASSY

(a) Using a screwdriver, hold the spring back disconnect the

brush from the brush holder. Disconnect the 4 brushers

and remove the brush holder.

4. REMOVE STARTER ARMATURE ASSY

(a) Using a plastic–faced hammer, tap the yoke and remove

the armature.

A51183

A55637

A55638

5. INSPECT STARTER ARMATURE ASSY

(a) Using an ohmmeter, check that there is continuity be-

tween the segments of the commutator.

(b) Using an ohmmeter, check that there is no continuity be-

tween the commutator and armature coil core.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

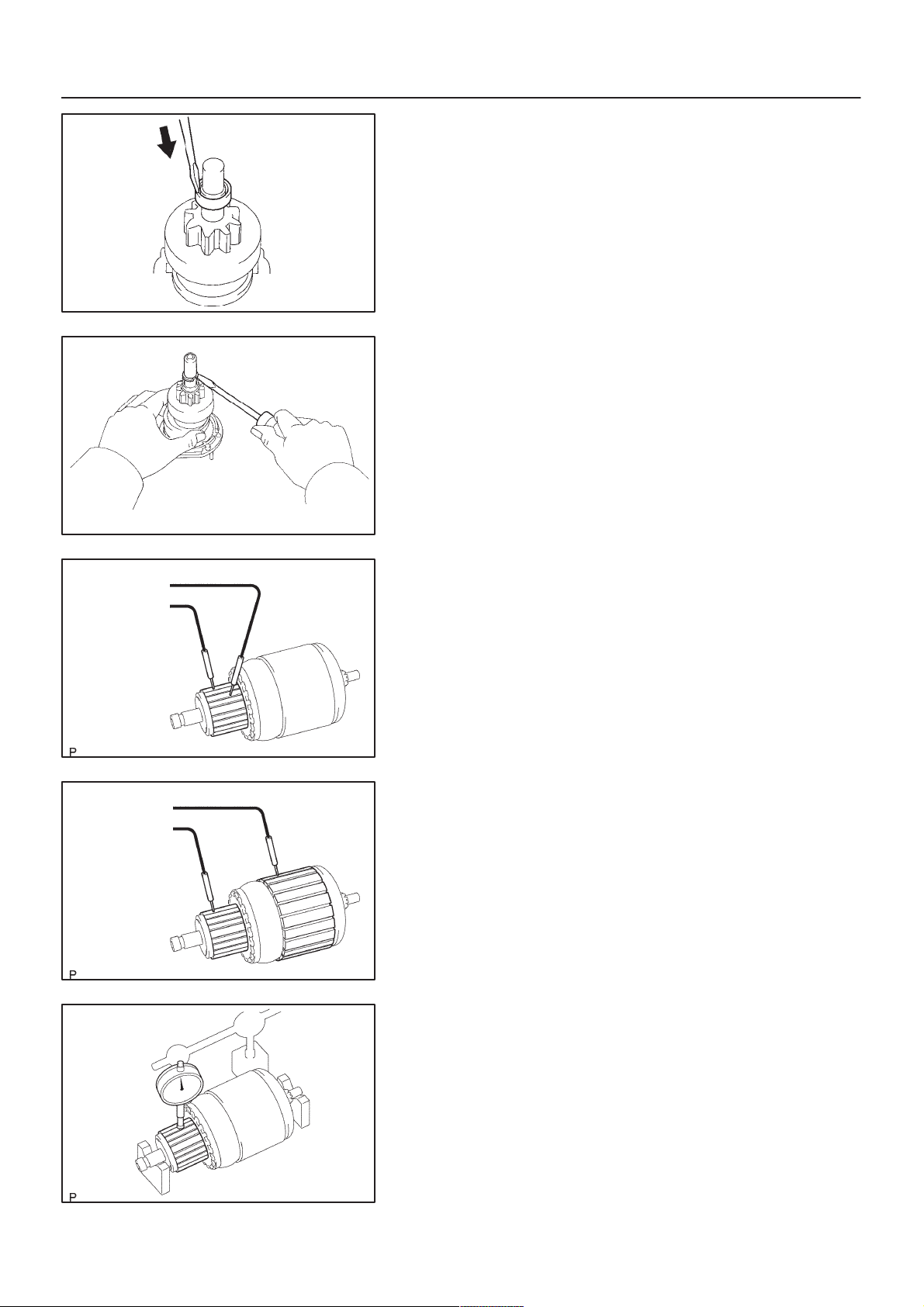

(c) Place the commutator on V–blocks.

(d) Using a dial gauge, measure the circle runout.

Maximum circle runout: 0.05 mm (0.002 in.)

A51186

19–20

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

(e) Using vernier calipers, measure the commutator diame-

ter.

Standard diameter: 35 mm (1.378 in.)

Minimum diameter: 34 mm (1.3386 in.)

A51187

(f) Check that the undercut depth is clean and free of foreign

materials. Smooth out the edge.

Standard undercut depth: 0.7 mm (0.0276 in.)

Minimum undercut depth: 0.2 mm (0.079 in.)

A51188

A55639

A55640

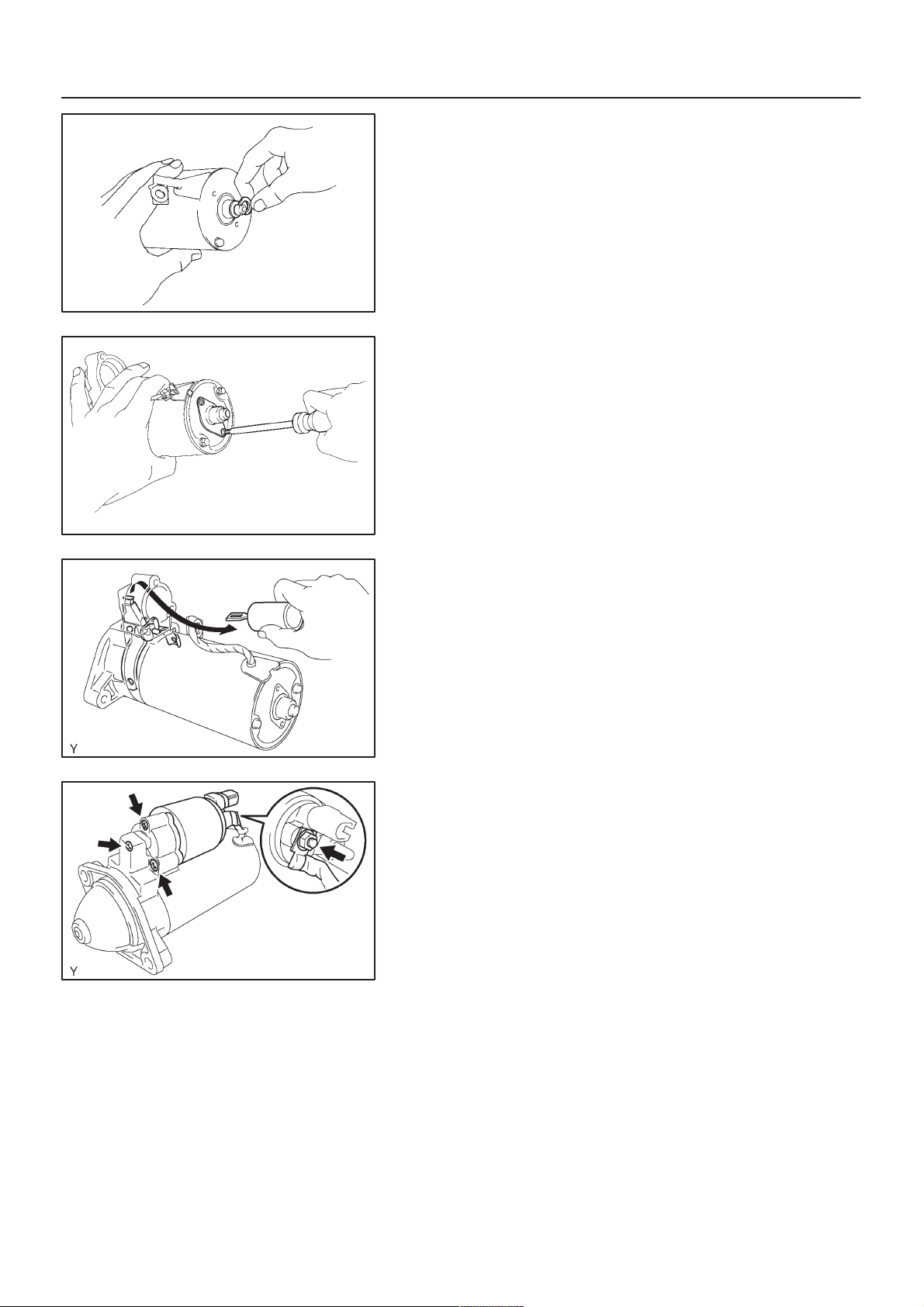

6. INSPECT STARTER YOKE ASSY

(a) Using an ohmmeter, check that there is continuity be-

tween the lead wire and field coil brush lead.

(b) Using an ohmmeter, check that there is no continuity be-

tween the field coil brush lead and yoke.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(c) Using vernier calipers, measure the brush length.

Standard length: 16.5 mm (0.6496 in.)

Minimum length: 9 mm (0.3543 in.)

A55641

A55642

19–21

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

7. INSPECT STARTER BRUSH HOLDER ASSY

(a) Using an ohmmeter, check that there is no continuity be-

tween the positive (+) and negative (–) brush holders.

(b) Using vernier calipers, measure the brush length.

Standard length: 16.5 mm (0.6496 in.)

Minimum length: 9 mm (0.3543 in.)

Lock

Terminal C

Free

Terminal 50

A55643

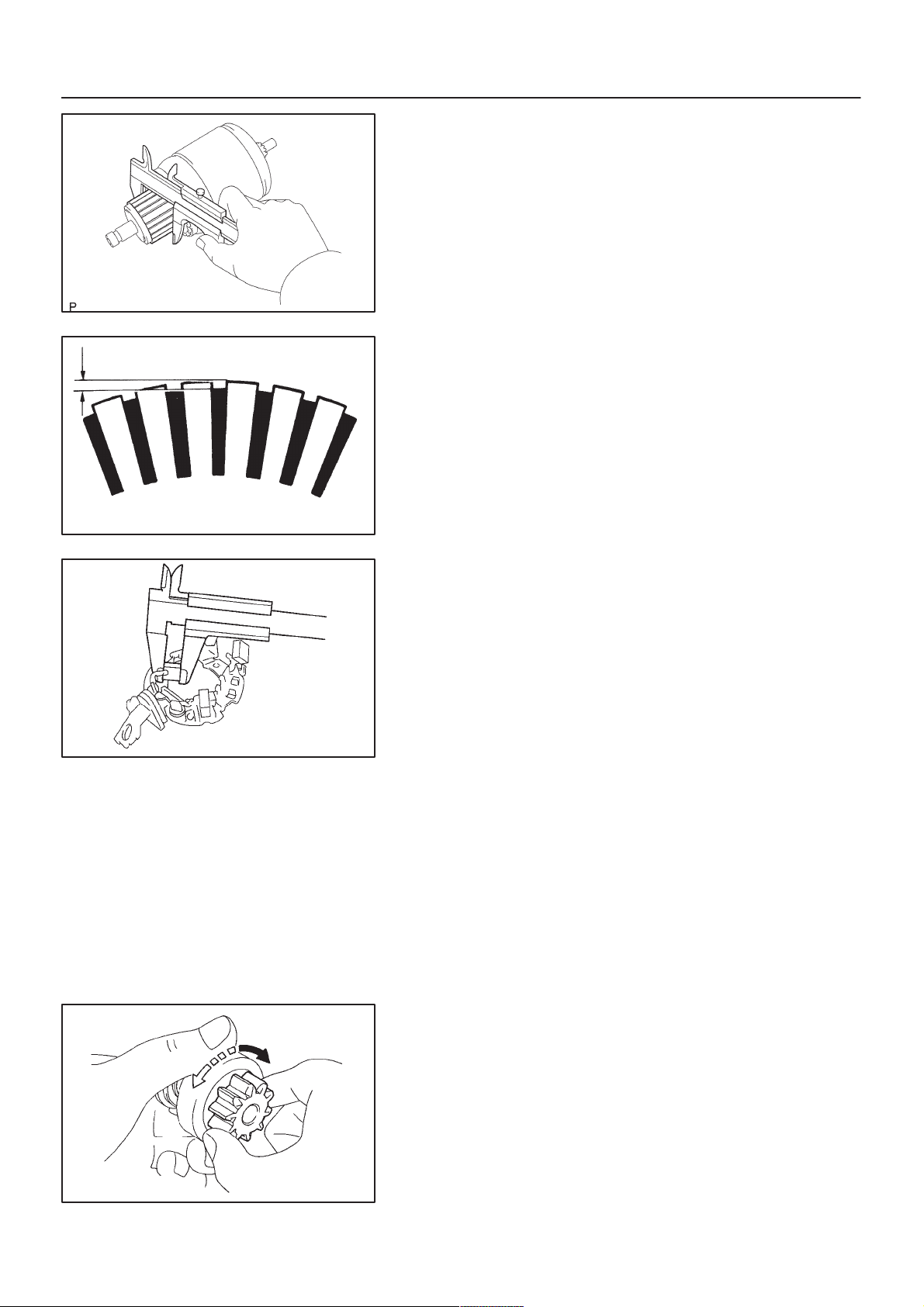

8. INSPECT STARTER CLUTCH SUB–ASSY

(a) Rotate the pinion gear clockwise, and check that it turns

freely. Try to rotate the pinion gear counterclockwise and

check that it locks.

A55624

9. INSPECT MAGNET STARTER SWITCH ASSY

(a) Using an ohmmeter, check that there is continuity be-

tween terminals 50 and C.

B55687

Terminal 50

Switch Body

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(b) Using an ohmmeter, check that there is continuity be-

tween terminal 50 and the switch body.

B55691

19–22

A51212

A55483

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

10. INSTALL STARTER ARMATURE ASSY

(a) Apply grease to the armature bearings.

(b) Using a press, press in armature.

11. INSTALL STARTER BRUSH HOLDER ASSY

(a) Align the claw of the brush holder with the claw groove of

the yoke.

(b) Place the brush on the yoke.

(c) Using a screwdriver, hold the brush spring back and con-

nect the brush into the brush holder. Connect the 4

brushes.

NOTICE:

Check that the positive (+) lead wires are not grounded.

12. INSTALL STARTER CLUTCH SUB–ASSY

A55646

A55635

(a) Apply grease to the ball.

(b) Insert the ball into the clutch shaft hole.

(c) Place the clutch on the drive housing.

(d) Install the drive housing to the magnetic switch with the

2 bolts.

Torque: 9.3 N!m (95 kgf!cm, 82 in.!lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

B13607

A55647

19–23

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

13. INSTALL STARTER YOKE ASSY

(a) Align the claws of the brush holder with the grooves of the

magnetic switch, and install the yoke and armature.

(b) Align the punch mark of the yoke with the line of the mag-

netic switch.

(c) Install the yoke and armature with the 2 through bolts.

Torque: 12.7 N!m (130 kgf! cm, 9 ft!lbf)

(d) Connect the lead wire to terminal C with the nut.

Torque: 5.9 N!m (60 kgf!cm, 52 in.!lbf)

A55633

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

–STARTING & CHARGING STARTER ASSY(2.2KW) (1CD–FTV)

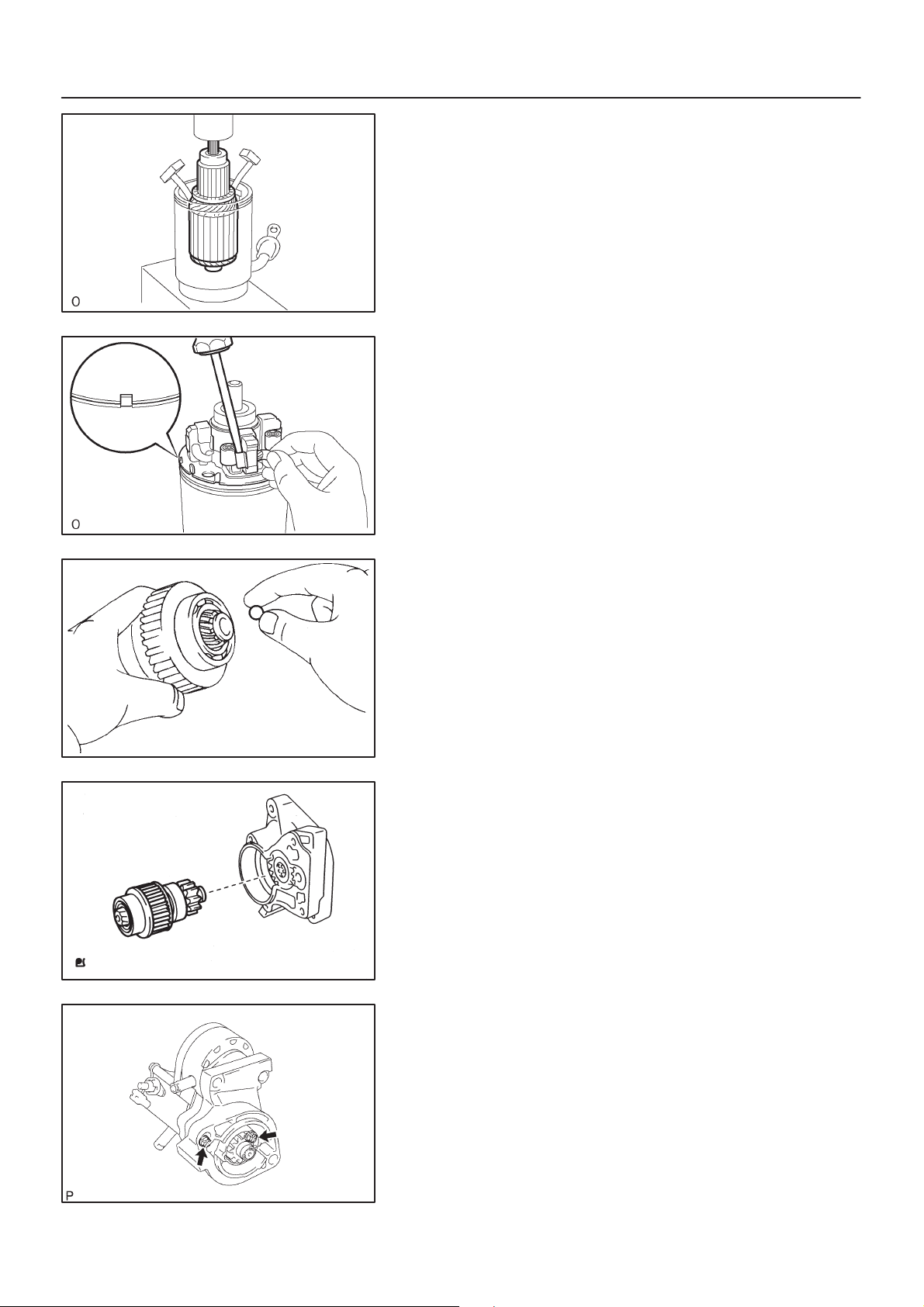

STARTER ASSY(2.2KW) (1CD–FTV)

COMPONENTS

Starter Armature Assy

Starter Yoke Assy

19–17

190AH–01

5.9 (60, 52 in.·lbf)

Starter Brush Holder Assy

12.7 (130, 9.0 )

9.3 (95, 82 in.·lbf)

12.7 (130, 9.0 )

Ball

Spring

9.3 (95, 82 in.·lbf)

Drive Housing

Starter Clutch Sub–Assy

Magnetic Switch

N·m (kgf·cm, ft·lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

: Specified torque

A62713

OVERHAUL

19–9

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

190AG–01

1. REMOVE MAGNET STARTER SWITCH ASSY

(a) Remove the nut, and disconnect lead wire from the mag-

net starter switch terminal.

(b) Remove the 3 screws, magnet starter switch and return

spring.

A62722

(c) Pull the plunger, and disconnect the plunger hook from

the upper side of the drive lever.

A62723

A62724

A62725

2. REMO VE STARTER COMMUTATOR END FRAM

COVER

(a) Remove the 2 screws and end fram cover.

(b) Using a feeler gauge, measure the armature thrust clear-

ance between the lock plate and end frame.

Standard thrust clearance: 0.3 mm (0.012 in.)

Maximum thrust clearance: 0.6 mm (0.024 in.)

If the thrust clearance is greater the than maximum, replace the

thrust washer.

(c) Remove the lock plate and thrust washer.

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

19–10

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

3. REMOVE STARTER YOKE ASSY

(a) Remove the 2 through bolts, and pull out the starter yoke

together with the armature.

A62726

4. REMOVE STARTER COMMUTATOR END FRAM ASSY

(a) Using a screwdriver, pry out the commutator end frame.

A62727

5. REMOVE STARTER ARMATURE ASSY

A62728

6. REMOVE STARTER BRUSH HOLDER ASSY

Rubber Cushion

7. REMOVE PLANET CARRIER SHAFT SUB–ASSY

(a) Remove the rubber cushion.

(b) Remove the planet carrier shaft and starter clutch assem-

bly.

A62729

8. REMOVE STARTER PINION DRIVE LEVER

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

A62730

19–11

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

9. REMOVE STARTER CLUTCH SUB–ASSY

(a) Using a screwdriver, tap in the stop collar towards the

starter clutch.

(b) Using a screwdriver, pry out the snap ring.

(c) Remove the stop collar from the shaft.

Continuity

No Continuity

A62953

10. INSPECT STARTER ARMATURE ASSY

(a) Using an ohmmeter, check that there is continuity be-

tween the segments of the commutator.

If there is no continuity between any segments, replace the armature.

A62961

(b) Using an ohmmeter, check that there is no continuity be-

tween the commutator and armature coil core.

If there is continuity, replace the armature.

(c) Check the commutator for the dirty and burnt surface.

If the surface is dirty or burnt, correct with sandpaper (No.400)

or a lathe.

A62962

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(d) Place the commutator on V–blocks.

(e) Using a dial indicator, measure the circle runout.

Maximum circle runout: 0.03 mm (0.0012 in.)

If the circle runout is greater than maximum, correct it on a lathe.

A62963

19–12

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

(f) Using vernier calipers, measure the commutator diame-

ter.

Standard diameter: 32.3 mm (1.272 in.)

Minimum diameter: 30.5 mm (1.201 in.)

If the diameter is less than minimum, replace the armature.

A62964

(g) Check that the undercut depth is clean and free of foreign

materials. Smooth out the edge.

Standard undercut depth: 0.9 mm (0.035 in.)

Minimum undercut depth: 0.3 mm (0.012 in.)

If the undercut depth is less than minimum, correct it with a

hacksaw blade.

A62965

A62966

11. INSPECT STARTER BRUSH HOLDER ASSY

(a) Using vernier calipers, measure the brush length.

Standard length: 14.5 mm (0.571 in.)

Minimum length: 9.0 mm (0.354 in.)

If the length is less than minimum, replace the brush holder.

12. INSPECT STARTER CLUTCH SUB–ASSY

(a) Check the gear teeth on the starter clutch for wear or dam-

age.

If the gear is damaged, replace it.

If damaged, replace the clutch assembly. If damaged, also

check the drive plate ring gear for wear or damage.

Free

Lock

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(b) Rotate the clutch pinion gear clockwise and check that it

turns freely. Try to rotate the clutch pinion gear counter-

clockwise and check that it locks.

If necessary, replace the starter clutch.

A62967

Return

19–13

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

13. INSPECT MAGNET STARTER SWITCH ASSY

(a) Push in the plunger and check that it returns quickly to its

original position.

If necessary, replace the magnetic switch.

A62968

Terminal 50

Terminal 50

Turn

Terminal C

Continuity

Continuity

Switch Body

(b) Using an ohmmeter, check that there is continuity be-

tween terminals 50 and C.

If there is no continuity, replace the magnetic switch.

A63797

(c) Using an ohmmeter, check that there is continuity be-

tween terminal 50 and the switch body.

If there is no continuity, replace the magnet starter switch.

A63798

14. INSPECT PLANET CARRIER SHAFT SUB–ASSY

(a) Turn the shaft, and check that it is not rough or worn.

If it feels rough or worn, replace the planet carrier shaft.

A63799

15. INSTALL STARTER PINION DRIVE LEVER

16. INSTALL STARTER CLUTCH SUB–ASSY

(a) Apply grease to the bushing and spline of the starter

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

clutch and planet carrier shaft.

19–14

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

(b) Place the starter clutch and stop collar on the planet carri-

er shaft as shown in the illustration.

A63800

(c) Install a new snap ring to the planet carrier shaft groove.

(d) Using a vise, compress the snap ring.

(e) Check that the snap ring fits correctly.

Drive Housing

Knock

Pin Hole

Drive Lever

Knock Pin

A63801

(f) Using a screwdriver, tap the stop collar to slide it onto the

snap ring.

A63802

17. INSTALL PLANET CARRIER SHAFT SUB–ASSY

(a) Set the planet carrier shaft and drive lever in position as

shown in the illustration.

(b) Align the holes of the drive housing with the knock pins.

(c) Install the planet carrier shaft and starter clutch to the

drive housing.

A63803

Rubber Cushion

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

(d) Install the rubber cushion.

A63804

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

19–15

SST

18. INSTALL STARTER BRUSH HOLDER ASSY

(a) Install the 4 brush retainers and 4 brush springs to the

brush holder.

(b) Using SST, install the 4 brushes to the brush holder.

SST 09950–60010 (09951–00340)

A63805

(c) Attach the brush holder to the armature.

SST

A63806

(d) Push the armature, and remove the SST.

SST

A63807

19. INSTALL STARTER YOKE ASSY

(a) Align the cushion rubber on the starter drive housing with

the cutout of the starter yoke.

(b) Install the starter yoke and armature assembly.

A63808

(c) Align the commutator end frame with the brush holder

rubber part as shown in the illustration.

(d) Install the commutator end frame with the 2 through bolts.

6.5 N·m (66 kgf·cm, 58 in.·lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

A63809

19–16

–STARTING & CHARGING STARTER ASSY(2.0KW) (1CD–FTV)

20. INS TALL STARTER COMMUTATOR END FRAM

COVER

(a) Install the thrust washer and lock plate.

(b) Check the armature thrust clearance between the lock

plate and the end frame cover. (See page 19–9)

A63810

(c) Pack grease to the commutator end cover.

(d) Install the commutator end fram cover with the 2 screws.

1.7 N·m (17 kgf·cm, 15 in.·lbf)

A62724

A63811

A62722

21. INSTALL MAGNET STARTER SWITCH ASSY

(a) Hang the plunger hook to the upper side of the drive lever.

(b) Install the return spring into the plunger.

(c) Install the return spring and magnet sarter switch with the

3 screws.

5.0 N·m (51 kgf·cm, 44 in.·lbf)

(d) Connect the lead wire to the magnet starter switch termi-

nal with the nut.

8.0 N·m (82 kgf·cm, 71 in.·lbf)

1CD–FTV ENGINE REPAIR MANUAL (RM927E)

Loading...

Loading...