Toyota 8FBCU20-32, 8FBCHU25 Repair Manual

8FBCU 20, 25, 28, 30, 32

8FBCHU 25

VOL. 1

Pub. No. CU346

SECTION INDEX

NAME SECTION

GENERAL 0

BATTERY 1

CONTROL SYSTEM 2

MULTI-FUNCTION DISPLAY 3

TROUBLESHOOTING 4

MOTOR 5

DRIVE UNIT 6

FRONT AXLE 7

REAR AXLE 8

STEERING 9

BRAKE 10

BODY 11

MATERIAL HANDLING SYSTEM 12

MAST 13

CYLINDER 14

OIL PUMP 15

OIL CONTROL VALVE 16

SAS FUNCTIONS 17

APPENDIX 18

Sections indicated by solid characters are included in this manual.

Sections indicated by half-tone characters: See vol. 2.

0-1

0

GENERAL

Page Page

EXTERIOR VIEWS .......................... 0-2

VEHICLE MODEL............................ 0-3

FRAME NUMBER............................ 0-4

HOW TO USE THIS MANUAL ..... 0-5

EXPLANATION METHOD ................ 0-5

TERMINOLOGY................................ 0-6

ABBREVIATIONS ............................. 0-6

SI UNITS ........................................... 0-7

OPERATIONAL TIPS ..................... 0-8

JACK-UP POINT ........................... 0-10

RECOMMENDED LUBRICANT

QUANTITY & TYPES ................. 0-20

LUBRICATION CHART................ 0-21

PERIODIC MAINTENANCE........ 0-22

PERIODIC REPLACEMENT OF

PARTS AND LUBRICANTS ..... 0-27

0

HOISTING THE VEHICLE ........... 0-11

CAUTION FOR TOWING............. 0-11

ATTENTIVE POINTS ON SAS ... 0-12

CIRCUIT TESTER ......................... 0-13

STANDARD BOLT & NUT

TIGHTENING TORQUE............. 0-15

BOLT STRENGTH CLASS

IDENTIFICATION METHOD ......... 0-15

PRECOAT BOLTS ......................... 0-18

HIGH PRESSURE HOSE FITTING

TIGHTENING TORQUE............. 0-18

WIRE ROPE SUSPENSION

ANGLE LIST................................. 0-19

SAFE LOAD FOR EACH

WIRE ROPE SUSPENSION

ANGLE........................................... 0-19

COMPONENTS WEIGHT ............ 0-20

0-2

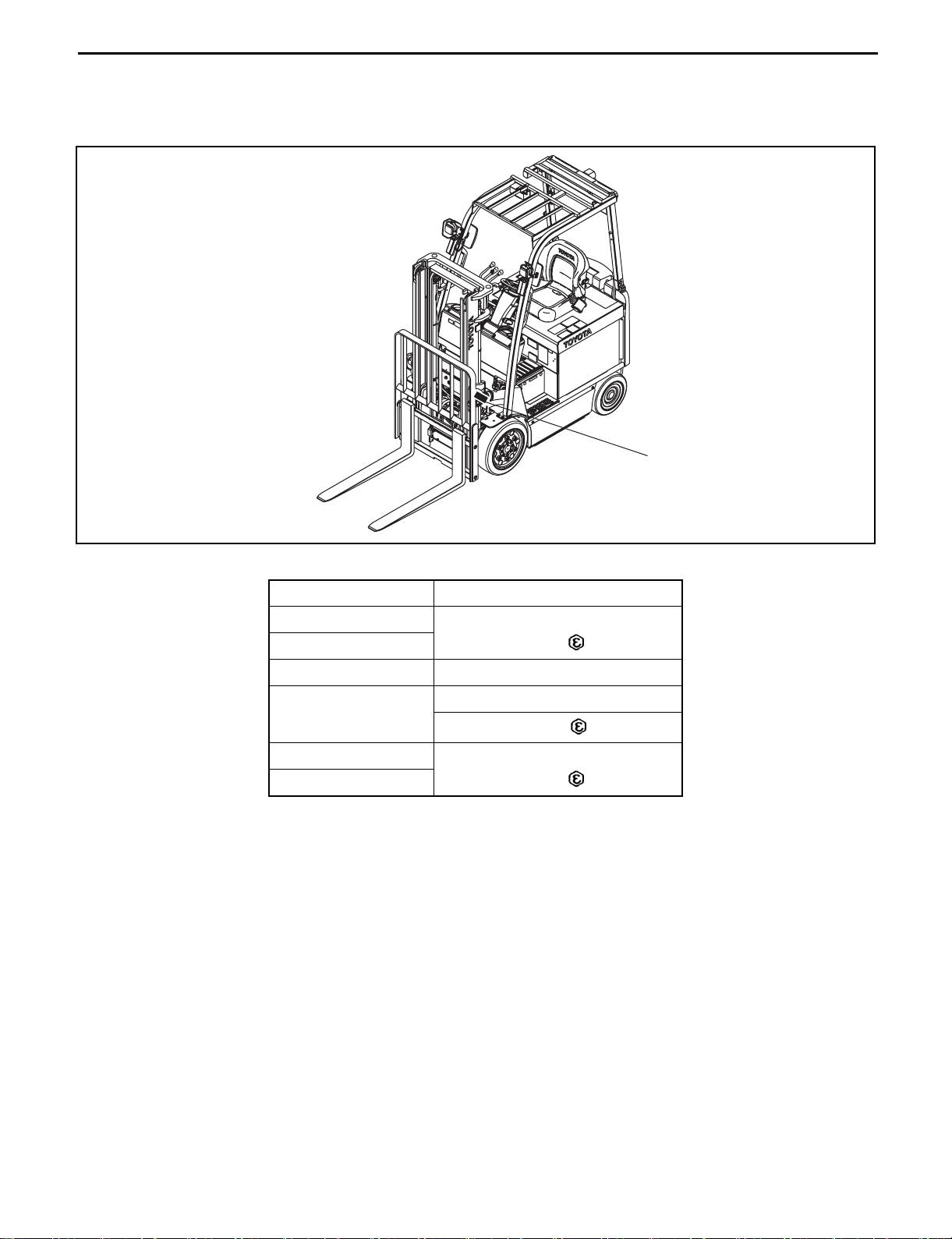

EXTERIOR VIEWS

0

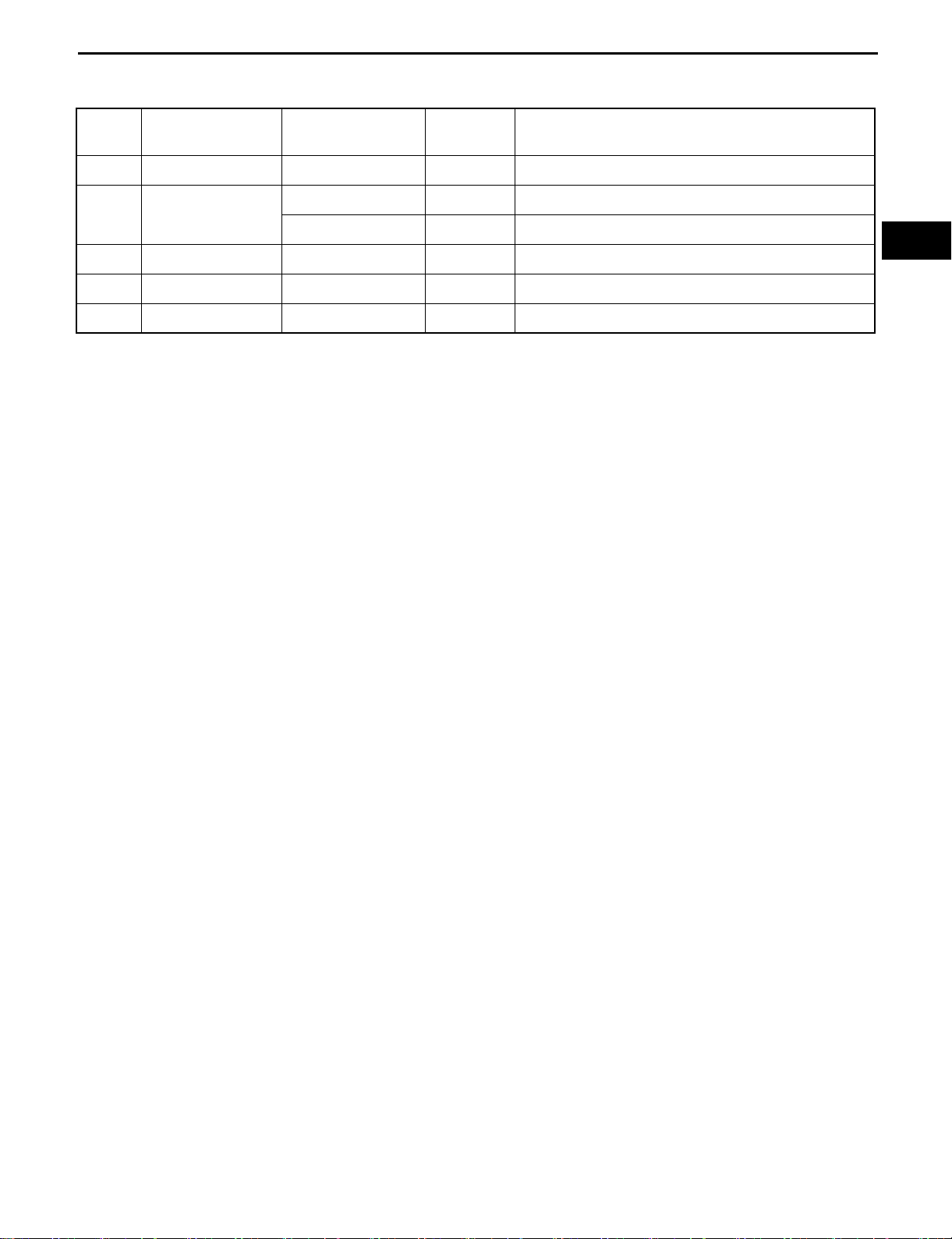

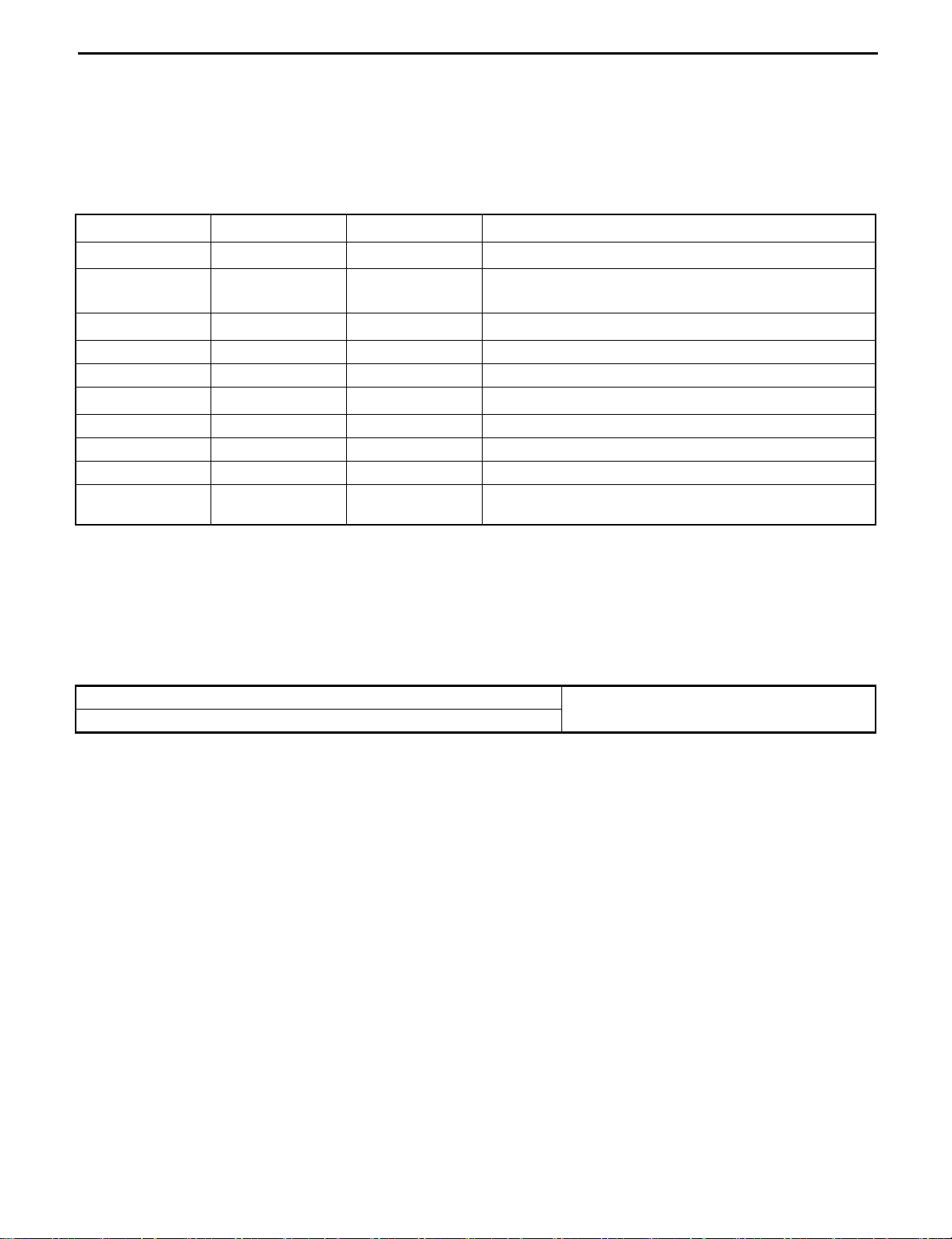

VEHICLE MODEL

0-3

Model

Code

20 4000 lbs 8FBCU20

25 5000 lbs

28 5500lbs 8FBCU28

30 6000 lbs 8FBCU30

32 6500 lbs 8FBCU32

Load Capacity Vehicle Model Voltage Remarks

8FBCU25

8FBCHU25

36V/48V

↑

↑

↑

↑

↑

0

USA·CANADA·MEXICO only

0-4

FRAME NUMBER

Frame No. Punching Position

Punching position

Vehicle Model Punching format

8FBCU20

8FBCU25

8FBCHU25 8FBCHU25-60011

8FBCU28

8FBCU30

8FBCU32

*: EEC spec.

* 8FBCU25 60011

* 8FBCU32 60011

8FBCU25-60011

8FBCU28-60011

* 8FBCU28 60011

8FBCU32-60011

HOW TO USE THIS MANUAL

EXPLANATION METHOD

1. Operation procedure

Example of description in pattern B

0-5

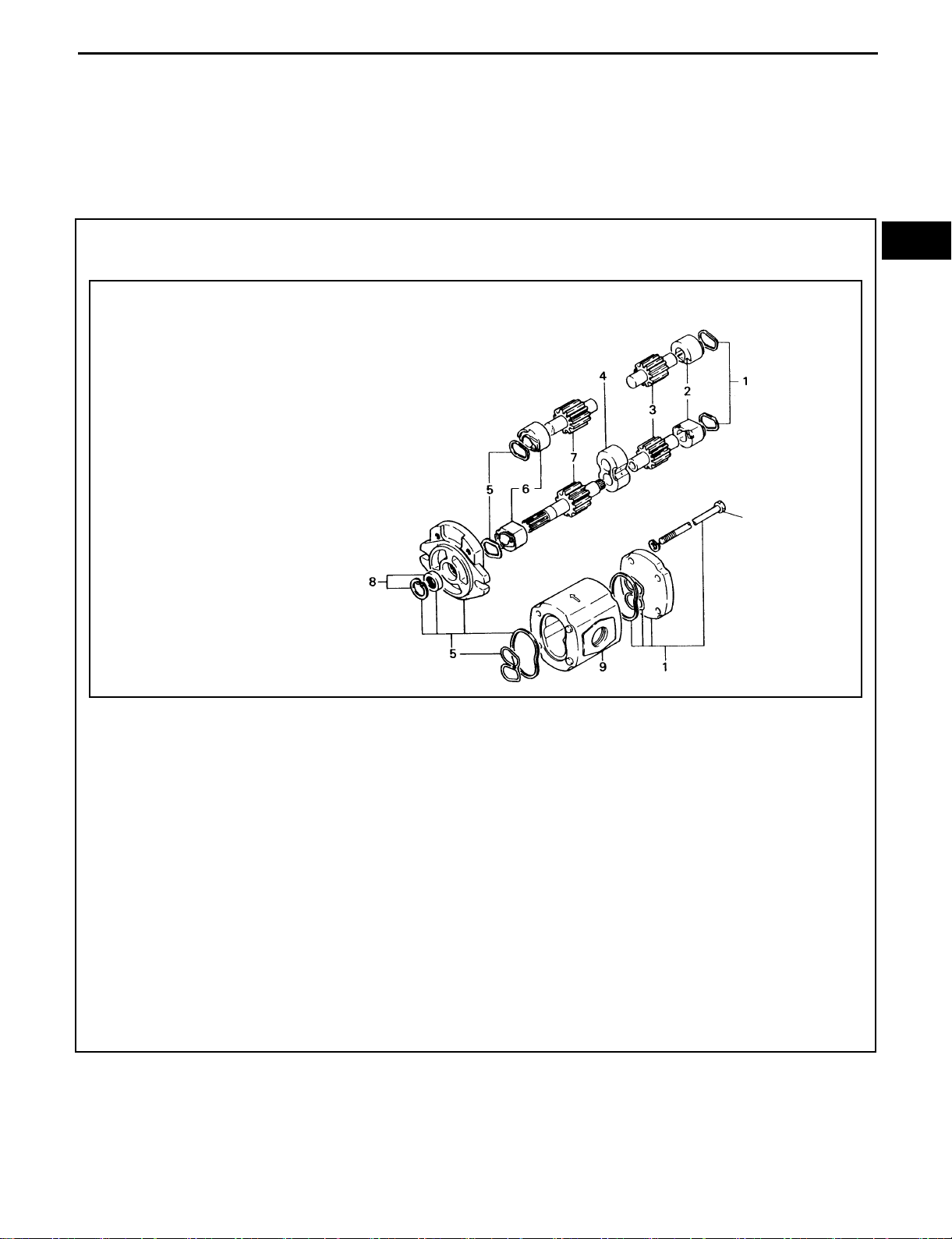

DISASSEMBLY·INSPECTION·REASSEMBLY

• Step Nos. are partially sometimes omitted in

illustrations.

• When a part requiring tightening torque

instruction is not indicated in the illustration,

the part name is described in the illustration

frame.

0

Tightening torque unit T = N·m (kgf·cm) [ft·lbf]

T = 46.1 to 48.1

(470 to 490)

[34.0 to 35.5]

Disassembly Procedure

1 Remove the cover. [Point 1]

2 Remove the bushing. [Point 2]

3 Remove the gear.

à Operation explained later

Point Operations

[Point 1]

Disassembly:

Put a match mark when removing the pump cover.

[Point 2]

Inspection:

Measure the bush inside diameter.

Limit: 19.12 mm (0.7528 in)

Explanation of key point for operation with an illustration

Ã

0-6

2. How to read components figures (Example)

(1) The components figure uses the illustration

in the parts catalog for the vehicle model.

Please refer to the catalog for checking the

part name.

The number at the right shoulder of each

components figure indicates the Fig.

number in the parts catalog.

(2) Refer to the parts catalog for the latest

information.

3. Matters omitted in this manual

This manual omits description of the following jobs, but perform them in actual operation:

(1) Cleaning and washing of removed parts as required

(2) Visual inspection (partially described)

FIG number in parts catalog

3201

TERMINOLOGY

Caution:

Important matters of which negligence may cause hazards on human body. Be sure to observe

them.

Note:

Important items of which negligence may cause breakage or breakdown, or matters in operation

procedure requiring special attention.

Standard: Values showing allowable range in inspection and adjustment.

Limit: Maximum or minimum allowable value in inspection or adjustment.

ABBREVIATIONS

Abbreviation (code) Meaning Abbreviation (code) Meaning

ASSY Assembly RR Rear

ATT Attachment SAE

Electronically controlled

EHPS

FHPS

LH Left hand SST Special service tool

FR Front STD Standard

OPS

fully hydraulic power

steering

Fully hydraulic power

steering

Operator Presence

Sensing

SAS System of active stability

SOL Solenoid

T= Tightening torque

Society of Automotive

Engineers (USA)

OPT Option {{T Number of teeth ({{)

O/S Oversize U/S Undersize

PS Power steering W/ With

RH Right hand L/ Less

0-7

SI UNITS

Meaning of SI

This manual uses SI units. SI represents the International System of Units, which was established to unify the various

systems of units used in the past for smoother international technical communication.

New Units Adopted in SI

Item New unit Conventional unit

2

Force*

*2

Torque

(Moment)

Pressure*

Revolving speed rpm rpm 1 rpm = 1 r/min

Spring constant*

Volume l cc 1 cc = 1 ml

Power W PS system 1 PS = 0.735499 kW

Heat quantity W·h cal 1 kcal = 1.16279 W·h

Specific fuel

consumption

2

↑↑mmHg 1 mmHg = 0.133322 kPa

2

N (newton) kgf 1 kgf = 9.80665 N

N·m kgf·cm 1 kgf·cm = 9.80665 N·m

Pa (pascal)

N/mm kgf/mm 1 kgf/mm = 9.80665 N/mm

g/W·h g/PS·h 1 g/PS·h = 1.3596 g/kW·h

kgf/cm

2

Conversion rate*

1 kgf/cm2 = 98.0665 kPa = 0.0980665 MPa

1

(1 [conventional unit] = X [SI unit])

<Reference>

* 1: X represents the value in SI units as converted from 1 [in conventional units], which can be used as the

rate for conversion between conventional and SI units.

* 2: In the past, kilogram [kg] representing mass was often used in place of weight kilogram [kgf], which

should be used as the unit of force.

Conversion between Conventional and SI Units

Equation for conversion

Value in SI unit = Conversion rate × Value in conventional unit

Value in conventional unit = Value in SI unit ÷ Conversion rate

Conversion rate: Figure corresponding to X in the

conversion rate column in the table above

When converting, change the unit of the value in conventional or SI units to the one in the conversion rate

column in the table above before calculation. For example, when converting 100 W to the value in

conventional unit PS, first change it to 0.1 kW and divide by the conversion rate 0.735499.

0-8

OPERATIONAL TIPS

1. Safe operation

(1) After jacking up, always support with wooden blocks or rigid stands.

(2) When hoisting the vehicle or its heavy component, use wire rope(s) with a sufficient reserve in load

capacity.

(3) Always disconnect the battery plug before the inspection or servicing of electrical parts.

2. Tactful operation

(1) Prepare the mechanic tools, necessary measuring instruments (circuit tester, megger, oil pressure

gauge, etc.) and SSTs before starting operation.

(2) Before disconnecting wiring, always check the cable color and wiring state.

(3) When overhauling functional parts, complicated portions or related mechanisms, arrange the parts

neatly to prevent confusion.

(4) When disassembling and inspecting such a precision part as the control valve, use clean tools and

operate in a clean location.

(5) Follow the described procedures for disassembly, inspection and reassembly.

(6) Replace, gaskets, packing and O-rings with new ones each time they are disassembled.

(7) Use genuine Toyota parts for replacement.

(8) Use specified bolts and nuts. Observe the specified tightening torque at the time of reassembly.

(Tighten to the center of the specified tightening torque range.)

If no tightening torque is specified, tighten the bolt or nut according to the standard tightening

torque table.

3. Protection of functional parts

(1) Thoroughly check each connector for any failure in or imperfect connection before reconnecting the

battery plug after the end of vehicle inspection or maintenance.

Failure in or imperfect connection of connectors related to controllers, especially, may

damage elements inside the controllers.

4. Confirming defect status

Do not start immediate disassembly or replacement, but first confirm if such disassembly or

replacement is actually needed.

5. Handling of waste fluid, etc.

When draining waste fluid from the vehicle, always receive it with an appropriate container.

Since careless or arbitrary discharge or disposal of oil, fuel, coolant, oil filter, battery or any other

harmful substance may cause adverse affect to people or environmental destruction, sort each waste

and always ask an authorized contractor for appropriate disposal.

6. Handling of electronic parts

(1) Never apply impacts to electronic parts such as a

microcomputer or relay.

(2) Never let electronic parts be exposed to a high

temperature or humidity.

(3) Do not touch connector pins since they may be

deformed or be damaged due to static electricity.

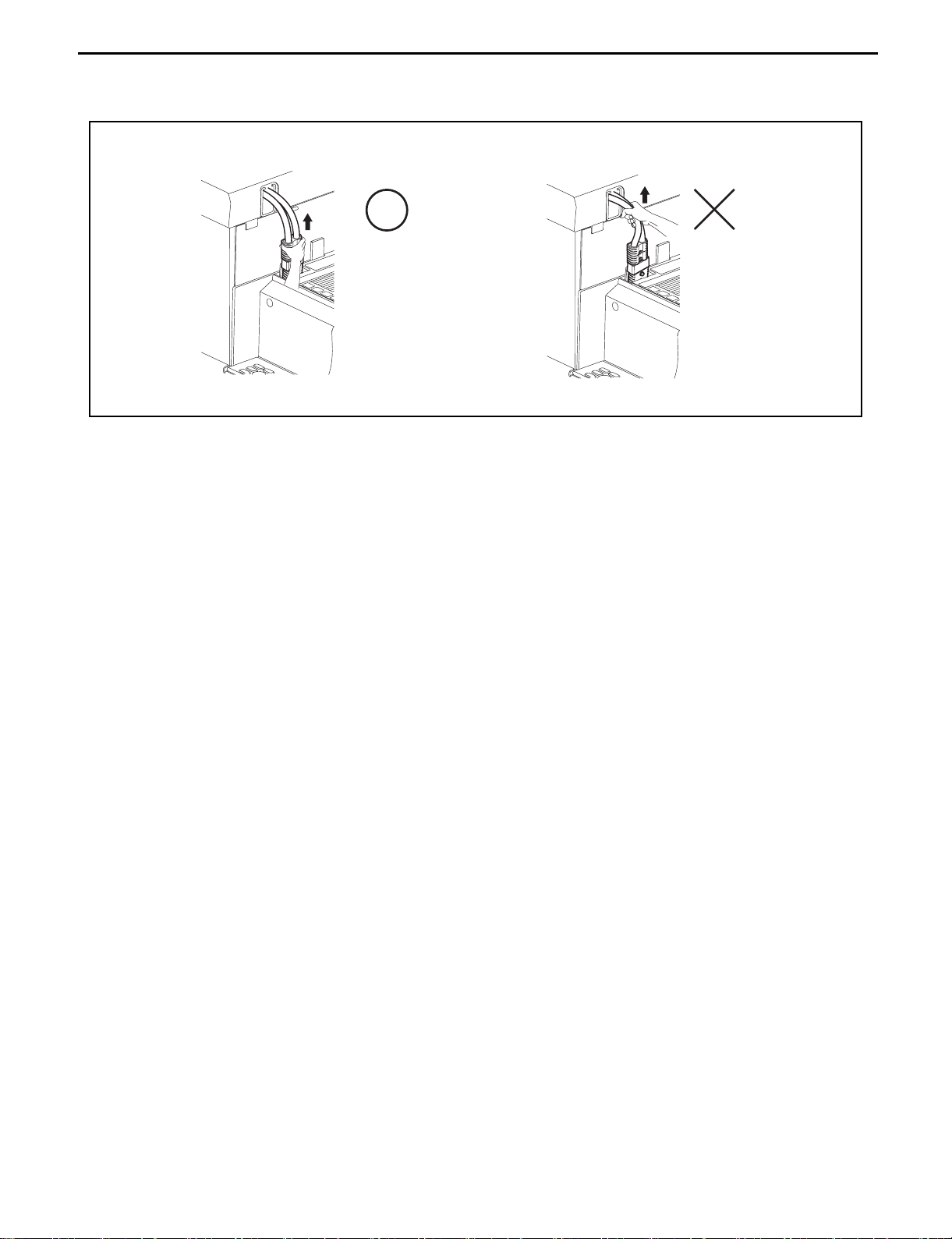

7. Disconnect the battery plug

When unplugging the battery plug, use the grip. Do not pull up the cable.

For example:

0-9

0-10

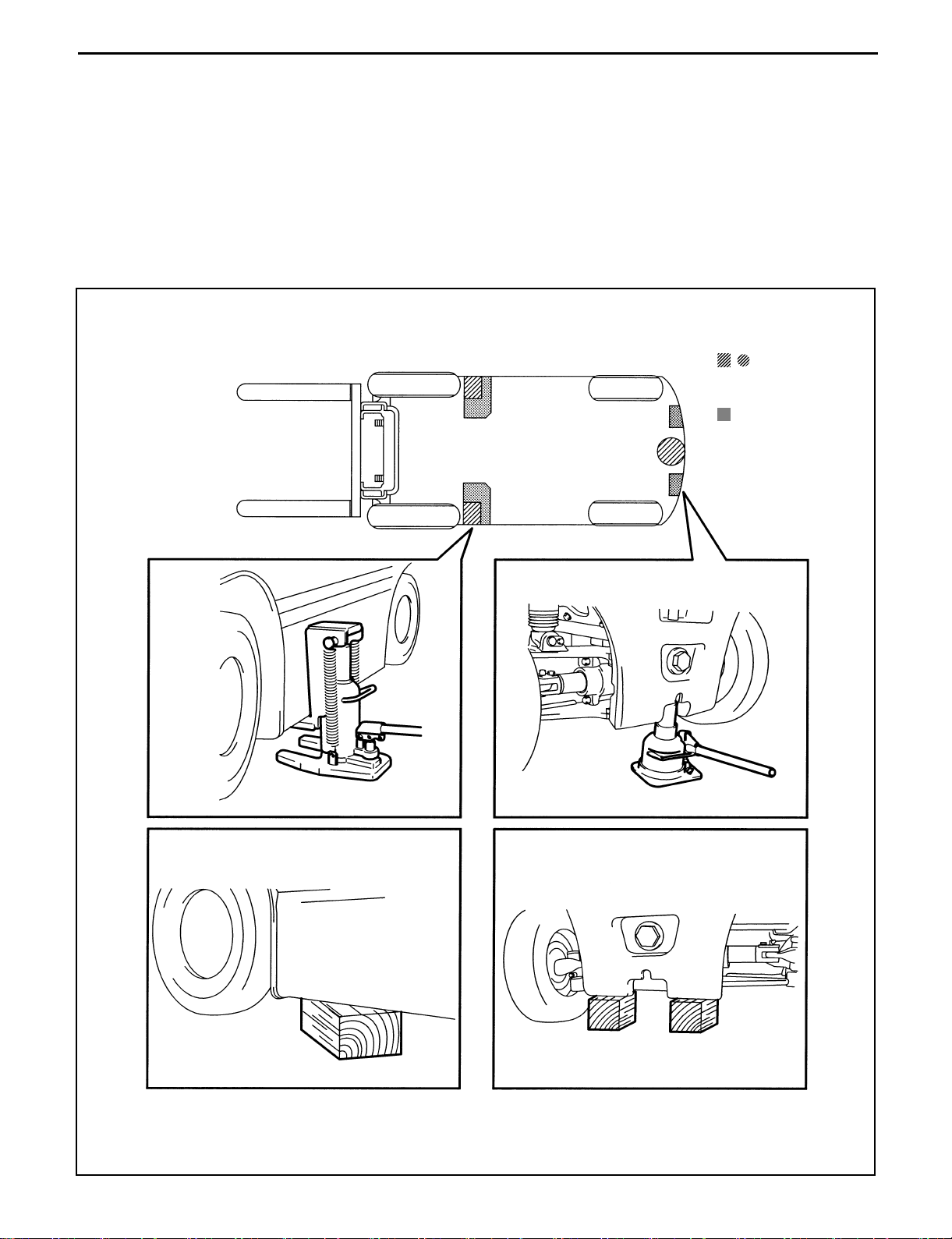

JACK-UP POINT

Strictly observe the following instructions when jacking up the vehicle.

• When a load is on the fork, unload it and park the vehicle on a flat floor. Be sure to avoid an inclined or

rugged place.

• Use a jack with ample capacity and jack up the vehicle at the specified jack-up point. Jacking up at any

other point will be dangerous.

• Never operate while the vehicle is held with a jack. Always support the frame with a wooden block after

jacking up.

• In any case, never let a part of the body (including hands and feet) be under the jacked-up vehicle.

:

Jack-up point

:

Wooden block or stand

setting point

0-11

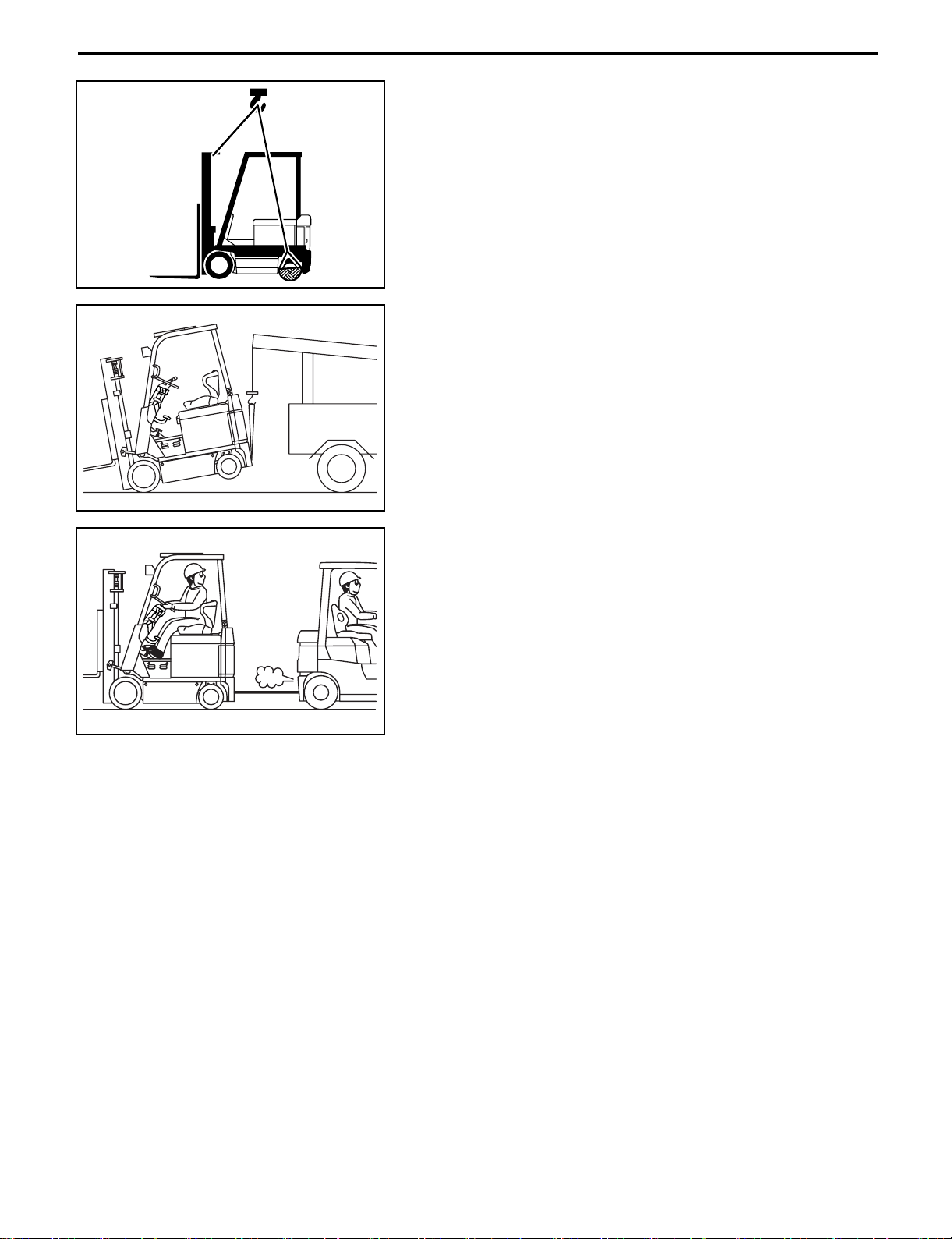

HOISTING THE VEHICLE

When hoisting the vehicle, use the mast hook on the front of

the vehicle and a wire net on the rear wheel.

Caution:

• Use wire ropes having sufficient strength.

• Never hoist the forklift by the weight hook holes or

head guard.

CAUTION FOR TOWING

1. When towing the forklift, always lift the rear wheels away

from the ground.

2. The traveling speed in towing must not exceed the

maximum traveling speed of the forklift.

3. Always set the key switch to OFF and the direction

switch to the neutral position before starting towing.

In case of towing by connection with a wire rope with the

operator on the forklift, however, set the key switch to

ON (PS operation) and always set the direction switch to

the neutral position.

4. Before towing, either remove the fork or take an action

to prevent fork contact with the ground due to bounding.

Loading...

Loading...