Toyota 6FG, 6FD10-30 Repair Manual

FOREWORD

This manual covers the service procedures of the TOYOTA FORKLIFT

6FGl6FD 10- 30. Please use this manual for providing quick, correct ser

vicing of the corresponding forklift models.

This manual deals with the above models as of January 1994. Please

understand that disagreement can take place between the descriptions

in the manual and actual vehicles due to change in design and specifica

tions. Any change or mod,ifications thereafter will be informed by

Toyota Industrial Equipment Parts

For the service procedures of the mounted engine, read the repair manu

als listed below as reference together with this manual.

(Reference)

Repair manuals related to this manual are as follows:

TOYOTA INDUSTRIAL EQUIPMENT 5K ENGINE

REPAIR MANUAL

&

Service News.

(No.CE617)

-

-

-

TOYOTA INDUSTRIAL EQUIPMENT 4Y ENGINE

REPAIR MANUAL

TOYOTA INDUSTRIAL EQUIPMENT 1DZ ENGINE

REPAIR MANUAL

TOYOTA INDUSTRIAL EQUIPMENT 22 ENGINE

REPAIR MANUAL

(No.CE602)

(No.CE618)

(No.CE625)

TOYOTA MOTOR CORPORATION

SECTION INDEX

I

NAME

GENERAL

ENGINE

CLUTCH

-

TORQUE CONVERTER

TRANSMISSION

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE

I

SECTION

REAR AXLE

STEERING

@

BODY

MATERIAL HANDLING SYSTEM

CYLINDER

OIL PUMP

OIL CONTROL VALVE

@

GENERAL

Page

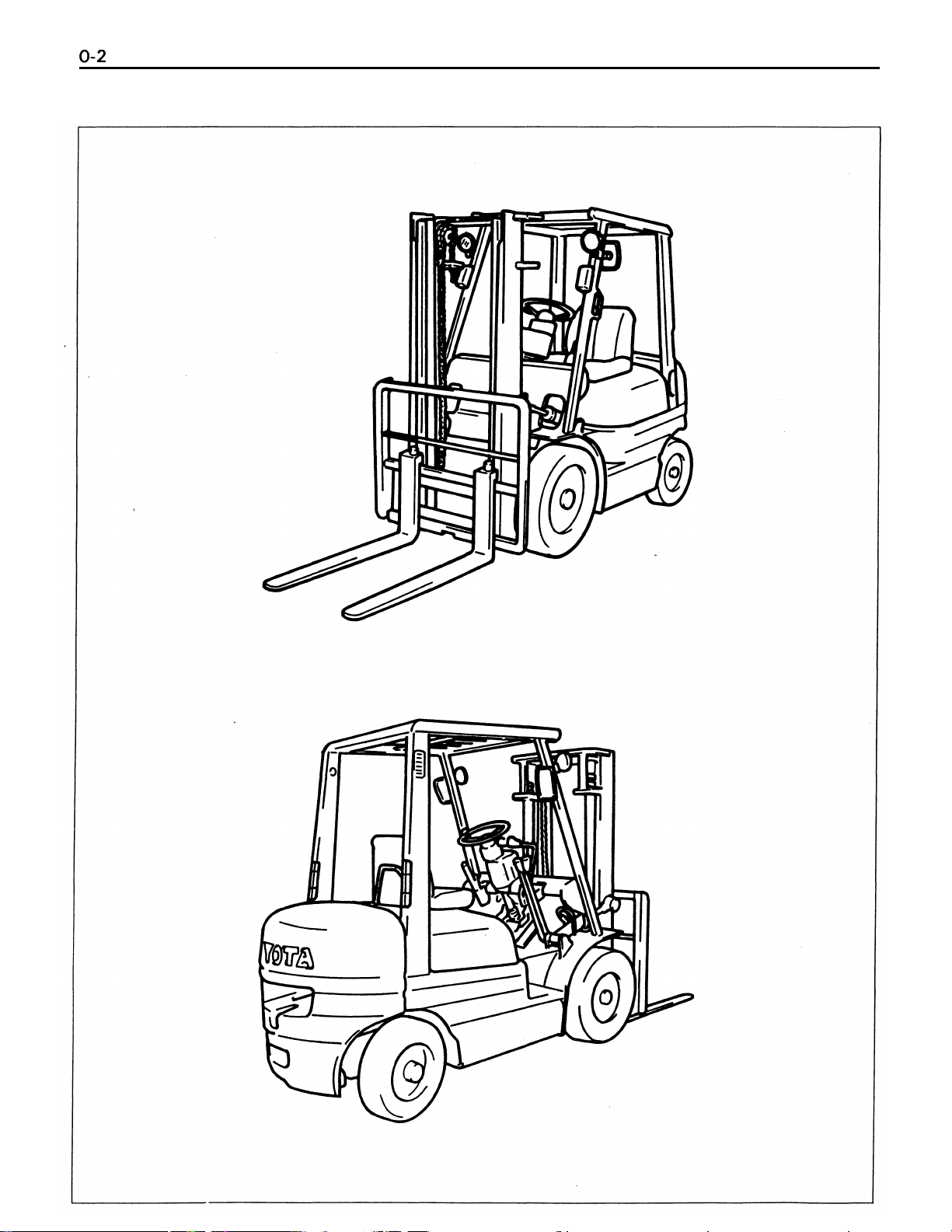

EXTERIOR VIEWS

VEHICLE MODEL

FRAME NUMBER

HOW TO READ THIS MANUAL

EXPLANATION METHOD

TERMINOLOGY

ABBREVIATIONS

OPERATIONAL TIPS

STANDARD BOLT

TORQUE

BOLT STRENGTH TYPE IDENTIFICATION

METHOD

TIGHTENING TORQUE TABLE

PRECOAT BOLTS

...........................................................

........................................................

...............................................

...............................................

................................................

.........................

......................................

.................................................

.................................................

...........................................

&

NUT TIGHTENING

...............................

...............................................

0-2

0-3

0-6

0-9

0-9

0-10

0-10

0-11

'0-1 2

0-12

0-13

0-14

HIGH PRESSURE HOSE FITTING

TIGHTENING TORQUE

WIRE ROPE SUSPENSION ANGLE LIST

SAFE LOAD FOR EACH WlRE ROPE

SUSPENSION ANGLE

COMPONENTS WEIGHT

RECOMMENDED LUBRICANT

QUANTITY

LUBRICATION CHART

PERIODIC MAINTENANCE

PERIODIC REPLACEMENT OF PARTS

AND LUBRICANTS

&

TYPES

.....................................

.......................................

.....................................

.......................................

........................................

..................................

...........................................

.............

0-14

0-15

0-15

0-16

0-17

0-19

0-21

0-27

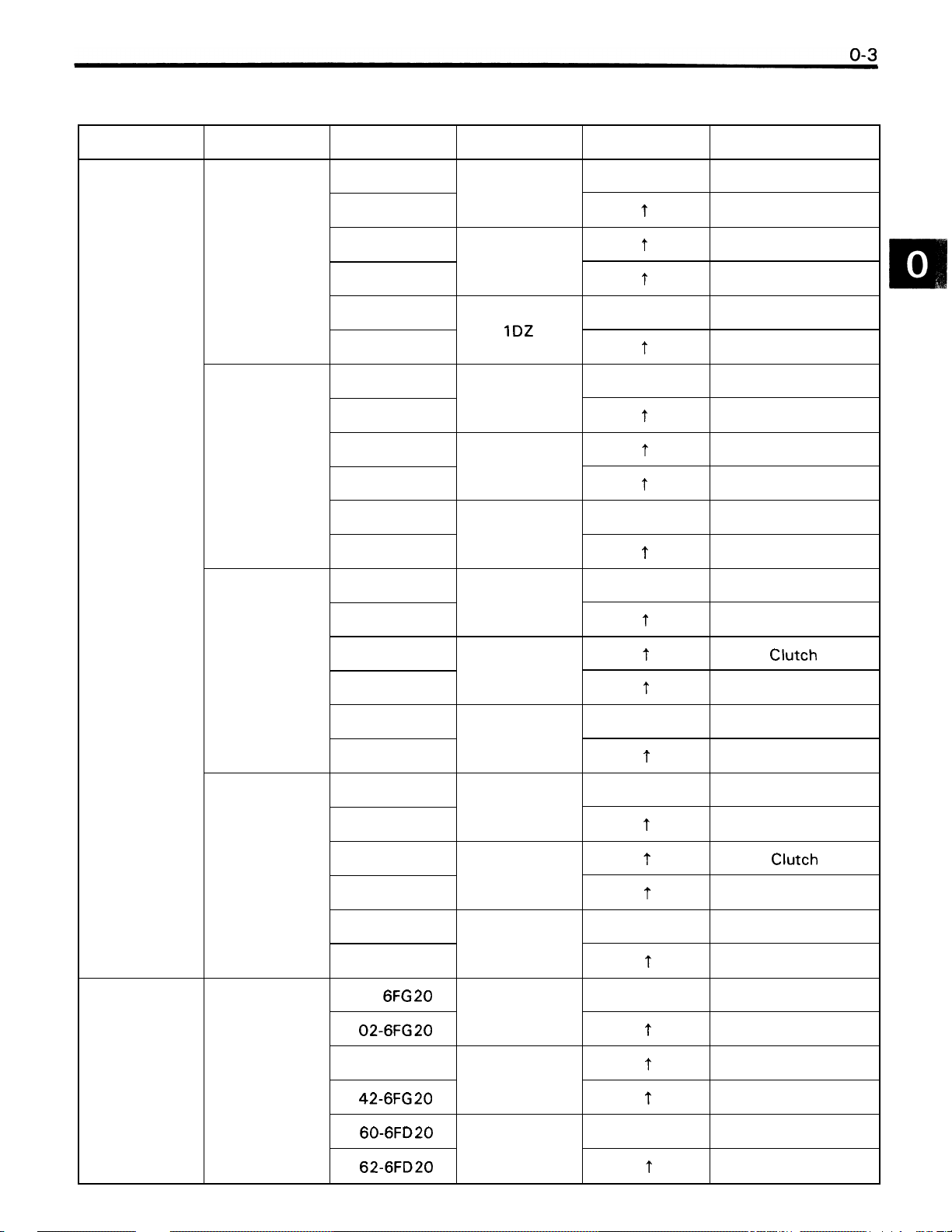

EXTERIOR VIEWS

VEHICLE

MODEL

Series

1 ton series

Load capacity

1.0 ton

1.35 ton

Model

6FG 10

-

6FG 10

02

-

6FG 10

40

-

6FG 10

42

6FD 10

-

6FD 10

02

6FG 14

02

-

6FG 14

-

6FG 14

40

40

-

6FG 1 4

-

6FD 14

02

02

-

6FG 1 5

6FD 14

6FG 1 5

Engine model

5K

4Y

1DZ

5K

4Y

1 DZ

5K

Engine type

Gasoline

t

t

t

Diesel

t

Gasoline

t

t

t

Diesel

t

Gasoline

t

Drive system

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

2 ton series

1.5 ton

1.75 ton

2.0 ton

-

6FG 1 5

40

-

6FG 1 5

42

6FD 1 5

02

-

6FD 1 5

6FG 18

-

6FG 1 8

02

-

6FG 18

40

-

6FG 18

42

6FD 18

-

6FD 18

02

6FG20

02-6FG20

40-6FG 20

42-6FG20

4Y

1 DZ

5K

4Y

1 DZ

5K

4Y

t

t

Diesel

t

Gasoline

t

t

t

Diesel

t

Gasoline

t

t

t

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

60-6FD20

62-6FD20

1 DZ

Diesel

t

Clutch

Torque converter

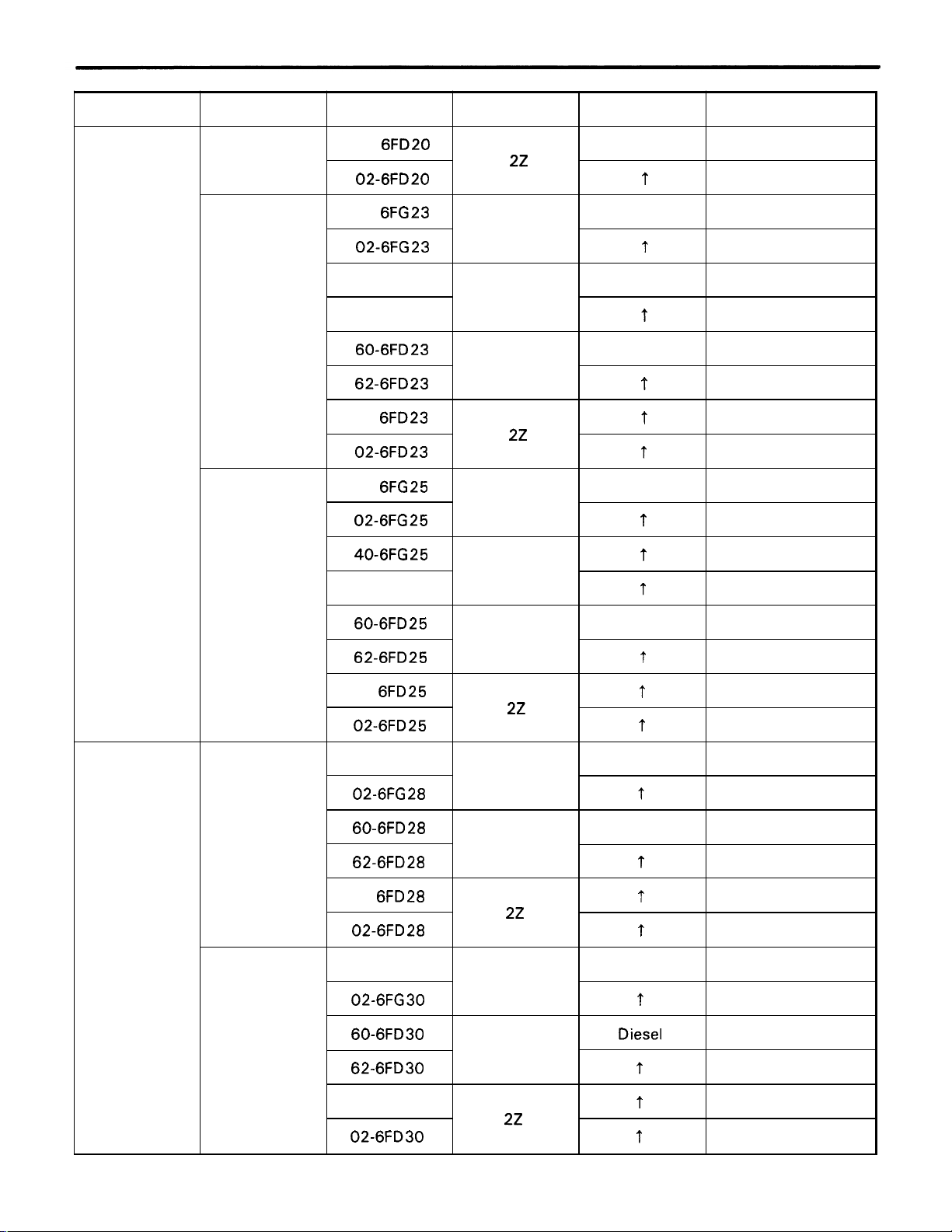

Series

Load capacity

Model

Engine model

Engine type

Drive system

2 ton series

2.0 ton

2.25 ton

2.5 ton

6FD20

02-6FD20

6FG23

02-6FG23

40-6FG 23

-

6FG 23

42

60-6FD23

62-6FD23

6FD23

02-6FD23

6FG25

02-6FG25

40-6FG25

42-6FG 25

60-6FD25

62-6FD25

5K

4Y

1

5K

4Y

1

22

DZ

22

DZ

Diesel

t

Gasoline

t

Gasoline

t

Diesel

t

t

t

Gasoline

t

t

t

Diesel

t

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

3 ton series

2.75 ton

3.0 ton

6FD25

02-6FD25

6FG 28

02-6FG28

60-6FD28

62-6FD28

6FD28

02-6FD28

6FG 30

02-6FG30

60-6FD30

62-6FD30

6FD 30

02-6FD30

4Y

1

22

4Y

1

22

22

DZ

DZ

't

t

Gasoline

t

Diesel

t

t

t

Gasoline

t

Diesel

t

t

t

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

Clutch

Torque converter

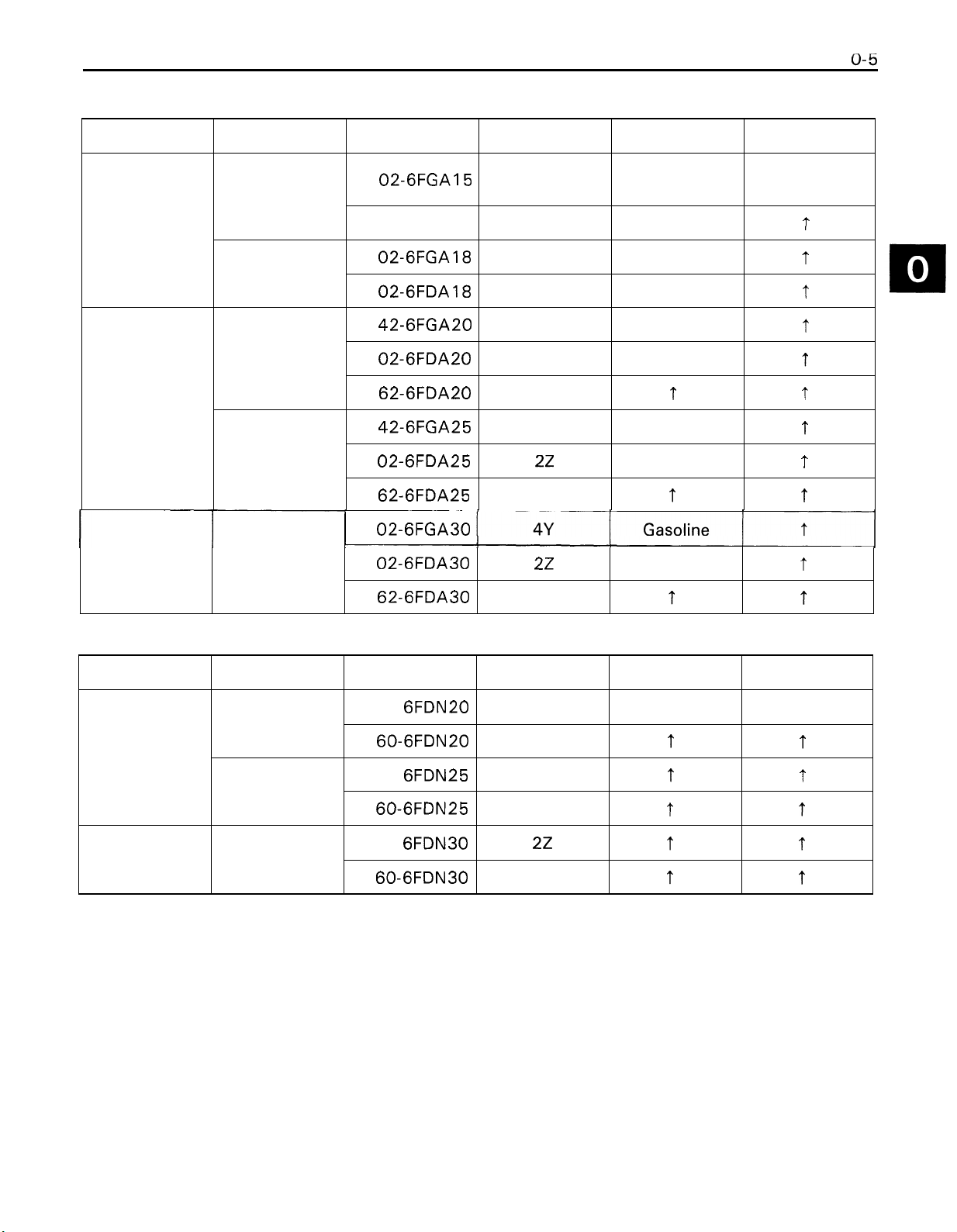

South Africa

Series

1 ton series

2 ton series

3 ton series

Load capacity

1.5 ton

1.75

ton

2.0 ton

2.5 ton

3.0 ton

Model

02-6FGA15

02-6FDA 15

02-6FGA18

02-6FDA18

42-6FGA20

02-6FDA20

62-6FDA20

42-6FGA25

02-6FDA25

62-6FDA25

02-6FGA30

pp

02-6FDA30

Engine model

5K

7

DZ

5K

1

DZ

4Y

Z

2

1 DZ

4Y

22

1 DZ

22

Engine type

Gasoline

Diesel

Gasoline

Diesel

Gasoline

Diesel

t

Gasoline

Diesel

t

Diesel

Drive system

Torque

converter

t

t

t

t

t

t

t

t

t

t

Indonesia

Series

2 ton series

3 ton series

Load capacity

2.0 ton

2.5 ton

3.0 ton

62-6FDA30

Model

6FDN20

60-6FDN20

6FDN25

60-6FDN25

6FDN30

60-6FDN30

1 DZ

Engine model

2 Z

1 DZ

2 Z

1 DZ

22

1 DZ

t

Engine type

Diesel

?

t

t

t

t

t

Drive system

Clutch

t

t

?

t

t

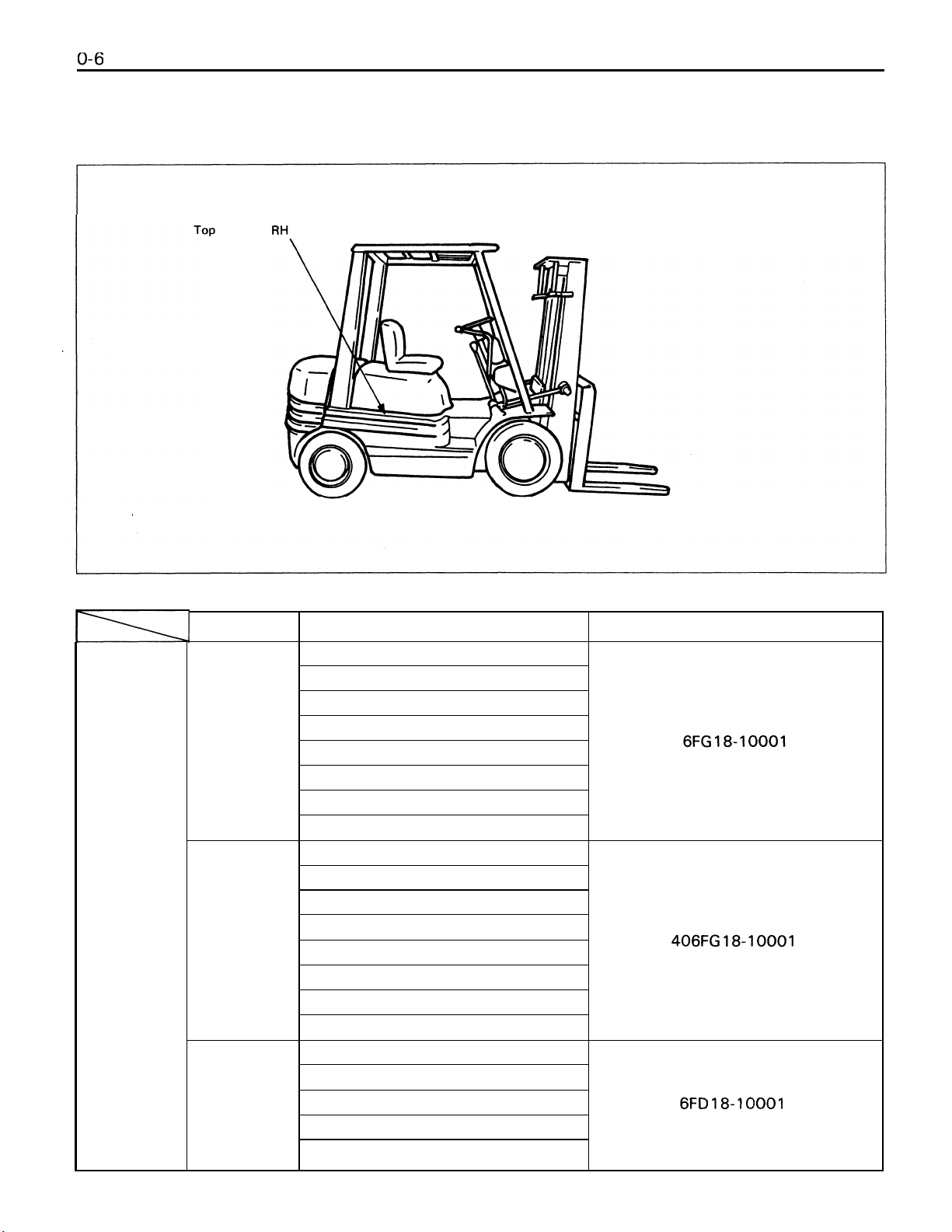

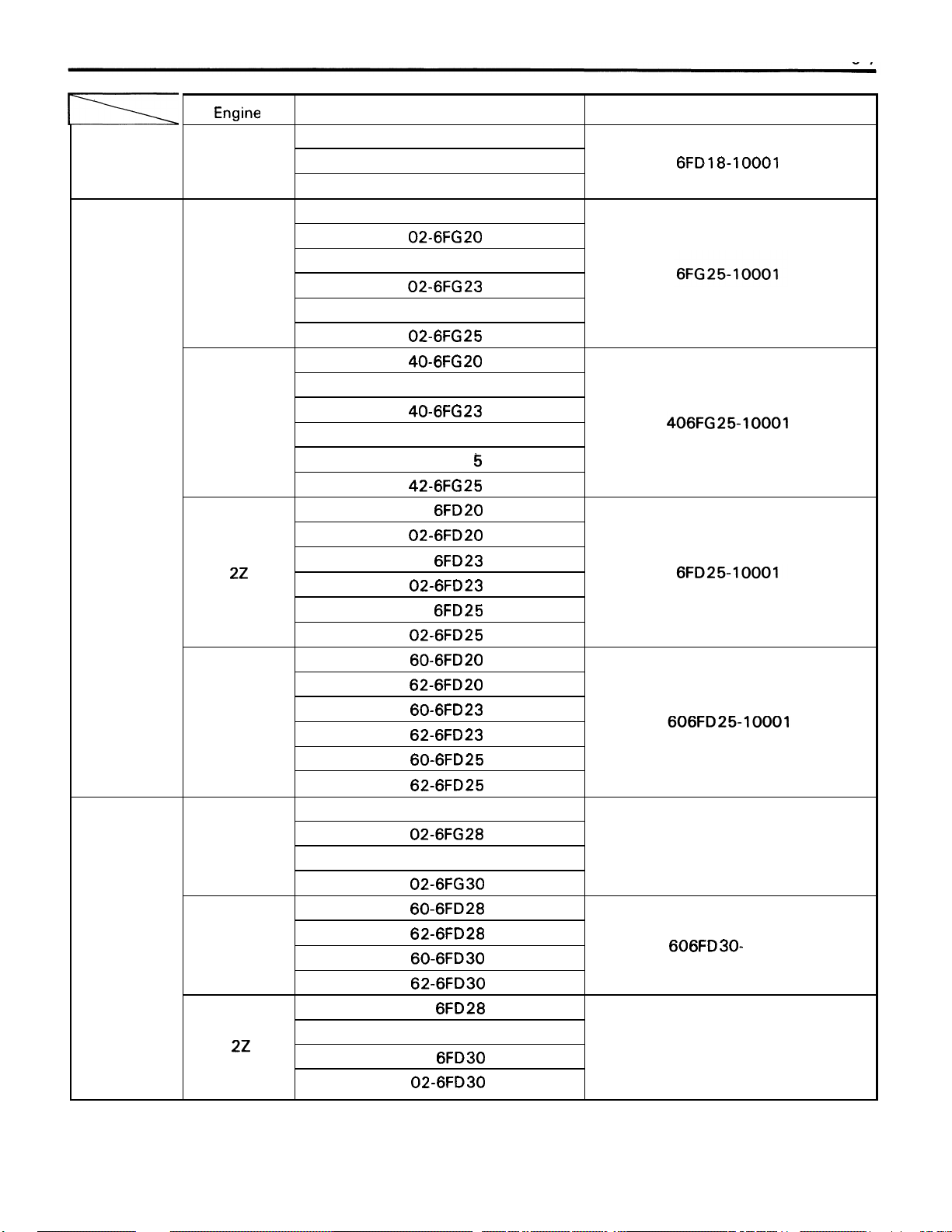

FRAME NUMBER

Frame

No. Punching Position

of

frame

1

ton series

Engine

5K

4Y

1 DZ

Model

-

6FG 10

02

02

-

6FG 14

-

6FG 1 5

02

6FG 1 8

02

-

6FG 1 8

40

-

6FG 10

-

6FG 10

42

40

-

6FG 14

42

-

6FG 14

-

6FG 15

40

-

6FG 1 5

42

40

-

6FG 18

-

6FG 1 8

42

6FD 10

-

6FD 10

02

6FD 14

02

-

6FD 14

6FD 1

Punching format

6FG 10

6FG 14

6FG 1 5

6FD18-10001

5

1

ton series

2

ton series

3

ton series

Eng~ne

1

DZ

5K

4Y

22

1 DZ

4Y

1

DZ

22

Model

02-6FD 1 5

6FD 18

-

6FD 18

02

6FG 20

02-6FG20

6FG 23

02-6FG23

6FG 2 5

02-6FG25

40-6FG20

42-6FG 20

40-6FG23

42-6FG 23

40

-

6FG 2

5

42-6FG25

6FD20

02-6FD20

6FD23

02-6FD23

6FD25

02-6FD25

60-6FD20

62-6FD20

60-6FD23

62-6FD23

60-6FD25

62-6FD25

6FG 28

02-6FG28

6FG 30

02-6FG30

60-6FD28

62-6FD28

60-6FD30

62-6FD30

6FD28

02-6FD 28

6FD30

02-6FD30

Punching format

6FD18-10001

6FG 30- 1

606FD30- 1 000

6FD 30- 1

000

000

1

1

1

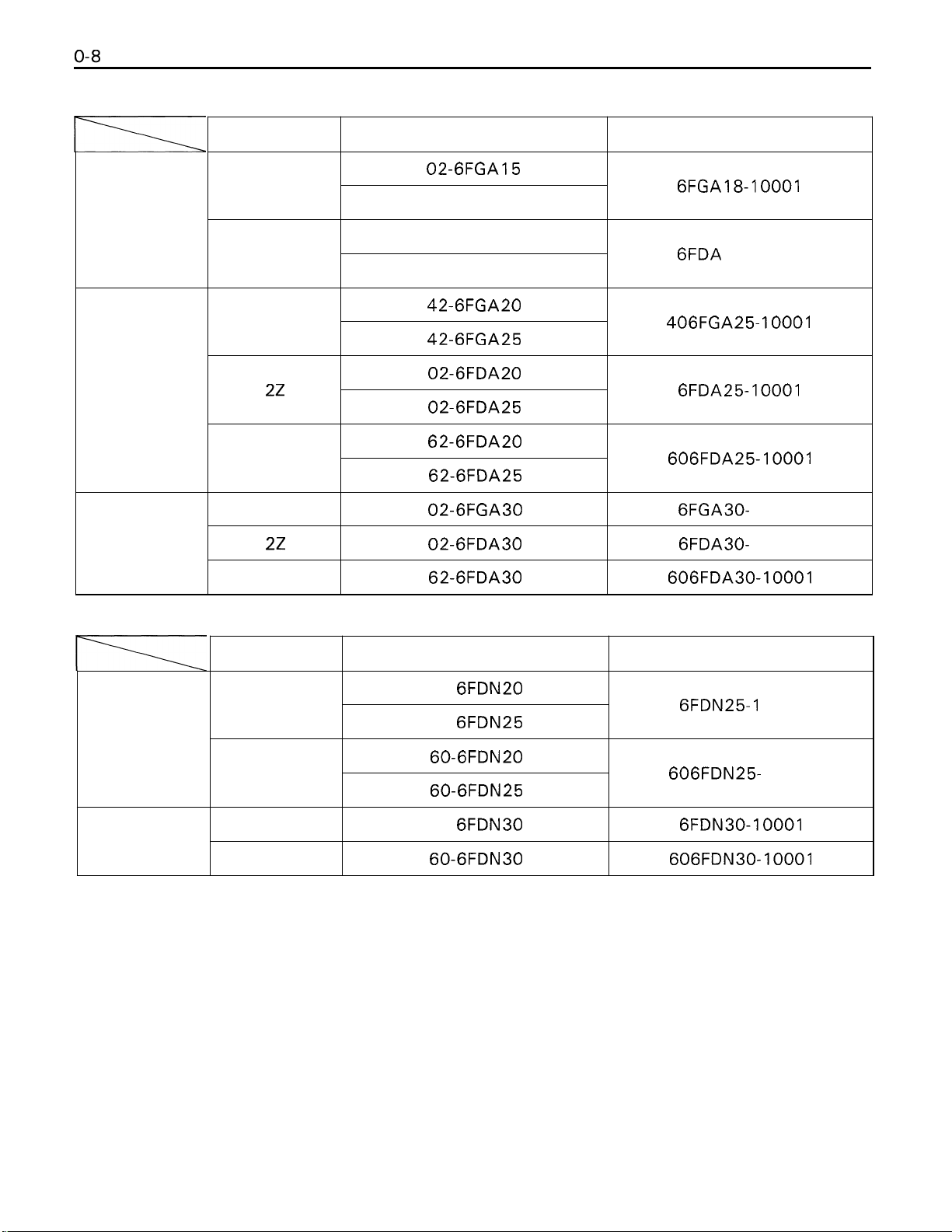

South

Africa

1

ton series

2

ton series

3

ton series

Engine

5K

1 DZ

4Y

22

1 DZ

4Y

22

1 DZ

Model

02-6FGA15

02-6FGA 18

-

02

6FDA 1

5

02-6FDA 18

42-6FGA20

42-6FGA25

02-6FDA20

02-6FDA25

62-6FDA20

62-6FDA25

02-6FGA30

02-6FDA30

62-6FDA30

Punching format

6FGA18-10001

6FDA 1 8- 1 000 1

406FGA25- 10001

6FDA25-10001

606FDA25-10001

6FGA30- 1000 1

6FDA30- 1000 1

606FDA30-10001

Indonesia

2

ton series

3

ton series

Engine

2

Z

1 DZ

2 Z

1 DZ

Model

6FDN20

6FDN25

60-6FDN20

60-6FDN25

6FDN30

60-6FDN30

Punching format

6FDN25-I 0001

606FDN25- 10001

6FDN30-10001

606FDN30-10001

HOW

TO

READ

THIS

MANUAL

EXPLANATION METHOD

1. Operation procedure

(1) The operation procedure is described in either pattern A or pattern B below.

Pattern A:

Pattern B:

followed by explanation of cautions and notes summarized as point operations.

Explanation of each operation step with a photo or illustration.

Explanation of operation procedure by indicating step numbers in one illustration,

Example of description

DISASSEMBLY -INSPECTION-REASSEMBLY

If a place or part cannot be indicated

directly, the part name is described on

the either side of the illustration.

1

Example:

Piping

in

pattern B

Tightening torque unit T = N-m (kg-cm)

Disassembly Procedure

Remove the cover.

1

2

Remove the bush

3

Remove the gear.

Point operations

[Point

Disassembly: Put a match mark when removing the pump cover

[Point

Inspection:

1

21

I

Explanation of key point for operation with an illustration

Measure the bush inside diameter.

Bush inside diameter limit:

[Point

[Point

21

I

11

cl

Operation explained later

2

19.1

mm

(0.7528

in)

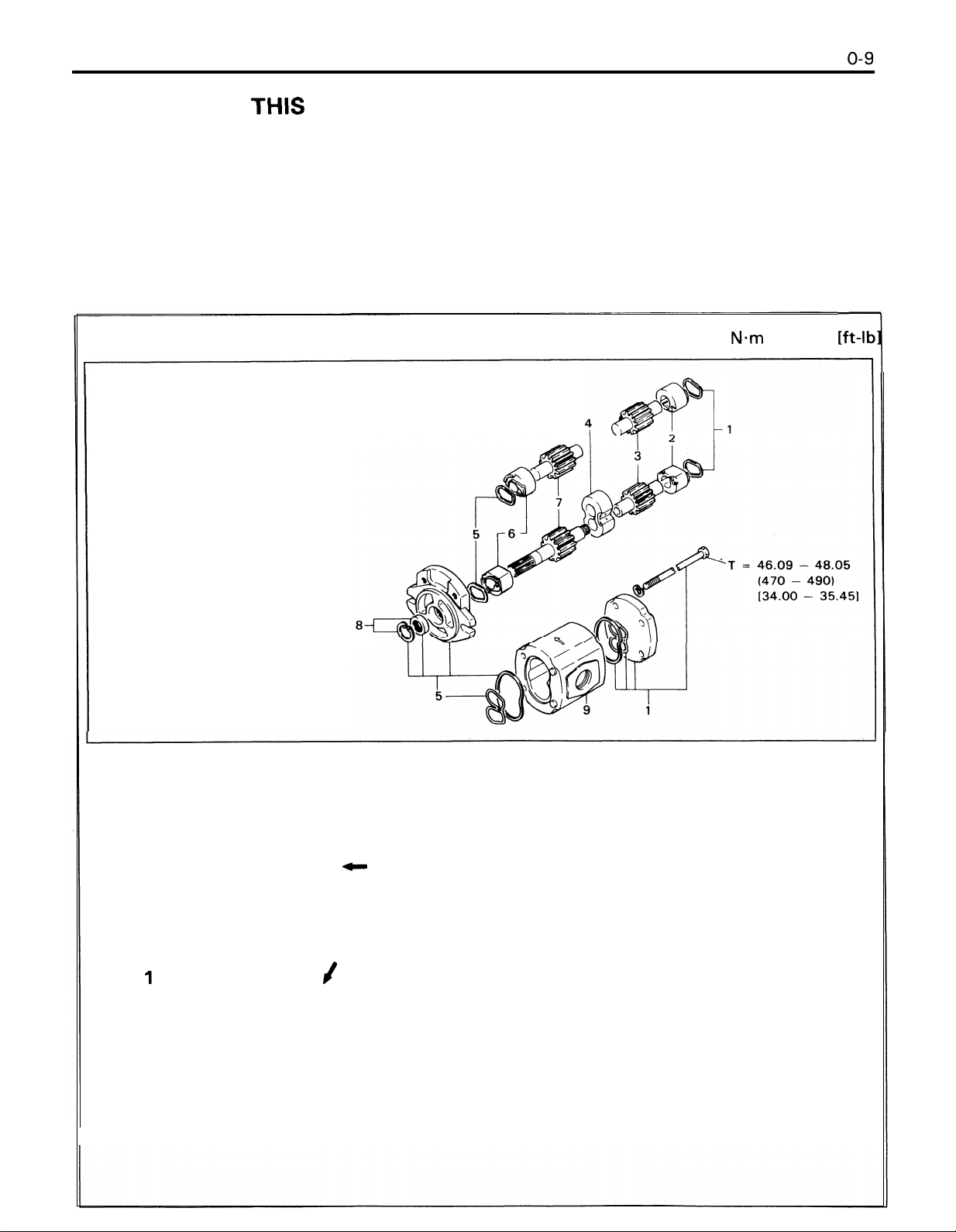

2.

How to read components figures (Example)

The components figure uses the illustra

(1

tion in the parts catalog for the vehicle

model. Please refer to the catalog for

checking the part name.

The number at the right shoulder of each

components figure indicates the Fig. num

ber in the parts catalog.

3.

Matters omitted in this manual

(1)

This manual omits description of the following jobs, but perform them in actual operation:

Cleaning and washing of removed parts as required

2

Visual inspection (partially described)

8

-

FIG number in parts catalog

-

I

TERMINOLOGY

Caution:

Important matters of which negligence may cause accidents. Be sure to abserve them.

Note:

important items of which negligence may cause accidents, or matters in operation procedure requiring special attention.

Standard: Values showing allowable range in inspection and adjustment.

Limit:

Maximum or minimum allowable value in inspection or adjustment.

ABBREVIATIONS

Abbreviation (code)

ASSY

H

L

LLC

OPT

01s

PS

RH

SAE

Meaning

Assembly

Left hand

Long life coolant

Option

Oversize

Power steering

Right hand

Society of Automotive

Engineers (USA)

Abbreviation (code)

SST

STD

=

T

OOT

U

IS

W/

L/

Meaning

Special service tool

Standard

Tightening torque

Number of teeth

Undersize

With

Less

(0

0)

OPERATIONAL

1. Safe operation

(1) After jacking up, always support with rigid stands.

(2) When hoisting the vehicle or its heavy component, use wire

load capacity.

(3) Always disconnect the battery plugs before the inspection or servicing of electrical parts.

2.

Tactful operation

(1

)

Prepare the mechanic tools, necessary measuring instruments (circuit tester, megger, oil pres

sure gauge, etc.) and SSTs before starting operation.

(2) Before disconnecting wiring, always check the cable color and wiring state.

(3) When overhauling functional parts, complicated portions or related mechanisms, arrange the parts

neatly to prevent confusion.

(4)

When disassembling and inspecting such a precision part as the control valve, use clean tools

and operate in a clean location.

(5)

Follow the described procedures for disassembly, inspection and reassembly.

(6)

Replace, gaskets, packings and O-rings with new ones each time they are disassembled.

(7)

Use genuine Toyota parts for replacement.

(8)

Use specified bolts and nuts. Observe the specified tightening torque at the time of reassembly.

If no tightening torque is specified, tighten the bolt or nut according to the standard tightening

torque table.

3.

Grasping the trouble state

When a trouble occurs, do not attempt immediate disassembly or replacement but first check if

the trouble requires disassembly or replacement for remedying.

TIPS

repe(s) with a sufficient reserve in

-

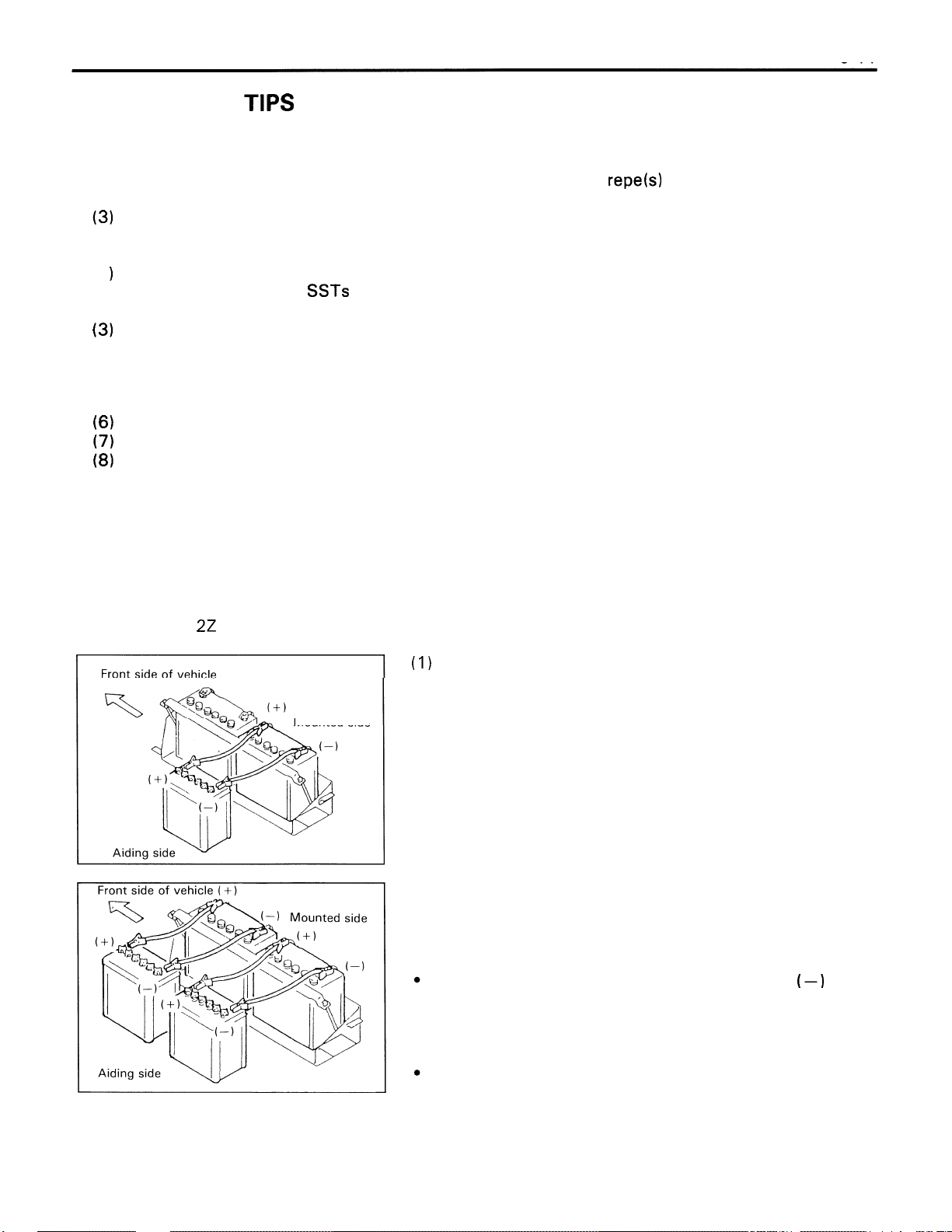

4.

Method for battery connection upon occurrence of run-down batteries on 24-V specification ve

hicle with

22

engine (with

12/24 V

Mounted

side

voltage switching system)

(1)

Connect a 12-V aiding battery to the one on the rear

side of the two mounted batteries.

(2)

If starting falls with one aiding battery, connect an

other aiding battery to the front side one of the

mounted batteries.

Caution:

As batteries are shorted when the negative

nal of the aiding battery on the front side of the vehicle

is connected to the body ground, connect the booster

cables to the vehicle side to each corresponding termi

nal.

Never connect between aiding batteries.

(-1

termi

-

-

-

-

(3)

When the batteries are required to charge by the

charger, remove the battery from the vehicle to charge

the battery.

Loading...

Loading...