Toyota 4 Runner 1993 User Manual

ST–1

–STARTING SYSTEM

STARTING SYSTEM

ST–2

–STARTING SYSTEM Starter

STARTER

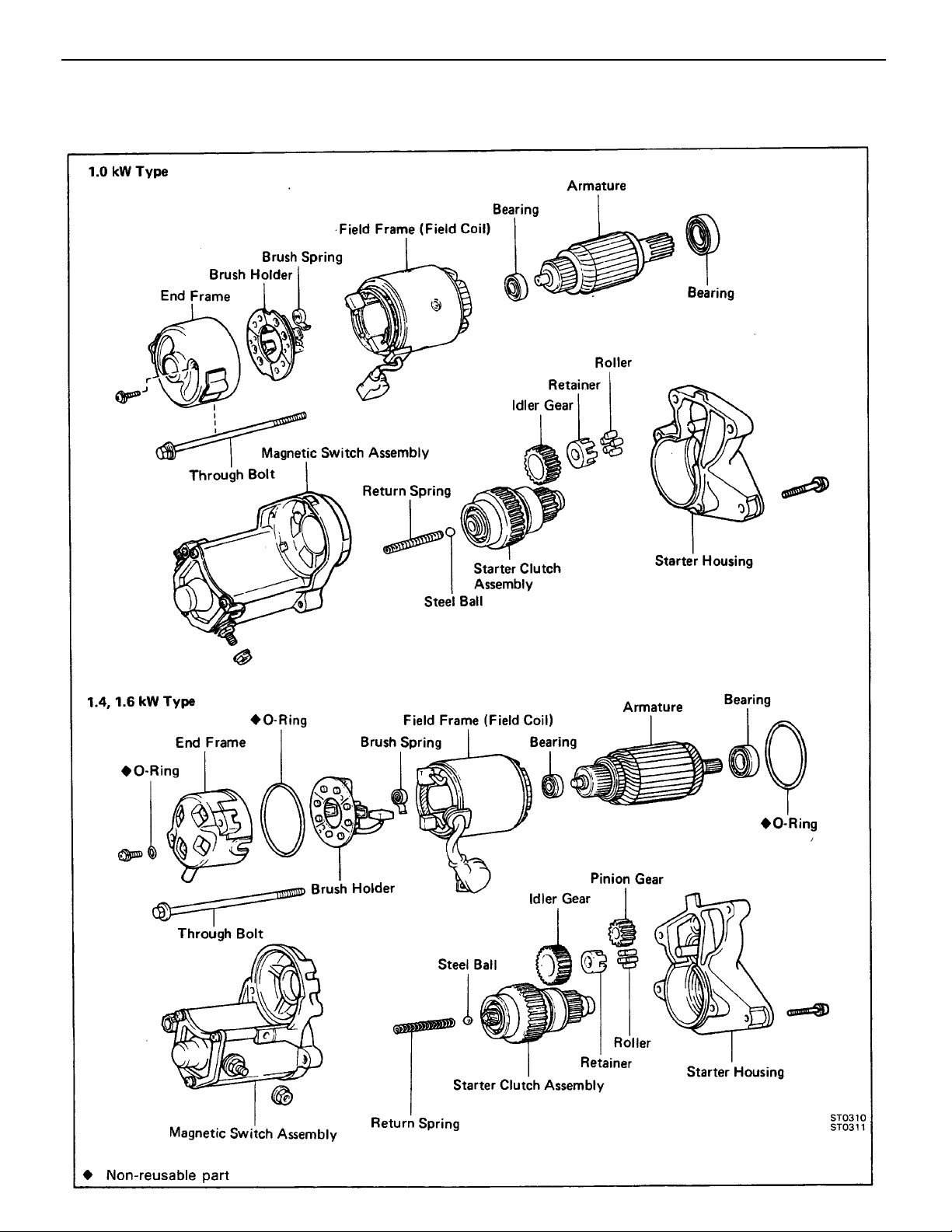

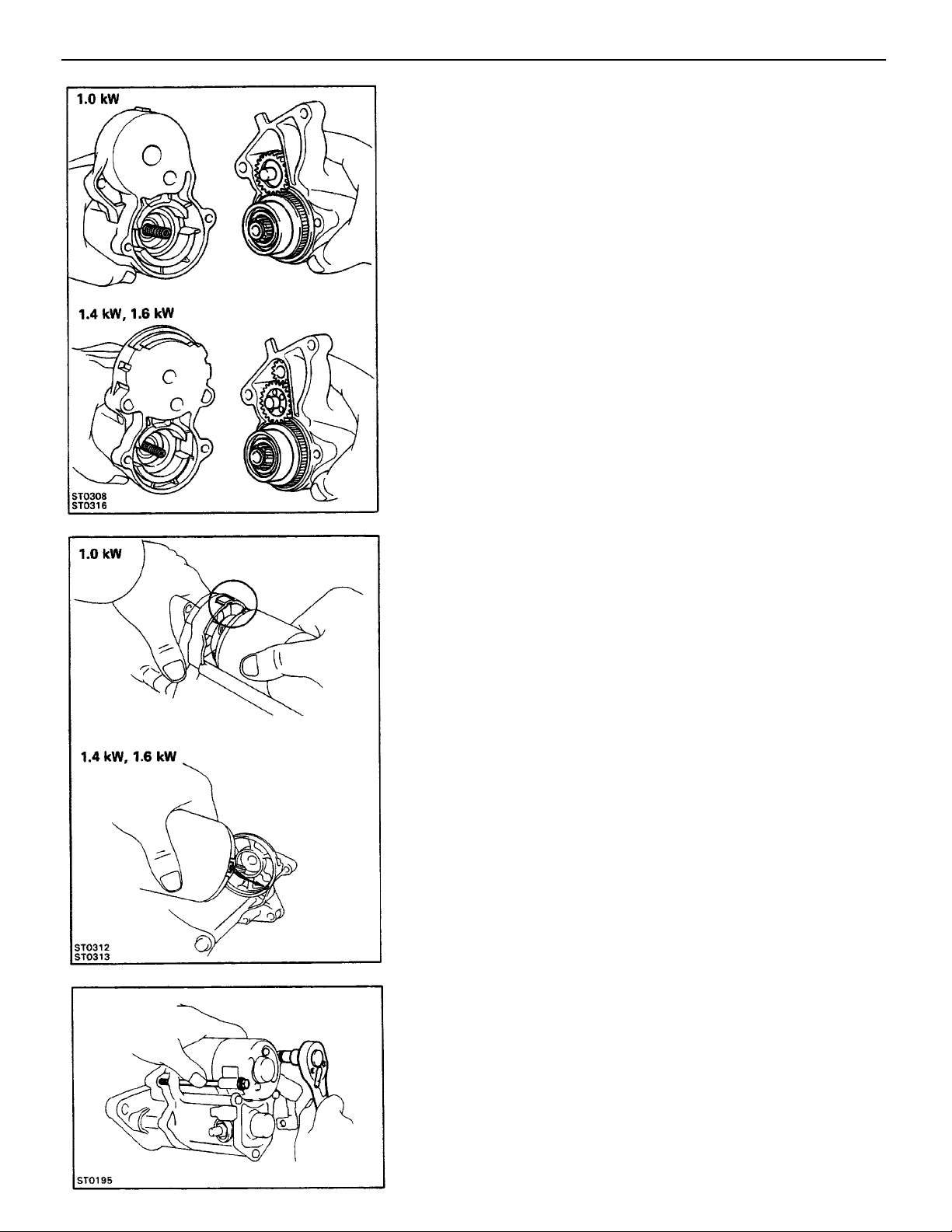

COMPONENTS

–STARTING SYSTEM Starter

ST–3

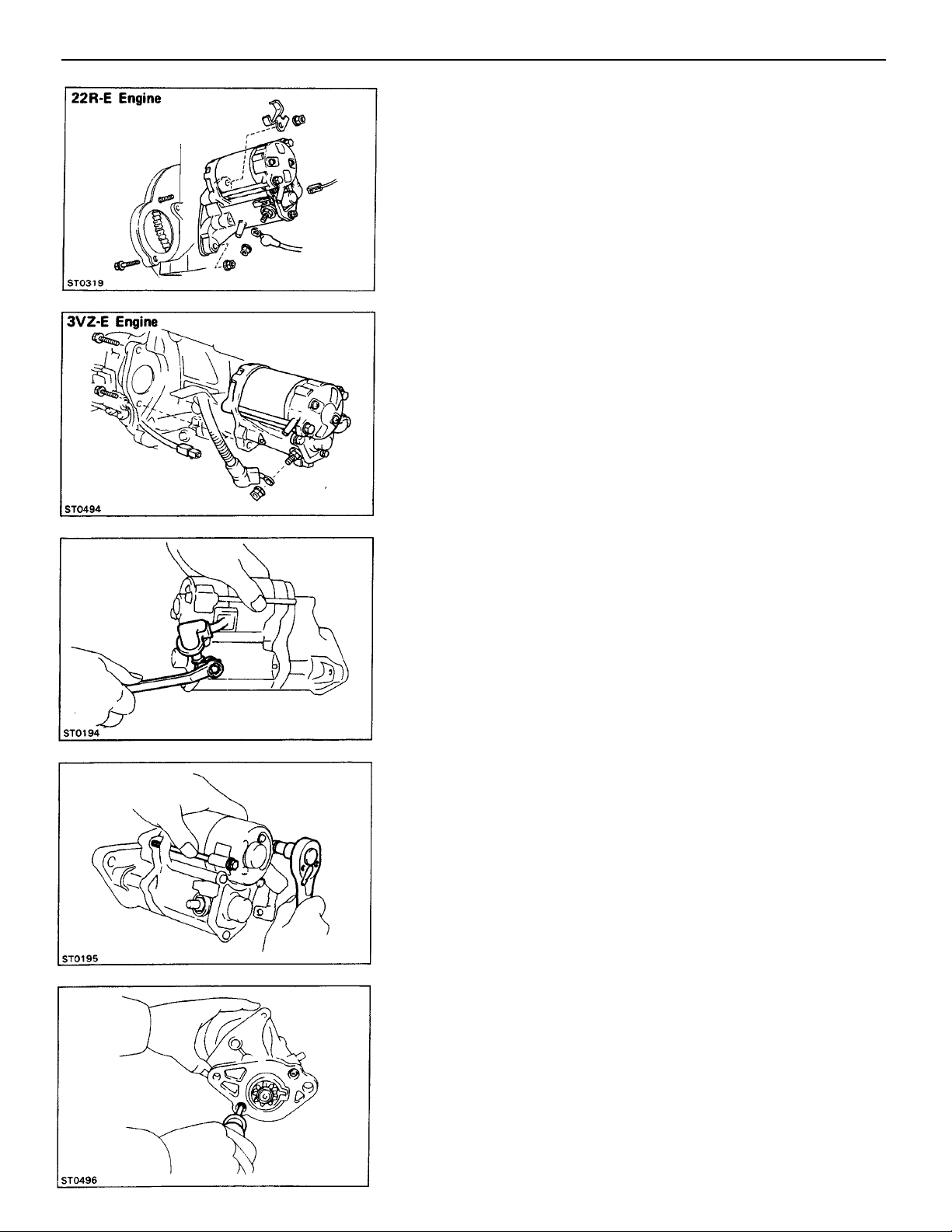

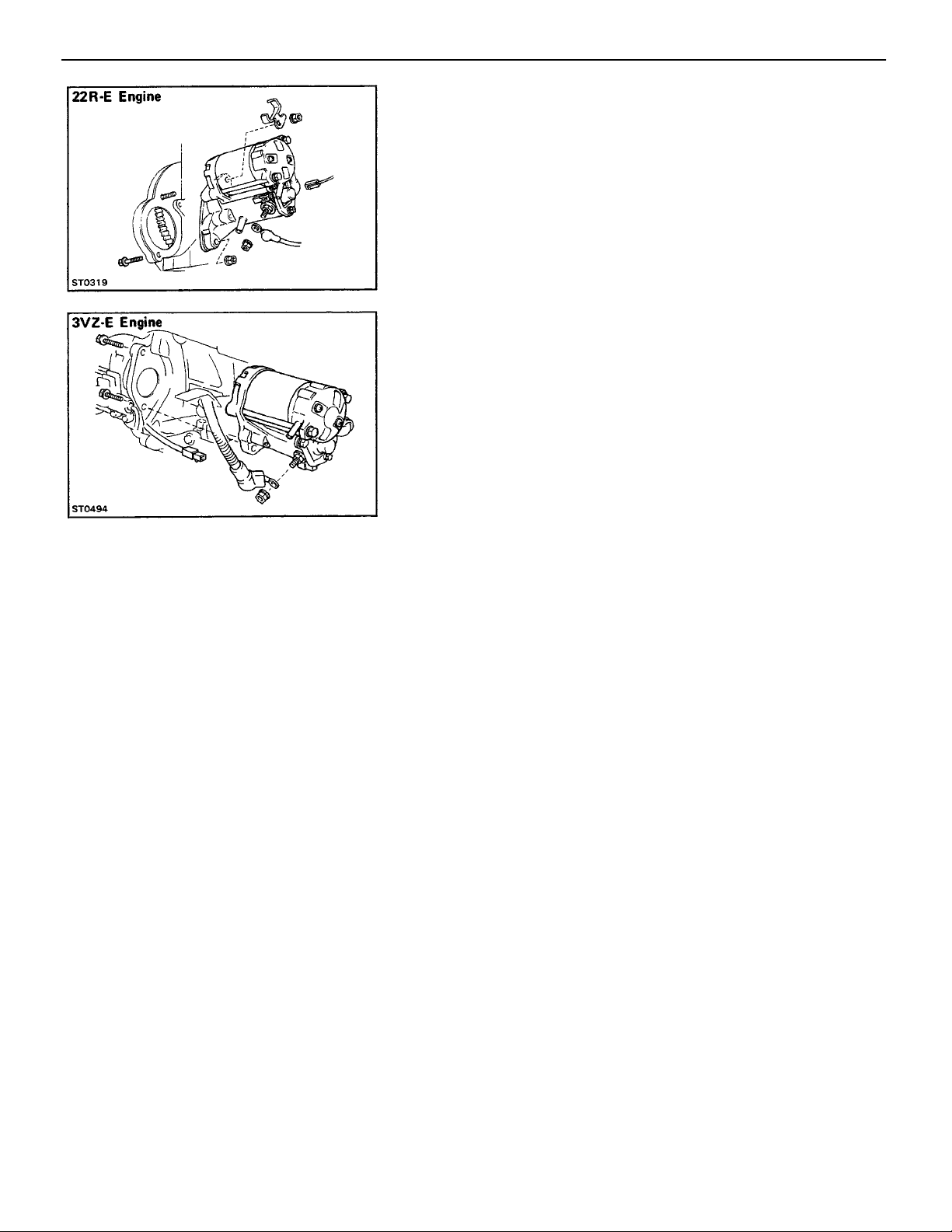

REMOVAL OF STARTER

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF

BATTERY

2. DISCONNECT TWO WIRES FROM STARTER

(a) Remove the nut and disconnect the battery cable from

the magnetic switch on the starter motor.

(b) Disconnect the other wire from terminal 50.

3. REMOVE STARTER MOTOR

(22R–E Engine)

Remove the nut and bolt, and remove the starter motor

from the flywheel bellhousing.

(3VZ–E Engine)

Remove the two mounting bolts, and remove the starter

motor from flywheel bellhousing.

DISASSEMBLY OF STARTER

(See page ST–2)

1. REMOVE FIELD FRAME WITH ARMATURE FROM

MAGNETIC SWITCH ASSEMBLY

(a) Remove the nut and disconnect the lead wire from

the magnetic switch terminal.

(b) Remove the two through bolts. Pullout the field

frame

with the armature from the magnetic switch assembly.

(c) (1.4,

1. 6 kW )

Remove the O–ring.

2. REMOVE STARTER HOUSING FROM MAGNETIC

SWITCH ASSEMBLY

(a) Remove the two screws.

ST–4

–STARTING SYSTEM Starter

(b) Remove the starter housing with the pinion gear

(1.4, 1.6 kW), idler gear, bearing and clutch assembly.

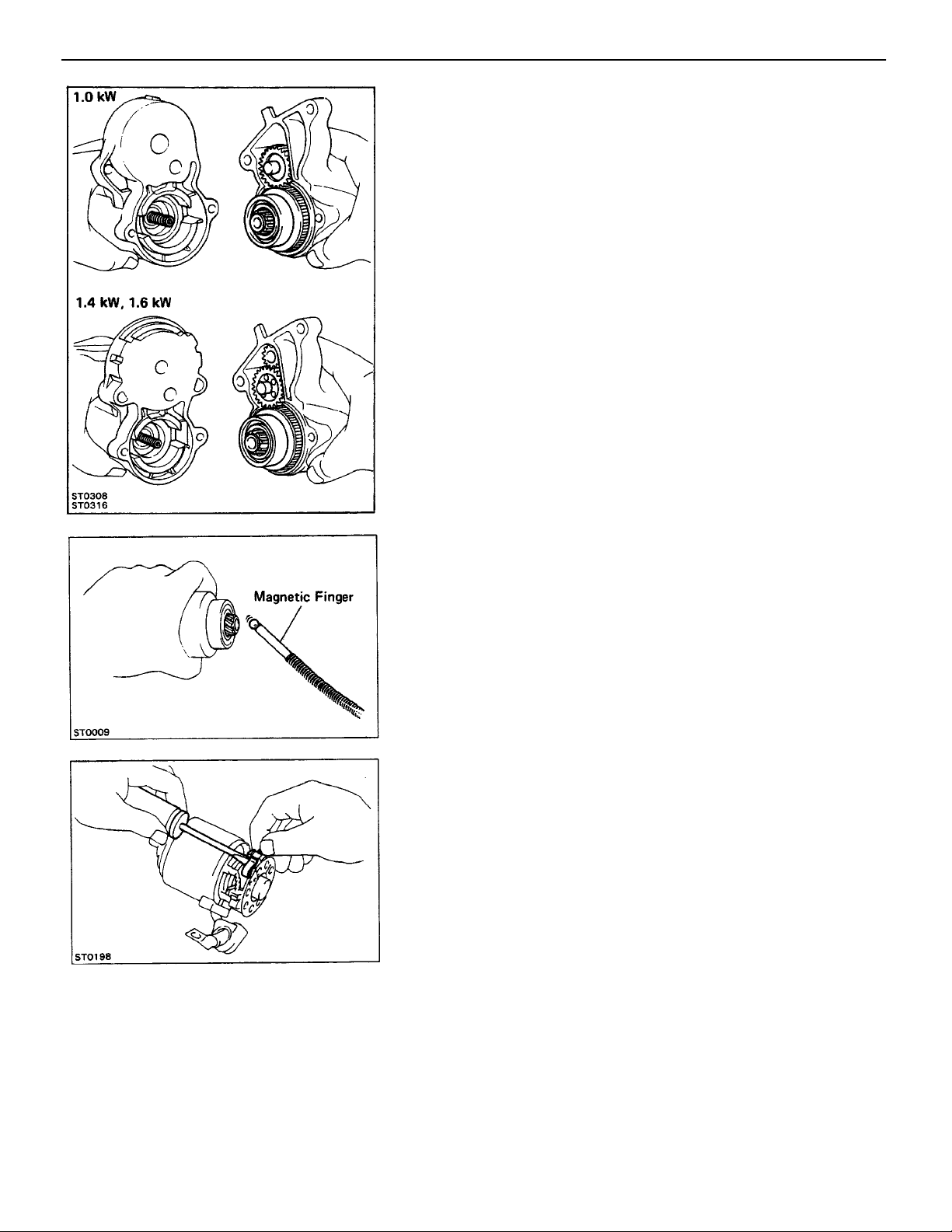

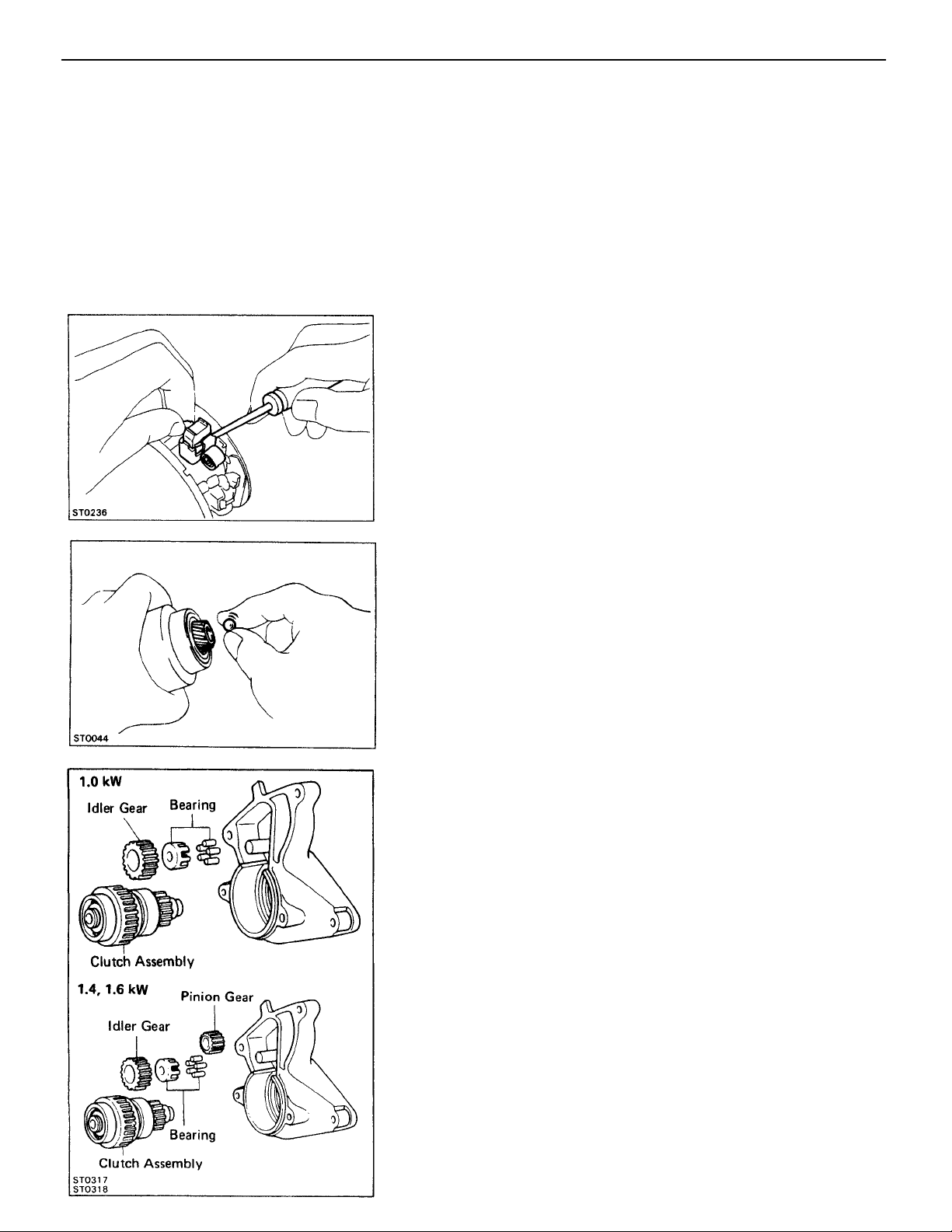

3. REMOVE CLUTCH ASSEMBLY AND GEARS FROM

STARTER HOUSING

4. REMOVE STEEL BALL AND SPRING

Using a magnetic finger, remove the spring and steel ball

from the clutch shaft hole.

5. REMOVE BRUSHES AND BRUSH HOLDER

(a) Remove the two screws and pull the end cover with

0–ring (1.4, 1.6 kW) off the field frame.

(b) Using a screwdriver, hold the spring back and discon–

nect the brush from the brush holder. Disconnect the

four brushes and remove the brush holder.

6. REMOVE ARMATURE FROM FIELD FRAME

–STARTING SYSTEM Starter

INSPECTION OF STARTER

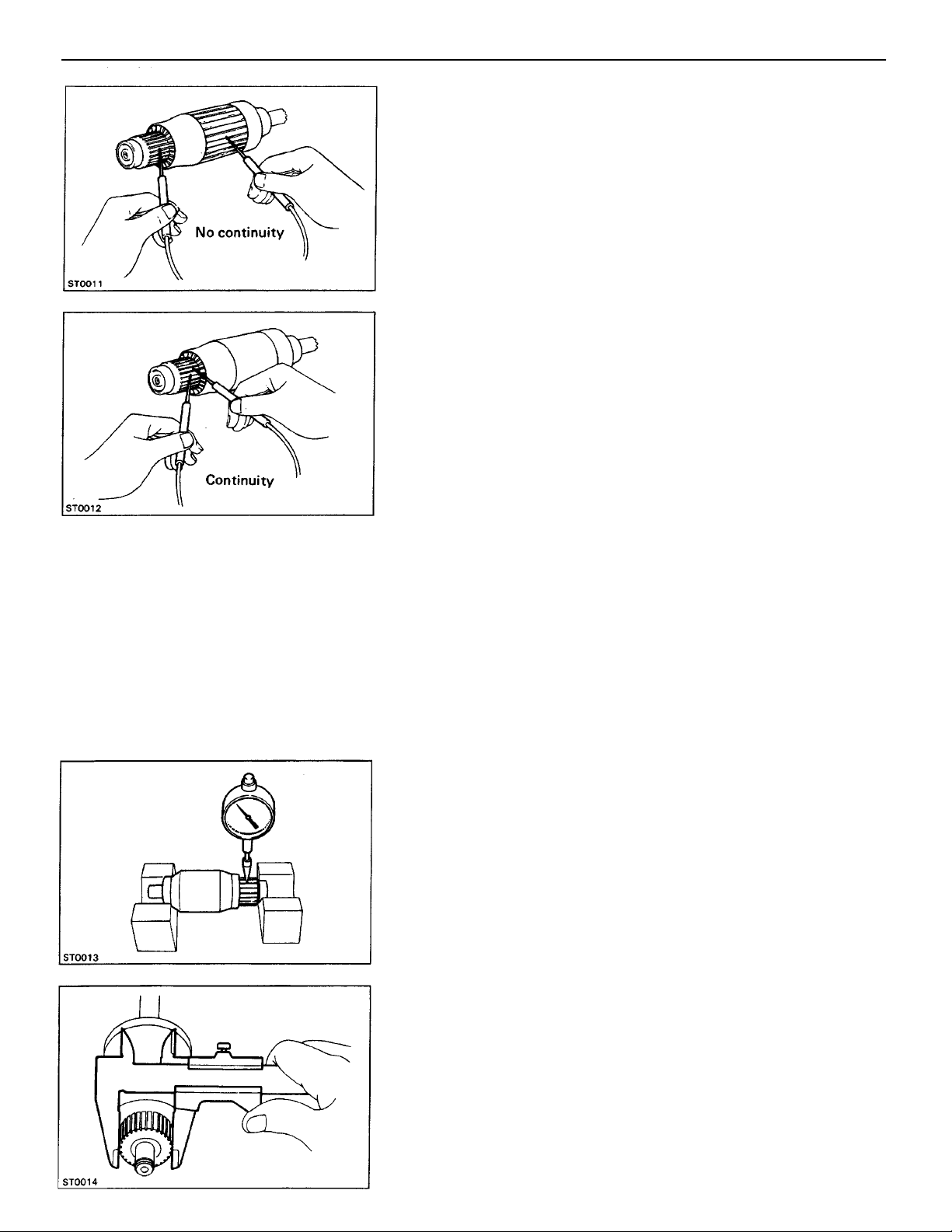

Armature Coil

1. INSPECT THAT COMMUTATOR IS NOT GROUNDED

Using an ohmmeter, check that there is no continuity be–

tween the commutator and armature coil core.

If there is continuity, replace the armature.

2. INSPECT COMMUTATOR FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between

the segments of the comrnutator.

If there is no continuity between any segment, replace the

armature.

ST–5

Commutator

1. INSPECT COMMUTATOR FOR DIRTY AND BURNT

SURFACES

If the surface is dirty or burnt, correct it with sandpaper

(No.400) or on a lathe.

2. INSPECT COMMUTATOR CIRCLE RUNOUT

(a) Place the commutator on V–blocks.

(b) Using a dial indicator, measure the circle runout.

Maximum circle runout: 0.05 mm (0.0020 in.)

If the circle runout is greater than maximum, correct it on

a lathe.

3. INSPECT COMMUTATOR DIAMETER

Using vernier calipers, measure the commutator diameter.

Standard diameter: 30 mm (1.18 in.)

Minimum diameter: 29 mm (11.14 in.)

If the diameter is less than minimum, replace the armature.

ST–6

–STARTING SYSTEM Starter

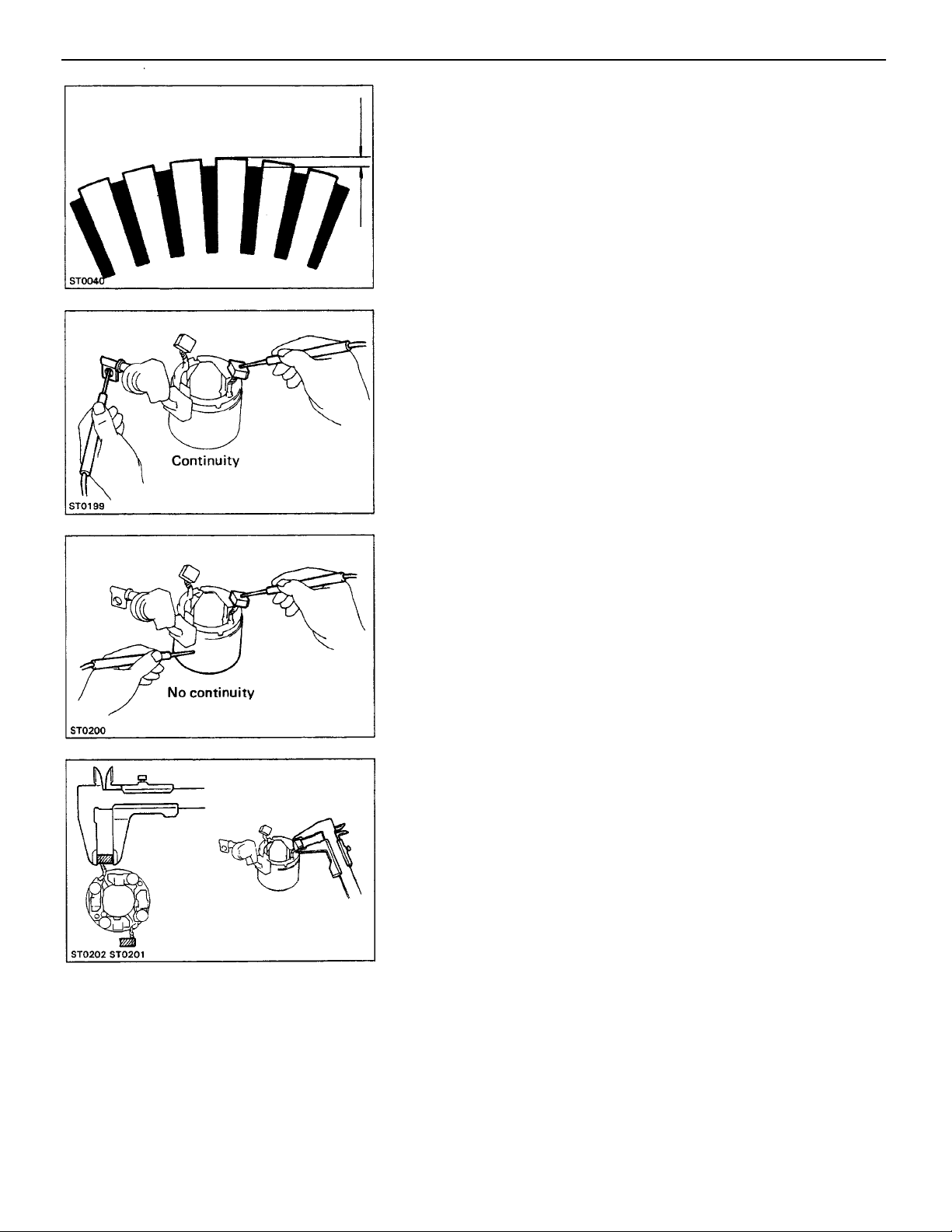

4. INSPECT UNDERCUT DEPTH OF SEGMENT

Check that the undercut depth is clean and free of foreign

material. Smooth out the edge.

Standard undercut depth: 0.6 mm (0.024 in.)

Minimum undercut depth: 0.2 mm (0.008 in.)

If the undercut depth is less than minimum, correct it with

a hacksaw blade.

Field Frame (Field Coil)

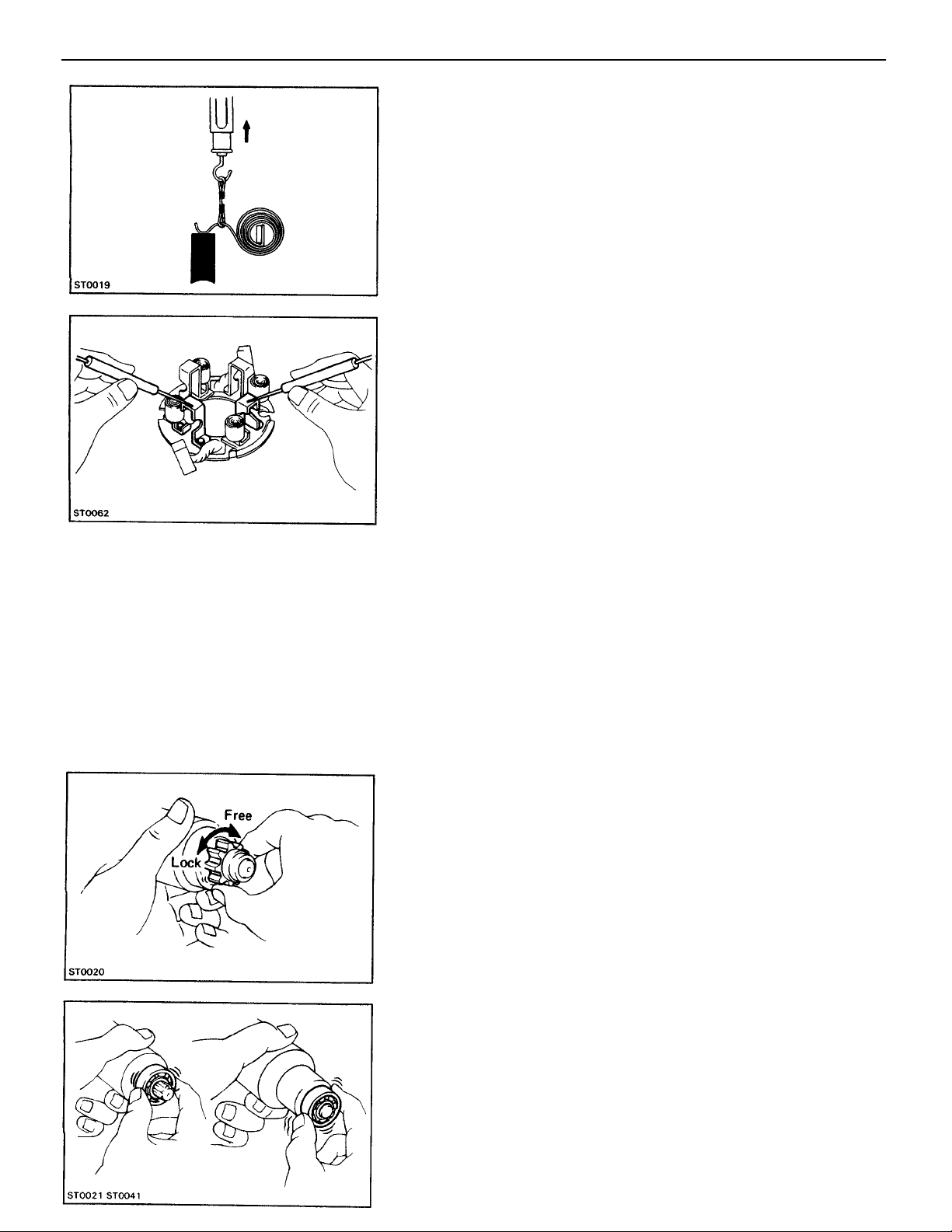

1. INSPECT FIELD COIL FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between

the lead wire and field coil brush lead.

If there is no continuity, replace the field frame.

2. INSPECT THAT FIELD COIL IS NOT GROUNDED

Using an ohmmeter, check that there is no continuity be–

tween the field coil end and field frame.

If there is continuity, repair or replace the field frame.

Brushes

INSPECT BRUSH LENGTH

Using vernier calipers, measure the brush length.

Standard length: 1.0 kW 13.5 mm (0.531 in.)

1.4 kW 15.5 mm (0.610 in.)

1.6 kW 15.5 mm (0.610 in.)

Minimum length: 1.0 kW 8.5 mm (0.335 in.)

1.4 kW 10.0 mm (0.394 in.)

1.6 kW 10.0 mm (0.394 in.)

If the length is less than minimum, replace the brush holder

and field frame.

–STARTING SYSTEM Starter

Brush Springs

INSPECT BRUSH SPRING LOAD

Take the pull scale reading the instant the brush spring

separates from the brush.

Standard installed load:

18 – 24 N (1.785 – 2.415 kgf, 3.9 – 5.3 1bf)

Minimum installed load:

12 N (1.2 kgf, 2.6 Ibf)

If the installed load is less than minimum, replace the brush

springs.

HINT: Take the pull scale reading the instant the brush

spring separates from the brush.

Brush Holder

INSPECT INSULATION OF BRUSH HOLDER

Using an ohmmeter, check that there is no continuity be–

tween the positive (+) and negative (–) brush holders.

If there is continuity, repair or replace the brush holder.

ST–7

Clutch and Gears

1. INSPECT GEAR TEETH

Check the gear teeth on the pinion gear, idler gear and

clutch assembly for wear or damage.

If damaged, replace the gear or clutch assembly.

If damaged, also check the flywheel ring gear for wear or

damage.

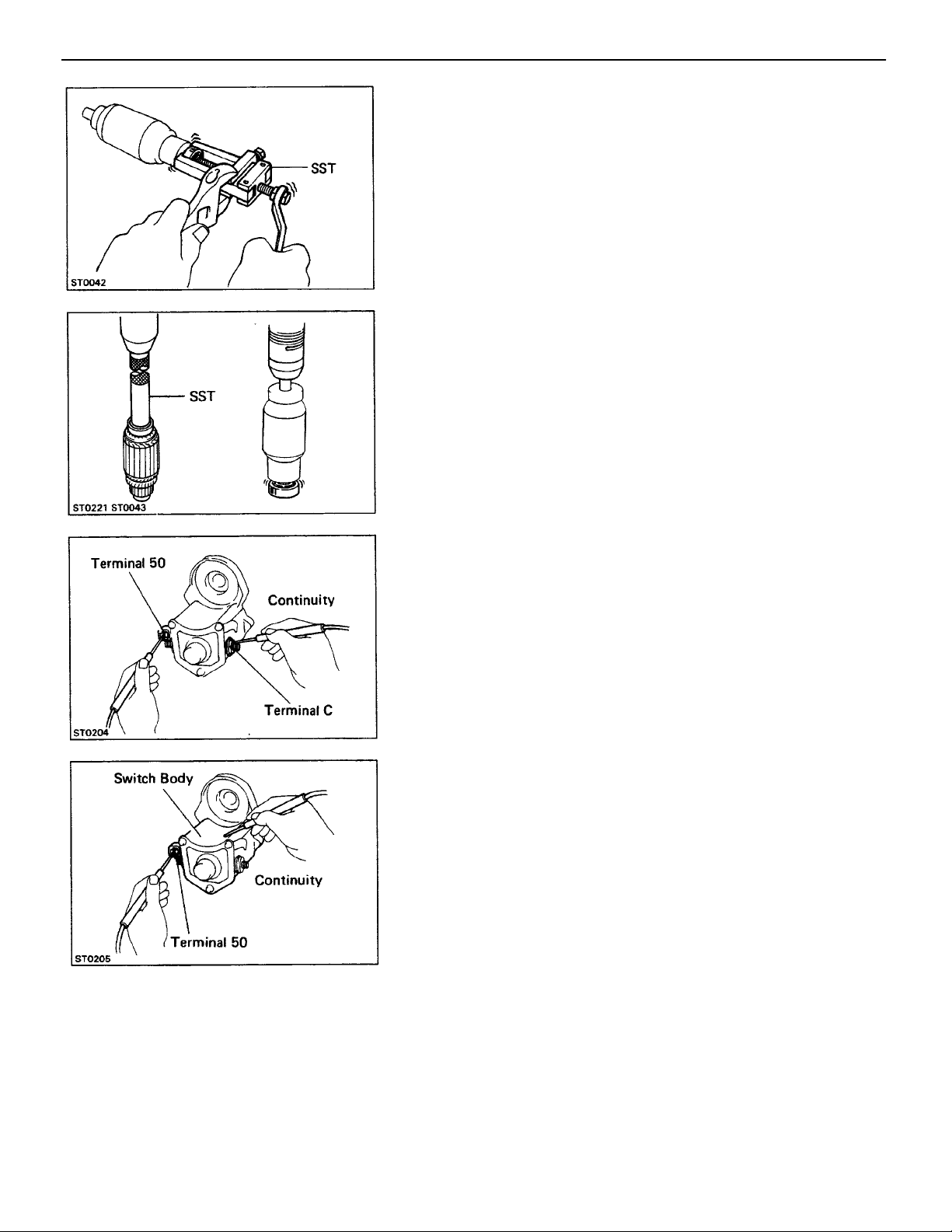

2. INSPECT CLUTCH

Rotate the clutch pinion gear clockwise and check that it

turns freely. Try to rotate the clutch pinion counterclock–

wise and check that it locks.

If necessary, replace the clutch assembly.

Bearings

1. INSPECT BEARINGS

Turn each bearing by hand while applying inward force.

If the resistance is felt or if the bearing sticks, replace the

bearing.

ST–8

–STARTING SYSTEM Starter

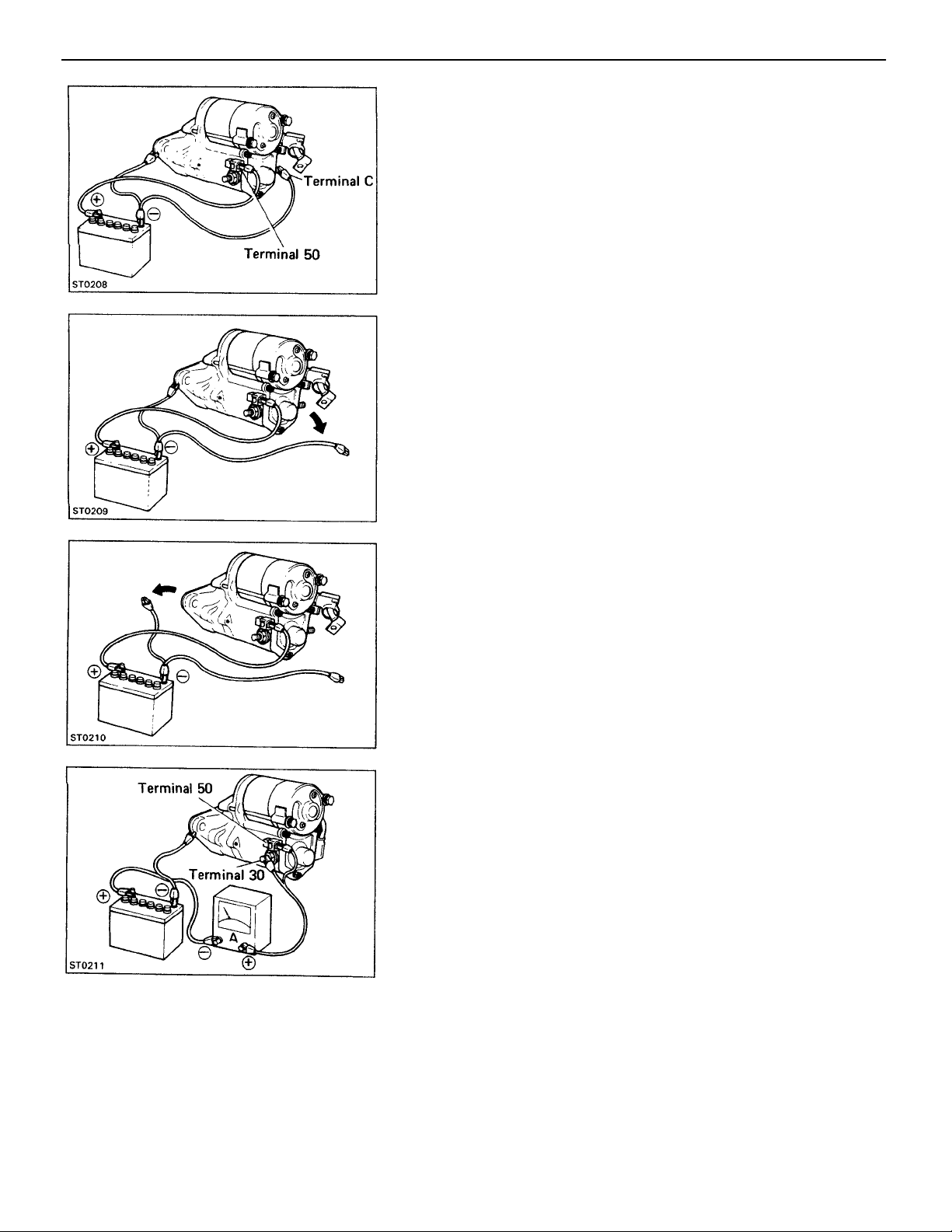

2. IF NECESSARY, REPLACE BEARINGS

(a) Using SST, remove the bearing.

SST 09286–46011

(b) Using SST and a press, press in a new bearing.

SST 1.0 kW 09285–76010

1.4 kW, 1.6 kW 09201–41020

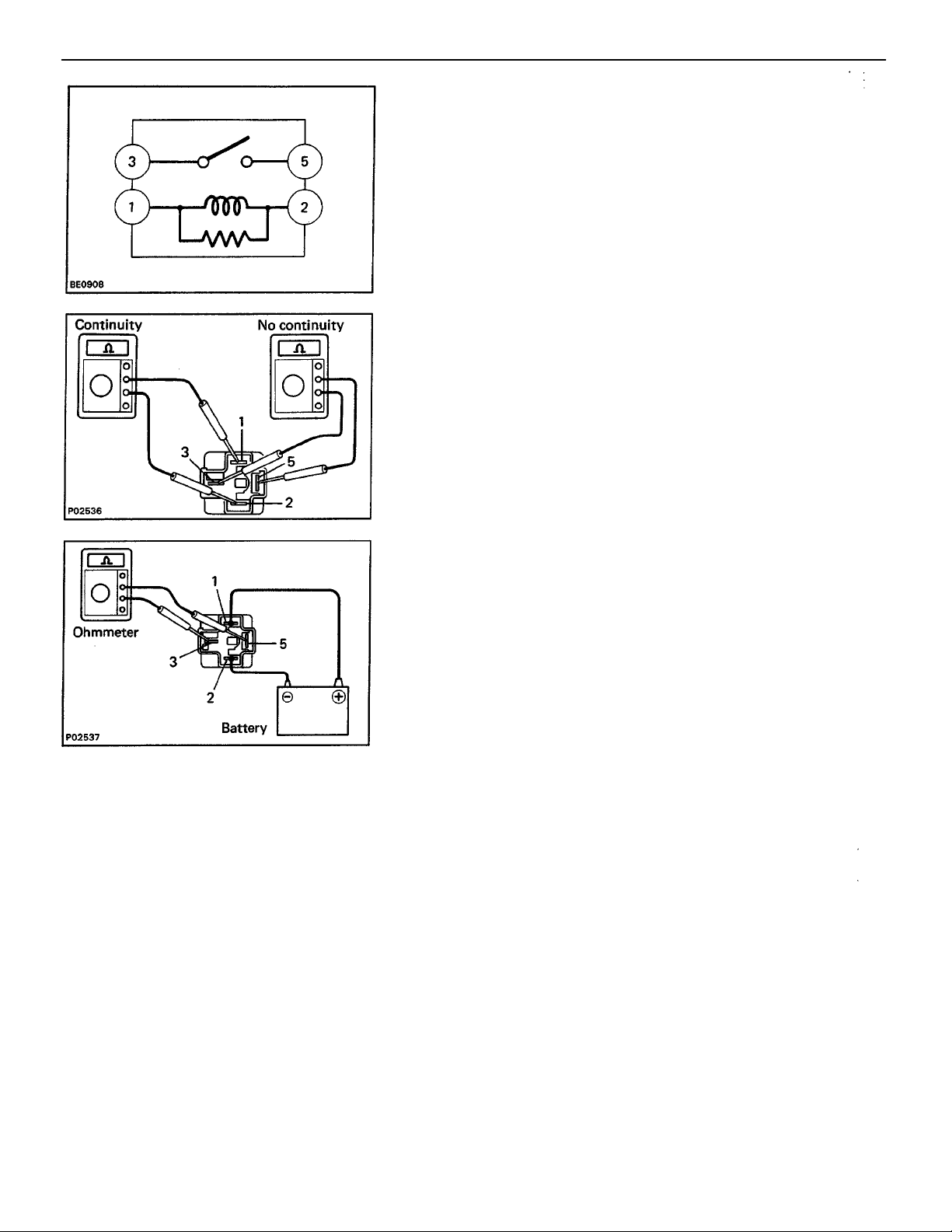

Magnetic Switch

1. PERFORM PULL–IN COIL OPEN CIRCUIT TEST

Using an ohmmeter, check that there is continuity between

terminals 50 and C.

Ifthere is no continuity, replace the magnetic switch as–

sembly.

2. PERFORM HOLD–IN COIL CIRCUIT TEST

Using an ohmmeter, check that there is continuity between

terminal 50 and the switch body.

If there is no continuity, replace the magnetic switch as–

sembly.

–STARTING SYSTEM Starter

ASSEMBLY OF STARTER

(See page ST–2)

HINT: Use high–temperature grease to lubricate the bear–

ings and gears when assembling the starter.

1. PLACE ARMATURE INTO FIELD FRAME

Apply grease to the armature bearings and insert the ar–

mature into the field frame.

2. INSTALL BRUSH HOLDER

(a) Place the brush holder over the frame.

(b) Using a screwdriver, hold the brush spring back, and

connect the brush into the brush holder. Connect the

four brushes.

HINT: Check that the positive (+) lead wires are not

grounded.

(c) (1.4 kW, 1.6 kW)

Place the 0–ring on the field frame.

(d) Install the end cover to the field frame with the two

screws.

ST–9

3. INSERT STEEL BALL INTO CLUTCH SHAFT HOLE

(a) Apply grease to the steel ball.

(b) Insert the steel ball into the clutch shaft hole.

4. INSTALL GEARS AND CLUTCH ASSEMBLY

(a) Apply grease to the gears and clutch assembly.

(b) Place the clutch assembly, idler gear, bearing and pin–

ion gear 11.4, 1.6 kW) in the starter housing.

ST–10

–STARTING SYSTEM Starter

5. INSTALL STARTER HOUSING

(a) Apply grease to the return spring.

(b) Insert the return spring into the magnetic hole.

(e) Place the starter housing on the magnetic switch and

install the two screws.

6. INSTALL FIELD FRAME WITH ARMATURE TO

MAGNETIC SWITCH ASSEMBLY

(a) (1.4, 1. 6 kW)

Place the O–ring on the field frame.

(b) Align the protrusion of the field frame with the cutout

of the magnetic switch.

(c) Install the two through bolts.

(d) Connect the lead wire to the magnetic switch ter-

mi¿na1 C, and install the nut.

–STARTING SYSTEM Starter

PERFORMANCE TEST OF STARTER

NOTICE: These tests must be performed within 3 to 5

seconds to avoid burning out the coil.

1. PERFORM PULL–IN TEST

(a) Disconnect the field coil lead wire from terminal C.

(b) Connect the battery to the magnetic switch as shown.

Check that the clutch pinion gear moves outward.

If the clutch pinion gear does not move, replace the mag–

netic switch assembly.

2. PERFORM HOLD–IN TEST

With battery connected as above with the clutch pinion

gear out, disconnect the negative (–) lead from terminal

C. Check that the pinion gear remains out.

If the clutch pinion gear returns inward, replace the mag–

netic switch assembly.

ST–11

3. INSPECT CLUTCH PINION GEAR RETURN

Disconnect the negative (–) lead from the switch body.

Check that the clutch pinion gear returns inward.

If the clutch pinion gear does not return, replace the mag–

netic switch assembly.

4. PERFORM NO–LOAD PERFORMANCE TEST

(a) Connect the battery and ammeter to the starter as

shown. .

(b) Check that the starter rotates smoothly and steadily

with the pinion gear moving out. Check that the am–

meter reads the specified current.

Specified current:

90 A or less at 11.5 V

ST–12

–STARTING SYSTEM Starter

INSTALLATION OF STARTER

1. INSTALL STARTER MOTOR ON TRANSAXLE

(22R–E Engine)

Place the starter motor in the flywheel bellhousing.

Install and torque the bolt and nut.

(3VZ–E Engine)

Place the starter motor in the flywheel bellhousing, and in–

stall and torque the starter mounting bolts.

Torque: 39 N–m (400 kgf–cm, 29 ft–lbf)

2. CONNECT TWO WIRES TO STARTER

Connect the connector to the terminal on the magnetic

switch. Connect the cable from the battery to the termi–

nal on the switch, and install the nut.

3. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

Check that the engine starts.

–STARTING SYSTEM Starter Relay, Clutch Start Switch

ST–13

STARTER RELAY

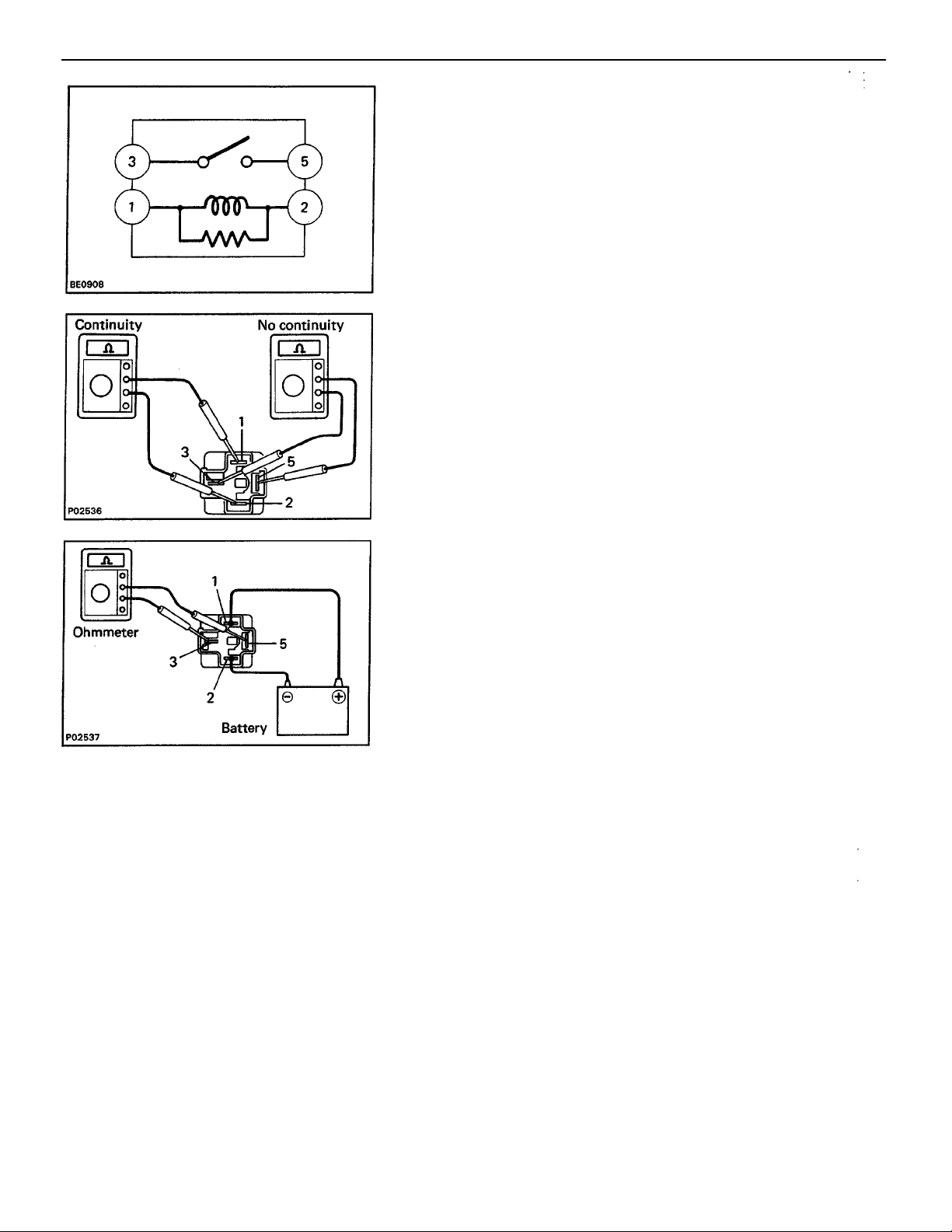

INSPECTION OF STARTER RELAY

LOCATION: The relay is located in the No. 1 junction block

on the driver’s side.

1. INSPECT RELAY CONTINUITY

(a) Using an ohmmeter, check that there is continuity be–

tween terminals 1 and 2.

(b) Check that there is no continuity between terminals

3 and 5.

If continuity is not as specified, replace the relay.

2. INSPECT RELAY OPERATION

(a) Apply battery voltage across terminals 1 and 2.

(b) Check that there is continuity between terminals 3 and*

5.

If operation is not as described, replace the relay.

CLUTCH START SWITCH (M/T only)

(See page CL–4)

–STARTING SYSTEM Starter Relay, Clutch Start Switch

ST–13

STARTER RELAY

INSPECTION OF STARTER RELAY

LOCATION: The relay is located in the No. 1 junction block

on the driver’s side.

1. INSPECT RELAY CONTINUITY

(a) Using an ohmmeter, check that there is continuity be–

tween terminals 1 and 2.

(b) Check that there is no continuity between terminals

3 and 5.

If continuity is not as specified, replace the relay.

2. INSPECT RELAY OPERATION

(a) Apply battery voltage across terminals 1 and 2.

(b) Check that there is continuity between terminals 3 and*

5.

If operation is not as described, replace the relay.

CLUTCH START SWITCH (M/T only)

(See page CL–4)

AC–1

–AIR CONDITIONING SYSTEM

AIR CONDITIONING SYSTEM

AC–2

–AIR CONDITIONING SYSTEM General Information

GENERAL INFORMATION

REFRIGERATION SYSTEM

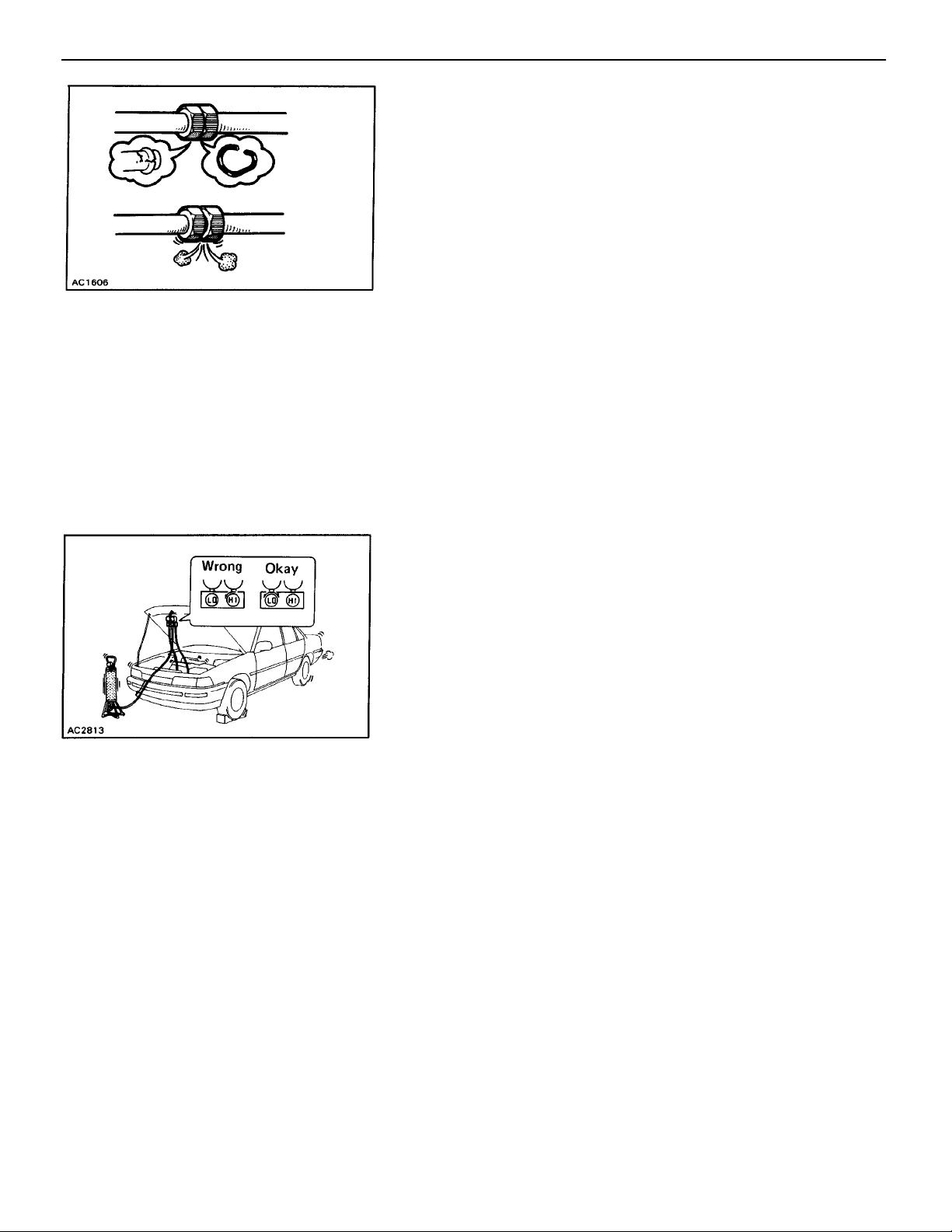

Prevention of Refrigerant Release and Excessive quantities

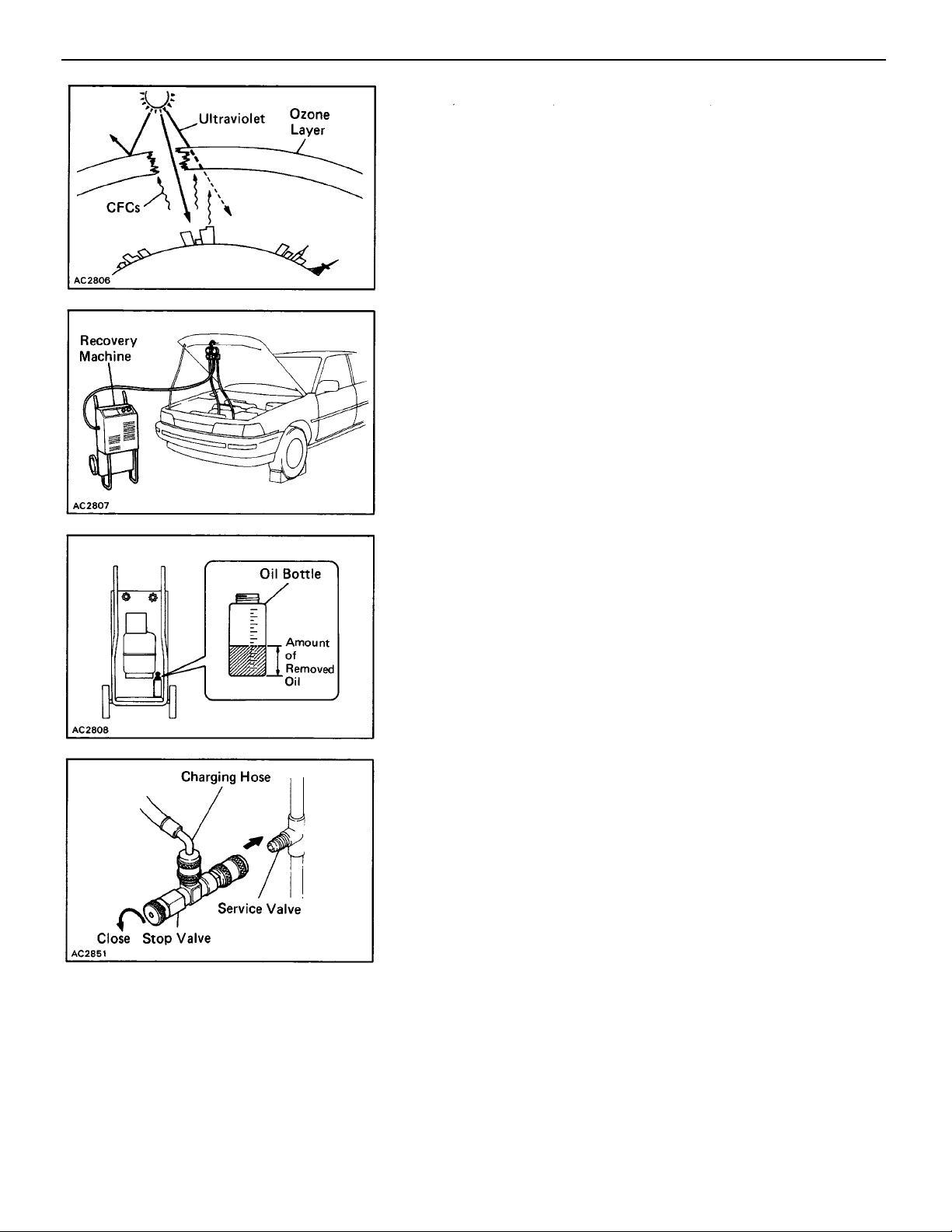

Refrigerant (CFCs) for automobile air conditionings is be–

lieved to cause harm by depleting the ozone layer which

helps to protect us from the ultraviolet rays of the sun.

Therefore, it is necessary to prevent release of refrigerant

to the atmosphere and to use the minimum amount when

servicing the air conditioning.

1. USE RECOVERY MACHINE TO RECOVER REFRIGERANT

When discharging refrigerant from the system as follows,

use a recovery machine to recover the refrigerant.

• Before replacing parts on the refrigerant line.

• When moisture or air gets in the refrigerant line.

• When excess refrigerant is charged.

NOTICE:

• When handling the recovery machine, always follow

the directions given in the instruction manual.

• After recovery, the amount of compressor oil removed

must be measured and the same amount added to the

system.

2. USE CHARGING HOSES WITH STOP VALVE WHEN

INSTALLING MANIFOLD GAUGE SET

To prevent release of refrigerant, using charging hoses

with a stop valve when installing the manifold gauge set

to the service valves on the refrigerant line.

3. TIGHTEN CONNECTING PARTS SECURELY

Follow the notices about tightening connecting parts in

step 6 on page AC–4.

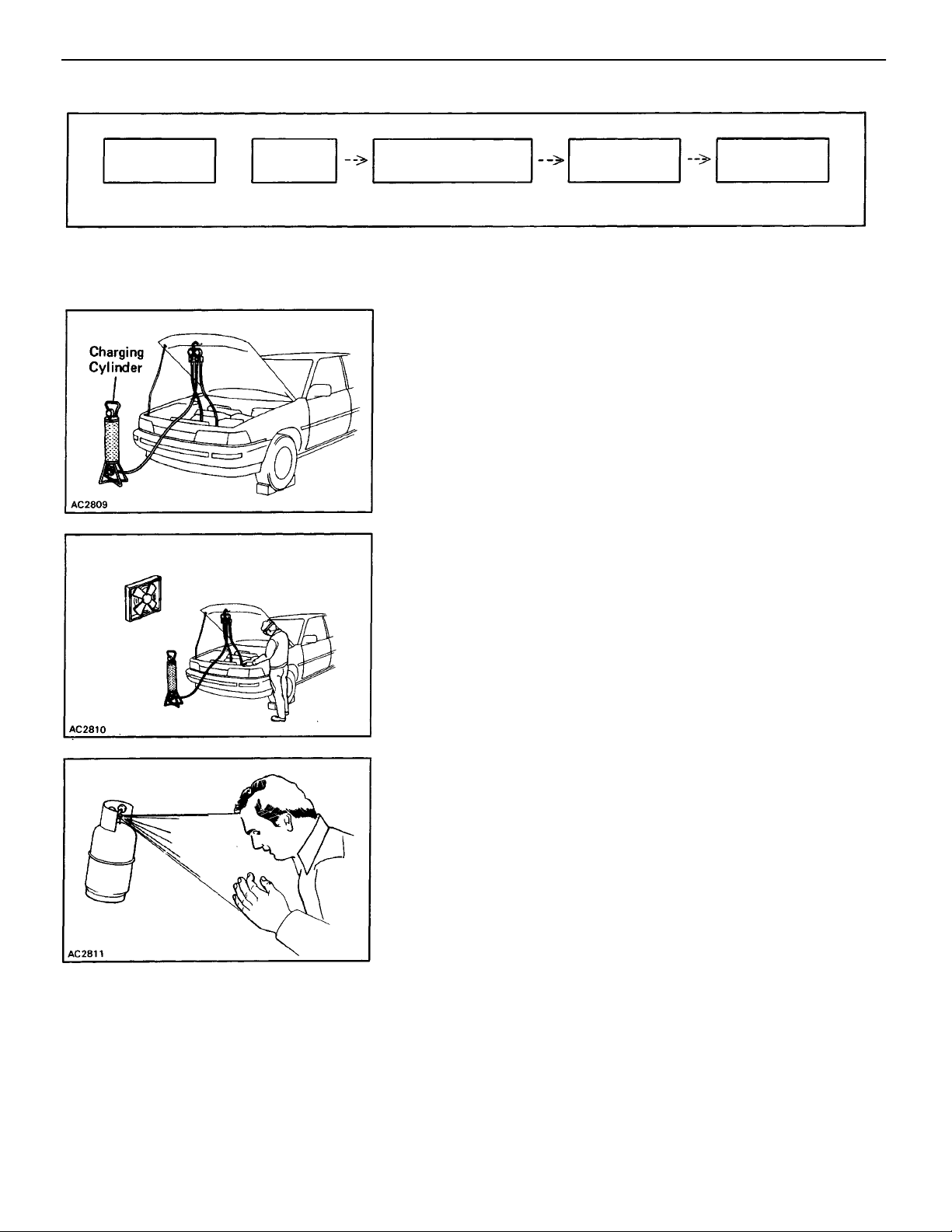

4. PROPERLY EVACUATE AIR FROM REFRIGERANT

SYSTEM

To prevent release and wasteful use of refrigerant, evac–

uate air with care from refrigeration system as follows;

• Do not evacuate before recovering refrigerant in

system.

Evacuation Process

Evacuation

10 minutes

or more

Airtight

Check

Leave for 5

minutes

–AIR CONDITIONING SYSTEM General Information

• Do not perform repeat evacuation of system.

Top–Up Charging of

Refrigerant

Refrigerant

Leak Check

Charging

Refrigerant

6. USE CHARGING CYLINDER TO CHARGE PROPER

AMOUNT OF REFRIGERANT

To prevent excessive use of refrigerant due to overcharg–

ing, use a charging cylinder to charge the proper amount

of refrigerant.

AC–3

Handling Precautions for Refrigerant

1. DO NOT HANDLE REFRIGERANT IN AN ENCLOSED

AREA OR NEAR AN OPEN FLAME

2. ALWAYS WEAR EYE PROTECTION

3. BE CAREFUL THAT LIQUID REFRIGERANT DOES NOT

GET IN YOUR EYES OR ON YOUR SKIN

If liquid refrigerant gets in your eyes or on your skin;

(a) Wash the area with lots of cool water.

CAUTION: Do not rub your eyes or skin.

(b) Apply clean petroleum jelly to the skin.

(c) Go immediately to a physician or hospital for profes–

sional treatment.

CAUTION: Do not attempt to treat yourself.

Handling Precautions for Refrigerant Container

1. NEVER HEAT CONTAINER OR EXPOSE IT TO NAKED

FLAME

2. BE CAREFUL NOT TO DROP CONTAINER AND NOT TO

APPLY PHYSICAL SHOCKS TO IT

AC–4

–AIR CONDITIONING SYSTEM General Information

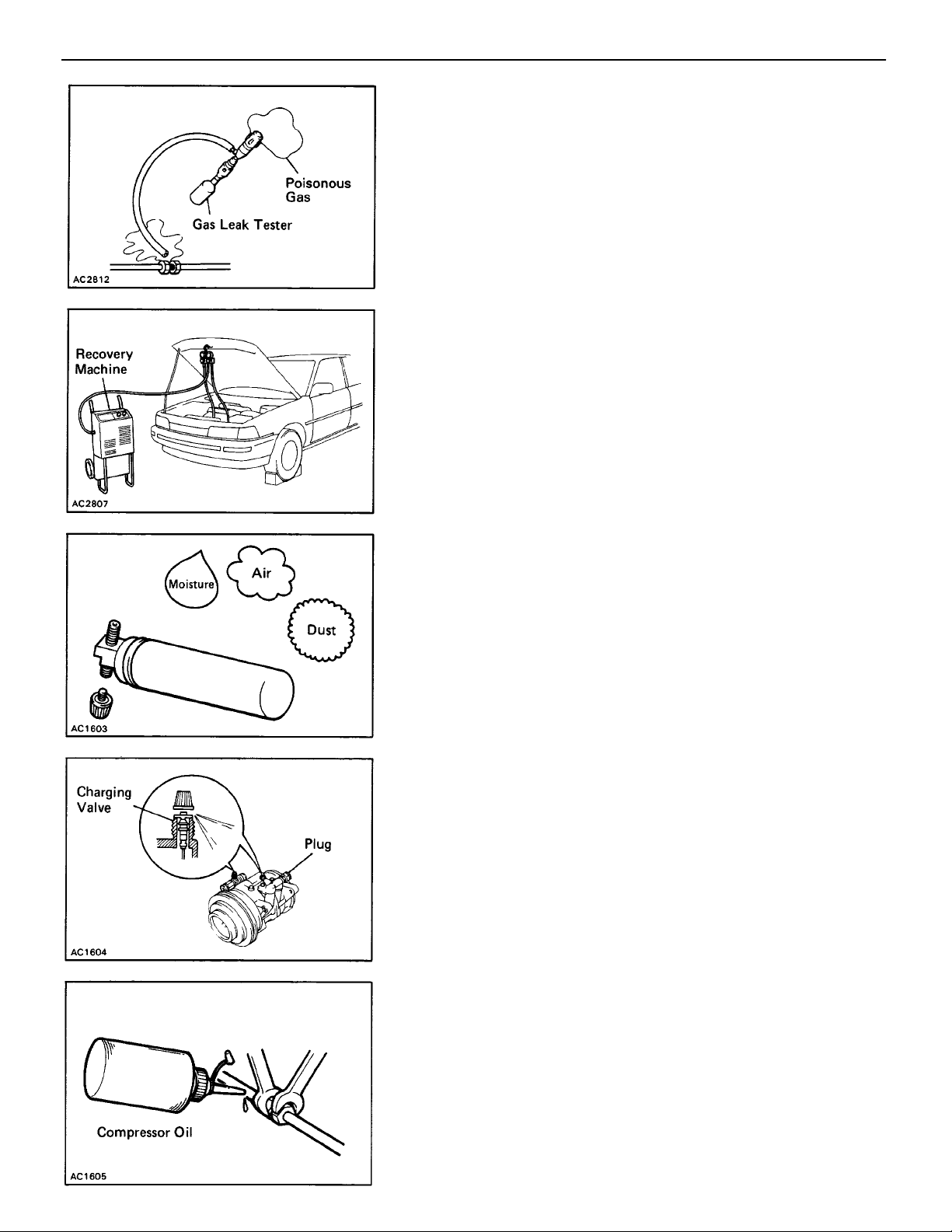

Handling Precautions for Gas–Cylinder Type Gas

Leak Tester

1. BEFORE USING TESTER MAKE SURE THAT THERE ARE

NO FLAMMABLE SUBSTANCES NEARBY

2. BE CAREFUL NOT TO INHALE POISONOUS GAS

If refrigerant gas comes in contact with flame, a poison–

ous gas is produced. During leak tests, do not inhale any

gas.

Precautions When Replacing Parts in

Refrigerant line

1. RECOVER REFRIGERANT IN SYSTEM BEFORE REMOV–

ING PARTS

Using a recovery machine, recover refrigerant in system

before removing the parts.

NOTICE: Do not release refrigerant to atmosphere.

2. INSERT PLUG IMMEDIATELY IN DISCONNECTED PARTS

Insert a plug immediately in the disconnected parts to

prevent the entry of moisture and dust.

3. DO NOT REMOVE PLUG FROM NEW PARTS UNTIL IM–

MEDIATELY BEFORE INSTALLATION

4. DO NOT USE BURNER FOR BENDING OR LENGTHENING

OPERATIONS ON TUBE

If the tubes are heated with a burner, a layer of oxidation

forms inside the tube, causing the same kind of trouble

as an accumulation of dust.

5. DISCHARGE GAS IN NEW COMPRESSOR FROM

CHARGING VALVE BEFORE INSTALLING IT

If the gas in new compressor is not discharged first, com–

pressor oil will spray out with gas when the plug is re–

moved.

6. TIGHTEN CONNECTING PARTS SECURELY

Securely tighten the connecting parts to prevent leaking

of refrigerant gas.

• Apply a few drops of compressor oil to 0–ring fittings

for easy tightening and to prevent leaking of refriger–

ant gas.

• Tighten the nuts using two wrenches to avoid twisting

the tube.

–AIR CONDITIONING SYSTEM General Information

• Tighten the O–ring fittings or the bolted type fittings to

the specified torque.

Precautions When Charging Refrigerant

1. DO NOT OPERATE COMPRESSOR WITHOUT ENOUGH

REFRIGERANT IN REFRIGERANT CYCLE

If there is not enough refrigerant in the refrigerant cycle,

oil lubrication will be insufficient and compressor burnout

may occur, so take care to avoid this.

AC–5

2. DO NOT OPEN HIGH PRESSURE VALVE OF MANIFOLD

GAUGE WITH COMPRESSOR OPERATING

If the high pressure valve is opened, refrigerant flows in

the reverse direction and could cause the charging cylin–

der to rupture, so open and close the low pressure valve

only.

3. BE CAREFUL NOT TO OVERCHARGE WITH REFRIGER–

ANT IN SYSTEM

If refrigerant is overcharged, it causes trouble such as in–

sufficient cooling, poor fuel economy, engine overheating

etc.

ELECTRICAL PARTS

Before removing and inspecting the electrical parts, set

the ignition switch to the LOCK position and disconnect

the negative (–) terminal cable from the battery..

AC–6

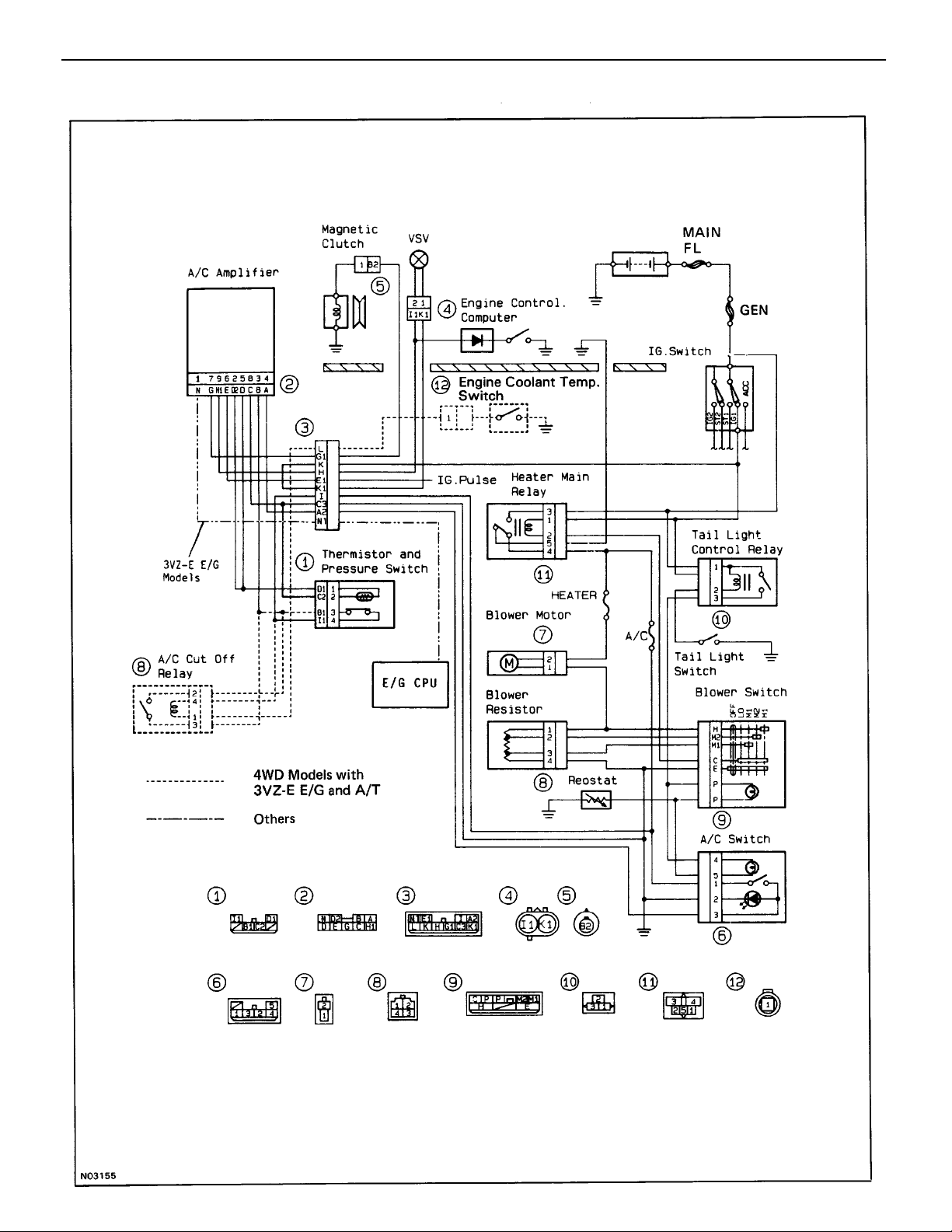

–AIR CONDITIONING SYSTEM Air Conditioning System Circuit

AIR CONDITIONING SYSTEM CIRCUIT

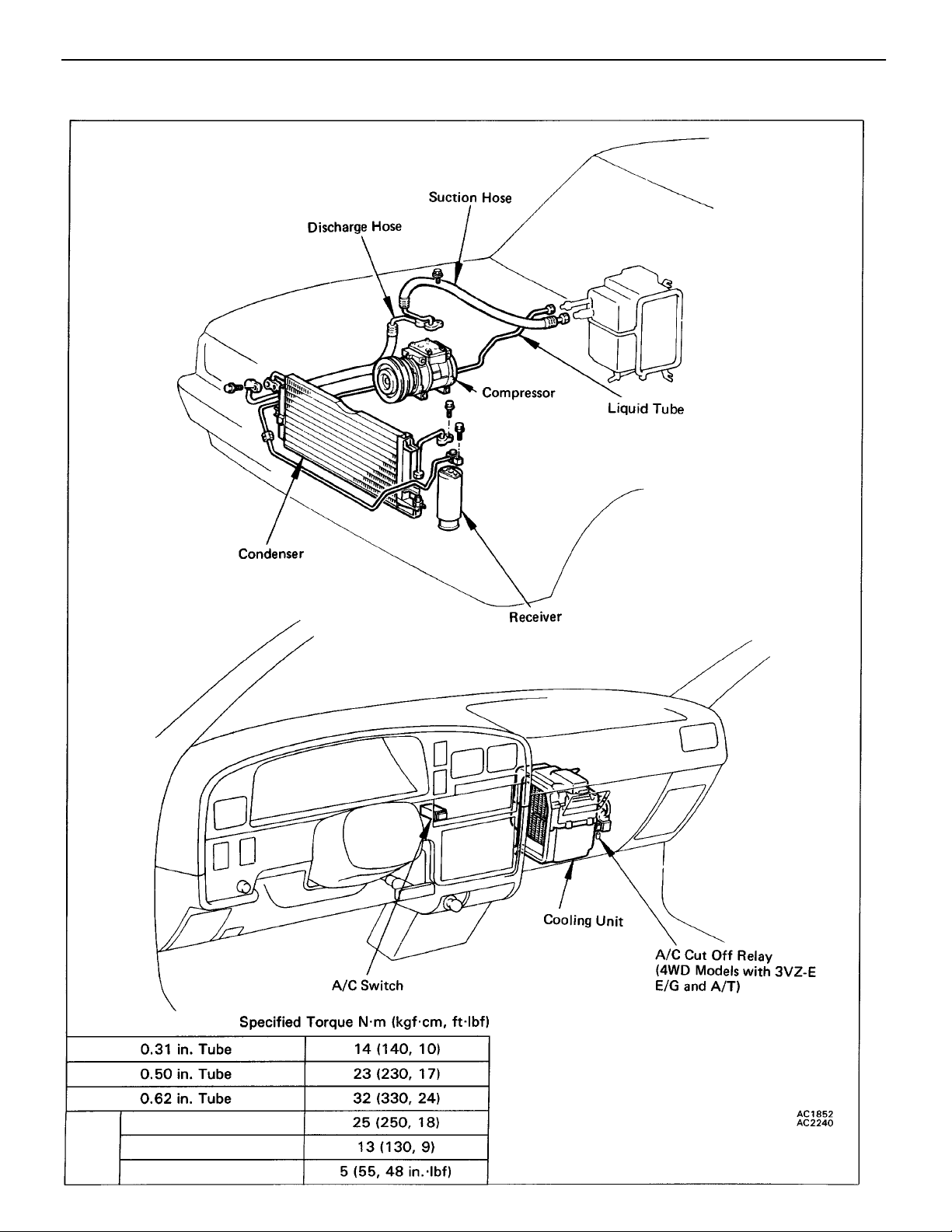

–AIR CONDITIONING SYSTEM System Components

SYSTEM COMPONENTS

AC–7

Bolted

Type

For Compressor

For Condenser

For Receiver

AC–8

–AIR CONDITIONING SYSTEM General Description

GENERAL DESCRIPTION

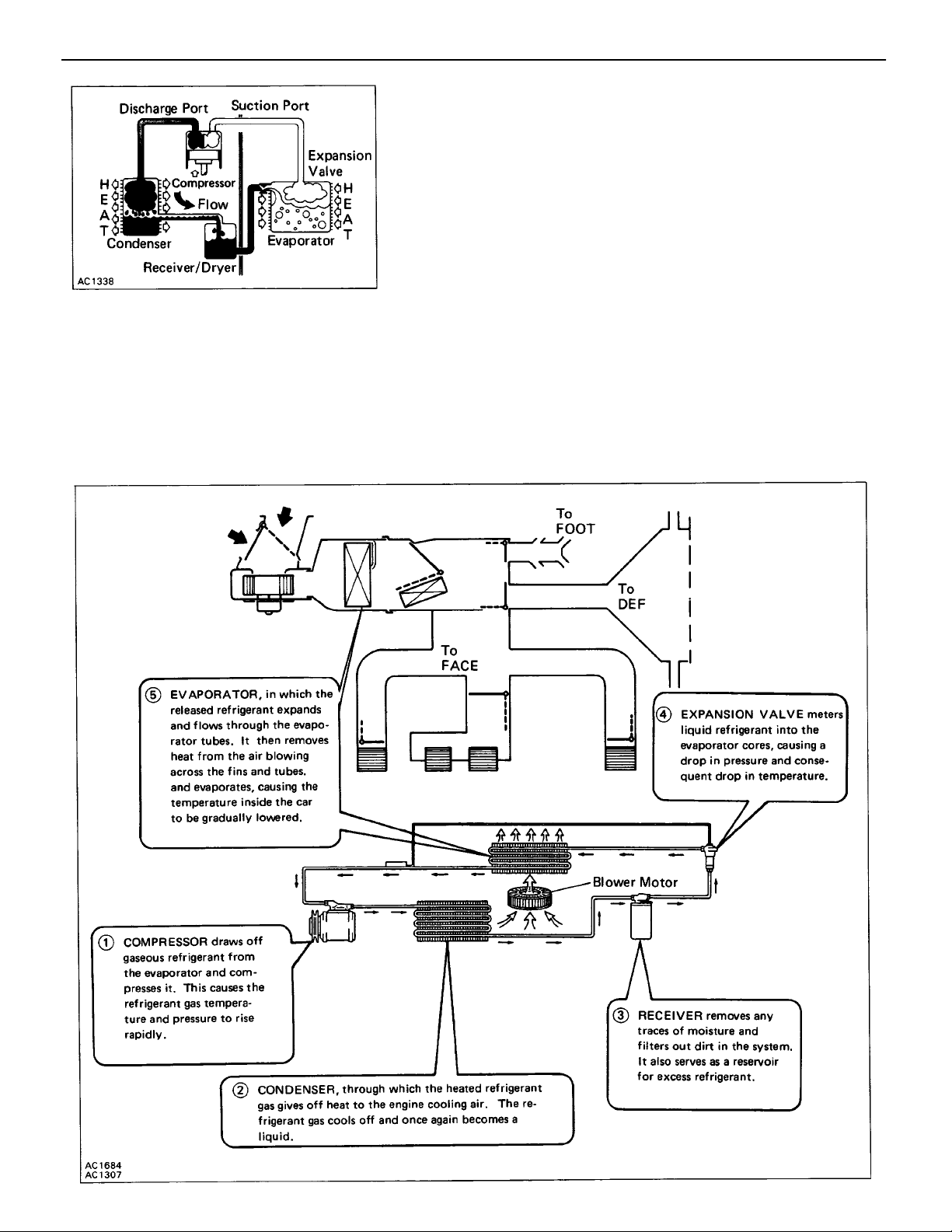

REFRIGERATION CYCLE

1. The compressor discharges high temperature and high

pressure refrigerant containing the heat absorbed from

the evaporator plus the heat created by the compressor

in a discharge stroke.

2. This gaseous refrigerant flows into the condenser. In the

condenser, the gaseous refrigerant condenses into liquid

refrigerant.

3. This liquid refrigerant flows into the receiver which stores

and filters the liquid refrigerant till the evaporator requires

the refrigerant.

4. The liquid refrigerant is changed by the expansion valve into a low temperature, low pressure liquid

and gaseous mixture.

5. This cold and foggy refrigerant flows to the evaporator. Vaporizing the liquid in the evaporator, the

heat from the warm air stream passing through the evaporator core is transferred to the refrigerant. All

the liquid is changed into the gaseous refrigerant in the evaporator and only heat–laden gaseous

refrigerant is drawn into the compressor. Then the process is repeated again.

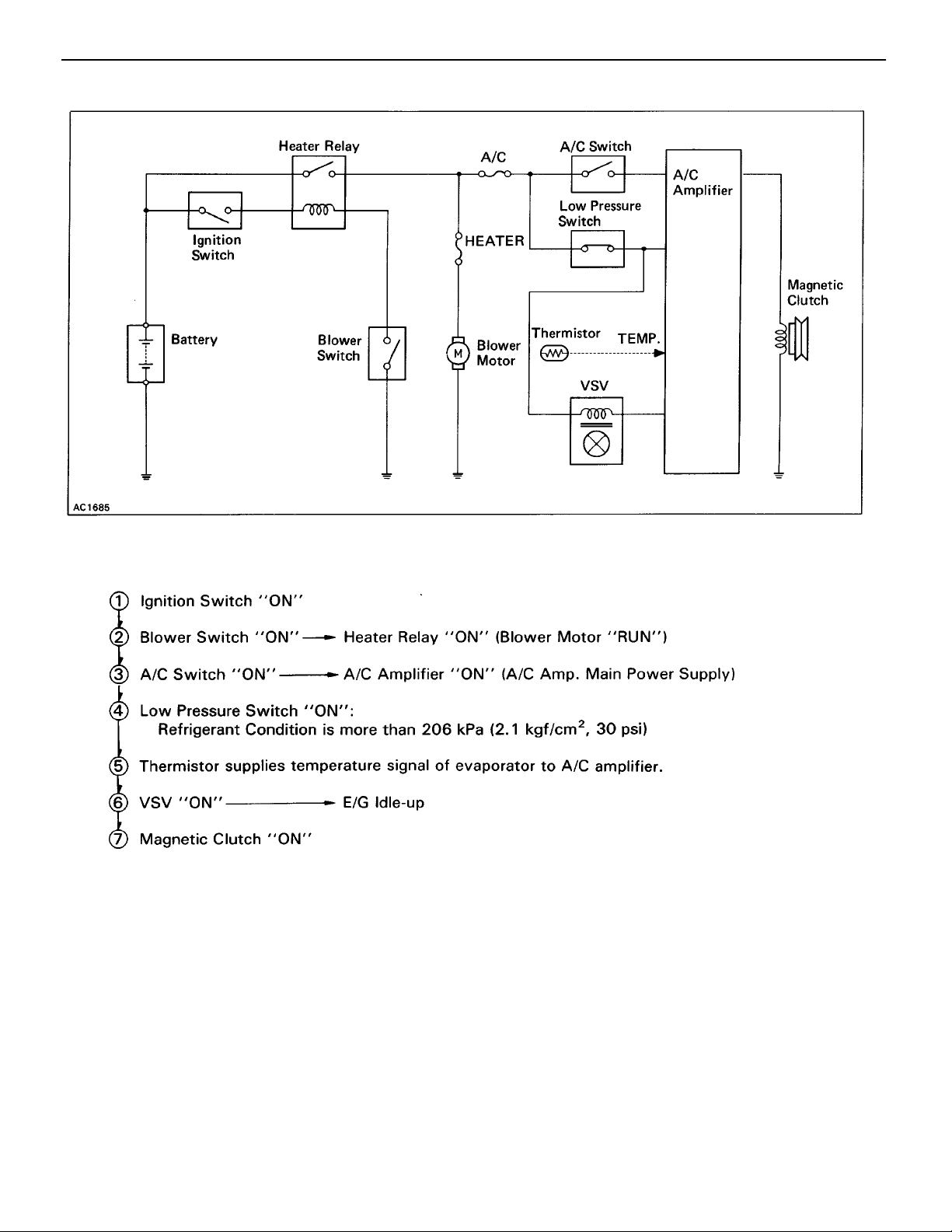

1. PRINCIPLE OF A/C ELECTRICAL CIRCUIT

–AIR CONDITIONING SYSTEM General Description

AC–9

2. HOW IS MAGNETIC CLUTCH ENERGIZED?

The general process until the magnetic clutch is energized as shown below.

AC–10

–AIR CONDITIONING SYSTEM Special Tools and Equipment

SPECIAL TOOLS AND EQUIPMENT

Tool

Ohmmeter

Voltage meter

Air conditioning service tool set

Magnetic clutch remover

Magnetic clutch stopper

Snap ring pliers

Part Name

ND OIL6,

SUNISO No.5GS or equivalent

Problem

No cooling or warm

air

Magnetic clutch does not engage

(a) A/C fuse blown

(b) Magnetic clutch faulty

(c) A/C switch faulty

(d) A/C amplifier faulty

(e) Wiring or ground faulty

(f) Refrigerant empty

(g) Heater relay faulty

(h) Pressure switch faulty

Compressor does not rotate properly

(a) Drive belt loose or broken

(b) Compressor faulty

Expansion valve faulty

Leak in system

Fusible plug on receiver blown or clogged

screen

Blower does not operate

(a) HEATER fuse blown

(b) A/C switch faulty

(c) Heater relay faulty

(d) Blower motor faulty

(e) Wiring or ground faulty

SSM (SPECIAL SERVICE MATERIALS)

07117–68040

TROUBLESHOOTING

Possible cause

SST No.

To diagnosis electrical system

To diagnosis electrical system

07110–58011

07112–66040

07112–76060

07114–84020

Part No. Use etc.

To evacuate and charge system

To remove pressure plate

To remove and install pressure plate

To remove pressure plate

Compressor

Remedy

Replace fuse and check for

short

Check magnetic clutch

Check switch

Check amplifier

Repair as necessary

Check refrigerant volume

Check heater relay

Check pressure switch

Adjust or replace drive belt

Check compressor

Check expansion valve

Test system for leaks

Check receiver

Replace fuse and check for

short

Check switch

Check heater relay

Check blower motor

Repair as necessary

Use

Page

AC–6

AC–17

AC–29

AC–31

AC–6

AC–16

AC–37

AC–29

AC–15

AC–17

AC–25

AC–23

AC–6

AC–29

AC–37

AC–37

AC–6

Cool air comes out

intermittently

Magnetic clutch slipping

Expansion valve faulty

Wiring connection faulty

Excessive moisture in system

A/C amplifier faulty

Check magnetic clutch

Check expansion valve

Repair as necessary

Evacuate and charge system

Check amplifier

AC–17

AC–25

AC–6

AC–31

AC–10

–AIR CONDITIONING SYSTEM SSM (Special Service Materials)

SPECIAL TOOLS AND EQUIPMENT

Tool

Ohmmeter

Voltage meter

Air conditioning service tool set

Magnetic clutch remover

Magnetic clutch stopper

Snap ring pliers

Part Name

ND OIL6,

SUNISO No.5GS or equivalent

Problem

No cooling or warm

air

Magnetic clutch does not engage

(a) A/C fuse blown

(b) Magnetic clutch faulty

(c) A/C switch faulty

(d) A/C amplifier faulty

(e) Wiring or ground faulty

(f) Refrigerant empty

(g) Heater relay faulty

(h) Pressure switch faulty

Compressor does not rotate properly

(a) Drive belt loose or broken

(b) Compressor faulty

Expansion valve faulty

Leak in system

Fusible plug on receiver blown or clogged

screen

Blower does not operate

(a) HEATER fuse blown

(b) A/C switch faulty

(c) Heater relay faulty

(d) Blower motor faulty

(e) Wiring or ground faulty

SSM (SPECIAL SERVICE MATERIALS)

07117–68040

TROUBLESHOOTING

Possible cause

SST No.

To diagnosis electrical system

To diagnosis electrical system

07110–58011

07112–66040

07112–76060

07114–84020

Part No. Use etc.

To evacuate and charge system

To remove pressure plate

To remove and install pressure plate

To remove pressure plate

Compressor

Remedy

Replace fuse and check for

short

Check magnetic clutch

Check switch

Check amplifier

Repair as necessary

Check refrigerant volume

Check heater relay

Check pressure switch

Adjust or replace drive belt

Check compressor

Check expansion valve

Test system for leaks

Check receiver

Replace fuse and check for

short

Check switch

Check heater relay

Check blower motor

Repair as necessary

Use

Page

AC–6

AC–17

AC–29

AC–31

AC–6

AC–16

AC–37

AC–29

AC–15

AC–17

AC–25

AC–23

AC–6

AC–29

AC–37

AC–37

AC–6

Cool air comes out

intermittently

Magnetic clutch slipping

Expansion valve faulty

Wiring connection faulty

Excessive moisture in system

A/C amplifier faulty

Check magnetic clutch

Check expansion valve

Repair as necessary

Evacuate and charge system

Check amplifier

AC–17

AC–25

AC–6

AC–31

AC–10

–AIR CONDITIONING SYSTEM Troubleshooting

SPECIAL TOOLS AND EQUIPMENT

Tool

Ohmmeter

Voltage meter

Air conditioning service tool set

Magnetic clutch remover

Magnetic clutch stopper

Snap ring pliers

Part Name

ND OIL6,

SUNISO No.5GS or equivalent

Problem

No cooling or warm

air

Magnetic clutch does not engage

(a) A/C fuse blown

(b) Magnetic clutch faulty

(c) A/C switch faulty

(d) A/C amplifier faulty

(e) Wiring or ground faulty

(f) Refrigerant empty

(g) Heater relay faulty

(h) Pressure switch faulty

Compressor does not rotate properly

(a) Drive belt loose or broken

(b) Compressor faulty

Expansion valve faulty

Leak in system

Fusible plug on receiver blown or clogged

screen

Blower does not operate

(a) HEATER fuse blown

(b) A/C switch faulty

(c) Heater relay faulty

(d) Blower motor faulty

(e) Wiring or ground faulty

SSM (SPECIAL SERVICE MATERIALS)

07117–68040

TROUBLESHOOTING

Possible cause

SST No.

To diagnosis electrical system

To diagnosis electrical system

07110–58011

07112–66040

07112–76060

07114–84020

Part No. Use etc.

To evacuate and charge system

To remove pressure plate

To remove and install pressure plate

To remove pressure plate

Compressor

Remedy

Replace fuse and check for

short

Check magnetic clutch

Check switch

Check amplifier

Repair as necessary

Check refrigerant volume

Check heater relay

Check pressure switch

Adjust or replace drive belt

Check compressor

Check expansion valve

Test system for leaks

Check receiver

Replace fuse and check for

short

Check switch

Check heater relay

Check blower motor

Repair as necessary

Use

Page

AC–6

AC–17

AC–29

AC–31

AC–6

AC–16

AC–37

AC–29

AC–15

AC–17

AC–25

AC–23

AC–6

AC–29

AC–37

AC–37

AC–6

Cool air comes out

intermittently

Magnetic clutch slipping

Expansion valve faulty

Wiring connection faulty

Excessive moisture in system

A/C amplifier faulty

Check magnetic clutch

Check expansion valve

Repair as necessary

Evacuate and charge system

Check amplifier

AC–17

AC–25

AC–6

AC–31

–AIR CONDITIONING SYSTEM Troubleshooting

TROUBLESHOOTING (Cont’d)

AC–11

Problem

Cool air comes out

only at high speed

Insufficient cooling

Insufficient velocity

of cool air

Possible cause

Condenser clogged

Drive belt slipping

Compressor faulty

Insufficient or too much refrigerant

Air in system

Condenser clogged

Drive belt slipping

Magnetic clutch faulty

Compressor faulty

Expansion valve faulty

Insufficient *or too much refrigerant

Air or excessive compressor oil in system

Receiver clogged

Water valve cable faulty

A/C amplifier faulty

Evaporator clogged or frosted

Air leakage from cooling unit or air duct

Air inlet blocked

Blower motor faulty

A/C amplifier faulty

Remedy

Check condenser

Check or replace drive belt

Check compressor

Check refrigerant volume

Evacuate and charge system

Check condenser

Check or replace drive belt

Check magnetic clutch

Check compressor

Check expansion valve

Check refrigerant volume

Evacuate and charge system

Check receiver

Reset water valve cable

Check amplifier

Clean evaporator fins or filters

Repair as necessary

Repair as necessary

Check blower motor

Check amplifier

Page

AC–24

AC–15

AC–17

AC–16

AC–24

AC–15

AC–17

AC–17

AC–25

AC–16

AC–23

AC–36

AC–31

AC–27

AC–37

AC–31

AC–12

–AIR CONDITIONING SYSTEM Troubleshooting

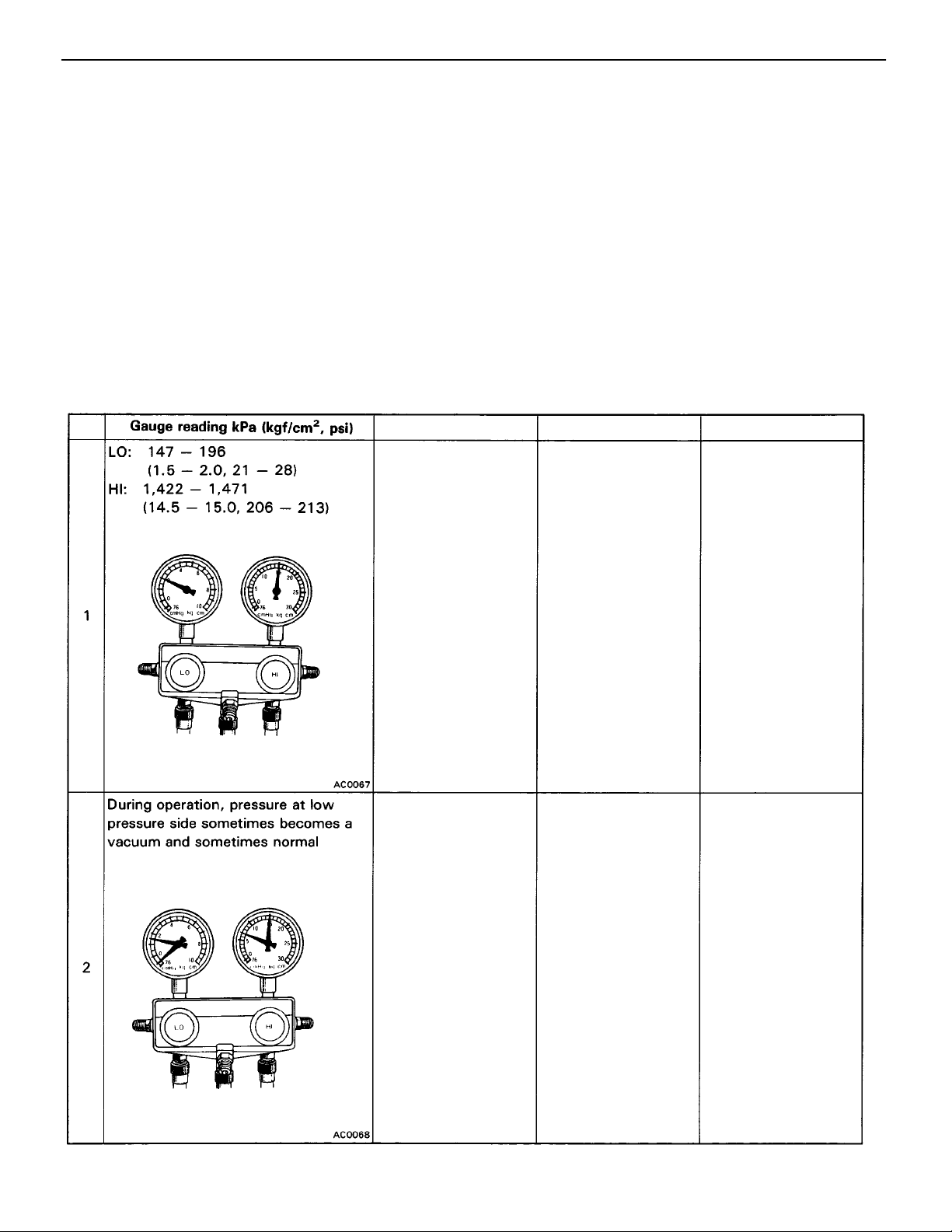

Inspection of Refrigeration System with Manifold Gauge Set

This is a method in which the trouble is located by using a manifold gauge set. (See ”Installation of Mani–

fold Gauge Set” on page AC–16. ) Read the manifold gauge pressure when the following conditions are

established:

(b) Engine running at 2,000 rpm

(a) Temperature at the air inlet with the switch set at RECIRC is 30 – 35

(c) Blower fan speed control switch set at high speed

(d) Temperature control switch set at max. cool side

HINT: It should be noted that the gauge indications may vary slightly due to ambient temperature condi–

tions.

NOTICE:

• Always recover refrigerant before removing the parts in the refrigerant line and evacuating air.

• Evacuate air and charge proper amount of purified refrigerant after installing the parts in the refriger-

ant line.

C (86 – 95F)

No.

Condition

Normal cooling

Periodically cools and

then fails to cool

Probable cause

Normally functioning

system

Moisture present in

refrigeration system

Remedy

(1) Replace receiver

(2) Remove moisture

in system through

repeatedly evacu–

ating air

–AIR CONDITIONING SYSTEM Troubleshooting

NOTICE:

• Always recover refrigerant before removing the parts in the refrigerant line and evacuating air.

• Evacuate air and charge proper amount of purified refrigerant after installing the parts in the refrigerant line.

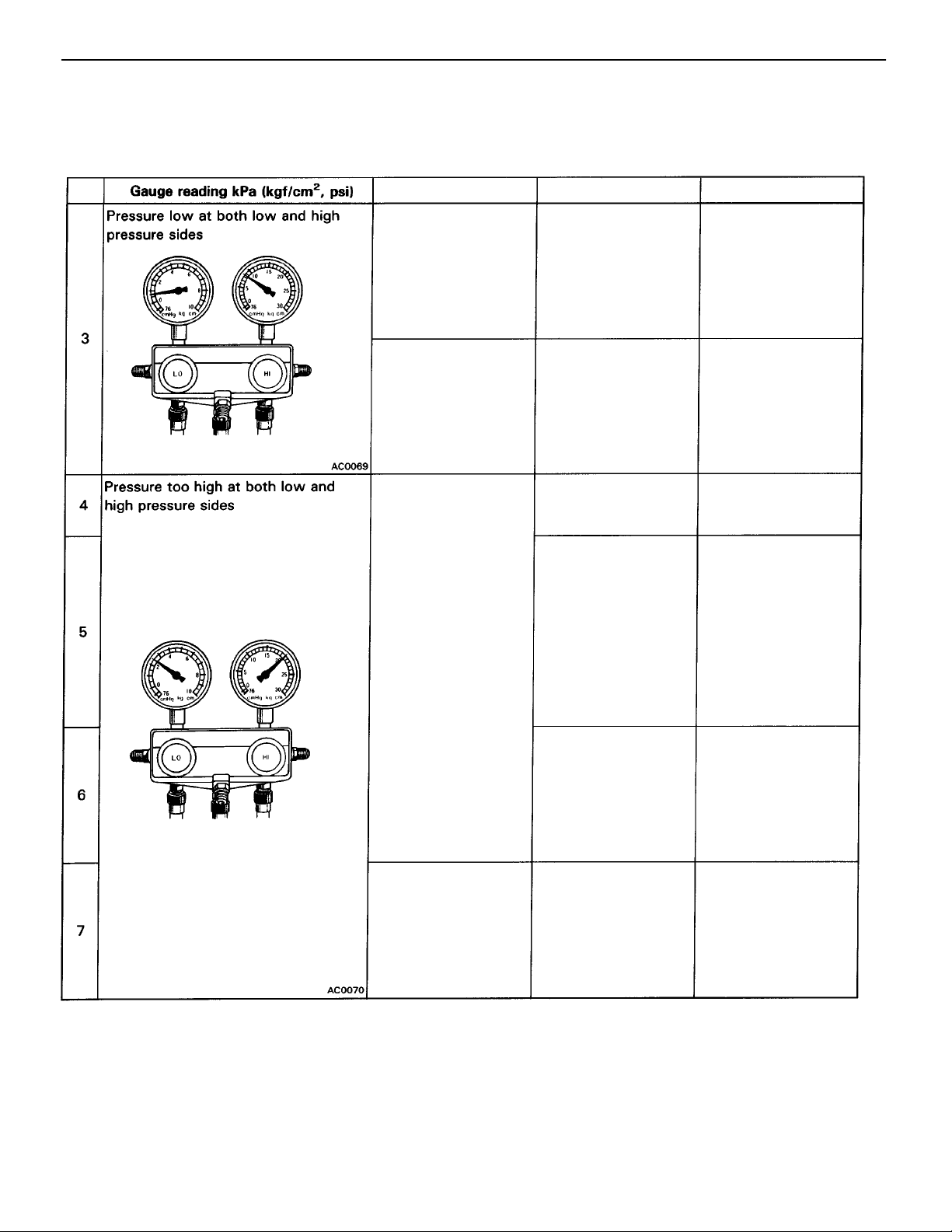

AC–13

No.

• Insufficient cooling

• Bubbles seen in

sight glass

• Insufficient cooling

• Frost on tubes from

receiver to unit

Insufficient cooling

• Insufficient cooling

• Frost or Large

amount of dew on

piping at low pres–

sure side

Probable causeCondition

Insufficient refrigerant

Refrigerant flow ob–

structed by dirt in re

ceiver

Insufficient cooling of

condenser

Refrigerant over–

charged

Air present in system

Expansion valve im–

properly mounted,heat

sensing tube defective

(Opens too wide)

Remedy

(1) Check for gas

leakage with gas

leak tester and

repair if necessary

(2) Add refrigerant

until bubbles dis–

appear

Replace receiver

(1) Clean condenser

(2) Check fan motor

operation

(1) Check amount of

refrigerant

If refrigerant is over–

charged

(2) Recover refriger–

ant

(3) Evacuate air and

charge proper

amount of purified

refrigerant

(1) Replace receiver

(2) Check compressor

oil to see if dirty

(3) Remove air in sys–

tem through re–

peatedly evacuat–

ing air

(1) Check heat sens–

ing tube installa–

tion condition

If (1) is normal

(2) Check expansion

valve and replace

if defective

Hint at 6:

These gauge indications are for when the refrigeration system has been opened and the refrigerant

charged without evacuating air.

AC–14

–AIR CONDITIONING SYSTEM Troubleshooting

NOTICE:

• Always recover refrigerant before removing the parts in the refrigerant line and evacuating air.

• Evacuate air and charge proper amount of purified refrigerant after installing the parts in the

refrigerant line.

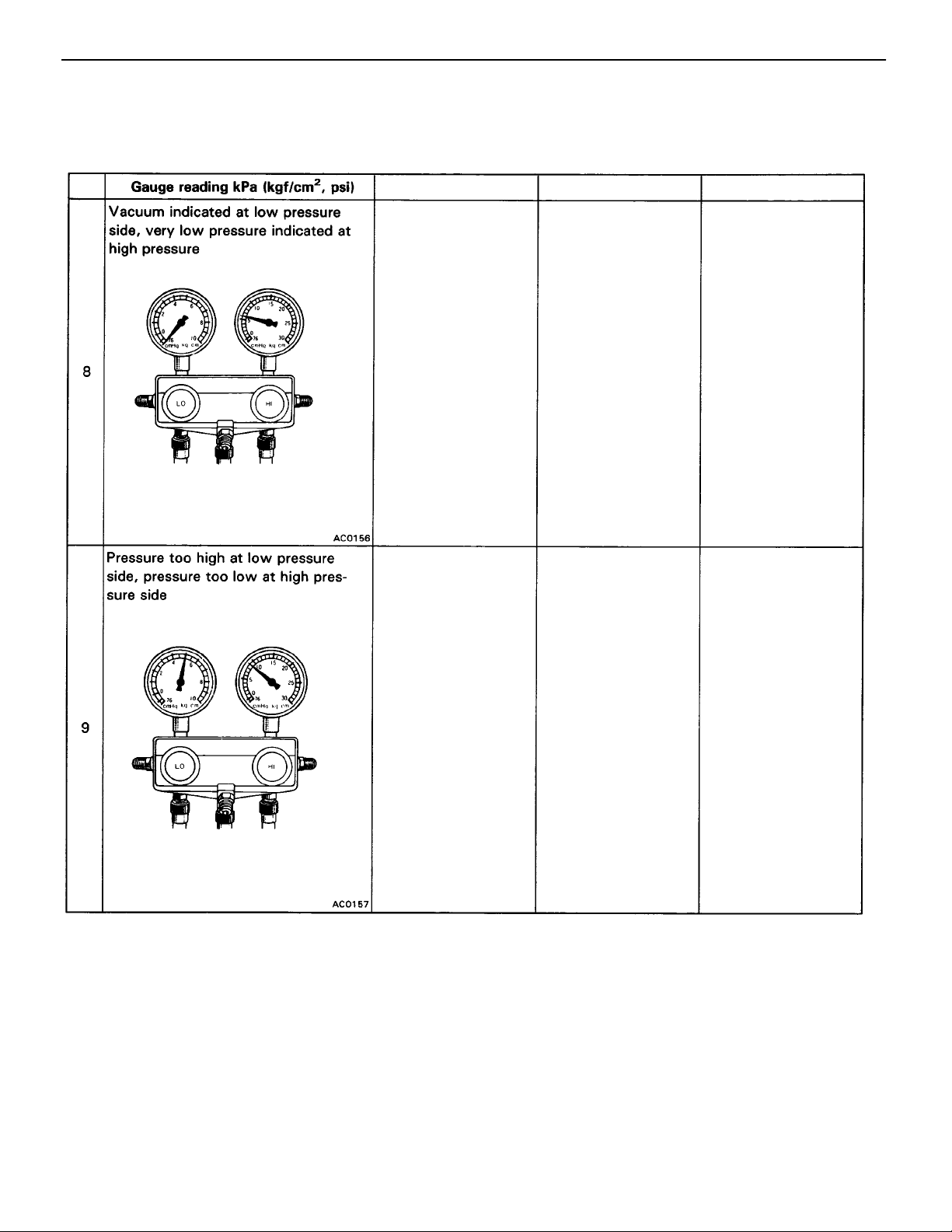

No.

Condition

• Does not cool

(Cools from time to

time in some cases)

• Frost or dew seen

on piping before

and after receiver or

expansion valve

Probable cause

Refrigerant does not

circulate

Remedy

(1) Check heat sens–

ing tube for gas

leakage and re–

place expansion

valve if defective

If

(1) is normal

(2) Clean out dirt in

expansion valve

by blowing with

air

If not able to re–

move dirt, replace

expansion valve

(3) Replace receiver

Does not cool

Insufficient compres–

sion

Repair or replace com–

pressor

Loading...

Loading...