Toyota 4 Runner 1987 User Manual

ARTICLE BEGINNING

Page

1

of 19OVERHAUL

- G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

APPLICATION

TRANSMISSION APPLICATION

Vehicle Application Transmission Model

1985-87 4WD Pickup, 4Runner G52

1985-89 Van (2WD & 4WD) G53

DESCRIPTION

The Toyota G52 and G53 5-speed transmissions are fully synchronized units. All forward gears are

helical cut and in constant mesh. Reverse gear is spur cut. Reverse and 5th gears are mounted on

the rear side of the intermediate plate. The floor shifter actuates a single control rod in the transfer

adapter which operates 3 shift rails mounted in the intermediate plate and the main case.

Page

2

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

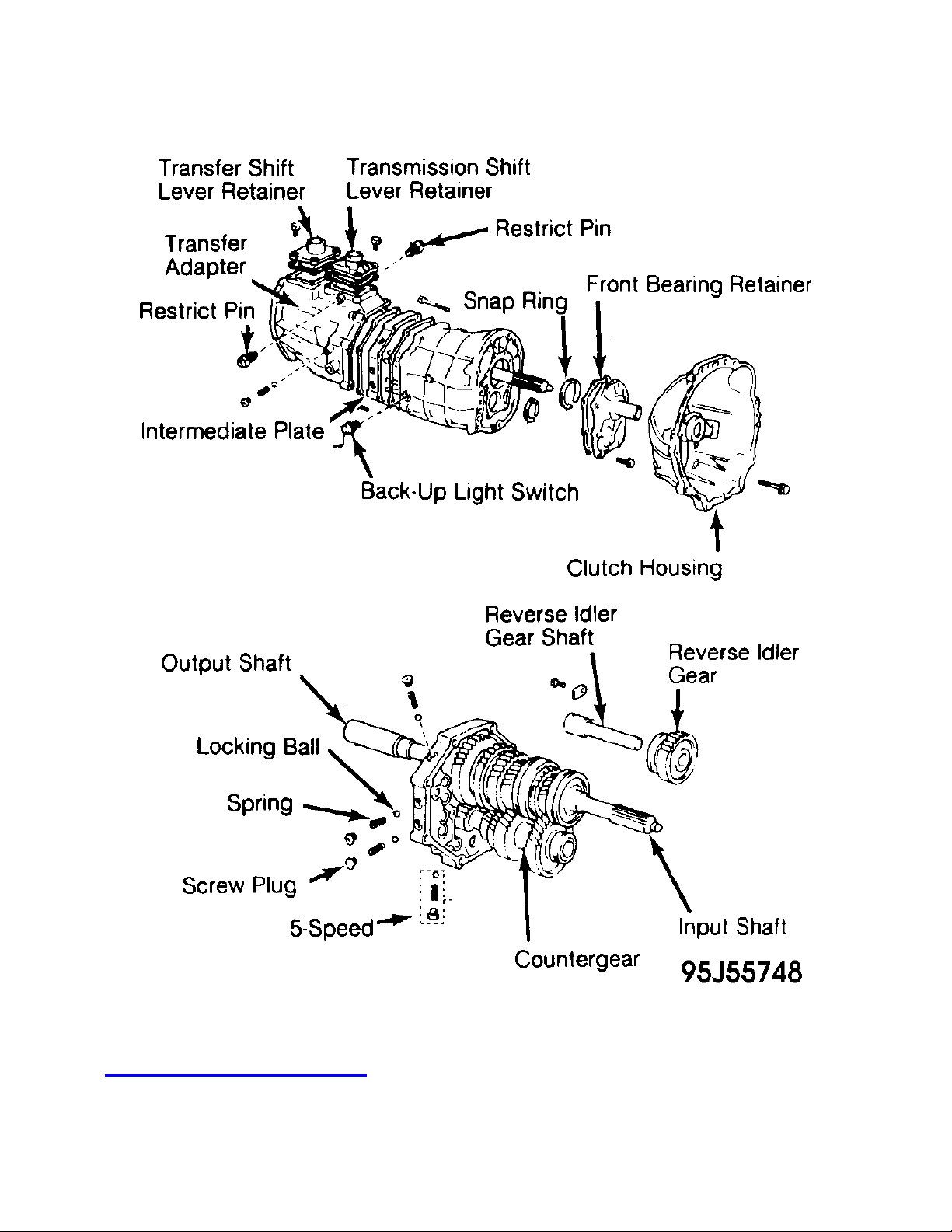

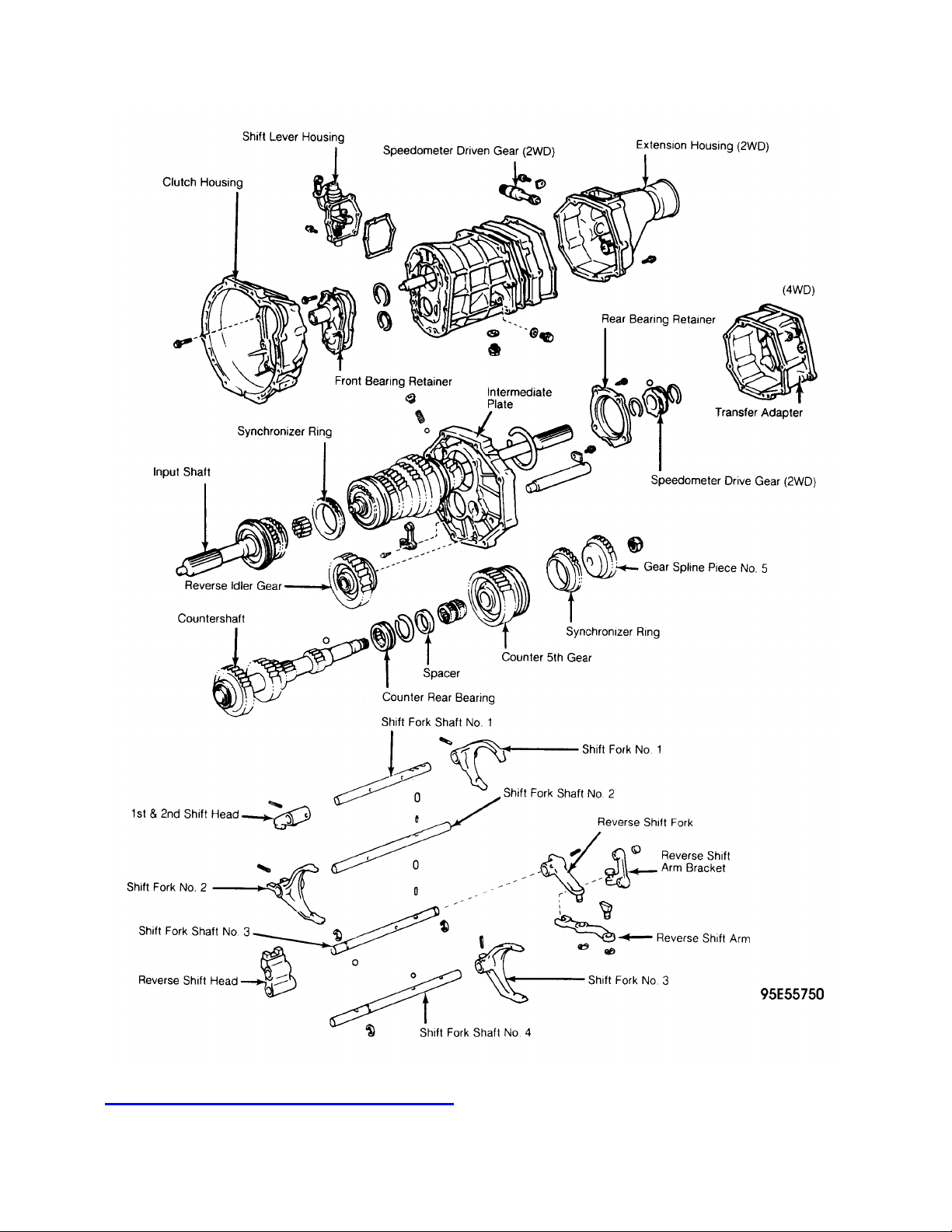

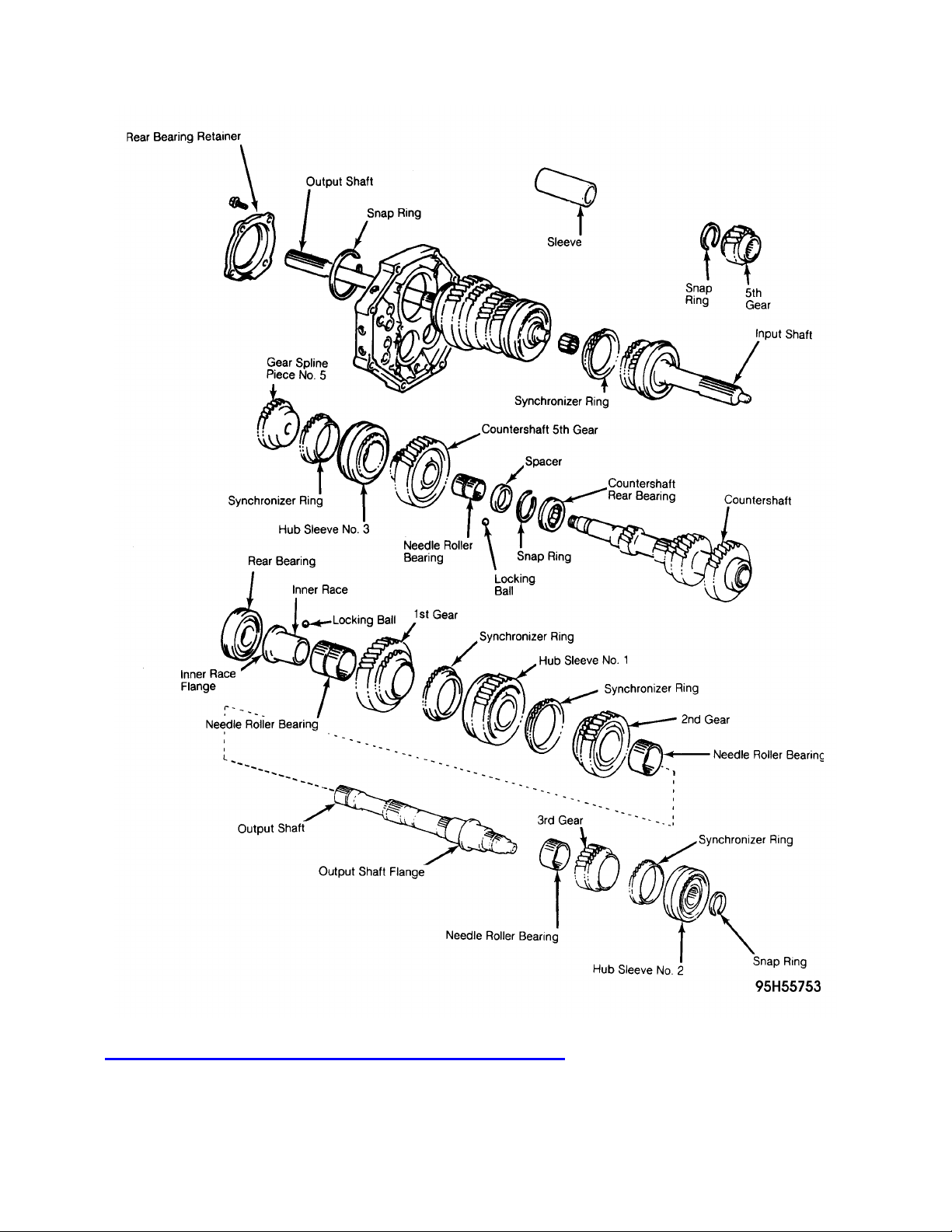

Fig. 1: Toyota G52 Transmission

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LUBRICATION & ADJUSTMENTS

Page

3

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

See appropriate TRANSMISSION SERVICING - M/T article in the MANUAL TRANS

SERVICE section.

For 1985 Toyota Vehicles, see TRANSMISSION SERVICING - M/T •

For 1986 Toyota Vehicles, see TRANSMISSION SERVICING - M/T •

For 1987 Toyota Vehicles, see TRANSMISSION SERVICING - M/T •

For 1988 Toyota Vehicles, see TRANSMISSION SERVICING - M/T •

For 1989 Toyota Vehicles, see TRANSMISSION SERVICING - M/T •

TROUBLE SHOOTING

See TROUBLE SHOOTING - BASIC PROCEDURES in the GENERAL TROUBLE

SHOOTING section.

REMOVAL & INSTALLATION

See appropriate TRANSMISSION REMOVAL & INSTALLATION - M/T article in the

MANUAL TRANS SERVICE section.

For 1985-86 Pickup & 4Runner, see TRANSMISSION REMOVAL & INSTALLATION

•

- M/T

For 1987 Pickup & 4Runner, see TRANSMISSION REMOVAL & INSTALLATION -

•

M/T

For 1985 Van, see TRANSMISSION REMOVAL & INSTALLATION - M/T •

For 1986 Van, see TRANSMISSION REMOVAL & INSTALLATION - M/T •

For 1987 Van, see TRANSMISSION REMOVAL & INSTALLATION - M/T •

TRANSMISSION DISASSEMBLY

G52 TRANSFER ADAPTER

Remove back-up light switch, shift lever retainer and restrict pins. Remove 9 clutch housing

1.

bolts. Using plastic hammer, remove clutch housing from transmission case. See Fig. 1 and

Fig. 2 .

Using Torx head socket, remove screw plug from transfer adapter. Remove spring and ball.

2.

Remove Allen head plug from rear face of transfer adapter. Remove shift lever housing set

bolt and lock washer.

Remove shift lever shaft and housing. Remove 8 transfer adapter bolts. Using plastic

3.

hammer, remove transfer adapter. Leave gasket attached to intermediate plate.

Page

4

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

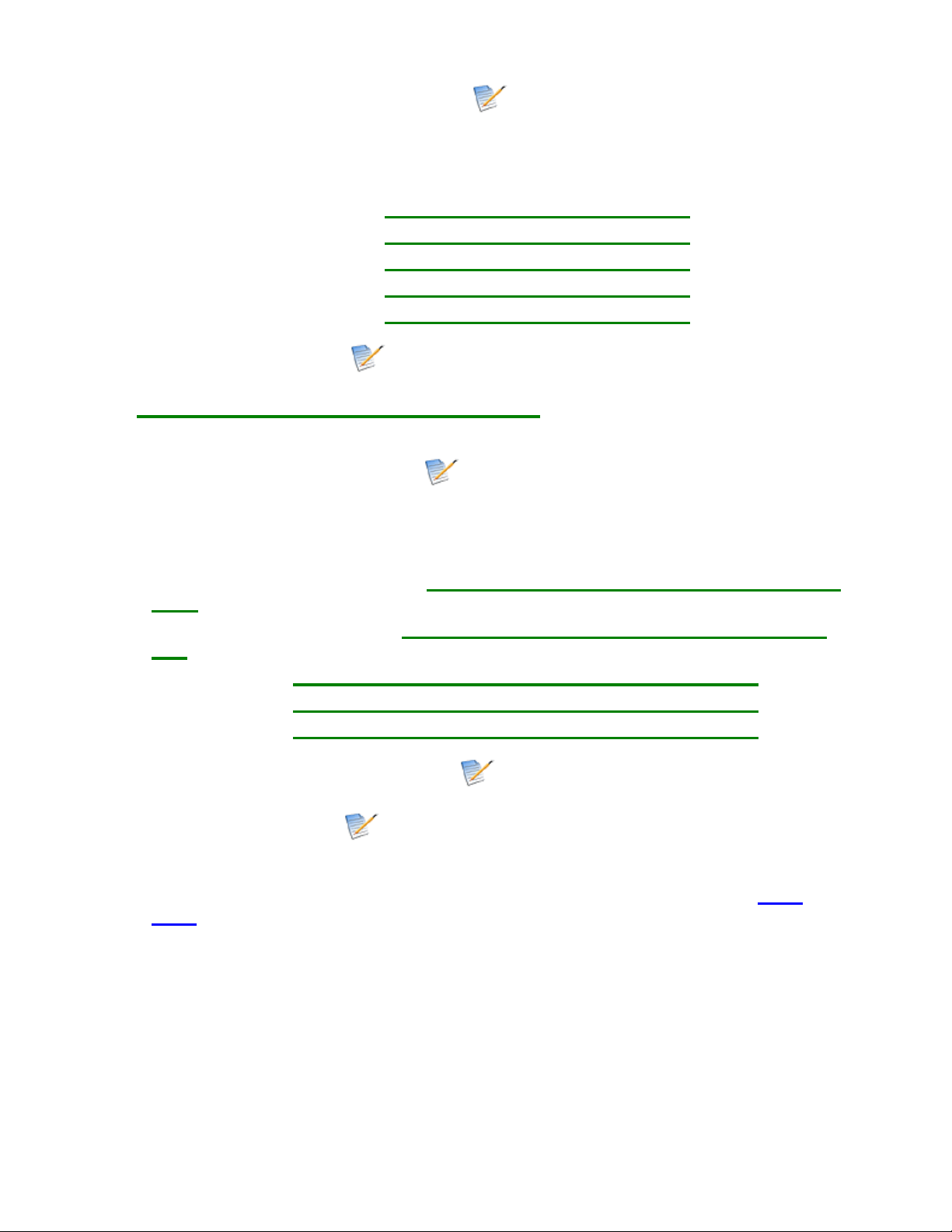

Fig. 2: Exploded View of Shift Forks & Shafts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

G53 EXTENSION HOUSING (2WD) OR TRANSFER ADAPTER (4WD)

Remove release fork and bearing. Remove back-up light switch and speedometer driven

1.

gear. Remove clutch housing from transmission.

Remove shift lever housing assembly. Remove 8 extension housing bolts. See Fig. 3 . Using

2.

plastic hammer, tap extension housing and remove.

Remove shift lever housing and shift and select lever. Leave gasket attached to intermediate

3.

plate.

Page

5

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

Fig. 3: G53 Case & Shifter Fork Assemblies

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INTERMEDIATE PLATE

Page

6

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

G52 Shift Fork Shafts

Remove front bearing retainer and 2 bearing snap rings from front of transmission case.

1.

Using plastic hammer, carefully separate transmission case from intermediate plate.

Install 2 long clutch housing bolts, plate washers and nuts in 2 bottom holes of intermediate

2.

plate. Install plate washers in reverse of normal. Mount intermediate plate in vise, with vise

jaw pressure on bolts. Increase or decrease plate washers so bolt tip and front tip surface of

nut are aligned and mounted evenly.

Using Torx head socket, remove 4 screw plugs, locking balls and springs from intermediate

3.

plate. Drive out 5 shift fork-to-shift rail pins. Remove 2 shift rail "E" rings.

Pull out shift fork shaft No. 4 from intermediate plate catching 2 interlock balls and pin. If

4.

they do not fall out, remove with magnet. Remove shift fork shaft No. 4 and shift fork No. 3.

Pull out shift fork shaft No. 5 from intermediate plate, and remove with reverse shift head.

5.

Pull out shift fork shaft No. 3 from intermediate plate catching 2 interlock pins as they fall

out. If they do not come out, remove with magnet.

Remove shift fork shaft No. 1 and interlock pin from intermediate plate catching interlock

6.

pin as it falls out. If it does not come out, remove with magnet. Pull out shift fork shaft No. 2

and remove shift forks No. 2 and No. 1.

G53 Shift Fork Shafts

Remove front bearing retainer and 2 snap rings. Using plastic hammer, carefully tap

1.

transmission case and separate from intermediate plate.

Install 2 clutch bolts, washers and nuts in 2 bottom holes of intermediate plate. Increase or

2.

decrease plate washers so bolt tip and front surface of nut are aligned. Mount intermediate

plate in vise with pressure on nuts and bolts, NOT intermediate plate.

Using Torx socket, remove 4 plugs. Remove 4 springs and balls, catching them by hand as

3.

they fall out. If they do not fall out, use magnet to remove. Drive out 4 pins. Remove 3 "E"

clips and No. 1 shift fork bolt. Pull out shift fork shaft No. 3 from intermediate plate.

Remove shift fork and shaft No. 3. Remove locking ball and reverse shift head. Pull out shift

4.

fork shaft No. 4 from intermediate plate, catching pins as they fall out. If they do not fall out,

remove with magnet.

Remove shift fork shaft No. 4. Remove shift fork shaft No. 2 from intermediate plate. Catch

5.

pin by hand when it falls from hole. If it does not fall out, remove with magnet.

Remove shift fork shaft No. 2 and shift fork No. 2. Pull out shift fork shaft No. 1 and remove

6.

shift fork No. 2, No. 1 and 1st and 2nd shift head.

Input, Output & Countershafts

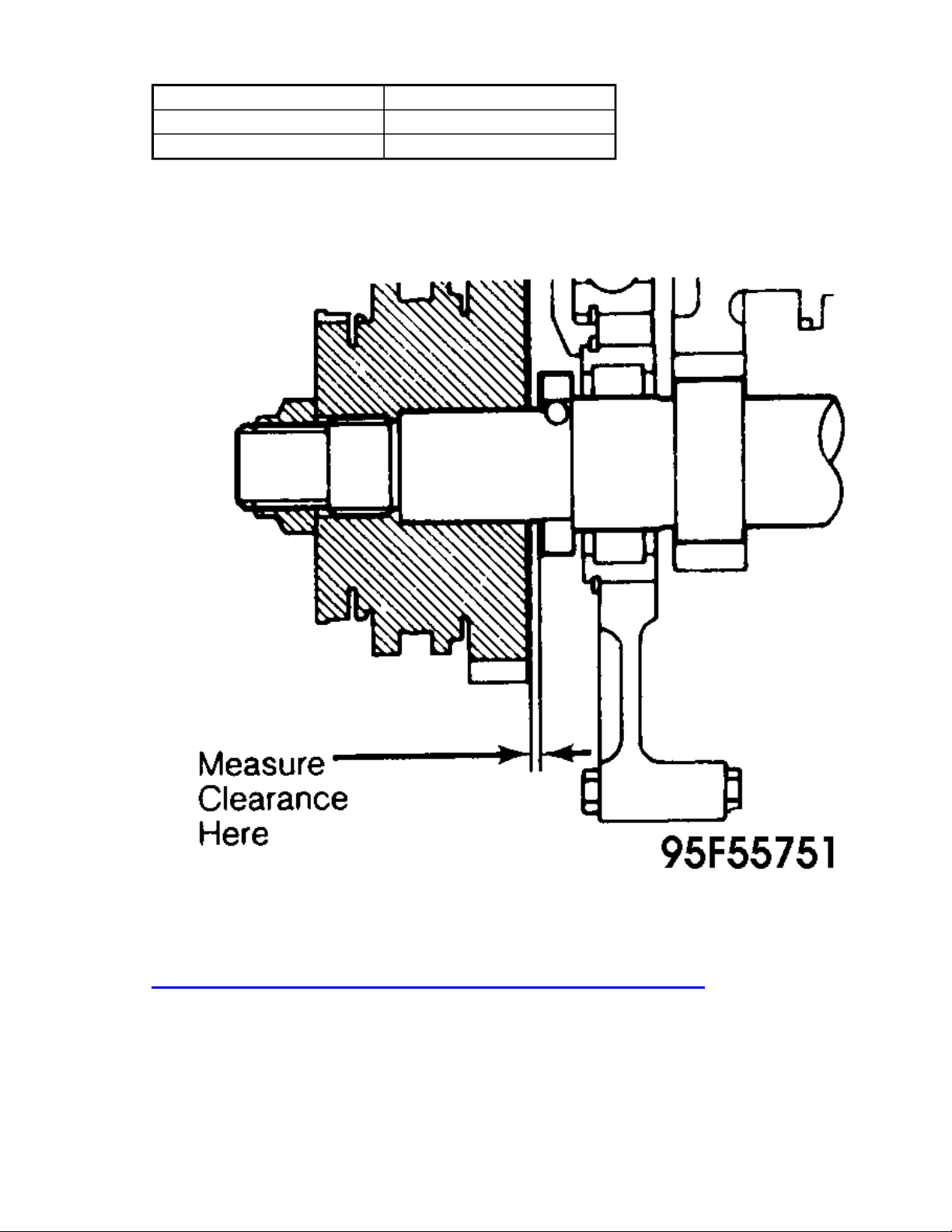

Remove reverse idler gear shaft stopper. Remove reverse idler gear and shaft. Remove

1.

reverse shift arm from reverse shift arm bracket. Measure countershaft 5th gear thrust

clearance. See Fig. 4 .

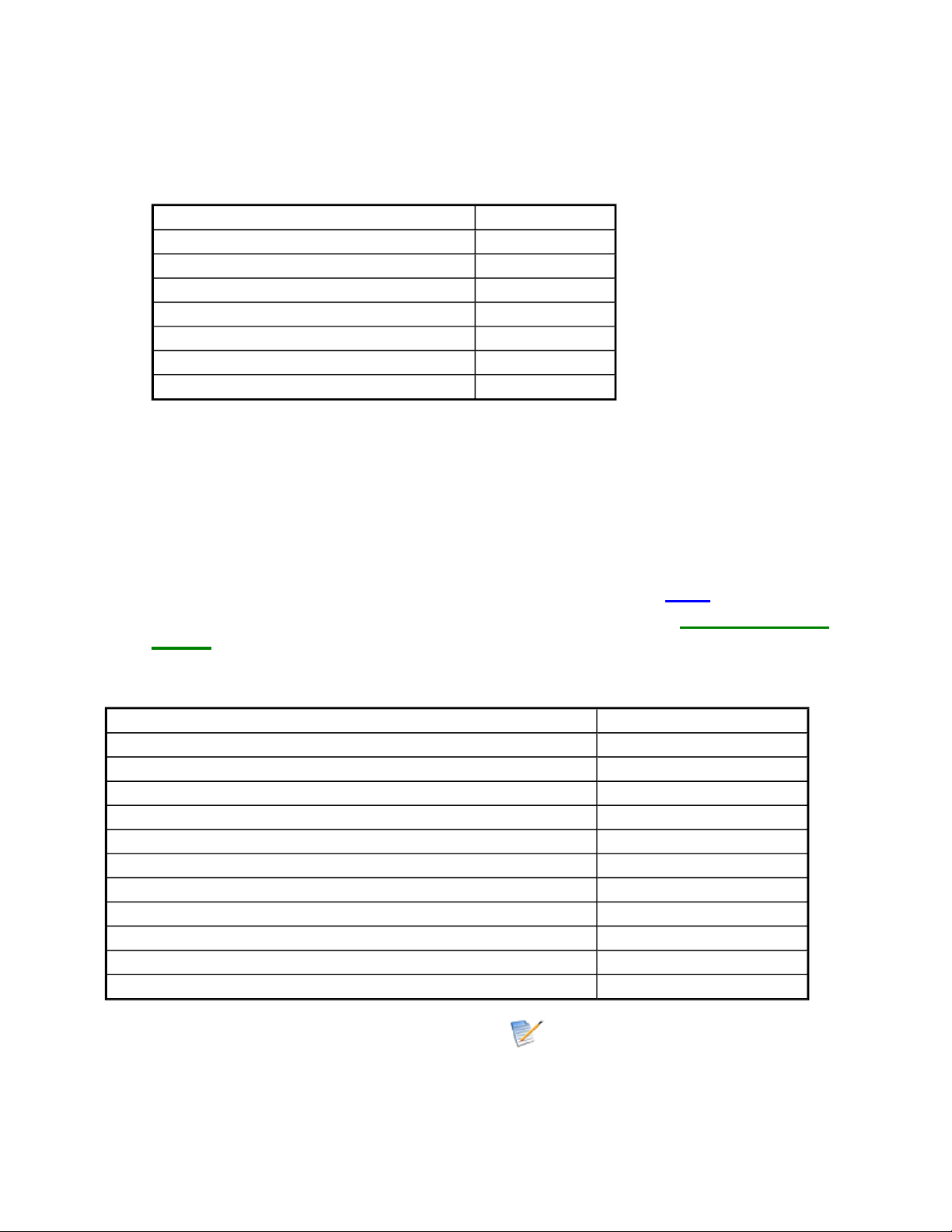

COUNTERSHAFT 5TH GEAR THRUST CLEARANCE

Application In. (mm)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

counter 5th gear. Remove spacer and ball.

2

.

Remove 2 bolts and reverse shift

arm bracket. Using Torx head socket, remove 4 rear

bearing retainer bolts.

Remove rear bearing snap ring.

3

.

Page

7

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

Standard .0039-.0118 (.10-.30)

Maximum .0118 (.30)

Fig. 4: Measuring Point For Countershaft 5th Gear Thrust Clearance

Loosen staked part of lock nut on gear spline piece No. 5. Remove lock nut. Using Puller

(09213-27010), remove gear spline piece No. 5, synchro ring, needle roller bearing and

Remove output shaft, countershaft and input shaft as a unit from intermediate plate by

Page

8

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

4.

pulling on countergear and tapping intermediate plate with plastic hammer. Remove input

shaft and needle roller bearings from output shaft. Remove countershaft rear bearing from

intermediate plate using Driver (09608-12010). Remove sleeve from output shaft using

Puller (09950-20016).

COMPONENT DISASSEMBLY & REASSEMBLY

OUTPUT SHAFT

Disassembly

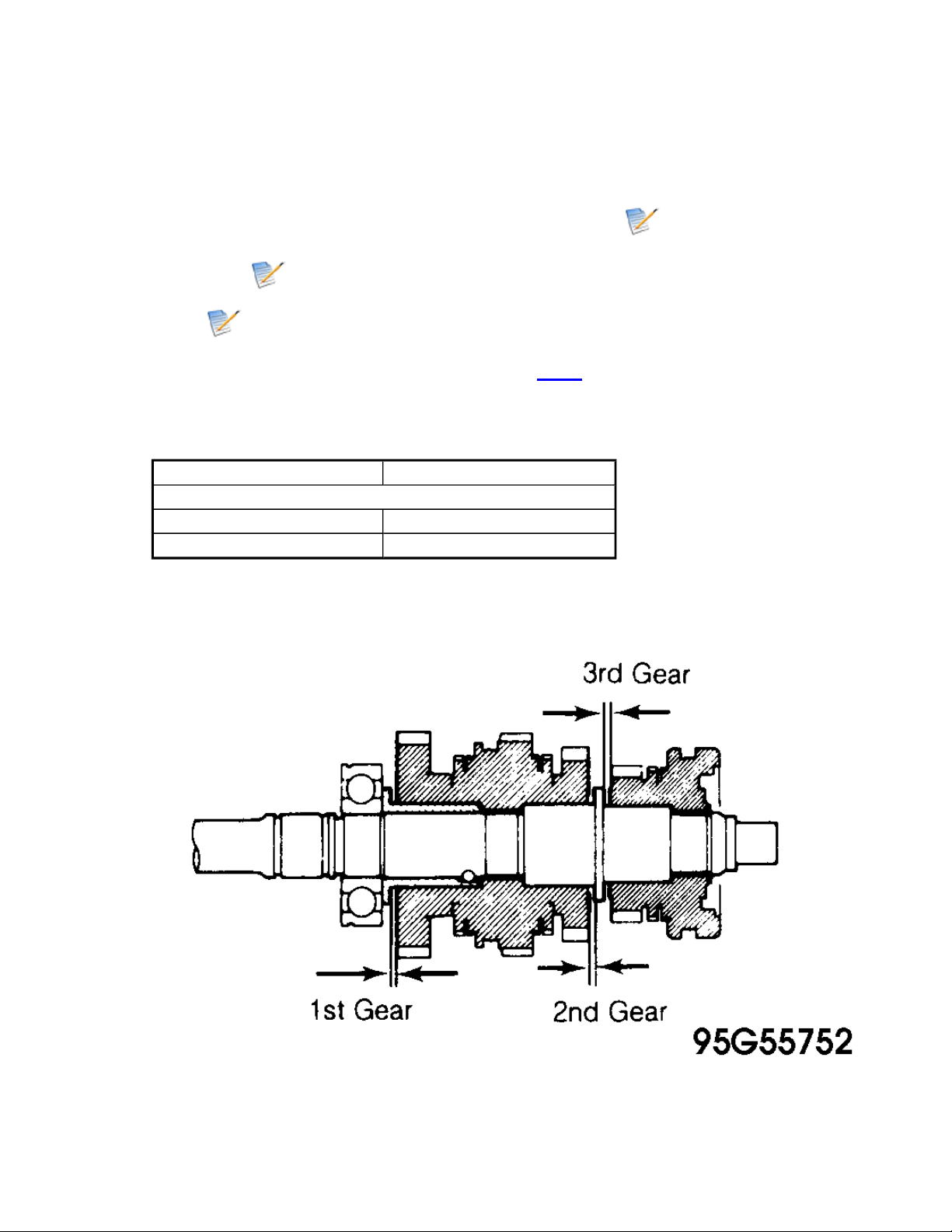

Measure end play of each gear on output shaft. See Fig. 5 . Remove snap ring and press 5th

1.

gear, rear bearing, 1st gear and inner race from output shaft. Remove needle roller bearing.

OUTPUT SHAFT GEAR THRUST CLEARANCES

Application In. (mm)

1st, 2nd & 3rd Gear

Standard .0039-.0098 (.10-.25)

Maximum .0098 (.25)

Fig. 5: Measuring Output Shaft Gear Thrust Clearances

Page

9

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Remove synchro ring. Remove locking ball using magnet. Press hub sleeve No. 1, synchro

2.

ring and 2nd gear off output shaft. Remove needle roller bearing.

Remove snap ring and press hub sleeve No. 2, synchro ring and 3rd gear off output shaft.

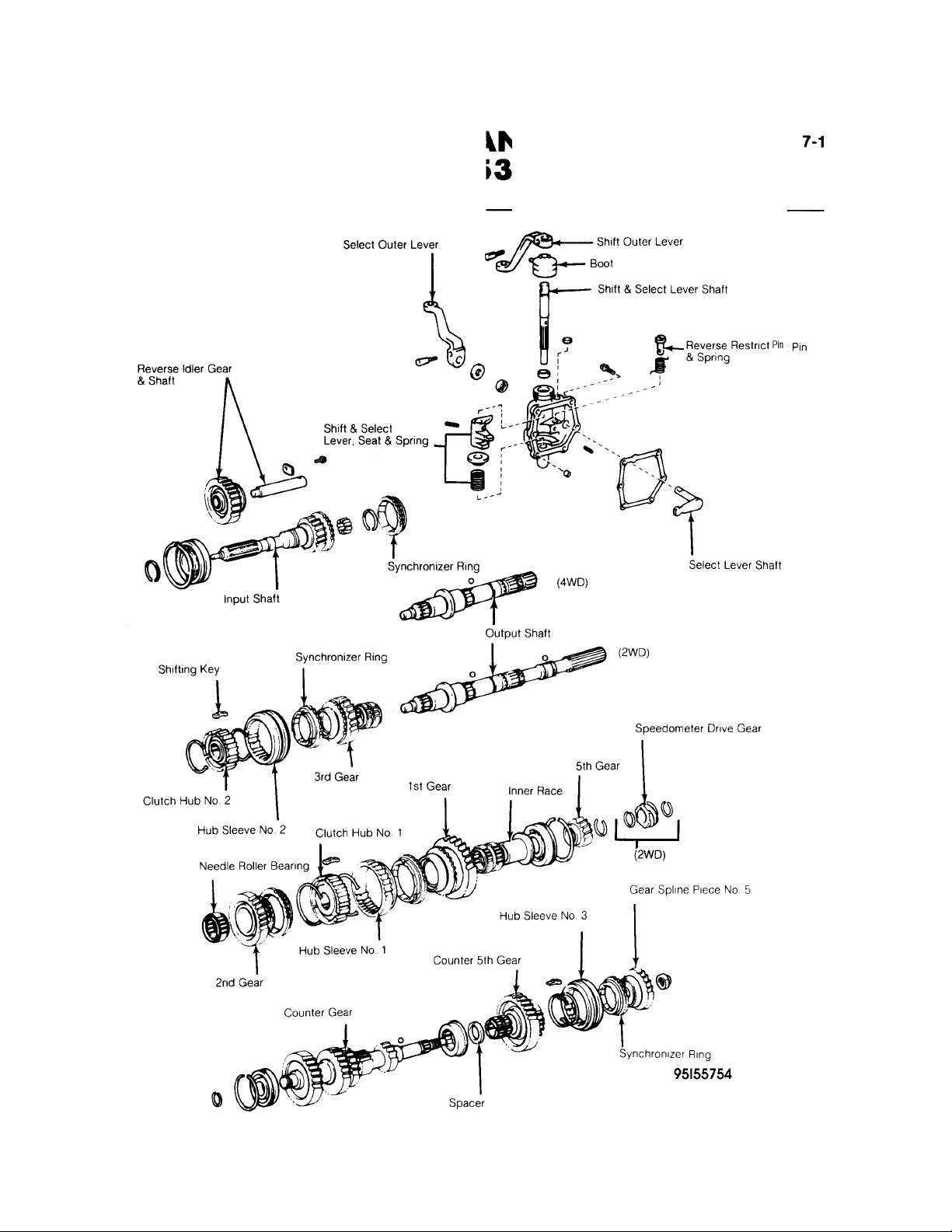

3.

See Fig. 6 or Fig. 7 . Remove needle roller bearing.

Page

10

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

Fig. 6: Exploded View of Toyota G52 Transmission Gears

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page

11

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

Page

12

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

Fig. 7: Exploded View of Toyota G53 Transmission Gears

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Cleaning & Inspection

Clean all parts in solvent. Inspect output shaft and inner race for wear or damage. Using

1.

caliper, measure output shaft flange thickness and inner race flange thickness. See OUTPUT

SHAFT SPECIFICATION table.

Using micrometer, measure outer diameter of output shaft journal surface and outer diameter

2.

of inner race. Mount output shaft between 2 "V" blocks and measure shaft runout at center

of shaft.

OUTPUT SHAFT SPECIFICATIONS

Application In. (mm)

Output Shaft Flange

Minimum Thickness .1890 (4.80)

Inner Race Flange

Minimum Thickness .1571 (3.99)

Inner Race Outer Diameter

Minimum Diameter 1.5348 (38.985)

Output Shaft Journal (Outer Diameter)

Minimum Diameter

2nd Gear 1.4954 (37.984)

3rd Gear 1.3773 (34.984)

Maximum Runout .002 (.05)

Using dial indicator, measure oil clearance between 1st gear and inner race with needle

3.

roller bearing installed. See GEAR-TO-SHAFT OIL CLEARANCE SPECIFICATIONS

table. If clearance exceeds limit, replace gear, inner race or needle roller bearing.

Measure oil clearance between output shaft and 2nd gear between shaft and 3rd gear.

4.

Measure oil clearance between countershaft and 5th gear. If clearance exceeds limit, replace

gear, needle roller bearing or shaft.

GEAR-TO-SHAFT OIL CLEARANCE SPECIFICATIONS

Application Standard In.

(mm)

Maximum In.

(mm)

1st Gear-to-Inner Race .00035-.00126 .00126

(.009.-032) (.032)

2nd Gear-to-Shaft .00035-.00130 .00130

(.009-.033) (.033)

3rd Gear-to-Shaft .00035-.00130 .00130

(.009-.033) (.033)

5th Gear-to-Countershaft .00035-.00126 .00126

(.009-.032) (.032)

Check all synchro rings for wear or damage. Turn ring and push in to check braking action.

Courtesy of TOYOTA MOTOR

SALES, U.S.A., INC.

Apply gear oil

to shaft and needle roller bearing. Place synchro ring on gear and align ring

slots with shifting keys. Install needle roller bearing in 3rd gear.

2

.

Page

13

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

5.

Measure clearance between synchro ring back and gear spline end. See SYNCHRO RING

CLEARANCE SPECIFICATIONS table.

SYNCHRO RING CLEARANCE SPECIFICATIONS

Application In. (mm)

Standard .039-.079 (1.0-2.0)

Maximum .031 (.80)

Measure clearance between shift forks and hub sleeves. Maximum clearance is .039" (1.0

6.

mm).

Reassembly

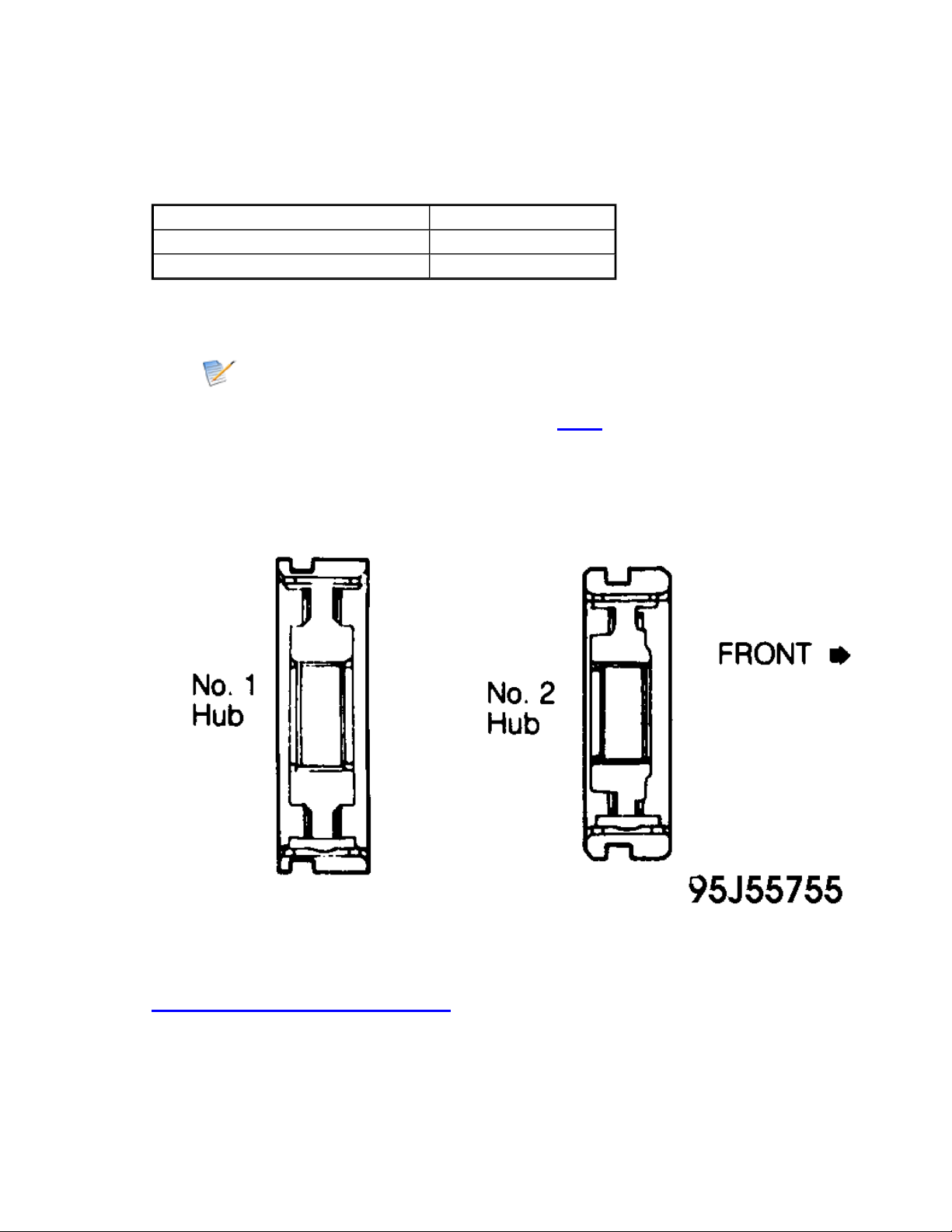

Install clutch hub and shifting keys in hub sleeve. See Fig. 8 . Install shifting key springs

1.

under shifting keys. Install key springs so end gaps are not in line.

Fig. 8: Sectional View of Clutch Hubs

Press 3rd gear and No. 2 hub sleeve on output shaft. Select and install snap ring from NO. 2

Page

14

of 19OVERHAUL

-

G52 & G53 5

-

SPEED

-

1987 Toyota 4Runner

10/5/2009

http://www.ondemand5.com/mric/common/asp/printart.aspx

3.

HUB SLEEVE SNAP RINGS table that will allow minimum axial end play. Using feeler

gauge, measure 3rd gear thrust clearance to ensure it is correct.

NO. 2 HUB SLEEVE SNAP RINGS

Mark Thickness (mm)

C-1 1.75-1.80

D 1.80-1.85

D-1 1.85-1.90

E 1.90-1.95

E-1 1.95-2.00

F 2.00-2.05

F-1 2.05-2.10

Install synchro ring on 2nd gear and align ring slots with shifting keys. Install needle roller

4.

bearing in 2nd gear. Press 2nd gear and No. 1 hub sleeve onto shaft.

Install locking ball in output shaft. Apply gear oil to needle roller bearing and assemble 1st

5.

gear, synchro ring, needle roller bearing and bearing inner race.

Install assembly on output shaft with synchro ring slots aligned with shifting keys. Turn

6.

inner race to align with locking ball.

Press bearing on output shaft with outer snap ring groove toward rear. Using feeler gauge,

7.

measure 1st and 2nd gear thrust clearance to ensure it is correct. See Fig. 5 .

Press 5th gear on end of output shaft. Select and install snap ring from 5TH GEAR SNAP

8.

RINGS that will allow minimum axial end play.

5TH GEAR SNAP RINGS

Mark Thickness (mm)

A 2.67-2.72

B 2.73-2.78

C 2.79-2.84

D 2.85-2.90

E 2.91-2.96

F 2.97-3.02

G 3.03-3.08

H 3.09-3.14

J 3.15-3.20

K 3.21-3.26

L 3.27-3.32

INPUT SHAFT & FRONT BEARING RETAINER

Inspect input shaft and bearing for wear or damage. If necessary, press new bearing on input

1.

shaft. Select and install snap ring from INPUT SHAFT SNAP RINGS table that will allow

minimum axial end play.

Loading...

Loading...