Page 1

W-603C

Videograbadoras

Contenido

Guía de servicio

Precauciones

Información de referencia

Especificaciones del producto

Desemsamble y reensamble

Ajuste y alineamiento

Vista explotada

Lista de partes de reemplazo

Diagrama a bloques

Diagramas PCB (Placa de Circuito Impreso)

Diagramas esquemáticos

Page 2

FILE NO. 120-200012

SERVICE MANUAL

VIDEO CASSETTE RECORDER

W-603C

PRINTED IN KOREA. APR, 2000

Page 3

TOTAL CONTENTS

◆ Service Guide

1. Precautions

2. Reference Information

3. Product Specifications

4. Disassembly and Reassembly

5. Alignment and Adjustment

6. Exploded View

7. Replacement Parts List

8. Block Diagram

9. PCB Diagrams

10. Schematic Diagrams

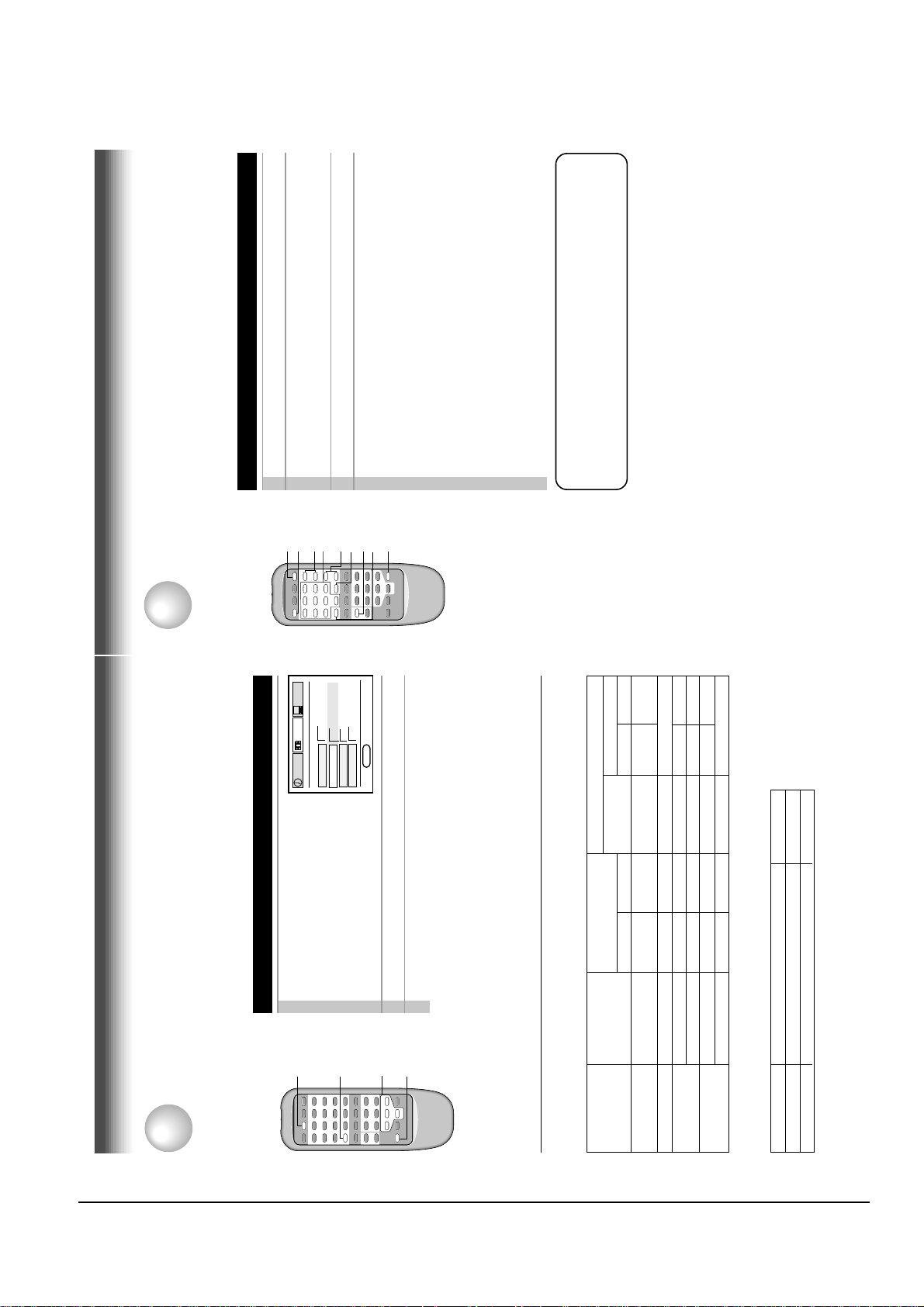

Page 4

Toshiba

I

SERVICE GUIDE

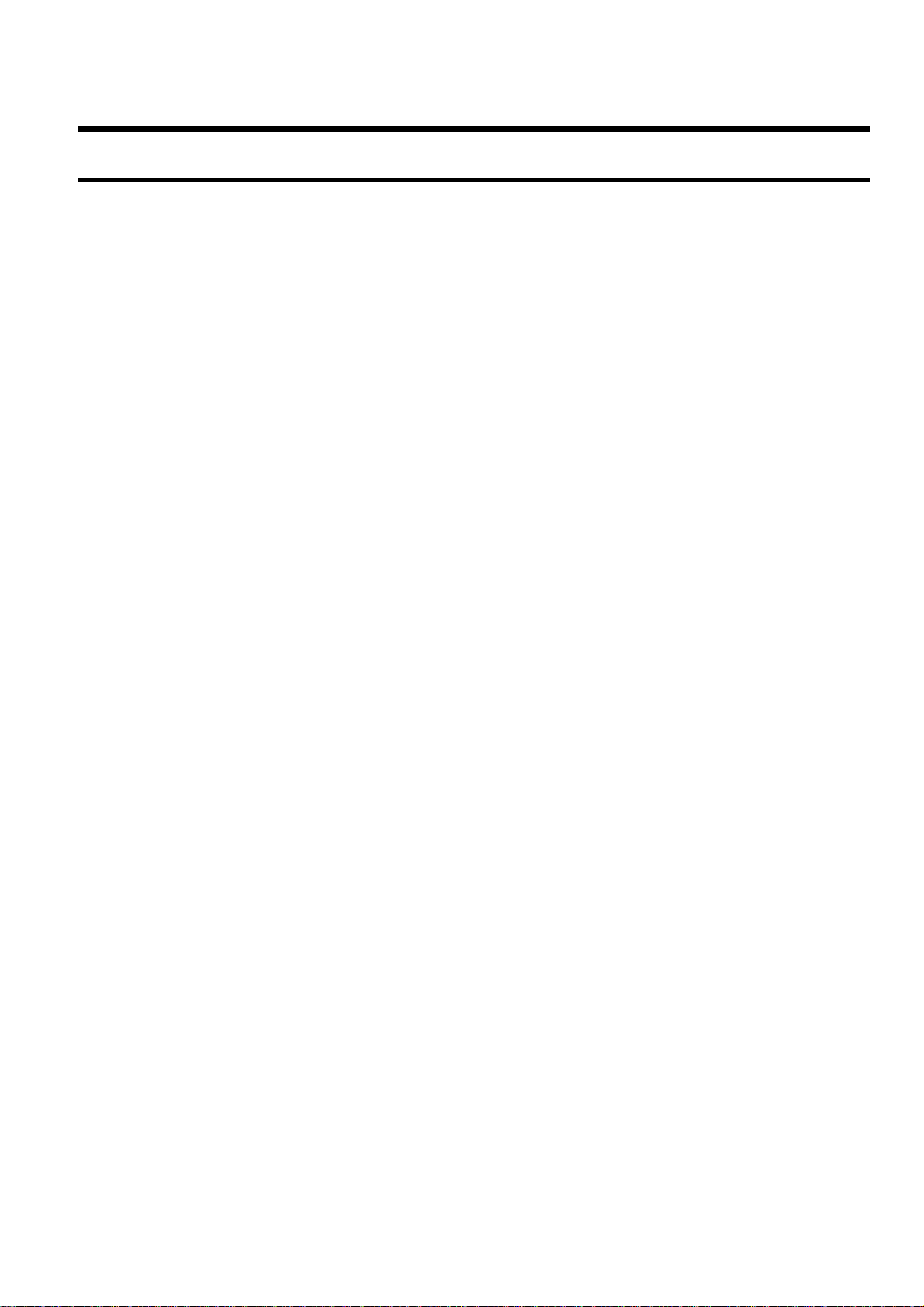

Assy Cylinder, the Capsrtan Motor & TM-Block are used for this model, as shown below.

Assy-Cylinder

How to identify the Assy-Cylinder

Fig. 1

1) Three kinds of the Assy-Cylinder as shown below.

Œ ALPS Cylinder ´ SEM Cylinder

Connector ; Pin 7 Connector ; Pin 5

Connector ; Pin 5

2) When replacing the Assy-Cylinder, be sure to replace only “SEM Cylinder”.

The only part-no of “SEM Cylinder” is shown in the “CH7. Replacement Parts List” of Service Manual.

3) When changing from ALPS (connector ; pin 7) cylinder to SEM (connector ; pin 5) cylinder.

- Change CN605 (Connector ; pin 7 pin 5)

- Change CN605B (Cable-Flat ; pin 7 pin 5)

4) After replacing the “SEM Cylinder”, use type

“C, D, G, H”

optional for “NVRAM Option Setting”. (See page 5-9)

The Maker of Assy Cylinder

1

2

ALPS

SEM

The Maker of Assy Capstan Motor

1

2

SANKYO

SEM

Two kinds of TM-Block

1

2

SIF available

Not SIF availablea

ALPS Cylinder SEM Cylinder

CONNECTOR ; Pin 7 or Pin 5

CONNECTOR ; Pin 5

Page 5

II

Toshiba

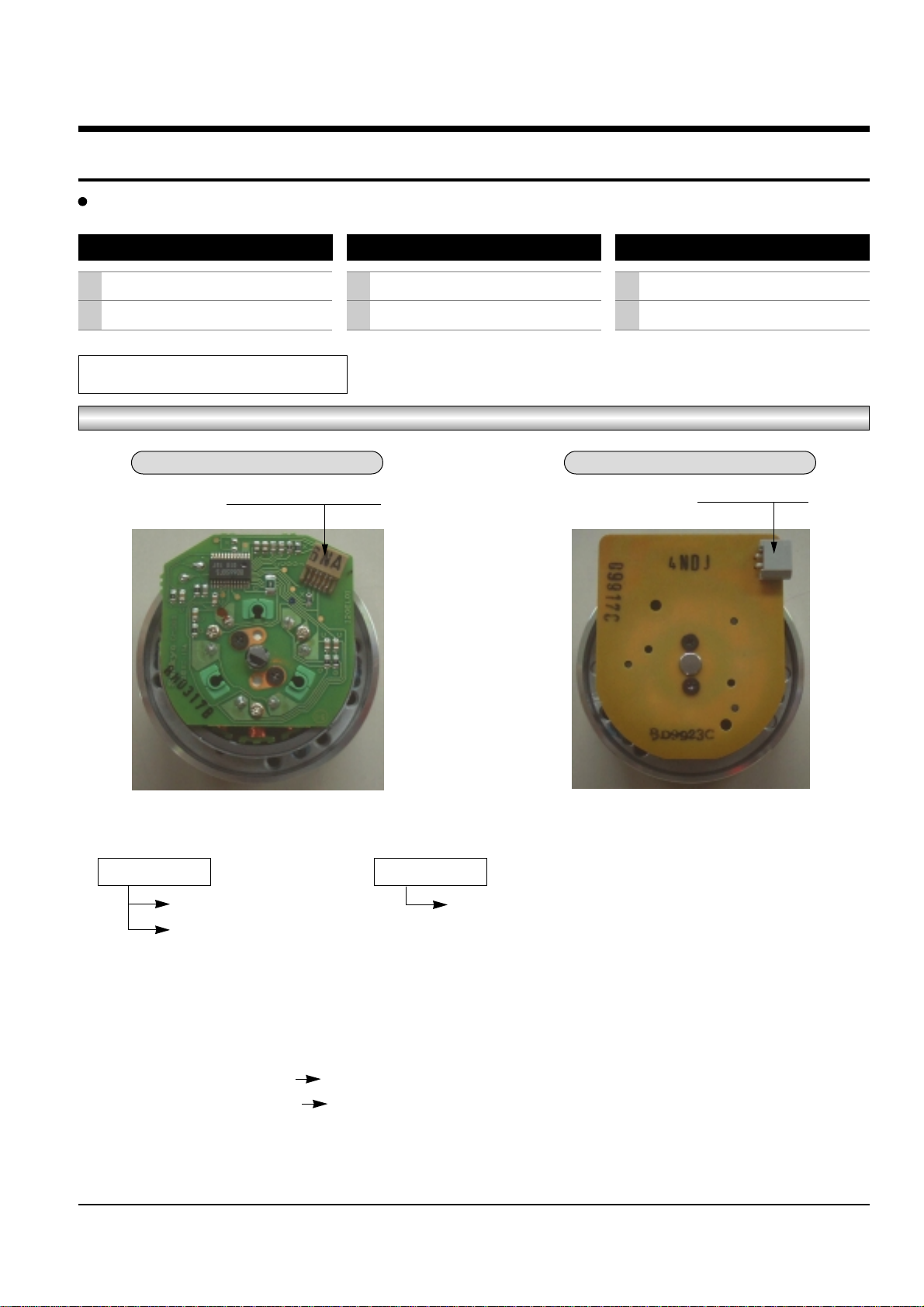

How to identify the Capstan Motor

Fig. 2

1) Two kinds of the Capstan Motor ΠSankyo Capstan Motor

´ SEM Capstan Motor

2) When replacing the Capstan Motor, be sure to replace only “SEM Capstan Motor”.

The only part-no of “SEM Capstan Motor” is shown in the “CH7. Replacement Parts List” of Service Manual.

3) After replacing the “SEM Capstan Motor”, use type

“E, F, G, H”

optional for “NVRAM Option Setting”. (See page 5-9)

Capstam Motor

TM-BLOCK

1) Two kinds of the TM-Blovk ΠSIF available

´ Not SIF available

2) How to identify TM-Block ; See page 5-11 (Fig. 5-21)

- In case there is VR501 ; Not SIF available

- In case there is no VR501 ; SIF available

3) When replacing the TM-Block as a service parts, be sure to replace only the TM-Block which is SIF available.

The only part-no of “SIF available” is shown in the “CH7. Replacement Parts List” of Service Manual.

4) After replacing “TM-Block”, use type

“B, D, F, H”

optional for “NVRAM Option Setting” regardless of VR501. (See page 5-9)

TOP VIEW

SANKYO CAPSTAN MOTOR SEM CAPSTAN MOTOR

CAPSTAN SHAFT CAPSTAN SHAFT

Page 6

Toshiba 1-1

1. Precautions

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all pretective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

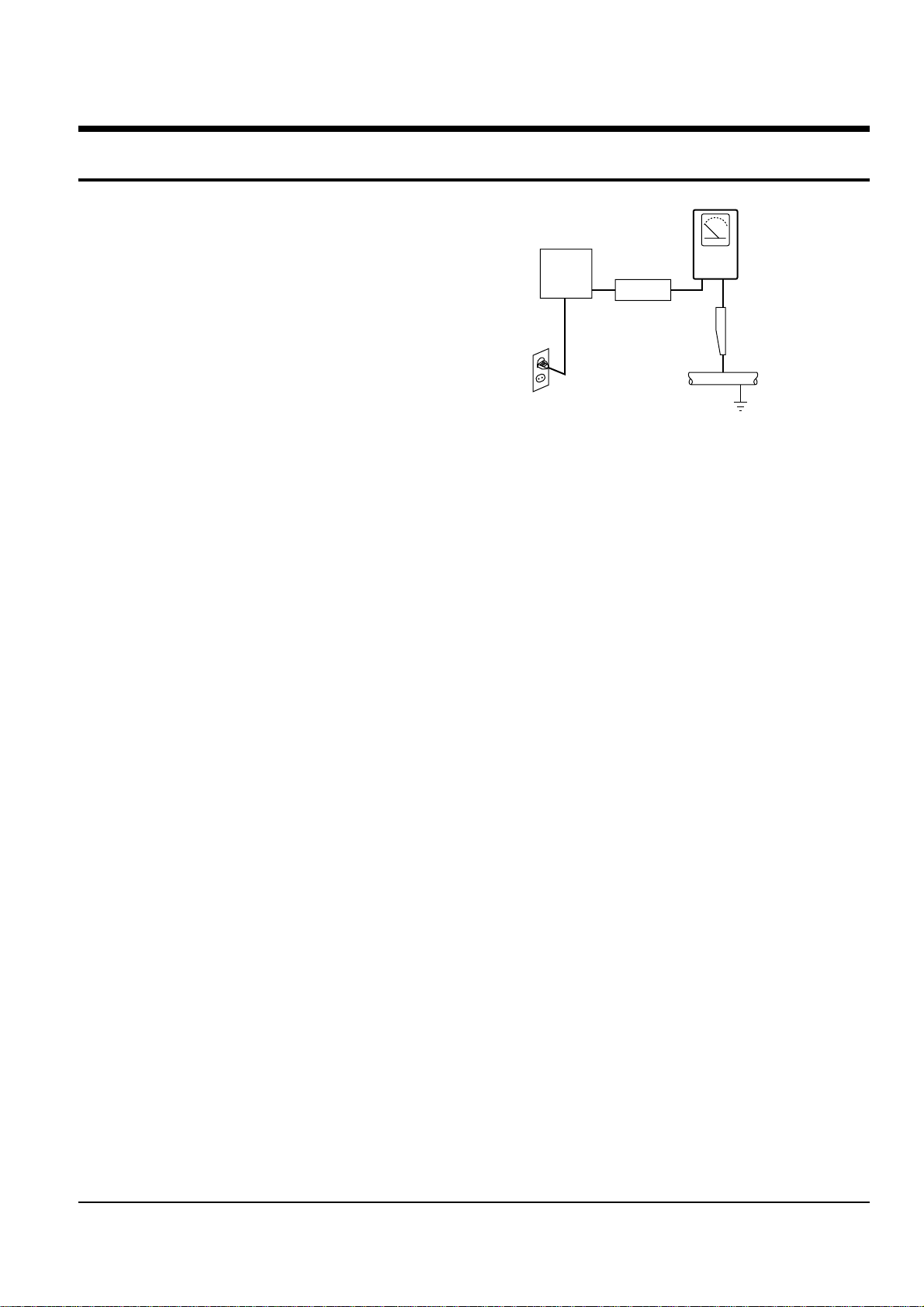

4. Leakage Current Hot Check (See Fig. 1-1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unit’s

AC switch first in the ON position and then OFF,

measure the current between a known erath

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

Fig. 1-1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by static

electricity.

10. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

Page 7

Precautions

1-2 Toshiba

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors.

Such alterations might create a safety hazard.

Also, any design changes or additions will void

the manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some “in-line” picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

“permanently attached” yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. Areplacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

Page 8

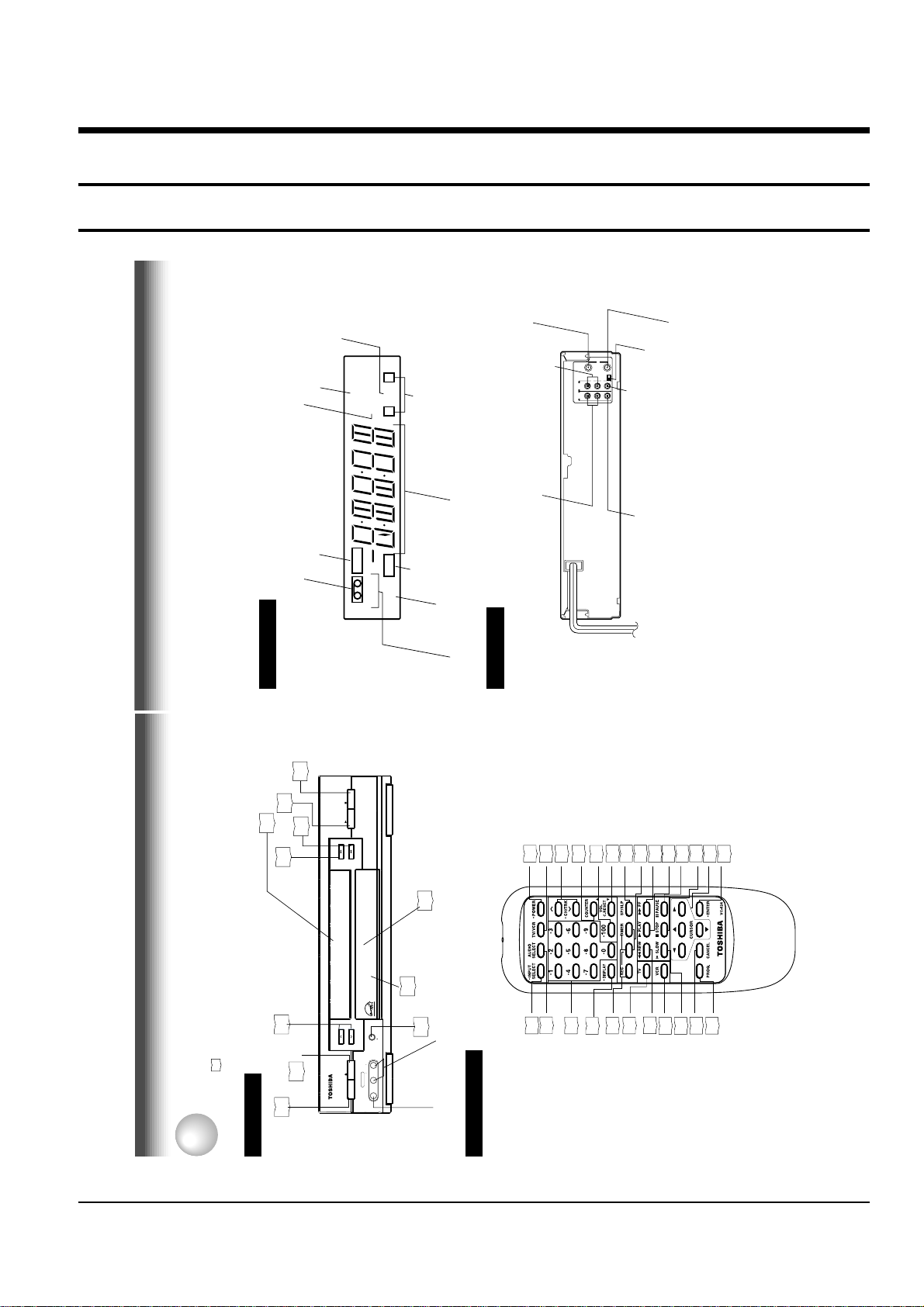

Toshiba 2-1

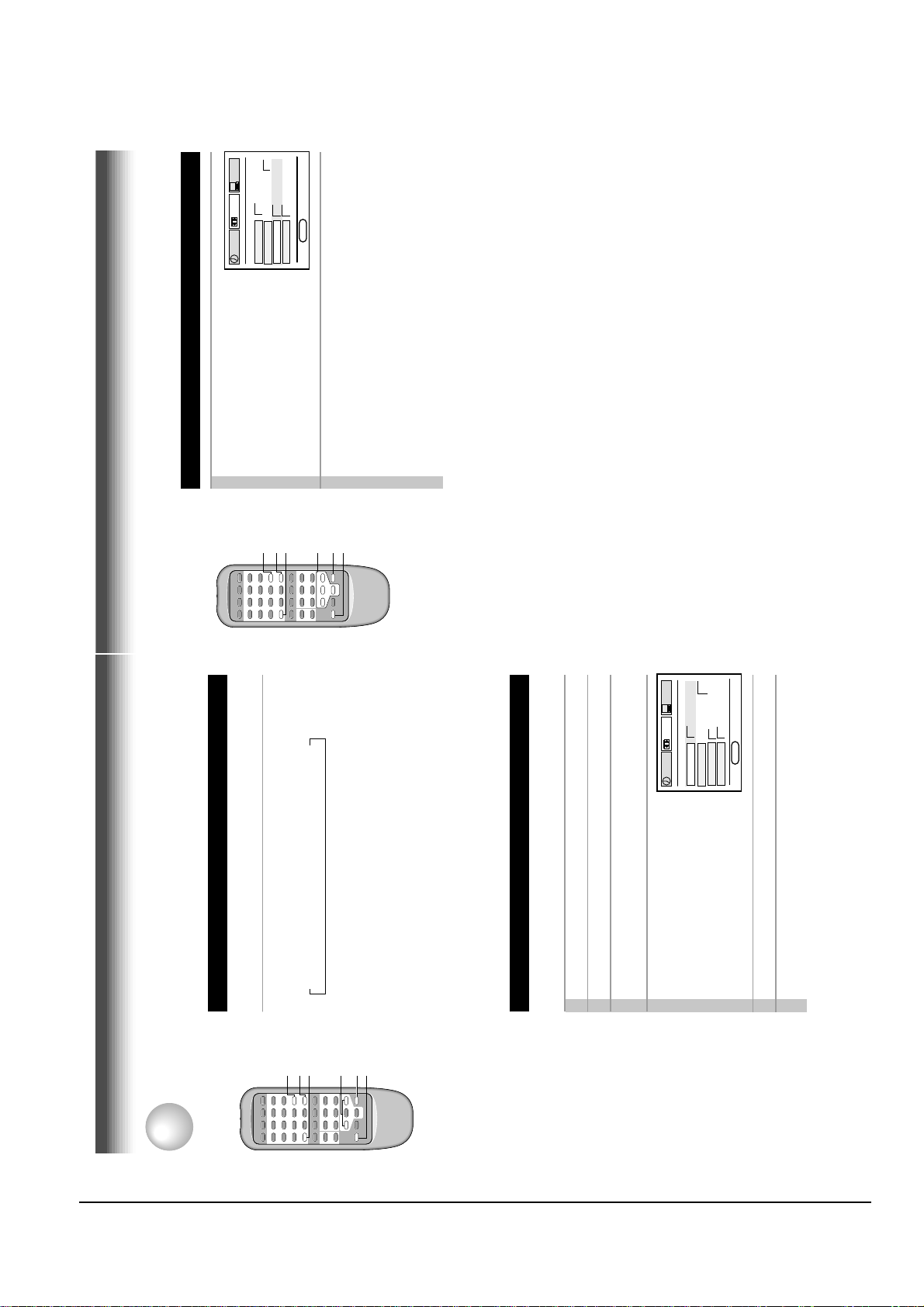

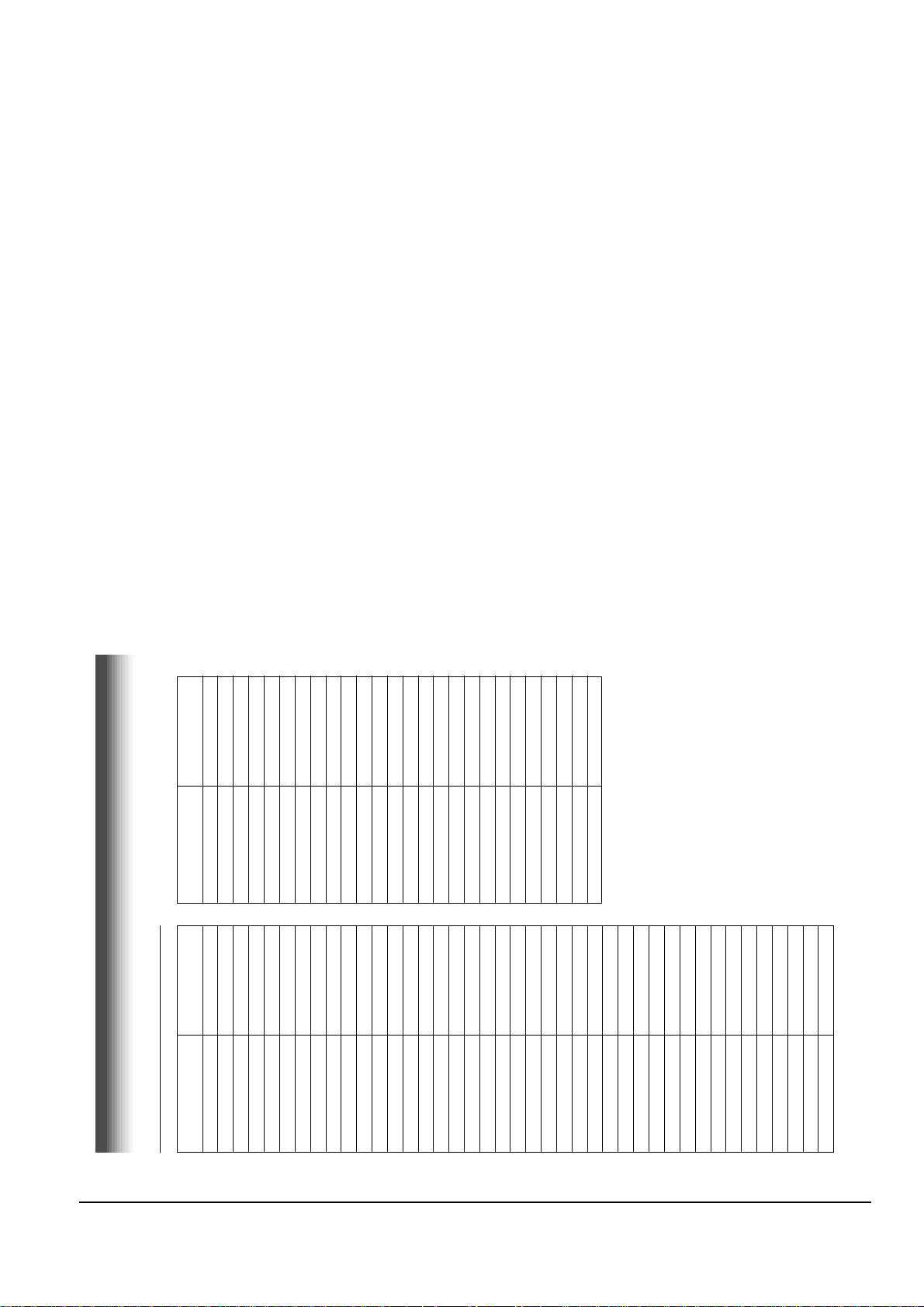

9

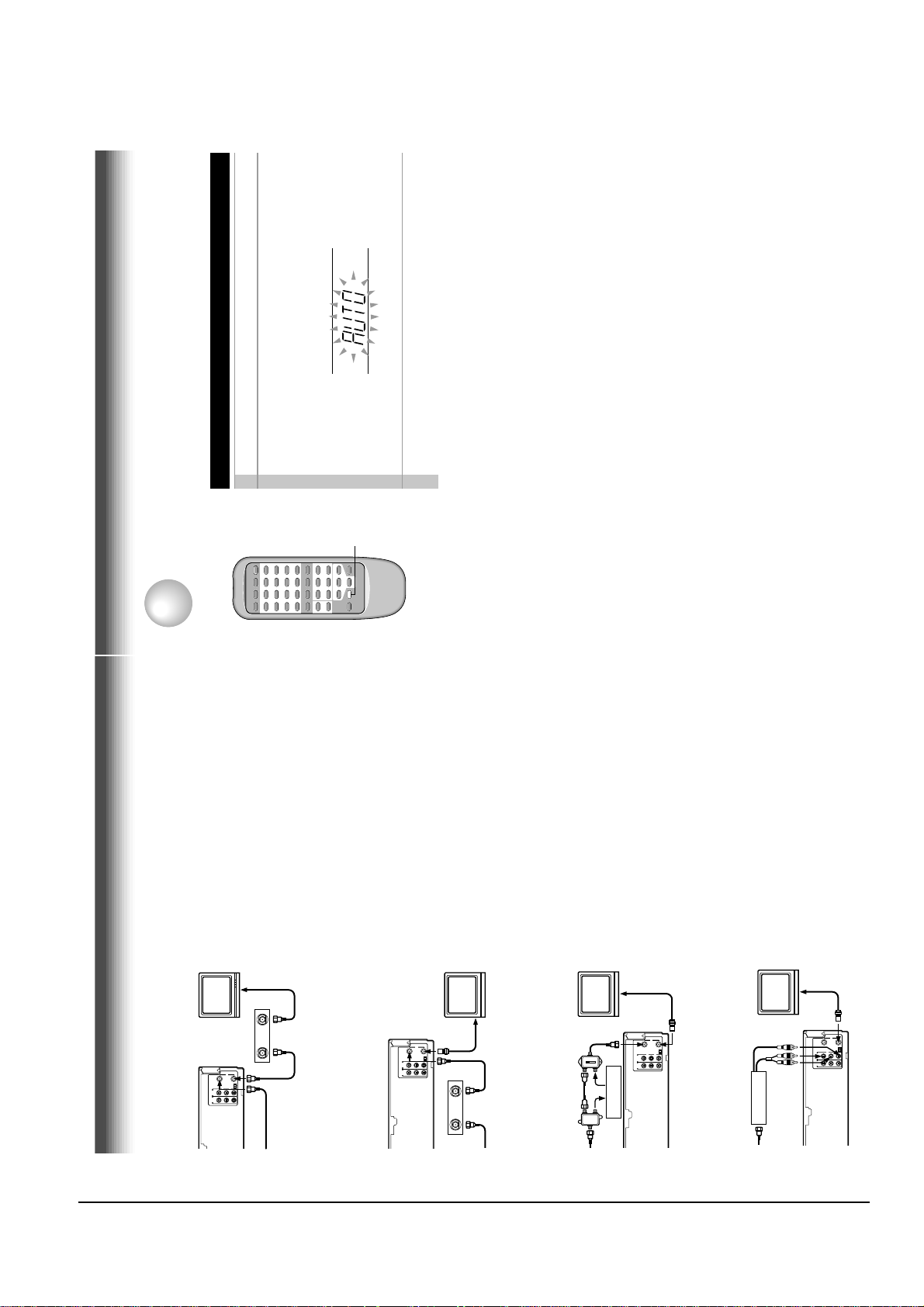

Rear Panel

LINE IN 1 AUDIO (Rear), 2 (Front) jacks

If the connected equipment is monaural (has one audio output jack), connect the L (MONO) side, the same

sound is recorded on both L and R on the Hi-Fi track.

Multifunctional

indicator

REC (Recording)

indicator

VCR indicator

Tape speed indicator (SP/SLP)

Cassette indicator

Timer recording indicator

STEREO indicator

Hi-Fi indicator

SAP indicator

Hi-Fi (L/R) indicators

L: Left channel

R:Right channel

off: Normal track

VCR Display

Hi-Fi

STEREO

SLP

SAP

VCR

REC

L R

TIMER

INTRODUCTION

L

R

CH selector (3/4)

LINE OUT AUDIO jacks (L, R)

LINE OUT VIDEO jack

RF IN (FROM ANT.) terminal

LINE IN 1 AUDIO jacks (L, R)

RF OUT (TO TV) terminal

LINE IN 1 VIDEO jack

CH

OUT

(

TO TV)

IN

(

FROM ANT.)

LINE

OUT

LINE

IN 1

VIDEO

AUDIO

34

RF

To wall outlet

2. Reference Information

2-1 Operation of Controls

STOP

19

PLAY

19

Cassete compartment

18

REW

19

FF

19

STOP

PLAY

FF

POWER

TV/VCR

CH/TRK

FF

REW

VCR Display

14

24

19

VOL/C.RESET

COUNTER

100

22

22

17

SP/SLP24TIMER

26

19

PLAY

19

PAUSE

20

STOP

CURSOR

19

14

ENTER

14

9

Remote

Sensor

Identification of Controls

INTRODUCTION

See the page in for details.

This manual shows the names of buttons in italics.

CHANNEL

24

EJECT

18

14

Front Panel

POWER

CHANNEL

EJECT

POWER

LINE IN 2

10

REC

L/MONO AUDIO R

VIDEO

REC

24

LINE IN 2 AUDIO

(L/MONO, R) jacks

LINE IN 2 VIDEO jack

Remote Control

24

22

24

24

28

REC

DISPLAY

INPUT SELECT

AUDIO SELECT

Number buttons

29

TV

19

REW

14

VCR

21

27

SLOW

CANCEL

14

PROG

8

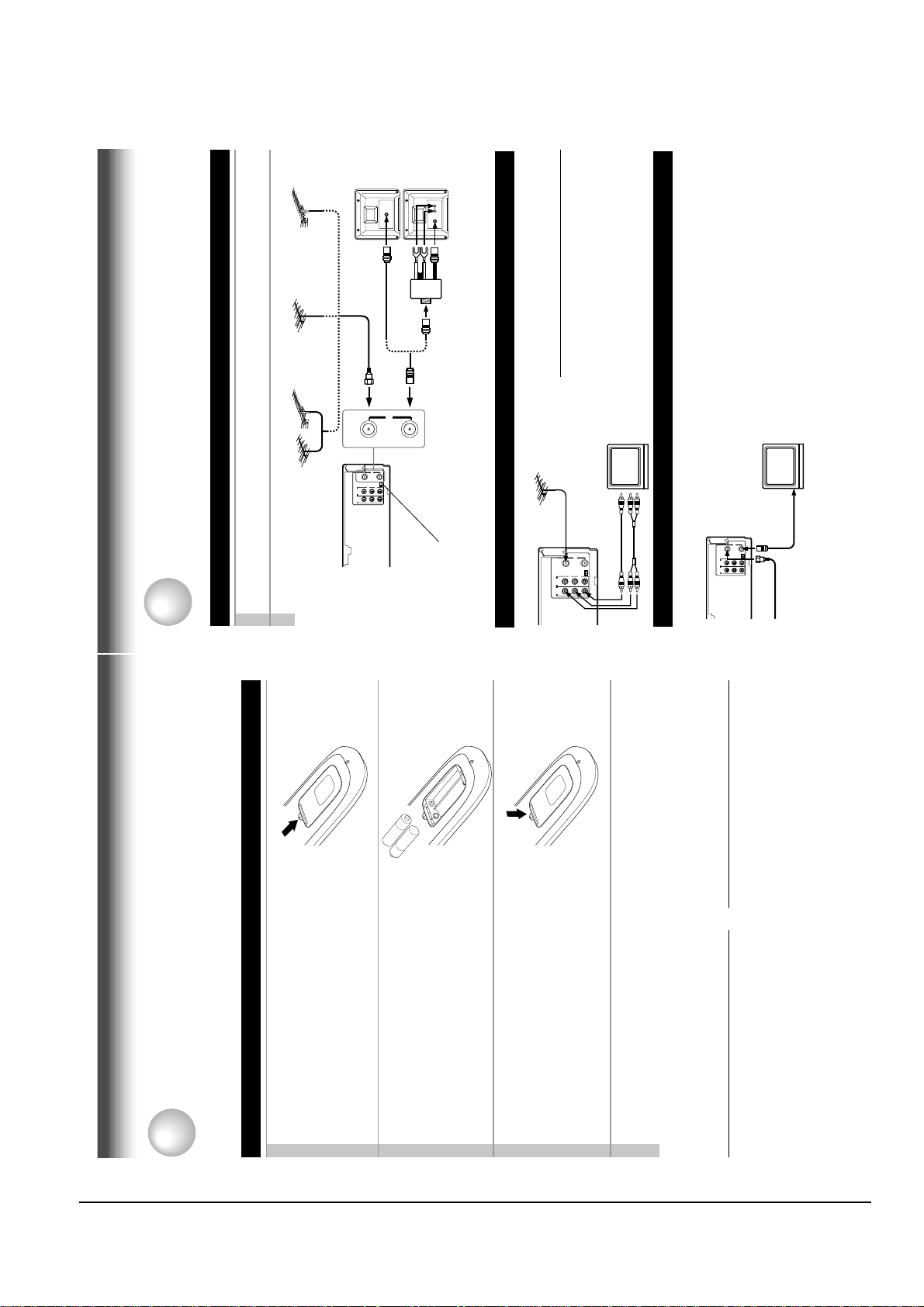

Page 9

Reference Information

2-2 Toshiba

11

PREPARATION

VHF UHF

VHF/UHF

L

R

CH

OUT

(

TO TV)

IN

(

FROM ANT.)

LINE

OUT

LINE

IN 1

VIDEO

AUDIO

34

RF

OUT

(

TO TV)

IN

(

FROM ANT.)

RF

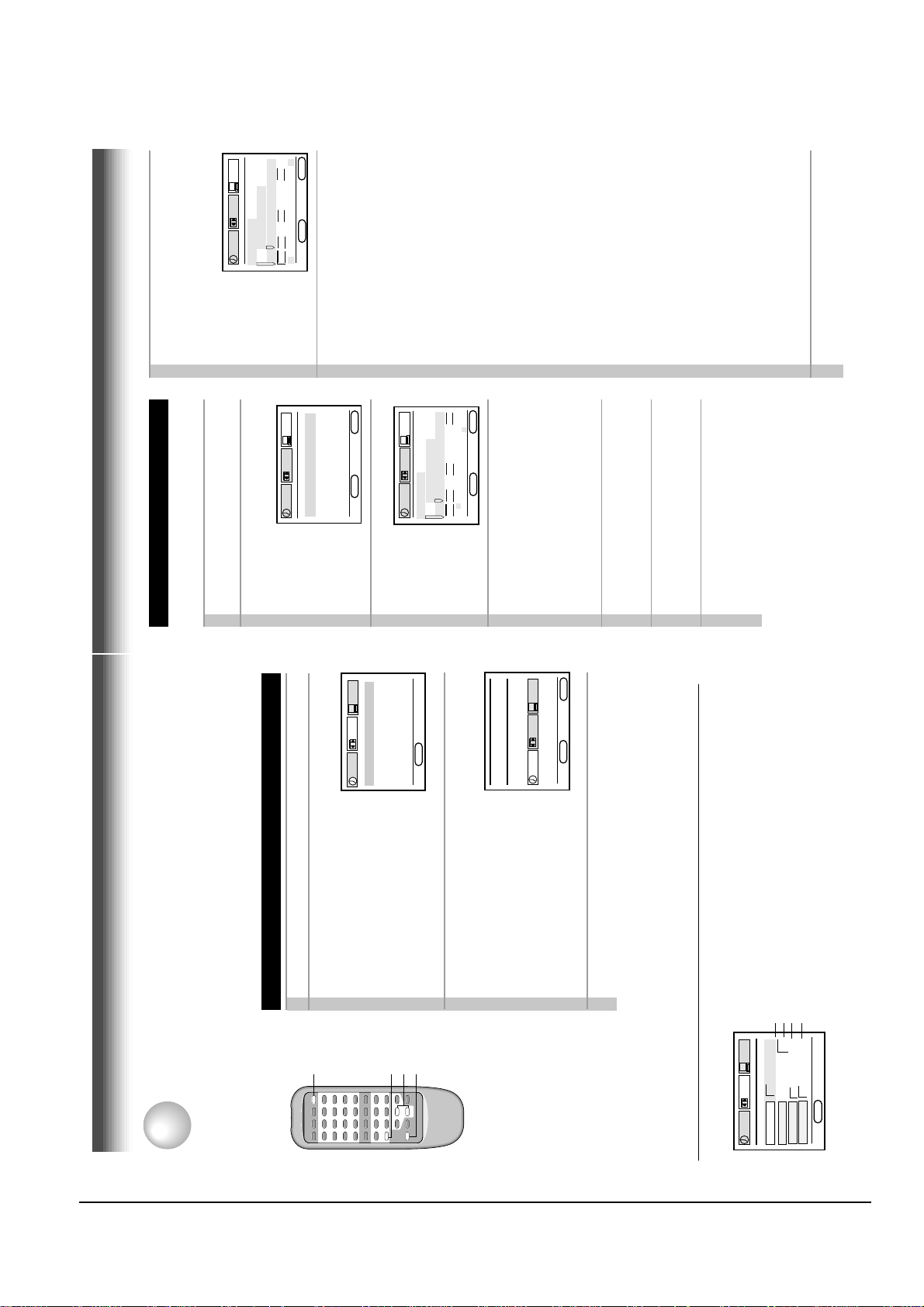

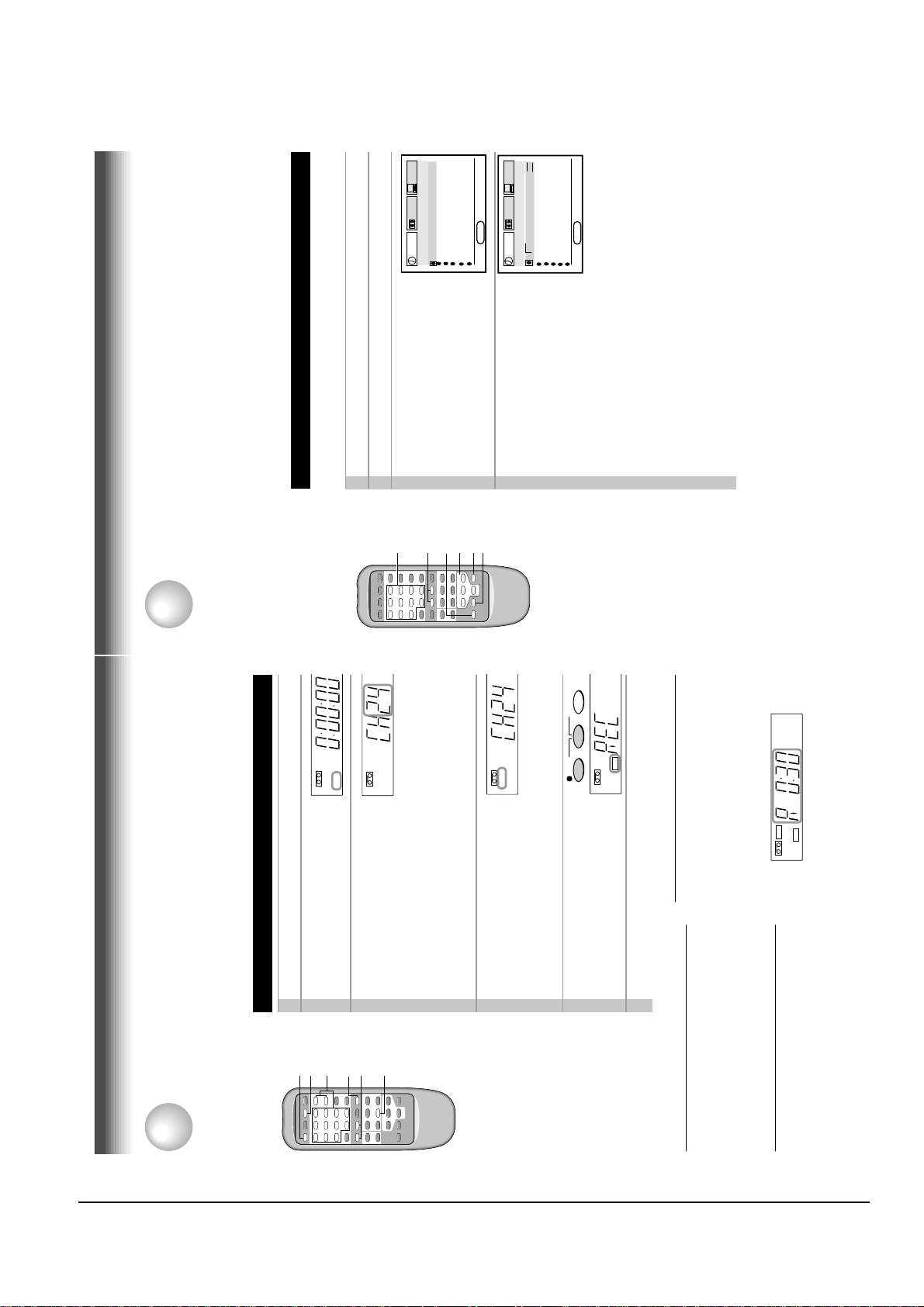

Antenna/VCR/TV Connection

1

Disconnect the antenna cable from your TV and connect it to the RF IN terminal on the

VCR.

2

Connect the RF OUT terminal to the TV.

AUDIO/VIDEO Connections

The AUDIO/VIDEO jacks are also available to connect your TV.

When connected your TV using the

AUDIO/VIDEO OUT jacks

To watch video pictures, set the video input mode

on your TV. For the video input mode, refer to

the manual of your TV.

Setting the VCR Output Channel

When the VCR is connected in this way, the VCR sends the output

signals to channel 3 or 4 on your TV. Set the output channel

selector (CH selector) of the VCR to “3” or “4”, whichever is vacant

in your area.

VHF/UHF

combinaion antenna

VHF antenna

only

UHF antenna

only

Antenna splitter

(not supplied)

1

2

Connections

Before you use this VCR, it is necessary to connect it to your TV. Several ways of connecting are

available depending on your use of TV or cable box. Select one which is applicable to your equipment.

PREPARATION

L

R

CH

OUT

(

TO TV)

IN

(

FROM ANT.)

LINE

OUT

LINE

IN 1

VIDEO

AUDIO

34

RF

LINE OUT VIDEO

VIDEO IN

AUDIO INLINE OUT AUDIO

Cable Connection

Choose one of the below according to your usage of the cable box.

This set-up will enable you to:

– record an unscrambled channel.

– watch an unscrambled channel while recording it.

– record an unscrambled channel while watching

another (only when you connect a cable-

compatible TV).

You will need to:

• select TV channel 3 or 4 to receive video signals.

• to record a channel while watching another, press

TV/VCR on the remote control to turn off the

“VCR” indicator in the VCR display and select a

desired channel on the TV (only when you connect

a cable-compatible TV).

L

R

CH

OUT

(

TO TV)

IN

(

FROM ANT.)

LINE

OUT

LINE

IN 1

VIDEO

AUDIO

34

RF

Incoming cable

+

+

This section explains how to get ready for remote control operation.

How to Use the Remote Control

PREPARATION

Open the battery compartment lid on the

rear panel.

Setting up the Remote Control

1

Install 2 batteries (“AA” size) following

2

the polarity diagrams.3Close the battery compartment lid.

Point the remote control at the VCR and press the buttons within the operating range.

Distance: within about 7 m from the front of the remote sensor

Angles: within about 30˚ in every direction

4

to a strong light source such as direct sunlight

or illumination (especially high-frequency

Caring for the remote control

Notes on batteries

lighting) when using the remote control.

• Do not expose the remote sensor of the VCR

depending on the conditions of use.

correctly, replace all batteries with new ones.

• The life of the batteries is about 1 year

• If the remote control does not operate

control or to place it on anything wet, and avoid

sharp impacts.

• Be careful not to spill water on the remote

long period of time, remove the batteries to

avoid possible damage from battery corrosion.

• If the remote control is not to be used for a

10

Page 10

Reference Information

Toshiba 2-3

13

PREPARATION

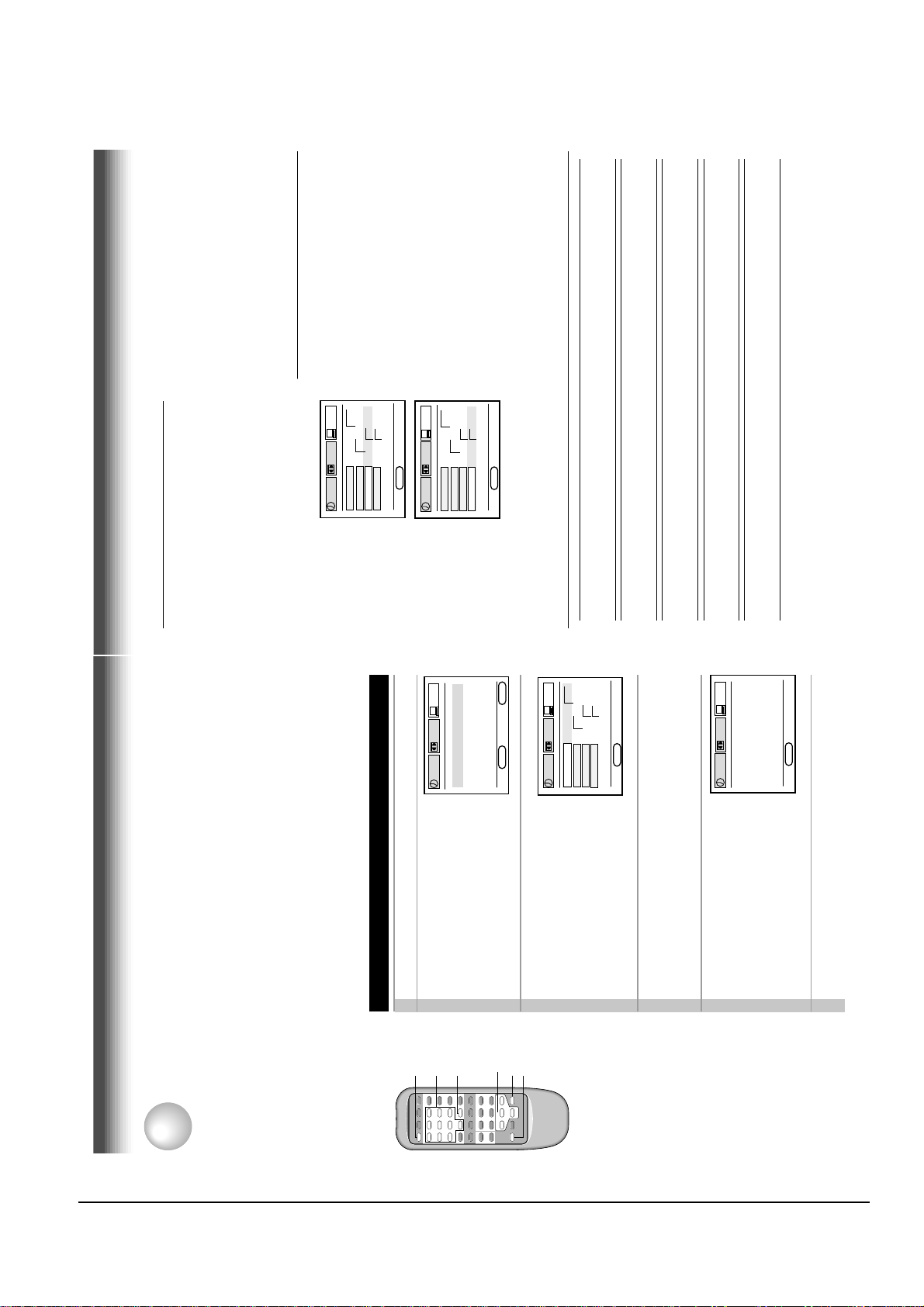

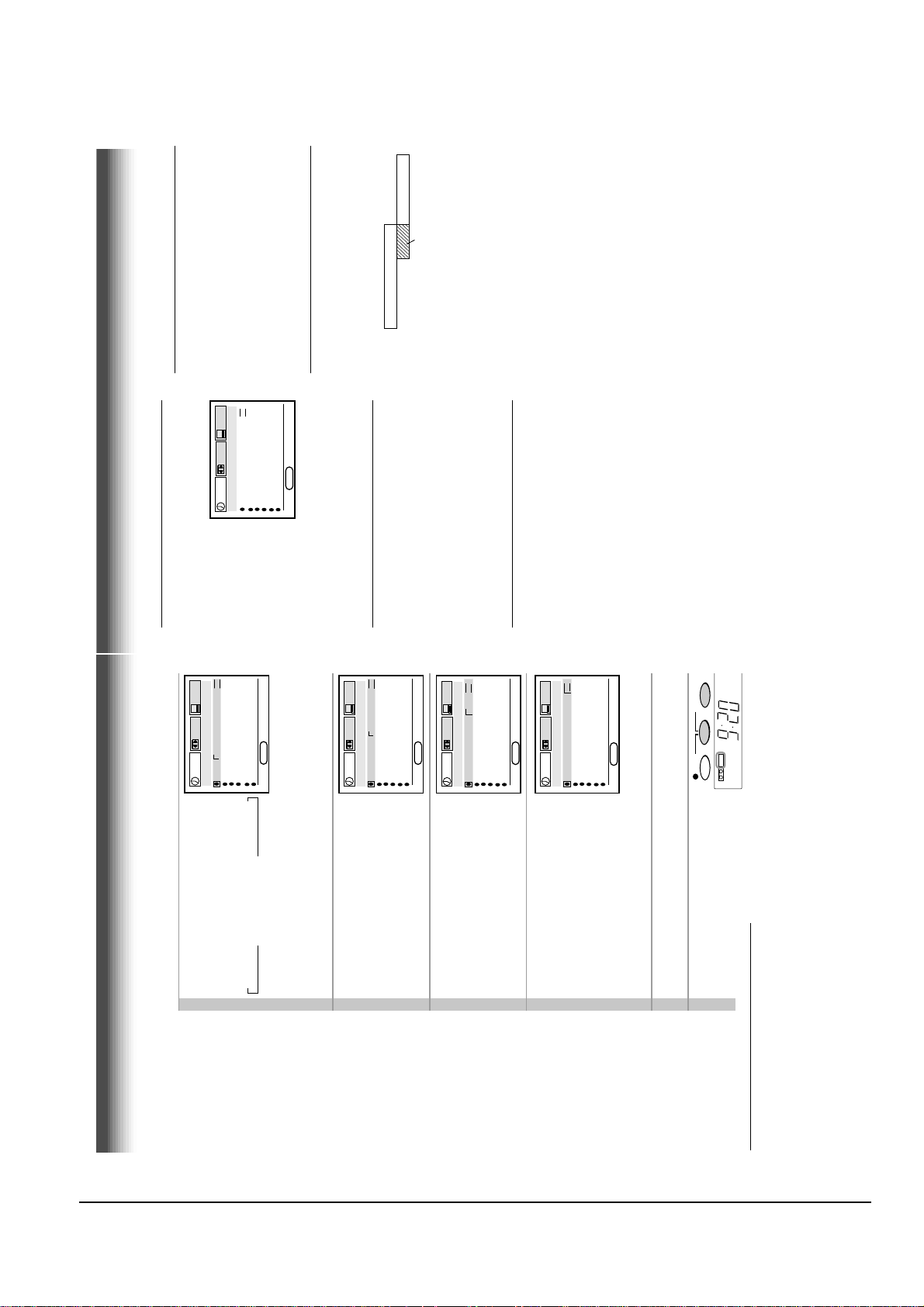

Auto Set Up

The VCR’s clock and tuner channels are set automatically when the VCR is plugged into the AC outlet.

PREPARATION

Auto Set up

1

Plug the VCR into the AC outlet2“AUTO” blink while the VCR automatically sets the clock

using the data broadcast by the local TV stations.

While “AUTO” is blinking, channel memory is also set

automatically.

3

When Auto set up has been completed, the VCR is on

standby mode.

Notes

• It may takes several minutes during the Auto set up

• Press CANCEL on the remote control to cancel the auto set up.

CANCEL

unscrambled channel which

comes bypassing the cable

box.

or unscrambled channel coming

through the cable box.

another (scrambled or unscrambled).

box.

or 4 according to the output channel of the VCR.

press TV/VCR on the remote control to turn off

the “VCR” indicator in the VCR display and select

This set-up will enable you to:

– record an unscrambled channel.

– watch an unscrambled channel while recording it.

– record an unscrambled channel while watching

You will need to:

• set TV channel to the output channel of the cable

• turn on the cable box and select cable channel 3

a desired cable channel on the cable box.

• to record a channel while watching another,

while recording it.

This set-up will enable you to:

– watch an unscrambled or scrambled channel

– record any channels through the cable box.

(See page 11.)

cable box, and select a desired cable channel

on the cable box.

indicator is not lit in the VCR display, set TV

You will need to:

• set TV channel 3 or 4 to receive video signals.

• set VCR channel to the output channel of the

channel to the output channel of the cable box.

• while the VCR is turned off or the “VCR”

while recording it.

This set-up will enable you to:

– watch an unscrambled or scrambled channel

another unscrambled channel (only when you

connect a cable-compatible TV).

– record an unscrambled channel while watching

• A/B switch “A”:record and watch an

• A/B switch “B”:record and watch a scrambled

box via the LINE IN 1 (AUDIO/VIDEO) jacks.

This set-up will enable you to:

– watch or record a channel through the cable

You will need to:

shows “L1”.

• press INPUT SELECT so that the VCR display

OUT

RF

IN

TO TV)

OUT

(

FROM ANT.)

(

CH

34

L

R

VIDEO

AUDIO

IN 1

LINE

OUT

LINE

Cable box

CH

34

IN

Incoming cable

RF

IN

TO TV)

OUT

(

FROM ANT.)

(

L

R

VIDEO

AUDIO

IN 1

LINE

OUT

LINE

Connections (continued)

RF

IN

TO TV)

OUT

(

FROM ANT.)

(

CH

34

L

R

VIDEO

AUDIO

IN 1

LINE

OUT

LINE

OUT

Cable box

IN

Incoming cable

A/B switch

A

A

B

A

B

B

Cable box

RF

IN

TO TV)

OUT

(

FROM ANT.)

(

CH

34

L

R

VIDEO

AUDIO

IN 1

LINE

OUT

LINE

Cable box

12

Page 11

Reference Information

2-4 Toshiba

15

PREPARATION

8

Press ENTER to start the “AUTO” clock

set feature.

After the VCR is turned off, it automatically

updates the clock using the data broadcast

by the local TV stations.

9

Select the options using CURSOR

( ) or ( ). Change the data using

CURSOR (▲) or (▼).

1) Set “SUMMER TIME

(Daylight-Saving Time)”.

DST start: Daylight-saving time begins on

the first Sunday in April. Because the

clock automatically changes from 2:00 AM

to 3:00 AM (forward one hour).

DST end: Daylight-saving time ends on

the last Sunday in October. The VCR

clock automatically changes from 2:00 AM

to 1:00 AM (back one hour).

remember that any part of a scheduled

Timer Recording that falls between these

two times will not be recorded.

AUTO: the VCR is using the clock data

Broadcast by the local TV stations.

IN: You want to use the DST function, and

you are leaving in the area that apply

Daylight-saving time.

OUT: You are not leaving in the area that

apply Daylight-saving time and you do not

want to use DST function.

2) Set “TIME ZONE”.

If you select “AUTO” for your time zone,

the VCR sets the clock using the first

Coordinated Universal Time information it

finds. If the time is not correct, select

another time zone or use the “MANU”

option.

3) Set “CLOCK DATA CH”.

If you don't know the clock data channel,

select “AUTO”. The VCR will scan

automatically to tune the channel carrying

the clock data.

If AUTO CLOCK SET is unsuccessful, set the

time and date through the “MANU” clock

set menu selection.

10

Press PROG..

Now the clock starts.

Setting the Clock

Example: To set the clock to 2:30 p.m. on

August 25 (summer time) 2000.

1

Press PROG..

The MENU screen appears on the TV.

2

Select “PRESET” using CURSOR ( ) or

( ), and press ENTER.

3

Press ENTER to select “CLOCK SET”.

4

Select “AUTO” or “MANU” using

CURSOR (▲) or (▼).

AUTO: The VCR automatically sets or

adjusts the clock.

If you select “AUTO” mode, proceed to step 8.

MANU: You can set the clock manually.

If you select “MANU” mode, proceed to next

step.

5

Vary the digits to set the hour.

CURSOR ▲: To increase.

CURSOR ▼ : To decrease.

6

Move to the next using CURSOR ( )

(To move back, press CURSOR ( ).)

7

Repeat step 5 and 6 to set the minutes,

month, day, and the year (by the last

two digits).

Proceed to step 10 to start the clock.

E

n

D : PROG

SET UP

PRESET

PROGRAM

ENTER

CLOCK SET

CH MEMORY

▼

▼

▼

▼

▼

▼

E

n

D : PROG

SET UP

PRESET

PROGRAM

ENTER

CLOCK SET

SUMMER TIME

TIME ZO

n

E CH

AUTO

AUTO

AUTO

PRESS E

n

TER

TO START SETTI

n

G

E

n

D : PROG

SET UP

PRESET

PROGRAM

ENTER

CLOCK SET

SUMMER TIME

TIME ZO

n

E CH

AUTO

AUTO

AUTO

AUTO

2

SCA

nn

I

n

G

n

O

W

* The clock is

revised by

broadcasting

signal at 8:00 A.M

every morning.

The language selection and clock setting must be set first when VCR is first plugged in or after it

encounters a power failure.

Initial Settings Using On-screen Display

PREPARATION

Preparation

ENTER

U

n

ME

PRESET

SET UP

PROGRAM

D : PROG

n

E

PRESET

SET UP

PROGRAM

English

Français

Español

D : PROG

n

E

1

2

Press POWER to turn on the VCR.

Press PROG..

The following screen appears on the TV.

Setting the Language

The screen turns to the MENU screen.

3

Press PROG. to return to the normal TV screen.

4

Select the language using CURSOR

(▲) or (▼) , and press PROG..

POWER

connection (page 11).

• Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video

• Press VCR to set the remote control operating the VCR.

CURSOR

VCR

PROG

Page 22

Page 28

To change the language, move down here and set to the desired one.

PRESET

SET UP

PROGRAM

Optional settings on the SET UP screen

Other optional settings can be made. Press ENTER while “SET UP” is selected on the MENU screen.

The screen turns to the SET UP screen.

Page 23

G FRA ESP

n

on off

120 160 180

GTH

on off

n

TER MEM

GUAGE E

n

D : PROG

n

n

LA

SAP SET

TAPE LE

COU

E

To exit, press PROG. twice.

14

Page 12

Reference Information

Toshiba 2-5

17

PREPARATION

To add channels

To erase channels

Channel reference chart

Number on the VCR

Corresponding channel number

TV

CATV STD (HRC/IRC)

CH NUMBER 1 2 3 4 5 6789

– 23456789

1(A-8)

234

5(A-7) 6(A-6)

7

89

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

10 11 12 13 A B C D E F G H I J K L M N O P Q

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

R S T U V W AA BB CC DD EE FF GG HH II JJ KK LL MM NN OO

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71…52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 ––

…

PP QQ RR SS TT UU VV WW XX YY ZZ AAA BBB 65 66 67 68 69 70 71

…

93 94 95 96 97 98 99 100 101 102 103

…

121 122 123 124 125

–––––––––––

…

–––––

93 94 A-5 A-4 A-3 A-2 A-1 100 101 102 103

…

121 122 123 124 125

3)Enter a channel number of 1 to 125 using

number buttons.

For more than 100 number, first press 100.

For CATV channels, refer to the chart below.

(For other orders, check with your cable

company.)

4)Repeat steps 2) and 3) to add or erase

channels as necessary.

5)Press PROG. three times to exit.

Selecting stored channels

Once the active channels have been stored, you

can select the channels in two ways below.

Number buttons

To enter digits of the channel number.

• For one-digit number, enter 0 before.

• For more than 100 number, first press 100.

• Each number button needs to be pressed

within 2 seconds.

CH/TRK buttons

To shift up or down the stored channel numbers.

CATV signals

• STD (standard) cable TV signals

• HRC (Harmonic Related Carriers) cable TV signals

• IRC (Incremental Related Carriers) cable TV signals

IRC is also called ICC (Incremental Coherent Carriers)

Adding or erasing channels

Adding channels

If a desired channel cannot be scanned

automatically because of a weak signal, it can be

added to the memory.

Erasing channels

You can erase a stored channel from the memory

if it is unnecessary.

1)Follow steps 1 to 3 of “Incoming Antenna/

CATV Signals”.

2)Select “ADD CH” or “ERASE CH” using

CURSOR (▲) or (▼).

E

n

D : PROG

SET UP

PRESET

PROGRAM

TV/CATV TV CATV

AUTO SCA

n

OFF O

n

ADD CH - - CH

ERASE CH - - CH

TO SET CH PUSH 0~9 KEYS

E n D : PROG

SET UP

PRESET

PROGRAM

TV/CATV TV CATV

AUTO SCA

n

OFF O

n

ADD CH - - CH

ERASE CH - - CH

TO SET CH PUSH 0~9 KEYS

Storing Channels on the VCR

PREPARATION

This section is required if you receive only normal TV or unscrambled cable channels, or use a cable box

between your TV and the VCR.

PRESET

SET UP

CLOCK SET

CH MEMORY

PROGRAM

▼

▼

Press PROG. to display the MENU screen.

Select “PRESET” using CURSOR

1

INPUT

( ) or ( ), and press ENTER.

2

SELECT

Number

buttons

100

Incoming Antenna/Cable(CATV) Signals

The VCR scans through all receivable TV and CATV channels and stores only the active

ones in your area into the memory. Once the storing is finished, you can select a desired

channel using CH/TRK.

Preparation

• Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video

connection (page 11).

• Press INPUT SELECT so that the channel number will appear if “L1” or “L2” is displayed in the VCR display.

Incoming Antenna/Cable(CATV) Signals

PRESET

ENTER

SET UP

D : PROG

n

E

CURSOR

PROGRAM

TV/CATV TV CATV

Select “CH MEMORY” using

CURSOR (▲) or (▼), and press

ENTER

ENTER.

3

1, 6

n

▼

OFF O

n

D : PROG

n

ADD CH - - CH

AUTO SCA

ERASE CH - - CH

E

PRESET

SET UP

2 CH on

n

PROGRAM

AUTO SCA

D : PROG

n

E

▼

▼

( ).

Set “TV/CATV“ to “TV” or “CATV” using CURSOR ( ) or

TV: To store channels received via the antenna.

CATV: To store channels received via the incoming cable.

Select “AUTO SCAN” using

CURSOR (▲) or (▼), and press

The VCR starts scanning and the

channels are stored in the VCR in

ascending order. When the scanning is

finished, the screen automatically

4

CURSOR ( ) to set to “ON”.

5

returns.

Press PROG. three times to exit.

6

16

Page 13

Reference Information

2-6 Toshiba

19

PLAYBACK

Adjusting the tracking

When playback starts, the VCR automatically adjusts the tracking for clear pictures and sound

(Digital Auto Tracking).

If the VCR cannot locate the best possible tracking point, hold down one of CH/TRK to adjust the

tracking manually.

Notes

• During the adjusting, the playback picture and sound may be distorted.

• The digital auto tracking is activated only in the playback mode.

• The noise on the screen may not be completely eliminated depending on the tape used, especially when the

tape was recorded on another VCR.

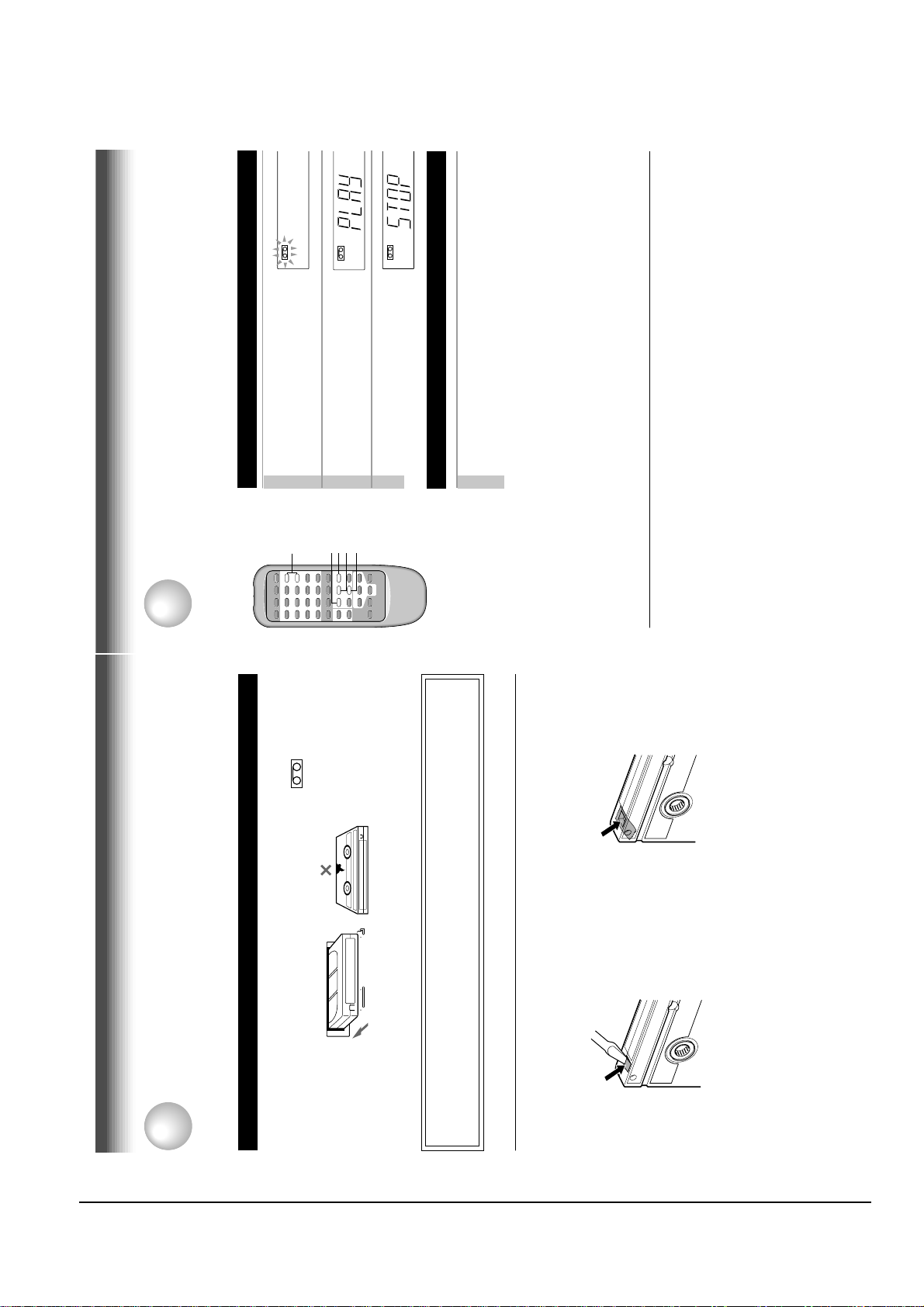

Basic Playback

1

Load a recorded cassette.

Power is turned on.

If the cassette has no safety tab,

playback starts automatically.

2

Press PLAY to start playback.

3

T o stop playback, press STOP.

To resume normal playback

Press PLAY again

Rewinding / Fast-forwarding

Press REW or FF in the stop mode.

PLAYBACK

Playback

This section explains the basic playback operation.

Preparation

• Select the video channel (3 or 4) or video input mode on the TV.

• Press VCR to set the remote control operating the VCR.

REW

CH/TRK

FF

3

2

1

Press PLAY during playback.

A tape runs at double speed

playback.

Double Speed Playback

TIMER

S

SLP

S

L

REC

TIMER

VCR

S L P

S

TIMER

L

REC

S L P

VCR

L

REC

VCR

Video Cassette Use

PREPARATION

Video Cassette Use

To record again

Cover the tab hole with adhesive tape.

Loading a cassette

Push the cassette into the cassette compartment with the window side facing up and the

label side towards the front. The VCR is automatically turned on. The indicator will

appear in the VCR display.

Warning

Do not insert your hands or any foreign objects into the compartment. This may result

Ejecting a cassette

Press EJECT. The cassette is ejected from the cassette compartment.

in injury or damage. Take special care with children to avoid accidents.

Precautions when using video cassettes

Video cassettes have a safety tab to prevent accidental erasure. If the tab has already been removed,

recording cannot be performed.

To prevent accidental erasure

Remove this safety tab with a screwdriver.

Avoid extreme humidity, vibrations or shock, strong magnetic fields (near a motor, transformer or

magnet) and dusty place.

• Avoid exposing cassettes to direct sunlight. Keep them away from heaters.

18

Page 14

Reference Information

Toshiba 2-7

21

PLAYBACK

Frame Advance

A picture advances frame by frame.

1

Press PLAY during still playback.

Each time you press PLAY, the picture advances one frame.

Slow-motion Picture

The tape runs at 1/7th or 1/15th the normal playback speed.

1

Press SLOW during playback.

The tape runs at about 1/7th the normal playback speed.

Each time you press SLOW, the speed alternates between 1/7th and

1/15th.

To resume normal playback

Press PLAY.

Notes

• The slow-motion picture mode is automatically cancelled after about 5

minutes and returns to normal playback.

• The slow-motion picture may flicker up and down. This is not a defect in the

unit.

Adjusting the Tracking Manually

If the slow-motion picture is noisy, hold down one of CH/TRK until the

best picture is obtained.

Note

The noise in the slow-motion picture may not be eliminated completely.

To resume normal playback

Press PAUSE.

Picture Search

PLAYBACK

You can play back a tape at various tape speeds.

Variable Speed Playback

Press FF or REW during playback.

A tape runs at 5 times or 7 times the normal playback speed so

that you can quickly locate a particular scene.

1

The tape runs at 5 times the normal playback speed.

To change the tape speed to 7 times the normal playback

speed, press and hold FF or REW.

If you release it, the tape speed returns to 5 times.

2

Note

If you press FF or REW during picture search, the mode changes to fast-

forwarding or rewinding.

To resume normal playback

Press PLAY.

FF

PLAY

REW

PAUSE

SLOW

Press PAUSE during playback.

Still Picture

The picture freezes.

A picture freezes so that you can watch closer.

1

To resume normal playback

Press PAUSE again.

Notes

• The still mode is automatically cancelled after about 5 minutes and returns to

normal playback.

frozen. This is not a defect in the unit.

• The still picture may shake if a picture of a fast-moving object or scene is

Adjusting Still Picture Stability

If the still picture is distorted or flickers, hold down one of CH/TRK until

the picture becomes stable.

Note

The distortion of the still picture may not be eliminated completely.

20

Page 15

Reference Information

2-8 Toshiba

23

PLAYBACK

1

On the SET UP screen, select

“COUNTER MEM.” using CURSOR

(

▲

) or (

▼

), and set to “ON” using

CURSOR ( ) or ( ).

2

Press PROG. twice to exit.

The memory-stop feature allows you to quickly return to a

counter reading of “0H00M00S” from any point on the tape.

Memory stop is automatically turned on whenever the time

counter with memory is displayed on the TV screen. This is

convenient when you want to watch a segment of the tape

repeatedly. You may also discover other useful application for

this feature.

Notes: If you are rewinding the tape and the VCR stops at

“0H00M00S M”, press REW again to continue

rewinding.

If you press the FF (fast-forward) button and the time

counter never reaches “0H00M00S M” between that

point and the end of the tape, the VCR will continue to

fastforward to the end of the tape.

Memory Stop Feature (Zero Return)

▼

▼

COUNTER

CURSOR

C.RESET

DISPLA Y

ENTER

PROG

E

n

D : PROG

SET UP

PRESET

PROGRAM

TAPE LE

n

GTH

120 160 180

COU

n

TER MEM

on off

LA

n

GUAGE E

n

G FRA ESP

SAP SET

on off

PLAYBACK

These functions will help your playback.

Useful Functions in Tape Operation

Counter Function

You can view the clock, linear time counter or tape remaining

time in the VCR display or on the TV screen.

→ Linear time counter → Tape remaining time (RT) → Clock

Each time you press COUNTER, the VCR display changes in

sequence as follows:

COUNTER

The indication above will also appear on the TV screen by pressing

DISPLAY. They are switchable with COUNTER.

To reset the linear time counter to “0:00:00”

The counter is automatically reset to “0:00:00” when a cassette is

ejected. If you want to reset at another point, such as the beginning of a

new recording, just press C. RESET.

PROG

ENTER

CURSOR

C.RESET

DISPLA Y

clock.

Notes

• The linear time counter does not work on non-recorded portions on the tape.

• When the tape is ejected or the VCR is turned off, the display changes to

• If the tape rewinds back over “0:00:00”, “–” appears in the VCR display.

• The displayed time of the linear time counter is only an approximation.

▼

▼

Turn on the VCR and load a cassette.

Press PROG. to display the MENU screen.

Select “SET UP” using CURSOR ( ) or ( ), and press

Tape Remaining Time

To view the tape remaining time in the VCR display, select the

tape length beforehand.

1

ENTER.4Select the length of the tape, using

2

3

PRESET

SET UP

on off

120 160 180

GTH

on off

n

TER MEM

n

PROGRAM

SAP SET

TAPE LE

COU

▼

▼

CURSOR ( ) or ( ).

T120: for a T-120 tape or shorter

T160: for a T-140 or T-160 tape

T180: for a T-180 tape

G FRA ESP

n

GUAGE E

D : PROG

n

n

LA

E

Press PROG. twice to exit.

Press COUNTER.

The remaining time (“RT - : - -”) appears in the VCR display.

5

6

and the cassette type.

Notes

• The displayed remaining time is an approximation.

• The remaining time is calculated according to the tape speed (SP or SLP)

22

Page 16

Reference Information

Toshiba 2-9

25

RECORDING

Timer Programming Procedure

Example: To record cable channel 25 in the SP tape speed from

9:30 p.m. until 10:00 p.m. on August 30. Today is August 25.

1

Load a cassette with the safety tab attached.

2

Press PROG. to display the MENU screen.

3

Select “PROGRAM” using CURSOR

( ) or ( ), and press ENTER.

4

Move to the next using CURSOR

( ), and select the channel number

25 by pressing number buttons 2

and 5 or using CURSOR (

▲

) or (

▼

).

• To record a cable program from the connected cable box:

Enter the cable channel number using CURSOR (

▲

), (

▼

) or by

pressing number buttons.

If your cable box is not remote-controllable, choose the desired

channel (1 to 125) on the cable box.

To make corrections:

Press CURSOR ( ) to move back to the item, or CURSOR ( ) to

forward.

(Continued)

Timer Program Recording

The programmable timer allows you to record up to 6 different programs over one month.

Preparation

• Select the video channel (3 or 4) or video input mode on the TV.

• Make sure that the clock is set correctly (page 15).

• Store the channels on the VCR (pages 16 and 17).

• If you record cable channels, finish the cable box set-up (pages 12), and turn on the cable box.

RECORDING

E

n

D : PROG

SET UP

PRESET

PROGRAM

CH DATE O

n

OFF SPD

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

E

n

D : PROG

SET UP

PRESET

PROGRAM

CH DATE O

n

OFF SPD

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

2 5 -/-- -:- - -:- - SLP

▼

▼

▼

▼

▼

CANCEL

3

2,9

10

4

CURSOR

TIMER

REC

S L P

Basic Recording

This section explains the basic recording operation.

Recording a TV Program

RECORDING

Preparation

• Select the video channel (3 or 4) or video input mode on the TV.

box.

• If you record cable channels via the cable box, finish the cable box set-up (pages 12), and turn on the cable

VCR

Load a cassette with the safety tab attached.

Press TV/VCR so that the “VCR”

indicator appears in the VCR display.

1

2

3

INPUT

SELECT

2

S

H

ST

L

TIMER

REC

S L P

VCR

Select a channel to record with

CHANNEL on the VCR, or CH/TRK

If you see “L1” or “L2” in the VCR display, press INPUT SELECT so

or number buttons on the remote

control.

channel number of the cable box or “L1” appear, depending on your

connection. (See pages 11 – 12.)

that the channel number appears.

• If you record cable channels via the cable box, make the output

3

4

6

5

TIMERREC

TIMER

S

L

REC

S L P

VCR

TIMER

S

L

REC

S L P

VCR

Press SP/SLP to select the

recording tape speed.

SP: Suitable for general recording with

better picture and sound quality.

SLP: Suitable for tripling recording time, but with less picture and

sound quality than using the SP tape speed.

Press REC on the VCR, or

simultaneously press both REC on

4

5

the remote control.

Recording starts.

Recording off time setting

Press STOP to stop recording.

6

NPUT SELECT

To record from other

connected equipment

In step 3, press I

to switch the display as follows:

L1: To record via the LINE IN 1

jacks on the rear panel.

Watching a TV program while

L2: To record via the LINE IN 2

jacks on the front panel.

recording another

SAP

Hi-Fi

STEREO

L R

TIMER

By setting the recording off time, the recording

stops and the VCR is turned off automatically.

While recording, press simultaneously both REC

on the remote repeatedly to set the desired off

time.

Each time you press REC, each half-hour up to

“VCR” indicator.

selector on the TV.

1)While recording, press TV/VCR to turn off

2) Choose another channel using the channel

REC

S L P

VCR

about 4 hours appear cyclically.

Skipping unnecessary scenes while

recording

Press PAUSE to stop recording momentarily. To

resume recording, press PAUSE again.

Notes

• To cancel the recording in progress, press

Note

The VCR automatically shifts to the stop mode if the

POWER on the VCR.

recording pause mode continues for 10 minutes.

24

Page 17

Reference Information

2-10 Toshiba

27

RECORDING

If a power failure occurs during the

timer program recording

• When a power failure has occurred, “- -:- -”

appears in the VCR display. Since the

programmed contents have been cleared,

reset the clock and timer programming.

• When power has failed for a short time, the

colon of the current time display blinks. The

programmed contents are not affected. Reset

the clock.

Overlaps of the programs

If two timer programs overlap, the recording start

time of program 1 has priority over the recording

off time of program 2.

Program 1

(Start time)

Program 2

(Start time)

Overlapped portion

(not recorded)

Confirming the timer programs

Press PROG while timer recording.

The screen for confirming will appear.

This screen can be sure only in the Timer

Recording mode.

Changing/cancelling the timer

programs

1)If the TIMER indicator is lit, turn the VCR on by

pressing POWER.

2)With steps 2 to 9, change the items.

To cancel a program, select the program you

want to cancel in step 4, and press CANCEL.

The line is then cleared.

3)Press POWER to return to the timer standby

mode.

Error indication

The blinking “TIMER” indicator appears in the

VCR display if you press both TIMER when:

–– a cassette is not loaded.

–– the loaded cassette has no safety tab.

In these cases, a recording can not be made.

E n D : PROG

SET UP

PRESET

PROGRAM

CH DATE O

n

OFF SPD

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

2 5 8/30 9:30 10:00 SP

P

M

P

M

PRESET

OFF SPD

n

SET UP

CH DATE O

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

2 5 8/30 -:- - -:- - SLP

- - -/-- -:- - -:- - -

PROGRAM

- - -/-- -:- - -:- - -

E n D : PROG

…

SU →

).

WKLY

▼

SA ←

) or (

WKLY

▲

→ 7/25 →

…

▼

Move to the next using CURSOR

( ), and set the recording date

using CURSOR (

The date changes as follows:

MO~FR ←

→ 8/25 → 9/25 →

5

PRESET

M

P

OFF SPD

n

SET UP

CH DATE O

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

2 5 8/30 9:30 -:- - SLP

PROGRAM

[WKLYSA]: You can record TV programs on the same

…

D : PROG

n

E

▼

[WKLYSU]

channel on the day and time every week.

[MO~FR]: You can record TV programs on the same channel on the

day and time Monday through Friday.

Move to the next using CURSOR

( ), and set the hour and minutes

of the recording start time.

6

Move to the next, and set the

7

M

P

PRESET

M

P

OFF SPD

n

SET UP

CH DATE O

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

2 5 8/30 9:30 10:00 SLP

PROGRAM

recording off time.

M

P

PRESET

M

P

OFF SPD

n

SET UP

CH DATE O

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

- - -/-- -:- - -:- - -

2 5 8/30 9:30 10:00 SP

PROGRAM

E n D : PROG

).

▼

) or (

▲

Move to the next, and select the

tape speed (SP) using CURSOR

(

D : PROG

n

E

).

▼

▼

For the tape speed “AUTO (Auto Speed

Select)”, see below.

Repeat steps 4 to 8.

To set another program, press CURSOR

( ), and select the next line pressing

CURSOR (

8

SAP

Hi-Fi

STEREO

L

TIMERREC

TIMER

according to the tape used on the SET UP screen

(page 22).

Notes

• Make sure that the tape length is selected correctly

• When the SLP tape speed is selected and the tape

Press PROG..

Now programming is completed.

Press both TIMER simultaneously.

The power turns off and the VCR enters

the timer standby mode.

9

10

length is not sufficient to record the program to the

end, the program cannot be recorded to the end.

where the recording tape speed is switched from

SP to SLP with the Auto Speed Select feature.

• The picture will be distorted when playing the part

Auto Speed Select

If you are not sure the tape is long enough for

timer program recording in the SP tape speed,

set the recording tape speed to “AUTO”.

Recording starts in the SP tape speed and the

VCR automatically selects the tape speed to

Timer Program Recording (continued)

record the program to the end. If the tape length

is not long enough, the tape speed automatically

changes from SP to SLP.

26

Page 18

Reference Information

Toshiba 2-11

29

ADDITIONAL INFORMATION

Setting Control Codes

1

Press TV to set the remote control operating your TV.

2

3

Release TV.4Point the remote control at your TV and use each button

listed below to make sure that your TV is operated correctly.

POWER To turn the TV on or off.

CH/TRK To select TV channels in the upper or lower

direction.

VOL To adjust TV sound level.

INPUT SELECT To select an external source such as a VCR.

Number buttons To select TV channels. When selecting channels

1 to 9, first enter 0 and then the desired number.

100 To substitute for 100 channel key.

DISPLAY To turn on or off TV’s screen display.

ENTER To use for the TV’s ENTER key.

Important

Some TVs may not respond to all the operations above, or

may not be operated at all with this remote control. In this

case, operate your TV with its own remote control.

Notes

• For some brands, several control codes (brand codes) are allocated. Try

each of them until the buttons work on your TV.

• If you replace the remote control’s batteries, set the brand code again.

Multi Brand Remote Control

The remote control can be compatible with various brands of TV by setting their control codes. The

TOSHIBA code has initially been set to control TOSHIBA TVs.

ADDITIONAL INFORMATION

While holding down TV. enter the two digits of your TV’s

brand code (listed on page 30) using number buttons.

DISPLA Y

ENTER

POWER

CH/TRK

VOL

100

INPUT

SELECT

Number

buttons

1,2,3

PRESET

G FRA ESP

n

on off

120 160 180

GTH

on off

n

TER MEM

GUAGE E

n

n

D : PROG

n

LA

SAP SET

TAPE LE

E

COU

SET UP

PROGRAM

▼

▼

), and set to “ON” using

▼

) or (

▲

On the SET UP screen (page 14),

select “SAP SET” using CURSOR

(

Recording the SAP/Stereo Broadcast

This VCR can receive or record MTS (Multichannel TV Sound) broadcasts. By connecting the VCR to

your stereo system or stereo TV, you will experience the SAP or stereo sound.

MTS Broadcast Compatibility

RECORDING

Preparation

Connect a stereo TV or stereo system to the AUDIO OUT jacks of the VCR.

CURSOR ( ) or ( ).

1

DISPLA Y

AUDIO

SELECT

1

Press PROG. twice to exit.

Perform a recording.

2

3

SAP (Second Audio Program broadcast):

A separate audio program, usually broadcast in a second language with the

2

R“SAP”“STEREO”

STEREO

L

Hi-Fi sound track

Contents of recorded sound

track (Mono)

Normal sound

On-Screen Display

(Press DISPLAY.)

main language.

on the SET UP

screen

Setting of “SAP SET”

Selecting a sound

Type of receiving

Sounds recorded on the tape

According to your setting of “SAP SET” on the SET UP screen, the sound is recorded onto different

broadcast

tracks of the tape as below. Set “SAP SET” to “ON” or “OFF” appropriately.

“ON” lit not lit MONO MONO SAP

“ON” or “OFF” not lit not lit MONO MONO MONO

“ON” or “OFF” not lit lit MONO (MIXED)

Regular

(monaural audio)

Stereo

“ON” lit lit MONO MONO SAP

“OFF” lit not lit MONO MONO MONO

Regular+SAP

STEREO

“OFF” lit lit MONO (MIXED)

Stereo+SAP

Sounds in playback

You can play SAP and/or stereo broadcasts with this VCR. Press AUDIO SELECT to select a desired

Sound output

SAP

Stereo

L , R indicators in the VCR display

R (right) is on.

Both R (right) and L (left) are on.

Desired sound

SAP sound

Stereo sound

sound.

Note

When the TV is connected to the RF OUT terminal of the VCR, the output sound is monaural.

28

Page 19

Reference Information

2-12 Toshiba

Brand Code

Pulser 14

Quasar 07, 15

Radio Shack 13

Brand name of your TV

Brand Code

Toshiba 01

Brand name of your TV

Table of Brand Codes

RCA 02

Bell & Howell 09

Carver 10

Celebrity 03

Realistic 09, 11, 13

Runco (NEC) 14

Citizen 12

Curtis Mathes 09, 12

Samsung 11, 12

Dumont 14

Sanyo 09

Scotch 11

Electro band 03

Emerson 09, 11

Scott 11

Sears 01, 02, 09, 10, 11

Sharp 08, 13

Sony 03

Fisher 09

GE 02, 07, 11

Gibralter 14

Goldstar 11

Soundesign 11

Supreme 03

Sylvania 10

Tandy 08

Technics 07, 15

Techwood 07

Teknika 04, 10, 12

TMK 11

Victor 05

Vidikron 10

Vidtech 11

Wards 10, 11, 13

Zenith 14

Hallmark 11

Hitachi 06

Infinity 10

JBL 10

JCB 03

JVC 05

LXI 01, 02, 09, 10, 11

Magnavox 10

Marantz 10

Megatron 06, 11

Memorex 04, 09, 11

MGA 04, 11

Midland 02, 07, 14

Mitsubishi 04, 11

Motorola 08

MTC 12

NAD 01, 11

Nikko 11

Optimus 09

Optonica 08

Panasonic 07, 10, 15

Penney 01, 02, 07, 11, 12

Philco 10

Philips 10

Princeclub 12

Prism 07

Proscan 02

Proton 11

30

Page 20

Reference Information

Toshiba 2-13

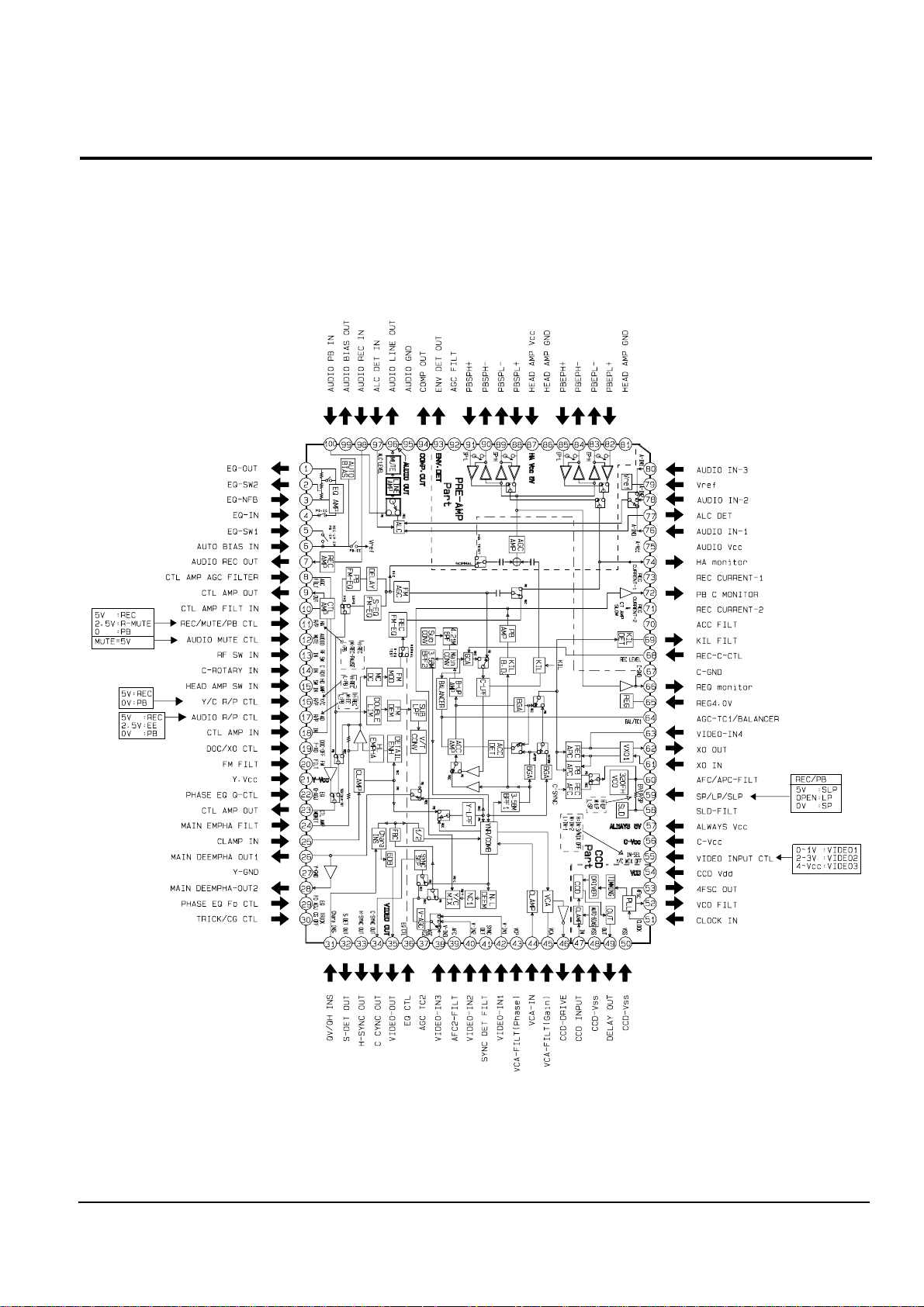

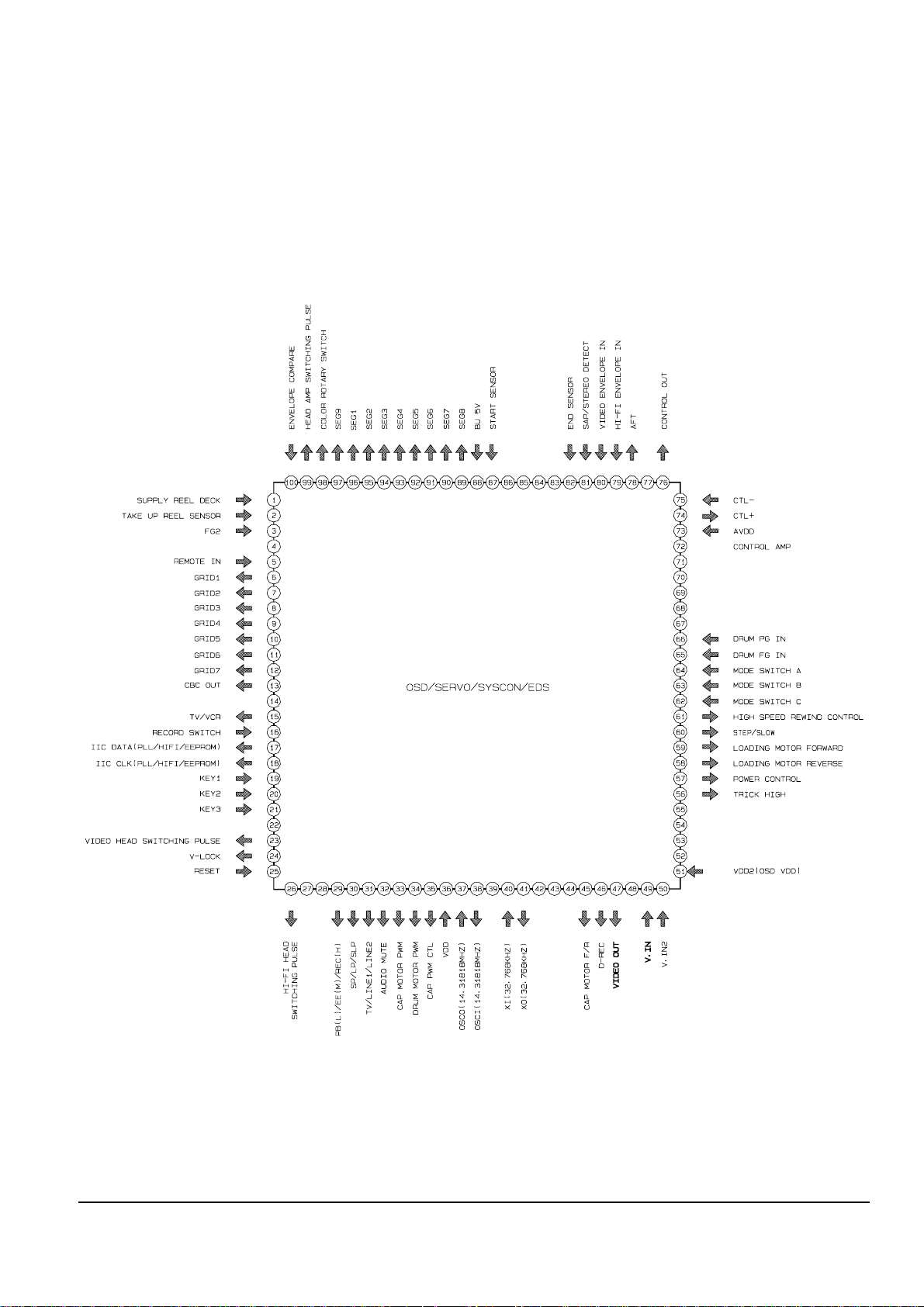

2-2-1 IC301 (LA71072M)

2-2 IC Blocks

Page 21

Reference Information

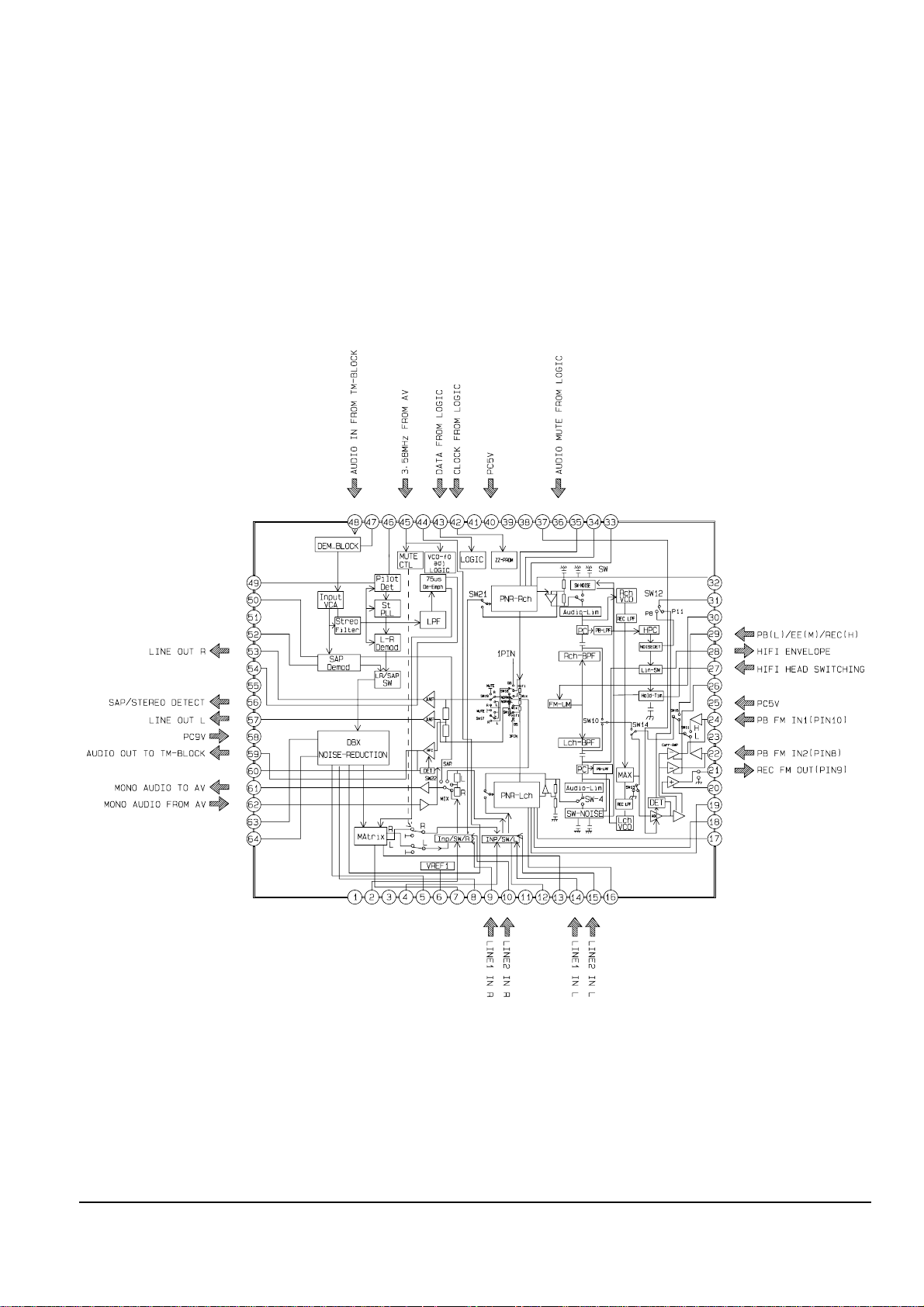

2-14 Toshiba

2-2-2 IC501 (AN3662)

Page 22

Reference Information

Toshiba 2-15

2-2-3 IC601 (MN101D02X)

Page 23

Reference Information

2-16 Toshiba

MEMO

Page 24

OPERATION DESCRIPTION

Toshiba 3-1

3. Product Specifications

Specifications and features are subject to change without notice.

Power supply

Power consumption

External dimensions

Mass

Channels received

Antenna input/output terminals

Signal system

Recording/Playback system

Cassette

Tape speed

Video recording/Playback time

Fast forward/Rewind time

Video input

Video output

Audio input

Audio output

Audio frequency range(Hi-Fi)

Audio dynamic range(Hi-Fi)

Utilization conditions

120V AC, 60Hz

18W

430 x 94 x 252 mm (W.H.D)

3.0 kg

VHF : Channels 2-13

UHF : Channels 14-69

CATV : Channels A7-A1, A-CC, 66-125

UHF/VHF : 75ohm F type connector

Standard NTSC

Recording : VHS format (SP, SLP)

Playback : VHS format (SP, LP, SLP)

Video cassette with VHS mark

SLP : 11.1 mm/s,

SP : 33.4 mm/s

SLP : 480 minutes,

SP : 160 minutes (When T-160 video cassette is used.)

Within approx. 120 s (When T-120 video cassette is used.)

1V(p-p), 75 ohm, unbalanced, negative sync., pin jack

1V(p-p), 75 ohm, unbalanced, negative sync., pin jack

Line input : 308 mV(rms), more than 47 Kohm, pin jack

Line input : 308 mV(rms), more than 47 Kohm, pin jack

20Hz - 20KHz

68dB

Temperature : 5°C to 40°C

Humidity : less than RH 80%

Page 25

Product Specifications

3-2 Toshiba

MEMO

Page 26

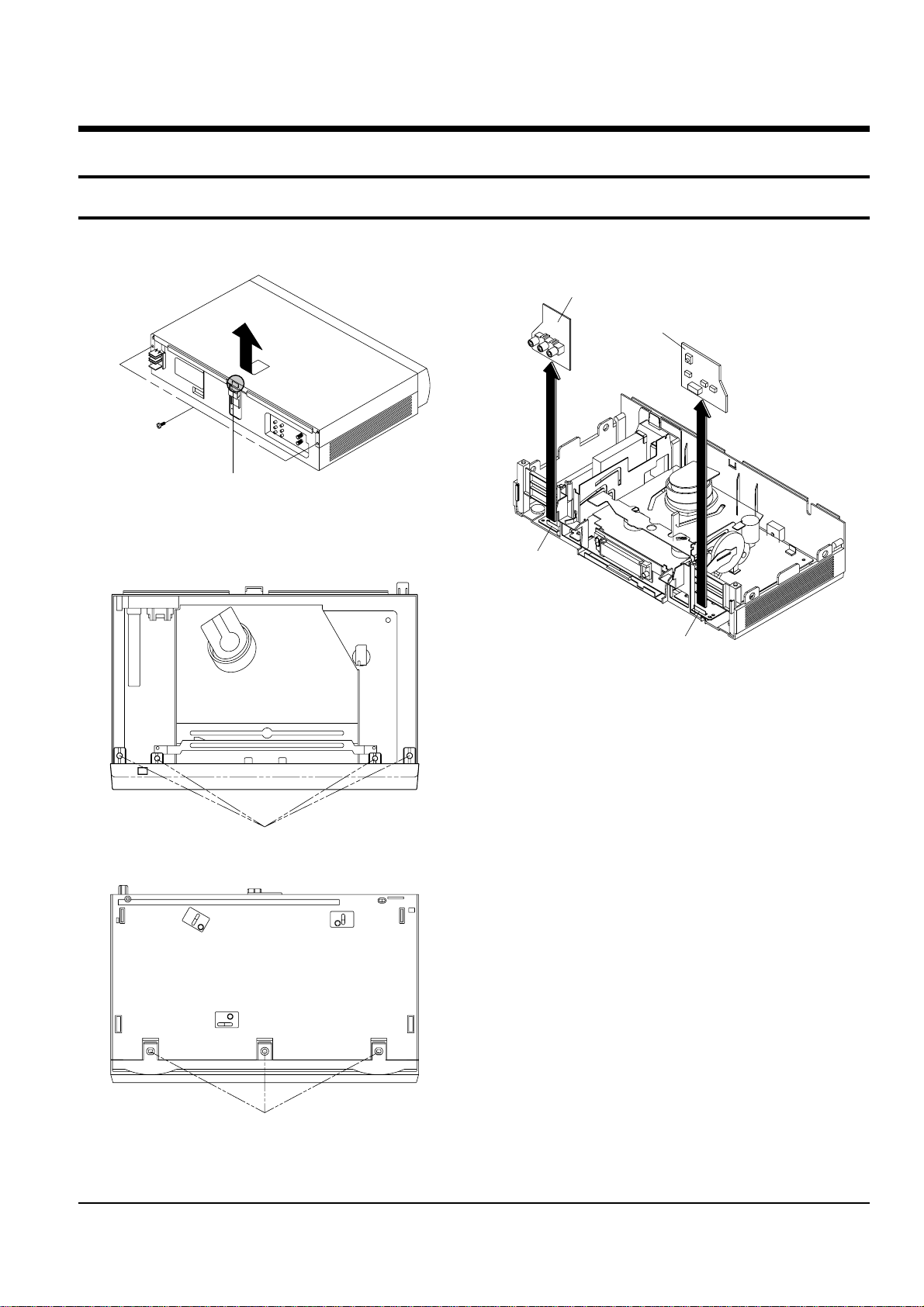

Toshiba

4-1

4. Disassembly and Reassembly

4-1 Cabinet Assembly

4-1-1 Cabinet Top Removal

ΠREMOVE 2 SCREWS

´ Lift up the Cabinet Top in the direction of

arrow by releasing the Hook.

Fig. 4-1 Cabinet Top Removal

4-1-2 Ass’y Front Panel Removal

Disconnect the CN701 from the Main PCB and then

lift the Jack PCB up.

CN701

CN703

Disconnect the CN703 from the Main PCB and then

lift the Key PCB up.

Fig. 4-2 Ass’y Front Panel Removal

4-1-3 Jack PCB/Key PCB Removal

Fig. 4-3 Jack PCB/Key PCB Removal

ΠRELEASE 4 HOOKS

´ RELEASE 2 HOOKS

(Top View)

(Bottom View)

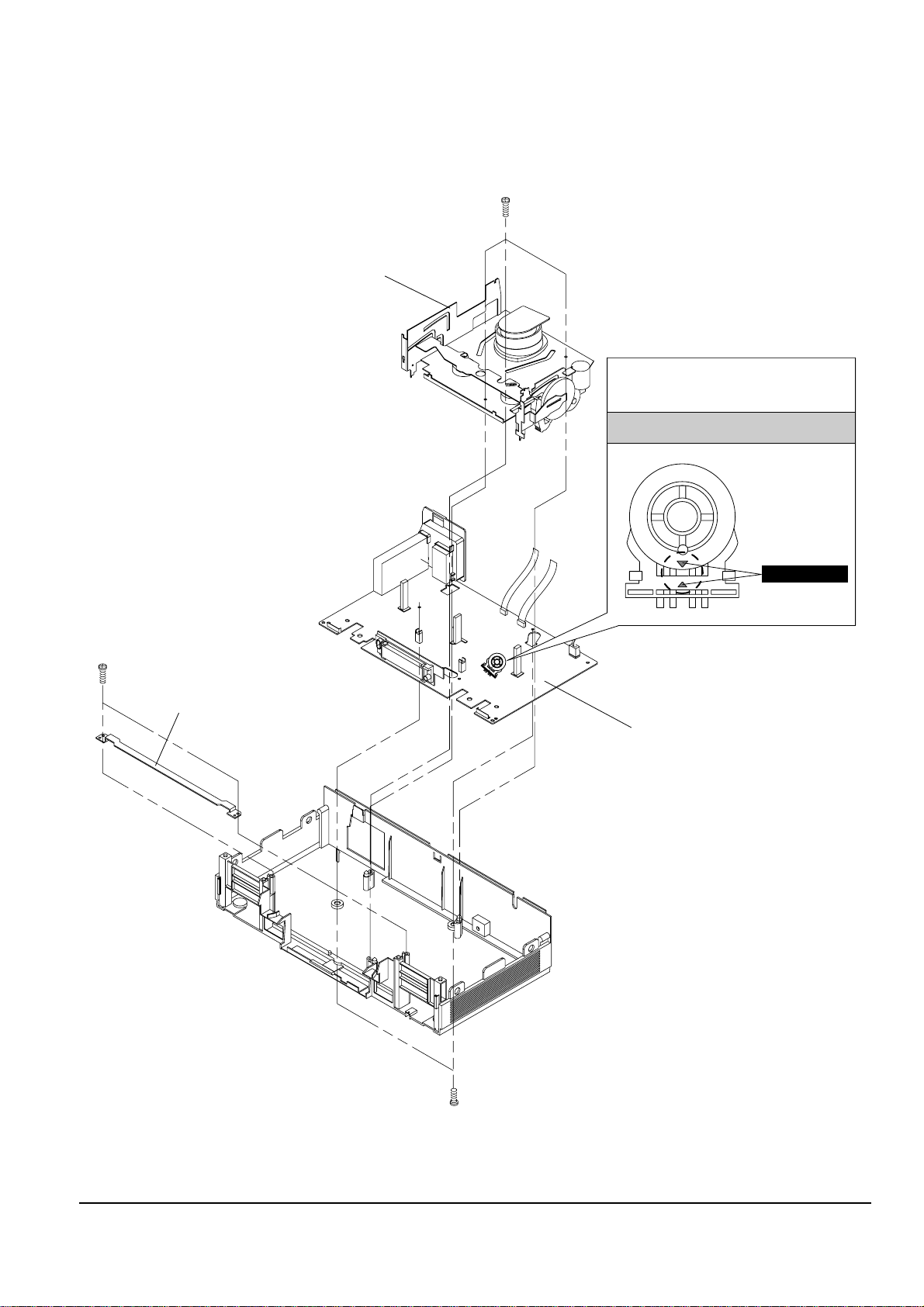

Page 27

4-2

Toshiba

Disassembly and Reassembly

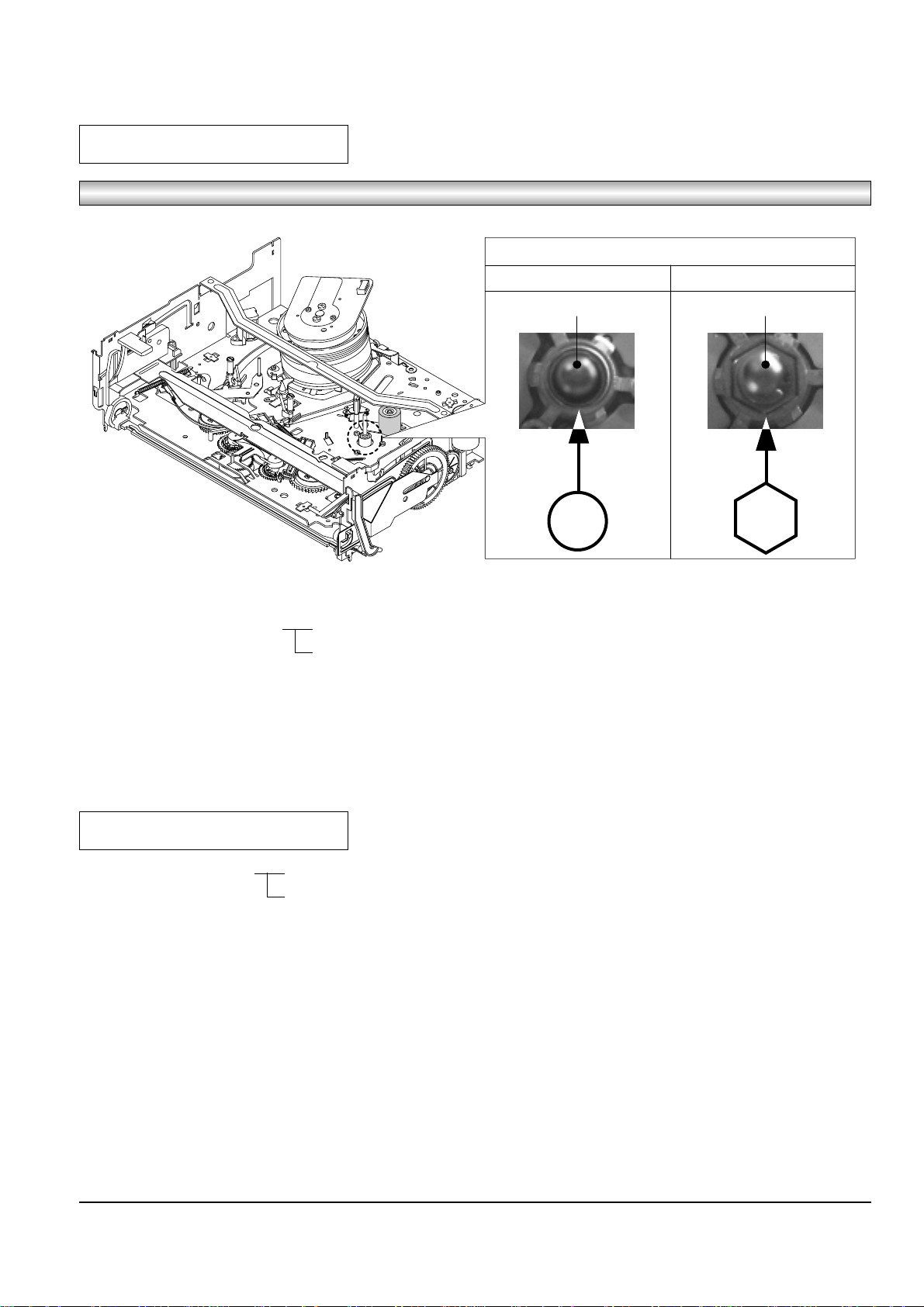

4-1-4 Chassis Removal

¨ REMOVE 3 SCREWS

ˆ LIFT THE ASS'Y FULL DECK UP.

ΠREMOVE 2 SCREWS

´ REMOVE BRACKET-FRAME

ˇ REMOVE 2 SCREWS

Ø LIFT THE ASS'Y MAIN PCB UP TO REMOVE.

MODE SWITCH

ASSEMBLY POINT

When installing the ass'y full deck on the Main PCB,

be sure to align the assembly point of mode switch.

Fig. 4-4 Chassis Removal

Page 28

Toshiba

4-3

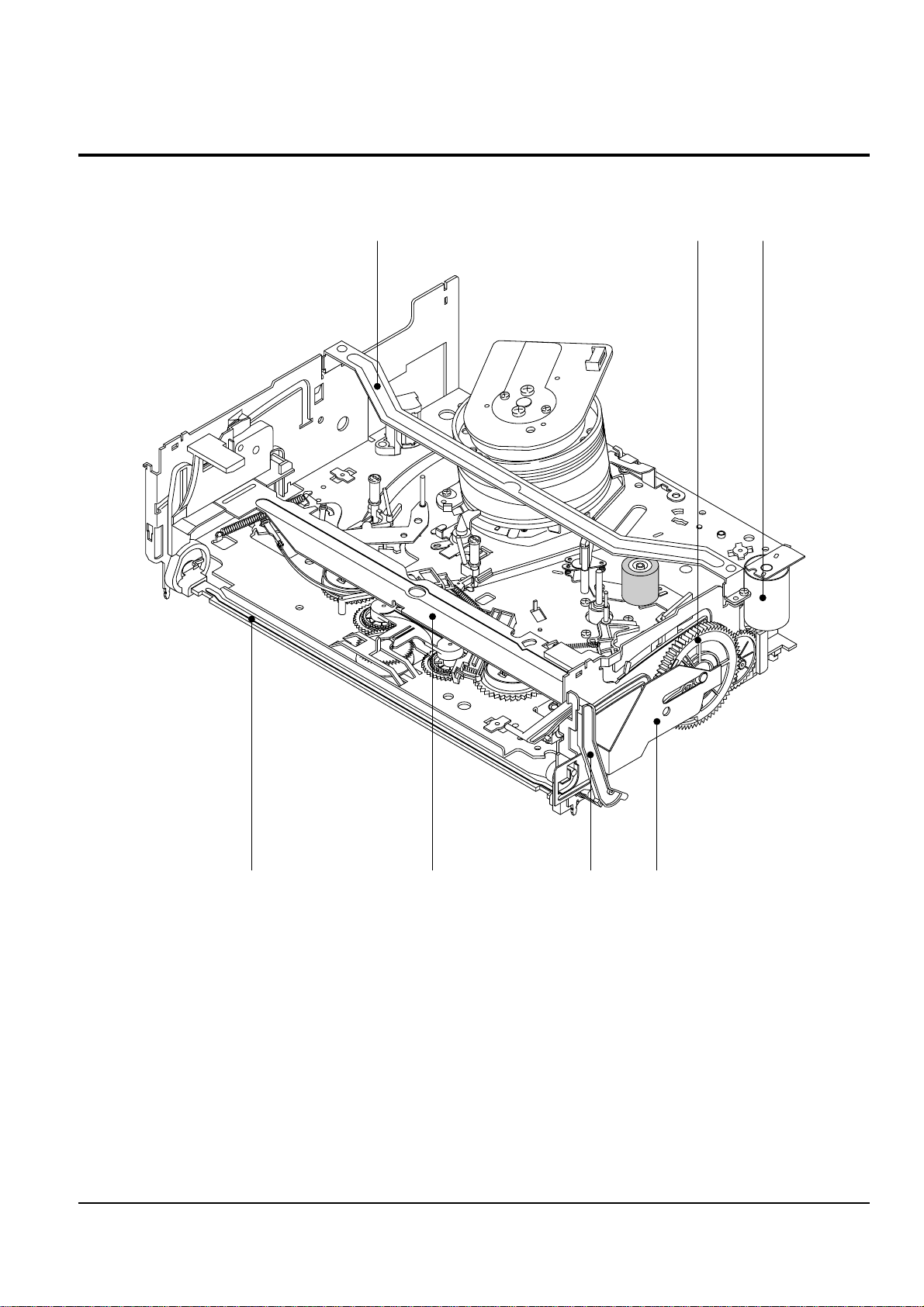

4-2 Deck Parts Locations

4-2-1 Top View

Œ

´

ˇ

¨

ˆ

Ø

∏

Fig. 4-5 Top parts Location-1

ΠBRACKET FL TOP (Optional)

´ GEAR FL CAM

ˇ MOTOR LOADING ASS’Y

¨ LEVER FL ARM ASS’Y

ˆ HOLDER FL CASSETTE ASS’Y

Ø LEVER FL DOOR

∏ SLIDER FL DRIVE

Page 29

4-4

Toshiba

Disassembly and Reassembly

Œ

´ˇ

¨

ˆ

Ø

∏

”

’

˝

Ô

Ò

ÚÆı

Ò

Fig. 4-6 Top Parts Location-2

ΠFE HEAD

´ PLATE CYLINDER C

ˇ CYLINDER ASS’Y

¨ PLATE CYLINDER B

ˆ PLATE CYLINDER A

Ø ACE HEAD ASS’Y

∏ UNIT PINCH ASS’Y

” LEVER #9 GUIDE ASS’Y

’ LEVER TENSION ASS’Y

˝ BAND BRAKE ASS’Y

Ô DISK S REEL

LEVER S BRAKE ASS’Y

Ò GEAR IDLE

Ú LEVER IDLE

Æ LEVER T BRAKE ASS’Y

ı DISK T REEL

Page 30

Disassembly and Reassembly

Toshiba

4-5

4-2-2 Bottom View

Œ

´

ˇ

¨

ˆØ∏

”

’˝

Ô

Fig. 4-7 Bottom Parts Location

ΠGEAR JOINT 1

´ GEAR JOINT 2

ˇ BRAKET GEAR

¨ MOTOR CAPSTAN ASS’Y

ˆ LEVER T LOAD ASS’Y

Ø GEAR LOADING DRIVE

∏ LEVER S LOAD ASS’Y

” HOLDER CLUTCH ASS’Y

’ BELT PULLEY

˝ SLIDER CAM

Ô SLEEVE TENSION

Page 31

4-6

Toshiba

Disassembly and Reassembly

4-3-1 Braket FL Top Removal (Optional)

1) Remove 2 screws Œ.

2) Remove the Bracket FL Top ´.

Note : Take care not to change assembly direction.

Π2 SCREWS

´ BRACKET FL TOP

4-3-2 Lever FL Door Removal

1) Rotate the Lever FL Door Πin the direction of

arrow “A”.

2) Release the Hook ´, remove the Lever FL Door Œ

in the direction of arrow “B”.

´ HOOK

ΠLEVER FL DOOR

"A"

"B"

4-3 Main Deck

Fig. 4-8 Braket FL Top Removal

Fig. 4-9 Lever FL Door Removal

Page 32

Disassembly and Reassembly

Toshiba

4-7

4-3-3 Holder FL Cassette Ass’y Removal

1) Remove the Lever FL Door. (Refer to Fig. 4-9)

2) Pull the Holder FL Cassette Ass’y Œ to the eject

position.

3) Pull the Holder FL Cassette Ass’y Œ as grasping

the Holder FL Cassette Ass’y Œ and Lever FL

Cassette-R ´ in the same time to release hooking

from Main Base until the Boss [A], [B] of Holder

FL Cassette Ass’y Œ is taken out from the Rail [C],

[D].

4) Lift the Holder FL Cassette Ass’y Œ in the direction of arrow “B” in this time, you have to grasp

the Lever FL Cassette-R ´ continuously until the

Holder FL Cassette Ass’y Œ is taken out completely.

Note : Be sure to insert Lever FL Cassette-R ´ in the

direction of “A” to prevent seperation and breakage

of the Lever FL Cassette-R ´ at disassembling and

reassembling.

ΠHOLDER FL

CASSETTE ASS'Y

´ LEVER FL CASSETTE-R

BOSS [A]

BOSS [B]

RAIL [C]

RAIL [D]

"A"

"B"

4-3-4 Lever FL Arm Ass’y Removal

1) Remove the Lever FL Door. (Refer to Fig. 4-9)

2) Remove the Holder FL Cassette Ass’y.

(Refer to Fig. 4-10)

3) Release the Hook Πin the direction of arreow

“A”, pull out the Lever FL Arm Ass’y ¨ from the

Boss of Main Base.

4) Remove the Lever FL Arm Ass’y ¨ in the direction of arrow “B”.

Assembly : When reinstalling, be sure to reassemble

Lever FL Arm Ass’y ¨ after you insert the Boss ´ in

Groove [A] of Slider FL Drive ˇ.

ΠHOOK

´ BOSS

¨ LEVER FL ARM

ASS'Y

ˇ SLIDER FL DRIVE

GROOVE [A]

"A"

"B"

Fig. 4-10 Holder FL Cassette Ass’y Removal

Fig. 4-11 Lever FL Arm Ass’y Removal

Page 33

4-8

Toshiba

Disassembly and Reassembly

4-3-5 Slider FL Drive Removal

1) Pull the Slider FL Drive Πto the front direction.

2) Remove the Slider FL Drive Πin the direction of

arrow. (Refer ti Fig. 4-12)

ΠSLIDER FL DRIVE

4-3-6 Bracket Gear, Gear FL Cam, Gear Joint 1, 2

Removal

1) Remove screw Œ.

2) Lift the Bracket Gear ´.

3) Remove the Gear FL Cam ˇ.

4) Lift the Gear Joint 2 ¨, Gear Joint 1 ˆ.

ΠSCREW

´ BRACKET GEAR

ˇ GEAR FL CAM

ˆ GEAR JOINT 1

¨ GEAR JOINT 2

Fig. 4-12 Slider FL Drive Removal

Fig. 4-13 Bracket Gear, Gear FL Cam, Gear Joint 1, 2 Removal

Page 34

Disassembly and Reassembly

Toshiba

4-9

4-3-7 Assembly of Gear FL Cam, Gear Joint 1, 2

1) Be sure to align dot mark of Gear Joint 1 Πwith

dot mark of Gear Joint 2 ´ as shown Fig. 4-14

(Refer to Timing Point 1), confirm the Timing Point

2 of the Gear Joint 2 ´ and Slider Cam ˇ.

2) Align the Gear FL Cam ¨ with the Gear Worm

Wheel Post as shown detail drawing. (Refer to

Timing Point 3)

ΠGEAR JOINT 1

´ GEAR JOINT 2

ˇ SLIDER CAM

TIMING POINT 1

¨ GEAR FL CAM

GEAR WORM WHEEL

POST

TIMING POINT 2

TIMING POINT 3

4-3-8 Holder Worm, Gear Worm, Gear Worm

Wheel Removal

1) Release the Hook [A] in the direction of arrow and,

remove the Holder Worm Œ.

2) Remove the Gear Worm ´.

3) Remove the Gear Worm Wheel ˇ. (After remov-

ing the Gear FL Cam as shown Fig. 4-13)

Note : Secure the Hook [A] after installing the Holder

Worm Œ.

ΠHOLDER WORM

´ GEAR WORM

HOOK [A]

ˇ GEAR WORM WHEEL

Fig. 4-14 Assembly of Gear FL Cam, Gear Joint 1, 2

Fig. 4-15 Holder Worm, Gear Worm, Gear Worm Wheel Removal

Page 35

4-10

Toshiba

Disassembly and Reassembly

4-3-9 Motor Loading Ass’y Removal

1) Remove the screw Œ.

2) Remove the Motor Loading Ass’y ´.

ΠSCREW

´ MOTOR LOADING ASS'Y

4-3-10 Gear Loading Drive, Slider Cam,

Lever T, S Load Ass’y Removal

1) Remove the Belt Pulley. (Refer to Fig. 4-33)

2) Remove the Gear Loading Drive Πafter releasing

Hook [A] in the direction arrow as shown in detail

drawing.

3) Remove the Slider Cam ´.

4) Remove the Lever T, S Load Ass’y ˇ, ¨.

ΠGEAR LOADING DRIVE

ˇ LEVER T LOAD ASS'Y

HOOK [A]

´ SLIDER CAM

¨ LEVER S LOAD ASS'Y

Fig. 4-16 Motor Loading Ass’y Removal

Fig. 4-17 Gear Loading Drive, Slider Cam, Lever T, S Load Ass’y

Removal

Page 36

Disassembly and Reassembly

Toshiba

4-11

4-3-11 Assembly of Gear Loading Drive,

Slider Cam, Lever T, S Load Ass’y

1) When reinstalling, be sure to align dot of Lever T

Load Ass’y Œ with dot of Lever S Load Ass’y ´

as shown in drawing. (Refer to Timing Point 1)

2) Insert the Pin A, B, C, D into the Slider Cam ˇ

hole.

3) Be sure to align dot of Lever T Load Ass’y and dot

of Gear Loading Drive ¨. (Refer to Timing Point 2)

4) Align dot of Gear Loading Drive with mark of

Slider Cam as shown in drawing.

(Refer to Timing Point 3)

´ LEVER S LOAD ASS'Y

Œ

LEVER T LOAD ASS'Y

PIN A

PIN C

PIN B

PIN D

LEVER T

LOAD ASS'Y

LEVER S

LOAD ASS'Y

ˇ SLIDER CAM

¨ GEAR LOADING DRIVE

TIMING POINT 1

TIMING POINT 2

TIMING POINT 3

4-3-12 Lever Tension Ass’y, Band Brake Ass’y,

Sleeve Tension Removal

1) Remove the Spring Tension Œ.

2) In bottom side of Deck, remove the Sleeve Tension

´ after rotating it right or left as liftinig locking

edge of Sleeve Tension.

3) Remove the side “a” of the Band Brake Ass’y ¨ in

the direction of arrow “A” from the Lever Tension

Ass’y ˇ.

4) Remove the side “b” of the Band Brake Ass’y ¨ in

the direction of arrow “B” from the Main Base.

Note :

1) When replacing the Lever Tension Ass’y, be sure to

apply oil in the Sleeve Tension.

2) Take care not to touch stain on the felt side, and

not to be folded and broken Band Brake Ass’y.

¨ BAND BRAKE ASS'Y

´ SLEEVE TENSION

ˇ LEVER TENSION ASS'Y

ΠSPRING TENSION

"A"

"B"

a

b

Fig. 4-18 Assembly of Gear Loading Drive,

Slider Cam, Lever T, S Load Ass’y

Fig. 4-19 Lever Tension Ass’y, Band Brake Ass’y, Sleeve Tension

Removal

Page 37

4-12

Toshiba

Disassembly and Reassembly

4-3-13 Lever S, T Brake Ass’y Removal

1) Release the Hook [A] and the Hook [B], [C] in the

direction of arrow as shown in Fig. 4-20.

2) Lift the Lever S, T Brake Ass’y Œ, ´ with Spring

Brake ˇ.

Assembly :

1) Assembly the Lever S Brake Ass’y Œ on the Main

Base.

2) Assembly the Lever T Brake Ass’y ´ with Spring

Brake ˇ.

Note : Take extreme care not to be folded and transformed spring Brake at removing or reinstalling.

ˇ SPRING BRAKE

´ LEVER T BRAKE ASS'Y

ΠLEVER S BRAKE ASS'Y

HOOK [A]

HOOK [C]

HOOK [B]

4-3-14 Lever Idle Ass’y Removal

1) Push the Lever Idle Πin the direction of arrow

“A”, “B”.

2) Lift the Lever Idle Œ.

Assembly :

1) Apply oil in two Bosses of Lever Idle Œ.

2) Assemble the Gear Idle ´ with the Lever Idle Œ.

Note : When replacing the Gear Idle ´, be sure to

add oil in the boss of Lever Idle Œ.

ΠLEVER IDLE

´ GEAR IDLE

´ GEAR IDLE

HOOK [A]

"A"

"B"

Fig. 4-20 Lever S, T Brake Ass’y Removal

Fig. 4-21 Lever Idle Ass’y Removal

Page 38

Disassembly and Reassembly

Toshiba

4-13

4-3-15 Disk S, T Reel Removal

1) Lift the Disk S, T Reel Œ, ´.

´ DISK T REEL

ΠDISK S REEL

4-3-16 Holder Clutch Ass’y Removal

1) Remove the Washer Slit Œ.

2) Lift the Holder Clutch Ass’y ´.

Note : When you reinstall Holder Clutch Ass’y ´.

1) Check the condition of spring as shown in

detail A.

2) Don’t push Holder Clutch Ass’y down with excessive force. Just insert Holder Clutch Ass’y into post

center with dead force and rotate it smoothly.

Be sure to confirm that spring is in the slit of

Gear Center Ass’y as shown in detail B.

´ HOLDER CLUTCH ASS'Y

ΠWASHER SLIT

<BAD>

<GOOD>

<BAD>

<GOOD>

SPRING

SPRING

DETAIL A

DETAIL B

Fig. 4-22 Disk S, T Reel Removal

Fig. 4-23 Holder Clutch Ass’y Removal

Page 39

4-14

Toshiba

Disassembly and Reassembly

4-3-17 Lever Up Down Ass’y, Gear Center Ass’y

Removal

1) Remove the 2 hooks in the direction of arrow as

shown Fig. 4-24 and lift the Lever Up Down Ass’y

Œ.

2) Lift the Gear Center Ass’y ´.

´ GEAR CENTER ASS'Y

ΠLEVER UP DOWN ASS'Y

4-3-18 Assembly of Lever Up Down Ass’y,

Gear Center Ass’y

1) Insert the Lever Up Down Ass’y Œ in the 2 rectan-

gular holes on Main Base.

2) Lift the Lever Up Down Ass’y Œ about 35 degree.

(Refer to Fig. 4-25)

3) Insert Ring ¨ of the Gear Center Ass’y ´ in the

Guide ˆ of the Lever Up Down Ass’y Œ.

4) Insert the Gear Center Ass’y ´ in the post Ø on

Main Base.

5) Push down the Lever Up Down Ass’y Œ for locking of the Hook ∏.

Note :

1) Take care not to separate and loose the Spring Up

Down.

2) When assembling the Gear Center Ass’y, don’t

push down too much.

MAIN BASE

ΠLEVER UP DOWN ASS'Y

ˆ GUDIE

´ GEAR CENTER ASS'Y

¨ RING

ˇ GEAR

Ø POST

∏ HOOK

35˚

Fig. 4-24 Lever Up Down Ass’y, Gear Center Ass’y Removal

Fig. 4-25 Assembly of Lever Up Down Ass’y, Gear Center Ass’y

Page 40

Disassembly and Reassembly

Toshiba

4-15

4-3-19 Guide Cassette Door Removal

1) Lift the Hook [A].

2) Rotate the Guide Cassette Door Πin the direction

of arrow.

Note : After reinstalling the Guide Cassette Door Œ

secure the Hook [A].

ΠGUIDE CASSETTE DOOR

HOOK [A]

4-3-20 Unit Pinch Ass’y, Plate Joint, Spring Pinch

Drive Removal

1) Lift the Unit Pinch Ass’y Œ.

2) Remove the Plate Joint ´ from Lever Pinch Drive.

3) Remove the Spring Pinch Drive ˇ.

Note :

1) Take extreme care not to touch the grease on the

Roller Pinch.

2) When reinstalling, be sure to apply grease on the

post pinch roller.

ΠUNIT PINCH ASS'Y

´ PLATE JOINT

ˇ SPRING PINCH DRIVE

Fig. 4-26 Guide Cassette Door Removal

Fig. 4-27 Unit Pinch Ass’y, Plate Joint, Spring Pinch Drive

Removal

Page 41

4-16

Toshiba

Disassembly and Reassembly

4-3-21 Lever #9 Guide Ass’y Removal

1) Remove the Spring #9 Guide Œ.

2) Lift the Lever #9 Guide Ass’y ´ in the direction of

arrow.

Note :

1) Take extreme care not to touch the grease on the

tape Guide Post.

2) After reinstalling, check the bottom side of the Post

#9 Guide to stick to the top side of Main Base.

´ LEVER #9 GUIDE ASS'Y

ΠSPRING #9 GUIDE

4-3-22 FE Head Removal

1) Remove the screw Œ.

2) Lift the FE Head ´.

ΠSCREW

´ FE HEAD

Fig. 4-28 Lever #9 Guide Ass’y Removal

Fig. 4-29 FE Head Removal

Page 42

Disassembly and Reassembly

Toshiba

4-17

4-3-23 ACE Head Removal

1) Pull out the FPC from connector of ACE Head

Ass’y ´.

2) Remove the screw Œ.

3) Lift the ACE Head Ass’y ´.

ΠSCREW

´ ACE HEAD ASS'Y

4-3-24 Slider S, T Ass’y Removal

1) Move the Slider S, T Ass’y Œ, ´ to slot, and then

lift it to remove. (Refer to arrow)

´ SLIDER T ASS'Y

ΠSLIDER S ASS'Y

Fig. 4-30 ACE Head Removal

Fig. 4-31 Slider S, T Ass’y Removal

Page 43

4-18

Toshiba

Disassembly and Reassembly

4-3-25 Cylinder Ass’y Removal

1) Remove the 3 Screws Œ, ˇ, ˆ.

2) Remove the Plate Cylinder A, B, C ´, ¨, Ø in the

direction of arrow.

3) Lift the Cylinder Ass’y ∏.

Note :

1) When reinstalling, push the Plate Cylinder A, B ¨,

Ø in the reverse of arrow and then, tighten the

2 Screws ˇ, ˆ.

2) Take care not to touch the Cylinder Ass’y and the

tape guide post at reinstalling Plate Cylinder C ´.

3) Take care not to touch the Cylinder Ass’y with

screw driver at reinstalling the Plate Cylinder C ´.

ˆ

SCREW

∏

CYLINDER ASS'Y

Œ

SCREW

´

PLATE CYLINDER C

ˇ

SCREW

¨

PLATE CYLINDER B

Ø

PLATE CYLINDER A

4-3-26 Belt Pulley Removal

1) Remove the Belt Pulley Œ.

Note : Take extreme care not to touch the grease on

Belt Pulley Πat assembling or reassembling.

ΠBELT PULLEY

Fig. 4-32 Cylinder Ass’y Removal

Fig. 4-33 Belt Pulley Removal

Page 44

Disassembly and Reassembly

Toshiba

4-19

4-3-27 Motor Capstan Ass’y Removal

1) Remove the 3 Screws Œ.

2) Remove the Motor Capstan Ass’y ´.

Assembly :

1) Match the 3 holes of Motor Capstan Ass’y ´ to the

3 holes of Main Base as attending not to drop or

knock the Motor Capstan Ass’y.

2) Tighten the 3 Screws in the direction of arrow as

shown detail drawing.

Note :

1) Don’t reuse the removed screws from Motor

Capstan Ass’y.

2) After tightening screws, check if there is gap

between the head of screws and the top side of

Main Base. There should have no gap between the

head of screws and the top side of Main Base.

3) After reinstalling, adjusting the tape transport

system again.

Π3 SCREWS

´ MOTOR CAPSTAN ASS'Y

B

C

A

<DETAIL>

4-3-28 How to Eject the Cassette Tape

(If the unit does not oprate on condition that is

inserted into housing ass’y)

1) Remove the Holder worm Πand the Gear Worm

´.

2) Turn the Gear Worm Wheel ˇ counterclockwise

with screw driver. (Refer to arrow)

ΠHOLDER WORM

´ GEAR WORM

SCREW DRIVER

ˇ GEAR WORM WHEEL

Fig. 4-34 Motor Capstan Ass’y Removal

Fig. 4-35

3) When Slider S, T are approched in the position of

unloading, rotate holder Clutch counterclockwise

after inserting screw driver in the hole of frame’s

bottom in order to wind the unwinded tape.

(Refer to Fig. 4-36)

(If you rotate Gear Worm Wheel continuously

when tape is in state of unwinding, you may cause

a tape contam

ination by grease and tape damage.

Be sure to wind the unwinded tape in the state of

set horizently.)

4) Rotate Gear Worm Wheel ˇ counterclockwise

using screw driver again up to the state of eject

mode and then pick out the tape.

(Refer to Fig. 4-35)

FRAME

Fig. 4-36

Page 45

4-20

Toshiba

Disassembly and Reassembly

4-4 The table of clearing, Lubrication and replacement time about principal parts

1) The replacement time of parts is not life of parts.

2) The table 4-1 is that the VCR Set is in normal condition (normal temperature, normal humidity).

The checking period may be changed owing to the condition of use, runtime and environmental conditions.

3) Life of the Cylinder Ass’y is depend on the condition of use.

4) See exploded view for location of each parts.

<Tbale 4-1>

∆ : Cleaning O : Check and replacement in necessary ◆ : Add Oil

T

A

P

E

P

A

T

H

S

Y

S

T

E

M

D

R

I

V

I

N

G

* Parts Name

Checking Period

Remark

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

POST TENSION ∆∆∆∆∆∆∆∆∆∆

SLANT POST S, T ∆∆∆∆∆∆∆∆∆∆

#8 GUIDE SHAFT ∆∆∆∆∆∆∆∆∆∆

CAPSTAN SHAFT ∆∆∆∆∆∆∆∆∆∆

#9 GUIDE POST ∆∆∆∆∆∆∆∆∆∆

#3 GUIDE POST ∆∆∆∆∆∆∆∆∆∆

GUIDE ROLLER S, T ∆∆∆OOOOOOO

CYLINDER ASS’Y ∆ OOOOOOOOO

FE HEAD ∆∆∆OOOOOOO

ACE HEAD ∆ OOOOOOOOO

PINCH ROLLER ∆ OOOOOOOOO

POST REEL S, T ◆◆◆◆◆

SLEEVE TENSION ◆◆◆◆◆

POST CENTER ◆ ◆◆◆◆

LEVER IDLE BOSS (2Point)

◆◆◆◆◆

CAPSTAN MOTOR PULLEY

∆∆∆∆∆OOOOO