TOSHIBA SX2809 Service Manual

Teléfonos inalámbricos

Contenido y precauciones de seguridad

Controles de operación

SX-2809

Procedimientos de alineamiento

Diagrama a bloques

Diagramas esquemáticos

Procedimiento de localización de fallas

Carta de voltajes de transistores y de IC

Identificación de terminales de semiconductores

Localización de partes eléctricas

Diagramas de conexiones (alambrado)

Vistas explotadas y lista de partes mecánicas

Lista de partes

Lista de partes del ensamble

Especificaciones

FILE NO. 2B0-9912

SERVICE MANUAL

CORDLESS TELEPHONE

SX-2809

PUBLISHED IN JAPAN, Dec., 1999

CONTENTS

SAFETY PRECAUTIONS...................................................................................................................... 1

OPERATING CONTR OLS..................................................................................................................... 2

ALIGNMENT PROCEDURE.................................................................................................................. 3

BLOCK DIAGRAMS .............................................................................................................................. 6

SCHEMATIC DIA GRAMS...................................................................................................................... 8

TROUBLESHOOTING HINTS ............................................................................................................. 12

IC AND TRANSISTOR VOLTAGE CHART ........................................................................................... 18

SEMICONDUCTOR LEAD IDENTIFICATION ..................................................................................... 23

ELECTRICAL PARTS LOCATION .......................................................................................................25

WIRING DIAGRAMS ........................................................................................................................... 27

EXPLODED VIEW AND MECHANICAL PARTS LIST.......................................................................... 29

PARTS LIST ........................................................................................................................................ 33

ASSEMBLY PARTS LIST..................................................................................................................... 44

SPECIFICATIONS ............................................................................................................................... 45

SAFETY PRECAUTIONS

Before returning any models to the customer, a safety check of the entire instrument should be made.

The service technician must be sure that no protective device built into the instrument by the man ufacture

has become defective or inadvertently degraded during servicing.

1.WARNING:

Alterations of the design or circuitry of these models should not be made.

Any design changes or additions such as, but not limited to, circuit modifications, auxiliary speaker

jacks, switches, grounding, active or passive circuitry, etc. may alter the safety characteristics of these

models and potentially create a hazardous situation for the user.

Any design alterations or additions will void the manufacturer’s warranty and will further relieve the

manufacturer of responsibility for personal injury or property damage resulting therefrom.

2.PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis hav e special characteristics. These characteristics

often pass unnoticed and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts that have these

special safety characteristics are identified in this manual and its supplements; electrical components

having such f eatures are identified b y a

any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts that do not have the same safety characteristics as specified in the parts list may create shock, fire

or other hazards.

in the schematic diagram and the parts list. Before replacing

1

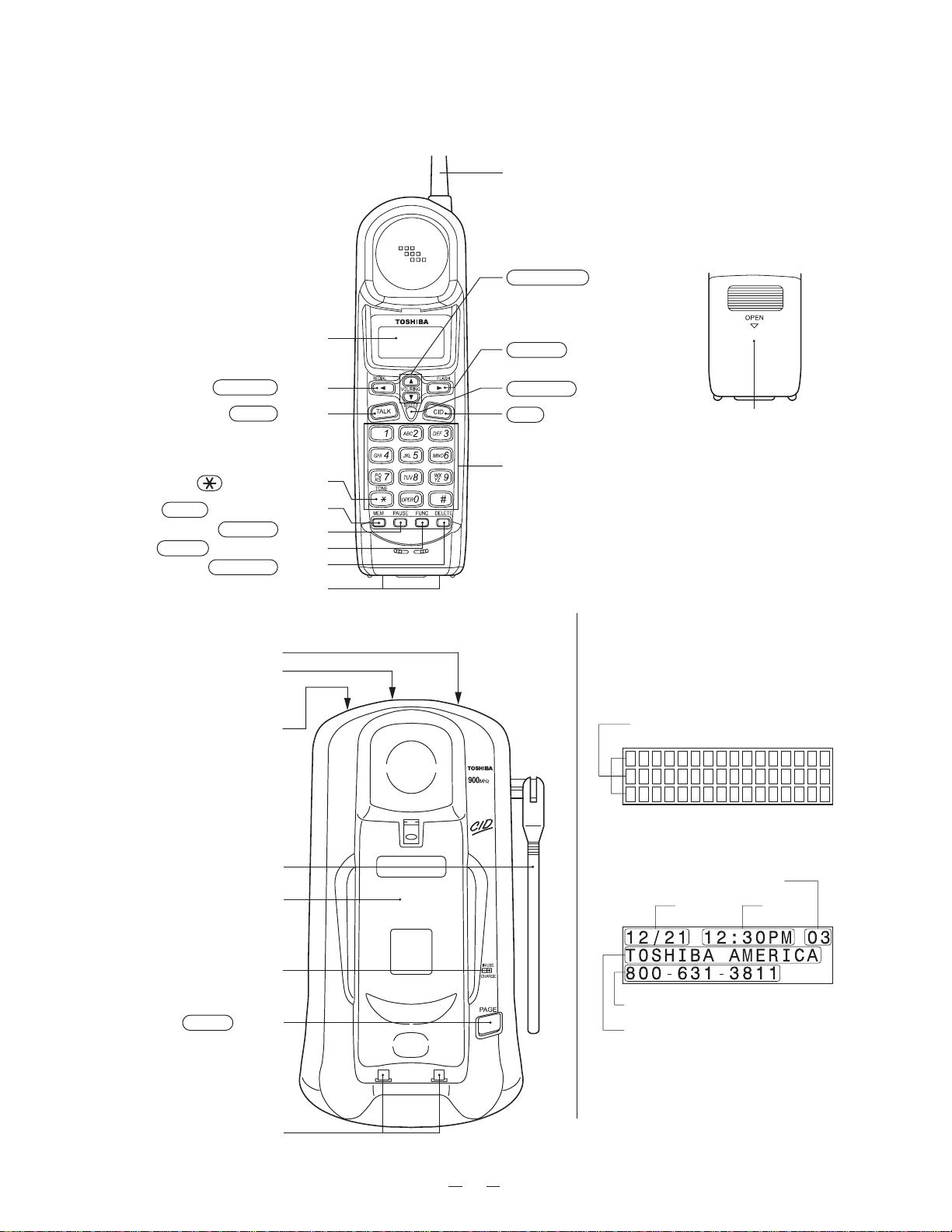

OPERATING CONTROLS

HANDSET CONTROLS AND FUNCTIONS

Antenna

VOL/RING Button

Liquid Crystal Display (LCD)

SPREAD SPECTRUM CALLER ID

REDIAL Button

TALK Button

FLASH Button

SELECT Button

CID (Caller ID) Button

Dialpad

(TONE) Button

MEM (Memory) Button

PAUSE Button

FUNC (Function)Button

DELETE Button

Charging contacts

BASE UNIT CONTROLS LCD

TONE/PULSE Switch

DC in 9V Jack

LINE Modular Jack

SPREAD SPECTRUM

ALL DIGITAL

CALLER ID

CORDLESS

TELEPHONE

SX-2809

Dot matrix display

Battery compartment

Base Antenna

Cradle

IN USE/CHARGE LED

PAGE Button

Charging contacts

Caller ID indication example

Number of calls

Date Time

Caller's telephone number

Caller's name

2

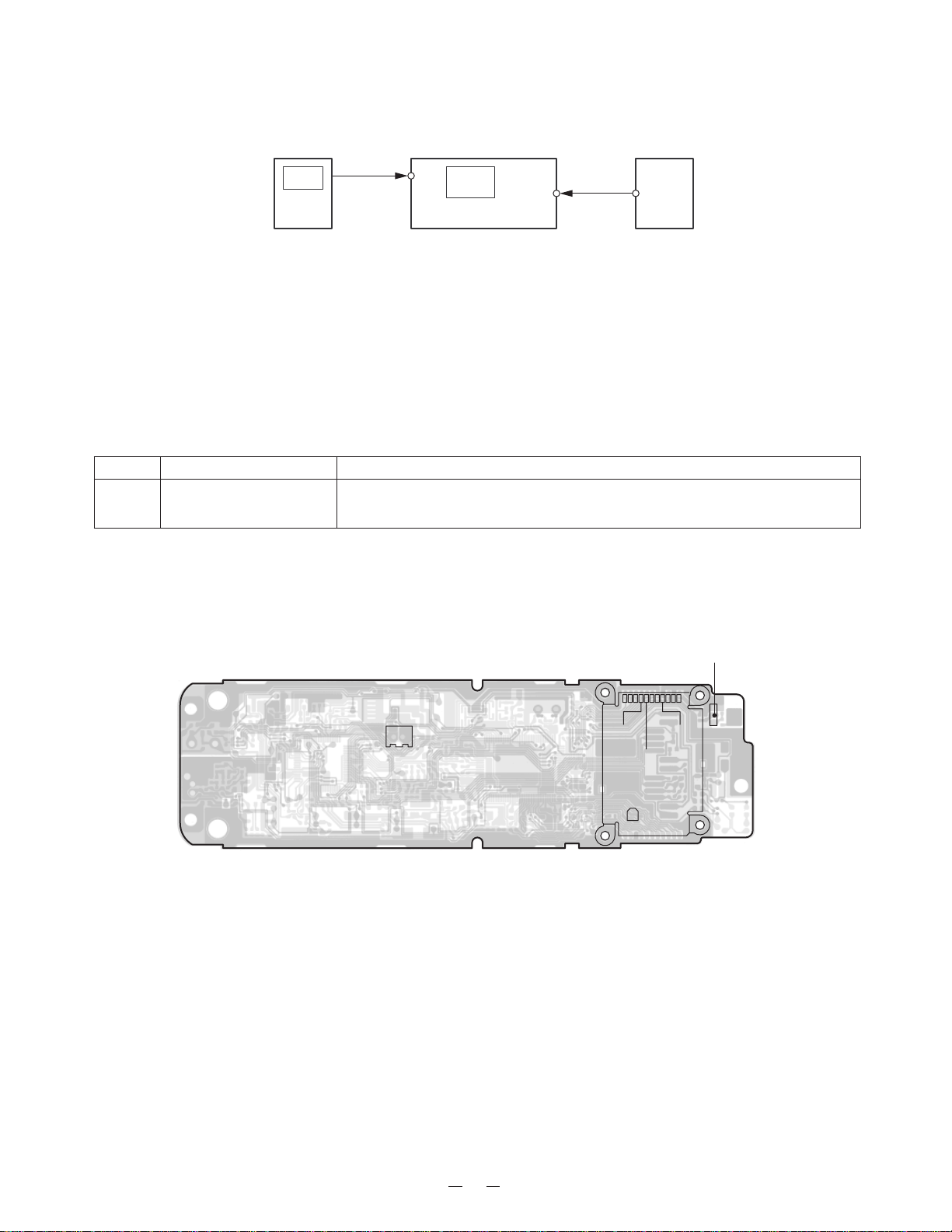

Base Unit

Transmitter Section

ALIGNMENT PROCEDURE

Connections

Power

Meter

J7

RF T est

Point

BASE Main Unit

RF

PCB J3

DC IN

DC9V

AC

Adapter

AC 120V

60Hz

Preset

a) Connect the “TXPWR0 (TP312)” and “TXPWR1 (TP324)” to “G (TP322)” with using wires.

b) Remove the plug J8 from the J7.

c) Supply the DC Power to Base Main PCB (J3).

d) Press the TALK button on Handset unit to link Base with Handset unit.

Alignment Procedure

step

1

Adjutment

RT301

Remarks

Connect the P o w er Meter to RF test point on the Base Main PCB.

Adjust RT301 for 11 dBm ±0.5 dB reading on the Pow er Meter.

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

RF PCB

TXPWR1(TP324)

TXPWR0(TP312)

G(TP322)

RT301

J3

DC IN

J7

RF TEST POINT

3

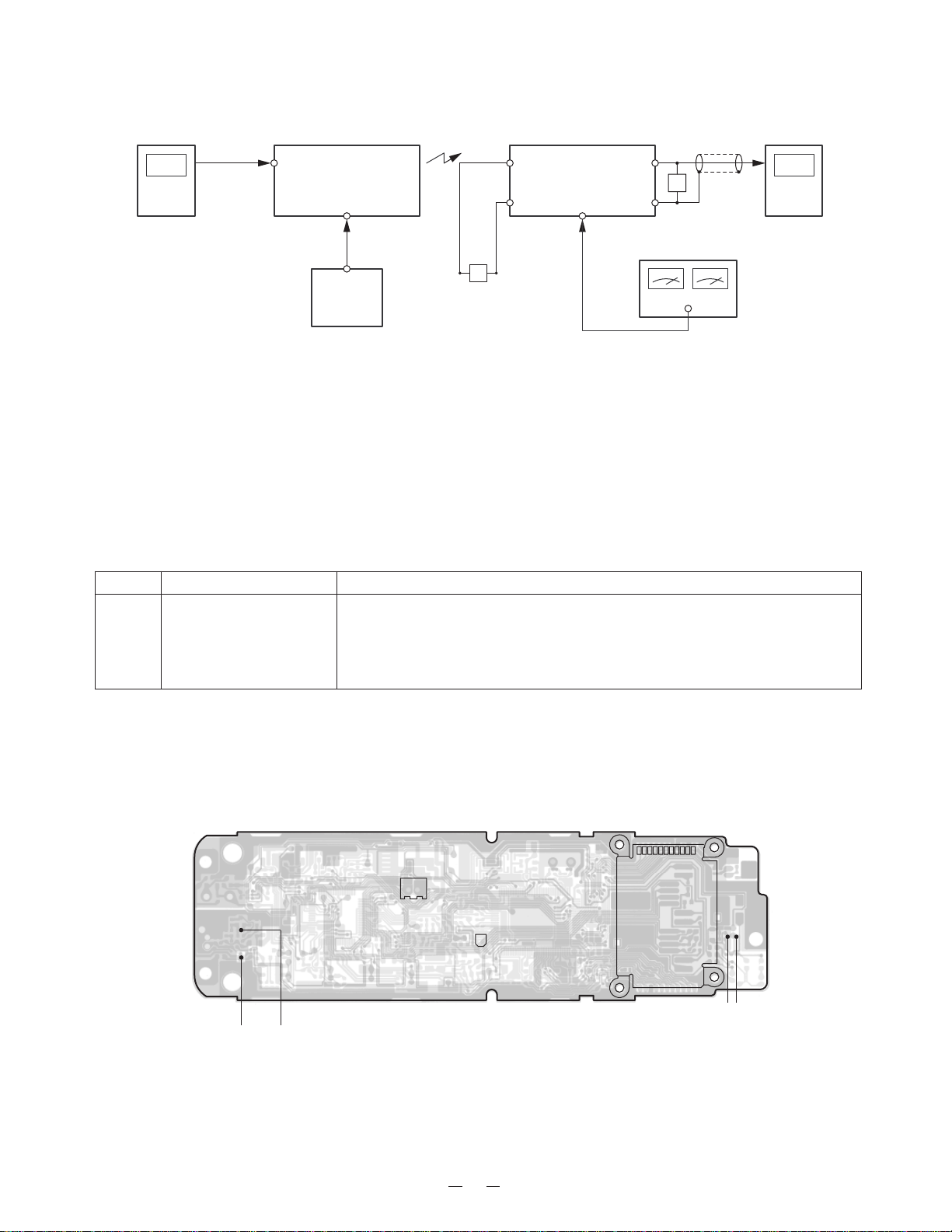

Handset Unit

Transmitter Section

Connection

HANDSET Main Unit

Power

Meter

J604

RF T est

Point

RF

PCB J605

DC IN

DC3.8V

Preset

a) Connect the “TXPWR0 (TP512)” and “TXPWR1 (TP524)” to “G (TP522)” with using wires.

b) Remove the plug J606 from the J604.

c) Supply the DC Power to HANDSET Main PCB (J605).

d) Press the TALK button on Handset unit to link Base with Handset unit.

Alignment Procedure

DC

PWR

Supply

step

Adjutment

Remarks

Connect the Po w er Meter to RF test point on the HANDSET Main PCB.

1

RT501

Adjust RT501 for 11 dBm ±0.5 dB reading on the Pow er Meter.

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset Main PCB

J605

TXPWR1

(TP524)

TXPWR0

(TP215)

RF PCB

RT501

RF TEST POINT

G(TP522)

J604

4

Receiver Section

Connection

Preset

a) Supply the DC P o wer to HANDSET Main PCB (J605).

b) Supply the DC P o w er to BASE Main PCB (J3).

c) Press the TALK button on Handset unit to link Base with Handset unit.

d) Set the Handset to SP VOL “Low” position.

Alignment Procedure

AF Gen. BASE Main Unit HANDSET Main Unit AC Volt Meter

(Zo=600ohm)

1kHz

-19.5dBm

J2

TEL JACK

J3

DC JACK

AC

Adapter

AC 120V

60Hz

RF

Link

+ C

MIC

GND

-

(C=47µF)

WHT(+)

SP

Test Point

BLK(-)

J605

DC IN

Z

Dummy Load

(Z=150ohm)

DC Power Supply

DC3.8V

step

Adjutment

Remarks

Connect the AF Generator to the TEL JACK (J2) on the Base Main PCB.

1

RT601

Make sure that the output is 1 kHz -19.5 dBm from the AF Generator.

Connect the AC Voltmeter across a 150 ohm load to the SP connector.

Adjust RT601 for -28 dBV ±0.5 dB reading on the AC Voltmeter.

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset Main PCB

J605

RF PCB

RT601

MIC GND

-

+

SP TEST POINT

5

Base Unit

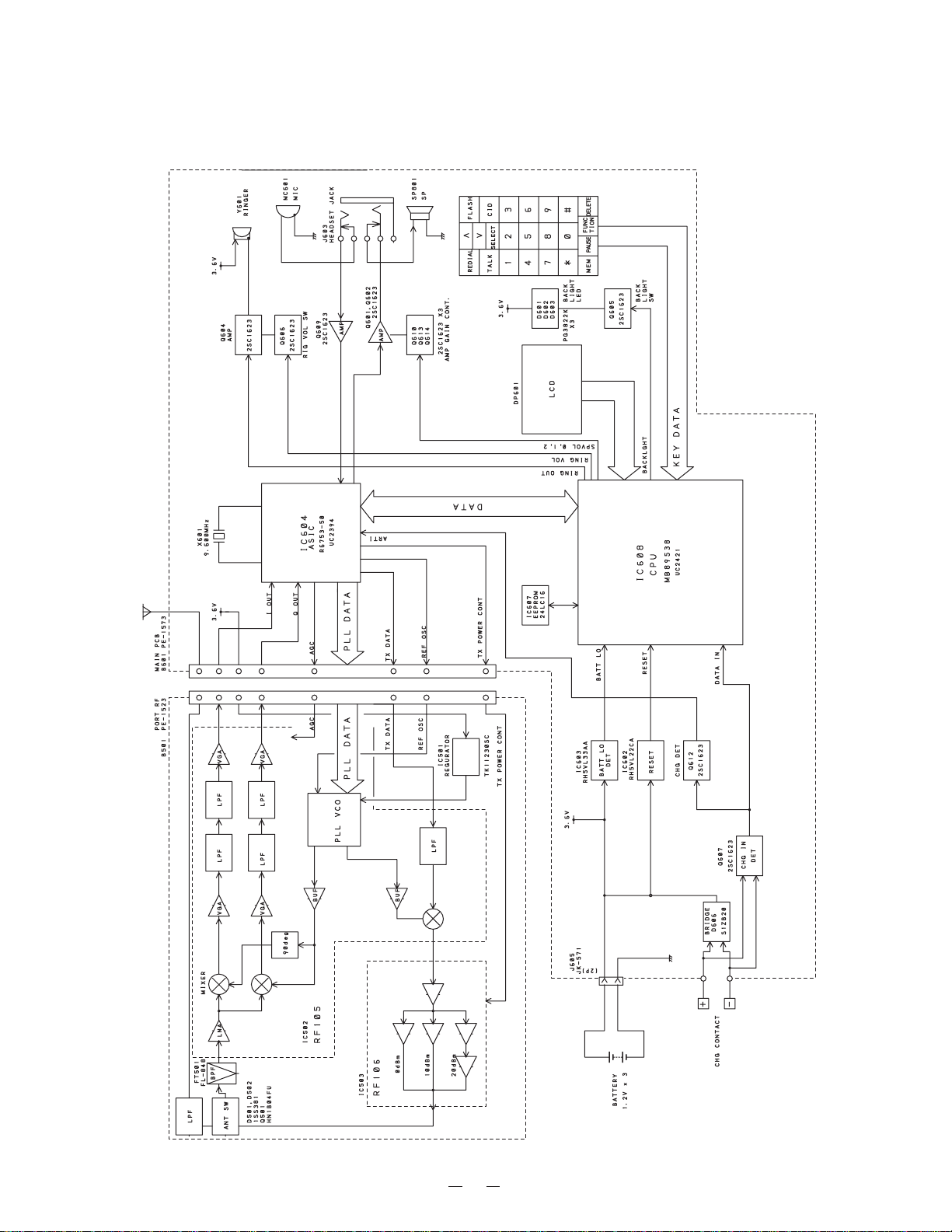

BLOCK DIAGRAMS

6

Handset Unit

7

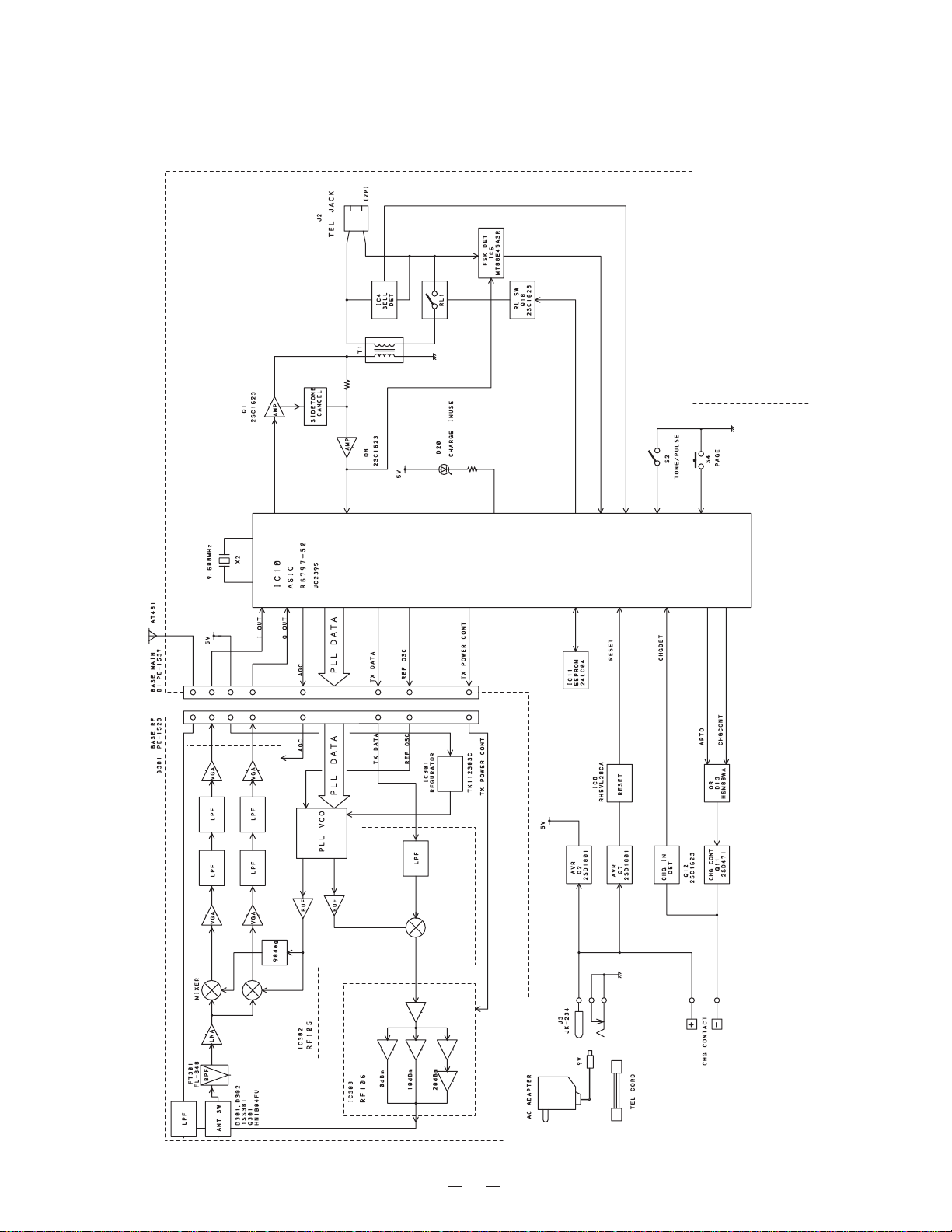

Base Unit

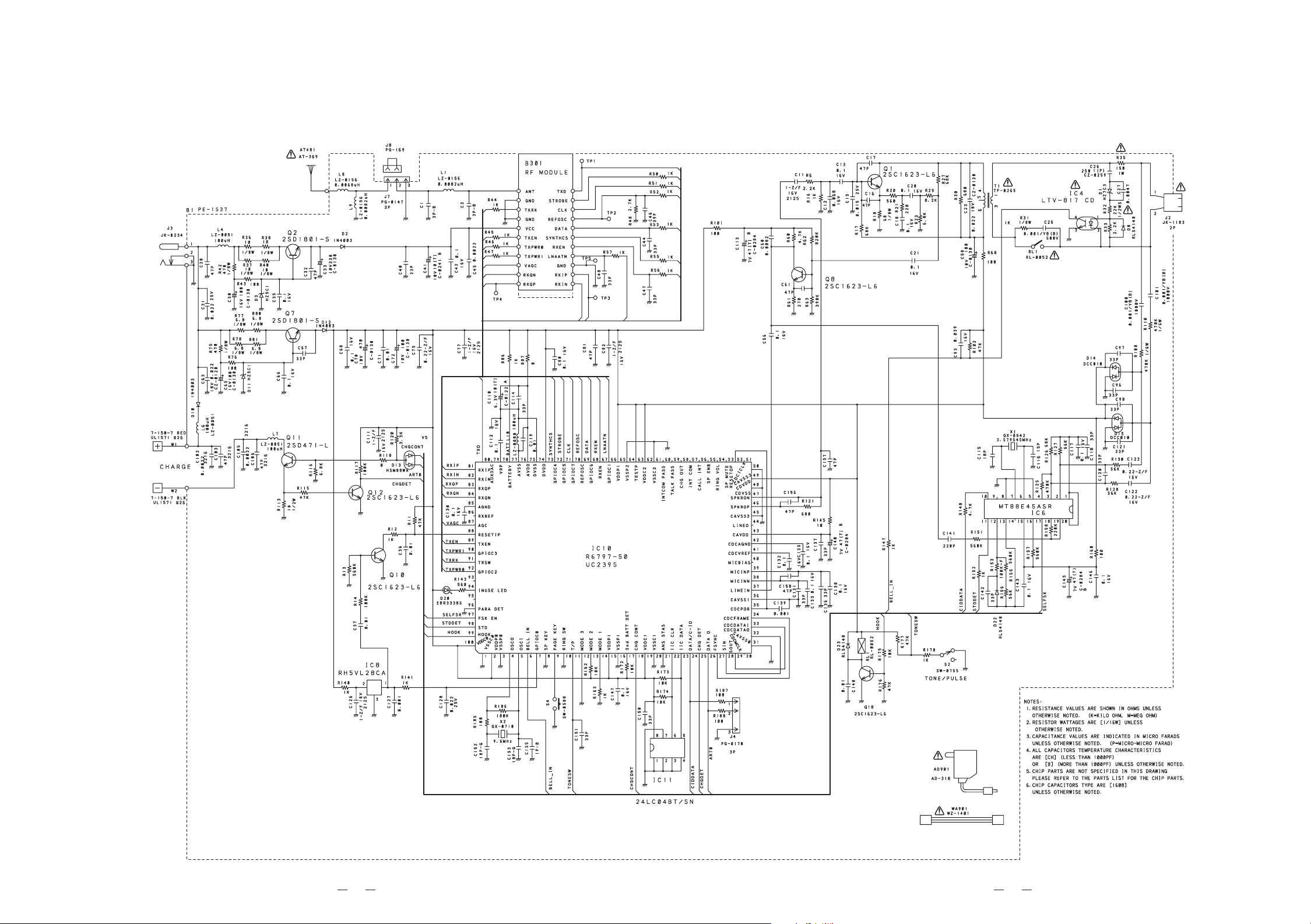

SCHEMATIC DIAGRAMS

8

9

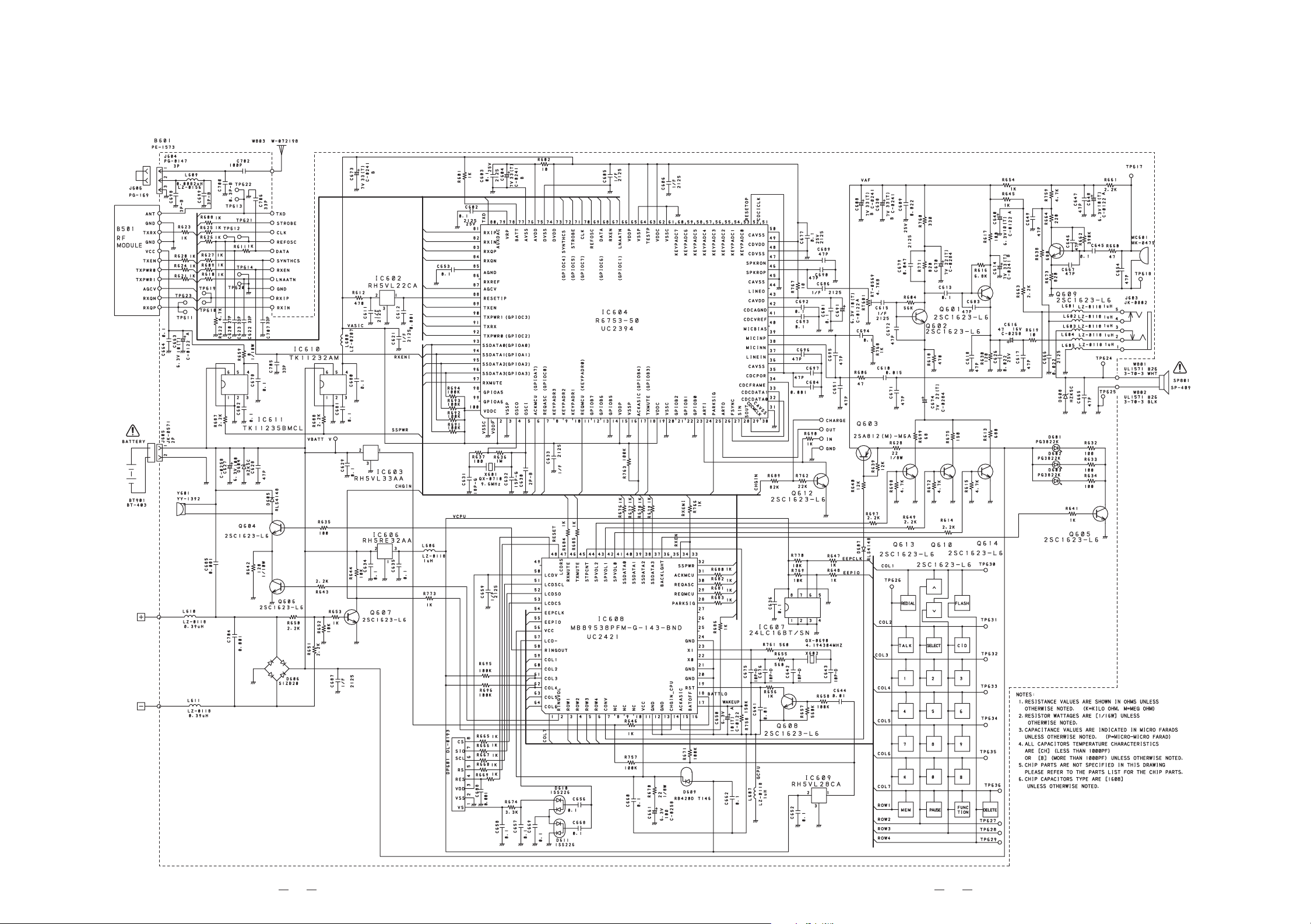

Handset

10

11

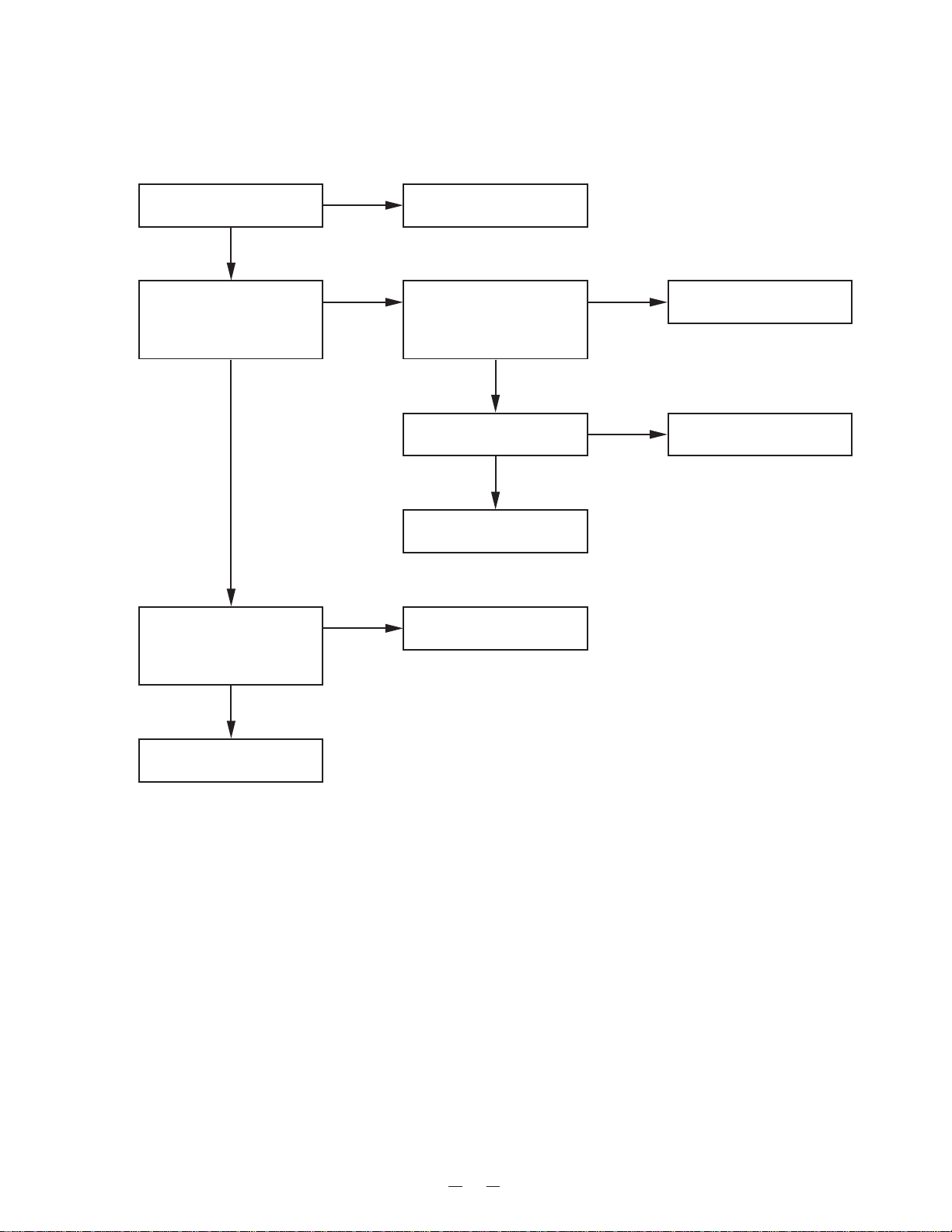

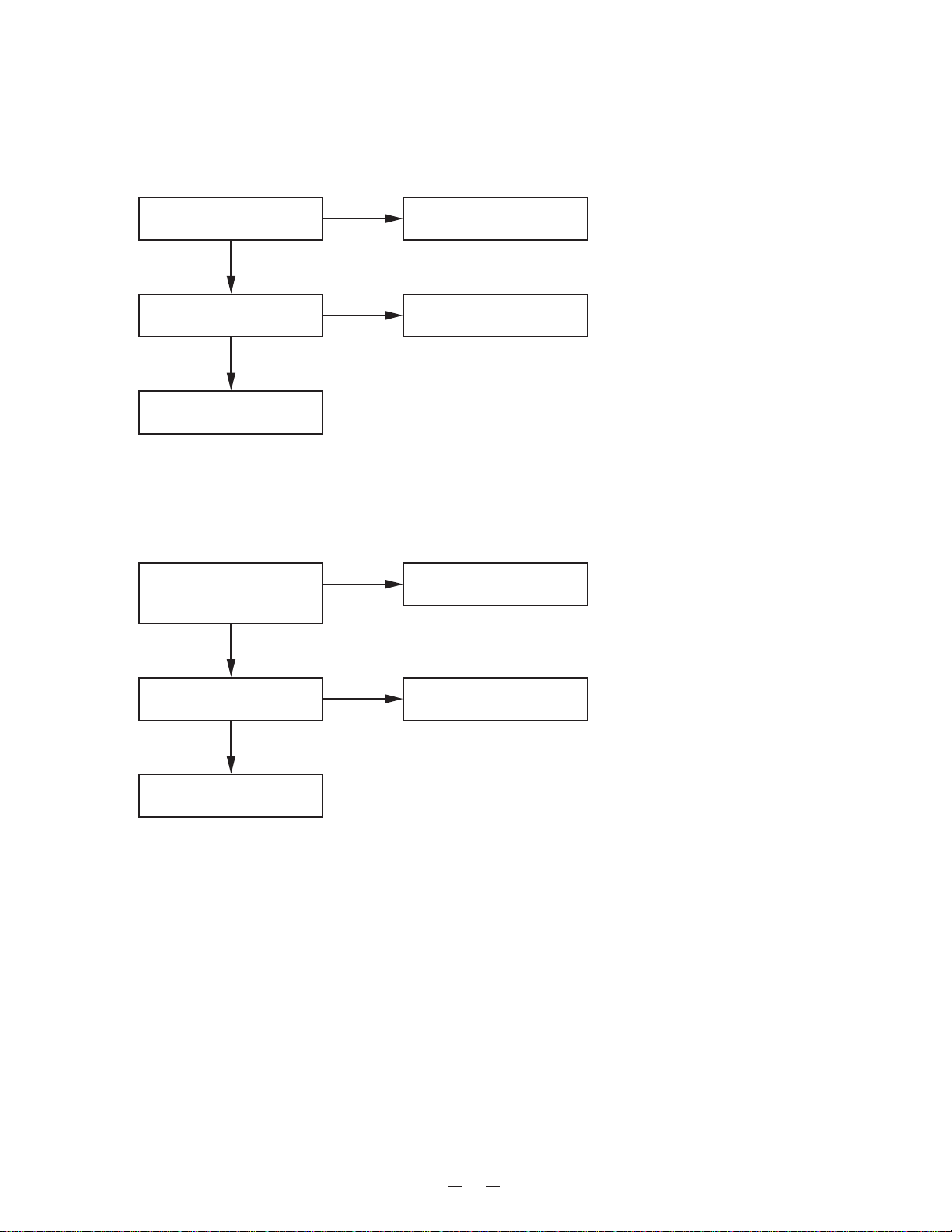

TROUBLESHOOTING HINTS

1. The bell does not ring.

When the PAGE SW of the

base is pressed, does the

ringer on the handset ring?

When the TEL SG is joined

with the base to make bell

signal, is there pulse wave

at pin 6 of IC10?

Check IC10 and its peripheral

circuit.

BASE UNIT

OK

OK

NG

NG

See 2. The bell does not ring

& page does not ring.

Check IC10 and TEL network

circuit.

If you want to reset the unit to the factory settings

1) Set the T/P switch to TONE position.

2) Press and hold the “PAGE” key about 2 seconds while turning the power on.

The IN USE LED will flash one time.

3) Press the “PAGE” k e y again, then the IN USE LED will light for about 4 seconds and the base unit will be reset.

HANDSET

Deletion of the Caller ID memory

To delete the Caller ID memory in the EEPROM, proceed with the following process:

1) Connect the battery with pressing and # buttons, and keep pressing the buttons continuously for

approximate 2 seconds.

2) Release buttons when entering TEST mode with beep.

3) Press CID button.

4) A confirmation beep will sound after about 8 seconds, then the data for caller ID is deleted.

(Note: Do not disconnect the battery until you hear the confirmation beep, otherwise the data may not be

completely deleted.)

12

2. The bell does not ring & page does not ring.

Can the base and handset

be connected?

OK

Press handset DIAL key

while in TALK MODE.

Can key touch sound be

heard from the ringer?

OK

When the PAGE SW of the

base is pressed, does pin 9

of IC10 change from high to

low?

NG

NG

NG

See 3. The base and handset

cannot be connected.

When the key of the handset

is pressed, can the pulse

output at pin 58 of IC608 be

seen?

OK

At the Q604 collector, can

the pulse wave be seen?

OK

Check RINGER Y601.

Check S1.

NG

NG

Check IC608.

Check R635.

Check IC10.

OK

13

3. The base and handset cannot be connected.

Base Unit

Check whether D20 will light

when the handset is charged.

Check whether the base

transmit data intermittently.

Check IC10.

Handset Unit

Check whether D601, D602

and D603 flash when the

TALK key is pressed.

OK

OK

OK

NG

NG

NG

Check whether the power

line is shorted.

Check RF unit.

Check whether the power

line is shorted.

Check whether the handset

transmit data intermittently.

OK

Check IC604 and IC608.

NG

Check RF unit.

14

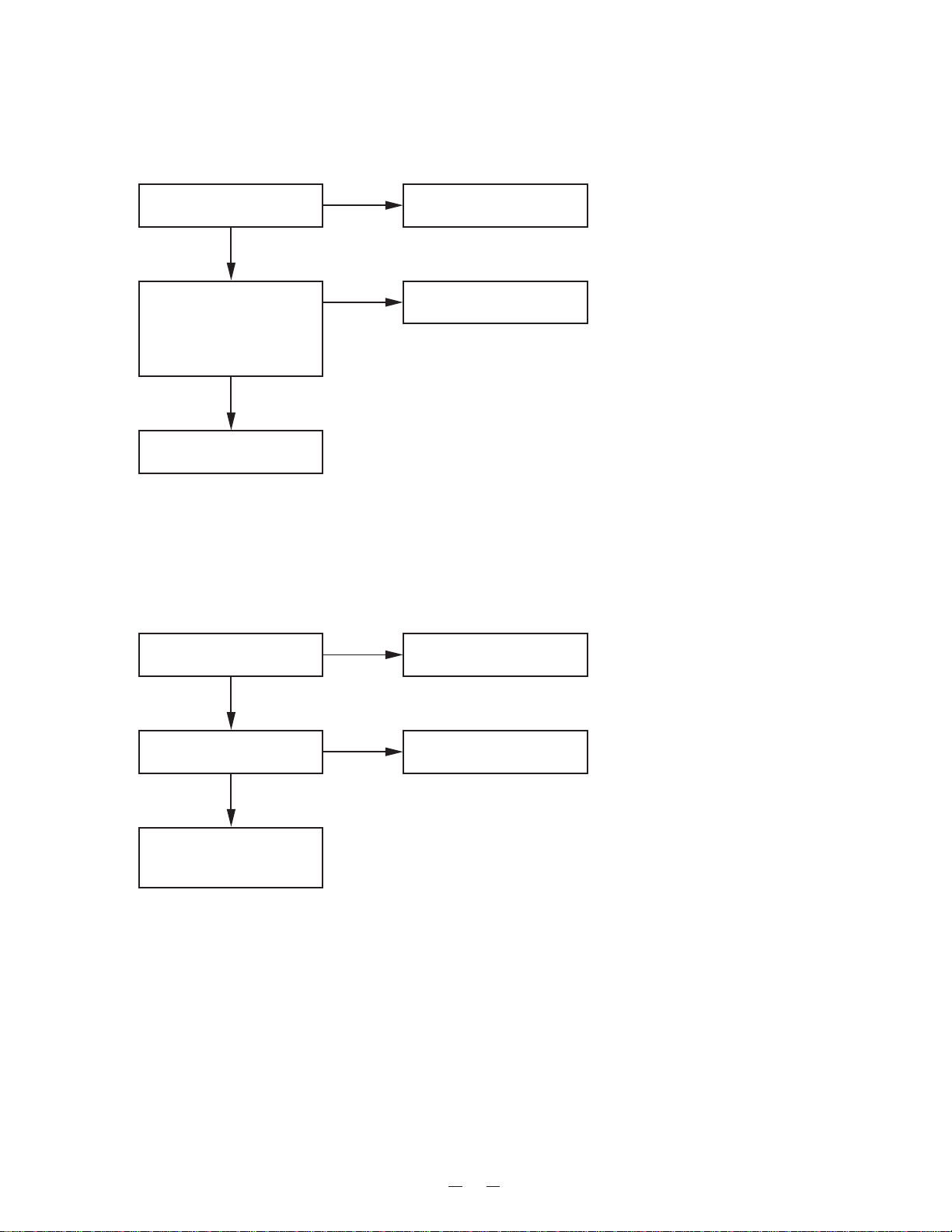

4. Cannot make a phone call (pulse).

Can the base and handset

be connected?

NG

See 3. The base and handset

cannot be connected.

OK

While in TALK MODE, press

dial key of the handset.

Check whether square

waveform from pin 99 of

IC10 is fed.

NG

Check IC10.

OK

Check Q18, RL1 and their

peripheral circuits.

5. Cannot make a phone call (tone).

Can the base and handset

be connected?

NG

See 3. The base and handset

cannot be connected.

OK

Can tone signal be heard

from the handset speaker?

OK

Check the base TEL-line

circuit and RELAY control

circuit.

NG

Check whether the wave form

is fed from pin 47 of IC10.

15

Loading...

Loading...