Page 1

Page 2

Safety Precautions

This manual contains important information for the operator to operate this product safely and cor

rectly and avoid bodily injury and property damage.

Grasp the meanings of the following marks and their descriptions before reading this manual.

•Hazard Classifications

Indicates a potentially hazardous situation which, if not avoided, could result in

<^WARNING

/j\cAUTIQN

(Note) 1. Serious injury means loss of sight, injury, burns (high temperature, low temperature), electrical

shock, fracture, or intoxication which leaves aftereffects or requires hospitalization or need to

go the hospital for a long time.

2. Injury means hurt, burn, or electric shock which does not require hospitalization orgoing to the

hospital fora long time.

3. Property damage means extended breakdown of assets and materials.

serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, can result in

minor or moderate injury, or property damage. It can also be used to alert

against unsafe practices.

•Notation of Markings

Indicates a "may not" mark.

Q

O

A

(Note) The descriptions of forbiddance, mandatory, and caution marks are subject to change,

depending on the labels on the main unit.

The concrete forbiddance is indicated with a pictograph or wording.

Indicate a mandatory action that you should never fail to do.

The concrete content is indicated inside or near the circle with a pictograph or wording.

Indicates a caution.

The concrete content is indicated inside or near the triangle.

6F8C0926

Page 3

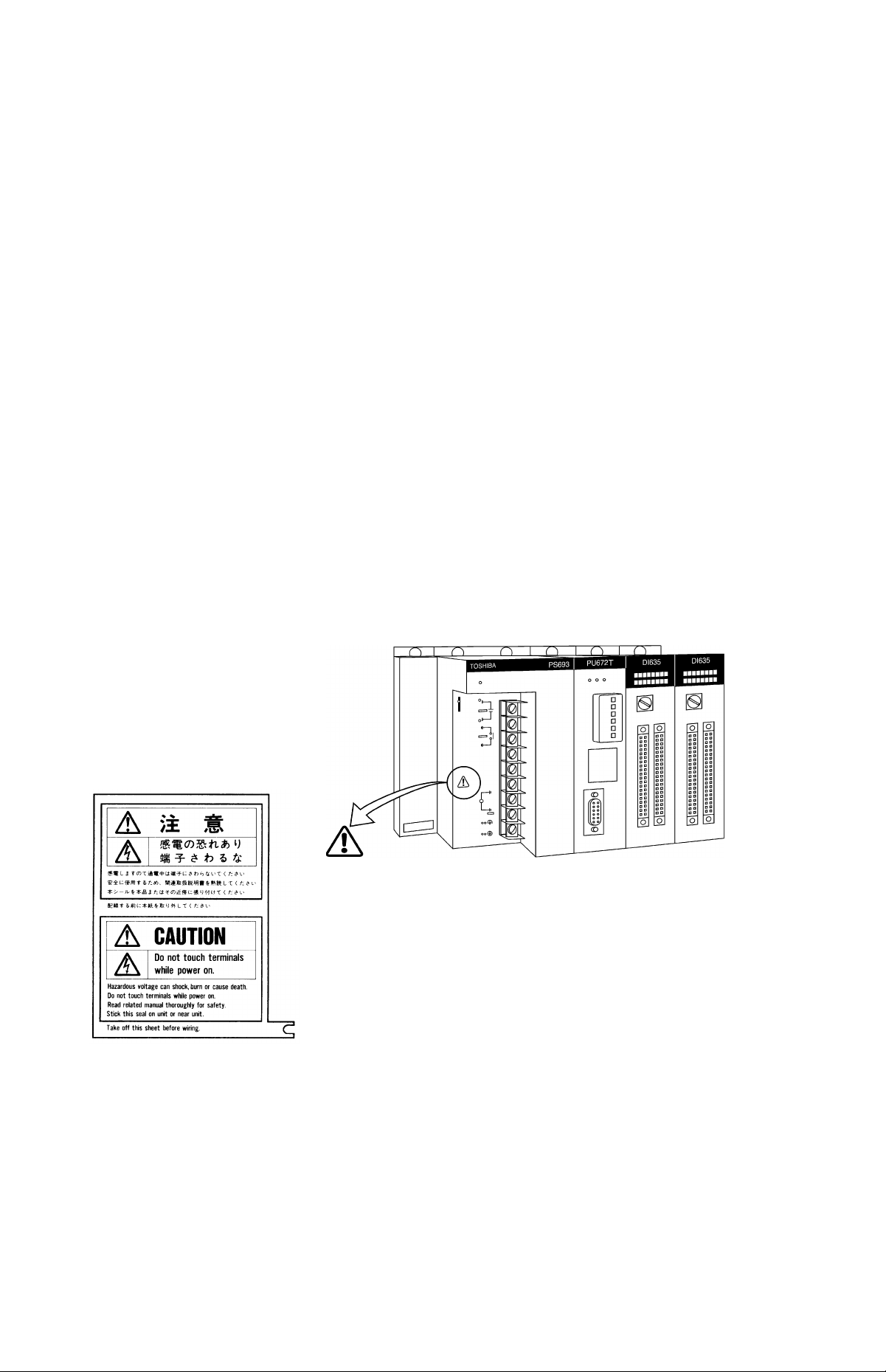

Make sure warning markings are attached on the model 2000.

If any of them are missing or the wording is illegible, contact Toshiba’s Service Department.

[Warning Mark on the model 2000]

This is the warning mark for dangerous location. It is attached to the equipment at positions

where there is a risk of electric shock and at positions where there is a risk of damage to

the equipment through incorrect wiring.

A

(1) Keep hands away from terminals, especially the input terminal of the power supply while power is

on, to avoid the risk of electric shock.

(2) Turn off power before installing or removing modules, terminal blocks, or wires.

(3) Applying excess power voltage to the model 2000 can cause failure or malfunction. Apply power of

the specified ratings described in this manual.

(4) Turn off the power of the tool (a personal computer, etc.) before connecting the connector to the tool

port. Afterwards, turn on power.

Avoid short-circuiting between the tool connector pins with the cover, etc.

Take the following precautions where this mark is found.

[Safety Label]

The safety label as shown on the left both in Japanese and English

is attached to the power supply terminal of the model 2000. (exept

the 24Vdc input power supply module)

Remove the mount paper before wiring

Peel off either of the Japanese and English labels from the mount

paper and stick it to the model 2000 or near the power terminal

where it can be readily seen.

In the event the seal is damaged, contact the dealer.

NOTE

Marks printed at pages in this manual should always be read carefully.

Be sure to read them in handling your model 2000.

Sequence Controller S2T

Page 4

2. Precautions on Installation

^WARNING

Mandatory

Be sure to ground the model 2000. The

protective ground terminal of the model 2000

must be connected to an external protective

earth.

Operation without grounding may cause

accidental fire or shock.

A CAUTION

»

Mandatory

Avoid the following locations when installing or

storaging the model 2000.

• Locations where there is dust, salinity or ion

particles

• Locations where there are corrosive gases

(SO2, HjS) or flammable gases

• Locations where vibration or shock occurs

beyond the allowance

• Locations where there is condensation due

to sharp temperature variations

• Locations where the ambient temperature

exceeds the allowance range

• Locations where the relative humidity

exceeds the allowance range

• Locations where the model 2000 is exposed

to direct sunlight

• Locations where strong electric radiation or

magnetic field is generated

»

Mandatory

Improper the installation or wiring of the

system can cause not only insufficient

performance but also malfunction and failure of

the model 2000.

Installation in an unspecified direction or

improper installation can cause fall-off, fire,

interference, or malfunction of the model 2000.

»

Mandatory

Install the model 2000 at a place where

maintenance and inspection are easy to do.

Otherwise, recovery from failure may take

much more time, leading to a serious accidents.

Gr

Forbidden

Do not cover the hole of the model 2000, and

the ventilator/air inlet of the system.

Otherwise, overheating, etc. can cause fire or

malfunction.

Mandatory

Avoid entering wire scraps or other foreign

debris into the model 2000, and related

equipment. Otherwise, it can cause fire, failure

or malfunction.

6F8C0926

III

Page 5

3. Precautions on Wiring

<!>WARNING

Mandatory

Be sure to turn off power before wiring.

Otherwise, it can cause electric shock or

malfunction of the model 2000.

ACAUTION

Mandatory

Apply power of the specified ratings

described in the manual.

Applying excess power voltage to the model

2000 can cause explosion or fire.

Mandatory

Be sure to use crimp-style terminal with

insulating sheath or insulating tape to cover

the conductive parts when wiring modules so

that no conductive parts are exposed.

Handle the terminal cover with care so as not

to fall off or get damaged.

Be sure to fix the cover on the terminal block

after wiring.

An exposed conductive part can cause

electrical shock.

a

Mandatory

It is assumed that the users have general

knowledge of industrial electrical control

systems.

IV

Sequence Controller S2T

Page 6

4. Precautions for Operation

^WARNING

»

Mandatory

Configure emergency stop interlocking circuit

outside the model 2000. Otherwise, failure

and malfunction of the model 2000 can cause

human injury, machine damage or serious

accidents.

ACAUTION

o

Forbidden

The power supply modules, the CPU modules,

the direct I/O modules and the expansion

interface are dedicated to the model 2000.

Mount them on the bases of the model 2000.

Do not use them by themselves for other

purposes.

Otherwise, it can cause electrical shock or

injury or malfunction.

»

Mandatory

Be sure to keep the terminal block covers

closed during power ON. Do not touch the

terminals. Otherwise, it can cause electrical

shock or injury.

»

Mandatory

When you attempt to perform program change,

forced output, RUN/HALT controls, etc during

operation, carefully check for safety.

Improper operation or negligence in checking

safety conditions can cause machine damage

or serious accidents.

«

Mandatory

Mount the modules on the base securely until

they click, and fix them on the base with

screws.

Insufficient installation can cause failure or

malfunction.

«

Mandatory

Sample programs and circuits described

in this manual are provided for explaining

the operations and applications of the S2T.

You should test completely before using

them as a part of your application system.

6F8C0926

»

Mandatory

Set the operating switches of the model

2000 according to this manual.

Improper setting can cause failure or

malufunction.

»

Mandatory

Install fuses suited to the load current

capacity in the external circuits for the relay

output module, preventing from overload.

Otherwise it can cause machine damage or

accidents.

Page 7

O

Mandatory

Configure the external circuit to turn on power

according to the following sequence.

Turn on the power of model 2000

^ Turn on the power for the I/O module and

external load power supplies

Otherwise, it can cause machine damage,

malfunction or accidents.

»

Mandatory

It is recommended to use an external power

supply that provides power for both the I/O

module and the loads. If not possible,

configure the external circuit so that the

external power required for output modules

and power to the loads are switched ON/OFF

simultaneously.

Also, be sure to turn off power to the loads

before turning off power to the S2 T for system

safety.

Sr

Forbidden

Turn off power immediately if the S2T or

related equipment emitting smoke or odor.

Operation under such situation can cause f ire

or electrical shock. Also unauhorized repairing

will cause fire or serious accidents. Do not

attempt to repair. Contact Toshiba for

repairing.

5. Safety Precautions on Maintenance and Inspection

<!>WARNING

»

Mandatory

Turn off power when removing any units,

modules, terminal blocks or wired cables after

installing.

Otherwise exposed conductive pants of wire

or on the rear of terminal blocks can cause

electrical shock.

Sr

Forbidden

Do not disassemble or modify the S2T and

related equipment in hardware nor software.

Otherwise it can cause failure, malfunction,

electrical shock or injury.

(Sr

Forbidden

Be sure not to connect the opposite electrode

of the battery or charge, the battery.

Also, do not try to disassemble the battery or

make it short-circuited or throw it into fire or

use it in overheated condition.

Otherwise it can cause fire or explosion.

VI

Sequence Controller S2T

Page 8

ACAUTION

0^

Forbidden

Be careful not to hit or fall off the model 2000

by accident.

Excess shock can cause failure.

Mandatory

Touch a grounded metal part to discharge the

static electricity on your body before touching

the model 2000.

Otherwise, charged static electricity on your

body can cause malfunction or failure.

Mandatory

Use soft cloth to clean the model 2000.

Use water-dipped and squeezed cloth to clean

it if dirty.

Leaving the model 2000 dirty can cause

mistaking or malfunction.

9

Mandatory

Place any modules removed from the unit on a

conductive mat or conductive bag (containing

a spare board, etc.) on an grounded desk.

Otherwise, static electricity can damage

components of the module.

0

Forbidden

Do not apply benzene and thinner when

cleaning the model 2000.

Otherwise, it can cause deformity or

descoloration the panel or case of the model

2000.

6.Safety Precautions on Replacing Components

<^WARNING

Mandatory

Turn off power of the model 2000 before

replacing the power fuse or warning fuse.

Otherwise, it can cause electrical shock or fire.

6F8C0926

Mandatory

Replace the fuse or battery with a new one

specified.

Otherwise, it may malfunction or cause fire.

VII

Page 9

»

Mandatory

The relays used in the relay output module

have ON/OFF life mechanically.

Use them within their mechanical life times is

described in this manual.

Replace the module if exceeded.

Acaution

a

Mandatory

In an annual average temperature of 30°C or

less, replace the battery every four years;

replace it every two years in an average

annual temperature higher than 30°C.

An exhausted battery can cause malfunction

and lose data and programs stored in S2T,

resulting in machine damage or accidents,

depending on the application.

7. Safety Precautions in Daily Operation

C^WARNING

«

Mandatory

Apply power of the specified ratings (voltage

fluction range, frequency, output rating, etc.)

described in this manual.

Otherwise, it can cause malfunction,

machine damage or fire due to overheat.

«

Mandatory

Turn off power immediately if the ambient

temperature or internal temperature exceeds

beyond normal range or if failure is occurred in

the model 2000.

Contact Toshiba for repairing.

Operation under such situation can cause fire

or electrical schock.

Vili

Sequence Controller S2T

Page 10

ACAUTION

0

Forbidden

Do not touch any components, terminals,

connectors or printed circuit boards in the

module.

Otherwise, it can cause the 1C or LSI or the

like to be broken by static electricity, resulting

in failure or malfunction.

Also, the edge of components can cause

injury.

0

Forbidden

Do not disassemble or modify the S2T and

related equipment.

Otherwise, it can cause malfunction or failure.

0

Forbidden

Do not forcibly bend or pull or distort the

power cord and other cables. Otherwise, they

can be cut off or cause overheat.

0

Forbidden

Do not enter wire scraps or other foreign

debris into the S2T and related equipment.

Also, do not insert metal parts into them.

They can cause fire or accidents.

8. Safety Precautions on Disposal

^WARNING

Forbidden

Do not throw lithium batteries into fire.

Otherwise, they can explode.

ACAUTION

Mandatory

Observe local regulations for disposal of the

lithium batteries or the model 2000.

6F8C0926

IX

Page 11

Limitation of Appiications

■ The model 2000 has been designed and manufactured for use in an industrial environment.

However, the model 2000 is not intended to be used for systems which can endanger human

life (note 1).

■ Consult Toshiba if you intend to use the model 2000 for a special application which involves

human life and has great influence on the maintenance of the public function (note 2). This is

why such application requires special care on the operation, maintenance, and control of the

system (note 3).

(Note 1) The systems which can endanger human life are life maintenance systems, equip

ment installed in the surgery, and other medical equipment.

(Note 2) The systems which involve human life and have great influence on the maintenance

of the public function mean the main control system of a nuclear power plant, safety

and protection system of a nuclear power facility, transport operation and control sys

tems for mass transportation, control systems of aviation and space systems, and

other systems and subsystems where safety is critical.

(Note 3) "Special care" means to build a safety system (foolproof design, fail safe design,

redundancy design, etc.) in full consultation with Toshiba’s engineers.

Immunity

Toshiba is not liable for any loss caused by fire, earthquake, action by a third party, or other

accidents, or the operator’s intentional or accidental misuse, incorrect use, or use under

abnormal condition.

Toshiba is not liable for any incidental loss caused by the use or non-use of this product, such

as loss of business profits, suspension of business, or loss or change of data on memory.

Toshiba is not liable for the loss caused by an operation contradictory to any of the instructions

stated in this manual.

Toshiba is not liable for the loss caused by an incorrect operation in combination with other

equipment.

Toshiba is not liable for the loss caused by a malfunction in combination with an application

program made by the customer.

NOTE:

Use cellular phones and PHSs at least one meter away from the working the model 2000

transmission cables, and I/O bus cable. Otherwise, the system can malfunction.

Sequence Controller S2T

Page 12

About this manual

This manual describes an overview, specification, and installation, operation, and

maintenance and inspection of the hardware of Toshiba’s sequence controller S2T for

the Integrated Controller Vseries model 2000 (hereinafter called "S2T," which is also

called "model 2000" or the "equipment" when no distinction is needed).

The following types of S2T are available to realize cost-performance suited to your

application.

• PU662T: CPU station module, 32K-steps, 90 ns/basic instruction, RS485 port

• PU672T: CPU station module, 64K-steps, 90 ns/basic instruction, RS485 port,

1MB memory

At first, be sure to read "Safety Precautions" before operating the model 2000.

Read this manual throughly before using the S2T. Also, keep this manual and

related manuals so that you can read anytime while the S2T is in operation.

This manual has been written for users who are familiar with Programmable Control

lers and industrial control equipment. Contact Toshiba if you have any questions

about this manual.

6F8C0926

XI

Page 13

The S2T Related Manual

The following documents are available for S2T .

S2T User’s Manual - Basic Hardware (6F8C0926)

Describes the S2T system configuration, and explains the specifications, installa

tion, wiring, maintenance and troubleshooting for the S2T’s basic hardware.

S2T Use’s Manual - Functions (6F8C0928)

Provides the information for designing S2T user program, such as S2T internal

operation, memory configuration, I/O allocation.

T Series Instruction Set (Ladder, SFC) (UM-TS03***-E004)

Detailed explanations of ladder and SFC programming, two of the languages of the

S2T/T3H/T3/T2N/T2E/T2/T1S/T1 programmable controllers.

T-PDS for Windows Basic Operation Manual (UM-TS03***-E038)

Installation and basic key operations of the T-series Program Development System

(T-PDS) software for windows.

T series Computer Link Function User’s Manual (UM-TS03***-E008)

Describes the Tseries computer link configuration, and explains the protocol, soft

ware procedure, wiring to communicate between the Tseries PCs.

High Function Analog Mdule User’s Manual (6F8C0860)

Describes the specifications and operation of high function Analog Mudule

(AD668/DA664/TC618/RT614).

Pulse Input Module Manual (PI632/PI672) (6F8C0841)

Describes the specifications and operation of Pulse Input Module (PI632/PI672).

Communication Interface Module Manual (CF611) (6F8C0843)

Describes the specifications and operation of Communication Interface Module

(CF611).

2-Axis Positioning Controller Manual (MC612) (6F8C0842)

Describes the specifications and operation of 2-Axis Positioning Module(MC612).

XII

TOSLINE-S20 User’s Manual (6F8C0890)

Describes the system configuration, and explains the functions, performance and

operation of TOSLINE-S20.

Sequence Controller S2T

Page 14

TOSLINE-F10 User’s Manual (6F8C0844)

Describes the system configuration, and the specifications, wiring and operationg

of remote I/O data link system TOSLINE-F10.

DeviceNet Scanner Module Manual (6F8C0845)

Describes the system configuration,and explains the specifications, installation,

wiring of Device Net.

Ethernet Module Operation Manual (6F8C0879)

Describes the specifications, wiring and operating of Ethernet Module (EN611/

EN631/EN651)

6F8C0926

XIII

Page 15

CONTENTS

Safety Precautions.......................................................................i

Limitation of Applications............................................................x

Immunity.....................................................................................X

About this manual..................................................................................xi

The S2T Related Manual......................................................................xii

Chapti System Configuration

1.1 S2T configuration as Station Module

1.1.1 S2T basic configuration............................................................2

1.1.2 S2T System configuration

1.1.3 Unit configuration......................................................................5

1.2 S2T CPU Module

1.2.1 Overview.................................................................................10

1.2.2 Status display LEDs...............................................................11

1.2.3 Operation Mode Switch..........................................................11

1.2.4 Setting Switches of Operation Mode

1.2.5 Programmer port of RS232C..................................................13

1.2.6 LINK port of RS485................................................................ 14

1.3 Computer link mode

1.3.1 Computer link function............................................................18

............................................................

........................................................

........................................................

.........................

................................

......................................

1

2

3

10

12

18

XIV

1.3.2 System configuration..............................................................19

1.3.3 Setup procedure

1.3.4 RS-485 cable connection.......................................................21

1.3.5 RS-232C cable connection.....................................................23

1.3.6 Mode setting...........................................................................23

1.3.7 Communication parameter setting

1.3.8 Computer link protocol............................................................25

.....................................................................

.........................................

20

24

1.4 Free ASCII mode.............................................................27

1.4.1 Free ASCII communication function.......................................27

1.4.2 System configuration..............................................................29

1.4.3 Setup procedure

1.4.4 RS-485 cable connection.......................................................31

1.4.5 Mode setting...........................................................................32

1.4.6 Communication parameter setting

.....................................................................

.........................................

30

33

Sequence Controller S2T

Page 16

------------

1.4.7 Message format......................................................................34

1.4.8 Programming..........................................................................35

1.4.9 Related instruction..................................................................40

CONTENTS

1.4.10 Sample programs

1.5 Units................................................................................51

1.5.1 Bases

1.5.2 Expansion interface................................................................53

1.5.3 Expansion cables

1.6 Power Supply Module......................................................54

1.6.1 Power Supply Module.............................................................54

1.6.2 Power capacity consideration.................................................57

1.7 I/O Modules.....................................................................60

1.8 Network Modules

.....................................................................................

Chapt2 Specifications

2.1 General Specifications

2.2 External dimensions........................................................68

...................................................................

...................................................................

............................................................

.................................

....................................................

48

51

53

62

65

65

2.3 I/O Module Specification

.................................................

70

ChaptS Precautions for I/O Modules..........111

3.1 Precautions for DC Input Modules

3.2 Precautions for AC Input Modules.................................115

3.3 Precautions for DC Output Modules..............................117

3.4 Precautions for AC Output Modules..............................120

3.5 Precautions for Relay Output Modules

3.6 Precautions for Analog Input Modules

3.7 Precautions for Analog Output Modules........................123

...................................

.........................

..........................

121

Ill

122

Chapt4 Installation and Wiring..................125

4.1 Operating environment..................................................125

4.2 Installing bases

.............................................................

126

6F8C0926

4.3 Mounting the Modules...................................................127

XV

Page 17

CONTENTS-------------

4.3.1 Basic procedure for mounting/removing the modules. . . 127

4.3.2 Installing/removing of the module cover

4.4 Connecting expansion units

4.5 Grounding......................................................................133

4.5.1 Check points for grounding...................................................133

4.5.2 Grounding methods..............................................................134

4.6 Wiring of the power supply

4.7 I/O wiring.......................................................................139

4.8 Wiring of the computer link

4.9 Power up/down sequence

4.10 Safety circuit..................................................................144

..........................................

............................................

...........................................

.............................................

ChaptS Maintenance and Checking

5.1 Daily checking items......................................................145

5.2 Periodical checking items..............................................146

..............................

............

131

132

136

141

143

145

5.3 Maintenance parts.........................................................147

5.4 Battery Replacement.....................................................148

Disposal of the battery 150

5.5 Fuse Replacement........................................................151

Chapt6 Troubleshooting

6.1 Troubleshooting procedure

6.2 Checking the power supply

6.3 Checking the S2T CPU

6.4 Checking user program

6.5 Checking input...............................................................158

6.6 Checking output

6.7 Troubles due to external factors

............................................................

.............................

..........................................

...........................................

.................................................

.................................................

....................................

153

153

155

156

157

159

160

XVI

Sequence Controller S2T

Page 18

Chapt.1 System Configuration

The Integrated Controller Vseries has some features as mentioned before. The Sta

tion Module with station bus (internal high-speed data bus) interface can perform to

exchange common data between them on real time.

• Station Module

The Station Module is shown as below table. These can be mounted on the dedi

cated basic base and perform complex control combining each functionality.

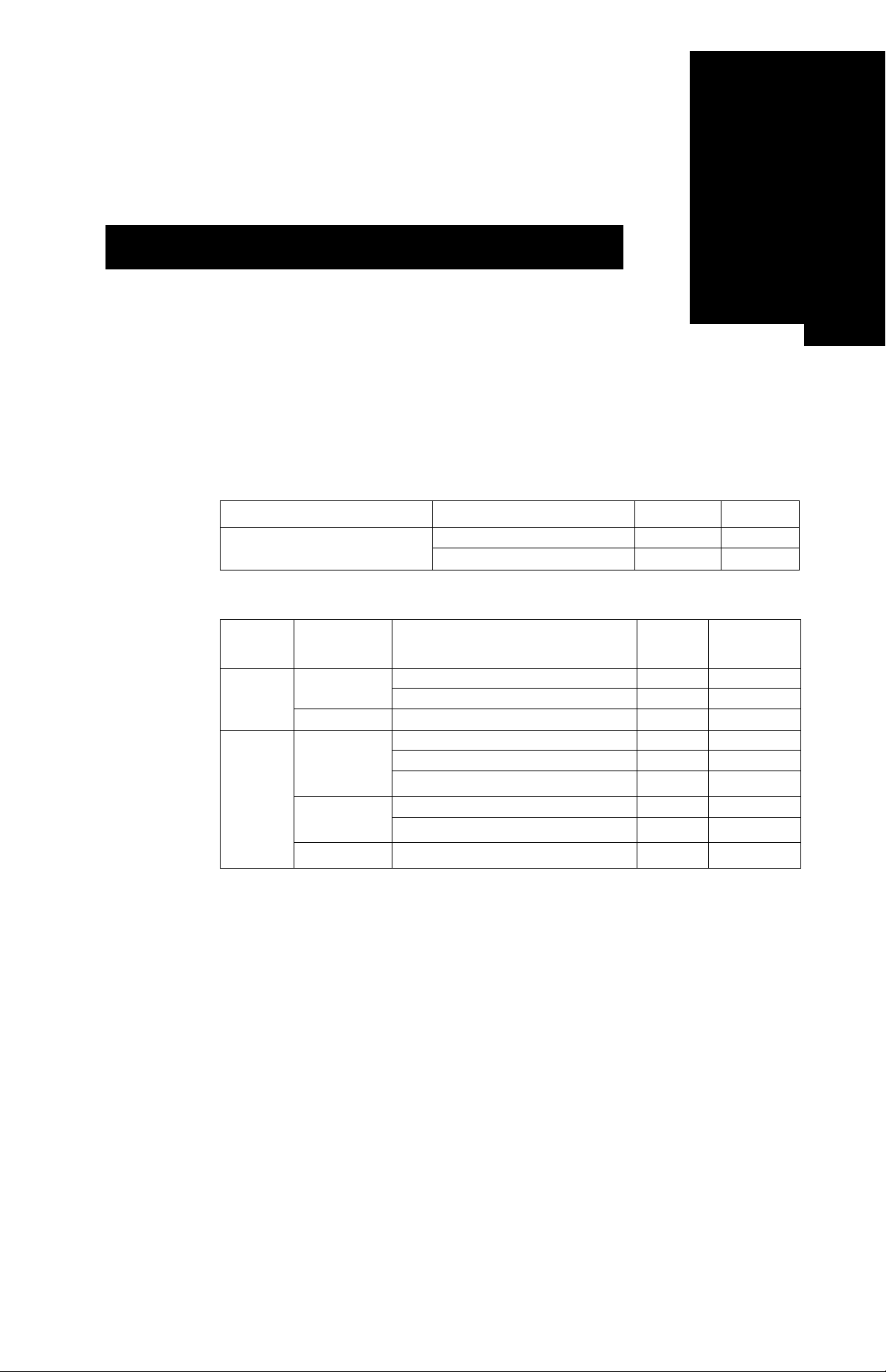

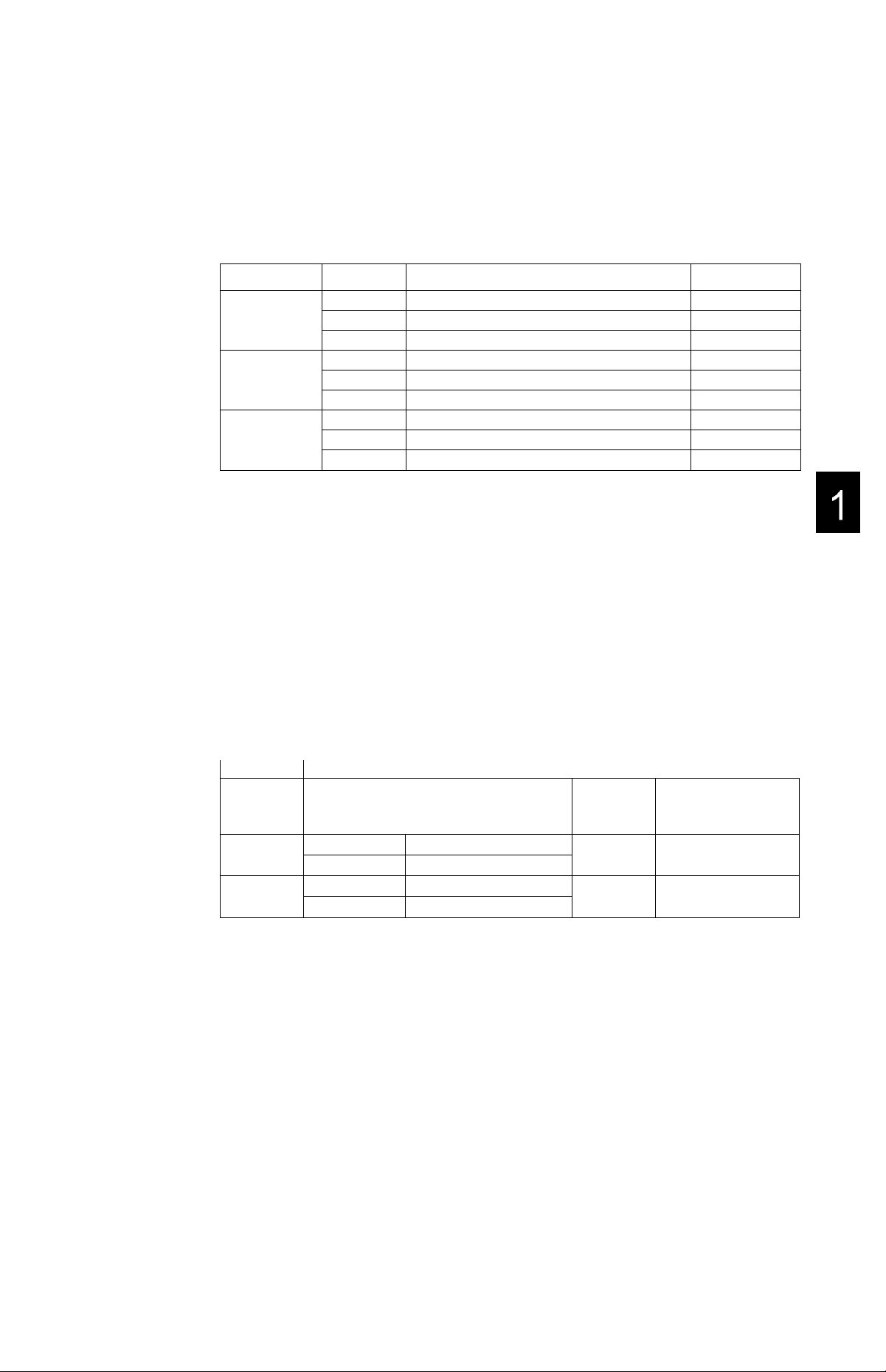

Table1-1 S2TCPU

1

Description Specification

Sequence

Controller

Table1-2 Station Module

Item Description Specification

Controller

Network

*1: underdevelopment

*2: The above modules are performed on the main base with station bus.

Please refer to Section 1.1 or 1.3 for details of the ^stem configuration.

Sequence

Controller

Compute

Ethernet 10BASE5 EN611

TC-netIO 16KW, 10Mbps,co-axial CN611

TC-net20

32K-step

64K-step

32K-step

64K-step

WIndows-NT HDD

10BASE2

100BASE-TX, 10BASE-T

16KW, 10Mbps,co-axial. Double bus

16KW, 20Mbps,optical,Double Loop bus

PU662T

PU672T

Type

PU662T 1

PU672T 1

C2PU35

EN631

EN651

CN612

CN623*''

Type Remarks

No. of

Occupied slot

2

1

1

1

1

1

1

6F8C0926

Page 19

Chapt.1 System Configuration

1.1 S2T configuration as Station Module

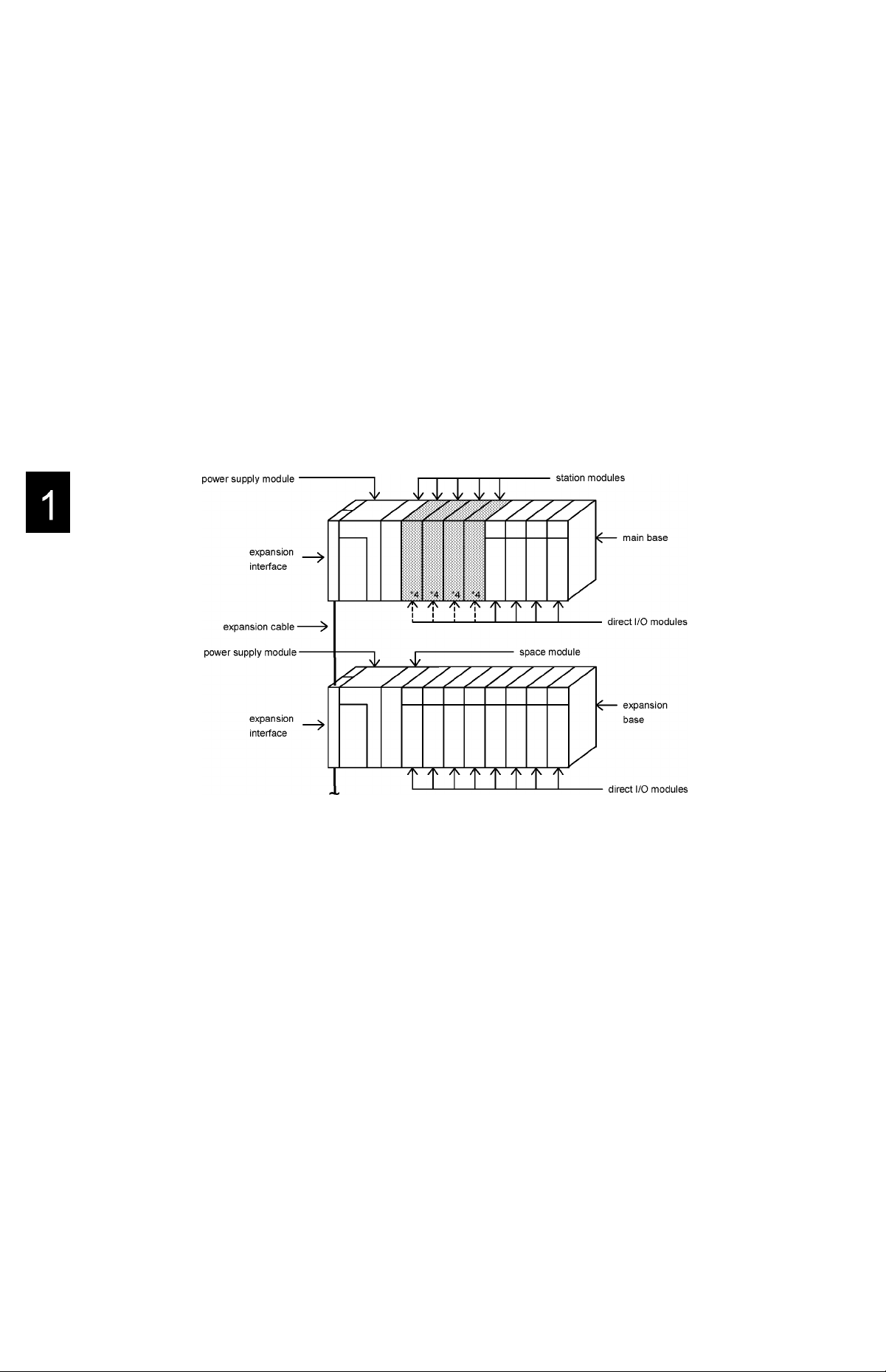

1.1.1 S2T basic configuration

According to variety of industrial applications, a basic unit or with expansion units are

selected.

The basic unit is composed of a main base, a power supply module, station modules

and direct I/O modules, and an expansion interface is added using expansion units.

The expansion unit is composed of an expansion base, a power supply module,

direct I/O modules and an expansion interface.

Each expansion interface modules are connected with expansion cables.

Up to three expansion units can be connected in the S2T.

The S2T accesses direct I/O modules via the G2-bus in the model 2000.

Basic unit

*4: The digital / analog I/O modules can be mounted in the *4 slots in place of the station modules.

Fig.1-1-1 An example of S2T basic configuration as station module

Expansion unit

Sequence Controller S2T

Page 20

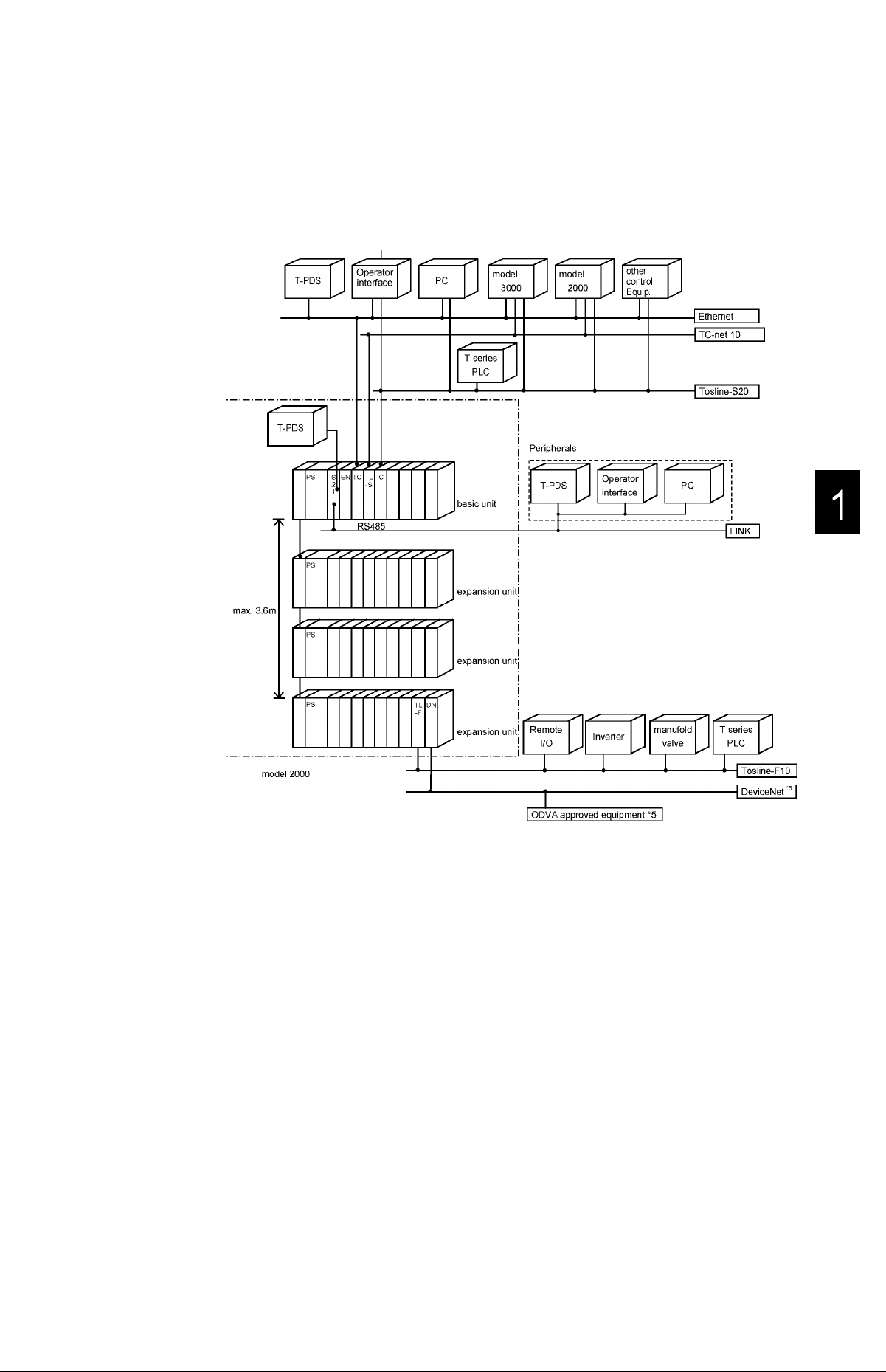

1.1.2 S2T System configuration

The S2T provide a functional, economical and compact solution to user applications

in automotive, machine control and process control, by using station modules and

direct I/O modules.

1.1 S2T configuration as Station Module

*5: DeviceNet is a registered trademark of the Open DeviceNet Vender Association, Inc.

Fig.1-1-2 An example of S2T system configuration as station module

6F8C0926

Page 21

Chapt.1 System Configuration

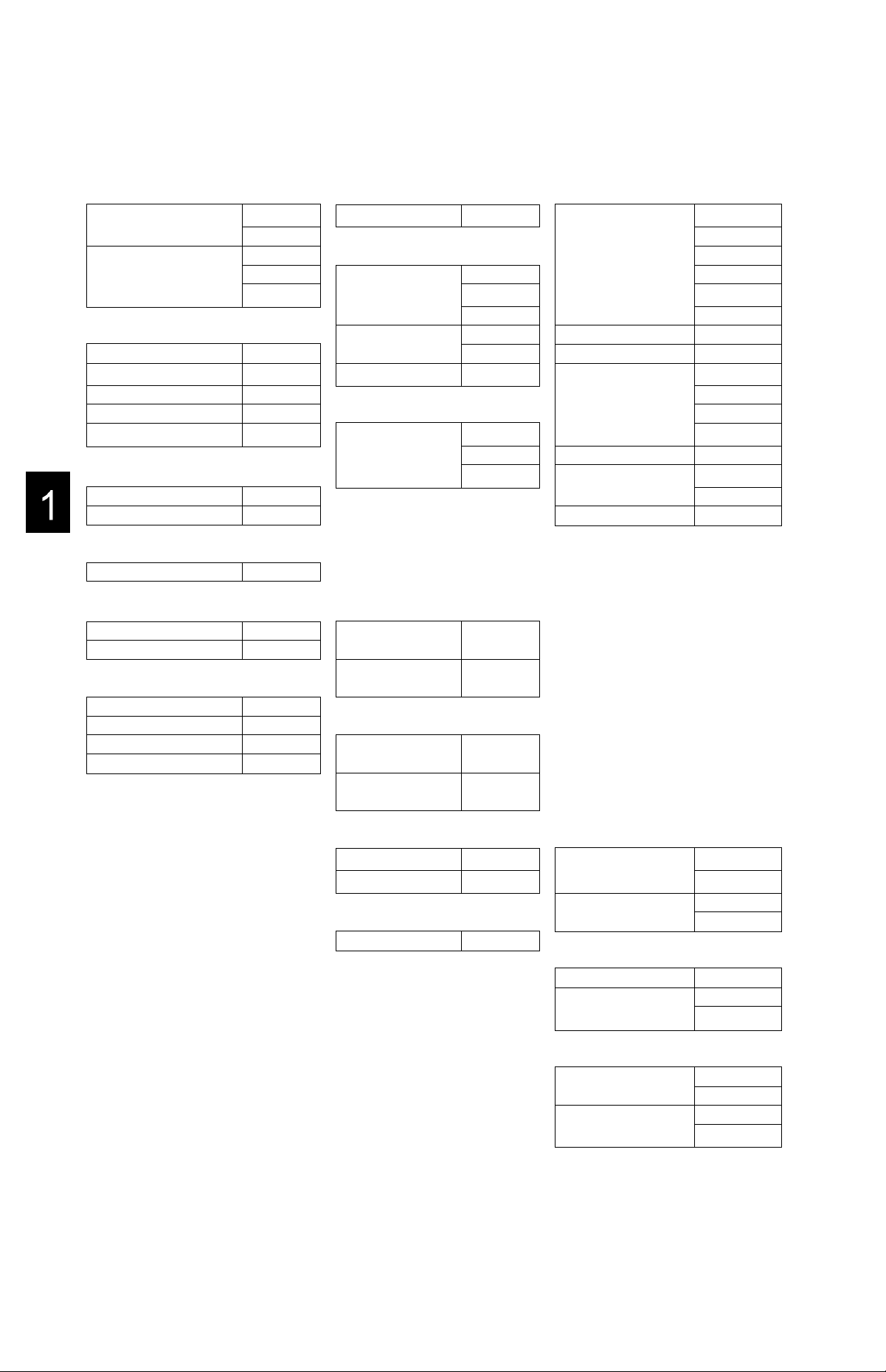

• Basic configuration

Base

Main base

Expansion base

Power supply module

100, 200Vac input PS691

100-240Vac input PS693

100-240Vac input

24Vdc input

tOOVdc input

S2T CPU module

32k-step

64k-step

Expansion interface

Standard IF661

Optional

Space module SP600

Unit cover SP601

Expansion cable for standard

0.3m

0.5m

0.7m CS6R7

1.2m

BU648E

BU643D

BU668

BU666

BU664

PS694

PS632

PS652

PU662T

PU672T

CS6R3

CS6R5

CS6*1

• station Module

Control module

Computer

Network module

TOSLINE-S20 SN625

TC-net10 CN611

TC-net20

Open Network module

Ethernet EN611

Serial, CompactFash interface

Serial, Compact

flash interface

C2PU35

SN626

SN627

CN612

CN623*''

EN631

EN651

CF612

•Software tool

Programming tool T-PDS

Windows-NT/98

(Japanese)

Windows-NT/98

(English)

TOSLINE-S20tool S-LS

Windows-/NT/98

(Japanese)

Windows-/NT/98

(English)

MW33J2

MW33E2

MW23J*

MW23E*

■1

• Direct I/O module

Digital input/output module

24Vdc input

100-120Vac input IN653

200-240Vac input IN663

Transistor output

(source type)

Triac output AC663

Relay output

Changect detect CD633

Analog input/output module

Analog input

Analog output

Serial interface

Serial interface CF611

DI632D

DI633

DI634

DI635

DI635H

DI653

D0633

D0634

D0635

D0633P

R0662S

R0663

AD624

AD674

AD628S

AD638S

AD668

RT614

TC618

DA622

DA672

DA664

*1: underdevelopment

*4: function limited

DDE server soft

Japanese Edition

English Edition PV33E2

Connecting cable

5m

PV33J2

CJ905

Network module

TOSLINE-S20

TOSLINE-F10 UN611

Network module

DeviceNet

FL-net FL611

Intelligent I/O module

Pulse input

Positioning control MC612

SN621*'’

SN622*“’

UN612

DN611A

FL612

PI632

PI672

MC614*''

Sequence Controller S2T

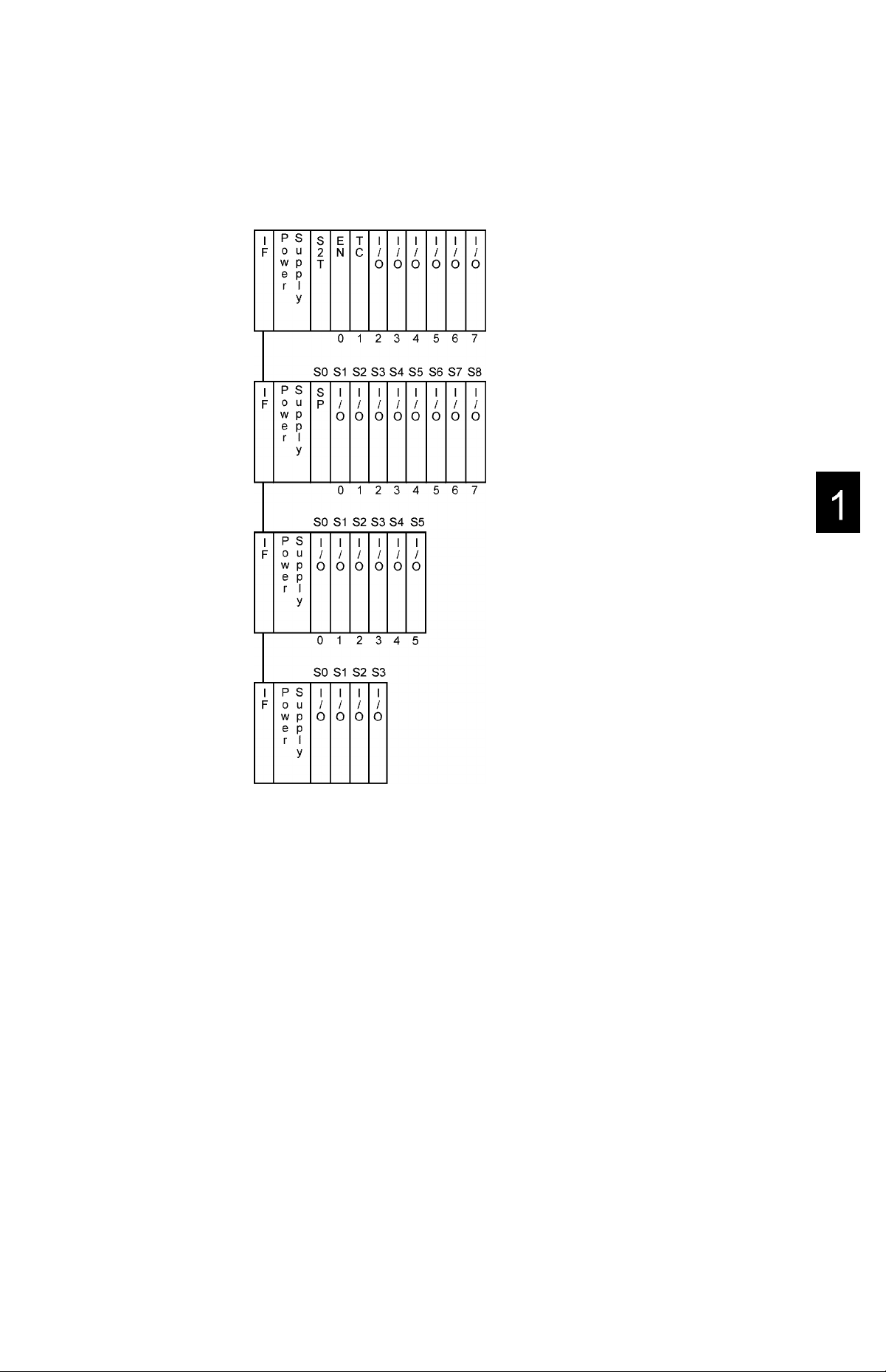

Page 22

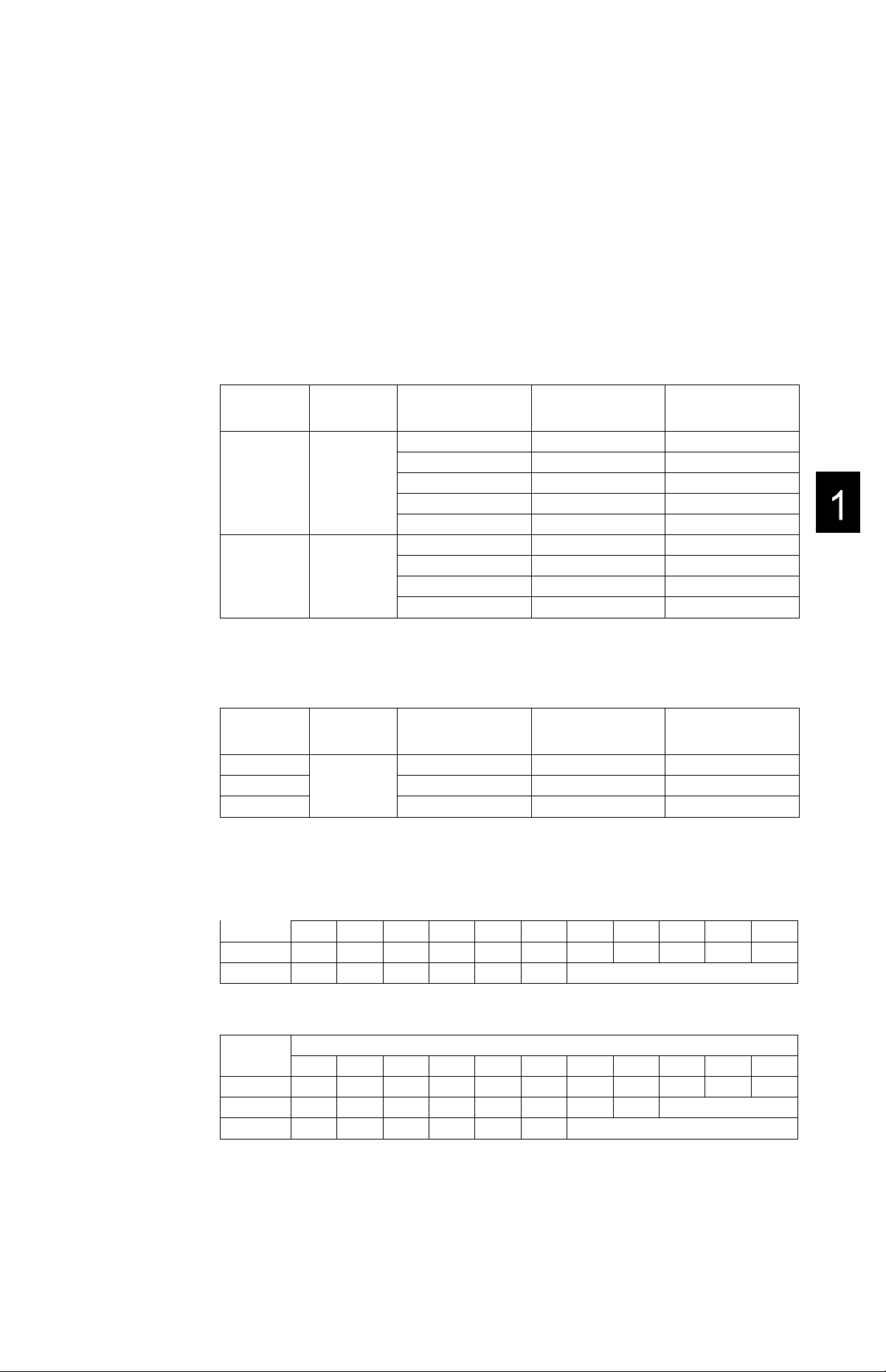

1.1.3 Unitconfiguration

Some examples of minimum/maximum configuration are shown as below.

Basic unit

The main base dedicated for station module is used. The control module S2T should

be mounted on SO that is the left end slot of the base. Other station modules are

mounted on from S1 to S4 (BU648E) where two connectors are.

The digital/analog input/output module can be mounted on slots for station module.

These modules should be mounted on the right slot of station modules.

Table1-1-1 Main base

1.1 S2T configuration as Station Module

Type

BU648E For

Basic unit

BU643D For

Basic unit

Description

Slot No.

for station Module

5

4

3 6

2 7

1

4

3

2 2

1

Slot No.

for Direct I/O Module

Expansion unit

Table1-1-2 Expansion base

Type

BU668

BU666 0 6

BU664

Description

For

Expansion

unit

Space slot No.

1

0

Slot No.

for Direct I/O Module

Remarks

4

5

8

0

1

3

Remarks

8

4

6F8C0926

Module implementation from base view

Tablel-1 -3 Basic unit Module implementation

Slot

PIF

BU648E

BU643D

PS 0

- -

- - CPU

CPU

Tablel-1-4 Expansion unit Module implementation

PIF

BU668 - - X 10 10 10 10 10 10 10 10

BU666

BU664

- -

- -

PS 0

lO 10 10 10 10 10

lO 10 10 10

1 2

ALL ALL ALL ALL

ALL ALL ALL

1 2

3

Slot

3

4

4

5 6

10 10 10 10

5 6

7

7

8

8

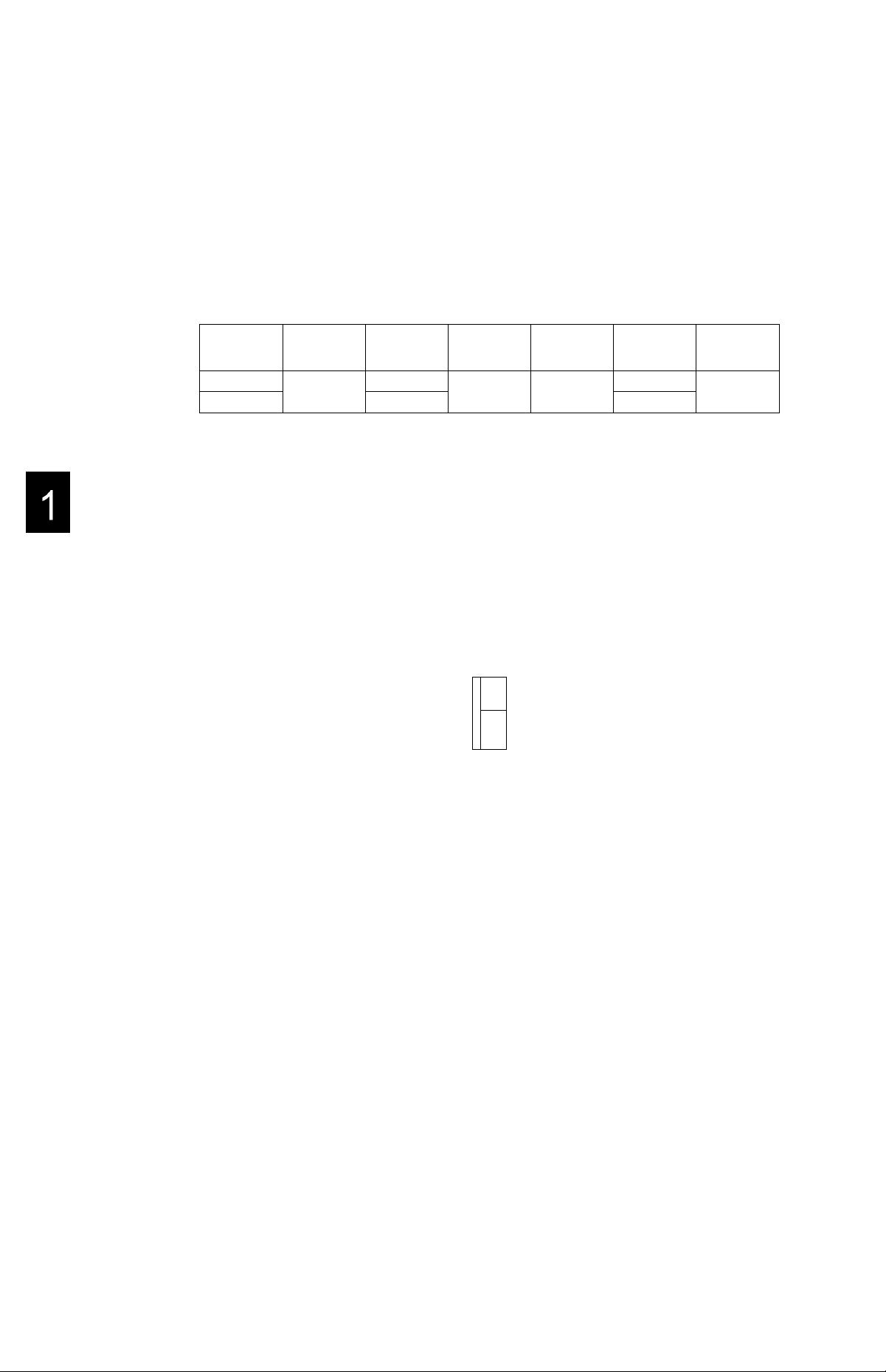

Page 23

Chapt.1 System Configuration

PIF:Slot for expansion interface IF661

PS:Slot for power supply module

0 to 8:Slot number of base

CPU:Slot for CPU module S2T

IO:Slot for I/O module

AlhSlot for Station module,I/O module

Module implementation from each module view

Tablet-1-5 CPU module

NOTE

One module

occupied slot

PU672T 1

PU662T 1

C2PU35

2

BU648E BU643D

0 0

0 0 X X X

1 ''-3

S2T(PU672T,PU662T) used in Basic unit slot number "0".

Tablet-1-6 expansion interface

BU648E BU643D

IF661

Tablet-1-7 Network module

BU648E BU643D

EN651

EN611

EN631

SN625

SN626

SN627

UN611

UN612

DN611A

FL611

FL612

1 ~ 4

1 ~ 4

1 ~ 4

1 ~ 4

1 ~ 4

1 ~ 4

5~8

5 ~ 8

1 ~ 8

1 ~8

1 ~ 8

1 ~3

1 ~3

1 ~3

1 ~3

1 ~3

1 ~3

X

X

X

X

X

Slot

BU668 BU666

X X X

1 '^2

Slot

BU668 BU666

PIF

Slot

BU668 BU666

X X X

X X X

X X X

X X X

X X X

X X X

1 ~8 0 ~ 5 0~3

1 ~ 8 0 ~ 5 0 ~ 3

1 ~ 8 0 ~ 5 0 ~ 3

1 ~8 0 ~ 5 0~3

1 ~ 8 0 ~ 5 0 ~ 3

X X X

BU664

BU664

BU664

6

Sequence Controller S2T

Page 24

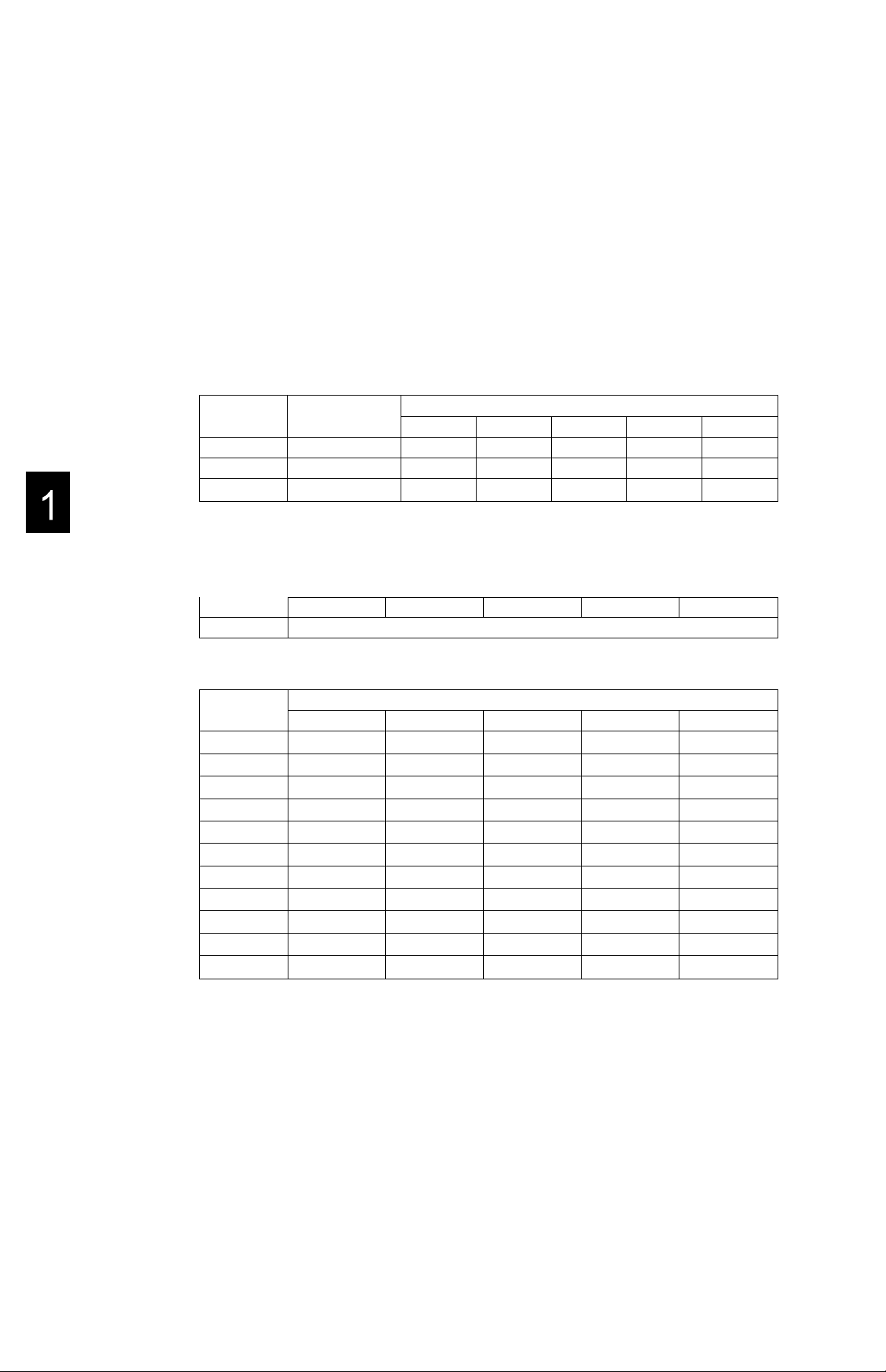

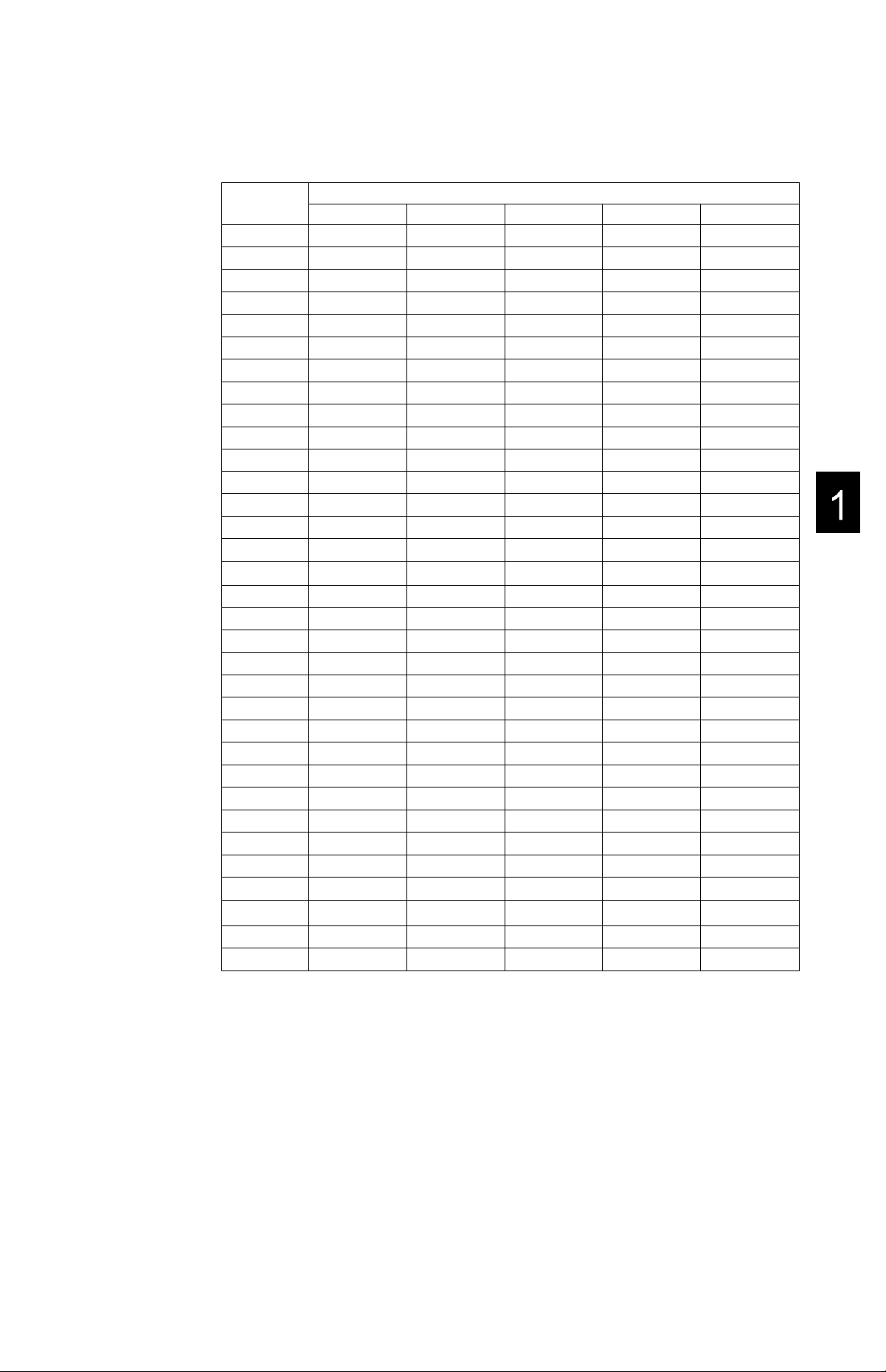

Table1-1-8 Direct I/O module, others

BU648E BU643D

DI632D

DI633

DI653

DI634

DI635

DI635H

I N653

I N663

D0633

D0633P

D0634

D0635

AC663

R0662S

R0663

CD633 *■'

AD624L

AD634L

AD624

AD674

AD628S

AD638S

AD668

TC618

RT614

DA622L

DA622

DA672

DA664

PI632 *■'

PI672 *■'

MC612

CF611

1 ~8

1 ~ 8

1 ~ 8

1 ~8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~8

1 ~ 8

1 ~8

1 ~8

1 ~ 8

1 ~8

1 ~8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

1 ~ 8

5~8

5~8

5~8

5 ~ 8

1.1 S2T configuration as Station Module

Slot

BU668 BU666

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~8 0 ~ 5 0~3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

1 ~

3 1 ~ 8 0 ~ 5 0 ~ 3

X

X

X

X

1 ~8 0 ~ 5 0~3

1 ~8 0 ~ 5 0~3

1 ~8 0 ~ 5 0~3

1 ~ 8 0 ~ 5 0 ~ 3

BU664

6F8C0926

*1: When you use CD633, PI632, PI672 with interrupt function, implement in the Basic

unit in which S2T exists.

Page 25

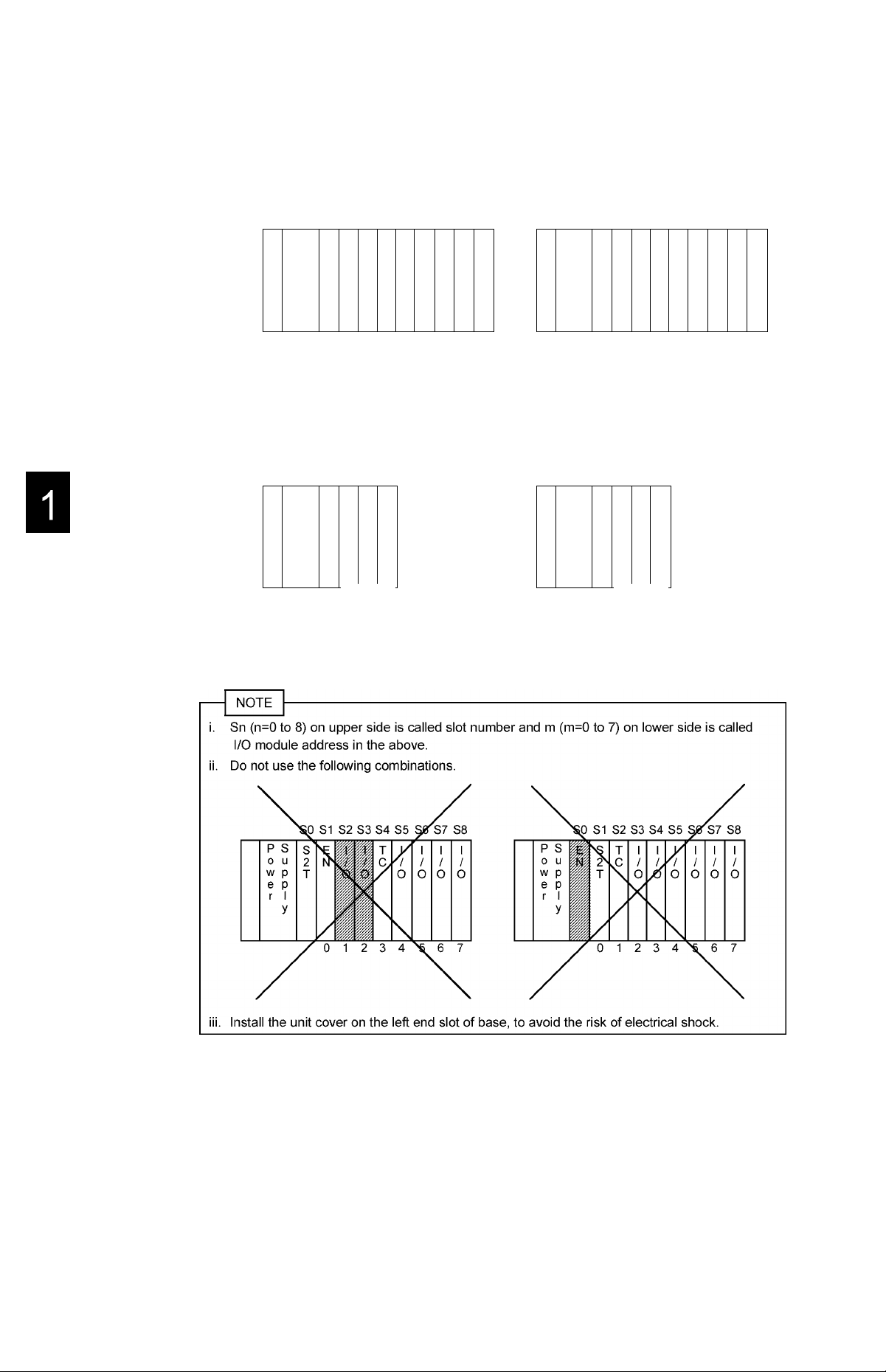

Chapt.1 System Configuration

(1) Minimum Configuration

• Exampies of BU648E

so S1 S2 S3 S4 S5 S6 S7 S8 SO S1 S2 S3 S4 S5 S6 S7 S8

p

s

u

0

c

’

W

e

r

T

s

U

L

2

1

p T

S

p

2

0

y

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7

E E T 1 1 1 1

N N

/ / / /

c

0 0 0 0

p

s

u

0

c

W

e

r

E T 1 1 1 1 1 1

s

U

p T

p

2 N

/ / / / / /

c

0 0 0 0 0 0

y

Main unit with 5 station moduies

and 4 i/0 moduies

UC*: unit cover

Exampies of BU643D

so SI S2 S3

P s

u

0 u

c

*

w p

e p

s

2 L 2 N

T

r 1

y

T

E

c

i

S

2

0

0 1 2 0 1 2

Using high performance

CPU, 4 siots

Main unit with 3 station moduies

and 6 i/0 moduies

so SI S2 S3

P s

U

0

C

w p

e p

s

U

2 L L /

T

r 1

y

T F 1

i

S

2

0

0

Using high performance

CPU, 2 siots

8

Sequence Controller S2T

Page 26

(2) Maximum Configuration

1.1 S2T configuration as Station Module

Number of I/O points (using 64-point I/O module)

SO S1 S2 S3 S4 S5 S6 S7 S8

Basic unit

Expansion unit

#1

Expansion unit

#2

384 points/BU648E

896 points/BU668

1,280 points/BU666

Expansion unit

#3

0 12 3

1,536 points/BU664

NOTE

IV.

The expansion interface should be mounted on each unit.

Two expansion connectors are fitted on the expansion interface. The upper side connector is

for input from previous unit and the lower side connector is for output to the next unit.

V. Up to a maximum of 3 expansion units can be connected.

vi. There is no limit on combinations of the types of the rack.

vii. Using BU668, the SO slot can’t be used and a space module SP600 should be mounted on SO.

The space module SP600 should be mounted on other vacant slots to avoid the risk of electri

cal shock.

6F8C0926

Page 27

Chapt.1 System Configuration

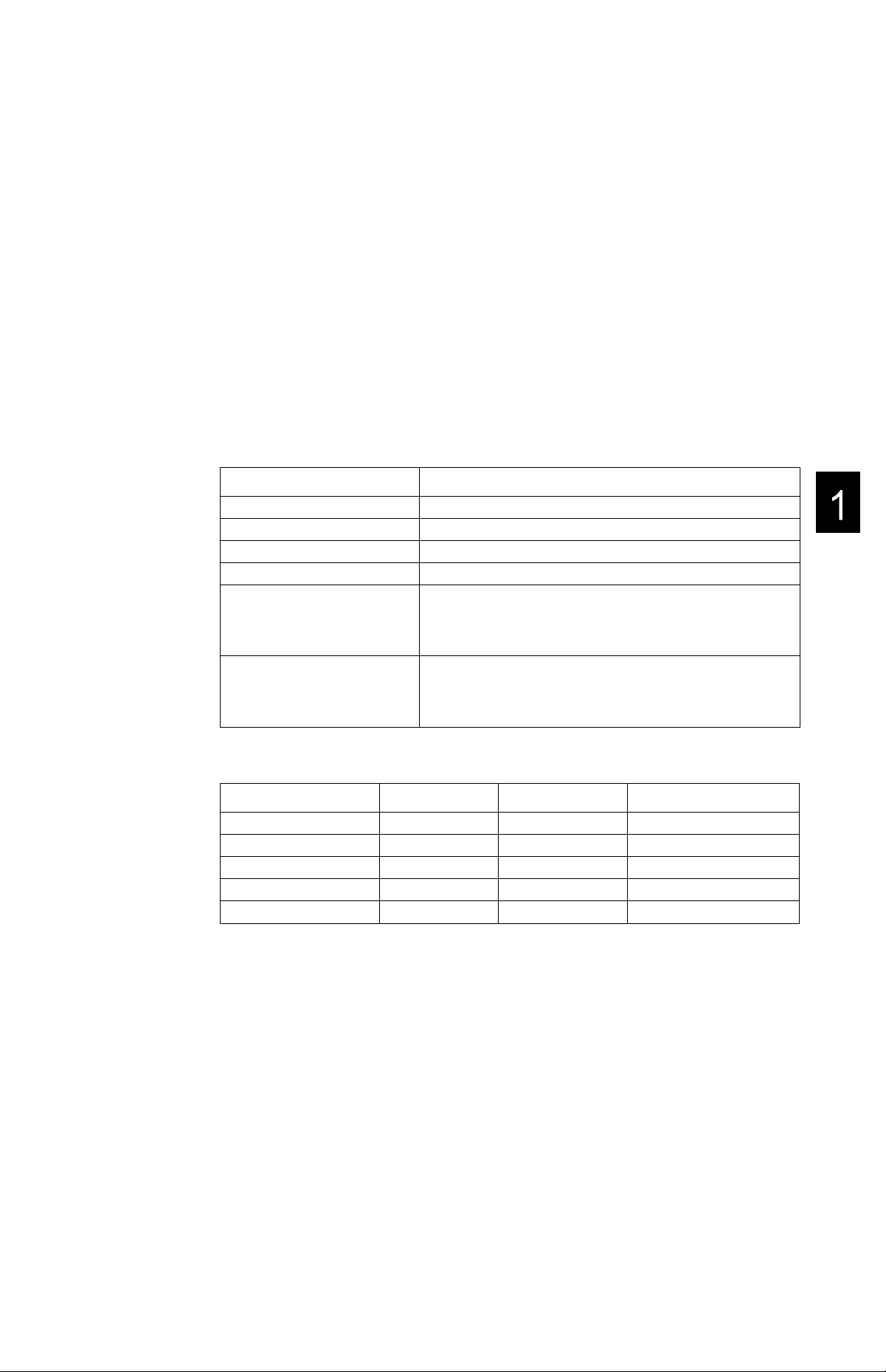

1.2 S2T CPU Module

1.2.1 Overview

The S2T CPU module performs user program, reading input data from the direct I/O

module and writing output data to the direct I/O module.

The S2T has two types of CPU modules.

Type

PU662T

PU672T

Program

language

Ladder +

SFC

Program

Capacity

32KS

64KS

Battery Memory

Built-in

RAM +

FlashROM

Expanded

memory

—

1MB

Link port

RS485

Built-in

When user program and parameter data are kept in the built-in flash ROM of the

S2T, user system will come back to be well quickly if any trouble occurs.

The S2T has the built-in two communication ports, one Programmer port and one

LINK port which is equipped for variety of peripherals, displays and PCs etc.

The front view of the S2T is shown as below. The operation mode switch, setting

switches of operation mode, status display LEDs are provided on the front panel.

Operation Mode Switch

(HALT, RUN)

Setting Switches

of Operation mode

PU672T

□

□

M

n

■ □

□

N

Ip

i

Status display LEDs

(RUN, FauLT, BATtery)

■ LINK port

Battery module cover

w

Programmer port

PROG

Fig.1-2-1 S2T CPU front view

10

Sequence Controller S2T

Page 28

1.2.2 Status display LEDs

These LEDs show operation states of the S2T.

Status display LEDs

1.2 S2T CPU Module

Name Display States

RUN (Green)

FLT (Red) Lit CPU abnormal or I/O abnormal

BAT (Green)

Lit

Blink HOLD Mode

Out Stopped state (HALT Mode) or Error Mode

Blink

Out Normal

Lit

Blink Battery caution

Out

1.2.3 Operation Mode Switch

The Operation Mode Switch is provided on the CPU module.

This switch controls S2T operation (RUN/HALT).

HALT-----------------Stop user program execution (HALT mode)

A

RUN -Start user program execution (RUN mode)

U

Remark

Operating state (RUN Mode)

CPU abnormal

Battery normal

Battery abnormal or no battery

CPU status is shown below after power up or after the operation mode is changed to

RUN from H

Setting

Position

HALT SW-1=OFF

RUN SW-1=OFF

ALT mode.

SW-1=ON

SW-1=ON

Initial Load Program

exe: executed

-: not executed

exe

exe

Operation

mode

HALT

RUN

-

Operation Mode

Change by the

Programming tool

Not available

available

As shown the above table, initial load (user program transfer from Flash ROM to

RAM) performs when setting SW-1 to OFF.

NOTE

i. The operation mode switch is set to HALT at the factory.

ii. Normally the programming is activated in the HALT mode,

ill. For details of the operation mode, see "S2T user's manual".

iv. The RAM is back-up by both internal capacitor and built-in battery of the S2T. When they go

down and the S2T can't keep retentive area in the RAM, CPU checks user program BCC.

CPU registers error if error is occurred.

6F8C0926 11

Page 29

Chapt.1 System Configuration

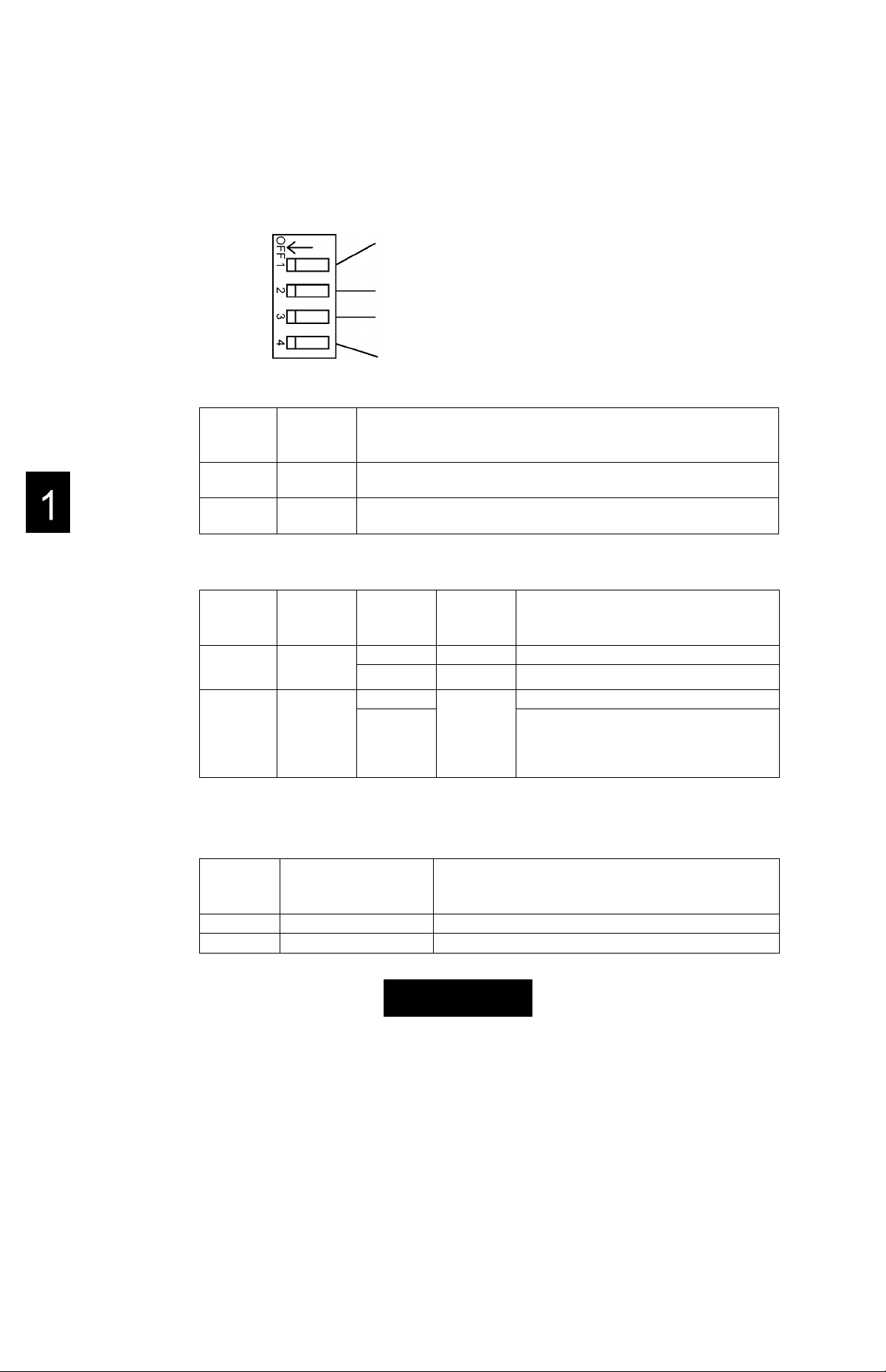

1.2.4 Setting Switches of Operation Mode

These switches are provided under the battery cover on the CPU front panei.

They controi the foiiowing fanctions. (SW-1 is ON, SW2, 3, 4 are set to OFF at the factory.)

SW-1 ROM/RAM Switch

Setting

Position

SW-1

OFF

ON RAM

Function

ROM Starts up after the content of the Flash ROM has been transferred to

the RAM. (Initial Load)

Starts up on the content of the RAM.

(No program transfer)

SW-2 RUN/Stand-by Switch

Setting

Position

SW-2

OFF

ON

Function

Automatic

RUN

Stand-by

. ROM/RAM Switch

_RUN/Stand-by Switch

•Programmer Port Parity :CPU reads this status oniy when power

Reserved (fixed to OFF)

at power up and at the beginning of the RUN mode

Operation

Mode

Switch

HALT HALT

RUN RUN

HALT HALT

RUN

Mode after

power up

:CPU reads this status when power is

changed from OFF to ON or when operation

mode is changed to RUN.

:CPU reads this status oniy when power

turns to ON.

turns to ON.

CPU operation

Remarks

Automatic RUN start occurs.

Starts up in the HALT mode. Ready to start

operation by an operate command from the

programming tool or by shifting the operation

mode switch.(^^LT^RUN)

is OFF, mode is set to Automatic RUN.

SW-3 Programmer Port Parity

Setting

Position

SW-3

OFF

ON

Odd Parity 8 bit Data, 9600bps, Data length is libit.

No Parity 8 bit Data, 9600bps, Data length is lObit.

Function

Remarks

<J>CAUTION

Mandatory

Set the switches of the CPU and I/O modules according to each instructions.

Mis-setting can cause malfunction or system accidents.

12 Sequence Controller S2T

Page 30

1.2.5 Programmer port of RS232C

The programmer (T-PDS) is connected to this programmer port.

Connector type of CPU side is female , 9-pin D-SUB connector.

The S2T’s RS232C programmer port can accept the computer link protocol (data

read/write). This results in easy connection to a higher level computer, an operator

interface unit, etc. directly.

General specifications and the connector pin assignment of programmer port are

shown below.

For details of T-series computer link protocol, see T-series User’s manual

- Computer Link (UM-TS03***-E008).

General specifications

1.2 S2T CPU Module

Item

Interface Conforms to RS232C

Configuration

Transmission distance 15m max.

Transmission speed

Frame format Start bit 1 bit

Supported command DR (Data Read)

One to One

9600bps (fixed)

Data 8bit

Parity odd/none (selected by SW.3)

stop bit 1 bit

DW (Data Write)

ST (Status read)

TS (Test text)

Pin assignment of programmer port

Signals No. of pins Symbols

Transmission data

Receive data

Signal ground 5 SO

Request To Send

Clear To Send 8 CTS

3

2 RXD S2T ^ Host

7

TXD S2T ^ Host

RTS

Specifications

Direction

S2T - Host

S2T ^ Host

S2T ^ Host

6F8C0926

NOTE

Other pins except the above table should not be connected.

13

Page 31

Chapt.1 System Configuration

1.2.6 LINK port of RS485

The S2T supports the following communication function mode on the LINK port.

Computer link mode

The computer link mode is used to connect between the S2T and a master computer

(included an operator interface, etc.).

By preparing the communication software based on the Toshiba’s computer link protocol

on the master computer, the following functions become available by the master

computer. The computer link protocol is a simple ASCII message communication

system.

Up to 32 S2T can be connected to a master computer on the RS-485 communication

line. (one-to-N configuration)

• Reading data (register/device value) from the S2T

• Writing data (register/device value) into the S2T

• Monitoring the S2T operation status (RUN/HALT/ERROR)

• Controlling the S2T operation mode (RUN/HALT)

The programmer can be connected to this link as a master computer.

One to N configuration

Master Computer

IRS232C/485 cqnyerterj

RS485(1km max.)

S2T S2T S2T

Fig.1-2-2 An example of computer link system configuration

• •

max.32

14 Sequence Controller S2T

Page 32

1.2 S2T CPU Module

Free ASCII mode

The free ASCII mode is used to connect between the S2T and various serial ASCII

devices, such as a micro computer, bar code reader, printer, display, etc.

By using this mode, the S2T can work as a communication master. Therefore, the

S2T can communicate with other PLCs using the computer link protocol, and can

control variable speed drives (such as Toshiba’s VF-S7) using its communication

protocol

S2T

Max. 32 devices

In this mode, user defined ASCII messages can be transmitted and/or received

through the link port of the S2T.

The ASCII message (one set of transmission characters) means a string of ASCII

characters which is ended by specified trailing code. The default setting of the trailing

code is CR (carriage return code = HOD)

Applicable message format (default trailing code):

1 2

3

4 N-1 N

CR

N: message length = 512 bytes max.

In other words, the S2T cannot be used for the data communication in which the

transmission message is ended by two or more types of trailing code.

6F8C0926

15

Page 33

Chapt.1 System Configuration

Transmission specifications

The communication parameter is set by writing it into the information memory of the

S2T with the programmer.

Tablel -2-1 Computer link mode

Item

Interface Conforms to RS-485 (4-wire system)

Transmission mode Half-duplex

Synchronizing

Transmission speed

Flame format Start bit 1 bit (fixed)

Protocol T-series computer protocol (ASCII),

Configuration One to N (32 max.)

Transmission distance 1 km max

Cable connection

Asynchronous

300, 600, 1200, 2400, 4800, 9600, 19200 bps

Data 7/8 bit

Parity even/odd/none

Stop bit 1/2 bit (NOTE)

T-series programmer protocol (Binary)

6-pin removable terminal block

Specifications

Table1-2-2 Free ASCII mode

Item

Interface Conforms to RS-485 (4-wire system)

Transmission mode Half-duplex

Synchronizing

Transmission speed

Flame format Start bit 1 bit (fixed)

Trans mission code ASCII

Message length

Configuration One to N (32 max.)

Transmission distance 1 km max

Cable connection

Asynchronous

300, 600, 1200, 2400, 4800, 9600, 19200 bps

Data 7/8 bit

Parity even/odd/none

Stop bit 1/2 bit (NOTE)

512 byfes max

6-pin removable terminal block

Specifications

16

NOTE

The following combinations of frame format are available.

Start bit

1 7 non 2

1 7

1 7

1

1

1

Data Length

8

8

8 even/odd

Parity Stop bit

even/odd

even/odd

non 1

non 2

Sequence Controller S2T

1

2

1

Page 34

Pin assignment of LiNK port

For details of wiring, see Section 1.3 or 1.4.

1.2 S2T CPU Module

Signals No. of pins Symbols

Transmission data A 1 TXA S2T^M aster

Transmission data B 2 TXB S2T^M aster

Receive data A 3

Receive data B 5

Termination Resistor 4 TERM

Signal ground 6 SG

RXA Master^S2T

RXB Master^S2T

Direction

—

—

6F8C0926 17

Page 35

Chapt.1 System Configuration

1.3 Computer link mode

1.3.1 Computer link function

In the computer link system, the S2T waits for receiving a request message issued

from the master computer.

When a request message is issued, the S2T checks the station number contained in

the request message. And when the station number designation matches the S2T’s

station number setting, the S2T processes the request and returns the response.

This is why each S2T must have a unique station number in the one-to-N

configuration. Otherwise, more than S2T’s may attempt to process the request,

resulting in faulty response.

The following figure illustrates the processing sequence when a request to station

number 3 is issued.

#1 #2

#3

#4

#5 #6

#7 #32

® The request message is sent from the master to all the connected S2T’s.

(request for station #3 in this example)

® The request message is interpreted and processed in the S2T which has the

same station number as request.

(station #3 S2T in this example)

® Processing result is returned as response to the master.

NOTE

Available station number is 1 to 32. The station number is set in the S2T’s system information

memory.

18

Sequence Controller S2T

Page 36

1.3 Computer link mode

Tablel-SSupplementary function for computer link

The following supplementary function are prepared for applying to various system

control using computer link function.

S2T

resister

Response delay mode on the

SW038

SW057

programmer port

(RS232C)

Response delay mode on the

LINK port (RS485)

1.3.2 System configuration

The following figure shows the system configuration using computer link function.

S2T, link port (RS-485), one-to-N configuration (N is max. 32) is available. If the

master computer has RS-232C interface only, the RS-232C/RS-485 converter (ADP6237B) can be used.

S2T, programmer port (RS-232C), one-to-one contiguration is available.

One-to-N configuration

(S2T: RS-485)

Master Computer

Name

Function

Setting value: 0-30

A response message is issued from the S2T after

(setting value *10) ms.

Setting value: 0-30

A response message is issued from the S2T after

(setting value *10) ms.

6F8C0926

Max. 32

One-to-one configuration

(S2T : RS-232C)

Master Computer

RS-232C

(15 m max.)

S2T

19

Page 37

Chapt.1 System Configuration

1.3.3 Setup procedure

The following chart shows the setup procedure of the computer link mode.

Connect the S2T to the master computer by RS-485

or RS-232C interface. Refer to section 1.3.4 or 1.3.5

Select the computer link mode by setting the SW

resister, Refer to section 1.3.6

Set the station number, baudrate, parity, data bit

length, and stop bit. Refer to section 1.3.7

Once writing into the EEPROM, the setting is

effective until change mode.

Refer to section 1.3.8 and the separate “T-series

Computer Link manual” for the computer link protocol

20

Sequence Controller S2T

Page 38

1.3.4 RS-485 cable connection

Cable connection examples show as below.

• Below figure shows an example of cable connection using the RS-232C/RS-485

converter (ADP-6237B).

• Use shielded twisted-pair cable for data communication suited to RS-485

standard. The cable shield should be connected to single -point ground.

One to one configuration

1.3 Computer link mode

Master

computer

RS-232C/RS-485 converter

(ADP-6237B)

connector block

S2T

S2T, removable terminal block is provided for cable connection.

Short between RXA and TERM for termination at both the S2T and the ADP-

6237B.

If the master has RS-485 (or RS-422) interface and the S2T is connected to the

master directly, connect termination resistor 1/2 W - 120 Q between RXA and

RXB at the master end.

6F8C0926 21

Page 39

Chapt.1 System Configuration

One to N configuration

RS-232C/RS485

converter

(ADP-6237B)

Shielded twisted-pair cable

Relaying

terminal

block

S2T

Termination

resistors

220 £5

S2T, removable terminal block is provided for cable connection.

Connect termination resistor 1/2 W - 220 Q. between RXA and RXB, and between

TXA and TXB at the both terminal stations.

Use shielded twisted-pair cable for data communication suited to RS-485

standard. The cable shield should be connected to single-point ground.

22 Sequence Controller S2T

Page 40

1.3.5 RS-232C cable connection

Cable connection examples show as below.

• Use shielded twisted-pair cable for data communication suited to RS-232C

standard. The cable shield should be connected to single -point ground.

1.3 Computer link mode

Master

computer

RXD

TXD

DTR

SG

DSR

RTS

CTS

Shielded twisted-pair cable

15 m max.

S2T

(RS-232C)

1

SG

2 RXD

TXD

3

4

5 SG

6 5 Vdc

7

RTS

8 CTS

9 5 Vdc

S2T, D-Sub 9-pin female connector is provided. Use D-Sub 9-pin male connector

as cable side.

RTS signal (pin 7) of the S2T is ON while power on.

CTS signal (pin 8) of the S2T has no mean on Communication control.

1.3.6 Mode setting

The operation mode of the S2T’s link port is selected by the special resister provided

on the S2T CPU module.

The operation mode is internally set at the timing of power-up. Setting changes while

power on is not effective.

To select the computer link mode, the special resister SW069 set to "0". (SW069=0)

At the factory, the computer link mode is selected.

S2T

resister

SW069

Name

link port operation mode 0: computer link mode

2: Free ASCII mode

Function

6F8C0926

23

Page 41

Chapt.1 System Configuration

1.3.7 Communication parameter setting

The communication parameter is set by writing it into the system information memory

of the S2T.

Turn the S2T to HALT mode, then set the communication parameter in the system

information.

(T-PDS screen example)

T-PDS32 for Windows - [UNTITLED] - Ma

F_ile Edit VieiAi Search PLC D.ebug Oommenl Option Windoyv idelp

«I malgjal

-laj

i-PLC Date & Time

Date:

System Comments:

¡=:^sTem =

OFFLINE

Memory Capacity:

PLC Version:

T-PDS Version:

Memory Size & Scan T'“c~ I Retentive Memory Area... | Computer Link... I

-------------

* ■ ■ ■ ^—' —- - ■ fc

Steps Used:

PLC Type:

64KS /8KW

0

S2T

T-PDS32 for Windows V2.1 4

____________________________

_____________________

After the communication parameter setting, write it into the S2T’s built-in EEPROM

before turning off power.

PC.:~n I

Wotfe ^

(T aian% r 'Smii

fiError Status & Diag. Msg.=

ErrorDiag. Msg. |

|rr;;;OK;.r;3 cancel | Help

----

------------------------------------------------------------------'

Comm Port: Baud Pate:

I ^

I“

: 1

Parity:

Data Bits:

Stop Bits:

96Ü0

Cdd

S

Set station number, baudrate, parity, data bit length,

and stop bit.

-¡g|

■-.M

24 Sequence Controller S2T

Page 42

1.3.8 Computer link protocol

This section introduces the general message format of the T-series computer link

protocol and the types of commands which are used for the S2T.

For details of the T-series computer link protocol, refer to the separate manual

"T-series Computer Link Operation Manuai".

Generai message format

1 2 3 4 5 6 7

( A ADR CMD DATA & SUM )/; CR

Checksum creation range

Text contents

1.3 Computer link mode

Max.255bytes

(

A Format identification code (FI41)

ADR

..........

Start code (H28) Ibyte

Ibyte

Station number

2byte

01 (H3031) through 32(H3332)

CMD

DATA

&

SUM

.........

........

..........

Command 2byte

Data field - depending on the command (max.244bytes)

Checksum delimiter (FI26)

Checksum

Ibyte

2byte

ASCII code of the lowest one byte of the sum obtained by

addingfrom the start code ’(’ to the checksum delimiter

See the following example.

)

?

..........................

End code (H29) Ibyte

End code (H3B)

Ibyte

in case of halfway of entire data

CR Carriage return code (FIOD) Ibyte

Checksum creation example:

A

(

1

0

T

s

& 9

7

CR

)

/\

= H28

■(’

‘A’ = H41

‘0’ = H30

‘1’

= H31

‘S’ = H53

‘T’ = H54

■&’ = H26

Lower two digits

HI 97-^ Sum

6F8C0926

25

Page 43

Chapt.1 System Configuration

List of computer link commands supported by the S2T

The following computer link commands are available for the S2T.

Request

command

-

-

TS Test Loop back test

ST

ER

DR

DW

MR

MW

SR System Info 1 Read Reads S2T’s system

S2

TR

RT Clock-calendar Read Reads clock-calendar data

WT Clock-calendar Write

EC PLC Control Changes S2T operation status

BR System Info Block

RB Program Block Read

CR Comment Block Read Reads S2T’s comments

BW System Information

WB Program Block Write

cw

Function name Description

Computer Link

Error Response

PLC Error Response The request command was

PLC Status Read

PLC Error Status Read Reads error code registered in

Data Read Reads registers/devices data

Data Write Writes registers/devices data

Expanded file register

data Read

Expanded file register

data Write

System Info 2 Read Reads S2T’s system

Diagnostic Message

Read

Read

Block Write

Comment Block Write Writes S2T’s comments

Format error was detected in

the request message

rejected by S2T

S2T returns the same text

Reads S2T operation status ST

the S2T

from the S2T

into the S2T

Reads the data in the expan

sion memory as expanded file

resister

Writes the data in the expan

sion memory as expanded file

resister

information 1

information 2

Reads user-defined error

information from the S2T

from the S2T

Writes clock-calendar data into

the S2T

Reads S2T’s system

information, block by block

Reads S2T’s program

block-by-block

block-by-block

Writes S2T’s system

information block-by-block

Writes S2T’s program

block-by-block

block-by-block

Response

command

CE

EE

TS

ER

DR

ST

MR

ST

SR

S2

TR

RT

ST

ST

BR

RB

CR

ST

ST

ST

Remarks

Response

only

Response

only

26

For details of the T-series computer link protocol, refer to the separate manual

"T-series Computer Link Operation Manual".

Sequence Controller S2T

Page 44

1.4 Free ASCII mode

1.4.1 Free ASCII communication function

The free ASCII mode is used to connect between the S2T and various serial ASCII

devices, such as a micro computer, bar code reader, printer, display, etc.

By using this mode, the S2T can work as a communication master. Therefore, the

S2T can communicate with other PLCs using the computer link protocol, and can

control variable speed drives (such as Toshiba’s VF-S7) using its communication

protocol.

In this mode, user defined ASCII messages can be transmitted and/or received

through the serial port of the S2T, link port (RS-485).

The ASCII message (one set of transmission characters) means a string of ASCII

characters which is ended by specified trailing code. The default setting of the trailing

code is CR (carriage return code = HOD).

Applicable message format (default trailing code):

1.4 Free ASCII mode

1 2

4 N-1 N

3

CR

N: message length = 512 bytes max.

In other words, the S2T cannot be used for the data communication in which the

transmission message is ended by two or more types of trailing code.

NOTE

The Free ASCII mode works as half-duplex communication system.

Therefore, simultaneous operation of transmitting and receiving is not possible.

6F8C0926 27

Page 45

Chapt.1 System Configuration

In the free ASCII mode, communication (message transmitting and receiving) is

controlled by S2T’s user program.

The expanded transfer (XFER) instruction is used for transmitting and receiving

messages.

Transmitting:

To transmit, the user prepares the message in the S2T registers in the format of

ASCII character. The message must be ended by a specified trailing code. Then

executes the XFER instruction to start transmission.

S2T

n n-1

CR

RS-485

„В”

“A”

Receiving:

When a message is received, it is stored in the receive buffer. Then, by using the

XFER instruction, the message is read and stored in the designated S2T registers in

the format of ASCII character.

S2T

Register

MSB LSB

“1" “0”

“3"

“5"

CR

“2"

“4"

“6”

XFER

instruction

Receiver

and

Receive

buffer

n-1 n

“6" CR

RS-485

28

The S2T supports the hexadecimal to ASCII conversion (FITOA) instruction and the

ASCII to hexadecimal conversion (ATOFI) instruction. These instructions are useful

to handle ASCII characters. Refer to sectioni .4.9.

Sequence Controller S2T

Page 46

1.4.2 System configuration

The following figure shows the system configuration using free ASCII communication

faction.

The S2T is connected to the serial ASCII device(s) through RS-485.

S2T

1.4 Free ASCII mode

Max. 32 devices

4or2 wire system selecting function (RS-485)

Either 4-wire system control or 2-wire system control can be selected in order to

connect various serial ASCII device(s) by using the following special function device.

S2T

resister

S688 RS-485

Wiring configuration

Name

OFF: 4-wire system

ON : 2-wire system(This function is available when

selecting 9600 or 19200bps.)

Function

6F8C0926

29

Page 47

Chapt.1 System Configuration

1.4.3 Setup procedure

The following chart shows the setup procedure of the free ASCII mode.

Connect the S2T to the serial ASCII devlce(s) by RS-485

interface. Refer to section 1.4.4

Select the free ASCII mode by setting the SW resister,

Refer to section 1.4.5

Set the baudrate, parity, data bit length, and stop bit.

Refer to section 1.4.6

Refer to section 1.4.8 for communication (transmitting

and receiving messages)

Once writing into the EEPROM, the setting is effective

until change mode

30

Sequence Controller S2T

Page 48

1.4.4 RS-485 cable connection

Cable connection examples show as below.

• Use shielded twisted-pair cable for data communication suited to RS-485

standard. The cable shield should be connected to single -point ground.

One to one configuration : 4-wire system

1.4 Free ASCII mode

S2T

____A......................

TXA

TXB RXB

RXA TXA

TERM

RXB TXB

SG SG

1 XX

>

ZD0(

Shielded twisted-pair cable

.......................................

Serial ASCII device

A

_____

RXA

1 ............................................................................................... 1/

1 km max.

R: 1/2 W-120 £2

• S2T, removable terminal block is provided for cable connection.

• Short between RXA and TERM for termination at the S2T.

• Connect termination resistor 1/2 W - 120 Q between RXA and RXB at the serial

ASCII device.

One to one configuration : 2-wire system

S2T

Shielded twisted-pair cable

Serial ASCII device

On the S2T, removable terminal block is provided for cable connection.

Short between RXA and TERM for termination at the S2T.

Connect termination resistor 1/2 W - 120 Q between RXA and RXB at the serial

ASCII device.

6F8C0926

31

Page 49

Chapt.1 System Configuration

One to N configuration : 4-wire system

S2T

Shielded twisted-pair cable

Serial ASCII device

220n

On the S2T, removable terminal block is provided for cable connection.

Connect termination resistor 1/2 W - 220 Q. between RXA and RXB, and between

TXA and TXB at the both terminal stations.

1.4.5 Modesetting

The operation mode of the S2T’s link port is selected by the special resister provided

on the S2T CPU module.

The operation mode is internally set at the timing of power-up. Setting changes while

power on is not effective.

To select the computer link mode, the special resister SW069 set to "2". (SW069=2)

At the factory, the computer link mode is selected.

S2T

resister

SW069

Name

link port operation mode 0: computer link mode

2: Free ASCII mode

Function

32 Sequence Controller S2T

Page 50

1.4.6 Communication parameter setting

The communication parameter is set by writing it into the system information memory

of the S2T.

Turn the S2T to HALT mode, then set the communication parameter in the system

information.

(T-PDS screen example)

1.4 Free ASCII mode

T-PDS32 for Windows - [UNTITLED] - Ma

File Edit View Search ^LO Debug Gamment Option WindodM jHelp

-¡g|

ilJ Stell g I a I

-laj

-PLC Date & Time

Date:

System Comments:

I

-----------------------

Memory Capacity 64KS / 8KW

Steps Used 0

PLC Type S2T

PLC Version

T-PDS Version T-PDS32 for Windows V2.14

Memory Size S Scan T'pr

OFFLINE

_________

| Retentive Memory Area... Computer Link...

After the communication parameter setting, write it into the S2T’s built-in EEPROM

before turning off power.

-Staf\:W6tie-

(* ^ncTfeiii c

:Error Status & Diag. Msg.^=

|C:r.g.KZT.51 cancel I

Set baudrate, parity, data bit length, and stop bit.

Station number is ignored.

Diag. Msg.

Comm Port: Baud Rate:

1 ^

■" r

Data Bits:

Stop Bits:

Parity:

96ÜQ

Cdd

S

J

■zi

6F8C0926

33

Page 51

Chapt.1 System Configuration

1.4.7 Message format

The transmission message is composed by ASCII characters and a specified trailing

code. The default setting of the trailing code is CR (carriage return code = HOD).

Refer to section 1.4.8 for setting the trailing code other than CR.

shown below.

The maximum length of a message is 512 bytes. An example of the message is

1 2

"1" "2" "A" "B" "7"

"0"

3

4

5 6

7

"8" "9" CR

8 9

In the above figure, "x" means an ASCII character. For example, "0" is H30.

The number (1 to 9) shown on each character means the order of transmitting or

receiving.

When the above message is received or transmitted, the data arrangements in the

S2T registers are as follows.

Transmission message

Register

n "1"

n+1 "A" "2"

n+2 "7" "B"

n+3

n+4

„g„

8 7

"0"

"8"

CR

CR

The message length is 1 byte, only trailing code, then receive operation ignore the

message.

34 Sequence Controller S2T

Page 52

1.4.8 Programming

(1) Changing the trailing code

The default setting of the trailing code is CR (carriage return code = HOD).

The trailing code can be changed by writing the desired code into SW068 at the

first scan.

SW068 HOO

Sample program:

(Sub-program 1)

14

2-[END 1

1.4 Free ASCII mode

8 7

New trailing code

(H0003)

GG0G3 MGU SUGGGT-

The above program is an example to change the trailing code to H03. The

new trailing code H0003 is written into SW068 in the sub-program 1 (initial

program).

(2) Data receive operation

When a message is received, it is stored in the receive buffer. The receive

buffer is a temporally memory, which has 512 bytes capacity. The expanded

transfer (XFER) instruction is used to read the message from the receive buffer

and to store it into user registers.

XFER instruction (message receive):

Input ^ ^ ^ER e ^ C J— Output

Operand A: Source

F__________________8 7

A HOO I

A+1 HOOOO

Operand 6: Parameter

F

В

B+1

B+2

Transfer length

Execution status

Receive message length (bytes)

H30

■ S2T link port (receiving)

■ 256 (256 words) fixed

<4

6F8C0926

Operand C: Destination register

F 8 7

C

C+1

HOO Register type

starting register address

-

---

-

Indirectly designated register

HOO: XWrrW

H01: W

H02: LW

H03: RW

H04: D

H05: F

35

Page 53

Chapt.1 System Configuration

Operation:

When the input condition of the XFER instruction comes ON, the read operation

is started. The execution status is monitored by B+1 as follows.

B+1 (Execution status): HOOOO ^ Normal complete

H0001 ^ Communication error (parity error, framing error)

H0002 ^ Message length over (more than 512 bytes)

H0003 ^ Receive buffer over flow

H0004 _ Receive time-out (see below)

The receive time-out is detected when the time from the starting character to the

trailing code exceeds the following time.

Long scan cyele or short receive message, low baudrate avoid the receive time-out.

Baudrate Time-out setting

300, 600, 1200 bps 30 seconds

2400 bps 15 seconds

4800 bps 7 seconds

9600 bps 3 seconds

19200 bps 1.5 seconds

Sample program:

00048 MOU D10001C 00000 MOU D1001T-

-C 00004 MOU D1002TC 01100 MOU D1003T-

- I-C 00Z56 MOU D10041C 00000 MOU D10051C 00000 MOU D1006]

R0100 R0101 R0102

Tf

---

T1—rC RST S00511CD1000 XFER D1004 ^ D1002]

SO051

—Li—T-CD1005 = 000001CD1006 <> 00000TC SET R0101>

H51005 <> 00000T-

S0051

R010O

—Ml

------

[ RST R0101TC RST R01021-

Rung 1: Sets the parameters for the XFER instruction.

The registers of 256 words starting with Dll00 are reserved to store

the received message.

Rung 2: When R0100 is set to ON, the read operation is started.

If the operation is completed normally, the received message is

stored in D1100 and after, and R0101 is set to ON.

If the message could not be received normally by some error, R0102

is set to ON.

-[SET R0102T-

--------------------------------------

-------------------------

36

Rung 3: When R0100 is reset to OFF, the result status (R0101 and R0102)

are reset to OFF.

Sequence Controller S2T

Page 54

1.4 Free ASCII mode