Page 1

DIAGNOSTIC FUNCTION MANUAL

FOR

MODEL SSA-340A

SERVICE TEST SYSTEM

(ZD730=136E*C)

No. 2D730-I 36E*C

TOSHIBA CORPORATION

@ TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

Page 2

REVISION RECORD

No. 2D730-136E*C

REV. DATE

(hlAliYY)

INI. 02/'95

*A

111'95 121'95 upgrade is supported.

REASON

Mr. Nakajima

Mr. Yamazaki

"B lo/'96 121'96 upgrade is supported.

"C 071'98 101'98 upgrade is supported.

PAGE

/AUTHOR CHANGED No.

-_-----

P. 4-113 to

115

Mr. Okumoto

Mr. Okumoto

SER.

DOC.

PRODUCT.

TM-WW

R-l

*

Page 3

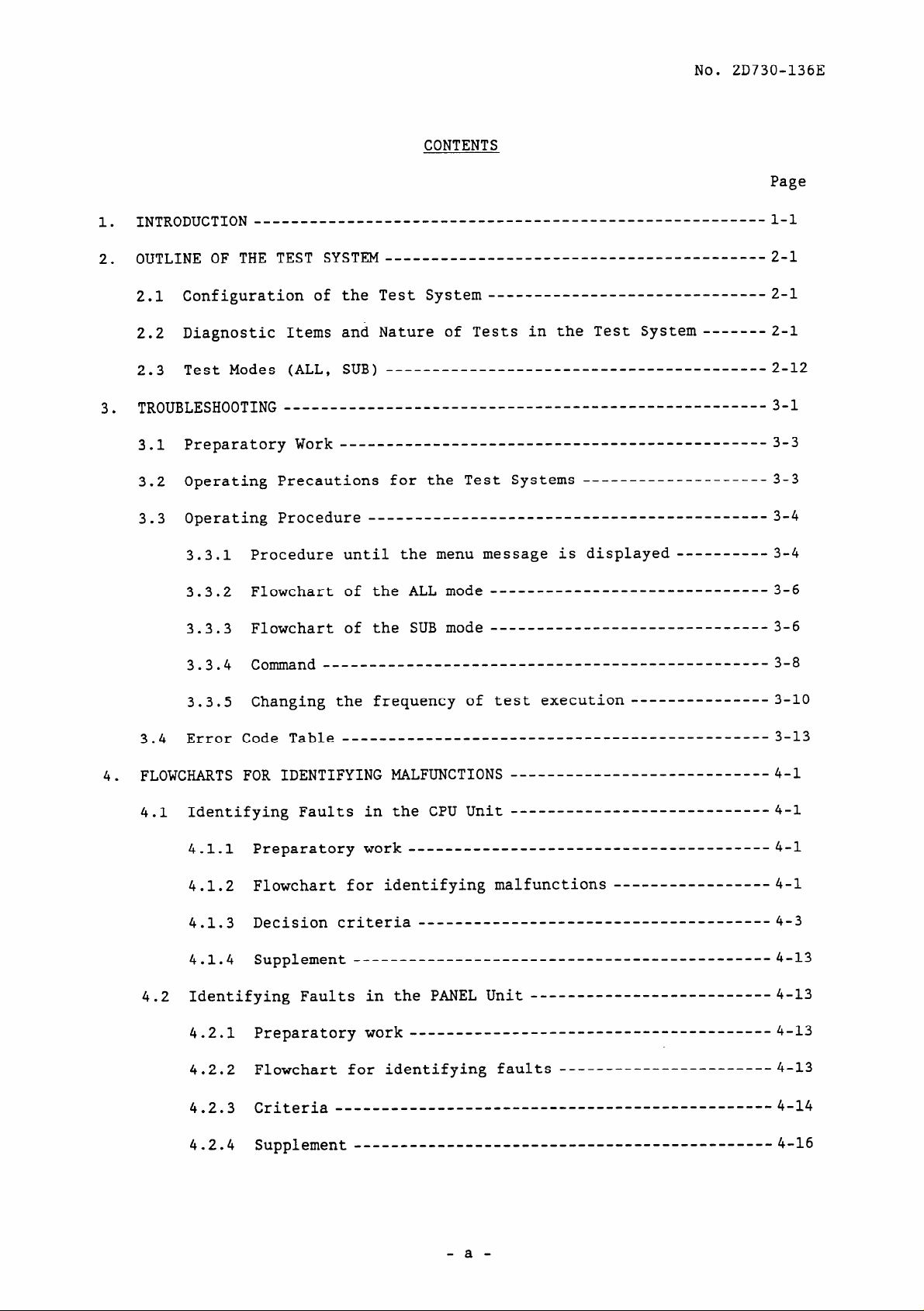

CONTENTS

No. 2D730-136E

Page

INTRODUCTION

1.

OUTLINE OF THE TEST SYST~_~~~_____~~~~~__~~~~~~~~~~~~~~~~~~~~~~~~~2~1

2.

____________________-------

2.1 Configuration of the Test System

____________________~~~~~~~~

____________________~~~~~~~~~~

2.2 Diagnostic Items and Nature of Tests in the Test System-------2-l

2.3 Test Modes (ALL, SUB)

TROUBLESHOOTING _______~____~~~~___~~~~~_~~~~~~~~~~~~~~~~~~~~~~____~3~1

3.

--------------

3.1 Preparatory Work ---------------

____________________-------

____________________~~~~~~~~~~~

3.2 Operating Precautions for the Test Systems --------------------3-3

3.3 Operating Procedure ___~~~~__~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~_~~~3~4

3.3.1 Procedure until the menu message is displayed ----------3-4

3.3.2 Flowchart of the ALL mode ~~~~~~~~~~~~~~~~~~~~~~~~~~__~~3~6

3.3.3 Flowchart of the SUB mode ~~~~_~~~~~~~~~~~~~~~~~~~~~___~3~6

3.3.4 Command ___________________________--____----___~~~~____3_S

l-l

2-l

2-12

3-3

3.3.5 Changing the frequency of test execution---------------3-10

3.4 Error Code Table ______~~~~_~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~3~13

FLOWCHARTS FOR IDENTIFYING MALFUNCTIONS

4.

4.1 Identifying Faults in the CPU Unit

4.1.1 Preparatory work________~_____~~~~~_~~~~~~_______~_____4~~

____________________~~~~~~~~

_______________--___~~~~~~~~

4.1.2 Flowchart for identifying malfunctions -----------------4-l

4.1.3 Decision criteria____~~~~_-__~~~~~~~~~~~~~_~_~~~~~_~~~~4~3

4.1.4 Supplement----------- ____________________~~~~~~~~~~~~~~ 4-13

4.2 Identifying Faults in the PANEL Unit

____________________------

4.2.1 Preparatory work_~_______~___~_~--~~---------------~~~-4-13

4.2.2 Flowchart for identifying faults -----------------------4-13

4.2.3 Criteria ____________________~~~~~~~~~~~~~~~~~~~~~~~~~~~ 4-14

4.2.4 Sunnlement ____________________~~~~~~~~~~~~~~~~~~~~~~~~~ 4-16

4-l

4-l

4-13

-a-

Page 4

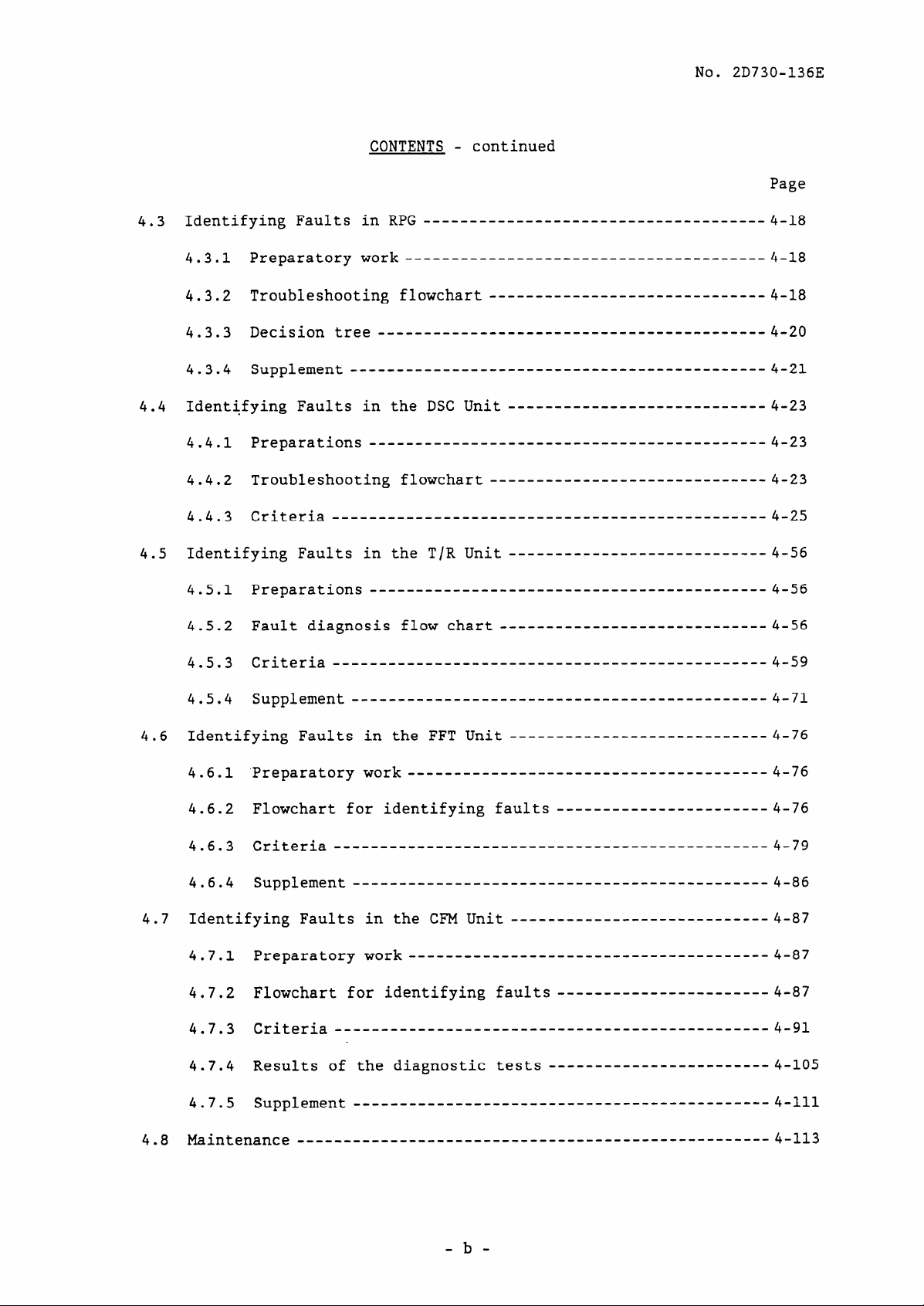

CONTENTS - continued

No. 2D730-136E

Page

4.3 Identifying Faults in RPG ____________________~~~~~~~~~~~~~~~~~

4.3.1 Preparatory work ____________________~~~~~~~~~~~~~~~~~~~

4.3.2 Troubleshooting flowchart ____________________~~~~~~~~~~

4-18

4-18

4-18

4.3.3 Decision tree ______-__-__________~~~~~~~~~~~~~~~~~~~~~~ 4-20

4.3.4 Supplement _________-__________~~~~~~~~~~~~~~~~~~~~~~~~~ 4-21

4.4 Identifying Faults in the DSC Unit

____________________~~~~~~~~

4-23

4.4.1 Preparations _______-____________~~~~~~~~~~~~~~~~~~~~~~~ 4-23

4.4.2 Troubleshooting flowchart------------------------------4-23

4.4.3 Criteria ____________________~~~~~~~~~~~~~~~~~~~~~~~~~~~

4-25

4.5 Identifying Faults in the T/R Unit----------------------------4-56

4.5.1 Preparations

_______-____________~~~~~~~~~~~~~~~~~~~

4.5.2 Fault diagnosis flow chart ____________________~~~~~~~~~

4.5.3 Criteria ____________________~-~~~~~~~~~~~~~~~~~~~~~~~~~

____4_56

4-56

4-59

4.5.4 Supplement ____________________~~~~~~~~~~~~~~~~~~~~~~~~~ 4-71

4.6 Identifying Faults in the FFT Unit----------------------------4-76

4.6.1 Preparatory work

____________________~~~~~~~~~~~~~~~

--m-4-76

4.6.2 Flowchart for identifying faults -----------------------4-76

4.6.3 Criteria ____________________~~~~~~~~~~~~~~~~~~~~~~~~~~~ 4-79

4.6.4 Supplement ~~~~~~~~~~___~__~~~~~~~~~~~__~~~~~~~~~_~~~~~~4~~~

4.7 Identifying Faults in the CFM Unit ----------------------------4-87

4.7.1 Preparatory work_~_~________~~~~~_~~~______~~~_____~~~~4~87

4.7.2 Flowchart for identifying faults -----------------------4-87

4.7.3

4.7.4 Results of the diagnostic tests ------------------------4-105

4.7.5 Supplement

4.8 Maintenance

____________________~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

____________________~~~~~~~~~~~~~~~~~~~~~

----4-111

4-113

-b-

Page 5

CONTENTS - continued

No. 2D730-136E

Page

5. APPENDIX ____________________~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~-~~~~~~~

5.1 Error Codes for Self-diagnosis ___-________________~~~~~~~~~~~~

5.2 Patch Menu Operation ____________________~~~~~~~~~~~~~~~~~~~~~~

<.

5.2.1 Applicable equipment ____________________~~~~~~~~~~~~~~~

5.2.2 Starting ____________________~~~~~~~~~~~~~~~~~~~~~~~~~~~

5.2.3 Memory R/W & dump ____________________~~~~~~~~~~~~~~~~~~

5.2.4 Coordinate check (X,Y) ____________________~~~~~~~~~~~~~

5.2.5 Image cant external value set

5.2.6 Address & data value save

____________________------

______________________________5_g

5-1

5-1

5-5

5-5

5-5

5-6

5-7

5-7

- c -

Page 6

INTRODUCTION

1.

No. 2D730-136E

Test systems are service

test units for the ultrasonic diagnostic

equipment model SSA-340A.

This manual explains the diagnostic procedures.

Furthermore,

operates normally,

since certain PWBs can be checked only if the system

it is necessary to perform testing in the following

order.

(1) CPU unit

(2) RPG

(3) DSC unit

(4) T/R unit

(5) FFT unit

(6) CFM unit

(7) PANEL unit

l-1

Page 7

OUTLINE OF THE TEST SYSTEM

;2-----_

2.

No. 2D730-136E

If a malfunction occurs,

with respect to PWBs and PWB blocks,

responsible for the malfunction by displaying error codes.

the test system will indicate the test results

identifying those which are

Alternately,

the test system will indicate a pattern which permits assessment of the

quality of each block.

Tests principally involve the CPU unit, PANEL unit, RPG, DSC unit, T/R

unit, FFT unit, and CFM unit.

Although not all units are included, it is

possible to test the basic units required for generating an image.

Therefore,

troubleshooting is expedited if the test system succeeds in

helping identify faulty units.

Furthermore,

at the time of maintenance and checking it is possible to

assess changes in ultrasonic wave transmission which-are difficult to

observe during- the normal service period; degradation of system

performance;

and memory errors of any addresses caused by faulty

reception.

In addition,

there are guidelines for test performance frequency.

is useful for checking faults that occur infrequently, caused by RS-232C

communication errors.

2.1 Configuration of the Test System

This

This test system is incorporated in the main unit of the diagnostic

ultrasound system.

This manual describes the operating procedures for the test system.

2.2 Diagnostic Items and-Nature of Tests in the Test System

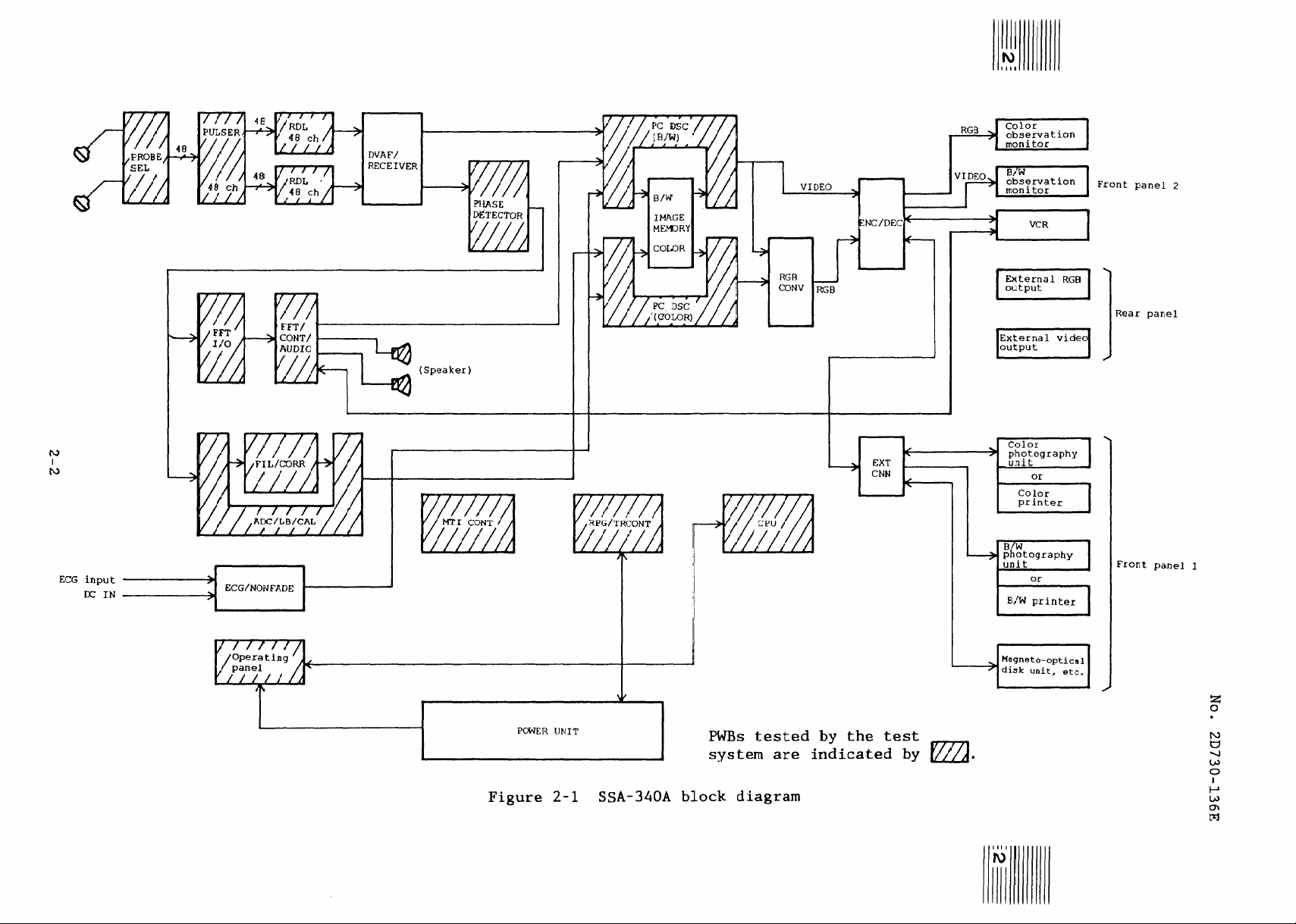

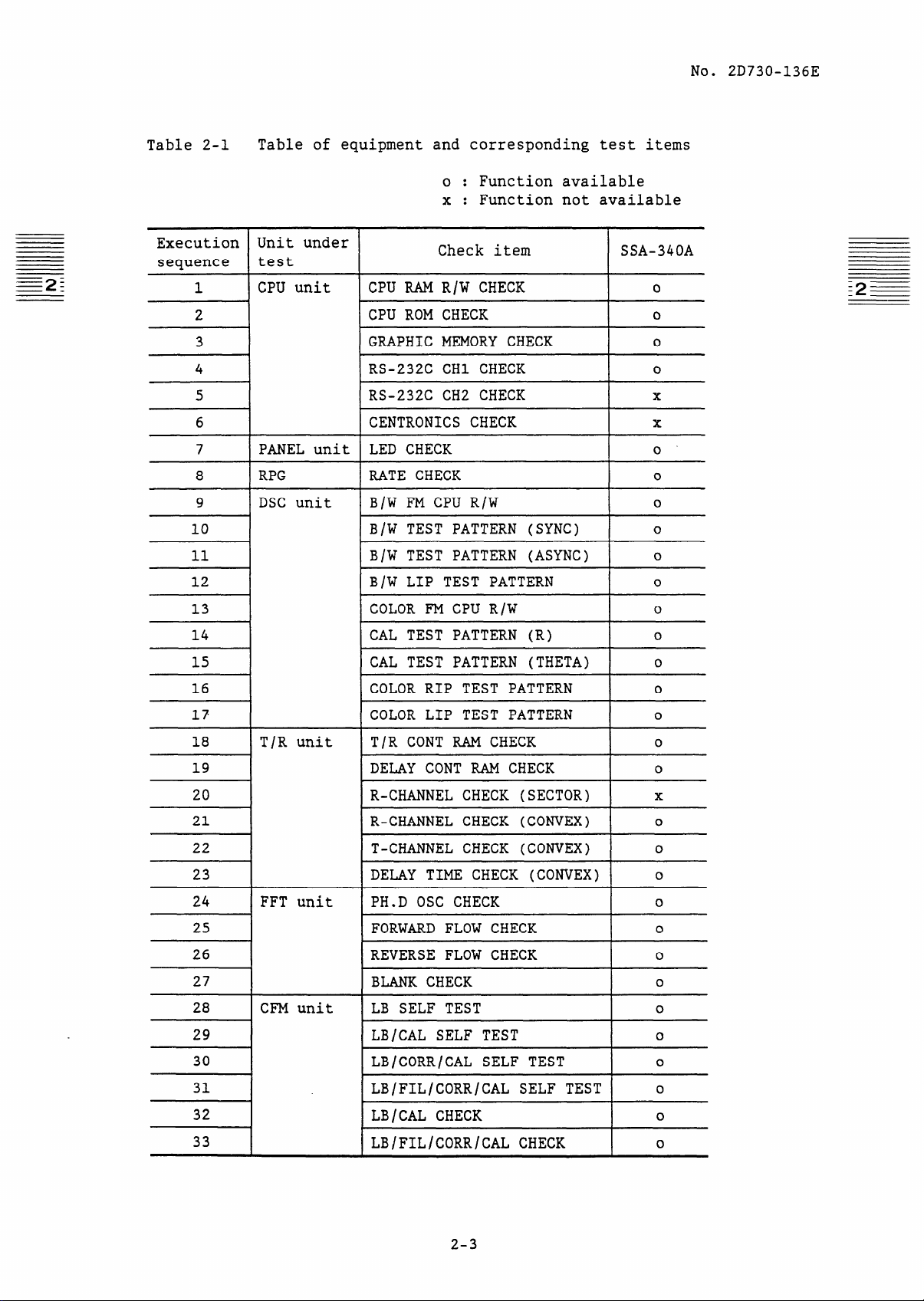

PWBs which are tested by the test system are shown in figure 2-1 to

figure 2-3.

Details concerning each test item are given in tables 2-1

and 2-2.

2-l

Page 8

No. 2D730-136E

Page 9

No. 2D730-136E

Table 2-1

Execution Unit under

seauence

3 GRAPHIC MEMORY CHECK 0

4 RS-232C CHl CHECK 0

5

6 CENTRONICS CHECK X

7 PANEL unit LED CHECK 0

8

-4 DSC unit

Table of equipment and corresponding test items

test

RS-232C CH2 CHECK X

RPG

I ~

RATE CHECK

T

1 B/W FM CPU R/W

B/W TEST PATTERN (SYNC)

r- ~~

1 B/W TEST PATTERN (ASYNC) 1 o

B/W LIP TEST PATTERN

I

COLOR FM CPU R/W

I

CAL TEST PATTERN (R)

I

1 CAL TEST PATTERN (THETA) ) o

0 : Function available

x: Function not available

Check item SSA-340A

0

I

0

I

0

I_

24

25

26

27

28

29

30

31

32

33

COLOR RIP TEST PATTERN

I

COLOR LIP TEST PATTERN

I

T/R unit 1 T/R CONT RAM CHECK

DELAY CONT RAM CHECK 0

R-CHANNEL CHECK (SECTOR) X

1 R-CHANNEL CHECK (CONVEX) 1 o

1 T-CHANNEL CHECK (CONVEX) 1 o

1 DELAY TIME CHECK (CONVEX) 1 o

FFT unit

CFM unit

PH.D OSC CHECK

I

FORWARD FLOW CHECK

I

REVERSE FLOW CHECK

I

I

I

I

1 LB/FIL/CORR/CAL SELF TEST 1 o

LB/CAL CHECK

LB/FIL/CORR/CAL CHECK

I

I

I

I

I

I

0

0

0

0

0

0

0

0

2-3

Page 10

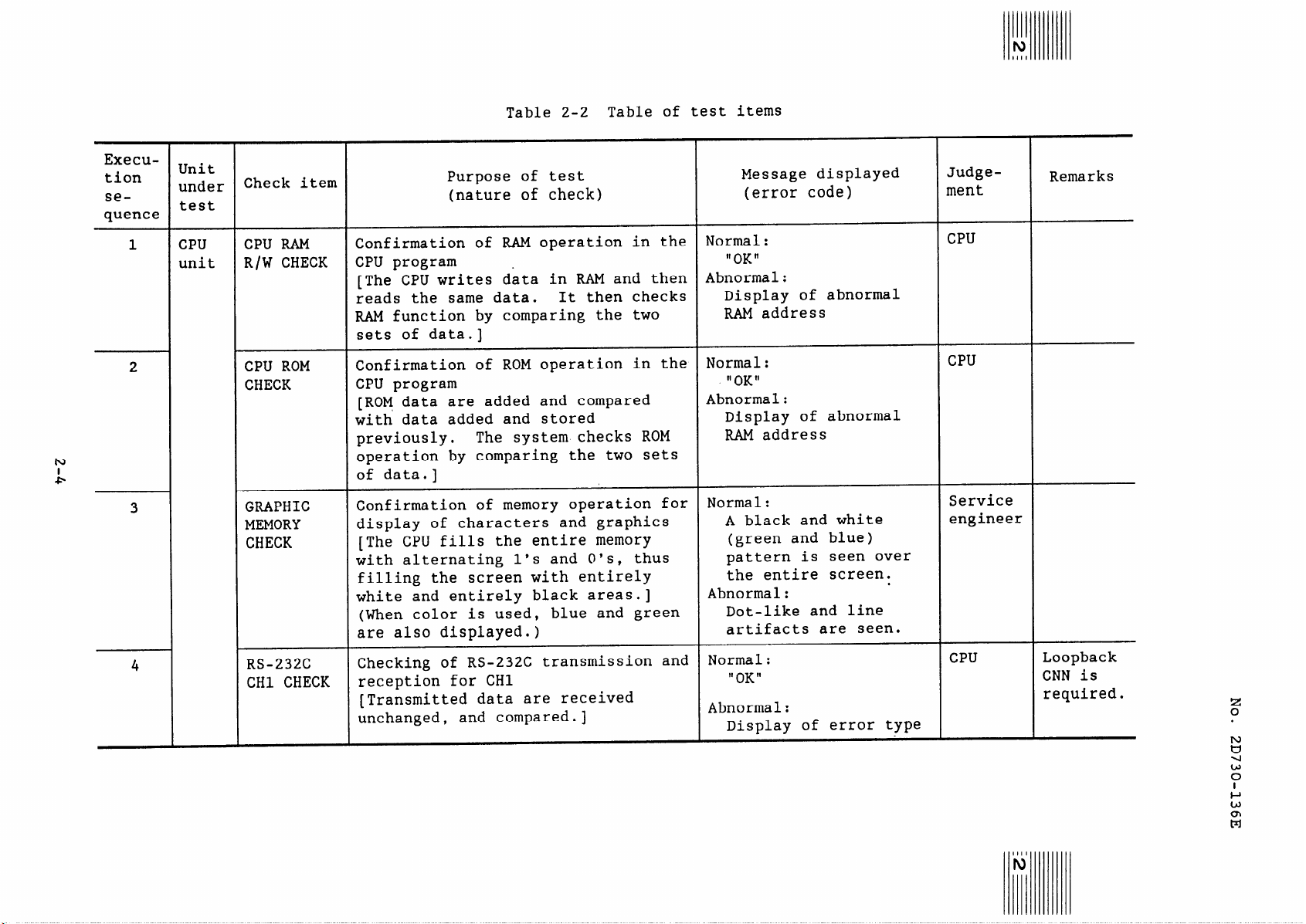

Table 2-2 Table of test items

Execution

se-

quence

1

2

3

4

Unit

under

test

CPU

unit

Check item

CPU RAM

R/W CHECK

CPU ROM

CHECK

GRAPHIC

MEMORY

CHECK

RS-232C

CHl CHECK

Purpose of test

(nature of check)

Confirmation of RAM operation in the

CPU program

[The CPU writes data in RAM and then

reads the same data.

It then checks

RAM function by comparing the two

sets of data.]

Confirmation of ROM operation in the

CPU program

[ROM data are added and compared

with data added and stored

previously.

The system checks ROM

operation by comparing the two sets

of data.]

Confirmation of memory operation for

display of characters and graphics

[The CPU fills the entire memory

with alternating l's and O's, thus

filling the screen with entirely

white and entirely black areas.]

(When color is used, blue and green

are also displayed.)

Checking of RS-232C transmission and

reception for CHl

[Transmitted data are received

unchanged,

and compared.]

Message displayed

(error code)

Normal:

'OK"

Abnormal:

Display of abnormal

RAM address

Normal:

11 OK II

Abnormal:

Display of abnormal

RAM address

Normal:

A black and white

(green and blue)

pattern is seen over

the entire screen.

Abnormal:

Dot-like and line

artifacts are seen.

Normal:

” OK "

Abnormal:

Display of error type

Judge-

Remarks

ment

CPU

CPU

Service

engineer

.

CPU

Loopback

CNN is

required.

Page 11

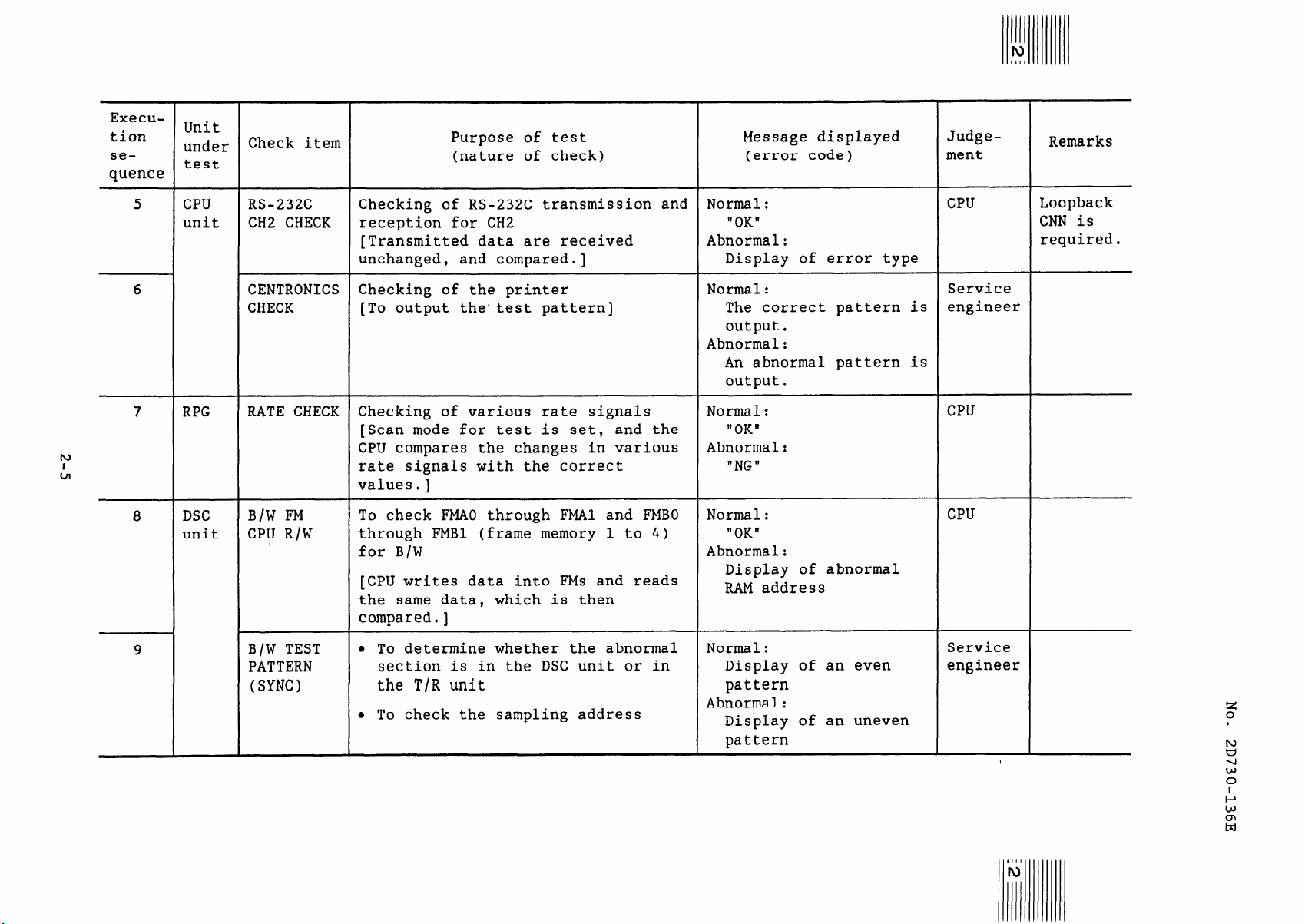

Execution

sequence

Unit

under

test

Check item

Purpose of test

(nature of check)

Message displayed

(error code)

Judgement

Remarks

5

CPU

unit

RS-232C

CH2 CHECK

6 CENTRONICS

CHECK

7 RPG

8

DSC

unit

9

RATE CHECK Checking of various rate signals

B/W FM

CPU R/W

B/W TEST

PATTERN

(SYNC)

Checking of RS-232C transmission and

reception for CH2

[Transmitted data are received

unchanged, and compared.]

Checking of the printer

[To output the’ test pattern]

[Scan mode for test is set, and the

CPU compares the changes in various

rate signals with the correct

values.]

To check FMAO through FMAl and FMBO

through FMBl (frame memory 1 to 4)

for B/W

[CPU writes data into FMs and reads

the same data, which is then

compared.]

l To determine whether the abnormal

section is in the DSC unit or in

the T/R unit

l To check the sampling address

Normal:

"OK"

Abnormal:

Display of error type

Normal:

The correct pattern is

output.

Abnormal:

An abnormal pattern is

output.

Normal:

t1 OK II

Abnormal:

"NG"

Normal:

"OK"

Abnormal:

Display of abnormal

RAM address

Normal:

Display of an even

pattern

Abnormal:

Display of an uneven

pattern

CPU

Service

engineer

CPU

CPU

Service

engineer

Loopback

CNN is

required.

Page 12

Execution

se-

quence

Unit

under

test

Check item

Purpose of test

(nature of check)

Message displayed

(error code)

Judge-

ment

Remarks

tu

b

10

11

12

13

DSC

unit

B/W TEST

PATTERN

(ASYNC)

B/W LIP

TEST

PATTERN

COLOR FM

CPU R/W

CAL TEST

PATTERN

(R)

l To determine whether the abnormal

section is in the DSC unit or in

the T/R unit

l To check the multistage

transmission

To determine whether the abnormality

is before the output section or

after in the DSC unit

[The test pattern is input in the

linear interpolation circuit.]

To check FMAO through FM2 and FMBO

through FM82 (frame memory 1 to 6)

for COLOR

[CPU writes data into FMs and reads

the same data, which is then

compared.]

l To check the interpolation

function (RIP) in the DSC unit

l To determine whether the

abnormality is in the MT1 unit or

in the DSC unit

[Interpolation check in the DSC

r-direction and threshold check in

the e-direction]

Normal:

Display of an even

pattern

Abnormal:

Display of an uneven

pattern

Normal:

Display of a pattern

of the interpolated

vertical lines

Abnormal:

Display of an

abnormally

interpolated pattern.

Normal:

” OK ”

Abnormal:

Display of abnormal

RAM address

Normal:

Display of an even

pattern interpolated

in the r-direction

Abnormal:

Display of an

abnormally

interpolated pattern

Service

engineer

Service

engineer

CPU

Service

engineer

(RIP: Radius direction

interpolation)

Page 13

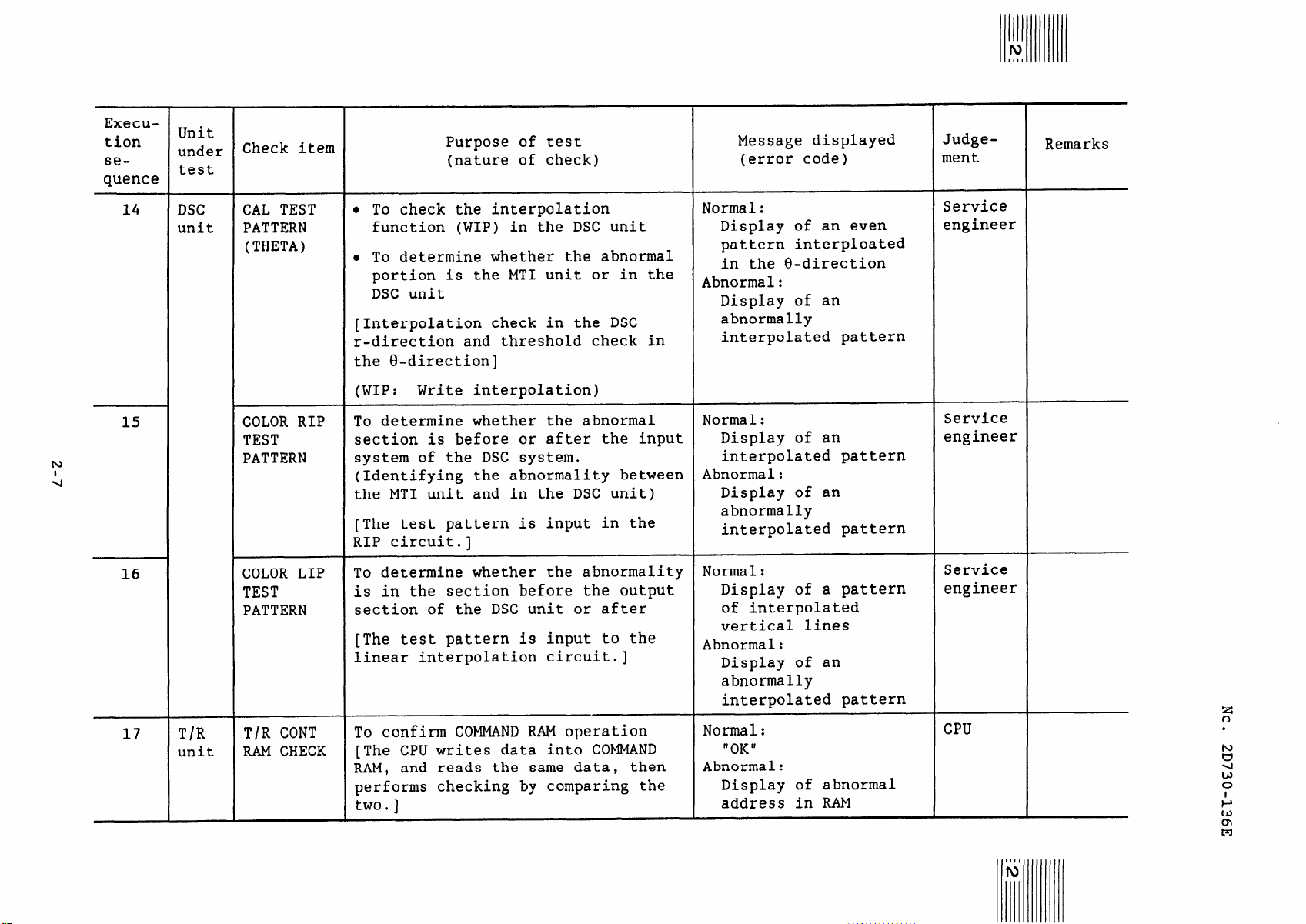

Execution

se-

quence

Unit

under

test

Check item

Purpose of test

(nature of check)

Message displayed

(error code)

Judge-

ment

Remarks

14

15

16

DSC

unit

CAL TEST

PATTERN

(THETA)

COLOR RIP

TEST

PATTERN

COLOR LIP

TEST

PATTERN

l To check the interpolation

function (WIP) in the DSC unit

l To determine whether the abnormal

portion is the MT1 unit or in the

DSC unit

[Interpolation check in the DSC

r-direction and threshold check in

the 8-direction]

(WIP:

Write interpolation)

To determine whether the abnormal

section is before or after the input

system of the DSC system.

(Identifying the abnormality between

the MT1 unit and in the DSC unit)

[The test pattern is input in the

RIP circuit.]

To determine whether the abnormality

is in the section before the output

section of the DSC unit or after

[The test pattern is input to the

linear interpolation circuit.]

Normal:

Display of an even

pattern interploated

in the U-direction

Abnormal:

Display of an

abnormally

interpolated pattern

Normal:

Display of an

interpolated pattern

Abnormal:

Display of an

abnormally

interpolated pattern

Normal:

Display of a pattern

of interpolated

vertical lines

Abnormal:

Display of an

abnormally

interpolated pattern

Service

engineer

Service

engineer

Service

engineer

17

T/R

unit

T/R CONT

RAM CHECK

To confirm COMMAND RAM operation

[The CPU writes data into COMMAND

RAM, and reads the same data, then

performs checking by comparing the

two.]

Normal:

"OK"

Abnormal:

Display of abnormal

address in RAM

CPU

Page 14

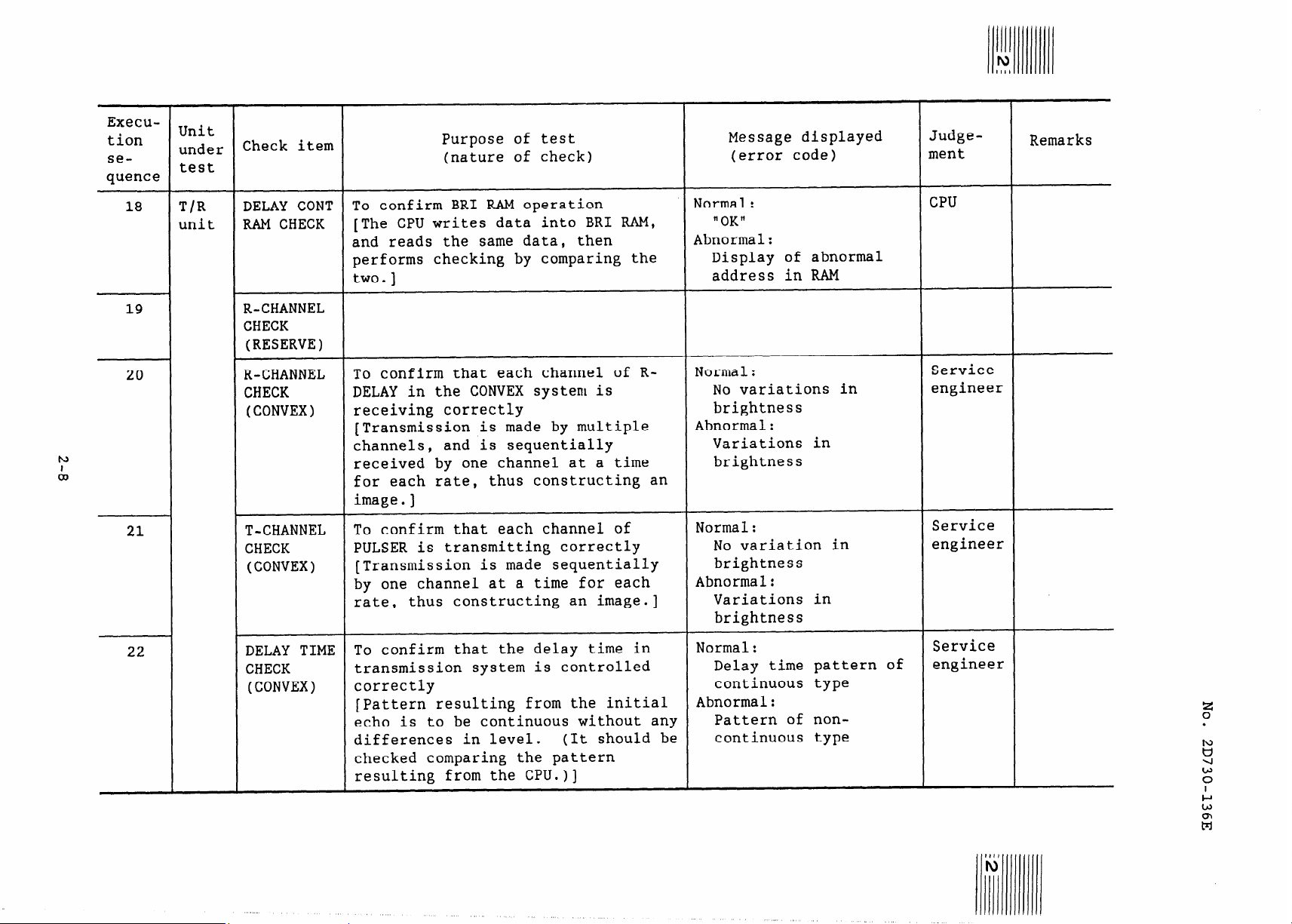

Execution

sequence

Unit

under

test

Check item

Purpose of test

(nature of check)

Message displayed

(error code)

Judgement

Remarks

18

19

20

21

T/R

unit

DELAY CONT

RAM CHECK

R-CHANNEL

CHECK

(RESERVE)

R-CHANNEL

CHECK

(CONVEX)

T-CHANNEL

CHECK

(CONVEX)

To confirm BRI RAM operation

[The CPU writes data into BRI RAM,

and reads the same data, then

performs checking by comparing the

two.]

To confirm that each channel of RDELAY in the CONVEX system is

receiving correctly

[Transmission is made by multiple

channels, and is sequentially

received by one channel at a time

for each rate, thus constructing an

image.]

To confirm that each channel of

PULSER is transmitting correctly

(Transmission is made sequentially

by one channel at a time for each

rate,

thus constructing an image.]

Normal:

"OK"

Abnormal:

Display of abnormal

address in RAM

Normal:

No variations in

brightness

Abnormal:

Variations in

brightness

Normal:

No variation in

brightness

Abnormal:

Variations in

brightness

CPU

Service

engineer

Service

engineer

22

DELAY TIME

CHECK

(CONVEX)

To confirm that the delay time in

transmission system is controlled

correctly

[Pattern resulting from the initial

echo is to be continuous without any

differences in level.

checked comparing the pattern

resulting from the CPU.)]

(It should be

Normal:

Delay time pattern of

continuous type

Abnormal:

Pattern of noncontinuous type

Service

engineer

Page 15

Execution

se-

quence

Unit

under

test

Check item

Purpose of test

(nature of check)

Message displayed

(error code)

Judge-

ment

Remarks

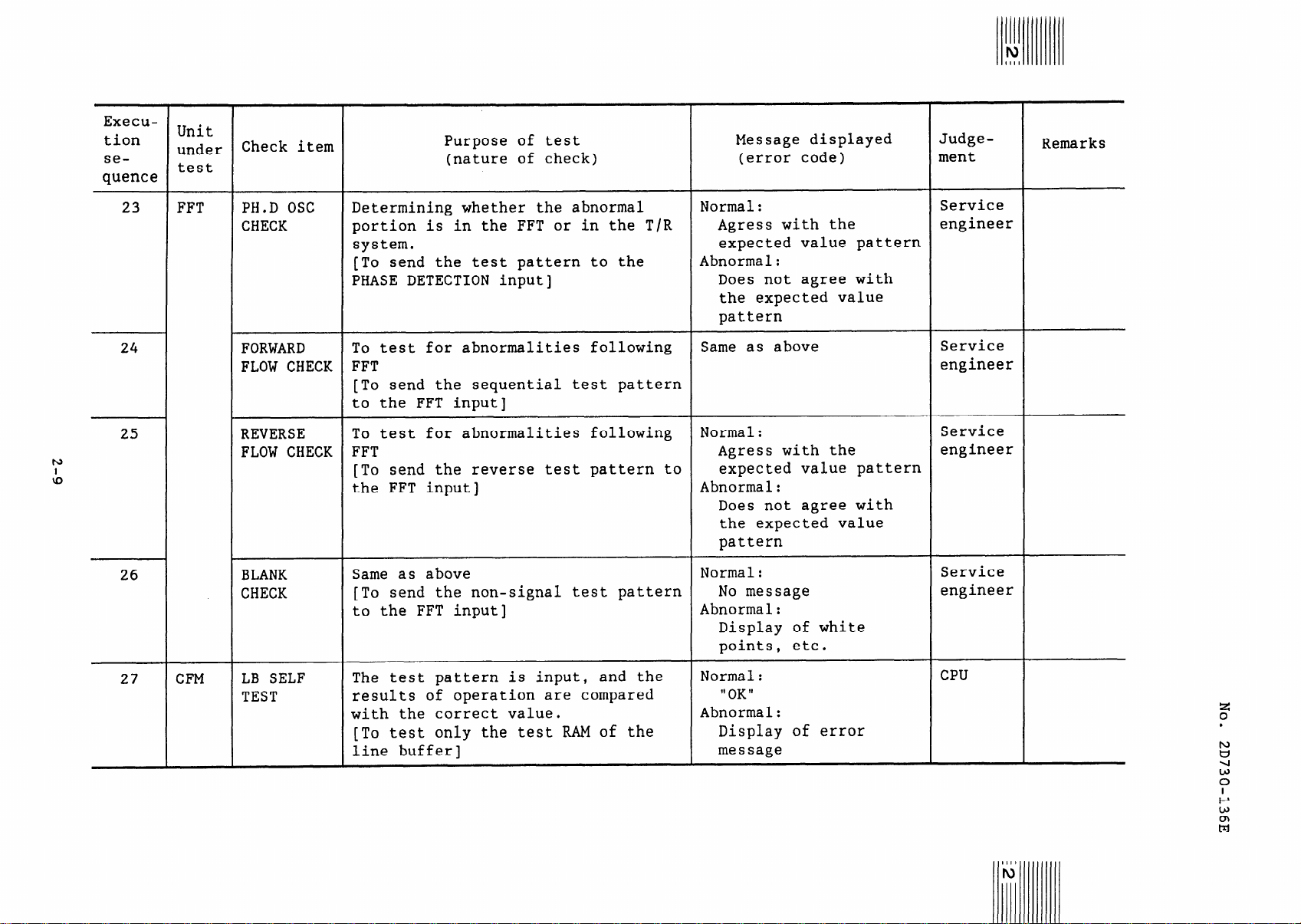

N

\o

23

24

25

26

FFT

PH.D OSC

CHECK

FORWARD

FLOW CHECK

REVERSE

FLOW CHECK

BLANK

CHECK

Determining whether the abnormal

portion is in the FFT or in the T/R

system.

[To send the test pattern to the

PHASE DETECTION input]

To test for abnormalities following

FFT

[To send the sequential test pattern

to the FFT input]

To test for abnormalities following

FFT

[To send the reverse test pattern to

the FFT input]

Same as above

[To send the non-signal test pattern

to the FFT input]

Normal:

Agress with the

expected value pattern

Abnormal:

Does not agree with

the expected value

pattern

Same as above

Normal:

Agress with the

expected value pattern

Abnormal:

Does not agree with

the expected value

pattern

Normal:

No message

Abnormal:

Display of white

points, etc.

Service

engineer

Service

engineer

Service

engineer

Service

engineer

27

CFM

LB SELF

TEST

The test pattern is input, and the

results of operation are compared

with the correct value.

[To test only the test RAM of the

line buffer]

Normal:

II OK II

Abnormal:

Display of error

message

CPU

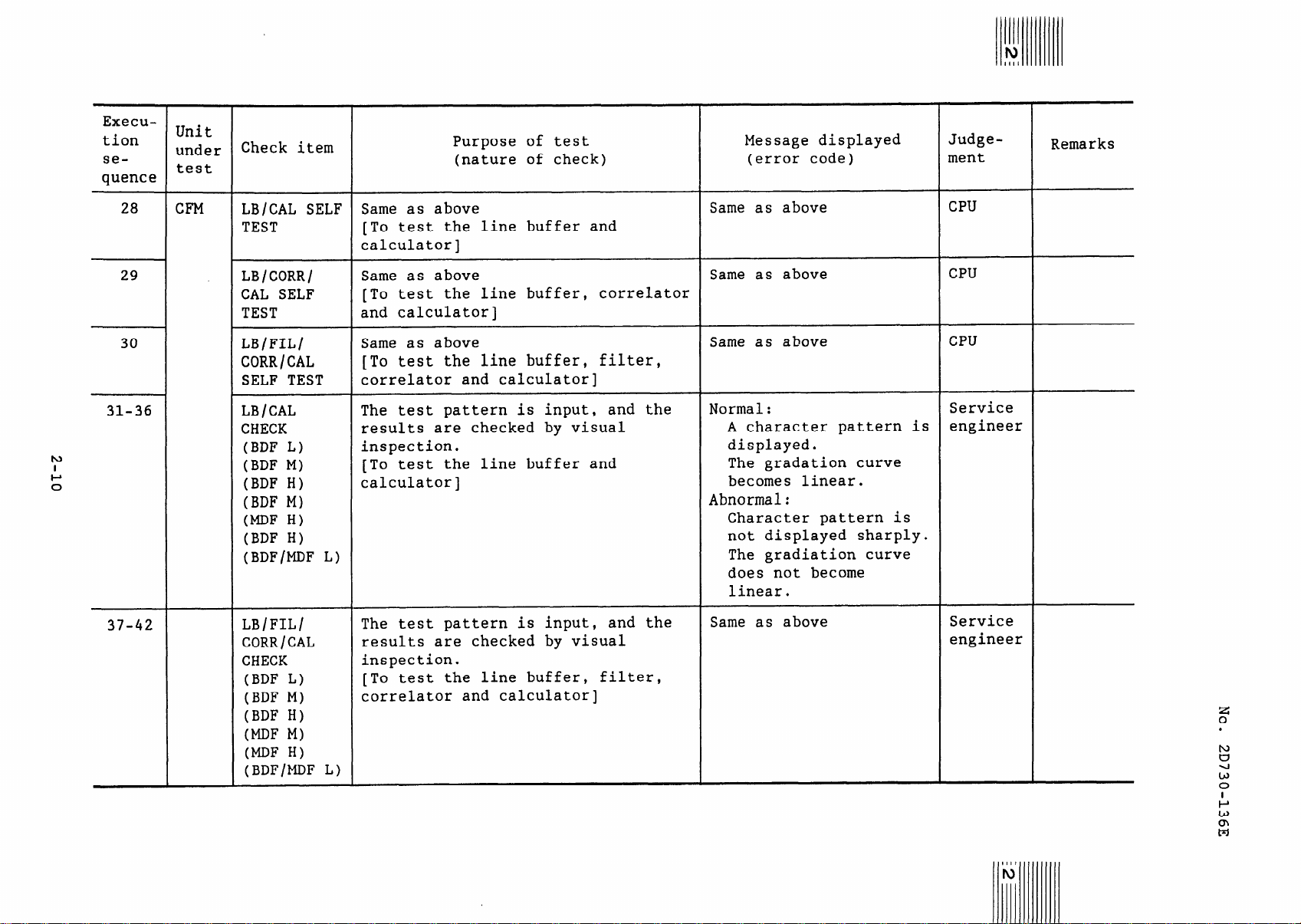

Page 16

Execution

sequence

Unit

under

test

Check item

Purpose of test

(nature of check)

Message displayed

(error code)

Judge-

ment

Remarks

28

29

30

31-36

37-42

CFM

LB/CAL SELF

TEST

LB/CORR/

CAL SELF

TEST

LB/FIL/

CORR/CAL

SELF TEST

LB/CAL

CHECK

(BDF L)

(BDF M)

(BDF H)

(BDF M)

WDFH)

(BDF H)

(BDF/MDF L

LB/FIL/

CORR/CAL

CHECK

(BDF L)

(BDF M)

(BDF H)

WDFM)

WFH)

(BDF/MDF L)

Same as above

[To test the line buffer and

calculator]

Same as above

[To test the line buffer, correlator

and calculator]

Same as above

[To test the line buffer, filter,

correlator and calculator]

The test pattern is input, and the

results are checked by visual

inspection.

[To test the line buffer and

calculator]

The test pattern is input, and the

results are checked by visual

inspection.

[To test the line buffer, filter,

correlator and calculator]

Same as above

Same as above

Same as above

Normal:

A character pattern is

displayed.

The gradation curve

becomes linear.

Abnormal:

Character pattern is

not displayed sharply.

The gradiation curve

does not become

linear.

Same as above

CPU

CPU

CPU

Service

engineer

Service

engineer

Page 17

2-11

No. 2D730-136E

Page 18

2.3 Test Modes (ALL, SUB)

(1) ALL mode (general-purpose test mode for beginners)

No. 2D730-136E

All tests are conducted using this test mode.

faulty units are not identified.

This, however,

the serviceman to get the final diagnostic results.

(2) SUB mode (test mode for experts)

Use this test mode to conduct a specific test if the faulty sections

can be guessed from the symptoms.

takes a long time and requires several operations by

Use this mode if the

;2E

2-12

Page 19

TROUBLESHOOTING

3.

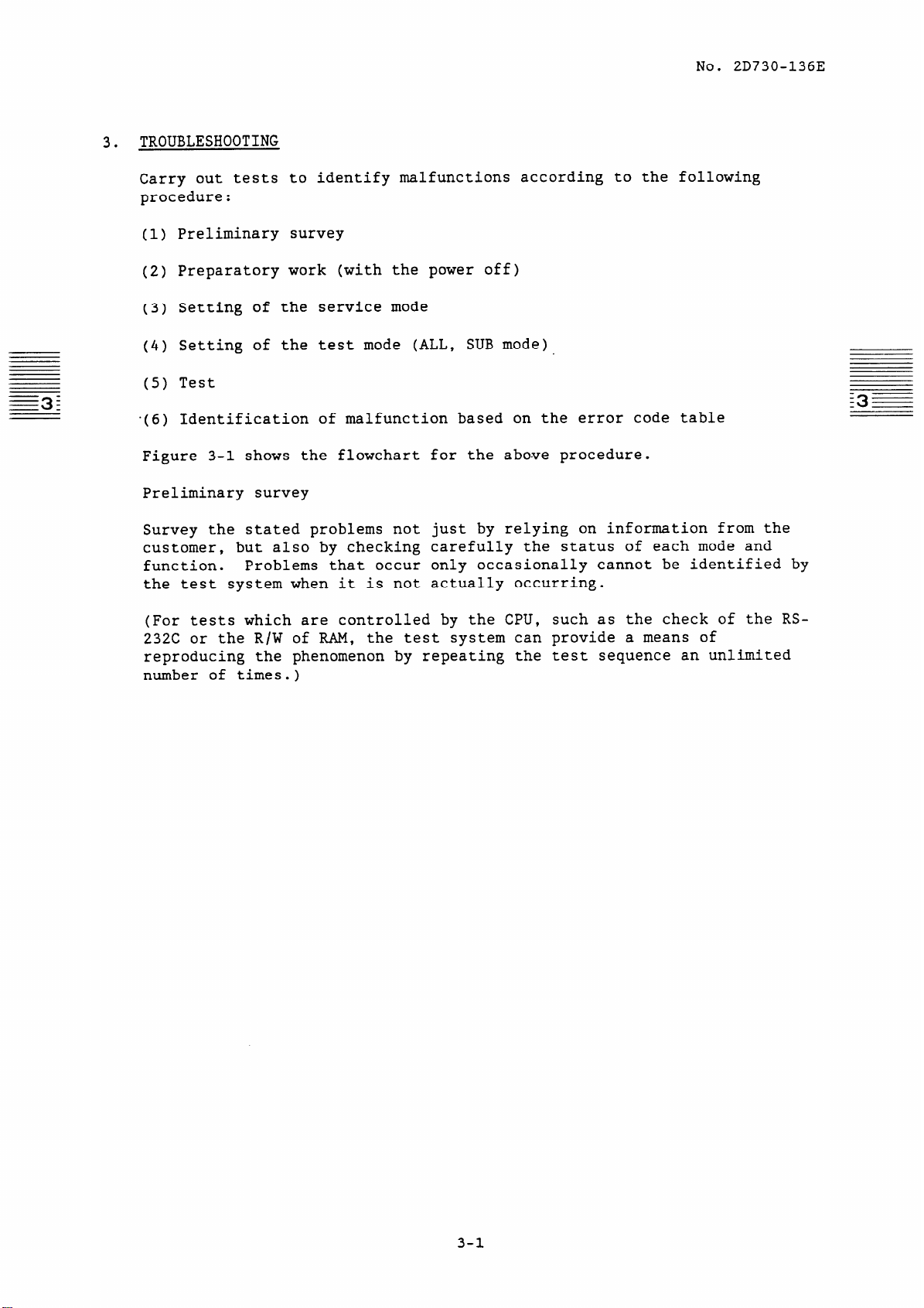

Carry out tests to identify malfunctions according to the following

procedure:

(1) Preliminary survey

(2) Preparatory work (with the power off)

(3) Setting of the service mode

(4) Setting of the test mode (ALL, SUB mode)_

(5) Test

*(6) Identification of malfunction based on the error code table

Figure 3-l shows the flowchart for the above procedure.

Preliminary survey

No. 2D730-136E

Survey the stated problems not just by relying on information from the

customer,

function.

but also by checking carefully the status of each mode and

Problems that occur only occasionally cannot be identified by

the test system when it is not actually occurring.

(For tests which are controlled by the CPU, such as the check of the RS232C or the R/W of MM, the test system can provide a means of

reproducing the phenomenon by repeating the test sequence an unlimited

number of times.)

3-1

Page 20

No. 2D730-136E

Preparatory work

(5

,

I

Prcparc tools, etc.

J.

1

. Connect the specified probe

(See section 3.2. (I)).

l Set the B-GAIN to MAX.

l Set the DEPTH to 10 cm.

3

Turn on the power.

to display the

SETTING menu

Move the cursor to [SERVICE]

in the SETTING menu and

I

press I .

I 0

0

_____-__---____

*

i

4

. ..* . . . . .

t

I

___

. Rcfcrcncc manual for the test system

(This manual)

. Set of gcncral service tools

l Jigs rcquircd Tar the test

* : The proccdurcs for entering the SERVICE

menu differ dcpcnding on the site.

__________----

1

I

(Carry)

Press @ , @ on the

keyboard. At this time, the system

enters the SERVICE menu.

Move the cursor to [TEST] in

the SERVICEmcnu and 1

At this time, WSTj is highlighted and the TV screen

changes to the screen for testing.

t

Enter numbers

(for example, [0]

the keyboard.

Carry out various tests.

I

Error codes and messages will bc

displayed.

I

+

@ ) from

/o/

-

At thus tlmc, the system enters the

_________----- 1

__-

.

I

I

Identify faulty PWBs using the

error code table.

I

I

Figure 3-1

3-2

Page 21

3.1 Preparatory Work

Prepare the required tools/devices (such as a return connector) in

accordance with the "Preparatory work" in section 4.

(ex. LOOP BACK CNN)

3.2 Operating Precautions for the Test Systems

No. 2D730-136E*C

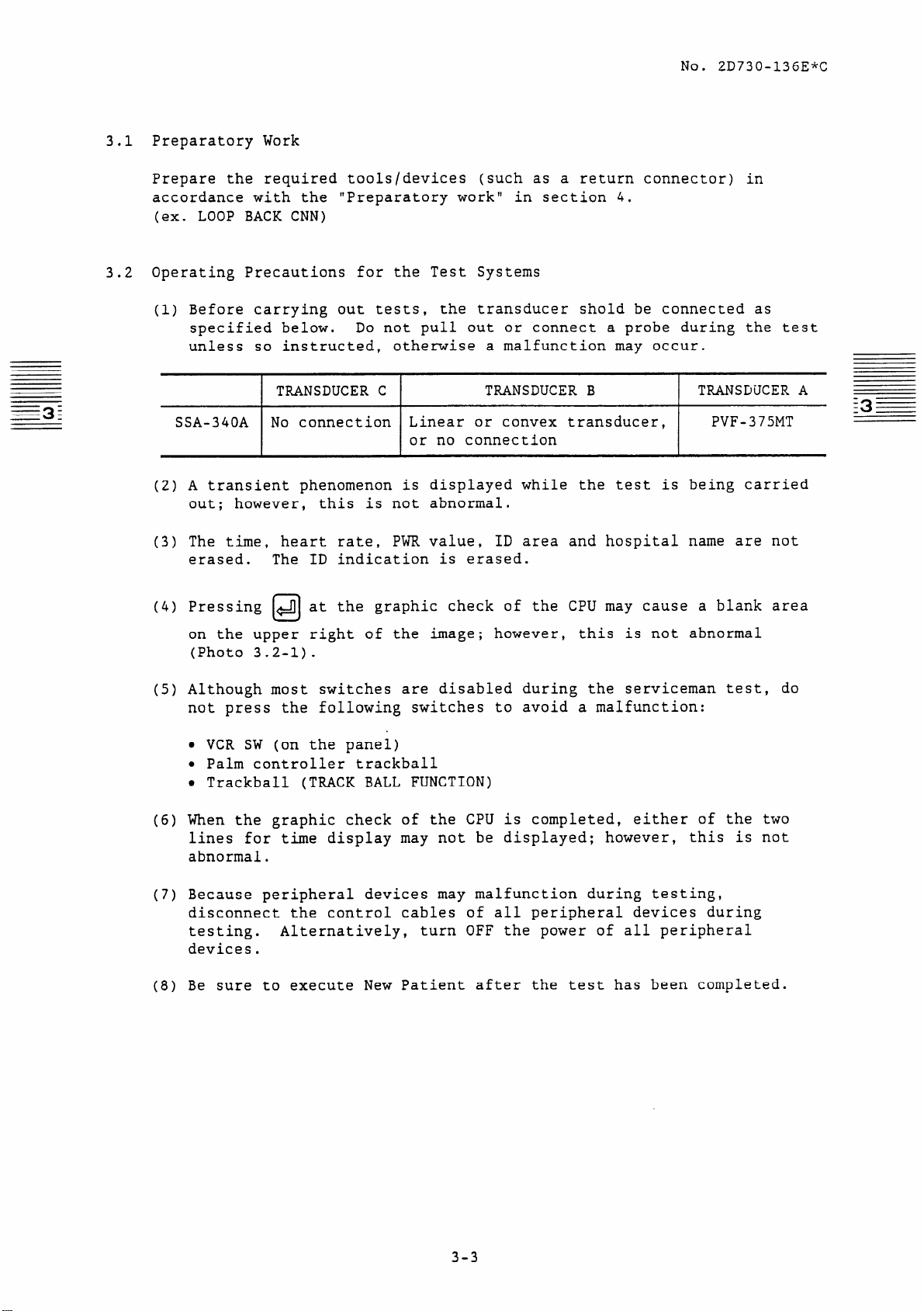

(1) Before carrying out tests,

specified below.

unless so instructed,

Do not pull out or connect a probe during the test

otherwise a malfunction may occur.

1 TRANSDUCER C )

SSA-340A

No connection Linear or convex transducer,

the transducer shold be connected as

TRANSDUCER B

TRANSDUCER A

I

PVF-375MT

or no connection

(2) A transient phenomenon is displayed while the test is being carried

out; however,

(3) The time, heart rate, PWR value,

erased.

The ID indication is erased.

this is not abnormal.

ID area and hospital name are not

(4) Pressing (/LJI1 at the graphic check of the CPU may cause a blank area

on the upper right of the image; however, this is not abnormal

(Photo 3.2-l).

(5) Although most switches are disabled during the serviceman test, do

not press the following switches to avoid a malfunction:

l VCR SW (on the panel)

l Palm controller trackball

l Trackball (TRACK BALL FUNCTION)

(6) When the graphic check of the CPU is completed, either of the two

lines for time display may not be displayed; however, this is not

abnormal.

(7) Because peripheral devices may malfunction during testing,

disconnect the control cables of all peripheral devices during

testing. Alternatively,

turn OFF the power of all peripheral

devices.

(8) Be sure to execute New Patient after the test has been completed.

3-3

Page 22

No. 2D730-136E

Photo 3.2-l

3.3 Operating Procedure

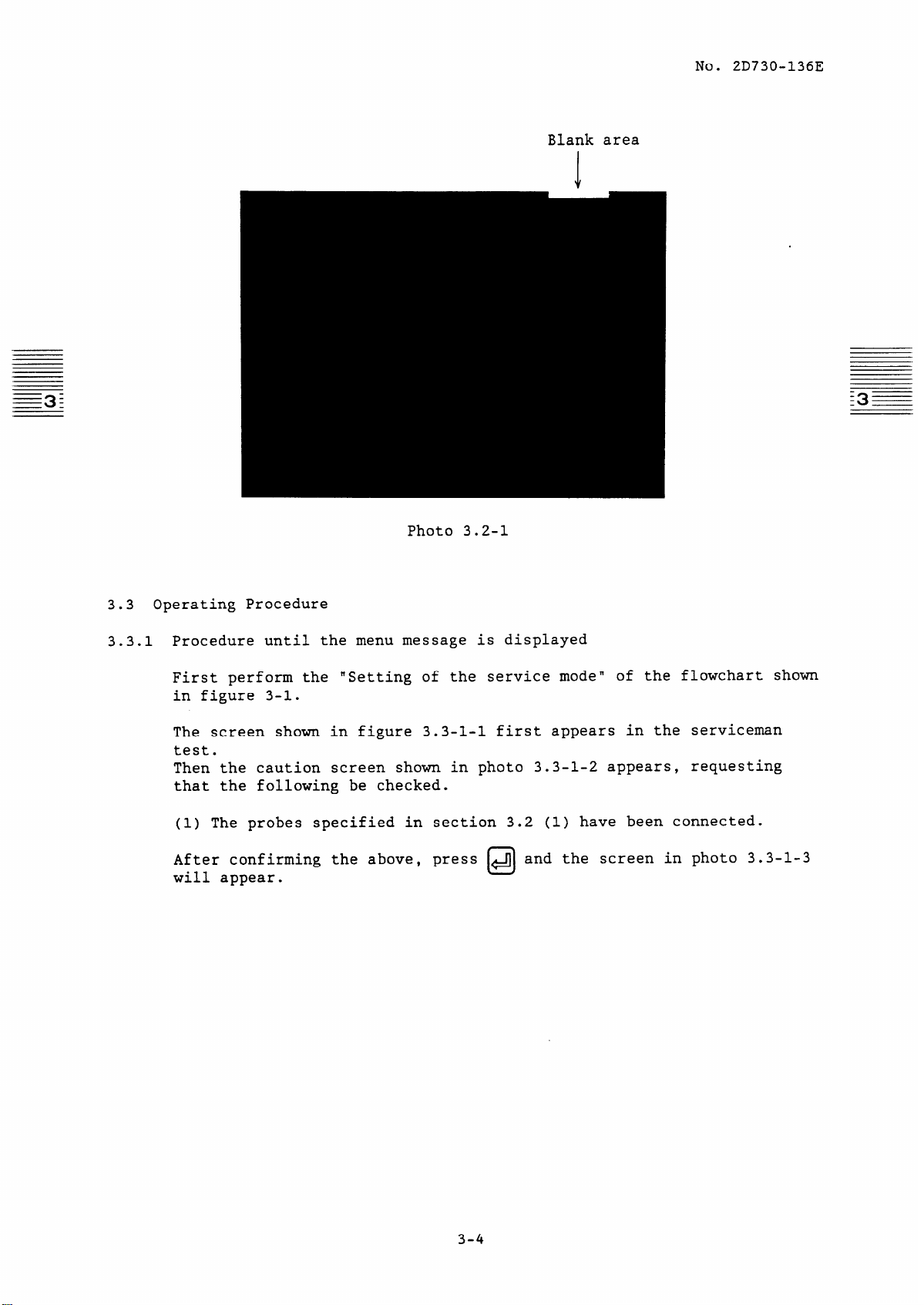

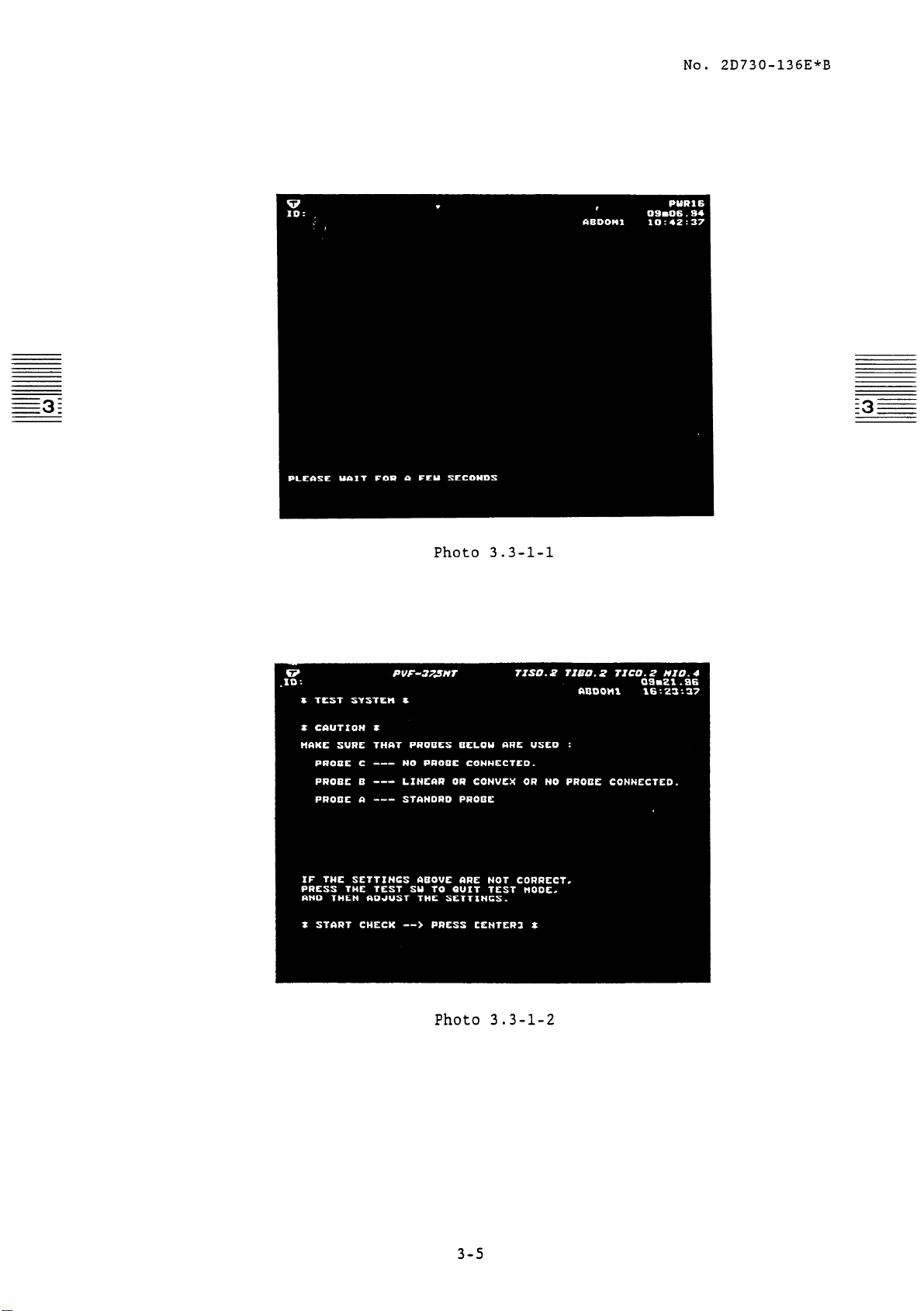

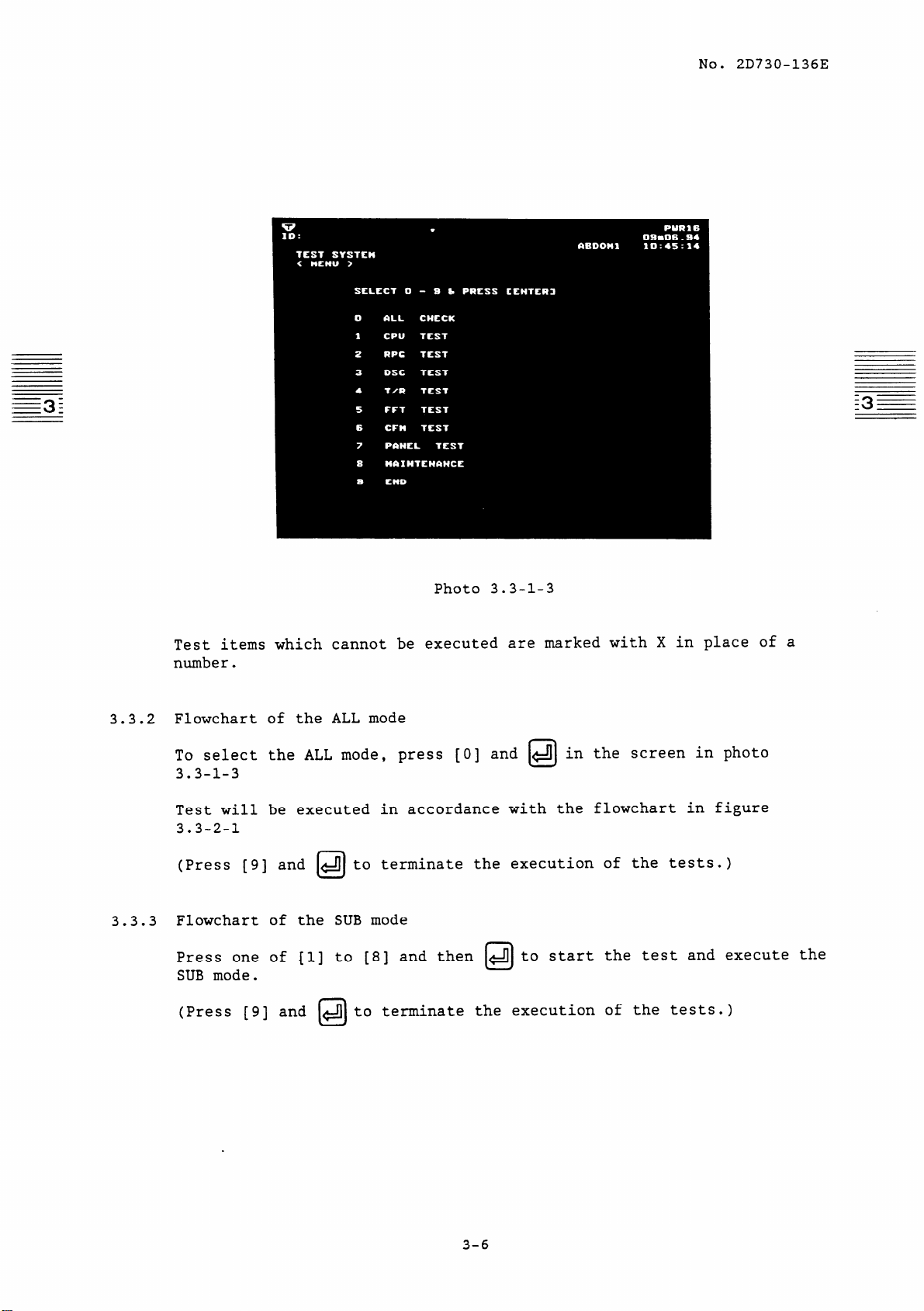

3.3.1 Procedure until the menu message is displayed

First perform the

in figure 3-1.

The screen shown in figure 3.3-l-l first appears in the serviceman

test.

Then the caution screen shown in photo 3.3-l-Z appears, requesting

that the following be checked.

(1) The probes specified in section 3.2 (1) have been connected.

After confirming the above, press &J and the screen in photo 3.3-l-3

will appear.

"Setting of the service mode" of the flowchart shown

0

3-4

Page 23

No. 2D730-136E*B

Photo 3.3-l-l

Photo 3.3-l-Z

3-5

Page 24

No. 2D730-136E

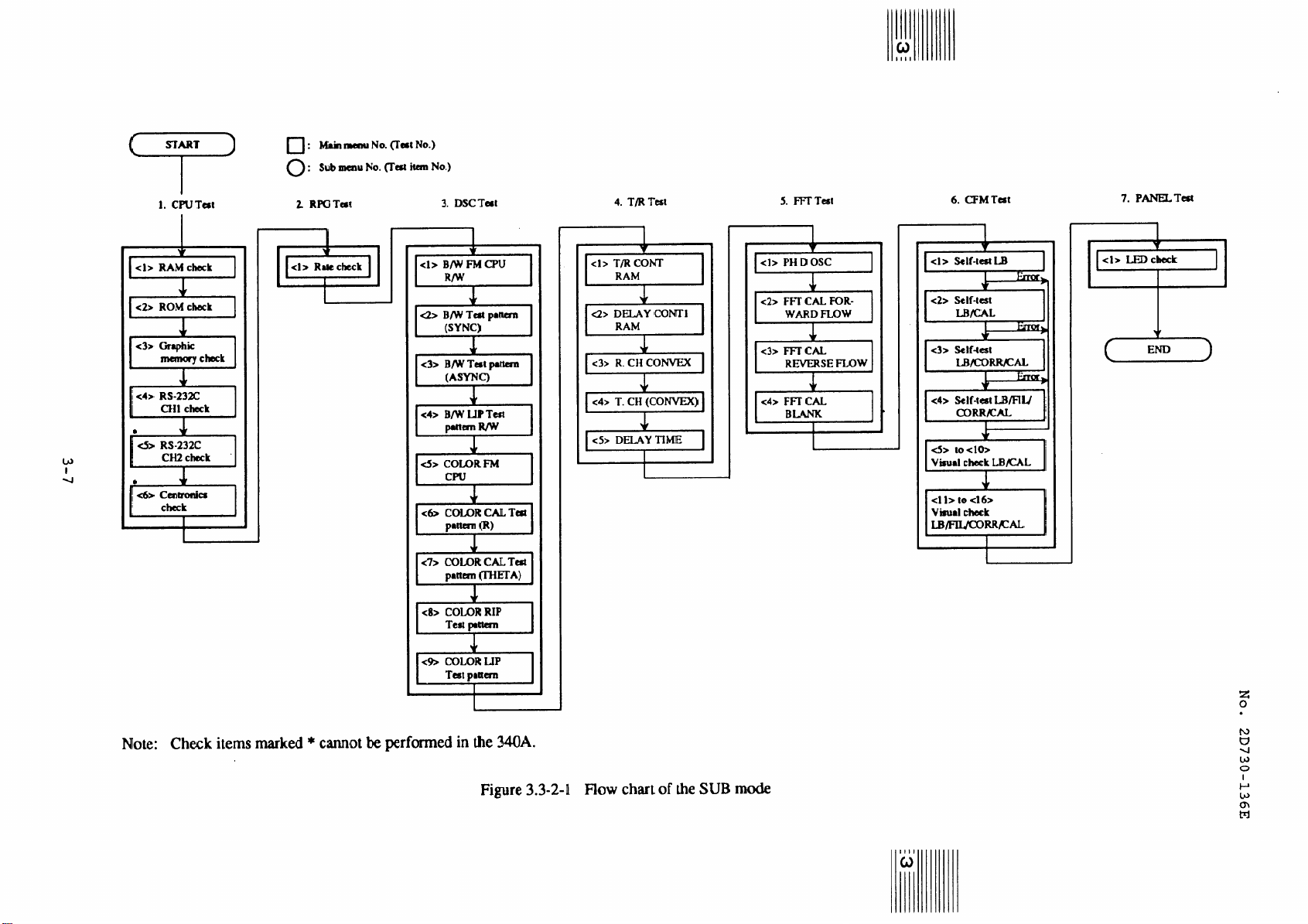

Test items which cannot be executed are marked with X in place of a

number.

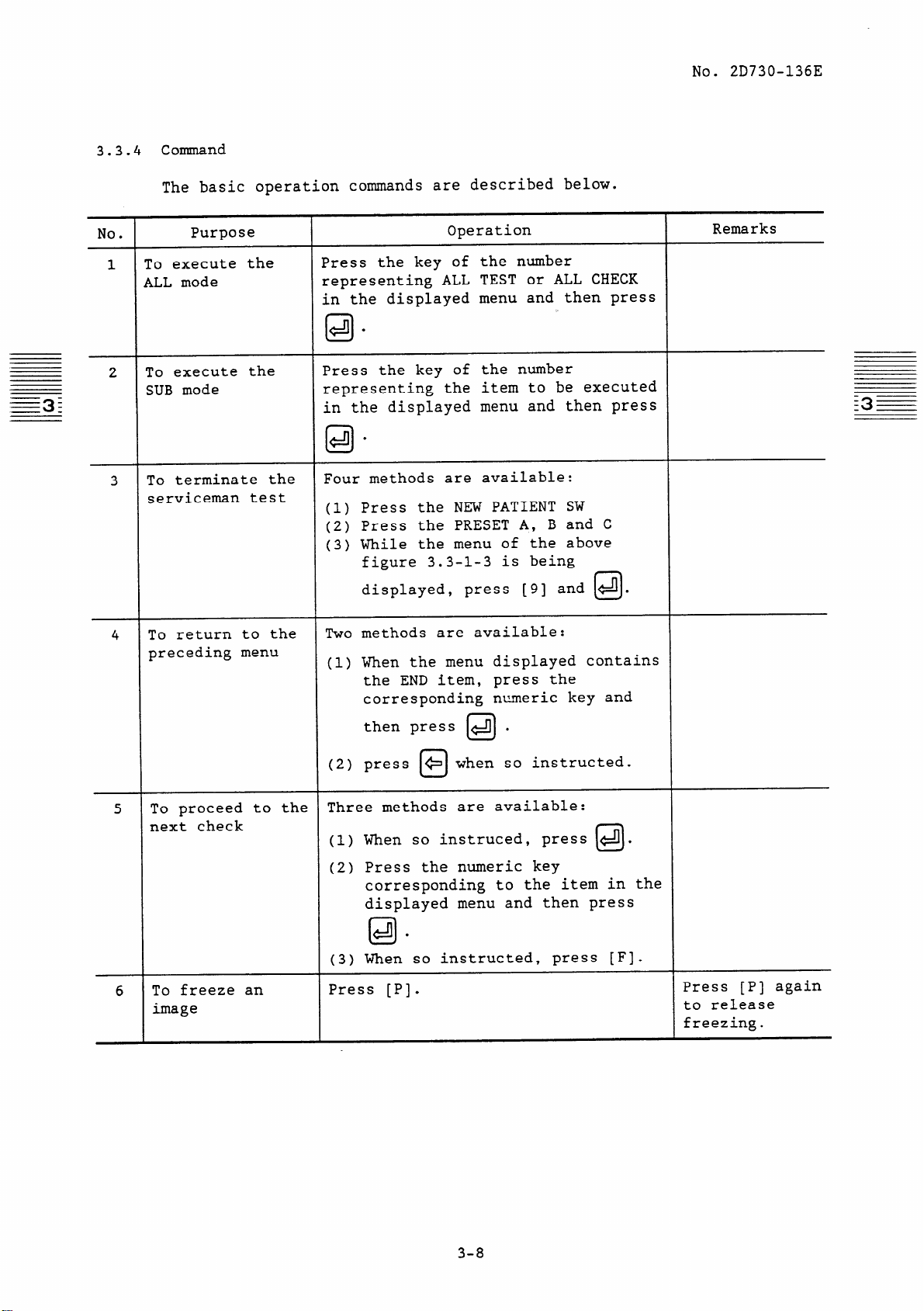

3.3.2 Flowchart of the ALL mode

To select the ALL mode,

3.3-l-3

Test will be executed in accordance with the flowchart in figure

3.3-2-l

(Press [9] and mto terminate the execution of the tests.)

3.3.3 Flowchart of the SUB mode

Press one of Cl] to [8] and then 4 to start the test and execute the

SUB mode.

(Press [9] and

mto terminate the execution of the tests.)

press [0] and 4 in the screen in photo

Photo 3.3-l-3

0

U

3-6

Page 25

I

1

!!I

ii

0

A

1

_,I!

No. 2D730-136E

Page 26

3.3.4 Cormnand

The basic operation commands are described below.

No. 2D730-136E

No.

1

2

3

Purpose

:o execute the

LLL mode

Co execute the

XJB mode

To terminate the

,

serviceman test

To return to the

4

preceding menu

Operation

Press the key of the number

representing ALL TEST or ALL CHECK

in the displayed menu and then press

.

4

IO

Press the key of the number

representing the item to be executed

in the displayed menu and then press

Four methods are available:

(1) Press the NEW PATIENT SW

(2) Press the PRESET A, B and C

(3) While the menu of the above

figure 3.3-l-3 is being

displayed, press [9] and 4.

Two methods are available:

(1) When the menu displayed contains

the END item, press the

corresponding numeric key and

0

Remarks

I

To proceed to the

5

next check

To freeze an

6

image

then press 141 .

(2) press + when so instructed.

Three methods are available:

When so instruced, press 4.

(1)

Press the numeric key

(2)

corresponding to the item in the

displayed menu and then press

@I

When so instructed, press [F].

(3)

Press [PI.

U

0

.

Press [P] again

to release

freezing.

3-8

Page 27

No. 2D730-136E

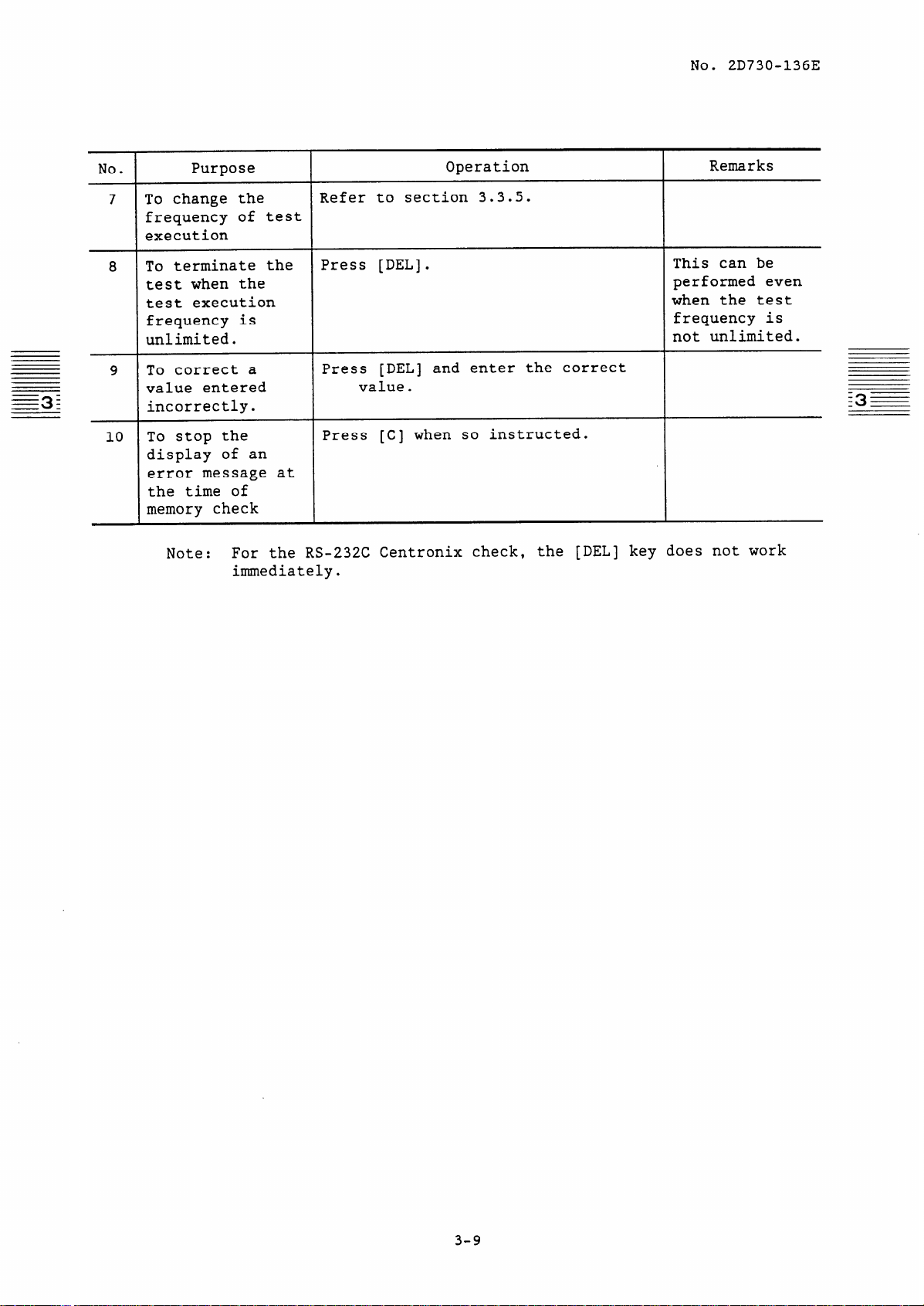

No.

7

Purpose

To change the

frequency of test

execution

To terminate the

8

test when the

test execution

frequency is

unlimited.

To correct a

9

value entered

incorrectly.

To stop the

10

display of an

error message at

the time of

memory check

Note:

Operation

Refer to section 3.3.5.

Press [DEL].

Press [DEL] and enter the correct

value.

Press [C] when so instructed.

For the RS-232C Centronix check,

immediately.

I

Remarks

This can be

performed even

when the test

frequency is

not unlimited.

I

the [DEL] key does not work

3-9

Page 28

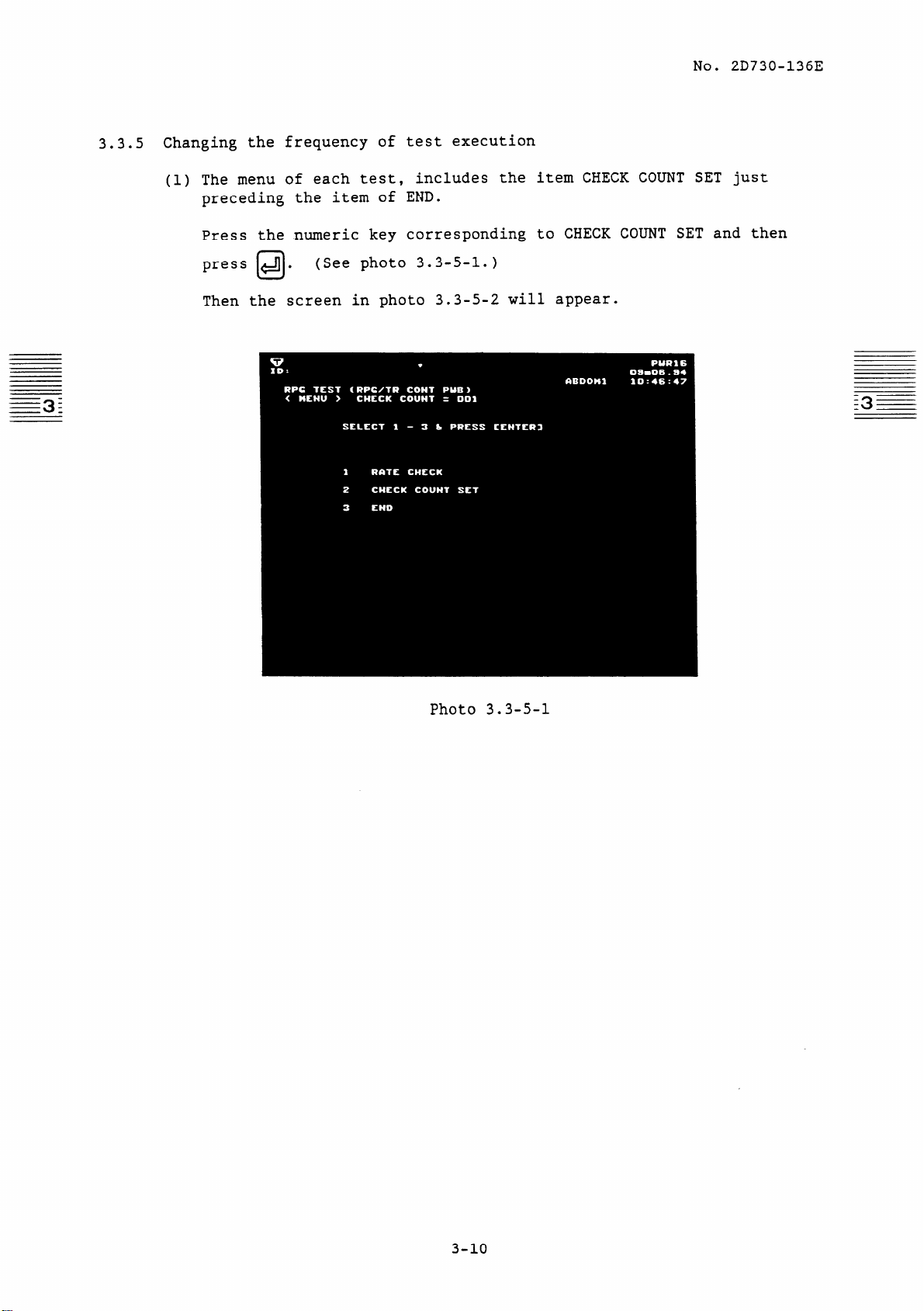

3.3.5 Changing the frequency of test execution

No. 20730-136E

(1) The menu of each test,

preceding the item of END.

Press the numeric key corresponding to CHECK COUNT SET and then

press +Jj.

Then the screen in photo 3.3-5-2 will appear.

0

(See photo 3.3-5-l.)

includes the item CHECK COUNT SET just

Photo 3.3-5-l

3-10

Page 29

No. 2D730-136E

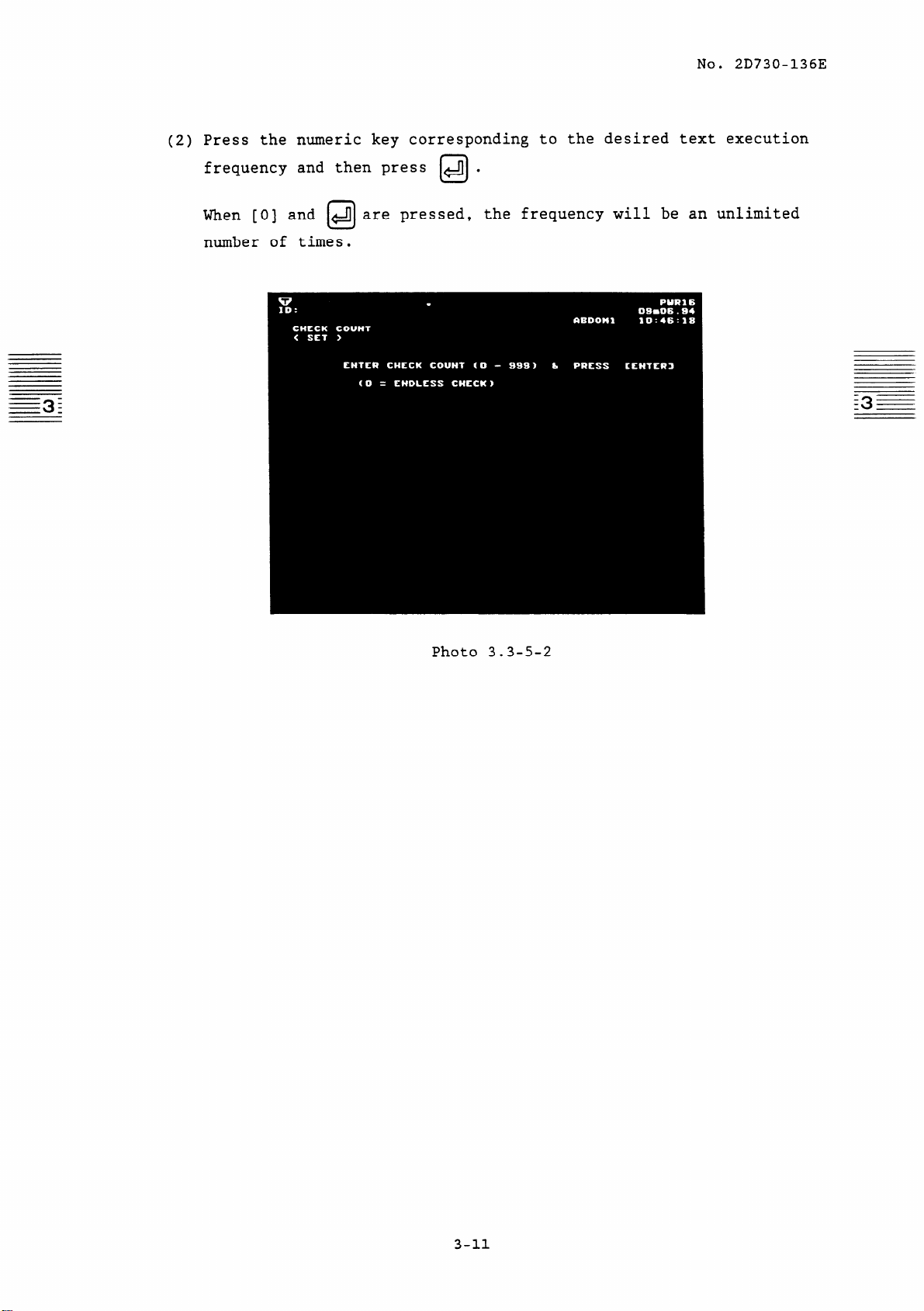

(2) Press the numeric key corresponding to the desired text execution

frequency and then press 4 .

When [0] and

number of times.

141 are pressed,

U

the frequency will be an unlimited

Photo 3.3-5-2

3-11

Page 30

No. 29733-136Z

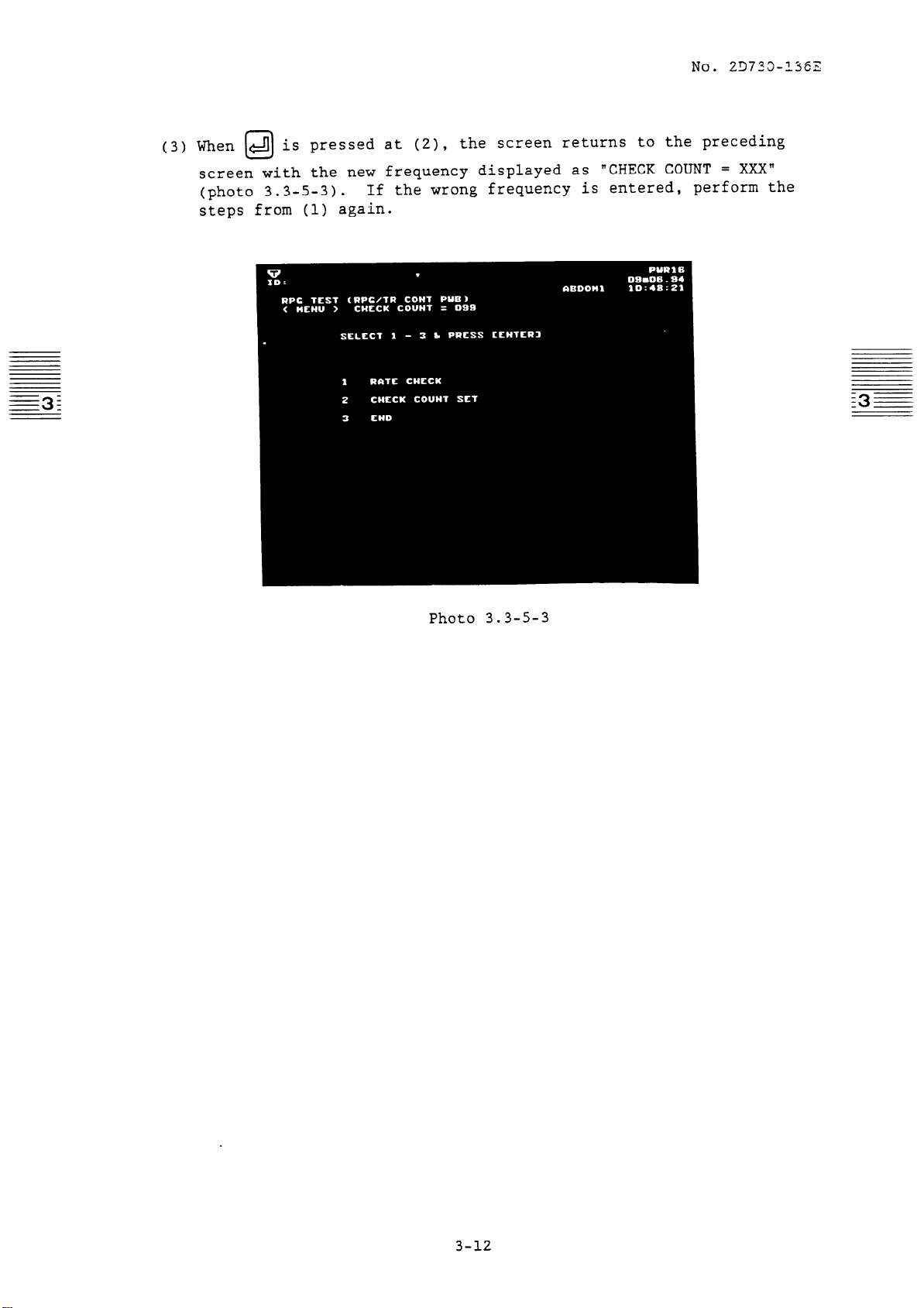

(3) When a is pressed at (2),

screen with the new frequency displayed as "CHECK COUNT = XXX"

(photo 3.3-5-3).

steps from (1) again.

If the wrong frequency is entered, perform the

the screen returns to the preceding

Photo 3.3-5-3

3-12

Page 31

3.4 Error Code Table

The error codes for visual check are described below.

No. 20730-136E

Error

code

CPU 00 CPU

CPU 01 CPU

PNL 00 PANEL

DSC 01 PC DSC

DSC02

DSC 03 B & W DSC

(--

DSC 04 ADC/LB/CAL

DSC 05 Ditto

DSC 06 CFM DSC and the

DSC 07 ADC/LB/CAL

PWB error

has occurred

CPU

I

RPG/TR CONT

B b W DSC

CFM DSC

RGB CONVERTER

subsequent PWBs

CFM DSC

RGB CONVERTER

Detail of the error

Graphic memory abnormal

Centronics abnormal

I

Sampling address abnormal

Raster address abnormal

FM-OUT GA abnormal or abnormal

/ between FM-OUT GA and GAMMARAM 1 No* 4 Of 4*4*3

RIP abnormal, etc.

WIP abnormal, etc.

FM-IN SC abnormal, etc.

FM-OUT GA abnormal, etc.

Reference

No. 3 of 4.1.3

No. 6 of 4.1.3

I

4.2.3

No. 2 of 4.4.3

No. 3 of 4.4.3

No. 6 of 4.4.3

No. 7 of 4.4.3

No. 8 of 4.4.3

No. 9 of 4.4.3

.

T/R 00

T/R 02 )

T/R 03

FFT 01 PHASE DETECTOR

FFT UNIT

FFT 02 FFT/CONT/AUDIO

FFT 03 FFT AUDIO &

L/M FFT CONT

FFT 04 FFT AUDIO &

L/M FFT CONT

Reception system abnormal

Reception system abnormal

I

Transmission system abnormal

I

Delay-line system abnormal

I

Analog system abnormal

(PHASE DETECTOR FFT I/O)

Digital system abnormal

FFT/CONT/AUDIO

Digital system abnormal (FFT)

Digital system abnormal (FFT)

4.5

4.5

I

4.5

I

4.5

I

4.6.2

4.6.2

4.6.2

4.6.2

3-13

Page 32

No. 2D730-136E

E3;

Error

code

CFMOl

to

cFMo3

cFMo4

to

CFMOS

CFM06

CFMll

to

cFM13

cFM14

to

cFM15

CFM16

PWB error

has occurred

CAL section on the

ADC/LB/CAL PWB

(BDF)

CAL section on the

ADC/LB/CAL PWB

(MDF)

CAL section on the

ADC/LB/CAL PWB

(BDF/MDF)

ADC/LB/PWB and

FIL/CORR PWB (BDF)

ADC/LB/CAL PWB and

FIL/CORR PWB (MDF)

ADC/LB/CAL PWB and

FIL/CORR PWB

(BDF/MDF)

Detail of the error

Abnormal ROM table and control

system in the BDF channel

system.

Abnormal ROM table and control

system in the MDF channel

system.

Abnormal ROM table and control

system in the BDF/MDF channel

system.

Abnormal control system and.

memory channel in the BDF

channel system

Abnormal control system and

memory channel in the MDF

channel system.

Abnormal control system and

memory channel in the BDF/MDF

channel system.

Reference

No. 5 to 7 of

4.7.3

No. 8 to 9 of

4.7.3

No. 10 of

4.7.3

No. 11 to 13

of 4.7.3

No. 14 to 15

of 4.7.3

No. 16 of

4.7.3

3-14

Page 33

FLOWCHARTS FOR IDENTIFYING MALFUNCTIONS

4.

4.1 Identifying Faults in the CPU Unit

4.1.1 Preparatory work

The following preparatory work is required before carrying out the

tests for the CPU which are listed below:

(1) When the RS-232C interface is checked

(a) The power to the ultrasonic diagnostic equipment is switched

OFF.

(b) Connect the loopback connector to the PS-232C connector on the

bottom of the main panel of the diagnostic ultrasound

equipment.

No. 2D730-136E

For the loopback connector,

use the connector to which the

following pins have been connected in the shell of the

DSUB-25s connector.

I) SD (pin 2) - RD (pin 3)

(c) The power to the ultrasonic diagnostic equipment is switched

ON, and the CPU test is selected.

4.1.2 Flowchart for identifying malfunctions

The flow of processing of the CPU test system is shown as a flowchart.

Figure 4.1-1 shows the processing flow of the entire CPU test system.

Since actual processing will proceed according to this flowchart when

the test system is operated,

it is recommended that the fault be

diagnosed while confirming the processing currently being performed

with respect to the entire test system by referring to this flowchart.

4-l

Page 34

4-2

No. 2D730-136E

f

Page 35

4.1.3 Decision criteria

This section shows decision criteria (normal or abnormal) for results

of the tests performed according to the flowchart in section 4.1.2,

depending on the messages

Items which do not match the normal data shown here are faults as test

results and faulty portions.

No. 2D730-136E

resulting from images obtained.

4-3

Page 36

No. 2D730-136E

Photo 4.1-l

[No. 0]

CPU test menu

Application:

Selection of CPU test menu

(Refer to photo 4.1-l)

Outline:

To perform selected CPU

tests by function

0 ALL CHECK

To perform RAM'CHECR, ROM

4

CHECK, GRAPHIC MEMORY

CHECK, RS-232C CHl CHECK,

RS-232C CH2 CHECK,

CENTRONICS CHECK

sequentially.

RAM CHECK

1

To check RAM operation.

+

ROM CHECK

2

To check ROM operation.

+

GRAPHIC MEMORY CHECK

3

To check graphic memory

-+

operation.

RS-232C CHl CHECK (For the

4

160A/270A/250A and 140A

CPUS)

To check RS-232C interface

+

CHl operation.

RS-232C CH2 CHECK

X

To check RS-232C interface

+

CH2 operation.

CENTRONICS CHECK

X

To check CENTRONICS

+

interface operation.

4-4

Page 37

No. 2D730-136E

7 CHECK COUNT

+ To set the frequency of the

CPU test.

(This is preset

at a frequency of one

normally.)

8 END

+ To complete the CPU test

and return to the main

menu.

Procedure:

+ To input the No. of the

test which is to be

performed

Example . . . . . ROM CHECK

Input 123

H in that

order.

Note:

Before performing a check,

including the RS-232C CHl

CHECK, RS-232C CH2 CHECK,

and CENTRONICS CHECK, refer

to 4.1.1 Preparatory work.

4-5

Page 38

No. 2D730-136E

Photo 4.1-Z

[No. 13

Application:

Operation check of RAM for

the CPU program

Outline:

After data is written into

RAM, data is read, then

compared with the written

data. If they do not match,

non-matching addresses are

indicated.

Procedure:

The CPU carries out the

test automatically and

displays the message in 1):

**Jr CPU RAM CHECK Jr**

1)

Results are displayed

2)

unit.

CPU RAM CHECK

sequentially in the RAM

i4E

When test results are

3)

normal:

The displayed image is as

shown in photo 4.1-2.

The system advances to the

next CHECK (CPU ROM CHECK)

when

The CPU test menu is

displayed when + is

pressed.

is pressed.

+JJ

n

0

4-6

Page 39

No. 2D730-136E

4) When test results are

abnormal:

Based on the results of

comparison, abnormal

addresses are displayed.

Bits set to "1" indicate

bits with abnormal RAM.

If [F] is pressed, advances

to the next address.

If [C] is pressed,

completes the present MM

check, and performs the

next RAM check.

Operation upon completion

of all addresses is the

same as in 3) above.

RAM showing abnormal

addresses in the above

tests are faulty.

Replace the CPU PWB.

;4=

4-7

Page 40

z:.

IIt CPU ROM CHECK tf*

* CPU PUB

13Y (X08)

12Y (X10)

1DY (X18) 665E OK

12v (X30)

1DV (X38)

12T (X40)

1DT (X48)

12R (X50)

1DR (X59)

END

llF7 OK

FPZF OK

1645 OK

6763 OK

5161 OK

F674 OK

BDPl OK

DD25 OK

RBDOMl

PUR16

llml7.94

20:!56:55

No. 2D730-136E

[No. 21 CPU ROM CHECK

Application:

Operation check of ROM for

the CPU program

Outline:

Checksum is performed by

reading the contents of ROM,

then comparison is made with

the previous checksum

results,

and IC locations and

checksum results (OK =

normal) are indicated.

Procedure:

Photo 4.1-3

The CPU carries out the test

automatically, and displays

the message in 1):

1) *** CPU ROM CHECK ***

2) Results are displayed

sequentially for each ROM

unit.

3) When test results are normal:

The displayed image is as

shown in photo 4.1-3.

With Isl) ON, the system

advances to the next CHECK

(GRAPHIC MEMORY).

With u ON,

the CPU test

menu is displayed.

4) When test results are

abnormal:

:4=

4-8

The location of abnormal ROM

is displayed.

Operations upon completion of

all ROM CHECKS are the same

as those in 3) above.

Abnormal ROM is identified

from the above results.

Faulty ROM should be

replaced.

Page 41

No. 2D730-136E

Photo 4.1-4

[No. 31

Application:

Operation check of CPU

GRAPHIC MEMORY

Outline:

"1" and "0" are written on 6

planes of GRAPHIC MEMORY.

The CRT screen will appear

black and white.

(With the color display, the

CRT screen will appear green

and blue.)

Procedure:

Check visually that the CRT

screen displays a normal

black and white pattern.

*Jr* GRAPHIC MEMORY CHECK *Jr*

(Refer to photo 4.1-4)

GRAPHIC MEMORY CHECK

Photo 4.1-5

The test starts when 4 is

2)

pressed.

When test results are

3)

normal:

The CRT screen becomes

"white"

4.1-5.

pressed,

becomes "black" as shown in

photo 4.1-6, permitting

visual check.

If [F] is pressed, the next

GRAPHIC MEMORY CHECK is

performed.

After checking 6 planes of

GRAPHIC MEMORY, the system

advances to the next CHECK

when 4 is pressed.

(RS-232C CHl CHECK).

as shown in photo

Then, when [F] is

the CRT screen

U

0

4-9

The CPU test menu is

displayed when + is

pressed.

0

Page 42

Page 43

No. 2D730-136E

[No. 41 RS-232C (CHl) CHECK

Application:

Transmission and reception

check for the CPU RS-232C

interface CHl

Outline:

The contents of

transmission from the

equipment and reception

from the return connector

are compared, and-if the

two do not agree, an error

is indicated.

Procedure:

Photo 4.1-8

The CPU carries out the

test automatically and

displays the message in 1):

1) **Jr RS-232C (CHl) CHECK ***

2) When test results are

normal:

The displayed image is as

shown in photo 4.1-8.

The system advances to the

next CHECK when 4 is

pressed.

(RS-232C CH2 CHECK).

The CPU test menu is

displayed when + is

pressed.

3) When test results are

abnormal:

0

0

Photo 4.1-9

An error message is

displayed as shown in photo

4.1-9.

Types and meanings of error

messages are given in table

4.1-1.

Operations after display of

an error message are the

same as in 2) above.

4-11

Page 44

No. 2D730-136E

Note:

Before performing this

CHECK, refer to 4.1.1

Preparatory work.

If the return connector is

not connected, a NO ANSWER

BACK occurs.

-4i

No.

5

6

Error message

FRAMING ERROR

OVERRUN ERROR

PARITY ERROR

TIME OUT ERROR

NO ANSWER BACK

COMPARE ERROR

Table 4.1-1

Error messages

Meaning

Format of 1 character received is not correct.

Before 1 character received is processed, the next

character is received.

A parity error has occurred within 1 character

received.

Transmission could not be performed within one minute

upon completion of preparation.

Text could not be received.

Transmitted and received text do not agree.

4-12

Page 45

4.1.4 Supplement

No. 2D730-136E

The checksum value must be registered prior to the CPU ROM check.

different registration methods are available.

(1) Refer to subsection 4.8.

(2) This method clears the preset data,

preset data.

Turn on No. 3 of the DIP SW on the CPU PWB.

(a)

Turn on the power.

(b)

When the following message is displayed, key-in Y:

w

INITIALIZE PRESET DATA

ARE YOU SURE?

After the initial screen displaying a B mode image appears,

(d)

turn off No.

Note:

4.2 Identifying Faults in the PANEL Unit

The above procedure has been already performed before

shipment from the factory.

3 of the DIP SW.

Two

and requires resetting of the

4.2.1 Preparatory work

No preparatory work is required.

4.2.2 Flowchart

for identifying faults

START

cr’

The LED on the panel

blinks at intervals of

approx. 1 second.

Figure 4.2-l

4-13

Page 46

4.2.3 Criteria

(Purpose) To identify faults in the PANEL unit.

(Outline) Turns the LEDs of the switches

No. 2D730-136E”B

indicated by

of approximately one second.

in figure 4.2-2 ON/OFF at intervals

Not all LEDs on the PANEL are turned

OFF/ON at intervals of about 1 s

(Some LEDs may be always on, always

off, or going OFF/ON at intervals other

than 1 s).

I

(1) Either the LEDs of switches not on

. _

the full keyboard are abnormal

(2) Ke LEDs of switches on the

keyboard are abnormal.

It is highly probable that the

PANEL is faulty.

1

No

I

Both groups

(1) and (2) are abnormal.

l

I

.

It is highly probable that the CPU

PWB or the cable between the

CPU and the PANEL is faulty. .

(If the panel data bus is faulty,

LEDs in both groups (1) and (2)

will be abnormal, regardless of the

panel’s condition.)

Note : The above is based on the assumption that the D & D MOTHER PWB

is normal.

4-14

Page 47

No. 2D730-136E*B

a

” . . . . . . . . . . .

” . . . . . & . . . . . M

” .r... . . . . . M

“z+

” . . . . . . . . . . w

“WM

Figure 4.2-2

Panel of the SSA-340A

4-15

Page 48

4.2.4 Supplement

No. 2D730-136E

CPU

I=-

AA

Data bus

Address bus

Figure 4.2-3

a

Trackball, STC VR data 1 D&D MOTHER

INITIAL

Peripheral control signal path

1 I

b .

*

I

Cable

1

PAN-EL

4-16

Page 49

Page 50

4.3 Identifying Faults in RPG

4.3.1 Preparatory work

None

4.3.2 Troubleshooting flowchart

Troubleshooting procedures for RPG faults are shown in the flowchart.

<RPG CHECK>

START

cr’

Checking of various enable

signals, raster addresses, OF,

generated in the RFG

No. 2D730-136E

4-18

Page 51

Signal names and functions which can be checked using this test program and PWB names which utilize these signals

are shown in the table below.

c-

Signal name

(between

boards)

BSAENO

MlSAENO

MZSAENO

DSAENO

FFTCMDO

BDFSAENO

MDFSAENO

DFINTO

Function

Signal showing B mode echo

sampling rate

k

Signal showing Ml mode echo

sampling rate

Signal showing M2 mode echo

sampling rate

Signal showing D mode echo o

sampling rate

Signal showing MDF mode

echo sampling rate

Signal showing initial CFM

operation sampling rate

PWB utilizing the signal

B & W DSC CFM DSC IMAGE MEMORY FFT/CONT/AUDIO MIT CONT ECG/NON FADE

CPU

o

o

0

0

0

0 0

0

0

0

0

0

0

0

0

0

0

0

0

0

DFA*O

(3 bit)

TRAST*O

(12 bit)

DRAST*O

(12 bit)

ID signal showing position

of transmission focus

Raster address for 0

transmission and reception

Raster address for

indication

o

0

0

0

0

0

0

Page 52

4.3.3 Decision tree

From the test results, normal (OK) or abnormal (NG) is determined for

each signal as shown below.

No. 2D730-136E

If NG is indicated,

and the PWB should be replaced.

it is highly likely that the RPG PWB is faulty,

4-20

Page 53

4.3.4 Supplement

The RPG test program is activated when the host CPU sets test scan

mode with respect to the RPG.

[Specification of test scan mode]

(1) Each enable signal is set to the enable condition sequentially for

each rate,

(2) Focus

B : FO, F3, F4, F5, F6, F7 (6 step CF)

Ml : Fl

M2 : F2

(3) Number of B mode raster lines : 240

The raster address ranges from 0 to 239 in the upper 8 bits.

as shown in the attached timing chart.

_.

No. 2D730-136E

(4) M-mode position

Ml : 55 (H)

M2 : AA (H)

[Functions of the Host CPU]

Sets test scan mode in the I/O port of the RPG.

(1)

By setting data 0 --> 1

(2)

--> 0 in the I/O port #70/19 TSTSYNCl bit,

the leading edge of this signal serves as a trigger for generating

the rate once.

Each time the rate is generated once,

(3)

#7O/lC, lD,

and it is checked whether such data agrees with the

data is read from I/O port

data shown in the attachment.

For NG, the NG decision is made with respect to the signal in the

(4)

specific bit,

By generating the rate 8 x 240 = 1920 times, one frame is

(5)

completed and DOFO is generated,

with respect to the CPU.

and the signal name is indicated.

thereby causing OF interruption

The CPU completes the test upon

confirmation of this interruption.

4-21

Page 54

s

_L

1 eqep alod 30 sanTaA anzLl

1

__

,-- .

_-----

3IIOL #

r

C

___

._.

I:

c

c

_-a

.

-me

.-_

1T

.

L

I:

C

we_

_

._ _

me-

-r

__ _-_--.

a----_

(H) T 0 0

‘Ioz

ZOT

80C

0 9 9

oz5

OT 9

CMOqlZ 66 EUlIt?S

08L

_-----.

ahoqo St? aumS

-----.

ahoqe se sues

(H) 0

aI/of i

0 00

0

00

0

vv

25

05s

OT 0

ovv

010

ozo

055

ovv

ozo

No. 2D730-136E

Page 55

4.4 Identifying Faults in the DSC Unit

4.4.1 Preparations

No preparations are required to test the DSC.

4.4.2 Troubleshooting flowchart

Figure 4-11 shows a flowchart for DSC unit test system processing.

This flowchart shows the actual processing flow.

When operating the test system, perform troubleshooting by checking

the current processing on the flowchart.

No. 2D730-136E

4-23

Page 56

<DSC TEST>

0: ALL

CHECK

B/W FMAO-I, FMBO-1

B/W DSC test pattern

Ckk

I

Color FMAO-2, FMBOR/W check

I

cola crJcul8ta tcu

paean check

I

I

Cola LIP test Pattun

ChCCk

I

B/W FMAl

R/W check

I

B/W FMBO

R/W check

B/W FMBl

R/W check

RETURN

I

I

I I I

1: B/WFM 2: BIWTEST 3: B/WTEST

CPuR/w

I

I

I

I

PATTERN PA-lTERN

(SYNC)

(ASYNC)

c

B/W

P&k

4: R/wLrP

TEST FJMRAM PATIERN

PAlTERN R/W

5: COLOR 6: CALTEST

Cola FMBO

R/W check

I

I

(RI

7: CALTEST

PATI-ERN PRIP TEST

(THETA)

8: COLOR

PATTERN

9: COLOR

LIP TEST

PATTERN

lo: END

Figure 4-l 1

Page 57

4.4.3 Criteria

This section describes the criteria for normality or abnormality,

based on the messages displayed on the screen, for the results of

tests performed according to the flowchart.

If any test item does not meet the requirements, it is rejected.

No. 2D730-136E

4-25

Page 58

NO

No. 2D730-136E

Frame memory error.

Faulty PWB:

B&WDSC

(CPV)

I

Faulty PWB: CPU B & W DSC

4

NG

OK

Raster address or transmission

stage count error.

Faulty PWB:

B&WDSC

RPG/IR CONT

Figure 4-12

4-26

No error in LIP and

subsequent units

I

Page 59

No. 2D730-136E

NO

Faulty PWB: CPU B_& W DSC

,

Frame memory ermr.

Faulty PWB:

CFMDSC .

(CPv)

I

Sampling address error.

Faulty PWB:

CFM DSC

NG

NG

END

OK

OK

The DSC unit is normal.

No signal is sent from the CFM unit.

Raster address error

Faulty PWB:

CFM DSC

RPGIrR CONT

A

b

4-27

Page 60

OK

No. 2D730-136E

No error in RIP and

END

A

Figure 4-13

No error in LIP and

subsequent units

I

4-28

Page 61

No. 2D730-136E

Note:

If the gradation is abnormal, proceed to the test of the next

item.

If the gradation becomes normal at item "n", it shows

that the path of the signal at item "n-l" not included in the

signal of item "n" is abnormal.

Abnormal Normal

Item "n" Item "n-l"

2

3

{ I

4

4 B & W DSC

___

8

8

9

B & W DSC

CFM unit, CFM DSC

CFM DSC

Faulty PWB

yr---- 1 CFM DSC, RGB CONVERTER

4-29

Page 62

Image mode at the time of DSC test

No. 2D730-136E

No. 2

B/W TEST PATTERN (SYNC)

No. 3

B/W TEST PATTERN (ASYNC)

No. 4

B/W LIP TEST PATTERN

TV display

I

Display mode

!4tB

B-Dual

FMA

FMB

I

TV1

TV2

B-Dual

No. 6

CAL TEST PATTERN (R)

No. 7

CAL TEST PATTERN (THETA)

No. 8

COLOR RIP TEST PATTERN

No. 9

COLOR LIP TEST PATTERN

TV?

FMA

TV?

FMA FMB

,

TV?

TV2

FMB

TV2

TV2

MtB

B-Dual

I

B-Dual

B-Dual

4-30

Page 63

No. 2D730-136E

Photo 4.4-l

[No. 0]

CPU test menu

Application:

The DSC test mode is

selected.

(See photo 4.4-l)

Outline:

The DSC function test is

selected.

0 ALL CHECK

The following checks are

sequentially performed:

B/W FM CPU R/W, B/W TEST

PATTERN (SYNC), B/W TEST

PATTERN (ASYNC), B/W LIP

TEST PATTERN, COLOR FM CPU

R/W, CAL TEST PATTERN (R),

CAL TEST PATTERN (THETA),

COLOR RIP TEST PATTERN,

COLOR LIP TEST PATTERN

1 B/W FM CPU R/W

+ B/W FMA, FMB are checked.

2 B/W TEST PATTERN (SYNC)

-+ The sampling address is

checked by the rate

synchronization test

pattern.

3 B/W TEST PATTERN (ASYNC)

+ The raster address is

checked by the rate asyn-

chronization test pattern.

4 B/W LIP TEST PATTERN

+ Determining whether the

error position is in the

system preceding the B/W

DSC unit or in the system

following the B/W DSC unit.

4-31

5 COLOR FM CPU R/W

+ COLOR FMAO to 2, FMBO to 2

R/W is checked.

Page 64

No. 2D730-136E

6 CAL TEST PATTERN (R)

The sampling address and

+

r-direction thresholds are

checked.

7

CAL TEST PATTERN (THETA)

The raster address and

+

r-direction and e-direction

thresholds are checked.

COLOR RIP TEST PATTERN

0

The RIP test pattern is

-+

checked.

COLOR LIP TEST PATTERN

9

Determining whether the

+

error position is in the

system preceding the color

DSC unit or in the system

following the color DSC

unit.

11

-LA END

+ The DSC tests are

completed,

and the screen

returns to the main menu.

Procedure:

Enter the test number.

Example . . .

B/W TEST PATTERN (SYNC)

Input [2] @ in that

order.

Caution:

Characters should be

displayed on the screen.

If no characters are

displayed,

either the CPU,

B&W DSC, or CPM DSC PWB is

abnormal.

4-32

Page 65

No. 20730-1363

Photo 4.4-2

[No. l]

Application:

FM memory IC operation is

checked.

Outline:

Data is written into RAM,

then read.

data does not match the

written data, the address

is displayed.

Procedure:

The CPU carries out the

test automatically, and

displays the message in 1):

**** B/W FM RAM CHECK ***Jr

1)

The result is displayed

2)

sequentially for each RAM.

B/W FM CPU R/W

If the read

i4E

When F'MAO is completed,

3)

FMAl and FMBO are checked

in that order.

When the test results are

4)

normal,

photo 4.4-2 is displayed.

When 4 is pressed, it

proceeds to the next check

(B/W TEST PATTERN (SYNC)).

When * is pressed, the

DSC test menu is displayed.

The error address and the

comparison result are

displayed.

set to 1 is an error bit in

the RAM.

the image shown in

0

0

A bit which is

4-33

Page 66

No. 2D730-136E

If the [F] key is pressed,

the next address is tested.

When [C] is pressed, this

check is terminated.

The operations when all

addresses have been tested

are the same as the

operations described in 4).

4-34

Page 67

Page 68

4-36

4

3

ml

X

a

+-

No. 2D730-136E

Page 69

Page 70

No. 2D730-136E

3) When +!I is pressed, the

When + is pressed, the

Note:

0

operation proceeds to the

next check (B/W LIP TEST

PATTERN).

U

DSC test menu is displayed.

When both check results,

B/W TEST PATTERN (ASYNC)

and B/W TEST PATTERN

(SYNC).

unit is normal.

is sent from the Receiver.

are normal, the DSC

No signal

4-38

Page 71

4-39

u4

0

No. 2D730-136E

Page 72

Page 73

No. 2D730-136E

Note:

If the check result is

normal and no pattern is

displayed when B/W TEST

PATTERN (SYNC) or B/W TEST

PATTERN (ASYNC) is checked,

the error is in the system

from the FM-IN SC to the

FM- OUT.

4-41

Page 74

BaW DSC

Flow chart of B/W LIP TEST PATTERN signal

ENC/

DEL

I

Character

t

I

CONTROL

,

.

BLOCK

66000

BLOCK

7

0 RPG

*

o HOST

CPU

Page 75

Photo 4.4-6

No. 2D730-136E

[No. 51 COLOR FM CPU R/W

Application:

EM memory IC operation is

checked.

Outline:

Data is written into RAM,

then read.

data does not match the

written data, the address

at which the discrepancy

has occurred is displayed.

Procedure:

The CPU carries out the

test automatically, and

displays the message in 1):

If the read

**** CF'M FM RAM CHECK ****

1)

The result is displayed

2)

sequentially for each RAM.

When FMAO is completed,

3)

F'MAl and F'MA3 are checked

in that order.

When the test result is

4)

normal,

photo 4.4-6 is displayed.

When 4 is pressed, the

operation proceeds to the

next check (CAL TEST

PATTERN (R)).

When m

DSC test menu is displayed.

If COLOR FM CPU R/W is

selected,

is displayed when the &/

key is pressed.

the image shown in

U

is pressed, the

the DSC test menu

0

4-43

The error address and the

5)

comparison result are

displayed.

set to 1 is an error bit in

the MM.

A bit which is

Page 76

No. 2D730-136E

l If the [F] key is

pressed,

is tested.

When [C] is pressed, this

check is terminated.

The operations when all

the addresses have been

tested are the same as

the operations in 4).

the next address

4-44

Page 77

Page 78

No. 2D730-136E

l If the pattern is

otherwise abnormal, the

error is in the

CALCULATOR PWB or CPM DSC

PWB.

l If no pattern is

displayed, the error is

in the CALCULATOR PWB,

CPM DSC PWB, or RGB CONV

PWB.

3) When m is pressed, the

system proceeds to the next

check (CAL TEST PATTERN

(THETA)).

When + is pressed, the

Note:

U

DSC test menu is displayed.

If both check results, CAL

TEST PATTERN (R) and CAL

TEST PATTERN (THETA), are

normal,

normal. No signal is sent

from the CPM unit.

the DSC unit is

4-46

Page 79

4-47

No. 2D730-136E

Page 80

Page 81

No. 2D730-136E

l If the pattern is

otherwise abnormal the

error is in the

CALCULATOR PWB or CPM DSC

PWB.

0 If no pattern is

displayed,

in the CALCULATOR PWB,

CF'M DSC PWB or RGB CONV.

the error is

3) When +lJ is pressed, the

- (COLOR RIP TEST PATTERN).

Note:

0

proceeds to the next check

When + is pressed, the

U

DSC test menu is displayed.

If both check results, CAL

TEST PATTERN (THETA) and

CAL TEST PATTERN (R) are

normal,

normal.

from the CPM unit.

the DSC unit is

No signal is sent

4-49

Page 82

%

3

3

Y

d

%

’ a

El

E

x

3

. 1

I

.

I I

5

L

4-50

% (

z

L

I

4

1

8s~

9

L

No. 2D730-136E

Page 83

Page 84

4-52

f

v

:

I-

No. 2D730-136E

Page 85

Page 86

No. 2D730-136E

When the test results are

3)

abnormal:

0 When interpolation is not

performed normally, the

error is in the FM-OUT

GA.

0 When no pattern is

displayed or the color

tone is incorrect, the

error is in the CPM DSC

PWB or RGB CONVERTER PWB

subsequent to the FM-OUT

GA.

If ALL CHECK or COLOR LIP

4)

TEST PATTERN is selected,

the DSC test menu is

displayed when the + key

is pressed.

0

.

g4E

4-54

Page 87

P-l

k’

l-l

No. 2D730-136E

Page 88

4.5 Identifying Faults in the T/R Unit

4.5.1 Preparations

Ultrasonic jelly is required in the items listed below:

No. 2D730-136E

(1) T/R test item No.

(2) T/R test item No.

4.5.2 Fault diagnosis flow chart

Figure 4.5-l shows the processing for the T/R test.

4 R-channel check (CONVEX)

5 T-channel check (CONVEX)

4-56

Page 89

<T/R TEST>

Tut mode sclactim

0: ALL

CHECK

Command RAM R/w

I

ChCCk I

Rccqxion chumcl chat

(=W

I

1

2 DLCONT

RAM

CHJXK

I

I

( RETURN )

Figure 4.5 1

l’hcT/Rtcstis

complctcd 8nd Ihc.

main mu is

displayed once again

I

1

Page 90

Troubleshooting procedure

No. 2D730-136E

[Suspcctcd PM’B 1

,

IOK

NG

NG

NG

NG

NG

* RPG/l-R CONT PWB

* RPG/T’R CONT PWB

PROBE SELECTOR PWB

R-DELAY PWB

*

w PROBE SELECTOR

r

* R-DELAY PWB

PULSER PWB *

*

PULSER PWB

‘*

1 END ]

* The RAM check function (command RAM,

of RPGjTR CONT PWB.

There is a slight chance that RPG/TR CONT is defective, in addition

to the PWBs with Jr.

Notes: 1.

If more than one PWB, identify the dcfcctive PWB by

checking the patterns of test results.

BRI RAM) does not check whole

Prior to replacing PWBs,

check that cables are connected

correctly and are not cut off.

2.

The DVAF/RECEIVER cannot be checked using the test program.

These PWBs must be checked separately.

4-58

Page 91

4.5.3 Criteria

No. 2D730-136E

[No. 13 T&R TEST MENU

Purpose:

T&R test menu selection

Outline:

Select the test for each

block.

0 ALL CHECK

The following tests are

executed sequentially.

1 T&R CONT RAM CHECK

Photo 4.5-l

The RAM for T/R CONTl and

delay time data is checked

for read and write.

2 DELAY CONT RAM CHECK

The RAM for DELAY CONT

delay time data is checked

for read and write.

x R-CHANNEL CHECK (RESERVE)

4 R-CHANNEL CHECK (CONVEX)

Each channel of the convex

reception system is

checked.

5 T-CHANNEL CHECK (CONVEX)

Each channel of the sector

transmission system is

checked.

6 DELAY TIME CHECK (CONVEX)

2

4-59

The sector transmission -

reception delay time is

checked.

7 CHECK COUNT SET

Page 92

No. 2D730-136E

8 END

The T&R test is completed.

The [No. l] menu is

displayed.

Procedure:

_ Enter the number of the

test to be executed.

Example . . . . . R-CHANNEL

CHECK (CONVEX)

Press the [4] and

in that order.

@J keys

4-60

Page 93

No. 2D730-136E

Photo 4.5-2

[No. 21

Purpose:

Operation check for T/R

delay time RAM

Outline:

Data is written into the

MM.

compared with the written

data.

each other,

data are displayed.

Procedure:

The CPU executes the test

automatically and displays

the message below:

1) "***T/R CONT RAM CHECK***"

is displayed.

T/R CONT RAM CHECK

The data is read and

If they do not match

the address and

2) The result is displayed for

each RAM.

3) When the test result is

normal,

photo 4.5-2 is displayed.

When the 4 key is

pressed,

executed.

When the + key is

pressed,

displayed.

4) When the test result is

abnormal,

address and the results of

comparison are displayed.

the message in

0

the next check is

0

menu [No. l] is

the abnormal

4-61

Page 94

No. 20730-1363

When the [F] key is

pressed,

is checked.

When the [C] key is

pressed,

check is terminated.

After all the addresses are

checked:

the next address

the current RAM

When the 4 key is

pressed,

executed.

When the + key is

pressed, the [No. l] menu

is displayed.

The RAM containing the error

address is faulty.

the RPG/TR CONT PWB.

0

the next check is

0

Replace

4-62

Page 95

No. 2D730-136E

Photo 4.5-3

[No. 31

Purpose:

BRI RAM operation check

Outline:

Data is written into the

MM, then the data is read

and compared with the

written data.

not match each other, the

address and data are

displayed.

Procedure:

The CPU automatically

executes the test and

displays the message below:

1) "***DL CONT RAM CHECK***"

is displayed.

DELAY CONT MM CHECK

If they do

2) The result is displayed for

each RAM.

3) When the test result is

normal:

a) The message in photo

4.5-3 is displayed

When the 4 key is

pressed,

is executed.

When the C=, key is

pressed,

displayed.

0

the next check

U

menu [No. l] is

4-63

Page 96

No. 2D730-136E

4) When the test result is

abnormal, the abnormal

address and the result of

comparison are displayed.

When the [F] key is

pressed, the next address

is checked.

When the [C] key is

pressed,

check is terminated.

After all the addresses are

checked:

the current RAM

When the 4 key is

pressed, the next check is

executed.

When the + key is

pressed, the menu [No. l]

is displayed.

The RAM containing the error

address is faulty. Replace

the RPG/TR CONT PWB.

0

n

;4---

4-64

Page 97

Page 98

No. 2D730-136E

When the + key is

pressed,

u

menu [No. l] is

displayed.

When the [SPACE] key is

pressed,

the first half and

the second half of the

channels are switched.

(See the figure below.)

If the values of the STC

controls are set too high,

the brightness of the line

of a faulty channel

increases, making it

difficult to detect faulty

channels.

CH64

t

m129

cH5

@WI

I

Examples:

Photo 4.5-4 shows an

example of a normal result

for channels 5 to 64.

Photo 4.5-S shows an

example of a normal result

for channels 65 to 124.

For abnormal results, the

defective ch is black.

4-66

Page 99

Page 100

No. 2D730-136E

Example

Photo 4.5.6 shows an

example of normal 5 to 64

ch and photo 4.5.7 shows

an example of normal 64 to

124 ch.

The marker on the raster

is displayed every 10

channels.

If the channel for the

transmission system is

defective,

the raster

corresponding to the

channel is black.

The gain dial has no

effect,

so adjust the STC

to clarify the black area.

;4=

4-68

Loading...

Loading...