Toshiba RDXS-54-SU Service manual

FILE NO. 810-200568

DOCUMENT CREATED IN JAPAN, JULY, 2005

SERVICE MANUAL

DIGITAL VIDEO

HDD/DVD VIDEO RECORDER

RD-XS54SU

Jul., 2005

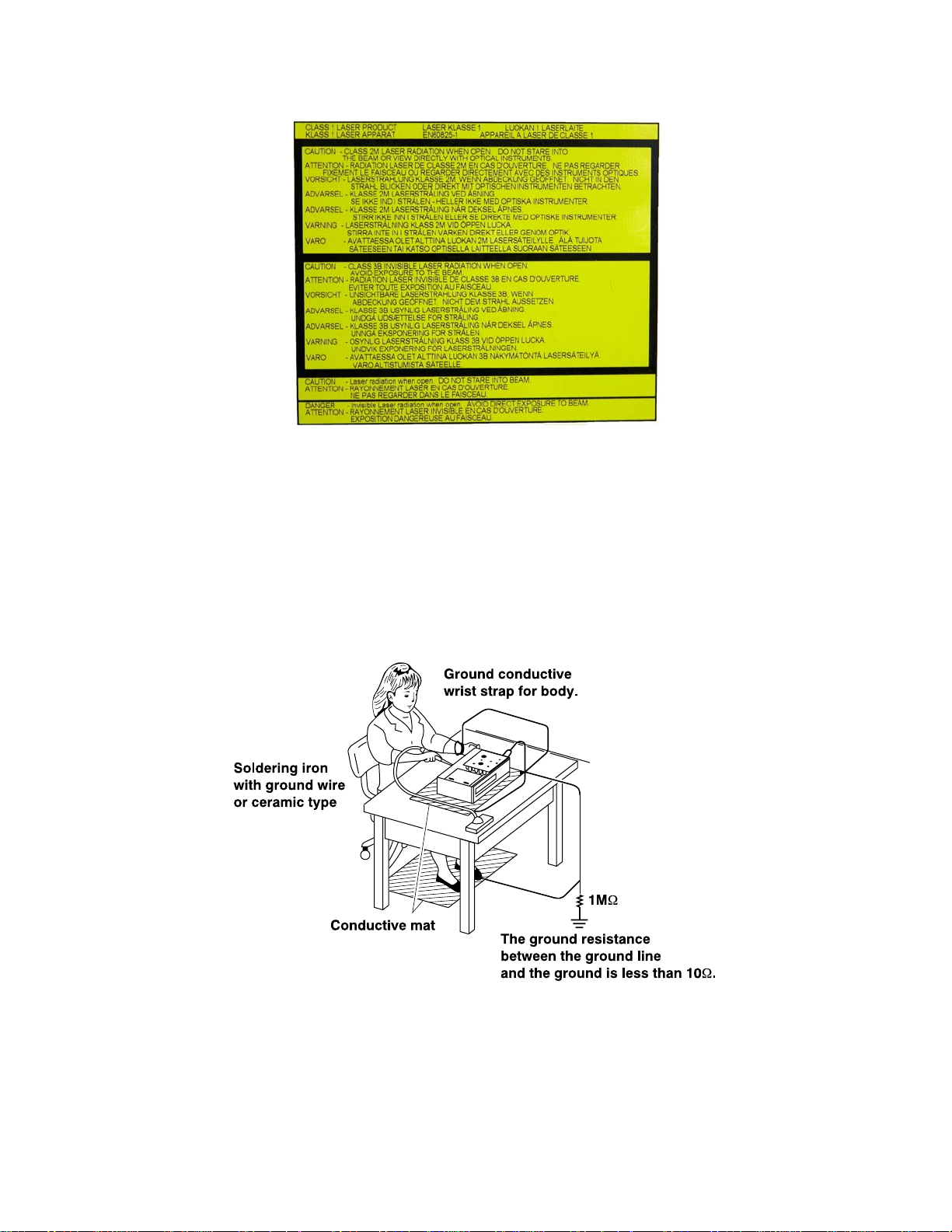

LASER BEAM CAUTION LABEL

When the power supply is being turned on, you may not remove this laser cautions label. If it removes, radiation of a laser

may be received.

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement,

its life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to

protect the laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

·

“DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

·

Manufactured under license from QSound Labs, Inc. U.S. patent Nos. 5,105,462, 5,208,860 and 5,440,638 and various foreign counterpart. Copyright

·

QSound Labs, Inc. 1998-2002. QXpander

In the United States, TV GUIDE and other related marks are registered marks of Gemstar-TV Guide International, Inc. and/or of its affiliates. In

·

Canada, TV GUIDE is a registered mark of Transcontinental Inc., and is used under license by Gemstar-TV Guide International, Inc.

The TV Guide On Screen system is manufactured under license from Gemstar-TV Guide International, Inc. and/or one of its affiliates.

·

The TV Guide On Screen system is protected by one or more of the following issued United States patents 6,498,895, 6,418,556, 6,331,877, 6,239,794;

·

6,154,203; 5,940,073; 4,908,713; 4,751,578; 4,706,121.

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC.

·

TM

is a trademark of QSound Labs, Inc. All rights reserved.

SAFETY NOTICE

SAFETY PRECAUTIONS

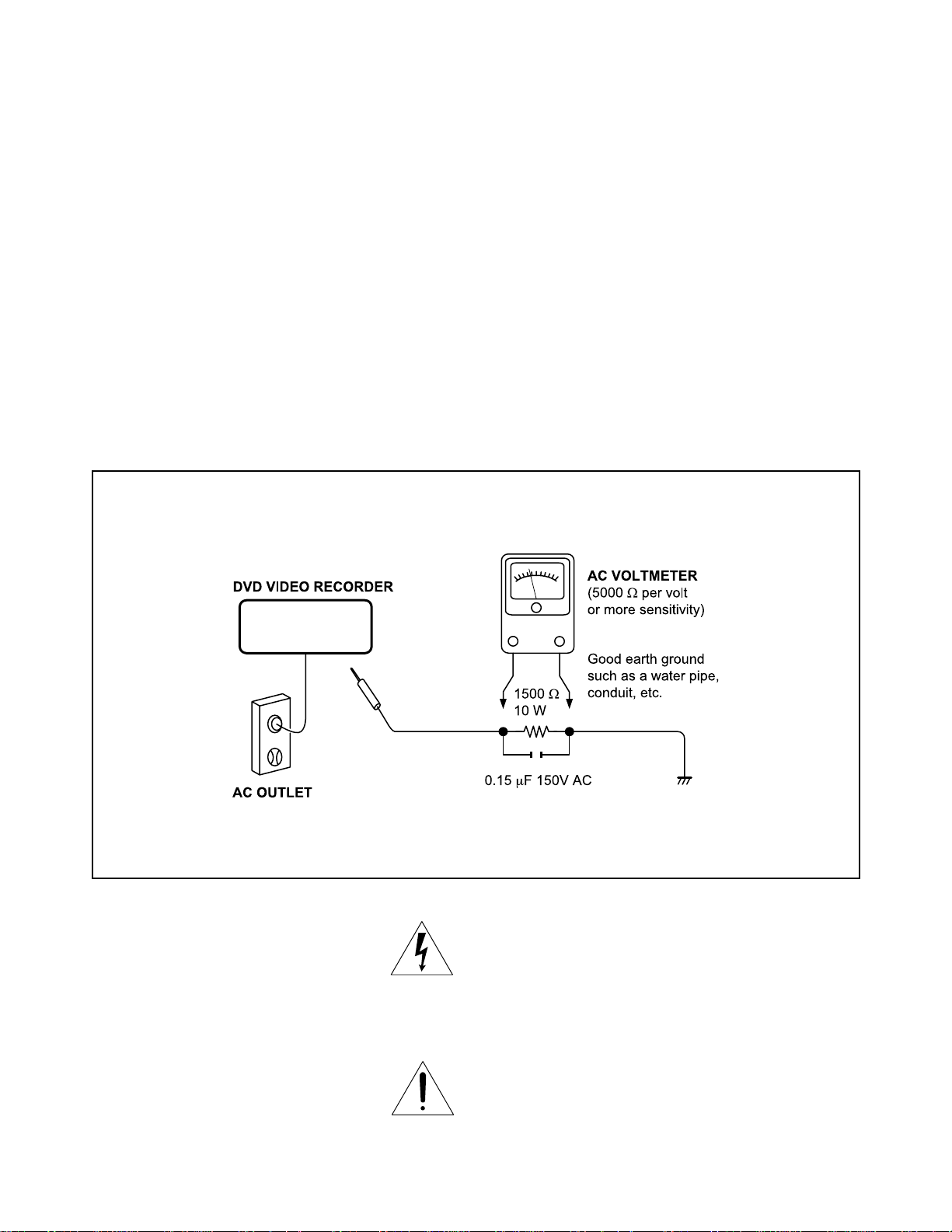

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 Ω per volt or more sensitivity.

Connect a 1500 Ω 10 W resistor, paralleled by a 0.15 μF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 Ω resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD VIDEO RECORDER

power plug reversed.

NEVER RETURN A DVD VIDEO RECORDER TO

THE CUSTOMER WITHOUT TAKING NECESSARY

CORRECTIVE ACTION.

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

1. OPERATING INSTRUCTIONS

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

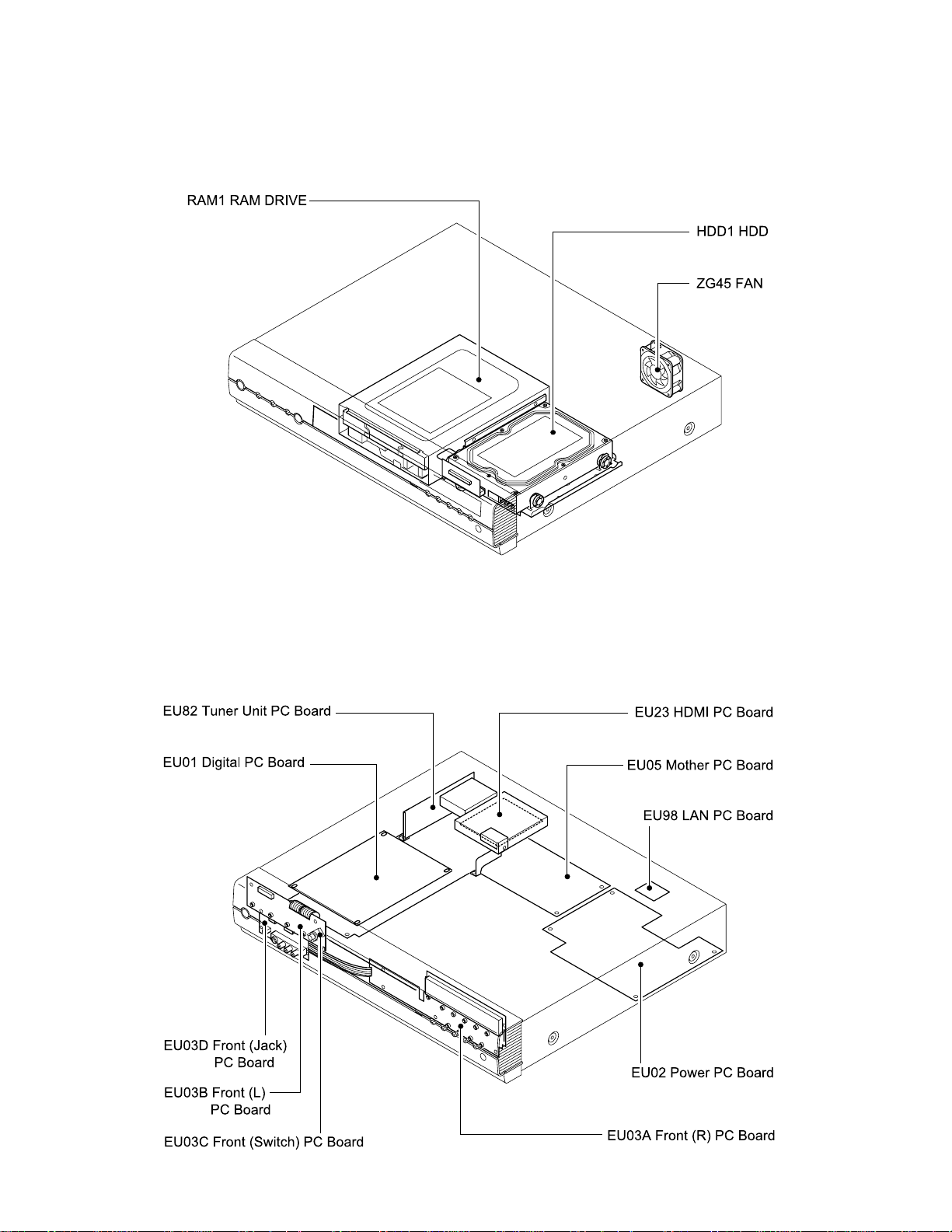

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

2-2. Location of PC Boards

1. Replacement of Mechanical Parts

1-1. Cabinet Replacement

1-1-1. Top Cover

1-1-2. HDD

1-1-3. Front Panel

1-1-4. RAM Diver

1-1-5. Rear Panel

1-1-6. Fan

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

1-2. Solid Resistor Indication

1-3. Capacitance Indication

1-4. Inductor Indication

1-5. Waveform and Voltage Measurement

1-6. Others

2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram

4. CIRCUIT DIAGRAMS

4-1. Power Supply Circuit Diagram

4-2. Front Circuit Diagram

4-2-1. Front Jack Circuit Diagram

4-2-2. Front Circuit Diagram (L/SW), (R)

4-3. Digital Circuit Diagram

4-3-1. Digital 1 Circuit Diagram

4-3-2. Digital 2 Circuit Diagram

4-3-3. Digital 3 Circuit Diagram

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

SECTION 2

1-2. PC Board Replacement

1-2-1. Digital PC Board

1-2-2. Tuner Unit PC Board

1-2-3. HDMI PC Board

1-2-4. LAN PC Board

1-2-5. Mother PC Board

1-2-6. Power PC Board

1-2-7. Front (R), Front (L/SW), Front (Jack) PC Board

2. WIRING CONNECTION DIAGRAM

SECTION 3

SERVICING DIAGRAMS

4-4. Mother Circuit Diagram

4-4-1. Tuner Circuit Diagram

4-4-2. Audio Circuit Diagram

4-4-3. Timer Circuit Diagram

4-4-4. Video Circuit Diagram

4-5. Tuner Unit Circuit Diagram

4-6. HDMI Circuit Diagram

4-7. LAN Circuit Diagram

5. PC BOARDS

5-1. Front Jack PC Board

5-2. Front Switch PC Board

5-3. Front (L) PC Board

5-4. Front (R) PC Board

5-5. Tuner Unit PC Board

5-6. LAN PC Board

5-7. HDMI PC Board

5-8. Digital PC Board

5-9. Mother PC Board

SAFETY PRECAUTION

NOTICE

ABBREVIATIONS

1. EXPLODED VIEWS

1-1. Packing Assembly

1-2. Chassis Assembly

2. PARTS LIST

SECTION 4

PARTS LIST

GENERAL DESCRIPTIONS

SECTION 1

GENERAL DESCRIPTIONS

1. OPERATING INSTRUCTIONS

Please refer to the owner's manual about the contents.

SECTION 1

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

2-2. Location of PC Boards

Fig. 1-2-1

Fig. 1-2-2

SECTION 2

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

CAUTIONS BEFORE STARTING PART REPLACEMENT

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to ground as required.

Many screws are used inside the unit. To prevent the screws from missing or dropping, etc. always use a magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care of

the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improperly,

the screw holes will be easily damaged and the parts can not be fixed.

1. REPLACEMENT OF MECHANICAL PARTS

ADJUSTMENT PROCEDURES

PART REPLACEMENT AND

1-1. Cabinet Replacement

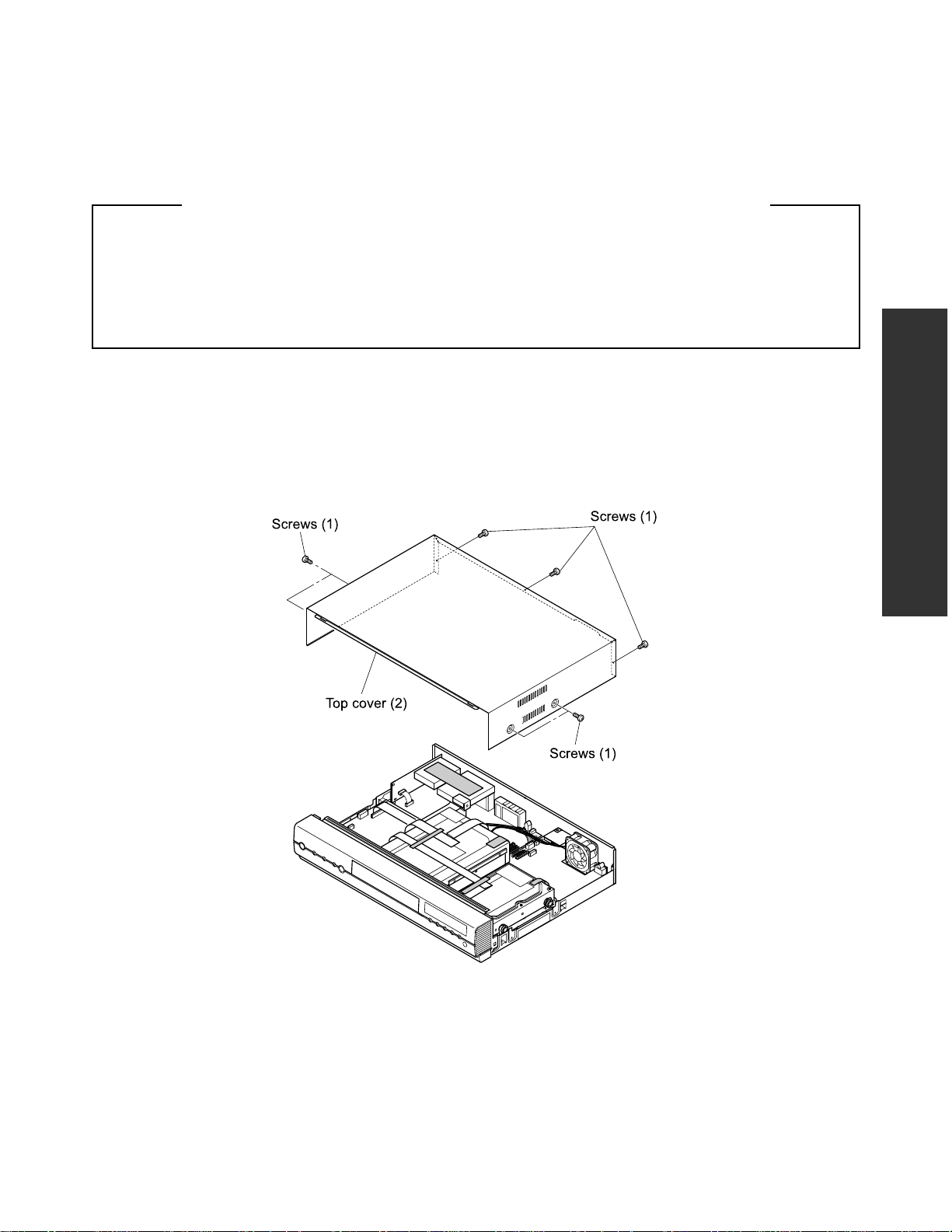

1-1-1. Top Cover

1. Remove seven screws (1), then remove the top cover (2).

SECTION 2

Fig. 2-1-1

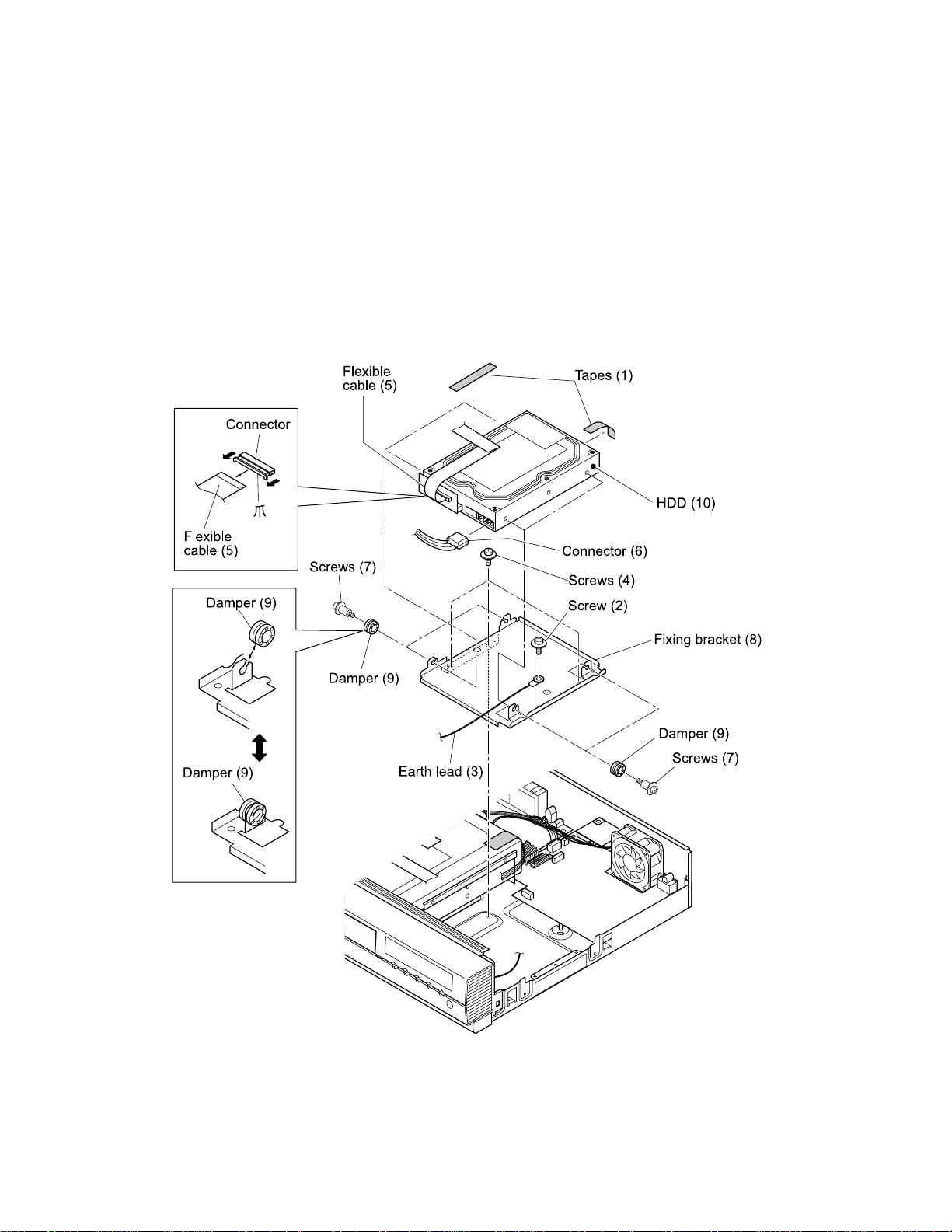

1-1-2. HDD

1. Remove the top cover. (Refer to item 1-1-1.)

2. Peel off two tapes (1).

3. Remove the screw (2) and the erath lead (3).

4. Remove four screws (4).

5. Disconnect the flexible cable (5) and the connector (6).

6. Remove four screws (7), and remove the dumper (9) and the HDD (10) from fixing bracket (8).

Note:

• After replacing, attach the tape (1) to its original position.

Fig. 2-1-2

Loading...

Loading...