Toshiba RAV-SM404SDT-E, RAV-SM454SDT-E, RAV-SM564SDT-E INSTALLATION MANUAL

AIR CONDITIONER (SPLIT TYPE)

Installation Manual

Indoor Unit

Model name:

Slim Duct Type

RAV-SM404SDT-E

RAV-SM454SDT-E

RAV-SM564SDT-E

Not accessible to the general public

Vente interdite au grand public

Non accessibile a clienti generici

No destinado al público en general

Installation Manual

Air conditioner

Manuel d’installation

Climatiseur

Installations-handbuch

Klimagerät

(Split type) 1

(Type split) 39

(Split-typ) 77

Kein öffentlicher Zugang

English

Français

Deutsch

Manuale di installazione

Condizionatore d’aria

Manual de instalación

Aire acondicionado

(Tipo split)115

(Tipo split) 153

Italiano

Español

Slim Duct Type

Thank you very much for purchasing TOSHIBA Air Conditioner.

Please read this Installation Manual carefully before installing the Air Conditioner.

• This Manual describes the installation method of the indoor unit.

• For installation of the outdoor unit, follow the Installation Manual attached to the outdoor unit.

Installation Manual

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the ozone layer.

Contents

1 ACCESSORY PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 PRECAUTIONS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 SELECTION OF INSTALLATION PLACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 DRAIN PIPING WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 AIR DUCTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 REFRIGERANT PIPING AND EVACUATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 ELECTRICAL WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9 APPLICABLE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12 TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-EN

–1–

Slim Duct Type

1 ACCESSORY PARTS

Accessory parts

Part name Q’ty Shape Usage

Installation Manual 2 These manual (Be sure to hand over to customers)

Insulating pipe 2 For insulation pipe connecting section

Washer 8 M10 × Ø34 For hanging-down unit

Hose band 1 For connecting drain pipe

Flexible hose 1 For adjusting of drain pipe centering

Heat insulator 1 For insulating drain connecting section

Owner’s Manual 1 (Be sure to hand over to customers)

Installation Manual

2 PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety.

Observe them without fail.

• After the installation work, perform a trial operation (test run) to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install (including moving)/

maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone wires.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Install the refrigerant pipe securely during the installation work before operating the air

conditioner.

If the air conditioner is operated with the valve open and without the refrigerant pipe, the compressor sucks

air and the refrigeration cycle is overpressurized, which may cause a burst or injury.

• When moving the air conditioner for the installation into another place, be very careful not to enter

any gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes

abnormally high and it resultingly causes pipe burst and injuries on persons.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

EN

–2–

2-EN

Slim Duct Type

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that

the concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas

might generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix.

To prevent external forces applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• For the refrigerant recovery work (collection of refrigerant from the pipe to the compressor), stop

the compressor before disconnecting the refrigerant pipe.

If the refrigerant pipe is disconnected while the compressor is working with the valve open, the compressor

sucks air and the refrigeration cycle is overpressurized, which may cause a burst or injury.

Installation Manual

CAUTION

New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

• The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its

pressure is approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant,

refrigerating oil has also been changed. Therefore, during installation work, be sure that water, dust, former

refrigerant, or refrigerating oil does not enter the refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of

charging port of the main unit and installation tools are changed from those for the conventional refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust

does not enter.

To Disconnect the Appliance from Main Power Supply.

• This appliance must be connected to the main power supply by means of a switch with a contact separation

of at least 3 mm.

• The installation fuse must be used for the power supply line of this conditioner.

• Tighten the flare nut with a torque wrench in the specified manner.

Excessive tightening of the flare nut may cause a crack in the flare nut after a long period, which may result

in refrigerant leakage.

• Wear heavy gloves during the installation work to avoid injury.

3-EN

–3–

Slim Duct Type

Installation Manual

3 SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner at enough strong place to withstand the weight of the unit.

If the strength is not enough, the unit may fall down resulting in injury.

• Install the air conditioner at a height 2.5m or more from the floor.

If you insert your hands or others directly into the unit while the air conditioner operates, it is dangerous

because you may contact with revolving fan or active electricity.

CAUTION

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks and stays around the unit, a fire may occur.

Upon approval of the customer, install the air conditioner in a place that satisfies the

following conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be ensured for safety maintenance and check.

• Place where drained water will not cause any problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of

sulfide gas (hot spring).

(Should the unit be used in these places, special protective measures are needed.)

• A restaurant kitchen where a lot of oil is used or place near machines in a factory (Oil adhering to the

heat exchanger and resin part (fan) in the indoor unit may reduce the performance, generate mist or

dew drop, or deform or damage resin parts.)

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into the window of the neighbor house. (Outdoor unit)

• Place where noise of the outdoor unit is easily transmitted.

(When install the outdoor unit on the boundary with the neighbor, pay due attention to the level of

noise.)

• Place with poor ventilation. (Before air ducting work, check whether value of air volume, static pressure

and duct resistance are correct.)

• Do not use the air conditioner for special purposes such as preserving food, precision instruments, or

art objects, or where breeding animals or growing plants are kept. (This may degrade the quality of

preserved materials.)

• Place where any of high-frequency appliances (including inverter devices, private power generators,

medical equipment, and communication equipment) and inverter-type fluorescent light is installed.

(A malfunction of the air conditioner, abnormal control, or problems due to noise to such appliances/

equipment may occur.)

• When the wireless remote controller is used in a room equipped with an inverter-type fluorescent light

or at a place exposed to direct sunlight, signals from the remote controller may not be received

correctly.

• Place where organic solvent is used.

• Place where special spray is used frequently.

EN

–4–

4-EN

Slim Duct Type

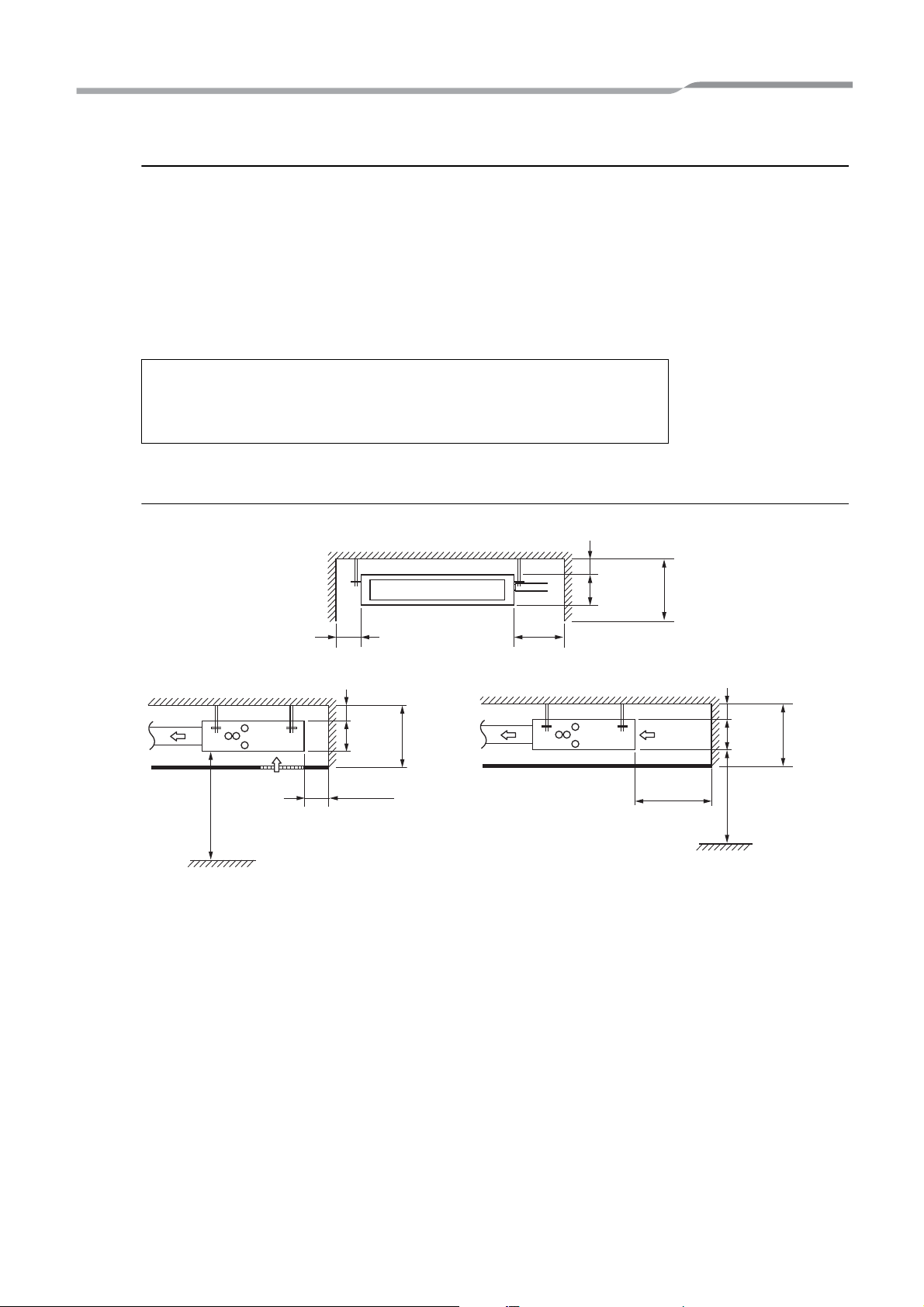

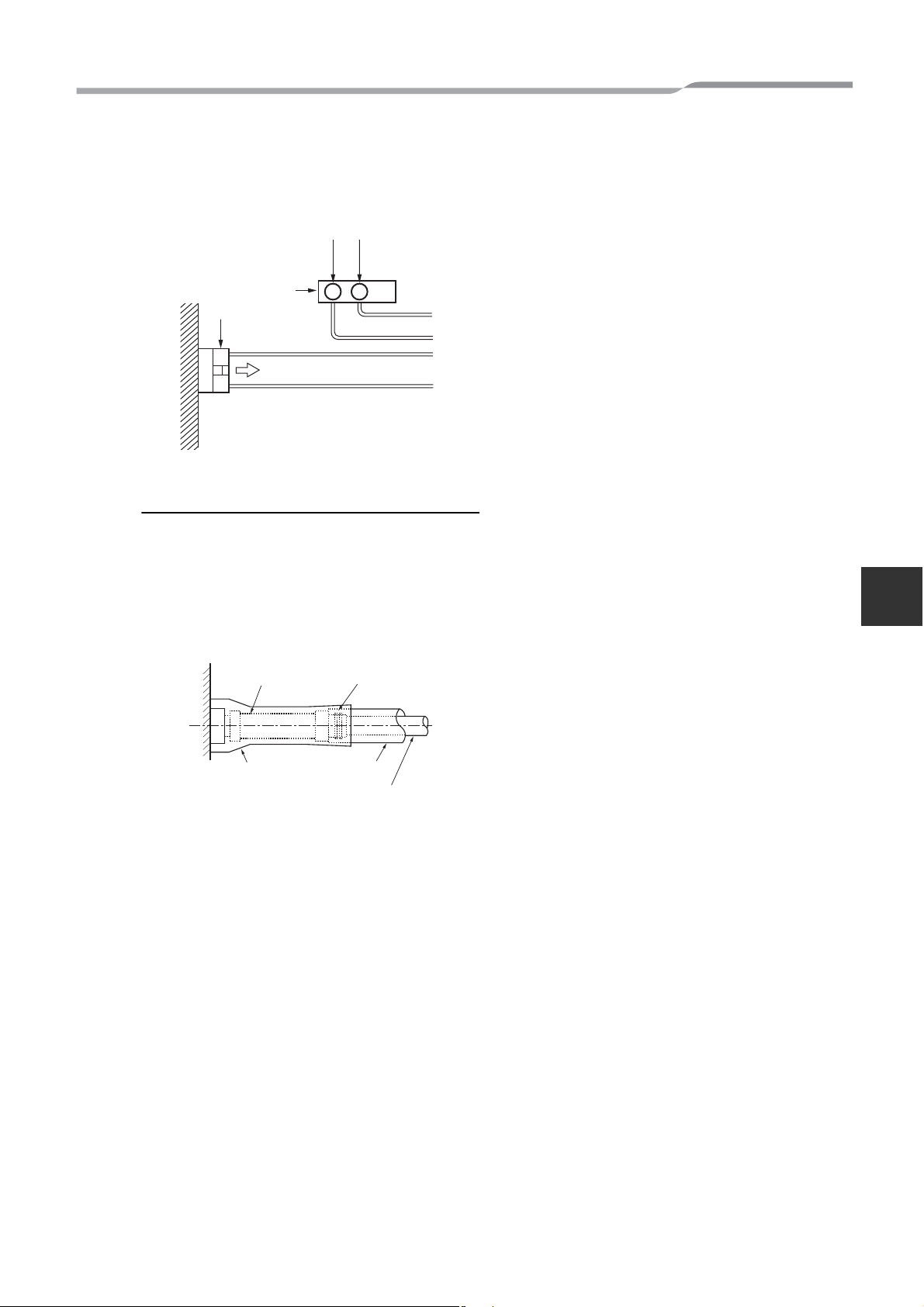

Installation under high-humidity atmosphere

In some cases including the rainy season, especially inside of the ceiling may become high-humidity

atmosphere (dew-point temperature: 23°C or higher).

1. Installation to inside of the ceiling with tiles on the roof

2. Installation to inside of the ceiling with slated roof

3. Installation to a place where inside of the ceiling is used for pathway to intake the fresh air

• In the above cases, additionally attach the heat insulator to all positions of the air conditioner, which

come to contact with the high-humidity atmosphere. In this case, arrange the side plate (Check port)

so that it is easily removed.

• Apply also a sufficient heat insulation to the duct and connecting part of the duct.

[Reference] Dewing test conditions

Installation space (Unit:mm)

Reserve space required for maintenance the indoor unit and service work.

Installation Manual

Indoor side: 27°C dry bulb temperature

24°C wet bulb temperature

Air volume: Low air volume, operation time 4 hours

Ceiling

<Under air Inlet>

Air outlet

2500 or more

Floor surface

100 or more

5 or more

210

50 or more

Air outlet

235

or more

Ceiling

250

or more

5 or more

210

<Back air Inlet>

Air outlet

300 or more

Floor surface

235 or more

5 or more

210

2500 or more

235

or more

5-EN

–5–

Slim Duct Type

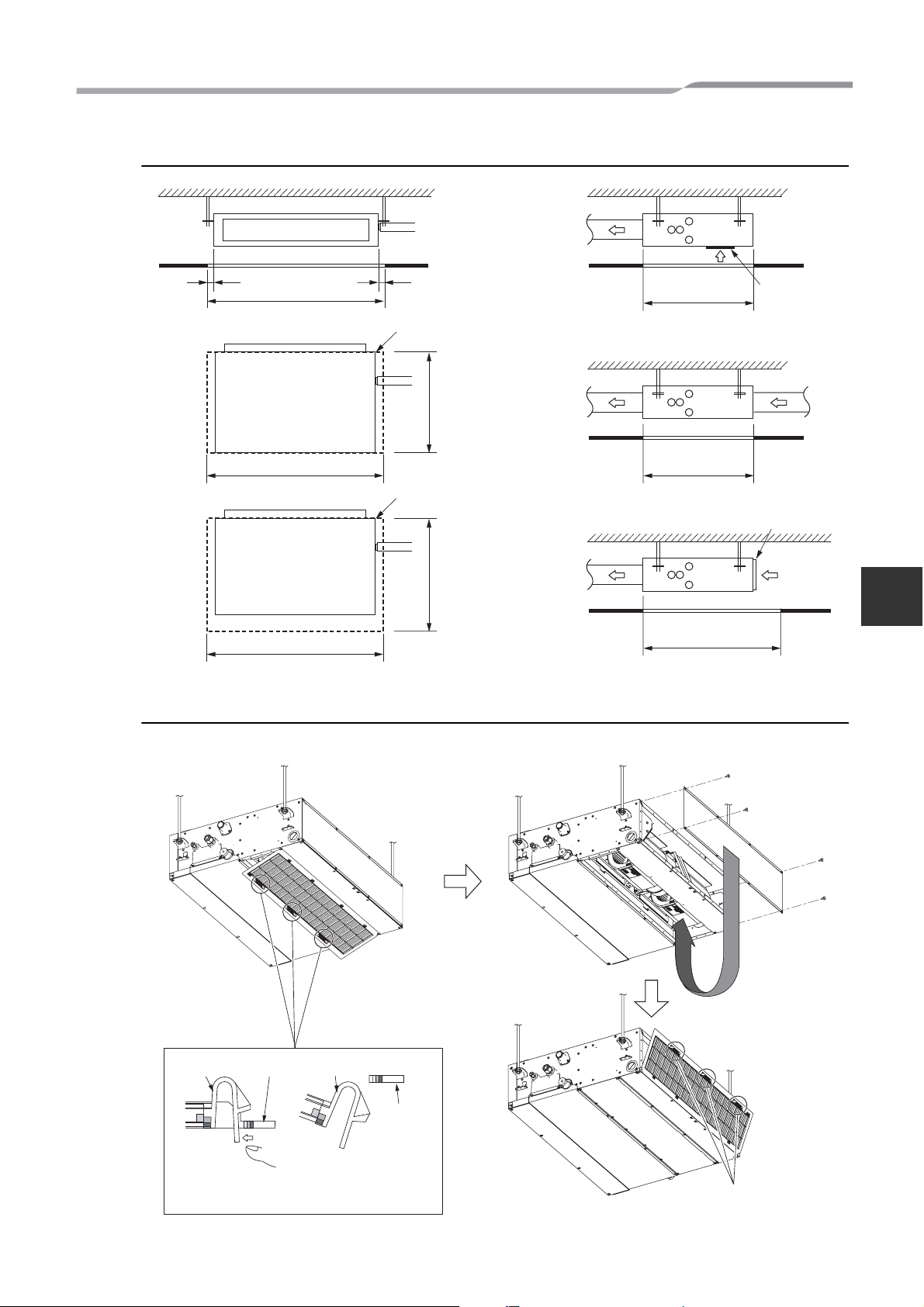

Service space (Unit:mm)

Installation Manual

Air outlet

Ceiling

Arranging the to back air inlet type

50

945

Service door (Ceiling opening)

945

Service door (Ceiling opening)

945

50

645

745

645

645

Air filter

Air filter

EN

745

Air filter

Remove the filter from the main unit while

pushing down on the tabs.

Main unit Air filter

Force

(after remover)

Main unit

<Back air inlet>

Remove the cover plate

and then fix it to the

bottom surface.

Do surely hooking

to the main unit.

–6–

6-EN

Slim Duct Type

Notification of filter cleaning term setup

The lighting term setup of the filter sign (Notification of filter cleaning) of the remote controller can be

changed according to the condition of installation.

For setup method, refer to “Change of lighting term of filter sign” and “To secure better effect of heating”

in the Applicable controls of this Manual.

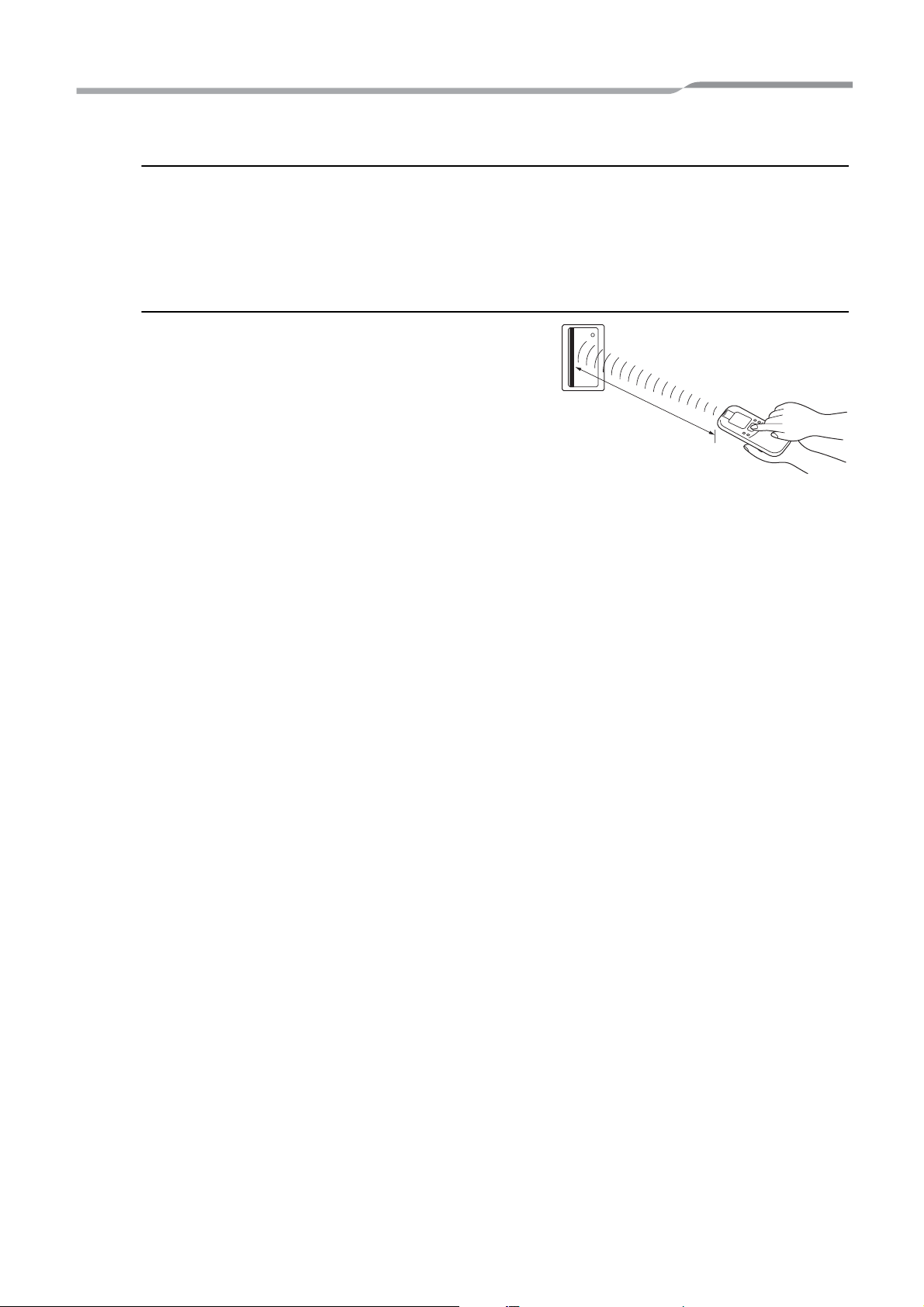

In case of wireless type

The sensor of indoor unit with wireless remote controller

can receive a signal 8m or less.

Based upon it, determine a place where the remote

controller is operated and the installation place of the

indoor unit.

• To prevent a malfunction, select a place where is not

influenced by a florescent light or direct sunlight.

• Two or more (Up to 6 units) indoor units with wireless

remote controller can be installed in the same room.

Installation Manual

8

m

o

r

l

e

s

s

7-EN

–7–

Slim Duct Type

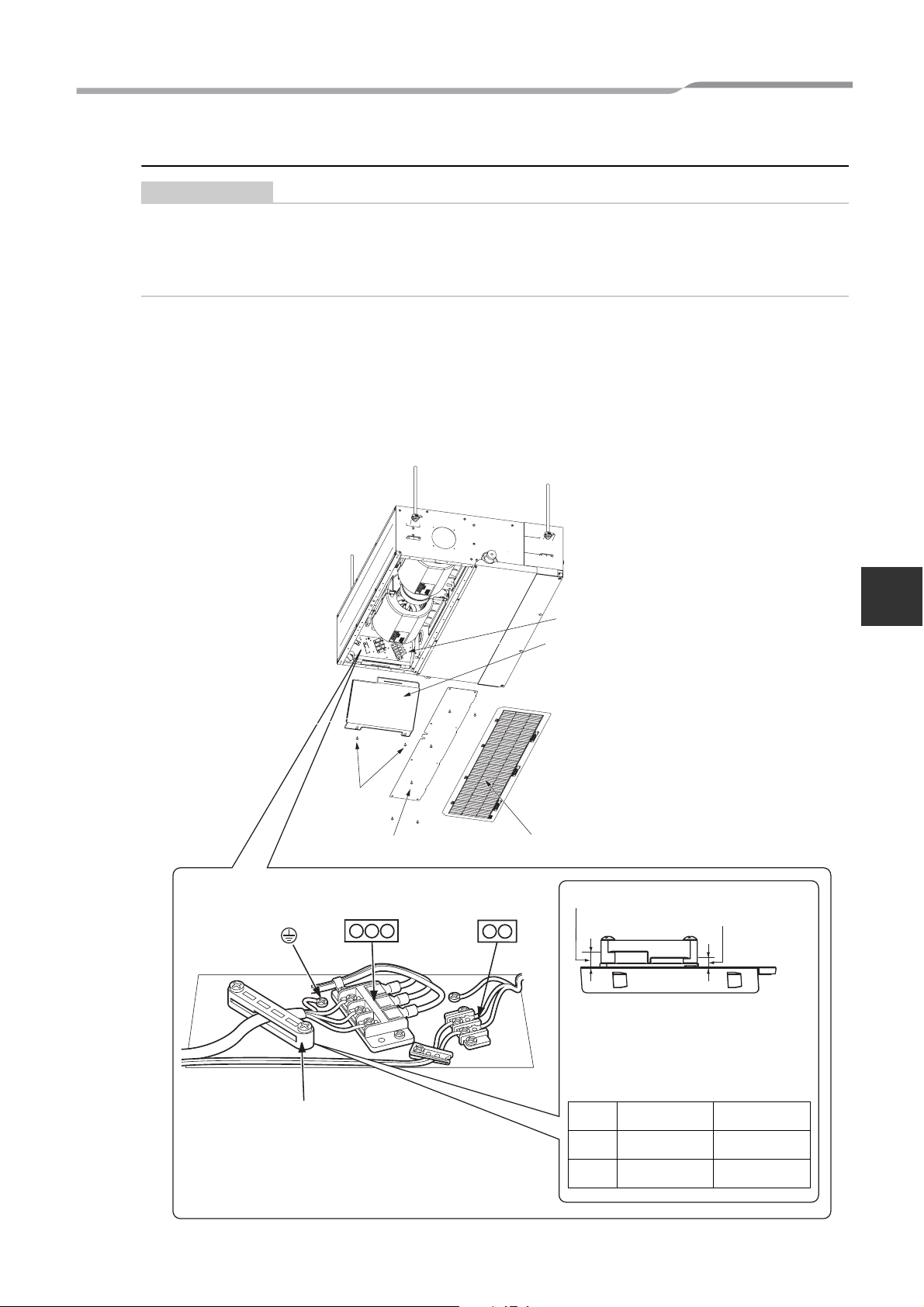

4 INSTALLATION

• Install the air conditioner certainly to sufficiently withstand the weight.

• If the strength is insufficient, the unit may fall down resulting in human injury.

• Perform a specified installation work to guard against strong wind or earthquake.

• An incomplete installation can cause accidents by the units falling and dropping.

REQUIREMENT

Strictly comply with the following rules to prevent damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit. (Even units are packaged)

• Carry in the indoor unit as it is packaged if possible. If carrying in the indoor unit unpacked by

necessity, be sure to use buffering cloth, etc. to not damage the unit.

• To move the indoor unit, hold the hooking metals (4 positions) only.

Do not apply force to the other parts (refrigerant pipe, drain pan, foamed parts, or resin parts, etc.).

• Carry the package by two or more persons, and do not bundle it with plastic band at positions other

than specified.

Installation Manual

WARNING

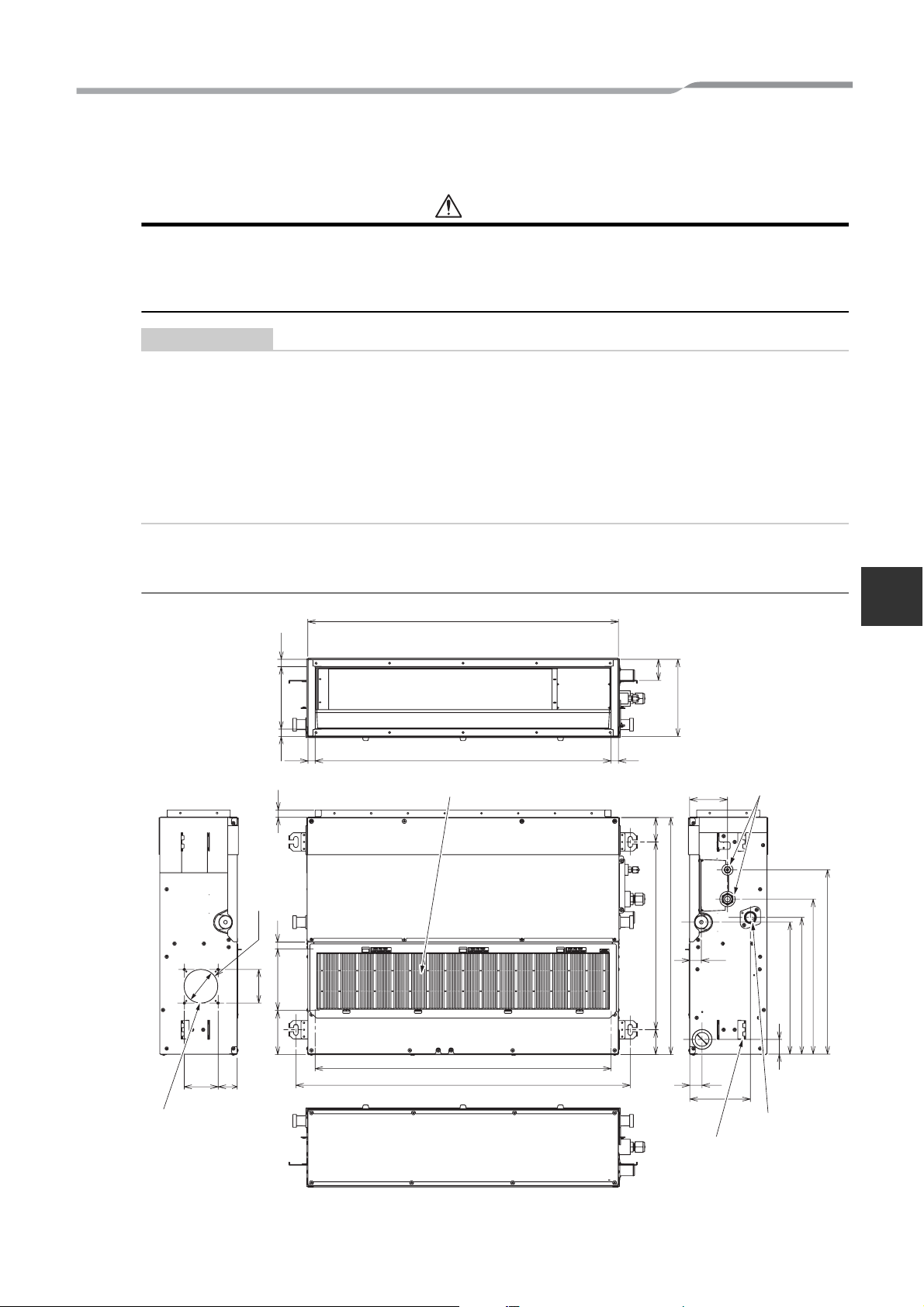

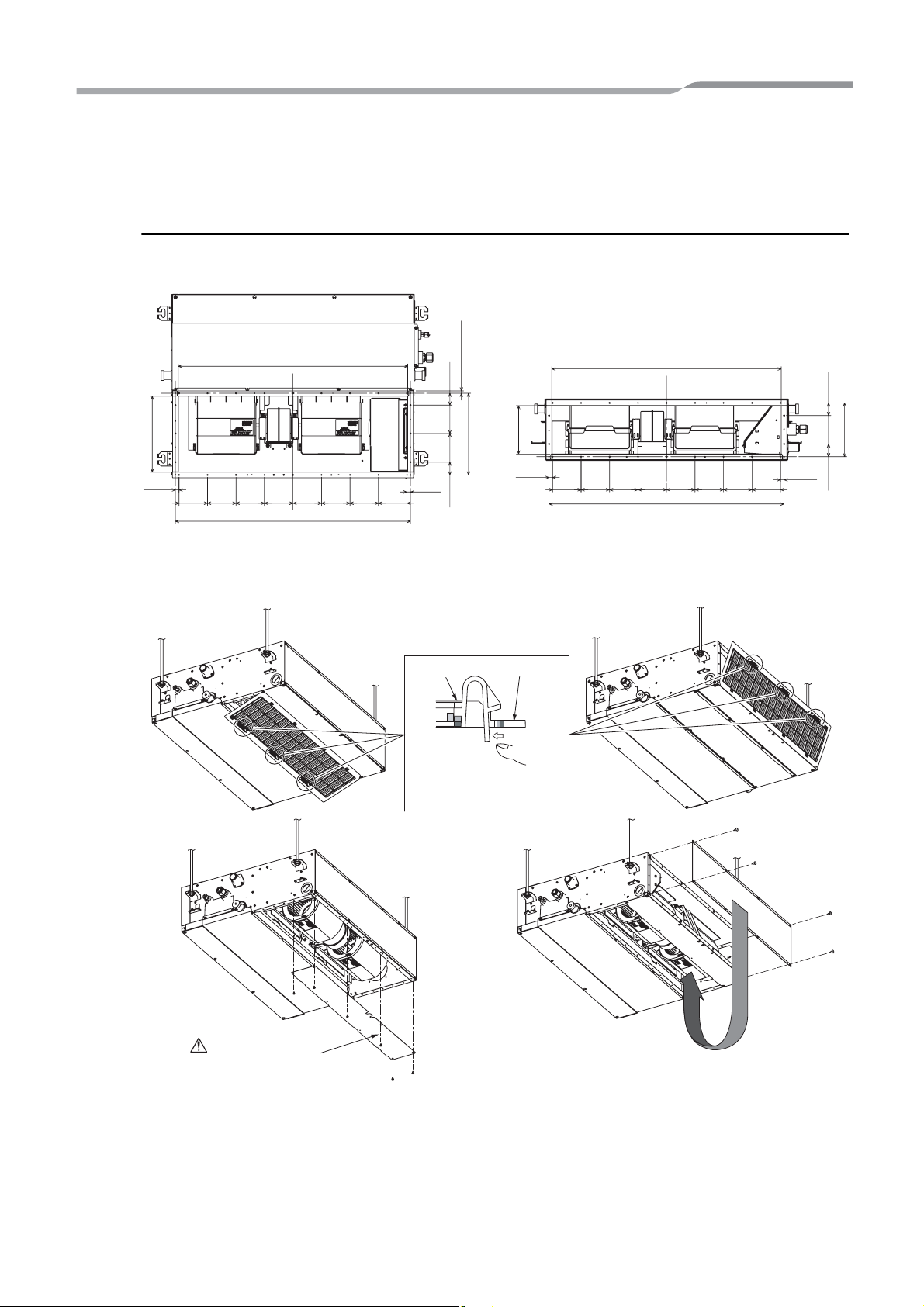

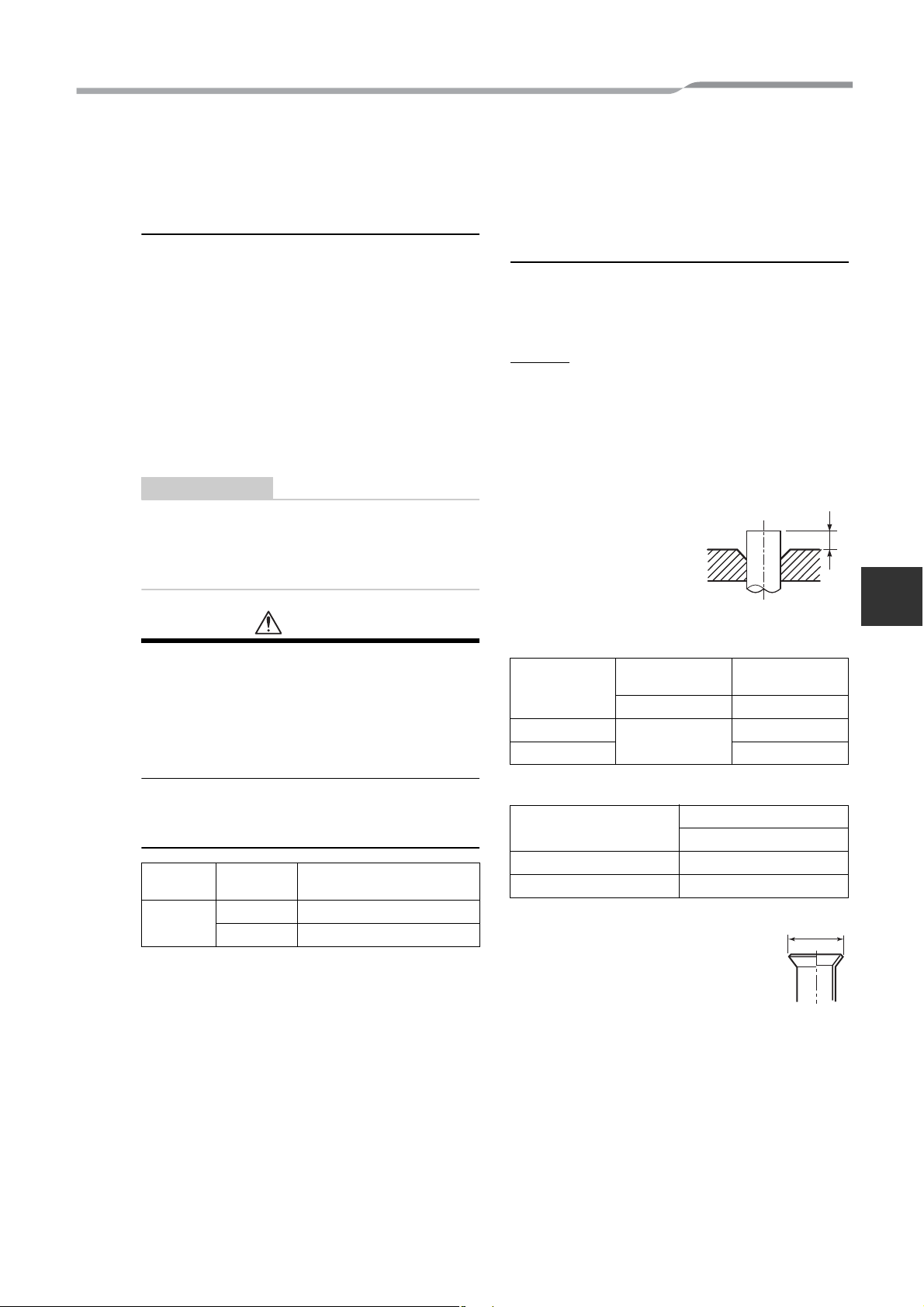

External view (Unit:mm)

845

21

57

Ø92

168

4-Ø4

80

(inside)

21

20

19

168

21

(inside)

803

Air filter

21

67

511

210

Refrigerant piping

103

645

31

359

372

422

EN

502

59

80

Fresh air inlet

(knock-out hole)

120

805

910

–8–

67

Hung-up plate

40

33

163

Drain-up port

8-EN

Slim Duct Type

Installation Manual

Opening hole on ceiling

and placing of hanging bolt

• Considering the indoor unit and the hanged-up

piping/wiring work, determine the installation

position and direction.

• After installation position of the indoor unit has

been determined, open a hole on the wiring and

place the hanging bolt.

• For opening size of the ceiling and the hanging

bolt pitch, see the external view.

• When the ceiling has already boarded, draw the

drain pipe, refrigerant pipe, inter-unit wire

between indoor and outdoor units, central

control system wire, and remote controller wire

up to the position where pipes and wires are

connected before hanged-up the indoor unit.

The hanging bolts and nuts will be procured

locally.

Hanging bolt M10 or W3/8 4 pieces

Nut M10 or W3/8 12 pieces

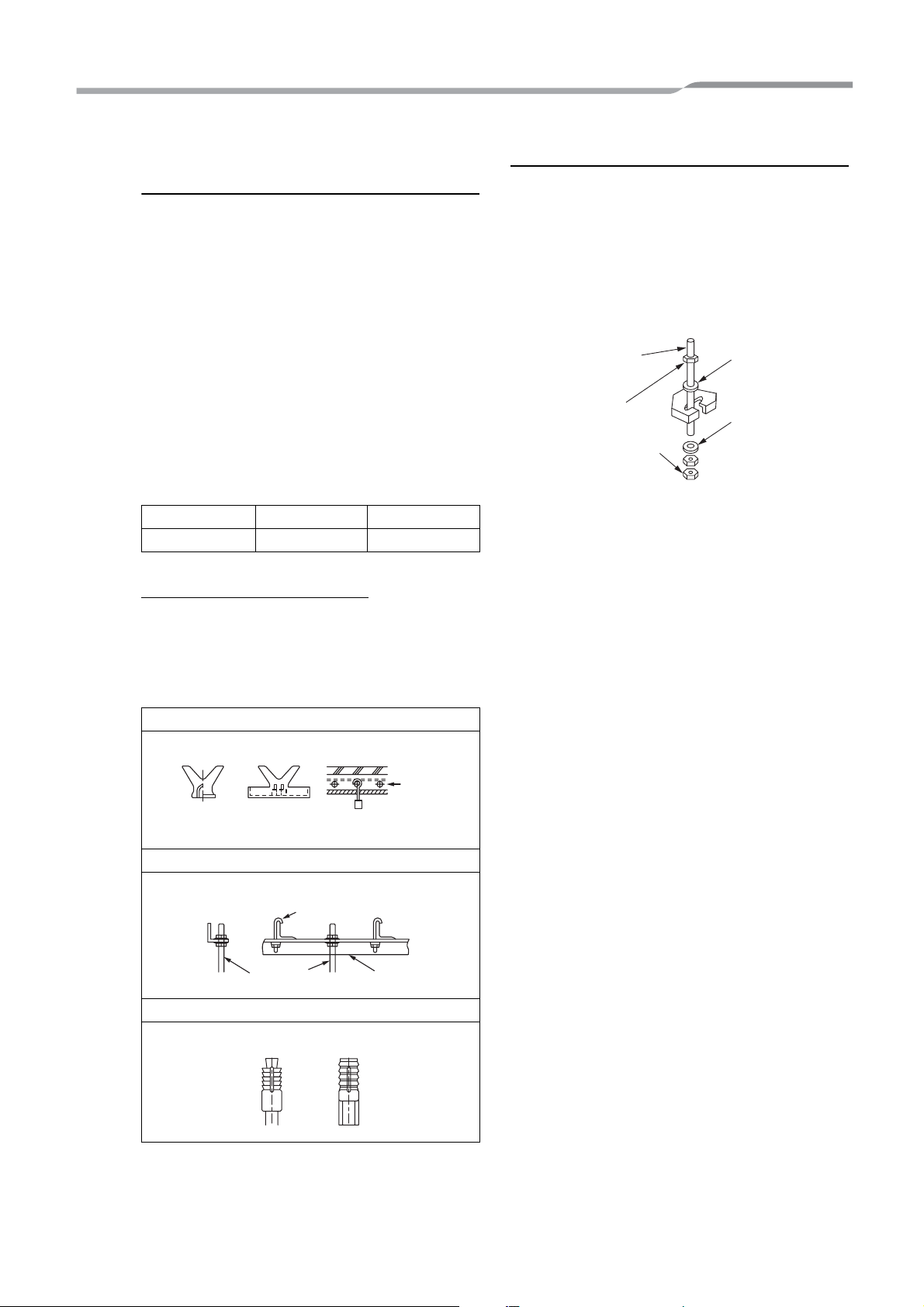

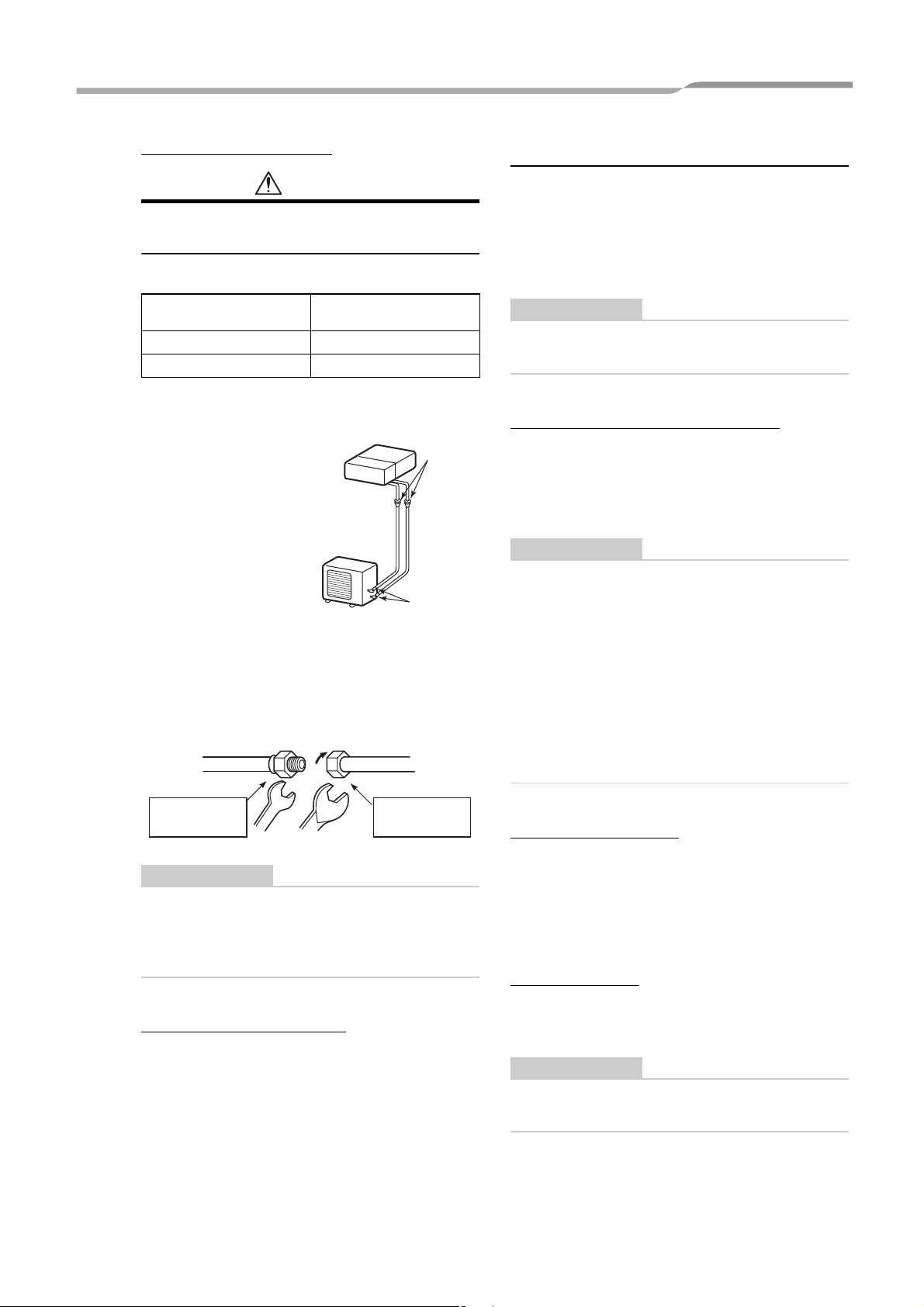

Installation of hanging bolt

Use M10 hanging bolts (4 pcs, to be local

procure).

Matching to the existing structure, set pitch

according to size in the unit external view as

shown below.

Installation of indoor unit

• Attach the nuts (M10 or W3/8: Procured locally)

and the attached washers (Ø34) to the hanging

bolt.

• Put washers at up and down of T-groove of the

hanging bracket of the indoor unit to hang down

the indoor unit.

• Using a level vial, check that four sides are

horizontal. (Horizontal degree: Within 5mm)

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Nut

(W3/8 or M10)

(1) Required those other than M10 flat washer at site.

(2) To prevent falling-off of bolt (safety), be sure to set it just

under the hanging bracket as shown in the figure.

(910mm × 511mm)

(1)

M10 flat washer

(Accessory)

(2)

M10 flat washer

(Accessory)

New concrete slab

Install the bolts with insert brackets or anchor bolts.

Rubber

(Blade type

bracket)

Use existing angles or install new support angles.

Use a hole-in anchors, hole-in plugs, or a hole-in bolts.

(Slide type

bracket)

Steel flame structure

Hanging bolt

Hanging bolt Support angle

Existing concrete slab

Anchor bolt

(Pipe hanging

anchor bolt)

9-EN

–9–

Slim Duct Type

5 DRAIN PIPING WORK

Installation Manual

CAUTION

• Following the Installation Manual, perform

the drain piping work so that water is

properly drained, and apply a heat insulation

so as not to cause a dew droping.

Inappropriate piping work may result in water

leakage in the room and wet of furniture.

Pipe material/Insulator and size

The following materials for piping work and

insulating process are procured locally.

Hard vinyl chloride pipe socket for

Pipe material

Insulator

Connection of flexible hose

• Insert the soft socket of the attached flexible

hose into the connecting port of the drain pipe

until it strikes against the end.

• Align the attached hose band to the end of the

pipe connecting port, and then tighten it surely.

VP25

Hard vinyl chloride pipe VP25

(Nominal outer diameter Ø32mm)

Foamed polyethylene foam,

thickness: 10mm or more

REQUIREMENT

• Be sure to perform heat insulation of the drain

pipes of the indoor unit.

• Never forget to perform heat insulation of the

connecting part with the indoor unit.

An incomplete heat insulation causes dew droping.

• Set the drain pipe with downward slope (1/100

or more), and do not make swelling or trap on

the piping. It may cause an abnormal sound.

Heat insulator

1.5m to 2m

1/100 or more

downward

Support

bracket

• For length of the traversing drain pipe, restrict

to 20m or less.

In case of a long pipe, provide support

brackets with interval of 1.5 to 2m in order to

prevent waving.

Arched

shape

NO

GOOD

Trap

• Set the collective piping as shown in the below

figure.

As long as possible (100mm or more)

VP25

VP25 VP25

EN

Top view

Side view

Air outlet

OK

max

45°

max

45°

NO GOOD

Side view

Air outlet

Riser (Trap)

Side view

Air outlet

90° Bend

REQUIREMENT

• Be sure to fix the soft socket with the attached

hose band and set the tightening position at

upper side.

• Use the attached flexible hose by bending it

with 45° or less so that no breakage or

clogging occurs.

VP30 or more

Downward slope

1/100 or more

• The hard vinyl-chloride pipe cannot be directly

connected to the drain pipe connecting port of

the indoor unit.

For connection with the drain pipe connecting

port, be sure to fix the attached flexible hose.

Drain pipe connecting port

(Hard socket)

Align the attached hose band to the

end of hose, set the tightening

position upward, and then tighten it.

Soft socket

Indoor unit

Adhesive agent prohibited

Hard socket

Ø25 vinyl chloride pipe

(Local supply)

Socket for VP25

(Local supply)

• Adhesive agent cannot be used for the pipe

connecting port (hard socket) of the indoor

unit.

Be sure to use the attached hose band for

fixing, otherwise damage or water leakage of

the drain pipe connecting port is caused.

–10–

10-EN

Slim Duct Type

Installation Manual

Connection of drain pipe

• Connect the hard socket (local supply) to the

hard socket side of the attached flexible hose

which has been installed.

• Connect the drain pipes (local supply)

successively to the connected the hard socket.

REQUIREMENT

• Using adhesive agent for vinyl chloride,

connect the hard vinyl chloride pipes certainly

so that water does not leak.

• It requires several times to dry and harden the

adhesive agent.

(Refer to Guide Manual of the adhesive agent.)

In this time, be sure not to apply force to the

connecting section with the drain pipes.

Drain up

When a downward grading cannot be secured on

the drain pipe, a drain-up work is possible.

• Set the height of the drain pipe within 850mm

from the bottom surface of the indoor unit.

• Draw out the drain pipe within 300mm from the

end of the drain pipe connecting port of the

indoor unit, and then raise it vertically.

• After the drain pipe has been raised, set a

grading so that it is immediately bent

downward.

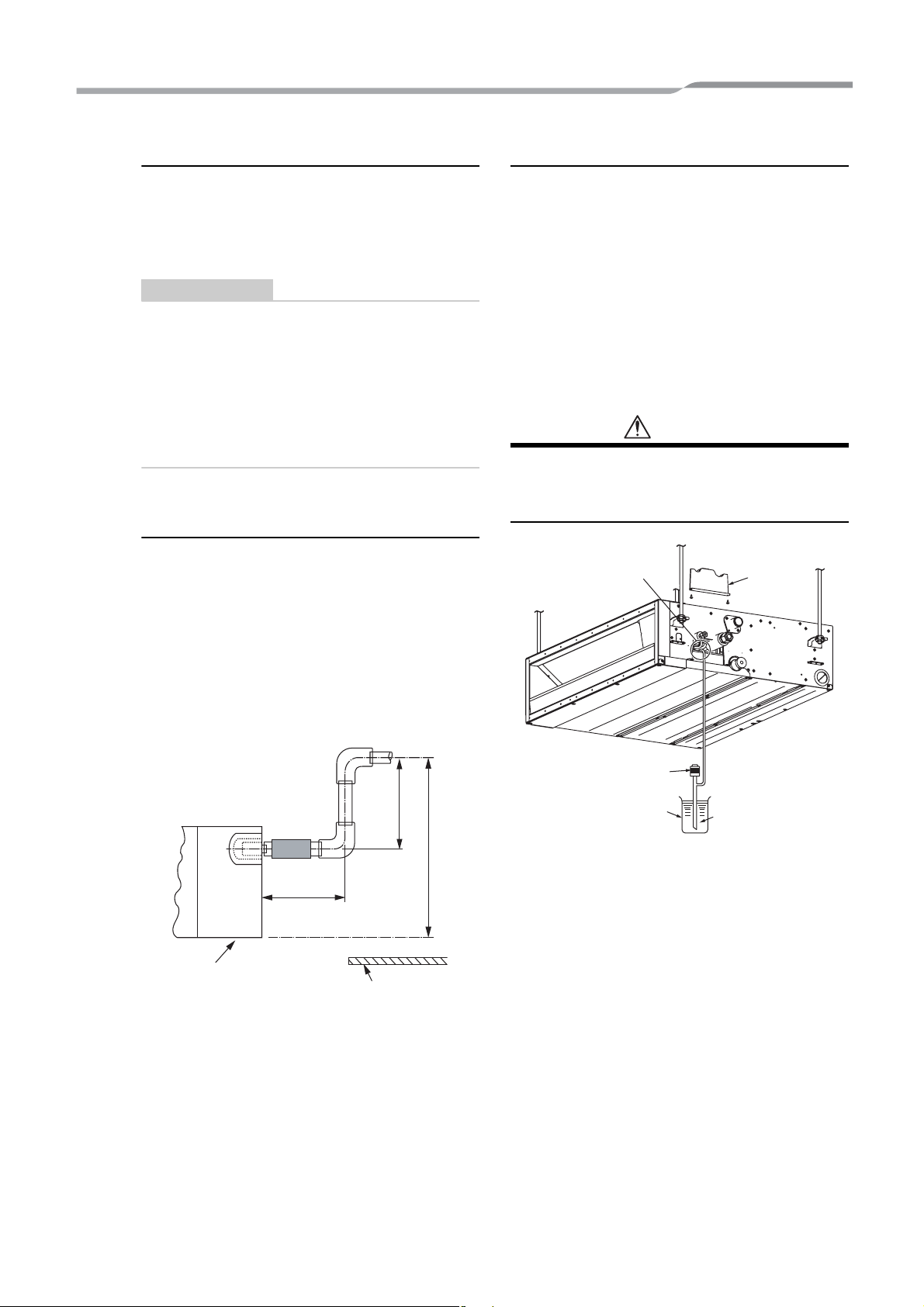

Check the draining

After drain piping work, check that water drain is

properly performed and water does not leak from

the connecting part of the pipes. In this time,

check also there is no abnormal sound of the

motor of the drain pump. Be sure to check draining

when installed in the heating period.

When the electric work has finished:

• Pour water as shown in the following figure,

check water is drained from the drain pipe

connecting port in COOL mode, and then check

there is no water leak from the drain pipes.

CAUTION

Pour water slowly.

If it is poured urgently, water is spread inside of

the indoor unit resulted in a trouble.

Insert the edge of hose

into the drain pan and

bend it downward.

Cover

plate

Indoor unit

300mm

or less

Rising up

687mm or less

Rising up 850mm or less

Underneath of ceiling

Pump

Vessel

• If the electric work has not yet finished, pull out

the float switch connector (CN34 : Red) from the

electric parts box, and check draining by

plugging the single phase 220–240V power to

the terminal blocks ➀ and ➁.

If doing so, the drain pump motor operates.

• Test water drain while checking the operation

sound of the drain pump motor.

(If the operation sound changes from

continuous sound to intermittent sound, water is

normally drained.)

Water

(1500cc~2000cc)

11-EN

–11–

Slim Duct Type

• After the check, the drain pump motor runs,

connecting the float switch connector.

(In case of check by pulling out the float switch

connector, be sure to return the connector to the

original position.)

Heat insulating process

CN34

(RED)

Power

terminals

Black

Pull out connector CN34 (Red)

from P.C. board.

Black

1 2

Installation Manual

Single phase

220–240V

White

Red

• After drain check, using the attached heat

insulator for drain connecting section, wrap the

flexible hose without clearance from the end of

the drain pipe connecting port of the indoor unit.

• Covering the attached heat insulator for drain

connecting section, wrap the drain pipe with

heat insulator (local supply) without clearance.

Flexible hose

Attached heat insulator

Heat insulator to be

procured locally

Hose band

Hard vinyl chloride pipe

EN

–12–

12-EN

Slim Duct Type

6 AIR DUCTING

Arrangement

Referring to the following dimensions, manufacture duct at the local site.

<Under air inlet> <Back air inlet>

Installation Manual

266

12.5

805

100100100

100100

825

100

100 100

12.5

45.3 41.5100100

or less

8.2

286.8

170

12.5

805

12.5

100

100100

100100

100 100 100

825

44.3 100 44.3

Be sure to mount an air filter to the air inlet side; otherwise decrease of capacity and etc. may be caused.

<Under air inlet> <Back air inlet>

Air filter Main unit

Force

Remove the filter from the

main unit while pushing

down on the tabs.

188

13-EN

CAUTION

Take out this cover plate.

Remove the cover plate and

then fix it to the bottom surface.

–13–

Slim Duct Type

Connecting method of the duct

Duct:Insulation material

(Local supply)

Heat insulator with sticking material (100mm-width Local supply)

Aluminum tape (Local supply)

Flange

Connect a duct to the

inside of the flange

Installation Manual

Flange (Local supply)

Aluminum tape (Local supply)

Air outlet side

Aluminum tape

(Local supply)

Indoor unit

Cover a screw

Air inlet side

Aluminum tape (Local supply)

Under surface

Heat insulator with sticking material (100mm-width Local supply)

CAUTION

Incomplete heat insulation of the supply air flange and sealing may occur dewing resulted in falling of

water drop.

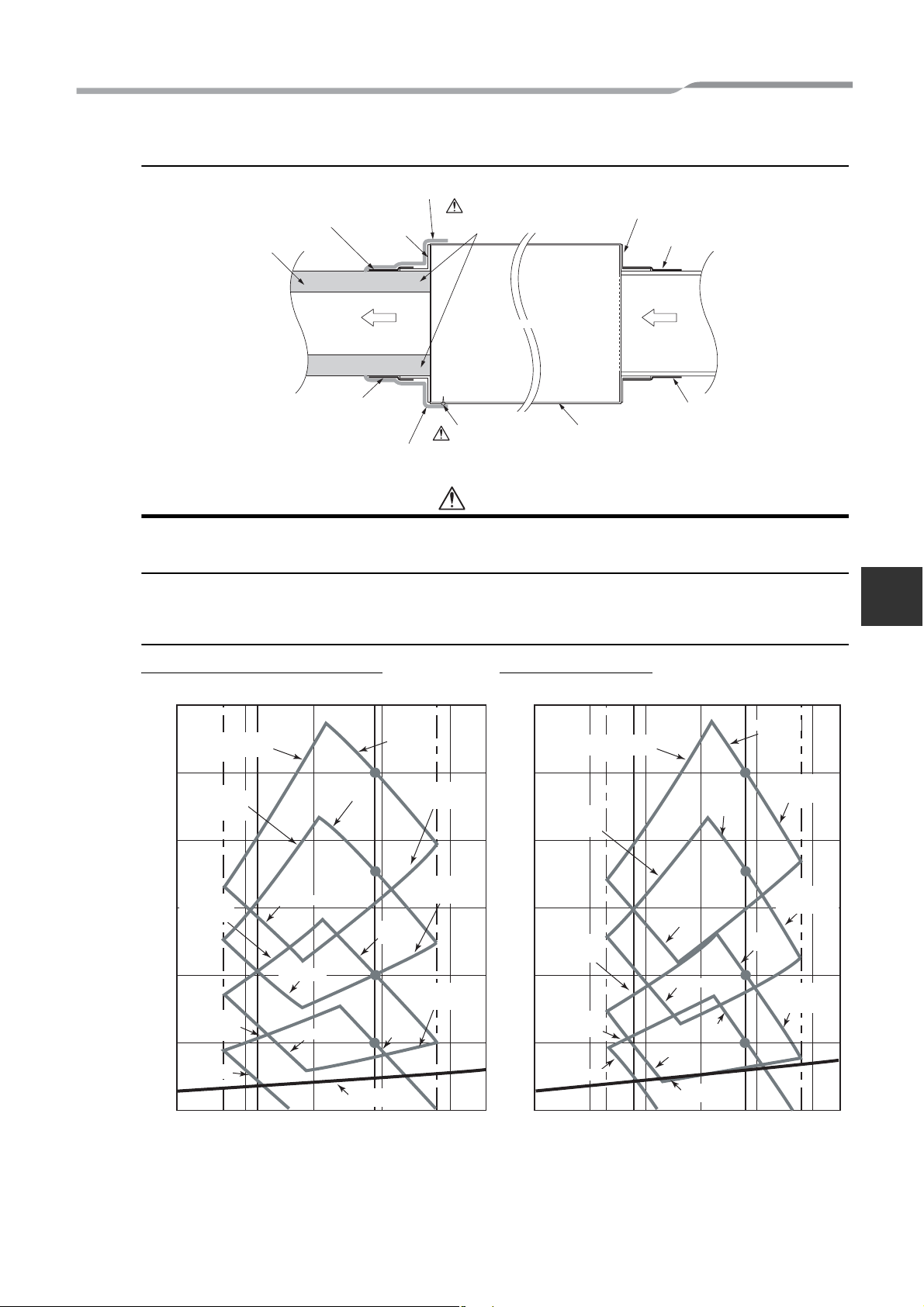

Static presure characteristics

RAV-SM404SDT-E/454SDT-E RAV-SM564SDT-E

60

Upper limit of external

static pressure (50Pa)

50

Upper limit of

external static

pressure (35Pa)

40

Standard air volume : 690 m³/h

High (50Pa)

High

(35Pa)

Lower limit of

external static

pressure (50Pa)

60

50

Upper limit of

external static

pressure (35Pa)

40

Upper limit of external

static pressure (50Pa)

Standard air volume : 780 m³/h

High (50Pa)

Lower limit of

external static

High

(35Pa)

pressure (50Pa)

EN

30

20

External static pressure (Pa)

10

0

400

Upper limit of

external static

pressure

(20Pa)

Upper limit of

external static

pressure (10Pa)

Low (10Pa)

Lower limit of

external static

High

(20Pa)

High

(10Pa)

pressure (35Pa)

Lower limit of

external static

pressure (20Pa)

Low (50Pa)

Low (35Pa)

Low (20Pa)

Standard filter

pressure loss

500 600 700 800

Air volume (m³/h)

–14–

30

20

External static pressure (Pa)

10

0

400

Low (50Pa)

Upper limit of

external static

pressure (20Pa)

Upper limit of

external static

pressure (10Pa)

Low (20Pa)

Low (10Pa)

500 600 700 900800

Air volume (m³/h)

Low (35Pa)

Standard filter

pressure loss

High

(10Pa)

Lower limit of

external static

pressure (35Pa)

High

(20Pa)

Lower limit of

external static

pressure (20Pa)

14-EN

Slim Duct Type

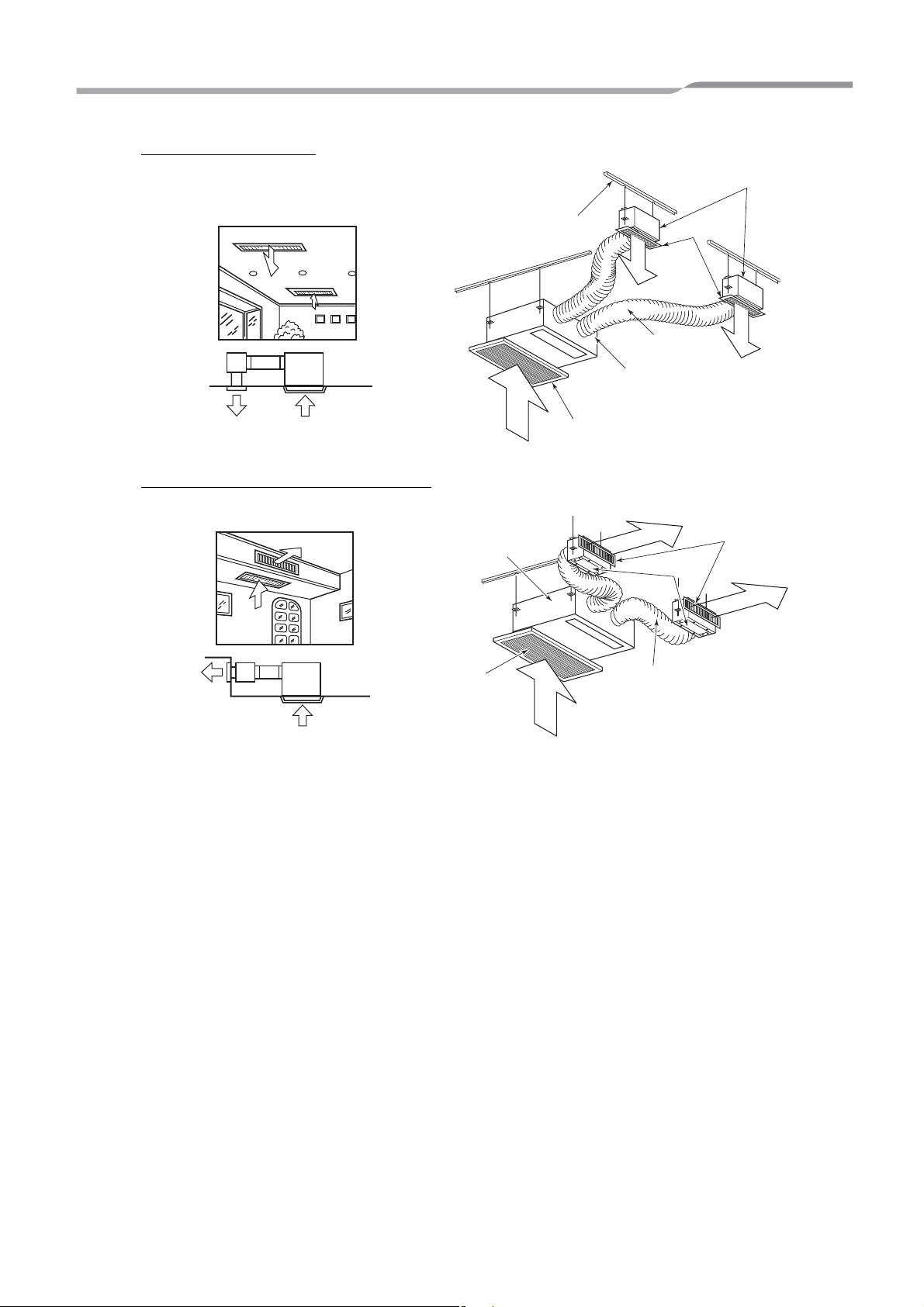

Concealed duct type

Installation Manual

Supply chamber

Ledge ceiling concealed duct type

Returning

Indoor unit

Return air grille

Returning

Channel

Return air grille

Supply grille

Supplying

200mm (diam.)

round duct

Indoor unit

Supplying

Supply

chamber

200mm (diam.)

round duct

Supplying

Supply grille

Supplying

15-EN

–15–

Slim Duct Type

Installation Manual

7 REFRIGERANT PIPING AND EVACUATING

Refrigerant Piping

1. If the outdoor units are to be mounted on a wall,

make sure that the supporting platform is

sufficiently strong. The platform should be

designed and manufactured to maintain its

strength over a long period of time, and

sufficient consideration should be given to

ensuring that the outdoor unit will not fall.

2.

Use copper pipe with 0.8 mm or more thickness.

3. Flare nut and flare works are also different from

those of the conventional refrigerant.

Take out the flare nut attached to the main unit

of the air conditioner, and use it.

REQUIREMENT

When the refrigerant pipe is long, provide support

brackets at intervals of 2.5 to 3m to clamp the

refrigerant pipe. Otherwise, abnormal sound may

be generated.

CAUTION

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of the

connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

Permissible Piping Length

and Height Difference

They vary according to the outdoor unit.

For details, refer to the Installation Manual

attached to the outdoor unit.

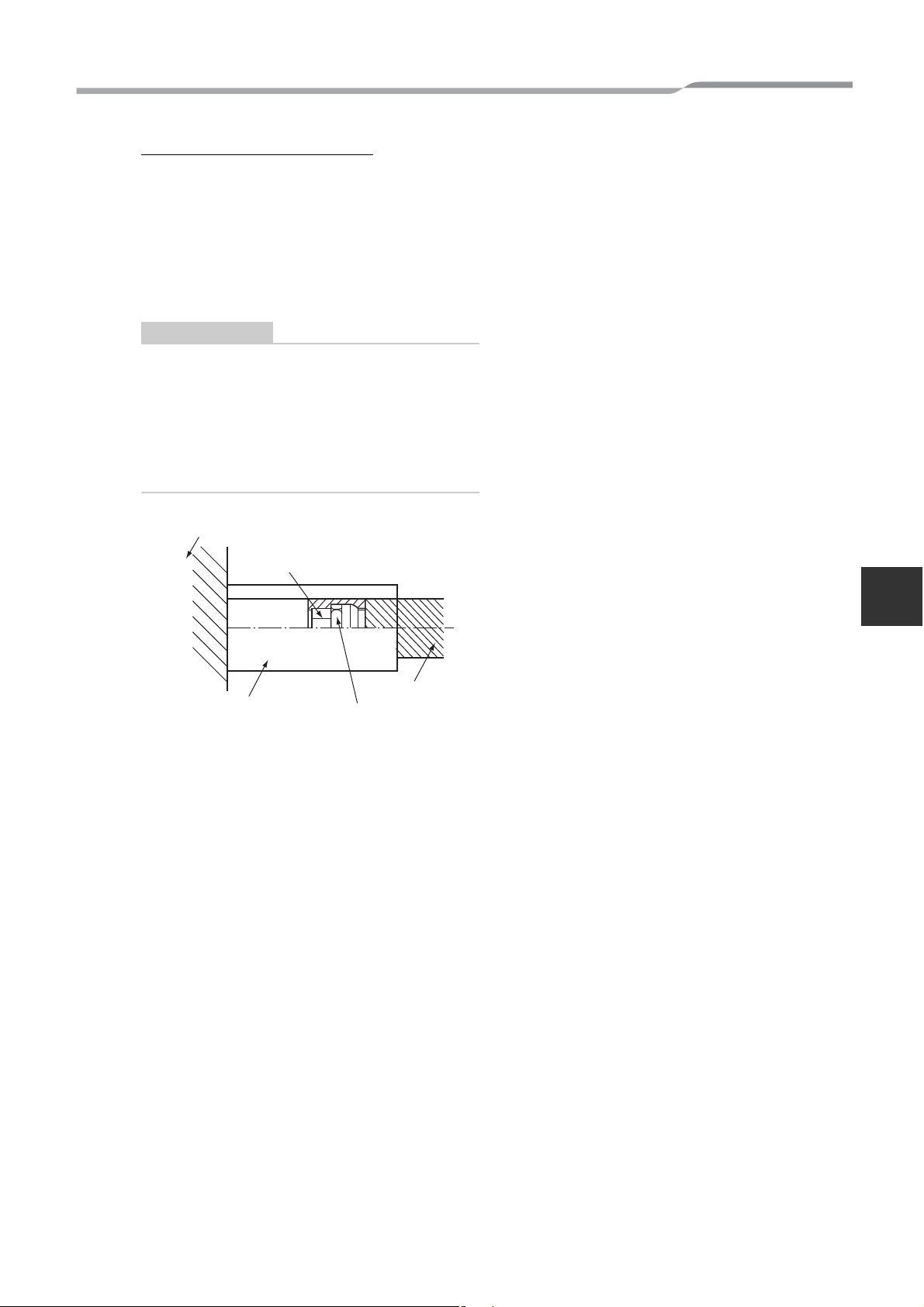

Flaring

• Cut the pipe with a pipe cutter.

Remove burrs completely.

Remaining burrs may cause gas leakage.

• Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those

of refrigerant R22, the flare tools newly

manufactured for R410A are recommended.

However, the

conventional tools can be

used by adjusting

projection margin of the

copper pipe.

▼ Projection margin in flaring : B (Unit : mm)

Rigid (Clutch type)

Outer diam. of

copper pipe

6.4

12.7 2.0 to 2.5

R410A tool

used

R410A R410A

0 to 0.5

Conventional

tool used

1.5 to 2.0

B

EN

Pipe size

Model

name

Pipe size

RAV- SM404, 454, 564 type

Gas side 12.7 mm

Liquid side 6.4 mm

▼ Flaring diam. meter size : A (Unit : mm)

+0

A

Outer diam. of copper

pipe

6.4 9.1

12.7 16.6

* In case of flaring for R410A with the

conventional flare tool, pull it out

approx.

0.5 mm more than that for R22 to

adjust to the specified flare size.

The copper pipe gauge is useful for

adjusting projection margin size.

–0.4

R410A

A

–16–

16-EN

Slim Duct Type

Installation Manual

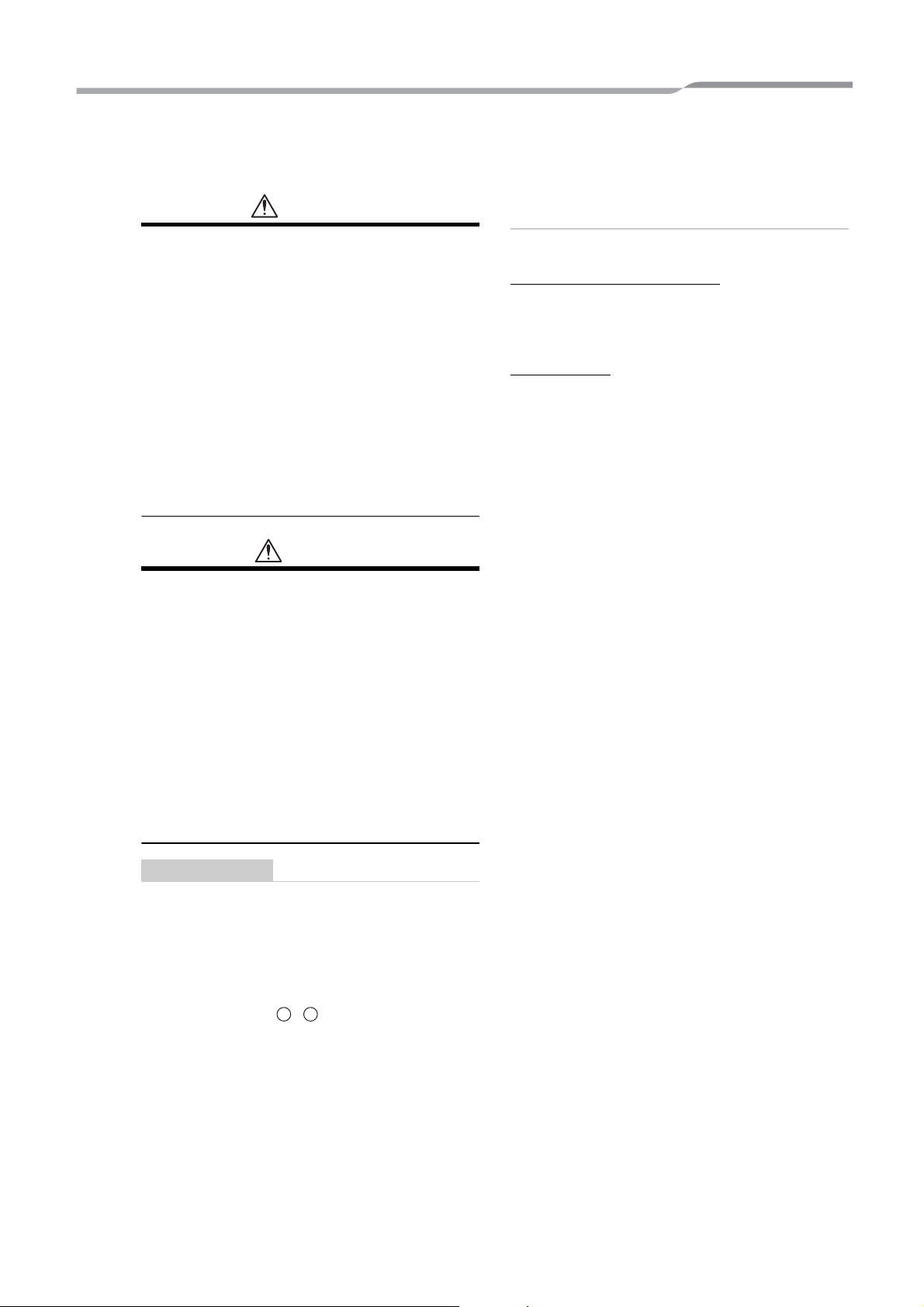

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

(Unit : N•m)

Outer diam. of copper

▼

Tightening torque of flare pipe connections

pipe

6.4 mm (diam.) 14 to 18 (1.4 to 1.8 kgf•m)

12.7 mm (diam.) 50 to 62 (5.0 to 6.2 kgf•m)

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times)

Therefore, using a

torque wrench, tighten

the flare pipe connecting

sections which connect

the indoor and outdoor

units of the specified

tightening torque.

Incorrect connections

may cause not only a

gas leak, but also a

trouble of the refrigeration cycle.

Align the centers of the connecting pipes and

tighten the flare nut as far as possible with your

fingers. Then tighten the nut with a spanner and

torque wrench as shown in the figure.

Half union Flare nut

Tightening torque

Flare at

indoor

unit side

Flare at

outdoor

unit side

Air purge

Using a vacuum pump, perform vacuuming from

the charge port of valve of the outdoor unit.

For details, follow to the Installation Manual

attached to the outdoor unit.

• Never use the refrigerant sealed in the outdoor

unit for air purge.

REQUIREMENT

For the tools such as charge hose, etc., use those

manufactured exclusively for R410A.

Refrigerant amount to be added

For addition of the refrigerant, add refrigerant

“R410A” referring to the attached Installation

Manual of outdoor unit.

Be sure to use a scale to charge the refrigerant of

specified amount.

REQUIREMENT

• Charging an excessive or too little amount of

refrigerant causes a trouble of the compressor.

Be sure to charge the refrigerant of specified

amount.

• A personnel who charged the refrigerant

should write down the pipe length and the

added refrigerant amount in the nameplate

attached to the service panel of the outdoor

unit. It is necessary to troubleshoot the

compressor and refrigeration cycle

malfunction.

Externally

threaded side

Use a wrench to secure. Use a torque wrench to tighten.

Internally

threaded side

REQUIREMENT

Tightening with an excessive torque may crack

the nut depending on installation conditions.

Tighten the nut within the specified tightening

torque.

Piping with outdoor unit

• Shape of valve differs according to the outdoor

unit.

For details of installation, refer to the Installation

Manual of the outdoor unit.

Open the valve fully

Open the valve of the outdoor unit fully. A 4mmhexagonal wrench is required for opening the

valve.

For details, refer to the Installation Manual

attached to the outdoor unit.

Gas leak check

Check with a leak detector or soap water whether

gas leaks or not, from the pipe connecting section

or cap of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for

HFC refrigerant (R410A, R134a, etc.).

17-EN

–17–

Slim Duct Type

Thermal insulation process

Apply thermal insulation for the pipes separately

at liquid side and gas side.

For the thermal insulation to the pipes at gas side,

be sure to use the material with heat-resisting

temperature 120°C or higher.

Using the attached thermal insulation material,

apply the thermal insulation to the pipe connecting

section of the indoor unit securely without gap.

REQUIREMENT

• Apply the thermal insulation to the pipe

connecting section of the indoor unit securely

up to the root without exposure of the pipe.

(The pipe exposed to the outside causes water

leak.)

• Wrap heat insulator with its slits facing up

(ceiling side).

Installation Manual

Indoor unit

Heat insulation pipe

(Accessory)

Union

Flare nut

EN

Heat

insulator of

the pipe

–18–

18-EN

Slim Duct Type

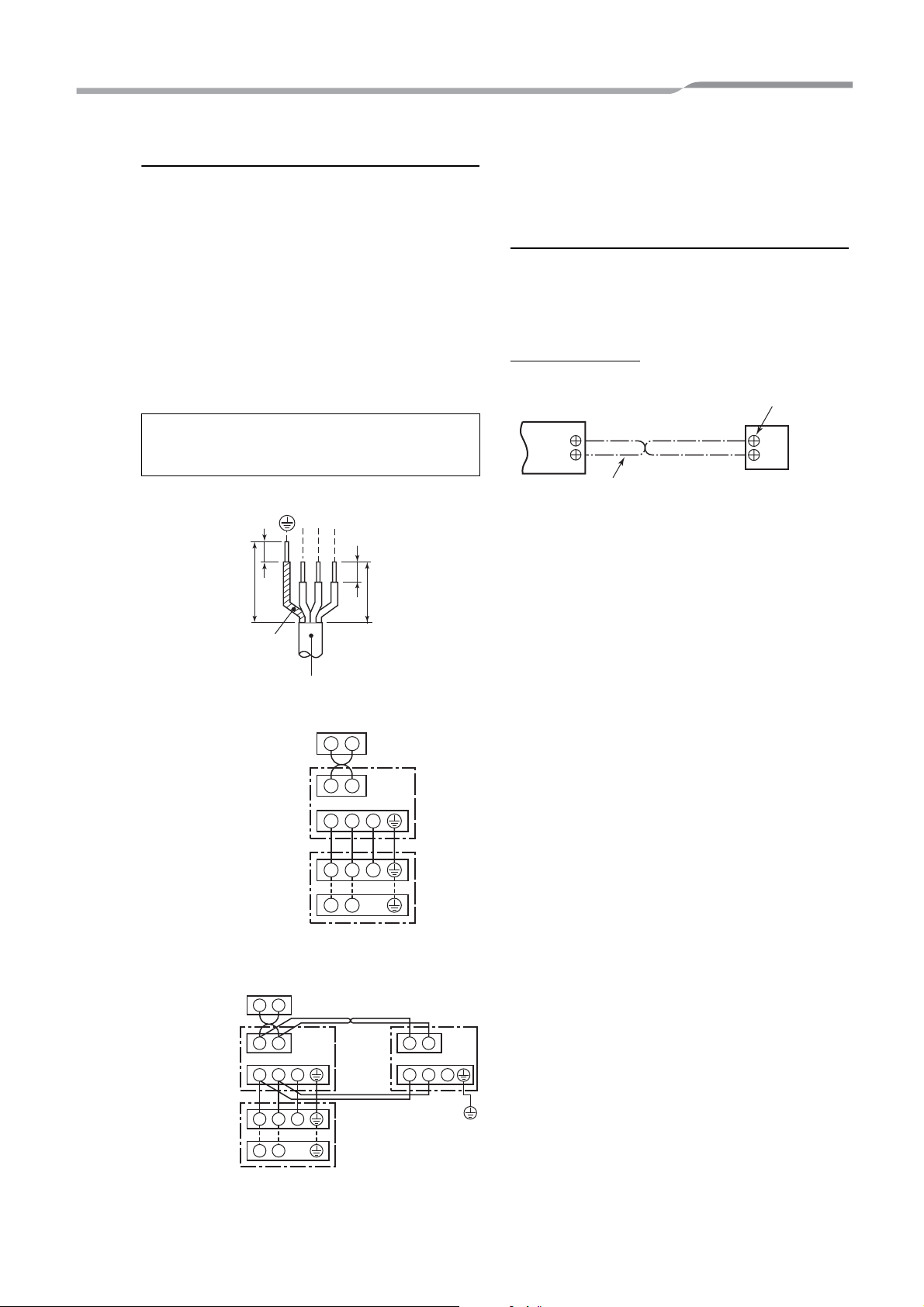

8 ELECTRICAL WORK

WARNING

1. Using the specified wires, ensure to connect

the wires, and fix wires securely so that the

external tension to the wires do not affect the

connecting part of the terminals.

Incomplete connection or fixation may cause a

fire, etc.

2. Be sure to connect earth wire. (grounding

work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for

telephone wires.

3. Appliance shall be installed in accordance

with national wiring regulations.

Capacity shortage of power circuit or incomplete

installation may cause an electric shock or a fire.

Installation Manual

• Do not turn on the power of the indoor unit until

vacuuming of the refrigerant pipes completes.

Remote controller wiring

2-core non polarity wire is used for the remote

controller wiring.

How to wire

1. Connect the connecting wire to the terminal as

identified with their respective numbers on the

terminal block of indoor and outdoor unit.

H07 RN-F or 60245 IEC 66 (1.5 mm

2. Insulate the unsheathed redundant cords

(conductors) with electrical insulation tape.

Process them so that they do not touch any

electrical or metal parts.

2

or more)

CAUTION

• This indoor unit has no power cord.

• If incorrect/incomplete wiring is carried out, it will

cause an electrical fire or smoke.

• Be sure to install an earth leakage breaker that is

not tripped by shock waves.

If an earth leakage breaker is not installed, an

electric shock may be caused.

• Be sure to use the cord clamps attached to the

product.

• Do not damage or scratch the conductive core

and inner insulator of power and inter-connecting

wires when peeling them.

• Use the power cord and Inter-connecting wire of

specified thickness, type, and protective devices

required.

REQUIREMENT

• For power supply wiring, strictly conform to the

Local Regulation in each country.

• For wiring of power supply of the outdoor units,

follow the Installation Manual of each outdoor

unit.

• Never connect 220–240V power to the

terminal blocks ( , , etc.) for control wiring.

(Otherwise, the system will fail.)

• Perform the electric wiring so that it does not

come to contact with the high-temperature part

of the pipe.

The coating may melt resulting in an accident.

• After connecting wires to the terminal blocks,

provide a trap and fix wires with the cord

clamp.

• Run the refrigerant piping line and control

wiring line in the same line.

A B

19-EN

–19–

Slim Duct Type

Wire connection

REQUIREMENT

• Be sure to connect the wires matching the terminal numbers. Incorrect connection causes a trouble.

• Be sure to pass the wires through the bushing of wiring connection port of the indoor unit.

• Keep a margin (Approx. 100mm) on a wire to hang down the electric parts box at servicing, etc.

• The low-voltage circuit is provided for the remote controller. (Do not connect the high-voltage circuit)

• Before remove the electric parts cover, remove the cover plate and air filter.

• Remove the cover of the electric parts box by taking off the mounting screws (2 positions) and pushing

the hooking section. (The cover of the electric parts box remains hanged to the hinge.)

• Tighten the screws of the terminal block, and fix the wires with cord attached to the electric parts box.

(Do not apply tension to the connecting section of the terminal block.)

• Be sure to set a loop for the connecting wire of the storing part of the indoor unit electric parts;

otherwise the electric parts box cannot be drawn out in service time.

• Mount the cover of the electric parts box without pinching wires.

Installation Manual

Earth

Cord clamp

Screw

(2 positions)

Cover plate

Power supply

terminal block

1

23

Air filter

Remote controller

terminal block

B

A

Electric parts box

Electric parts box cover

Side D (Space: 8.5mm)

Side C (Space: 4mm)

Select side C or D for the power cable

clamping position referring to the following

table according to the cable type and

diameter.

* Cable clamp can be attached on either

right or left side.

When twin system are connected, clamp two

cables with one cable clamp.

Wire

type

Cabtyre

cable

Cabtyre

cable

Specification

4-core stranded

wire 2.5mm²

4-core stranded

wire 1.5mm²

Cable clamping

position

Side D

Side C

EN

–20–

20-EN

Slim Duct Type

Installation Manual

Wiring

1. Remove a screw and then remove cover of the

electric parts box.

2. Strip wire ends (10 mm).

3. Match wire colors with terminal numbers on

indoor and outdoor units’ terminal blocks and

firmly screw wires to the corresponding

terminals.

4. Connect the ground wires to the corresponding

terminals.

5. Fix the wire with cord clamp.

6. Fix cover of the parts box and the terminal block

surely with the fixing screws.

Make a loop on the wire for margin of the length

so that the electric parts box can be taken out

during servicing.

N

L

3

10

70

2

1

10

50

* For details of wiring/installation of the remote

controller, refer to the Installation Manual

enclosed to in the remote controller.

Remote Controller Wiring

• Strip off approx. 9mm the wire to be connected.

• Non polarity, 2 core wire is used for wiring of the

remote controller. (0.5mm² to 2.0mm² wires)

Wiring diagram

Terminal block for

remote controller

wiring of indoor unit

A

B

Remote controller wire

(Procured locally)

Terminal block

Remote

A

controller

B

unit

Earth line

Connecting wire

▼ Single system

Remote controller

Remote controller

wiring

Indoor side

Indoor/Outdoor

connecting wires

Outdoor side

A B

1

1

L N

220-240V~

▼ Synchronous twin system

Remote controller

Remote controller

wiring

Indoor side

Indoor/Outdoor

connecting wires

Outdoor side

A B

1

223

1

3

L N

220-240V~

223

3

Remote controller

inter-unit wiring

Indoor

side

Indoor power

inter-unit wiring

A B

1 2 3

21-EN

–21–

Slim Duct Type

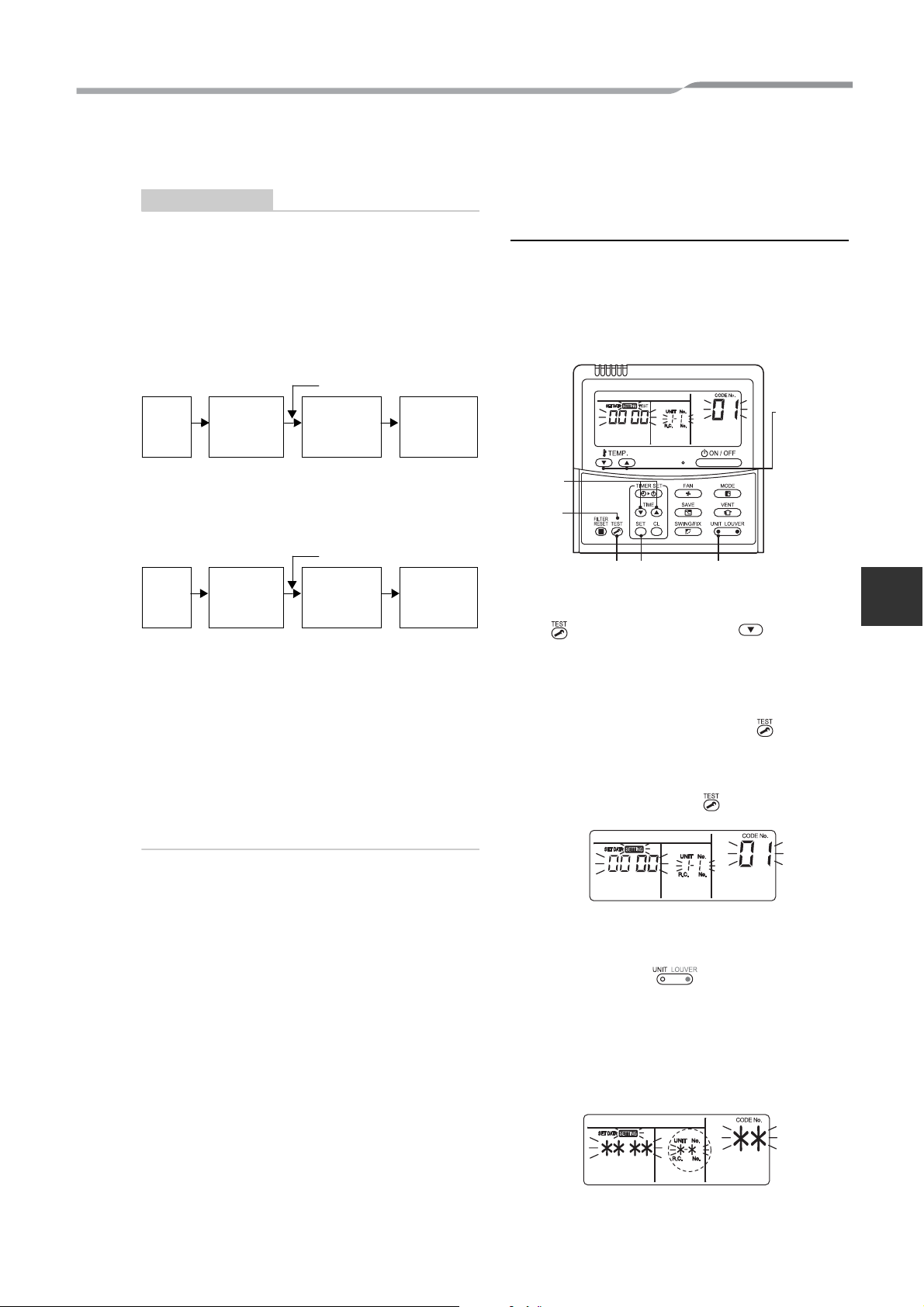

9 APPLICABLE CONTROLS

Changing of settings of for

REQUIREMENT

• When you use this air conditioner for the first

time, it takes approx. 5 minutes until the

remote controller becomes available after

power-on. This is normal.

<When power is turned on for the first time

after installation>

It takes approx. 5 minutes until the remote

controller becomes available.

Approx. 5 minutes

Power

on

“SETTING”

flashes

“SETTING”

goes out

Remote

controller

is available

applicable controls

Basic procedure for changing settings

Change the settings while the air conditioner is not

working.

(Be sure to stop the air conditioner before making

settings.)

Installation Manual

1

3

<When power is turned on for the second

(or later) time>

It takes approx. 1 minute until the remote

controller becomes available.

Approx. 1 minutes

Power

on

• Normal settings were made when the indoor

unit was shipped from factory.

Change the indoor unit settings as required.

• Use the wired remote controller to change the

settings.

* The settings cannot be changed using the

“SETTING”

flashes

wireless remote controller, sub remote

controller, or remote-controllerless system

(for central remote controller only).

Therefore, install the wired remote controller

to change the settings.

“SETTING”

goes out

Remote

controller

is available

4

6

5

1

Procedure 1

Push button and temp. setup button

simultaneously for at least 4 seconds.

After a while, the display flashes as shown in the

figure.

Confirm that the CODE No. is [01].

• If the CODE No. is not [01], push button to

erase the display content, and repeat the

procedure from the beginning.

(No operation of the remote controller is

accepted for a while after button is pushed.)

(* Display content varies with

the indoor unit model.)

2

EN

–22–

Procedure 2

Each time you push button, indoor unit

numbers in the control group change cyclically.

Select the indoor unit you want to change settings

for.

The fan of the selected unit runs. You can confirm

the indoor unit for which you want to change

settings.

22-EN

Slim Duct Type

Installation Manual

Procedure 3

Using temp. setup / buttons, specify

CODE No. [ ].

Procedure 4

Using timer time / buttons, select

SET DATA [ ].

Procedure 5

Push button. When the display changes from

flashing to lit, the setup is completed.

• To change settings of another indoor unit,

repeat from Procedure

• To change other settings of the selected indoor

unit, repeat from Procedure

Use button to clear the settings.

To make settings after button was pushed,

repeat from Procedure

2.

3.

2.

Procedure 6

When settings have been completed, push

button to determine the settings.

When button is pushed, “SETTING” flashes

and then the display content disappears and the

air conditioner enters the normal stop mode.

(While “SETTING” is flashing, no operation of the

remote controller is accepted.)

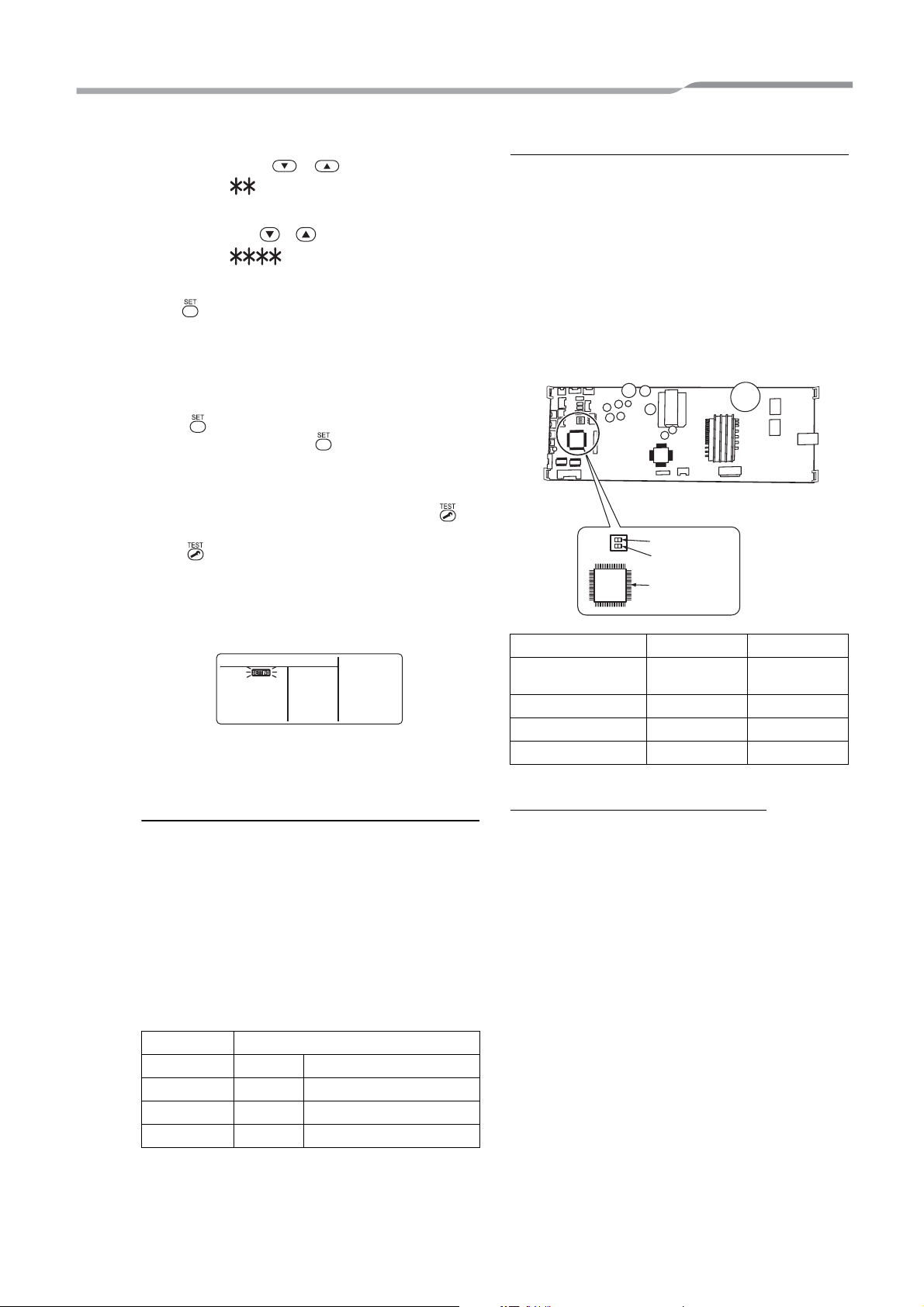

When wireless remote controller is used

Change the external static pressure setting with

the DIP switch on the receiver section P.C. board.

For details, refer to the manual of the wireless

remote controller kit. The settings can also be

changed with the switch on the indoor

microcomputer P.C. board.

* However, once the setting is changed, setting to

0001 or 0006 is possible but setting to 0000

requires a setting data change to 0000 using the

wired remote controller (separately sold) with

the normal switch setting (factory setting).

SW501-1

SW501-2

MCU(IC501)

Setup data SW501-1 SW501-2

0000

(Factory shipping)

0001 ON OFF

0003 OFF ON

0006 ON ON

OFF OFF

Setup of external static

pressure

Be sure to set up a tap change based upon the

resistance (external static pressure) of the duct to

be connected.

To set up a tap change, follow to the basic

operation procedure (

• Specify [5d] to the item code in procedure

• For the setup data of procedure

setup data of the external static pressure to be

set up from the following table.

<Change on wired remote controller>

Setup data External static pressure

0000 10 Pa Standard (At shipment)

0001 20 Pa High static pressure 1

0003 35 Pa High static pressure 2

0006 50 Pa High static pressure 3

1 o 2 o 3 o 4 o 5 o 6 ).

3.

4, select a

To restore the factory settings

To return the DIP switch settings to the factory

settings, set SW501-1 and SW501-2 to OFF,

connect a separately sold wired remote controller,

and then set the data of CODE No. [5d] to “0000”

in “Setup of external static pressure” on this page.

23-EN

–23–

Loading...

Loading...