Toshiba RAV-SM2242DT-E, RAV-SM2804AT8-E, RAV-SM2802DT-E, RAV-SM2244AT8-E SERVICE MANUAL

E10-351

High Static Duct 8, 10HP

— Digital Inverter —

Indoor Unit

RAV-SM2242DT-E

RAV-SM2802DT-E

RAV-SM2242DT-TR

RAV-SM2802DT-TR

Outdoor Unit

Engineering

Data Book

RAV-SM2244AT8-E

RAV-SM2804AT8-E

Engineering Data

Contents

1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Refrigerating Cycle Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Sensible Capacity Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Part Load Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 Sound Characteristics (NC Curve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Fan Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

EN 1

Engineering Data

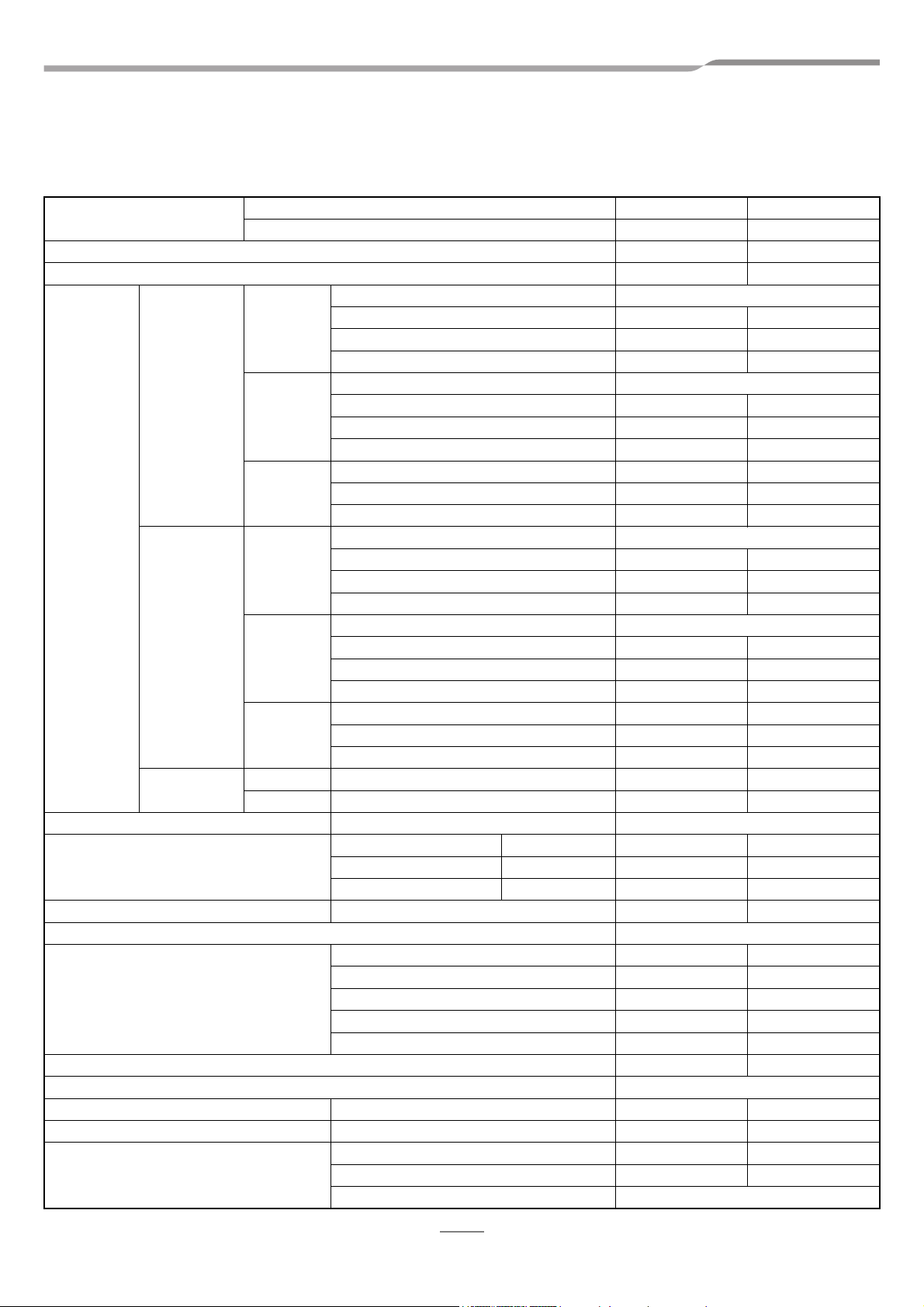

1 Specifications

1-1. Indoor Unit (Concealed Duct High Static Pressure Type)

Model

Cooling capacity (min.-max.) (kW) 20.0 (9.8-22.4) 23.0 (9.8-27.0)

Heating capacity (min.-max.) (kW) 22.4 (9.8-25.0) 27.0 (9.8-31.5)

Cooling

Electrical

characteristics

Heating

Maximum current

Appearance Main unit Zinc hot dipping steel plate

Outer dimension

Total weight Main unit (kg) 160 160

Heat exchanger Finned tube

Fan unit

Air filter None (Local procure) None (Local procure)

Controller (Sold Separately) RBC-AMT32E, AS21E2

Sound pressure level H/M/L (dB•A) 54 55

Sound power level H/M/L (dB•A) 74 75

Connecting pipe

Indoor unit RAV-SM2242DT-E RAV-SM2802DT-E

Outdoor unit RAV-SM2244AT8-E RAV-SM2804AT8-E

Power supply (V) 50Hz / 1ph / 220-240V

Indoor unit

Outdoor unit

To ta l

Indoor unit

Outdoor unit

To ta l

Indoor unit (A) 15.0 15.0

Outdoor unit (A) 18.0 20.0

Running current (A) 5.25-4.81 5.25-4.81

Power consumption (kW) 1.12 1.12

Power factor (%) 97 97

Power supply (V) 50Hz / 3N~ / 380-415V

Running current (A) 9.83-9.00 12.33-11.29

Power consumption (kW) 6.08 7.63

Power factor (%) 94 94

Power consumption (kW) 7.20 (3.26-9.09) 8.75 (3.36-12.76)

EER 2.78 2.63

Energy efficiency class * D D

Power supply (V) 50Hz / 1ph / 220-240V

Running current (A) 5.25-4.81 5.25-4.81

Power consumption (kW) 1.12 1.12

Power factor (%) 97 97

Power supply (V) 50Hz / 3N~ / 380-415V

Running current (A) 8.68-7.95 11.36-10.40

Power consumption (kW) 5.37 7.03

Power factor (%) 94 94

Power consumption (kW) 6.49 (2.57-7.45) 8.15 (2.57-11.01)

COP 3.45 3.31

Energy efficiency class * B C

Main unit Height (mm) 470 470

Width (mm) 1380 1380

Depth (mm) 1250 1250

Fan Centrifugal fan Centrifugal fan

Standard air flow at 137Pa/ (at Mid tap) (m3/h) 3600 4200

Fan Speed 1 1

Motor (W) 370×3 370×3

External static pressure (H/M/L) (Pa) 196/137/68.6 196/137/68.6

Gas side (mm) 28.6 28.6

Liquid side (mm) 12.7 12.7

Drain port (mm) 32 (VP25)

2 EN

Engineering Data

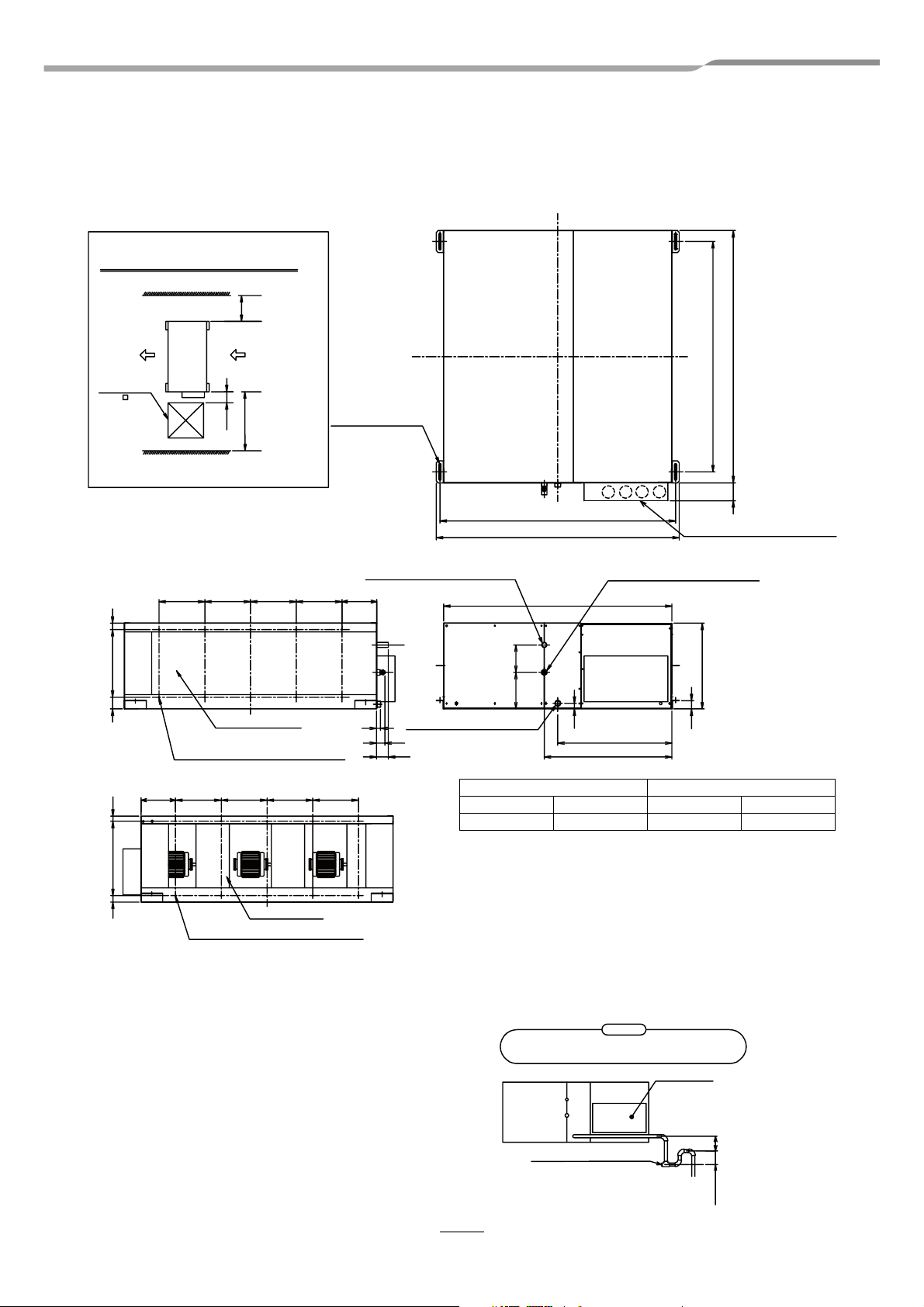

2 Dimension

RAV-SM2242DT-E, RAV-SM2802DT-E / RAV-SM2242DT-TR, RAV-SM2802DT-TR

(Unit:mm)

Space required for installation and serving

Service space

Service space

or more

200

Check port

600

Service space

or more

200

1000

Hole for hanging bolt

(4-12 × 92)

(Hanging bolt mounting pitch)

1260

1380100

37065

35 406 29

25035250

Screw hole for duct mounting (10-M6)

250

190

Screw hole for duct mounting (10-M6)

250

Air discharge port

250 250

250

Air suction port

250

Refrigerant pipe connecting port

*

(Gas side Brazed)

190

Drain pipe connecting port (V25)

22

Taper screw for R1,25.4 pipes

46

65

Diameter of pipe connecting port Diameter of connecting pipe

*

The diameter of connecting gas side on the indoor unit is 22.2, and therefore

please use the accessory joint for installation.

<Installation Notice>

1. Be sure to set a check port at the right of air discharge port.

2. Set to slope the drain piping downward at 1/100 and be sure to set a drain trap

on its way as shown below figure.

3. Please avoid the installation on the place where oil disperses or is shrouded by

oil smoke, such as kitchen or mechanical factory.

4. Indoor unit does not have air filter its inside. So be sure to set an air filter (local

arrangements) in the position maintained easily such as a suction grills. (If there

is no air filter, dusts are blocked in the air heat exchanger and it may cause

failure or water leak in air-conditioner.)

5. Please hang the main unit horizontally.

(Hanging bolt mounting pitch)

1288

150200

1328

1250

Refrigerant pipe connecting port

*

(Liquid side Ø12.7 Flared)

31

624

698

Electric parts box

Power supply/communication piping

port (Ø26) (Under electric parts box)

470

45

Liquid side Gas side Liquid side Gas side

Ø12.7 Ø22.2 Ø12.7 Ø28.6

Be sure to set the plug and to make it to be able to cleaning,

because garbage in drain piping piles up easily in drain trap.

Attention

Check panel

EN 3

Plug

(Check and cleaning port)

or moreor more

100

50

Loading...

Loading...