Page 1

INSTALLATION MANUAL

MANUEL DINSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

MANUAL DE INSTALAÇÃO

INSTALLATIEHANDLEIDING

AIR CONDITIONER (SPLIT TYPE)

CLIMATISEUR (TYPE SPLIT)

KLIMA GERÄT (SPLIT-SYSTEM)

CONDIZIONATORE D'ARIA (TIPO MULTIAMBIENTI)

APARATO DE AIRE ACONDICIONADO (TIPO SPLIT)

AR CONDICIONADO (TIPO SPLIT )

AIRCONDITIONER (GESPLITST TYPE)

<4-Way Air Discharge Cassette Type>/<Type cassette à 4 voies de soufflage>

<4-Wege-Belüftungskassette>/<Tipo a cassetta con scarico d'aria a 4 vie>

<Modelo de casete de distribución de aire de 4 vías>/<Descarga de ar tipo cassete de 4 vias>

Heat Pump Model/Modèle à thermopompe

Geräte mit Heizung/Modello con pompa di riscaldamento

Modelo con bomba de calor/Modelo de bomba térmica

Indoor Unit/Unité intérieure Outdoor Unit/Unité extérieure

Raumeinheit/Unità interna Außengerät/Unità esterna

Unidad interior/Unidade interior Unidad exterior/Unidade exterior

RAV-SM560UT-ERAV-SM800UT-E RAV-SM560AT-E/RAV-SM800AT-E

RAV-SM1120UT-ERAV-SM1400UT-E RAV-SM1120AT-E/RAV-SM1400AT-E

Please read this Installation Manual carefully before installing the Air Conditioner.

• This Manual describes the installation method of the indoor unit.

• For installation of the outdoor unit, follow the Installation Manual

attached to the outdoor unit.

Veuillez lire attentivement ce Manuel d’installation avant d’installer le climatiseur.

• Ce manuel décrit la procédure d’installation de l’unité intérieure.

• Pour installer l’unité extérieure, reportez-vous au Manuel d’installation fourni

avec l’unité extérieure.

Bitte lesen Sie dieses Handbuch sorgfältig, bevor Sie mit der Installation des Klimagerätes beginnen.

• In diesem Handbuch wird die Installation der Raumeinheit beschrieben.

• Um die Außeneinheit zu installieren, folgen Sie den Anweisungen in dem Handbuch, das der Außeneinheit beiliegt.

Prima di installare il condizionatore d’aria, leggere con attenzione questo manuale d’installazione.

• Questo manuale descrive il metodo d’installazione dell’unità interna.

• Per l’installazione dell’unità esterna, fare riferimento al manuale d’installazione fornito insieme all’unità esterna.

Lea atentamente este Manual de instalación antes de proceder a la instalación del aparato de aire acondicionado.

• Este manual describe el método de instalación de la unidad interior.

• Para la instalación de la unidad exterior, consulte el Manual de instalación que acompaña a la unidad exterior.

Leia atentamente o presente Manual de Instalação antes de instalar o Ar Condicionado.

• O presente manual descreve o método de instalar a unidade interior.

• Para a instalação de uma unidade exterior, siga o Manual de Instalação que acompanha a unidade exterior.

Lees deze installatiehandleiding zorgvuldig door voordat u de airconditioner gaat installeren.

• Deze installatiemethode beschrijft de installatiemethode van de binnenunit.

• Zie voor de installatie van de buitenunit, de installatiehandleiding bij de buitenunit.

Page 2

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the conventional refrigerant R22 in order to prevent destruction of the ozone layer .

UTILISATION DU NOUVEAU REFRIGERANT

Ce climatiseur est d’un type inédit qui utilise le nouveau réfrigérant HFC (R410A) au lieu du réfrigérant traditionnel

R22, afin d’éviter la destruction de la couche d’ozone.

EINFÜHRUNG EINES NEUEN KÜHLMITTELS

Dies ist ein neuartiges Klimagerät. Anstatt des herkömmlichen Kühlmittels R22 verwendet es das neue ozonschichtschonende HFC Kühlmittel R410A.

ADOZIONE DI UN NUOVO REFRIGERANTE

Questo condizionatore d'aria è di un tipo nuovo che adotta un nuovo refrigerate HFC (R410A) al posto del

refrigerante convenzionale R22, per prevenire la distruzione dello strato di ozono dell'atmosfera terrestre.

ADOPCIÓN DE NUEVO REFRIGERANTE

Este aparato de aire acondicionado es un modelo reciente que incorpora el nuevo refrigerante HFC (R410A) en

lugar del refrigerante convencional R22 para así evitar daños en la capa de oz ono.

ADOPÇÃO DO NOVO REFRIGERANTE

Este ar condicionado é um modelo novo que adopta um novo refrigerante HFC (R410A) em vez do refrigerante

convencional R22 para evitar a destruição da cama de ozono.

TOEPASSING VAN EEN NIEUW KOELMIDDEL

Deze airconditioner is een nieuwe type dat werkt met een nieuw koelmiddel HFC (R410A) in plaats van met het

conventionele koelmiddel R22, als bijdr age om de aantasting v an de oz onlaag te reduceren.

ХЙПИЕФЗУЗ НЕПХ ШХКФЙКПХ

Фп рбсьн Клймбфйуфйкь еЯнбй нЭпт фэрпт рпх хйпиефеЯ нЭп шхкфйкь HFC (R410A) уфз иЭуз фпх ухмвбфйкпэ шхкфйкпэ

R22 рспкеймЭнпх нб впзиЮуей уфзн рспуфбуЯб фпх ьжпнфпт.

Page 3

CONTENTS

Accessory parts and Parts to be procured locally ........ 1

1

PRECAUTIONS FOR SAFETY.................................... 2

2

SELECTION OF INSTALLATION PLACE ................... 4

3

DRAIN PIPING WORK ................................................. 9

4

REFRIGERANT PIPING ............................................ 11

SOMMAIRE

Pièces accessoires et pièces non fournies.................. 20

1

MESURES DE SECURITE ........................................ 21

2

SELECTION DU LIEU D’INSTALLATION ................. 23

3

INSTALLATION DES TUYAUX D’EVACUATION ....... 28

4

TUYAUX DE REFRIGERANT .................................... 30

INHALT

Zubehör und bauseits bereitzustellende Teile ............. 39

1

SICHERHEITSVORKEHRUNGEN ............................ 40

2

AUSWAHL DES AUFSTELLUNGSORTES............... 42

3

INSTALLATION DES ABLAUFROHRS ..................... 47

4

KÜHLMITTELLLEITUNGEN ..................................... 49

INDICE

Accessori e parti da acquistare sul posto.................... 58

1

PRECAUZIONI PER LA SICUREZZA....................... 59

2

SCELTA DEL POSTO D’INSTALLAZIONE ............... 61

3

LAVORO PER TUBAZIONE DI SCARICO................. 66

4

TUBAZIONI DEL REFRIGERANTE .......................... 68

5

EVACUATING............................................................. 12

6

ELECTRICAL WORK................................................. 14

7

TEST RUN ................................................................. 17

8

TROUBLESHOOTING............................................... 18

9

MAINTENANCE......................................................... 19

5

EVACUATION DE L’AIR ............................................. 31

6

INSTALLATION ELECTRIQUE.................................. 33

7

ESSAI DE FONCTIONNEMENT................................ 36

8

DEPANNAGE ............................................................. 37

9

ENTRETIEN ............................................................... 38

5

ENTLÜFTEN DER ROHRLEITUNGEN ..................... 50

6

ELEKTROINSTALLATION......................................... 52

7

TESTLAUF................................................................. 55

8

FEHLERBESEITIGUNG ............................................ 56

9

WARTUNG ................................................................. 57

5

SVUOTAMENTO ........................................................ 69

6

ESECUZIONE DEI COLLEGAMENTI ELETTRICI.... 71

7

FUNZIONAMENTO DI PR OVA .................................. 74

8

GUIDA PER I PROBLEMI DI FUNZIONAMENTO ..... 75

9

MANUTENZIONE ...................................................... 76

ENGLISH

FRANCAIS

DEUTSCHNEDERLANDS

ITALIANOESPAÑOLPORTUGUÊS

CONTENIDO

Componentes accesorios y

componentes de obtención local .................................. 77

1

PRECAUCIONES PARA SU SEGURIDAD ............... 78

2

SELECCIÓN DEL LUGAR DE INSTALACIÓN ......... 80

3

TRABAJOS DE CANALIZACIÓN DE DESAGÜE..... 85

4

TUBERÍA DE REGRIGERANTE ............................... 87

ÍNDICE

Acessórios e peças adquiridas localmente ................. 96

1

PRECAUÇÕES DE SEGURANÇA............................ 97

2

SELECÇÃO DO LOCAL DE INSTALAÇÃO ............. 99

3

INSTALAÇÃO DA TUBAGEM DE DRENAGEM ...... 104

4

TUBAGEM DE REFRIGERANTE ............................ 106

INHOUD

Accessoires en niet meegeleverde onderdelen......... 115

1

VOORZORGSMAA TREGELEN V OOR UW

VEILIGHEID ............................................................. 116

2

KEUZE VAN DE LOCATIE VOOR DE INSTALLA TIE .

3

AFVOERLEIDINGEN............................................... 123

4

KOELMIDDELLEIDINGEN ...................................... 125

118

5

EVACUACIÓN ............................................................ 88

6

TRABAJOS EN EL SISTEMA ELÉCTRICO ............. 90

7

PRUEBA DE FUNCIONAMIENTO............................. 93

8

SOLUCIÓN DE PROBLEMAS .................................. 94

9

MANTENIMIENTO ..................................................... 95

5

EVACUAÇÃO........................................................... 107

6

LIGAÇÕES ELÉCTRICAS....................................... 109

7

ENSAIO DE FUNCIONAMENTO............................. 112

8

RESOLUÇÃO DE PROBLEMAS ............................ 113

9

MANUTENÇÃO ....................................................... 114

5

ONTLUCHTEN......................................................... 126

6

ELEKTRISCH GEDEELTE ...................................... 128

7

WERKINGSTEST .................................................... 131

8

STORINGEN VERHELPEN ..................................... 132

9

ONDERHOUD.......................................................... 133

Page 4

Accessory parts and Parts to be procured locally

H Accessory parts

Q’ty

1

2

1

2

4

1

Shape

This

manual

——

M5 x 16L

Part name

Installation

Manual

Heat insulating

pipe

Installation

pattern

Installation

gauge

Pattern fixing

screw

Heat insulator

<Separate sold parts>

Shape

Part name

Standard wired

remote controller

Q’ty

1

Usage

(Be sure to hand over to customers)

For heat insulation of pipe

connecting section

For confirmation of ceiling opening

and main unit position

For positioning of ceiling position

(united with installation pattern)

For attach the installation pattern

For heat insulation of drain

connecting section

Usage

Model

RBC-AMT21E

Part name

Washer

Hose band

Flexible hose

Heat insulator

Owner’s

Manual

Part name

Ceiling panel

Q’ty

8

1

1

1

1

Q’ty

1

Shape

Usage

For hanging-down unit

For connecting drain pipe

For adjusting core-out of drain

pipe

For sealing of wire connecting port

(Be sure to hand over to customers)

Shape

Usage

Model

RBC-U21PG (W)-E

H Parts to be procured locally

Connecting pipe (Liquid side)

(6.35mm (diam.), Nominal (diam.) 1/4” thick 0.8mm)

RAV-SM560UT-E, RAV-SM560AT-E

(9.52mm (diam.), Nominal (diam.) 3/8” thick 0.8mm)

RAV-SM800UT-E, RAV-SM800AT-E

Connecting pipe (Gas side)

(12.7mm (diam.), Nominal (diam.) 1/2” thick 0.8mm)

RAV-SM560UT-E, RAV-SM560AT-E

(15.9mm (diam.), Nominal (diam.) 5/8” thick 1.0mm)

RAV-SM800UT-E, RAV-SM800AT-E

Power supply cord

2.5mm² (H07RN-F or 245IEC66) or 3.5mm² (AWG-12)

Connecting cable (indoor and outdoor cable)

H07RN-F or 245IEC66 (1.5mm² or more)

Thermal insulation for refrigerant pipe

(10mm or more, thermal insulating foam polyethylene)

Thermal insulation for drain pipe

(10mm or more, foam polyethylene)

Drain pipe (Outer 26mm (diam.))

Tapes

Grounding cable (2.0mm (diam.) or more)

1

Page 5

1

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

PRECAUTIONS FOR SAFETY

CAUTION New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its pressure

is approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil

has also been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or

refrigerating oil does not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging

port of the main unit and installation tools are charged from those for the conventional refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does

not enter. Moreover, do not use the existing piping because there are problems with pressure-resistance force

and impurity in it.

ENGLISH

CAUTION To Disconnect the Appliance from Main Power Supply.

This appliance must be connected to the main power supply by means of a switch with a contact separation of

at least 3 mm.

The installation fuse (25A D type

) must be used for the power supply line of this conditioner.

WARNINGS

• Ask an authorized dealer or qualified installation professional to install/maintain the air

conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting cable correctly.

If the connecting cable is connected in a wrong way, electric parts may be damaged.

• When moving the air conditioner for the installation into another place, be very careful not

to enter any gaseous maller other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes

abnormally high and it resultingly causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the

safety interlock switches.

• Exposure of unit to water or other moisture before installation may cause a short-circuit of

electrical parts.

Do not store it in a wet basement or expose to rain or water.

2

Page 6

1

PRECAUTIONS FOR SAFETY

• After unpacking the unit, examine it carefully if there are possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to

ensure that the concentration of refrigerant leakage occur in the room does not exceed the

critical level.

• Install the air conditioner securely in a location where the base can sustain the weight

adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the

Installation Manual. Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified cables for wiring connect the terminals securely fix. To prevent external

forces applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible

gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

3

Page 7

2

SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner at enough strong place to withstand the weight of the unit.

If the strength is not enough, the unit may fall down resulting in injury.

• Install the air conditioner at a height 2.5m or more from the floor.

If you insert your hands or others directly into the unit while the air conditioner operates, it is dangerous

because you may contact with revolving fan or active electricity.

CAUTION

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible

gas.

If a combustible gas leaks and stays around the unit, a fire may occur.

Upon approval of the customer, install the air conditioner in a place that satisfies the

following conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be ensured for safety maintenance and check.

• Place where drained water will not cause any problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide gas

(hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into the window of the neighboring house. (For outdoor unit)

• Place where noise of the outdoor unit is easily transmitted.

(When installing the air conditioner on the boundary with the neighbor, pay due attention to the level of noise.)

• Place with poor ventilation. (Before air ducting work, check whether value of air volume, static pressure and

duct resistance are correct.)

Installation space

Secure the specified space in the figure for installation and servicing.

15 or more

1000 or more

1000 or more

1000

or more

271

or more

4

Page 8

2

SELECTION OF INSTALLATION PLACE

Selection of installation place

In case of continued operation of the indoor unit under

high-humidity conditions as described below, dew may

condense and water may drop.

Especially, high-humidity atmosphere (dew point

temperature : 23°C or more) may generate dew inside the

ceiling.

1. Unit is installed inside the ceiling with slated roof.

2. Unit is installed at a location using inside of the ceiling

as fresh air take-in path.

3. Kitchen

If installing a unit at such place, put insulating material

(glass wool, etc.) additionally on all the positions of the

indoor unit which come to contact with high-humidity

atmosphere.

Advice

Set a check service opening panel at right side of the unit

(size: 450 x 450mm or more) for piping, maintenance, and

servicing.

Ceiling height

Model RAV-

SM560UT-E, SM800UT-E

Possible installe ceiling height

Up to 3.8m

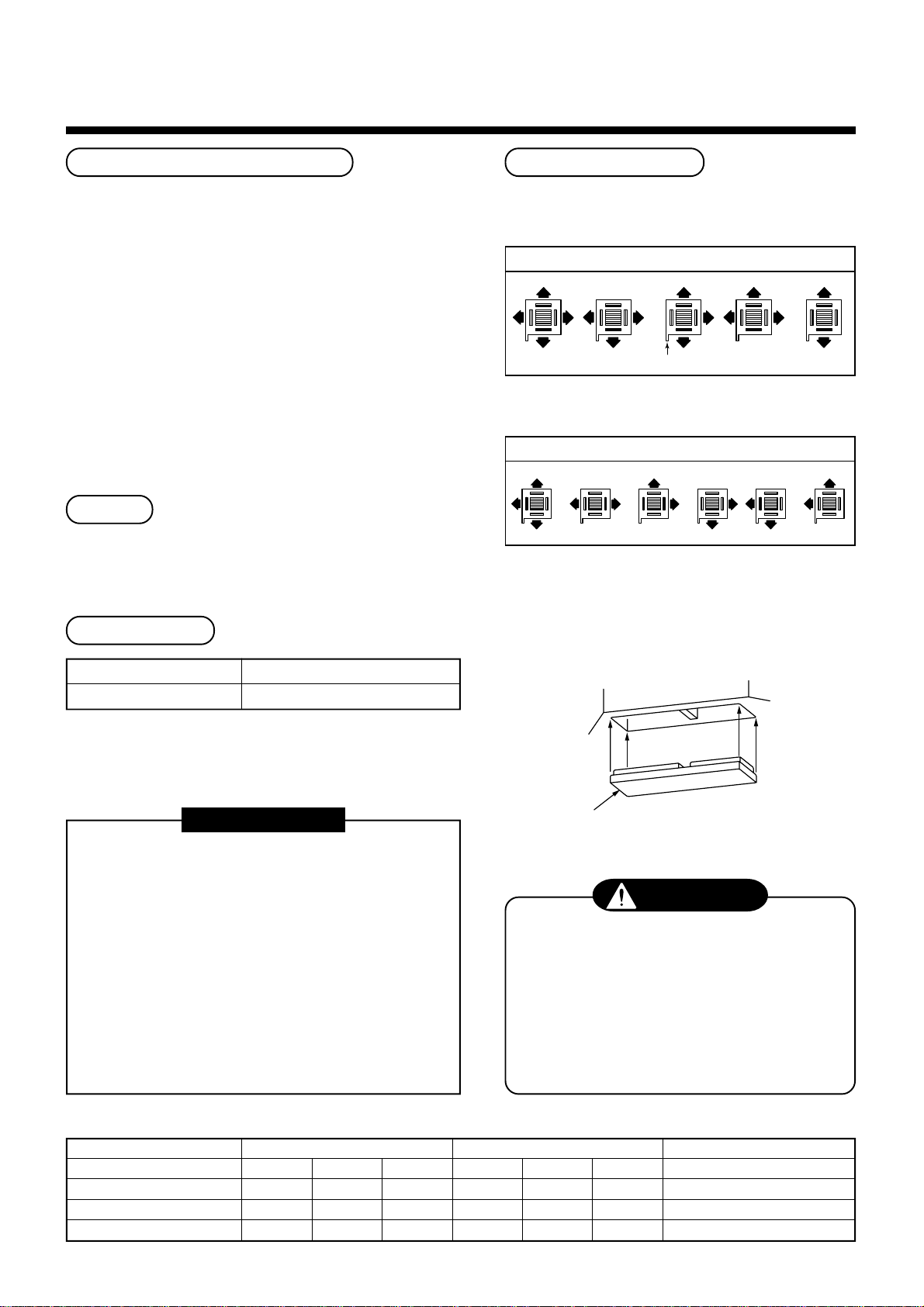

Discharge direction

As shown in the following figure, No. of

discharge directions can be selected according

to the shape of rooms and installation position.

RAV-SM560UT-E to RAV-SM800UT-E

Refrigerant pipe side

As shown in the following figure direction are

not acceptable.

RAV-SM560UT-E to RAV-SM800UT-E

• To change discharge direction, use a shielding

plate.

• When attaching a shielding plate, remove the

ceiling panel and insert the shielding plate into

the discharge port as shown in the figure below.

When the height of the ceiling exceeds the distance of the

item Standard/4-way in Table below, the hot air is difficult to

reach the floor. Therefore, it is necessary to change the

setup value of the high ceiling switch or discharge direction.

REQUIREMENT

• When using the air conditioner with 2-way discharge

system with the standard setting (at a shipment), it

may stop abnormally in heating. Therefore, change

the setting switch according to the number of

discharge direction and the ceiling height.

• When using the air conditioner with 2-way/3-way

discharge system, a strong wind blows directly if

the ceiling height is lower than the standard.

Therefore, change the setting switch according to

height of the ceiling.

• When using the high ceiling (1) or (2) with 4-way

discharge system, the draft is apt to be felt due to

drop of the discharge temperature.

Shielding plate

(Prepared locally)

WARNING

Install the air conditioner certainly to sufficiently

withstand the weight.

If the strength is insufficient, the unit may fall

down resulting in human injury.

Perform a specified installation work to guard

against an earthquake.

An incomplete installation can cause accidents

by the units falling and dropping.

Height list of ceiling possible to be installed (Unit : m)

Model

No. of discharge direction

Standard (at shipment)

High ceiling (1)

High ceiling (2)

RAV-SM560UT-E

4-way 3-way 2-way

2.8 3.2 3.5

3.2 3.5 3.8

3.5 3.8 —

RAV-SM800UT-E

4-way 3-way 2-way

3.0 3.3 3.6

3.3 3.5 3.8

3.6 3.8 —

High ceiling setup

Set data

0000

0001

0003

5

Page 9

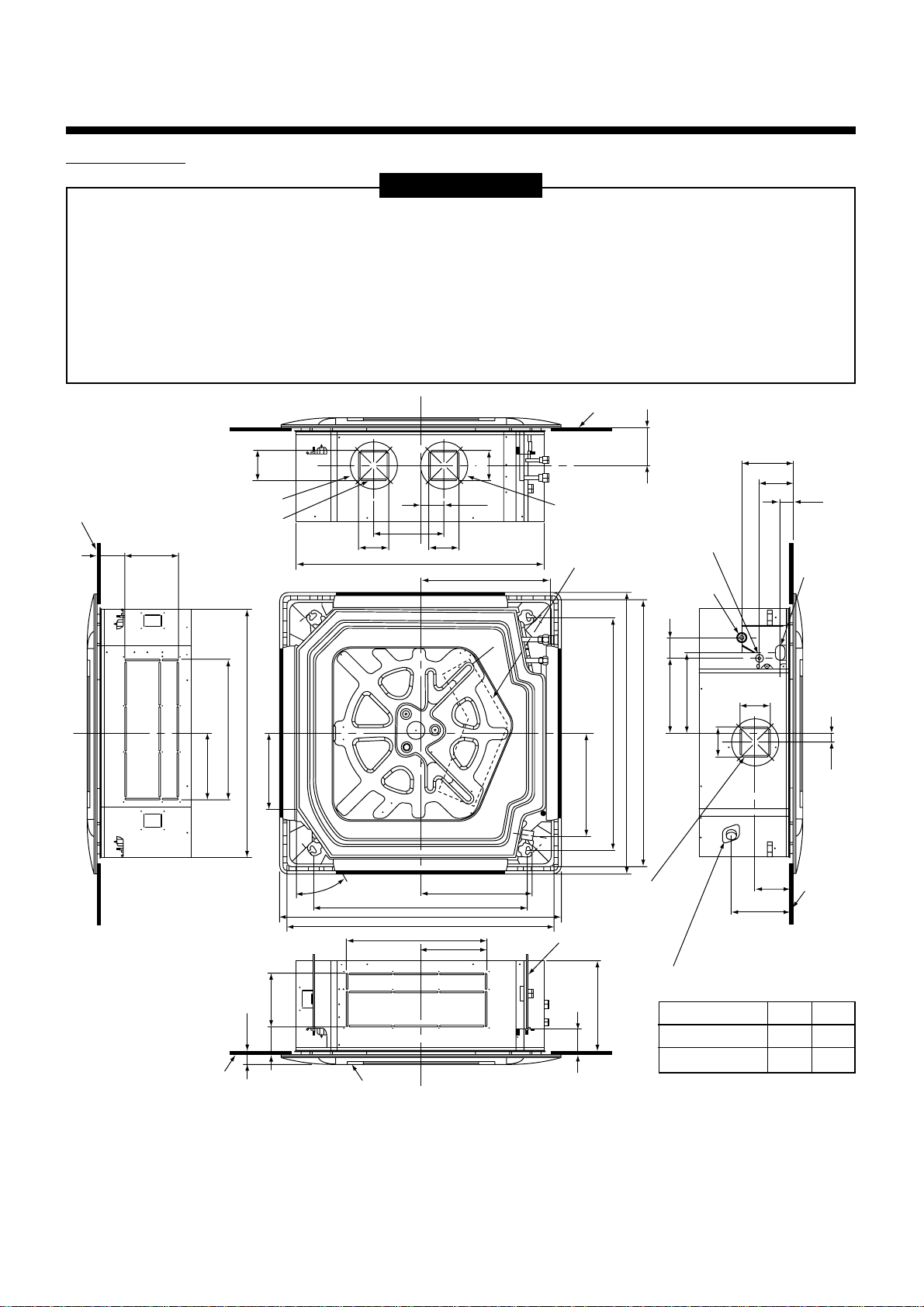

External view

REQUIREMENT

Strictly comply with the following rules to prevent damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit. (Even units are packaged)

• Carry in the indoor unit as it is packaged if possible. If carrying in the indoor unit unpacked by necessity, be

sure to use buffering cloth, etc. to not damage the unit.

• To move the indoor unit, hold the hooking metals (4 positions) only.

Do not apply force to the other parts (refrigerant pipe, drain pan, foamed parts, or resin parts, etc.).

• Carry the package by two or more persons, and do not bundle it with PP band at positions other than

specified.

Ceiling bottom surface

Ceiling bottom surface

12097

105

Ø162

Knockout square

hole for divide duct

For Ø150

(2 positions)

480

227

840 Unit external dimension

254.5

240

105 105

840 Unit external dimension

35˚

723 Hanging bolt pitch

950 Panel external dimension

860 to 910 Ceiling opening dimension

480

227

80

434.5

381.6

105

Ø162

Electric parts box

790 Hanging bolt pitch

345.5

950 Panel external dimension

Knockout square hole

for divide duct

For Ø150

Hanging bolt

M10 or Ø3/8

(To be procured locally)

Drain pipe connecting port

130

Refrigerant pipe

connecting port

A

Refrigerant pipe

connecting port

B

70

250

270

105

860 to 910 Ceiling opening dimension

173

113

105

130

210

45

Take-in port

of pipes

30

Ceiling

bottom

surface

Ceiling bottom

surface

12097

35

Ceiling panel (sold separately)

256

88

RAV-SM560UT-E

RAV-SM800UT-E

AB

Ø6.4 Ø12.7

Ø9.5 Ø15.9

Considering pipe/wire connecting work inside the ceiling after the indoor unit has been hanged, select an installation

place and determine piping direction.

• If the ceiling has already been set before hanging the main unit, prepare refrigerant pipe, drain pipe, indoor

connecting wire, remote controller cord, etc. up to the place where pipe and wire can be connected.

• Check the size of the indoor unit, and match the indoor unit size, with ceiling opening size and that position using

the attached installation pattern.

(Attach the pattern to the lower side of indoor unit with attached four screws M5 x 16L.)

6

Page 10

Indoor unit

Level vial (Horizontal: within 5mm)

Hanging bolt

Hanging

metal

Installation

gauge

Ceiling board

1) 20 to 30

mm

2) 12 to 17

mm

Installation

gauge

2) 20 to

30mm

1) 12

mm

+5

–0

Ceiling

board

Indoor unit

2

SELECTION OF INSTALLATION PLACE

Opening a ceiling and installation of hanging bolts

<Treatment of ceiling>

The ceiling differs according to structure of building. For details, consult your constructor or interior finish contractor.

In the process after the ceiling board has been removed, it is important to reinforce ceiling foundation (frame) and to

keep horizontal level of installed ceiling correctly in order to prevent vibration of ceiling board.

(1) Cut and remove the ceiling foundation.

(2) Reinforce the cut surface of ceiling foundation, and add ceiling foundation for fixing the end of ceiling board.

<Installation of hanging bolt>

Use M10 hanging bolts (4 pcs, to be local procure). Matching to the existing structure, set pitch according to size in

the unit external view as shown below.

New concrete slab

Install the bolts with insert brackets or anchor

bolts.

Rubber

(Blade type

bracket)

(Slide type

bracket)

Anchor bolt

(Pipe hanging

anchor bolt)

Steel flame structure

Use existing angles or install new

support angles.

Hanging bolt Support angle

Installation of ceiling opening and hanging bolt

Adjust nut position (lower side) so that clearance between the

attached washer (lower side) and ceiling board is 88mm.

Hanging bolt

88mm

Ceiling boards

Nut (Upper side)

Washer

(Upper side)

(Hanging bracket

main unit)

Washer

(Lower side)

Nuts (Lower side)

Level

Hanging bolt

Hanging bracket

Hanging bolt

Existing concrete slab

Use a hole-in anchors, hole-in

plugs, or a hole-in bolts.

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Nut

(W3/8 or M10)

(1)Required those other than M10 flat washer at site.

(2)To prevent falling-off of bolt (safety), be sure to

set it just under the hanging bracket as shown

in the figure.

(1)

M10 flat washer

(Accessory)

(2)

M10 flat washer

(Accessory)

• Hang up the main unit by hanging the nut of hanging bolt to

T groove of hanging bracket of the main unit.

• Using the level vial, etc., set the horizontal level of the main

unit within 5mm.

• Using the installation gauge, check and adjust the positional

relation between the main unit and ceiling opening hole, and

hanging-up height of the main unit. (Direction to be used is

indicated on the installation gauge.)

1) Check lower side of the indoor unit locates at position (12

to 17) mm higher than the lower surface of the ceiling

board. (4 corners)

2) Check clearance between side of the indoor unit and the

ceiling board is 20 to 30mm. (Common to 4 corners)

7

Page 11

REQUIREMENT

Before installation of the indoor unit, be sure to

remove the cushion for transportation between the

fan and the bell mouth. Running the unit without

removing the cushion may damage the fan motor.

Be sure to remove the cushion for transportation

between the fan and the bell mouth.

Installation of ceiling panel

(Sold separately)

Install the ceiling panel according to Installation

Manual attached with it after piping/wiring work has

completed.

Check that installation of indoor unit and ceiling

opening part is correct, and then install it.

REQUIREMENT

Joint the connecting sections of ceiling panel,

ceiling surface, ceiling panel and indoor unit

closely.

Any gap between them will cause air leakage and

this generate condensation or water leakage.

Installation of ceiling opening and

hanging bolt

For installation of the wired remote controller, follow

the Installation Manual attached with the remote

controller.

• Pull out the remote controller cord together with the

refrigerant pipe or drain pipe.

Be sure to pass the remote controller cord through

upper side of the refrigerant pipe and drain pipe.

8

Page 12

3

e

DRAIN PIPING WORK

CAUTION

• Following the Installation Manual,

perform the drain piping work so that

water is properly drained, and apply a

heat insulation so as not to cause a dew.

Piping/Heat insulating material

Require the following materials for piping and heat

insulating at site.

Piping

Hard vinyl chloride pipe VP25

(Outer dia. : Ø32mm)

Inappropriate piping work may result in

water leakage in the room and wet of

furniture.

Heat insulator

Foam polyethylene :

Thickness 10mm or more

REQUIREMENT

• Be sure to perform heat insulation of the drain pipes of the indoor unit.

1.5m to 2m

• Never forget to perform heat insulation of the connecting part with the indoor

unit. An incomplete heat insulation causes dewing.

• Set the drain pipe with downward slope (1/100 or more), and do not make

Heat

insulator

1/100 or more

downward

swelling or trap on the piping. It may cause an abnormal sound.

• For length of the traversing drain pipe, restrict to 20m or less.

Arched

shape

In case of a long pipe, provide support brackets with interval of

1.5 to 2m in order to prevent waving.

As long as possible (10cm)

VP25

VP25

Trap

VP25

• Set the collective piping as shown in

the right figure.

• Be sure not to apply force to the

VP30 or more

Downward slope

1/100 or more

connecting part of the drain pipe.

• The hard vinyl-chloride pipe cannot be directly connected to the drain pipe connecting port of the indoor unit.

For connection with the drain pipe connecting port, be sure to use/fix the attached flexible hose with the hose

band, otherwise a damage or water leak is caused on the drain pipe connecting port.

Drain pipe connecting

port (Hard socket)

Attached hose band

Attached flexible hose

VP25 vinyl chloride pipe

(To be local procure)

Drain pipe

connecting port

(Transparent)

Align the attached hose band to the

end of hose, set the tightening

position upward, and then tighten it.

Flexible hose

(Accessory)

VP25 vinyl chloride pip

(To be local procure)

Support

bracket

Extended

ventilating pipe

Soft socket

Hard socket

Socket for VP25

(To be local procure)

Indoor unit body

Socket for VP25 vinyl chloride pipe

(To be local procure)

Adhesive inhibited :

Use the attached flexible hose and hose band for connecting the drain hose to the clear drain socket.

If applying the adhesive, socket will be damaged and cause water leakage.

Flexible hose

Use the attached flexible hose to adjust core discrepancy

of the hard vinyl chloride pipe or to adjust the angle.

• Do not use the flexible hose as stretched, or do not

deform it more extent than that in the following figure.

• Be sure to fix the soft end of the flexible hose with the

attached hose band.

max

45˚

max

45˚

• Use the flexible hose on a horizontal level.

9

Riser (Trap)

90˚ Bend

Page 13

Connection procedure

Check the draining

Connect a socket and a hard vinyl chloride pipe.

• Using adhesive agent for vinyl chloride pipe, connect

the drain pipes certainly so that water does not leak.

• It takes approx. 10 hours to dry and harden the

adhesive agent. During this period, do not apply

force to the connecting part with the drain pipe.

Perform heat insulating.

• As shown in the figure, cover the flexible hose and

hose band with the attached heat insulator up to the

bottom of the indoor unit without gap.

Flexible hose

Attached heat insulator

Heat insulator to be

procured locally

Hose band

Hard vinyl chloride pipe

Drain up

When a downward grading cannot be secured on the

drain pipe, drain-up up to 640mm is possible.

Set downward grading immediately after raising up

vertically.

Rising up

640mm or less

In the test run, check that water drain is properly

performed and water does not leak from the

connecting part of the pipes.

Be sure to check draining also when installed in

heating period.

Using a pitcher or hose, pour water (1500 to 2000cc)

into the discharge port before installation of the ceiling

panel.

Pour water gradually so that water does not spread on

the motor of the drain pump.

Heat

exchanger

Drain pan

• After the electric work has finished, pour water

during COOL mode operation.

• If the electric work has not yet finished, pull out the

float switch connector (CN34 : Red) from the electric

parts box, and check draining by plugging the single

phase 220/230/240V power to the terminal blocks 1

and 2.

If doing so, the drain pump motor operates.

• Test water drain while checking the operation sound

of the drain pump motor.

(If the operation sound changes from continuous

sound to intermittent sound, water is normally

drained.)

After the check, the drain pump motor runs,

connecting the float switch connector.

(In case of check by pulling out the float switch

connector, be sure to return the connector to the

original position.)

Indoor unit

360mm

or less

Underneath of ceiling

Rising up 850mm or less

10

CN34

(RED)

Single phase 220/230/240V

1 2

White

Red

Black

Pull out connector CN34 (Red) from P.C. board.

Black

Page 14

4

Half union

Flare nut

Externally

threaded side

Internally

threaded side

Use a wrench to secure.

Use a torque wrench to tighten.

REFRIGERANT PIPING

Refrigerant Piping

1. If the outdoor units are to be mounted on a wall,

make sure that the supporting platform is

sufficiently strong. The platform should be

designed and manufactured to maintain its strength

over a long period of time, and sufficient

consideration should be given to ensuring that the

outdoor unit will not fall.

2. Use copper pipe with 0.8 mm or more thickness.

3. Flare nut and flare works are also different from

those of the conventional refrigerant.

Take out the flare nut attached to the main unit of

the air conditioner, and use it.

CAUTION

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of

the connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

• Flaring dia meter size : A (Unit : mm)

+0

A

-

Outer diam. of copper pipe

6.35

9.52

12.7

15.9

In case of flaring for R410A with the conventional

*

R410A R22

9.1 9.0

13.2 13.0

16.6 16.2

19.7 19.2

0.4

flare tool, pull it out approx.

0.5 mm more than that for R22 to

adjust to the specified flare size.

The copper pipe gauge is useful

for adjusting projection margin size.

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

A

Permissible Piping Length and Heat

The maximum piping length from the outdoor to indoor unit

30 m (Chargeless 20m) 50 m (Chargeless 20m)

(RAV-SM560AT-E) (RAV-SM800AT-E)

The maximum height difference outdoor/indoor unit

Outdoor unit is above Outdoor unit is below

30m 15m

Flaring

Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured for

R410A are recommended.

However, the conventional tools

can be used by adjusting

projection margin

of the copper pipe.

• Projection margin in flaring : B (Unit : mm)

Rigid (Clutch type)

Outer diam. of

copper pipe

6.35 to 9.52

R410A tool used

R410A R22

0 to 0.5 (Same as left)

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

(Unit : N•m)

Outer diam. of copper pipe

6.35 mm (diam.)

9.52 mm (diam.)

12.7 mm (diam.)

15.9 mm (diam.)

Tightening torque

14 to 18 (1.4 to 1.8 kgf•m)

33 to 42 (3.3 to 4.2 kgf•m)

50 to 62 (5.0 to 6.2 kgf•m)

63 to 77 (6.3 to 7.7 kgf•m)

• Tightening torque of flare pipe connections

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times) Therefore, using a torque

wrench, tighten the flare pipe connecting sections

which connect the indoor

and outdoor units of the

specified tightening torque.

B

Incorrect connections may

cause not only a gas

leak, but also a trouble

of the refrigeration cycle.

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with your fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

Flare at

indoor

unit side

Flare at

outdoor

unit side

Imperial (Wing nut type)

Outer diam. of copper pipe

6.35 or 9.52

12.7 or 15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

11

Page 15

5

EVACUATING

AIR PURGE

Evacuate the air in the connecting pipes and in the

indoor unit using vacuum pump.

Do not use the refrigerant in the outdoor unit.

For details, see the manual of vacuum pump.

Use a vacuum pump

Be sure to use a vacuum pump with counter-flow

prevention function so that inside oil of the pump does

not flow backward into pipes of the air conditioner

when the pump stops.

1. Connect the charge hose from the manifold valve to

the service port of the gas side packed valve.

2. Connect the charge hose to the port of vacuum

pump.

3. Open fully the low pressure side handle of the

gauge manifold valve.

4. Operate the vacuum pump to start evacuating.

Perform evacuating for about 35 minutes if the

piping length is 30 meters total for model SM560

and 50 meters for model SM800

(assuming a pump capacity of 27 liters per minute.)

Then confirm that the compound pressure gauge

reading is –101 kPa ( –76 cmHg).

5. Close the low pressure side valve handle of gauge

manifold.

REQUIREMENT

• Charging an excessive or too little amount of

refrigerant causes a trouble of the compressor.

Be sure to charge the refrigerant of specified

amount.

• A personnel who charged the refrigerant should

write down the pipe length and the added

refrigerant amount in the nameplate attached to

the service panel of the outdoor unit. It is

necessary to troubleshoot the compressor and

refrigeration cycle malfunction.

Open the valve fully

Open the valve of the outdoor unit fully. A 4mmhexagonal wrench is required for opening the valve.

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap

of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for

HFC refrigerant (R410A, R134a, etc.).

6. Open fully the valve stem of the packed valves

(both sides of Gas and Liquid).

7. Remove the charging hose from the service port.

8. Securely tighten the caps on the packed valves.

REQUIREMENT

For the tools such as charge hose, etc., use those

manufactured exclusively for R410A.

Refrigerant amount to be added

For addition of the refrigerant, add refrigerant “R410A”

referring to the attached Installation Manual.

Be sure to use a scale to charge the refrigerant of

specified amount.

Thermal insulation process

Apply thermal insulation for the pipes separately at

liquid side and gas side.

For the thermal insulation to the pipes at gas side, be

sure to use the material with heat-resisting

temperature 120°C or higher.

Using the attached thermal insulation material, apply

the thermal insulation to the pipe connecting section of

the indoor unit securely without gap.

REQUIREMENT

Apply the thermal insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to

the outside causes water leak.)

12

Page 16

5

EVACUATING

Packed valve handling precautions

• Open the valve stem all the way out ; do not try to

open it beyond the stopper.

• Securely tighten the valve stem cap at the torque as

follows:

Gas side (15.9 mm

Gas side (12.7 mm

Gas side (9.52 mm (diam.))

Liquid side (6.35 mm

Service port

(diam.)

)

63 to 77 N•m (6.3 to 7.7 kgf•m)

(diam.)

)

50 to 62 N•m (5.0 to 6.2 kgf•m)

33 to 42 N•m (3.3 to 4.2 kgf•m)

(diam.)

)

14 to 18 N•m (1.4 to 1.8 kgf•m)

14 to 18 N•m (1.4 to 1.8 kgf•m)

Hexagonal wrench is required.

–101kPa

(–76cmHg)

Handle Lo

Charge hose

Packed valve

at liquid side

Compound

pressure gauge

Packed valve at gas side

Pressure gauge

Manifold valve

Handle Hi

(Keep fully closed)

Charge hose

Vacuum pump

adapter for

counter-flow

prevention

Vacuum

pump

Service port

(Valve core (Setting pin))

<For RAV-SM800AT-E model>

• As shown in the figure, be sure to use a double

spanner to loosen or tighten the flare nut of the valve

at gas side. If using a single spanner, the nut cannot

be tightened with necessary tightening torque.

On the contrary, use a single spanner to loosen or

tighten the flare nut of the valve at liquid side.

Cover

Cap

Piping valve

Loosened

SM800 type valve at gas side

Tightened

Flare nut

Cover

Never put the spanner or

torque wrench, etc. on

the cover.

The valve may be broken.

13

Page 17

6

ELECTRICAL WORK

WARNING

1. Using the specified cables, ensure to connect the wires, and fix wires securely so that the

external tension to the cables do not affect the connecting part of the terminals.

Incomplete connection or fixation may cause a fire, etc.

2. Be sure to connect earth wire. (Grounding work)

Do not connect the earth wire to gas pipe, city water pipe, lightning rod, or the earth wire of telephone.

Incomplete grounding causes an electric shock.

3. For electric work, strictly follow the Local Regulation in each country and the Installation

Manual, and use an exclusive circuit.

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a fire.

CAUTIONS

• This indoor unit has no power cord.

• If incorrect/incomplete wiring is carried out, it will cause an electrical fire or smoke.

• Be sure to install an earth leakage breaker that is not tripped by shock waves.

If an earth leakage breaker is not installed, an electric shock may be caused.

• Be sure to use the cord clamps attached to the product.

• Do not damage or scratch the conductive core and inner insulator of power and inter-connecting cables when

peeling them.

• Be sure to comply with local regulations on running the wire from outdoor unit to indoor unit (size of wire and

wiring method etc.)

• Use the power cord and Inter-connecting cable of specified thickness, type, and protective devices required.

REQUIREMENT

• For power supply wiring, strictly conform to the Local Regulation in each country.

• For wiring of power supply of the outdoor units, follow the Installation Manual of each outdoor unit.

• Never connect 220/230/240V power to the terminal blocks (A, B, etc.) for control wiring.

(Otherwise, the system will fail.)

• Perform the electric wiring so that it does not come to contact with the high-temperature part of the pipe.

The coating may melt resulting in an accident.

• After connecting cables to the terminal blocks, provide a trap and fix cables with the cable clamp.

• Run the refrigerant piping line and control wiring line in the same line.

• Do not turn on the power of the indoor unit until vacuuming of the refrigerant pipes completes.

Remote controller wiring

2-core non polarity cable is used for the remote controller wiring.

How to wire

1. Connect the connecting cable to the terminal as identified with their respective numbers on the terminal block of

indoor and outdoor unit. H07 RN-F or 245 IEC 66 (1.5 mm

2. Insulate the unsheathed redundant cords (conductors) with electrical insulation tape.

Process them so that they do not touch any electrical or metal parts.

3. For inter-unit wiring, do not use a wire jointed to another on the way.

2

or more)

14

Page 18

6

ELECTRICAL WORK

Cable connection

REQUIREMENT

• Be sure to connect the cables matching the terminal numbers. Incorrect connection causes a trouble.

• Be sure to pass the cables through the bushing of cabling connection port of the indoor unit.

• Keep a margin (Approx. 100mm) on a cable to hang down the electric parts box at servicing, etc.

• The low-voltage circuit is provided for the remote controller. (Do not connect the high-voltage circuit)

• Remove the cover of the electric parts box by taking off the mounting screws (3 positions) and pushing the

hooking section. (The cover of the electric parts box remains hanged to the hinge.)

• Connect the indoor/outdoor connection cables and REMOCON cable to the terminal block of the electric parts

box. (Do not apply tension to the connecting section of the terminal block.)

• Tighten the screws of the terminal block, and fix the cables with cord clamp attached to the electric parts box.

(Do not apply tension to the connecting section of the terminal block.)

• Using the attached thermal insulation material, seal the pipe connecting port. Otherwise, dewing may be caused.

• Mount the cover of the electric parts box without pinching cables.

(Mount the cover after cabling on the ceiling panel.)

Cabling

connecting

port

P.C. board

Power supply

terminal block

1 2 3 A B

Remote controller

ABC

Hinge

Screws at 3 positions

terminal block

Hooking section

Electric parts box

Louver connector (CN33: White)

Cover of electric parts box

<Thermal insulation to cabling connecting port>

Adhered surface

Cord clamp

Cord clamp

Notched section

Cabling on the ceiling panel

According to the Installation Manual of the ceiling panel, connect the connector (5P: White) of the ceiling panel to the

connector (CN33: White) on P.C. board of the electric parts box.

15

Page 19

Cabling

T

f

c

R

(

r

it

rt

R

nt

1. Remove a screw and then remove cover of the

electric parts box.

2. Strip wire ends (10 mm).

3. Match wire colors with terminal numbers on indoor

and outdoor units’ terminal blocks and firmly screw

wires to the corresponding terminals.

4. Connect the ground wires to the corresponding

terminals.

5. Fix the cable with cord clamp.

6. Fix cover of the parts box and the terminal block

surely with the fixing screws.

Cabling diagram

erminal block

or remote controller

abling of indoor unit

A

B

emote controller cable

Local procure)

emote controller cabling

Approx. 200mm

W

Connecting

part

W : White

B : Black

Remote

B

Remote controller unit o

cable from sensor part

controller un

or sensor pa

Make a loop on the cable for margin of the length

so that the electric parts box can be taken out

during servicing.

10

70

Earth line

123

Connecting

cable

10

50

Cable from remote

controller unit

Remote controller

Remote controller

cable

Indoor side

Indoor/Outdoor

connecting cable

Outdoor side

(Single phase 220/230/240V)

Wire joi

A B

1 2 3

1 2 3

L N

• For details of cabling/installation of the remote

controller, refer to the Installation Manual attached to

in the remote controller.

Remote Controller Cabling

• Strip off approx. 14mm the cable to be connected.

• Non polarity, 2 core cable is used for cabling of the

remote controller.

• Twist cable of the remote controller to be connected

with cable of the remote controller unit (or sensor),

and press-fit them with a wire joint.

Wire joints (White: 2 pieces) are included in the

attachments to the remote controller (sold

separately) or the wireless remote controller kit (sold

separately).

16

Page 20

3

4

7

Before test run

• Before turning on the power supply, carry out the following procedure.

1) Using 500V-megger, check 1MΩ or more exists between the terminal block 1 to 3 and the earth.

2) Check the valve of the outdoor unit being opened fully.

• To protect the compressor at activation time, leave power-ON for 12 hours or more be for operating.

How to execute a test run

Using the remote controller, operate the unit as usual.

For the procedure of the operation, refer to the attached Owner’s Manual.

A forced test run can be executed in the following procedure if the operation stops by thermo.-OFF.

In order to prevent a serial operation, the forced test run is released after 60 minutes have passed and returns to the

usual operation.

TEST RUN

If 1MΩ or less is detected, do not run the unit. Do not apply to the remote controller circuit.

CAUTION

When the remote controller is used for the first time, it accepts an operation approx. 5 minutes after the power

supply has been turned on.

It is not a trouble, but is because the setup of the remote controller is being checked.

For the second power-ON time and after, approx. 1 minute is required to start the operation by the remote controller.

NOTE

Do not use the forced test run for cases other

than the test run because it applies an

excessive load to the devices.

In case of wired remote controller

Procedure

Keep button pushed for 4 seconds or more. [TEST] is

1

2

3

displayed on the display part and the selection of mode in the test

mode is permitted.

Push button.

Using button, select the operation mode, [COOL] or [HEAT].

• Do not run the air conditioner in a mode other than [COOL] or

[HEAT].

• The temperature controlling function does not work during test run.

• The detection of error is performed as usual.

1, 5

Description

SET

2,

UNIT

CL

TEST

4

5

After the test run, push button to stop a test run.

1

(Display part is same as procedure

Push check button to cancel (release from) the test run mode.

([TEST] disappears on the display and the status returns to a

normal.)

.

17

Page 21

8

TROUBLESHOOTING

Confirmation and check

When a trouble occurred in the air conditioner, the

check code and the indoor unit No. appear on the

display part of the remote controller.

The check code is only displayed during the operation.

If the display disappears, operate the air conditioner

according to the following “Confirmation of error

history” for confirmation.

Confirmation of error history

When a trouble occurred on the air conditioner, the

trouble history can be confirmed with the following

procedure. (The trouble history is stored in memory up

to 4 troubles.)

The history can be confirmed from both operating

status and stop status.

3

Check code

SET

UNIT No.

R.C. No.

Indoor unit No. in which

an error occurred

UNIT

CL

CODE No.

2

1

Procedure

When pushing [SET] and buttons at the same time for 4

seconds or more, the following display appears.

If [Service check] is displayed, the mode enters in the trouble history

mode.

1

2

3

1. Check the troubles according to the above procedure.

2. Ask an authorized dealer or qualified service (maintenance) professional to repair or maintain the air conditioner.

3. More details of the service code are explained in Service Manual.

• [01 : Order of trouble history] is displayed in CODE No. window.

• [Check code] is displayed in CHECK window.

• [Indoor unit address in which an error occurred] is displayed in

UNIT No.

Every pushing of [ , ] button used to set temperature, the trouble history stored in memory is

displayed in order.

The numbers in CODE No. indicate CODE No. [01] (latest) → [04] (oldest).

REQUIREMENT

Do not push

After confirmation, push button to return to the usual display.

button because all the trouble history of the indoor unit will be deleted.

CL

Description

CODE No.

UNIT No.

R.C. No.

18

Page 22

10

MAINTENANCE

Before maintenance, be sure to turn off the leakage breaker.

Cleaning of air filter

•If

• Clogging of the air filter reduce cooling/heating performance.

is displayed on the remote controller, maintain the air filter.

Cleaning of panel and air filter

Preparation :

1. Turn off the air conditioner by the remote controller.

2. Open the suction air port.

• Slide the button of the suction air port inward, and open the suction

port slowly while holding it.

Suction grille

Clean the panel and air filter with water:

• Wipe down the panel and air filter with a sponge or towel moistened

with a kitchen detergent. (Do not use any metallic brush for cleaning.)

• Carefully rinse the panel and air filter to wash out the detergent.

• After rinsing the panel and air filter with water, dry it in the shade.

3. Close the suction air port.

• Close the suction air port, slide the button outward, and fix the

suction port securely.

CAUTION

• Do not start the air conditioner while leaving the panel and air filter removed.

• Push the filter reset button. (

Cleaning of Air Filters

• If the air filters are not cleaned, it not only reduce the cooling

a performance of air conditioner but causes a failure in the air

conditioner such as water falling in drops.

Preparation :

1. Stop the operation by remote controller.

2. Dismount the air filter.

indication will be turn off.)

Suction grille

Strap to

prevent falling

Air filter

Button

Button

Push

Use a vacuum cleaner to remove dust from the filters or wash them with water.

• After rinsing the air filters with water, dry them in the shade.

• Set the air filter into the air conditioner.

Cleaning of discharge flap

The discharge flap can be removed to clean.

1. Remove the discharge flap.

• Holding the both ends of the discharge flap,

remove the flap sagging the center downward.

2. Cleaning with water

• If the dirt is terrible, clean the flap by tepid

water with neutral detergent or water.

3. Mount the discharge flap.

• First push in one side of the flap, and then insert

the other side sagging the center downward.

Be careful to the direction of the flap when mounting.

Mount the flap so that the side with the mark faces upward and the arrow direction of the mark directs.

1

Insert

2

Insert in the flap sagging

down the center downward.

19

Page 23

Pièces accessoires et pièces non fournies

H Pièces accessoires

Nom de la pièce Quantité Forme Emploi

Manuel

d’installation

Tuyau à isolation

thermique

Gabarit

d’installation

Calibre

d’installation

Vis de fixation

du gabarit

Isolant thermique

1

2

1

2

4

1

Ce manuel

——

M5 x 16L

(Assurez-vous de le remettre

aux clients.)

Isolation thermique des

sections de raccordement des

tuyaux

Vérification de l’ouverture du

plafond et de la position de

l’unité principale

Positionnement du plafond

(avec le gabarit d’installation)

Fixation du gabarit d’installation

Isolation thermique des

sections de raccordement du

tuyau d’évacuation

<Pièces vendues séparément>

Nom de la pièce Quantité Forme Emploi

Nom de la pièce Quantité Forme Emploi

Rondelle

Collier de

serrage

Flexible

Isolant

thermique

Manuel du

propriétaire

Nom de la pièce Quantité Forme Emploi

8

1

1

1

1

Suspension de l’unité

Raccordement du tuyau

d’évacuation

Réglage de la saillie du tuyau

d’évacuation

Scellement de l’orifice de

raccordement des câbles

(Assurez-vous de le remettre

aux clients.)

FRANCAIS

Télécommande

avec fil standard

1

Modèle

RBC-AMT21E

H Pièces non fournies

Tuyau de raccordement (côté liquide)

((diam.) 6.35 mm, (diam.) nominal 1/4", épaisseur 0.8 mm)

RAV-SM560UT-E, RAV-SM560AT-E

((diam.) 9.52 mm, (diam.) nominal 3/8", épaisseur 0.8 mm)

RAV-SM800UT-E, RAV-SM800AT-E

Tuyau de raccordement (côté gaz)

((diam.) 12.7 mm, (diam.) nominal 1/2", épaisseur 0.8 mm)

RAV-SM560UT-E, RAV-SM560AT-E

((diam.) 15.9 mm, (diam.) nominal 5/8", épaisseur 1.0 mm)

RAV-SM800UT-E, RAV-SM800AT-E

Cordon d’alimentation

2.5 mm² (H07RN-F ou 245IEC66) ou 3.5 mm² (AWG-12)

Panneau pour

plafond

1

Modèle

RBC-U21PG (W)-E

Câble de raccordement (câble intérieur et extérieur)

H07RN-F ou 245IEC66 (1.5 mm² ou plus)

Isolation thermique du tuyau de réfrigérant

(10 mm ou plus, polyéthylène expansé thermo-isolant)

Isolation thermique du tuyau d’évacuation

(10 mm ou plus, polyéthylène expansé)

Tuyau d’évacuation ((diam.) ext. 26 mm)

Rubans

Câble de terre ((diam.) 2.0 mm ou plus)

20

Page 24

1

• Assurez-vous de respecter toutes les règles locales, nationales et internationales.

• Lisez attentivement ces “MESURES DE SECURITE” avant l’installation.

• Les mesures décrites ci-après comprennent des points importants concernant la sécurité.

Observez-les scrupuleusement.

• Après l’installation, faites un essai de fonctionnement pour vous assurer de l’absence de problèmes.

Reportez-vous au Manuel du propriétaire pour expliquer au client comment utiliser l’unité et effectuer son entretien.

• Mettez l’interrupteur général (ou le disjoncteur) hors tension avant d’effectuer l’entretien de l’unité.

• Demandez au client de conserver le Manuel d’installation avec le Manuel du propriétaire.

MESURES DE SECURITE

ATTENTION Installation du climatiseur utilisant le nouveau réfrigérant

• Ce climatiseur utilise le nouveau réfrigérant HFC (R410A) qui ne détruit pas la couche d’ozone.

Le réfrigérant R410A se distingue par son absorption aisée de l’eau, de la membrane oxydante ou de l’huile ainsi

que par sa pression, qui est d’environ 1.6 fois celle du réfrigérant R22. Outre l’utilisation du nouveau réfrigérant,

l’huile réfrigérante a elle aussi été remplacée. Par conséquent, durant l’installation, assurez-vous que l’eau, la

poussière, le réfrigérant précédent ou l’huile réfrigérante n’entrent pas dans le circuit de réfrigération.

Pour éviter de remplir du réfrigérant et de l’huile réfrigérante inappropriés, la taille des sections de raccordement de

l’orifice de remplissage de l’unité principale et les outils d’installation sont différents de ceux qui sont utilisés pour le

réfrigérant traditionnel.

En conséquence, les outils exclusifs sont requis pour le nouveau réfrigérant (R410A).

Quant aux tuyaux de raccordement, utilisez des tuyaux neufs et propres conçus pour le R410A et veillez à ce que

l’eau ou la poussière n’y entrent pas. En outre, n’utilisez pas la tuyauterie existante, qui pose des problèmes de

résistance à la pression et d’impureté.

ATTENTION Pour déconnecter l’appareil du secteur

Cet appareil doit être connecté au secteur via un interrupteur ayant une séparation de contact d’au moins 3 mm.

Le fusible d’installation (25A de type D

climatiseur.

) doit être utilisé pour la ligne d’alimentation de ce

AVERTISSEMENT

• Demandez à un revendeur autorisé ou à un installateur professionnel d’installer le climatiseur/

d’effectuer son entretien.

Une installation inadéquate peut se solder par une fuite d’eau, une électrocution ou un incendie.

• Mettez l’interrupteur général ou le disjoncteur hors tension avant d’entreprendre l’installation

électrique.

Assurez-vous que tous les interrupteurs soient hors tension. La non-observation de cet avertissement peut se

solder par une électrocution.

• Branchez correctement le câble de raccordement.

Si le câble de raccordement est mal branché, les composants électriques peuvent s’endommager.

• Lorsque vous déplacez le climatiseur pour l’installer ailleurs, faites très attention à ce qu’aucun

corps gazeux autre que le réfrigérant spécifié n’entre dans le circuit de réfrigération.

Si l’air ou tout autre gaz se mélange au réfrigérant, la pression gazeuse du circuit de réfrigération augmentera

anormalement et pourra faire éclater les tuyaux et blesser quelqu’un.

• Ne modifiez pas cette unité en démontant ses carters de protection ou en by-passant ses

verrous de sûreté.

• Exposer l’unité à l’eau ou à l’humidité avant l’installation peut provoquer un court-circuit.

Ne la rangez pas dans un sous-sol humide et ne l’exposez pas à la pluie ou à l’eau.

21

Page 25

• Après avoir déballé l’unité, examinez-la attentivement pour vous assurer qu’elle n’est pas

endommagée.

• Ne l’installez pas dans un endroit susceptible d’augmenter ses vibrations.

• Afin d’éviter de vous blesser (avec des bords tranchants), faites attention lorsque vous

manipulez les pièces.

• Effectuez l’installation conformément au Manuel d’installation.

Une installation inadéquate peut se solder par une fuite d’eau, une électrocution ou un incendie.

• Si le climatiseur est installé dans une petite pièce, prenez les mesures appropriées pour

garantir que la concentration de fuite de réfrigérant dans la pièce ne dépasse pas le niveau

critique.

• Installez solidement le climatiseur dans un endroit qui supporte son poids de manière adéquate.

• Effectuez l’installation spécifiée pour protéger le climatiseur contre un tremblement de terre.

Si le climatiseur n’est pas installé de manière appropriée, il peut tomber et provoquer des accidents.

• Si le gaz réfrigérant a fui durant l’installation, aérez immédiatement la pièce.

Si le gaz réfrigérant qui a fui entre en contact avec le feu, un gaz nocif peut se dégager.

• Après l’installation, assurez-vous que le gaz réfrigérant ne fuie pas.

Si le gaz réfrigérant fuit dans la pièce et s’écoule près d’un appareil ignigène, comme une cuisinière, un gaz nocif

peut se dégager.

• L’installation électrique doit être effectuée par un électricien professionnel conformément au

Manuel d’installation. Assurez-vous que le climatiseur utilise une alimentation exclusive.

Une alimentation de puissance insuffisante ou une installation inappropriée peuvent provoquer un incendie.

• Utilisez les câbles spécifiés et raccordez-les bien aux bornes.

Evitez qu’une pression externe ne s’exerce sur les bornes et ne les affecte.

• Observez les règles de la compagnie d’électricité locale lorsque vous raccordez les câbles

d’alimentation.

Une mise à la terre inappropriée peut provoquer une électrocution.

• N’installez pas le climatiseur dans un endroit susceptible d’être exposé à des gaz inflammables.

Si un gaz inflammable fuit et stagne autour de l’unité, il peut provoquer un incendie.

22

Page 26

2

SELECTION DU LIEU D’INSTALLATION

AVERTISSEMENT

• Installez le climatiseur dans un endroit suffisamment résistant pour supporter son poids.

Si l’endroit n’est pas assez résistant, l’unité peut tomber et provoquer des blessures.

• Installez le climatiseur à un minimum de 2.5 m de hauteur du sol.

Insérer directement vos mains ou autres dans le climatiseur durant son fonctionnement est dangereux car vous

pourriez entrer en contact avec le ventilateur en rotation ou l’électricité active.

ATTENTION

• N’installez pas le climatiseur dans un endroit susceptible d’être exposé à des gaz inflammables.

Si un gaz inflammable fuit et stagne autour de l’unité, il peut provoquer un incendie.

Sur autorisation du client, installez le climatiseur dans un endroit remplissant les conditions

suivantes.

• Un endroit où l’unité puisse être installée à l’horizontale.

• Un endroit où un espace suffisant permette d’effectuer son entretien et son inspection en toute sécurité.

• Un endroit où l’eau évacuée ne posera aucun problème.

Evitez d’installer le climatiseur dans les endroits suivants.

• Un endroit où l’air est riche en sel (zone de bord de mer) ou en gaz sulfureux (source chaude). (Si l’unité devait

être utilisée dans ces endroits, des mesures de protection particulières s’avèreraient nécessaires.)

• Un endroit exposé à l’huile, à la vapeur, aux fumées d’huile ou aux gaz corrosifs.

• Un endroit à proximité duquel un solvant organique est utilisé.

• Un endroit proche d’une machine génératrice de hautes fréquences.

• Un endroit où l’air refoulé souffle directement sur la fenêtre de la maison voisine. (Pour l’unité extérieure)

• Un endroit où le bruit de l’unité extérieure se transmet facilement. (Lorsque vous installez le climatiseur dans un

endroit confinant avec votre voisinage, prêtez attention au niveau sonore.)

• Un endroit peu ventilé. (Avant d’installer les conduits d’air, vérifiez si les valeurs du débit d’air, de la pression

statique et de la résistance des conduits sont correctes.)

Espace requis pour l’installation

Assurez l’espace d’installation et d’entretien spécifié sur la figure.

15 ou plu

1000 ou plu

1000 ou plu

1000

ou plus

271

ou plu

23

Page 27

Sélection du lieu d’installation

En cas de fonctionnement continuel de l’unité intérieure

dans les conditions de forte humidité décrites ci-après, de

la condensation pourrait se former et l’eau dégouliner.

En particulier, une atmosphère très humide (température du

point de saturation : 23°C ou plus) pourrait former de la

condensation à l’intérieur du plafond.

1. Unité installée dans un plafond dont le toit est en ardoise.

2. Unité installée dans un endroit utilisant l’intérieur du

plafond comme canal d’admission d’air frais.

3. Cuisine

Si vous installez une unité dans un tel endroit, mettez un

matériau isolant (laine de verre, etc.) supplémentaire sur

tous les points de contact de l’unité intérieure avec

l’atmosphère très humide.

Conseil

Pratiquez un regard à droite de l’unité (taille : 450 x 450 mm

ou plus) pour l’inspection et l’entretien de la tuyauterie.

Hauteur du plafond

Modèle RAV-

SM560UT-E, SM800UT-E

Lorsque la hauteur de plafond dépasse la distance indiquée

au point Standard/4 voies du tableau ci-dessous, l’ai chaud

atteint difficilement le sol. Par conséquent, il est nécessaire

de modifier la valeur définie de la hauteur de plafond ou le

sens de soufflage.

Hauteur de plafond possible

pour l’installation

Jusqu’à 3.8 m

Sens de soufflage

Comme indiqué sur la figure ci-dessous, le n° de

voies de soufflage peut être sélectionné en

fonction de la forme des pièces et de la position

d’installation.

RAV-SM560UT-E à RAV-SM800UT-E

Côté tuyau de réfrigérant

Comme indiqué sur la figure ci-dessous,

certaines voies de soufflage sont inacceptables.

RAV-SM560UT-E à RAV-SM800UT-E

• Pour modifier le sens de soufflage, utilisez une

plaque de protection.

• Lorsque vous fixez la plaque de protection, démontez

le panneau pour plafond et insérez la plaque de

protection dans l’orifice de soufflage comme indiqué

sur la figure ci-dessous.

CONDITIONS REQUISES

• Lors de l’utilisation du climatiseur ayant un système à

2 voies de soufflage avec la configuration standard

(au départ de l’usine), le mode Chauffage pourrait

s’arrêter anormalement. Par conséquent, modifiez le

commutateur de réglage en fonction du nombre de

sens de soufflage et de la hauteur de plafond.

• Lors de l’utilisation du climatiseur ayant un système à

2/3 voies de soufflage, le souffle est fort et direct si la

hauteur de plafond est inférieure au standard.

Par conséquent, modifiez le commutateur de réglage

en fonction de la hauteur de plafond.

• Lors de l’utilisation des modèles Plafond haut (1) ou

(2) ayant un système à 4 voies de soufflage, il est

possible de sentir le courant en cas de chute de la

température de soufflage.

Installez solidement le climatiseur dans un endroit

suffisamment résistant pour supporter son poids.

Si l’endroit n’est pas assez résistant, l’unité peut

tomber et provoquer des blessures.

Effectuez l’installation spécifiée pour protéger le

climatiseur contre un tremblement de terre.

Une unité mal installée peut tomber et provoquer

des accidents.

Liste des hauteurs de plafond possibles pour l’installation (unité : m)

Modèle RAV-SM560UT-E RAV-SM800UT-E Réglage de la hauteur de plafond

N˚ de voies de soufflage

Standard (au départ de l’usine)

Plafond haut (1)

Plafond haut (2)

4 voies 3 voies 2 voies

2.8 3.2 3.5

3.2 3.5 3.8

3.5 3.8 —

4 voies 3 voies 2 voies

3.0 3.3 3.6

3.3 3.5 3.8

3.6 3.8 —

Plaque de protection

(non fournie)

AVERTISSEMENT

Données définies

0000

0001

0003

24

Page 28

2

SELECTION DU LIEU D’INSTALLATION

Vue extérieure

CONDITIONS REQUISES

Observez scrupuleusement les règles suivantes pour éviter d’endommager les unités intérieures et de vous blesser.

• Ne posez aucun objet lourd sur l’unité intérieure. (Les unités sont emballées à plat.)

• Si possible, transportez l’unité intérieure telle qu’elle est emballée. Si vous êtes obligé de transporter l’unité

intérieure déballée, assurez-vous d’utiliser des chiffons, etc. pour ne pas l’endommager.

• Pour déplacer l’unité intérieure, tenez seulement les crochets métalliques (4 points).

N’exercez aucune force sur les autres pièces (tuyau de réfrigérant, bac d’évacuation, pièces expansées ou pièces

en résine, etc.).

• Portez l’emballage à deux personnes ou plus et ne l’empaquetez pas avec du ruban adhésif sur des points autres

que ceux qui sont spécifiés.

Surface inférieure du plafond

Surface inférieure

du plafond

Trou carré de passage

des gaines divisées

Pour Ø150 (2 points)

12097

227

Surface inférieure

du plafond

105

Ø162

105 105

840 Dimension extérieure de l’unité

480

254.5

840 Dimension extérieure de l’unité

35˚

723 Pas du boulon de suspension

950 Dimension extérieure du panneau

De 860 à 910 Dimension de l’ouverture du plafond

12097

35

Panneau pour plafond (vendu séparément)

240

480

227

80

434.5

381.6

105

Ø162

Boîtier électrique

345.5

790 Pas du boulon de suspension

Trou carré de passage

des conduits divisés

Pour Ø150

Boulon de suspension,

M10 ou Ø3/8

(non fourni)

256

88

130

Orifice de

raccordement du

tuyau de réfrigérant

A

Orifice de

raccordement du

tuyau de réfrigérant

B

70

250

270

950 Dimension extérieure du panneau

De 860 à 910 Dimension de l’ouverture du plafond

Orifice de raccordement

du tuyau d’évacuation

RAV-SM560UT-E

105

105

210

173

113

130

AB

Ø6.4 Ø12.7

Ø9.5 Ø15.9RAV-SM800UT-E

45

Orifice

d’entrée

des tuyaux

Surface

inférieure

du plafond

30

En tenant compte du raccordement des tuyaux/câbles à l’intérieur du plafond après avoir suspendu l’unité intérieure,

choisissez un lieu d’installation et déterminez l’orientation des tuyaux.

• Si le plafond a été posé avant de suspendre l’unité principale, amenez le tuyau de réfrigérant, le tuyau d’évacuation, le

câble de raccordement de l’unité intérieure, le cordon de la télécommande, etc. jusqu’au lieu de raccordement des

tuyaux et des câbles.

• Vérifiez la taille de l’unité intérieure et faites correspondre la taille de cette dernière avec celle de l’ouverture du plafond