Toshiba RAV-SM1102AT-E, RAV-SP802AT-E, RAV-SP562AT-E, RAV-SM562AT-E, RAV-SP1102AT-E SERVICE MANUAL

...

FILE NO. A05-018

Revised: Jul/25/2005

SERVICE MANUAL/INTEGRATION

SPLIT TYPE

INDOOR UNIT

<DIGITAL INVERTER>

RAV-SM562UT-E RAV-SM562BT-E RAV-SM562CT-E

RAV-SM802UT-E RAV-SM802BT-E RAV-SM802CT-E

RAV-SM1102UT-E RAV-SM1102BT-E RAV-SM1102CT-E

RAV-SM1402UT-E RAV-SM1402BT-E RAV-SM1402CT-E

<SUPER DIGITAL INVERTER>

RAV-SP1102UT-E

• Service Manual for RAV-SM✻✻✻KRT and RAV-SM✻✻✻XT contact the Sales company or Dealer.

OUTDOOR UNIT

<DIGITAL INVERTER>

RAV-SM562AT-E RAV-SM802AT-E RAV-SM1102AT-E RAV-SM1402AT-E

<SUPER DIGITAL INVERTER>

RAV-SP562AT-E RAV-SP802AT-E RAV -SP1102AT-E RAV-SP1402AT-E

R410A

PRINTED IN JAPAN, Jan.,2006 ToMo

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the con ventional

refrigerant R22 in order to prevent destruction of the oz one layer.

WARNING

Cleaning of the air filter and other parts of the air filter involves dangerous work in high places, so be sure to ha ve

a service person do it. Do not attempt it yourself. The cleaning diagram for the air filter is there for the service

person, and not for the customer.

NOTE

A direct current motor is adopted for indoor f an motor in the Concealed Duct Standard Type air conditioner.

Caused from its characteristics, a current limit works on the direct current motor. When replacing the highperformance filter or when opening the service board, be sure to stop the fan. If an above action is ex ecuted

during the fan operation, the protective control works to stop the unit operation, and the check code “P12”

may be issued. However it is not a trouble. When the desired operation has finished, be sure to reset the

system to clear “P12” error code using the leak breaker of the indoor unit. Then push the operation stop

button of the remote controller to return to the usual operation.

CONTENTS

SAFETY CAUTION ............................................................................................ 4

1. SPECIFICATIONS ...................................................................................... 9

1-1. Indoor Unit........................................................................................................... 9

1-2. Outdoor Unit...................................................................................................... 17

1-3. Operation Characteristic Curve....................................................................... 19

2. AIR DUCTING WORK .............................................................................. 22

2-1. Static Pressure Characteristics of Each Model ............................................. 22

3. CONSTR UCTION VIEWS (EXTERNAL VIEWS) ...................................... 24

3-1. Indoor Unit......................................................................................................... 24

3-2. Outdoor Unit...................................................................................................... 28

4. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM.............................. 31

4-1. Indoor Unit/Outdoor Unit ................................................................................. 31

5. WIRING DIAGRAM................................................................................... 39

5-1. Indoor Unit......................................................................................................... 39

5-2. Outdoor Unit (Wiring Diagram)........................................................................ 42

6. SPECIFICATIONS OF ELECTRICAL PARTS.......................................... 46

6-1. Indoor Unit......................................................................................................... 46

6-2. Outdoor Unit...................................................................................................... 48

6-3. Accessory Separate Soldparts........................................................................ 50

– 2 –

7. REFRIGERANT R410A............................................................................ 51

7-1. Safety During Installation/Servicing ............................................................... 51

7-2. Refrigerant Piping Installation....................................................................... 51

7-3. Tools .................................................................................................................. 55

7-4. Recharging of Refrigerant ............................................................................... 55

7-5. Brazing of Pipes................................................................................................ 56

8. CONTROL BLOCK DIAGRAM................................................................. 58

8-1. Indoor Control Circuit....................................................................................... 58

8-2. Control Specifications...................................................................................... 59

8-3. Indoor Print Circuit Board................................................................................ 68

9. CIRCUIT CONFIGURATION AND CONTROL SPECIFICATIONS .......... 69

9-1. Indoor Control Circuit....................................................................................... 69

9-2. Outdoor Controls.............................................................................................. 70

10. TROUBLESHOOTING.............................................................................. 79

10-1. Summary of Troubleshooting........................................................................... 79

10-2. Check Code List................................................................................................ 81

10-3. Error Mode Detected by LED on Outdoor P.C. Board .................................... 84

10-4. Troubleshooting Procedure for Each Check Code ........................................ 85

11. REPLACEMENT OF SERVICE INDOOR P.C. BOARD.......................... 101

12. SETUP AT LOCAL SITE AND OTHERS................................................ 105

12-1. Indoor Unit....................................................................................................... 105

12-2. Setup at Local Site / Others ........................................................................... 112

12-3. How to set up central control address Number ........................................... 114

13. ADDRESS SETUP ................................................................................. 115

13-1. Address Setup ................................................................................................ 115

13-2. Address Setup & Group Control.................................................................... 116

13-3. Address Setup ................................................................................................ 117

14. DETACHMENTS ..................................................................................... 119

14-1. Indoor Unit...................................................................................................... 119

14-2. Outdoor Unit.................................................................................................... 135

15. EXPLODED VIEWS AND PARTS LIST.................................................. 160

15-1. Indoor Unit....................................................................................................... 160

15-2. Outdoor Unit.................................................................................................... 174

15-3. Replacement of Main Parts (Sold Separately).............................................. 182

16. CORD HEATER INSTALLATION WORK ............................................... 184

– 3 –

SAFETY CAUTION

The important contents concerned to the saf ety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

Indication

DANGER

WARNING

CAUTION

∗ Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage ( ∗) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Explanation

[Explanation of illustrated marks]

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

(Refer to the Parts disassembly diag r am (Outdoor unit).)

If removing the label during parts replace, stick it as the original.

DANGER

Turn “OFF” the breaker before removing the front panel and cabinet, otherwise an electric

shock is caused by high voltage resulted in a death or injur y.

During operation, a high voltage with 400V or higher of circuit (∗) at secondary circuit of the highvoltage transformer is applied.

Turn off breaker.

Execute discharge

between terminals.

Prohibition

If touching a high voltage with the naked hands or body, an electric shock is caused even if using an

electric insulator.

∗ : For details, refer to the electric wiring diagram.

When removing the front panel or cabinet, execute short-circuit and discharge between highvoltage capacitor terminals.

If discharge is not executed, an electric shock is caused by high voltage resulted in a death or injury.

After turning off the breaker, high voltage also keeps to apply to the high-voltage capacitor.

Do not turn on the breaker under condition that the front panel and cabinet are removed.

An electric shock is caused by high voltage resulted in a death or injury.

– 4 –

Check earth wires.

Prohibition of modification.

Use specified parts.

Do not bring a child

close to the equipment.

Insulating measures

No fire

WARNING

Before troubleshooting or repair work, check the earth wire is connected to the earth

terminals of the main unit, otherwise an electric shock is caused when a leak occurs.

If the earth wire is not correctly connected, contact an electric engineer for rework.

Do not modify the products.

Do not also disassemble or modify the parts. It may cause a fire, electric shock or injury.

For spare parts, use those specified (

If unspecified parts are used, a fire or electric shock may be caused.

∗: For details, refer to the parts list.

Before troubleshooting or repair work, do not bring a third party (a child, etc.) except

the repair engineers close to the equipment.

It causes an injury with tools or disassembled parts.

Please inform the users so that the third party (a child, etc.) does not approach the equipment.

Connect the cut-off lead cables with crimp contact, etc, put the closed end side

upward and then apply a water-cut method, otherwise a leak or production of fire is

caused at the users’ side.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle. When using a gas stove, etc, be sure to put out fire

before work; otherwise the oil mixed with refrigerant gas may catch fire.

2) Do not use a welder in the closed room. When using it without ventilation, carbon

monoxide poisoning may be caused.

3) Do not br ing inflammables close to the refrigerant cycle, otherwise fire of the welder may

catch the inflammables.

∗∗

∗).

∗∗

Refrigerant

Check the used refrigerant name and use tools and materials of the parts which

match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a

position on the outdoor unit where is easy to see. To prevent miss-charging, the route of the

service port is changed from one of the former R22.

For an air conditioner which uses R410A, never use other refrigerant than R410A.

For an air conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating cycle and an injury due to breakage may be caused.

Do not charge refrigerant additionally.

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in

the refrigerating cycle changes resulted in change of air conditioner characteristics or

refrigerant over the specified standard amount is charged and an abnormal high pressure is

applied to the inside of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute

vacuuming, and then newly recharge the specified amount of liquid refrigerant. In this time,

never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrig erant

or air other than R410A into the specified refrigerant.

If air or others is mixed with the refrigerant, abnormal high pressure generates in the

refrigerating cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak.

If the refrigerant gas leaks in the room, poisonous gas generates when gas touches to fire

such as fan heater, stove or cocking stove though the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit.

When the equipment is moved or repaired, be sure to recover the refrigerant with recovering device. The refrigerant cannot be recovered in the outdoor unit; otherwise a serious

accident such as breakage or injury is caused.

Assembly/Cabling

After repair work, surely assemble the disassembled parts, and connect and lead the

removed cables as before. Perform the work so that the cabinet or panel does not

catch the inner cables.

If incorrect assembly or incorrect cable connection was done, a disaster such as a leak or

fire is caused at user’s side.

– 5 –

WARNING

Insulator check

Ventilation

Be attentive to

electric shock

Compulsion

After the work has finished, be sure to use an insulation tester set (500V mugger) to

check the resistance is 2M

metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s

side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of the

refrigerant and the closed room full with gas is dangerous because a shortage of oxygen

occurs. Be sure to execute ventilation.

When checking the circuit inevitably under condition of the power-ON, use rubber

gloves and others not to touch to the charging section.

If touching to the charging section, an electric shock may be caused.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down

and tighten the service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking

stove though the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such

as a multi air conditioner in a sub-room, it is necessary that the density does not the

limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is

caused.

For the installation/moving/reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric

shock or fire is caused.

ΩΩ

Ω or more between the charge section and the non-charge

ΩΩ

Check after rerair

Check after reinstallation

Put on gloves

Cooling check

After repair work has finished, check there is no trouble.

If check is not executed, a fire, electric shock or injury may be caused. For a check, turn off

the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test

run to check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused. Before test run, install the

front panel and cabinet.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

CAUTION

Be sure to put on gloves (

If not putting on gloves, an injury may be caused with the parts, etc.

(∗) Heavy gloves such as work gloves

When the power was turned on, start to work after the equipment has been

sufficiently cooled.

As temperature of the compressor pipes and others became high due to cooling/heating

operation, a burn may be caused.

∗∗

∗) during repair work.

∗∗

– 6 –

• New Refrigerant (R410A)

This air conditioner adopts a new HFC type refrigerant (R410A) which does not deplete the ozone layer.

1. Safety Caution Concerned to New Refrigerant

The pressure of R410A is high 1.6 times of that of the former refrigerant (R22). Accompanied with change of

refrigerant, the refrigerating oil has been also changed. Therefore, be sure that water, dust, the former

refrigerant or the former refrigerating oil is not mixed into the refrigerating cycle of the air conditioner with

new refrigerant during installation work or service work. If an incorrect work or incorrect service is performed, there is a possibility to cause a serious accident. Use the tools and materials exclusive to R410A to

purpose a safe work.

2. Cautions on Installation/Service

1) Do not mix the other refrigerant or refrigerating oil.

For the tools e xclusive to R410A, shapes of all the joints including the service port differ from those of the

former refrigerant in order to prev ent mixture of them.

2) As the use pressure of the new refrigerant is high, use material thickness of the pipe and tools which are

specified for R410A.

3) In the installation time, use clean pipe materials and work with great attention so that water and others do

not mix in because pipes are affected by impurities such as water, oxide scales, oil, etc. Use the clean

pipes.

Be sure to brazing with flowing nitrogen gas. (Never use gas other than nitrogen gas.)

4) For the earth protection, use a vacuum pump for air purge.

5) R410A refrigerant is azeotropic mixture type refrigerant. Therefore use liquid type to charge the refrigerant. (If using gas for charging, composition of the refrigerant changes and then characteristics of the air

conditioner change.)

3. Pipe Materials

For the refrigerant pipes, copper pipe and joints are mainly used. It is necessary to select the most appropriate pipes to conform to the standard. Use clean material in which impurities adhere inside of pipe or joint to a

minimum.

1) Copper pipe

<Piping>

The pipe thickness, flare finishing size , flare nut and others differ according to a refrigerant type.

When using a long copper pipe for R410A, it is recommended to select “Copper or copper-base pipe without

seam” and one with bonded oil amount 40mg/10m or less . Also do not use crushed, deformed, discolored

(especially inside) pipes. (Impurities cause clogging of expansion valves and capillary tubes.)

<Flare nut>

Use the flare nuts which are attached to the air conditioner unit.

2) Joint

The flare joint and socket joint are used for joints of the copper pipe. The joints are rarely used for installation of the air conditioner. However clear impurities when using them.

– 7 –

4. Tools

q

q

g

1. Required T ools for R410A

Mixing of different types of oil may cause a trouble such as generation of sludge, clogging of capillary , etc.

Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive f or R410A (Those which cannot be used for conventional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

air conditioner installation

No. Used tool Usage

Flare tool Pipe flaring Yes *(Note 1) Yes

Copper pipe gauge for

adjusting projection

margin

Torque wrench Connection of flare nut Yes No No

Gauge manifold

Charge hose

V acuum pump adapter Vacuum evacuating Yes No Yes

Electronic balance for

refrigerant charging

Refrigerant cylinder Refrigerant charge Y es No No

Leakage detector Gas leakage check Yes No Yes

Charging cylinder Refriger ant charge (Note 2) No No

Flaring by

conventional flare tool

Evacuatin

charge, run check, etc.

Refrigerant charge Yes Y es Yes

, refrigerant

Existence of

uipment

new e

for R410A

Yes *(Note 1) *(Note 1)

Yes No No

R410A

Whether

conventional

equipment can be

used

Conventional air

conditioner installation

Whether new e

can be used with

conventional refrigerant

uipment

(Note 1) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

(Note 2) Charging cylinder for R410A is being currently developed.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also f or R22 are necessary

as the general tools.

1) Vacuum pump

Use vacuum pump by

attaching vacuum pump adapter.

2) Torque wrench

3) Pipe cutter

4) Reamer

7) Screwdriver (+, –)

8) Spanner or Monkey wrench

9) Hole core drill

10) Hexagon wrench (Opposite side 4mm)

11) Tape measure

12) Metal saw

5) Pipe bender

6) Level vial

Also prepare the following equipments for other installation method and run check.

1) Clamp meter

2) Thermometer

3) IInsulation resistance tester

4) Electroscope

– 8 –

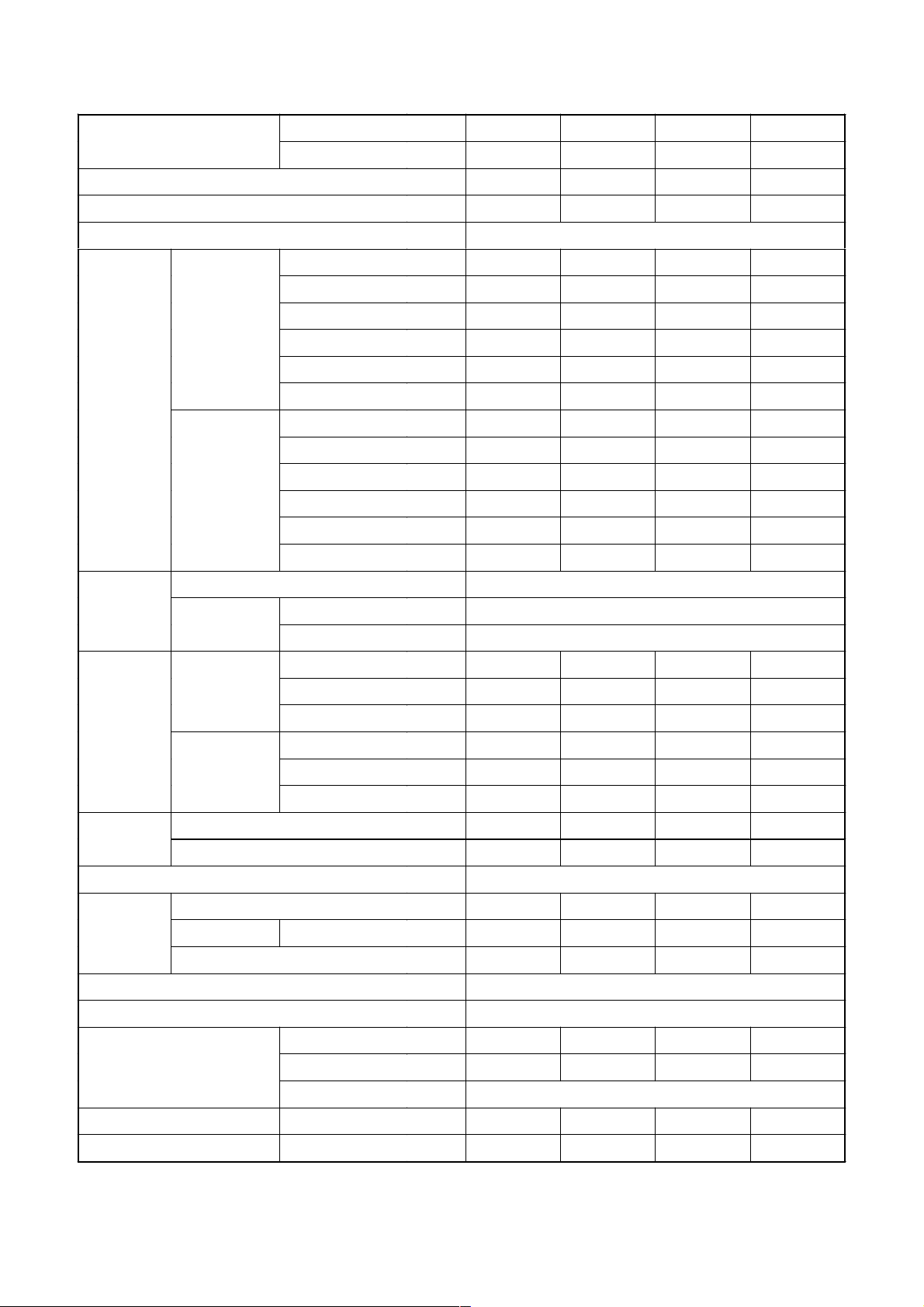

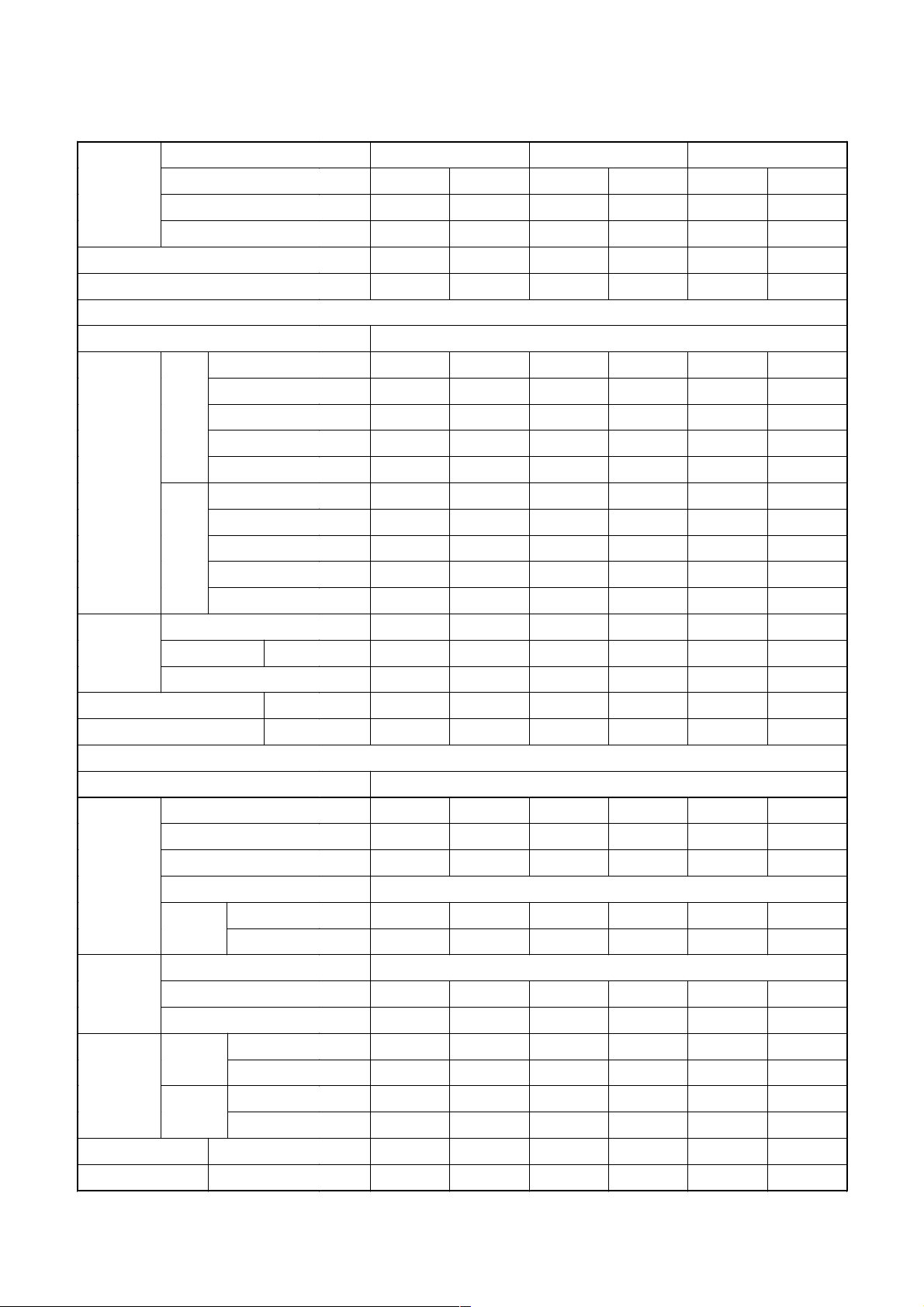

1. SPECIFICATIONS

1-1. Indoor Unit

1-1-1. 4-Way Air Discharge Cassette Type

<Digital Inverter>

Model

Cooling capacit y (kW) 5.3 7.1 10.0 12.3

Heating capacity (kW) 5.6 8.0 11.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Cooling

Electrical

characteristics

Heating

Main unit Zinc hot dipping steel plate

Ceiling panel

(Sold separately)

Outer

dimension

Ceiling panel

(Sold separately)

Main unit (kg)21222226

Total weight

Ceiling panel (Sold separately) (k g) 4.5 4.5 4.5 4.5

Heat exchanger Finned tube

Fan Turbo fan Turbo fan Turbo fan Turbo fan

Standard air flow H/M/L (m³/min) 17.5/13.9/12.1 20.0/15.7/13.6 24.0/19.0/16.0 33.0/25.0/20.0Fan unit

Motor (W) 60 60 60 90

Air filter TCB-LF1601UE, UFM1601UE, UFH16 01UE

Controller (Sold separately) RBC-AMT31E2, AS21E2, TCB-SC 642TLE2, AX21U(W)-E2

Sound pressure level H/M/L (dB•A) 32/29/27 34/31/28 39/36/33 42/38/34

Sound power level H/M/L (dB•A) 47/44/42 49/46/43 54/51/48 57/53/49

Indoor unit RAV- SM562UT-E SM802UT-E SM1102UT-E SM1402UT-E

Outdoor unit RAV- SM562AT-E SM802AT-E SM1102AT-E SM1402AT-E

Running current (A) 8.42 – 7.72 11.32 – 10.37 16.30 – 16.00 19.20 – 17.60

Power consumption (kW) 1.76 2.34 3.52 4.09

Power factor (%) 95 94 98 97

EER (W/W) 3.01 3.03 2.84 3.01

Energy efficiency class * B B C B

Energy rating ** 3.5 3.5 3.0 3.5

Running current (A) 6.89 – 6.32 11.22 – 10.28 16.10 – 14.80 18.70 – 17.20

Power consumption (kW) 1.44 2.32 3.48 4.00

Power factor (%) 95 94 98 97

COP (W/W) 3.89 3.45 3.22 3.50

Energy efficiency class * A B C B

Energy rating ** 5.0 3.5 3.5 4.0

Model RBC-U21PG (W)-E2Appearance

Panel color Moon-white (Muncel 2.5GY 9.0/0.5)

Height (mm) 256 256 256 320

Width (mm) 840 840 840 840Main unit

Depth (mm) 840 840 840 840

Height (mm) 35 35 35 35

Width (mm) 950 950 950 950

Depth (mm) 950 950 950 950

Gas side (mm) 12.7 15.9 15.9 15.9

Liquid side (mm) 6.4 9.5 9.5 9.5Connecting pipe

Drain port (mm) VP25

– 9 –

* : IEC standard, ** : AS standard

<Super Digital Inverter>

Model

Cooling capacit y (kW) 5.3 7.1 10.0 12.5

Heating capacity (kW) 5.6 8.0 11.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Cooling

Electrical

characteristics

Heating

Indoor unit RAV- SM562UT-E SM802UT-E SM1102UT-E SM1402UT-E

Outdoor unit RAV- SP562AT-E SP80 2AT-E SP1102AT-E SP1402AT-E

Running current (A) 7.17 – 6.57 8.95 – 8.21 11.24 – 10.31 16.51 – 15.14

Power consumption (kW) 1.53 1.93 2.40 3.56

Power factor (%) 97 98 97 98

EER (W/W) 3.46 3.68 4.17 3.51

Energy efficiency class * A A A A

Energy rating ** ————

Running current (A) 5.62 – 5.15 9.42 – 8.63 12.28 – 11.25 16.60 – 15.22

Power consumption (kW) 1.20 2.03 2.62 3.58

Power factor (%) 97 98 97 98

COP (W/W) 4.67 3.94 4.27 3.91

Energy efficiency class * A A A A

Energy rating ** ————

Main unit Zinc hot dipping steel plate

Ceiling panel

(Sold separately)

Outer

dimension

Ceiling panel

(Sold separately)

Main unit (kg)21222626

Total weight

Ceiling panel (Sold separately) (k g) 4.5 4.5 4.5 4.5

Heat exchanger Finned tube

Fan Turbo fan Turbo fan Turbo fan Turbo fan

Standard air flow H/M/L (m³/min) 17.5/13.9/12.1 20.0/15.7/13.6 28.0/22.0/18.0 33.0/25.0/20.0Fan unit

Motor (W) 60 60 90 90

Air filter TCB-LF1601UE, UFM1601UE, UFH16 01UE

Controller (Sold separately) RBC-AMT31E2, AS21E2, TCB-SC 642TLE2, AX21U (W)-E2

Model RBC-U21PG (W)-E2Appearance

Panel color Moon-white (Muncel 2.5GY 9.0/0.5)

Height (mm) 256 256 320 320

Width (mm) 840 840 840 840Main unit

Depth (mm) 840 840 840 840

Height (mm) 35 35 35 35

Width (mm) 950 950 950 950

Depth (mm) 950 950 950 950

Gas side (mm) 12.7 15.9 15.9 15.9

Connecting pipe

Sound pressure level H/M/L (dB•A) 32/29/27 34/31/28 39/36/33 42/38/34

Sound power level H/M/L (dB•A) 47/44/42 49/46/43 54/51/48 57/53/49

Liquid side (mm) 6.4 9.5 9.5 9.5

Drain port (mm) VP25

* : IEC standard, ** : AS standard

– 10 –

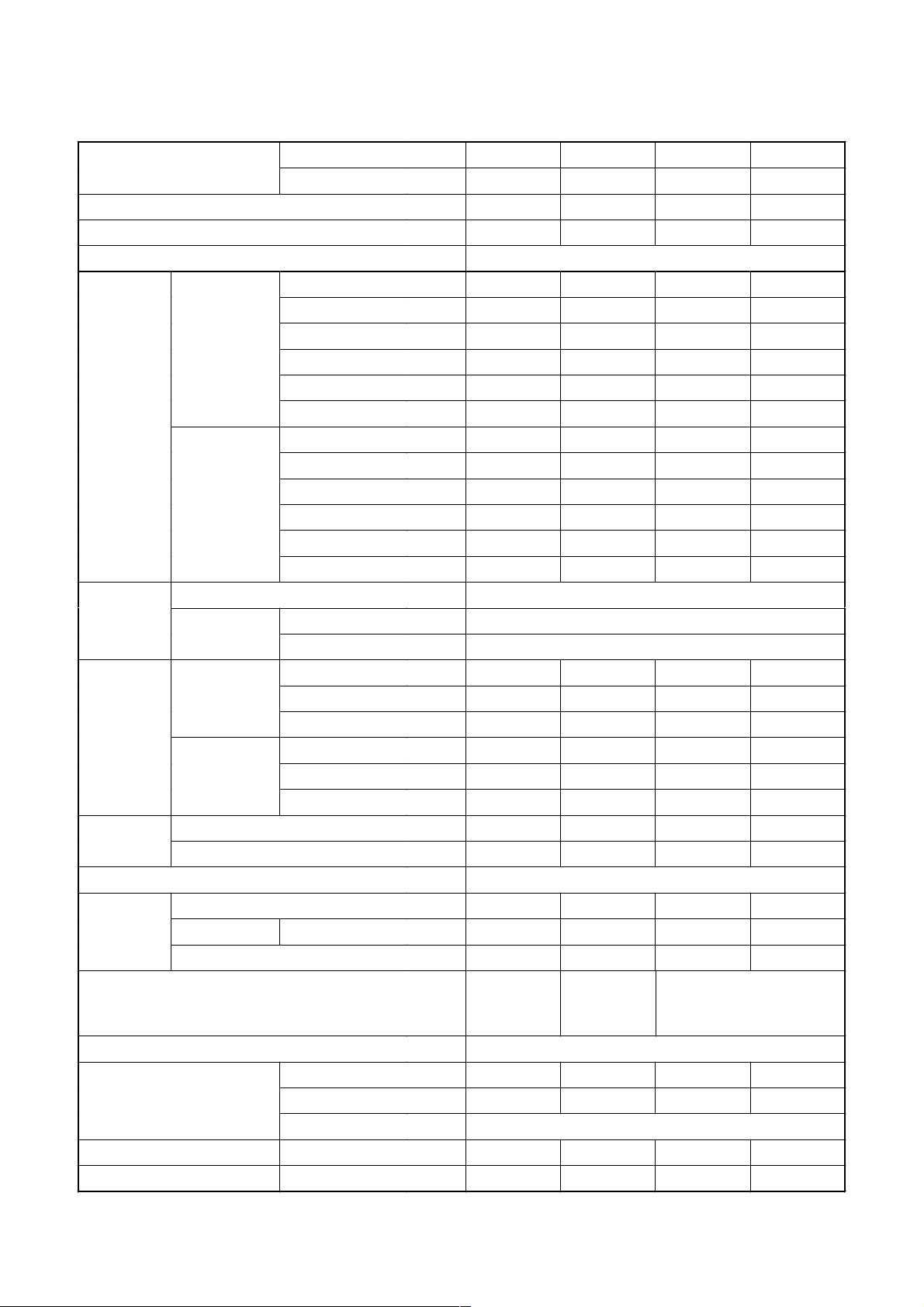

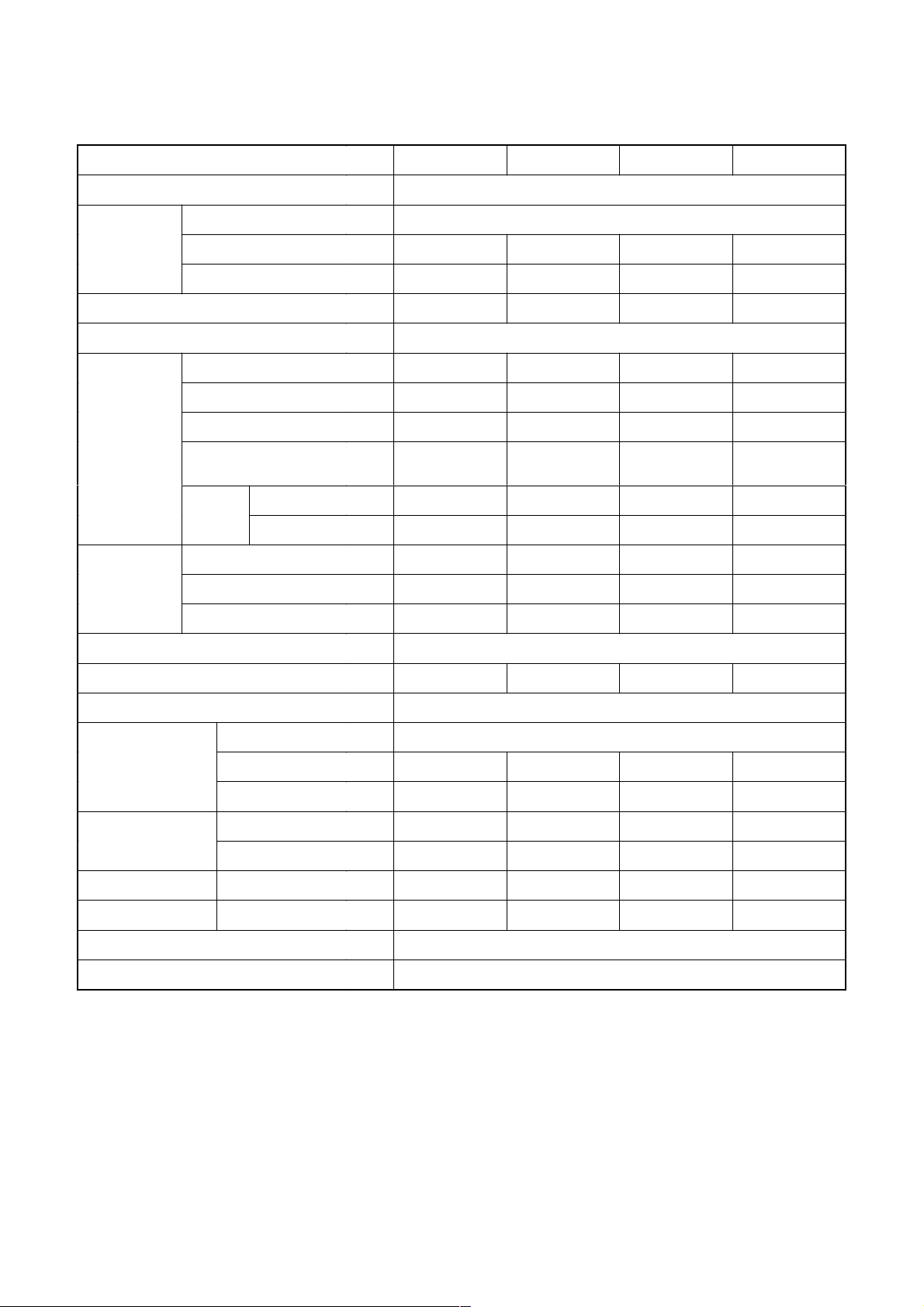

1-1-2. Concealed Duct Type

<Digital Inverter>

Model

Cooling capacit y (kW) 5.0 7.1 10.0 12.5

Heating capacity (kW) 5.6 8.0 11.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Cooling

Electrical

characteristics

Heating

Main unit Zinc hot dipping steel plate

Appearance

Outer

dimension

Total weight

Heat exchanger Finned tube

Fan unit

Air filter TCB-

Controller (Sold separately) RBC-AMT31E2, AS21E2, TCB-SC642TLE2, AX21E2

Sound pressure level H/M/L (dB•A) 40/37/33 40/37/34 42/39/36 44/41/38

Sound power level H/M/L (dB•A) 55/52/48 55/52/49 57/54/51 59/56/53

Ceiling panel

(Sold separately)

Ceiling panel

(Sold separately)

Main unit (kg)30395454

Ceiling panel (Sold separately) (k g) ————

Fan Centrifugal Centrifugal Centrifugal Centrifugal

Standard air flow H/M/L (m³/min) 13.0/11.9/9.8 19.0/16.2/13.3 27.0/23.0/18.9 33.0/28.0/23.1

Motor (W) 120 120 120 120

Indoor unit RAV- SM562BT-E SM802BT-E SM1102BT-E SM1402BT-E

Outdoor unit RAV- SM562AT-E SM802AT-E SM1102AT-E SM1402AT-E

Running current (A) 8.99 – 8.24 12.23 – 11.21 16.50 – 15.10 20.70 – 19.00

Power consumption (kW) 1.78 2.53 3.56 4.42

Power factor (%) 90 94 98 97

EER (W/W) 2.81 2.81 2.81 2.83

Energy efficiency class * C C C C

Energy rating ** 3.0 3.0 3.5 3.0

Running current (A) 8.18 – 7.50 11.65 – 10.68 14.56 – 13.35 18.88 – 17.31

Power consumption (kW) 1.71 2.41 3.14 4.03

Power factor (%) 95 94 98 97

COP (W/W) 3.27 3.32 3.57 3.47

Energy efficiency class * C C B B

Energy rating ** 3.0 3.5 5.0 4.0

Model —

Panel color —

Height (mm) 320 320 320 320

Width (mm) 700 1000 1350 1350Main unit

Depth (mm) 800 800 800 800

Height (mm) ————

Width (mm) ————

Depth (mm) ————

UFM21BE

UFM61BE

Gas side (mm) 12.7 15.9 15.9 15.9

Liquid side (mm) 6.4 9.5 9.5 9.5Connecting pipe

Drain port (mm) VP25

UFM11BFCE

UFM31BE

UFH51BFCE

UFM71BE

UFM21BFCE

UFM 41BE

UFH61BFCE

UFH 81BE

– 11 –

* : IEC standard, ** : AS standard

<Super Digital Inverter>

Model

Cooling capacit y (kW) 5.0 7.1 10.0 12.5

Heating capacity (kW) 5.6 8.0 11.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Cooling

Electrical

characteristics

Heating

Main unit Zinc hot dipping steel plate

Appearance

Outer

dimension

Total weight

Heat exchanger Finned tube

Fan unit

Air filter TCB-

Controller (Sold separately) RBC-AMT31E2, AS21E2, TCB-SC642TLE2, AX21E2

Sound pressure level H/M/L (dB•A) 40/37/33 40/37/34 42/39/36 44/41/38

Sound power level H/M/L (dB•A) 55/52/48 55/52/49 57/54/51 59/56/53

Ceiling panel

(Sold separately)

Ceiling panel

(Sold separately)

Main unit (kg)30395454

Ceiling panel (Sold separately) (k g) ————

Fan Centrifugal Centrifugal Centrifugal Centrifugal

Standard air flow H/M/L (m³/min) 13.0/11.9/9.8 19.0/16.2/13.3 27.0/23.0/18.9 33.0/28.0/23.1

Motor (W) 120 120 120 120

Indoor unit RAV- SM562BT-E SM802BT-E SM1102BT-E SM1402BT-E

Outdoor unit RAV- SP562AT-E SP80 2AT-E SP1102AT-E SP1402AT-E

Running current (A) 6.51 – 5.97 9.74 – 8.93 11.72 – 10.74 18.09 – 16.58

Power consumption (kW) 1.39 2.10 2.50 3.90

Power factor (%) 97 98 97 98

EER (W/W) 3.60 3.38 4.00 3.21

Energy efficiency class * A A A A

Energy rating ** ————

Running current (A) 7.26 – 6.66 9.74 – 8.93 11.72 – 10.74 16.70 – 15.31

Power consumption (kW) 1.55 2.10 2.50 3.60

Power factor (%) 97 98 97 98

COP (W/W) 3.61 3.81 4.48 3.89

Energy efficiency class * A A A A

Energy rating ** ————

Model —

Panel color —

Height (mm) 320 320 320 320

Width (mm) 700 1000 1350 1350Main unit

Depth (mm) 800 800 800 800

Height (mm) ————

Width (mm) ————

Depth (mm) ————

UFM21BE

UFM61BE

Gas side (mm) 12.7 15.9 15.9 15.9

Liquid side (mm) 6.4 9.5 9.5 9.5Connecting pipe

Drain port (mm) VP25

UFM11BFCE

UFM31BE

UFH51BFCE

UFM71BE

UFM21BFCE

UFM 41BE

UFH61BFCE

UFH 81BE

– 12 –

* : IEC standard, ** : AS standard

1-1-3. Under Ceiling Type

<Digital Inverter>

Model

Cooling capacit y (kW) 5.0 7.0 10.0 12.3

Heating capacity (kW) 5.6 8.0 11.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Cooling

Electrical

characteristics

Heating

Indoor unit RAV- SM562CT-E SM802CT-E SM1102CT-E SM1402CT-E

Outdoor unit RAV- SM562AT-E SM802AT-E SM1102AT-E SM1402AT-E

Running current (A) 8.71 – 7.98 12.23 – 11.21 16.20 – 14.90 21.18 – 19.40

Power consumption (kW) 1.82 2.53 3.51 4.52

Power factor (%) 95 94 98 97

EER (W/W) 2.75 2.77 2.85 2.72

Energy efficiency class * D D C D

Energy rating ** 2.5 2.5 3.0 2.5

Running current (A) 7.85 – 7.19 11.94 – 10.95 14.84 – 13.61 19.40 – 17.78

Power consumption (kW) 1.64 2.47 3.20 4.14

Power factor (%) 95 94 98 97

COP (W/W) 3.41 3.24 3.50 3.38

Energy efficiency class * B C B C

Energy rating ** 4.0 4.0 5.0 3.5

Main unit Shine white

Ceiling panel

(Sold separately)

Outer

dimension

Ceiling panel

(Sold separately)

Main unit (kg)21253333

Total weight

Ceiling panel (Sold separately) (k g) ————

Heat exchanger Finned tube

Fan Centrifugal Centrifugal Centrifugal Centrifugal

Standard air flow H/M/L (m³/min) 13.0/11.2/10.0 18.5/16.7/14.6 27.5/24.0/21.2 30.0/26.0/23.1Fan unit

Motor (W) 30 40 80 80

Air filter Attached main unit

Controller (Sold separately) RBC-AMT31E2, AS21E2, TCB-SC642TLE2, AX21E2

Model —Appearance

Panel color —

Height (mm) 210 210 210 210

Width (mm) 910 1180 1595 1595Main unit

Depth (mm) 680 680 680 680

Height (mm) ————

Width (mm) ————

Depth (mm) ————

Gas side (mm) 12.7 15.9 15.9 15.9

Connecting pipe

Sound pressure level H/M/L (dB•A) 36/33/30 38/36/33 41/38/35 43/40/37

Sound power level H/M/L (dB•A) 51/48/45 53/51/48 56/53/50 58/55/52

Liquid side (mm) 6.4 9.5 9.5 9.5

Drain port (mm) VP25

* : IEC standard, ** : AS standard

– 13 –

<Super Digital Inverter>

Model

Cooling capacit y (kW) 5.0 7.1 10.0 12.5

Heating capacity (kW) 5.6 8.0 11.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Cooling

Electrical

characteristics

Heating

Indoor unit RAV- SM562CT-E SM802CT-E SM1102CT-E SM1402CT-E

Outdoor unit RAV- SP562AT-E SP80 2AT-E SP1102AT-E SP1402AT-E

Running current (A) 6.61 – 6.06 9.47 – 8.93 11.24 – 10.31 18.09 – 16.58

Power consumption (kW) 1.41 2.10 2.40 3.90

Power factor (%) 97 98 97 98

EER (W/W) 3.55 3.38 4.17 3.21

Energy efficiency class * A A A A

Energy rating ** ————

Running current (A) 7.03 – 6.44 10.20 – 9.35 11.72 – 10.74 17.39 – 15.94

Power consumption (kW) 1.50 2.20 2.50 3.75

Power factor (%) 97 98 97 98

COP (W/W) 3.73 3.64 4.48 3.73

Energy efficiency class * A A A A

Energy rating ** ————

Main unit Shine white

Ceiling panel

(Sold separately)

Outer

dimension

Ceiling panel

(Sold separately)

Main unit (kg)21253333

Total weight

Ceiling panel (Sold separately) (k g) ————

Heat exchanger Finned tube

Fan Centrifugal Centrifugal Centrifugal Centrifugal

Standard air flow H/M/L (m³/min) 13.0/11.2/10.0 18.5/16.7/14.6 27.5/24.0/21.2 30.0/26.0/23.1Fan unit

Motor (W) 30 40 80 80

Air filter Attached main unit

Controller (Sold separately) RBC-AMT31E2, AS21E2, TCB-SC642TLE2, AX21E2

Model —Appearance

Panel color —

Height (mm) 210 210 210 210

Width (mm) 910 1180 1595 1595Main unit

Depth (mm) 680 680 680 680

Height (mm) ————

Width (mm) ————

Depth (mm) ————

Gas side (mm) 12.7 15.9 15.9 15.9

Connecting pipe

Sound pressure level H/M/L (dB•A) 36/33/30 38/36/33 41/38/35 43/40/37

Sound power level H/M/L (dB•A) 51/48/45 53/51/48 56/53/50 58/55/52

Liquid side (mm) 6.4 9.5 9.5 9.5

Drain port (mm) VP25

* : IEC standard, ** : AS standard

– 14 –

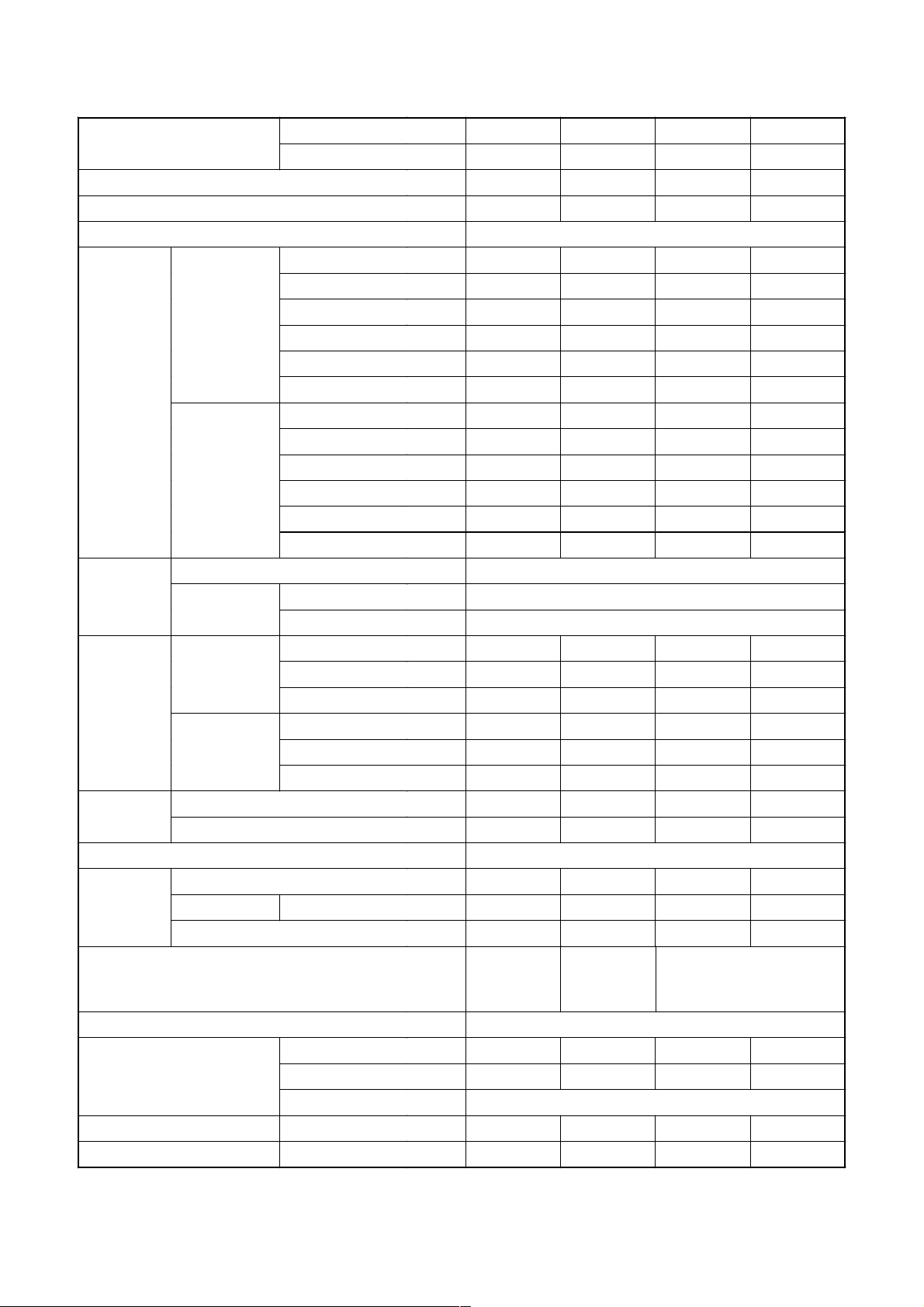

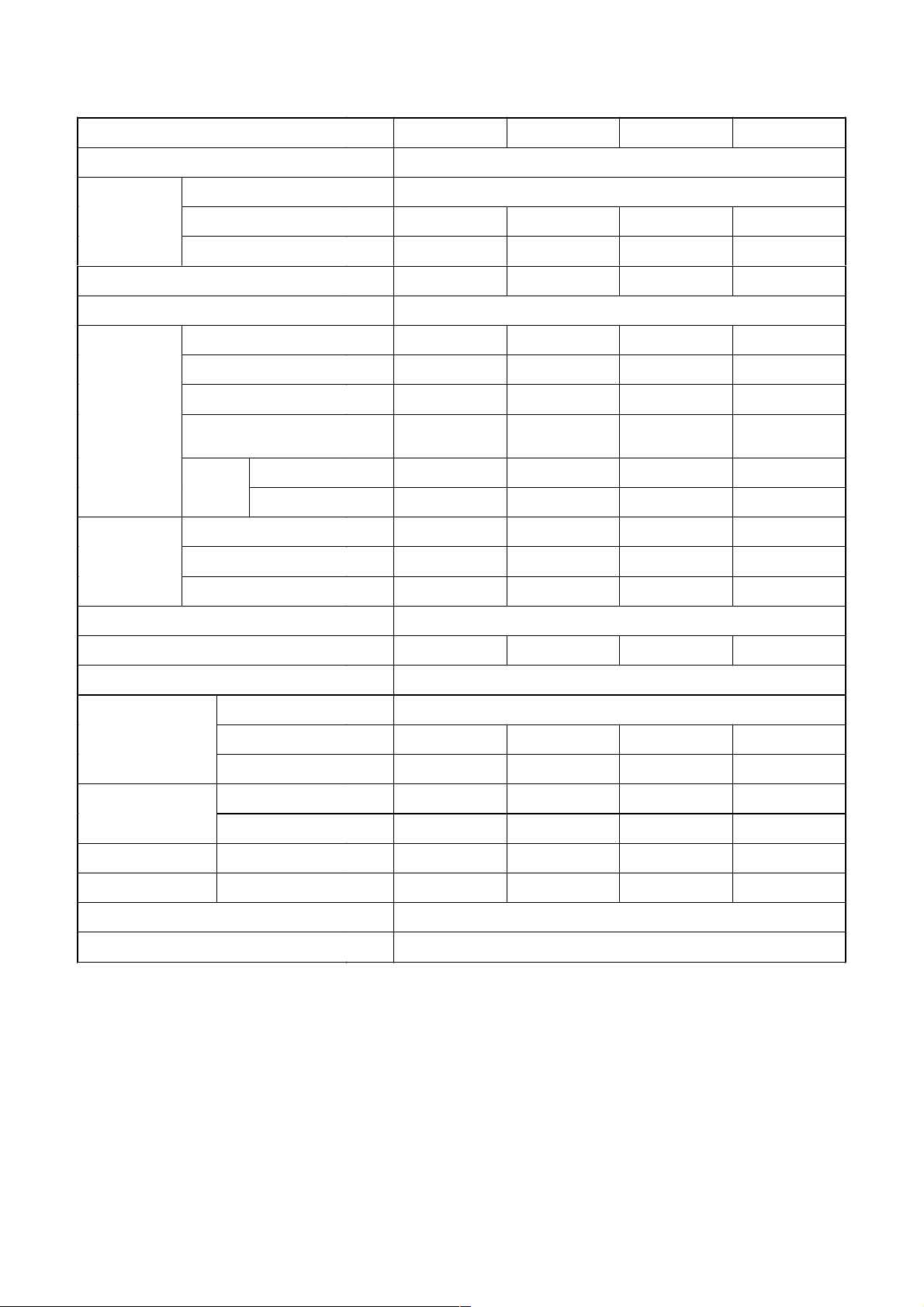

1-1-4. Twin T ype

<Digital Inverter>

Type 4-Way Air Cassette Concealed Duct Under Ceiling

Model

Cooling capacity (kW) 10.0 12.5 10.0 12.5 10.0 12.3

Heating capacity (kW) 11.2 14.0 11.2 14.0 1 1.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Electrical

characteristics

Fan unit

Sound pressure level H /M/L (dB•A) 32/29/27 34/31/28 40/37/33 40/37/34 36/33/30 38/36/33

Sound power level H/M/L (dB•A) 47/44/42 49/46/43 55/52/48 55/52/49 51/48/45 53/51/48

Power supply 1 phase 230V (220 – 240V) 50Hz (Power exclusive to outdoor is required.)

Inter

connecting

pipes

Fan unit

Connecting

pipe

Sound pressure level Cooling/Heating (dB•A) 53/54 53/54 53/54 53/54 53/54 53/54

Sound power level Cooling/Heating (dB•A) 70/71 70/71 70/71 70/71 70/71 70/71

Indoor unit 1 RAV- SM562UT-E SM802UT-E SM562BT-E SM802BT-E SM562CT-E SM802CT-E

Indoor unit 2 RAV- SM562UT-E SM802UT-E SM562BT-E SM802BT-E SM562CT-E SM802CT-E

Outdoor unit RAV- SM1102AT-E SM1402AT-E SM1102AT-E SM1402AT-E SM1102AT-E SM1402AT-E

Indoor unit

Running current (A) 16.33–14.97 19.17–17.57 16.51–15.14 20.71–18.99 16.28–14.92 21.18–19.42

Power consumption (kW) 3.52 4.09 3.56 4.42 3.51 4.52

Cooling

Heating

Fan Turbo fan Turbo fan Centrifugal Centrifugal Centrifugal Centrifugal

Standard air flow H/M/L (m³/min)

Motor (W) 60 60 120 120 30 40

Standard length (m) 7.5 7.5 7.5 7.5 7.5 7.5

Min. length (m) 5 .0 5.0 5.0 5.0 5.0 5.0

Max. total length (m) 50 50 50 50 50 50

Over 30m 40g/m (31m to 50m)

Height

difference

Fan Propeller fan

Standard air flow high (m³/min)757575757575

Motor (W) 100 100 100 100 100 100

Gas side

Liquid side

Power factor(%)989798979897

EER (W/W) 2.84 3.06 2.81 2.83 2.85 2.72

Energy efficiency class * C B C C C D

Running current (A) 14.56–13.35 18.74–17.18 14.56–13.35 18.88–17.31 14.84–13.61 19.40–17.78

Power consumption (kW) 3.14 4.00 3.14 4.03 3.20 4.14

Power factor(%)989798979897

COP (W/W) 3.57 3.50 3.57 3.47 3.50 3.38

Energy efficiency class * B B B B B C

17 . 5/13 .9 /12.1 20. 0/15 .7 /13.6

Outdoor unit

Outdoor lower (m) 30 30 30 30 30 30

Outdoor high(m)303030303030

Main (mm) 15.9 15.9 15.9 15.9 15.9 15.9

Sub (mm) 12.7 15.9 12.7 15.9 12.7 15.9

Main (mm) 9.5 9.5 9.5 9.5 9.5 9.5

Sub (mm) 6.4 9.5 6.4 9.5 6.4 9.5

13.0/1 1.9/9 .8

19 . 0/16 .2 /13.3 13 . 0/11.2/10.0 18. 5/16 .7/14 .6

– 15 –

* : IEC standard

<Super Digital Inverter>

Type 4-Way Air Cassette Concealed Duct Under Ceiling

Model

Cooling capacity (kW) 10.0 12.5 10.0 12.5 10.0 12.3

Heating capacity (kW) 11.2 14.0 11.2 14.0 1 1.2 14.0

Power supply 1 phase 230V (220 – 240V) 50Hz

Electrical

characteristics

Fan unit

Sound pressure level H /M/L (dB•A) 32/29/27 34/31/28 40/37/33 40/37/34 36/33/30 38/36/33

Sound power level H/M/L (dB•A) 47/44/42 49/46/43 55/52/48 55/52/49 51/48/45 53/51/48

Power supply 1 phase 230V (220 – 240V) 50Hz (Power exclusive to outdoor is required.)

Inter

connecting

pipes

Fan unit

Connecting

pipe

Sound pressure level Cooling/Heating (dB•A) 49/51 53/54 49/51 53/54 49/51 53/54

Sound power level Cooling/Heating (dB•A) 66/68 70/71 66/68 70/71 66/68 70/71

Indoor unit 1 RAV- SM562UT-E SM802UT-E SM562BT-E SM802BT-E SM562CT-E SM802CT-E

Indoor unit 2 RAV- SM562UT-E SM802UT-E SM562BT-E SM802BT-E SM562CT-E SM802CT-E

Outdoor unit RAV- SP1102AT-E SP1402AT-E SP1102AT-E SP1402AT-E SP1102AT-E SP1402AT-E

Indoor unit

Running current (A) 11.24–10.31 16.51–15 .14 1 1. 72–10.74 18.09–16.58 11.24–10.31 18.09–16.58

Power consumption (kW) 2.40 3.56 2.50 3.90 2.40 3.90

Cooling

Heating

Fan Turbo fan Turbo fan Centrifugal Centrifugal Centrifugal Centrifugal

Standard air flow H/M/L (m³/min)

Motor (W) 60 60 120 120 30 40

Standard length (m) 7.5 7.5 7.5 7.5 7.5 7.5

Min. length (m) 5 .0 5.0 5.0 5.0 5.0 5.0

Max. total length (m) 50 50 50 50 50 50

Over 30m 40g/m (31m to 50m)

Height

difference

Fan Propeller fan

Standard air flow high (m³/min) 125 125 125 125 125 125

Motor (W) 63 + 63 63 + 63 63 + 63 63 + 63 63 + 63 63 + 63

Gas side

Liquid side

Power factor(%)979897989798

EER (W/W) 4.17 3.51 4.00 3.21 4.17 3.21

Energy efficiency class * A A A A A A

Running current (A) 11.95–10.95 16.60–15 .22 1 1. 95–10.95 16.70–15.31 11.95–10.95 17.39–15.94

Power consumption (kW) 2.55 3.58 2.55 3.60 2.55 3.75

Power factor(%)979897989798

COP (W/W) 4.39 3.91 4.39 3.89 4.39 3.79

Energy efficiency class * A A A A A A

17.5/13.9/12.1 20.0/15.7/13.6

Outdoor unit

Outdoor lower (m) 30 30 30 30 30 30

Outdoor high(m)303030303030

Main (mm) 15.9 15.9 15.9 15.9 15.9 15.9

Sub (mm) 12.7 15.9 12.7 15.9 12.7 15.9

Main (mm) 9.5 9.5 9.5 9.5 9.5 9.5

Sub (mm) 6.4 9.5 6.4 9.5 6.4 9.5

13.0/1 1.9/9 .8

19.0/16.2/13.3 13.0/11.2/10.0 18.5/16.7/1 4.6

– 16 –

* : IEC standard

1-2. Outdoor Unit

g

<Digital Inverter>

Model name

Power supply 1 phase 230V (220 – 240V) 50Hz (Power exclusive to outdoor is required.)

Ty pe Hermetic comp re sso r

Motor (kW) 1.1 1.6 2.5 3.0Compressor

Pole 4 4 4 4

Refrigerant char ged (kg) 1.0 1.7 2. 8 2.8

Refrigerant control Pulse motor valve

Standard length (m) 7.5 7.5 7.5 7.5

Min. length (m) 5.0 5.0 5.0 5.0

Inter connecti n

pipe

Outer

dimension

Max. total length (m) 30 30 50 50

Additional refrigerant charge under

long piping connector

Height

difference

Height (mm) 550 550 795 795

Width (mm) 780 780 900 900

Depth (mm) 290 290 320 320

Outdoor lower (m) 30 30 30 30

Outdoor higher (m ) 30 30 30 30

RA V- SM562AT-E SM802AT-E SM1102AT-E SM1402AT-E

20g/m

(21m to 30m)

40g/m

(21m to 30m)

40g/m

(31m to 50m)

40g/m

(31m to 50m)

Appearance Silky shade (Muncel 1Y8.5/0.5)

Total weight (kg) 38 42 77 77

Heat exchanger Finned tube

Fan Propeller fan

Standard air flow (m³/h) 40 45 75 75Fan unit

Motor (W) 43 43 100 100

Connecting pipe

Sound pressure level Cooling/Heating (dB•A) 46/48 48/50 53/54 53/54

Sound power level Cool ing/Heating (dB•A) 63/65 65/67 70/71 70/71

Outside air temperature, Cooling (°C) 43 to –15

Outside air temperature, Heating (°C) 15 to –15

Gas side (mm) 12.7 15.9 15.9 15.9

Liquid side (mm) 6.4 9.5 9.5 9.5

– 17 –

<Super Digital Inverter>

g

Model name

Power supply 1 phase 230V (220 – 240V) 50Hz (Power exclusive to outdoor is required.)

Ty pe Hermetic comp re sso r

Motor (kW) 2.0 2.0 3.75 3.75Compressor

Pole 4 4 4 4

Refrigerant char ged (kg) 1.5 2.1 2.95 2.95

Refrigerant control Pulse motor valve

Standard length (m) 7.5 7.5 7.5 7.5

Min. length (m) 5.0 5.0 5.0 5.0

Inter connecti n

pipe

Outer

dimension

Max. total length (m) 50 50 70 70

Additional refrigerant charge under

long piping connector

Height

difference

Height (mm) 795 795 1340 1340

Width (mm) 900 900 900 900

Depth (mm) 320 320 320 320

Outdoor lower (m) 30 30 30 30

Outdoor higher (m ) 30 30 30 30

RA V- SP562AT-E SP802AT-E SP1102AT-E SP1402AT-E

20g/m

(21m to 50m)

40g/m

(31m to 50m)

40g/m

(31m to 70m)

40g/m

(31m to 70m)

Appearance Silky shade (Muncel 1Y8.5/0.5)

Total weight (kg) 55 62 95 95

Heat exchanger Finned tube

Fan Propeller fan

Standard air flow (m³/h) 57 57 125 125Fan unit

Motor (W) 63 63 63 + 63 63 + 63

Connecting pipe

Sound pressure level Cooling/Heating (dB•A) 46/47 47/49 49/51 53/54

Sound power level Cool ing/Heating (dB•A) 63/64 64/66 66/68 70/71

Outside air temperature, Cooling (°C) 43 to –15

Outside air temperature, Heating (°C) 15 to –15

Gas side (mm) 12.7 15.9 15.9 15.9

Liquid side (mm) 6.4 9.5 9.5 9.5

– 18 –

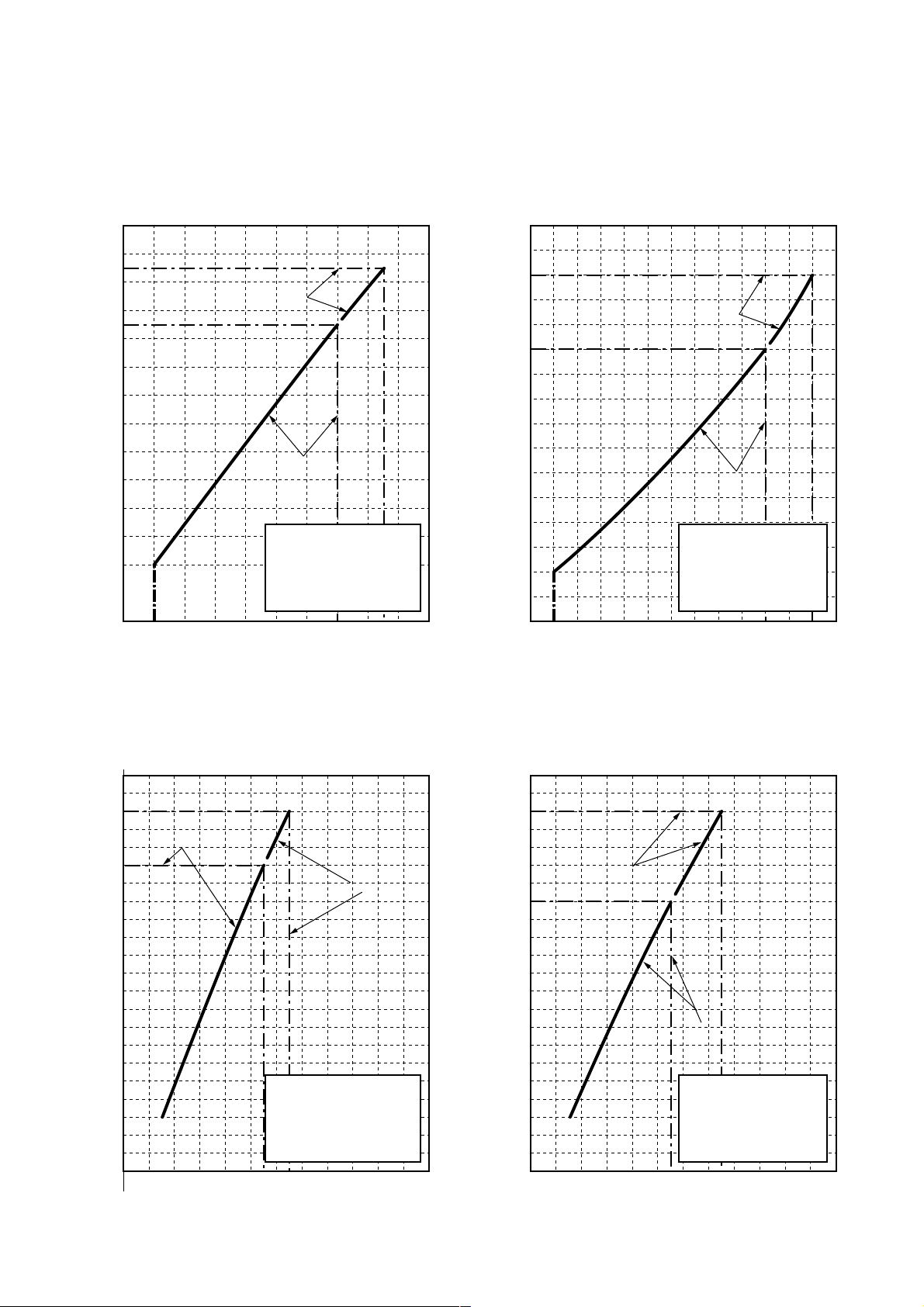

1-3. Operation Characteristic Curve

• Operation characteristic curve <Digital Inverter>

RAV-SM562AT-E, RAV-SM802AT-E

<Cooling> <Heating>

14

12

10

8

6

Current (A)

4

2

0

0 20 40 60708090100

RAV-SM802AT-E

RAV-SM802AT-E

RAV-SM562AT-E

RAV-SM562AT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

Compressor speed (rps)

16

14

RAV-SM802AT-E

12

10

8

RAV-SM802AT-E

Current (A)

6

4

2

0

0 20406080100120

RAV-SM562AT-E

RAV-SM562AT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

Compressor speed (rps)

RAV-SM1102AT-E, RAV-SM1402AT-E

<Cooling> <Heating>

22 22

20

RAV-SM1102AT-E

RAV-SM1102AT-E

18

16

14

12

10

Current (A)

8

6

4

2

0

0204060

RAV-SM1402AT-E

RAV-SM1402AT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

80 100 120

20

18

RAV-SM1402AT-ERAV-SM1402AT-E

16

14

12

10

Current (A)

8

6

4

2

0

0 204060

Compressor speed (rps)

RAV-SM1102AT-ERAV-SM1102AT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

80 100 120

Compressor speed (rps)

– 19 –

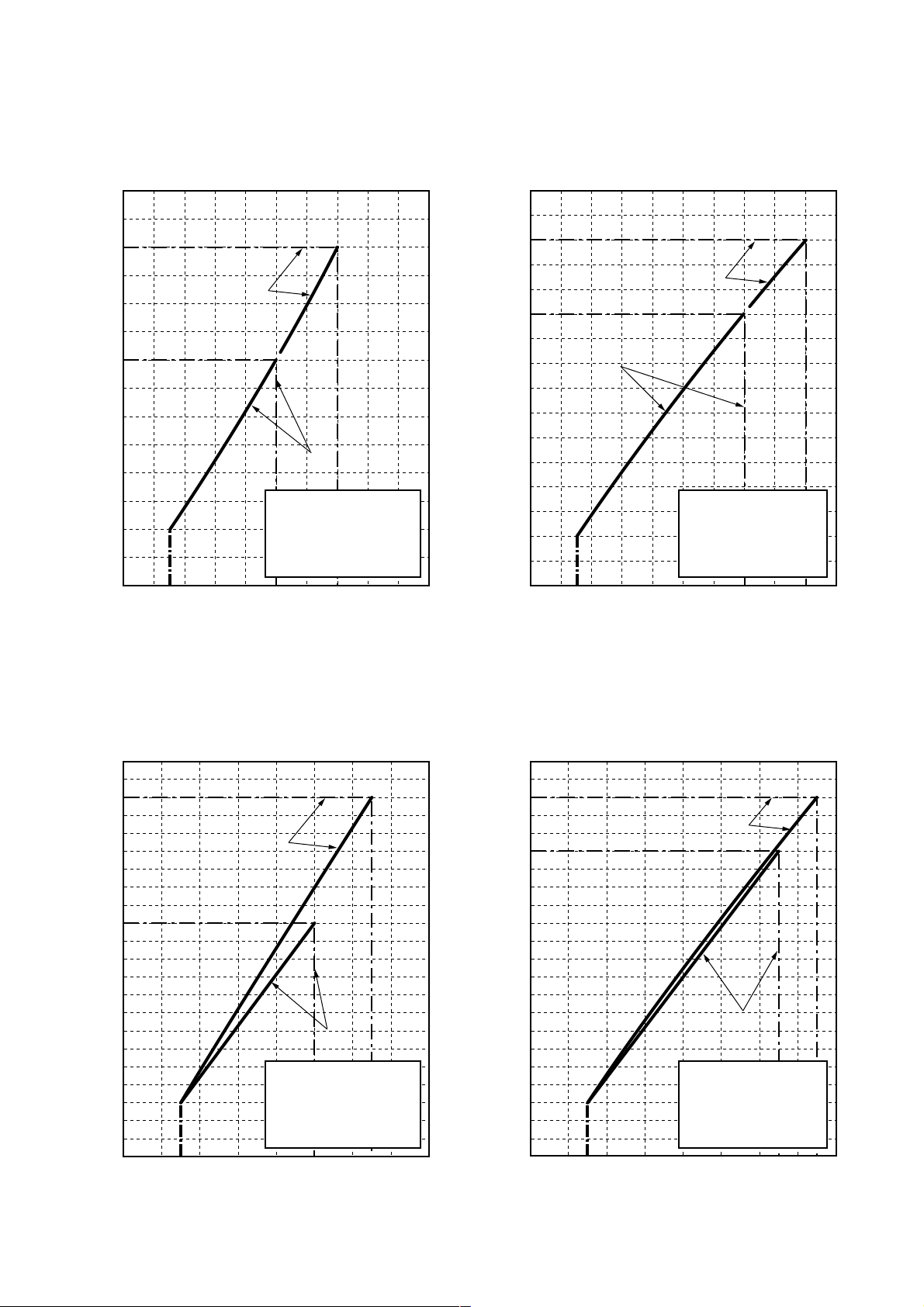

• Operation characteristic curve <Super Digital Inverter>

RAV-SP562AT-E, RAV-SP802AT-E

<Cooling> <Heating>

14

12

RAV-SP802AT-E

RAV-SP802AT-E

10

8

6

Current (A)

4

2

0

0 20406050 70 80 100

RAV-SP562AT-ERAV-SP562AT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

Compressor speed (rps) Compressor speed (rps)

16

14

RAV-SP802AT-E

12

10

RAV-SP562AT-E

RAV-SP562AT-E

8

RAV-SP802AT-E

Current (A)

6

4

2

0

0 204060 908070 100

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

RAV-SP1102AT-E, RAV-SP1402AT-E

<Cooling> <Heating>

22

20

18

16

14

12

10

RAV-SP1402AT-E

RAV-SP1402AT-E

Current (A)

8

RAV-SP1102AT-E

6

4

2

0

020406080

RAV-SP1102AT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

22

20

18

16

14

12

10

Current (A)

8

6

4

2

0

020406080

RAV-SP1402AT-E

RAV-SP1402AT-E

RAV-SP1102AT-E

RAV-SP1102AT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

Compressor speed (rps)

Compressor speed (rps)

– 20 –

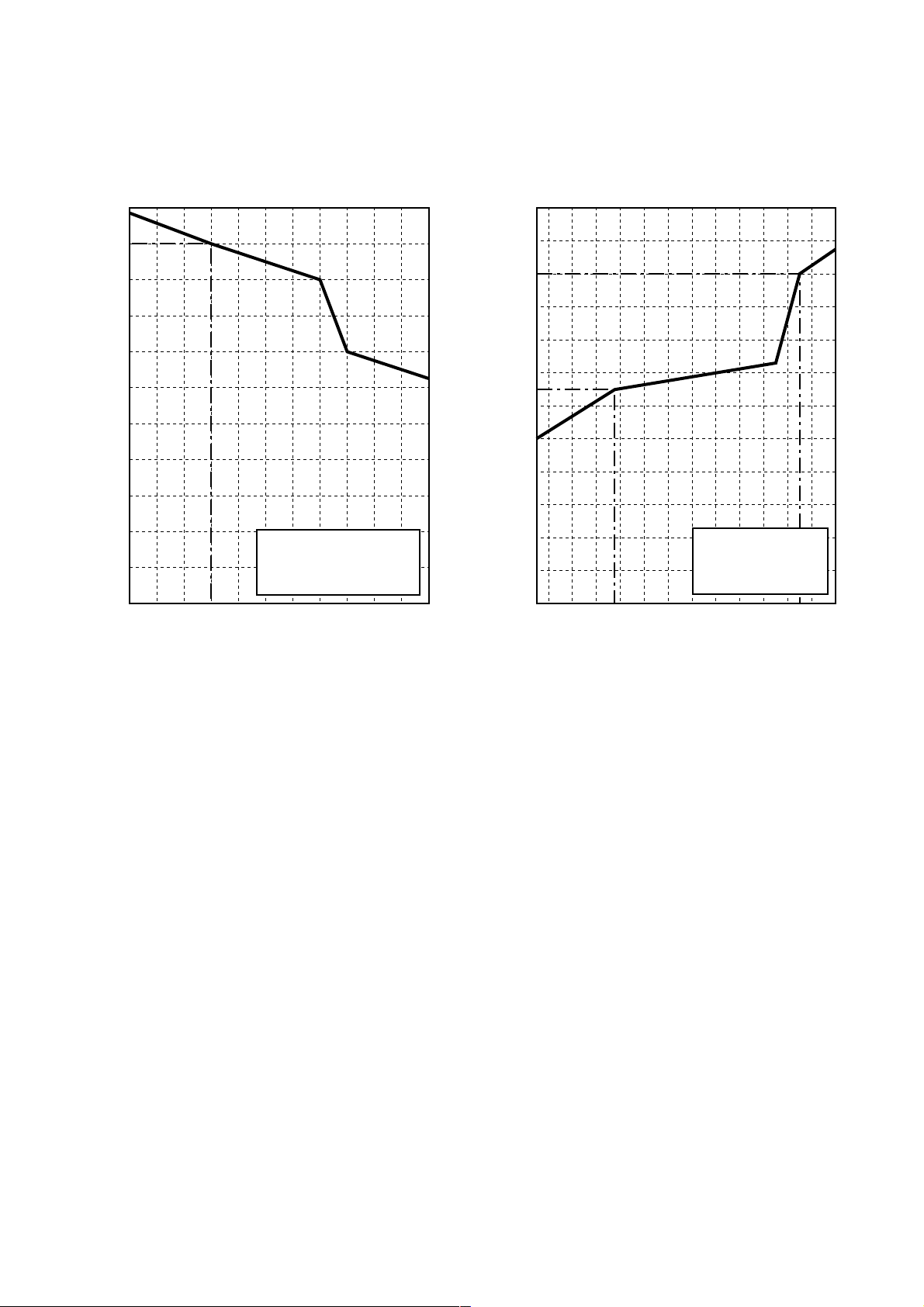

• Capacity variation ratio according to temperature

RAV-SM562AT-E, RAV-SM802AT-E, RAV-SM1102AT-E, RAV-SM1402AT-E

RAV-SP562AT-E, RAV-SP802AT-E, RAV-SP1102AT-E, RAV-SP1402AT-E

<Cooling> <Heating>

105

100

95

90

85

80

75

70

Capacity ratio (%)

65

60

55

50

32 33 34 35 36 37 38 39

Outsoor temp. (˚C)

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length : 7.5m

40

41 42 43

120

110

100

90

80

70

60

50

Capacity ratio (%)

40

30

20

10

0

-14-12-10-8-6-4-20246810

• Conditions

Indoor : DB20˚C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (˚C)

– 21 –

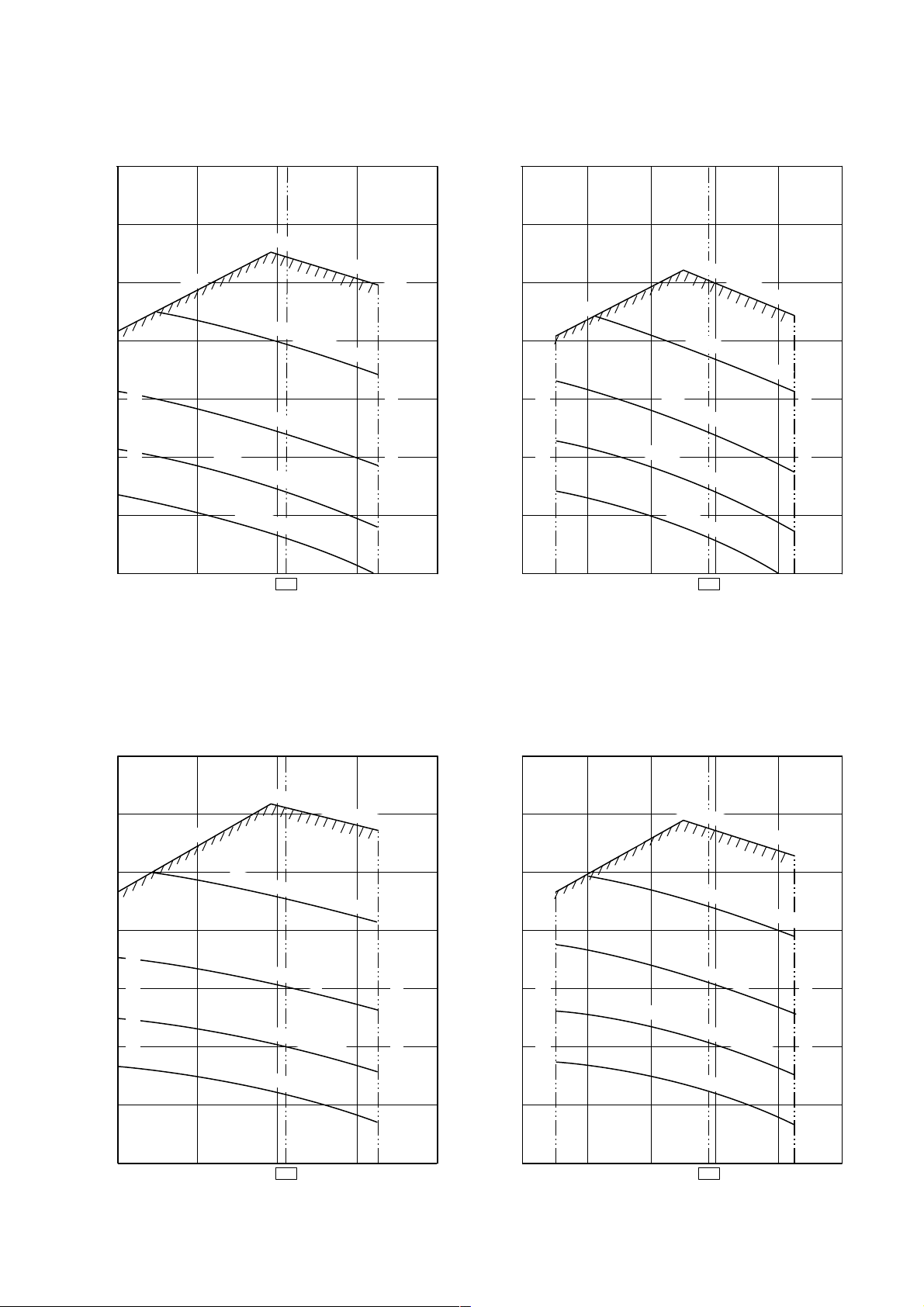

2. AIR DUCTING WORK

2-1. Static Pressure Characteristics of Each Model

RAV-SM562BT-E, RAV-SM802BT-E, RAV-SM1102BT-E, RAV-SM1402BT-E

Fig. 1 RAV-SM562BT-E (Round duct)

140

120

100

Usable lim

80

60

Static pressure (Pa)

40

Air volume limit (Min.)

20

0

500 700 780 900

Standard air volume 780m³/h

High static pressure 2H tap

it

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

Air volume m³/h

140

120

100

80

60

Static pressure (Pa)

40

Air volume limit (Max.)

20

Fig. 3 RAV-SM802BT-E (Round duct)

Standard air volume 1140m³/h

High static pressure 2H tap

Usable limit

Air volume limit (Min.)

0

800

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

1000

Air volume m³/h

Air volume limit (Max.)

12001140 1300

Fig. 2 RAV-SM562BT-E (Square duct)

140

120

108

100

80

60

Usable limit

Static pressure (Pa)

40

Air volume limit (Min.)

20

0

500 700 780 900

Standard air volume 780m³/h

High static pressure 2H tap

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

Air volume m³/h

140

120

100

80

60

Static pressure (Pa)

40

Air volume limit (Max.)

20

Fig. 4 RAV-SM802BT-E (Square duct)

Standard air volume 1140m³/h

High static pressure 2H tap

Usable limit

Air volume limit (Min.)

0

800

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

1000

Air volume m³/h

Air volume limit (Max.)

12001140 1300

– 22 –

0

Fig. 5 RAV-SM1102BT-E (Round duct)

Fig. 7 RAV-SM1402BT-E (Round duct)

140

120

Standard air volume 1620m³/h

140

120

Standard air volume 1980m³/h

High static pressure 2H tap

High static pressure 2H tap

100

100

Usable limit

High static pressure 1H tap

80

60

Standard H tap

Static pressure (Pa)

40

Air volume limit (Min.)

20

0

1200

Low static pressure H tap

Standard L tap

1620

Air volume limit (Max.)

2000

80

60

Static pressure (Pa)

40

20

0

1200 1800

Air volume m³/h

Usable limit

Air volume limit (Min.)

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

1980

Air volume m³/h

Air volume limit (Max.)

2200 2400

Fig. 6 RAV-SM1102BT-E (Square duct)

140

120

Usable limit

100

80

60

Static pressure (Pa)

40

Air volume limit (Min.)

20

Low static pressure H tap

Standard air volume 1620m³/h

High static pressure 2H tap

High static pressure 1H tap

Standard H tap

Standard L tap

Air volume limit (Max.)

Fig. 8 RAV-SM1402BT-E (Square duct)

140

120

100

80

60

Usable limit

Static pressure (Pa)

40

Air volume limit (Min.)

20

Standard air volume 1980m³/h

High static pressure 2H tap

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

Air volume limit (Max.)

0

1200

1620

Air volume m³/h

2000

– 23 –

0

1200 1800

Air volume hm³/h

1980

2200 240

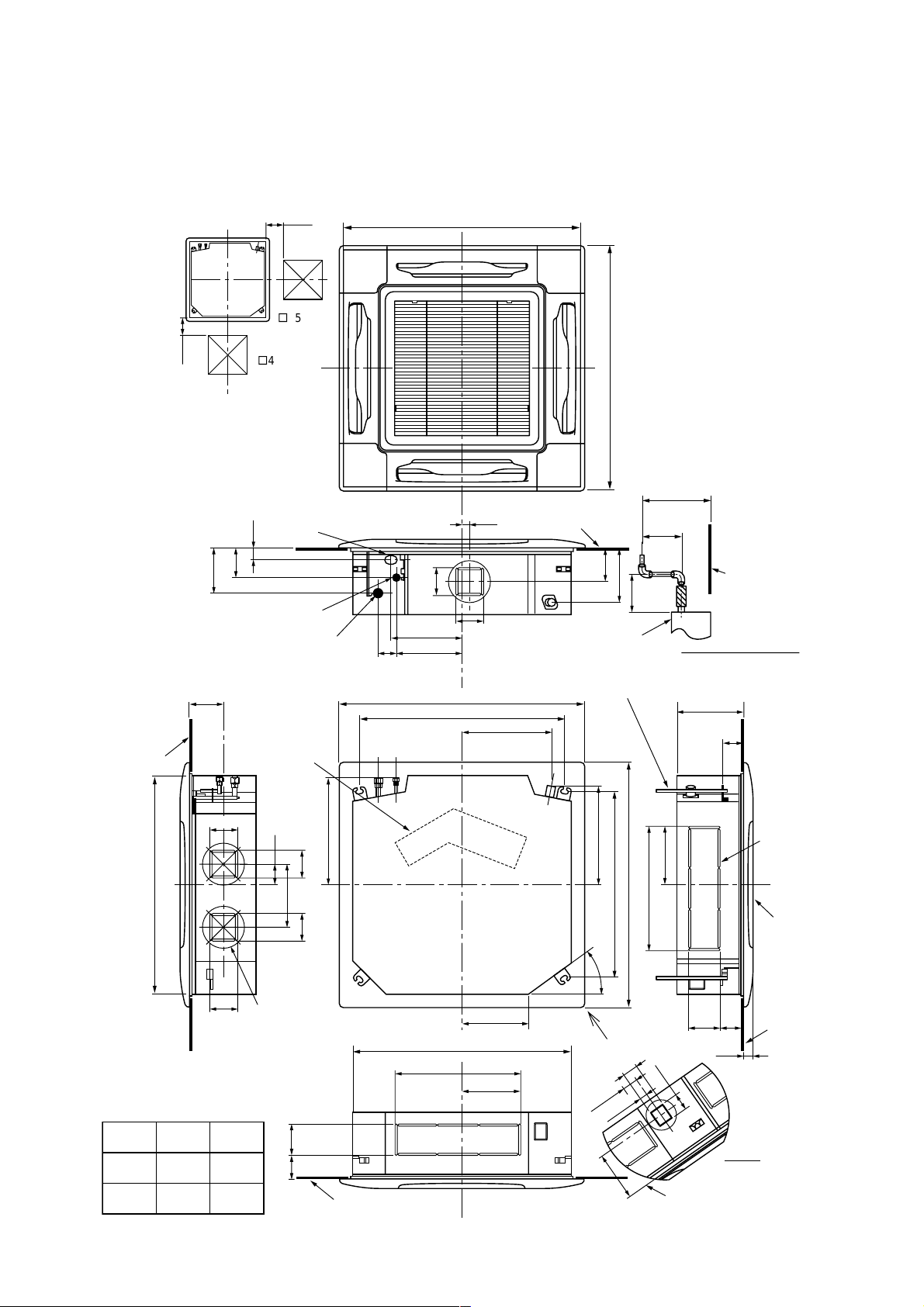

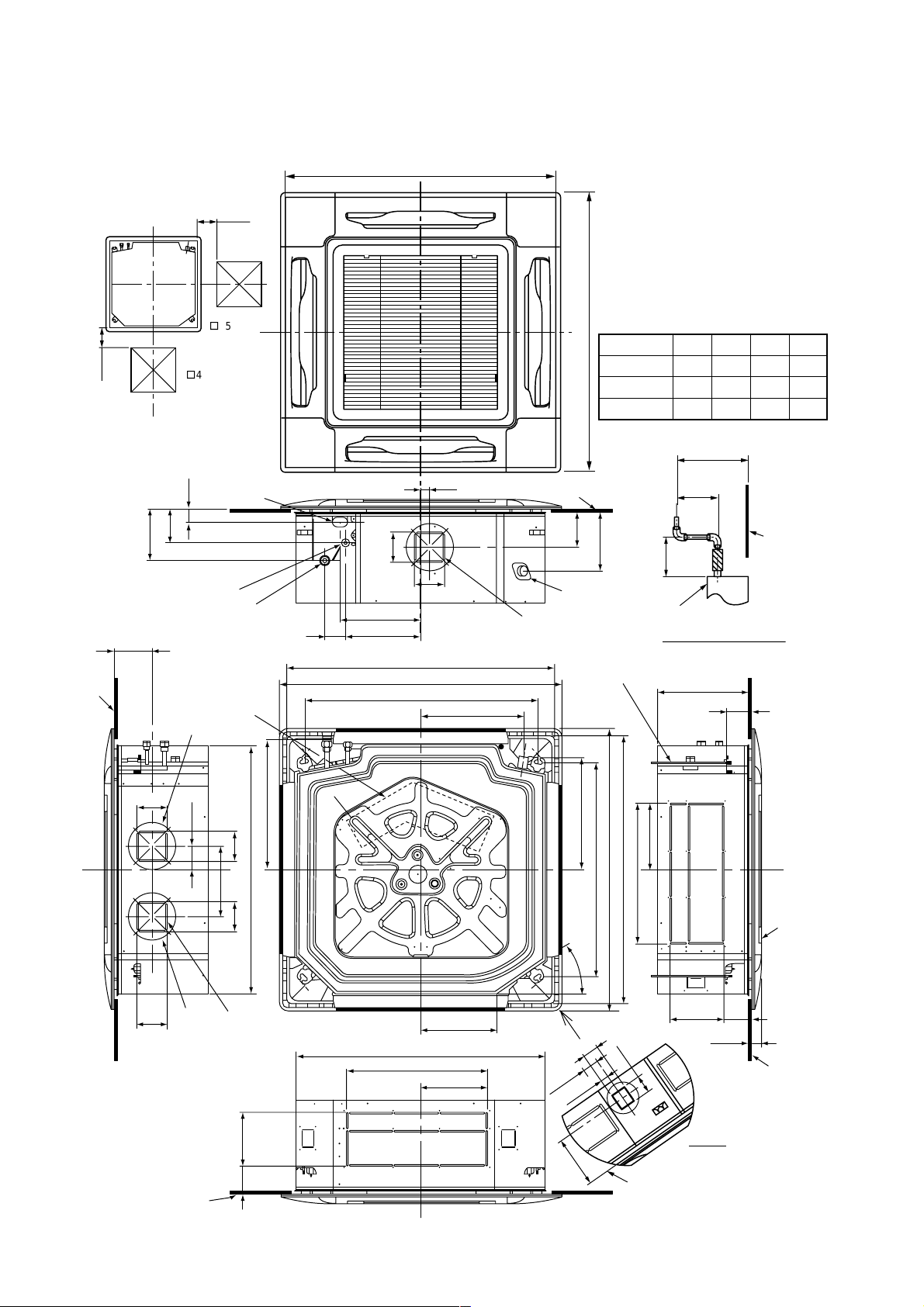

3. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

3-1. Indoor Unit

3-1-1. 4-Way Air Discharge Cassette Type

RAV-SM562UT-E, RAV-SM802UT-E

Surface

under ceiling

200

113

173

Refrigerant pipe

connecting port A

130

200

Check port

(¨450)

Check port

(¨450)

Cable draw-in port

45

Refrigerant pipe

connecting port B

Electric

parts box

860 to 910 Recommended external size

30

105

270

25070

950 Panel external dimension

790 Hanging bolt pitch

346.5

860 to 910 Recommended external size

Surface

under ceiling

Hanging bolt M10 or W3/8

Procured locally

130

210

360

Indoor unit

Standing

640 or less

Standing

850 or less

Drain up standing size

256

Surface

under ceiling

88

SM562

SM802

840 Unit external dimension

A

Ø6.4

Ø9.5

150

105

Ø12.7

Ø15.9

Knockout

97

35

Z view

for

humidifier

Ceiling

panel

(Sold

separately)

Surface

under ceiling

80

Ø162

B

415.0

105105

240

254.5

840 Hanging bolt

480

227

12097

Surface under ceiling

381.6

227

480

723 Hanging bolt pitch

950 Panel external dimension

35

˚

64

57

57.5

25

188

Surface under ceiling

120

– 24 –

RAV-SM1102UT-E, RAV-SM1402UT-E, RAV-SP1102UT-E

860 to 910 Recommended external size

200

Check port

(¨450)

200

Check port

(¨450)

Take-in port of pipes

45

30

SM1102UT

SM1402UT

SP1102UT

860 to 910 Recommended external size

Ceiling bottom surface

A

B

Ø12.7

Ø15.9

Ø12.7

Ø15.9

Ø9.5 319183Ø15.9

Standing

850 or less

Standing

640 or less

C

120

183

D

256

319

113

173

Refrigerant pipe connecting port

Ceiling

bottom

surface

A

Refrigerant pipe connecting port

B

130

Ø162

105

80

Electric parts box

434.5

240

105 105

840 Unit external dimension

105

105

270

250

70

860 to 910 Ceiling opening dimension

950 Panel external dimension

790 Hanging bolt pitch

Knockout square hole

for divide duct

For Ø150

345.5

130

210

Drain pipe

connecting port

Hanging bolt

M10 or Ø3/8

(To be procured locally)

381.6

227

480

723 Hanging bolt pitch

950 Panel external dimension

860 to 910 Ceiling opening dimension

35˚

360

Indoor unit

Drain up standing size

D

88

Surface

under ceiling

Ceiling panel

(sold separately)

Ø162

105

Ceiling bottom surface

Knockout square

hole for divide duct

for Ø150

(2 positions)

C97

254.5

840 Unit external dimension

480

227

– 25 –

57.5

188

57

25

C

64

Z view

Surface under ceiling

97

35

Ceiling bottom

surface

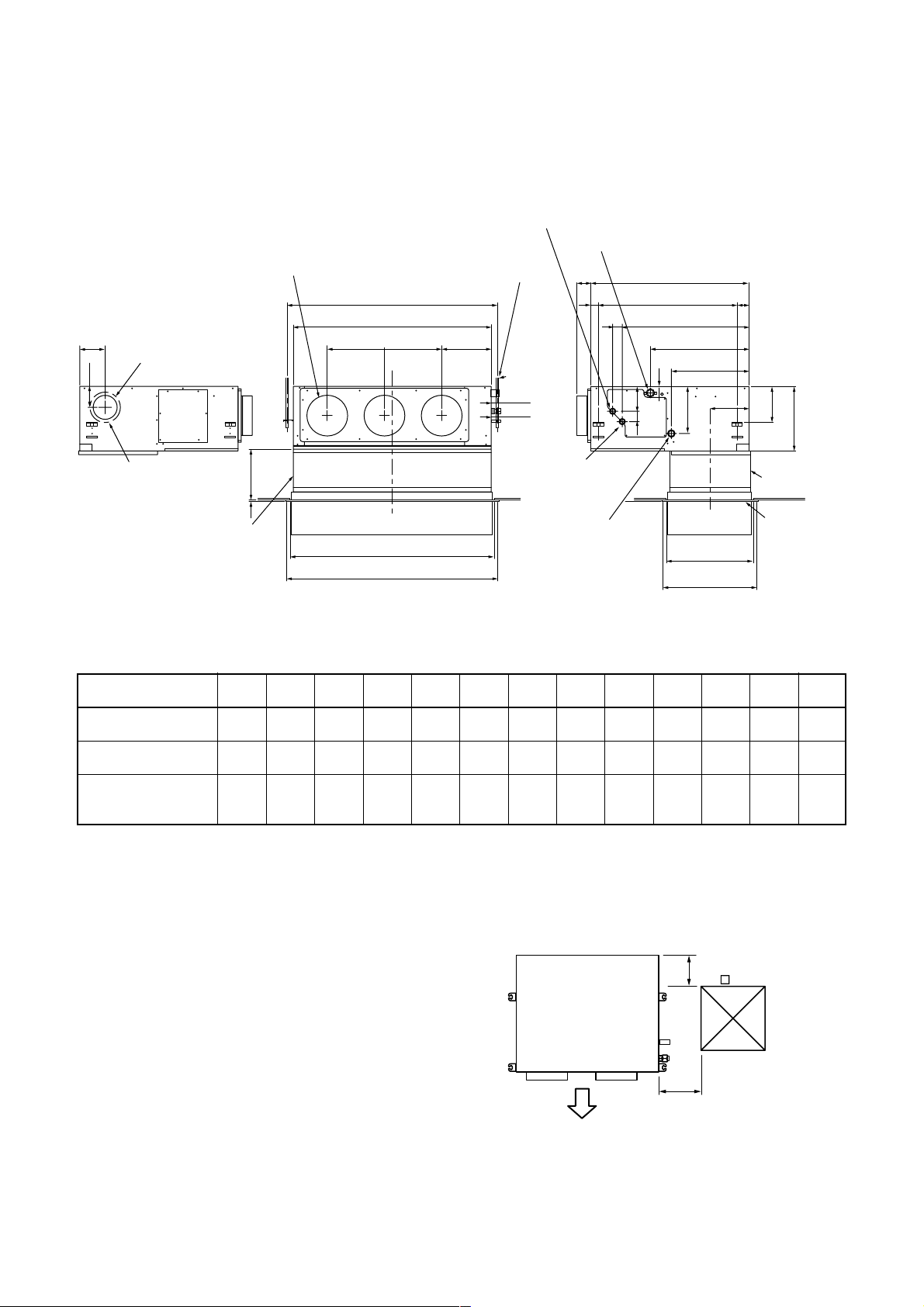

3-1-2. Concealed Duct Type

RAV-SM562BT-E, RAV-SM802BT-E, RAV-SM1102BT-E, RAV-SM1402BT-E

129

110

Knock-out hole Ø125

(Air take-in port)

6-Ø4 T apping screw

undersized hole Ø160

• Dimension

Discharge port flange

N-Ø200

60 to 260

9

Suction port canvas

(Separate sold)

Refrigerant pipe connecting port

(Gas side ØF)

Hanging bolt pitch B

Main unit dimension A

J = M x K H

C

Ceiling open size D

Panel external dimension E

Hanging bolt

4-M10 screw

(Arranged locally)

44

49

Refrigerant pipe

connecting port

(Liquid side ØG)

Drain pipe connecting port

for vinyl chloride pipe

(Inner dia. 32, VP. 25)

75

Main unit dimension 800

Hanging bolt pitch 700

50

131

50

Ø26 Power supply,

remote controller

cable take-out port

638

498

393

41

196

243

Panel C.L

410

Ceiling open size

470

Panel external

dimension 500

5941

174

Suction port

flange

(Separate sold)

Suction port

panel

(Separate sold)

320

ABCDEFGHJKMNO

RAV-SM562BT

RAV-SM802BT

RAV-SM1102BT

RAV-SM1402BT

700 766 690 750 780 12.7 6.4 252 280 280 1 2 410

1000 1066 990 1050 1080 15.9 9.5 252 580 290 2 3 410

1350 1416 1340 1400 1430 15.9 9.5 252 930 310 3 4 410

NOTE 1 :

For maintenance of the equipment, be sure to install

a check port A at the position as shown below.

NOTE 2 :

Using the drain up kit sold separately, drain-up by 300 (mm)

from drain pipe draw-out port of the main unit is necessary.

The drain-up over 300mm or more is impossible.

Plane view of main unit

(Pipe side)

Discharge side

Check port A

300

100

450

– 26 –

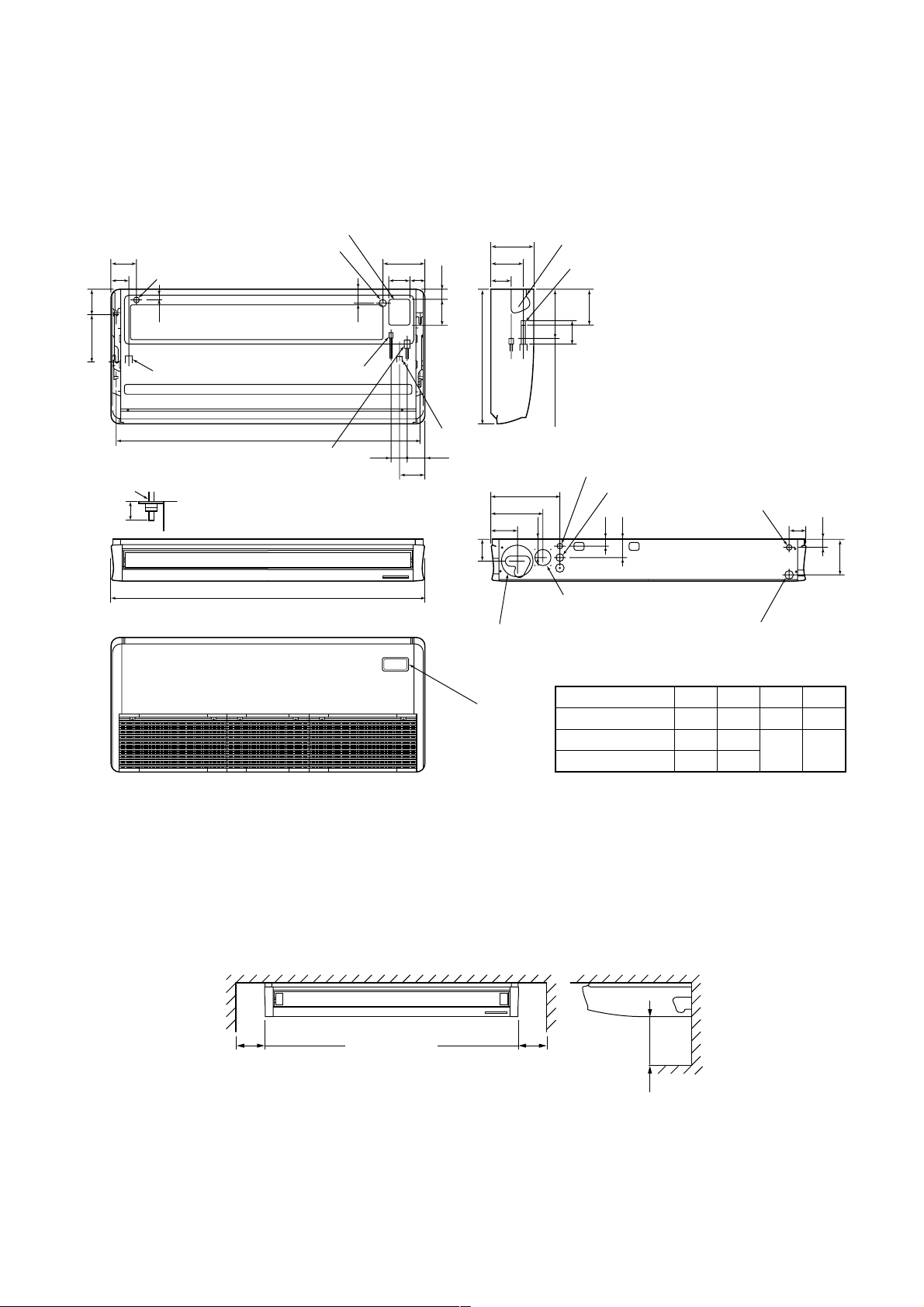

3-1-3. Under Ceiling Type

RAV-SM562CT-E, RAV-SM802CT-E, RAV-SM1102CT-E, RAV-SM1402CT-E

128

84

170320

(Hanging position)

Hanging bolt

50

Within

Upper pipe draw-out port (Knockout hole)

Power supply cable take-in port (Knockout)

Remote controller cable take- in port

(Knockout hole)

53

Left drain size

B (Hanging position)

Refrigerant pipe (Gas side ØD)

Ceiling surface

Unit

Refrigerant pipe

(Liquid side ØC)

A

216

110

70

75 97

76

50

130

680

Drain pipe connecting port

146

145

Pipe hole on wall (Ø100 hole)

210

167

105

347

262

135 84

Outside air take-in port

(Duct sold separately)(Knockout hole Ø92)

Pipe draw-out port (Knockout hole)

Drain port VP20

(Inner dia. Ø26, hose attached)

114

41

200 (Liquid pipe)

216 (Gas pipe)

Remote controller cable take- in port

Power supply cable take-in port (Knockout hole)

Remote controller cable take- in port

90

32

(Knockout hole)

92

Drain left pipe draw-out port (Knockout hole)

32

171

Wireless sensor

mounting section

250 or more250 or more

Model name A B C D

562CT

802CT

1102CT, 1402CT

910

1180

1595

855

1125

1540

Ø6.4 Ø12.7

Ø9.5 Ø15.9

500 or more

– 27 –

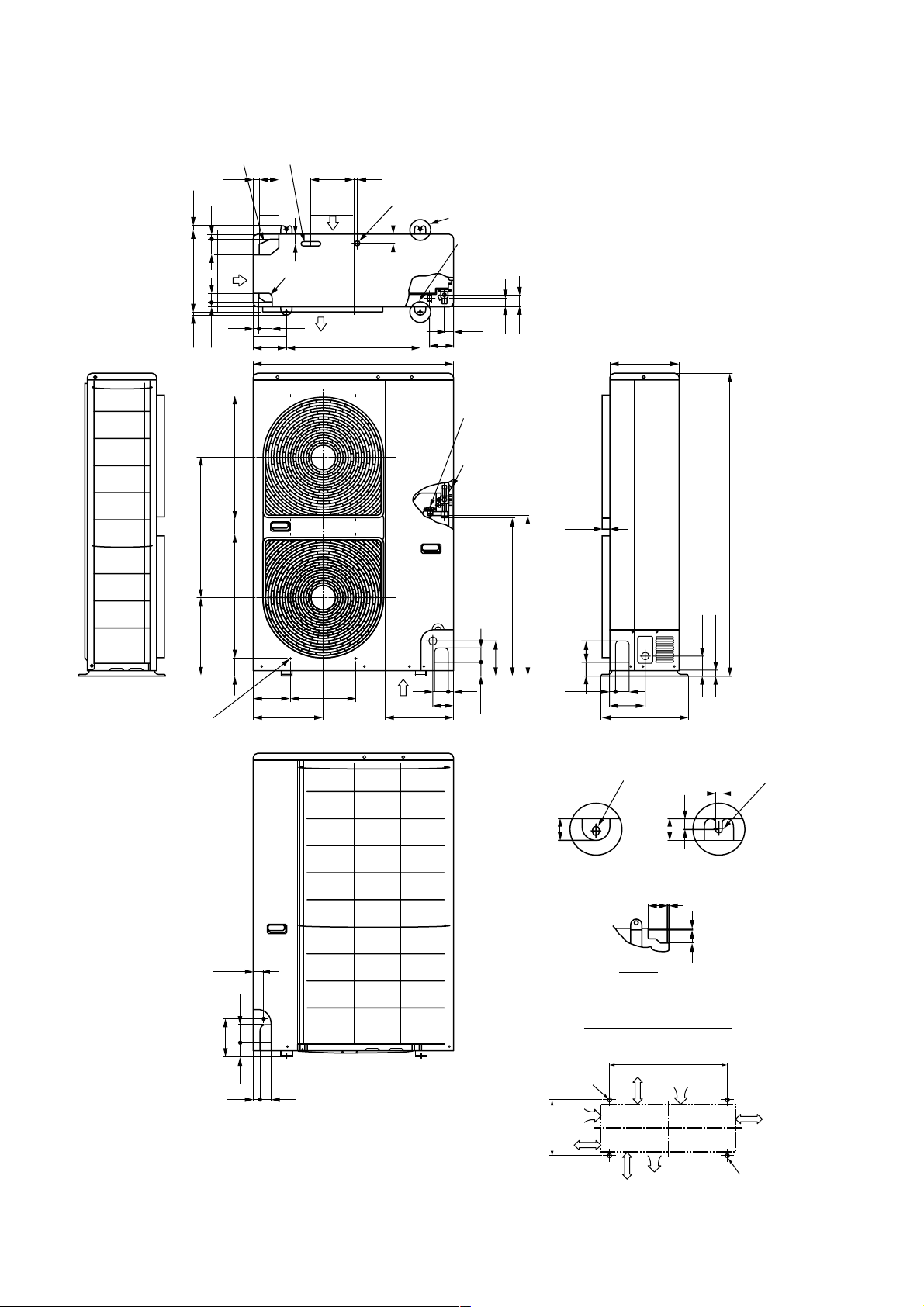

3-2. Outdoor Unit

RAV-SM562AT-E, RAV-SM802AT-E

Drain hole

(2-Ø20 × 88 long hole)

69.5 147

320

306

Ø6 hole pitch

For anchor bolt)

(Long hole pitch

21

550

290

A legs

6

48335

30

B legs

44952

Drain hole (Ø25)

60

600

108 125

30

20

2-Ø11 × L14 long hole

(For Ø8-Ø10 anchor bolts)

483 257

108

90

2-Ø11-14 U-shape hole

54

(For Ø8-Ø10 anchor bolts)

Connecting pipe port

Gas flare side

RAV-SM562AT -E: Ø12.7

( )

RAV-SM802AT -E: Ø15.9

Connecting pipe port

Liquid flare side

RAV-SM562AT-E: Ø6.4

( )

RAV-SM802AT-E: Ø9.5

8-Ø6 hole

(For fixing outdoor unit)

25

22

157 79

21

145

31 143

8

Space required for service

2-Ø11 × 14 U-shape holes

(For Ø8–Ø10 anchor bolt)

32

Discharge guard

150

or more

320

500

or more

600

54

38

R15

3

320

Ø11 × 14 U-shape hole

Details of A legs Details of B legs

2-Ø6 hole

Product

external line

150

or more

500

780

600

Suction port

Discharge

port

Discharge guide mounting hole

(4-Ø4.5 embossing)

Discharge

port

Ø11 × 14 U-shape holes

320

3

137

93

71

300

or more

(Minimum

distance up to wall)

2-Ø11 × 14 long hole

(For Ø8–Ø10 anchor bolt)

2-Ø6 hole

Product

external

line

R15

38

54

600

Charge port

342

54

Earth

terminal

– 28 –

RAV-SM1102AT-E, RAV-SM1402AT-E / RAV-SP562AT-E, RAV-SP802AT-E

Knockout

(For draining)

21

Suction

port

365 17.517.5

40 70

(Long hole pitch

for anchor bolt)

21

565 101

Drain hole (Ø20 × 88 Burring hole)

29 90 191 20

Knockout

(For draining)

6026

314

43

Suction

port

Discharge

port

300150

900

Drain hole (Ø25 Burring hole)

Part B

40

39

Part A

95

43

Handles

(Both sides)

Refrigerant pipe connecting port

Flare at liquid side

Ø6.4: RAV-SP562AT-E

( )

Ø9.5: RAV-SP802AT-E

Refrigerant pipe connecting port

Flare at gas side

Ø12.7: RAV-SP562AT-E

( )

Ø15.9: RAV-SP802AT-E

47

Installation bolt hole

(Ø12 × 17 U-shape holes)

17.5

4040

Details of B part

Details of A part

17.5

Installation bolt hole

(Ø12 × 17 U-shape holes)

2

Discharge guide

mounting hole

(4-Ø4 Embossing)

1

60 90

58

27

161

32028

400

264

300

795

25

85

2

Z

2

46

165

60 80

30 45

1

307

2760

96

2-Ø12 × 17 U-shape holes

(For Ø8–Ø10 Anchor bolt)

264

6760

154

1

Knockout for lower piping

Space required for service

150

or more

365

500

or more

Z views

Suction port

150

or more

Discharge

port

600

86 7

7

58

150

or more

Discharge

port

(Minimum

distance up to wall)

2-Ø12 × 17 long hole

(For Ø8–Ø10 Anchor bolt)

– 29 –

RAV-SP1102AT-E, RAV-SP1402AT-E

Knockout (Drain)

365 17.517.5

350 625

Discharge guide

mounting port

(8-Ø3 embossing)

70 21

Suction

port

21 40

9029

Knockout (Drain)

26

150

56567 60 565

164 300

314

Drain hole (Ø20 x 88)

191 20

Suction

port

Drain hole (Ø25)

43

60

Discharge port

600

900

B legs

A legs

40

43

40

108

Refrigerant pipe

connecting port

(Ø9.5 flare at liquid side)

Refrigerant pipe

connecting port

(Ø15.9 flare at gas side)

54

28

706

715

67

154

60 27

z

95

307 400

60

60 90

27

Mountig bolt hole

(Ø12 x 17 long hole)

161

320

58

1340

89

25

Mountig bolt hole

(Ø12 x 17 U-shape hole)

12

20

46

8060

165

32 45

40

Details of A legs Details of B legs

2-Ø12 x 17 U-shape holes

(For Ø8–Ø10 anchor bolt)

150

or more

365

– 30 –

40

86 7

Z view

58 7

Space required for service

600

Suction port

150

or more

Discharge

port

500

or more

Discharge

port

2-Ø12 x 17 long hole

(For Ø8–Ø10 anchor bolt)

150

or more

(Minimum

distance up to wall)

Loading...

Loading...