Toshiba RAV-104 Series, RAV-134 Series, RAV-164 Series, RAV-264 Series, RAV-364 Series Installation Instructions Manual

...

1401006601R06

HEAT PUMP TYPE RAV-104NH, SBH, TUH, TUH-1-PE SUPER MULTI

TYPE POMPE A CHALEUR RAV-134CH, KH, NH, TUH, TUH-1-PE RAV-134AH-PE

WARMEPUMPENMODELL RAV-134CHR, KHR-PE RAV-134AH-PE

TIPO APOMPA DI CALORE RAV-164BH, CH, KH, NH, SH, TUH, TUH-1, UH-PE RAV-164AH-PE

MODELO BOMBA TERMICA RAV-164CHR, KHR, SHR-PE RAV-164AH-PE

WARMTEPOMP MODEL RAV-264BH, CH, KH, NH, SH, UH-PE RAV-264AH/AH8-PE

RAV-264CHR, KHR, SHR-PE RAV-264AH/AH8-PE

RAV-364BH, CH, UH-PE RAV-364AH8-PE

RAV-364CHR-PE RAV-364AH8-PE

RAV-464BH, CH, UH-PE RAV-464AH8-PE

RAV-464CHR-PE RAV-464AH8-PE

COOLING-ONLY TYPE RAV-134C, TU, TU-1-PE RAV-134A-PE

TYPE A REFROIDISSEMENT RAV-164B, C, K, TU, TU-1, U-PE RAV-164A-PE

KUHLMODELL RAV-264B, C, K, U-PE RAV-264A/A8-PE

TIPO AREFRIGERAZIONE RAV-364B, C, U-PE RAV-364A8-PE

MODELO REFRIGERANTE RAV-464B, C, U-PE RAV-464A8-PE

KOELING MODEL

HFC

AIR CONDITIONER SPLIT TYPE SYSTEM

CONDITIONNEUR D’AIR TYPE SPLIT SYSTEM

KLIMAANLAGE GETEILTE BAUWEISE

ACONDICIONADOR DE AIRE TIPO SPLIT

CONDIZIONATORE D’ARIA TIPO SPLIT

AIRCONDITIONER SPLIT MODEL

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTALLATIONSANLEITUNG

INSTRUCCIONES DE INSTALACIÓN

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIEVOORSCRIFTEN

INDOOR UNITS OUTDOOR UNITS

MODULES INTERIEURS MODULES EXTERIEURS

INNENANLAGEN AUSSENANLAGEN

UNITÀ INTERNE UNITÀ ESTERNE

UNIDADES INTERIORES UNIDADES EXTERIORES

BINNENDELEN BUITENDELEN

GB

F

D

E

NL

I

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 2 ~

INSTALLATION INSTRUCTIONS

Please read these instructions carefully before starting the installation.

This equipment should only be installed by suitably trained operatives.

In all cases ensure safe working practice: Observe precautions for persons in the vicinity of the

works.

Ensure that all local, national and international regulations are satisfied.

Check that the electrical specifications of the unit meet the requirements of the site.

Carefully unpack the equipment, check for damage or shortages. Please report any damage

immediately.

These units comply with EC Directive:

73/23/EEC (Low Voltage Directive) and 89/336/EEC (Electro Magnetic Compatibility)

Accordingly, they are designated for use in commercial and industrial environments.

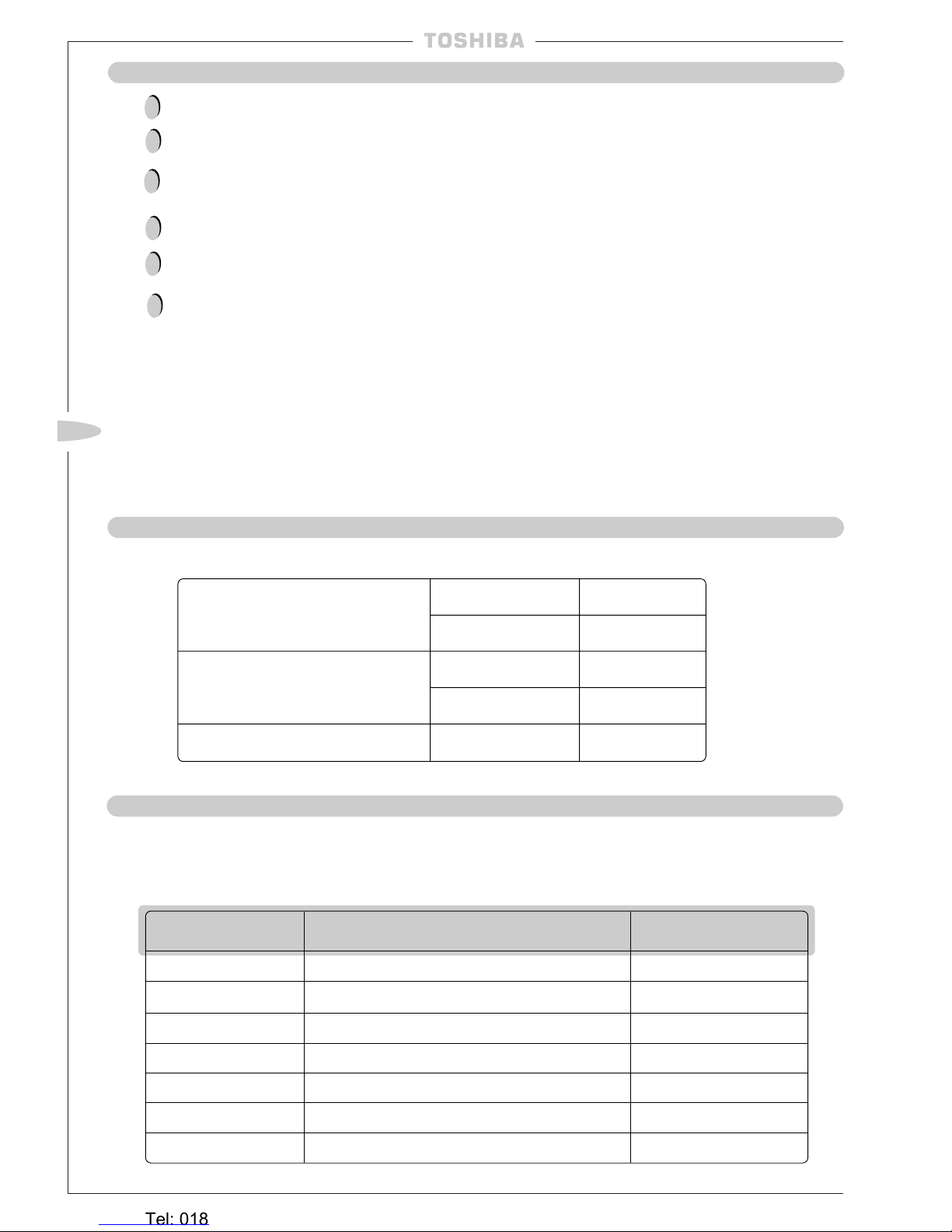

OPERATING CONDITIONS

KEY TO MODEL NAMES

Throughout this booklet, various types of indoor units will be referred to by model codes.

Details are shown in the table below:

UNIT DESCRIPTION HEAT PUMP CODE COOLING ONLY CODE

BUILT-IN DUCT TYPE BH, SBH B

CEILING TYPE CH (WIRED REMOCON), CHR (INFRARED REMOCON)C

WALL MOUNTED TYPE KH (WIRED REMOCON), KHR (INFRARED REMOCON)K

FLOOR CARCASE TYPE NH —

PAINTED FLOOR TYPE SH (WIRED REMOCON), SHR (INFRARED REMOCON)—

2-WAY CASSETTE TYPE TUH, TUH-1 TU, TU-1

4-WAY CASSETTE TYPE UH U

!

!

!

!

!

!

OUTDOOR TEMPERATURE

–2 ~ 43˚CCOOLING

–10 ~ 21˚CHEATING

ROOM TEMPERATURE

18 ~ 32˚CCOOLING

15 ~ 29˚CHEATING

ROOM HUMIDITY <80% COOLING

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 3 ~

GB

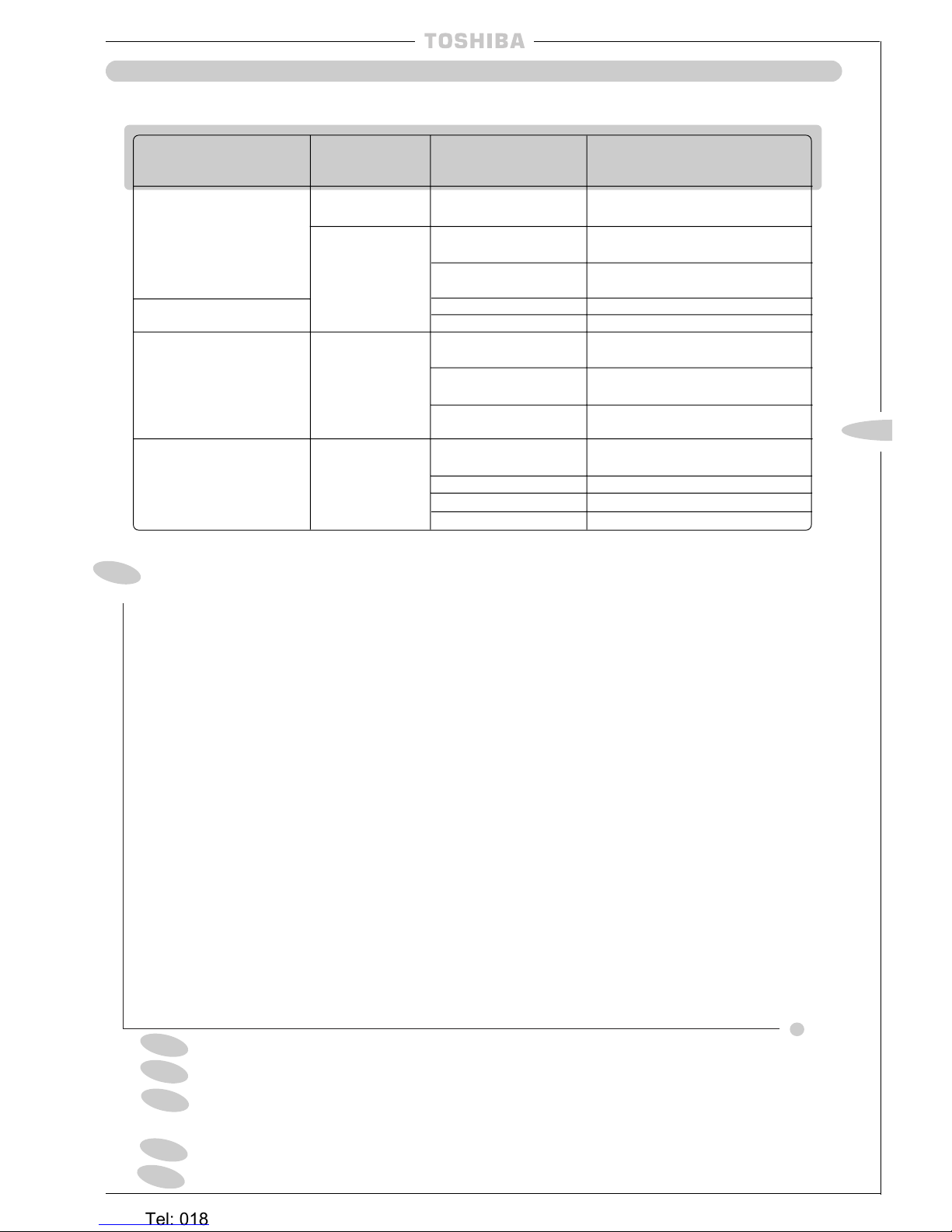

OPTIONAL ACCESSORIES

The following

optional

accessories are available:

CONTENTS...

Installation Instructions, Operating Conditions & Key to Model Names 2

Accessories 3 – 4

Outdoor Unit Location, Precautions, Service Space, Mounting 5 – 7

Indoor Unit Location, Precautions, Service and Installation Space 8 – 10

Unit Installation

BH/B units

11 – 12

Unit Installation

CH/CHR/C units

13 – 14

Unit Installation

KH/KHR/K units

15

Unit Installation

NH units

16

Unit Installation

SBH units

17

Unit Installation

SH/SHR units

18 – 19

Unit Installation

TU/TUH, TU-1/TUH-1 units

20

Unit Installation

UH/U units

21 – 22

Fresh Air Inlet, Details of Cut Out Hole 23

Air Outlet Duct, Details of Cut Out Hole 24

Drain Piping, Precautions, Piping Material and Heat Insulator, 25

Fixing the Drain Pan, Drain Hose Attachment 25

Drainage Check, Trial Run, Wired Remote Controller, Infra-Red 26

Refrigerant Piping, Precautions, Material and Sizes, 27

Permissible Piping Length and Head, Pipework Installation, System Purging 27

Additional Refrigerant, Heat Insulation, Pressure Measurement 28

Electrical Wiring, Precautions, Power Supply Specs and Wiring 29

Wiring Between Units, Connecting the Remote Controller and Group Control 30

Remote Controller, Installation of Remote Controllers, Heat Pump AI Models 31

and Cooling Only Models, Installation of AI Room Remote Controllers, Precautions, 31 – 32

Heat Pump models AI Room Remote Controller, Flush Wall Mounting, Wall Surface Mounting 31 – 32

Location of Infra-Red Remote Controller, Installing the Infra-Red Remote, 33

Infra-Red Remote Controller Mounting 33

Improving System Efficiency, Air Flow Adjustment, Increasing Heating Effect 33

Heat Pump Twin Set-up 34 – 35

Cooling Only Twin Kit Set-up 36 – 38

Final Installation Checks, Environmental Issues

39

E

I

NL

D

F

GB

Passer à la page 41 pour lire le manuel d’installation en français.

Die deutsche Montageanleitung finden Sie auf Seite 79.

Por favor, vaya a la página 117 para seguir las instrucciones del manual de

instalacíon en lengua española.

Il manuale d’installazione italiano è a pagina 155.

Zie bladzijde 193 voor de Nederlandse Installatichandleiding.

A

CCESSORY

M

ODELTYPE

A

CCESSORY

N

O

B

ASEMODEL

N

O

2-WAYC

ASSETTE

RBC-U133PG(W)-PE RAV-104, 134, 164TUH/TUH-1-PE

RBC-U134PG(W)-E RAV-134, 164TU/TU-1-PE

C

EILINGPANEL

RBC-U264PG(W)-E RAV-164, 264UH-PE

RAV-164, 264U-PE

4-WAYC

ASSETTE

RBC-U464PG(W)-E RAV-364, 464UH-PE

RAV-364, 464U-PE

I

NFRAREDCEILINGPANEL

RBC-U264PGR(W)-E RAV-164, 264UH-PE

RBC-U464PGR(W)-E RAV-364, 464UH-PE

RBC-RK162BE-PE RAV-164BH-PE

RAV-164B-PE

F

ILTERKIT

B

UILT INDUCT

RBC-RK262BE-PE RA V-264BH-PE

RA V-264B-PE

RBC-RK462BE-PE RAV-364, 464BH-PE

RAV-364, 464B-PE

43A01001 RAV-134CH, 134CHR, 134C-PE

RAV-164CH, 164CHR, 164C-PE

P

AINTEDBACKPANELKIT

C

EILINGSUSPENDED

43A01002 RAV-264CH, 264CHR, 264C-PE

(10 pack)

43A01003 RAV-364CH, 364CHR, 364C-PE

43A01004 RAV-464CH, 464CHR, 464C-PE

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 4 ~

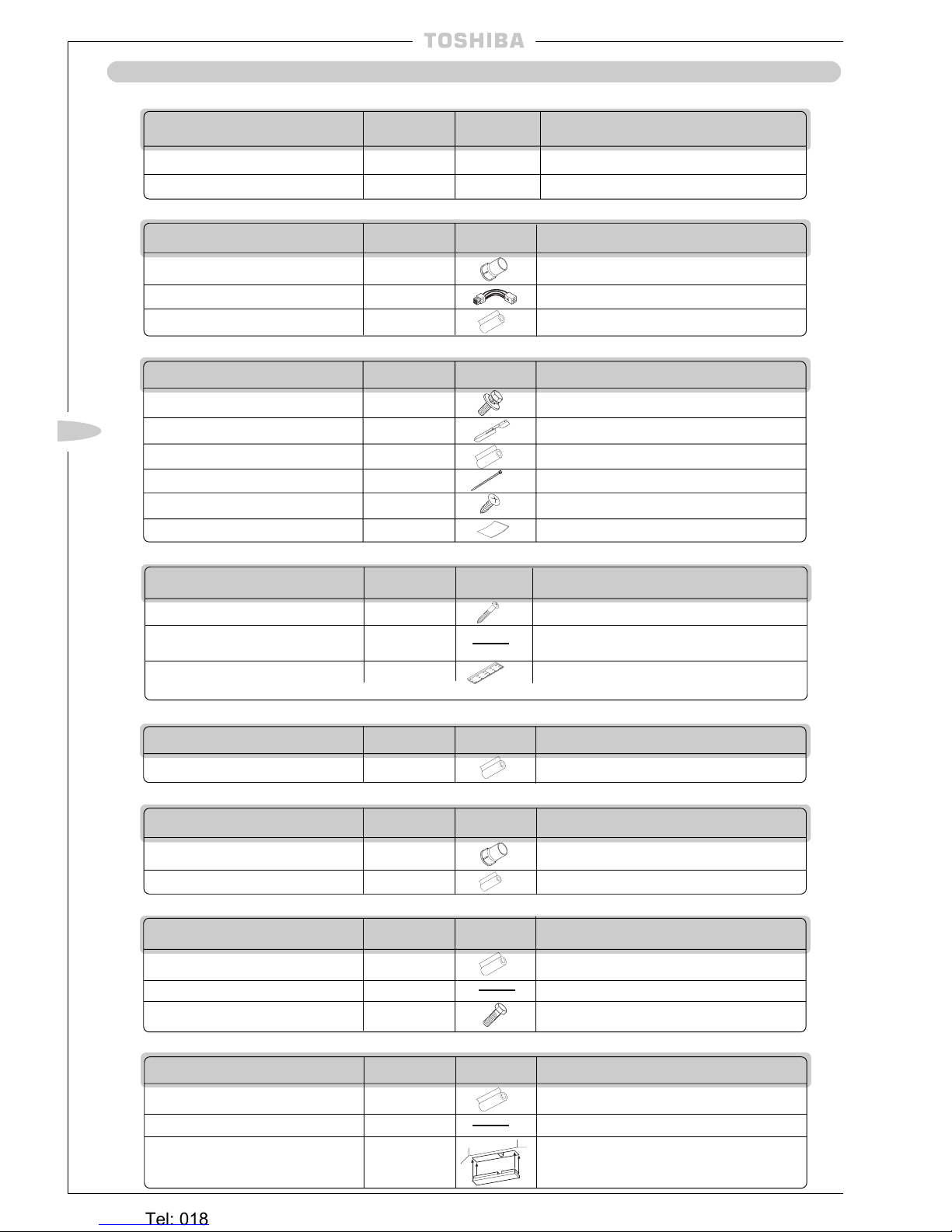

ACCESSORIES

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Owner’s Manual 1 — For use by customers

Installation instructions 1 This book —

COMMON

BH, B Units

TUH, TU, TUH-1, TU-1 Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

PVC Socket 1 For drainpipe connection

Connector assembly 1 For fan motor tap changing

Pipe insulation 2 For insulating the pipe connections

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Screws – 5.1mm dia x 45mm long

8 For fixing the installation bracket

Template for installation of 1 For ease of marking the

indoor unit location of installation bracket

Installation bracket* 1 For mounting the indoor unit on the wall

*This part is temporarily attached to the back of the indoor unit

NH Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Pipe insulation 2 For insulating the pipe connections

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Pipe insulation 2 For insulating the pipe connections

Cardboard template 1

For installation of the cassette and ceiling panel

Bolt (M5 x 20mm) 4 To secure the panel to the cassette

UH, U Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Pipe insulation 2 For insulating the pipe connections

Cardboard template 1

For installation of the cassette and ceiling panel

Insulation block

4 (164/264)

For 2-directional and

2 (364/464)

3-directional air outlet

CH, CHR, SH, SHR, C Units

KH, KHR, K Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Hexagon bolt 4 For securing the hangers

Drain piping fixing plate 1 For fixing rear side drain piping

Pipe insulation 2 For insulating the pipe connections

Nylon band 10

For fixing drain piping and pipe insulation

Tapping Screw 2

For fixing the side panels after installing the unit

Insulator 1 For insulating the knock-out position

SBH Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

PVC Socket 1 For drainpipe connection

Pipe insulation 2 For insulating the pipe connections

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 5 ~

GB

OUTDOOR UNIT LOCATION

Avoid installing the outdoor unit in the following locations:

Where there is danger of flammable gas leakages.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas).

The air conditioner is prone to failure when used under this condition unless special maintenance

is provided.

Where the airflow from the outdoor unit may cause annoyance.

Where the operating noise of the outdoor unit may cause annoyance.

Where the foundation is not strong enough to fully withstand the weight of the outdoor unit.

Where the water drainage may cause a nuisance or a hazard when frozen.

Where strong winds may blow against the air outlet of the outdoor unit.

(The high pressure switch could be tripped if a strong wind should blow against the air outlet

during cooling operation). Where this condition is likely to be present, protect the outdoor unit

against winds, for example by:

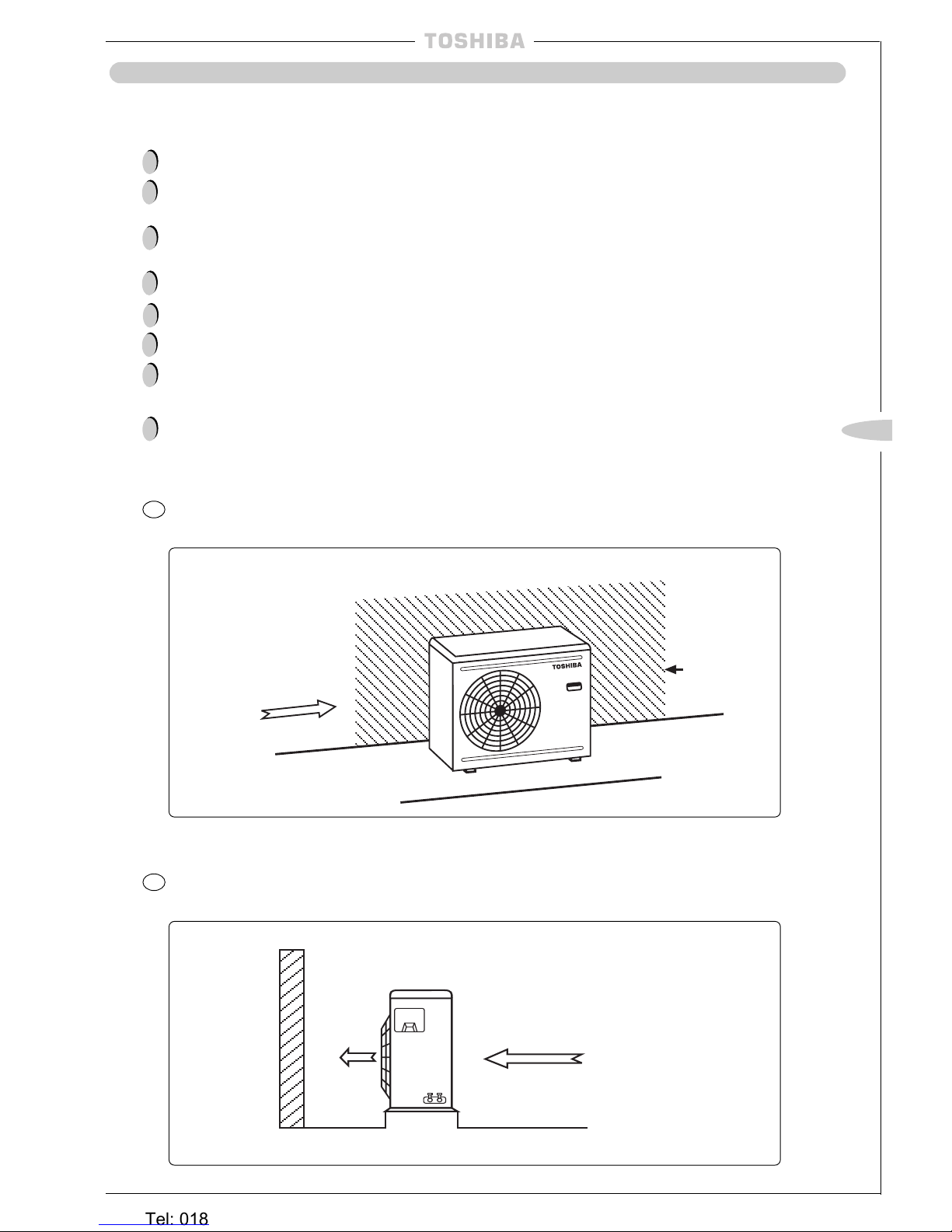

Precautions

2

Installing the outdoor unit with the air outlet facing the wall, such as on an exposed rooftop:

Strong

Strong wind

Rooftop

Airflow

Wall

1

Installing the outdoor unit in parallel with the building so that it can be protected by other buildings:

!

!

!

!

!

!

!

!

Building

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 6 ~

OUTDOOR UNIT LOCATION

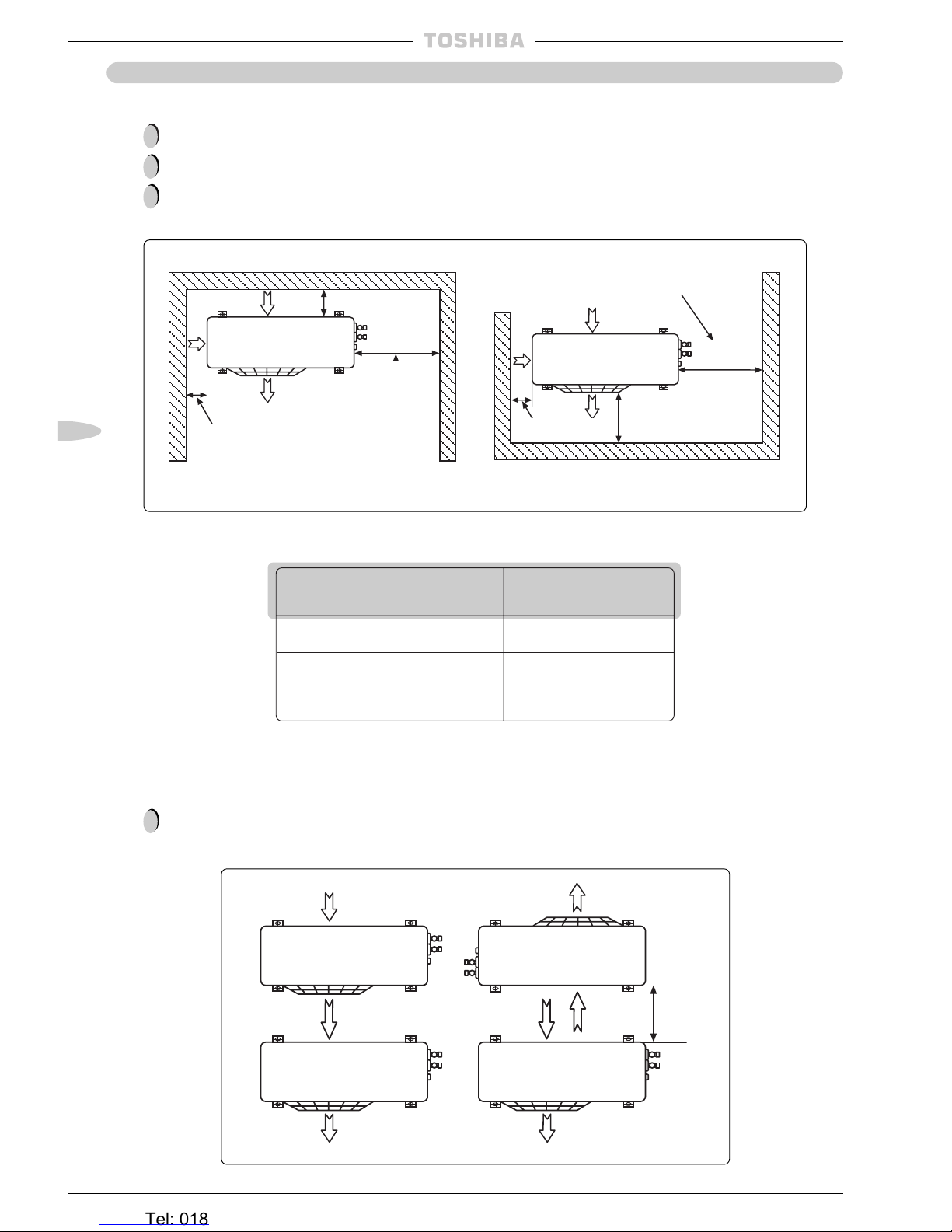

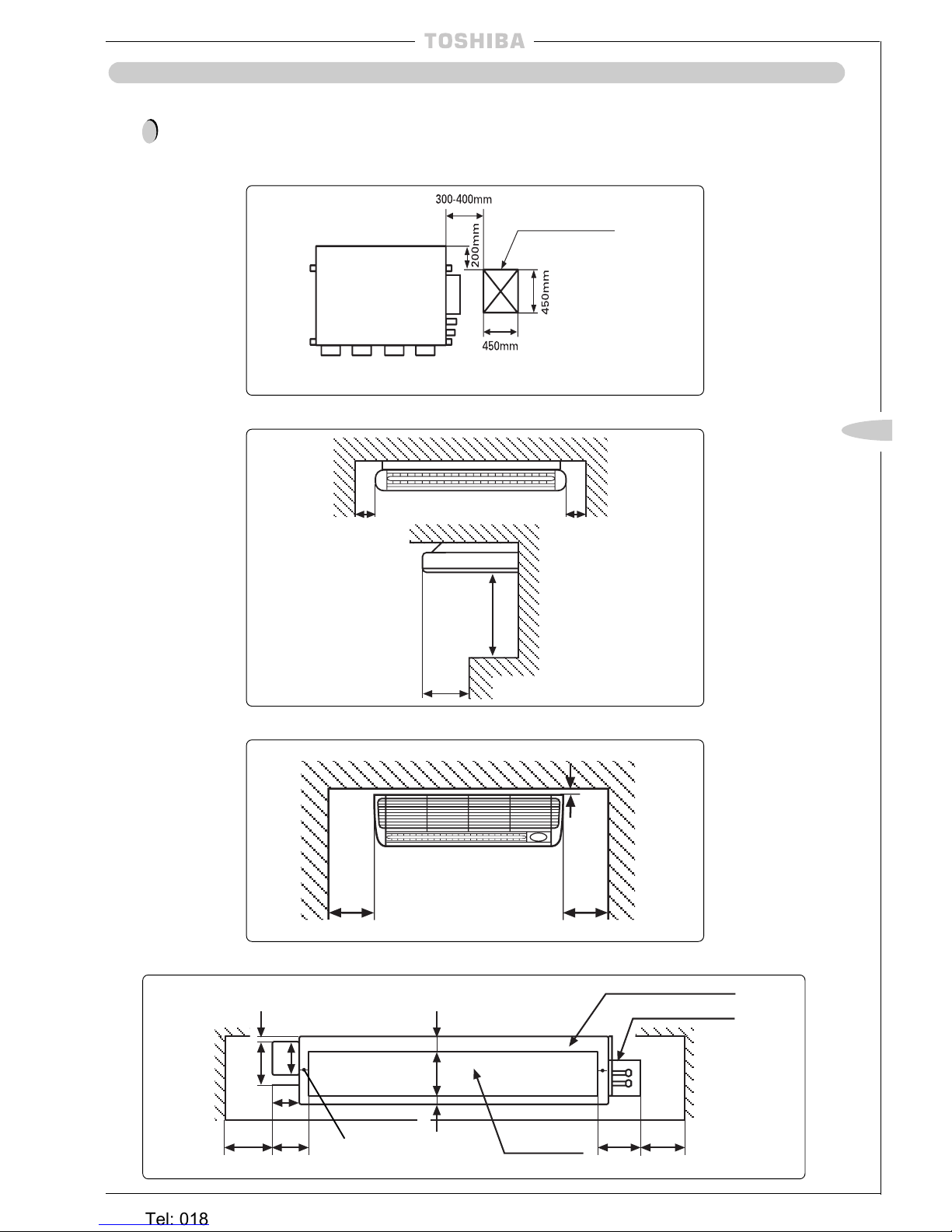

Ensure that there is sufficient space around the outdoor unit for operation, installation and servicing;

Any obstructions of the airflow must be at least 300mm from the front of the unit;

All dimensions are minimum.

Service Space

150mm or

more

Air inlet facing the wall

(Wiring and piping space)

500mm or more

300mm or more

Air outlet facing the wall

Do not allow units to be situated so that outlet air from one unit is discharged directly into the intake

of another unit as indicated below:

Mounting

Airflow Path

Model A(mm)

RAV-364AH8/A8 150

RAV-464AH8/A8 150

Remaining models 100

!

!

!

!

A: mm or more

(see table below)

(Wiring and

piping space)

500mm or more

3

7

300mm

min

A: mm or more

(see table below)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 7 ~

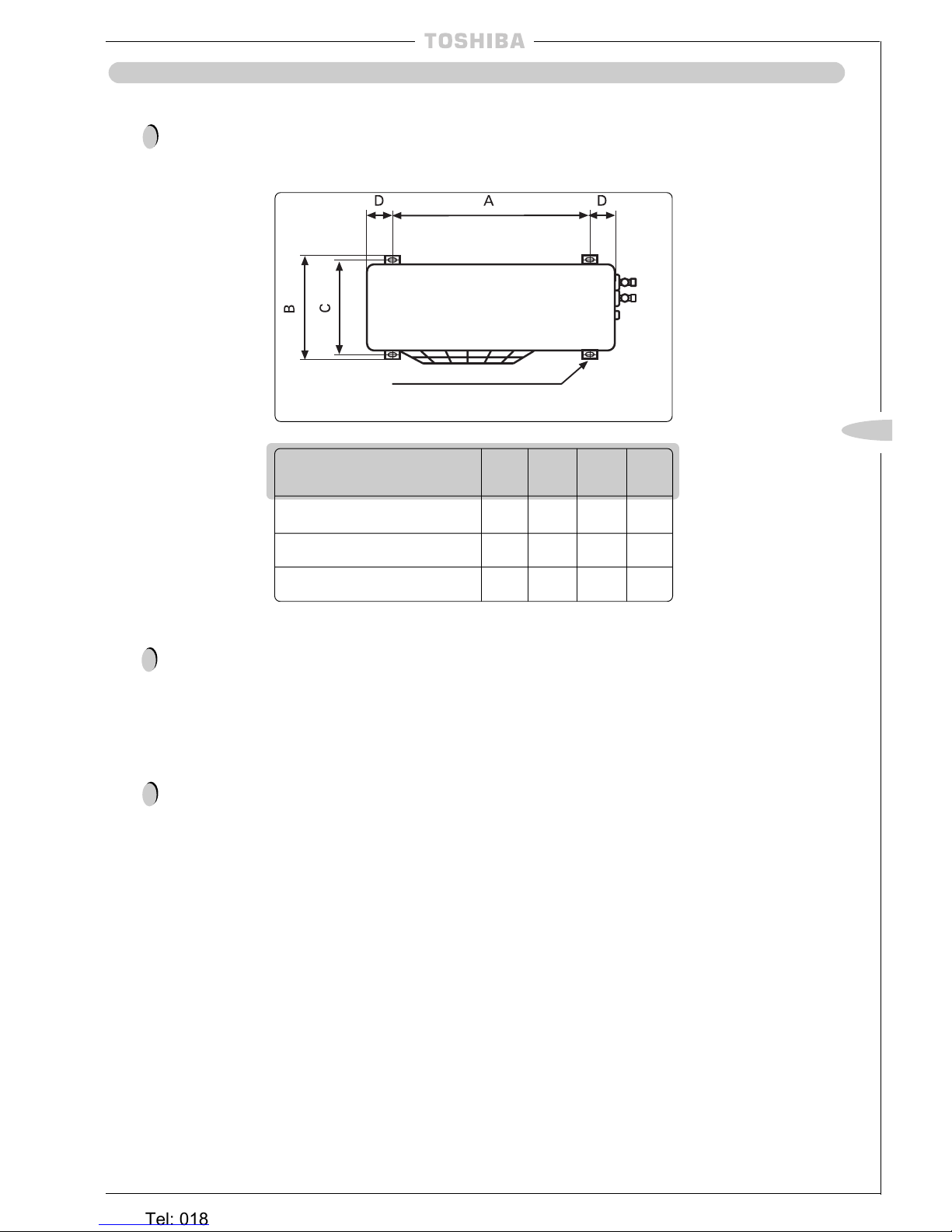

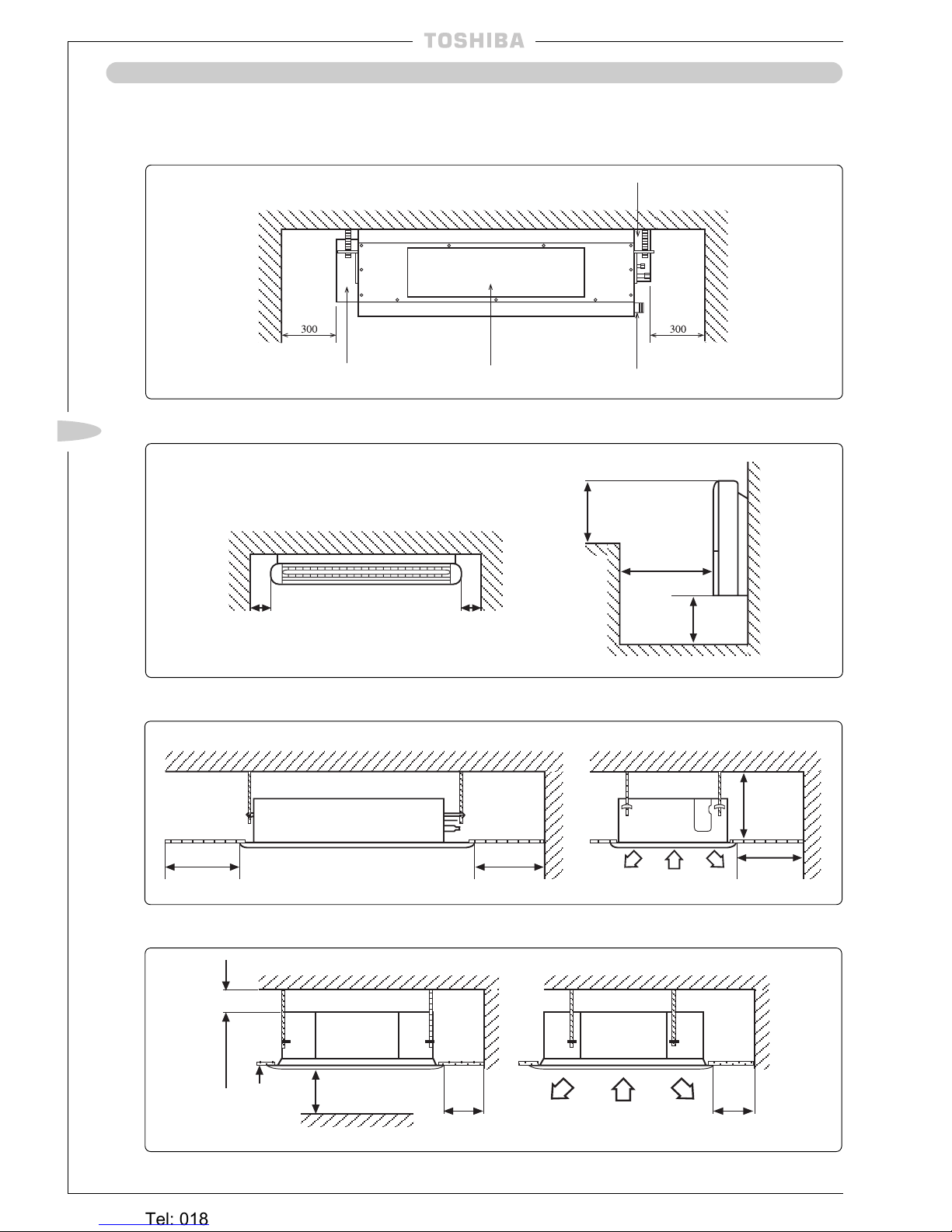

OUTDOOR UNIT LOCATION

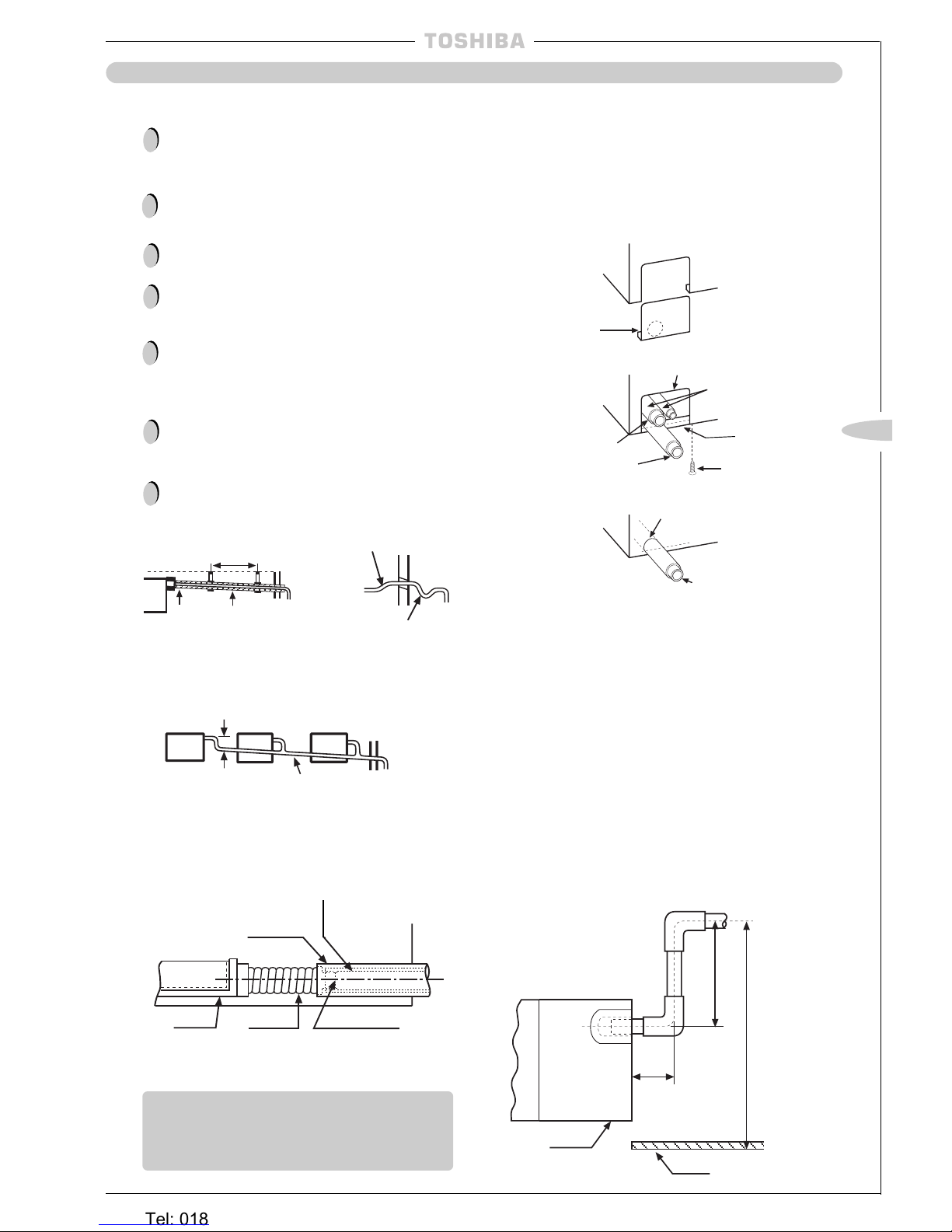

Secure the outdoor unit to a sturdy and flat foundation using four anchor bolts.

The anchor bolt pitch is shown in the diagram below:

Mounting

continued

4 x (12mm x 18mm) Slots

Model A B C D

RAV-364AH8/A8 840 440 416 45

RAV-464AH8/A8 840 440 416 45

Remaining models 790 364 340 45

In areas subject to heavy snowfalls, protect the outdoor unit from snow as follows:

(i) Install the unit on a stand which will keep the unit above the level of the standing snow.

(ii) The stand must facilitate water drainage.

(iii) Install snow protection hoods over the air intake and outlet. Ensure that the airflow is not

affected.

Failure to take adequate measures in this respect may result in the unit malfunctioning.

!

!

(MM) (MM)

(MM) (MM)

!

GB

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 8 ~

~ 8 ~

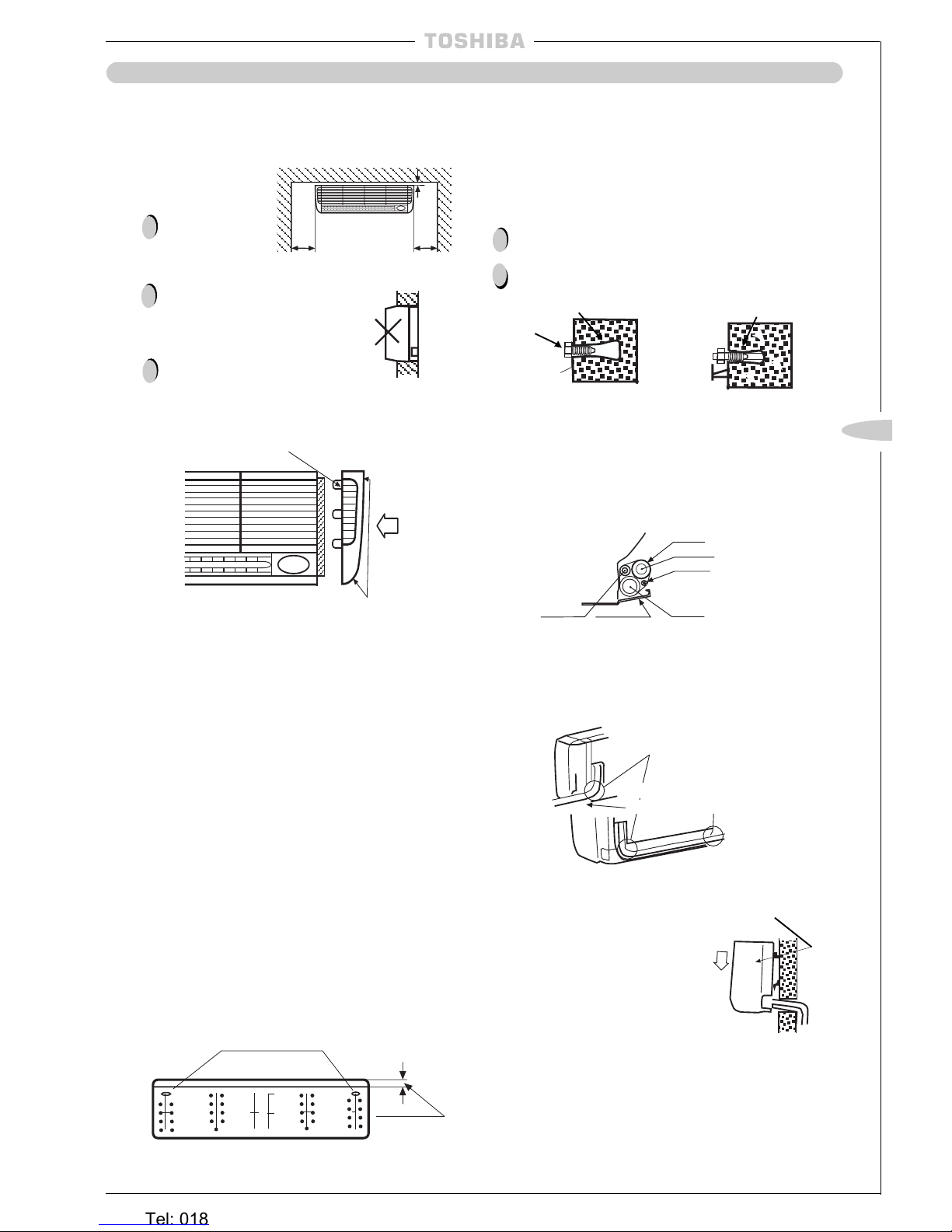

INDOOR UNIT LOCATION

Avoid installing the indoor unit in the following locations:

Where there is danger of flammable gas leakages.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas).

The air conditioner is prone to failure when used under this condition unless special maintenance

is provided.

Where high concentrations of organic solvent are present.

Where a machine that generates high frequencies is operated.

Where the unit will not be horizontal.

Where the ceiling height is more than 3m.

Where the floor/wall/ceiling structure is unable to support the weight of the unit.

Where it is not possible to fix the unit hangers,

e.g.

window glass.

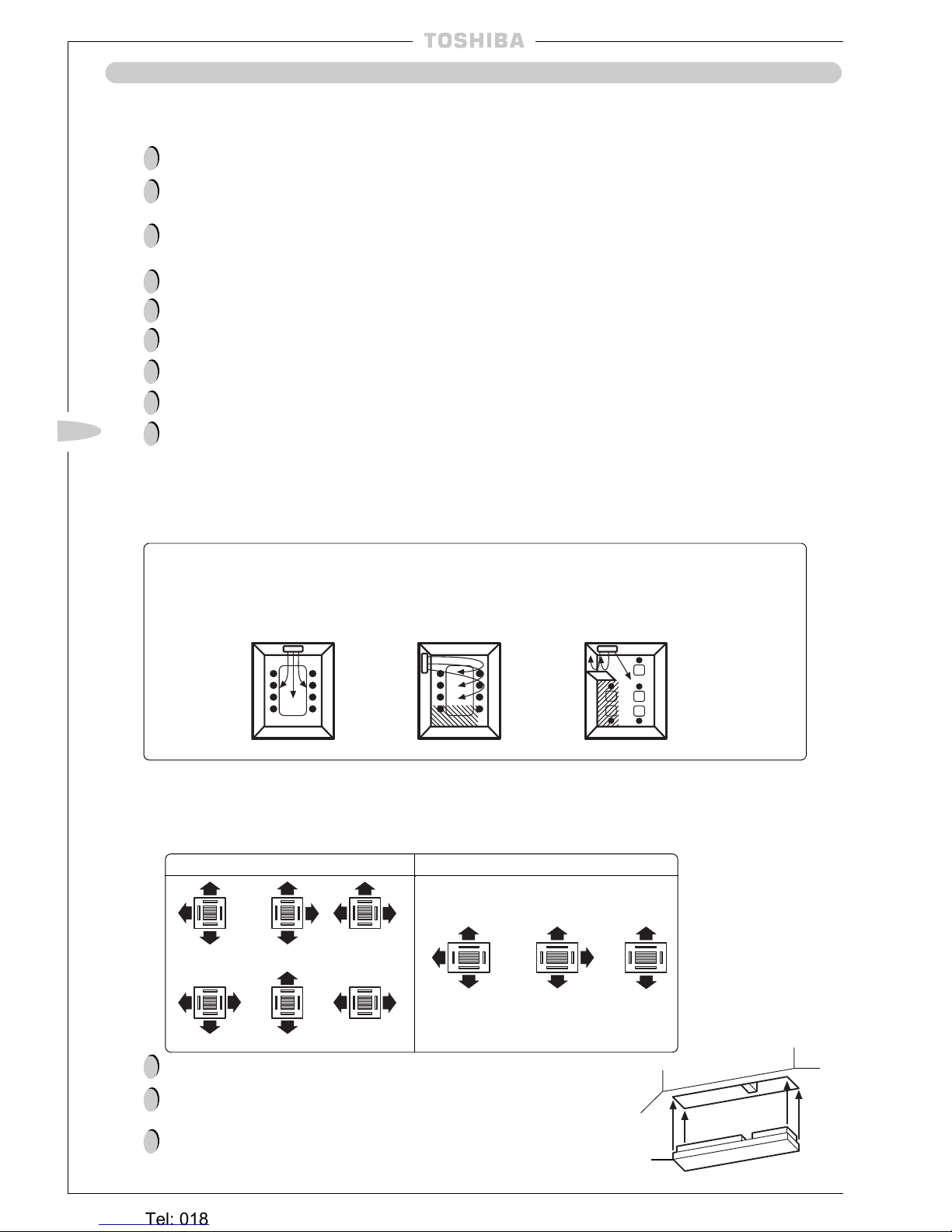

Locate the unit so as to provide uniform circulation of chilled air.

Location Precautions

Good location —

Evenly cooled

Bad location —

Oblique-line

area not well

cooled \\\\\

Bad location —

Oblique-line

area not well

cooled /////

7

7

3

If a good location is not possible, use a fan to circulate the air evenly throughout the room.

— UH/U Units only —

Choose the number of airflows that are required, depending on the shape of the room and the location of the indoor unit.

Insulation

Block

RAV-164/264UH/U RAV-364/464UH/U

!

!

!

!

!

!

!

!

!

!

!

!

— CH/CHR/C and KH/KHR/K Units only —

Avoid locating the unit as shown in the 7-marked figures below:

It is not possible to block the air flow from the longer sides of the unit.

The number of airflow directions cannot be adjusted after installation.

Insert insulation blocks, which are supplied as accessories,

at each side where the airflow is not required,

as shown in the diagram opposite.

3-way 3-way 3-way

3-way 3-way 2-way

3-way 2-way 2-way

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 9 ~

GB

~ 9 ~

INDOOR UNIT LOCATION

ALWAYS ENSURE THAT THERE IS SUFFICIENT SPACE AROUND THE INDOOR UNITS FOR

INST ALLATION AND SERVICING:

Service and Installation Space

BH/B Units

CH/CHR/C Units

KH/KHR/K Units

300mm or more

30mm or more

300mm or more

500mm or

more

400mm

or

more

150mm

or more

!

Provide an inspection

hole in this position

Inspection hole

150mm

or more

NH Units

Minimum

Upper Plate/Duct Plate

Minimum

60mm

25mm

20mm

140mm

65mm

90mm

150mm

100mm

Drain Catch

Fixing location to

floor/base

160mm

145mm

Air Outlet

150mm

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 10 ~

~ 10 ~

INDOOR UNIT LOCATION

Service and Installation Space

continued

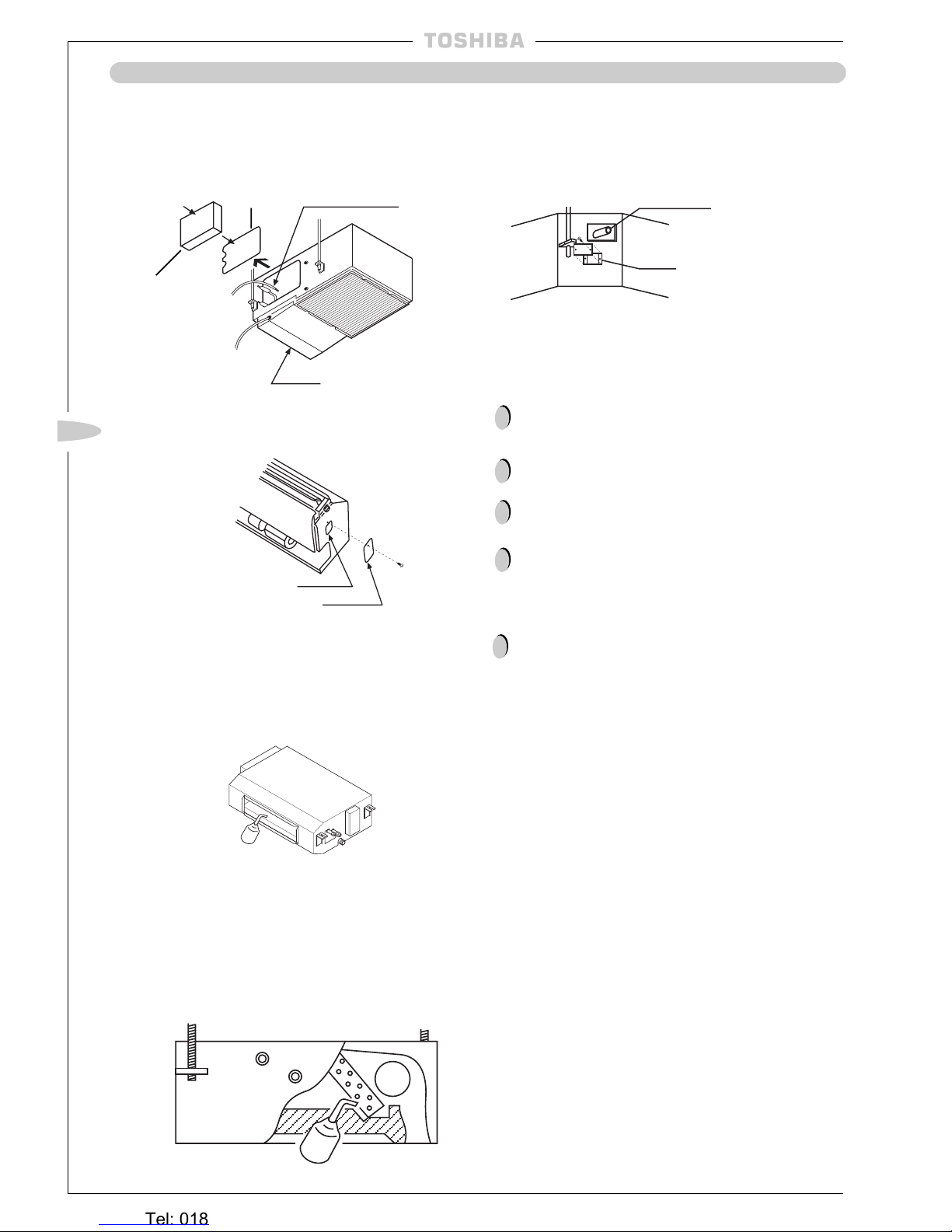

SBH Units

SH/SHR Units

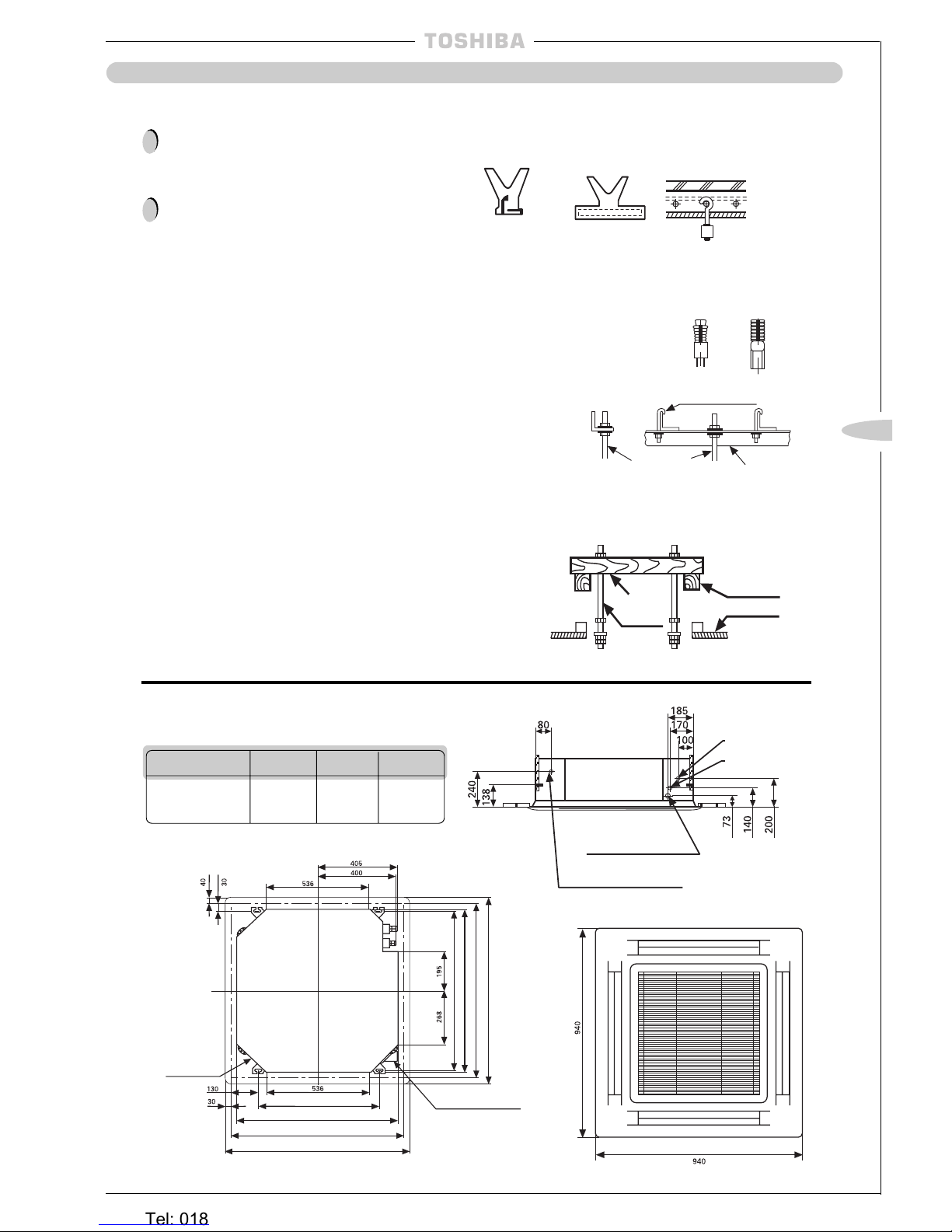

TUH, TUH-1/TU, TU-1-PE Units

UH/U Units

Plan View

150mm

or more

150mm

or more

400mm

or more

500mm

or more

150mm

or more

600mm 600mm

600mm

200mm

15mm or more

1000mm

or more

Obstacle

1000mm

or more

Ceiling

1000mm or more

Terminal box (wiring connections)

Drain pipe connections

Air Outlet

Electrical box

(PCB, transformer, MF capacitor)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 11 ~

GB

~ 11 ~

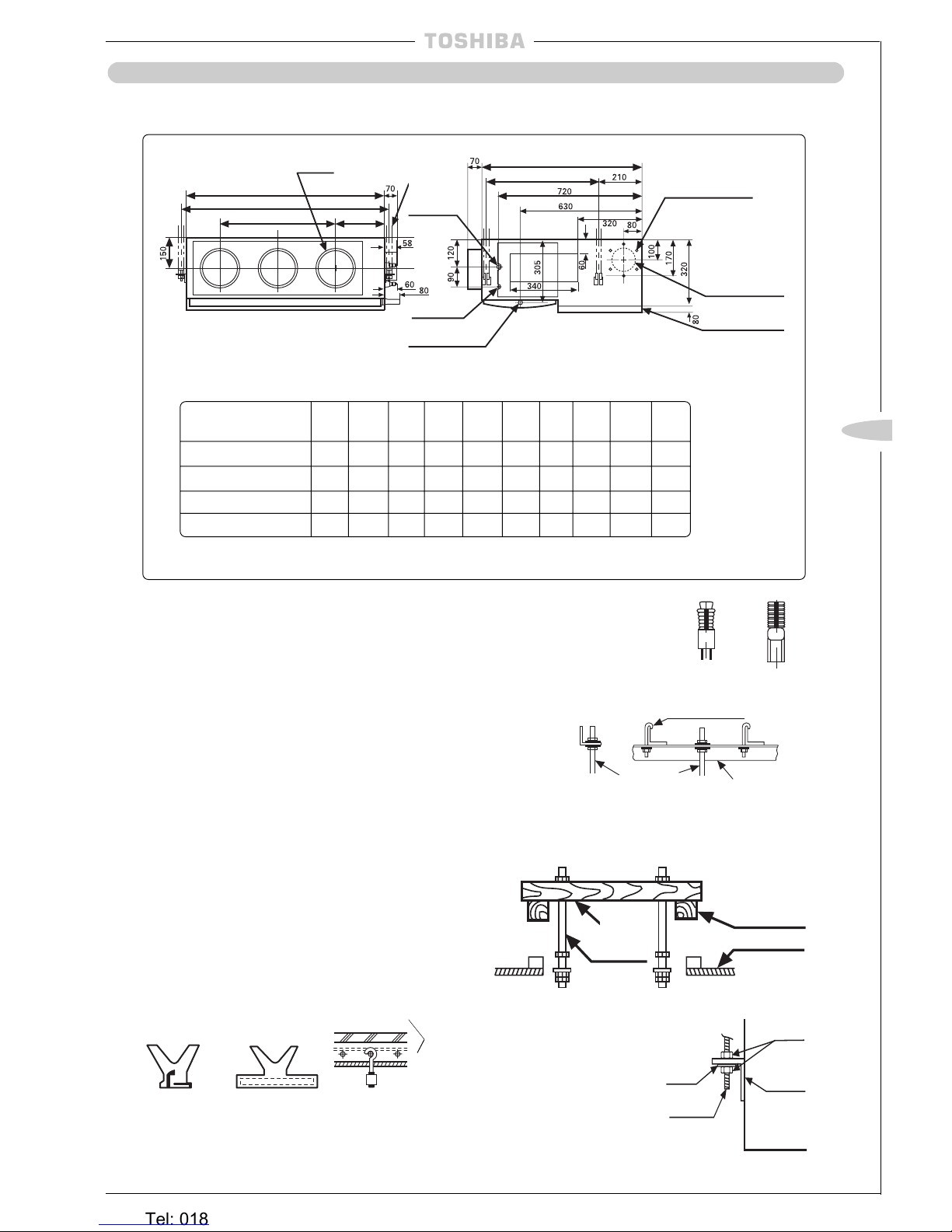

INDOOR UNIT LOCATION

l

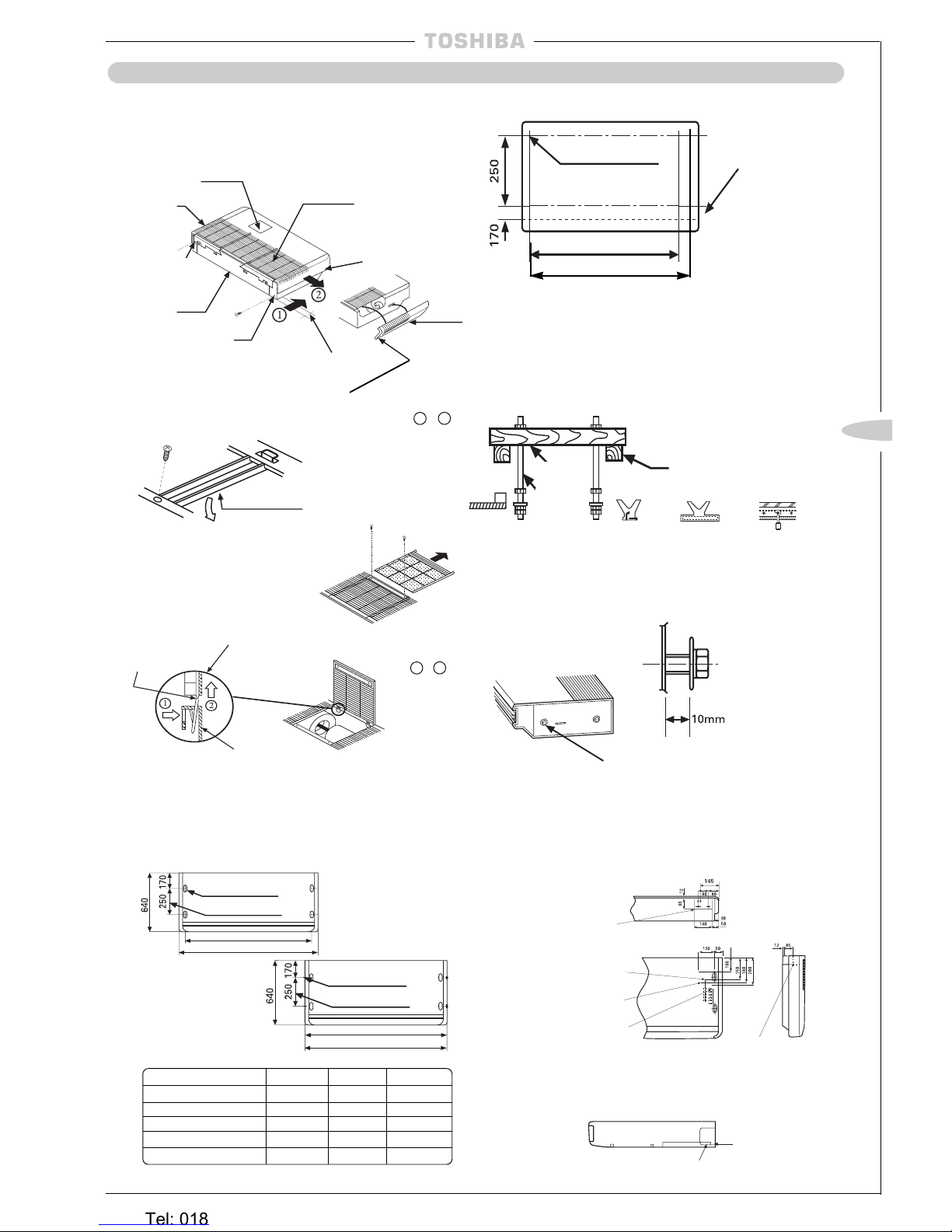

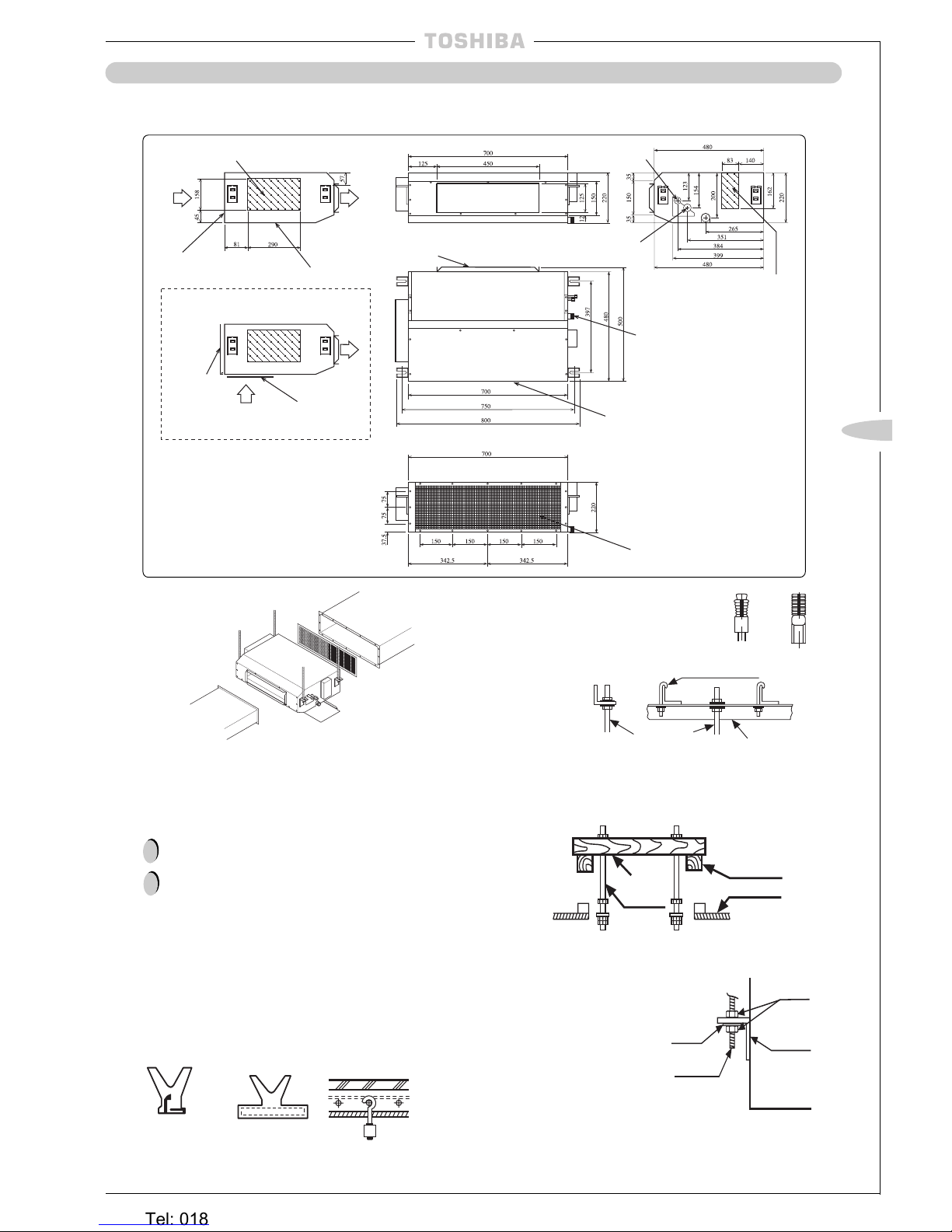

Check the dimensions of the unit illustrated in the following figure:

Unit Installation –

BH/B Units

Installing Ø 10 Hanging Bolts (4 pieces)

l

Install the hanging bolts at the intervals shown in the

following figure.

l

Use Ø 10 hanging bolts (to be locally procured).

Ceiling preparation:

The actual procedure differs according

to the structure. Consult your builder or whoever was

responsible for the interior of the house/building.

Removal of part of the ceiling plate:

(1) In order to ensure that the ceiling is kept perfectly

horizontal and to prevent the ceiling from vibrating, the

ceiling framework must be reinforced.

(2) Cut and remove part of the ceiling framework.

(3) Reinforce the ends of the ceiling framework where it was

cut and add framework to secure the ends.

l

Some piping and wiring connections must be made in the

ceiling after the unit has been suspended. After selecting where

the unit will be installed, decide on the direction of the piping

connection. If the ceiling is already installed, prepare the

refrigerant pipes, drain pipe, indoor to outdoor unit connection

wiring and the remote control cord at the piping and wiring

connection positions before suspending the indoor unit.

Hanger

bolt

Hanging bolt

Hanging

bolt

Beam

Ceiling

Model (RAV-) A B E Ø F Ø G H J K M N

264BH 1000 1050 1080 15.9 9.5 252 580 290 2 3

364BH/B, 464BH/B 1350 1400 1430 19.0 9.5 252 930 310 3 4

164BH/B 700 750 780 12.7 6.4 252 280 280 1 2

264B 1000 1050 1080 15.9 9.5 252 580 290 2 3

Sliding bracket

Reinforcing

bar

Foundation bolt

(Foundation bolt for

hanging the piping)

Angular bracket

for support

Installation on a wooden structure:

Place a length of wood of the appropriate size across two

beams and install the hanging bolts onto this length of wood.

Installation on a steel frame:

Use the angular

bracket in

the structure

or install

one for support.

Installation on an existing concrete slab:

Use hole-in anchors, hole-in plugs

or hole-in bolts for the installation.

Hanging Unit

(1) Raise the unit by using a lift-

ing device, then secure the

hangers to the hanging

bolts. Be sure to fix the nuts

onto both the upper and

under side of the hanger

and the washer (under side

only);

(2) Install the unit horizontally

by using a level. Failure to

do this will cause water

leakages.

Nut

Hanger

Hanging

Bolt

Washer

How to Install the Hanging Bolts

Installation on a newly installed concrete slab:

Use insert brackets or foundation bolts for the installation.

Cross

length of

wood

Knife shaped

bracket

(Gas ø F)

Hanging Bolt Pitch B

Refrigerant Pipe

Connection

Unit Dimension A

Hanging Bolt

4-M10

Provided at site

Nx Ø200

Air Outlet

Drain pipe connection

(inner diameter 32)

(diameter 32 minimal for PVC pipes)

Refrigerant pipe

connection

(liquid ø G)

Hanging Bolt Pitch:565

Unit Dimension:800

J = M x K

(H)

6 x Ø4 holes (Ø160)

Fresh air inlet Ø125

cut-out (other side)

Filter kit

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 12 ~

~ 12 ~

INDOOR UNIT LOCATION

Unit Installation –

BH/B Units continued

Connection of Ducting

Remove the duct connection assembly (attachment)

before connecting the supply duct.

!

Flexible duct

The maximum length of

flexible ducting is 10m.

l

To connect the shelter

board under the lower air

inlet of unit, prepare the

shelter board locally, as

shown below.

!

Model (RAV-) A B C

264BH/B 700 1000 2

364BH/B, 464BH/B 1050 1350 2

164BH/B 400 700 —

Optional Accessory

l

A TOSHIBALong-Life Filter Kit is available as an

optional accessory.

l

The Filter Kit can be installed on either the lower or

rear air inlet of the Duct Type unit.

l

To connect square duct, prepare the connection flange

locally as shown below:

RAV-164BH/B

Supply Flanges

RAV-264BH/B

RAV-364BH/B, RAV-464BH/B

Return Flanges

RAV-164BH/B

RAV-264BH/B

RAV-364BH/B, RAV-464BH/B

Shelter Board C x Ø6 holes

Supply duct

(local procurement)

12 – ø 6 holes

14 – ø 6 holes

14 – ø 6 holes

14 – ø 6 holes

18 – ø 6 holes

22 – ø 6 holes

4 x Ø6 holes

Return duct (local

procurement)

Shelter board

(local procurement)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 13 ~

GB

~ 13 ~

INDOOR UNIT LOCATION

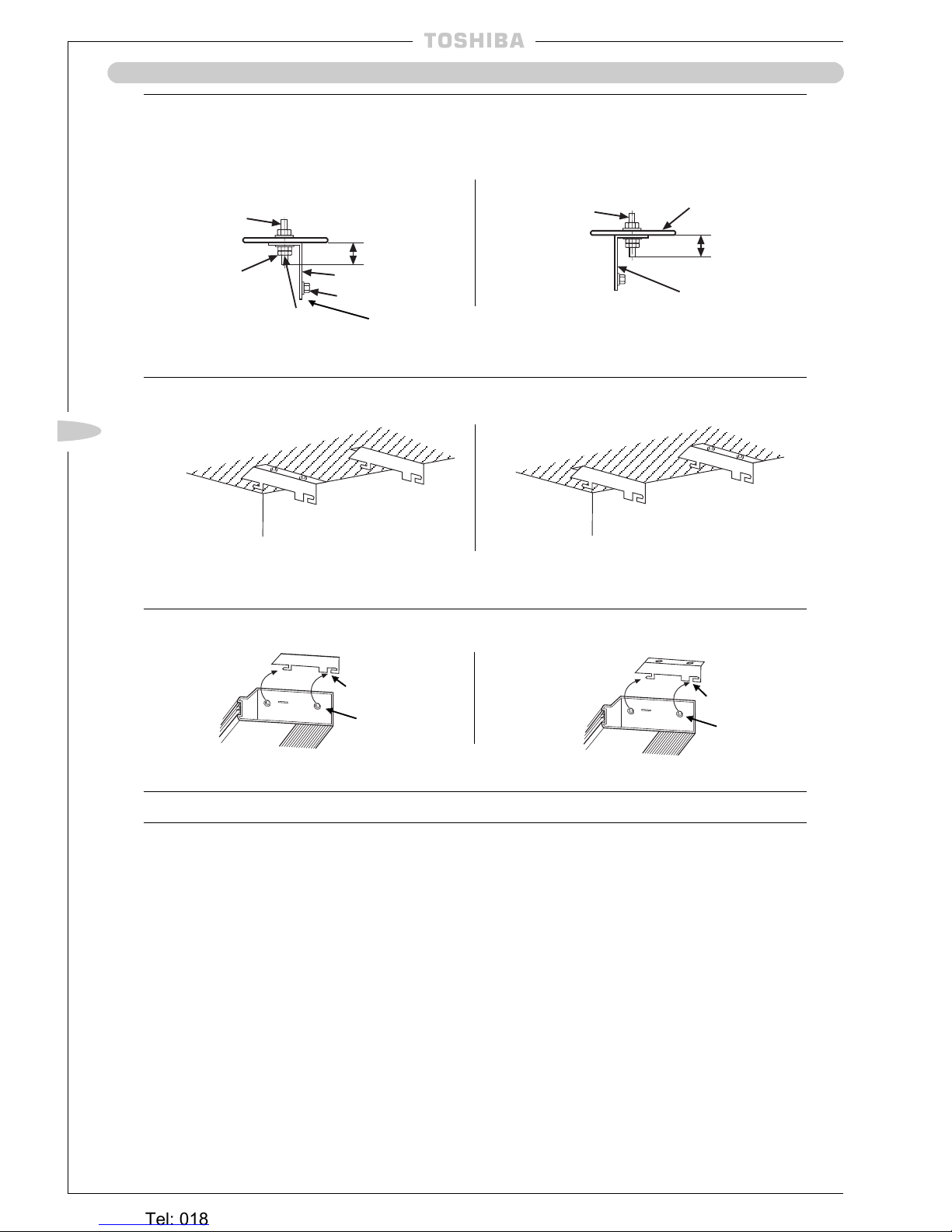

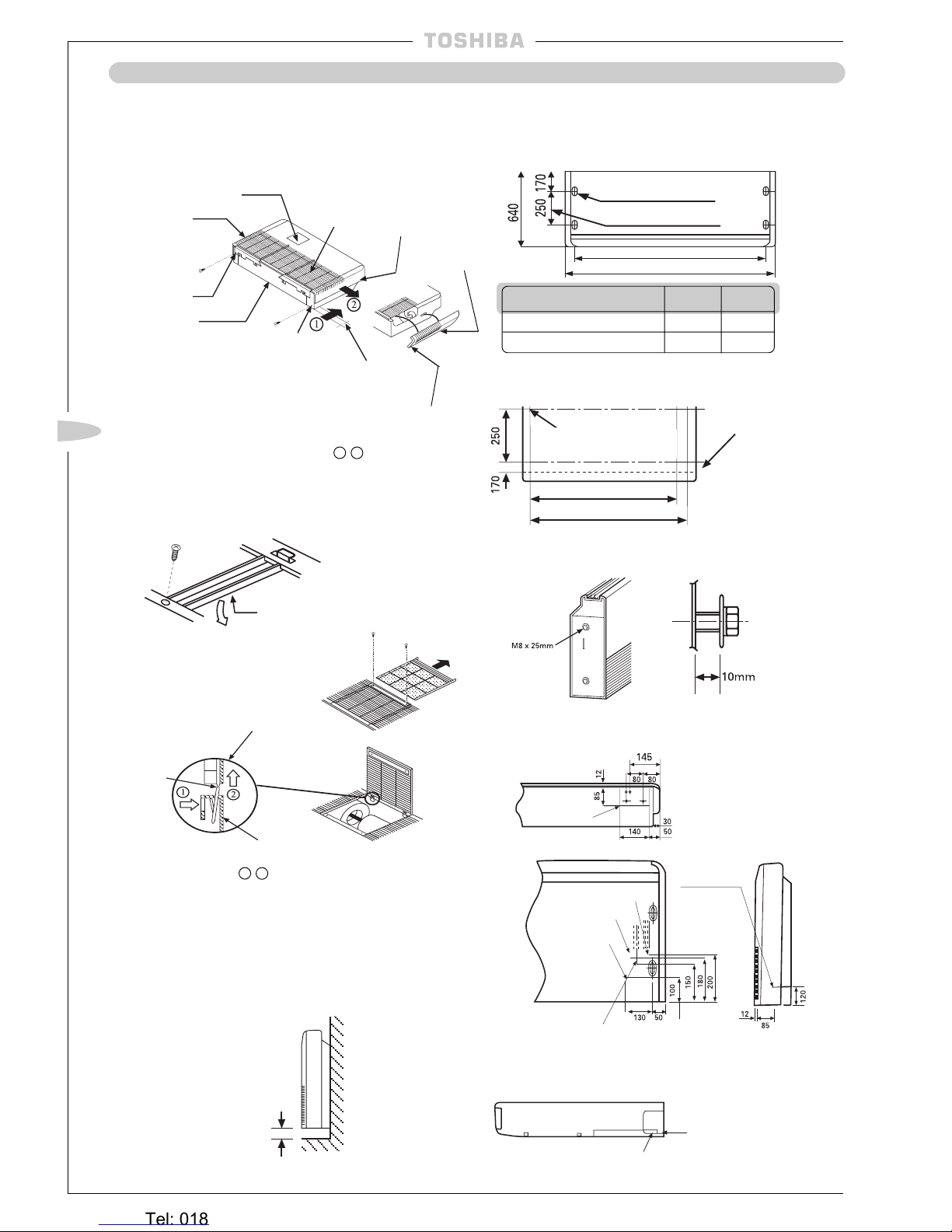

Unit Installation –

CH/CHR/C Units

Before Installation

1 Take off the accessories.

2 Remove

the hanger

(left, right).

4 Remove the side panels by hand.

Slide them in order of 1 - 2 .

5 Pull the air filter

out then remove

the inlet grille fixing

screws.

Side

panel

(left)

Body

Inlet grille

10-20mm

l Securely fix left

and right side panels

with a screw

supplied after unit

installation.

Installing Ø 10 Hanging Bolts

Ø Hanging Bolts are procured locally

l

Install hanging bolts at the spacings shown below.

Shipping fixture

(centre)

Detail figure of the hinge

portion

INNER HANGING

OUTER HANGING

Hole for hanging bolt

Bmm (Hanging bolt pitch)

Amm

Model (RAV-) Amm Bmm Cmm

134CH/CHR/C 1030 920 1020

164CH/CHR/C 1030 920 1020

264CH/CHR/C 1230 1120 1220

364CH/CHR/C 1430 1320 1420

464CH/CHR/C 1630 1520 1620

The positions of the hanging bolts are printed on the carton

box. (The size is not printed.)

Position of hanging bolt

(ø10 printed)

Bmm (inner hanging)

Cmm (outer hanging)

Installing method of the Hanging Bolt

Newly-built concrete slab

Install hanging bolts with

inserts, embedded bolts, etc.

Wooden-strutted room

Install hanging bolts on a square

wooden piece placed over beams.

Edge

(sharp

insert)

(Slide

insert)

Embedded bolt

of piping

Reinforcing bar

Installing Hexagon Bolt

(accessory)

Allow a spacing of

about 10mm

M8 x 25mm hexagon bolts (4)

Determining installation position and direction

of the piping and wiring

BACK VIEW

Knock out

(rear attachment)

Gas line connection

Knock out

(right or left attach-

ment)

Liquid line connection

TOP VIEW

Opening Knock Out Hole

Cut the slit

portion by a

saw or knife

In case of

right or left

attachment

Slit

3 Remove all the

metal shipping fixtures (left corner,

centre, right corner).

Side panel

(right)

Wooden

piece

Hanging

bolt

Drain connection

(OD 20mm)

Beam

Hole for hanging bolt

Cmm (Hanging bolt pitch)

Amm

(4 – 12 x 27 slots)

Hanging bolt pitch

(4 – 12 x 27 slots)

Hanging bolt pitch

l The dotted

line indicates

the rear end

of the unit. To

be detached

on the dotted

line.

Embedded

bolt

SIDE VIEW

To remove the

inlet grille take the

hinge portion off in

order of 1 - 2 .

Hinge

Body

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 14 ~

~ 14 ~

INDOOR UNIT LOCATION

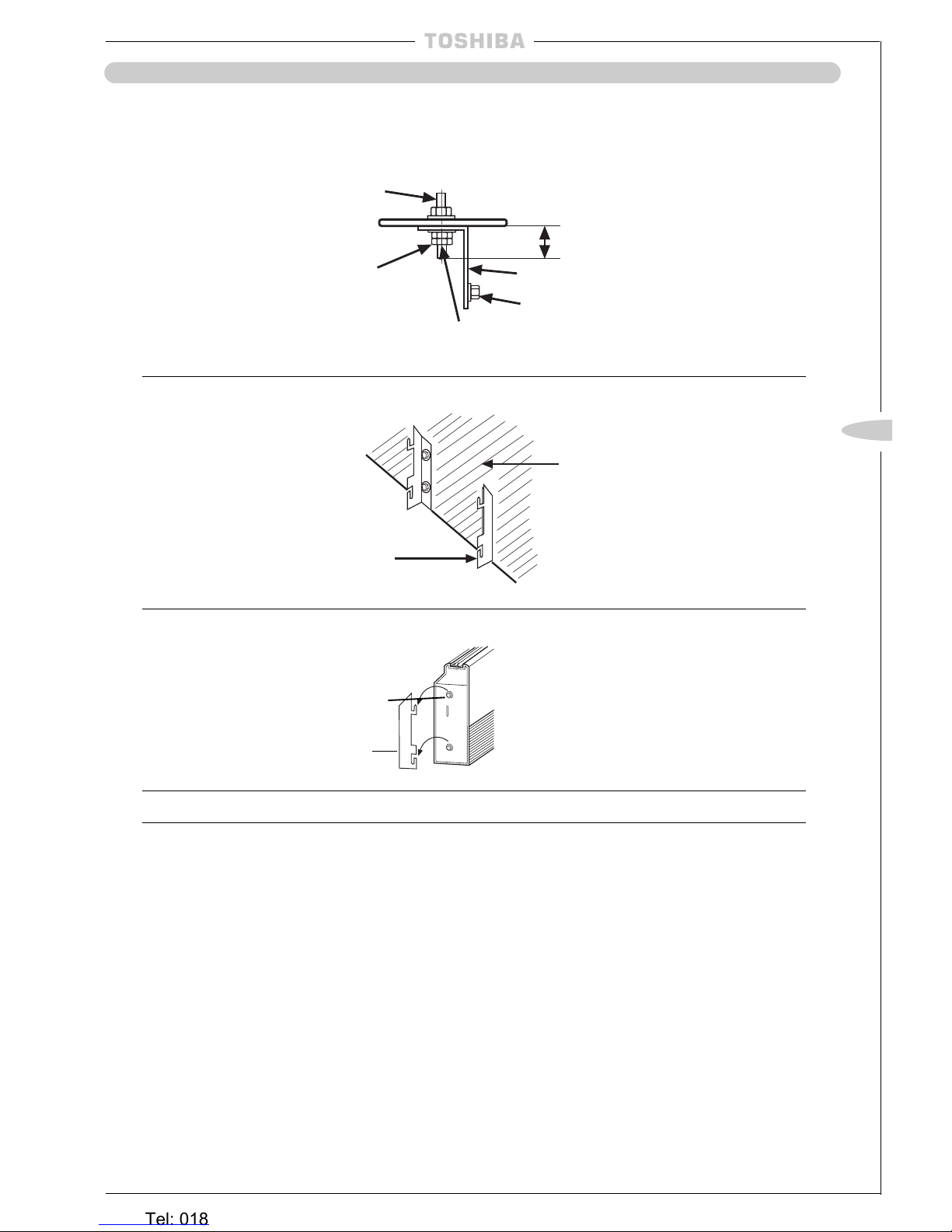

Hanging the Indoor Unit

(1) Fitting Hanger

INNER HANGING

OUTER HANGING

Hanging bolt

Ceiling board

Bolt cover

40mm or less*

Hanger

Hexagon bolt

Side panel (right)

M10 Plate

washer

Double nut

Hanging bolt

Body

(2) Fitting State of Hanger

Ceiling

Ceiling

Wall

Wall

In case of inner hanging, adjusting height of indoor unit is

impossible after hanging – adjust it at this state

(3) Hanging the Indoor Unit

Fit the Hexagon bolts of the unit into slit grooves

(4) Fasten the Hexagon bolts to hang the unit

Remote Control Cord, CH/C Models only

l

Wire the cord over the refrigerant piping and the drain piping.

l

If the cord was wired under the piping, it would cause difficulty in pulling out the air filter.

Ceiling board

40mm or less*

Hanger

*Allow a jutting out length of 40mm or less

Slit grooves

Hexagon bolt

Hexagon bolt

Slit grooves

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 15 ~

GB

~ 15 ~

INDOOR UNIT LOCATION

Unit Installation –

KH/KHR/K Units

l

When mounting the indoor unit on the wall, follow the

instructions below:

Precautions

To drain well make

sure the unit is

mounted horizontally

or tilted slightly to the

right as seen from

the front.

Do not embed the

unit in the wall.

When installing the

side panel, remove

the air filter (on the

right or left) and

make sure the lugs

are in the lug holes.

Then, push the side

panel until it fits

securely to the unit.

l The indoor unit weighs up to 30kg including the bracket.

Before mounting the unit, make sure the wall is strong enough.

30mm or more

(Horizontal or

tilted slightly to

the right)

300mm

or more

300mm

or more

Indoor unit

Lugs

Installing Installation Bracket

l

Referring to the template, determine the location of the

indoor unit and cut the pipe hole as indicated.

l

When passing

the refrigerant pipe through a wall in which a

lath is used, be sure to utilize pipe insulation.

In the case of a wooden wall (large wall):

(1) According to the distance between the indoor unit and the

ceiling, determine the vertical position (height) of the

installation bracket;

(2) Adjust the lateral position of the installation bracket with-

out changing the height so that each screw hole in the

bracket comes in the centre of a pillar or stud;

(3) In the case of a wooden wall, the distance between the

pillars is usually 900mm or 1,800mm (2,700mm) and within this length, studs are located at intervals of 300 to

500mm. Be sure to install the bracket securely by driving

the accessory screws into the pillars and studs. At this

time, in order to prevent the indoor units from falling forward, be sure to firmly fix the unit by tightening the screws

in the holes at both ends of the bracket (those indicated

by oblique lines on the template);

(Holes indicated by oblique lines on the template)

Wider side

(4) Make pilot holes before fitting screws.

In the case of a reinforced concrete wall:

(1) In the selected areas on the reinforced concrete wall, bore

holes at intervals of 480mm, and fit anchors;

(2) Attach the installation bracket to the wall by screwing bolts

or nuts into the anchors.

However, in the case where the hole anchors are used,

the depth of the holes should be adjusted so that the nut

heads extend no more than 15mm.

Precautions

There may be a wire conduit embedded in the wall. Check the

blue prints with the builder;

Make sure that the installation bracket is fitted securely before

mounting the indoor unit.

!

!

!

!

!

Clip anchor

Bolt

Installation

bracket

Nut w/threaded

hole 8mm dia.

Less than 15mm

In the case of the pipe on the back:

l Using the template, position the pipe hole and bore the

hole slightly downward.

Binding of Pipes and Drain Hose

(1) In the case of the right-side pipe and the left-side pipe

bind the pipes and the drain hose as shown in the figure

below being careful that they do not protrude out of the

back of the indoor unit.

Tape

Gas pipe

Cable

Screw holding side

panel

Lower cabinet

Drain hose

(2) Make sure the drain hose does not sag.

(3) Apply proper insulation on both pipes, otherwise they

will sweat or cause a problem.

(4) Be cautious while bending the pipes to assure their

bending radius is 100mm or more.

Right-side pipe exit

While bending, bend the pipe holding the bending portion by hand

Left-side pipe exit

(5) Cut out the knockout portion for the pipe with a knife

and smooth the edge.

Installation

bracket

Installation of Indoor Unit

(1) Pass the pipe through the pipe hole in

the wall and mount the indoor unit on

the upper end of the installation

bracket.

(2) Move the indoor unit to the right and

left checking to see that the upper end

of the bracket is fitted in the unit.

(3) Make sure the lower end of the

pipe-holding bracket hooks the lower

cabinet to prevent the indoor unit from

moving upward.

Removal of Indoor Unit’s Right Side Panel

(1) Remove the air filter and then remove the side panel.

(2) Unfasten the right screw of the right end inlet grille.

(3) Remove the two screws holding the side panel.

(4) The side panel has lugs located on the front edge. Hold

the rear edge of the panel and pull forward to remove.

(5) To replace the removed side panel, locate lugs and push

firmly in place.

Installation of right side

panel

Liquid pipe

Side panel knockout

Concrete

wall

Hole in anchor

Concrete

wall

Hang

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 16 ~

~ 16 ~

INDOOR UNIT LOCATION

Unit Installation –

NH Units

(1) There are EPS cushions protecting the unit from

damage during transportation. They are located under

both side plates. Remove the EPS cushions before

installation. Also, remove the transportation tape from

the electrical box.

(2) Install the indoor unit before construction of the

architectural surround.

Fixing the Unit

l When fixing the indoor unit to the floor or wall, use ø8mm

anchor bolts using the fixing point on the unit.

Front surface

Fixing onto the Floor Over-view

Model A B

RAV-104NH-PE 586 610

RAV-134/164/264NH-PE 880 910

Fixing onto the Wall – Front View

l Note: If you are fixing the rear plate onto the wall please

remove the electrical box as shown.

Floor Holes on

rear plate

(1) Remove the two

screws from the

top of the electrical

bracket.

(2) Slide the box along

as indicated by the

arrow and remove

from the unit.

Electrical box

To connect the duct, prepare the connection flange

locally as shown:

RAV-104NH-PE

RAV-134/164/264NH-PE

Connection of Ducting

Architectural Surround

Air Outlet Grille

(local procurement)

Supply Duct

(local procurement)

Duct Joint Plate

Unit

Duct Outlet

The indoor unit has two choices of air outlet. The indoor

unit will already be positioned in the vertical air outlet

direction, if a side/horizontal air outlet direction is required

the following operations are required:

(1) Remove the duct joint plate and front up plate by

removing the screws as indicated below.

Duct joint plate

Front up plate

Screws

Front of unit

SIDE VIEW

(2) Place the duct joint plate

as shown opposite and fix

by screws.

(3) Place the front up plate as

shown opposite and fix by

screws.

How to Remove the Electrical Box

Fixing

screws (x2)

5-Ø4.7 Hole

8-Ø4.7 Hole

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 17 ~

GB

INDOOR UNIT LOCATION

l

Check the dimensions of the unit illustrated in the following figure:

Unit Installation –

SBH Units

Connection of Ducting

Air outlet

duct (local

procurement)

Air inlet duct

(local procurement)

Shelter board

(factory fitted)

Ensure design of the air inlet duct work allows access

to replace or clean the filter.

!

The maximum static pressure of the Air Outlet duct

should not exceed 30Pa/3mmAq.

!

Hanging Unit

(1) Raise the unit by using a lift-

ing device, then secure the

hangers to the hanging

bolts. Be sure to fix the nuts

onto both the upper and

under side of the hanger

and the washer (under side

only);

(2) Install the unit horizontally

by using a level. Failure to

do this will cause water

leakages.

Nut

Hanger

Hanging

Bolt

Washer

Installation on a steel frame:

Use the angular

bracket in the

structure or install

one for support.

Cross

length

of wood

Hanging

bolt

Beam

Ceiling

Installation on a wooden structure:

Place a length of wood of the appropriate size across two

beams and install the hanging bolts into this length of wood.

Installation on an existing concrete slab:

Use hole-in anchors, hole-in plugs

or hole-in bolts for the installation.

How to Install the Hanging Bolts

Installation on a newly installed concrete slab:

Use insert brackets or foundation bolts for the installation.

Knife-shaped

bracket

Sliding

bracket

Reinforcing

bar

Foundation

bolt

(Foundation bolt for

hanging the piping)

Hanging

bolt

Angular bracket

for support

Hanger bolt

Installing Ø 10 Hanging Bolts (4 pieces)

l

Install the hanging bolts at the intervals shown in the

above figure.

l

Use Ø 10 hanging bolts (to be locally procured).

l

The filter is factory fitted to the rear of the unit as

shown above.

l

If lower air inlet is required, remove the filter and 6

screws from the shelter board, reposition shelter board

on to the rear of the unit and replace the filter.

Refrigerant pipe

connection

(Gas ø12.7)

Refrigerant pipe

connection

(Liquid ø6.4)

Washable filter

Air outlet

Air inlet

Filter

Filter

Hanging bolt pitch

Hanging bolt

pitch

Unit dimension

Unit dimension

Unit dimension

Optional Air Flow (Lower air inlet)

Shelter board

Shelter board

Air

flow

Air flow

Terminal box

wiring connections

Drain pipe connection

(1" BSP threaded

connection)

Electrical box

(PCB, Transformer and MF Capacitor)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 18 ~

~ 18 ~

INDOOR UNIT LOCATION

Unit Installation –

SH/SHR Units

Before Installation

(1) Take off the accessories.

Side

panel

(left)

(2)

Remove

the hanger

(left, right).

(4) Remove the side

panels by hand. Slide

them in order of

1 - 2 .

(5) Pull the air filter out then remove the inlet grille fixing

screws.

10-20mm

Detailed figure of

the hinge portion

Body

In case of removing the inlet

grille take the hinge portion off

in order of 1 - 2 .

Installing Hexagon Bolts

(accessory)

Allow a

spacing of

about

10mm

Determining installation position and direction

of the piping and wiring

BOTTOM VIEW

Knock out

Gas line connection

Liquid line

connection

Knock out

(rear

attachment)

Body

Recommended Mounting Height

l

It is recommended that the unit is mounted

150mm above the floor.

150mm or more

l The positions of the hanging bolts are printed on the

carton box (the size is not printed).

Bmm (inner hanging)

Cut the slit portion

by a saw or knife

In case of right or left attachment

Opening knock out hole

BACK VIEW

Drain connection

(OD 20mm)

Knock out

(right or left

attachment)

SIDE VIEW

Installing Ø 10 Wall Bolts

Ø Wall Bolts are procured locally

l Install wall bolts at the spacings shown below.

INNER HANGING

Hole for expanded bolt

(4 – 12 x 27 slots)

Wall bolt pitch

Bmm (Wall bolt pitch)

Amm

Model A B

164SH/SHR 1030 920

264SH/SHR 1230 1120

Side panel

(right)

l Securely fix left

and right side

panels with a

screw supplied

after unit

installation.

Inlet grille

Shipping fixture

(centre)

Slit

l The

dotted line

indicates the

rear end of the

unit. To be

detached on

the dotted line.

(3) Remove all the

metal shipping fixtures (left, corner,

centre, right corner).

Amm

Hinge

Position of hanging bolt

(ø 10 printed)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 19 ~

GB

~ 19 ~

INDOOR UNIT LOCATION

Unit Installation –

SH/SHR Units continued

Hanging the Indoor Unit – SH/SHR Units continued

(1) Fitting Hanger

Wall

M10

Plate washer

Double nut

(2) Fitting of Hanger

Hanger

Wall

(3) Hanging the Indoor Unit

Hexagon bolt

Hanger

(4) Fasten the Hexagon Bolts to Hang the Unit

Remote Control Cord,

SH Models only

l

Wire the cord over the refrigerant piping and the drain piping.

l

If the cord was wired under the piping, it would cause difficulty in pulling out the air filter.

40mm or less*

Hanger

Hexagon bolt

*Allow a bolt length of 40mm or less

Fix the hexagon bolts from

the unit in the hangers

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 20 ~

~ 20 ~

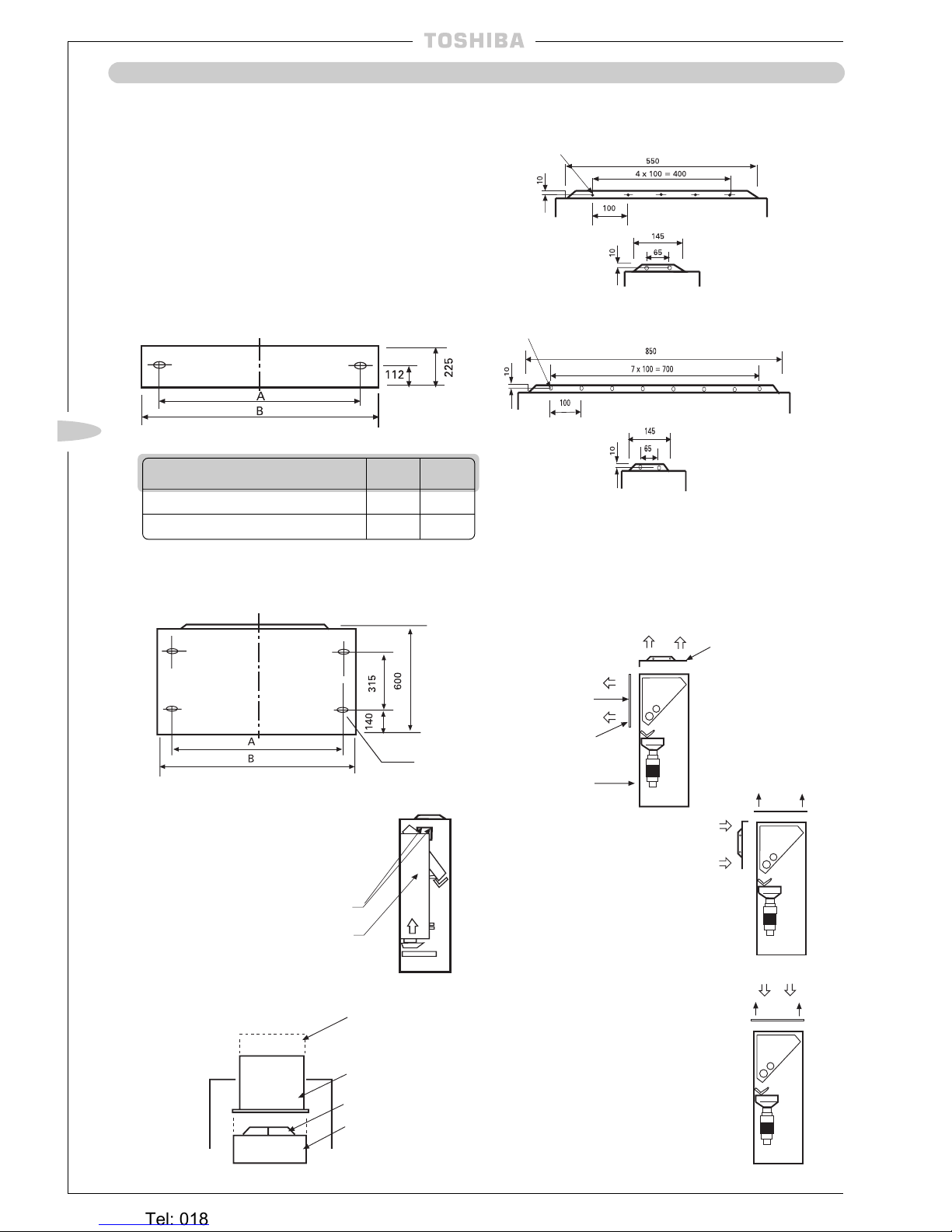

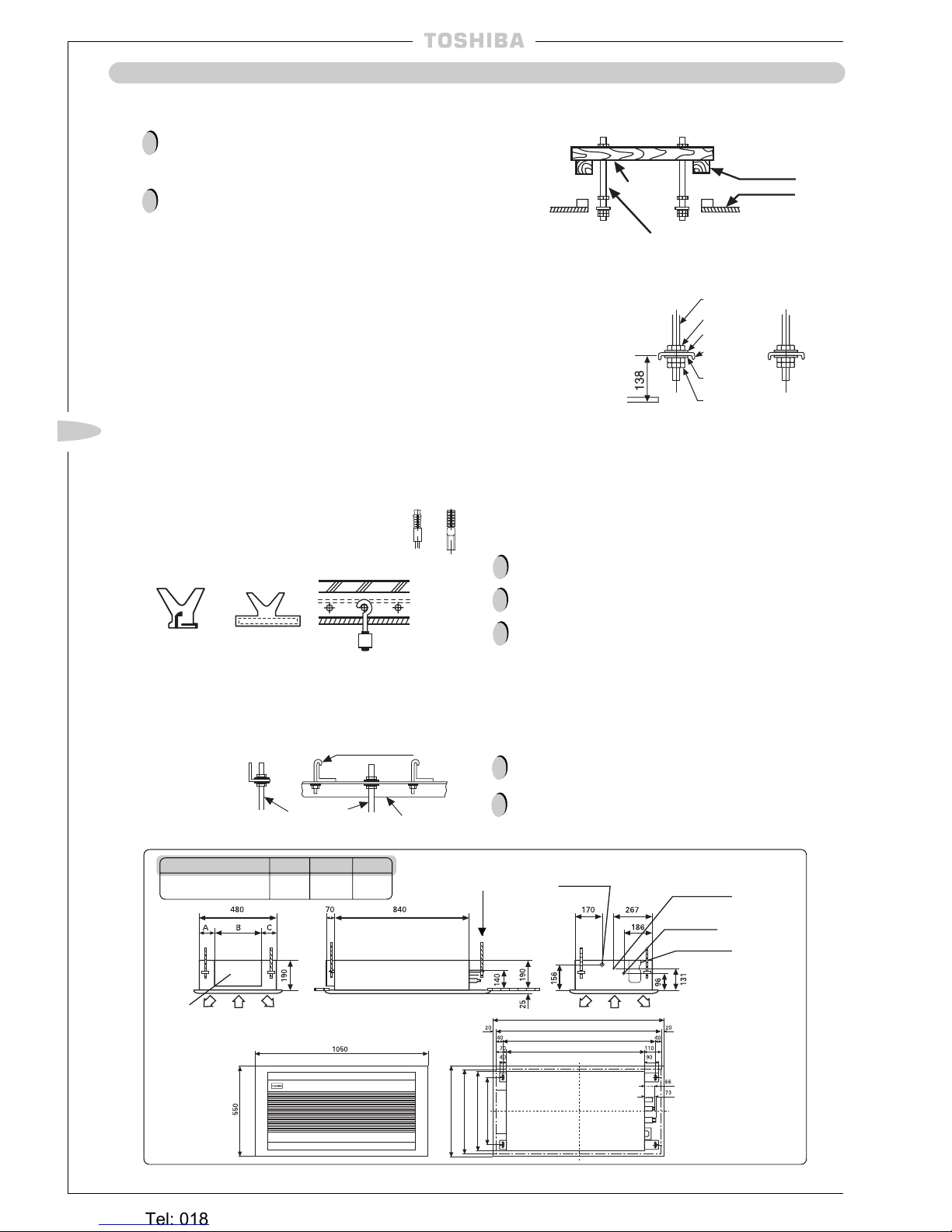

INDOOR UNIT LOCATION

Unit Installation –

TUH/TUH-1, TU/TU-1 Units

Installing Ø 10 Hanging Bolts (4 pieces)

l

Install the hanging bolts at the intervals shown in the

following figure.

l

Use ø 10 hanging bolts (to be locally procured).

Ceiling preparation:

The actual procedure differs according

to the structure. Consult your builder or whoever was

responsible for the interior of the house/building.

(1)

Removal of part of the ceiling plate:

In order to ensure that the ceiling is kept perfectly

horizontal and to prevent the ceiling from vibrating the

ceiling framework must be reinforced;

(2) Cut and remove part of the ceiling framework;

(3) Reinforce the ends of the ceiling framework where it was

cut and add framework to secure the ends.

l

Some piping and wiring connections must be made in the

ceiling after the unit has been suspended. After selecting where

the unit will be installed, decide on the direction of the piping

connection. If the ceiling is already installed, prepare the

refrigerant pipes, drain pipe, indoor to outdoor unit connection

wiring and the remote control cord at the piping and wiring

connection positions before suspending the indoor unit.

How to Install the Hanging Bolts

Installation on a newly installed concrete slab:

Use insert brackets or foundation bolts for the installation.

Check the dimensions of the unit illustrated in the

following figure. Use the accompanying template for

installation and adjust the position of the body of the

unit to the position of the opening on the ceiling.

Secure the cardboard template to the body of the

indoor unit with four bolts (M5 x 20mm), supplied with

the ceiling panel.

!

!

Knife-shaped

bracket

Sliding

bracket

Reinforcing

bar

Foundation

bolt

(Foundation bolt for

hanging the piping)

Beam

Ceiling

Installation on a wooden structure:

Place a length of wood of the appropriate size across two

beams and install the hanging bolts onto this length of wood.

l

Hang the nut of

hanger bolt on the

U shape groove in

the body hanger.

l

Check the level of

the body by using a

spirit level.

Installation on an existing concrete slab:

Use hole-in anchors, hole-in plugs or hole-in bolts for the

installation.

(1) Check that the distance between the bottom of the indoor unit

and the underside of the ceiling is 3mm (four corners).

(2) Check that the distance between the side of the indoor unit

and the ceiling is 600mm (common to the left and right sides).

(3) Check that the distance between the front side of the indoor

unit (piping side) and the ceiling board is 200mm, and between

the back of the indoor unit and the ceiling is 50mm.

l

Tighten the upper nut and fix the position of the unit.

Precautions

Since the unit contains a drain pump and a float switch, the body

must be level.

If the body is installed in a tilted state the float switch will not

function properly and thus will cause water leakage.

Models TUH-1/TU-1: No drain socket is fitted to the drain pan on

the above models. If the drain pan needs to be removed after

installation and operation, ensure that the drain pan is kept level to

avoid any water from spilling over.

!

!

!

Installation of Ceiling Panel:

Install the ceiling panel following the installation manual supplied

with it.

Precautions

Before installing the ceiling panel, check that the body of the unit

has been installed correctly against the ceiling.

The ceiling panel and ceiling face must contact closely. The ceiling

panel and the contact side of the body must contact closely. Any

gap between them will cause air leakage and thus generate

condensation.

Hanging

bolt

Angular

bracket for

support

Installation on a steel

frame:

Use the angular

bracket in the

structure or install

one for support.

Hanger bolt

Panel outer dimension 1050

Ceiling opening 1010

Hang bolt pitch 930

840

Wiring connection

TU/TUH only

Wiring connection

TU-1/TUH-1 only

(Gas Ø 12.7)

(Liquid Ø 6.4)

(Outer Ø 25.5)

Drain pipe connection

Hanger bolt

(4- M10)

Hang bolt pitch 410

480

Ceiling opening 510

Panel outer dimension 550

Hanging Unit

l

Adjusting the positions of the nuts (lower side) so that

the distance between the washer (lower side) and the

ceiling is 140mm.

Ceiling

Nut (upper side)

Hanger

Washer (upper side)

Hanger of body

Washer (lower side)

Nut (lower side)

Hanging bolt

Cross

length of

wood

Refrigerant pipe connection

Refrigerant pipe connection

!

!

ABC

TUH/TU Units 80 290 110

TUH-1/TU-1 Units 75 330 75

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 21 ~

GB

~ 21 ~

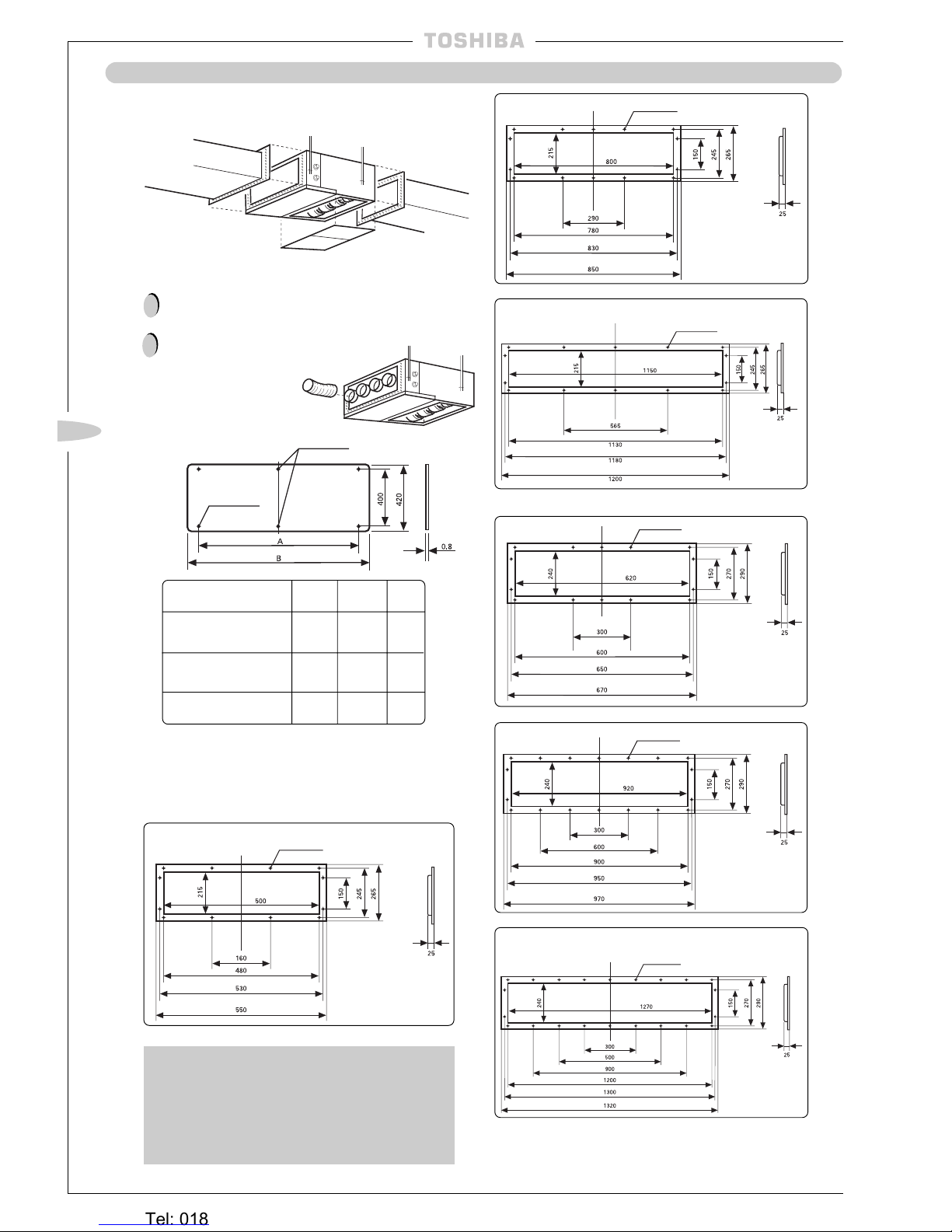

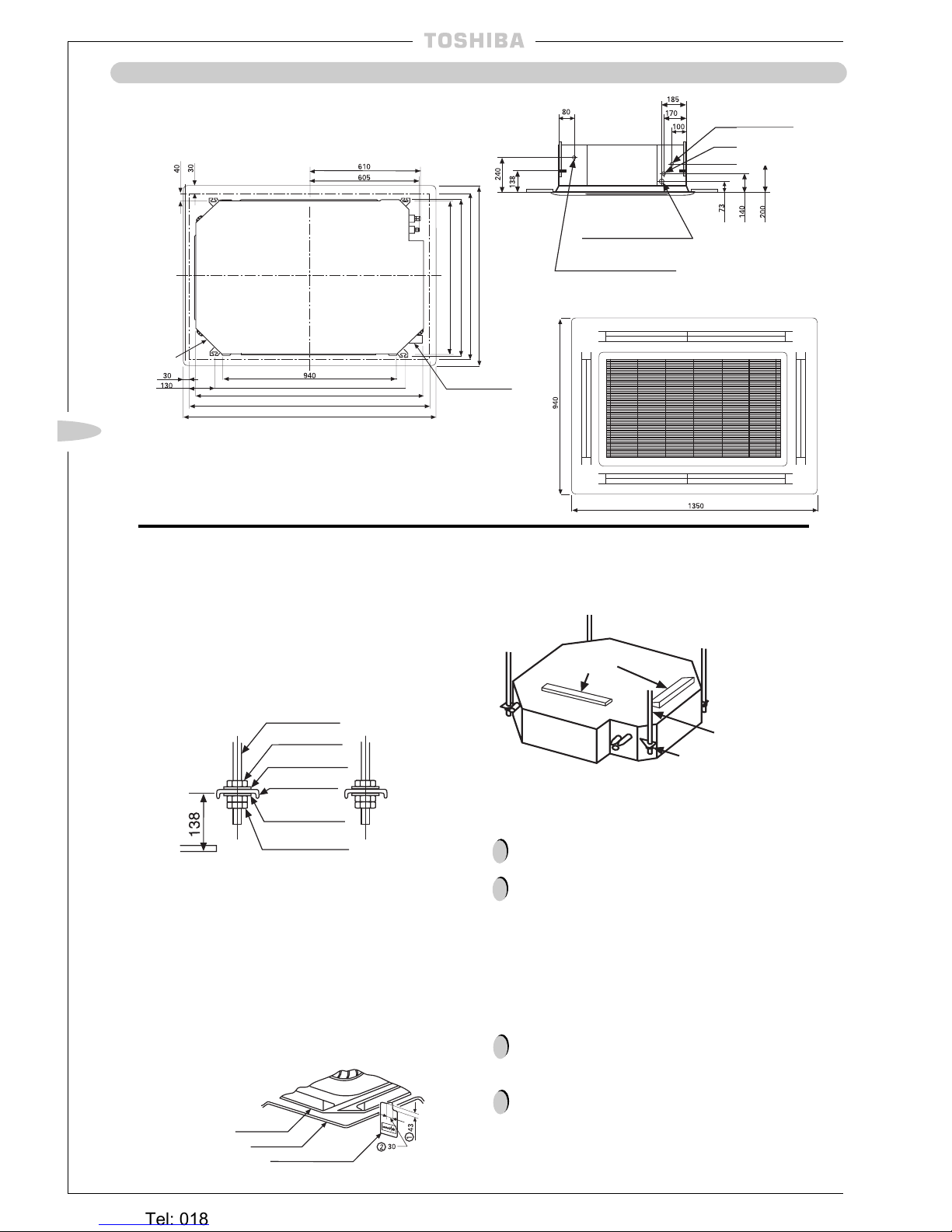

Unit Installation –

UH/U UNITS

Check the dimensions of the unit illustrated in the

following figure. Use the accompanying template for

installation and adjust the position of the body of the

unit to the position of the opening on the ceiling.

Secure the cardboard template to the body of the

indoor unit with four bolts (M5 x 20mm).

!

!

Installing Ø 10 Hanging Bolts (4 pieces)

l

Install the hanging bolts at the intervals shown in the

following figure.

l

Use Ø 10 hanging bolts (to be locally procured).

Ceiling preparation:

The actual procedure differs according

to the structure. Consult your builder or whoever was

responsible for the interior of the house/building.

(1)

Removal of part of the ceiling plate:

In order to ensure that the ceiling is kept perfectly

horizontal and to prevent the ceiling from vibrating the

ceiling framework must be reinforced;

(2) Cut and remove part of the ceiling framework;

(3) Reinforce the ends of the ceiling framework where it was

cut and add framework to secure the ends.

l

Some piping and wiring connections must be made in the

ceiling after the unit has been suspended. After selecting where

the unit will be installed, decide on the direction of the piping

connection. If the ceiling is already installed, prepare the

refrigerant pipe, drain pipe, indoor to outdoor unit connection

wiring and the remote control cord at the piping and wiring

connection positions before suspending the indoor unit.

Installation on a steel frame:

Use the angular

bracket in the

structure or install

one for support.

Cross

length

of wood

Hanging

bolt

Beam

Ceiling

Installation on a wooden structure:

Place a length of wood of the appropriate size across two

beams and install the hanging bolts into this length of wood.

Installation on an existing concrete slab:

Use hole-in anchors, hole-in plugs

or hole-in bolts for the installation.

How to Install the Hanging Bolts

Installation on a newly installed concrete slab:

Use insert brackets or foundation bolts for the installation.

Knife-shaped

bracket

Sliding

bracket

Reinforcing

bar

Foundation

bolt

(Foundation bolt for

hanging the piping)

Hanging

bolt

Angular

bracket for

support

Hanger bolt

RAV-164UH/U

RAV-264UH/U

880 (CEILING OPENING)

Wiring connection (Gland

Plate 3 x Ø20 holes)

Drain pipe connection

(1'' BSP threaded connection)

940 (PANEL DIMENSION)

Drain Pipe

(1'' BSP Threaded Connection)

820 (EXTERNAL CASSETTE DIMENSION)

800 HANGER BOLT PITCH

820 (EXTERNAL DIMENSION PITCH)

880 (CEILING OPENING)

940 (PANEL DIMENSION)

Fresh Air Inlet

620 (HANGER BOLT PITCH)

Refrigerant pipe

connection (Gas ØA)

Refrigerant pipe

connection (Liquid ØB)

Model (RAV-) 164UH/U 264U 264UH

ØA 12.7 15.9 15.9

ØB 6.4 9.5 9.5

INDOOR UNIT LOCATION

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 22 ~

~ 22 ~

Unit Installation

– UH/U Units continued

Hanging Unit

l

Adjusting the positions of the nuts (lower side) so that

the distance between the washer (lower side) and the

ceiling is 138mm.

l

Hang the nut of hanger bolt on the U shape groove in

the body hanger.

l

Check the level of the body by using a spirit level.

l

Adjust the location and height of the indoor unit in

relation to the ceiling opening by using the installation

gauge provided in the template.

(A diagram to use the part is indicated on the installation

gauge)

(1) Ensure that the distance between the bottom of the

indoor unit and the underside of the ceiling is 43mm in

all 4 corners.

(2) Ensure the gap between the side of the indoor unit and

the ceiling is 30mm all the way around.

l

Tighten the upper nut and fix the position of the unit.

Precautions

Since the unit contains a drain pump and a float switch, the

body must be level.

If the body is installed in a tilted state, the float switch will

not function properly and thus will cause water leakage.

Installation of Ceiling Panel:

Install the ceiling panel following the installation manual supplied with it.

Precautions

Before installing the ceiling panel, check that the body of

the unit has been installed correctly against the ceiling.

The ceiling panel and ceiling face must contact closely. The

ceiling panel and the contact side of the body must contact

closely. Any gap between them will cause air leakage and

thus generate condensation.

!

!

!

!

Hanger

Level

Tighten firmly

Indoor Unit

Ceiling

Installation Gauge

Hanger

Nut

Washer

Washer

Hanger

Nut

RAV-364UH/U

RAV-464UH/U

Wiring connection

(Gland Plate 3 x Ø20 holes)

Drain pipe connection

(1'' BSP threaded connection)

1290 CEILING DIMENSION

1350 PANEL DIMENSION

1230 EXTERNAL CASSETTE DIMENSION

Condensate Pipe 1'' BSP

Threaded Connection

1030 HANGER BOLT PITCH

800 HANGER BOLT PITCH

820 (EXTERNAL DIMENSION PITCH)

880 (CEILING OPENING)

940 (PANEL DIMENSION)

Fresh Air Inlet

INDOOR UNIT LOCATION

Refrigerant pipe connection

(ø19.0 Gas side)

Refrigerant pipe connection

(ø9.5 Liquid side)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 23 ~

GB

~ 23 ~

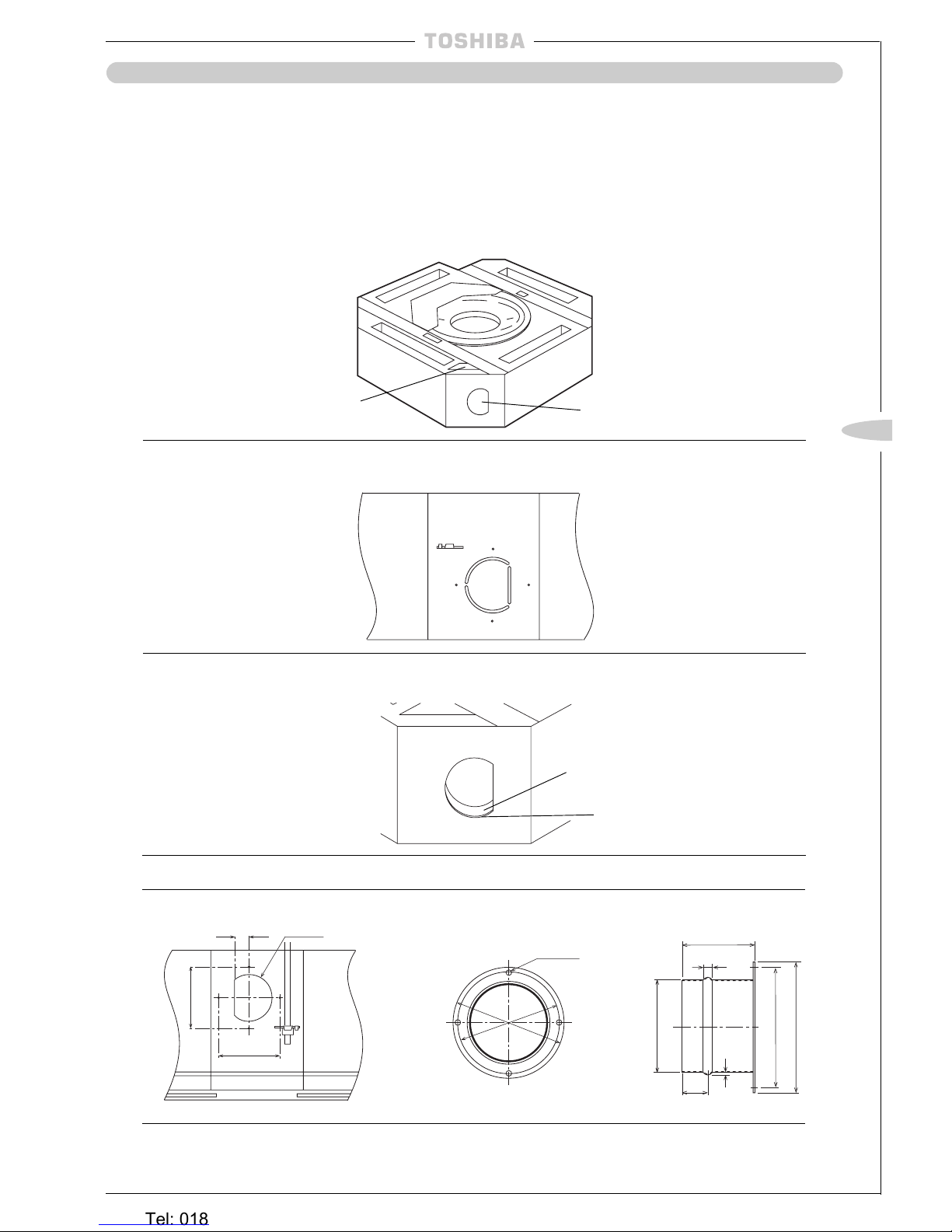

INDOOR UNIT LOCATION

(2) Carefully cut through the slots of the ‘D’ shape with a knife ensuring the blade does not penetrate

more than 30mm.

Thermal Insulator

(5) Add a spigot to the side of the indoor unit and attach using the 4 screw holes as shown below:-

Air Inlet Spigot (ø100)

Fresh Air Inlet

Details of Cut Out Hole

(1) The cut out hole is a ‘D’ shape half-cut hole on the side of the indoor unit located on the opposite side from

the pipe work.

(3) Cut the 3 metal tabs to remove the ‘D’ shape metal part and the thermal insulator from the

indoor unit.

Metal

Fresh Air Inlet

l

These models have a cut out hole in the cabinet to enable external air to enter the indoor unit.

l

Before installing the unit, remove the cut out hole and insulation block and fit a spigot to connect the duct

before hanging the unit.

(6) Add thermal insulation around the spigot to eliminate the possibility of condensation forming on the metal sur-

faces.

Drain Pan

Insulation Block

(4) Remove the insulation block located in the drain pan, above the fresh air inlet.

32 ø100

130

130

4-ø6

ø144

ø130

80

10

30

2

ø97

ø130

ø144

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 24 ~

~ 24 ~

INDOOR UNIT LOCATION

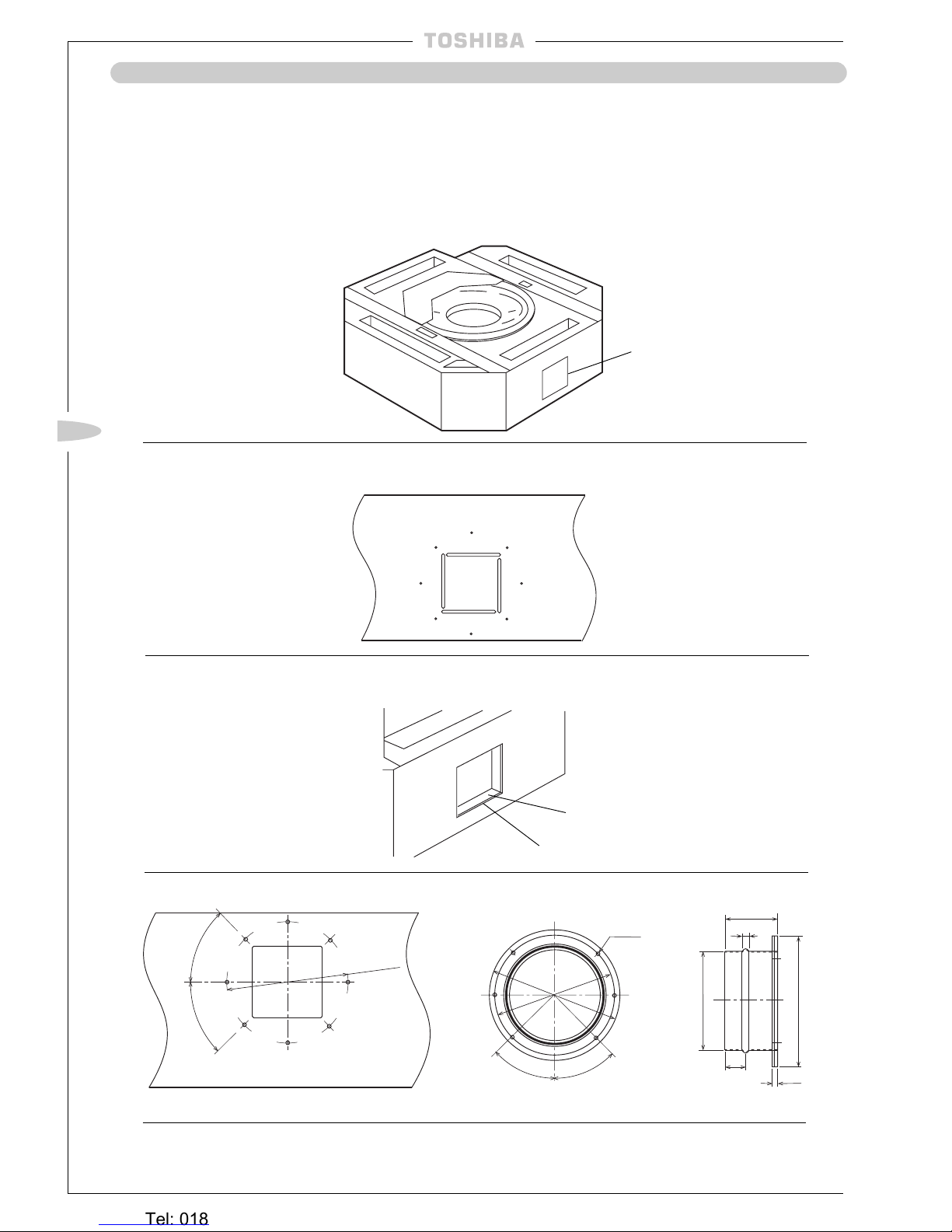

Air Outlet Duct

l

To improve air distribution in a room it is possible to divide the air outlet into the room. This is acheived by

adding a distribution duct. Only one duct can be used per unit.

l

Before installing the unit remove the cut out hole and fit a spigot to connect the duct before hanging the unit.

(2) Carefully cut through the slots of the rectangular shape with a knife ensuring the blade does not penetrate

more than 30mm.

Thermal Insulator

(4) Add a spigot to the side of the indoor unit and attach using the 6 screw holes as shown below:-

Air Outlet Spigot (ø150)

Air Outlet Duct

Details of Cut Out Hole

(1) The cut out hole is a rectangular shape half-cut hole located on two sides of the unit.

(3) Cut the 4 metal tabs to remove the rectangular metal part and the thermal insulator from the

indoor unit.

Metal

(5) Add thermal insulation around the spigot to eliminate the possibility of condensation forming on the

metal surfaces.

6-ø6

ø 180

45°

45°

ø150

6

80

10

30

ø200

45°

ø 180

45°

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 25 ~

GB

~ 25 ~

UH/U

l

Connection to the unit is via a 1’’ BSP male connection

– to ensure a waterproof seal, PTFE thread tape must

be used. The maximum lift of the condensate pump

from the drain outlet is 360mm and the maximum

overall lift from the underside of the ceiling to the centre

of the drain piping is 600mm. These values must not be

exceeded otherwise unit flooding will occur when the

drain pump is switched off.

360mm (max)

100mm

(max)

600mm (max)

Ceiling

Cassette

DRAIN PIPING

Ensure that the drain piping indoors is correctly

heat-insulated otherwise condensation will result.

Also, insulate the section which connects it to the

indoor unit.

If nylon cable ties are used to secure the insulation,

do not over-tighten them causing the deformation of

the heat insulation because this will reduce the

effectiveness of the insulation.

Use hard PVC adhesive for joining the pipes to

ensure that there will be no leakage.

Take care not to apply any force or pressure at the

unit side where the drain piping exits the indoor

unit.

The drain piping must be placed on a downward

gradient (1/100 or greater) and there should be no

upward or downward curves in the pipe which

obstruct the drainage, unless a drain pump is

employed.

The drain pipe should not extend for more than

20m horizontally. If the pipe has to be extended

horizontally for a considerable distance it must be

sufficiently supported to prevent warpage, also

increasing the gradient is recommended.

When one drainage system is used for a multiple

number of indoor units, install the piping as shown

below:

!

!

!

!

!

!

15-20m

Support clamp

Insulator

Downward gradient

1/100 or greater

Make this distance as long as possible – approx 10cm

Downward gradient

1/100 or greater

Upward

curve

Downward

curve

Piping Material and Heat Insulator

Heat Insulator*

Hard PVC pipe**

Drain pan Drain hose Hard PVC adhesive

*

Heat Insulator:

Polyethylene foam (thickness 6mm)

**

Piping Material:

Hard PVC pipe nominal diameter inside Ø20mm

Fixing the Drain Pan

CH/CHR/C

Rear Attachment

SH/SHR

Bottom Attachment

l

Screw the drain pipe fixing plate to the lower part of the

rear/bottom knockout and attach the drain pipe with the

nylon band. The knot in the nylon band should be on

the inner side (above the drain pipe fixing plate). When

the drain pipe alone is attached to the rear/bottom, use

the drain pipe knockout only.

Cut the slit

portion with a

saw

Rear/Bottom knockout

Nylon band

(supplied)

Drain Pipe

(Use the screw

from shipping

fixture)

Screw

Drain pipe

fixing plate

(supplied)

Refrigeration

pipes

CH/CHR/C

Right or Left attachment of Drain Hose

l

For attachment on the left, open up the knockout.

Attach the drain hose from right to left and the plug

from left to right. The plug is not tapered and should be

fully inserted. After attaching the pipe, seal the remaining gap in the knockout with the heat insulating material

supplied (cut to an appropriate shape).

Precautions

Drain Pipe

!

Rear knockout for drain

pipe

7

3

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 26 ~

~ 26 ~

BH/B

units

l

Remove the electrical box and service panel, then pour

water on the drain pan. Confirm that the water drains

correctly.

CH/CHR/C, SH/SHR

units

l

When piping is completed pour water on the drain pan

through the inspection hole to make sure that the water

drains correctly.

Service

Panel

Drain pan

Inspection hole

Inspection cover

KH/KHR/K

units

l

It is not possible to add water the drain pan to confirm

correct drainage. To do this, the unit must be operated

in the COOL mode.

SBH

units

l

Pour 500ml water directly into the drain pan via the AirOutlet-Duct prior to additional duct work being attached

to confirm water drains correctly.

NH

units

l

Pour water into the drain catch on the side of the unit

and ensure that the water drains correctly.

TUH/TUH-1, TU/TU-1

units

l

Pour about 500ml of water into the drain pan using a

wash bottle as shown in the diagram below. Once

connection with the electric power source has been

made, test the drainage by running the unit in the

COOL mode.

500ml wash bottle

500ml wash bottle

Air-Outlet-Duct

UH/U

units

l

Remove the sevice panel located below the drain

connection as shown below. Pour about 500ml of water

into the drain pan and then operate the unit in the

COOL mode to confirm the water is removed from the

unit.

Service panel

Drain socket

Hose for pouring water

DRAIN PIPING

Precautions

The power must be applied to the unit for at least 12

hours before operating the unit. This is to ensure the

compressor is fully warmed by the heater, otherwise

the unit may malfunction.

Do not under any circumstance, force the unit to

operate by using the magnetic contactor test button.

Before conducting the Trial Run, be sure to remove all

packaging from the unit and check that the service

valves are open.

A Forcible Trial Run can be carried out, either cooling

or heating, regardless of the room temperature.

TUH/TUH-1, TU/TU-1

units only

When operating the unit for the first time, press the

LOUVER button on the remote control. This ensures

the louvers are in the correct position.

!

!

!

!

!

Wired Remote Controller

l

To execute a cooling operation Trial Run, set the

operating mode to the COOL position and keep the

ON/OFF button pressed. Temperature (L) and Fan

Speed (AUTO) will be displayed.

l

To start a heating Trial Run, set the operating mode to

HEAT position and keep the ON/OFF button pressed.

This will set temperature to H and initiate a heating Trial

Run.

l

Press the ON/OFF switch after the completion of the

Trial Run.

Electrical

box

Drainage Check

Trial Run

l

With the infra-red remote controller, only a cooling trial

run can be executed.

l

To invoke a cooling trial run, set the operation change

over switch on the infra-red receiver (on the indoor unit)

to COOL MANUAL.

l

During a trial run the operation cannot be changed by

the use of the remote controller.

l

Set the switch on the receiver to REMOTE CONTROL

after the completion of the test run.

Infra-Red Remote Controller

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 27 ~

GB

REFRIGERANT PIPING

Precautions for R407C Outdoor Units

R407C outdoor units use synthetic oils which are extremely hygroscopic. Therefore ensure that

the refrigerant system is NEVER exposed to air or any form of moisture.

Mineral oils are unsuitable for use in these units and may lead to premature system failure.

Use only equipment which is suitable for use with R407C. Never use equipment which has been

used with R22.

R407C should only be charged from the service cylinder in the liquid phase. It is advisable to use

a gauge manifold set equipped with a liquid sight glass fitted in the centre (entry) port.

!

!

!

!

Material and Sizes

Materials and pipes required for connection between the indoor and outdoor units.

Piping material:

Seamless, deoxidised copper piping for air conditioning (refrigeration quality tube).

!

If models RAV-364AH8/A8; 464AH8/A8 are installed with a pipe length of more than 30m, the diameter

of the gas pipe must be increased to Ø22.2mm (

7

/

8

").

!

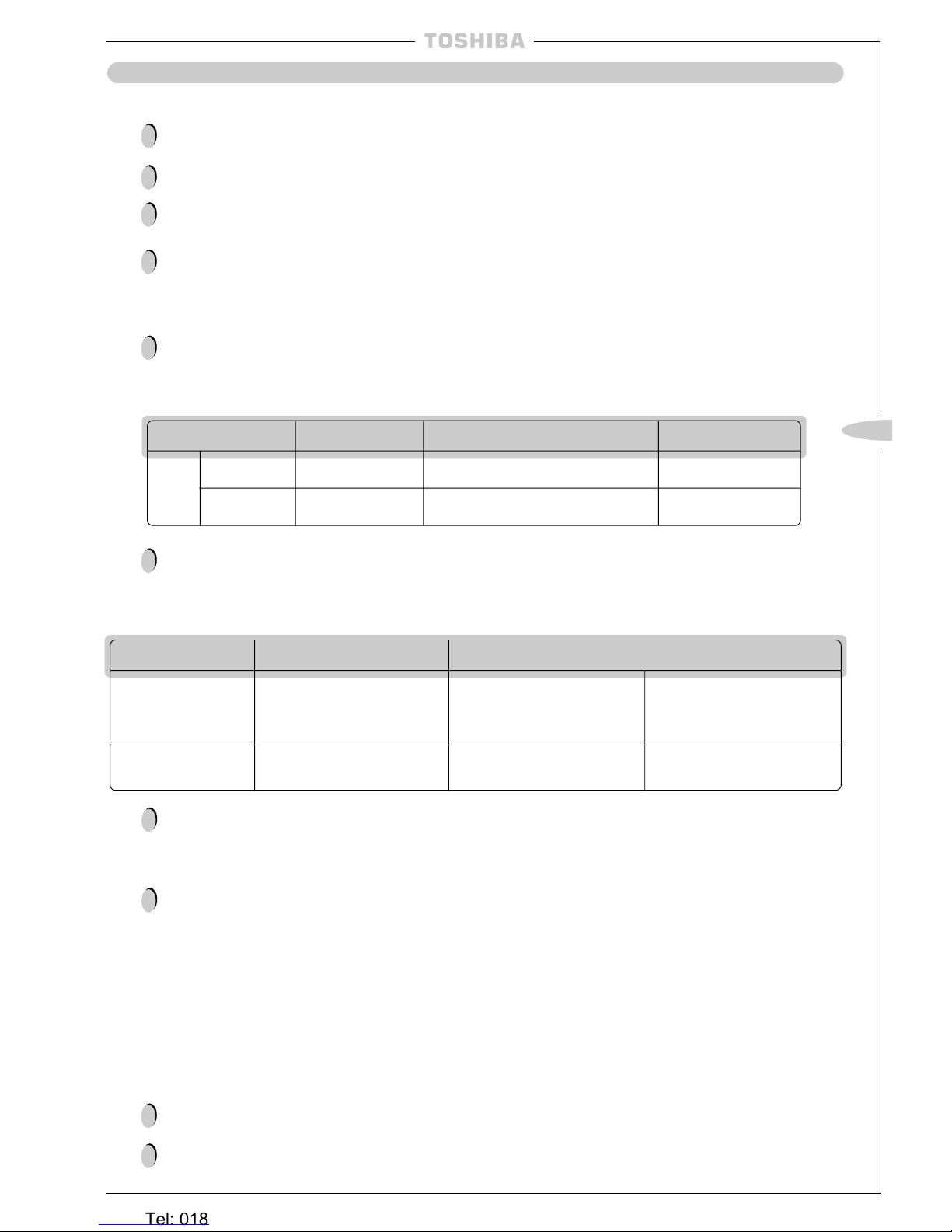

Permissible Piping Length and Head

Model (RAV-)

134AH/A

164AH/A

264AH/AH8/A/A8

364AH8/A8

464AH8/A8

The maximum piping length from the

outdoor unit to the indoor unit

The maximum height difference from the outdoor unit to the indoor unit –

When the outdoor unit is above

When the outdoor unit is below

30m 30m 15m

50m 50m 20m

Limit the total number of bends in the pipework to 10 or less.

When installing the pipework it is essential that the following points are adhered to:

(i) Cleanliness is essential – keep the pipework securely sealed at all times during the installation.

(ii) No sight glass should be fitted to the liquid pipe.

(iii) Do not incorporate an oil trap in vertical pipework.

(iv) Displace all air with oxygen-free-nitrogen.

!

!

Pipework Installation

When removing air and dehydrating refrigerant pipework, use an approved type of vacuum pump

only. Do NOT use the factory charge to purge the air.

Ensure a vacuum is drawn at -76cmHg (-1.013 x 105Pa) at both the liquid and gas sides.

!

System Purging

!

Model (RAV-) 134/164AH/A 264A/A8 264AH/AH8 364/464AH8/A8

Gas side Ø12.7mm (

1

/

2

") Ø15.9mm (

5

/

8

") Ø19.0mm (

3

/

4

")

Liquid side Ø6.4mm (

1

/

4

") Ø9.5mm (

3

/

8

") Ø9.5mm (

3

/

8

")

Piping

Size

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 28 ~

REFRIGERANT PIPING

Additional Refrigerant

The amount of refrigerant put into the outdoor unit at the factory is sufficient to fill up to 20m of

refrigerant pipework.

If the length of the refrigerant pipework is 20m or less, addition of refrigerant at the installation site

is unnecessary.

If the length of the pipework exceeds 20m, extra refrigerant must be added. Refer to the table

below for details of the extra amounts.

Overcharge or undercharge of refrigerant in the outdoor unit will cause malfunction of

the compressor.

The prescribed amount of the replenishment of the refrigerant is shown in the table below:

!

!

!

!

134AH-PE

164AH-PE

264AH/AH8-PE

364AH8-PE

464AH8-PE

134A-PE

164A-PE

264A/A8-PE

364A8-PE

464A8-PE

0.18 0.35 — — — — 0.79 1.05 1.23 1.4 — — — —

0.18 0.35 — — — — 0.94 1.2 1.38 1.55 — — — —

0.18 0.35 — — — — 1.64 1.9 2.08 2.25 — — — —

0.18 0.35 0.53 0.7 0.88 1.05 2.44 2.7 2.88 3.05 3.23 3.4 3.58 3.75

0.25 0.5 0.75 1.0 1.25 1.5 3.13 3.5 3.75 4.0 4.25 4.5 4.75 5.0

0.18 0.35 — — — — 0.79 1.05 1.23 1.4 — — — —

0.18 0.35 — — — — 0.94 1.2 1.38 1.55 — — — —

0.18 0.35 — — — — 1.64 1.9 2.08 2.25 — — — —

0.18 0.35 0.53 0.7 0.88 1.05 2.44 2.7 2.88 3.05 3.23 3.4 3.58 3.75

0.25 0.5 0.75 1.0 1.25 1.5 3.13 3.5 3.75 4.0 4.25 4.5 4.75 5.0

ADD ONLY R407C REFRIGERANT TO THESE UNITS

!

Heat Insulation

Provide heat insulation on the refrigerant piping on both the liquid side and gas side separately,

and ensure that all joints in the insulation are vapour sealed.

Since the temperature of the piping on the gas side increases during heating operations, the heat

insulating material used must be able to withstand temperatures of more than 120˚C –

HEAT PUMP TYPES ONLY.

Use the pipe insulation supplied in the accessory pack to insulate the piping connecting section on

the indoor unit side.

!

!

!

Pressure Measurement

Connect the pressure gauge to the locations in the table below when measuring the pressure during operation.

A gauge is required since check joints are used for the connecting sections.

!

!

High-pressure side Low-pressure side

During cooling Check joint in the outdoor unit Gas side packed valve

During heating Gas side packed valve Check joint in outdoor unit

Note: During cooling operation, the pressure in the packed valve on the liquid side reduces.

MODEL

(RAV-)

Recharge amount if unit is reclaimed

(kg)

±50g

Less

than

5m

Less

than

20m

Less

than

25m

Less

than

30m

Less

than

35m

Less

than

40m

Less

than

45m

Less

than

50m

Additional amount of refrigerant to add at

installation site (kg)±50g

Less

than

20m

Less

than

25m

Less

than

30m

Less

than

35m

Less

than

40m

Less

than

45m

Less

than

50m

Filled

at

Factory

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 29 ~

GB

~ 29 ~

Precautions

This guide should be read and utilised in conjunction with the official published regulations and

codes of practice, be they local, national or international.

Each air conditioning system will have its own discrete power supply, with overload current

protection.

Install a multi-pole isolation switch (with 3mm separation) in the power supply circuit.

The current protective device will prevent and protect the supply cable against overcurrent.

The circuit protection must be selected having due regard to the compressor starting current, such

that the supply cables when sized correctly, are also protected.

The cable should be selected to match the nominal load of the system, in addition to the losses

associated with corrections for length, temperature, impedance, etc. In accordance with local

codes of practice.

Earth both the indoor and the outdoor units by attaching an Earth wire. Ensure this is carried out

according to National Wiring Regulations.

After having made the connection to the terminal board, secure the cables with a cable clamp.

Wiring for the power supply must be performed by a qualified electrical engineer or technician

only.

Do not allow the cables (used for the power supply and for wiring between the units) to come into

contact with valves or pipes not covered with insulators. Secure these cables to the parts of the

pipes with heat insulation fitted.

Use the Ø20mm knockouts provided on the units (except KH/KHR/K), to fit cable glands to hold

the cables securely at the point where they enter the electrical box or unit.

!

!

!

!

!

!

!

!

!

!

!

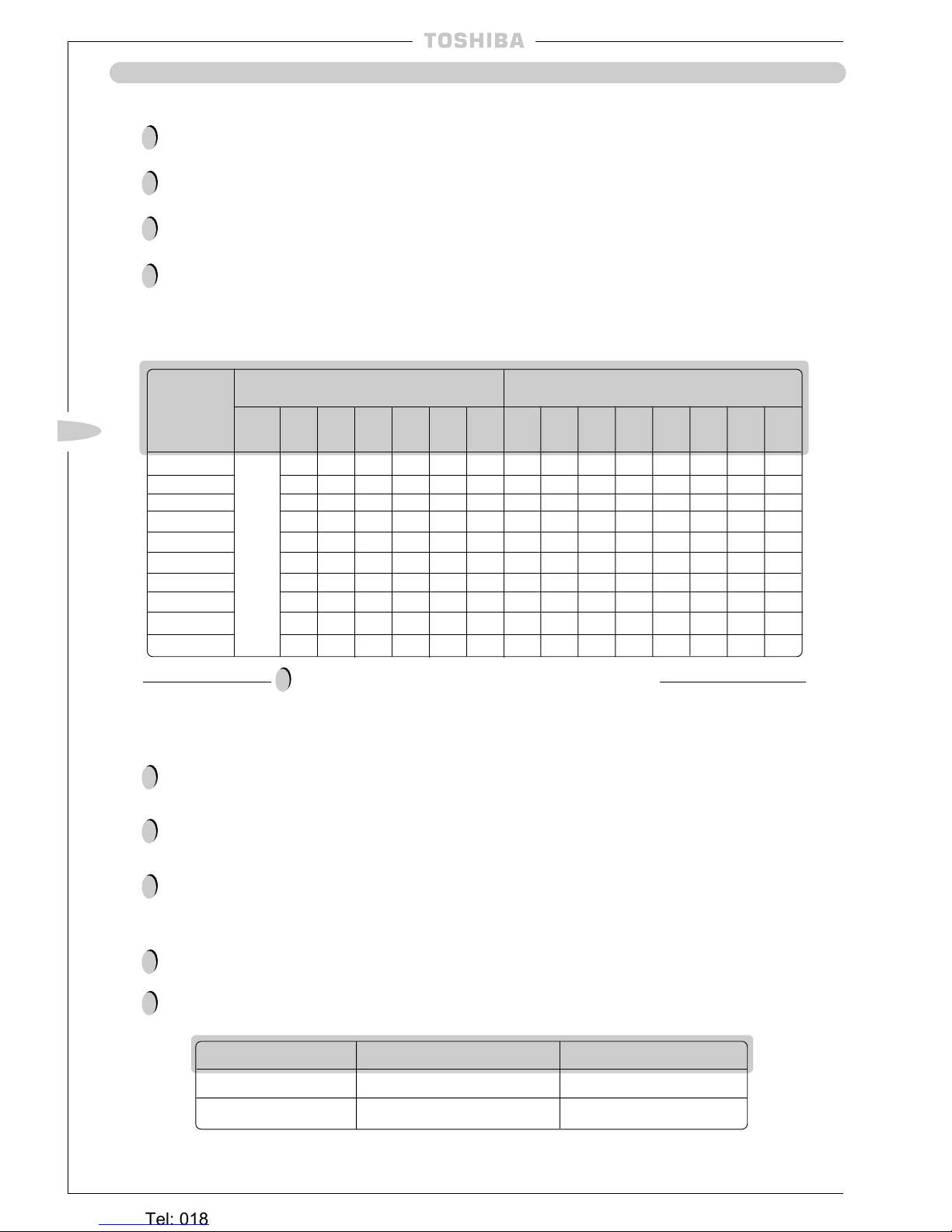

Power Supply Specifications

Power Supply Wiring

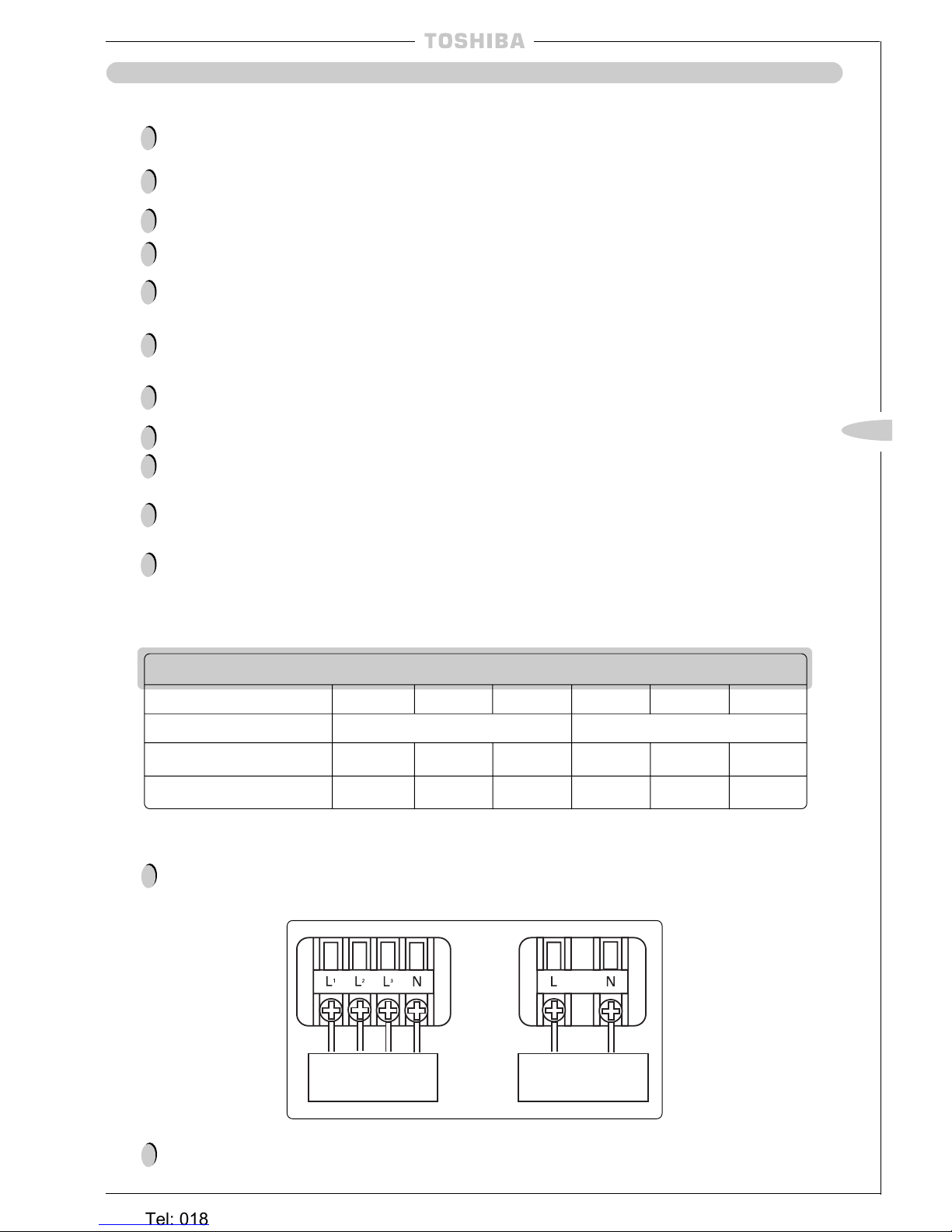

For a 3-phase model (4 wires), connect the power wiring to the L1, L2, L3 and N terminals on the

power supply terminal block of the outdoor unit. For a single phase model, connect the power

wiring to the L and N terminals (

see drawing below

):

380/415V 50Hz

3 phase 4 wires

220/240V 50Hz

Single phase

!

Models RAV-264AH8/A8, RAV-364AH8/A8, RAV-464AH8/A8 are equipped with a reverse phase

protector. If the compressor does not start, interchange phase L2 with phase L3 of the power supply.

!

ELECTRICAL WIRING

Main Circuit

Model (RAV–) 134AH/A 164AH/A 264AH/A 264AH8/A8 364AH8/A8 464AH8/A8

Power Supply 220/240V – 1PH – 50Hz 380/415V – 3PH – 50Hz

Starting current (A) 60 60 80 25 42 50

Running current (A) 10.7 11.1 14.8 4.7 6.8 8.5

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

~ 30 ~

~ 30 ~

ELECTRICAL WIRING

Wiring Between Units

Connect the wires between the units correctly. Errors made in the connections can result in the

unit malfunctioning.

Connect the control wires between the outdoor unit and indoor unit as shown in the figure below:

!

!

Connect the central

remote controller here

(OPTION)

Connect the remote

controller here

(OPTION)

Connect wiring between

indoor and outdoor unit here

Connecting the Remote Controller —

BH, CH, KH, NH, SBH, SH, TUH, TUH-1, UH only

Any standard 3-core cable operating at 12VAC with a cross-sectional area ranging from 0.3mm2to

0.75mm2and with a maximum length of 500 metres can be used.

When routing this cable, care should be taken to ensure that it is not in direct contact with mains

cable or routed in duct or conduit containing power cables.

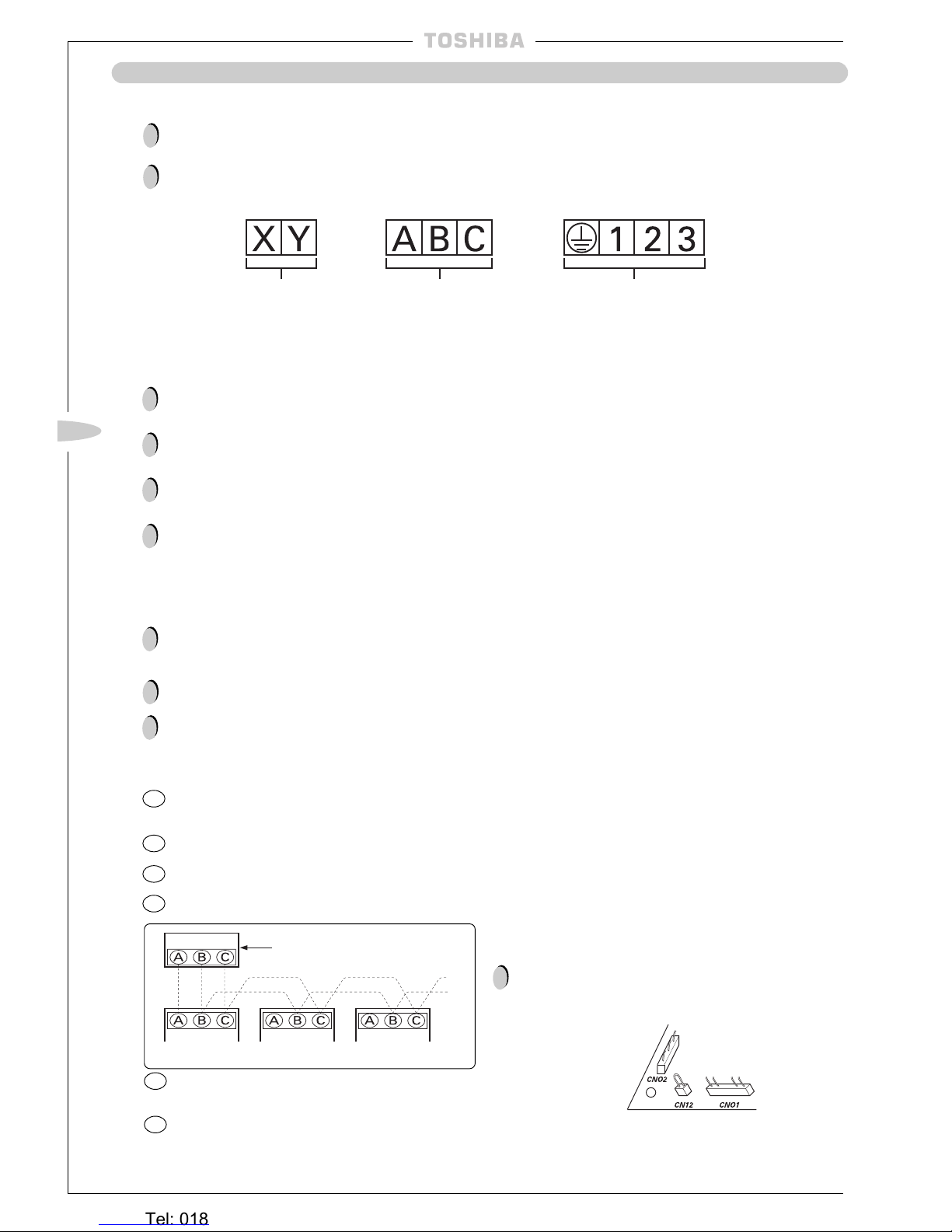

Connect the terminals A, B and C on the remote controller with the terminals A, B and C on the

indoor unit terminal block, ensuring that the terminals are matched up correctly.

Full instructions on the setting and operation of this controller are included in the owner’s manual,

supplied with the remote controller.

!

!

!

!

Group Control –

BH, CH, KH, NH, SBH, SH, TUH, TUH-1, UH only

Up to 16 air conditioners can be controlled as a group using a single remote controller. (The

control circuit for each indoor unit originates at the outdoor unit from the incoming phase

connection marked L or L1. It is important that on a group system that all the control circuits

throughout the group are derived from the same phase.)

No parts (except for the connecting cable) are required for group control.

Proceed with the power cable connections and with the wiring connections between the indoor

and outdoor units in exactly the same way as for individual air conditioner operation.

Connect the remote controller and the indoor unit in the following sequence:

1

Connect together the terminals A, B and C on both the remote controller and indoor unit No.1

ensuring that the terminals are matched up correctly;

2

Connect together terminals B and C on indoor units No.1 and No.2;

3

Connect together terminals B and C on indoor units No.2 and No.3;

4

Proceed in the same way to make the necessary connections up to indoor unit No.16;

!

!

!

Remote controller

Indoor unit (No.1)

Indoor unit Indoor unit

(No.2 – No.16)

Precautions

Use cables with a cross-sectional area of at

least 0.75mm2to connect the indoor units. The

maximum length of 500 metres for the remote

controller cable denotes the maximum length

from the remote controller to the furthest

indoor unit.

!

5

Leave the (CN12) connector in unit No.1 but remove

from any further indoor units to prevent malfunction due to miswiring.

6

Set the rotary switch position on each indoor unit to a different number, starting with position 1 for

unit No.1 which is connected to the remote controller. This will also ensure that each unit will start

up at a slightly different time therefore ensuring no increase in start-up current.

(Indoor unit terminal blocks)

Heronhill - for all your Toshiba requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 01823 665807

Loading...

Loading...